Patents

Literature

146results about How to "Increase joint area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

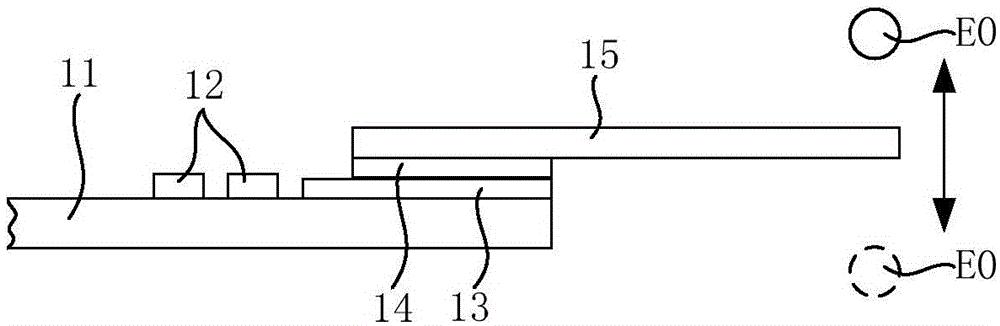

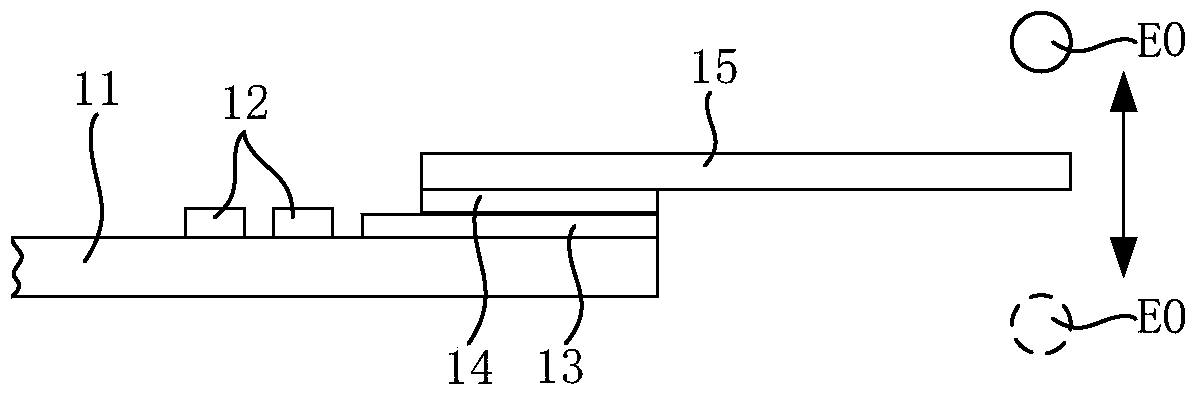

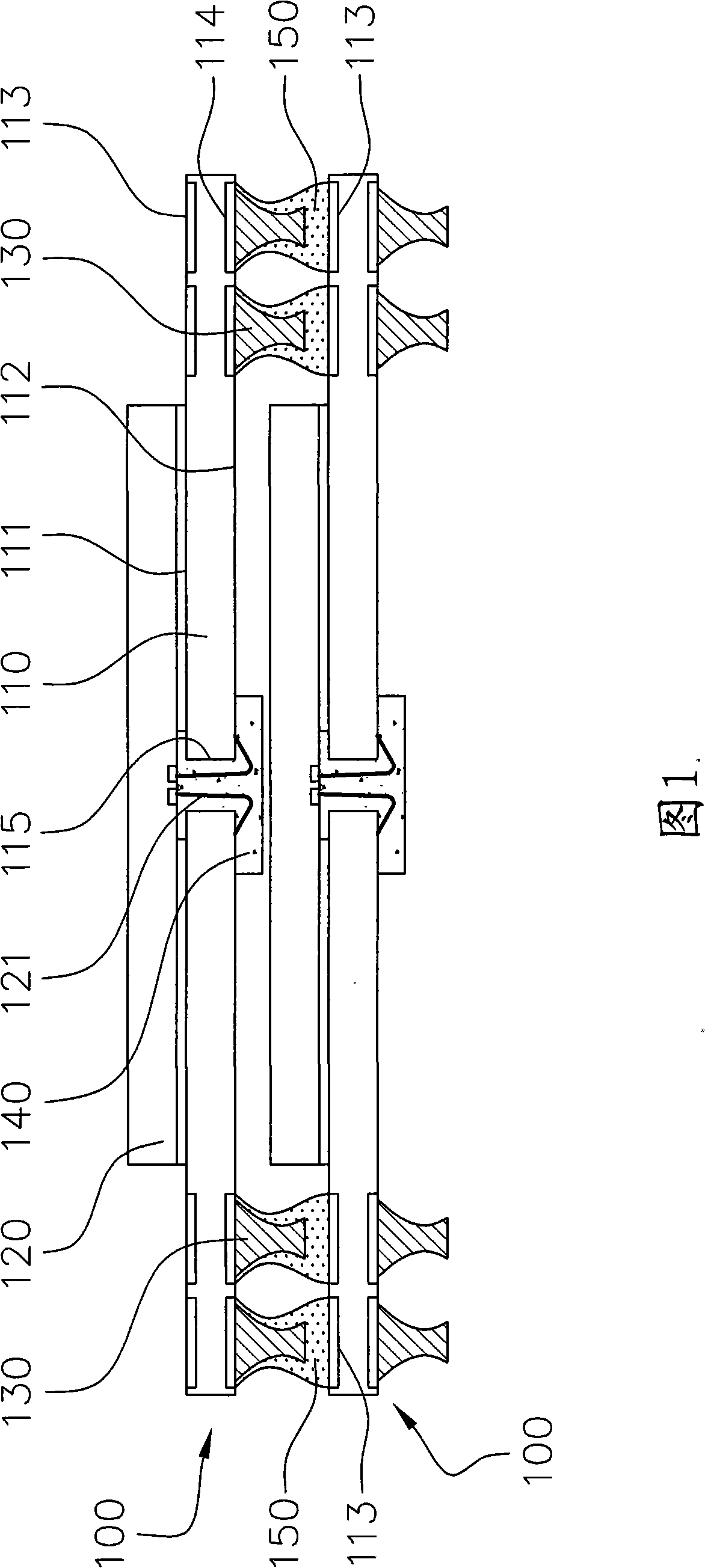

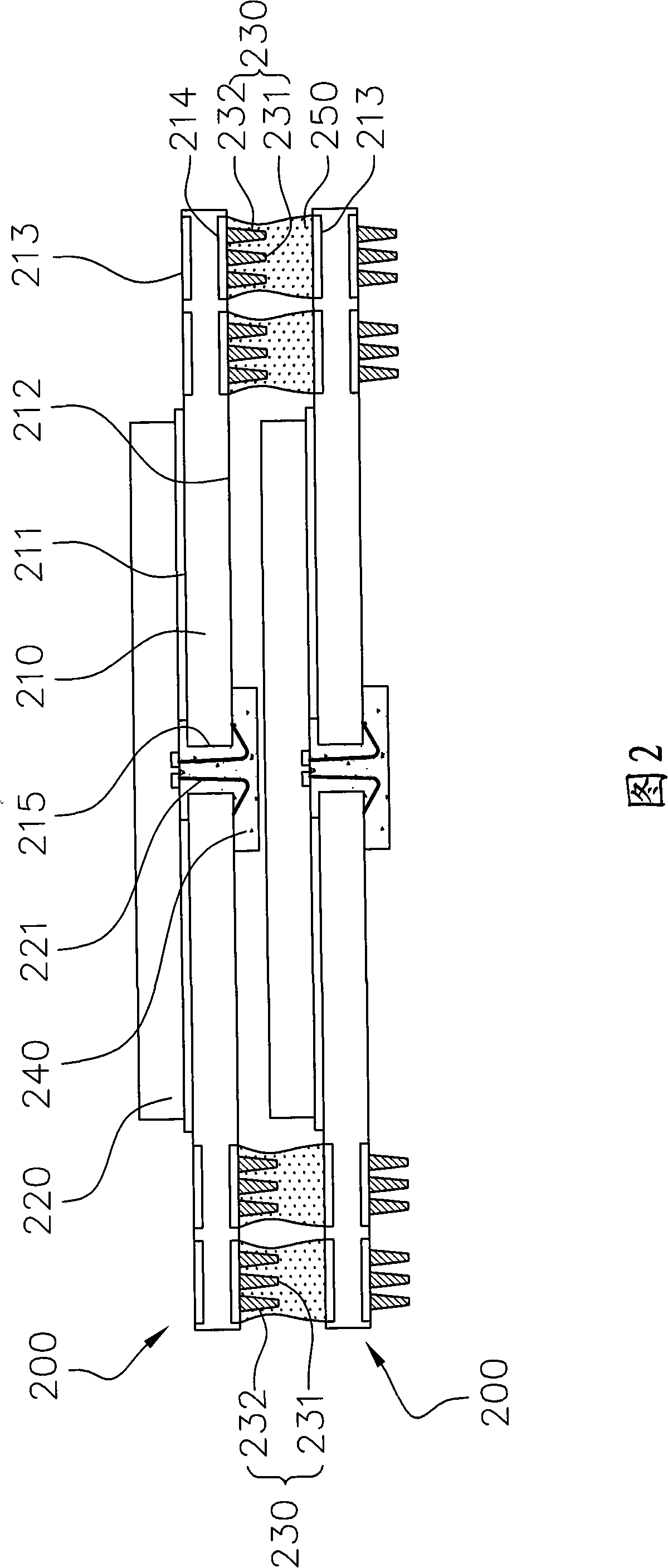

LED filament and filament type LED bulb

ActiveCN105090782AHigh bonding strengthIncrease joint areaPoint-like light sourceElectric circuit arrangementsNeck partsEngineering

The invention relates to an LED filament and a filament type LED bulb using the LED filament. The LED filament comprises a carrier, LED chips arranged on the carrier, and an electric conduction pin fixedly connected with the carrier. The electric conduction pin is electrically connected with the LED chips. The electric conduction pin comprises a pin head part, a pin tail part and a pin neck part used connected with the pin head part and the pin tail part. The entity width of the pin neck part is smaller than the maximum entity width of the pin head part. The pin neck part with the reduced entity width is obtained through the mode of internally reducing the width of the pin head part relative to the pin neck part or opening a through hole in the pin neck part or other modes, the pin neck part becomes a weak point of the electric conduction pin; and in this way, when stress is generated, the pin neck part acts firstly, and the joint of the pin head part and the carrier or the carrier itself can be protected.

