Patents

Literature

416results about How to "Guaranteed duration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

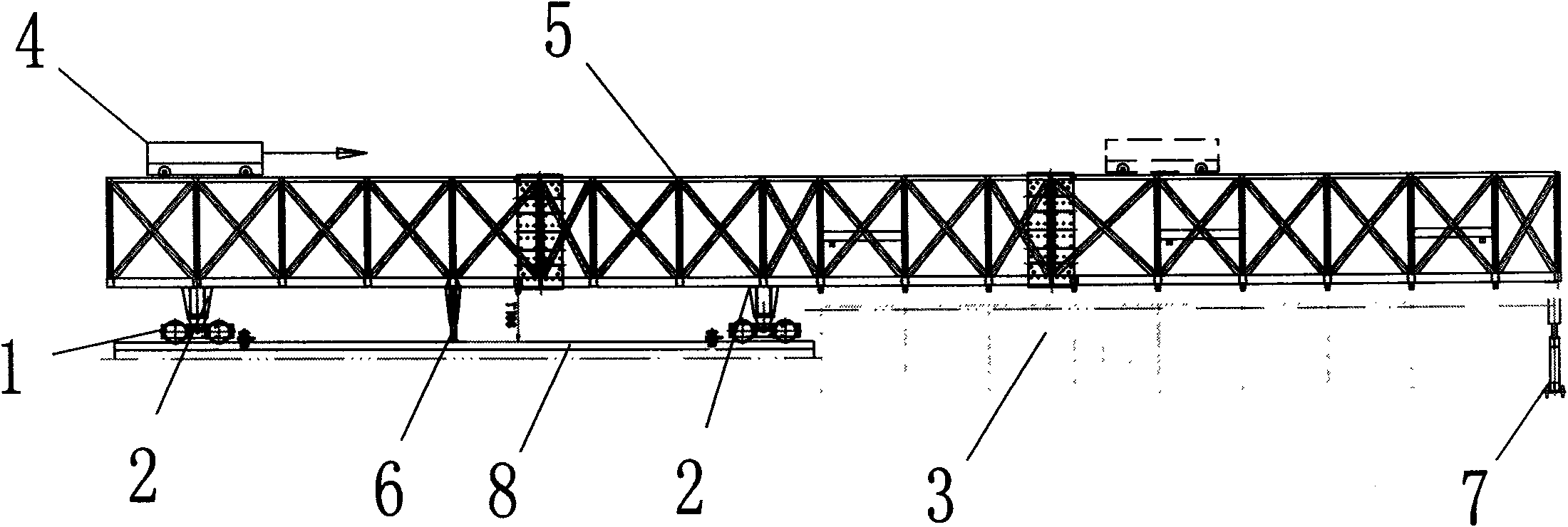

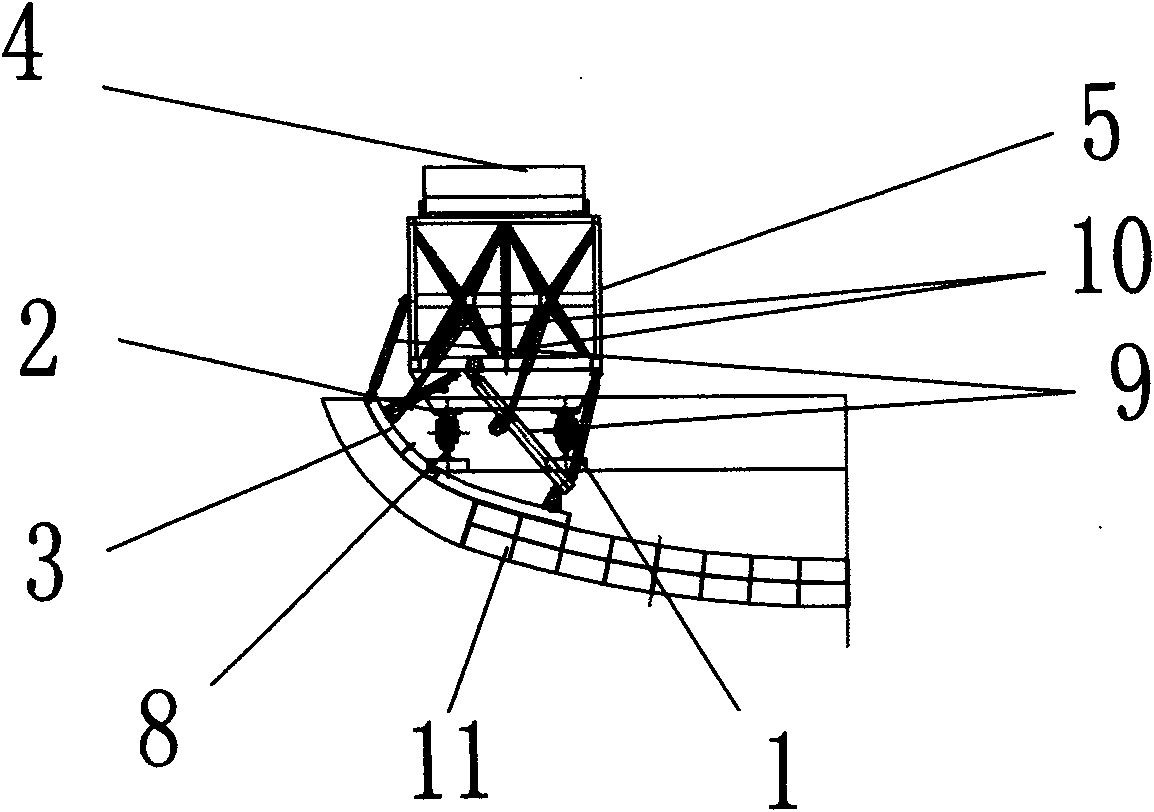

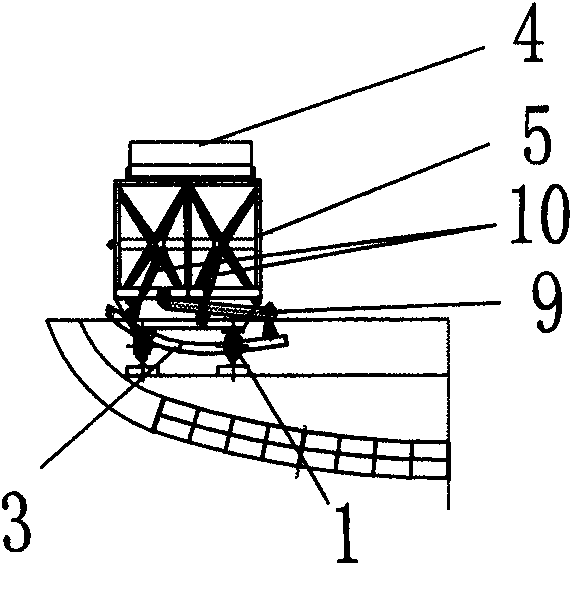

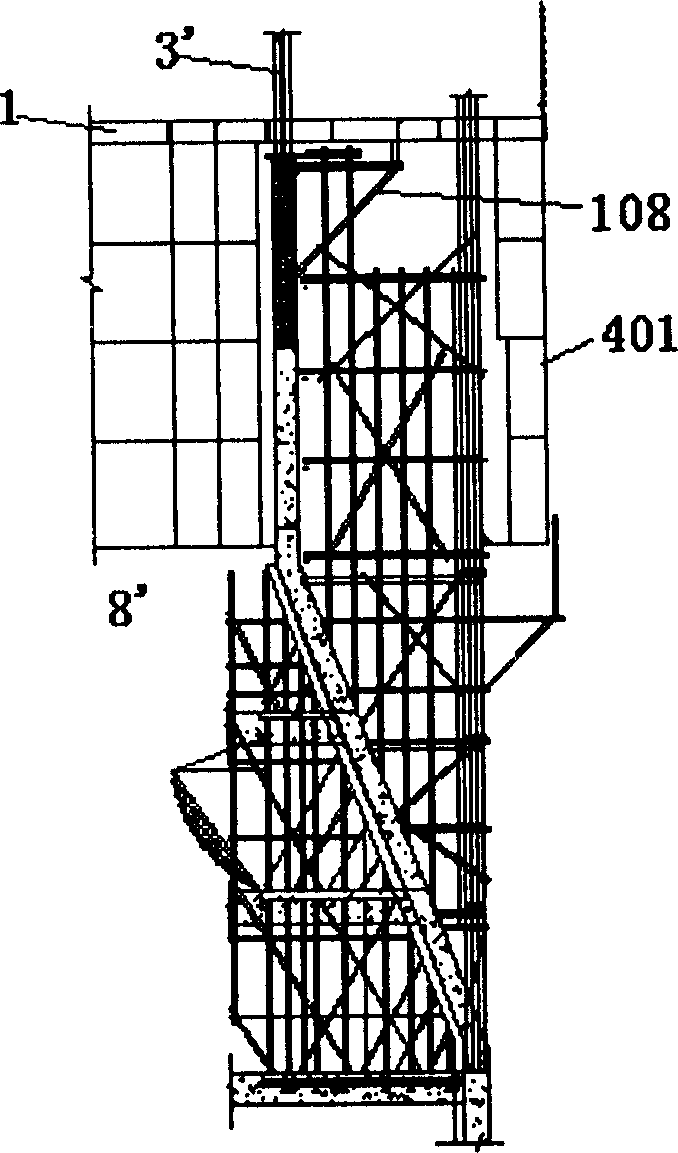

Self-propelled inverted arch template construction method

The invention discloses a self-propelled inverted arch template construction method for a tunnel, which comprises the following construction steps of: setting out a control line for an inverted arch digging section and a longitudinal construction joint according to the design requirement; performing smooth-wall blasting digging on an inverted arch of the tunnel; moving an inverted arch trestle in place; conveying inverted arch stone slag out of the tunnel by using an excavator and a conveying device and abandoning the stone slag in a slag field, and cleaning an inverted arch base; assembling an inverted arch end template; laying steel rails, and moving the inverted arch template to longitudinally move in place per se; starting a hydraulic device to lower the inverted arch template, and supporting the template firmly by using a screw jack; pouring inverted arch concrete; and curing the concrete with equal strength, folding the screw jack, withdrawing a hydraulic cylinder, and releasing a die. The construction method has low cost, is convenient to operate, and improves the construction efficiency; and the longitudinal construction joint is vibrated densely compared with common template construction, and has positive effect of improving the construction quality of tunnel engineering.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

BIM-based pre-assembling method for double-curved glass curtain wall

ActiveCN106013535AEliminate biasImprove installation accuracyWallsBuilding material handlingSolid componentPoint cloud

The invention relates to a BIM-based pre-assembling method for a double-curved glass curtain wall. The method includes the following steps that three-dimensional models of glass curtain wall components are established according to a modeling standard; detailed glass curtain wall component drawings are guided out and numbered, and then processing and production are carried out; three-dimensional scanning is carried out on the processed glass curtain wall components, point cloud data are obtained, and three-dimensional point cloud models are established through the point cloud data; the three-dimensional point cloud models and the three-dimensional models are compared to obtain deviation values of glass curtain wall component solid bodies, and glass curtain wall component information is adjusted till the deviation values meet glass curtain wall standard requirements; and overall pre-assembling of the three-dimensional point cloud models meeting the requirements is simulated in Revit, accumulative errors in the assembling process are eliminated till the pre-assembled three-dimensional point cloud models are completely matched with the three-dimensional models, and then the glass curtain wall components are delivered out of a factory and delivered to a construction site for solid component installation. By means of the method, the problems that the double-curved glass curtain wall is large in field installation difficulty, low in installation efficiency and low in precision are solved.

Owner:SHANGHAI BAOYE GRP CORP

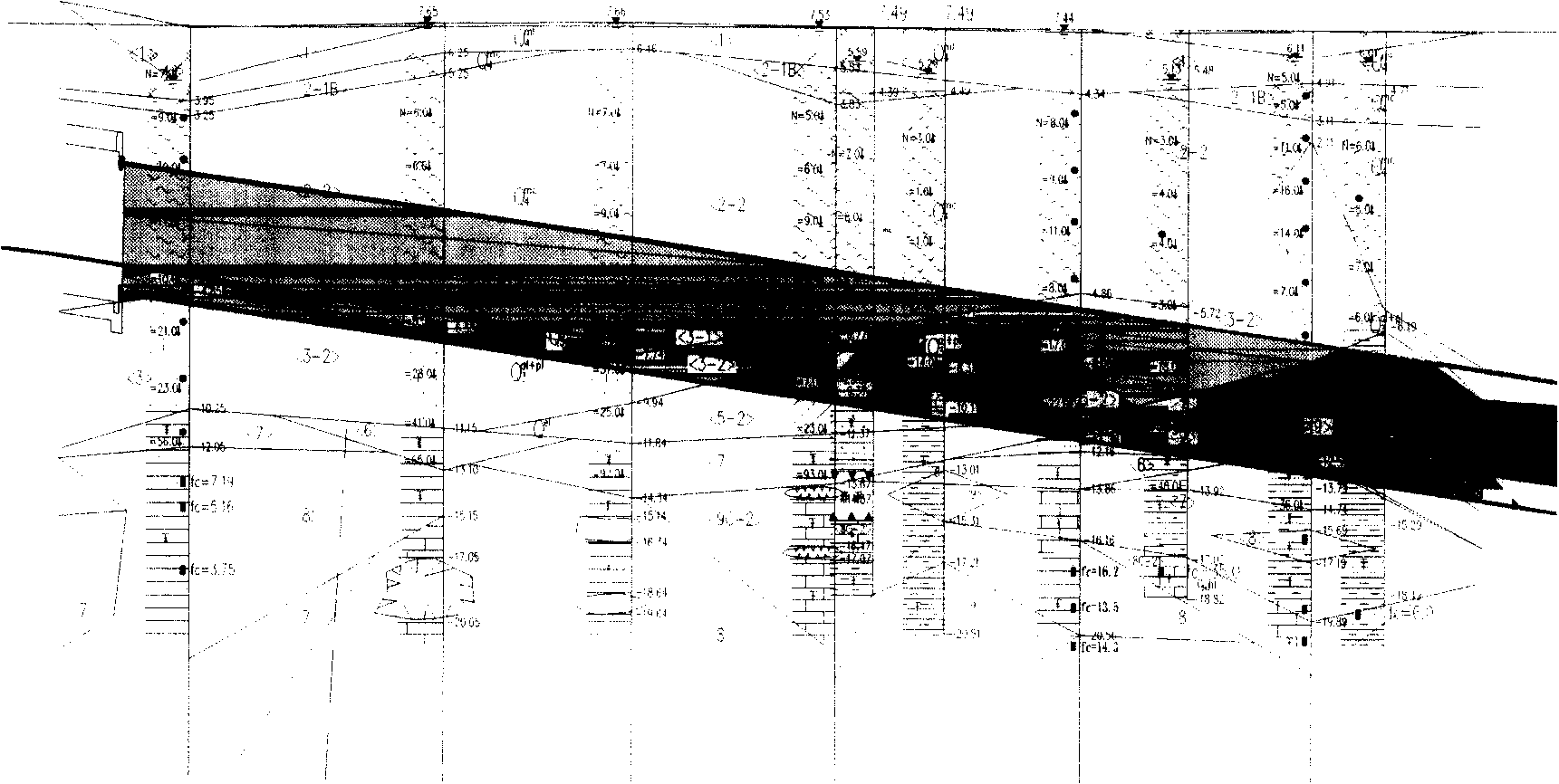

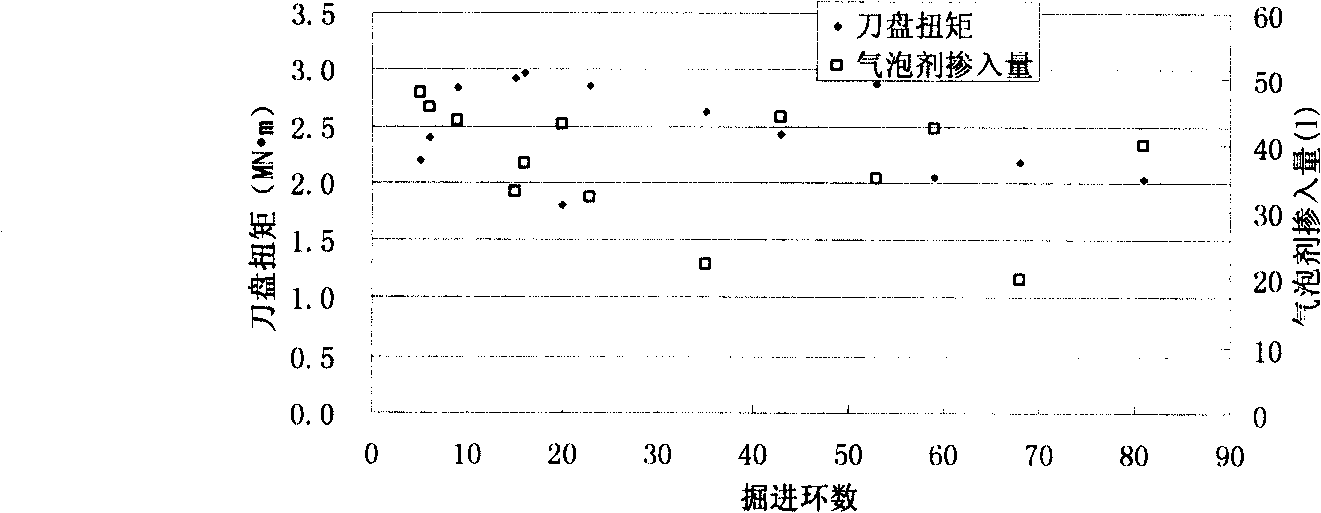

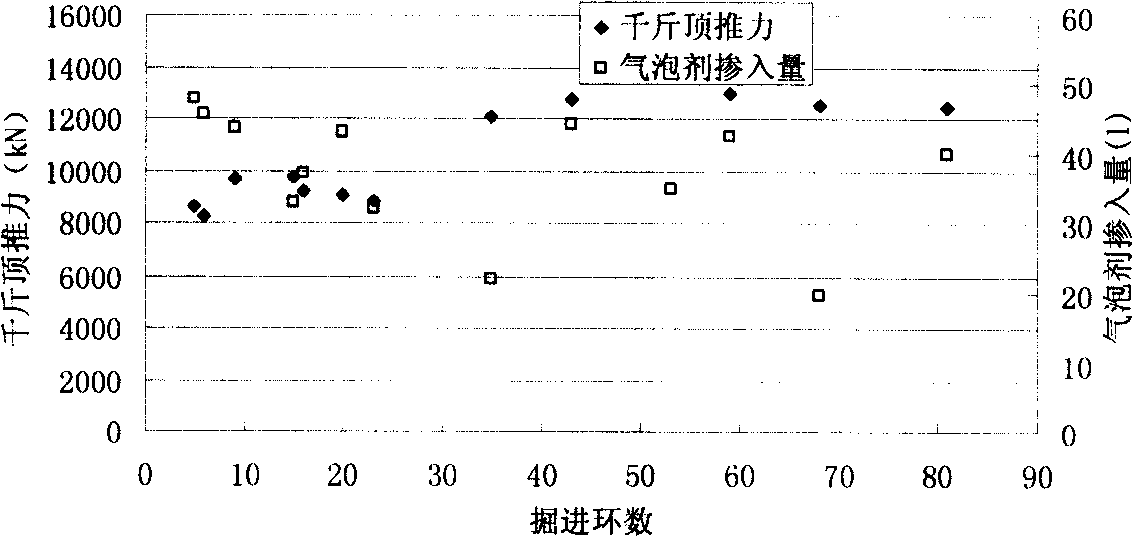

Construction method of composite soil pressure balance tunnel shielding machine for traversing shallow-buried water-rich sand layer

ActiveCN101403307AScientific and reasonable technical solutionsEasy to implementTunnelsEngineeringPressure balance

The invention discloses a construction method that a composite soil pressure balanced shield machine passes through a shallow sand layer rich in water, pertaining to the technical field of tunnel construction. When the composite soil pressure balanced shield machine passes through the shallow sand layer rich in water, an injecting system is arranged at the position of a pressure plate and a cutter head of the shield machine so as to inject a matter-a foaming agent, or bentonite, or a macromoleclar polymer, or the mixture of the three, which has the performances of rapid volume expansion and viscosity increase after absorbing water, into the front shallow sand layer rich in water; the shallow sand layer rich in water is rapidly expanded, soil entering an integral pressure cabin is caused to form plastic flow state, and the soil is caused to reach the permeability coefficient of lower than the magnitude of 10<-5>cm / s which is needed by the construction and the caving degree of 10 to 15cm. The technical proposal is scientific and reasonable, simple and easy to implement, can acquire obvious technique effect, adopts the composite soil pressure balanced shield machine for passing through the shallow sand layer rich in water successfully and acquires satisfactory construction quality as well as guarantees the construction period.

Owner:URBAN MASS TRANSIT ENG CO LTD OF CHINA RAILWAY 11TH BUREAU GRP

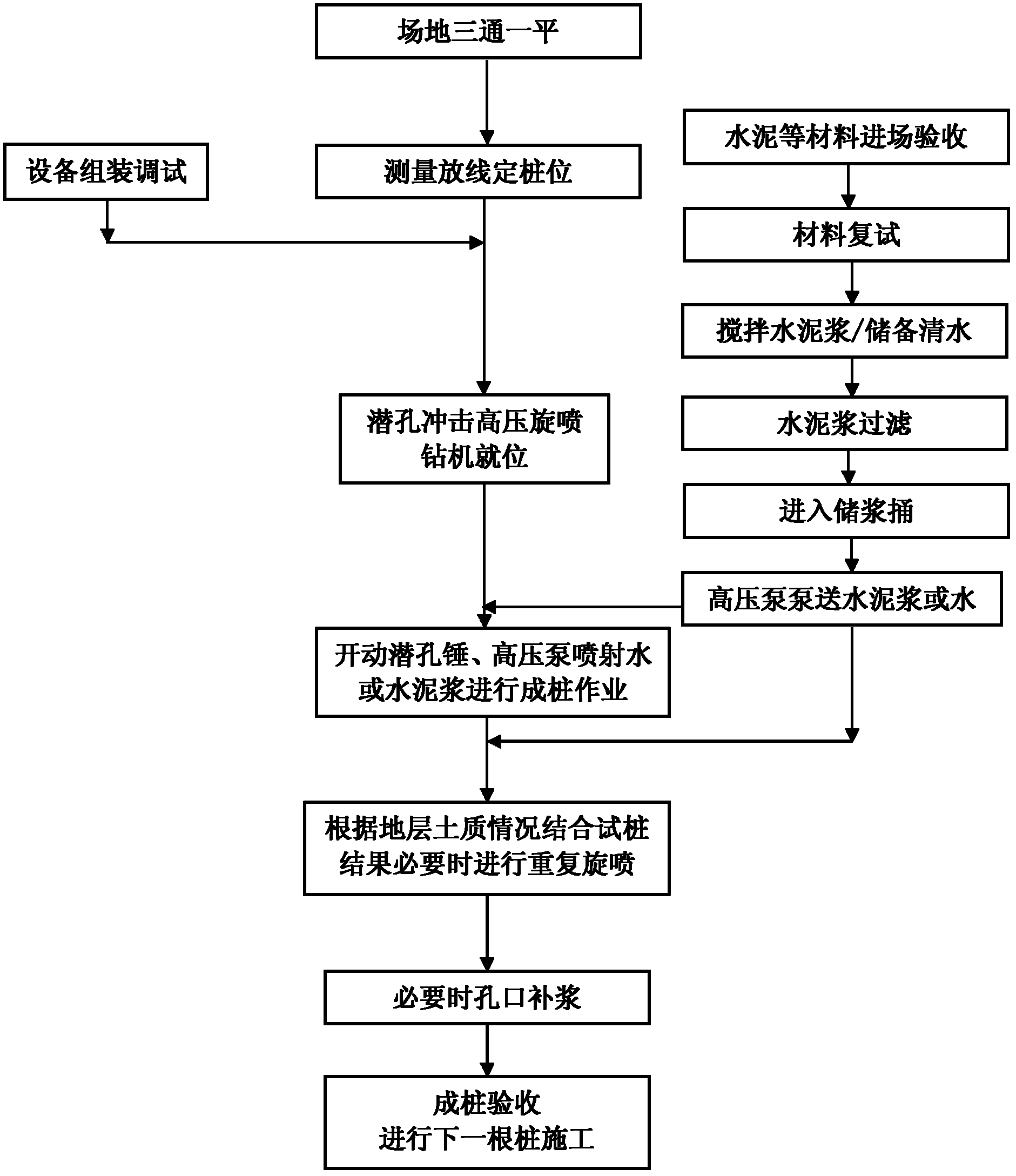

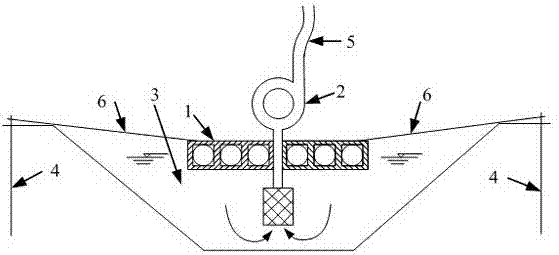

Construction process and equipment for downhole impacting high-pressure jet grouting pile

ActiveCN102322058ASimple mechanical structureStrong stratum adaptabilityDrill bitsDrilling rodsDamage effectsWater jet

Owner:BEIJING RONGCHUANG GEOTECHNICAL ENG CO LTD

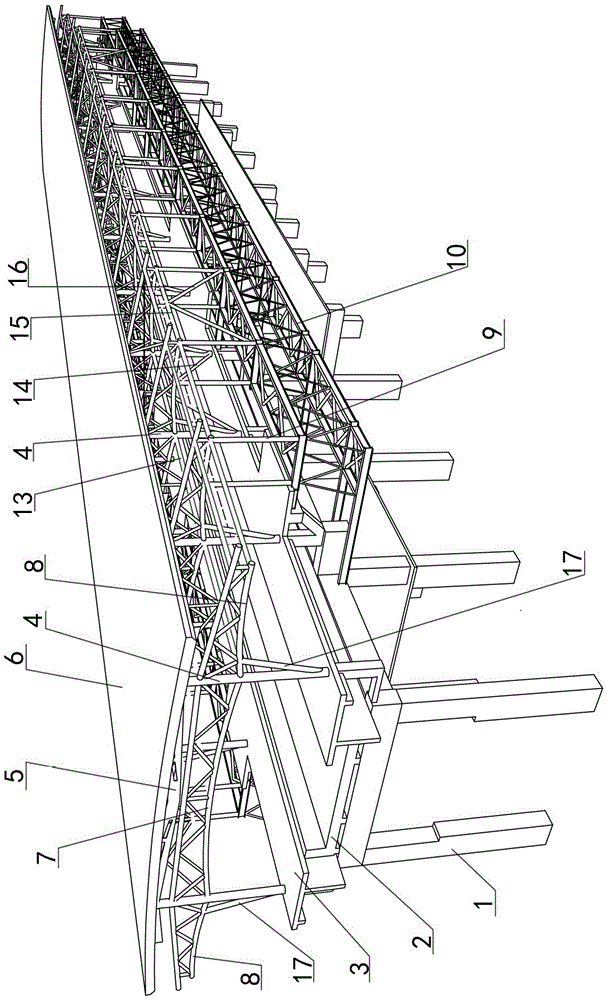

Steel trussed beam and flexible arch bridge construction method with vault pushing

