Patents

Literature

87results about How to "With antistatic function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

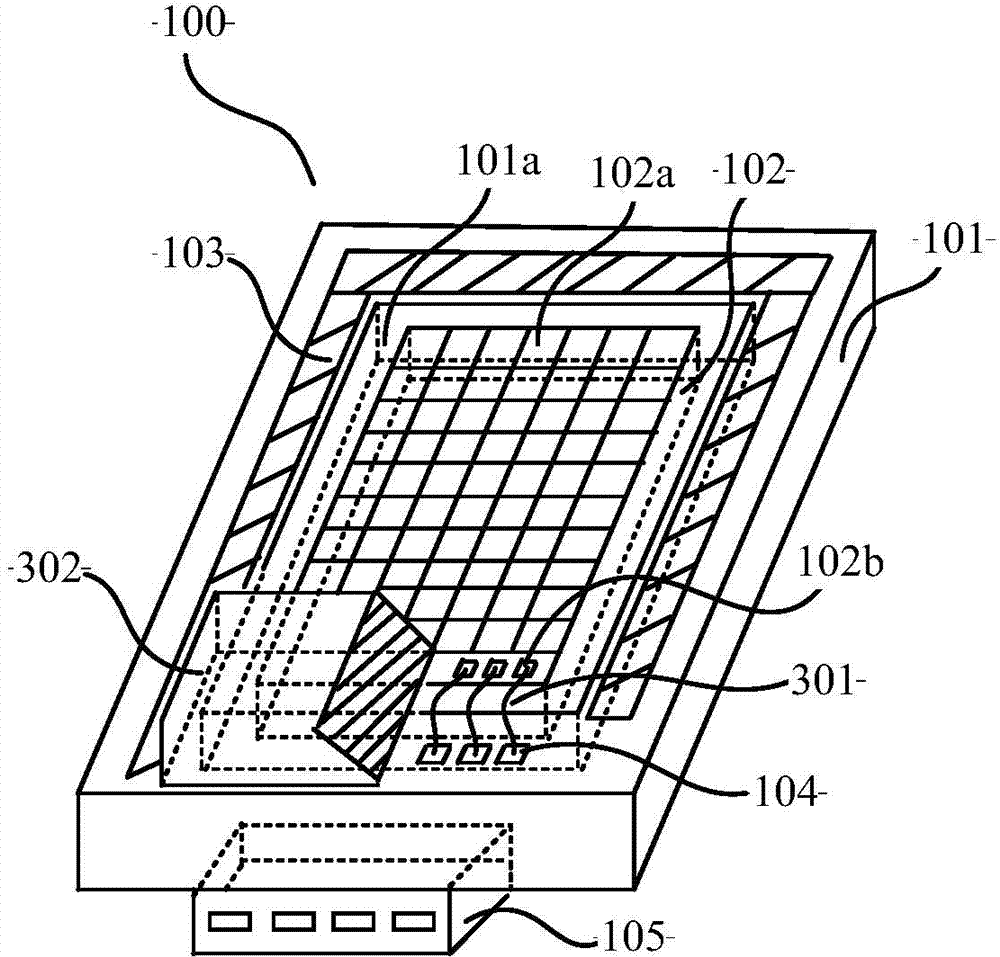

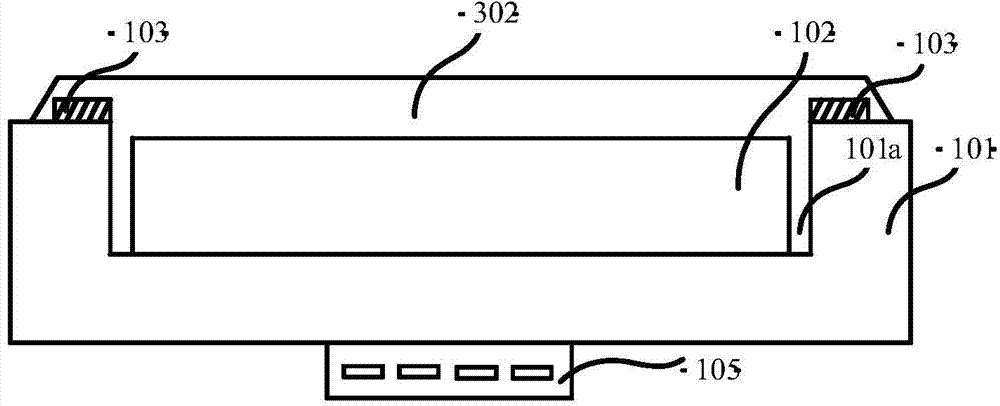

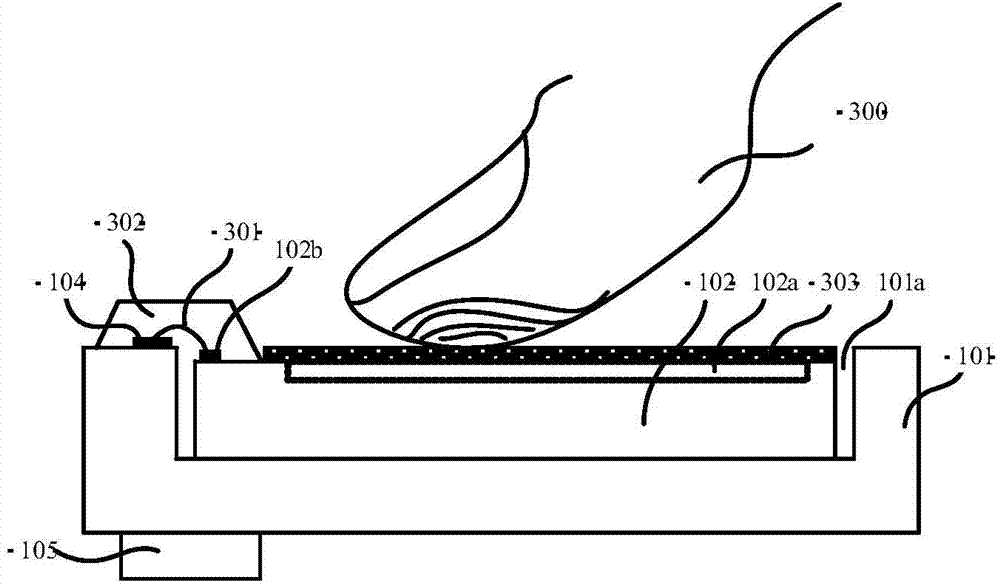

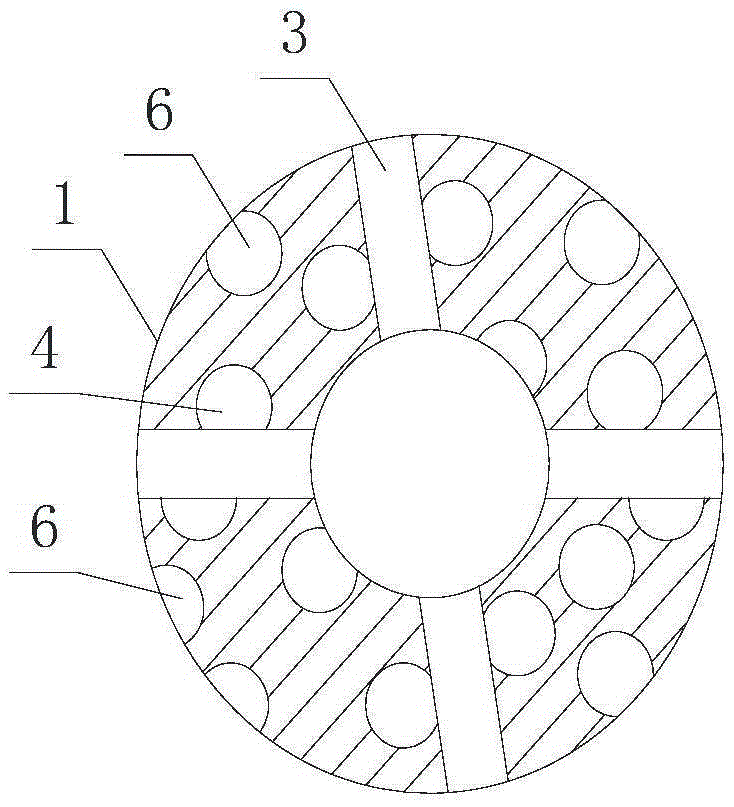

Packaging structure of capacitive fingerprint sensor

ActiveCN103886299ALow costSimple packaging processSolid-state devicesCharacter and pattern recognitionFingerprintGround plane

A packaging structure of a semiconductor capacitive fingerprint sensor comprises a semiconductor sensor tube core, a groove type substrate made of insulation materials, a connecting wire, a connector assembly and an injection package structure. The sensor tube core is supported by and fixed at the bottom of a substrate groove through binding agents, the front face or the back face or the side face of the substrate groove is provided with a plurality of multilevel interconnection leads and contact through holes electrically connected between the multilevel interconnection leads, and a connecting welding disc formed by one or more conducting metal edge bars is printed on the grooved face of the substrate. The connecting wire is used for connecting pins of the sensor tube core and the connecting welding disc of the substrate, and the connector assembly is used for enabling the groove type substrate and a printed circuit board to be electrically connected. The connecting welding disc is connected with one or more grounding pins of the connection assembly through the interconnection leads arranged on the front face or the back face of the substrate and located between levels. One or more grounding pins of the connection assembly are electrically connected with the ground plane of the printed circuit board, and the tube core pins, the substrate conducting metal edge bars and the connection wire are packaged through the injection package structure.

Owner:成都费恩格尔微电子技术有限公司 +1

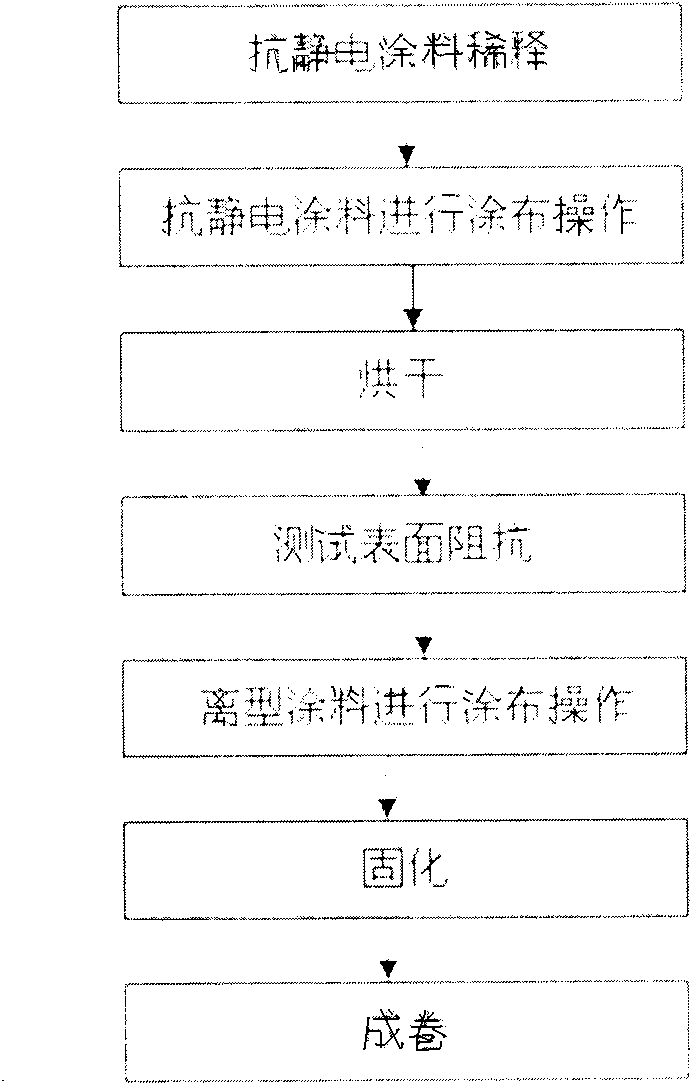

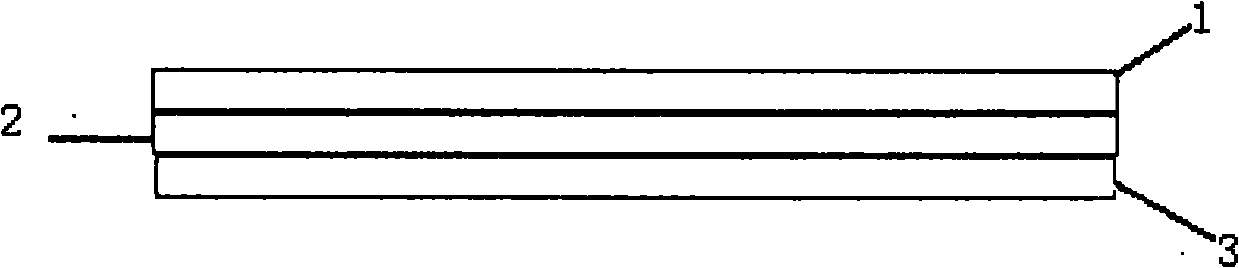

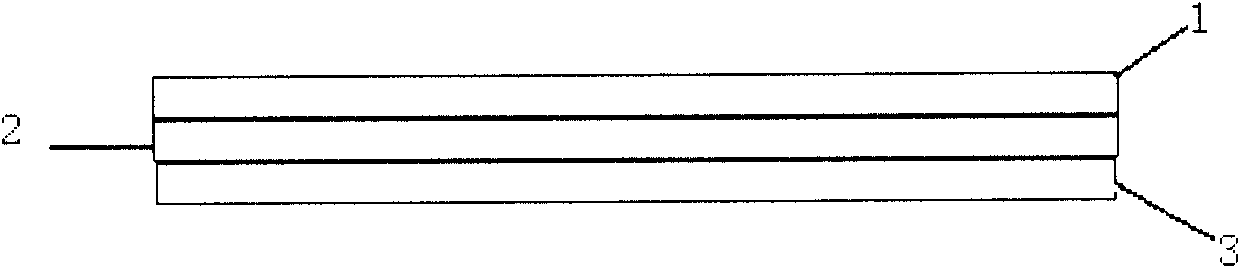

Anti-static release film and manufacturing method thereof

InactiveCN101885253ASimple manufacturing methodSolve antistaticSynthetic resin layered productsConductive coatingPolyethylene glycol

The invention discloses an anti-static release film and a manufacturing method thereof. The anti-static release film comprises three layers, wherein the first layer is a base material of which the main component is polyethylene glycol terephthalate (PET); the second layer is a conductive coating of which the main component is a conductive macromolecular compound with a polythiophene and polyaniline-containing co-orbit macromolecular structure; and the third layer is a release agent coating of which the main component is an addition organic silicon material. The manufacturing method comprises the following steps of: firstly, diluting and coating an anti-static coating; secondly, drying the coating; thirdly, testing surface impedance, and finally, coating a release coating and solidifying the coating to form a roll. The anti-static release film has the advantages of high release force and conductivity, and release and anti-static effects.

