Patents

Literature

2980results about "Forming/stuttering elements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Building construction using structural insulating core

InactiveUS20100058700A1Easy to fixEasy to placeCeilingsWallsConcrete beamsStructural insulated panel

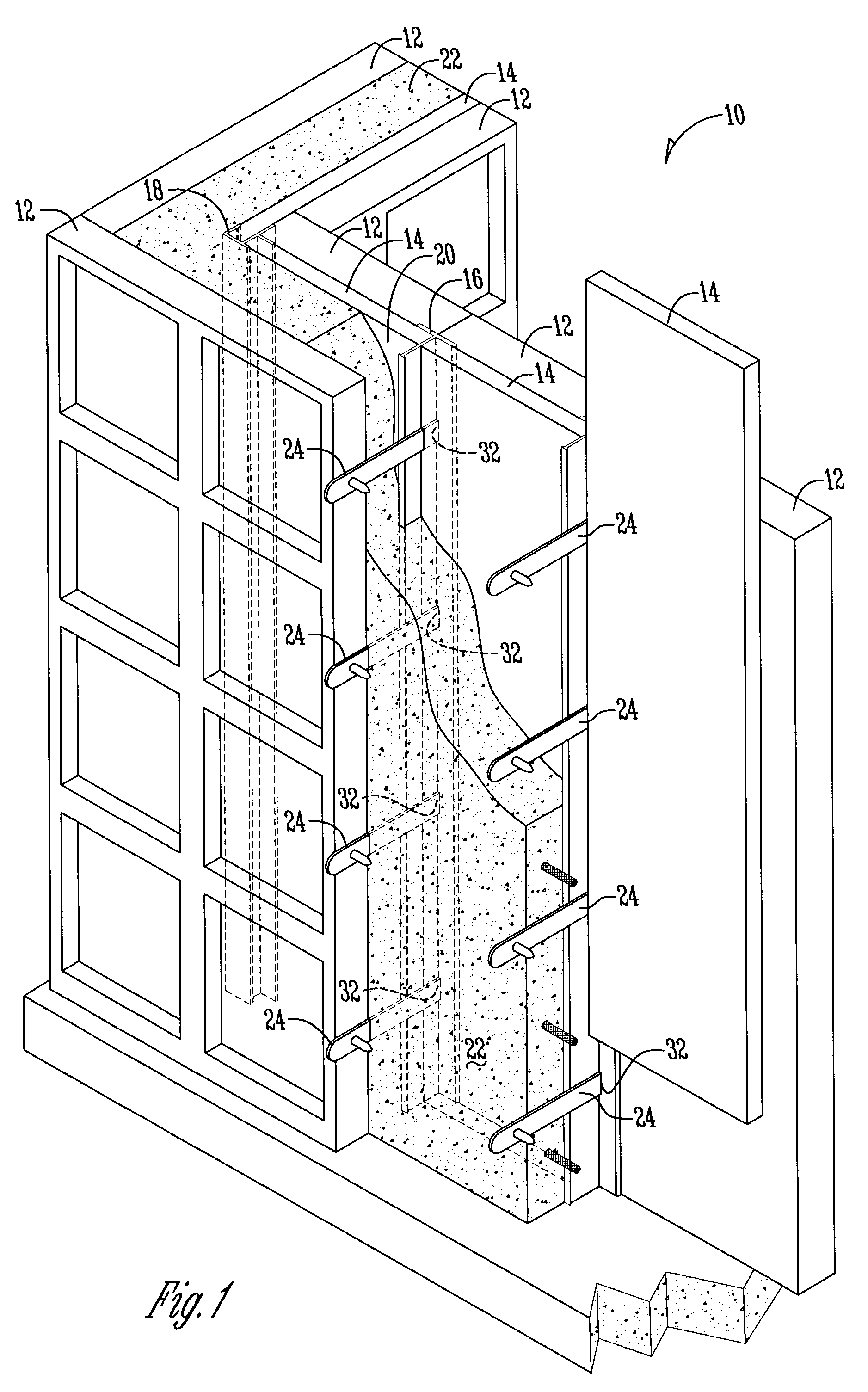

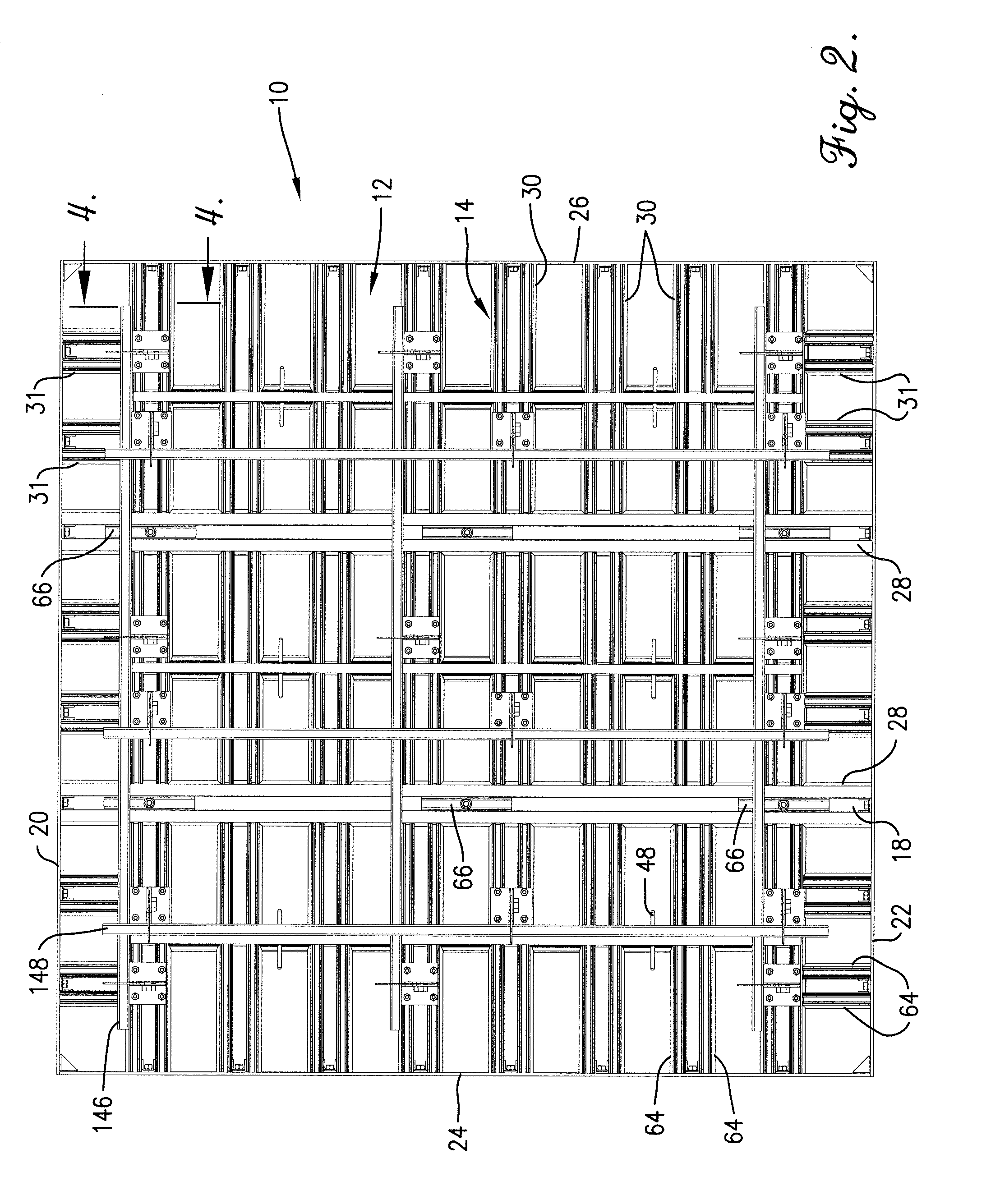

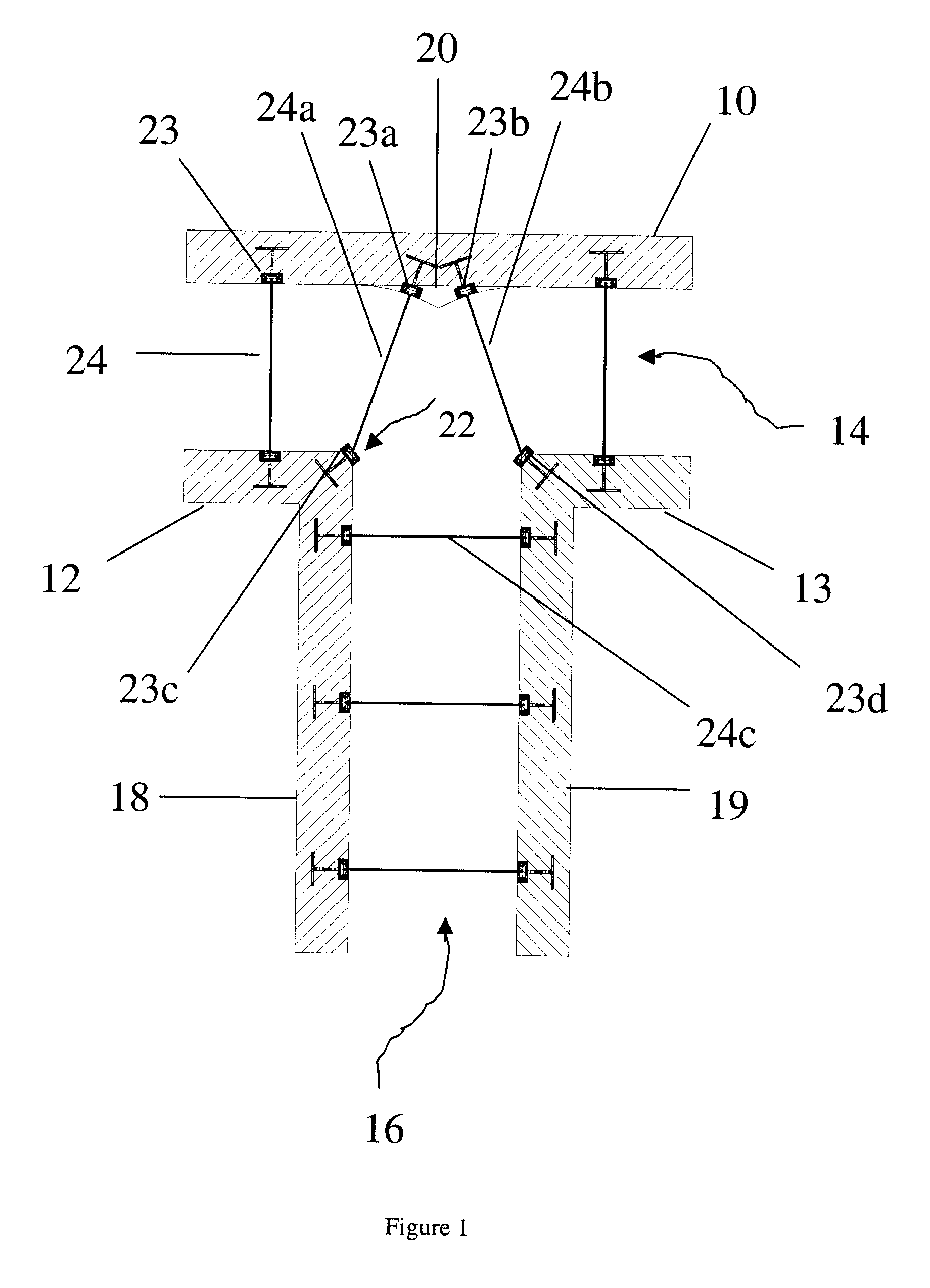

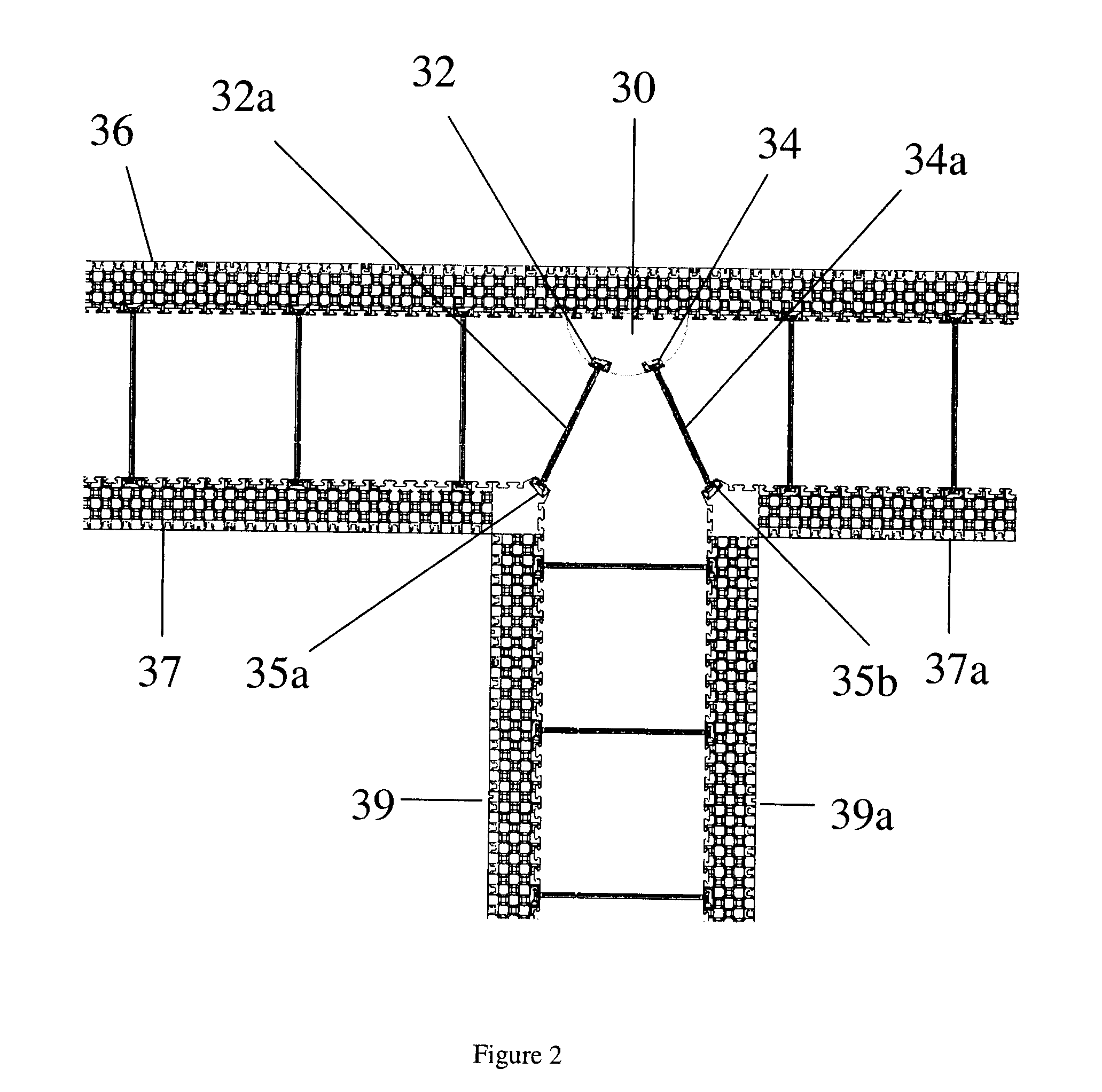

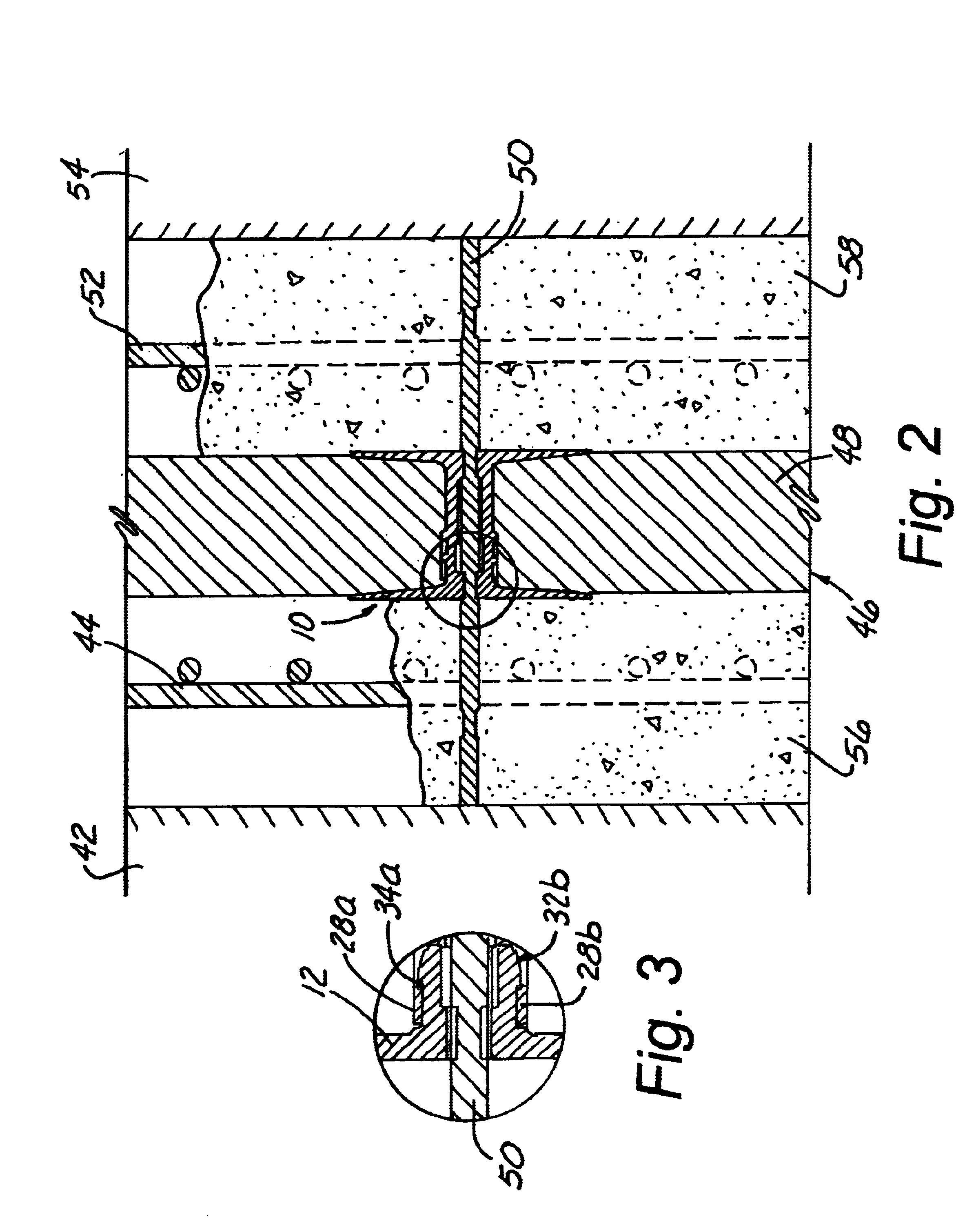

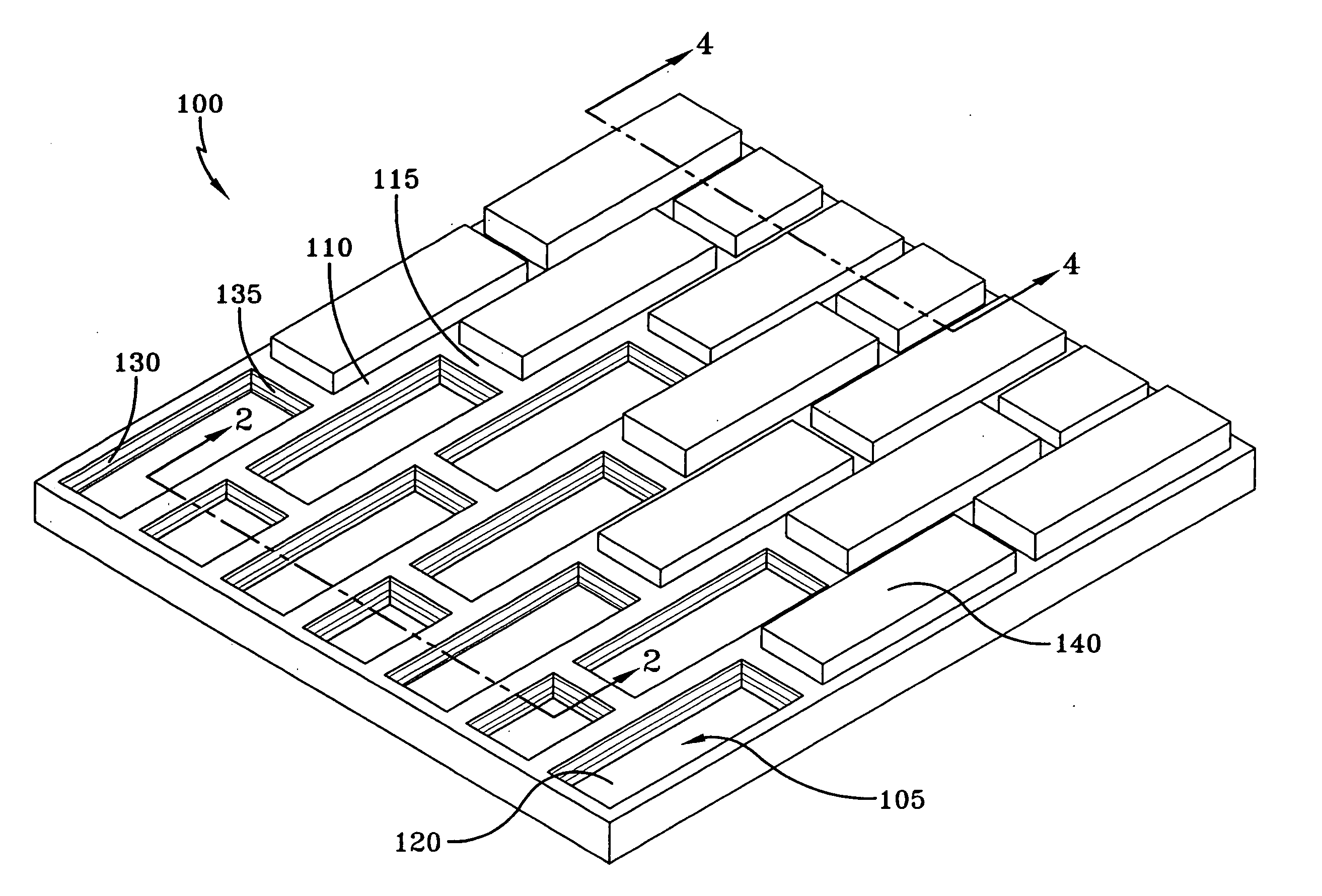

The present invention relates to an improved wall system where a wall form mold has a structural insulated core assembled to form a structural insulated panel (SIP) to form a concrete beam and concrete column to be poured anywhere within the wall as well as between building modules when placed together and erected vertically. The interlocking wall molds interlock within the wall as well as between panels and modules. The wall panels allow concrete columns and beams to be formed with an ICF in any size and shape. The structural insulated core consists of interlocking foam spacers and support channels which can be glued or screwed together to form an independent wall or as part of a precast wall with columns and beams integrated within the wall panels. Expanded and insulating flanges within the wall forming mold separates the wall forming structure from the wall surfaces.

Owner:LEBLANG DENNIS WILLIAM

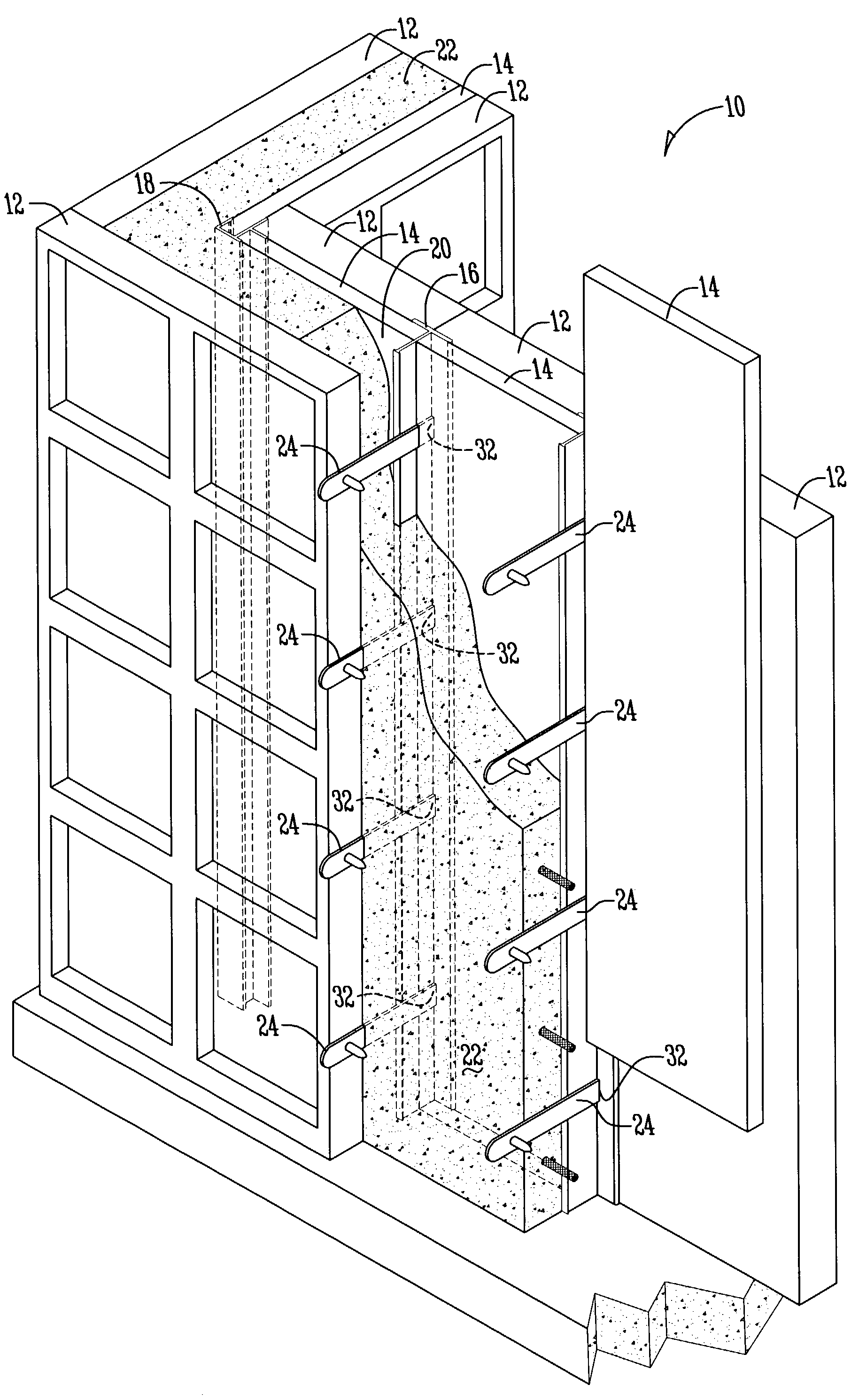

Insulated concrete wall system and method of making same

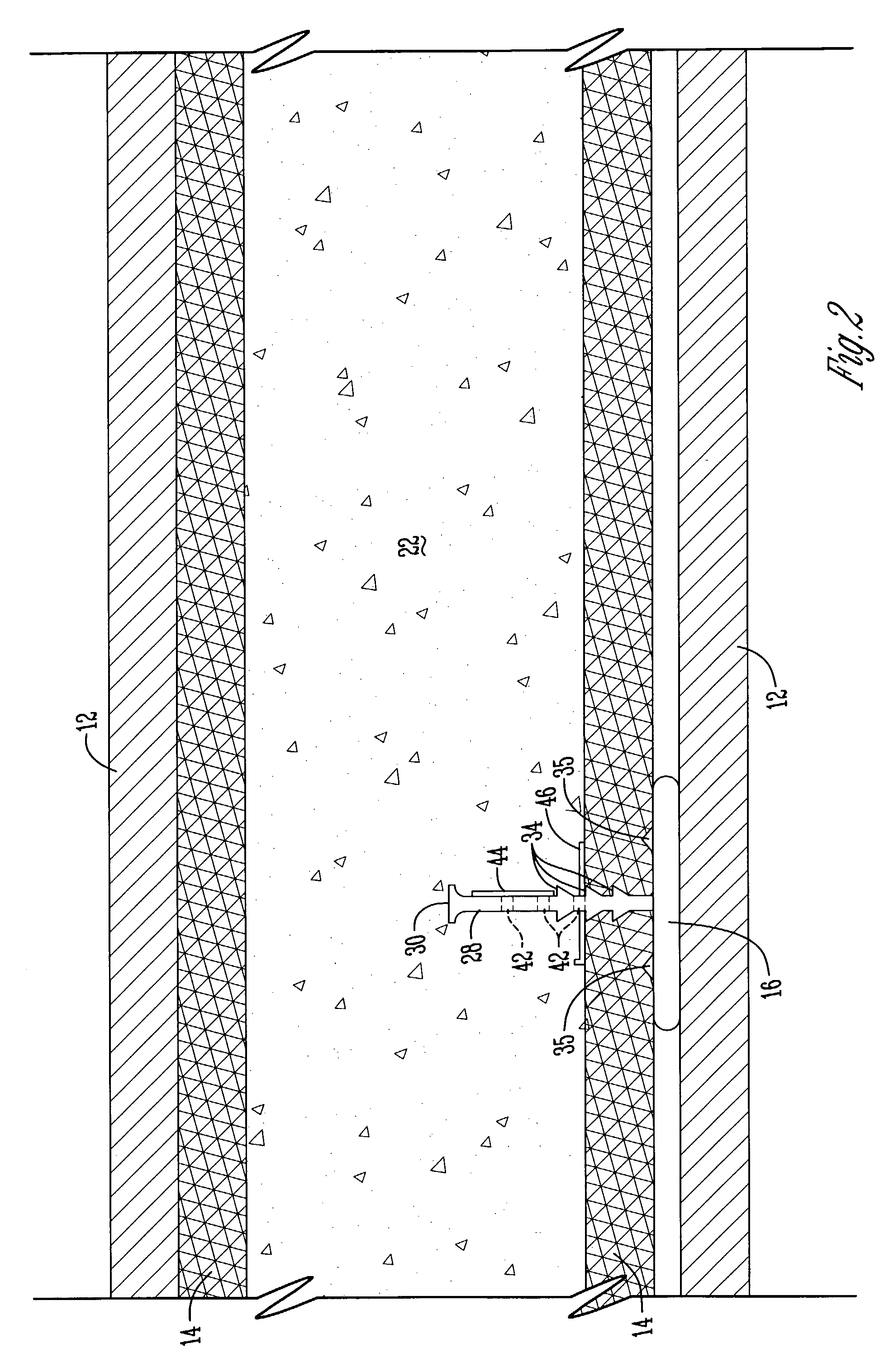

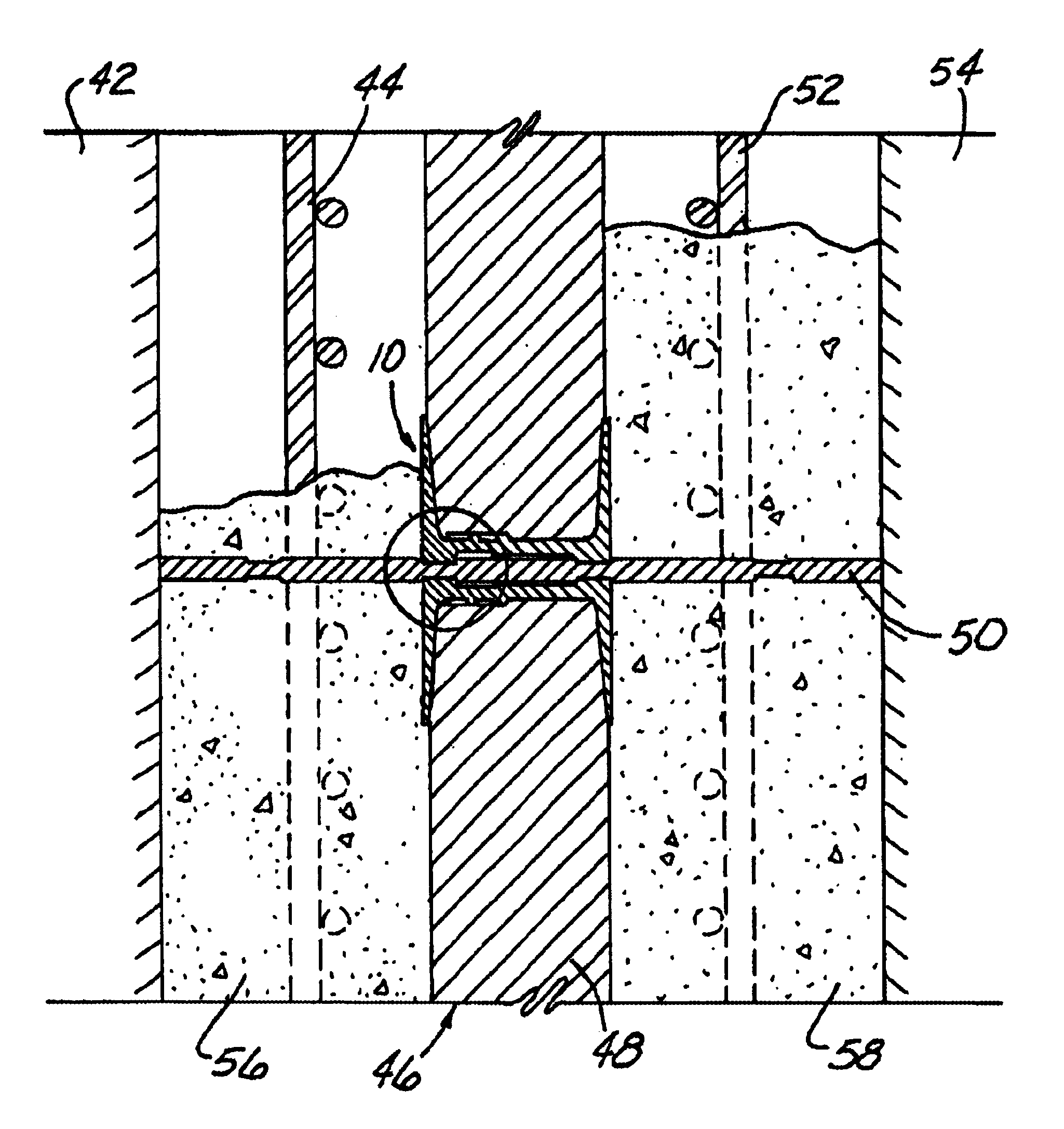

A method and system for installing an insulated concrete wall includes insulation panels placed in an upright manner. Generally T-shaped wall studs are placed next to the insulation panels such that the front section of the wall stud is on the outside of the insulation panels and an anchoring section of the wall stud extends beyond the insulation panels into the gap into which concrete will later be poured. Concrete pouring forms are placed so as to render the gap into which concrete will be poured a desired thickness. The wall stud may also include slots for receiving cross-ties that secure the concrete pouring forms in proper position and retaining nubs that prevent the insulation panels from floating when concrete is poured. Concrete is then poured into the gap, surrounding the anchoring section the T-shaped wall stud.

Owner:BURGETT FERRALL

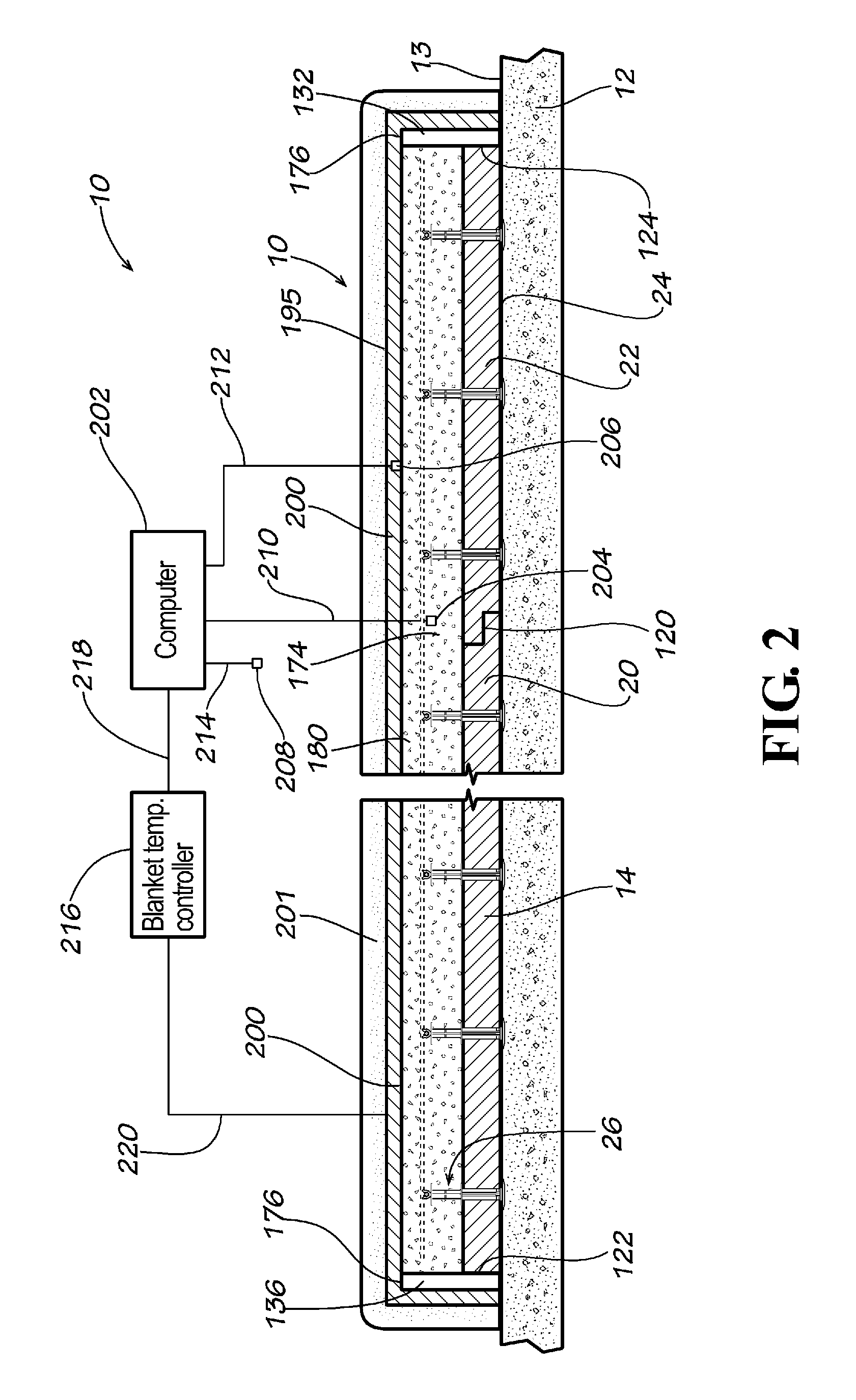

Method for electronic temperature controlled curing of concrete and accelerating concrete maturity or equivalent age of concrete structures and objects

ActiveUS8532815B1Selective heatingSolid waste managementResistance/reactance/impedenceElectronic temperatureMaterials science

