Preparation method of black gray expandable polystyrene

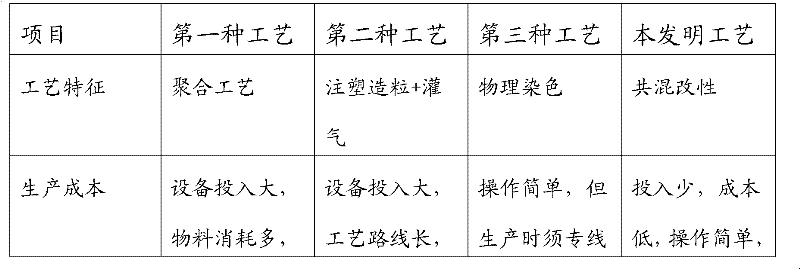

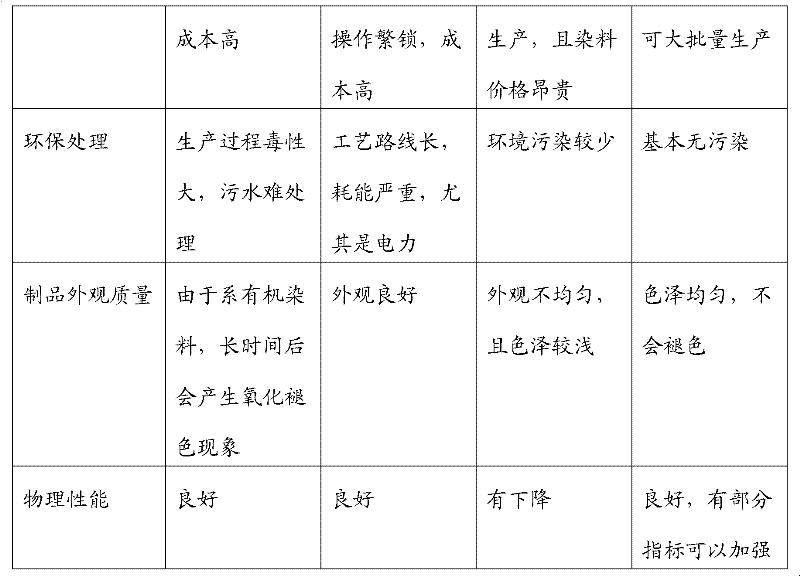

An expandable polystyrene, gray technology, applied in the fields of structural parts and handicraft helmet applications, packaging and building materials, can solve the problems of cumbersome manufacturing process, high manufacturing cost, toxic dyes, etc. Production cost and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Adopt 50Kg average particle diameter in the ordinary grade expandable polystyrene resin of 0.7mm, add binder (the weight of binder is 0.05% of expandable polystyrene weight), mix 5 minutes on high-speed mixer , the mixing speed is 500RPM, then add half of the powder, blend and modify for 40 minutes, then add half of the powder (the weight of the powder is 1% of the expandable polystyrene weight), blend and modify for 50 minutes, then discharge material, clean up the mixer, and obtain black-gray expandable polystyrene EPS resin after blending and modification, and then pre-foam and mold the EPS to obtain black-gray ordinary EPS foam products. The product can meet the requirements of black and gray color, and has little effect on the physical strength of the product, and the foam surface has good antistatic function. Surface impedance at 10 8-9 , has excellent anti-static performance, and can be used in high-end anti-static electronic packaging products. The performance...

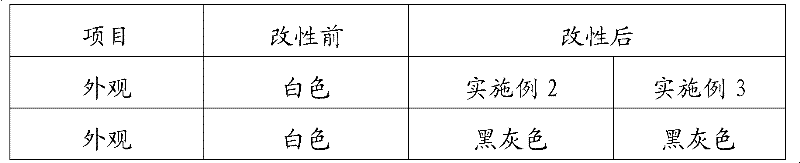

Embodiment 2

[0037] Adopt 50Kg average particle diameter in the flame-retardant grade expandable polystyrene resin of 0.7mm, add binder (the weight of binder is 1.0% of expandable polystyrene weight), mix on high-speed mixer 5 Minutes, mixing speed is 800RPM, then add 1 / 3rd powder, blend modification 40 minutes, then add 1 / 3 powder, blend modification 40 minutes, finally add remaining 1 / 3rd powder ( The weight of the powder is 3% of the expandable polystyrene weight), blending and modifying for 40 minutes, and the total time is 130 minutes, then discharge, clean up the mixer, and obtain the black gray flame retardant after the blending modification. Type expandable polystyrene EPS resin, and then the EPS is pre-foamed and molded to obtain a black-gray flame-retardant grade EPS foam product, which can meet the requirements of black-gray color, and the foam product The flame retardant performance is increased by 10-20%, the thermal conductivity is reduced by 5-10%, the physical strength is s...

Embodiment 3

[0040] Adopt 50Kg average particle diameter in the flame-retardant grade expandable polystyrene resin of 1.1mm, add binder (the weight of binder is 2.0% of expandable polystyrene weight), mix 10 on high-speed mixer Minutes, mixing speed is 1000RPM, then add 1 / 3rd powder, blending modification 30 minutes, then add 1 / 3rd powder, blending modification 30 minutes, finally add remaining 1 / 3rd powder ( The weight of the powder is 20% of the expandable polystyrene weight), blending and modifying for 30 minutes, and the total time is 100 minutes, then discharge, clean up the mixer, and obtain the black-gray flame-retardant compound after blending and modifying. Type expandable polystyrene EPS resin, and then the EPS is pre-foamed and molded to obtain a black-gray flame-retardant grade EPS foam product, which can meet the requirements of black-gray color, and the foam product The flame retardant performance is increased by 10-20%, the thermal conductivity is reduced by 5-10%, the physi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com