Owner:李刚

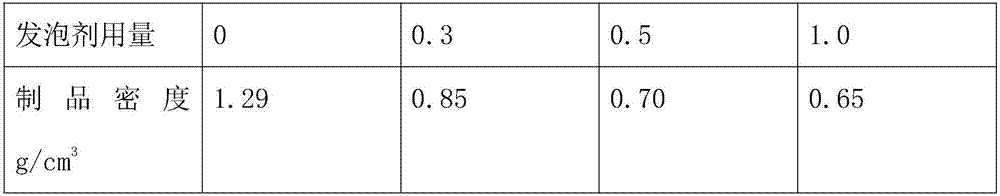

Wood plastic composite section bar and production technology thereof

InactiveCN107501805AImprove mechanical propertiesReasonable formula designProduction rateFoaming agent

The invention discloses a wood plastic composite section bar and a production technology thereof. The wood plastic composite section bar comprises the following raw materials in parts by weight: 40-60 parts of PVC, 10-15 parts of wood powder, 20-30 parts of CACO3, 1-3 parts of a stabilizer, 1-2 parts of a foaming agent, 1-2 parts of a lubricating agent and 4-6 parts of processing additives. The wood plastic composite section bar is reasonable in formula design, has a coupling toughening function, is capable of promoting the mechanical properties of material, is beneficial to the promotion of rigidity and thermal deformation of products and is available for indoor and outdoor wood plastic products and products with higher requirement on thermal deformation; a toughening agent CPE is added, so that the toughness of the product is higher; the wood plastic composite section bar has high heat stability, weather fastness and anti-ultraviolet function; the section bar is high in compatibility with resin, high in dispersibility, and capable of increasing production rate and promoting the surface glossiness of products; the wood plastic composite section bar has anti-fogging and antistatic functions; the wood plastic composite section bar is suitable for production wood plastic skirting lines, door pocket lines, sill lines, ecological wood, hollow panels, floor boards, stair railings, ventilated windows, micro-foamed cabinet panels, wave panels, and other products.

Owner:安徽淮宿建材有限公司

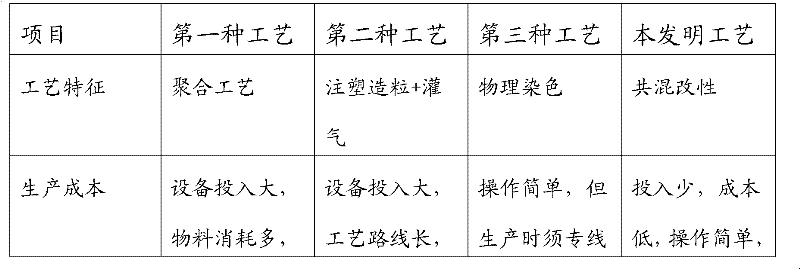

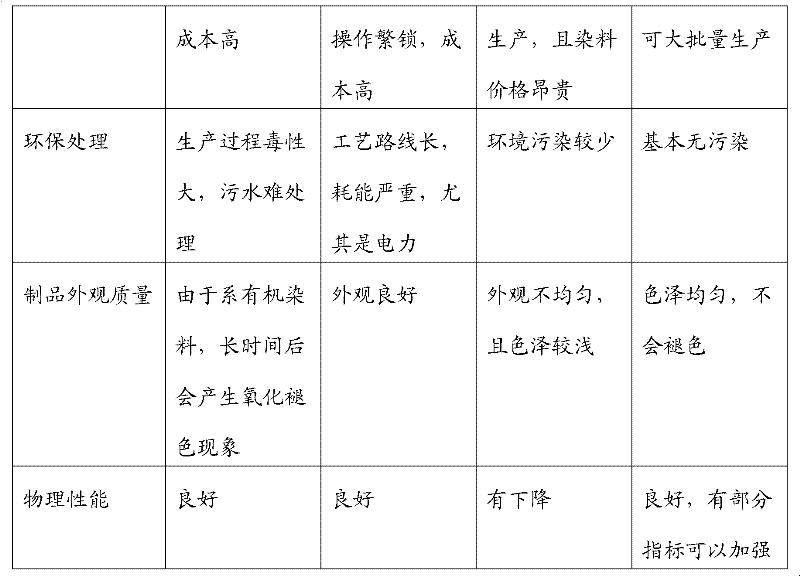

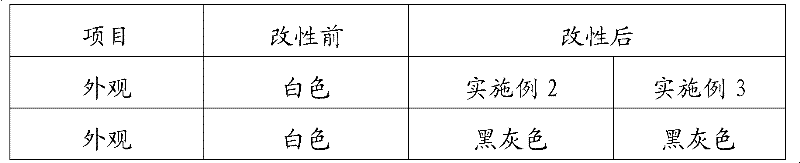

Preparation method of black gray expandable polystyrene

The invention relates to a preparation method of black gray expandable polystyrene. The method comprises the following steps of: adding a binding agent into expandable polystyrene, and mixing to obtain expandable polystyrene particles; and then adding powder into the expandable polystyrene particles, and performing blending modification treatment to obtain the black gray expandable polystyrene. Through the preparation method provided by the invention, the technological flow is greatly shortened, the production cost is reduced, the production efficiency is increased, and the related physical properties of the product are improved.

Owner:天津新龙桥工程塑料有限公司

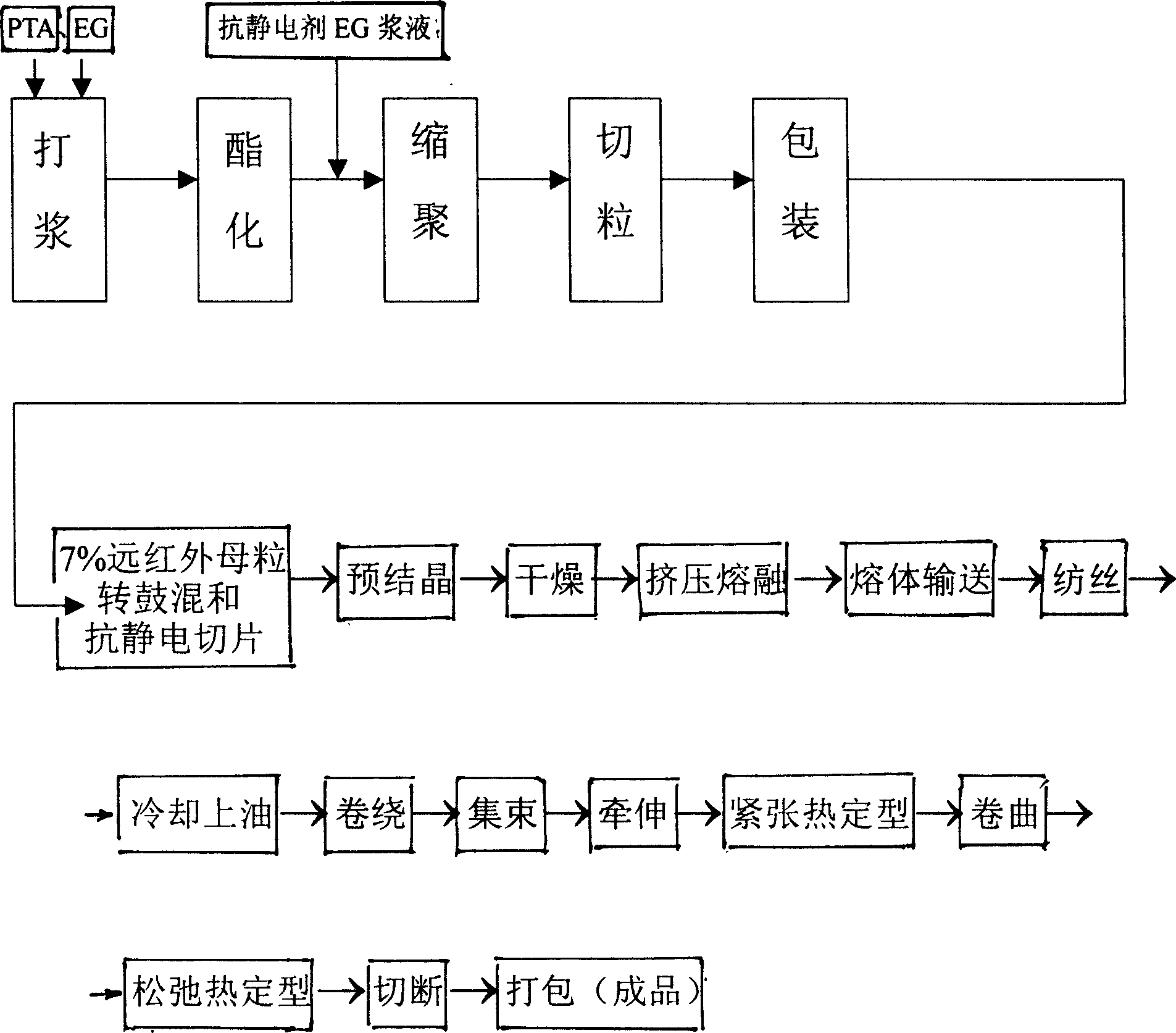

Method for manufacturing far infrared-antistatic polyester fiber

InactiveCN1763276AWith far infraredWith antistatic functionElectroconductive/antistatic filament manufactureHollow filament manufactureFiberPolymer science

The invention discloses a making method of far-infrared antistatic polyester fiber, which is characterized by the following: generating BHET terephthalic glycol ester monomer after the esterifying reaction of raw PTA terephthalic acid and EG glycol ester in the heating condition; leading the material into polyaxe; adding the preparing modulated functional additive of inorganic antistat EG glycol ester slurry in the atmospheric polycondensation reaction stage; starting pressure-relief reaction after a while; generating the polyester microtome section by cooling the fondant; textiling the far-infrared-and-antistatic compound function polyester short fiber after mixing the antistatic polyester microtome section and nanometer far-infrared ceramic powder. The technological program is mature and easy to operate, which can produce everlasting far-infrared-and-antistatic compound functional polyester short fiber.

Owner:天津石油化工公司化纤厂

Method for preparing self-dispersion nano-level conducting polyaniline

The invention relates to a manufacture method for electric conductive polyaniline that is made from aniline monomer taking oxidative polymerization. The feature is that cyclodextrin is added during the oxidative polymerization process, and the mol ratio of aniline monomer and cyclodextrin is 1: (0.1-1.2). The method is easy to operate and has environment protection process.

Owner:EAST CHINA UNIV OF SCI & TECH

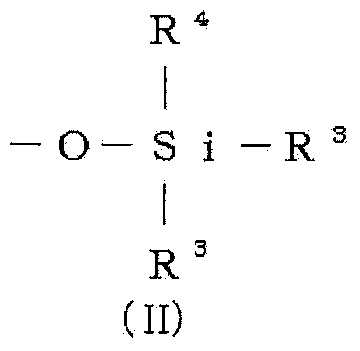

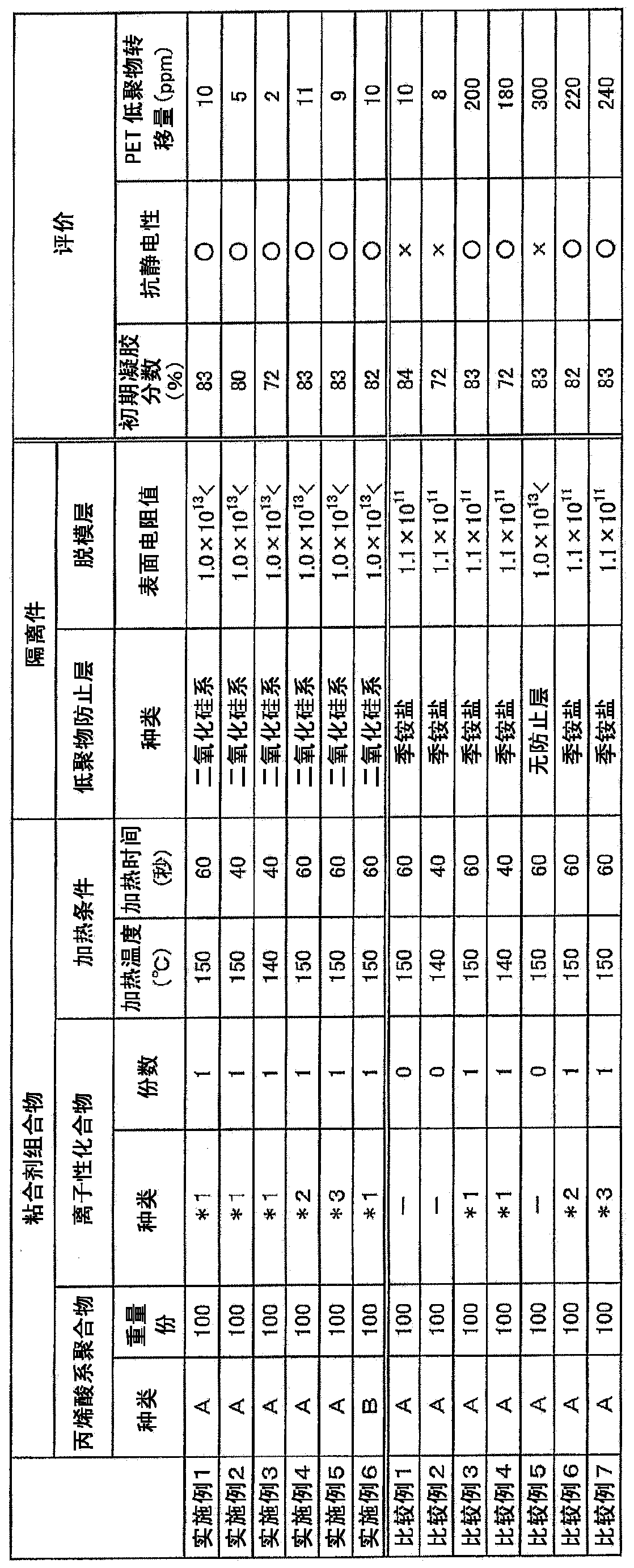

Separator-attached adhesive layer, method for producing the same and adhesive layer-attached optical film with separator

ActiveCN104231959ALower surface resistance valueWith antistatic functionNon-macromolecular adhesive additivesLayered productsPolymer scienceOligomer

The object of the invention is to provide a separator-attached adhesive layer capable of inhibiting an oligomer contained in the base film used for a separator from migrating into the pressure-sensitive adhesive layer, even an adhesive layer containing ionic compositions are formed on the separator. A separator-attached adhesive layer of the present invention including an adhesive layer on a separator, wherein the separator includes a base film and an oligomer prevention layer, and a release layer provided in this order on the base film, and the release layer has a surface resistance value of 1.0*1013[Omega] / - or more, and the adhesive layer is formed from an adhesive composition including a base polymer and an ionic compound and is provided on the release layer of the separator.

