Patents

Literature

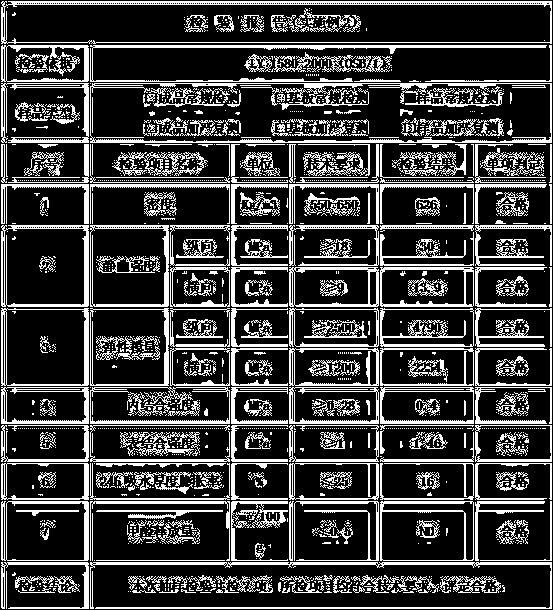

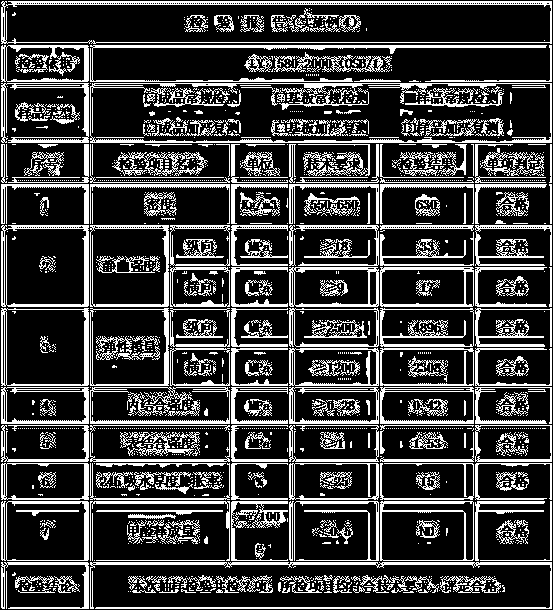

51results about How to "Fiber length" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