Owner:KAISTAR LIGHTING (XIAMEN) CO LTD +1

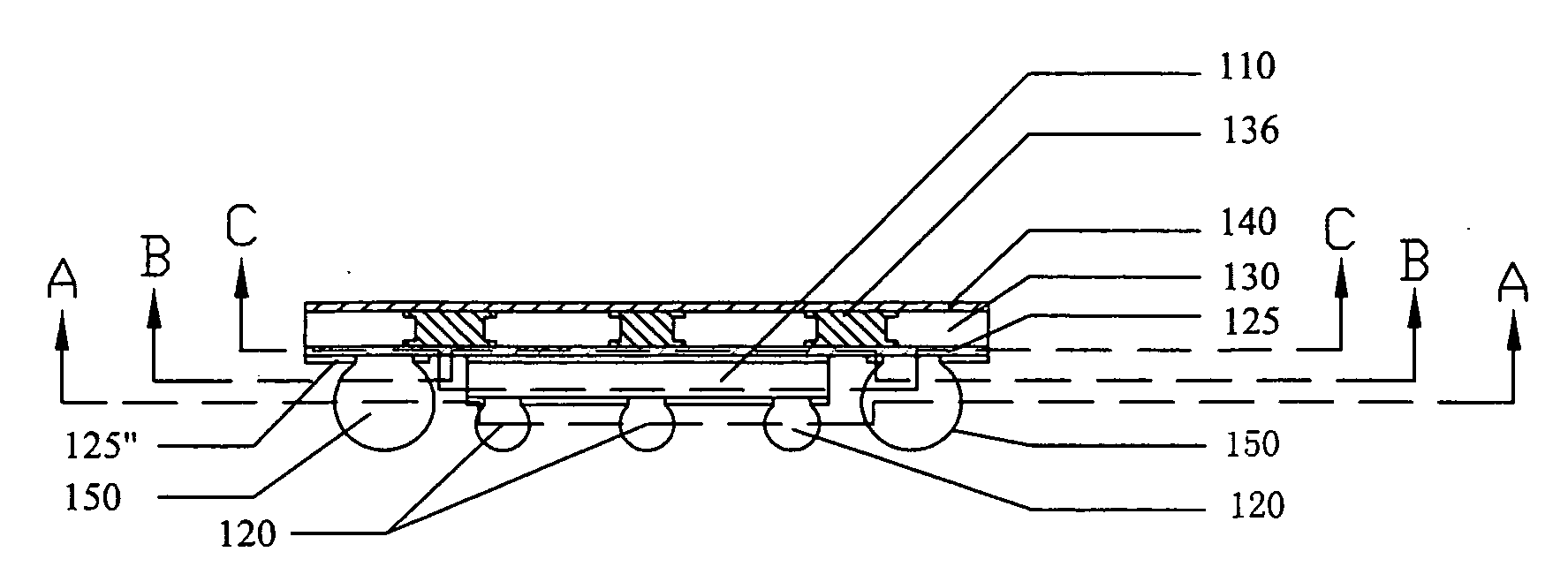

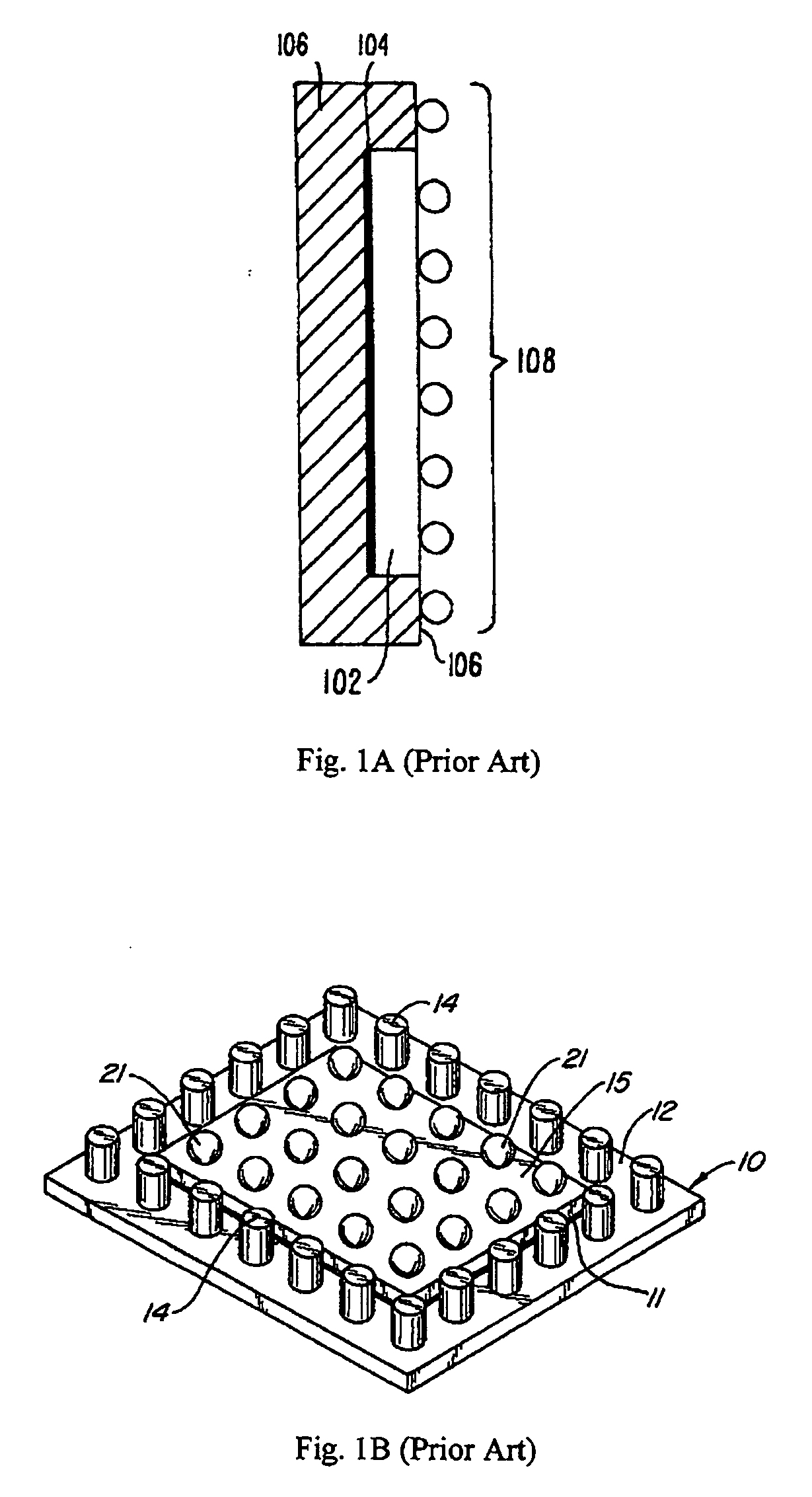

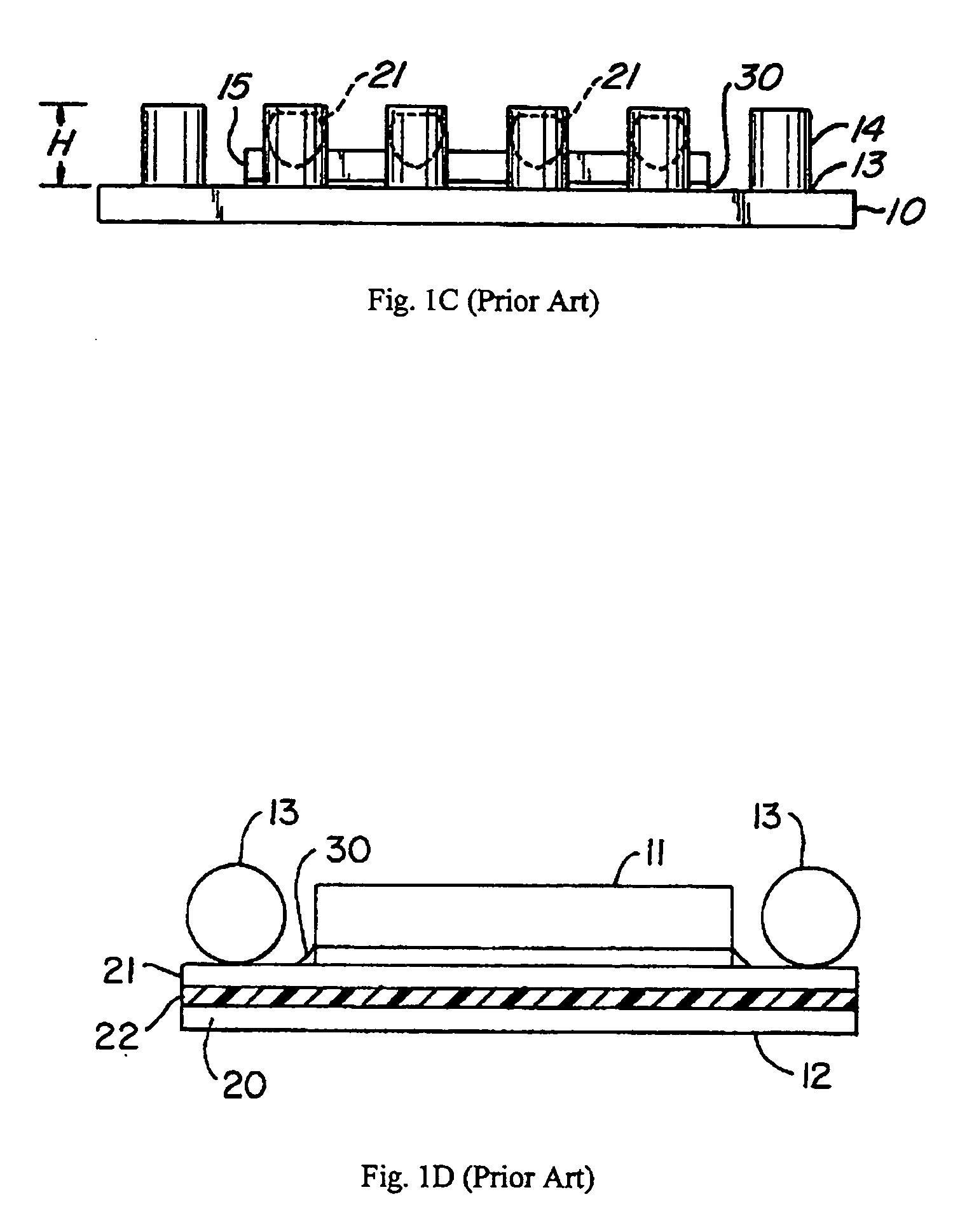

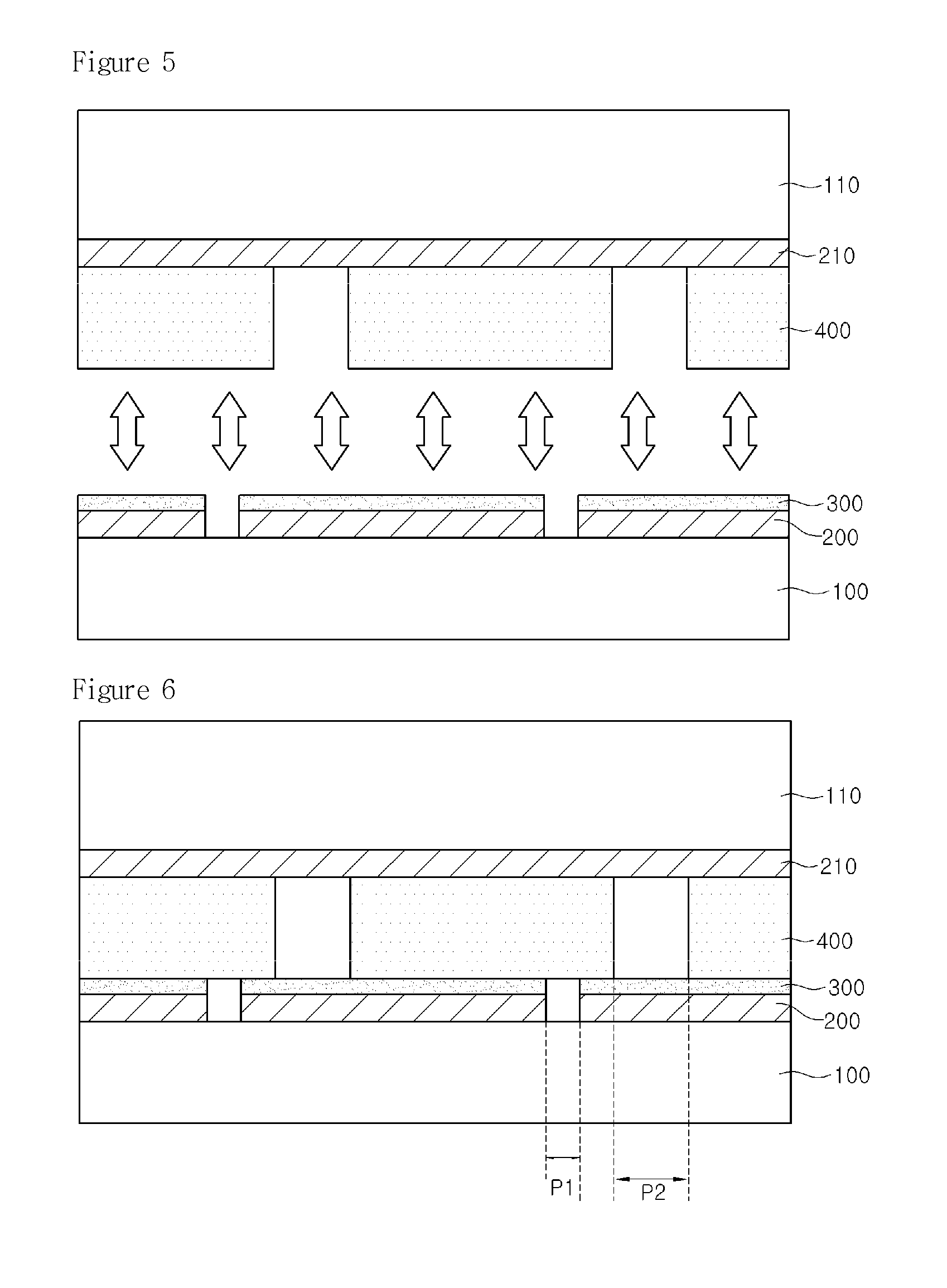

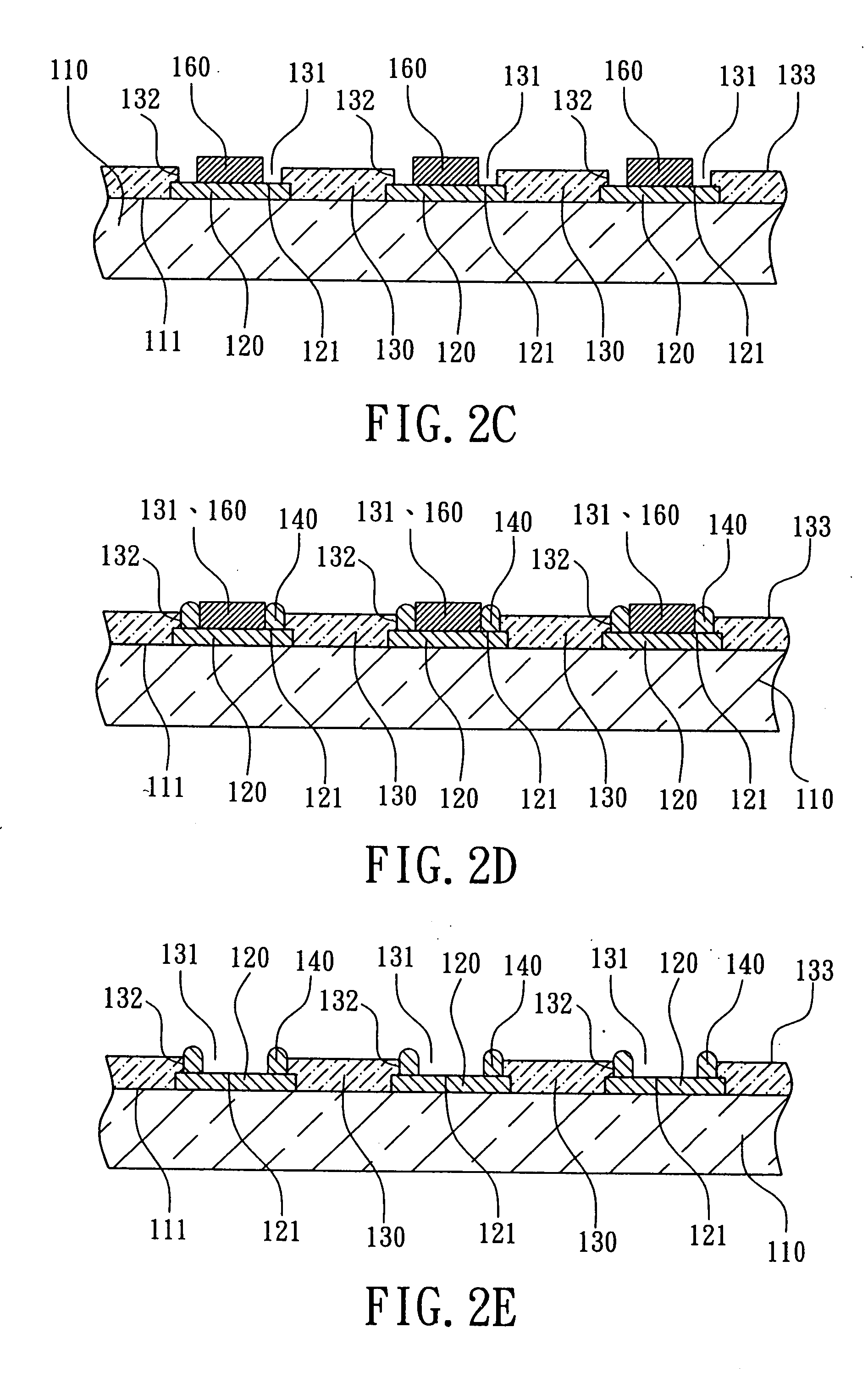

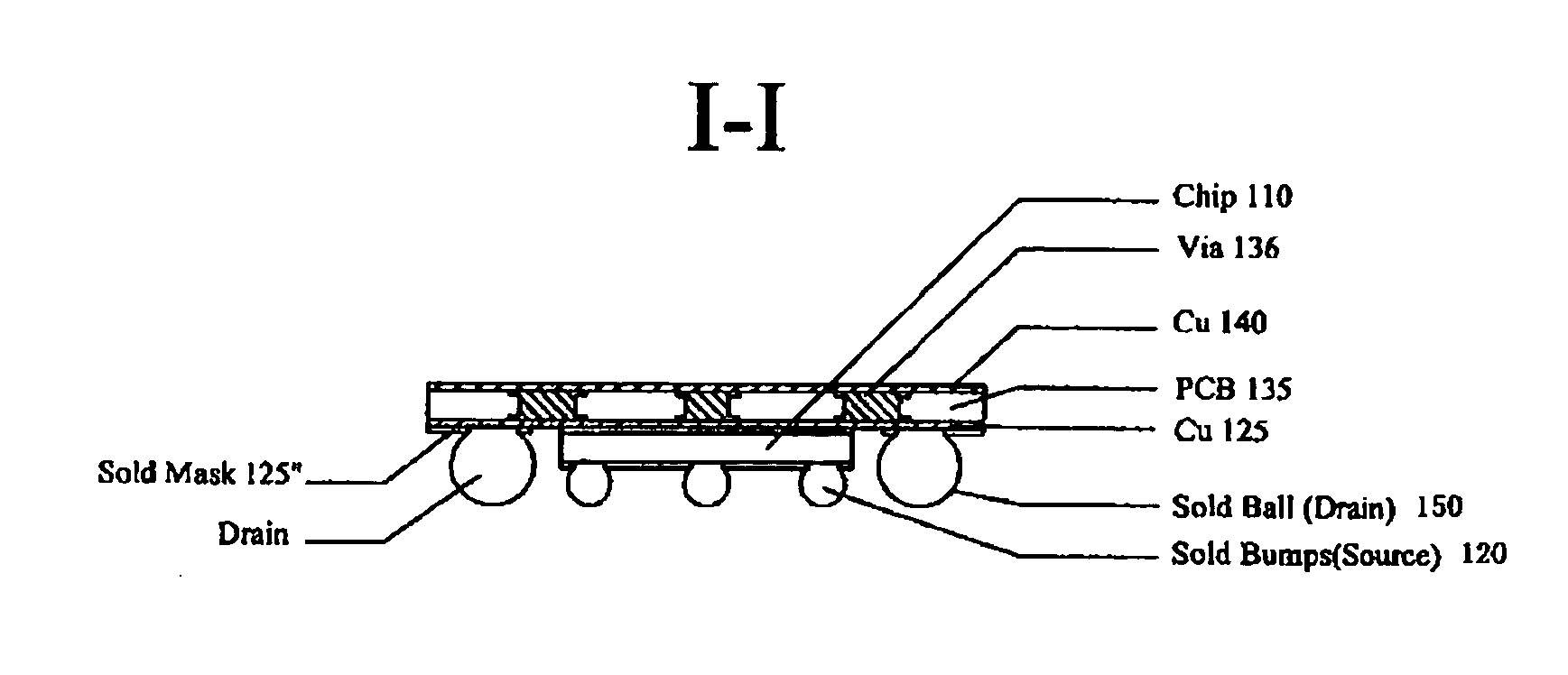

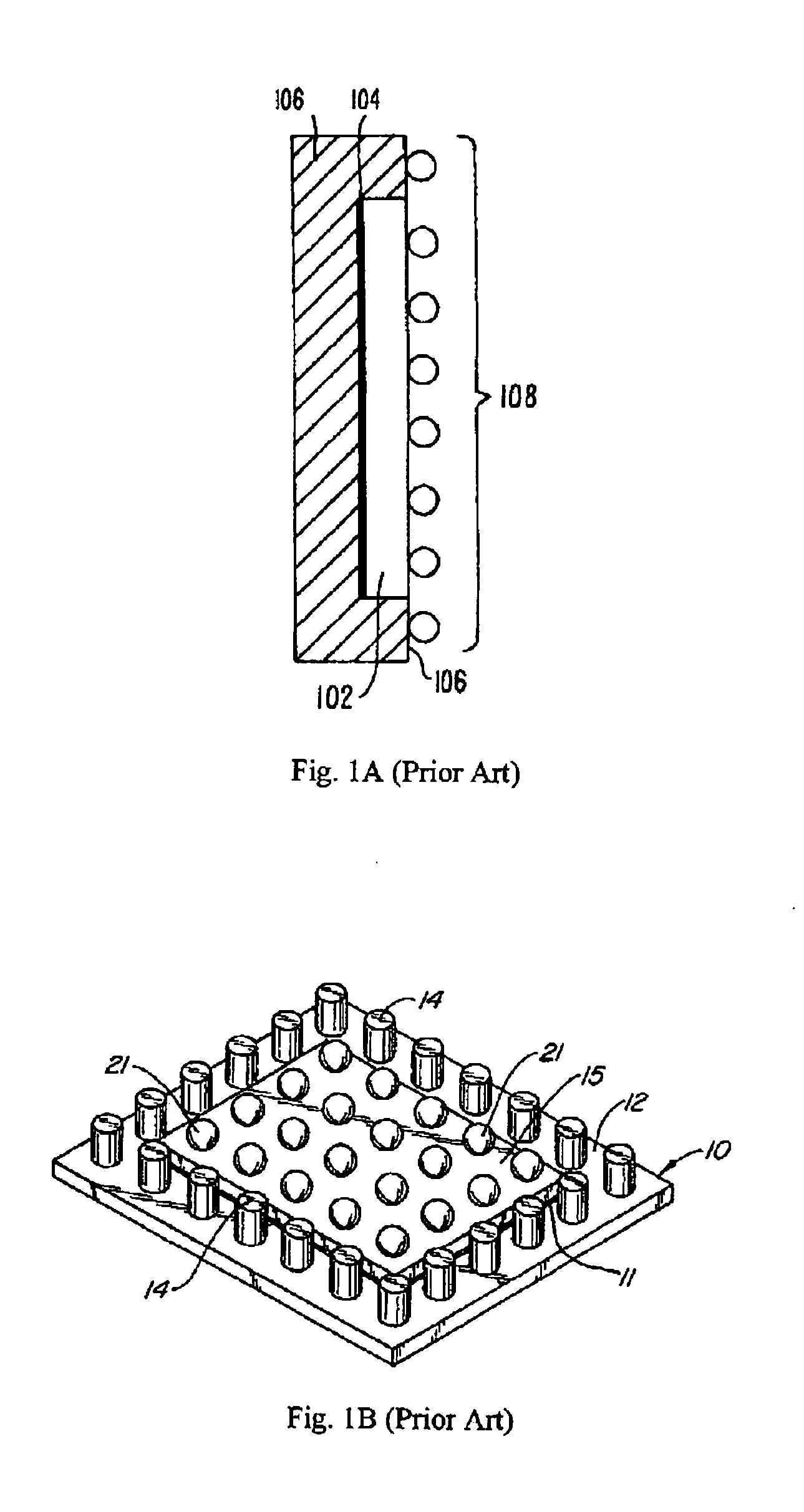

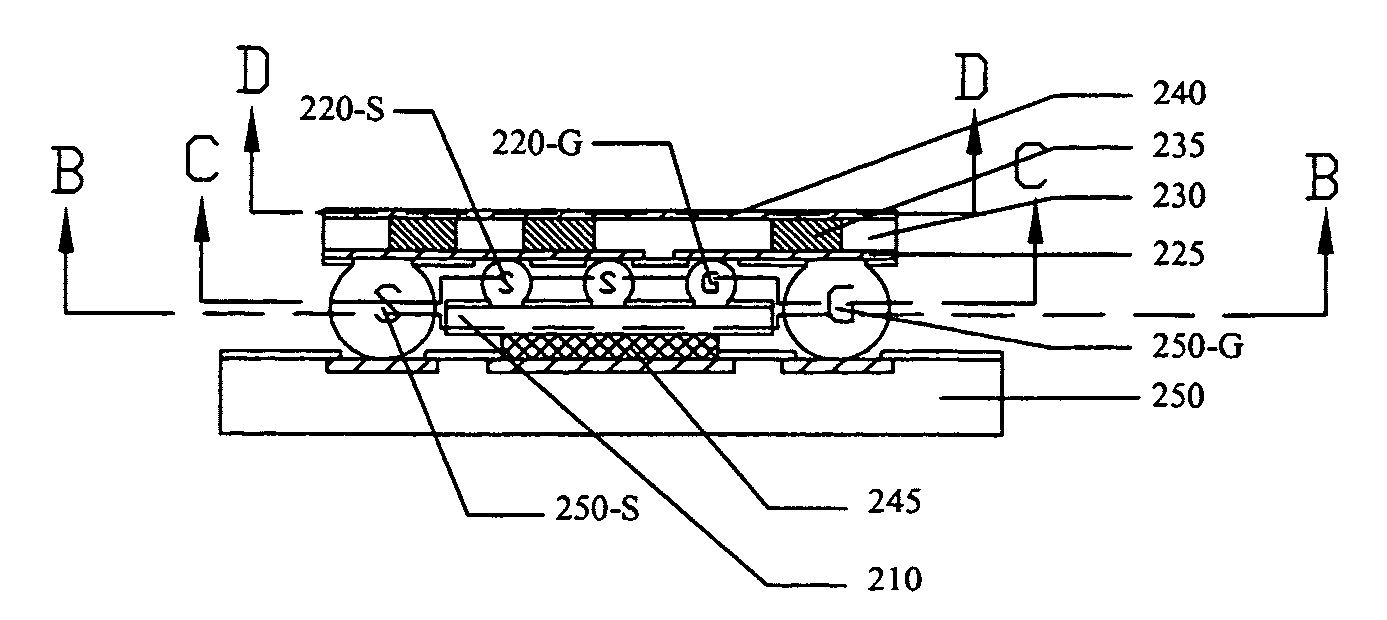

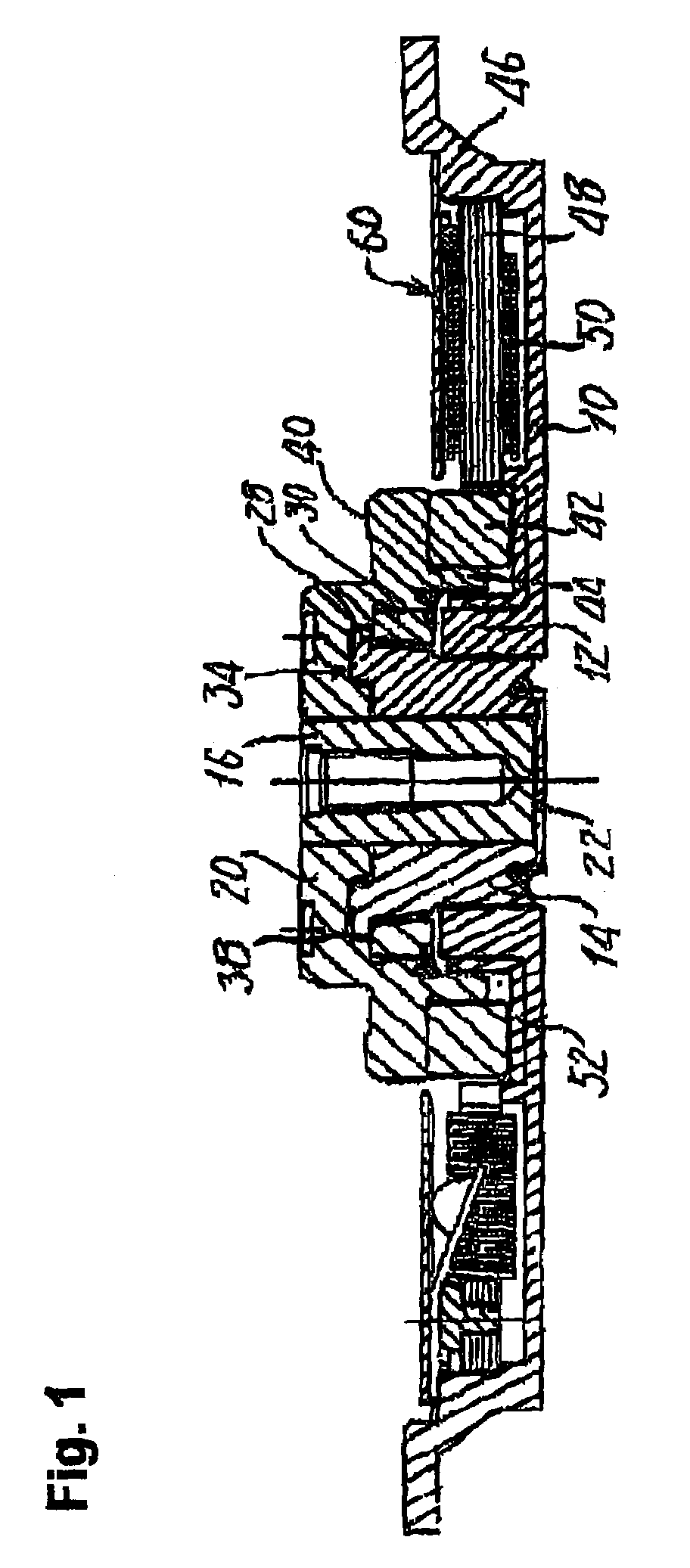

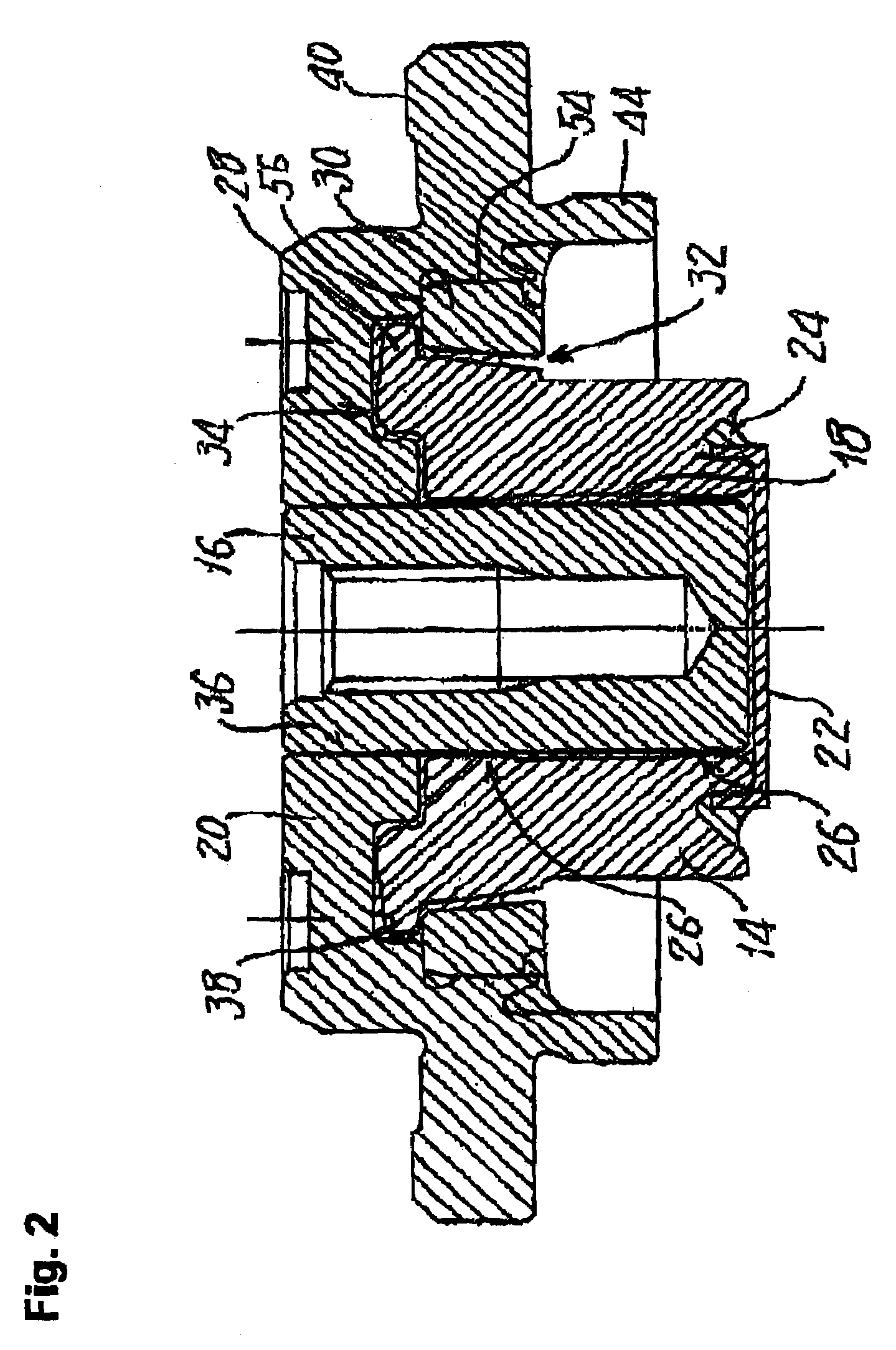

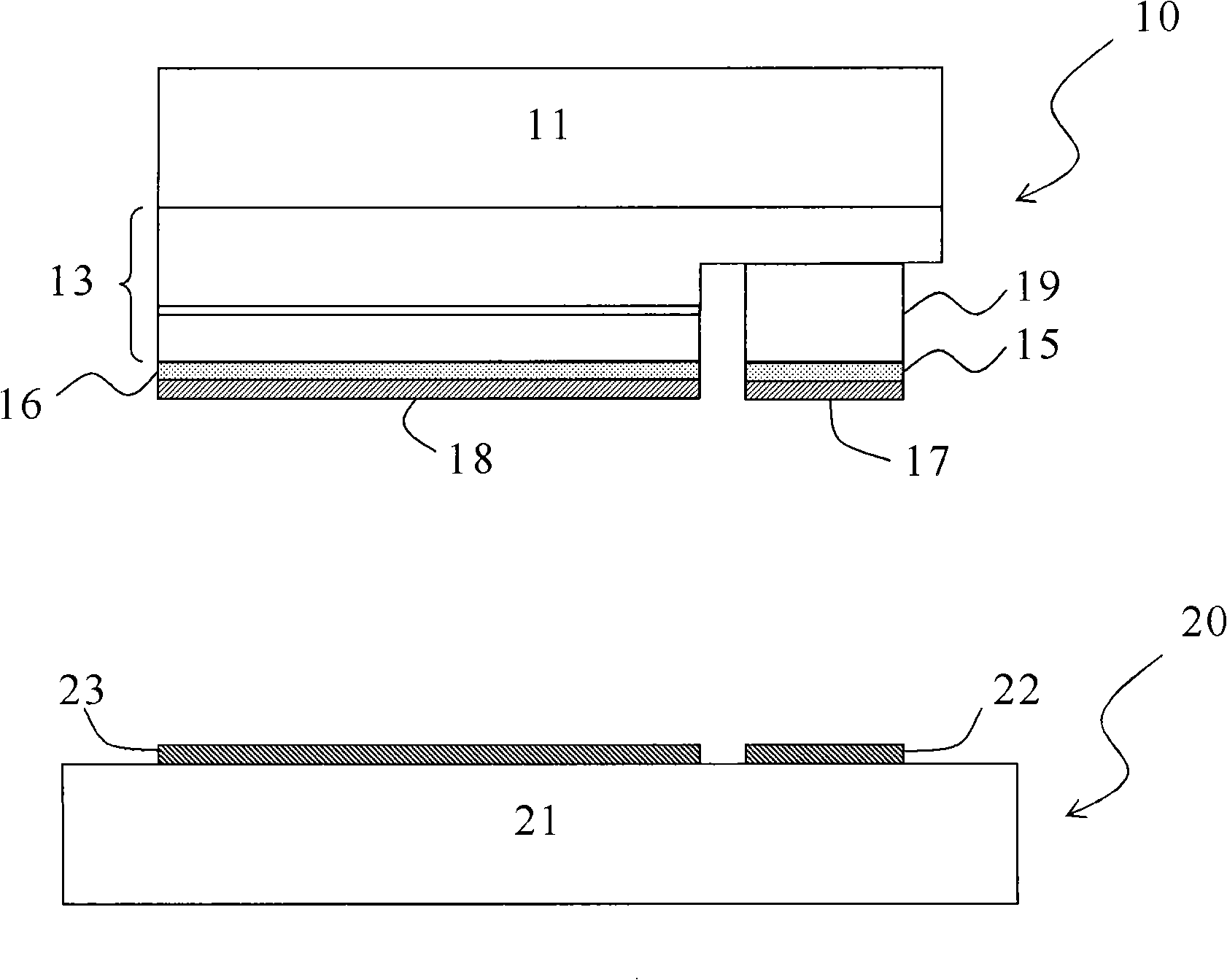

Vertically packaged MOSFET and IC power devices as integrated module using 3D interconnected laminates

ActiveUS20070085187A1Reduce decreaseOptimizationSemiconductor/solid-state device detailsSolid-state devicesMOSFETSurface mounting

An electronic package for containing at least a top packaging module vertically stacked on a bottom packaging module. Each of the packaging modules includes a semiconductor chip packaged and connected by via connectors and connectors disposed on a laminated board fabricated with a standard printed-circuit board process wherein the top and bottom packaging module further configured as a surface mountable modules for conveniently stacking and mounting to prearranged electrical contacts without using a leadframe. At least one of the top and bottom packaging modules is a multi-chip module (MCM) containing at least two semiconductor chips. At least one of the top and bottom packaging modules includes a ball grid array (BGA) for surface mounting onto the prearranged electrical contacts. At least one of the top and bottom packaging modules includes a plurality of solder bumps on one of the semiconductor chips for surface mounting onto the prearranged electrical contacts. The laminated board of the bottom packaging modules further has a thermal expansion coefficient substantially the same as a printed circuit board (PCB) whereby a surface mount onto the PCB is less impacted by a temperature change

Owner:ALPHA & OMEGA SEMICON LTD

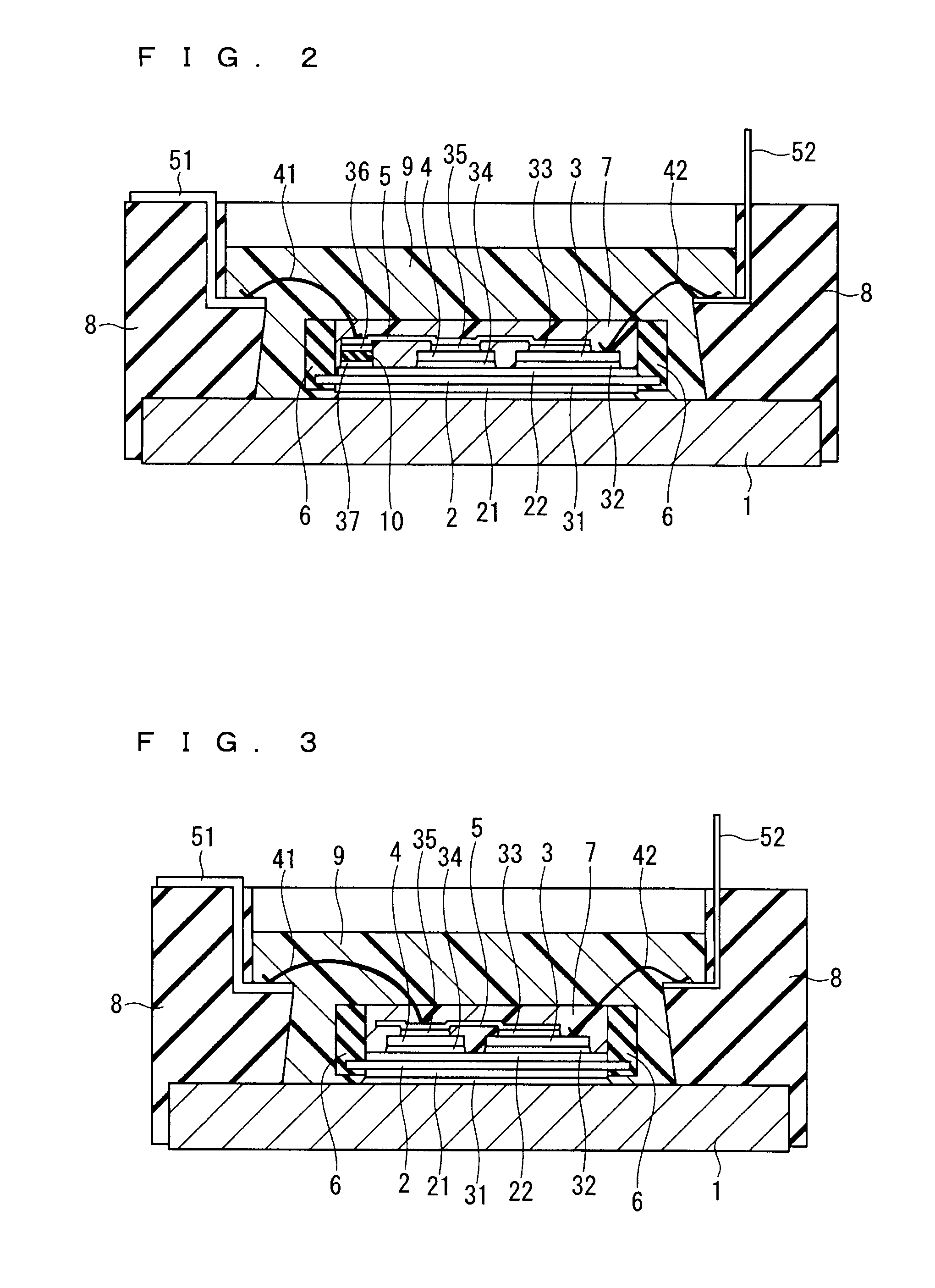

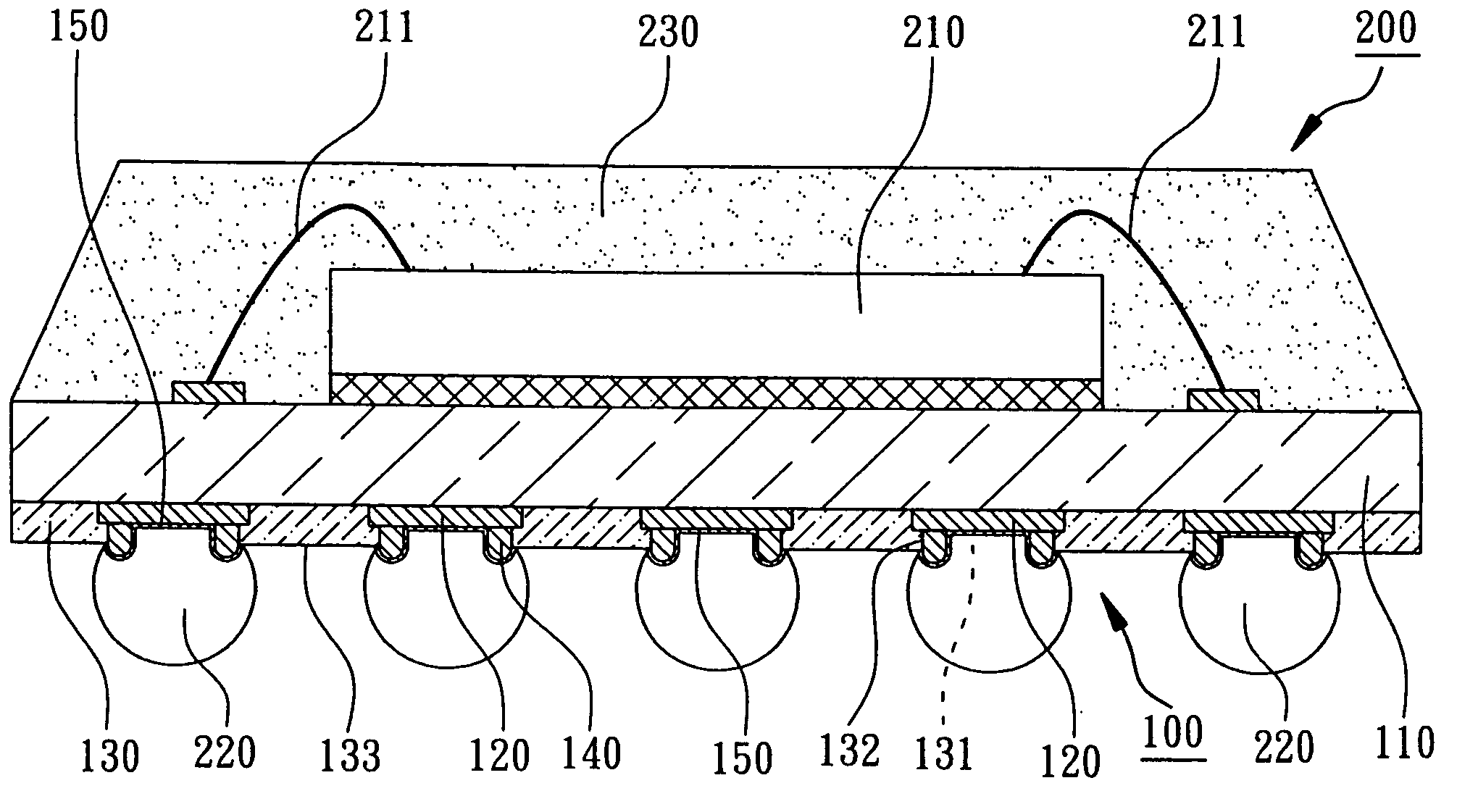

Semiconductor module

InactiveUS20130009298A1Reduce manufacturing costMaintain reliabilitySemiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor

A semiconductor module includes: an insulating plate; a plurality of metal patterns formed on the insulating plate and spaced apart from each other; a power device chip solder-joined on one the metal pattern; a lead frame solder-joined on the metal pattern to which the power device chip is not solder-joined, and on the power device chip; an external main electrode provided to an outer casing, and joined by wire bonding to the lead frame above the metal pattern to which the power device chip is not joined; and a sealing resin formed by potting to seal the power device chip, the lead frame, and the metal patterns.

Owner:MITSUBISHI ELECTRIC CORP

led filament and filament led bulbs

ActiveCN105090782BHigh bonding strengthIncrease joint areaElectric circuit arrangementsLight fasteningsLED filamentEngineering

A LED filament and a LED filament bulb using the same are disclosed. The LED filament includes a carrier, a LED chip disposed on the carrier and a conductive lead connected to the carrier. The conductive lead is electrically connected to the LED chip and includes a lead head portion, a lead tail portion and a lead neck portion connecting the lead head portion with the lead tail portion. A solid body width of the lead neck portion is less than a maximum solid body width of the lead head portion. Because the lead neck portion with reduced solid body width can function as a vulnerable position of the conductive lead, when a stress is applied onto the conductive lead, the lead neck portion would first take action and therefore the bonding location between the lead head portion and the carrier or the carrier itself can be protected.

Owner:KAISTAR LIGHTING (XIAMEN) CO LTD +1

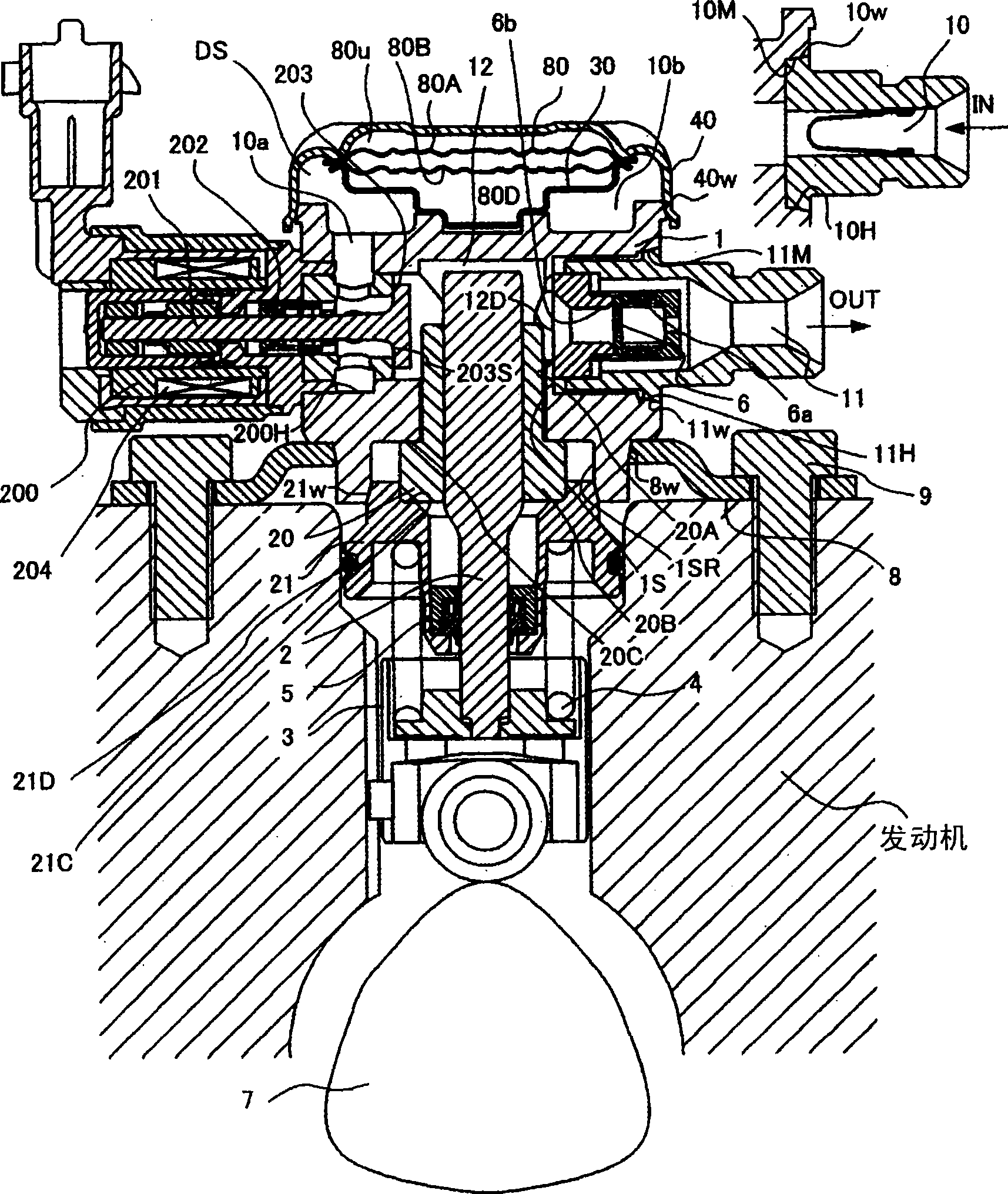

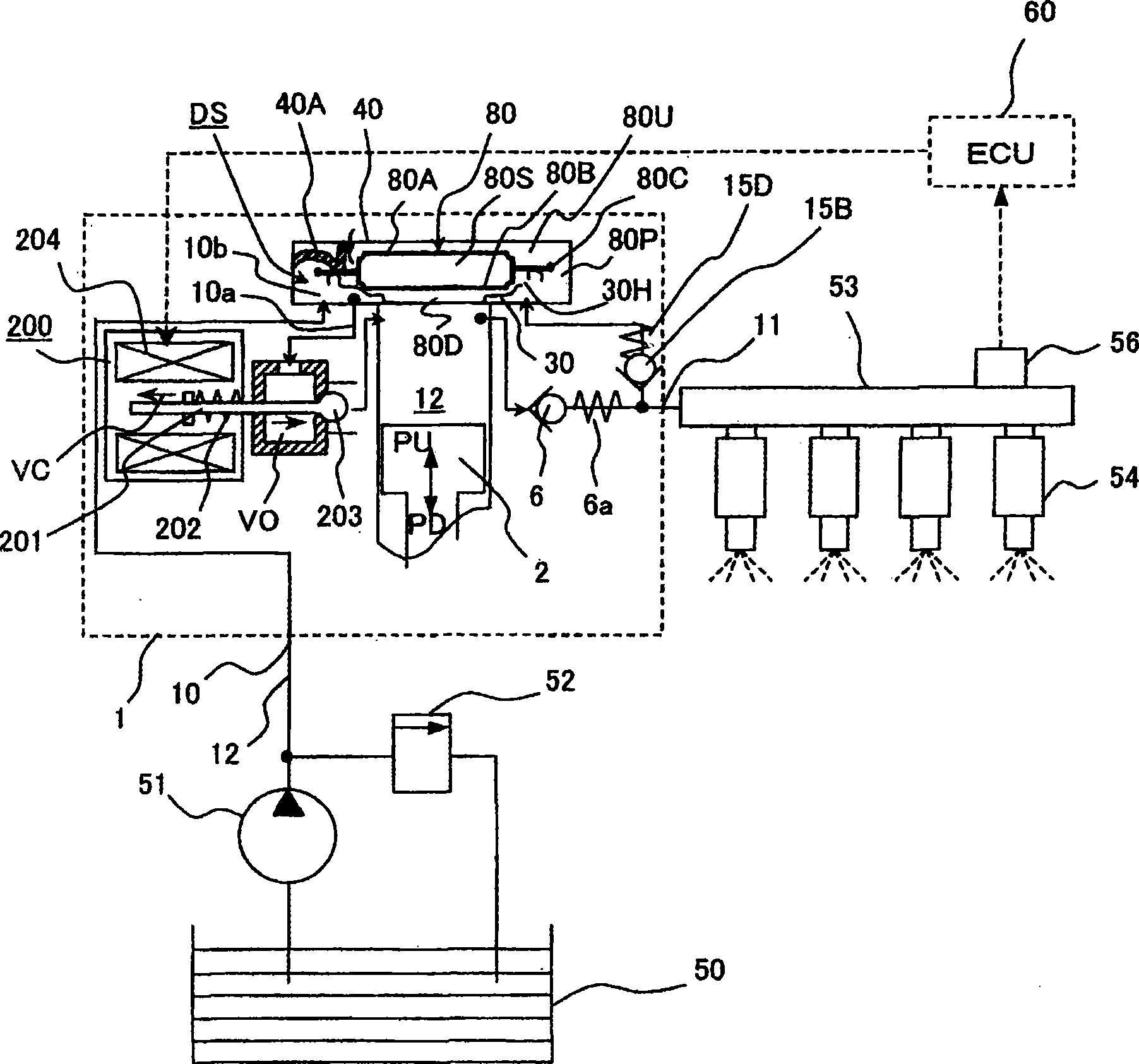

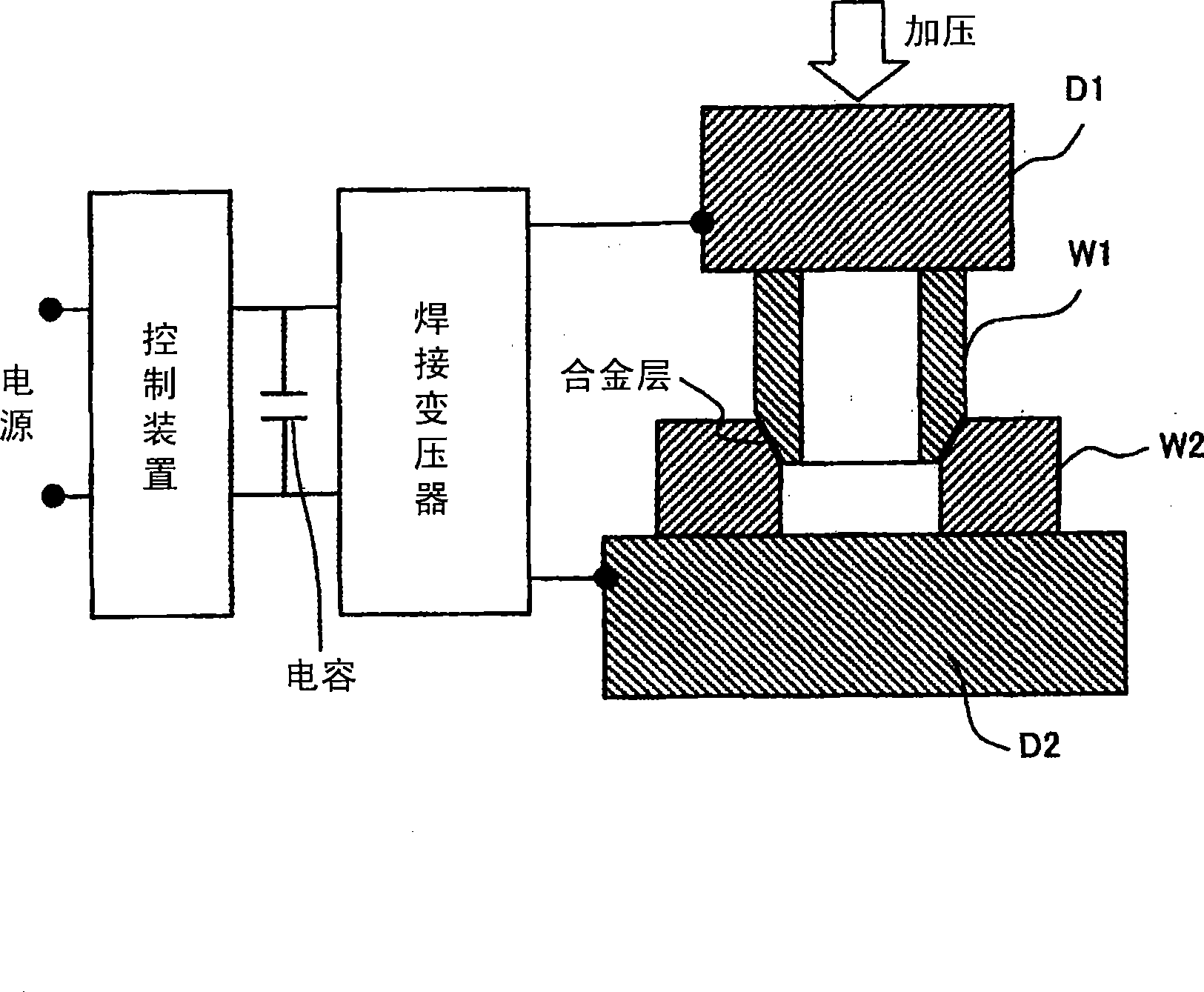

High-pressure fuel supply pump and the manufacturing method

InactiveCN101424235ARealize the joint functionRealize the sealing functionTubular articlesHollow articlesInlet valveMetallic materials

An object of this invention is to provide such a welded structure of and welding method for two metallic parts fitted together at a tubular section in a high-pressure fuel supply pump, that enables rapid joining of both metallic parts by staking (press-fitting included), screw fastening, and / or laser welding, offers high welding strength and sufficient fluid sealability, and keeps the metallic materials free from thermal changes in composition. While an electric current is supplied to any one of the welding connection surfaces formed between a pump housing and cylinder in a high-pressure fuel supply pump, between the pump housing and an installation flange, between the pump housing and an intake or discharge joint, between the pump housing and a pulsation-absorbing damper cover, between the pump housing and a relief valve mechanism, and between the pump housing and an electromagnetically driven intake valve mechanism, the particular two sections are pressed against each other to generate, along the connection surface, a plastic flow not causing melting or fusion due to heat, and form a diffusion-weld region at the connection surface by using the plastic flow and the application of the pressure.

