Patents

Literature

162 results about "Diameter control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Diameter Credit-Control Application, is a networking protocol for Diameter application used to implement real-time credit-control for a variety of end user services.

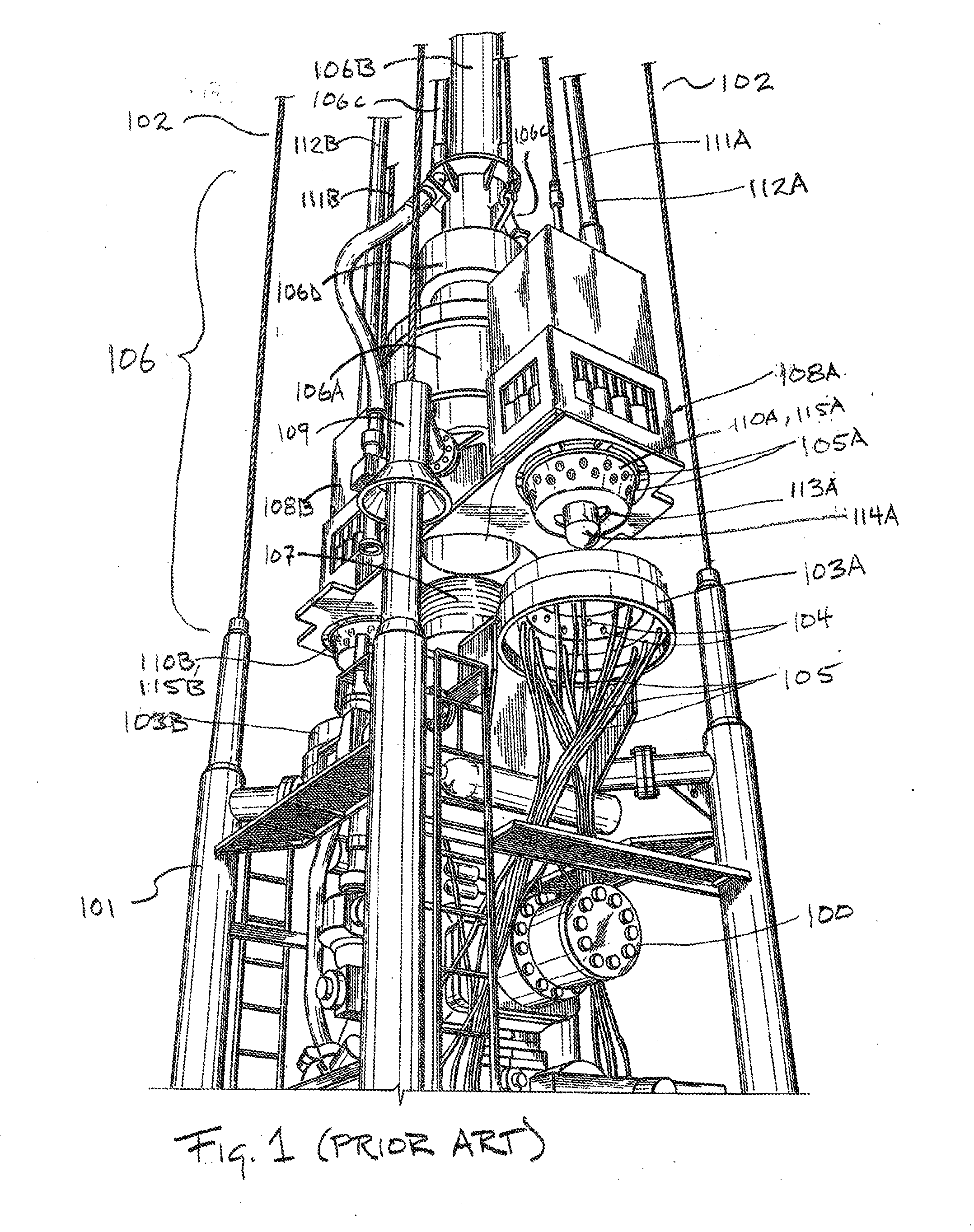

Retrievable hydraulic subsea bop control pod

Systems and methods for improved hydraulic control systems for actuation of subsea equipment in deep water are disclosed. The hydraulic control system relies on smaller fluid flow associated with a hydraulic pressure pulse to actuate the small volume actuation control valve. In one embodiment, the system includes small diameter control umbilical hoses and pilot-operated valves with low actuation volumes. Particularly, a hydraulic control system for reducing the signal time to a subsea blowout preventer in water depth up to and greater than about 5000 feet. Some embodiments comprise a valve arrangement which hydraulically actuate one side of a hydraulic control function, while simultaneously evacuating the opposing circuit both at the seabed and at the surface. Some embodiments comprise an umbilical hose located proximate the center of an umbilical bundle. Preferably, the umbilical hose has a plurality of layers of reinforcing fibers which increase with the diameter of the reinforcement layer.

Owner:DIAMOND OFFSHORE DRILLING

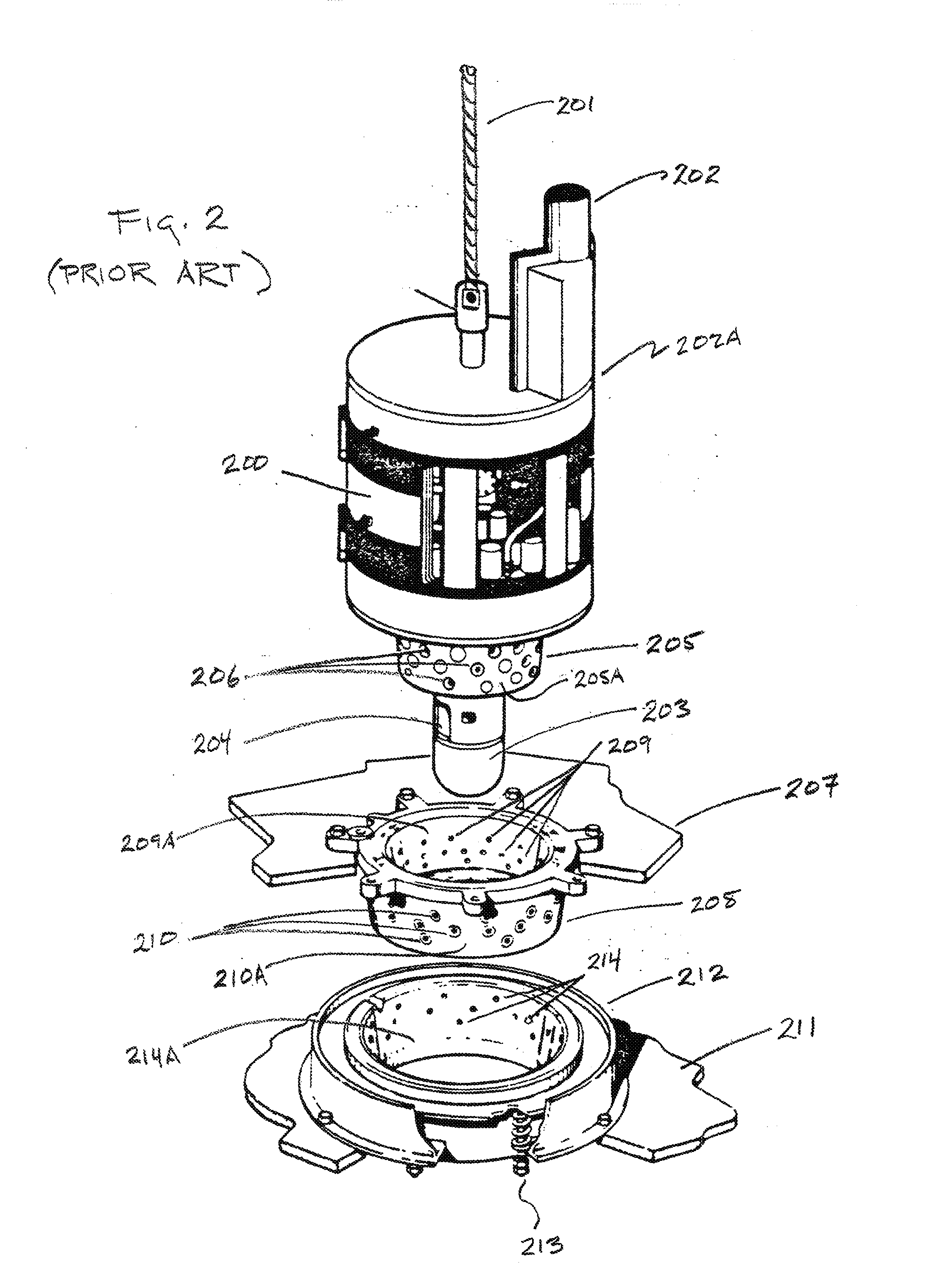

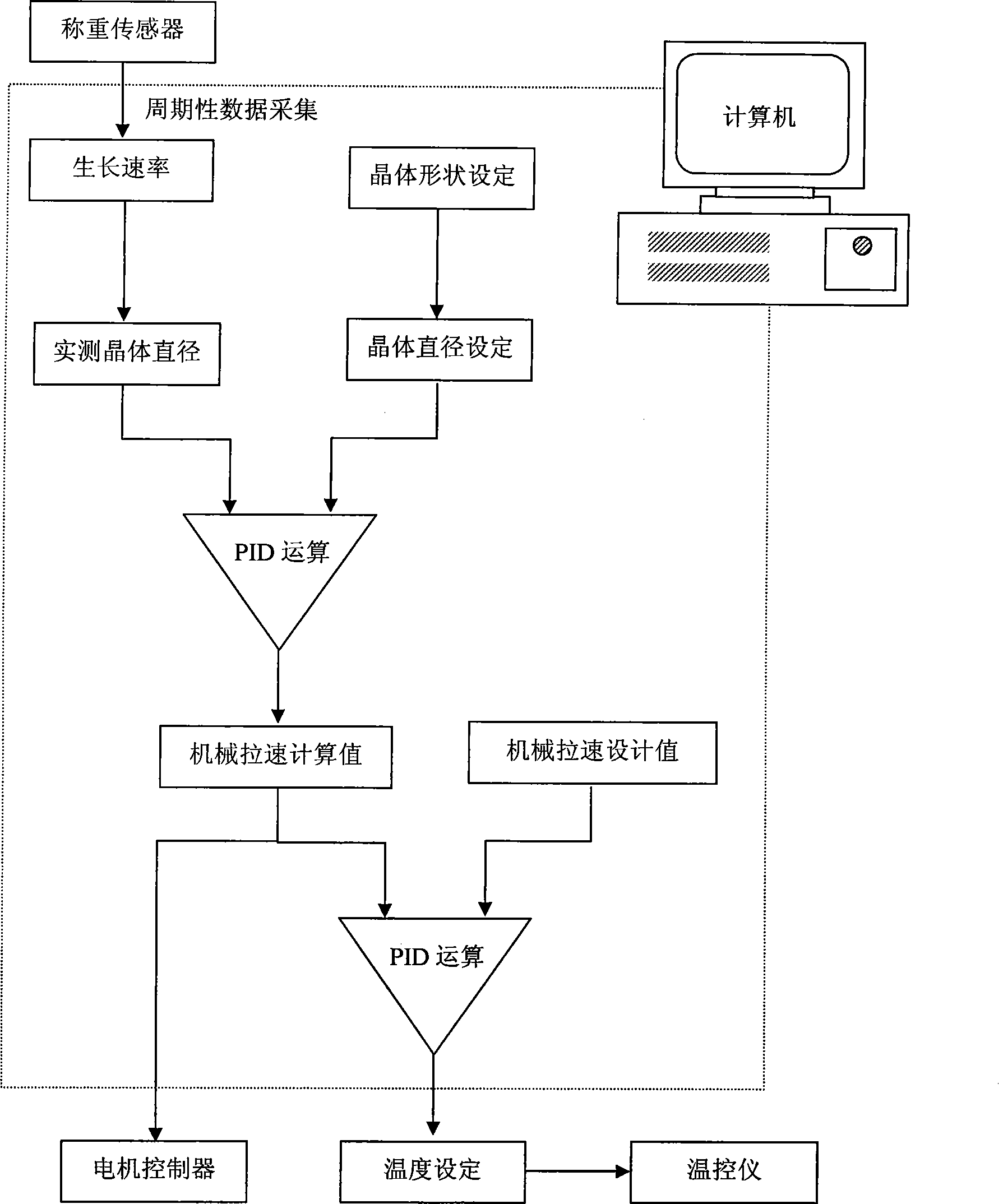

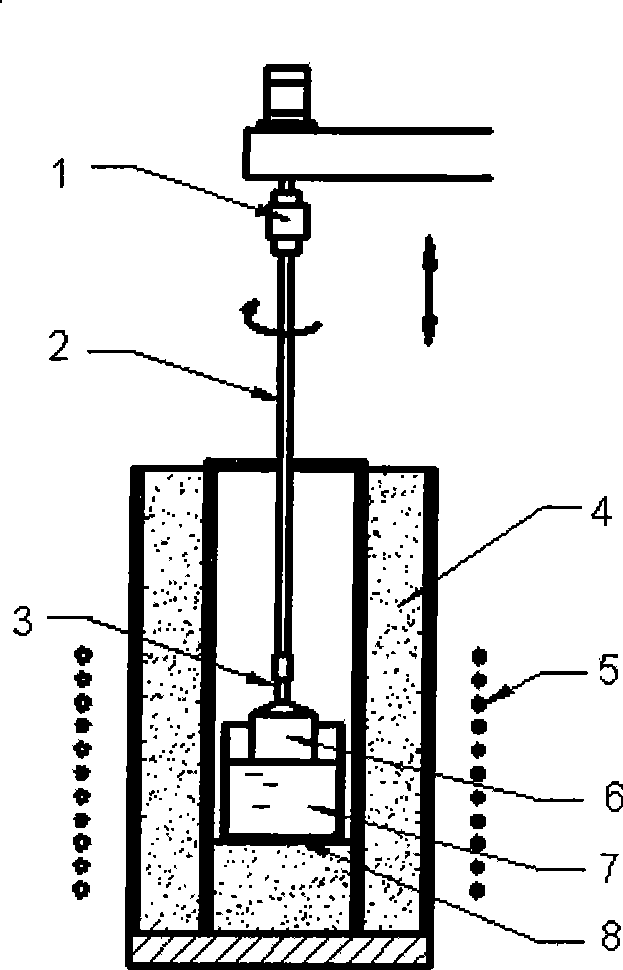

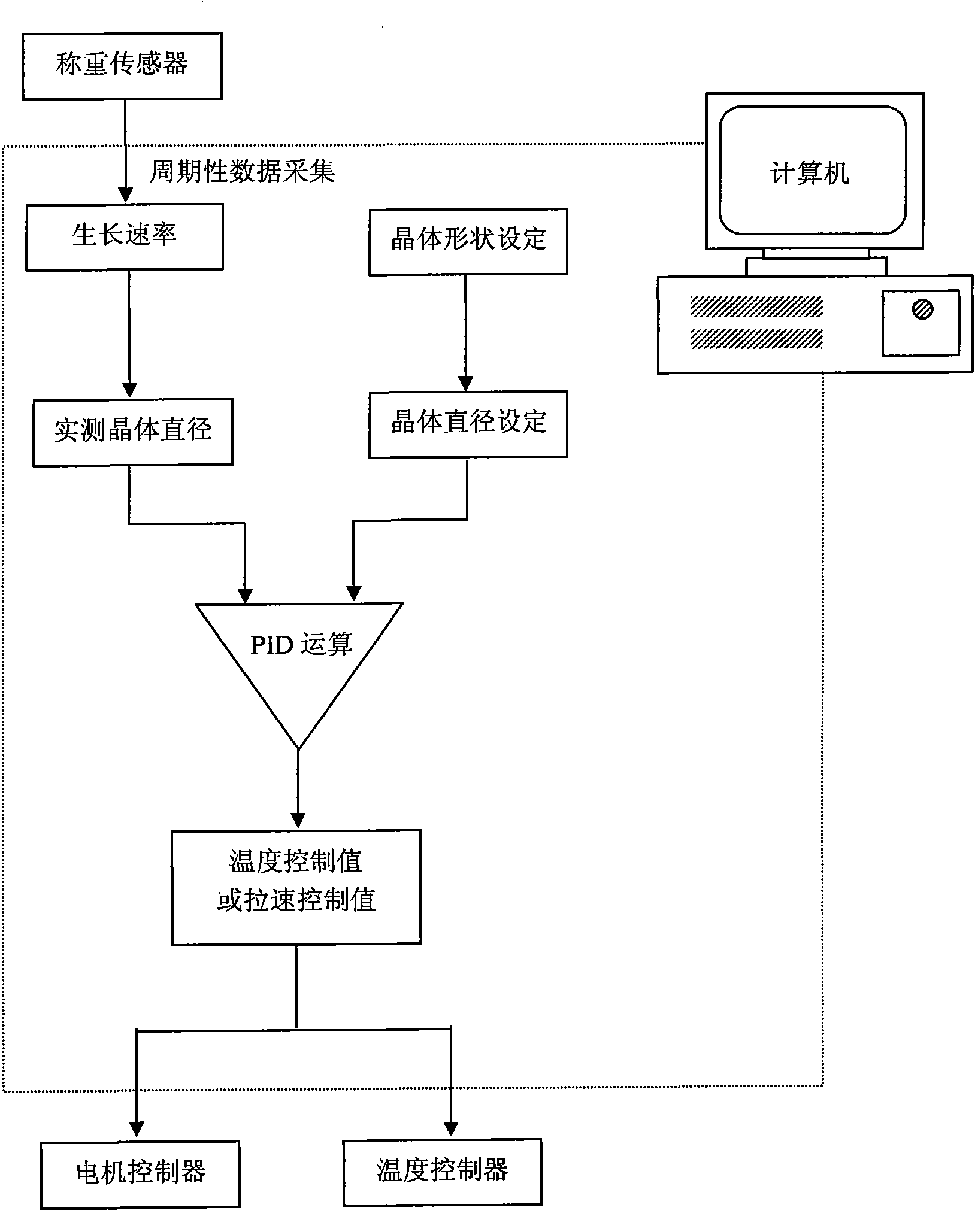

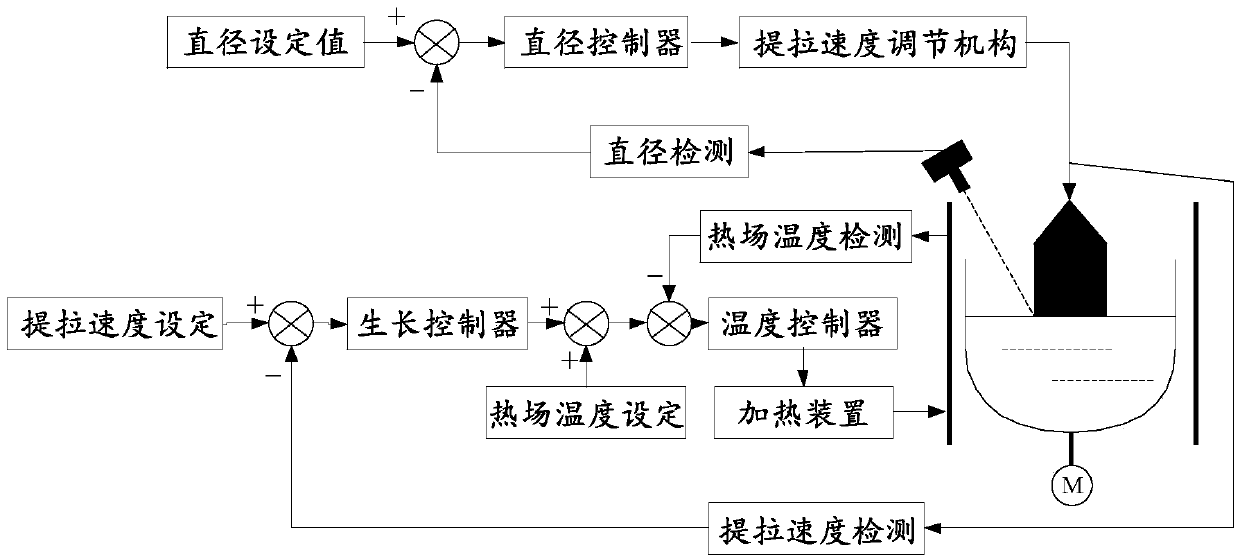

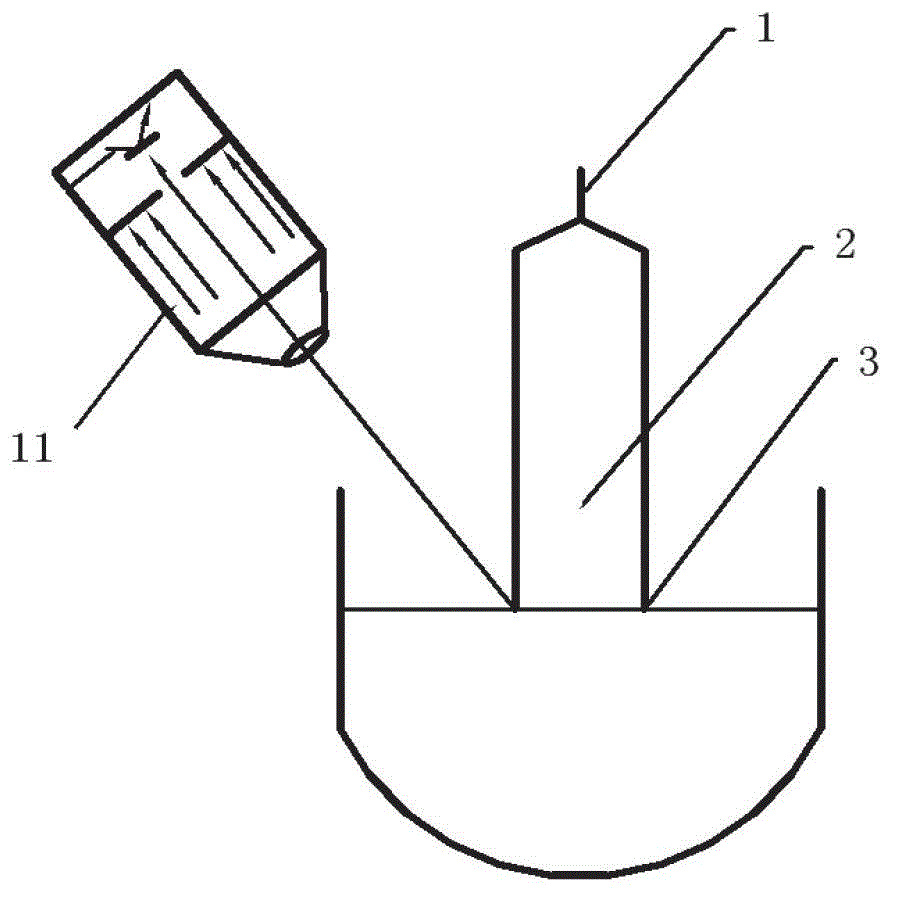

Control method of crystal growth by crystal pulling method

InactiveCN101392404AQuick responseGood isometric controlBy pulling from meltCzochralski methodEngineering

The invention relates to a control method for crystal growth by Czochralski method. A weight signal of a growing crystal is obtained by the sampling of a computer and is converted, according to a signal processing method, to a crystal diameter feedback signal independent of the growth rate; the crystal diameter feedback signal is compared with the preset crystal diameter value to acquire a signal error, and then the calculated value of a mechanical pulling speed for the control of a seed crystal is gained by the PID calculation of the signal error; the calculated value of the mechanical pulling speed is compared with the preset mechanical pulling speed value to get a new signal error, and the temperature (or power) is controlled through the PID calculation of the new signal error. The pulling speed is controlled by a primary control circuit while the temperature is controlled by a secondary control circuit; the constant diameter control of the growing crystal is realized by the synergism of the pulling speed circuit and the temperature circuit. The control method has the advantages of rapid response speed, good constant diameter control effect, smoother crystal surface, higher crystal growth rate and production efficiency, and the using of the control method is not affected by the material of the crystal and can be applied to most growing processes of Czochralski method.

Owner:惠梦君

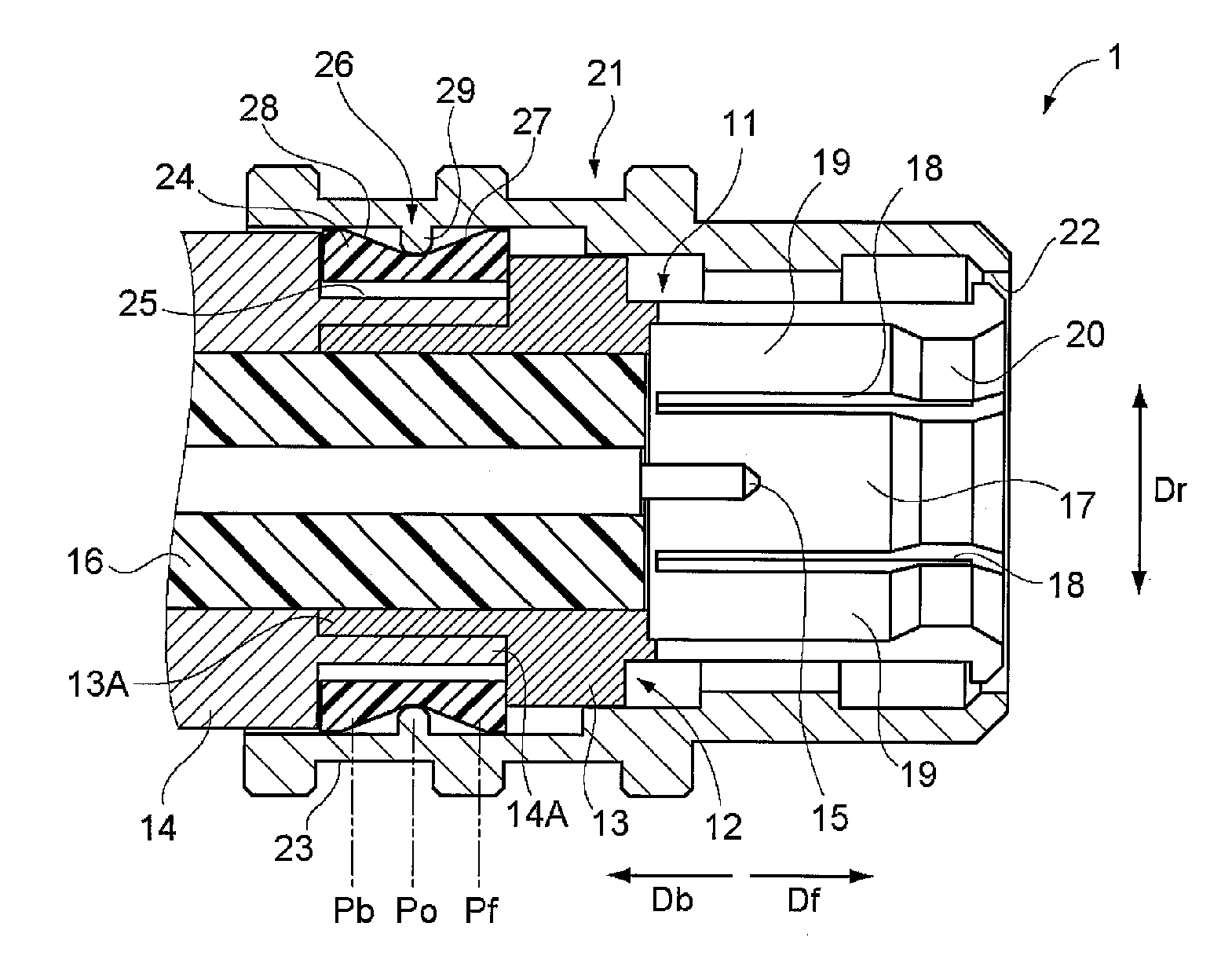

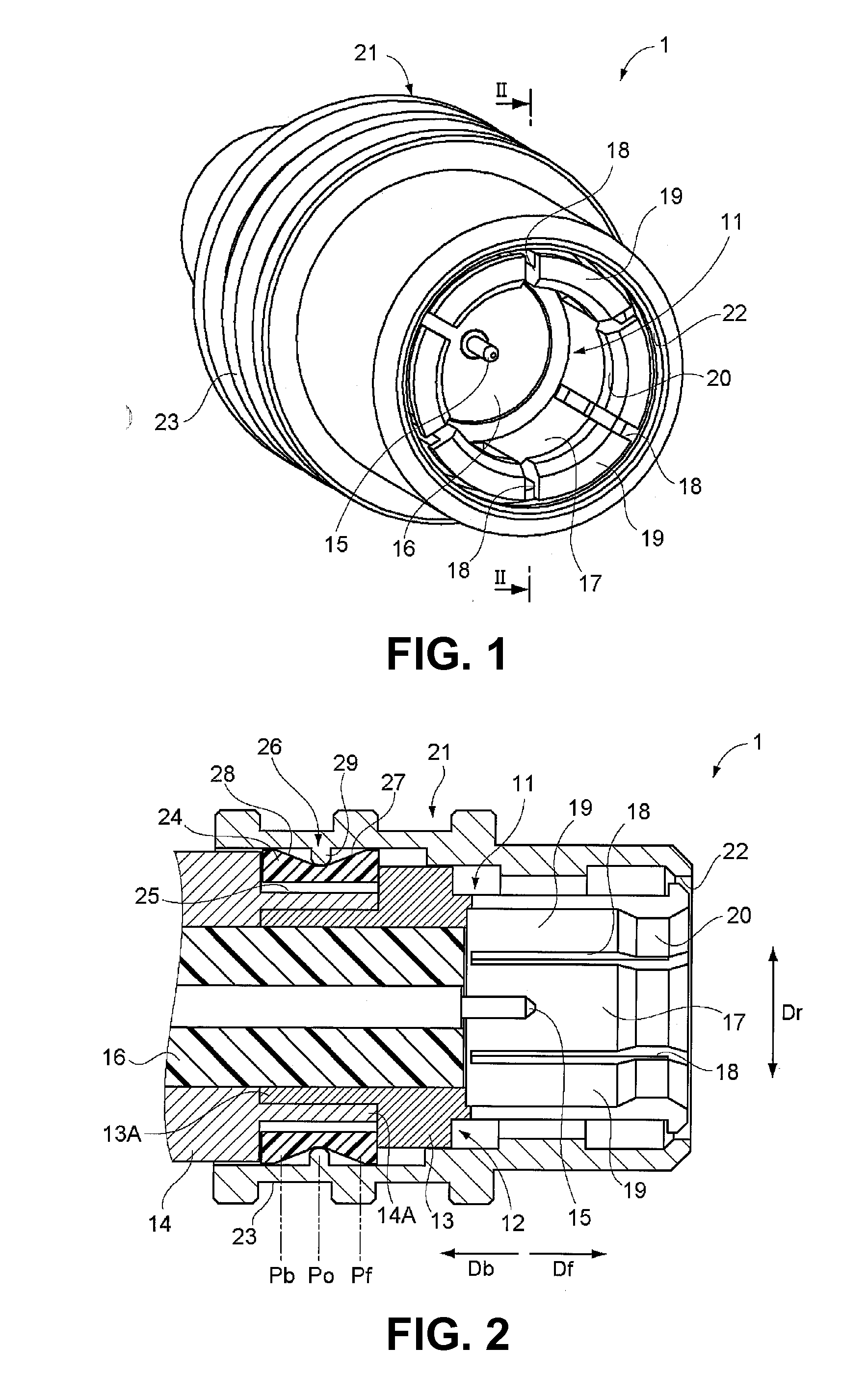

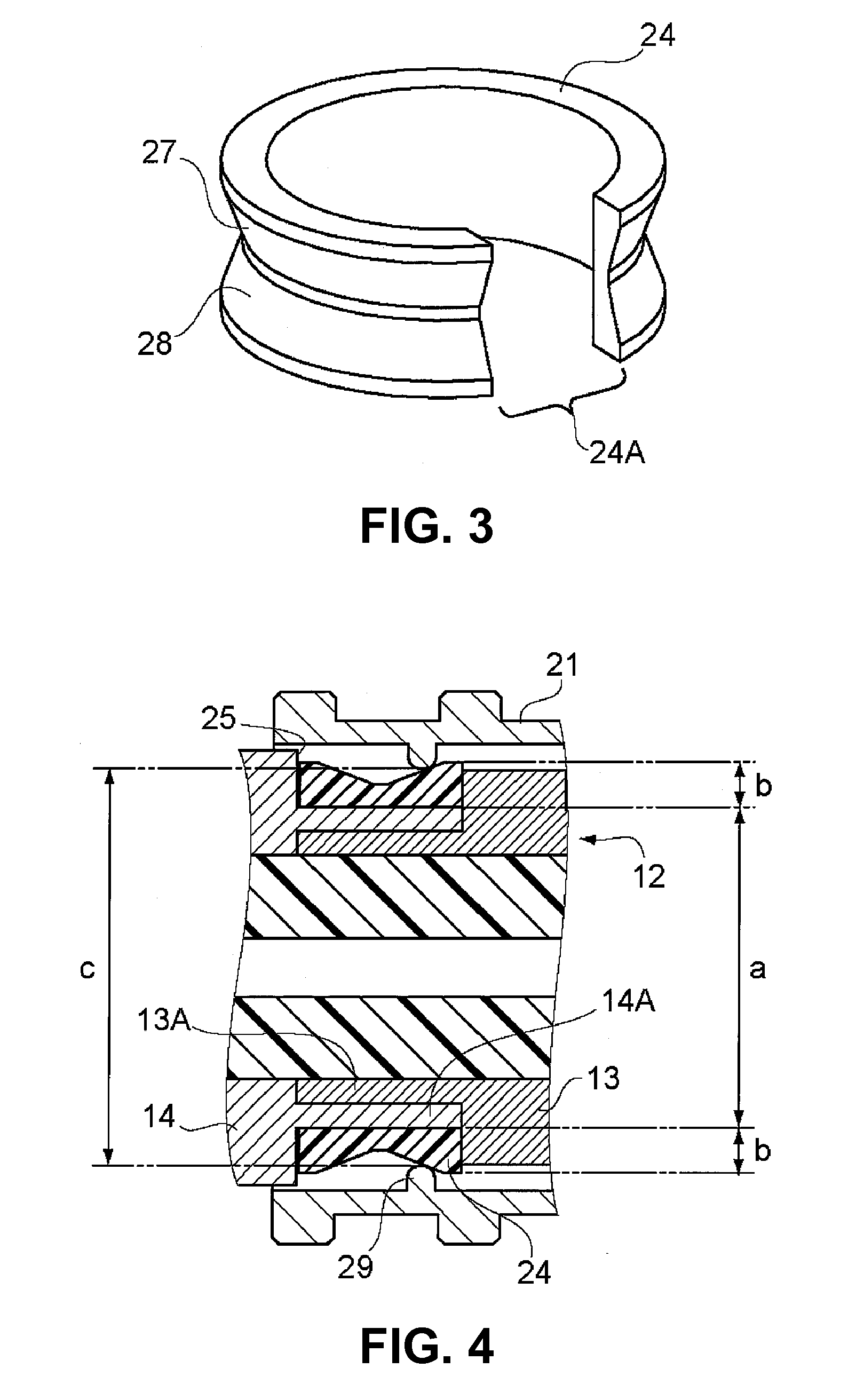

Connector

InactiveUS20120252282A1Simple configurationSmall sizeCoupling device detailsTwo-part coupling devicesEngineeringDiameter control