ActiveCN102373671AEnsure driving safetySolve construction problemsBridge erection/assemblyControl systemConstruction engineering

The invention discloses a steel trussed beam and flexible arch construction method with vault pushing, which comprises the following steps of: building an assembly support in the side span of a steel trussed beam, assembling a guide beam and the steel trussed beam into an integral space on the assembly support, arranging a horizontal continuous jack and a mechanical, electrical and hydraulic control system on the assembly support, pushing the steel trussed beam forward by using the horizontal jack, and continuing next round of assembly work on the rear assembly support whenever one round is pushed forward. By using the steel trussed beam and flexible arch construction method with vault pushing provided by the invention, the steel trussed beam and the flexible arch are erected outside the operating limit of a highway, and the construction difficult across the highway is solved.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +1

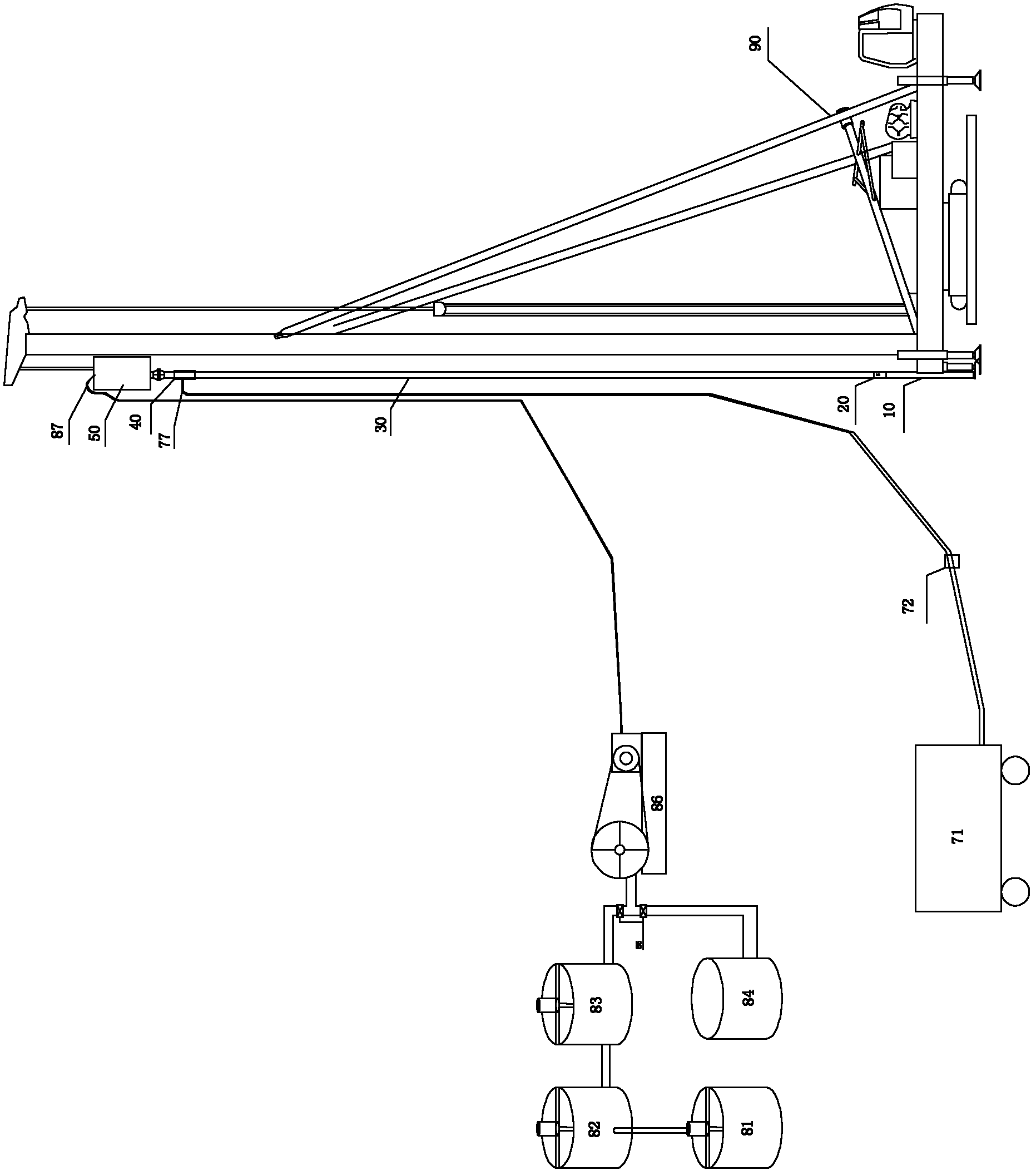

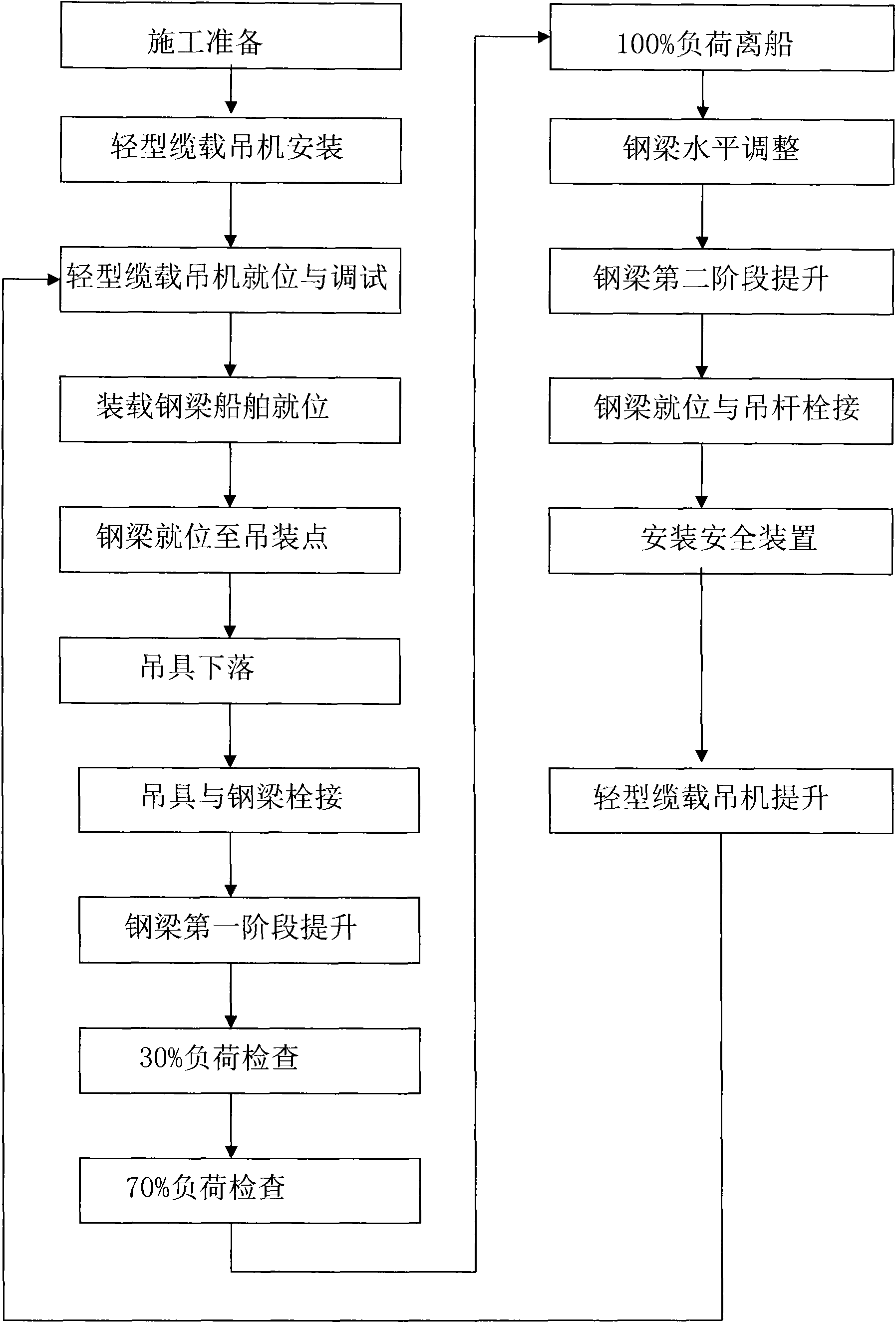

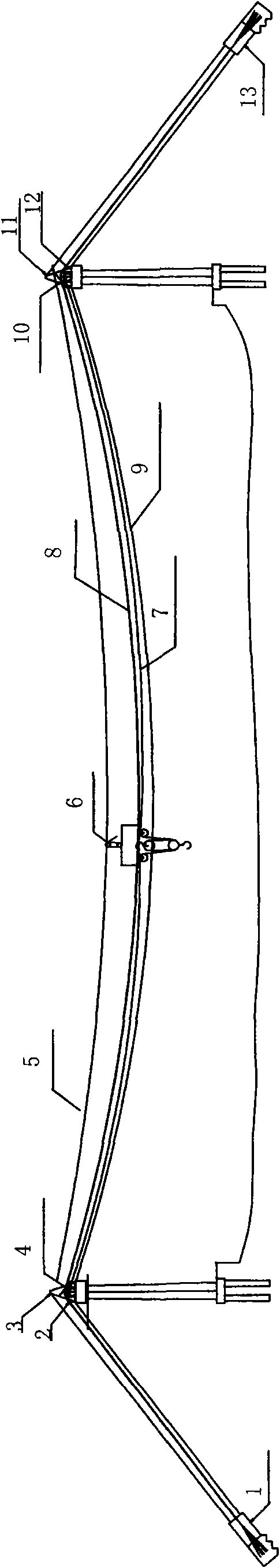

Process method for construction of steel-structured suspension bridge and light type cable carrying crane specially used in same

InactiveCN101684639AReduce weightSimple structureSuspension bridgeBridge erection/assemblyStructural engineeringLightering

The invention provides a process method for the construction of a steel-structured suspension bridge and a light type cable carrying crane specially used in the same, wherein the process flow comprises the steps of construction preparation, assembly of the light type cable carrying crane, the positioning and debugging of the light type cable carrying crane, the positioning of a ship carrying steelbeams, the lifting of the steel beams up to the hoisting point, the descent of a lifting device, the bolting connection of the lifting device and the steel beams, the first stage lifting of the steelbeams, the 30-percent load detection, the 70-percent load detection, the 100-percent load detection, the horizontal adjustment of the steel beams, the second stage lifting of the steel beams, the positioning of the steel beams and boiling connection of a lifting rod, the assembly of a security device, the lifting of the light type cable carrying crane, the movement positioning of the light type cable carrying crane; and the special light type cable carrying crane consists of a load-bearing mechanism, a load-lifting mechanism, a traveling mechanism, an anchoring mechanism and a weight-balancing beam. The process method and the special light type cable carrying crane have the advantages of light weight, simple structure, easy processing, convenient assembly and disassembly, no waterway occupation, big free space brought to transport barges and waterway traffic, high flexibility and maneuverability, high lifting speed, low construction cost, low labor intensity of workers and the suitability for the construction of the suspension bridge.

Owner:CHINA FIRST METALLURGICAL GROUP

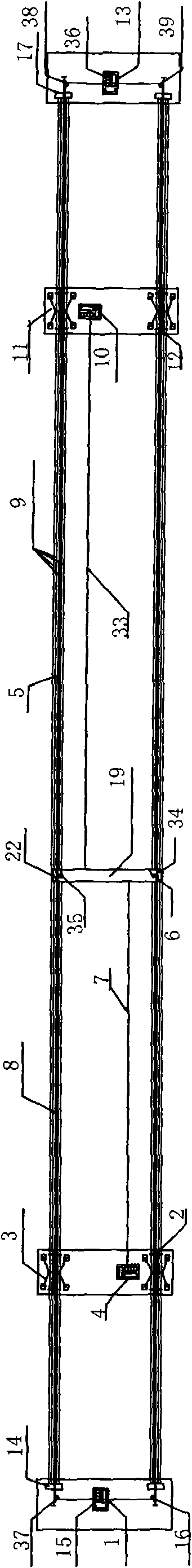

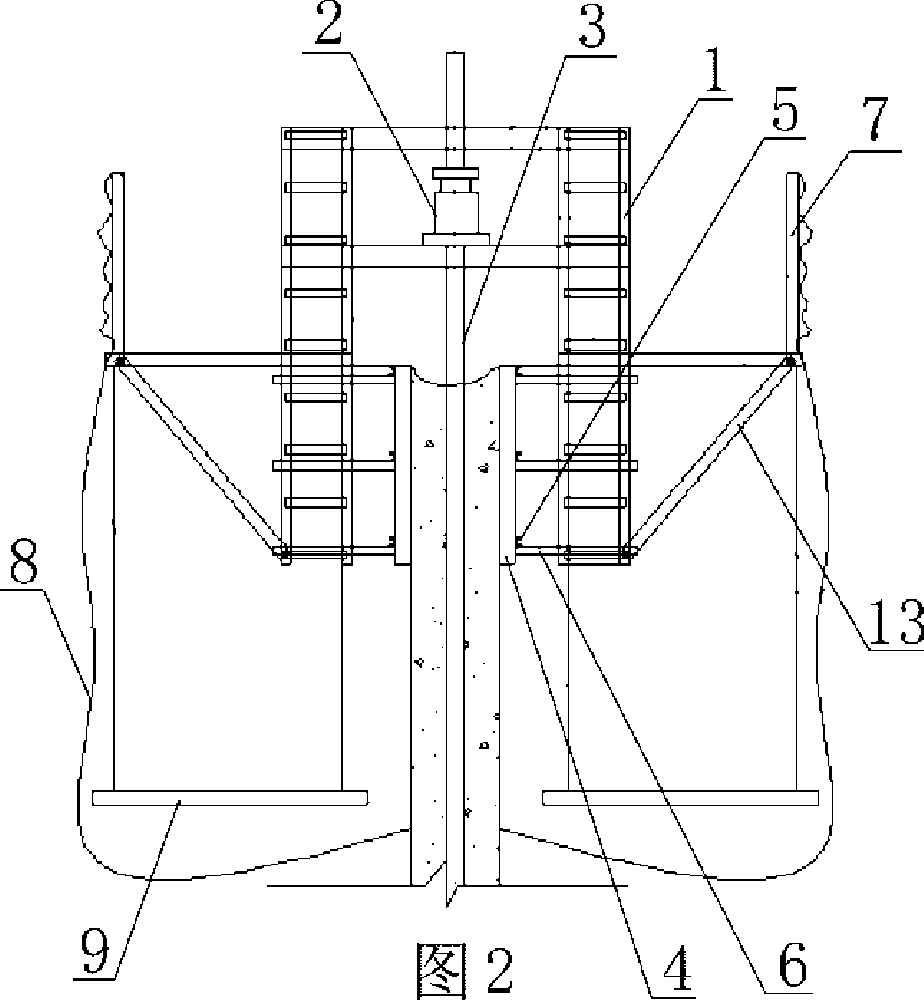

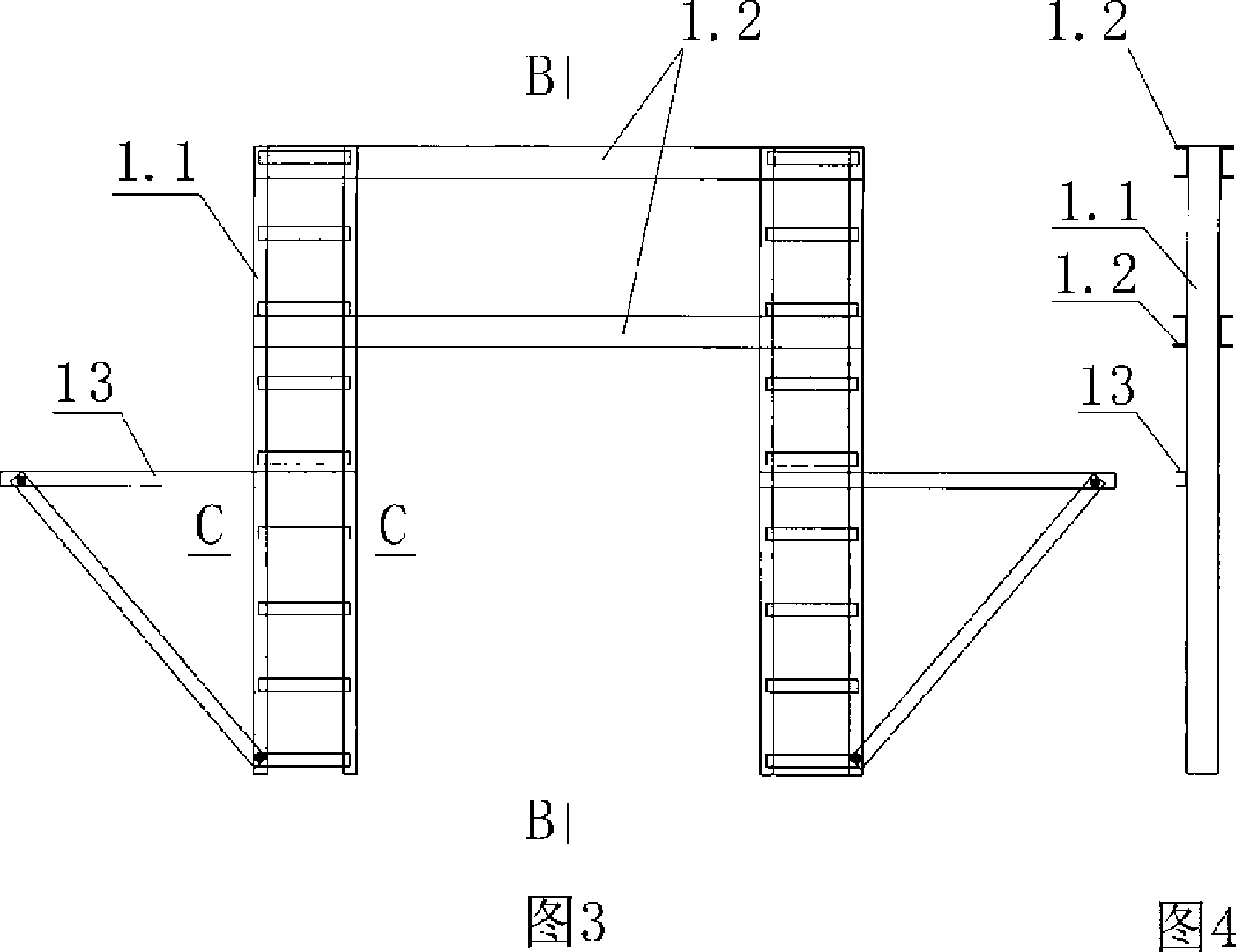

Cabin top steel beam hydraulic hoisting and positioning apparatus of cylinder cabin structure building and construction method thereof

Disclosed is a steel beam hydraulic lifting emplacing device on the top of silo structure building, which comprises a sliding formwork device and a hydraulic lifting system, and is characterized in that the sliding formwork lifting frames of the sliding formwork device are connected with an inside formwork, an outside formwork, and an operating platform, a scissors support is connected between two lifting frame upright columns, the sliding formwork lifting frame is also connected with a steel beam supporting frame, the steel beam support frame is connected with the steel beam on the top of the silo to form a lifting integration, the hydraulic lifting system is utilized to be the lifting power system for the lifting integration, and the hydraulic lifting system is composed of a hydraulic jack, a support rod, a hydraulic console, and an oil circuit. The invention can rapidly, conveniently, reliably, and safely complete the construction task of mounting the steel beam on the top of the silo, without using large scale hoisting equipment, thereby avoiding the problems of difficult emplacement and lower efficiency of large scale hoisting equipment. The device of the invention can be widely applied to the hoisting and emplacement construction for the steel frame on the top of silo buildings.

Owner:THE THIRD CONSTR ENG CO LTD OF CHINA CONSTR SECOND ENG BUREAU +1

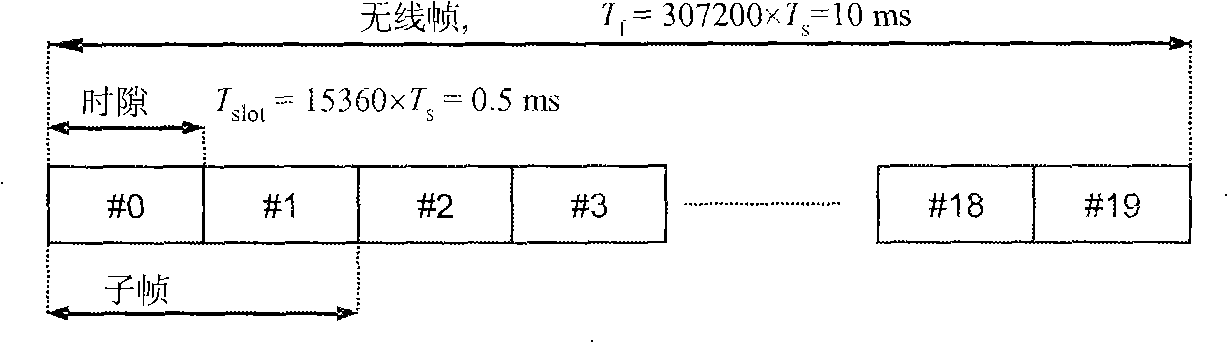

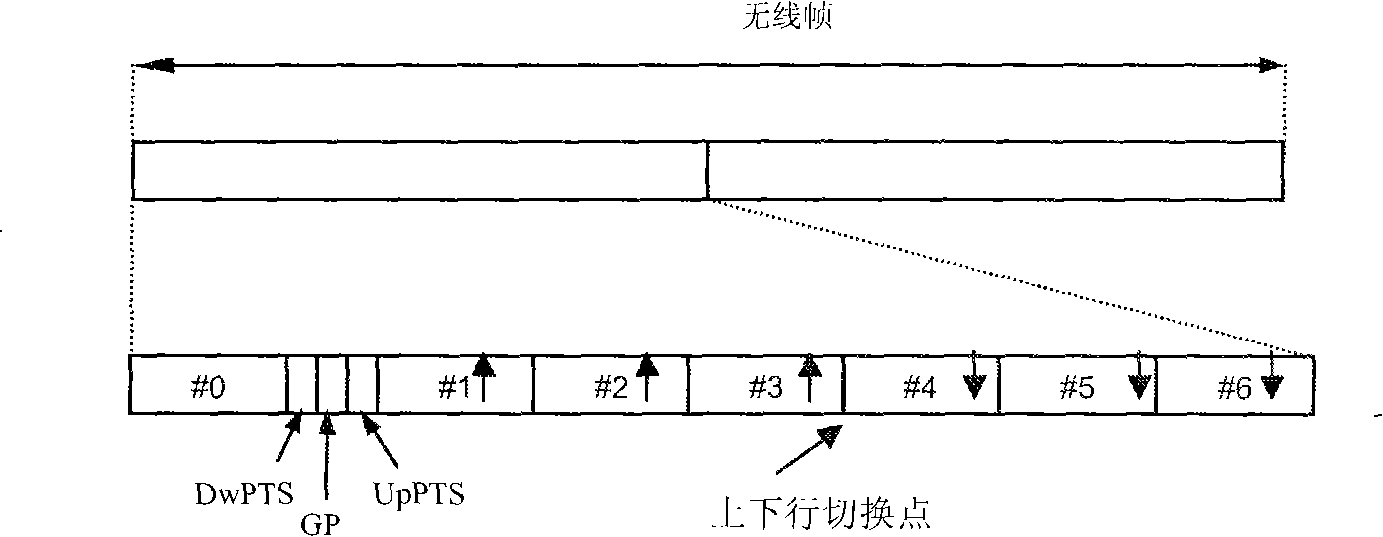

TDD OFDMA system ascending control signaling transmission method and device

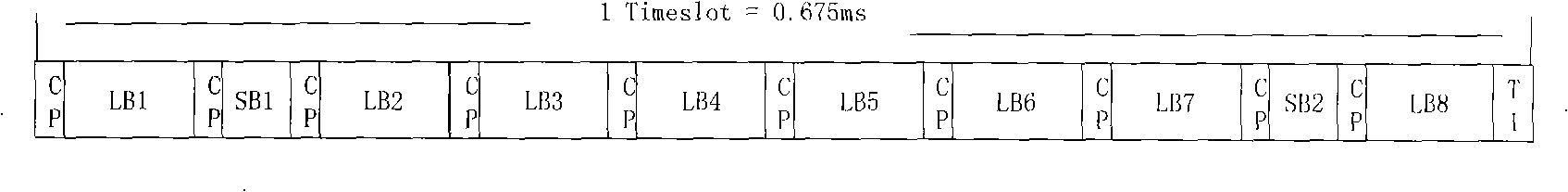

ActiveCN101272175AChange quantityFlexible configurationSignal allocationTime-division multiplexTime domainControl signal

The invention relates to a method for transmitting uplink control signaling of a time-division duplexing orthogonal frequency-division multi-access system and a device, which is a proposed specific technical scheme of separately transmitting the non-data correlation control signaling for long-term evolution time-division duplexing (LTE TDD). A control signaling processing unit reserves a frequency band for an uplink control channel according to the total amount of the uplink control signaling, and configures the reserved frequency band at two sides of the frequency domain occupied by the uplink time slot so as to ensure that the uplink control signaling of a terminal UE is transmitted at the position of the reserved frequency band and on the bandwidth and provides a plurality of schemes for reserving the frequency band position and bandwidth. The transmitting uplink control signaling is transmitted in each reserved uplink control channel in the mode of frequency hopping in the sub-frame. Each terminal UE or a group of UEs corresponds to an FH sequence and a plurality of pilot frequency schemes are provided. In the method, the reserved frequency band is configured aiming at the system working bandwidth and positions of uplink and downlink switching points. The method is characterized by low implementation complexity and also sufficient utilization of resources, the transmission is carried out in the mode of frequency hopping in the sub-frame and the time domain and frequency domain diversity can be simultaneously utilized.

Owner:DATANG MOBILE COMM EQUIP CO LTD

Direct local skirt border reversing construction for central island

InactiveCN1982546AReduce distortionEnsure safetyArtificial islandsBuilding constructionsSupporting systemPurlin

A job practice of which center island is done in sequence and partial skirts done inversely, comprising the following steps : set up exterior-protected construction, purlin and steel upright columns around the foundation ditch; dig on basin pattern for the first time to the depths to structural plane of purlin, earthwork are unified dig beneath the designed to the surrounding medium plate in the foundation ditch, pour the surrounding medium plate; dig for the second time with basin pattern downwards from the position of foundation ditch medium plate to the bottom of the designed foundation ditch, pour the center island plate; after the center island plate meets the maintenance time request of plate, construct in sequence to close the medium plate, setting fetching holes; then use medium plate for support system, construct criss-cross structural upper plate and plates in inverse zones. This construction method is convenient, save labor force and resources, improves the progress of the project, shorten the construction period.