Owner:HITACHI LTD

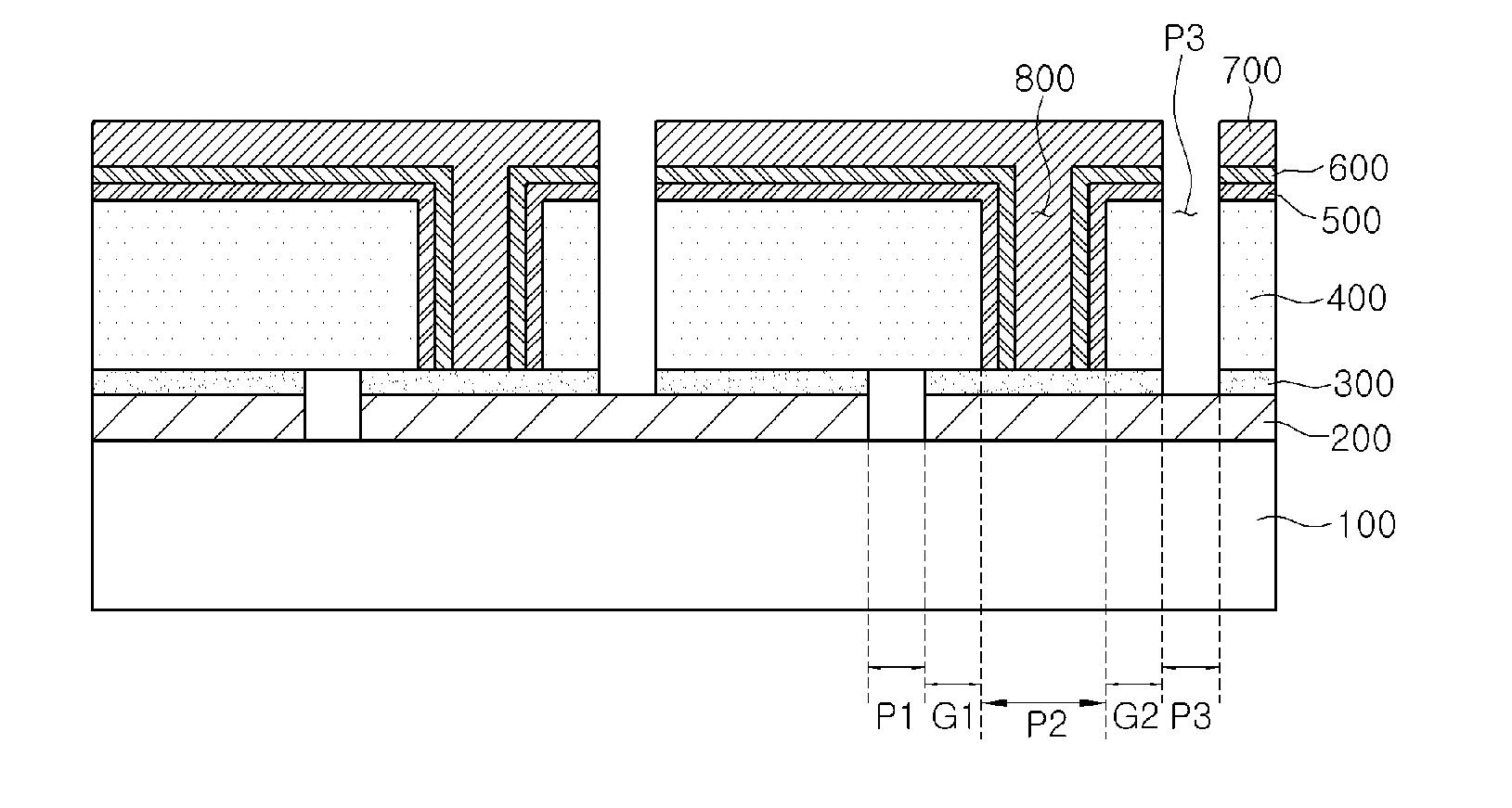

Battery and solar method for manufacturing the same

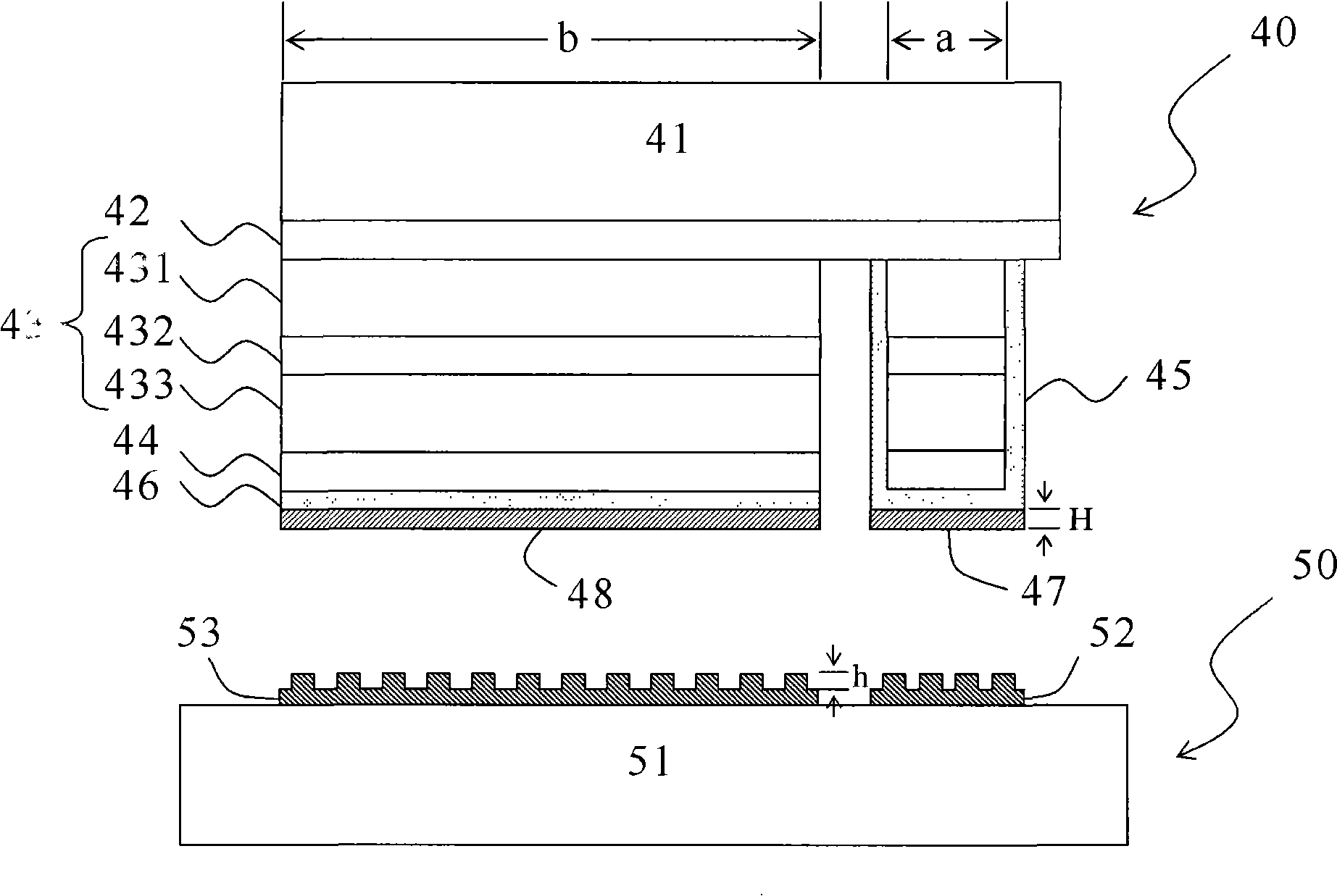

InactiveUS20120199191A1Improve featuresIncrease joint areaFinal product manufactureSemiconductor/solid-state device manufacturingEngineeringSolar battery

A solar battery according to the embodiment of the present invention includes an rear electrode formed on a substrate and separated by an first through-hole; an light absorbing layer formed on the rear electrode including the first through-hole; a second through-hole exposing the rear electrode through the light absorbing layer; a buffer layer formed on the upper surface and the side surface of the light absorbing layer; a front electrode layer formed on the buffer layer; and a connection wiring extending from the front electrode layer and formed within the second through-hole.

Owner:LG INNOTEK CO LTD

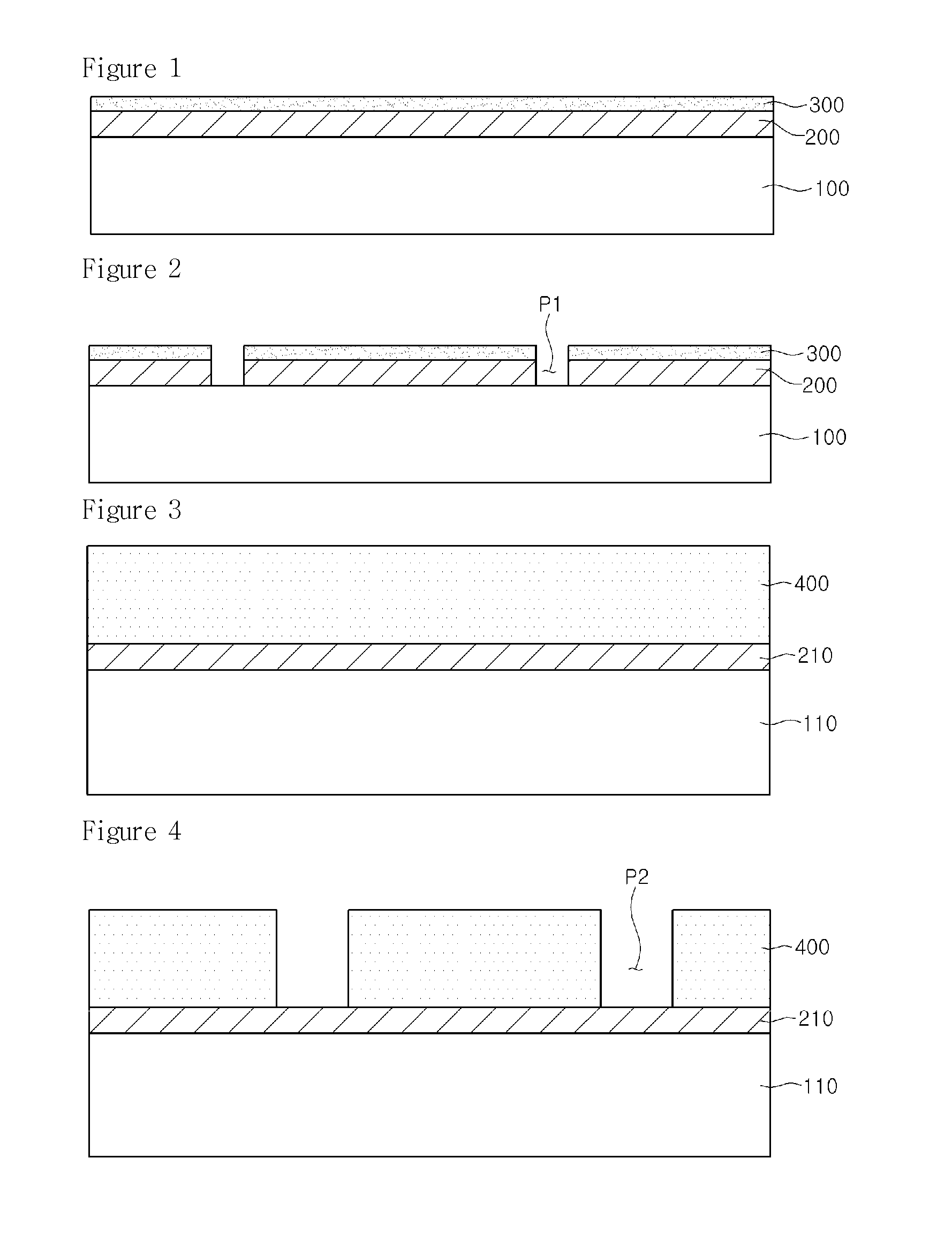

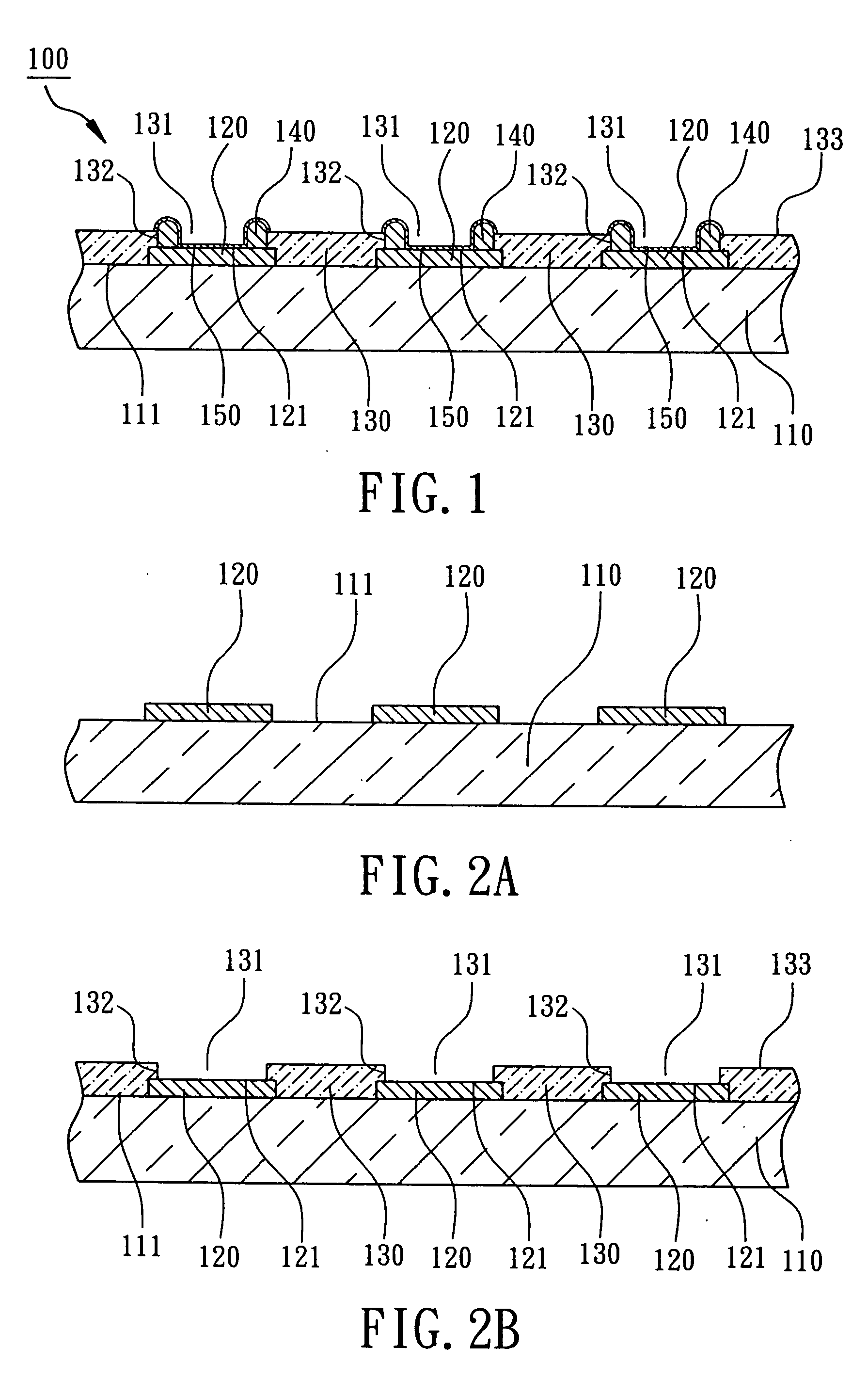

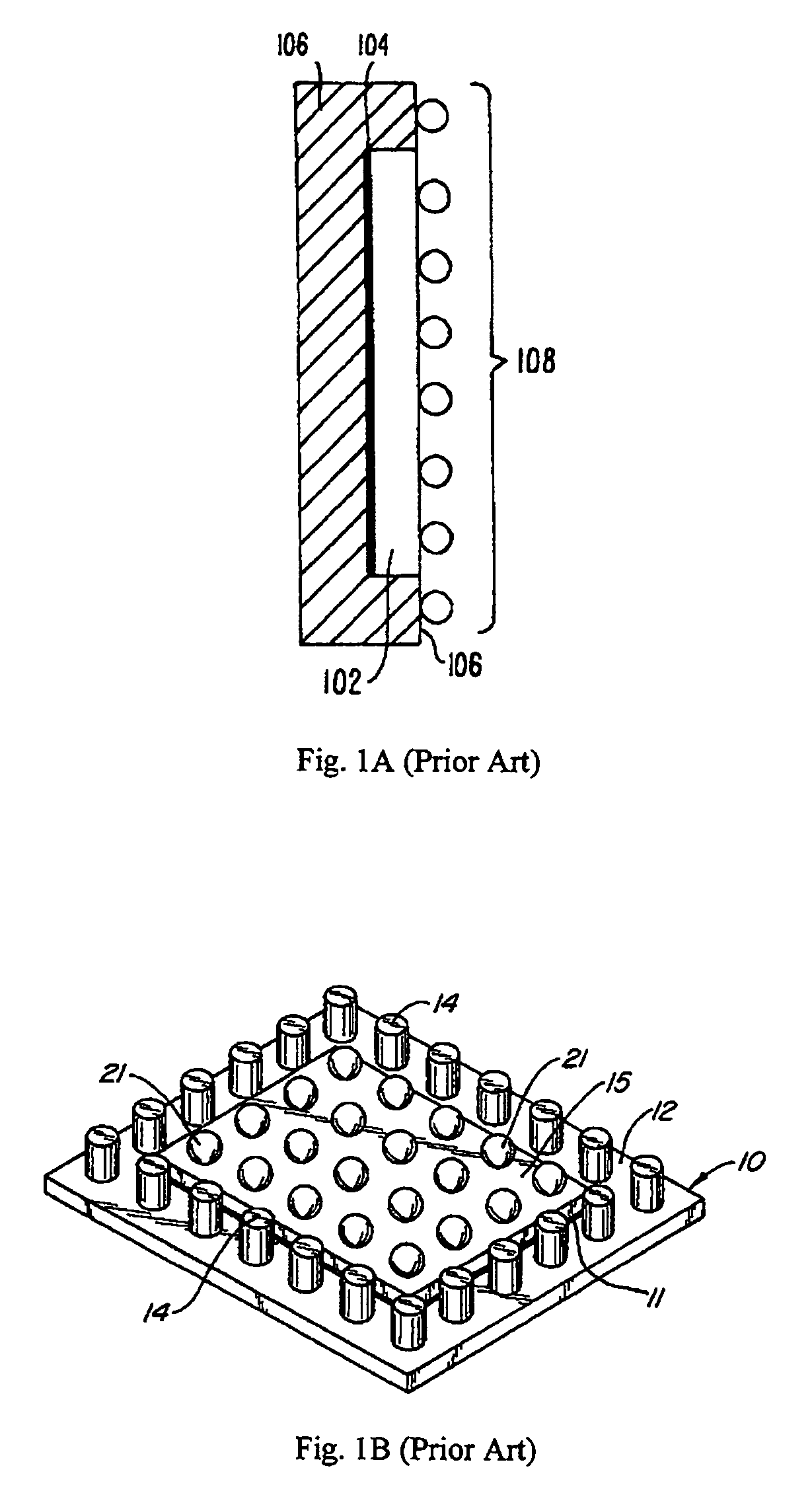

Ball grid array package substrate and method for manufacturing the same

InactiveUS20050017375A1Improve welding strengthGood solder wettabilityPrinted circuit assemblingFinal product manufactureSolder maskSolder ball

A ball grid array package substrate includes a substrate body having a surface. A least a ball pad and a solder mask are formed on the surface of the substrate body. The solder mask has an opening corresponding to the ball pads to enable the ball pad to have an exposed surface out of the opening of the solder mask. A patterned reinforcing metal layer is formed on the exposed surface of ball pads along a sidewall of the opening of the solder mask so that the sidewall of the opening will not directly contact the solder balls. Solder balls can be reflowed on the ball pads and the patterned reinforcing metal layers to increase jointing area and improve the shear strength of the solder balls.

