Construction method for filling mortar combined stone dam

A construction method and flush filling technology, which can be applied to infrastructure engineering, dams, wall dams, etc., can solve the problems of inconvenient mechanized construction of grouted masonry structures, low material source utilization rate required by particle size, and low operating efficiency. Sufficient sources of stone, simplified construction process, and high operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

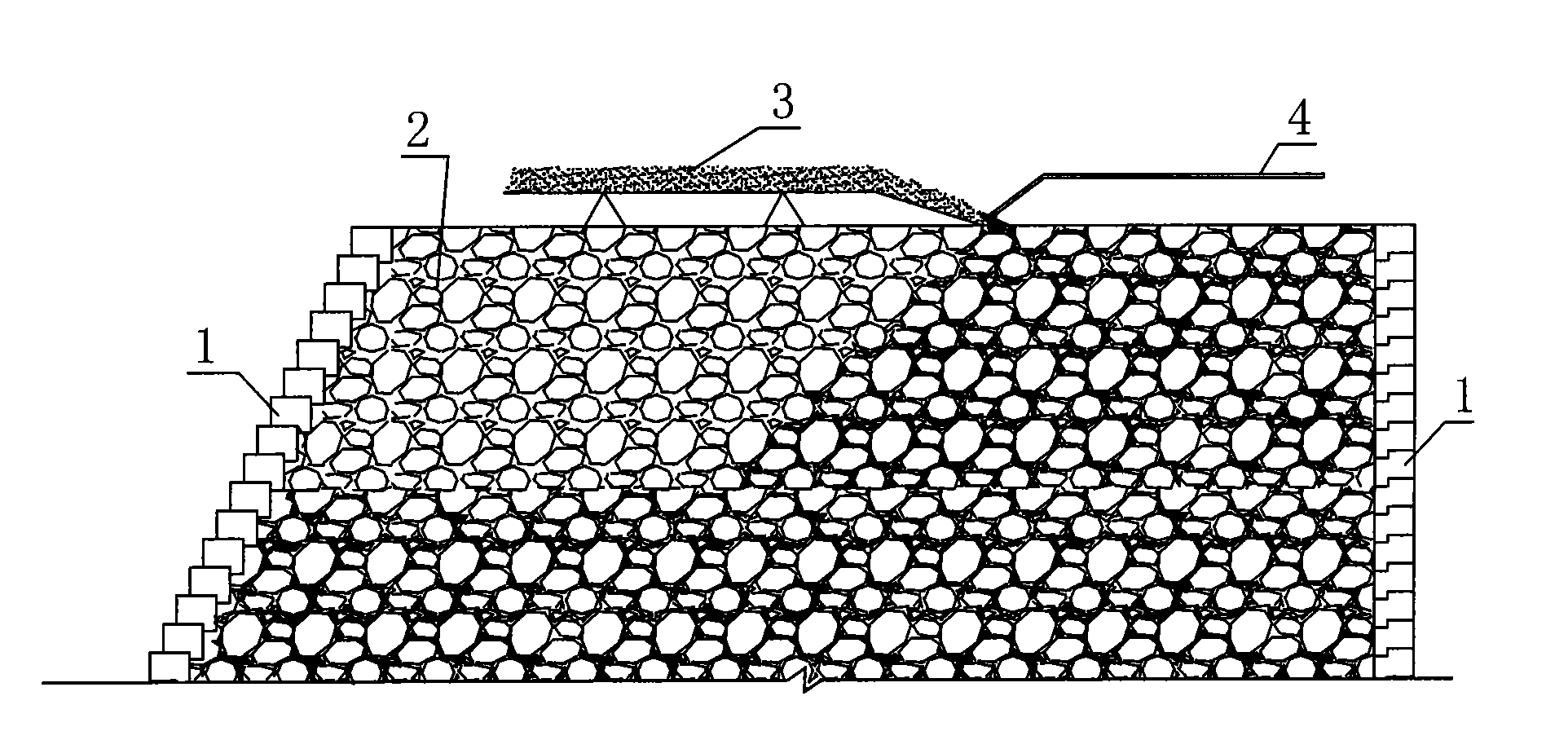

[0032] Example 1: Construction methods for the treatment of defects in masonry gravity dams or masonry gravity retaining walls

[0033] The masonry gravity dam or masonry gravity retaining wall is not saturated with mortar, and holes are drilled in rows from bottom to top on one side or both sides, and the holes are drilled from bottom to top to the top of the dam, and the sand is washed with slurry. The method is to use cement slurry or mixed slurry mixed with fly ash to directly fill the dam body with sand, so that the masonry body forms a complete mortar stone body. For the grouted masonry gravity dam, the dam body anti-seepage can be used to replace the concrete face plate or core The wall is impermeable.

Embodiment 2

[0034] Example 2: Construction methods for defect treatment of rock-fill face dams or rock-fill face core dams

[0035] For the holes or cracks caused by the leakage or collapse of the rockfill face, the drill holes are arranged in rows, and the cement slurry or the mixed slurry mixed with fly ash is used to flush the sand into the drill holes according to the order from bottom to top to form a bond between the face plate and the mortar stone. Unify the anti-seepage body. For the defects of the core wall of the rockfill face dam, use drill holes to set flower pipes, and also use the slurry sand washing operation method to fill the sand with cement slurry or cement mixed slurry mixed with fly ash to form a required thickness at the defect site. Mortar stone body to remedy core wall defects.

Embodiment 3

[0036] Embodiment 3: The construction mode that adopts mortar concretion to building foundation

[0037] Fill the stone material according to the size required by the foundation to the top surface of the foundation elevation, and the surrounding baffle adopts a slurry drainage structure, and then starts from one side and arranges multiple points to the opposite side, and uses the slurry sand washing operation method to directly fill the stone gap with cement slurry Filling with sand, turning the foundation into a mortar stone structure, using this simple process to form a mortar stone body completely replaces the mortar masonry construction process, which has low requirements for stone materials, fast construction progress, and low cost.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com