Patents

Literature

39results about How to "Limit translation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

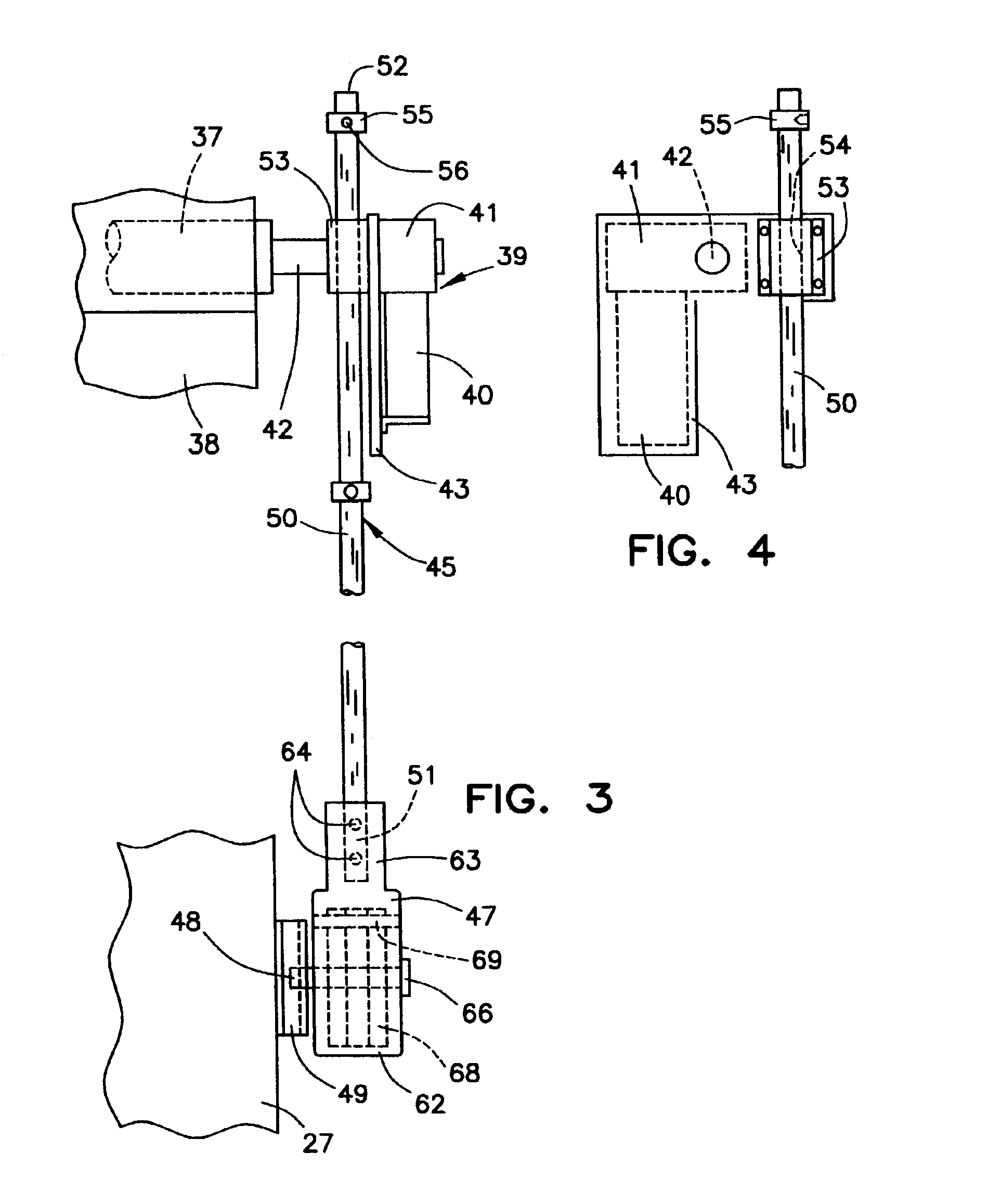

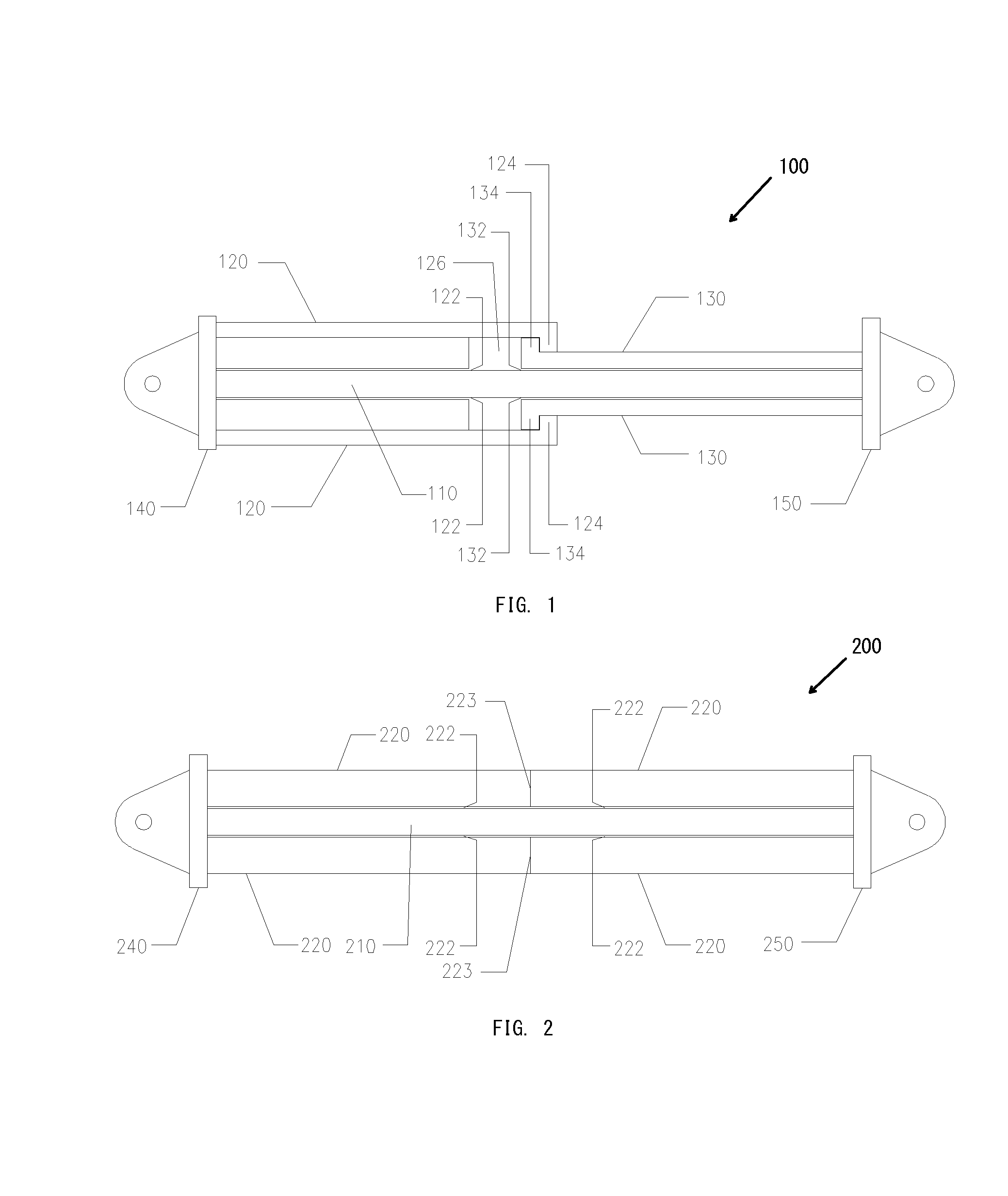

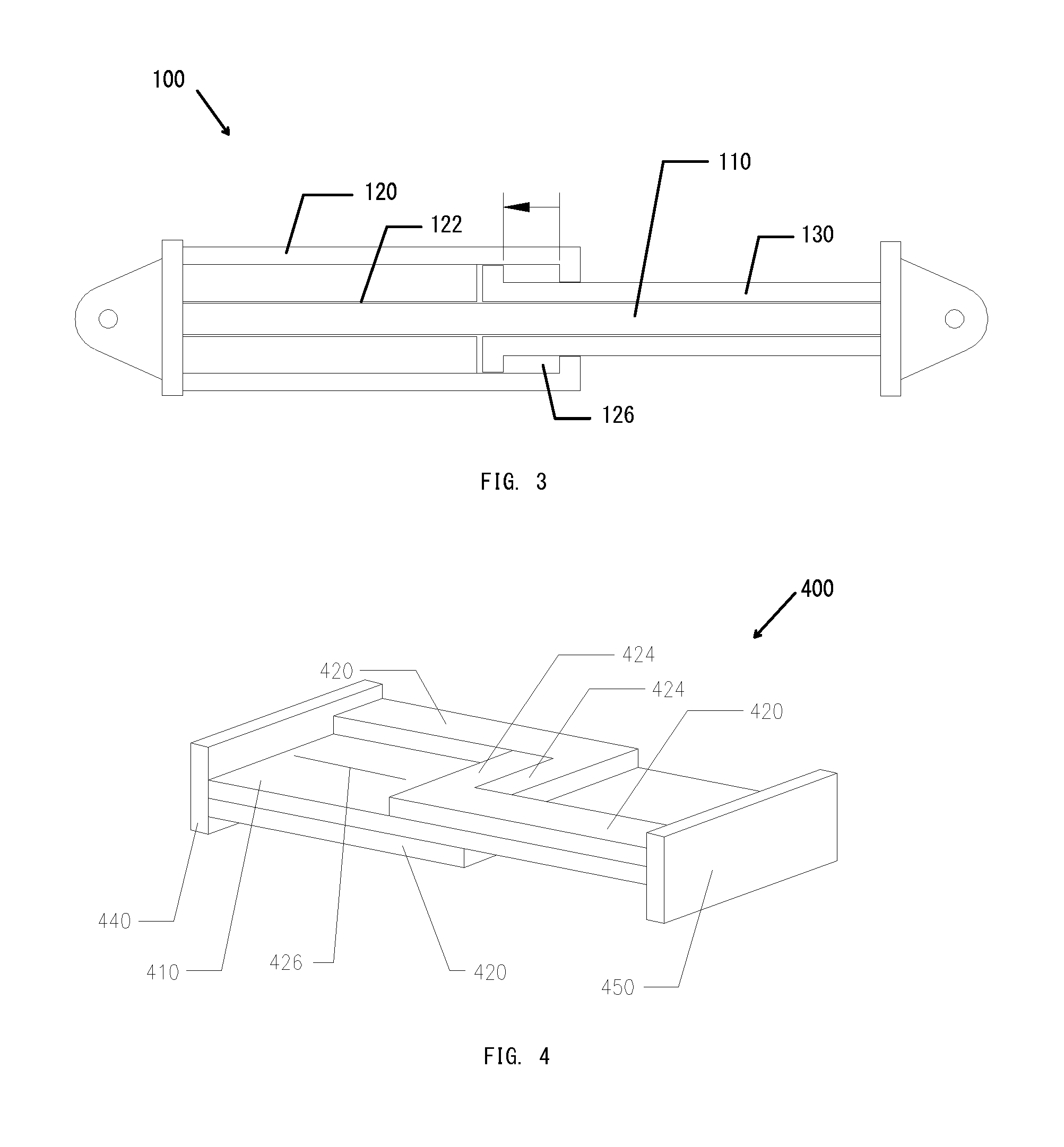

3-D construction modules

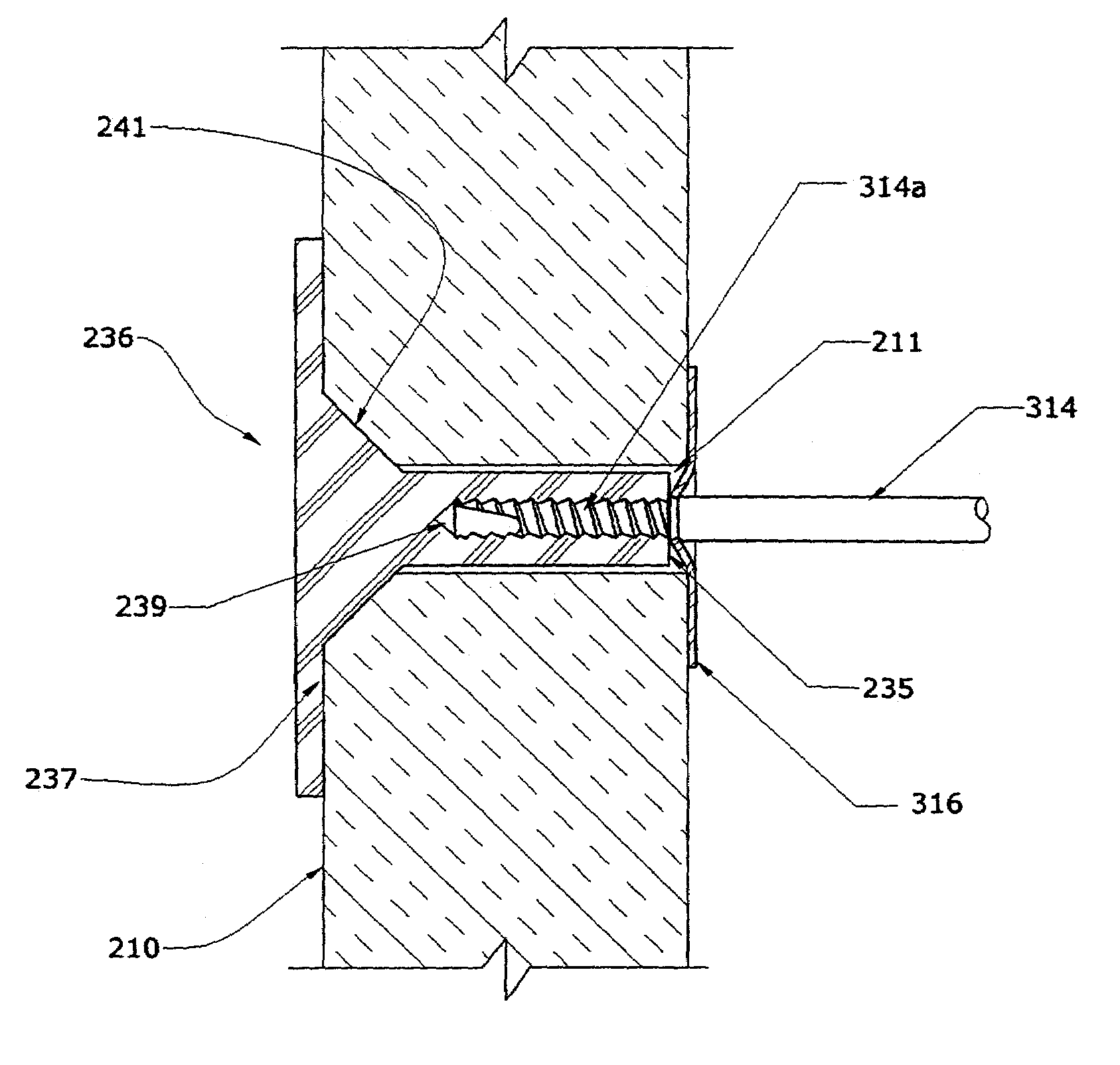

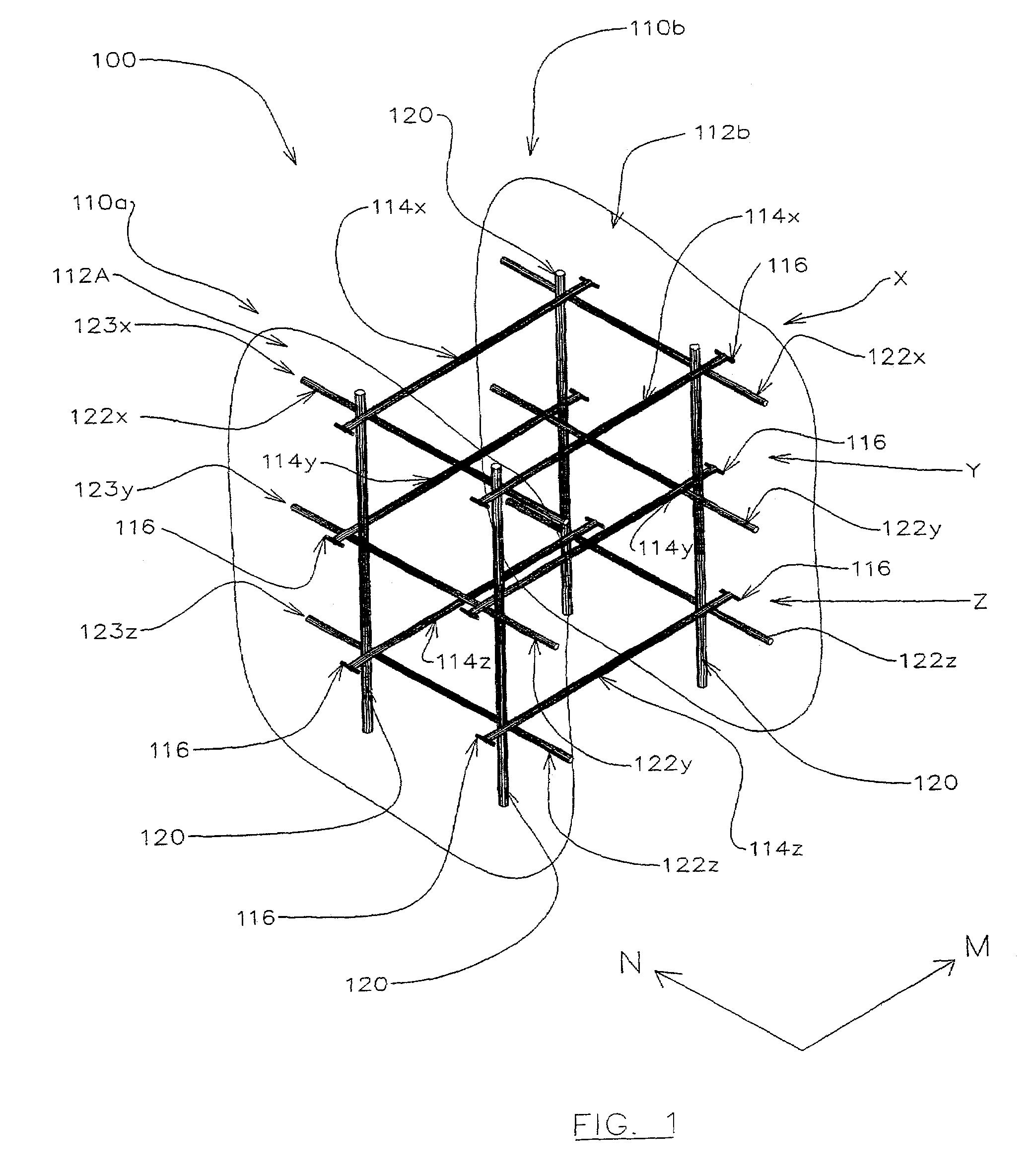

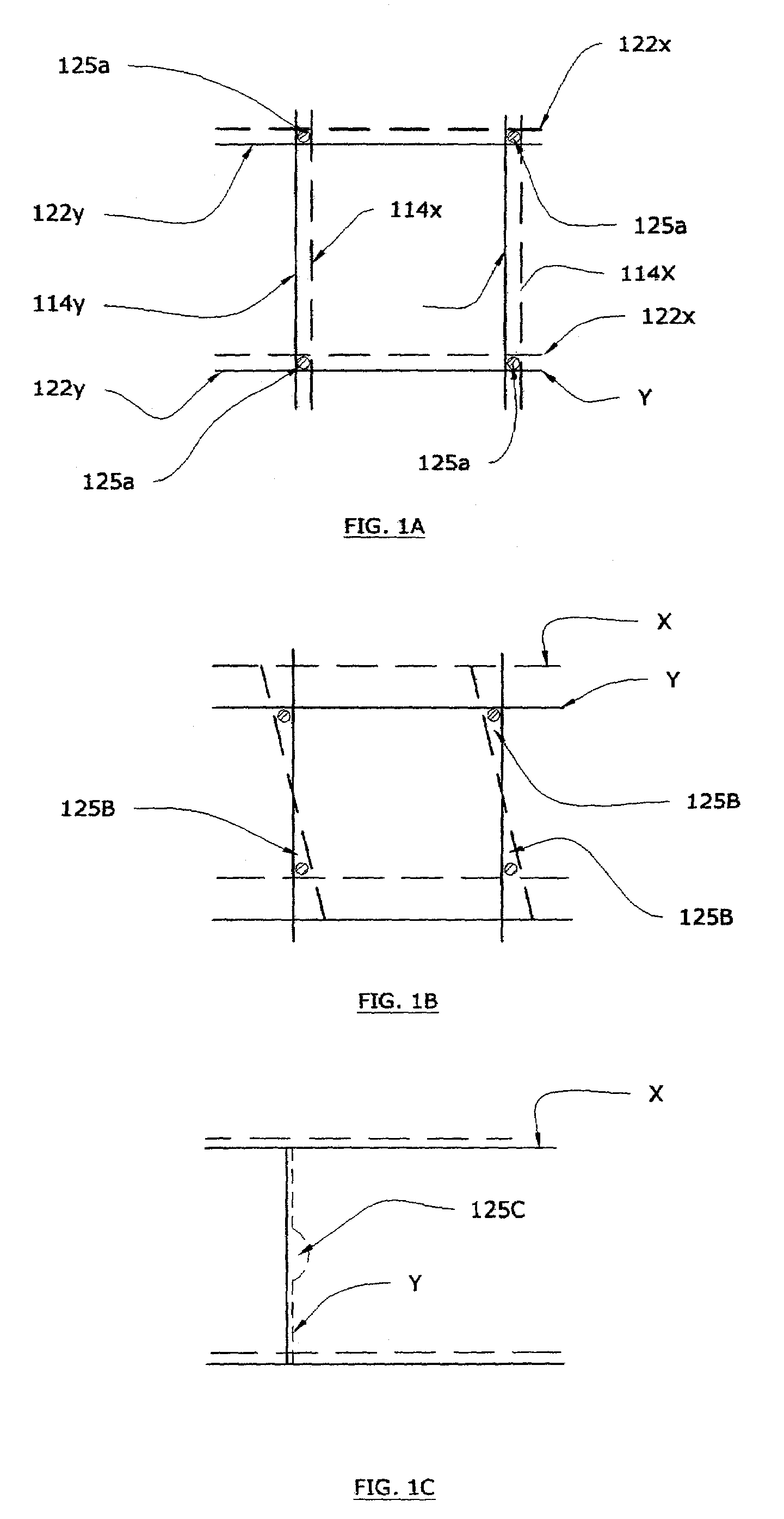

A 3D construction module comprising at least one vertically upstanding panel with first and second mesh layers oriented generally transversely and longitudinally. The first and second mesh layers have at least one rod member mounted to said panel and are vertically spaced from each other. The rod members form a first horizontally projected retention cell to restrict translation of a bar held in said retention cell between said first and second mesh layers. A third mesh can also be provided to form a second retention cell between said second and third mesh layers. The first and second retention cells restrict translation movement longitudinally and transversely of a vertical reinforcement member held in said first and second retention cells, and restrict rotation of the vertical reinforcement member about both a longitudinal axis and a transverse axis of the said 3D construction module. Horizontal reinforcement meshes are features of the invention. Other features of the invention include a trough for holding melted panel material, connectors for connecting rods to panels and associated stopper members. Also included are bracers for joining connectors and other devices related to panel connections.