Owner:ADVANCED SEMICON ENG INC

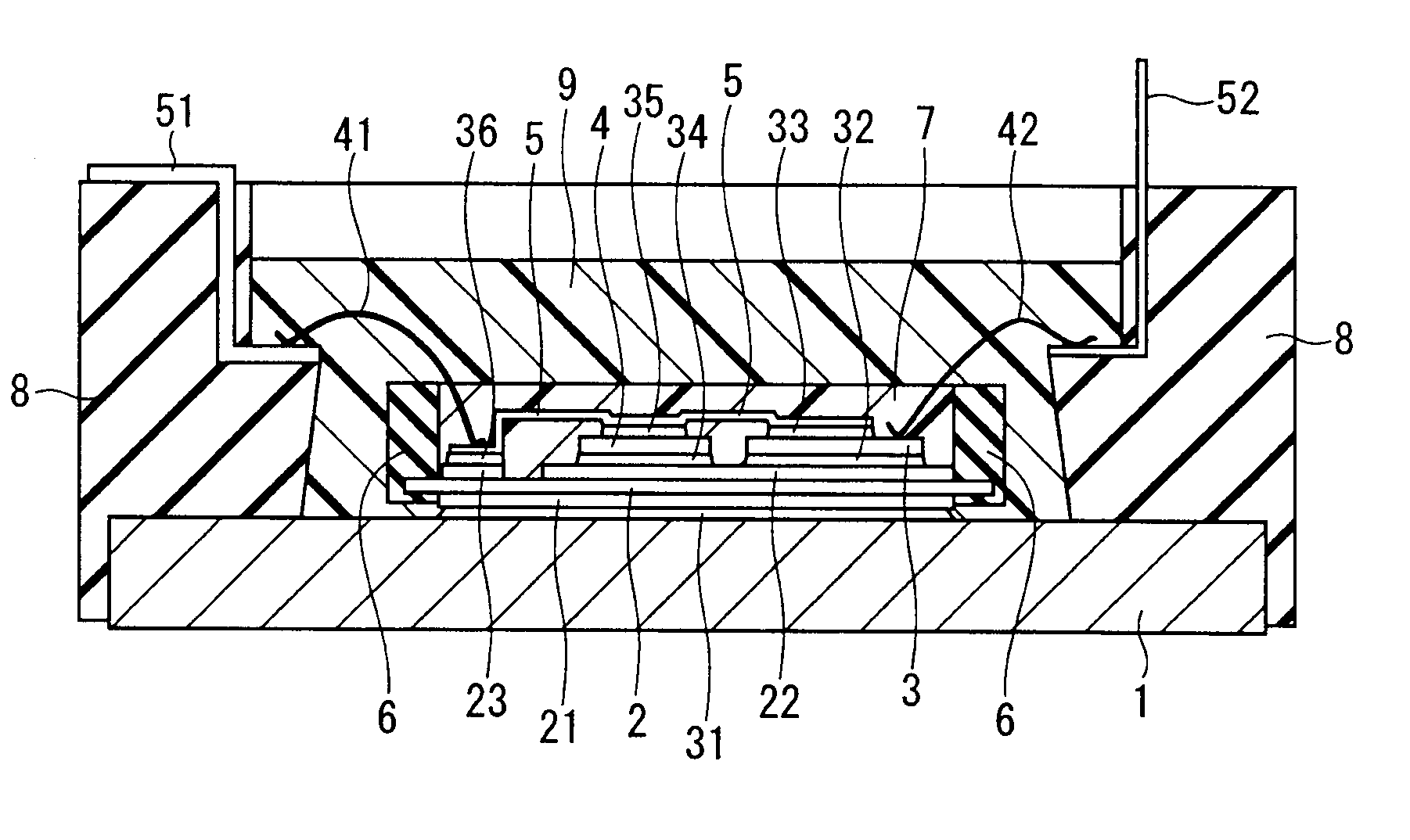

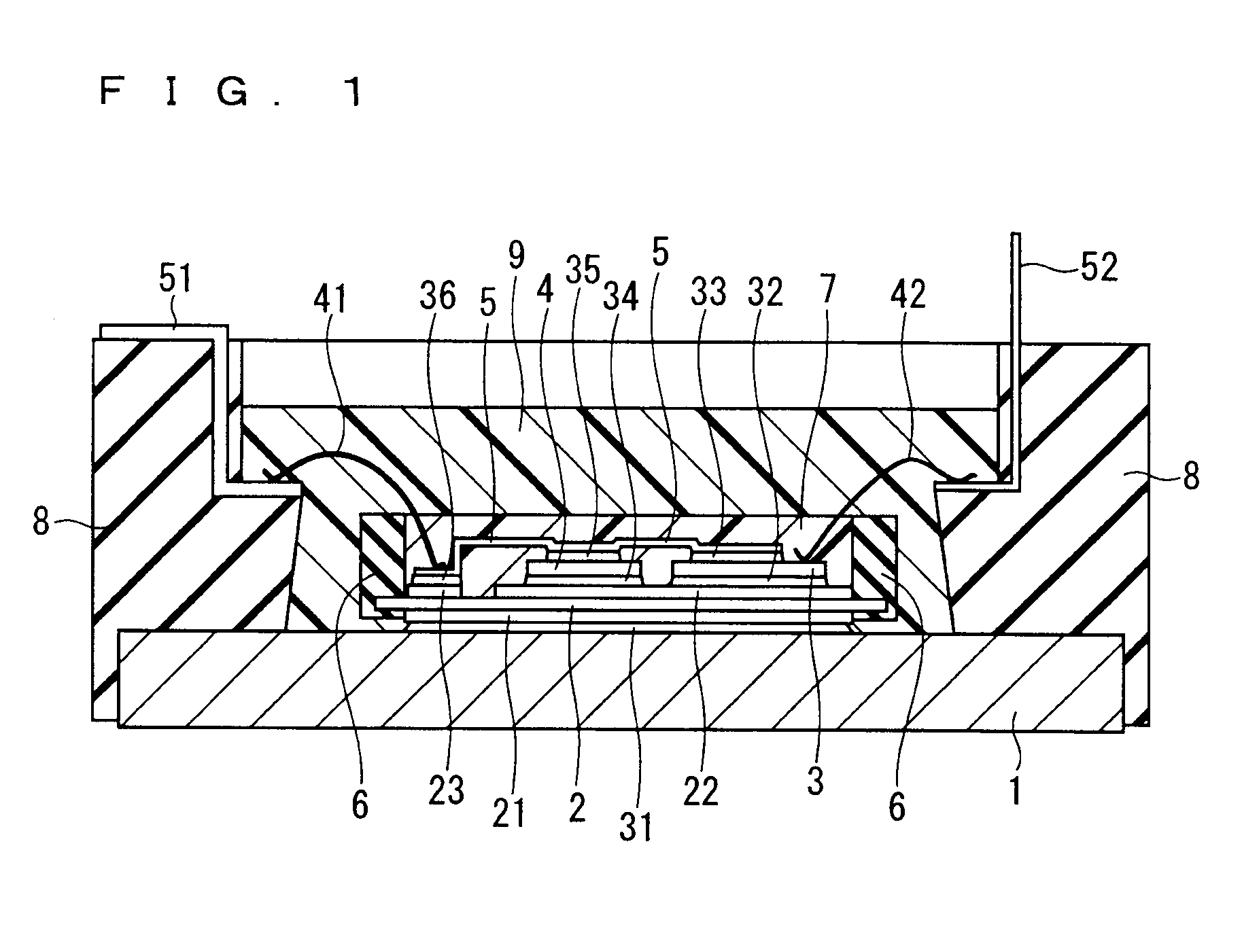

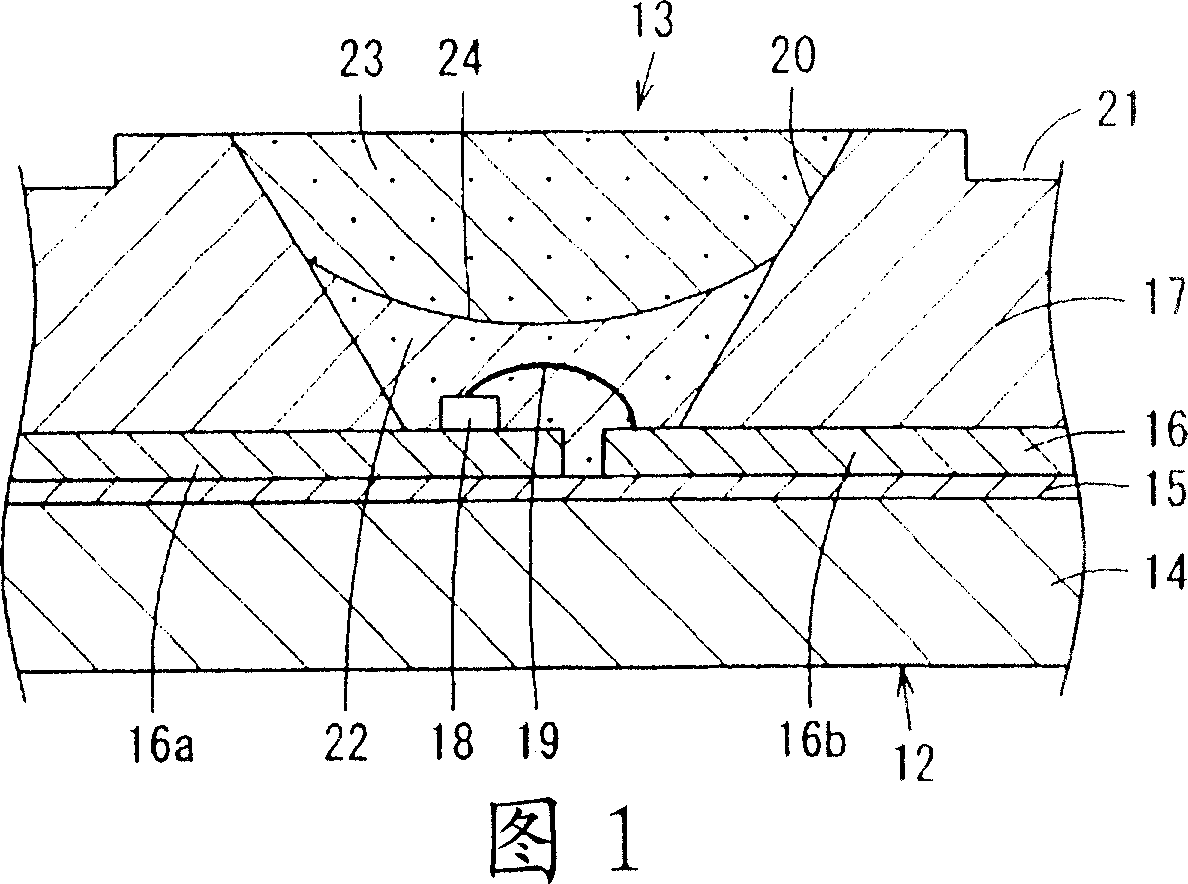

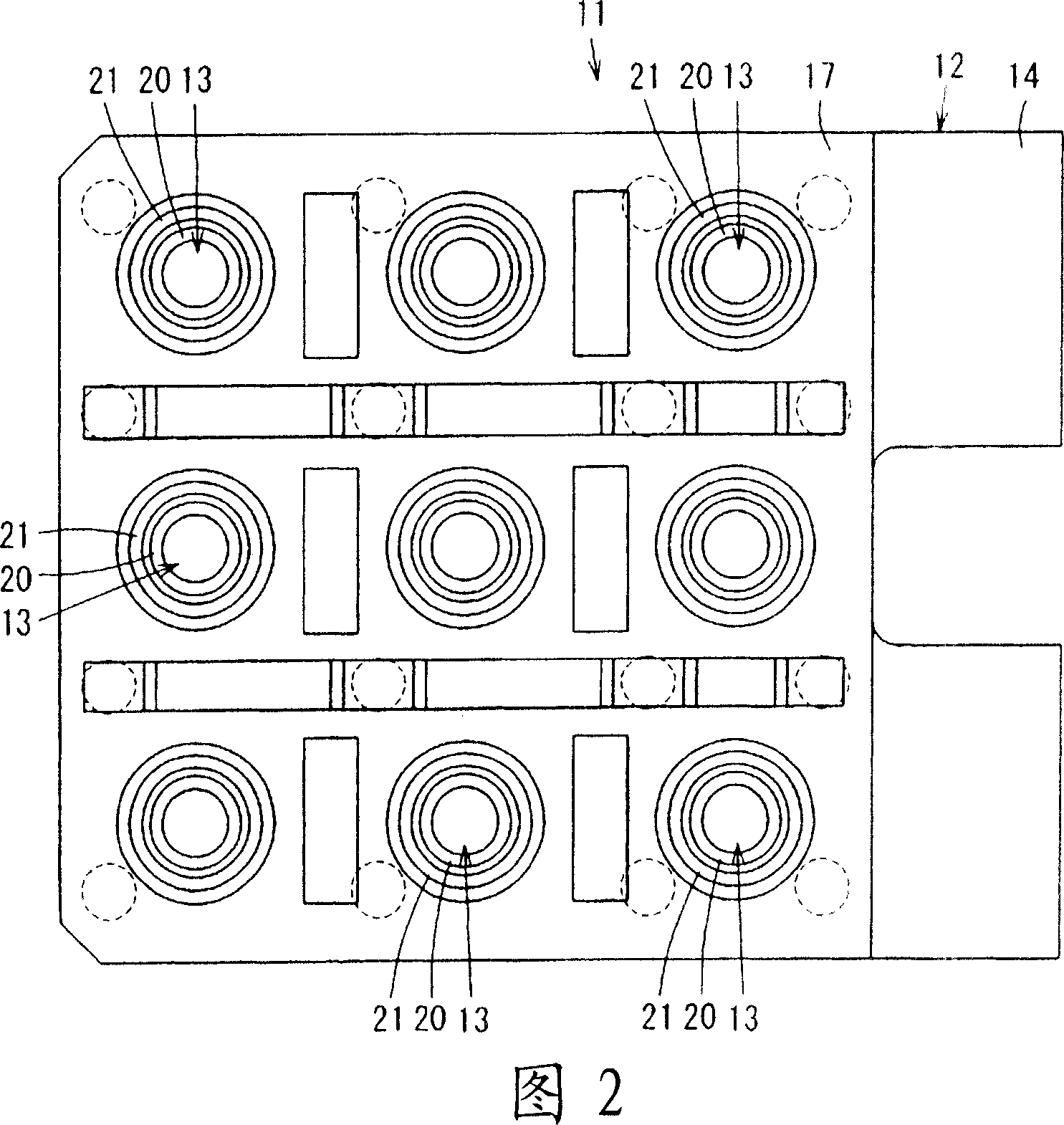

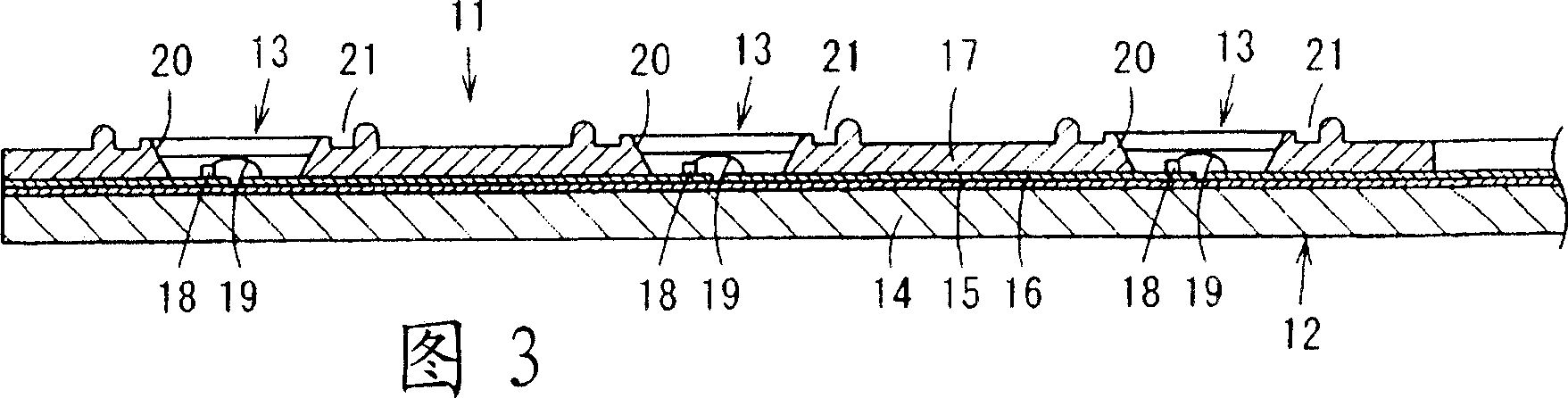

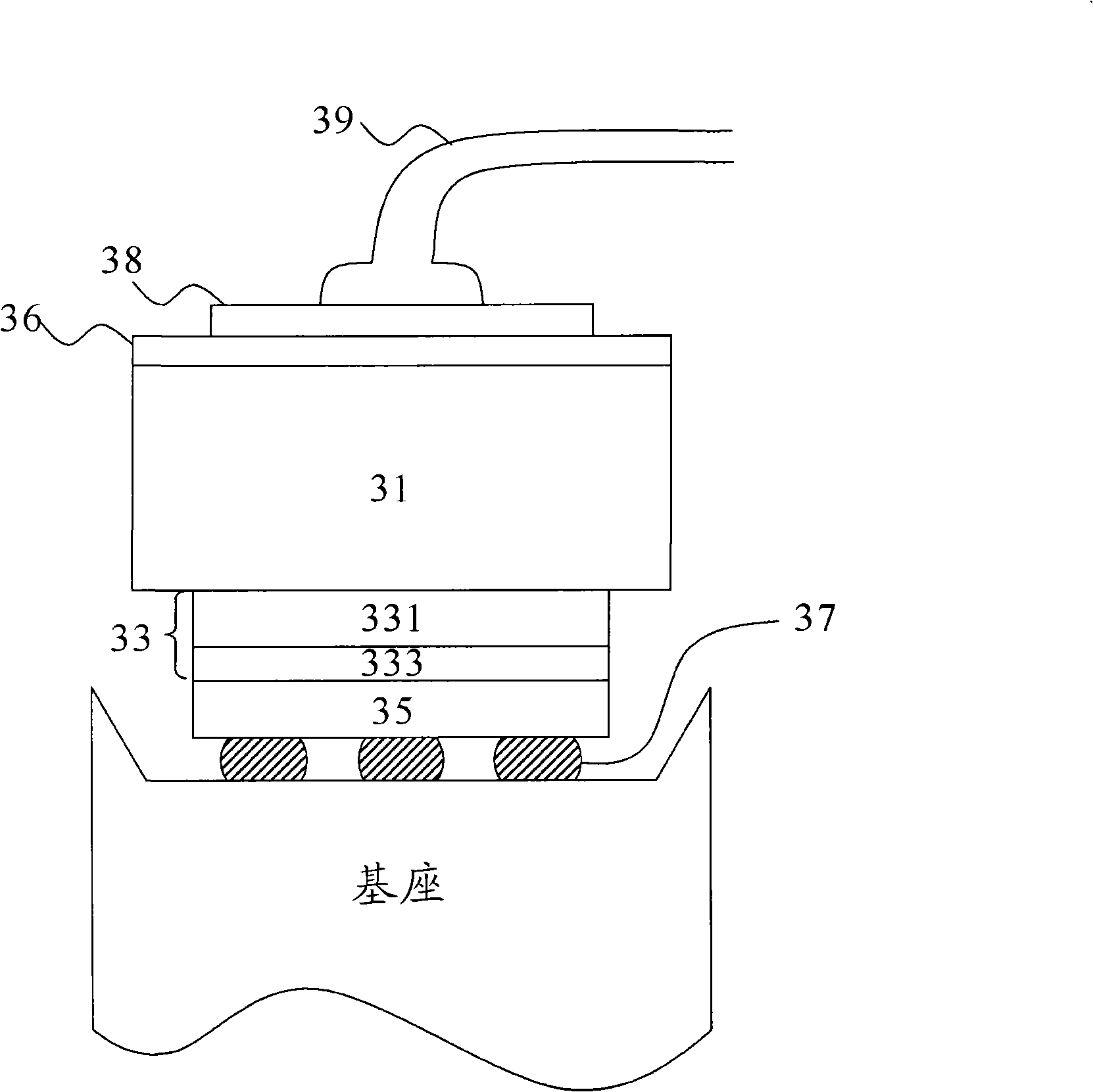

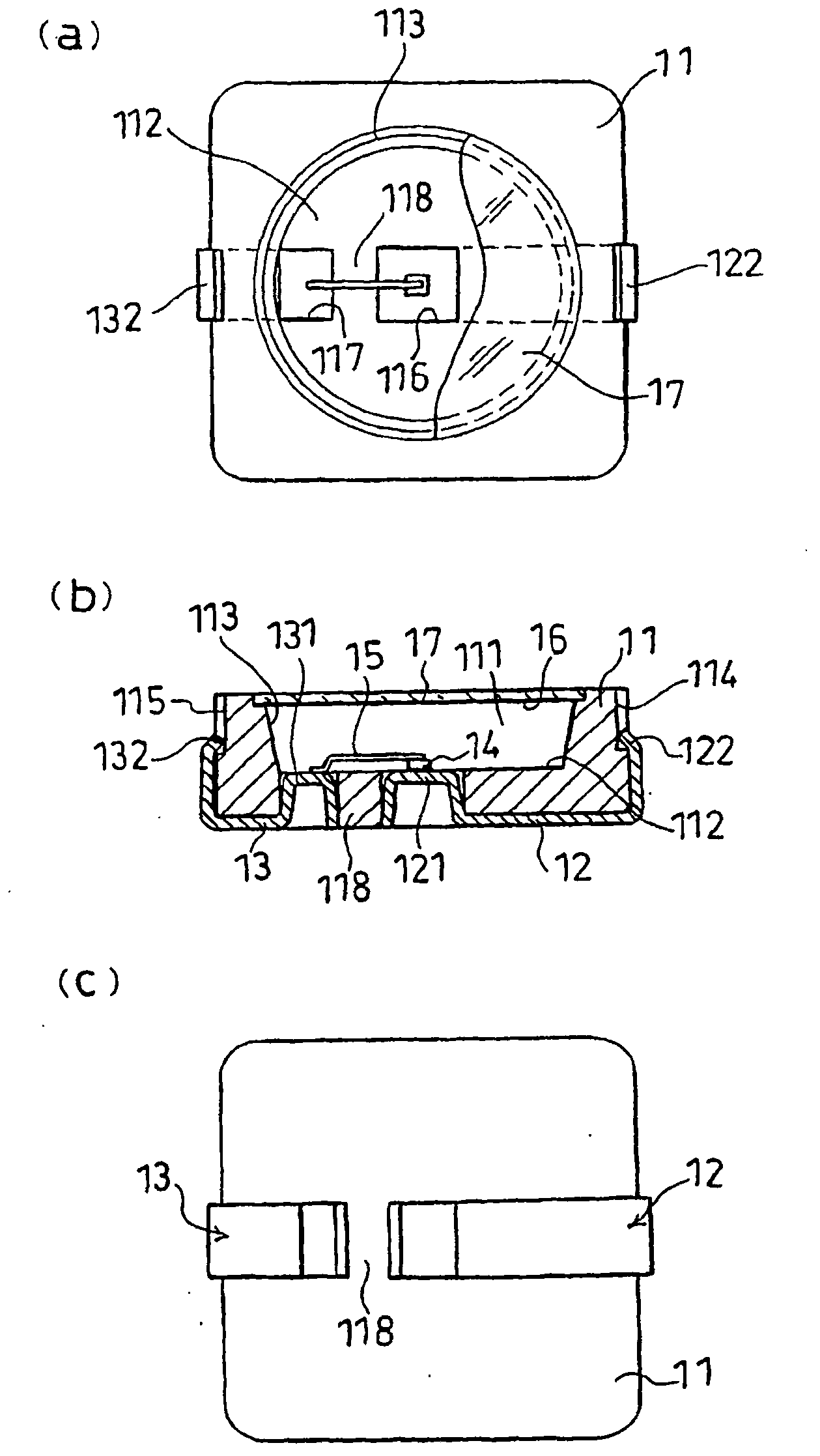

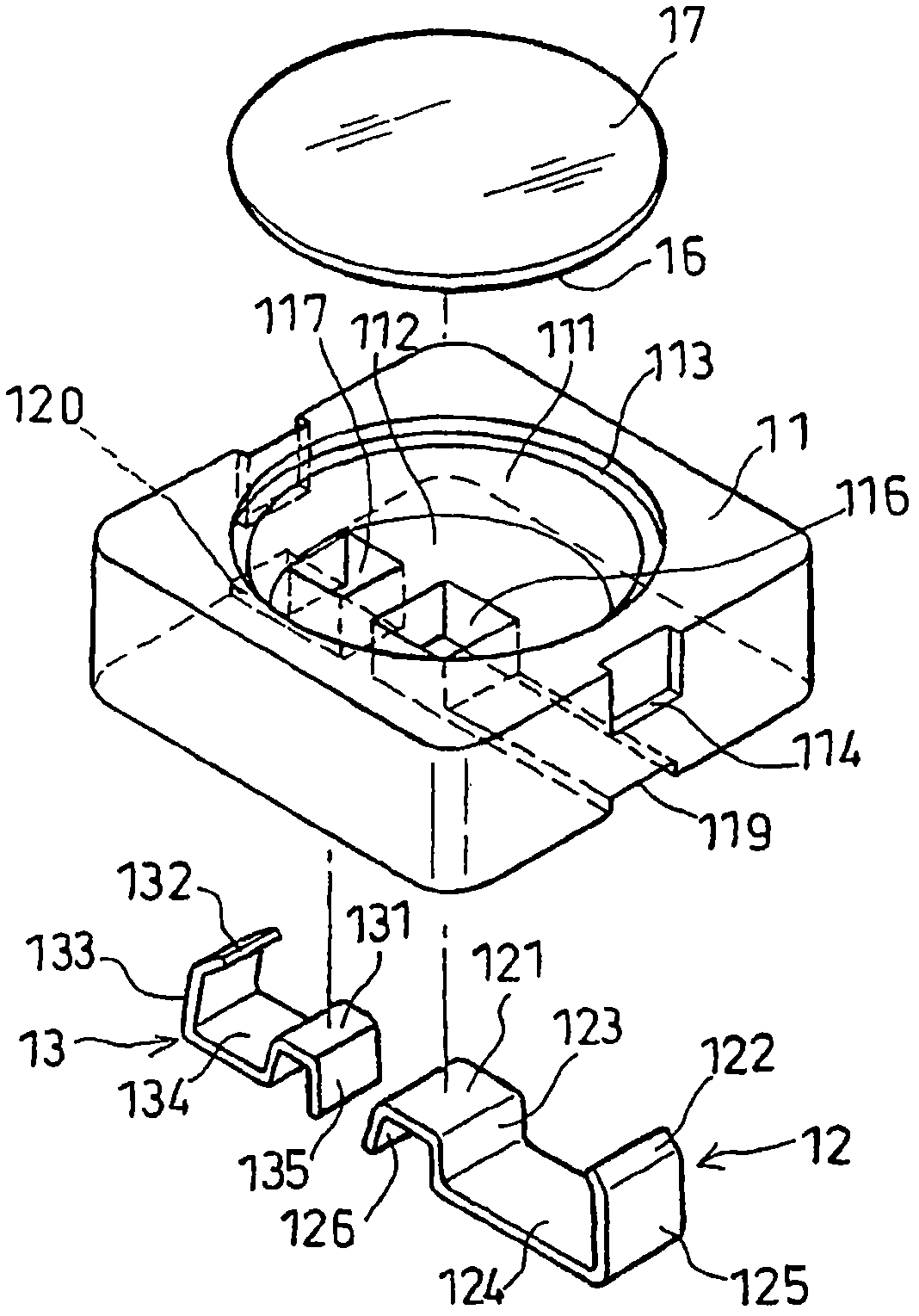

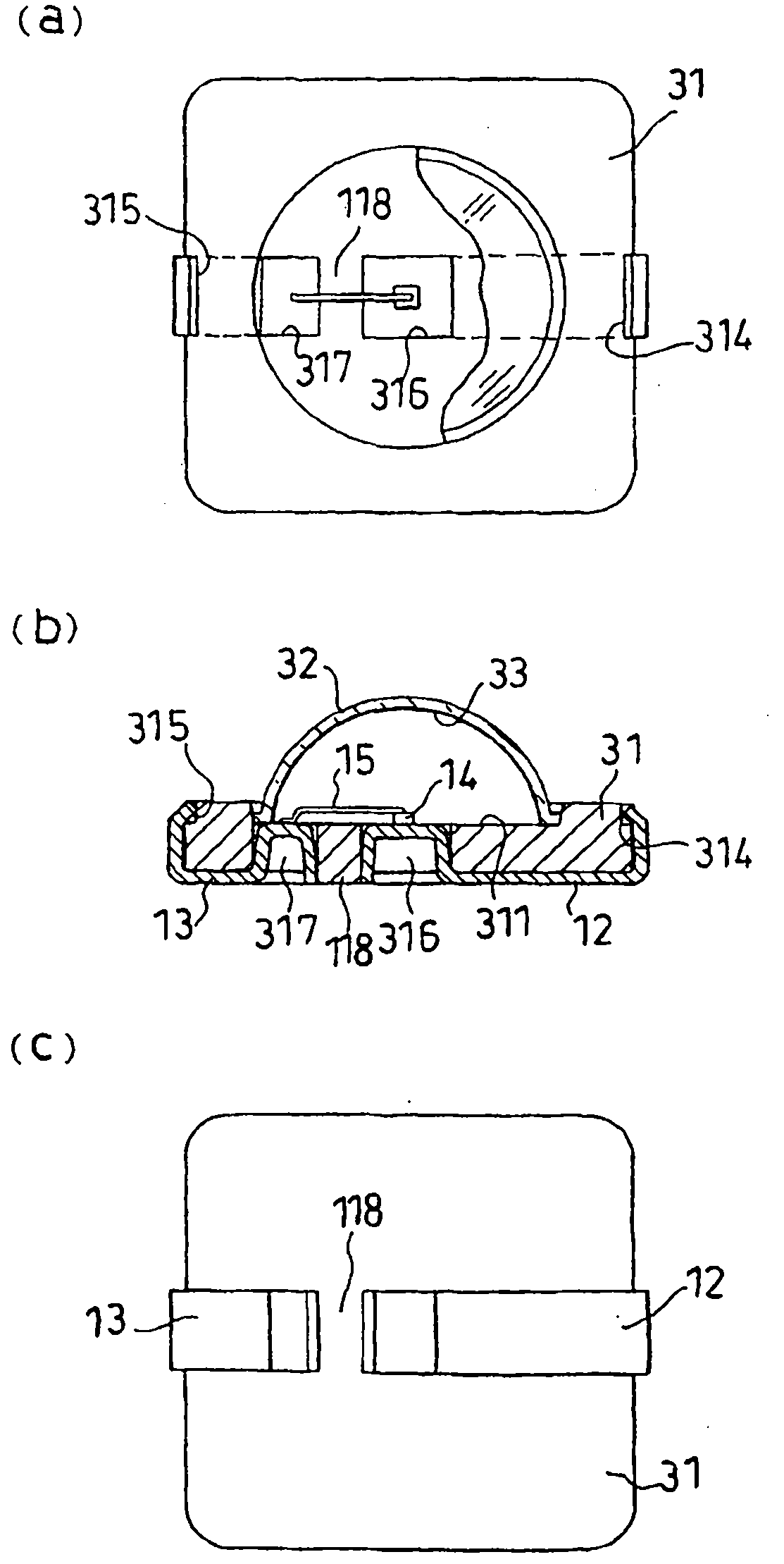

Light-emitting device and illuminating device

InactiveCN1934721AReduce color unevennessImprove luminous efficiencySolid-state devicesSemiconductor devicesPhosphorLight emitting device

Disclosed is a light-emitting device (11) wherein the luminous efficiency is improved and color variations in the emitted light are reduced. Specifically, a light-emitting diode element (18) is covered with a diffusion layer (22) wherein a diffusing agent is added to a resin. A phosphor layer (23) wherein a phosphor is added to a resin is arranged on top of the diffusion layer (22). The light from the light-emitting diode element (18) is diffused by the diffusion layer (22). By exciting the phosphor layer (23) with the light diffused at the diffusion layer and having the phosphor layer (23) emit a light, the luminous efficiency is improved and color variations in the emitted light are reduced.

Owner:TOSHIBA LIGHTING & TECH CORP

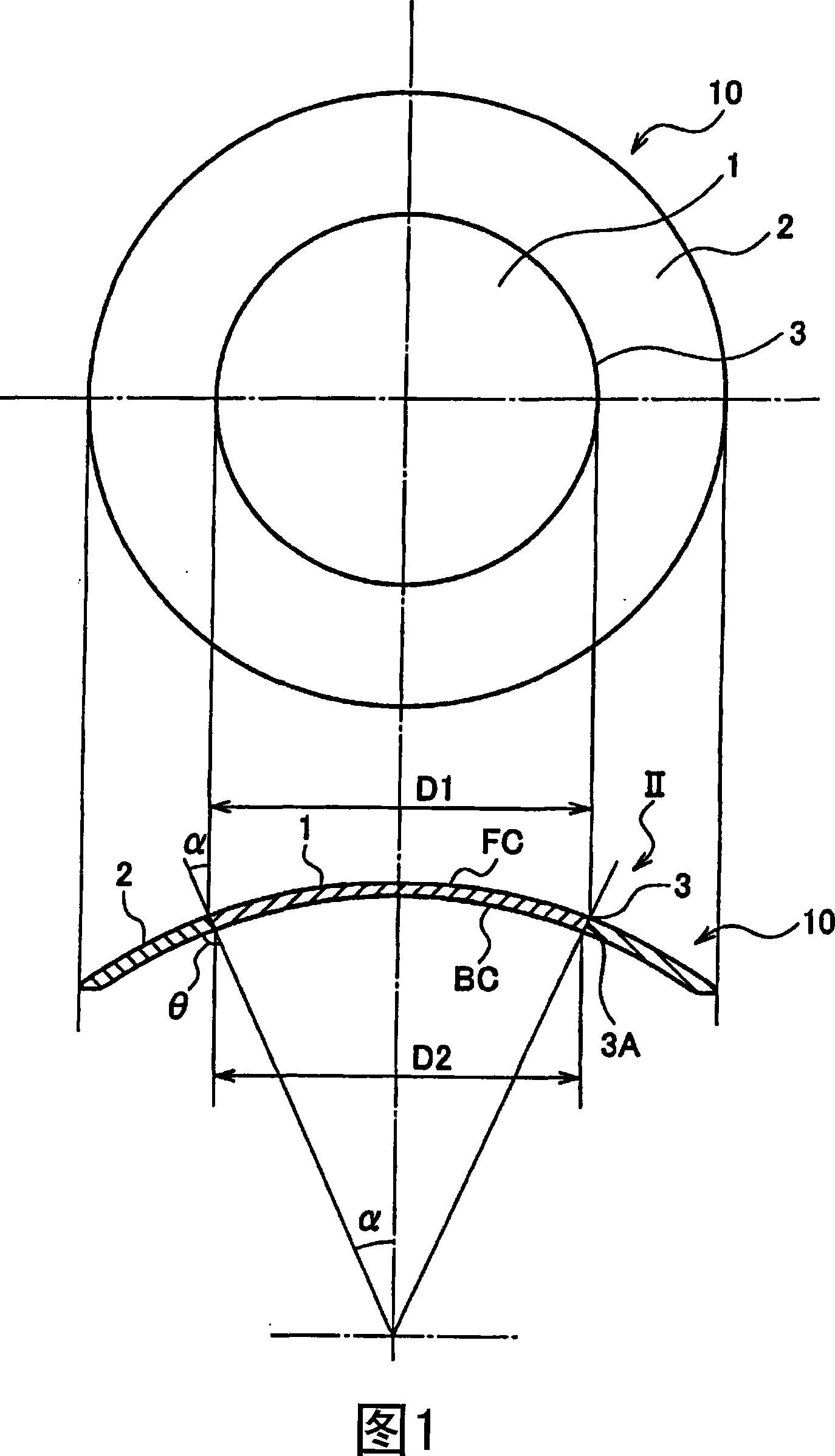

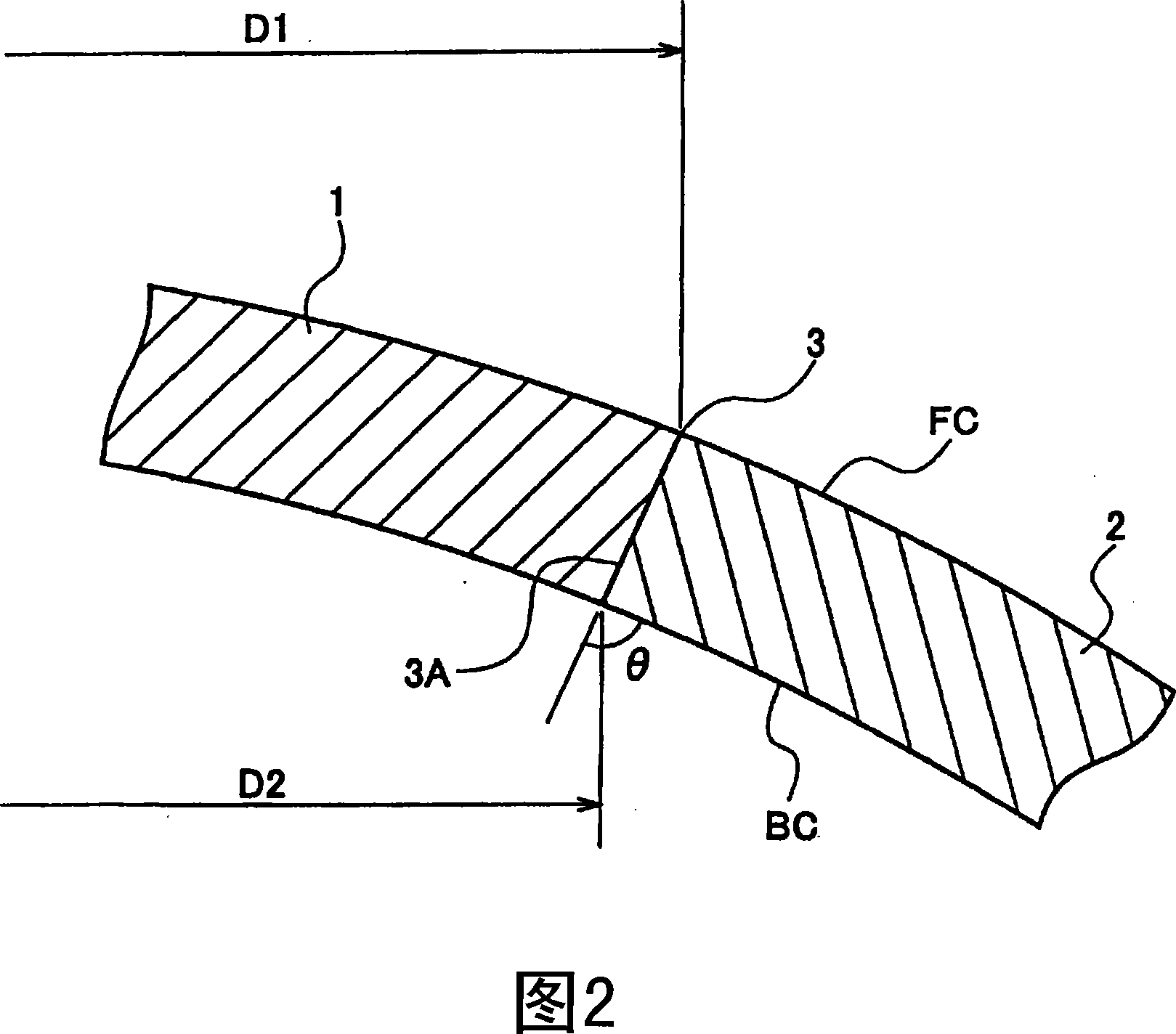

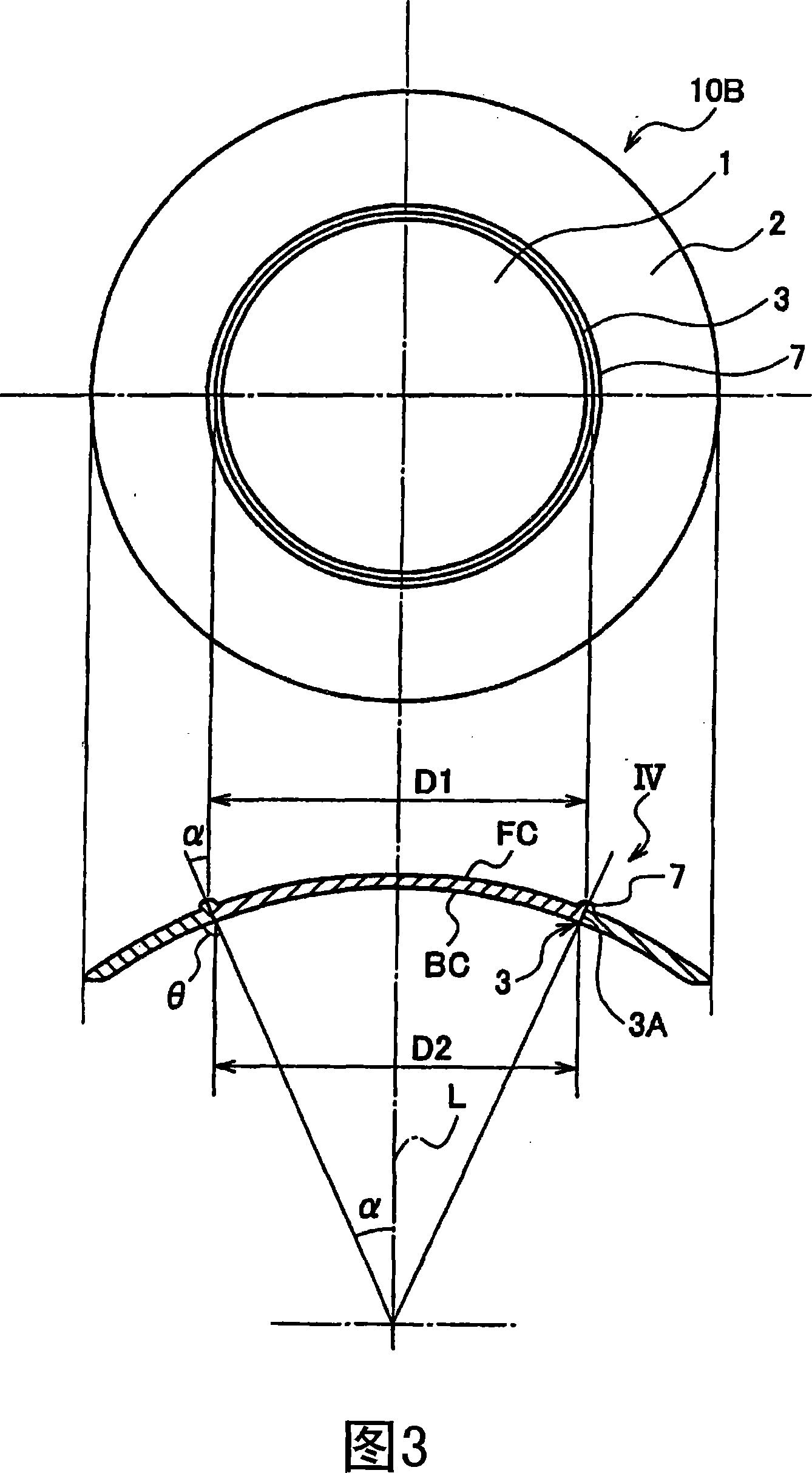

Composite contact lens and production method for lens material

ActiveCN101076752AAvoid breakingHigh strengthSpectales/gogglesOptical articlesOptical axisCircular cone

To increase strength against pulling / tearing that occurs at a normal handling and that advances from the convex surface to the concave surface of a lens or from the concave surface to the convex surface in a shearing direction, and to improve an attaching feeling. A composite contact lens consisting of a hard material at the center and a soft material having a water containing property at the periphery, wherein the joining surface 3A between the central hard portion (1) and the peripheral soft portion (2) is constituted of a single conical surface so inclined that the diameter D1 of the hard portion (1) at a lens convex surface FC is larger than the diameter D2 of the hard portion (1) at a lens concave surface BC, and the inclination angle a of the conical surface is so set that an angle formed by the joining surface 3A and the concave surface BC is about 90 degrees. An annular protrusion (7) projecting forward with respect to the convex surface curve of an optical unit and forming a concentric circle with respect to the lens's optical axis L is formed on the joint portion (3) between the central hard portion (1) and the peripheral soft portion (2) on the lens convex surface FC side.

Owner:HOYA CORP

Packaging configurations for vertical electronic devices using conductive traces disposed on laminated board layers

ActiveUS20070080443A1OptimizationReduces thermal mismatch problemSemiconductor/solid-state device detailsSolid-state devicesPrinted circuit boardEngineering

This invention discloses an electronic package for containing a vertical semiconductor chip that includes a laminated board having a via connector and conductive traces distributed on multiple layers of the laminated board connected to the via connector. The semiconductor chip having at least one electrode connected to the conductive traces for electrically connected to the conductive traces at a different layer on the laminated board and the via connector dissipating heat generated from the vertical semiconductor. A ball grid array (BGA) connected to the via connector functioning as contact at a bottom surface of the package for mounting on electrical terminals disposed on a printed circuit board (PCB) wherein the laminated board having a thermal expansion coefficient in substantially a same range the PCB whereby the BGA having a reliable electrical contact with the electrical terminals.

Owner:ALPHA & OMEGA SEMICON LTD

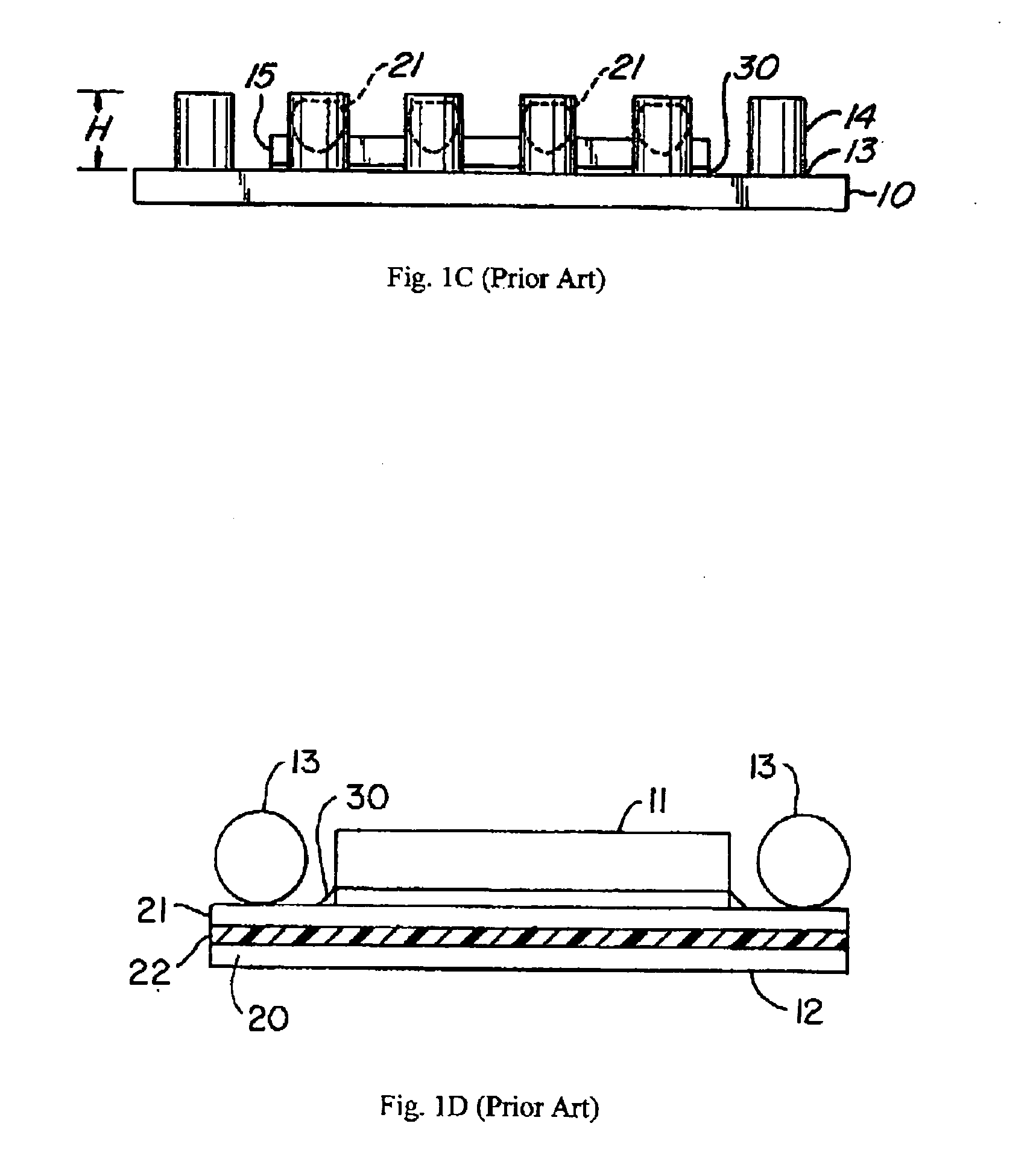

Method for making formaldehyde-free high-strength artificial plate

InactiveCN1460580AEliminate pollutionIncrease joint areaFlat articlesDomestic articlesHigh intensityUltimate tensile strength

The production method of formol-free high-strength artificial plate includes the following steps: firstly, pulverizing crop straw and stalk into 0.1-6 mm, adding MDI adhesive, stirring and mixing them, making the uniformly-mixed raw material into plate blank, prepressing and forming under the condition of 300-400 k N / sq.M, then thermosetting at 140-200 deg.C and 2500-3500 kN / sq.M, cooling, edging and polishing so as to obtain the invented artificial plate.

