Package for light emitting diode, light emitting device, and light emitting device manufacturing method

A technology for light-emitting diodes and light-emitting devices, which is applied in electrical components, electrical solid-state devices, circuits, etc., to achieve the effects of high reliability, long life, and excellent mass productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

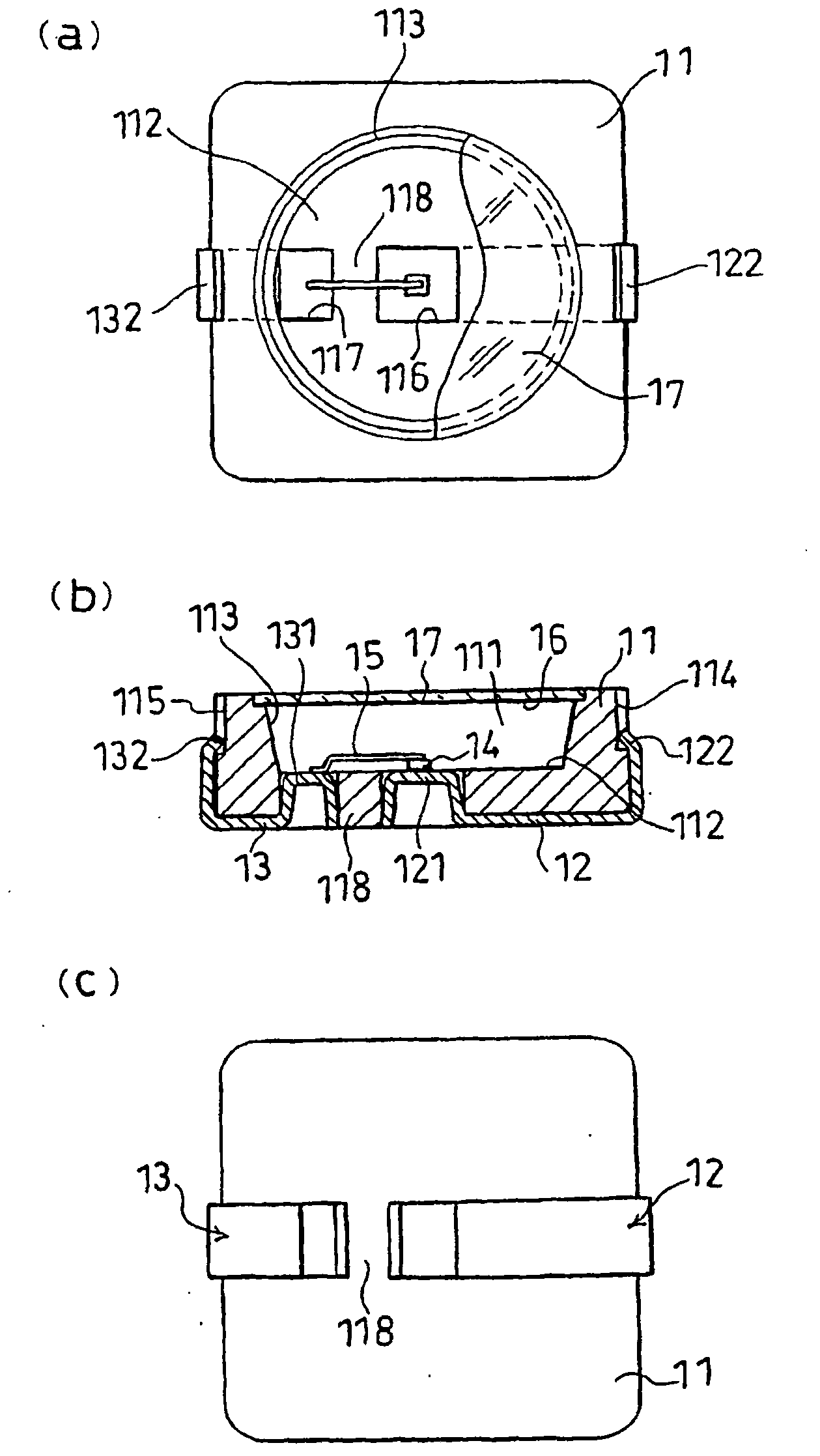

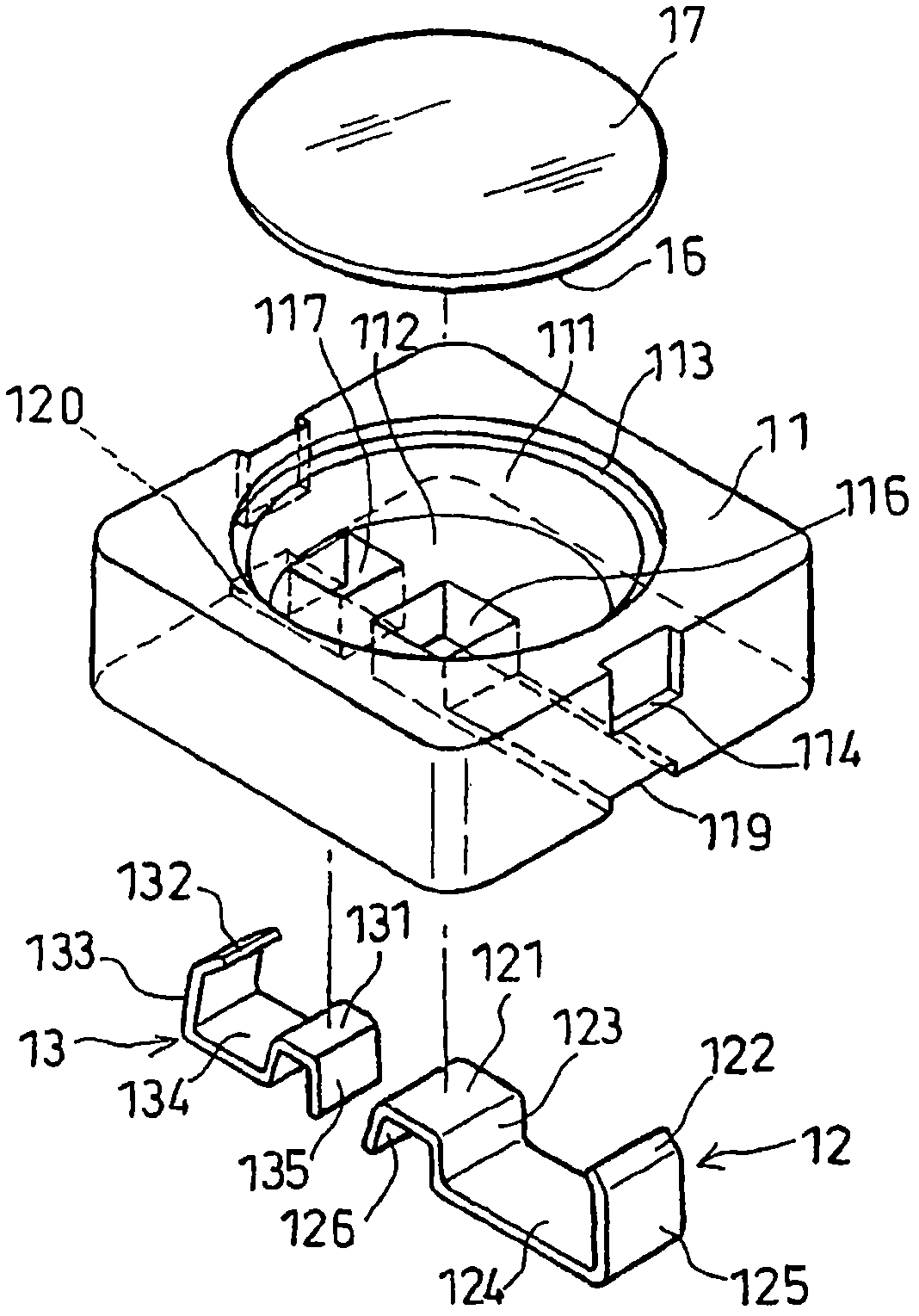

[0115] figure 1 (a) to (c) are the first embodiment of the present invention, (a) is a top view of the light emitting device, (b) is a cross-sectional view of the light emitting device, and (c) is a bottom view of the light emitting device. figure 2 It is an assembly perspective view for explaining the first embodiment of the light emitting diode package of the present invention. exist figure 1 (a)~(c) and figure 2 Among them, the package for a light emitting diode is constituted by at least a ceramic molded body 11 , a first conductive member 12 , and a second conductive member 13 .

[0116] The above-mentioned ceramic molded body 11 includes a space 111 composed of recesses, an inner bottom 112 as the bottom of the space, a reflective surface 113 formed around the inner bottom 112, a first opening 116 and a first opening 116 formed on the inner bottom 112. Two openings 117, the first engaging portion 114 and the second engaging portion 115 formed on the side, and the ...