Owner:CIUPERCA ROMEO ILARIAN

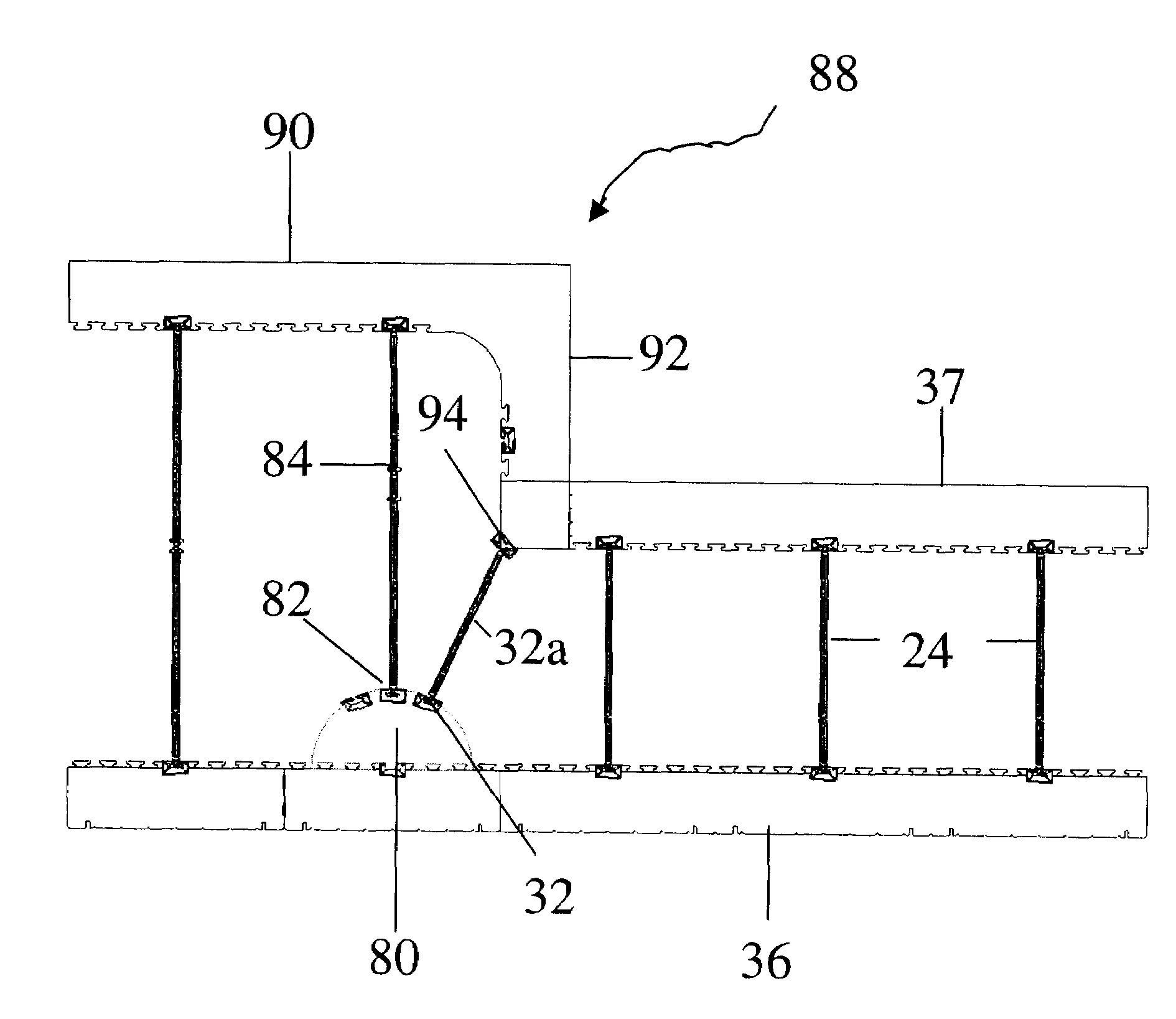

Reinforced insulated concrete form

Owner:CIUPERCA ROMEO ILARIAN

Collapsible concrete forms

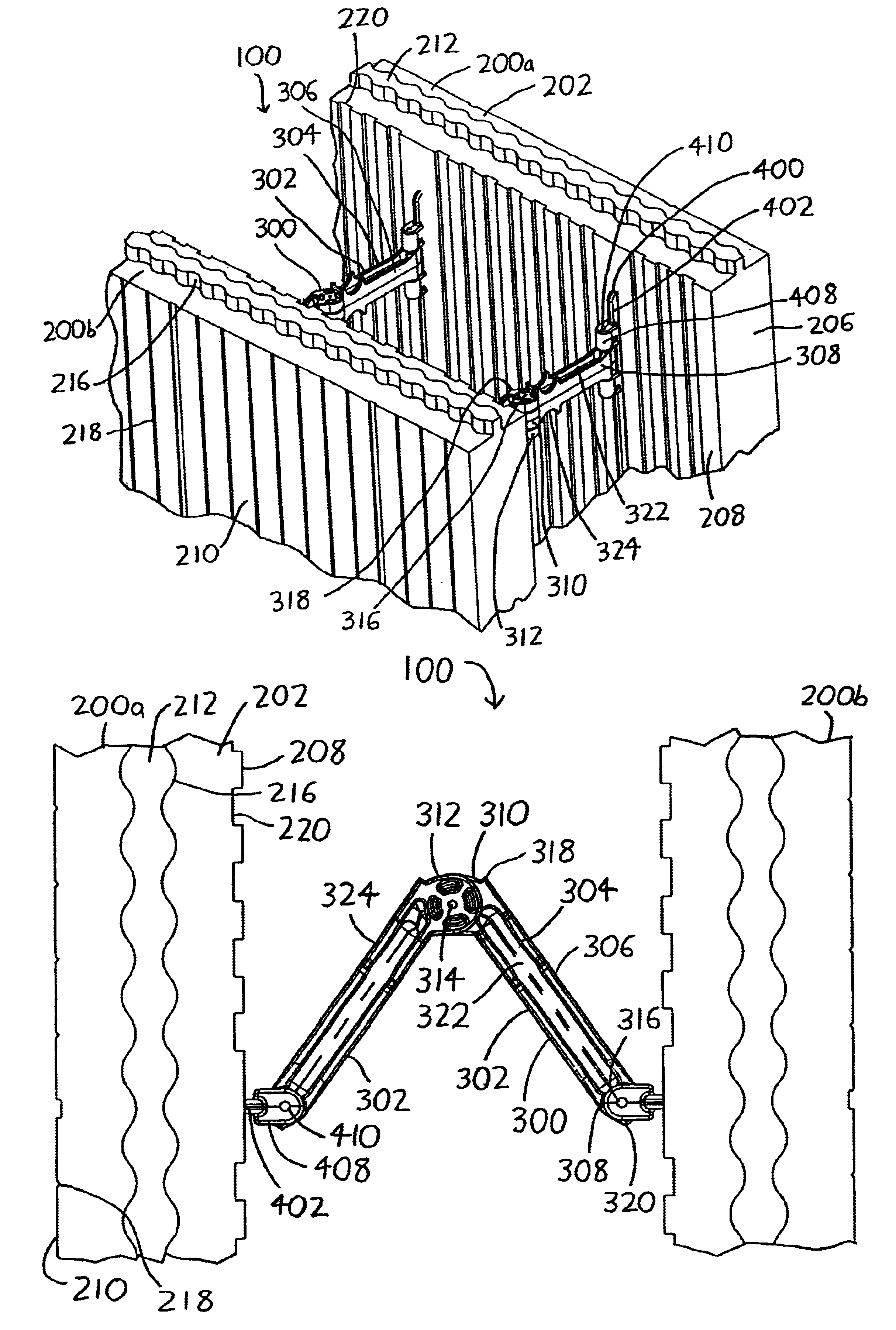

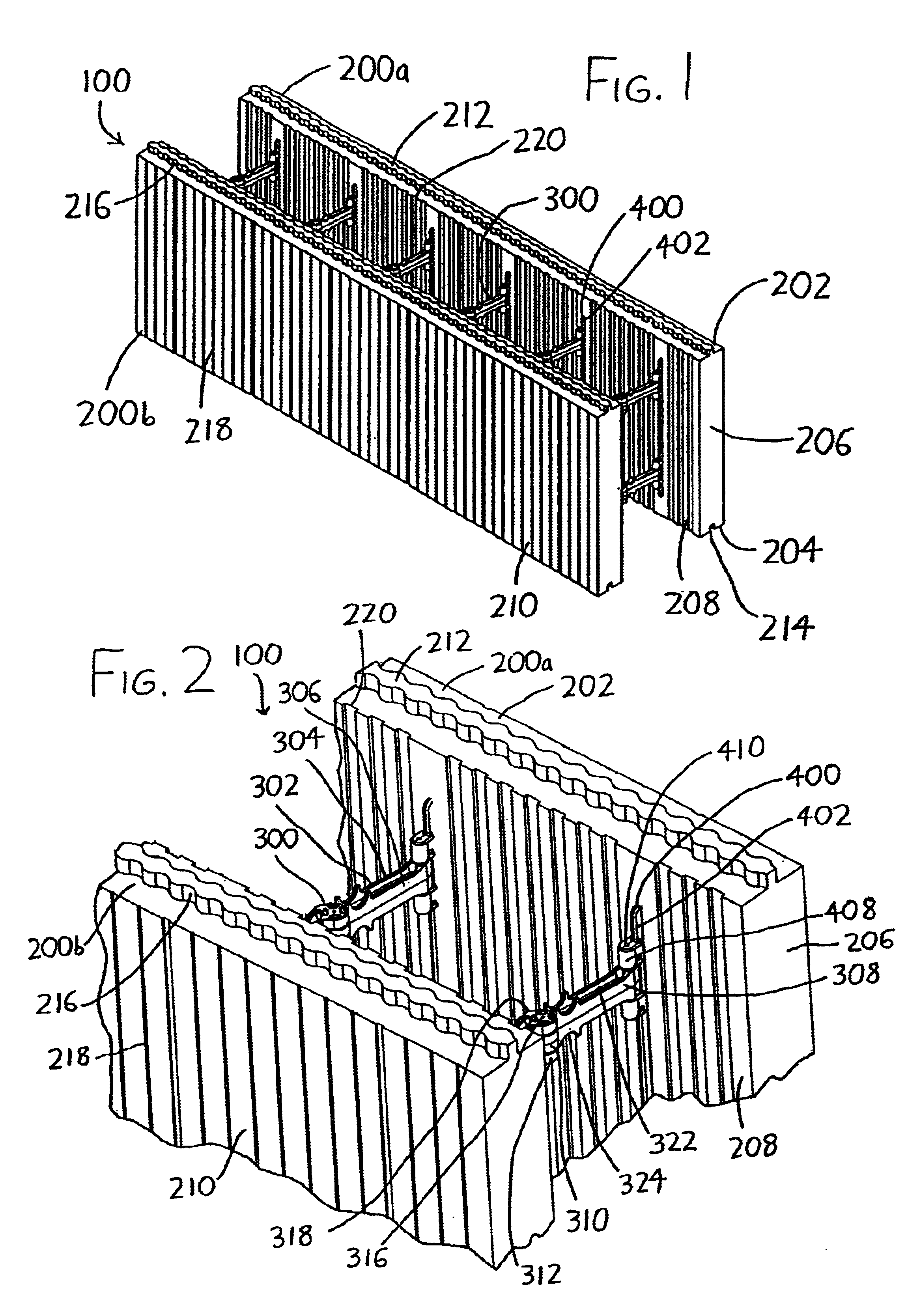

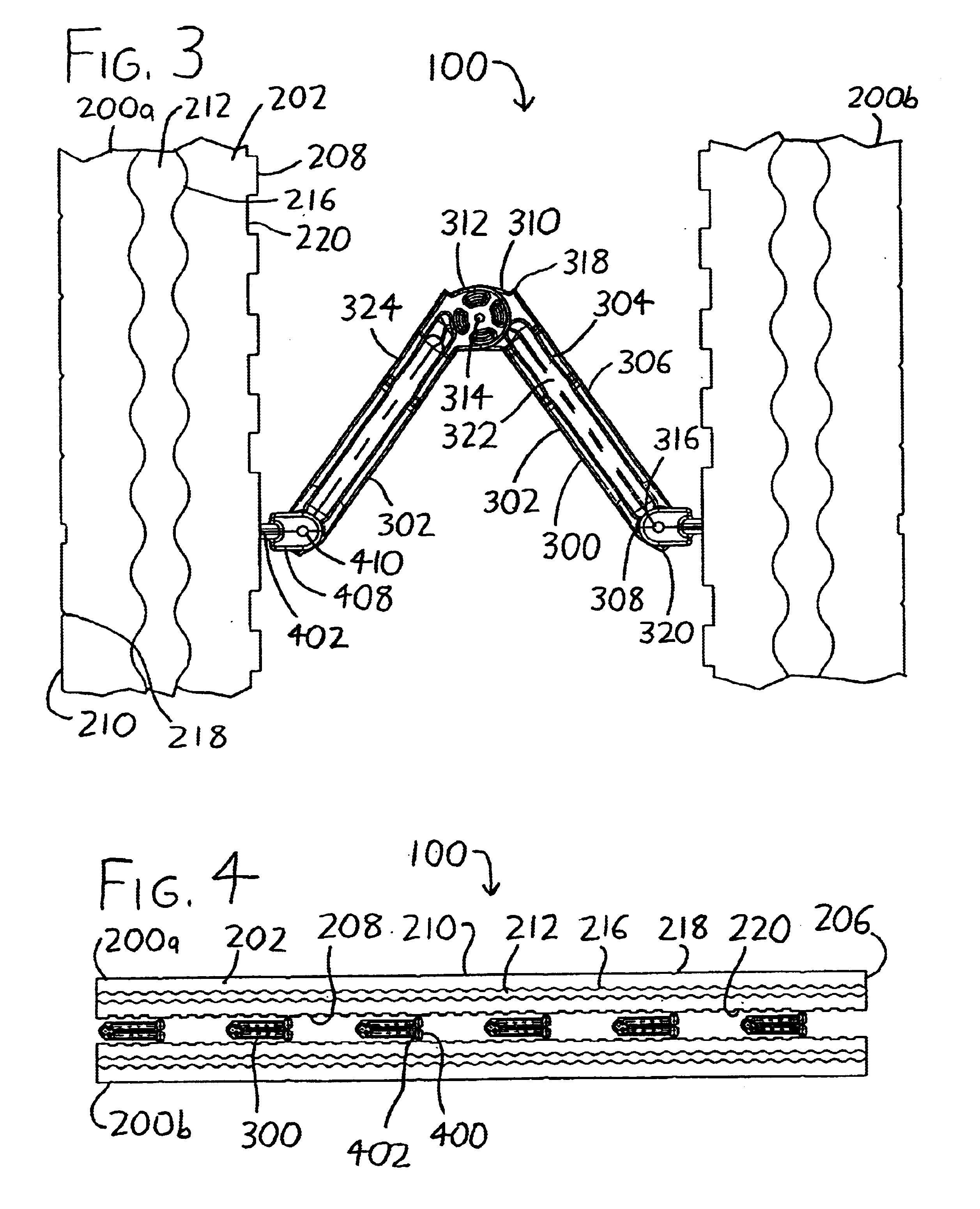

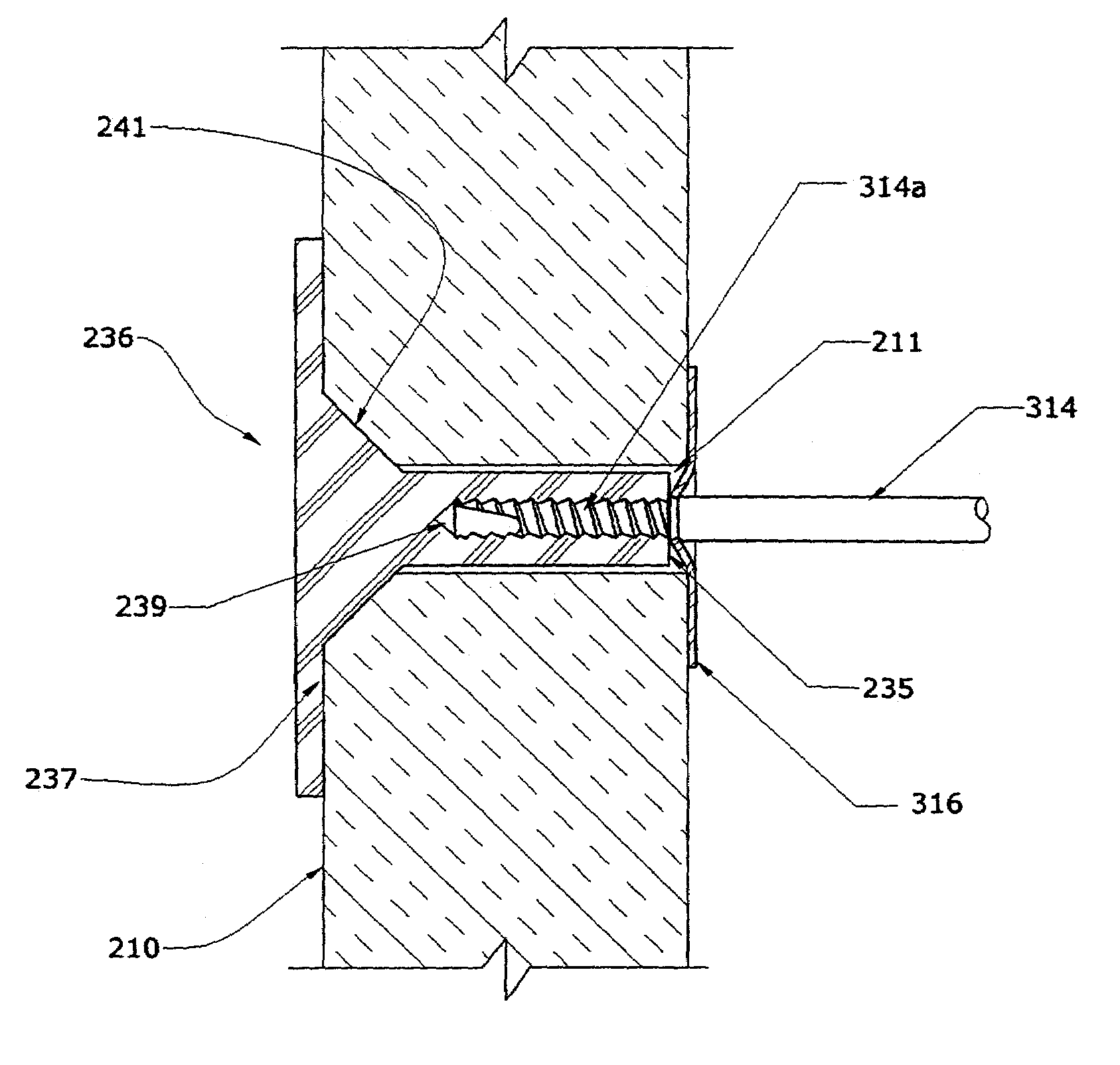

InactiveUS6915613B2Easy to storeLost storage volumeWallsForming/stuttering elementsEngineeringMechanical engineering

A concrete form unit includes opposing sidewalls which are preferably made of foamed plastic or other insulating material. Articulated spacers extend between and connect the sidewalls, and are capable of folding about themselves both at an elbow situated between the sidewalls, and also at their junctures with the sidewalls. The folding ability of the spacers allow the sidewalls to convert between a collapsed state wherein the sidewalls are in close adjacent relationship and the spacer links are oriented at least substantially parallel to each other and at least substantially parallel to the sidewalls, and an expanded state wherein the sidewalls are in distant spaced relationship with the spacer links being oriented at least substantially parallel to each other and at least substantially perpendicular to the sidewalls. The collapsed form unit therefore assumes an overall box-like shape, and therefore the collapsed form units are easily stored and shipped with minimal lost storage volume.

Owner:TIBERION BLOCK LLC

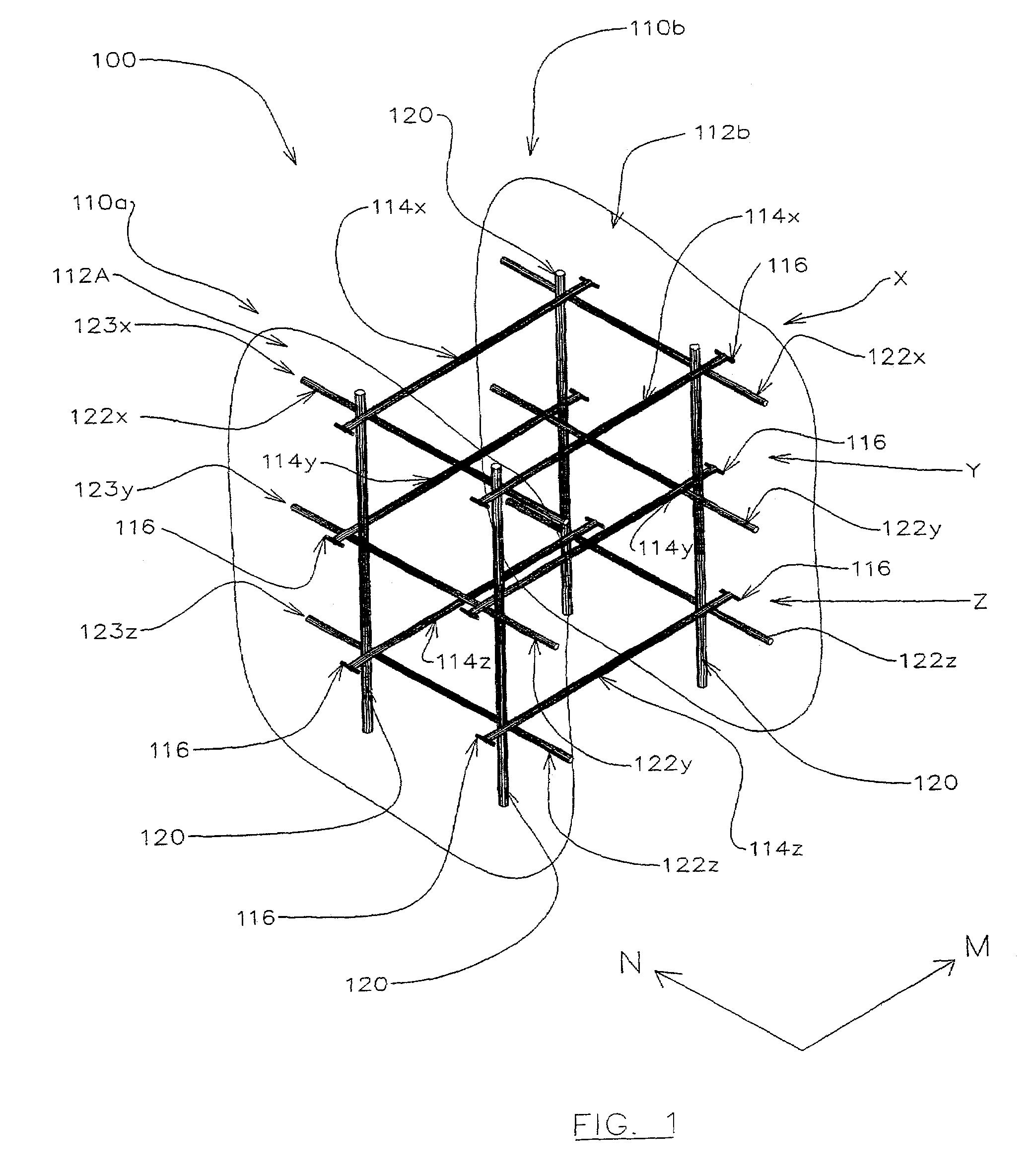

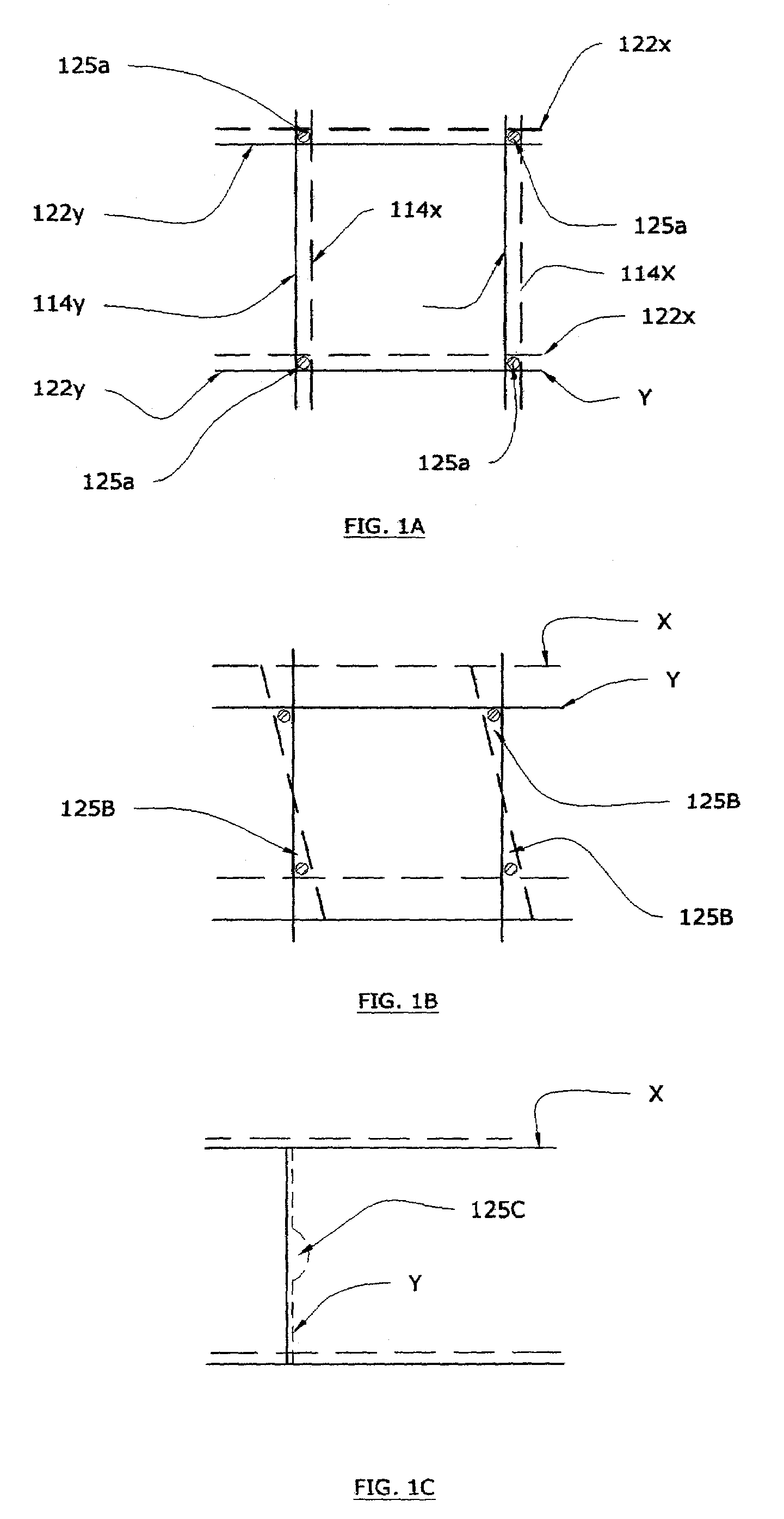

3-D construction modules

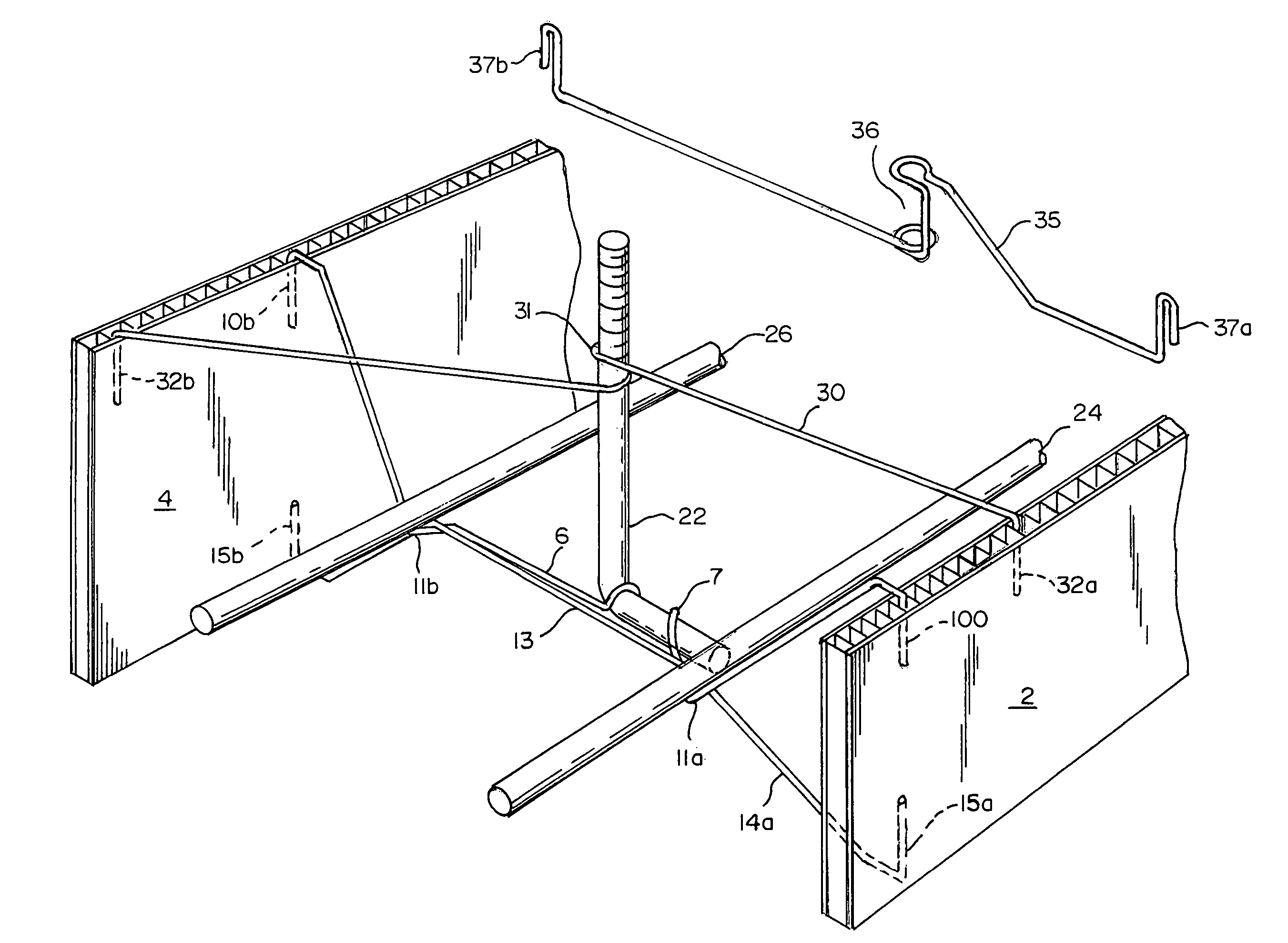

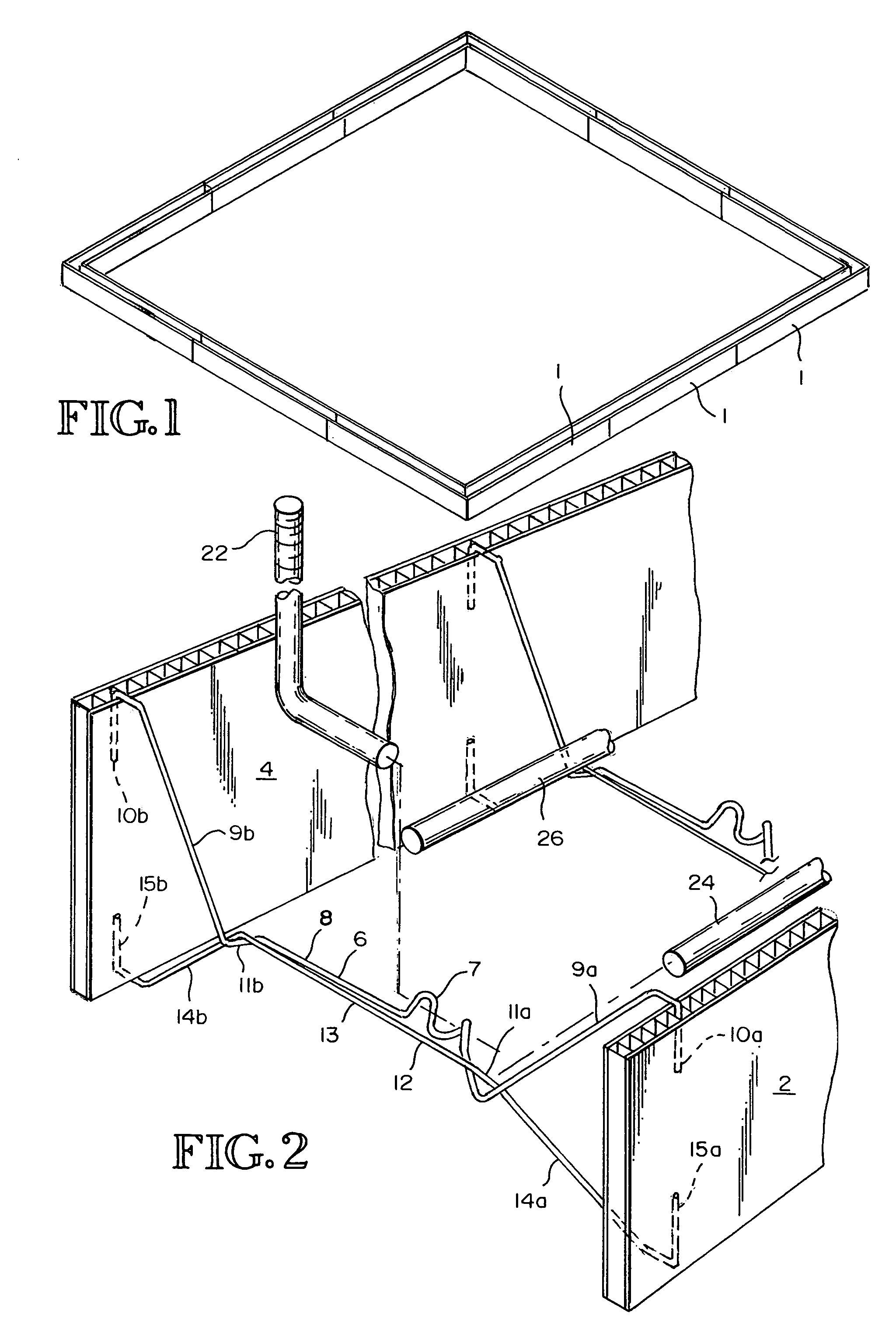

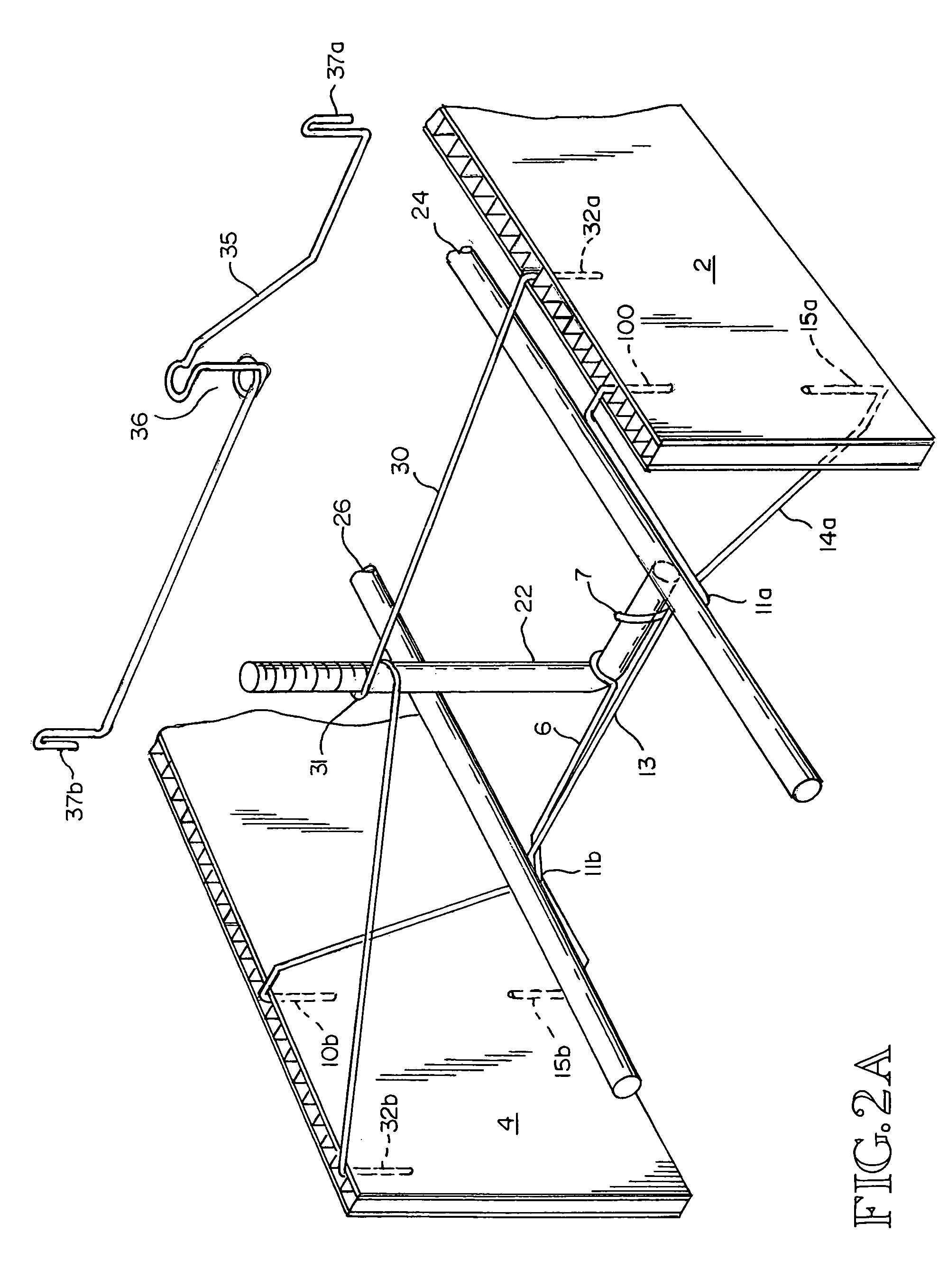

A 3D construction module comprising at least one vertically upstanding panel with first and second mesh layers oriented generally transversely and longitudinally. The first and second mesh layers have at least one rod member mounted to said panel and are vertically spaced from each other. The rod members form a first horizontally projected retention cell to restrict translation of a bar held in said retention cell between said first and second mesh layers. A third mesh can also be provided to form a second retention cell between said second and third mesh layers. The first and second retention cells restrict translation movement longitudinally and transversely of a vertical reinforcement member held in said first and second retention cells, and restrict rotation of the vertical reinforcement member about both a longitudinal axis and a transverse axis of the said 3D construction module. Horizontal reinforcement meshes are features of the invention. Other features of the invention include a trough for holding melted panel material, connectors for connecting rods to panels and associated stopper members. Also included are bracers for joining connectors and other devices related to panel connections.