Owner:SHANGHAI COMPAK ENVIRONMENTAL PROTECTION EQUIP CO LTD

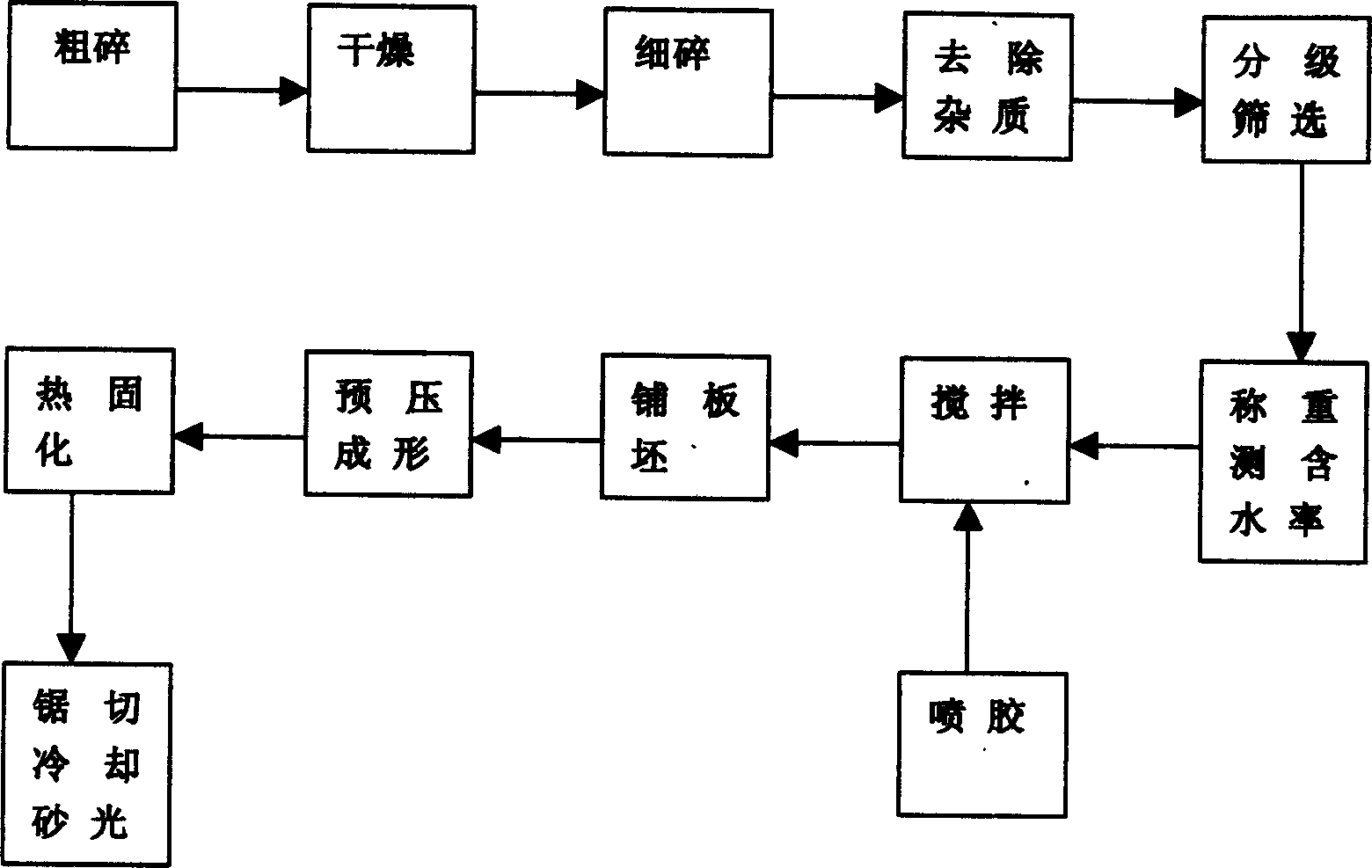

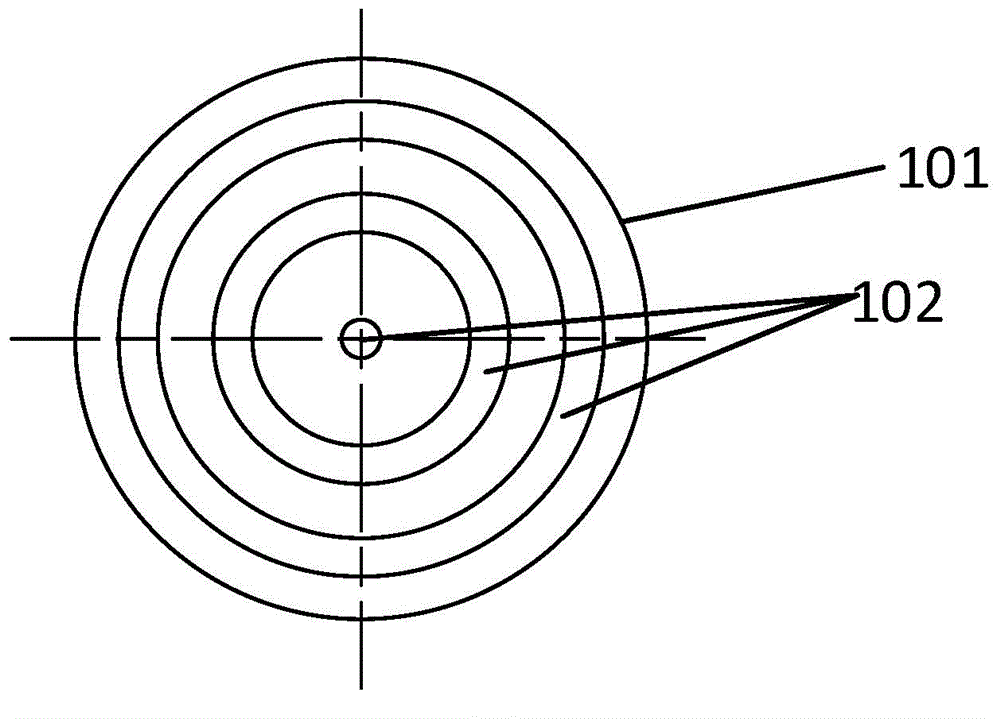

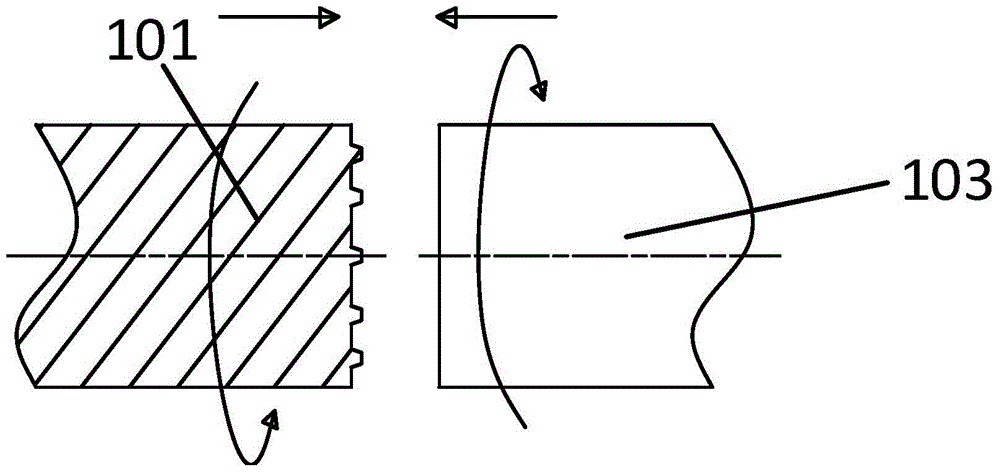

Friction welding method for copper and aluminum end faces

InactiveCN105522272AIncrease joint areaReduce oxide impuritiesNon-electric welding apparatusConcentric ringSurface oxidation

The invention discloses a friction welding method for copper and aluminum end faces. The method comprises the following steps that S1, a plurality of concentric ring-shaped or round bosses are formed on the copper or aluminum end face of a to-be-welded object with the copper or aluminum end face, and the section of each boss is in the shape of a trapezoid with the lower bottom connected with the copper or aluminum end face; S2, edges and corners of the bosses are removed; S3, acid pickling is conducted on the copper or aluminum end face, and a surface oxide layer is removed; and S4, the copper or aluminum end face is connected to another to-be-welded object with the copper or aluminum end face through friction welding. The copper and aluminum end faces are provided with the bosses and grooves, the bosses and the grooves are spliced, and thus the splicing area is increased; furthermore, the copper and aluminum end faces are treated before and during friction welding, the quantity of oxide impurities is reduced, and thus the splicing strength is improved.

Owner:JIANGSU JIAMENG ELECTRICAL EQUIP

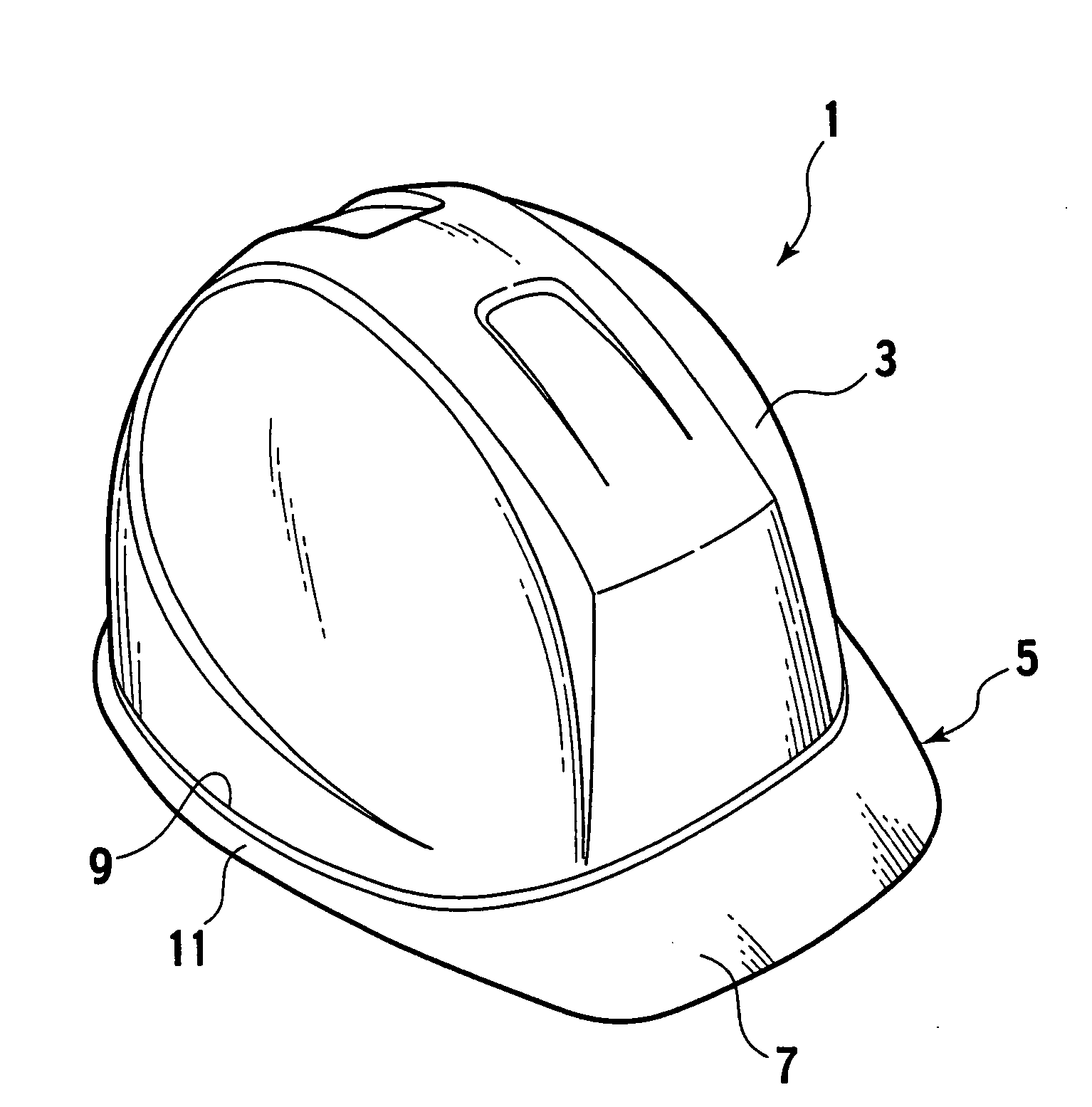

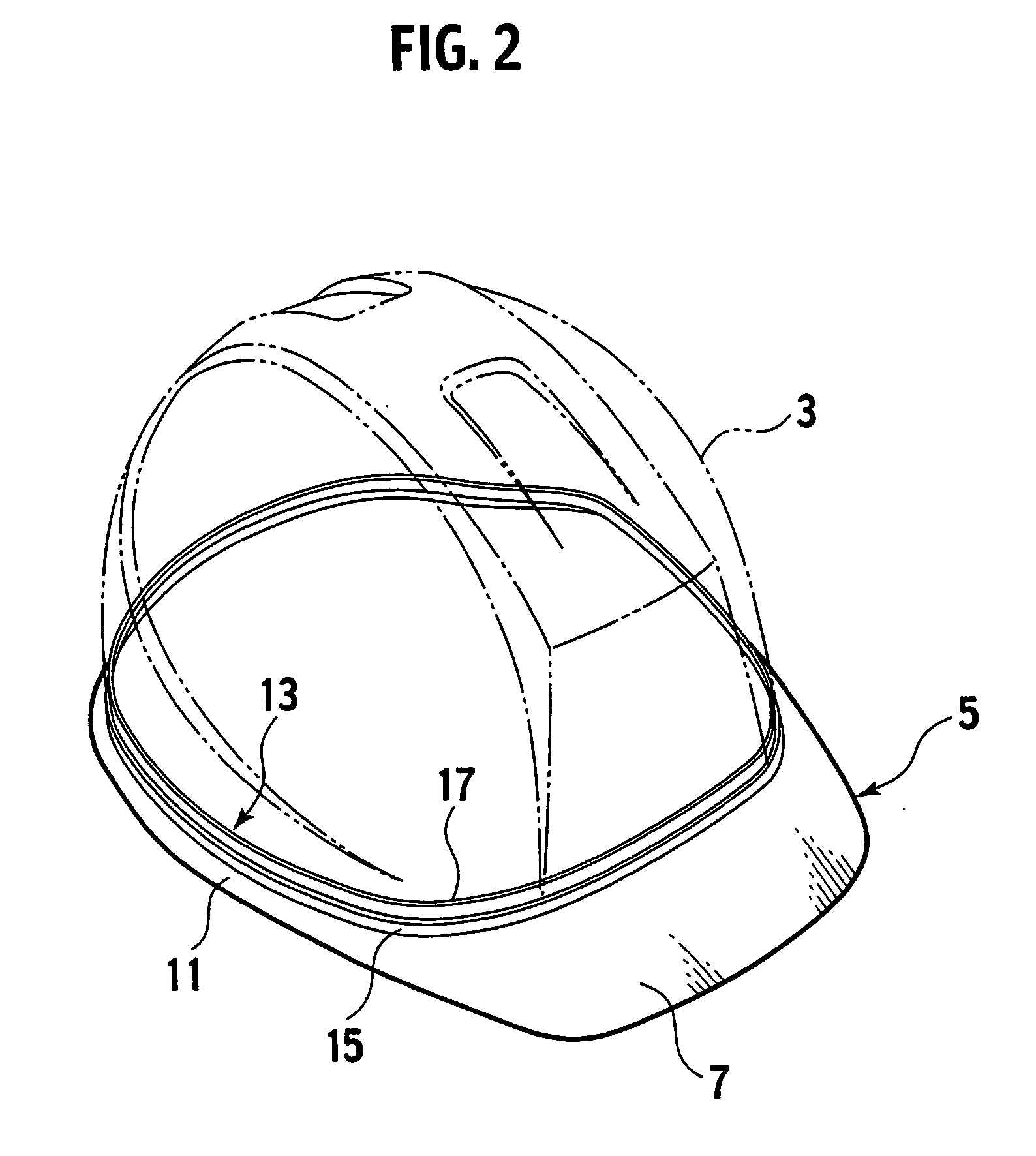

Helmet With Visor

InactiveUS20080250546A1Increase joint areaJoining is strengthenedEye treatmentDomestic articlesEngineeringVisor

A helmet 1 with a visor formed by integrally joining the preliminarily injection-molded visor 5 to a cap body 3, wherein an opening end edge 9 formed on the cap body is joined to the outer side of a joining wall 17 formed on the visor 5, and the joining wall 17 is held by the opening end edge 9 and a tongue-shaped part 31 formed on the inside of the cap body 3. The joined faces of the visor 5 and the cap body 3 are joined to each other by fusing, an intruding engagement part intruded in a through hole 22 formed in the joining wall 17 is formed at the opening end edge of the cap body 3, and the joining portion of the visor and the cap body is formed in annular shapes.

Owner:MIDORI ANZEN

Vertical packaged IC device modules with interconnected 3D laminates directly contacts wafer backside

ActiveUS7829989B2Reduce decreaseOptimizationSemiconductor/solid-state device detailsSolid-state devicesThermal dilatationSurface mounting

An electronic package for containing at least a top packaging module vertically stacked on a bottom packaging module. Each of the packaging modules includes a semiconductor chip packaged and connected by via connectors and connectors disposed on a laminated board fabricated with a standard printed-circuit board process wherein the top and bottom packaging module further configured as a surface mountable modules for conveniently stacking and mounting to prearranged electrical contacts without using a leadframe. At least one of the top and bottom packaging modules is a multi-chip module (MCM) containing at least two semiconductor chips. At least one of the top and bottom packaging modules includes a ball grid array (BGA) for surface mounting onto the prearranged electrical contacts. At least one of the top and bottom packaging modules includes a plurality of solder bumps on one of the semiconductor chips for surface mounting onto the prearranged electrical contacts. The laminated board of the bottom packaging modules further has a thermal expansion coefficient substantially the same as a printed circuit board (PCB) whereby a surface mount onto the PCB is less impacted by a temperature change.

Owner:ALPHA & OMEGA SEMICON LTD

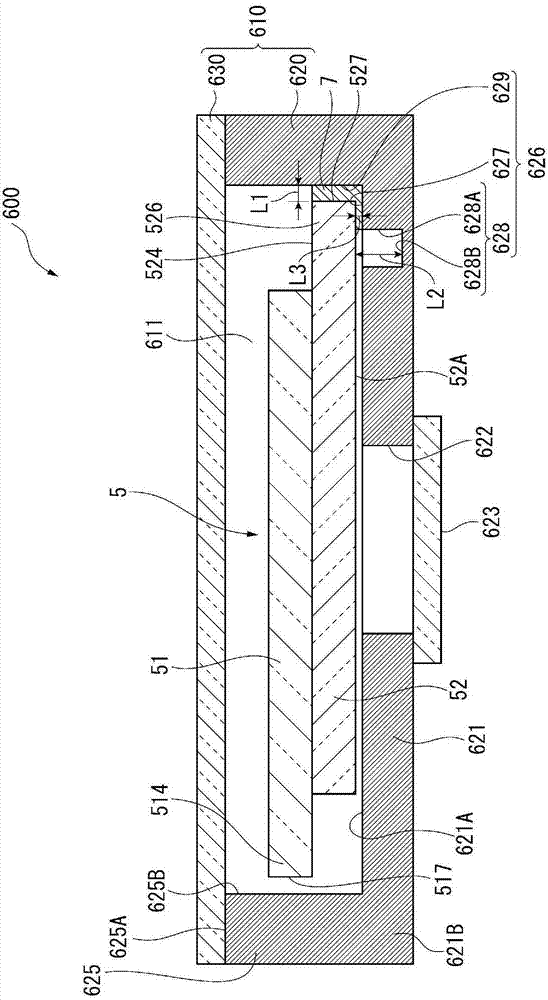

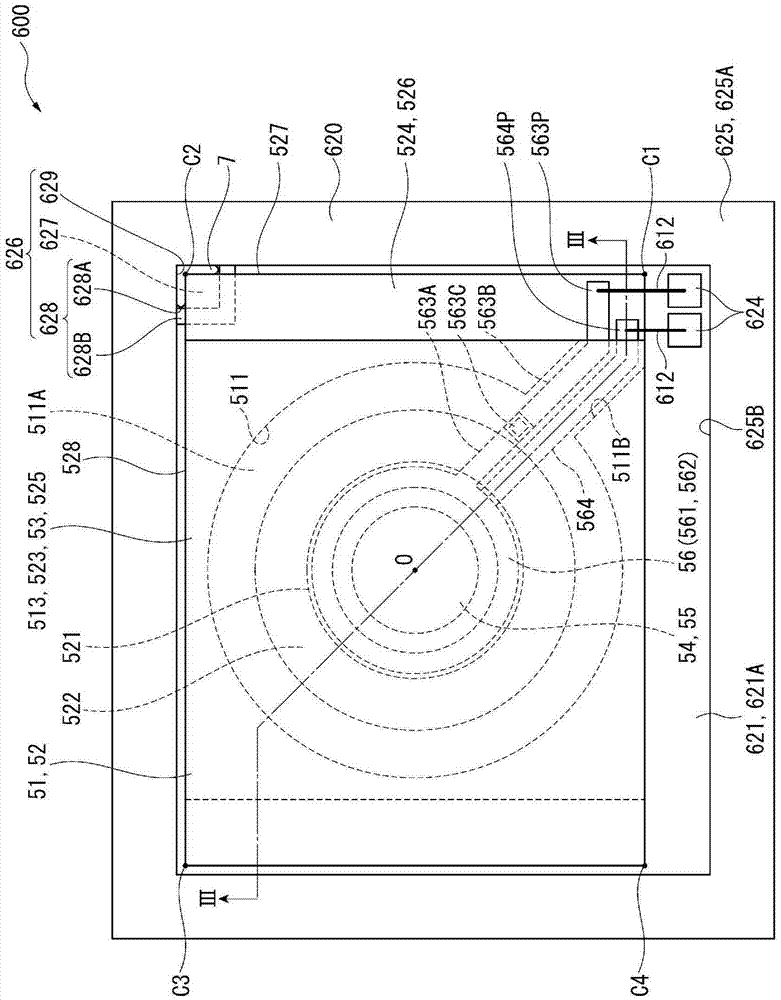

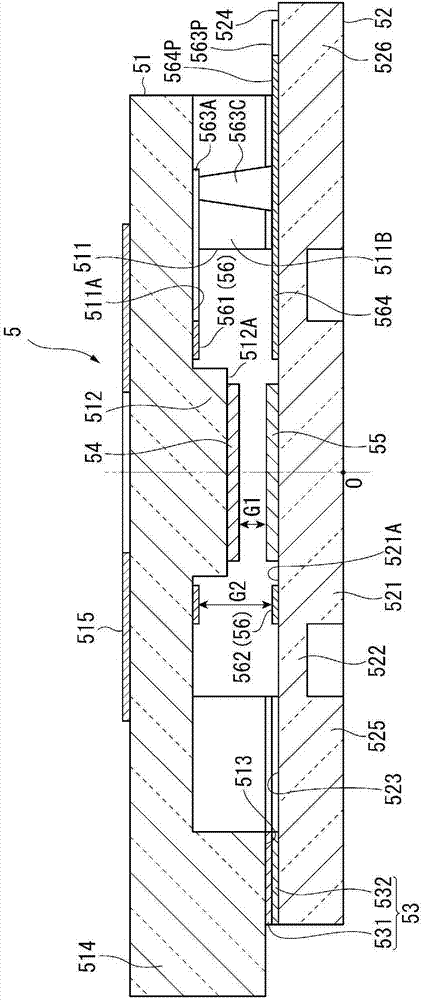

Optical filter device, optical module, electronic device, and MEMS device

InactiveCN104516101AAvoid deflectionReduce performanceMovable microstructural devicesOptical elementsOptical ModuleComputer module

An optical filter device includes a wavelength variable interference filter, a housing that stores the wavelength variable interference filter, and a bonding member that fixes a movable substrate to the housing. The housing includes a fixing portion that comes into contact with the bonding member, the fixing portion includes a pedestal fixing surface (first surface) facing a portion of a surface of the movable substrate, a sidewall fixing surface (second surface), continuous with a portion of a periphery of the pedestal fixing surface, which faces a lateral side of the movable substrate, and an intersection surface (third surface) continuous from a remaining portion in a periphery of the pedestal fixing surface in a direction away from the movable substrate, and the bonding member is provided between the substrate surface and the pedestal fixing surface, and between the lateral side and the sidewall fixing surface.

Owner:SEIKO EPSON CORP

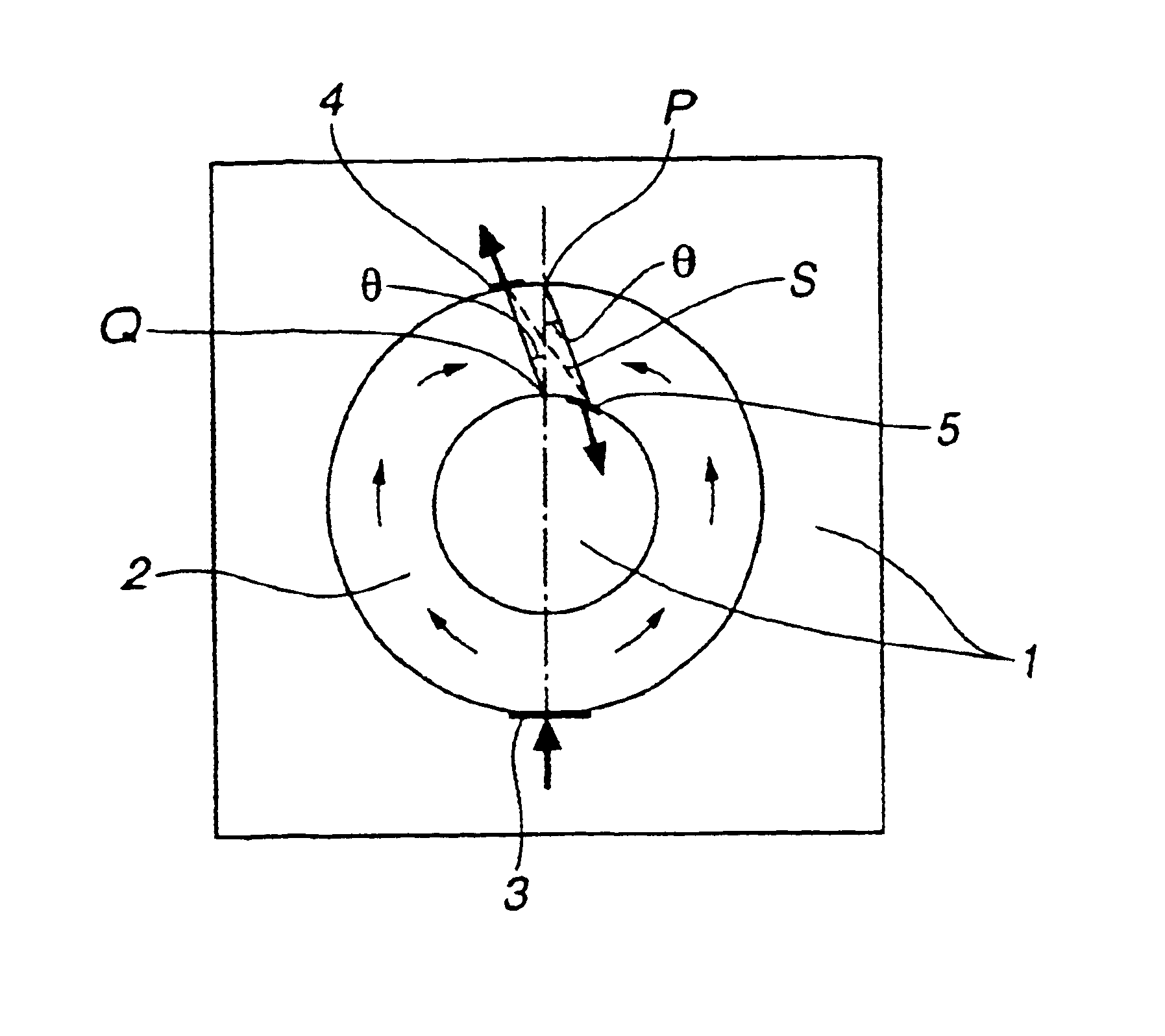

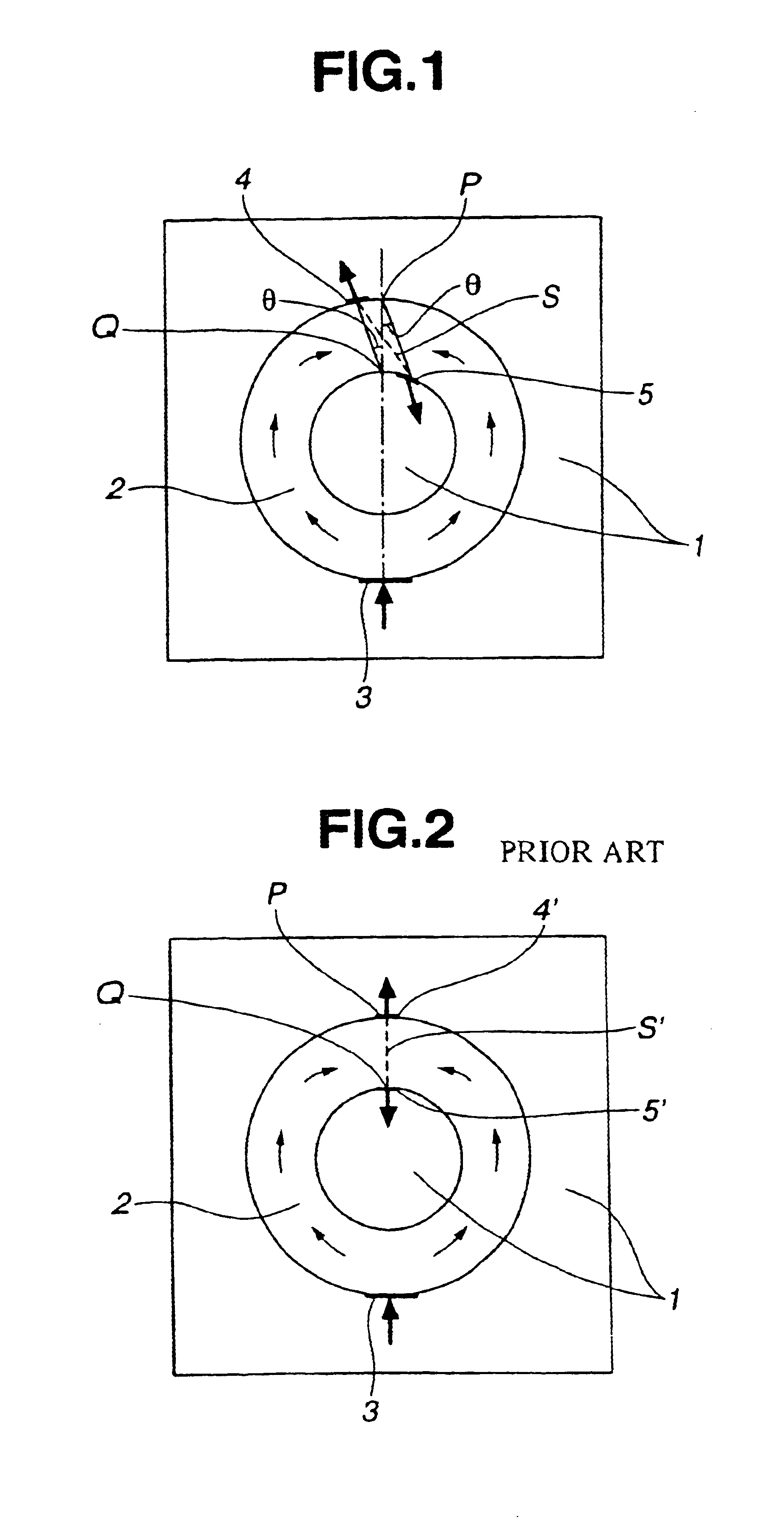

Motors with oil dynamic pressure bearing, oil dynamic pressure bearing devices and method for manufacturing the same

InactiveUS7059771B2Improve rigidityIncrease dynamic pressureShaftsBearing componentsEngineeringDynamic pressure

A motor with fluid dynamic pressure bearing is disclosed. The motor includes a dynamic pressure bearing member having a concave section that is concave in an axial direction, a rotary shaft that is rotatively supported by the dynamic pressure bearing, and a rotary member that is joined to the rotary shaft in one piece along a joint section between the rotary member and the rotary shaft, and rotatively driven by electromagnetic drive force, an expanded diameter section that is provided on the dynamic pressure bearing member. A fallout preventing member is provided on the rotary member, which overlaps the expanded diameter section of the dynamic pressure bearing member in the axial direction to prevent the rotary shaft from falling out of the dynamic pressure bearing member. The concave section of the rotary member opposes in the axial direction the expanded diameter section of the dynamic pressure bearing member, wherein the expanded diameter section is placed inside the concave section, and the joining section between the rotary member and the rotary shaft overlaps the expanded diameter section in the radial direction.

Owner:NIDEC CORP

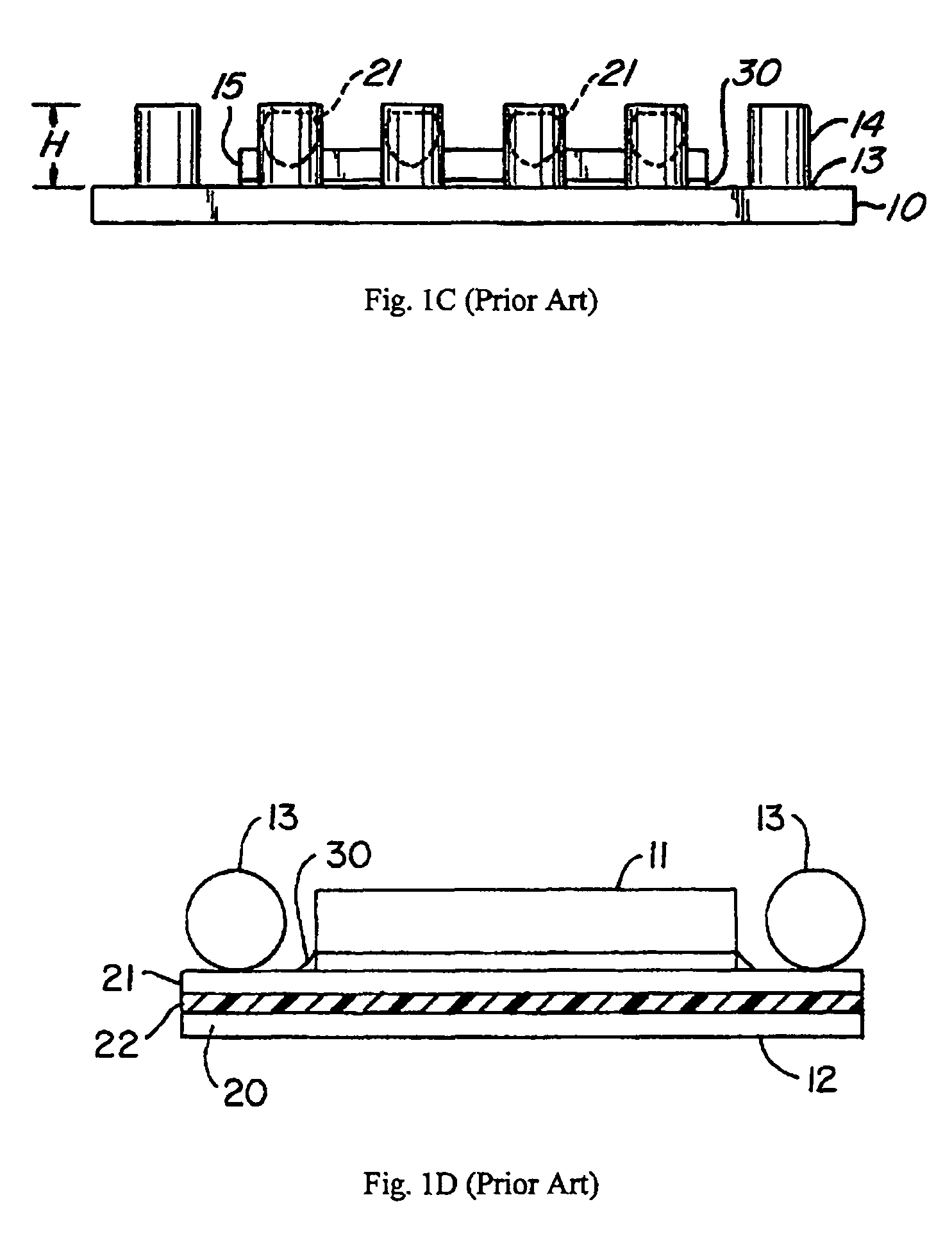

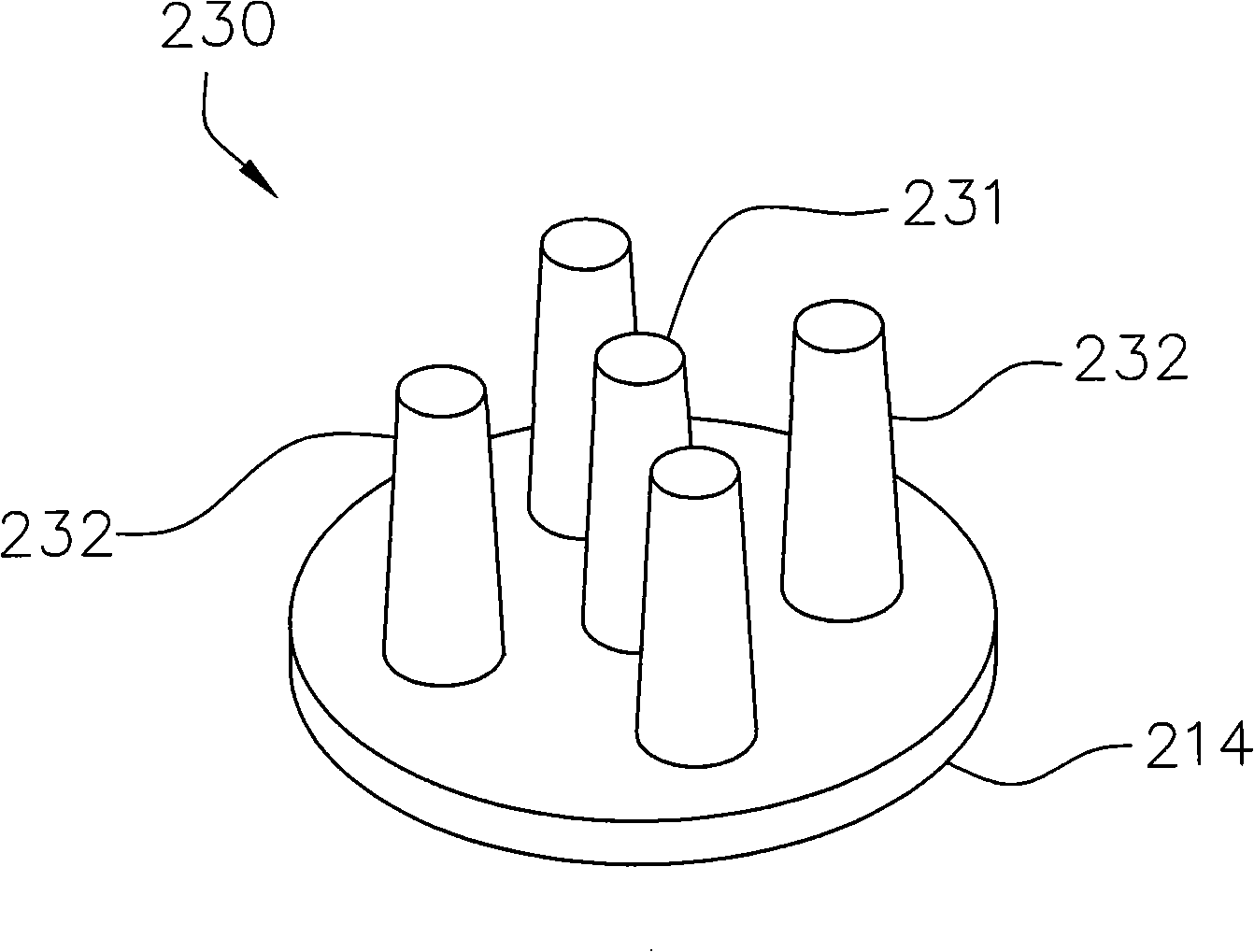

Stackable semiconductor encapsulation construct for multi-cylinder body

InactiveCN101355070AIncrease joint areaIncreased complexitySemiconductor/solid-state device detailsSolid-state devicesElectrical conductorSemiconductor package

The invention relates to a polycylinder stackable semiconductor packaging structure. The structure mainly comprises a wafer carrier, a wafer and a plurality of downwards convex block groups, wherein the wafer carrier has a plurality of switchover pads on an upper surface and a plurality of external pads on a lower surface; the wafer is arranged on and is electrically connected with the wafer carrier; the downwards convex block groups are correspondingly arranged on the external pads, and each downwards convex block group connected with each external pad consists of a plurality of conducting cylinders; and a solder filling gap is arranged between adjacent conducting cylinders of the same downwards convex block group. The stackable semiconductor packaging structure is used to increase welding area and perplex the shape of a welding interface, thereby achieving high durability of welding spots and reducing the growing possibility of cracks. In addition, the convex block group arranged on each external pad has the solder filling gap, solder can be filled and stored in the convex block group, so that a plaque does not extrude the solder to cause bridging short circuit even when inclined or warped; therefore, the structure is particularly suitable for practical use.