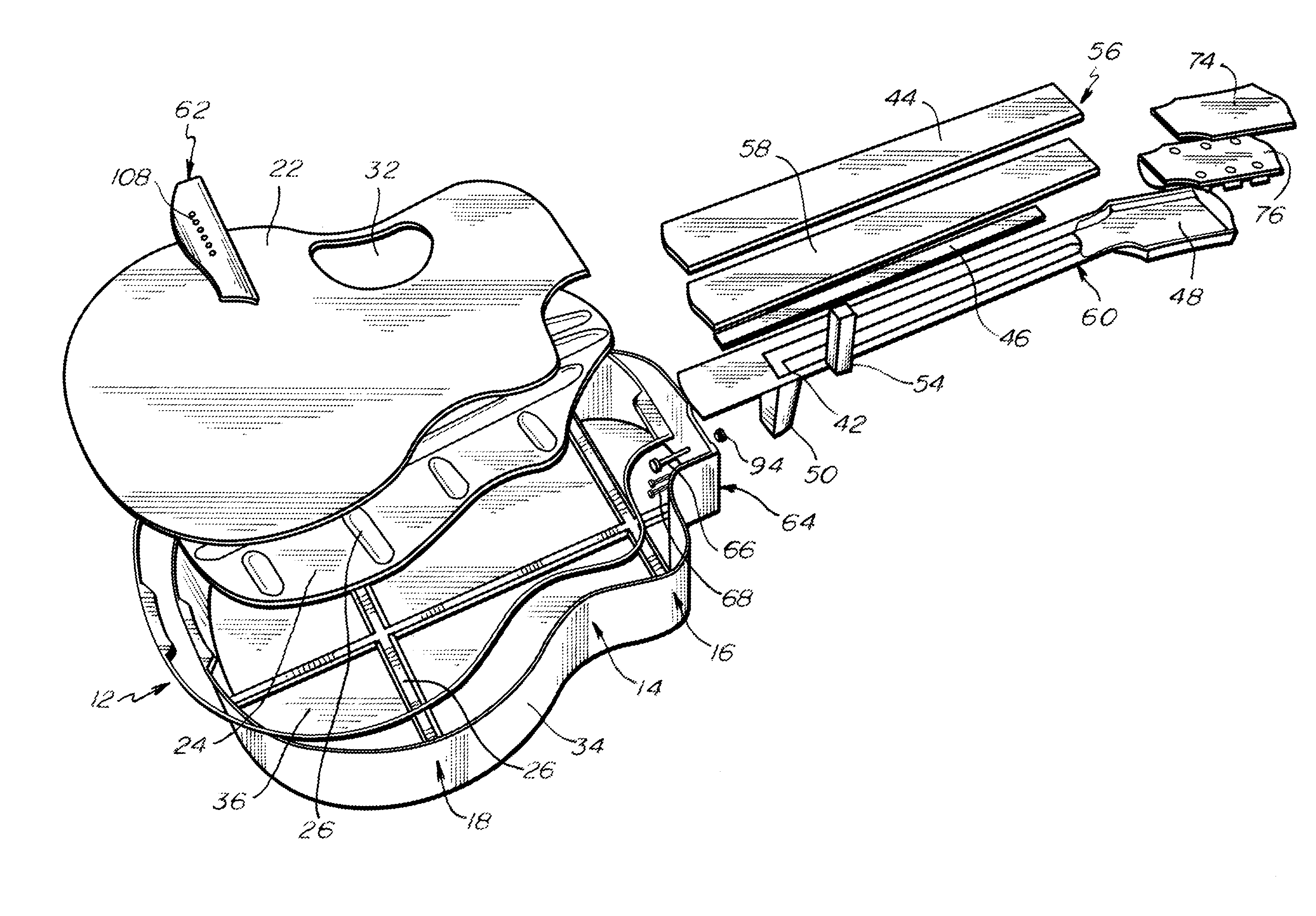

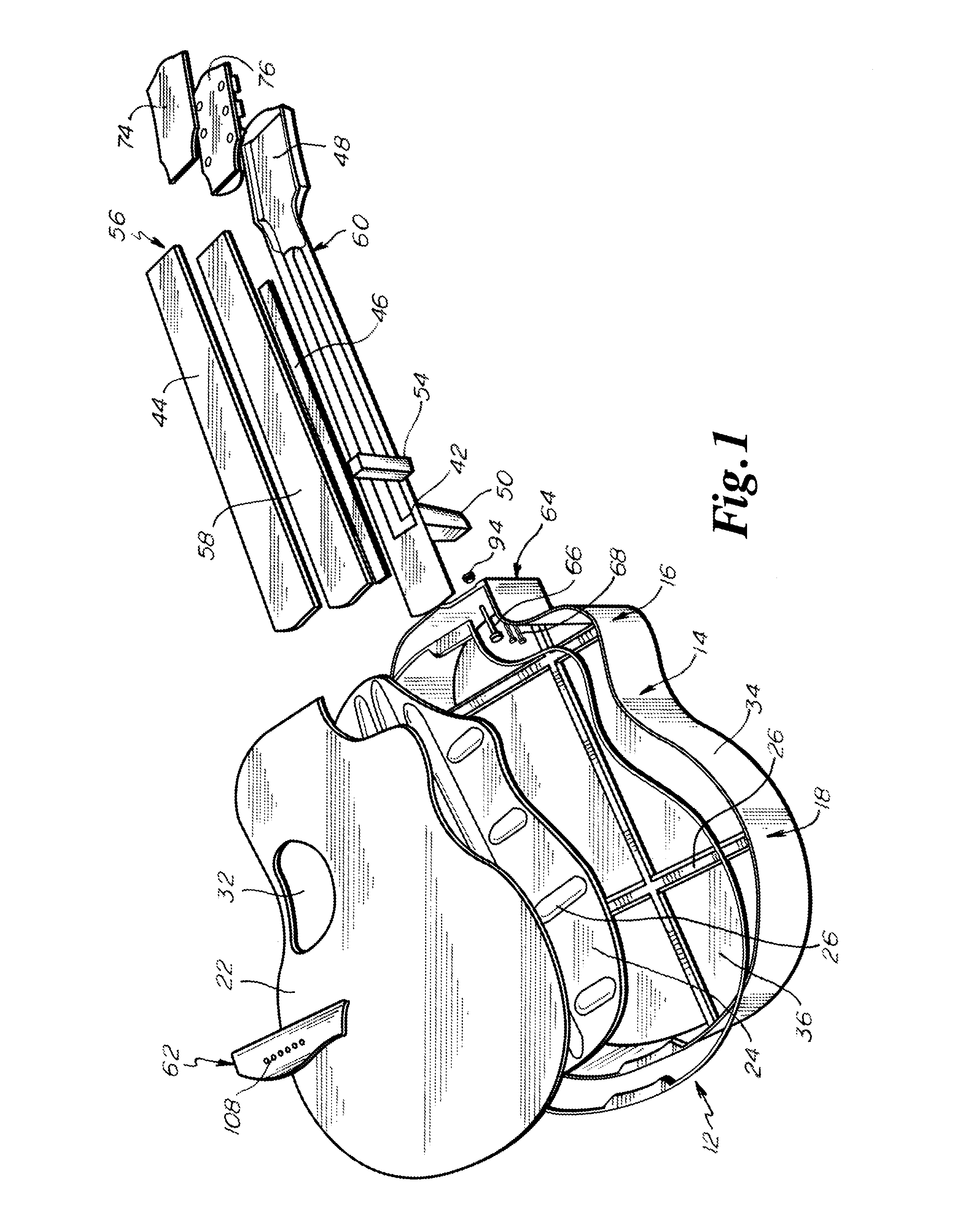

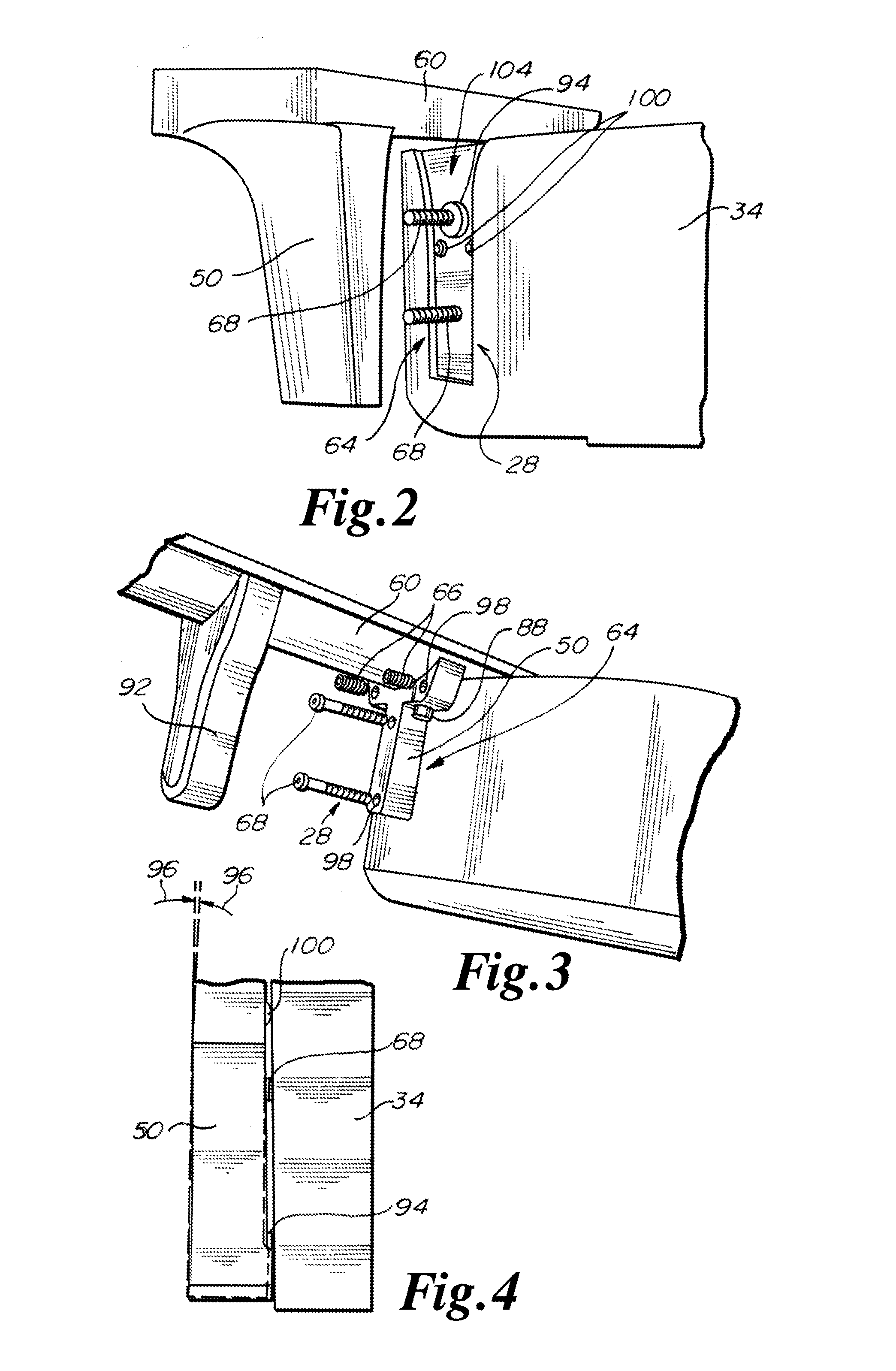

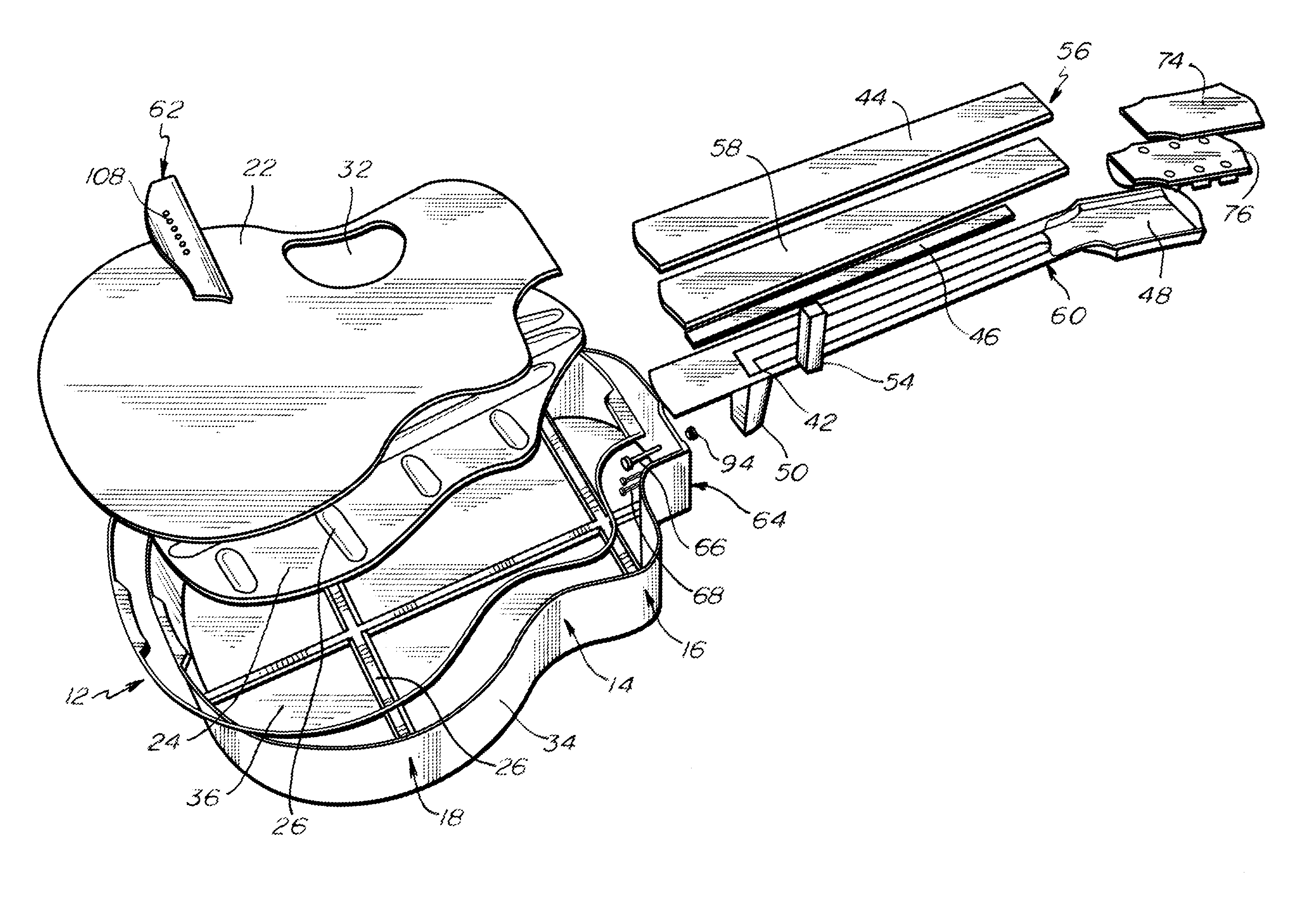

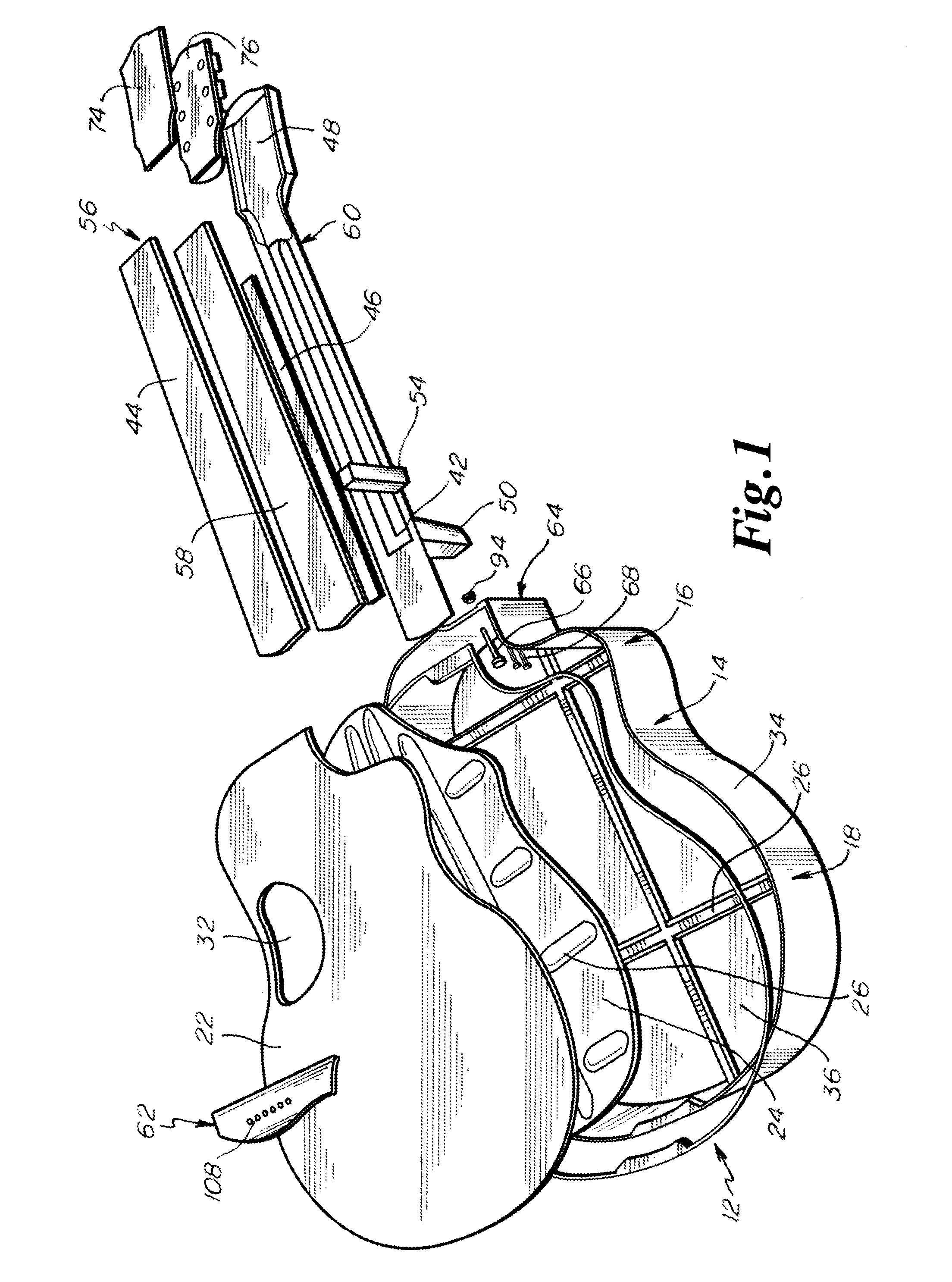

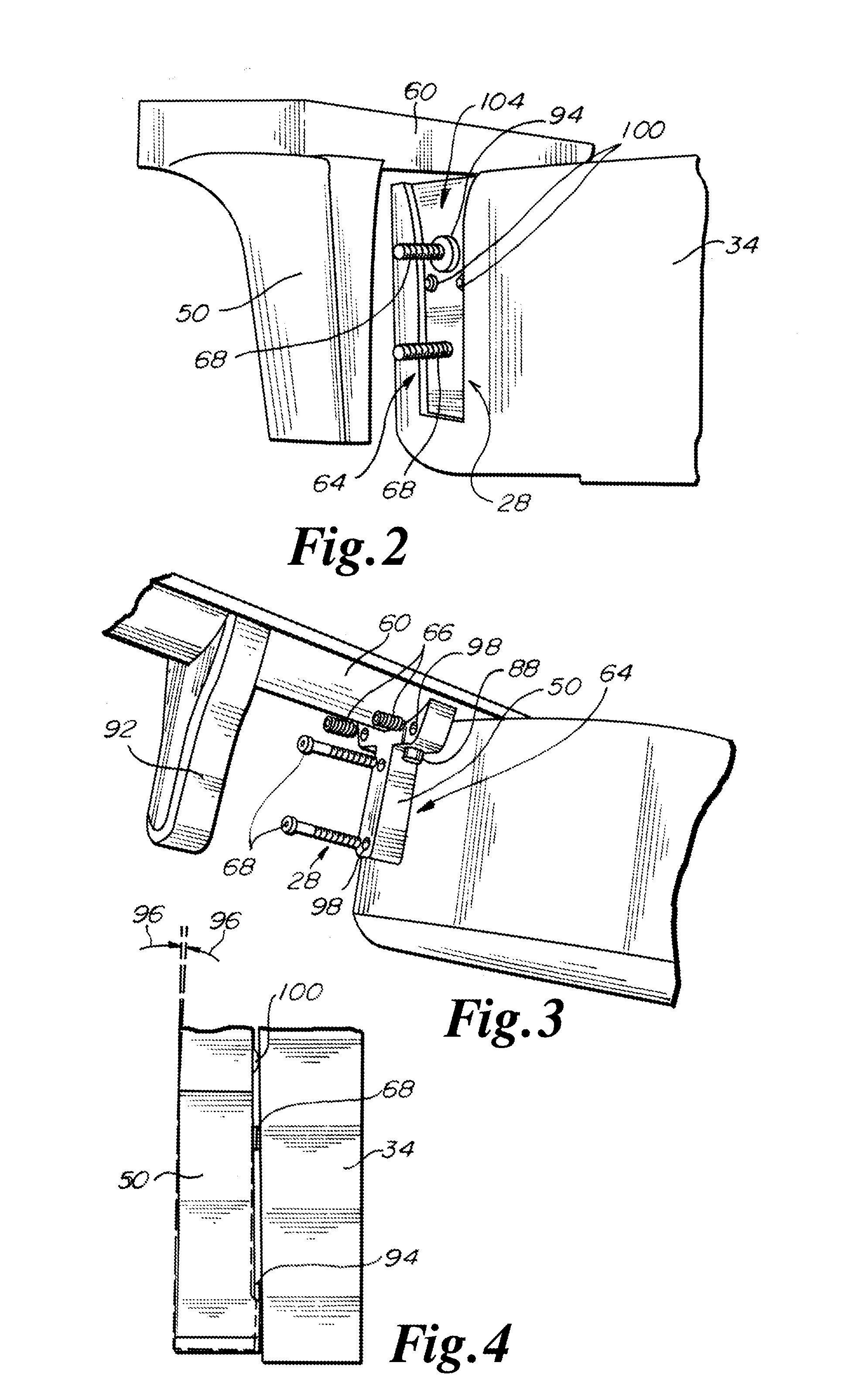

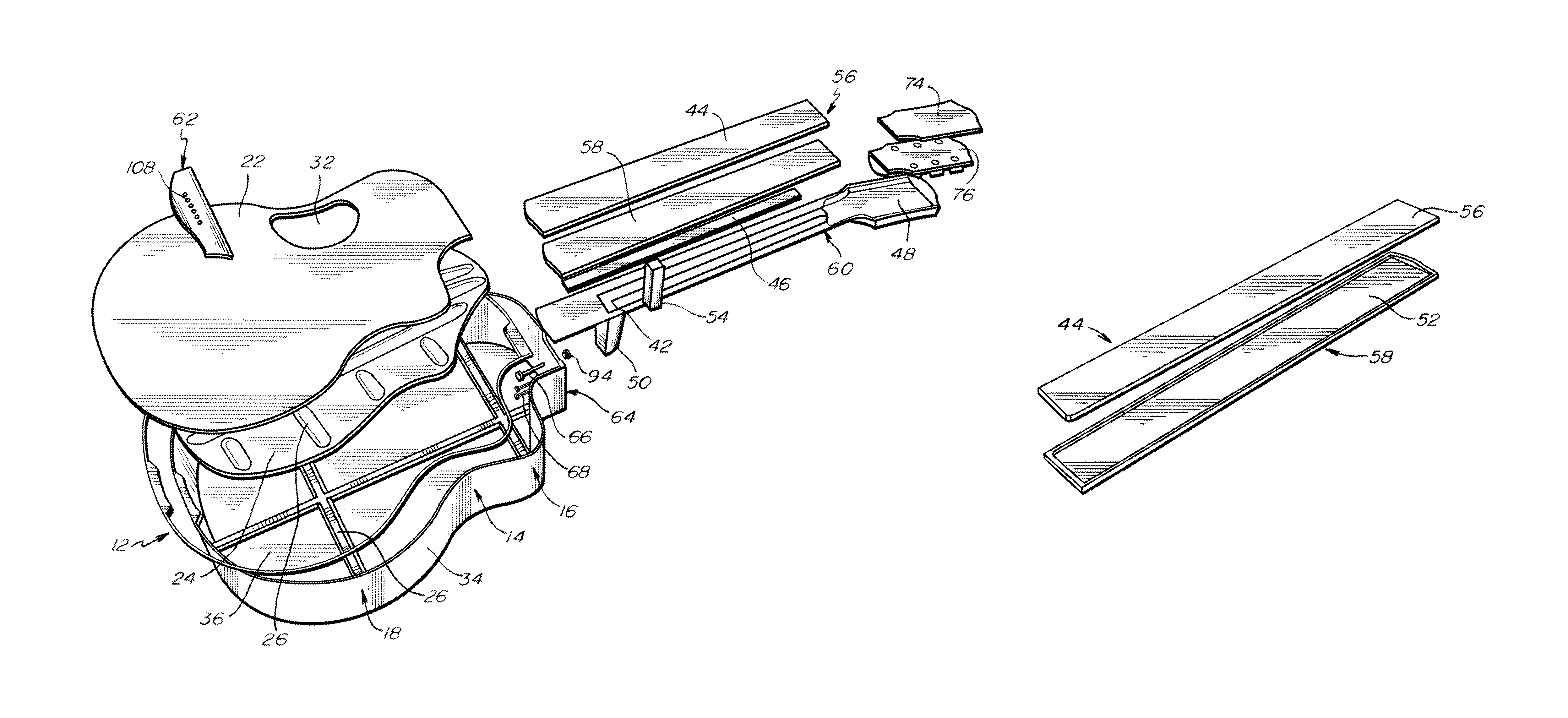

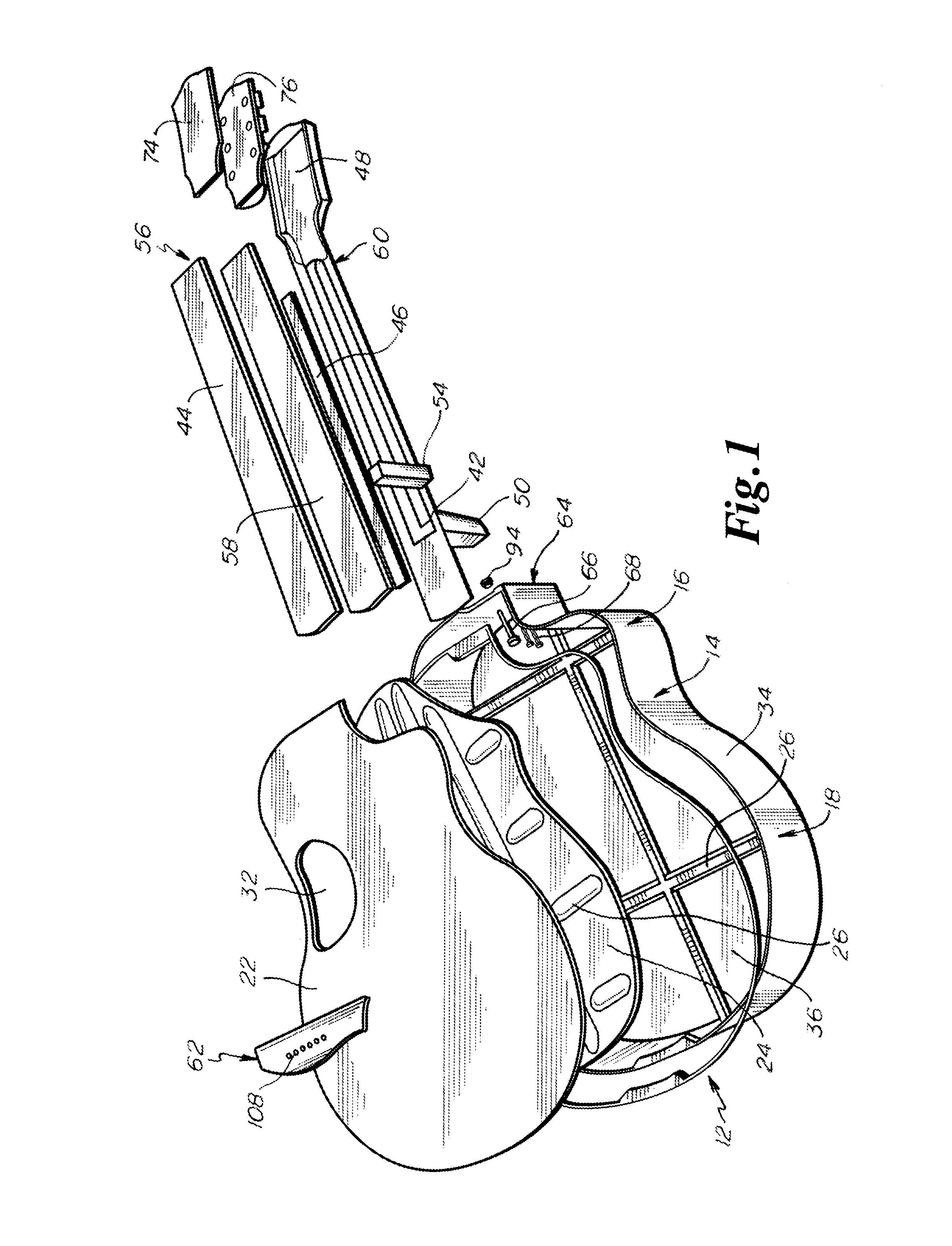

Carbon Fiber Guitar

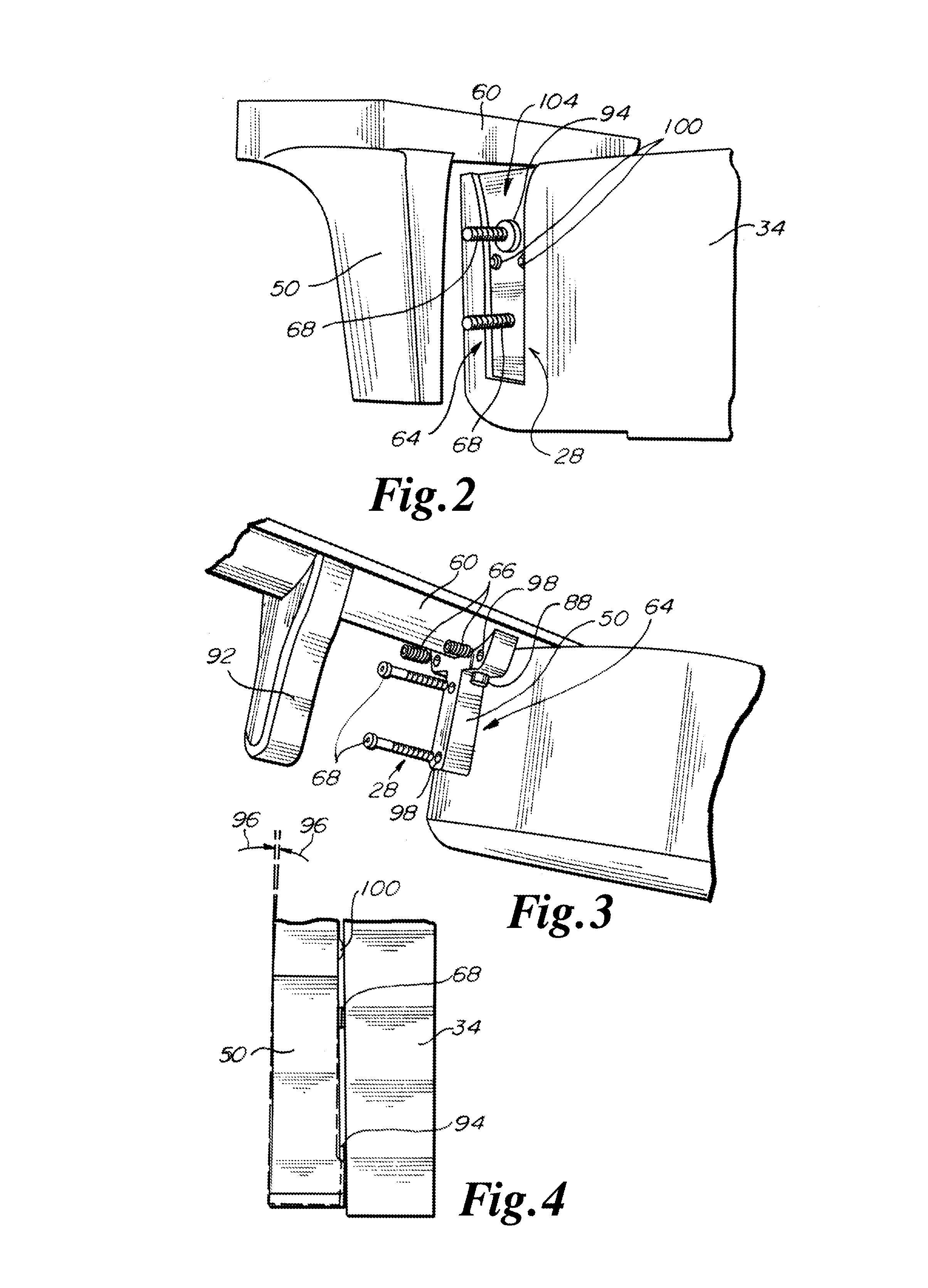

A stringed musical instrument has a molded sound box and neck where the sound box is formed of between 20% to 60% carbon fibers, or other suitable fibers, and a polymeric resin or binder. The composition of materials utilized in the sound box is selected to increase stiffness and to control the tone of the instrument. The sound box includes an adjustable attachment mechanism having a pivot which is used to secure the neck to the sound box. The sound box includes a molded bracing structure having a plurality of braces and a molded bridge having a plurality of pockets which are used to enhance the structure for the sound box and provide a desired tone quality for the stringed instrument. The neck may include a molded neck insert and a molded fingerboard which are used to enhance the stiffness and stability of the neck.

Owner:MCP IP

Method for preparing pulp by gramineous straw and use of obtained pulp

The invention discloses a method for preparing pulp by gramineous straw. The method sequentially comprises the following steps: (1) pre-treating the gramineous straw as a raw material; (2) physically pulping to obtain a straw fiber reinforced polymer (FRP); (3) adding water to the straw FRP obtained in step (2), thread-rolling and grinding until length of the straw FRP is 10-20mm to obtain fiber pulp; (4) decoloring or coloring the fiber pulp; and (5) mixing the fiber pulp treated in step (4) with the conventional chemical pulp or waste pulp based on the dry weight ratio of 1:0.1-10, then adding water for diluting the obtained mixed pulp, and finally obtaining the mixed pulp raw material. The invention further discloses use of the obtained pulp in preparation of the pulp molding product. The pulp obtained by the method takes the waste crop-the gramineous straw as the raw material and has the characteristics of low raw material cost, wide use, good industrial application prospect and the like.

Owner:NANJING BIOFUNCTION CO LTD

Method for producing corrugated paper and textile spool paper by manioc slag and wine stillage slag

InactiveCN101413225ASufficient raw materialsQuality improvementNon-fibrous pulp additionSecondary cellulose fibresSocial benefitsBobbin