Owner:NITTO DENKO CORP

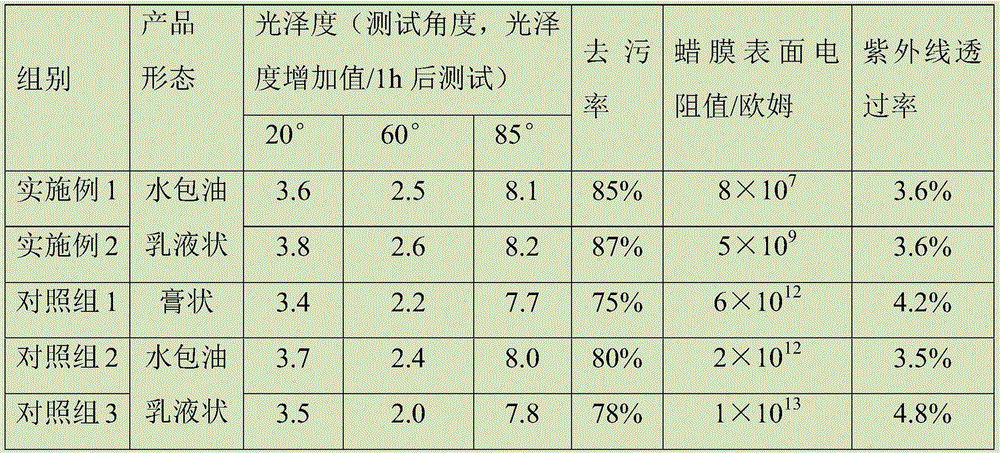

Cleaning and polishing integrated antistatic automobile polishing wax and preparation method thereof

ActiveCN106085247AHas the function of absorbing ultraviolet raysIncrease brightness functionInorganic/elemental detergent compounding agentsCationic surface-active compoundsEmulsionAntistatic agent

The invention relates to the field of polishing wax, and specifically relates to a cleaning and polishing integrated antistatic automobile polishing wax and a preparation method thereof. The cleaning and polishing integrated antistatic automobile polishing wax comprises, by mass, 1%-4% of an antistatic agent, 5%-10% of an emulsion, 25%-35% of a compound solution, 1%-2% of a brightener, 0.1%-0.3% of an ultraviolet absorbent, 0.1%-0.2% of a preservative, and 55%-65% deionized water. The antistatic agent is a polymer of sulfonated styrene and maleic acid or a sulfonated polystyrene polymer; the solute of the emulsion is a mixture of carnauba wax, paraffin, Fischer-Tropsch wax and an emulsifier, the solvent is the emulsifier, the mass fraction of the solute is 15%-20%, and in the solute, the carnauba wax, paraffin, and Fischer-Tropsch wax are in a mass ratio of 2:4:1-2:8:1. The automobile polishing wax provided by the invention integrates the functions of cleaning and dust removing, polishing, ultraviolet protection, static resistance, sterilizing and the like, and is convenient to use.

Owner:DONGGUAN UNIV OF TECH

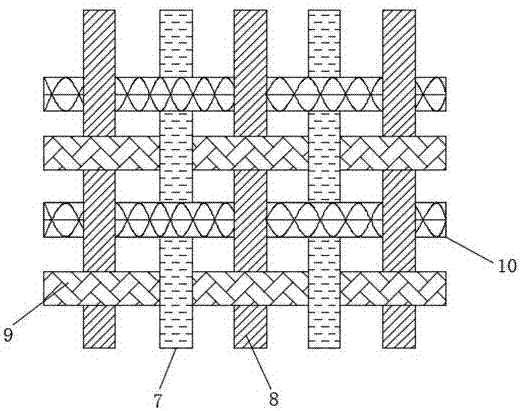

Antistatic textile fabric

ActiveCN103722799AReduce coefficient of frictionWith antistatic functionSynthetic resin layered productsPolymer scienceHuman skin

The invention relates to antistatic textile fabric. The fabric comprises inner layer fabric and outer layer fabric, wherein the inner layer comprises the following components in parts by weight: 65-82 parts of purified cotton, 8-22 parts of real silk, and 10-23 parts of antistatic silk intertextures; while the outer layer comprises the following components in parts by weight: 61-79 parts of bamboo fibers, 11-19 parts of cotton fibers, and 12-28 parts of spandex fibers; the antistatic textile fabric is anti-static, so that static generated due to a probable friction between a dehydrated fiber and human skin can be prevented; the fabric is simple in structure, and the friction coefficient of the fabric can be effectively reduced, the generation of static charges during fraction can be reduced as well, therefore the fabric is highly static-free.

Owner:江苏康溢臣生命科技有限公司

Anti-static polyether ketone ketone powder coating and preparation method thereof

ActiveCN106675360ALow densityImprove conductivityPolyether coatingsPowdery paintsSpray coatingKetone

The invention relates to a polyether ketone ketone powder coating, and concretely relates to an anti-static polyether ketone ketone powder coating and a preparation method thereof. The coating is prepared from polyether ketone ketone resin and a conductive agent with the mass ratio being (99 to 99.8) : (1 to 0.2), wherein the conductive agent is a compound conductive material prepared by coating the surface of a carbon-series conductive filler with silver powder. The anti-static polyether ketone ketone powder coating provided by the invention adopts the compound conductive material as the conductive agent, so that the conductivity of the anti-static polyether ketone ketone powder coating is better than the conductivity of a carbon-series conductive agent which is independently used according to the same usage amount, and compared with a metal series, the density of the conductive agent is smaller, and the power utilization rate during electrostatic spraying is high; the anti-static polyether ketone ketone powder coating is prepared by adopting a hot bonding technology, the conductive agent and the base resin are dispersed uniformly and bonded tightly, and the recycled powder coating can be reutilized without the need for re-treating, so that the waste is reduced; an electrostatic spraying coating has the alternative conductivity being 7.10*10<8> to 3.25*10<4>s / m under the frequency of 103Hz, and has an anti-static function.

Owner:SHANDONG KAISHENG NEW MATERIALS

Aromatic, hydrophilic and antistatic composite functional polyester fibers as well as preparation method and application

InactiveCN105803574AImprove hydrophilic abilityWith antistatic functionElectroconductive/antistatic filament manufactureFilament/thread formingPolyesterPolymer science

The invention discloses a preparation method of aromatic, hydrophilic and antistatic composite functional polyester fibers. High-temperature-resisting powdery essence is selected and uniformly mixed with low-smelting-point polyester powder, an antistatic agent, a dispersant, a coupling agent and an anti-oxidant, and then the mixture is extruded and granulated to prepare aromatic polyester master batches. Double-screw-rod composite spinning equipment is adopted, a mixture of the aromatic polyester master batches and low-smelting-point polyester slices is used as a core and a constant-pressure cation dyeable polyester chip is used as a skin to prepare the aromatic, hydrophilic and antistatic composite functional polyester fibers. The composite functional polyester fibers prepared by the invention can release aromatic flavor for a long period and have washing endurance; the hydrophilic property is strong and the moisture regain reaches more than 0.8 percent; the aromatic, hydrophilic and antistatic composite functional polyester fibers have an antistatic function and the specific resistance is M*10<7>omega.CM (M is more than or equal to 1.0 and less than 10); the aromatic, hydrophilic and antistatic composite functional polyester fibers are easily colored and strong in color fastness.

