Patents

Literature

1335 results about "Purlin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In architecture, structural engineering or building, a purlin (or historically purline, purloyne, purling, perling) is any longitudinal, horizontal, structural member in a roof except a type of framing with what is called a crown plate. In traditional timber framing there are three basic types of purlin: purlin plate, principal purlin and common purlin.

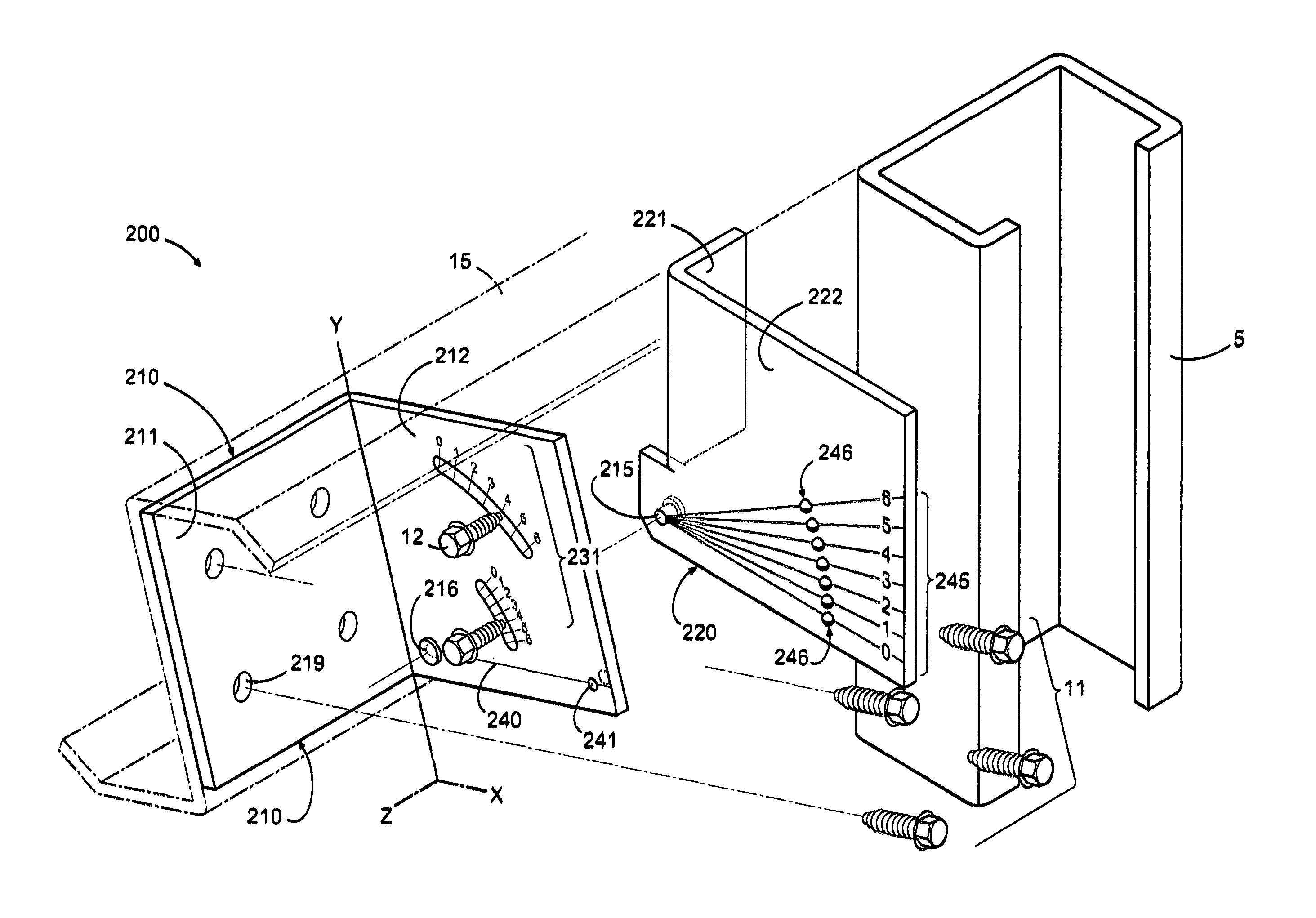

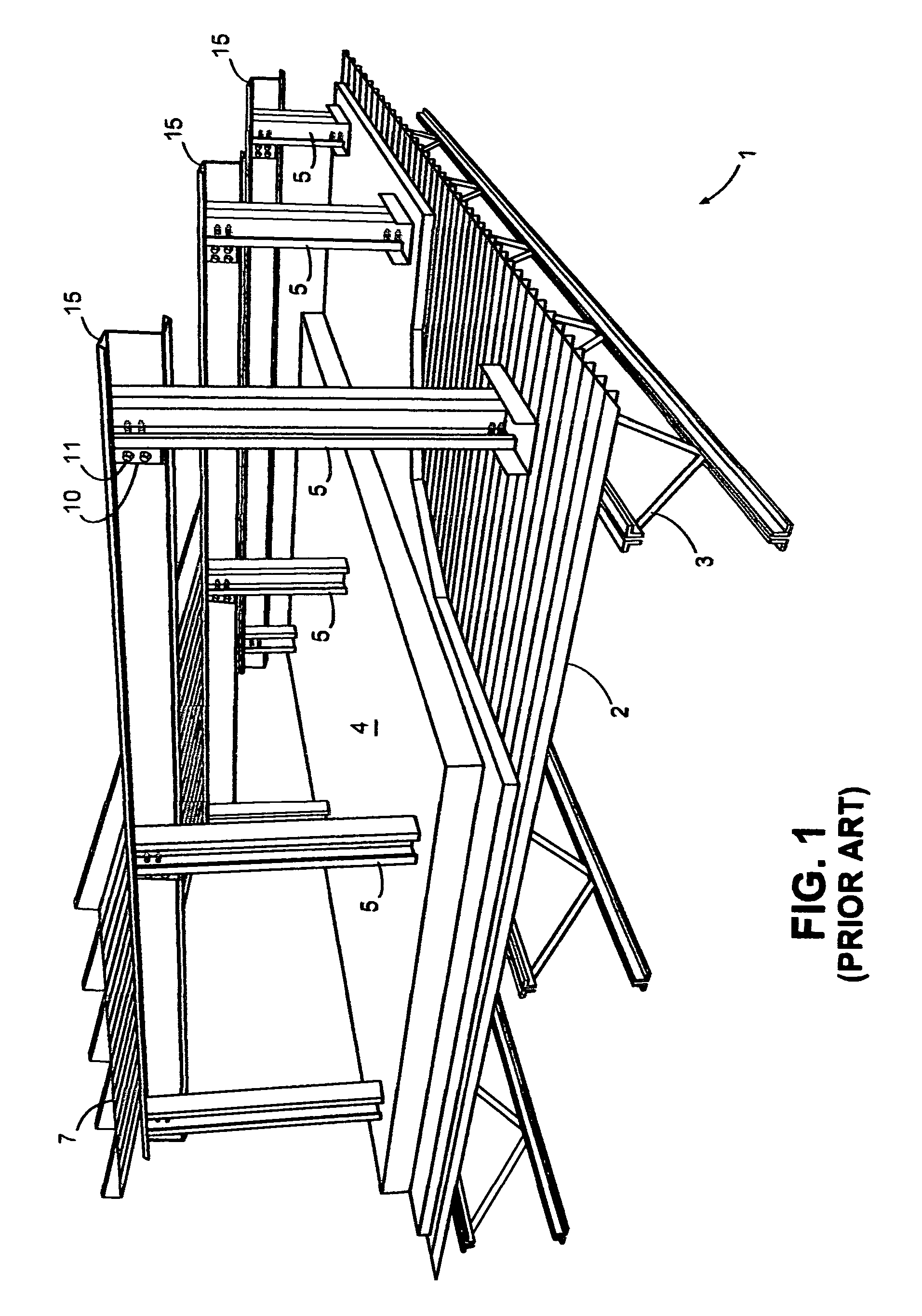

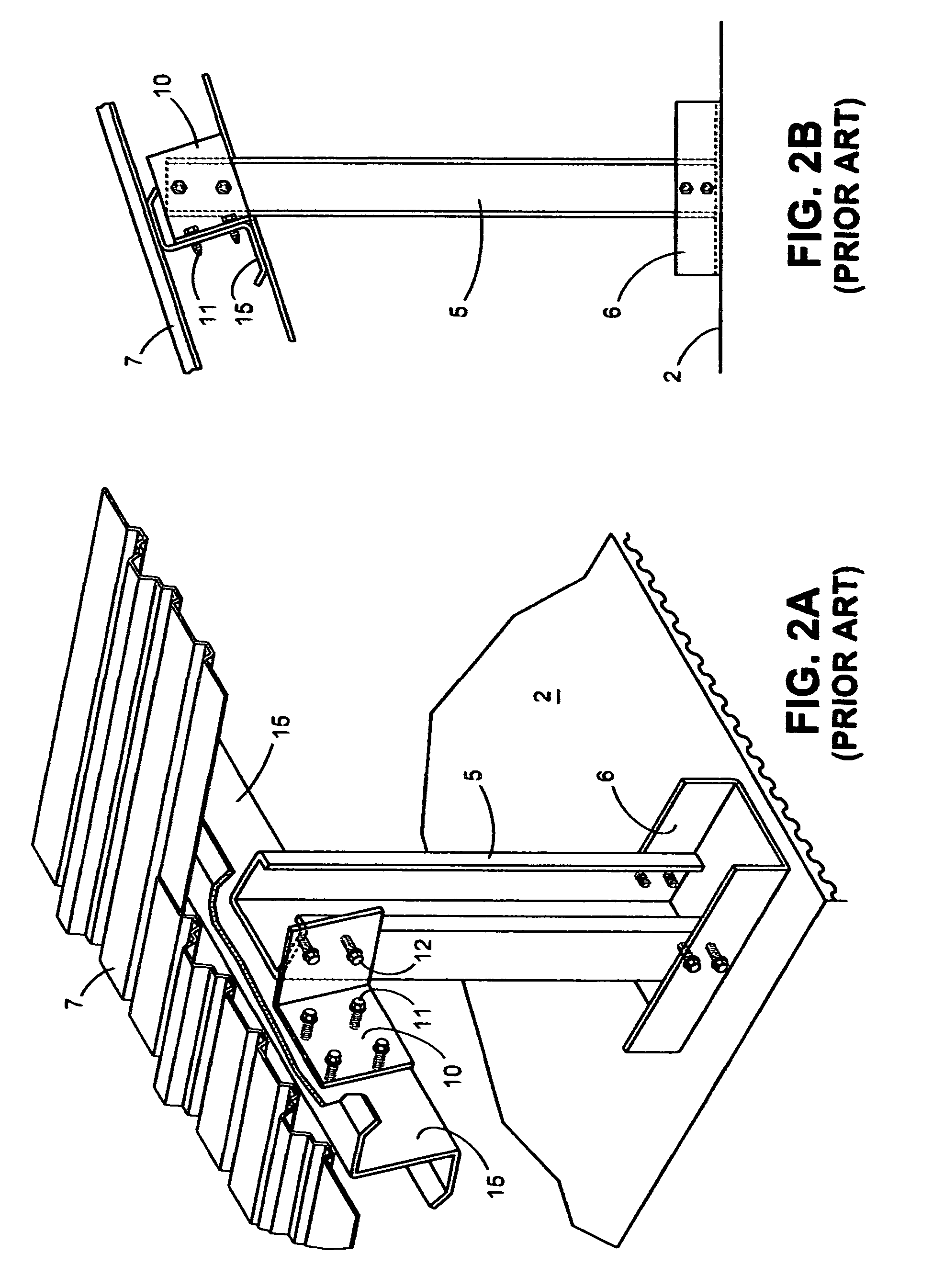

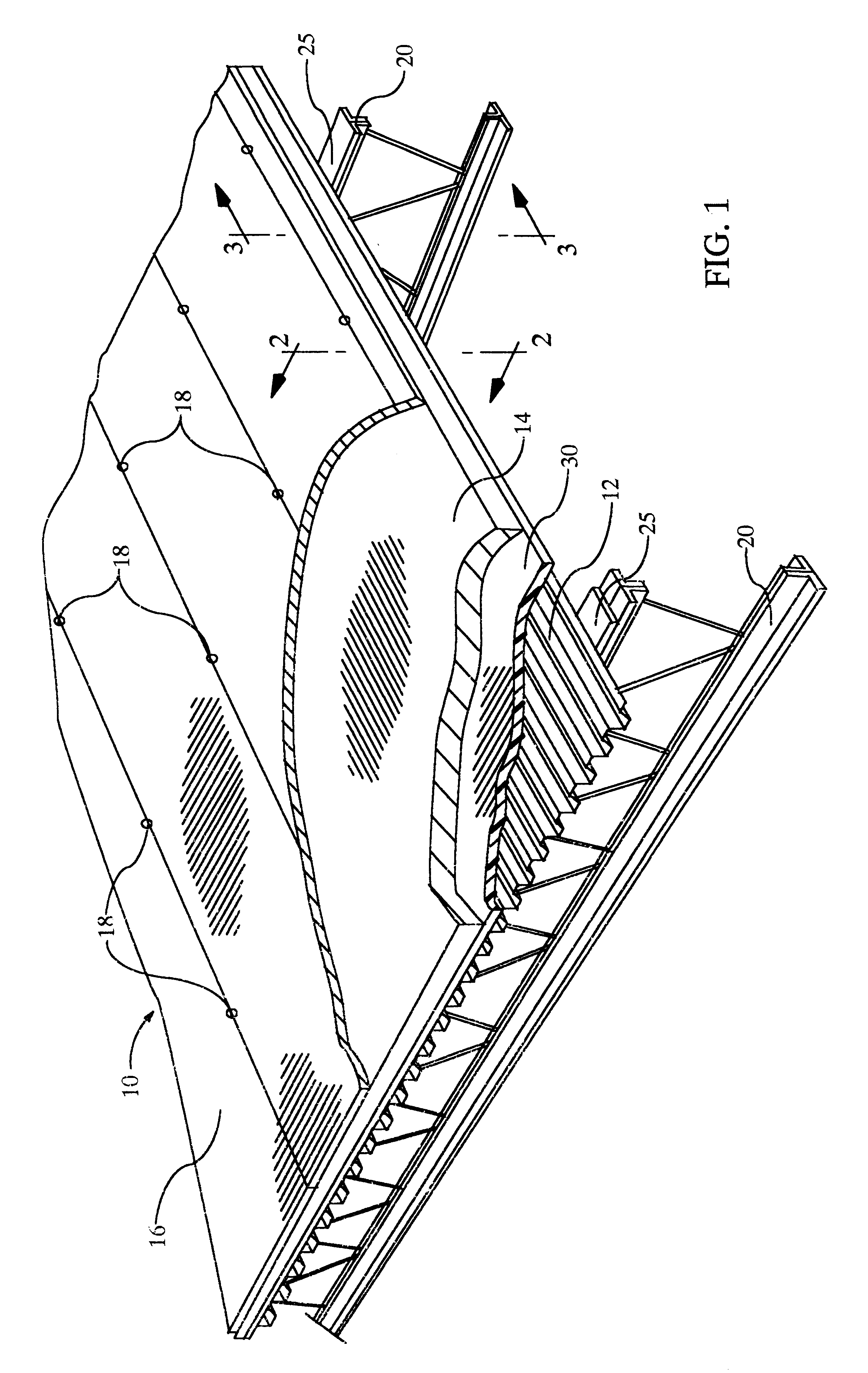

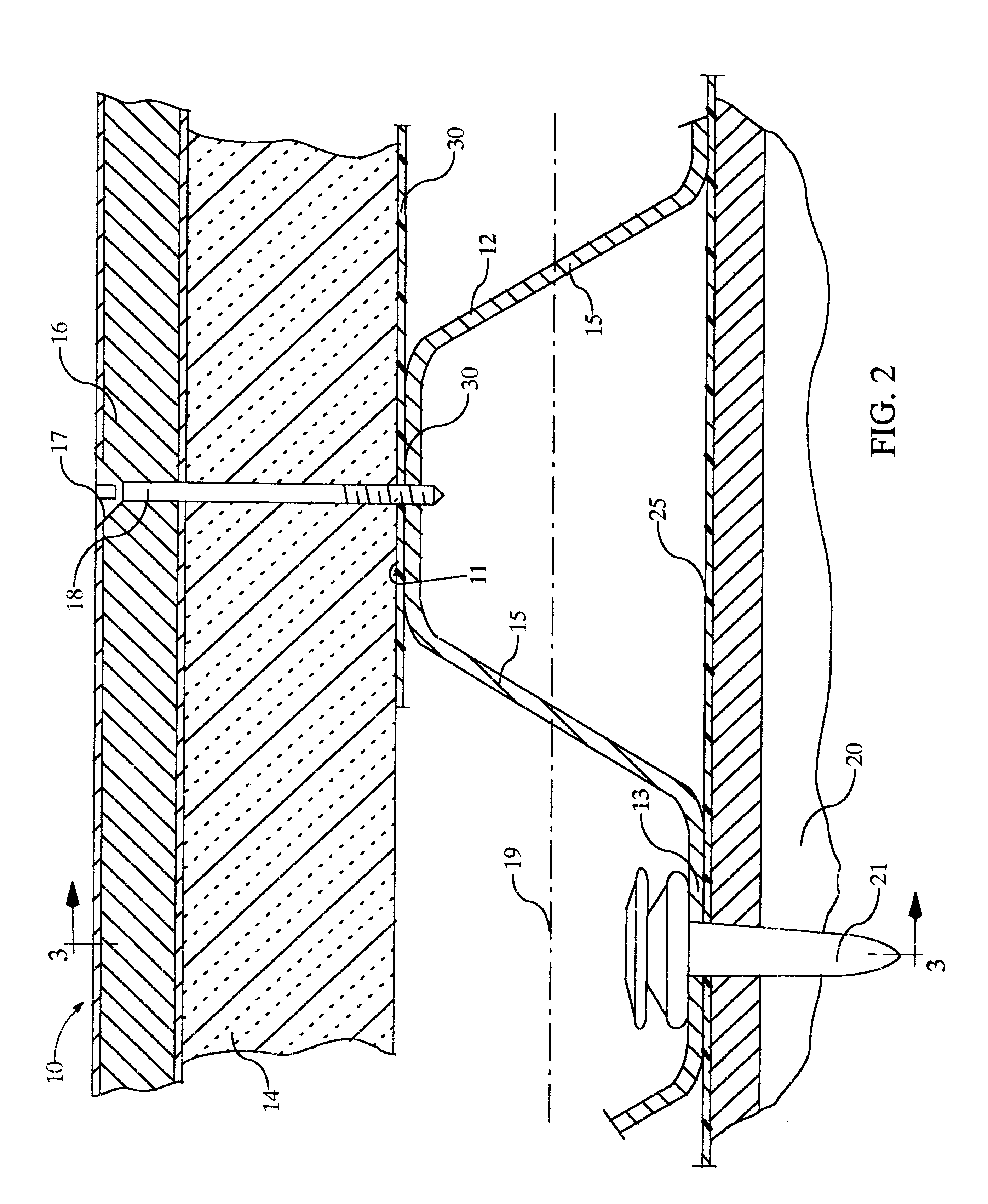

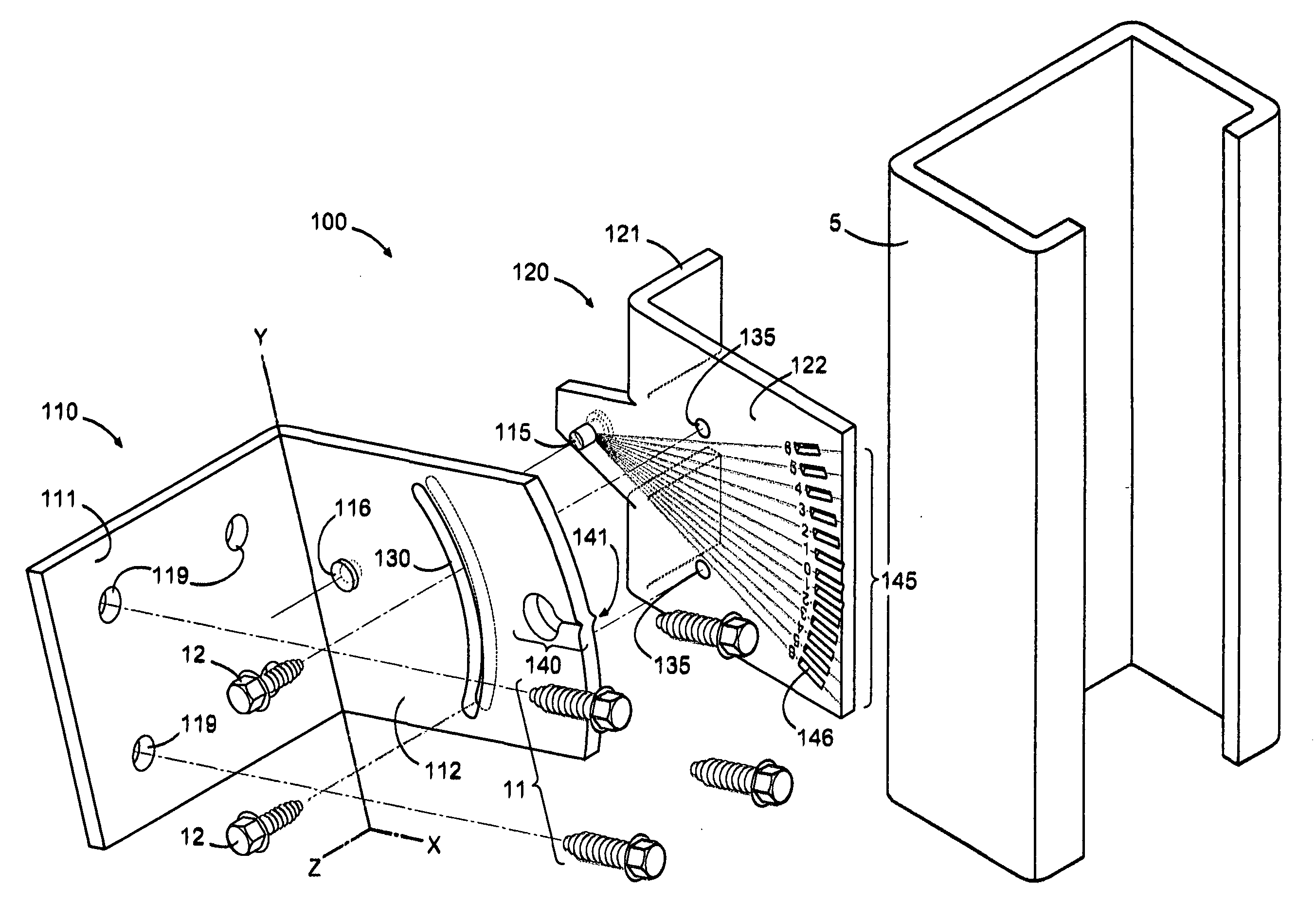

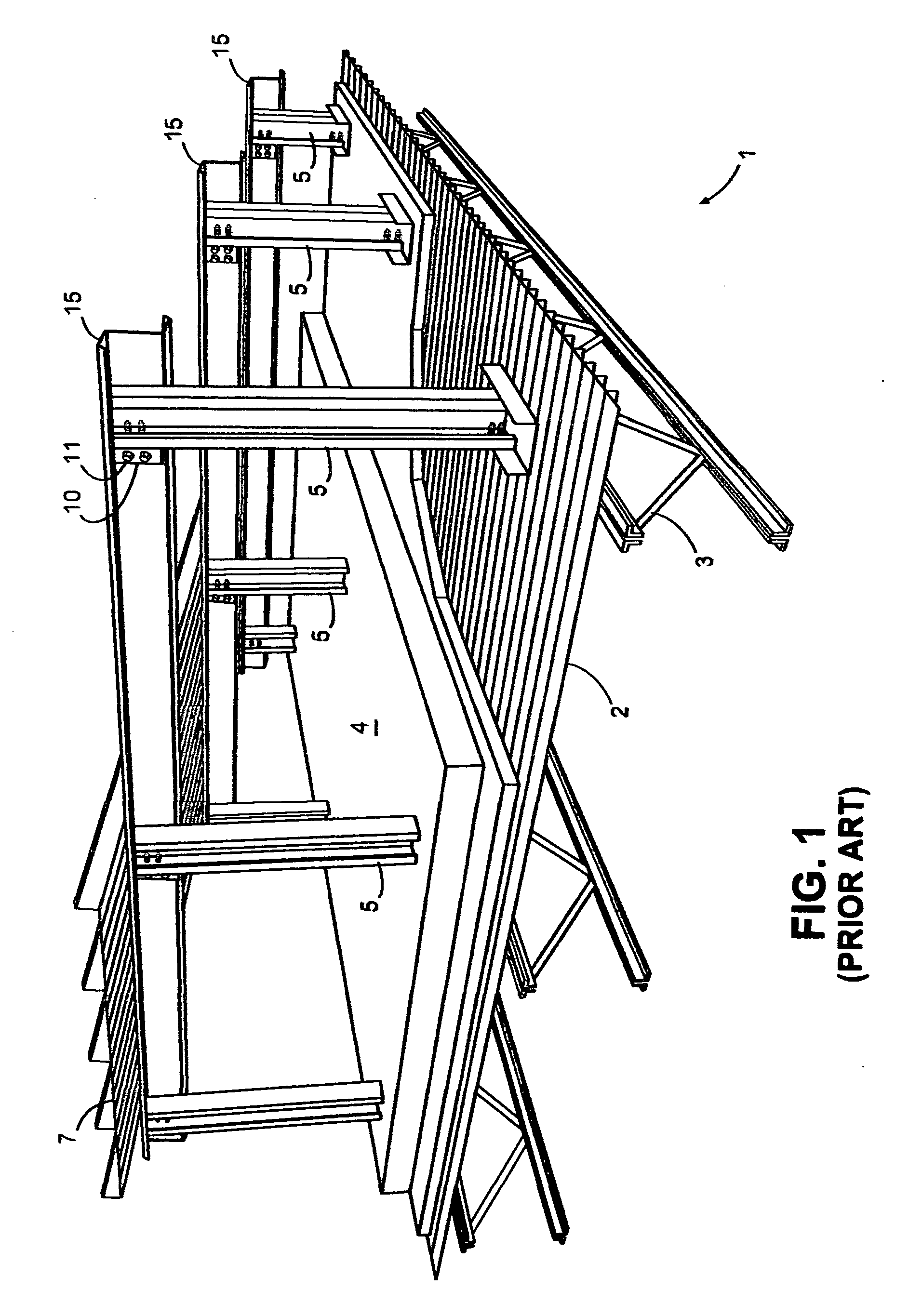

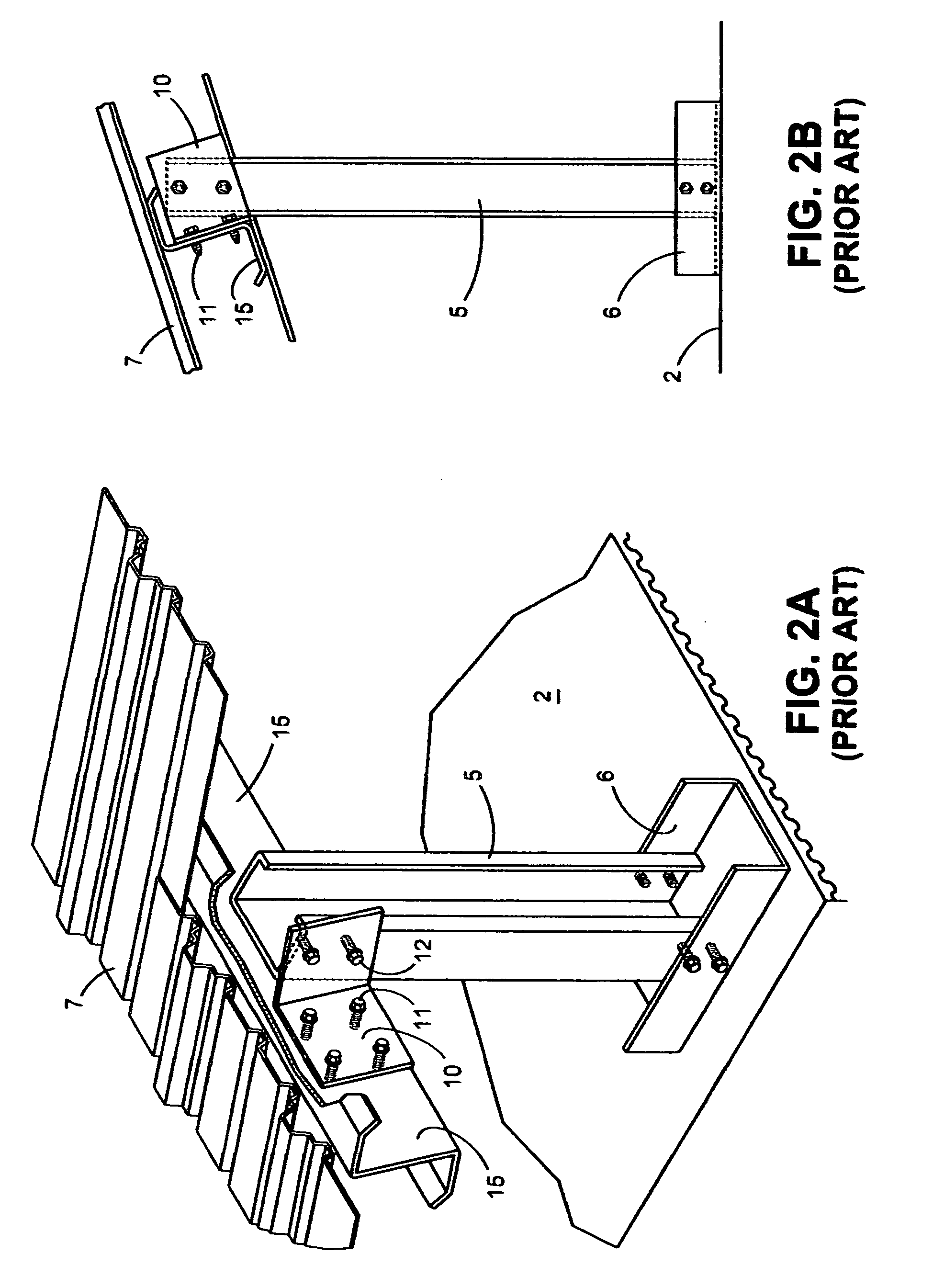

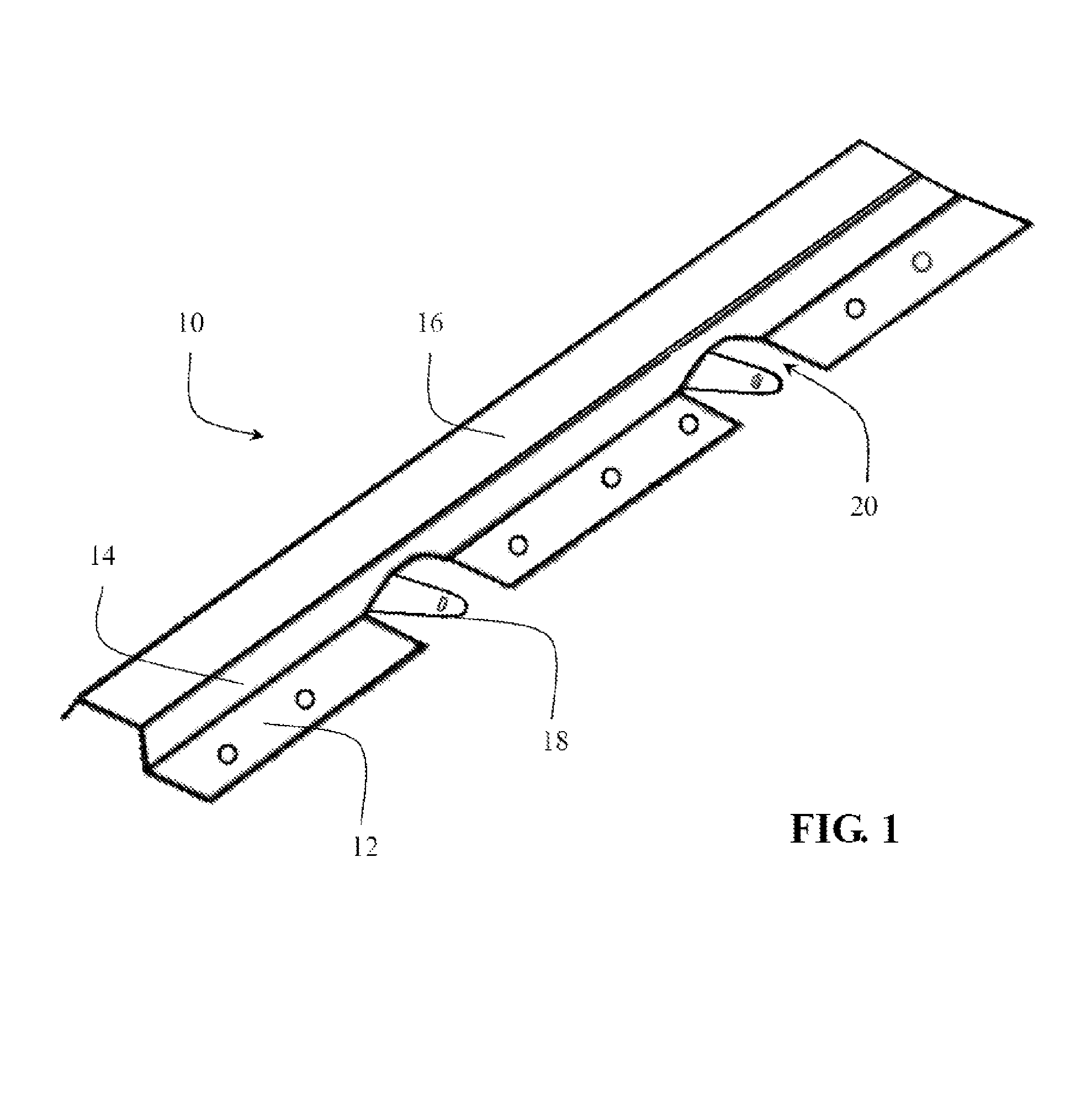

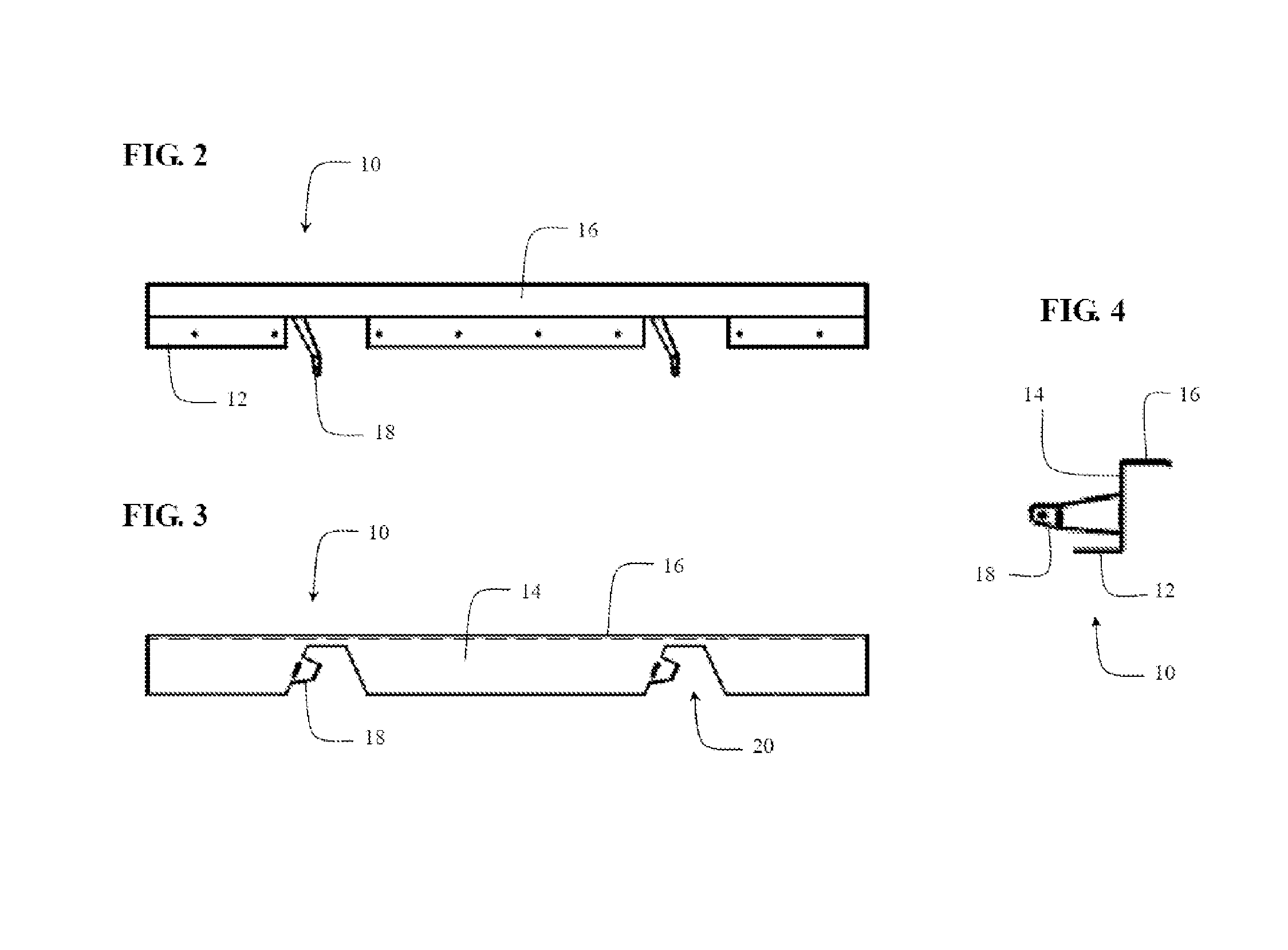

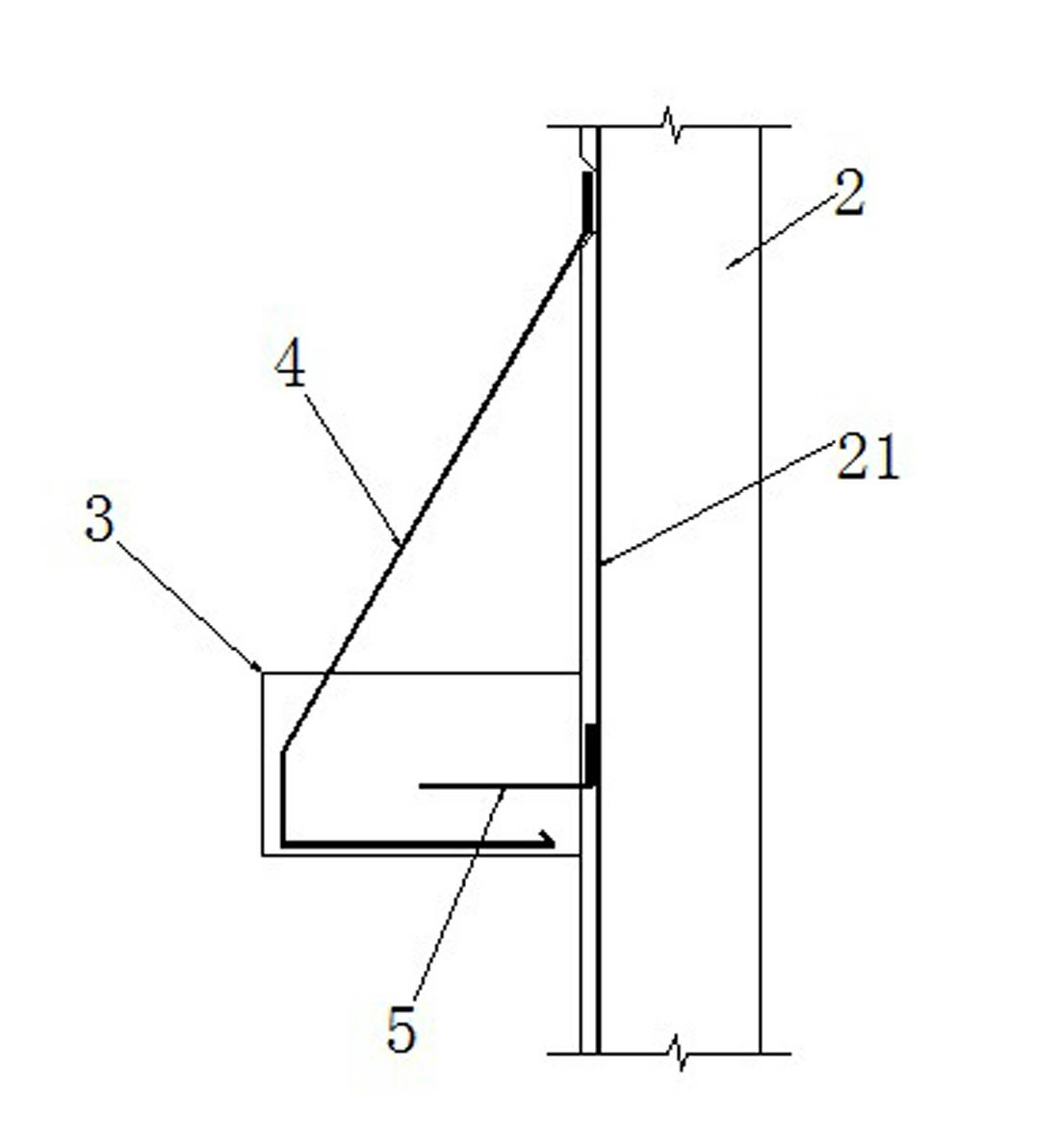

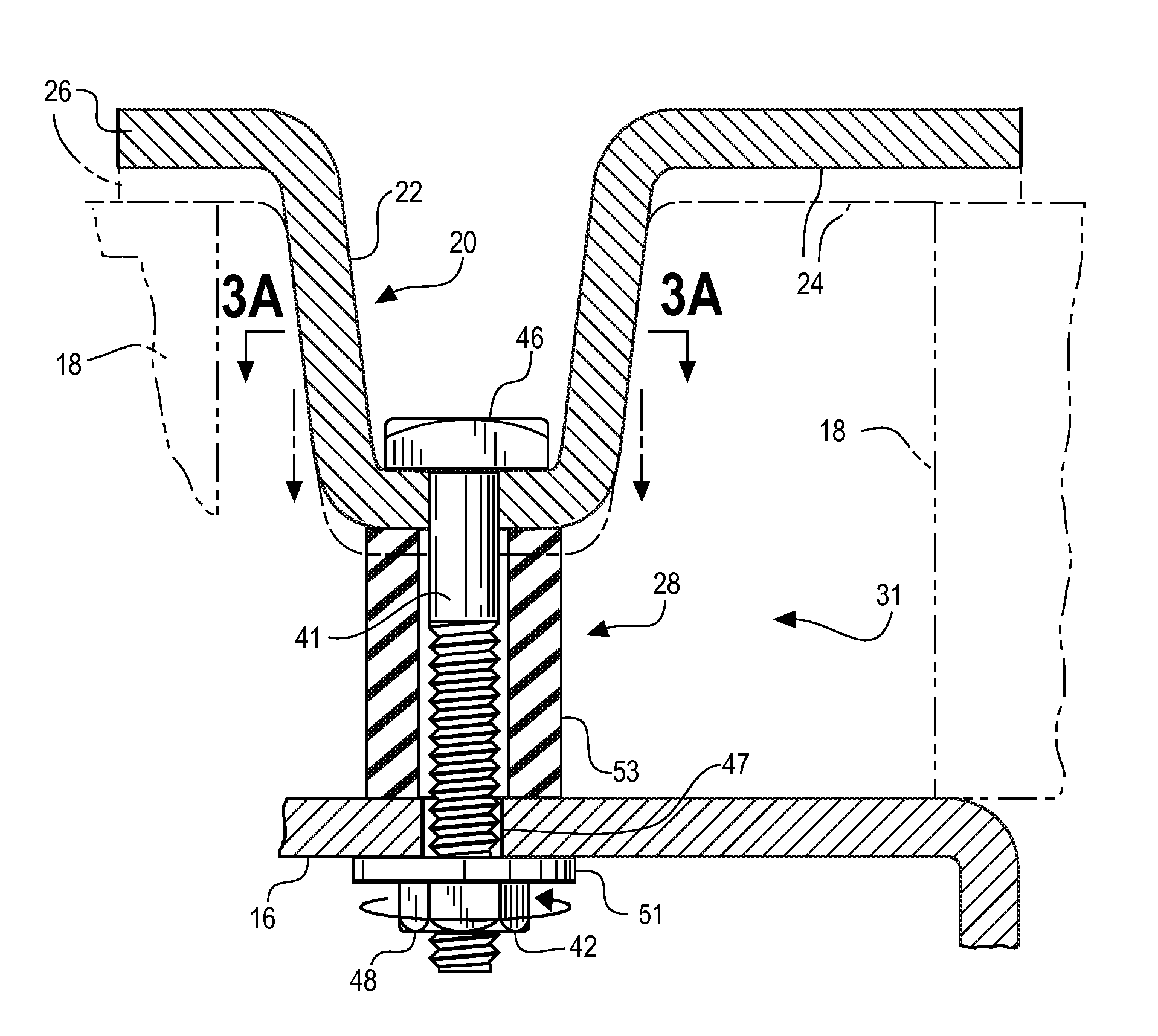

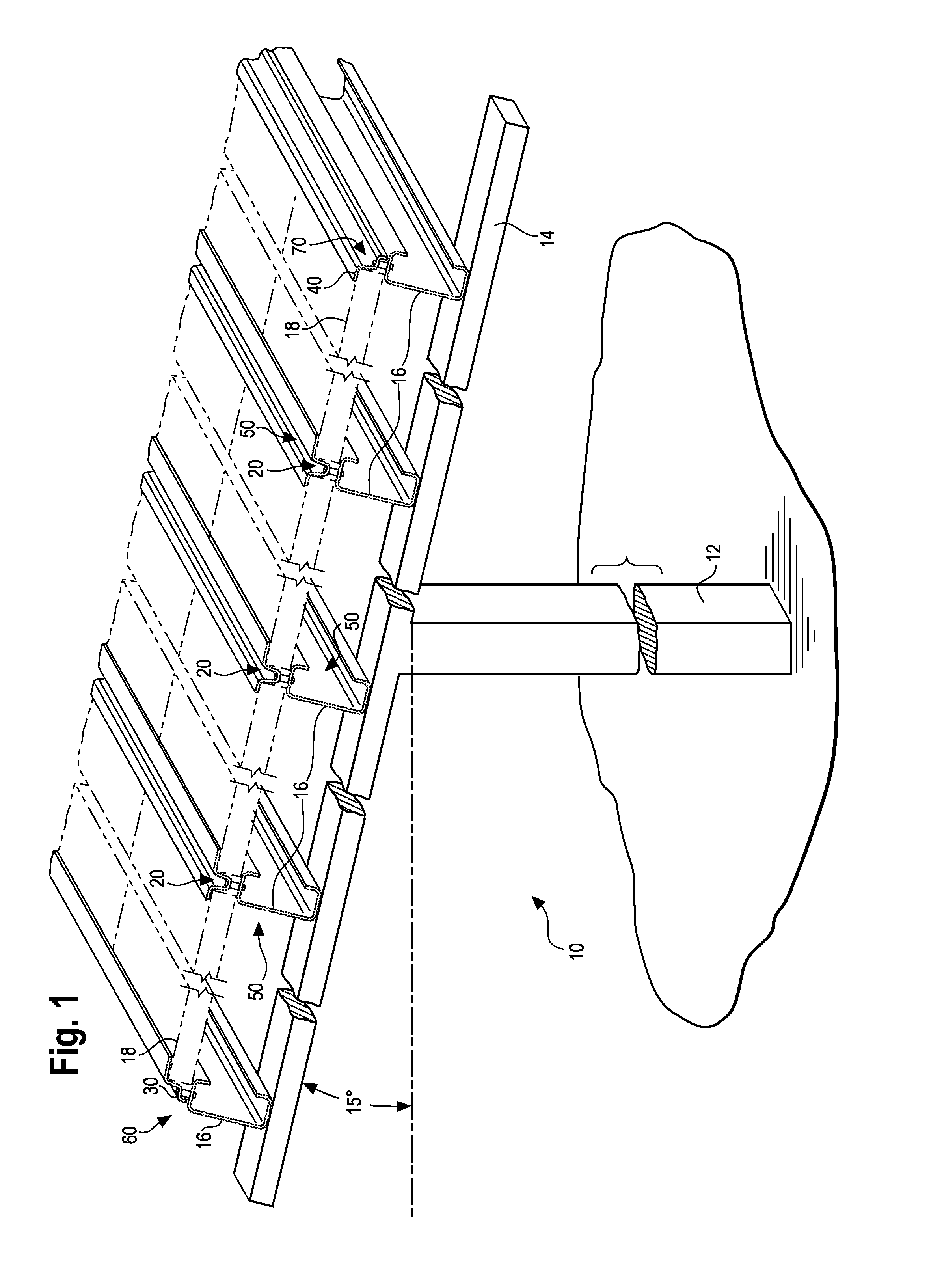

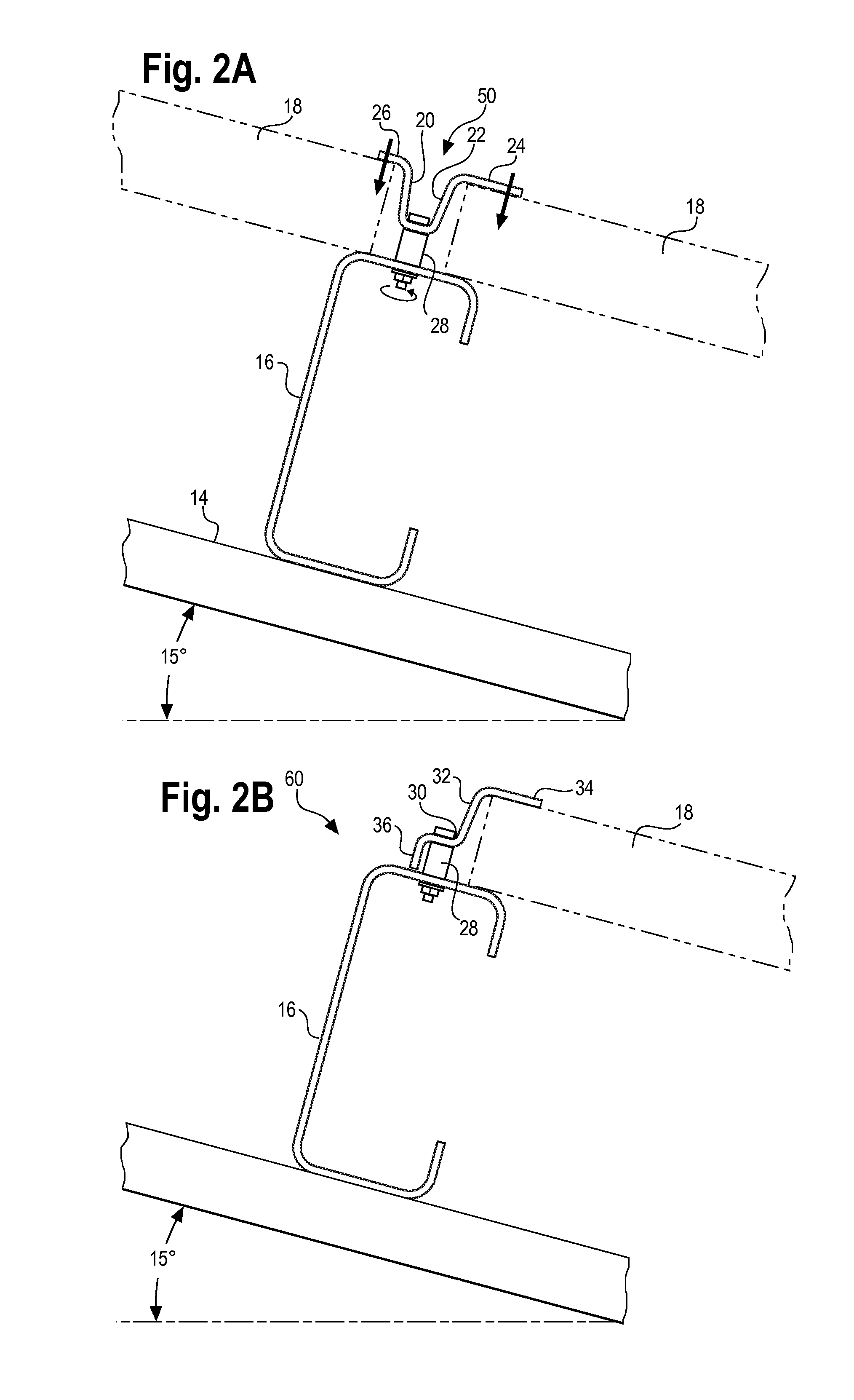

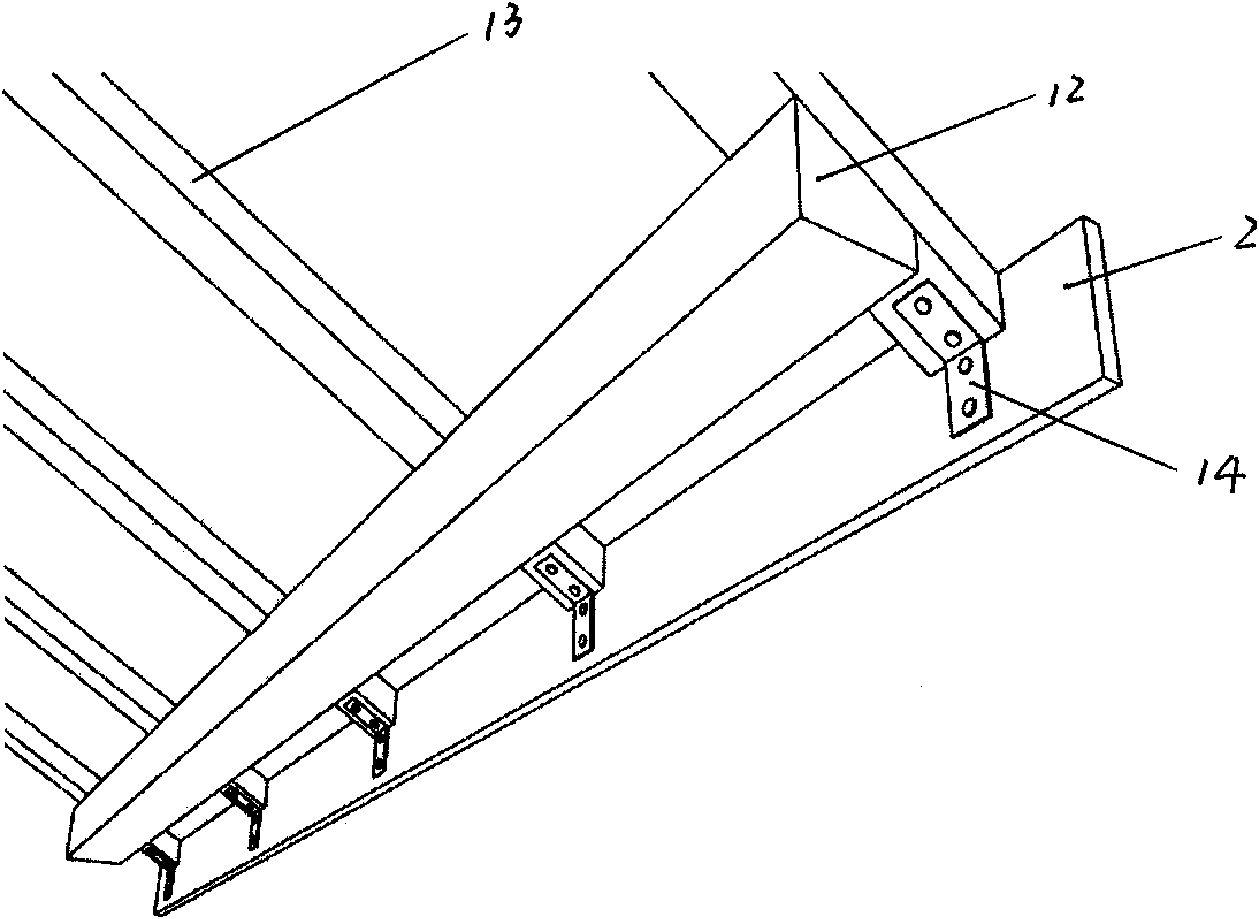

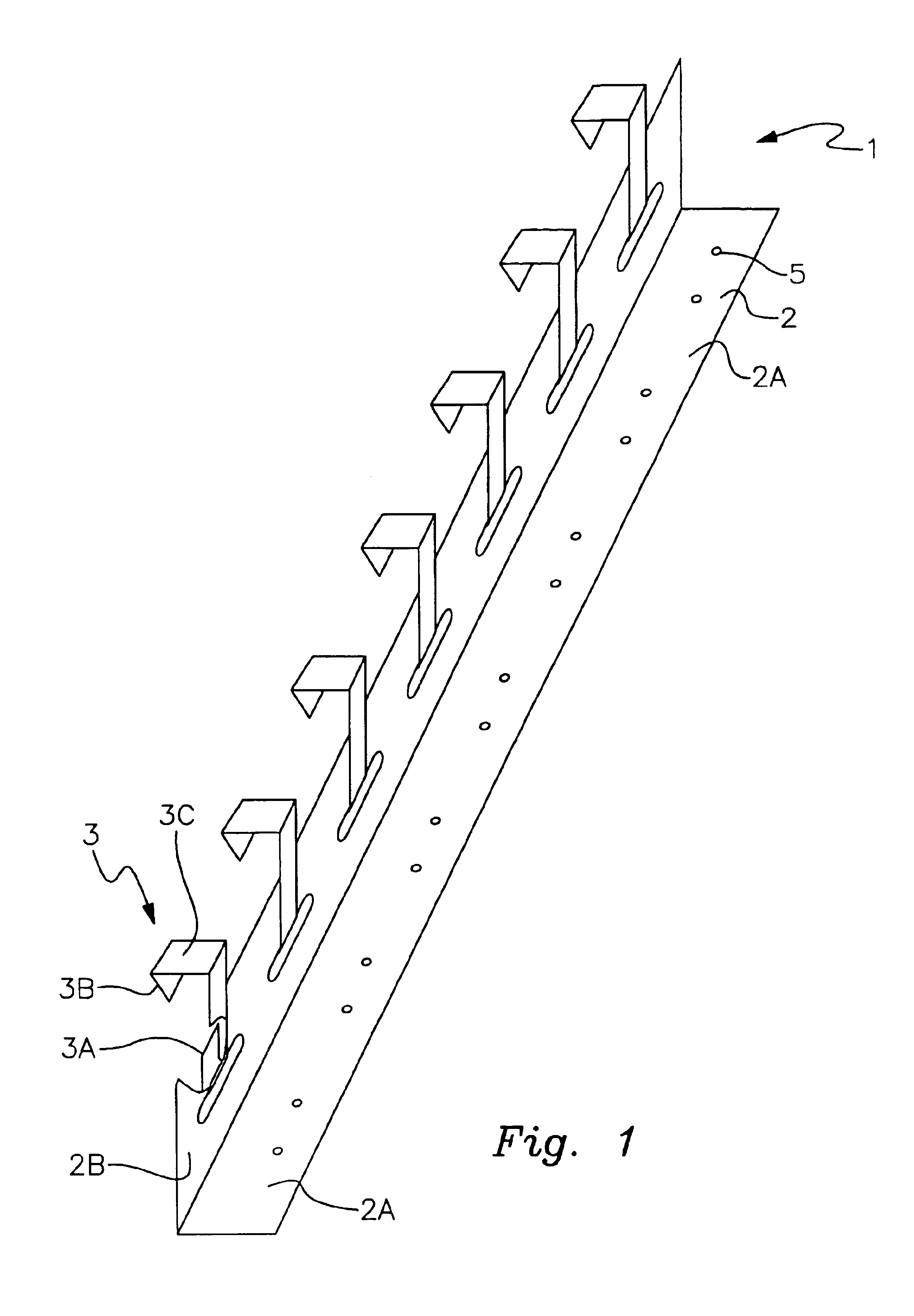

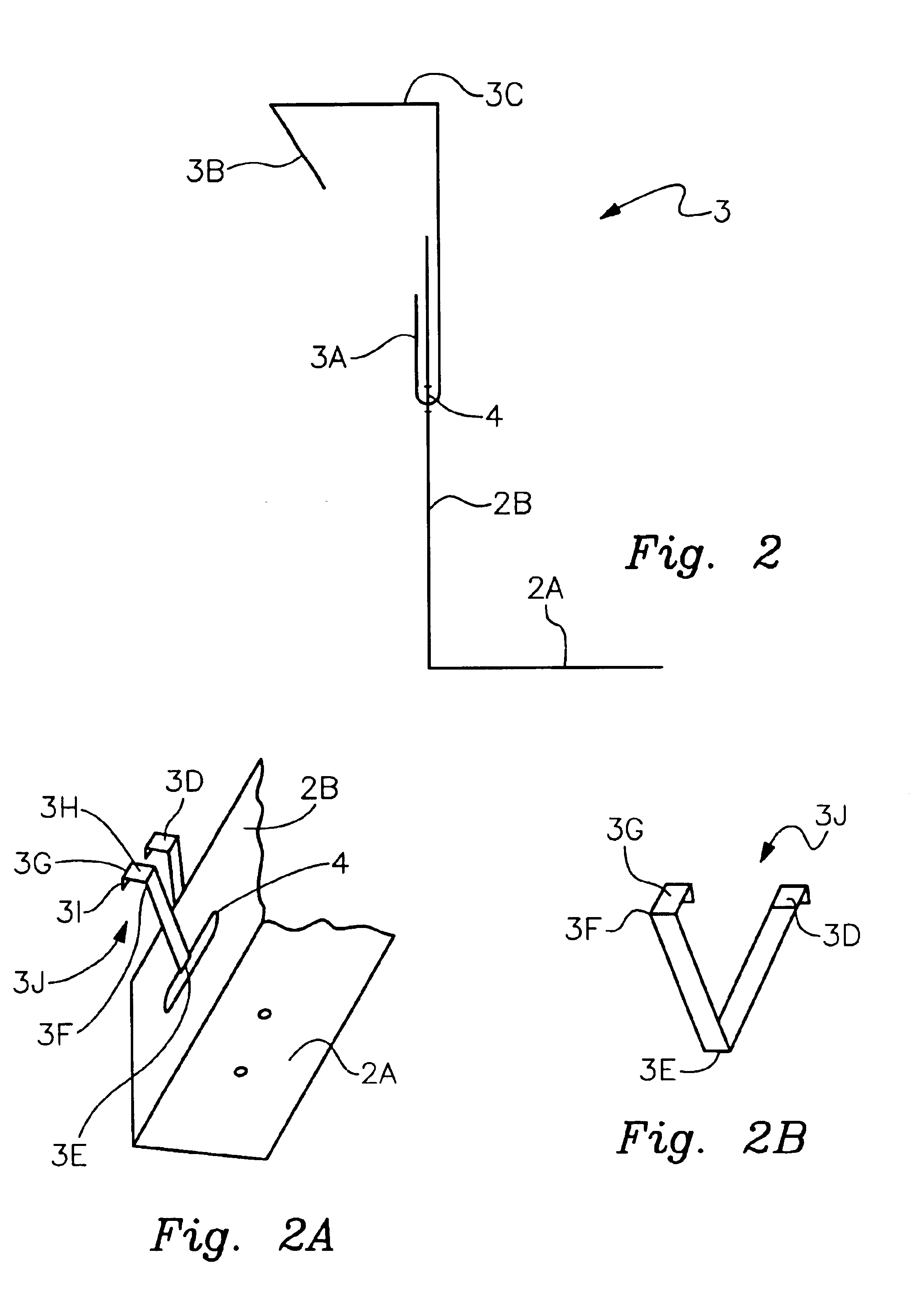

Roofing bracket and system

Various novel roofing brackets and roofing systems are disclosed. A first embodiment can be considered a roofing bracket to be coupled to a vertical post and a horizontal purlin of a roofing system whereby the horizontal purlin is positioned to support roof panels at a requisite pitch. The roofing bracket includes a reference brace and a clip. The reference