The invention discloses a method for producing corrugated paper and bobbin paper by manioc waste and lees. The manioc waste and the lees are purified, ground, washed, and dehydrated respectively; impurities are removed; plant fiber is retained; the mixture of treated manioc waste and lees is mixed with waste paper stock according to the proportion of 1-7 to 3-9; and a paper-making additive is properly added to produce the corrugated paper and the bobbin paper. The method fully utilizes production wastes, namely the manioc waste and the lees to produce good and cheap corrugated paper and bobbin paper. The methd has the advantages of adequate production raw materials, low cost, simple and convenient operation, good product stability, large market potential, and high product profit, prolongs industrial chains of the manioc waste and the lees, solves the waste utilization problem of the prior manioc waste and lees, also reduces the environmental protection pressure of enterprises, improves the economical benefit of the enterprises, drives surrounding villages to be commonly prosperous, and has good social benefit and environmental protection benefit.

Owner:GUANGXI MINGYANG ENVIRONMENTAL PAPER PRODS

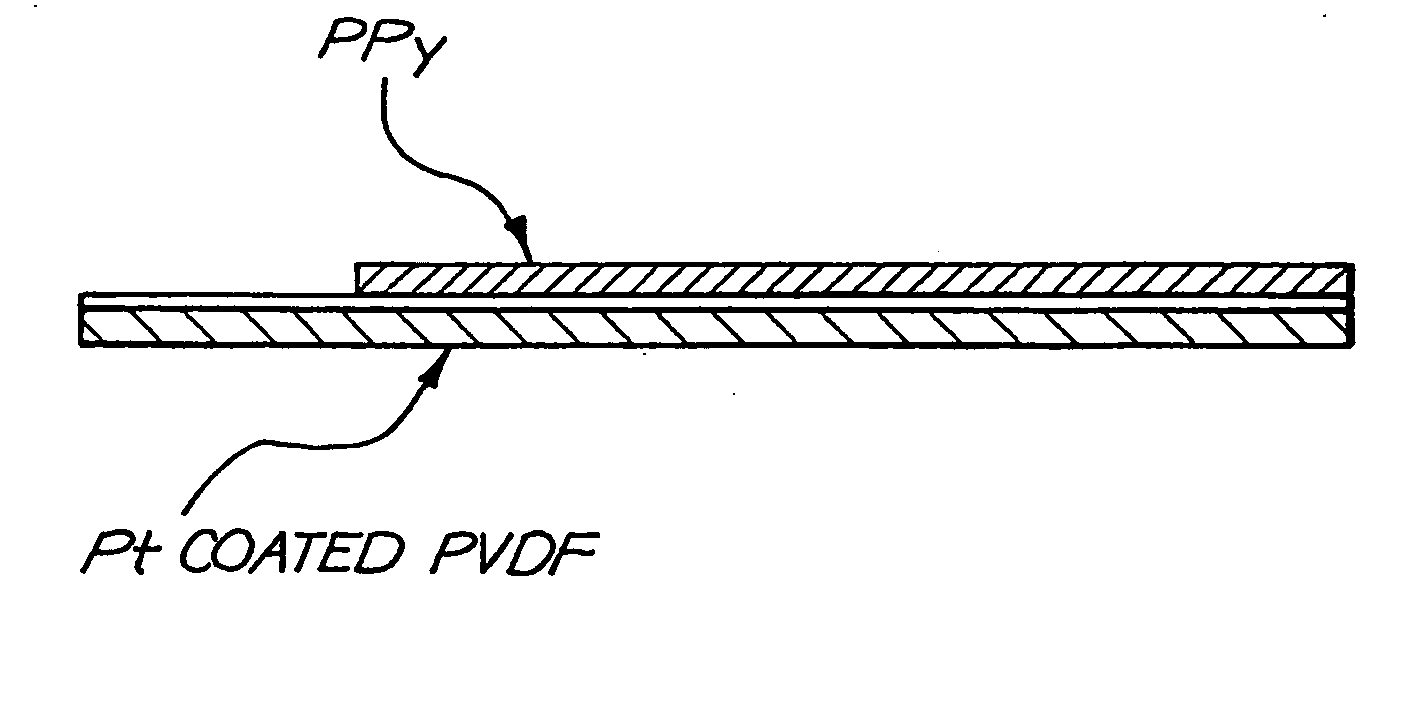

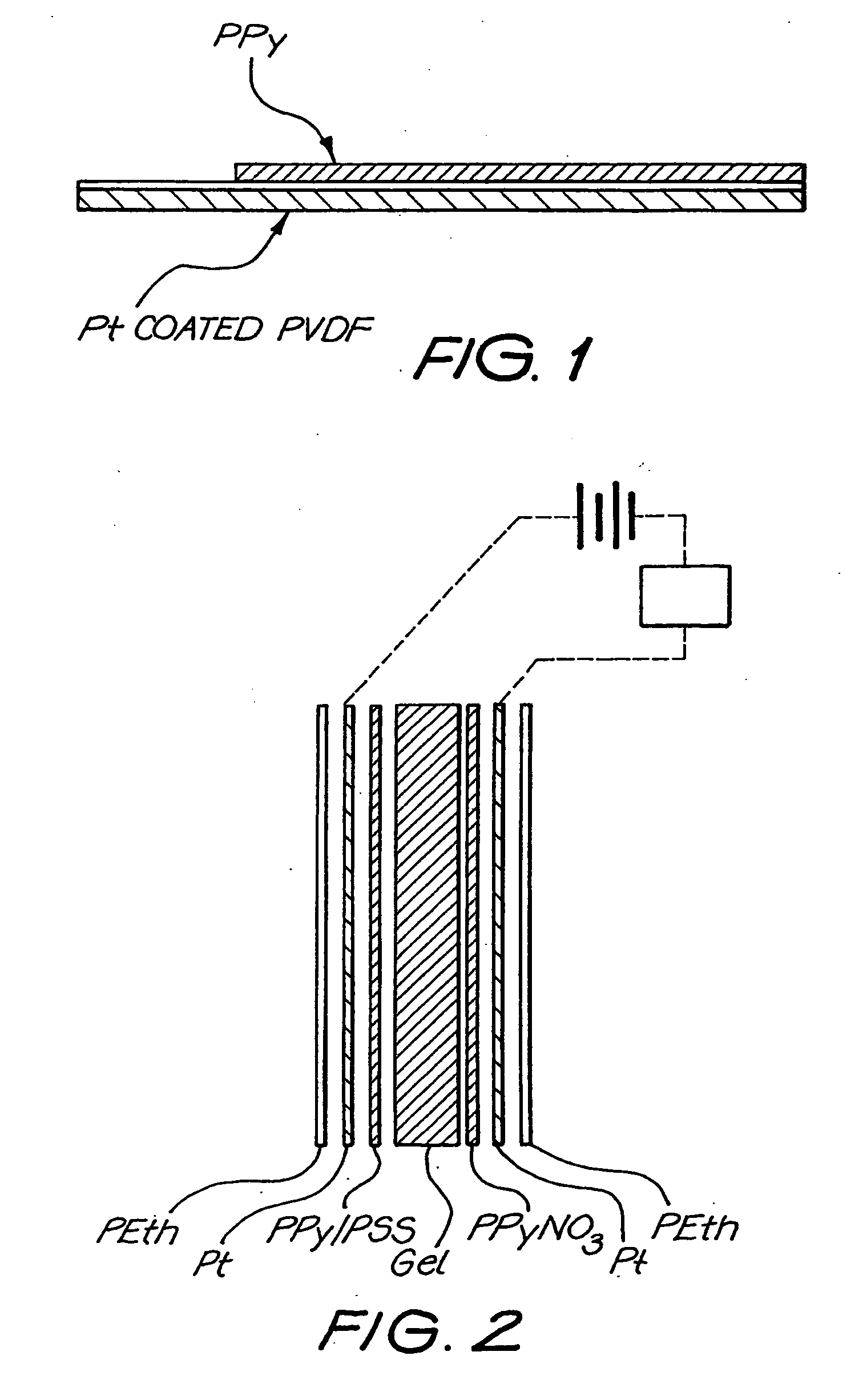

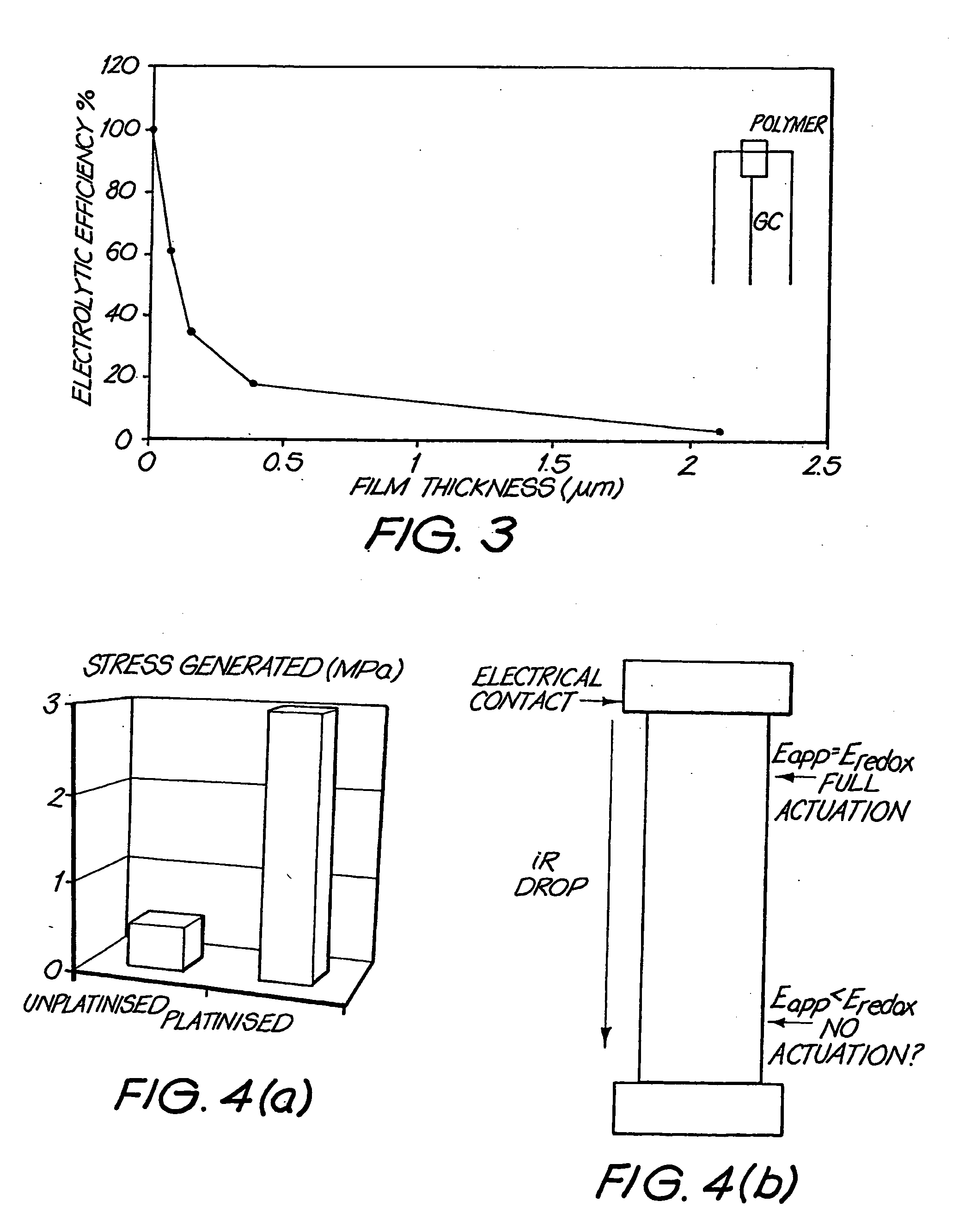

Electromechanical actuator and methods of providing same

InactiveUS20050006989A1Improve featuresGood electrochemical propertiesPiezoelectric/electrostriction/magnetostriction machinesLighting and heating apparatusElectrical conductorConductive polymer

An electromechanical actuator comprising an inherently conducting polymer and a conductor for conducing voltage along the polymer from a first end region thereof. The conductor is adapted for axially extending and contracting with axial expansion and contraction of the polymer. In one form, the conductor is in the form of a helix embedded in the polymer and extends along substantially the entire length of the polymer. Also disclosed is a method for manufacture of the electromechanical actuator.

Owner:UNIV OF WOLLONGONG

Sheet laminating preparation method for sisal fiber reinforced polypropylene composite material

The present invention adopts the sisal hemp fiber as fiber raw material, and uses the nonwoven fabric of thermoplastic resin PP, film, powder material and its fiber as resin base body, and adopts thefollowing steps: pretreating sisal hemp fiber and making it into fiber felt, hot-pressing and forming, selecting and using a certain number of fiber felts, delaminating and sand wiching pp nonwoven fabric or film, under the condition of a certain temp. and pressure hot-pressing and forming or mixing PP fiber (PP powder) directly with sisal hemp fibre, making them into fiber felt and then hot-pressing and forming so as to obtain the invented sisal hemp fiber reinforced polypropylene composite material.