Owner:BRAVINSKI LEONID G

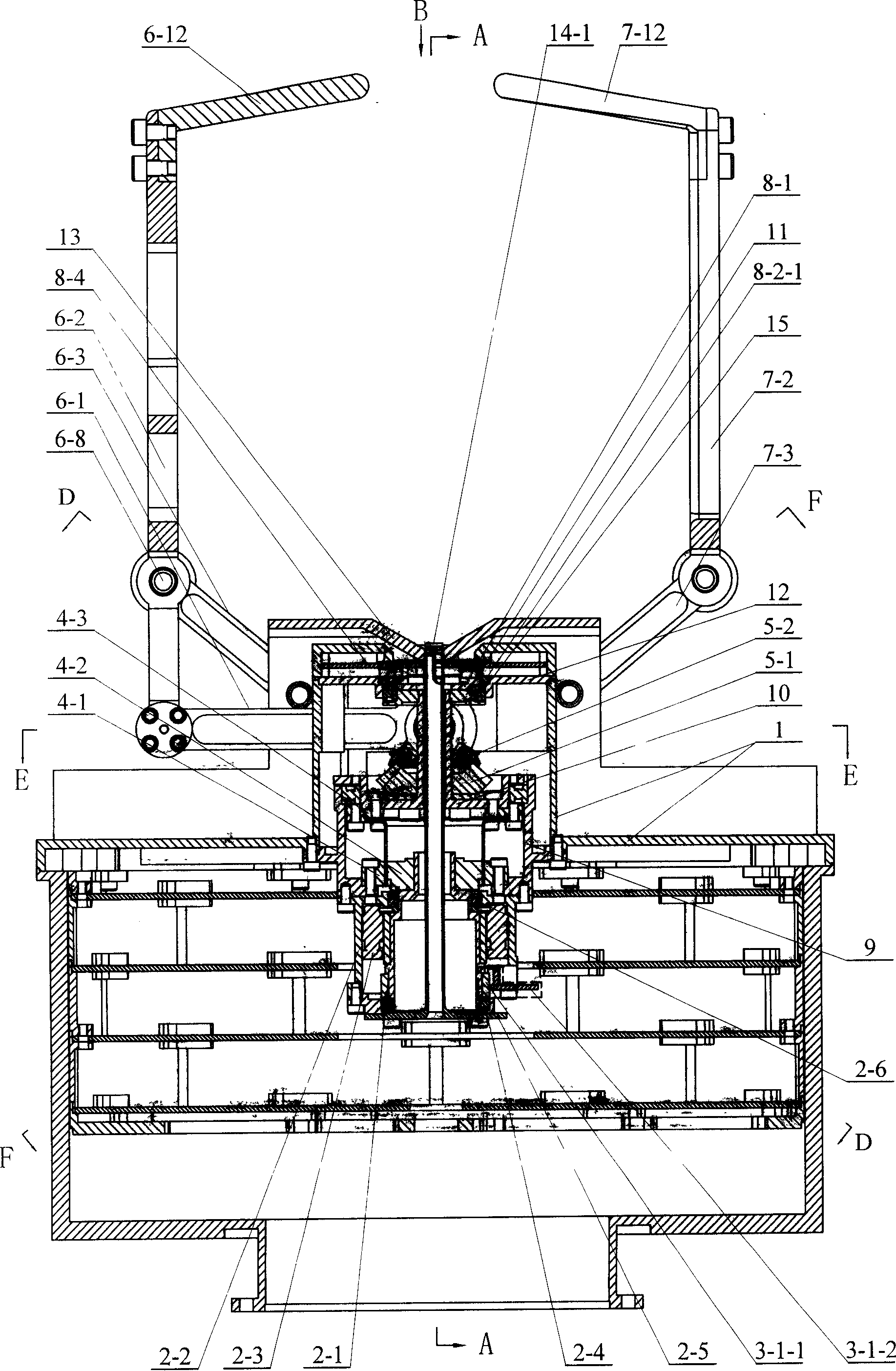

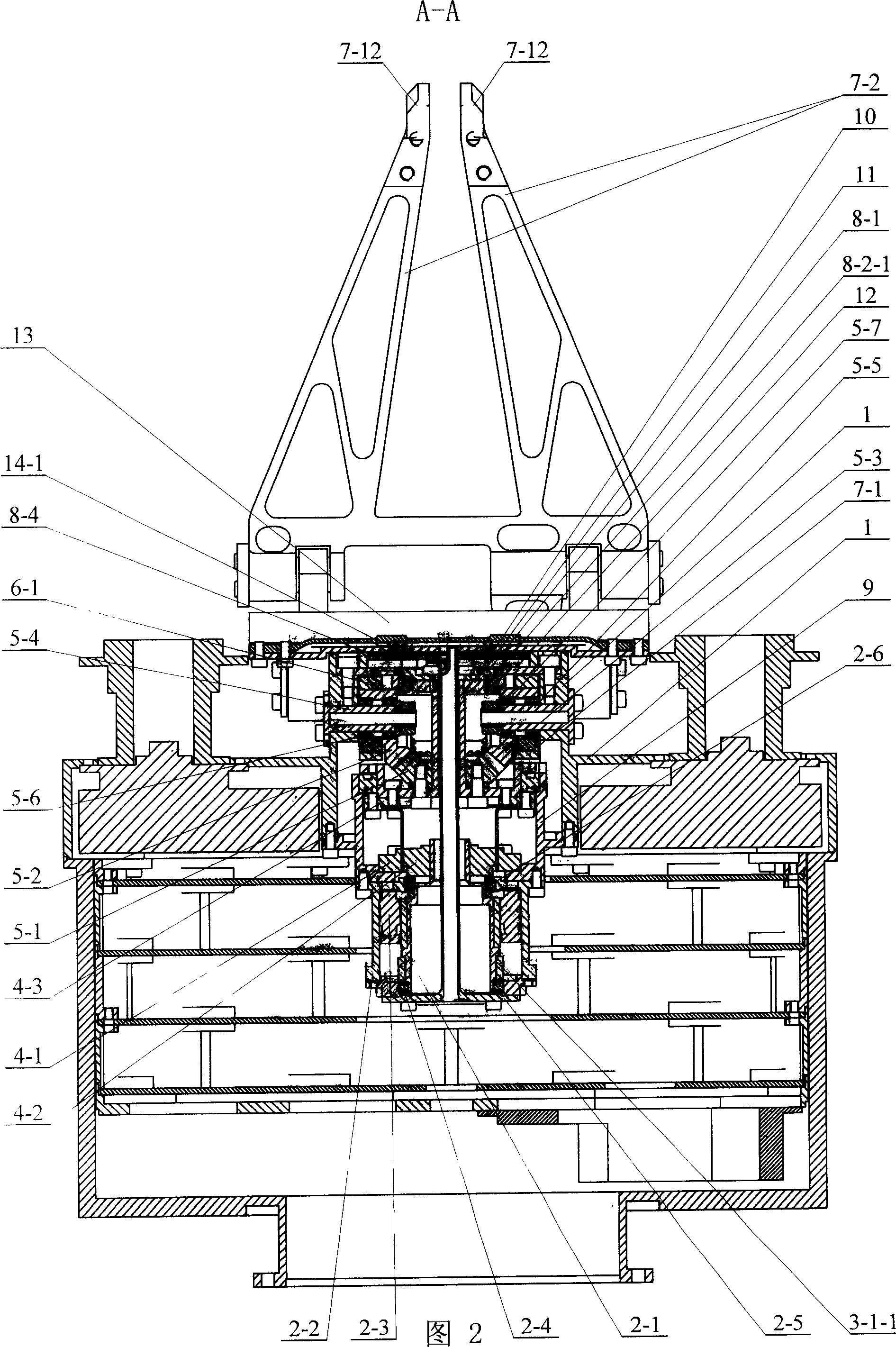

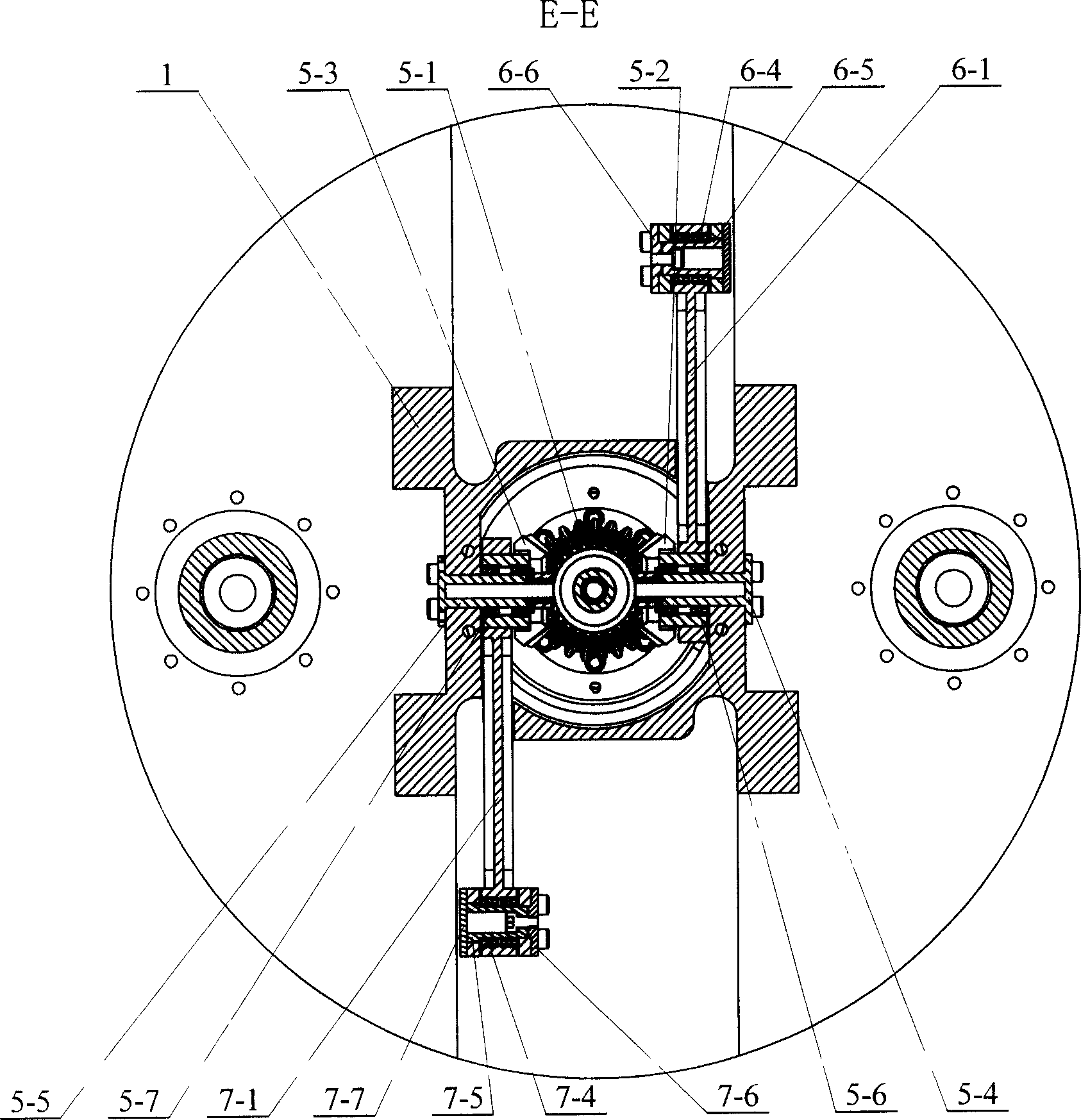

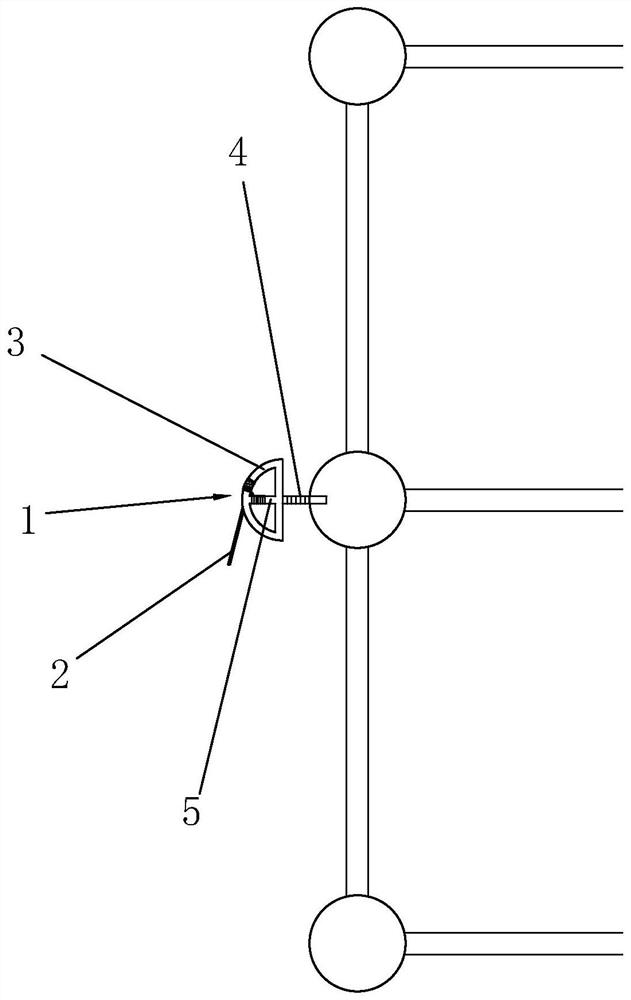

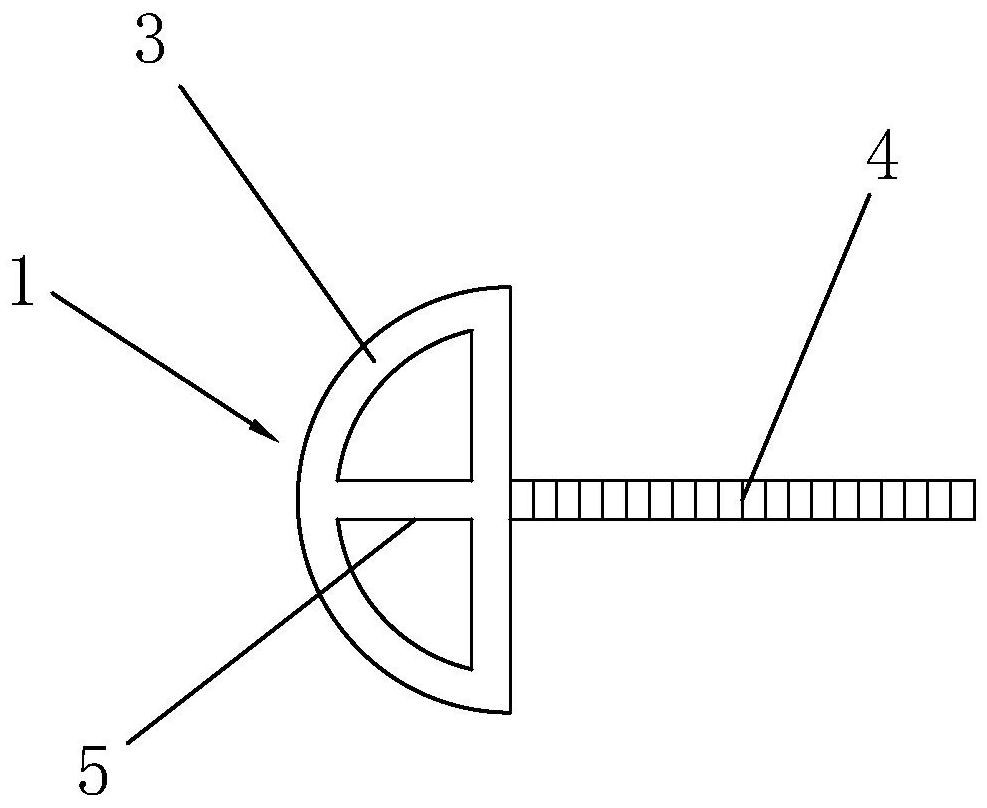

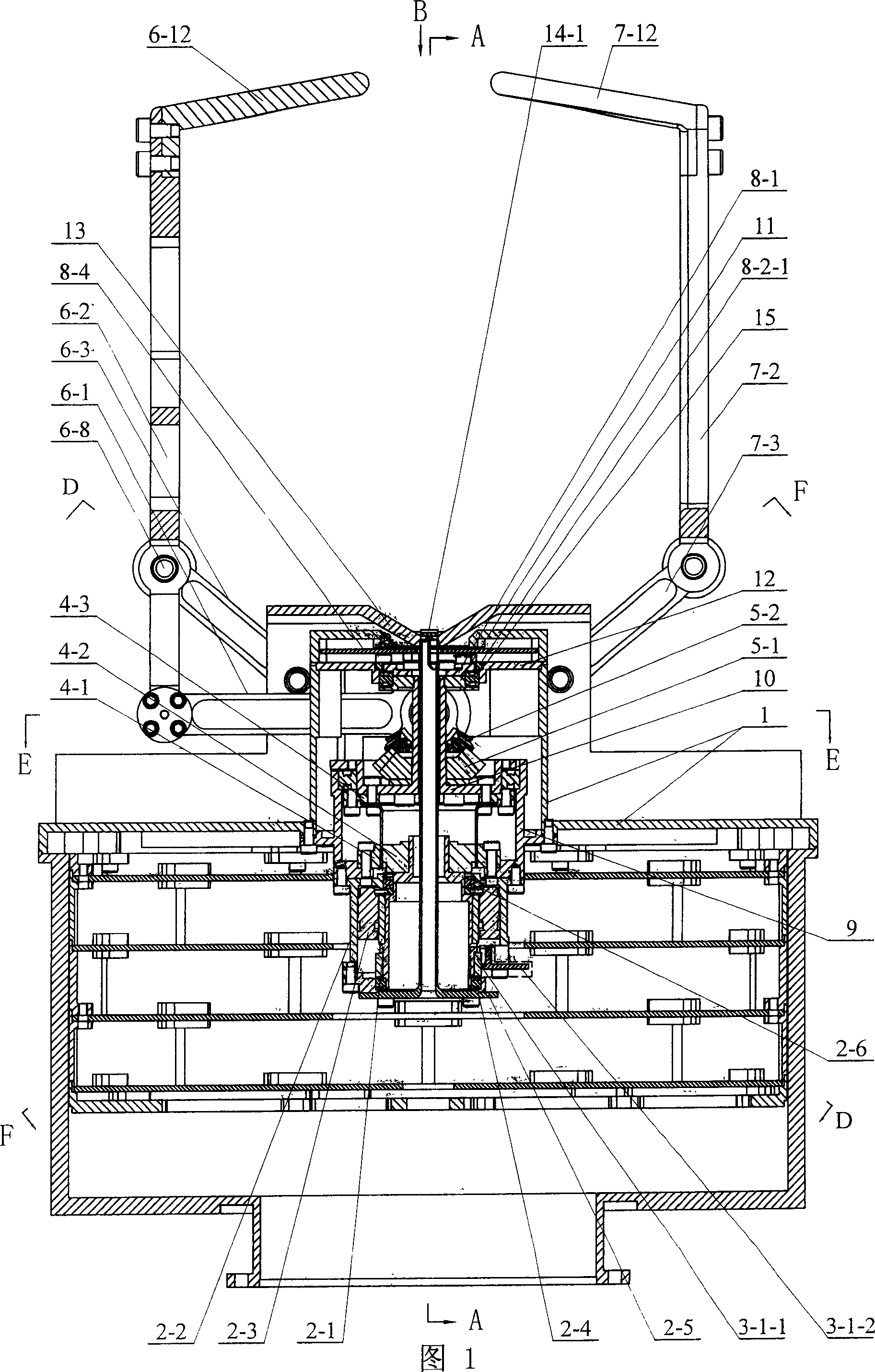

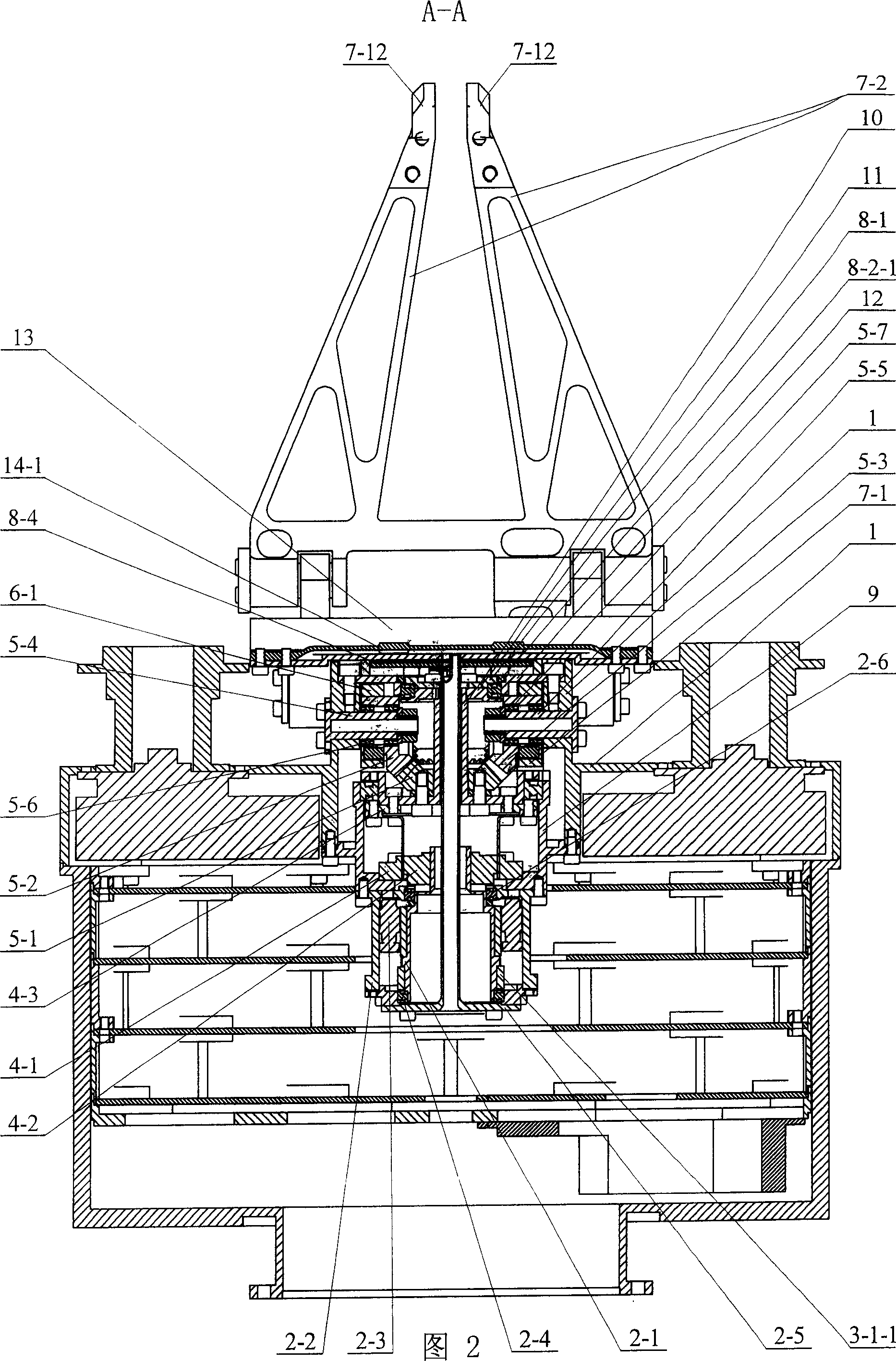

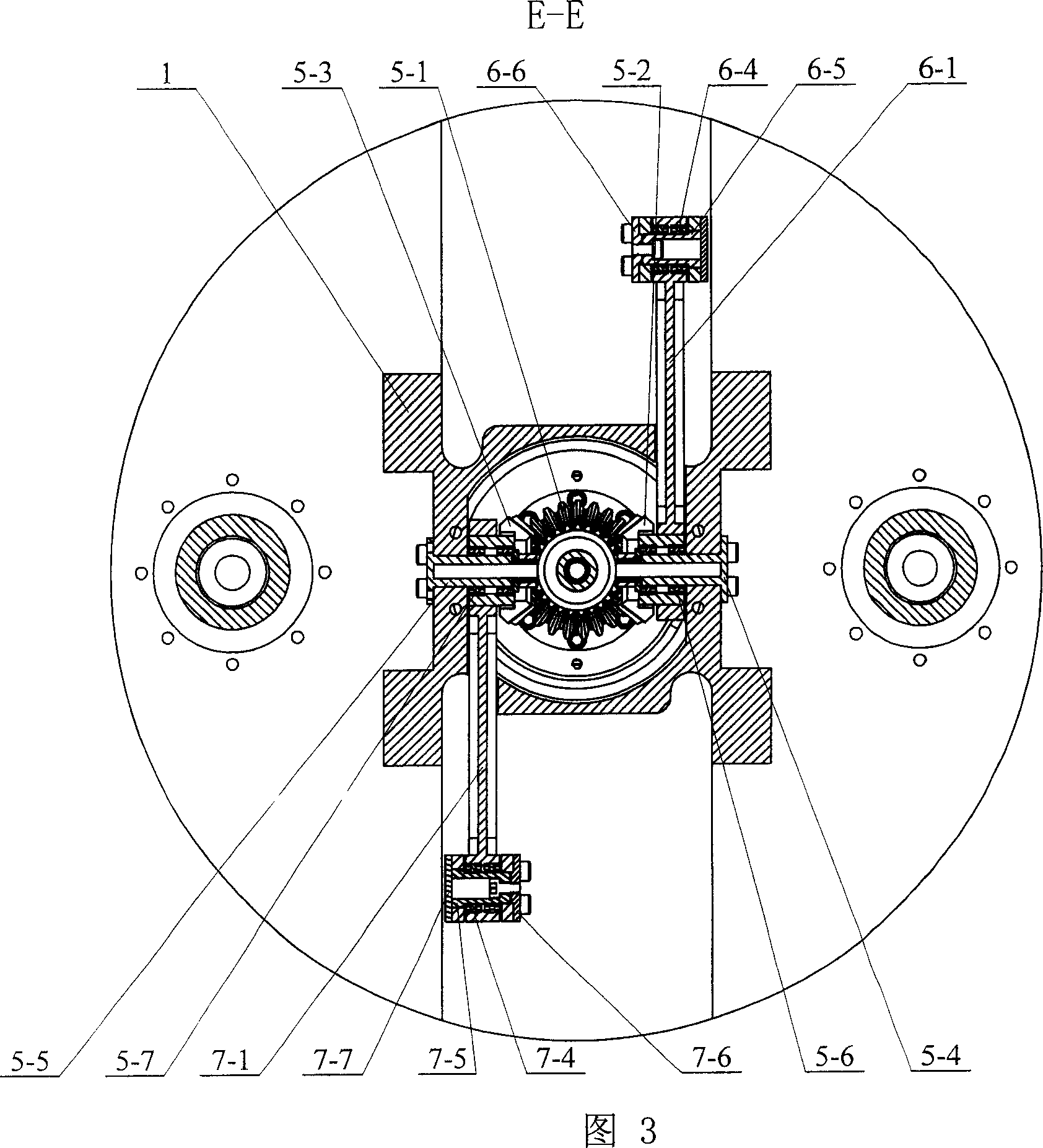

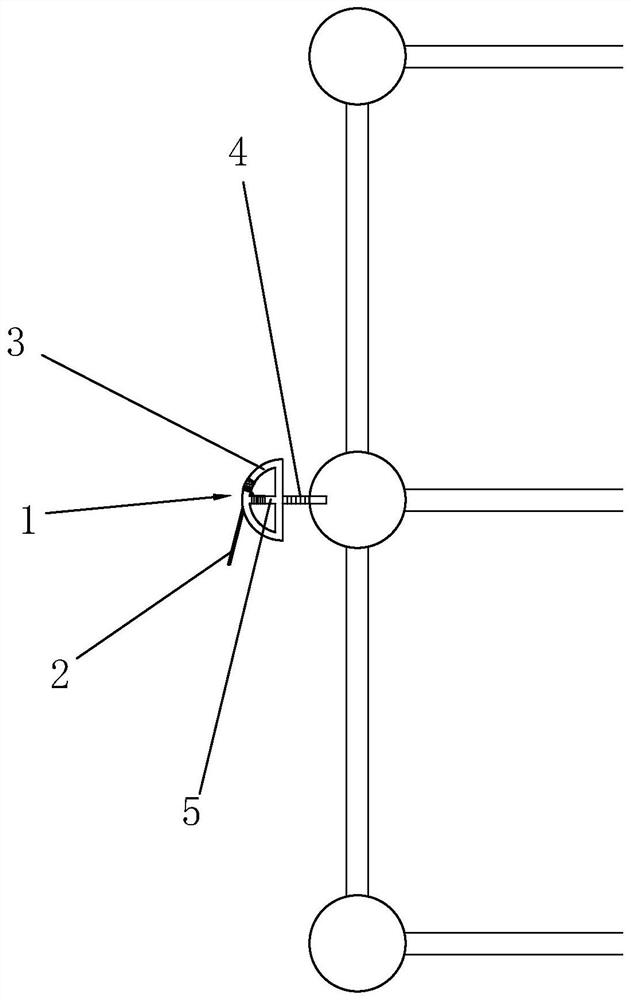

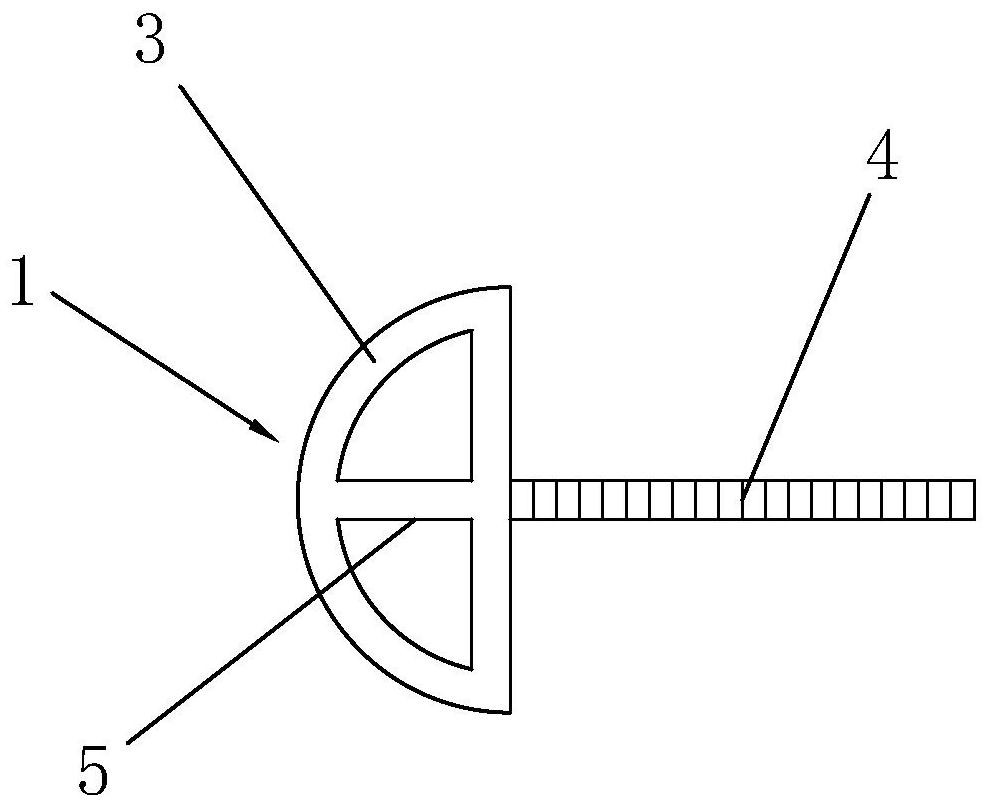

Space robot paw

A grip of space robot is disclosed, which features wide capture range and high locating precision. The motor position sensor is fixed to motor driver connected to supporting sleeve fixed to harmonic speed reducer installed to mainshaft of motor and connected with drive flange. Said drive flange is fixed to shaft-end flange connected with finger position sensors. The gear drive unit on drive flange is connected respectively with the single-finger and dual-finger 4-connection-rod units. The contact sensor is arranged in V-shaped slot on shell.

Owner:HARBIN INST OF TECH

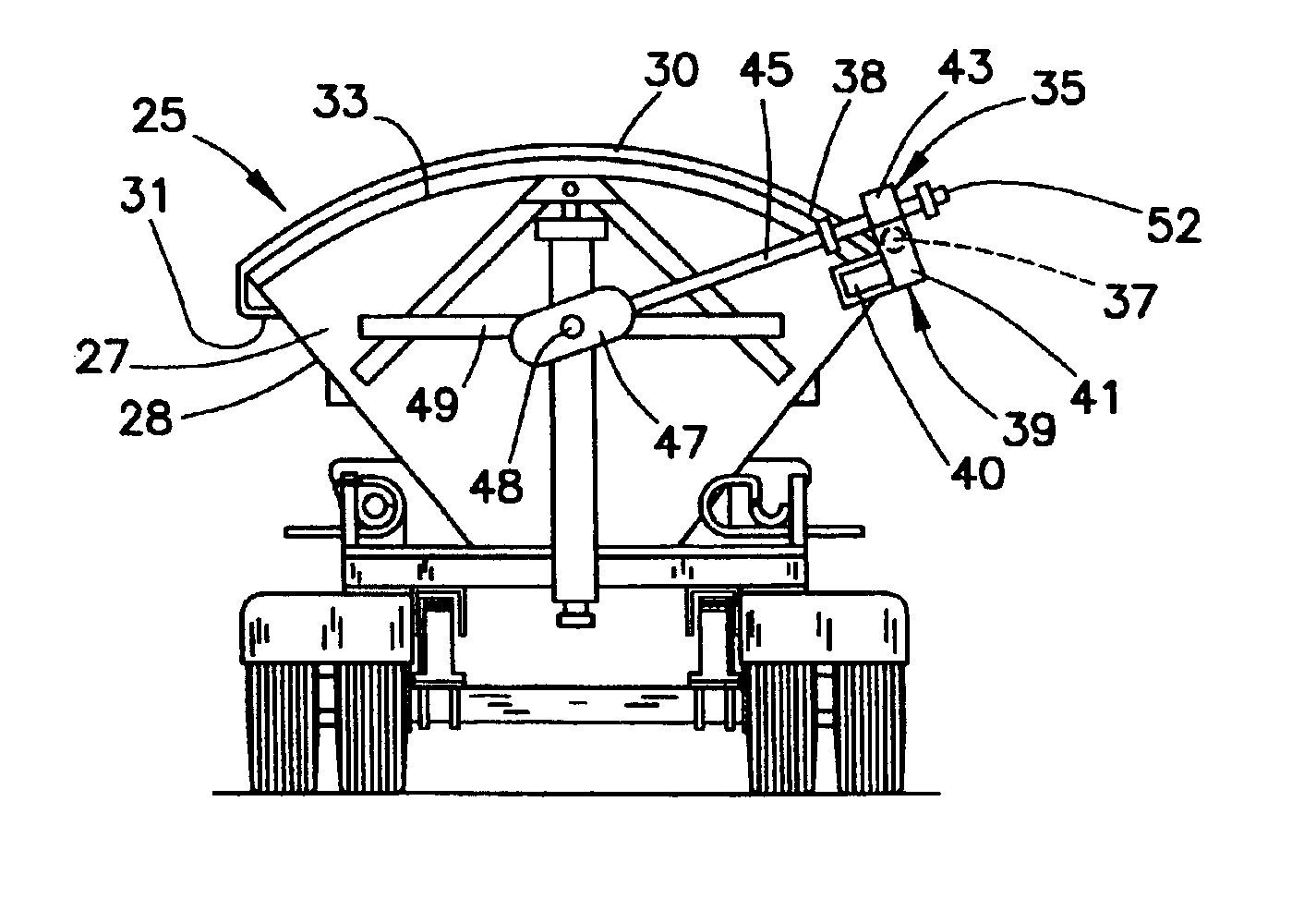

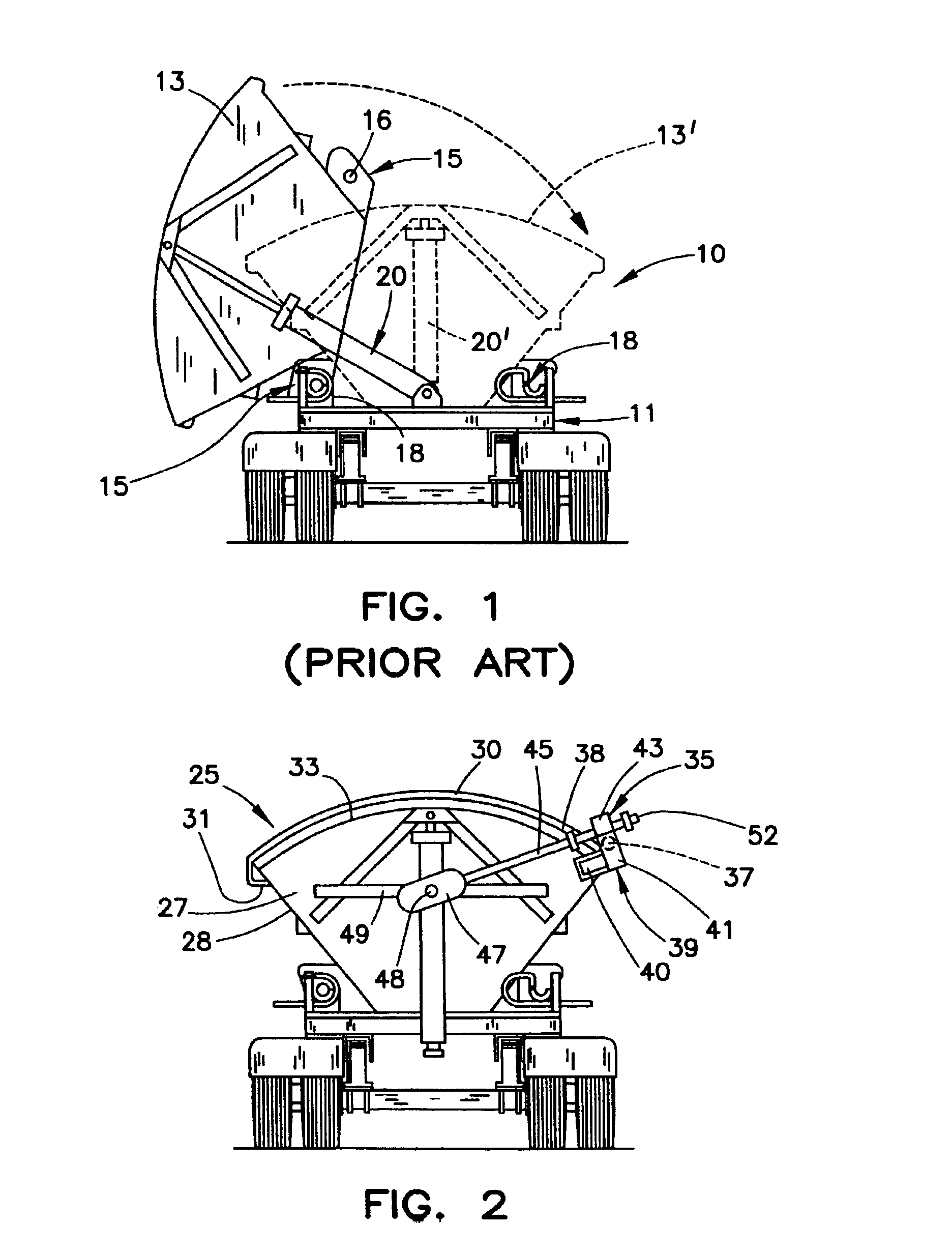

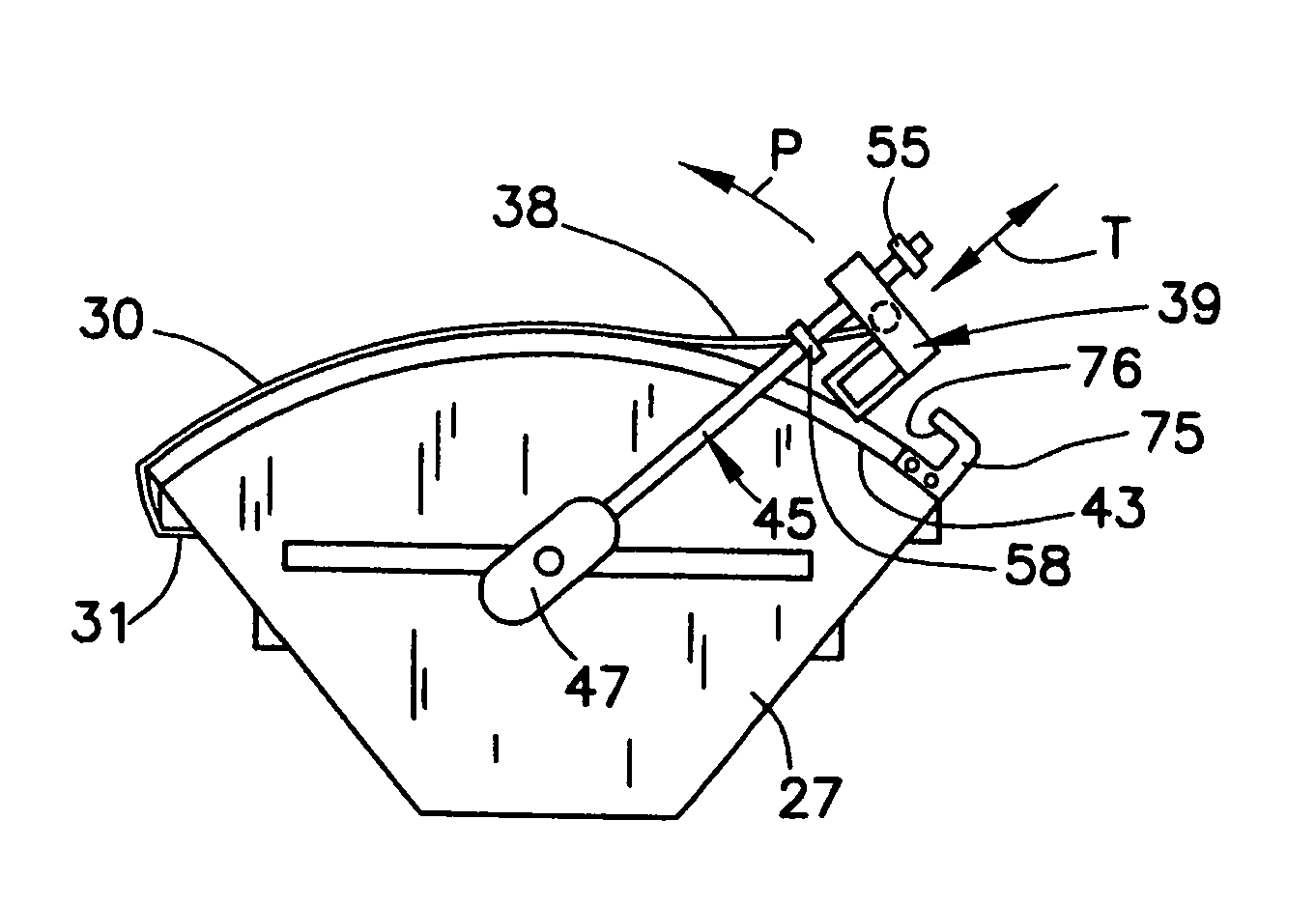

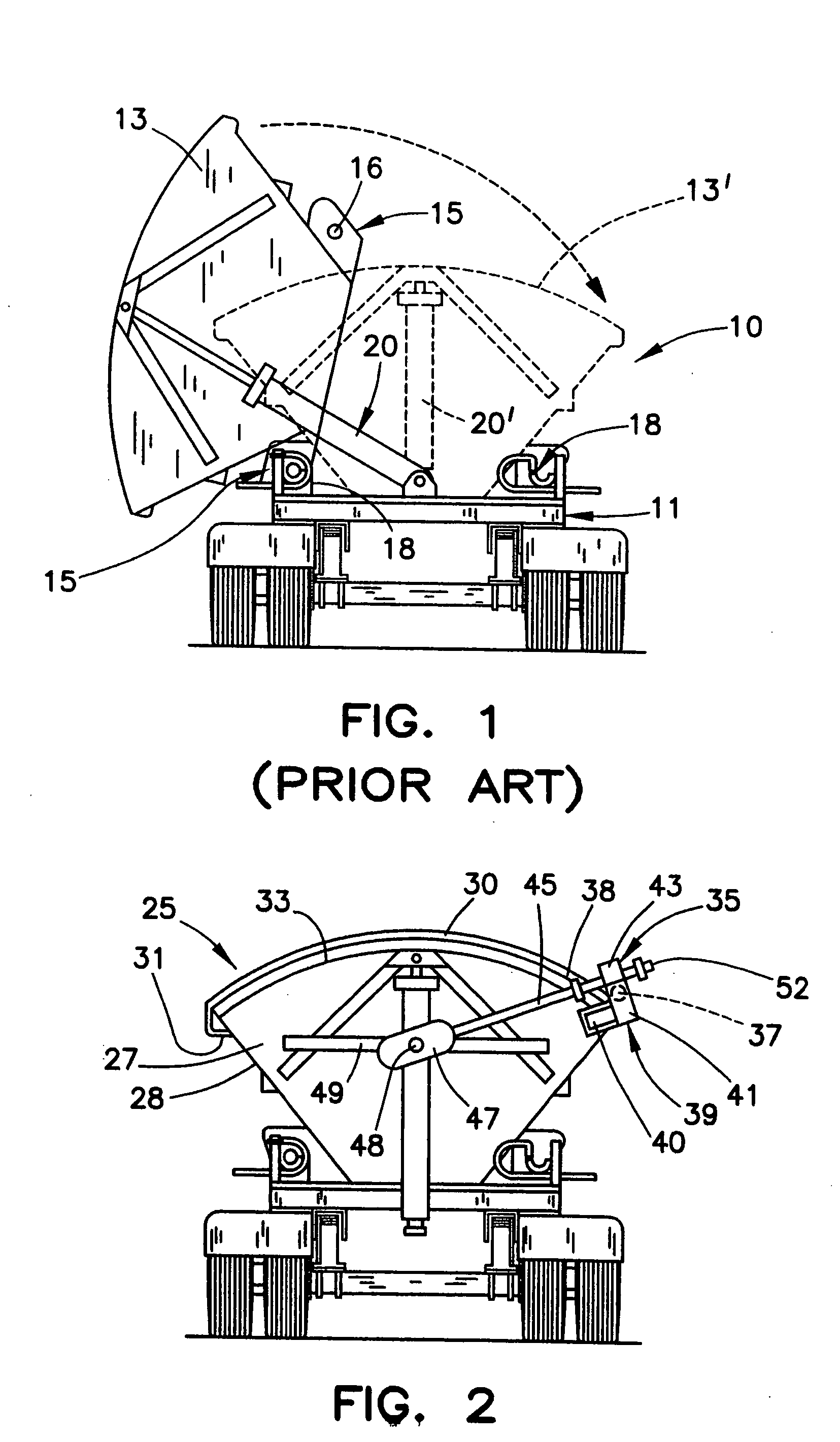

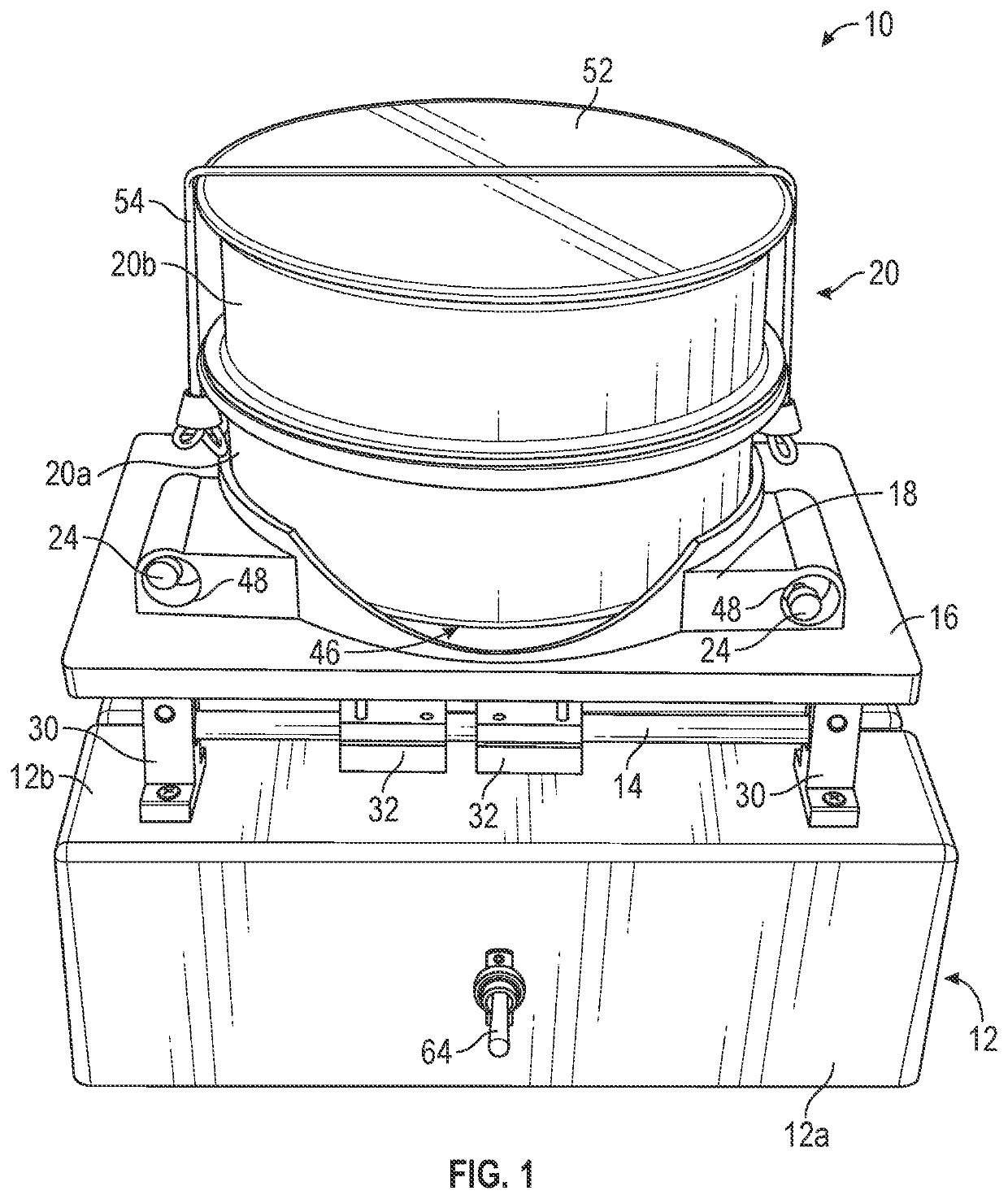

Cover system for a side-dump container

InactiveUS6857682B2Easy to implementEasily accommodated heaped loadRemovable external protective coveringsLoad coveringEngineeringMechanical engineering

A deployment apparatus for a flexible cover sized to cover a side-dump container comprises first and second swing arm assemblies pivotally mounted at a pivot point to opposite sides of the container. A drive assembly connected to the roll tube of the flexible cover is operable to rotate the roll tube so that the flexible cover winds around the roll tube. The drive assembly is slidably supported on one of the swing arms so that the mechanism translates along the length of the swing arm as it winds the flexible cover around the roll tube. A stop is provided on the swing arm between the pivot point and the free end to limit the translation of the drive assembly along swing arm. In another form, the drive assembly is fixed to a swing arm that is slidably received in a pivoting spring mechanism.

