Patents

Literature

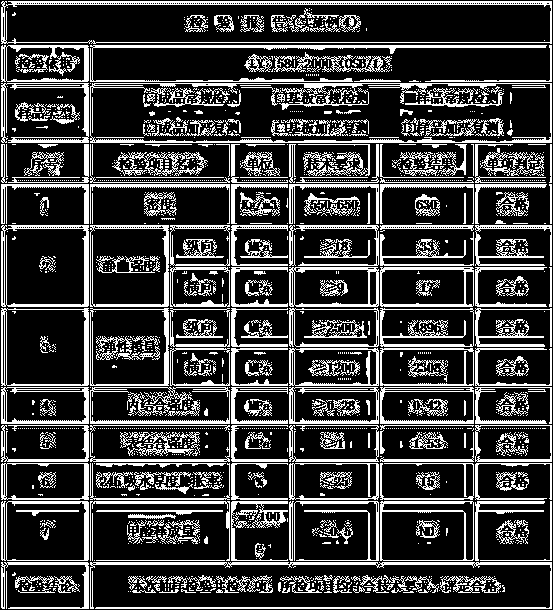

160results about How to "High static bending strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

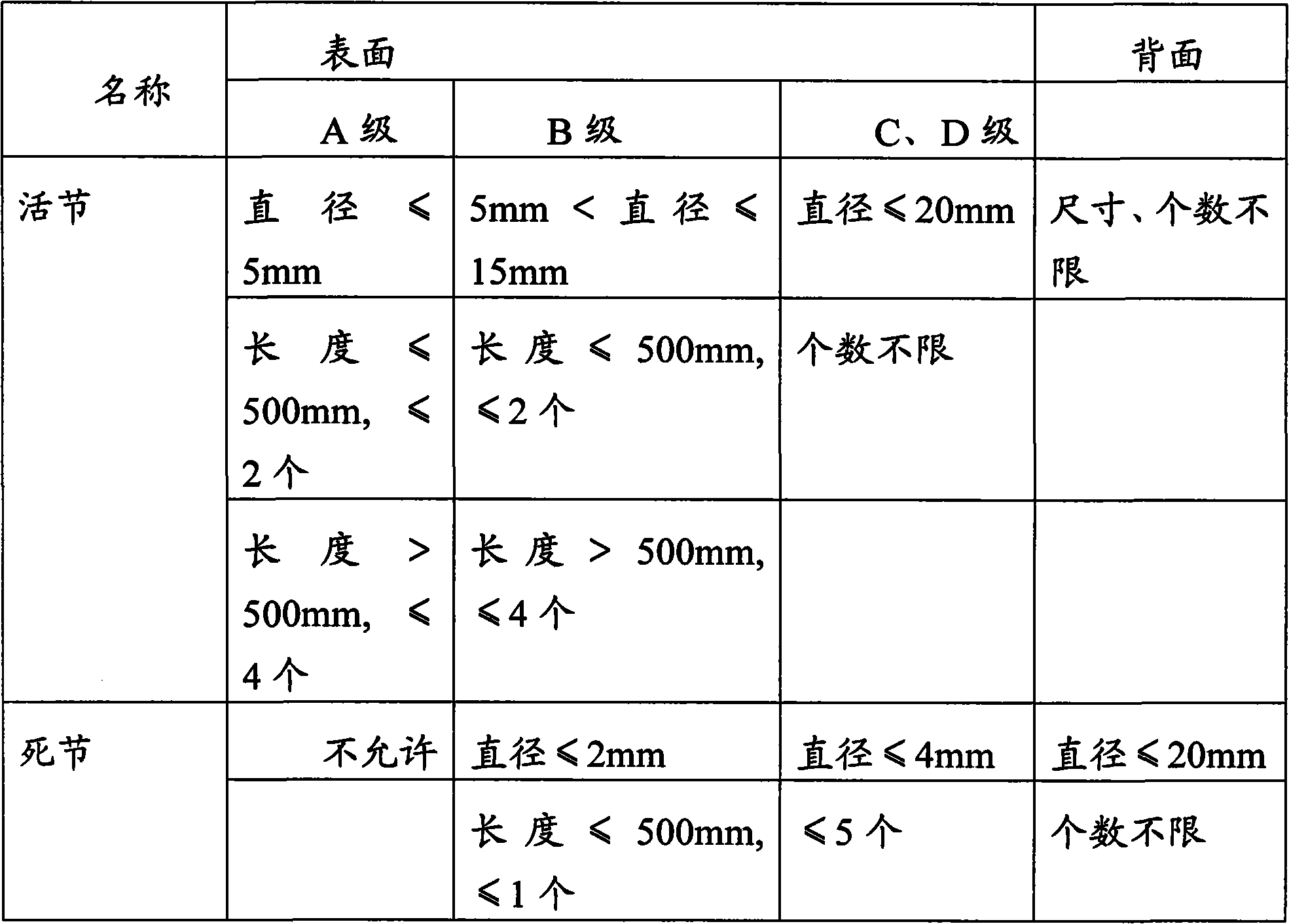

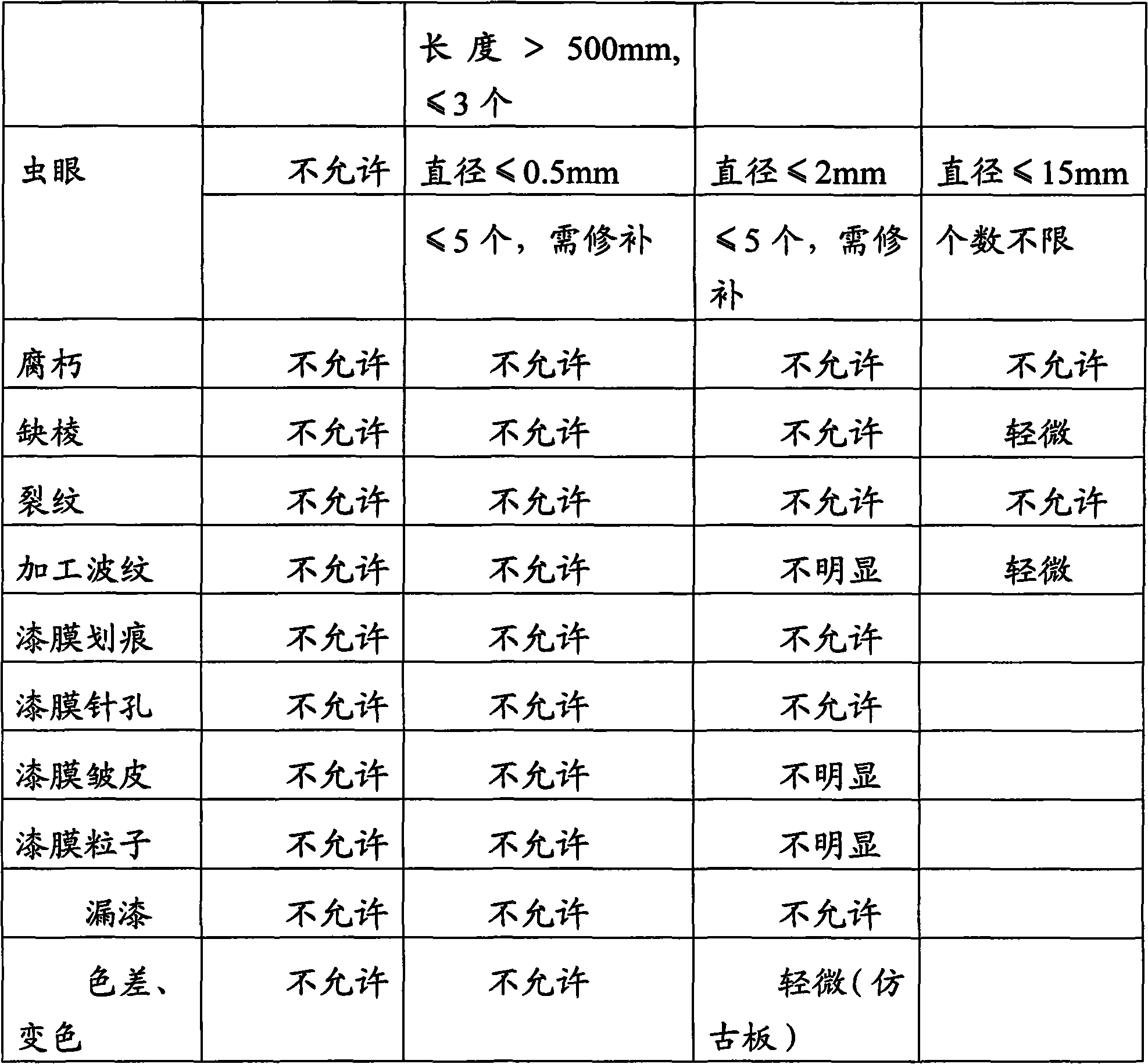

High-intensity wood plastic composite board and fabrication method thereof

InactiveCN101708614AEasy to produceHigh strengthWood veneer joiningFlat articlesMechanical propertyWhite oil

The invention relates to a wood plastic composite, in particular to a high-intensity wood plastic composite board and a fabrication method thereof. The method for fabricating the high-intensity wood plastic composite board comprises the following steps: treating nano titanium dioxide with silane coupling agent to obtain modified nano titanium dioxide; mechanically stirring the modified nano titanium dioxide, plastic particles, maleic anhydride grafted plastic particles, calcium stearate and the like, and extruding and pelleting all the materials to obtain modified plastic particles; mechanically stirring the modified plastic particles, wood flour, terpene resin, chopped glass fiber, white oil, antioxidant and the like, and extruding, melt-blending and pelleting all the materials to obtain high-intensity wood plastic composite particles; and finally extruding the high-intensity wood plastic composite particles with a machine to mold the high-intensity wood plastic composite board. The high-intensity wood plastic composite board has extremely wide application range, and is applied to the fields such as transportation, construction, decoration, ornament, municipal works, garden and park, packaging and the like. The high-intensity wood plastic composite board has the advantages of reproducibility, low cost and higher mechanical properties such as static bending strength and the like, thereby being an ideal material for replacing wood. Compared with traditional wood plastic composites, the high-intensity wood plastic composite board has longer service life, and is a novel upgrade product of the present wood plastic composites.

Owner:江苏森诺塑胶科技有限公司

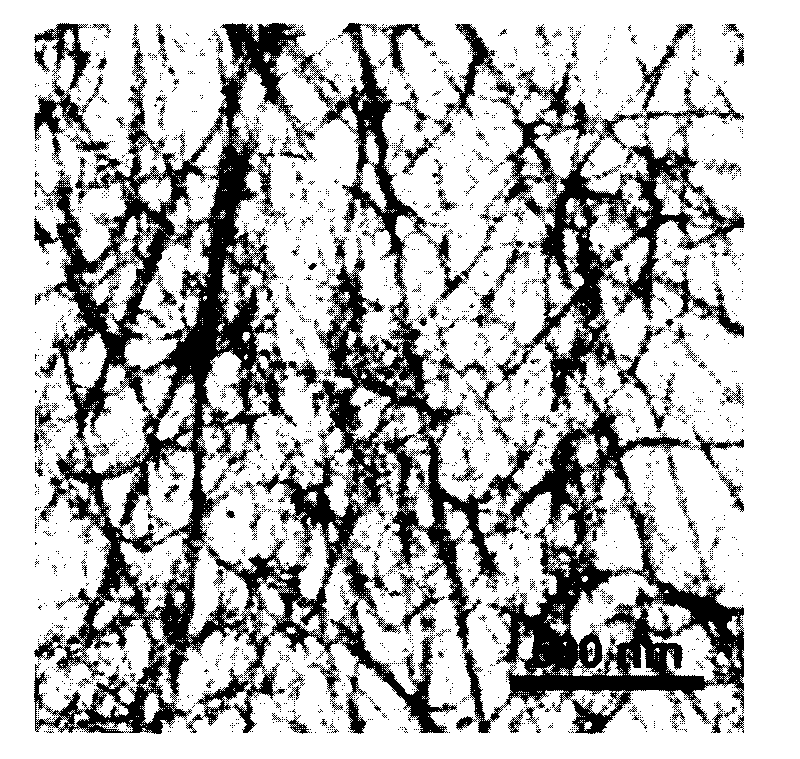

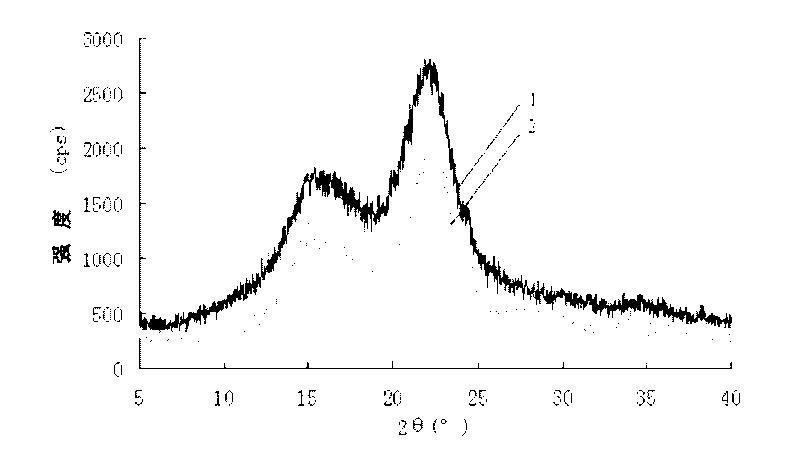

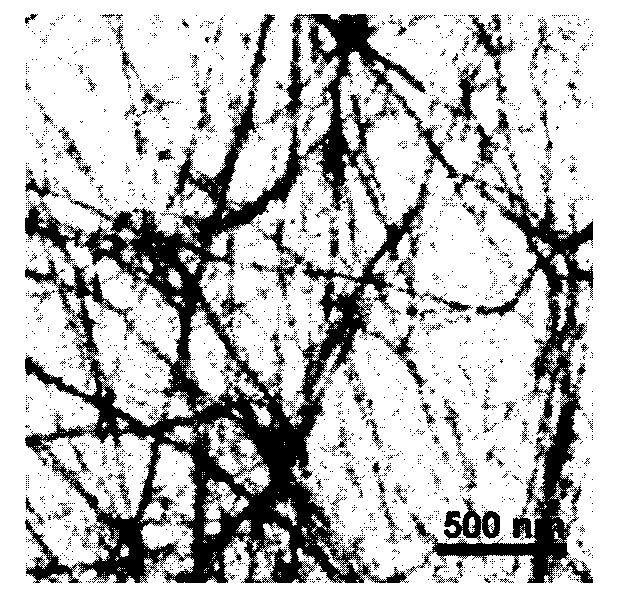

Method for preparing lignocellulosic nanofibrils

ActiveCN101691698AHigh yieldReduce forcePulping with acid salts/anhydridesPulping with inorganic basesAcetic acidFibril

The invention discloses a method for preparing lignocellulosic nanofibrils, which relates to a method for preparing nanofibrils. The method solves the problems that the traditional cellulose fiber manufactured by taking timber as a raw material has poor strengthening and toughening effects and cellulose fibrils obtained through the preparation have low yield. The method comprises the steps of: 1, extracting wood meal; 2, mixing raw materials and performing heating treatment on the mixture; 3, then adding glacial acetic acid and sodium chlorite into the mixture, and performing heating treatment after the mixing; 4, removing lignin; 5, removing hemicellulose; 6, re-removing the lignin; 7 re-removing the hemicellulose; and 8, performing ultrasonic crushing treatment to obtain the lignocellulosic nanofibrils. The yield of the manufacturing method is between 80 and 90 percent and is high; and the lignocellulosic nanofibrils prepared by the method have good strengthening and toughening effects.