Owner:SUN YAT SEN UNIV

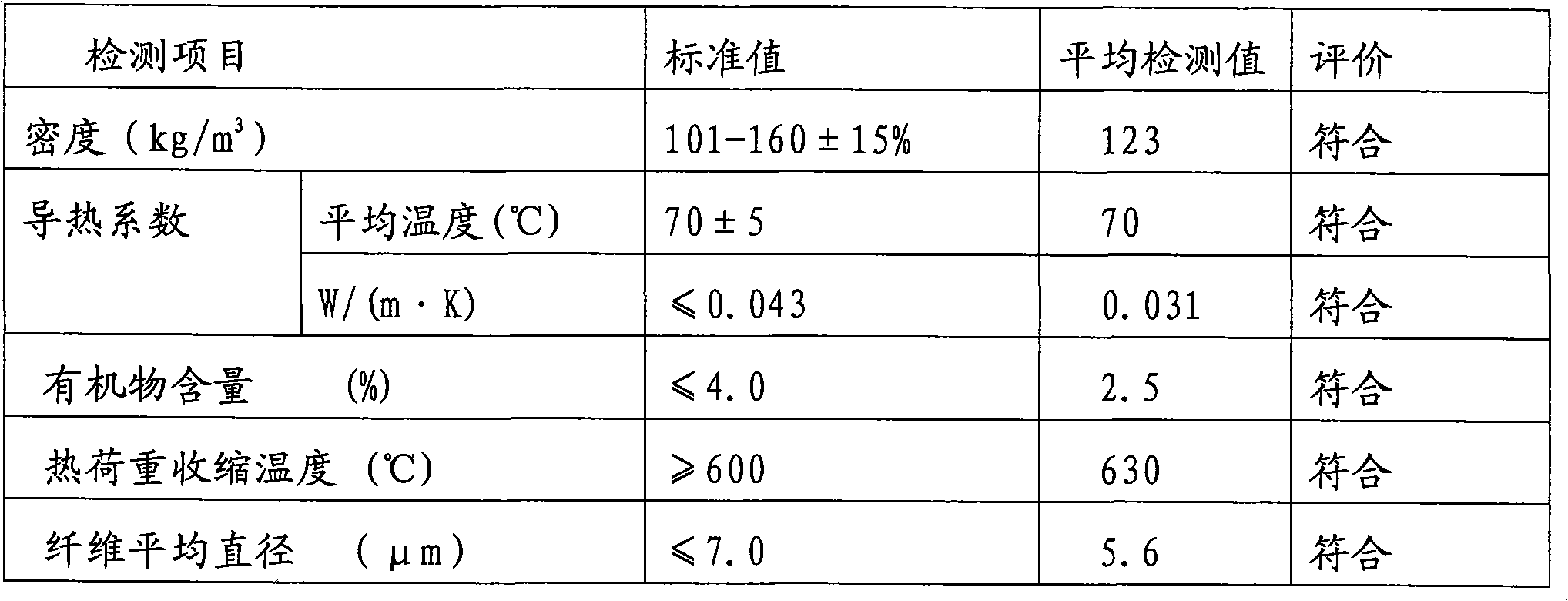

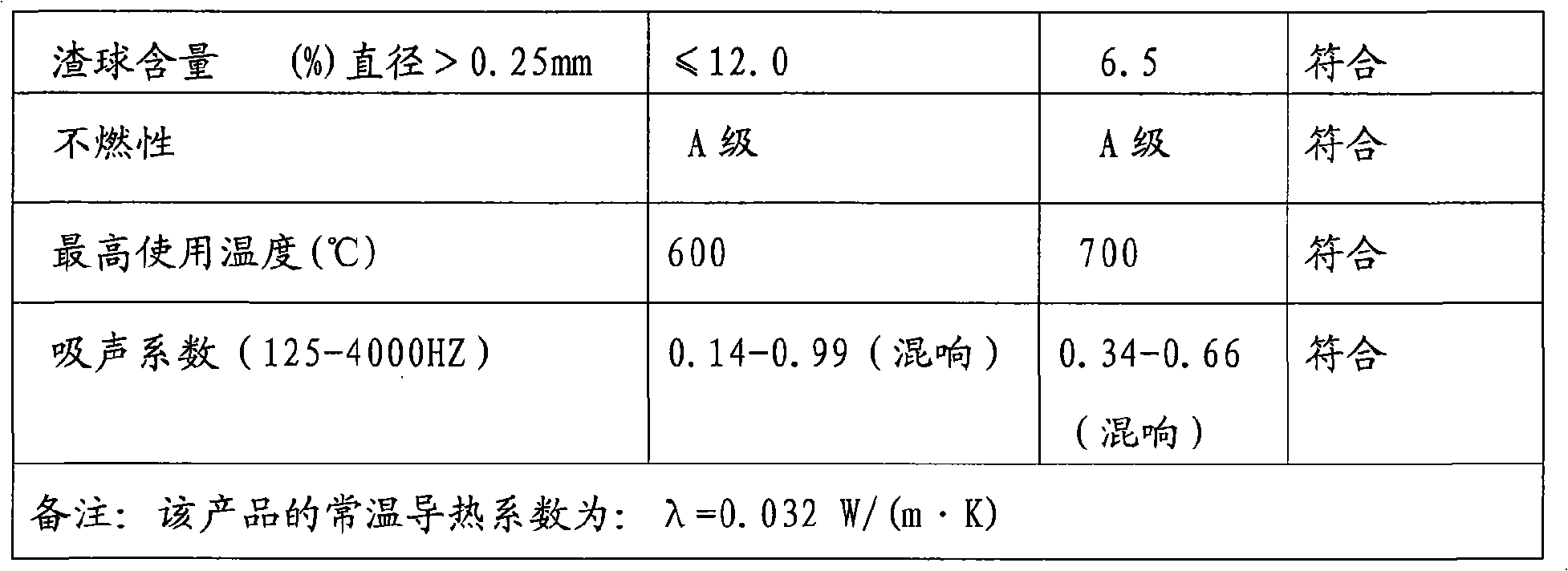

Hollow-core rock wool and preparation method and applications thereof

InactiveCN101538122AFiber lengthIncrease elasticityGlass making apparatusJet aeroplaneChemical industry

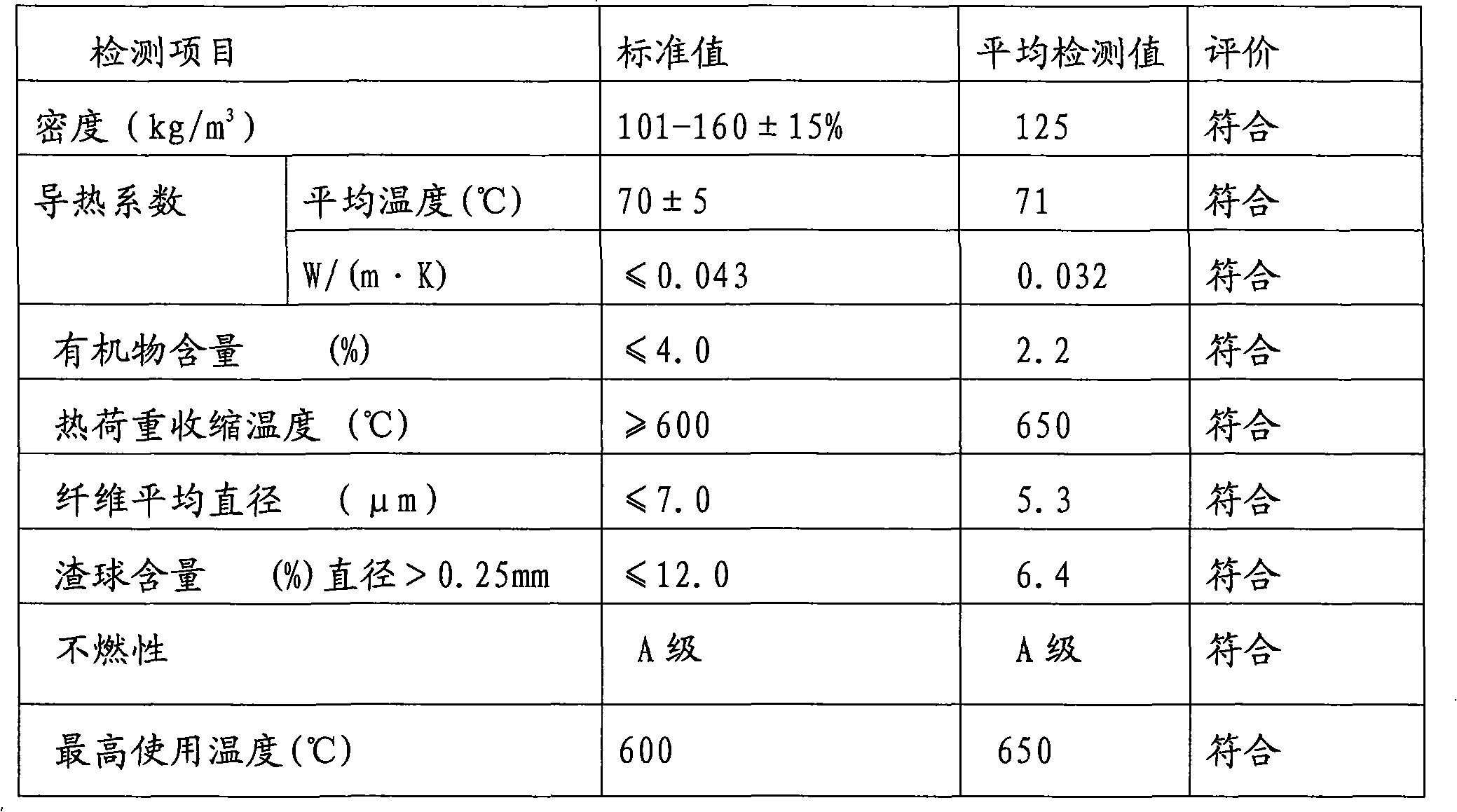

The invention discloses a hollow-core rock wool and a preparation method and applications thereof, belonging to the field of temperature-preservation and heat-insulation materials. The hollow-core rock wool consists of the following materials by weight percentage: 60-70% of basalt, 20-30% of dolomite, 2-6% of diabase, and 4-8% of fluorite. After being mixed evenly, the materials are put into a cupola and melted at high temperature of 900-1000 DEG C, and then the hollow-core rock wool is obtained. The rock wool has long fiber, good temperature-preservation and heat-insulation properties, fireproofing capability, good elasticity, strong tensile force and good hand-feel, thus being head and shoulders above the slag cotton. All properties are in full compliance with standards of nation, national defense, industry, aerospace, navigation, construction, petroleum, chemical industry, and agriculture. The hollow-core rock wool can be used for the industries such as electric power, chemical industry, petroleum, construction, metallurgy, textile, shipping, automobile, train, airplane, heating pipe and the like, and is the temperature-preservation and heat-insulation material of industrial equipment such as pipeline storage tanks, boiler flues, heat exchangers, large airports, gyms, large-scale cold storage and the like, and civil building engineering.

Owner:鞠加会

Lead-acid storage battery separator and preparation method thereof

InactiveCN104852002AReasonable structureTightly bondedFinal product manufactureCell component detailsGlass fiberPolyester

The invention discloses a lead-acid storage battery separator which comprises 85-95 percent by weight of superfine glass fibers, 4-10 percent by weight of polyester fibers and 1-5 percent of cellulose acetate fibers. A preparation method comprises the following steps: pulping the superfine glass fibers for 5-10min and then adding the polyester fibers and the cellulose acetate fibers, pulping for 8-12min, forming and beating to enter a drying system at a constant speed, drying at a temperature of 160-2500 DEG C, winding and cutting to obtain the lead-acid storage battery separator. The lead-acid storage battery separator prepared by adopting the preparation method is reasonable in structure; the polyester fibers and the cellulose acetate fibers are added, so that the advantages of insulation, isolation and storage of an acid liquor of an existing AGM separator can be kept, the relatively high mechanical strength, excellent puncture resistance and excellent compression rebound property are obtained, the performance of a storage battery is improved, the service life of the storage battery is prolonged, and the application is relatively wide.

Owner:QIDONG HENGRUI POWER SUPPLY TECH CO LTD

Carbon Fiber Guitar

A stringed musical instrument has a molded sound box and neck where the sound box is formed of between 20% to 60% carbon fibers, or other suitable fibers, and a polymeric resin or binder. The composition of materials utilized in the sound box is selected to increase stiffness and to control the tone of the instrument. The sound box includes an adjustable attachment mechanism having a pivot which is used to secure the neck to the sound box. The sound box includes a molded bracing structure having a plurality of braces and a molded bridge having a plurality of pockets which are used to enhance the structure for the sound box and provide a desired tone quality for the stringed instrument. The neck may include a molded neck insert and a molded fingerboard which are used to enhance the stiffness and stability of the neck.

Owner:MCP IP

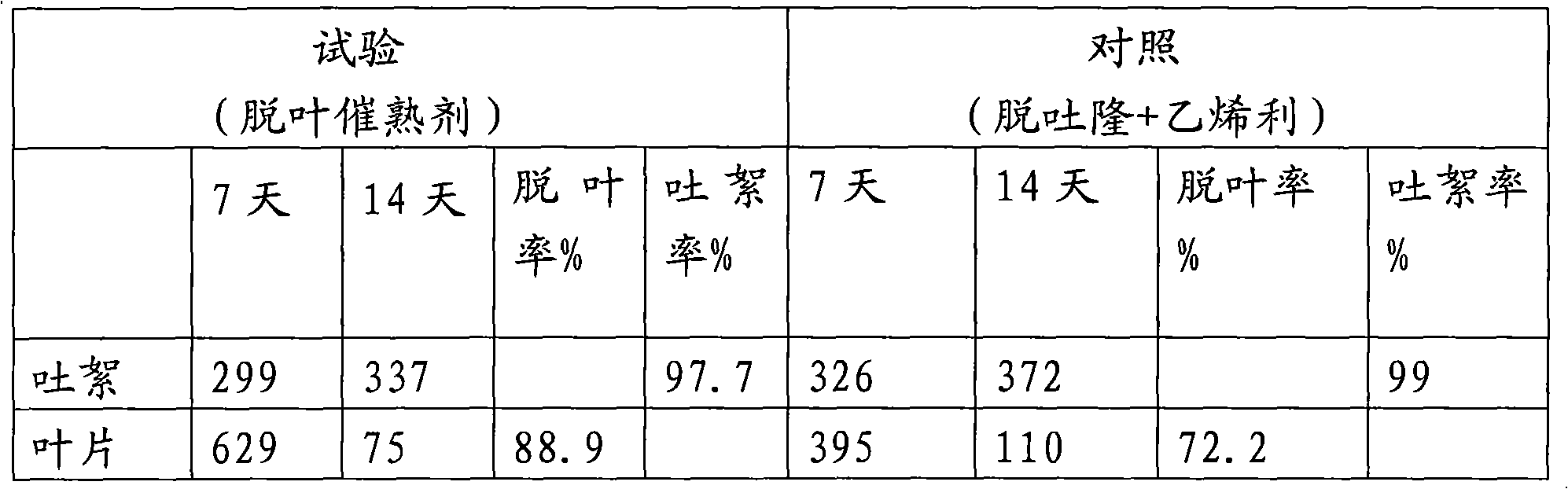

High-efficiency defoliating and ripening agent used before picking cotton

InactiveCN101971862AQuickly promote ripening and sheddingPromote ripening and sheddingBiocidePlant growth regulatorsFiberRipening

The invention provides a high-efficiency defoliating and ripening agent used before picking cotton. The high-efficiency defoliating and ripening agent is prepared by the following steps of: fully stirring 250 to 850 kilograms of ethrel, 55 to 200 kilograms of thidiazuron, 0.50 to 1.90 kilograms of DT34 auxiliary agent and 0.15 to 0.60 kilograms of DM12 auxiliary agent in a reaction kettle in turn; fully dissolving 15 to 53 kilograms of water and 0.18 to 0.22 kilograms of silicone antifoaming agent in advance to obtain solution; adding the solution; and stirring for 25 to 30 minutes at normal temperature and normal pressure to obtain a finished product. The defoliating and ripening agent is sprayed in an application dosage of 80 to 120ml / mu when the cotton fiber grow rate is over 60 to 70 percent before picking the cotton. The defoliating and ripening agent is sprayed at 6 to 8 pm in September to October of the maturation period of the cotton; rainy days are avoided; and the defoliating and ripening agent can be re-sprayed if the defoliating and ripening agent is caught in the rain. The product combines the efficiencies of ripening and defoliating, saves labor, time and effort, greatly improves labor production efficiency and cotton quality rate, and lays a solid foundation for manual fast harvest and mechanical one-time harvest. Compared with a conventional single product, the picking period is 15 to 20 days earlier and the average defoliation rate is over 90 percent.