Owner:AERO INDS

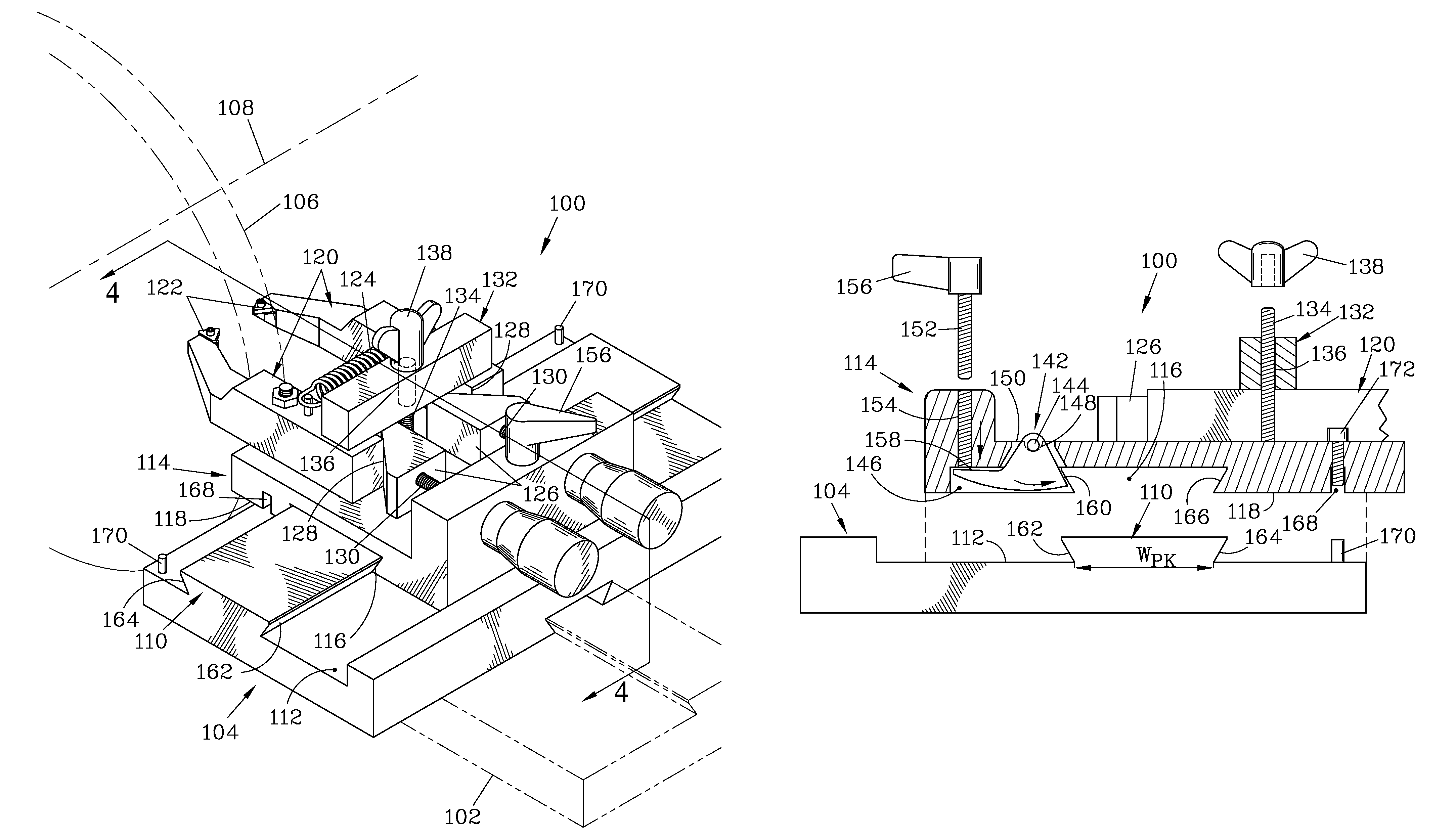

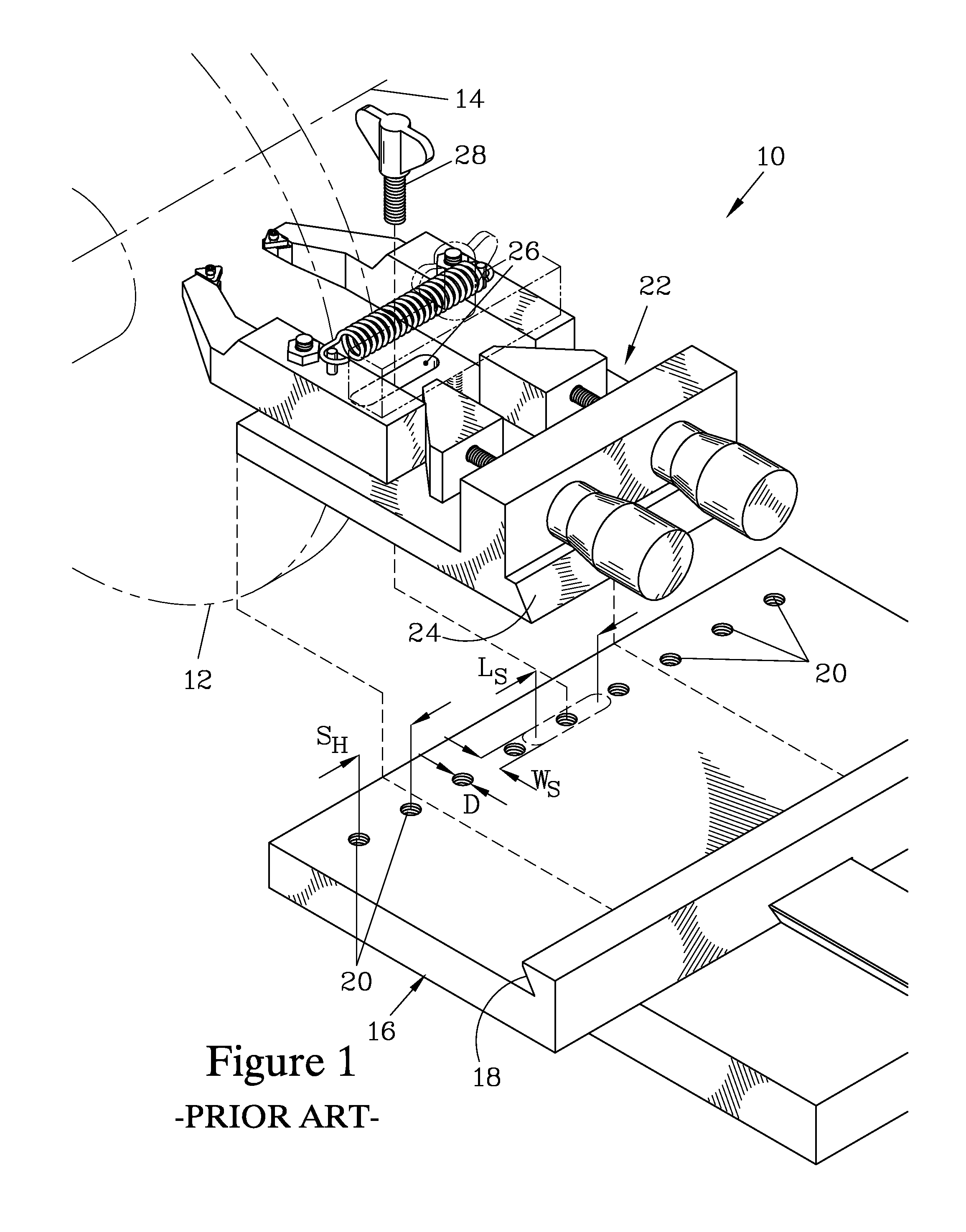

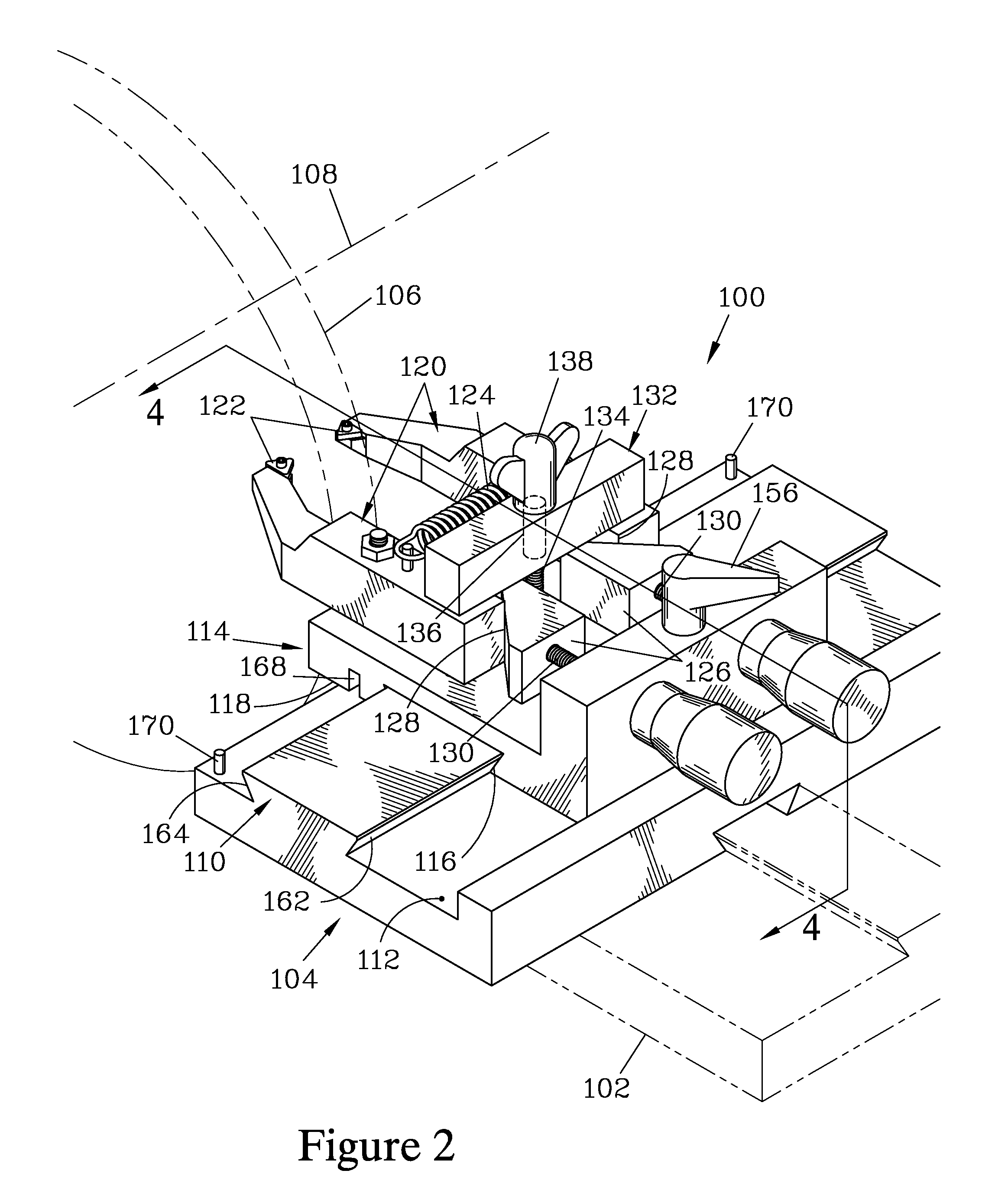

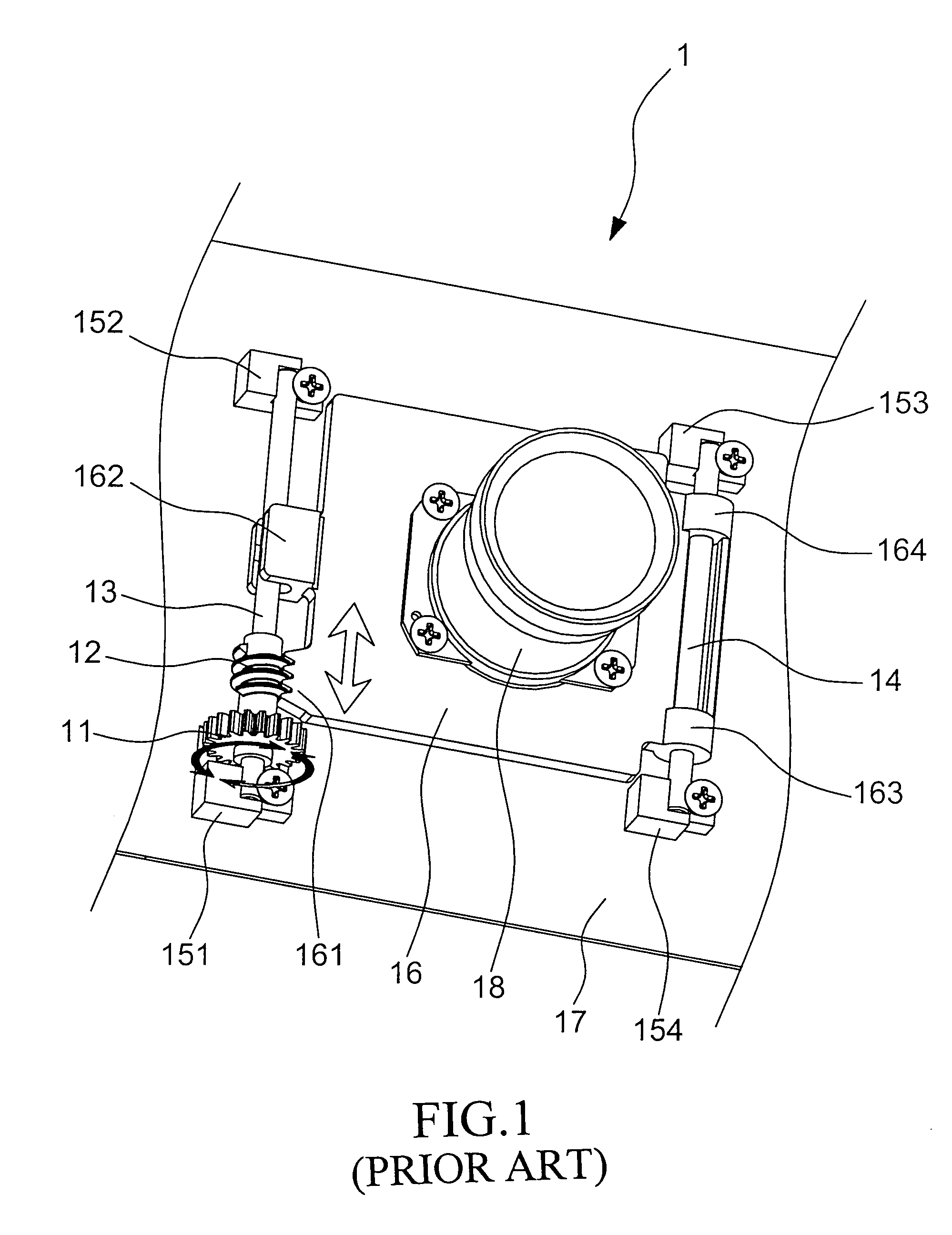

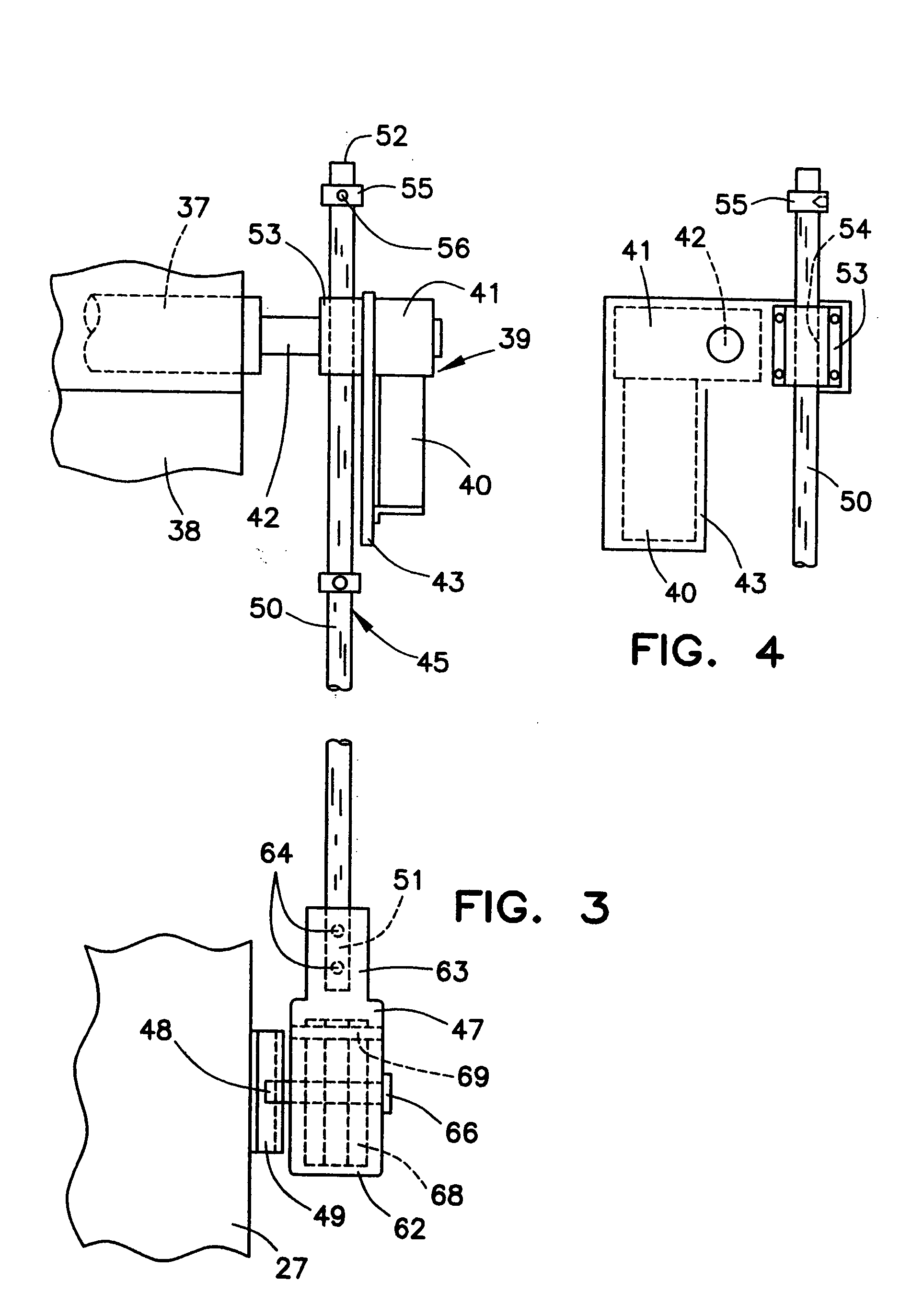

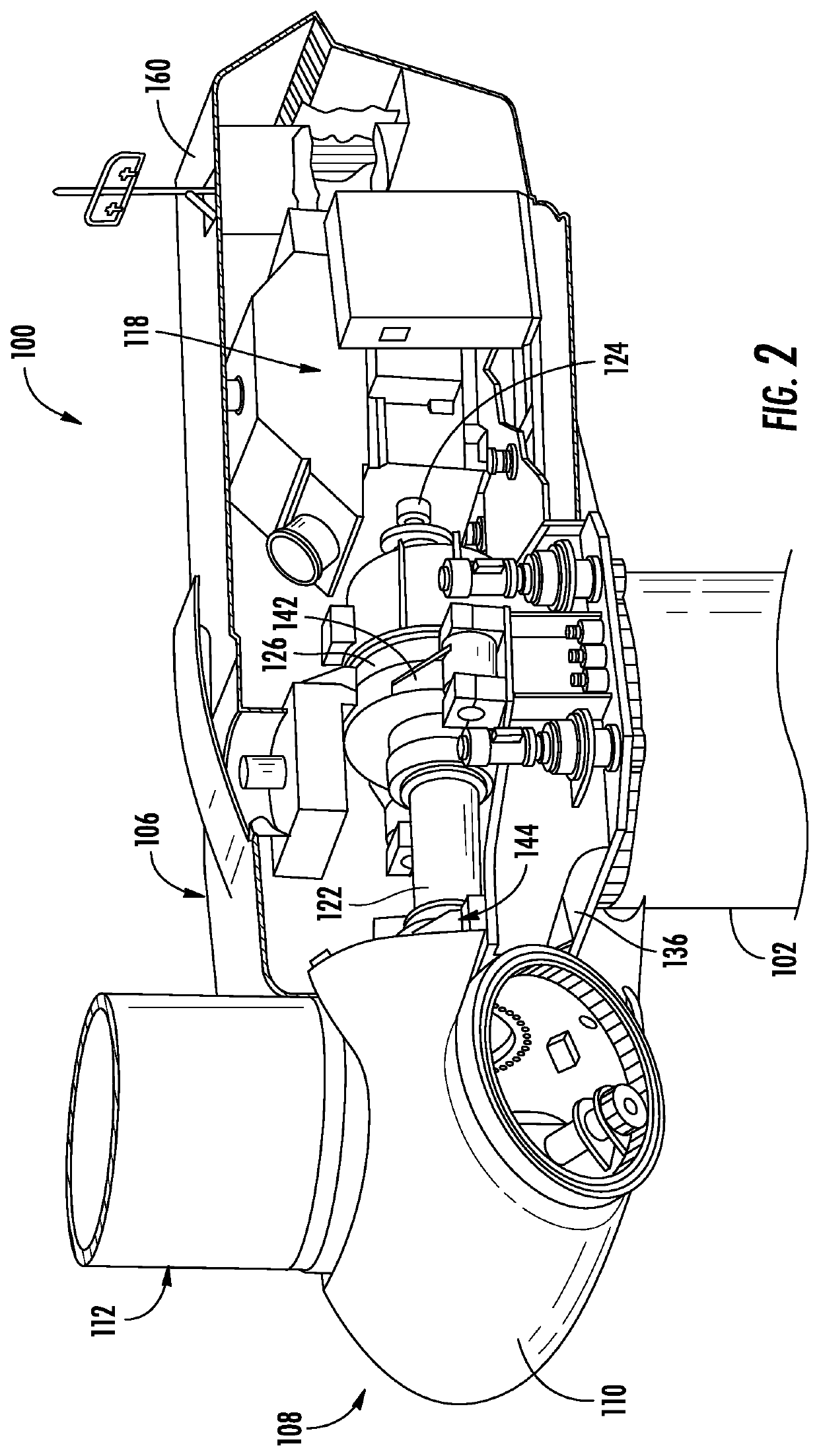

Cutting head assembly for on-vehicle brake lathe

ActiveUS7712401B1Limit motionEasy to separatePortable latheTool holdersTool bitMechanical engineering

A cutting head assembly holds a pair of tool bits for an on-vehicle brake disk lathe having a platform. The cutting head assembly has a platform key fixed to the platform and extending parallel to a brake disk axis of rotation. The cutting head assembly also has a plate having a plate keyway that slidably engages the platform key. Tool bit arms are adjustably mounted to the plate and support the tool bits. A locking structure connected to the plate locks the platform key with respect to the plate keyway, and the interaction of the locking structure with the plate and the platform key creates a compressive load between the plate and the platform as the platform key is locked with respect to the plate keyway.

Owner:BONITA IP

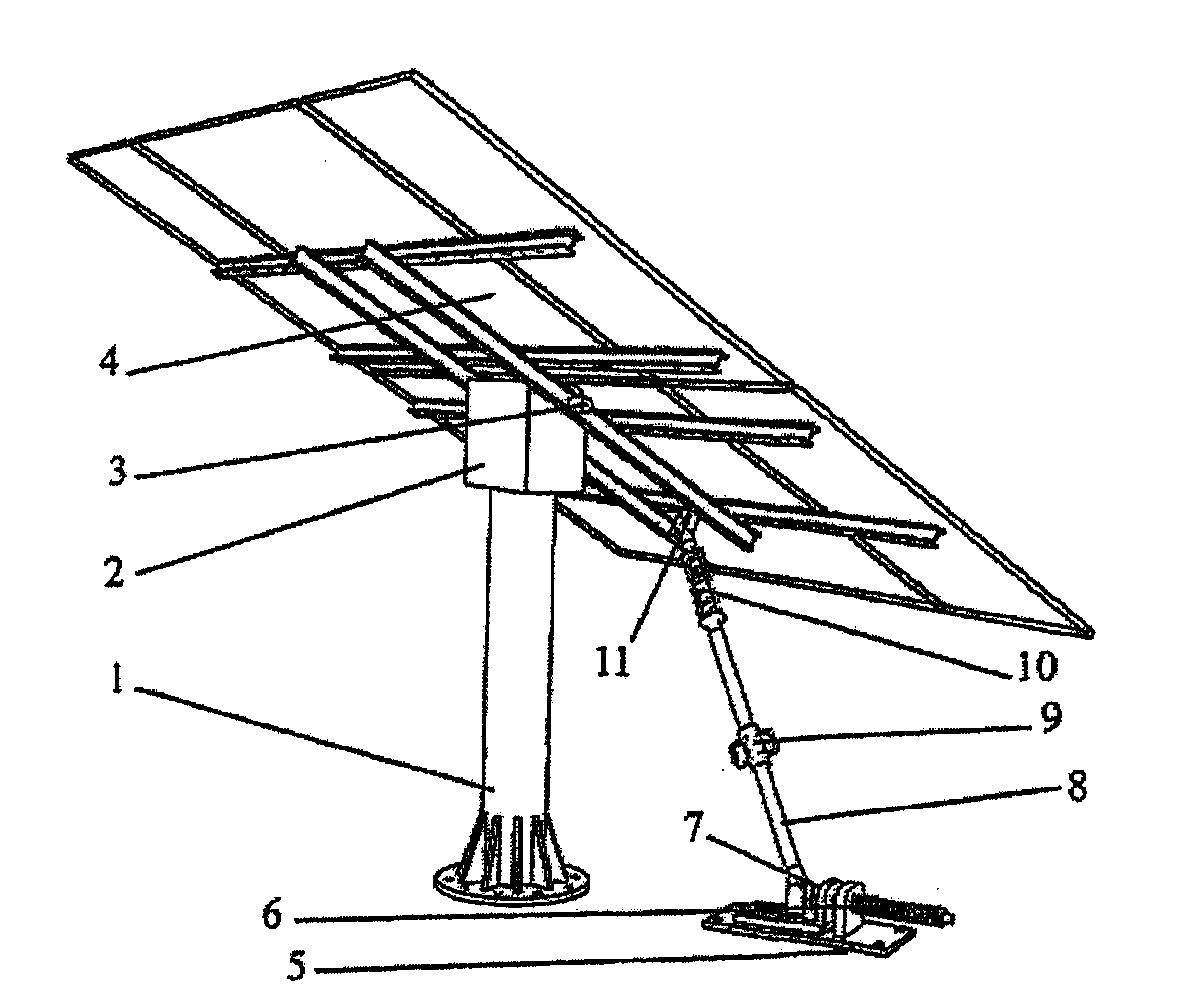

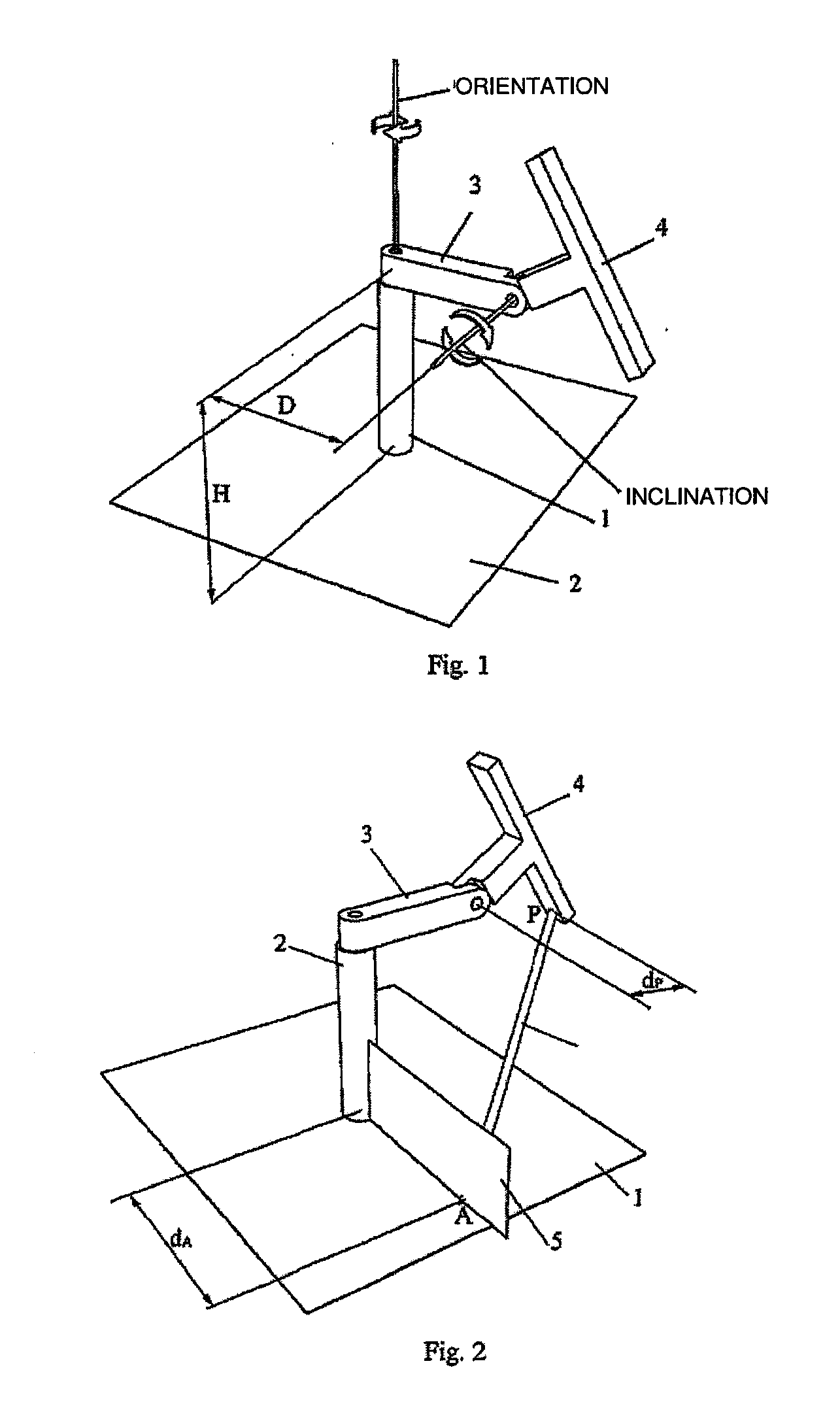

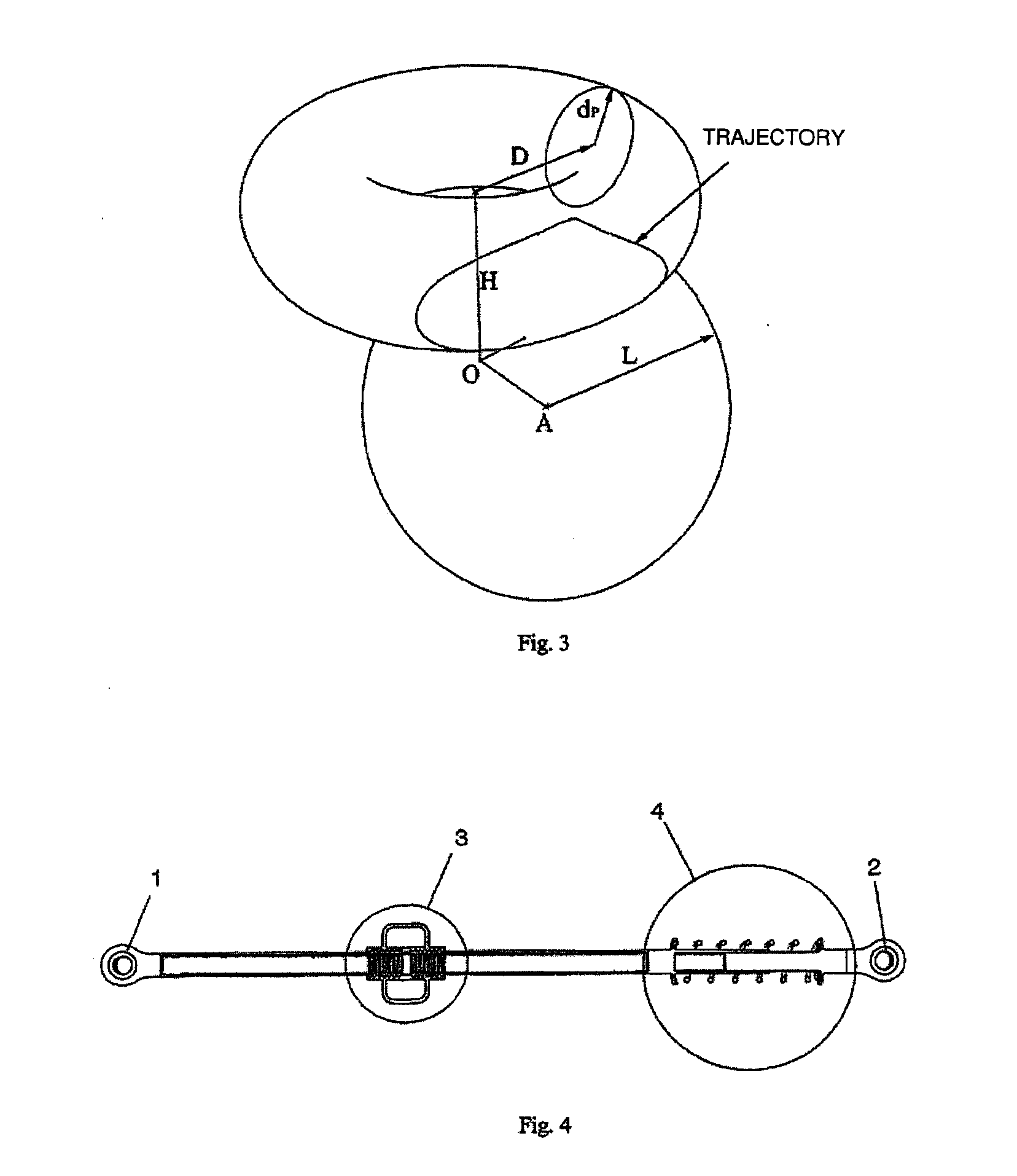

Solar tracker with movement in two axes and actuation in only one of them

InactiveUS20090301466A1Reduce vibrationLimit translationSolar heating energySolar heat collector controllersEngineeringMechanical engineering

According to FIG. 6, it consists of a solar tracking device with two axes of rotation, which is actuated only in one of them by virtue of the incorporation into the mechanism of a support bar of adjustable length (8), which is articulated at its two ends and anchored via one side to the body that tracks the sun (4) and via the other side to an adjustable support (5) joined to the base of the actual tracker or to the ground. In turn, the bar is equipped with a shock-absorbing spring system (10) that allows it to be operated as a dynamic control element for the whole assembly.

Owner:HUMANES ASENSIO JESUS ANGEL +1

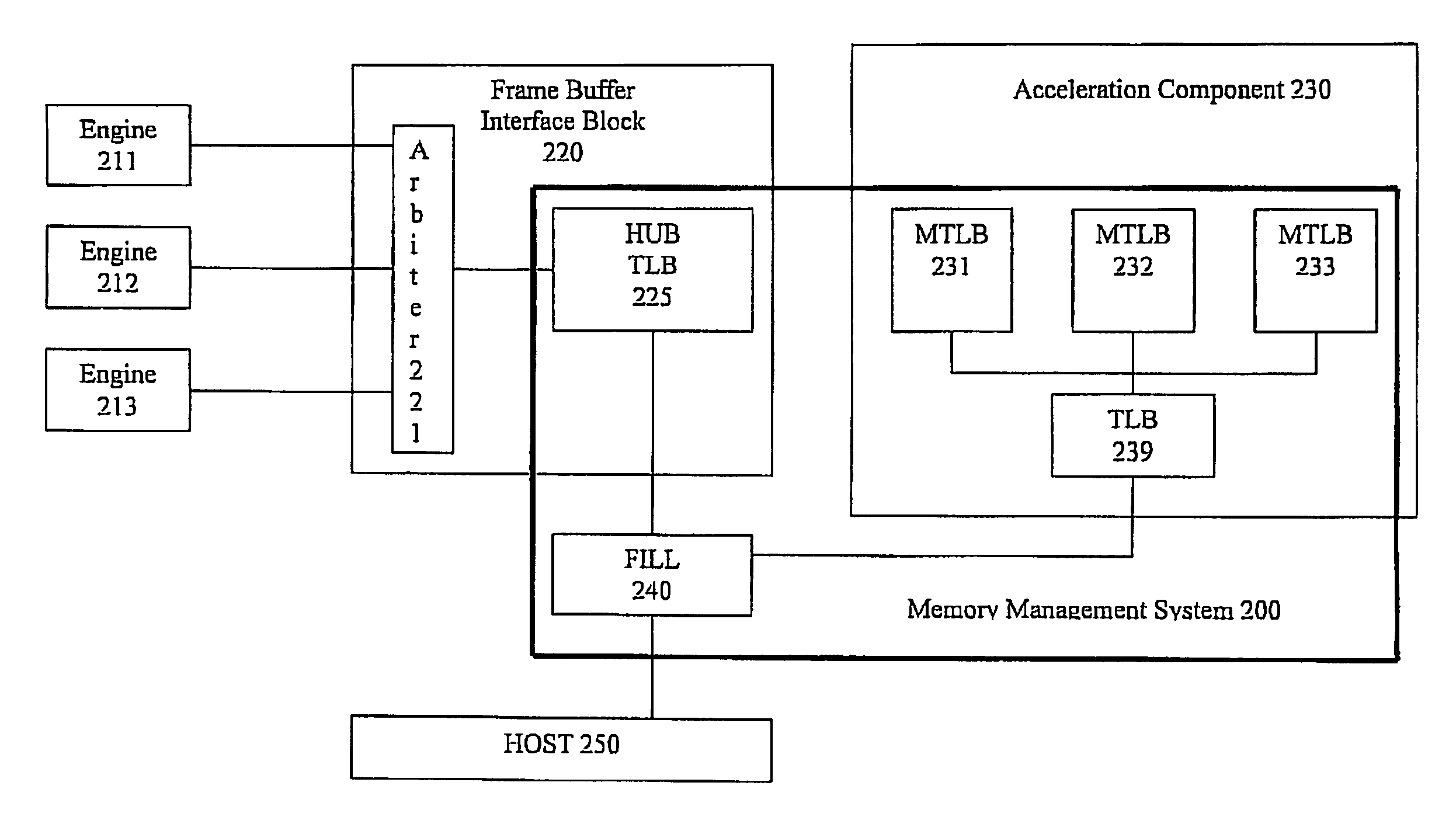

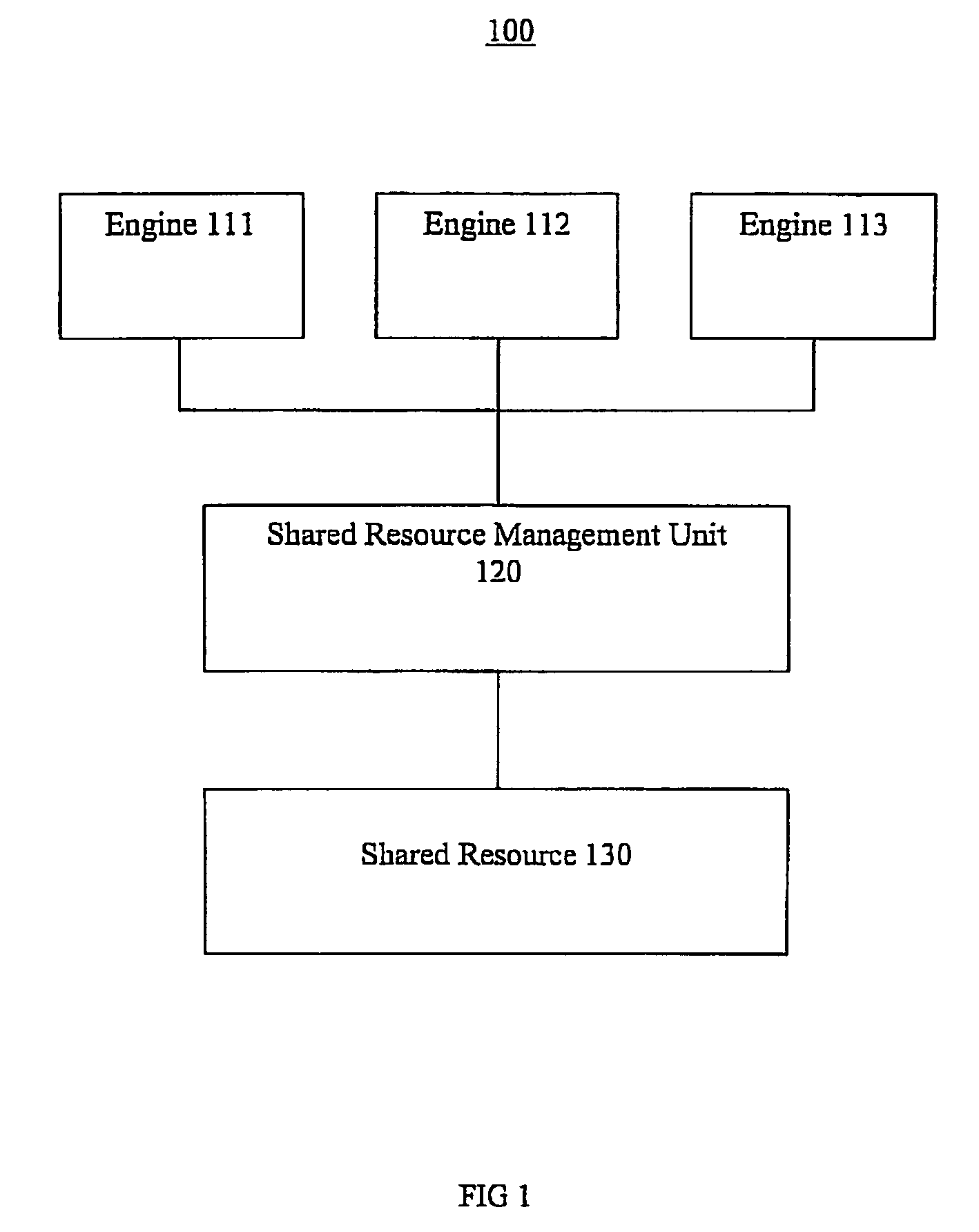

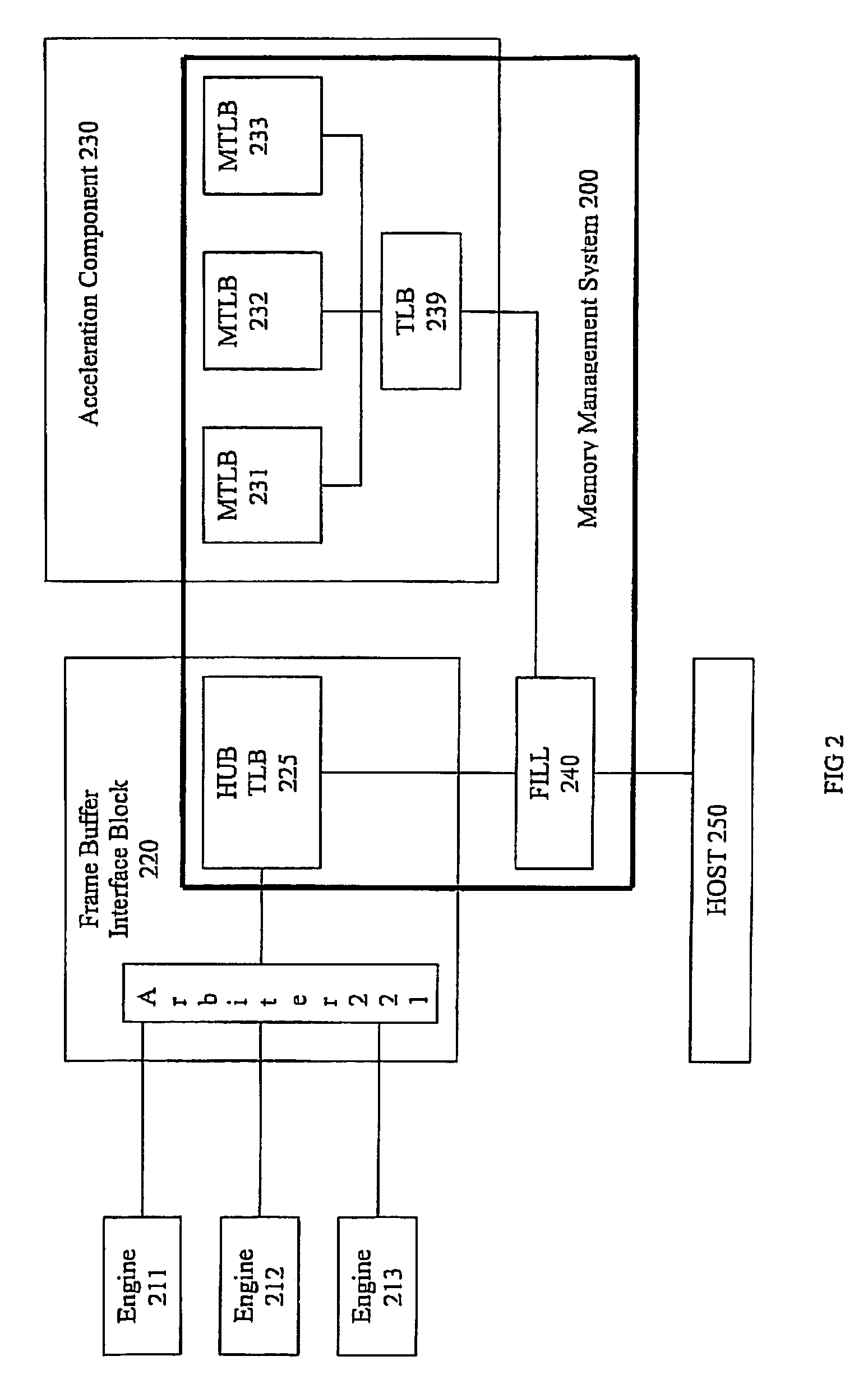

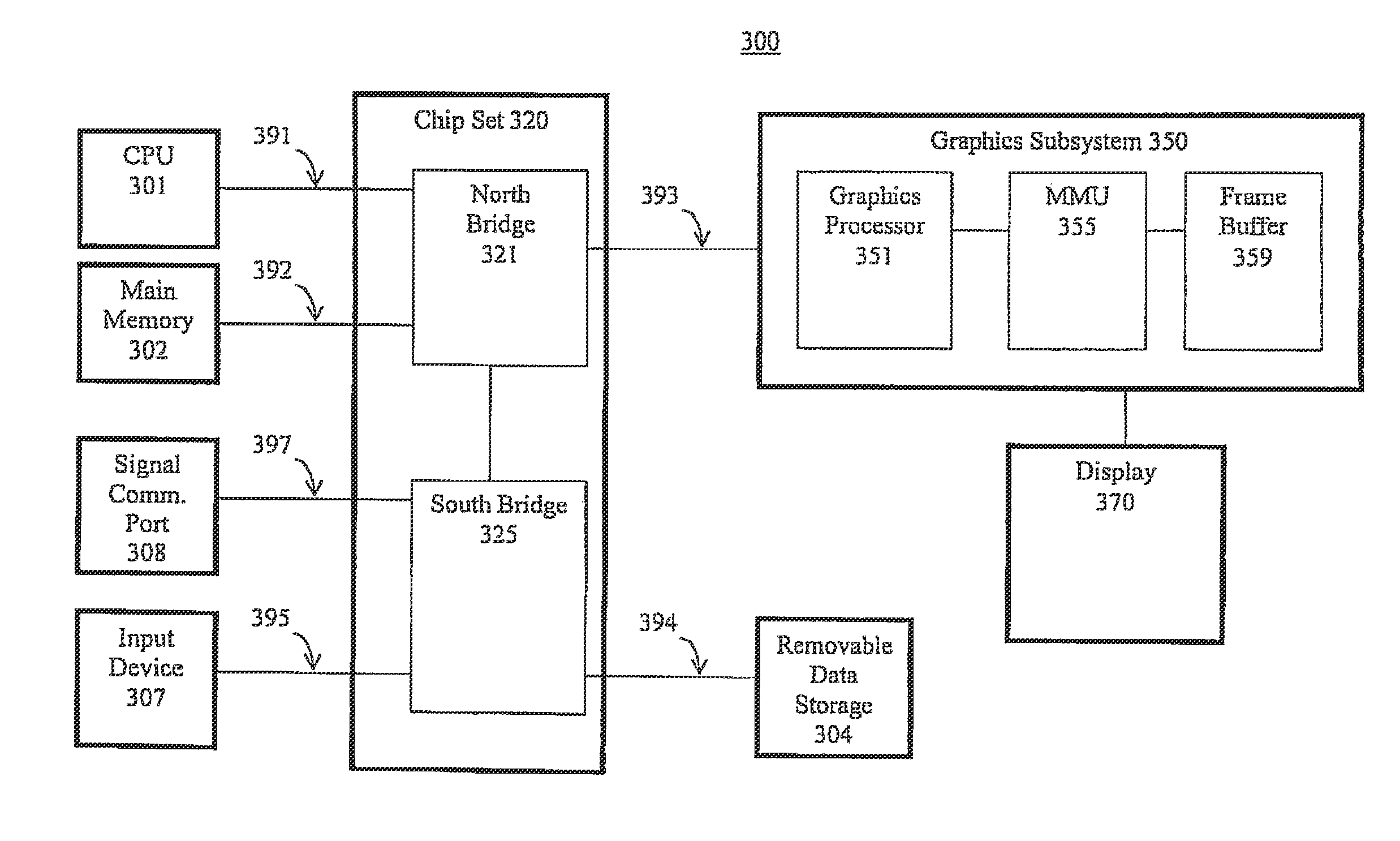

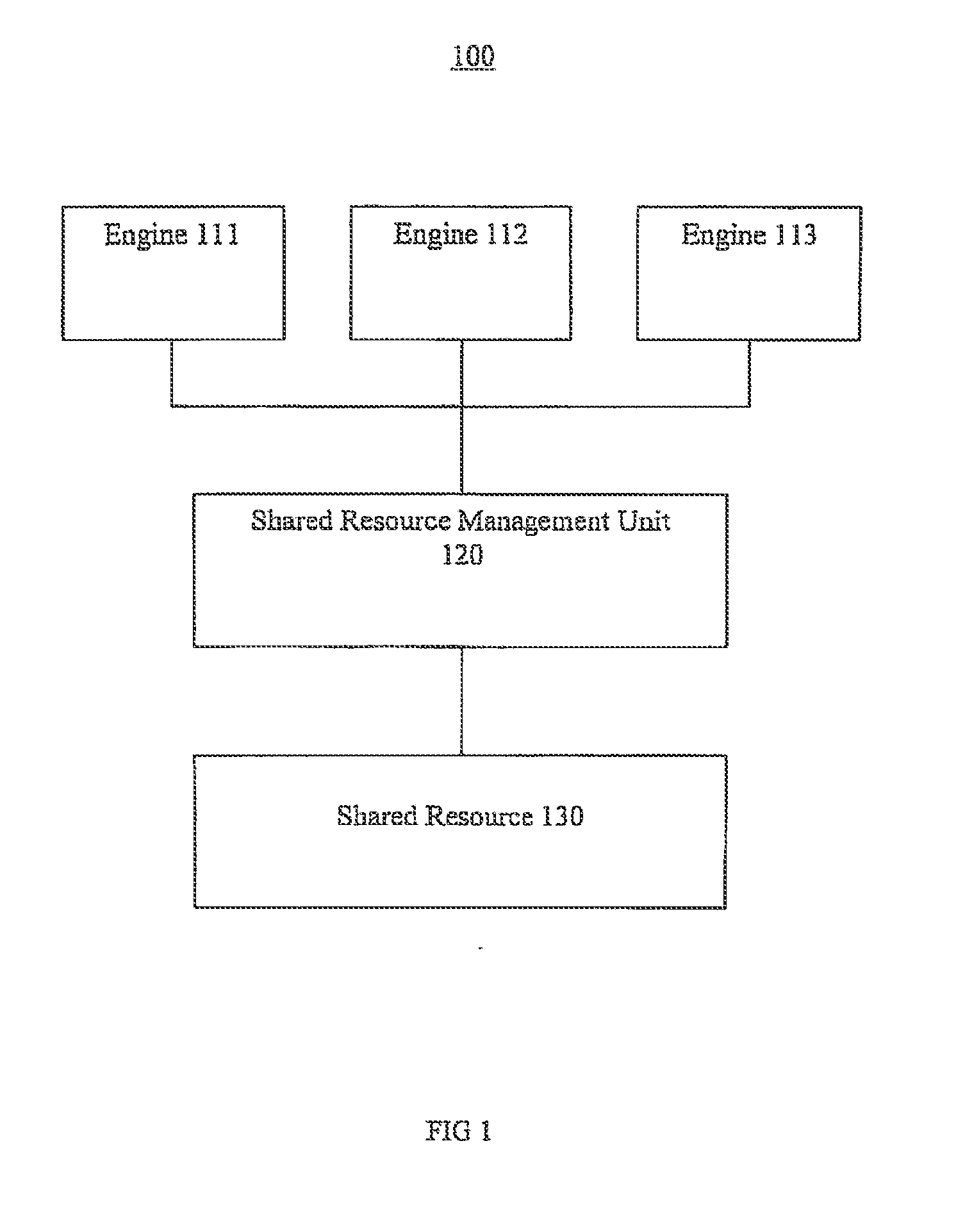

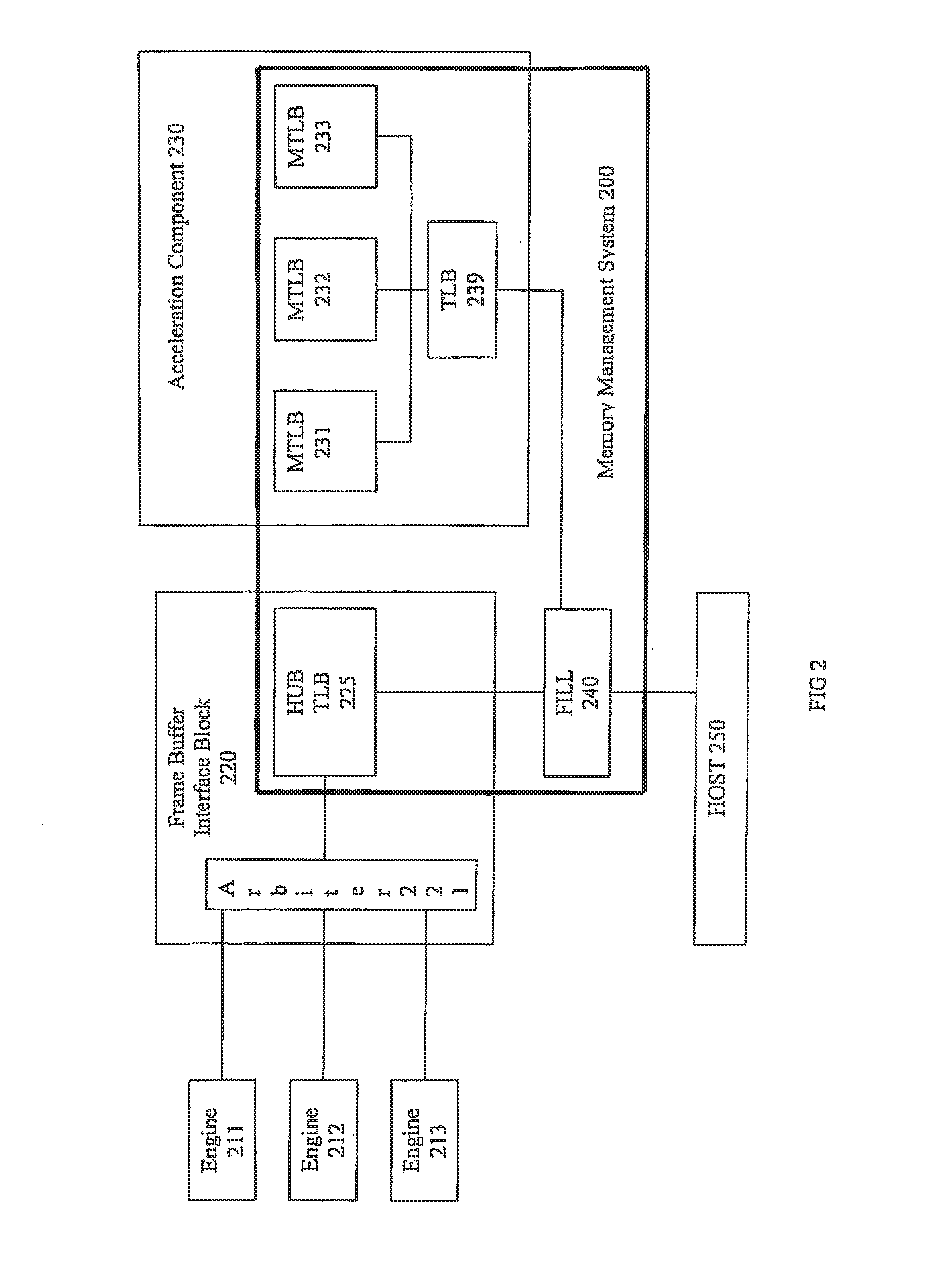

Override system and method for memory access management

ActiveUS8504794B1Efficient and flexible accessLimit translationMemory architecture accessing/allocationNon-redundant fault processingData bufferVirtualization

A memory management system and method are described. In one embodiment, a memory management system includes a memory management unit for virtualizing context memory storage and independently controlling access to the context memory without interference from other engine activities. The shared resource management unit overrides a stream of access denials (e.g., NACKs) associated with an access problem. The memory management system and method facilitate access to memory while controlling translation between virtual and physical memory “spaces”. In one embodiment the memory management system includes a translation lookaside buffer and a fill component. The translation lookaside buffer tracks information associating a virtual memory space with a physical memory space. The fill component tracks the status of an access request progress from a plurality of engines independently and faults that occur in attempting to access a memory space.