Owner:BRAVINSKI LEONID G

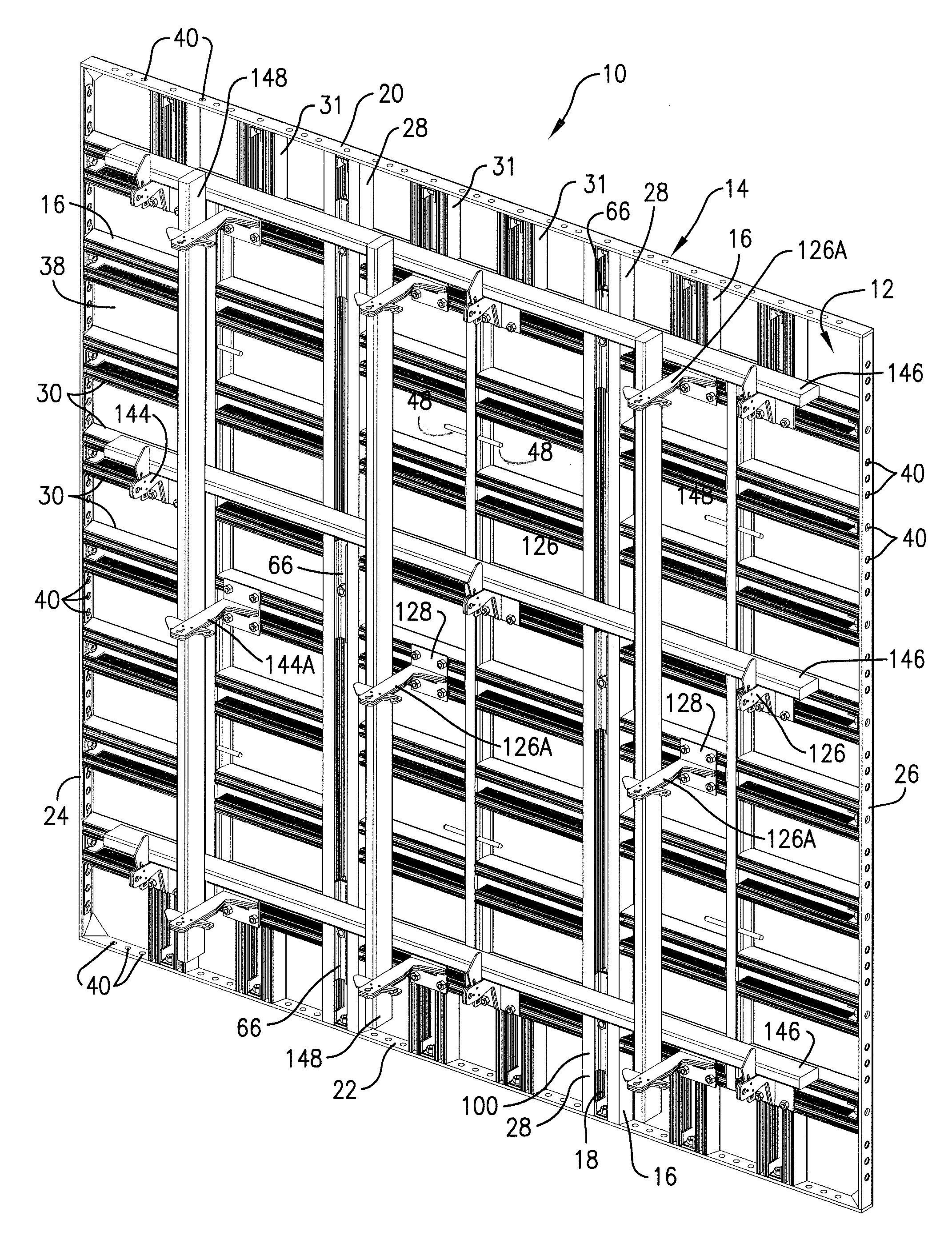

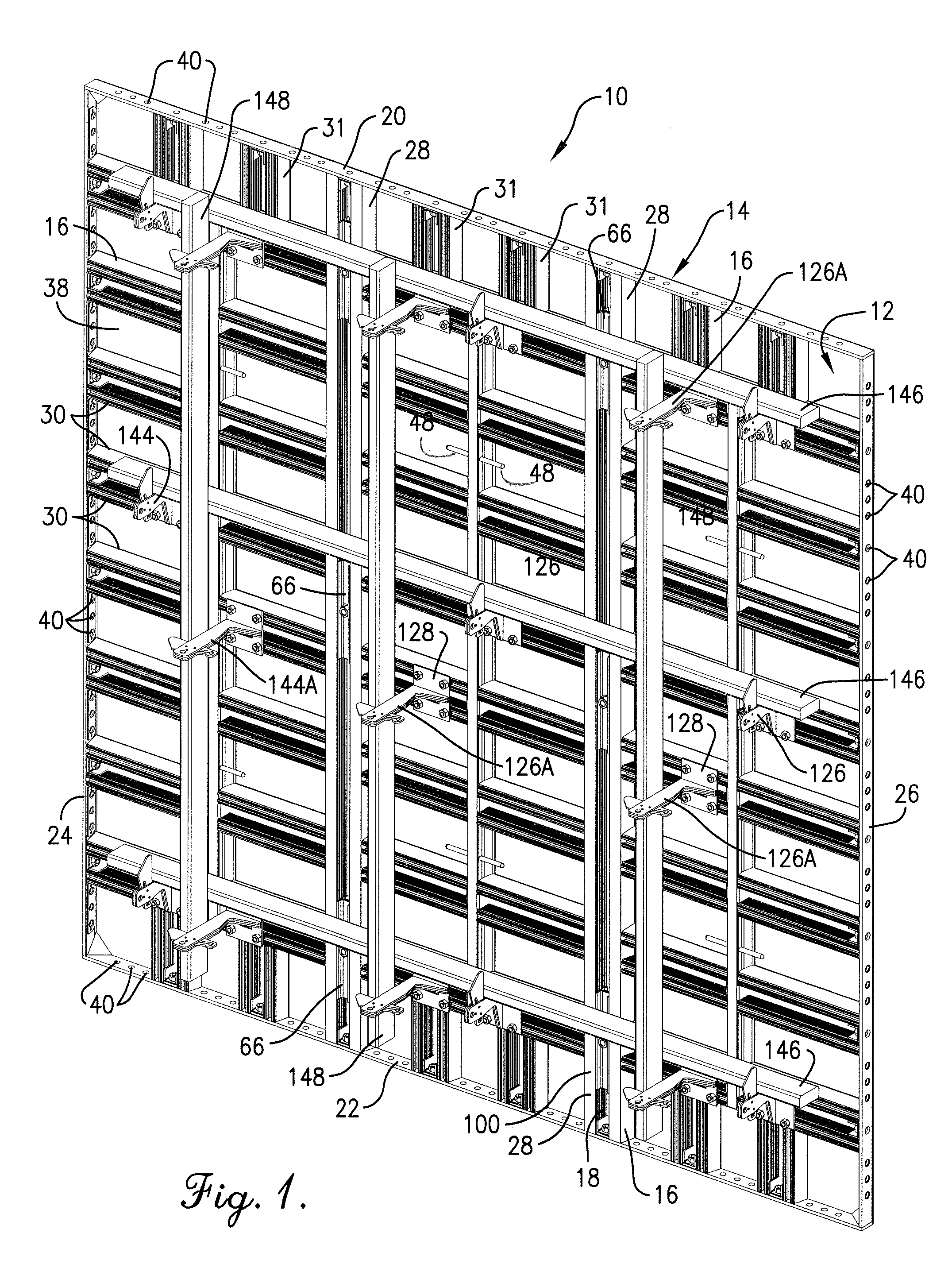

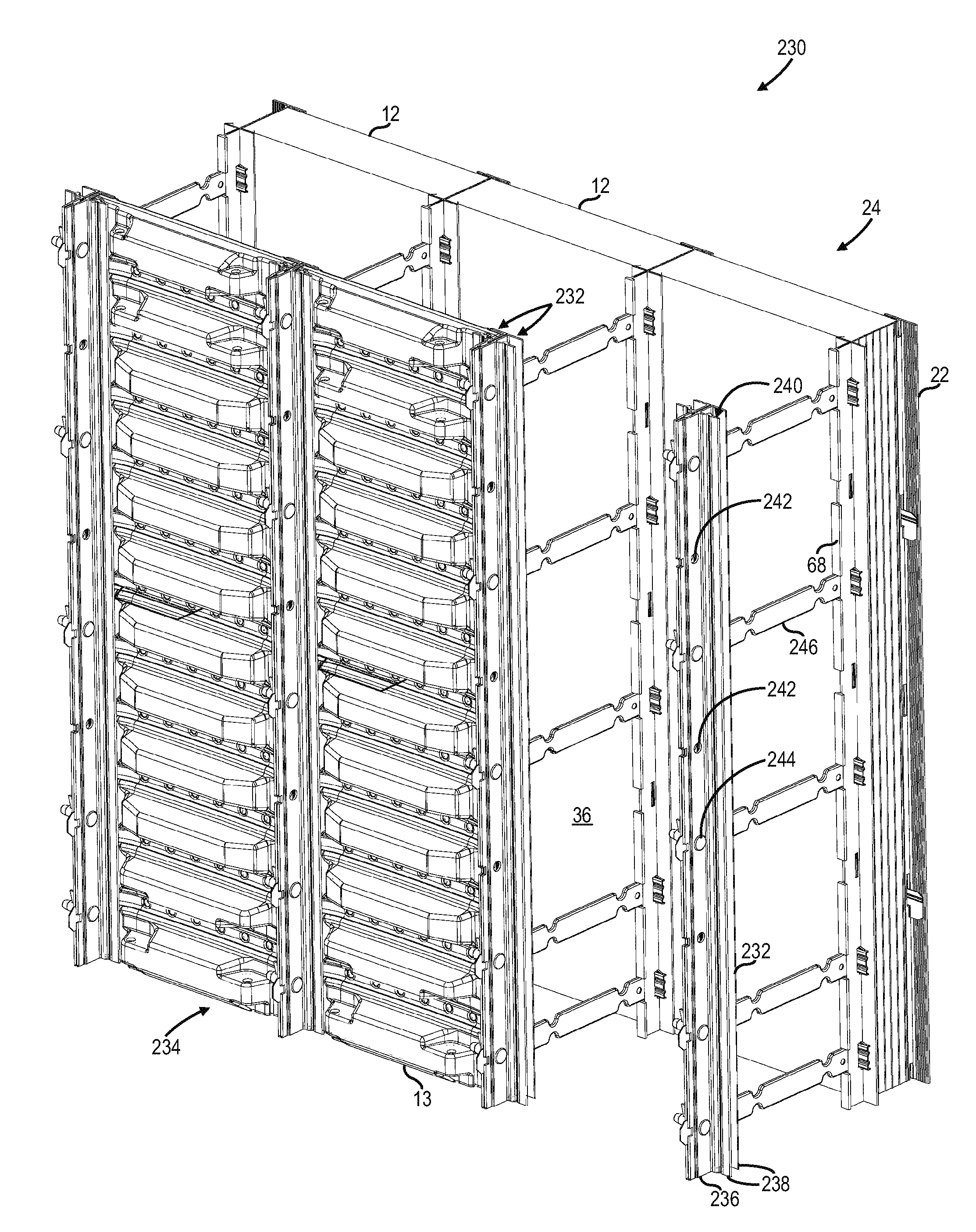

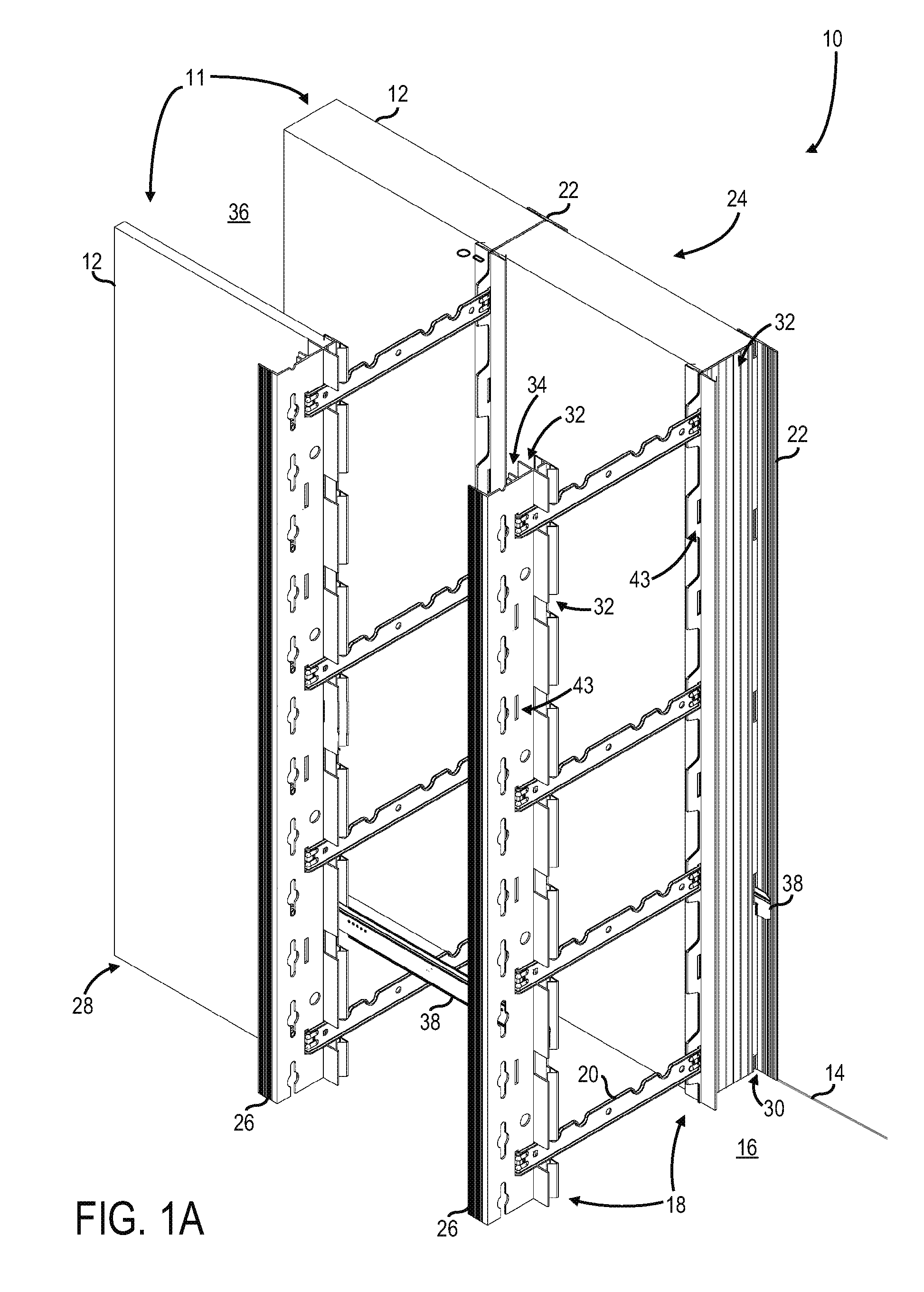

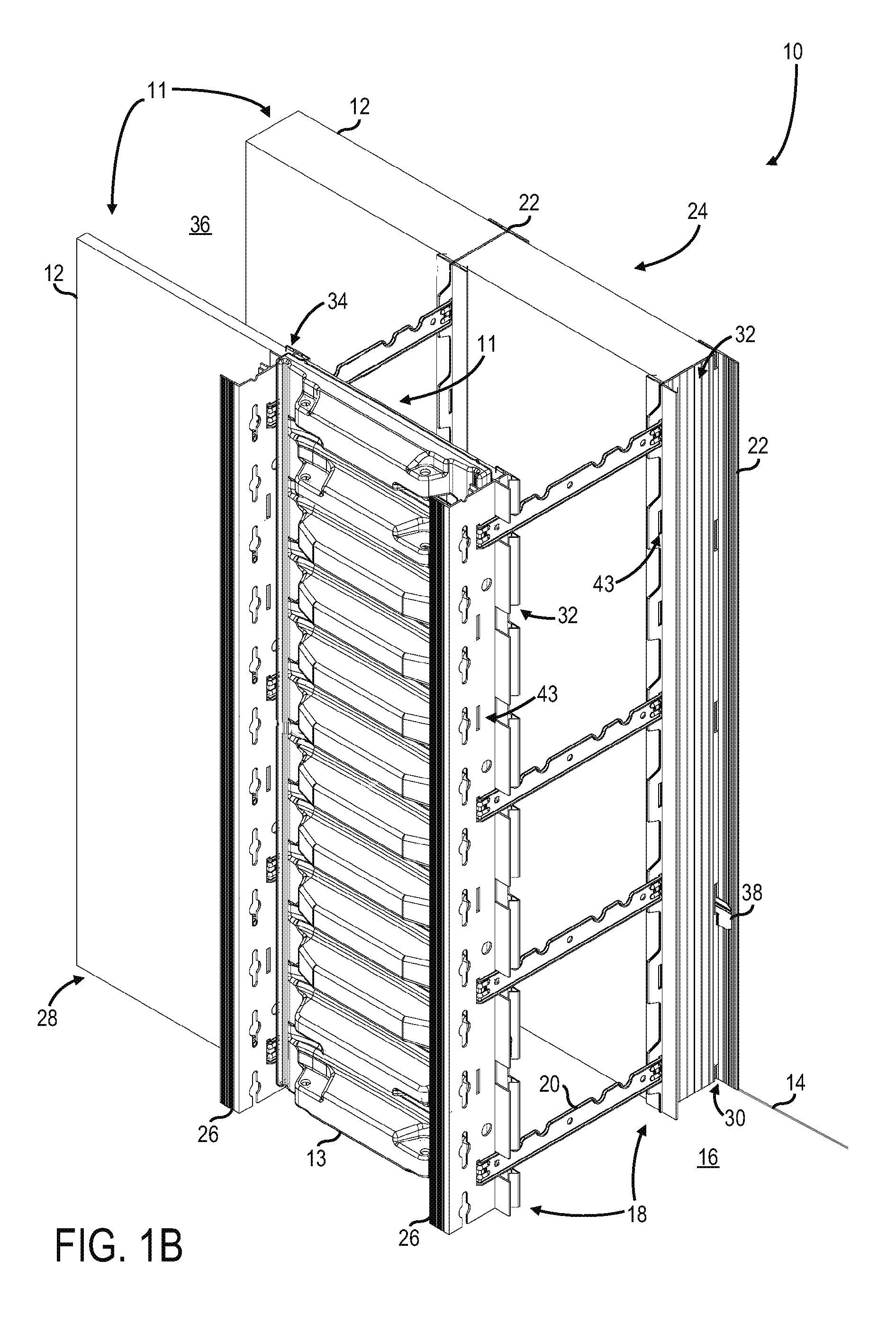

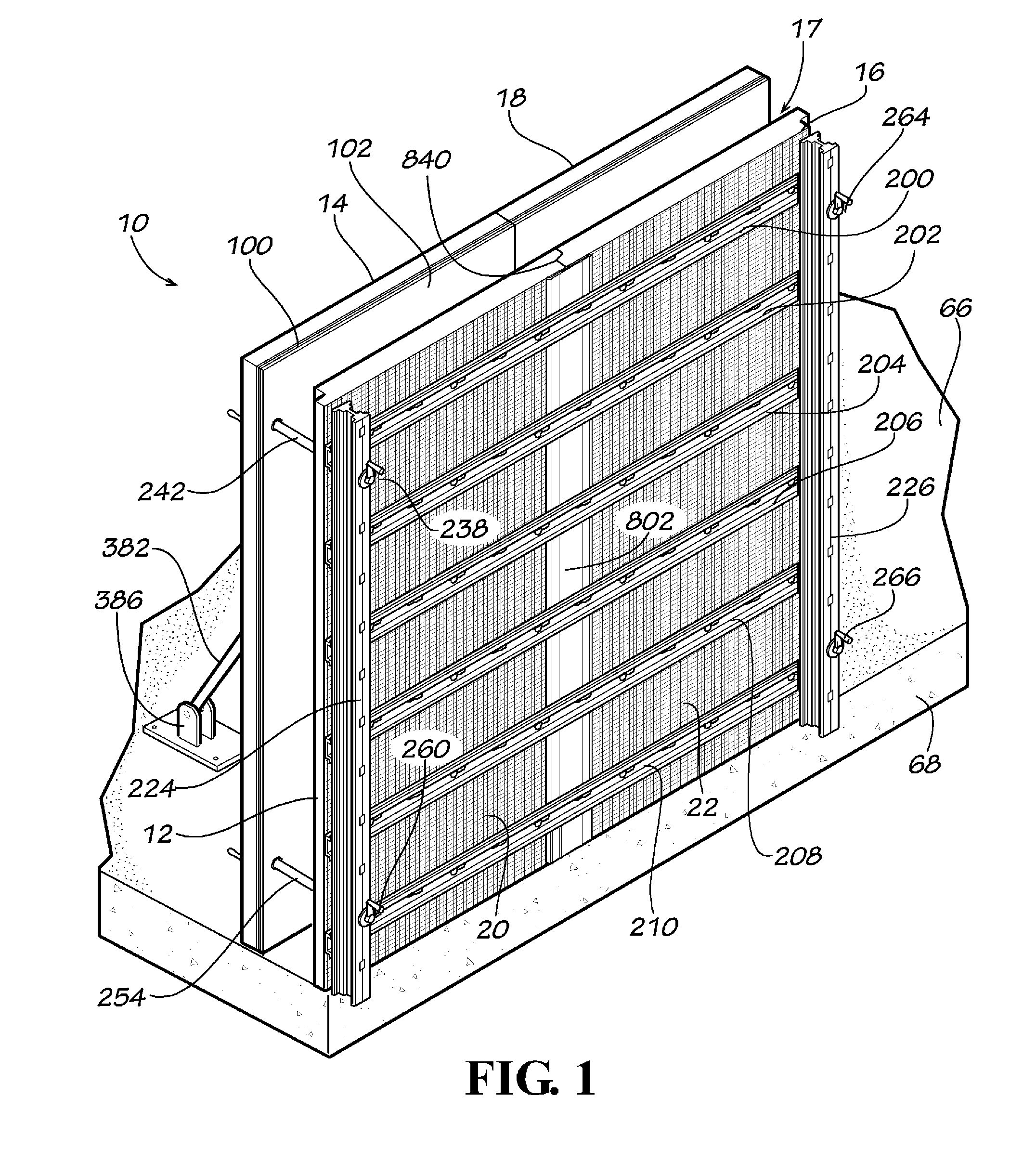

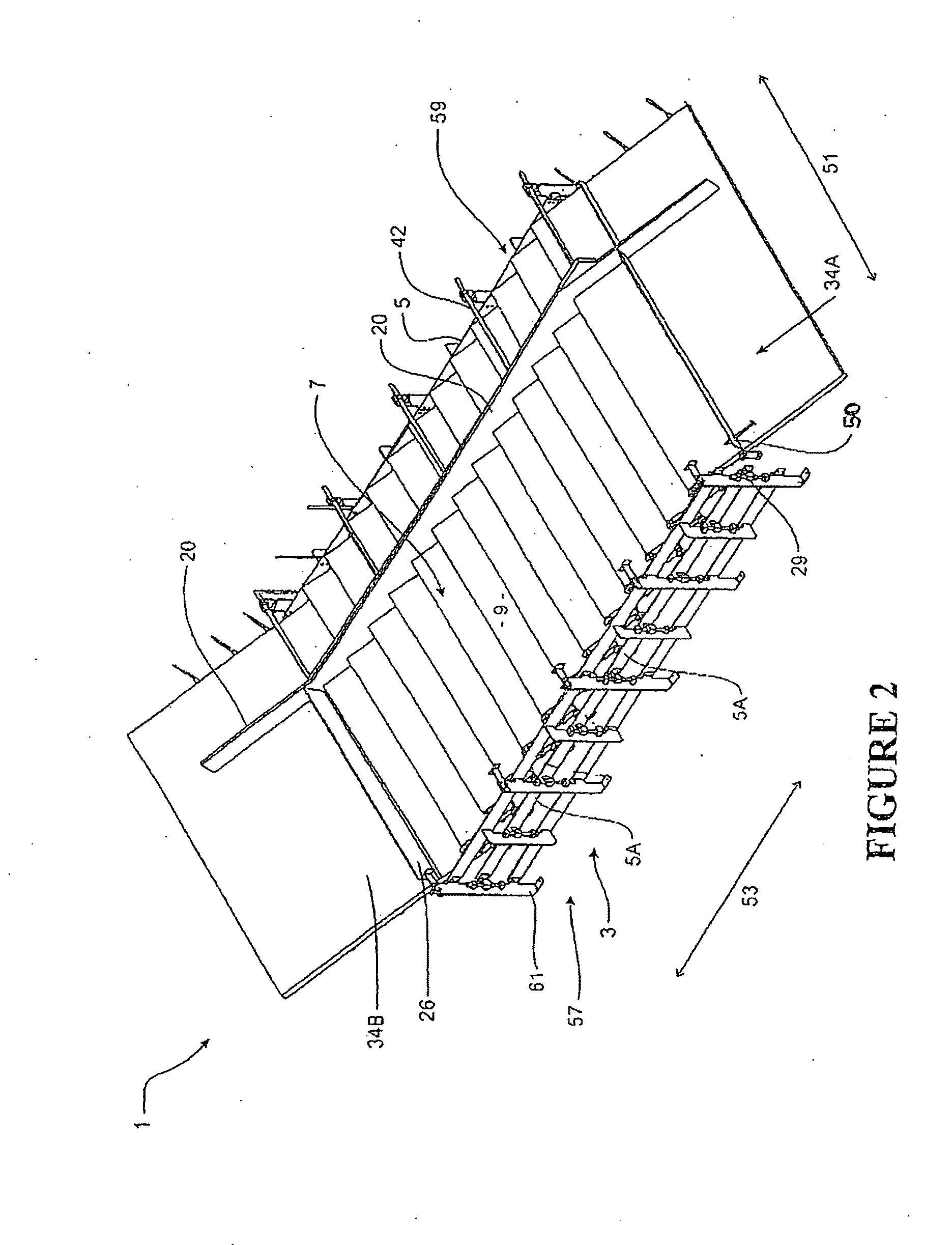

Lightweight Crane-Set Forming Panel

InactiveUS20080173788A1Easy to useReinforce against deflectionCeramic shaping apparatusForms/shuttering/falseworksEngineeringSurface plate

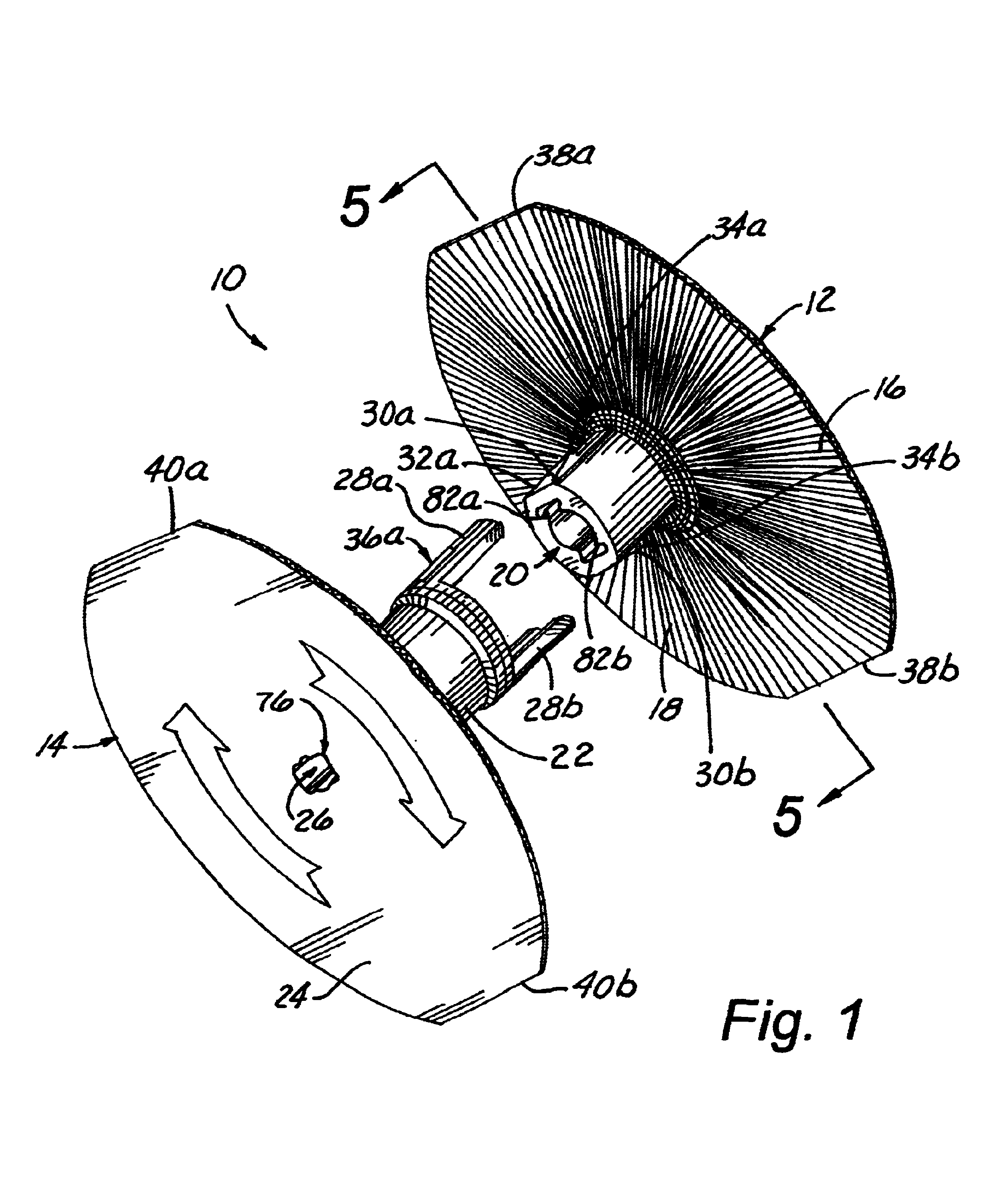

A forming panel is provided which is particularly useful as a large, crane-set forming panel for forming concrete walls. The forming panel includes a face plate and a frame, the frame including channels having a slot extending longitudinally therealong. The slot is adapted to receive a filler insert having a bushing which includes a flexible barrier having a brush-like element with a plurality of filaments extending into a passage configured to receive either a tie bar or a tie rod. The forming panel preferably includes a shiftably mounted bracket for supporting a waler, scaffold or strongback thereon, wherein the bracket includes an arm which may be pivoted to a position substantially parallel to the frame and its mounting plate for transport and / or storage. The face plate may be provided as a multilayered composite panel and the frame may include rails having grooves on the side opposite the face plate which receive flexible barriers for inhibiting the passage of fine particles of concrete therepast.

Owner:WESTERN FORMS

Insulated concrete form and method of using same

InactiveUS8756890B2Improve sound insulationImproved curing environmentCeilingsConstruction materialEngineeringInsulating concrete form

Owner:CIUPERCA ROMEO ILARIAN

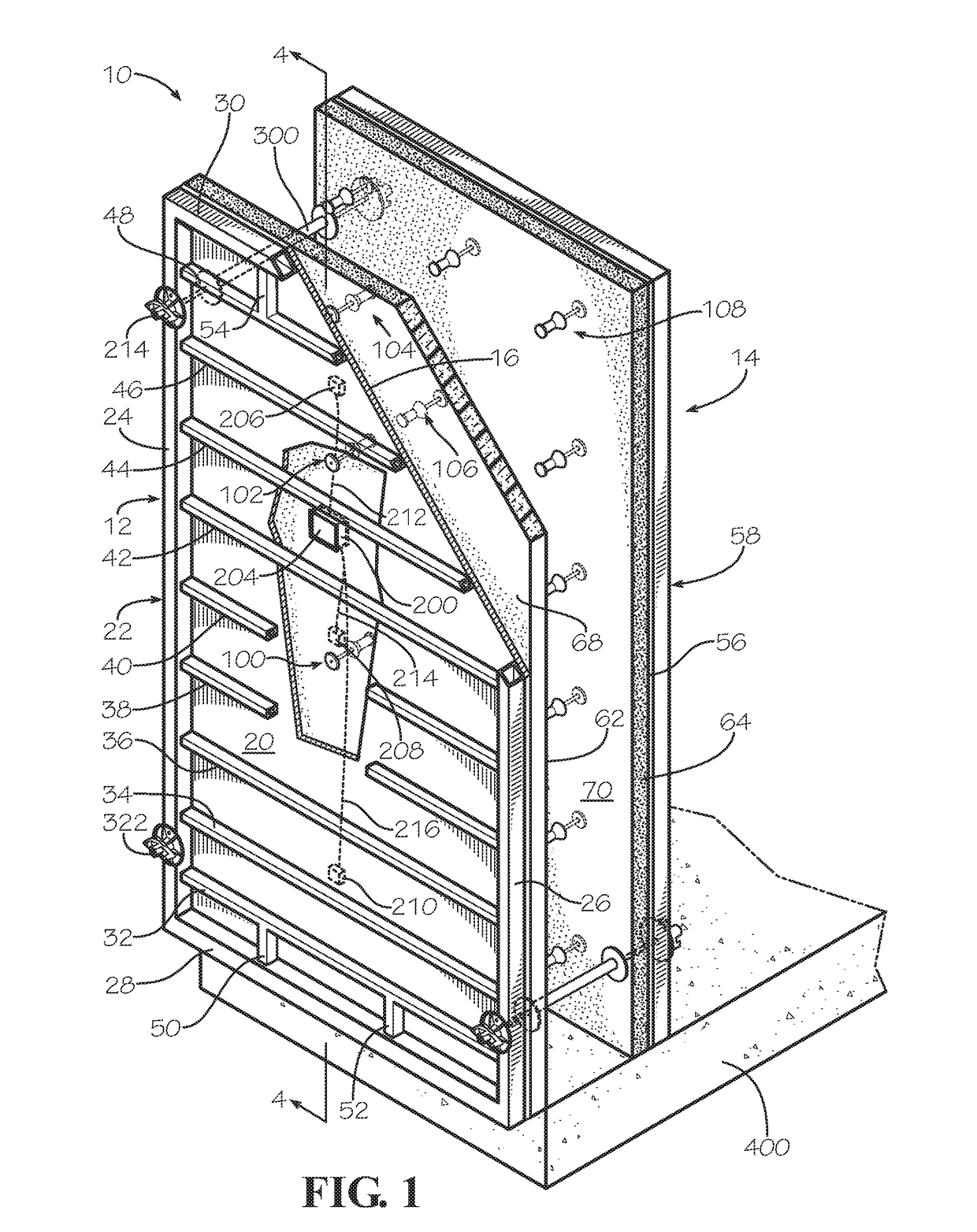

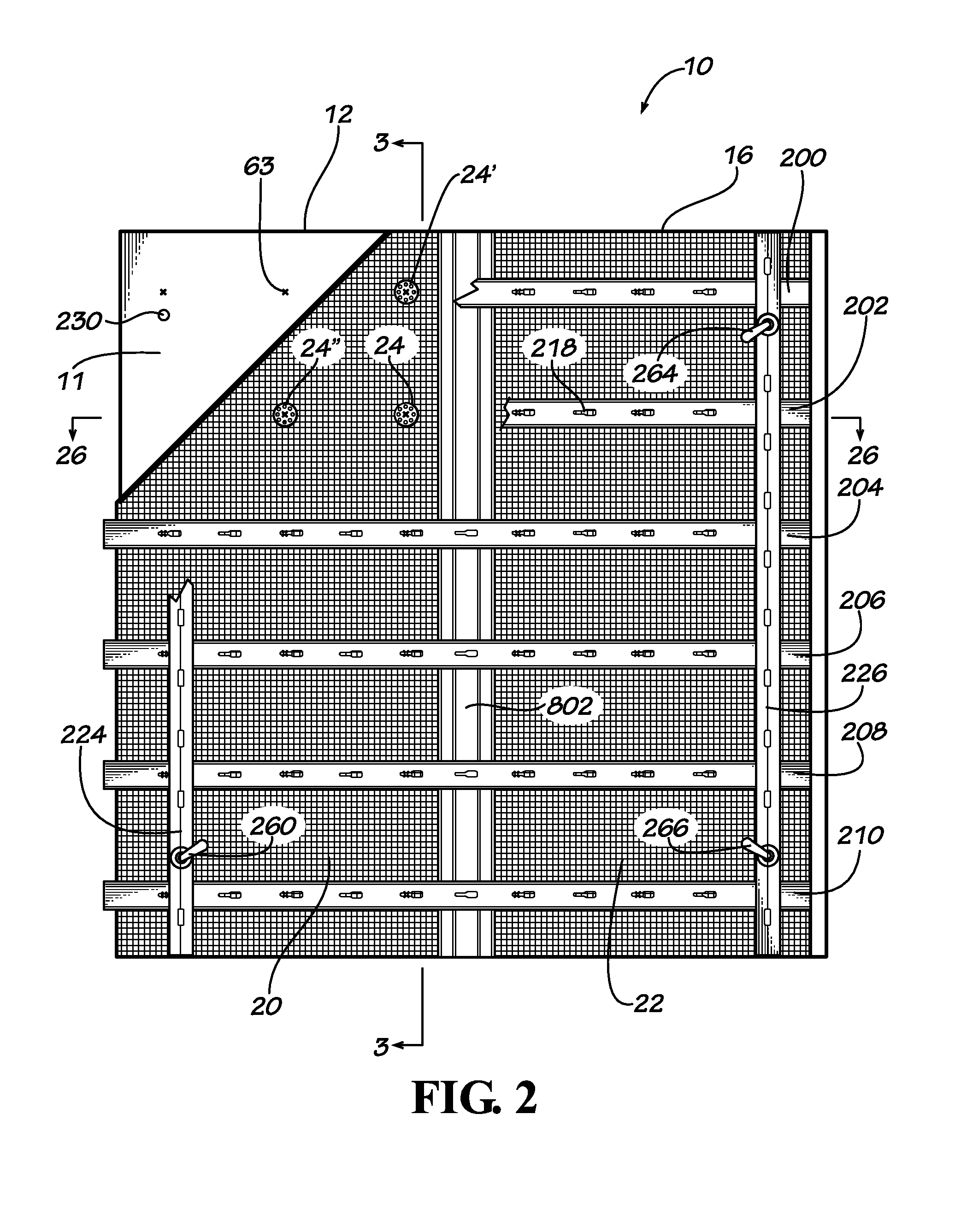

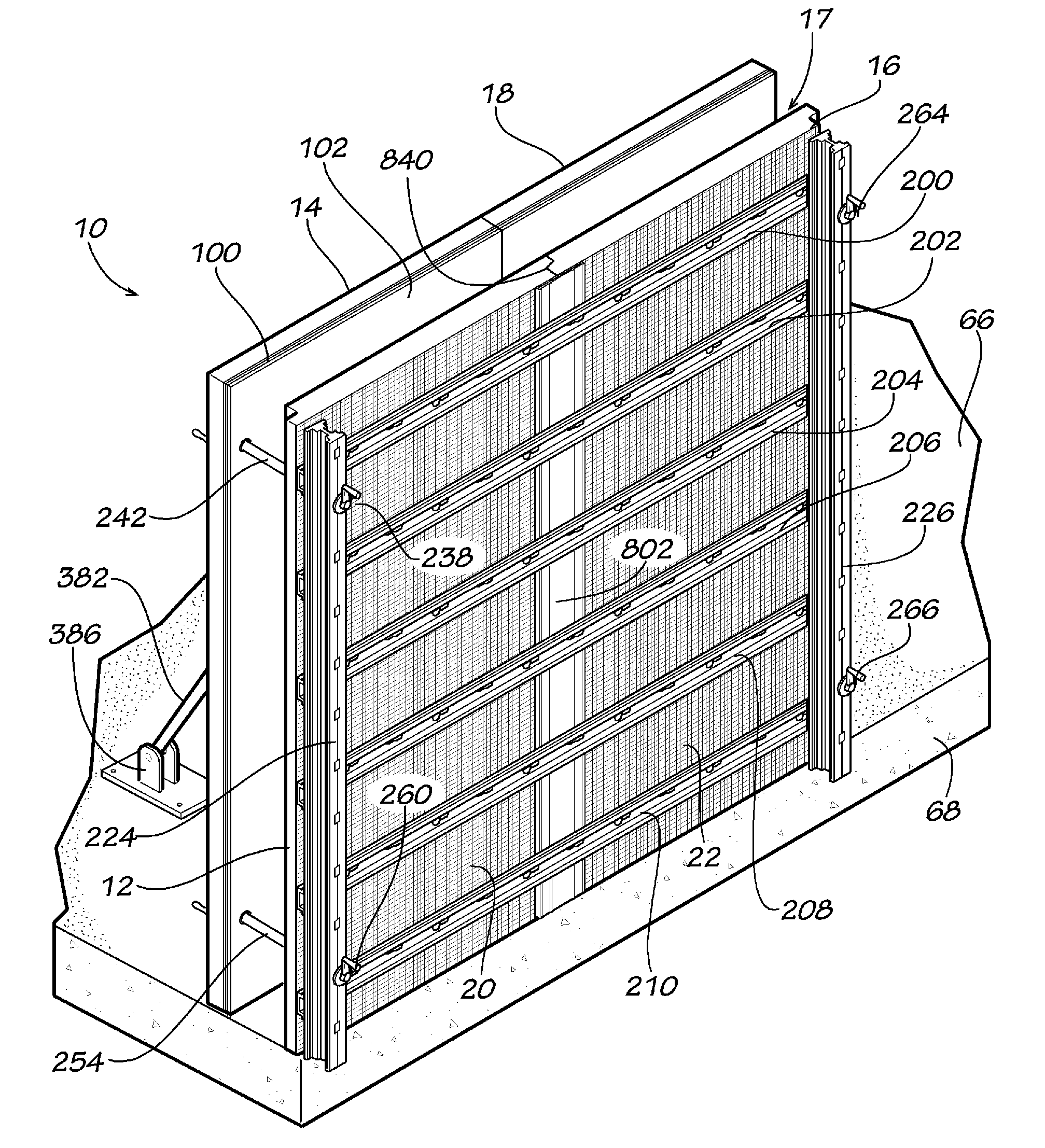

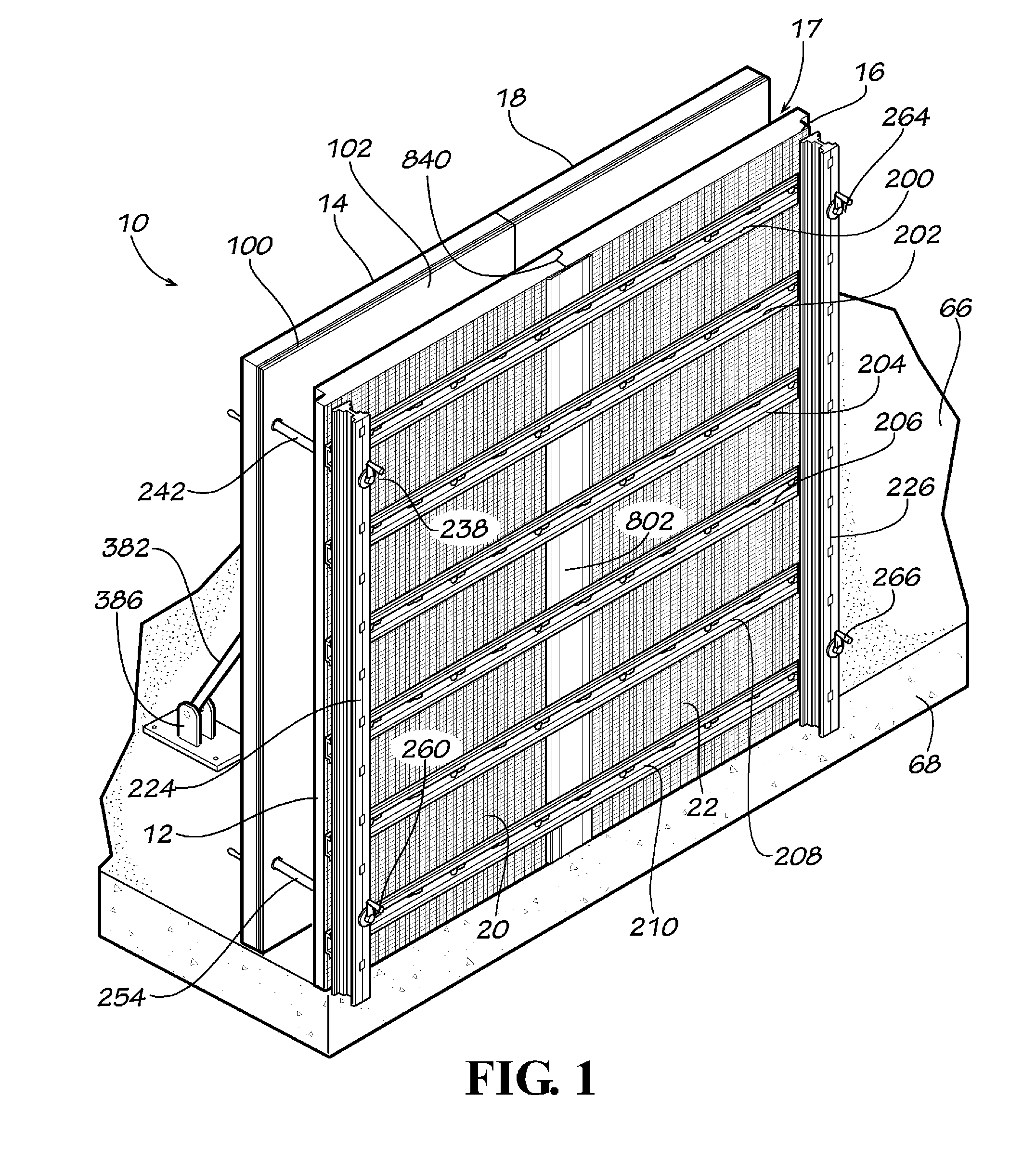

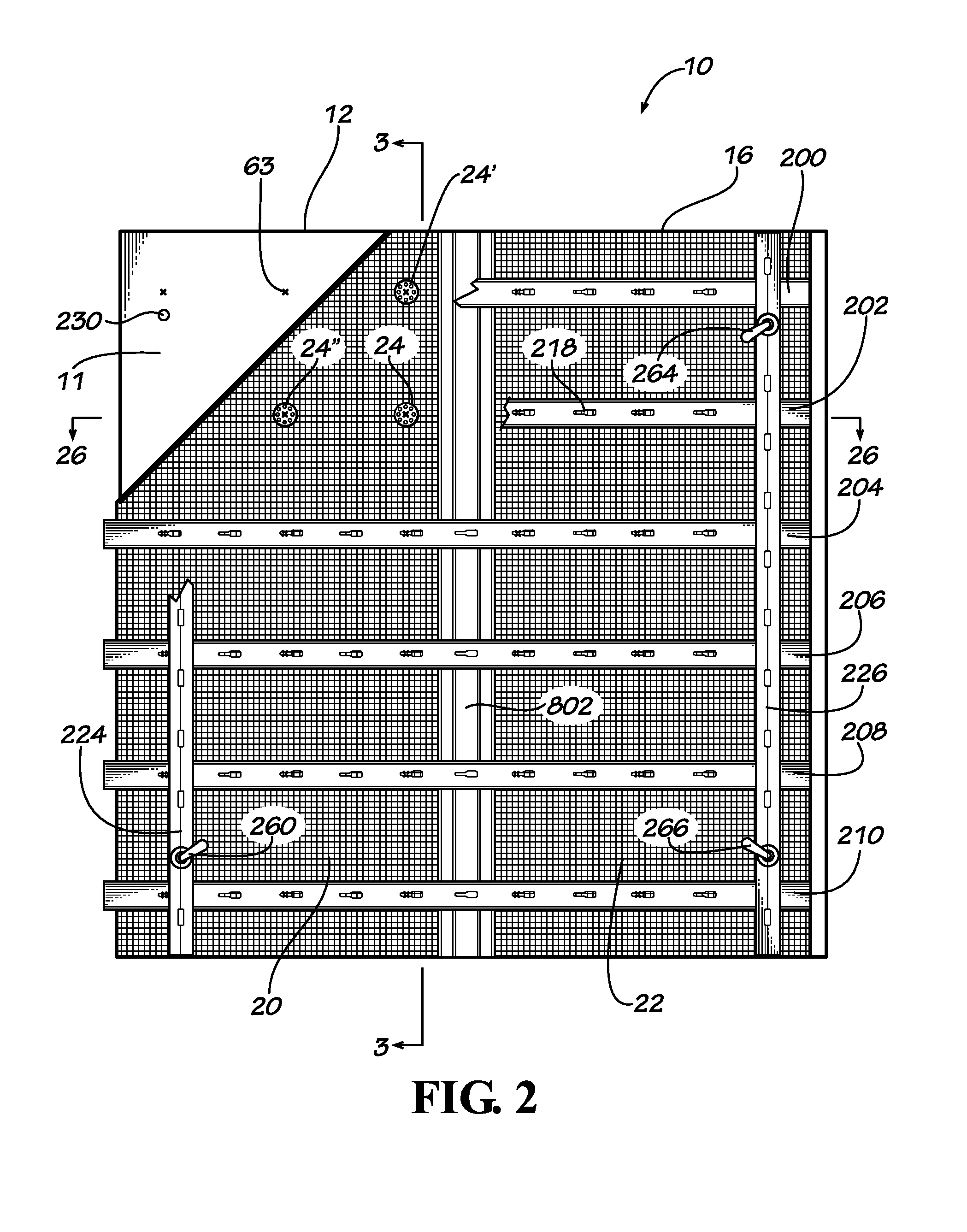

High strength adjustable vertical concrete form

A construction form system for forming concrete walls for use as above grade walls, foundations, frost walls, exterior envelopes, and the like, is disclosed. The system includes a plurality of pairs of opposing vertical forming panels spaced from each other to define a forming cavity disposed to receive a hardenable material. Each pair of opposing forming panels comprises an inner panel forming part of an inner wall and an outer panel forming part of an outer wall. The system also includes an outer rail positioned between each adjacent pair of outer forming panels and an inner rail positioned between each adjacent pair of inner forming panels. The inner forming panels comprise support panels configured to be selectively addable and removable from between each adjacent pair of inner rails prior to and subsequent to a pouring of the hardenable material into the cavity.