brace includes a first brace face positioned planarly parallel with the vertical post and a second brace face extending at an angle angle from the first brace face and positioned planarly parallel with the vertical post. The clip includes a first clip face positioned to be fastened generally flush with the horizontal purlin and a second clip face extending at an angle from the first clip face and positioned to be fastened planarly parallel with the vertical post. The second clip face is coupled to the first brace face at a pivot point such that the clip can be rotated a particular angle relative to the reference brace. The angle of rotation is consistent with the requisite pitch of the roofing system.

Owner:GP INNOVATIVE CONCEPTS

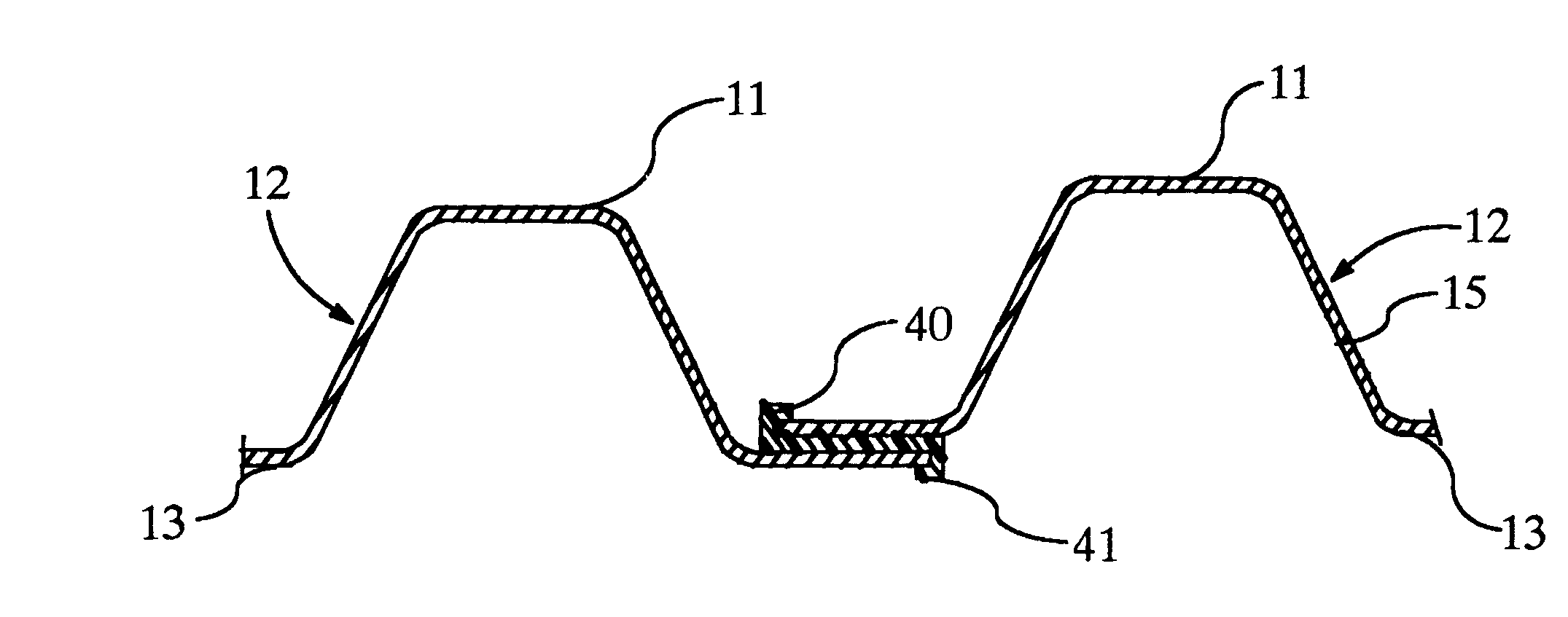

Sound control system for steel roof decks

InactiveUS6250036B1Cancel noiseReduce frictionBuilding roofsRoof covering using slabs/sheetsPurlinControl system

A steel roof deck diaphragm to provide structural rigidity to a building wherein loads of varying intensity can cause movement of structural members, which tends to generate noise when two members rub or work against each other. Corrugated sheets of high tensile steel are supported from below and span the distance between purlins, the corrugated sheets having over-lapping side edges and end edges and upper and lower surfaces. Non-metallic strips of felt form spacers positioned between the over-lapping side edges and end edges to prevent generation of noise resulting from relative movement of the corrugated sheets.

