Patents

Literature

1810results about How to "Improve physical performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel waterproof air previous polyurethane artificial leather and preparation thereof

ActiveCN101440578AGood waterproof and breathableImprove physical performanceSynthetic resin layered productsTextile shapingPolyurethane adhesiveChemistry

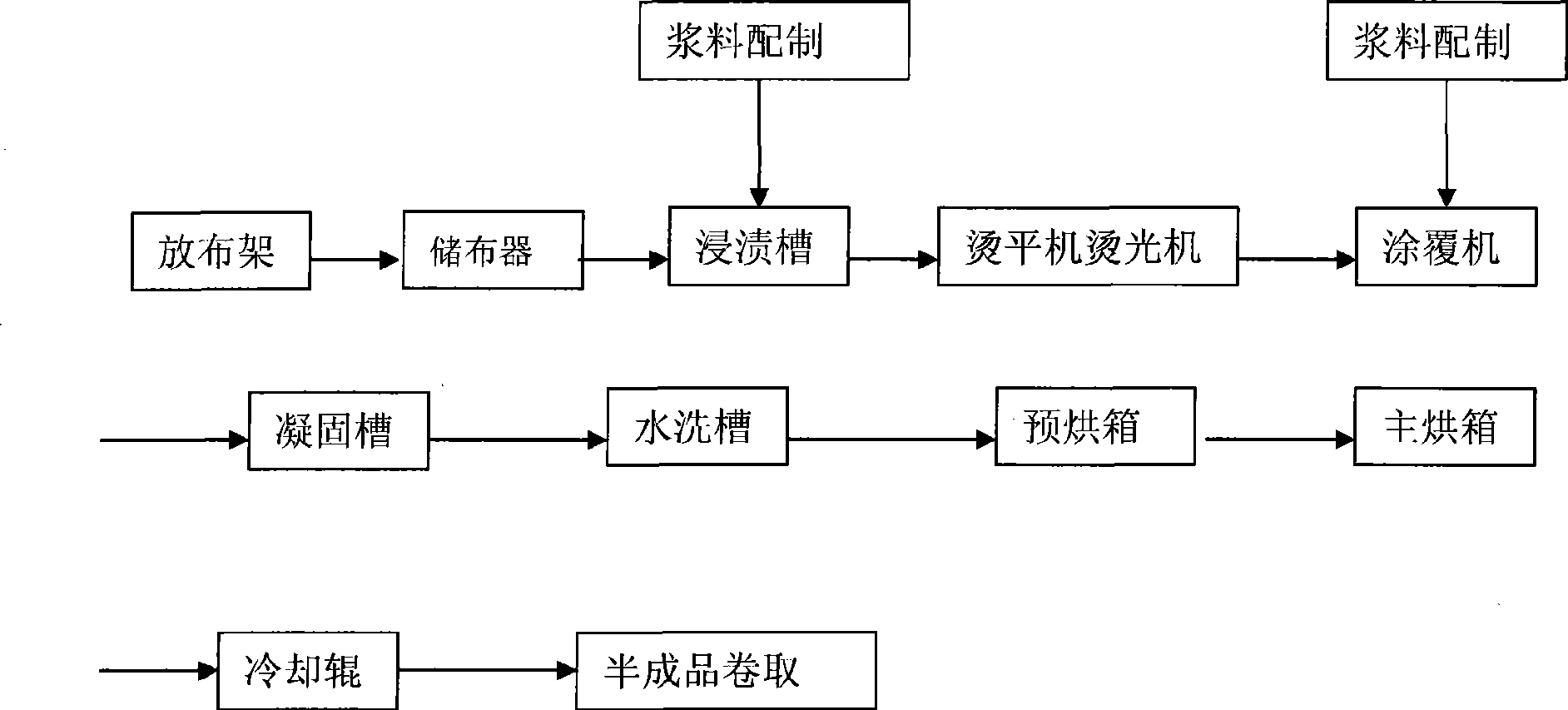

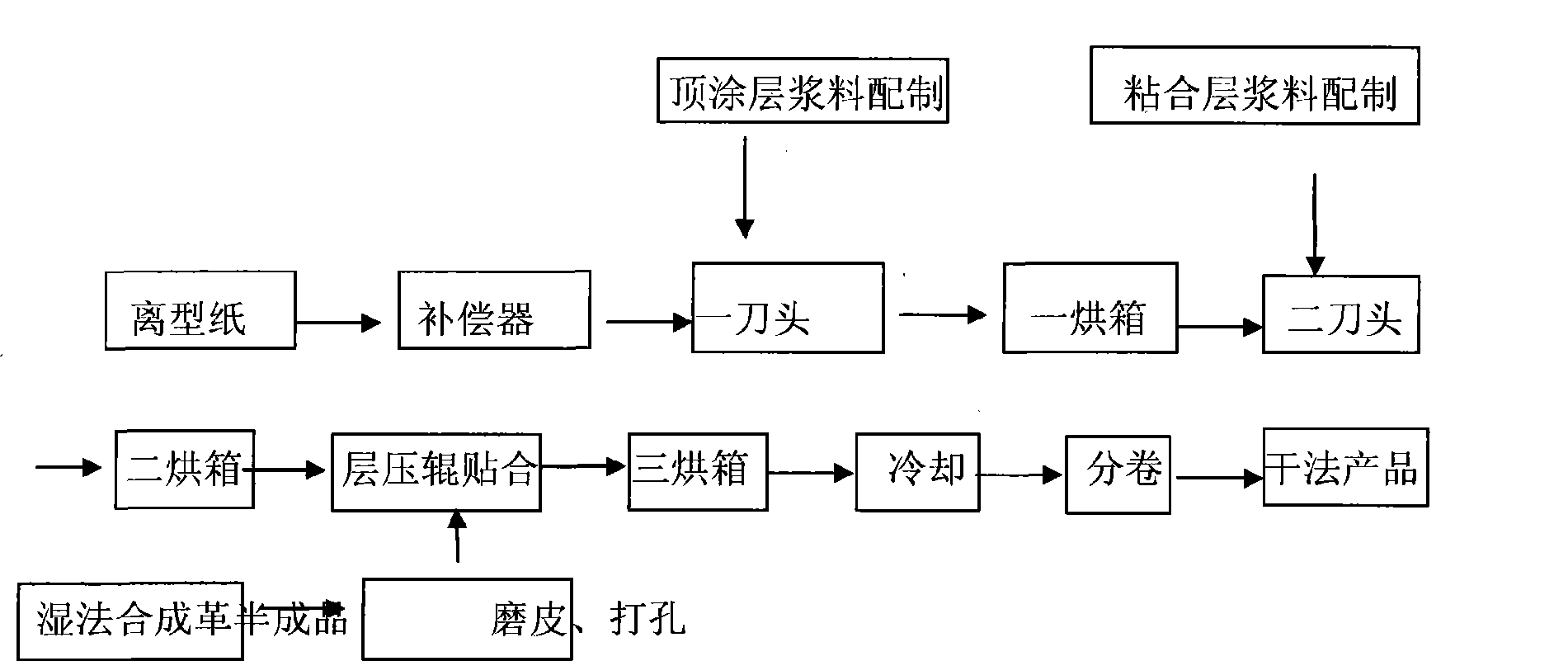

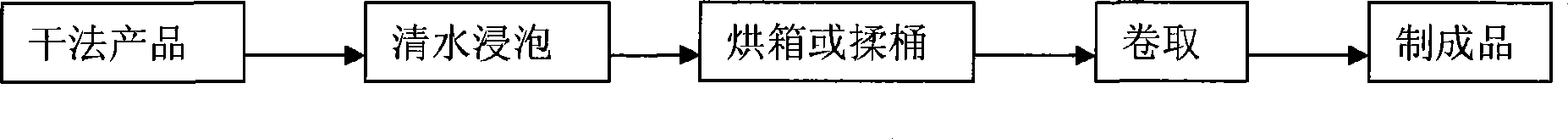

The invention discloses novel waterproof and moisture-permeable polyurethane synthesized leather and a method for manufacturing the same. The novel waterproof and moisture polyurethane synthesized leather consists four layers, namely, base cloth, a thermoplastic wet-process polyurethane wet-process coating coated on the base cloth, a dry-process polyurethane adhesive layer and a top coat, wherein thermoplastic wet-process polyurethane wet-process slurry is coated on the base cloth to form a semi-finished product of wet-process synthetic leather, the wet-process synthetic leather is punched and ground to make holes on the thermoplastic wet-process polyurethane wet-process coating, and the dry-process polyurethane adhesive layer and the top coat are arranged sequentially on the thermoplastic wet-process polyurethane wet-process coating. Both the dry-process polyurethane adhesive layer and the top coat are provided with micropores. The top coat contains pigment. The synthetic leather manufactured has excellent waterproof and moisture-permeable performance like natural leather, high wear resistance, high-hydration, high-frequency hot cutting, low temperature resistance and other functions as well as excellent three-dimension patterns and fullness.

Owner:ANHUI ANLI MATERIAL TECH

Polyisocyanate curing agent and preparation method thereof

The invention relates to a polyisocyanate curing agent and a preparation method thereof, belonging to the curing agent field. The preparation method comprises the following steps: adopting diisocyanate monomer and a mixture of divalent alcohol and trivalent alcohol to react in cosolvent and obtain branched polyisocyanate, performing hydrophilic chain-extending reaction in the presence of catalyst,adding sealing agent to seal end and protect, adding neutralizer for neutralization and salt-formation, using a small amount of visbreaking protective solvent for dilution to ensure the total mass content to be 50-70% and preparing the ionic room temperature hydrolysis capped polyisocyanate curing agent, wherein, the molar ratio of diisocyanate monomer to divalent alcohol and trivalent alcohol 1:0.1-0.4:0.01-0.20. The invention is a polyisocyanate curing agent with low viscosity, good dispersibility and dendritic molecular structure which can increase the mechanical properties, water resistance and adhesive force of waterborne polyurethane surface material in sport fields and meet the pavement demand of sport fields and venues.