Owner:NORTHEAST FORESTRY UNIVERSITY

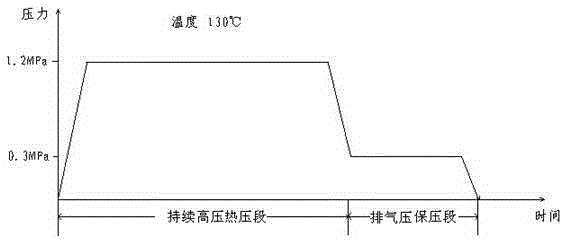

Method for producing high-density recombined wood

InactiveCN102172940AHigh static bending strengthHigh surface hardnessWood compressionVeneer manufactureHigh densityEngineering

The invention relates to a method for producing high-density recombined wood, which is used for manufacturing plates and recombined module timber by the following steps of planning, processing by high-temperature steam, drying, dipping glue, draining glue, drying after draining glue, tidying or weaving, balancing for nourishing, pressing to shape, solidifying at a high temperature and the like. The density of the high-density recombined wood can reach 0.7-1.2kg / cm<3>; the high-density recombined wood has the characteristics of peculiar texture, fine grain, excellent performance, small possibility of cracking and deforming and the like, does not need to prevent insects, prevent mildew, prevent corrosion, prevent from cracking and the like, and can be directly used for the fields of floor, furniture, building and the like. The method disclosed by the invention has simple working procedures, and abandoned secondarily secondary small fuel wood and secondary small wood are utilized to produce plates and module wood, thereby changing waste materials into things of value, and greatly saving forest resource. The wood is an ideal log substitute.

Owner:浙江仕强竹业有限公司

Process for producing formaldehyde-removing solid wood flooring

ActiveCN101804655AReduce energy consumptionTake advantage ofLiquid surface applicatorsWood compressionSolid woodWear resistant

The invention relates to a process for producing formaldehyde-removing solid wood flooring. The process comprises the following steps of: forming a solid wood flooring block, sanding the block, removing dust, coloring, coating UV putty coat I, solidifying I, sanding I, coating UV putty coat II, solidifying II, sanding II, coating wear resistant base coat, semi-solidifying I, coating transparent UV base coat, solidifying III, sanding III, coating UV finishing coat, semi-solidifying II, coating formaldehyde-removing UV wear resistant finishing coat, solidifying IV, and forming the finished product. The solid wood flooring produced by the process has the advantages of good colour and lustre, clear texture, high anti-bending static bending strength, good surface abrasion resistance, stable size, small deformation and special effects on adsorbing and degrading free formaldehyde in indoor air.

Owner:临江市宝健木业有限责任公司

Bamboo-wood composite board and preparation method thereof

InactiveCN101745947AFully absorbedReach the designed drug loadingWood veneer joiningThermal compressionHigh surface

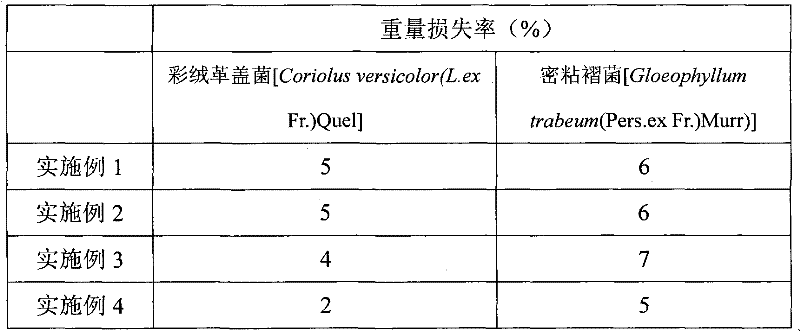

The invention relates to an anti-corrosion bamboo-wood composite board and a preparation method thereof. The preparation method of the anti-corrosion bamboo-wood composite board comprises the following steps: firstly preparing anti-corrosion bamboo strips and heat-treated wood; next, respectively assembling and compressing the anti-corrosion bamboo strips and the heat-treated wood into anti-corrosion bamboo wood and a heat-treated sheet material; and then carrying out assembling and hot compression on the anti-corrosion bamboo wood and the heat-treated sheet material to obtain the anti-corrosion bamboo-wood composite board. The bamboo-wood composite board prepared by the method of the invention has excellent corrosion resistance which reaches the corrosion resisting level specified in national standard GB / T13942.1-1992 Method for Laboratory Test of Natural Decay Resistance of Woods, and also has very high surface abrasion resistance and high mechanical strength which reach the national standards in GB / T 18103-2000 national composite floor.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

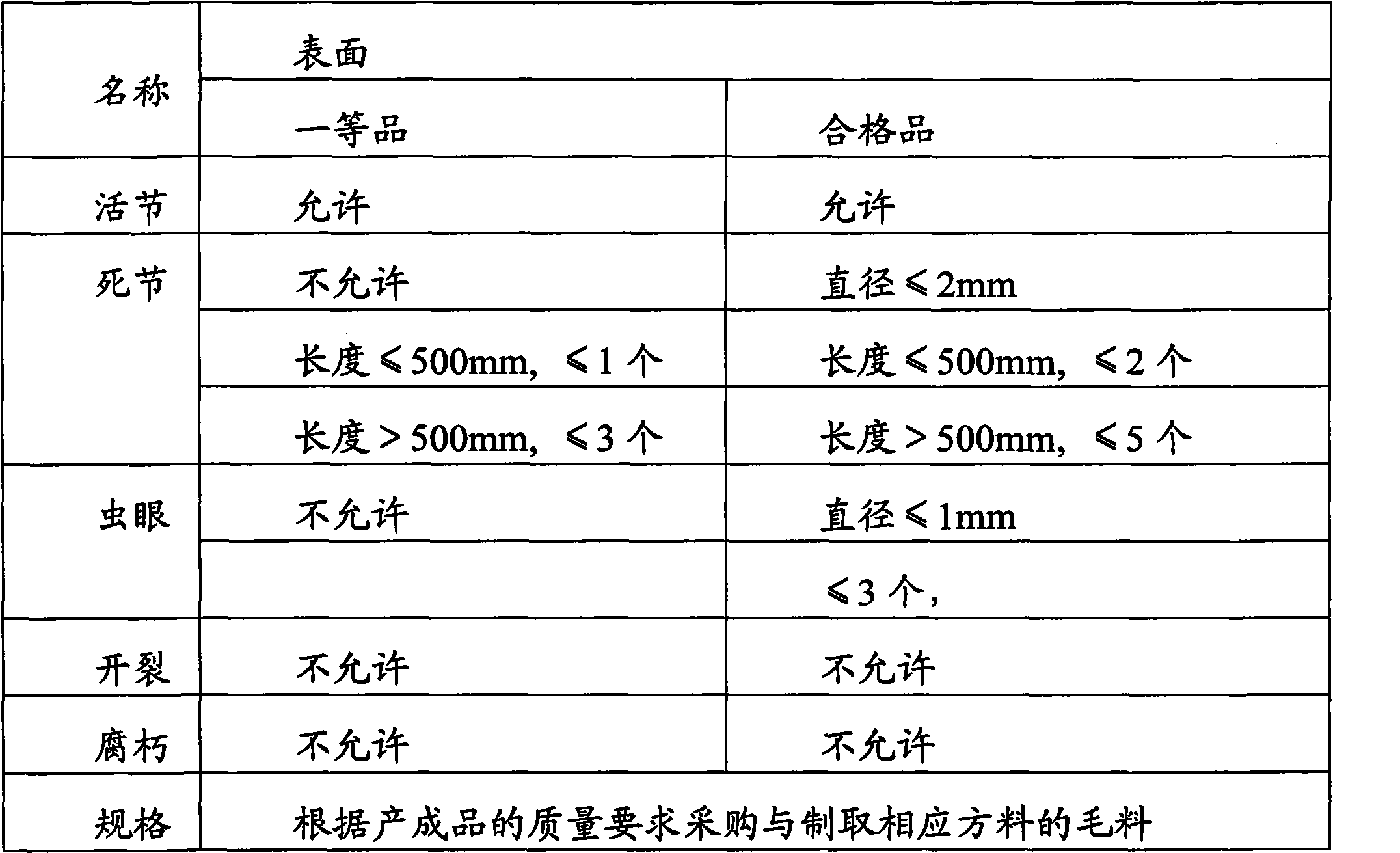

Method for making formaldehyde-free high-strength artificial plate

InactiveCN1460580AEliminate pollutionIncrease joint areaFlat articlesDomestic articlesHigh intensityUltimate tensile strength

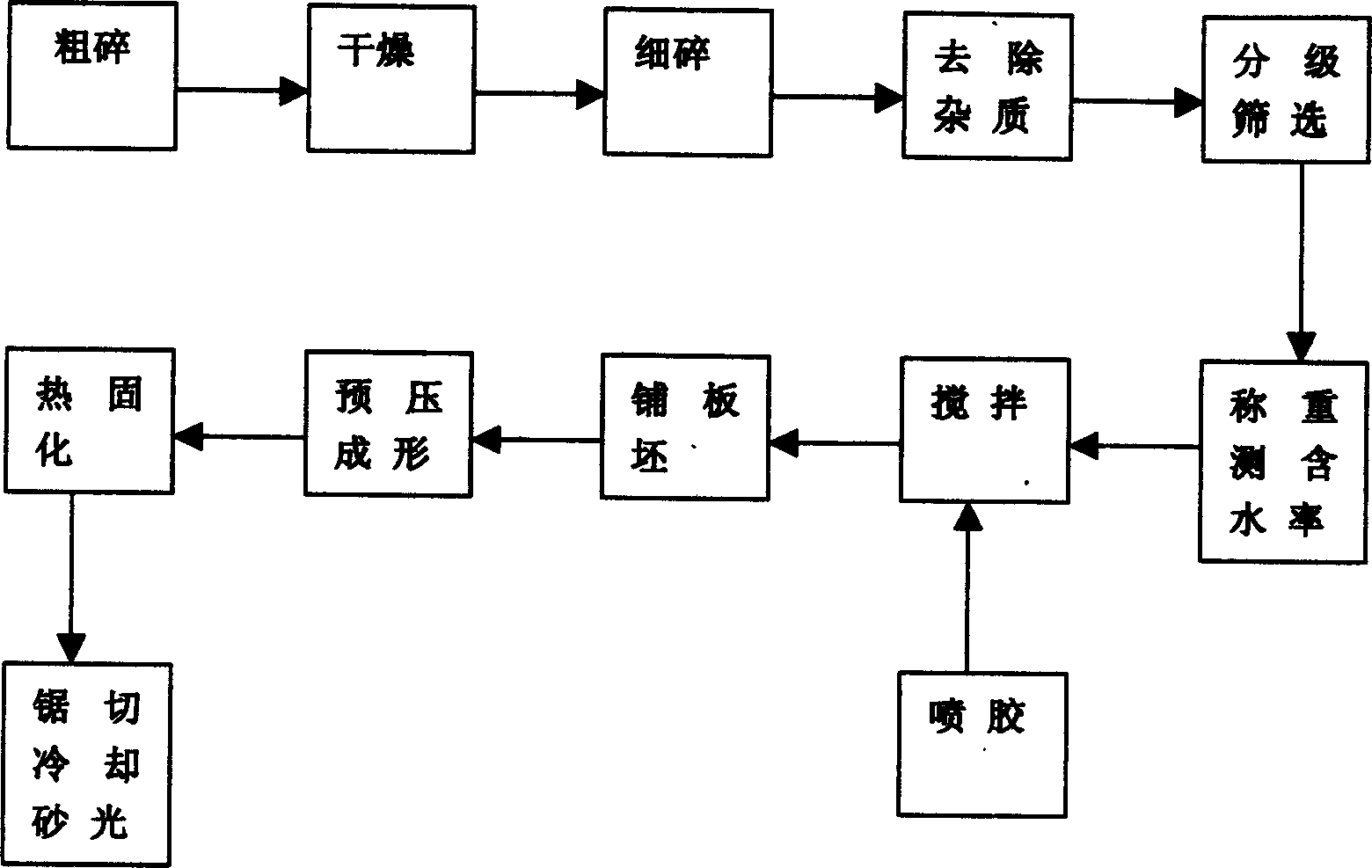

The production method of formol-free high-strength artificial plate includes the following steps: firstly, pulverizing crop straw and stalk into 0.1-6 mm, adding MDI adhesive, stirring and mixing them, making the uniformly-mixed raw material into plate blank, prepressing and forming under the condition of 300-400 k N / sq.M, then thermosetting at 140-200 deg.C and 2500-3500 kN / sq.M, cooling, edging and polishing so as to obtain the invented artificial plate.

Owner:SHANGHAI COMPAK ENVIRONMENTAL PROTECTION EQUIP CO LTD

Method for producing bamboo board

InactiveCN1970259AUniform densityHigh static bending strengthFlat articlesDomestic articlesFiberBleach

It relates to bamboo plate production method. 1) it processes bamboo fiber to thread bamboo sheet, 2) bleach, carbonize and dry after modifying property, 3) soaking the said bamboo sheet in glue agent, dry to the water content 10-12%, taking the bamboo plate of the corresponding weight based on 1.1-1.3g / cm3 intensity to fill into the mold, 5) sending the bamboo sheet to heat compressor with compression force 6-10 MPa for 30-60 minutes, setting the compression temperature 100+-5DEG C for melamine resin adhesive, or 135+-5DEG C for phenol aldehyde resin adhesive, and 6)process the compressed plate. The made bamboo plate is even in intensity, high in static curve strength and hardness, anti wearing and good in stability.

Owner:DASSO INDASTRIAL GRUP KO LTD +1

Method for manufacturing high intensity plywood for engineering structure by utilizing fast growing wood

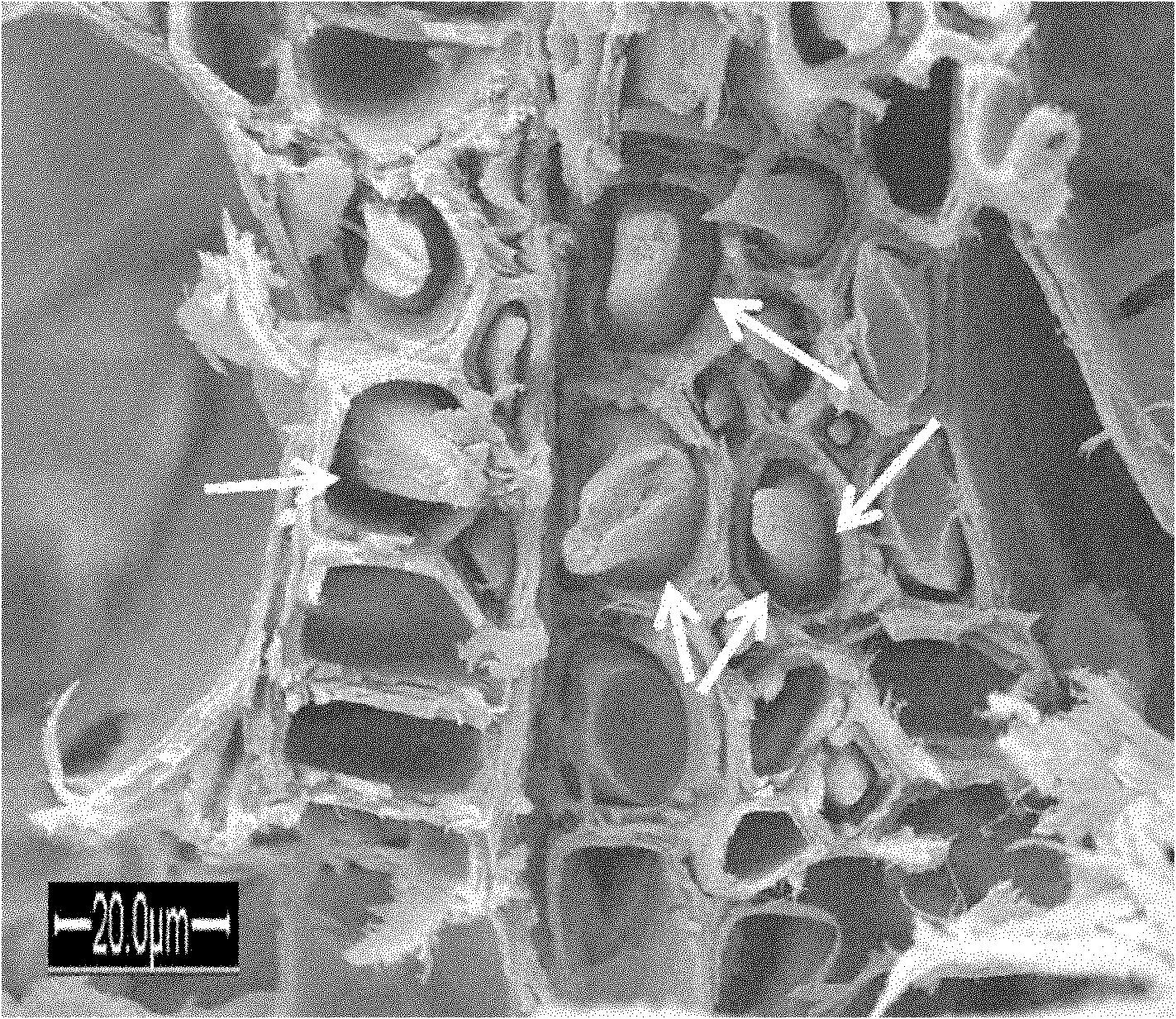

InactiveCN103991113AHigh static bending strengthIncrease elasticityWood treatment detailsWood veneer joiningWeather resistanceSingle plate

The invention provides a method for manufacturing high intensity plywood for an engineering structure by utilizing fast growing wood. The method comprises the following steps of (1) single plate rotary cutting, (2) modified liquid preparation, (3) single plate reinforced processing, (4) gluing assembly prepressing, (5) plate blank hot press forming, and (6) veneering or film covering processing. The method for manufacturing the high intensity plywood for the engineering structure by utilizing the fast growing wood has the advantages that firstly modified liquid reinforced processing is carried out on the single plates of the fast growing wood, the intensity of the single plates of each layer is improved to a large extent, the reinforcing degree of the single plates can be adjusted through the weight gain rate of the single plates, and the weight gain rate of the reinforced single plates can be reduced from outside to inside in a graded mode to save cost and fully perform the intensity performance of single plates of all layers; thus, plywood products gain extremely high static bending intensity, elasticity modulus and surface hardness under the condition of a low compression rate, the thickness swelling rate of the products is small, the dimensional stability of the products is good, and reinforcer gives the products good rotproofness and weather resistance at the same time.