Owner:TF FORMING SYST

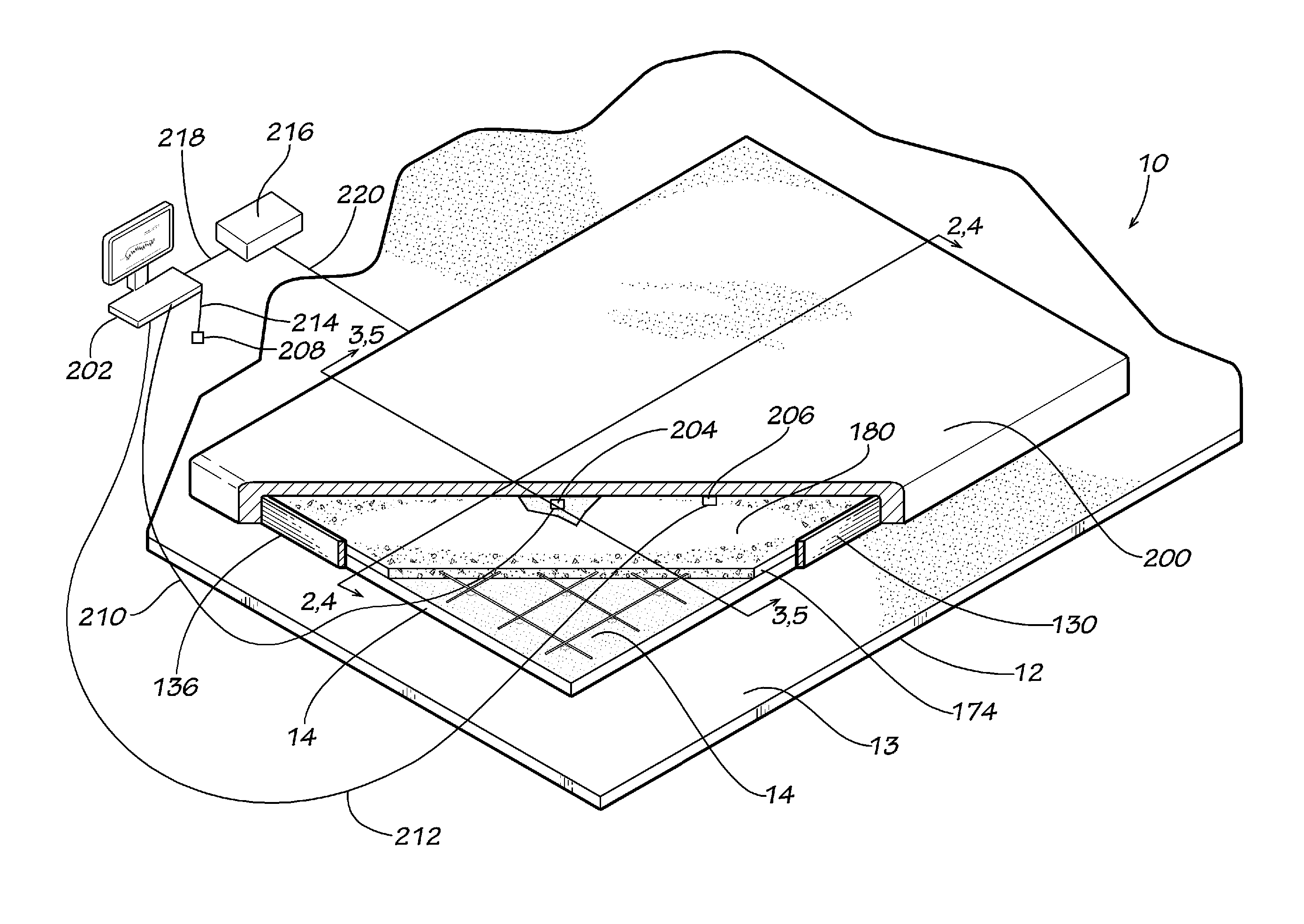

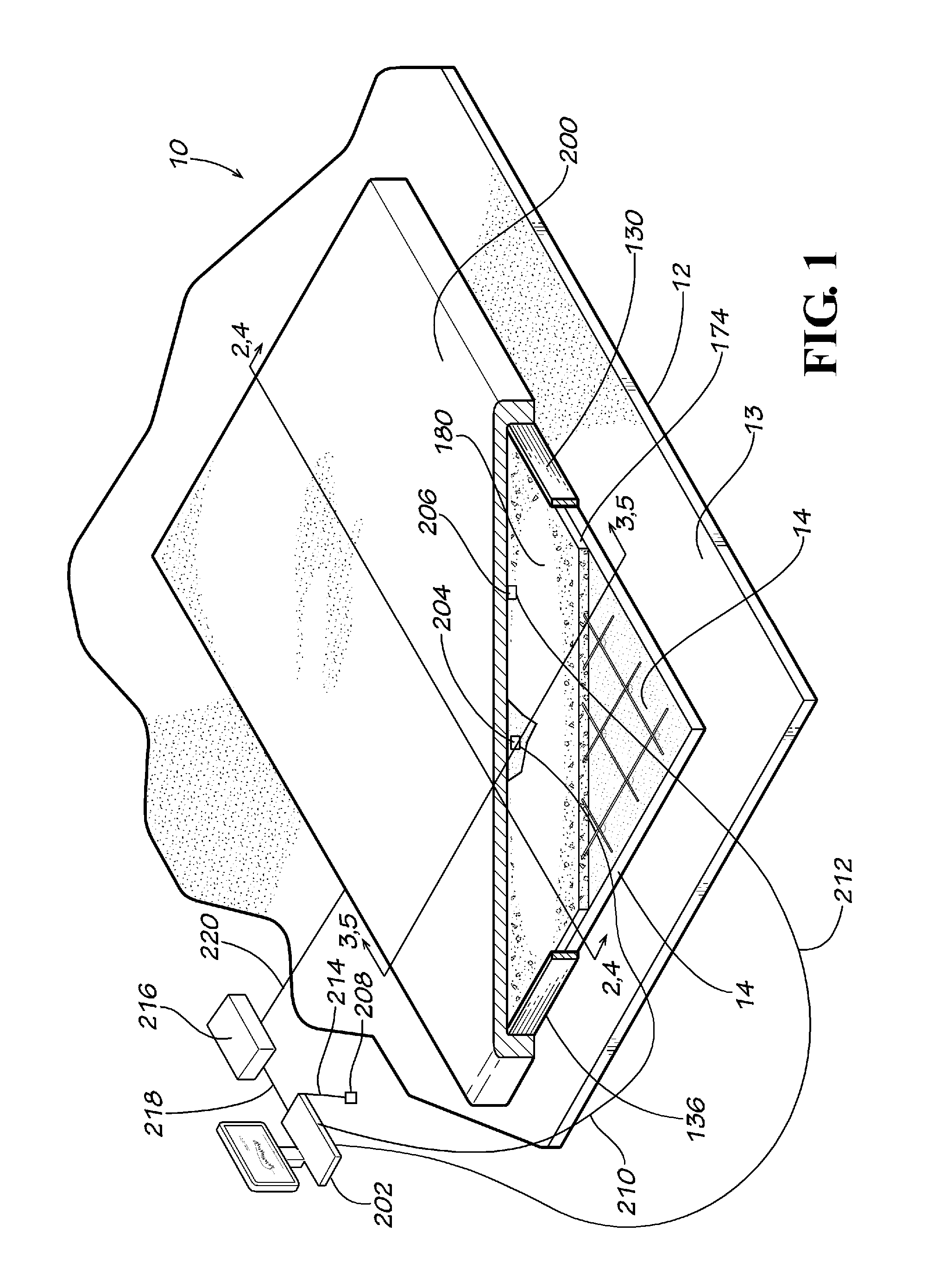

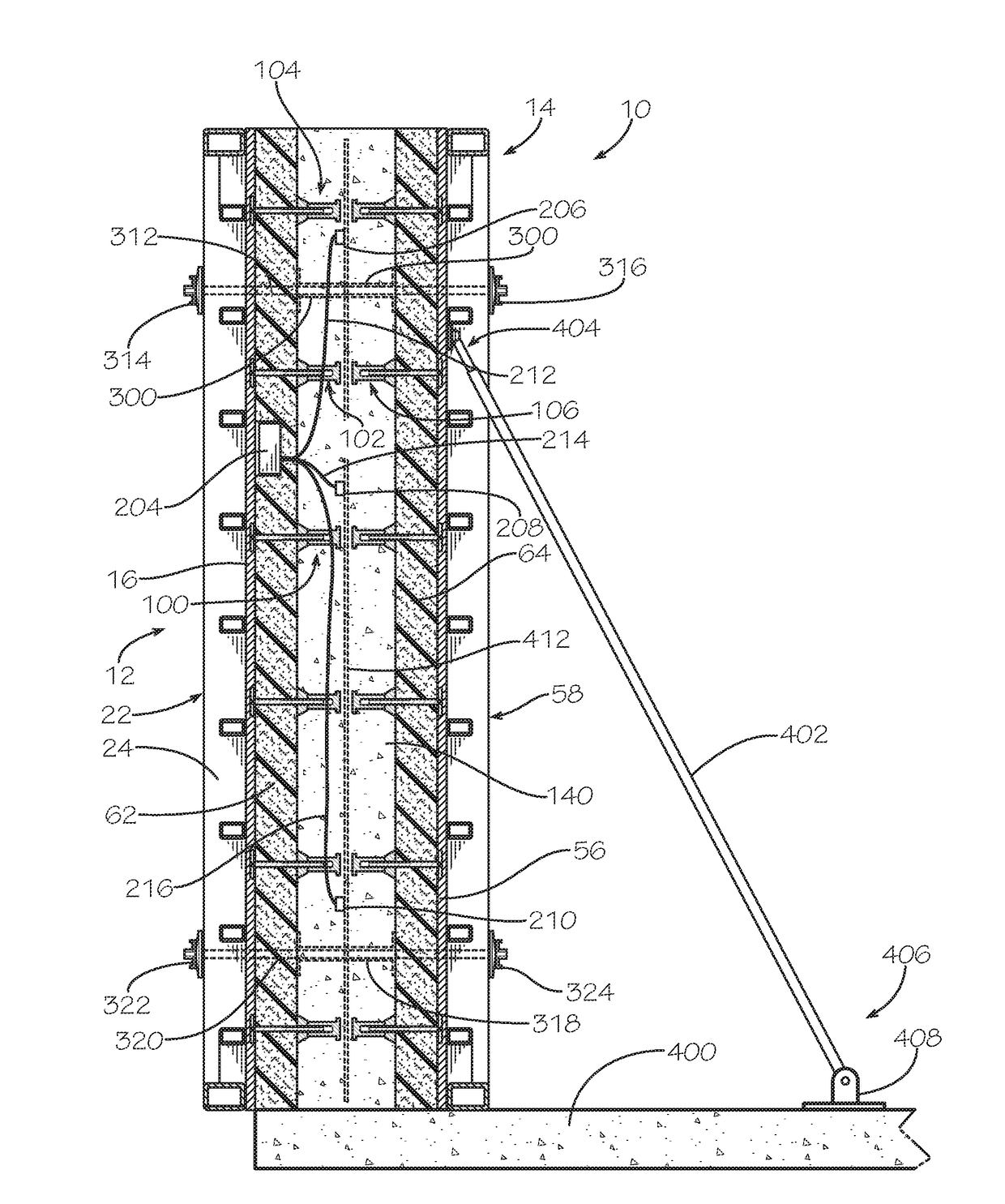

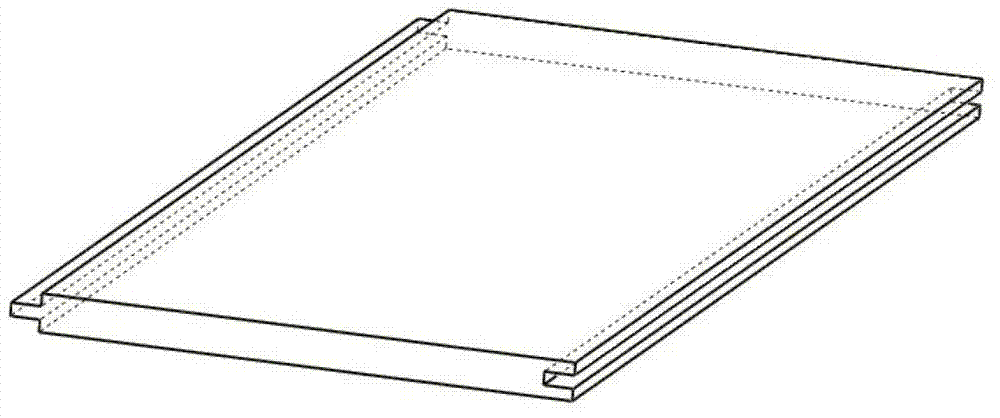

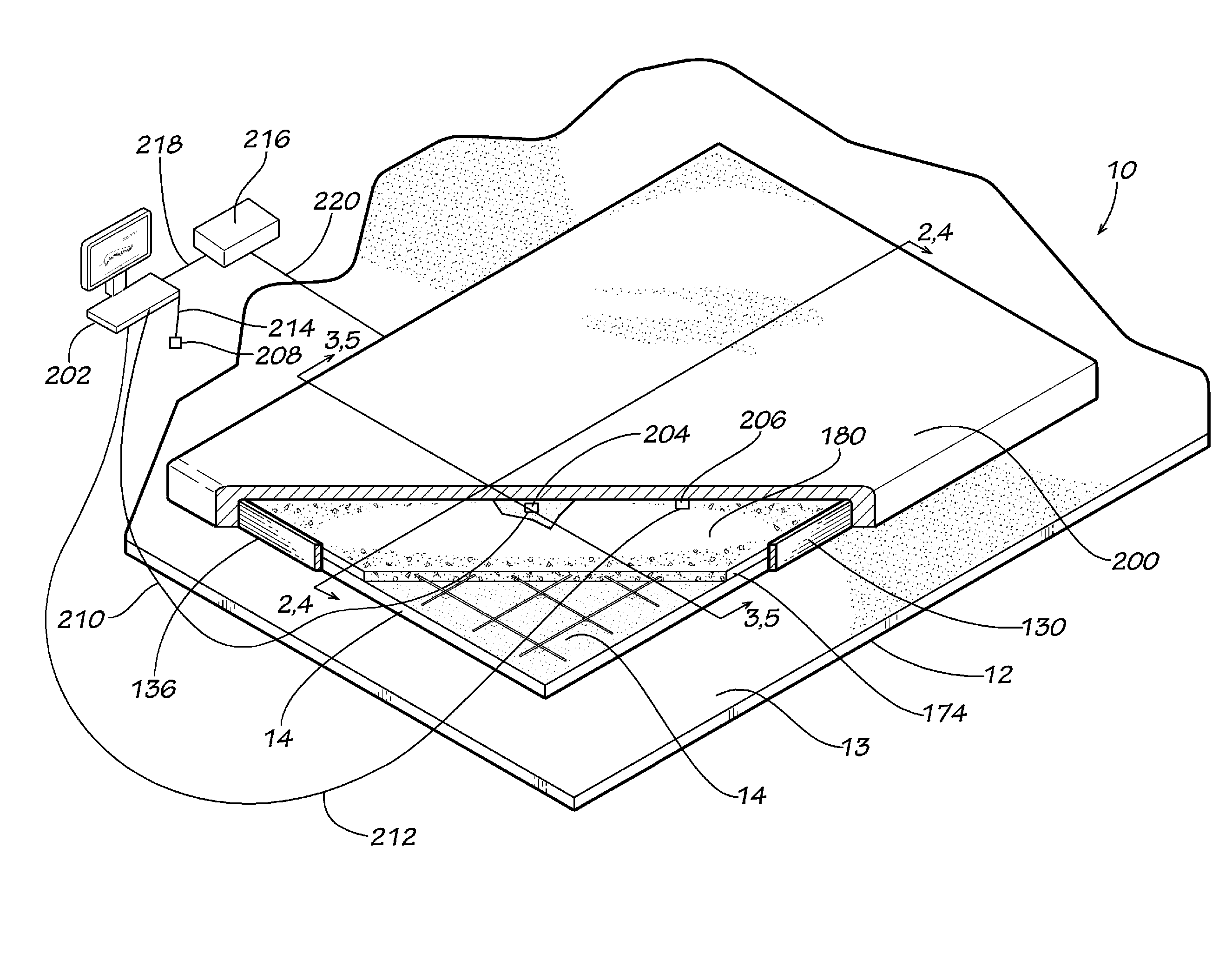

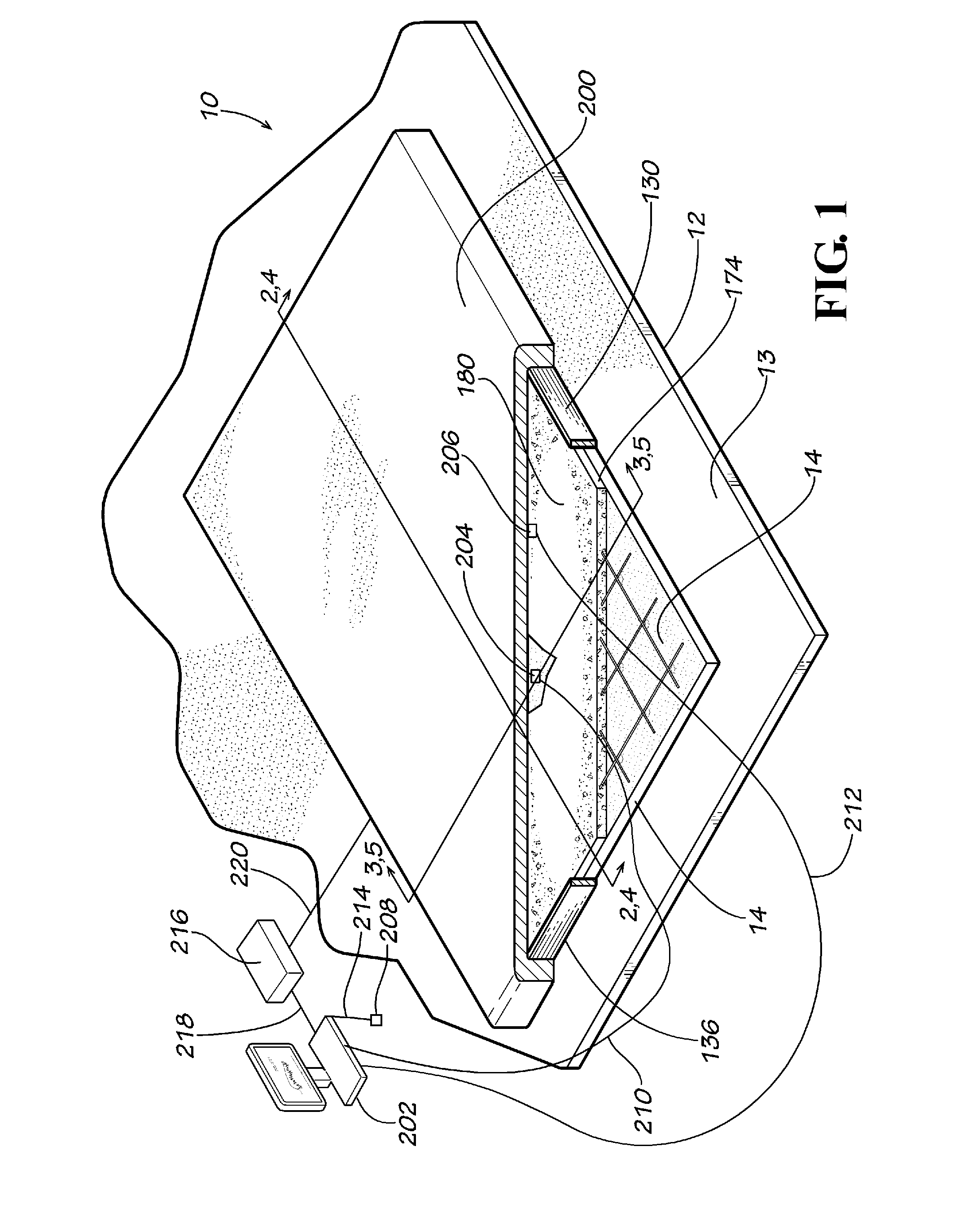

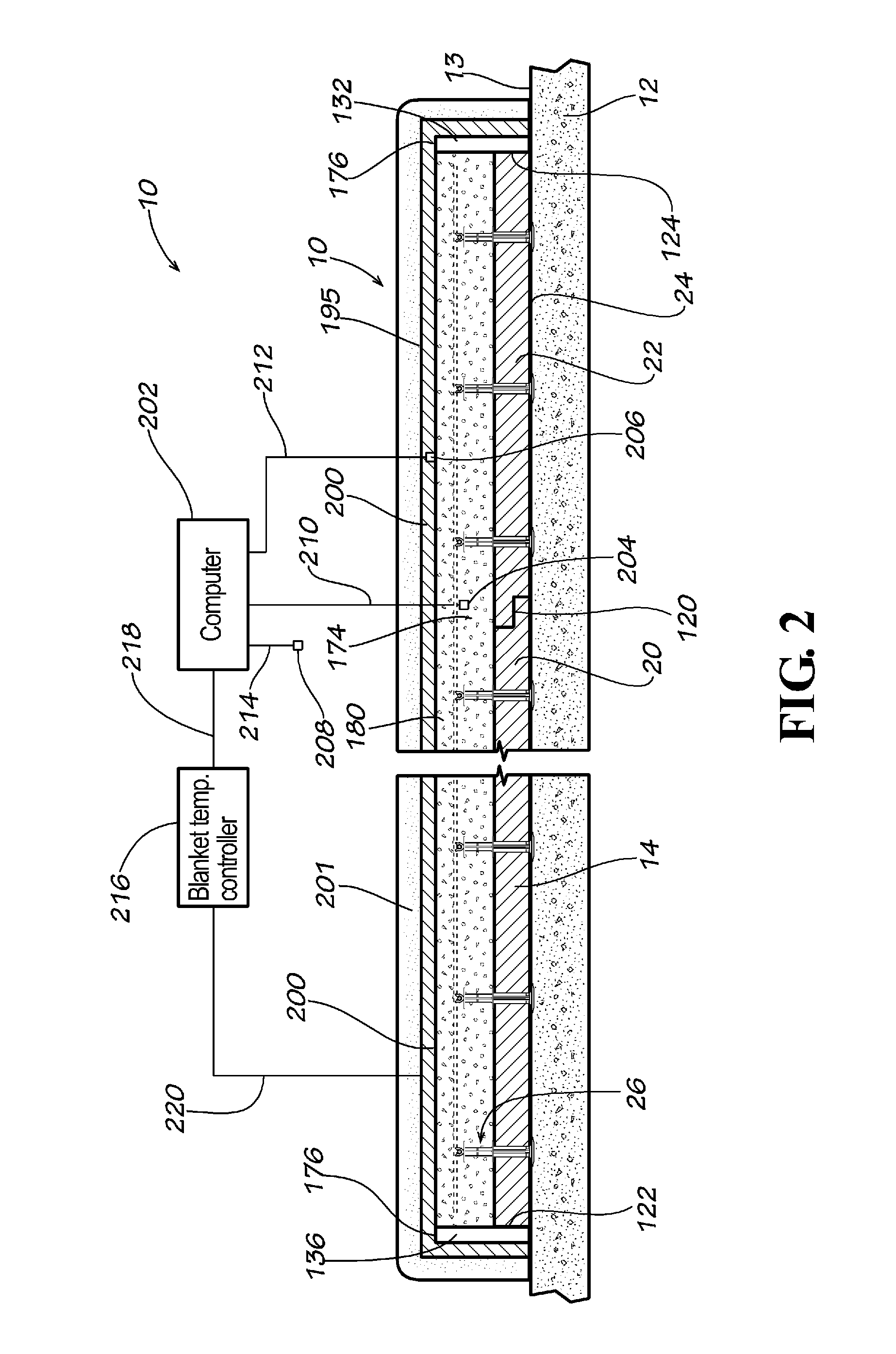

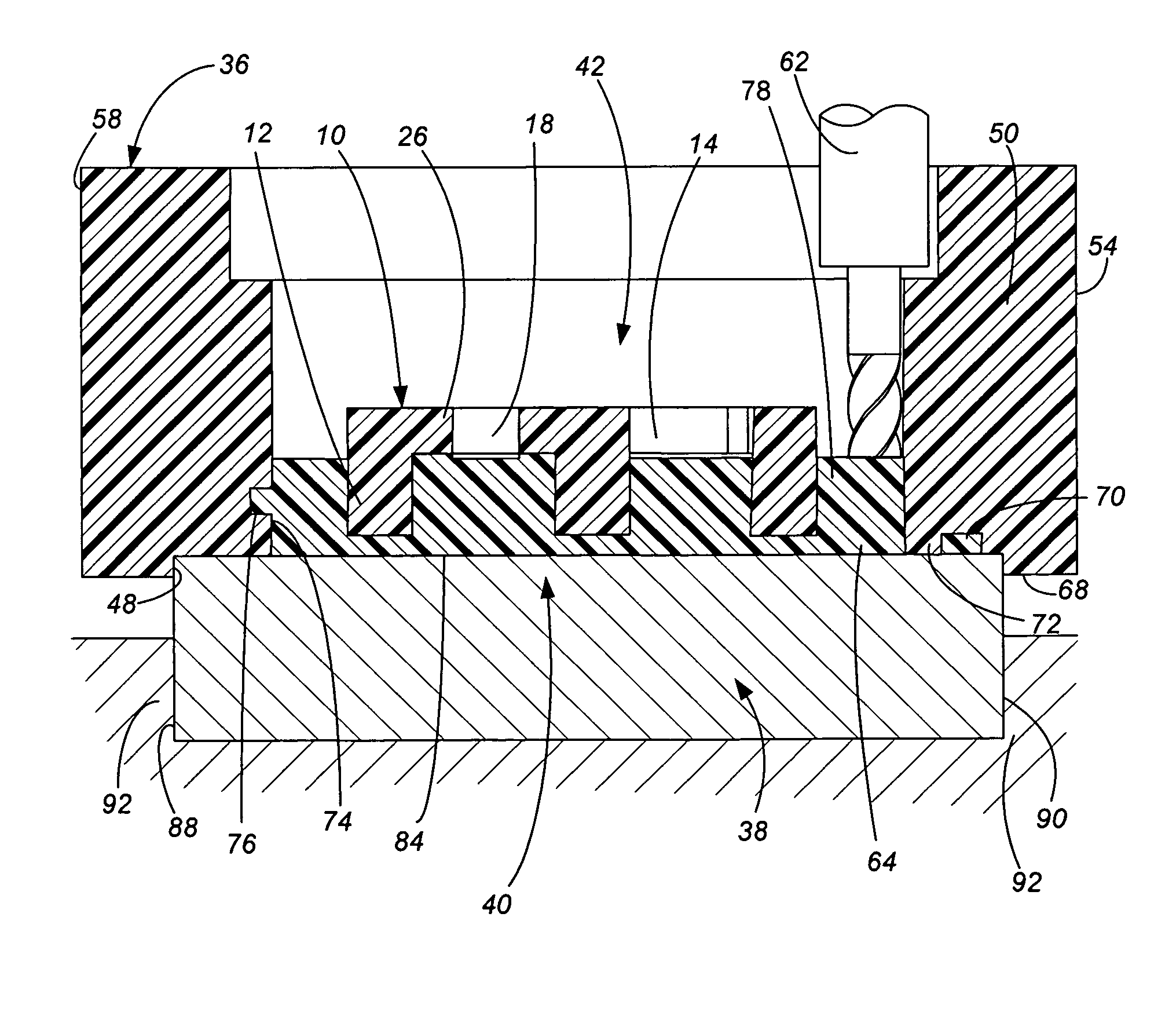

Self-annealing concrete, self-annealing concrete forms, temperature monitoring system for self-annealing concrete forms and method of making and using same

ActiveUS20170218614A1Improved curing environmentAvoid insufficient heatingConstruction materialWallsForming faceTemperature monitoring

The invention comprises a product. The product comprises a first removable concrete form having a concrete forming face and a first insulating panel insert having a first primary surface and an opposite second primary surface, wherein the second primary surface of the first insulating panel insert contacts the concrete forming face of the first removable concrete form. The product also comprises an elongate anchor member having an enlarged portion and an elongate portion, the elongate portion having a first end and an opposite second end, wherein the enlarged portion is disposed adjacent the first end and contacts the second primary surface of the first insulating panel insert and wherein the elongate portion extends through the first insulating panel insert and extends outwardly from the first primary surface of the first insulating panel insert. A method of using a removable insulated concrete form system is also disclosed.

Owner:CIUPERCA ROMEO ILARIAN

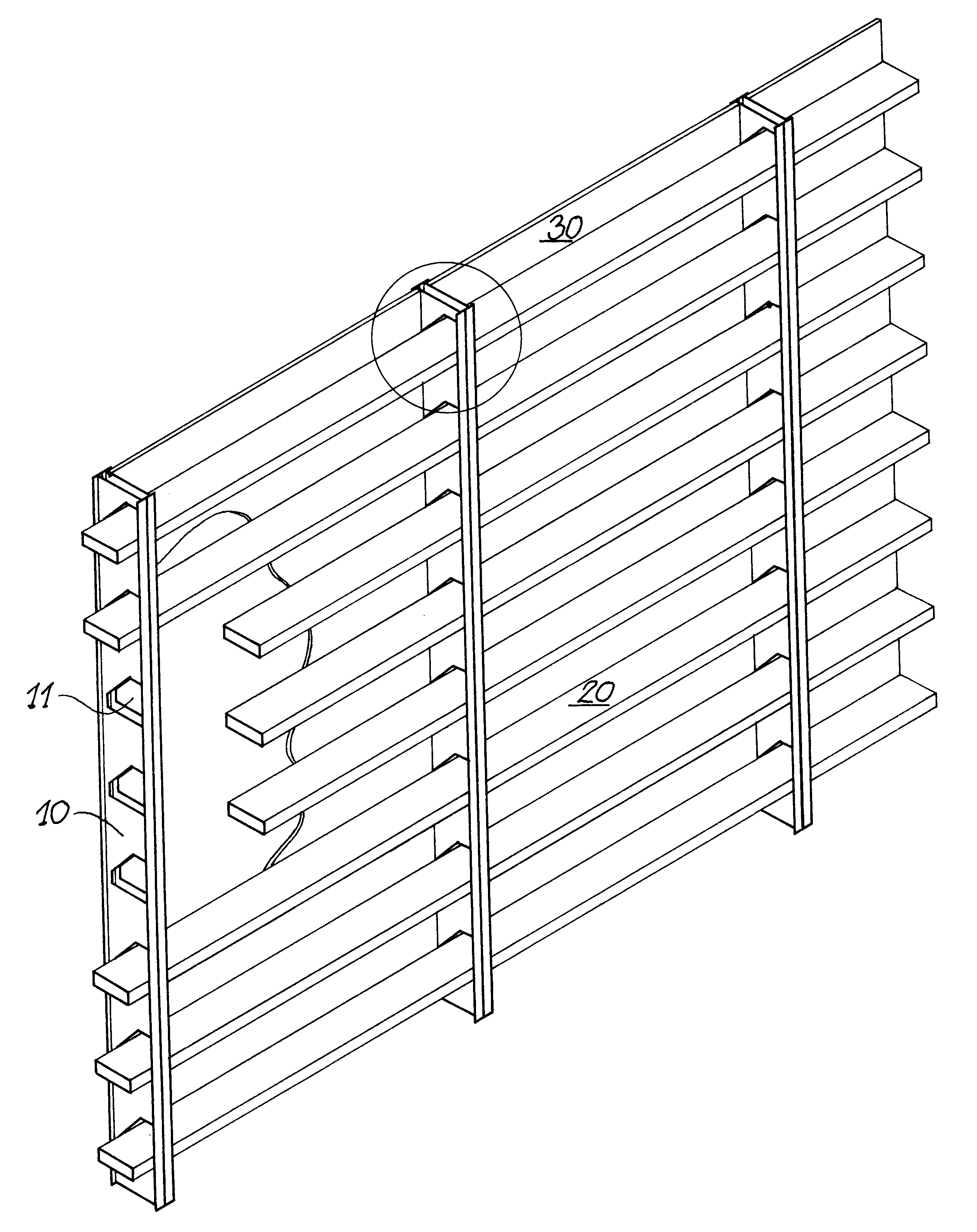

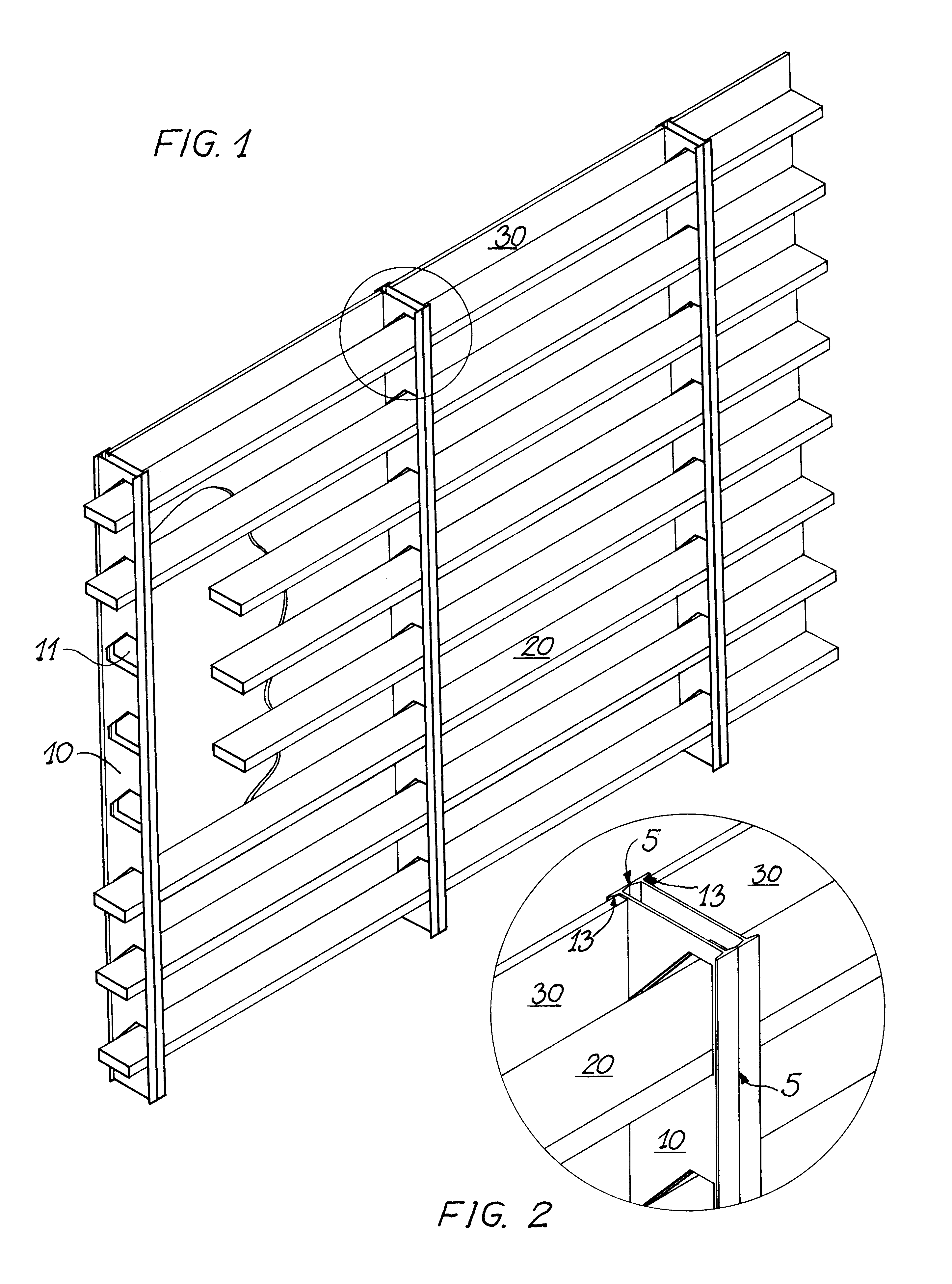

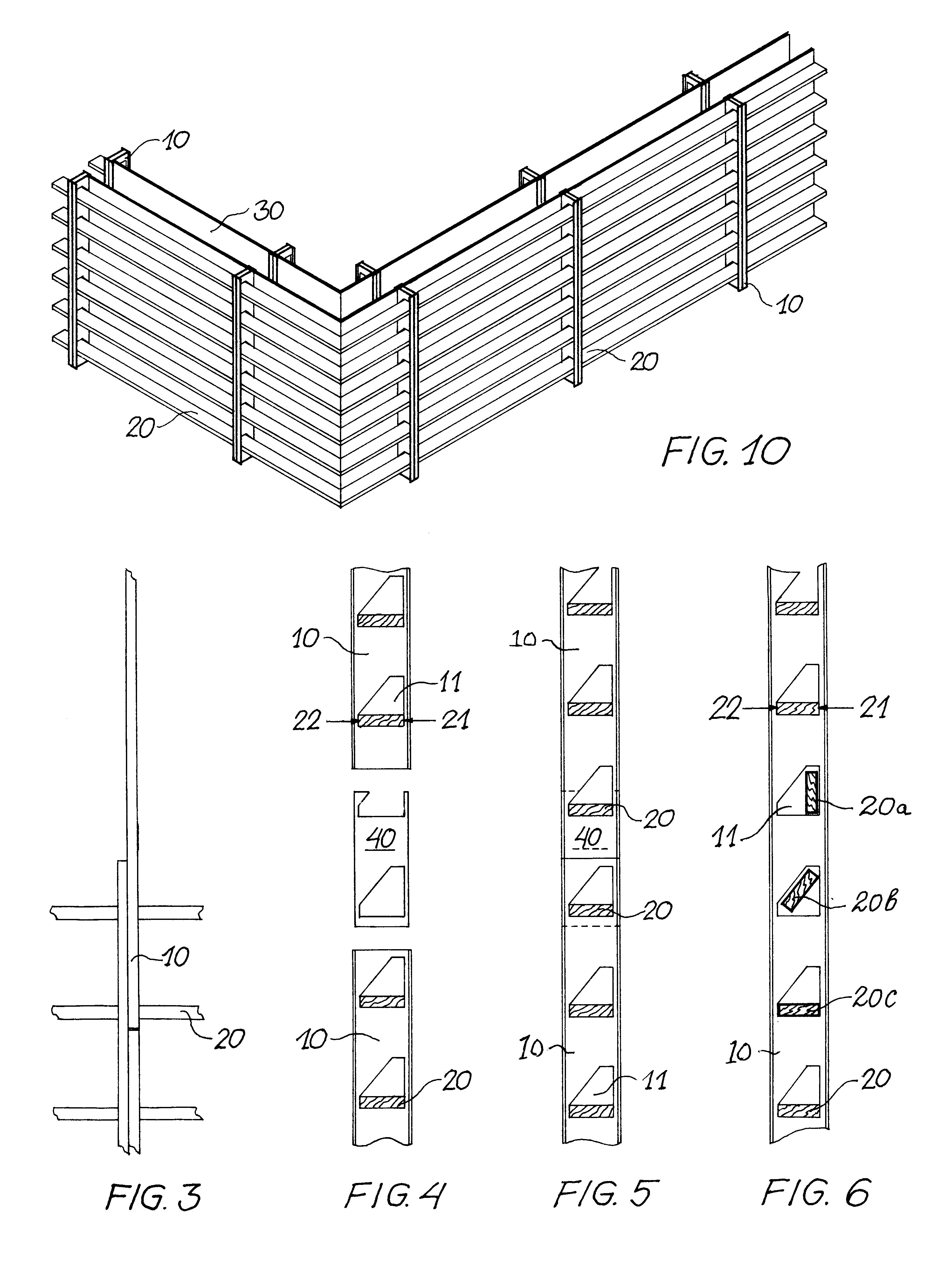

Sub-rigid fast-form barrier system

The invention disclosed herein is remarkable in its simplicity and promises wide commercial application as the labor costs for construction become increasingly prohibitive. The extraordinary absence of nails, screws, bolts, welds or any other fastening device allows these barriers to compete with many conventional barrier systems, such as those employed for fencing, vehicular trailer beds, removable stages, and scale models or toys of all fabrications mentioned plus many more. In this age time is money and the erection speed this barrier system offers may well revolutionize conventional "post and beam" framing. The invention is specifically aimed at eccentric beam loading where barriers must be economically fabricated to withstand hurricane force winds, earthquake reactions, or liquid concrete pressure in a sub-rigid manner. The Fast-Form System will offer insurers building products that will protect their interests for any and all applications. When the barriers disclosed herein are utilized for concrete formwork, contractors will have a new option that embraces standard building products, with barrier fabrication accomplished in half the time of the systems that precede it.