Owner:广州市合工大实力新材料研究院有限公司 +1

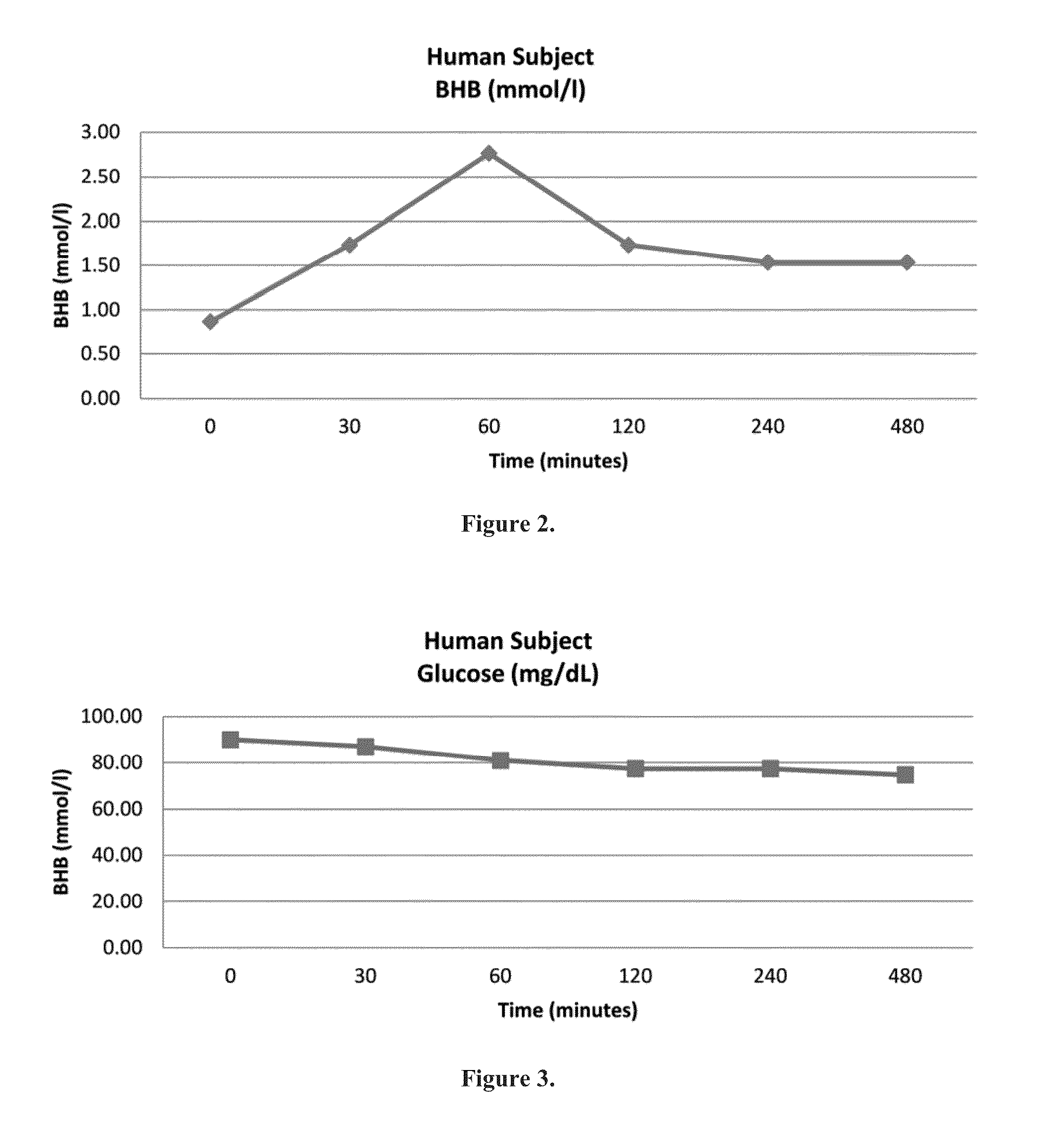

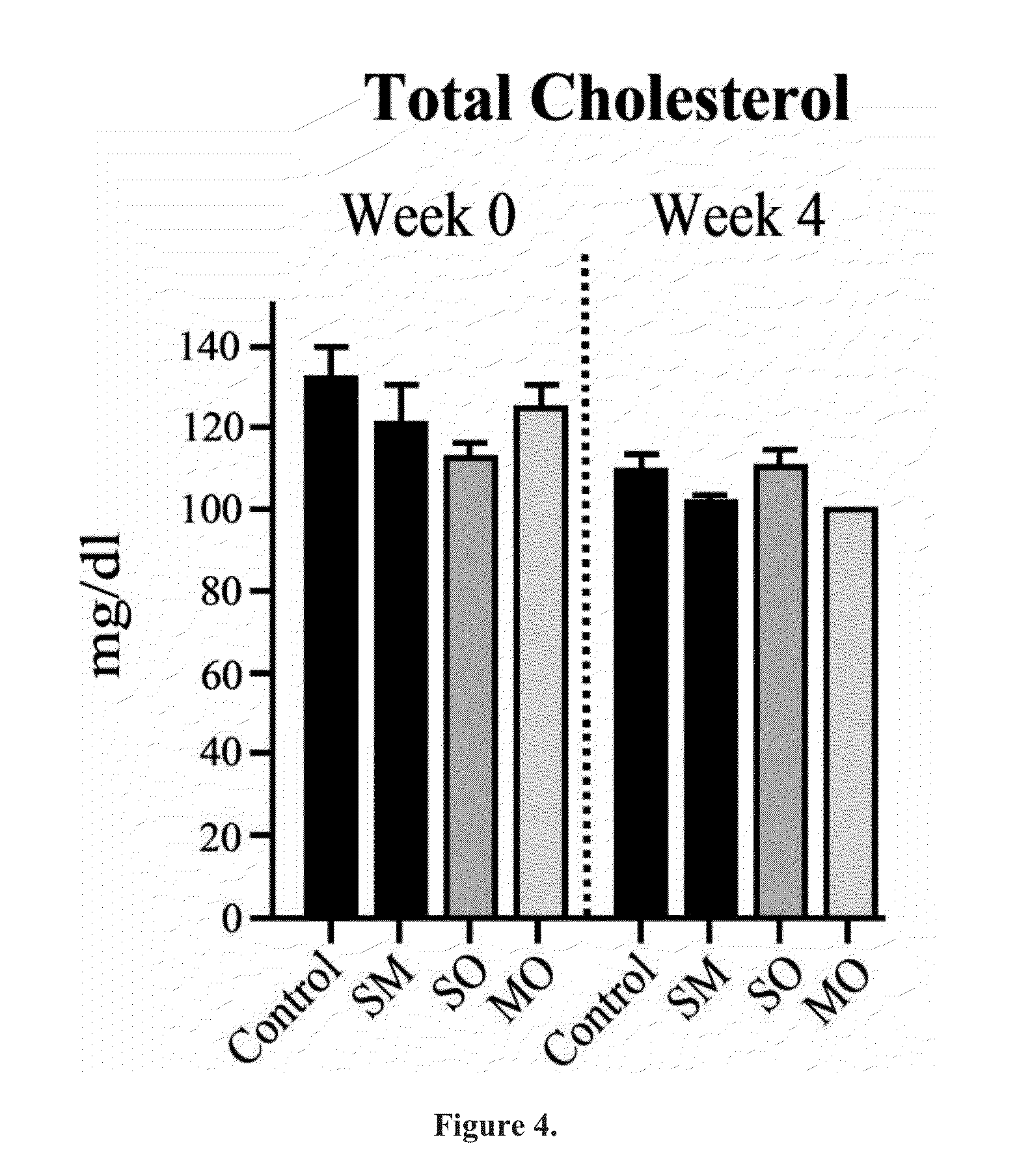

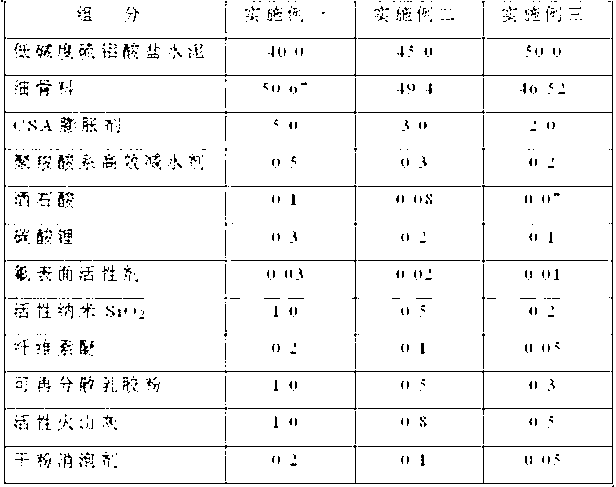

Compositions and methods for producing elevated and sustained ketosis

ActiveUS20140350105A1Rapid and sustained elevationImprove metabolic healthBiocideHydroxy compound active ingredientsKetoneSignificant elevation

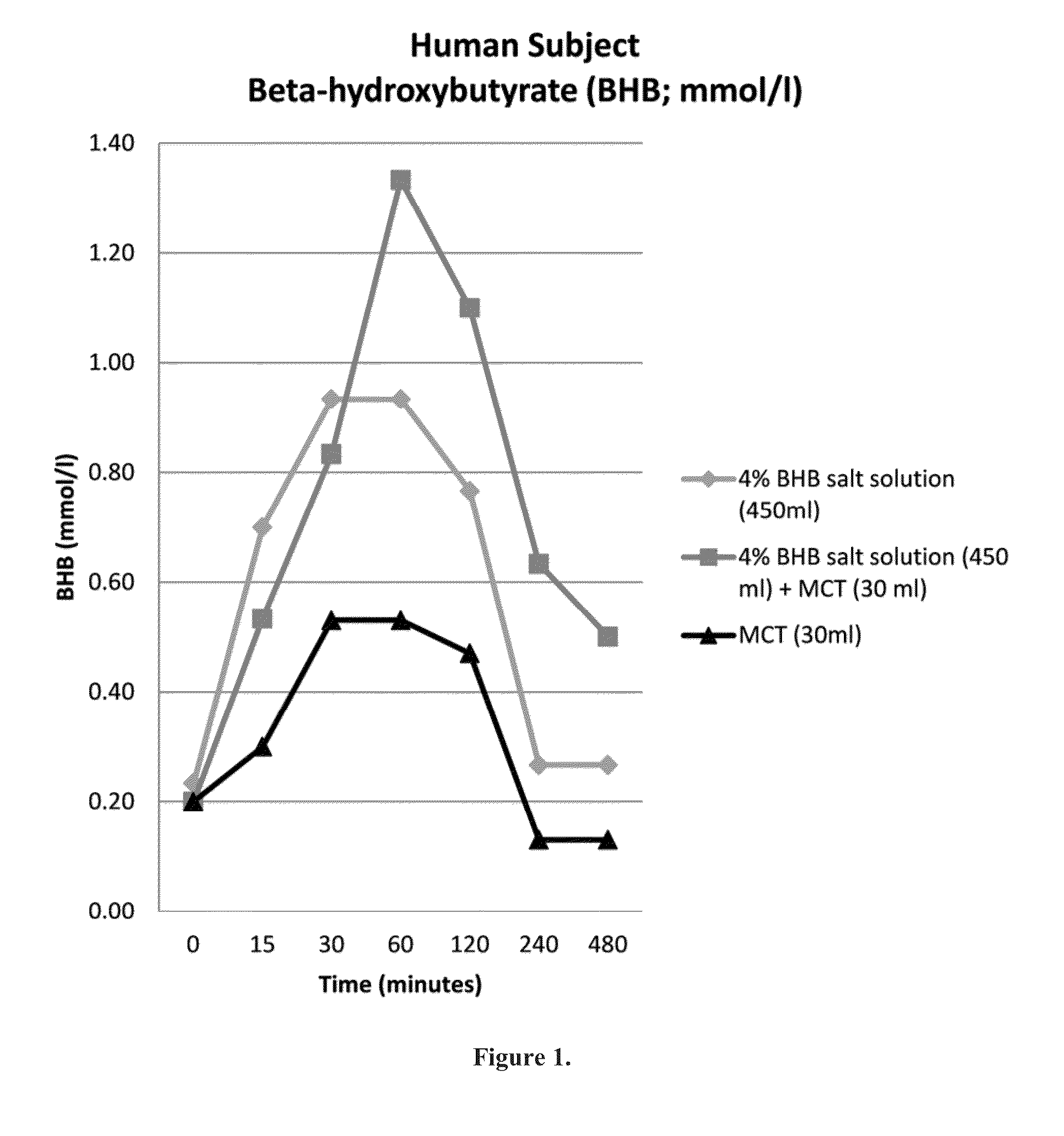

Beta-hydroxybutyrate mineral salts in combination with medium chain fatty acids or an ester thereof such as medium chain triglycerides were used to induce ketosis, achieving blood ketone levels of (2-7 mmol / L), with or without dietary restriction. The combination results in substantial improvements in metabolic biomarkers related to insulin resistance, diabetes, weight loss, and physical performance in a short period of time. Further, use of these supplements to achieve ketosis yields a significant elevation of blood ketones and reduction of blood glucose levels. Use of these substances does not adversely affect lipid profiles. By initiating rapid ketosis and accelerating the rate of ketoadaptation, this invention is useful for the avoidance of glucose withdrawal symptoms commonly experienced by individuals initiating a ketogenic diet, and minimizes the loss of lean body mass during dietary restriction.

Owner:UNIV OF SOUTH FLORIDA

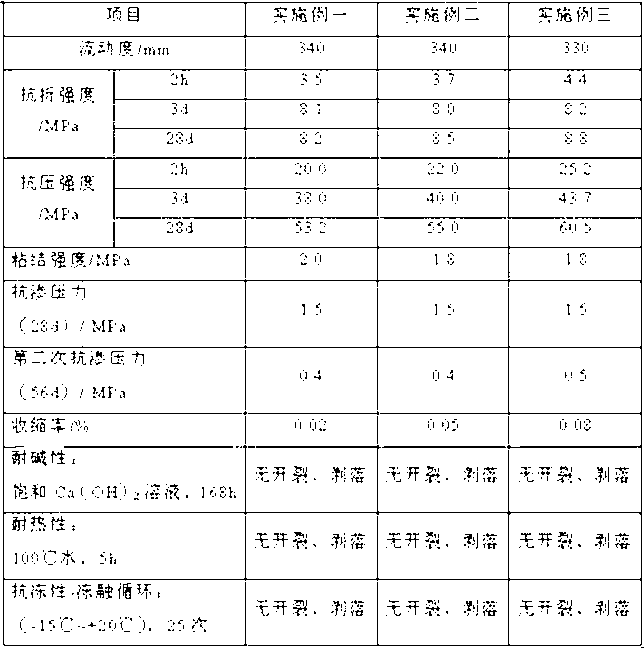

Concrete healant

The invention discloses concrete healant, which comprises following components by weight percent: 30 to 55 percent of gelatinization materials, 40 to 65 percent of fine aggregates, 0.1 to 0.5 percent of water reducing component, 0.05 to 0.5 percent of early-strengthening component, 0.05 to 0.2 percent of delayed-coagulation component, 0.2 to 1.0 percent of nano materials, 0.5 to 1.0 percent of high-activity substances, 0.01 to 0.2 percent of water retention thickening component, 0.2 to 2.0 percent of polymer and 0.02 to 0.2 percent of defoaming agent. The concrete healant not only has characteristics of good mobility, fast strength development, high adhesion strength and small retraction, but also can fill active substances into original concrete gaps and can produce compact crystals, so that the cohesion strength of the new and the old concrete interfaces can be remarkably improved, and the concrete healant is applicable to the concrete mending projects of bridges, caves, industrial workshops and civil construction.

Owner:苏州市姑苏新型建材有限公司

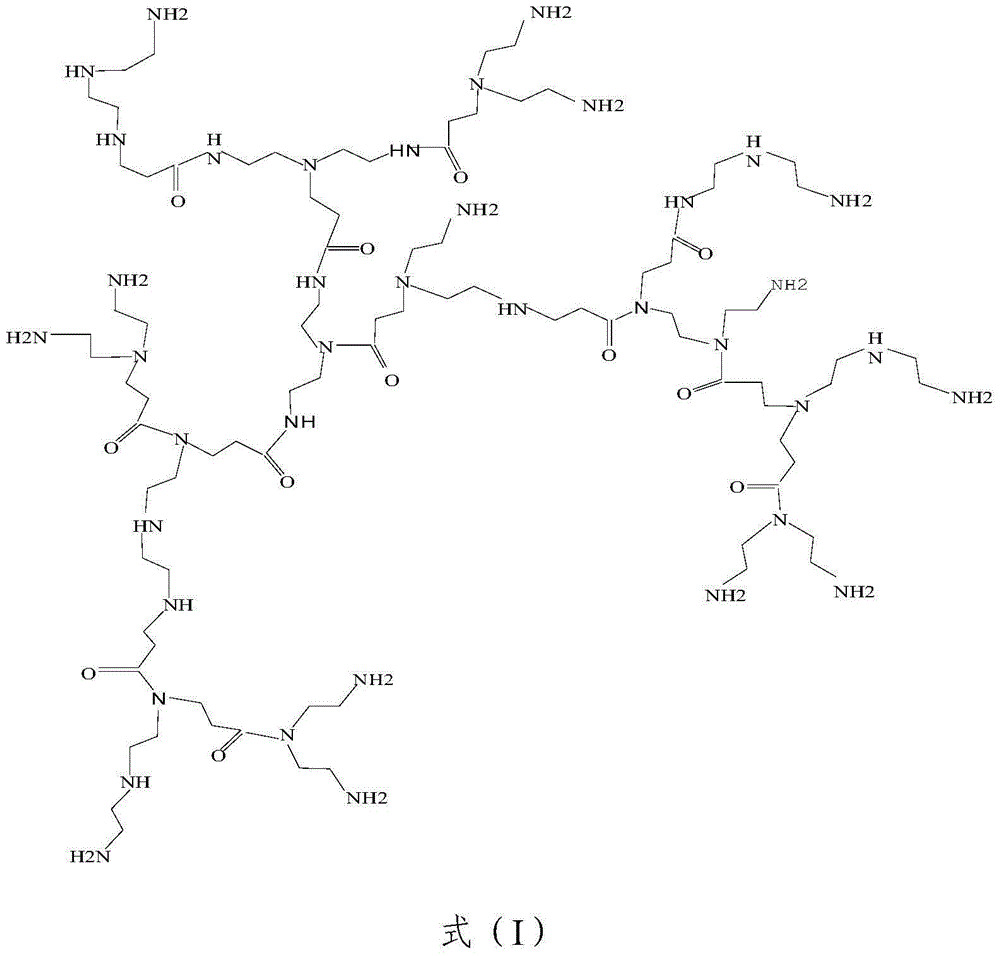

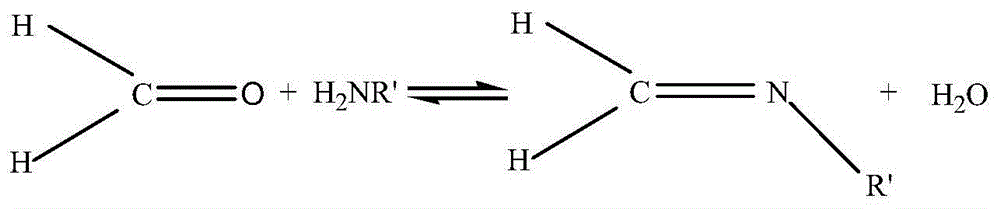

Formaldehyde catching agent and preparation method thereof

ActiveCN104645800ANon-volatileNo irritating smellDispersed particle separationPolyamine CompoundMethyl acrylate

The invention provides a formaldehyde catching agent. An efficient macromolecular type formaldehyde catching agent is synthesized by performing addition polycondensation reaction on a methyl acrylate monomer and a polyamine compound to generate an amino-group-enriched hyperbranched polymer and adding corresponding auxiliaries. According to the catching agent, formaldehyde is caught by using an amino group of the hyperbranched polymer and film forming fixing is implemented by using a carbon framework of an acrylate type substance; modification is realized by the corresponding various auxiliaries, so that the physical performance and the formaldehyde elimination effect are improved. The formaldehyde catching agent has the characteristics of no toxicity, no volatility and no irritating odor, and secondary harm to a human body is avoided; the formaldehyde catching agent can be limitlessly dissolved in water, is mild in property, free from corrosion, easy to add and spray, high in film forming property and durable.