Owner:NANJING FORESTRY UNIV +1

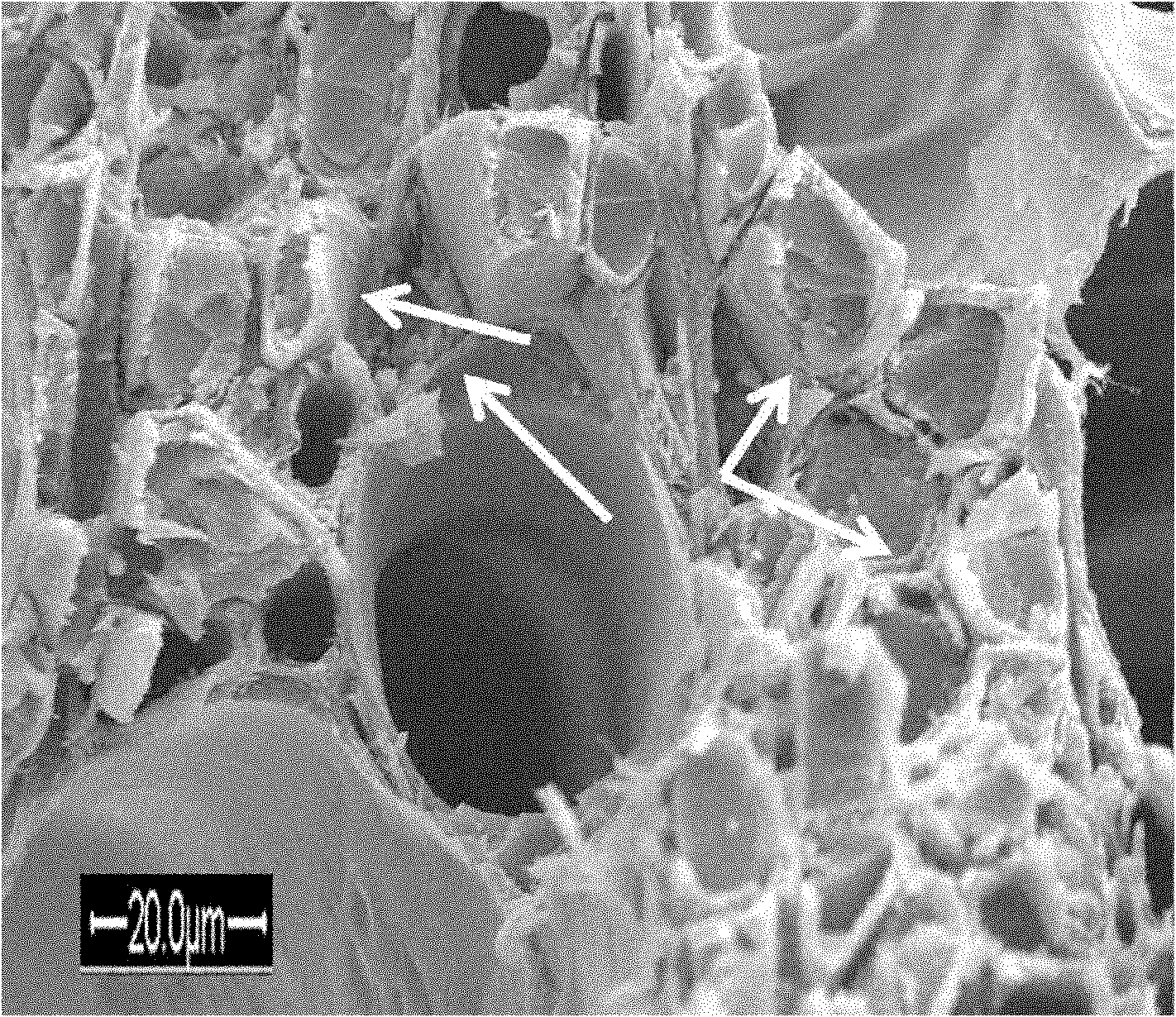

Wood working process

InactiveCN101913181AImprove carrying capacityHigh densityWood impregnation detailsHigh densityMass ratio

The invention provides a wood working process, which comprises the following steps of: the preparation of first mixed solution; the preparation of second mixed solution; square stock impregnation, namely, impregnating a square stock into the first mixed solution to make the square stock absorb the first mixed solution until reaching a completely saturated state, and placing the square stock impregnated in the first mixed solution into the second mixed solution for impregnation to make spaces among wood cells of the square stock absorb the mixed solution until the mass ratio of furfural to the wood is 0.3-0.5:1; hot-pressing, namely, performing hot-pressing on the impregnated square stock; cutting, namely, cutting the square stock into required wood boards; and sanding and notching, namely, sanding and notching the wood boards. The wood boards obtained by the wood working process provided by the invention have the characteristics of high load-bearing properties, high density, high durability, strong bending strength, low water absorption and low expansion ratio.

Owner:尹侃

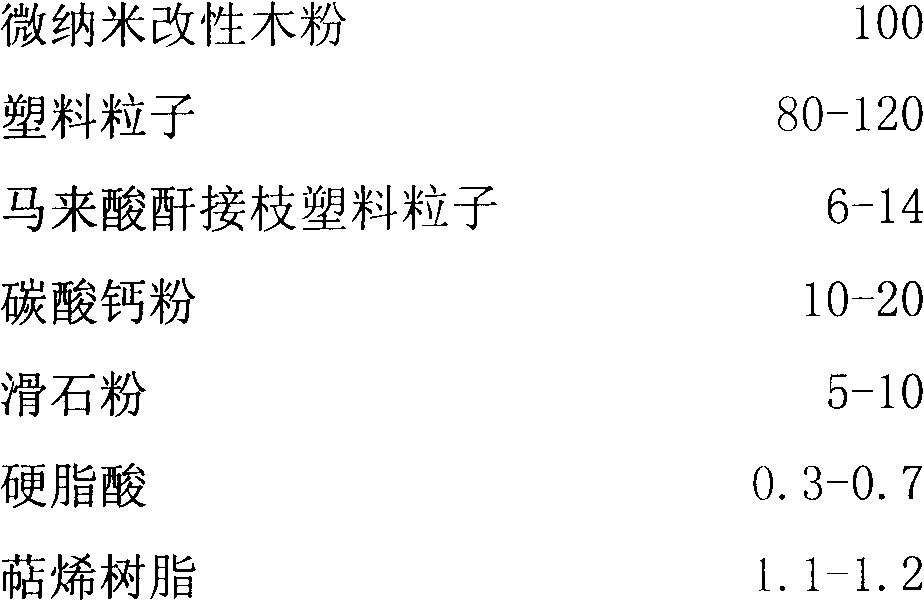

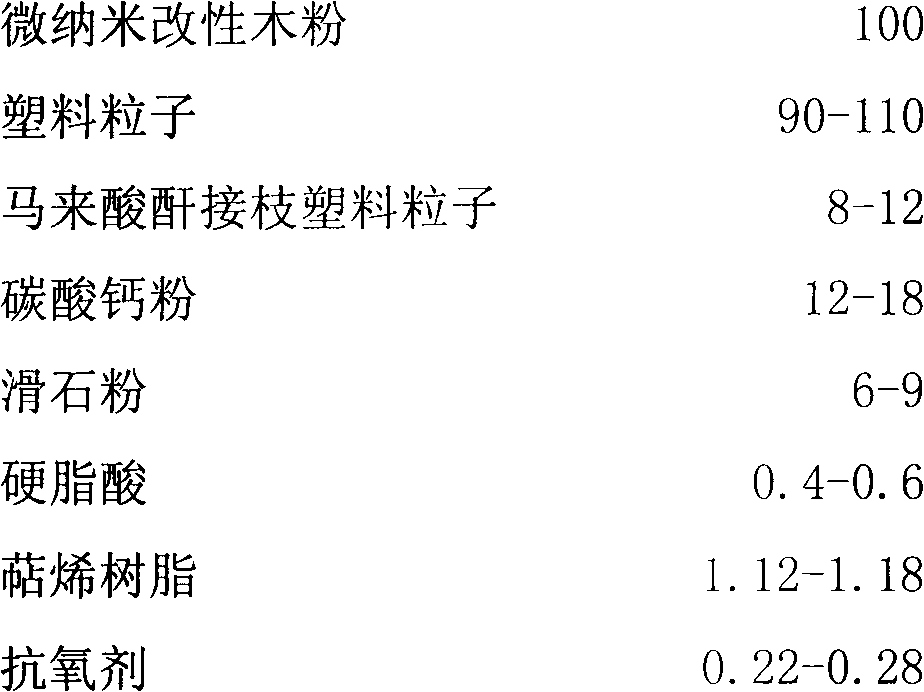

A kind of micro-nano reinforced plastic wood composite material board and preparation method thereof

The invention relates to a wood plastic material, in particular to a micro nanometer-enhanced wood plastic composite board and a preparation method thereof. The preparation method comprises the following steps of: hydrolyzing ethenyl triethoxy silane, and modifying wood powder by sealing pressurization reaction; mixing plastic granules, maleic anhydride grafting plastic granules, calcium carbonate powder and stearic acid, and extruding to obtain modified plastic granules; blending the modified plastic granules, the modifying wood powder, talcpowder, terpene resin and an antioxidant and granulating to obtain micro nanometer-enhanced wood plastic granules; and extruding the micro nanometer-enhanced wood plastic granules to form the micro nanometer-enhanced wood plastic board. The micro nanometer-enhanced wood plastic board can be recycled, is low in cost, has high mechanical properties and is an ideal material for replacing wood; and compared with the conventional wood material, the micro nanometer-enhanced wood plastic composite board has a longer service life, is a novel upgrading and updating product of the conventional wood plastic material, and can be widely applied in fields of traffic, buildings, decoration, municipal administration, gardens, packaging and the like.

Owner:江苏福瑞森塑木科技股份有限公司

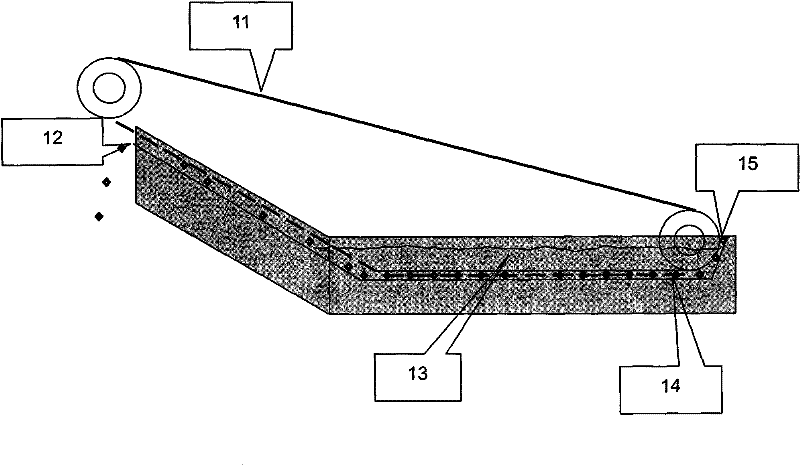

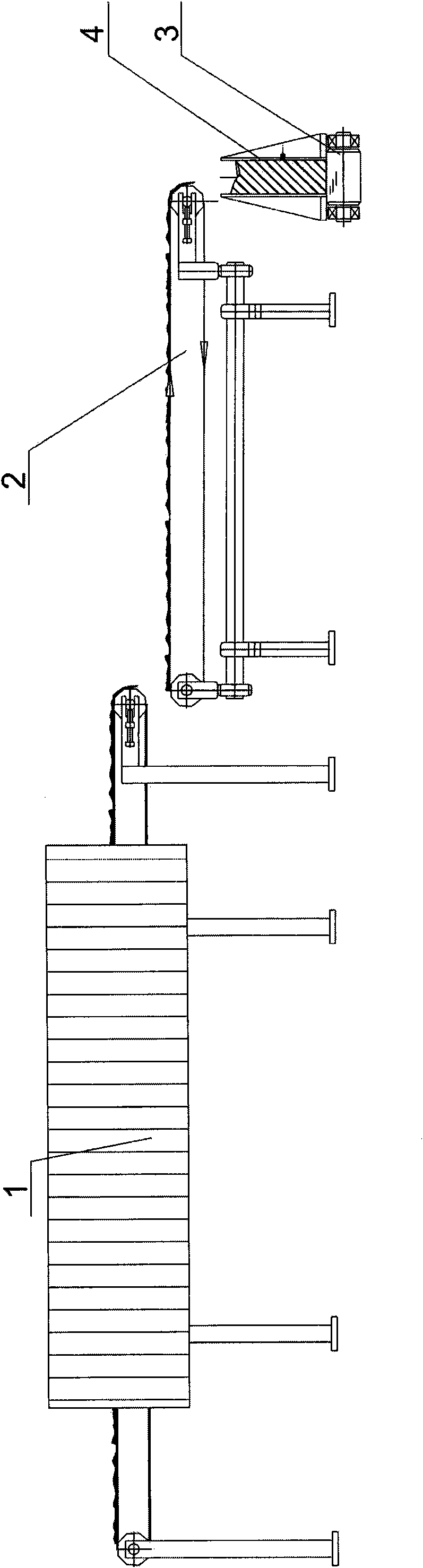

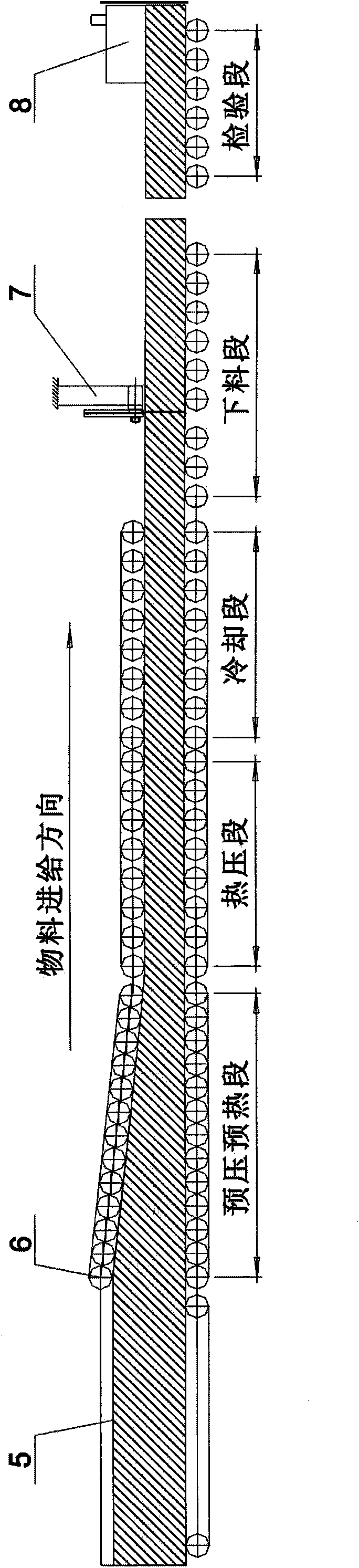

Continuous hot-pressing method for large-section section

InactiveCN102107454AIncrease temperatureImprove plasticityWood working apparatusFlat articlesMicrowaveSingle plate

The invention discloses a continuous hot-pressing method for a large-section section. The method comprises a pretreatment process, a continuous hot-pressing process and a post-treatment process, and is characterized in that: the continuous hot-pressing process comprises the following steps of: A, preheating and prepressing; B, hot-pressing and curing; and C, cooling to guarantee quality. In the method, a continuous blanking mode is adopted, the preheating and the prepressing are increased, and a microwave or high-frequency heating technology is adopted during hot pressing. By the method, a non-lumber small-diameter class bamboo material, a secondary material of poor quality, a single-plate residual material, saw dust and the like are machined into a high-quality material; and the method has the advantages of wide material sources, simple and convenient material manufacturing process, high utilization rate of the material, convenience of operation, low energy consumption, investment saving and the like. Meanwhile, the method can be used for machining the material with any length in a continuous pressing mode and can also be used for machining the material with the thickness of 500mm.