Owner:SHANGHAI NO 7 CONSTR

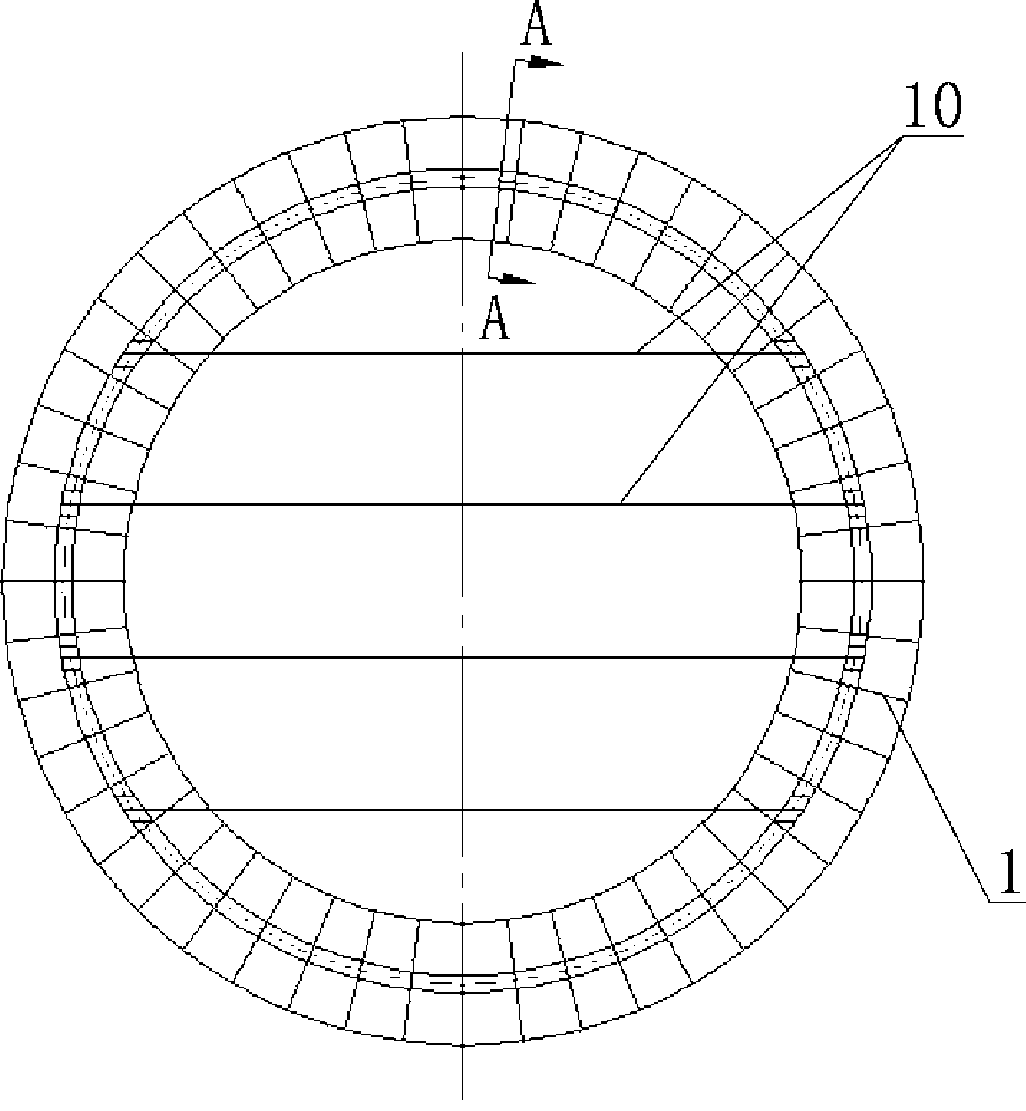

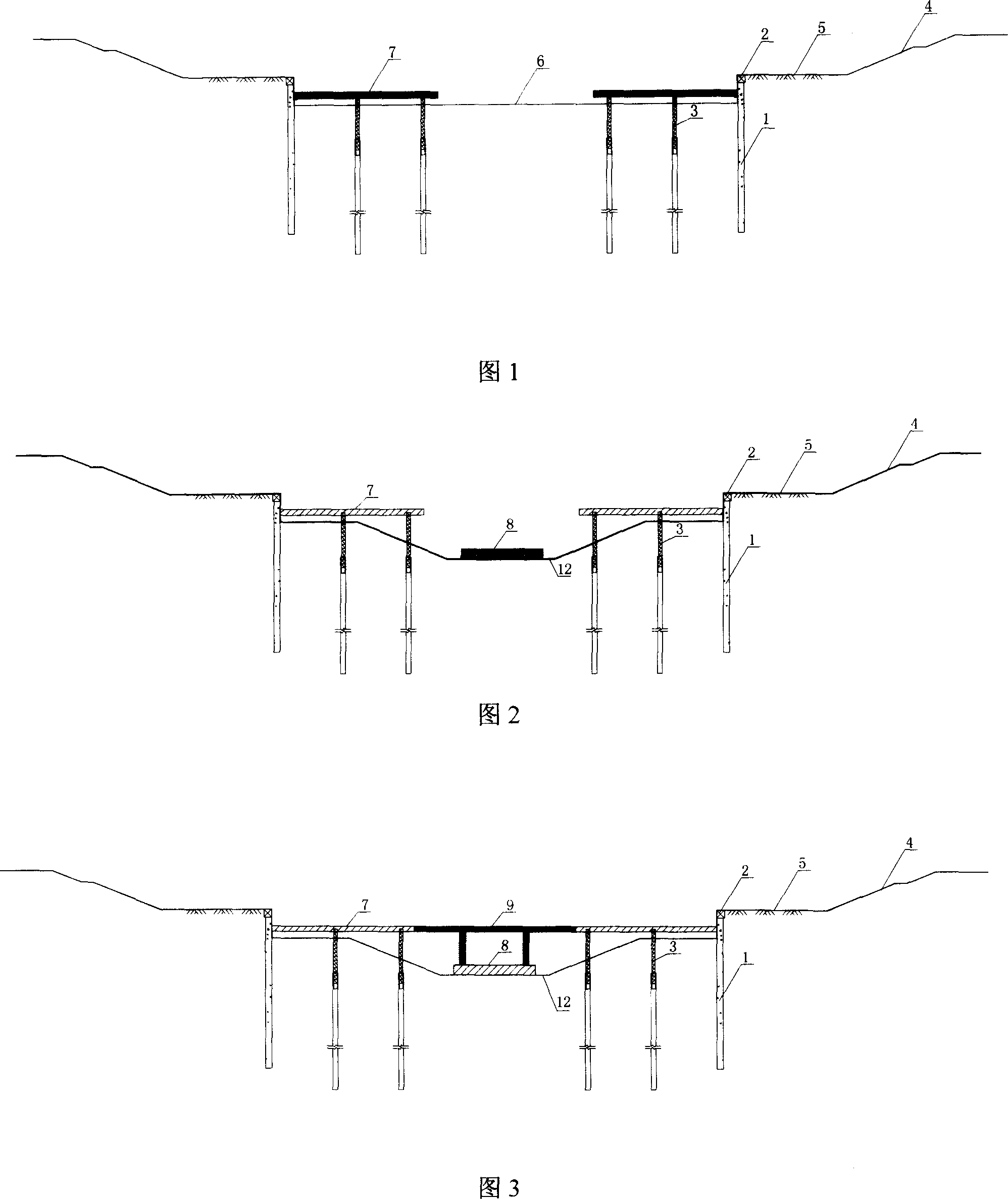

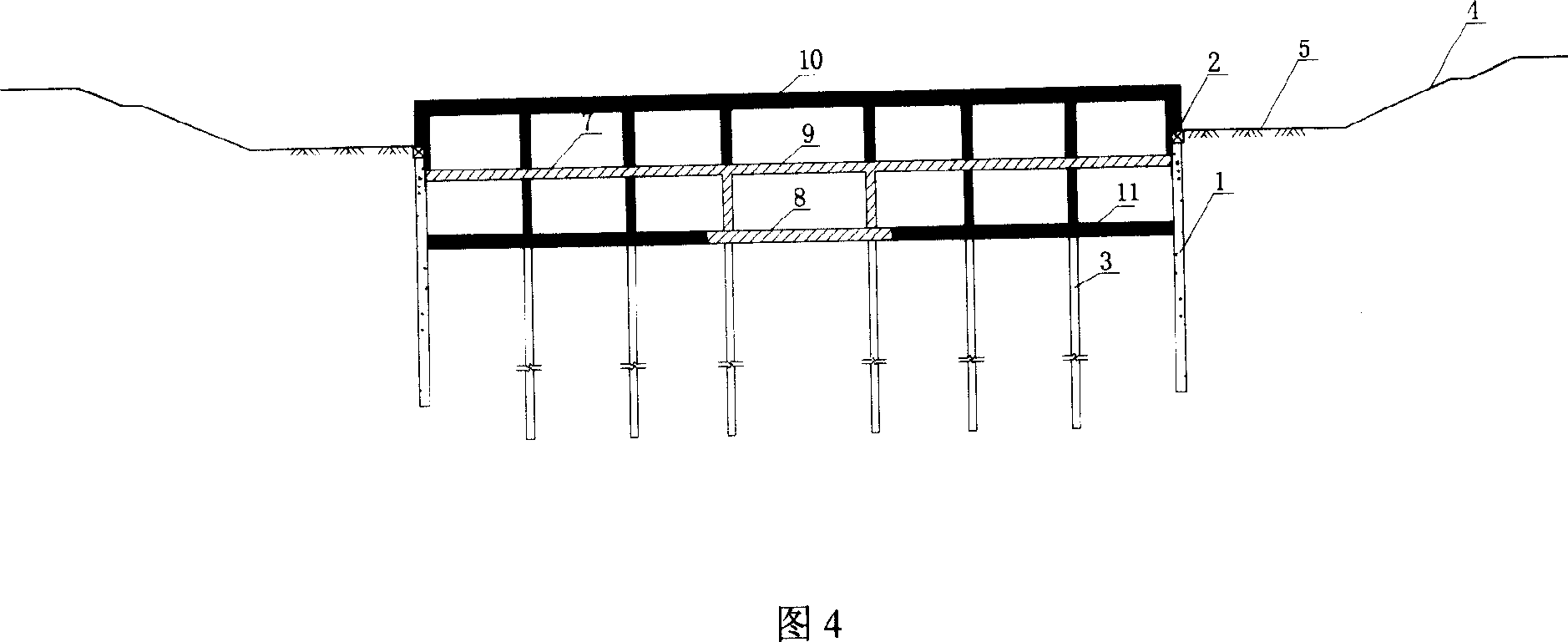

Prestressed ultrahigh-performance concrete continuous box girder bridge and construction method thereof

ActiveCN102352597ASimple construction methodGuaranteed durationBridge erection/assemblyBridge materialsPre stressBox girder

The invention discloses a prestressed ultrahigh-performance concrete continuous box girder bridge which comprises piers and an ultra-high performance concrete box girder. The box girder has a wholly or partially external prestressed system in the longitudinal direction of the box girder bridge and mainly comprises a top plate, a bottom plate, a web plate and a diaphragm plate, wherein at least one of the top plate, the bottom plate, the web plate and the diaphragm plate is a sheet. The construction method of the prestressed ultrahigh-performance concrete continuous box girder bridge is a segmental prefabricating and suspended-splicing method and mainly comprises the following steps: constructing pile foundations and the piers, mounting blocks No.0 on the piers, splicing all sections of the box girder symmetrically on two sides of the blocks No.0 in a suspending way, erecting side spans by using a support erecting method, carrying out side span closure, carrying out midspan closure, and stretching prestressed steel strands in all construction stages to finish construction. The prestressed ultra-high performance concrete continuous box girder bridge has the advantages of simple structure and light dead weight, the crack risk of the box girder is reduced, and the method is suitable for constructing a long-span bridge.

Owner:HUNAN UNIV

BIM technology-based curtain wall mounting design method

InactiveCN108460189AEliminate biasImprove installation accuracyGeometric CADDesign optimisation/simulationPoint cloudEngineering

The invention discloses a BIM technology-based curtain wall mounting design method. The method comprises the following steps of (1) importing a two-dimensional drawing of a curtain wall to BIM software Revit, and building three-dimensional models of to-be-mounted curtain wall unit members according to modeling specifications; (2) exporting detail drawings according to the three-dimensional modelsof the to-be-mounted curtain wall unit members, and performing processing production according to the detail drawings of the curtain wall unit members by a factory; (3) building three-dimensional point cloud models of the curtain wall unit members by utilizing fixed point cloud information; (4) adjusting information of the curtain wall unit members by using a processing device; and (5) simulatingwhole pre-mounting of the curtain wall in the Revit according to the three-dimensional point cloud models of the curtain wall unit members meeting specification requirements, and according to a pre-mounting process, performing entity member mounting. The BIM technology-based curtain wall mounting design method solves the problems of high field mounting difficulty, low mounting efficiency and low precision of the curtain wall.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

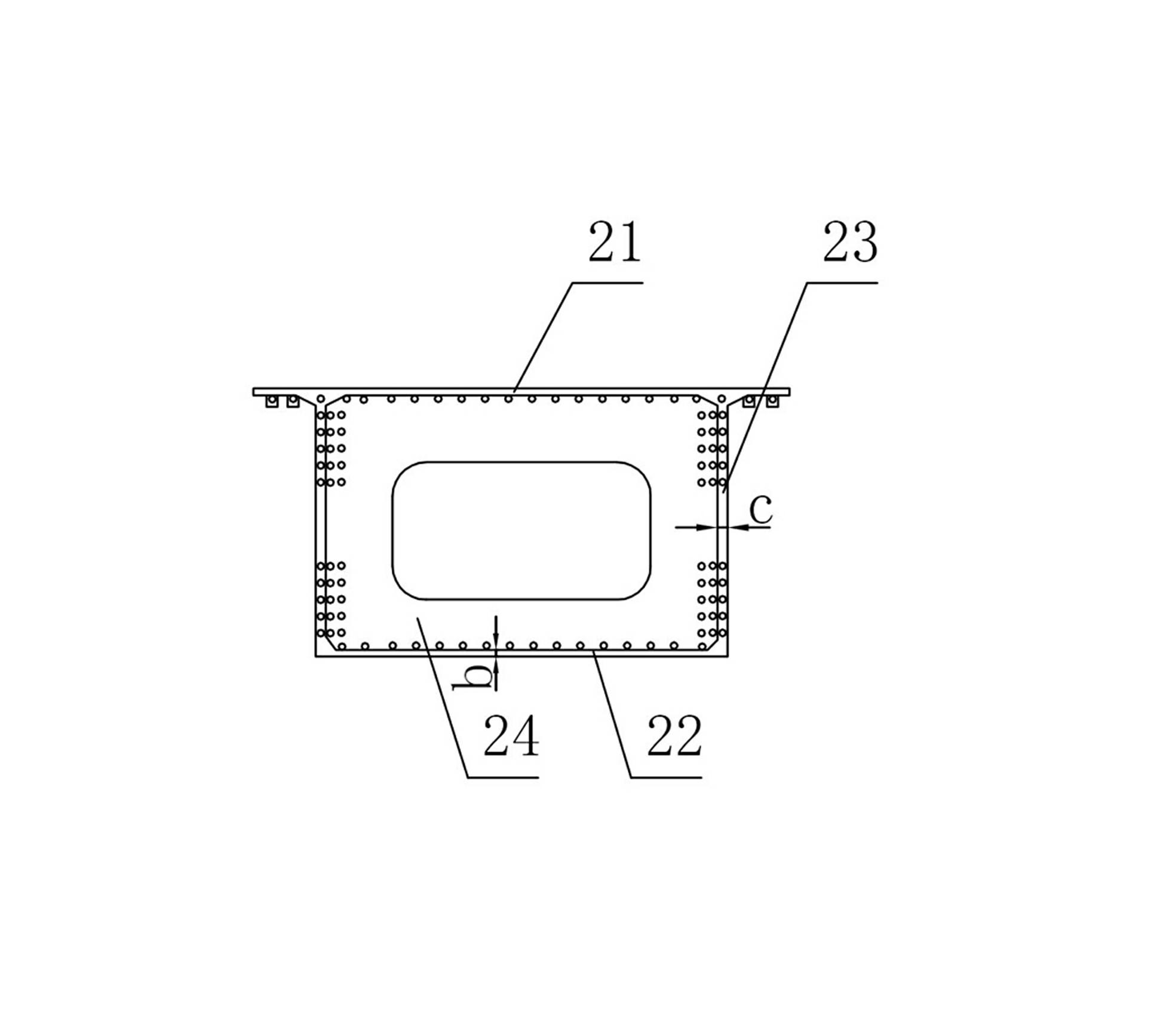

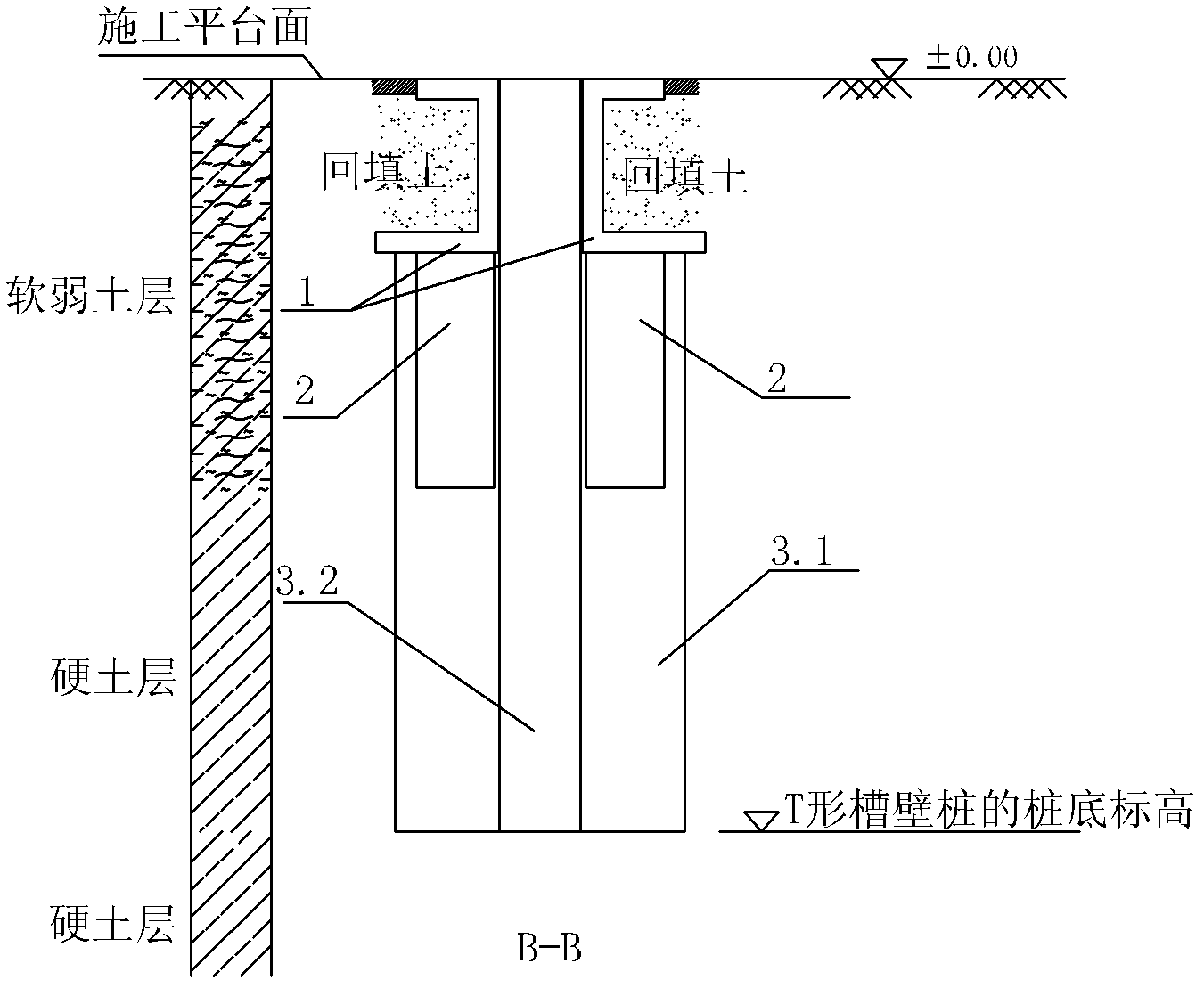

Ultra-deep T-shaped trench-wall pile in soft-toped hard-bottomed soil layer and trench forming method

InactiveCN102561361AReduce post-construction settlementReduce horizontal displacementSoil-shifting machines/dredgersExcavationsEngineeringSoil horizon

The invention discloses an ultra-deep T-shaped trench-wall pile in a soft-toped hard-bottomed soil layer and a trench forming method. The trench forming method includes the steps: firstly, pre-reinforcing soft soil at each external corner of a T-shaped trench wall; secondly, digging a guide wall foundation pit, treating the extremely soft soil layer at the bottom area of a guide wall to lead the bearing capacity of the foundation bottom of the guide wall to be larger than or equal to 100kPa; and thirdly using the trench forming way of 'drilling and gripping'. By the method, trench forming efficiency can be improved greatly, cost is lowered, and evident economy is achieved.

Owner:CCCC FOURTH HARBOR ENG CO LTD +1

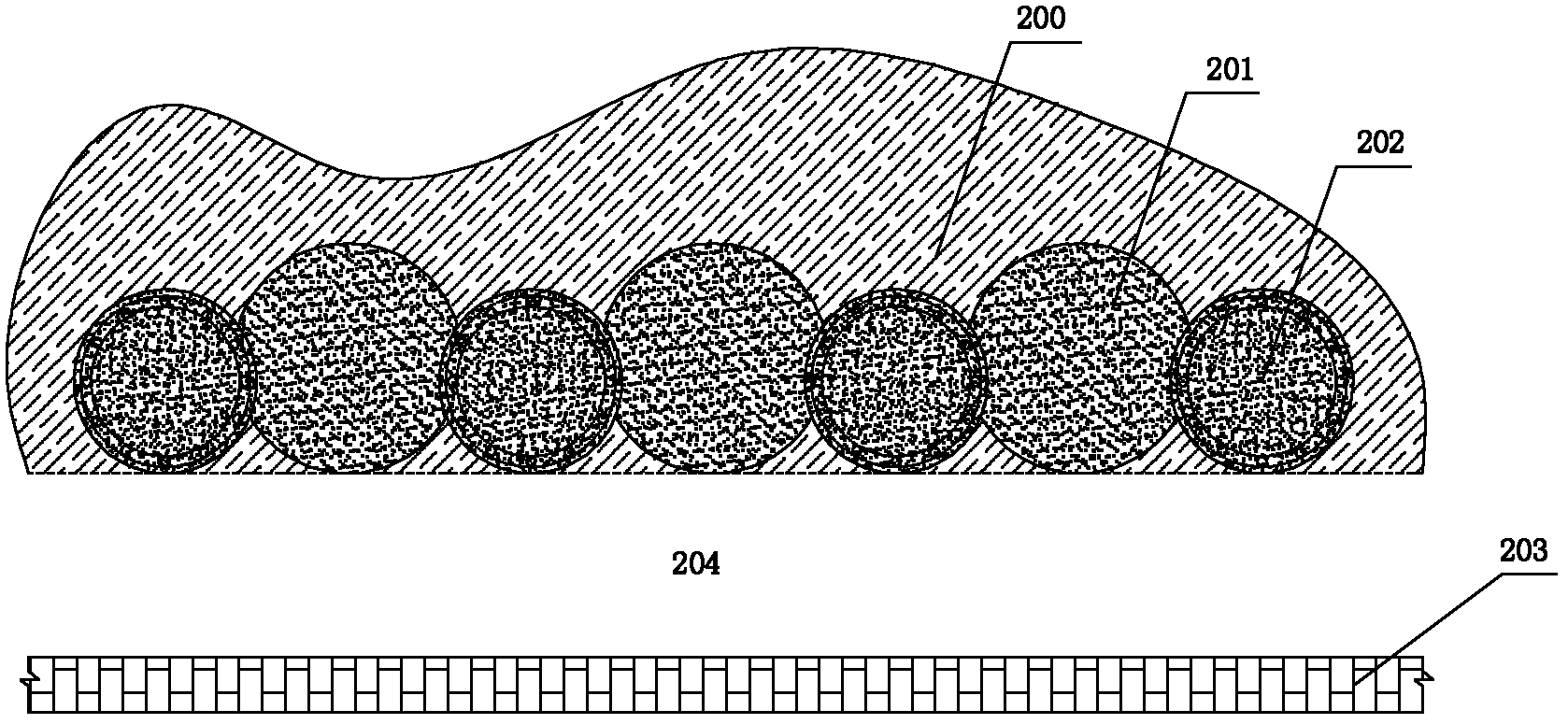

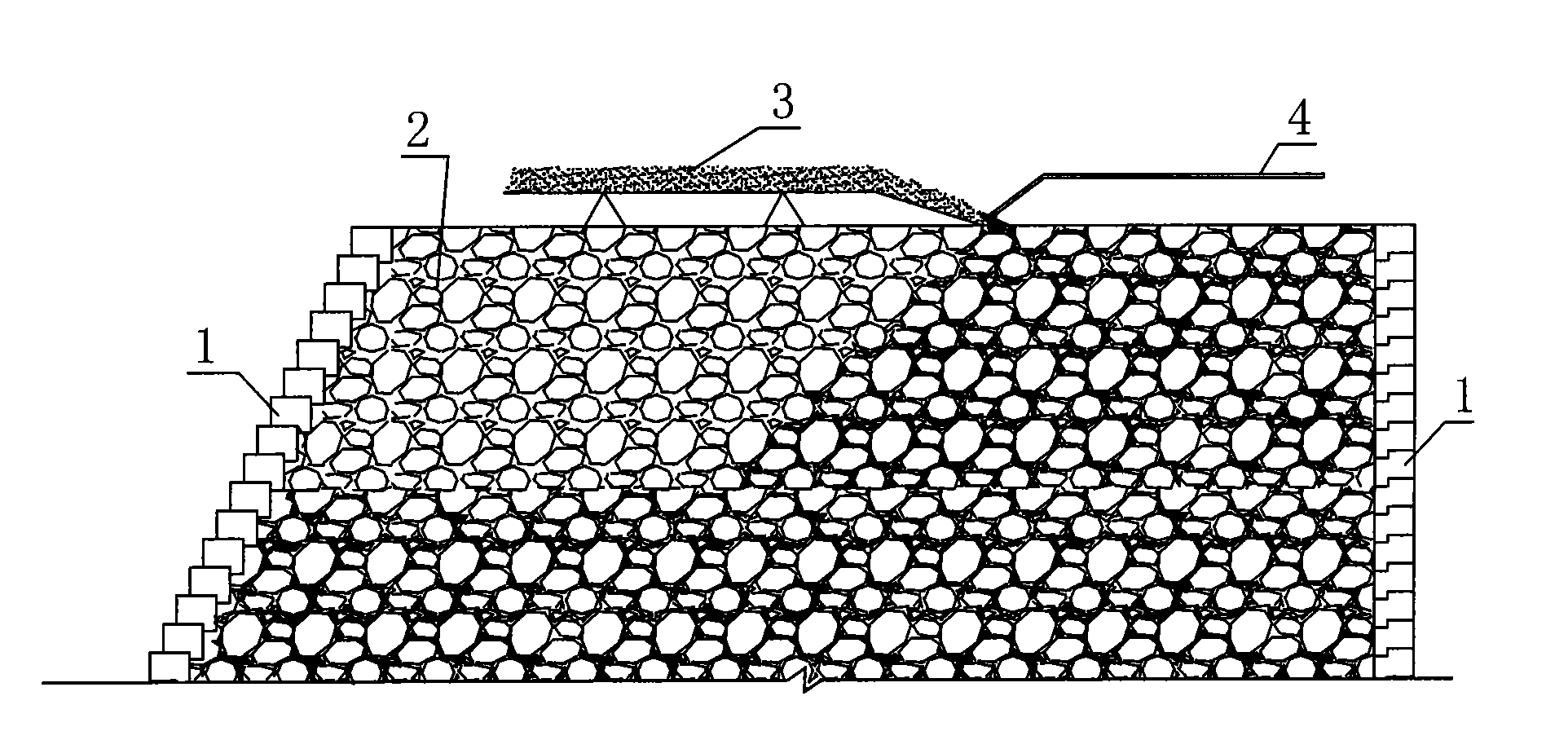

Construction method for filling mortar combined stone dam

ActiveCN101581088AIncrease self-impermeabilityTake advantage ofFoundation engineeringWall damsDiameter controlFly ash

The invention discloses a construction method for filling a mortar combined stone dam, which combines a mortar grouting and filling method and a rock-fill dam filling construction process, and solves the problems that a stone masonry structure is inconvenient to use mechanical construction and has low working efficiency, and a rock-fill dam has higher requirement on grain diameters of filling stones, lower material source utilization rate, high manufacturing cost and the like. The construction method comprises the following steps: filling stones in a dam shell till reaching the thickness requirement of a filling layer, flattening the stones, and then carrying out mortar sand removal operation on the top surface of the filling layer, namely directly filling previously prepared cement mortar or cement mixed mortar doped with admixture fly ash into the screened sand quantitatively supplied by a mortar conveying device in gaps of the filled stones through the mortar conveying device to form the mortar combined stone dam similar to the mortar masonry stone dam. The process flow is simple, the application range is wide, the maximum block diameter control and grade matching requirements are not needed, the stone source is abundant, the thickness of the filling layer is large, the roller compaction is not needed, the construction speed is high, the working efficiency is high, the construction cost is reduced, and the formed dam mortar masonry is compact and has good quality.