Owner:POWERTECH TECHNOLOGY

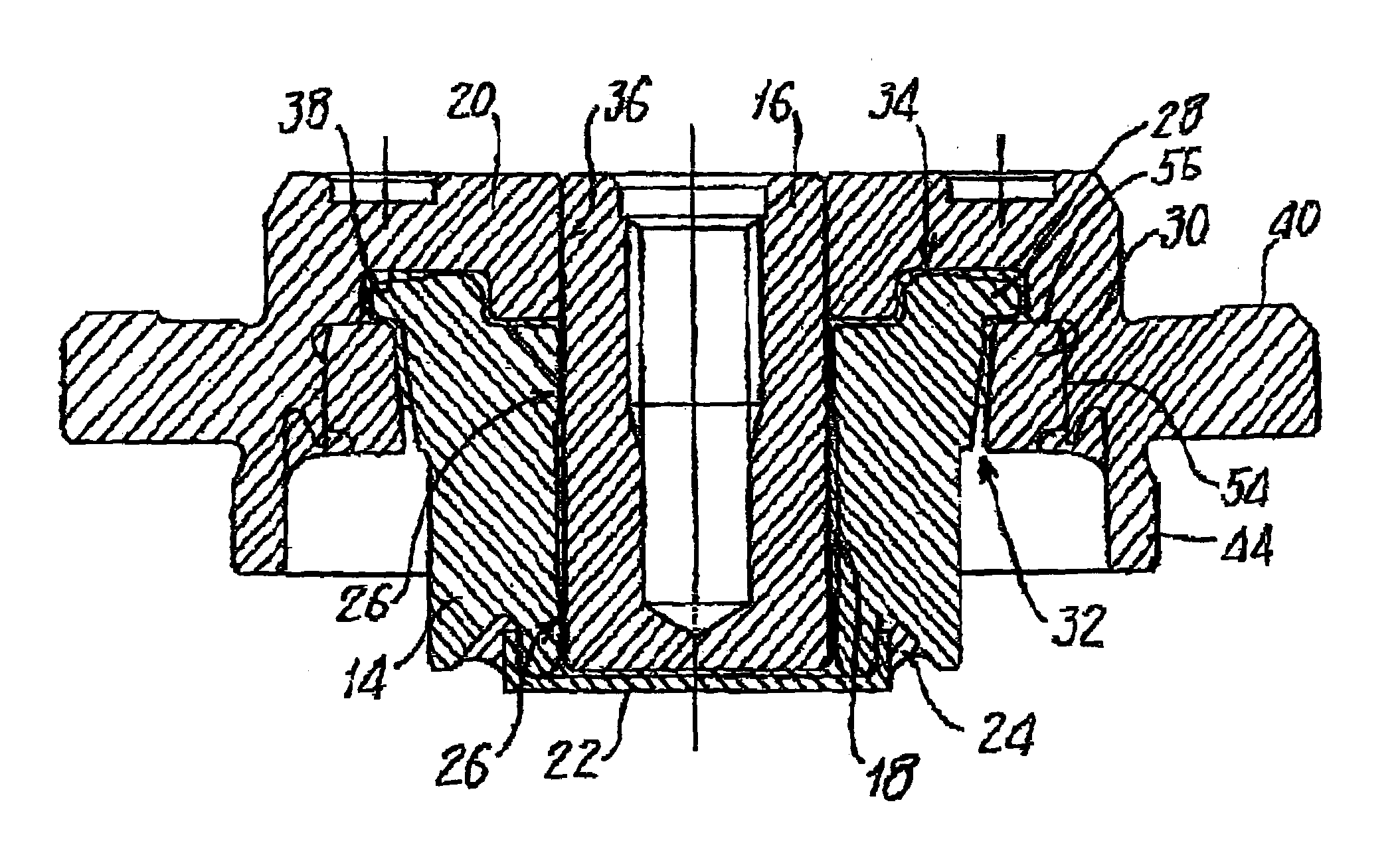

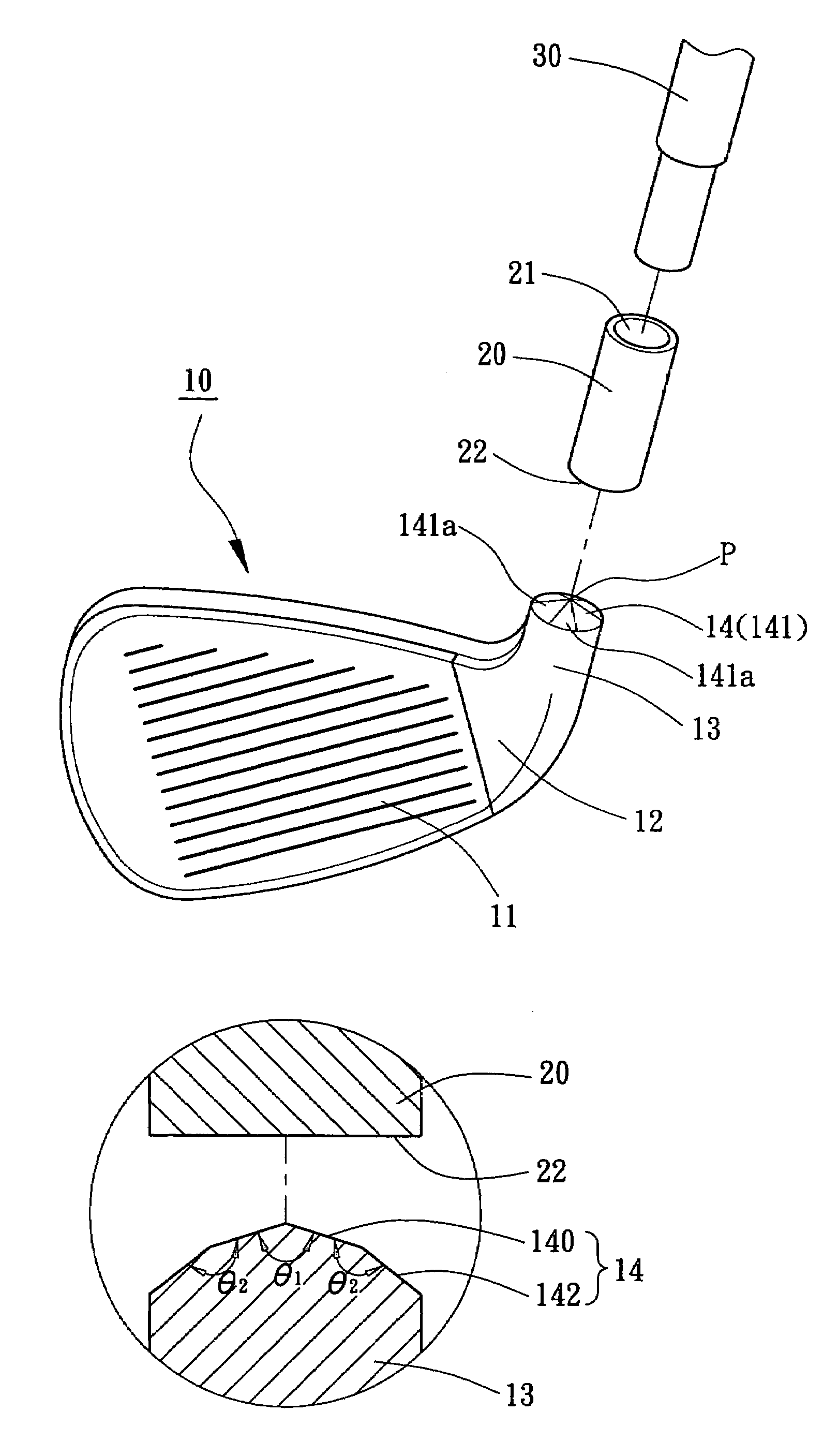

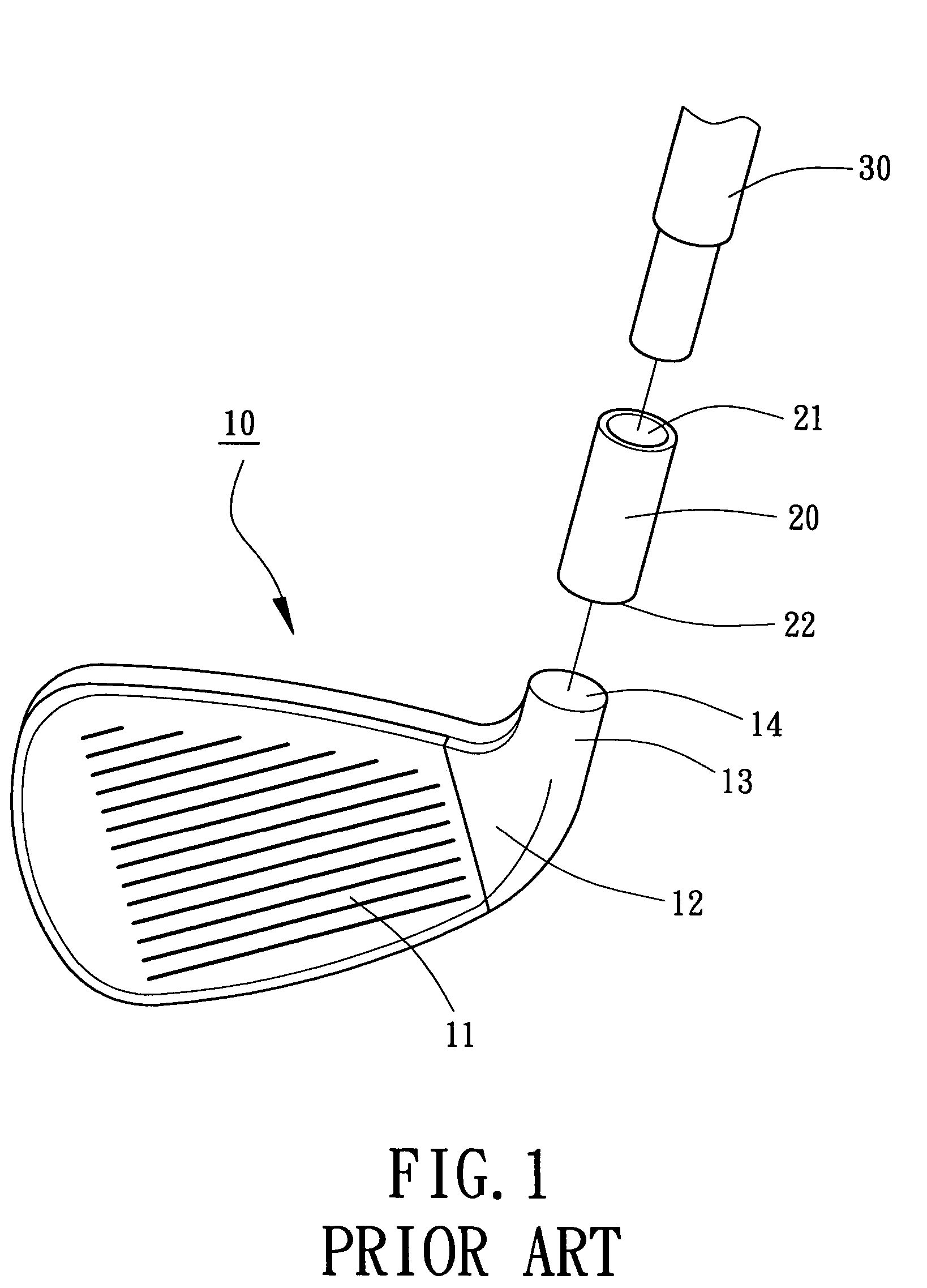

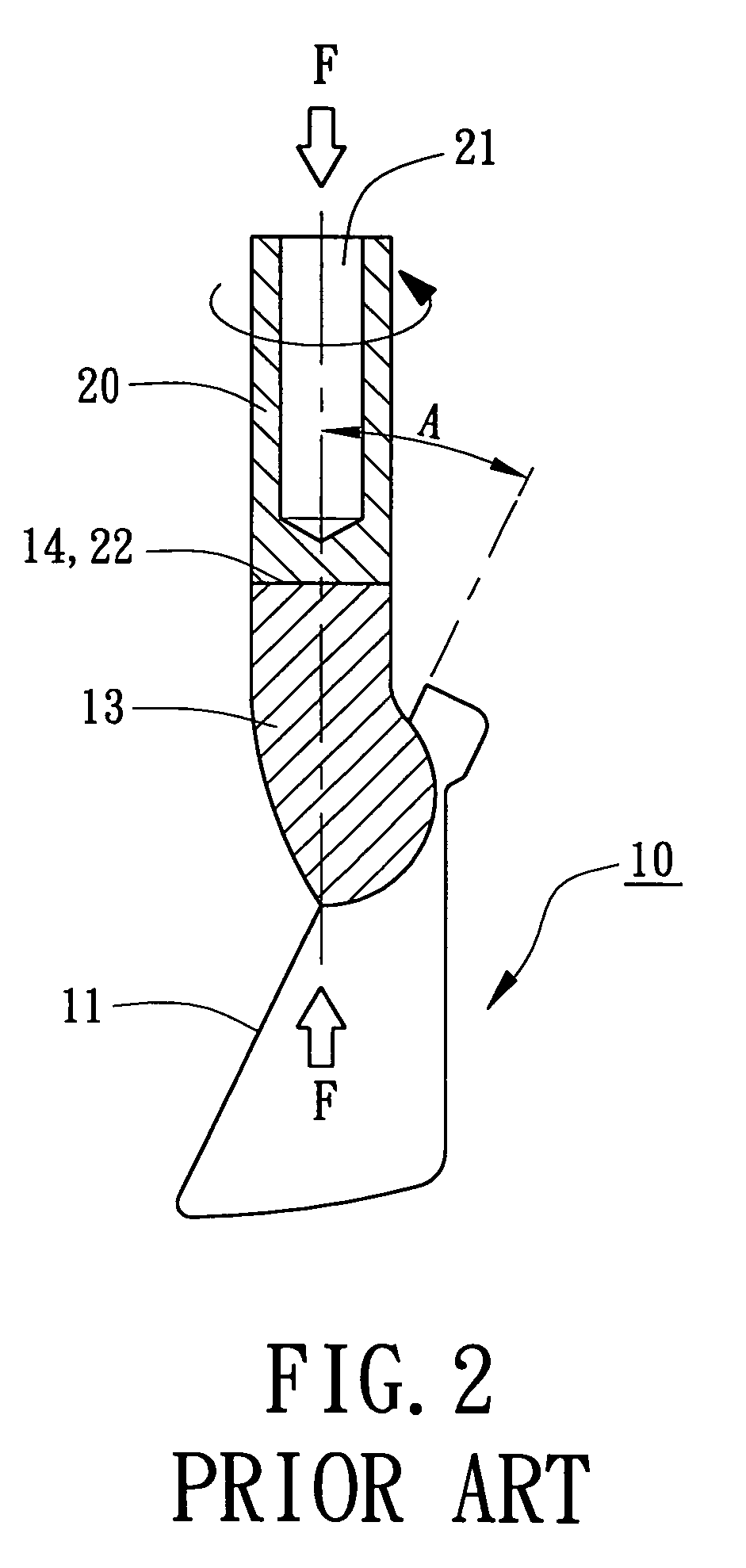

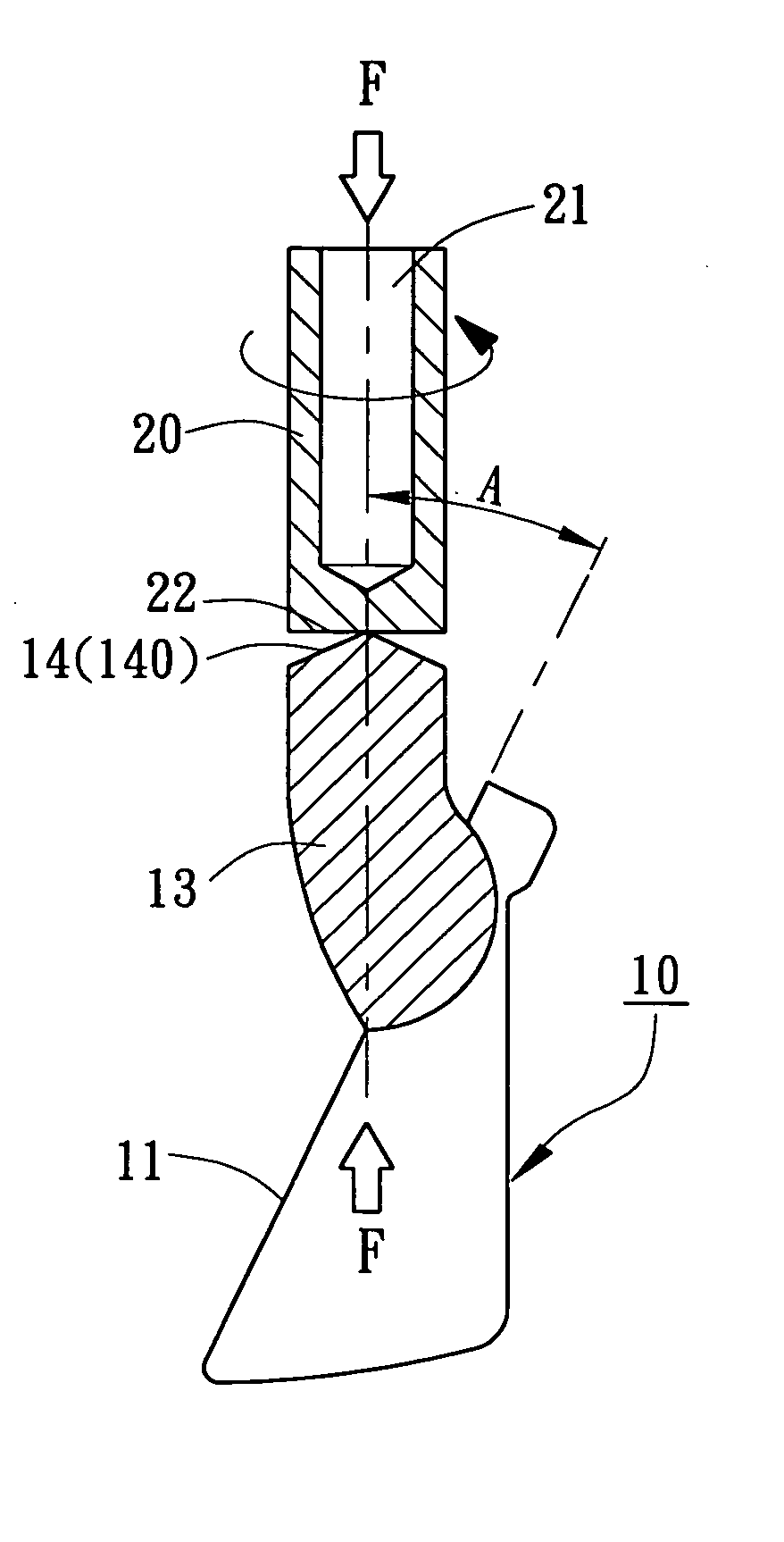

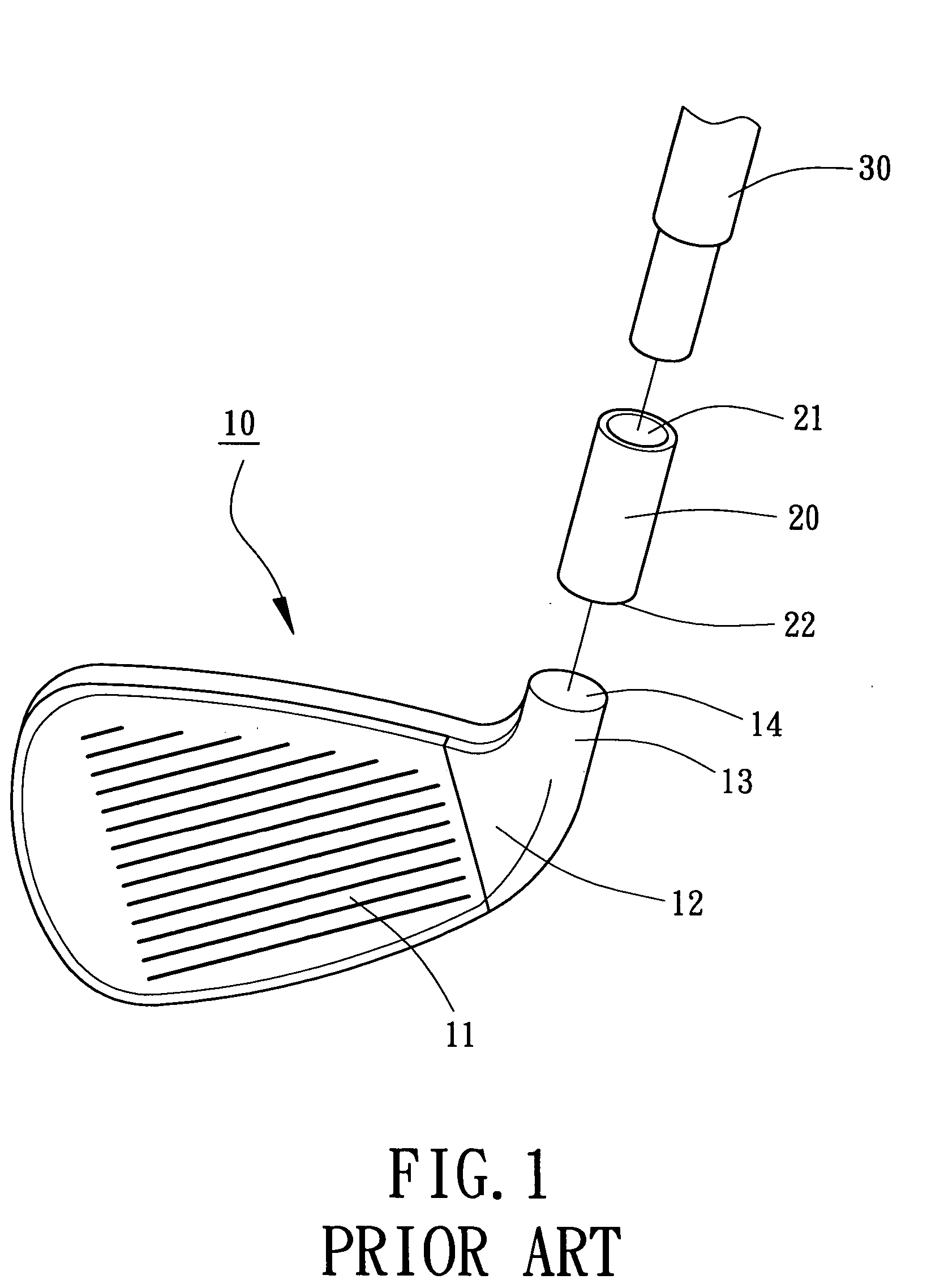

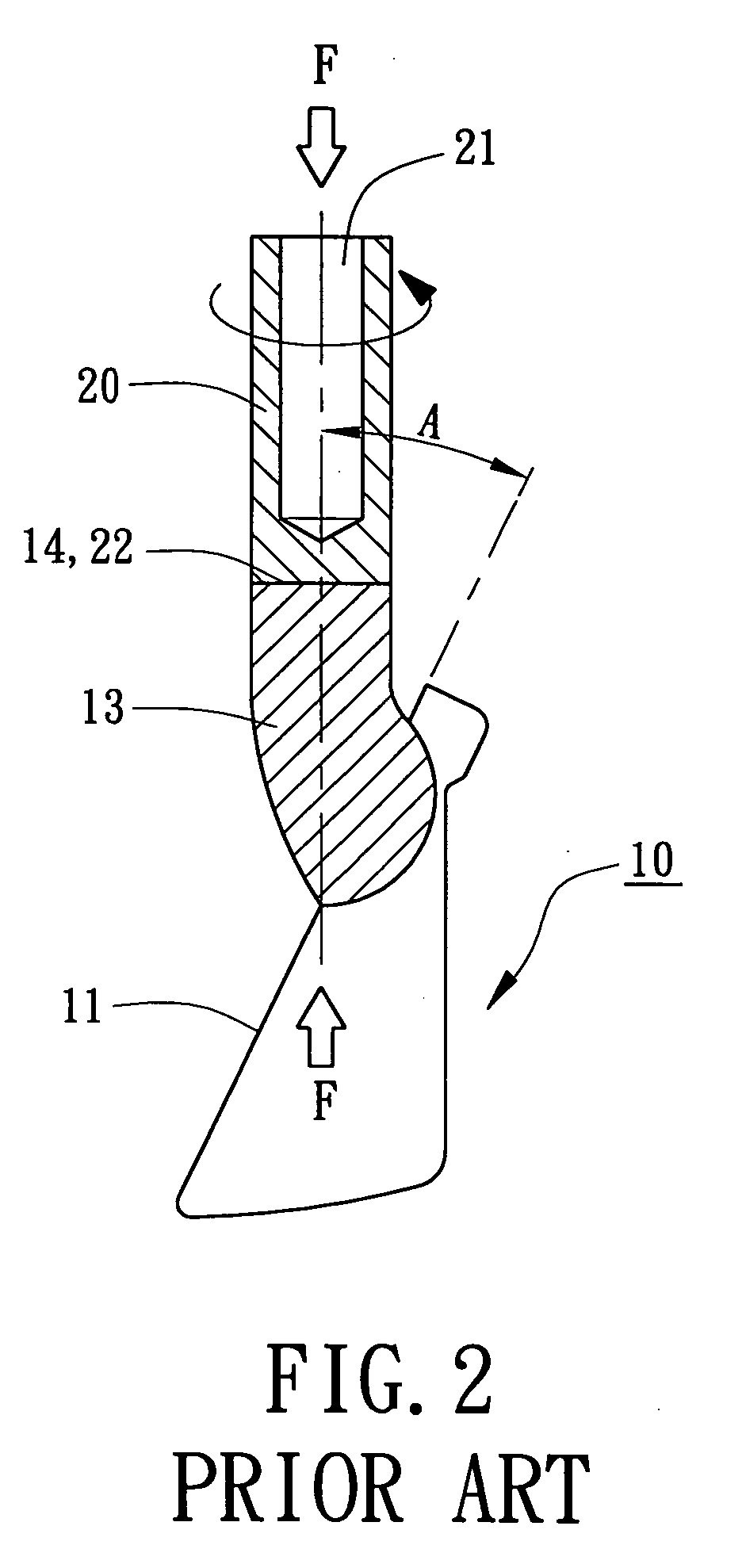

Golf club head with a structure for friction welding and manufacturing method therefor

InactiveUS7086960B2Prolong lifeIncrease joint areaGolf clubsRacket sportsFriction weldingMetallic materials

A golf club head includes a first portion forming a part of a head body of the golf club head and a second portion forming another part of the head body. The first portion is made of a first metal material and includes an abutting portion. The second portion is made of a second metal material and includes an abutting portion. At least one inclined or arcuate surface for friction welding is formed on the abutting portion of the first portion. The inclined or arcuate surface for friction welding provides the abutting portion of the first portion and the abutting portion of the second portion with improved bonding strength and increased joining area when joining the first portion and the second portion together by welding friction to form a golf club head product. A method for manufacturing a golf club head by friction welding is also disclosed.

Owner:FUSHENG PRECISION

Golf club head with a structure for friction welding and manufacturing method therefor

InactiveUS20050124432A1Prolong lifeIncrease joint areaGolf clubsRacket sportsFriction weldingMetallic materials

A golf club head includes a first portion forming a part of a head body of the golf club head and a second portion forming another part of the head body. The first portion is made of a first metal material and includes an abutting portion. The second portion is made of a second metal material and includes an abutting portion. At least one inclined or arcuate surface for friction welding is formed on the abutting portion of the first portion. The inclined or arcuate surface for friction welding provides the abutting portion of the first portion and the abutting portion of the second portion with improved bonding strength and increased joining area when joining the first portion and the second portion together by welding friction to form a golf club head product. A method for manufacturing a golf club head by friction welding is also disclosed.

