Patents

Literature

1206 results about "Quartz crucible" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

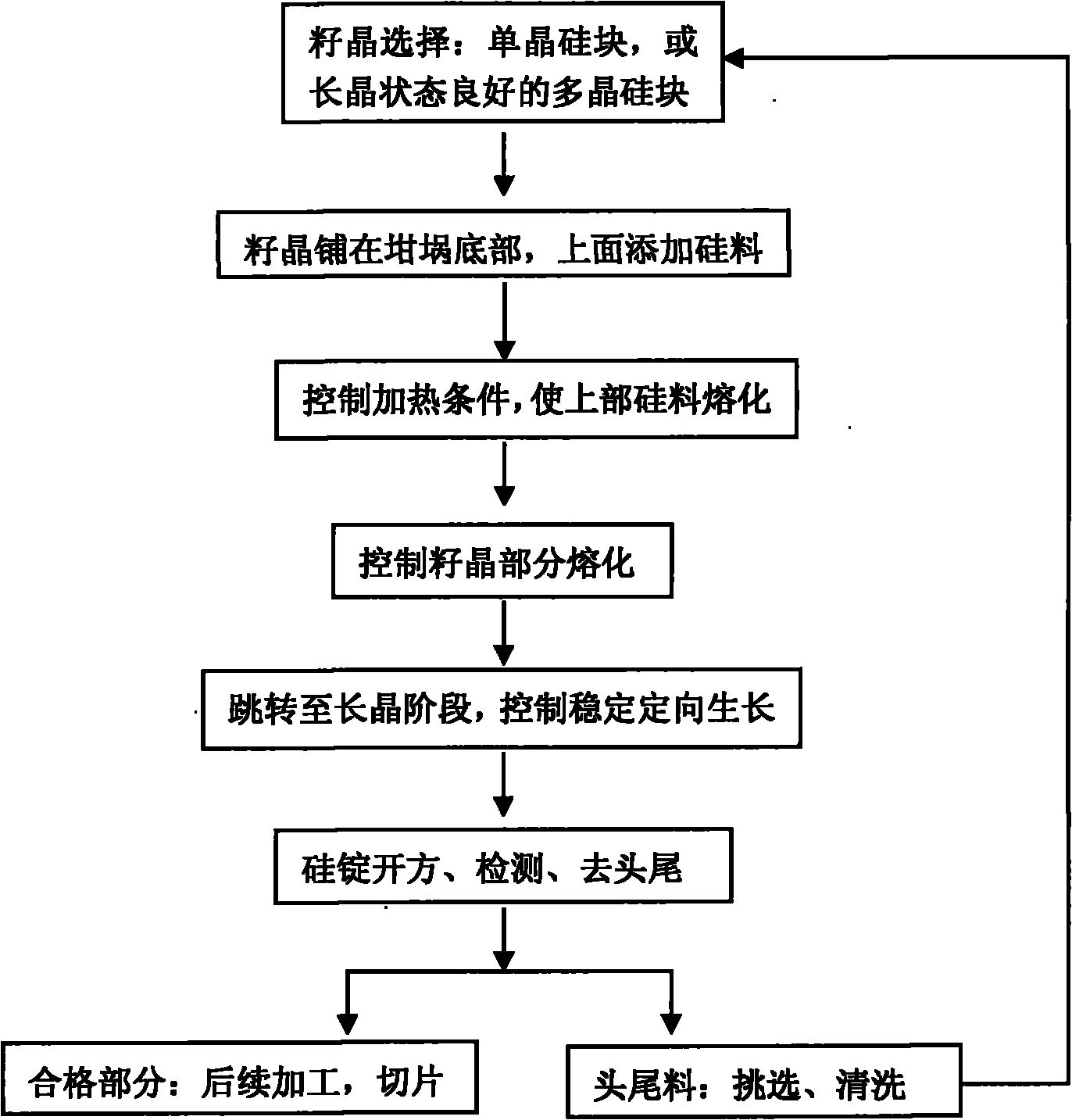

Ingot casting method for quasi-monocrystalline silicon

InactiveCN101864594ALow costImprove efficiencyPolycrystalline material growthAfter-treatment detailsIngot castingSeed crystal