Owner:沈阳乾玉水利有限公司

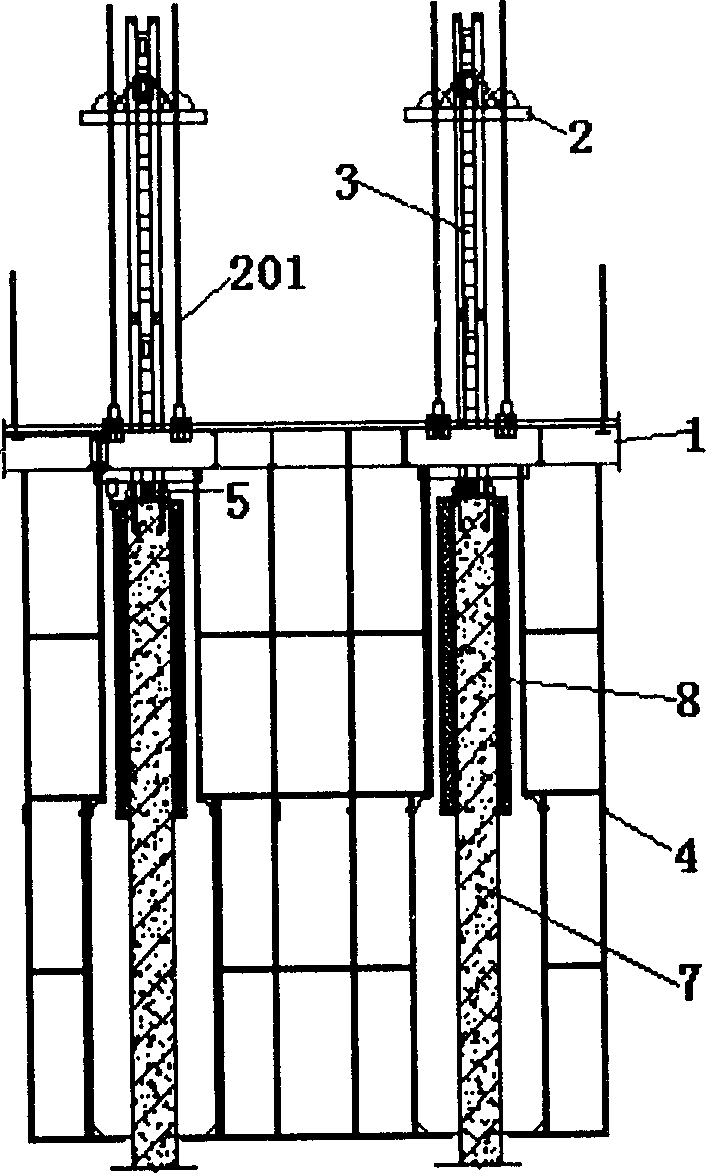

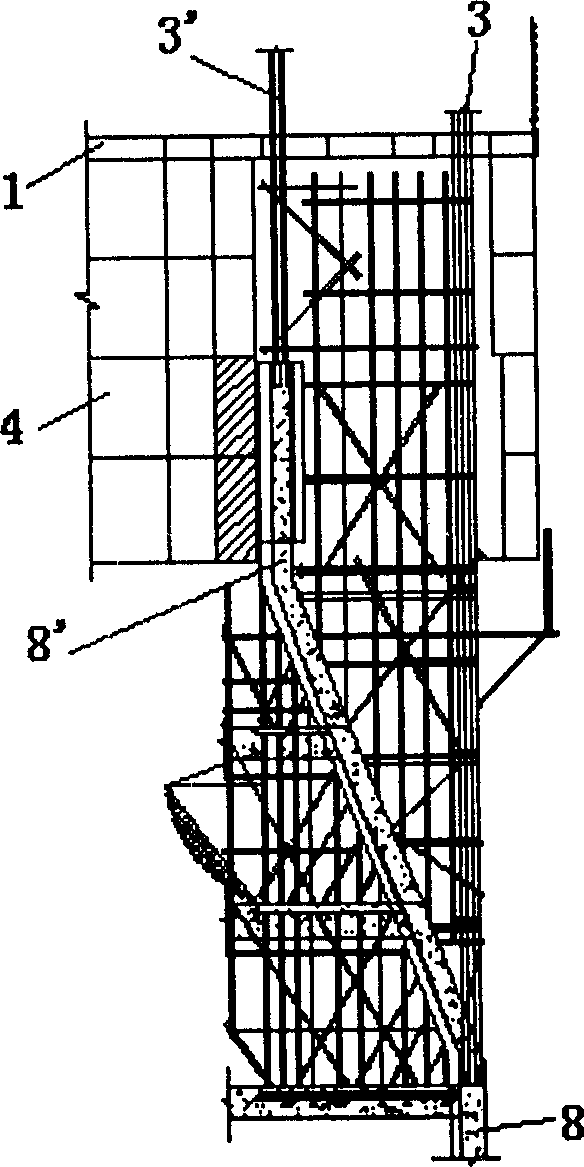

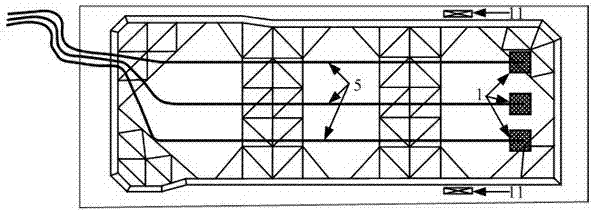

Autolifting type variable-shape diassembllable integrated lifting steel plateform system and construction method thereof

ActiveCN1793590AMeet construction needsImprove integrityForms/shuttering/falseworksBuilding support scaffoldsFalseworkSteel columns

The invention discloses a self-rising deformable removable integral lifting steel platform system for ultrahigh varying-layer plane construction and the construction method thereof, comprising steel platform, plate lifter, flexible steel column, hanging staging and bearing pin, where the hanging staging is fixed with the steel platform, the steel platform is deformable and comprises primary and secondary beams, the junction of the two beams is provided with a rolling device, the secondary beam can take the primary beam as orbit to move relative to the primary through the rolling device. The invention uses the various construction columns installed in core tube sharing walls as support and climbing guide rails, uses the plate lifter as power, lifts the whole steel platform system by lifting screw rods connected with the steel platform, and arranges trolleys on partial secondary steel beams to make them able to move inward along the primary steel beam to the preset position at last, and completes the plane deformation of the steel platform and meets construction requirements for the core tube variation.

Owner:SHANGHAI CONSTR NO 1 GRP

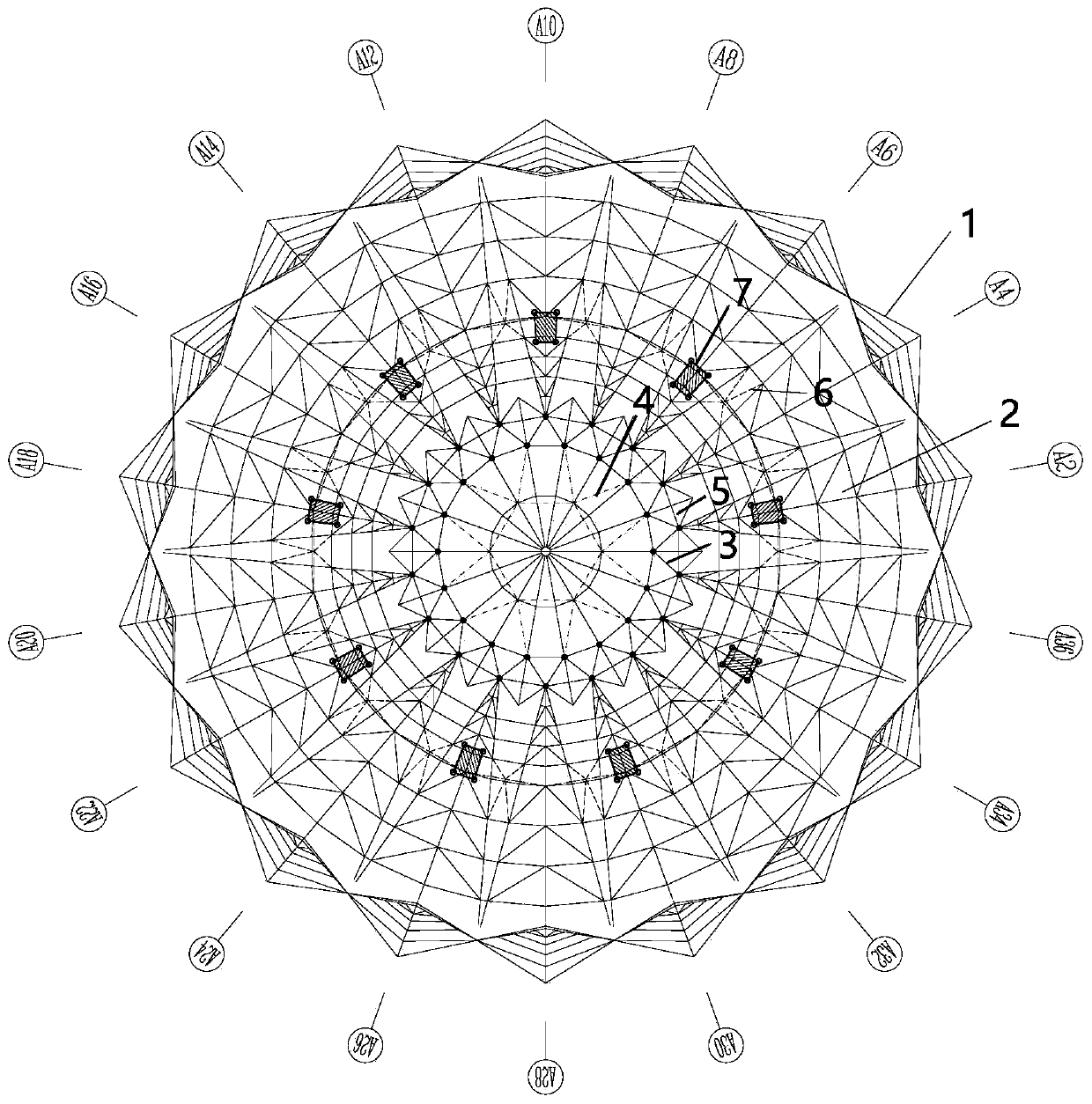

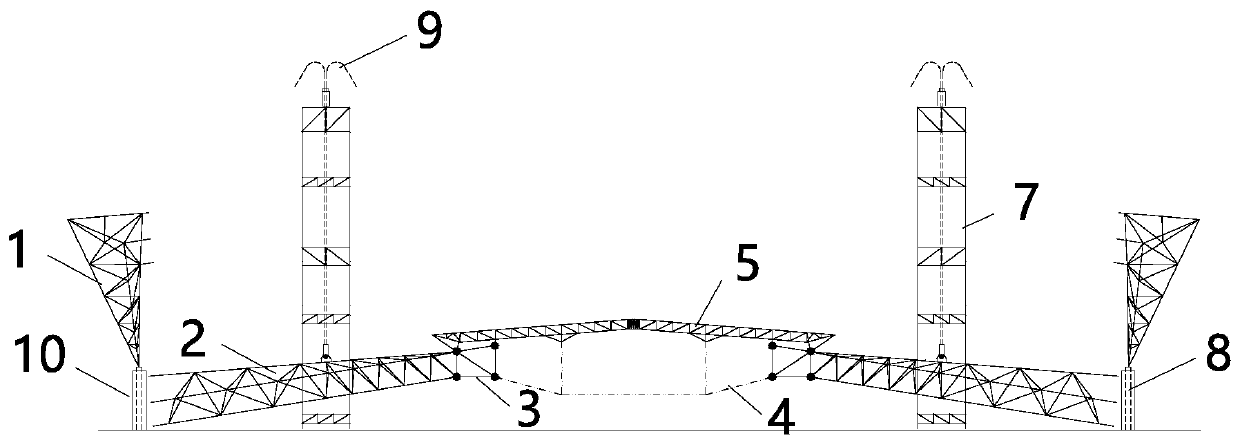

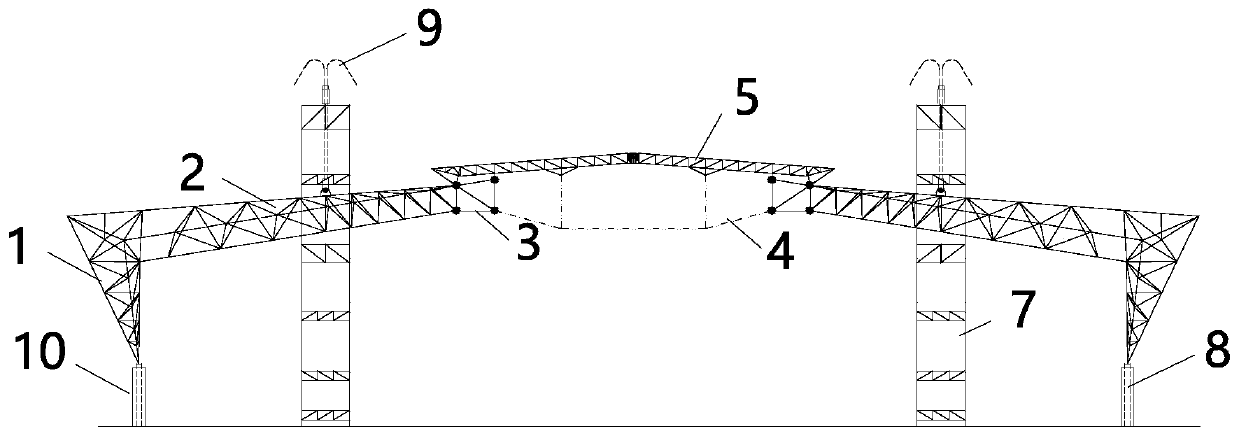

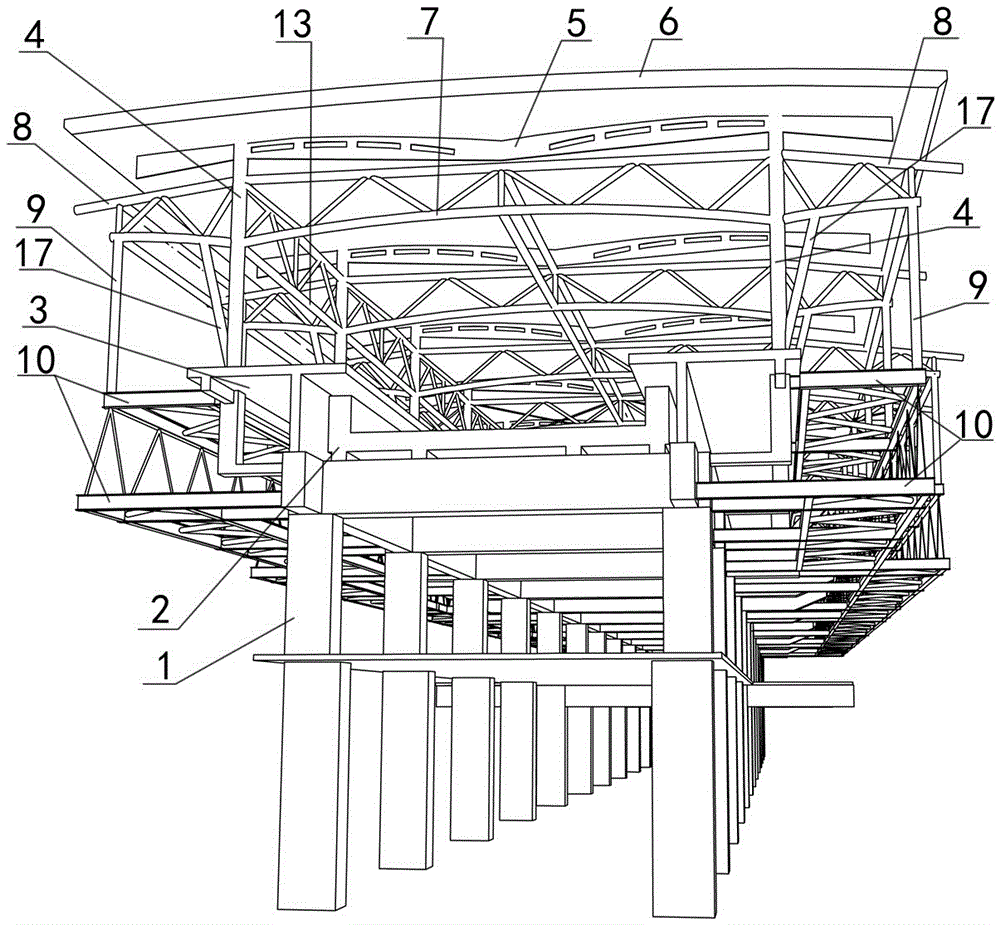

Overall lifting construction method of large complex composite structure steel roof

InactiveCN110130652AQuality assuranceImprove ergonomicsBuilding material handlingControl systemStructural engineering

The invention discloses an overall lifting construction method of a large complex composite structure steel roof. According to the overall lifting construction method, a lifting support is arranged onthe corresponding position in a house, a composite structure roof (including a truss girder, an annular net rack, a pull rope and a roof secondary girder) is assembled in situ through the ground in the house, truss column house exterior hoisting and composite structure roof assembling are conducted synchronously, after roof system ground assembling and pull rope mounting are completed, ground initial tensioning is conducted, ten lifting power is provided for the roof through a lifting jack and a hydraulic control system, thus the composite structure steel roof is overall lifted and descended,and the lifting jack vertically moves to achieve linear adjustment of the roof truss girder, column joint butting and an overall roof system.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +1

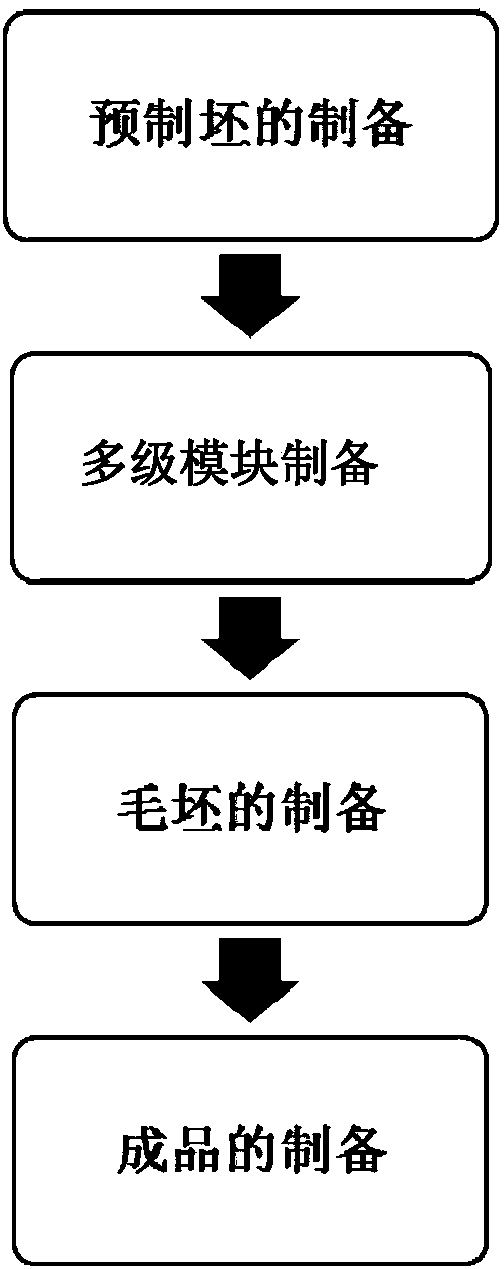

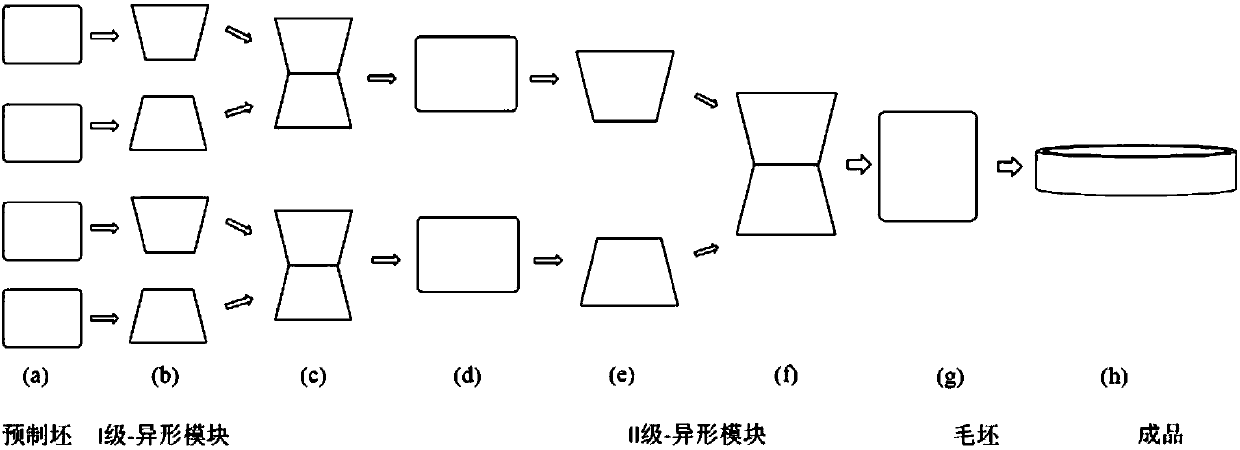

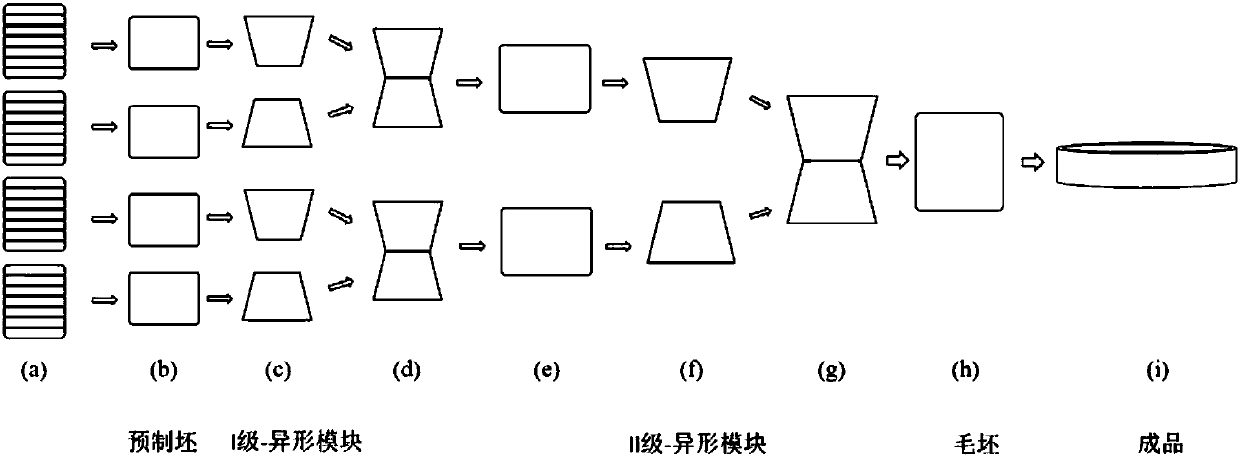

Modular metal constructing forming method

InactiveCN107717341AReliable qualityGuaranteed durationElectron beam welding apparatusEngine componentsForgingMetal

The invention relates to a modular metal constructing forming method. According to the method, a large forging preformed blank is divided into multistage modules to be constructed correspondingly according to concrete conditions, finally, the blank is formed, and parts or components are machined. The constructing quality of the method is more reliable and controllable, each module can be detectedafter being forged, and it is ensured that the modules are recycled after qualification; multiple pieces can be fed during feeding, the project duration can be effectively guaranteed. The method can improve the yield of large metal constructing forming, can greatly improve the production efficiency under the condition of using the same specification press, solves the bottleneck problem in the manufacturing process of large constructed formed forgings, and reduces the production cost.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