Owner:FUSHENG PRECISION

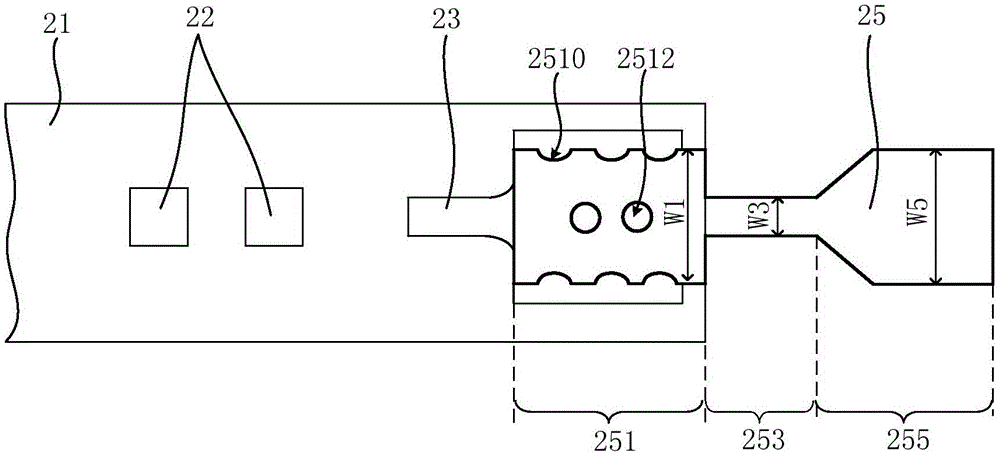

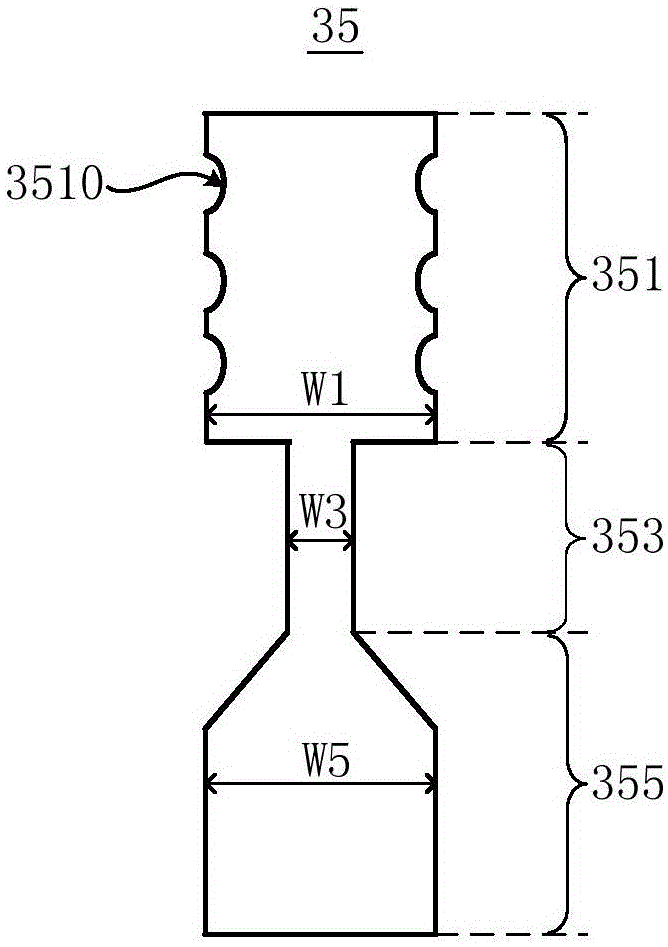

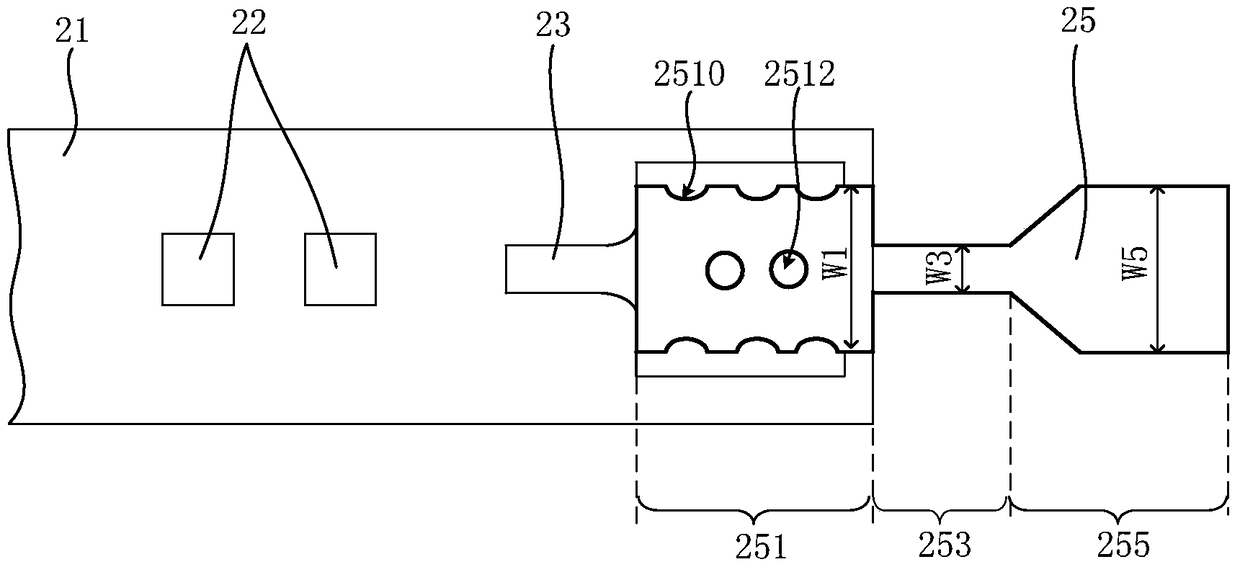

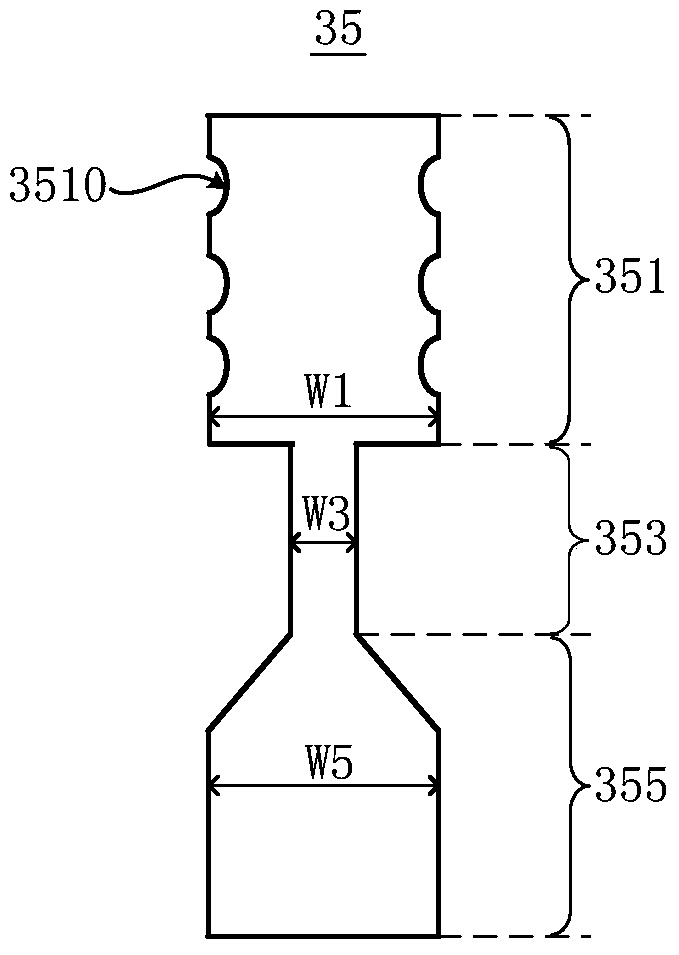

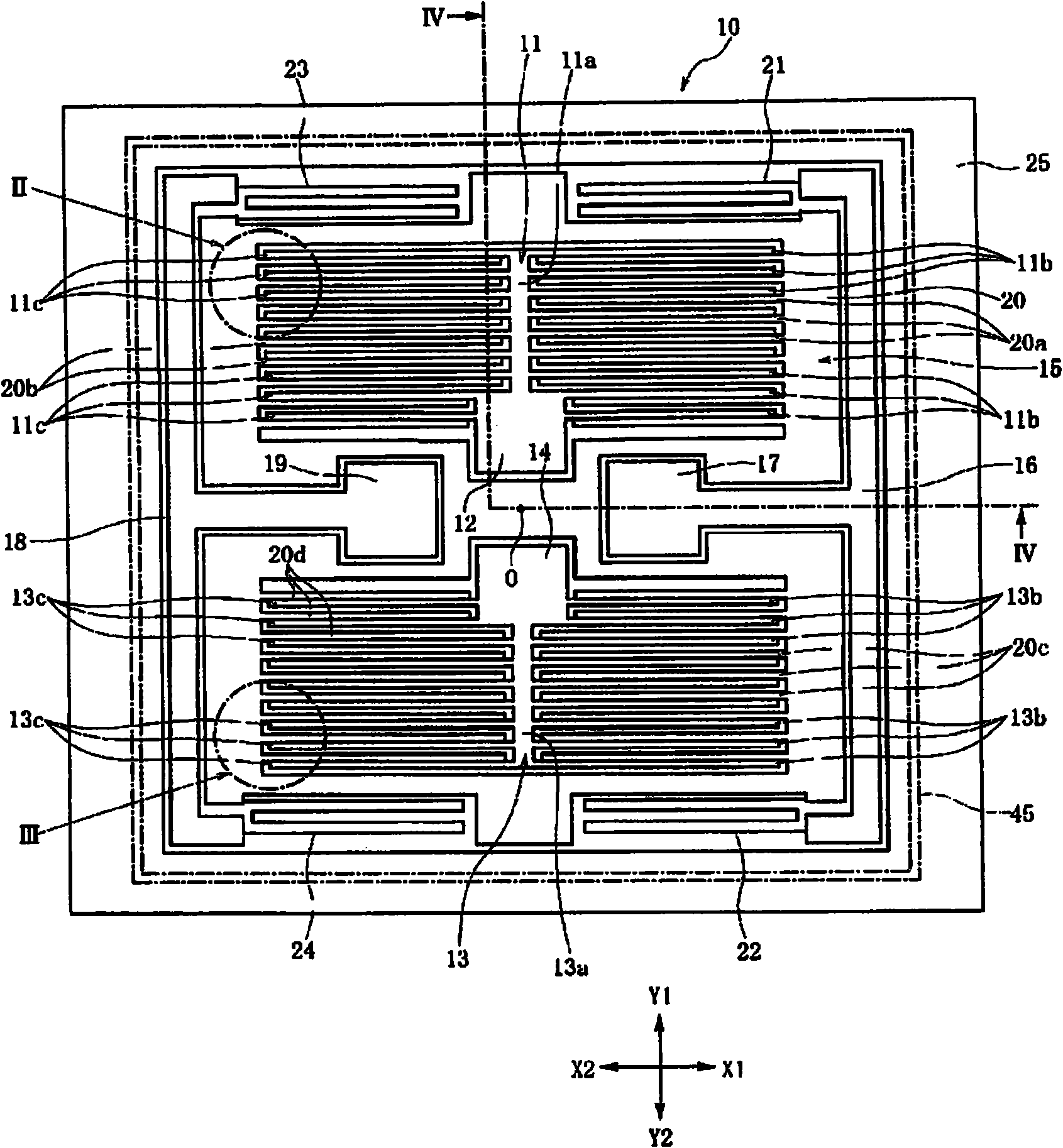

Mems sensor

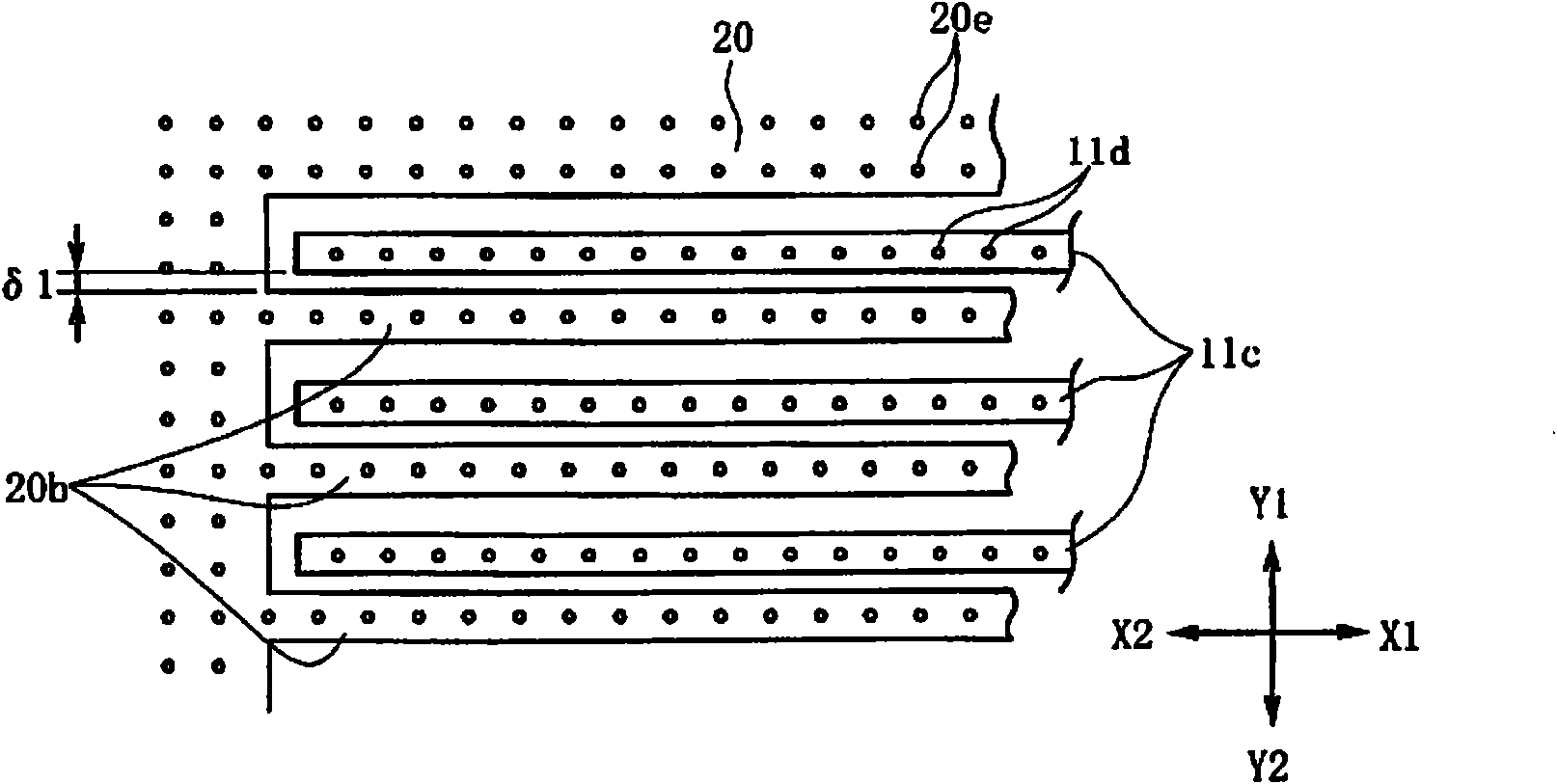

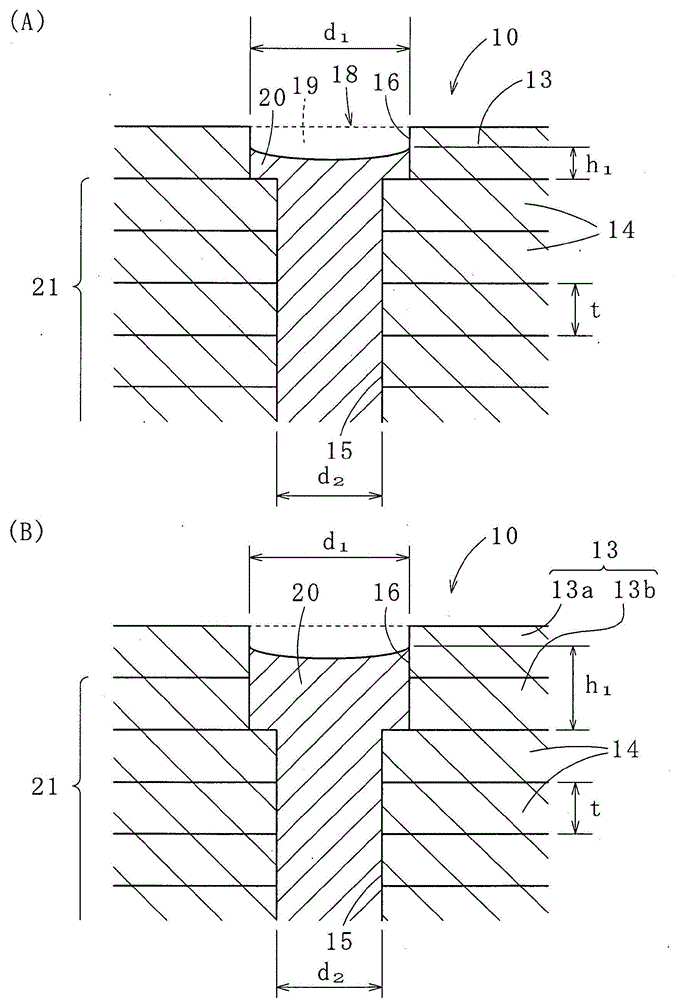

InactiveCN102160185AIncrease joint areaImprove joint strengthAcceleration measurement using interia forcesSolid-state devicesMems sensorsElectrical and Electronics engineering

Provided is an MEMS sensor wherein especially a structure for bonding each supporting conductive section of a movable electrode section and a fixed electrode section, which are supported on a first substrate side, with a lead layer embedded in an insulating layer on the side of a second substrate which faces the first substrate with a space therebetween is improved. The MEMS sensor has a first substrate (1), a second substrate (2), and a functional layer, which is arranged between the substrates and has the movable electrode section, the fixed electrode section and the supporting conductive section. On the surface of the second substrate (2), a second insulating layer (30), a lead layer (35) and a connecting electrode section (32) which is electrically connected to the lead layer and is individually connected to each supporting conductive section are arranged. On the surface of the second insulating layer (30), a recessed section (37) which penetrates to reach even the surface of the lead layer is formed. The connecting electrode section (32) has a recessed region (32a) conforming to the shape of the recessed section (37), and a connecting region (32b) which extends long on the surface of the second insulating layer (30) from one end section in the recessed region. The supporting conductive section (17) and a connecting region (32b) of the connecting electrode section (32) arebonded to each other.

Owner:ALPS ALPINE CO LTD

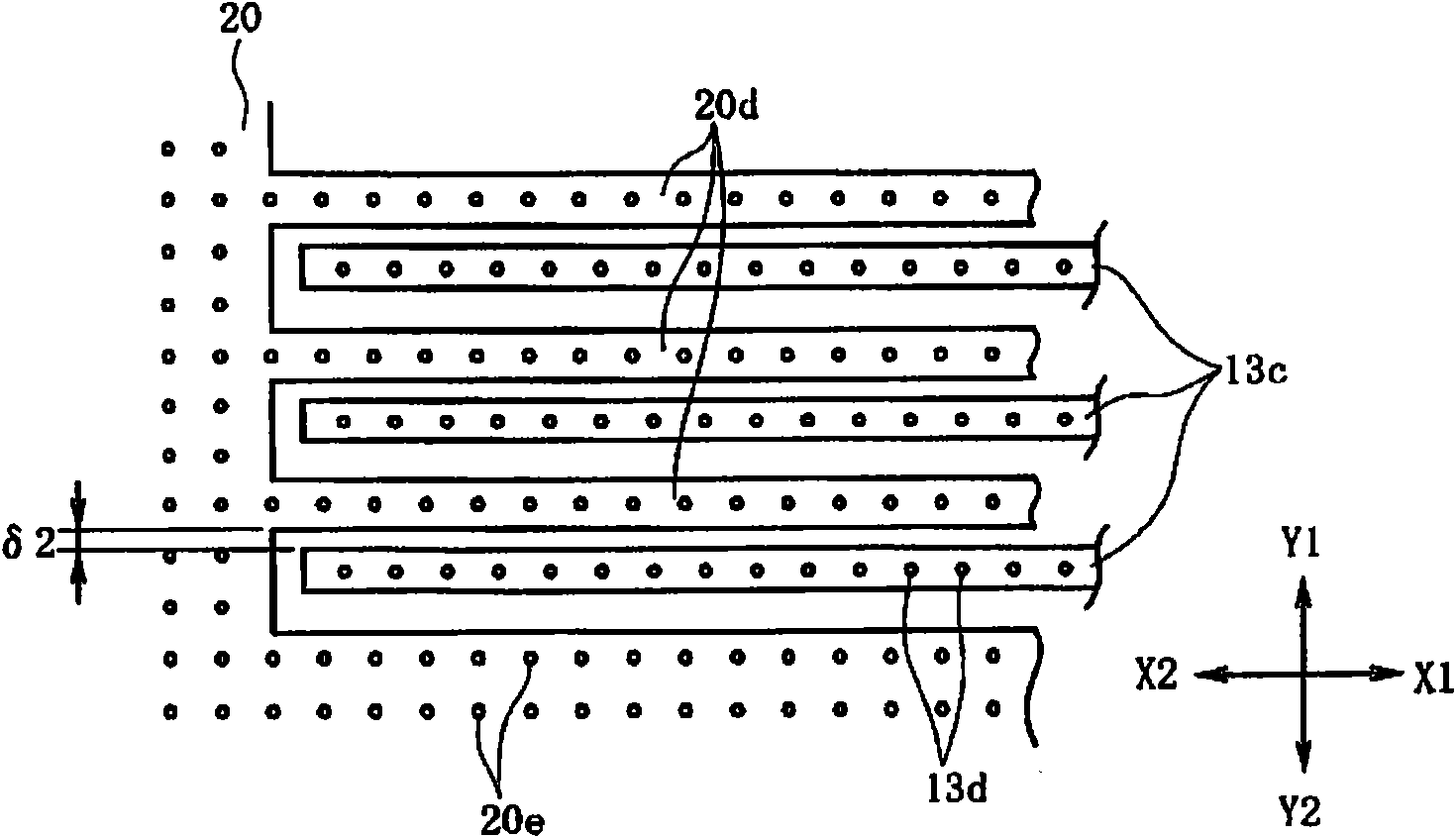

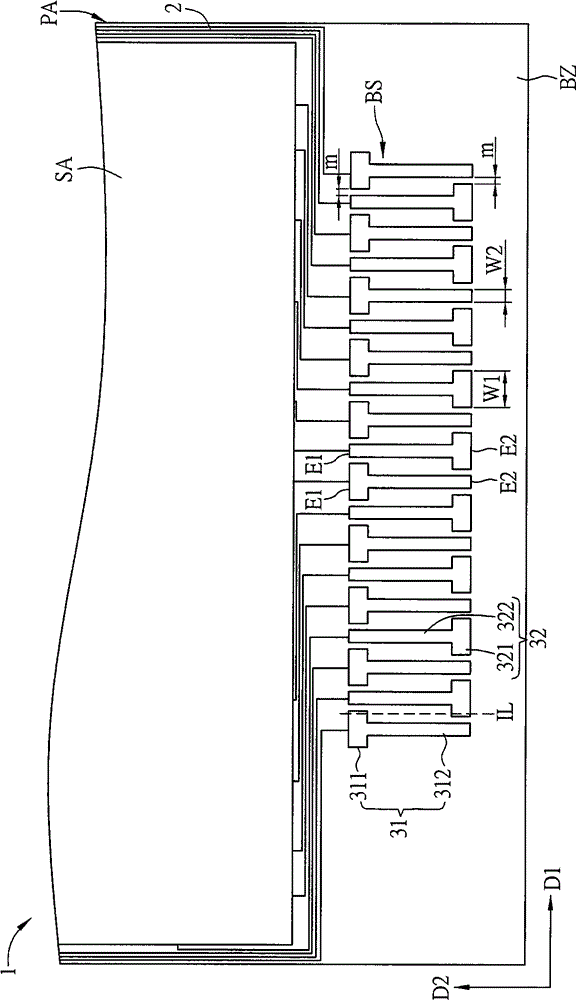

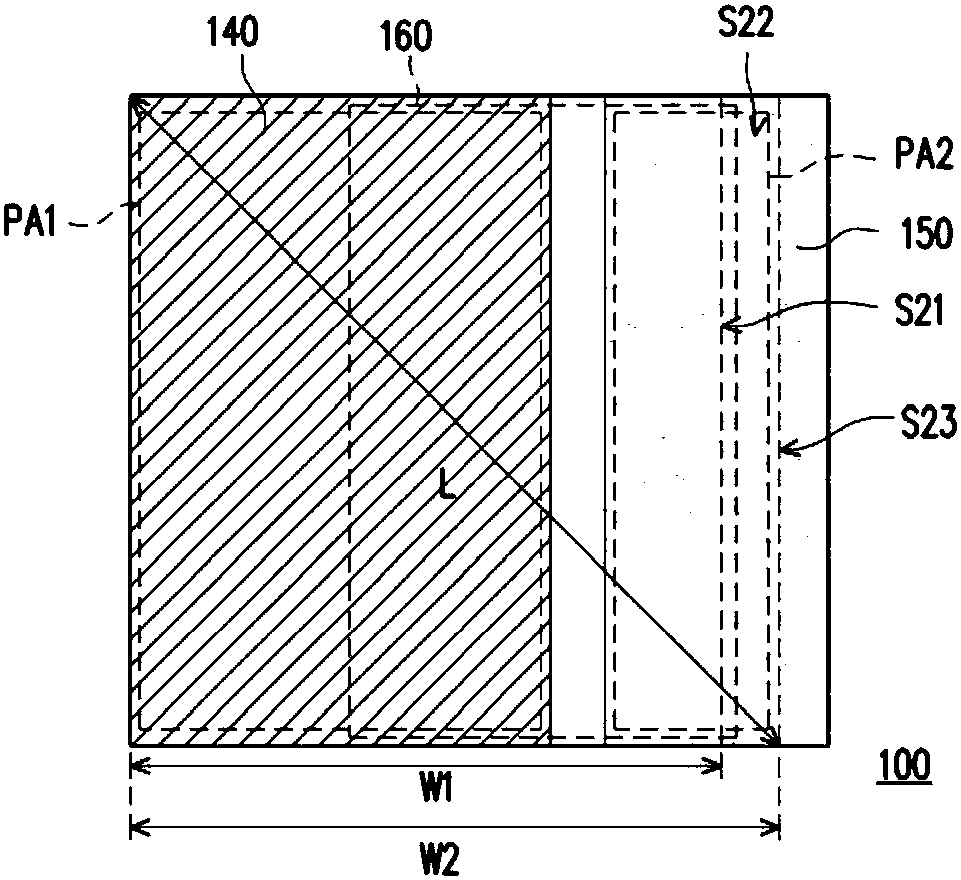

Touch panel and bonding structure thereof

InactiveCN106155395AImprove bindingAvoid easy separationInput/output processes for data processingStructural engineeringMechanical engineering

The invention provides a touch panel and a bonding structure thereof. The bonding structure comprises multiple first bonding pads and multiple second bonding pads. The first bonding pads are arranged in a bonding area in sequence in the first direction, and the second bonding pads and the first bonding pads are alternately arranged in the bonding area in sequence in the first direction; the second bonding pads and the first bonding pads are electrically insulated from each other, and projection locations of the adjacent first bonding pads and second bonding pads in the first direction are partially overlapped or tangent. Therefore, the bonding strength of the bonding pads and a circuit board can be improved.

Owner:TPK TOUCH SYST XIAMEN

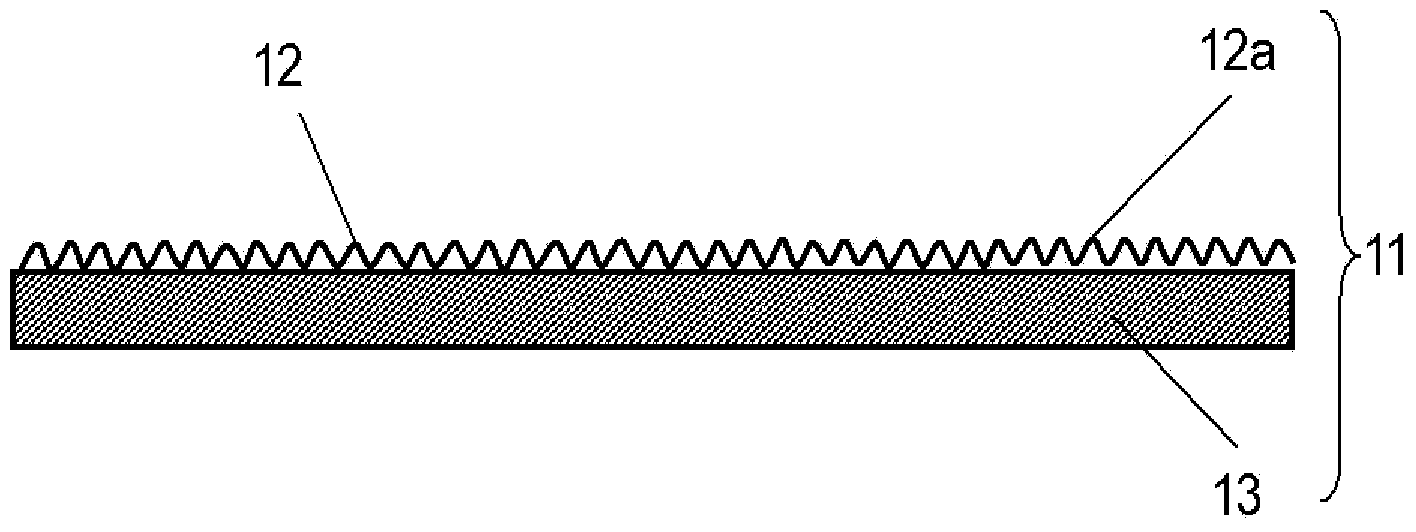

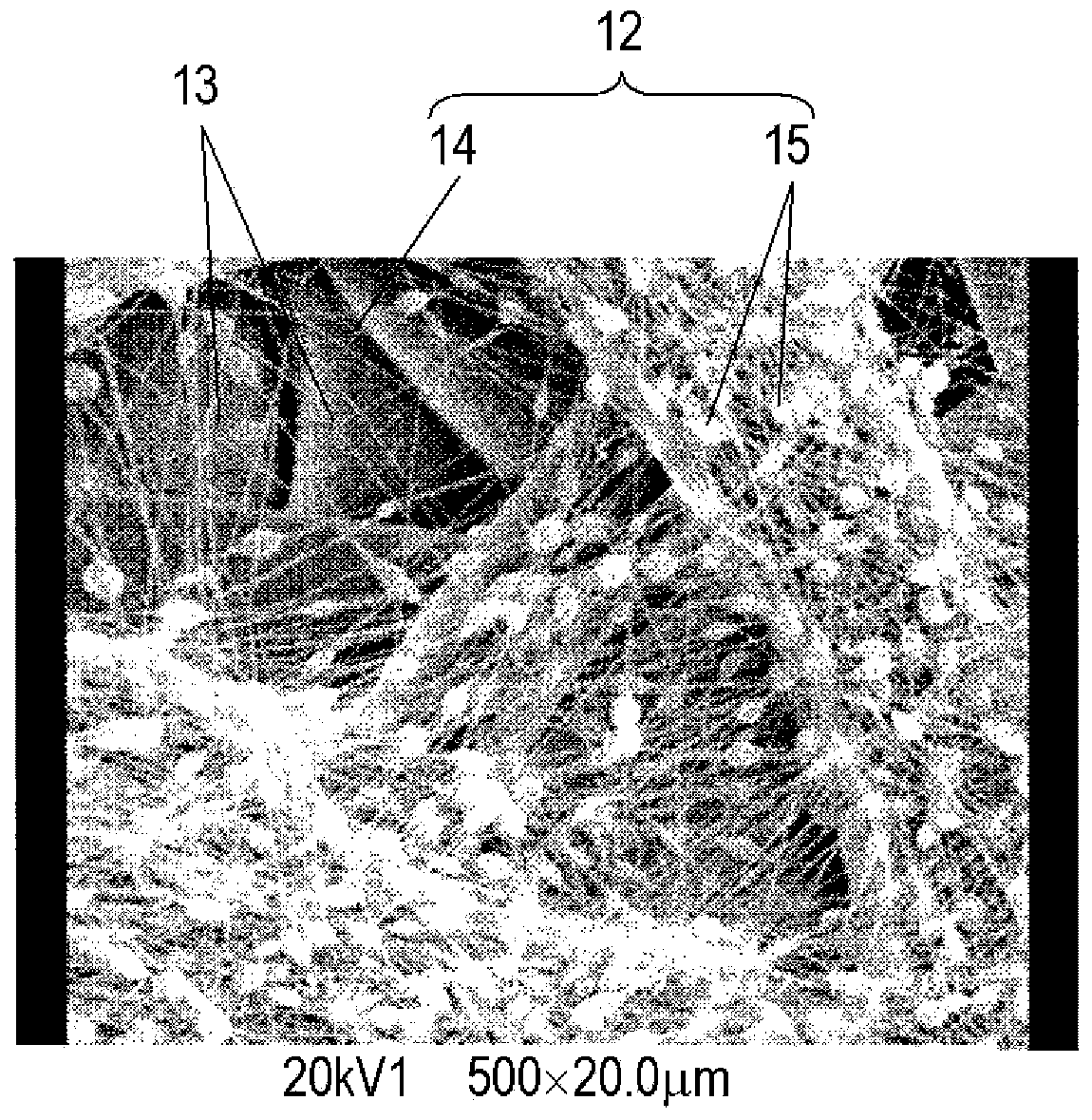

Filter medium for air filters, air filter, air purifier provided with air filter and air purifier with humidifying function

ActiveCN103732302ADoes not clog the openingIncrease joint areaLighting and heating apparatusMembrane filtersSurface layerAir purifiers

A filter medium for air filters of the present invention comprises a fine fiber layer configured from fine fibers having an average fiber diameter of 100 nm to 1000 nm and a base material for holding the fine fiber layer. The fine fibers are moniliform fibers consisting of fibers and beads and the fine fibers and the base material are welded by fusing the surface layer of the beads.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Light element device and method for manufacturing same

ActiveCN101359704AIncrease joint areaImprove bonding yieldSemiconductor/solid-state device detailsSolid-state devicesLight-emitting diodeDiode

The invention discloses a luminous element and a fabrication method thereof. The luminous element comprises a luminous diode and a pedestal; wherein the luminous diode is composed of electrodes and a junction layer formed on the electrodes, and the pedestal comprises a junction pad and a plurality of lug bosses and / or pits which are formed on the junction pad. The method for fabricating the luminous diode includes the following steps: providing a luminous diode which has electrodes and a junction layer which is arranged on the electrodes; providing a pedestal which comprises at least a junction pad; forming a plurality lug bosses and / or pits on the junction pad; and jointing the luminous diode and the pedestal.

Owner:EPISTAR CORP

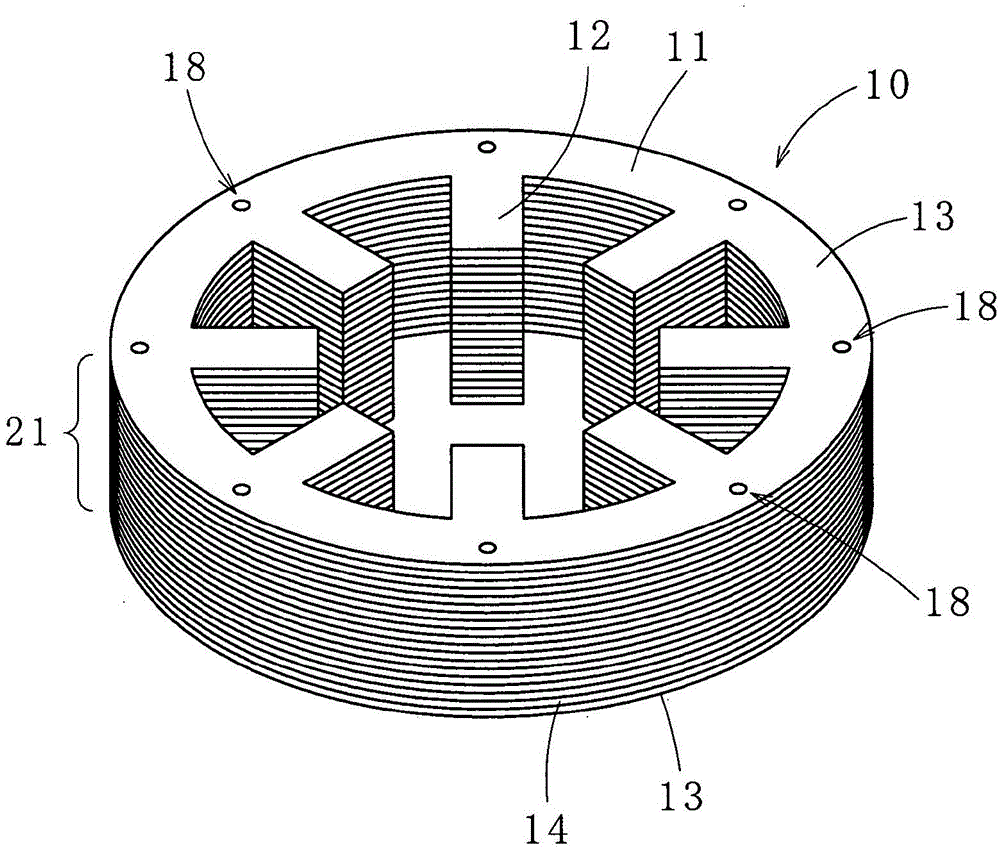

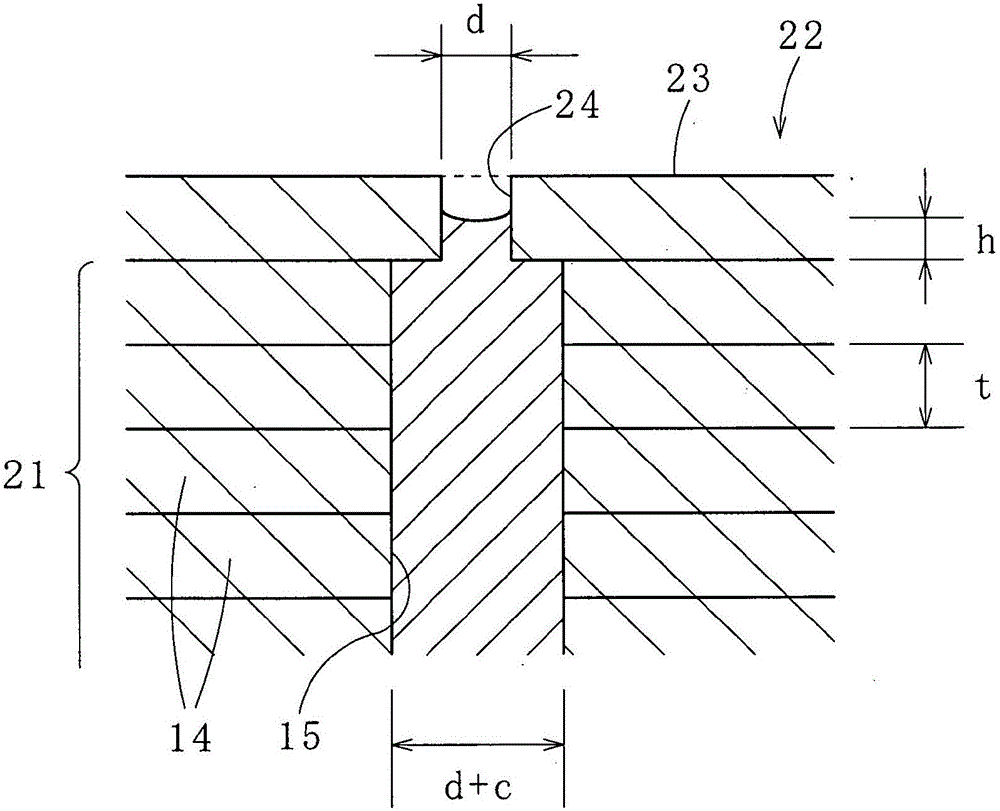

Laminated core and method for manufacturing the same

ActiveCN104578462AEnsure joint strengthPrevent peelingMagnetic circuit rotating partsMagnetic circuit stationary partsEngineeringUltimate tensile strength

A laminated core 10 including a plurality of laminated iron core pieces, each of the iron core pieces being connected in a laminating direction by filling resin in a plurality of resin holes penetrating the laminated core 10 in the laminating direction, and a method for manufacturing the laminated core 10, by making a junction area of an iron core piece (A) 13 and resin larger than a junction area of an iron core piece (U) 14 and resin, the iron core piece (A) 13 being provided on an end in an axial direction, the iron core pieces (U) 14 being arranged at positions other than the end in the axial direction, or by providing locking portions at tip portions of resin, acquired joint strength of the iron core piece (A) 13.