Owner:NVIDIA CORP

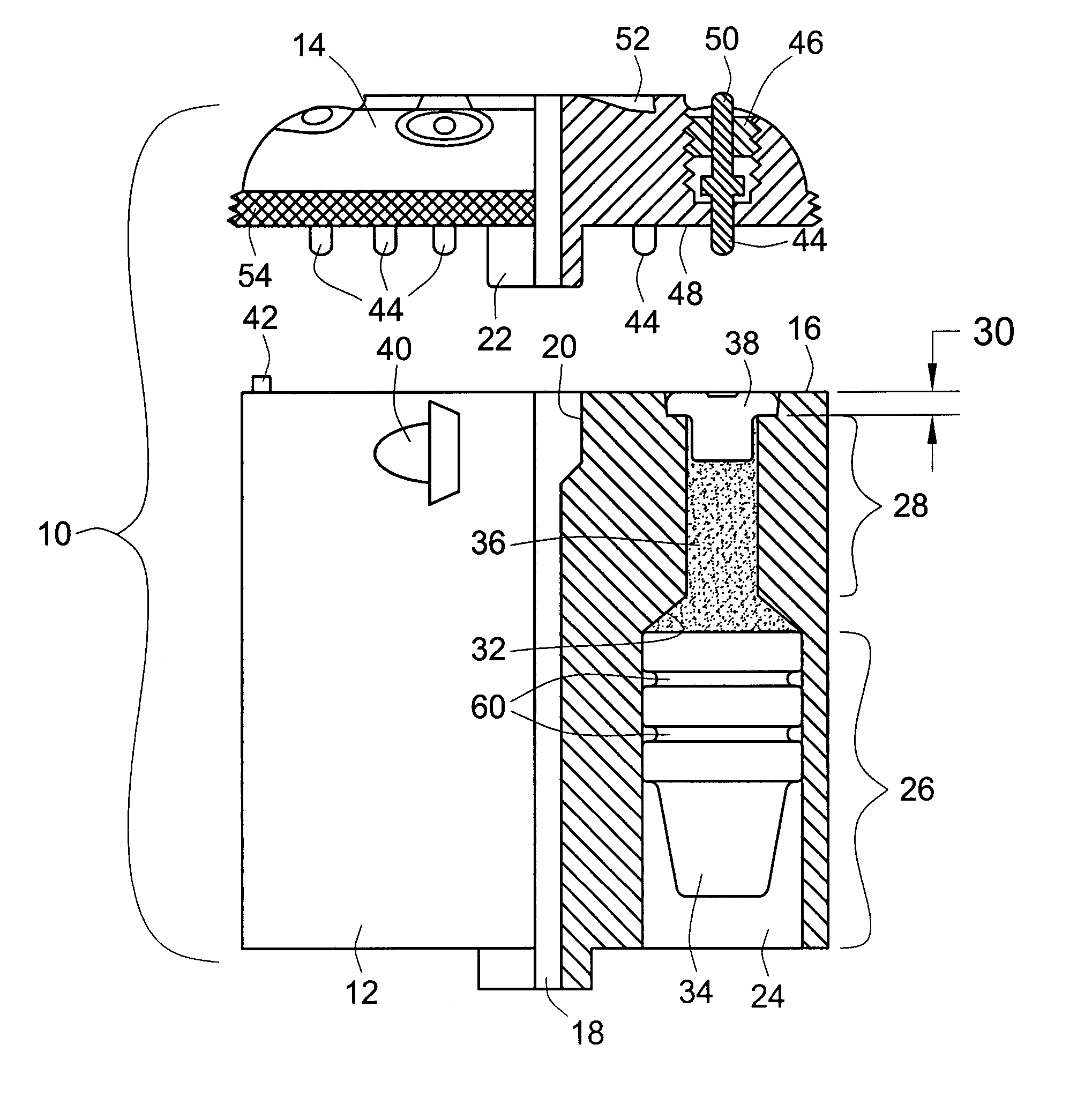

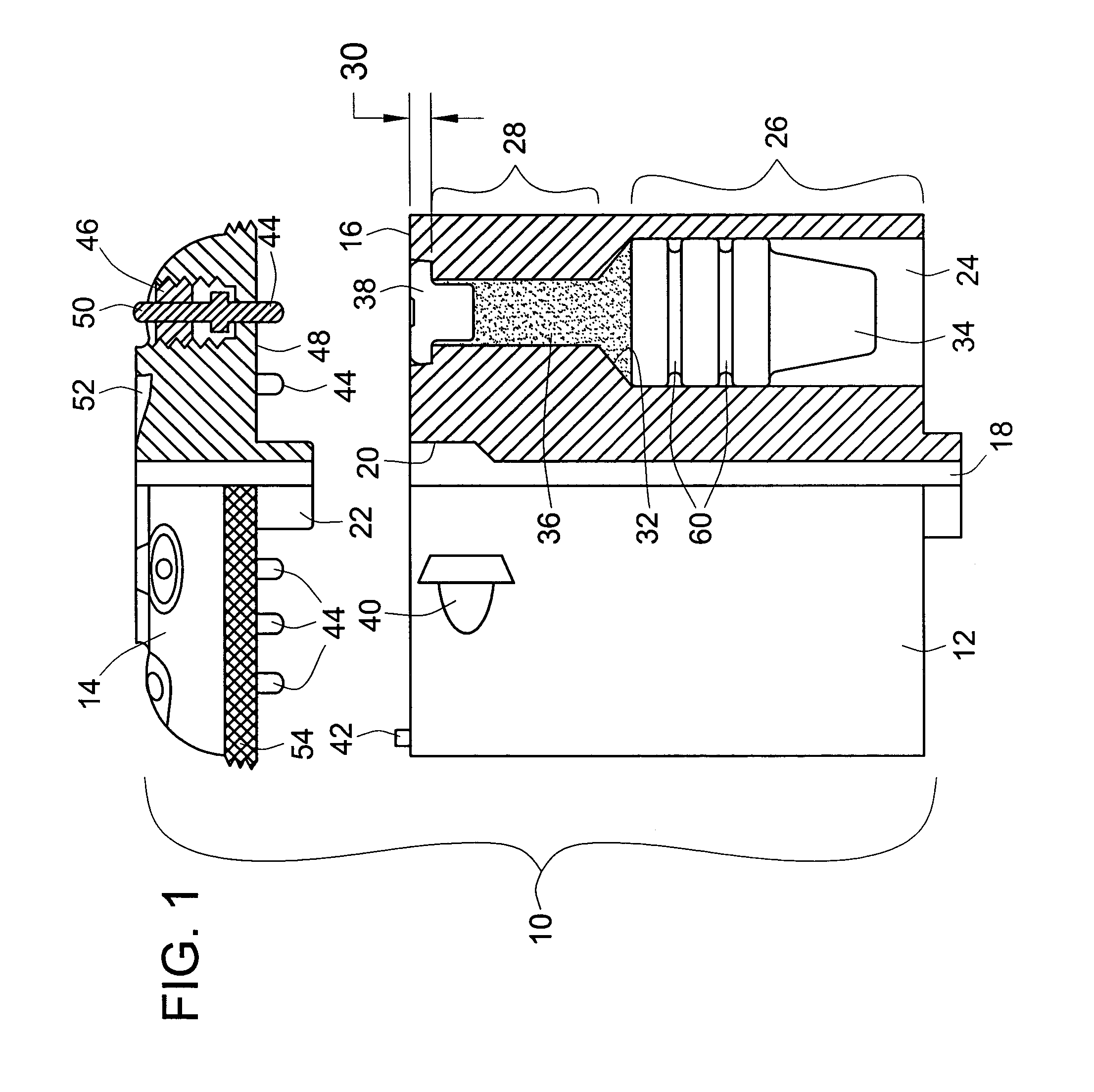

Smokeless cylinder for muzzle-loading revolver

InactiveUS20050016050A1Relieve stressAccurately indexedFiring/trigger mechanismsPistolsModem deviceEngineering

A replacement cylinder that enables the use of modem smokeless gunpowder in a black powder muzzle-loading revolver is provided. The cylinder includes a main cylinder body and a removable cylinder cap. The main cylinder body includes a number of chambers, each of which having a projectile portion, a propellant portion and a primer portion. The cylinder cap includes a number of captured firing pins positioned therein. During operation, the cylinder cap is allowed to axially translate relative to the main cylinder body. A method of muzzle-loading the cylinder of the invention using modern smokeless gunpowder and a primer is also provided and is facilitated by the provision of a loading plate.

Owner:HOWELL JR KENNETH P

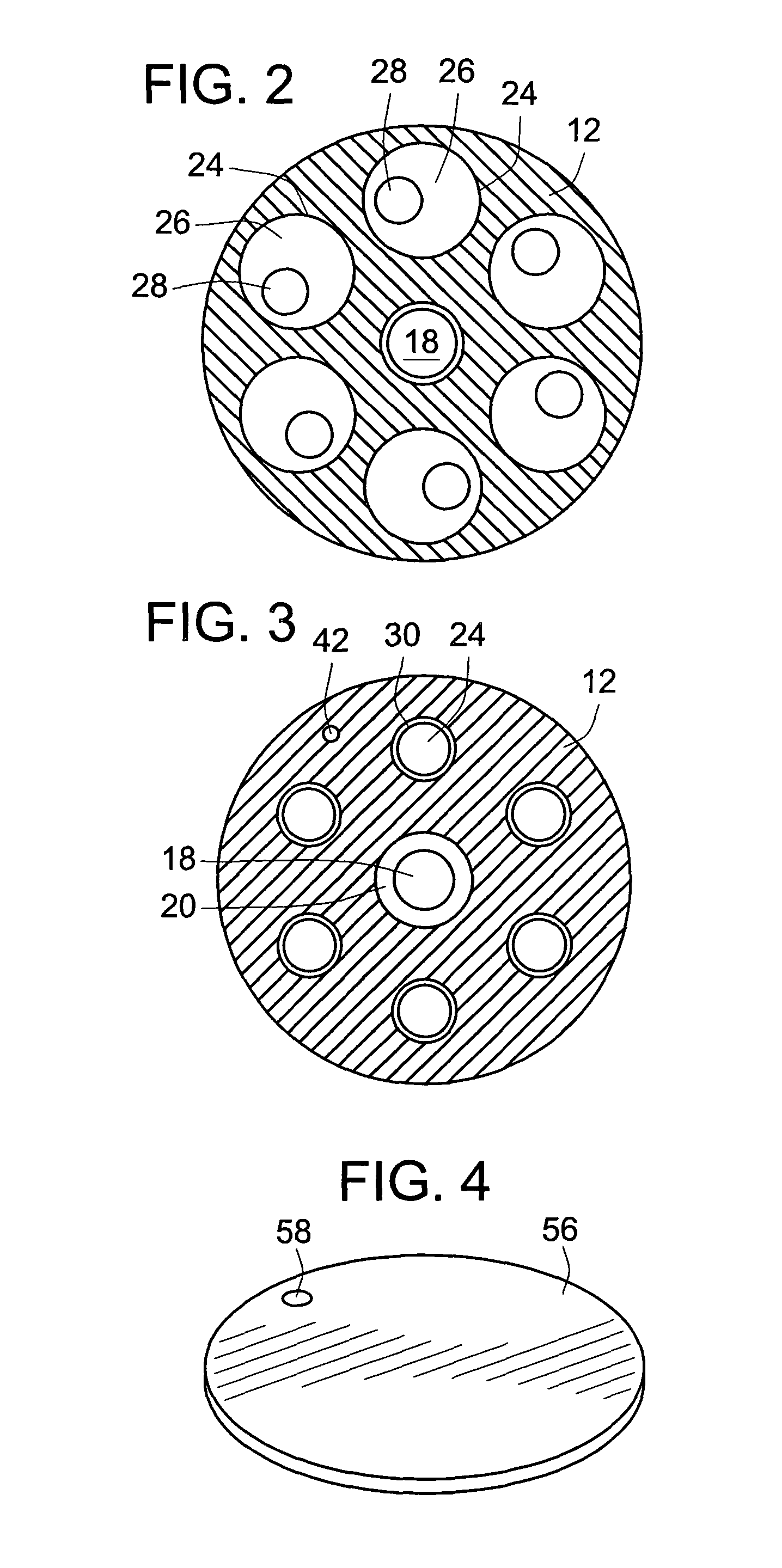

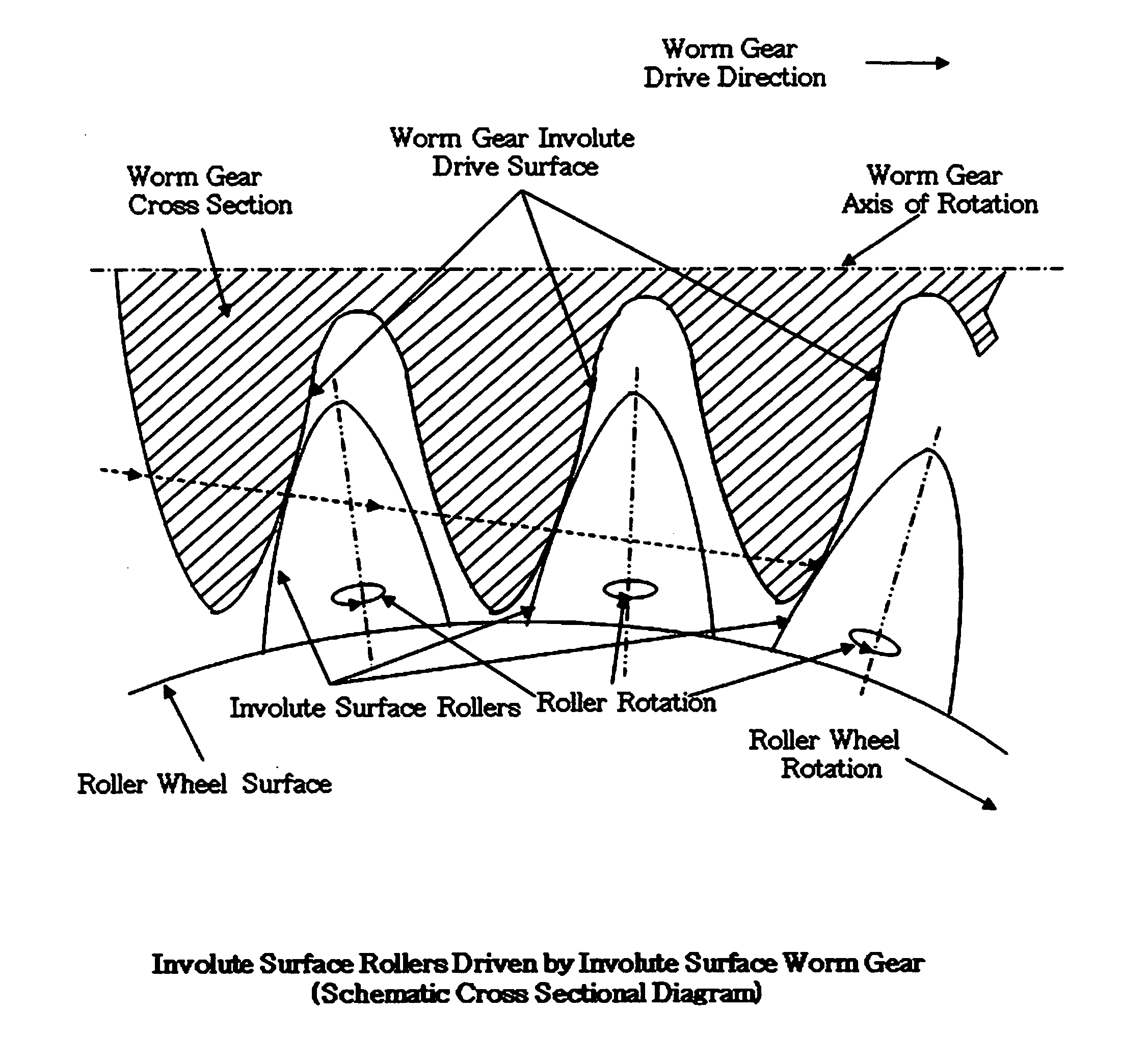

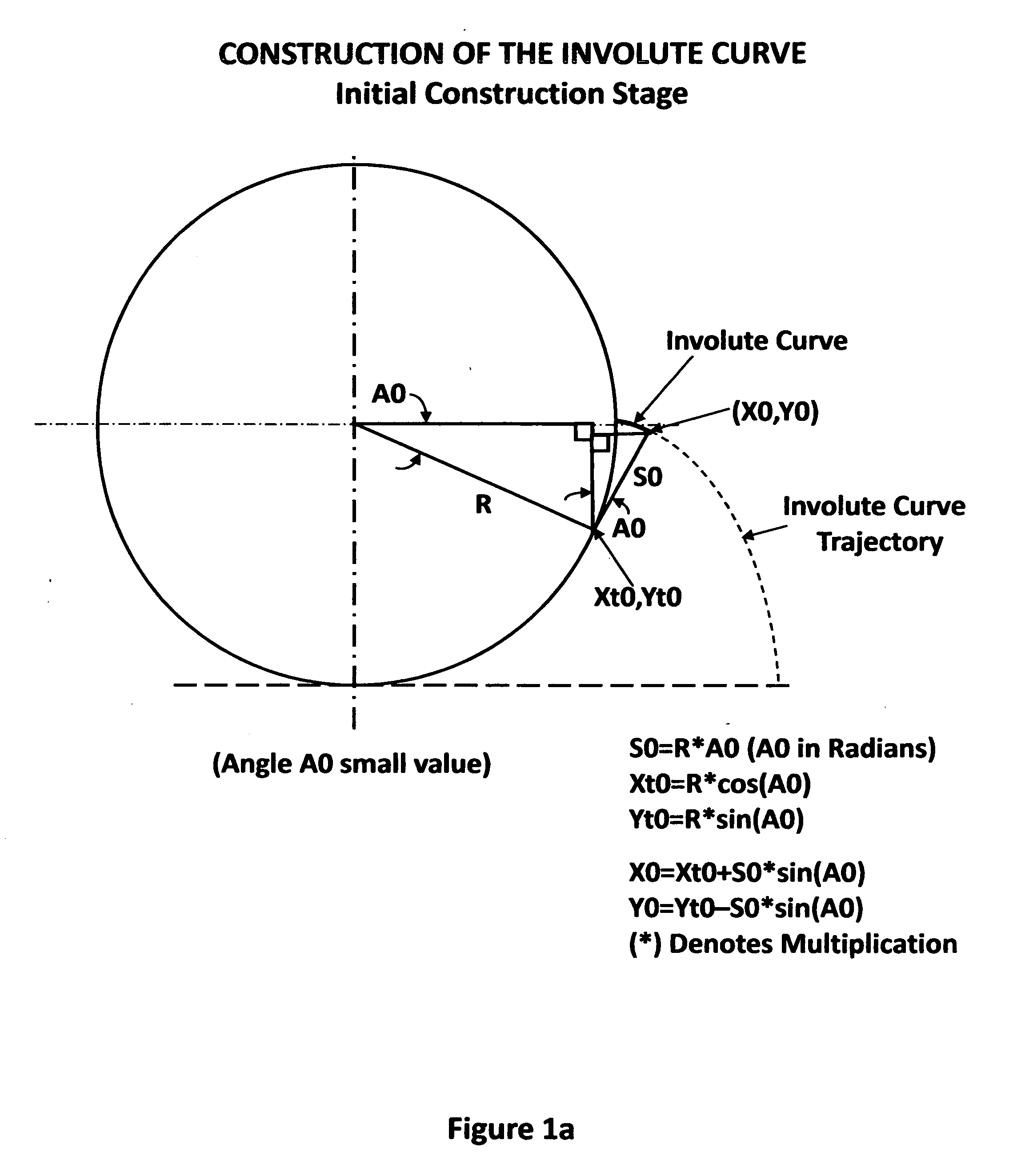

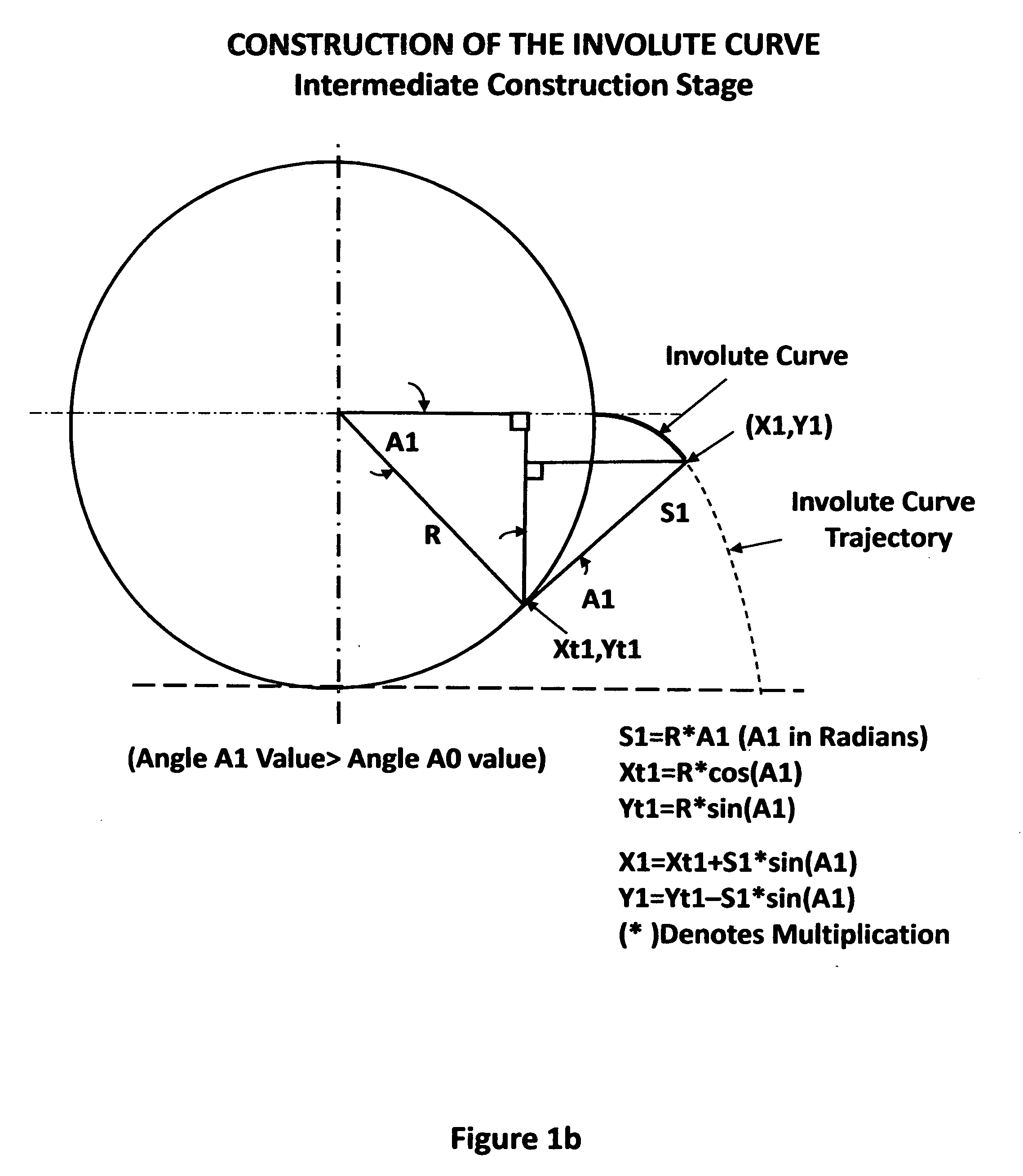

Conjugate roller drive

InactiveUS20100212444A1Readily apparentEfficient energy transferPortable liftingToothed gearingsEnergy lossWorm drive

This invention provides improvements to worm drives for mechanical power transmission and roller wheels and the worm screws for use in such drives. The principal innovation is utilizing conjugate mesh between the worm screw and the roller wheel by shaping both the surfaces of the threads of the worm screw and the driven surfaces of the roller tips so that they become conjugate surfaces that accomplish the most efficient energy transfer.Previous worm drive approaches have emphasized conforming shapes for the roller tips and the worm screw as well as certain other techniques in an attempt to compensate certain inherent limitations to energy transfer between driving and driven surfaces. This has caused greater energy losses in the gearing mechanism with corresponding decreased power transfer efficiency. The use of conjugate shapes for the roller tips and the driving worm gear surface represents a significant improvement to the concept.

Owner:SMITH THOMAS DAVID

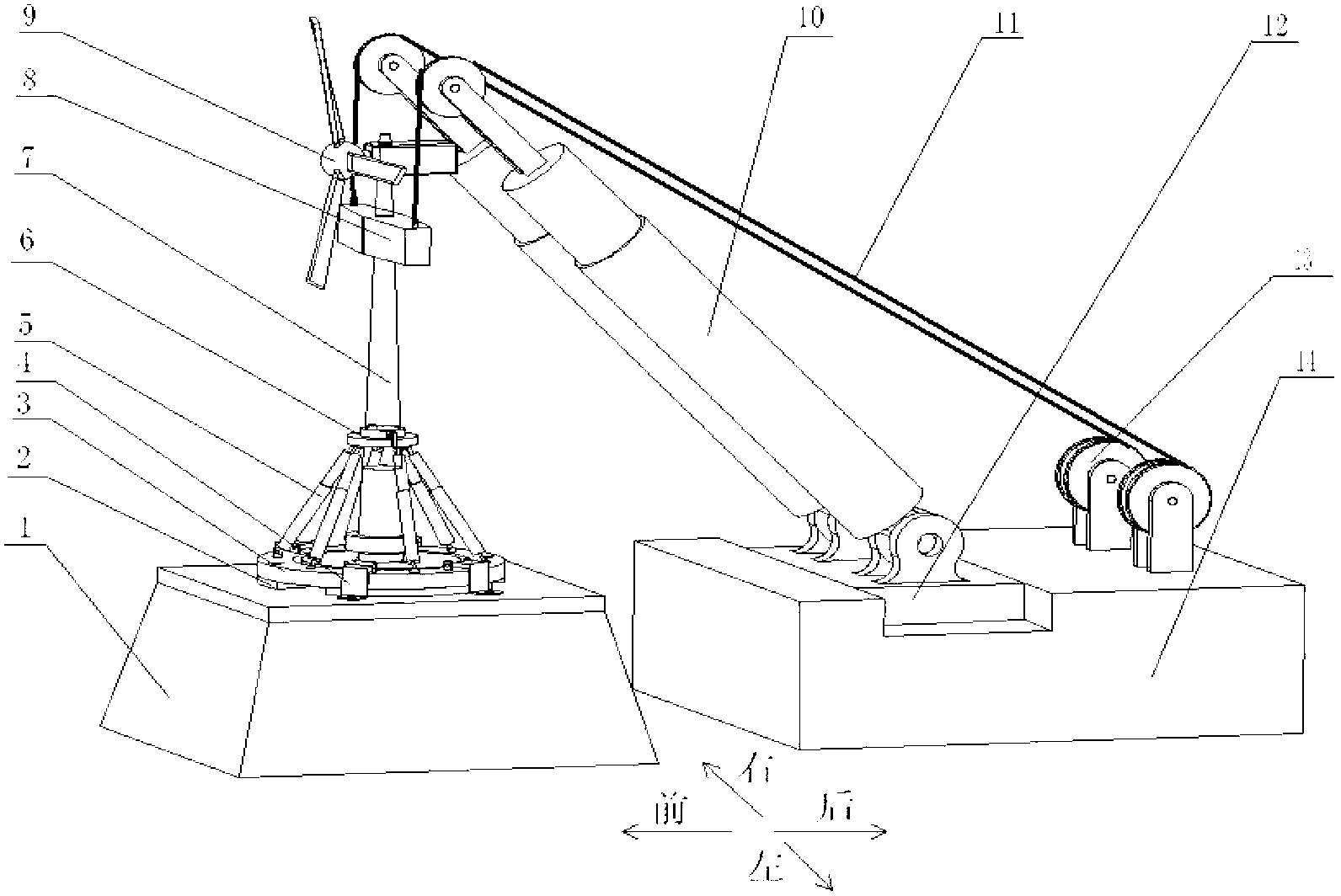

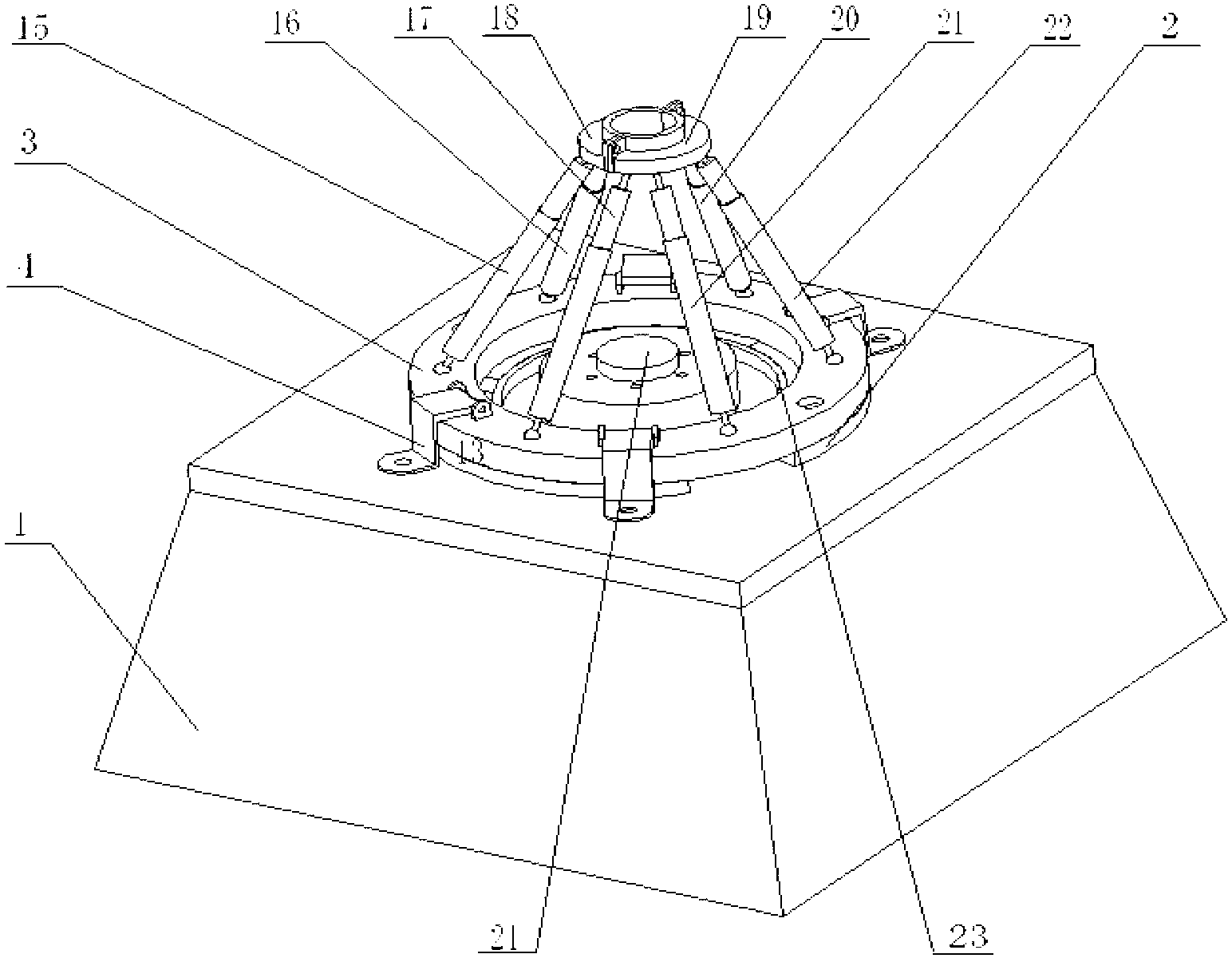

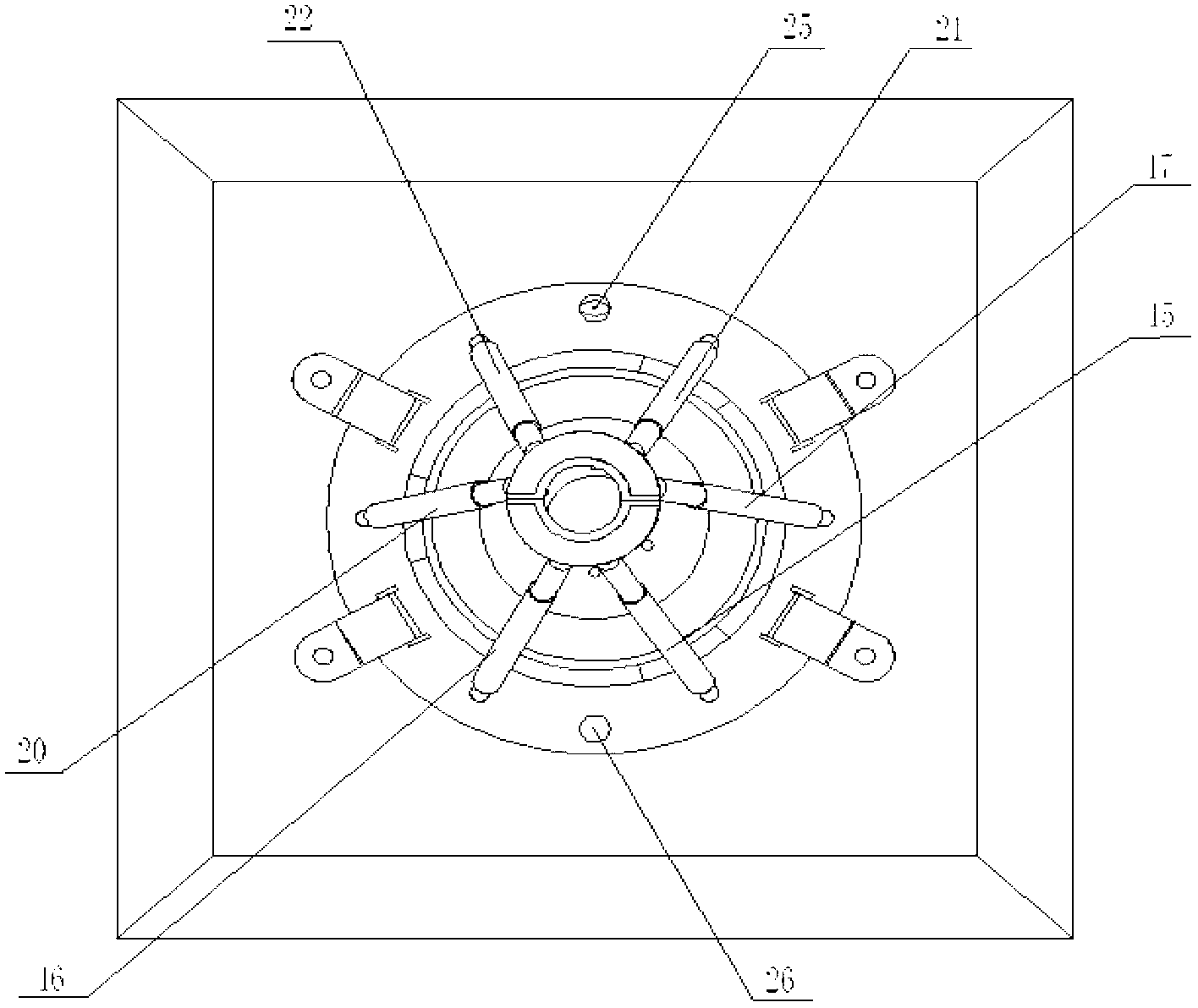

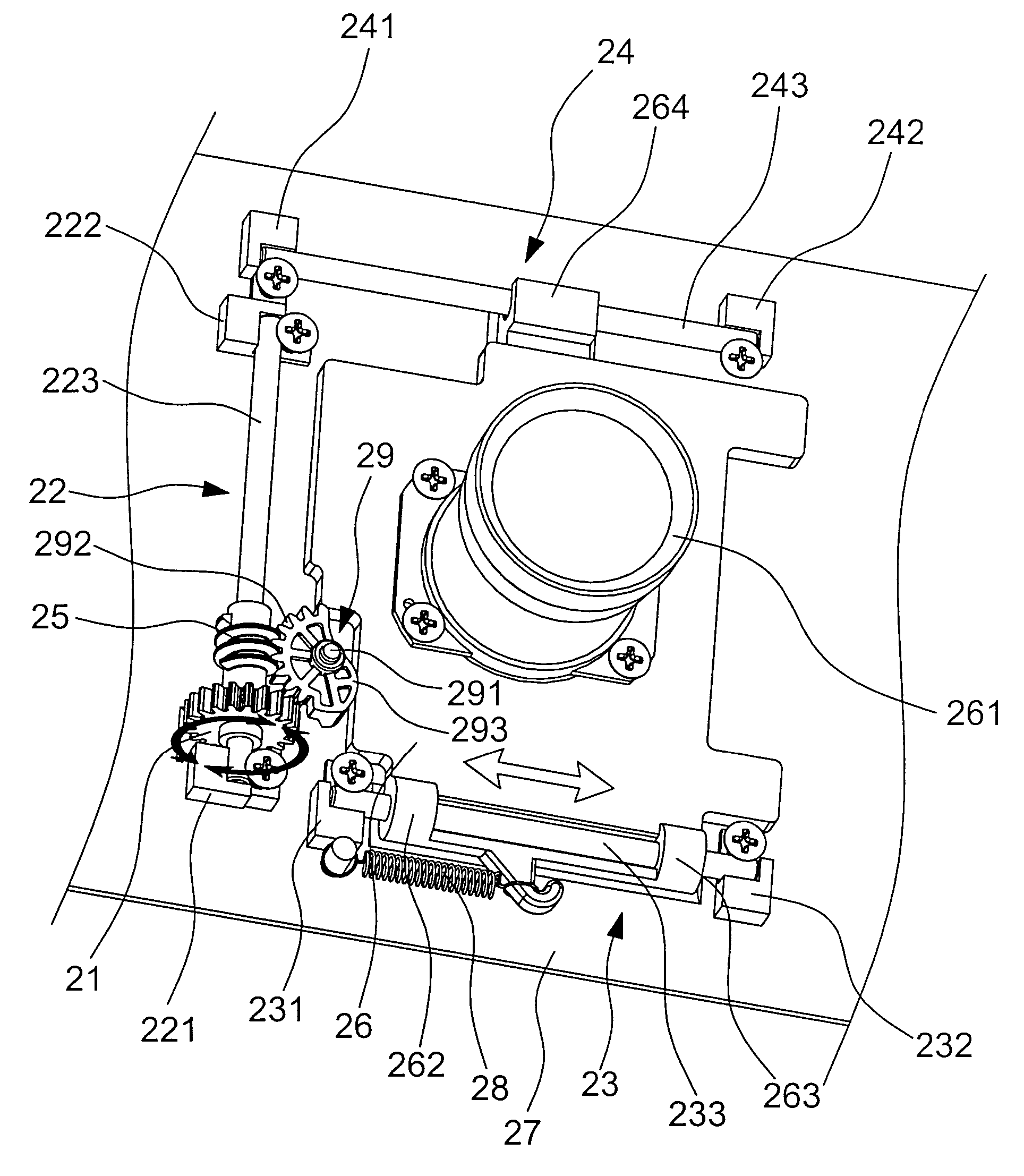

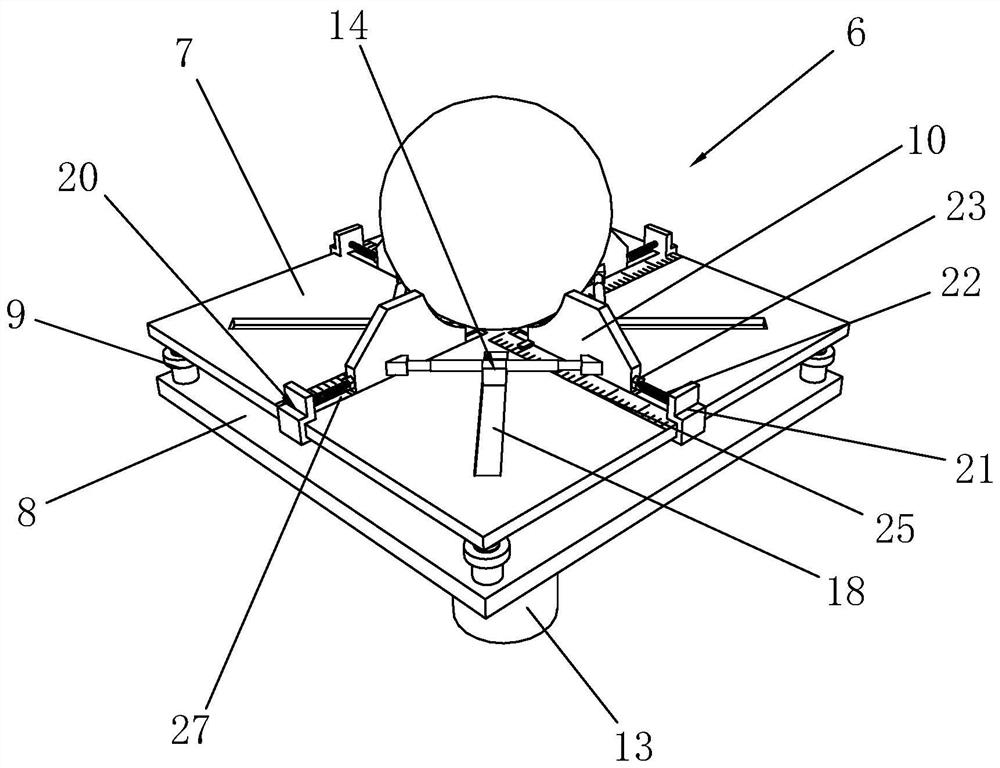

Installation device for offshore wind generating set

InactiveCN102705178AIncrease stiffnessHigh speedFinal product manufactureAssembly machinesWork unitPulp and paper industry

The invention discloses an installation device for an offshore wind generating set. The installation device comprises a positioning mechanism, a fan, a six-dimensional parallel mechanism, a tower pedestal platform and a crane ship; the six-dimensional parallel mechanism is fixed on the tower pedestal platform through the positioning mechanism; the fan penetrates through the six-dimensional parallel mechanism and is fixed through the six-dimensional parallel mechanism; and the crane ship is connected with a fixing mechanism. The six-dimensional parallel mechanism with three working units is adopted in the installation device and does not have a working dead angle, so that deflection of positive deviation and negative deviation of a fan tower cylinder can be realized, and bolt holes in a bolt hole cylinder tower pedestal on fan tower cylinder flanges are quickly aligned. The six-dimensional parallel mechanism can play a role in buffering when the fan tower cylinder declines, so that collision impact between the fan tower cylinder and the tower pedestal is reduced. The six-dimensional parallel mechanism has a series of advantages of high rigidity, high speed, high bearing capacity, small errors, high precision, good power performance and the like and is easy to control, so that positioning and buffering integration of the fan tower cylinder can be realized, and the manufacturing cost is greatly reduced.