Owner:NELSON THOMAS PAGE

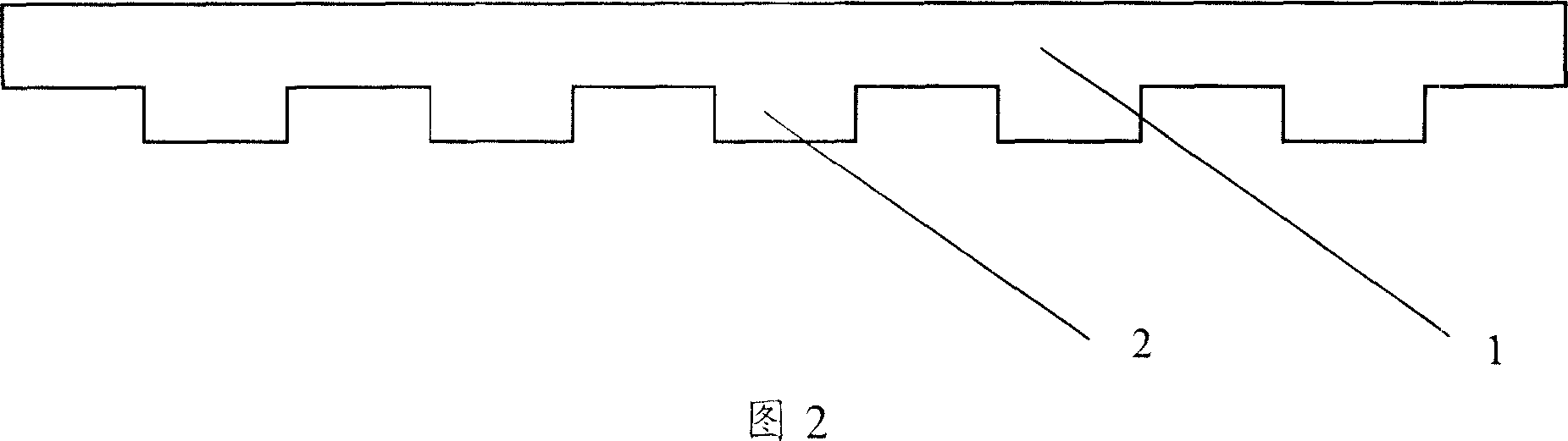

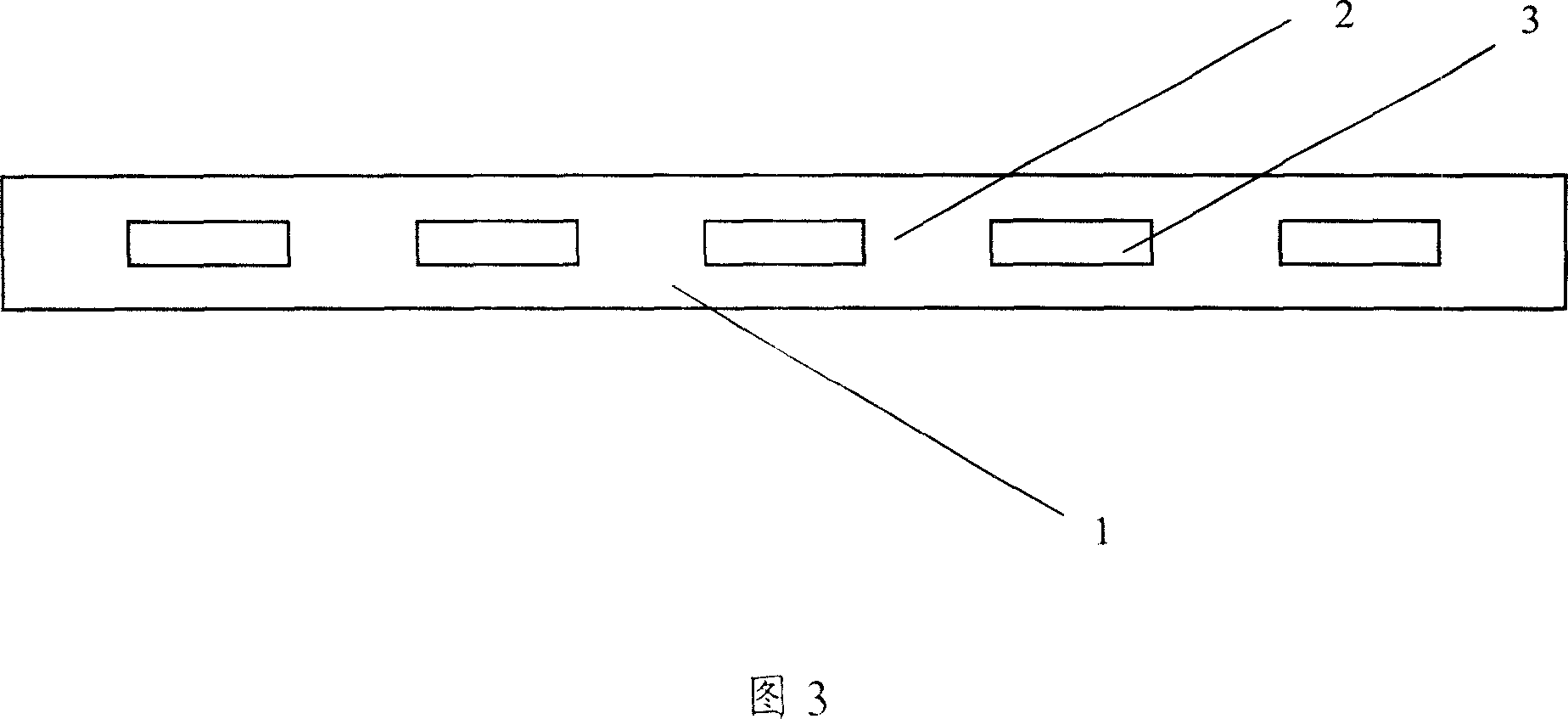

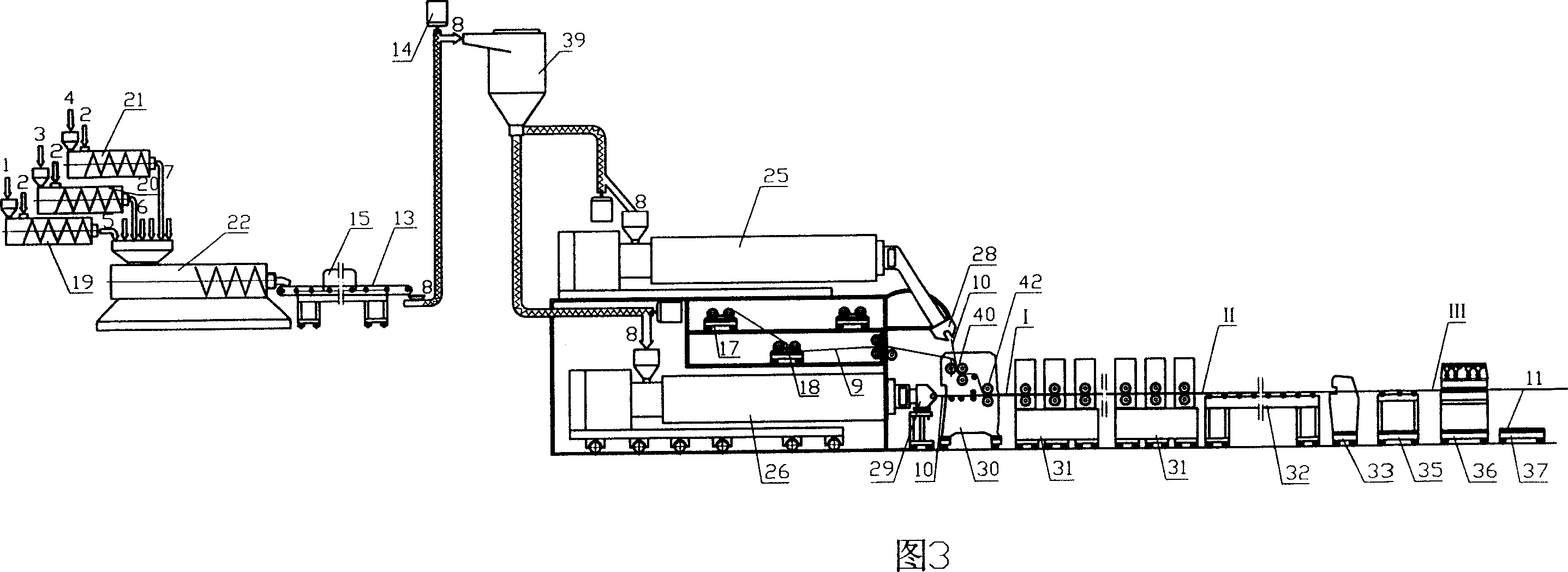

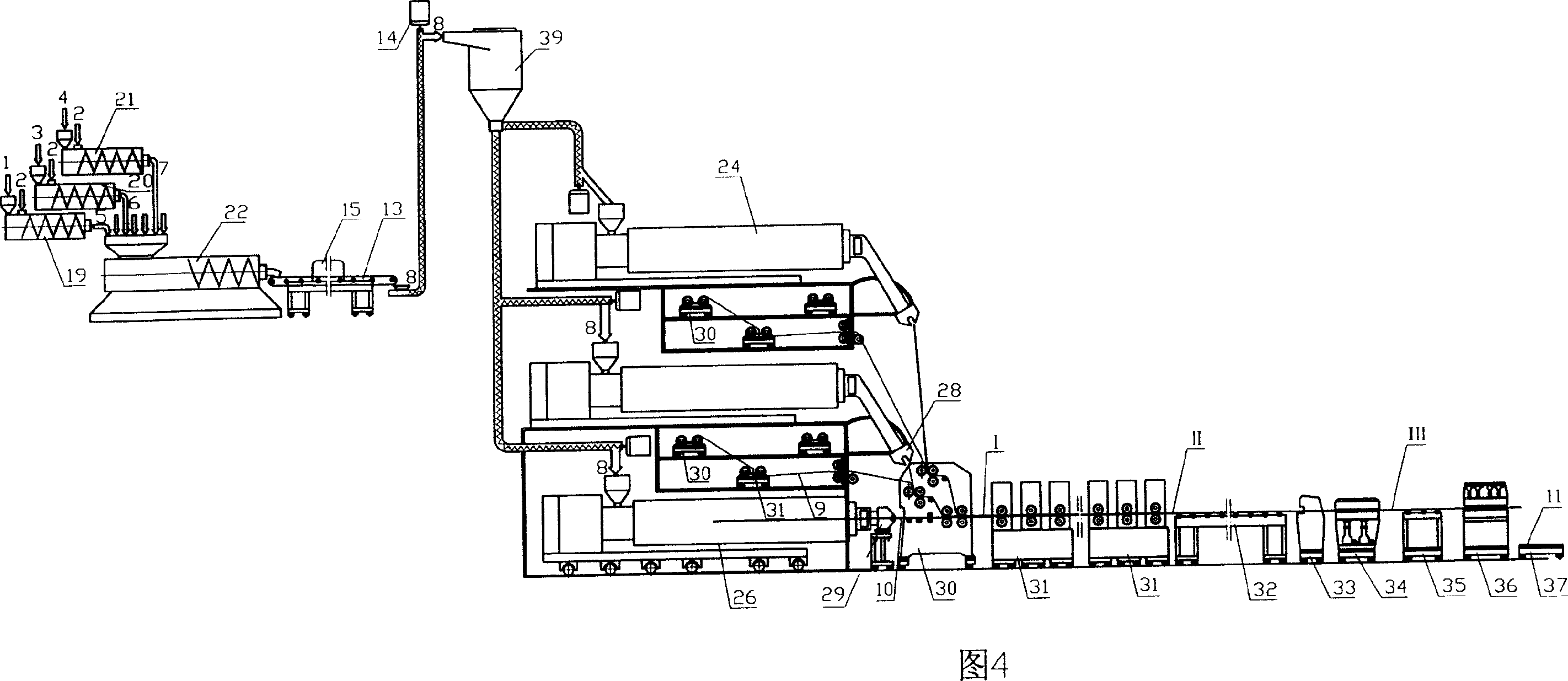

High-transverse-strength pultrusion structural sheet material and manufacturing method thereof

ActiveCN103589127AImprove longitudinal strengthReduce weightForming/stuttering elementsYarnGlass fiber

The invention relates to a high-transverse-strength pultrusion structural sheet material and a manufacturing method thereof. The manufacturing method comprises that: alkali-free glass fiber roving, knitting felt and composite felt are drawn out from a creel and a felt shaft, and successively pass a yarn-guiding rack, a gum dipping tank, a pre-forming die apparatus; and glass fiber yarn and glass fiber felt subjected to infiltration and pre-forming enter a structural sheet material pultrusion die heated to a preset temperature, and sheet materials subjected to solidification forming are subjected to traction by a traction mechanism, fixed-length cutting and the like for being processed into a structural sheet material product with relatively large size and with a same shape as the die shape. The product is relatively high in transverse strength, light and high in strength, and can be subjected to secondary processing such as cutting, boring and the like. Additionally, concave-convex bayonets are arranged at the two sides of the sheet material, and the sheet material is widely applicable to buildings such as large-area building templates, wall plates, roof boards, furniture plates, decorative plates and the like, and also is applicable to other industries such as energy field and transportation field.

Owner:上海事升新材料有限公司

Wood plastic composite material building mould board, its preparation method and use

InactiveCN1948665AGood flexibilityGood compatibilityDomestic articlesForming/stuttering elementsWear resistantMechanical property

This invention discloses a kind of wood-plastic composite materials for construction template and its preparation methods and purposes. It belongs to building materials area. Against poor toughness, small strength and high cost defects of existing technologies, the main materials of this invention are PVC resin and / or plastic (new materials or waste materials) and wood fiber powder, the second materials are calcium power PE resins, short glass fiber, then adds the assistant, through mixing, heating, agitating, extrusion to matrix and cooling to shape, cutting steps to made into templates. It can increase the strength of plate by increasing various forms of reinforced structure in the process of preparation. It can be used for construct template of concrete processing. This invention can be recycled for several times, environmental protected, save resources and of low cost; the template are wear resistant and defend worms, non-absorbent, and hard to deform, with good mechanical properties, low coefficient of thermal conductivity, anti-acid and alkali.

Owner:四川自强科技有限公司

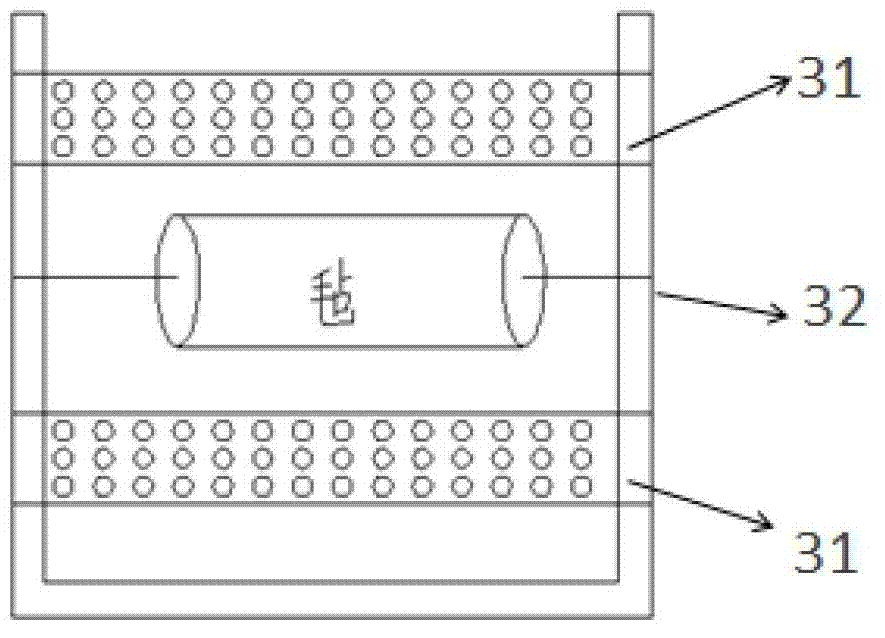

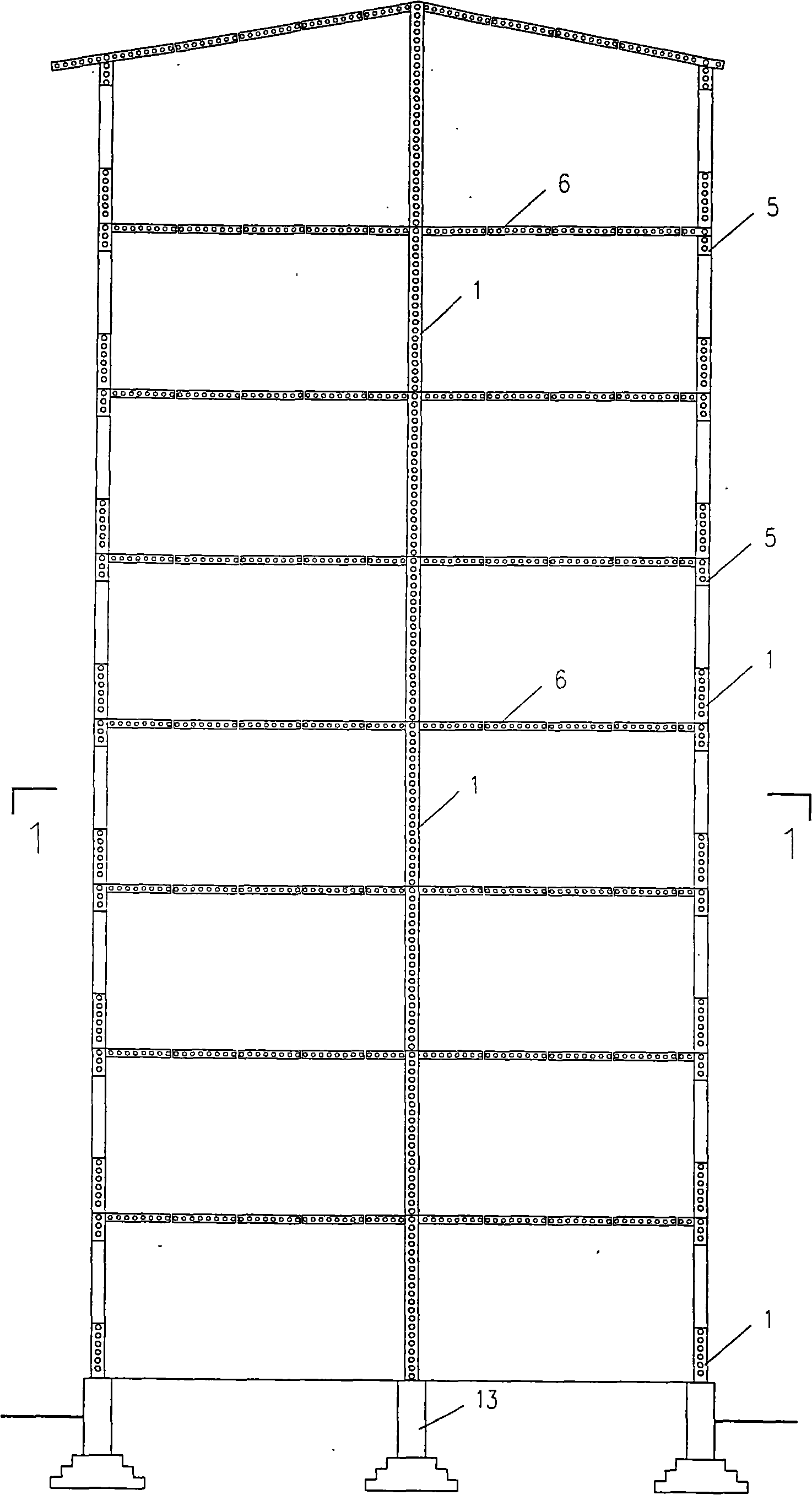

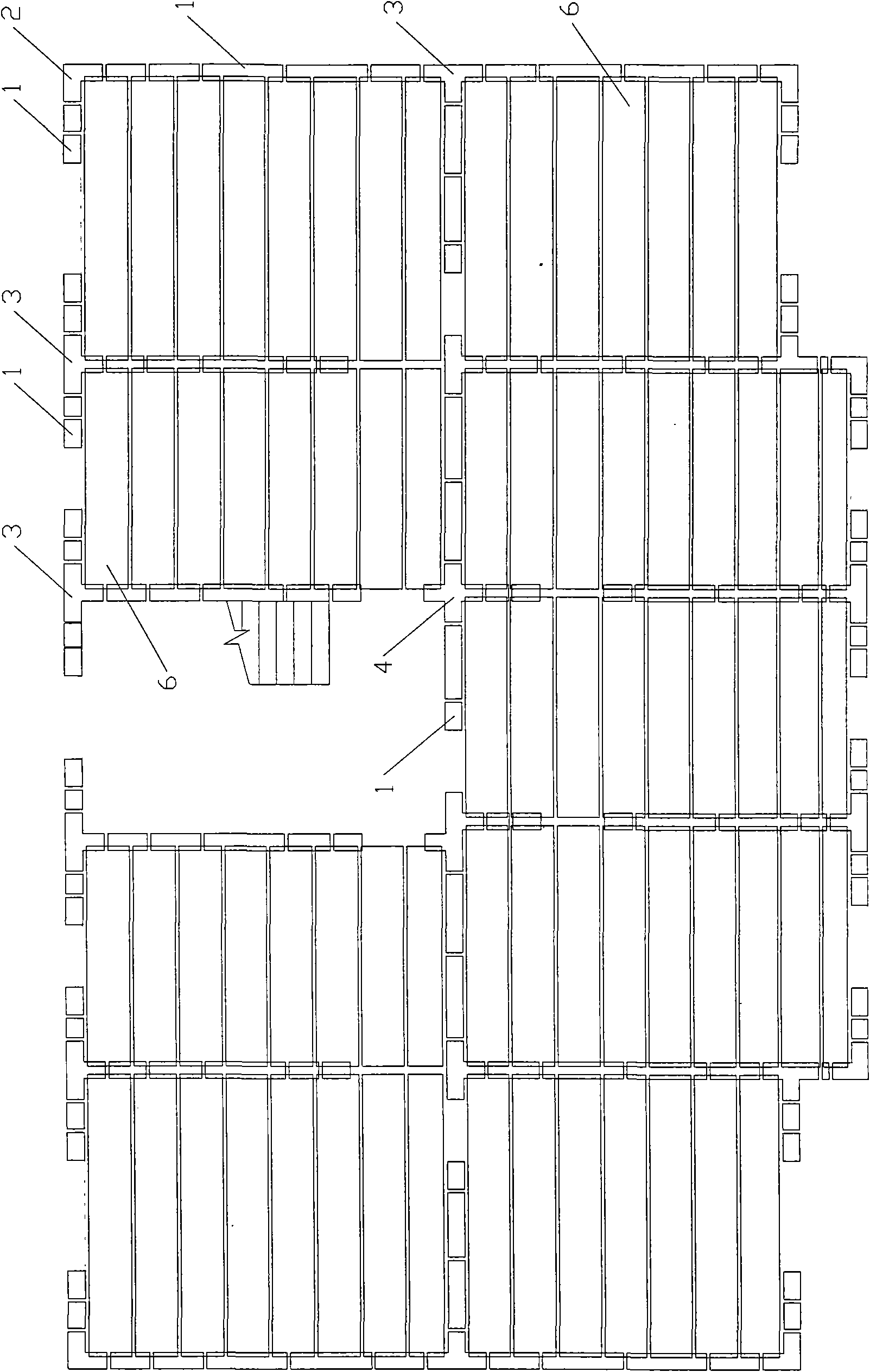

Shear wall structure building based on cross-hole prefabricated reinforced concrete template and construction method thereof

ActiveCN102061803AFlatness is easy to guaranteeReduce weightWallsBuilding reinforcementsRebarBuilding unit

The invention relates to a shear wall structure building based on a cross-hole prefabricated reinforced concrete template and a construction method thereof, belonging to the technical field of buildings and construction thereof. In the building, a wall template, an L-shaped column template, a T-shaped column template, a rectangular column template, a cruciform column template, a coupling beam template and a superstructure template which are free of removal are mutually connected to form a polyhedral space template system; all templates are the cross-hole prefabricated reinforced concrete templates; a longitudinal through hole and a lateral through hole, which are parallel to the surface, are arranged in the templates to form hollow hole paths in all directions; reinforcing steel bars and filling concrete are alternately inserted in the hollow hole paths to form a one-layer building unit or a single-layer building with the cast-in-place concrete shear wall structure; and multiple-layer building units are lapped and combined to form the multiple-layer building with the cast-in-place concrete shear wall structure. The shear wall structure building disclosed by the invention has the advantages of simpleness of processing, low production equipment investment, reduced construction working procedures, quickened construction speed, labor saving and the like.