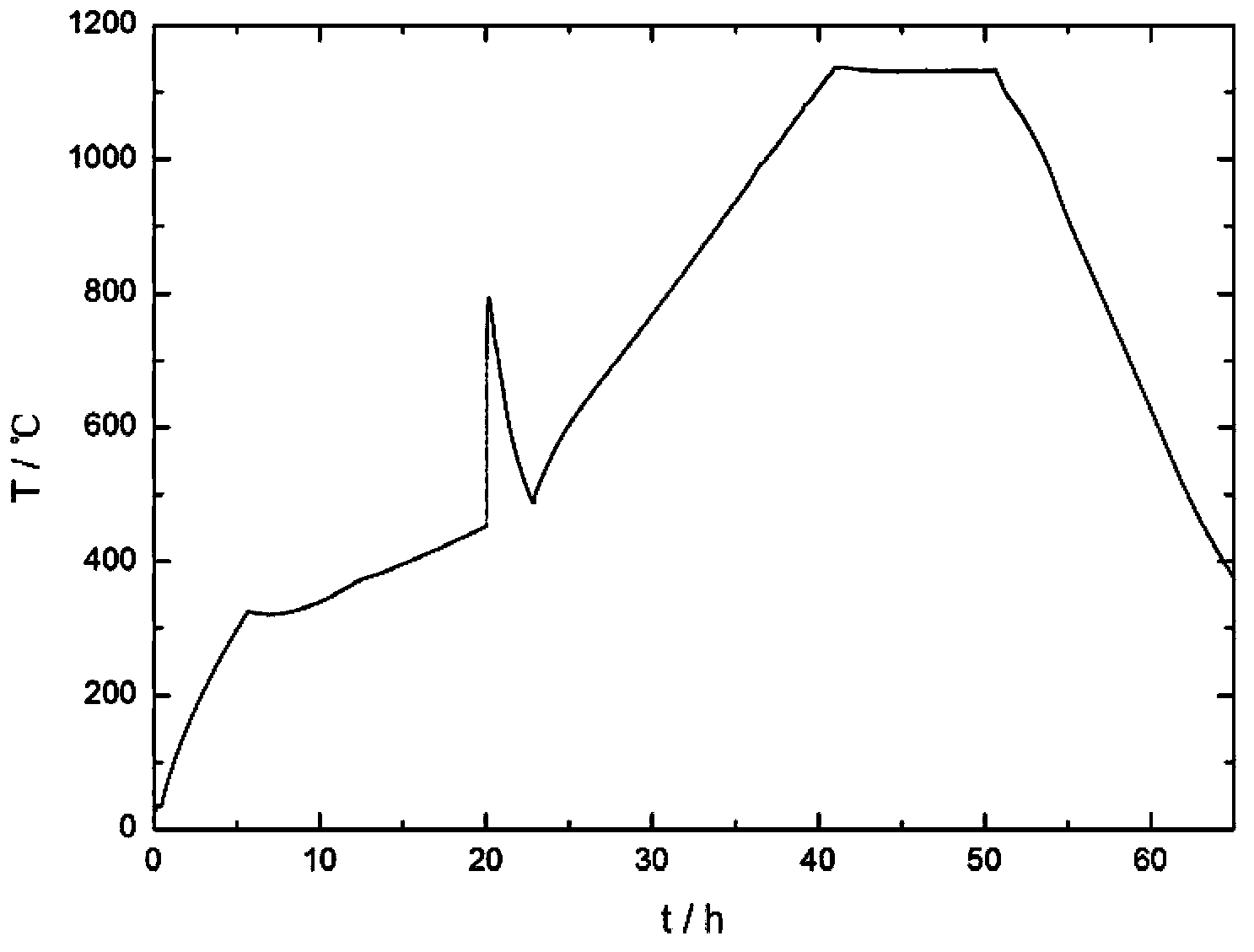

The invention relates to an ingot casting method for quasi-monocrystalline silicon, which comprises the following steps of: (1) laying seed crystals at the bottom of a quartz crucible and adding a silicon material and a doping agent on the seed crystals; (2) vacuumizing and heating the crucible with the materials, raising the temperature in sections to melt the silicon material on the upper part, when the seed crystals begin to melt at the later stage of melting, controlling the temperatures and heating rates of a heater and the bottom of the crucible to partially melt the seed crystals and then entering a crystal growing stage; (3) cooling the heater in sections at the stage of crystal growing to make silicon crystals grow along the direction of unmelted seed crystals, and annealing and cooling after the silicon crystals grows to obtain large-gain silicon ingots; and (4) performing subsequent treatment on the large-grain silicon ingots to obtain the quasi-monocrystalline silicon. In the method, melting and crystal growing and the like are finished in the same equipment and in the same crucible, and the seed crystals are melted by controlling the temperature of the bottom of the crucible and the heating rate of the heater, so that the method has the advantages of low cost, easy operation and suitability for mass production; and the prepared quasi-monocrystalline silicon has high conversion efficiency, and the seed crystals can be recycled.

Owner:晶海洋半导体材料(东海)有限公司 +1

Quartz crucibles having reduced bubble content and method of making thereof

A quartz crucible having reduced / controlled bubble content is disclosed, comprising an outer layer and an inner layer doped with elements and compounds that: a) react with oxygen and nitrogen at or near the fusion temperature of quartz; and b) form compounds that are thermally stable at temperatures of above 1400° C. and chemically stable in a SiO2 environment. A method to make a crucible having controlled bubble content is also disclosed, the method comprises the step of forming a crucible having an inner layer doped with a material that reacts with residual gases in the bubble such as nitrogen and oxygen and thus consume the gases in the bubbles and empty them in the fusion process.