Owner:袁永贵

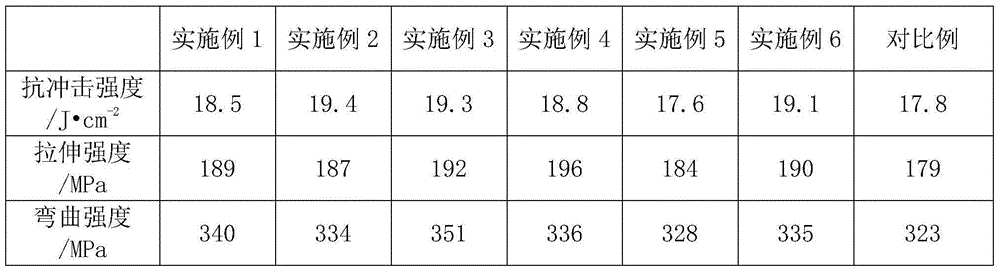

Preparation method for polyimide composite material for automobile

The invention provides a preparation method for a polyimide composite material for an automobile. The method comprises the following steps that 1, impurities in sisal fiber are removed, the sisal fiber is dried and added into a sodium hydroxide solution to be soaked, the sisal fiber is taken out to be washed to obtain alkalified sisal fiber, a silane coupling agent is dissolved into an acetic acid solution, the PH value is adjusted to be 7 through ammonium hydroxide, conditioning fluid is obtained after standing, and the alkalified sisal fiber is added into the conditioning fluid for ultrasonic dispersion and taken out for drying, taking, dispersion and smashing to obtain modified sisal fiber; 2, talcum powder is added into a mixing machine to be stirred, then a titanate coupling agent is added, and modified talcum powder is obtained after taking out and drying are performed; 3, polyimide, the modified sisal fiber and the modified talcum powder are added into a stirring machine for stirring and mixing and then taken out to be put into a mold for compression molding forming, and mold stripping is performed to obtain the polyimide composite material for the automobile. According to the preparation method, raw materials are cheap and easy to obtain, the production cost is saved, and the obtained composite material has the good mechanical performance, has the certain degradability and is environmentally friendly.

Owner:SUZHOU ZHENZHAN TECHCAL MATERIAL CO LTD

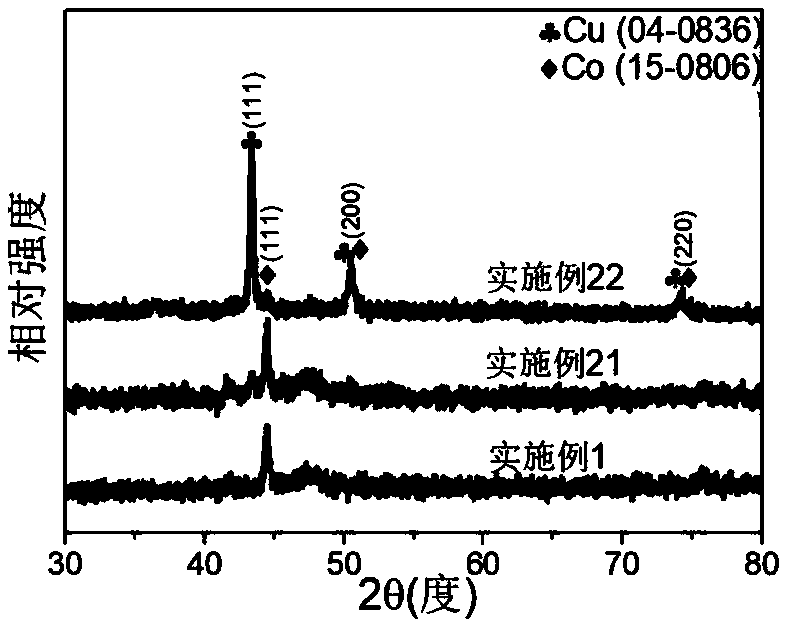

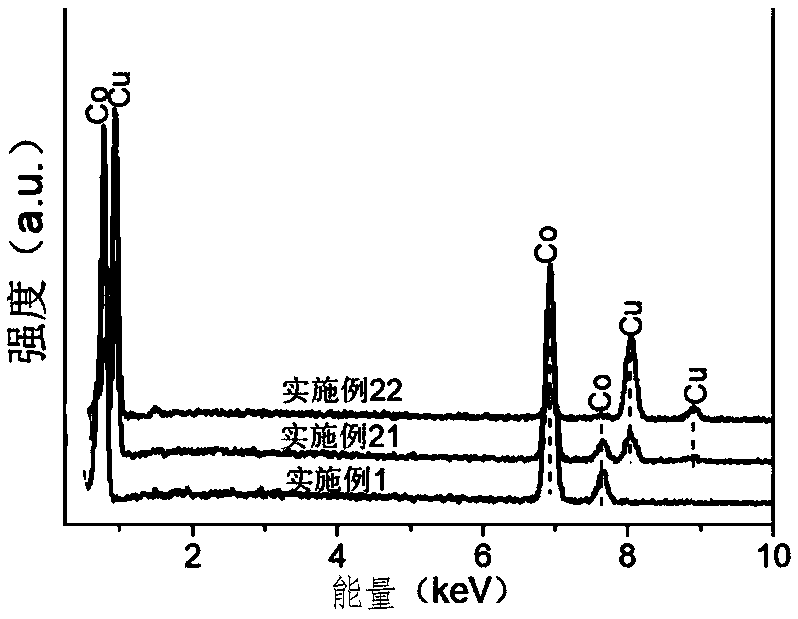

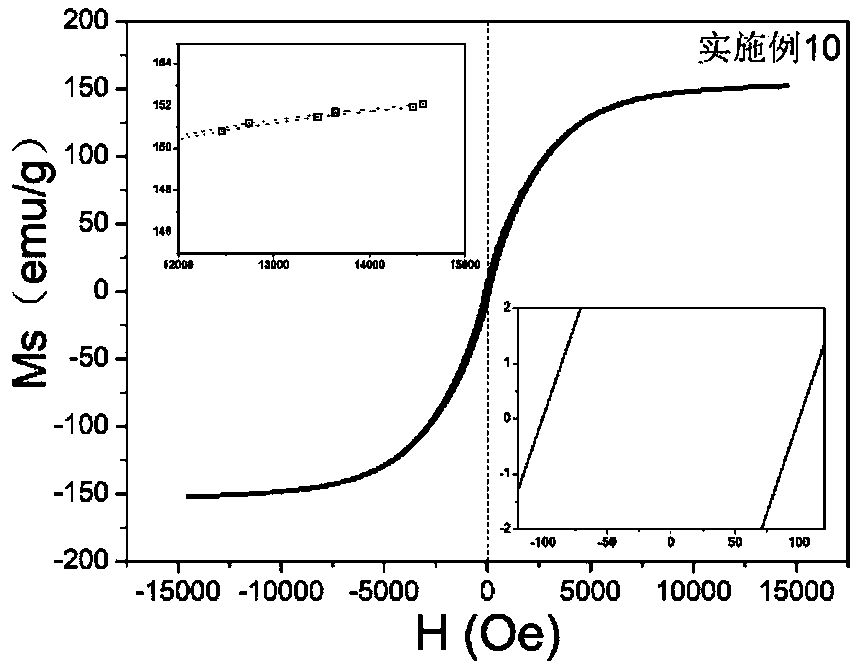

Bimetallic cobalt-based core-shell material as well as preparation method and application thereof

ActiveCN109261981AAdjustable sizeComposition adjustableTransportation and packagingMetal-working apparatusFiberHigh absorption

The invention relates to a bimetallic cobalt-based core-shell material and a preparation method and application thereof. A core of the bimetallic cobalt-based core-shell material is a magnetic metal Co, and a shell of the bimetallic cobalt-based core-shell material is a non-magnetic metal Ag or Cu; a shape of the bimetallic cobalt-based core-shell material is fibrous or spherical, a fiber diameteris 1.3 to 36 micrometer, and a spherical diameter is 1 to 7.3 micrometer; an atomic ratio of Co to Cu is 0.25 to 21.6, and the atomic ratio of Co to Ag is 59.8 to 74.8; a saturation magnetization strength ranges from 62.2 to 159.9 emu / g<-1>. The bimetallic cobalt-based core-shell material adopts an in-situ metal replacement method and has a microwave absorption characteristic of broadband and high absorption, wherein an effective frequency band width of which the reflectivity is less than or equal to -10dB is 5.1-7.76GHz; a bandwidth less than or equal to -20dB is 2.32-16.0GHz; a maximum reflection loss ranges from -52.5 dB to -19.7 dB. The bimetallic cobalt-based core-shell material has the advantages of simple process, easy industrial popularization, excellent material performance and good application prospect in the fields of catalysis, electrode materials, microwave absorption, high-density magnetic recording materials, sensors and the like.

Owner:ZHEJIANG NORMAL UNIVERSITY

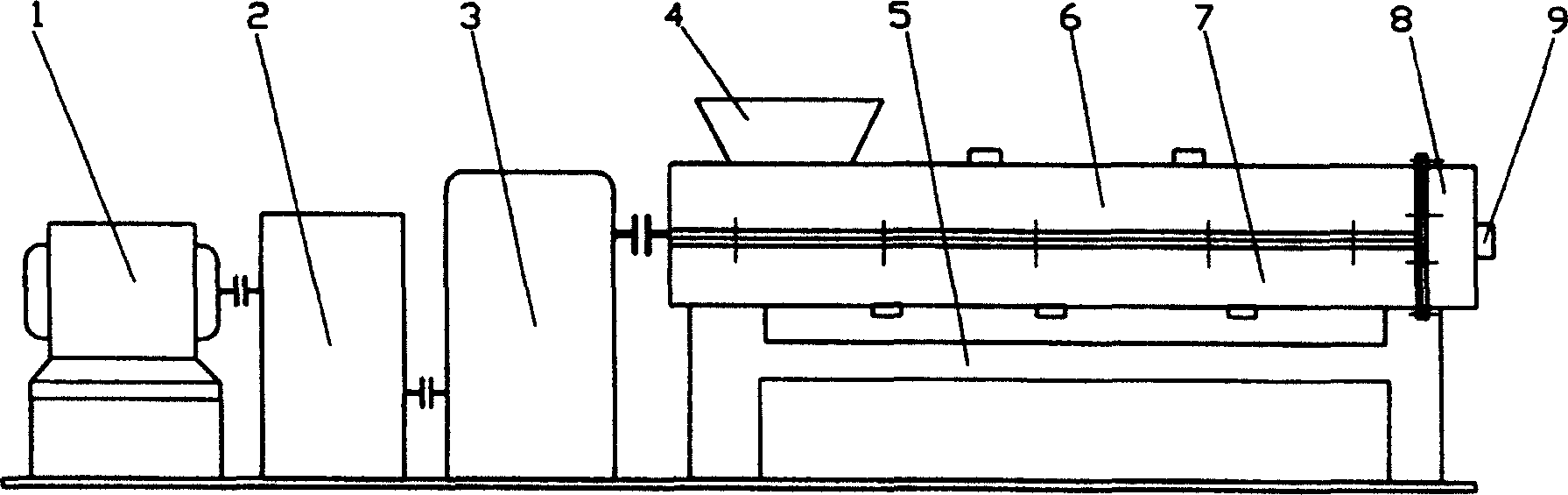

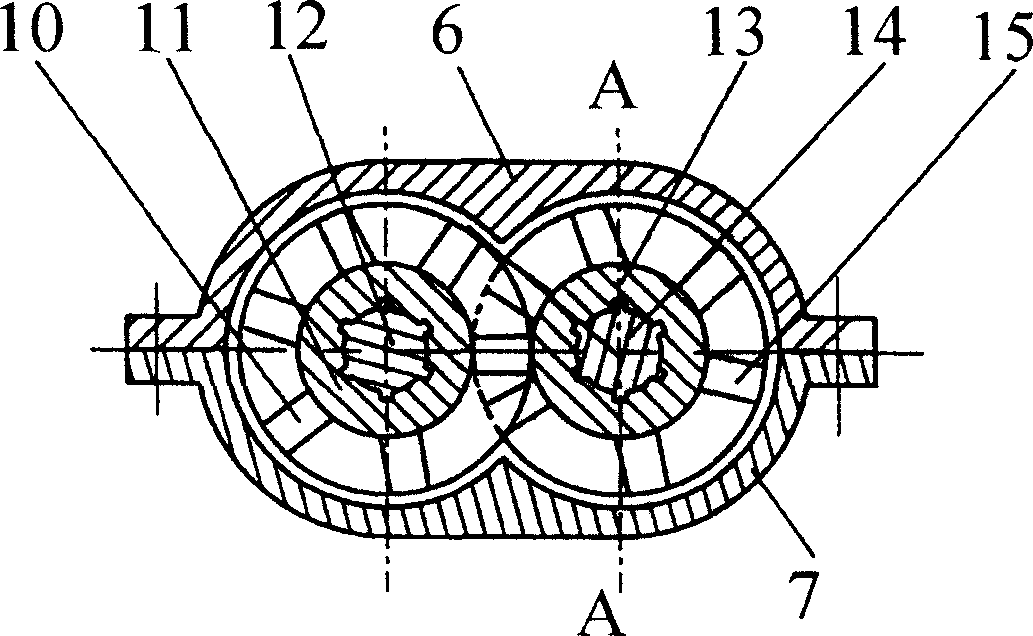

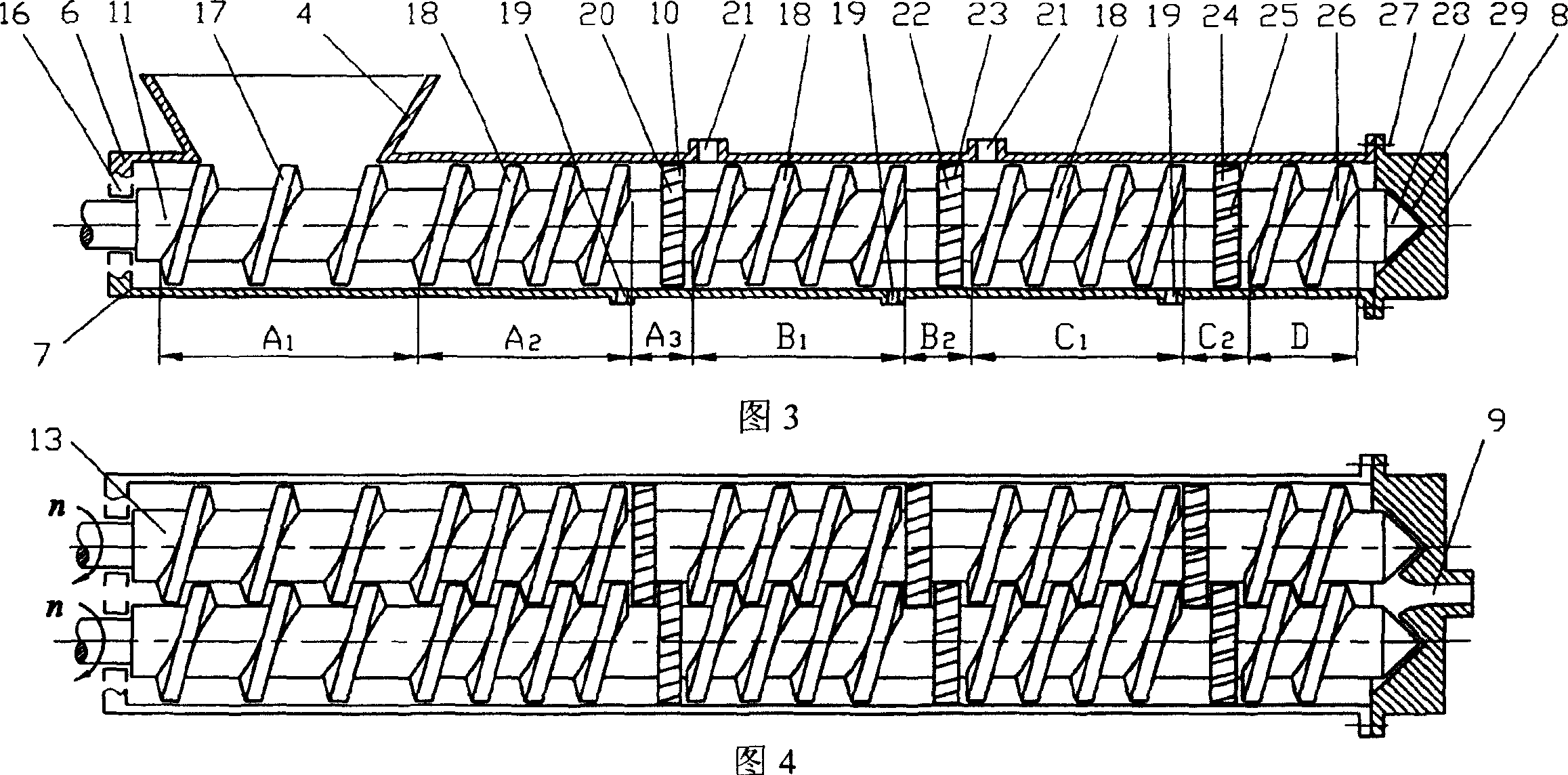

Double-screw fiberizer with tooth-shape disc

The present invention relates to one kind of double screw pulp grinder with toothed disc. The double screw pulp grinder features that inside the mutually buckled upper casing and lower casing, two parallel meshed screws with equal thread inner and outer diameter are mounted and made to rotate in the same direction and constitute one combined structure together with the toothed disc. The width of the inclined slot of the toothed disc is reduced gradually from the material inlet to the outlet, and the screws and the toothed disc are assembled onto the spline shaft with the splines. The present invention is used in producing paper pulp through extruding and shearing plant fiber between two rotating screws and has the features of great fiber length and high brooming effect of paper pulp, low power consumption, low water consumption and less exhaust.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Preparation method of immobilized lipase with purified cotton towel as carrier