Owner:HIGHTEX CO LTD ZHEJIANG

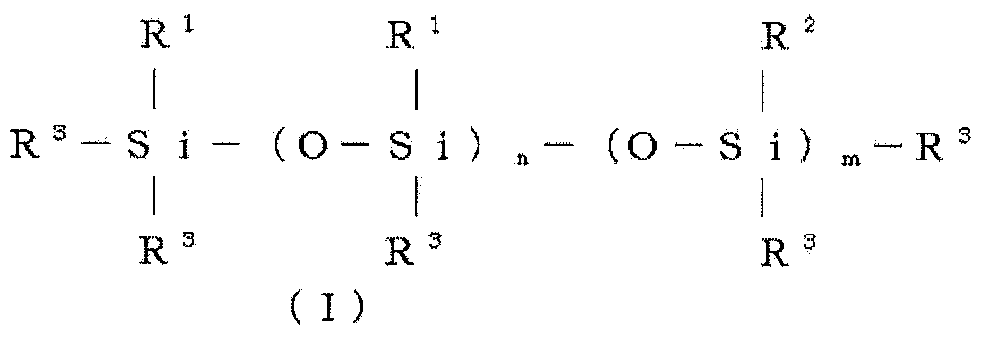

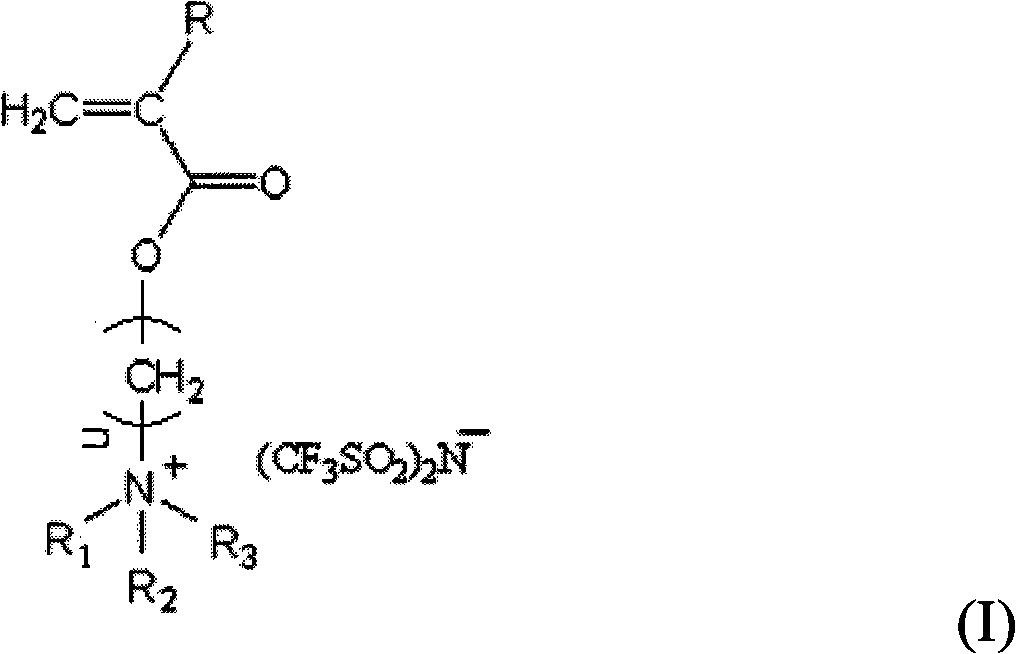

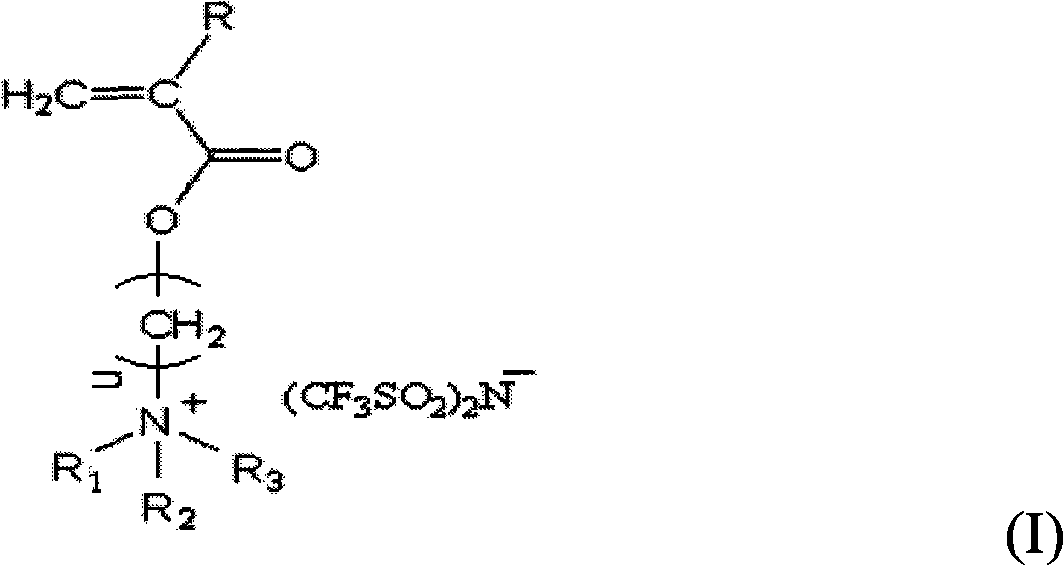

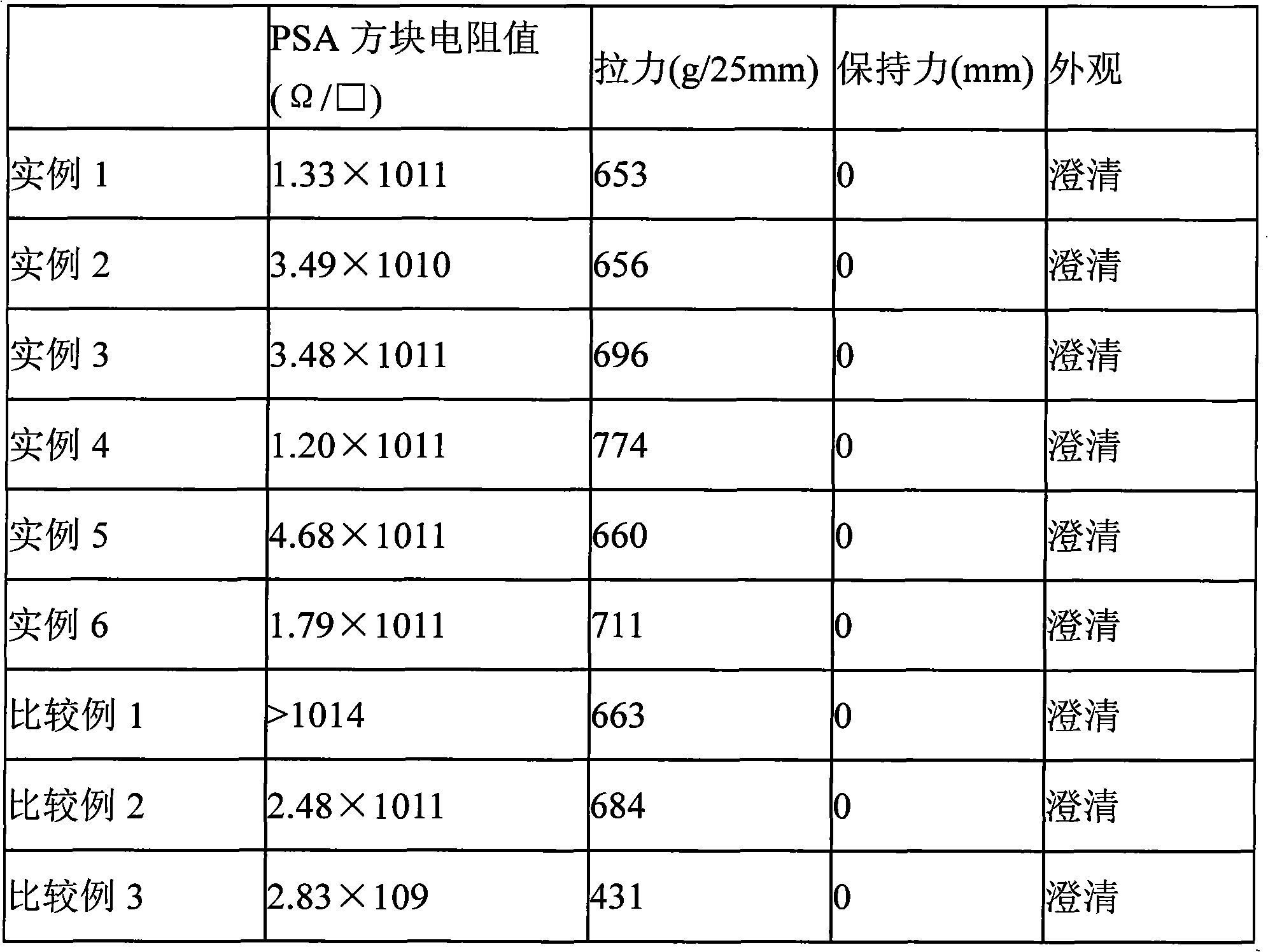

Antistatic ionic compound, oligomer thereof, copolymer thereof and pressure-sensing agglutinant component thereof

InactiveCN101898981AImprove antistatic performanceWith antistatic functionOrganic chemistryOther chemical processesIonOligomer

The invention relates to an antistatic ionic compound, an oligomer thereof, a copolymer thereof and a pressure-sensing agglutinant component thereof, wherein the pressure-sensing agglutinant component contains the ionic compound, the oligomer thereof, the copolymer thereof or the compound thereof containing (methyl) ammonium crylic esters cation and (CF3SO2)2N-anion, so the formed pressure-sensing adhering slice has an excellent antistatic property and a stable adhering property. The invention is suitable for being used in the plastics which easily generate static and the electronic products which have no static, such as a Polaroid, and the like.

Owner:BENQ MATERIALS +1

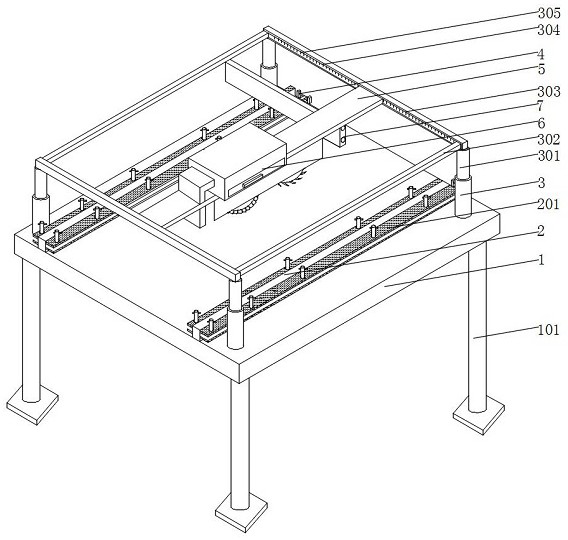

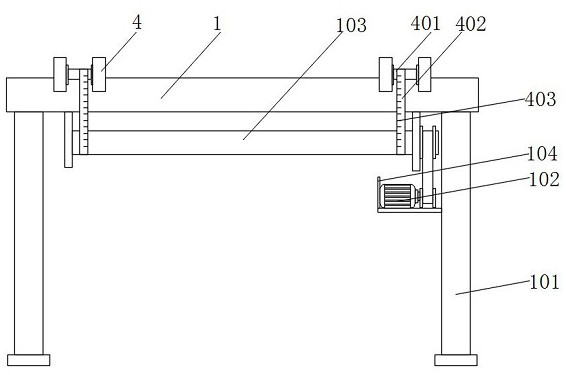

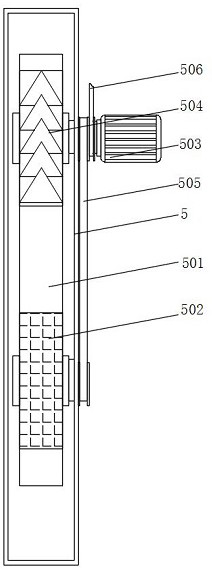

Computer case glass processing device with protection function

InactiveCN112817390AWith antistatic functionRolling is successfully realizedEdge grinding machinesGrinding drivesEngineeringMachining process

The computer case glass processing device with the protection function comprises a working platform, positioning frames, a processing plate and an anti-static processing plate; the positioning frames are fixed to the four corners of the top of the working platform, a cross rod is welded to the top of a telescopic column, a sliding groove is formed in the cross rod, a machining plate is slidably connected into the sliding groove, a cleaning box is fixed to the top of the machining plate, an anti-static machining plate is fixed to the bottom of the machining plate, a stretching frame is fixed to the back face of the working platform, a set of parallel clamps are installed at the top of the working platform, and the clamps are located on one side of the positioning frame. A series of elements are arranged, the device can be assisted in achieving longitudinal and transverse double-axis positioning in the machining process, synchronous cutting and grinding operation can be conducted on raw glass sheets, the machining efficiency of the device is improved, and the raw glass sheets can be subjected to antistatic film attaching machining, so that the invention has the antistatic function, and the use safety of the computer case is guaranteed.

Owner:东莞市信恒智能装备科技有限公司

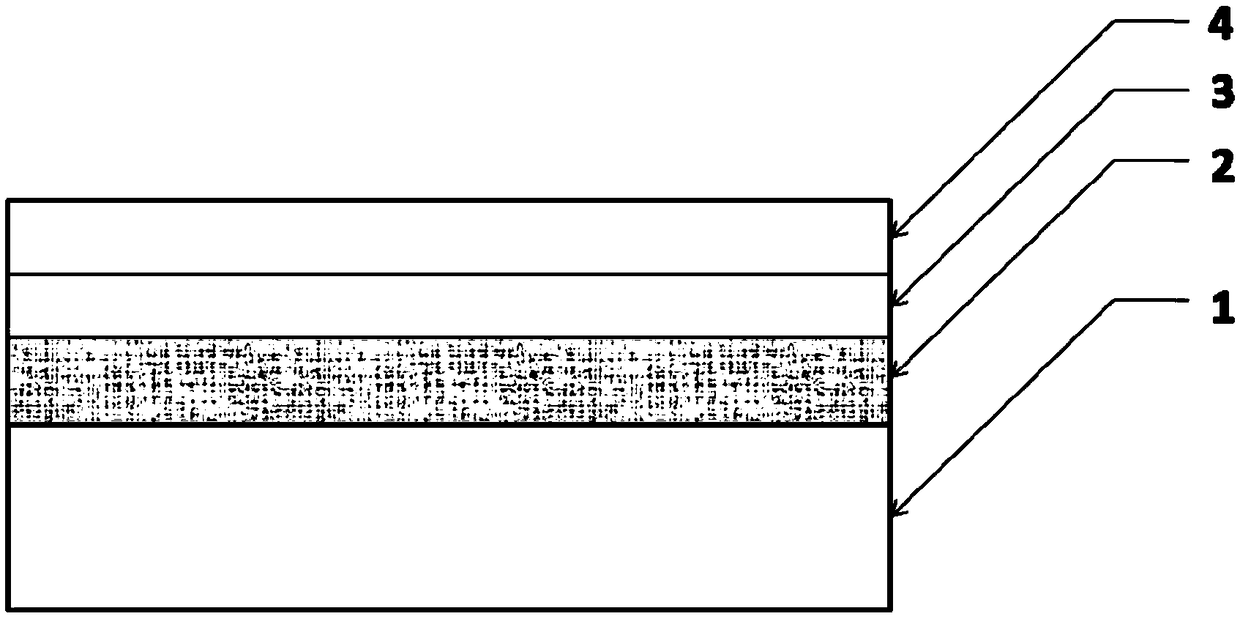

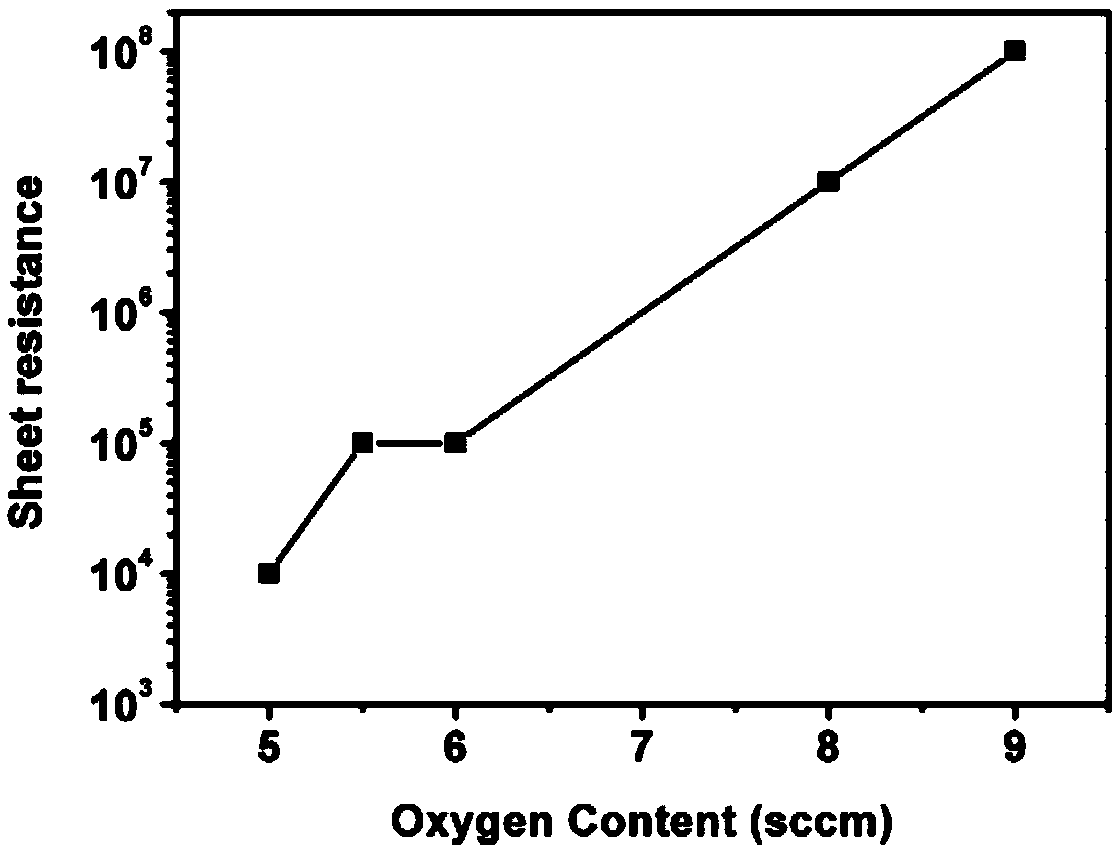

Composite transparent conductive film and preparation method thereof

ActiveCN108998772AHigh precisionMeet different levels of antistatic requirementsLiquid surface applicatorsVacuum evaporation coatingElectricityConductive polymer