Owner:陈滔

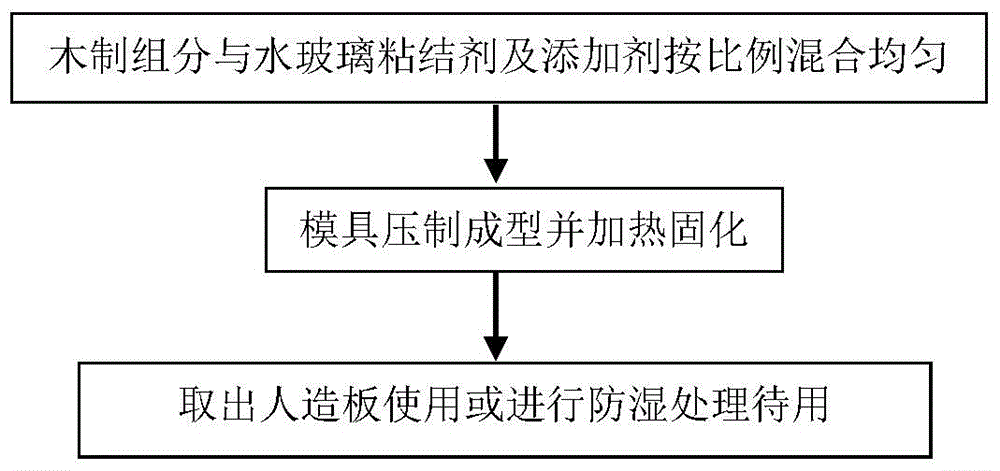

Inorganic binder refractory artificial board material and preparation method thereof

InactiveCN104962099AMeet the requirements of green environmental protectionSatisfy the use effectRefractoryHeat stability

The invention discloses an inorganic binder refractory artificial board material and a preparation method thereof. The inorganic binder refractory artificial board material comprises a wood component and an environment-pollution-free sodium silicate binder, wherein the modulus of the sodium silicate binder is 1.5-3.0. The preparation method comprises the following steps: uniformly mixing the wood component and sodium silicate binder, putting the mixture into a mold, compacting, heating for thermosetting, and demolding to obtain the inorganic binder refractory artificial board. The method can be used for preparing the inorganic binder refractory artificial board which has the advantages of no formaldehyde release, favorable static bending strength, favorable elastic modulus, favorable hydroscopic property, favorable heat stability and favorable fire resistance. The method has the advantages of wide raw material sources and low price.

Owner:HUAZHONG UNIV OF SCI & TECH

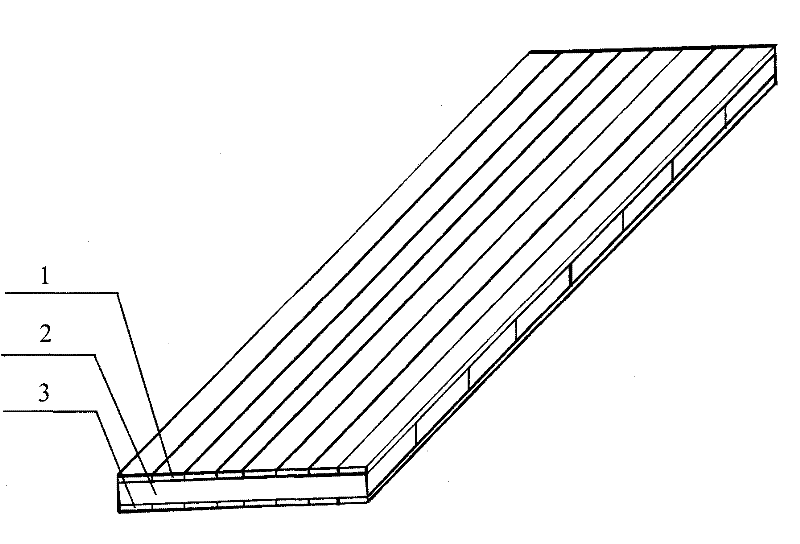

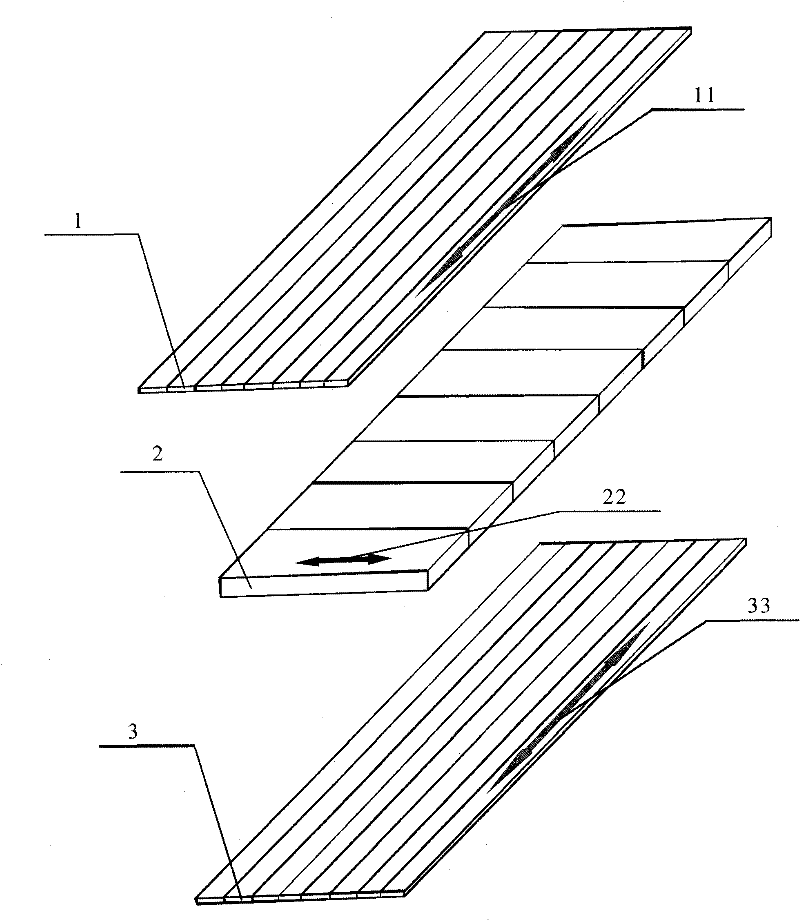

Multilayer solid wood composite door

InactiveCN101550796AOpposite sex reductionHigh static bending strengthWood working apparatusDoor leavesSolid woodEngineering

The invention relates to a multilayer solid wood composite door which is characterized in that a door body is of a single-board structure processed by clipping, carving, polishing and oiling multilayer solid wood composite boards. The method for manufacturing the multilayer solid wood composite board is as follows: (1) rotationally cutting logs into wood boards of 3 to 6 mm specification; (2) carrying out heat pressing and drying processes to the wood boards; (3) coating glue on two sides of the wood boards; (4) carrying out cold pressing; (5) carrying out heat pressing; and (6) sanding and polishing surfaces and carrying out final trimming and shaping. The invention has the beneficial effects of 1) obtaining the multilayer solid wood composite board with excellent physical mechanics property and machining property as the multilayer solid wood composite board is formed by hot-pressing multilayer rotationally-cut boards in a crisscross pattern; 2) obtaining integrated structure so as to restrict the sinking of door sides to the maximum extent; 3) gluing 5 to 11 layers of boards of 3 to 6 mm specification together so as to reduce the usage of glue and overcome the contamination caused by excessive formaldehyde; and 4) adopting the rotary-cutting technique to cut logs so as to enhance the utilization rate of wood.

Owner:孙伟范

Method for establishing moisture content gradient of shaving board

ActiveCN103950085AReduce drying energy consumptionGuaranteed drying qualityWood working apparatusFlat articlesWood shavingsSurface layer

The invention discloses a method for establishing a moisture content gradient of a shaving board. The method consists of three technological links, namely drying in levels, respective glue mixing and respective paving. The drying in levels is characterized in that two levels of drying systems are established and a shaving sorting procedure is set up between the first-level drying system and the second-level drying system; the shavings subjected to drying in levels are respectively stored, metered and mixed with glue, and the moisture content difference between shavings in a core layer and shavings on a surface layer are stabilized; after the shavings are metered, the shavings are respectively paved, and the moisture content gradient is finally established on a cross section of a blank of the shaving board. By the moisture content gradient, the moisture on the surface of the blank is quickly vaporized in the heating process, a steam impact effect is generated, the heat transfer speed is improved, the temperature rise speed of the core layer is improved and the aims of shortening hot-pressing time and improving hot-pressing efficiency are finally fulfilled; in addition, by establishing the moisture content gradient of the blank, the performance and the surface quality of the finished shaving board can be obviously improved, the static bending intensity of the board is improved, the made shaving board is more smooth in surface, and the sanding loss of the shaving board is reduced.