Owner:BEIJING CENT FOR PHYSICAL & CHEM ANALYSIS

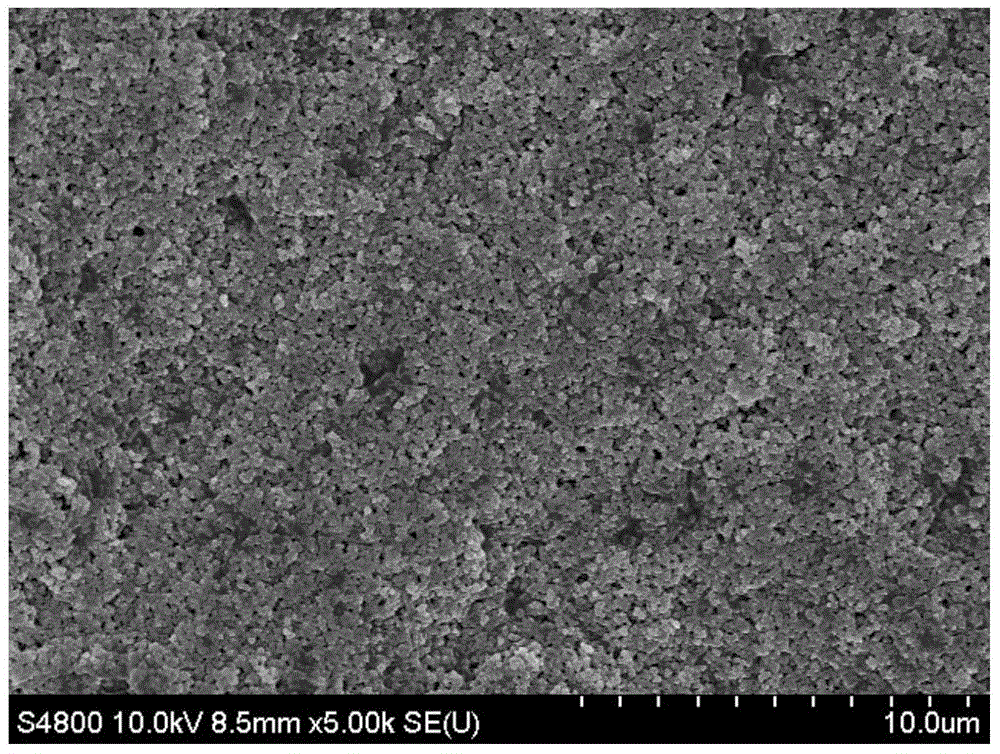

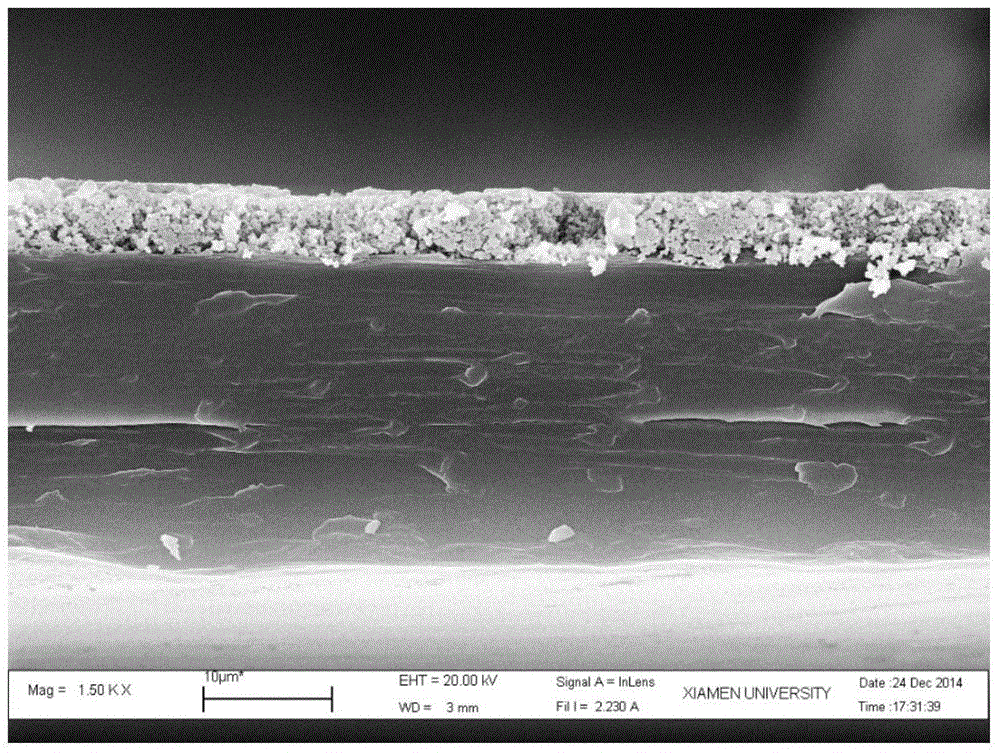

Dopamine-modifying ceramic composite separator and application thereof

ActiveCN105070868AImprove physical performanceImprove electrochemical performanceSecondary cellsCell component detailsLithiumCeramic composite

The invention discloses a dopamine-modifying ceramic composite separator and an application thereof. The dopamine-modifying ceramic composite separator comprises an organic separator base material and a ceramic layer arranged on the surface of the separator base material in a coated mode, wherein the thickness of the ceramic layer ranges from 0.1 micrometer to 20 micrometers. The dopamine-modifying ceramic composite separator further comprises dopamine polymers grown on the surfaces and the interiors of the separator base material and the ceramic layer in an in-situ mode. The dopamine polymers are copolymers of polydopamine or 5-hydroxy- polydopamine or polydopamine acrylamide and polydopamine acrylamide. The particle size of inorganic powder in the ceramic layer ranges from 5 nanometers to 10 micrometers. The molecular weight of materials of the organic separator base material ranges from 1,000 to 100,000,000. According to the dopamine-modifying ceramic composite separator, due to the dopamine polymers, potential safety hazards caused by powder falling and liquid leaking of the ceramic layer can be effectively reduced, and the physical performance and the electrochemical performance of the separator are effectively improved; meanwhile, due to the dopamine polymers, the stability of an interface between separator electrolysis and an electrode can be improved, lithium dendrites can be effectively suppressed through the improvement of the stability of the interface, and therefore the capacity holding capacity of a battery can be easily improved.

Owner:XIAMEN UNIV

High cold resistance polyvinyl chloride cable material and preparation method thereof

InactiveCN101260214AEasy to useExpand the usable rangeInsulated cablesInsulated conductorsPolyvinyl chlorideEngineering

The invention provides a polyvinyl chloride (PVC) cable material used in gelid state (minus 50 DEG C to minus 70 DEG C) and a preparation method of the cable material. During use, the cable material does not split and can be bent normally, thereby greatly increasing the application range of products. Moreover, the cable material is made from the following raw materials in portions by weight: PVC of 80 to 100 portions, dioctyl phthalate of 20 to 40 portions, dioctyl sebacate of 60 to 80 portions, dioctyl butane dicarboxylic acid of 4 to 8 portions, light activated calcium carbonate of 20 to 40 portions, lubricant of 1 to 3 portions , Ca-Zn composite stabilizer of 4 to 8 portions, antioxidant 1010 of 1 to 4 portions, frost resisting agent K175C of 0.5 to 5 portions and nitrile butadiene rubber of 20 to 50 portions.

Owner:WUXI DONGTIAN CABLE

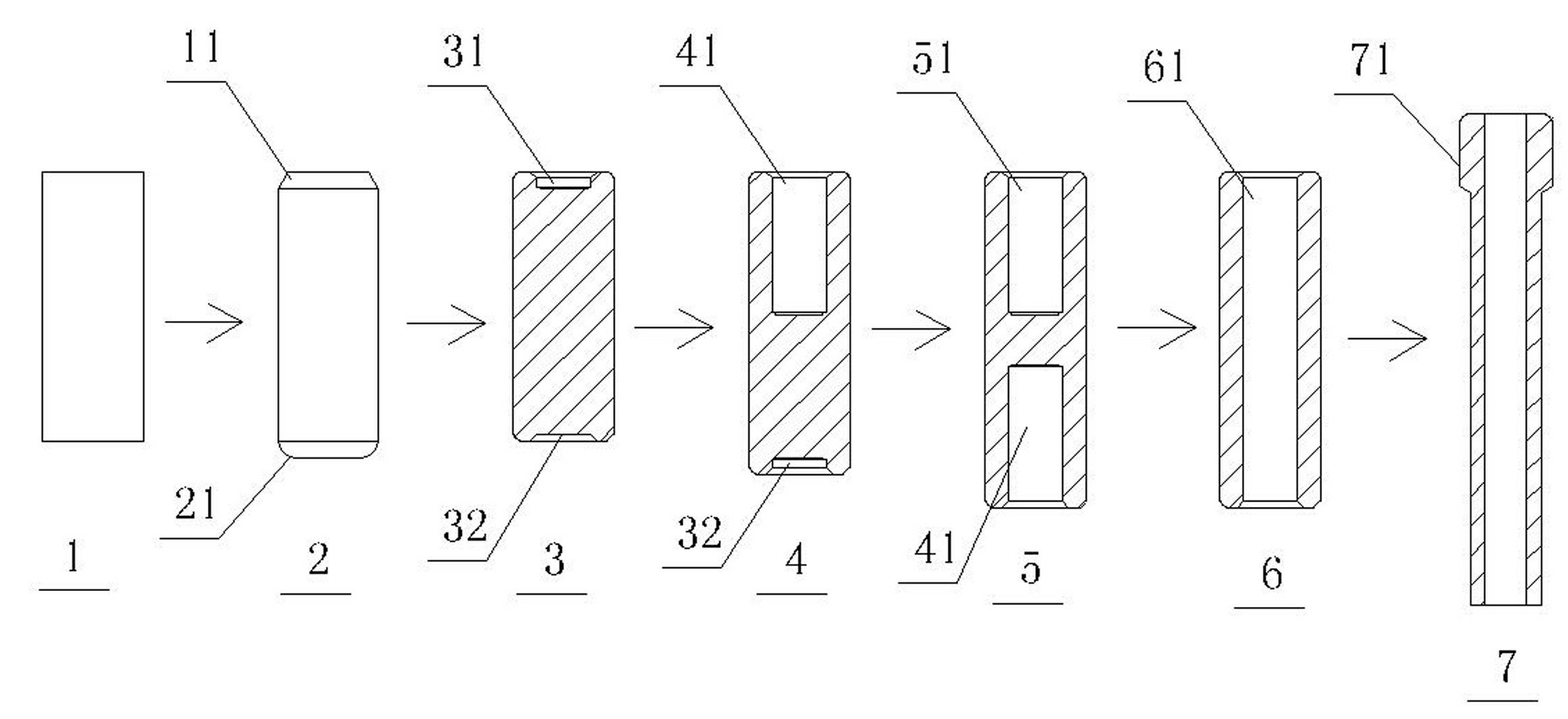

Process for manufacturing high-strength bolt

The invention provides a process for manufacturing a high-strength (above) bolt. The process comprises the following steps: selecting a proper steel material, and cutting out a cylindrical blank with proper size; molding the head part and the rod part of the bolt by adopting cold extrusion technology; heating; manufacturing the rod part, including coarse grinding and fine grinding; detecting injury by magnetic powder; manufacturing screw; and performing surface mechanical reinforcement and corrosion resistance treatment. The process solves the technical problems of insufficient strength and fatigue fracture which are easily generated on the bolt existing in the prior art for manufacturing the high-strength bolt, and is a high-strength bolt manufacturing process capable of improving tensile and fatigue strength resistance of the bolt.

Owner:浙江裕泰汽车配件有限公司

Heat insulation coating

InactiveCN101348639AImprove physical performanceGood weather resistanceReflecting/signal paintsLatex particleCordierite

The invention relates to thermal insulating paint which comprises the following compositions and contents in mass portion: 10.0 to 18.0 portions of water, 0.3 to 1.0 portion of wetting-dispersing agent, 0.3 to 1.0 portion of propanediol, 0.05 to 0.2 portion of a disinfecting agent, 0 to 5.0 portions of French chalk, 2.0 to 10.0 portions of titanium pigment, 1.0 to 5.0 portions of aciform cordierite powder, 5.0 to 15.0 portions of hollow glass bead, 0.1 to 0.2 portion of defoamer, 25.0 to 35.0 portions of modified acrylic acid latex, 0.15 to 0.3 portion of thickening agent, 0.15 to 0.3 portion of a flow agent and 0.1 to 1.0 portion of pH adjusting agent, wherein the modified acrylic acid latex is elastic acrylic acid latex by modifying fluorosilcone monomers and is provided with a core-shell structure and has the silicon fluoride distributed on the surface layer of latex particles. The thermal insulating paint is particularly suitable for forming a decorative surface layer in an external thermal insulating system of an external wall.