The invention discloses a preparation method of a composite transparent conductive film and application thereof in antistatic electricity. The composite transparent conductive film comprises a transition layer, a conductive layer and a protective layer, wherein the transition layer is formed on a glass or plastic surface substrate and is a polyurethane acrylate or polysiloxane coating; the conductive layer is one of an ITO film, an AZO film, an IZO film, a TiO2 film, a GAO film and a ZAO film, and is deposited on the transition layer; the protective layer is deposited on the conductive layer,and is one of silicon oxide, titanium nitride and silicon nitride. According to the invention, a problem that electrostatic charges are accumulated on a surface of a transparent piece is solved whilesalt spray and moist heat resistances and other environmental properties of the conductive layer are improved by controlling the thickness and density of the protective layer.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Health care environment-friendly fabric with high shape-preserving performance and production method thereof

InactiveCN108642648AHygroscopicWith skin careDyeing processWoven fabricsEngineeringMethods of production

The invention discloses a health care environment-friendly fabric with high shape-preserving performance and a production method thereof. The fabric adopts, by mass, 56% of mixed strand threads as warp yarn and 44% of spun silk strand threads as weft yarn and is prepared by means of warping and weaving processes; the mixed strand threads adopt, by mass, 40% of mixed covering yarn and 16% of real silk and are prepared by means of yarn doubling, two-for-one twisting and yarn steaming processes in a wool spinning technology; the mixed covering yarn comprises, by mass, 20% of mercerized wool fibers, 25% of aloe fibers, 25% soft fibers and 30% long-staple cotton fibers, wherein the long-staple cotton fibers are core yarn of the mixed covering yarn. According to the provided textile fabric and the production method thereof, aloe vera, soft silk, cotton, wool and the like which have the functions of environmental protection and health care are selected as raw materials, twisted with the realsilk and interwoven with spun silk, and a series of health care environment-friendly fabric with high shape-preserving performance, novel patterns, unique styles and the functions of absorbing moisture, achieving ventilation and protecting the skin are produced.

Owner:JIANGNAN UNIV

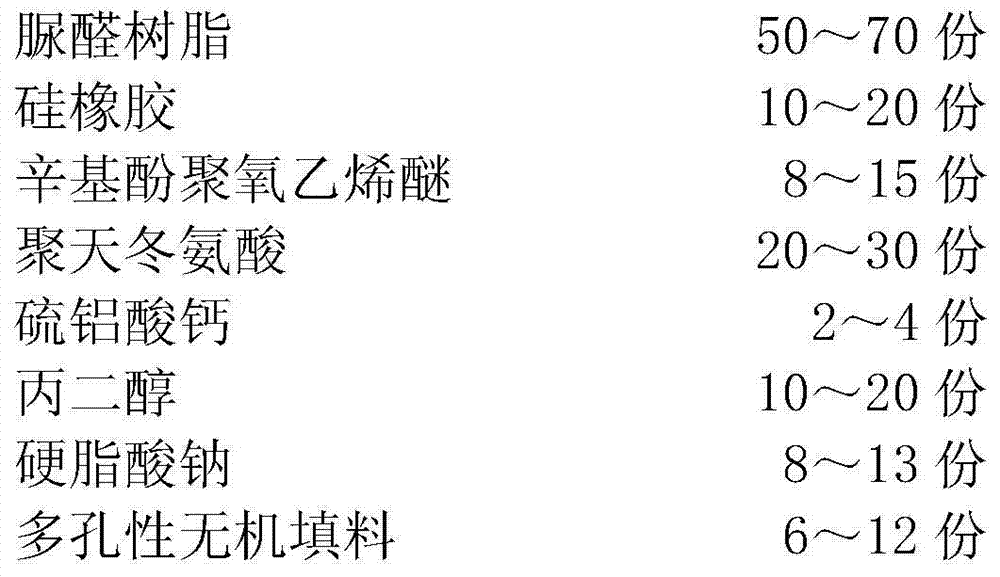

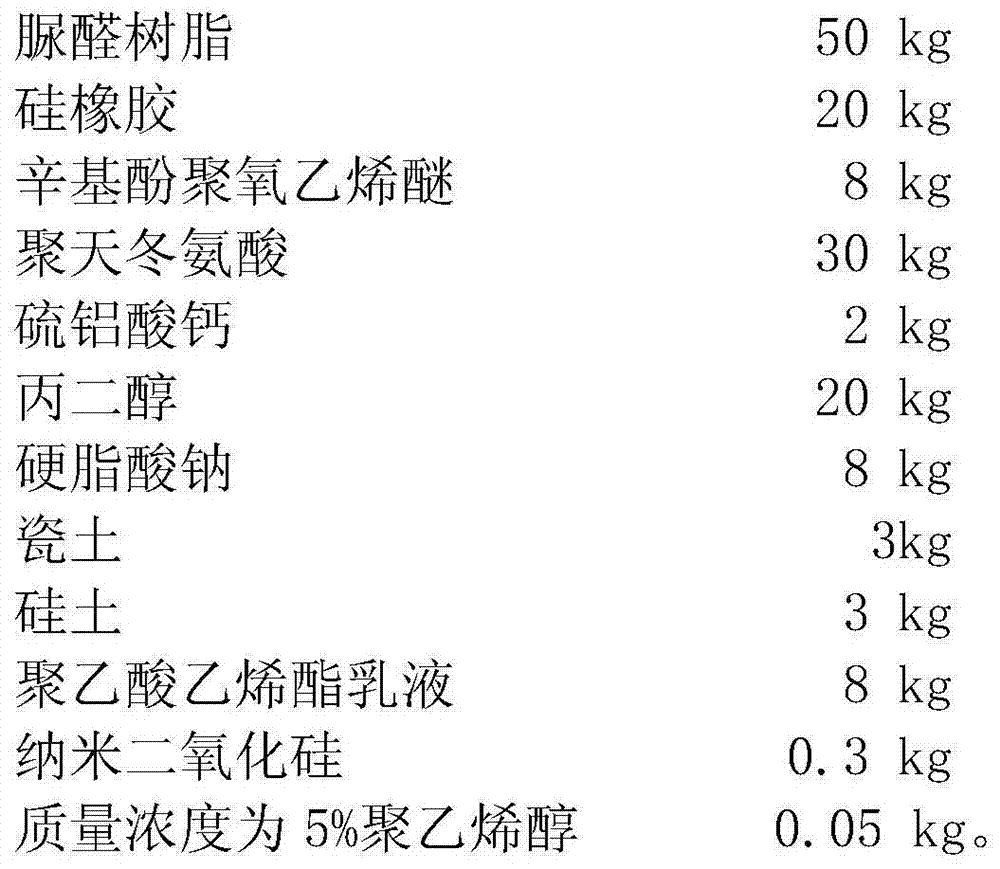

Adhesive for indoor plywood

InactiveCN104762039AIncrease productivityReduce formaldehydeMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesSodium stearateAdhesive

The invention relates to the technical field of adhesive, in particular to adhesive for indoor plywood. The adhesive comprises, by weight, 50-70 parts of urea resin, 10-20 parts of silicone rubber, 8-15 parts of octyl phenol polyoxyethylene ether, 20-30 parts of polyaspartic acid, 2-4 parts of calcium sulphoaluminate, 10-20 parts of propylene glycol, 8-13 parts of sodium stearate, 6-12 parts of porous inorganic filler, 3-8 parts of polyvinyl acetate emulsion, 1-5 parts of nano-silica and 5-10 parts of water. The adhesive for the indoor plywood is good in viscosity, has the antiseptic and anti-static functions and contains lower formaldehyde, the water resistance and aging resistance of the adhesive are improved greatly, and the service life of the adhesive is prolonged by half a year to one year. The adhesive is mainly applied to bonding of the inner plywood.

Owner:黄琳

Formaldehyde scavenger with pure natural plant extract and method for preparing formaldehyde scavenger

InactiveCN107497276ASimple extraction processBacteriostaticGas treatmentDispersed particle separationScavengerDistillation

The invention discloses a formaldehyde scavenger with pure natural plant extract and a method for preparing the formaldehyde scavenger, and belongs to the field of technologies for biologically extracting natural plants. The formaldehyde scavenger comprises, by weight, 20%-40% of Ocotea spp. extract liquid, 10%-40% of cinnamomum camphora leaf extract liquid, 10%-20% of herba houttuyniae extract liquid, 10%-20% of semen myristicae extract liquid, 10%-20% of platycladus orientalis extract liquid, 5%-20% of radix glycyrrhizae extract liquid and 5%-20% of folium eucalypti extract liquid. The weights of the Ocotea spp. extract liquid, the cinnamomum camphora leaf extract liquid, the herba houttuyniae extract liquid, the semen myristicae extract liquid, the platycladus orientalis extract liquid, the radix glycyrrhizae extract liquid and the folium eucalypti extract liquid is 100%. Processes for preparing plant extract liquid include utilizing water as an extracting agent; cooking plants, cooling the plants until the temperatures of the plants reach the normal temperature and carrying out filtering, closed fermentation and distillation. The formaldehyde scavenger and the method have the advantages that formaldehyde, harmful gas such as benzene and dimethylbenzene and undesirable odor can be efficiently decomposed by the formaldehyde scavenger prepared by the aid of the method, and the formaldehyde scavenger further has antibacterial, sterilization, deodorization and antistatic functions; the shortcomings of secondary pollution due to existing formaldehyde scavengers prepared from chemical reagents and existing formaldehyde scavengers mainly with chemical reagents and certain added plant extract liquid, poor formaldehyde scavenging effects and short shelf lives can be overcome.