Owner:SOUTHWEST FORESTRY UNIVERSITY

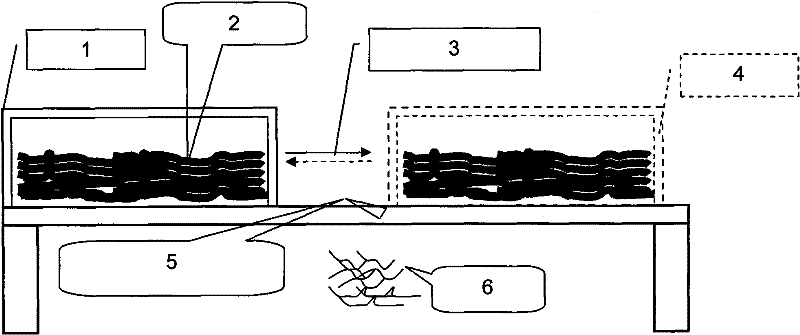

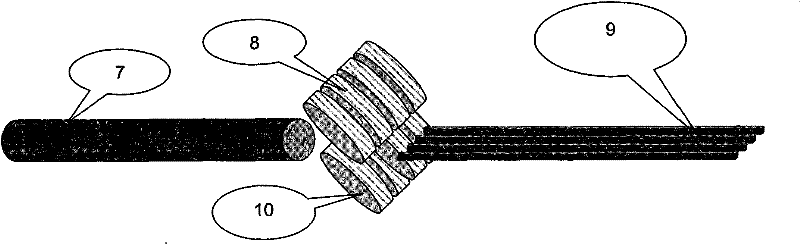

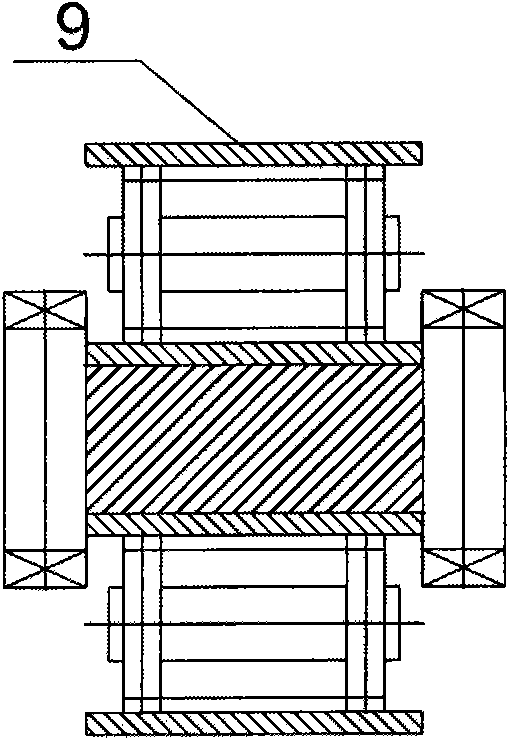

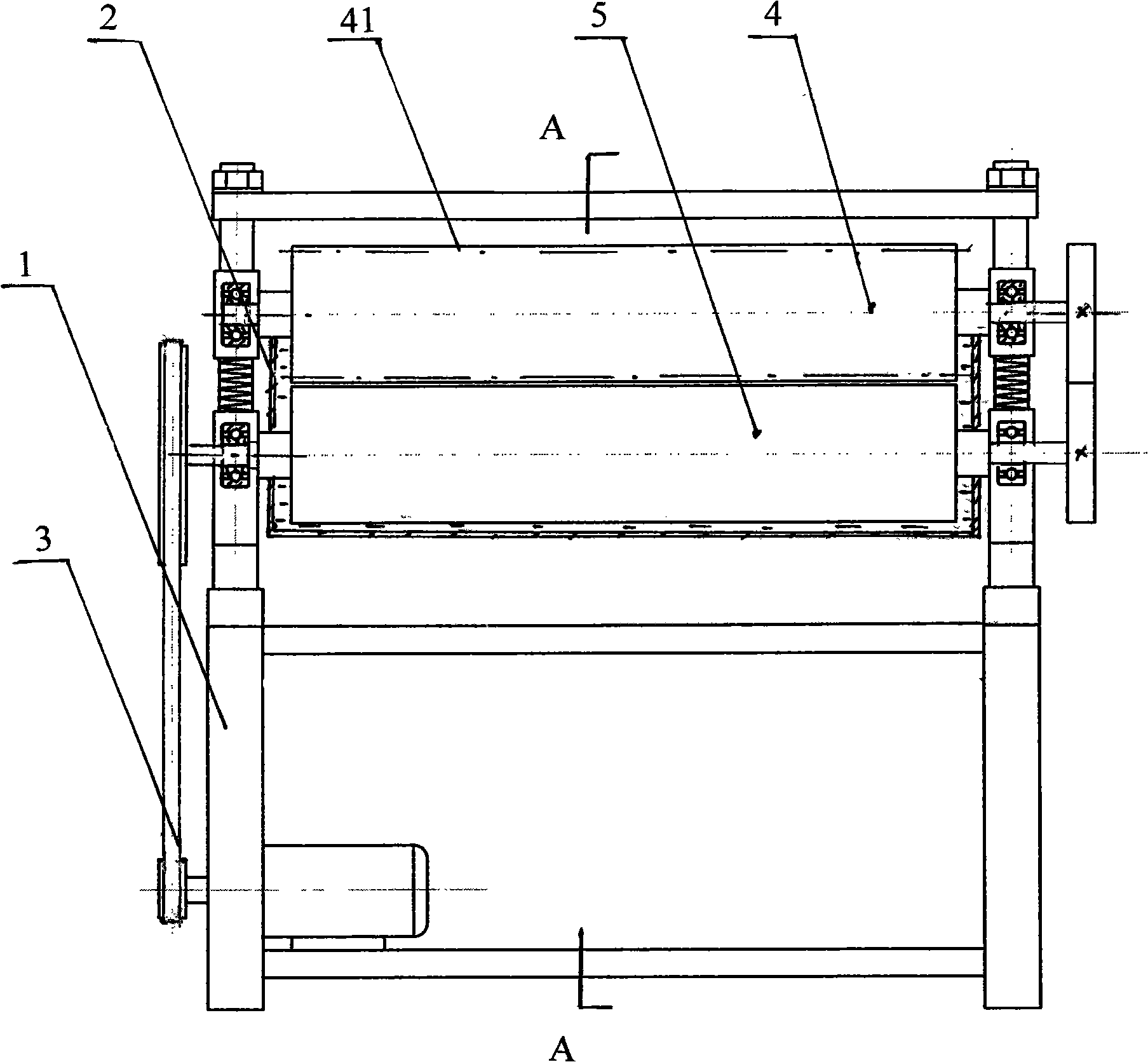

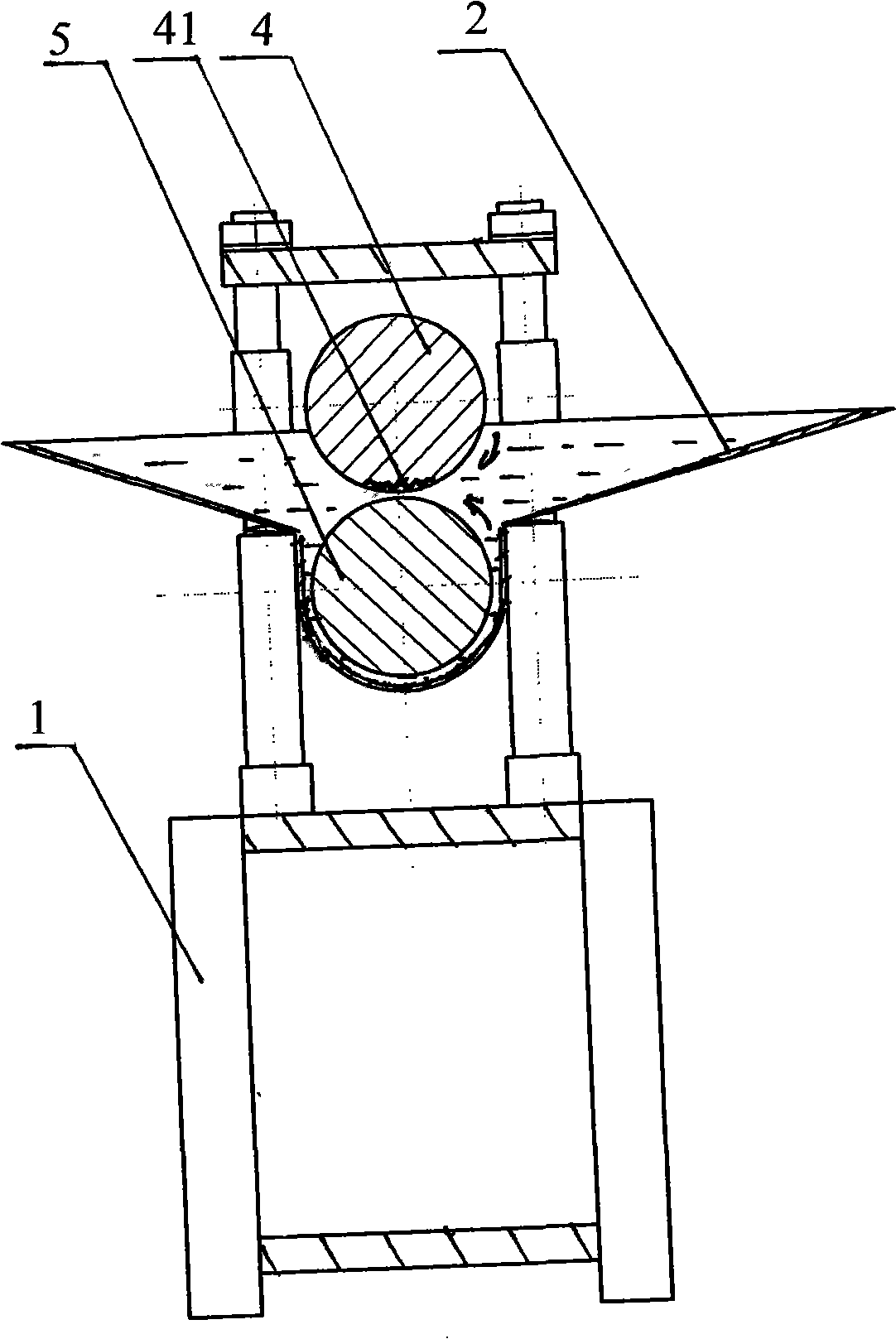

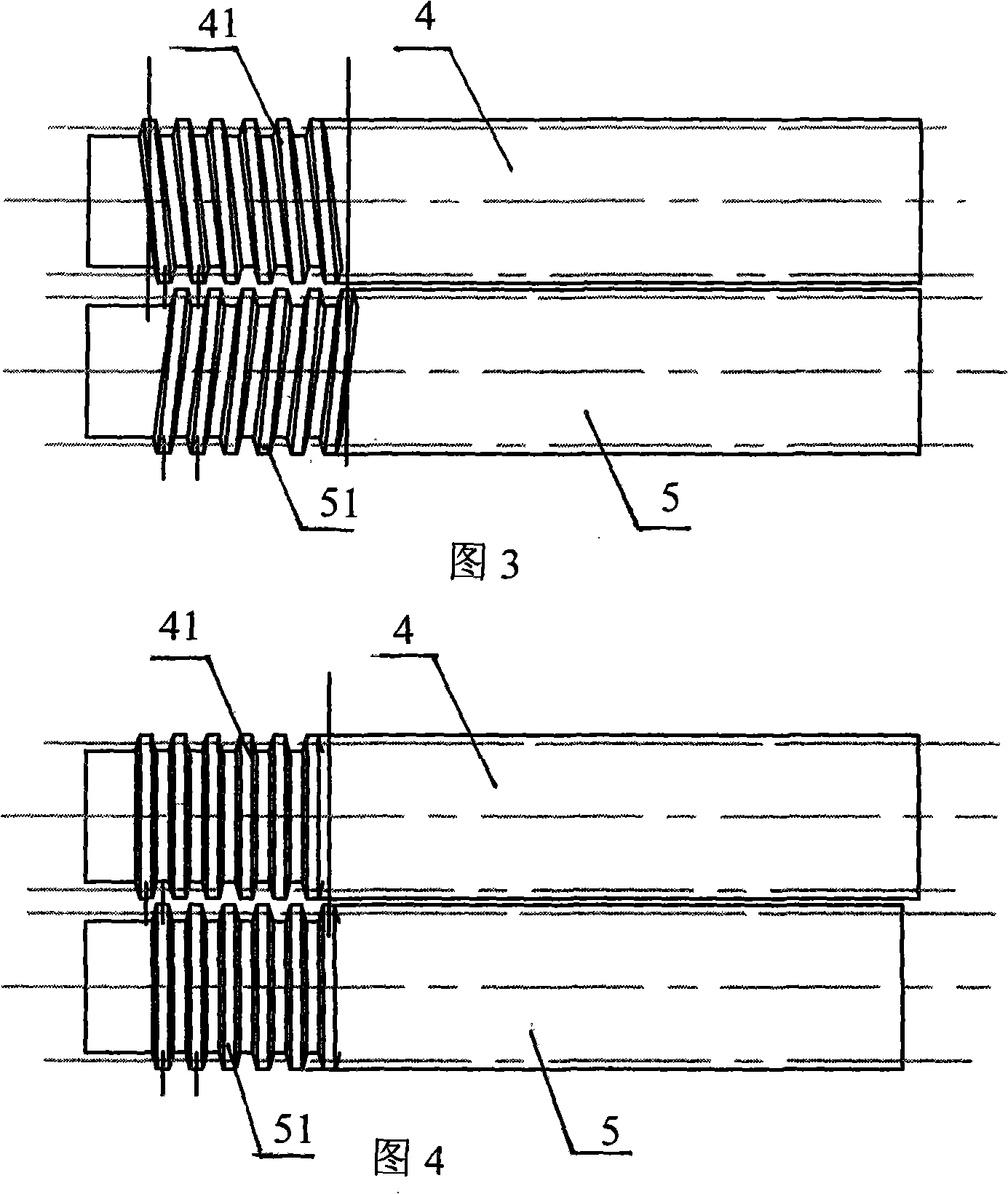

Untwining and gumming device for artificial board veneer

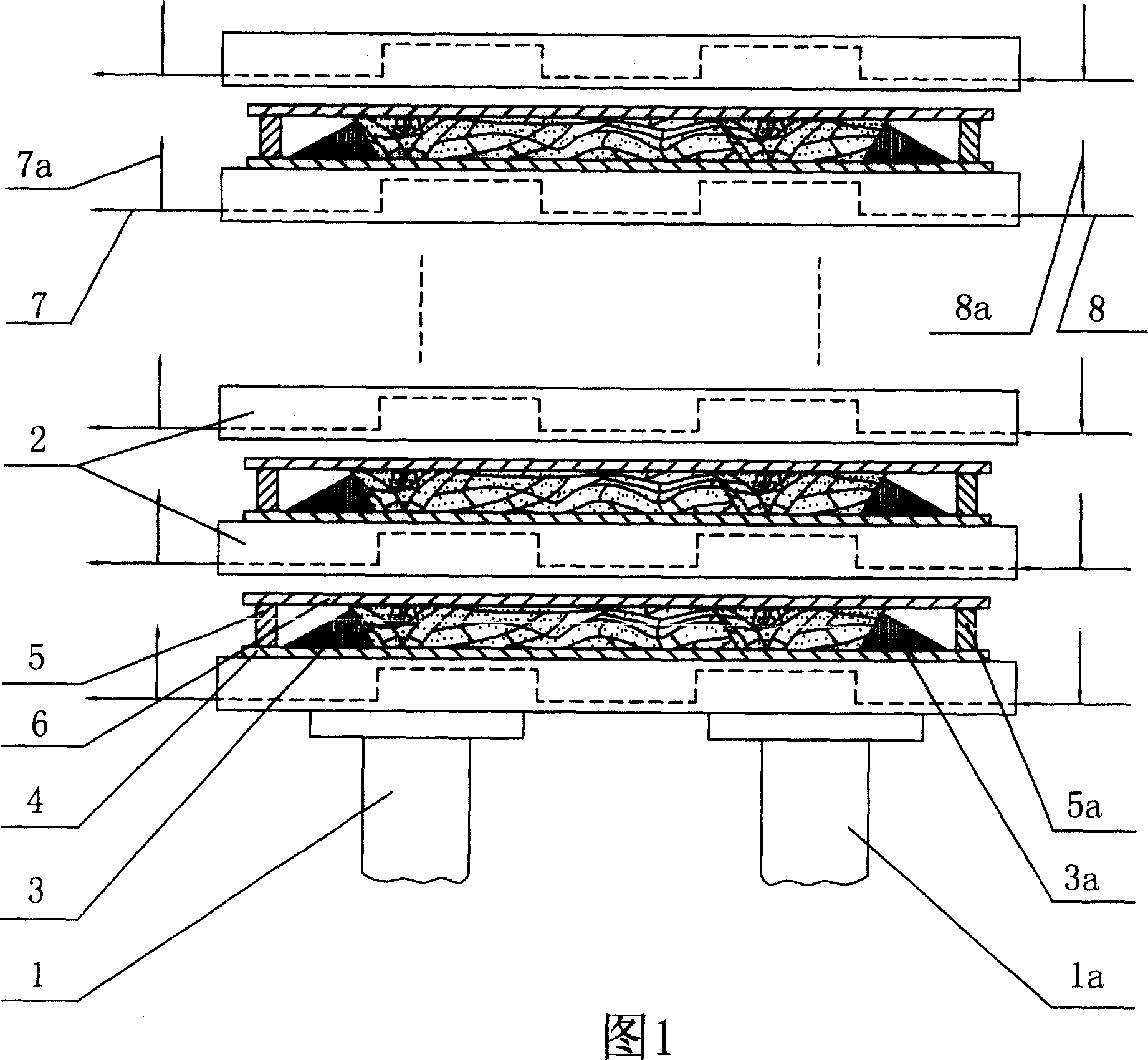

ActiveCN101269500AHigh densityHigh static bending strengthWood veneer joiningPressure impregnationHigh densityPulp and paper industry

The invention relates to an untwining and dipping device of veneers of an artificial board, which comprises a base seat, a glue groove, a driver, an upper squeeze roller and a lower squeeze roller. The glue groove, the driver, the upper squeeze roller and the lower squeeze roller are supported on a pedestal; the driver is connected with the upper squeeze roller and the lower squeeze roller which are opposite to each other and mutually distant; the outer margin of the upper squeeze roller presents a cylndrical surface which is provided with convex teeth, and the lower squeeze roller presents a cylndrical surface; therefore, coarse glue can be fully permeated in the veneers, and the artificial board which is lapped by the veneers can achieve the requiements of high density, high static bending strength, high elastic modulus, and high hardness performance index.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

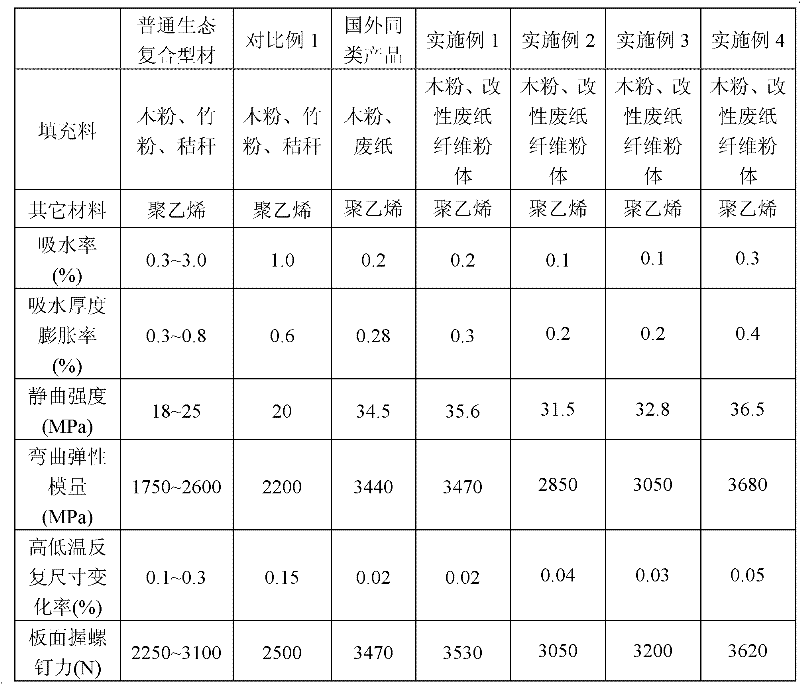

A kind of ecological composite material and preparation method thereof

InactiveCN102260386AEvenly dispersedIncrease the amount addedPaper recyclingWaste paper working-upFiberOligomer

The invention discloses an ecological composite material, which consists of a basic material and an assistant, wherein the basic material comprises the following raw materials in percentage by weight: 12 to 45 percent of modified waste paper fiber powder, 8 to 30 percent of wood meal and 25 to 80 percent of polyethylene; the preparation method of the modified waste paper fiber powder comprises: cutting waste paper into pieces, directly soaking the waste paper into soaking solution, filtering, draining, performing heat treatment at 95 to 130 DEG C for 10 to 120 DEG C, obtaining modified waste paper pieces, crushing the modified waste paper pieces by high-speed mixing and shearing, filtering and drying to obtain modified waste paper fiber powder; and the soaking solution may be ethanol and water mixed solution of one or two of vinylsilane and vinylsiloxane oligomer. The ecological composite material has high static bending strength and creep resistance. The invention also discloses a method for preparing the material. The method is simple in operation and easy to control.

Owner:浙江金磊窗业有限公司

Elastomer modified plastic-wood composite board and preparation method thereof

The invention relates to a plastic-wood material, particularly to an elastomer modified plastic-wood composite board and a preparation method thereof. Plastic particles, maleic anhydride grafted plastic particles, kaolin powder, hollow glass microspheres and stearic acid are placed in a mechanical stirring kettle to be stirred and then are extruded and granulated, so as to obtain modified plastic particles; and the modified plastic particles, wood powder, a polyolefin elastomer, a thermoplastic polyurethane elastomer and pigment are placed into the mechanical stirred kettle to be stirred and uniformly mixed, then are melted, blended and extrusion-molded and finally pass through a flat finish mold, so as to obtain the elastomer modified plastic-wood composite board. The elastomer modified plastic-wood composite board provided by the invention has the advantages as follows: the production-manufacturing is convenient, the degree of mechanization of the production process is higher, less labor is required, and the production cost is low; the consumption of plastics is low, environmental friendliness and creep deformation resistance are achieved, the strength and the rigidity are high, and the service life is longer; and the elastomer modified plastic-wood composite board can be widely applied to various fields such as transportation, decoration, municipal gardens and packaging.