Owner:CHINA NAT OFFSHORE OIL CORP +2

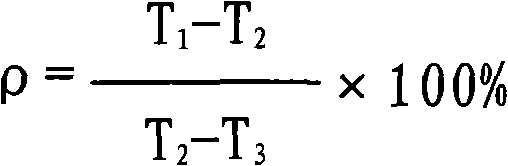

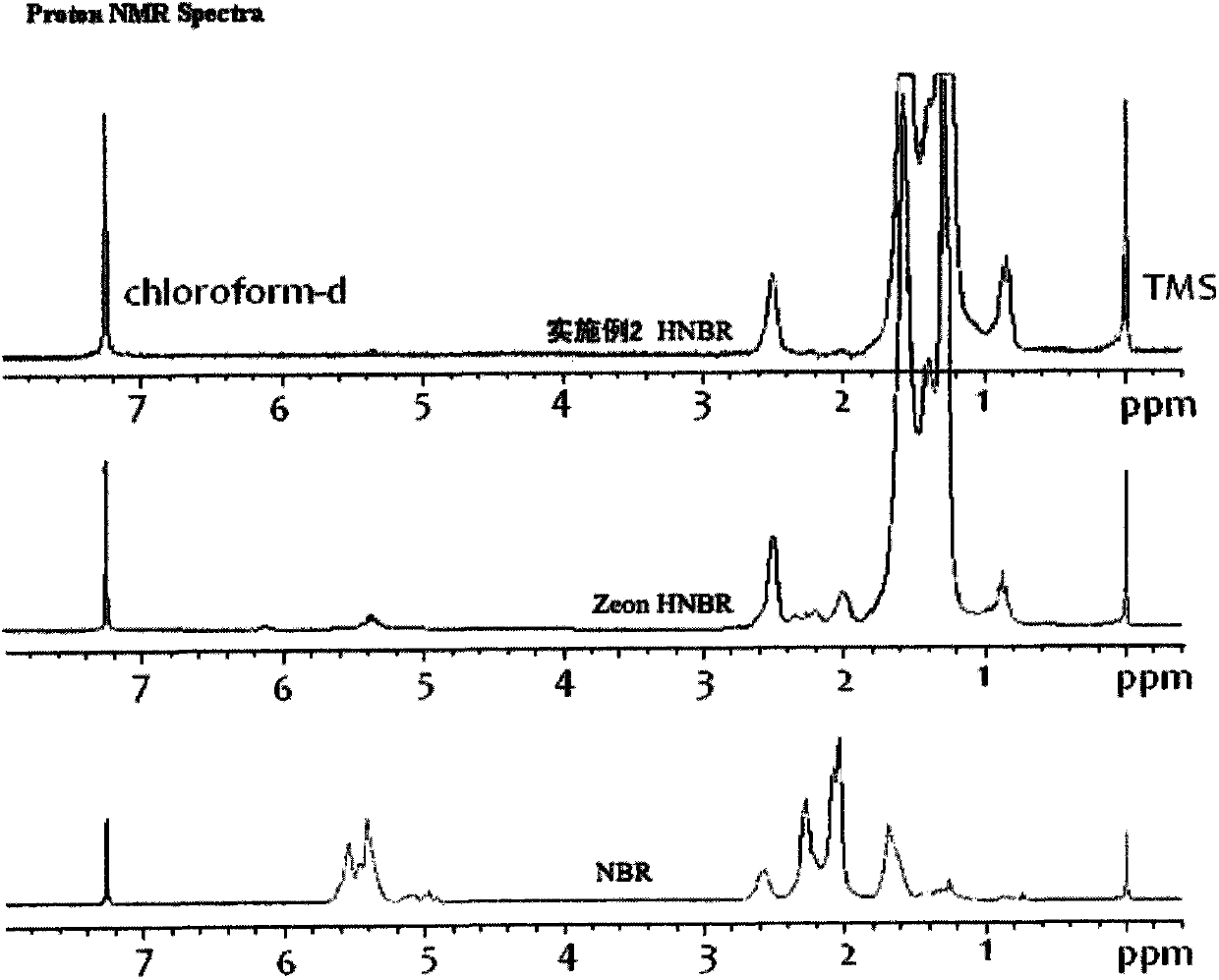

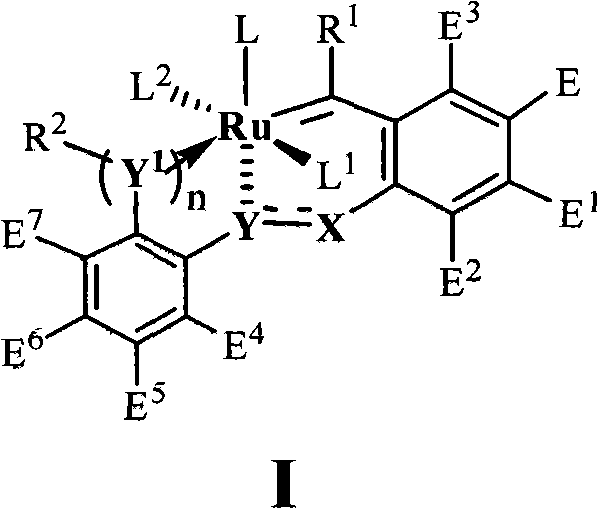

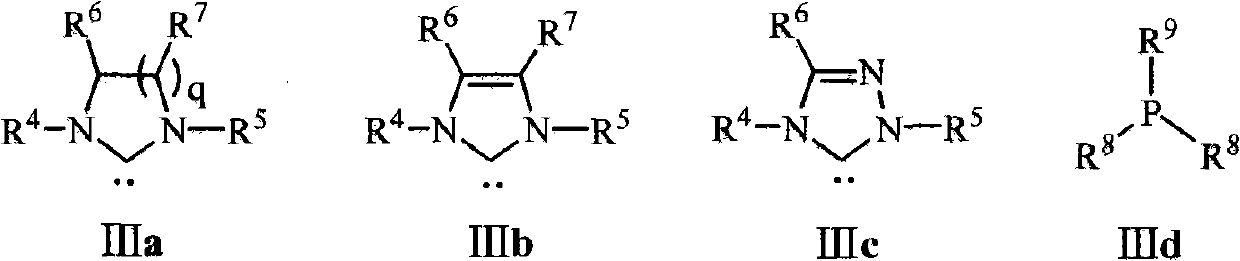

Preparation method of hydrogenated nitrile rubber and degradation and hydrogenation method of butadiene type rubber

The invention discloses a preparation method of hydrogenated butadiene special rubber, which comprises the following steps: subjecting butadiene rubber to a degradation reaction and a hydrogenation reaction under an action of a Zhan Catalyst as showed in the general formula I to obtain hydrogenated butadiene special rubber. The invention also provides a degradation reaction of the butadiene rubber, which is also under the action of a Zhan Catalyst as showed in the general formula I. The preparation method provided by the invention overcomes the shortcomings that the existing various types of catalysts can not be applicable to the preparation of low Mooney viscosity and high Mooney viscosity hydrogenated butadiene special rubber at the same time, so as to provide a preparation method of high-performance hydrogenated butadiene special rubber with a wide controllable Mooney viscosity range of 5-130. The catalyst used in the invention is the catalyst for both rubber degradation and hydrogenation reduction, so as to avoid a process requiring addition of the catalysts with different catalytic activities in two times respectively in the prior art. The method is simple, and easy to operate.

Owner:ZANNAN SCITECH

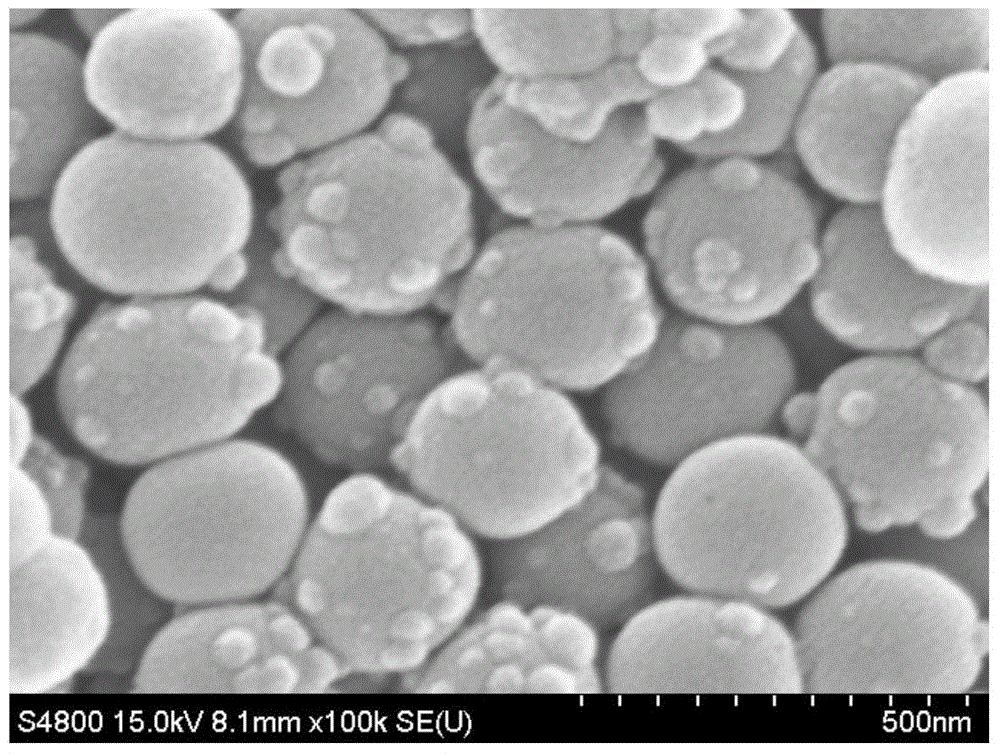

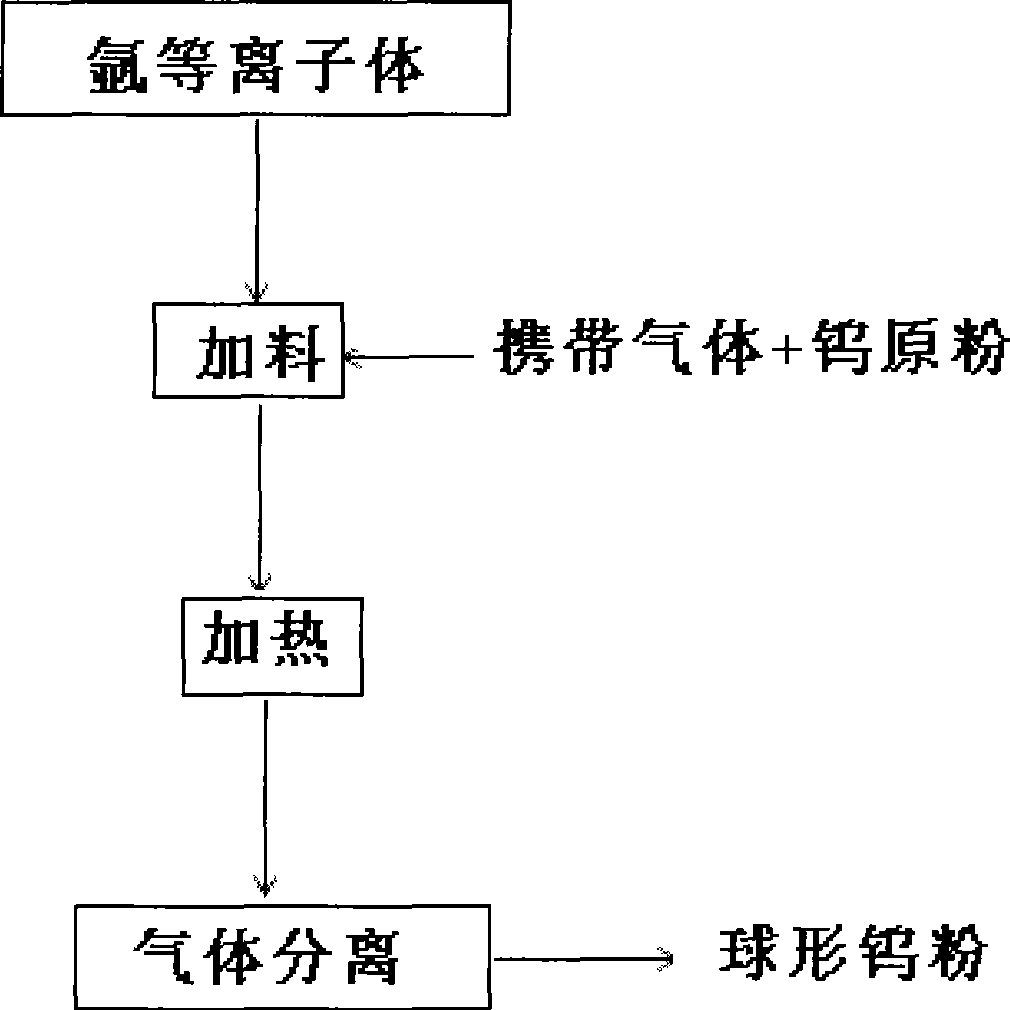

Preparation method of fine globular tungsten powder

The invention relates to a powder material preparation method, in particular to a method for preparing fine spherical tungsten powder. Plasma parameters are adjusted by building a stable argon plasma, thereby heating tungsten powder material and acquiring the fine spherical tungsten powder through the separation after cooling and solidification, and the obtained tungsten powder has better fluidity, higher density, purity and particle cleanliness of surface, and lower powder particle porosity compared with the tungsten original powder; and the method has advantages of changing shapes of tungsten powder particles, high sphericity, increasing the apparent density of powder, improving the tungsten powder fluidity and physical characteristics of the tungsten powder, and reducing costs.