Owner:SHANGHAI JIAO TONG UNIV

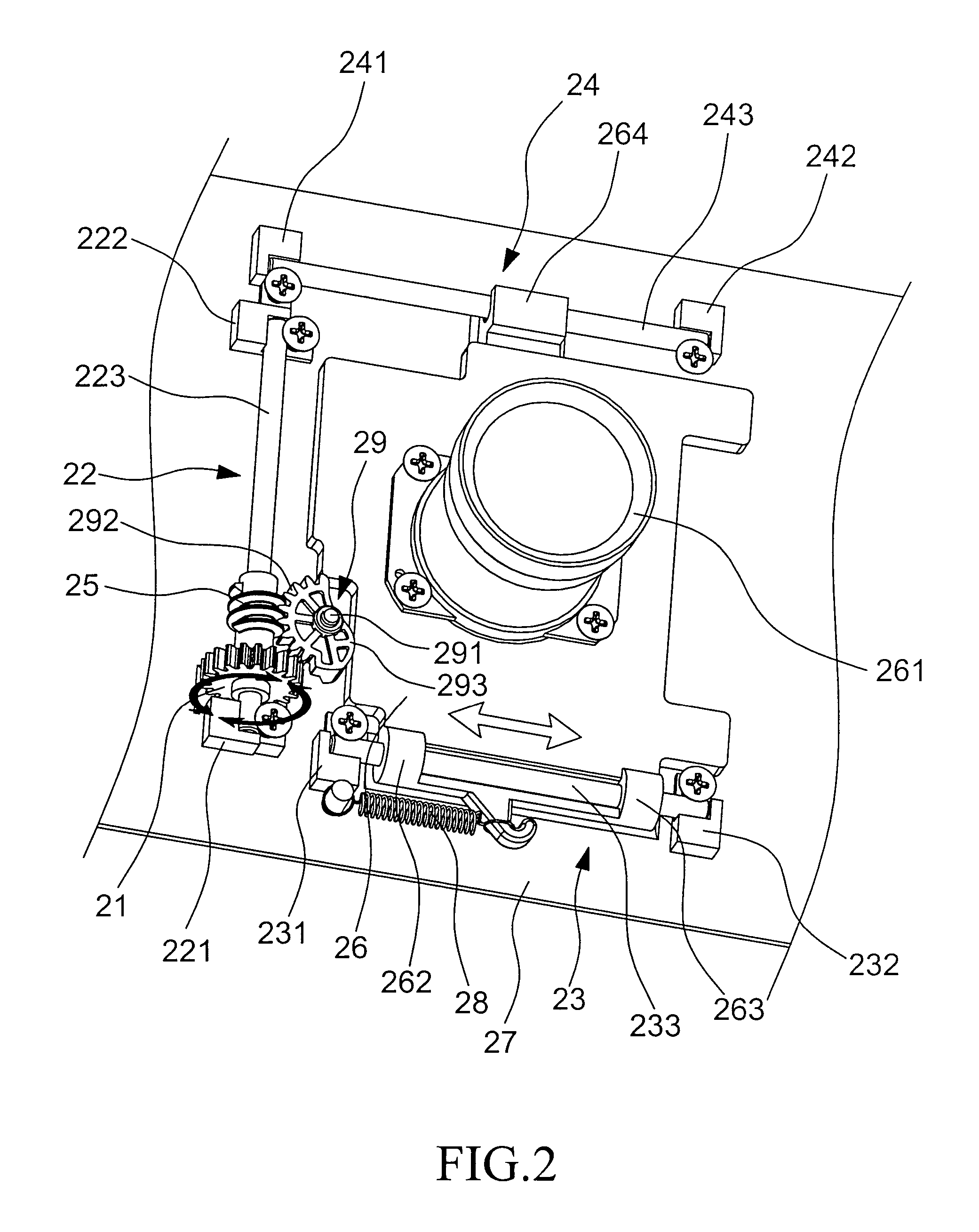

Projection lens shifting mechanism

The present invention relates to a projection lens shifting mechanism having: a driving apparatus, a first supporting apparatus, a transmitting apparatus, a movable plate and a second supporting apparatus. The transmitting apparatus is driven by the driving apparatus for changing a direction of the torque transmitted by the driving apparatus. The movable plate, on which a projection lens is mounted, is in contact with the transmitting apparatus to be driven by the transmitting apparatus to translate in a perpendicular direction with respect to the central axis of the driving apparatus, whereby providing a user-friendly interface, that is, when it is operated manually, a direction that the user applies force against the driving apparatus is consistent with that the movable plate translates. Furthermore, after two above mechanisms are combined, the projection lens can be positioned in any position of a two-dimensional plane.

Owner:CHI LIN OPTOELECTRONICS CO LTD

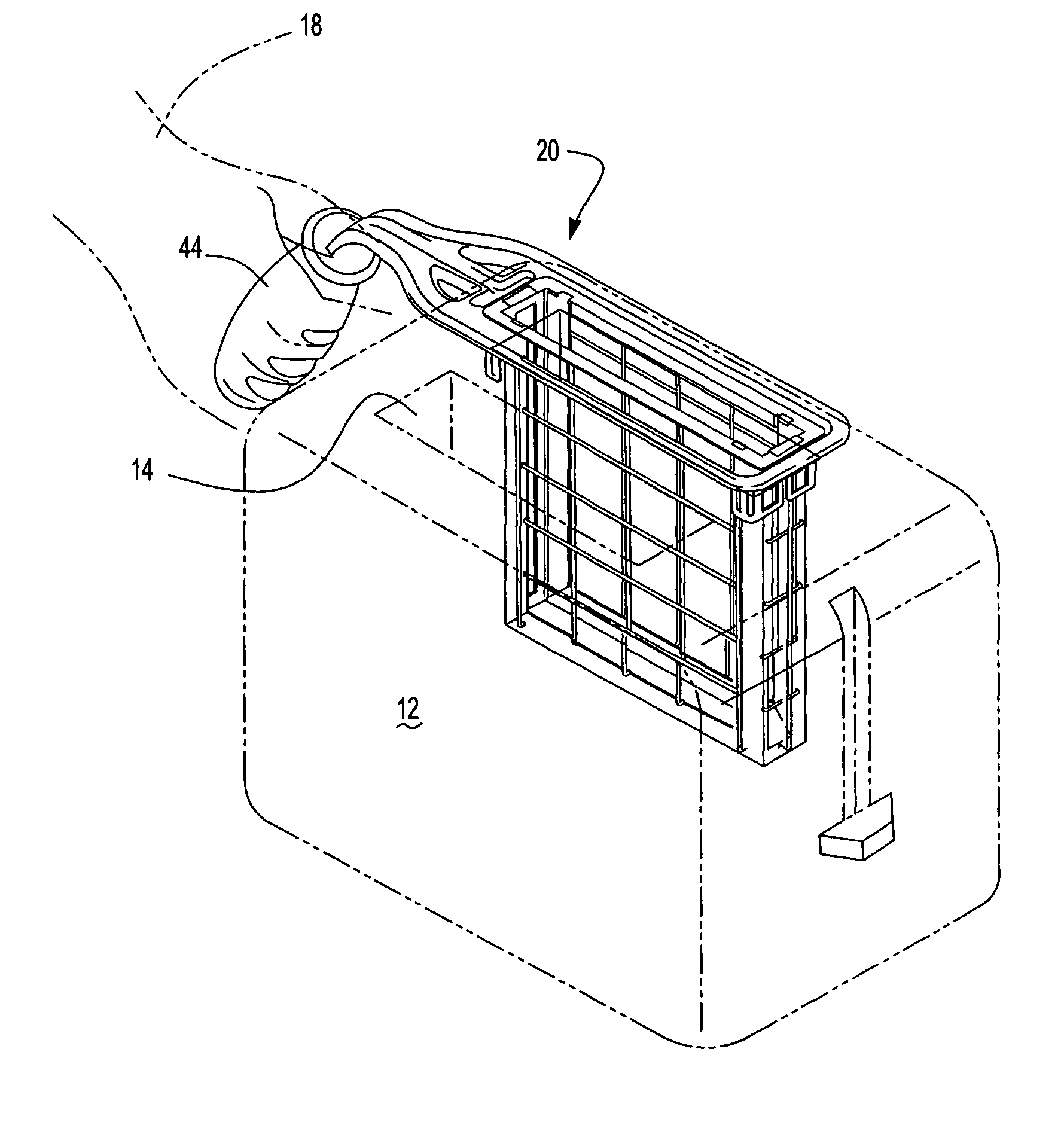

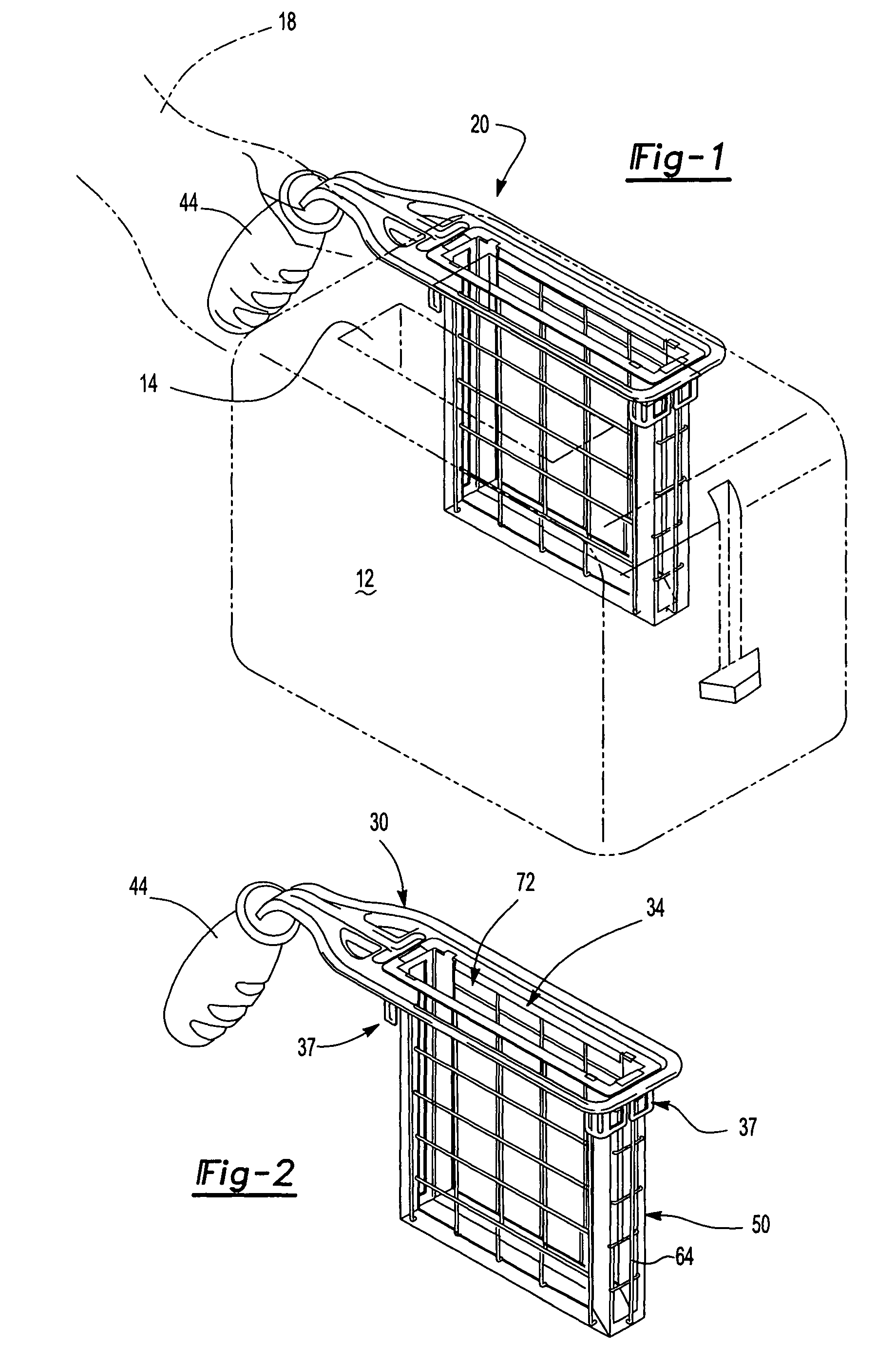

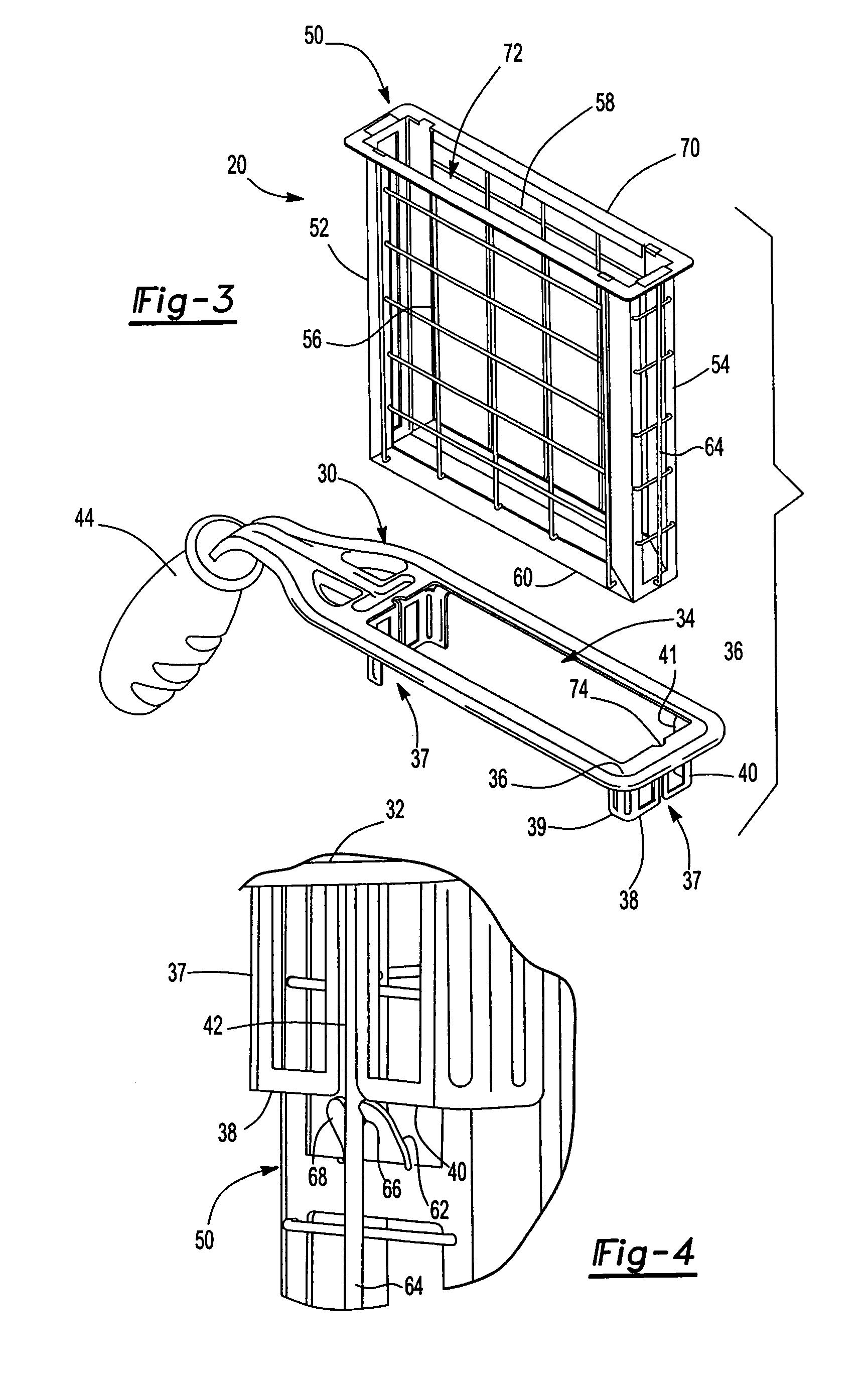

Removable toaster basket with handle

InactiveUS8240246B2Easy to insertEasy to removeMeat processingFood shapingEngineeringMechanical engineering

Owner:DAVIS RICK

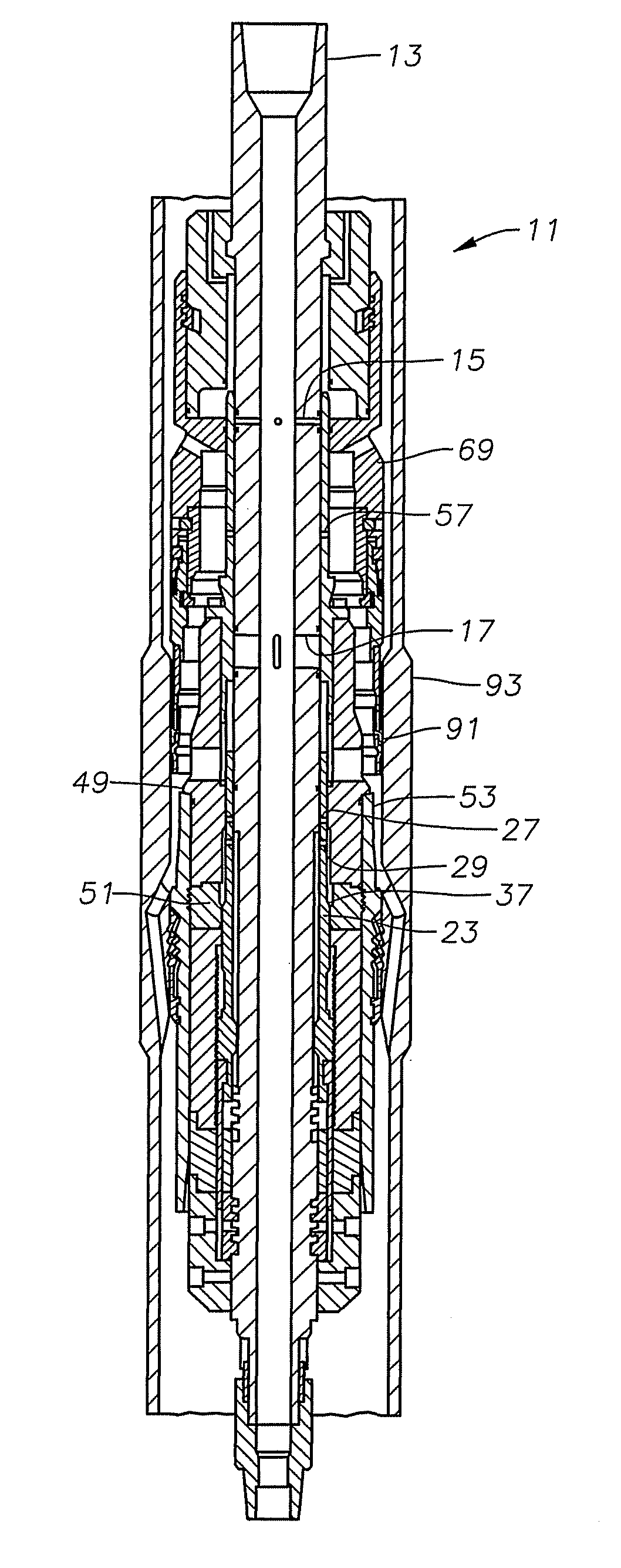

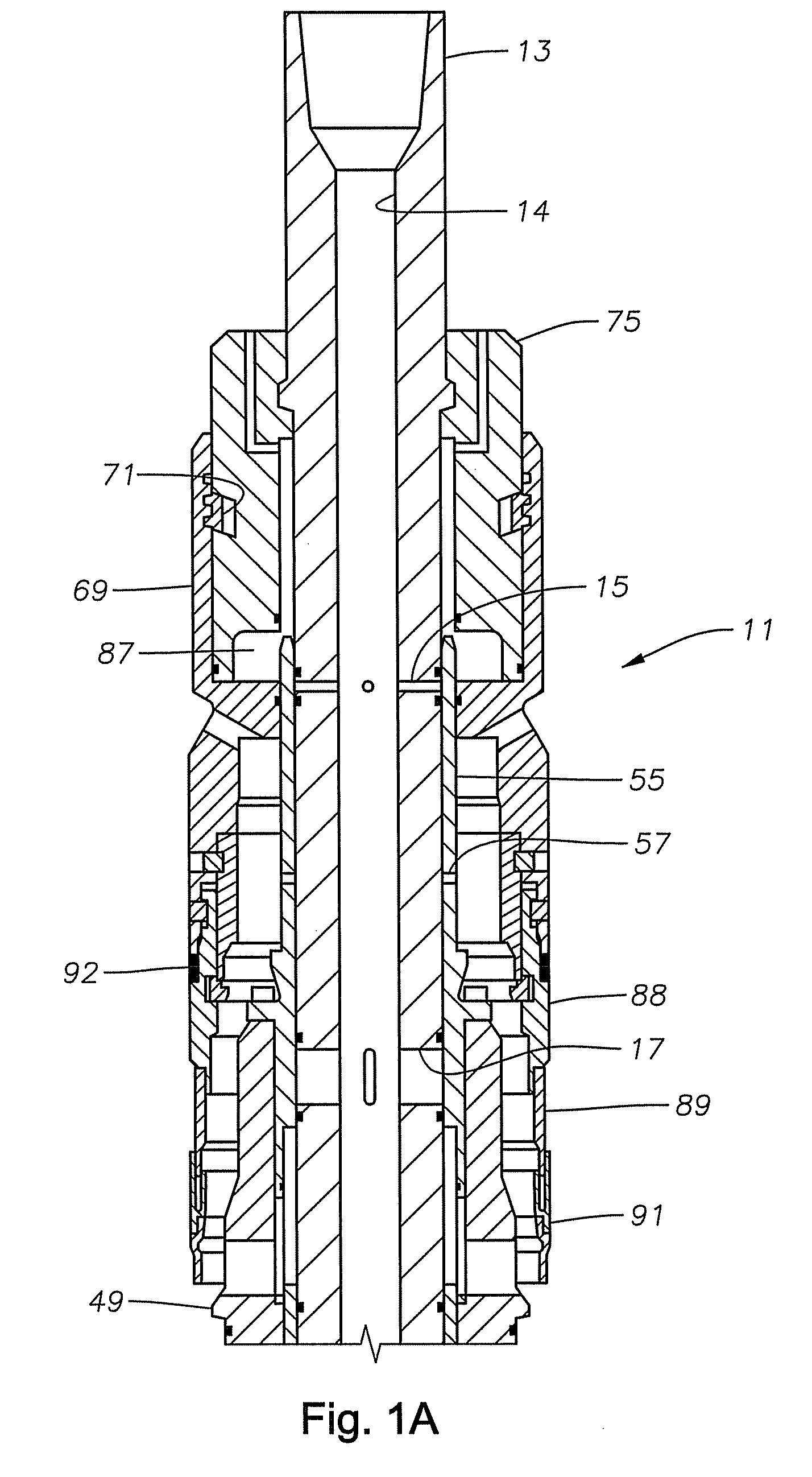

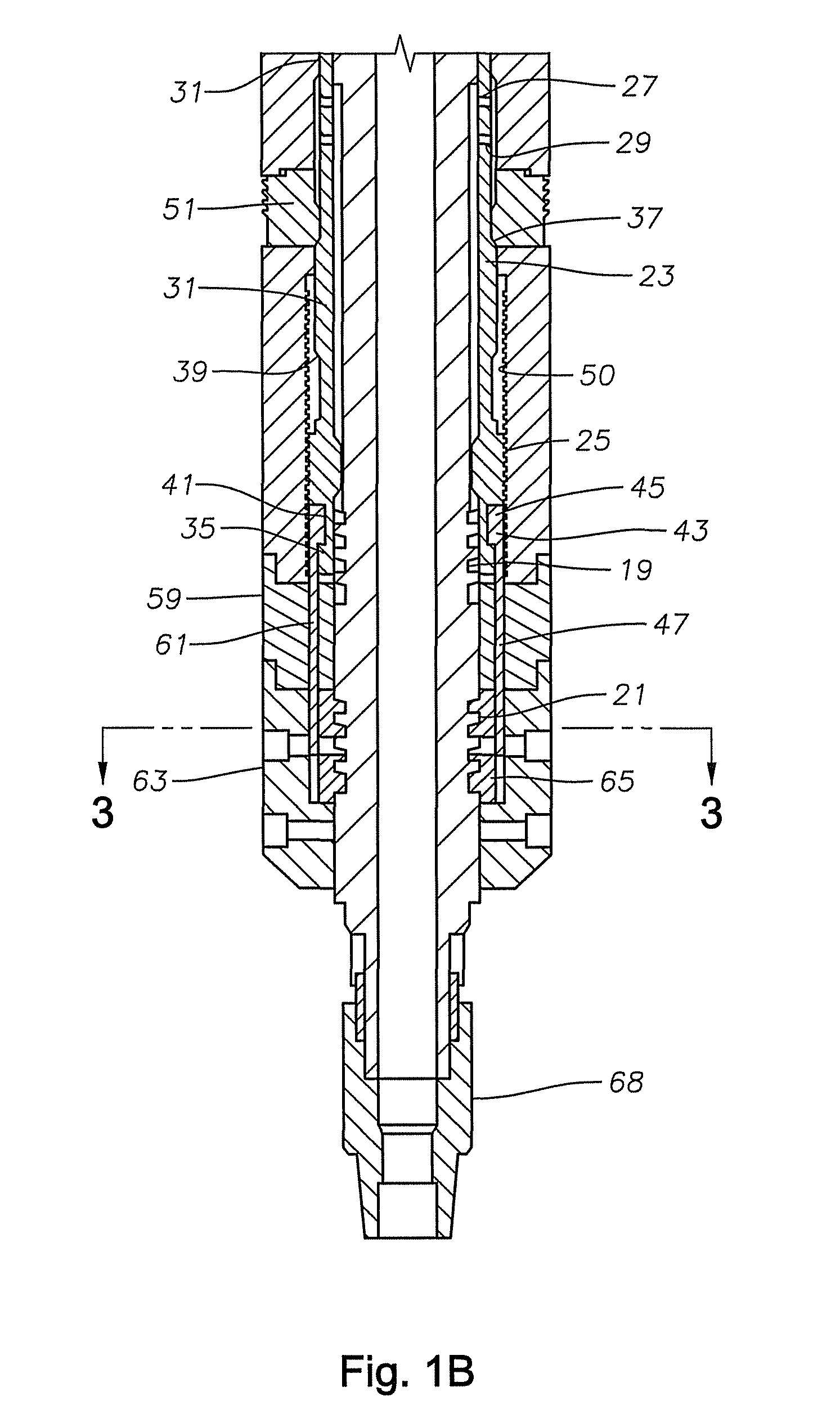

Running tool

Owner:VETCO GRAY

Override system and method for memory access management

InactiveUS20140164716A1Efficient and flexible accessLimit translationMemory architecture accessing/allocationInput/output to record carriersVirtualizationManagement unit

A memory management system and method are described. In one embodiment, a memory management system includes a memory management unit for virtualizing context memory storage and independently controlling access to the context memory without interference from other engine activities. The shared resource management unit overrides a stream of access denials (e.g., NACKs) associated with an access problem. The memory management system and method facilitate efficient and flexible access to memory while controlling translation between virtual and physical memory “spaces”. In one embodiment the memory management system includes a translation lookaside buffer and a fill component. The translation lookaside buffer tracks information associating a virtual memory space with a physical memory space. The fill component tracks the status of an access request progress from a plurality of engines independently and faults that occur in attempting to access a memory space

Owner:GLASCO DAVID B +3

Sacrificial energy dissipation mechanism

ActiveUS20160040739A1Limit translationBuilding repairsProtective buildings/sheltersEngineeringCompressive load

Structural devices for energy dissipation can be designed to provide asymmetrical responses to cyclic axial loading. The energy dissipation devices can be designed to provide a known or predictable response to tensile loading, along with a different known or predictable response to compressive loading. The devices may include a filament which bears a portion of both tensile and compressive loads and a bracing device which provides lateral support to the filament to prevent buckling. Interlocks or a similar restraining mechanism can be used to resist part of either a compressive or tensile load. These components can be configured in such a manner as to provide an asymmetric response.

Owner:STRUCTURAL FUSE

Installation method of curved steel latticed shell structure with gradually varied gable starting span

ActiveCN111809893AGuarantee the stability of the pullPrevent slidingBuilding material handlingArchitectural engineeringBall joint

The invention discloses an installation method of a curved steel latticed shell structure with a gradually varied gable starting span. The installation method comprises the following steps of a, construction preparation; b, splicing block by block and segment by segment; and c, installing a purline system and a roof panel structure. Connection between a steel wire rope and a ball joint is achievedthrough a steel wire rope pulling device, the pulling stability of the steel wire rope is guaranteed, the steel wire rope is prevented from sliding, the perpendicularity of a vertical gable structureis guaranteed, and damage to a rod piece of the latticed shell structure in the steel wire rope pulling process is avoided; and meanwhile, temporary fixing devices are used for supporting the ball joints on the inner sides of the gable latticed shell units, the construction safety performance is improved, and the temporary fixing devices can eliminate the influence of site flatness errors on themounting precision, mounting construction between the ball joints and the temporary fixing devices is better facilitated, construction operation is convenient, field construction is flexible and convenient, precision errors are easy to adjust, construction efficiency is high, installation quality is guaranteed, potential safety hazards of aloft work are reduced, and construction cost is reduced.

