Method for making formaldehyde-free high-strength artificial plate

A manufacturing method and technology of wood-based panels, applied in the direction of manufacturing tools, flat products, pretreatment of molding materials, etc., can solve the problems of poor bonding effect of straw, loose structure, volatilization of formaldehyde, etc., and achieve wide application and finished products The structure is compact and meticulous, and the effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

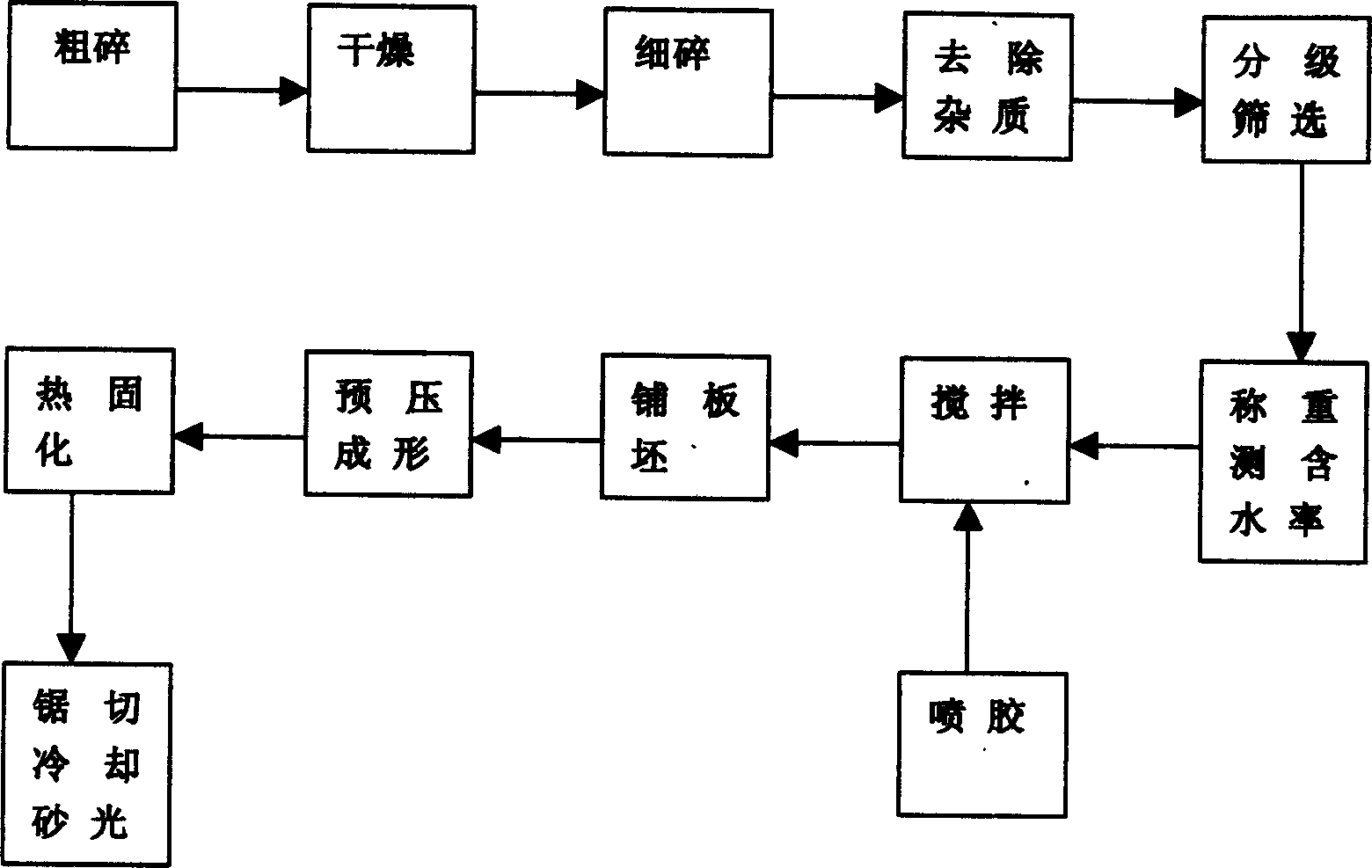

[0015] Combine now figure 1 The present invention will be described in detail.

[0016] The raw materials used in the present invention are discarded agricultural crop stalks in rural areas, such as wheat straw, corn stalks (including corn cobs after grain removal), sorghum stalks, rice stalks, etc., which are compressed and bundled for storage after collection. The bundled stalks are sent to the coarse crusher by the conveyor for coarse crushing, and the coarsely crushed stalks are sent to the dryer through the conveyor for drying until the moisture content is within the range of 11% to 17%. The dried straw material is sent to the homogenizer by a conveyor for mixing, and then goes through a magnetic separation to remove impurities such as iron and stones, and then enters a fine grinder to be crushed to a size of 0.1-6mm, and then is sent to the grading machine by an air conveyor. The sieve is sorted by size, and the dust is removed, and sent to the silo. The crushed straw ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com