InactiveCN102206622AHas electrostatic attractionImmobilization process is simpleOn/in organic carrierCross-linkFiber

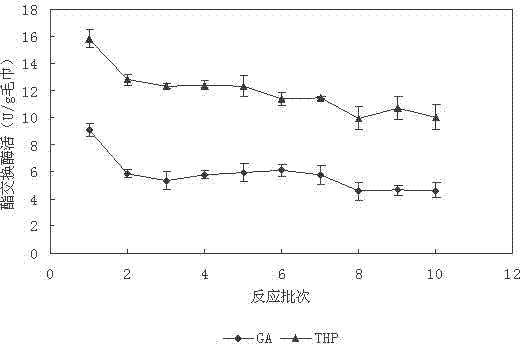

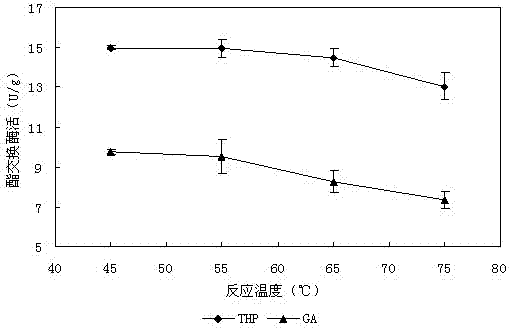

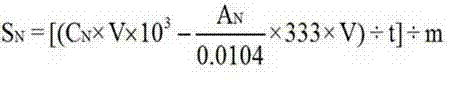

The invention provides a preparation method of an immobilized lipase with a purified cotton towel as a carrier. The method is an immobilization technique comprising the following steps of: adsorbing a polyethyleneimine aqueous solution with the purified cotton towel, adding a lipase solution after adsorption, vibrating with a constant-temperature shaking table, thus attaching the lipase to the purified cotton towel containing polyethyleneimine, removing the supernatant, and then cross-linking the purified cotton towel with the lipase and polyethyleneimine adsorbed by using a cross-linking agent. According to the invention, the towel carrier used by the preparation method has multiple gaps and long towel fibers, thus having a larger surface area, favoring the performing of immobilized-enzyme-catalyzed reaction, having very good mechanical strength, and the method can more easily separate the enzyme from the reaction system, compared with the granular carrier; the used cross-linking agent is tris(hydroxymethyl)phosphine which has a better cross-linking effect than glutaraldehyde; the used immobilization method has the advantages of mild conditions and multi-layer immobilization; and the obtained immobilized lipase has good temperature stability and high reaction activity, can shorten the reaction time and can be repeatedly used.

Owner:SOUTH CHINA UNIV OF TECH

Aldehyde-free face decorating all-bamboo or bamboo-wood composite oriented strand board and manufacturing method thereof

InactiveCN109623980AHigh static bending strengthHigh elastic modulusCane mechanical workingFlat articlesWood shavingsSurface layer

The invention discloses an aldehyde-free face decorating all-bamboo or bamboo-wood composite oriented strand board and a manufacturing method thereof. In the method, all-bamboo or bamboo-wood composite large sheets and wood shavings are adopted as a core layer, oversized materials and fine materials serve as a surface layer, multi-layer all-bamboo or bamboo-wood composite large sheets are overlapped, the surface is smooth after hot pressing, the face decorating condition is completely achieved, and the problem that an ordinary oriented strand board is rough in surface, and face decorating cannot be achieved is solved. Compared with an all-wood oriented strand board, the performance is more excellent. Bamboo and wood materials are selected as raw materials, the problem that existing strandboard wood raw materials are in shortage is solved, and the production cost is reduced; a large number of bamboo large sheets are used in the production technology, a biomass adhesion agent is used onthe surface layer, and the environment protection concept is sufficiently embodied; and the surface layer is the biomass adhesion agent, the core layer is isocyanate, formaldehyde emission is zero, and harm caused by board formaldehyde emission at present is avoided.

Owner:NANNING KETIAN SHUIXING TECH LTD CO

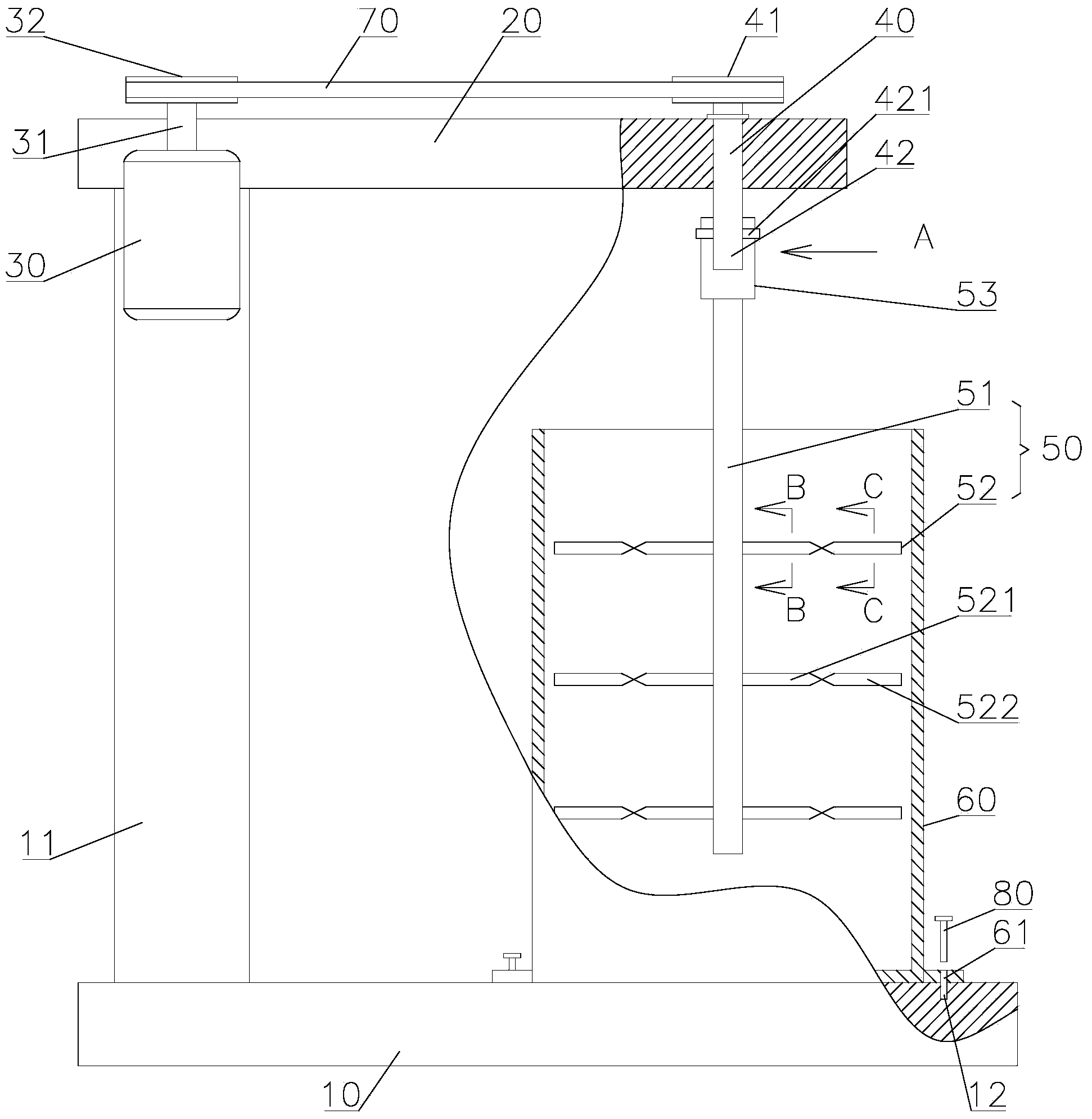

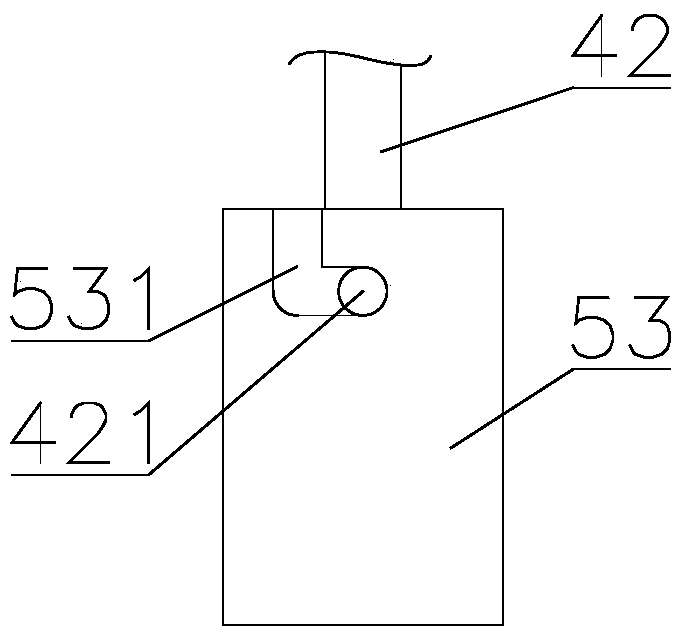

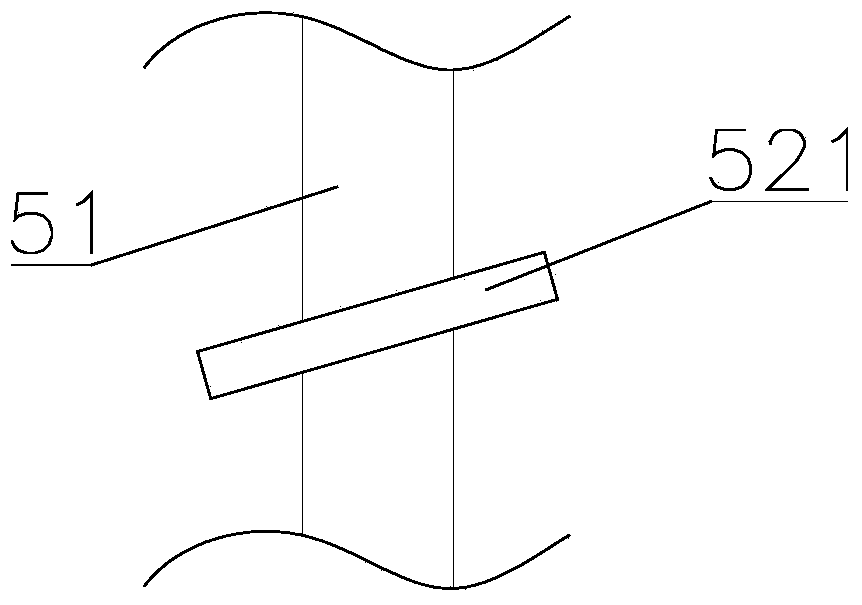

Carbon fiber guitar

A stringed musical instrument has a molded sound box and neck where the sound box is formed of between 20% to 60% carbon fibers, or other suitable fibers, and a polymeric resin or binder. The composition of materials utilized in the sound box is selected to increase stiffness and to control the tone of the instrument. The sound box includes an adjustable attachment mechanism having a pivot which is used to secure the neck to the sound box. The sound box includes a molded bracing structure having a plurality of braces and a molded bridge having a plurality of pockets which are used to enhance the structure for the sound box and provide a desired tone quality for the stringed instrument. The neck may include a molded neck insert and a molded fingerboard which are used to enhance the stiffness and stability of the neck.