Owner:SOUTHWESTERN INST OF PHYSICS

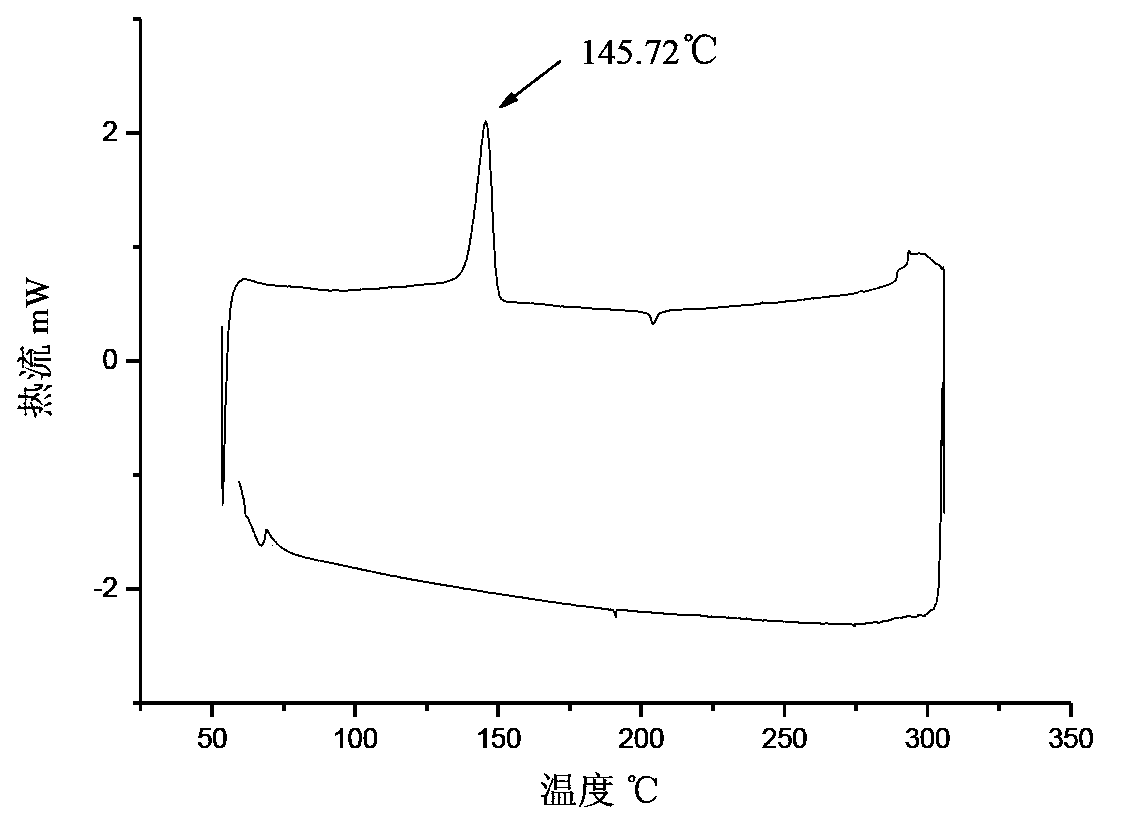

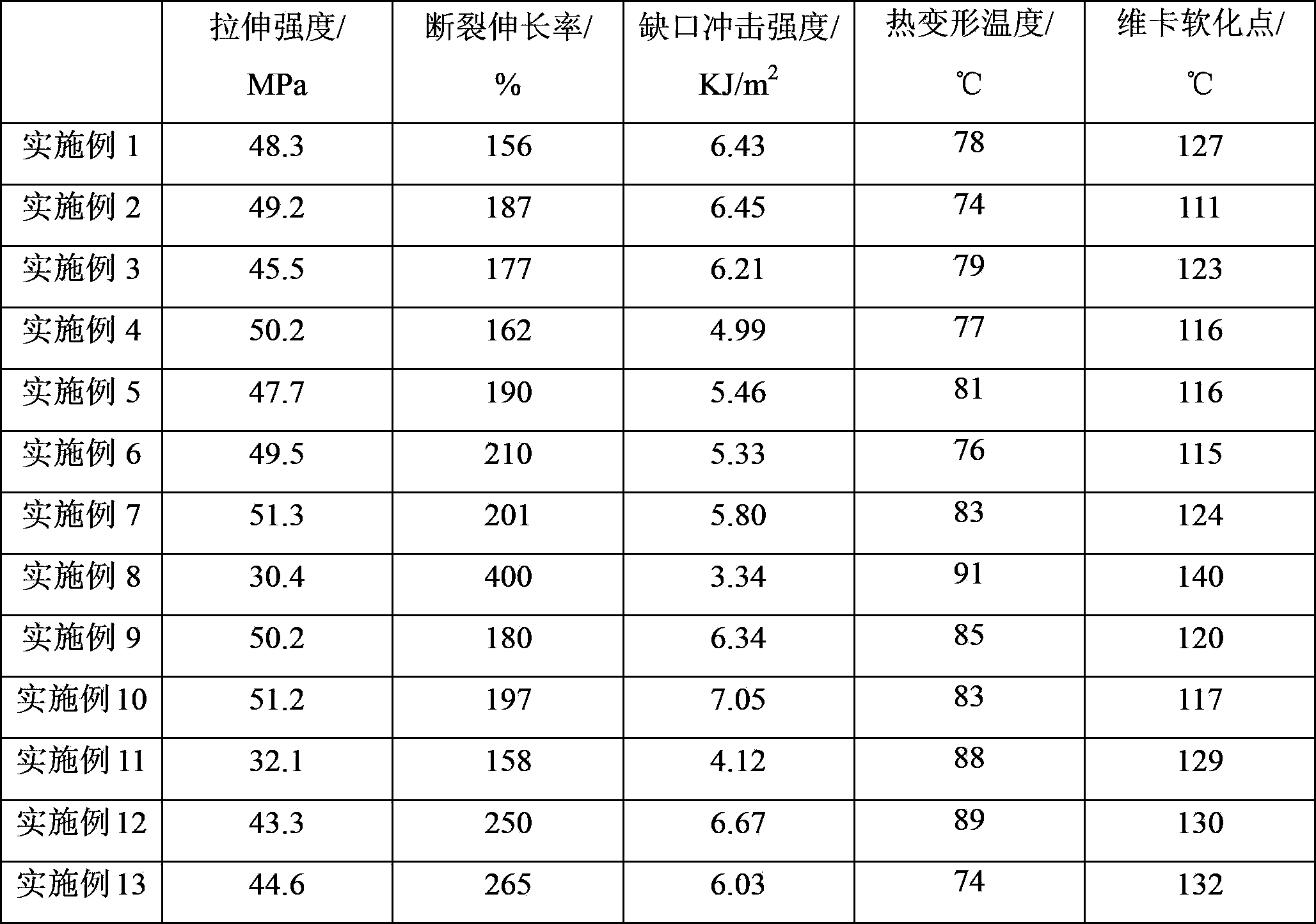

Novel heat-resistant high-toughness polylactic acid composite material and preparation method thereof

InactiveCN103819884AGuaranteed biodegradabilityExcellent mechanical properties and heat resistanceBiodegradable polyesterToughness

The invention belongs to the technical field of composite materials, and relates to a polylactic acid composite material and a preparation method thereof. The polylactic acid composite material is prepared from the following components in percentage by weight: 5 to 90 percent of polylactic acid, 5 to 80 percent of biodegradable polyester and 5 to 80 percent of heat-resistant master batch. The heat-resistant high-toughness polylactic acid composite material is obtained by continuous in-situ reaction extrusion. The composite material simultaneously has the characteristics of high toughness, high temperature resistance, low production cost, full biodegadability and the like.

Owner:SHANGHAI ZAIHE IND INVESTMENT CO LTD

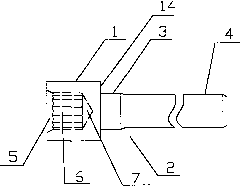

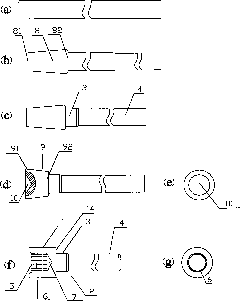

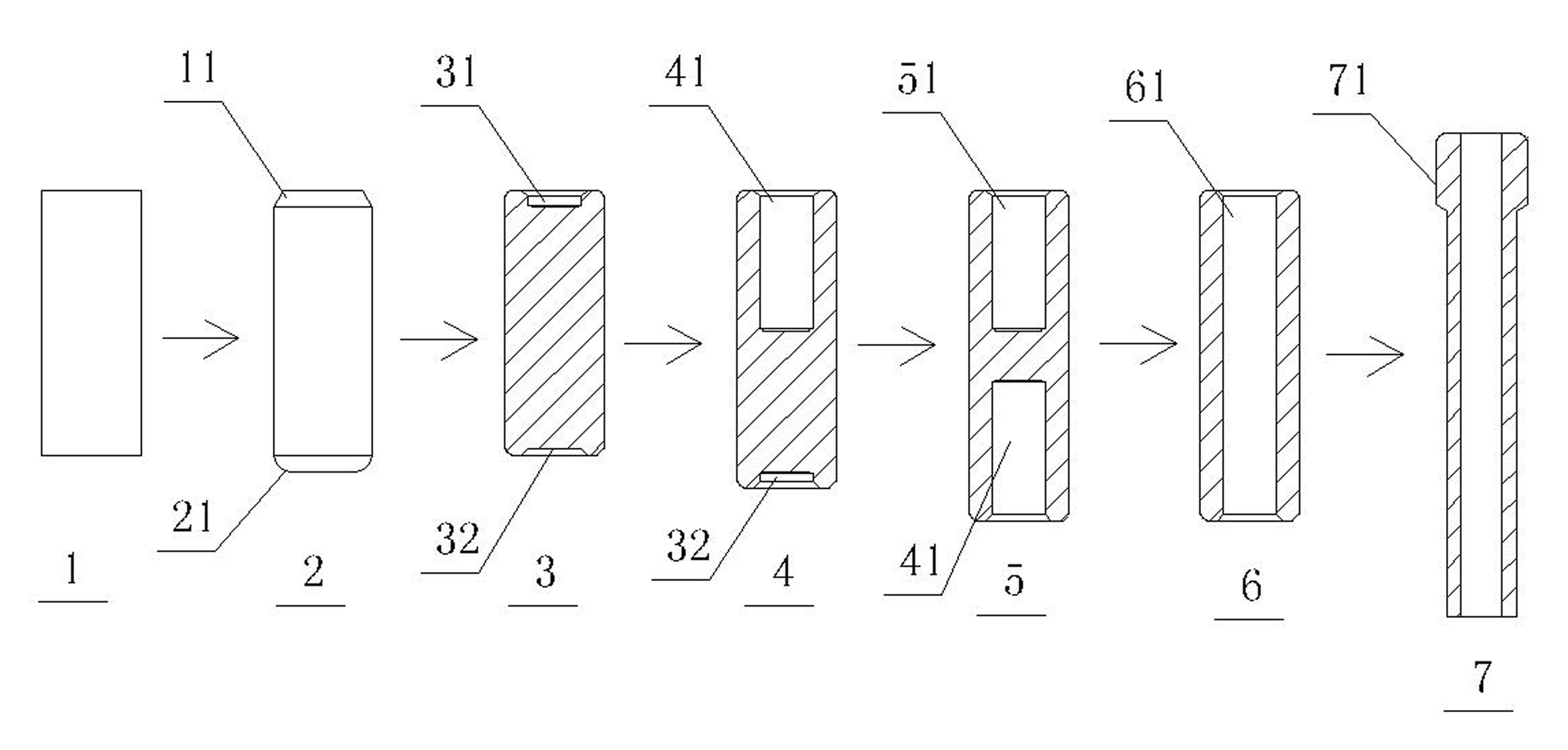

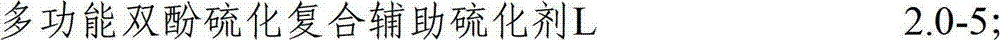

Method for manufacturing hose connector core

The invention provides a method for manufacturing a hose connector core, which comprises the following steps of: performing spheroidizing annealing on a wire rod blank material serving as a raw material; performing phosphate coating surface treatment on the wire rod blank material subjected to spheroidizing annealing; performing fine drawing sizing, and cutting a wire rod finished product material subjected to fine drawing sizing into single hose connector core blank materials; and manufacturing the blank of the hose connector core by using a seven-station cold heading method and a cold heading machine. The wire rod material is used for replacing a straight bar material and a broken material, so that the requirement of multi-station cold heading continuous production can be met, and the loss of a material head and a material tail is reduced; stations are reasonably designed, so that the physical property and the quality of a product are improved, and the product has good surface appearance; a material part is easily subjected to plastic deformation in the cold extrusion process, and the loss of a die is low; and finish machining production speed is doubled.

Owner:YUYAO HANGYI AUTOMOBILE PARTS

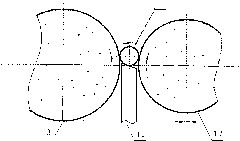

Agglutination type composite permanent magnetic material of neodymium, iron, boron and iron base soft magnetic powder and its preparing method

InactiveCN1431666ALow costImprove corrosion resistanceInorganic material magnetismMagnetic powderBall mill

The compoiste permanent mangetic material is composed of the mixed powder of neodymium, iron, boron and the iron base soft magnetic powder as wellas the macromolecule aggloomerant. The formula (weight percent) of the mixed powder and the macromolecule agglomerant are: the mixed powder 95%-98.5%, the macromolecule agglomerant 1.5%-5%. The formula (weight percent) of the mixed powder of neodymium, iron, boron and the iron base soft magentic powder are: neodymium, iron and boron magentic powder 10%-90%, the iron base soft magnetic powder 10%-90%. The manufacturing procedures are as follows. (1) Preparing the iron base soft magnetic powder: melting the iron base material, casting to ingots, quenching and crystallizing, finally ball milling in argon gas atmosphere. (2) Preparing the composite permanent magnetic material: cadding processing by silicane.

Owner:SICHUAN UNIV

Environment-friendly craft furniture processing method

ActiveCN103204029AAchieve softeningImprove anti-agingDecorative surface effectsWood treatment detailsCarbonizationProcess engineering

The invention discloses an environment-friendly craft furniture processing method. By processing trunks, branches and roots with conditioning fluid, softening, disinfecting and sterilizing of raw materials are realized and anti-ageing and physical performances of the raw materials are improved. By the processing method, utilization rate of the raw materials can be increased by 8-12%, and by high-temperature carbonization, disinfection and prevention of molding and being damaged by worms can be further realized.

Owner:六安皖智知识产权运营有限公司

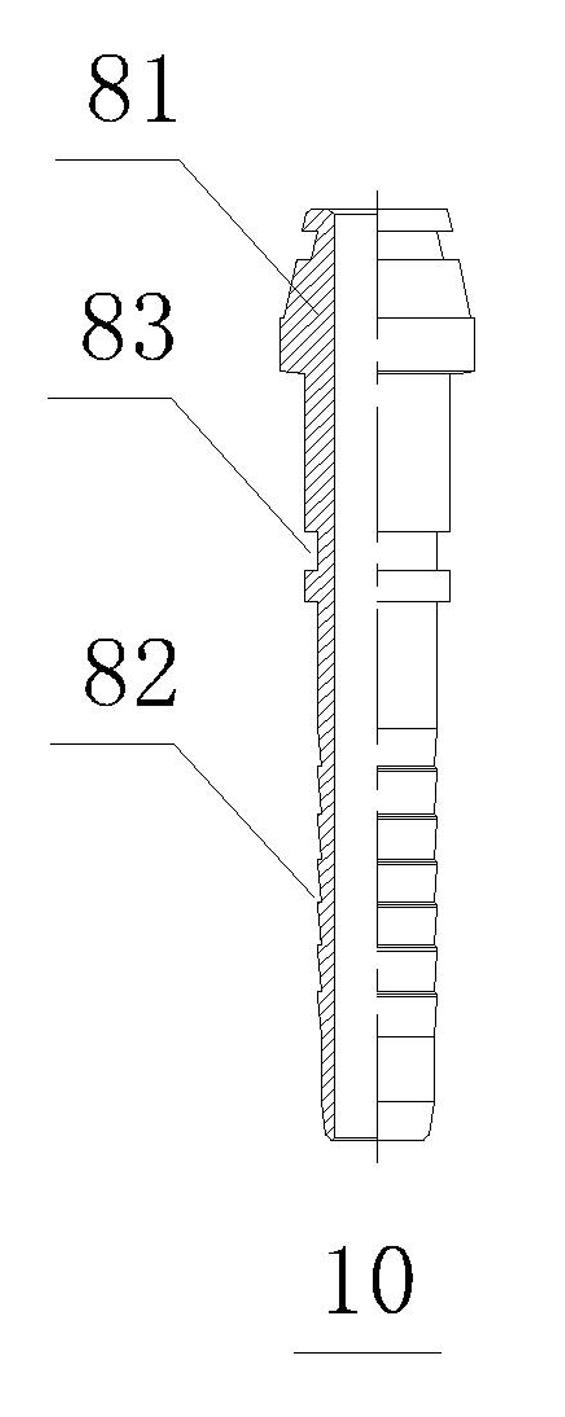

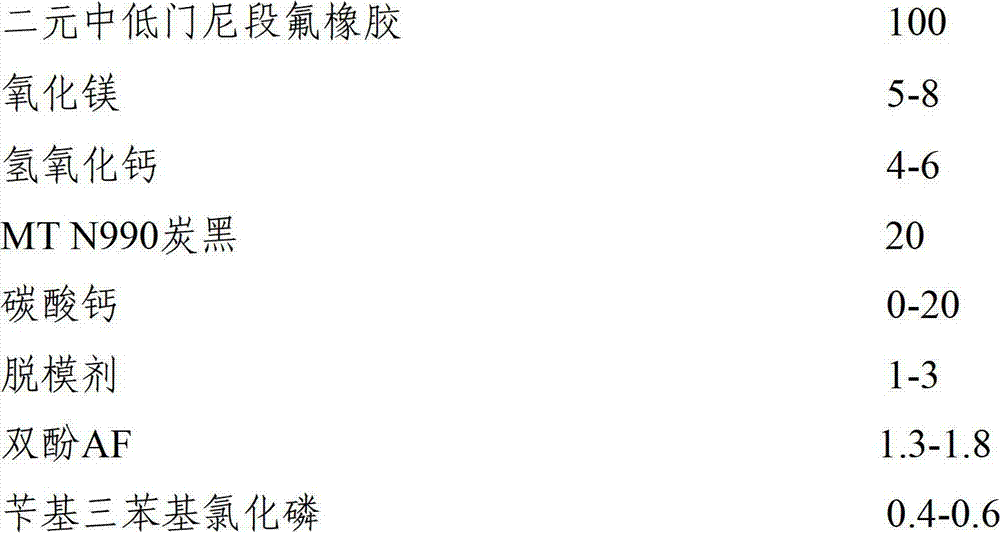

Fluororubber rubber compound and preparation method thereof

The invention provides a fluororubber rubber compound and a preparation method thereof. The fluororubber rubber compound is prepared by mixing binary intermediate-low monney sectional fluororubber rubber, reinforcing system (MT N990 carbon black and inorganic filler), acid absorbing system (active magnesium oxide and superfine calcium hydroxide), vulcanizing system (benzyl triphenyl phosphorus chloride and bisphenol AF), releasing agent (alfux and / or carnauba wax), and multifunctional bisphenol vulcanizing composite assistant vulcanizing agent L; the obtained fluororubber rubber compound has high stretching strength, and high extending rate, increases the scorching time by improving the liquidity of the rubber, therefore, high adaptability of the rubber to different manufacture technical environments and the vulcanizing environments can be ensured, the safety in vulcanizing can be improved, and as a result, the rejection rate of the products can be reduced. The fluororubber rubber compound provided by the invention is applicable to industries such as aerospace, aviation, car, metallurgy, petrochemical industry and electron and the like.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