Owner:MITSUI HIGH TEC INC

Injection mold and method for manufacturing injection molded articles

InactiveUS6855286B2Promote resultsIncrease joint areaEngine sealsFoundry mouldsMaterials scienceComposite material

Owner:SHIN ETSU CHEM IND CO LTD

Camera apparatus

InactiveCN1442718AEasy to adjustImprove joint strengthTelevision system detailsCamerasCamera lensComputer science

Owner:CASIO COMPUTER CO LTD

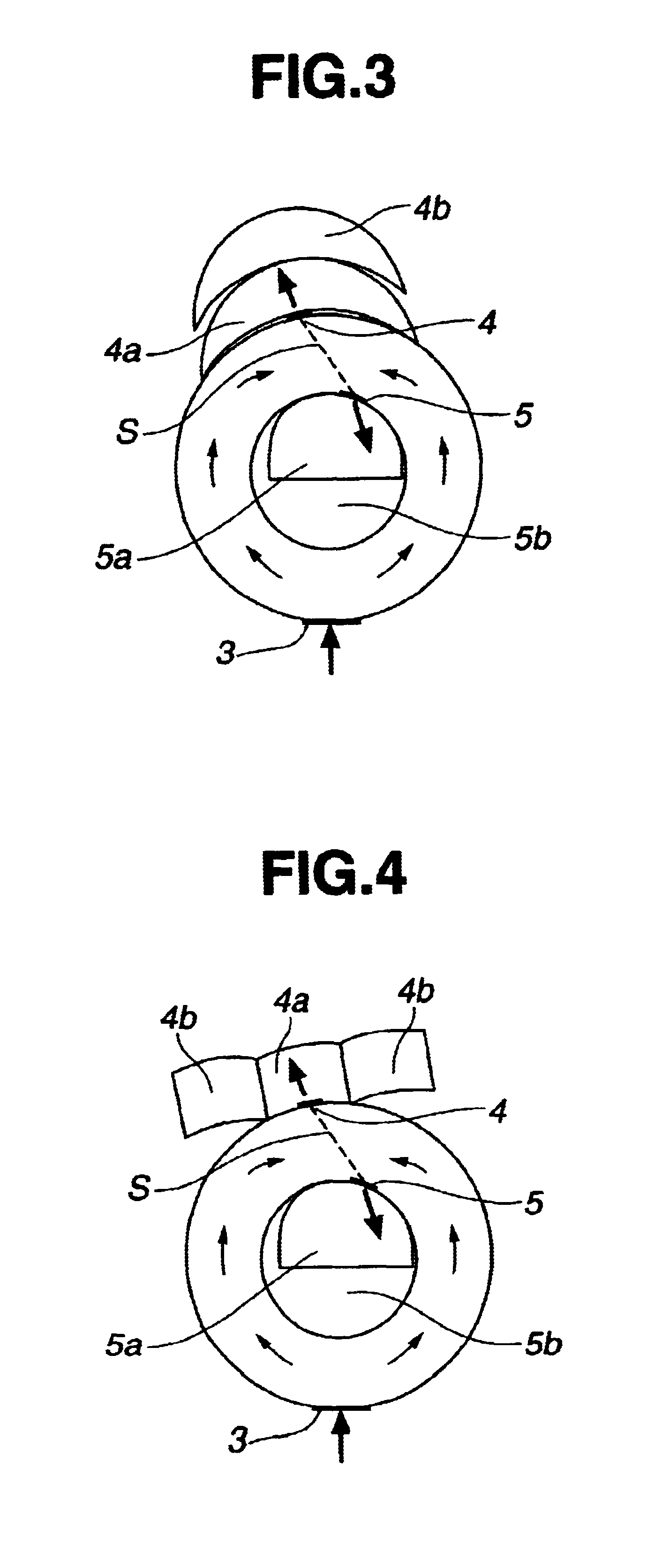

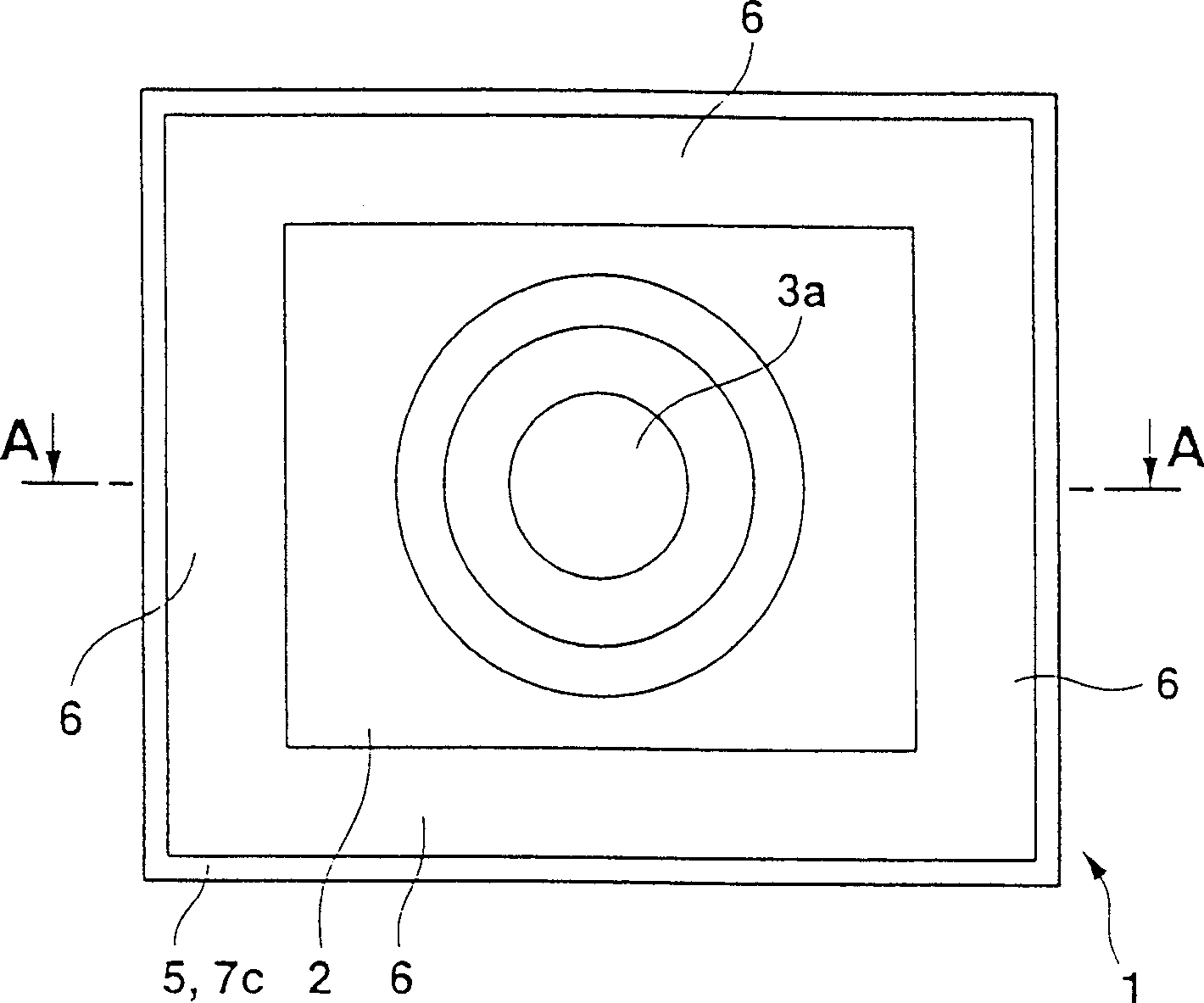

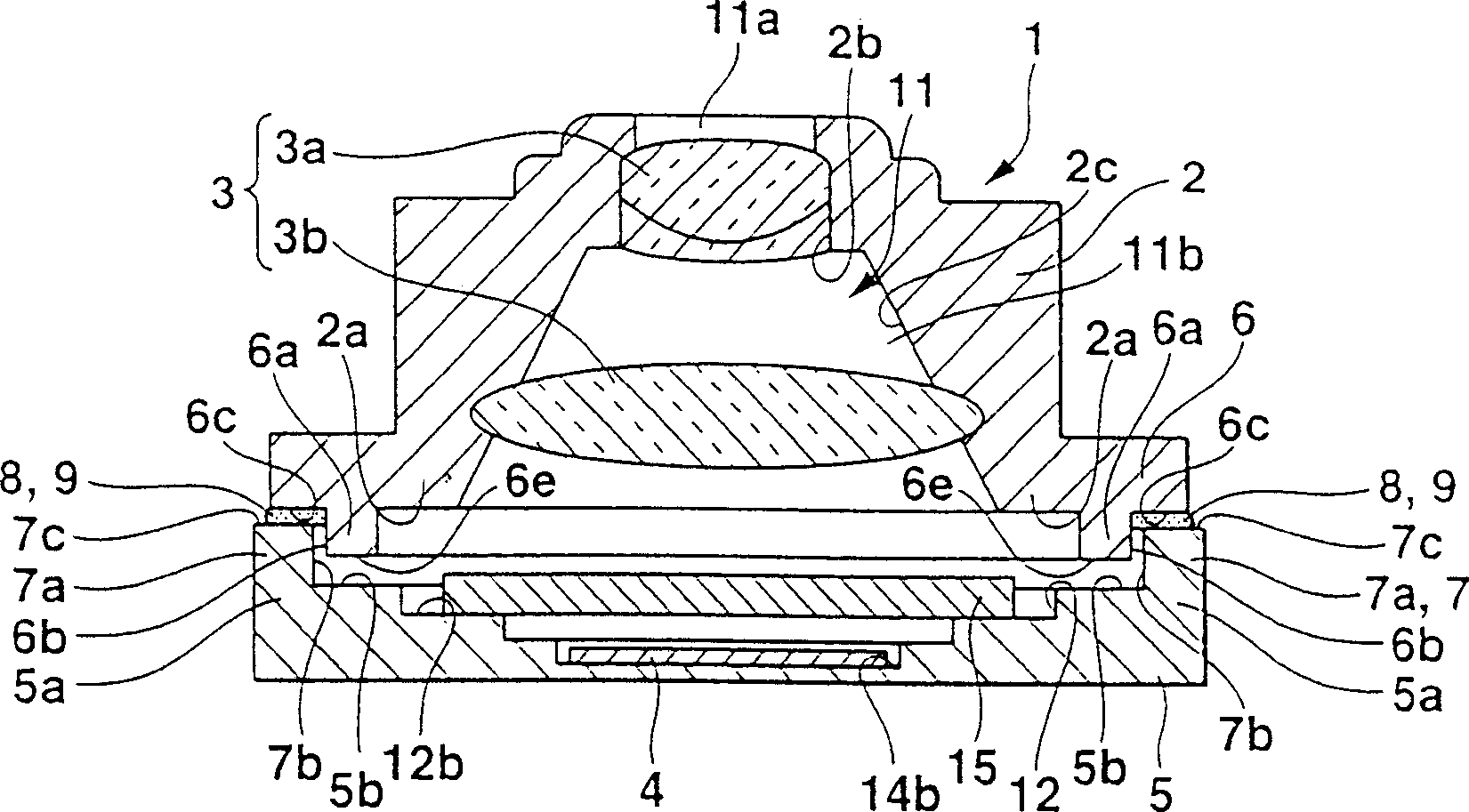

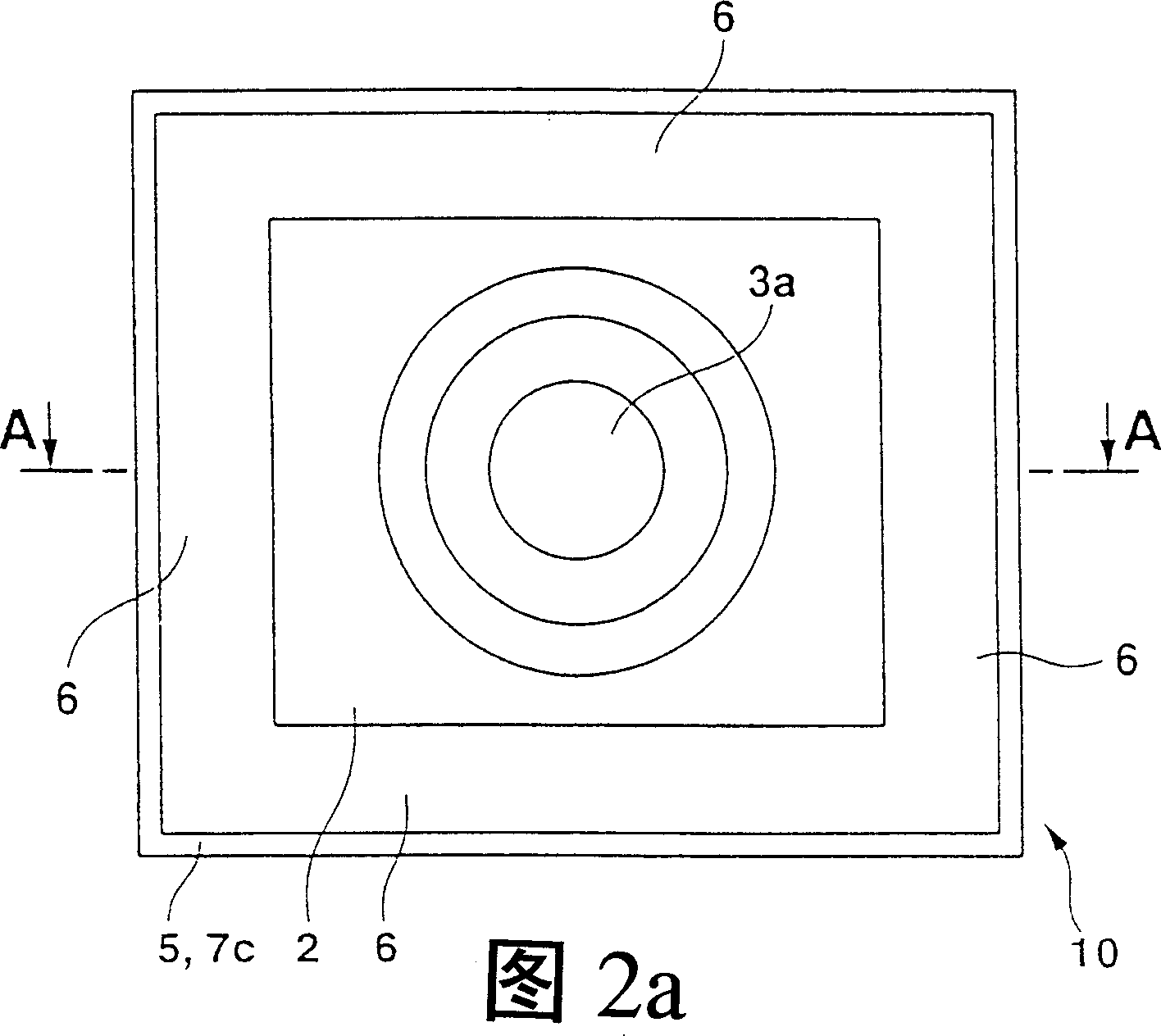

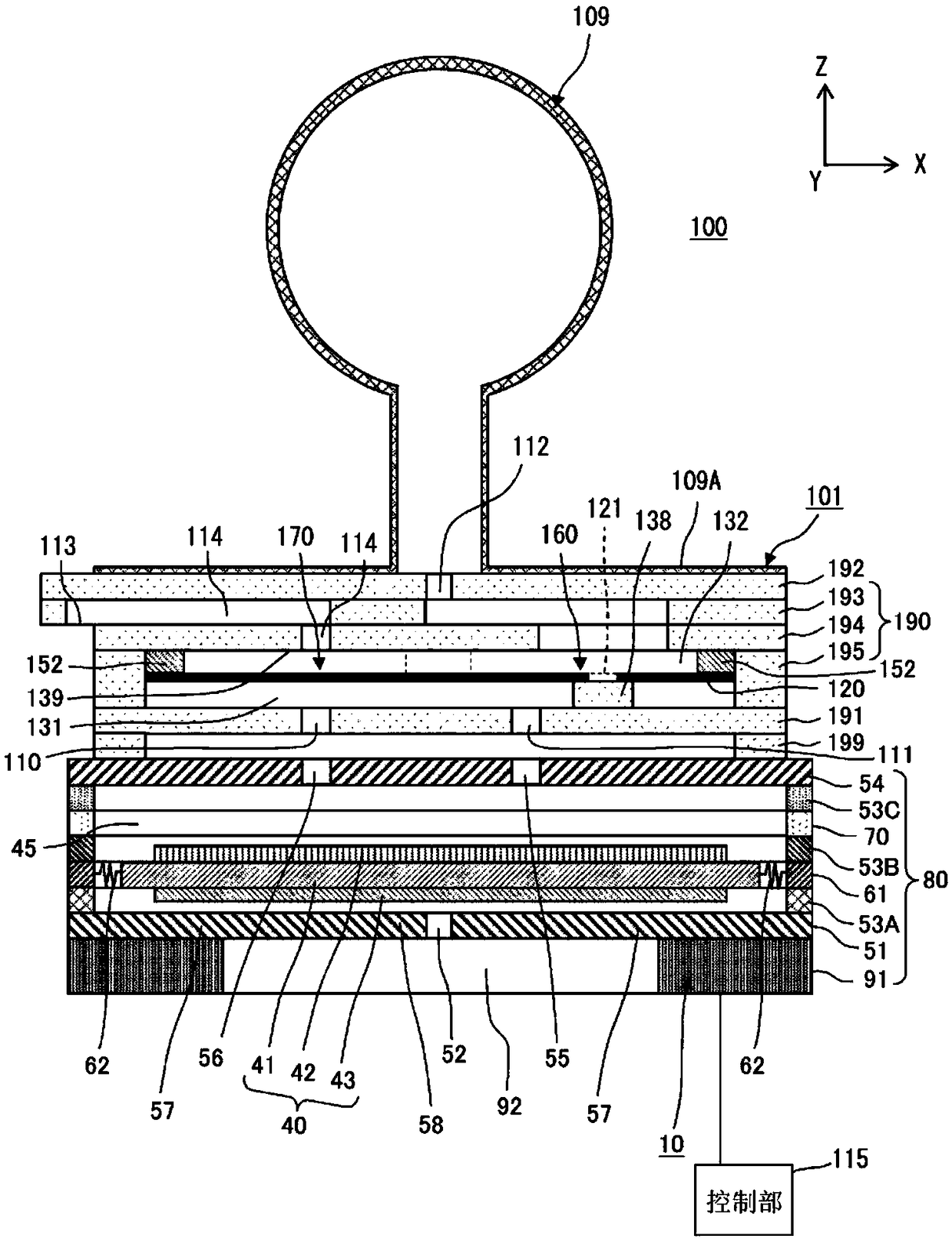

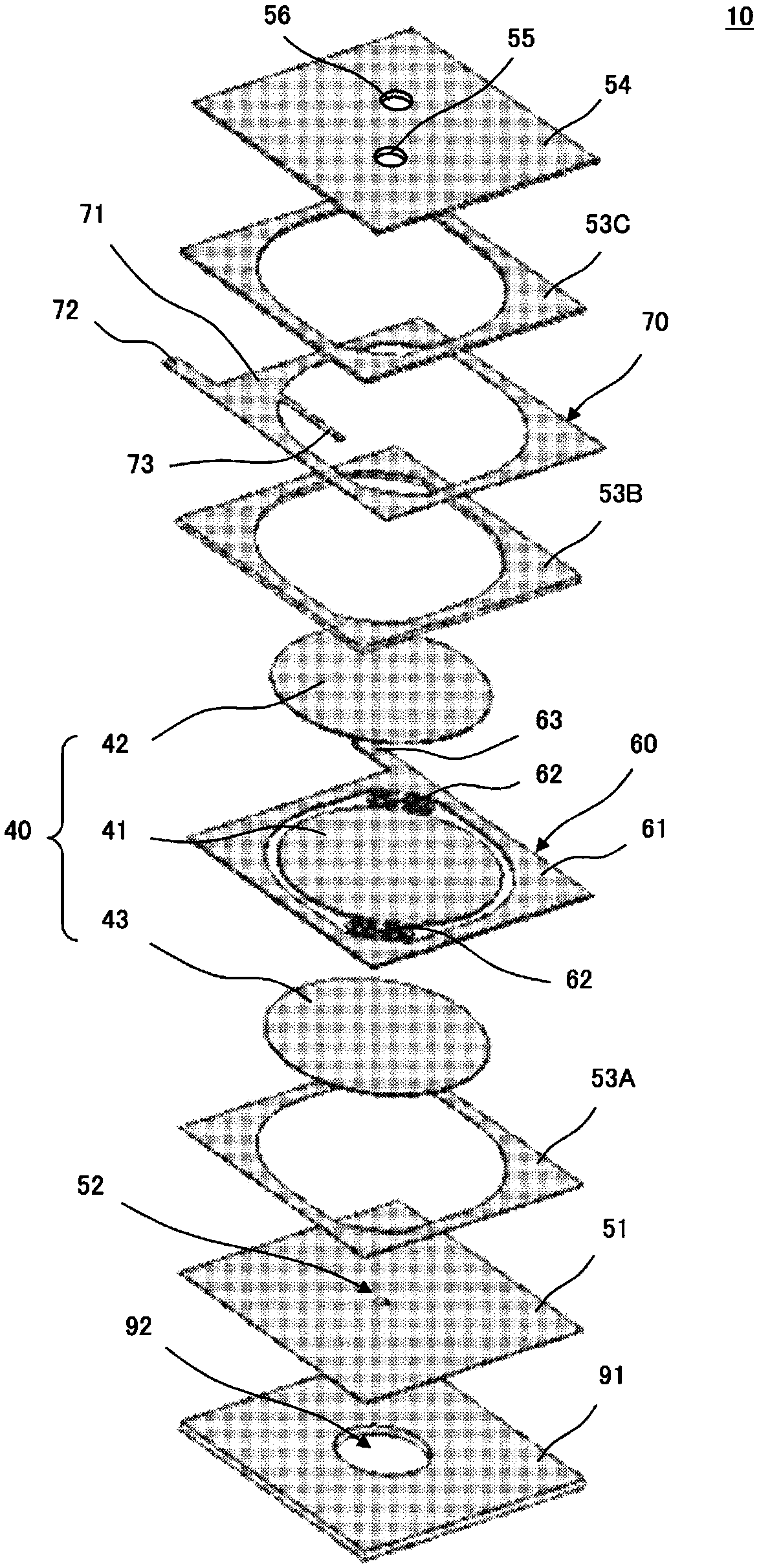

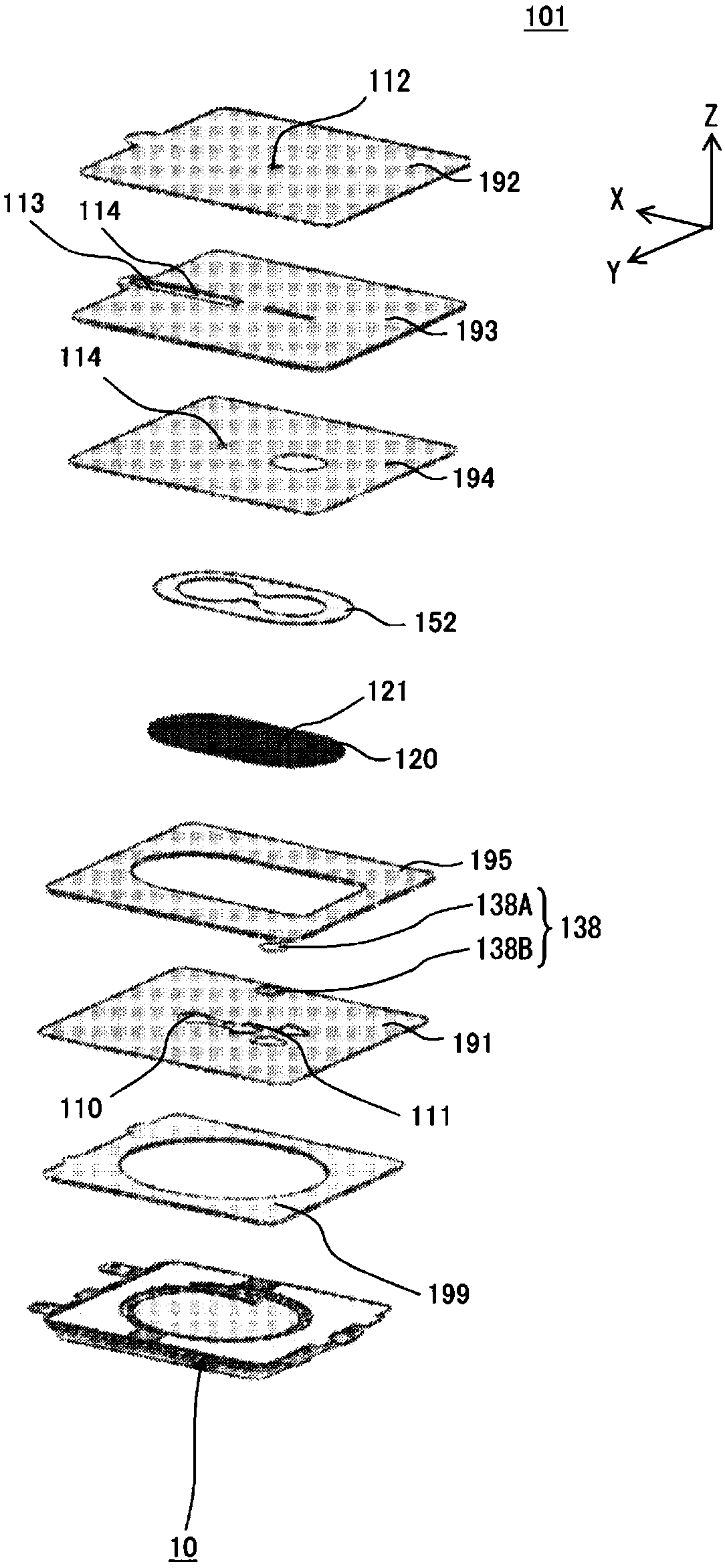

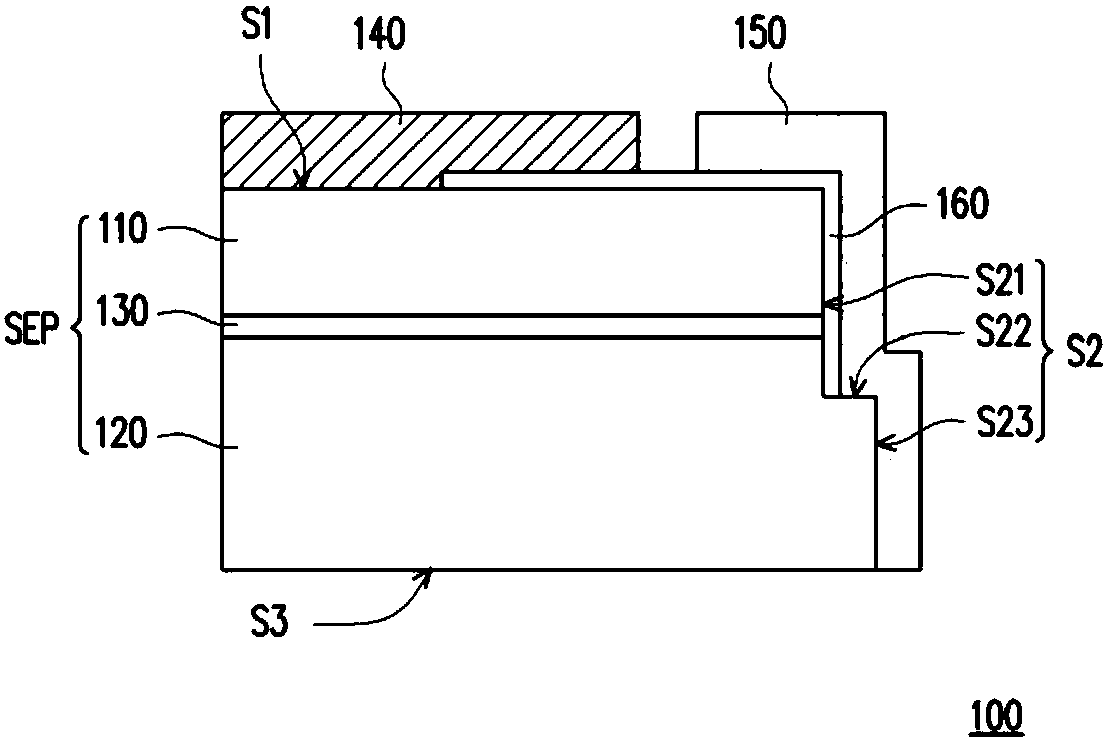

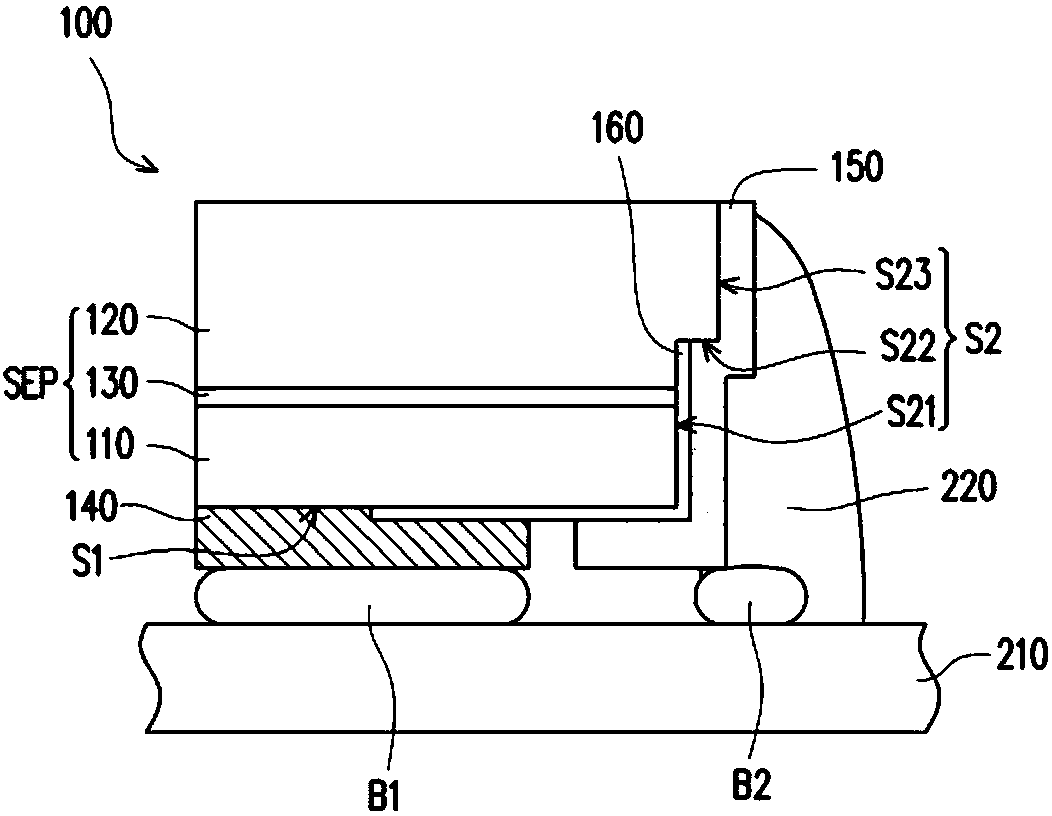

Valve, gas control device, and sphygmomanometer

ActiveCN108884823AAchieve low profileIncrease joint areaDiaphragm valvesEngine diaphragmsSphygmomanometerEngineering

This gas control device (100) comprises a pump (10), a valve (101), a cuff (109), and a control unit (115). The valve (101) comprises: a first plate (191) provided with a first ventilating hole (110)and a first ventilating hole (111); a flowpath-forming plate (190) provided with an exhaust hole (113) and an exhaust flowpath (114); a second plate (192) provided with a second ventilating hole (112); and a trim plate (199). The valve (101) and the cuff (109) are connected by joining an armband rubber tube (109A) of the cuff (109) to the periphery of the second ventilating hole (112) in the second plate (192) using an adhesive. The exhaust hole (113) is open to the atmosphere. The pump (10) has a pump housing (80) to which a discharge hole (55) and a discharge hole (56) are provided. The upper surface of the pump housing (80) is joined to the bottom surface of the trim plate (199) of the valve (101).

Owner:MURATA MFG CO LTD

Micro light emitting diode wafer

InactiveCN108288664AEasy to manufactureLarge luminous areaSemiconductor devicesLight-emitting diodeSemiconductor

The invention provides a micro light emitting diode wafer. The micro light emitting diode wafer comprises an epitaxy structure, a first electrode and a second electrode, wherein the epitaxy structurehas a first type doped semiconductor layer, a light emitting layer and a second type doped semiconductor layer and further comprises an upper surface and a side surface connected with the upper surface, the first electrode is arranged on the upper surface and is electrically connected with the first type doped semiconductor layer to provide first type carriers to enter the epitaxial structure fromat least a portion of the upper surface, the second electrode is arranged at the side surface and is electrically connected with the second type doped semiconductor layer to provide second type carriers to enter the epitaxial structure from at least a portion of the side surface, and the diagonal length of the micro light emitting diode wafer is greater than 0 and smaller than or equal to 140 microns. The micro light emitting diode wafer is advantaged in that the micro light emitting diode wafer is relatively easy to manufacture, and the light emitting area is relatively large.

Owner:PLAYNITRIDE

Package for light emitting diode, light emitting device, and light emitting device manufacturing method

InactiveCN102037578AEase of mass productionSolution to short lifeSolid-state devicesSemiconductor devicesFluorescenceLight emitting device

Owner:CI KASEI COMPANY

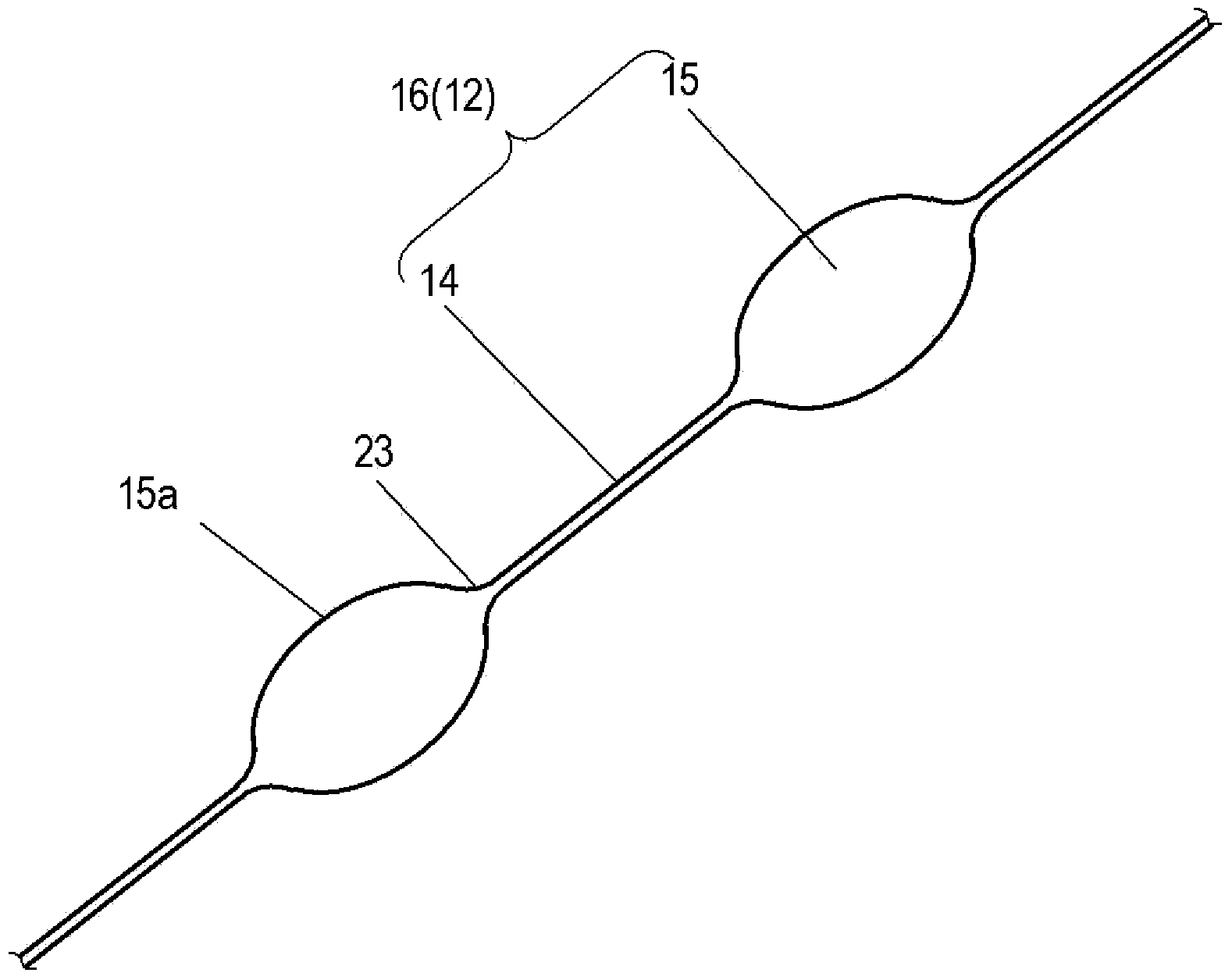

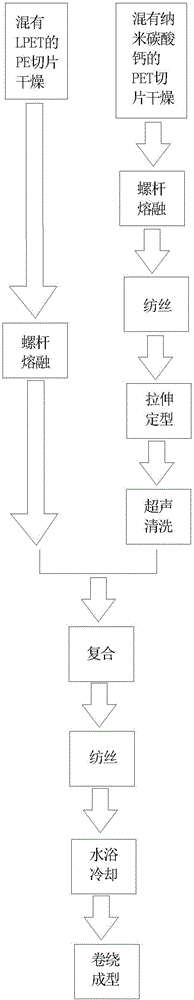

Composite monofilament applied to material filtering base cloth and preparing method thereof

ActiveCN105002596AImprove filtration efficiencyHigh porosityArtificial thread manufacturing machinesFilament/thread formingFiberPorosity

The invention discloses a composite monofilament applied to material filtering base cloth and a preparing method thereof. According to the composite monofilament applied to the material filtering base cloth, a low-temperature fusible material PE is adopted as a skin layer material of the composite monofilament, and a material PET with a high melting point is adopted as a middle core layer material of the composite monofilament, so that on the basis of maintaining bars of the monofilament, an adhesion point between the skin layer material and the middle core layer material is small, the porosity is large, and then the filtration efficiency of the material filtering base cloth adopting the composite monofilament is improved; meanwhile, according to the preparing method for the composite monofilament applied to the material filtering base cloth, the ultrasonic cleaning process is adopted for enabling ultrasounds to remove nanometer calcium carbonate on the surfaces of fibers in an ultrasonic water tank and enabling the surface of a middle core layer monofilament body to generate holes, the joint area between the middle core layer monofilament body and a skin layer is increased, the bond strength between the middle core layer monofilament body and the skin layer is better, the bonding firmness between the middle core layer monofilament body and the skin layer is enhanced, the wear-resisting property of the composite monofilament applied to the material filtering base cloth is improved, and the service life of the composite monofilament is prolonged.

Owner:WUXI JINTONG CHEM FIBER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com