Method to raise production efficiency of czochralski silicon mono-crystal

A technology of production efficiency and Czochralski silicon, which is applied in the directions of single crystal growth, single crystal growth, and self-melt pulling method, etc., can solve problems such as the limitation of production efficiency of Czochralski silicon single crystal, and save production maintenance time and operation Simple and time-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

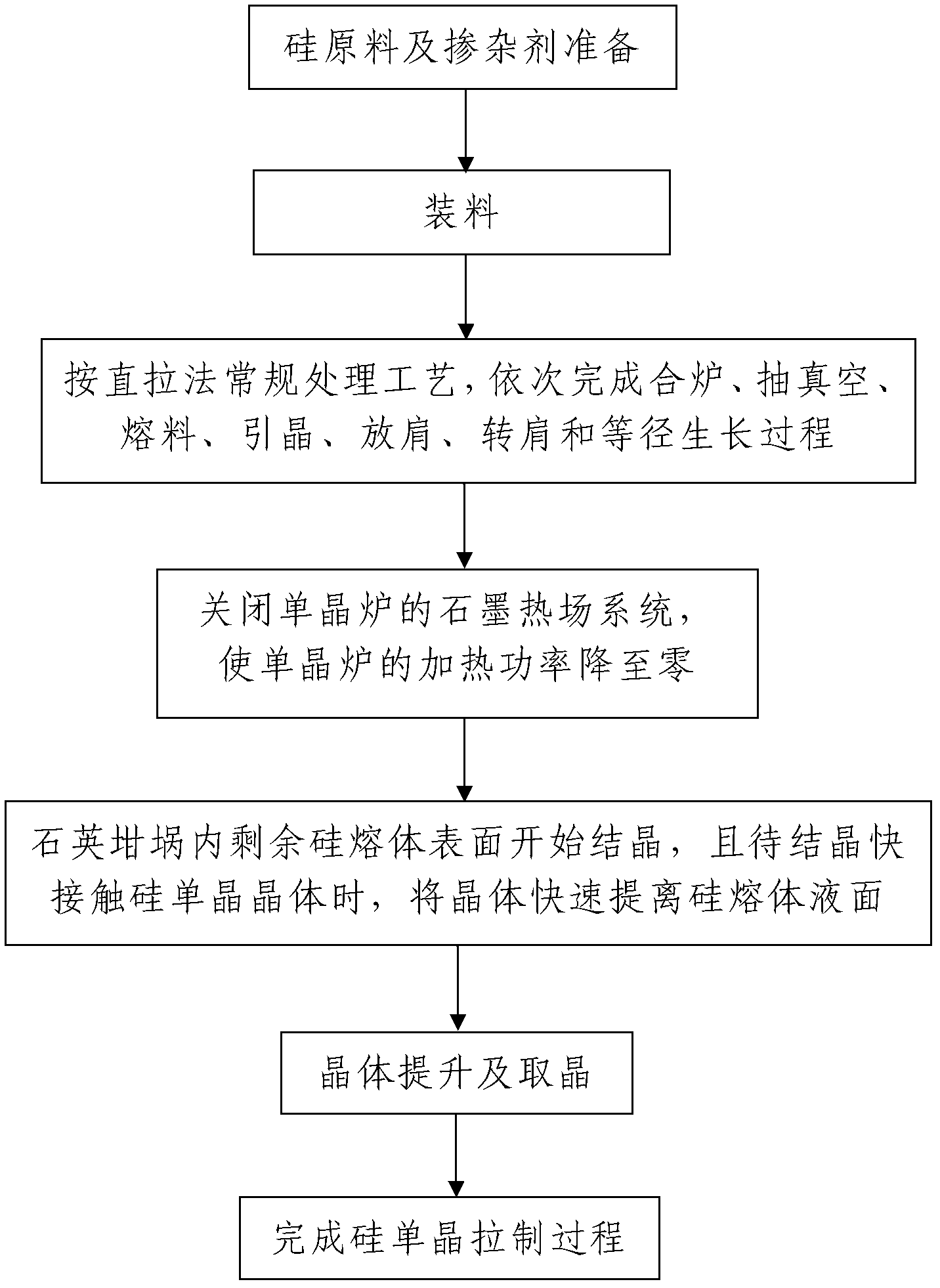

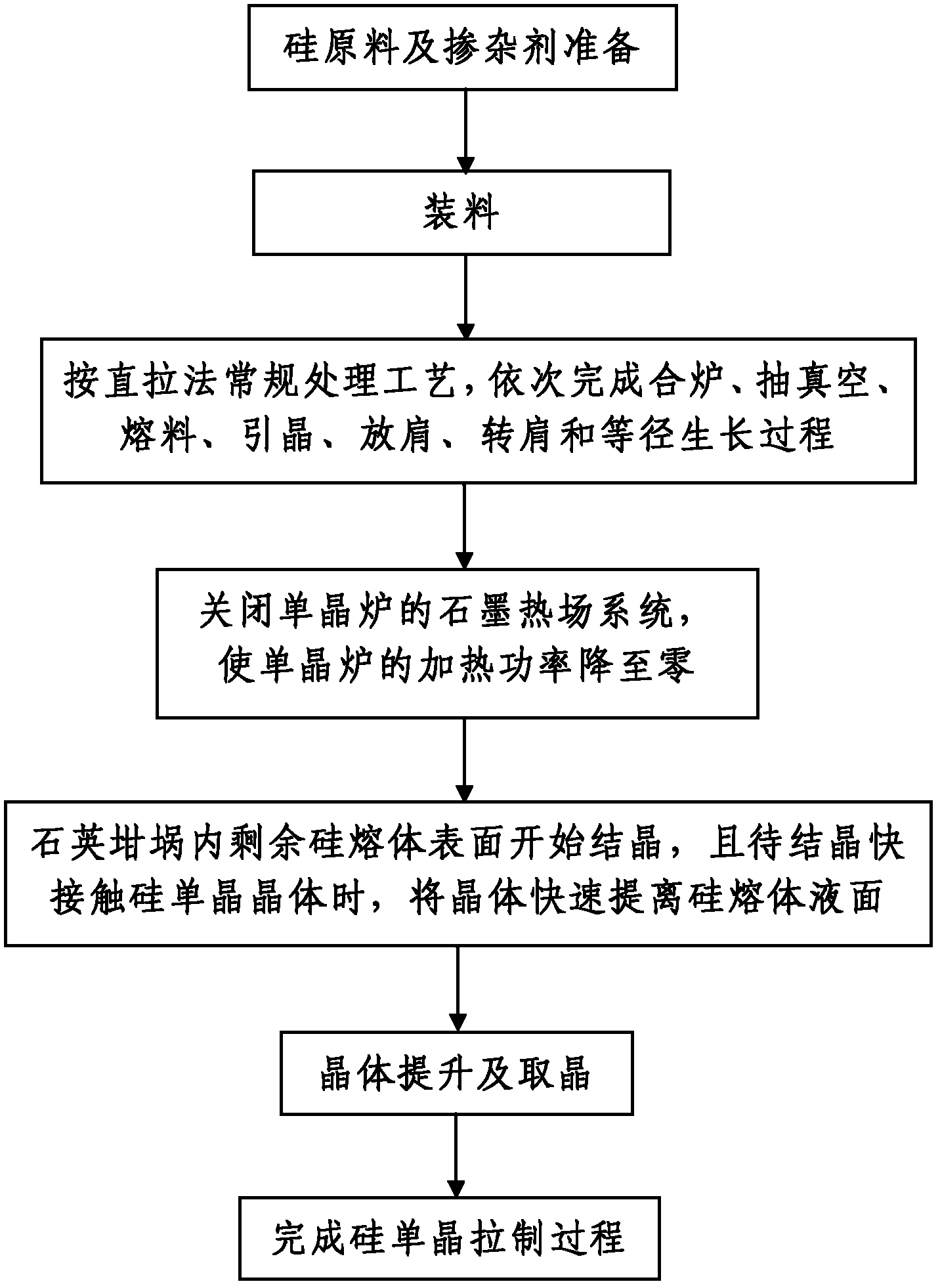

[0036] like figure 1 The shown method for improving the production efficiency of Czochralski silicon single crystal is characterized in that the method comprises the following steps:

[0037] Step 1. Preparation of silicon raw materials and dopants: According to the conventional preparation method of silicon raw materials for single crystal furnaces, silicon raw materials for growing Czochralski monocrystalline silicon are prepared, and according to the conventional cleaning treatment methods of silicon raw materials for single crystal furnaces, The prepared silicon raw material is cleaned; at the same time, according to the type and resistivity of the silicon single crystal to be produced, the type and amount of dopant to be added are determined, and the dopant used for growing Czochralski monocrystalline silicon is determined. Prepare.

[0038] In this embodiment, in the same way as the conventional method for preparing silicon raw materials for growing Czochralski single c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com