Fabrication process for fully hand-made leather slippers

InactiveCN102150970AImprove aestheticsImprove physical performanceShoemaking devicesCoatingManufacturing engineering

The invention discloses a fabrication process for fully hand-made leather slippers. The leather slippers fabricated by the process are durable, artistic, soft, comfortable, air permeable and have good effect of relieving foot stress. The fabrication process is characterized in that the fabrication process comprises the following steps: fabrication of upper sleeves, which adopts the method of scribing first and then cutting; splitting and leveling process: the process can be completed mechanically and manually, in order to further ensure the quality of sheet stock; edging: component edges are trimmed into slope shape according to specification requirements; upper making: positioning dot lines are drawn, and the processing and the assembling of upper surface components are required to be performed according to specific standards and regulations; brush coating; edge making: brush coating is performed to sheared upper components, and the margins of the upper surface components are folded inward, cohered and flattened according to templates; edge trimming; splicing or lapping: all the components are assembled together through splicing; internal liner implantation: the shape of the internal liner is formed according to the shape of the sole of a person; sewing; and vamp decoration.

Owner:李照洪

Design and manufacturing method of porous grid structure material

InactiveCN105499575AManufacturing flexibilityImprove performance qualityAdditive manufacturing apparatusTissue regenerationLaser scanningSize ratio

The invention discloses a design and manufacturing method of a porous grid structure material and aims to solve the problems of blindness and uncertainty in traditional manufacturing of a porous material and apply an effective design concept for the porous material to practical manufacturing. The design and manufacturing method comprises the following steps: obtaining a data image based on topological optimization simulation; performing three-dimensional rebuilding on the data image on Solid Works; importing to magics software as a unit grid structure; filling into various three-dimensional models of specific parts which need to adopt the grid structure at any size ratio; afterwards manufacturing the parts. According to the design and manufacturing method, firstly, the three-dimensional model of each part is imported to a computer on a worktable; the printing angle and the printing position are set according to the three-dimensional graph structure; a powder layer is sintered into a corresponding two-dimensional shape on the layer; powder with the same thickness is repeatedly laid on the worktable on which one layer of graph is sintered; laser scanning is still performed according to the scanning route of the layer until the overall three-dimensional graph is completed. The design and manufacturing method disclosed by the invention has the advantages of reducing the elasticity modulus of the part and realizing good mechanical properties.

Owner:BEIJING UNIV OF TECH

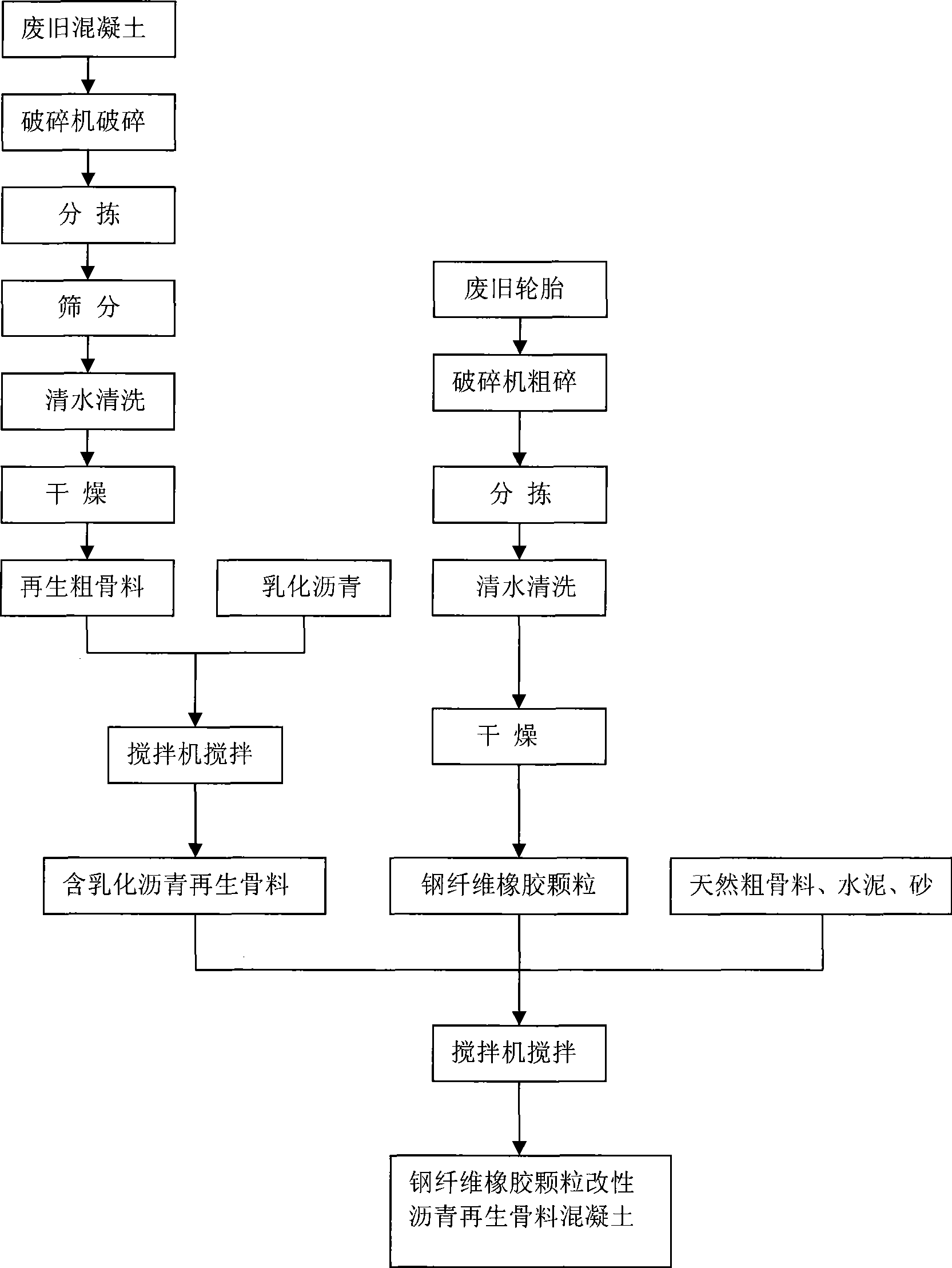

Method for regenerating aggregate concrete from steel fibre rubber granule modified asphalt

InactiveCN101381216AHigh dampingIncrease frictionSolid waste managementCrack resistanceEnergy absorption

The invention discloses a method for preparing steel fiber rubber particle modified asphalt recycled aggregate concrete. In the method, waste concrete is subjected to crushing, separating, screening, washing and drying to obtain the recycled aggregate, and the recycled aggregate is stirred with emulsified asphalt until the emulsified asphalt is covered on the surface of the recycled aggregate; waste tire is subjected to coarse crushing, separating, washing and drying to obtain the steel fiber rubber particle; and the recycled aggregate containing the emulsified asphalt, steel fiber rubber particles, natural aggregate, cement, sand and water are stirred according to certain ratio to obtain the steel fiber rubber particle modified asphalt recycled aggregate concrete. In the invention, the waste tire is subjected to crushing process to produce the steel fiber rubber, and the crack resistance, the heat preservation capability and the energy absorption and noise reduction capability of the asphalt recycled aggregate concrete are effectively improved by the modification of the steel fiber rubber; and the material is a circular economy building material, and by producing the material, the environmental pollution is reduced, and the performance of the material can be improved under the condition of not increasing cost.

Owner:GUANGDONG UNIV OF TECH

Method for preparing iron-free aluminium sulfate and superfine active carbon white utilizing aluminium first-class ore

InactiveCN1850607AConcentration easyDo not reduce the concentrationSilicaAluminium sulfatesSurface-active agentsActive particles

The invention discloses a method for preparing iron-free aluminum sulfate and superfine active white carbon black with bauxite, crushing the bauxite and removing dissociative iron source by magnetic separation, and then reacting with vitriol; adding in dithiocarbamate with medium and high molecular weights and multiple functionalities to remove iron ions by solid phase reaction, and filtering, where the filtrate is iron-free aluminum sulfate; washing filter residue with alkaline water solution, surface active agent water solution, and tap water, respectively, to neutralize it, then after reacting with alkali, filtering, making filtrate, inorganic acid and active particles react mutually, filtering, water-washing, and drying to obtain the superfine active white carbon black. And the method has simple process, and low cost, applied to industrialized production, where the iron content of the prepared aluminum sulfate is less than 15 ppm, and the grain size, specific surface area, tensile strength, added value of the superfine white carbon black are 0.5-5 mum, greater than 200 m2 / g, higher than 17.0 MPa, and high, respectively.

Owner:杭州百事特实业股份有限公司

Low smoke non-halogen one-stage process silane naturally crosslinked polyolefin cable material and preparation method thereof

ActiveCN102093625AReliable Extrusion PerformanceReliable degree of cross-linkingInsulated cablesInsulated conductorsMasterbatchLow smoke zero halogen

The invention relates to a low smoke non-halogen one-stage process silane naturally crosslinked polyolefin cable material and the cable material contains the raw materials of flame retardant masterbatch, catalyst masterbatch and crosslinking compounding agent. The preparation method comprises the following steps: mixing flame retardant masterbatch, catalyst masterbatch and crosslinking compounding agent in a sealed mixer for absorption, discharging after 3-5 hours, and packaging to obtain the low smoke non-halogen one-stage process silane naturally crosslinked polyolefin cable material finished product. Compared with the common low smoke non-halogen one-stage process silane naturally crosslinked polyolefin cable material, the temperature resistant grade and mechanical properties of the product of the invention can be increased and the problem that the common low smoke non-halogen polyolefin cable material is easy to crack can be eliminated.

Owner:中广核三角洲(江苏)塑化有限公司

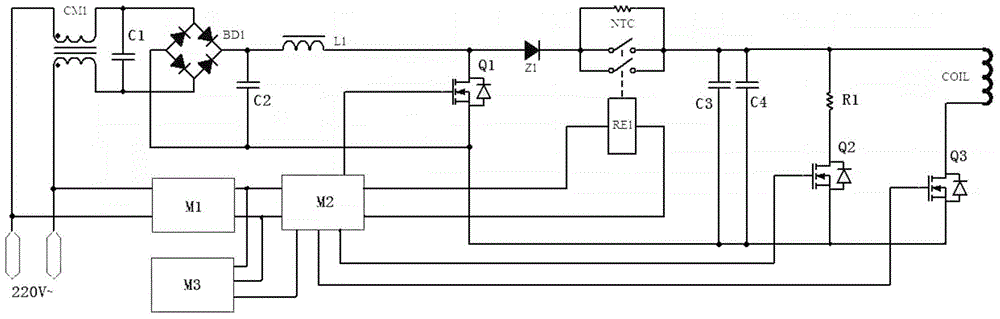

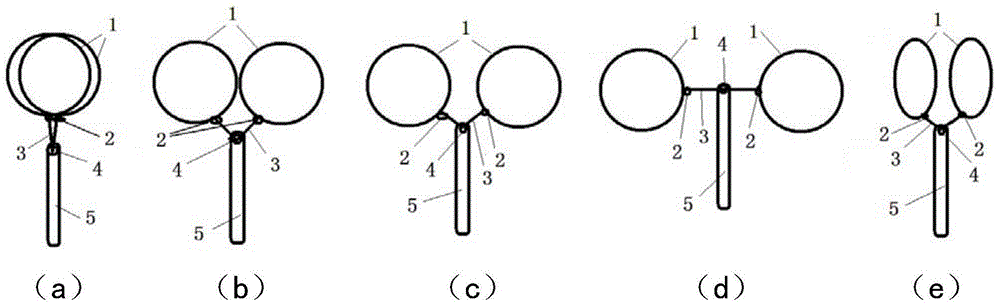

Magnetic device capable of performing facial beautifying and wrinkle removing on human body and beautifying method thereof

ActiveCN106540375AImprove securityImprove hygieneElectrotherapyMagnetotherapy using coils/electromagnetsWrinkle skinPower factor

The invention relates to a magnetic device capable of performing facial beautifying and wrinkle removing on a human body and a beautifying method thereof. The magnetic device is composed of an AC filtering circuit, a rectifying and DC filtering circuit, a power factor adjusting and boosting circuit, a startup slow starting circuit, a high-voltage energy storage circuit, an energy-storage capacitor discharging circuit, a safety protection discharging circuit, an auxiliary power supply module, a computer control module and an adjustment display module. The beautifying method comprises the steps that a central part of an inductance coil is placed at the part which needs to be beautified, the inductance coil keeps a small distance away from the skin or is slightly contacted with the skin, or a piece of soft tissue paper is arranged between the inductance coil and the part to be beautified; the output frequency of the inductance coil is controlled to be between 30Hz and 300Hz by the computer control module; the output magnetic intensity of the inductance coil is controlled and adjusted by the computer control module so as to set the stimulation intensity which gives rise to contraction of subcutaneous muscles; the action time is set to be between 0.4s and 3.0s, the interval time is 1.0s-3.0s, the beautifying time is 15-30min for one time, beautifying is performed once a day, and 10 times form a course of treatment.