Owner:LOADMASTER SYST

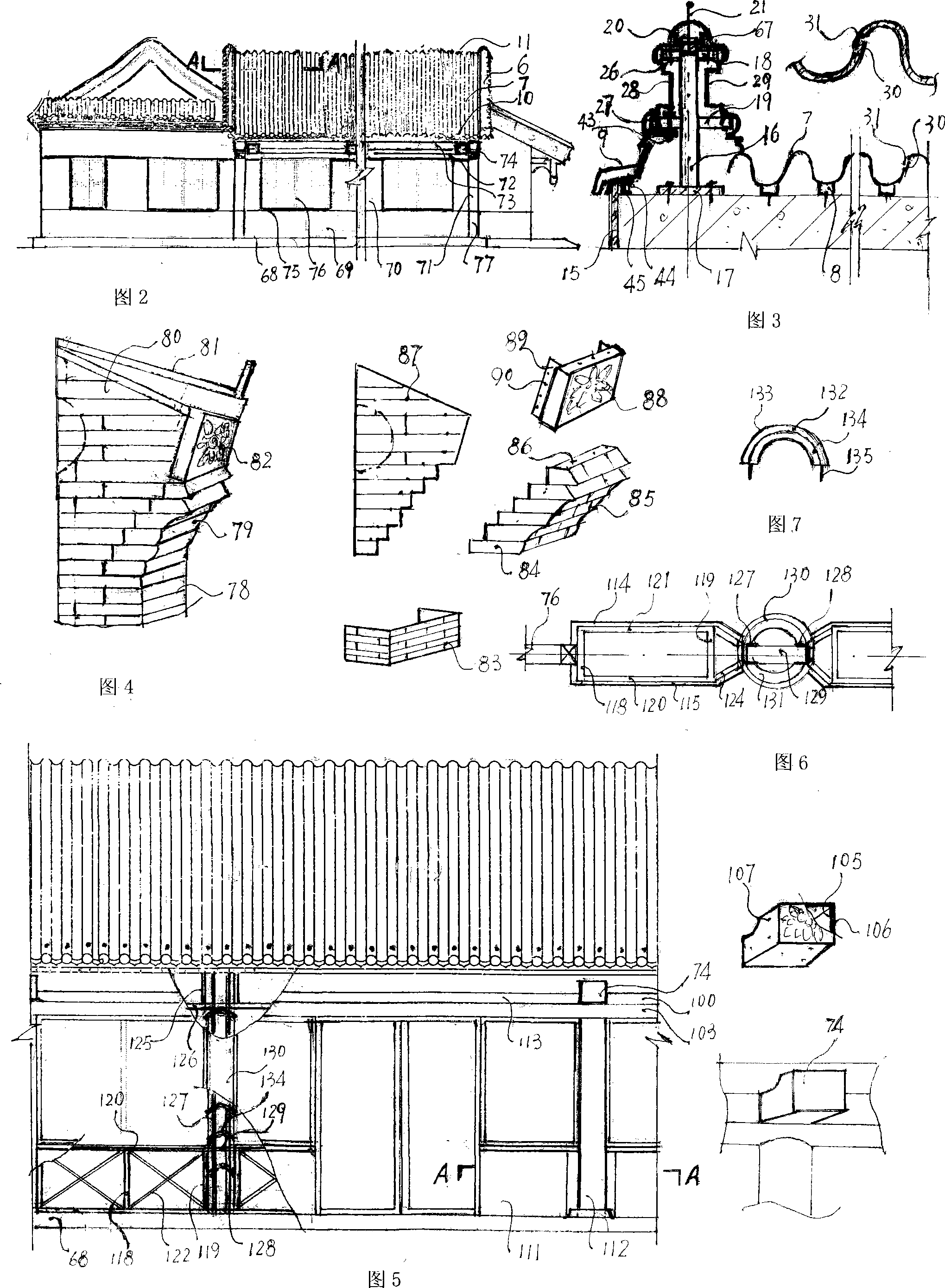

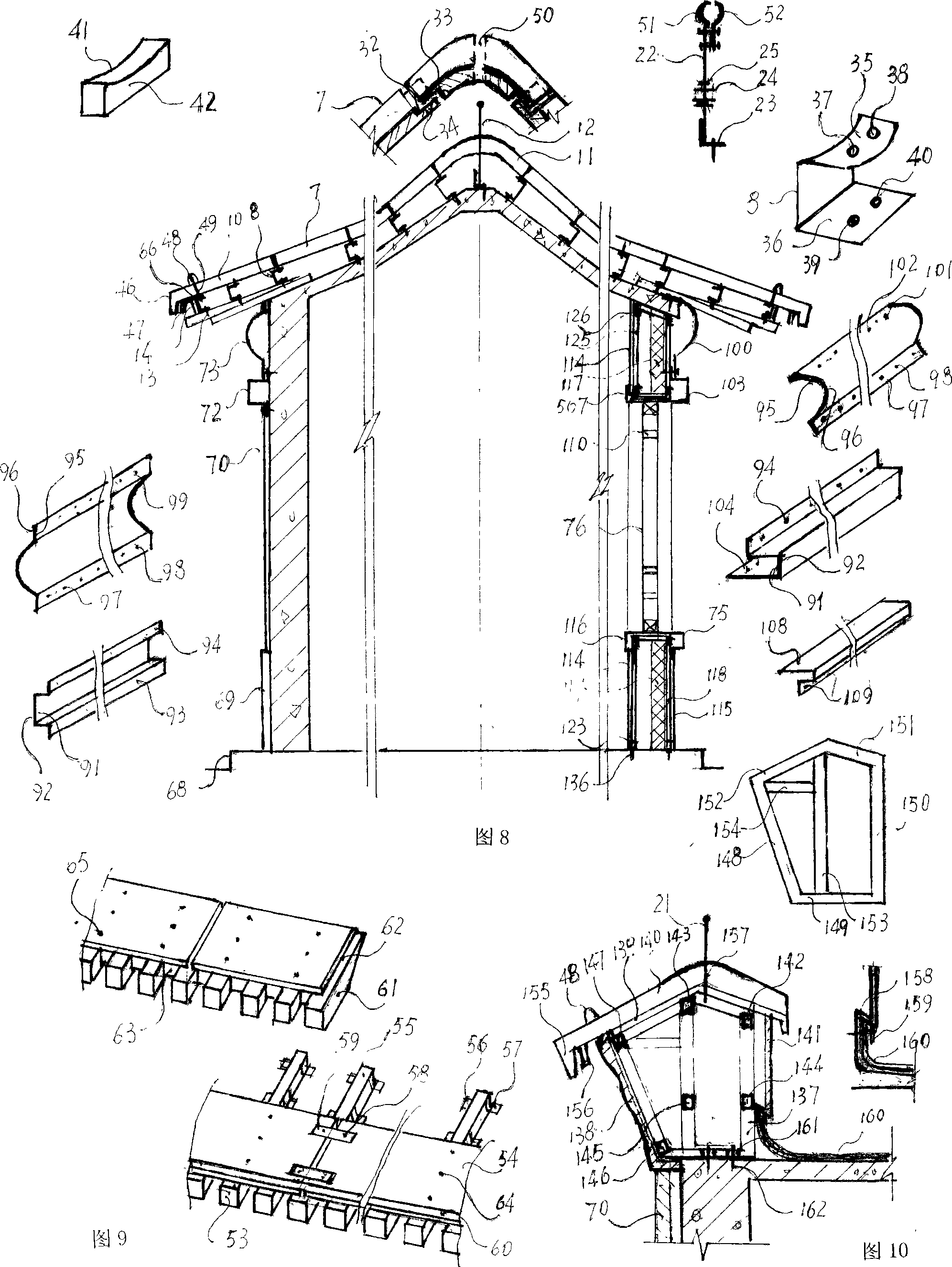

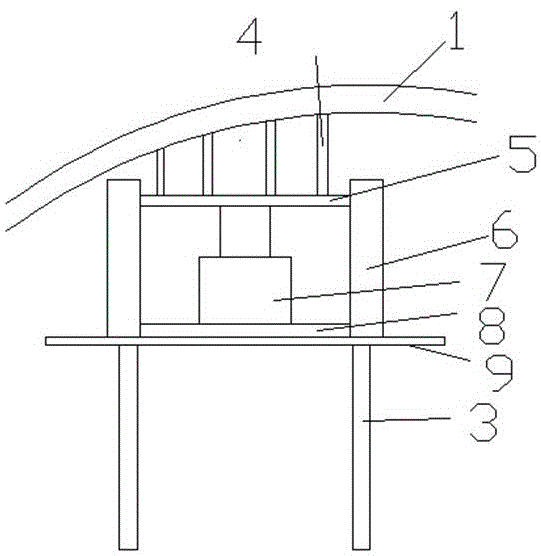

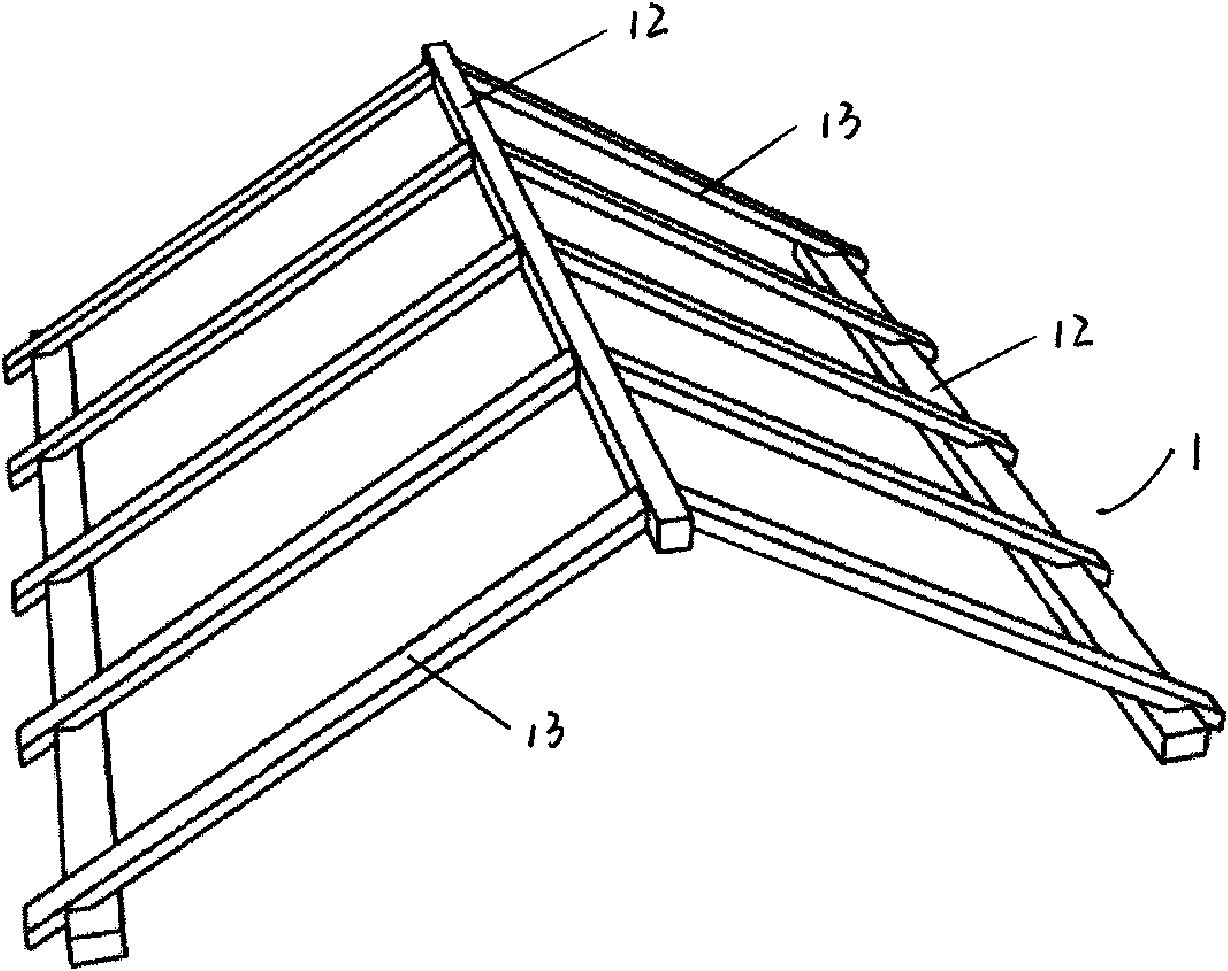

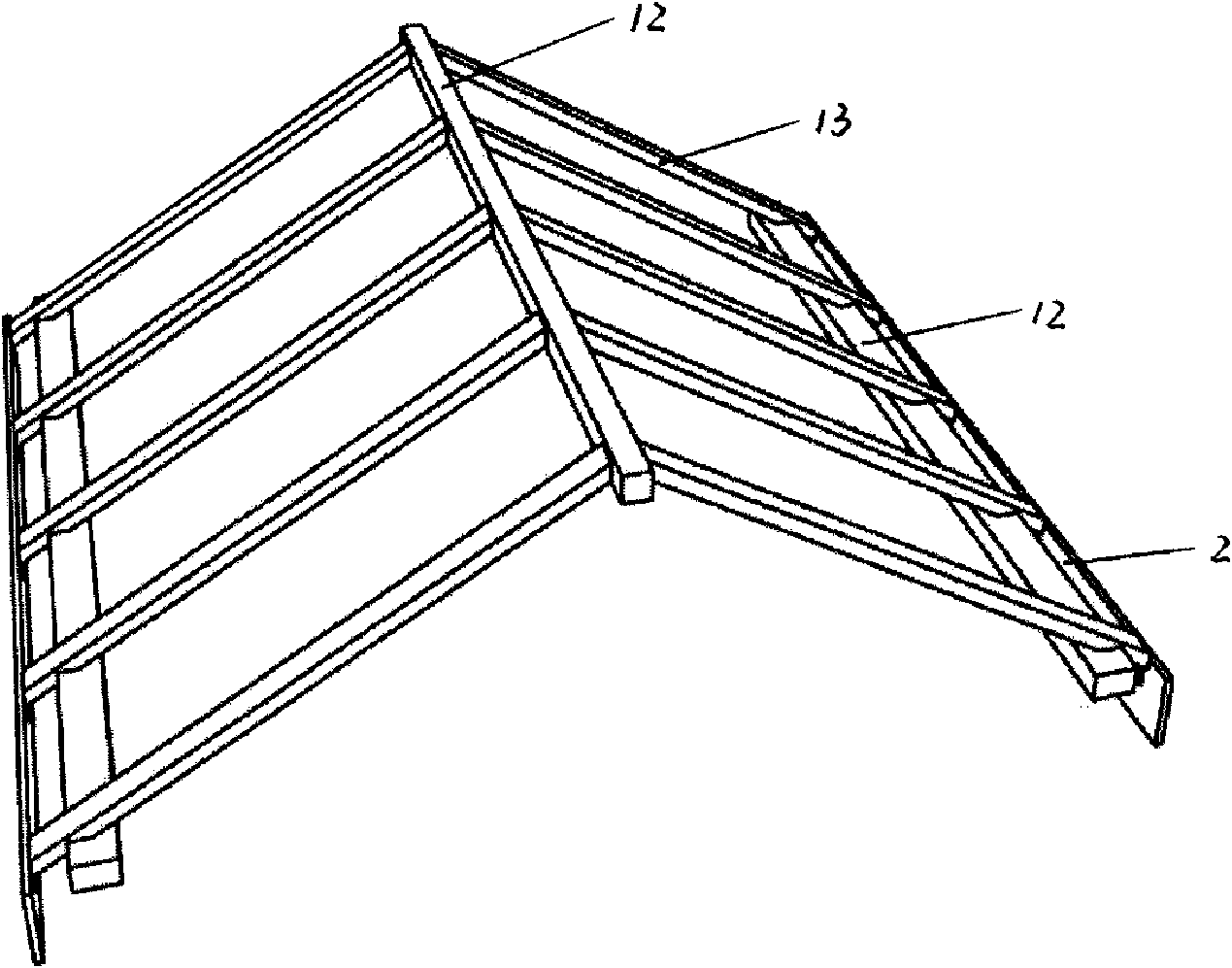

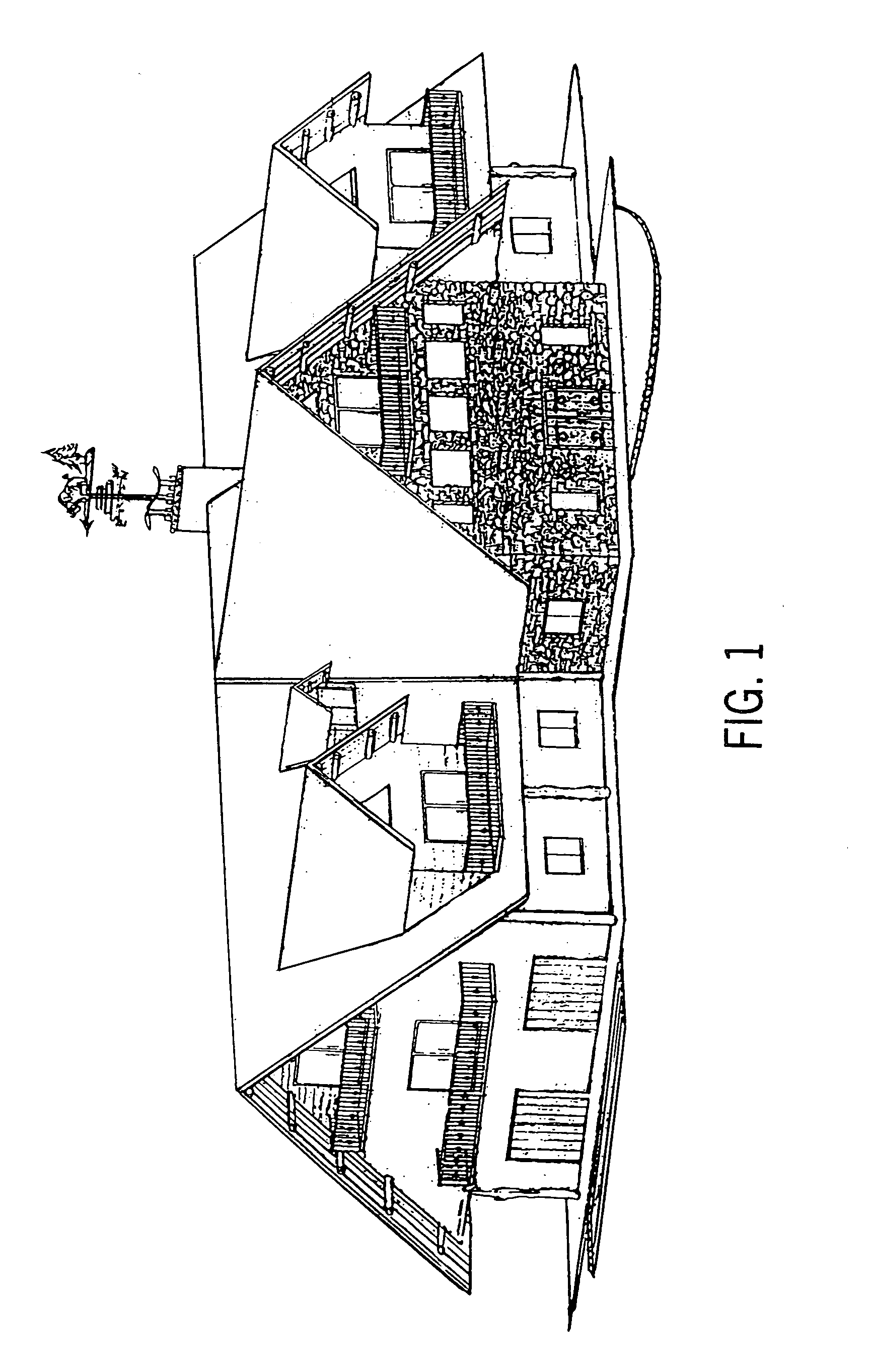

Novel energy-conserving emission reduction pseudo-classic architecture and construction method thereof

InactiveCN101457546AEliminate deforestationEliminate the destruction of vegetationBuilding roofsRoof covering using tiles/slatesRoof tileEaves

The invention relates to a novel archaized building which has the advantages of energy conservation and emission reduction and a construction method thereof. The invention is applicable to various archaized buildings, and the novel archaized building is characterized by comprising a Chinese round-ridge gabled roof 1, a gable and hip roof 2, a wall body, a flat roof eaves cap, a festoon gate, a verandah 3, a screen wall 4, a courtyard wall 5 and the like; completely based on the external shapes of the existing archaized buildings, the novel archaized building adopts lightweight steel construction as a structural support framework or a support member bar of purlins, square-columns, beams, rafters, pillars, the wall body and roofing tiles, and adopts modern construction materials such as thin steel plates, aluminium alloy plates, GRC or glass fiber reinforced plastic and the like which are made into various novel components and parts such as purlins, square-columns, pillars, the wall body and roofing tiles; factory production (including painting and colored drawing) is carried out, and the novel components and parts are assembled on-site and replace the existing traditional archaized building materials such as wooden beams, pillars, rafters, soil calcined tiles and the like as well as the retarded construction technology, thus achieving the aim of energy conservation and emission reduction, clean construction and installation, increment of working efficiency, reduction of erection time and cost reduction.

Owner:冯刚克

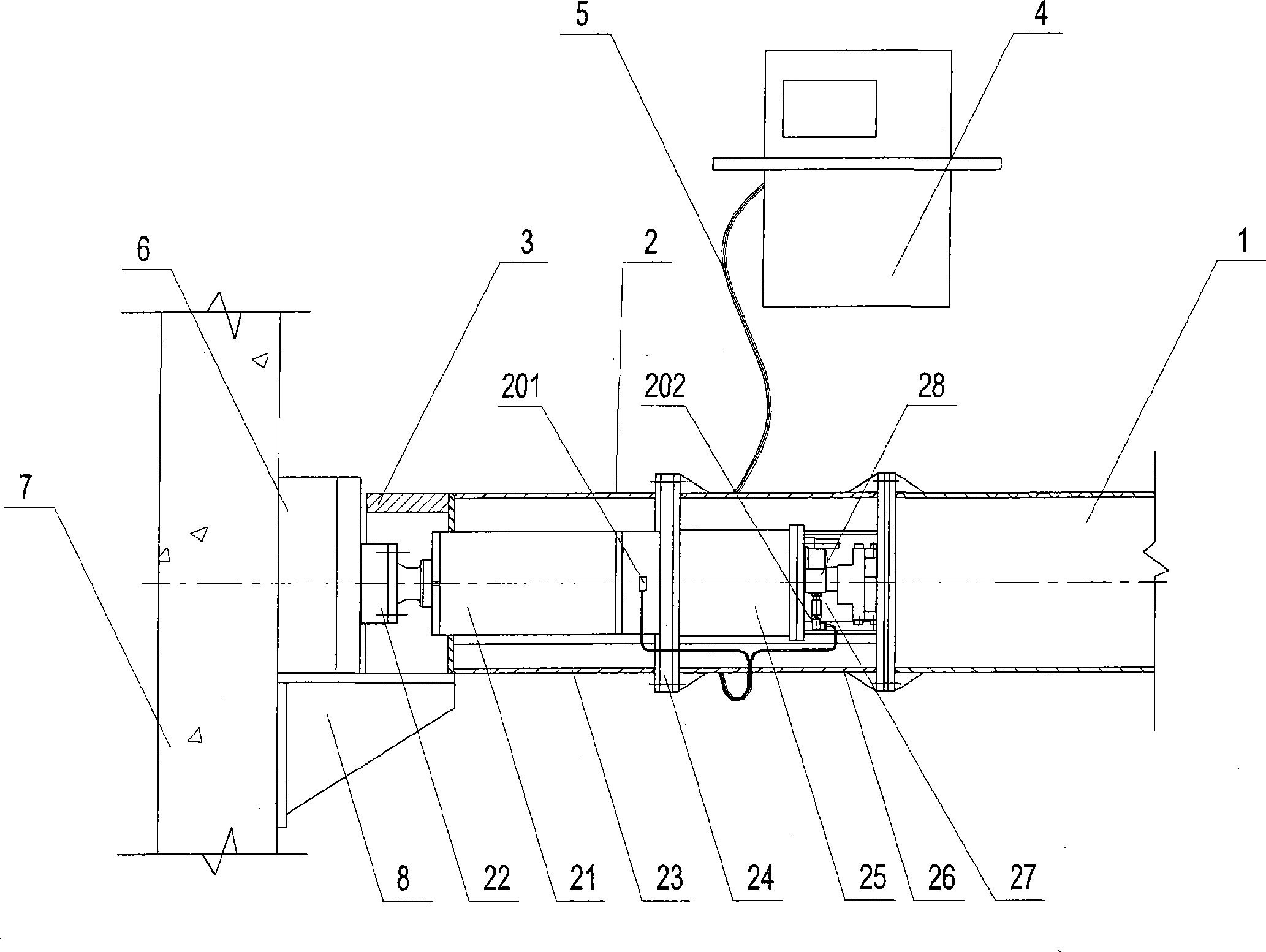

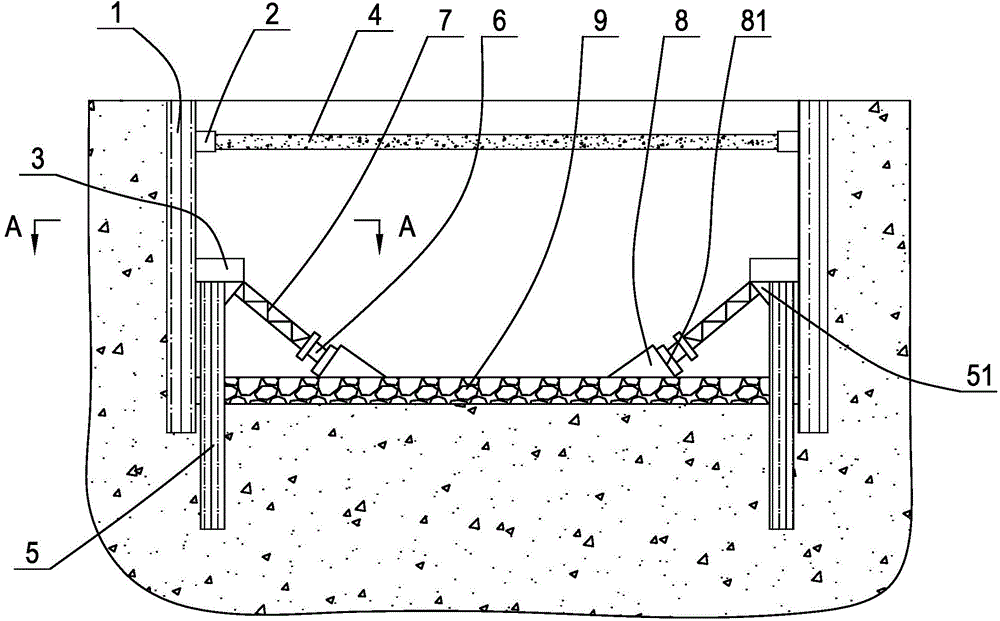

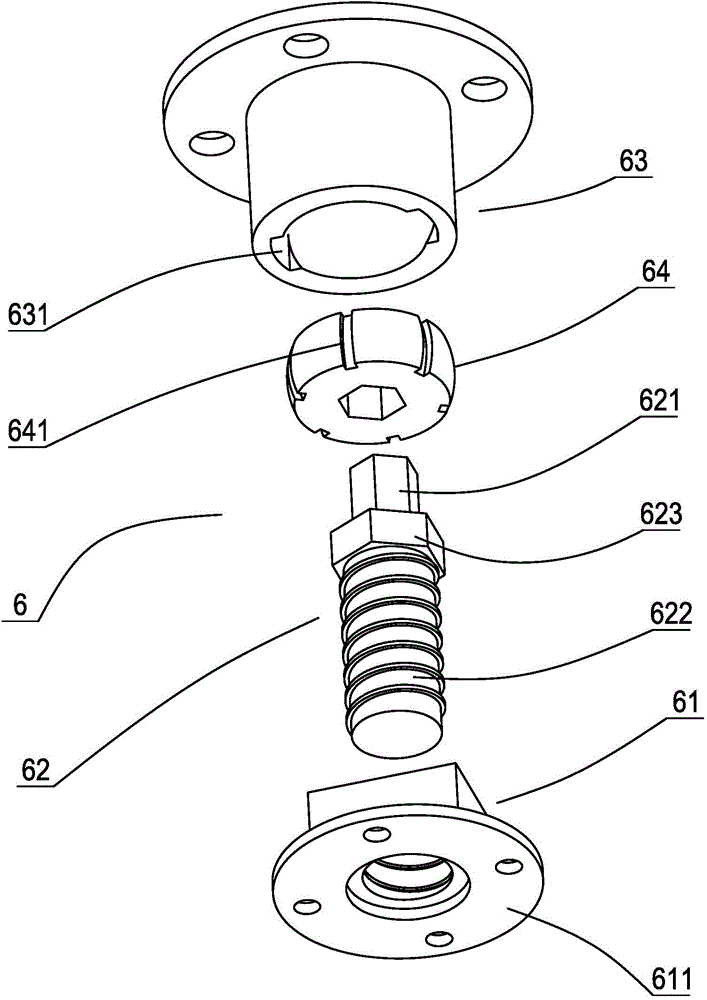

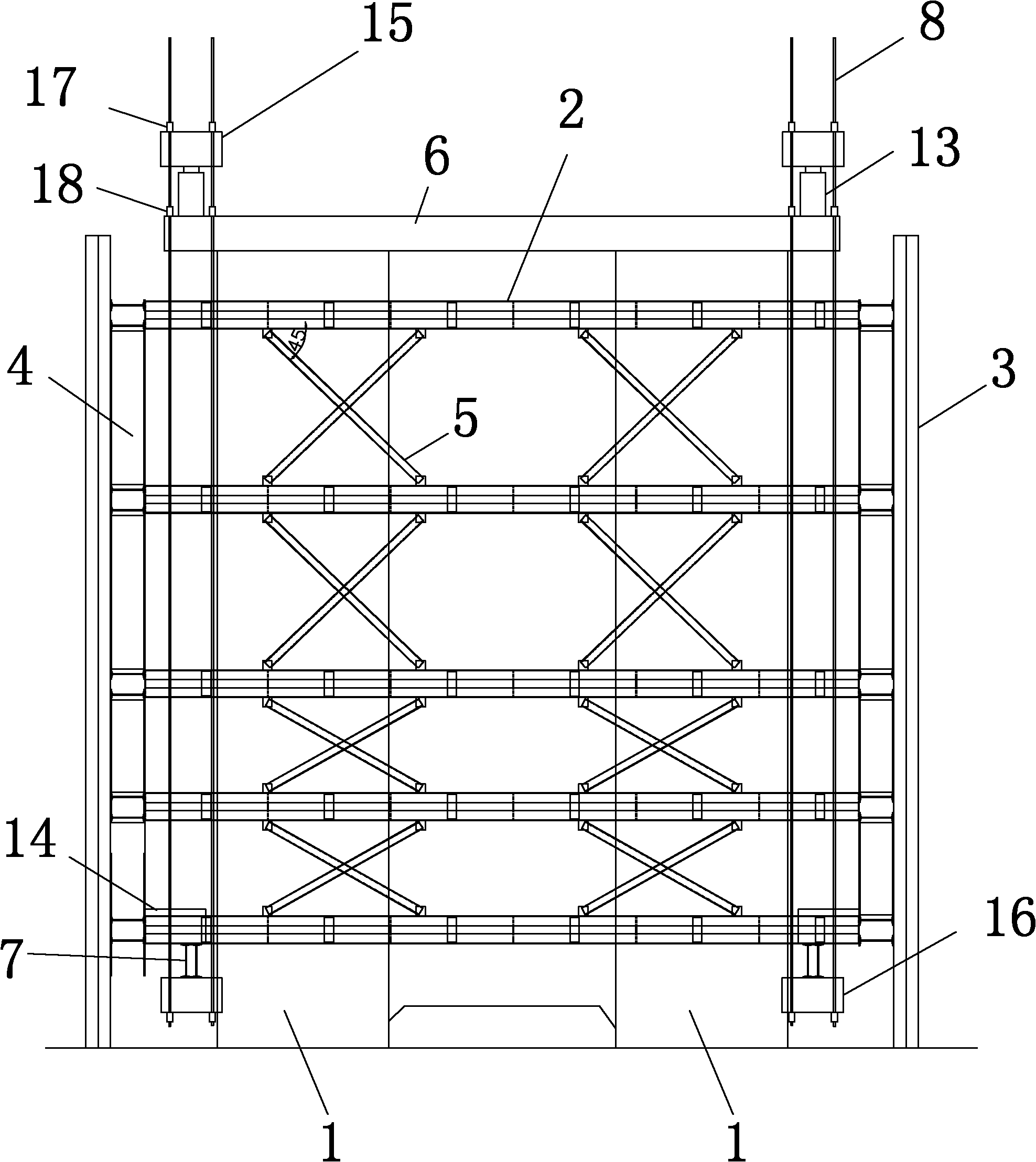

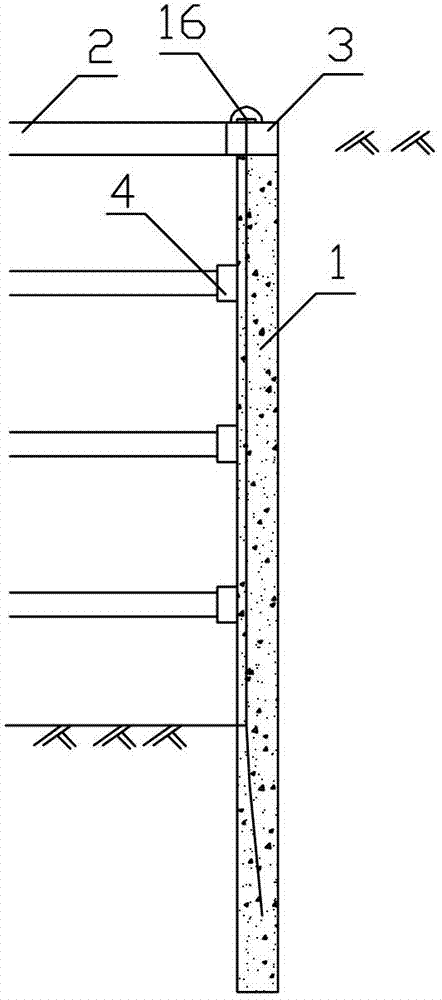

Foundation pit controllable hydraulic steel support and use thereof

The invention provides a controlled hydraulic steel support of a foundation pit and the application thereof, belonging to the field of construction engineering. The structure of the invention comprises a fixed end steel support, a flexible end steel support, a stopping device, an electric cabinet and a signal control cable; wherein, the fixed end steel support and the flexible end steel support are fixedly connected by a screw bolt as an integrated steel support, the stopping device is arranged between the fixed end steel support and a foundation pit enclosing purlin; wherein, the fixed end steel support is composed by a hydraulic oil cylinder, a spherical-hinge base, a seal cover, a route sensor, a connecting plate, a sealed oil tank, a supporting seat, a pressure sensor, an electric motor plus pump and a valve; the steel support device can compare the collected real-time information such as shaft force data, route change data and the like with support default value, the computer-controlled hydraulic system can realize the automatic adjustment and compensation of the support shaft force, and the support shaft force is adjusted according to the monitored results during construction to realize the requirements of controlling foundation pit deformation and guaranteeing safety during the foundation pit construction process. The controlled hydraulic steel support can be widely used for the pit protection during the foundation pit excavation process.

Owner:SHANGHAI TUNNEL ENGINEERING CO. LTD.