Owner:ZHONGQINGDA TECH HLDG CO LTD

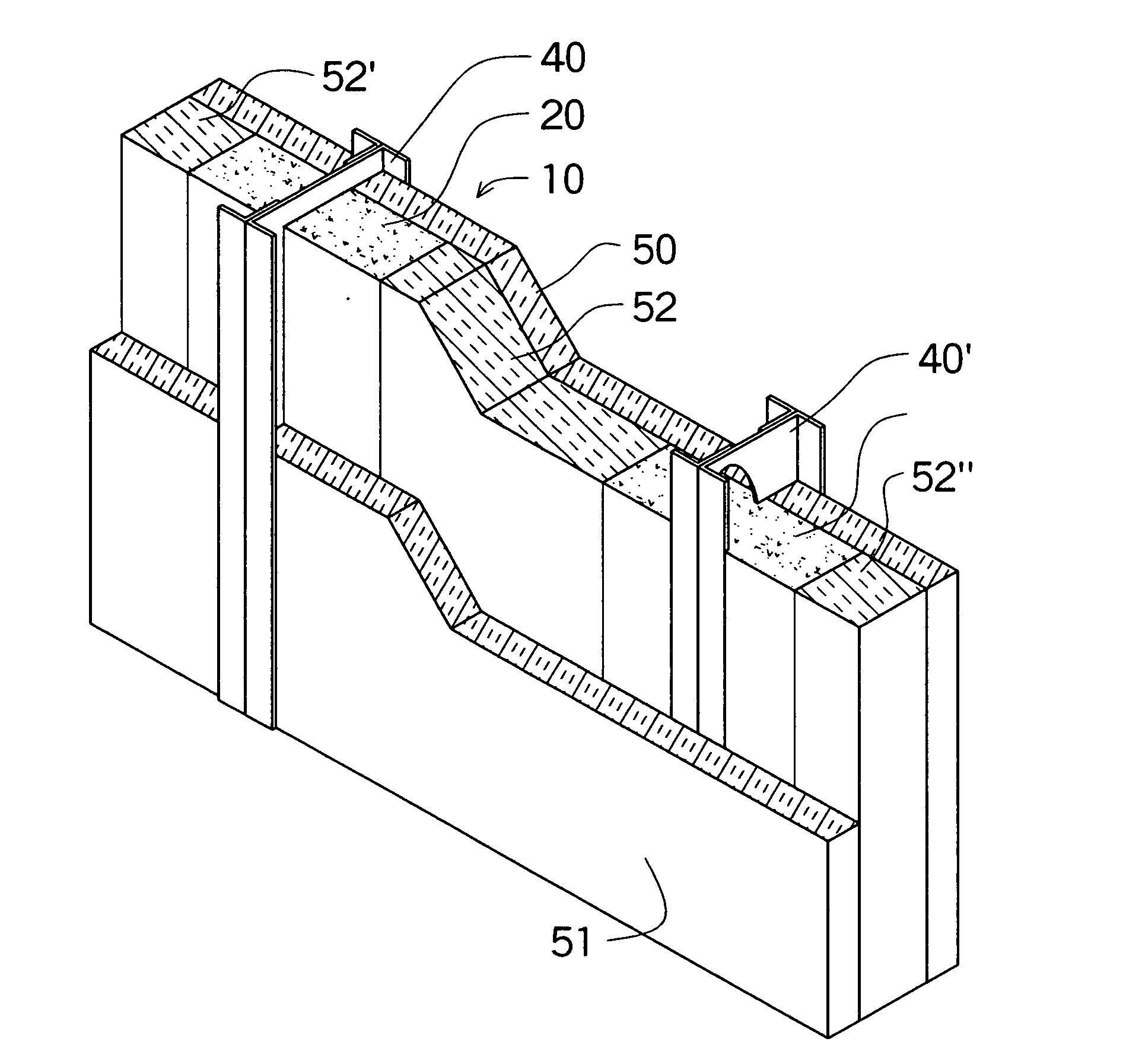

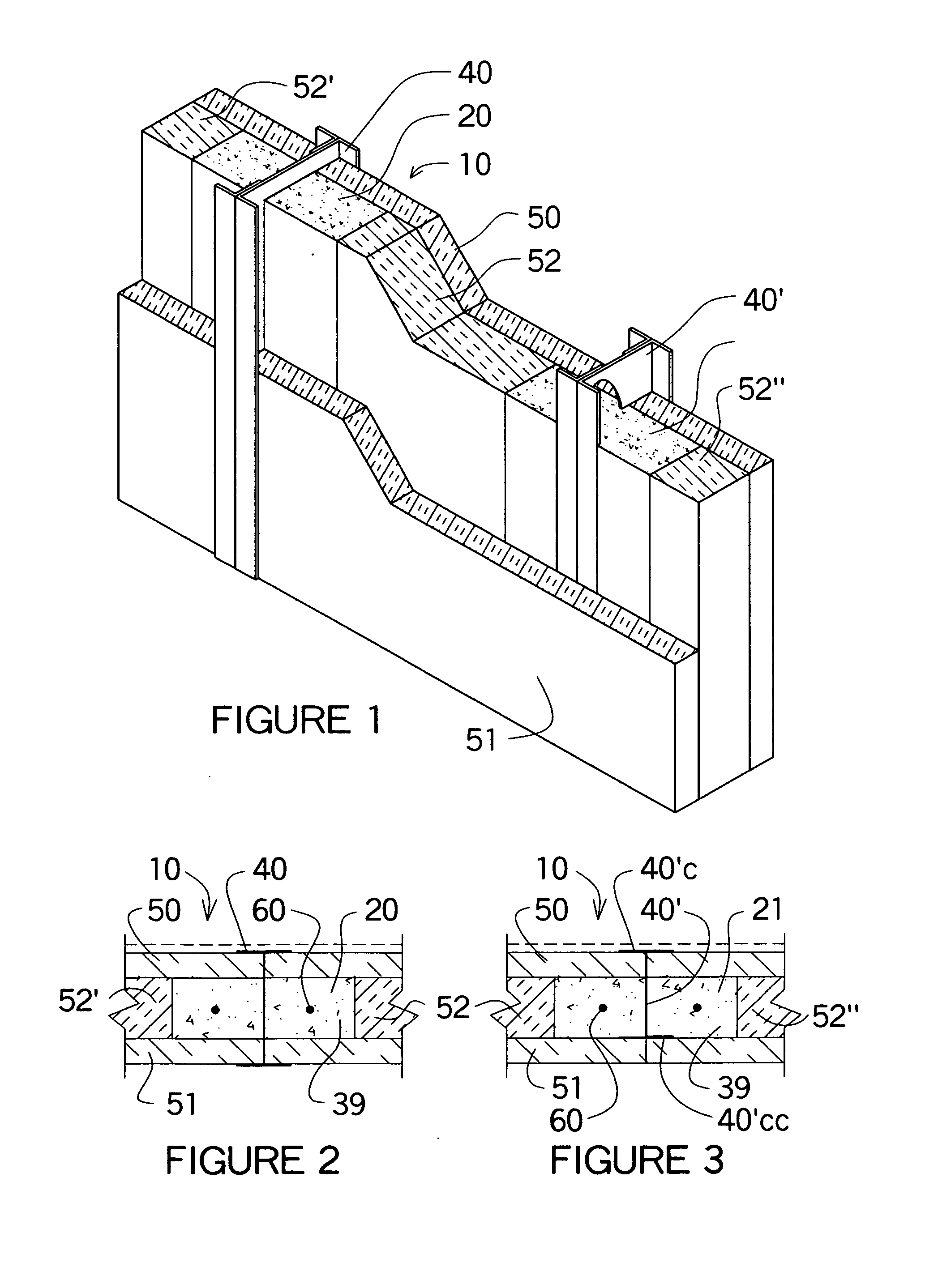

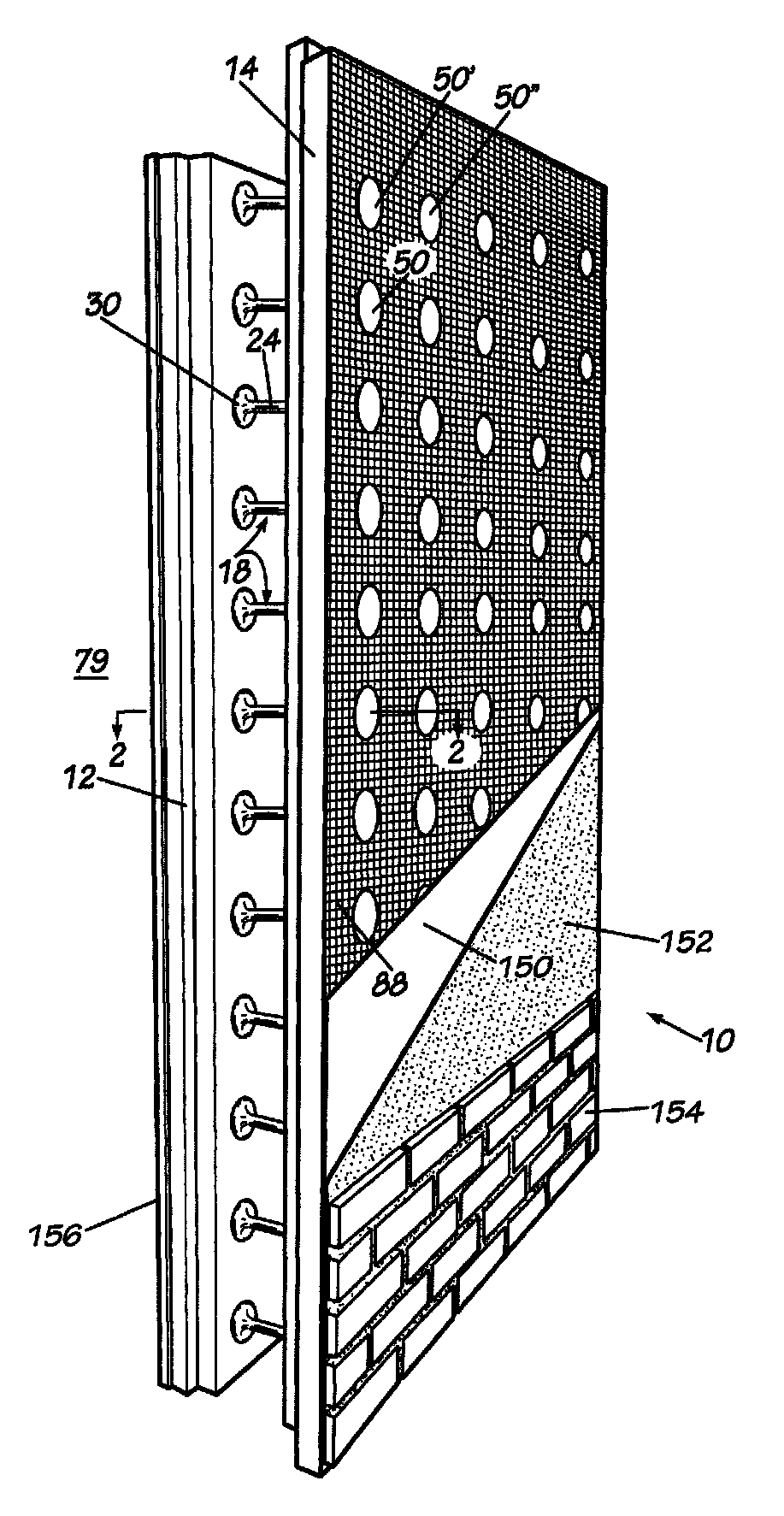

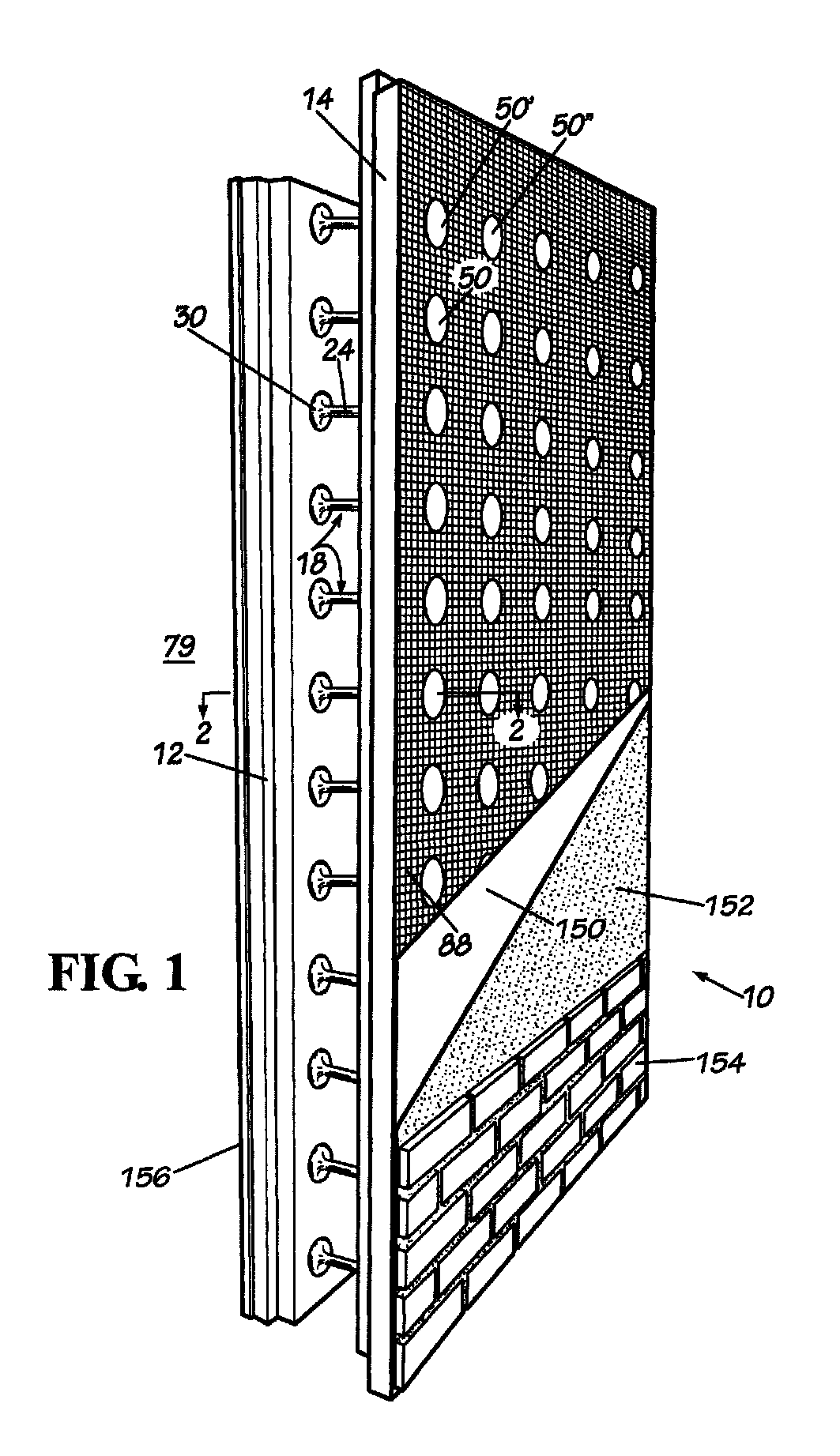

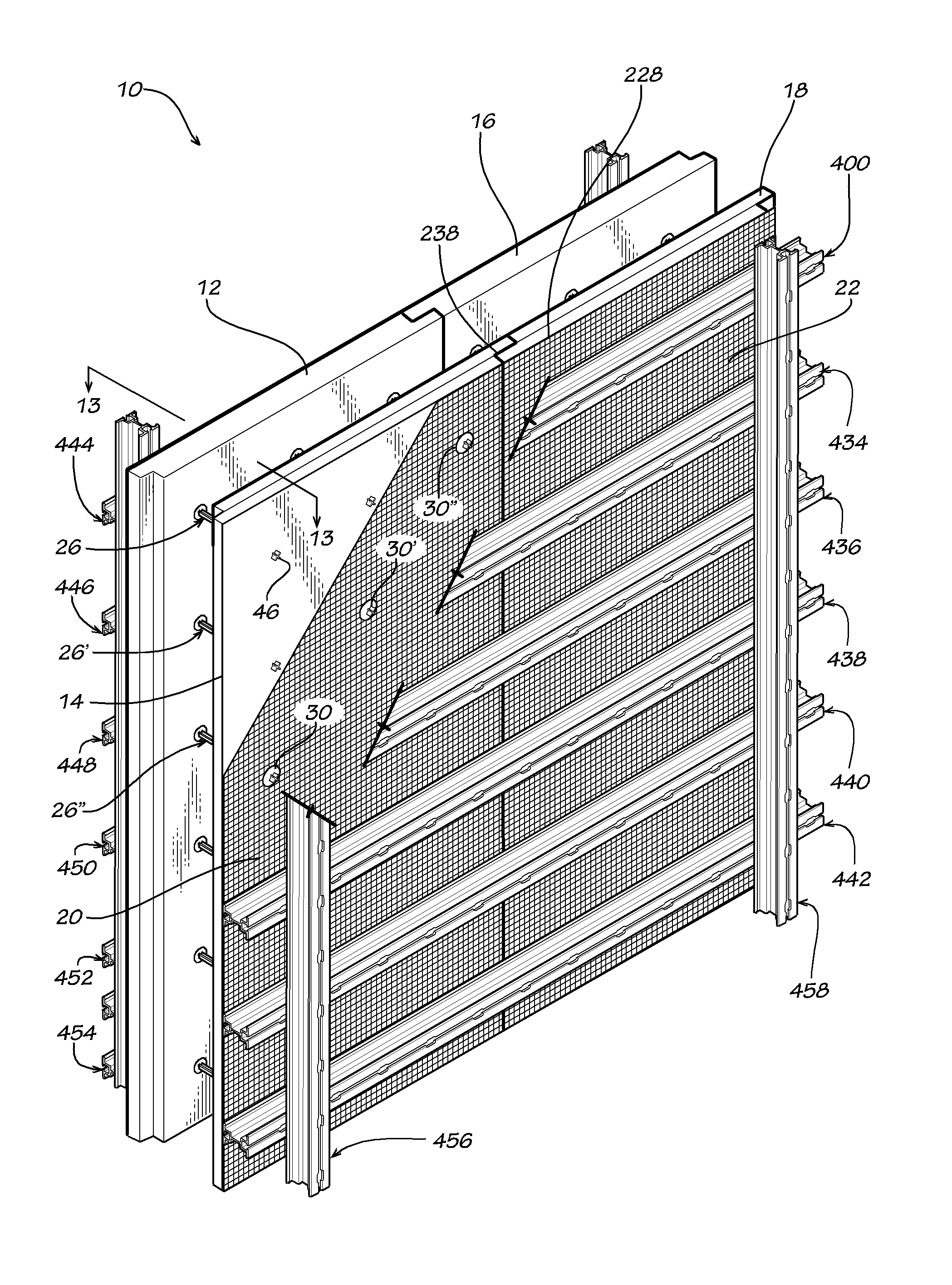

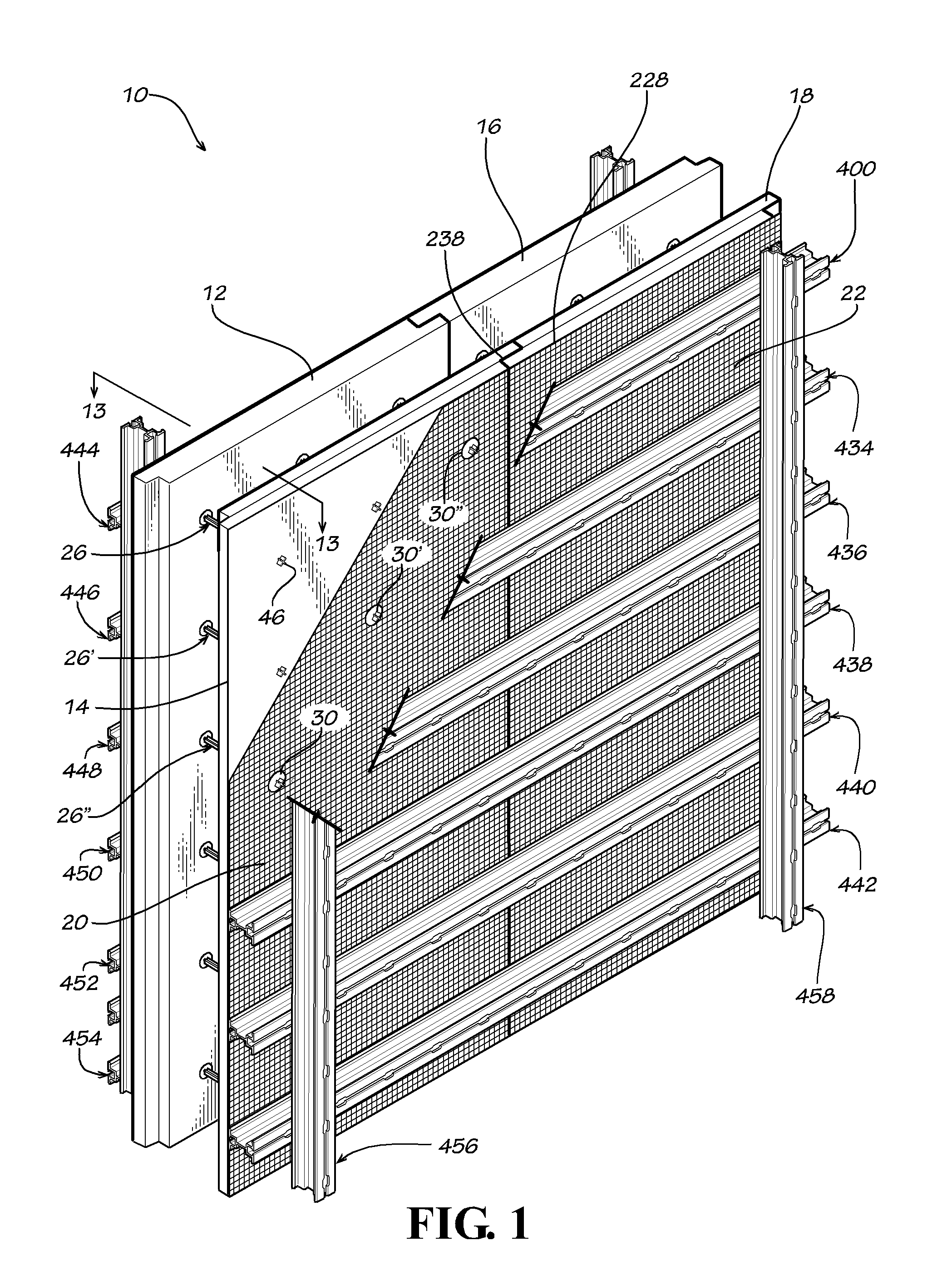

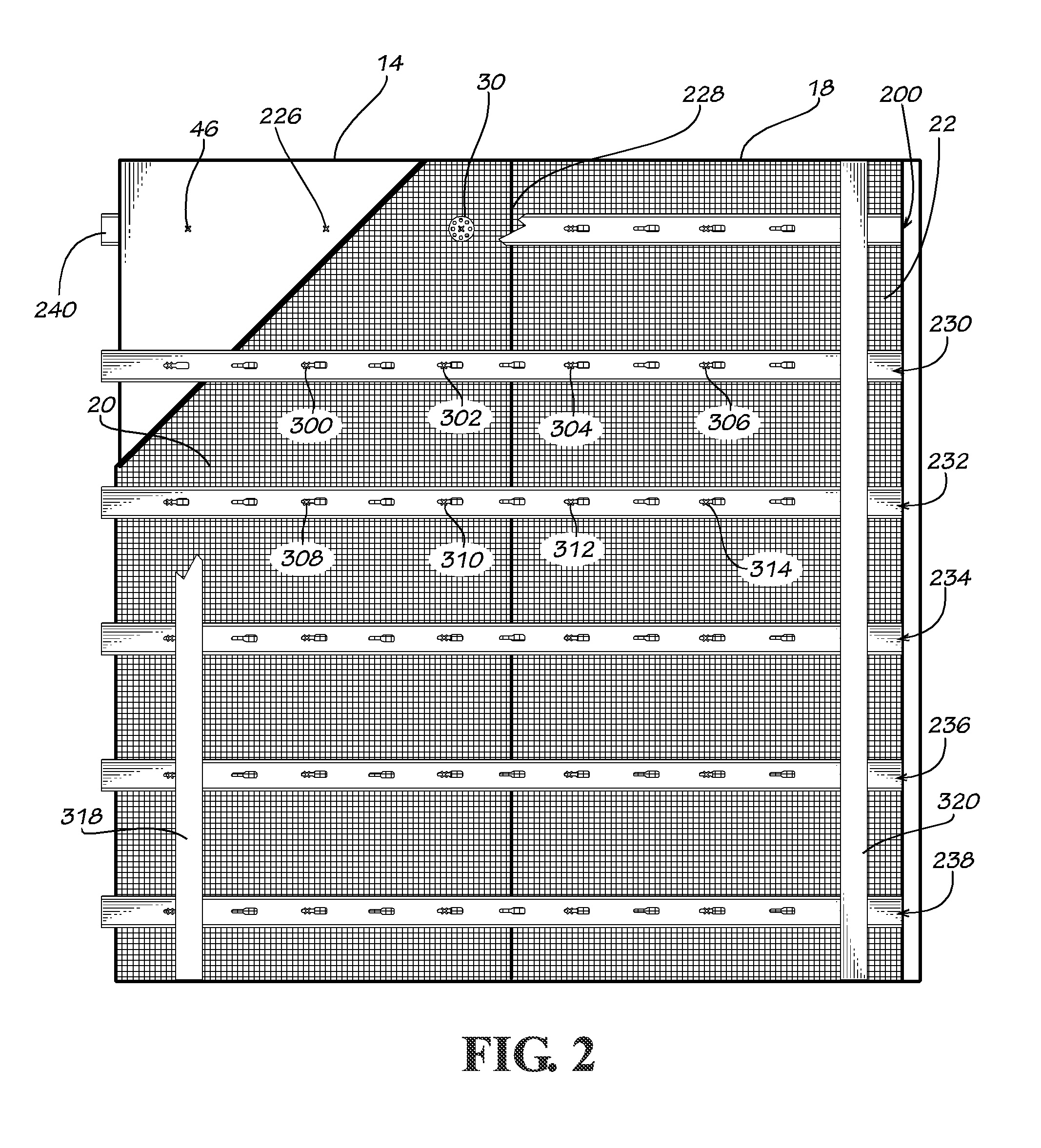

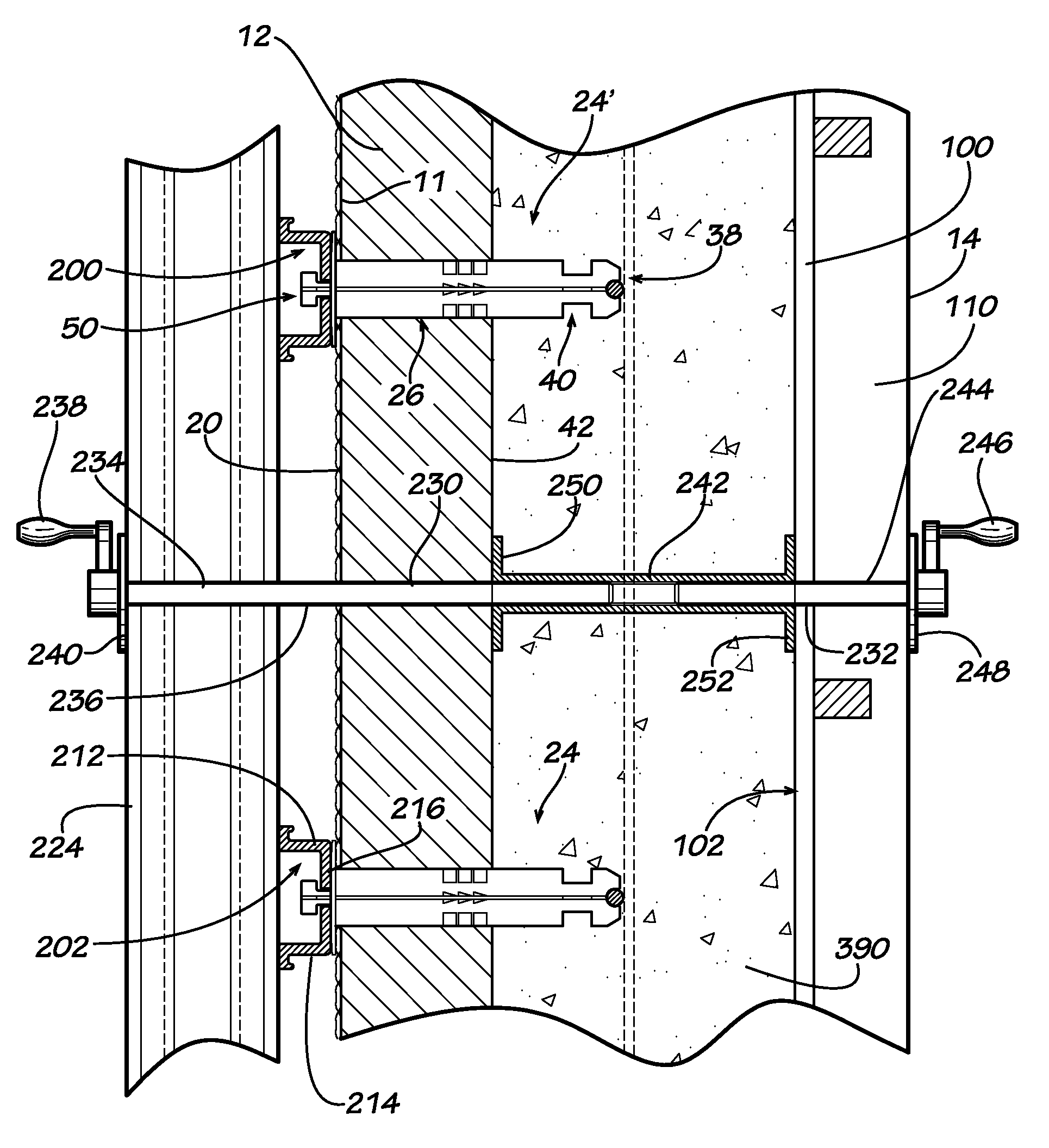

Hybrid insulated concrete form and method of making and using same

The invention comprises a product. The product comprises a foam insulating panel having a first primary surface and an opposite second primary surface. A removable concrete form is spaced from the foam insulating panel and a concrete receiving space is defined between the second primary surface of the foam insulating panel and the removable concrete form. A method of using a hybrid insulated concrete form is also disclosed.

Owner:CIUPERCA ROMEO ILARIAN

Hybrid insulated concrete form and method of making and using same

ActiveUS20140263942A1Retain heatEasy and inexpensive attachmentMoulding surfacesWallsInsulating concrete form

The invention comprises a product. The product comprises a foam insulating panel having a first primary surface and an opposite second primary surface. A removable concrete form is spaced from the foam insulating panel and a concrete receiving space is defined between the second primary surface of the foam insulating panel and the removable concrete form. A method of using a hybrid insulated concrete form is also disclosed.

Owner:CIUPERCA ROMEO ILARIAN

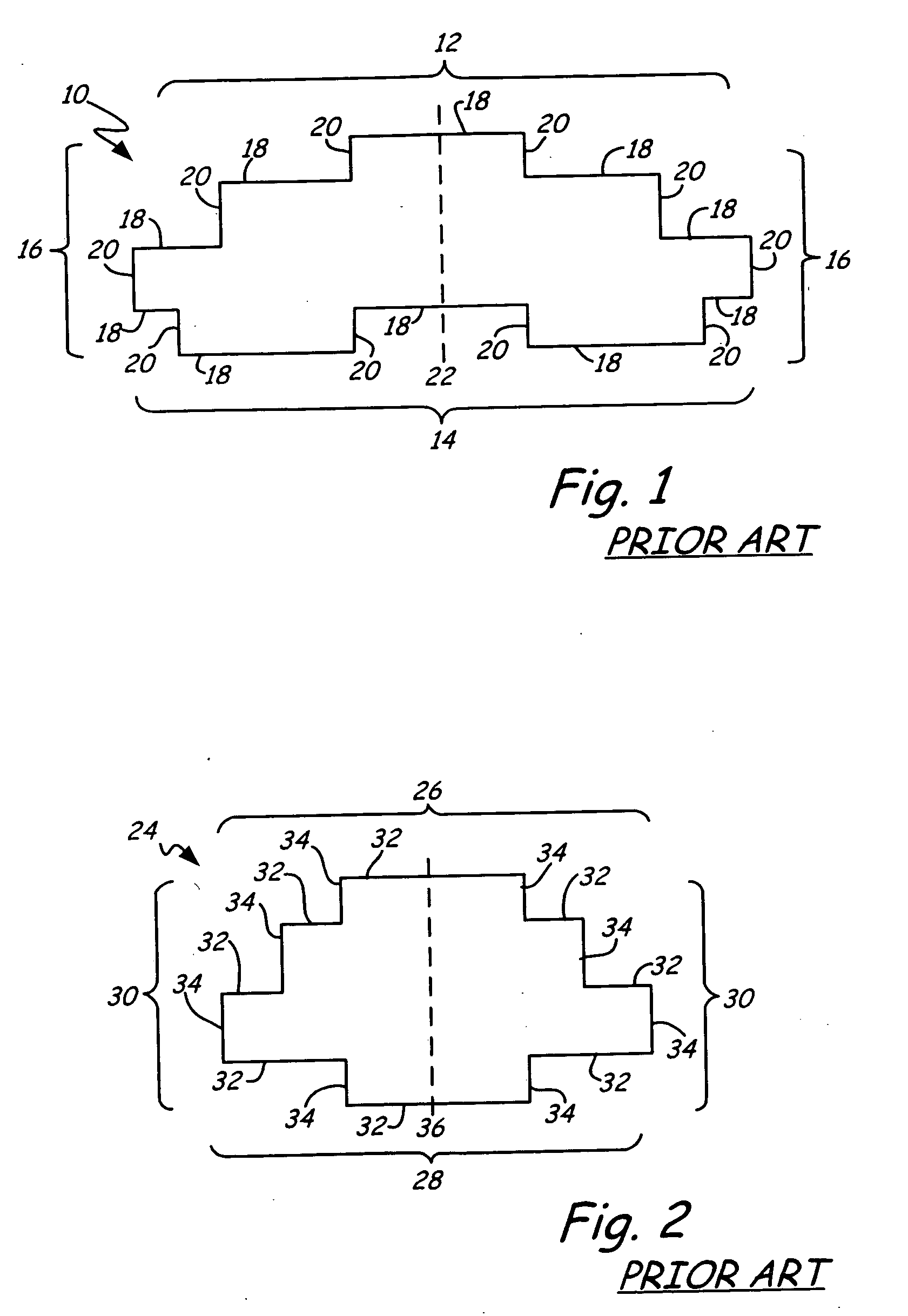

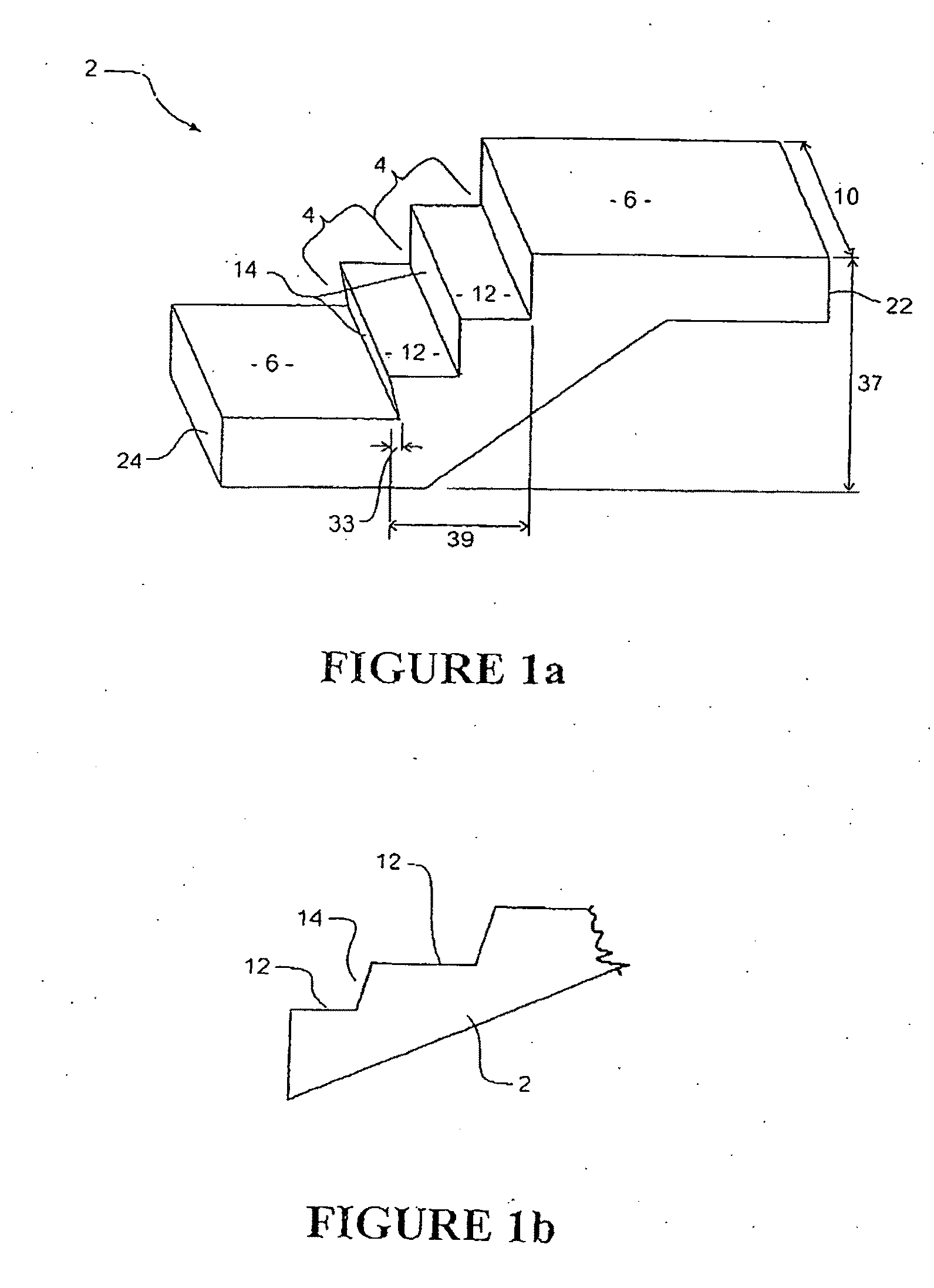

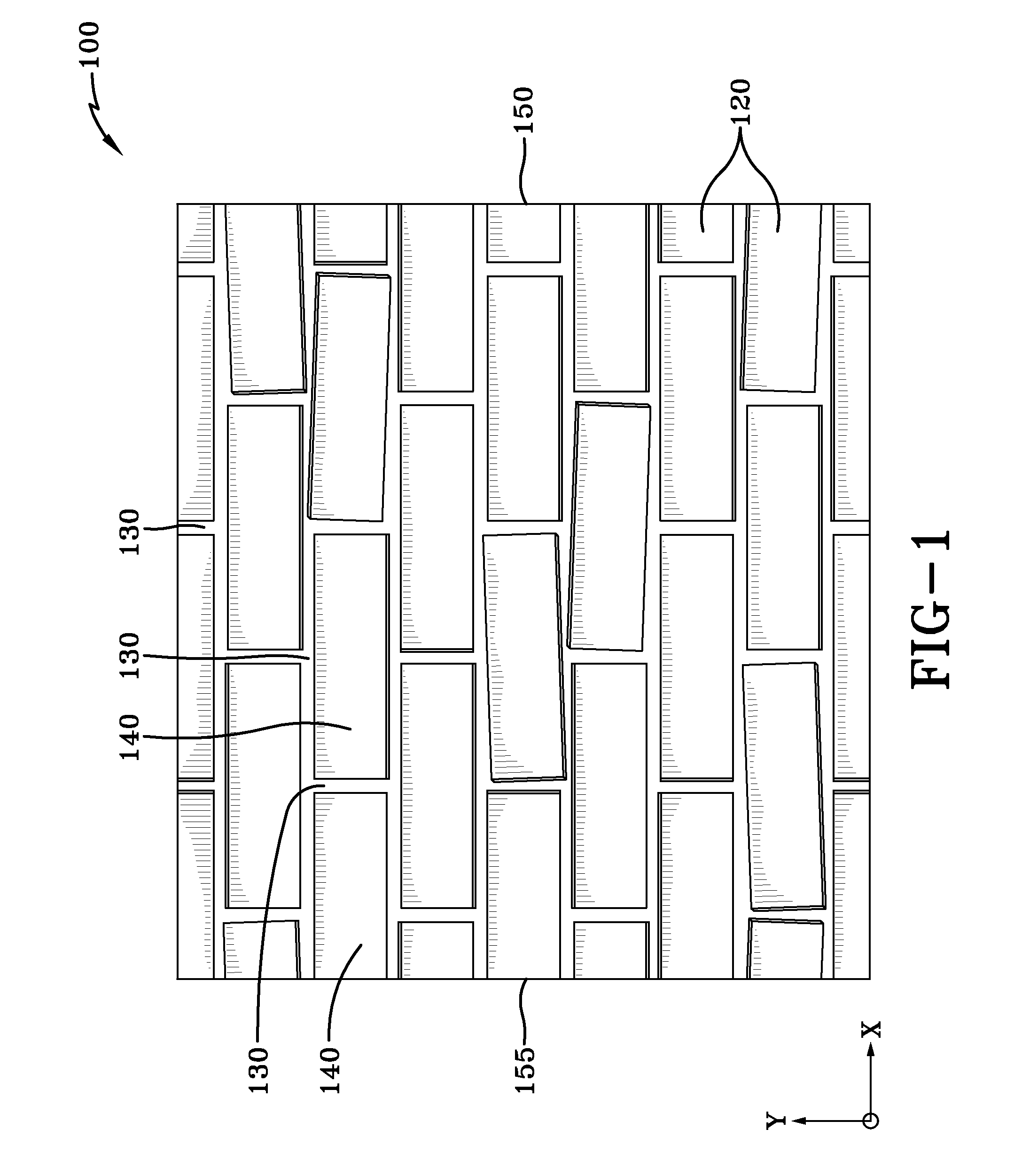

Brick formliner apparatus

ActiveUS7871054B2Seamless appearanceReduce chanceForms/shuttering/falseworksSurface layering apparatusBrickEngineering

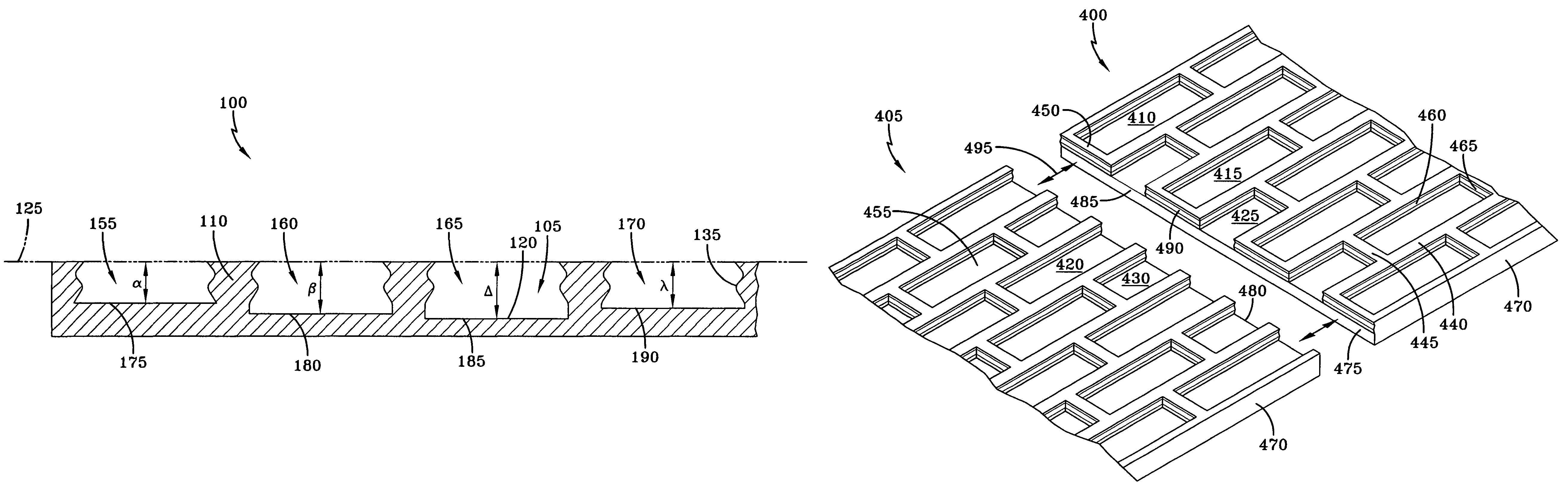

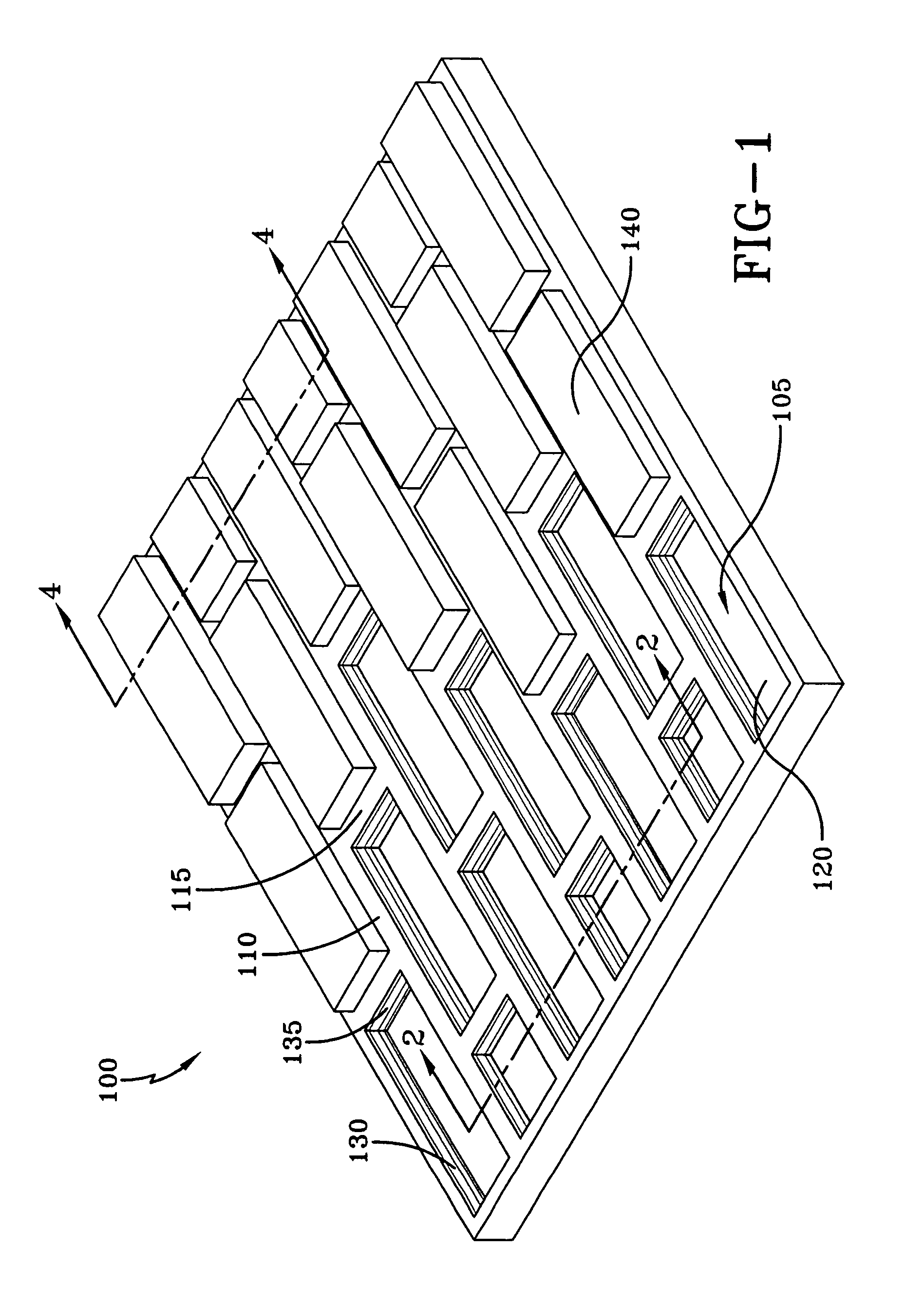

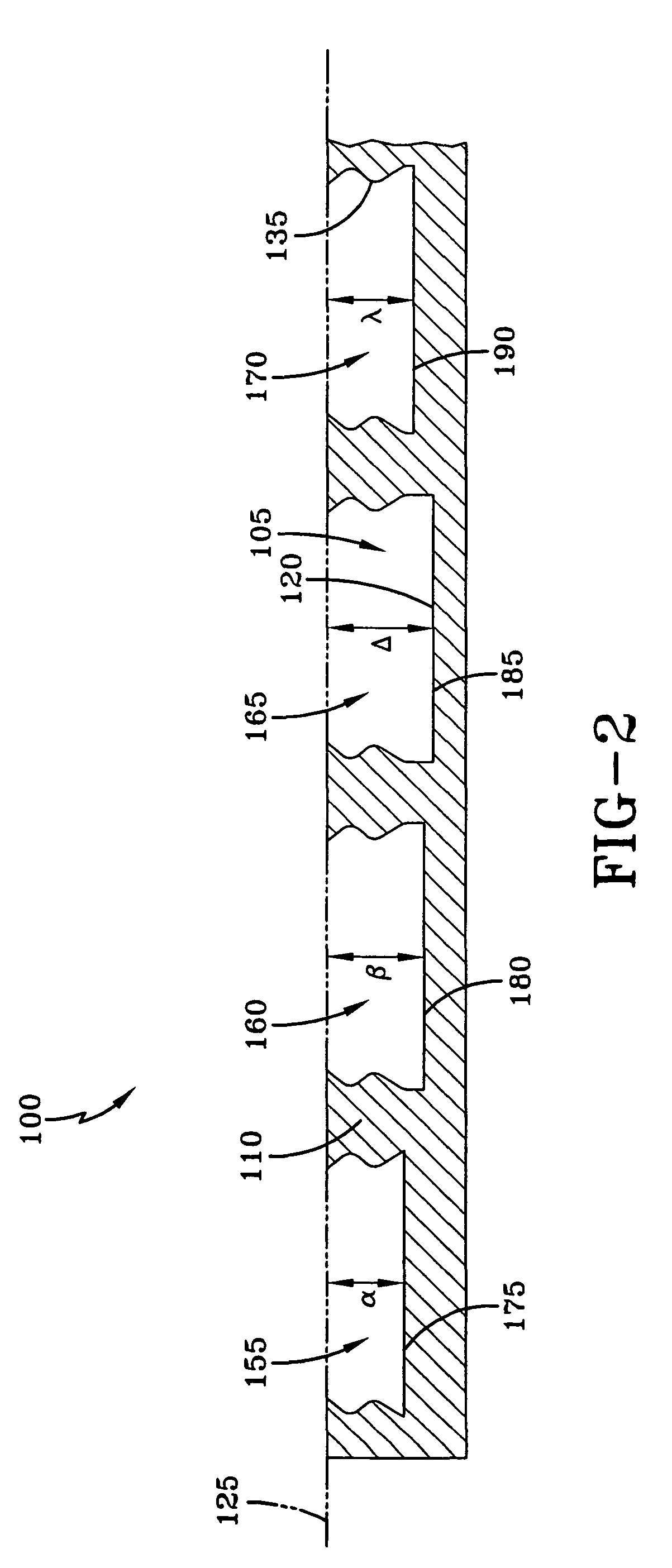

The present invention is a formliner apparatus comprising a plurality of substantially planar layers. The formliner further comprises a plurality of ribs extending in a direction away from the substantially planar layers and defining a plurality of recesses within the formliner in conjunction with the substantially planar layers, each of the plurality of ribs extending to a preselected rib plane. The present invention further comprises at least one resilient ridge on each rib defining each recess, each at least one resilient ridge extending into an adjacent recess, wherein each substantially planar layer is substantially parallel with the rib plane and located a preselected variance depth distance from the rib plane, each variance depth distance for at least some of the substantially planar layers being preselected from a preselected variance depth distance range, wherein each preselected variance depth distance not being equal to every other variance depth distance.

Owner:ARCHITECTURAL POLYMERS

Wood-plastic formwork for construction engineering

InactiveCN1987018AExcellent mechanical propertiesFlat and smooth appearanceSolid waste managementLaminationFiberGlass fiber

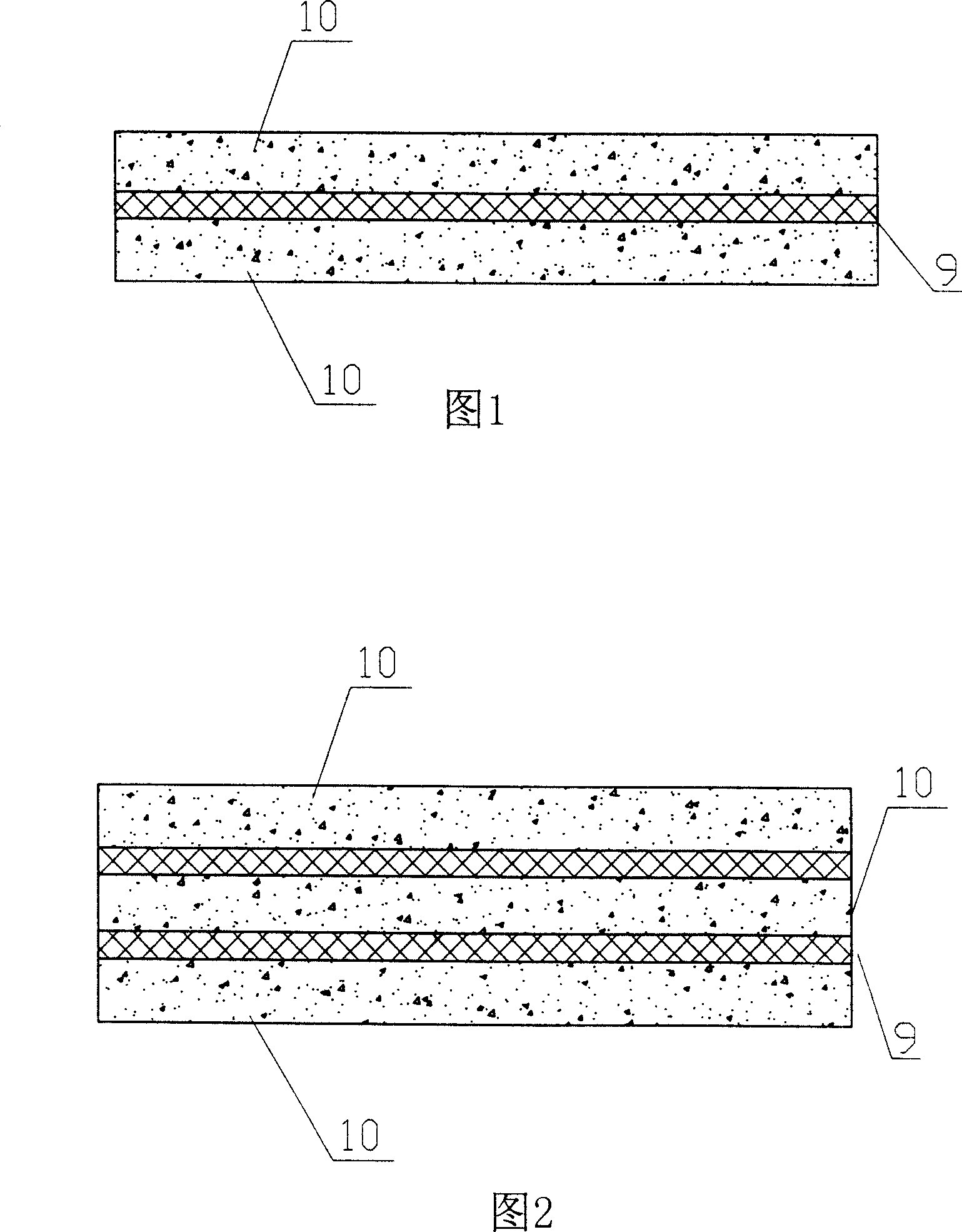

A wood-plastics shuttering board for building engineering is composed of at least two basic wood-plastic ply layers made of the filler (vegetative fibers, glass fibers and plastics) and assistant (calcium carbonate, modifier, coupling agent and lubricant), and at least one lattice material layer between two basic wood-plastic ply layers and with two adhesive layers coated on its both surfaces. Its manufacture technology is also disclosed.

Owner:徐肖虎

Fiber-reinforced plaster-free dismantle-free integrated heat-preservation template and exterior wall heat-preservation construction process

InactiveCN102071797AMeet flatness requirementsReduce thicknessWallsBuilding material handlingInsulation layerReinforced concrete

The invention relates to a fiber-reinforced plaster-free dismantle-free integrated heat-preservation template and an exterior wall heat-preservation construction process. The heat-preservation template is formed by compounding an expandable polystyrene (EPS) aggregate layer on the surface on one side of a fiber concrete plate. The process comprises the following steps that: a fiber concrete template and a fiber concrete composite heat-preservation template are vertically fixed on the two sides of the position of a pre-built wall body respectively, wherein the fiber concrete template and the fiber concrete composite heat-preservation template are fixed together through pull bolts; and reinforcements are arranged and concrete is poured between the fiber concrete template and the fiber concrete composite heat-preservation template, so that a reinforced concrete bearing wall body is formed. The integrated permanent dismantle-free heat-preservation template meets the requirements on heat preservation of an exterior wall and flatness of a plaster layer in place of the exterior wall template, an outer heat-preservation layer and the plaster layer. In the process, the template is not required to be removed, the heat preservation, heat insulation and water proofing performance are good, the thickness of the wall body is reduced, a great amount of materials and labor are saved, the construction period can be shortened, and the energy conservation requirement and the requirements on adhesion between the permanent template and a basic layer and flatness of a surface layer can be met. The template is suitable for high-rise and small high-rise buildings; the dwelling environment can be improved; the building function quality is improved; the building development benefit is improved; and the template has a wide application prospect.

Owner:ZHENGZHOU UNIV +2

Method for electronic temperature controlled curing of concrete and accelerating concrete maturity or equivalent age of precast concrete structures and objects and apparatus for same

ActiveUS20140088756A1Selective heatingSolid waste managementElectric heatingElectronic temperaturePrecast concrete

Owner:CIUPERCA ROMEO ILARIAN

Insulated concrete form panel reinforcement

An insulated concrete form (ICF) panel reinforcement is disclosed. The ICF comprises a main panel, a reinforcement on the main panel for stiffening the main panel, a spacer retention element integrated in the reinforcement for securing a spacer to the panel, and a first opposing panel opposite the main panel and having a first opposing spacer retention element integrated therein for securing the spacer to the first opposing panel. The ICF panel reinforcement is particularly useful at high stress locations in ICF systems, such as at T-wall intersections.