A connector to be connected to a mating connector, includes a connector main body including a cylindrical member, a supporting member disposed in the cylindrical member, a terminal supported on the supporting member, and a fitting portion having an engaging portion; a movable sleeve including a diameter control portion; an elastic deformation member disposed to be elastically deformable in a radial direction thereof; an accommodating portion disposed between the connector main body and the movable sleeve for accommodating the elastic deformation member; and a transmission unit for transmitting a force in the axial direction from the movable sleeve to the elastic deformation member when the movable sleeve moves, and for transmitting a force in the radial direction from the elastic deformation member to the movable sleeve when the elastic deformation member returns to an original shape.

Owner:HIROSE ELECTRIC GROUP

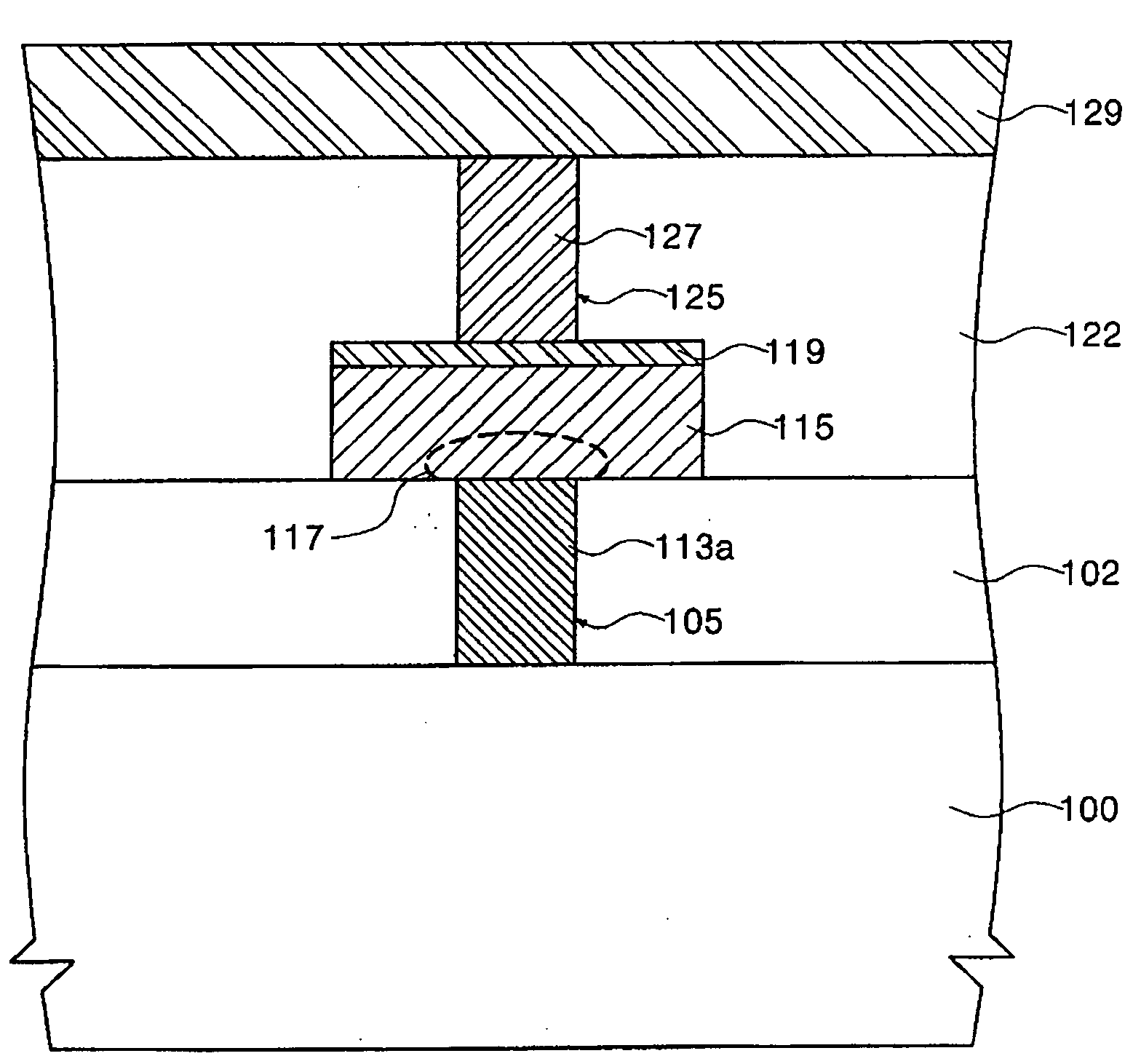

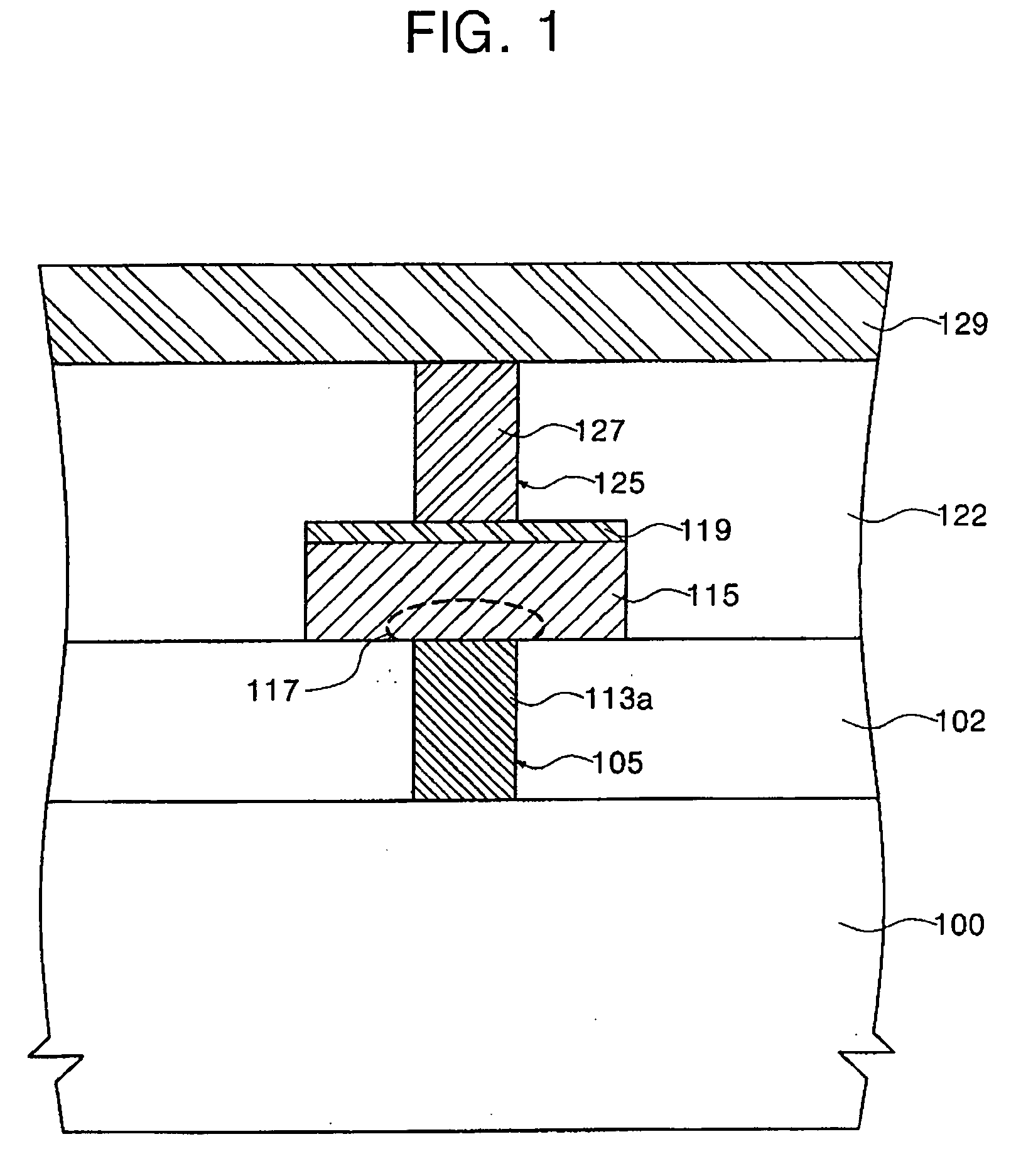

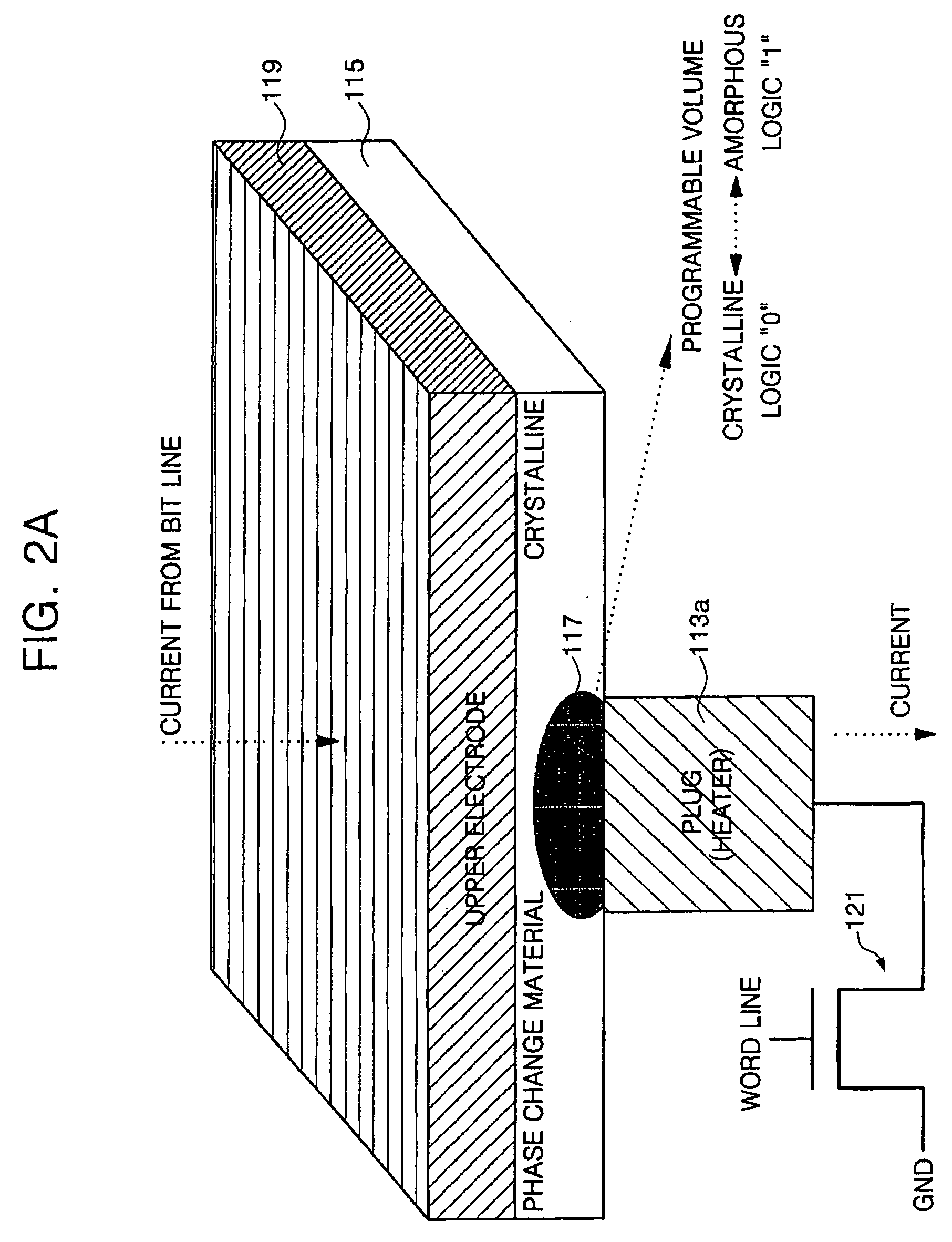

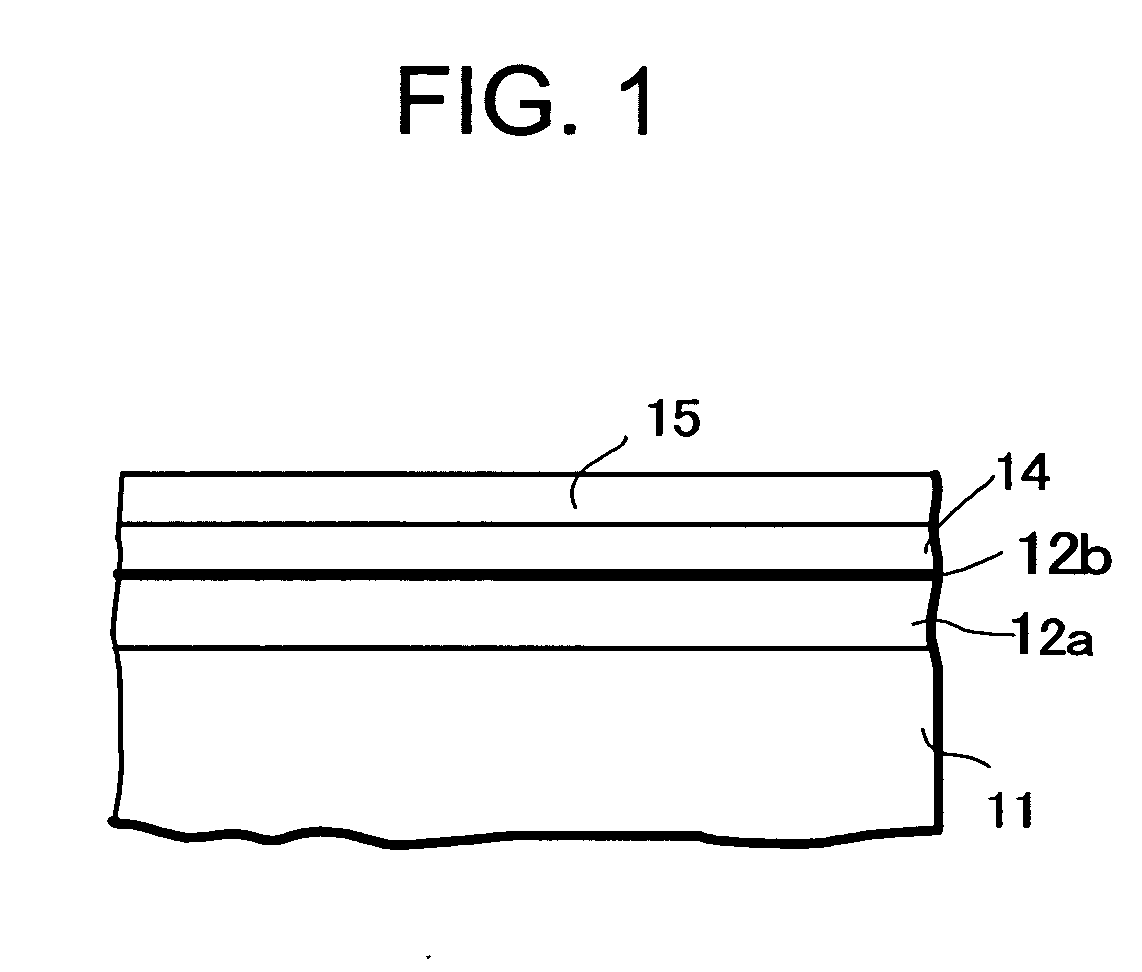

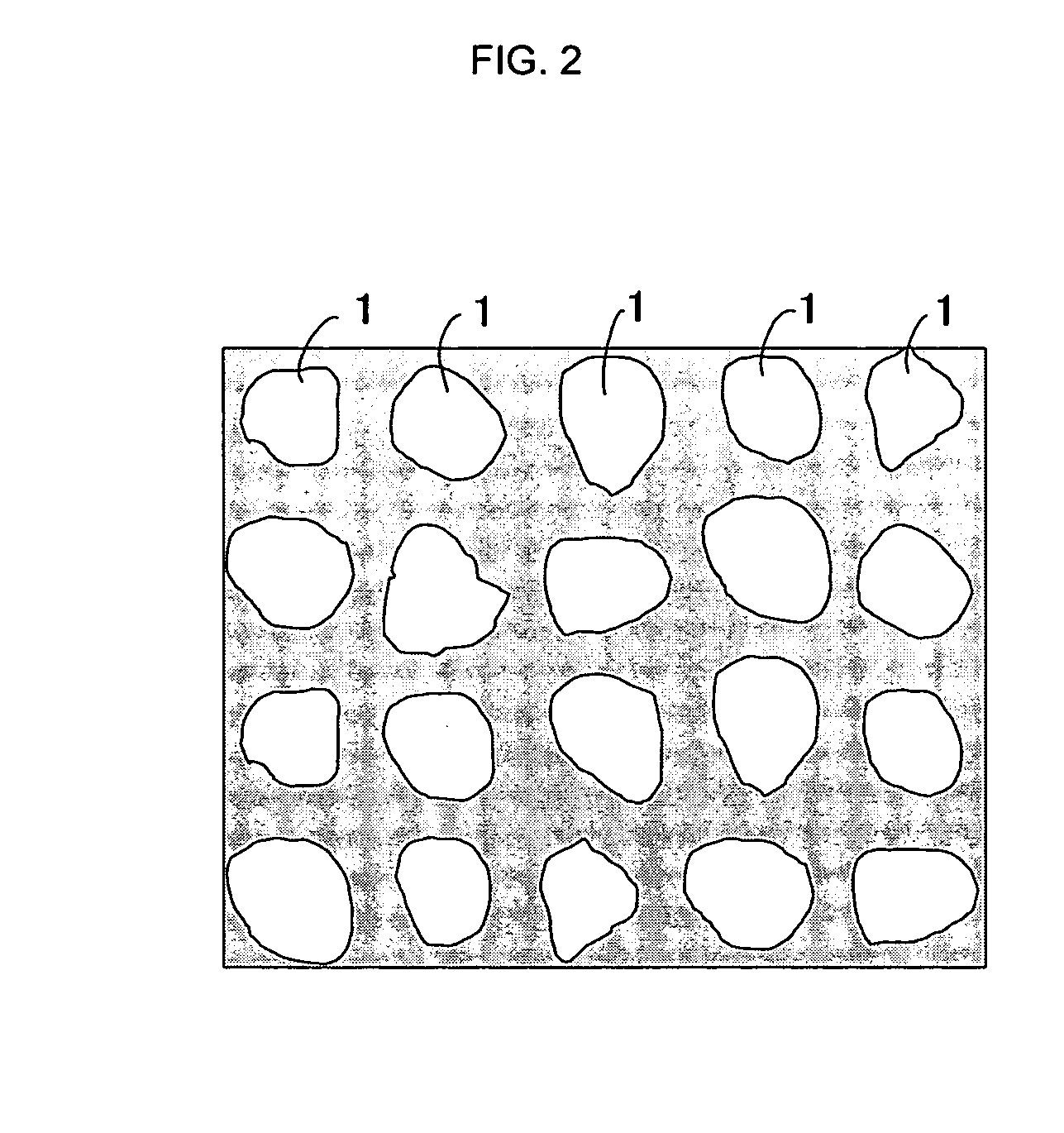

Multi-bit phase-change random access memory (PRAM) with diameter-controlled contacts and methods of fabricating and programming the same

InactiveUS20070155093A1Semiconductor/solid-state device manufacturingDigital storageRandom access memoryPhase change

A phase-change random-access memory (PRAM) device includes a chalcogenide element, the chalcogenide element comprising a material which can assume a crystalline state or an amorphous state upon application of a heating current. A first contact is connected to a first region of the chalcogenide element and has a first cross-sectional area. A second contact is connected to a second region of the chalcogenide element and having a second cross-sectional area. A first programmable volume of the chalcogenide material is defined in the first region of the chalcogenide element, a state of the first programmable volume being programmable according to a resistance associated with the first contact. A second programmable volume of the chalcogenide material is defined in the second region of the chalcogenide element, a state of the second programmable volume being programmable according to a second resistance associated with the second contact.