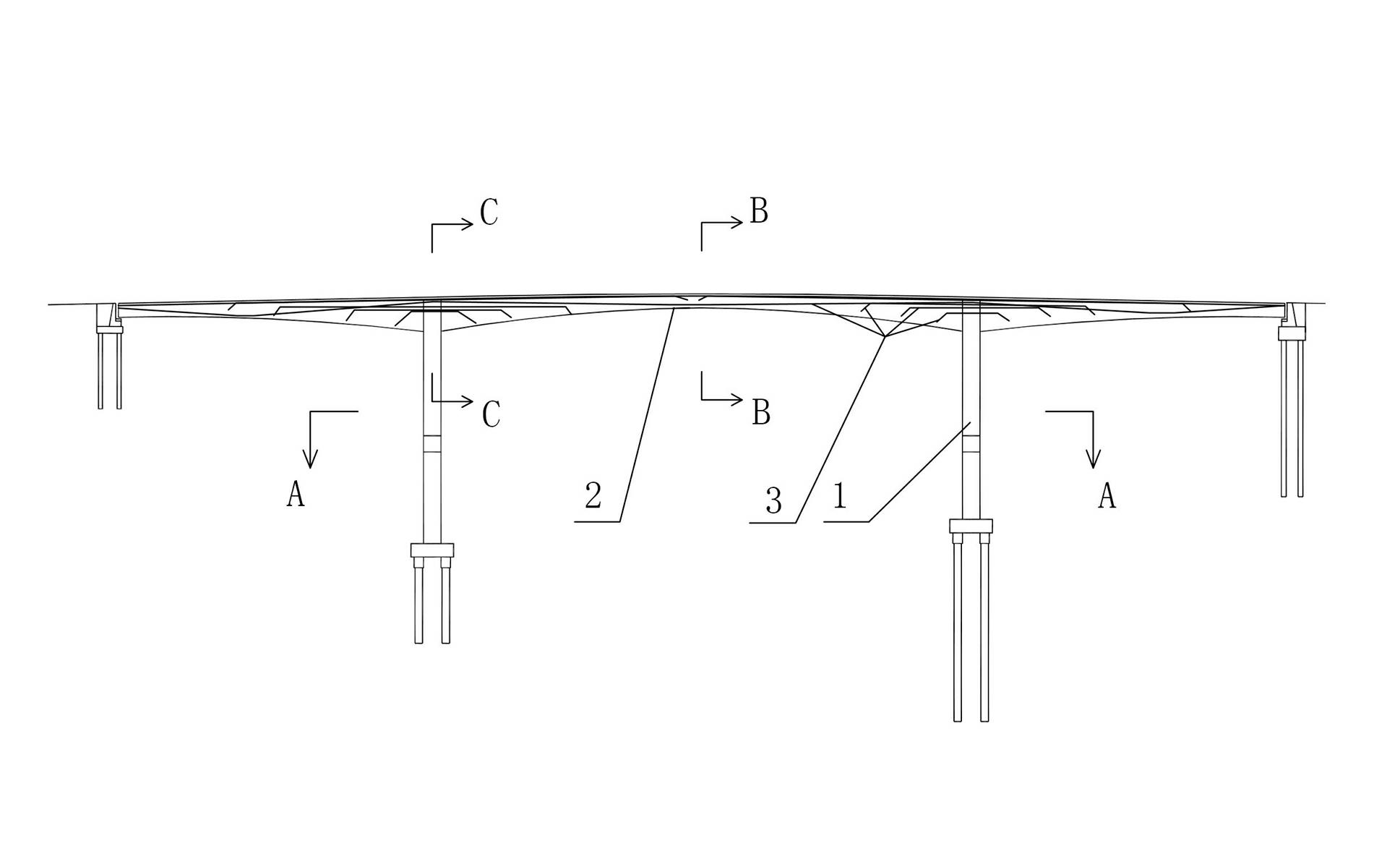

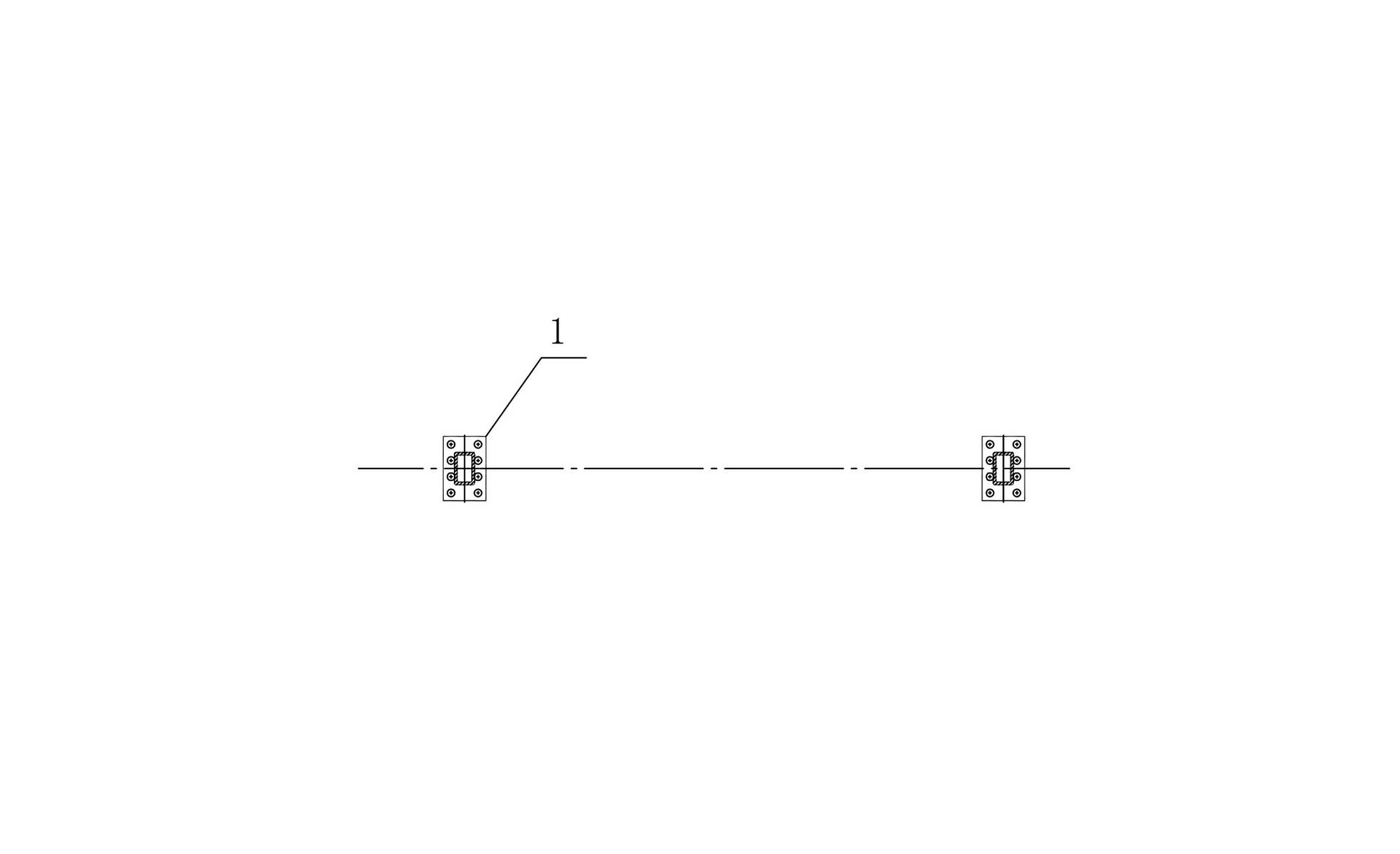

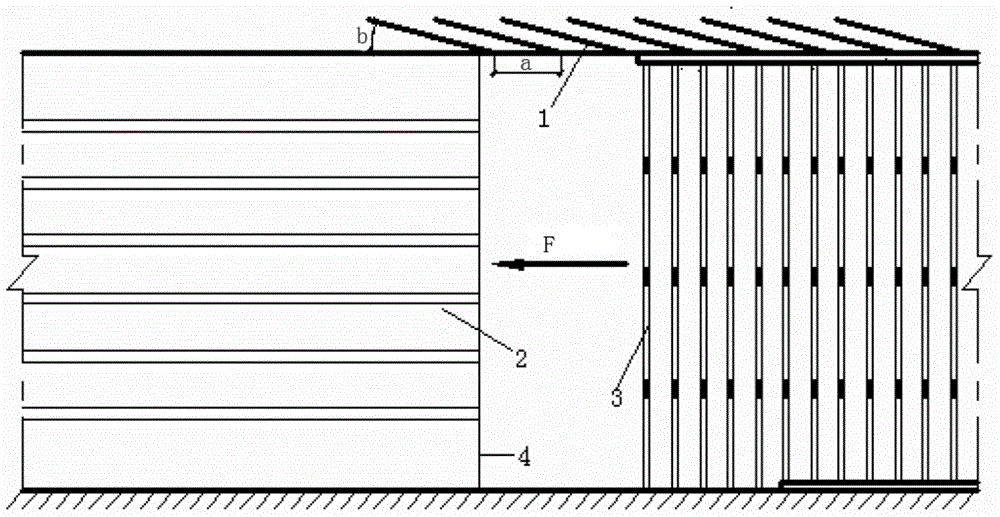

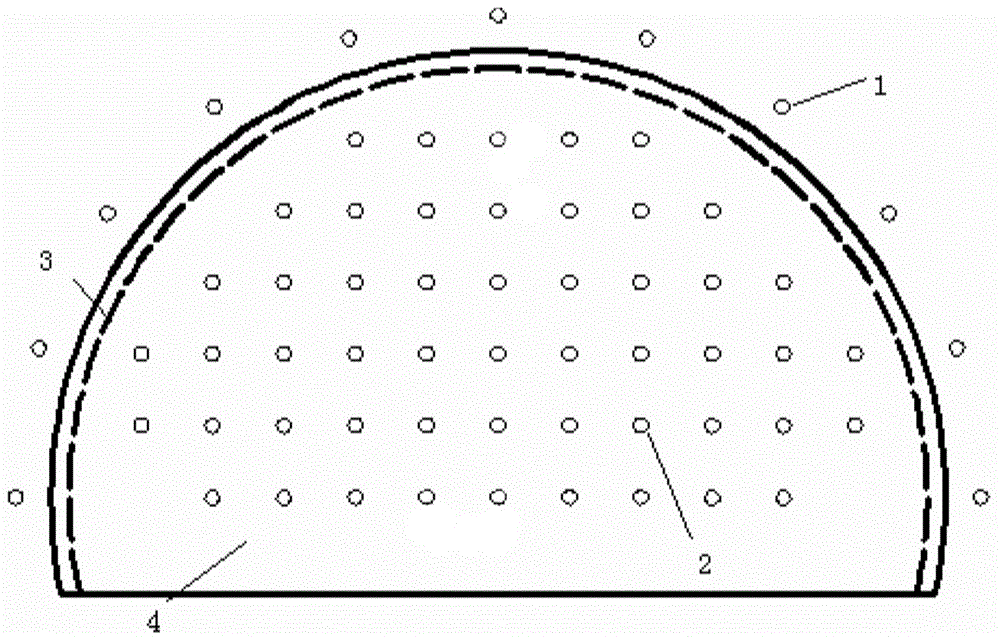

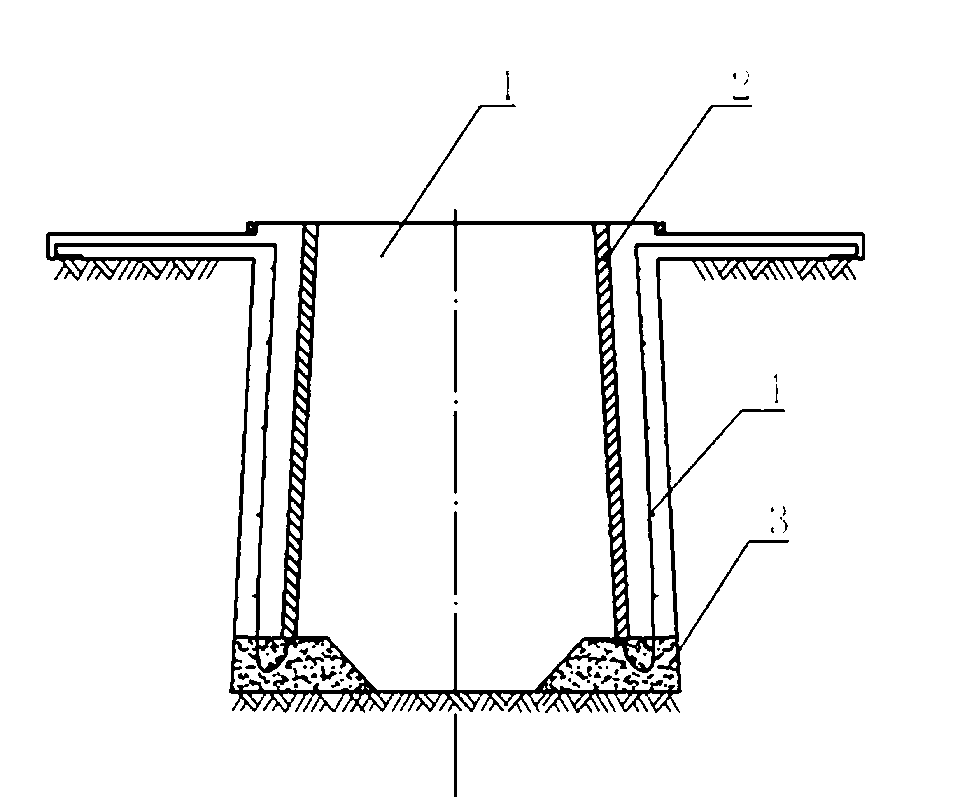

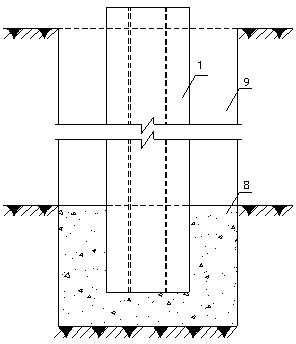

Pre-reinforcement method and pre-reinforcement structure for full section of tunnel

InactiveCN104314585ADoes not affect mechanical constructionImprove construction levelUnderground chambersTunnel liningConductor pipeContour line

The invention discloses a pre-reinforcement method and a pre-reinforcement structure for a full section of a tunnel. The method comprises the following steps: S1, arranging a plurality of conduits (1) in the surrounding rock of a to-be-excavated tunnel and along the contour line of a tunnel face (4), and grouting to the surrounding rock of the to-be-excavated tunnel through the conduits (1); S2, arranging a plurality of free-cutting anchor rods (2) in the to-be-excavated tunnel from the tunnel face (4); S3, excavating the tunnel face (4). The pre-reinforcement method and the pre-reinforcement structure disclosed by the invention are easy in field operation, reasonable in reinforcement cost, high in safety and good in reinforcement effect, and the problem that the working face of the tunnel collapses due to excessive extrusion deformation during a loess tunnel excavation and support process of full section excavation to influence the primary support stability is solved very well; as mechanized construction is not influenced by the free-cutting anchor rods during the construction process, so that the construction speed is quickened very well, the reasonable construction cost is kept, the construction safety, the construction quality, the construction period and the like are ensured, and the tunnel construction level is improved; the pre-reinforcement method and the pre-reinforcement structure have very good site construction value.

Owner:CHINA SHENHUA ENERGY CO LTD +1

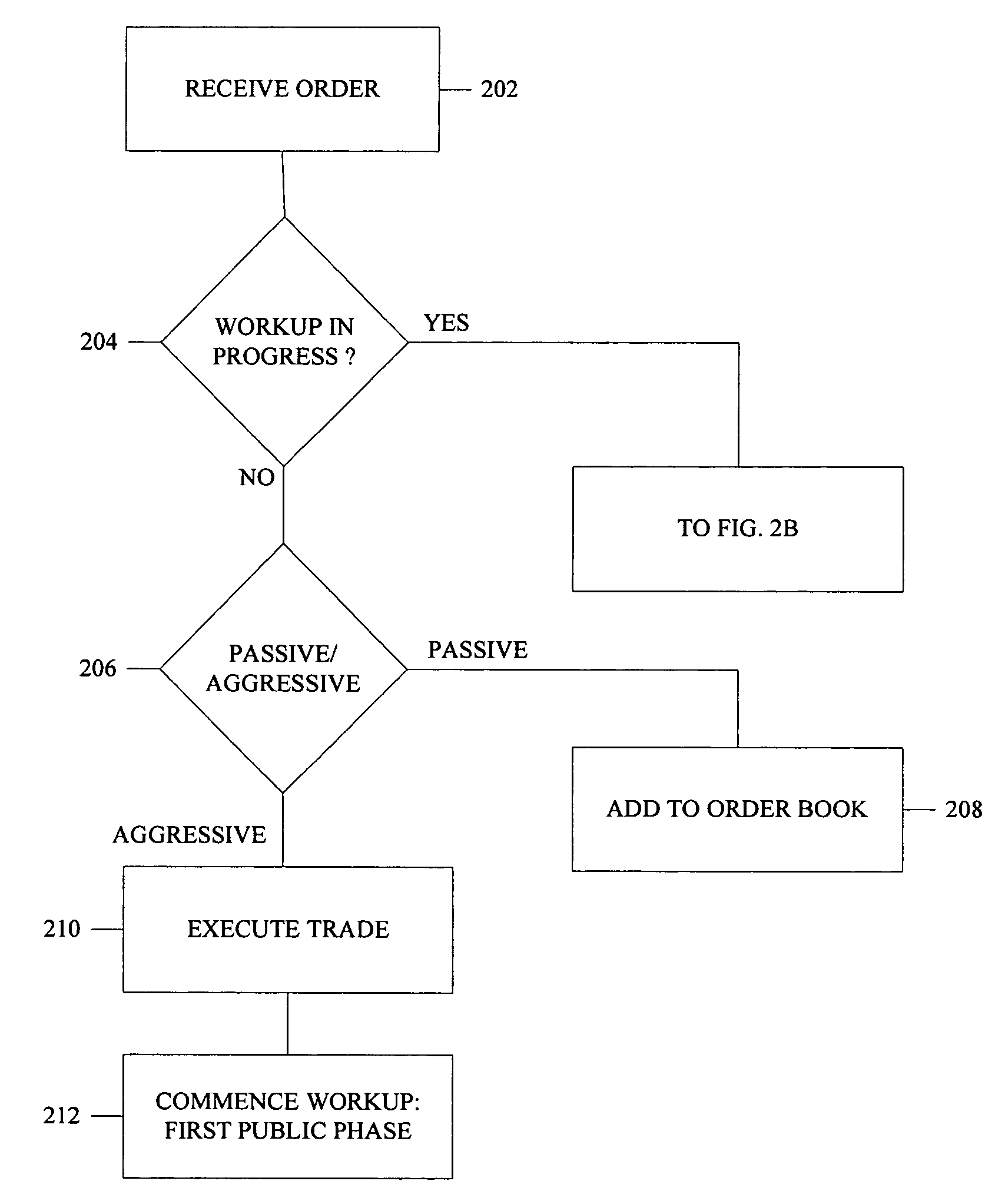

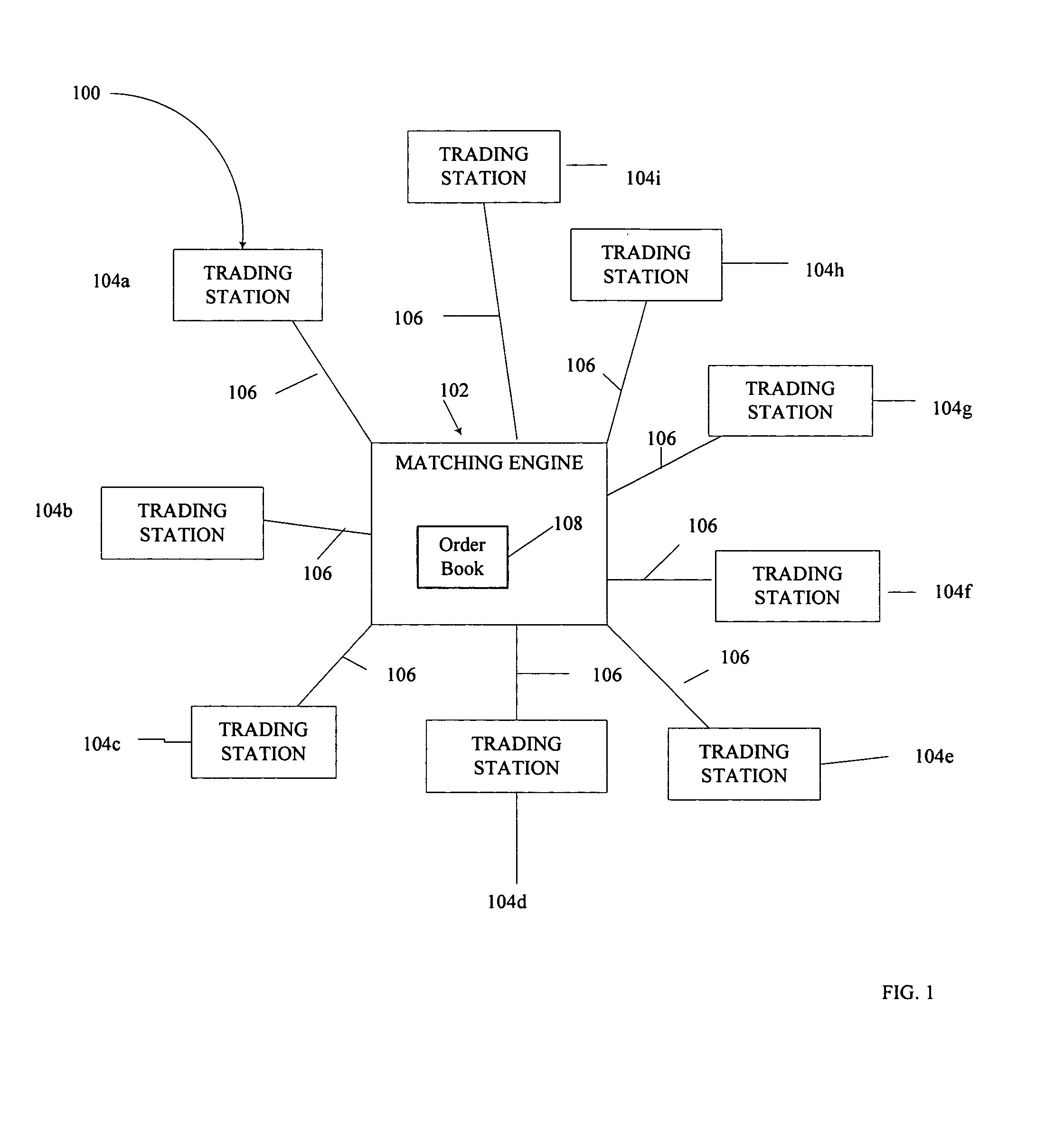

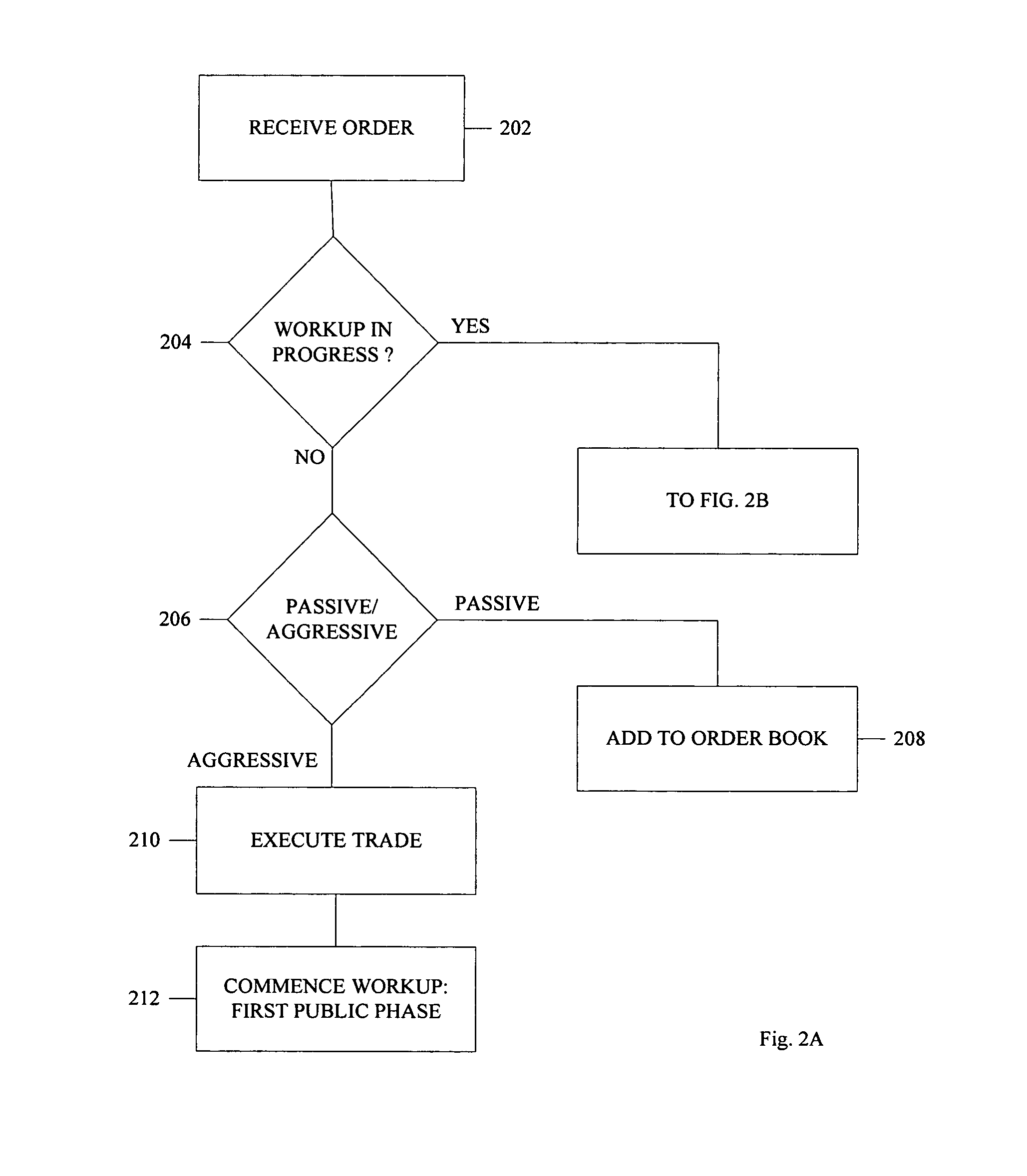

System and method for providing workup trading without exclusive trading privileges

A system and method are provided that preserve many of the advantages of traditional workups, including the ability to create a single deal extended in time, while avoiding aspects of prior art workup protocols that can be disadvantageous in particular trading environments and, particularly, avoiding the trading delays sometimes created by providing certain traders with exclusive trading privileges in highly-liquid, fast-moving trading environments. In a preferred embodiment, the present system comprises a distributed computer processing system programmed to provide a structured trading protocol that enhances trading efficiency and fairly distributes market opportunity to system users. More specifically, in a preferred embodiment, the present system is adapted to provide a plurality of workup phases each of which is designated a “public” phase and during which all trading is conducted on a first-come-first-served basis.