Owner:QICAIBEIKE NEW MATERIAL TECH CO LTD

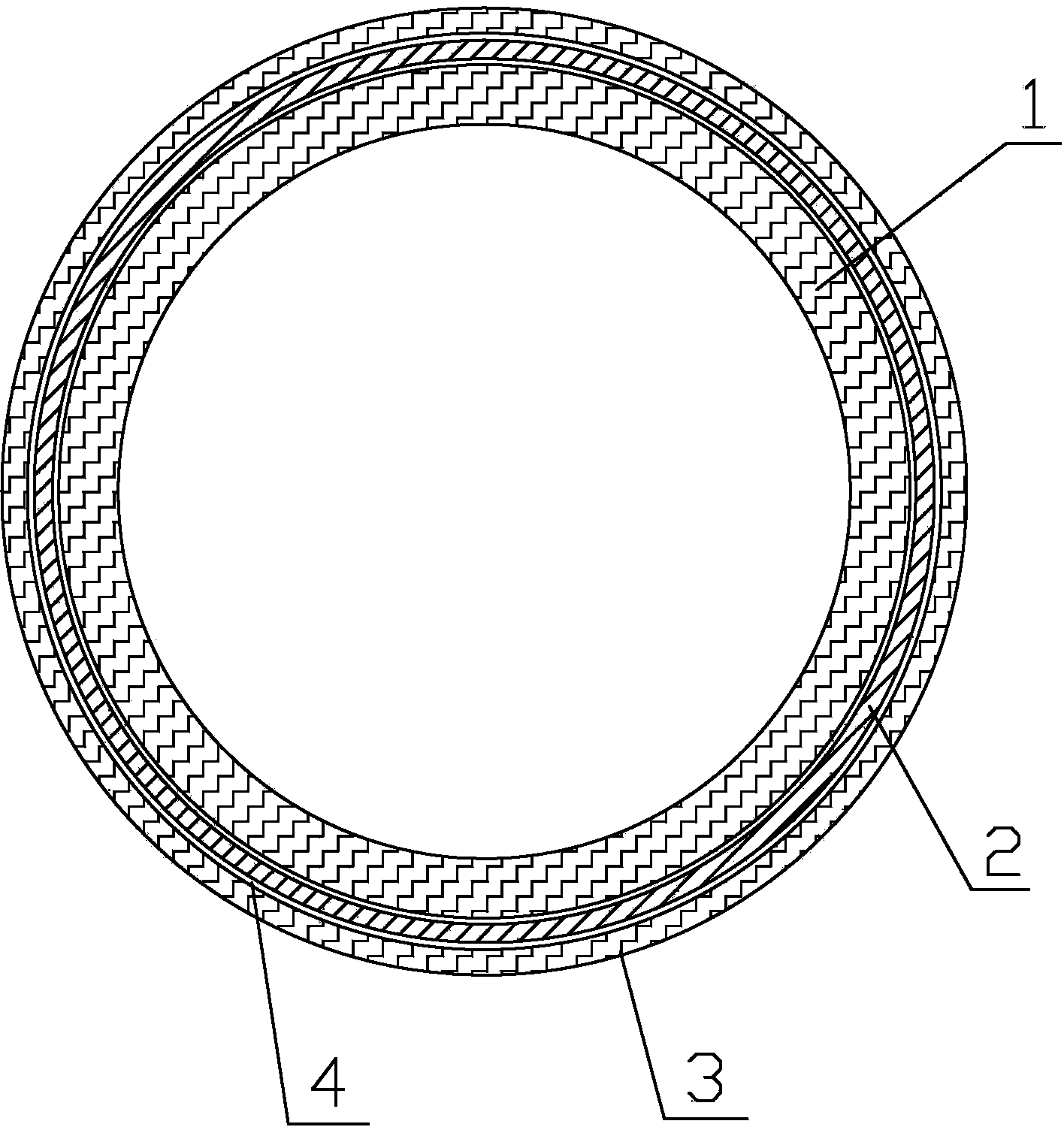

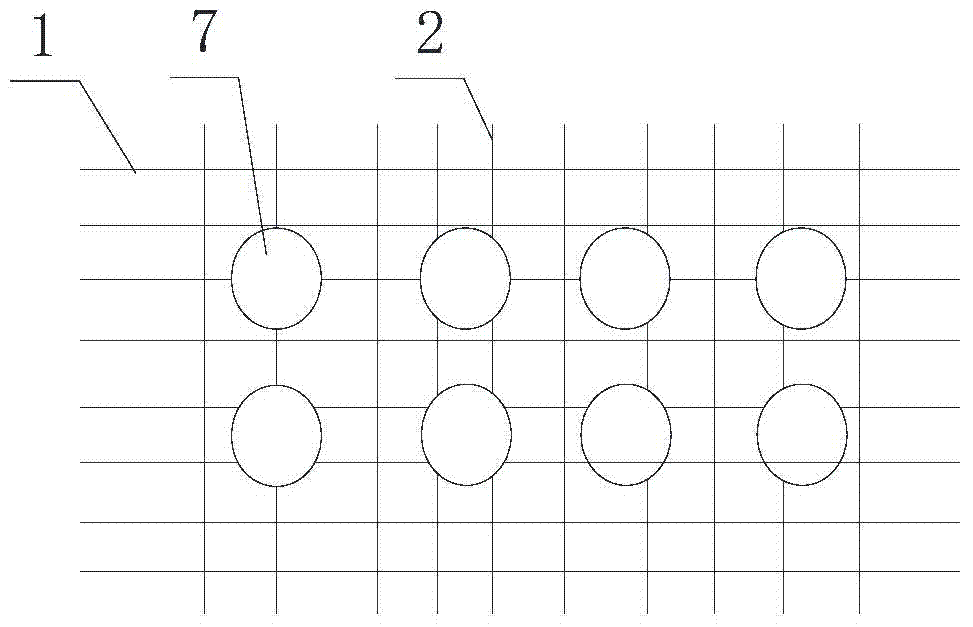

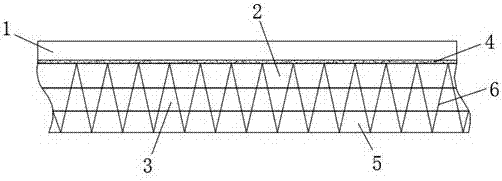

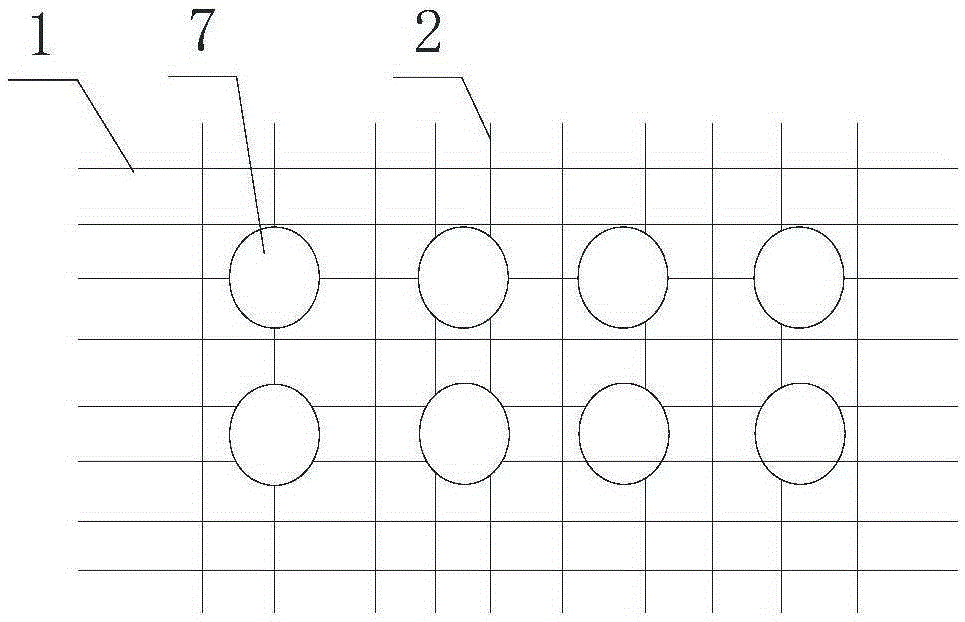

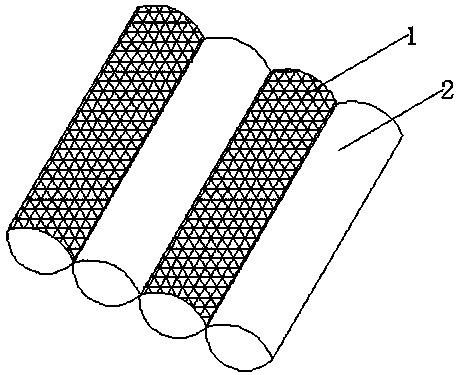

High-strength steel wire net framework polyethylene pipe

InactiveCN104279373AWith flame retardant functionWith antistatic functionRigid pipesMetal layered productsHot meltHigh intensity

The invention relates to a high-strength steel wire net framework polyethylene pipe. The high-strength steel wire net framework polyethylene pipe comprises an inner layer, a reinforcement layer and a protective layer, wherein the inner layer and the protective layer are both made of inflaming-retarding antistatic polyethylene materials, the reinforcement layer is composed of a steel wire net layer and a hot melt adhesive layer, a hot melt adhesive layer is arranged between the steel wire net layer and the inner layer, and another hot melt adhesive layer is arranged between the steel wire net layer and the protective layer. The steel wire net layer is composed of one or two layers of steel wire nets, hot melt adhesives are arranged between the two layers of steel wire nets, and the net holes of the outer-layer steel wire net are larger than those of the inner-layer steel wire net. Compared with the prior art, the materials of the inner layer and the outer layer of the polyethylene pipe have the inflaming-retarding and antistatic functions, and the polyethylene pipe can be used for ventilation or water feeding and drainage under a coal mine shaft; the middle reinforcement layer is a steel wire net framework composed of the steel wire nets and the hot melt adhesives, is high in strength and is low in manufacturing cost. The inner corners of the end surfaces of the polyethylene pipe are of a chamfering or arc-shaped corner structure, burr edges are not be generated at a pipe wall inner cavity in the sweat soldering process, and therefore normal flowing of media in the pipe is not hindered.

Owner:周忠明

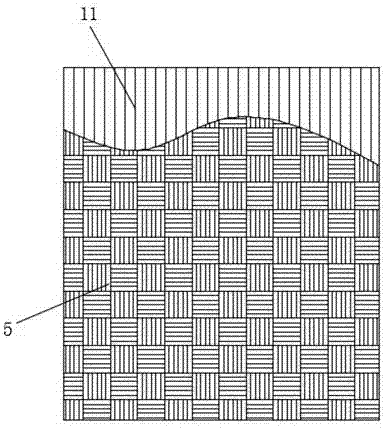

Water-absorption permeable fabric

ActiveCN104118162AStay fresh and comfortableHas health benefitsSynthetic resin layered productsWoven fabricsEngineeringFilament yarn

The invention provides a water-absorption permeable fabric with excellent water absorption performance and permeability. The fabric comprises a fabric body which is of a plain weaving structure formed by interweaving of warps and wefts; the warps are hollow PET polyester filaments; multiple through holes communicated with hollow cavities in the PET polyester filaments are formed in the surface of the PET polyester filaments; zeolite particles are embedded in the wall bodies of the PET polyester filaments; the wefts are bamboo fiber filaments; multiple grooves extending along the extending direction of the bamboo fiber filaments are formed in the side part of the bamboo fiber filaments.

Owner:HUZHOU CHENGXIN TEXTILE PRINTING & DYEING

Low-temperature-resistant sealing strip for window and preparation method of low temperature resistant sealing strip

The invention discloses a low-temperature-resistant sealing strip for a window. The low-temperature-resistant sealing strip is prepared from, by weight, 35-40 parts of nitrile butadiene rubber, 40-45 parts of natural rubber, 25-30 parts of butadiene styrene rubber, 20-25 parts of cis-polybutadiene rubber, 8-10 parts of sulphur, 7-11 parts of carbon black, 9-15 parts of carbon fibers, 5-10 parts of naphthenic oil, 12-14 parts of vaseline, 6-12 parts of dibutyl sebacate, 4-8 parts of diphenyl silanediol, 2-6 parts of diesel oil, 7-11 parts of epoxidized soybean oil, 13-16 parts of phthalic esters, 5-10 parts of alkylphenol ethoxylates, 8-12 parts of polyoxyethylene alkanolamide, 4-8 parts of talcum powder, 15-20 parts of quartz powder, 5-10 parts of titanium dioxide, 7-9 parts of sodium fluoride, 8-14 parts of tributyltin and 1-4 parts of benzotriazole. The low-temperature-resistant sealing strip for the window is high in low temperature resistance, antistatic and capable of delaying light aging and keeping long service life of the window.

Owner:ANHUI KATA DOOR & WINDOW

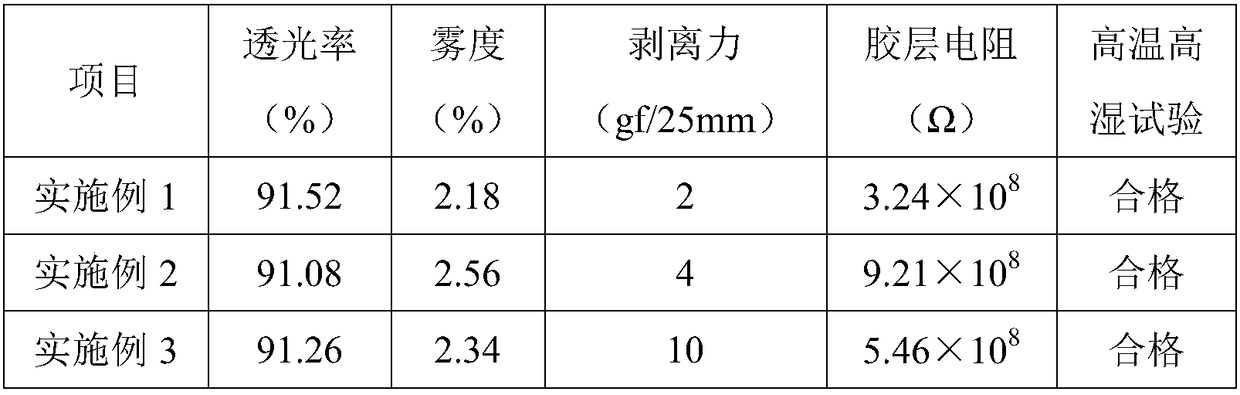

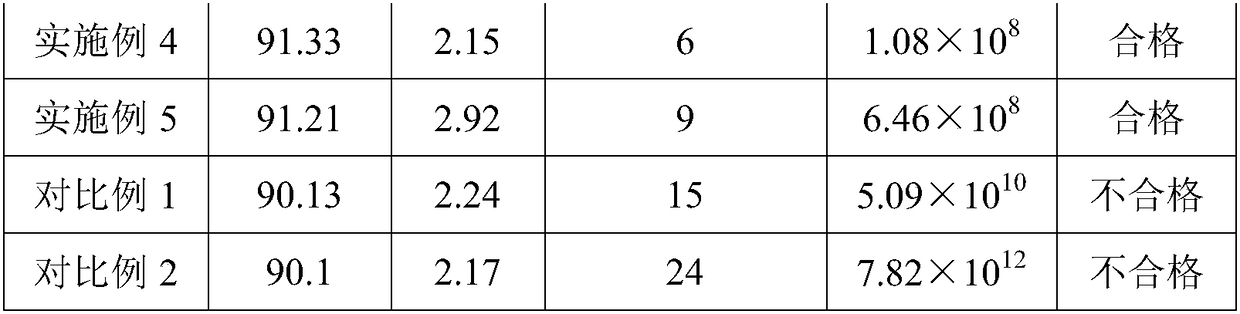

Preparation method of emulsion pressure-sensitive adhesive and polarizer protective film

ActiveCN108440708AReduce glue dispensing processStable performancePressure sensitive film/foil adhesivesElectrically-conducting adhesivesPolarizerFunctional monomer

The invention discloses a preparation method of an emulsion pressure-sensitive adhesive and a polarizer protective film. The pressure-sensitive adhesive is prepared from the following raw materials inparts by weight: 100-200 parts of deionized water, 0.5-1.5 parts of sulfonate reactive emulsifier, 2-5 parts of acyl-containing acrylic monomer, 15-40 parts of soft monomer, 5-15 parts of hard monomer, 4-8 parts of functional monomer and 1-4 parts of modified antistatic agent; the pressure-sensitive adhesive can directly coat the surface of a polyester film without additionally adding a curing agent and the antistatic agent, has the adhesive layer resistance below 109ohm and has antistatic property. When an adhesive layer of the polarizer protective film is pasted to the surface of a polarizer, after being subjected to high-temperature and high-humidity experiments for 500h, the protective film tightly pasted to the polarizer, and the defects such as air bubbles as well as residual adhesives and dark shadows during protective film tearing are avoided.