Owner:SAMSUNG ELECTRONICS CO LTD

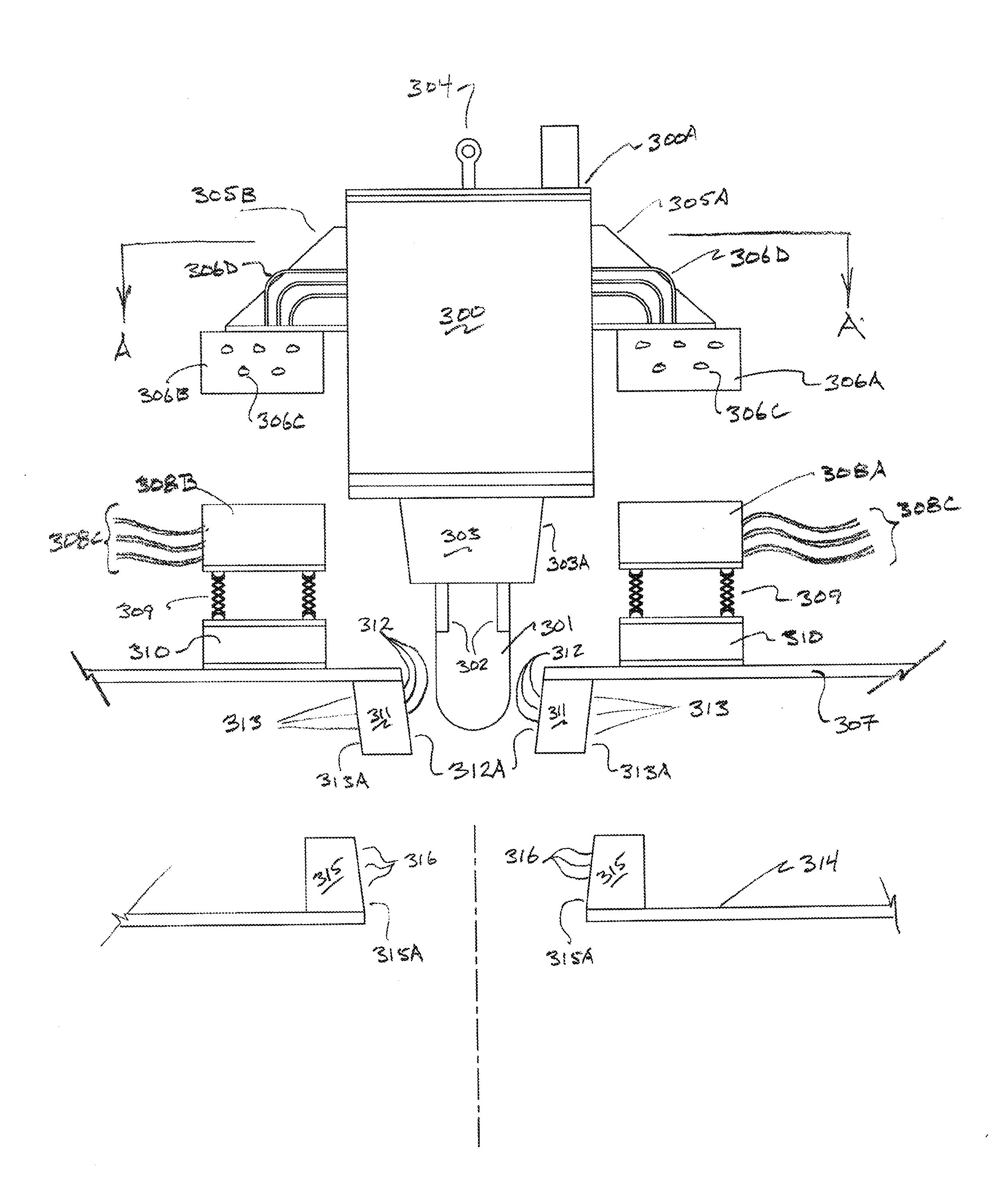

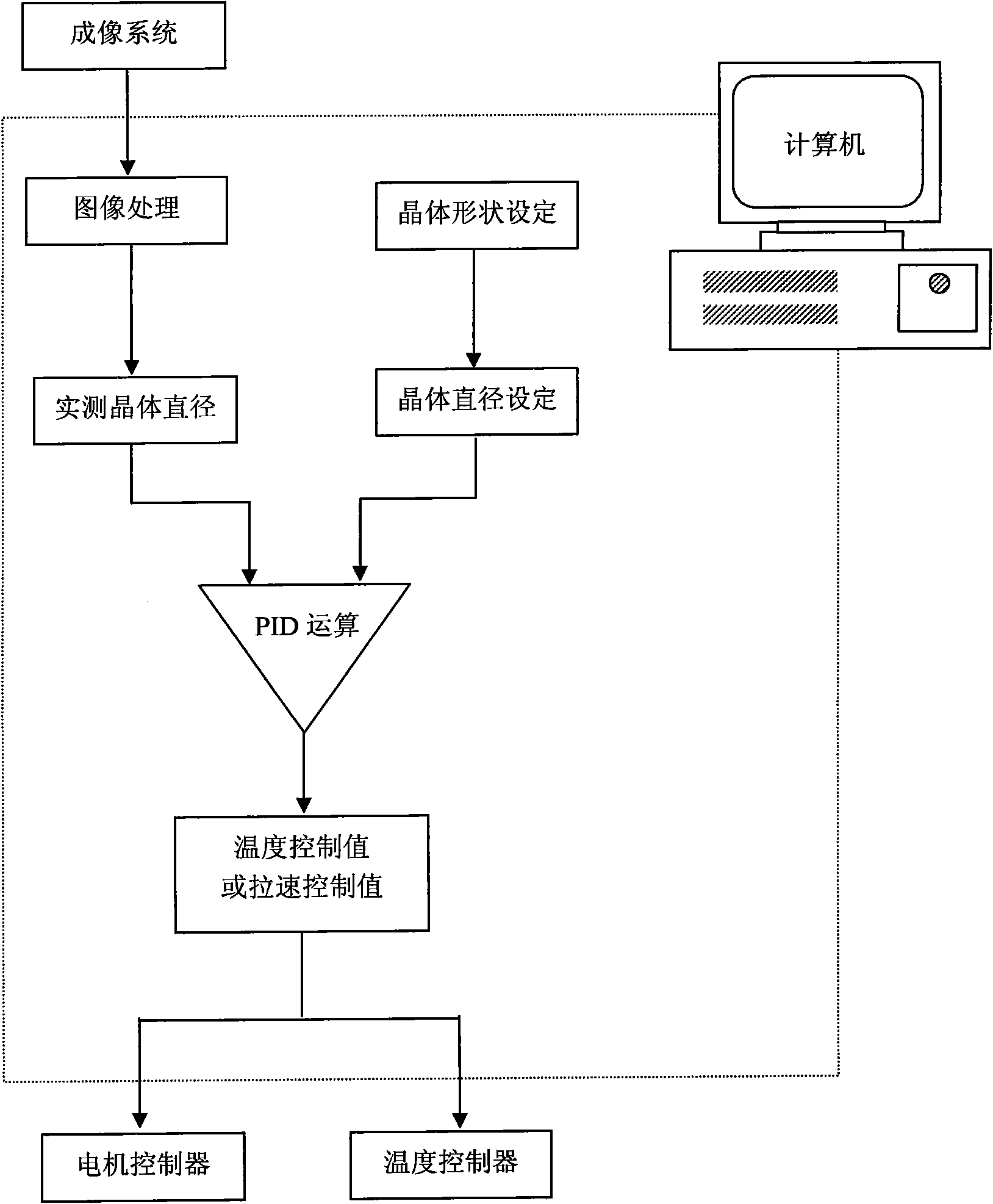

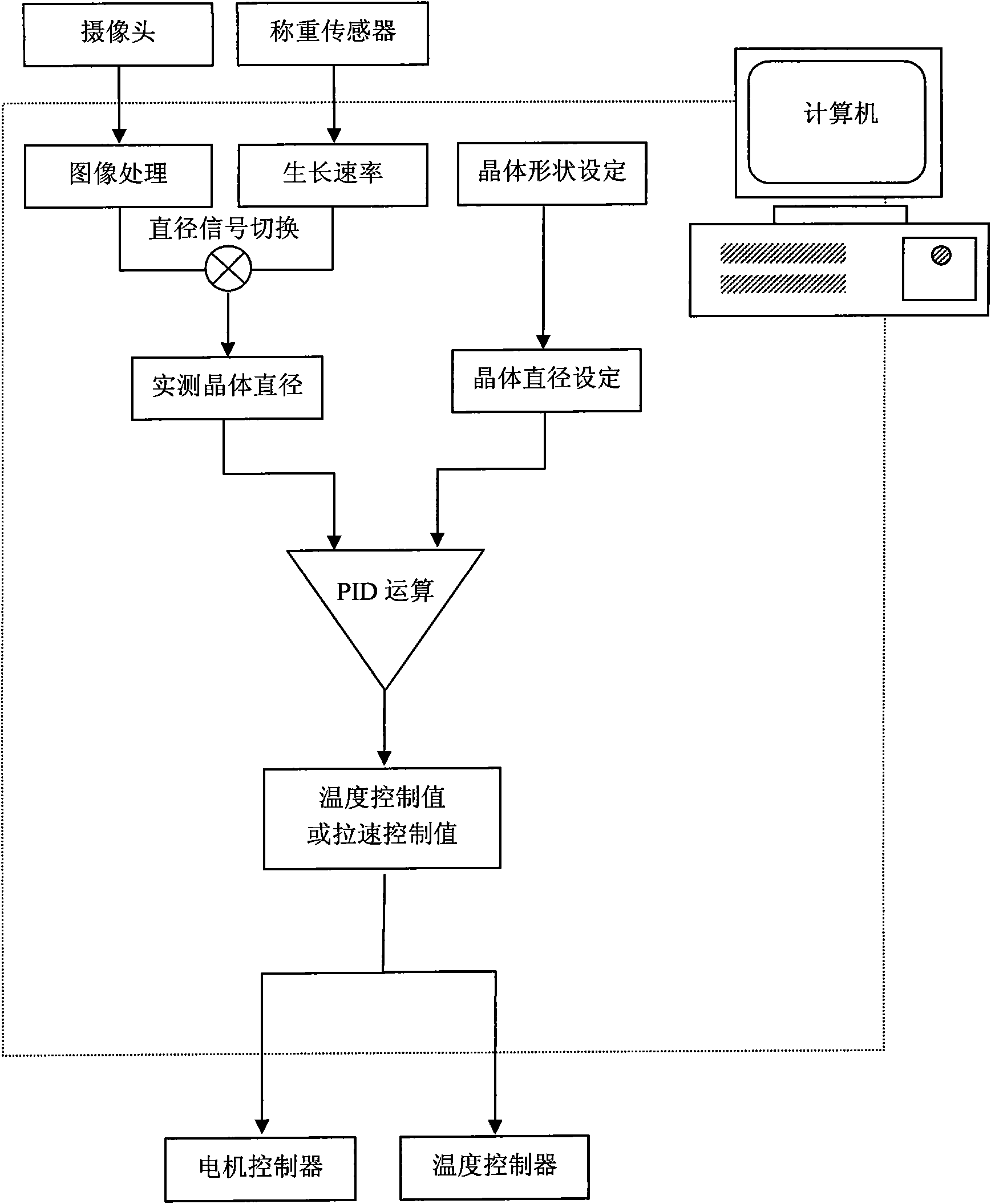

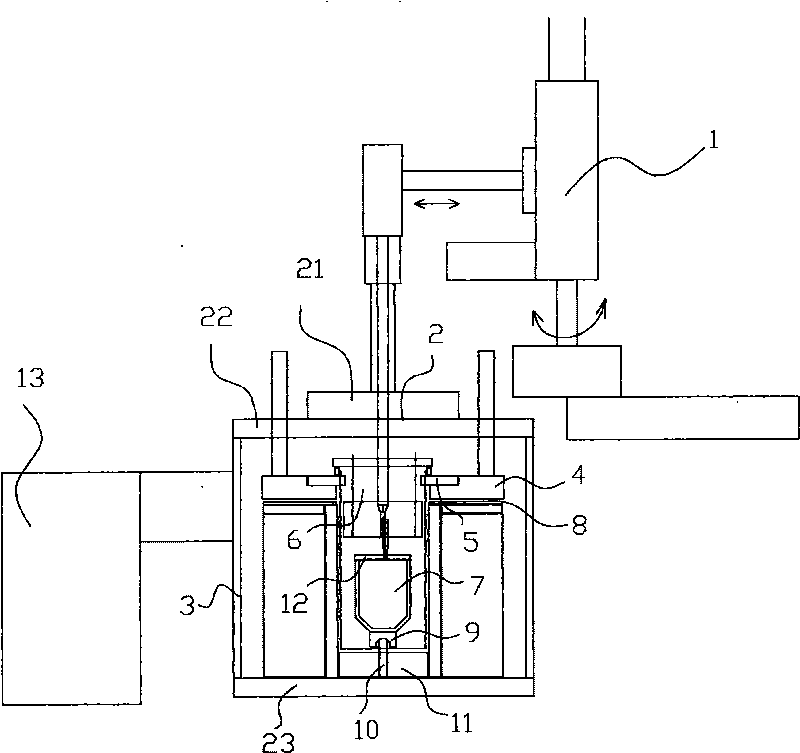

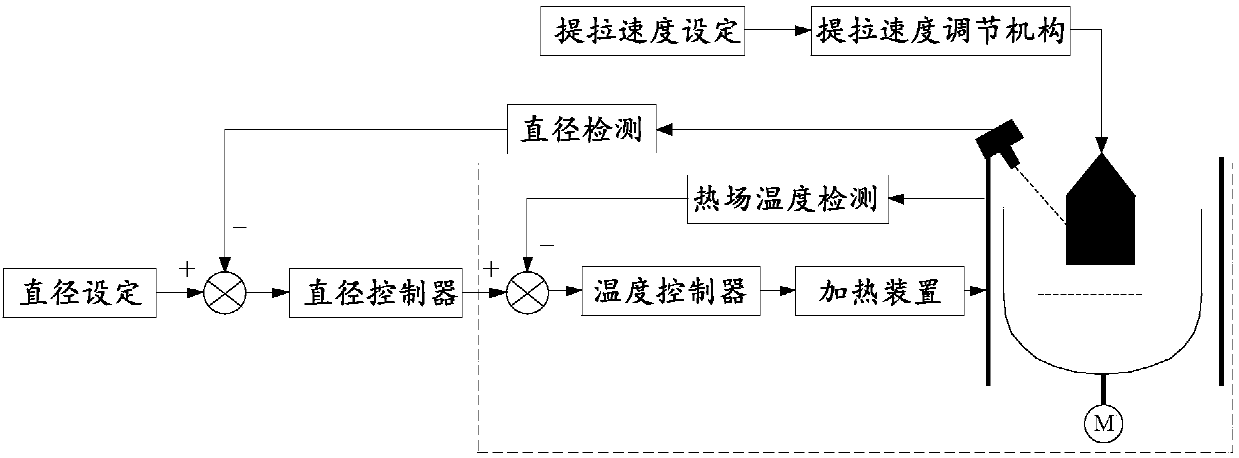

Diameter control method for czochralski crystal growing

The invention discloses a diameter control method for czochralski crystal growing, which comprises the following steps: acquiring crystal diameter signals in an imaging or weighing mode at different stages of the growth of crystals; comparing a crystal diameter feedback signal with a crystal diameter preset value to acquire a signal error; and acquiring a crystal mechanical pulling speed control value or a temperature control value through the PID calculation of the signal error. The method reads a diameter signal by using an imaging method, is high in precision, small in visual field, and avoids crucible rise in a seeding stage, as well as acquires diameter signals by a weighing method, avoids crucible rise and is free from visual field limitation and stable in signal in the following shoulder extension, diameter control and closing stages.

Owner:无锡市惠德晶体控制设备有限公司

Method for growing large-size high-temperature oxide crystals by using top-seeded temperature gradient method

InactiveCN101705516ARealize real-time controlSolve the problem of large thermal shockPolycrystalline material growthFrom frozen solutionsCzochralski methodCrucible

The invention relates to a method for growing large-size high-temperature oxide crystals by using a top-seeded temperature gradient method, which relates to a new process of crystal growth and comprises the following steps of: combining a Kyropoulos method, a Czochralski method (CZ), a heat exchange method (HEM), a temperature gradient technique (TGT) and a Bridgman-Stockbarge method together, creating a special high temperature vacuum crystal furnace with adjustable temperature gradient and temperature field center, and producing the large-size high temperature oxide crystals through charging, high vacuum pimping, material melting by temperature rise, crystal seed washing, real-time temperature field adjustment, seeding by CZ, multiple reducing processes, a shouldering process by CZ, an isodiametric process by the Kyropoulos method, heat exchange by HEM combined with isodiametric growth by a TGT technology (a diameter control technology is CZ weighting), ending and crucible separation by CZ and annealing. The method is also suitable for a high vacuum environment and an atmosphere protection environment. The method has the advantage that the lowest energy consumption and the lowest cost are utilized for producing multiple high-quality high-temperature oxide crystal material products.

Owner:UNIONLIGHT TECH

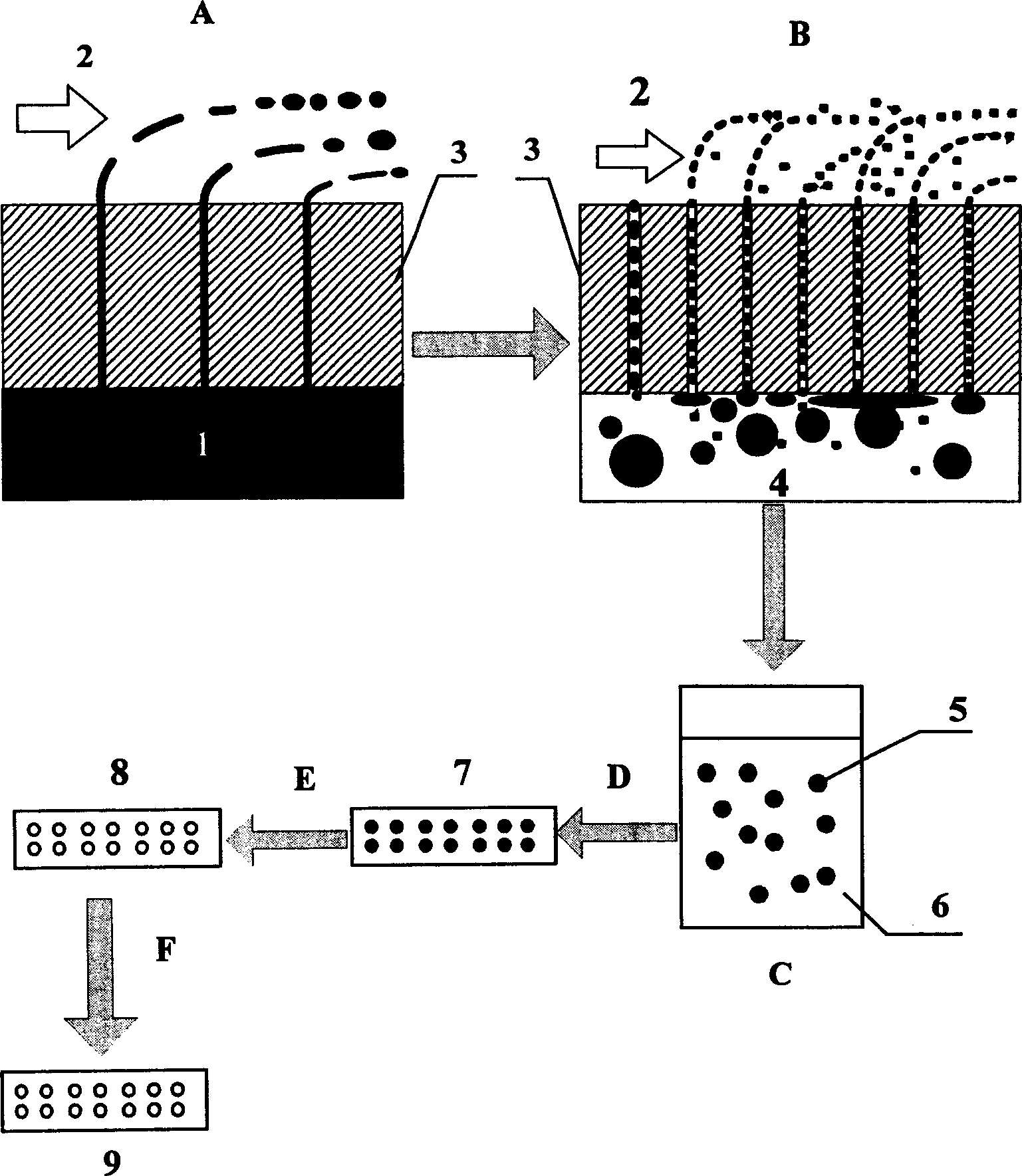

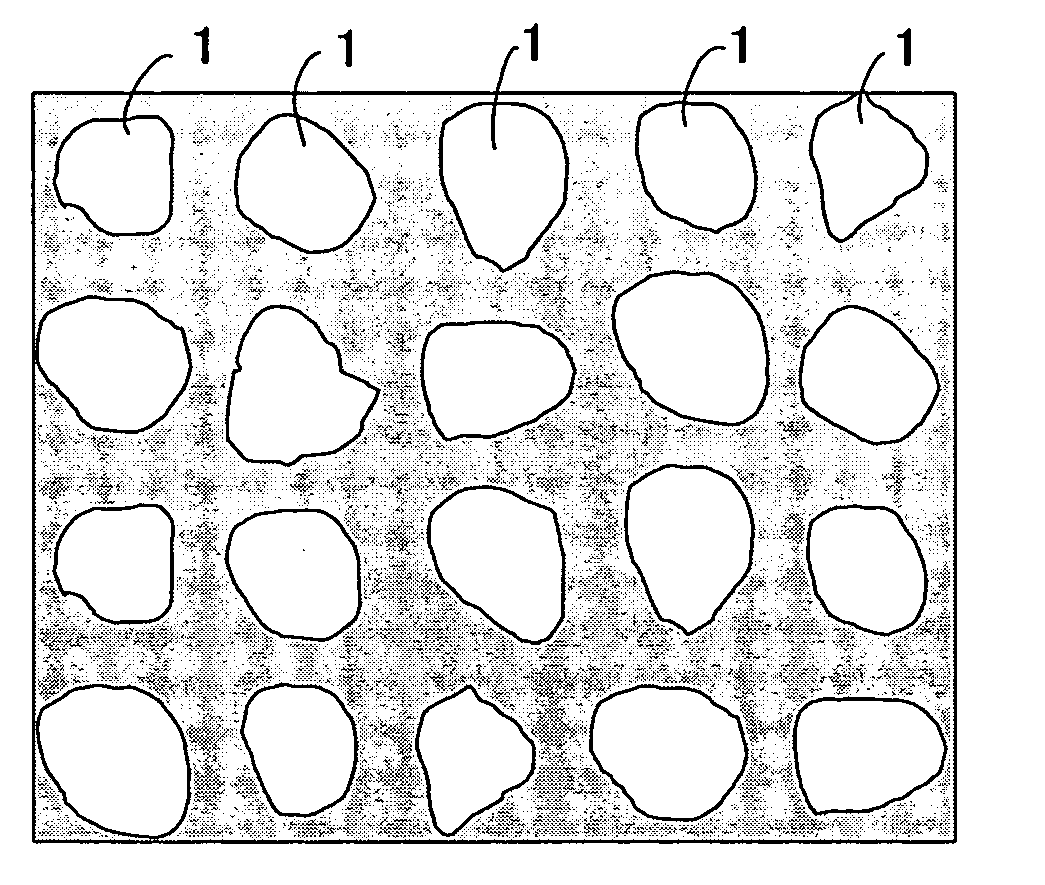

Process for preparing porous ceramic materials

The invention relates to a method of preparing porous ceramic material, especially relates to a bore diameter control method by film fluid jet emulsify technique, mainly applying to the preparation of ceramic material with regular pore construction. The specific technical project is as follows: a method of preparing porous ceramic material, is characterized by: use film fluid jet emulsify technique to control and prepare mono-disperse non-polar / polar emulsion, which means: the disperse phase flows into continuous phase through fenestra of film emulsified medium and form primary emulsion in the condition of shearing force; take said primary emulsion as discontinuous phase, which flows into continuous phase in the condition of fluid jet through fenestra and forms mono-disperse emulsion; take said emulsion as mold and disperse it into non-hydrosol which changes into gel through instable poly-condensation; the gel after leaving plate is burned to get high-ordered porous ceramic material.

Owner:NANJING UNIV OF TECH

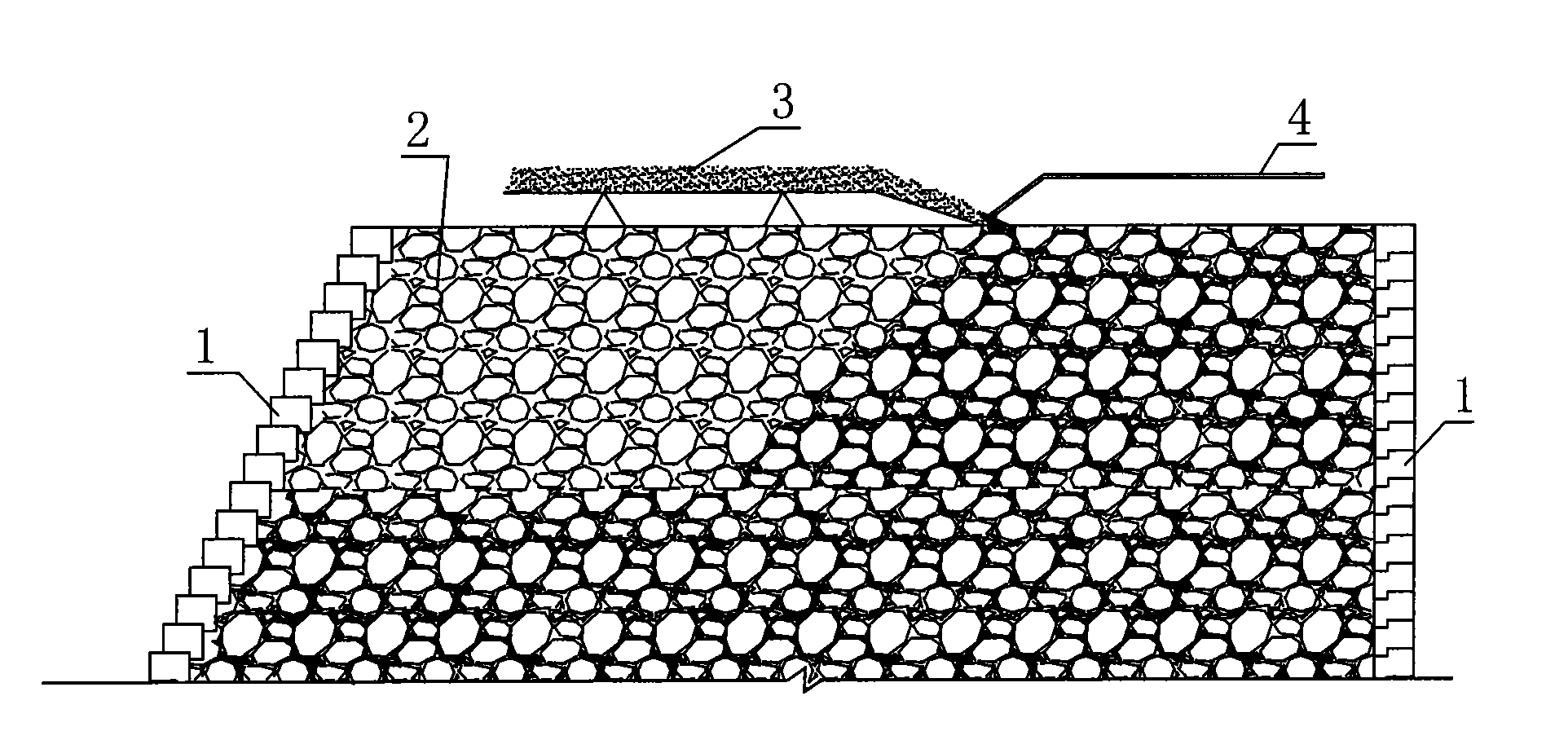

Construction method for filling mortar combined stone dam

ActiveCN101581088AIncrease self-impermeabilityTake advantage ofFoundation engineeringWall damsDiameter controlFly ash

The invention discloses a construction method for filling a mortar combined stone dam, which combines a mortar grouting and filling method and a rock-fill dam filling construction process, and solves the problems that a stone masonry structure is inconvenient to use mechanical construction and has low working efficiency, and a rock-fill dam has higher requirement on grain diameters of filling stones, lower material source utilization rate, high manufacturing cost and the like. The construction method comprises the following steps: filling stones in a dam shell till reaching the thickness requirement of a filling layer, flattening the stones, and then carrying out mortar sand removal operation on the top surface of the filling layer, namely directly filling previously prepared cement mortar or cement mixed mortar doped with admixture fly ash into the screened sand quantitatively supplied by a mortar conveying device in gaps of the filled stones through the mortar conveying device to form the mortar combined stone dam similar to the mortar masonry stone dam. The process flow is simple, the application range is wide, the maximum block diameter control and grade matching requirements are not needed, the stone source is abundant, the thickness of the filling layer is large, the roller compaction is not needed, the construction speed is high, the working efficiency is high, the construction cost is reduced, and the formed dam mortar masonry is compact and has good quality.

Owner:沈阳乾玉水利有限公司

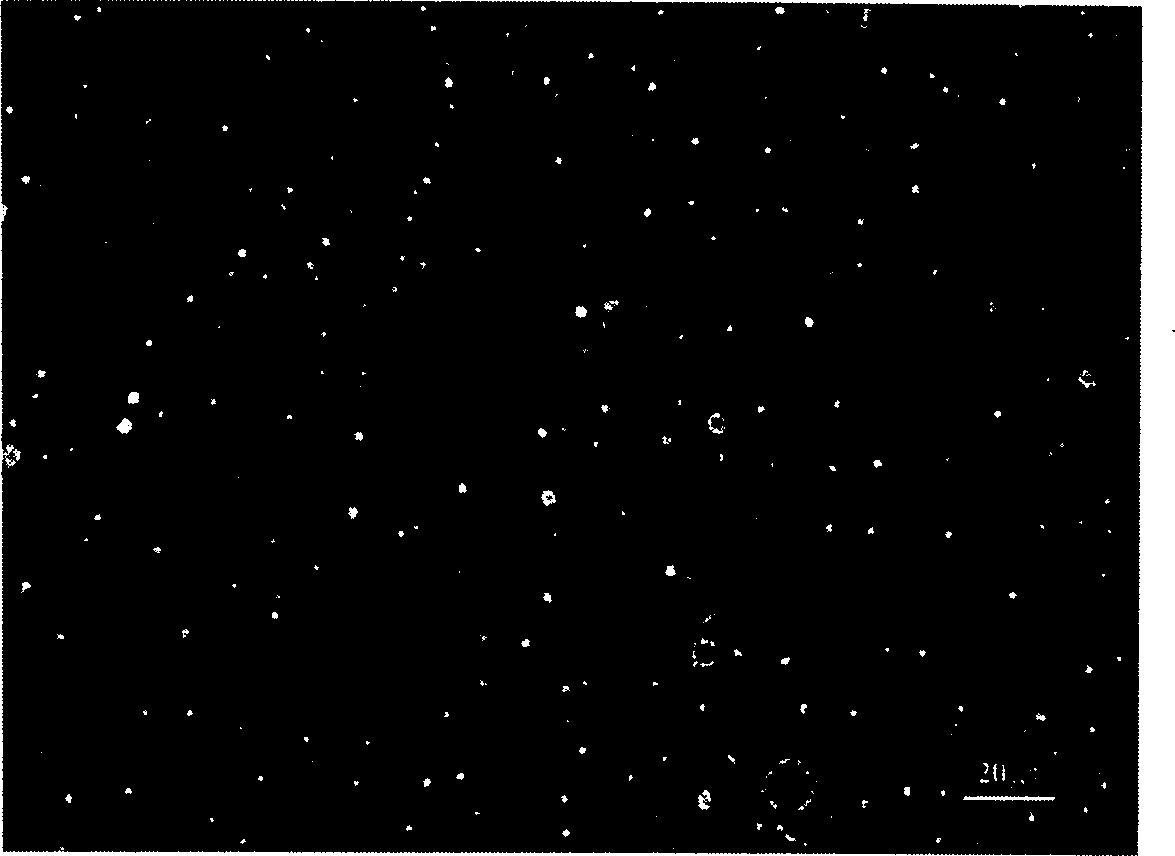

Mesoporous manganese oxide nano granule and preparation method thereof

InactiveCN101597085AImprove protectionSimple preparation processManganese oxides/hydroxidesMANGANESE ACETATESesquioxide

The invention relates to a mesoporous manganese oxide nano material and a preparation method thereof. In the invention, a uniformly distributed mesopore with the aperture of 2 to 10 nanometers and a mixture of oxyhydrogen manganese oxide and manganic manganous oxide or a mangano-manganic octoxide monocrystal granule or a manganese sesquioxide monocrystal granule with the granule particle diameter controlled within the range of 20 to 80 nanometers are prepared by the hydrothermal function of manganese metal, manganese acetate and ammonia and the subsequent calcination control, and the uniformly distributed mesoporous, the mixture of oxyhydrogen manganese oxide and manganic manganous oxide, the mangano-manganic octoxide monocrystal granule and the manganese sesquioxide monocrystal granule play a catalytic action to a toluene combustion reaction. The invention has simple preparation method, loose synthesizing condition, easy repetition and cheap raw materials and can carry out large-scale production.