Owner:浙江中南绿建科技集团有限公司

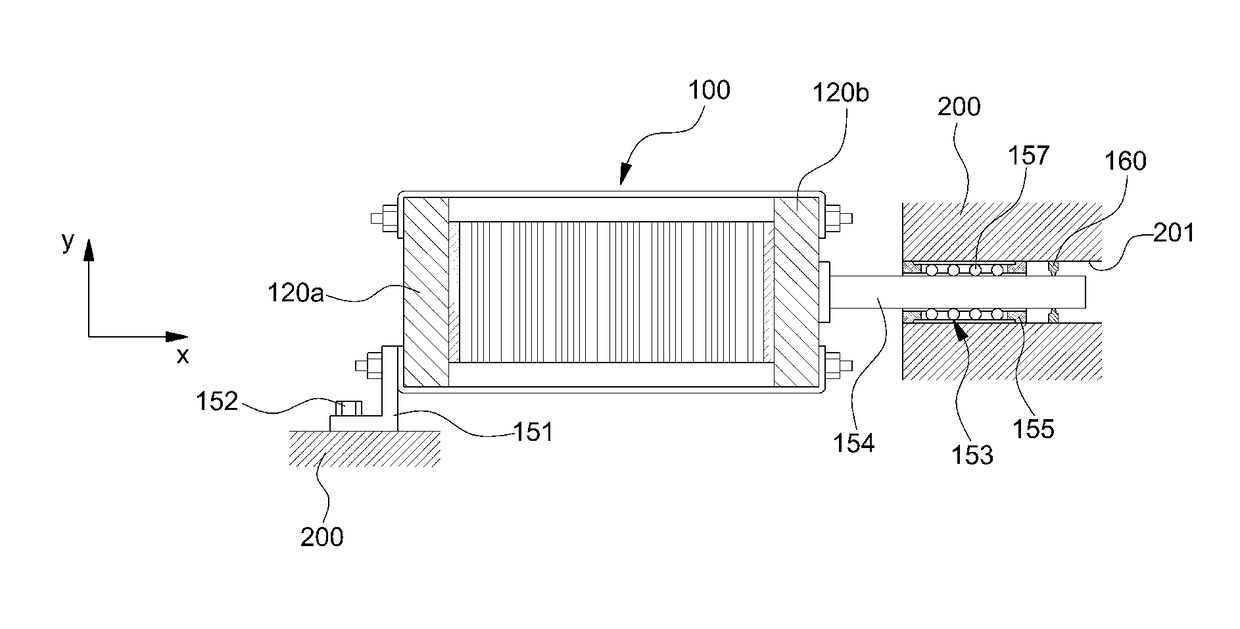

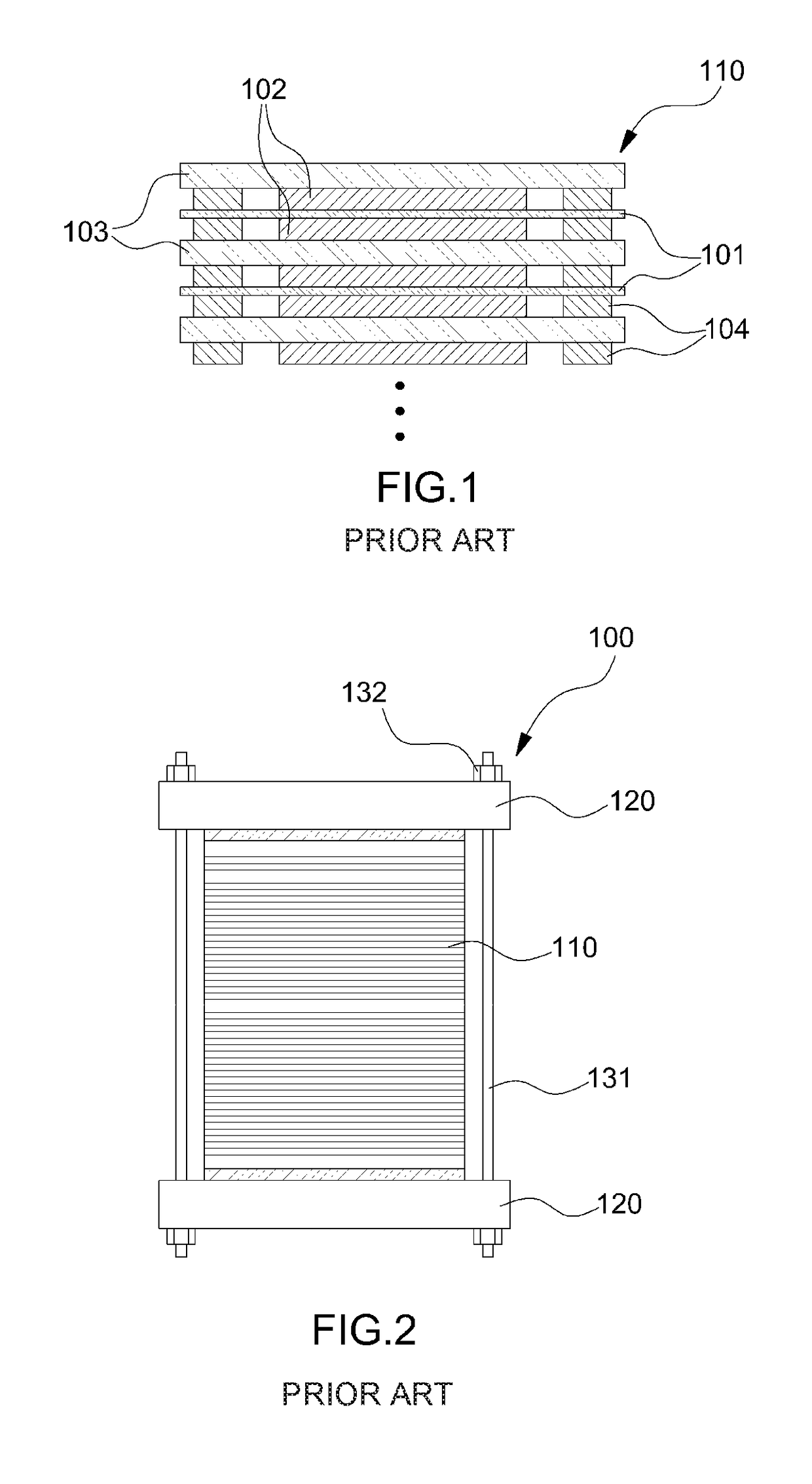

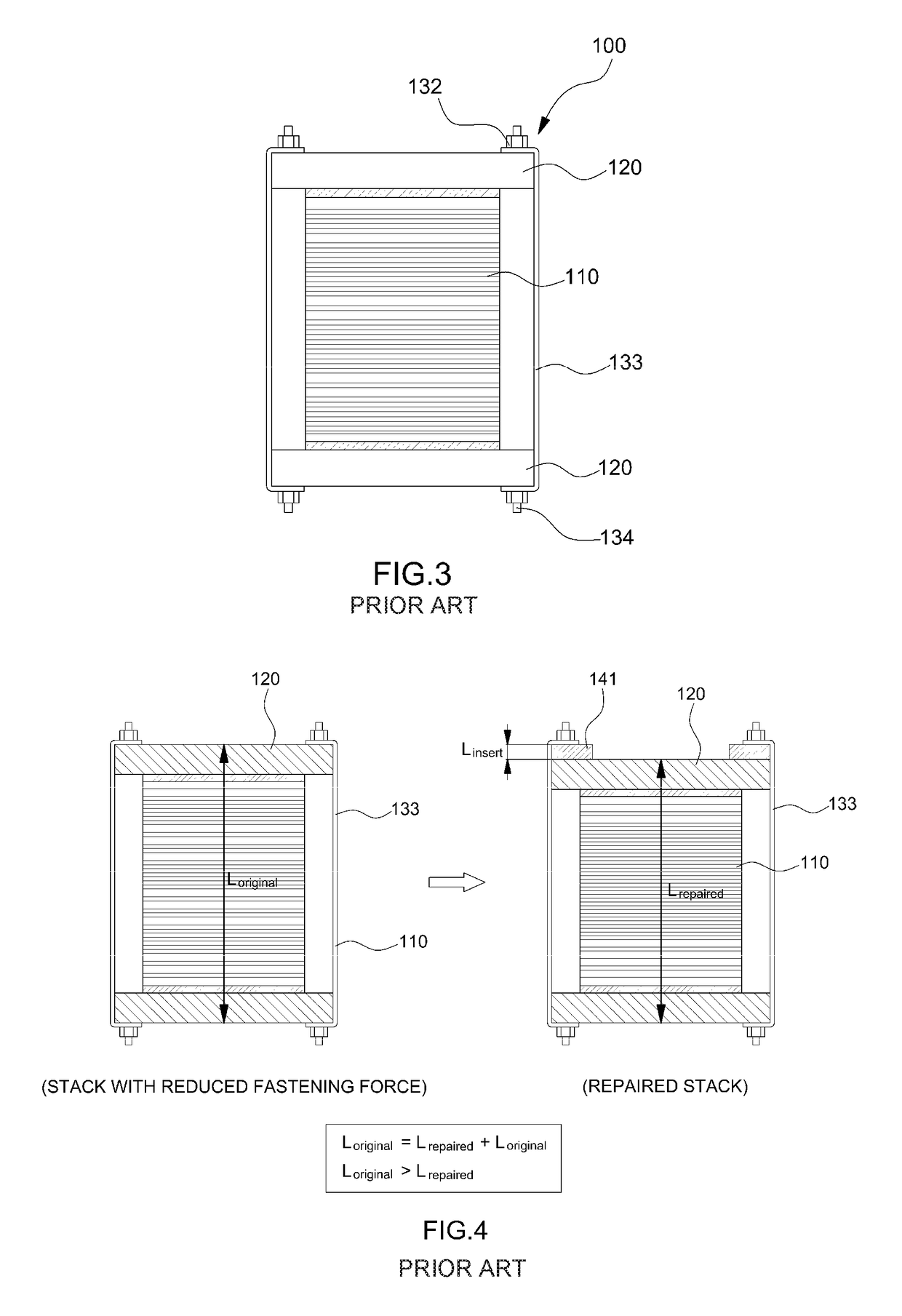

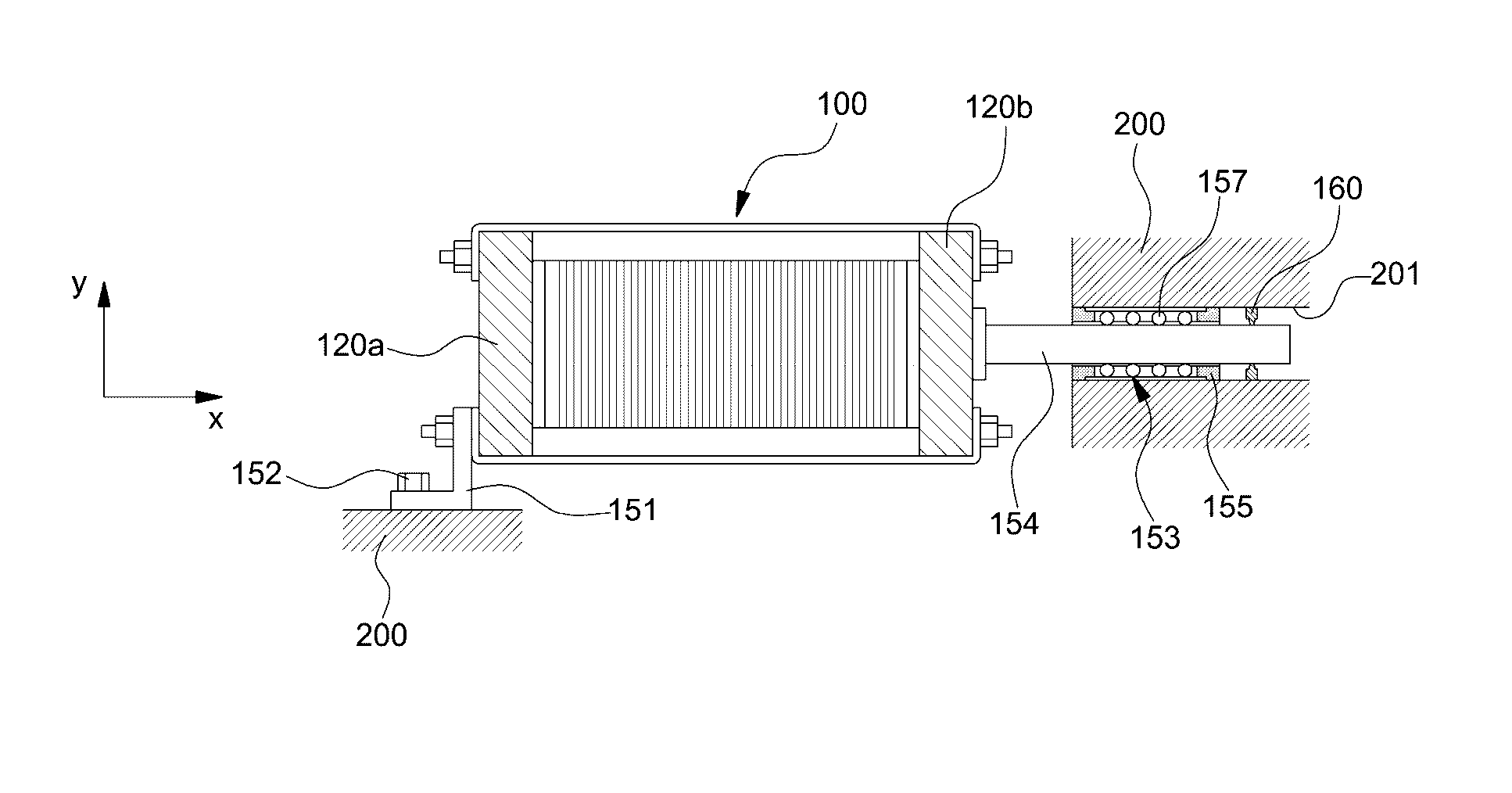

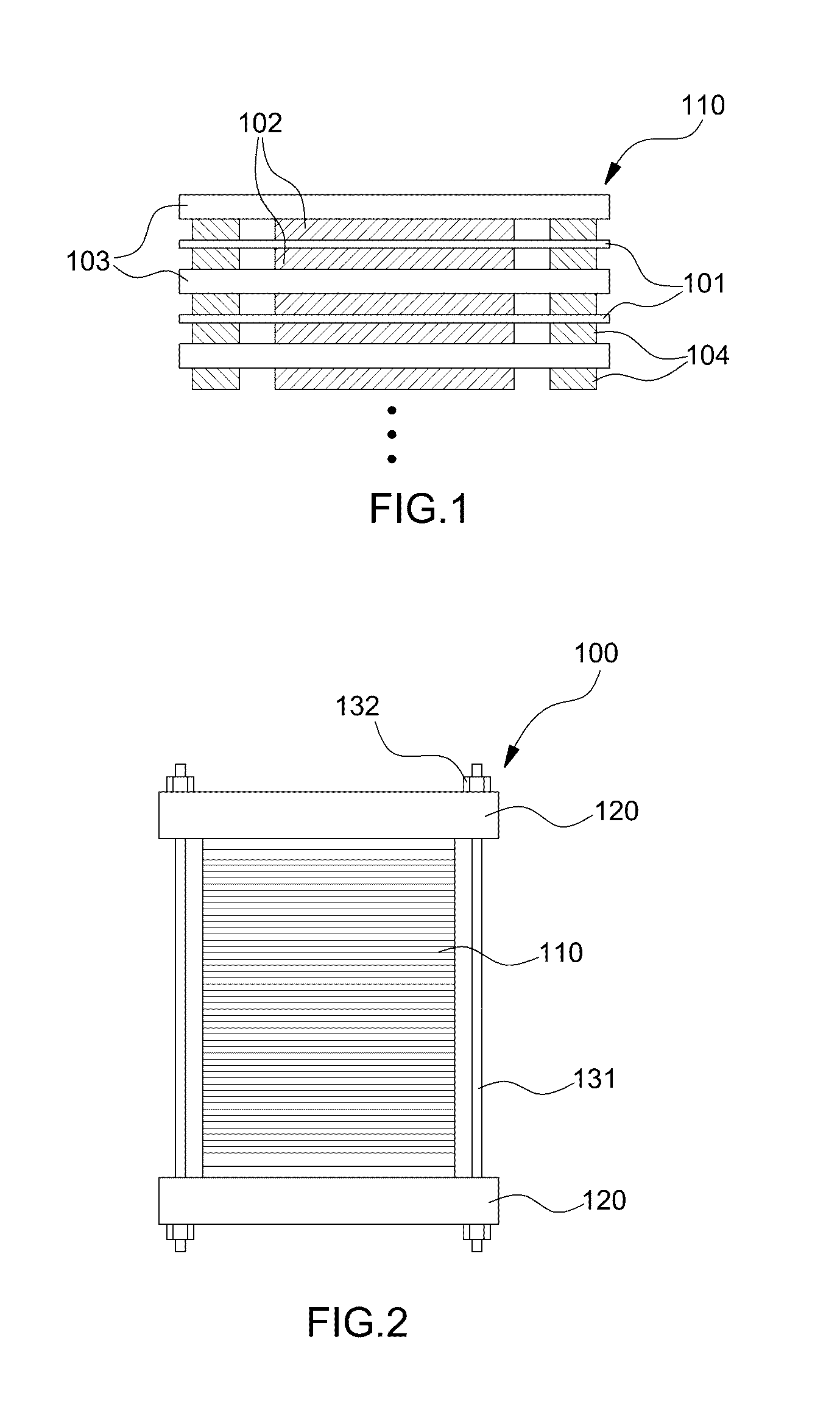

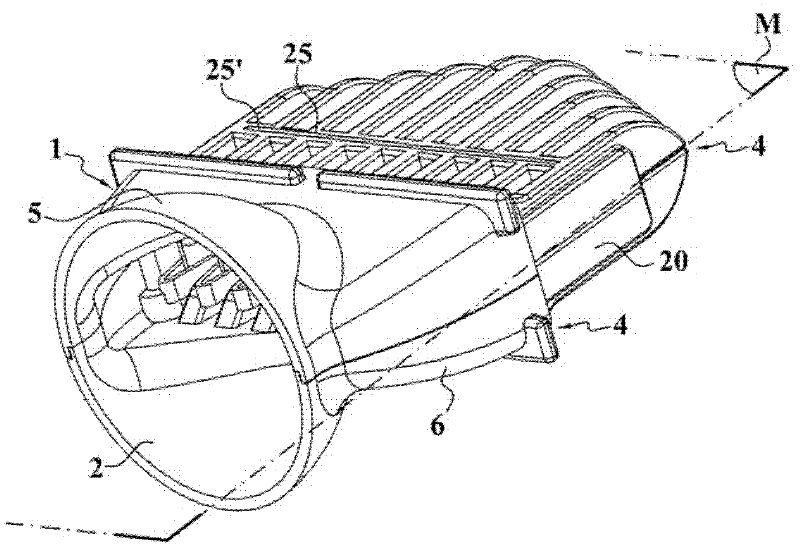

Structure for mounting fuel cell stack

A structure for mounting a fuel cell stack in an enclosure or a frame includes a first mounting mechanism for fastening and mounting a first mounting part located at a first side of the fuel cell stack in a longitudinal direction of the stack, which is a cell stacking direction, to the enclosure or the frame in a completely fixing fashion, and a second mounting mechanism for mounting a second mounting part located at a second side of the fuel cell stack in the longitudinal direction of the stack to the enclosure or the frame in a state of being movable in the longitudinal direction of the stack.

Owner:HYUNDAI MOTOR CO LTD

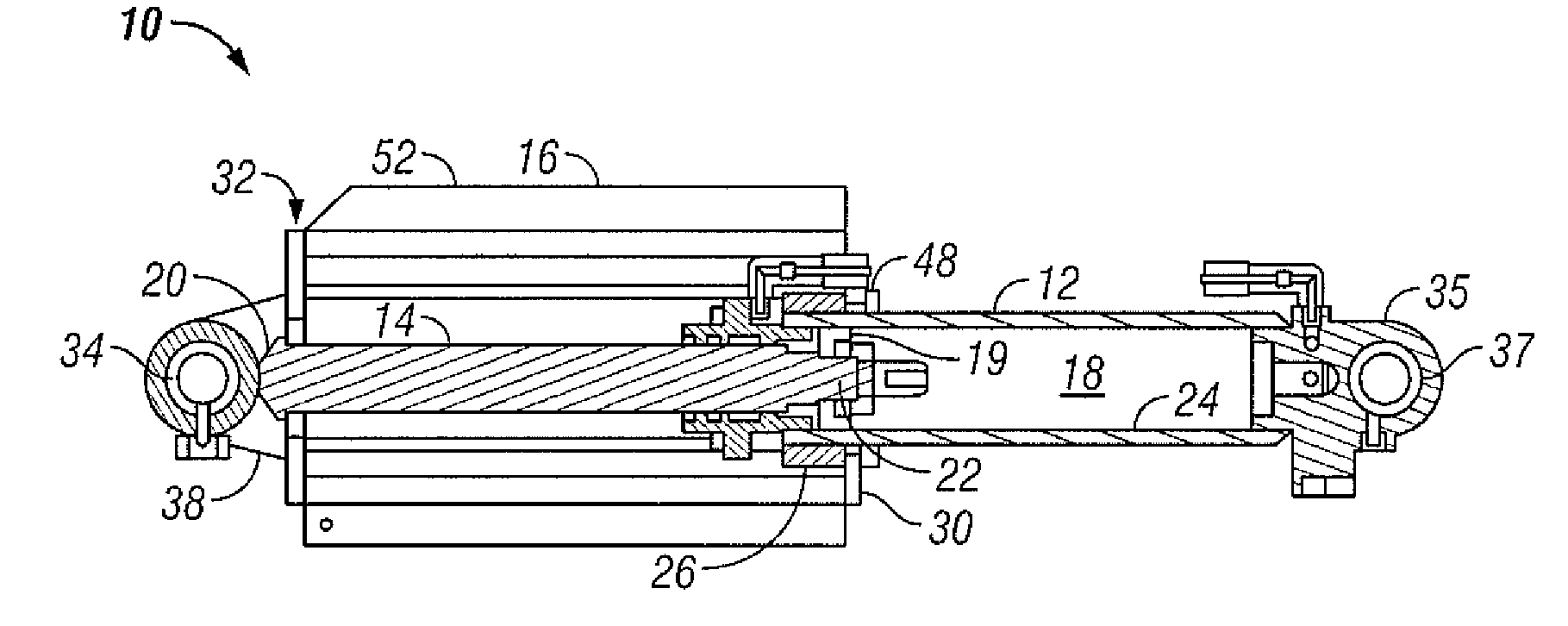

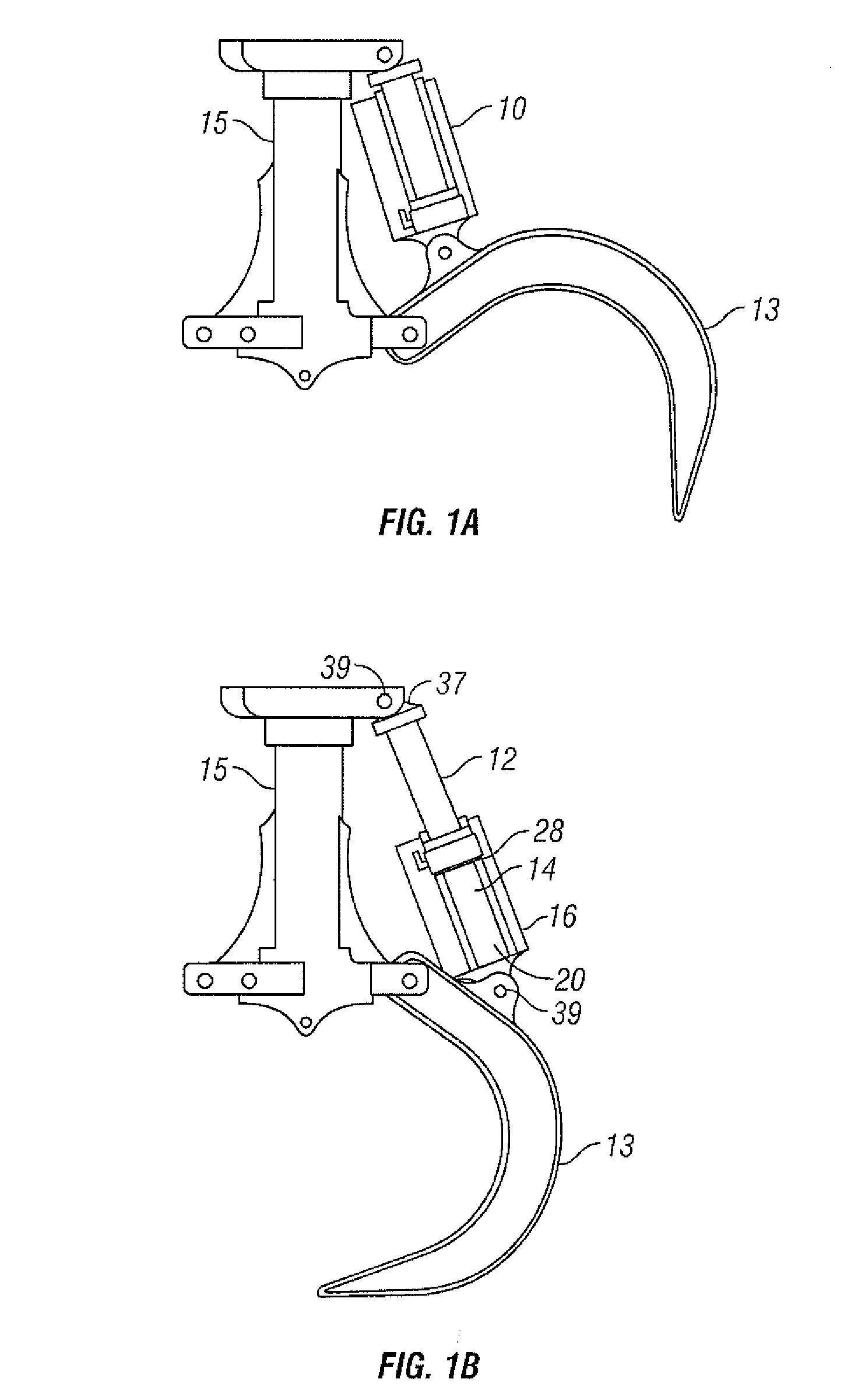

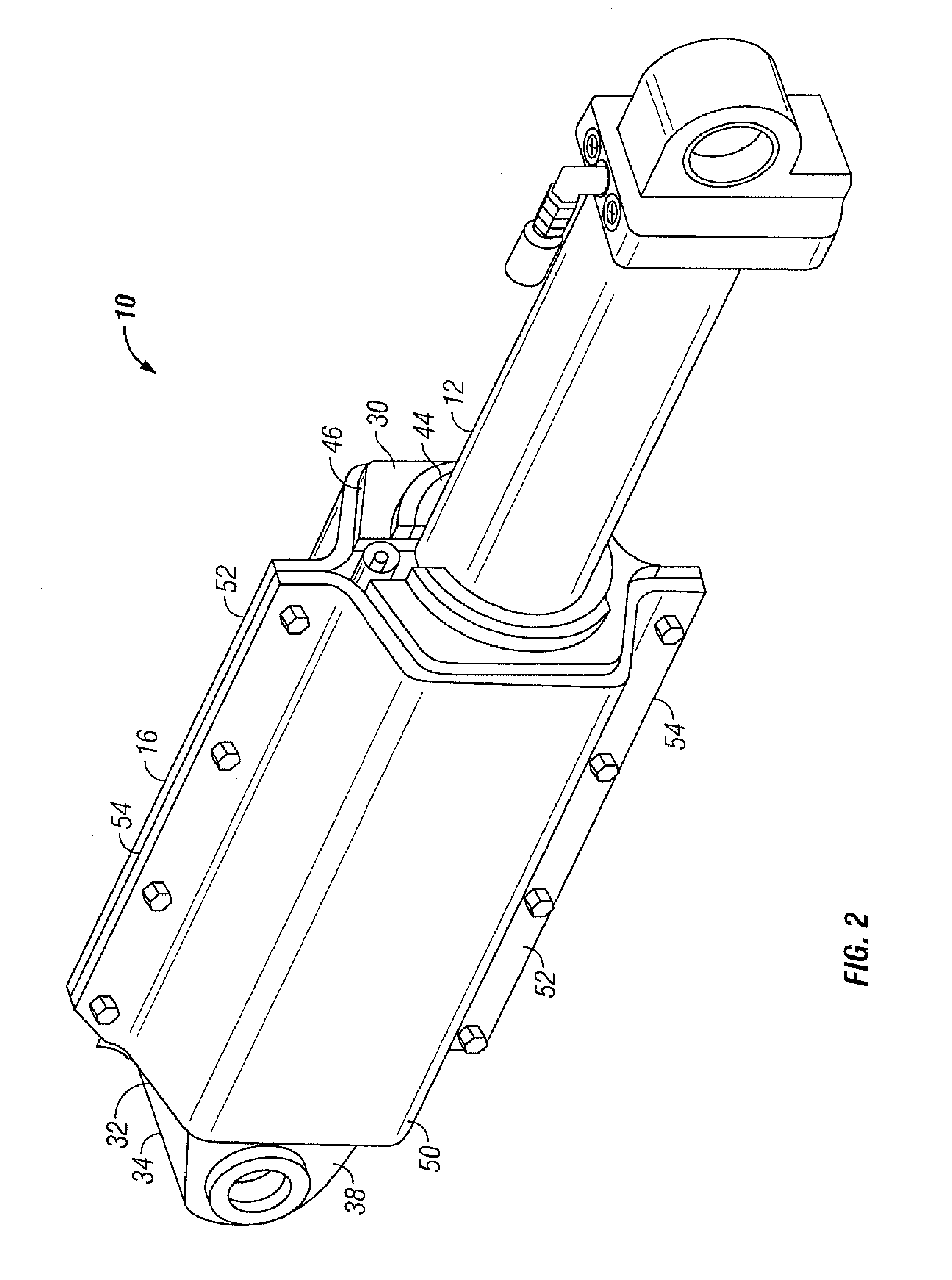

Actuator with a protective sleeve for a piston

ActiveUS20080168897A1Prevent fallingSimple designFluid-pressure actuatorsEngine componentsPistonEngineering

The invention relates to an actuator for heavy machinery including a cylinder, a piston and a protective sleeve. The cylinder forms a chamber for receiving a fluid, and includes an external flange extending radially and outwardly from the cylinder. The piston is operable to translate axially relative to the cylinder between an open position and a closed position, and includes a first extremity positioned outside the cylinder and a second extremity positioned within the chamber. The second extremity sealingly engages the chamber. The protective sleeve protects the piston in the open position, which is movable with the piston and operable to overlap at least a portion of the cylinder in the closed position. The protective sleeve includes an internal flange extending radially and inwardly from the protective sleeve and is positioned for abutting the external flange when the piston is in the open position. This abutment limits the axial translation of the piston out of the cylinder.

Owner:ROTOBEC

Structure for mounting fuel cell stack

A structure for mounting a fuel cell stack in an enclosure or a frame includes a first mounting mechanism for fastening and mounting a first mounting part located at a first side of the fuel cell stack in a longitudinal direction of the stack, which is a cell stacking direction, to the enclosure or the frame in a completely fixing fashion, and a second mounting mechanism for mounting a second mounting part located at a second side of the fuel cell stack in the longitudinal direction of the stack to the enclosure or the frame in a state of being movable in the longitudinal direction of the stack.

Owner:HYUNDAI MOTOR CO LTD

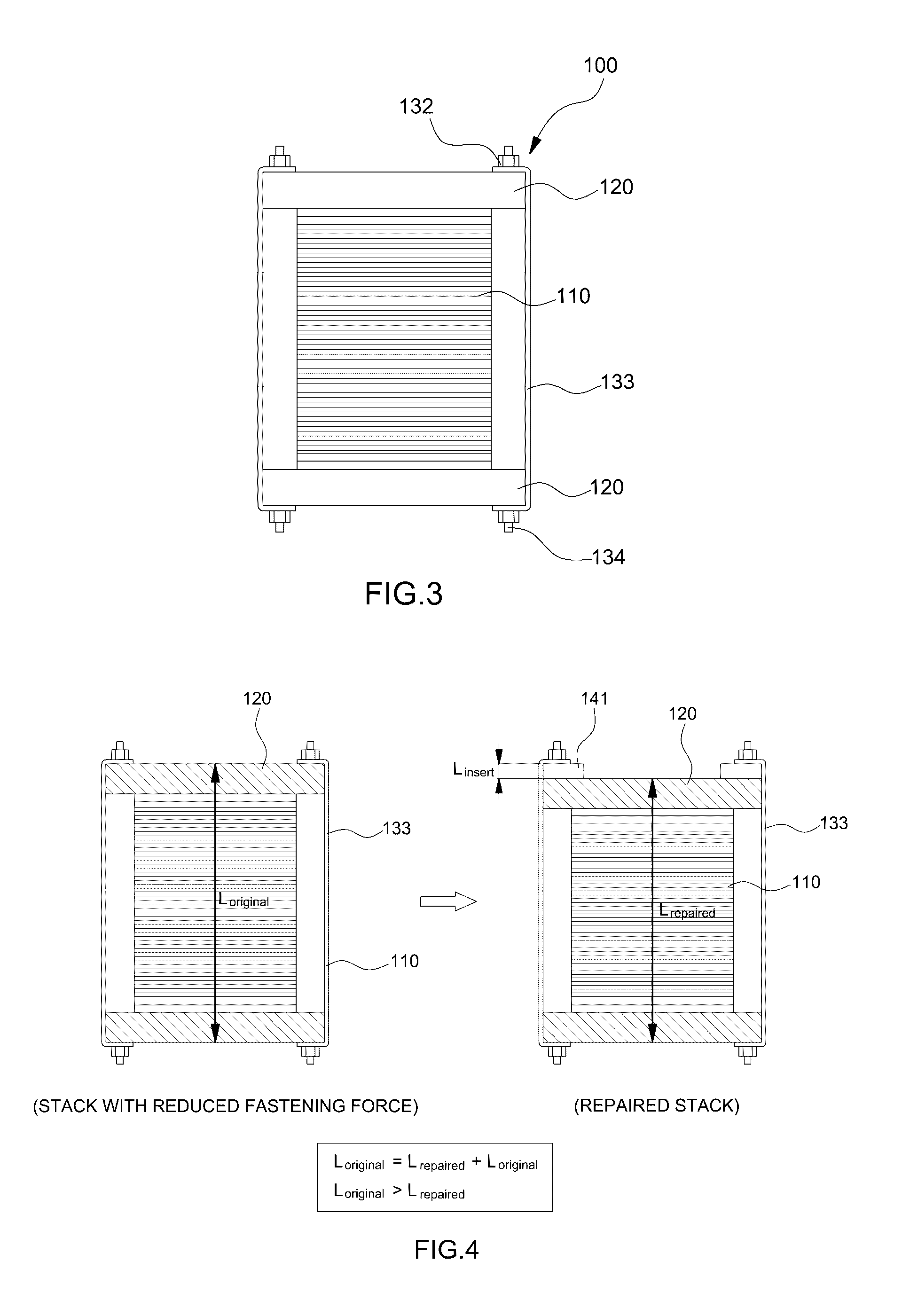

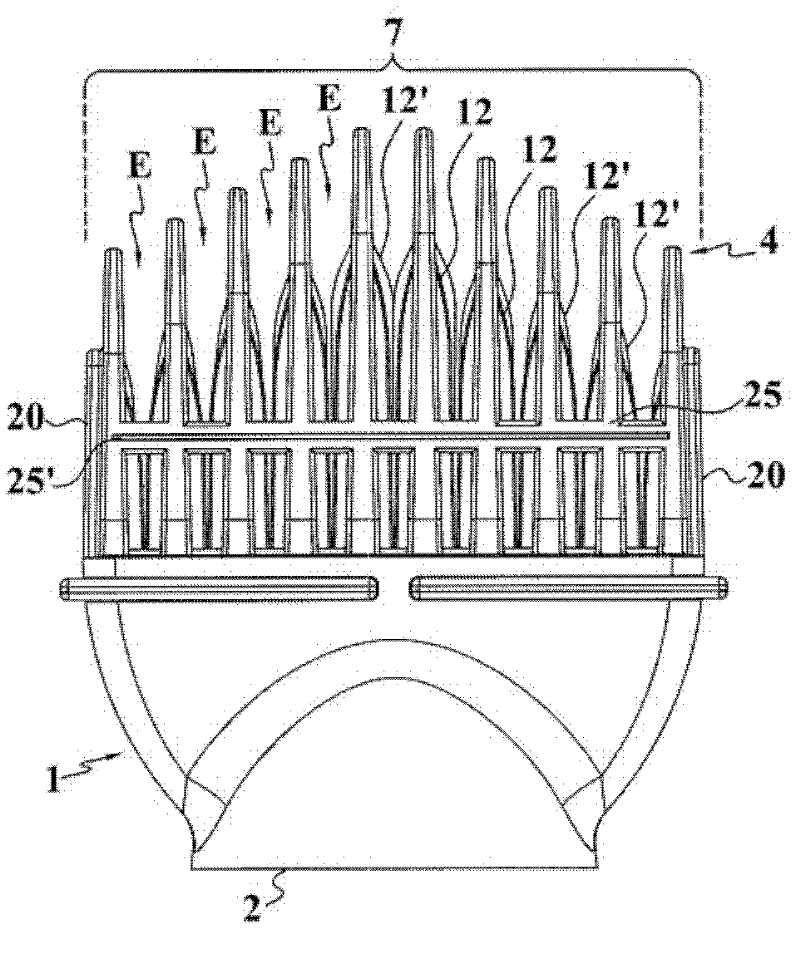

Hair styling accessory

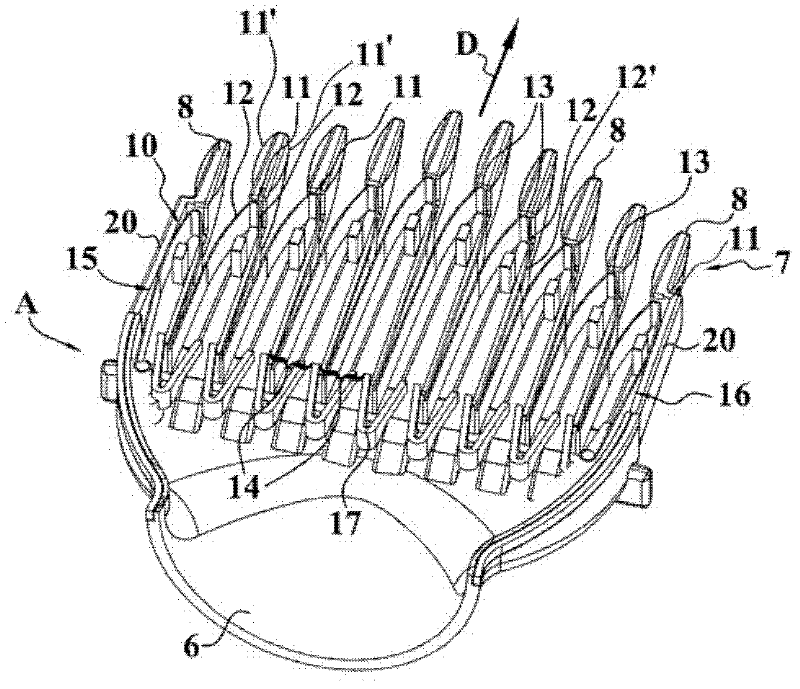

The present invention relates to a hair styling accessory which is used for being equipped on hair cutting equipment (S). The hair cutting accessory comprises a body (1) which is provided with a proximal end being assembled on the hair cutting equipment and a distal end (4) for shaping. The distal end (4) is connected with at least one hair guiding comb (7) and is connected with a hair lock gripping mechanism. The hair guiding comb (7) is provided with teeth (8) which are approximately parallel with a direction D. The clamping mechanism comprises a clamping comb (10) which is parallel with the guiding comb (7) and comprises clamping teeth (11). Each clamping tooth (11) has shape of U or V formed of elastic branches (12) that are connected at the level of a core to form a head (13), of the tooth, oriented towards the distal end (4). The opposite branches of the teeth define a hair gripping space (E) which is approximately parallel to the guiding teeth (8).

Owner:SEB SA

Cover system for a side-dump container

InactiveUS20050140163A1Limit translationPrevent removalRemovable external protective coveringsLoad coveringMechanical engineeringEngineering

A deployment apparatus for a flexible cover sized to cover a side-dump container comprises first and second swing arm assemblies pivotally mounted at a pivot point to opposite sides of the container. A drive assembly connected to the roll tube of the flexible cover is operable to rotate the roll tube so that the flexible cover winds around the roll tube. The drive assembly is slidably supported on one of the swing arms so that the mechanism translates along the length of the swing arm as it winds the flexible cover around the roll tube. A stop is provided on the swing arm between the pivot point and the free end to limit the translation of the drive assembly along swing arm. In another form, the drive assembly is fixed to a swing arm that is slidably received in a pivoting spring mechanism.

Owner:AERO INDS

Space robot paw

A grip of space robot is disclosed, which features wide capture range and high locating precision. The motor position sensor is fixed to motor driver connected to supporting sleeve fixed to harmonic speed reducer installed to mainshaft of motor and connected with drive flange. Said drive flange is fixed to shaft-end flange connected with finger position sensors. The gear drive unit on drive flange is connected respectively with the single-finger and dual-finger 4-connection-rod units. The contact sensor is arranged in V-shaped slot on shell.

Owner:HARBIN INST OF TECH

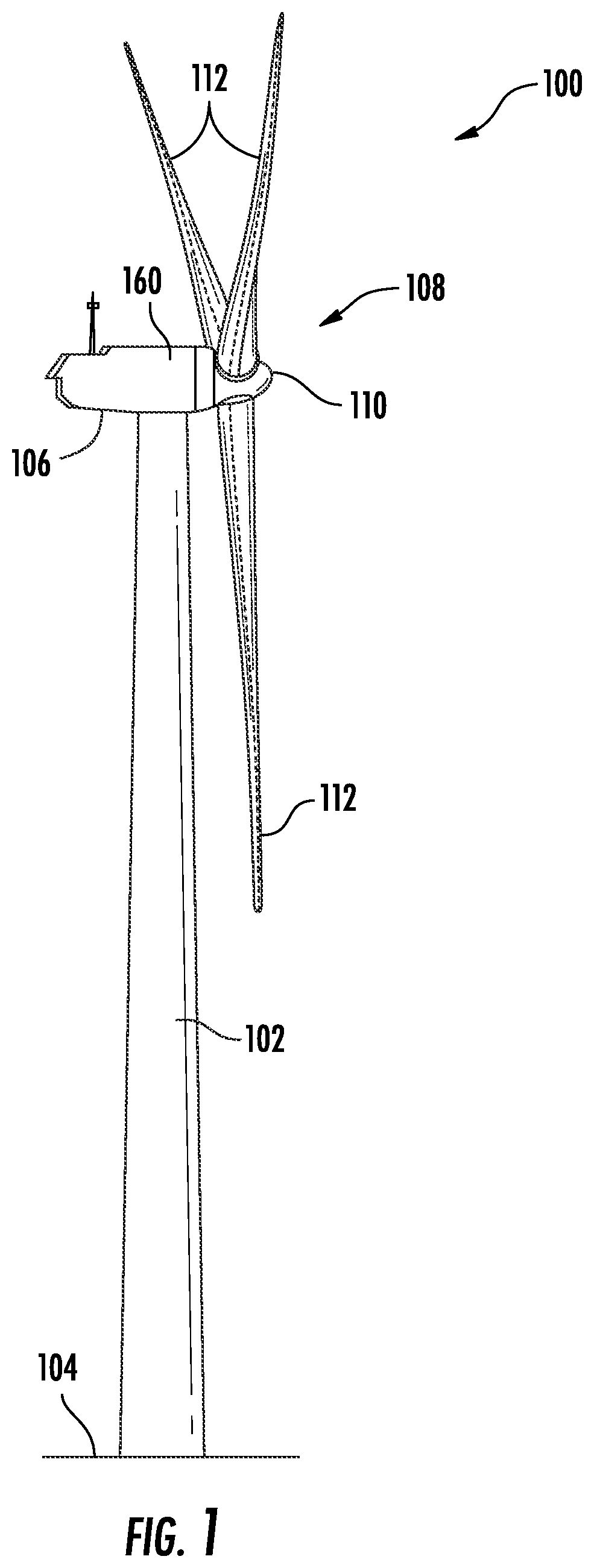

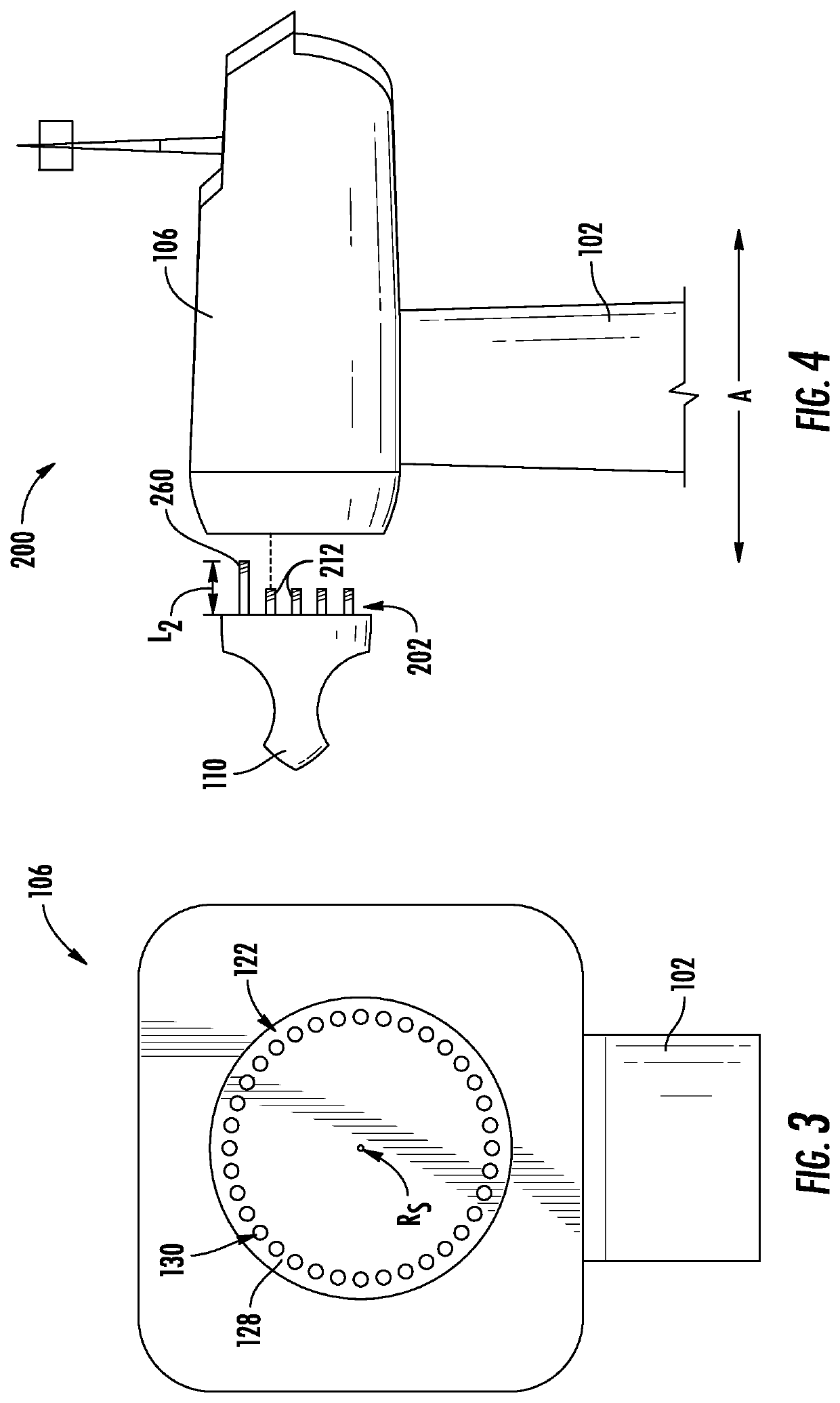

System and method for coupling a hub to a main shaft of a wind turbine

ActiveUS20210215184A1Limit translationEngine manufactureWind motor assemblyCouplingClassical mechanics

A system and method are provided for coupling a hub to a main shaft of a wind turbine. Accordingly, a plurality of fasteners are arranged within corresponding through holes of the hub of a wind turbine. At least one circumferential ridge segment is arranged radially adjacent to the head sections of the plurality of fasteners so as to resist a torque applied to each of the plurality of fasteners. A connection mechanism is utilized to secure the plurality of fasteners within the plurality of through holes so as to limit an axial translation of the plurality of fasteners prior to the coupling of the hub to the main shaft.