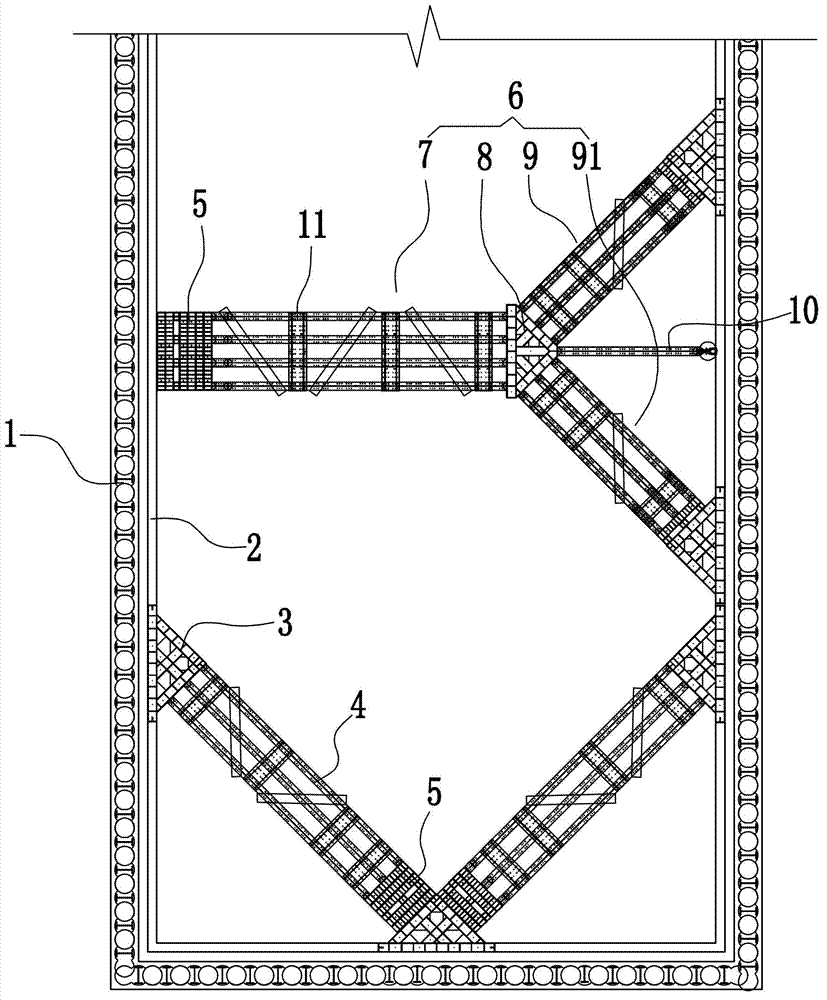

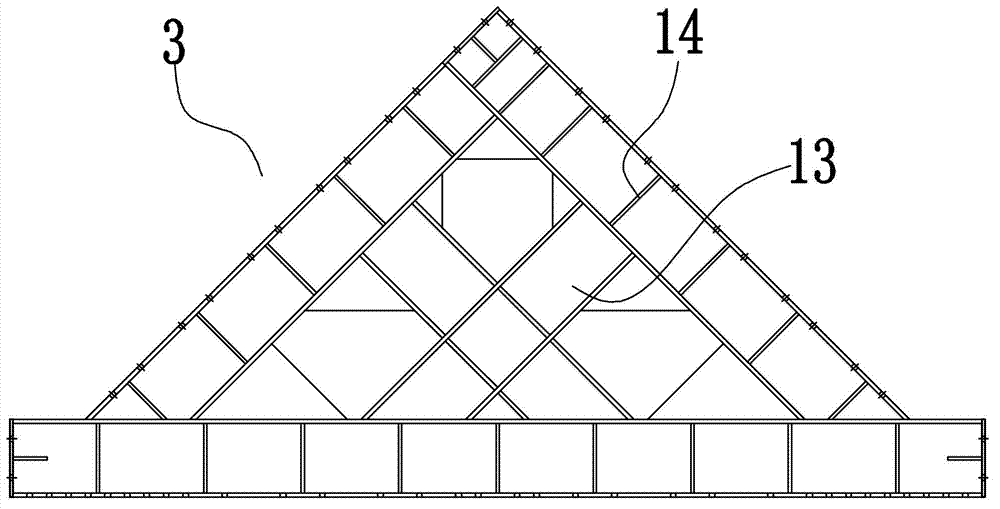

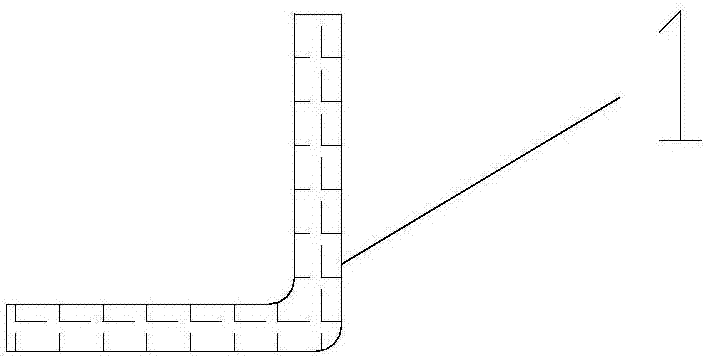

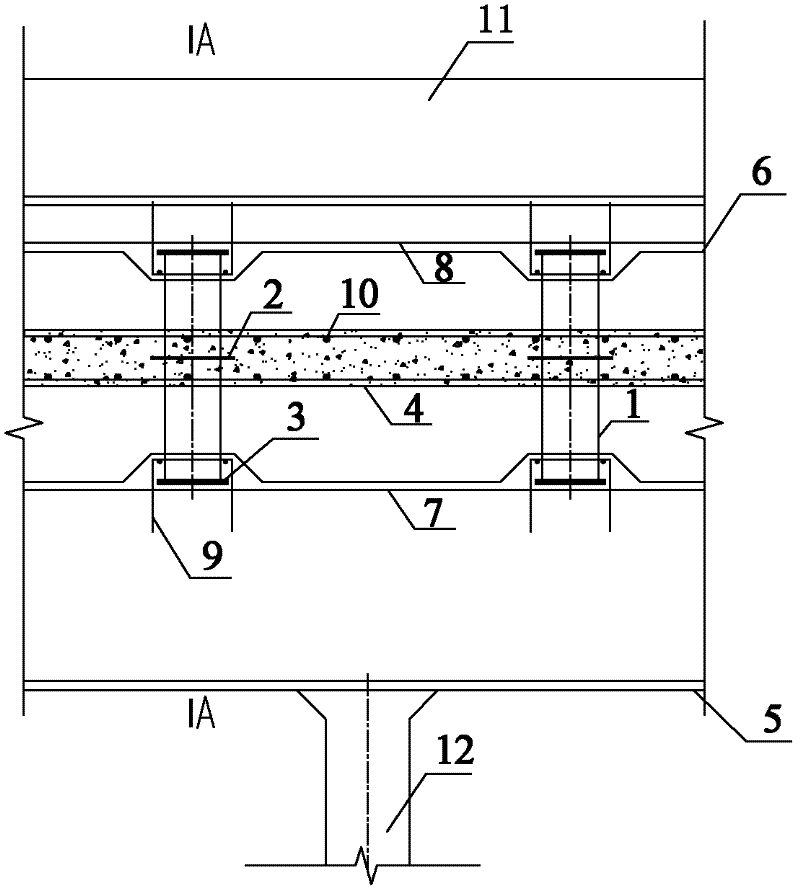

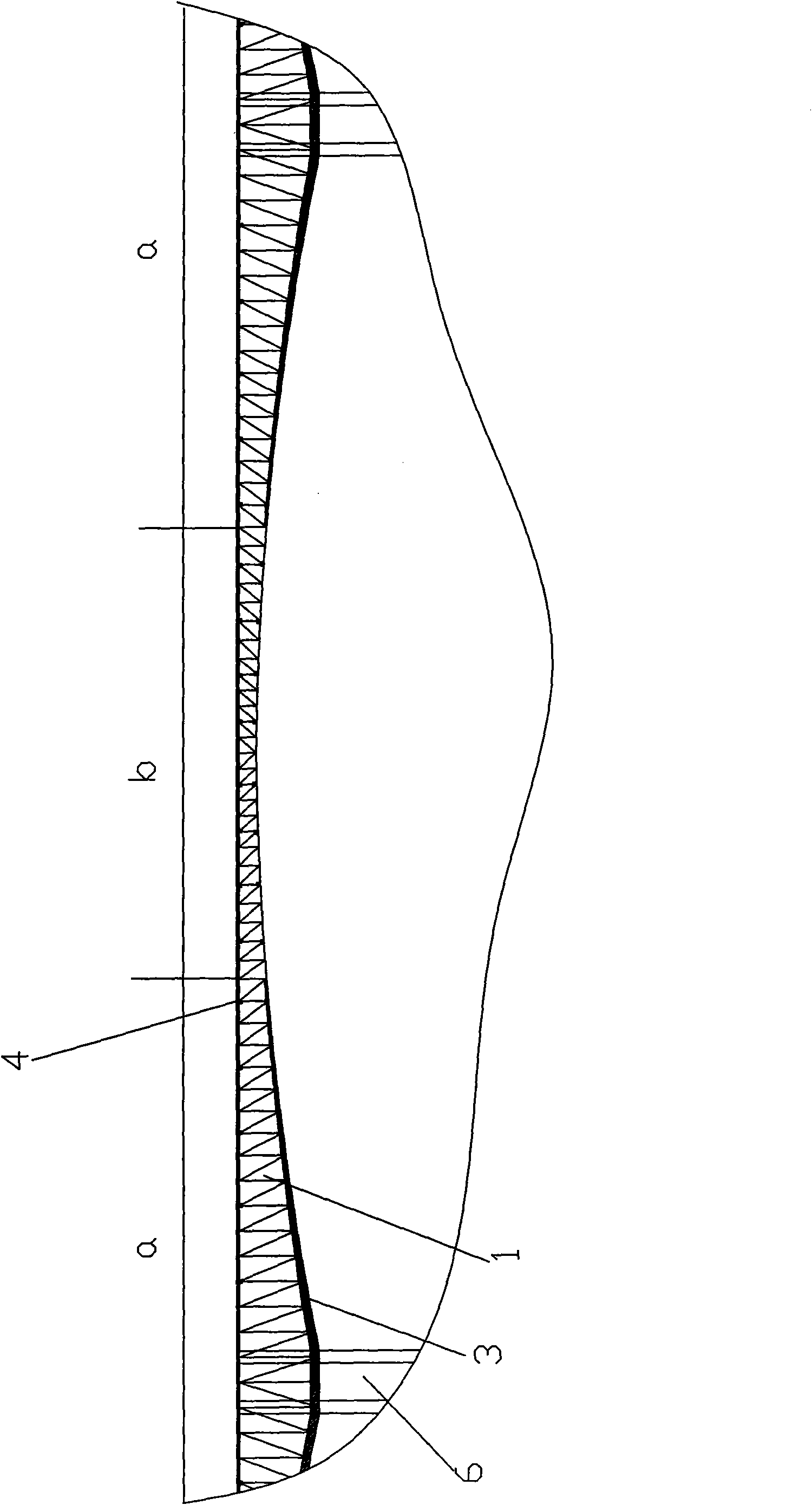

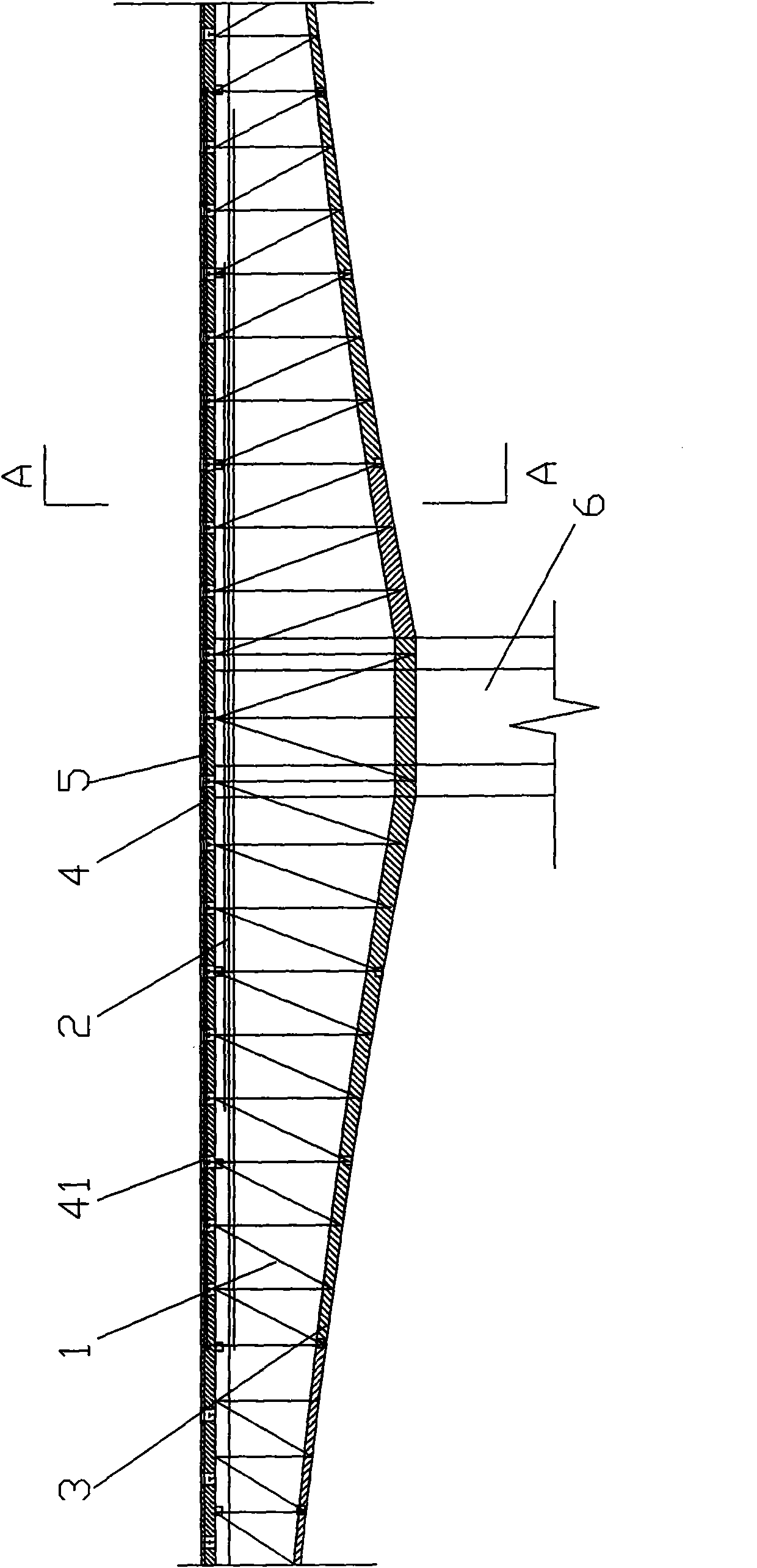

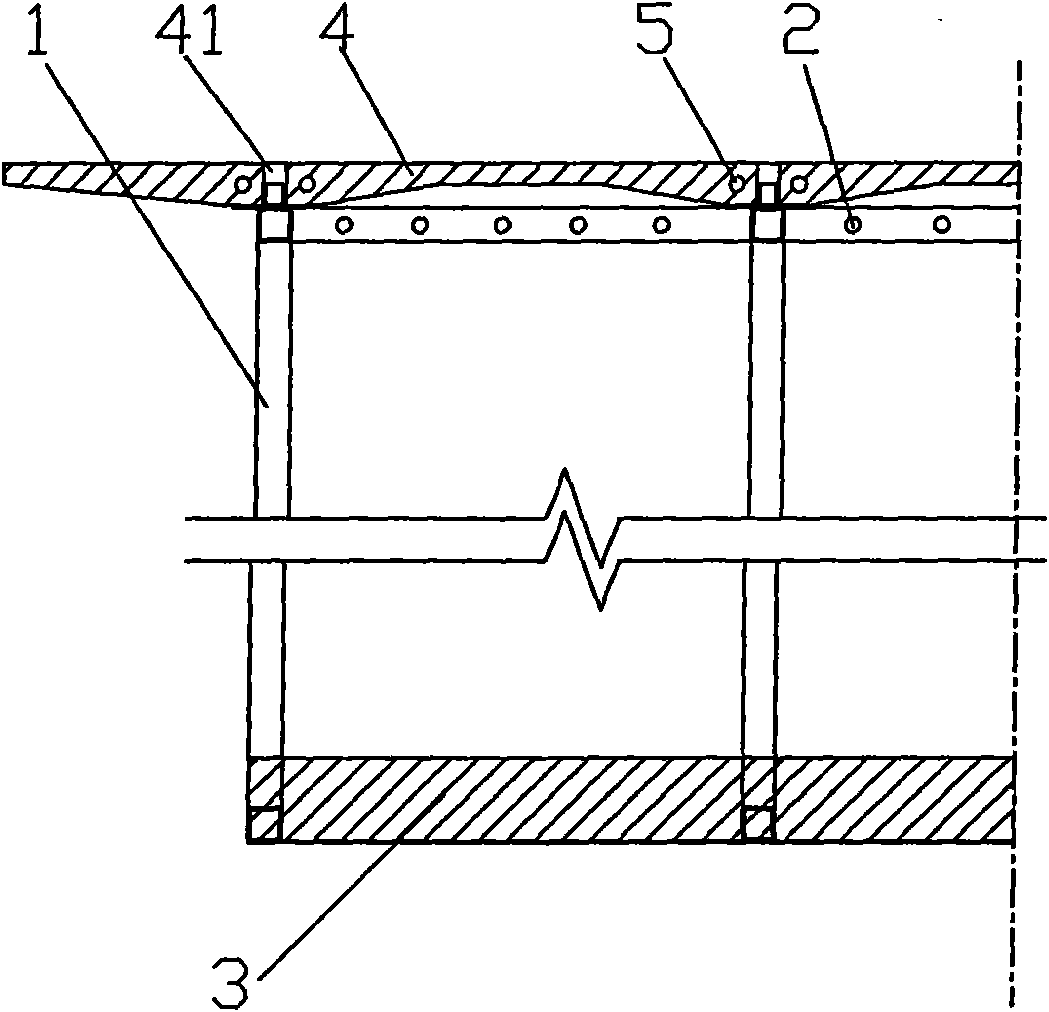

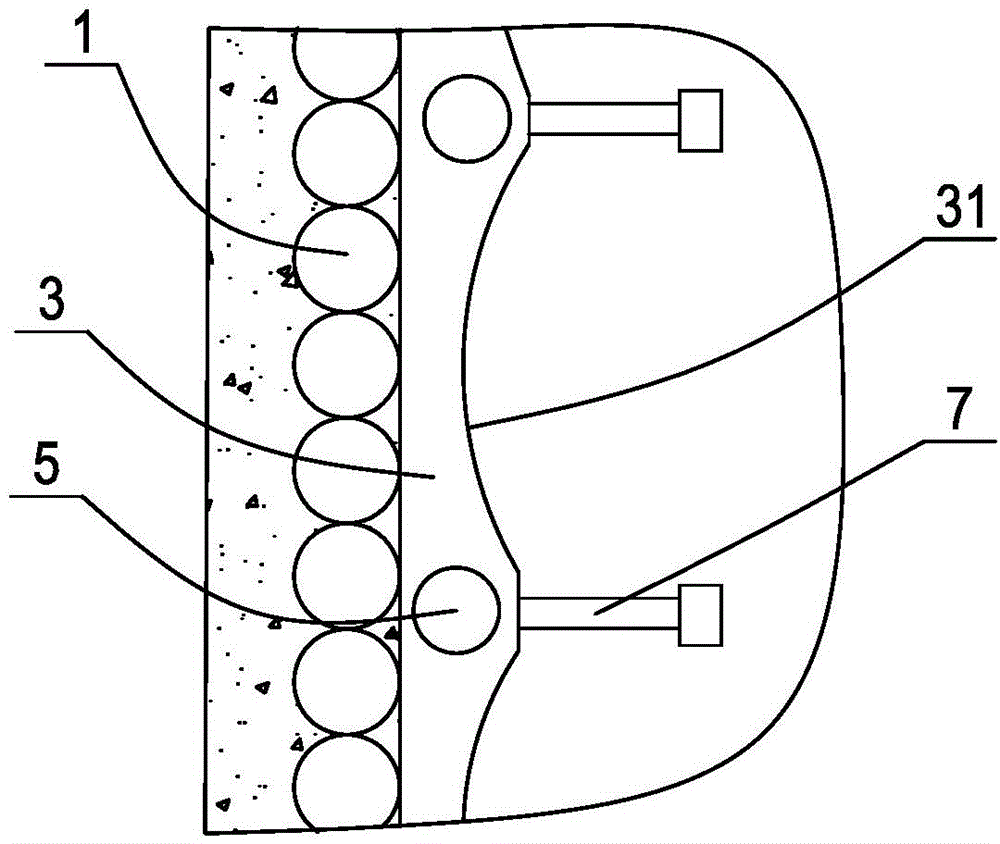

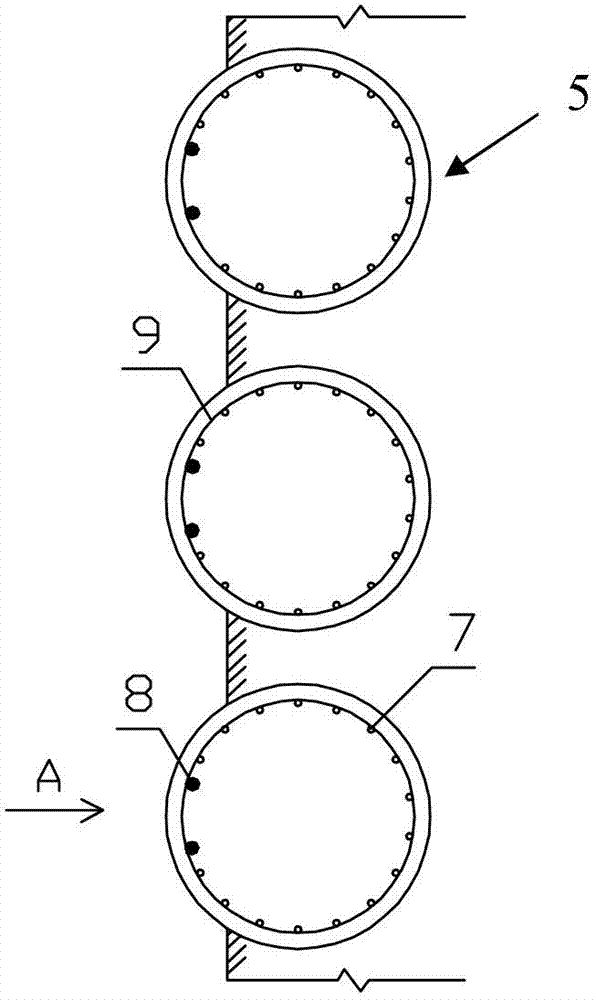

Detachable prestress supporting frame system

ActiveCN103161168AEasy to assemble and disassembleSave resourcesExcavationsPurlinStructural engineering

The invention discloses a detachable prestress supporting frame system and aims to provide a supporting frame system which is good in stability of a supporting structure of a foundation pit, can reduce supporting density to a supporting beam and provides larger working space for foundation pit mining operations on the premise of not influencing strength of the supporting structure of the foundation pit. The detachable prestress supporting frame system comprises a group of construction method piles and an enclosure purlin beam. The group of construction method piles are arranged on the edge of the foundation pit. The enclosure purlin beam is arranged on the inner side of the construction method piles. A plurality of triangular supporting members are arranged on the inner side of the enclosure purlin. Angle counter-supporting beams are arranged at the concave corner of the foundation pit. Each angle counter-supporting beam is arranged between two triangular supporting members on two adjacent sides of the concave corner. One end of each angle counter-supporting beam abuts against the side surface of one of the triangular supporting members. A prestress reserved member is arranged between the other end of each angle counter-supporting beam and another triangular supporting member. The prestress reserved member comprises two supporting parts which can be unfolded mutually, one of the two supporting parts abuts against the side surface of the triangular supporting member, and the other supporting part abuts against the end portion of the angle counter-supporting beam.

Owner:DONGTONG ROCK SOIL SCI & TECH HANGZHOU

Roofing bracket and system

Various novel roofing brackets and roofing systems are disclosed. A first embodiment can be considered a roofing bracket to be coupled to a vertical post and a horizontal purlin of a roofing system whereby the horizontal purlin is positioned to support roof panels at a requisite pitch. The roofing bracket includes a reference brace and a clip. The reference brace includes a first brace face positioned planarly parallel with the vertical post and a second brace face extending at an angle angle from the first brace face and positioned planarly parallel with the vertical post. The clip includes a first clip face positioned to be fastened generally flush with the horizontal purlin and a second clip face extending at an angle from the first clip face and positioned to be fastened planarly parallel with the vertical post. The second clip face is coupled to the first brace face at a pivot point such that the clip can be rotated a particular angle relative to the reference brace. The angle of rotation is consistent with the requisite pitch of the roofing system.

Owner:GP INNOVATIVE CONCEPTS

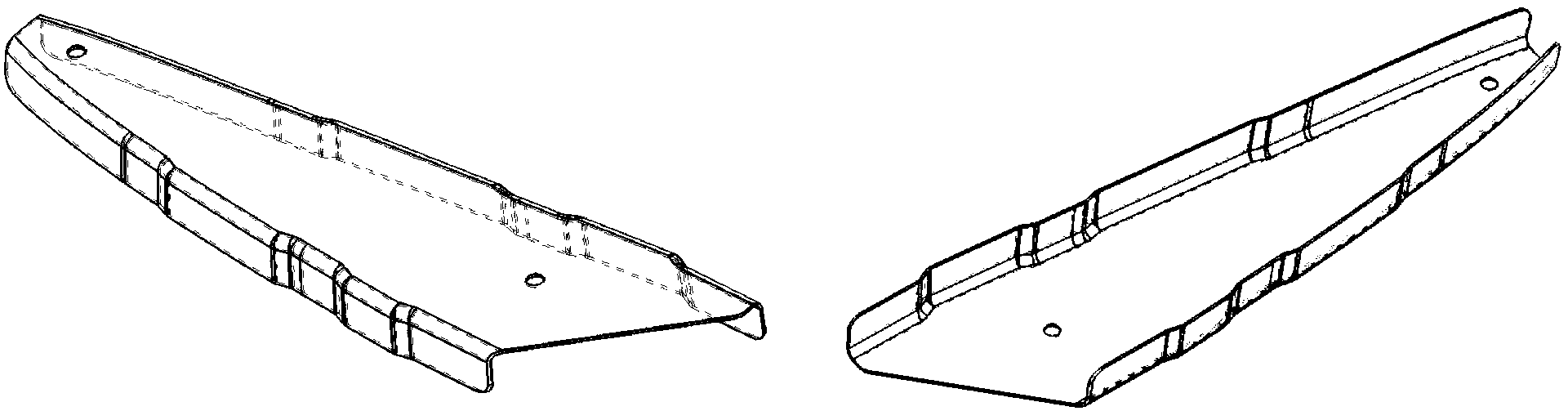

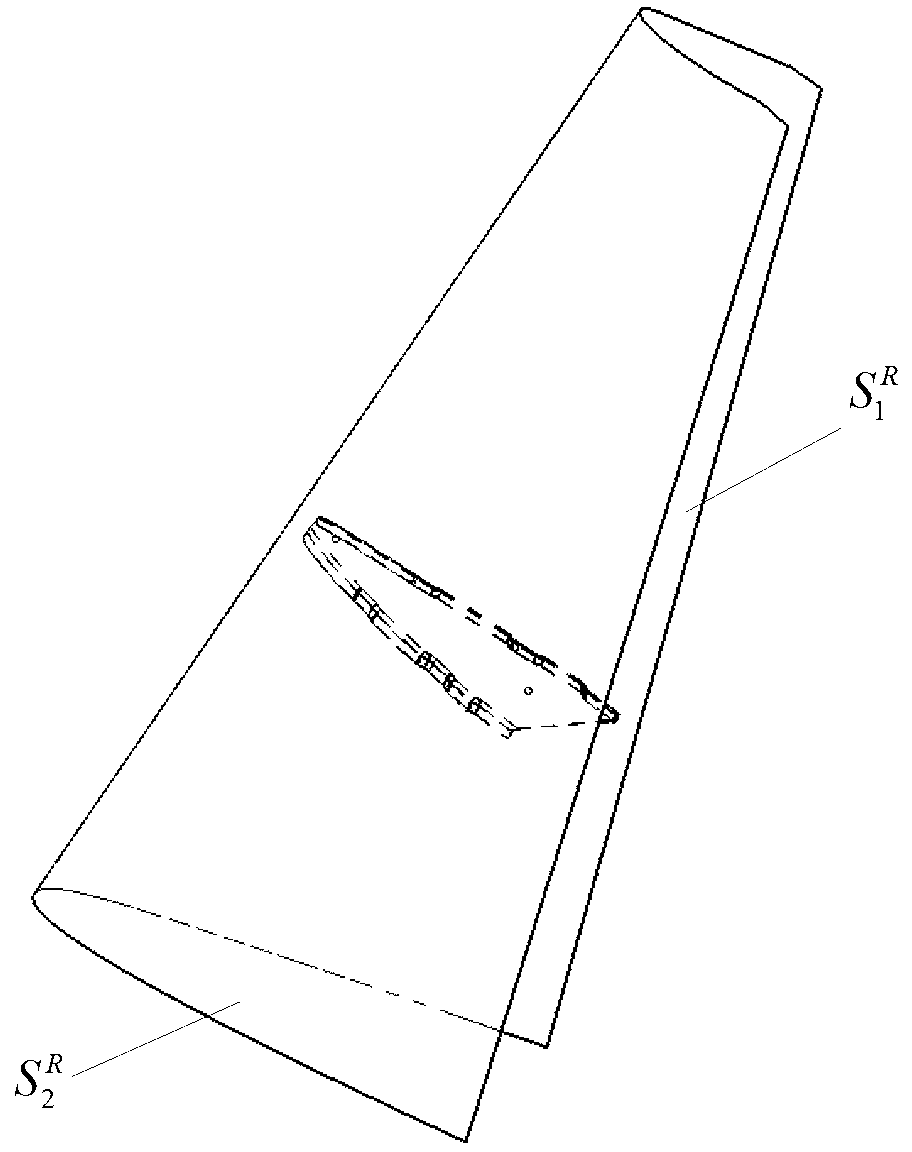

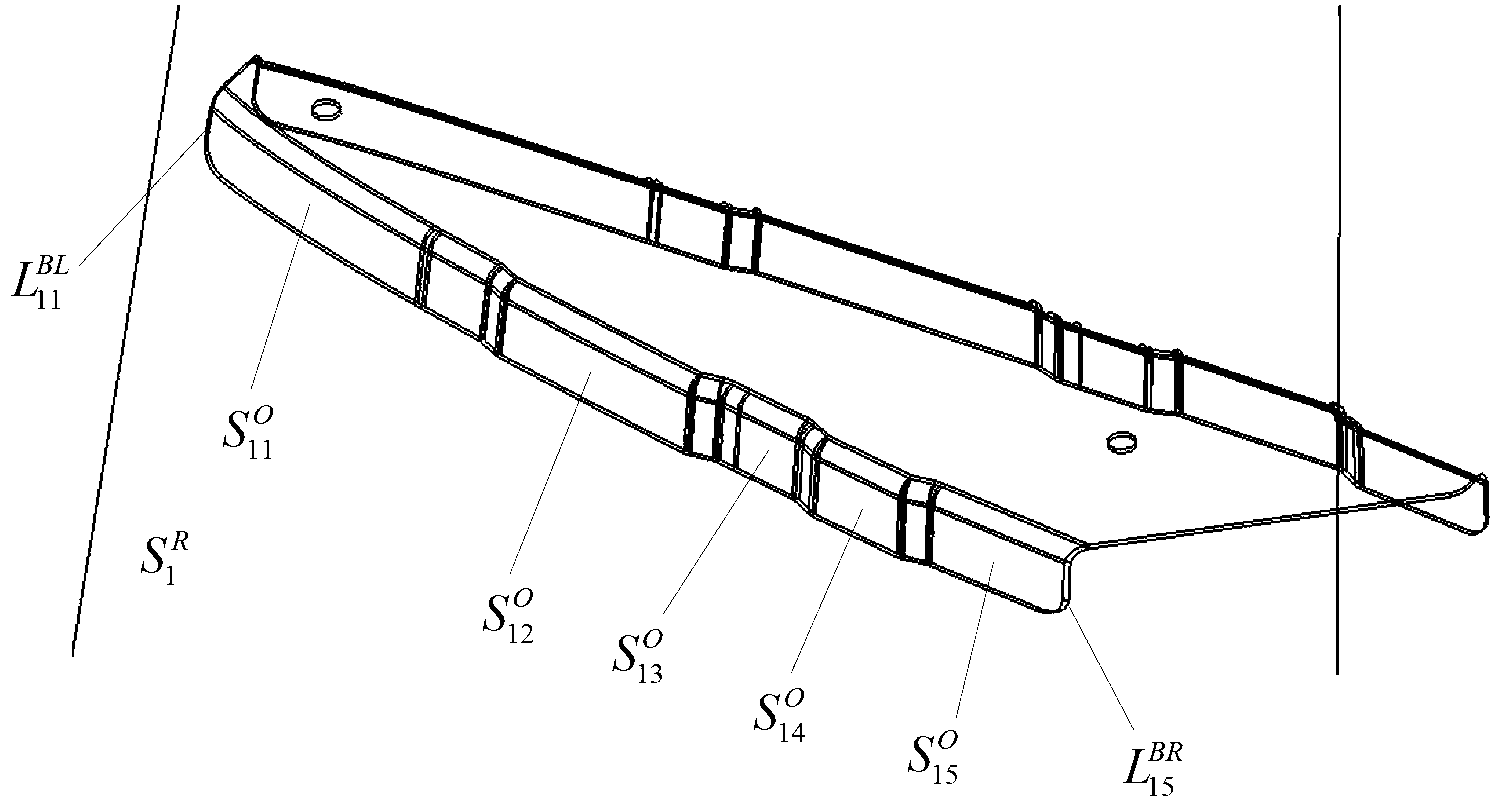

Design method of airplane frame and rib type sheet metal part processing model

The invention belongs to the technical field of aircraft manufacturing, and relates to a design method of an airplane frame and rib type sheet metal part processing model. According to design model of a part, a part processing model which can be directly applied to mold working molded surface design is designed. The design method is applicable to a frame and rib flange part with a variable camber, a variable cross-section, subsidence and a purlin notch. The design method is based on a flange reference plane, and the flange springback and compensation are taken into account.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