Owner:HEBEI UNIV OF TECH

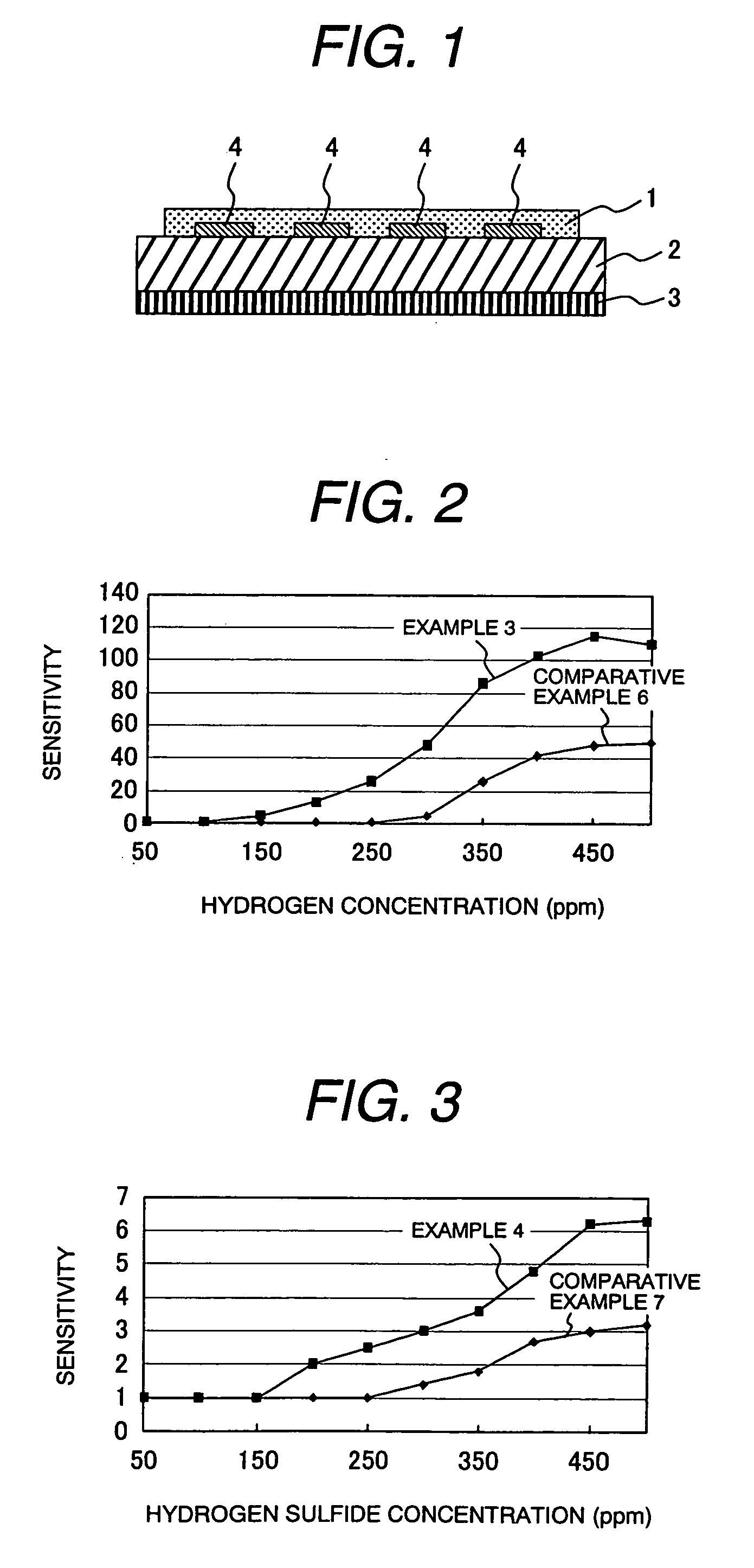

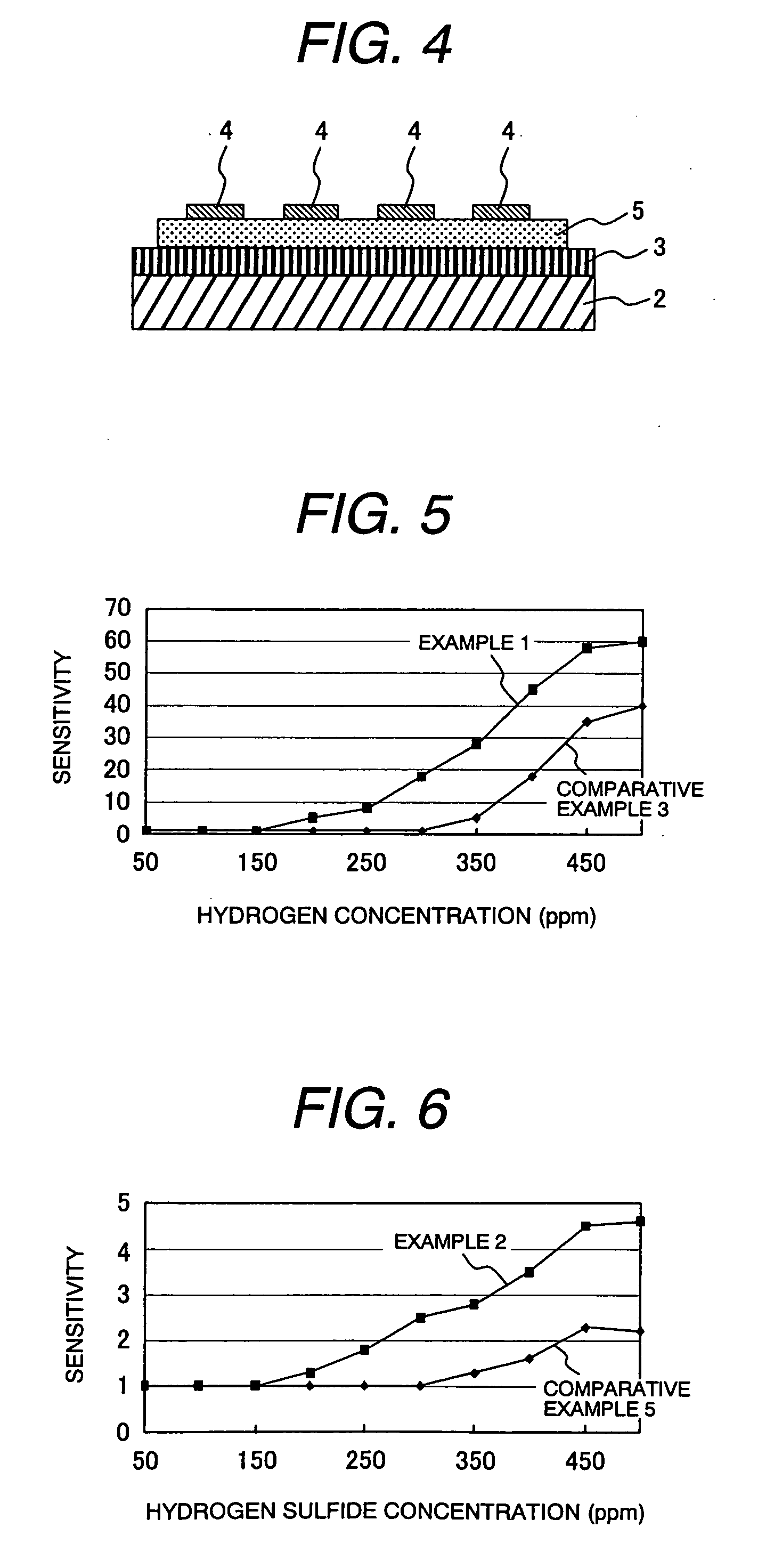

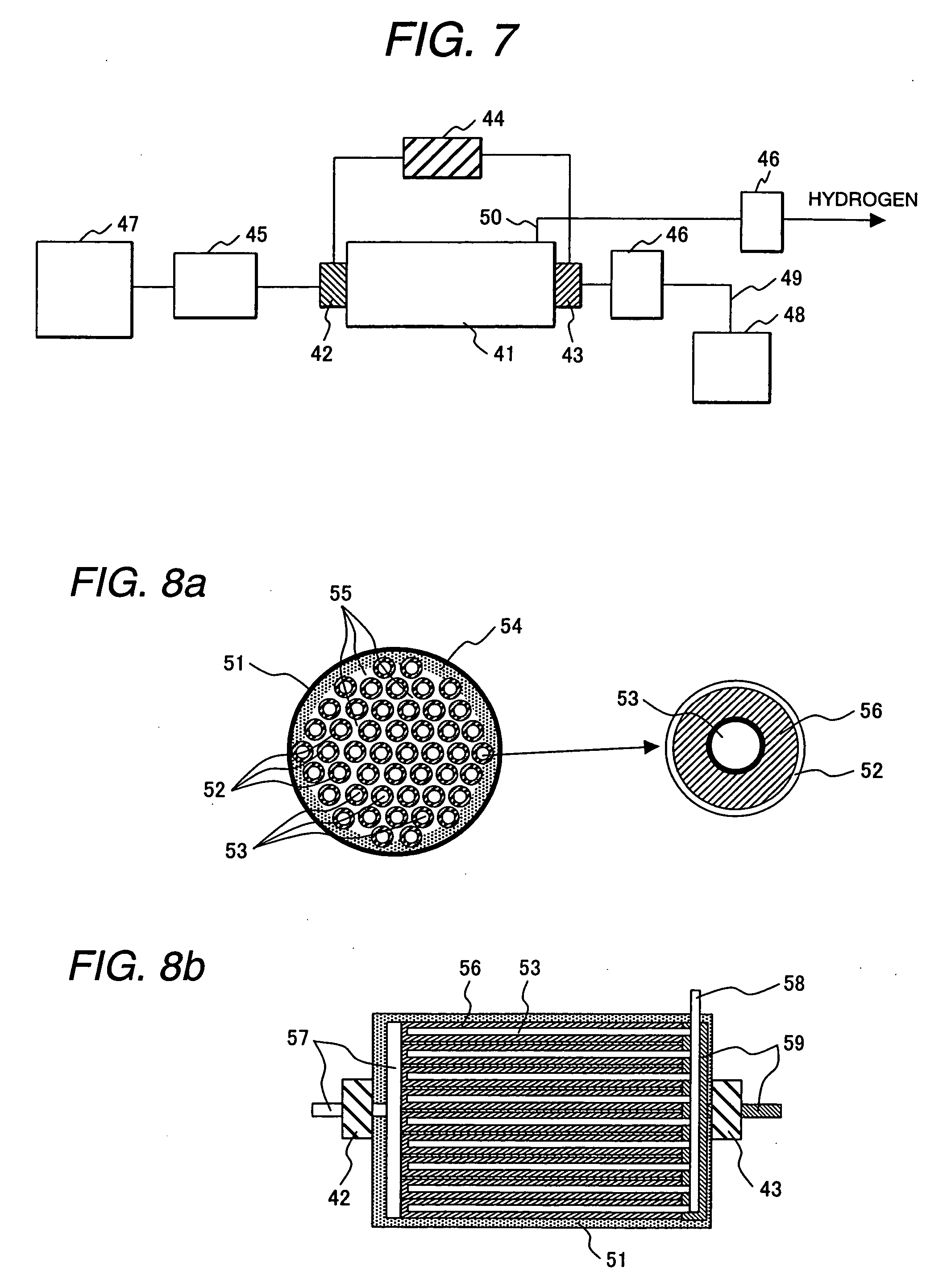

Metal oxide materials, production method thereof, and application thereof

InactiveUS20060292062A1Inhibit crystal growthPrevent crashMaterial nanotechnologyHydrogenMesoporous silicaDiameter control

A mesoporous metal oxide crystal material is provided. This material has realized a large specific surface area by controlling crystallite diameter in the formation of metal oxide crystals, and preventing collapse of the mesoporous structure associated with the crystal growth upon calcinations, to improve sensitivity and effectiveness of a gas detector element of the metal oxide material and photocatalyst. A metal oxide precursor is filled in the pores of a mesoporous template, and the resulting mesoporous silica having the metal oxide precursor filled therein is added to a hydrolytic aqueous solution to thereby promote hydrolysis of the metal oxide precursor in the interior of the pores and produce a large number of metal oxide crystals in the interior of the pores. Next, the metal oxide fine crystals are heated at 300° C. or higher for calcination with the crystallite diameter controlled in the range of 1 nm to 2 nm. The part of the temperate is subsequently dissolved by an aqueous solution of NaOH or HF to leave a metal oxide material having a mesoporous structure with the crystallite diameter of not 1 nm to 2 nm.