Owner:CME GRP

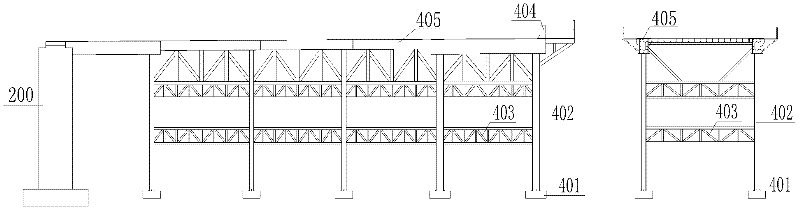

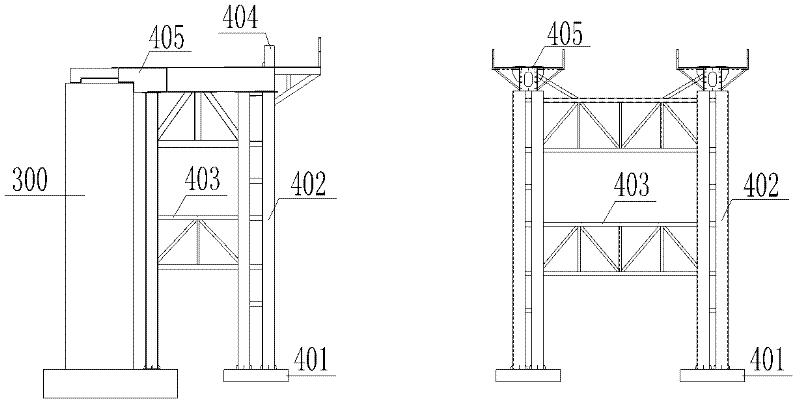

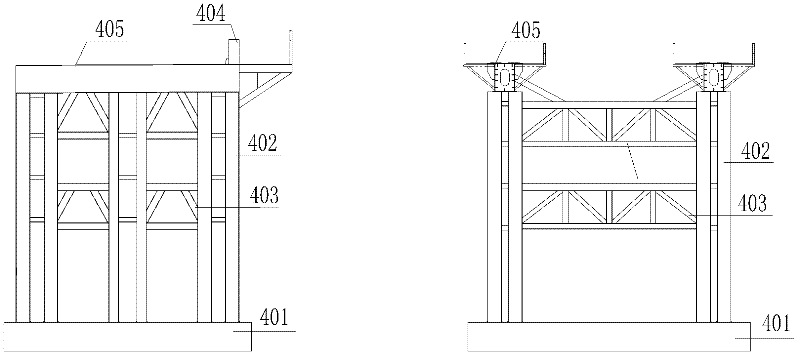

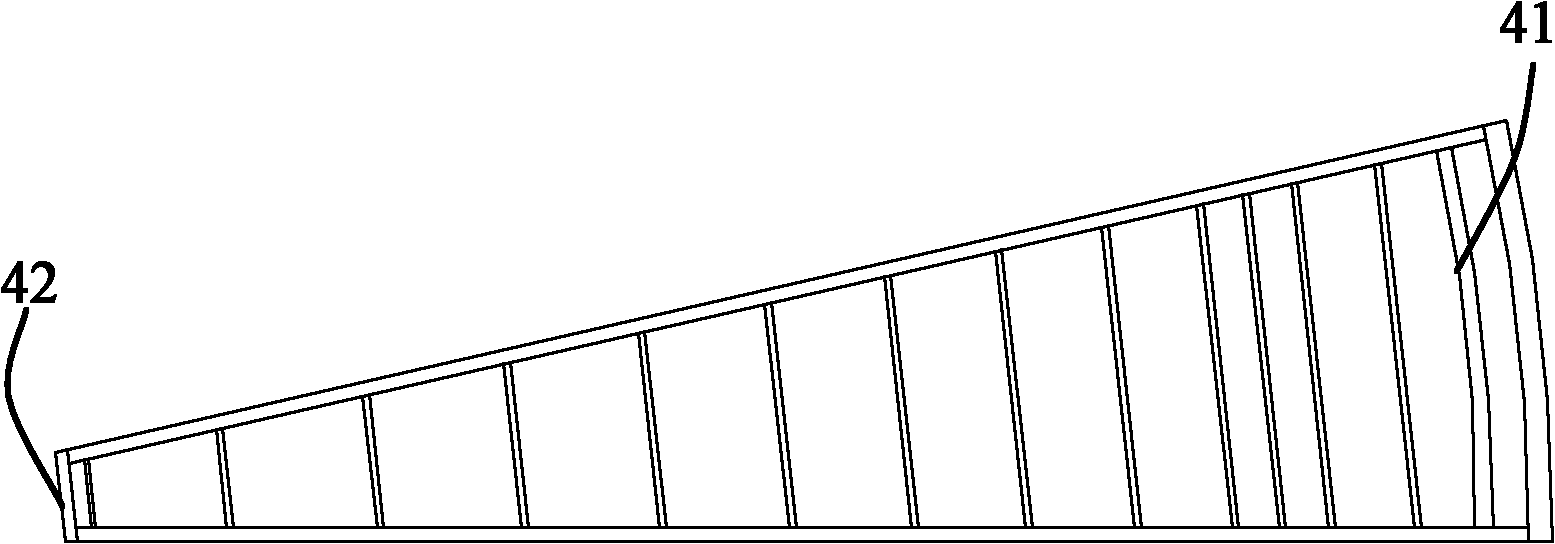

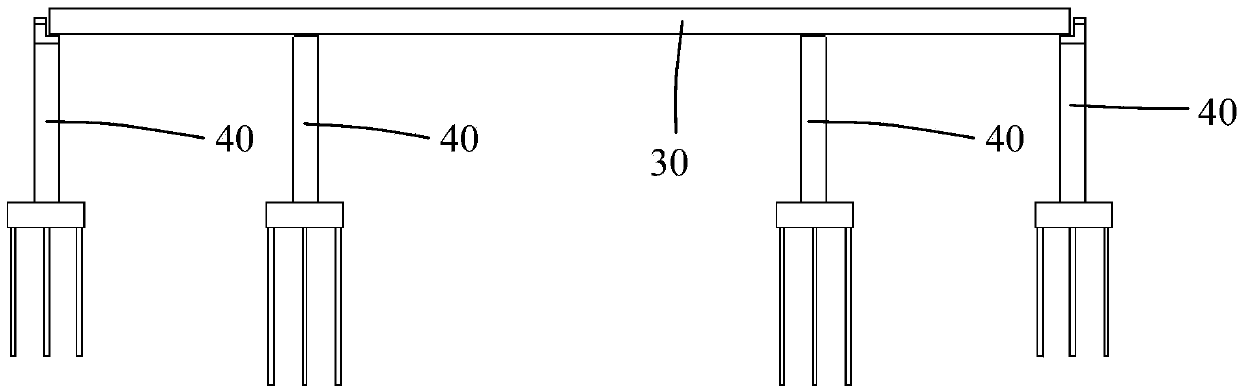

Moveable operating platform and method for constructing suspended ceiling of roof by using same

ActiveCN102409838ALow costGuaranteed durationBuilding material handlingBuilding support scaffoldsPurlinEngineering

The invention provides a moveable operating platform and a method for constructing a suspended ceiling of a roof by using the same. The moveable operating platform and the method are used for constructing suspended ceiling plates of a long-span saddle-shaped roof. The moveable operating platform comprises more than one unit platform, more than one suspending piece and more than one dragging device, wherein square tubes are welded into the unit platforms; the unit platforms are successively and detachably connected into a groove-shaped construction; the suspending pieces are fixed at an upper end of the groove-shaped construction; the upper ends of the suspending pieces are suspended on a cable rope; and the dragging devices are fixed on the groove-shaped construction and are connected to purlins of a roof structure by dragging wire ropes. When the moveable operating platform provided by the invention is used for suspending and assembling the long-span saddle-shaped roof, the unit platforms can be detached following the change in roof width, thereby saving a large amount of costs of repeatedly used materials of a full frame, being economical and ensuring construction period, construction quality and safety.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

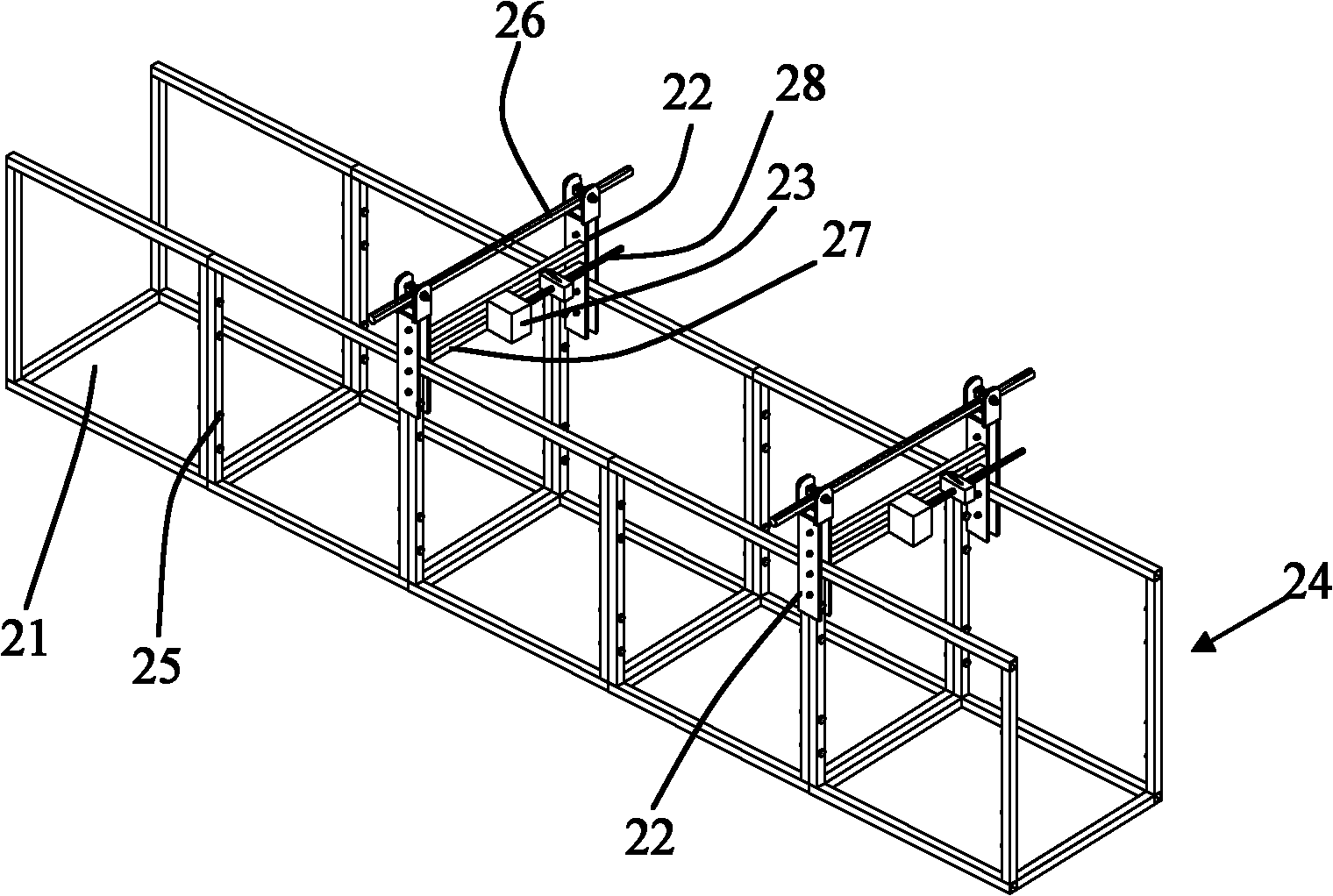

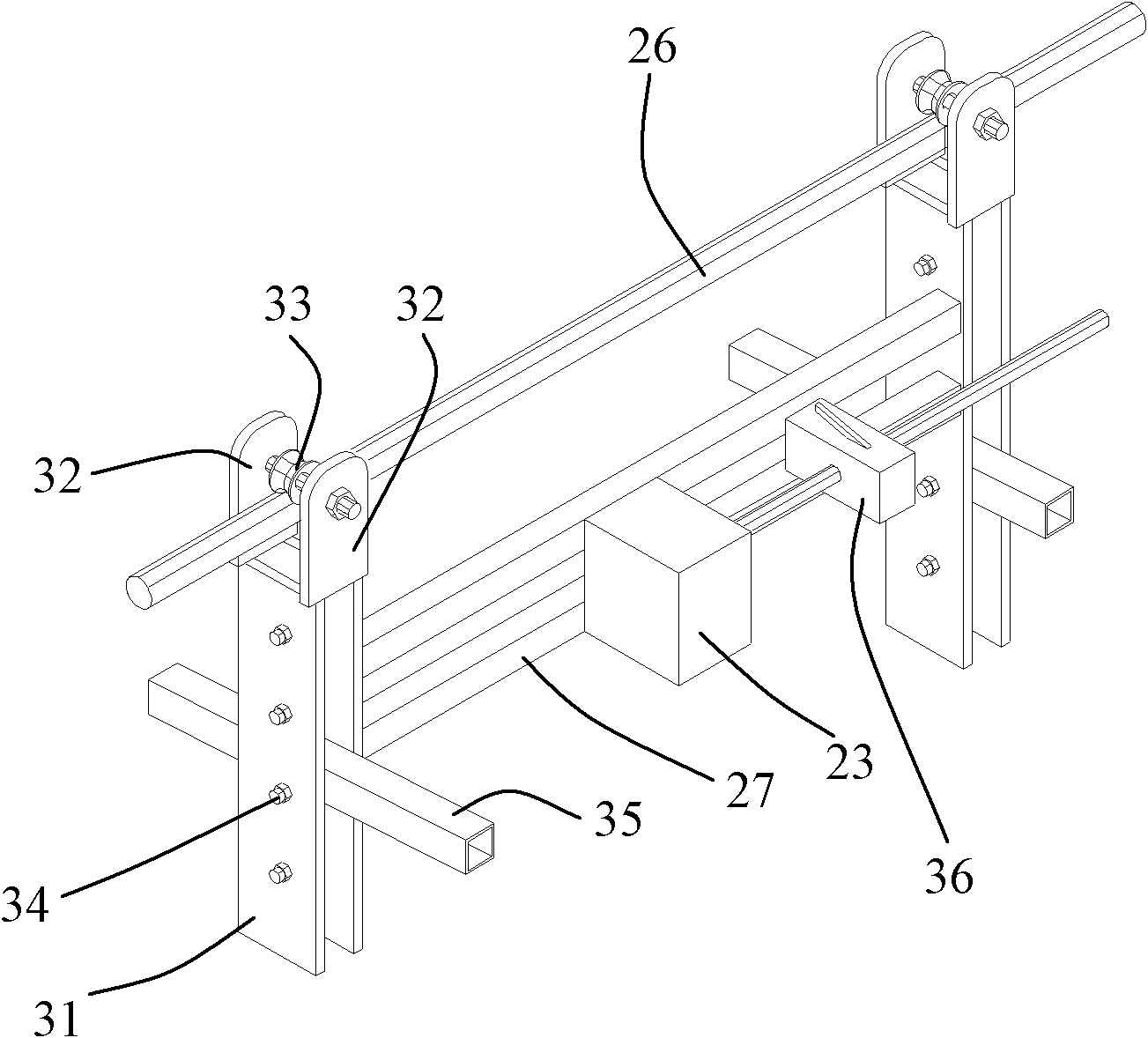

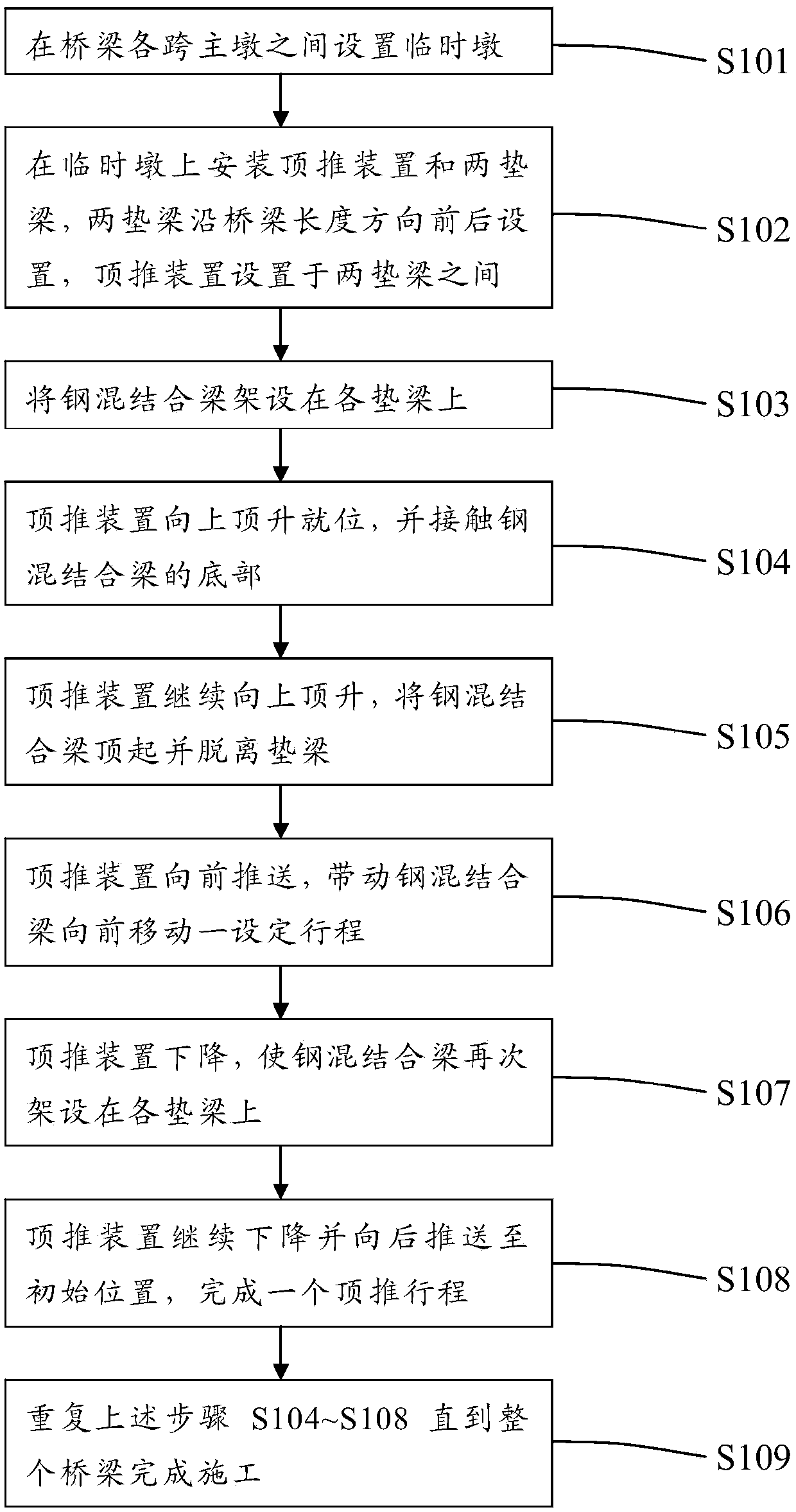

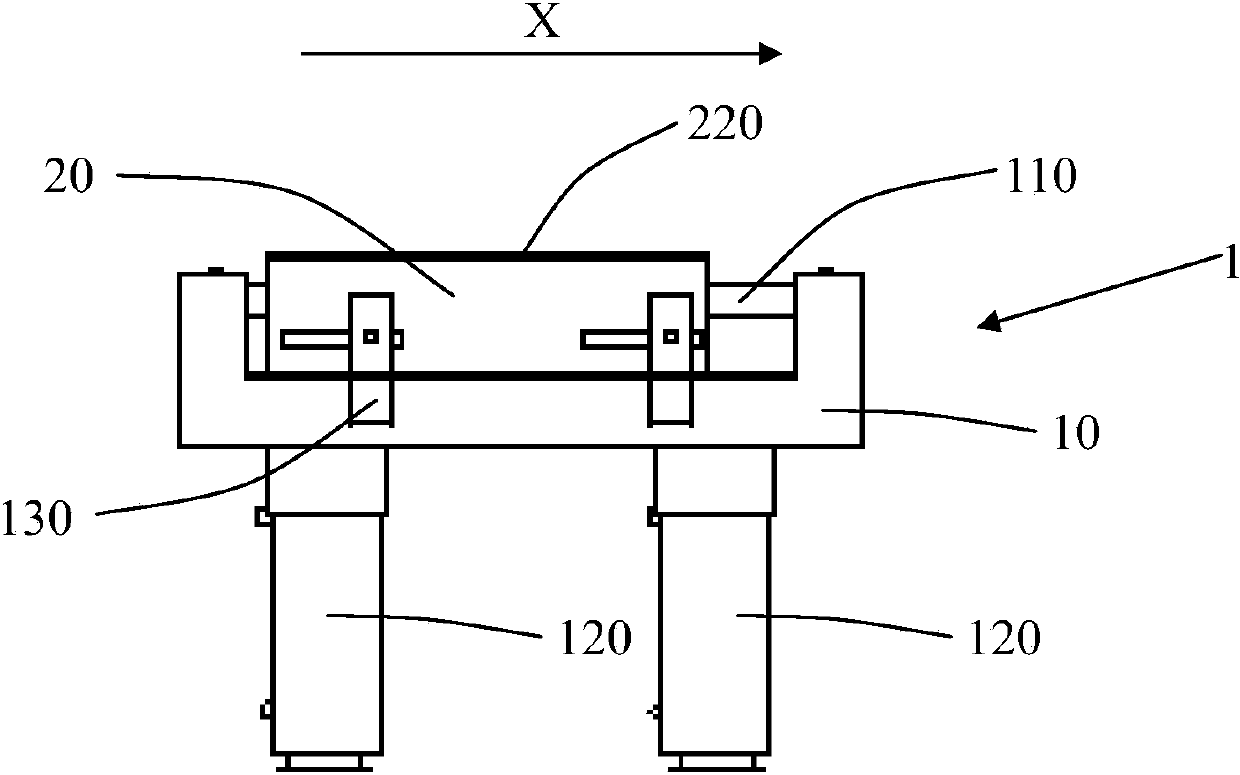

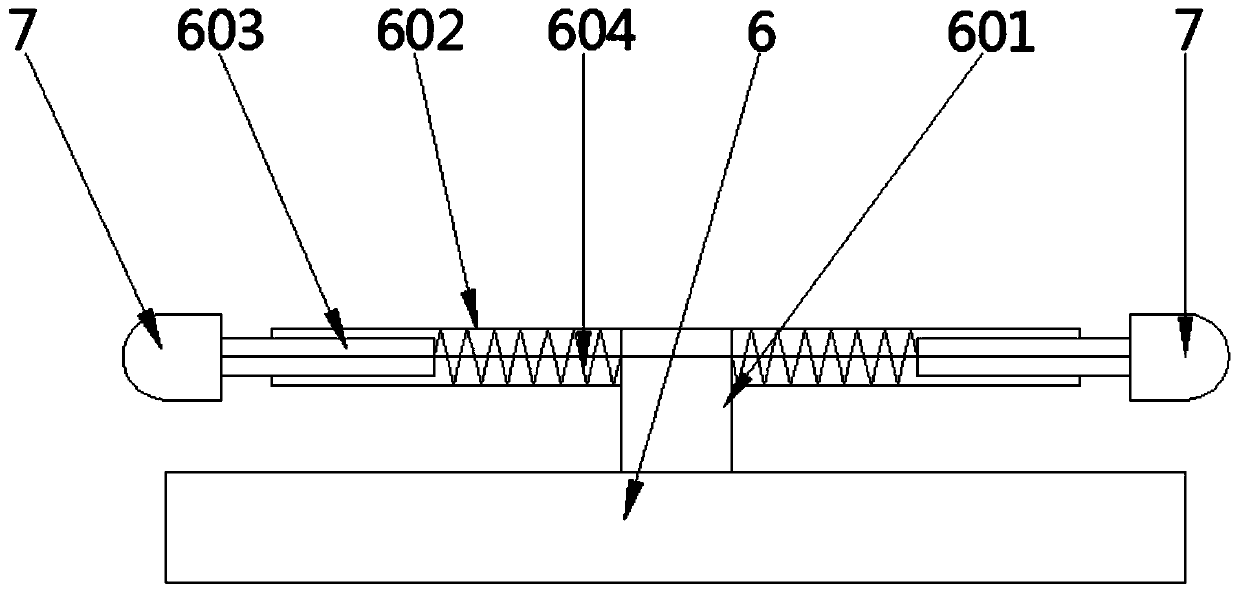

Walking type jacking construction method and device for large-span reinforced concrete combined beams

ActiveCN103993560AEasy to operateGuaranteed durationBridge erection/assemblyReinforced concreteEngineering

The invention provides a walking type jacking construction method and device for large-span reinforced concrete combined beams. The walking type jacking construction method comprises the following steps that temporary piers are arranged between all main piers of a bridge girder; a jacking device and two bearing beams are installed on each temporary pier, wherein each jacking device is arranged between the corresponding two bearing beams; the reinforced concrete combined beams are arranged on the bearing beams of the temporary piers; the jacking devices carry out upward jacking in place and make contact with the bottoms of the reinforced concrete combined beams; the jacking devices continue to carry out upward jacking, jack the reinforced concrete combined beams and break away from the bearing beams; the jacking devices are pushed forward and drive the reinforced concrete combined beams to move forward by a set stroke; the jacking devices descend so that the reinforced concrete combined beams can be arranged on the bearing beams of the temporary piers in a supporting mode again; the jacking devices continue to descend to the initial positions and are pushed backwards to the initial positions, so that a jacking stroke is finished; the above steps are conducted repeatedly until construction of the whole bridge girder is completed. According to the walking type jacking construction method and device for the large-span reinforced concrete combined beams, manpower, material resources and financial resources are saved on the premise of guaranteeing the construction period; meanwhile, the walking type jacking construction method and device for the large-span reinforced concrete combined beams have the advantages that construction and operation are convenient, safety and reliability are realized, efficiency is high, the construction period is short, and the comprehensive cost is low.

Owner:SHANGHAI TUNNEL ENG CO LTD +3

Foundation pit supporting method for manual dig-hole cement-soil steel pile

A foundation pit supporting construction method for a manual dig-hole cement-soil steel pile comprises the technological processes: manually digging cylindrical pile holes in a side-by-side or interval way; hoisting processed profile steels by a crane and then fixing the profile steels in the holes; pouring cement soil slurry well stirred in a stirrer in the pile holes, performing partial vibrating if necessary, so as to form cement-soil steel piles; manufacturing pile top coupling beams at the tops of the cement-soil steel piles; when foundation pits are deeper, adopting inner supports or detachable anchor rods to compositely support the cement-soil steel piles; hanging nets on the side surfaces of the cement-soil steel piles and then carrying out concrete spray when the foundation pits are dug; dismantling the anchor rods or the inner supports when the backfilling of foundation pit and the trough meets requirements; and finally removing the profile steels for recycle. The method has the advantages of being mainly suitable for hard soil in northern China, such as water-free dense sand gravel stratums where machinery construction is not available or the stratum suitable for manually digging, and being reduced in cost; the manual digging is economical and easy to implement; and the quality and construction period are ensured and the environment is protected.

Owner:深圳市南华岩土工程有限公司

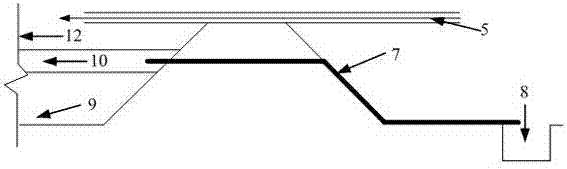

Construction method of digging and conveying earth of deep foundation pit through current scour

The invention relates to the construction field of earthwork projects of sand soil or fine-grained soil foundation pits, in particular to a construction method of digging and conveying earth of a deep foundation pit through current scour. The construction method includes the step of supporting and portioning the foundation pit, the step of digging a mud sucking pool, the step of installing a mud pump, the step of installing a high-pressure water pump and a water supplying water tank, the step of digging a soil abandoning area, the step of installing a mud conveying pipe and middle pressurizing equipment and the step of digging soil through current scour, and finally the mud is conveyed to the soil abandoning area through the mud conveying pipe, the mud sediments in the soil abandoning area, and clean water after sedimentation is discharged or reused. The construction method of digging and conveying earth of the deep foundation pit through current scour has the advantages that (1) the scheme of digging and conveying soil through hydraulic power well resolves the problem of work stoppage caused by road traffic control; (2) soil is conveyed through a water current pipeline instead of a land route, so that the influence on the city road traffic from large earthwork trucks is reduced; (3) the construction scheme of digging and conveying soil through hydraulic power lowers construction noise; (4) no large earthwork truck passes near the foundation pit in the construction process, and loads on a surrounding and protective structure are reduced.