Owner:G&S HUZHOU ENTERPRISES

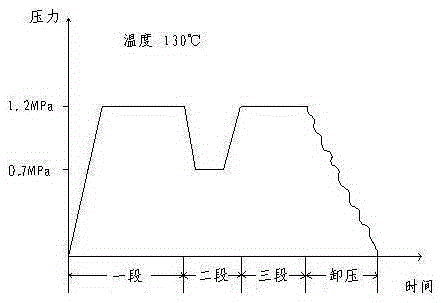

Hot pressing process for plywood

InactiveCN105382889AReduce energy consumptionExacerbated thermal movementWood veneer joiningMechanical engineeringIndustrial engineering

The invention discloses a hot pressing process for plywood. The hot pressing process for plywood includes a first hot pressing stage, a second hot pressing stage, a third hot pressing stage and a fourth non-polar pressure relief stage; hot pressing pressure of the three stages fluctuates, Brownian movement of the surface of a plate blank and internal plate layers is quickened, the hot pressing time of the plywood in each batch is greatly shortened by more than 10 min, and the bottleneck of the hot pressing working procedure in the plywood flow line production process is solved; and meanwhile, the plywood is better in performance and more stable.

Owner:栾金榜 +2

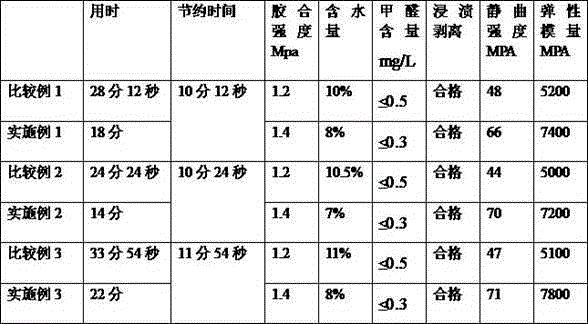

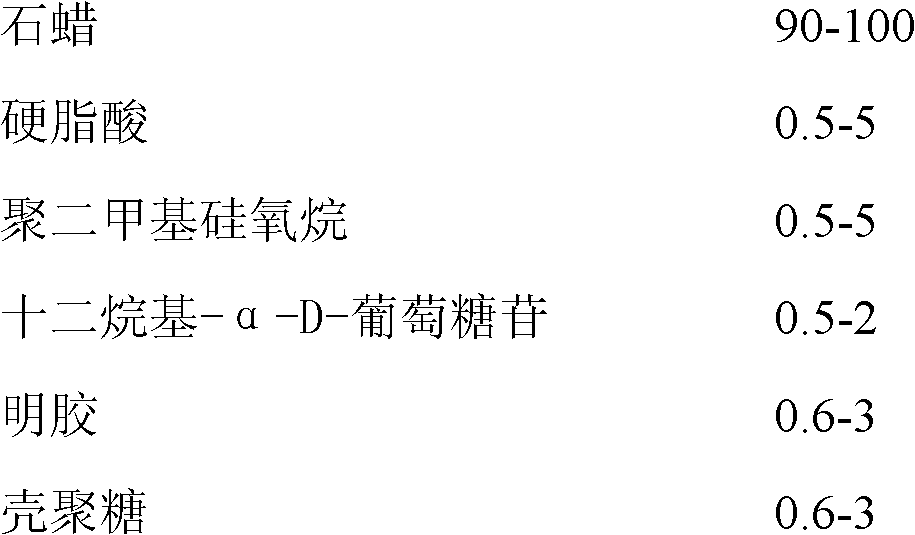

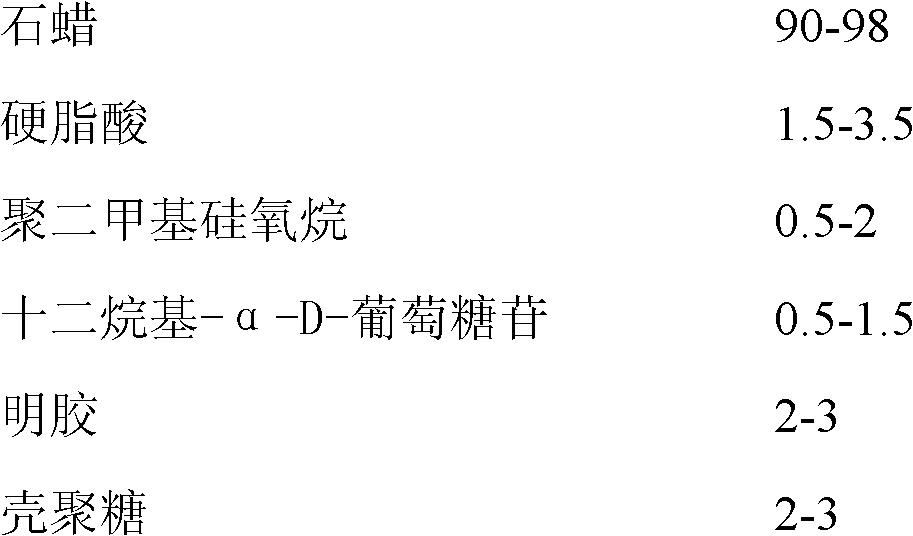

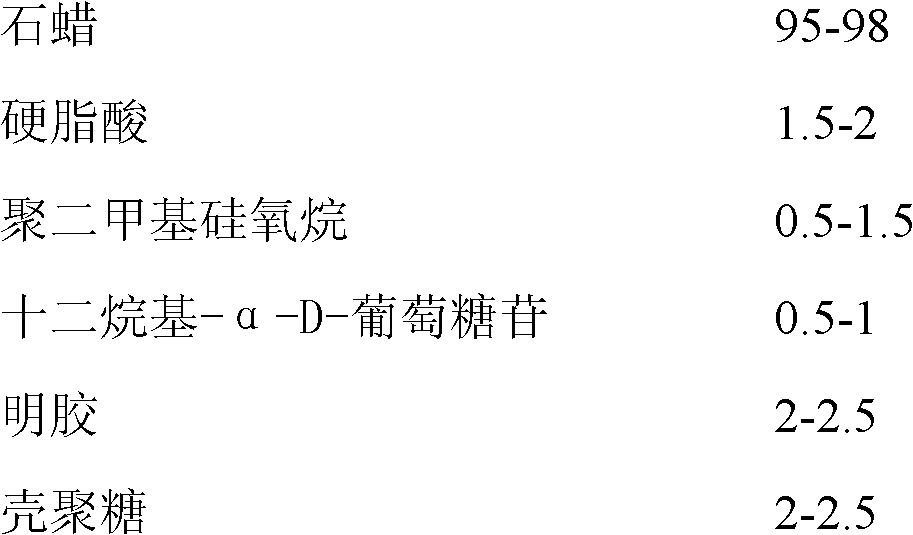

Water-proof and mildew-proof agent for artificial board and preparation method thereof

ActiveCN102952409AImprove waterproof and mildew resistanceEvenly distributedStearic acidUltimate tensile strength

The invention discloses a water-proof and mildew-proof agent for an artificial board and a preparation method thereof. The water-proof and mildew-proof agent comprises a capsule core and a capsule shell, wherein the capsule core is composed of paraffin, stearic acid and dodecyl-alpha-D-glucoside; and the capsule shell is composed of high molecular compound gelatin and chitosan. The preparation method comprises the following steps: melting the substances having water-proof property; under the action of the surfactant dodecyl-alpha-D-glucoside, dispersing in a hot gelatin and chitosan water solution in a nano particle state; and regulating the pH value, and quickly cooling to ensure that the gelatin and the chitosan are condensed into thin films coated on the nano particles of the substances having water-proof and mildew-proof property, thus forming nano capsules. The water-proof and mildew-proof agent prepared by the invention can reduce the instantaneous water absorption rate of the artificial board, improve the water-proof and mildew-proof property of the artificial board, enhance the internal bonding strength of the board, improve the product quality and save the cost by more than 20%.

Owner:ZHAOQING LIHE TECH DEV +3

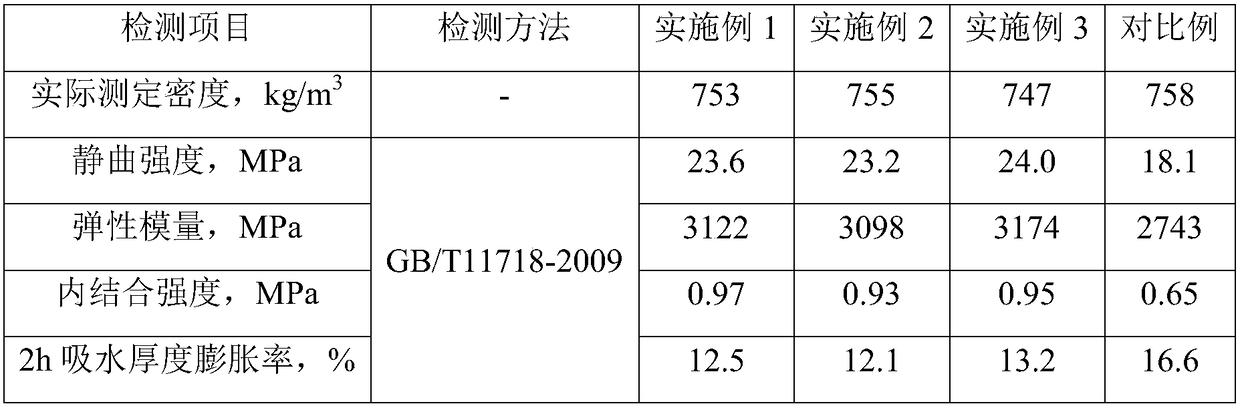

Environment-friendly flame-retardant non-adhesive fiberboard of crop straw and preparation method thereof

ActiveCN108656305AHigh bonding strengthImprove mechanical propertiesWood working apparatusDomestic articlesFiberFiberboard

The invention relates to an environment-friendly flame-retardant non-adhesive fiberboard of crop straw and a preparation method thereof. The fiberboard is prepared by the following steps that 1 ) wheat straw and sorghum straw are taken to be cut off correspondingly, and the wheat straw and the sorghum straw are soaked in water to obtain a softened material; 2 ) steam explosion is correspondingly carried out on the softened material to obtain wheat straw fiber and sorghum straw fiber; 3 ) nano calcium carbonate, nano zinc oxide are mixed with nano copper oxide, and modifying is carried out toobtain a modified additive A; nano zinc borate, the nano zinc oxide are mixed with the nano copper oxide, and modifying is carried out to obtain a modified additive B; 4 ) the wheat straw fiber and the sorghum straw fiber are mixed with the modified additive A to obtain a core layer mixture; the wheat straw fiber is mixed with the modified additive B to obtain a surface layer mixture; and 5 ) thecore layer mixture is taken as a core layer, the surface layer mixture is taken as a surface layer to be laid and pre-pressed to obtain a slab, after hot-pressing forming and post-treatment are carried out, the environment-friendly flame-retardant non-adhesive fiberboard is obtained. The fiberboard has no formaldehyde release and has good mechanical property, good anti-water, moisture-proof, anti-corrosion and antibacterial properties; and good in fireproof and flame-retardant effects, and suitable for popularization and application.

Owner:霸州市光洋人造板制造有限公司

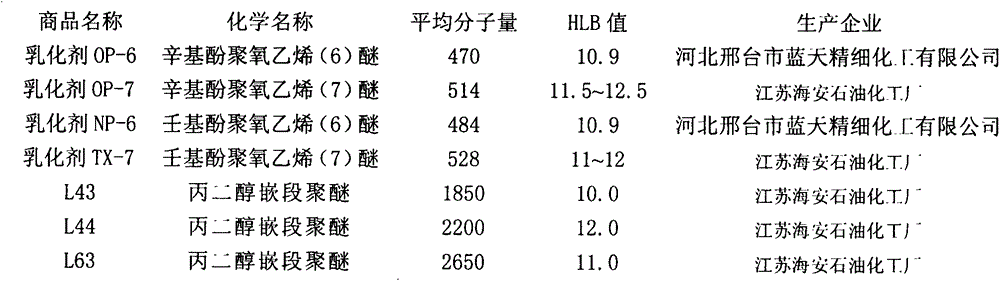

Emulsion paraffin for producing waterproof fiberboard and preparation method thereof

ActiveCN103146204AImprove waterproof performanceImprove stabilityOther chemical processesParaffin waxEmulsion

The invention relates to emulsion paraffin for producing a waterproof fiberboard. The emulsion paraffin comprises solid paraffin, an emulsifier, a colloid stabilizer, a waterproof agent and water. The emulsion paraffin is obtained by self-emulsification in one step based on weakly hydrophilic polyether and / or phenolic ether as the emulsifier and polyvinyl formal as the colloid stabilizer. The preparation method comprises the following steps of: adding solid paraffin, the emulsifier, the waterproof agent and water; heating to 90-95 DEG C to completely dissolve solid paraffin; then, adding the colloid stabilizer polyvinyl formal aqueous solution to self-emulsify the mixed system to form a milk white emulsion; and cooling the emulsion to room temperature to obtain the target product. The reaction process is free from stirring, the mixed liquid is self-emulsified, and the average grain diameter of product particle is not greater than 300nm.

Owner:GUANGXI RES INST OF CHEM IND CO LTD +2

Environment-friendly high-strength bamboo-wood compound shaving board

InactiveCN105365024AImprove performanceHigh static bending strengthFlat articlesDomestic articlesFiberAdhesive glue