Owner:HITACHI LTD

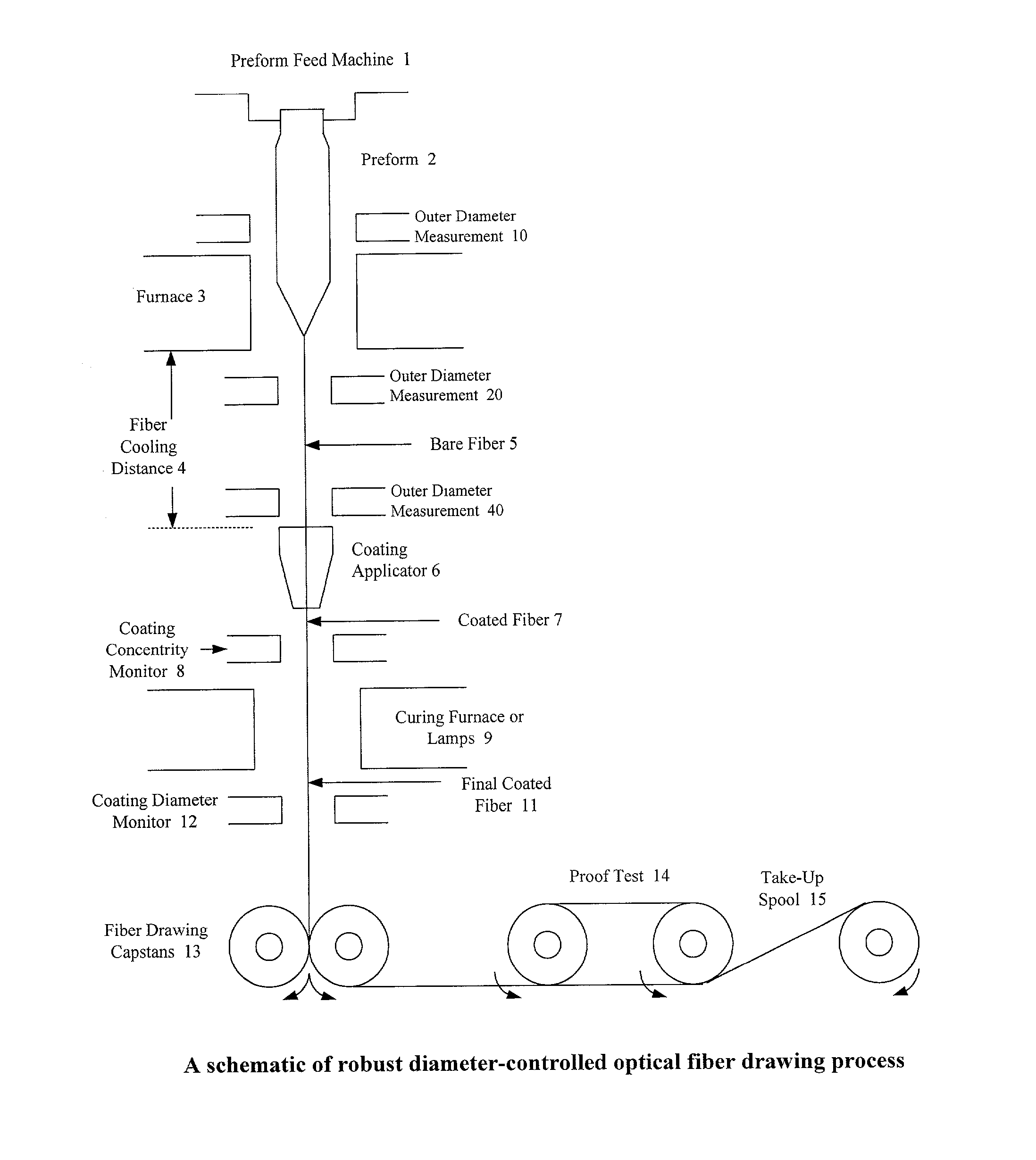

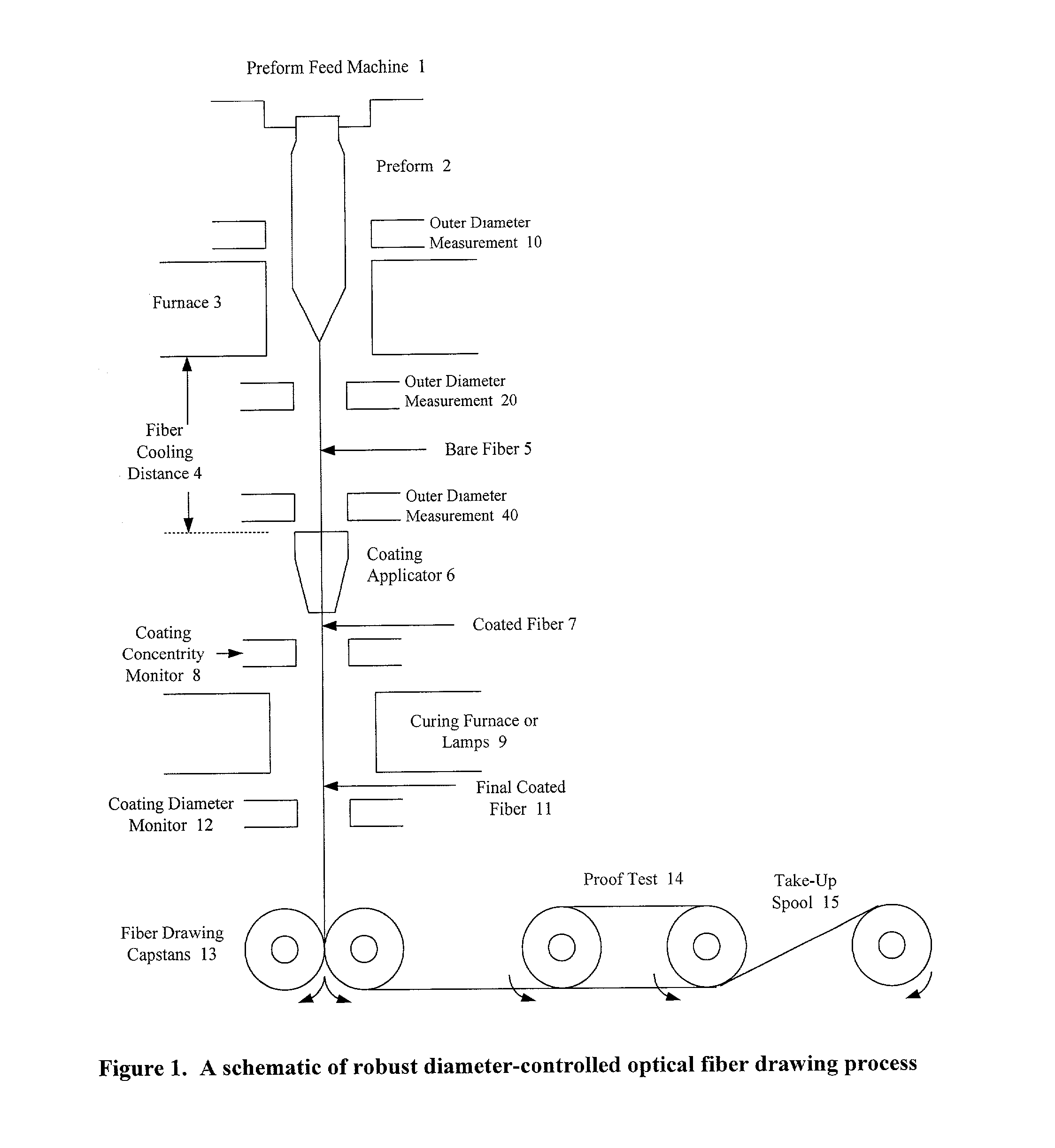

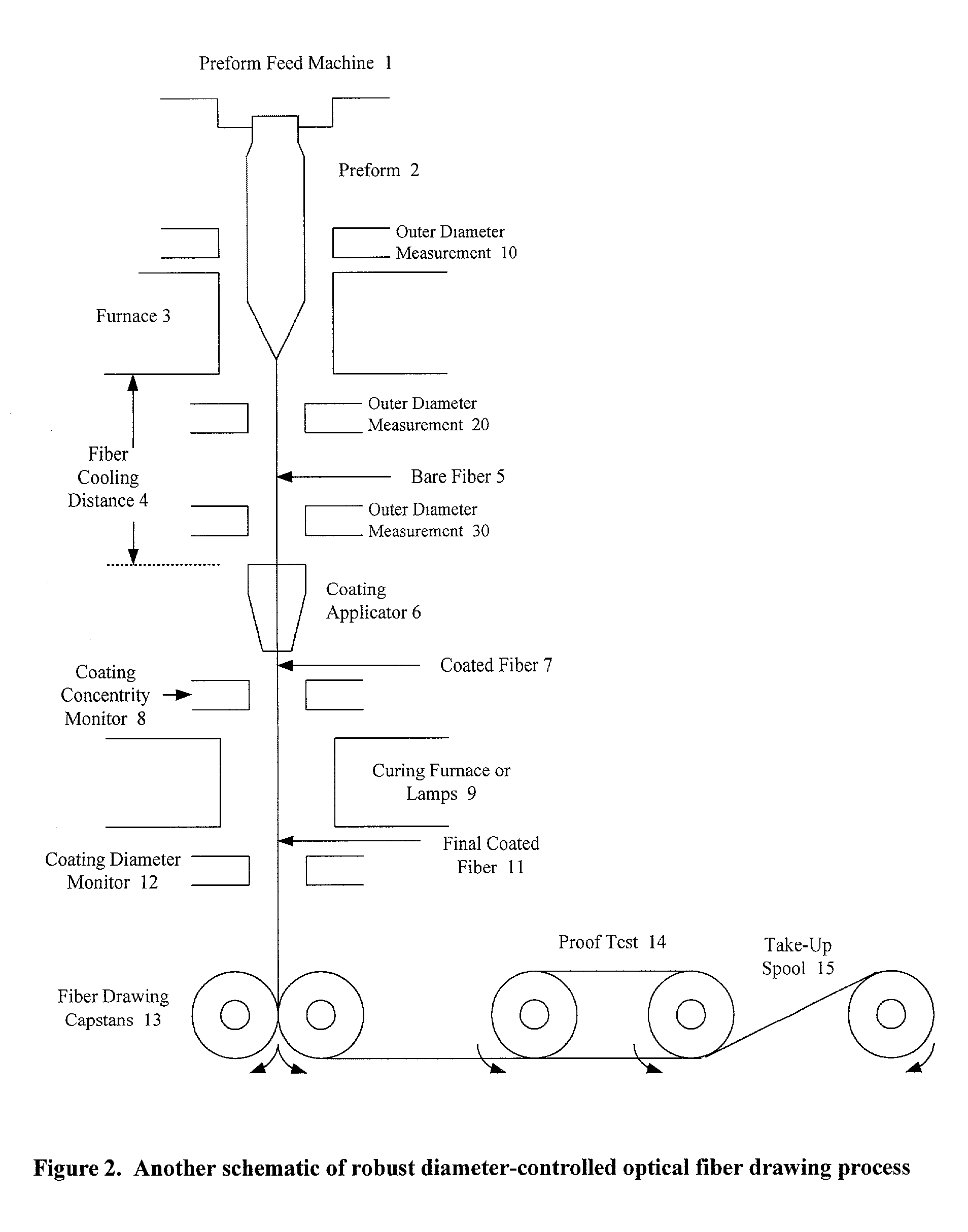

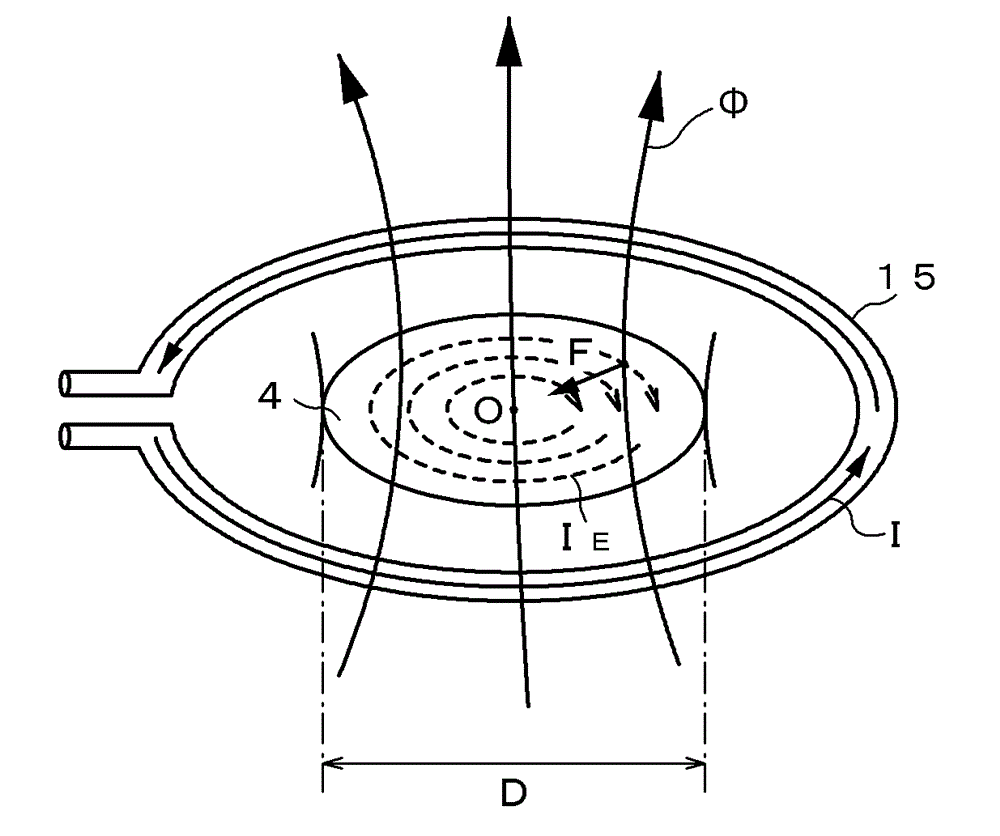

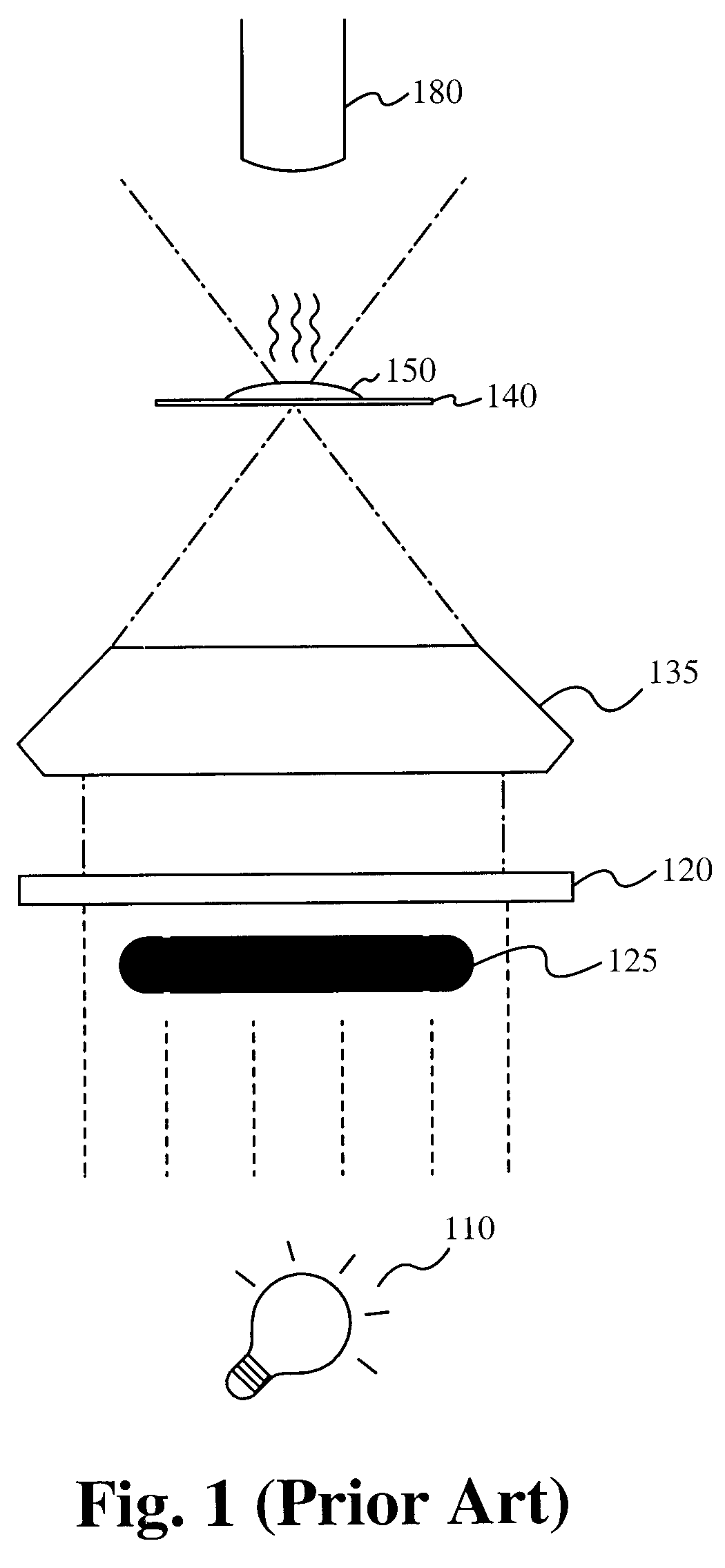

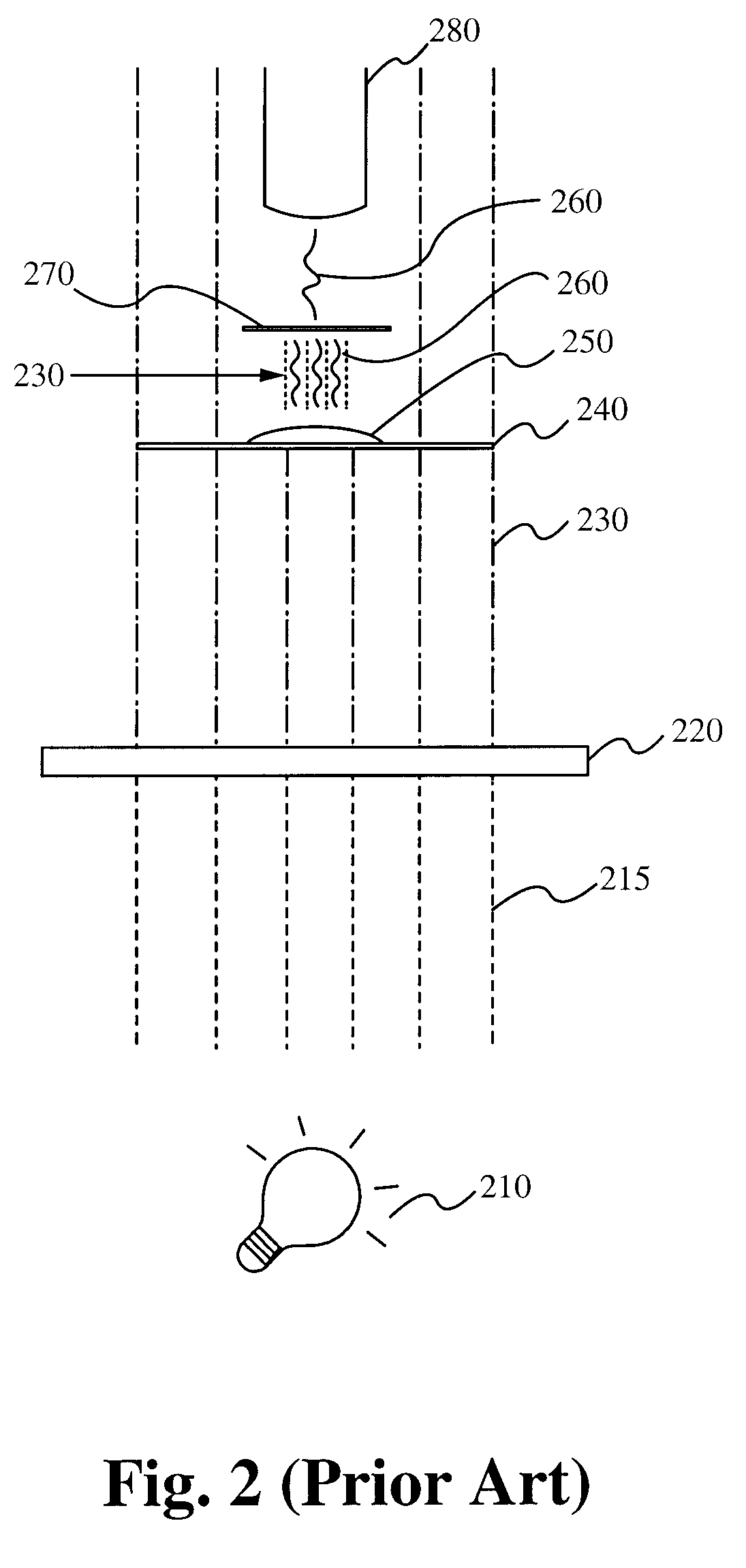

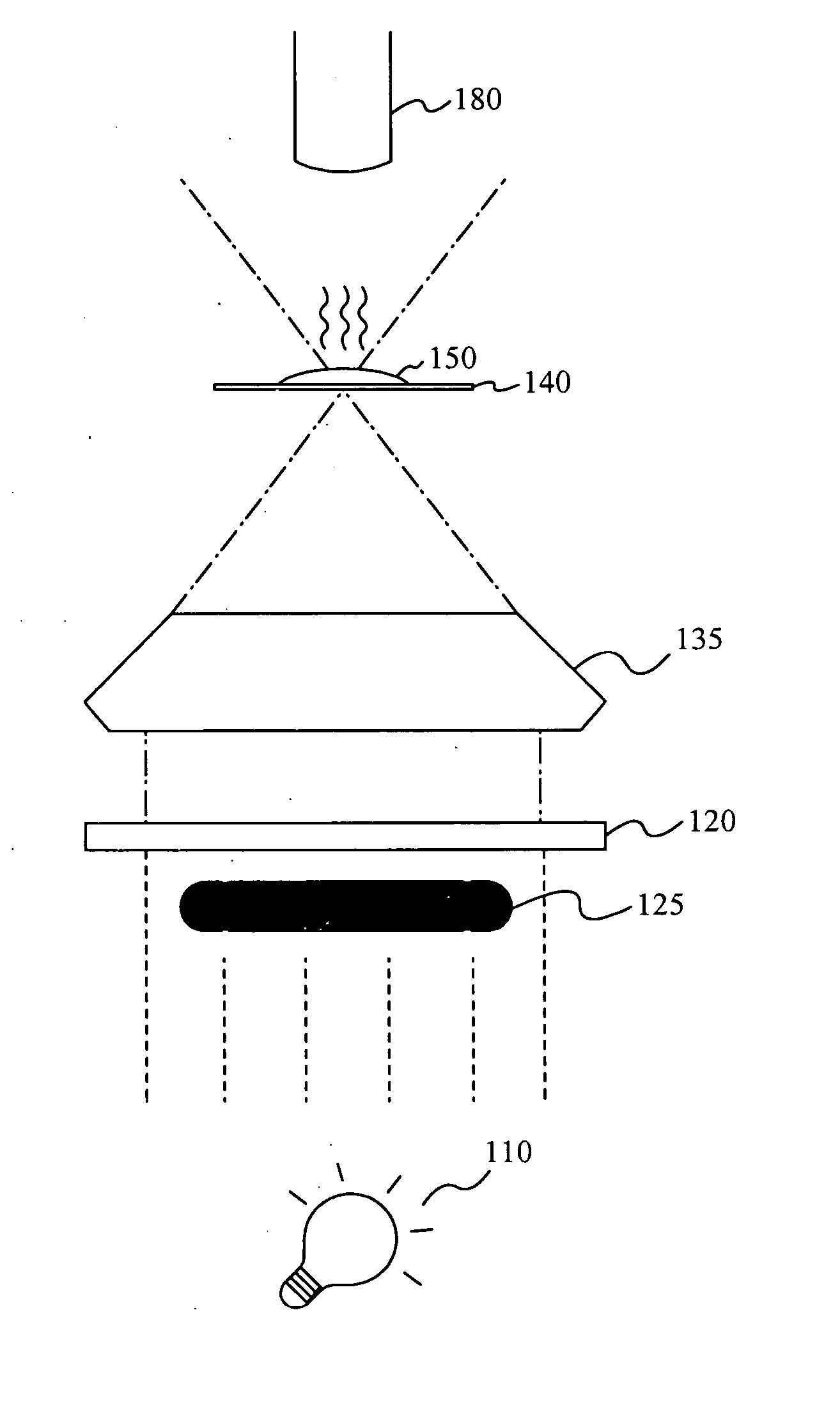

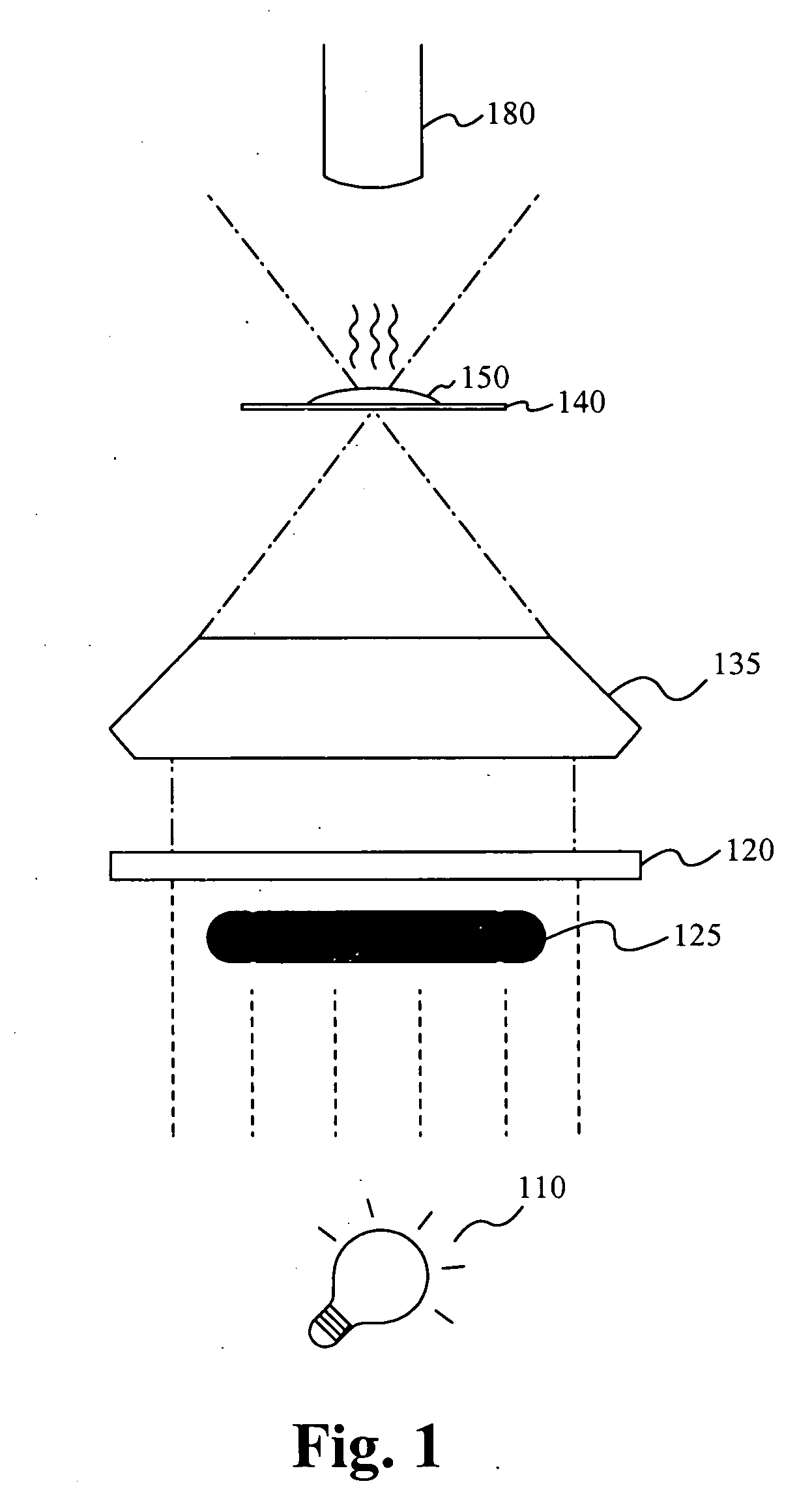

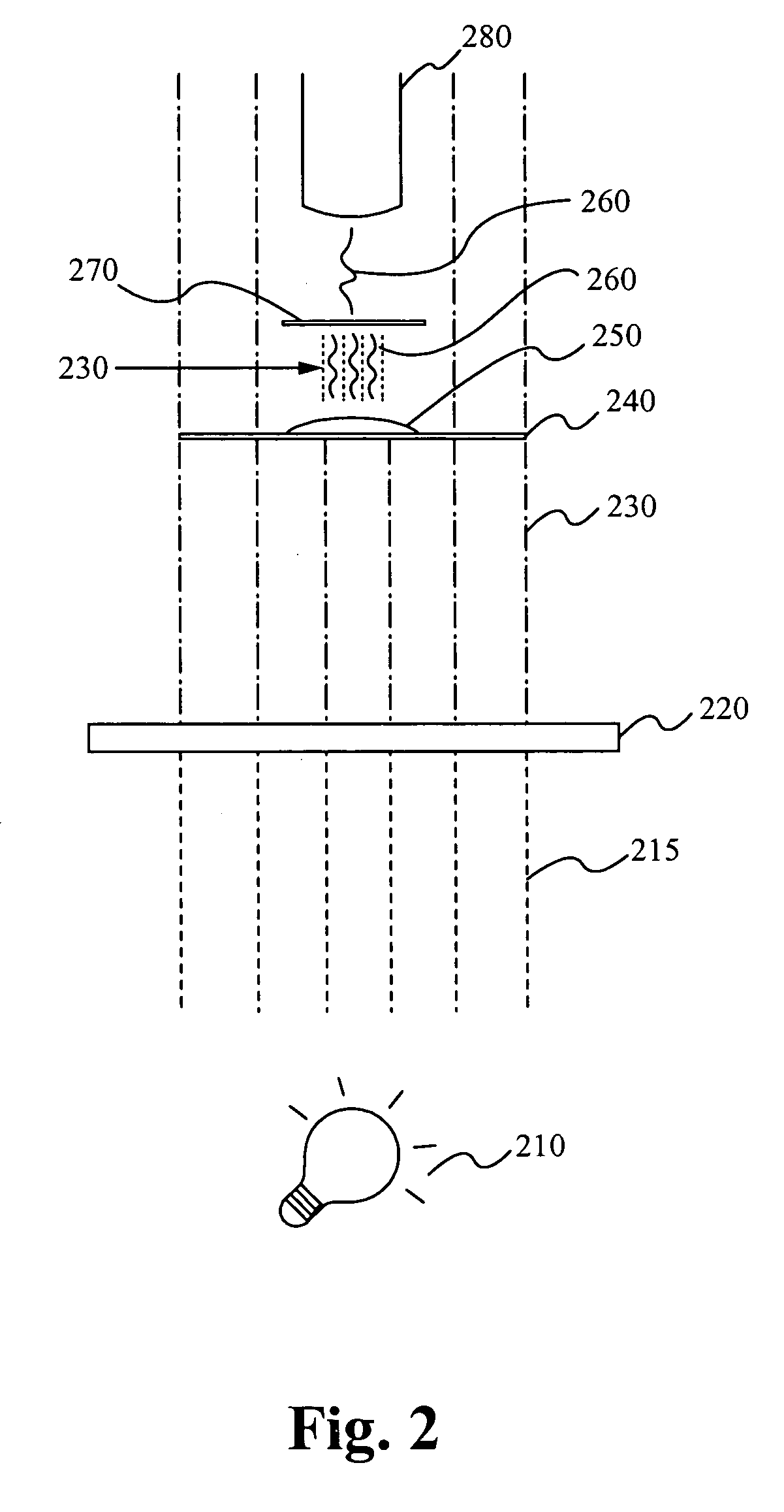

Robust diameter-controlled optical fiber during optical fiber drawing process

InactiveUS20020066292A1Glass fibre drawing apparatusMaterial analysis by optical meansDiameter controlOptical fiber cable

There is provided robust diameter-controlled optical fiber during optical fiber drawing process and an optical fiber drawing process which comprises drawing the optical fiber from a perform therefor under tension to form the optical fiber while heating and melting the preform, wherein an outer diameter of the preform is measured (at a safe position immediately) above the furnace, an outer diameter of the optical fiber on which no coating has been provided is measured at one process position or two process positions before coating, and drawing conditions are robustly controlled based on the deviation of the measured optical fiber diameter data and the measured preform diameter data from a preselected outer diameter of the optical fiber and a preselected outer diameter of the preform.

Owner:BEN SHENG TECH

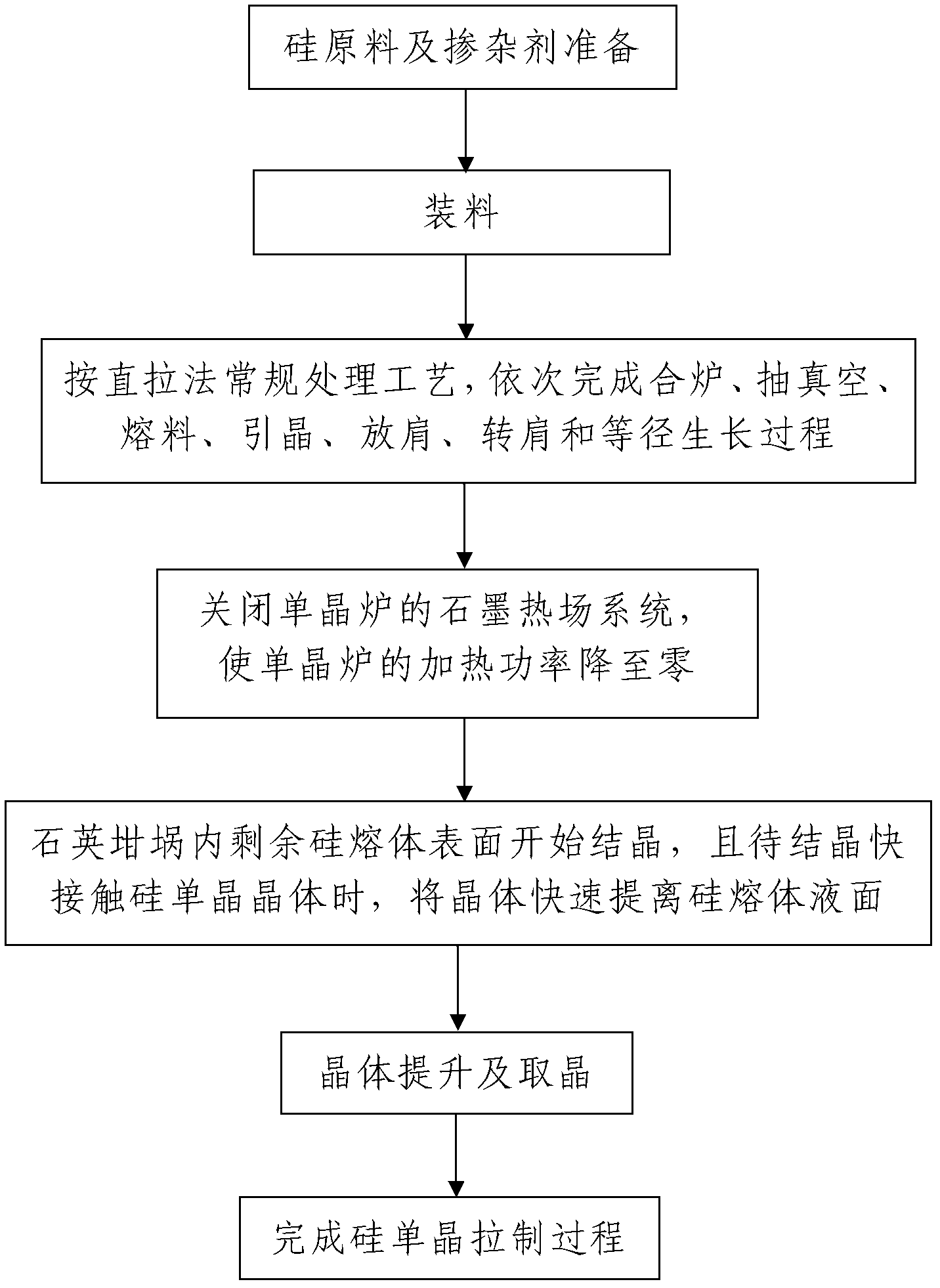

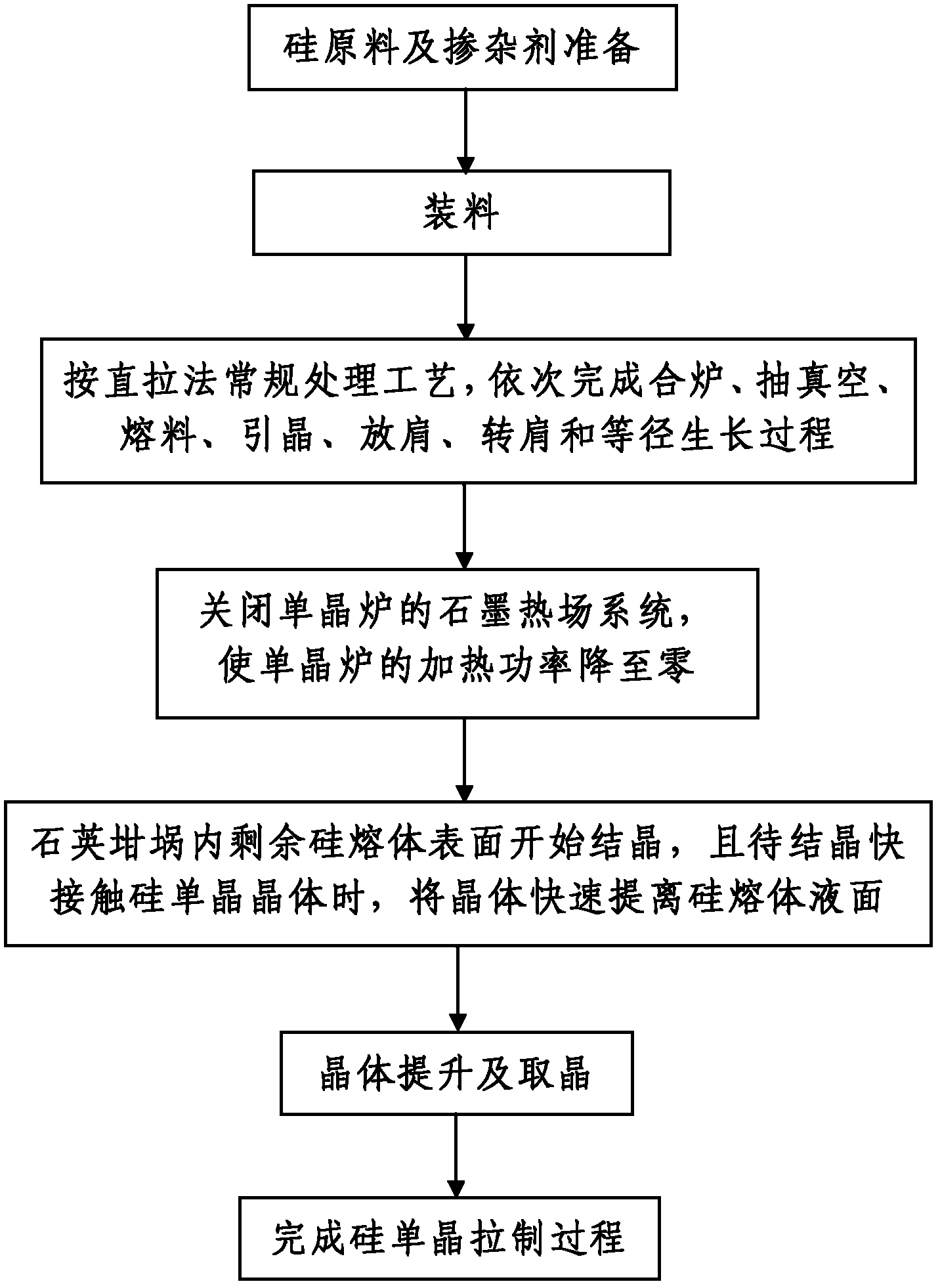

Method to raise production efficiency of czochralski silicon mono-crystal

InactiveCN102220634AReasonable designThe process steps are simplePolycrystalline material growthBy pulling from meltVacuum pumpingDopant

The invention discloses a method to raise production efficiency of czochralski silicon mono-crystal. The method comprises the following steps: 1. preparation of silicon raw material and a doping agent; 2. charging; 3. processing in a mono-crystal furnace: completing processes of furnace mixing, vacuum-pumping, stock melting, seeding, diameter controlling, casting speed increase and equal diametergrowth, according to a routine processing technology of a czochralski method; 4. post processing: first, a graphite thermal field system of the mono-crystal furnace is closed to lower thermal power of the mono-crystal furnace to zero; then residual silicon melt surface in a quartz crucible begins to crystallize, and when the crystals are about to contact silicon mono-crystals, the mono-crystals are lifted from the silicon melt liquid surface rapidly; last, crystal lifting and crystal collection are carried out to obtain silicon mono-crystal finished product. The invention has the advantages of reasonable design, simple method steps, convenient realization, easy grasp, good usage effect. An ending process of crystal drawing is omitted to increase production efficiency, so as to solve the problem that czochralski silicon mono-crystal production efficiency is restricted by a demanded ending process in the silicon mono-crystal production process.

Owner:XIAN HUAJING ELECTRONICS TECH

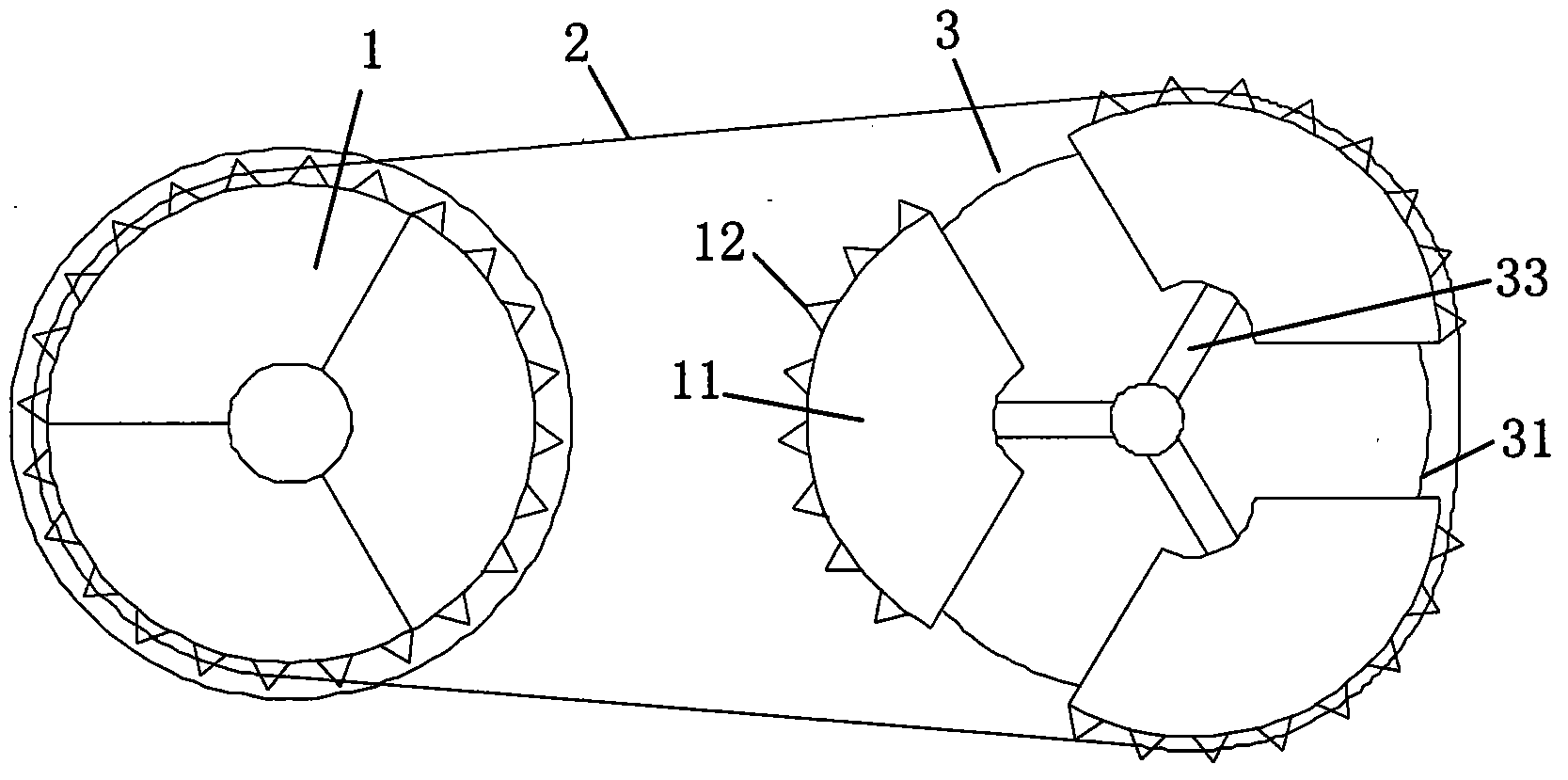

Variable-speed transmission mechanism for relay transmission of variable-diameter gears

ActiveCN104343914ASimple structureExcellent size and weightGearingPortable liftingDrive wheelTorque transmission

The invention discloses a variable-speed transmission mechanism for relay transmission of variable-diameter gears. The variable-speed transmission mechanism comprises two variable-diameter relay transmission gears, variable-diameter adjusting mechanisms, a power input shaft and a power output shaft, wherein the two variable-diameter relay transmission gears are connected with each other through a transmission gear group; the variable-diameter adjusting mechanisms are respectively arranged on the two variable-diameter relay transmission gears; the power input shaft is connected with one variable-diameter adjusting mechanism, and the power output shaft is connected with the other variable-diameter adjusting mechanism. Based on the basic principle of infinitely variable speed, through unique and novel design concept, variable transmission ratio of a main driven wheel is realized by utilizing a clack body combined type variable-diameter wheel body, effective variable-diameter control is realized through the variable-diameter adjusting mechanisms, and power transmission is realized through engagement of gear belts and gears; the variable-speed transmission mechanism is simpler in structure, superior in weight volume and lower in production and manufacturing costs; moreover, the variable-speed transmission mechanism is firmer in structure, the bearing load and torque transmission capacity are greatly improved, and the problems in the prior art that thermal decay exists and larger torques cannot be transmitted through friction transmission speed are solved, so that the variable-speed transmission mechanism can be widely applied to large-displacement automobiles.

Owner:谢瑞成

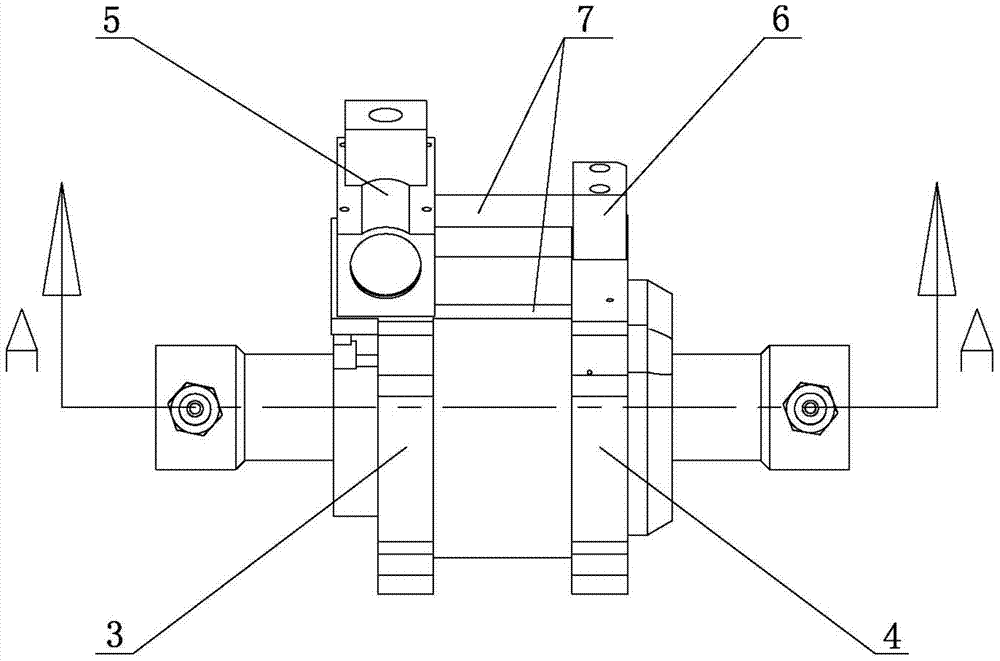

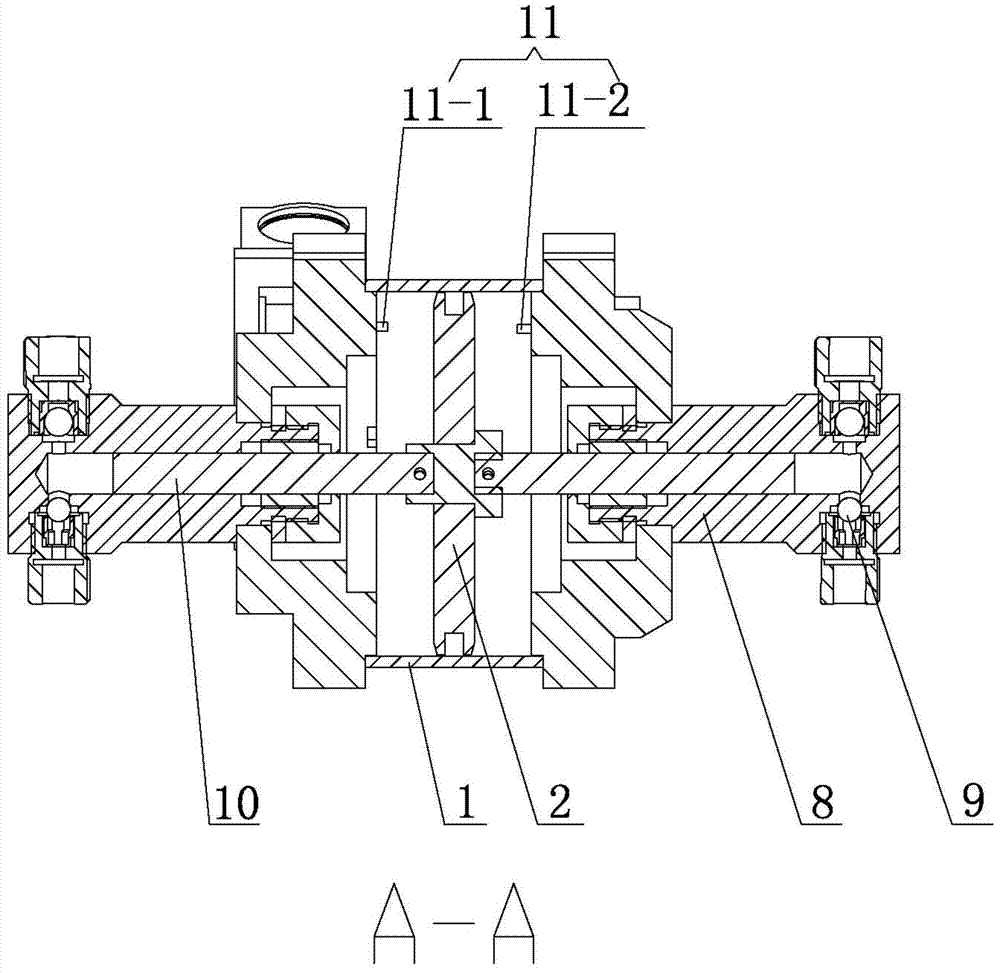

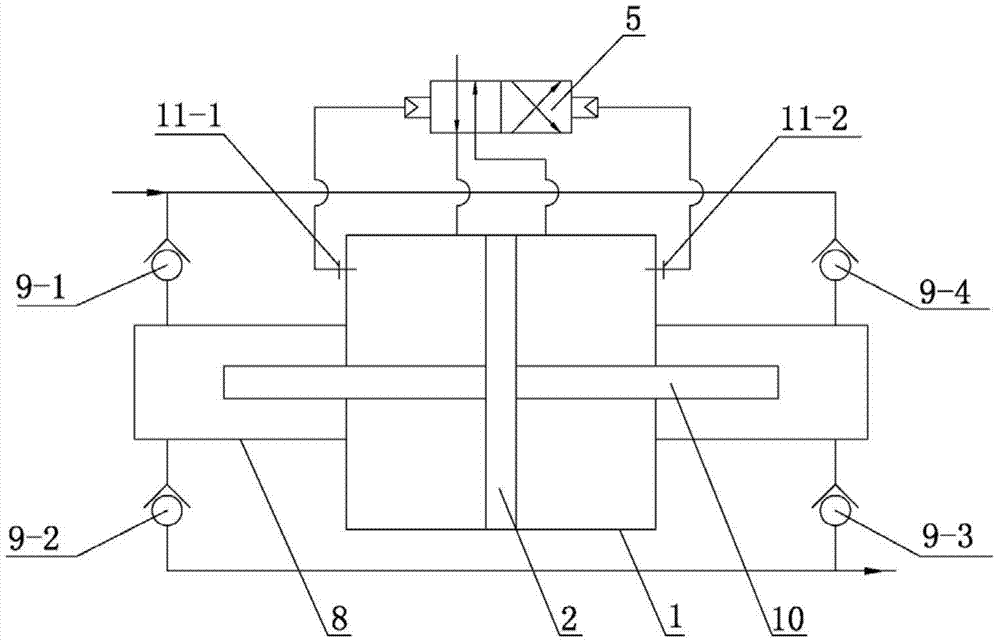

Pile-up valve type gas-driving liquid booster pump

InactiveCN103615365ALarge diameterImprove air flowPositive displacement pump componentsPiston pumpsEngineeringDiameter control

The invention relates to a pile-up valve type gas-driving liquid booster pump which comprises a low-pressure cylinder barrel, a booster piston, a front end housing, a rear end housing, a pile-up valve, a flow guiding head, an air guiding pipe, high-pressure cylinder barrels, one-way valves, plungers and pilot valves; the front end housing and the rear end housing are arranged at the two ends of the low-pressure cylinder barrel respectively; the booster piston is contained in the low-pressure cylinder barrel and the two ends of the booster piston are respectively provided with one plunger; the pile-up valve is installed on the front end cover and connected with the flow guiding head arranged on the rear end cover through the air guiding pipe; the high-pressure cylinder barrels are arranged on the end portion of the front end cover and the end portion of the rear end cover respectively and two one-way valves are arranged on each high-pressure cylinder barrel; the pivot valves are integrated into the front end cover and the rear end cover respectively. According to the pile-up valve type gas-driving liquid booster pump, the booster piston is controlled to automatically conduct reversing by the pile-up valve and external power is not needed; the pile-up valve is large in drift diameter and flow, the boosting speed is high, and the shortage that a small-drift-diameter control valve booster pump is low in boosting speed is overcome; meanwhile, the pump is a dual-purpose pump, so that high-pressure fluid is continuously output, pressure fluctuation is small, and efficiency is high.