Owner:GENERAL ELECTRIC CO

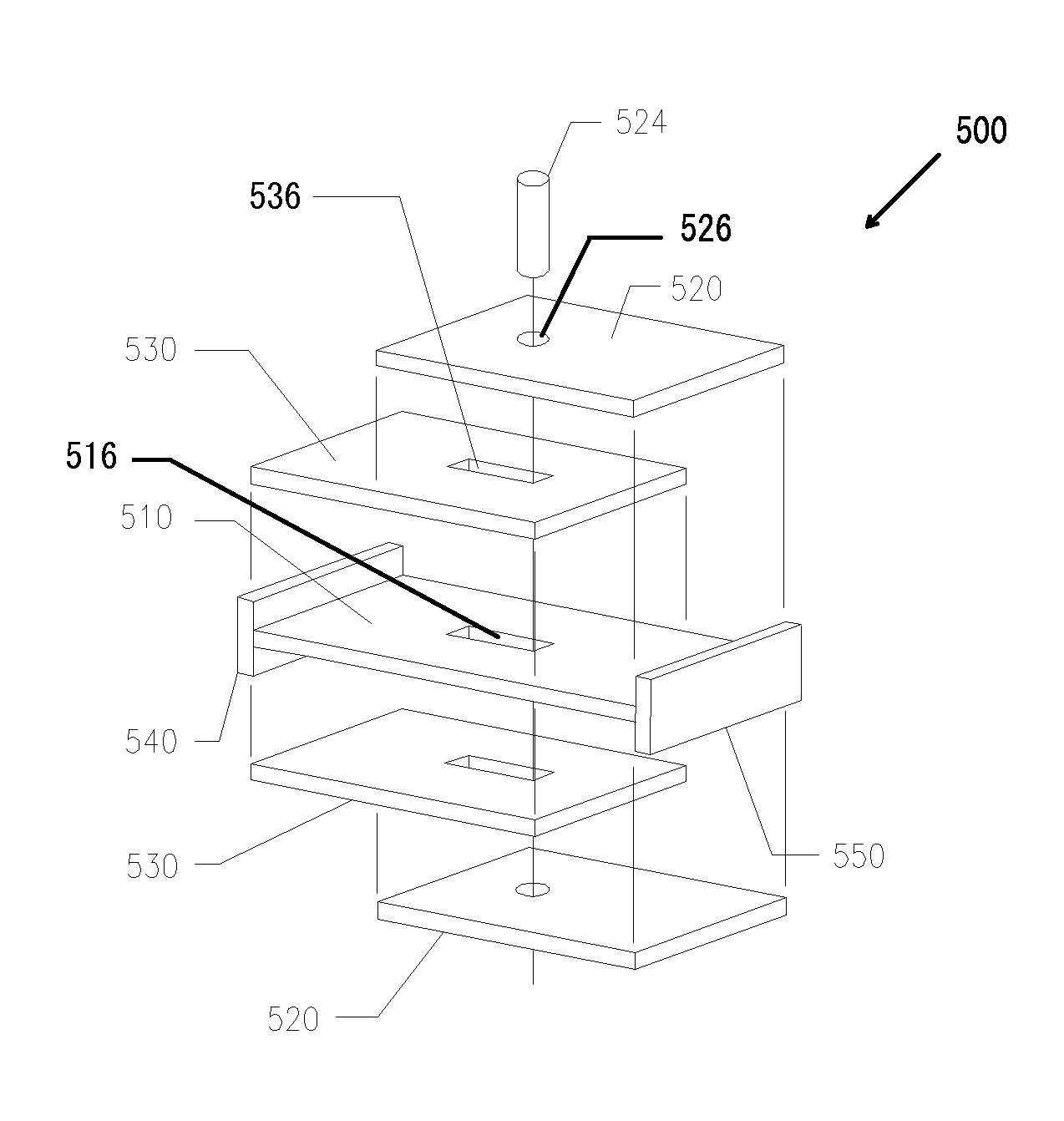

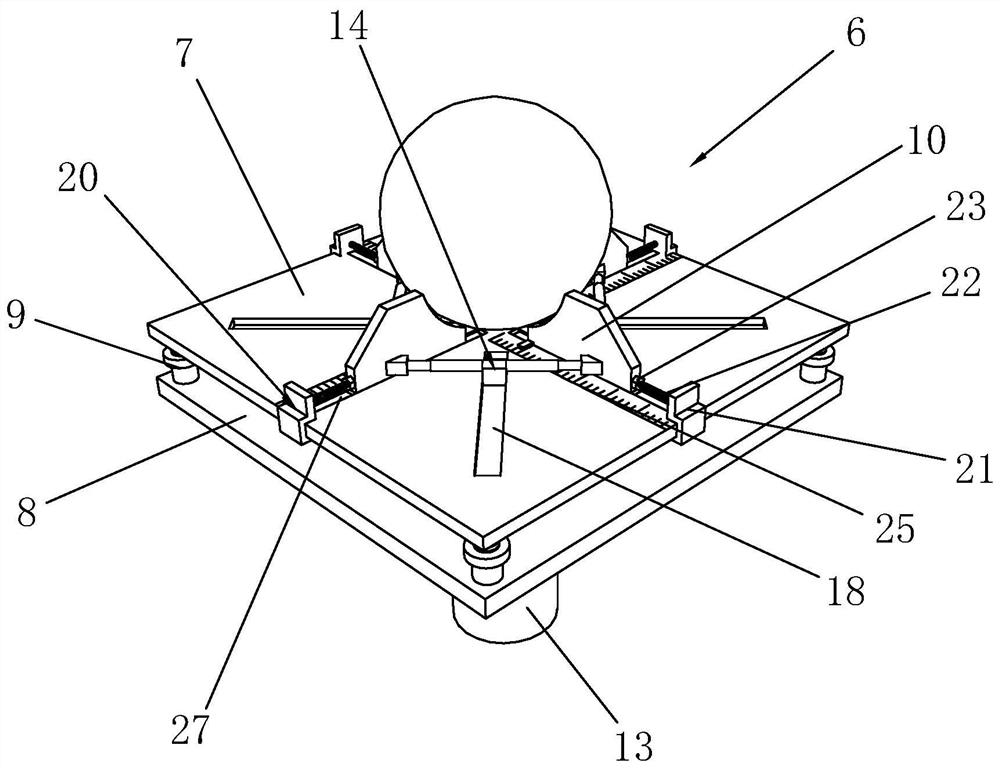

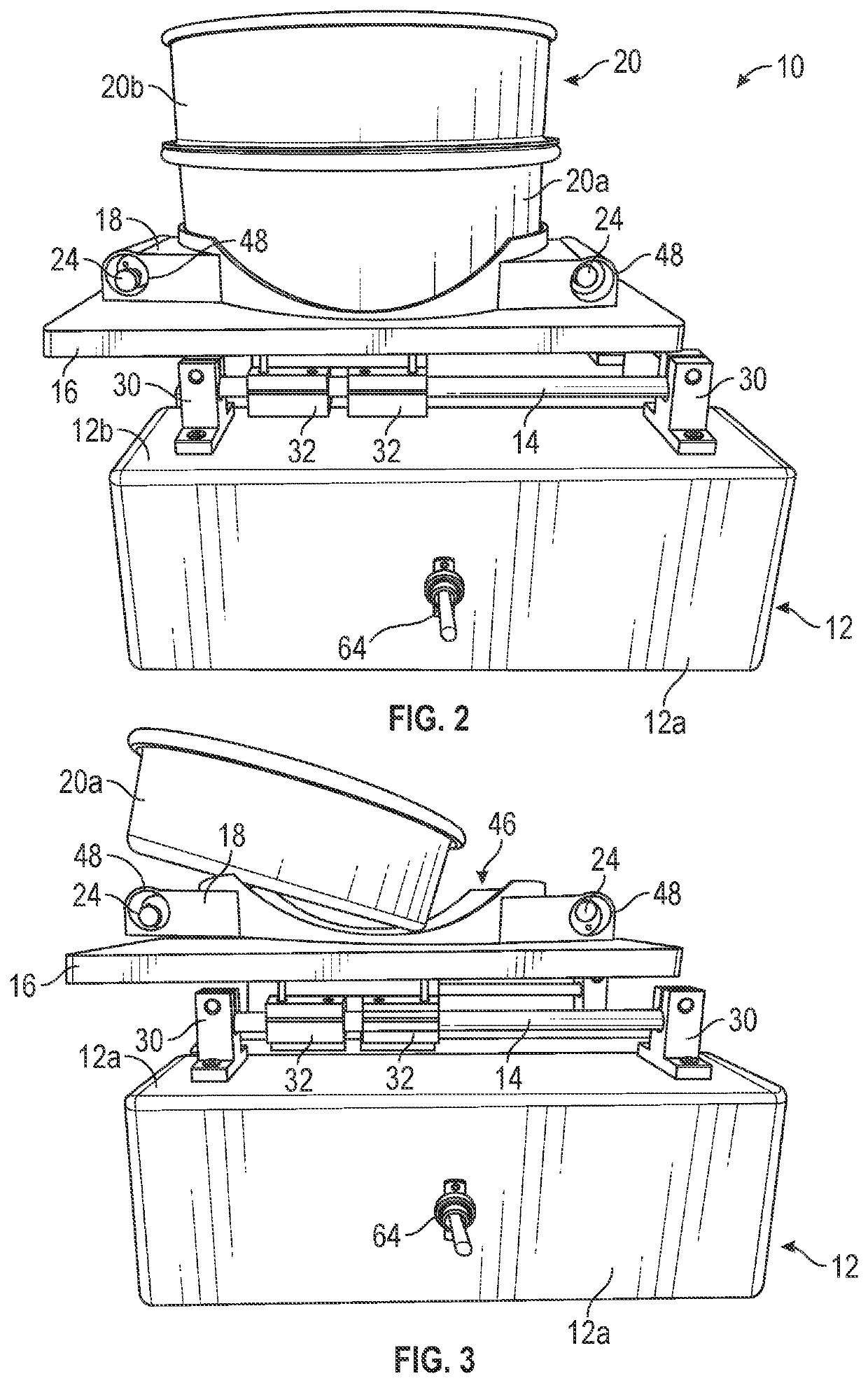

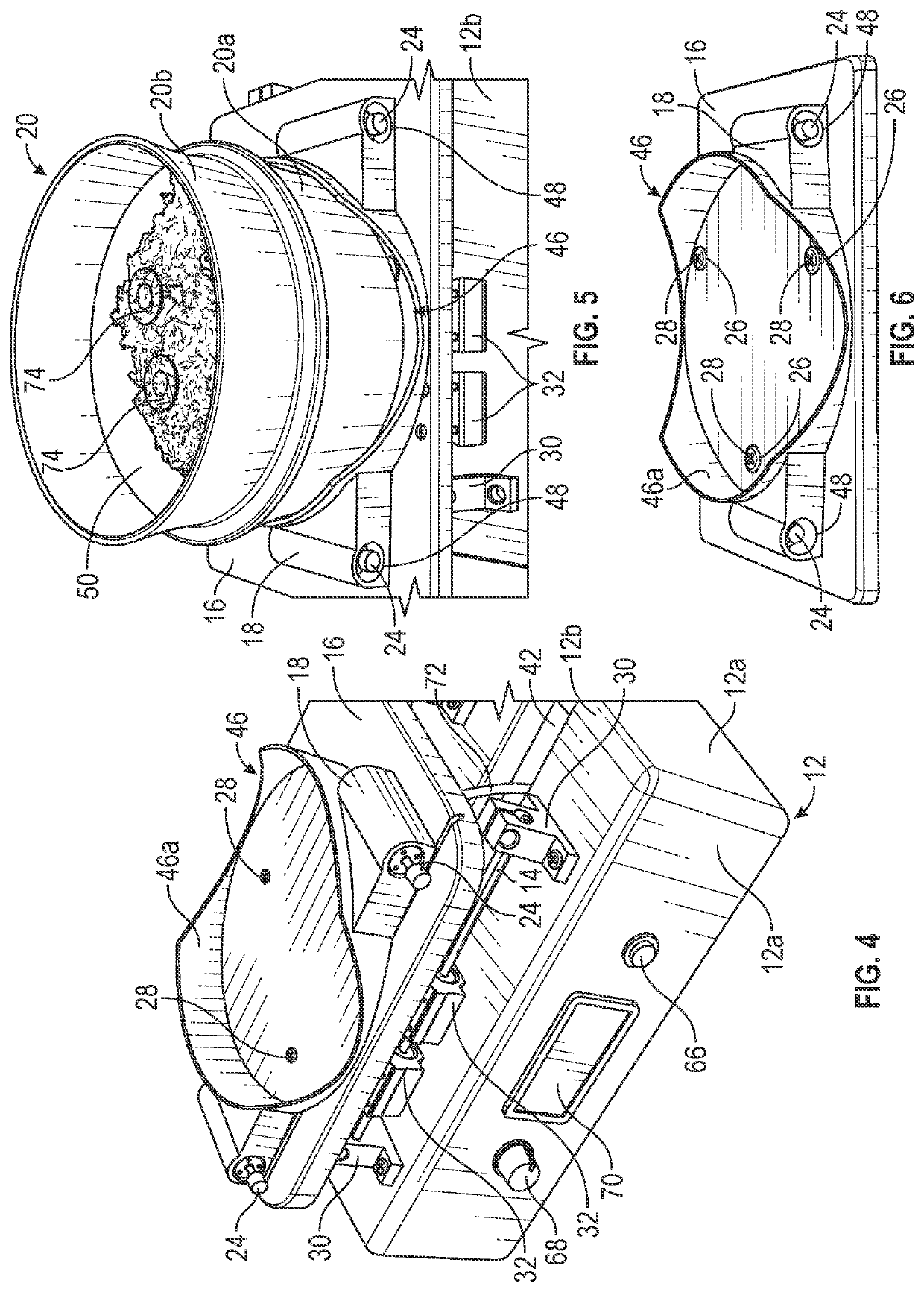

Plant product extraction apparatus

ActiveUS20210245199A1Easy to separateLimit translationSievingScreeningReciprocating motionAgricultural engineering

A plant product extraction apparatus or extractor is provided for separating or grading fine particles from a larger portion of material, such as separating trichomes from a stalk or flower of a plant. The apparatus imparts a plurality modes or patterns of oscillations and vibrations to a particle separator or sieve that holds the plant matter. A motor drives a back and forth motion to a support platform supporting a sieve. The sieve is constrained by a retention tray that is supported by the support platform. Vibratory motors provide rapid shaking vibration through the retention tray to the sieve. Agitators may be placed inside of the sieve to facilitate the separation of the plant materials. The various motors and locomotion patterns facilitate the separation of finer plant materials from a larger portion of a plant.

Owner:JOHNSON CHAD M

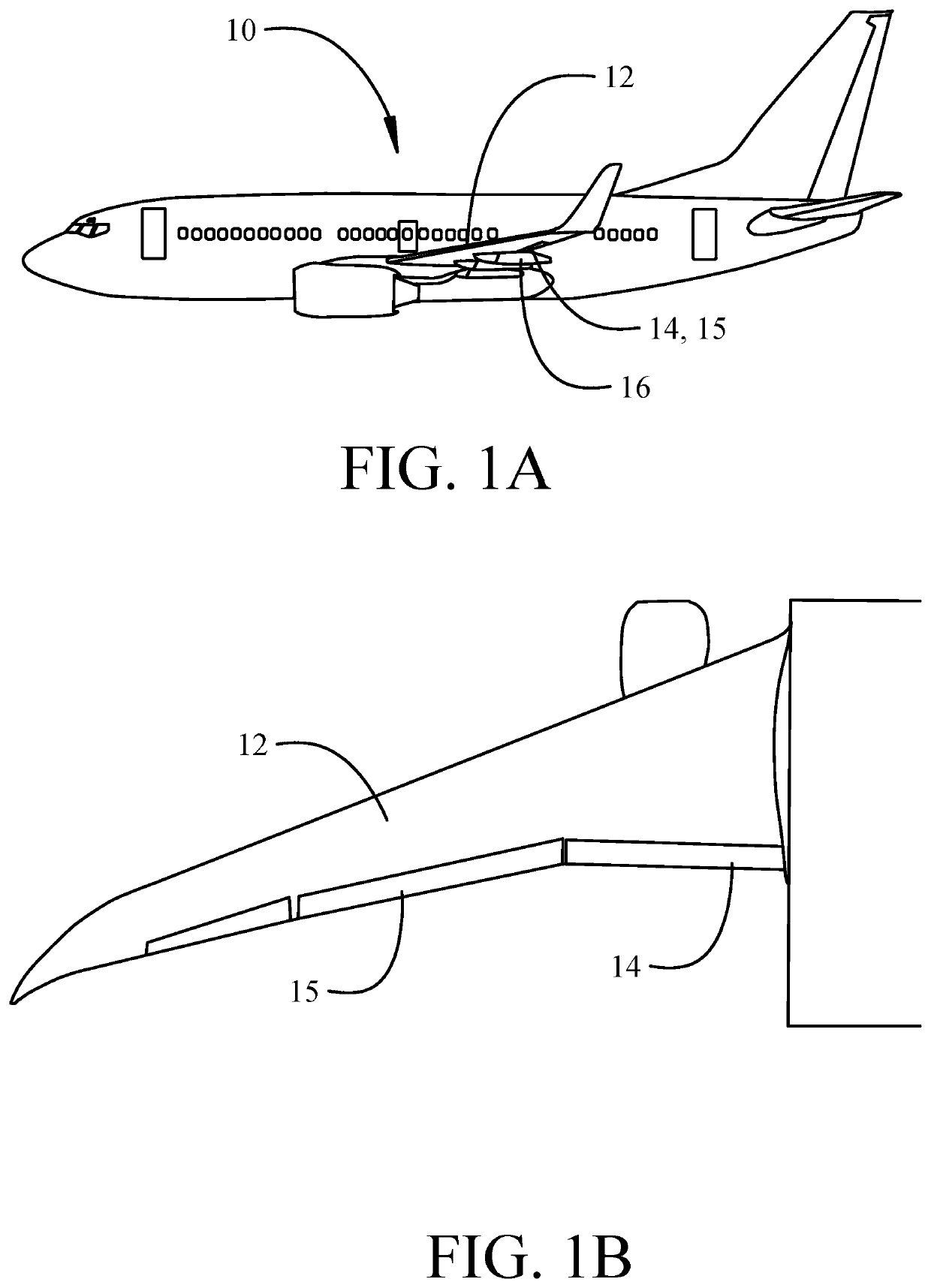

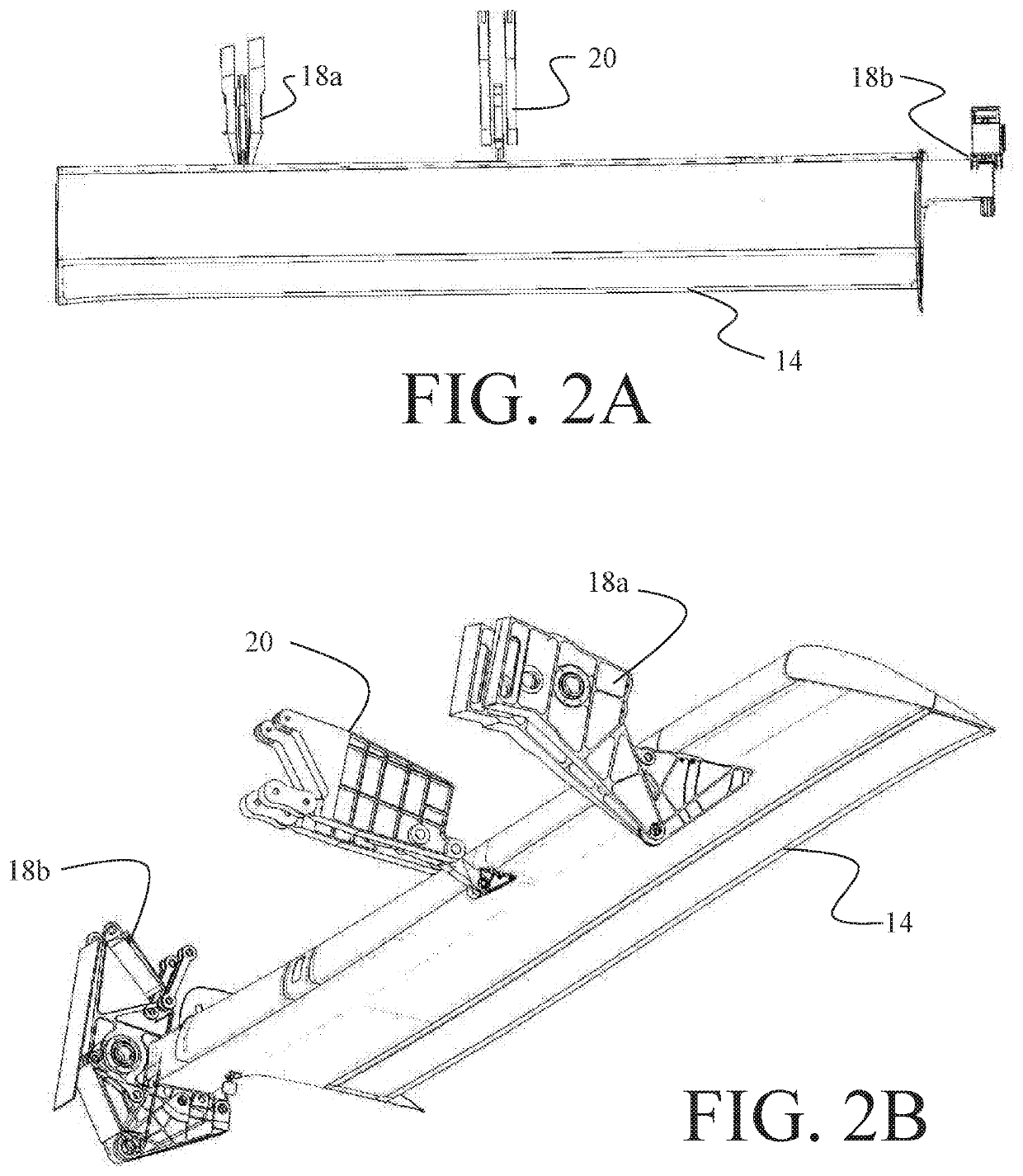

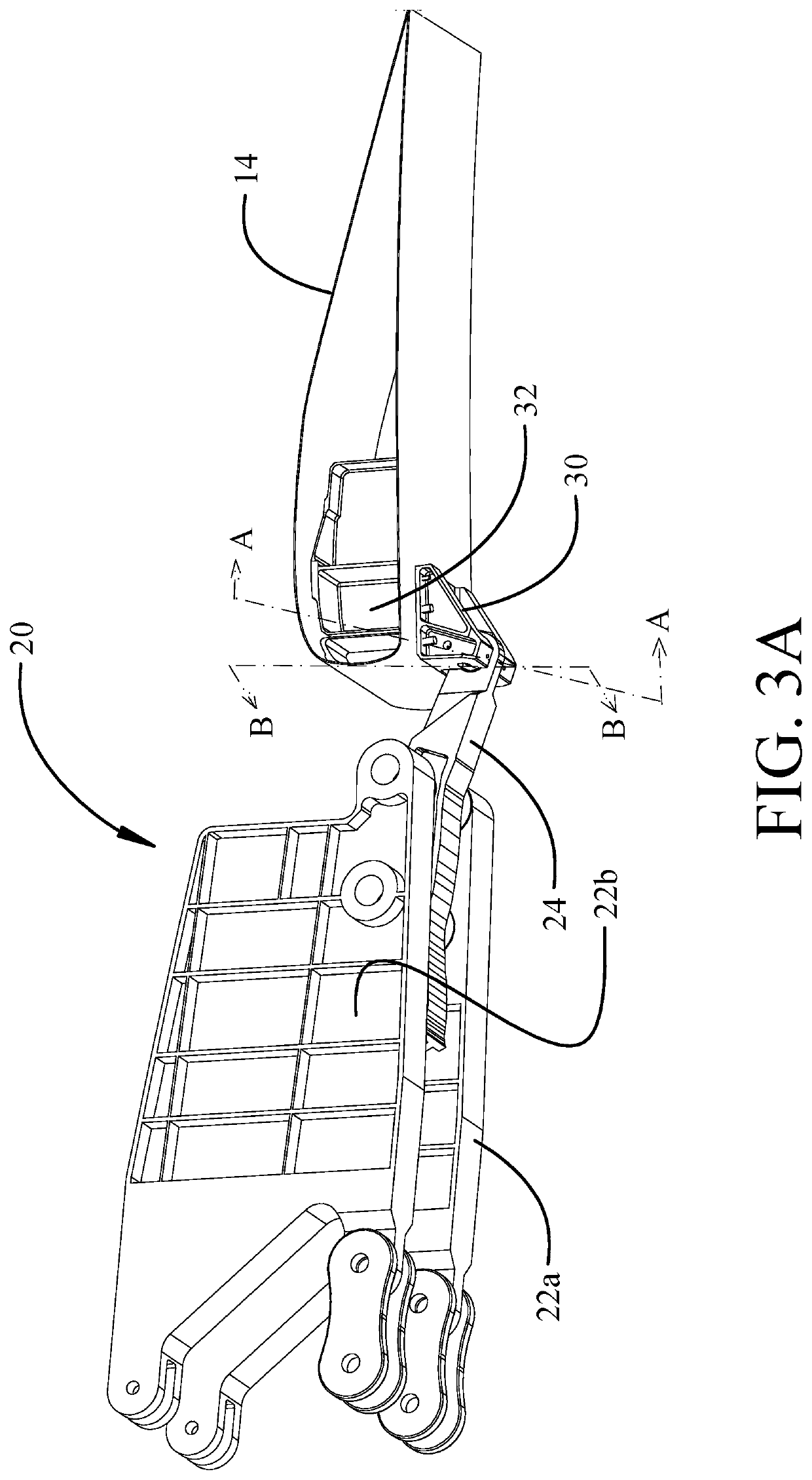

Self-aligning low load shear out joint

PendingUS20210062848A1Limit translationAircraft controlCouplings with disconnecting safety membersLow loadStructural engineering

A self-aligning support incorporates a support attachment fitting and a rotatable pin assembly having a primary load pin coupling the support attachment fitting to an attachment support, and inboard and outboard attachment claws engaged to end portions of the primary load pin. The rotatable pin assembly is configured to rotate relative to the support attachment fitting. At least one fuse pin extends through the primary load pin to limit translation of the primary load pin relative to the inboard and outboard claws.

Owner:THE BOEING CO

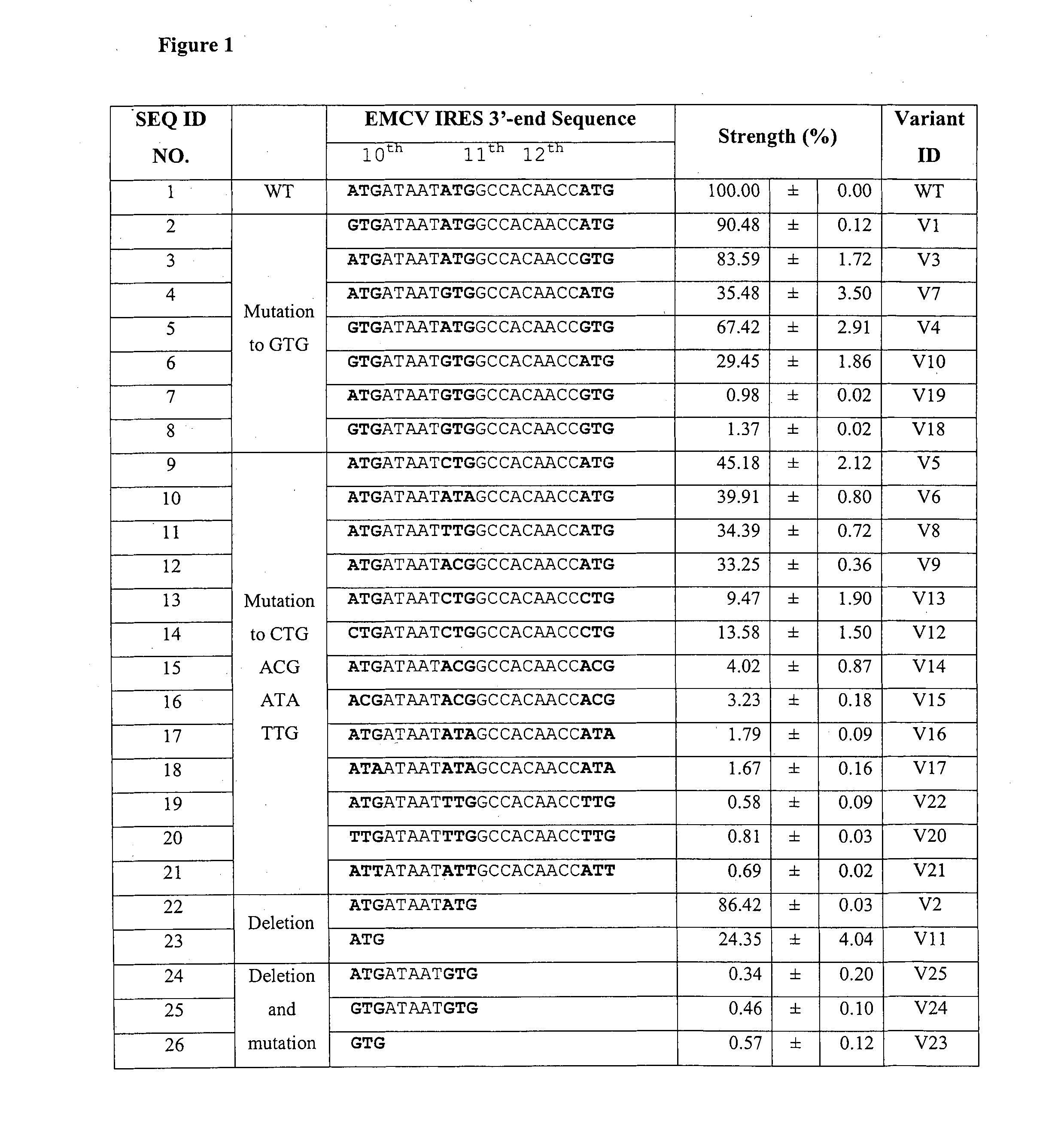

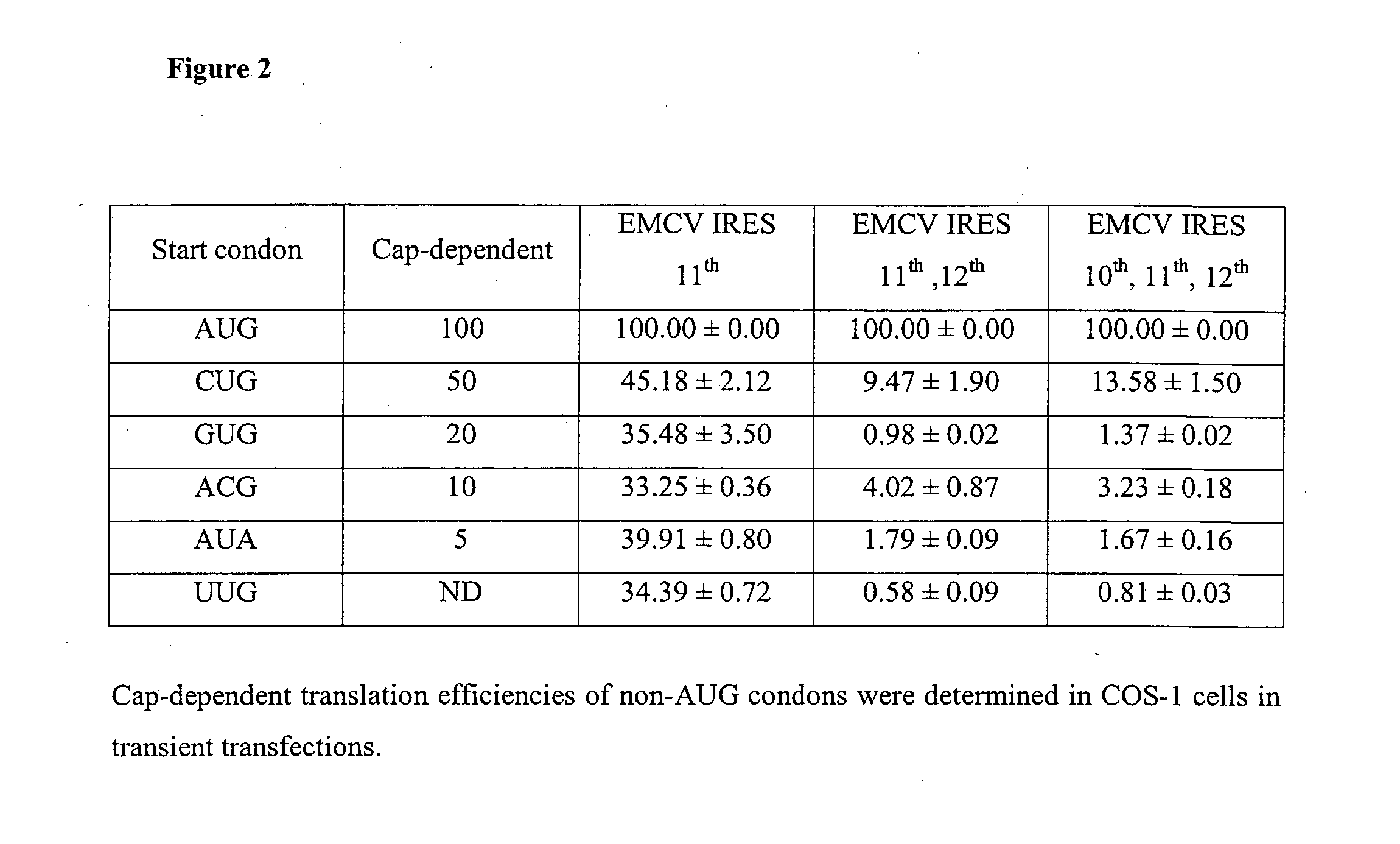

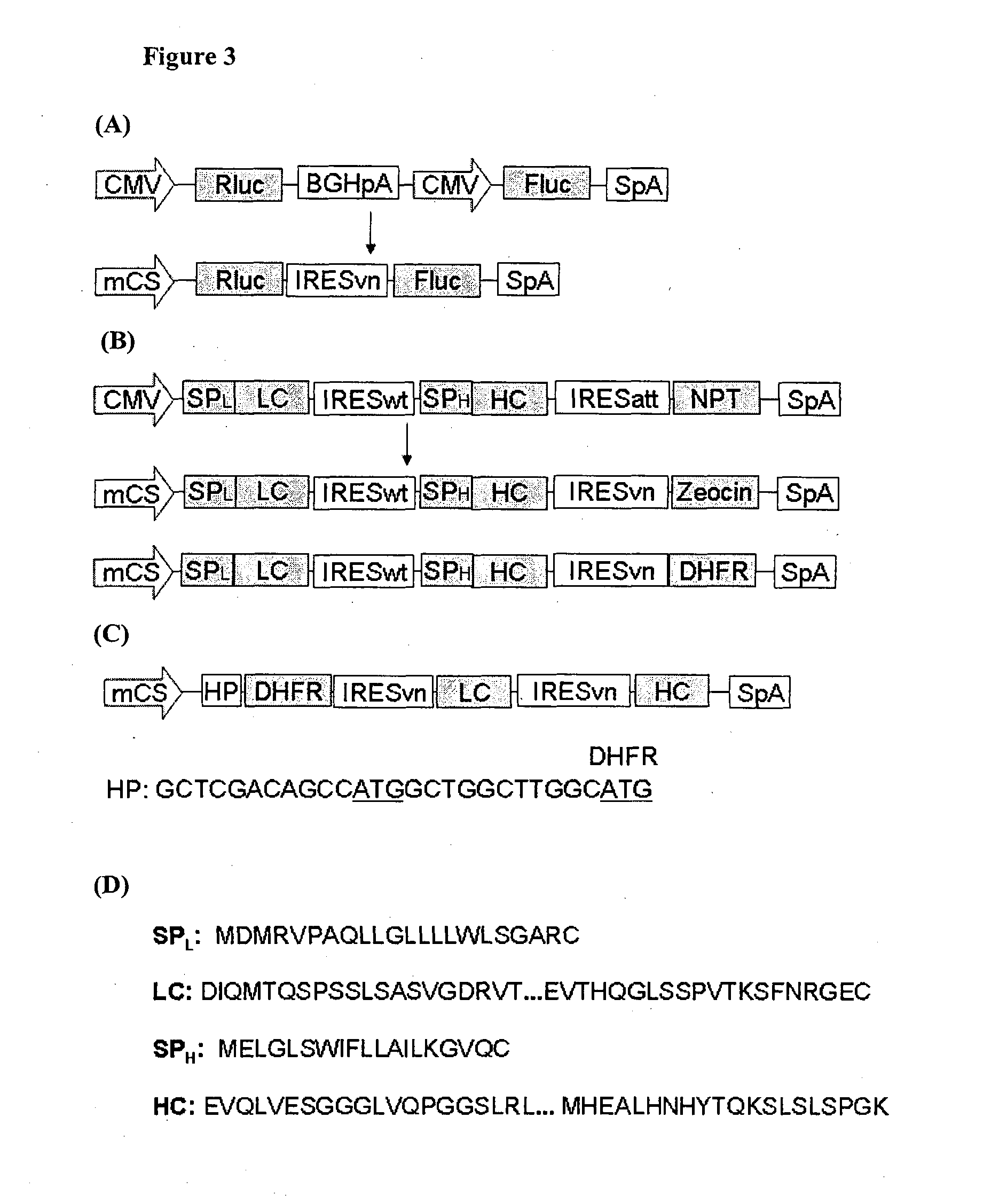

Mutated internal ribosomal entry site (IRES) for controlled gene expression

ActiveUS20160244746A1Reduce expressionReduce translationVectorsVector-based foreign material introductionGene coexpressionMutant

The present invention relates to a nucleic acid molecule comprising one or multiple mutant IRES elements. Further, the present invention relates to methods of enhancing gene expression and to methods of differentially controlling expression of one or multiple gene(s) of interest. In addition, the present invention relates to a kit for studying interactions or any application requiring co-expression of multiple genes.

Owner:AGENCY FOR SCI TECH & RES

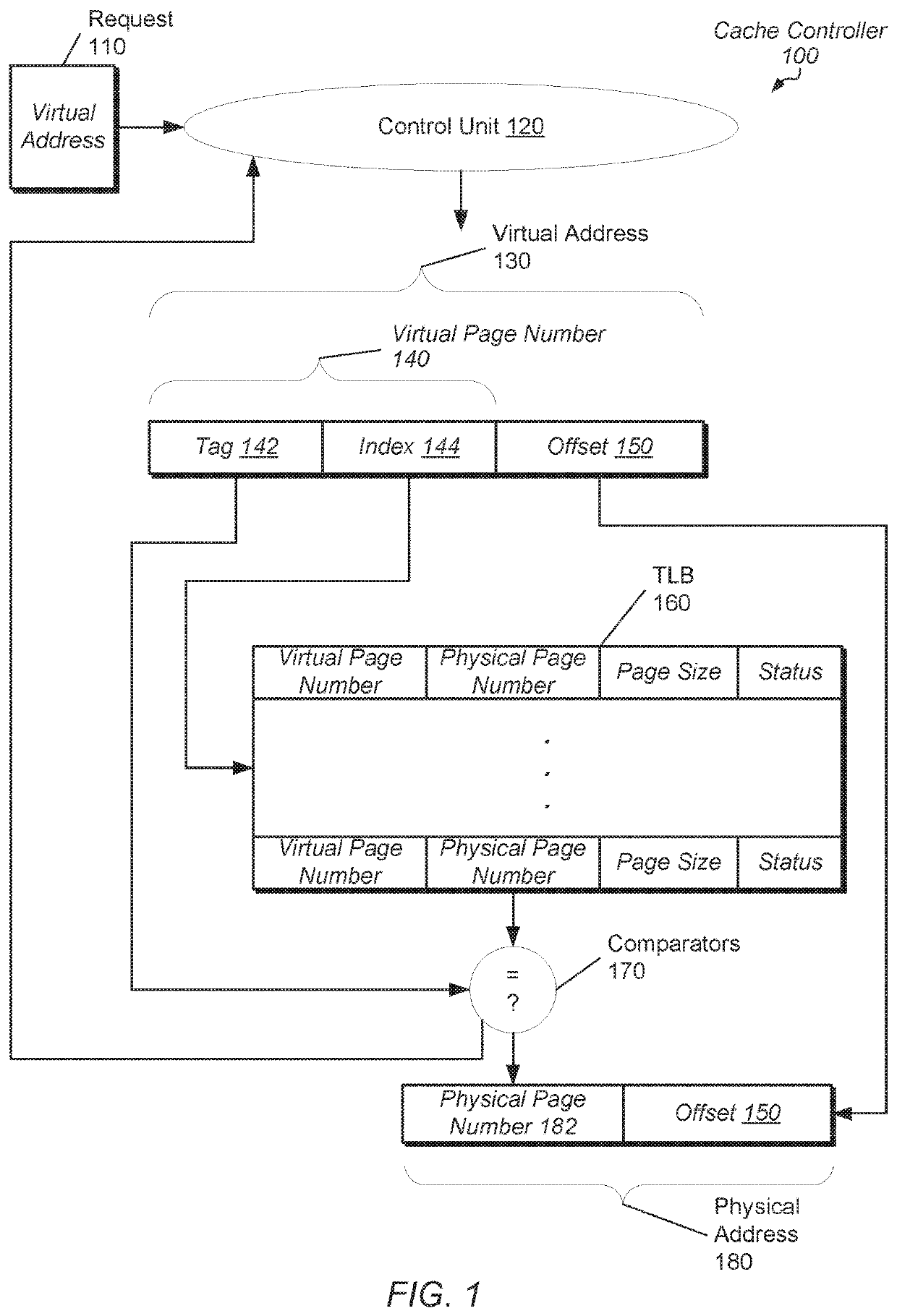

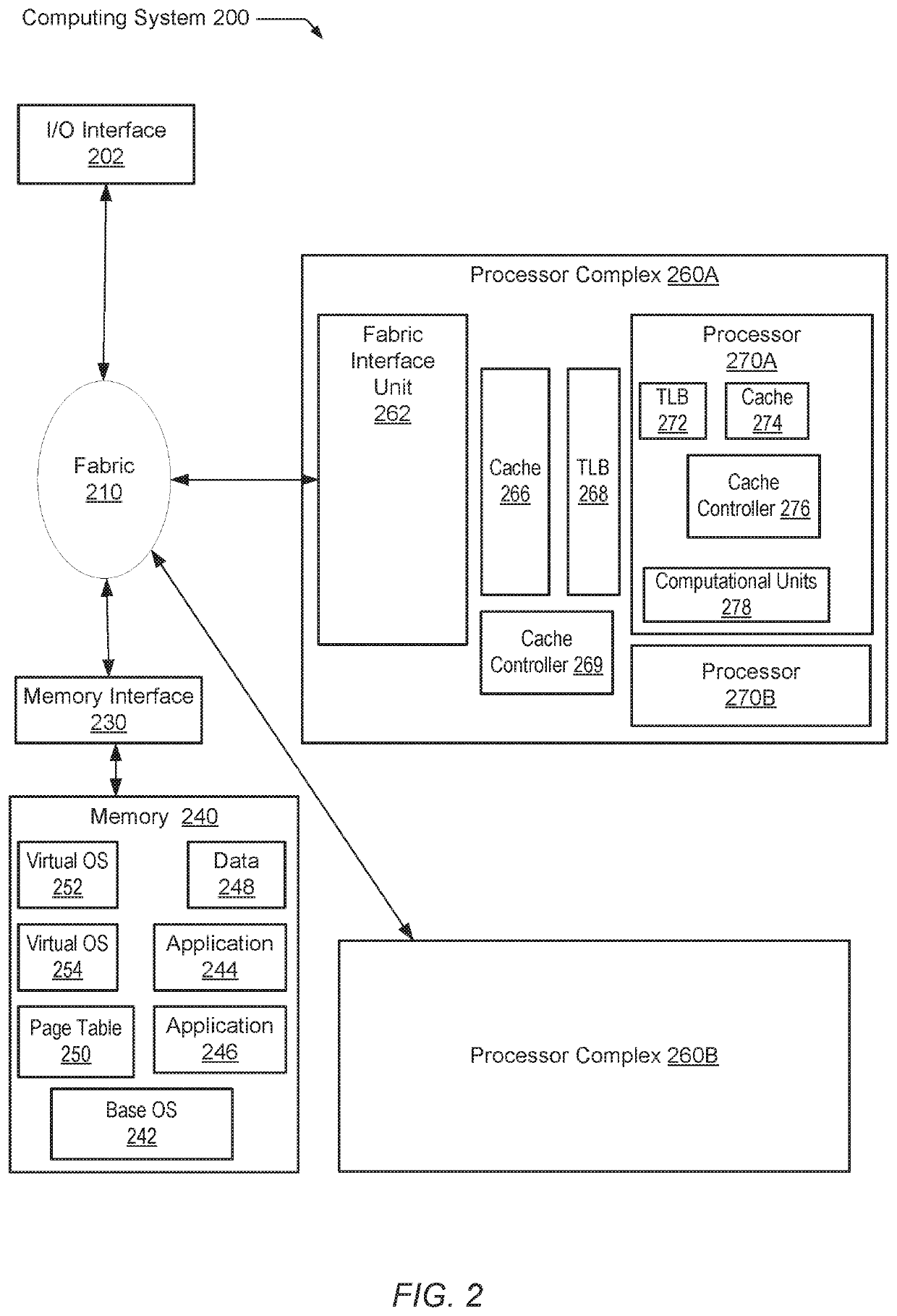

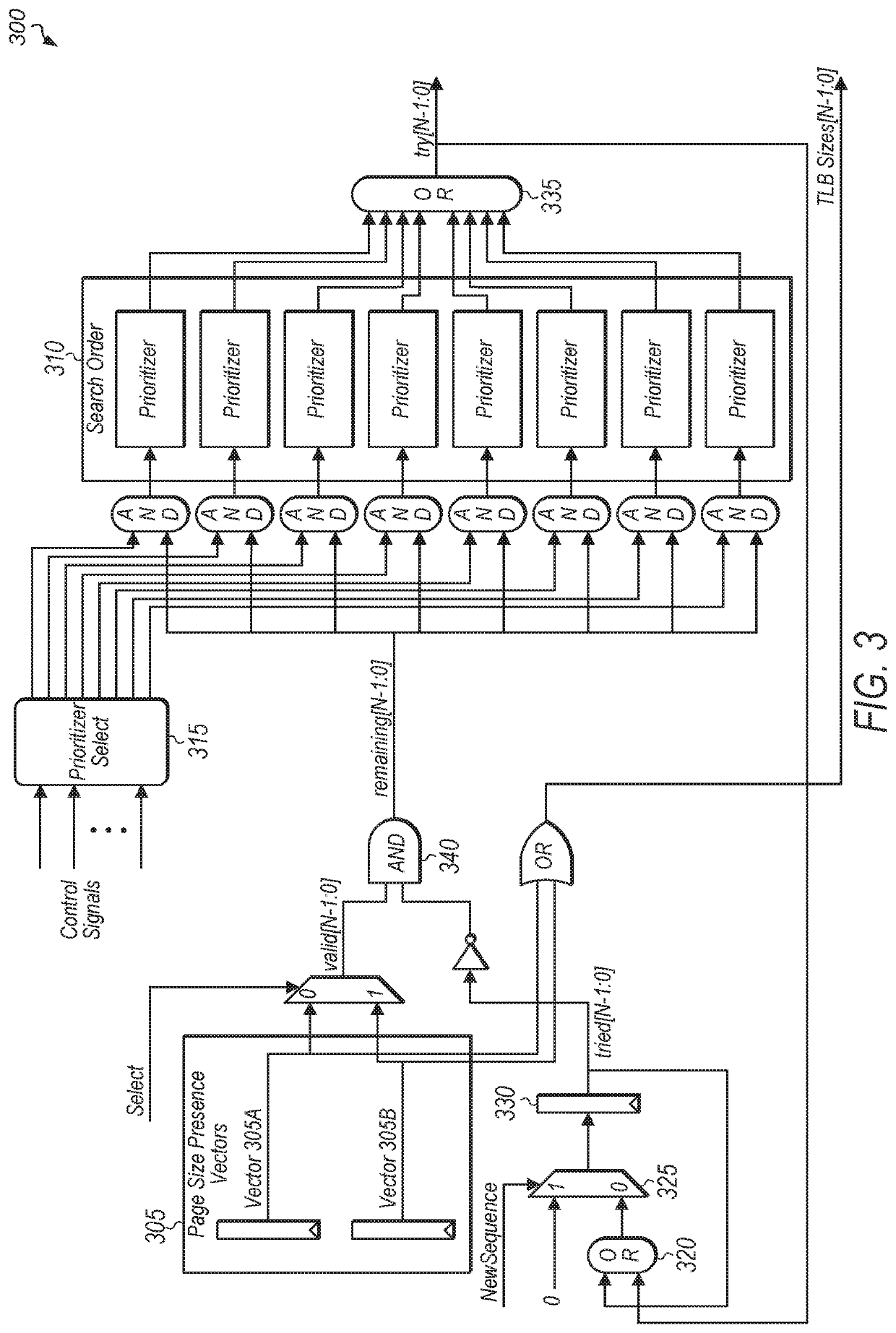

Limiting Translation Lookaside Buffer Searches Using Active Page Size

ActiveUS20220075735A1Limiting translation lookaside buffer (TLB) searchReduce in quantityMemory architecture accessing/allocationEnergy efficient computingComputational scienceParallel computing

Systems, apparatuses, and methods for limiting translation lookaside buffer (TLB) searches using active page size are described. A TLB stores virtual-to-physical address translations for a plurality of different page sizes. When the TLB receives a command to invalidate a TLB entry corresponding to a specified virtual address, the TLB performs, for the plurality of different pages sizes, multiple different lookups of the indices corresponding to the specified virtual address. In order to reduce the number of lookups that are performed, the TLB relies on a page size presence vector and an age matrix to determine which page sizes to search for and in which order. The page size presence vector indicates which page sizes may be stored for the specified virtual address. The age matrix stores a preferred search order with the most probable page size first and the least probable page size last.