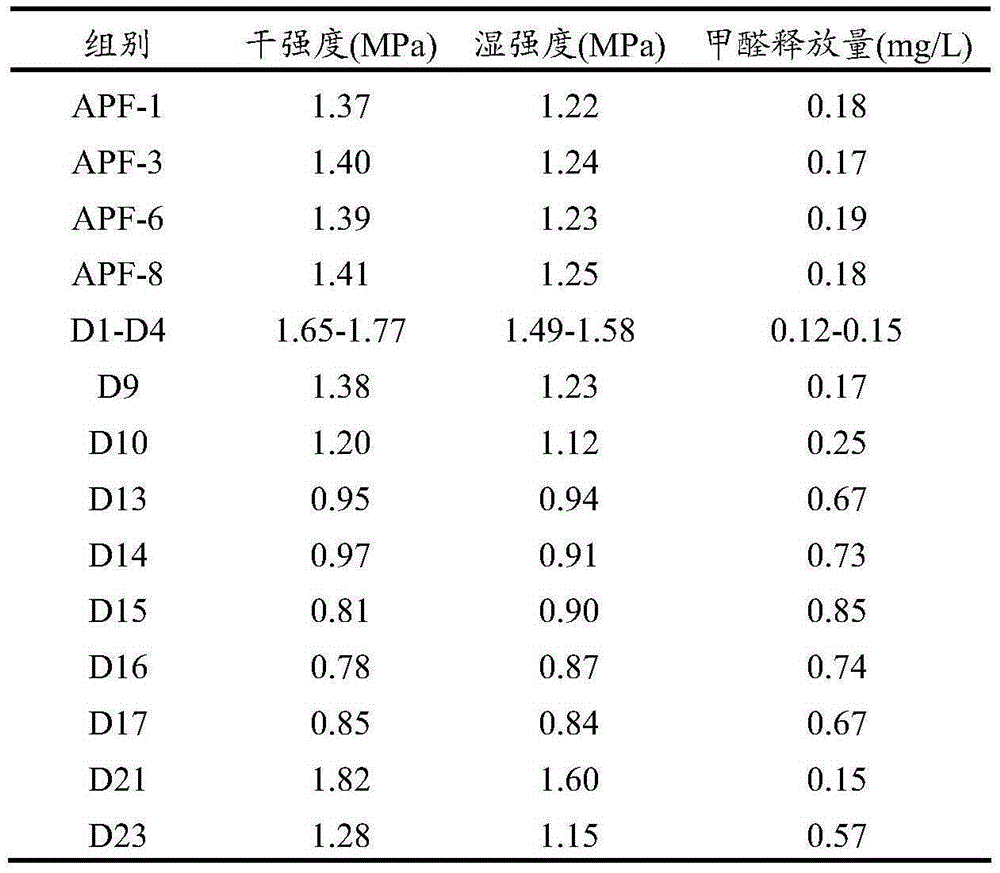

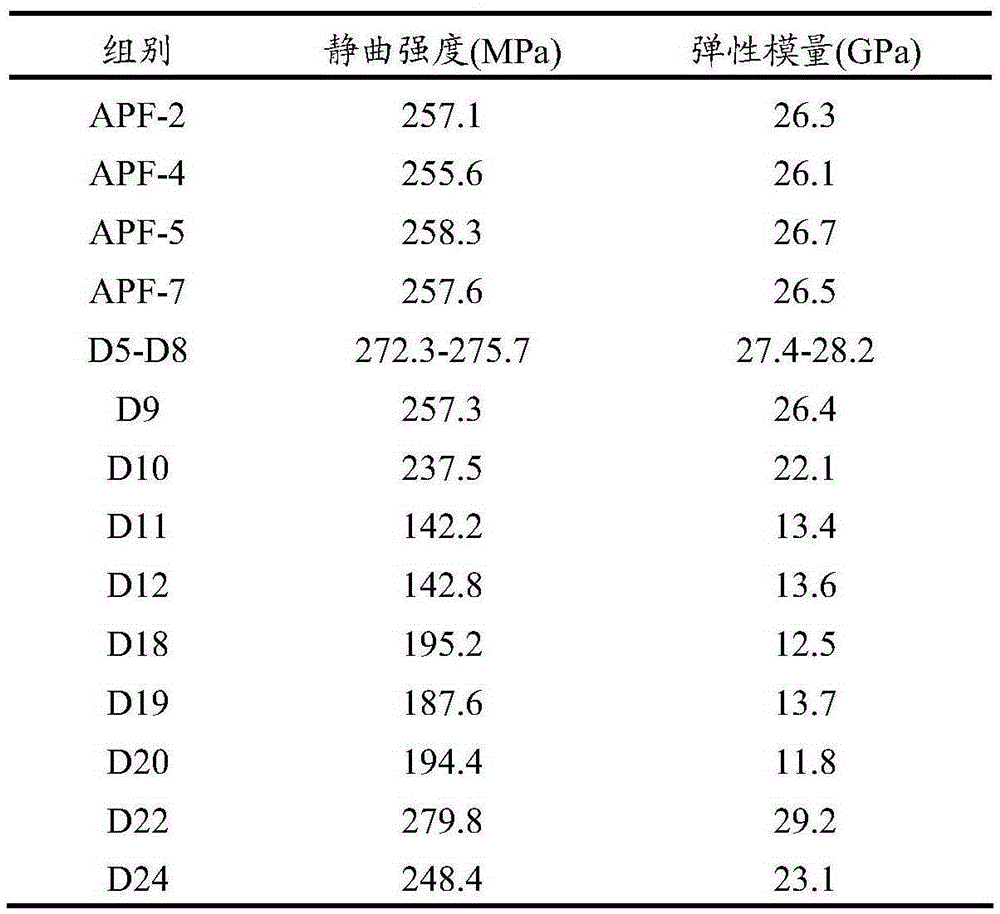

The invention discloses an environment-friendly high-strength bamboo-wood compound shaving board. An anti-corrosion step of bamboo fibers is omitted. Laccase of 8-10 U / g of bamboo fibers and galactosidase of 1-1.3 U / g of bamboo fibers are adopted to be preserved at a specific temperature for a certain period, proper high-temperature treatment is conducted after pressing is conducted, the bamboo fibers can be modified effectively, high intensity is kept while the use amount of glue is reduced, and the board is more resistant to abrasion and more durable. The environment-friendly high-strength bamboo-wood compound shaving board has the effects that the static bending intensity ranges from 26.1 MPa to 28.6 MPa, the internal bonding strength ranges from 1.21 MPa to 1.30 MPa, the free formaldehyde emission ranges from 2.4 mg to 2.6 mg per 100 g, and the water absorption expansion rate ranges from 4.1% to 4.6%.

Owner:丁芬

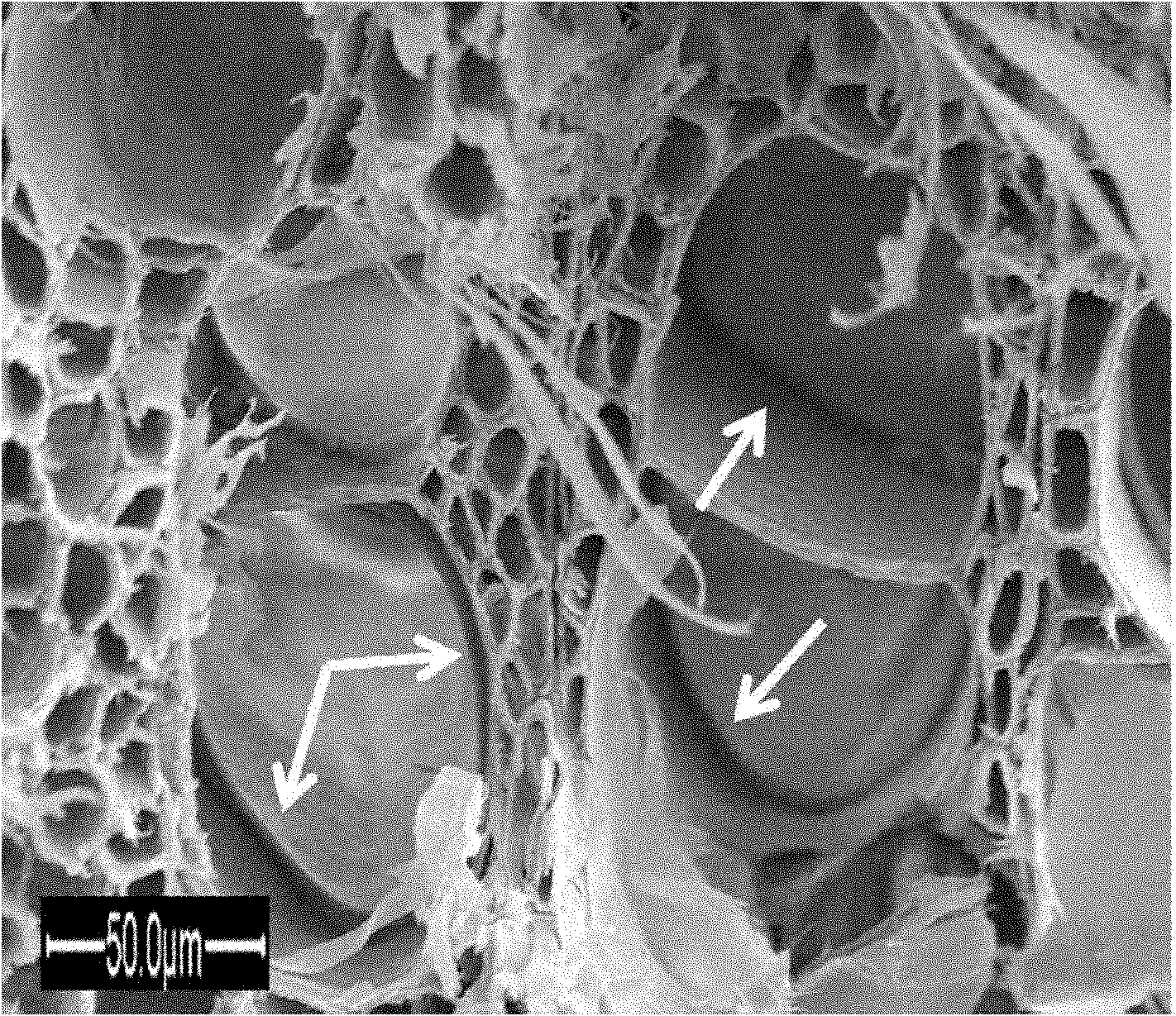

Preparation method of wood plastic composite with good interface compatibility

InactiveCN101966716AImprove interface compatibilityGood interface compatibilityOpen tank impregnationFunctional monomerVacuum pumping

The invention discloses a preparation method of a wood plastic composite with good interface compatibility and relates to the preparation method of the wood plastic composite. The preparation method can solve the problems of low mechanical strength and poor durability caused by poor interface compatibility between a polymer and the wood cell wall of the existing wood plastic composite. The method comprises the following steps: preparing a functional monomer, a reactive monomer, an initiator and a grafting promoter into impregnation solution, adding wood and the impregnation solution into a reaction tank, immersing the wood in the impregnation solution, firstly carrying out vacuum pumping, and then carrying out pressurization treatment for leading the impregnation solution to enter into a porous structure of the wood; and further carrying out heating treatment on the wood for polymerizing organic matters, and obtaining the wood plastic composite. The wood plastic composite can lead the polymer to be in close contact with pore walls, improve the compressive strength parallel to grain by 70%-120% in comparison with the wood which is not processed, lead the anti-inflation rate after carrying out continuous water immersion for 200h to be 53%-60% and improve the resistance to fungal erosion by 85%-94%, so that the wood plastic composite can be used as the material for indoor furniture and outdoor structures.

Owner:NORTHEAST FORESTRY UNIVERSITY

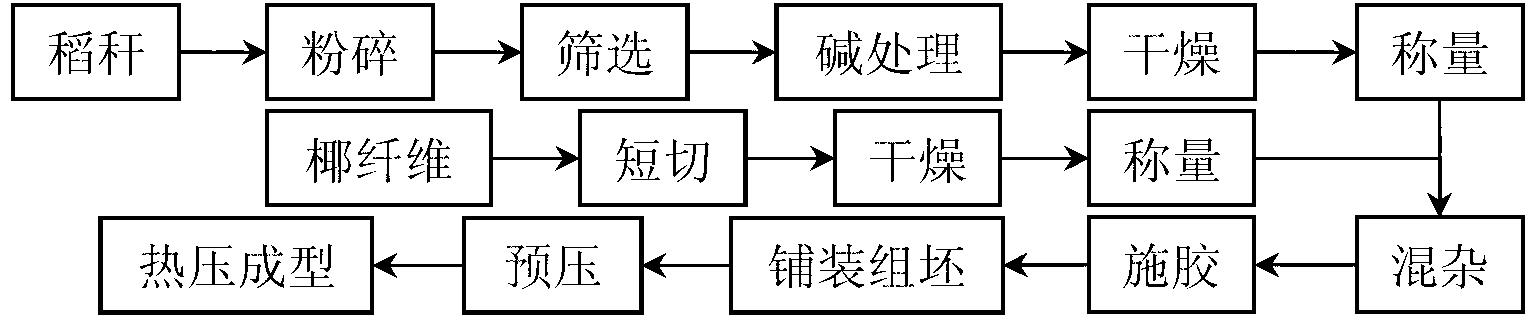

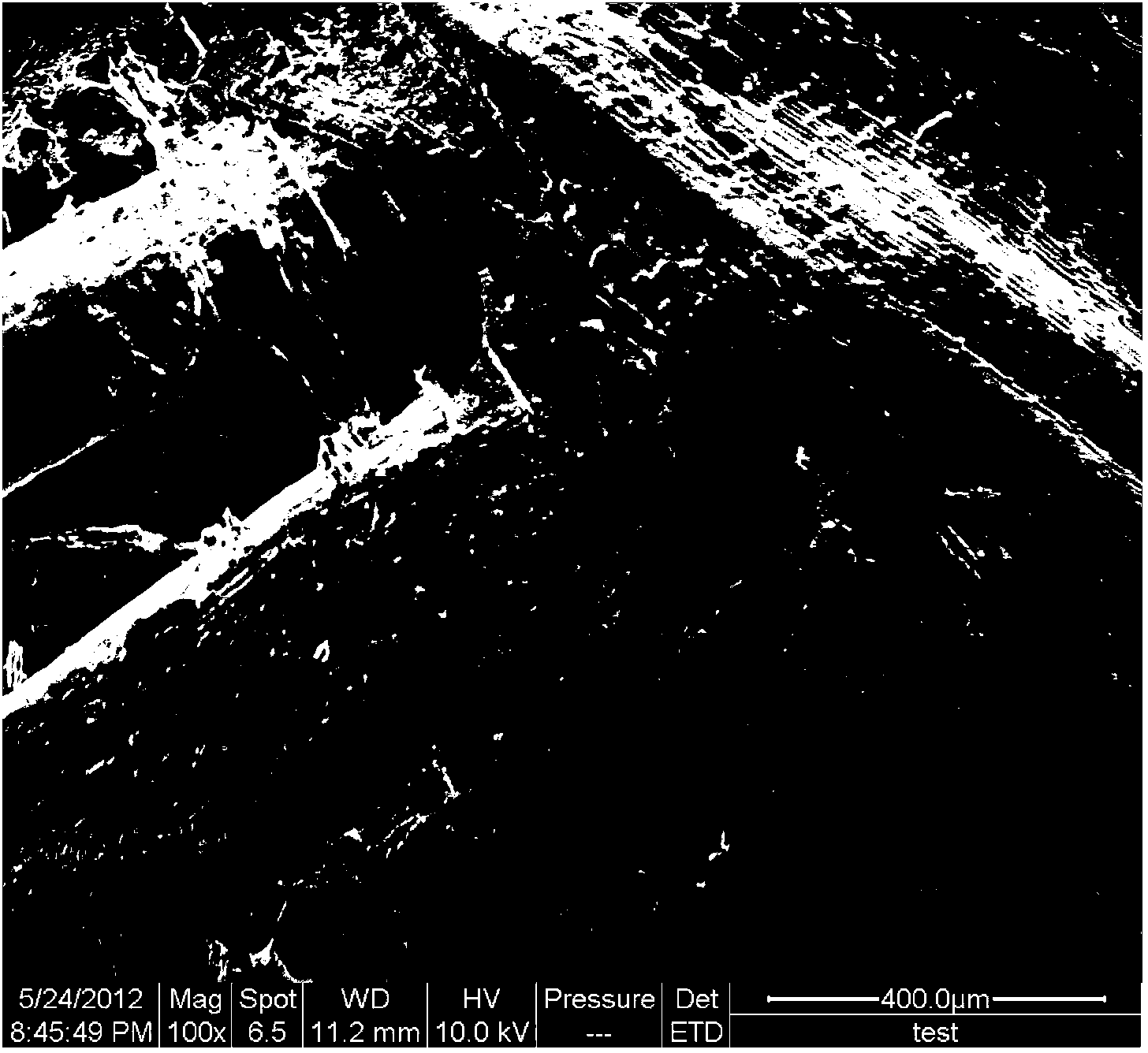

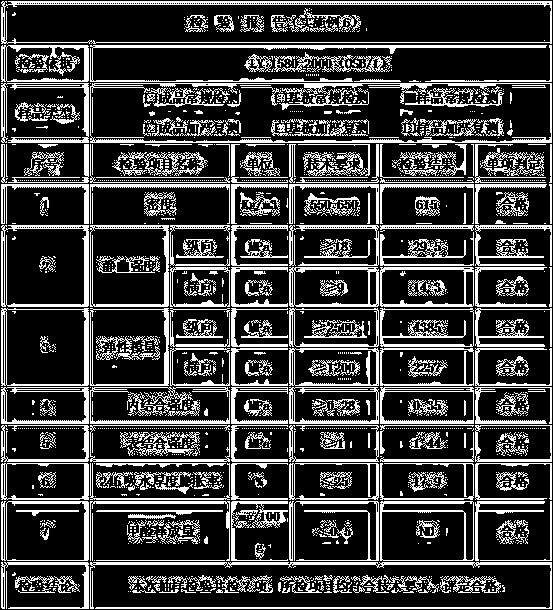

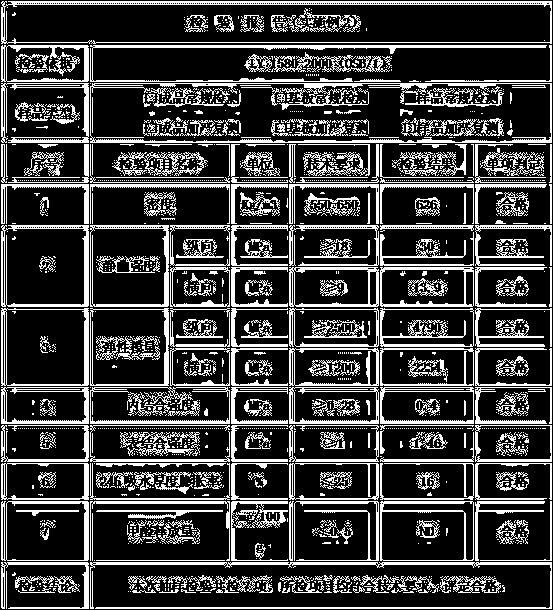

Coconut-fiber-reinforced crop straw composite material and manufacture method thereof

InactiveCN103072174ASimple preparation processImprove mechanical propertiesWood working apparatusFlat articlesAdhesiveToughness

The invention discloses a coconut-fiber-reinforced crop straw composite material and a manufacture method thereof, aiming to provide the strong-toughness and environment-friendly biomass composite material having good mechanical property, gluing property, toughness and vibration damping property. The coconut-fiber-reinforced crop straw composite material is formed by adding coconut fibers in crop straw units and uniformly dispersing as well as crossing and interconnecting the coconut fibers in a composite material system to form a bulky mesh structure, wherein the mass fraction of the coconut fibers in the system is 10-50%. The manufacture method comprises the following steps of: preparing and preprocessing of the straw units, preparing of the coconut fibers, unit mixing, gluing, paving and billet assembling, prepressing, hot-press or cold-press molding, postprocessing and the like. The coconut-fiber-reinforced crop straw composite material is free from isocyanate adhesives, so that the preparation cost of an artificial board can be reduced; and the coconut-fiber-reinforced crop straw composite material can be used as a structure material and a damping material and applied to bearing structures and in rigid use environments with frequent vibration fatigue actions and easily occurring impulse loads so as to play roles of bearing, supporting, damping and denoising, and thus, the application field of the crop straw artificial board is enlarged.