Owner:ZHEJIANG SCI-TECH UNIV

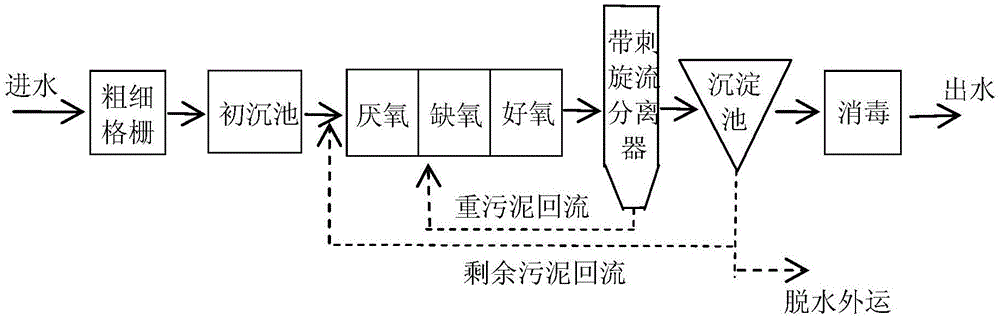

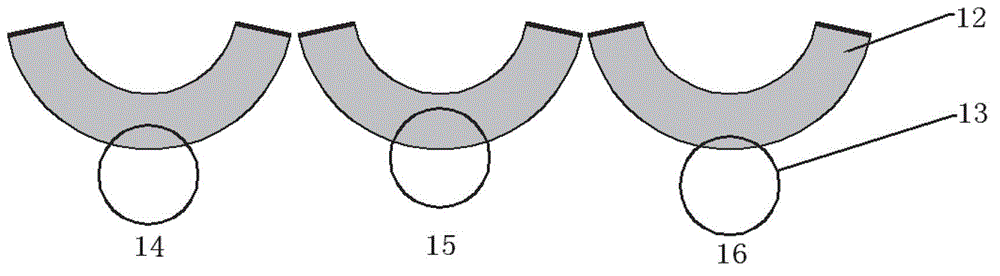

Continuous flow aerobic granule sludge culture and grain diameter control method and system

InactiveCN106746363AFine grainGuaranteed uptimeSpecific water treatment objectivesWater contaminantsCycloneSludge

The invention provides a continuous flow aerobic granule sludge culture and grain diameter control method. The continuous flow aerobic granule sludge culture and grain diameter control method comprises the following steps: 1) enabling input water to pass through a thick-fine grid and a primary sedimentation tank in sequence and then enter a biochemical tank; 2) pressing output water of the biochemical tank to a cyclone separator and carrying out light and weight sludge separation, wherein the cyclone separator is a built-in barb cyclone separator and is internally provided with barbs for controlling the grain diameter of granular sludge; 3) pressing and reflowing a separated heavy sludge mixed solution back to an oxygen-free tank; pressing a light sludge mixed solution to a sedimentation tank and carrying out sludge-water separation; after carrying out the sludge-water separation, taking one part of sludge as residual sludge and reflowing the residual sludge to the front end of an anaerobic tank; dehydrating the other part of the sludge and conveying the sludge to the outer side; enabling the output water of the sedimentation tank to pass through a disinfection facility and realizing up-to-standard discharging. The invention provides a continuous flow aerobic granule sludge culture and grain diameter control system. The granulation of aerobic sludge is promoted and the grain diameter of granules is controlled to be in an optimal range.

Owner:ZHEJIANG UNIV OF TECH +1

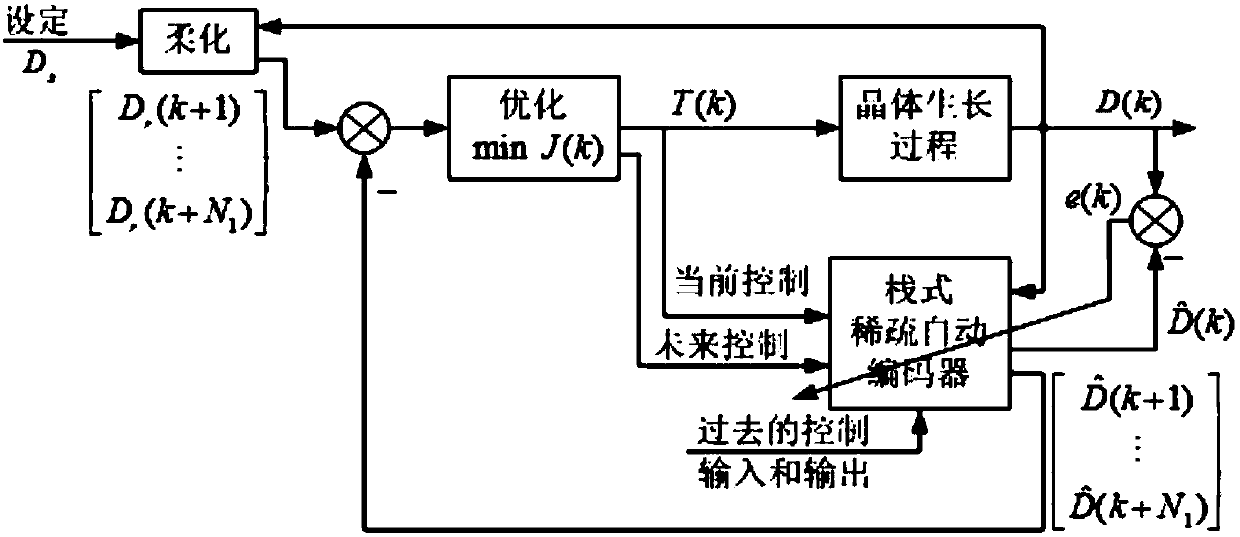

Silicon single crystal diameter control method based on constant-pull-speed control structure

ActiveCN107868979AAddressing control failuresPolycrystalline material growthBy pulling from meltSingle crystalModel parameters

The invention aims to provide a silicon single crystal diameter control method based on a constant-pull-speed control structure. The method comprises steps as follows: firstly, a non-linear large lagprediction model of the thermal field temperature-crystal diameter process is recognized according to thermal field temperature and crystal diameter data in a conventional silicon single crystal control structure, wherein delay parameters, input-output orders and model parameters in the prediction model are acquired through an output correlation delay determination algorithm, a Lipschitz factor and training of a stack sparsity automatic encoder, the stack sparsity automatic encoder is taken as the prediction model to be introduced into a non-linear general predictive control algorithm, and crystal diameter control is realized through the prediction model in a prediction control algorithm, feedback correction, rolling optimization and other strategies. The problems that the control effect becomes poor and control fails due to drastic fluctuation of the crystal pulling speed in the existing silicon single crystal diameter control process are solved.

Owner:XIAN ESWIN MATERIAL TECH CO LTD +1

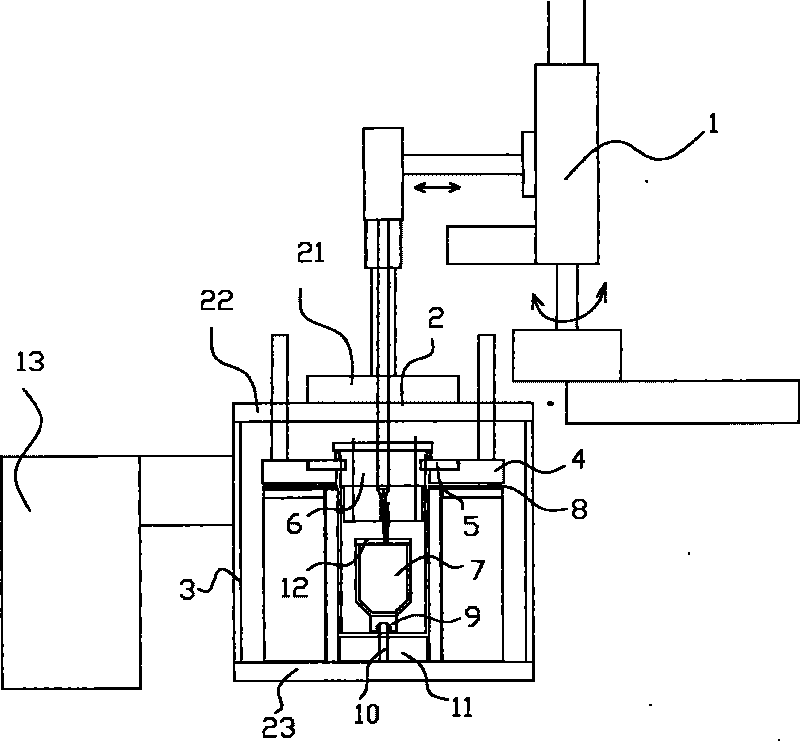

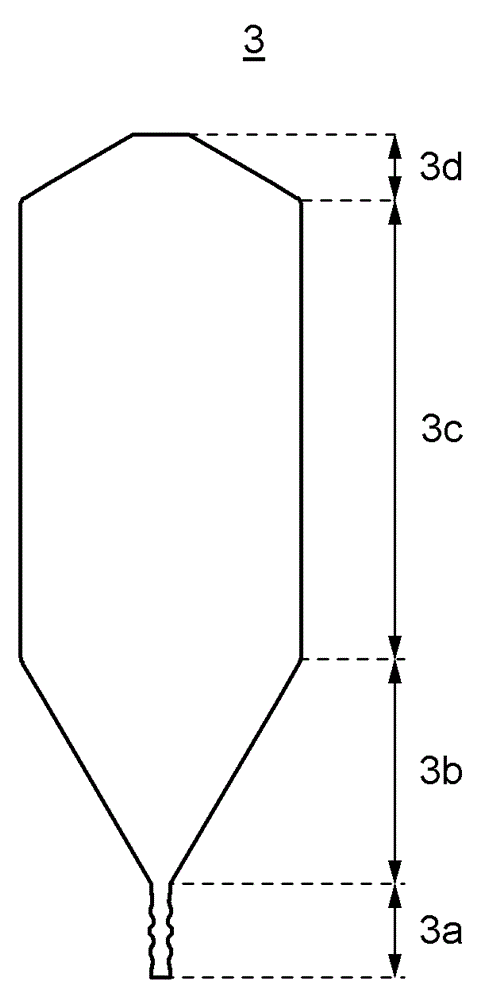

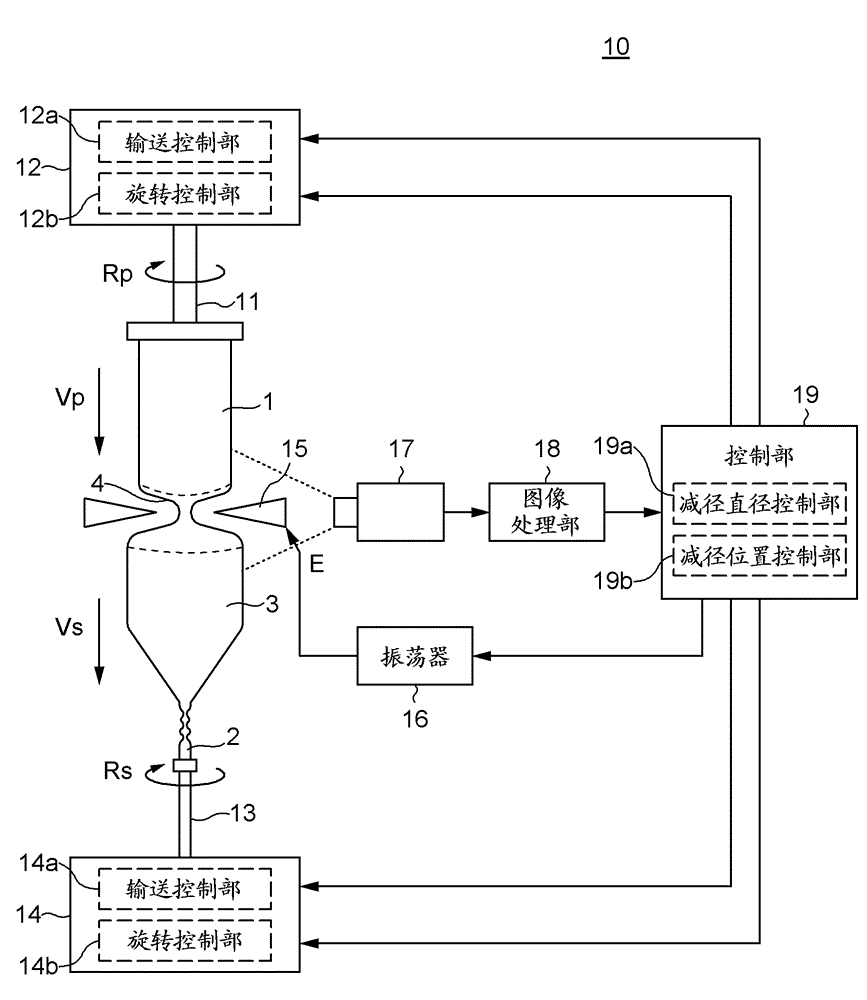

Single crystal manufacturing method and device

ActiveCN105297131AReliable no misalignmentReduce the frequency of misalignmentPolycrystalline material growthBy zone-melting liquidsPower flowEngineering

The invention provides a single crystal manufacturing method and device. The single crystal manufacturing method using the floating zone method comprises a welding process: heating the front end part of a raw material rod and melting the front end part of a raw material rod, and welding the front end part of a raw material rod to a seed crystal of a crystal conveying mechanism; a reducing process, reducing the diameter of the single crystal in the mode for realizing non-mal-position; a cone part forming process: expanding the diameter and enabling the single crystal to grow; and a straight body part forming process: enabling the single crystal to grow with maintained diameter. The reducing process includes: a diameter reducing control process: operating the current supplied to an induction heating coil and performing PID control for the reduced diameter of the single crystal; and a reducing position control process: operating the descent rate of the single crystal so as to perform PID control for the reducing position of the single crystal. Therefore, the reducing process automation can be realized and the mal-location generation frequency of the single crystal can be reduced after transferring to the cone part forming process.

Owner:SUMCO CORP

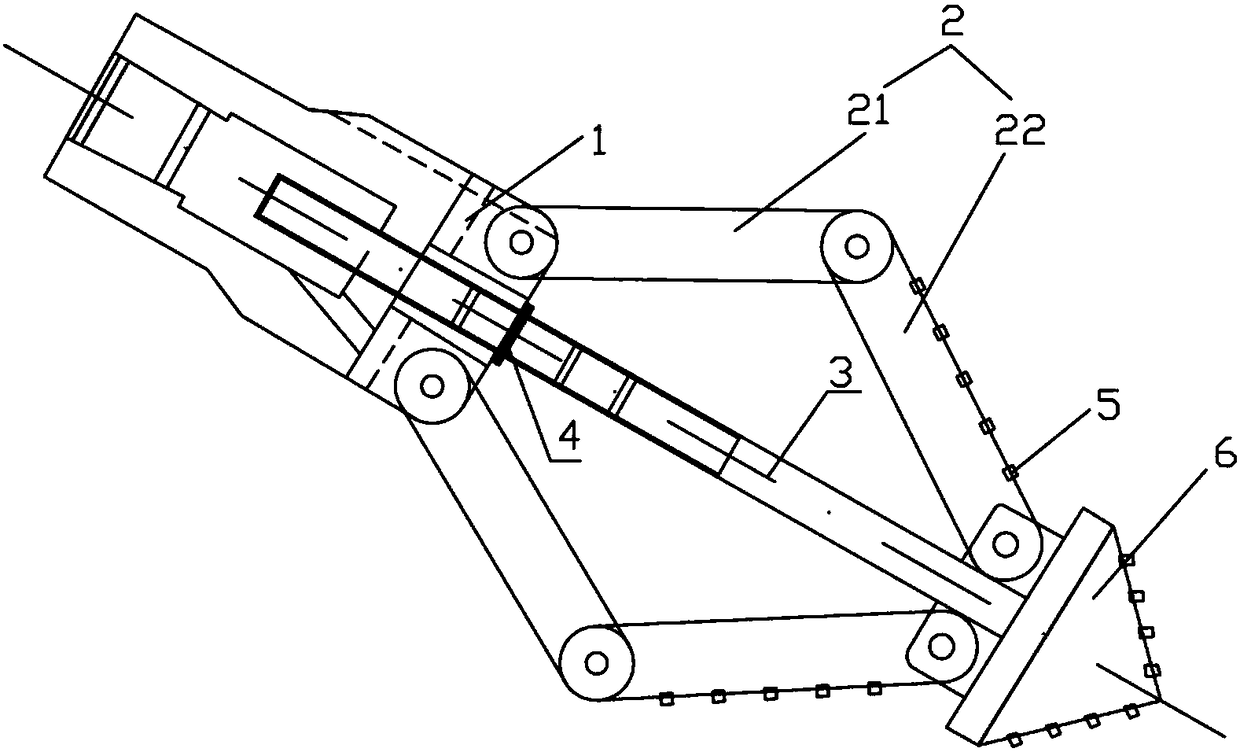

Soil layer variable-diameter machinery reamer bit and drilling method using same

Provided is a soil layer variable-diameter machinery reamer bit and a drilling method using the same. The soil layer variable-diameter machinery reamer bit comprises a base, a reaming telescopic arm,a transmission rod, a variable-diameter control rod and a drill; the reaming telescopic arm comprises a first connection rod and a second connection rod, the first end of the first connection rod is hinged to the base, the second end of the first connection rod is hinged to the first end of the second connection rod, the second end of the second connection rod is hinged to the drill, the drill isconnected to the transmission rod, the transmission rod is connected to the variable-diameter control rod, and the variable-diameter control rod is movably connected to the base. The soil layer variable-diameter machinery reamer bit and the drilling method using the same have the advantages of being capable of adjusting the diameter to ream and drill holes and advancing and retreating free at non-reaming sections.

Owner:铁科院(深圳)研究设计院有限公司

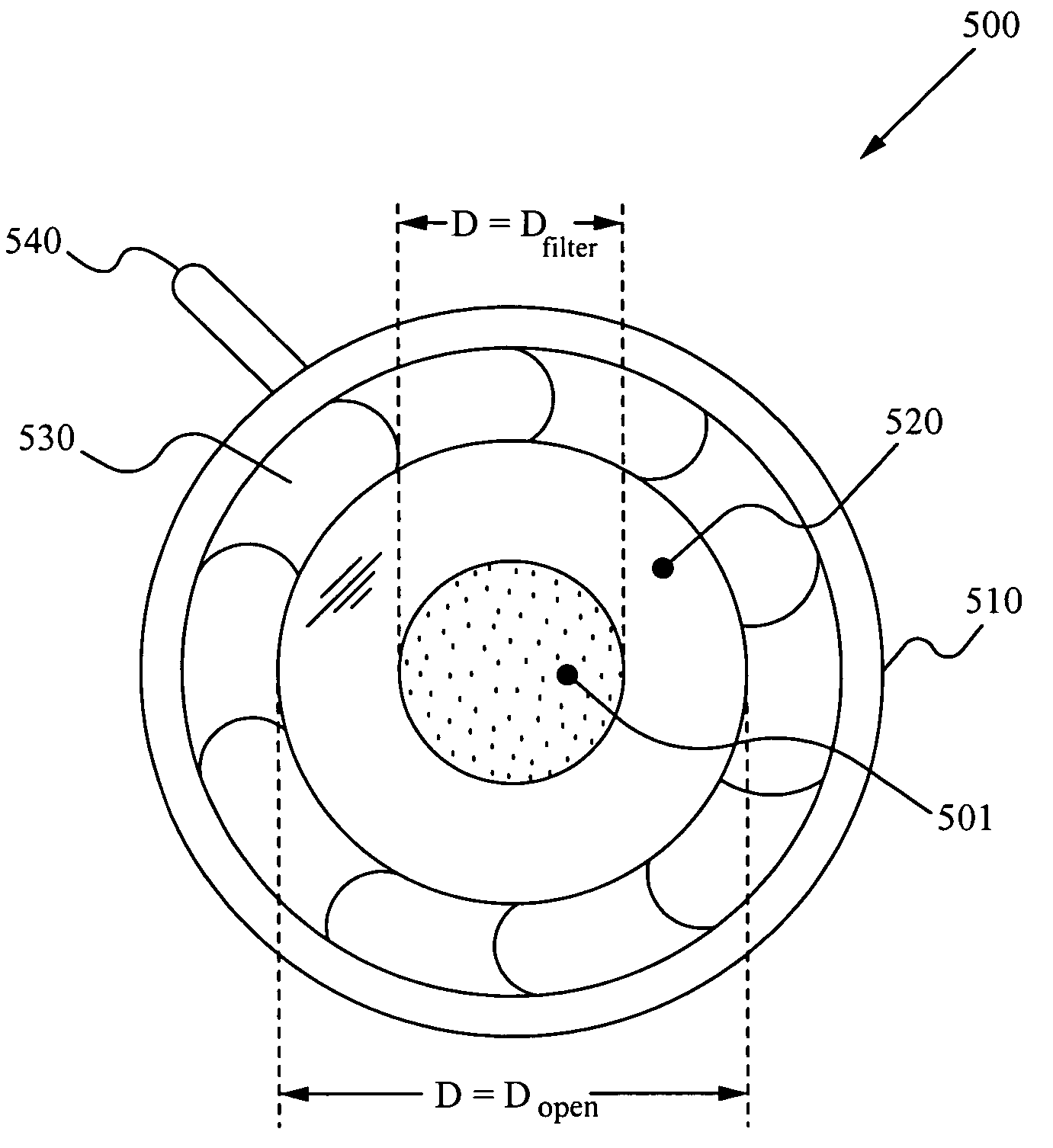

Simultaneous observation of darkfield images and fluorescence using filter and diaphragm

ActiveUS7688505B2More scattered lightMore dispersedMaterial analysis by optical meansMicroscopesFluorescenceDiameter control

An annular diaphragm and filter used for the simultaneous observation of darkfield images and fluorescence. The diaphragm has a variable diameter controlled by a lever and a removable filter. The diaphragm is used to adjust the amount of unfiltered incident light which produces darkfield images when directed on a sample. The removable filter is used to filter light to a particular frequency for producing fluorescence images. An Acousto-Optical Tunable Filter, or other such tunable filter may be used with the diaphragm. A method of using the diaphragm and filter is also disclosed.

Owner:AUBURN UNIV

Part diameter on-line control method of precise cylindrical grinding machine

ActiveCN102922427AHigh precision of diameter controlGood process repeatabilityGrinding feed controlControl systemCylindrical grinding

The invention belongs to mechanical methods, in particular to a part diameter on-line control method of a precise cylindrical grinding machine. The part diameter on-line control method is characterized in that a diameter measuring probe is adopted to measure part diameter on line, a part is provided with a rotation driving swinging head, a proximity sensitive switch is arranged near a swinging head output shaft used for driving the part to rotate, the proximity sensitive switch generates a pulse signal to output when the swinging head rotates by one circle, the part diameter on-line control system calculates the rotational speed of the part according to the pulse signal of the proximity sensitive switch, and calculates feed rate of a grinding wheel according to part diameter reduction speed detected by the measuring probe, a diameter measurement deviation caused by a helix line on the surface of the part is obtained by consolidation, a feed stopping signal is sent to the control system of the precise cylindrical grinding machine when reading of the measuring probe is reduced to the value of the diameter measurement deviation obtained by consolidation, feeding motion of the grinding wheel is stopped, the measuring probe is controlled to retract to an original position, and the helix line remained on the surface of the part is eliminated by using a polishing process. The scheme is simple, convenient, feasible, scientific and reasonable, and the precision in part diameter control is high.

Owner:JINHUA JG TOOLS MFG

Simultaneous observation of darkfield images and fluorescence using filter and diaphragm

ActiveUS20070139764A1More scattered lightMore dispersedMaterial analysis by optical meansMicroscopesFluorescenceAcousto-optics

An annular diaphragm and filter used for the simultaneous observation of darkfield images and fluorescence. The diaphragm has a variable diameter controlled by a lever and a removable filter. The diaphragm is used to adjust the amount of unfiltered incident light which produces darkfield images when directed on a sample. The removable filter is used to filter light to a particular frequency for producing fluorescence images. An Acousto-Optical Tunable Filter, or other such tunable filter may be used with the diaphragm. A method of using the diaphragm and filter is also disclosed.

Owner:AUBURN UNIV

Method of producing an electroluminescence phosphor

InactiveUS20050140272A1Discharge tube luminescnet screensElectroluminescent light sourcesPhosphorDiameter control

A method of producing an electroluminescence phosphor, which contains the steps of: mixing a phosphor matrix, a flux, an activator, and a particle diameter-controlling additive that does not enter into a crystal lattice of the phosphor matrix, to give a mixture; and baking the mixture, to produce the electroluminescence phosphor, the method containing the step of: adding an acidic or alkaline solution, to remove the particle diameter-controlling additive from the phosphor; an electroluminescence phosphor, which is produced by the method; and an electroluminescence device, which contains the electroluminescence phosphor.