Owner:APPLE INC

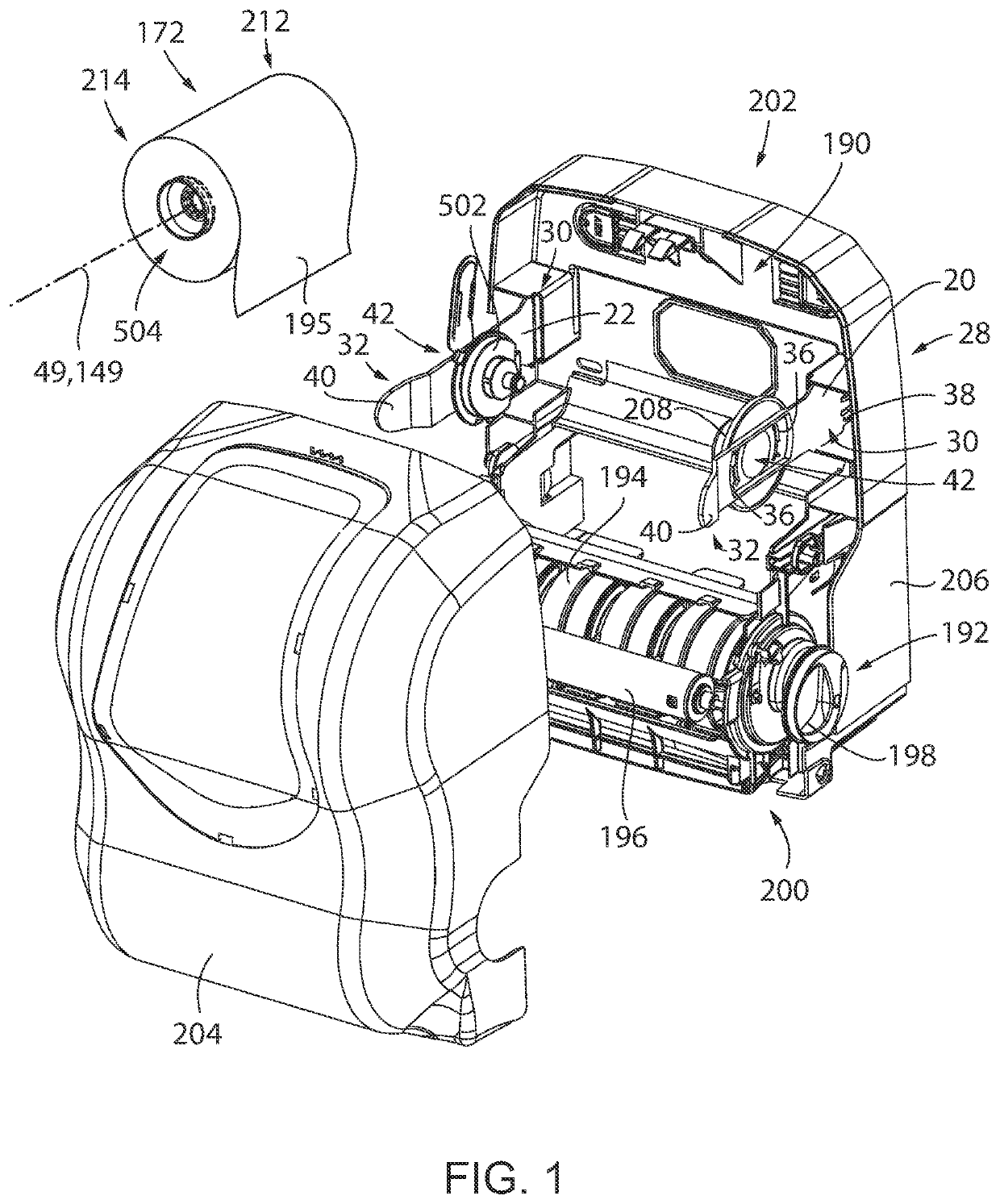

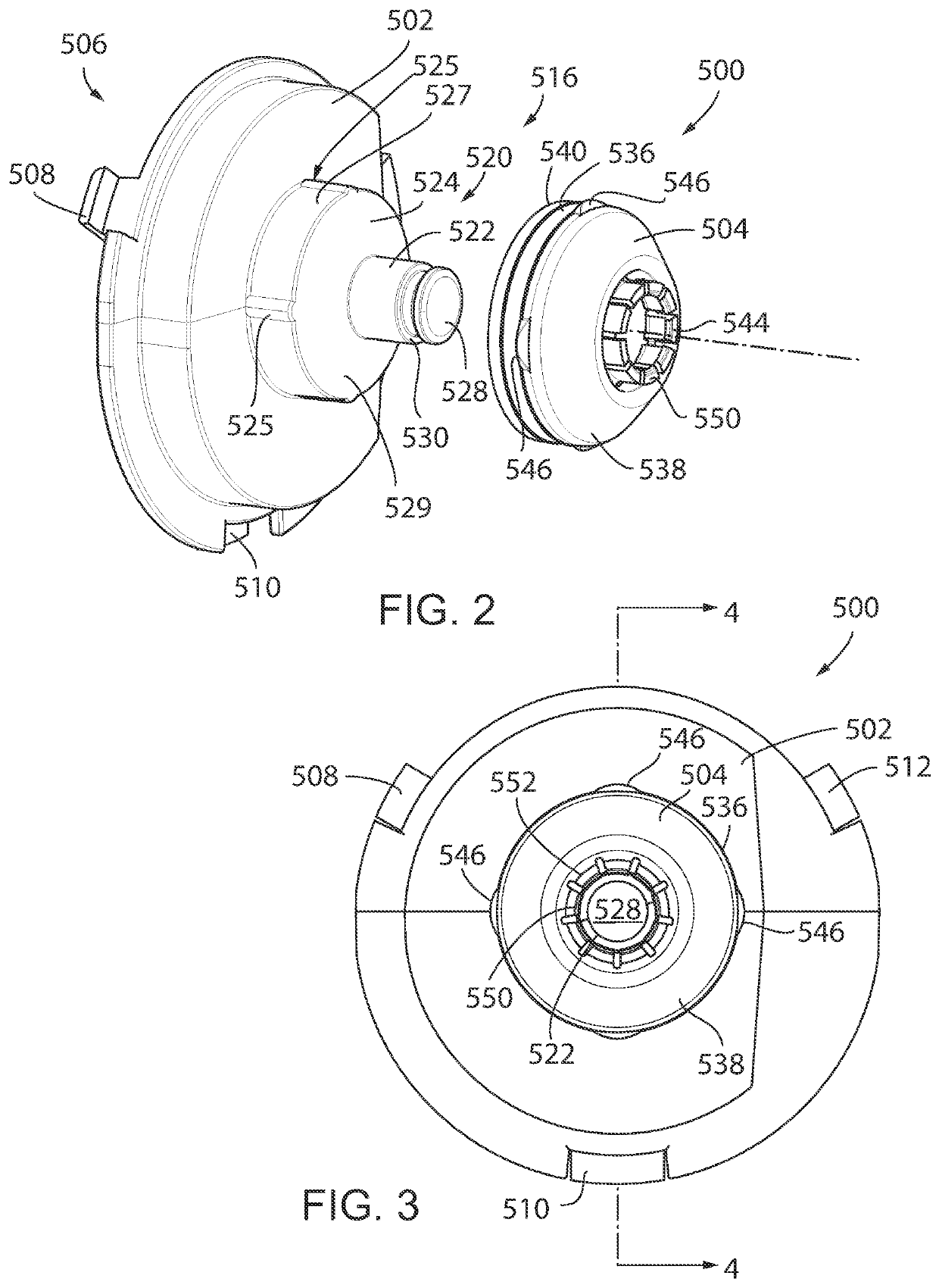

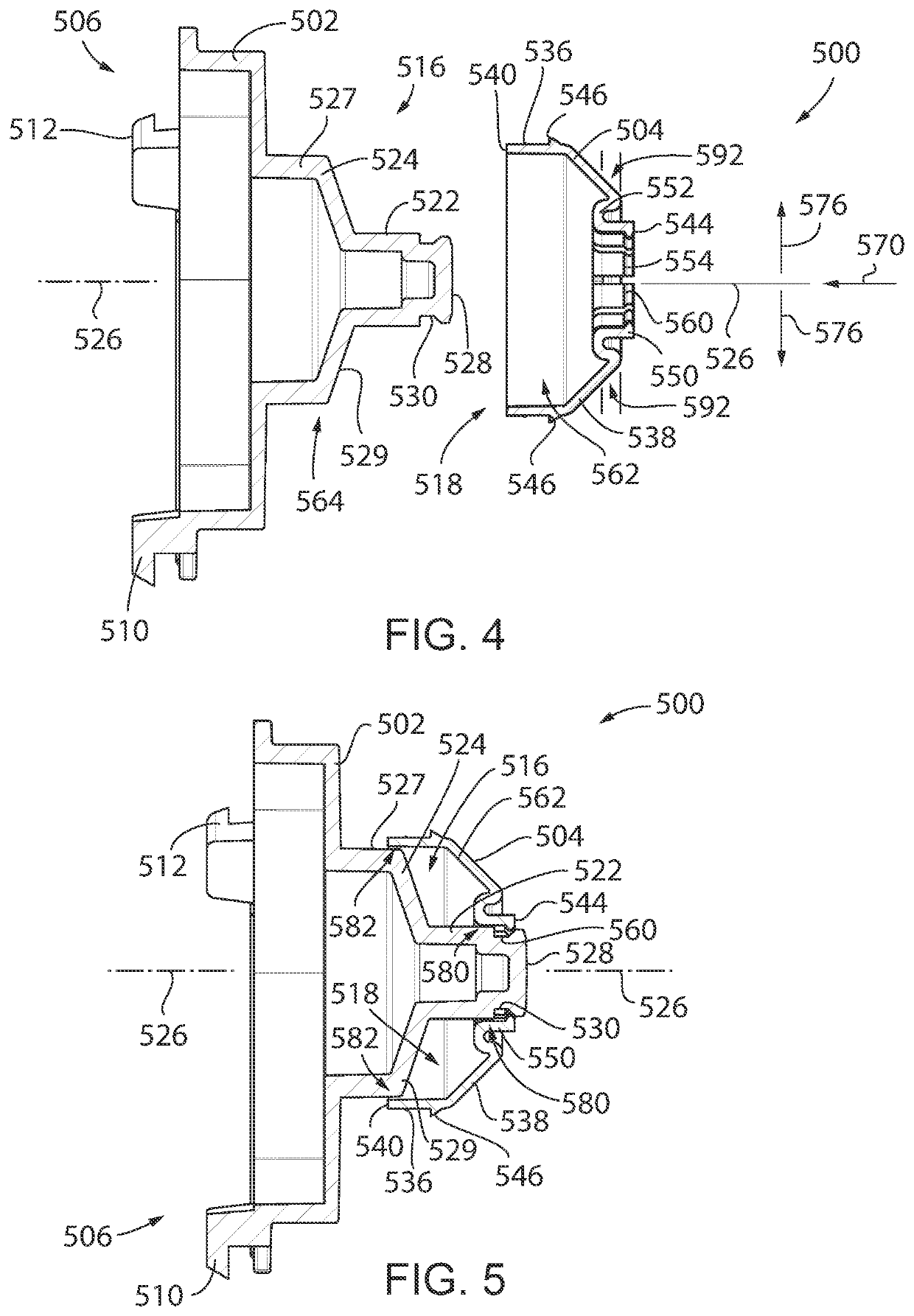

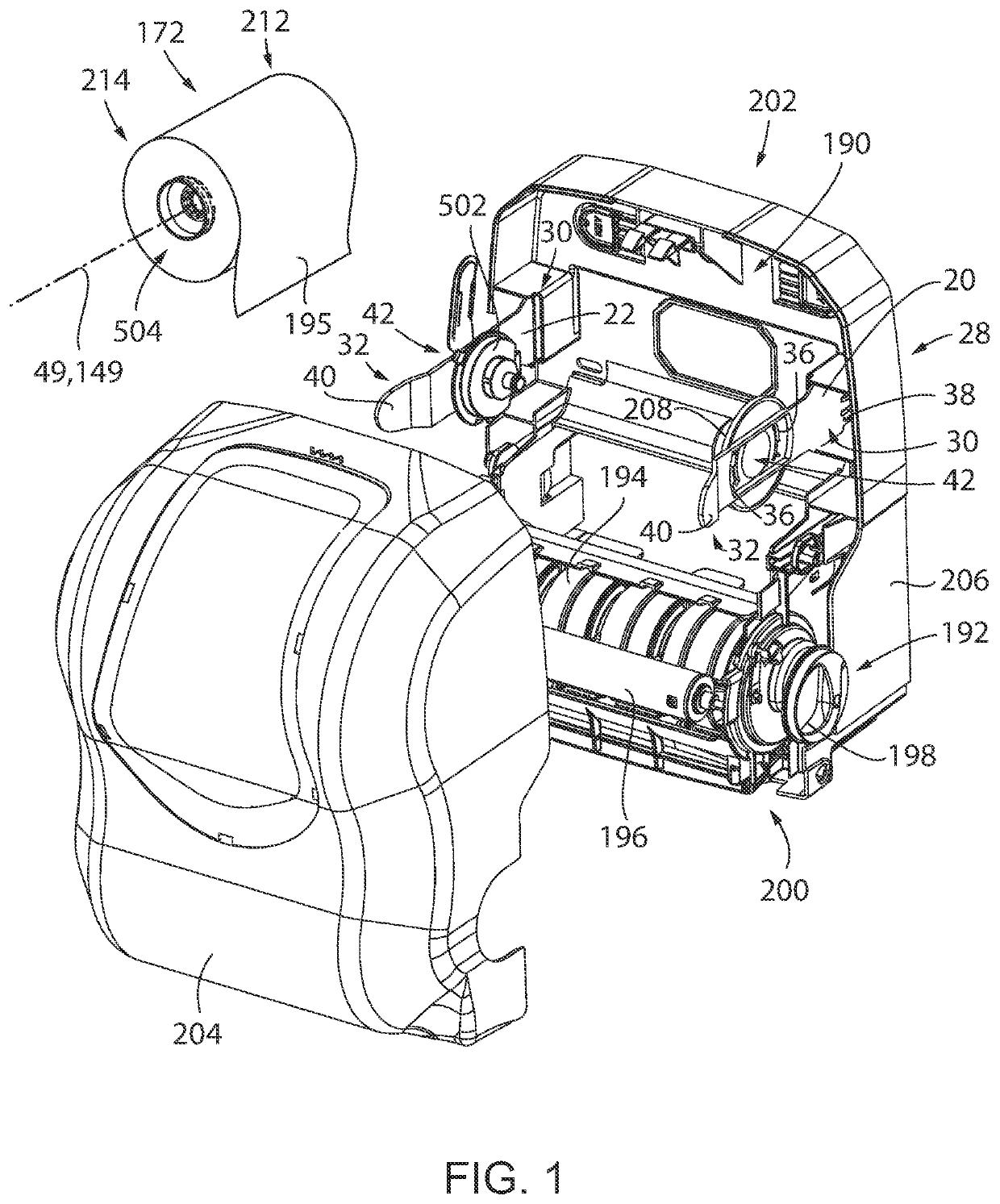

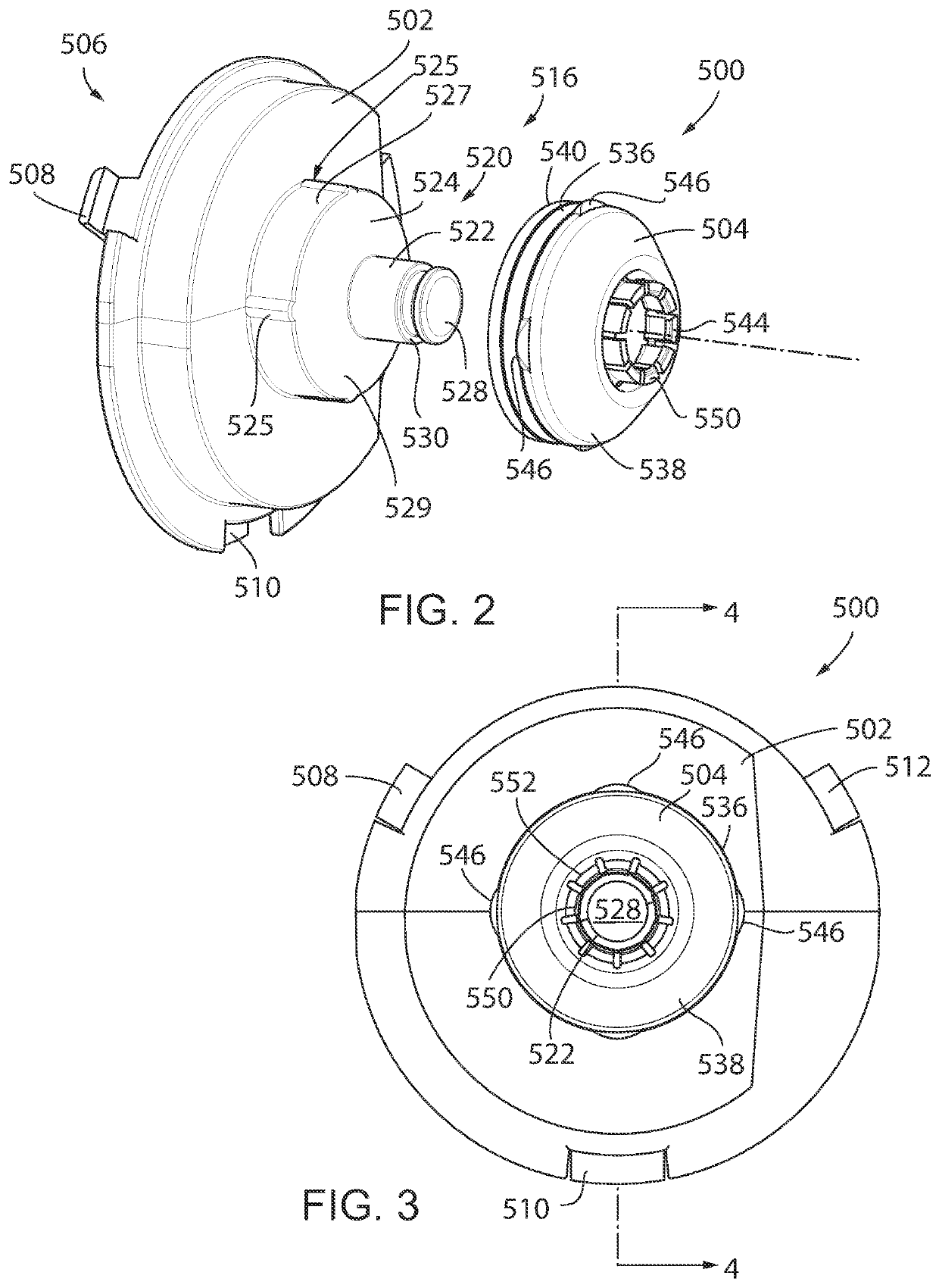

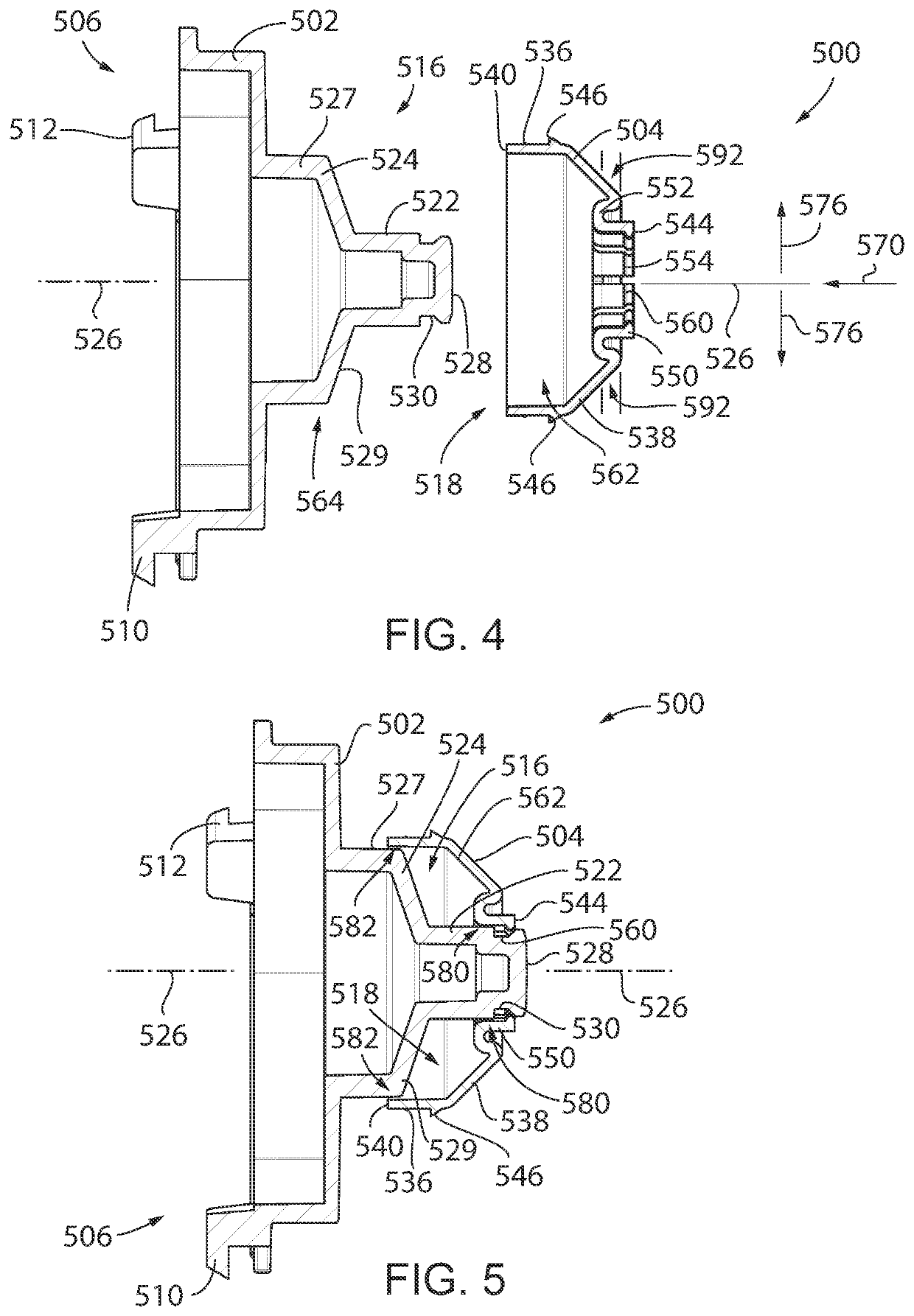

Rolled web material dispenser material lockout systems

ActiveUS11071417B2Increase flexibilityRolling resistanceDomestic applicationsStructural engineeringMechanical engineering

A lockout system that limits use of a rolled web material dispenser assembly to dispense only authorized rolls of web material. The lockout system includes a hub and an insert that cooperate with one another to define mating registration elements that removeably cooperate with one another and provide a rotational cooperation therebetween when engaged with one another. The insert is shaped to be received in a bore of discrete authorized roll of web material. In one embodiment, the insert includes an overlapping portion formed between opposing ends of the insert and preferably between rotational bearing surfaces associated therewith. In another embodiment, the hub supported by the dispenser is moveable relative to the dispenser and renders the hub unavailable for operative cooperation with inserts that are not configured for cooperation therewith.

Owner:SAN JAMAR INC

Rolled web material dispenser material lockout systems

ActiveUS20200323402A1Increase flexibilityRolling resistanceDomestic applicationsStructural engineeringMechanical engineering

A lockout system that limits use of a rolled web material dispenser assembly to dispense only authorized rolls of web material. The lockout system includes a hub and an insert that cooperate with one another to define mating registration elements that removeably cooperate with one another and provide a rotational cooperation therebetween when engaged with one another. The insert is shaped to be received in a bore of discrete authorized roll of web material. In one embodiment, the insert includes an overlapping portion formed between opposing ends of the insert and preferably between rotational bearing surfaces associated therewith. In another embodiment, the hub supported by the dispenser is moveable relative to the dispenser and renders the hub unavailable for operative cooperation with inserts that are not configured for cooperation therewith.

Owner:SAN JAMAR INC

An installation method for a curved steel reticulated shell structure with a gradual change in the starting span of the gable wall

ActiveCN111809893BGuarantee the stability of the pullPrevent slidingBuilding material handlingPurlinControl theory

The invention discloses a method for installing a curved steel reticulated shell structure with a gable starting span gradually changing, comprising the following steps: a. construction preparation; b. assembling block by block; c. installing a purlin system and a roof panel structure. The invention realizes the connection between the steel wire rope and the ball joint through the steel wire rope pulling device, ensures the stability of the steel wire rope pulling and setting, prevents the steel wire rope from sliding, ensures the verticality of the vertical gable structure, and avoids the rods of the reticulated shell structure during the steel wire rope pulling. At the same time, in the present invention, the ball joints inside the gable reticulated shell unit are supported by the temporary fixing device to increase the construction safety performance, and the temporary fixing device can also eliminate the influence of the site flatness error on the installation accuracy, which is more conducive to the ball joints The installation and construction between temporary fixtures are convenient for construction and operation, flexible and convenient for on-site construction, easy to adjust accuracy errors, high construction efficiency, guaranteed installation quality, reduced safety hazards for high-altitude operations, and reduced construction costs.

Owner:浙江中南绿建科技集团有限公司

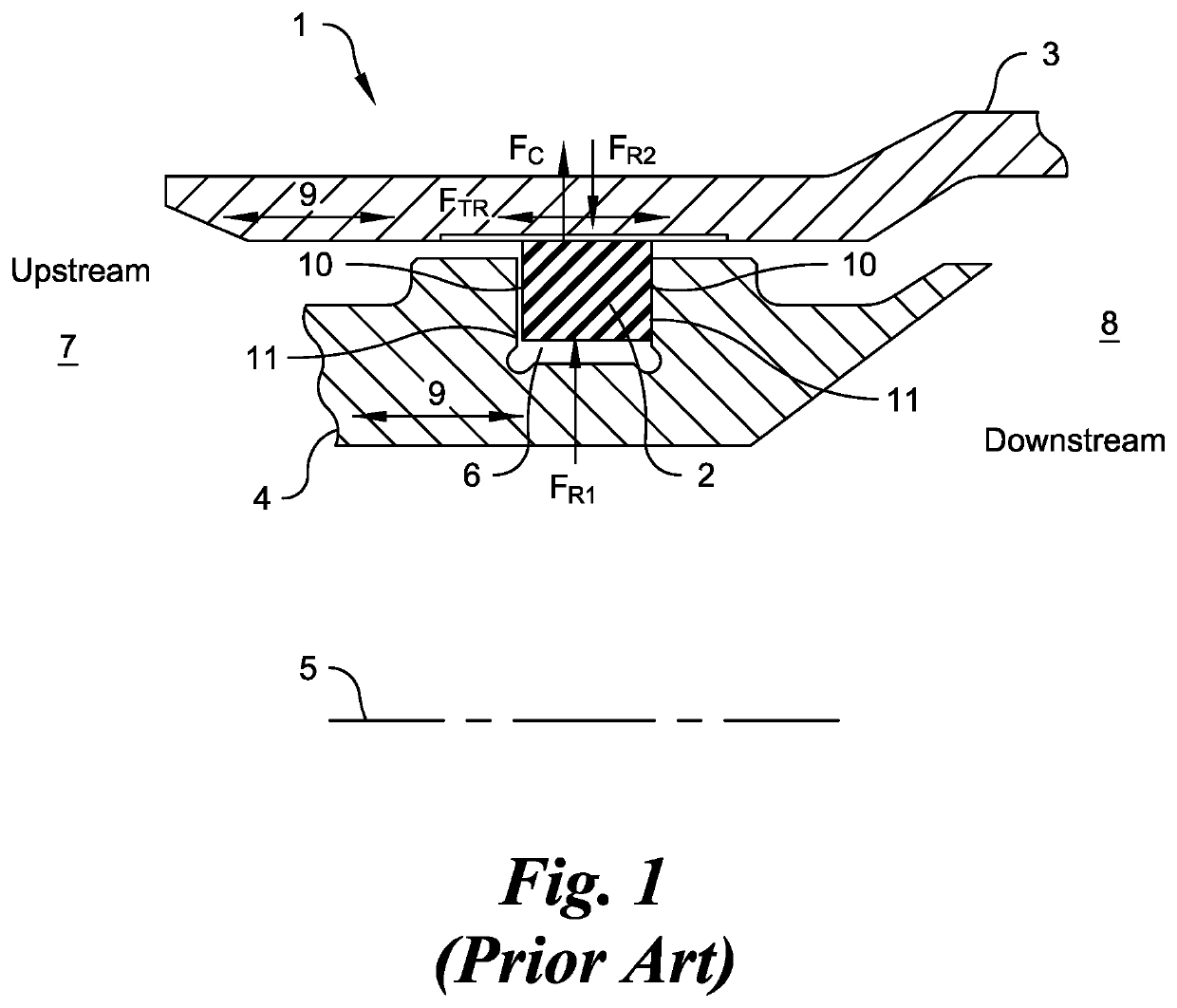

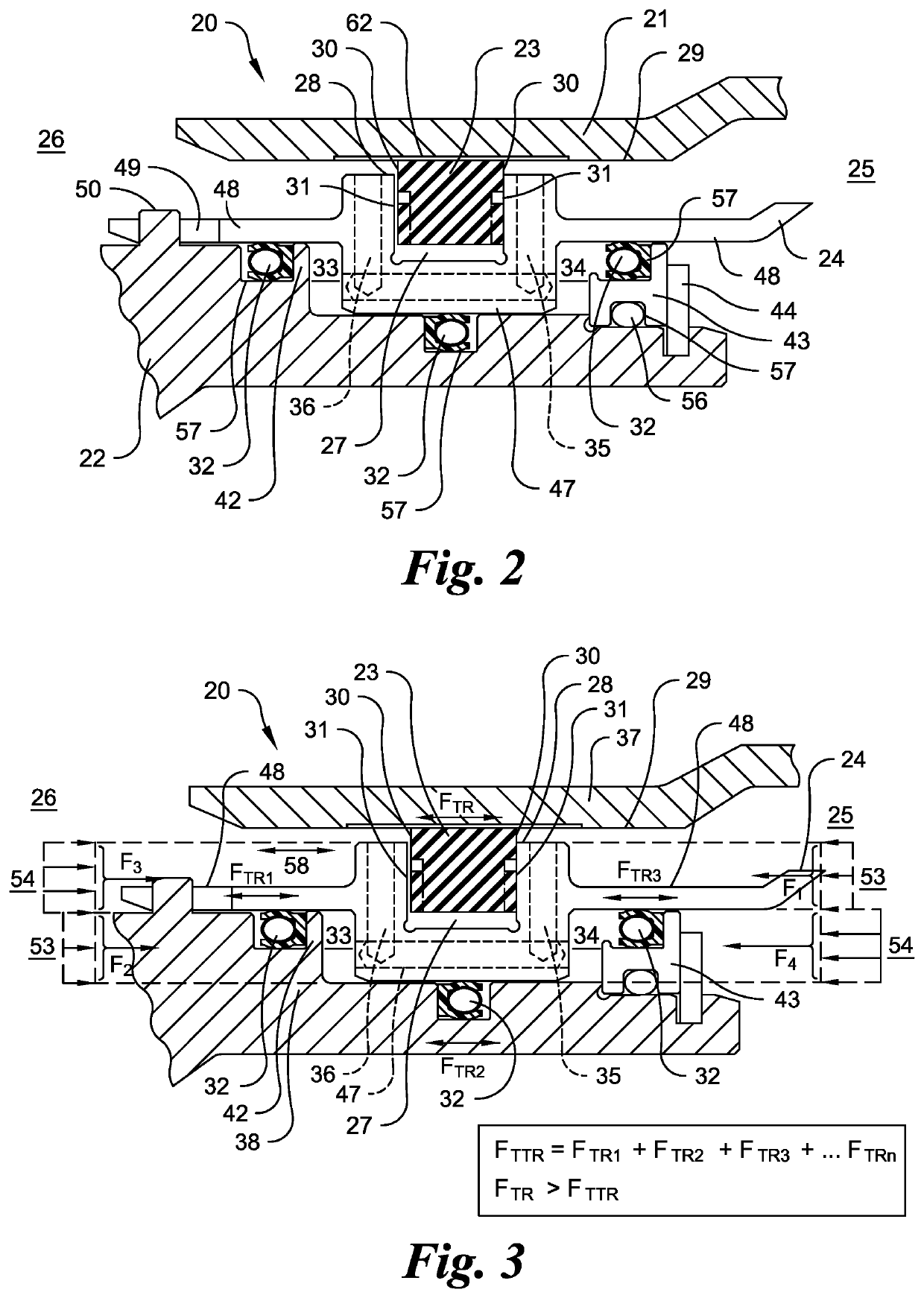

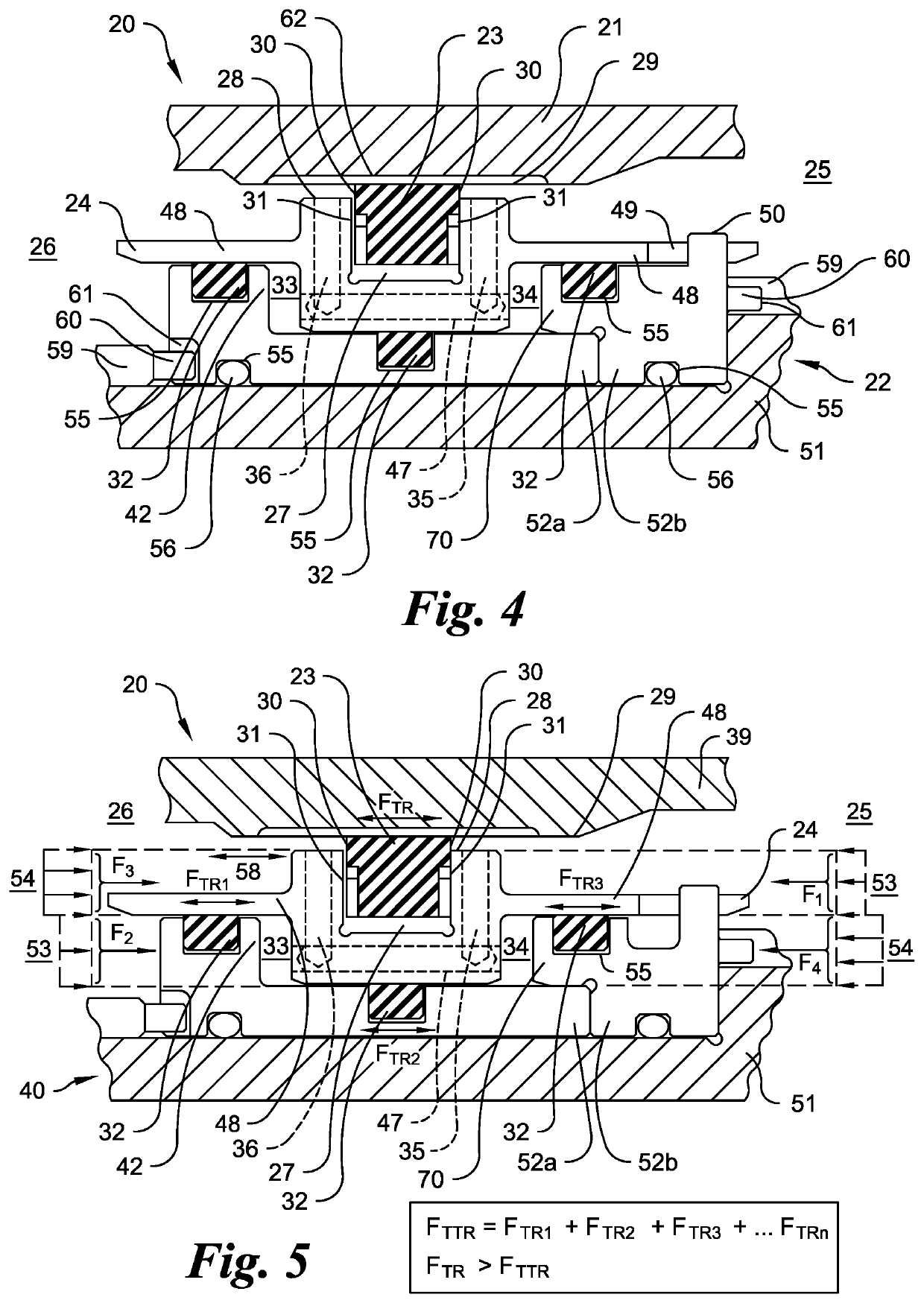

Intershaft Seal Assembly with Pressure-Balanced Translatable Carrier

ActiveUS20220136447A1Mitigating frictional face wearFrictional wearEngine sealsGas turbine plantsEngineeringHigh pressure chamber

An intershaft seal assembly for use between a rotatable outer structure and an inner structure within a turbine engine is presented. The assembly includes a primary sealing ring, a translatable carrier, a secondary sealing ring(s), a lower-pressure chamber, a higher-pressure chamber, a first channel(s), and a second channel(s). The primary ring is disposed within and extends from a circumferential groove about the carrier so as to sealingly engage the rotatable outer structure. The primary ring rotates within the groove and with the rotatable outer structure. Each secondary ring is interposed between the carrier and the inner structure. The carrier slidingly contacts the secondary ring(s). The lower-pressure chamber is generally defined by the carrier and the inner structure adjacent to a higher-pressure side. The higher-pressure chamber is generally defined by the carrier and the inner structure adjacent to a lower-pressure side. Each first channel traverses the carrier so that a gas from the lower-pressure side may enter the lower-pressure chamber. Each second channel traverses the carrier so that a gas from the higher-pressure side may enter the higher-pressure chamber. The sum of the translation-resistant forces (FTTR) encountered by the carrier is less than the translation-resistance force (FTR) encountered by the primary seal ring.

Owner:STEIN SEAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com