Owner:MCP IP

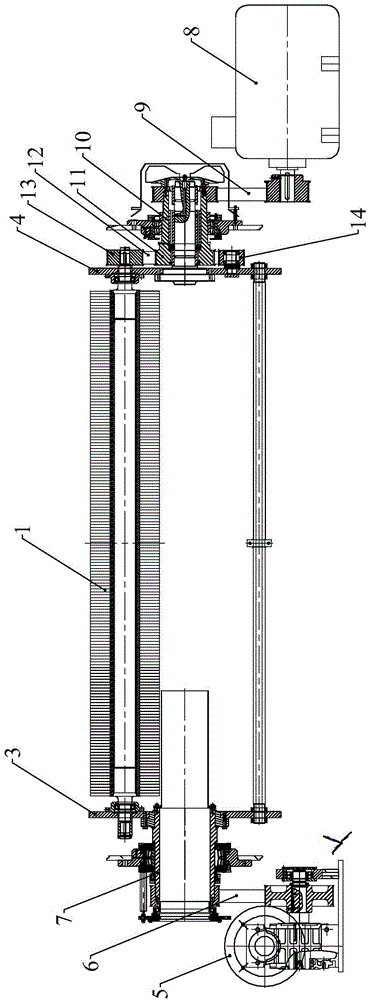

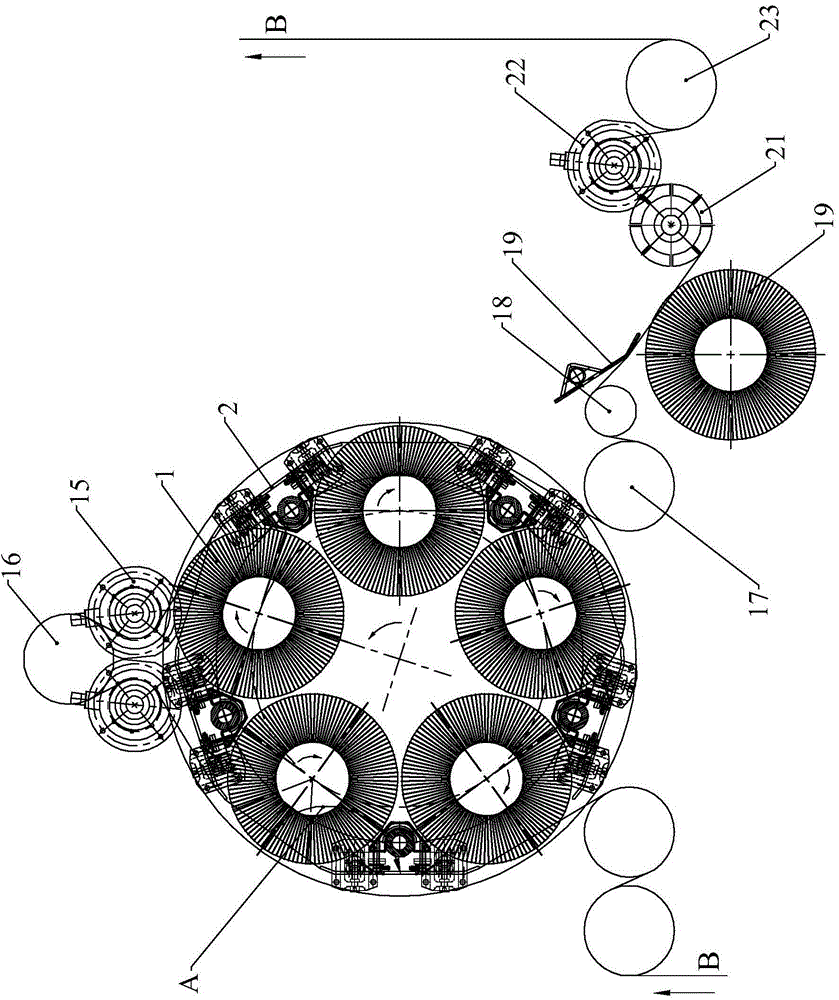

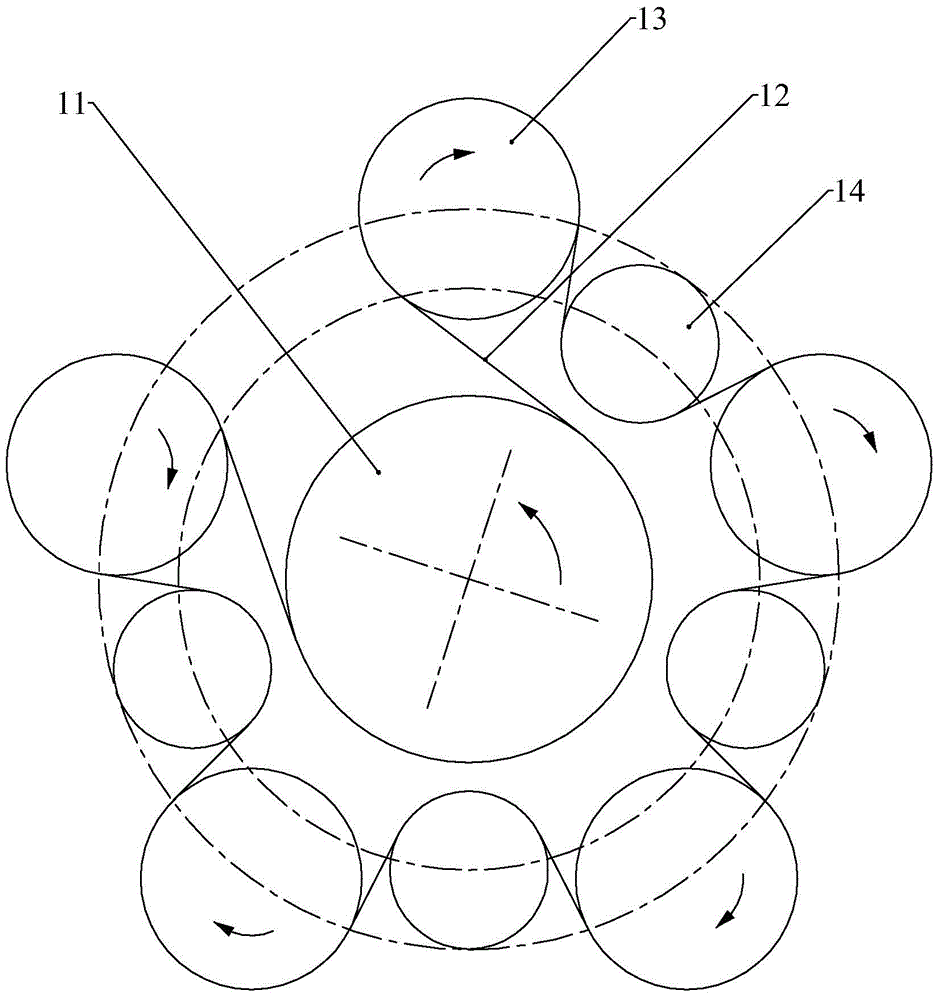

Sanding system of sanding machine

The invention relates to a sanding system of a sanding machine. The sanding system comprises a brush drum, a brush drum drive device, a brush roller drive device, a brush roller synchronous rotation device and a sanding arrangement device. The brush drum comprises five brush rollers and five adjustment plate devices. The five brush rollers are arranged on a left supporting plate and a right supporting plate through even distribution and arrangement frames of planet structures. The adjustment plate devices are arranged between the adjacent brush rollers. A brush drum motor drives a brush drum transmission device to form the brush drum drive device through a brush drum synchronous belt. The brush roller motor drives a brush roller transmission device through a synchronous belt. A main transmission belt wheel of the brush roller synchronous rotation device is driven by the brush roller transmission device. A brush roller double-sided synchronous belt changes the direction through tensioning belt wheels and drives five brush roller transmission belt wheels to synchronously rotate. An outlet drive roller of the sanding arrangement device drives sanding cloth to be subjected to sanding arrangement through the outlet brush roller by means of a cloth guide roller and an adjustment pressing plate. The sanding system has the advantages of being capable of saving energy, convenient to install and detach and good in sanding effect.

Owner:GUANGDONG RUITUO ENVIRONMENTAL PROTECTION MACHINERY

Vegetarian meat floss, preparation method of vegetarian meat floss, and two fiber fluffing machines used in method

ActiveCN104041812ASensory fibers are slenderTaste meaty and fibrousFood ingredientsFood shapingFiberSesamum

The invention discloses vegetarian meat floss. The vegetarian meat floss comprises the following ingredients in parts by weight: 30 to 45 parts of textured soybean protein, 20 to 30 parts of soybean flour, 10 to 20 parts of corn starch, 15 to 25 parts of soybean vegetable oil, 10 to 15 parts of white granulated sugar, 2 to 5 parts of sesames, 2 to 5 parts of nori and 5 to 10 parts of seasonings. The vegetarian meat floss has the advantages that fibers are slender, the taste is strong in meat fiber, the floss does not taste like powder and is not sticky and greasy, and the floss is crisp, chewable and capable of being stored at normal temperature. The invention also discloses a preparation method of the vegetarian meat floss and two fiber fluffing machines used in the method.

Owner:宁波市素莲食品有限公司

Method for producing corrugated paper and bobbin paper from cassava dregs and distiller's dregs

InactiveCN101413225BSufficient raw materialsQuality improvementNon-fibrous pulp additionSecondary cellulose fibresFiberCardboard

The invention discloses a cassava dregs distiller's dregs and a method for producing corrugated paper and bobbin paper. The cassava dregs and distiller's dregs are respectively purified, ground, cleaned, dehydrated, impurities are removed, and plant fibers are retained. 7:3-9 ratio mixing, appropriate amount of paper-making additives are added to produce corrugated paper and bobbin paper. The present invention makes full use of production wastes—cassava dregs and vinasse dregs to produce high-quality and cheap corrugated paper and bobbin paper. The production raw materials are sufficient, the cost is low, the operation is simple, the product is stable, the market potential is large, and the product profit is high. It extends the industrial chain of cassava dregs and distiller's grains, solves the current utilization problems of cassava dregs and distiller's grains, reduces the environmental protection pressure of enterprises, improves the economic benefits of enterprises, drives the common prosperity of surrounding rural areas, and has good social and environmental benefits.

Owner:GUANGXI MINGYANG ENVIRONMENTAL PAPER PRODS

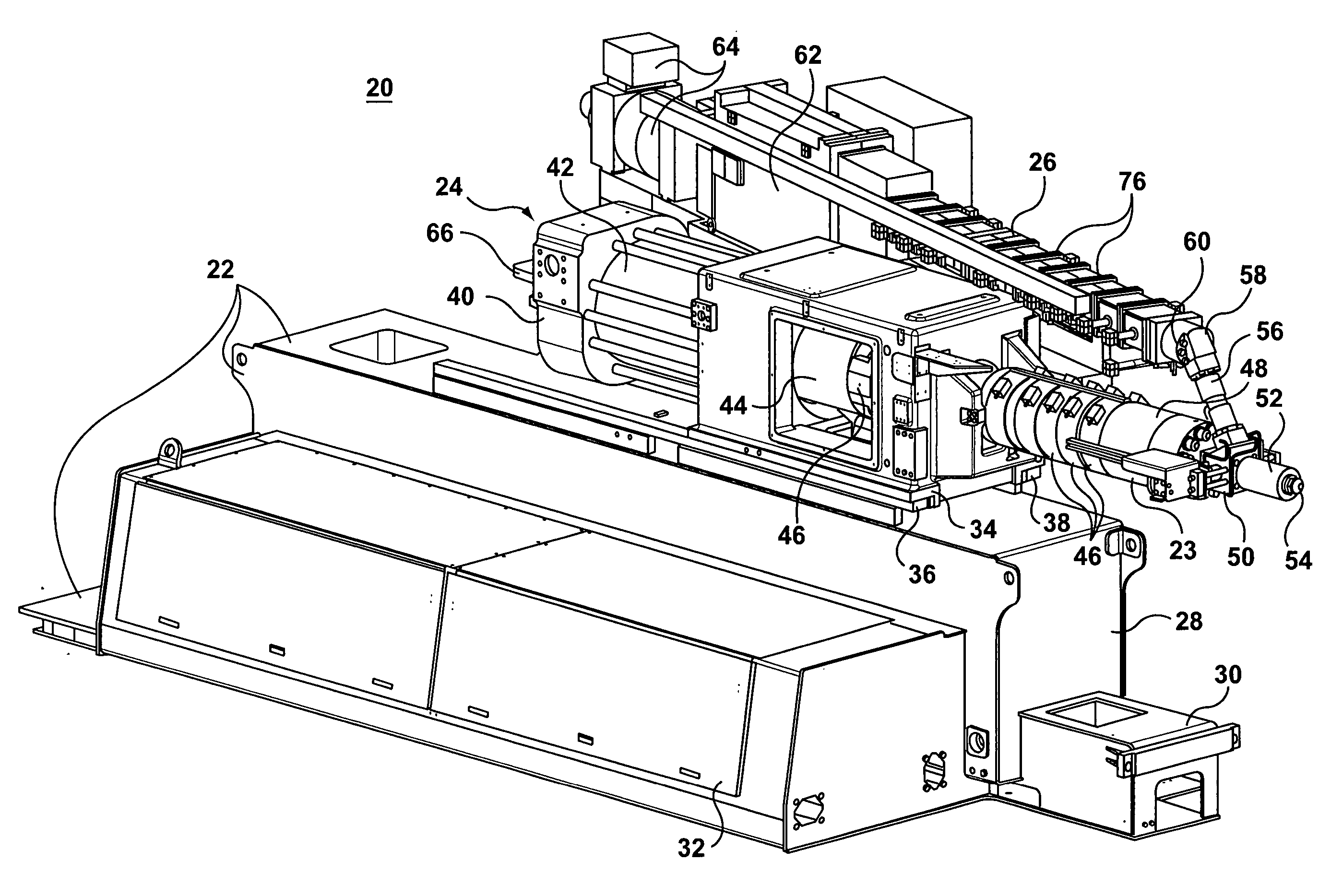

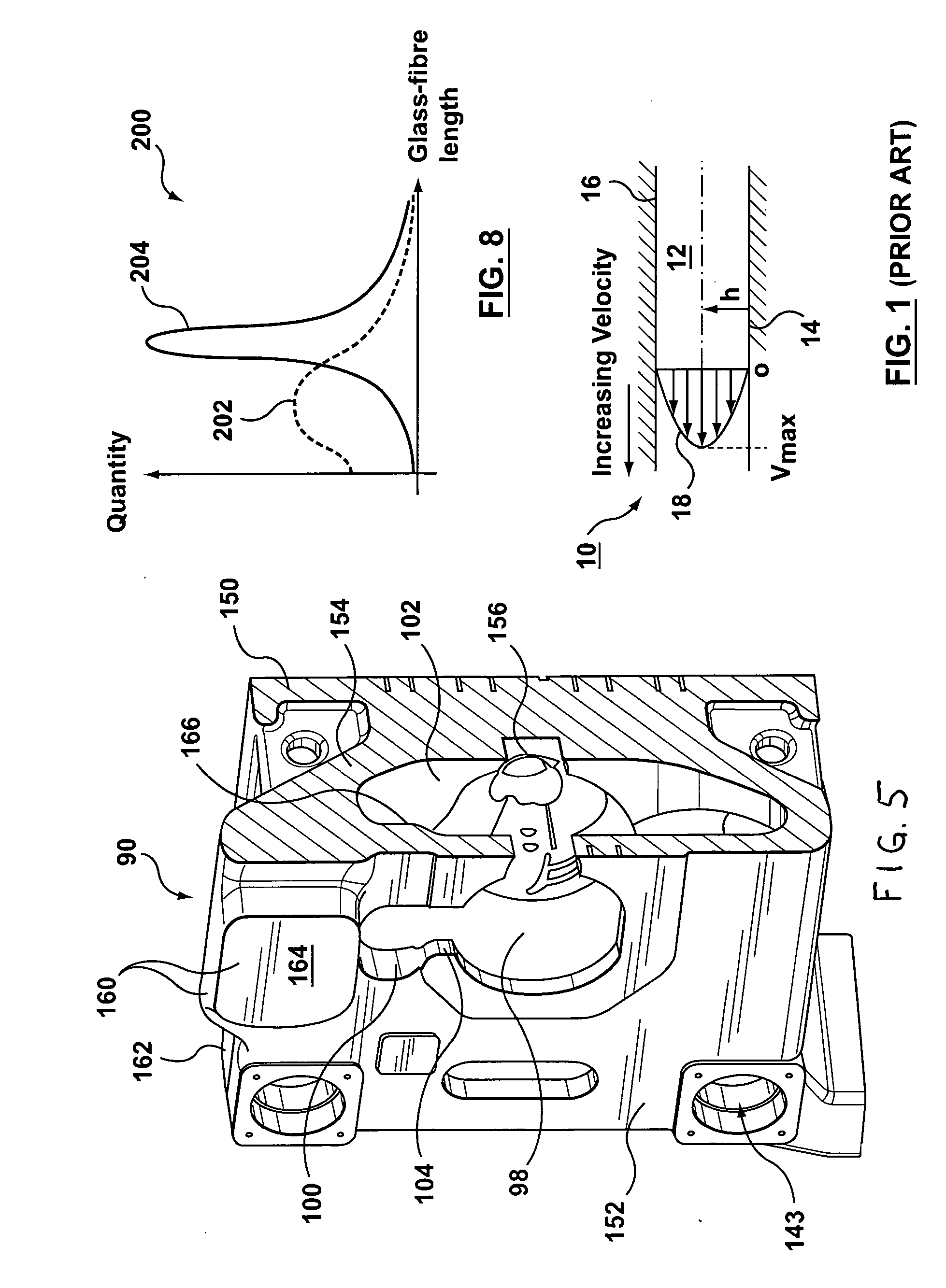

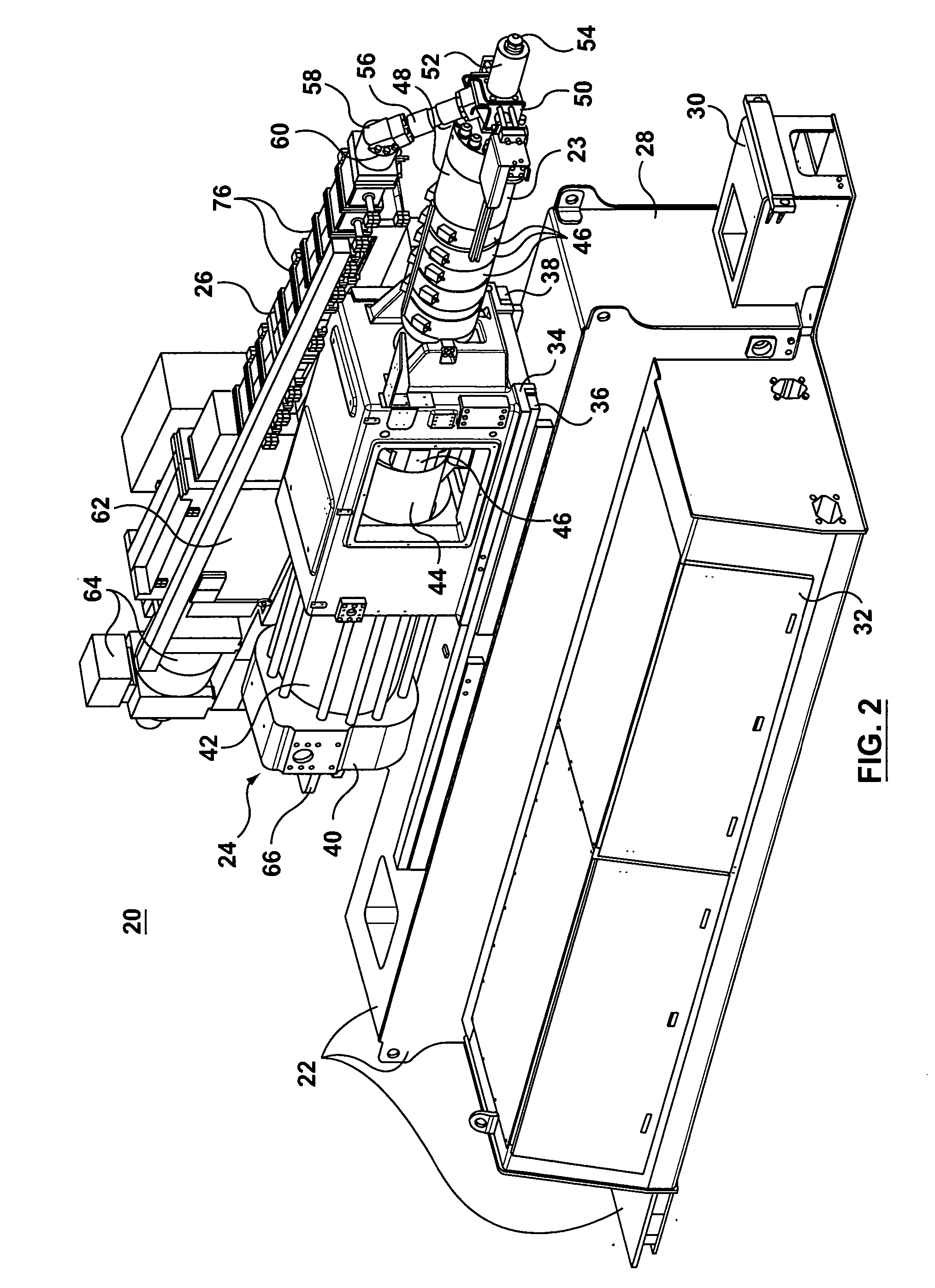

Molding machine plasticizing unit sub-assembly and a method of reducing shearing effects in the manufacture of plastic parts

In a molding machine (130), exemplified in FIG. 4, lateral and angled offsetting of a twin screw extruder (26) from a shooting pot assembly (24) permits shortening of a transfer channel (56). To additionally reduce shear effects arising from melt residence time a nozzle adaptor (52), the transfer channel (56) is located within a hollow cone (102) of a platen (90), the hollow cone (102) typically formed by an arch-shaped intermediate support structure (154) coupling together front (150) and rear (152) walls of the platen (90). To address bulk material removal brought about by the introduction of a barrel head, transfer channel (56) and extruder barrel tip within the hollow cone (102), reinforcement of an upper region of the rear wall (152) of the platen (90) is accomplished using a cross-member (160, 164). In an in-line compounding application, decreased lengths for the transfer channel (56) and nozzle adaptor (52) both reduce shear effects on the melt (by decreasing melt residence time) and thus an increased average fibre length in a molded part is achieved.