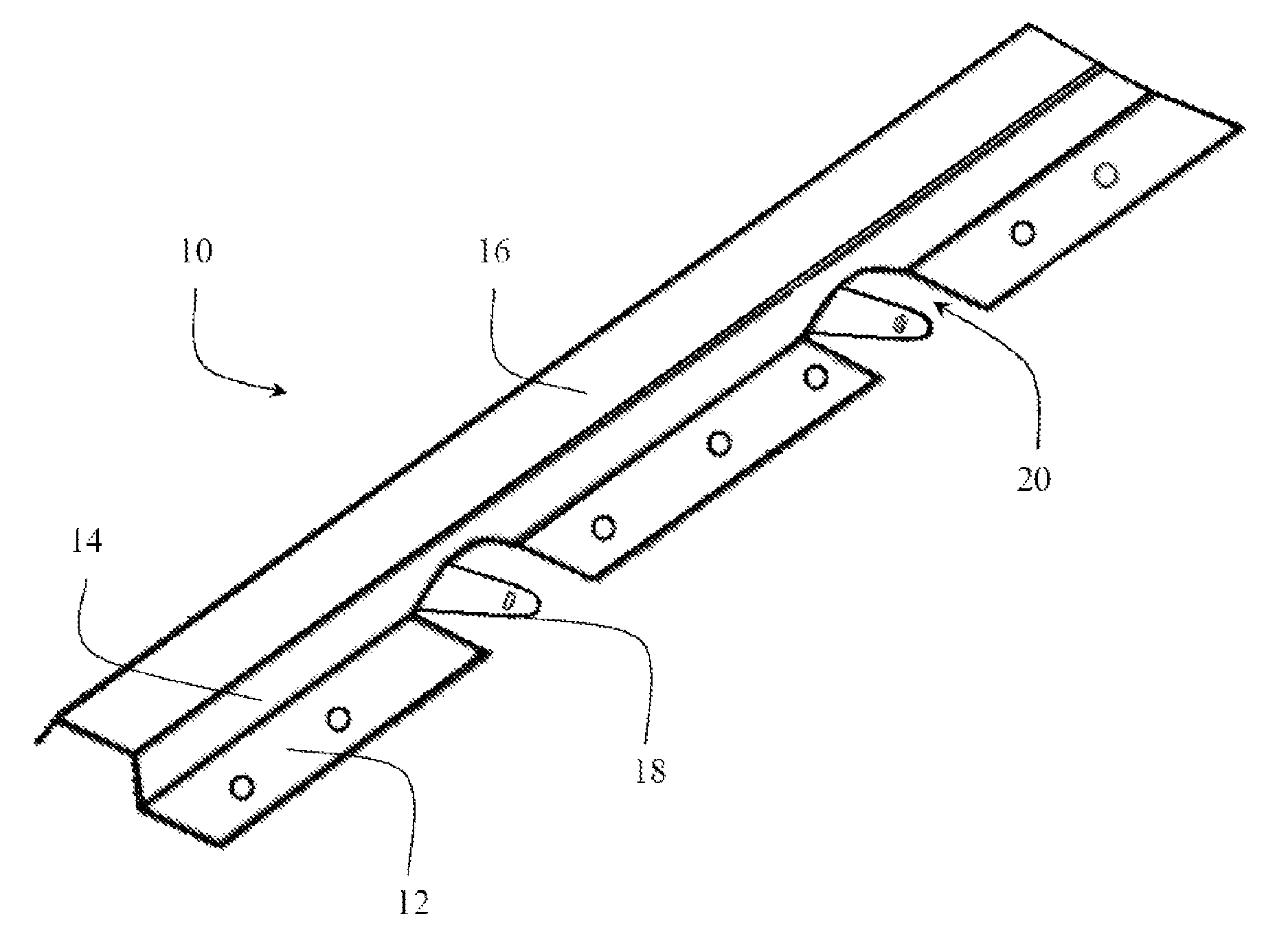

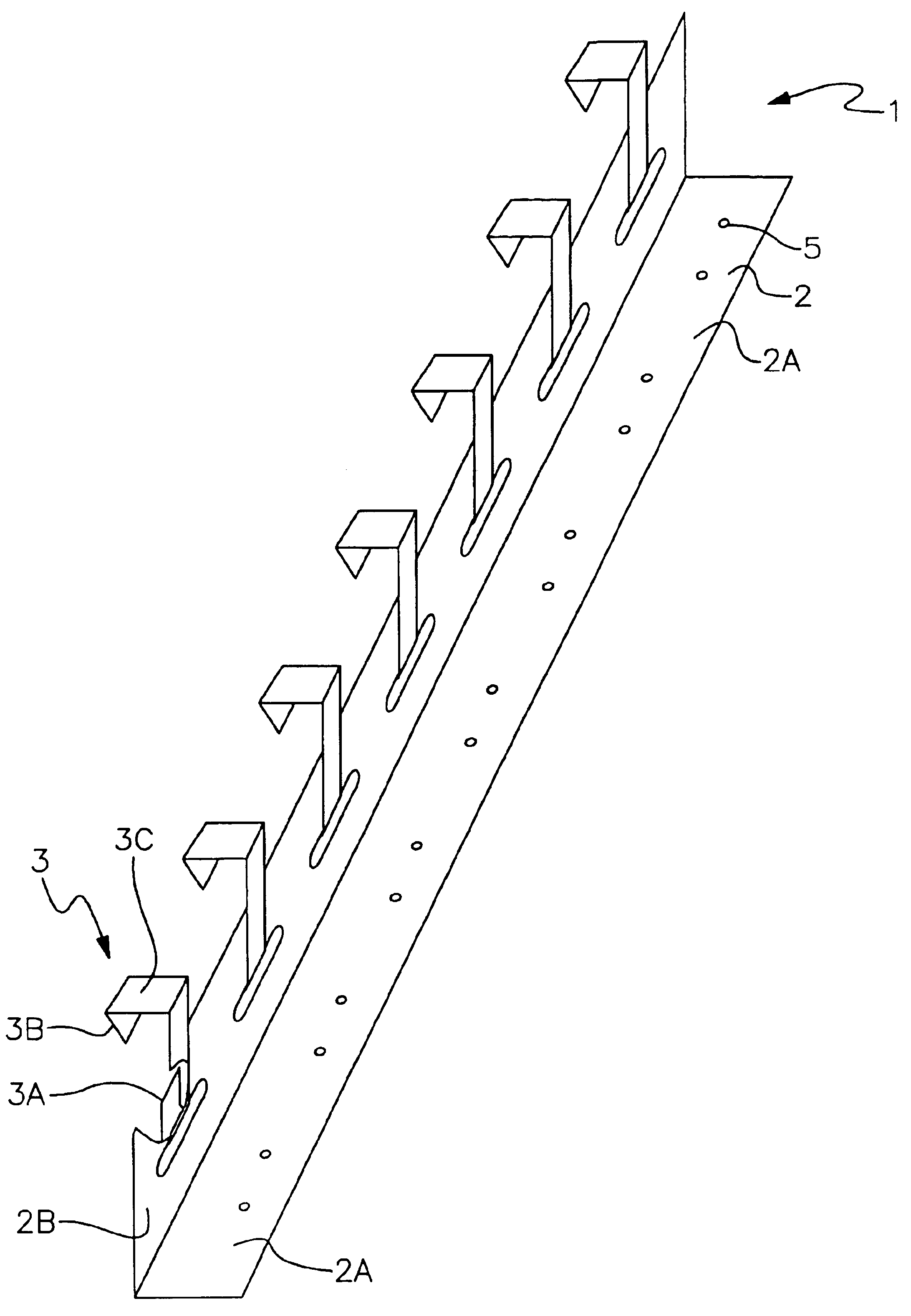

Standing-seam roof assembly bracket

ActiveUS8024906B1Strong and proper connectionAmple widthRoof covering using slabs/sheetsCeilingsSupporting systemPurlin

A bracket for use in retro-fitting metal clad buildings to facilitate attachment of new roof or wall panels of any desired profile, directly over existing ribbed or fluted panels of various configurations. Commonly known in the trades as a sub purlin or sub girt. Generally a one piece Z shaped metal bracket with a substantially vertical web between opposed top and bottom flanges in a parallel plane. The bottom flange and adjacent lower portion of the web contain a series of notches that allow the bracket to nest onto and over existing ribbed roof or wall panels. The top flange is automatically in position, lying flat and continuous, to receive and attach the new panels thereto. An ant-roll tab further connects the web to the existing roof panel. The solid portion of lower flange is preferred to be positioned directly above the underlying substructural support system members of the existing building to assure a structurally sound attachment of bracket to the building. Pre-punched holes in the solid portion of lower flange dictate required location, number and size of fasteners to be inserted through lower rib surface of existing panel into substructural system members.

Owner:ROOF HUGGER LLC

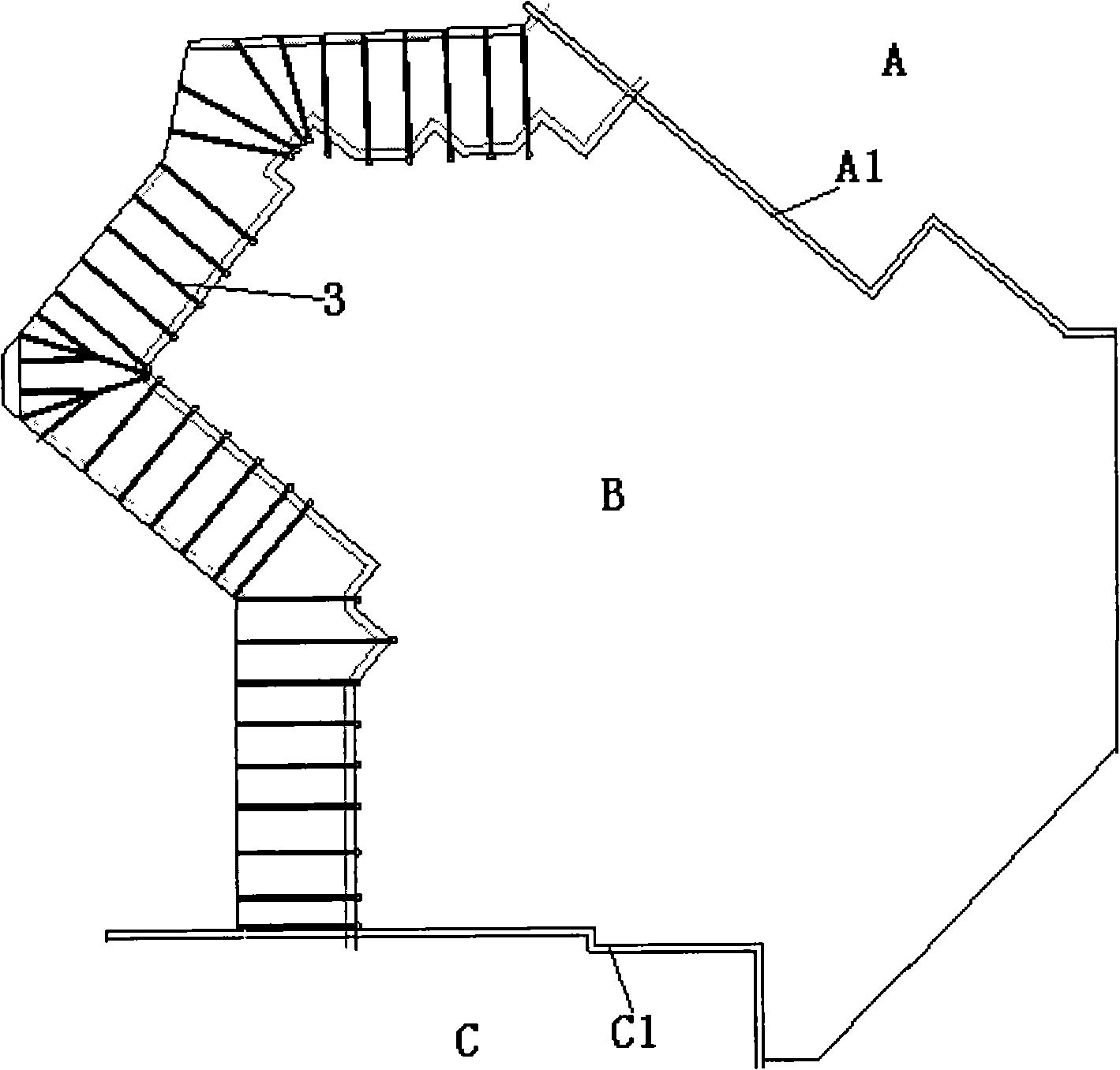

Direct local skirt border reversing construction for central island

InactiveCN1982546AReduce distortionEnsure safetyArtificial islandsBuilding constructionsSupporting systemPurlin

A job practice of which center island is done in sequence and partial skirts done inversely, comprising the following steps : set up exterior-protected construction, purlin and steel upright columns around the foundation ditch; dig on basin pattern for the first time to the depths to structural plane of purlin, earthwork are unified dig beneath the designed to the surrounding medium plate in the foundation ditch, pour the surrounding medium plate; dig for the second time with basin pattern downwards from the position of foundation ditch medium plate to the bottom of the designed foundation ditch, pour the center island plate; after the center island plate meets the maintenance time request of plate, construct in sequence to close the medium plate, setting fetching holes; then use medium plate for support system, construct criss-cross structural upper plate and plates in inverse zones. This construction method is convenient, save labor force and resources, improves the progress of the project, shorten the construction period.

Owner:SHANGHAI NO 7 CONSTR

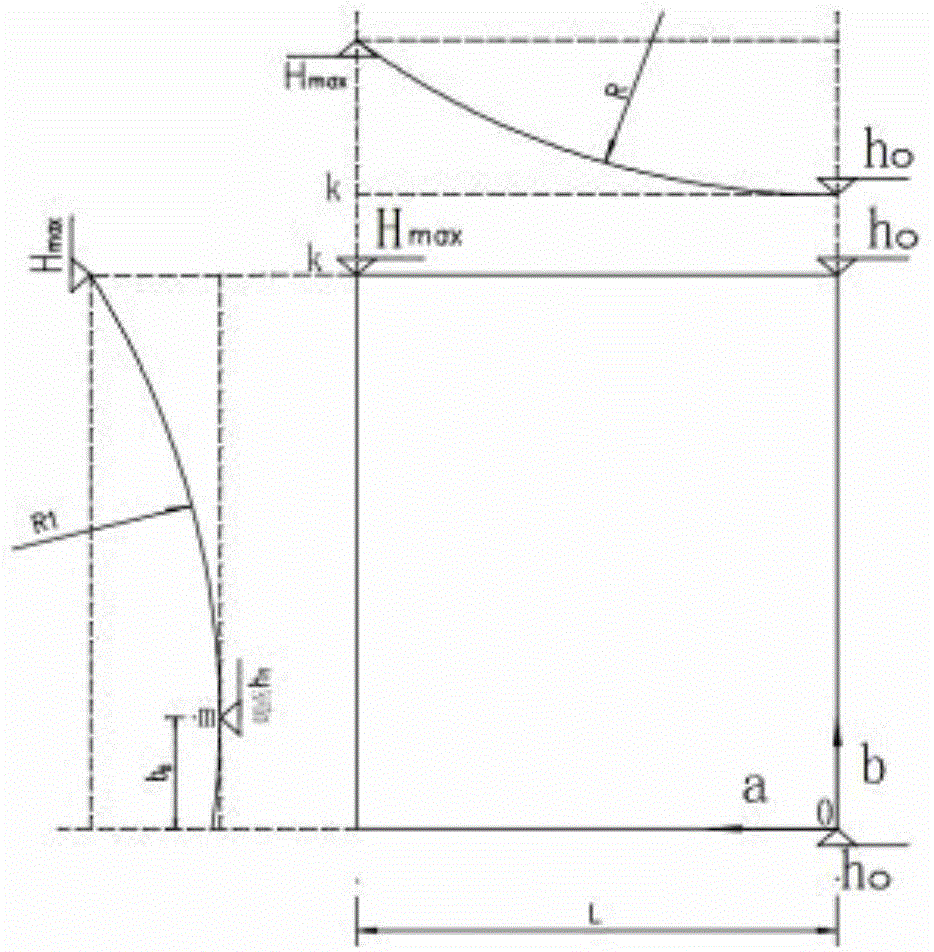

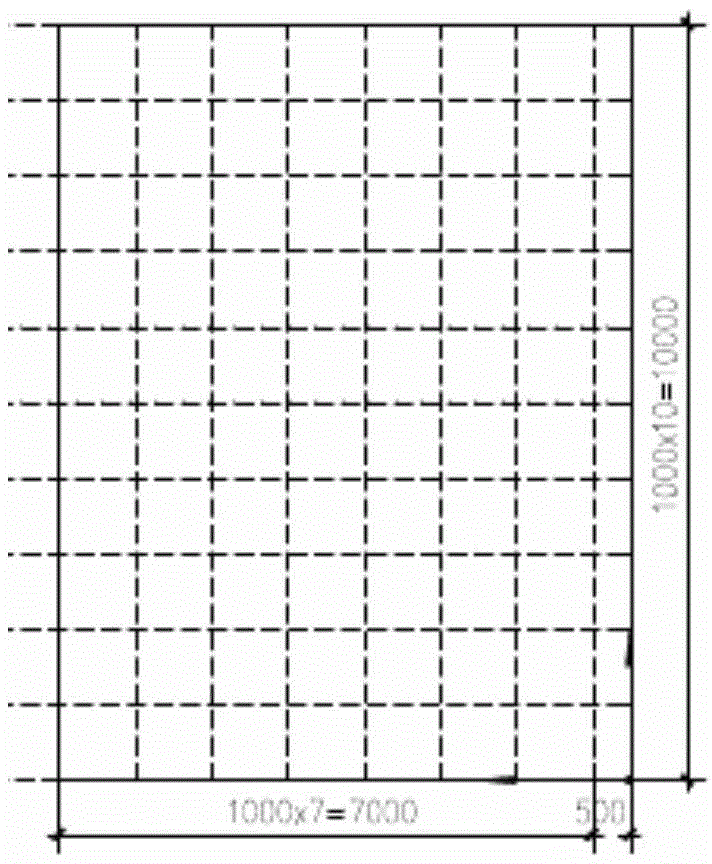

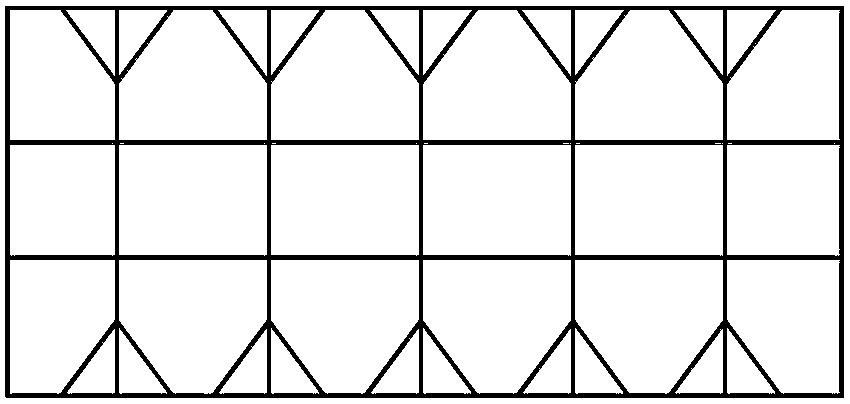

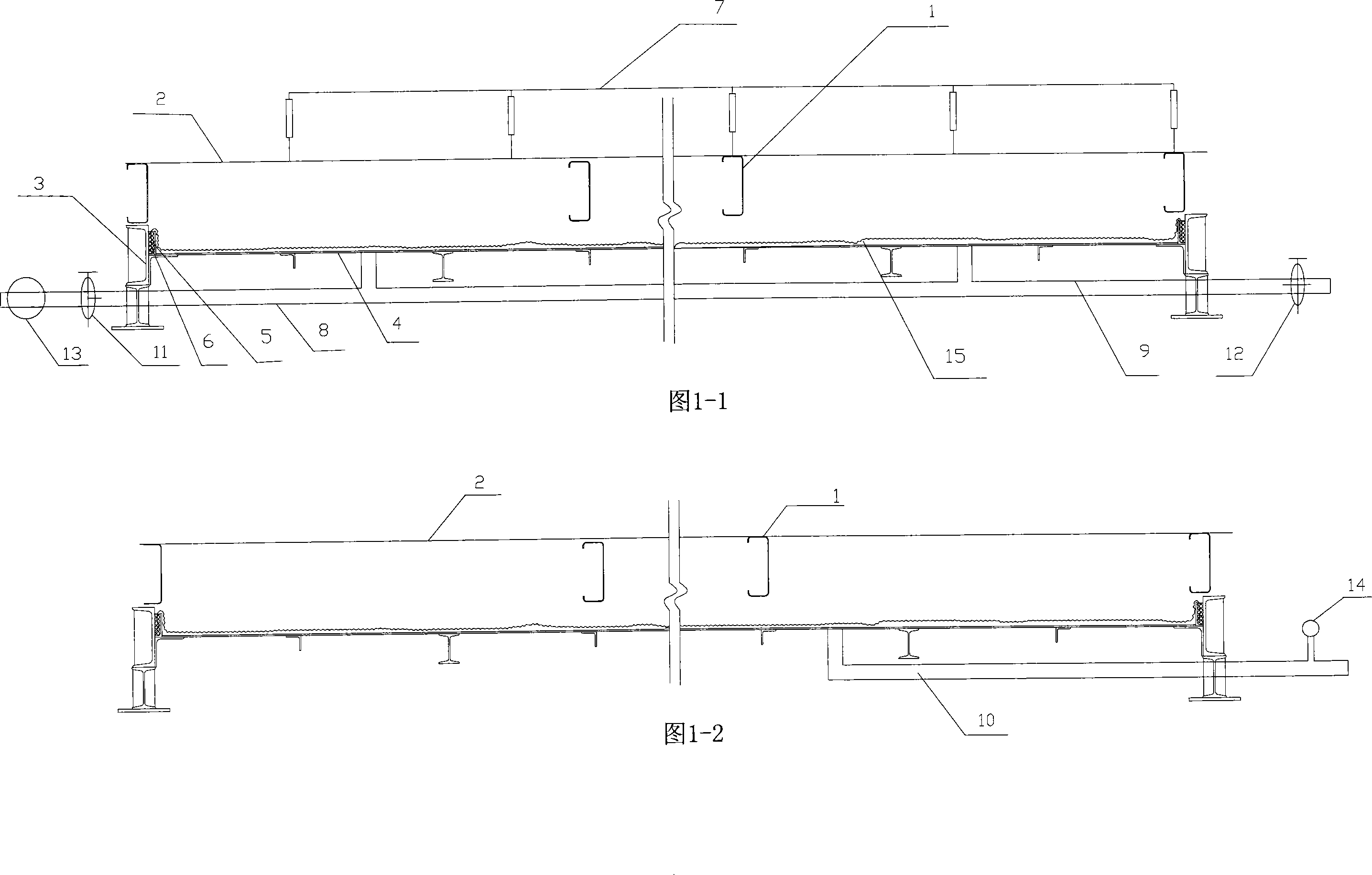

Measurement, control and construction method for curved roof formwork system

InactiveCN104818792AGuarantee the construction qualityPrecise positioningBuilding roofsForms/shuttering/falseworksPurlinRebar

The invention relates to the technical field of building construction, in particular to a measurement, control and construction method for a curved roof formwork system. Projection division is carried out on a curved surface of a concrete roof in measurement location, and the space elevation of any point on the curved surface can be accurately calculated through the coordinate plane conversion calculation formula. With the axis as the basis, the horizontal projection of the curved surface is divided into a plurality of small-specification grids, then the elevation of the grid nodes of the grids is calculated for carrying out measurement and location, and finally the grids are connected to form a smooth spatial curved surface for serving as the basis of setting up the curved roof formwork system. According to the elevation, back purlins are cut in a lofting mode, common formworks and bamboo clamp plates are used cooperatively for forming a bottom formwork of the curved roof formwork system, steel pipe cross rods are set up to support the bottom formwork, and bent steel bars are laid on the bottom formwork which is set up. According to the invention, the measurement difficulty and the construction labor intensity are lowered, the construction progress is accelerated and the construction quality is improved.

Owner:GUANGDONG DIANBAI CONSTR GRP

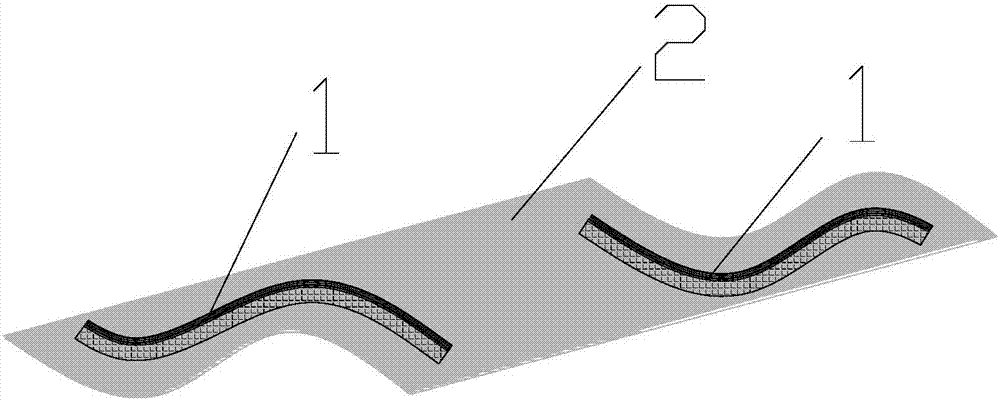

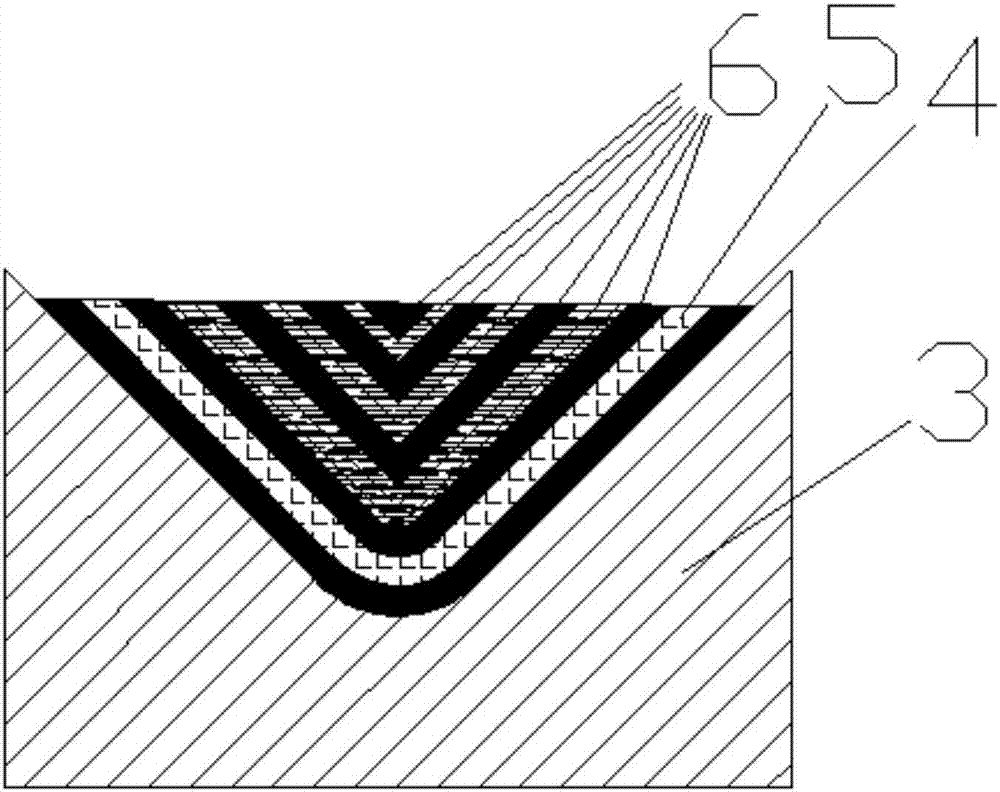

Co-curing forming technological method of variable-curvature composite stiffened wall plate

The invention belongs to the technical field of composite manufacturing and relates to a co-curing forming technological method of a variable-curvature composite stiffened wall plate. The co-curing forming technological method of the variable-curvature composite stiffened wall plate comprises the following steps of manufacturing a flexible long purlin core mold, conducting laying and pasting on a composite wall plate skin and a long purlin, assembling a long purlin green body and the skin and conducting packaging and curing formation. According to the co-curing forming technological method of the variable-curvature composite stiffened wall plate, the flexible long purlin core mold is used as the forming core mold, the flexibility of rubber and the rigidity, low density and other features of a fiber composite are combined, the composite flexible long purlin core mold is used for replacing a metal core mold and formed into a continuous structure, the rigidity of the core mold is controlled by adjusting the ratio of rubber in the flexible long purlin core mold, the long purlin green body with the composite part is laid and pasted to a laying and pasting mold, then the long purlin green body is transferred to a flexible long purlin mold, the long purlin is located to a skin blank through a long purlin locating clamping plate, the co-curing technological method is adopted to manufacture the stiffened wall plate of a variable-curvature structure, and during operation, the stiffened wall plate of the variable-curvature structure is easy to attach to a technology piece and is not influenced by curvature and shape.

Owner:AVIC BASIC TECH RES INST

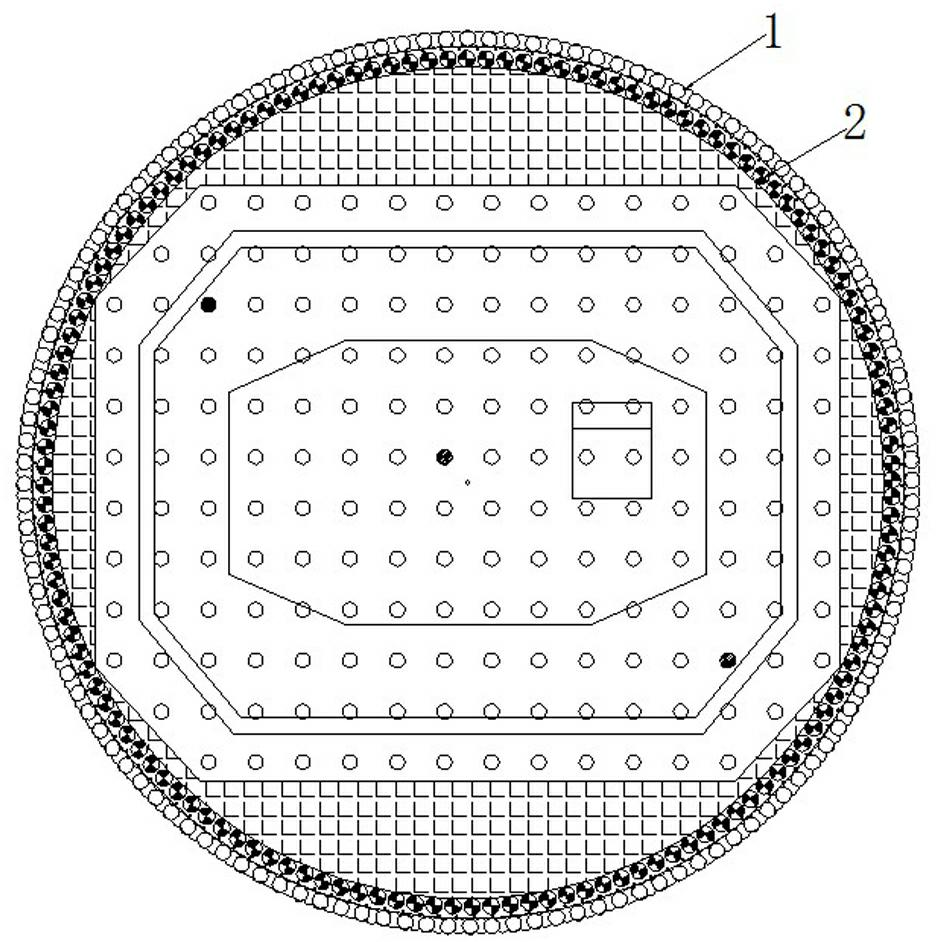

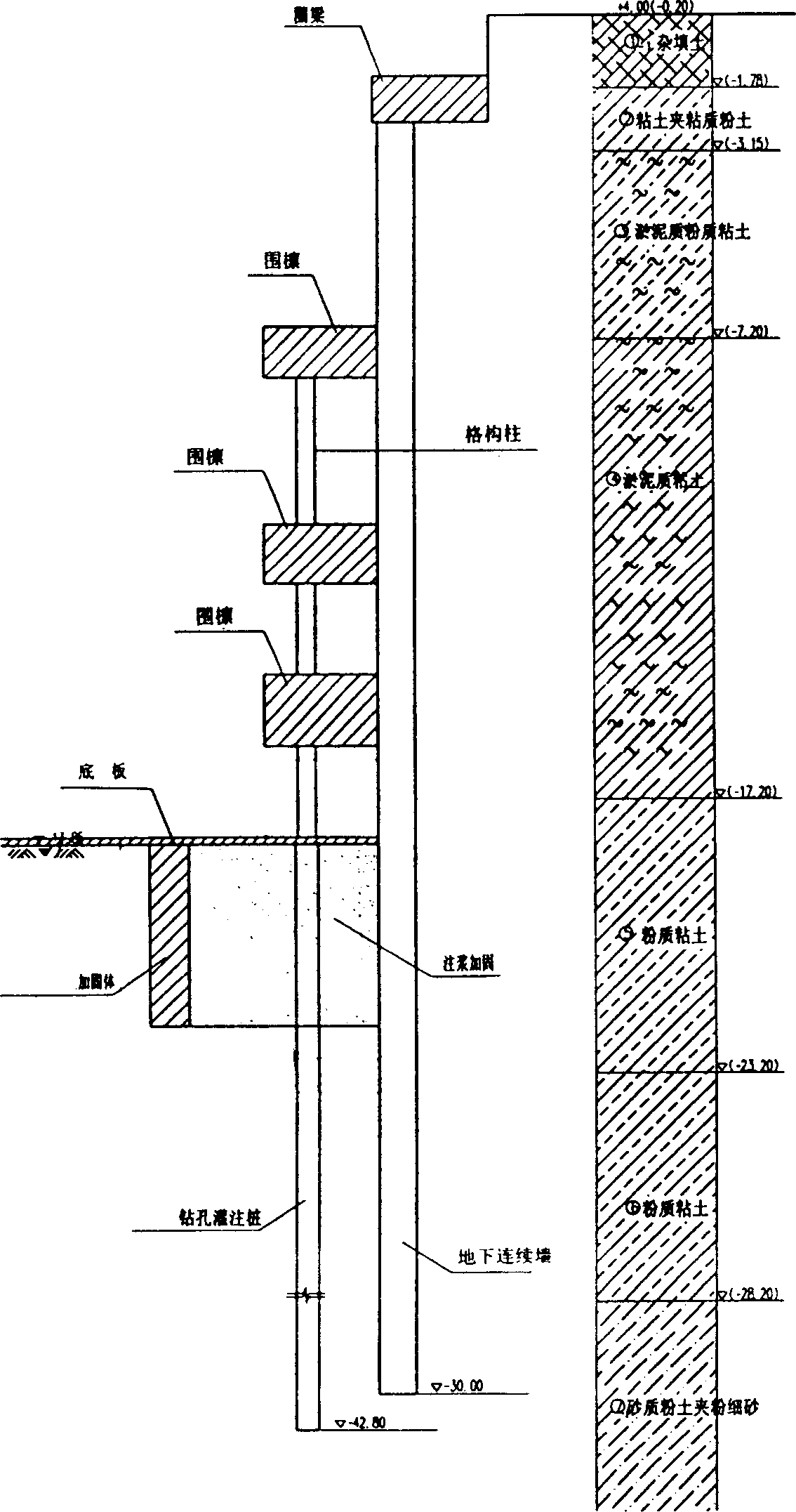

Supportless construction structure and supportless construction method for round deep base pit

InactiveCN102635120AConservation cost reductionFast constructionExcavationsBulkheads/pilesInternal pressurePurlin

The invention discloses a supportless construction structure and a supportless construction method for a round deep base pit. The supportless construction method comprises the steps as follows: carrying out three-shaft stirring pile construction, cast-in-situ bored pile construction, earth mass grouting reinforcement, earth excavation, first enclosing purlin construction, subsequent earth excavation, next enclosing purlin construction, subsequent earth excavation and cushion layer and bottom plate construction so as to obtain a deep base pit bracing structure mainly comprising a circle of three-shaft stirring pile, a circle of cast-in-situ bored pile and a plurality of enclosing purlins. The bracing structure has no supporting structure; the arch effect of the earth mass is utilized; the earth pressure on the bracing structure is reduced; the external load is converted into the internal pressure on the enclosing purlins by the arch effect of the enclosing purlins at the same time; the characteristic of good pressure resistance of concrete is brought into full play; and as no supports are provided, the processes of dismounting and replacing the supports are removed, so that the maintenance expense of the base pit is reduced and the construction speed is quick.