Owner:MINGYE CONSTR GRP

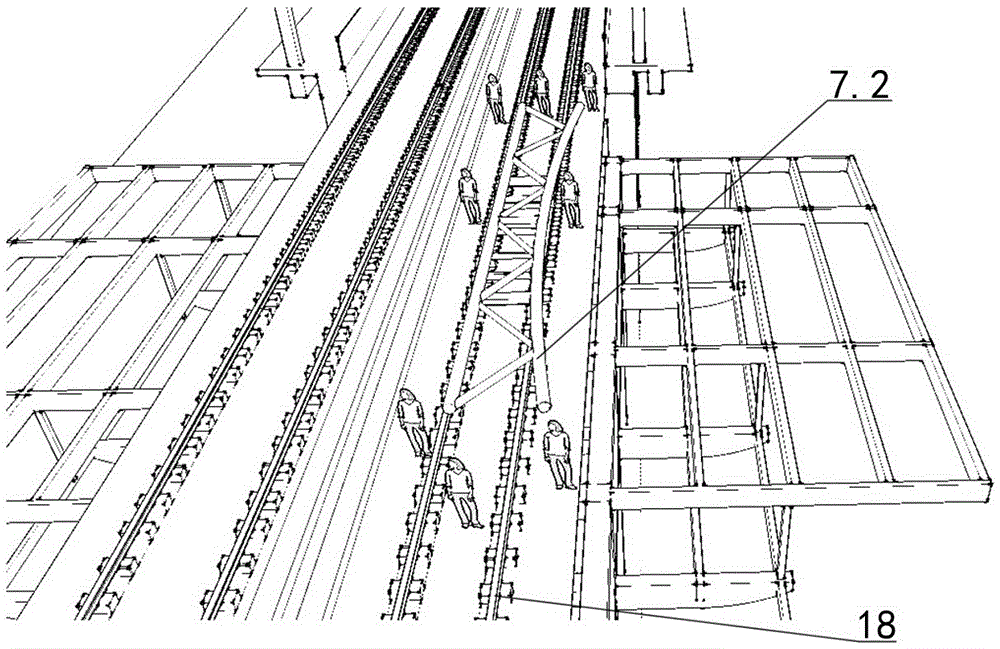

Construction method of widened and improved structure system for existing station platform

ActiveCN106088660AGuaranteed Node DurationSmall size errorBuilding repairsGirdersSubway stationSteel columns

The invention provides a construction method of a widened and improved structure system for an existing station platform, which comprises the following steps: pre-processing steel members of a widened steel structure of a station; reinforcing frame columns of an original frame structure; reinforcing bent steel columns; mounting middle beams; mounting side beams; and mounting a structure widened platform. According to the invention, the steel members of the widened and improved part of the station are divided into middle beams, cantilever side beams and a steel structure widened platform to be respectively constructed, so that the processes are reasonable, the construction time is accurate, and the construction period is ensured; and the early subway station which can not meet the existing passenger flow is widened and improved, thereby summarizing construction experience for a new trend of the future subway industry, filling up the blank of the track traffic industry and providing reference for future improved construction.

Owner:北京住总集团有限责任公司 +1

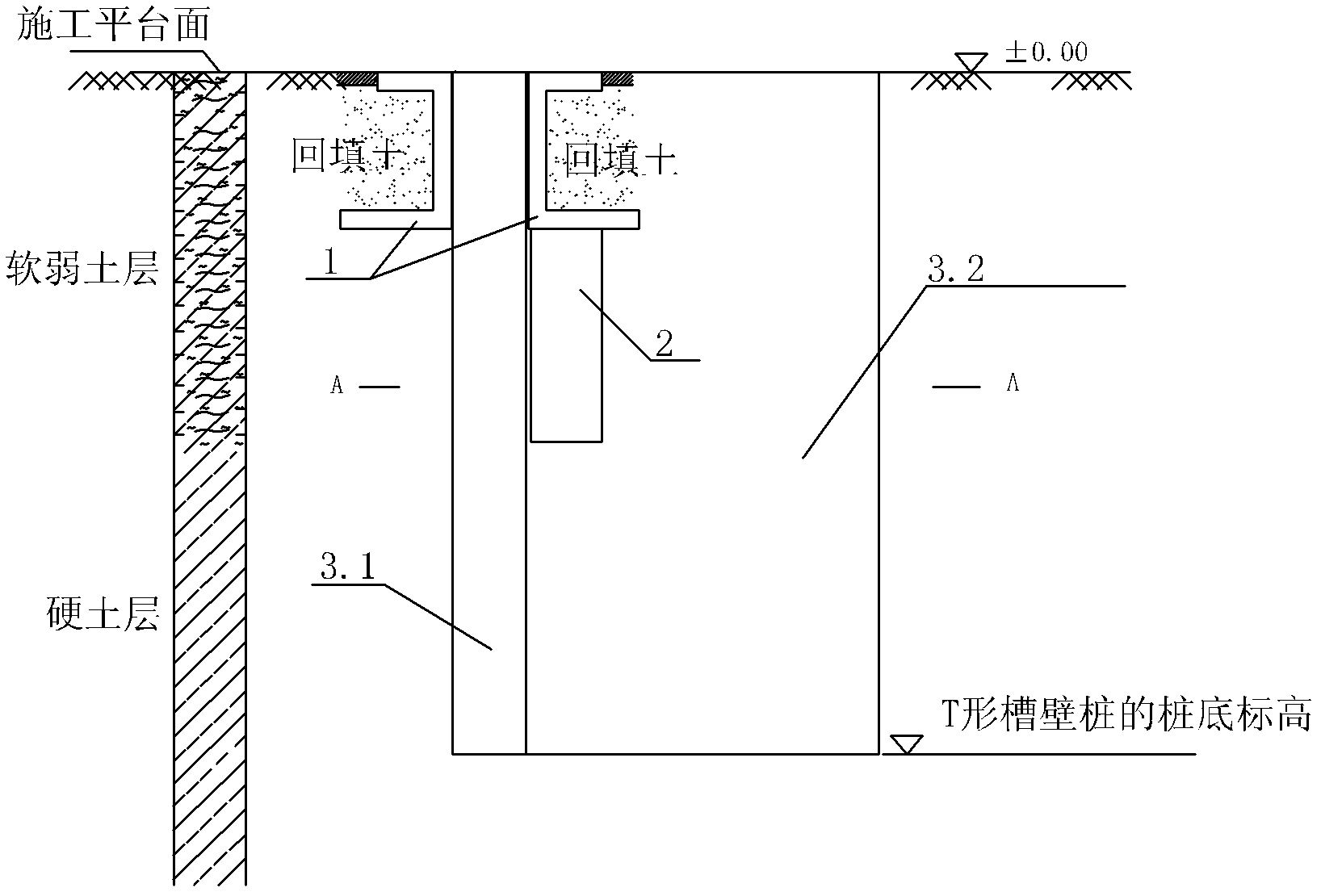

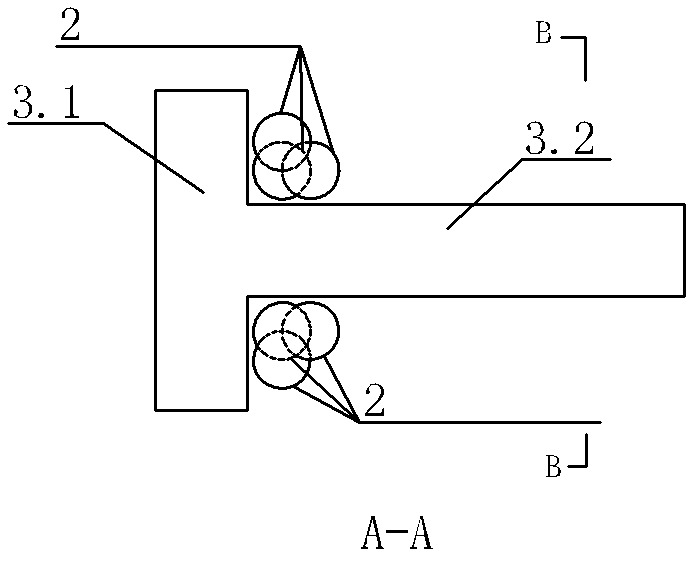

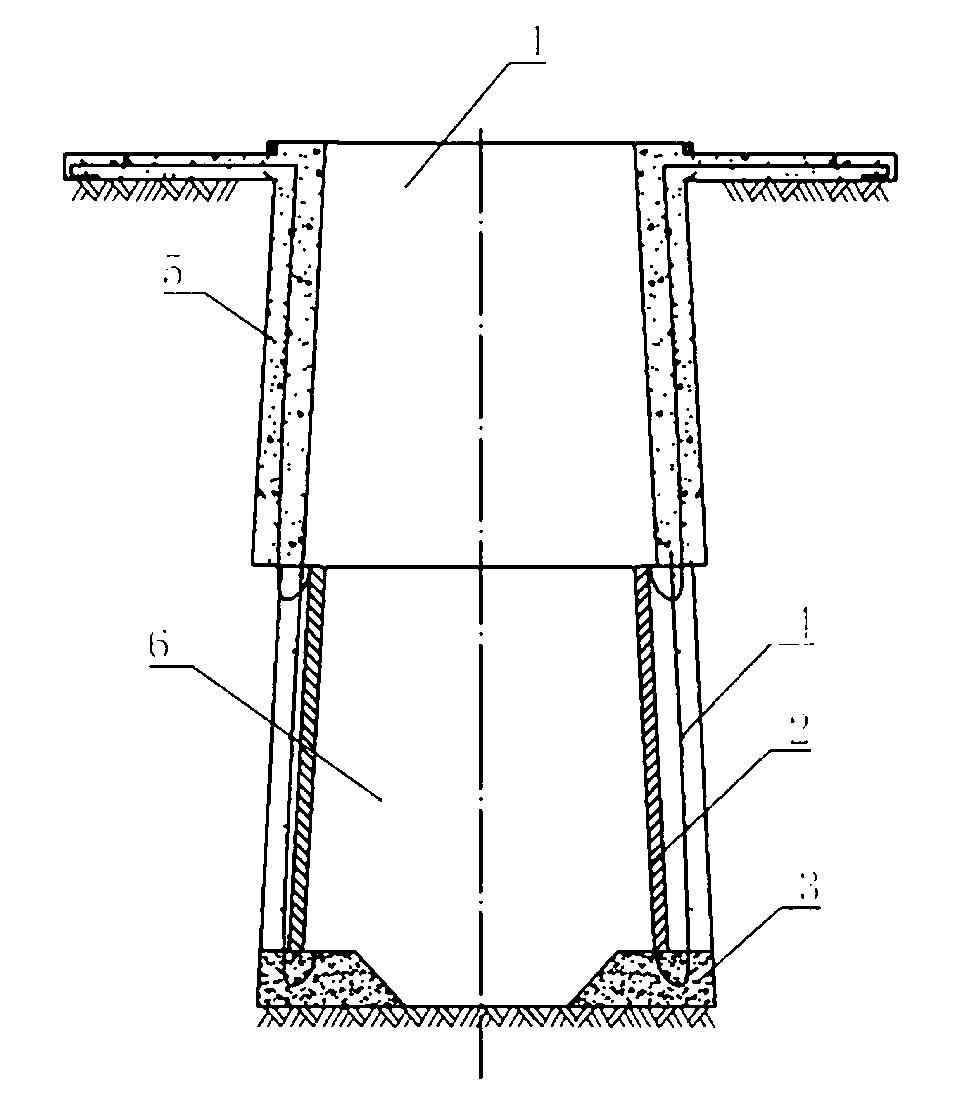

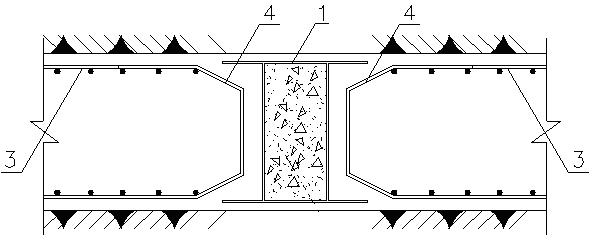

Steel reinforced concrete column type joint and construction method of underground diaphragm wall using same

ActiveCN102561404AIncrease stiffnessImprove anti-seepage performanceArtificial islandsUnderwater structuresReinforced concrete columnSlurry wall

The invention discloses a steel reinforced concrete column type joint and a construction method of an underground diaphragm wall using the same. The joint comprises a II-shaped section steel (1) and two later-stage groove-section reinforcing cages (3). The construction method mainly comprises the following steps of: (1) construction of the steel reinforced concrete column type joint; (2) construction of the groove section; and (3) reinforcement of a high-pressure rotary spraying pile at the joint. Through the steel reinforced concrete column type joint disclosed by the invention, the overall rigidity and anti-permeation performance of the groove-section connection structure of the underground diaphragm wall are enhanced; through the construction method of the underground diaphragm wall using the same, disclosed by the invention, the construction of the steel reinforced concrete column type joint and the construction of the groove section can be performed in a streamline manner, and the construction efficiency is improved; and moreover, the construction can be all performed according to a closed wall, and the length of the reinforcing cage is reduced, thereby being more favorable for guaranteeing the construction quality and construction period.

Owner:THE THIRD CONSTR OF CHINA CONSTR EIGHTH ENG BUREAU

Site mixing and blow-filling method of solidified dredged mud

InactiveCN104532817AAdvantages of in-situ mix blow-fill methodLow costIn situ soil foundationSoil preservationTreatment designResource utilization

The invention discloses a site mixing and blow-filling method of solidified dredged mud. The method comprises the steps of: (1) site mixing and blow-filling of the solidified dredged mud; (2) site solidification of the dredged mud; and (3) detection of the solidified dredged mud. The step (1) further comprises analysis of the soil texture of the dredged mud, selection of a curing agent, determination of a mixing ratio of the curing agent to the dredged mud, mixing of the curing agent and the dredged mud, reinforcing design of the solidified dredged mud and determination of the shear strength index, the modulus of compressibility of the solidified dredged mud and the thickness of a reinforced soil layer to achieve characteristic values of the bearing capacity of foundation soil and allowing deformation values of the foundation treatment design, and determination of the maintenance time of finished products. The step (2) is to finish the reinforcement of a shallow-layer soft soil foundation through mixing and solidifying the curing agent and the dredged mud. The site mixing and blow-filling method of the solidified dredged mud can achieve the purposes of guarantee of the construction days, reduction of the project cost, reasonable resource utilization and environmental protection.

Owner:SHANGHAI MARITIME UNIVERSITY

Suspension scaffold at gable at sloping roof eaves of high-rise building, and construction method thereof

Disclosed are a suspension scaffold at a gable at a sloping roof eaves of a high-rise building, and a construction method thereof. The suspension scaffold comprises overhang horizontal rods, inner rods, large transverse rods, vertical rods, small transverse rods, scaffold boards, a horizontal safety mesh, a facade safety mesh, facade large meshes, and wire ropes. The overhang horizontal rods include an upper row and a lower row. The inner ends of the overhang horizontal rods pass through exterior wall water-drill boreholes to be firmly locked to the inner rods. The large transverse rods and the vertical rods are erected in an inner row and an outer row outside an exterior wall. The lower large transverse rods are erected on the upper and lower rows of overhang horizontal rods. The lower portions of the vertical rods are firmly locked to the large transverse rods. The small transverse rods are connected between the inner and outer rows of vertical rods. The scaffold boards are laid on the lower row of overhang horizontal rods. The suspension scaffold and the construction method thereof have the advantages that construction safety, fast construction, easily guaranteed quality and low comprehensive cost are guaranteed; the problems in construction and protection of eaves of sloping-proof high-rise buildings are solved well; construction is safe, economical and fast, and construction quality is easily guaranteed.