Owner:FUJIFILM CORP

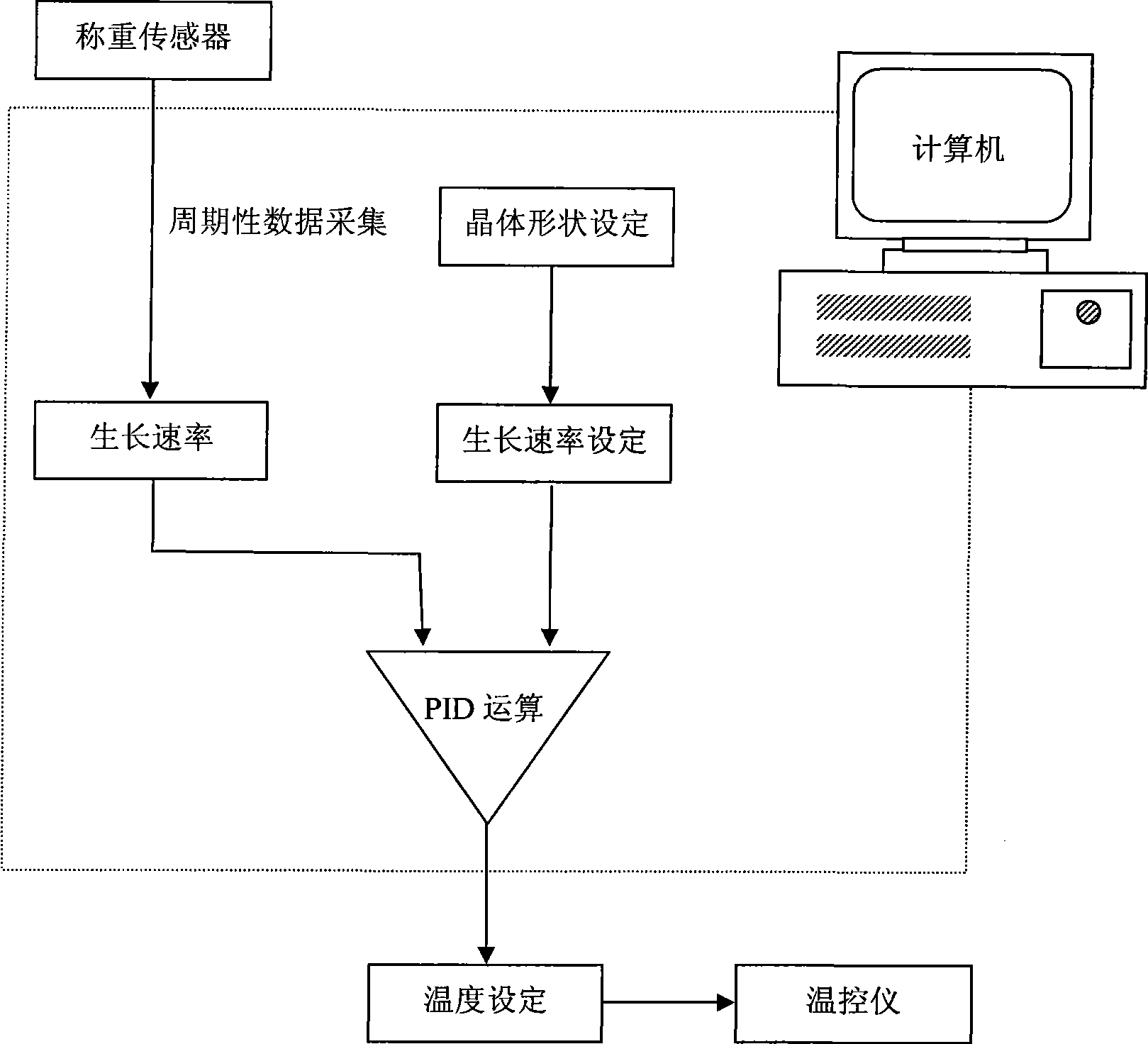

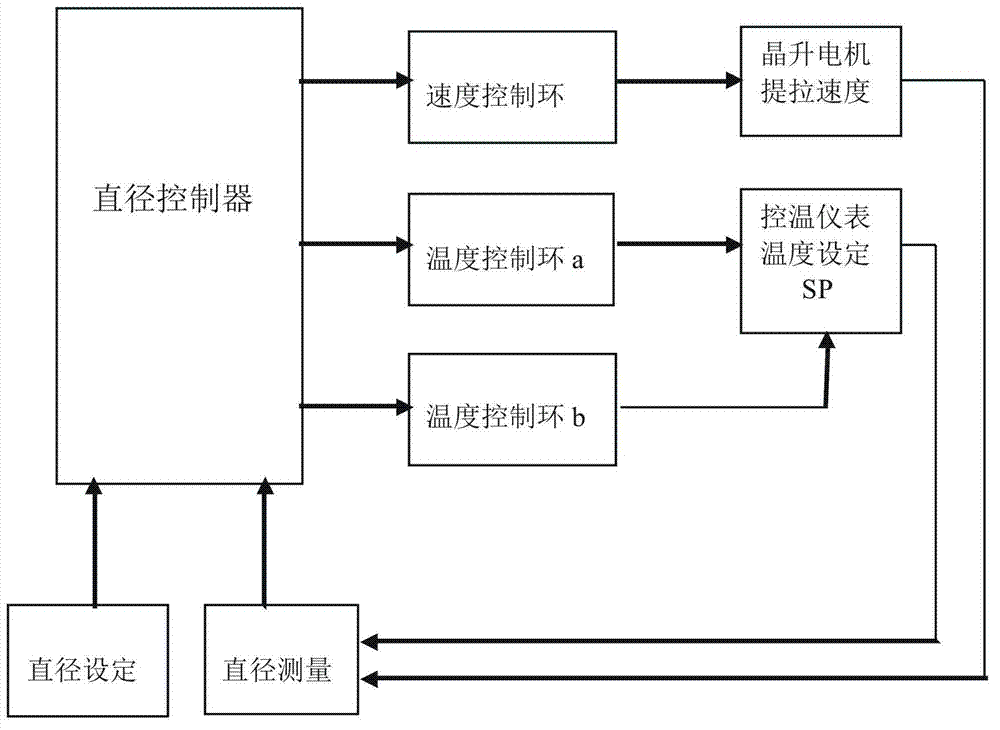

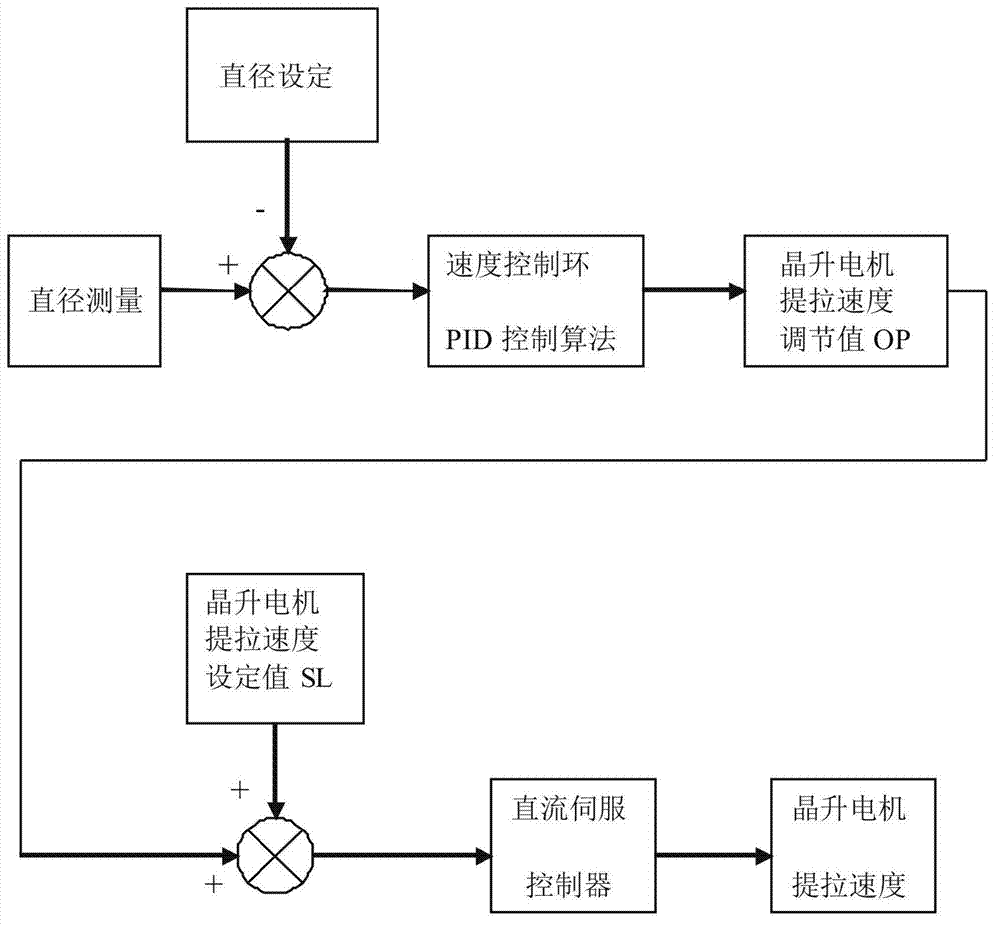

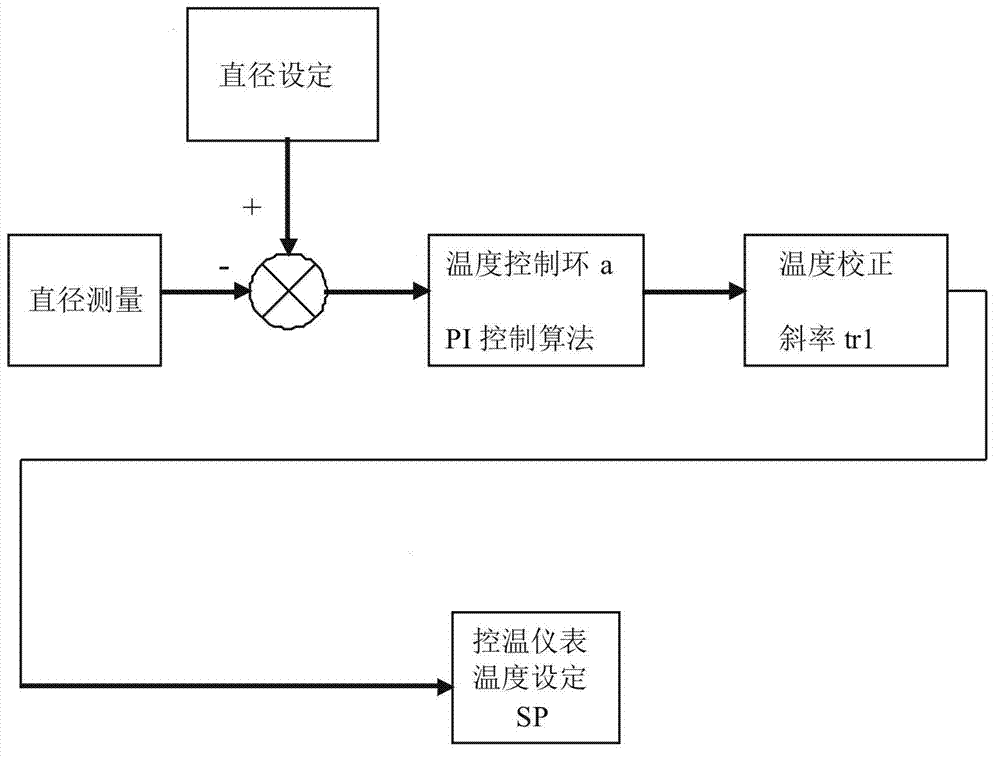

Automatic equal diameter controlling method for germanium single crystal straight-pull growth method

InactiveCN102758250AReduce wasteIncrease productivityBy pulling from meltTemperature controlSingle crystal

The invention discloses an automatic equal diameter controlling method for germanium single crystal straight-pull growth method, which includes the following steps: setting the diameter of the germanium crystal required to be prepared, setting the initial lifting speed SL of a crystal rise motor, and establishing a speed control ring, a temperature control ring a and a temperature control ring b. When a diameter measurement value deviates from a diameter set value during the growth process of the germanium single crystal, a diameter deviation e1 is formed between the diameter measurement value and the diameter set value, then the three control rings are matched mutually to automatically adjust lifting speed of the crystal rise motor and the temperature set SP of a temperature controller, so as to enable the diameter measurement value to be equal to the diameter set value. The automatic equal diameter controlling method improves the manual diameter control during the germanium single crystal production into automatic diameter control, improves the production efficiency, reduces the wastes caused by the follow-up polishing, rounding and slicing processes of the single crystal bar.

Owner:XAUT CRYSTAL GROWING TECH CO LTD

Totally-enclosed examination and repair process with pressure for feedwater piping

The invention relates to a water supply pipeline full-sealing maintenance process with pressure; the maintenance process is characterized in that: compressed air is used for expanding a balloon on the internal wall of the pipeline so as to form a sealing section which can hold back the leaked water of the pipe before the operation; after the operation is completed, the compressed air in the balloon is let out; the volume of the balloon is contracted under the action of the elastic force and the balloon can be taken out of a process hole; after the process hole is sealed, the pipeline running can be recovered. The technical performance and characteristic are that the sealing pressure is less than or equal to 0.1MPa, the maximum expansion diameter achieves 1200mm, and the diameter of the process hole is controlled below Phi 80mm. the maintenance process greatly improves the maintenance speed, quality and safety performance of the water supply pipeline, basically avoids the leakage of water medium in the maintenance operation, realizes the energy-saving and exhaust reducing of cleaned water and sewage water, improves the maintenance efficiency of the blast furnace water supply system and increases the safety performance of the blast furnace water supply system.

Owner:ANSHAN IRON & STEEL GROUP CORPORATION

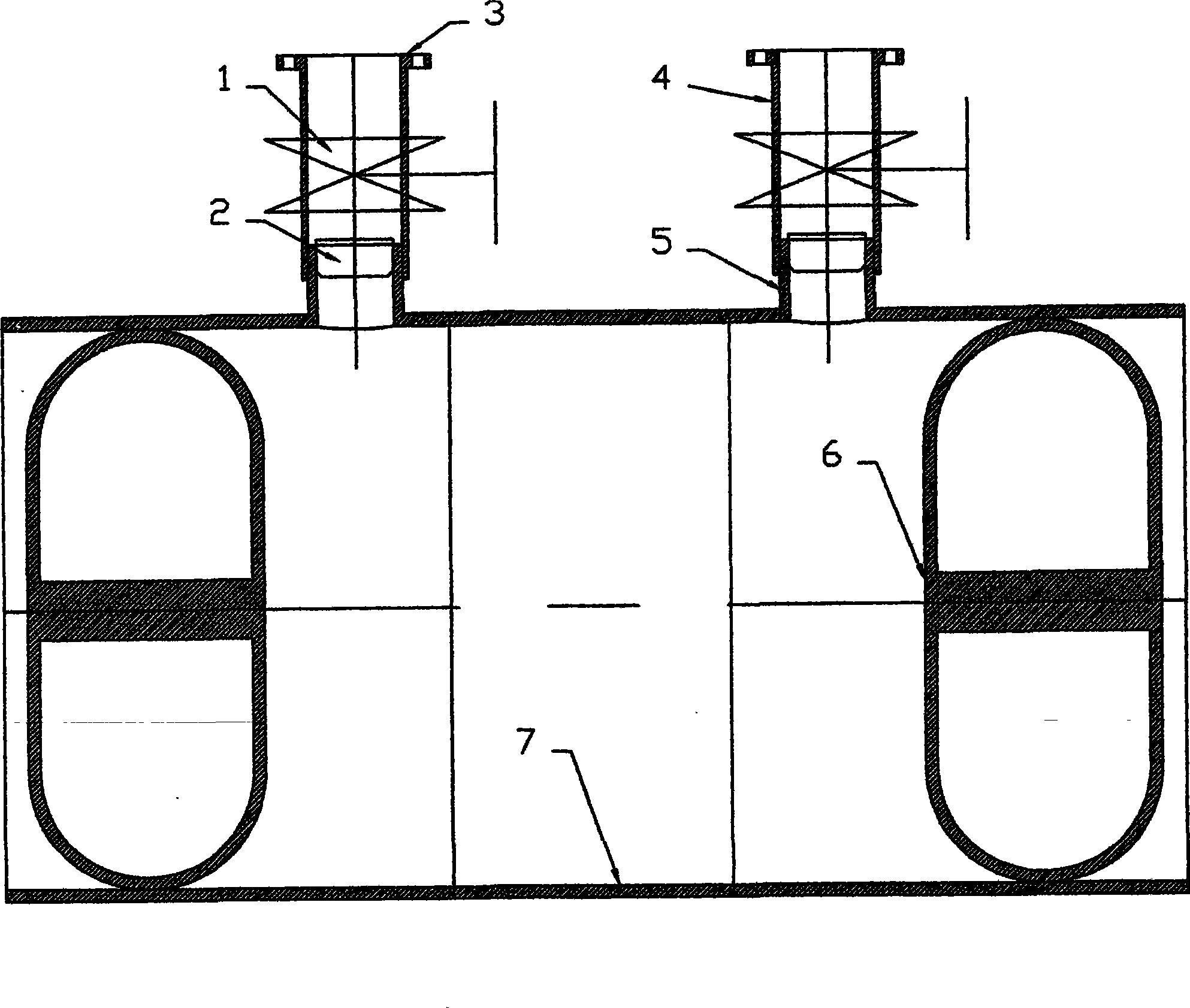

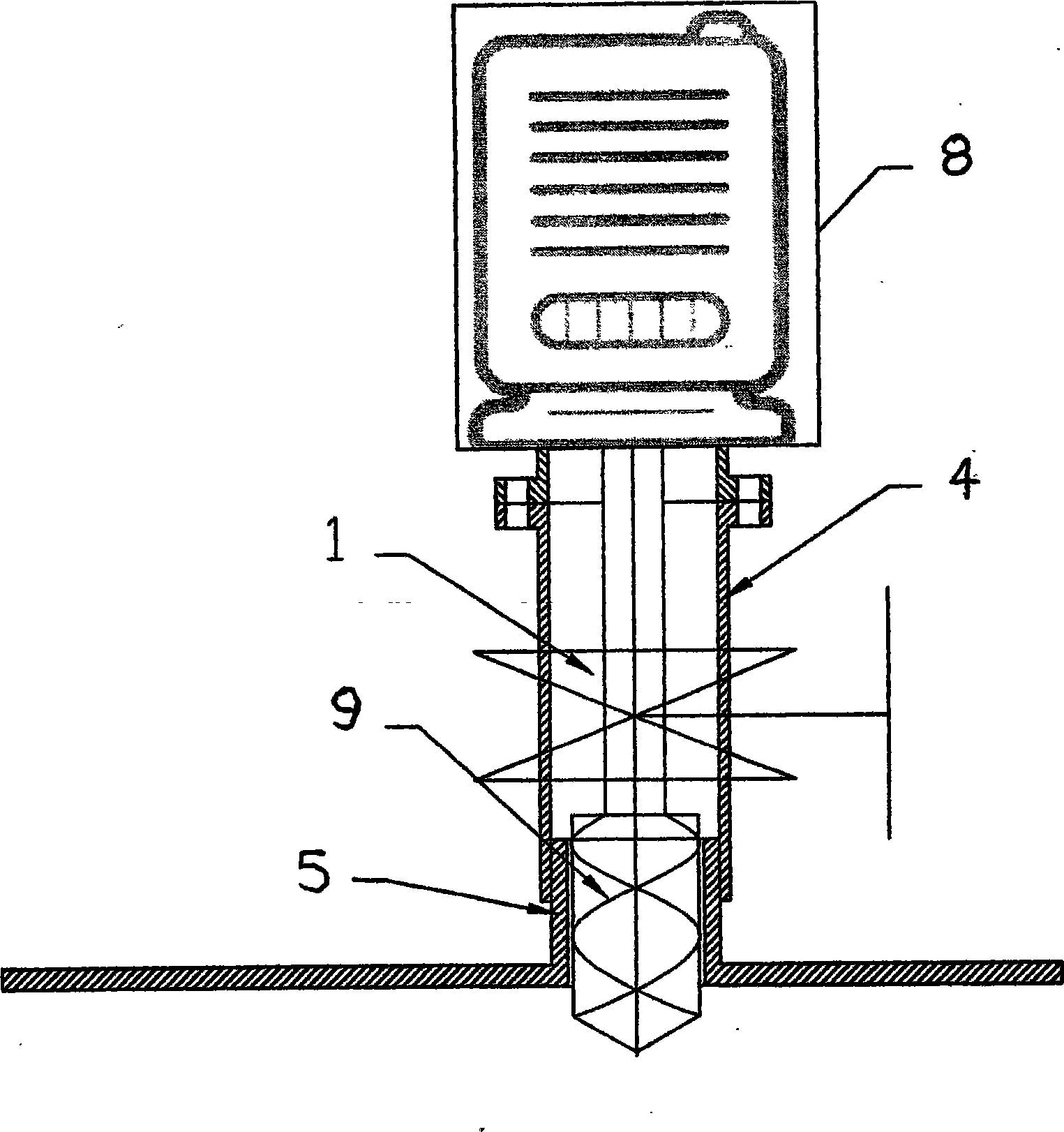

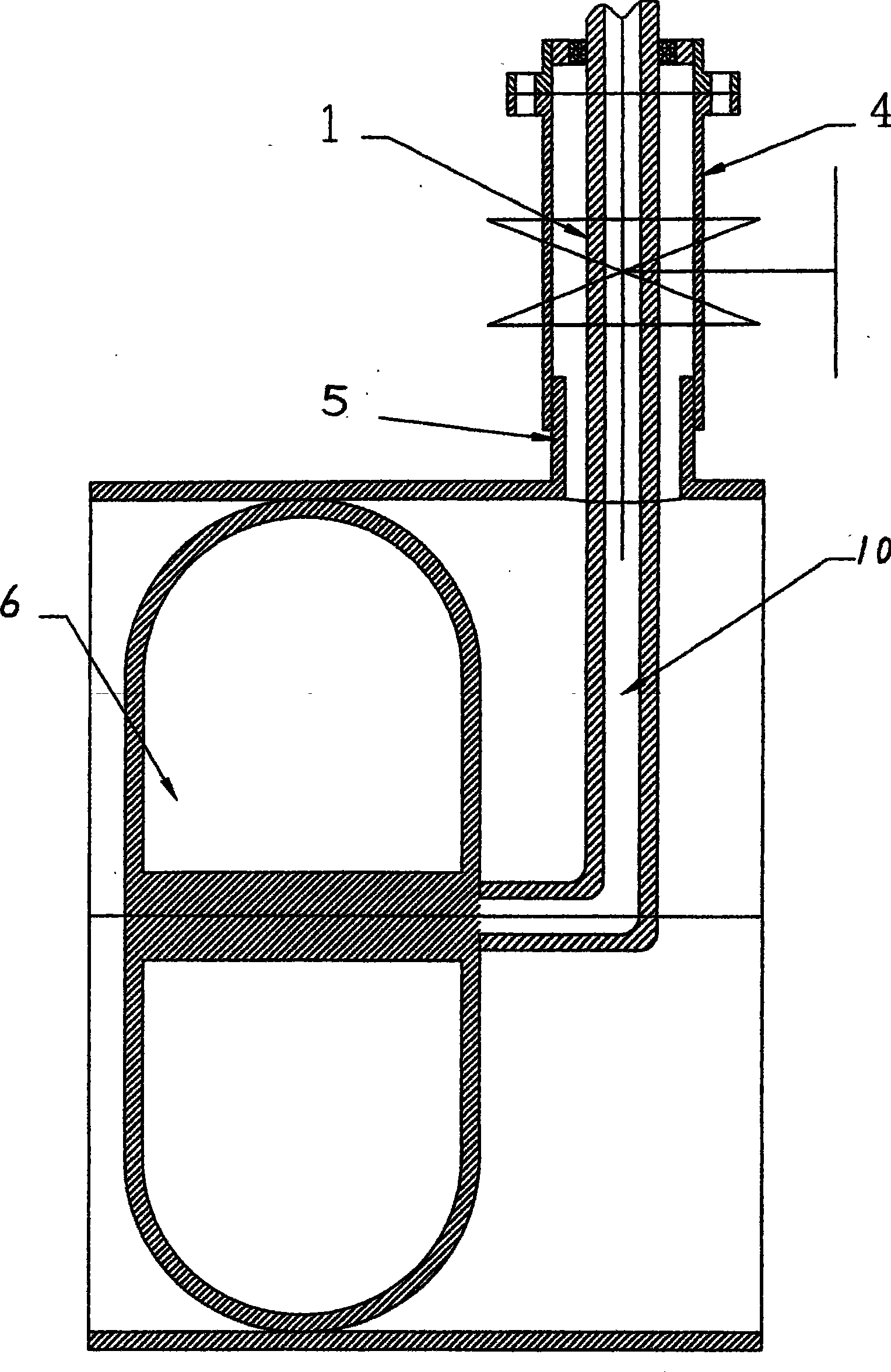

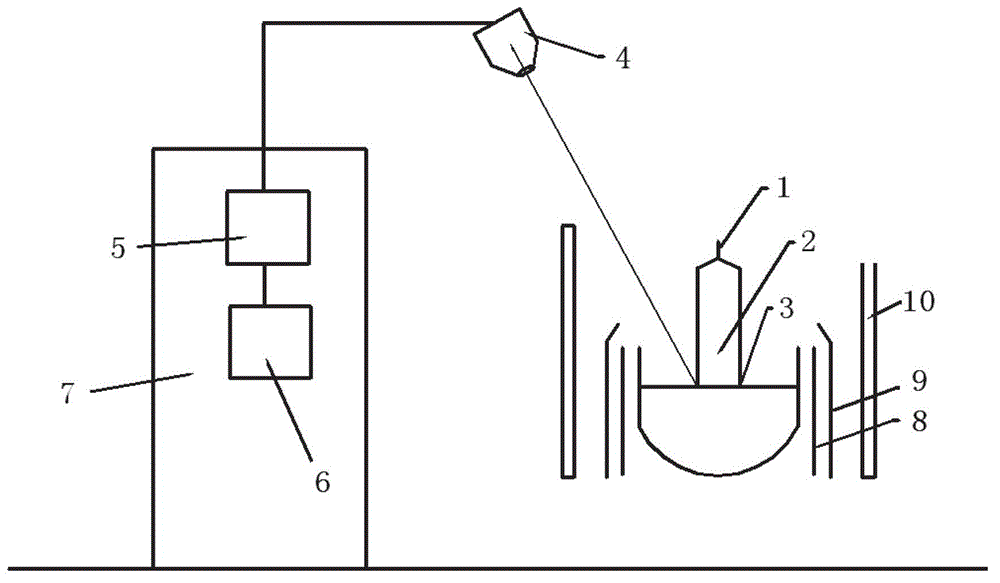

Measurement control system for diameter of Czochralski grown monocrystalline germanium

InactiveCN102912429AReduce labor intensityReduce transfer volumeBy pulling from meltAutomatic controlSingle crystal

A measurement control system for diameter of Czochralski grown monocrystalline germanium is characterized by comprising a camera, an image processor and an automatic control unit, the camera acquires images of equal-diameter growth of monocrystalline germanium, an image processor recognizes the position of an aperture of a solid-liquid interface and calculates curvature radius of the aperture of the solid-liquid interface to allow for equal-diameter growth of monocrystalline germanium by the automatic control unit. The measurement control system for diameter of Czochralski grown monocrystalline germanium has the advantages that an image processing card only analyzes an aperture part of acquired images, data transmission quantity is reduced, and the requirement of the system for hardware performance is reduced. Complex mapping from ellipse to circle is not required, and equal-diameter control can be achieved according to a change rule of the curvature radius only by acquiring the curvature radius of a specified point. The camera can integrally transmit the acquired growth images of monocrystalline germanium for image processing and analyzing, and accordingly multiple devices are convenient to monitor in real time by a production operator and labor strength of growth of monocrystalline germanium is lowered. The existing devices can be utilized to the maximum limit, and repeated design and investment of an electrical control system are avoided.

Owner:YUNNAN KIRO CH PHOTONICS

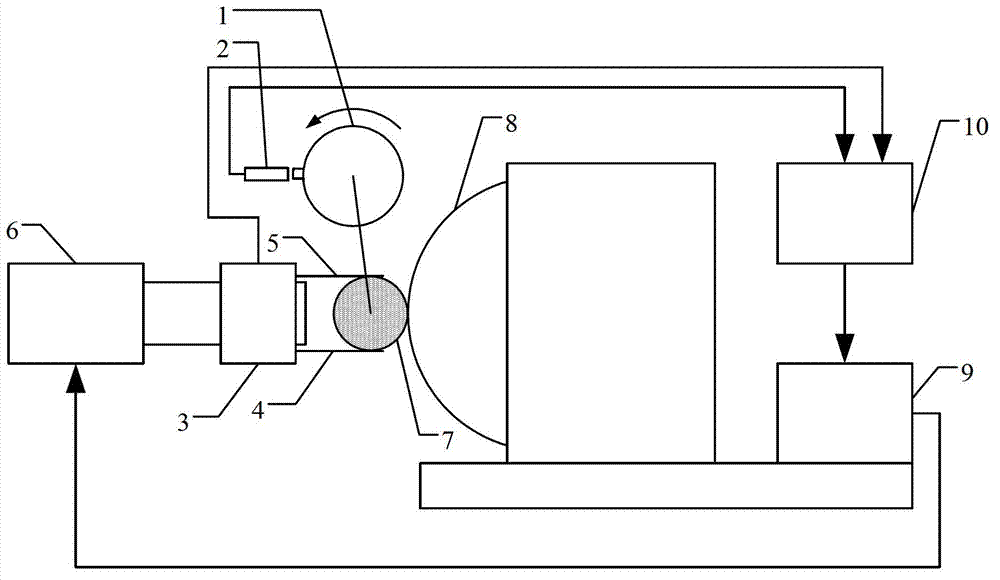

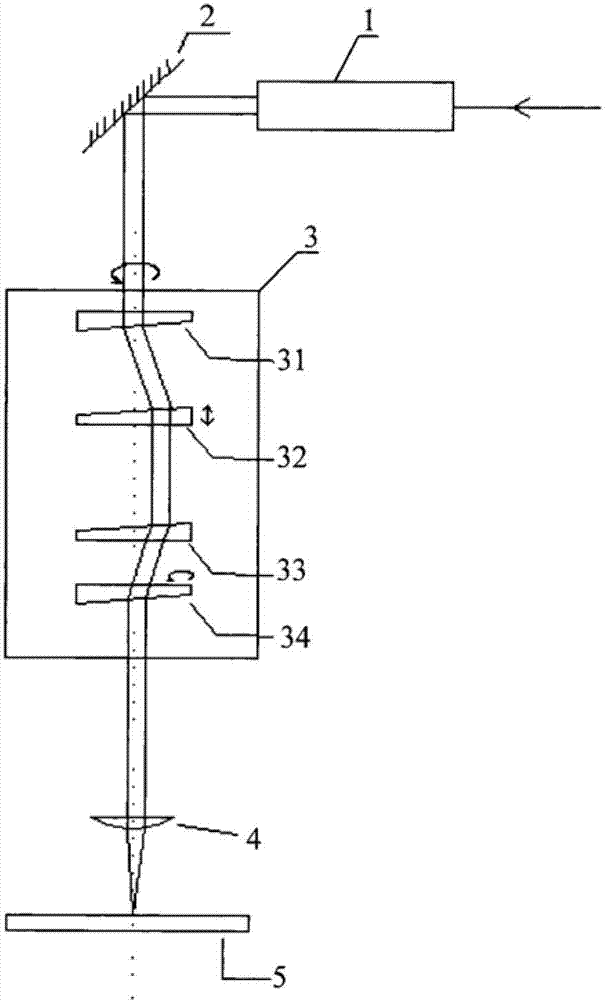

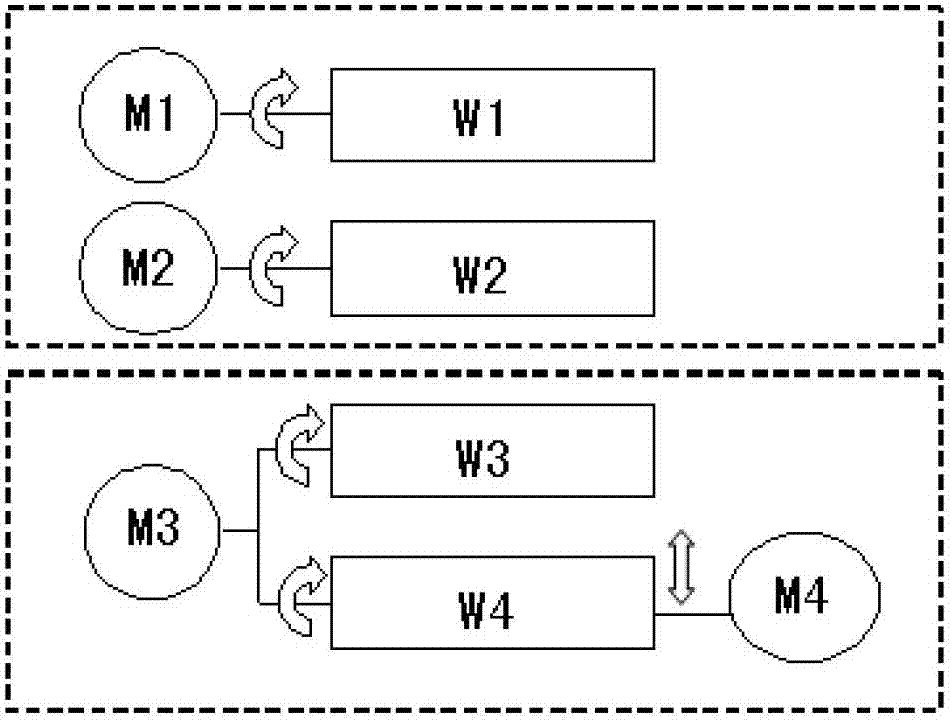

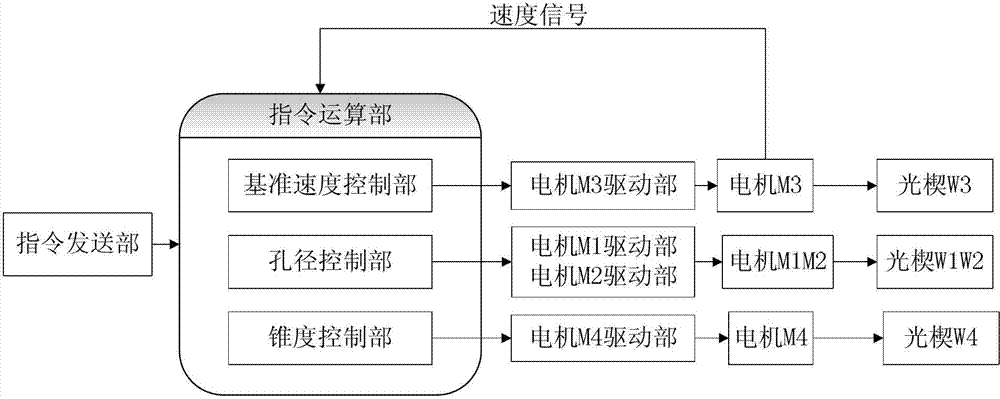

Drive motor control system and control method of laser-boring optical element

ActiveCN103028843AGuaranteed roundnessAchieve consistencyLaser beam welding apparatusMotor driveControl system

The invention discloses a drive motor control system with a plurality of optical wedges. The drive motor control system comprises an instruction sending part, an instruction operating part, a motor drive part, a plurality of motors and the plurality of optical wedges, wherein the instruction sending part is used for sending an initial instruction value to the instruction operating part; the instruction operating part is used for receiving an instruction signal sent by the instruction sending part, and generating an operation speed signal of the motors according to a fed-back real-time speed signal of the motors; and the motor drive part drives the motors to operate according to the operation speed signal sent by the instruction operating part, so that the motors drive the optical wedges to rotate. The instruction operating part comprises a reference speed control part, a bore diameter control part and a conical degree control part. The reference speed of the rotation of the whole optical wedge system is controlled by the speed control part; the turning radius of a light beam is changed by the bore diameter control part during a rotating process of the optical wedges; and the conical degree formed by rotating the light beam is changed by the conical degree control part.

