Plastic exposed concrete building template

A technology of fair-faced concrete and building formwork, which is applied in the direction of construction, building structure, formwork/formwork components, etc. It can solve the problems of low strength of the connection method, low number of formwork utilization, low formwork turnover times, etc., to achieve operation and handling Safe and reliable, easy to clean and maintain, and reduce cleaning and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing, the present invention is further described:

[0025] The formwork includes beam-column formwork 1, inner corner I2 and inner corner II3, outer corner I4 and outer corner II5, connecting piece I6 and connecting piece II7.

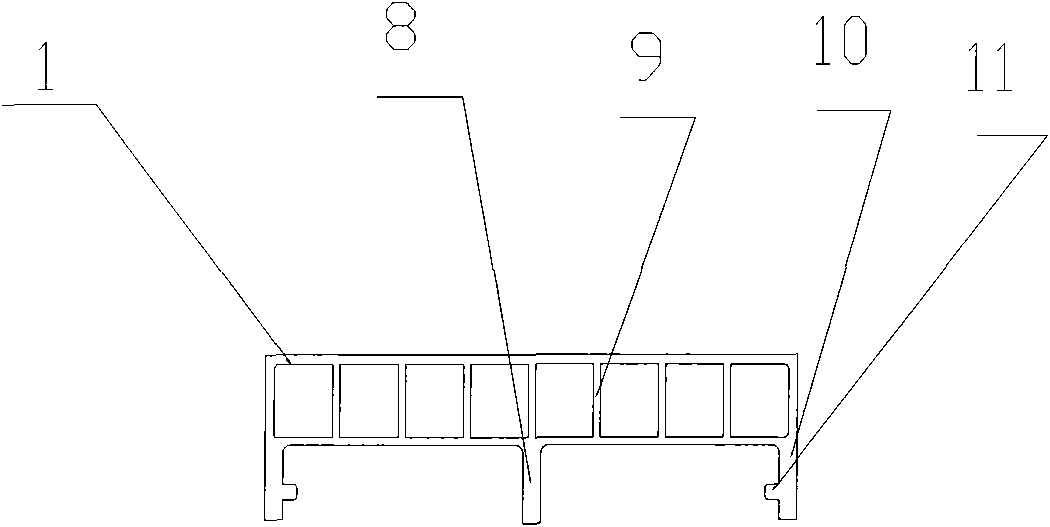

[0026] Such as figure 1 As shown, there are several reinforcing protrusions 8 on the plane of the beam-column formwork 1, and connecting protrusions 11 are provided on the reinforcing protrusions 10 at both ends. After the beam-column formwork 1 is connected with the connector I6 and connector II7, any Dimensional flat connection.

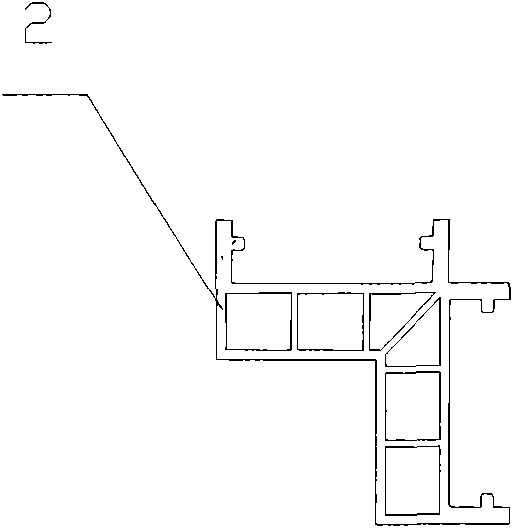

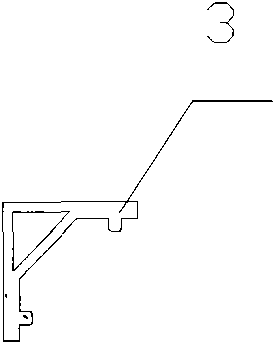

[0027] Such as figure 2 , image 3 As shown, the inner corner I2 and the inner corner II3 are integral structures, and are provided with reinforcing protrusions, and connecting protrusions are provided on the reinforcing protrusions at both ends.

[0028] Such as Figure 4 , Figure 5 As shown, both the male corner I4 and the male corner II5 are integral structures, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com