Direct local skirt border reversing construction for central island

A construction method and center island technology, applied in excavation, artificial islands, water conservancy projects, etc., can solve problems such as slow project progress, inconvenient construction process, and large excavation volume of underground earthwork, so as to ensure construction quality and reduce excavation The effect of saving cost and enclosure cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

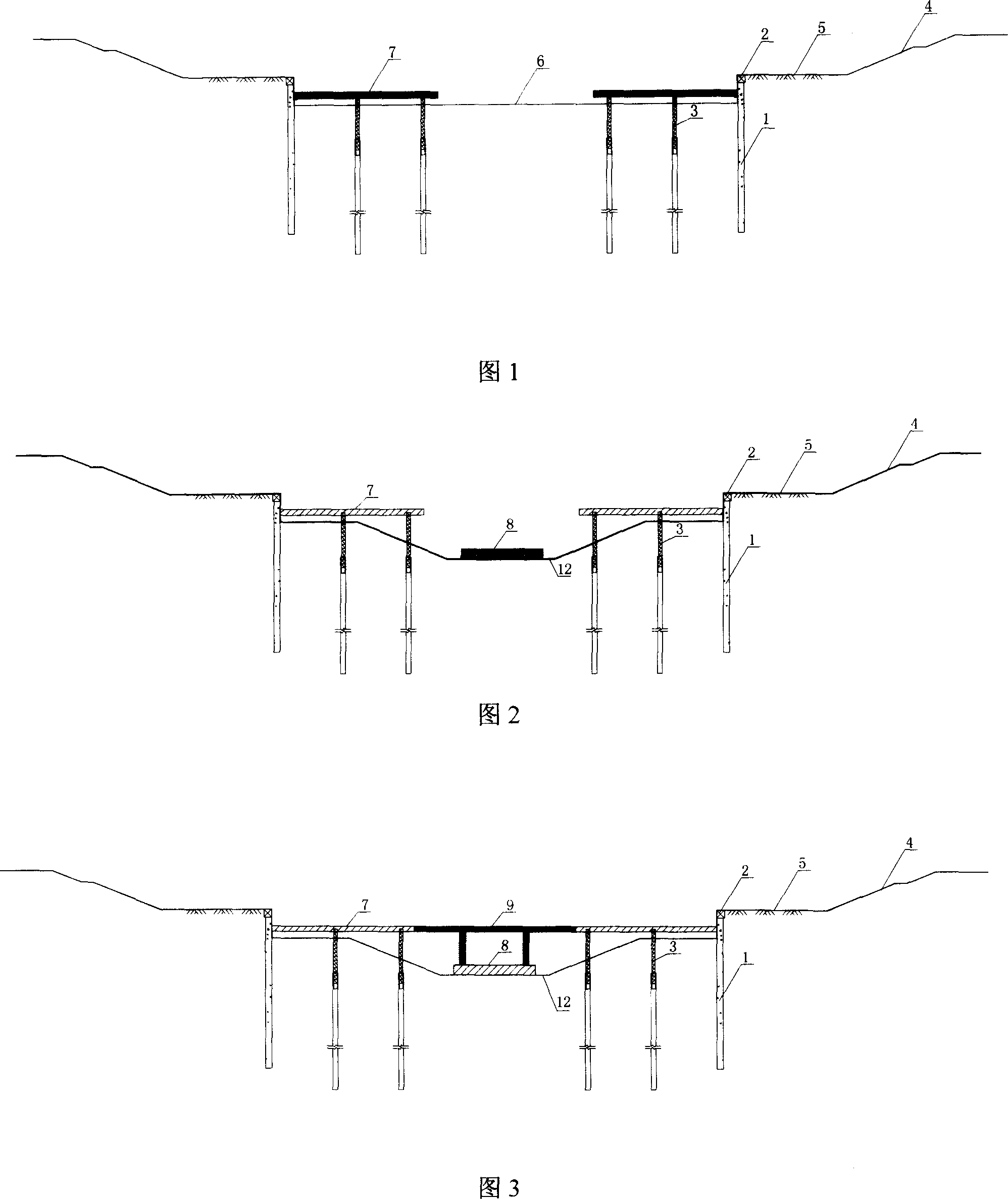

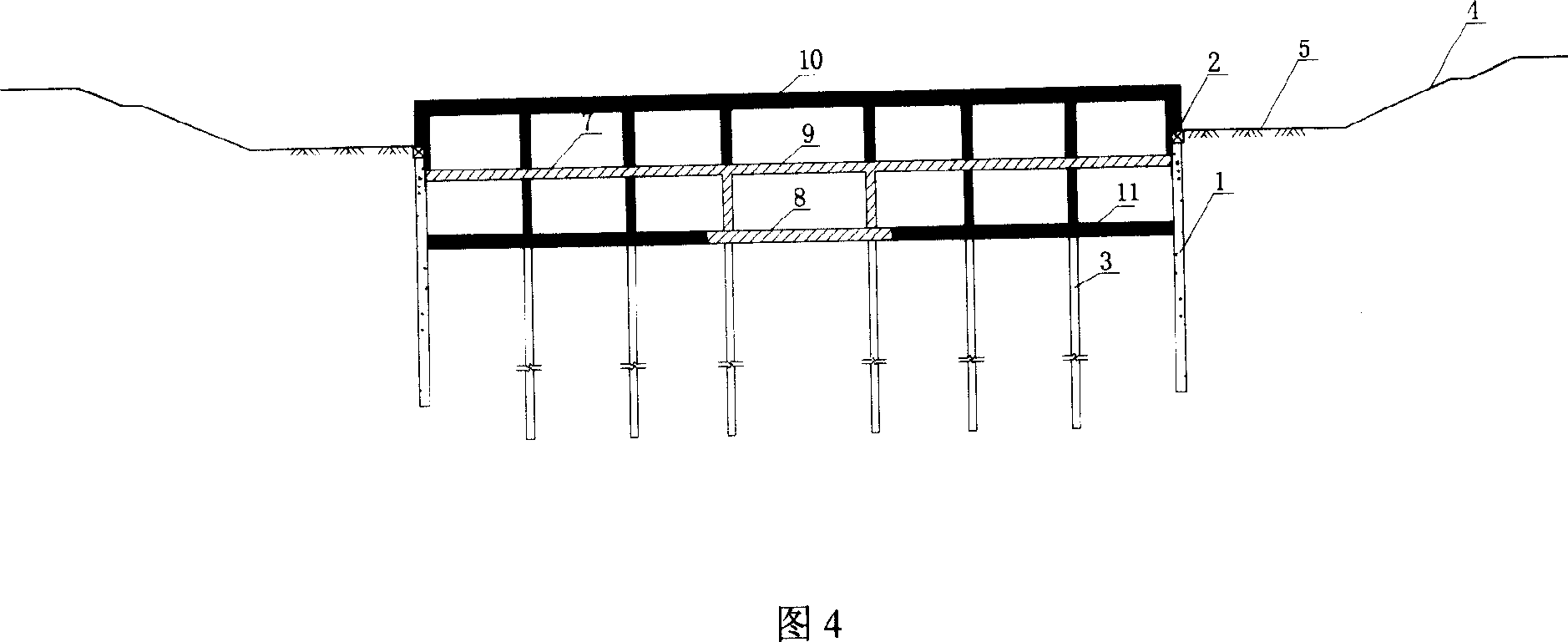

Method used

Image

Examples

Embodiment

[0033] In a project, the foundation pit area is large, up to 35000m 2 , with a depth of 13.4M, involving micro-confined water layers.

[0034] An 800mm thick underground diaphragm wall is used for the enclosure structure of the foundation pit of the underground garage and the shopping mall, and the flexible joint of the lock pipe is used for the diaphragm wall section. After the excavation of the foundation pit is completed, the diaphragm wall doubles as the side wall of the main structure, and there is no additional lining in the pit, and pilasters are set at the joints of the wall width.

[0035] The construction site of this project is wide, and there are site conditions for excavation and unloading of soil and temporary stacking of discarded soil around the foundation pit. Excavation and unloading will be carried out in advance. The unloading depth on the north side of the foundation pit is 6.8m, and the width of the unloading platform is ≥15m. The unloading depth of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com