Owner:张全胜

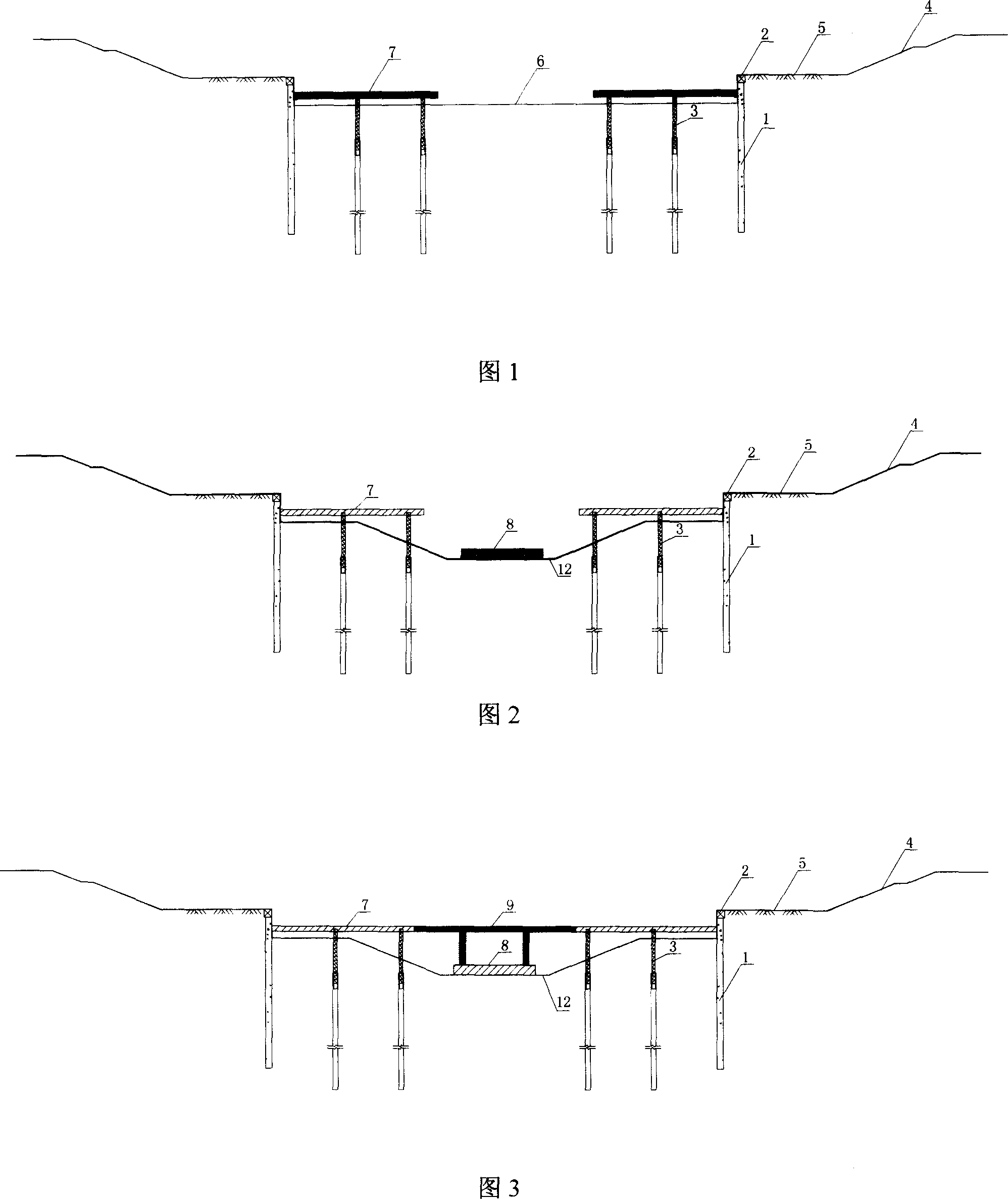

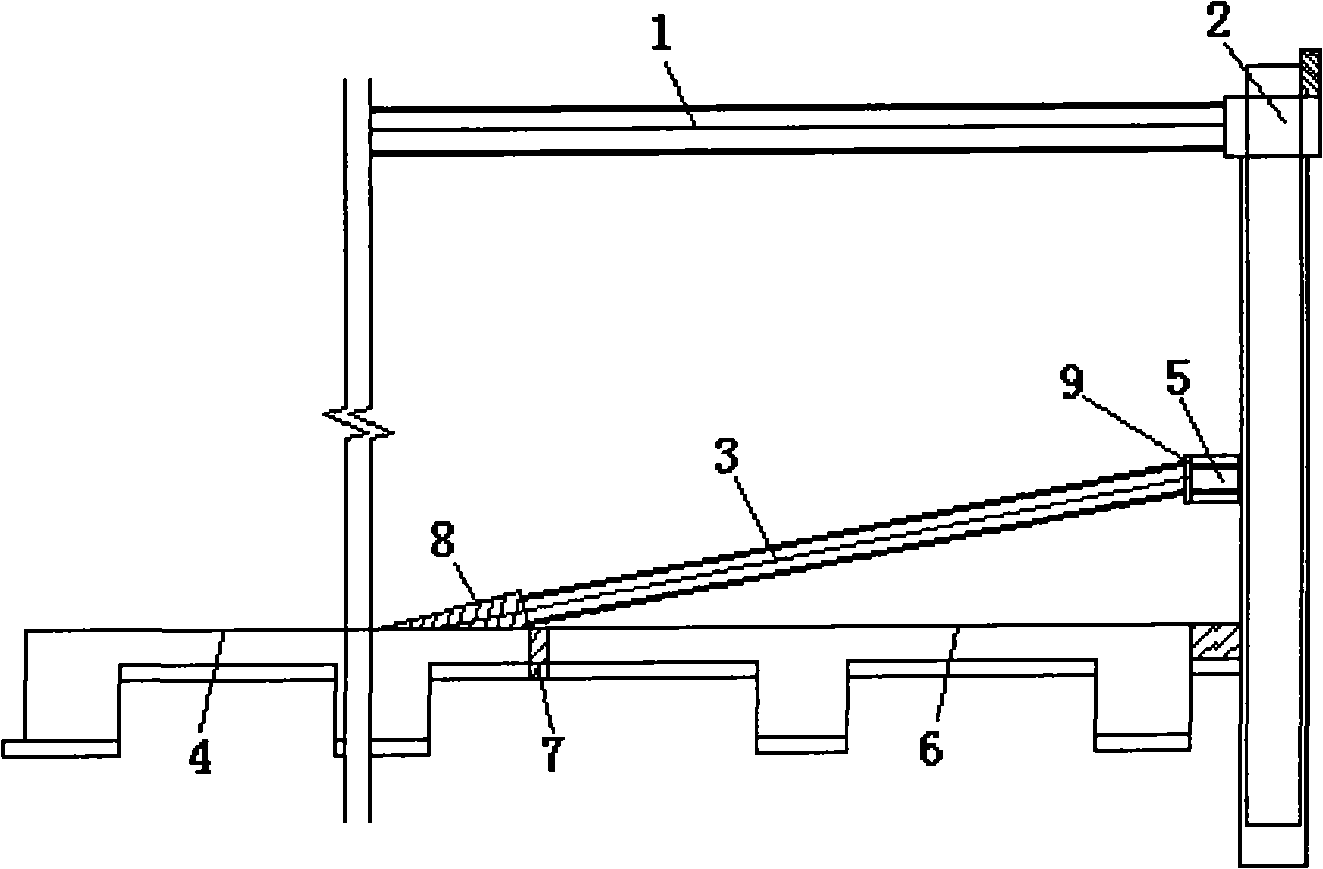

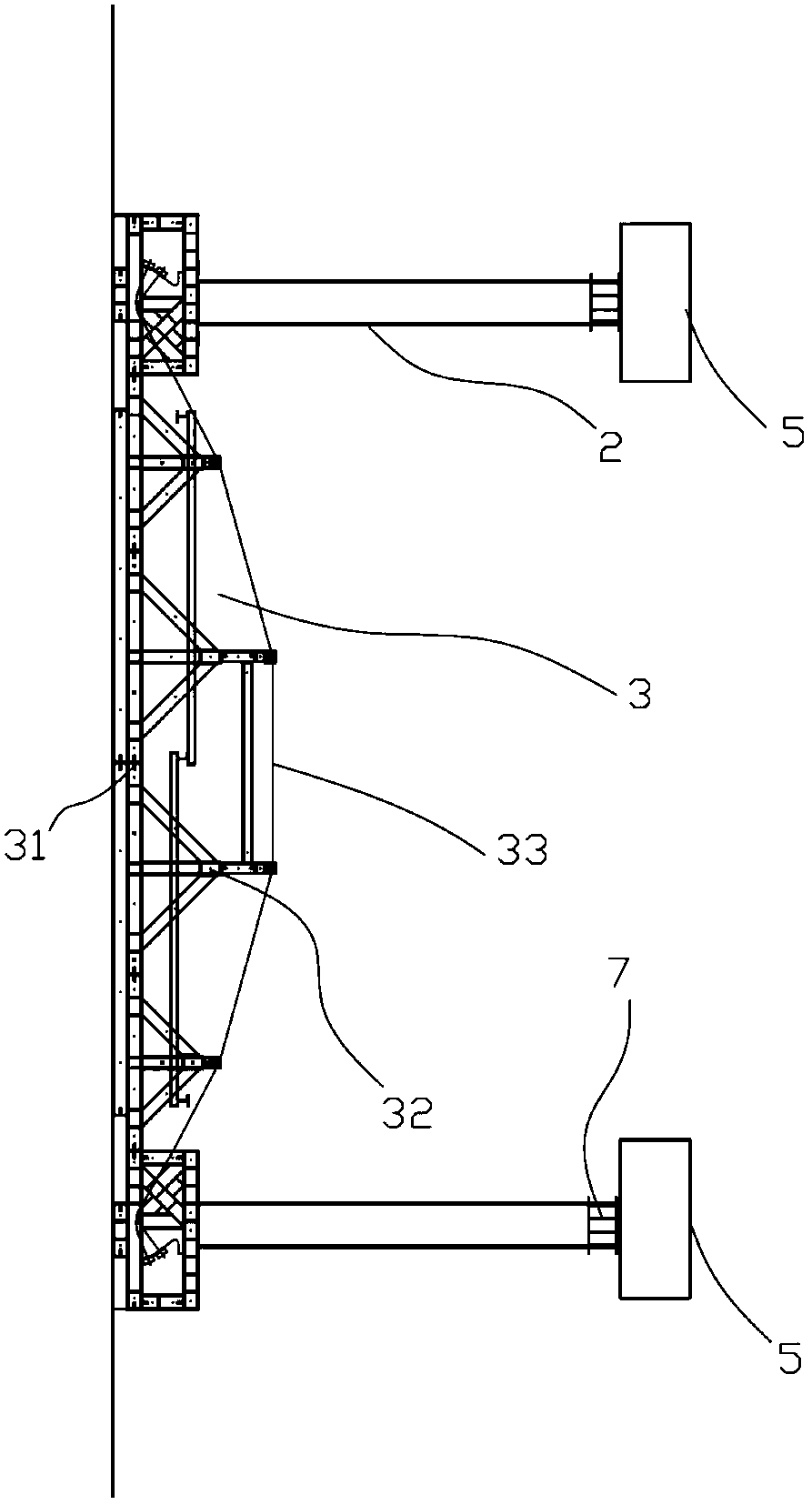

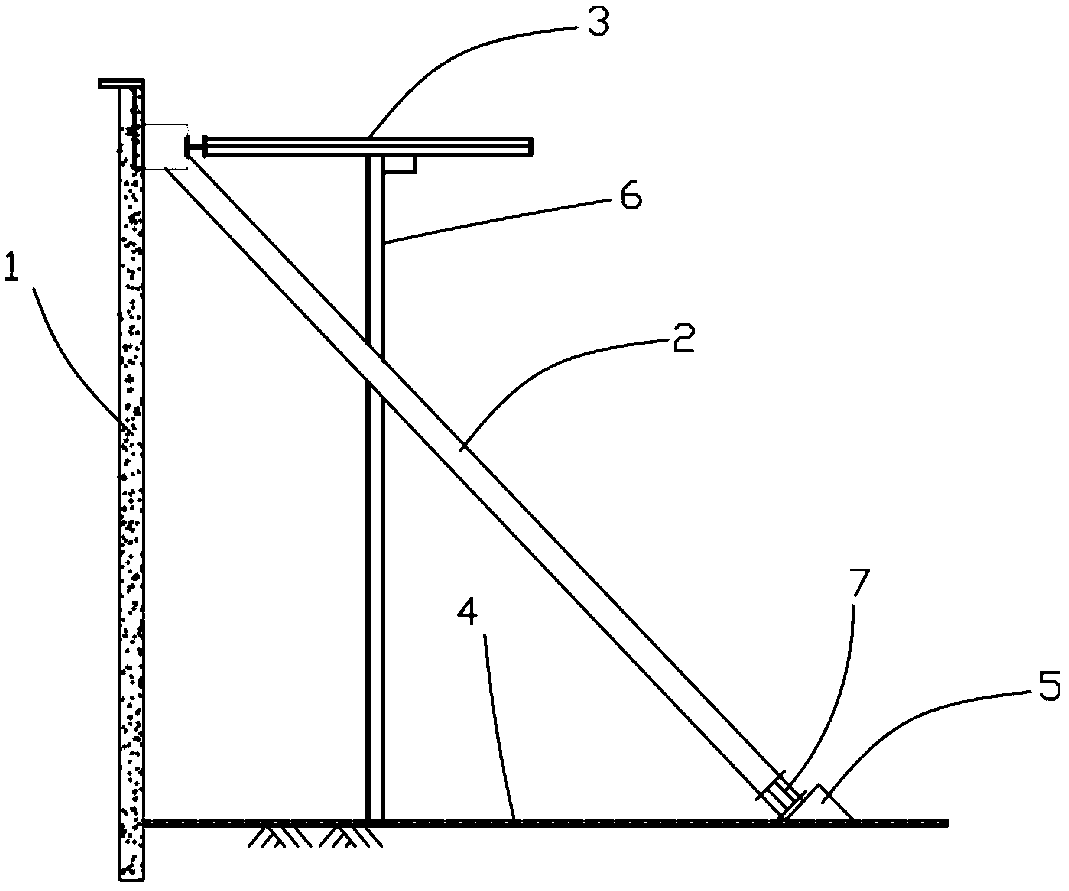

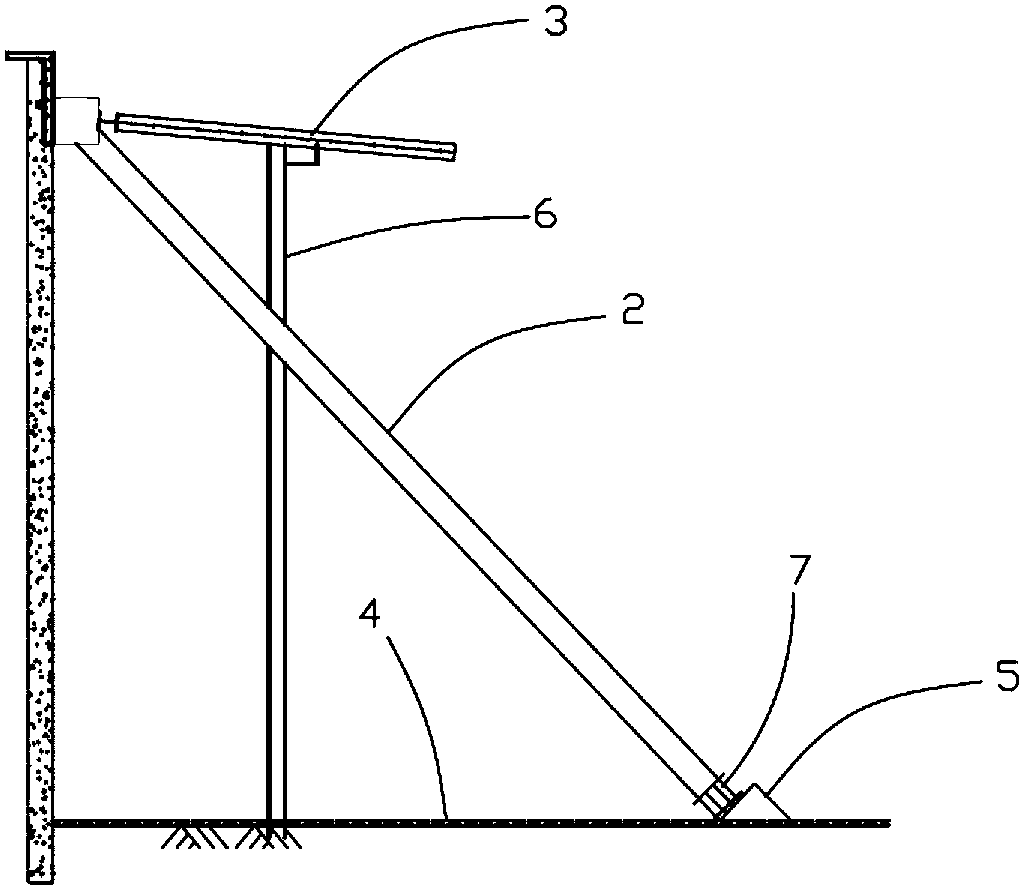

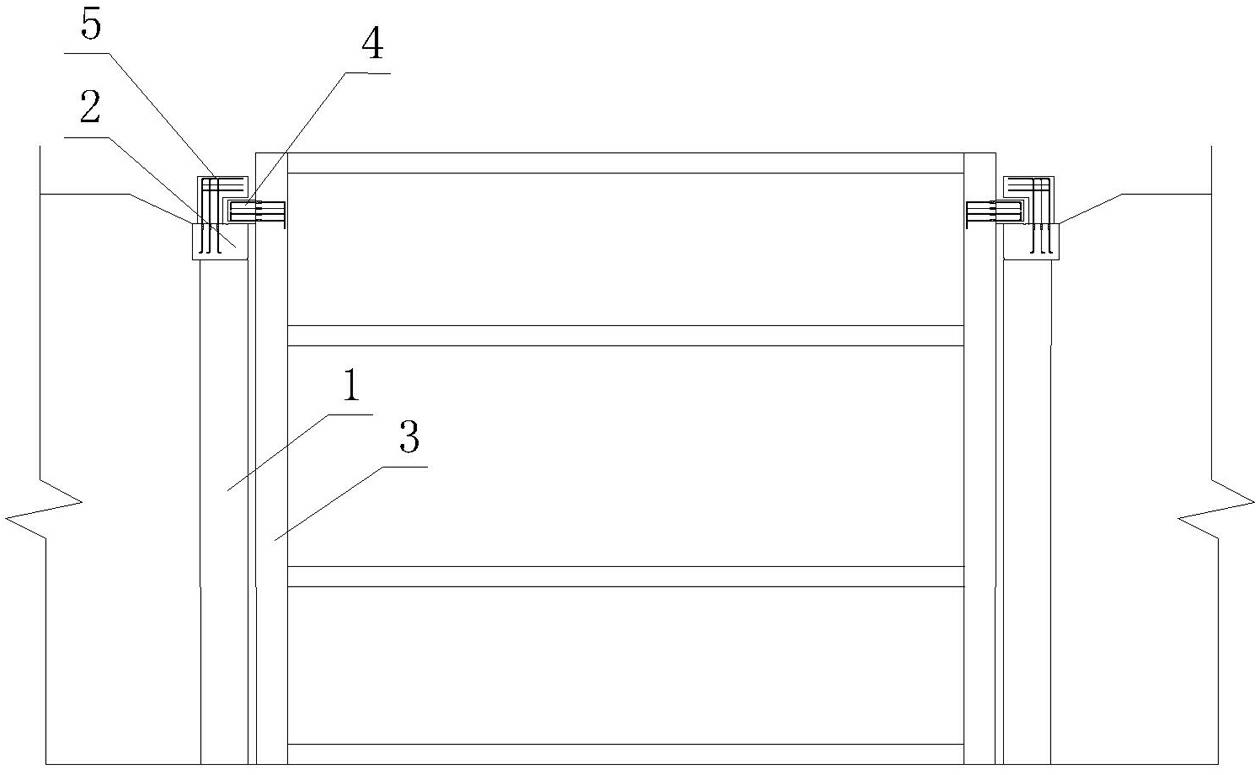

Support system and construction method for smoothening-digging partial center island foundation pit

ActiveCN101294390AReduce the time required for installationShorter dismantling timeExcavationsPurlinSupporting system

The invention discloses a system used for supporting a one-horizontal-strut and one-inclined-strut local mid-island foundation pit of a super large excavation, as well as the construction method thereof. The system comprises a horizontal steel strut which takes a first reinforced concrete purlin around the pit as a supporting purlin, and also comprises an inclined strut positioned at the inferior part of the horizontal steel strut and arranged along the local periphery of the foundation pit, the lower end of the inclined strut leans against on a foundation pit base plate which is subjected to excavation and concrete pouring, while the upper end leans against on a second reinforced concrete purlin arranged below the first reinforced concrete purlin, and a construction joint is arranged between the foundation pit base plate which is subjected to excavation and concrete pouring and a foundation pit which is unexcavated. The foundation pit supporting system as well as the construction method thereof provide a novel design idea for supporting the super large excavation, exerts the respective advantages of the support and the mid-island struts, reduces the earthwork construction difficulty under the second support, and also decreases the defects existing in the pure mid-island construction that too many overlong slopes exist.

Owner:SHANGHAI CONSTR NO 5 GRP CO LTD

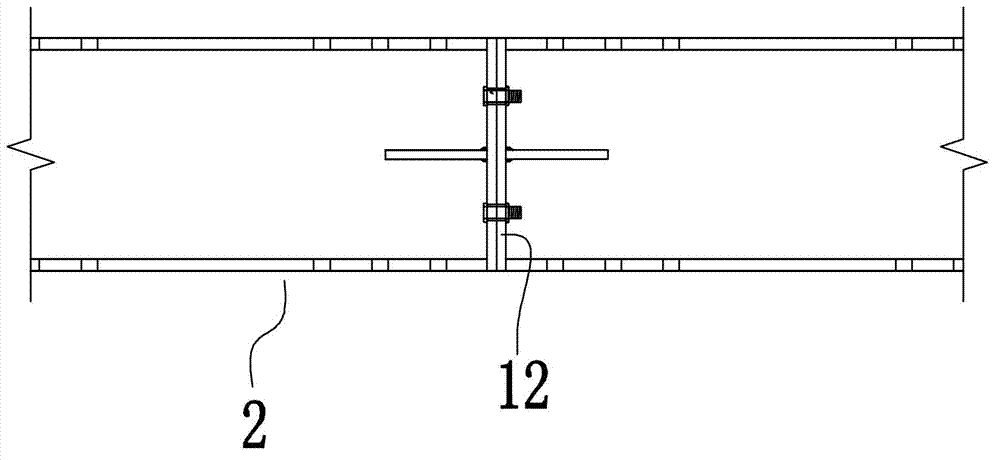

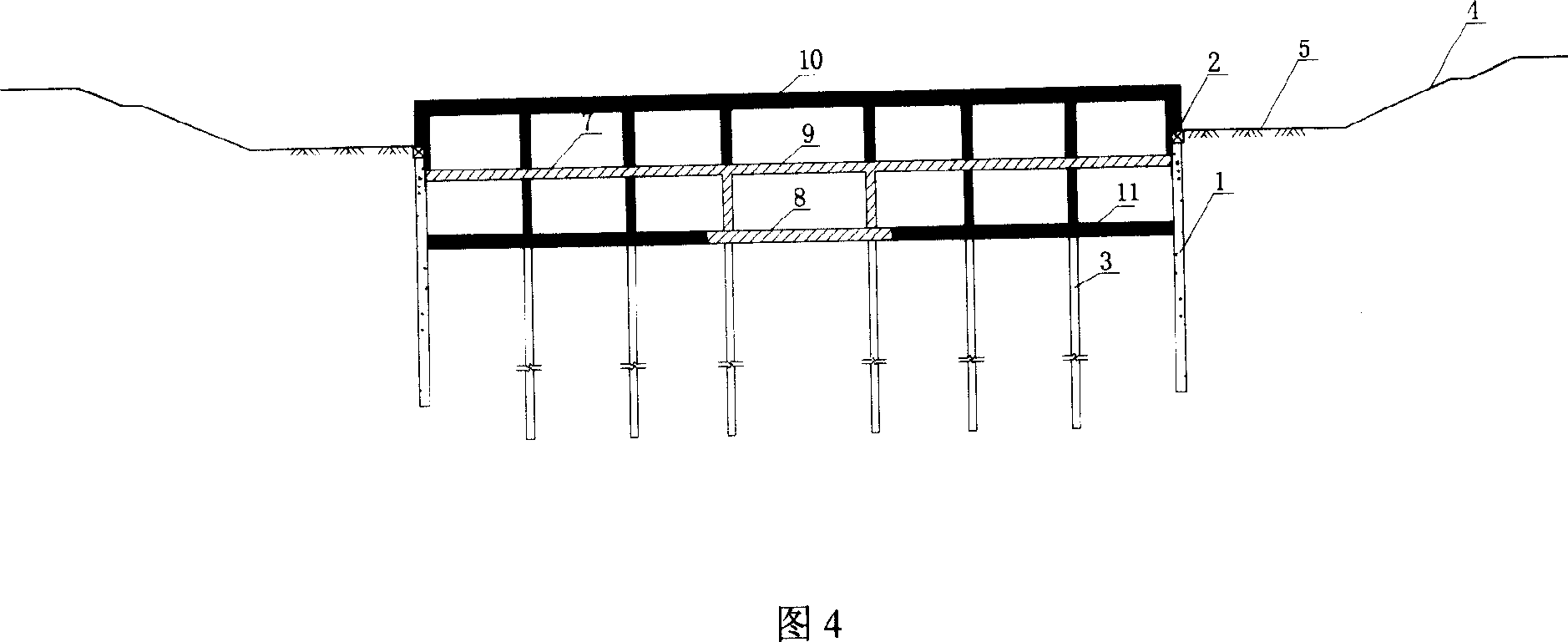

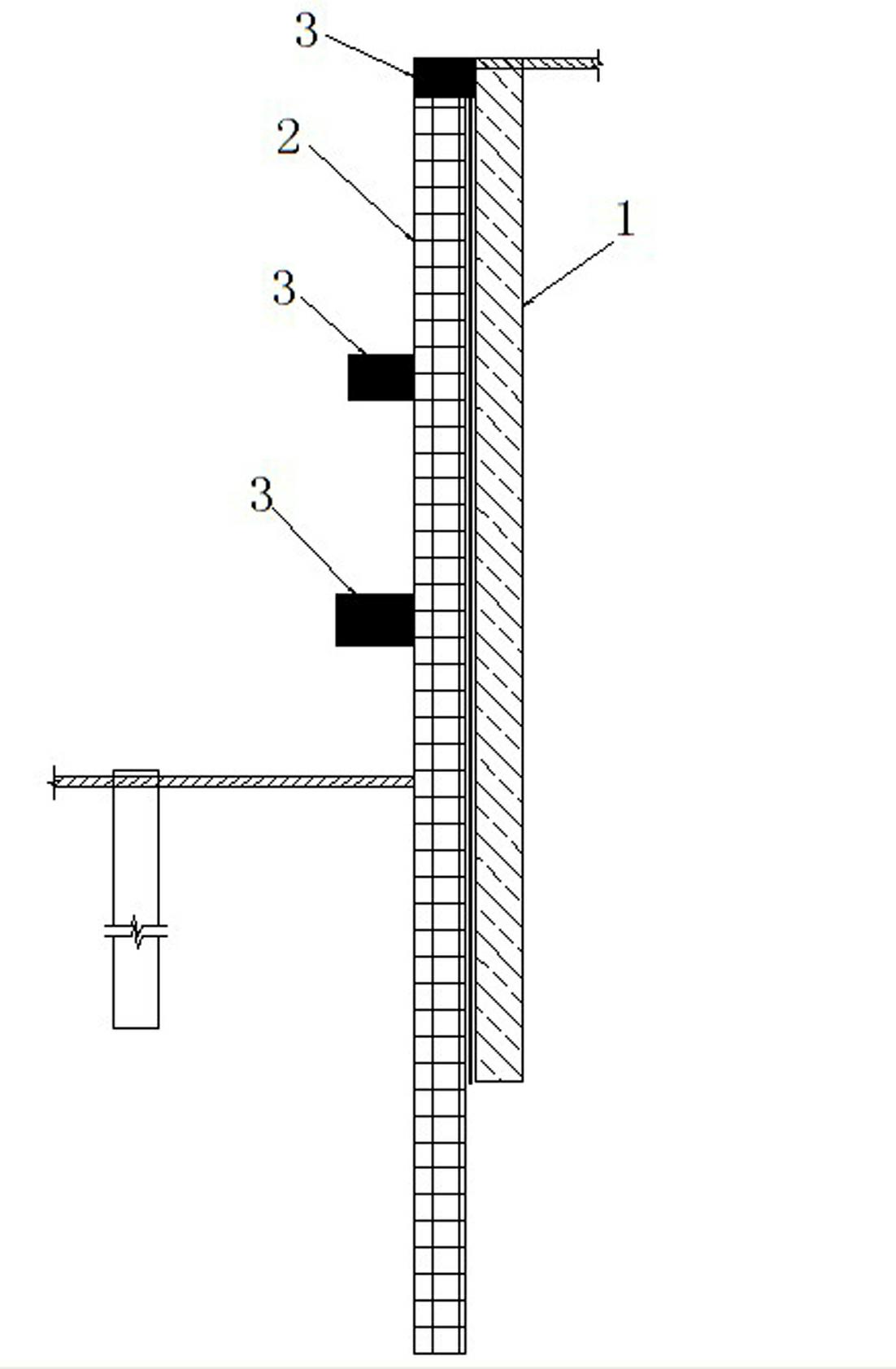

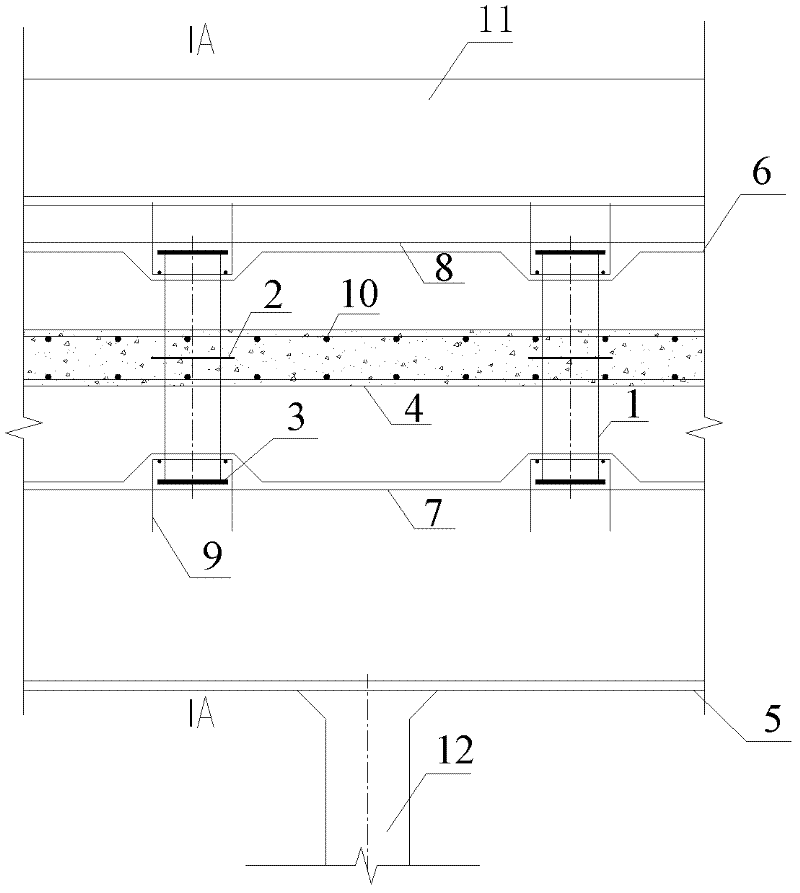

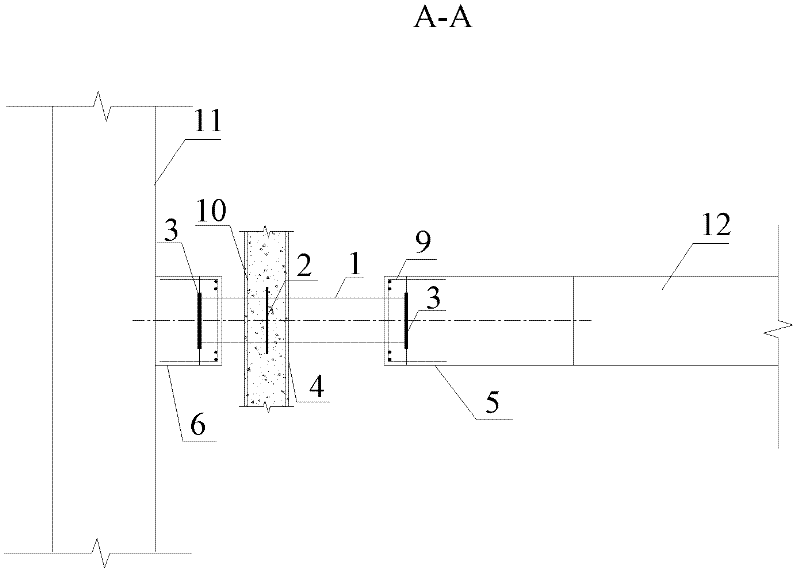

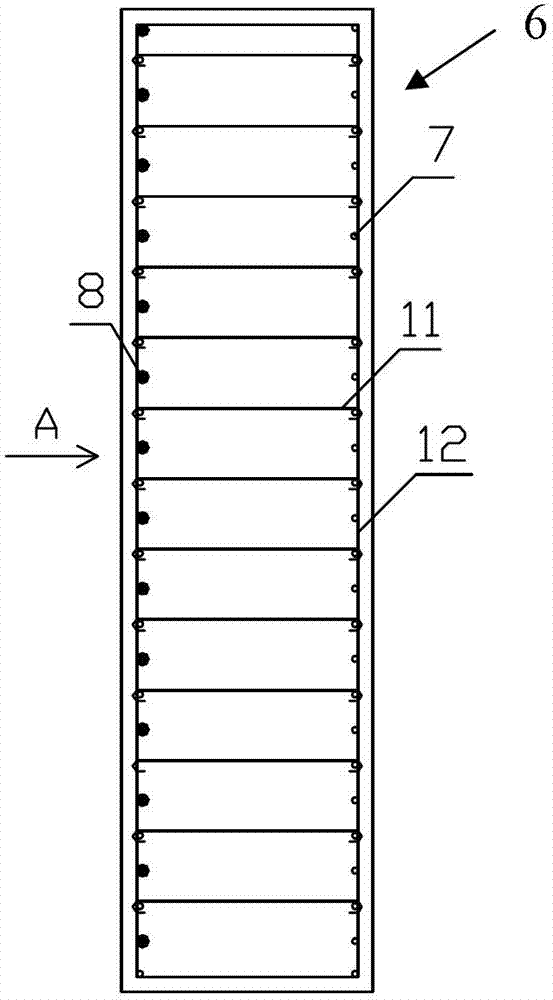

Support system of rear support removing type section steel-concrete double-enclosing-purlin foundation pit and construction method

InactiveCN102505696AReduce construction difficultyReach the force requirementExcavationsSupporting systemPurlin

The invention discloses a support system of a rear support removing type section steel-concrete double-enclosing-purlin foundation pit and a construction method. The support system comprises an enclosing wall located in the foundation pit, a plurality of horizontal supports located on the inner side of the enclosing wall, an enclosing purlin fixed on the enclosing wall and an enclosing purlin fixed on the horizontal supports. A plurality of bars of horizontally arranged section steel is arranged between the double enclosing purlins, and vertical steel bars in a structure wall penetrates through slits between the section steel and the double enclosing purlins from top to bottom. The structure is reserved all the time at a back building stage until a horizontally stressed system of an underground main body structure is formed and can support the enclosing wall, then part of section steel extending out of the inner side of the structure wall is removed, and a whole reinforced concrete support is removed. The fact that the stressed requirements of a horizontal support system at an excavation stage of the foundation pit are met is guaranteed, lateral deformation is resisted, construction progress is accelerated, cost is reduced, construction quality is improved, a novel designing idea is provided for a deep foundation pit support system with an oversized area, and construction difficulty of a rear support removing system at a structural back-building stage is reduced.