Owner:HUSKY INJECTION MOLDING SYST LTD

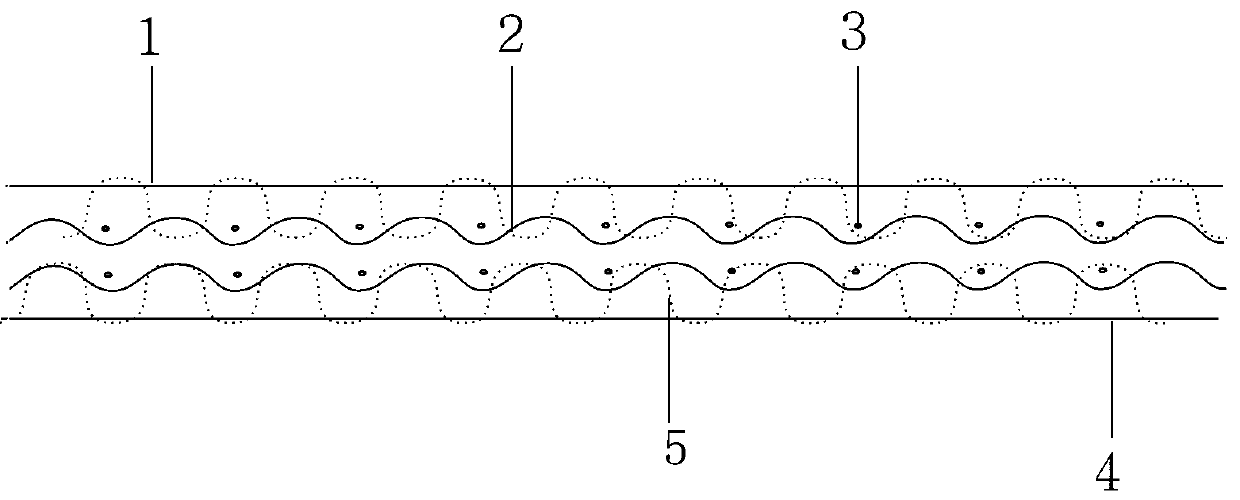

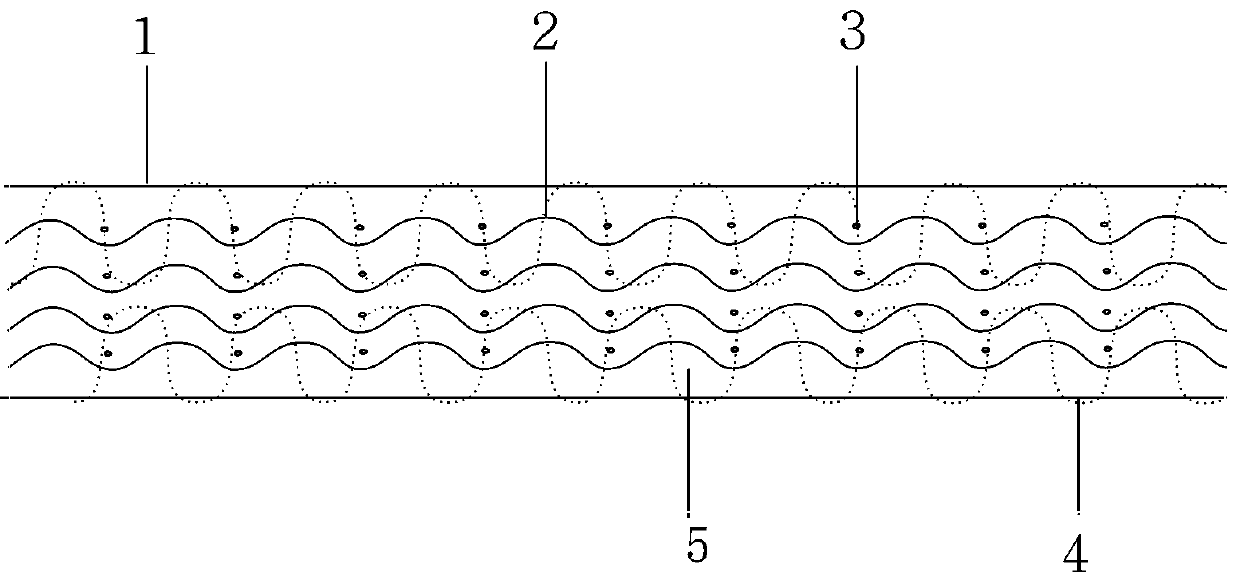

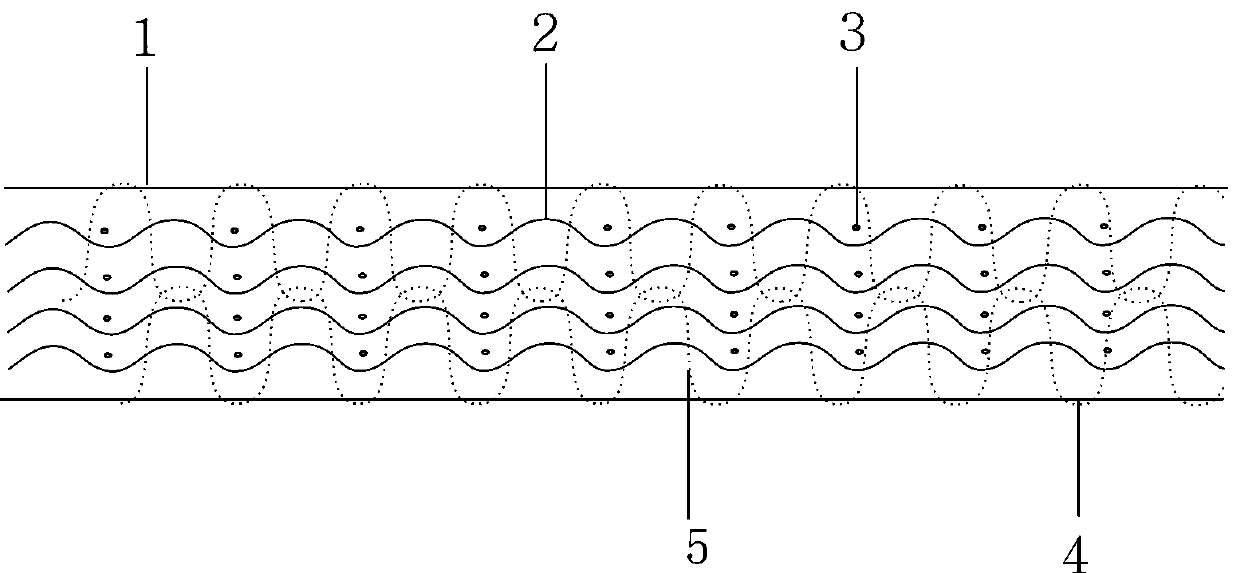

3-mode blended fibers in an engineered cementitious composite

ActiveUS20140191436A1Improve mechanical propertiesLarge specific surface areaSolid waste managementClimate change adaptationCement compositesCellulose fiber

Disclosed herein are fiber reinforced cement composite materials incorporating a 3-mode fiber blend that includes cellulose pulp and synthetic fibers in a ratio selected to provide the composite material with improved water absorption characteristics and the same or improved mechanical properties as compared to equivalent composite materials reinforced with predominantly or all cellulose fibers. Also disclosed herein are fiber blends comprised of a combination of cellulose fibers and polypropylene fibers adapted to reinforce cementitious composite articles manufactured by the Hatschek process and autoclave cured.

Owner:JAMES HARDIE TECH LTD

Skin-touch intramuscular effective patch and preparation method thereof

InactiveCN105797194AFiber lengthImprove compatibilityAbsorbent padsWoven fabricsBandageBiomedical engineering

The invention discloses a skin-touch intramuscular effective patch and a preparation method thereof.The skin-touch intramuscular effective patch comprises a fabric and a glue layer covering the fabric; the fabric is formed by weaving warp yarn and weft yarn; the weft yarn is all-cotton yarn; the warp yarn is spandex filaments with cores wrapped by combed cotton.Due to the fact that the combed cotton is adopted in the skin-touch intramuscular effective patch and proper elastic force is achieved in the warp direction, when the patch is attached to the human body, the shape of a bandage can be changed according to the shape of surface skin of the human body, and extremely high comfort is achieved.

Owner:CHANGZHOU DL MEDICAL & HEALTH EQUIP

Gel-free needle punching absorption core and sanitary accessories containing core

PendingCN110731863AImprove water absorptionReduce usage ratioAbsorbent padsBaby linensPolymer scienceCotton fibre

The invention relates to a gel-free needle punching absorption core. The core comprises a surface layer nonwoven layer, an intermediate layer and a bottom layer nonwoven layer, wherein the intermediate layer comprises one or more cotton fiber layers, and one or more high-water-absorption resin granule layers; and the core is formed through one or more needle punching working procedures. Through aneedle punching technology, bottom layer nonwovens and cotton gridding cloth are interwoven and combined, and a conventional composite core gelatinizing technology is not used, so that existence of chemical substances in products is reduced again, and the core does not contain a melt adhesive, and is environmental-friendly.

Owner:刘瑛

Processing method for nanometer bio-organic fertilizer

The invention discloses a processing method for a nanometer bio-organic fertilizer. According to the processing method, fungi residues are mixed with a nanometer material containing nitrogen, phosphorand potassium, so as to acquire the nanometer bio-organic fertilizer. The prepared nanometer bio-organic fertilizer utilizes the small-size benefit of the nanometer material to endow fertilizer ionswith magnetic effect, so that the fertilizer nutrient can be more easily absorbed by the plant and the growth of the plant can be effectively stimulated; the nanometer bio-organic fertilizer only needs to be applied for one time before sowing and cultivating, the fertilizer nutrient is capable of slowly releasing in soil and the fertilizer effect is capable of lasting for months; the yield of paddy, wheat, vegetables, fruits, and the like, can be increased by 5-8%, nitrate in crops can be reduced by about 80%, use rate of nitrogen fertilizer can be increased by 15-18% and the crops can mature7-10 days in advance.

Owner:四川大丰收农业科技有限公司

Dispersible non-woven fabric and method for producing the same

ActiveUS20170233912A1Promote decompositionAvoid environmental impactPaper/cardboardTissue/absorbent paperCellulose fiberNonwoven fabric

The present invention relates to a dispersible non-woven fabric, a method for producing a dispersible non-woven fabric and a wipe or tissue. The dispersible non-woven fabric comprises natural pulp fibers in an amount of from 70 to 90 wt.-% based on the total weight of the non-woven fabric and cellulosic fibers in an amount of from 10 to 30 wt.-% based on the total weight of the non-woven fabric. At least a part of the pulp fibers and of the cellulosic fibers are entangled with each other. At least 20% of the natural pulp fibers have a fiber coarseness of from 1.0 to 2.0 dtex.

Owner:GLATFELTER GERNSBACH GMBH & CO KG

Superfine glass wool and manufacturing method thereof

InactiveCN102010133AReduce manufacturing costWide range of product applicationsGlass making apparatusBoron trioxideMicrometer

The invention belongs to the field of a superfine glass wool and a manufacturing method thereof. The wool comprises carbon dioxide and boron trioxide, and the diameter of the wool is less than 2 micrometers. The manufacturing method comprises the following steps of: jetting raw materials with the diameter of 150 micrometers to glass silks with the diameter of 400 micrometers by using flames at 1560 DEG C and 1980 DEG C, and then forming the superfine wool when the jetting speed is greater than 610m / s. The superfine glass wool has the advantages of superfine form, uniform diameter, fire protection, sound absorption, heat preservation, insulation and low cost.

Owner:张学军

Fishskin and beef tendon pills and preparation method thereof

The invention provides fishskin and beef tendon pills. The raw materials of the fishskin and beef tendon pills comprise the following components in parts by weight: 100 parts of fishskin, 50-80 parts of beef tendons, 10-30 parts of sweet potato powder, and 5-10 parts of table salt. The fishskin and beef tendon pills are prepared through the following steps of mashing the raw materials, stirring the mashed materials, making the stirred materials into pills, and cooking the pills. The invention further provides a preparation method of the fishskin and beef tendon pills, and the preparation method comprises the following steps of removing fish meal from fresh fish, taking the fishskin, and shaving off fish scales; thoroughly cleaning the fishskin with water, fishing out the cleaned fishskin, and draining the fished-out fishskin; repeatedly beating the drained fishskin with an iron bar until the fishskin is in a slurry form so as to obtain fishskin pulp; adding the beef tendons and sweet potato powder in the fishskin pulp, and performing repeated beating continuously until mixed meat pulp with elasticity is obtained; adding the table salt in the mixed meat pulp, and repeatedly beating the meat pulp so as to enable the meat pulp is non-stick; putting the mixed meat pulp in a pill-outletting machine to obtain pills; cooking fresh pills, fishing out the cooked pills and draining the fished-out pills so as to obtain the fishskin and beef tendon pills; and packaging the fishskin and beef tendon pills which are naturally cooled. The fishskin and beef tendon pills provided by the invention not only are simple in preparation technology, but also are convenient to eat and convenient to cook.

Owner:湖北戴氏食品科技股份有限公司

Three-dimensional net rack bamboo filament wall

The invention provides a three-dimensional net rack bamboo filament wall, which is formed by a base material and a three-dimensional net rack buried in the base material, wherein the base material is prepared from the following materials in parts by weight: 10 to 15 parts of bamboo filaments, 4 to 6 parts of cements, 1 to 3 parts of perlites, 0.01 to 0.03 part of adhesion agent and 0.2 to 0.6 part of functional auxiliary material. The three-dimensional net rack bamboo filament wall provided by the invention adopts the bamboo filaments with wide sources, long fibers, good flexibility and small decomposing possibility as a main raw material, and utilizes the characteristic that the bamboo filament fibers are uniformly dispersed to interweave a spider web, so that the compactness of the wall can be improved; in addition, various functional components are matched, so that under the regulation of a three-dimensional net rack structure, the prepared wall has the excellent characteristics of heat insulation, fire and water resistance, shock and crack resistance, corrosion resistance and sound insulation, striking resistance, wear resistance, ageing resistance, high strength and light weight.

Owner:广东晶盈环保建材实业有限公司

Sheet laminating preparation method for sisal fiber reinforced polypropylene composite material

The present invention adopts the sisal hemp fiber as fiber raw material, and uses the nonwoven fabric of thermoplastic resin PP, film, powder material and its fiber as resin base body, and adopts the following steps: pretreating sisal hemp fiber and making it into fiber felt, hot-pressing and forming, selecting and using a certain number of fiber felts, delaminating and sand wiching pp nonwoven fabric or film, under the condition of a certain temp. and pressure hot-pressing and forming or mixing PP fiber (PP powder) directly with sisal hemp fibre, making them into fiber felt and then hot-pressing and forming so as to obtain the invented sisal hemp fiber reinforced polypropylene composite material.

Owner:SUN YAT SEN UNIV

Production technology of flat filament polyester top

ActiveCN110331452AFiber lengthIncrease brightnessNew-spun product collectionArtificial filament heat treatmentPolymer scienceFur garment

The invention discloses a production technology of a flat filament polyester top. The production technology comprises technological steps as follows: drying of raw materials, screw extrusion jet spinning, winding for bundling; tow aftertreatment, tow cutting-off for strip preparation, primary gilling, secondary gilling and balling gilling. The flat filament polyester top prepared with the method has flat filaments, long fiber, high brightness and high stereoscopic effect, touches elastic, soft and smooth, and is more suitable for dyeing than common chemical fiber, thereby being applicable to production of imitated fur garments.

Owner:ZHANGJIAGANG RONGCHANG POLYESTER TOPS

Production Technology of Flat Yarn Polyester Top

ActiveCN110331452BFiber lengthIncrease brightnessNew-spun product collectionArtificial filament heat treatmentPolyesterFiber

The invention discloses a production process of flat polyester wool tops. The process steps are as follows: raw material drying→screw extruding and spraying→winding and clustering→post-treatment of tow→cutting of tow to make sliver→one needle comb→two needle combs→ Comb into a ball. The flat yarn polyester wool top prepared by the above method has flat filaments, long fibers, high brightness, soft and smooth hand feeling, strong three-dimensional effect, and is more suitable for dyeing than ordinary chemical fibers, so it is suitable for the production of imitation fur clothing.

Owner:ZHANGJIAGANG RONGCHANG POLYESTER TOPS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com