Owner:CHINA KEHAN LASER FUJIAN

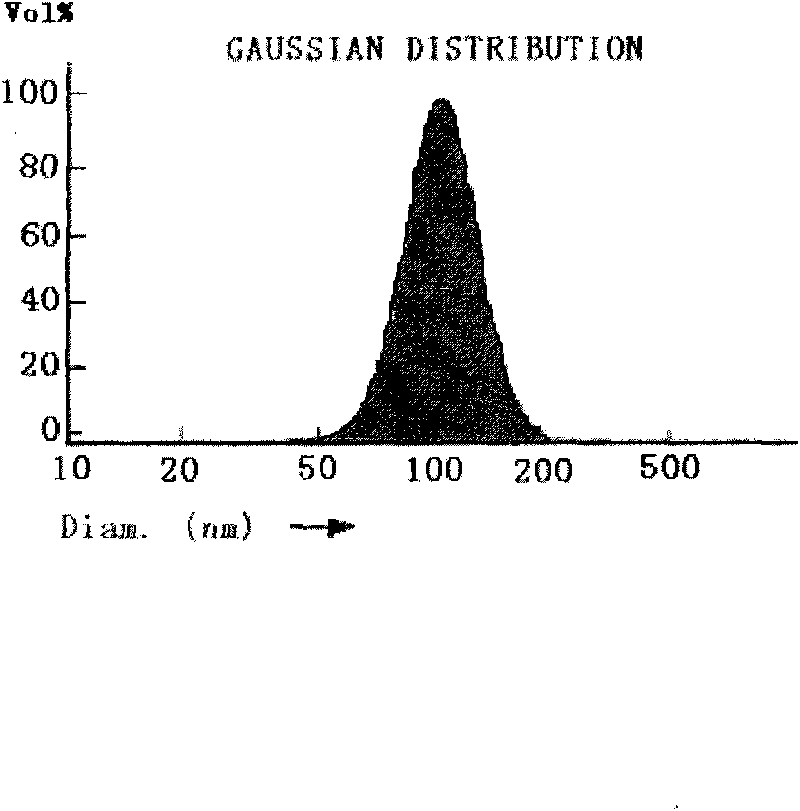

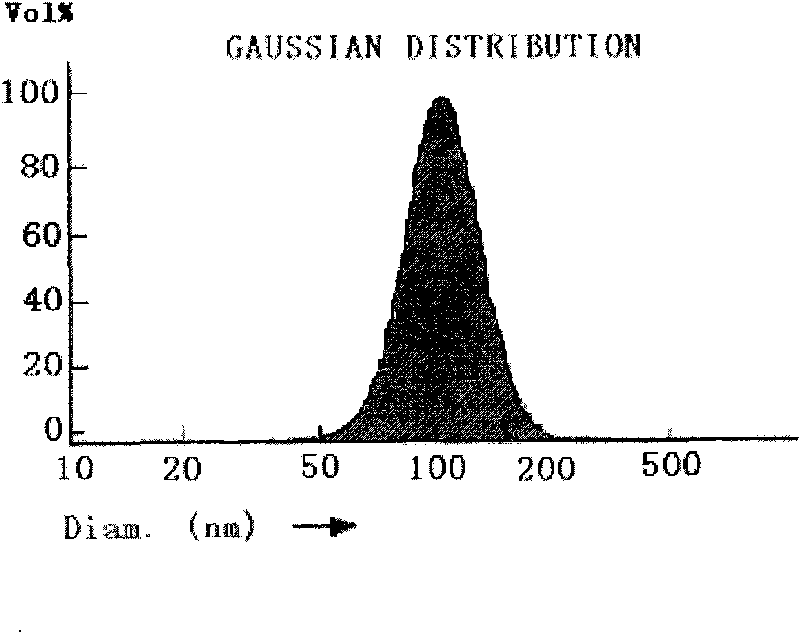

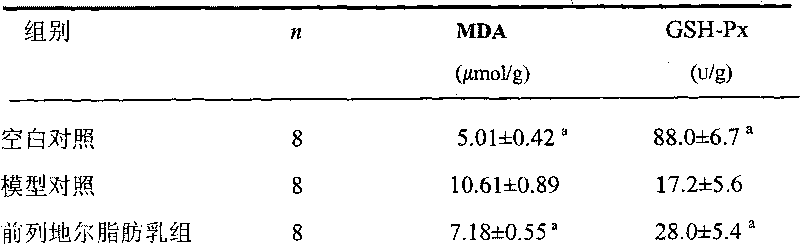

Prostaglandin E1 long-circulation fat microsphere preparation for intravenous injection and preparation method thereof

The invention relates to a formula and a preparation method of a prostaglandin E1 long-circulation fat microsphere for intravenous injection. The preparation comprises the following components: (1) a prostaglandin E1 medicine; (2) vegetable oil (dissolving oil diluted by a medicine); (3) an emulsion surfactant; (4) an emulsion preparation stabilizing agent, an emulsifying agent, a particle diameter control agent and a polyoxyalkylene phospholipid derivative increasing the half life of the fat microsphere in blood; (5) oleic acid or oleate which is used as the emulsion preparation stabilizing agent or the emulsifying agent; (6) an antioxidant; and (7) a complex compound (glycerol) controlling the cation concentration.

Owner:XIAN LIBANG PHARMA

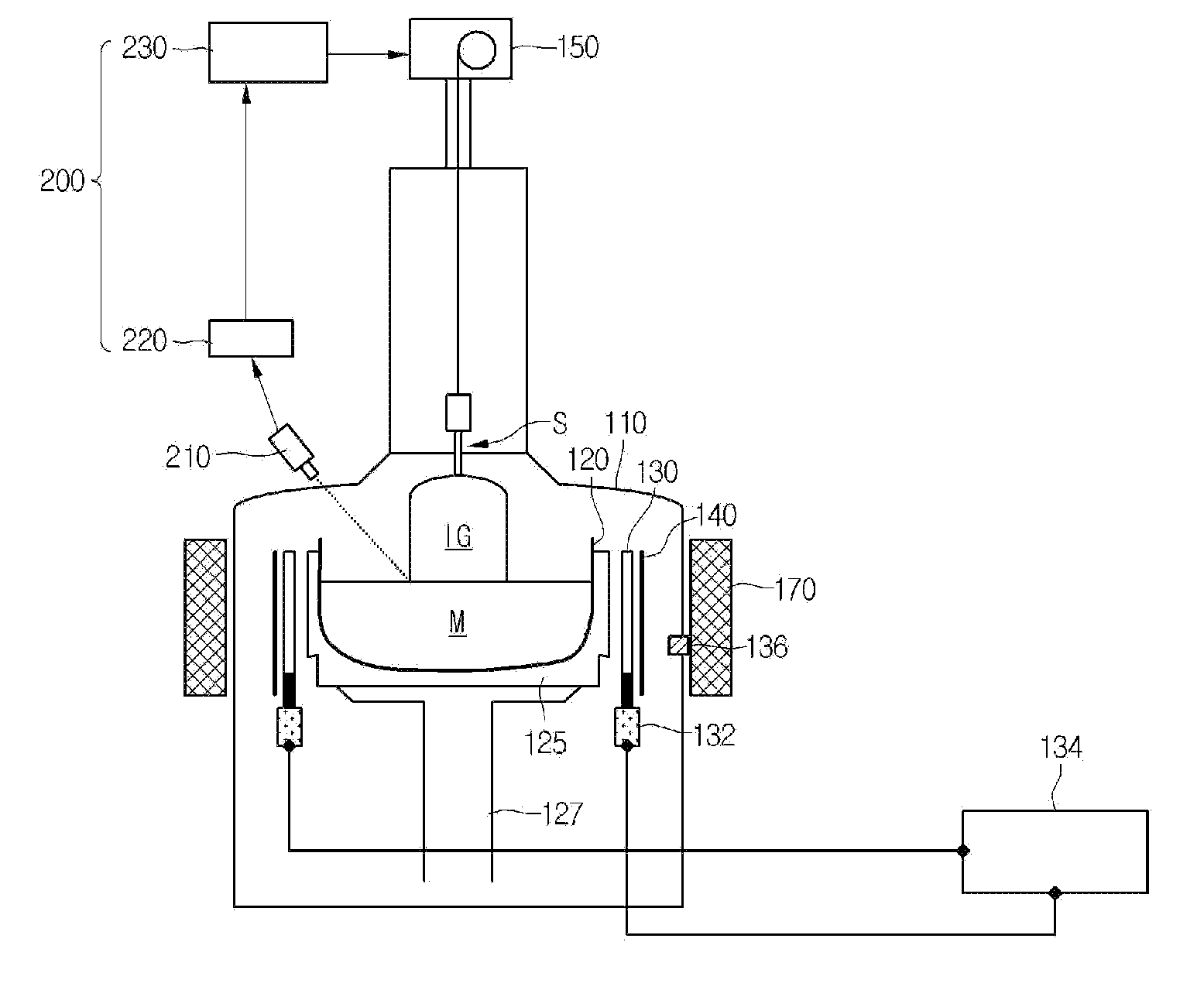

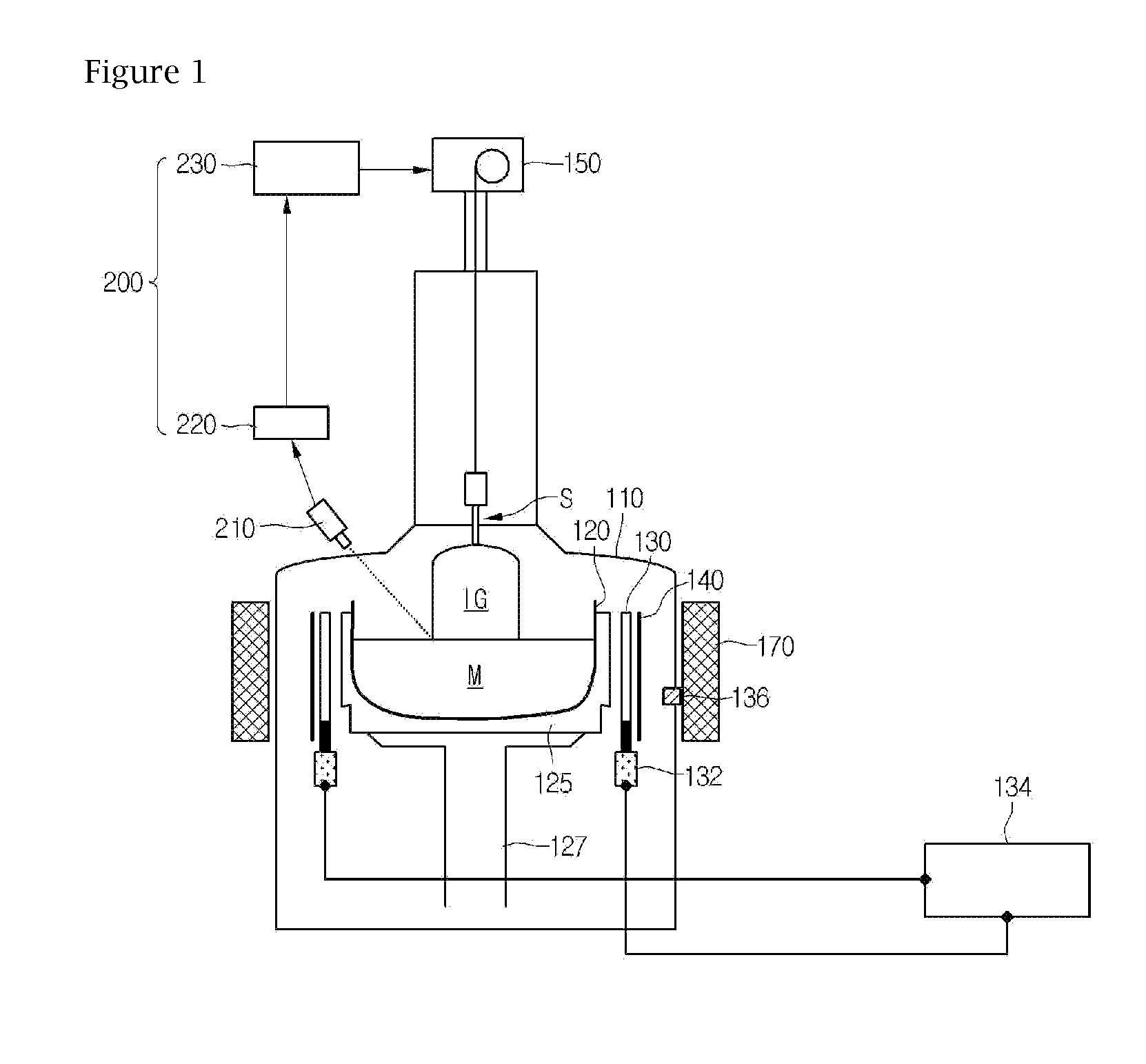

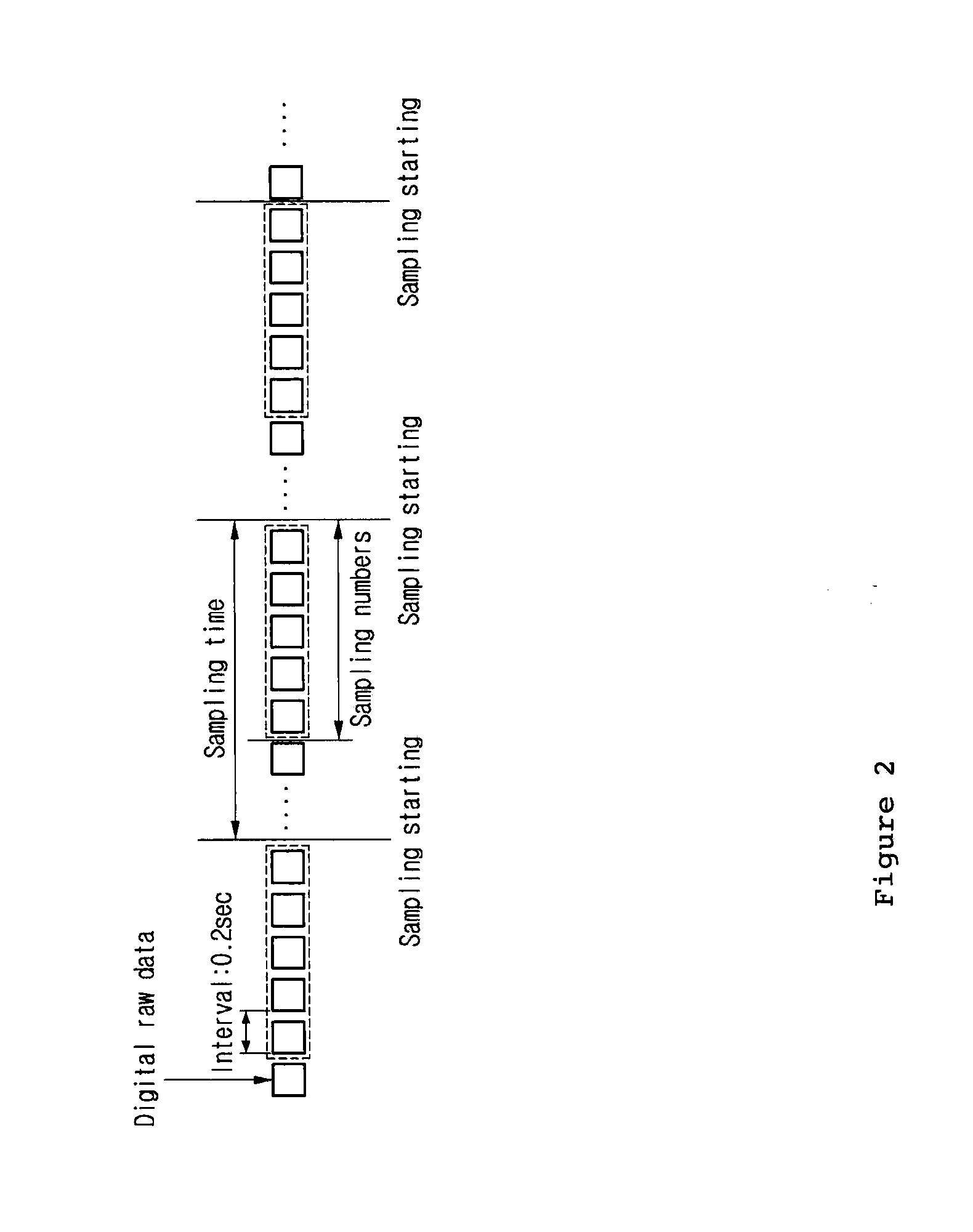

System of controlling diameter of single crystal ingot and single crystal ingot growing apparatus including the same

ActiveUS20120145071A1Cancel noiseEasy to controlBy zone-melting liquidsBy pulling from meltLow-pass filterIngot

Provides are a system of controlling a diameter of a single crystal ingot and a single crystal ingot growing apparatus including the same. The system of controlling a diameter of a single crystal ingot includes: a diameter measuring sensor measuring a diameter of a single crystal ingot; a Low-Pass Filter (LPF) removing short period noise from measured data from the diameter measuring sensor; and an Automatic Diameter Control (ADC) sensor controlling the diameter of the single crystal ingot through controlling of a pull speed by using data having the noise removed as current data.

Owner:LG SILTRON

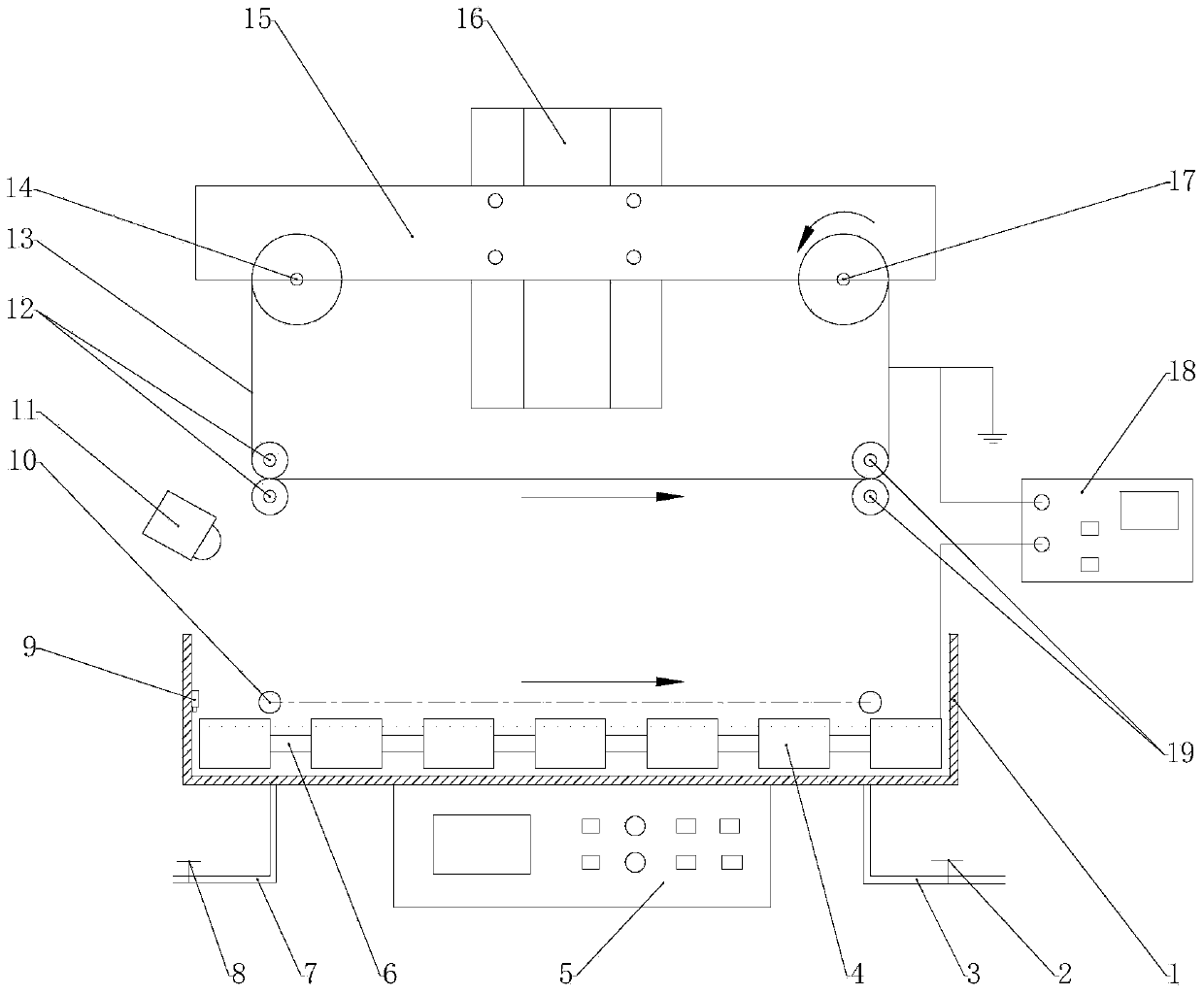

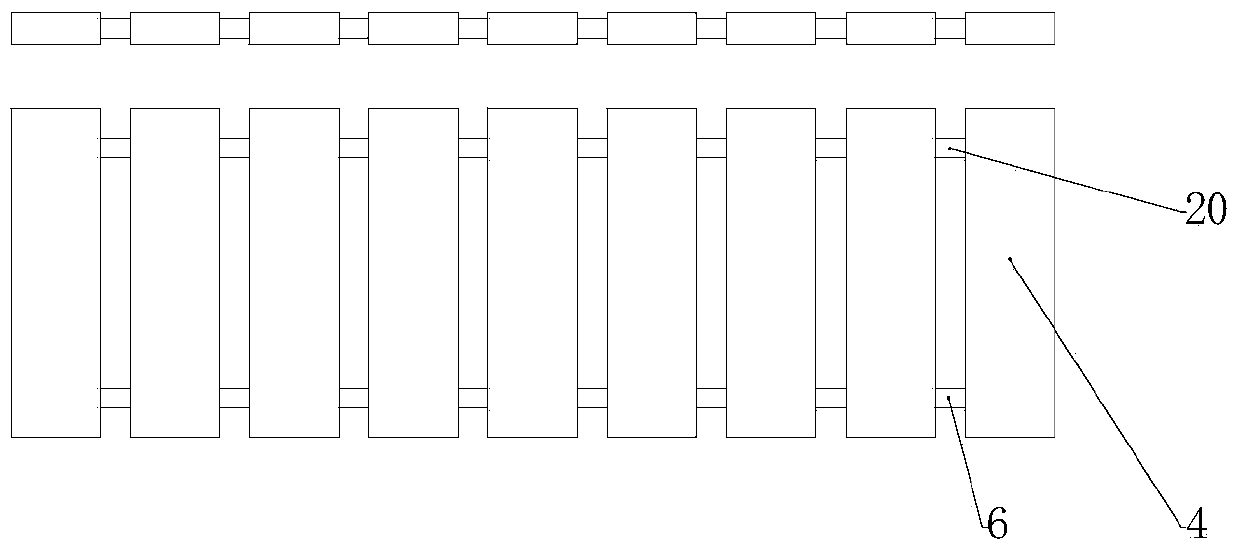

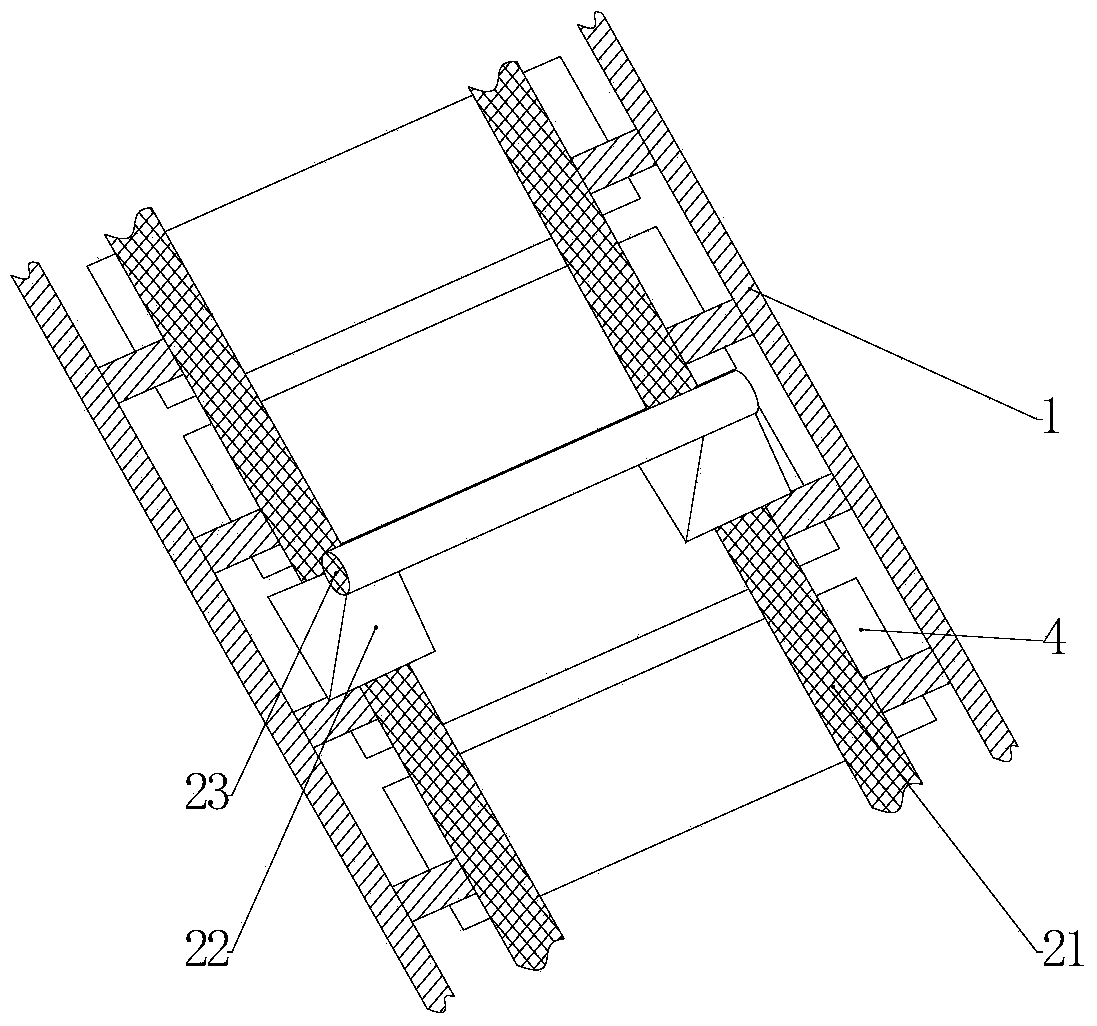

Electro-spinning device for auxiliary inducing of batch manufacturing of diameter-controllable nano-fibers

ActiveCN104178825AJet stabilityPlay the role of auxiliary guide supportArtificial thread manufacturing machinesFilament/thread formingBead shapeInlet valve

The invention discloses an electro-spinning device for auxiliary inducing of batch manufacturing of diameter-controllable nano-fibers, and relates to an electro-spinning device. The electro-spinning device comprises a solution trough, a liquid outlet valve, a fiber diameter control device, an ultrasonic vibration exciter, a liquid inlet pipeline, a liquid inlet valve, an ultrasonic liquid level sensor, auxiliary inducing devices, an industrial CCD image sensor and a collecting device, wherein the fiber diameter control device is provided with adjusting sliding blocks, precise screw rods and polish guide rods; each auxiliary inducing device is provided with linear guide rails, sliding blocks, a sliding block connecting rod and mounting bases; the collecting device is provided with auxiliary feeding rolling wheels, a collecting board, a feeding cylinder, a collecting device hanging board, a motor, a driving feed cylinder and feed auxiliary rolling wheels. According to the device, the ultrasonic vibration exciter is utilized to generate solution waves, and the auxiliary inducing device is utilized to perform jet flow injection control in a matching manner; intervals between polar plates are utilized to restrain a jet flow initial diameter and migration; the collecting device which can feed continuously and an auxiliary inducing process are utilized, and the image sensor is cooperatively used to recognize, so that the defects that the yield is low, the diameter distribution is large in difference, the bead-shaped structure is provided, and the nozzle is easy to block are overcome.

Owner:XIAMEN UNIV

Magnetic recording medium, method for manufacturing recording medium and magnetic recording apparatus

ActiveUS20050214592A1High density recordingIncreased signal noiseBase layers for recording layersRecord information storageRecording densityOxygen

A grain diameter controlling crystalline layer comprising crystalline grains of a metal selected from the group consisting essentially of Cu, Ni, Rh and Pt was formed on a substrate. Then, deposited atom layer of at least one element selected from the group consisting of oxygen and carbon was formed on the surface of the grain diameter control layer. A magnetic recording layer was deposited on the atoms deposited grain diameter controlling crystalline layer. Then a magnetic recording medium in which the magnetic crystalline grains has small grain diameter and small grain diameter distribution, and the magnetic recording medium shows increased signal to noise ratio at high recording density.

Owner:KK TOSHIBA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com