Owner:上海建瓴工程咨询有限公司 +1

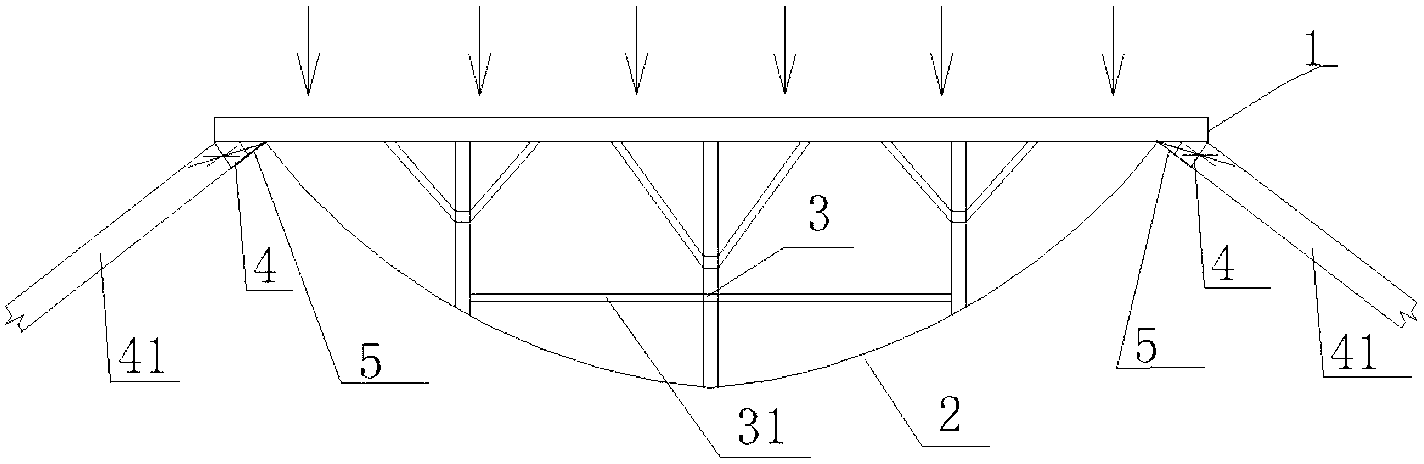

Long-span pre-stress fish belly sill for foundation pit support and mounting method thereof

The invention provides a long-span pre-stress fish belly sill. The long-span pre-stress fish belly sill is used for overcoming the defects of low rigidity, small span and insecure connection with opposite support of an encircling purlin of a supporting structure in the present foundation pit support. The encircling purlin has the advantages of high rigidity, long span, control deformation reliability, convenience in construction, reusability, and the like. The purposes of increasing the degree of safety of the foundation pit support, shortening the construction period and lowering the construction cost are achieved.

Owner:上海新强劲工程技术有限公司

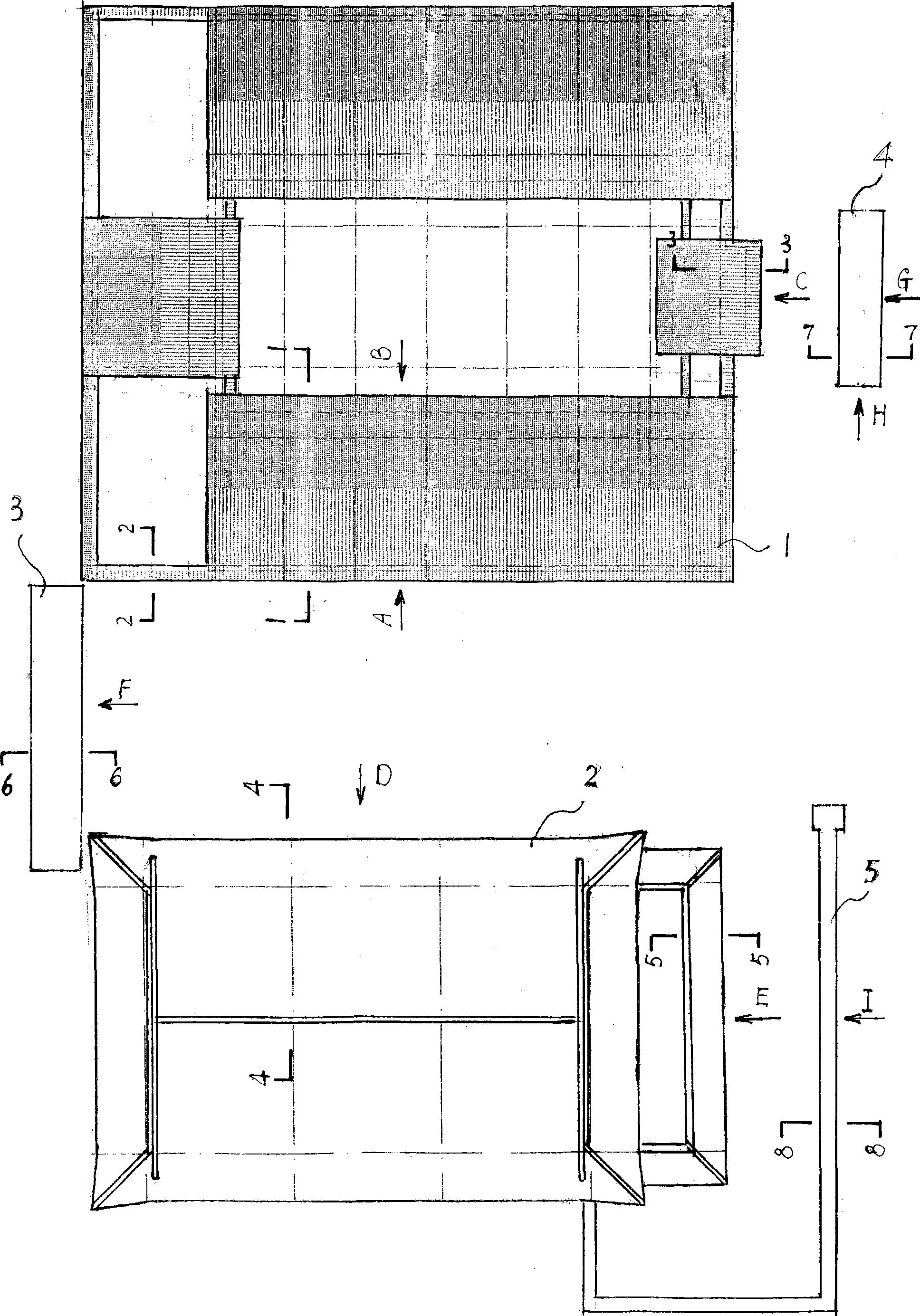

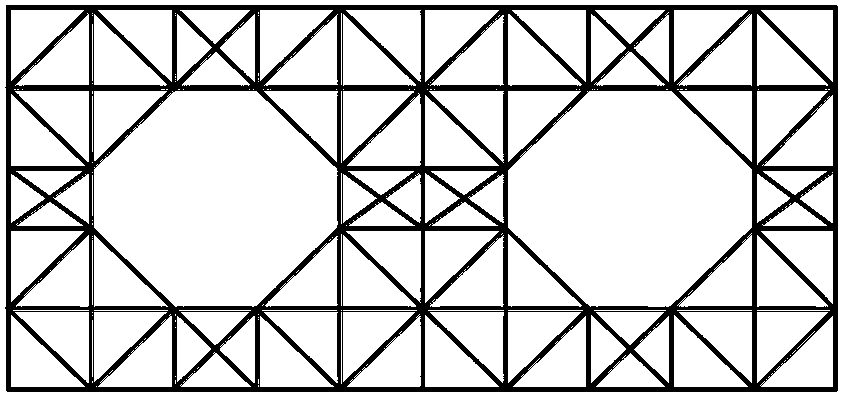

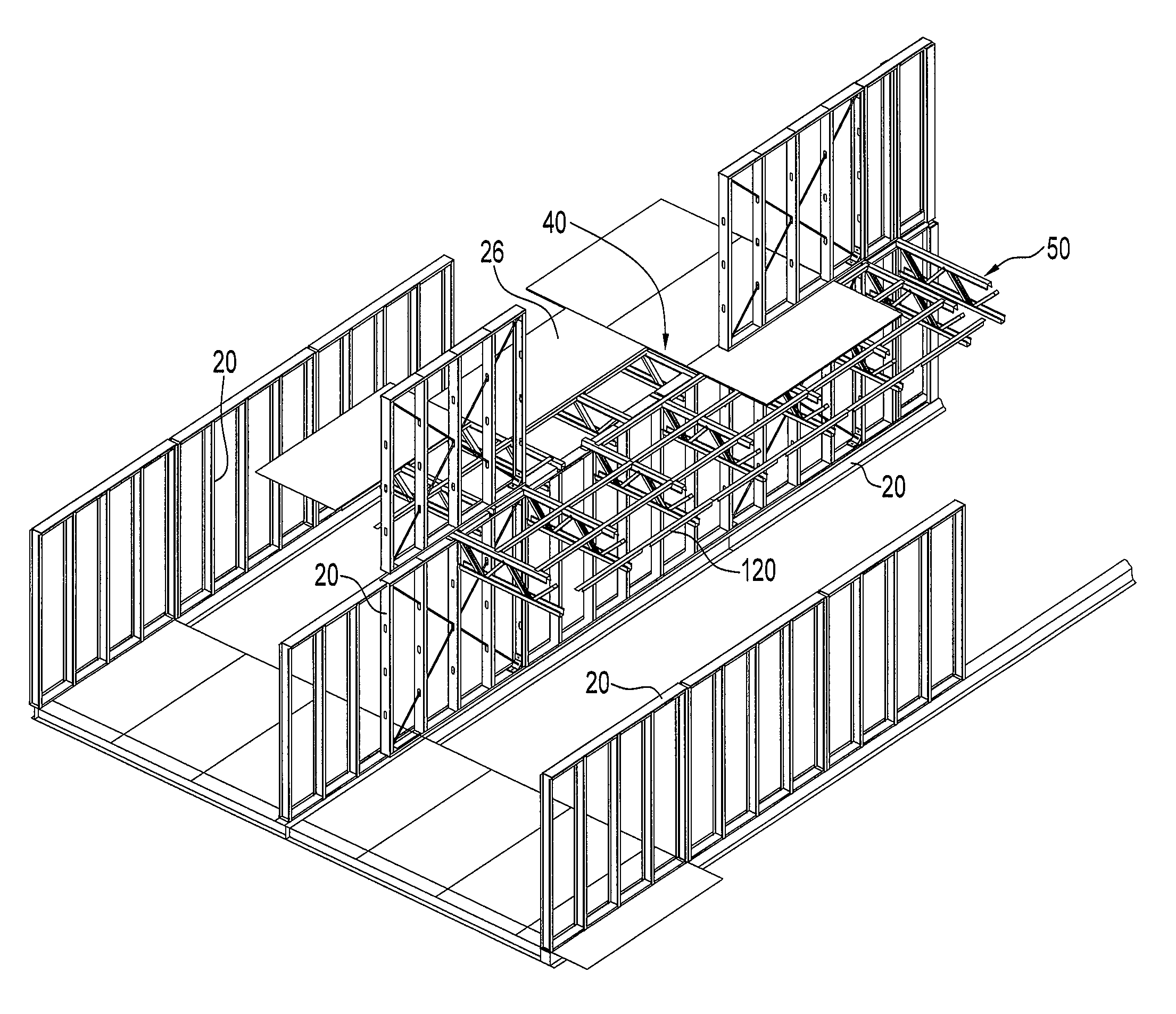

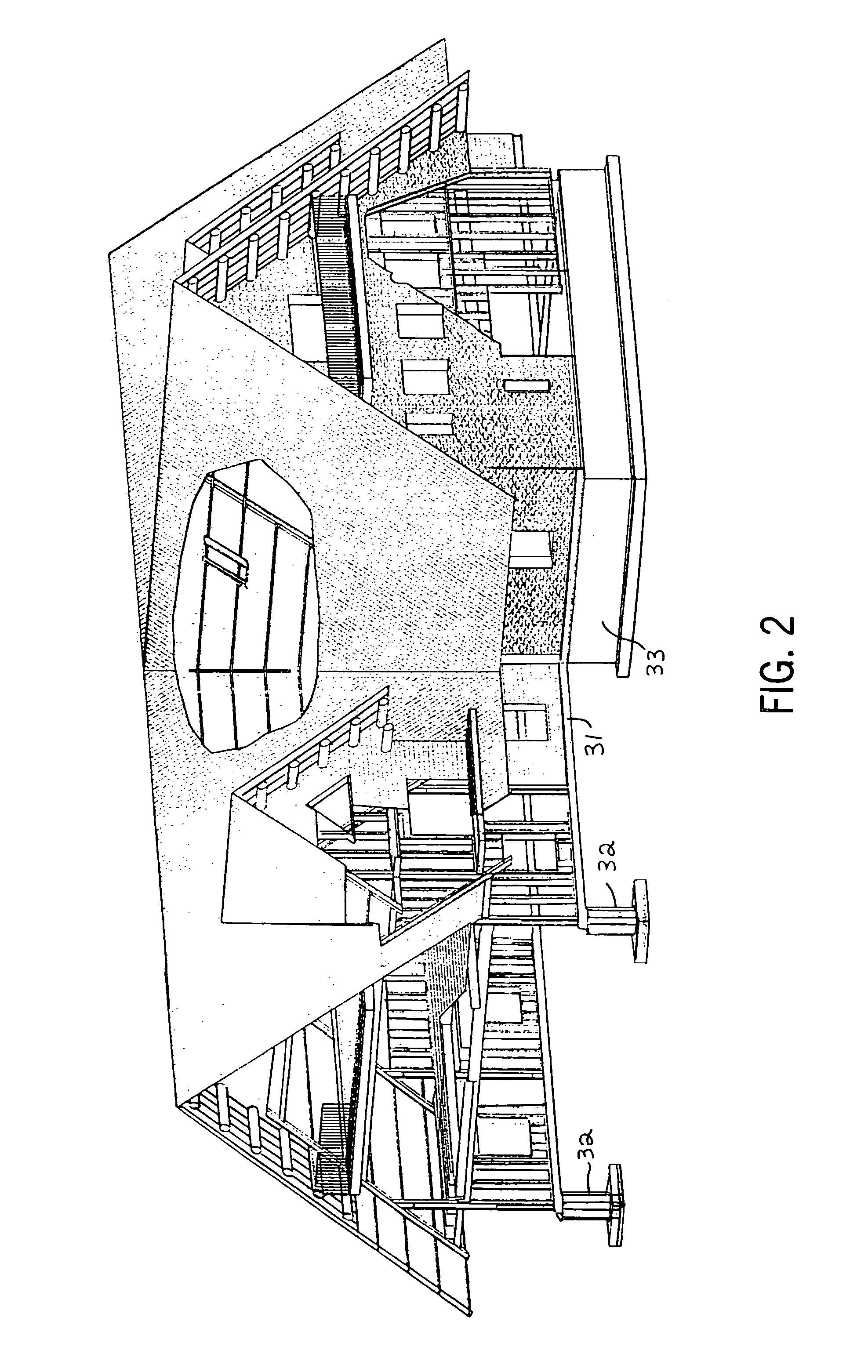

Truss and purlin support apparatus and a method of making and using same with building supports and floor and roof sheathing

A support apparatus is for use with building supports and floor or roof sheathing. The apparatus includes purlins and Pratt-style trusses. Each truss is supported on the building supports. Each truss includes top and bottom chords, and web members extending therebetween. Each purlin extends transversely of the trusses and has notches spaced along an underside thereof. Each notch is saddled over a top chord of one of the trusses, so as to restrict sliding movement of the purlins. The purlins support the floor or roof sheathing thereon. The top chord, the bottom chord, the web members, and the purlin members are constructed from roll-formed light gauge steel material.

Owner:GREINER WALDEMAR H

Solar panel support apparatus

A support apparatus for securing a row of solar panels to a support structure may include a fastener extending between and attaching an elongated clamp rail to a purlin. The fastener has a first non-rotatable end portion. A rotatable member is connected to a second end portion of the fastener for causing, when rotated, the clamp rail to close onto upper marginal edges of the row of solar panels along a continuous line of engagement therewith to help secure the solar panels in place on the purlin.

Owner:RI ENTERPRISES

Hoisting construction method for oversized span steel truss of roof of stadium grandstand

ActiveCN106836498AHigh security riskHigh cost of technologyBuilding roofsBuilding material handlingPurlinButt joint

The invention discloses a hoisting construction method for an oversized span steel truss of a roof of a stadium grandstand. The hoisting construction method comprises the following steps that A construction preparation work is conducted; B temporary supporting frames are mounted; C test hoisting is conducted; D trusses are symmetrically hoisted from two ends to the inner side in a sectioning mode; E concrete is poured into main truss arch feet; F purlins are mounted; G preliminary acceptance and supplement brushing of anti-corrosion and fireproof paint are conducted; H the temporary supporting frames are unloaded; J inspection and acceptance are conducted; and M the temporary supporting frames are dismounted. According to calculation of the hoisting weight and the length of hoisting parts, the large span steel truss is sectioned and assembled on the ground firstly, and then aerial butt joint hoisting is conducted, so that the construction period can be effectively saved, and mounting cost can be effectively reduced. The sectioned steel trusses adopt the temporary supporting frames to conduct temporary support, unloading supporting seats on the top of the supporting frames are welded to the steel trusses, and the load of a mounted main truss is borne by the temporary supporting frames, so that mounting safety of the steel truss is guaranteed, and compared with whole audience supporting frame erecting, cost is greatly saved.

Owner:河南靖扬建设工程有限公司

Complex heat-preservation roof and construction method thereof

ActiveCN101781917AAchieve ventilationAchieve heat preservationRoof covering using slabs/sheetsBuilding roofsPurlinThermal insulation

The invention relates to a building member, in particular to a complex heat-preservation roof and a construction method thereof. The roof comprises a roof truss, EPS boards and waterproof boards, the multiple EPS boards are arranged between purlins of the roof truss, and the waterproof boards are arranged on the EPS boards and the purlins; and the two end surfaces of the roof truss are also provided with the waterproof boards. The construction method is as follows: the EPS boards are arranged on the roof truss, the upper surface of each EPS board and the upper surfaces of the purlins are coplanar; reflecting films are stuck on the upper surfaces of the purlins and the EPS boards; the waterproof boards are assembled on the two sides of the lowest end of the roof truss, and then are paved on the previous layer until the surface of the roof truss is completely paved; a baffle is arranged on the roof truss and is provided with a first bracket, the first bracket is provided with an external pinchplate, and a drain tank is arranged on the first bracket by the external pinchplate; a second bracket is arranged below the first bracket, and a perforated plate is arranged on the second bracket; and the waterproof boards are used to seal the two end surfaces o the roof truss. The invention has the advantages of environment protection, heat preservation, thermal insulation, sound insulation, convenient installation and the like.

Owner:谭齐阳

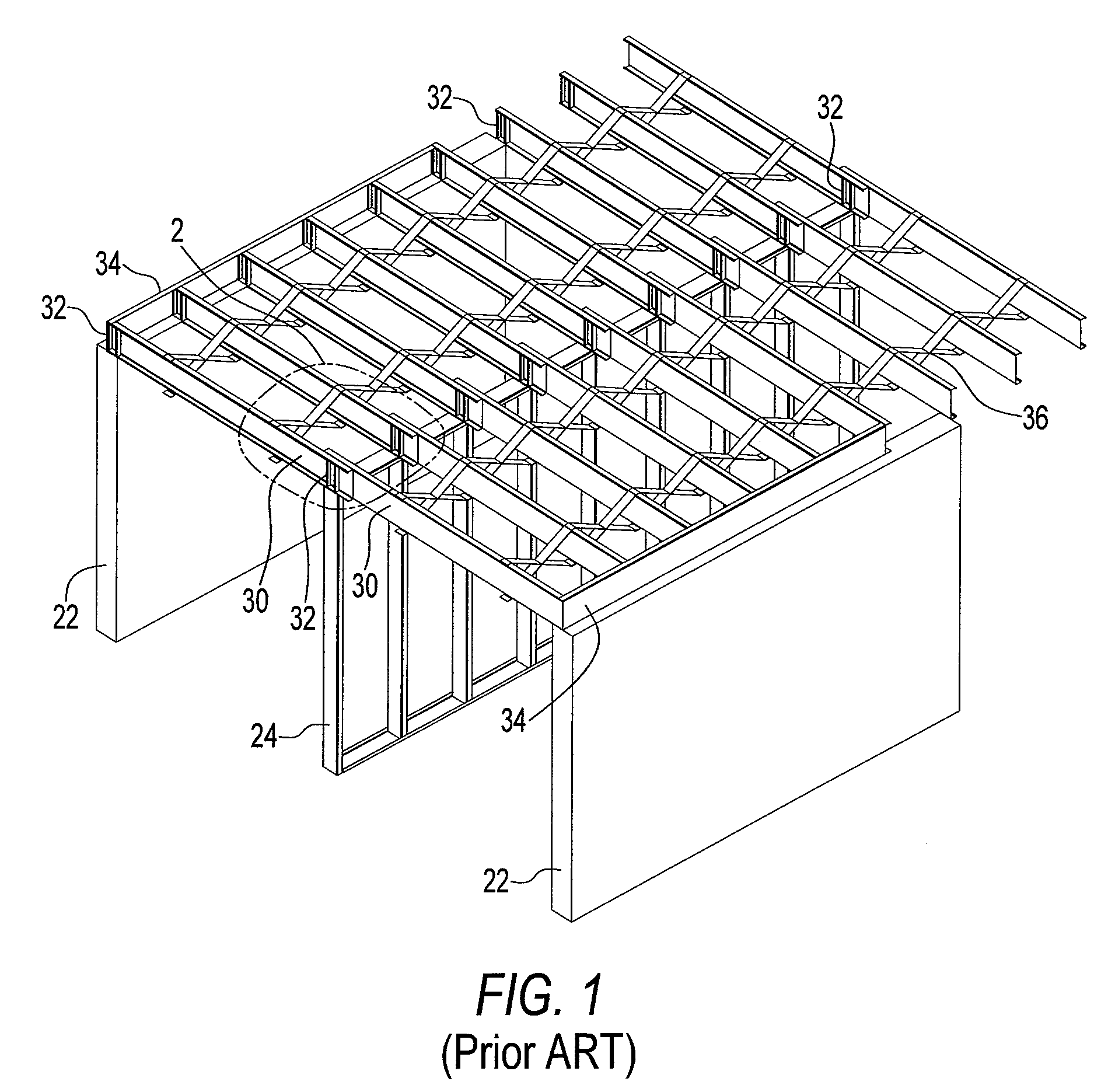

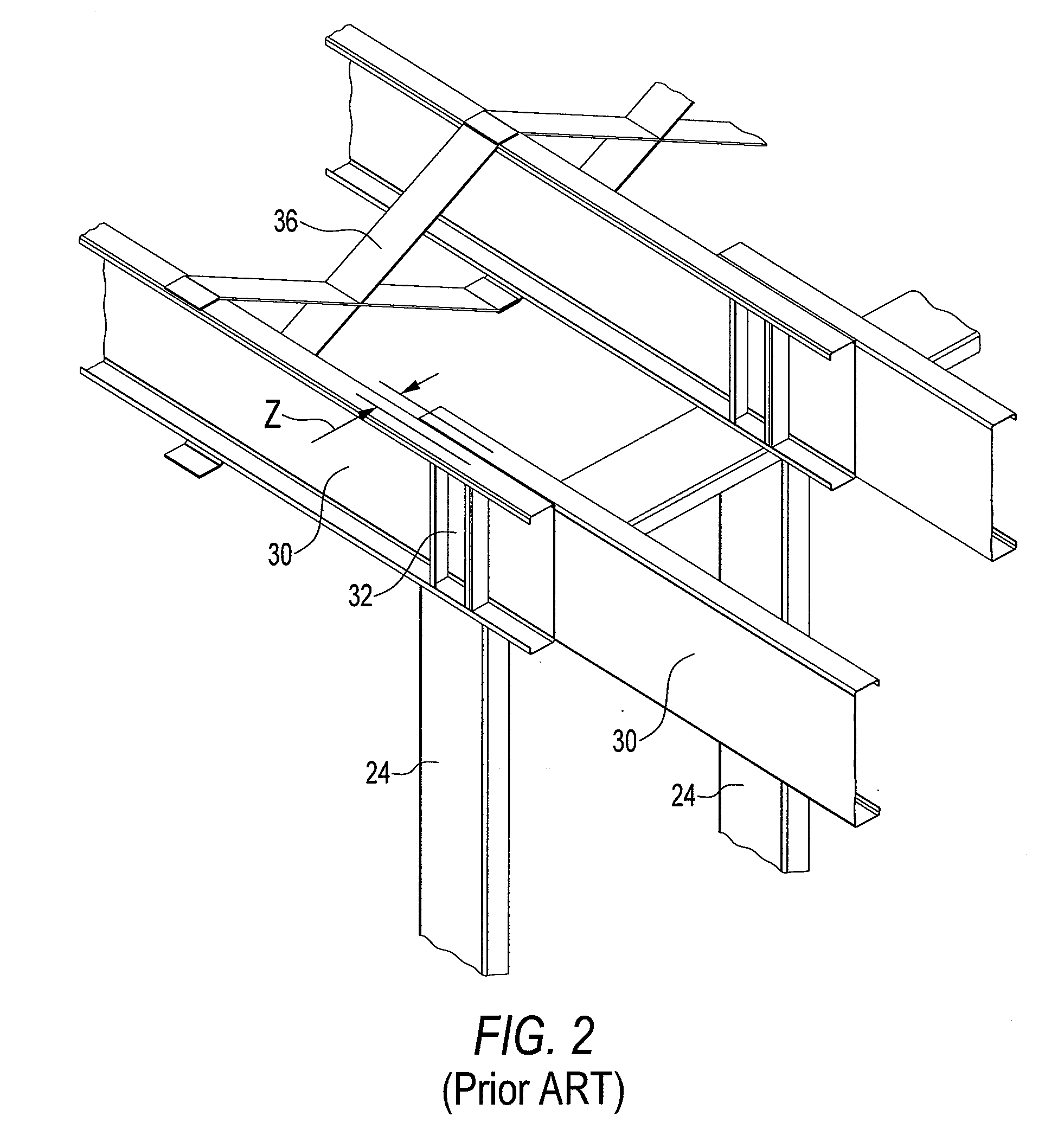

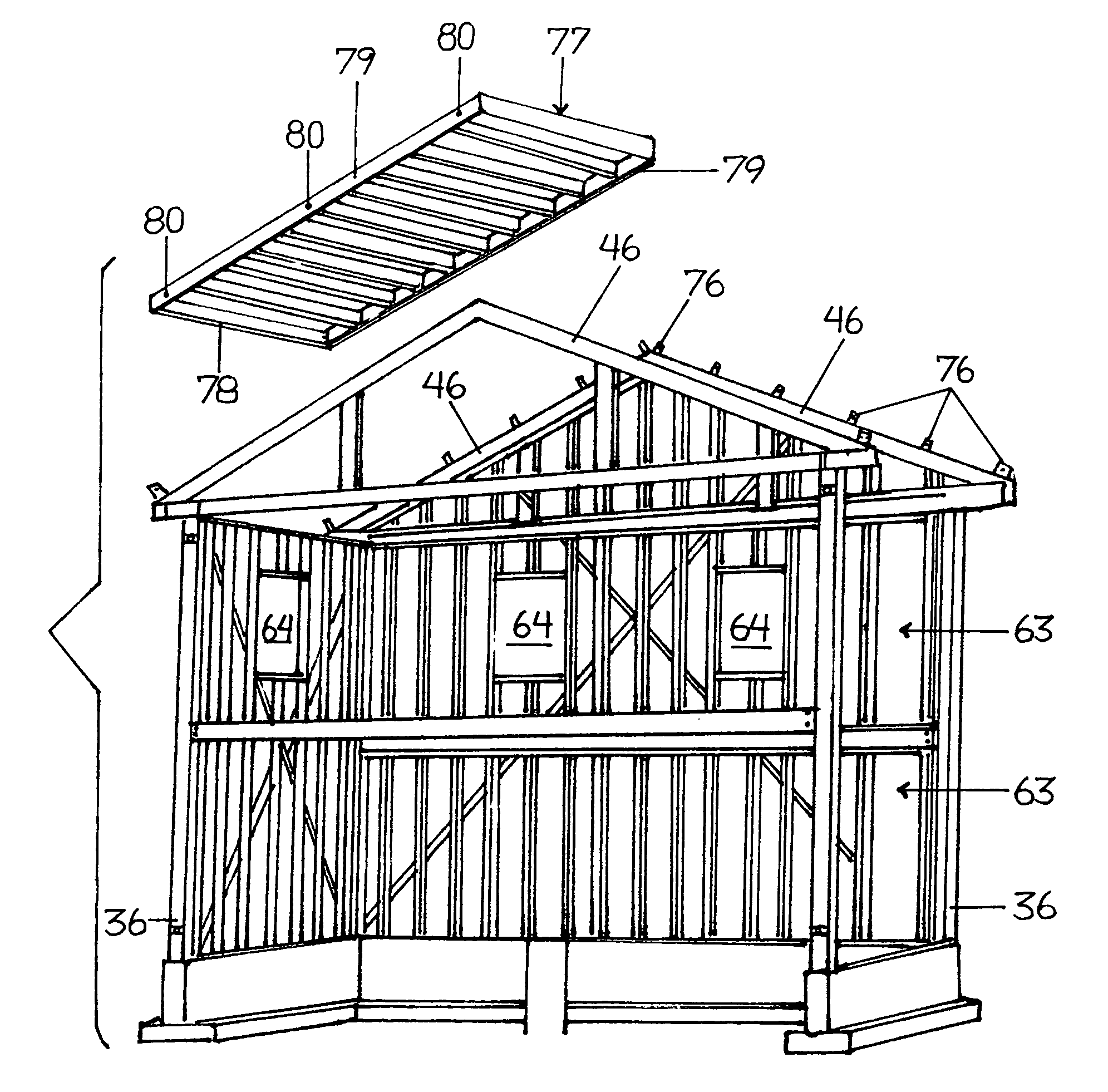

Structural steel framed houses with gable end frames, intermediate frames, and wall and roof panels having perimeters of C-shaped steel channels

InactiveUS7665251B1Easy to installEasy maintenanceBuilding roofsRoof covering using slabs/sheetsPurlinAbsolute minimum

Steel frames formed of rolled steel I-beams are connected by steel framed wall panels spanned by steel studs, and covered by steel framed roof panels spanned by steel purlins, making a structural frame completely formed of steel components bolted together. All components are precut and predrilled before transport to a construction site. A crane is used to raise steel frames and steel framed roof panels into position for bolted assembly, reducing construction times to absolute minimums. Entire structure is virtually lightning-proof, wind-proof, and earthquake resistant.

Owner:LANG STEVEN

Support free construction method for super large diameter circular deep foundation ditch

The invention discloses a method for processing super-large-diameter round hole without supports, which comprises following steps: building underground continuous wall; setting filling posts and supports; setting strengthen element; excavating and setting purlin. Compared to traditional method, the invention has strong stability, less excavating deformation, less rebound of hole-bottom, and less effect on around environment. The invention has no inner support structure; therefore, it has less cost with simple operation, quick time and high working efficiency.