Owner:PHIL INSUL CORP

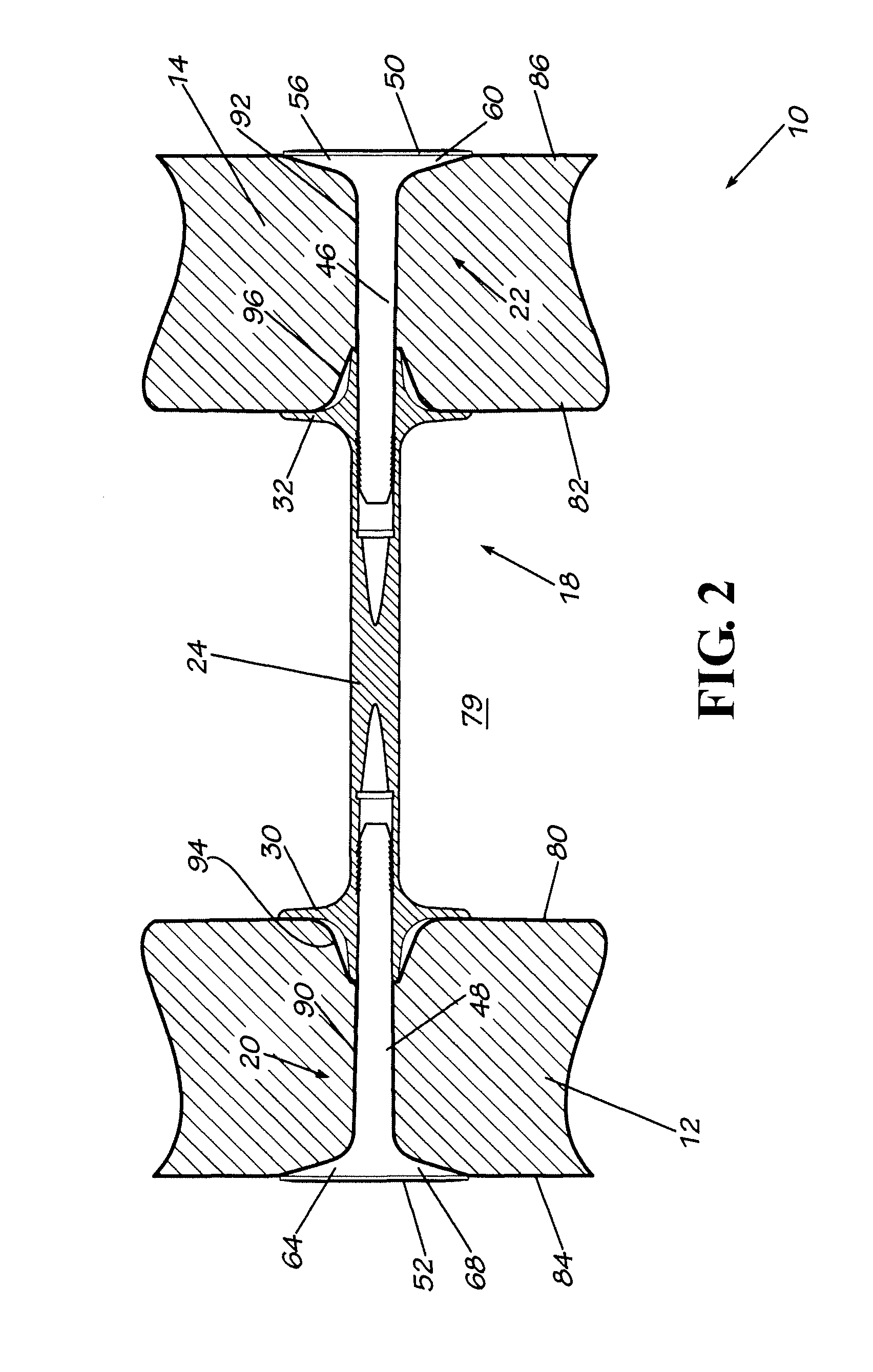

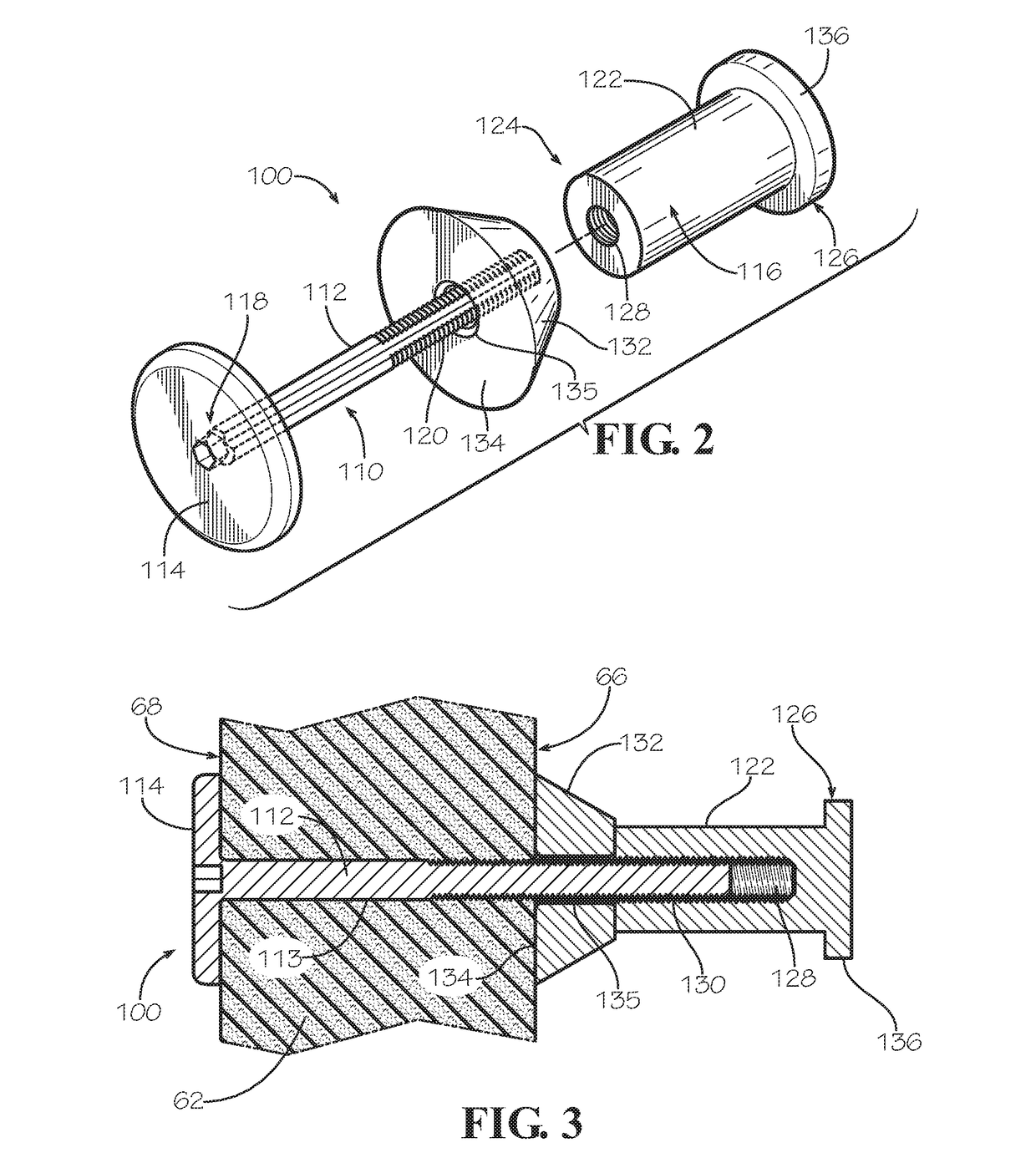

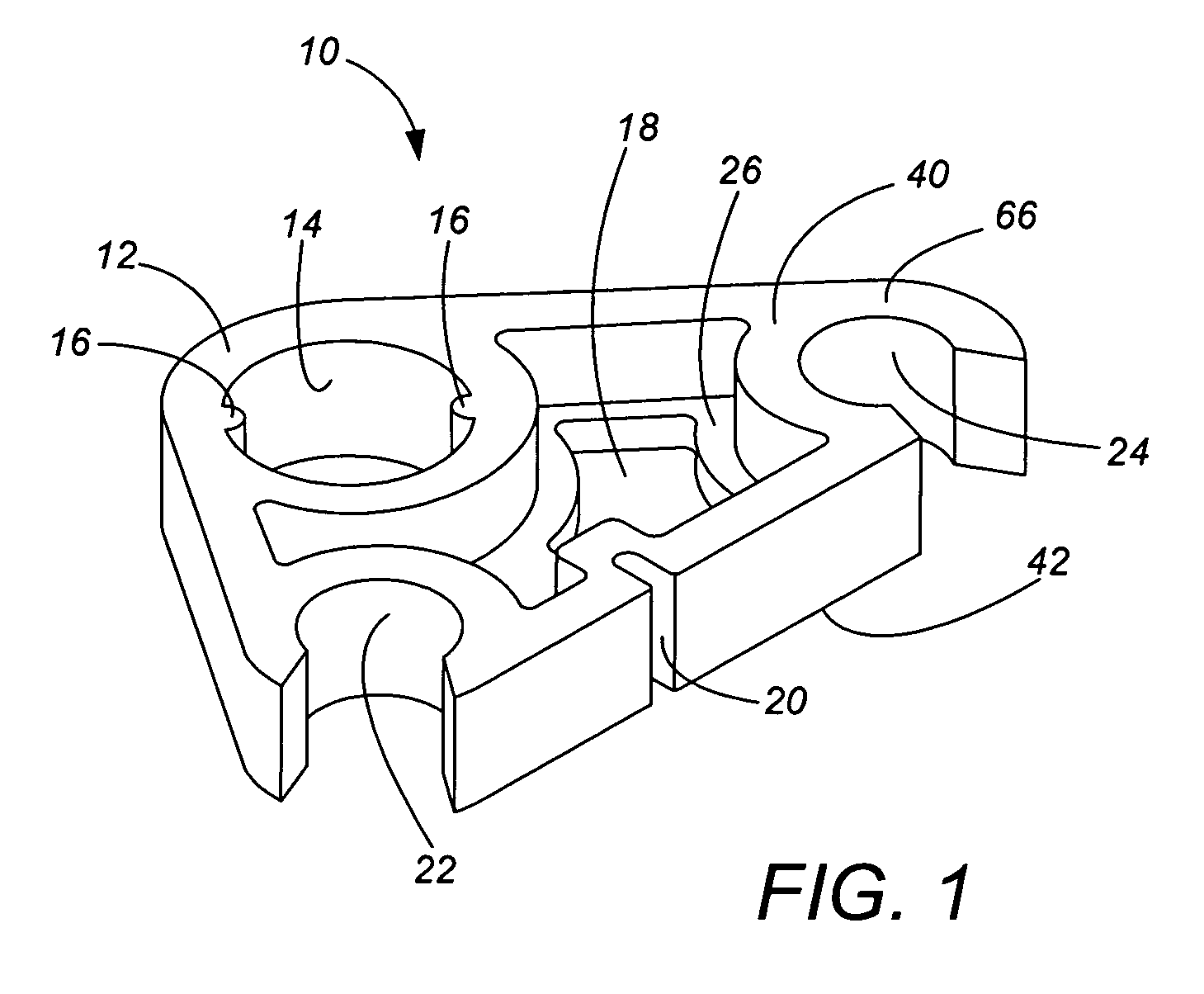

Connector assembly for insulated concrete walls

InactiveUS6945506B2Reduce laborSimplifies wall construction processConstruction materialForms/shuttering/falseworksMechanical engineeringBuilding construction

A through-insulation connector assembly for use in the construction of insulated concrete sandwich wall. The connector assembly includes a spool-shaped connector body comprised of two, interconnecting pieces and a tie that engages the connector body. The two pieces of the connector body are installed at the place of manufacture in a sheet of foam insulation board that will be used as the insulation layer in the construction of an insulated concrete sandwich wall.

Owner:COMPOSITE TECH CO LLC

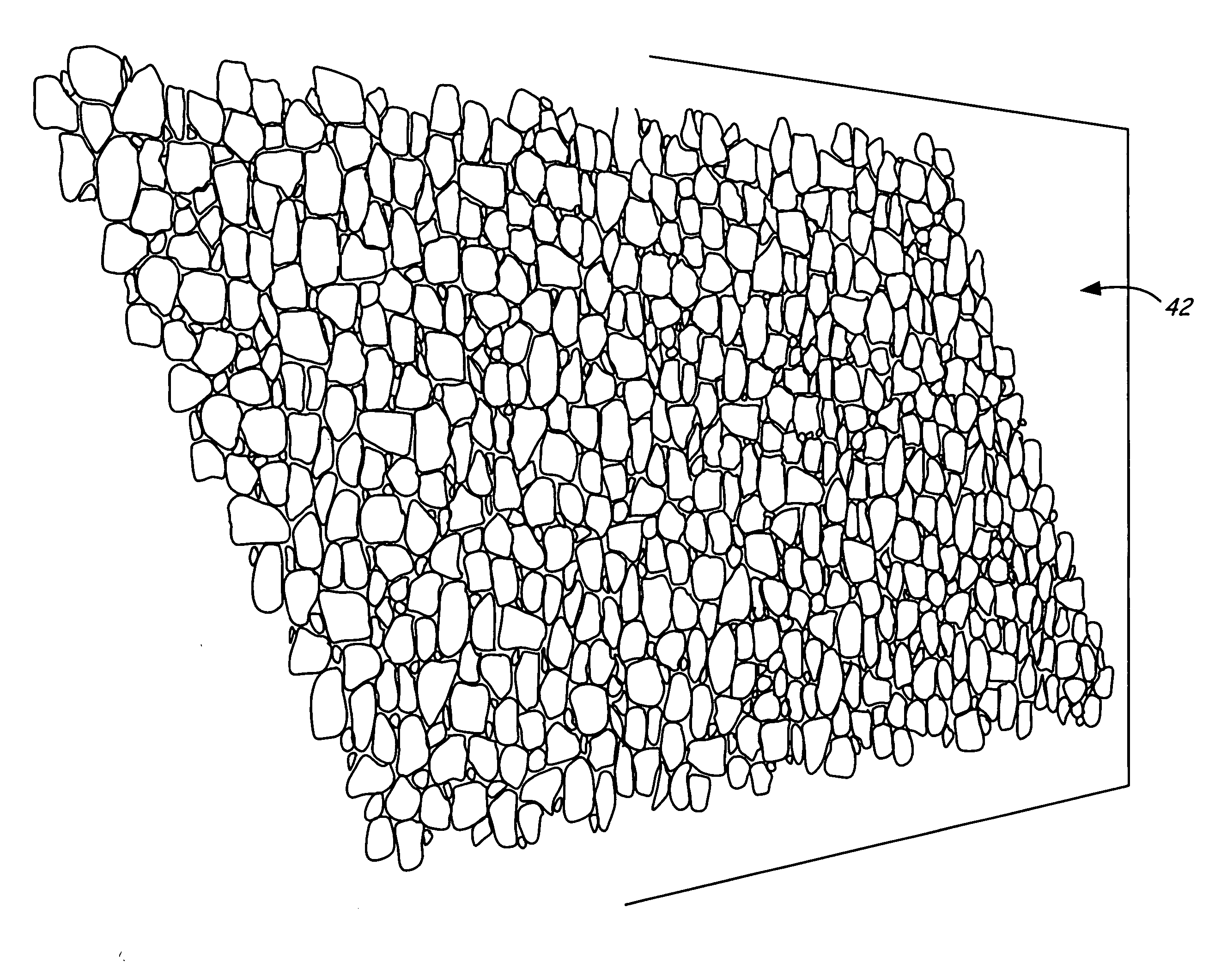

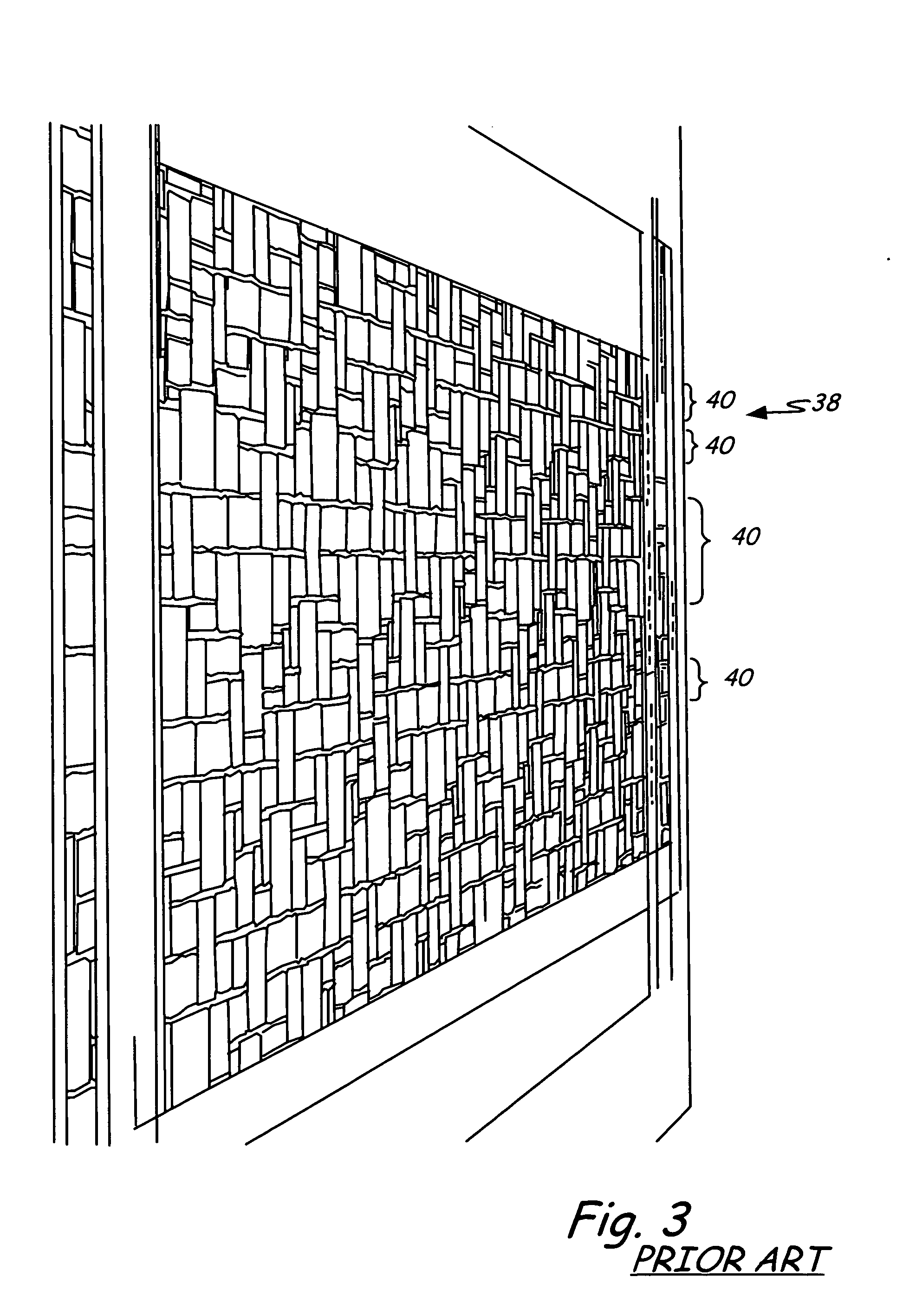

Form liner for creating a realistic stone wall pattern

The form liner of the present invention simulates a natural stone wall having a random pattern. The form liner comprises an outer edge and a surface that is contoured to resemble a plurality of stones held together by an adhesive substance. The outer edge of the form liner has six connection regions made up of multiple linear segments. No two adjacent connection regions are connected at a ninety degree angle and no linear segment of the fifth connection region lies along the same linear path as any linear segment of the sixth connection region.

Owner:NASVIK PAUL C

Foundation footing form and accessories

Moisture resistant foundation footing form sections constructed from corrugated plastic are disclosed. Supports for holding sections of reinforcing bar, and connecting the side walls of the form sections are included. Also disclosed are tabs and notches in the side walls for use with stakes to connect adjacent form sections. Form sections are disclosed for constructing a corner in a foundation footing form. Step-down forms are disclosed for constructing a foundation footing form on a construction site having surfaces of different elevations. The form sections can be secured in position with stakes, and leveling devices for leveling the form once it is secured in position are disclosed. The form sections disclosed herein can be reused, but they do not attract insects and therefore they do not have to be removed from finished foundation footings.

Owner:HUBER DONALD G +1

Formliner apparatus

ActiveUS20060091282A1Seamless appearanceReduce chanceForms/shuttering/falseworksSurface layering apparatusEngineeringRidge

The present invention is a formliner apparatus comprising a plurality of substantially planar layers. The formliner further comprises a plurality of ribs extending in a direction away from the substantially planar layers and defining a plurality of recesses within the formliner in conjunction with the substantially planar layers, each of the plurality of ribs extending to a preselected rib plane. The present invention further comprises at least one resilient ridge on each rib defining each recess, each at least one resilient ridge extending into an adjacent recess, wherein each substantially planar layer is substantially parallel with the rib plane and located a preselected variance depth distance from the rib plane, each variance depth distance for at least some of the substantially planar layers being preselected from a preselected variance depth distance range, wherein each preselected variance depth distance not being equal to every other variance depth distance.

Owner:ARCHITECTURAL POLYMERS

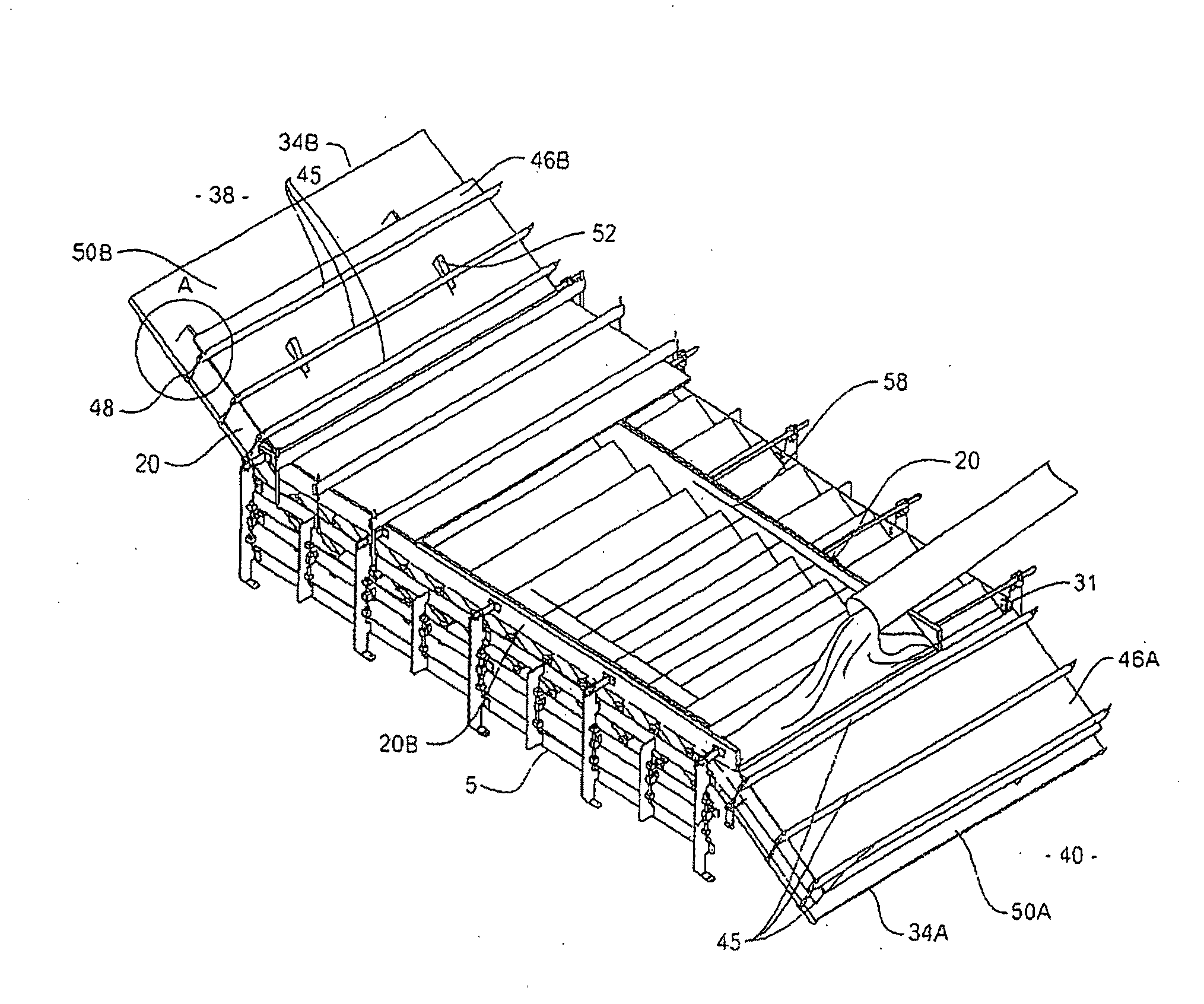

Stair forming apparatus and related methods

The invention relates to an adjustable stair forming apparatus, adapted to form a flight of stairs of a settable material. The flight of stairs including a series of treads interconnected by intermediate risers. The apparatus comprises, a frame to support a series of forming units provide a forming surface. Each forming unit, includes a tread defining formwork that includes a rectangular shaped tread forming surface, slidably and pivotally mounted to the frame from or toward a first major edge of the tread forming surface. The forming unit also has a riser defining formwork that includes a rectangular shaped riser forming surface with a first major edge adjustably mounted from or toward the opposite major edge of the tread forming surface. The riser forming surface at least in part co-extending with the tread forming surface in a stair width direction. The forming units each adjustably held in an array to the frame with a bearing surface of one forming unit supported by a tread forming surface of the adjacent forming unit.