Owner:NORTHEAST FORESTRY UNIVERSITY

Aldehyde-free face decorating all-bamboo or bamboo-wood composite oriented strand board and manufacturing method thereof

InactiveCN109623980AHigh static bending strengthHigh elastic modulusCane mechanical workingFlat articlesWood shavingsSurface layer

The invention discloses an aldehyde-free face decorating all-bamboo or bamboo-wood composite oriented strand board and a manufacturing method thereof. In the method, all-bamboo or bamboo-wood composite large sheets and wood shavings are adopted as a core layer, oversized materials and fine materials serve as a surface layer, multi-layer all-bamboo or bamboo-wood composite large sheets are overlapped, the surface is smooth after hot pressing, the face decorating condition is completely achieved, and the problem that an ordinary oriented strand board is rough in surface, and face decorating cannot be achieved is solved. Compared with an all-wood oriented strand board, the performance is more excellent. Bamboo and wood materials are selected as raw materials, the problem that existing strandboard wood raw materials are in shortage is solved, and the production cost is reduced; a large number of bamboo large sheets are used in the production technology, a biomass adhesion agent is used onthe surface layer, and the environment protection concept is sufficiently embodied; and the surface layer is the biomass adhesion agent, the core layer is isocyanate, formaldehyde emission is zero, and harm caused by board formaldehyde emission at present is avoided.

Owner:NANNING KETIAN SHUIXING TECH LTD CO

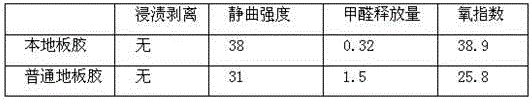

Flame-retardant furfural-modified urea-formaldehyde resin floor glue

InactiveCN104789173AImprove flame retardant performanceHigh oxygen indexMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesPolyvinyl acetateEmulsion

The invention discloses flame-retardant furfural-modified urea-formaldehyde resin floor glue which comprises the following components in parts by weight: 250-280 parts of formaldehyde, 120-130 parts of urea, 5-8 parts of furfural, 10-20 parts of polyvinyl acetate emulsion, 15-20 parts of a flame retardant A, and l0-15 parts of a flame retardant B. A preparation method of the floor glue comprises the following steps: adding measured formaldehyde, urea and furfural into a reaction kettle to obtain a solution, adjusting the PH value of the solution to be 8.0-8.5 with a sodium hydroxide solution, raising the temperature from room temperature to 70-75 DEG C, performing thermal reaction for 50-55 min; adding a formic acid solution to adjust the PH value of the reaction to be 5.2-5.5 after the thermal reaction, measuring the viscosity, when the viscosity reaches 22-25 Pa.s, adding the formic acid solution to adjust the PH value of the reaction to be 6.0, adding a measured polyvinyl acetate emulsion, raising the temperature to 85-90 DEG C, adding the measured flame retardant A after 10 min, performing thermal reaction for 70-75 min; then adding the measured flame retardant B, stirring the solution uniformly and performing reaction for 30-35 min and cooling to room temperature to obtain the flame-retardant furfural-modified urea-formaldehyde resin floor glue.

Owner:深圳宏耐木业有限公司

Formula and production method of copy paper

InactiveCN103643588AReduce weightHigh static bending strengthWater-repelling agents additionLuminescent/fluorescent substance additionSodium polyacrylateChemistry

The invention provides a formula and a production method of copy paper. The copy paper comprises the following components in percentage by weight: 5-10 percent of bleached softwood pulp, 3-5 percent of polylactic acid fiber, 20-40 percent of bleached hardwood pulp, 10-20 percent of alkaline peroxide mechanical pulp, 30-45 percent of straw pulp, 2-3 percent of a powdered ink adhesive agent, 0.2-0.5 percent of water solidification resin, and 3-5 percent of sodium polyacrylate. The production method comprises the following steps: pulping, proportioning, papermaking and forming, surface sizing, rewinding, cutting-sorting, and packaging for forming.

Owner:福建省晋江优兰发纸业有限公司

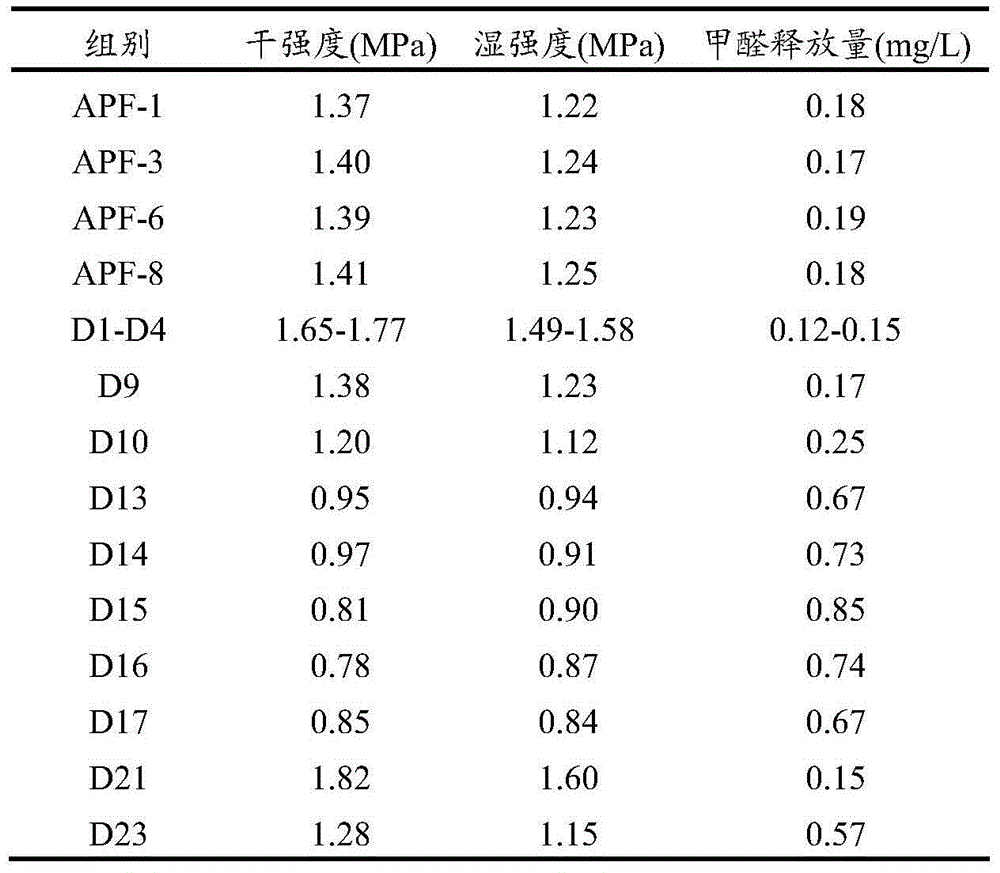

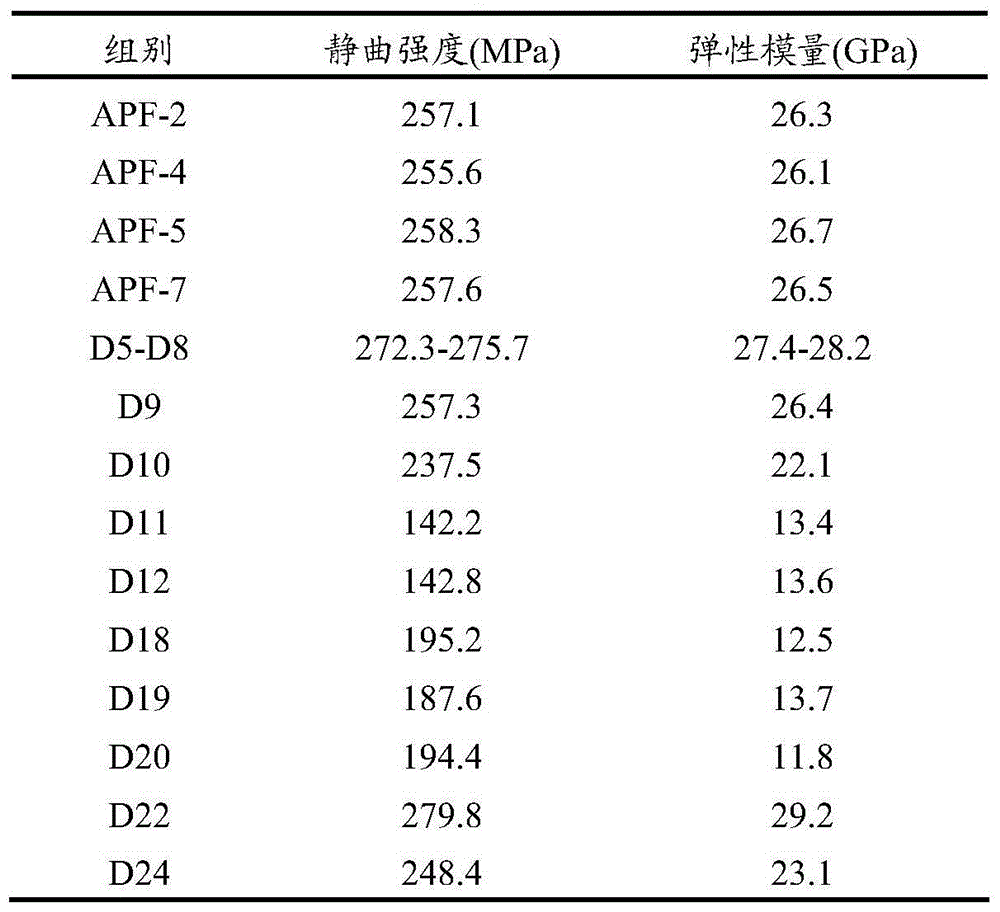

Nano-alumina-modified phenolic resin adhesive and its preparation method and use

ActiveCN104152088AImprove performanceHigh modulus of elasticityNon-macromolecular adhesive additivesMacromolecular adhesive additivesNano al2o3Resin adhesive

The invention relates to a nano-alumina-modified phenolic resin adhesive and its preparation method and use. Through use of nano-alumina, appropriate selection of assistant ingredients and improvement of processes, integral performances of the adhesive are effectively improved. The nano-alumina-modified phenolic resin adhesive has wide industrial application values in possessing manufacture of wood materials or bamboo materials such as bamboo wood plywood, a particieboard, an oriented particieboard, laminated wood, integrated wood materials and scrimber.

Owner:INT CENT FOR BAMBOO & RATTAN

A kind of nano-alumina modified phenolic resin adhesive and its preparation method and application

ActiveCN104152088BImprove performanceHigh modulus of elasticityNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesNano al2o3Resin adhesive

The invention relates to a nano-alumina-modified phenolic resin adhesive and its preparation method and use. Through use of nano-alumina, appropriate selection of assistant ingredients and improvement of processes, integral performances of the adhesive are effectively improved. The nano-alumina-modified phenolic resin adhesive has wide industrial application values in possessing manufacture of wood materials or bamboo materials such as bamboo wood plywood, a particieboard, an oriented particieboard, laminated wood, integrated wood materials and scrimber.

Owner:INT CENT FOR BAMBOO & RATTAN

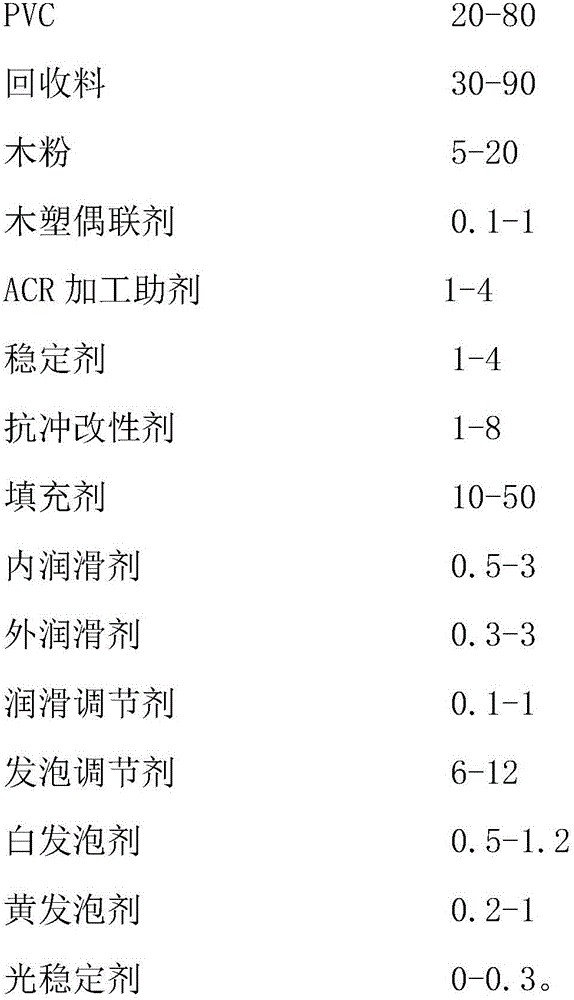

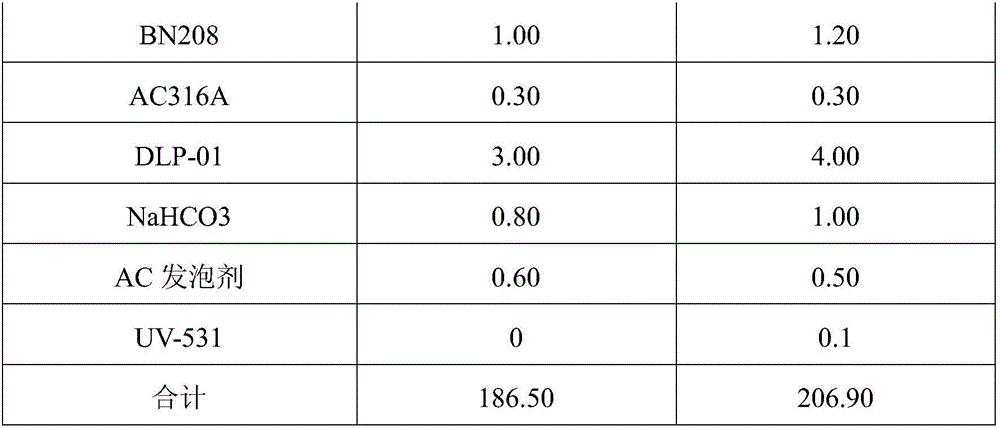

Wood and plastic building template and production method thereof

InactiveCN106221074AHigh static bending strengthHigh flexural modulusEngineeringCorrosion prevention

The invention provides a wood and plastic building template and a production method thereof. Reclaimed materials are used for designing a formula, and a production process is optimized according to formula raw material properties. Compared with the prior art, the production method is characterized in that the formula and the dosage proportion of raw materials are controlled to prepare the wood plastic building template, and the wood plastic building template has the advantages of high static bending intensity, high bending elastic modulus, high screw holding strength, flame retardance, good water resistance, acid and alkali resistance, corrosion prevention, energy saving and environment protection, and can be repeatedly recycled.

Owner:海螺(安徽)节能环保新材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com