Embodiment 2

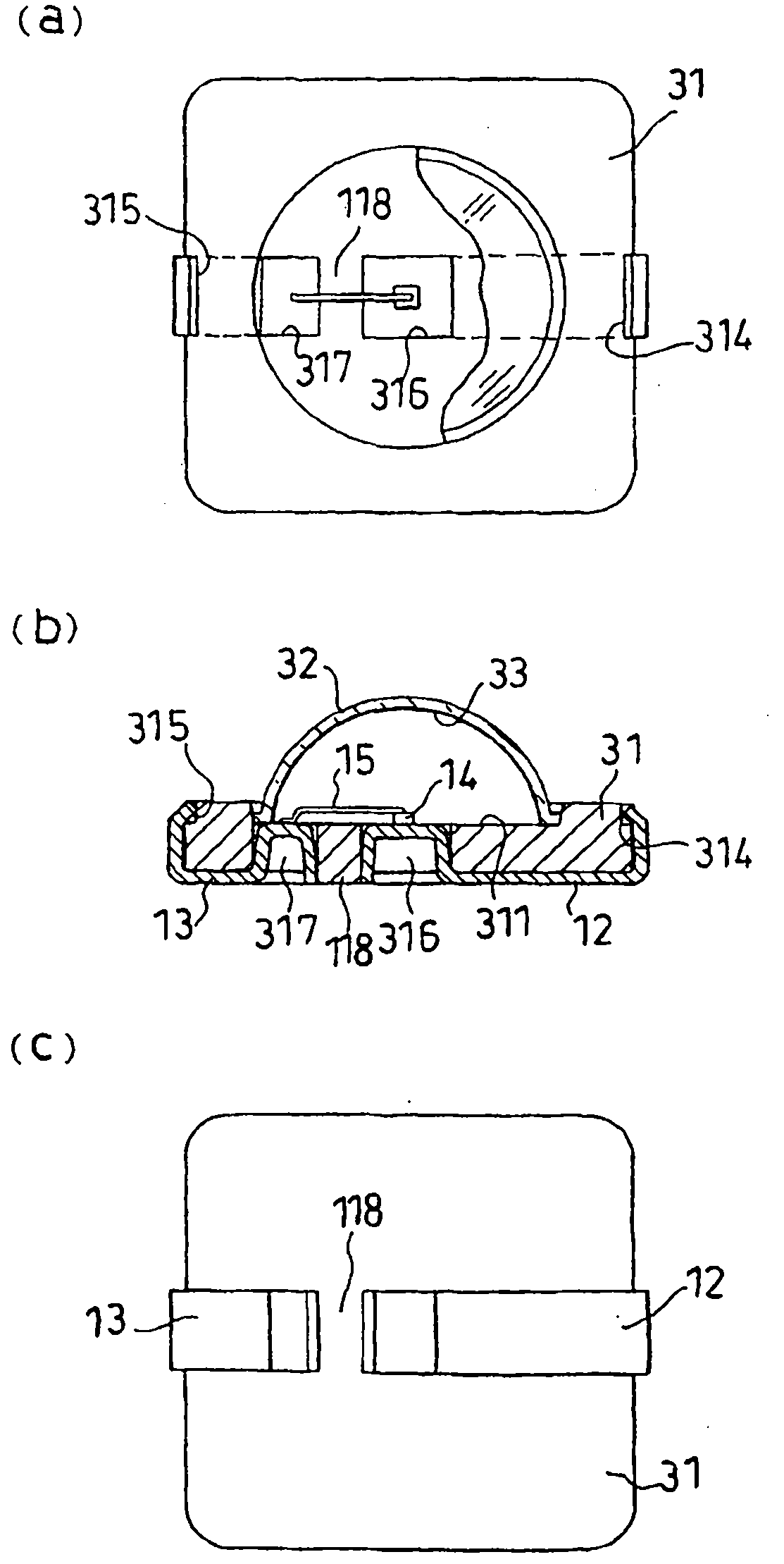

[0123] image 3 (a) to (c) are the second embodiment of the present invention, (a) is a top view of the light emitting device, (b) is a cross-sectional view of the light emitting device, and (c) is a bottom view of the light emitting device. exist image 3 In (a) to (c), the light-emitting device of the second embodiment is different from the first embodiment in that a ceramic substrate 31 and a hemispherical cover 32 on the ceramic substrate 31 are provided, and the cover 32 is formed with fluorescent light on the inner surface. The membrane body 33 of the body. A first opening 316 and a second opening 317 are formed on the ceramic substrate 31 , and a first engaging portion 314 and a second engaging portion 315 are formed on both sides.

[0124] The first conductive member 12 and the second conductive member 13 , the first opening 316 and the second opening 317 , the upper and lower electrode type LEDs 14 , and the metal member 15 are the same as those of the first embodim...

Embodiment 3

[0126] Figure 4 (a) and (b) are the third embodiment of the present invention, (a) is a plan view of a light emitting device in which a plurality of upper and lower electrode type light emitting diodes are connected in series, and (b) is a cross-sectional view of the light emitting device. exist Figure 4 In (a) and (b), in the light emitting device of the third embodiment, a plurality of light emitting devices of the second embodiment are connected in series on one ceramic substrate 41 . The first conductive member 12 and the fourth conductive member 13 of the third embodiment are the same as those of the second embodiment. The second conductive member 45 and the third conductive member 46 are provided with convex portions at both end portions, and are respectively fitted into the openings.

[0127] The upper and lower electrode type light emitting diodes 14-1, 14-2, 14-3 are placed on the convex portion of the above-mentioned conductive member, and are joined to the other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com