Owner:PATENT AGENCIES LTD

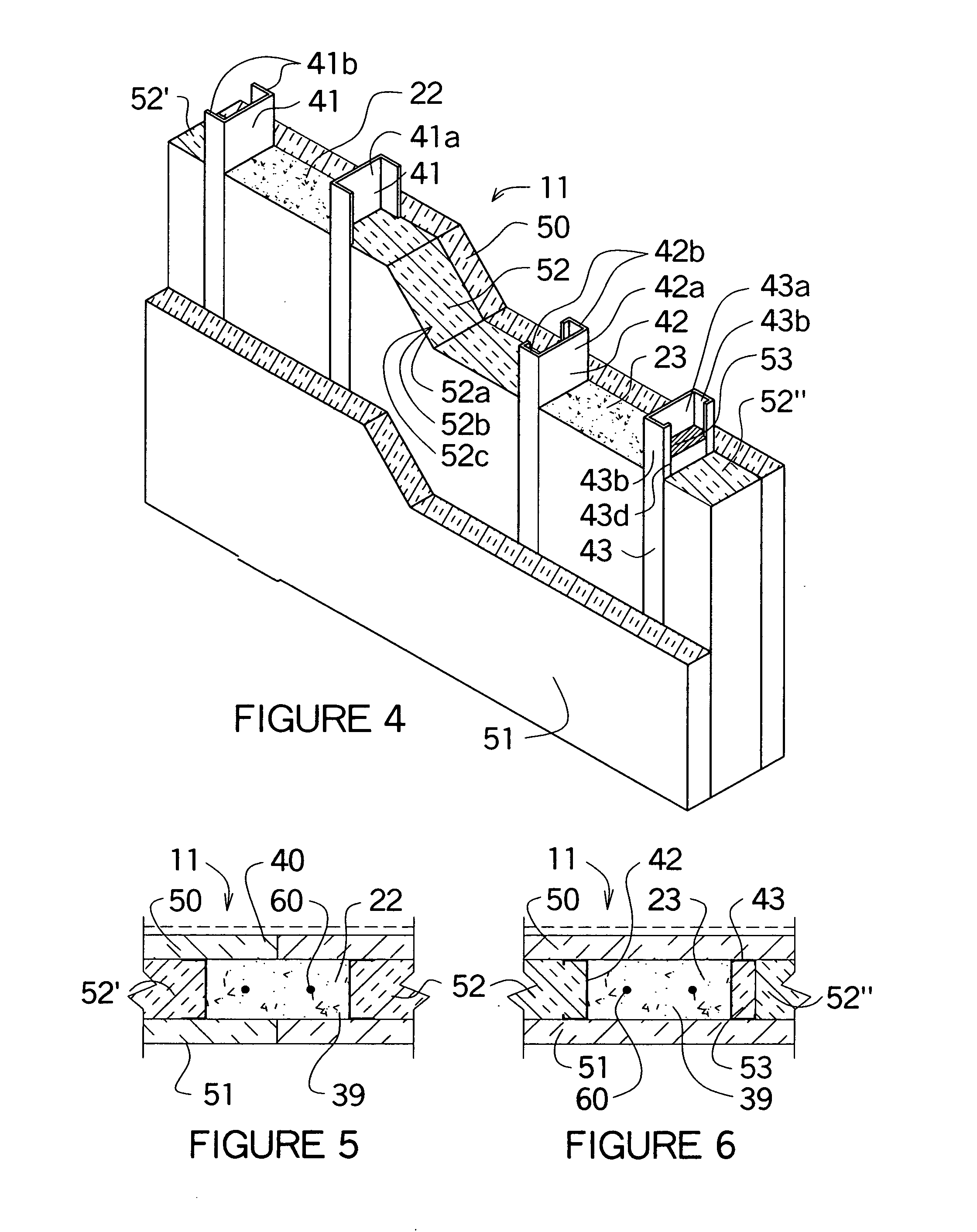

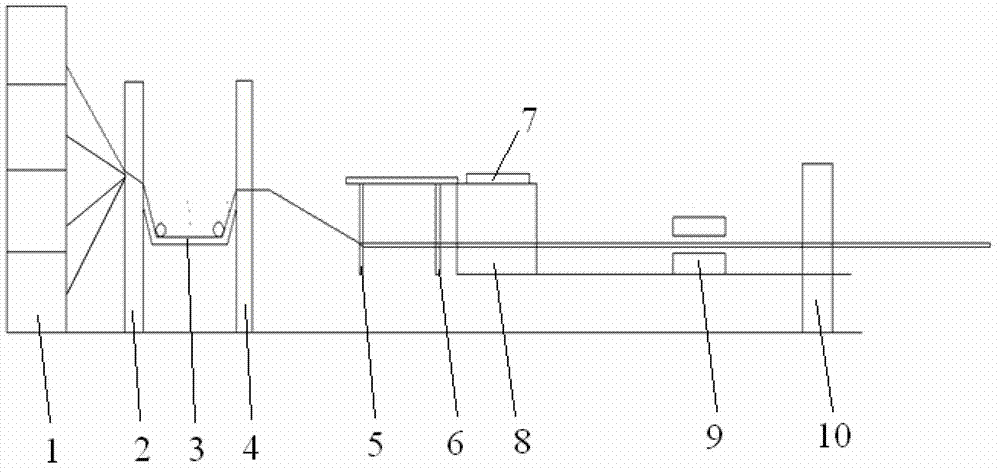

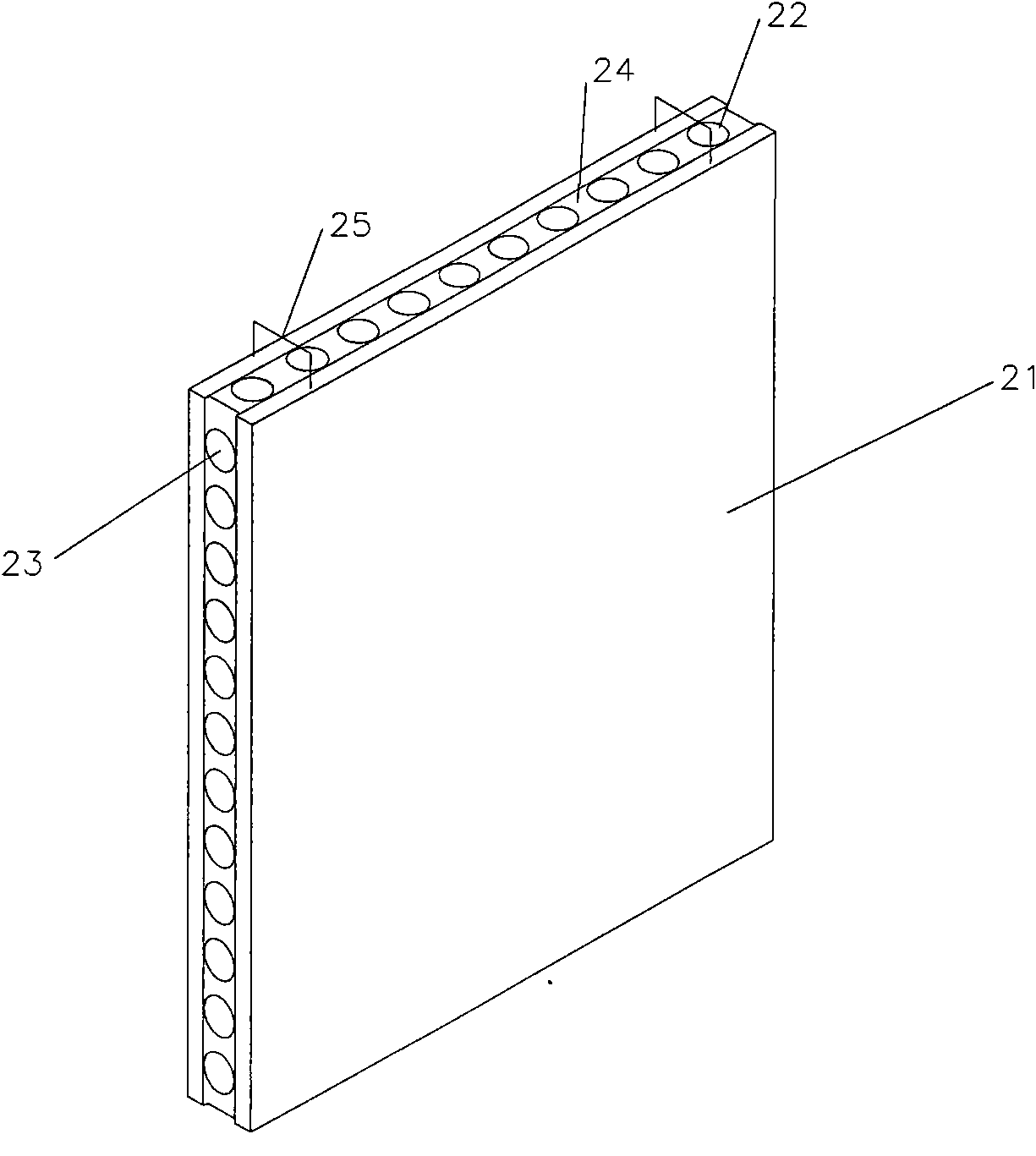

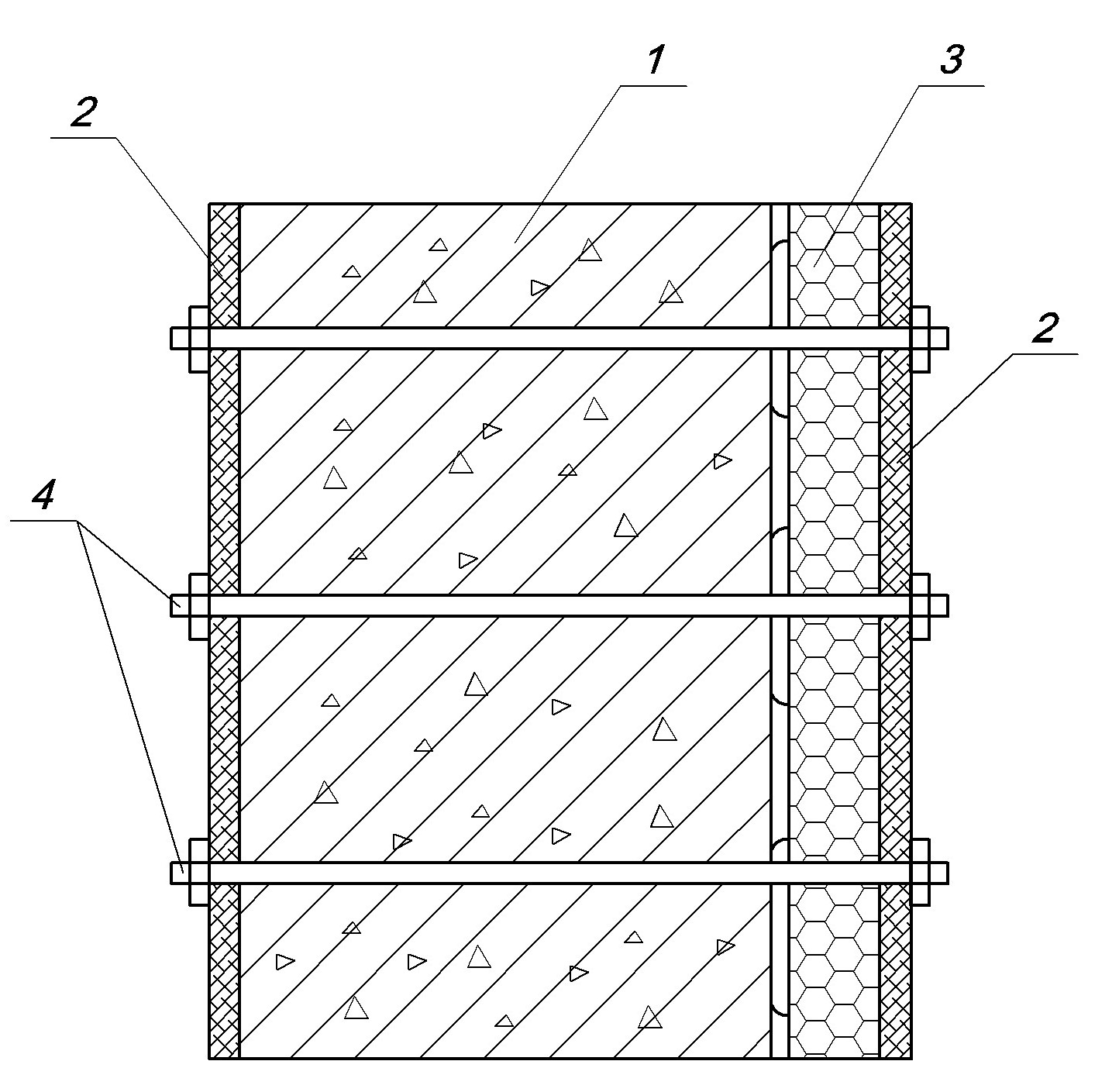

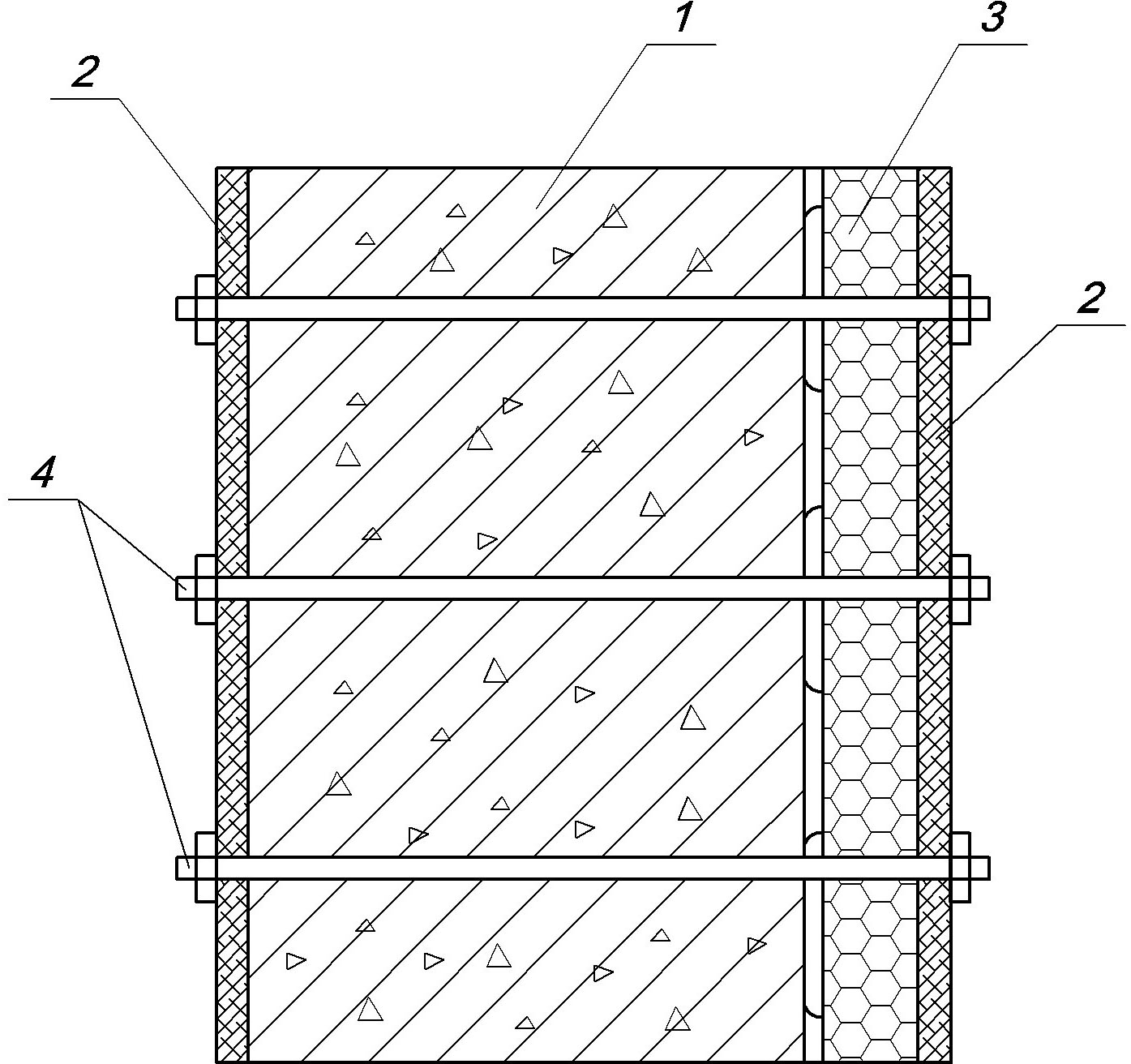

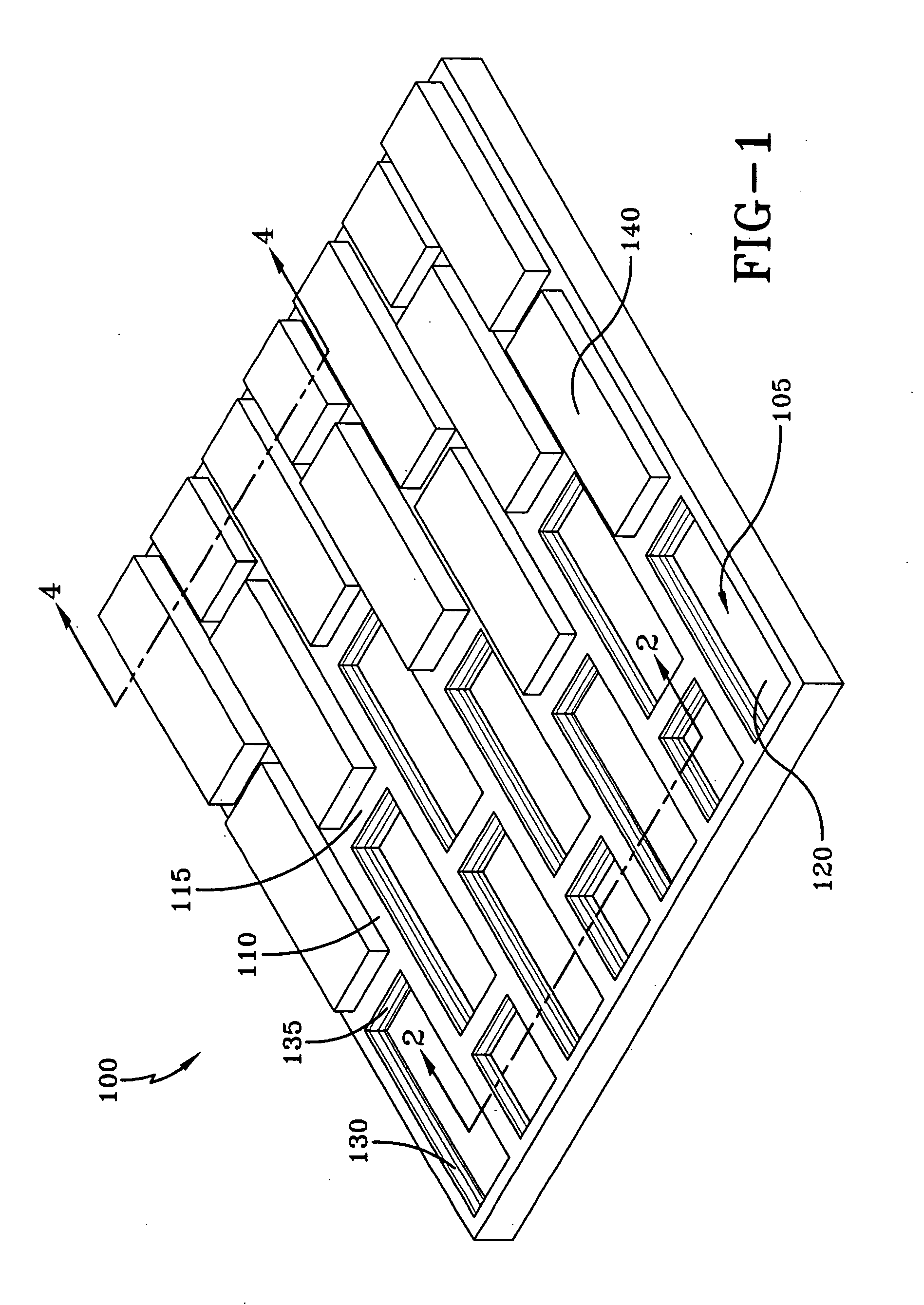

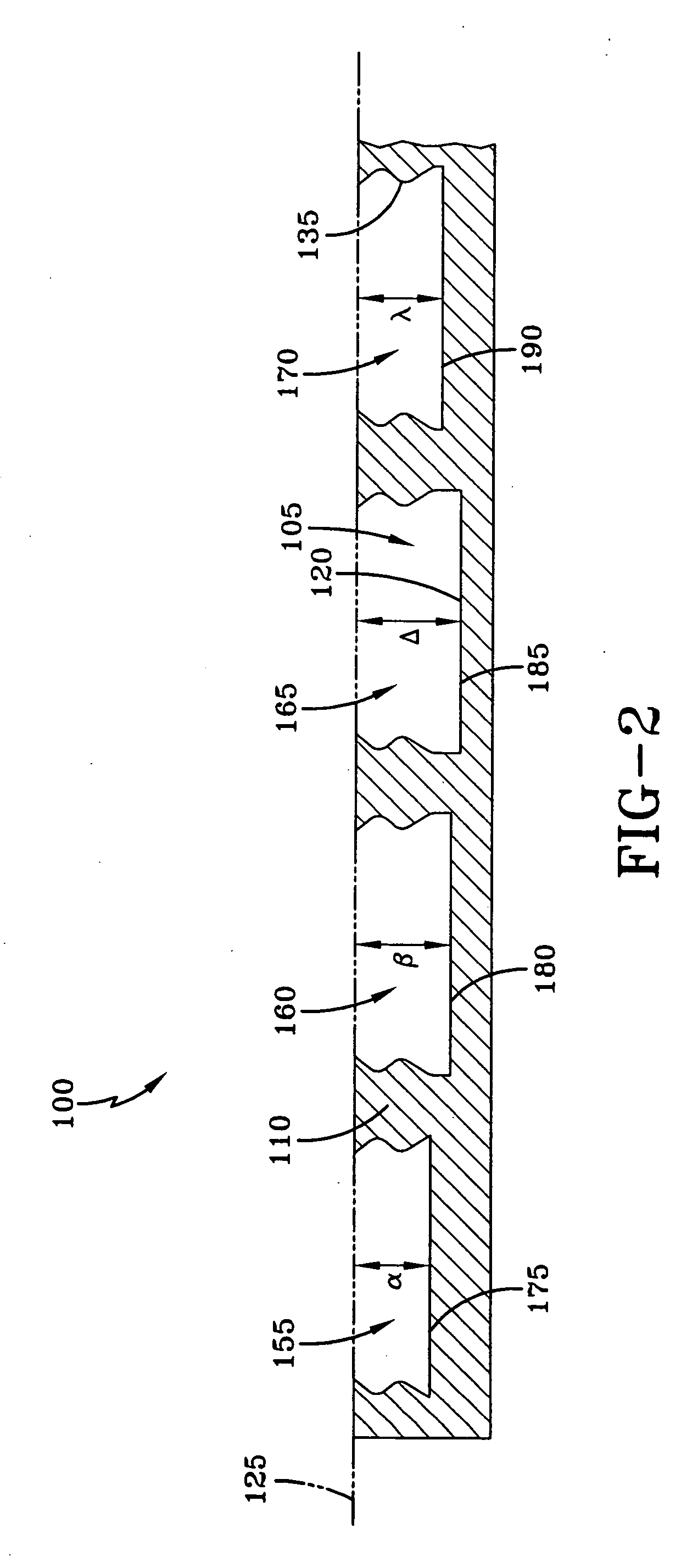

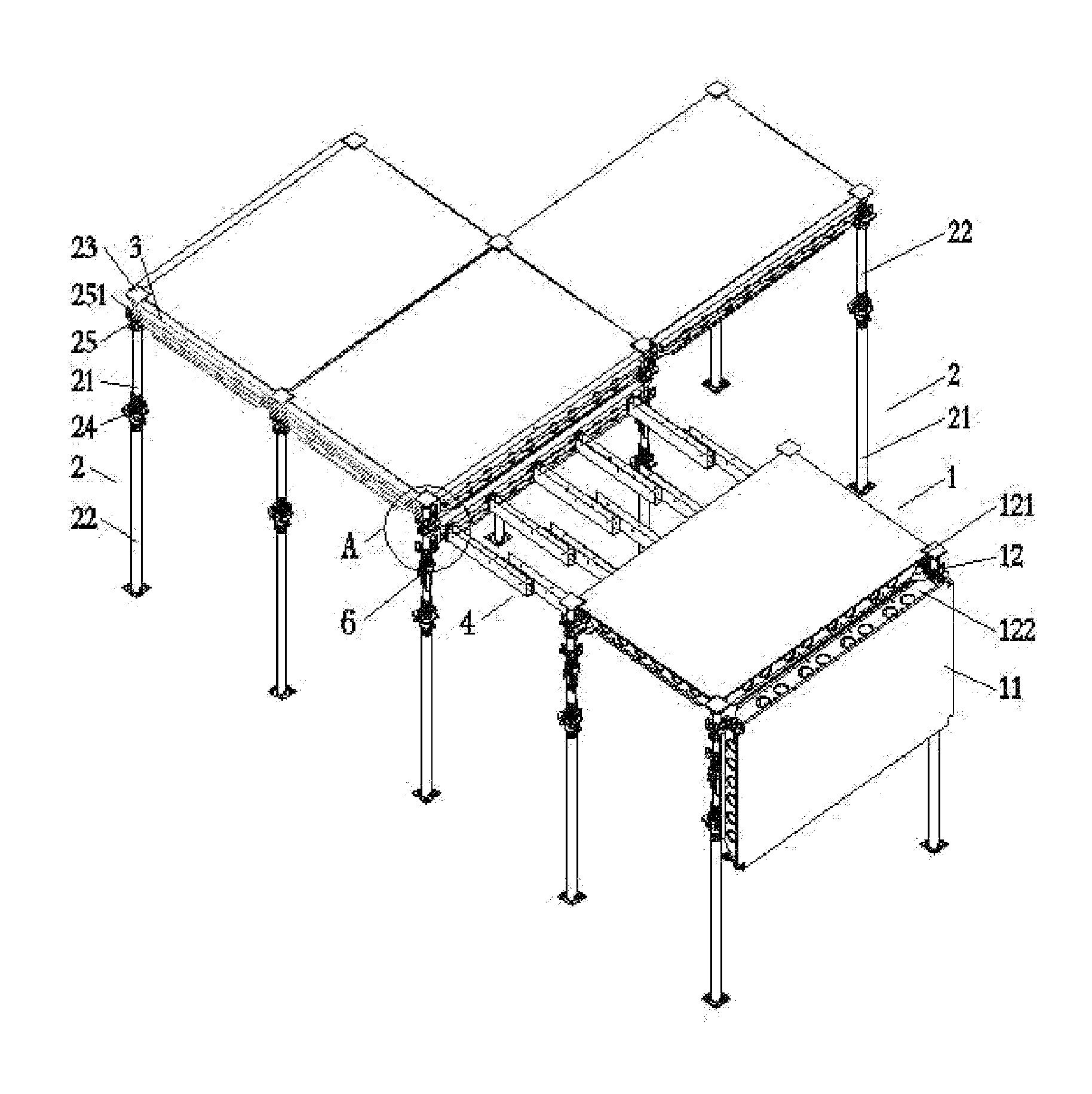

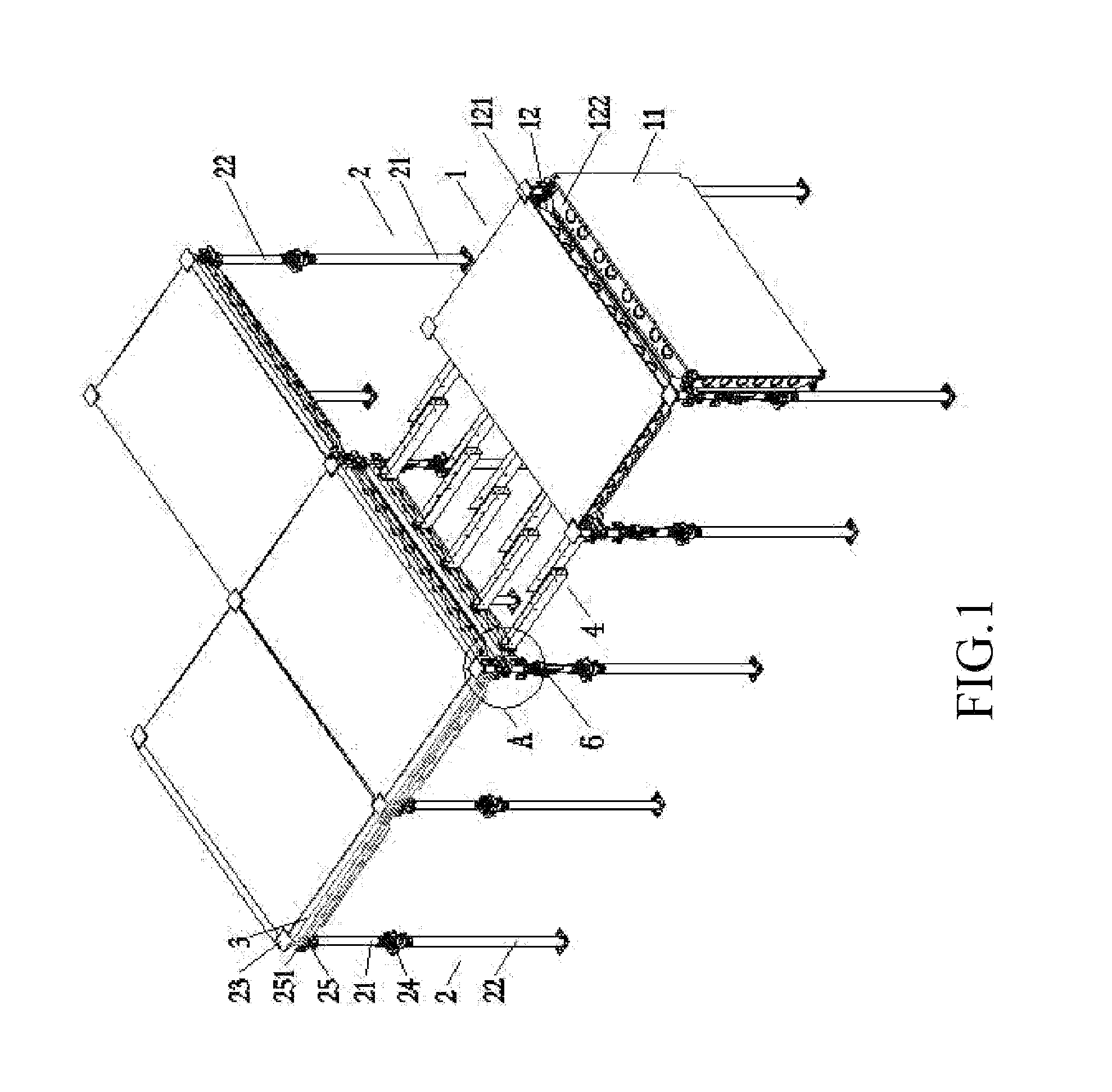

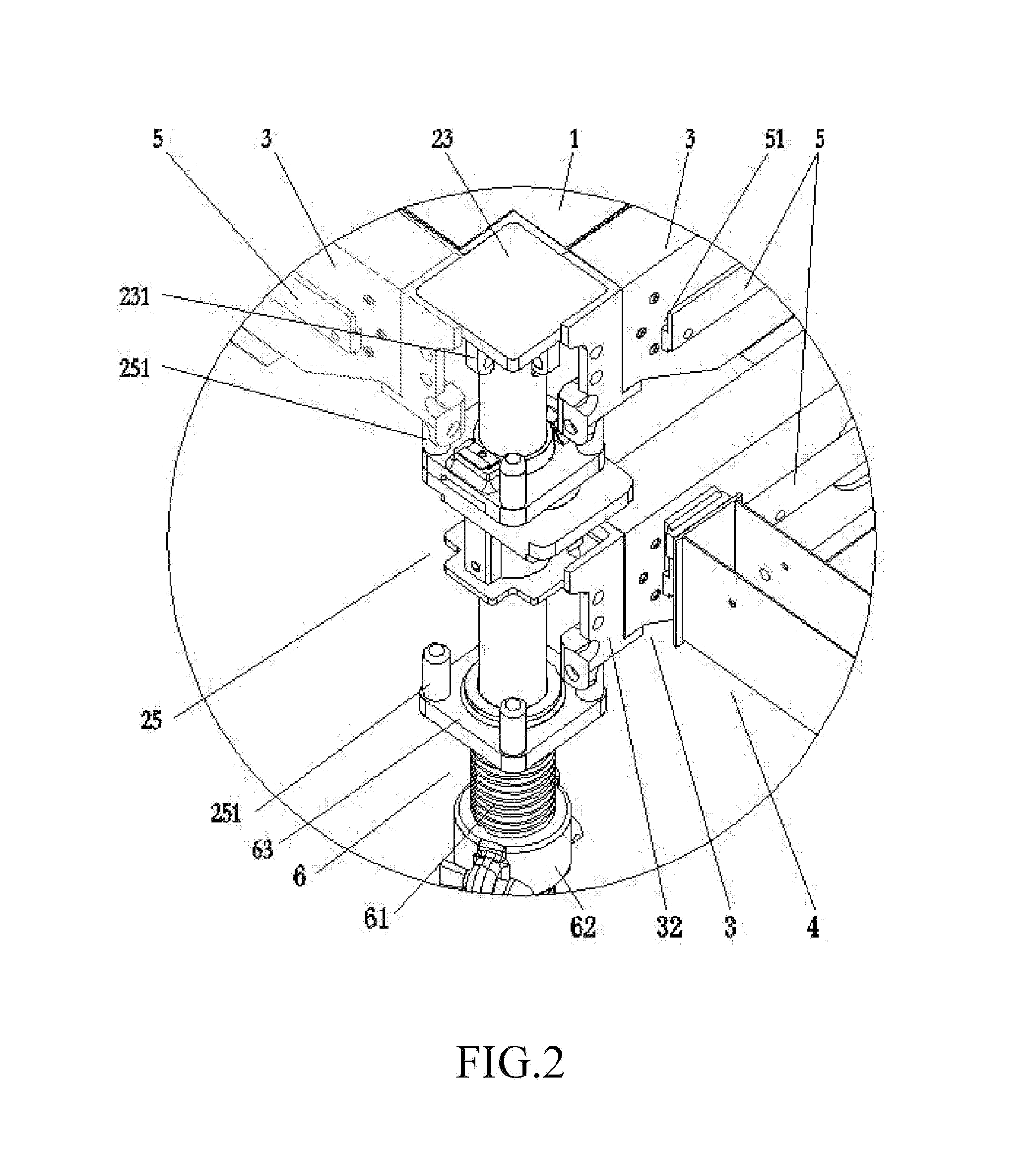

Early-removal formwork system for concreting of constructions comprising beams, plates and columns

ActiveUS20140263941A1Facilitate early stripping operationExtended service lifeForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksBuilding construction

An early-stripping formwork system for concreting of constructions comprising beams, slab and columns comprises several rectangular standard formworks (1), props with multiple early-stripping support mechanisms (2), several filler beams (3) and filler panels. The standard formwork (1) consists of a panel (11) and a formwork frame (12), and the formwork frame (12) is provided with L-shaped corners (121) at its four corners. Each of the early-stripping prop (2) consists of an upper support inner tube (21) and a lower support tube (22) which form a telescopic connection, a rectangular head plate (23) is disposed at the top end of the upper support inner tube (21), one corner of the head plate (23) fits an internal corner of any one of the L-shaped corners (121) on the formwork frame (12). A load-releasing mechanism (24) is connected between the upper support inner tube (21) and the lower support outer tube (22). An early stripping mechanism (25) for early stripping of the standard formwork (1) is disposed on the upper support inner tube (21), short posts (251) for supporting the formwork frame (12) are disposed at four corners of the early stripping mechanism (25), and a structure for preventing the formwork frame (12) from slipping outwards is formed between the short post (251) and the L-shaped corner (121). The formwork frame (12), the filler panel, the filler beam (3), and a bridge beam (4) may be all in a detachable combined structure. In the formwork system, transport and storage of the formwork are convenient, and manufacturing cost is reduced.

Owner:SHANDONG PRIMA FORMWORK CO LTD

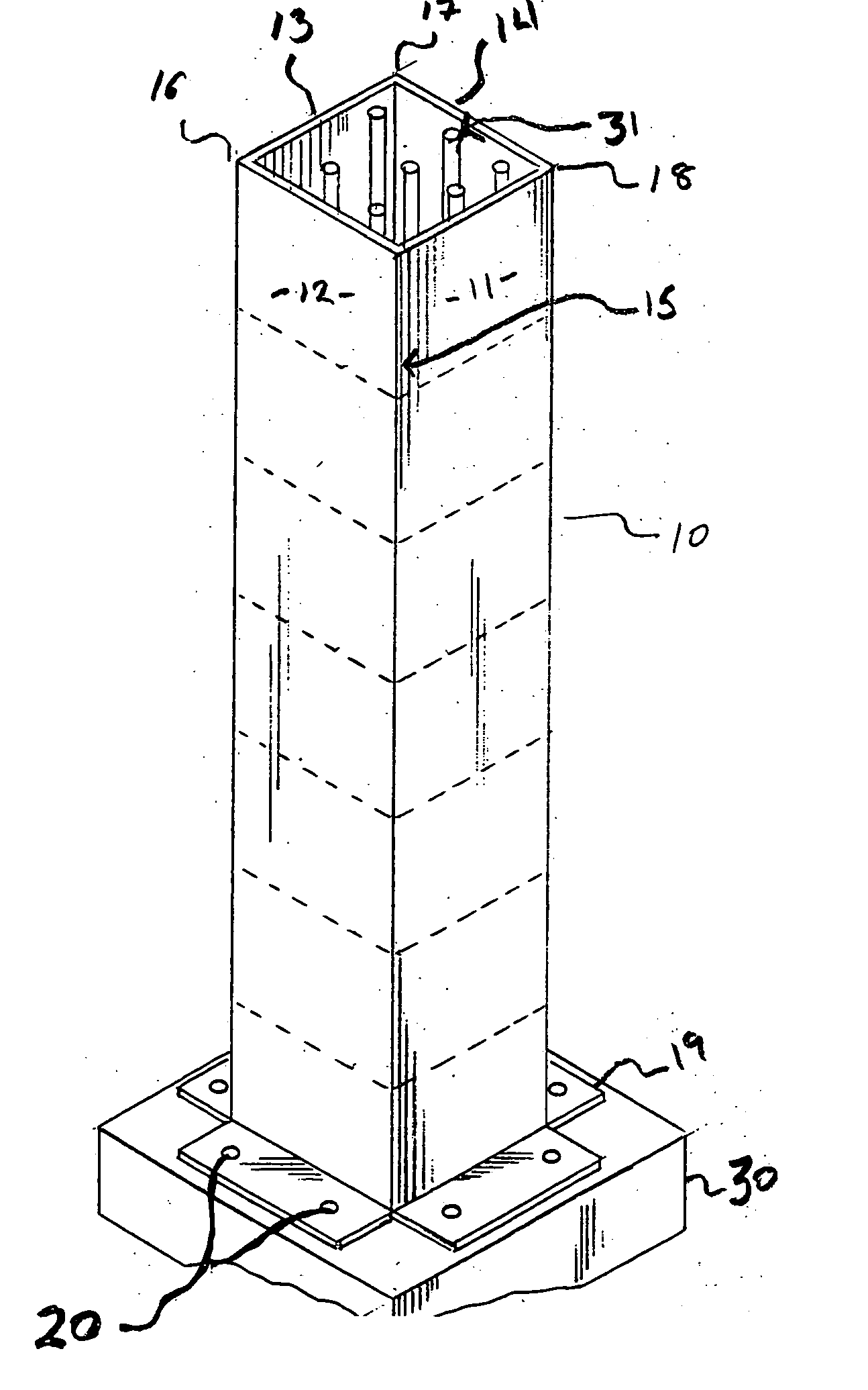

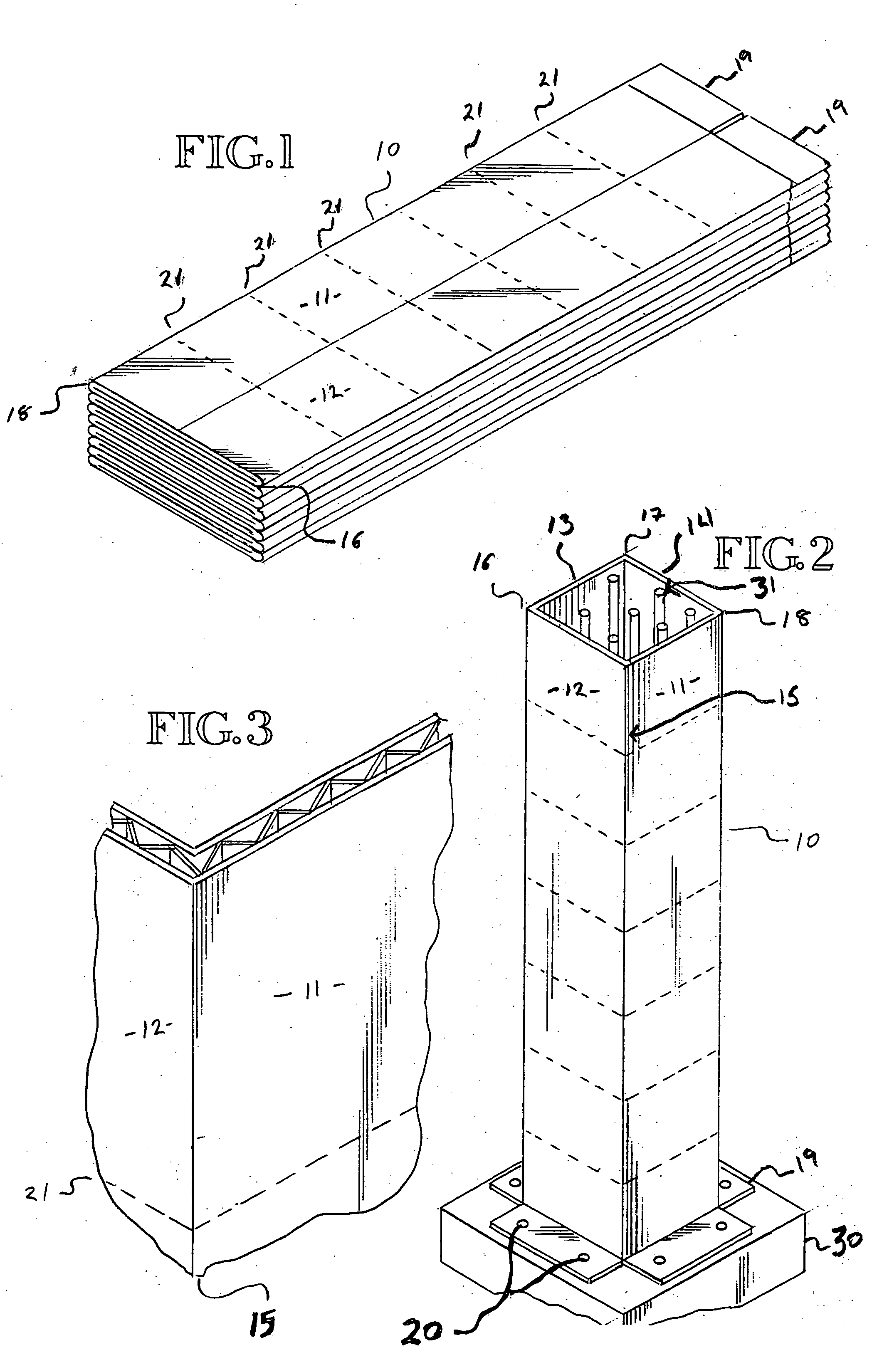

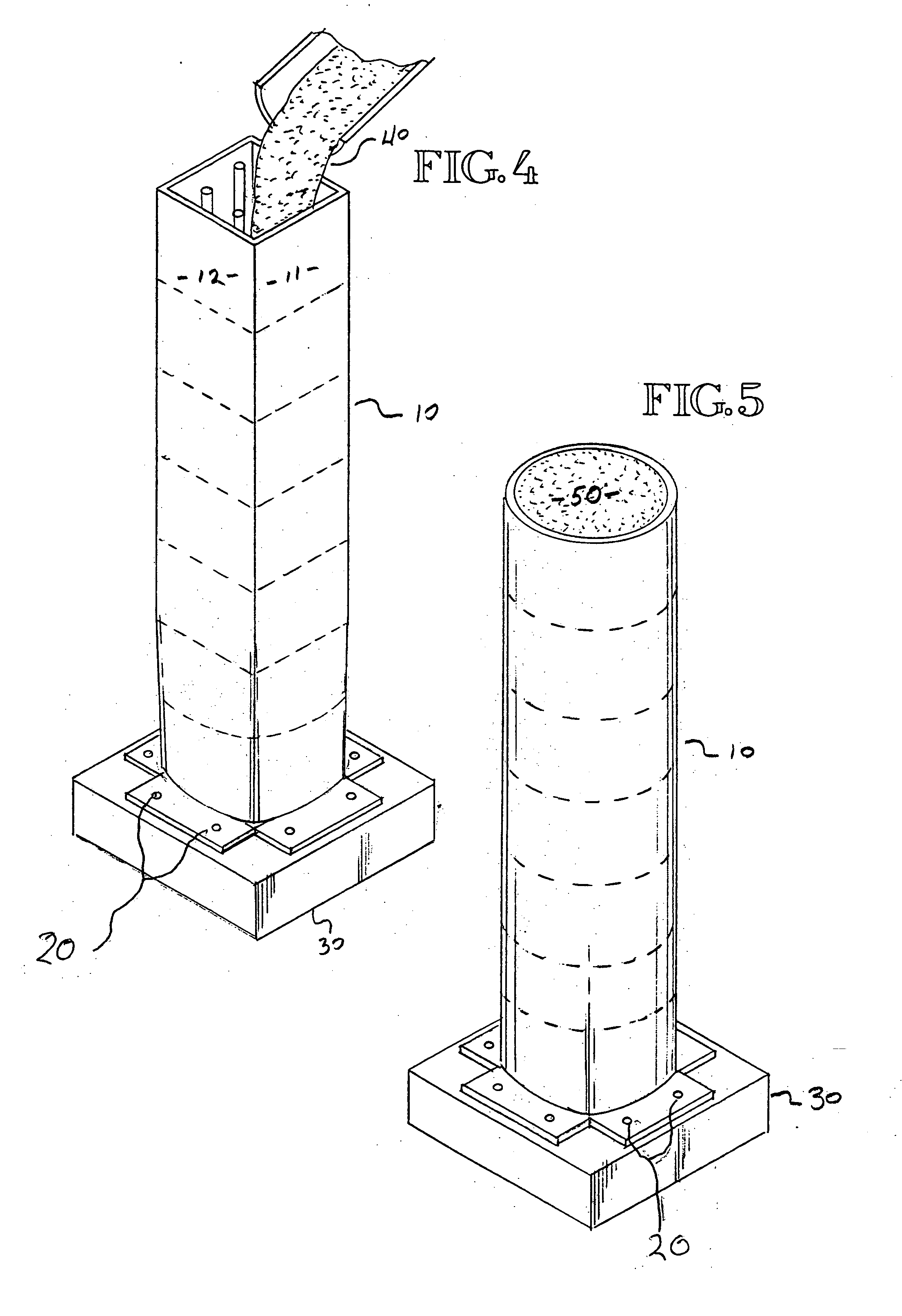

Forming apparatus and method for constructing concrete columns

InactiveUS20050066592A1Easy to storeEasy to transportWallsFoundation engineeringHydrostatic pressureRebar

The current invention discloses moisture resistant column forms constructed from corrugated plastic. The forms disclosed herein are lightweight and can be easily assembled at a construction site or remote location. The forms can be positioned over pre-placed sections of reinforcing bars, or sections of reinforcing bars can be placed into a form once it is in position. The forms disclosed in the current invention can be easily removed, but they do not attract insects and therefore do not have to be removed from columns after the concrete has dried. The forms disclosed herein have generally square perimeters when they are assembled and put in place, but after concrete is poured into the form, the side walls will undergo uniform deformation / displacement due to the hydrostatic pressure of the concrete and the resulting column will have a generally circular perimeter. A method of using the forms is also disclosed.

Owner:HUBER DONALD G +1

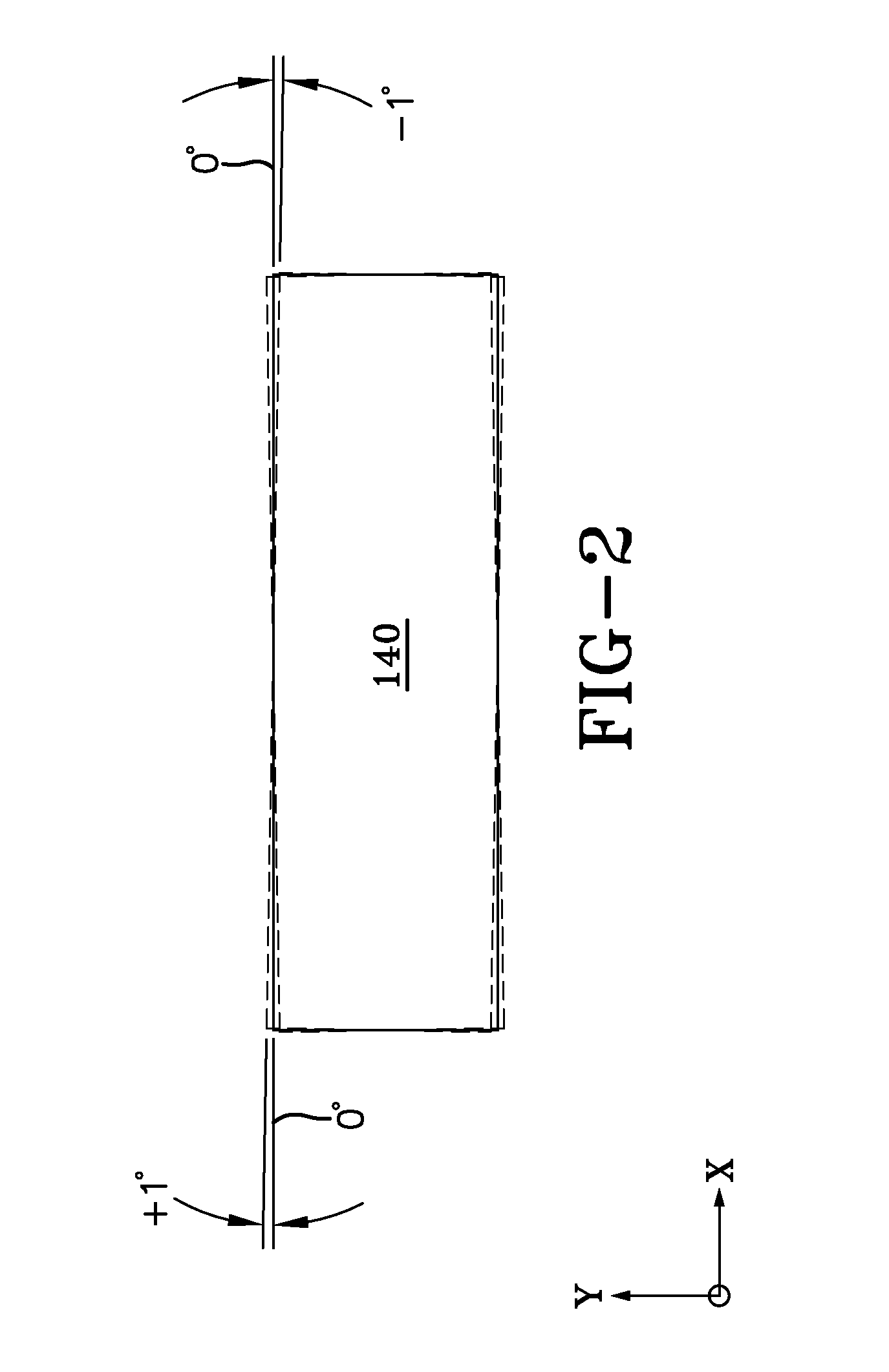

Variable angle formliner

A formliner and master mold are disclosed. The master mold corresponds with the formliner, which includes a plurality of courses, each course having a plurality of pockets, each pocket sized and configured to receive a decorative brick, and a plurality of ridges arranged and disposed to separate the pockets. In the embodiment, each pocket has an angle of rotation in the range of about −5.0° to about 5.0° and the angle of rotation of at least one pocket is other than 0°.

Owner:ARCHITECTURAL POLYMERS

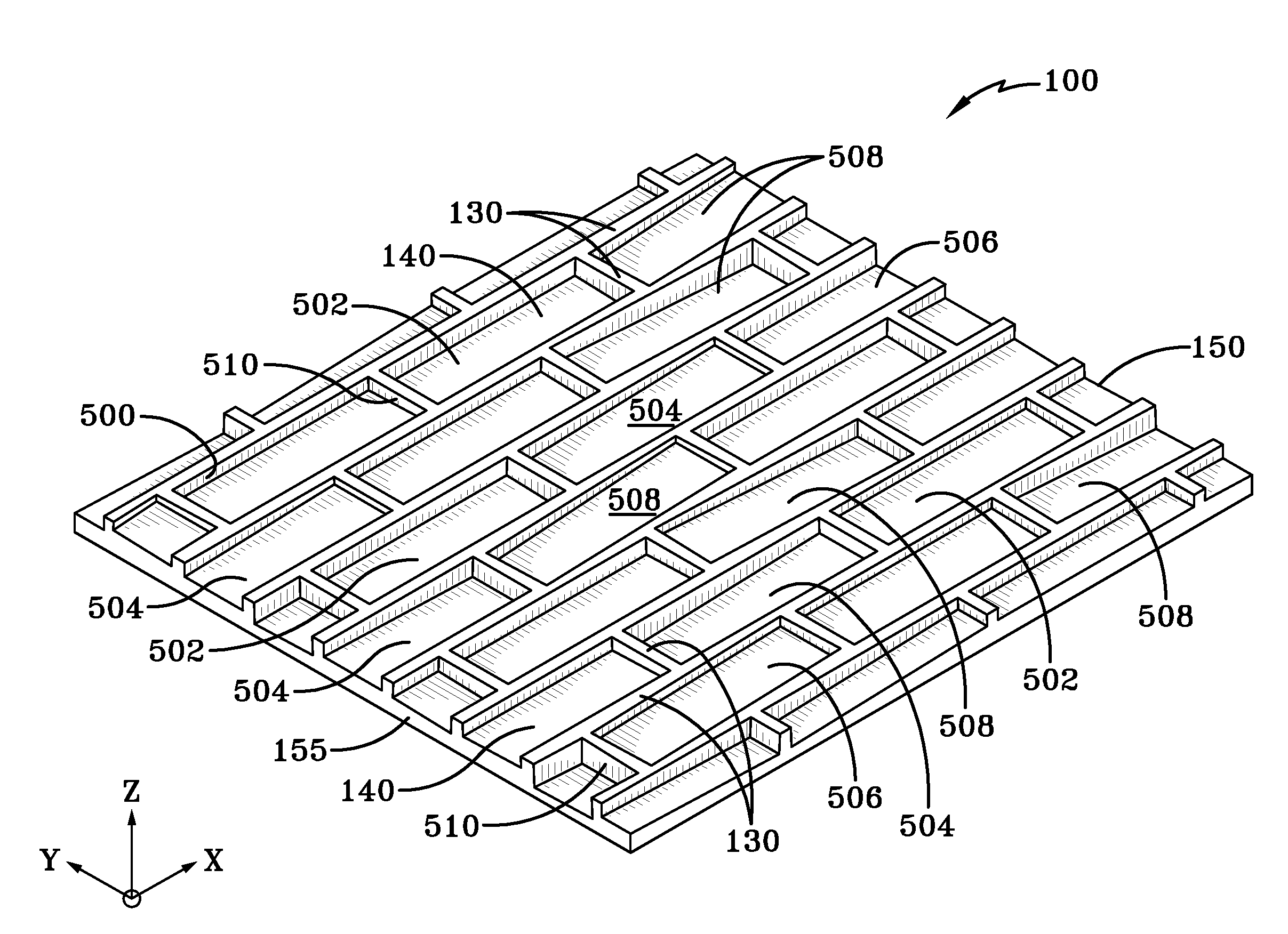

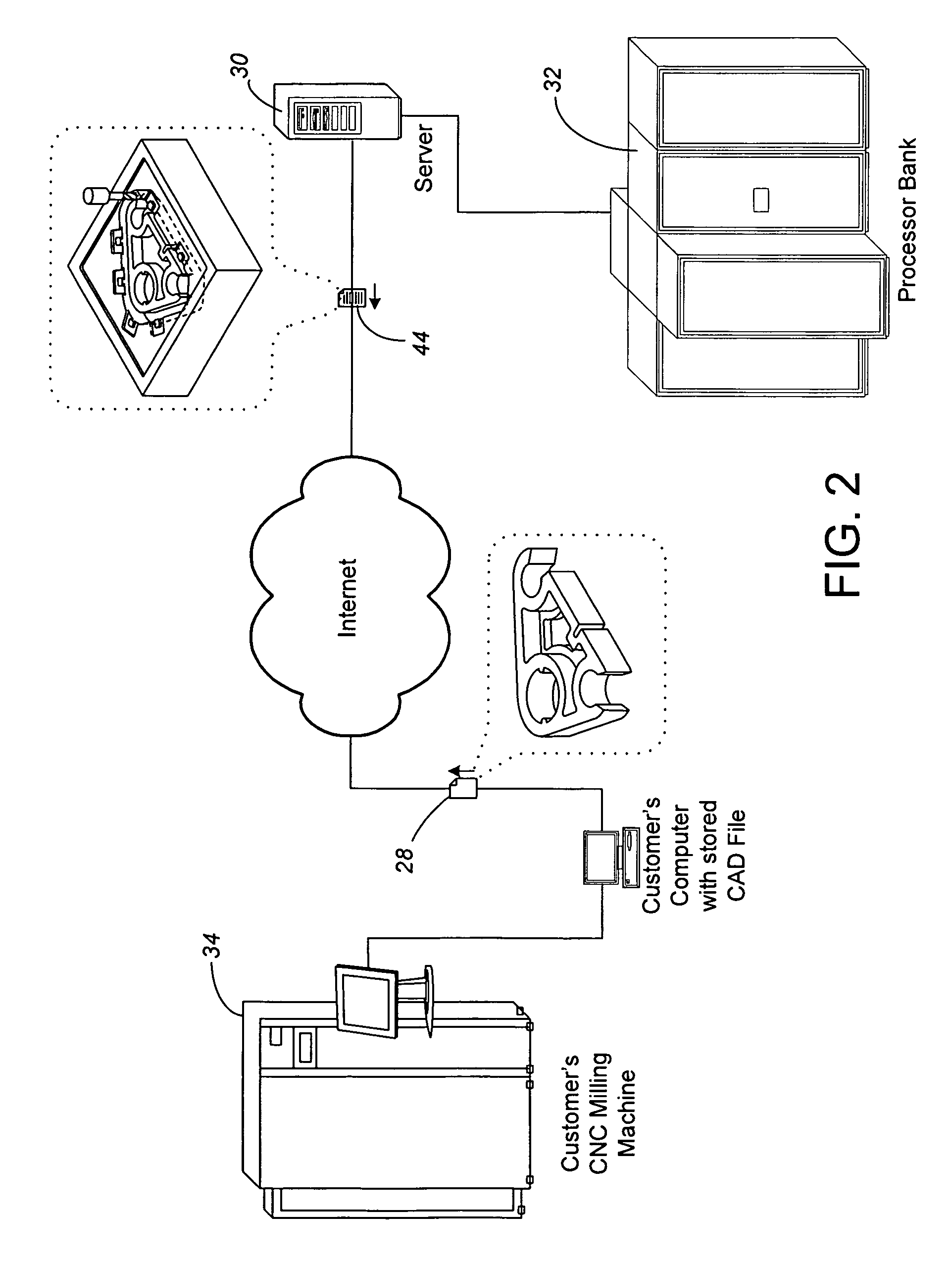

CNC instructions for solidification fixturing of parts

A customer transmits their 3D CAD file for a part to be total profile machined. Computer analysis of the transmitted CAD file produces CNC machining instructions, which are transmitted back to an address defined by the customer. The customer can then use the transmitted CNC machining instructions to total profile machine their own part using their own CNC mill at the location where the part is likely needed. The transmitted instructions include not only the tool paths for CNC machining of the total profile of the part, but also for additional features formed into the encircling portion of a material block from which the part is to be total profile machined. For instance, the CNC machining instructions transmitted back to the customer can define a registration recess and / or channels or undercuts for fluid support material on an A-side of a material block. After the A-side of the block is machined, the customer adds and solidifies fluid support material into the machined recess. The CNC mill is then used to machine a support surface into a portion of the solidified support material surface. A registration fixture is applied into contact with the support surface CNC machining on the B-side of the material block is then performed while the part is supported by the solidified support material, substantially separating the part from the encircling block of material. The support material is then removed, such as by dissolving, freeing the part from the encircling block of material.

Owner:PROTOLABS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com