Owner:HEFEI LUCKY SCI & TECH IND +1

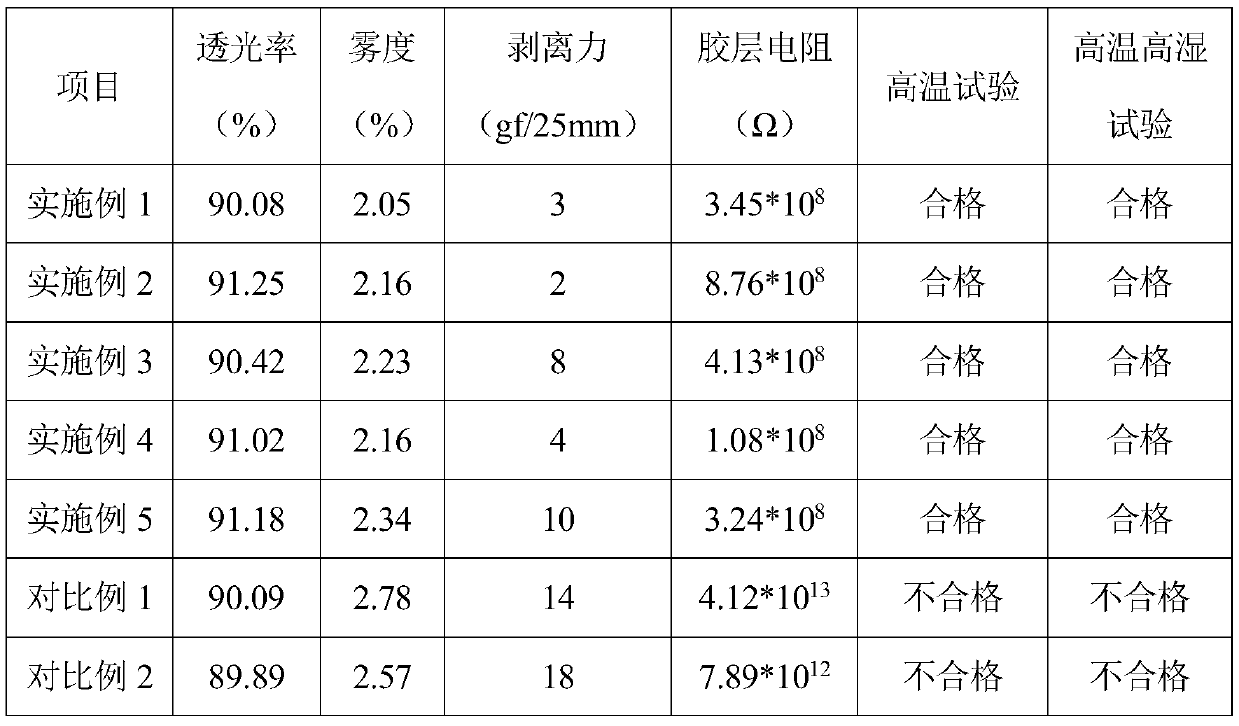

Emulsion pressure-sensitive adhesive for polarizer protective film, and polarizer protective film thereof

InactiveCN111187584AWith antistatic functionPrevent precipitationEster polymer adhesivesPressure sensitive film/foil adhesivesPolyesterSulfonate

The invention discloses an emulsion pressure-sensitive adhesive for a polarizer protective film, and the polarizer protective film thereof. The pressure-sensitive adhesive is prepared from the following raw materials in parts by weight: 100 to 200 parts of deionized water, 0.5 to 1.5 parts of a sulfonate reactive emulsifier, 1 to 4 parts of a double bond-containing quaternary ammonium salt monomer, 15 to 40 parts of a soft monomer, 5 to 10 parts of a hard monomer, 2 to 5 parts of a functional monomer and 1 to 4 parts of closed water-based isocyanate. According to the invention, the pressure-sensitive adhesive disclosed by the invention can be directly coated on the surface of a polyester film, an antistatic agent does not need to be added, the resistance of an adhesive layer is below 109 ohms, and the pressure-sensitive adhesive has an antistatic property; and when the polarizer protective film adhesive layer is attached to the surface of a polarizer, after high-temperature and high-temperature and high-humidity tests are carried out for 500 hours, the protective film and the polarizer are tightly attached, bubbles and bulges do not exist, and the defects of residual adhesive, shadows and the like do not exist when the protective film is torn off.

Owner:HEFEI LUCKY SCI & TECH IND

Coating application technology of radomes

InactiveCN106140590AReduce surface resistanceHas surface resistancePretreated surfacesPolyurea/polyurethane coatingsSolubilityElectrical resistance and conductance

The invention discloses a coating application technology of radomes. Acetic ether and PMA of diluting agents can dissolve coatings well, the drying speed of paint films is appropriate, the price is relatively low, the coatings comprise nanometer conductive powder so as to realize the antistatic function, the number of times of spraying the coatings is 1-3, the thickness of the coatings is 25-35 micrometers, the interval time of coating spraying is determined, the mass can be reduced, the permeability to radar waves is high, the curing time is determined, and the surface resistance of the coatings can be lowered. The radomes processed through the coating application technology have the advantages that the antistatic ability is high, the surface resistance is low, the market potential is huge and the prospect is wide.

Owner:HEFEI JIARUILIN ELECTRONICS TECH

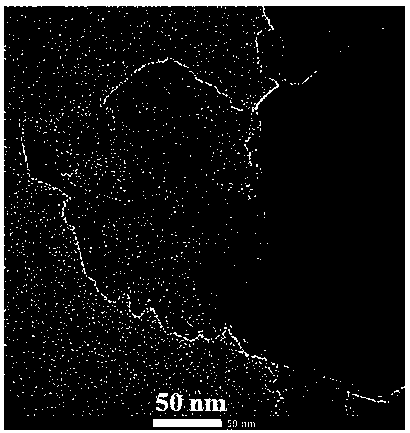

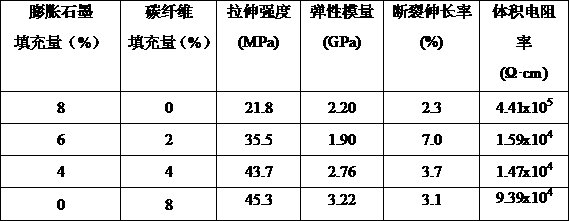

Preparation method of antistatic hard polyvinyl chloride material

The invention discloses a preparation method of an antistatic hard polyvinyl chloride material, and belongs to the technical field of functional material preparation. According to the preparation method, peeling of expandable graphite is carried out with microwave so as to obtain expanded graphite; expanded graphite and one-dimensional carbon fiber are taken as conductive filling materials, and are subjected to open mill blending with PVC, and hot pressing and cold pressing moulding so as to obtain the antistatic hard polyvinyl chloride material. According to the preparation method, peeling ofexpandable graphite and surface modification are realized based on microwave technology, so that a graphite two dimensional filling material system with surface PVC compatibility and containing nanometer graphite flakes is obtained, coordinating of the carbon fiber one-dimensional filling system is realized, construction of a network structure is realized, excellent mechanical properties and antistatic performance at a low filling amount are achieved. Hard PVC is provided with antistatic performance by the microwave expanded graphite / carbon fiber / PVC multicomponent filing system.

Owner:YANGZHOU UNIV

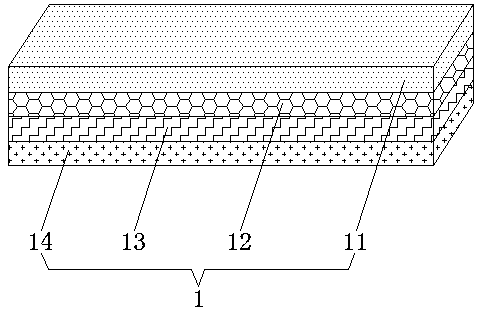

Comfortable and anti-static fabric

InactiveCN107234847AMoisture-absorbing and breathableComfortable to wearSynthetic resin layered productsCellulosic plastic layered productsPolyesterFiber

The invention discloses comfortable and anti-static fabric. The comfortable and anti-static fabric comprises a waterproof layer, a thermal insulation layer, a breathable layer and an antistatic layer, wherein the thermal insulation layer is arranged at the bottom of the waterproof layer, the breathable layer is arranged at the bottom of the thermal insulation layer, the antistatic layer is arranged at the bottom of the breathable layer, the breathable layer comprises linen yarn, bamboo fiber yarn, carbon fiber yarn and pearl fiber yarn which are woven in an alternate up-down manner, the linen yarn and the bamboo fiber yarn are arranged horizontally, the carbon fiber yarn and the pearl fiber yarn are arranged vertically, the antistatic layer comprises base cloth and metal filaments woven on the upper surface of the base cloth, and the metal filaments comprise polyester fiber yarn and silver fiber yarn winding the surface of the polyester fiber yarn. The comfortable and anti-static fabric is novel and reasonable in structure, ingenious in design and suitable for popularization.

Owner:YANCHENG FUTAI TEXTILE CO LTD

A water-absorbent and breathable fabric

ActiveCN104118162BStay fresh and comfortableHas health benefitsSynthetic resin layered productsWoven fabricsPolyesterPolymer science

Owner:HUZHOU CHENGXIN TEXTILE PRINTING & DYEING

Moisture-wicking, antibacterial and antistatic multifunctional fabric and production method thereof

ActiveCN104389076BImprove wearing comfortGuaranteed antistatic functionWoven fabricsYarnYarnMoisture absorption

The invention discloses a multifunctional fabric with moisture absorption and perspiration, antibacterial and antistatic properties and a production method thereof. The multi-functional fabric is made of 95-99% multi-functional blended yarn and 1-5% stainless steel anti-static yarn or conductive anti-static yarn; the multi-functional blended yarn is made of moisture-wicking fiber 50-80%, cotton Fiber 15-45% and silver fiber 5-10% are blended; stainless steel antistatic yarn is made of moisture-wicking fiber 35-45%, cotton fiber 10-30%, silver fiber 3-7% and stainless steel fiber 25-40% % blended; conductive yarn antistatic yarn is twisted from 3-5% organic conductive yarn and 95-97% multifunctional blended yarn. The multifunctional fabric produced by the invention has antistatic function, moisture absorption and perspiration function and antibacterial function, which can not only ensure the antistatic function of the fabric, but also greatly improve the air permeability of the fabric, improve the wearing comfort of the fabric, and have good antibacterial function.

Owner:ZHENGZHOU NO 4 COTTON TEXTILE

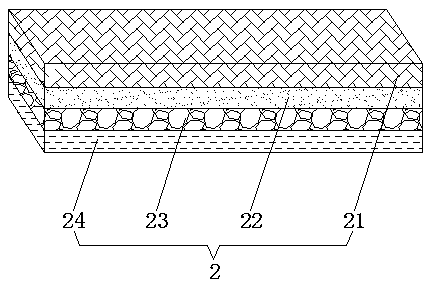

Nano flame-retardant antistatic air duct cloth and preparation method thereof

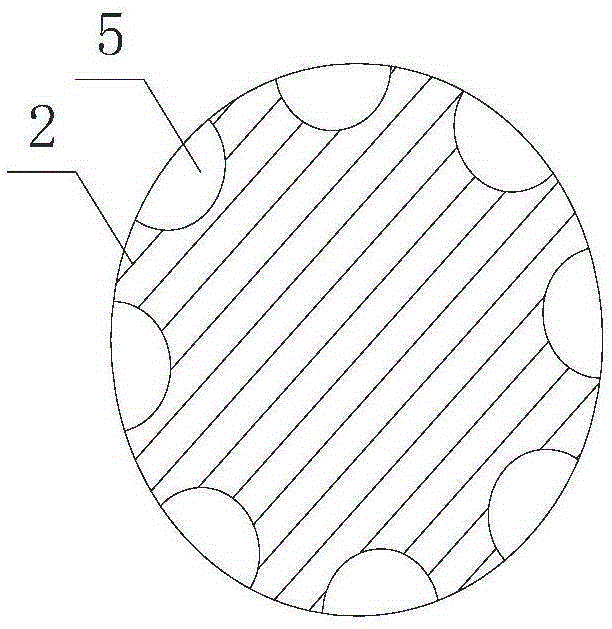

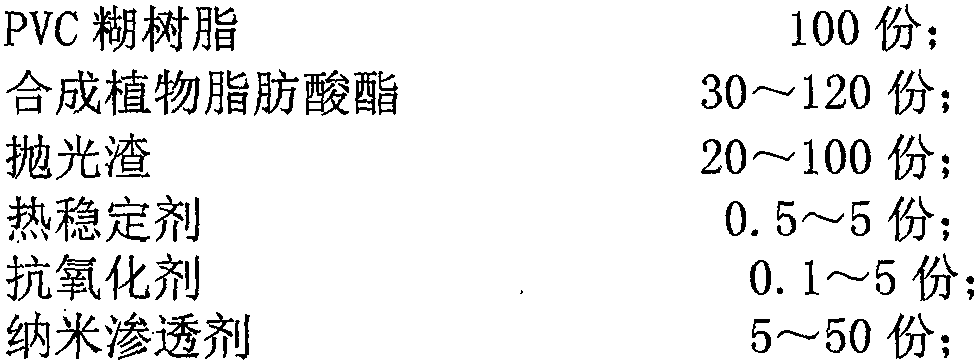

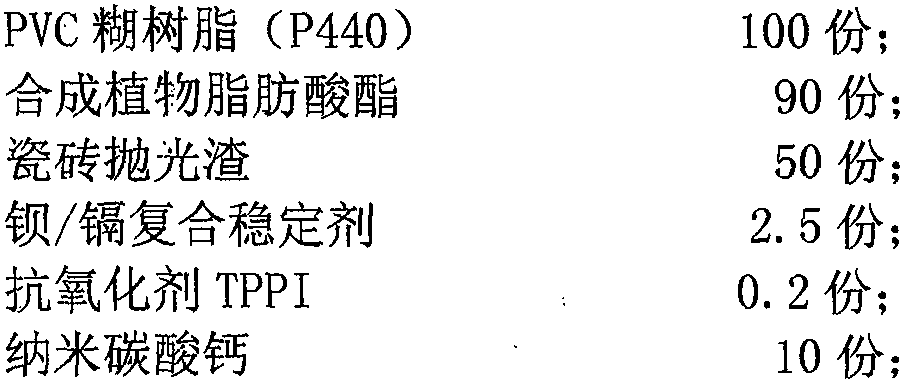

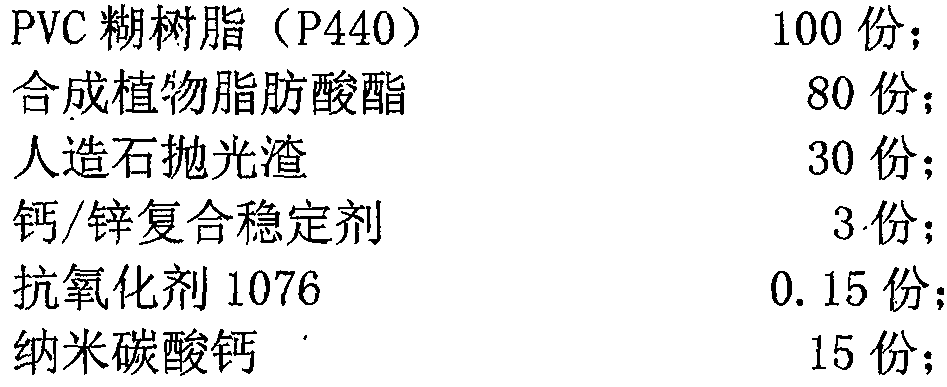

InactiveCN111320828ASolve sheddingSolve the problem of air leakage caused by broken skinPolymer sciencePlasticizer