Owner:湖南华医电磁医学研究院有限公司

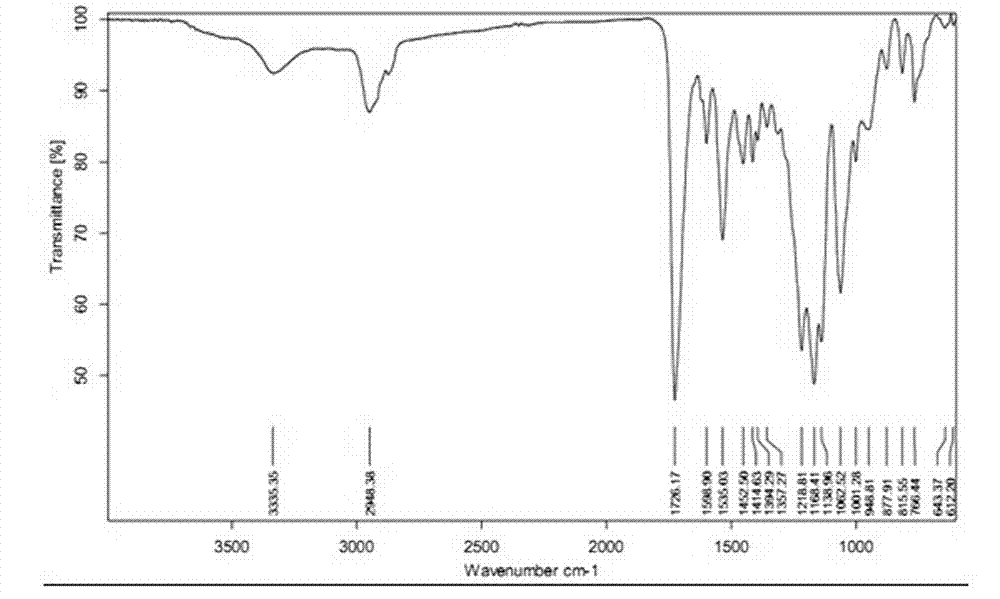

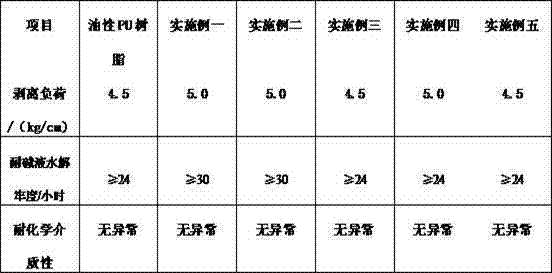

Method for preparing solvent-free waterborne polyurethane resin for synthesizing leather bonding layer

ActiveCN103937435AImprove physical performanceHigh bonding strengthPolyureas/polyurethane adhesivesSolventChemistry

The invention discloses a method for preparing a solvent-free waterborne polyurethane resin for synthesizing a leather bonding layer. The solvent-free waterborne polyurethane resin is prepared by adopting the steps of polymerization, emulsion and compounding. The method has the beneficial effects that no organic solvent is used in the preparation process, but water is used as a dispersion medium completely, so that the production is clean, the environmental pollution is reduced, the environmental-friendliness effect is good, and the production cost is lowered; through later chain extension stabilized by using ketimine, the bonding firmness and the toughness of the waterborne polyurethane resin are improved, and moreover due to addition of the additives such as a cross-linking agent, a leveling agent and a thickening agent in the compounding process, the leveling effect of a product is improved, the cross-linking curing degree is further improved, the product is more excellent in wearing resistance, solvent resistance and water resistance, good in bonding firmness, good in use effect and beneficial for popularization.

Owner:ZHEJIANG NAIHE IND

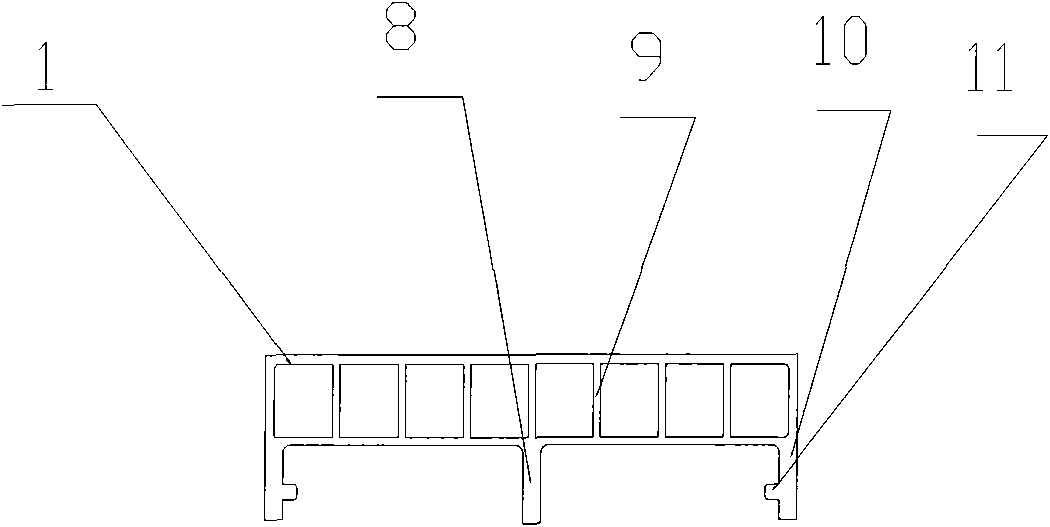

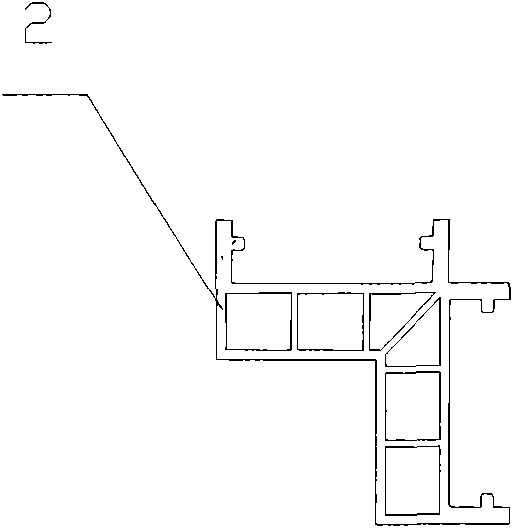

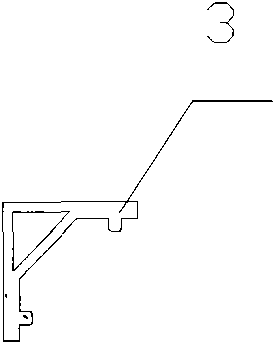

Plastic exposed concrete building template

InactiveCN101852012AEasy to cleanEasy maintenanceForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksFloor slabCross connection

The invention relates to a building template, in particular to a plastic exposed concrete building template. A connection structure of 90-degree corner is realized, quadrate, plane and cross connections of a beam and a pillar in any size are realized, and the connection strength is improved. The template comprises a beam column template (1), two types of internal corners, two types of external corners, and two types of connecting pieces, wherein the beam column template (1), the two types of internal corners, and the two types of external corners are provided with reinforcing bulges with connected bulge structures; when the beam column template (1) is connected with the internal corners or the external corners, the connection bulges of connected pieces are inserted into grooves (15) of the connecting piece I (6) and the connecting piece II (7) respectively, and fastened by a bolt (12) and a nut (16). The concrete building template is applied to the buildings of a stand column, a shear wall and a floor slab.

Owner:山西惠丰型材有限公司

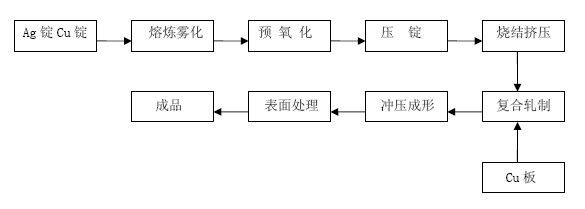

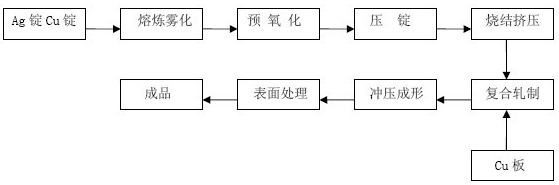

Silver copper oxide/copper composite electrical contact material and preparation process thereof

ActiveCN102054598AGuaranteed uniformityGrain refinementContactsMetal rolling arrangementsCopper oxideHigh pressure water

The invention discloses a silver copper oxide / copper composite electrical contact material and a preparation process thereof. The process comprises the following steps: mixing silver and copper according to certain proportions, and then, smelting the mixture in an intermediate frequency furnace; then, carrying out alloy atomization by using high pressure water atomizing equipment; baking after atomization to obtain powder; screening; putting the screened powder into an internal oxidization furnace for oxidizing at certain temperature and oxygen pressure; carrying out isostatic cool pressing after oxidization to form a billet; sintering and extruding to form a plate; and then, carrying out composite rolling with copper to obtain a finished product. Because the formula and process disclosed by the invention are reasonable, the produced electrical contact has the characteristics of high conductivity, uniform and fine tissue, high bonding strength between a working layer and a welding layer, fusion welding resistance, electrical arc erosion resistance and the like.

Owner:WENZHOU LONGSUN ELECTRICAL ALLOY CO LTD

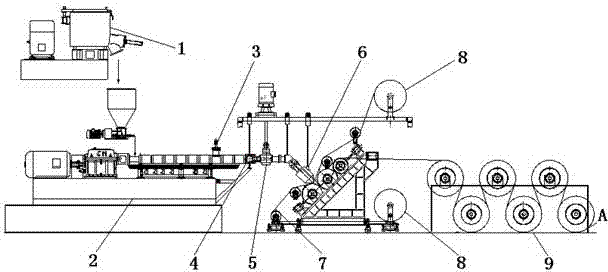

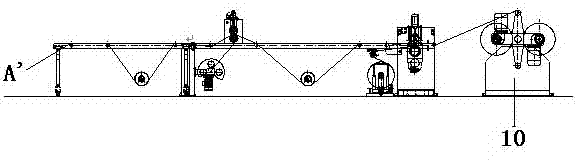

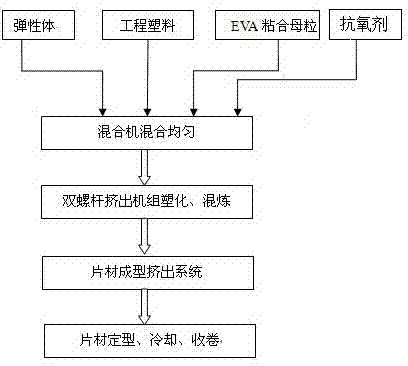

Shoe material hot-melt adhesive sheet and production process and equipment thereof

ActiveCN103613919AImprove physical performanceGood resilienceInsolesFlat articlesAntioxidantHot pressing

The invention discloses a shoe material hot-melt adhesive sheet. The shoe material hot-melt adhesive sheet comprises the following raw material components: 35-40% of elastomer, 45-50% of engineering plastic, 10-15% of EVA (ethylene vinyl acetate) binding masterbatch and 0.5-1.5% of antioxidant. A production process of the shoe material hot-melt adhesive sheet provided by the invention comprises the steps of mixing the elastomer, the EVA binder masterbatch, the engineering plastic and the antioxidant in a twin-screw extruder, pressurizing a melt by a melt pump, then enabling the melt to flow out of a T-shaped die head, hot-bonding double surfaces of polyester non-woven mesh fabric on the upper surface and lower surface of the melt of the sheet in a three-roller calendering machine, further calendering and shaping, cooling and shaping the sheet by a cooling roller cylinder after shaping, cutting edges, and then rolling or cutting according to a fixed size. The elastomer hot-melt adhesive sheet can be used for manufacturing finished products of shoe heads and back liners after being stamped by a mold, the shaped adhesive sheet finished products are placed into shoe inner liners and interlayers of shoe vamps for hot-pressing, binding and solidifying, and the production process flow is simplified and is suitable for mass production of an assembly line.

