Packaging structure of capacitive fingerprint sensor

A fingerprint sensor and packaging structure technology, which is applied in the field of semiconductor capacitive fingerprint sensor packaging structure, can solve the problems of difficult machine assembly, increased packaging difficulty, increased cost, etc., and achieves low cost, easy large-scale production, and simple packaging process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

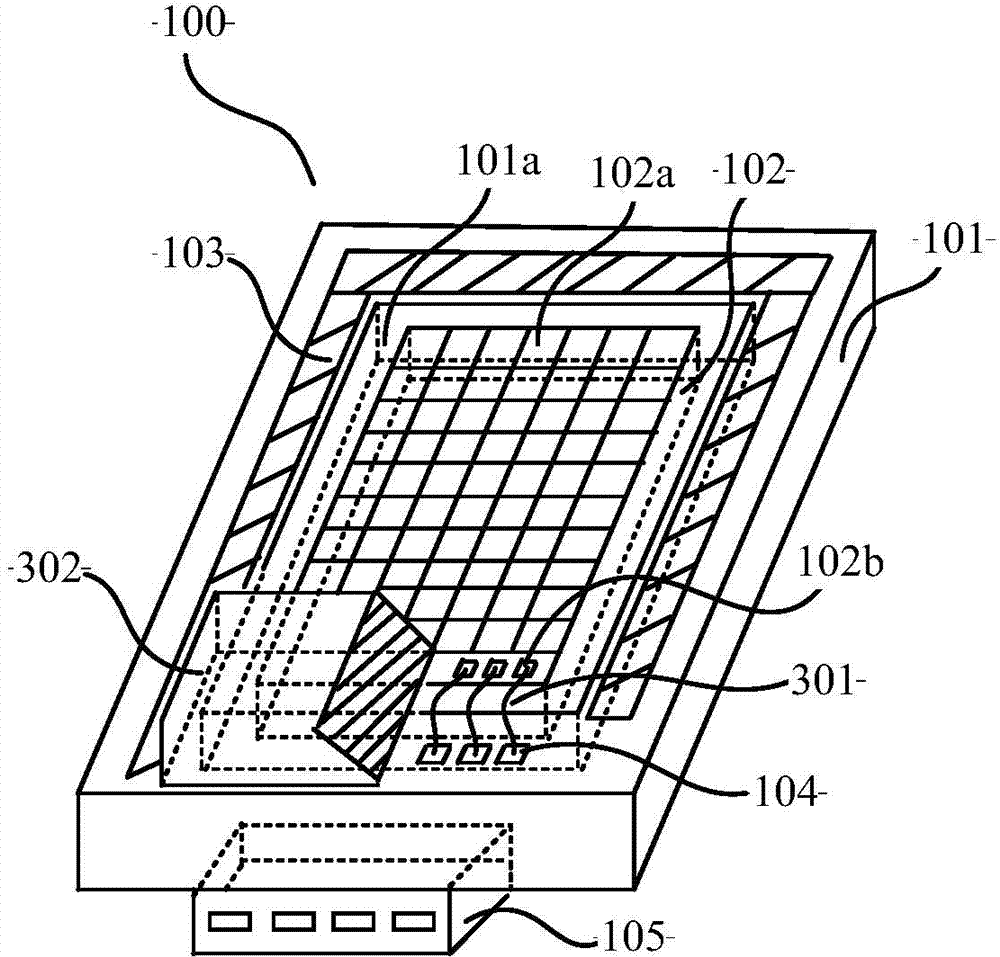

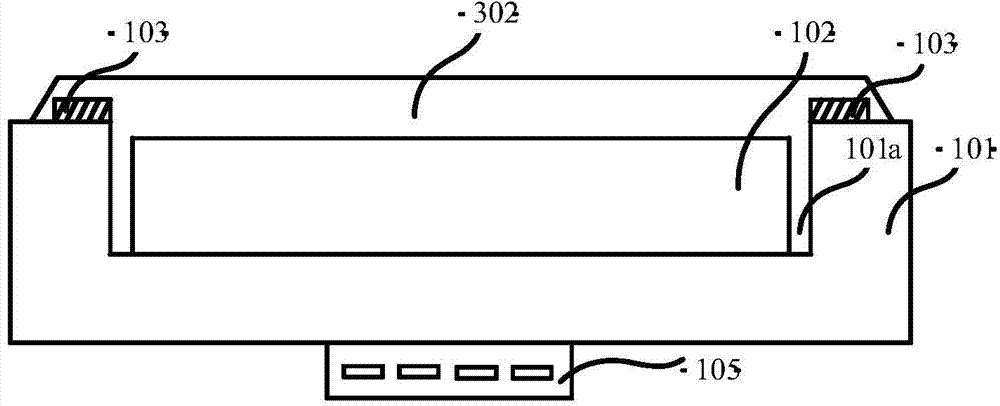

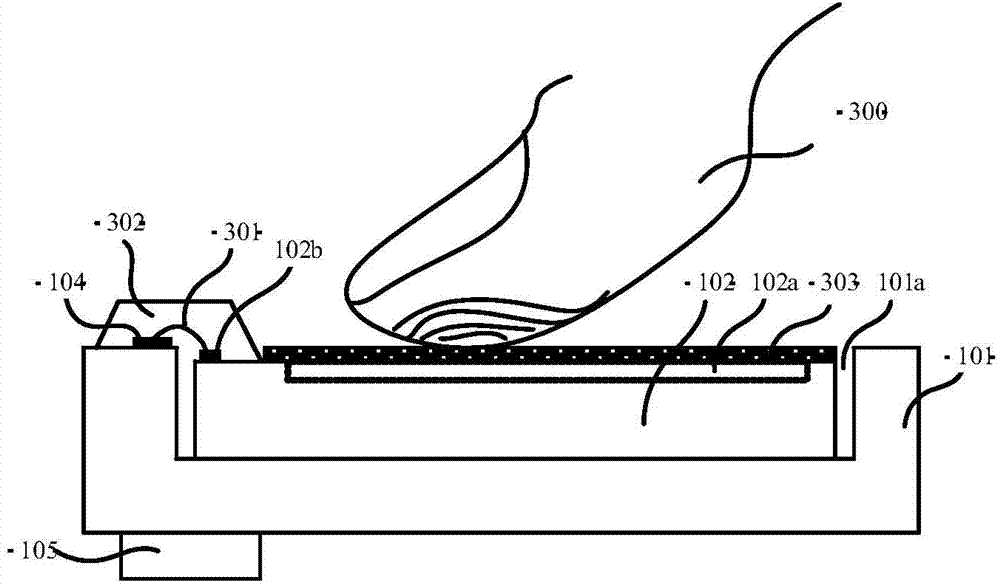

[0063] see Figure 1 to Figure 4 ,in, figure 1 Shown is a schematic structural view of the first embodiment of the packaging structure of the semiconductor capacitive fingerprint sensor of the present invention, wherein the packaging structure includes a planar fingerprint sensor assembly 100 . As shown in the figure, the planar sensor assembly 100 mainly includes a rectangular substrate 101 and a planar sensor die 102. A groove 101a is opened on the front side of the grooved substrate 101, and the length and width of the groove 101a are slightly larger than that of the planar sensor. In the die 102 , the depth of the groove 101 a is slightly higher than the height of the planar sensor die 102 . In this embodiment, the packaging structure can embed the sensor die 102 into the fixed area of the planar sensor die 102 at the bottom of the substrate groove 101a, and make the front surface of the planar sensor die 102 slightly lower than the substrate 101 on the horizontal plane...

Embodiment 2

[0074] Please refer to Figure 5 to Figure 9 ,in, Figure 5 Shown is a schematic structural view of the second embodiment of the package structure of the semiconductor capacitive fingerprint sensor of the present invention, wherein the package structure includes a strip-shaped fingerprint sensor assembly 200 . The strip fingerprint sensor assembly 200 mainly includes the grooved strip substrate 201 and the strip sensor die 202, with interconnection leads (not shown) formed on its front or back and possibly in each layer thereof, the A groove 201 a is formed on the front of the grooved strip substrate 201 . The length and width of the groove 201 a are slightly larger than the strip sensor die 202 , and the groove depth of the groove 201 a is slightly higher than the height of the die 202 . In this embodiment, the strip-shaped sensor die 202 is embedded in the strip-shaped sensor die 202 fixing area at the bottom of the substrate groove 201a, and the front surface of the strip-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com