Owner:ZHONGCHUAN NO 9 DESIGN & RES INST

Prestress steel purlin-concrete combined continuous rigid frame bridge and construction method thereof

InactiveCN101644024ALight weightReduce size requirementsBridge structural detailsBridge erection/assemblyPurlinPre stress

The invention discloses a prestress steel purlin-concrete combined continuous rigid frame bridge and construction method thereof. A steel purlin concrete combined structure with upper and lower swingplates is adopted, girder subsection adopts different combined interfaces according to stress demand of bridge under each construction stage and operating condition, set in vitro and vivo prestress beams are timely applied in batch, and material advantages of the two are fully played; compared with the existing prestress concrete continuous rigid frame bridge, self weight of the girder is greatlyreduced, spanning capacity is obviously increased, and sub structural engineering quantity and bearing capacity requirement of foundation soil are correspondingly reduced. The invention adopts prefabricated concrete bridge road plate for splice, and the prefabricated concrete bridge road plate is joined with the steel truss girder, thus stress is clear and performance is reliable; construction isobviously simplified, quality of each parts is easy to control and check, and disease hidden troubles that the conventional prestress concrete continuous rigid frame bridge is not reliable in curve prestress long strand performance, concrete is cracked in tension and deflection is excessive for a long time caused by contraction creep are avoided.

Owner:CHONGQING JIAOTONG UNIVERSITY

Supporting system reinforcement structure after foundation pit deepening

ActiveCN104099933AReduce construction costsSufficient lateral support strengthExcavationsPurlinSupporting system

The invention discloses a supporting system reinforcement structure after foundation pit deepening. The supporting system reinforcement structure after foundation pit deepening comprises pouring piles arranged around the edge of a foundation pit, first purlin beams connected with the pouring piles, and horizontal support beams connected between the first purlin beams, wherein a plurality of reinforcement piles are arranged at the inner sides of the pouring piles around the foundation pit at intervals, and the depth of each reinforcement pile is more than that of each pouring pile; the elevation of the upper end of each reinforcement pile is higher than that of the originally designed bottom surface before the foundation pit is not deepened, and second purlin beams connected with the reinforcement piles are arranged at the inner sides of the lower parts of the pouring piles; an arc-shaped notch is formed in the inner side surface of each second purlin beam between every two adjacent reinforcement piles, and a part, close to each second purlin beam, of each reinforcement pile is provided with an obliquely downward oblique supporting beam; the lower ends of the oblique supporting beams are connected with the bottom plates of the foundation pit through bracing mechanisms. The supporting system reinforcement structure after foundation pit deepening provided by the invention has the advantages that by reinforcing the pouring piles, the pouring piles do not need to be re-constructed when the foundation pit is deepened, the sufficient side supporting strength is ensured, the project quantity is substantially reduced, and the construction cost of a support system is reduced.

Owner:ZHEJIANG PROVINCE INST OF ARCHITECTURAL DESIGN & RES

Roof board wind resistance standard test device and test method

InactiveCN101236135ASolve problems that have no solid basisStructural/machines measurementPurlinSuction force

The invention discloses a roof board wind resistance standard testing device and a testing method. Through simulating the relationship between the deflection deformation of a metallic roof board and the wind load, the board thickness, the board profile and the purlin interval under the condition of a wind suction force, the testing method summarizes the test data of the wind suction resistance bearing capacity design of the die metallic roof board and supplies a domestic gap in the field. The invention solves the problem that currently the wind suction resistance bearing capacity design of the die metallic roof board lacks a reliable reference, thereby providing the standard reference for design staff to reasonably select the roof board profiles and optimize the design. The generalization and application of the roof board wind resistance standard testing device and the testing method have broad significance for the design and construction of the die metallic roof board under the action of the wind suction force.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

Foundation pit supporting structure with oblique support and pre-stress surrounding purlin

The invention provides a foundation pit supporting structure with an oblique support and a pre-stress surrounding purlin. An enclosure wall and an oblique steel support are arranged inside the foundation pit supporting structure; the enclosure wall is connected with the pre-stress surrounding purlin which is connected with one end of the oblique steel support; and the other end of the oblique steel support is connected with a base plate of a foundation pit. The foundation pit supporting structure with the oblique support and the pre-stress surrounding purlin has the advantages of substantially reducing the length and number of supports, saving materials and construction costs and being short in construction period and large in construction space.

Owner:SHANGHAI STRONG FOUND ENG

Connection structures between foundation pit support piles and outer walls of basement and construction method

InactiveCN102383443ALow costReduce the numberArtificial islandsUnderwater structuresAccessory structurePurlin

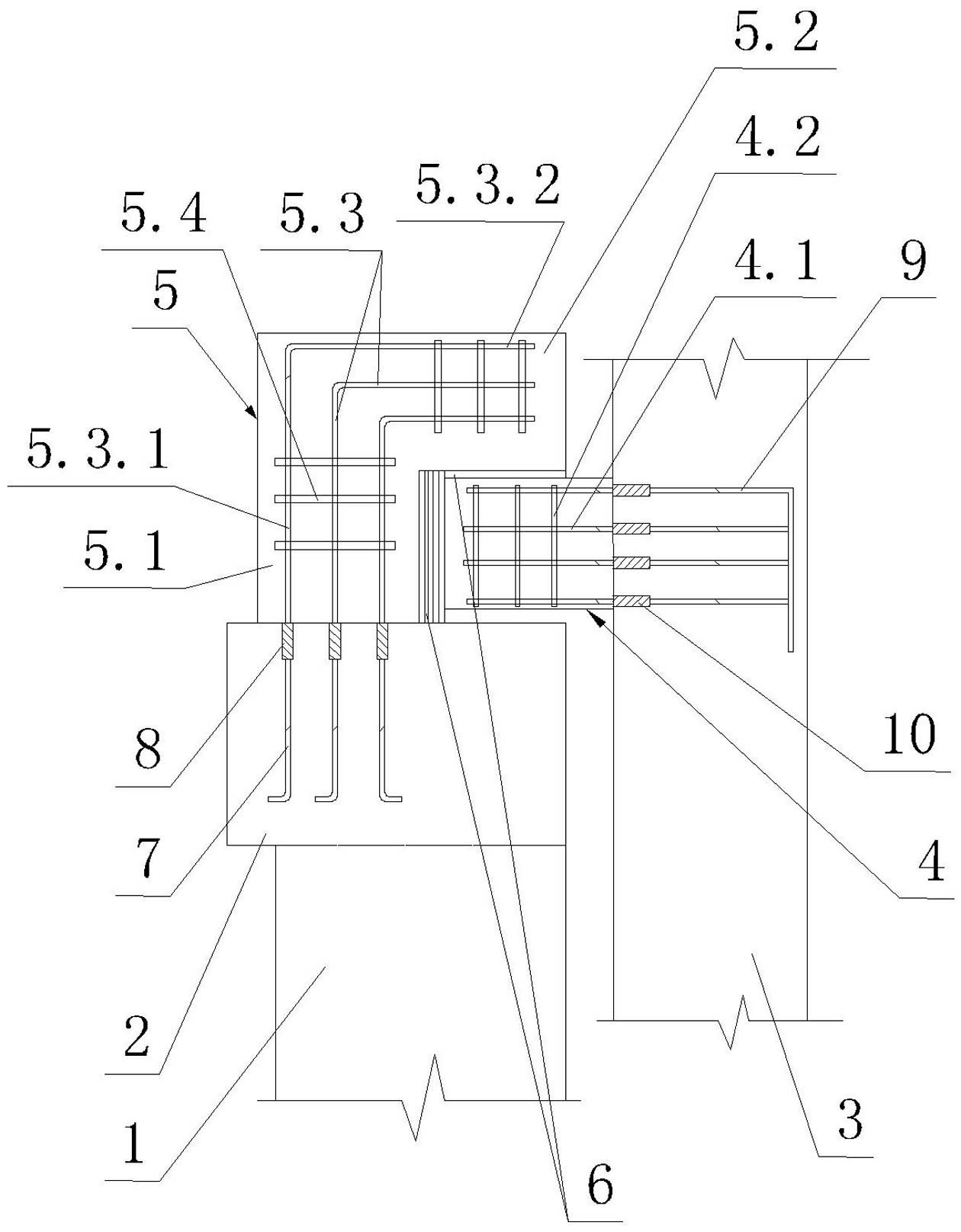

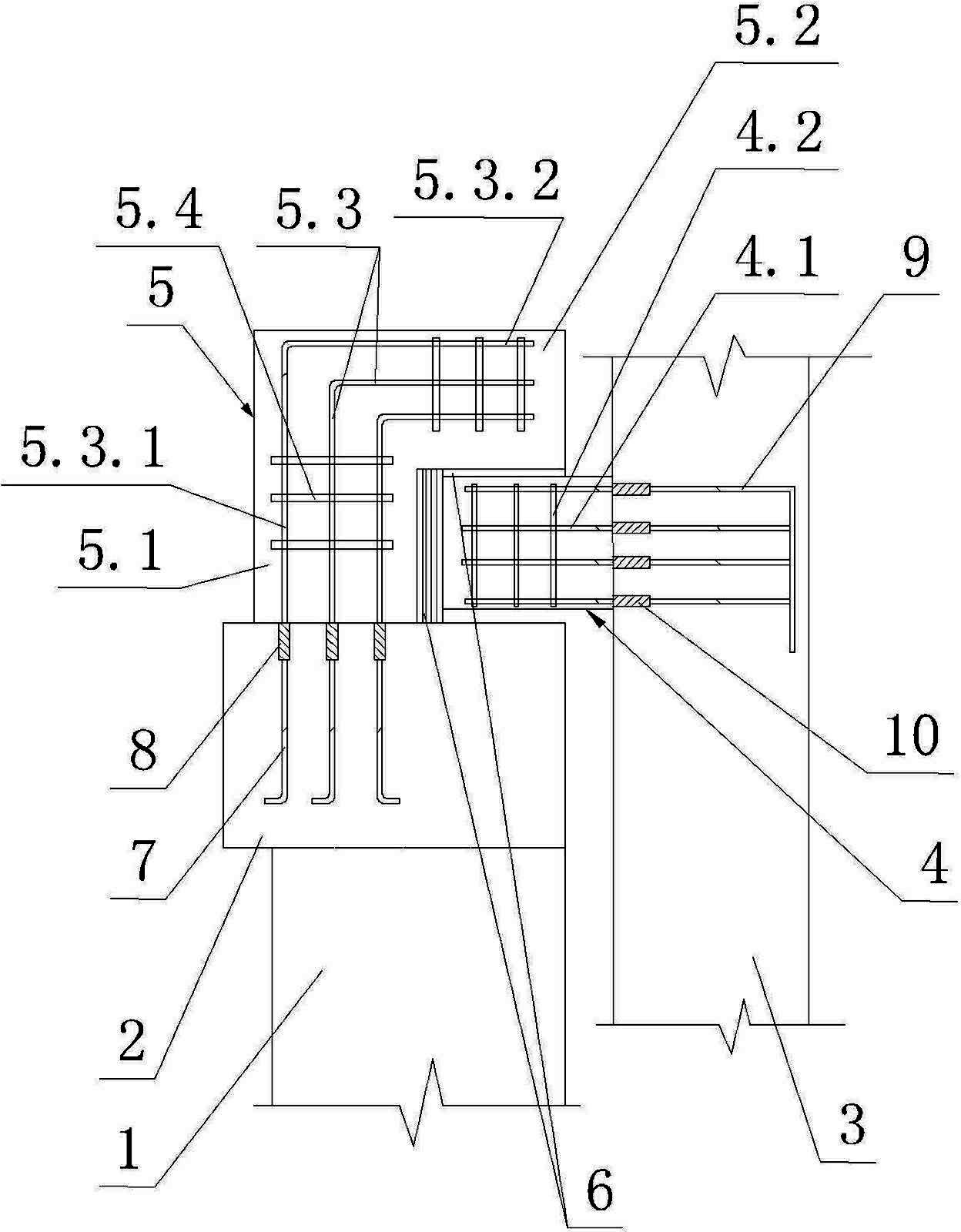

The invention discloses connection structures between foundation pit support piles and outer walls of a basement and a construction method. Each structure comprises a top beam (2) and an outer wall (3) of a basement, wherein a concrete bracket (4) protrudes out of the outer surface of the outer wall (3) of the basement; a concrete ring beam (5) is arranged on the top surface of the top beam (2); and a cross beam (5.2) of the concrete ring beam (5) presses the top surface of the concrete bracket (4). The construction method is characterized by pouring the concrete bracket (4) after pouring the outer wall (3) of the basement and then pouring the concrete ring beam (5) on the top beam (2) so that the cross beam (5.2) of the concrete ring beam (5) presses the top surface of the concrete bracket (4). The connection structures and the construction method have the following beneficial effects: wastes of such accessory structures as the foundation pit support piles (1), the top beams, circuit purlins and the like after construction of the basement structure can be avoided and the number of anti-buoyancy piles can be reduced.

Owner:DARONG CONSTR GROUP +1

Steel sheet pile coefferdam structure and topdown construction method thereof

ActiveCN102191777ARealize intermittent decentralizationHigh positioning accuracyLifting devicesFoundation engineeringPurlinPile cap

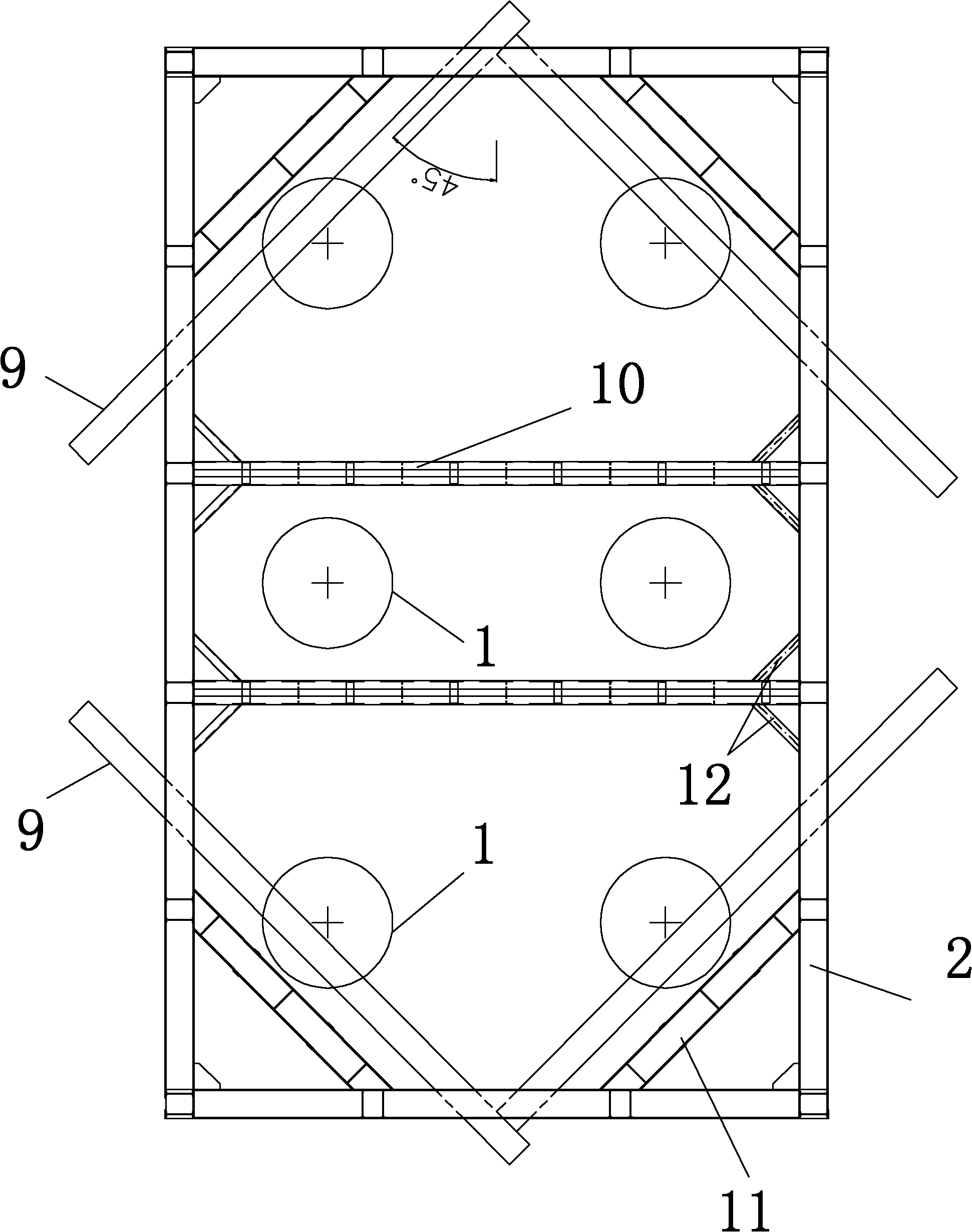

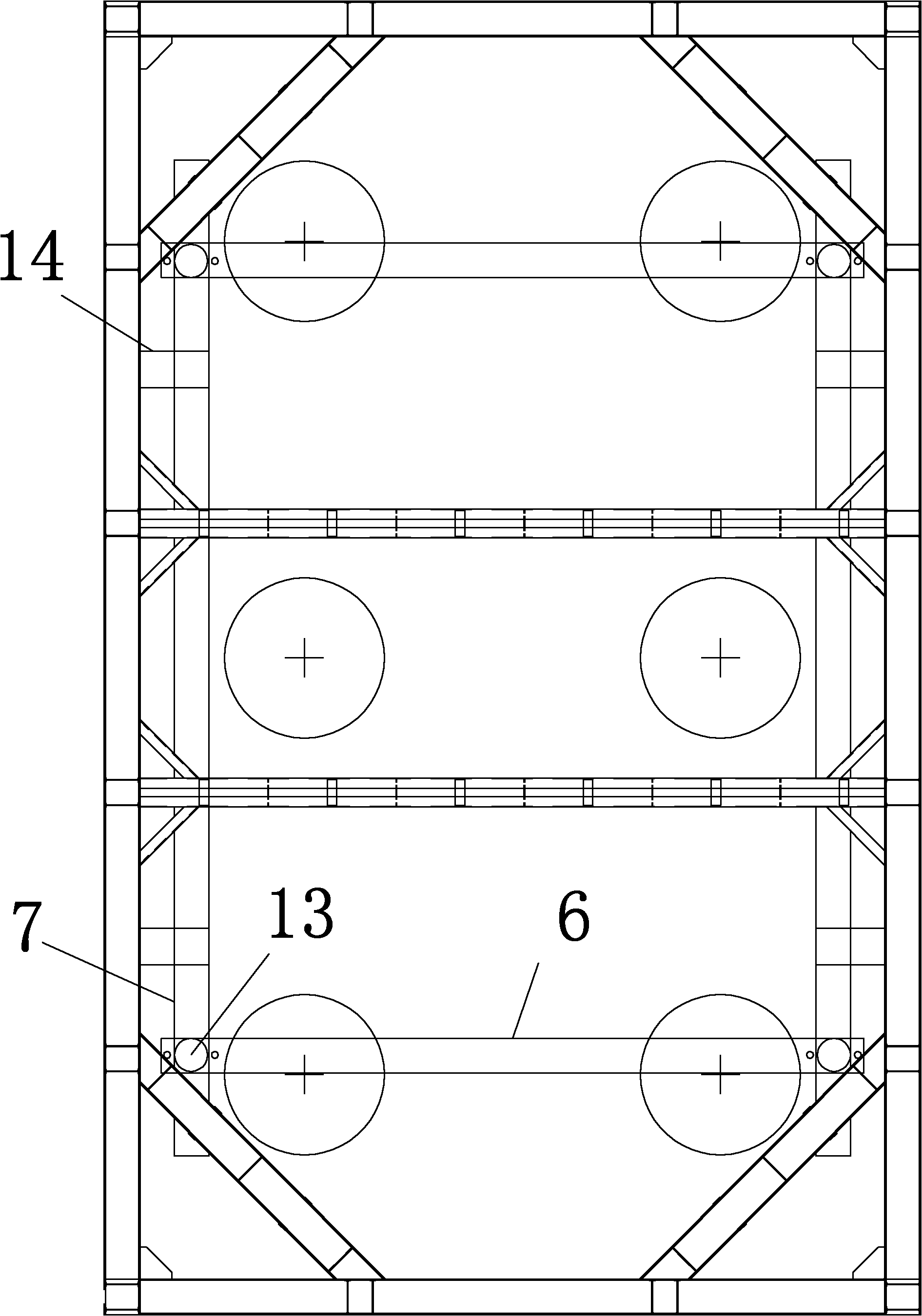

The invention discloses a steel sheet pile coefferdam structure comprising a steel protecting canister, a plurality of layers of circuit purlins and steel sheet piles, wherein the steel sheet piles are inserted into the peripheries of the circuit purlins; the lower part of the steel protecting canister is welded with a bracket to form a temporary supporting platform; the circuit purlins at the upper layer and the circuit purlins at the lower layer are connected through a vertical rid and a bridging at 45 degrees; the top of the steel protecting canister is fixedly provided with an upper outrigger; the upper outrigger is provided with lifting equipment; and a lower outrigger is welded below the circuit purlins at the lowermost layer and lifted by a lifting rope of the lifting equipment. The invention also discloses a topdown construction method of the steel sheet pile coefferdam structure. In the invention, the circuit purlins, the vertical ribs and the bridging at 45 degrees are installed by utilizing a lifting system under the preconditions without using large-size lifting equipment or utilizing a large-scale prefabricating field, and therefore the quality and the stability of a steel sheet pile coefferdam are ensured; and a highrise pile cap of a pier inside water is constructed with lowest cost and smallest construction risk, therefore the feasibility and the economy of a construction technology of the steel sheet pile coefferdam inside water are enhanced.

Owner:GUANGZHOU MUNICIPAL ENG GROUP

Roof panel clip

InactiveUS6904730B2Quick installationIncrease load capacityRoof covering using slabs/sheetsCeilingsPurlinEngineering

Owner:MITCHELL JAMES

Foundation pit containment structure with prestress ribs on vertical soil-retaining structure and construction method

InactiveCN102767186AReduce horizontal displacementReduce settlementExcavationsBulkheads/pilesPurlinReinforced concrete

The invention discloses a foundation pit containment structure with prestress ribs on a vertical soil-retaining structure and a construction method. The structure comprises the vertical soil-retaining structure, a plurality of horizontal supports, a reinforced concrete ring beam and a plurality of surrounding purlins, wherein the vertical soil-retaining structure is arranged on the edge of the inner side of a foundation pit and consists of a plurality of drilling concrete piles or concrete continuous walls which are arranged at intervals; the reinforced concrete ring beam is arranged on the top of the vertical soil-retaining structure; the surrounding purlins are arranged on the inner circumferential surface of the vertical soil-retaining structure at intervals from top to bottom; and the horizontal supports are connected to the reinforced concrete ring beam and a plurality of surrounding purlins along the transverse intervals of the foundation pit. The foundation pit containment structure with the prestress ribs on the vertical soil-retaining structure and the construction method have the advantages that phenomena of the inwards horizontal displacement of the vertical soil-retaining structure and settlement of the ground outside the foundation pit can be reduced, the bending rigidity of the vertical soil-retaining structure is improved, and the prestress ribs can be recycled, so that the construction cost can be reduced.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

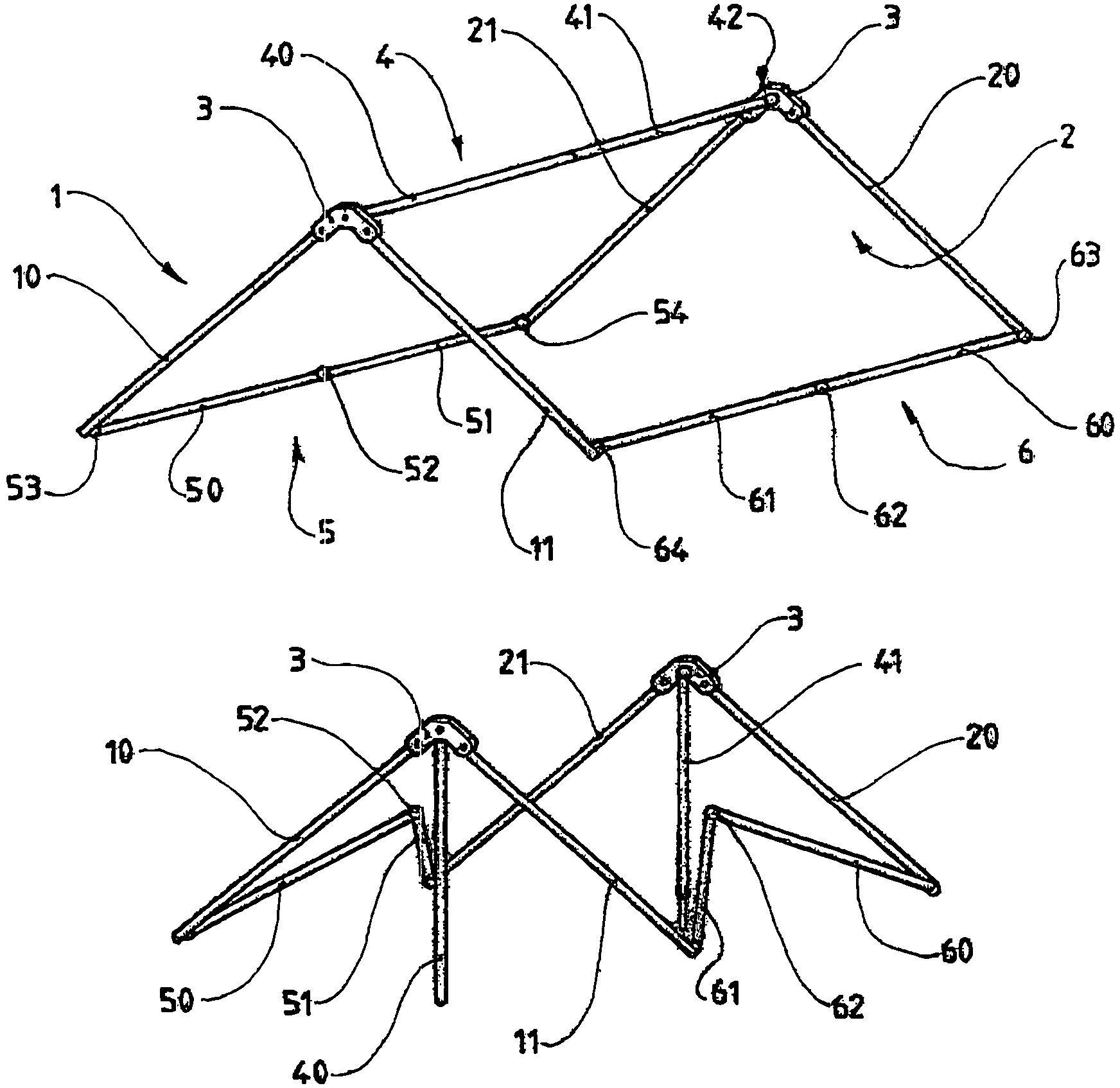

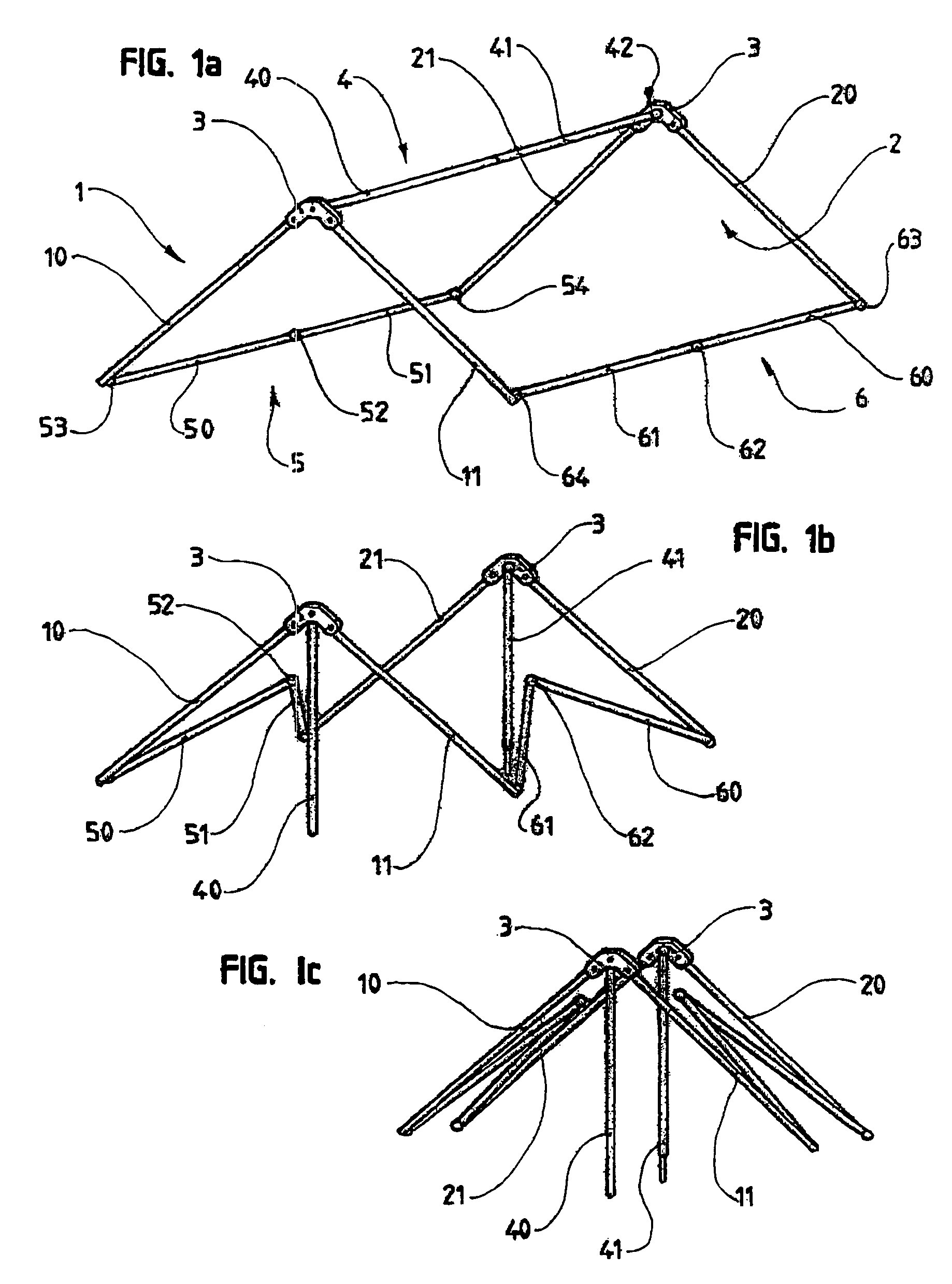

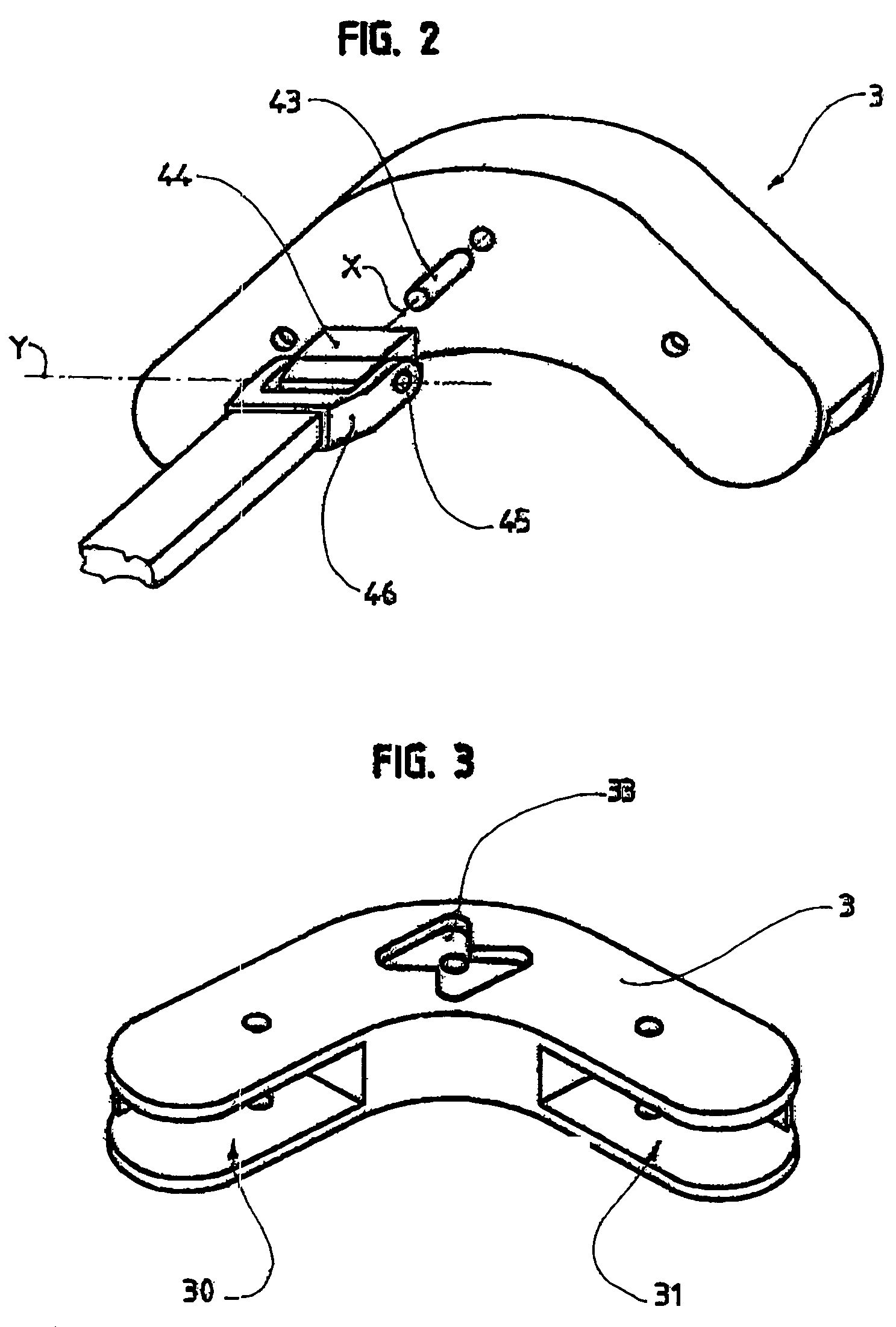

Folding modular structure for a tent or similar for fast mounting

Folding modular structure for a tent or similar for fast mounting includes an assembly of tubular profile bars permitting in particular to form at least two arches facing each other connected by at least two purlins one of which is a ridge. The ridge purlin is formed of the butting of two profile bars, made integral, each by their other end, with a ridge member. That other end includes, on the one hand, a pivoting device for pivoting, in a limited way through an indexing mechanism, on the ridge member according to an axis perpendicular to the plane of the arch. The pivoting device allows the folding back of the shape parallel to the arch, the butting of the two profile bars occurring through encasing means capable of ensuring their immobilization in axial pivoting according to angular positions defined by the indexing mechanism.

Owner:UTILIS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com