Owner:北京金港建设股份有限公司 +1

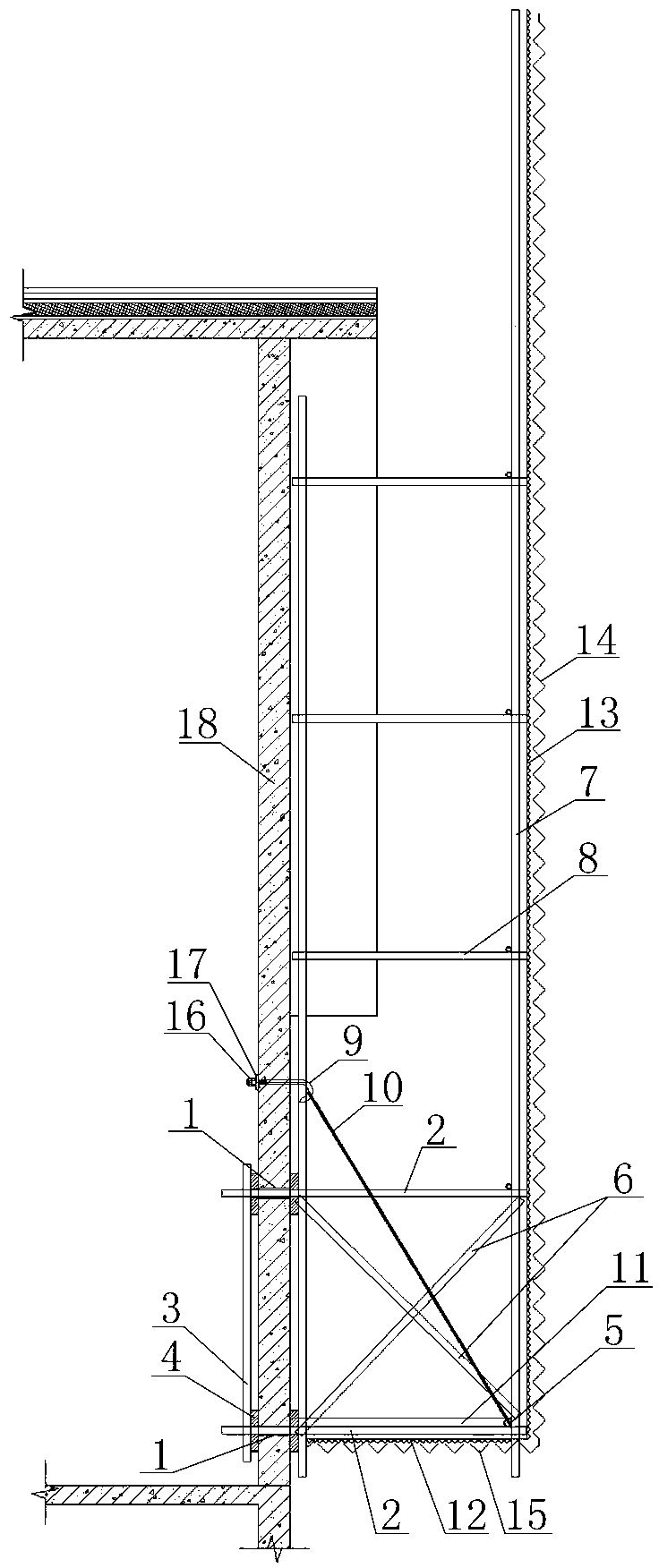

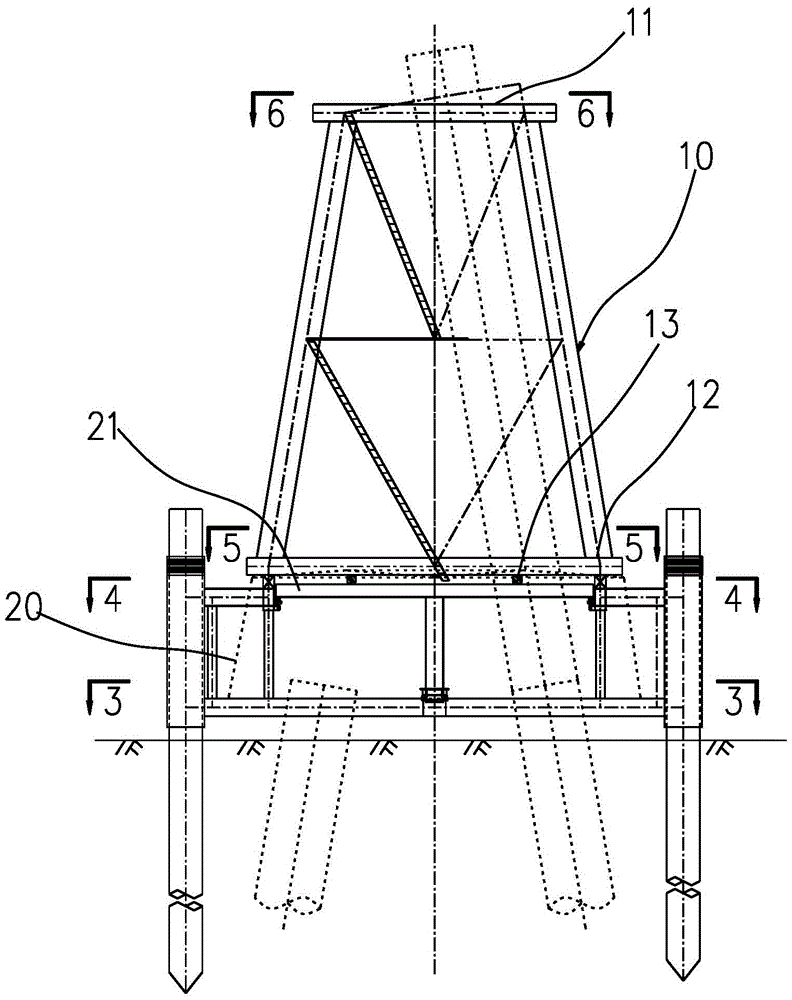

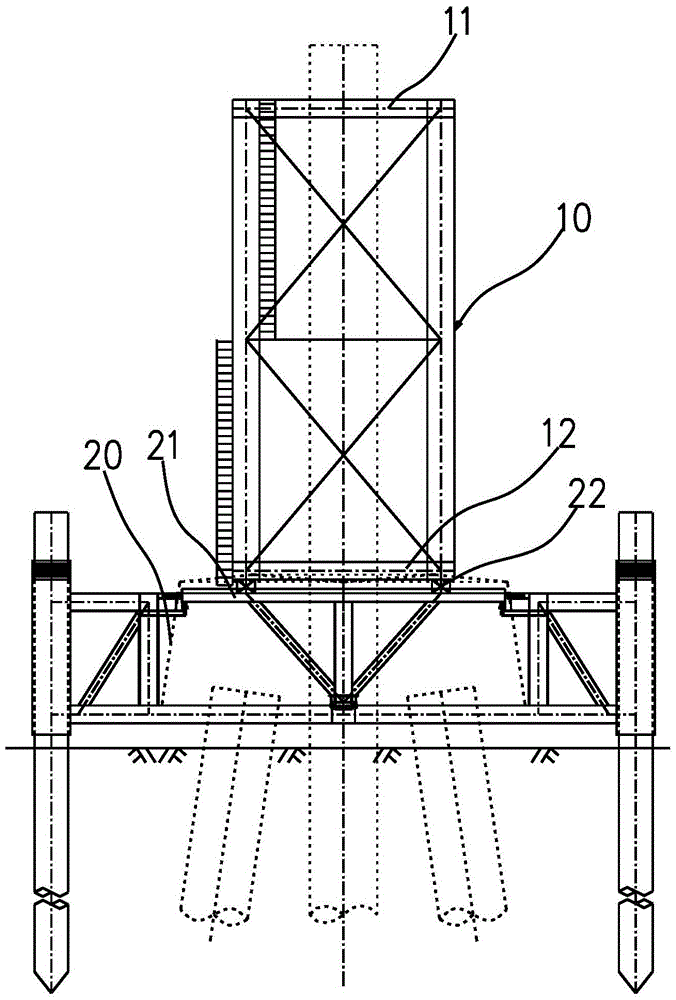

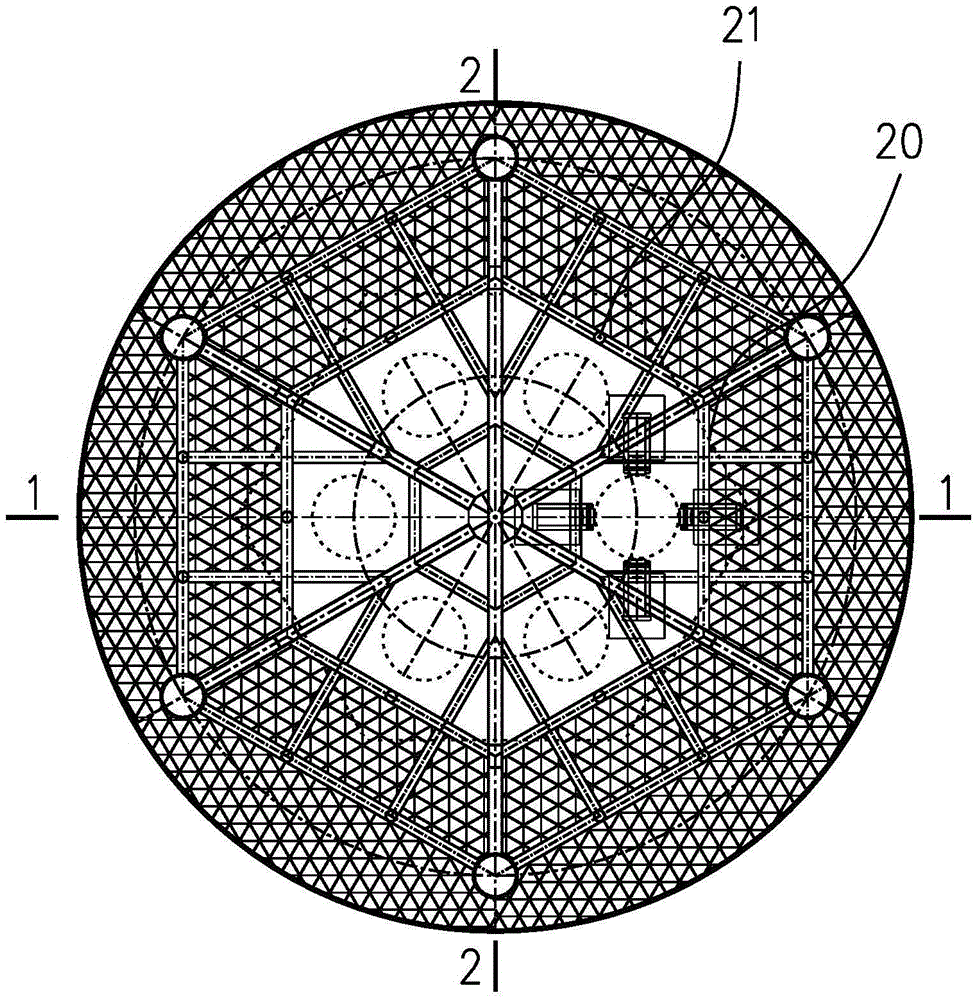

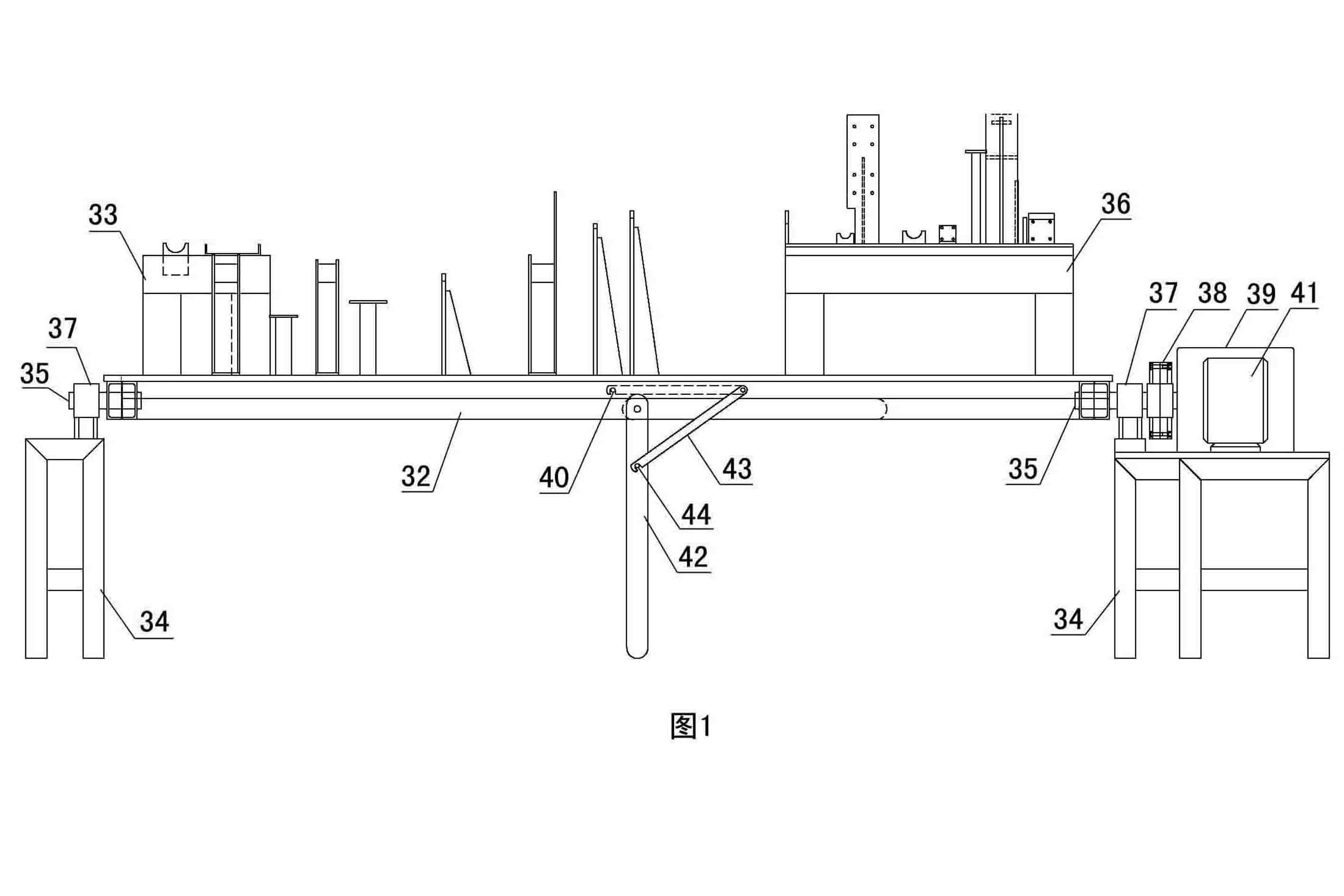

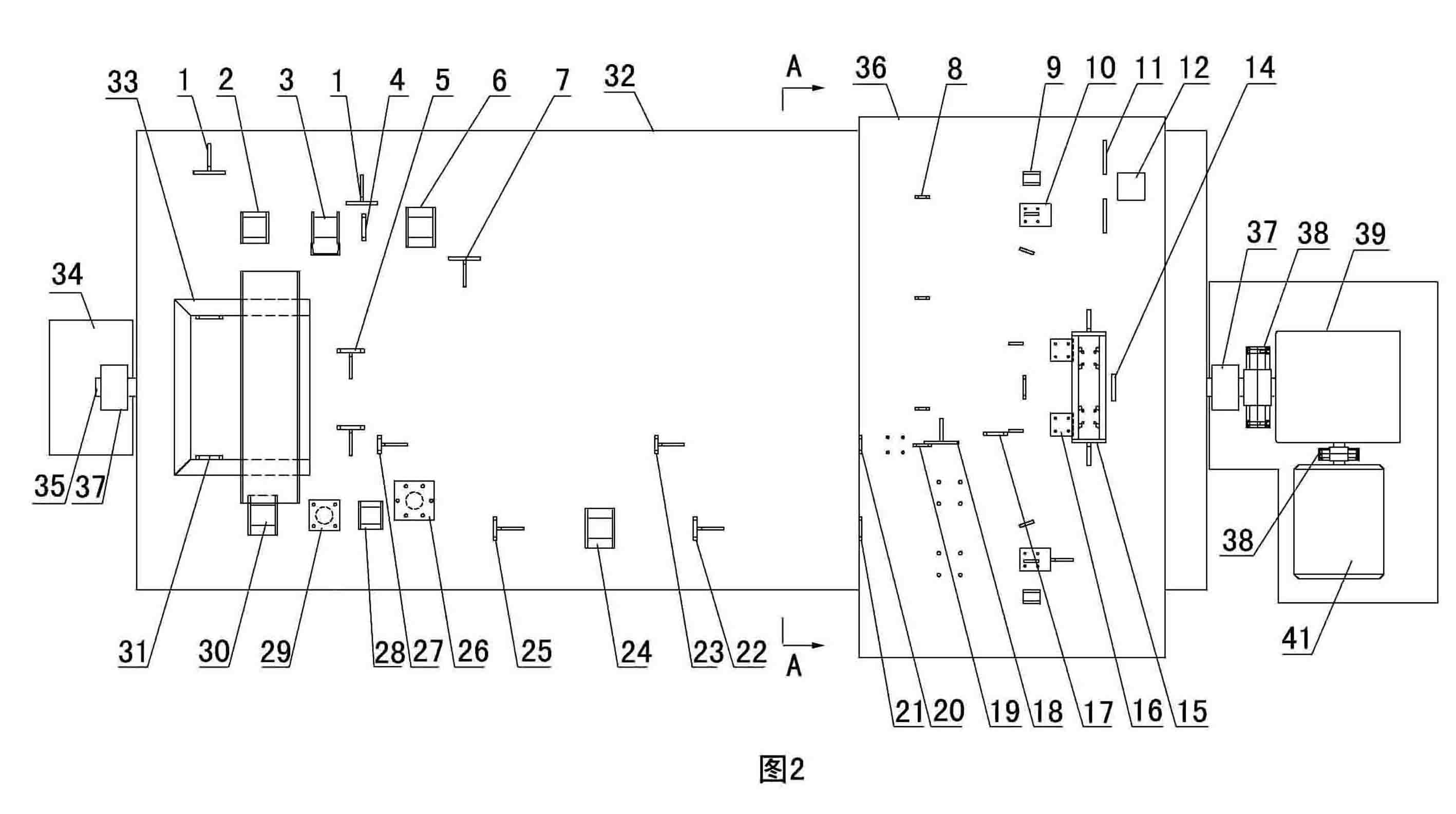

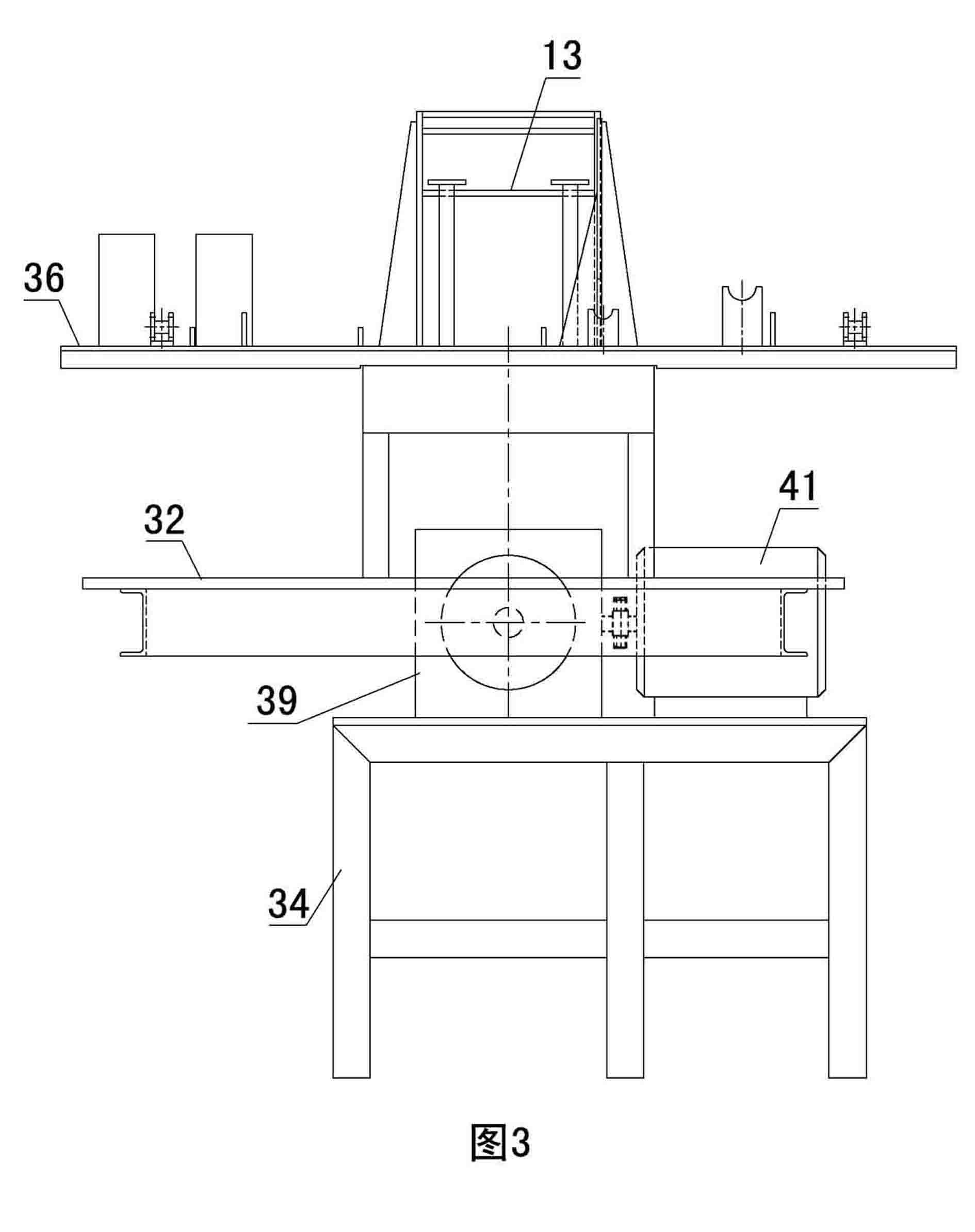

Positioning pile-driving guide frame and construction method thereof

The invention discloses a positioning pile-driving guide frame. The positioning pile-driving guide frame comprises a rack and a construction platform rotary plate used for driving the rack to rotate. An upper platform and a lower platform are arranged at the upper end and the lower end of the rack correspondingly. Skirt pile grippers are arranged on the upper platform and the lower platform correspondingly, the skirt pile gripper arranged on the upper platform is the upper platform skirt pile gripper, and the skirt pile gripper arranged on the lower platform is the lower platform skirt pile gripper. The center of an abdominal cavity of the upper platform skirt pile gripper coincides with the central axis of the rack. A driving mechanism is arranged between the lower platform skirt pile gripper and the lower platform and drives the lower platform skirt pile gripper to horizontally move. According to the positioning pile-driving guide frame, continuous inserting, driving and sinking conducted on inclined pile groups in abyssal regions are achieved, and the advantages of being simple in structure, convenient to construct and high in efficiency are achieved.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

Welding system for pipeline formation

InactiveCN101786214AReduce labor intensityFulfillment of interchangeability requirementsWelding/cutting auxillary devicesAuxillary welding devicesCouplingReduction drive

The invention relates to a welding system for pipeline formation, consisting of a welding device and an oil way tool. The oil way tool comprises two basic platform support frames and a basic platform connected between the two basic platform support frames. Both the left and right ends of the basic platform are fixedly connected with horizontal rotating shafts which are supported on the basic platform support frames in a rotating manner through a shaft seat. An electromotor is further fixed on one of the two basic platform support frames. The output end of the electromotor is connected with the input ends of a coupler and a decelerator, and the output end of the decelerator is further connected with the horizontal rotating shafts through the coupler. The system can position, assemble and weld aluminum alloy, stainless steel and common ferrous metal pipelines and the like and is convenient and simple to use, thereby meeting the requirement of interchangeability in the process of batch production, enhancing the labor productivity, alleviating the labor intensity for the operators, ensuring the consistency and quality of the products and guaranteeing the production period.

Owner:BEIJING SANXING AUTOMOBILE

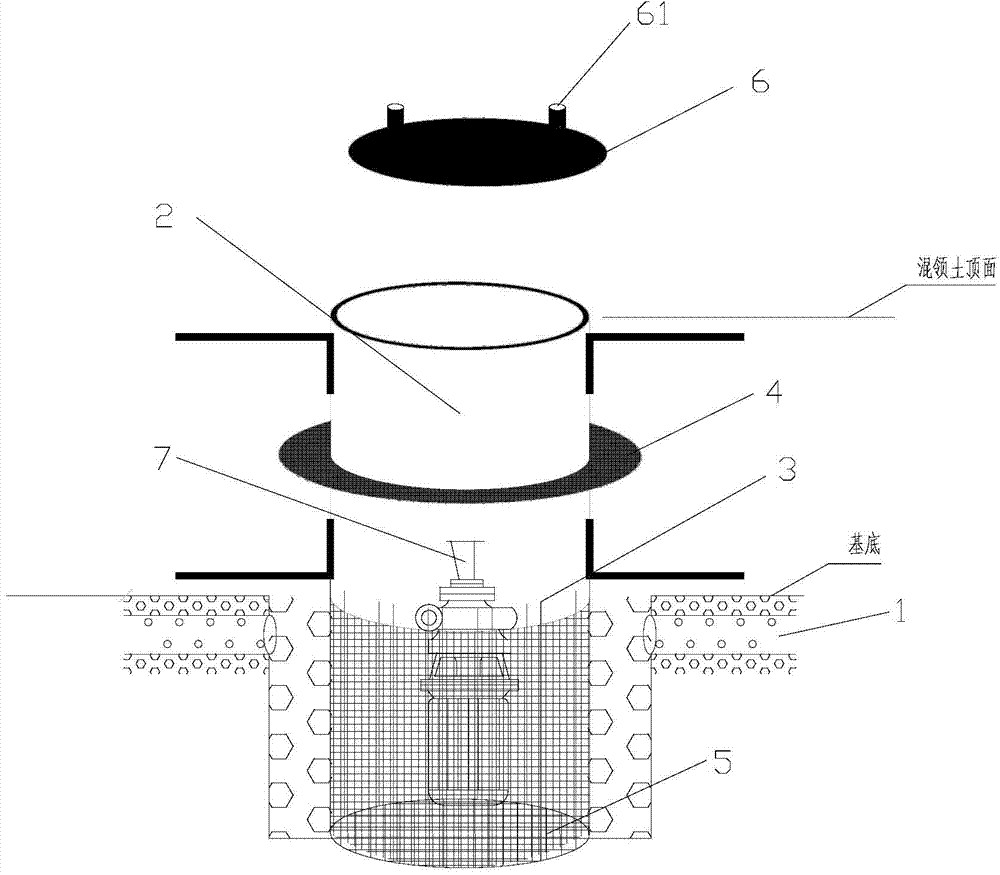

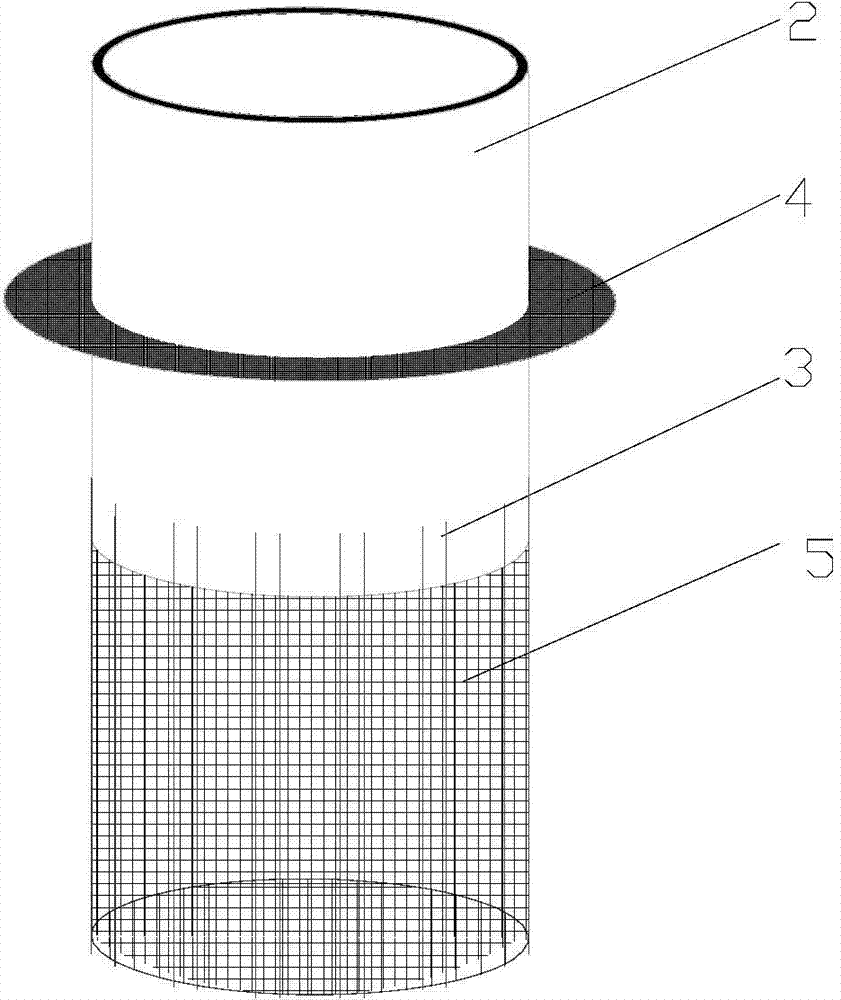

Water supply and drainage device for deep foundation pit and construction method based on water supply and drainage device

ActiveCN104846836AEffective isolationExtend your lifeFoundation engineeringEngineeringDrainage tubes

The invention discloses a water supply and drainage device for a deep foundation pit and a construction method based on the water supply and drainage device. The water supply and drainage device comprises a water collecting sleeve and a water suction pump, wherein the water suction pump is placed in the water collecting sleeve; the water collecting sleeve comprises a steel sleeve and a reinforcing bar grid; the reinforcing bar grid is arranged at the lower end of the steel sleeve and is integrally connected with the steel sleeve in a welded manner; the steel sleeve at the upper end of the water collecting sleeve is positioned in structural concrete; the reinforcing bar grid on the lower portion of the water collecting sleeve is positioned in a base below a structural bottom plate; and a plurality of drainage tubes are arranged on the periphery of the base. Compared with the prior art, the water supply and drainage device for the deep foundation pit and the construction method based on the water supply and drainage device have the advantages that a structural reserved hole is omitted, the structural waterproofing and the construction quality are greatly improved, the construction period is shortened, and the cost is reduced.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD

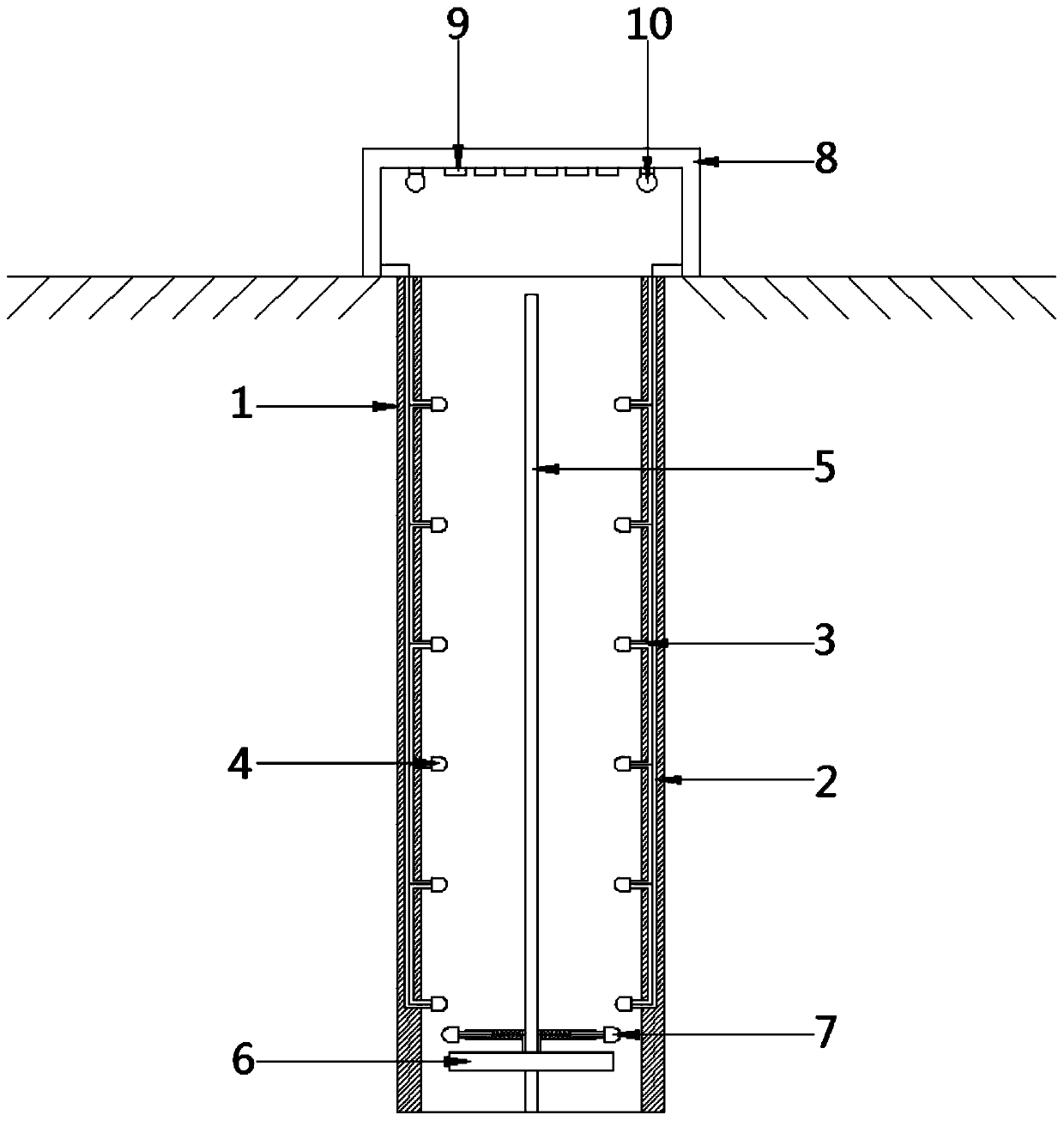

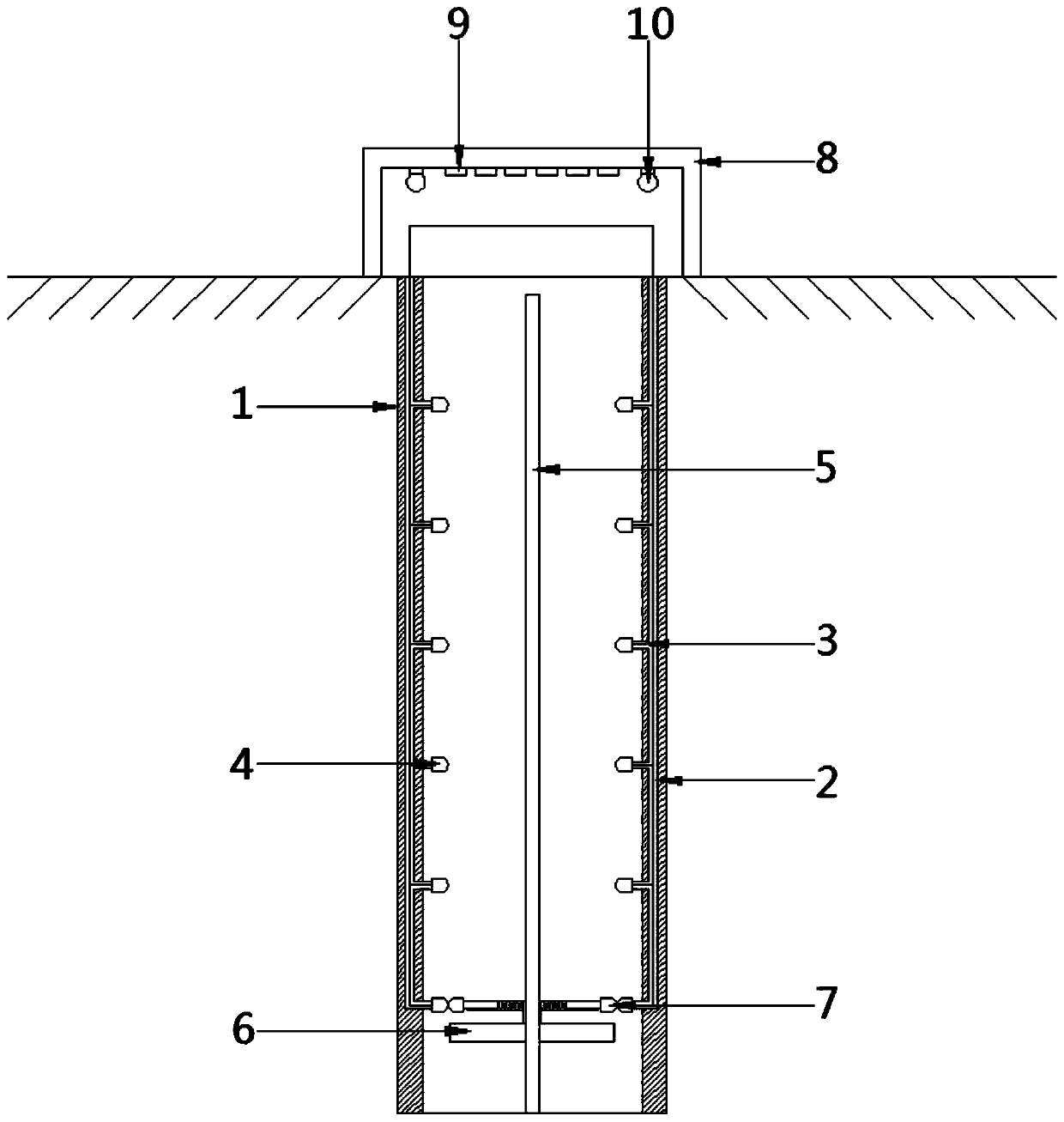

Goaf underground water level monitoring and early warning device and early warning method thereof

InactiveCN111121925ARealize the alarmRealize light alarmLevel indicators by floatsWater levelMechanical engineering

The invention, which belongs to the technical field of underground water level monitoring, discloses a goaf underground water level monitoring and early warning device and an early warning method thereof. The goaf underground water level monitoring and early warning device comprises an underground well; and two cavities are formed in the inner wall of the underground well in a bilateral symmetry mode. A plurality of groups of first conductive blocks are arranged on the inner wall of the underground well up and down; each first conductive block is connected with a fixed rod; the plurality of fixed rods on the two sides are communicated with the cavities on the two sides; two limiting rods are arranged in the underground well front and back; the two limiting rods are vertically arranged in parallel; the limiting rods are sleeved with floating blocks, the left end and the right end of each floating block are provided with two second conductive blocks, and the two second conductive blocksare connected through a wire. A support is arranged on the upper side of the underground well and is provided with a plurality of alarm indicator lamps and a buzzer alarm; and the support is further provided with a storage battery. Alarming can be conducted on water levels of different heights in the underground well; the structure is simple, the cost is low, and the early-warning alarm effect isgood.

Owner:刘福东

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com