The invention discloses a nano flame-retardant antistatic air duct cloth and a preparation method thereof. The nano flame-retardant antistatic air duct cloth is prepared by dipping synthetic fibrous base cloth into PVC flame-retardant antistatic plasticizing paste containing a nano penetrating agent, flattening the synthetic fibrous base cloth by a flattening machine, heating and plasticizing thesynthetic fibrous base cloth in a drying oven to prepare a covering film with a flat and smooth surface, and cooling the covering film to obtain the nano flame-retardant antistatic air duct cloth. Theplasticizing paste completely permeates into the synthetic fibers, and the problem of air leakage of an air duct caused by easy falling and skin breaking of a covering film in the prior art is solved. Synthetic vegetable fatty acid ester with flame-retardant and antistatic properties and stone, ceramic tiles and artificial stone polishing slag with flame-retardant and smoke-suppressing propertiesare added into the formula, so that the problem that the flame-retardant property is weakened due to the addition of a large amount of a small molecular plasticizer in the prior art is solved. A large amount of polishing slag taken as an inorganic filler is added, the production cost is reduced, the flame retardant property and smoke suppressing performance of the product are improved, the problems that the polishing slag is difficult to recycle and environmental pollution is caused by waste landfill are solved, and waste is turned into resources.

Owner:林铭昭

Superfine graphene anti-static down jacket fabric

InactiveCN109849462AAvoid drillingClean appearance and flowSynthetic resin layered productsHeating/cooling textile fabricsPolyesterFiber

Owner:吴江市飘逸纺织有限公司

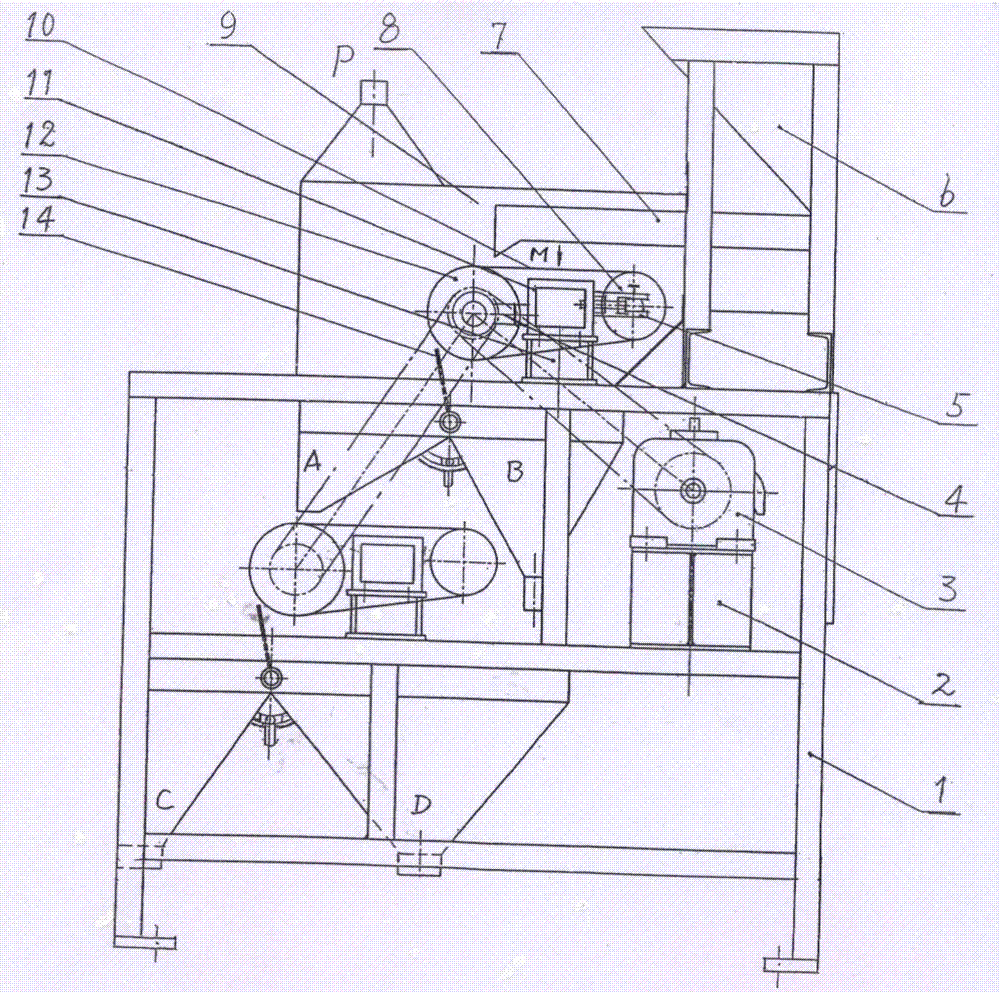

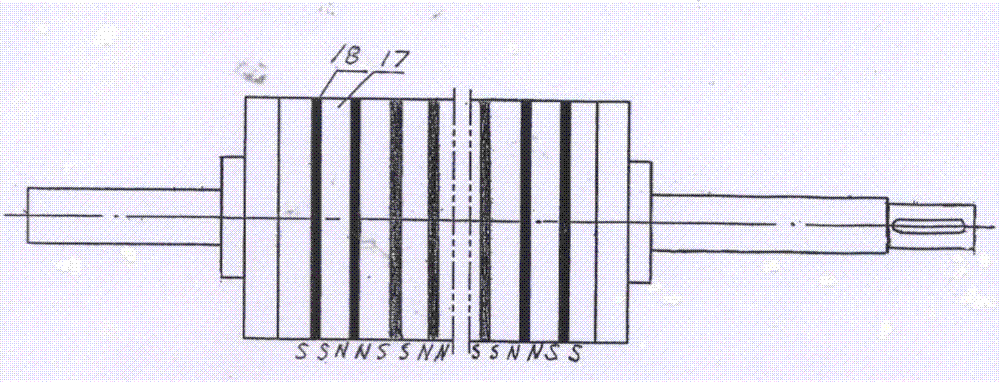

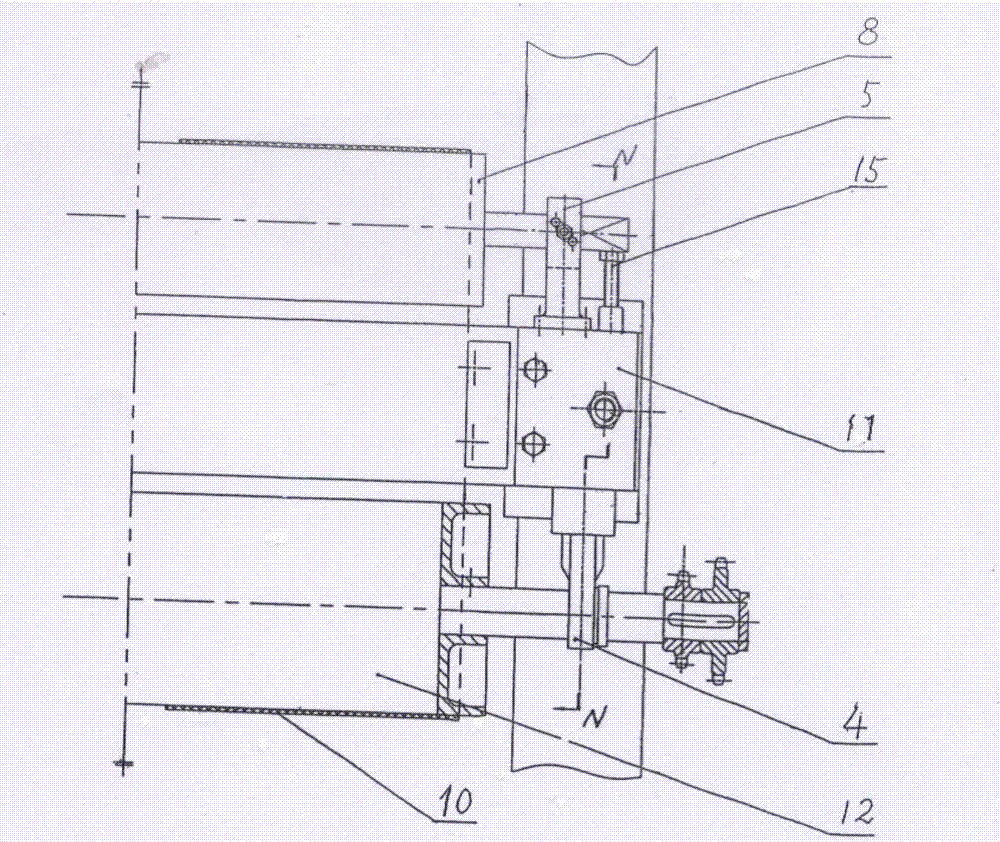

Weak-magnetic material recovering machine

InactiveCN102728464AHigh recovery rateReliable attractionMagnetic separationNeodymium iron boronEngineering

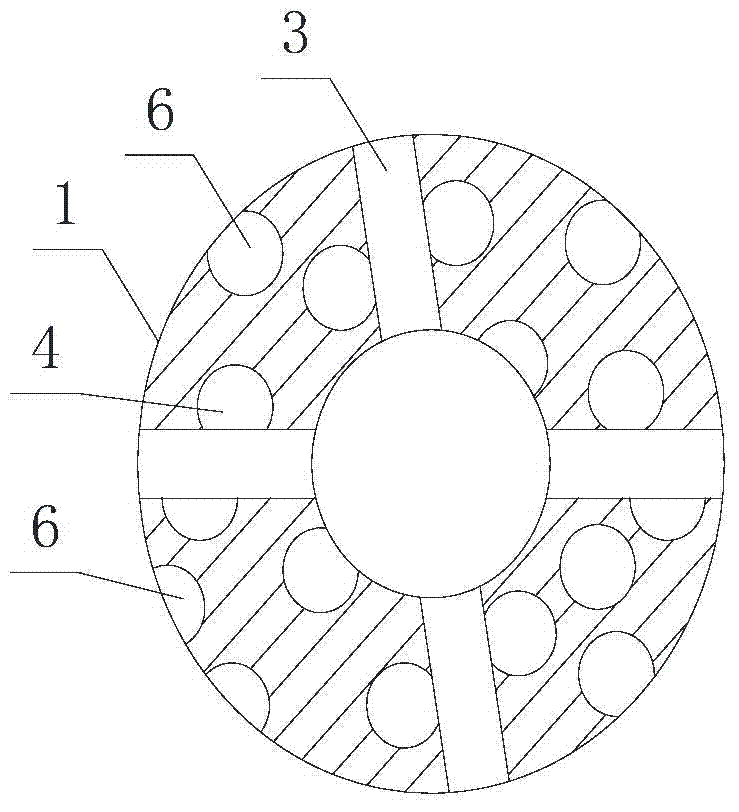

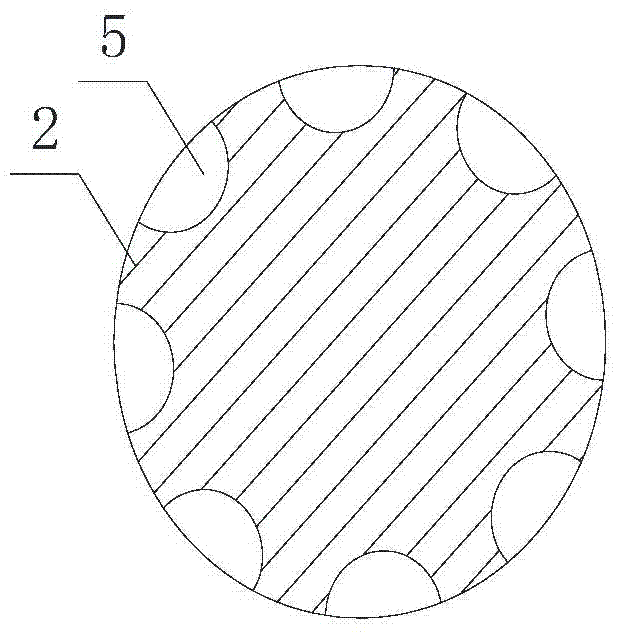

The invention discloses a weak-magnetic material recovering machine, which is characterized in that: the machine comprises a frame; a material storage is arranged above the frame; a vibration feeding apparatus is arranged in the frame below the material storage; a delivering belt tensioned by a magnetic roller and a redirecting roller is arranged below the vibration feeding apparatus; the rotation speed of the magnetic roller is changed through a variable-frequency and variable-speed motor connected therewith; a plurality of discharging hoppers are arranged below the delivering belt; and the magnetic roller and the redirecting roller are respectively arranged on two sides of the crossbeam with a ball bearing with an eccentric sleeve and an adjusting seat. The magnetic roller is formed by round disks manufactured by using a neodymium-iron-boron rare earth permanent magnetic material; a pole piece of soft iron is adopted between two round disks with a same polarity; the two round disks are alternately superposed, and are compressed to form a whole. According to the invention, precious weak-magnetic particles in mixed particles can be separated from other non-magnetic particles. A recovery rate is high, the purity is high, and a high economic benefit can be provided.

Owner:杭州太阳铸造工程技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com