Owner:江苏诚盟装备股份有限公司

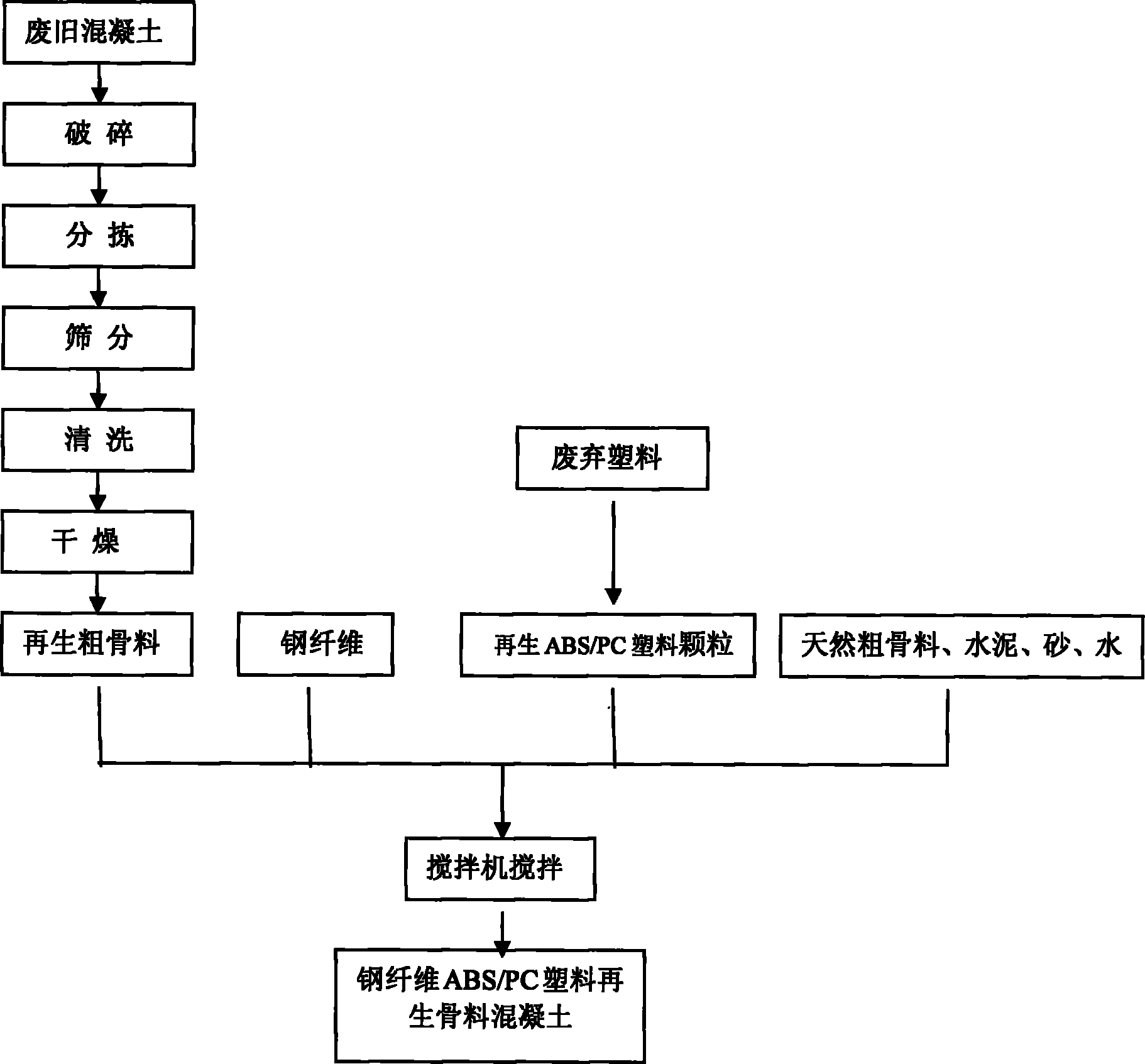

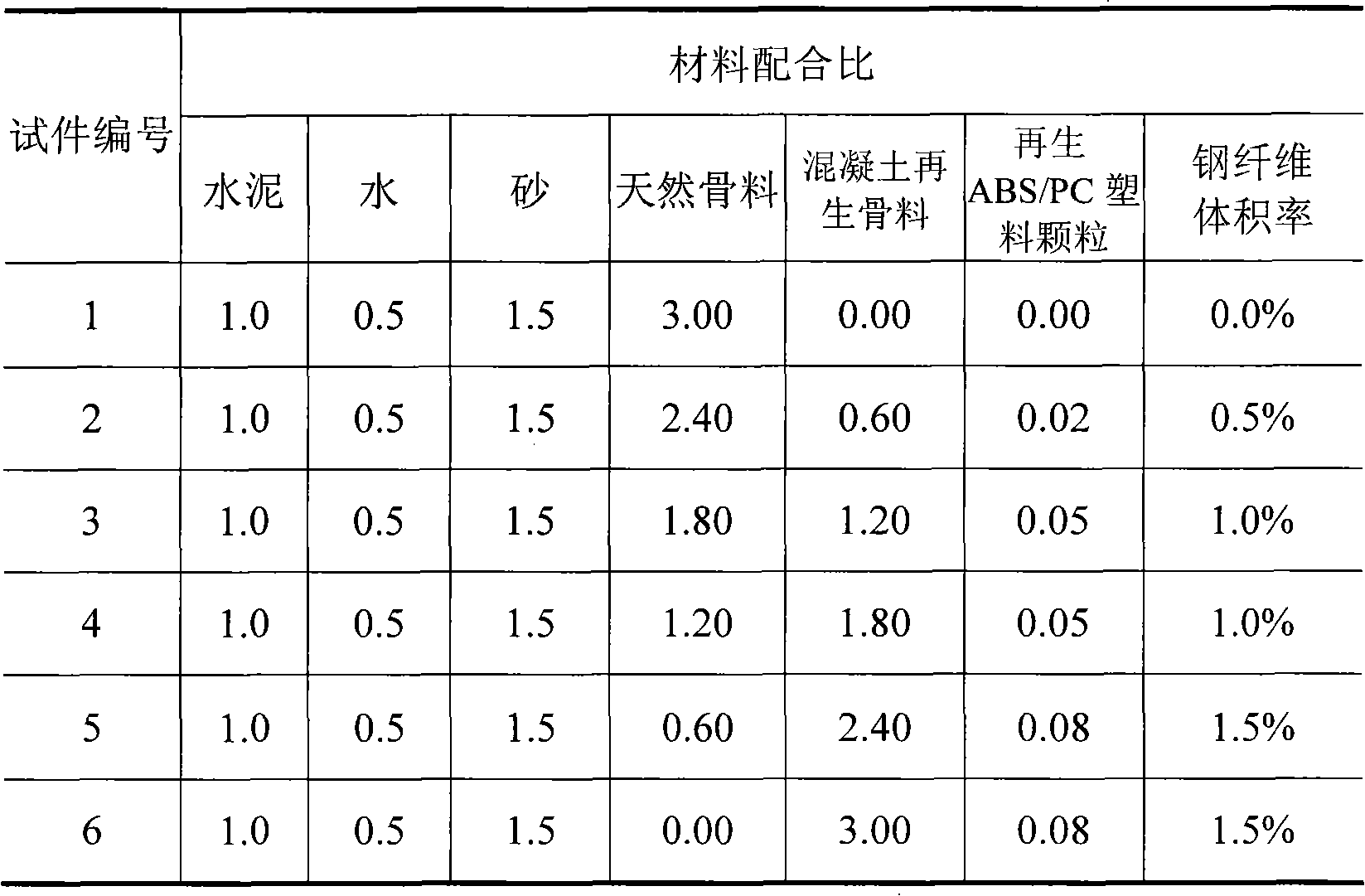

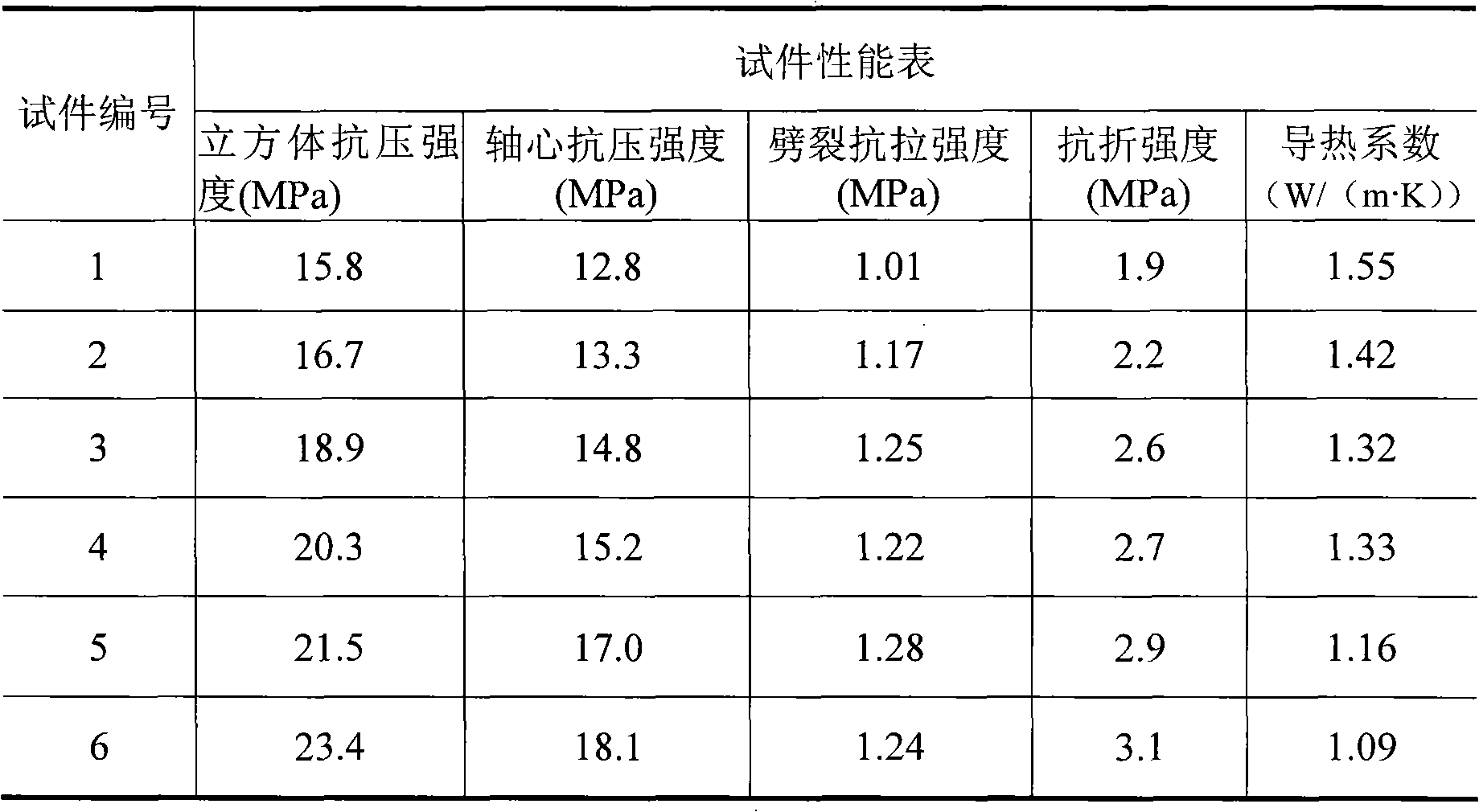

Preparation method for steel fiber ABS/PC plastic reclaimed aggregate concrete

ActiveCN101830029AHigh dampingIncrease frictionSolid waste managementCeramic shaping apparatusThermal insulationCompressive strength

The invention discloses a preparation method for steel fiber ABS / PC plastic reclaimed aggregate concrete, which comprises the following steps of smashing, separating, sieving, cleaning and drying waste building concrete to obtain reclaimed concrete aggregate; smashing waste ABS / PC plastics to obtain reclaimed ABS / PC plastic particles; and then stirring steel fibers, reclaimed ABS / PC plastic particles, reclaimed concrete aggregate, natural coarse aggregate, sand, cement and water in proportion. The toughness, rupture strength, compression strength, impact resistance and other properties of the reclaimed aggregate concrete can be effectively improved by steel fiber modification; the reclaimed ABS / PC plastic particles can improve the anti-cracking performance, thermal insulation performance, wear-resisting performance and compression strength of the concrete; and the production of the material can reduce the environment pollution and improve the performance of the material without increasing cost.

Owner:GUANGDONG DIANBAI CONSTR GRP

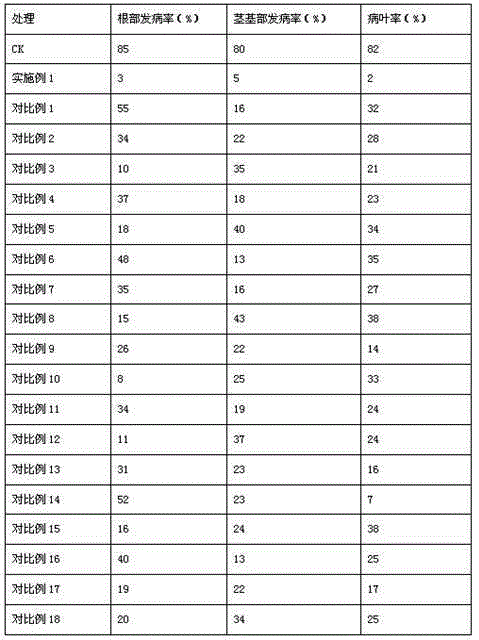

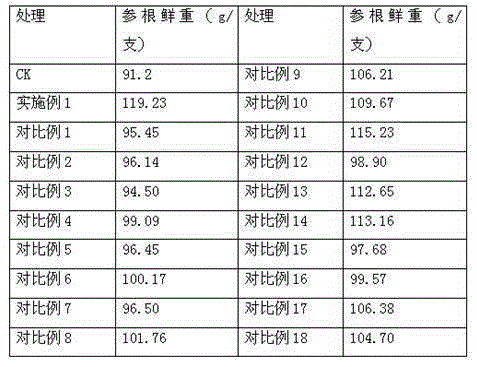

Anti-disease composite microbial fertilizer specially-used for American ginseng and preparation method thereof

InactiveCN105237110AMeet the nutritional requirements for growthPromote growthFertilizer mixturesPotassiumRoot rot

The invention belongs to the technical field of fertilizers and particularly relates to an anti-disease composite microbial fertilizer specially-used for American ginseng and also relates to the preparation method of the microbial fertilizer. The microbial fertilizer includes furfural residue, cassava residue, decayed cow dung, lignite humic acid, plant ash, tea residue, clay, mineralized yellow-brown potassium humate and a composite probiotic agent. The microbial fertilizer is balanced in nutrients and is abundant in microelements and can effectively increase productivity and improve fertility level of soil. The added composite probiotic agent can significantly inhibit the main diseases of the American ginseng, such as cylindrocarpon destructans diseases, root rot, damping off, black spot and the like. By means of the composite microbial fertilizer, the yield of the American ginseng is increased by 30-35% effectively and diseases rate is reduced by more than 90%. The fertilizer, when being used for long time, can effectively improve soil. The fertilizer is long-acting in fertilizer efficiency, achieves the effects in the whole growing period of American ginseng, and also has the effect of improving the quality of the American ginseng.

Owner:QINGDAO SHENLAN FERTILIZER IND

A kind of biodegradable composition and preparation method thereof

InactiveCN102295825AImproved hydrolysis resistance and thermal oxygen resistanceFast biodegradationConjugated synthetic polymer artificial filamentsArtifical filament manufactureCopolyesterPolymer chemistry

The invention discloses a biodegradable composition and a preparation method thereof, which consist of a biodegradable homopolyester (A), a biodegradable copolyester (B) and a chain extender (C), the total weight of which is 100 parts by mass Calculated, containing (A+B) is 95.0~99.9 parts and containing C is 0.1~5.0 parts, wherein the ratio of A:B is in the range of 1:9~9:1. The present invention finds that the compounding of biodegradable homopolyester with faster biodegradation rate and biodegradable copolyester with better processability in different proportions can not only endow the composition with proper biodegradation rate, but also improve the composition The physical properties and processing performance can be properly adjusted according to the requirements of different processing and application fields; we also found that by introducing a chain extender with long chain characteristics into the biodegradable resin composition, the combination after chain extension can be avoided It can prevent unnecessary gel phenomenon during processing and improve the heat resistance and stability of the material.

Owner:KINGFA SCI & TECH CO LTD +2

Multilayer coextrusion paper-like liquid packaging film

PendingCN101905776AGood dispersionGood compatibilityPackage recyclingFlexible coversMultilayer membraneFood packaging

The invention provides a multilayer coextrusion paper-like liquid packaging film. In resent years, people demand more dairy products, and the demand for the packaging films of various kinds of dairy products and liquid foods increases along with the continuous development of a UHT (Ultra Heat Treated) sterilization technology. According to incomplete statistics, only the consumption of milk packaging films reaches 7200 tons / year in 2009, and because liquid foods have self characteristics, liquid packaging films which are all made from 100% plastics are impossible to adopt a biodegradable packaging material to package the liquid foods so that gigantic pressure is brought to environmental protection, and a great amount of oil resources is consumed. Therefore, the field needs a material which can be used for packaging liquid, particularly a multi-layer liquid packaging film for packaging liquid dairy products and being capable of reducing the consumption of oil resources. According to one aspect of the invention, the invention provides the multilayer film is used for packaging liquid and can greatly reduce the consumption of plastic raw materials.

Owner:刘燕

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com