Owner:GENERAL ELECTRIC CO

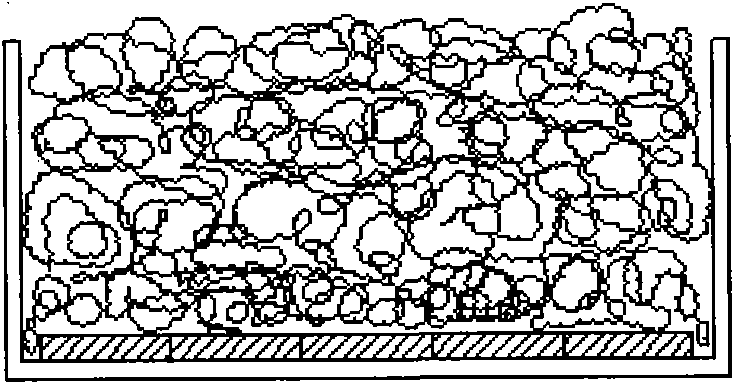

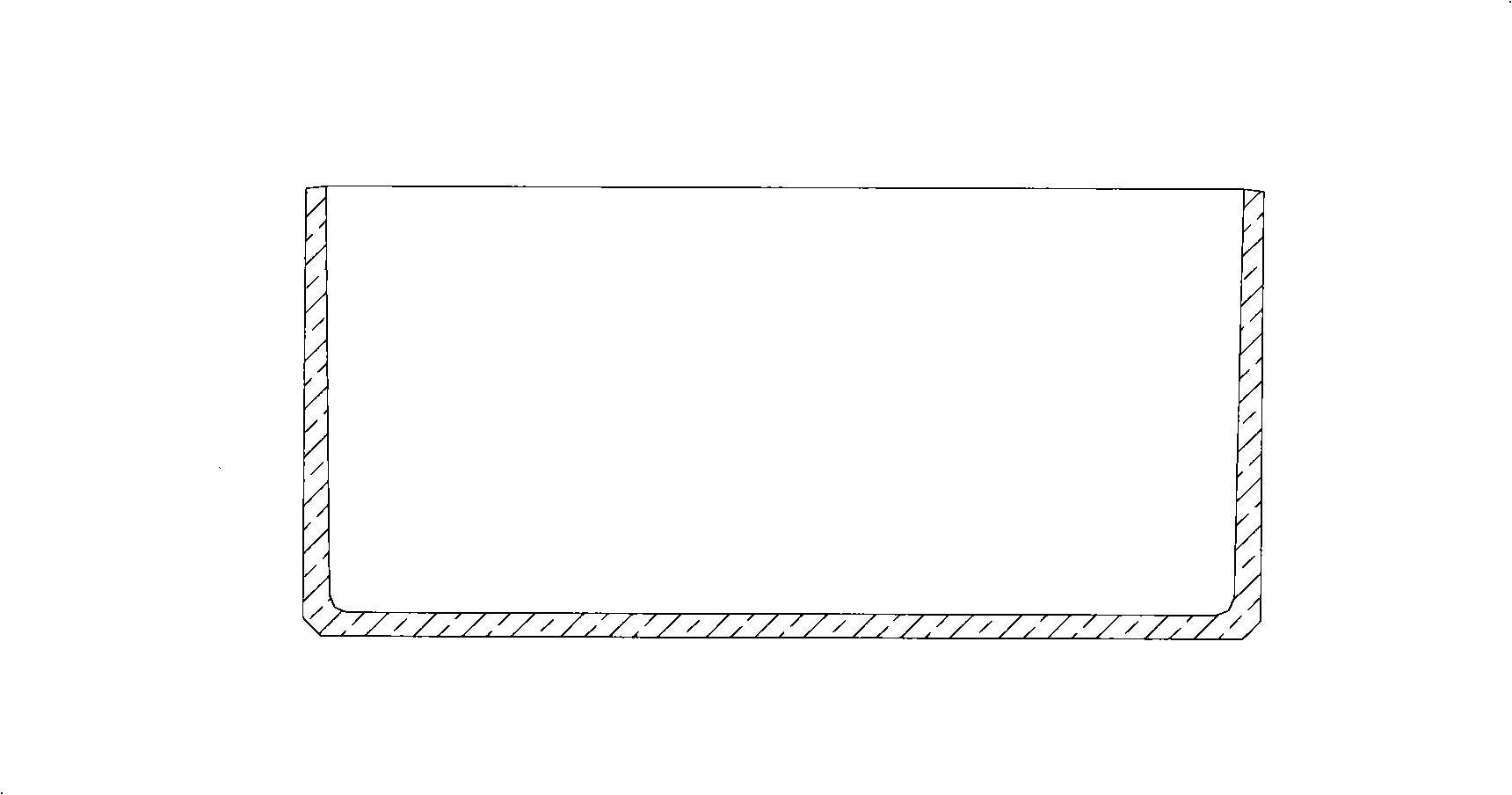

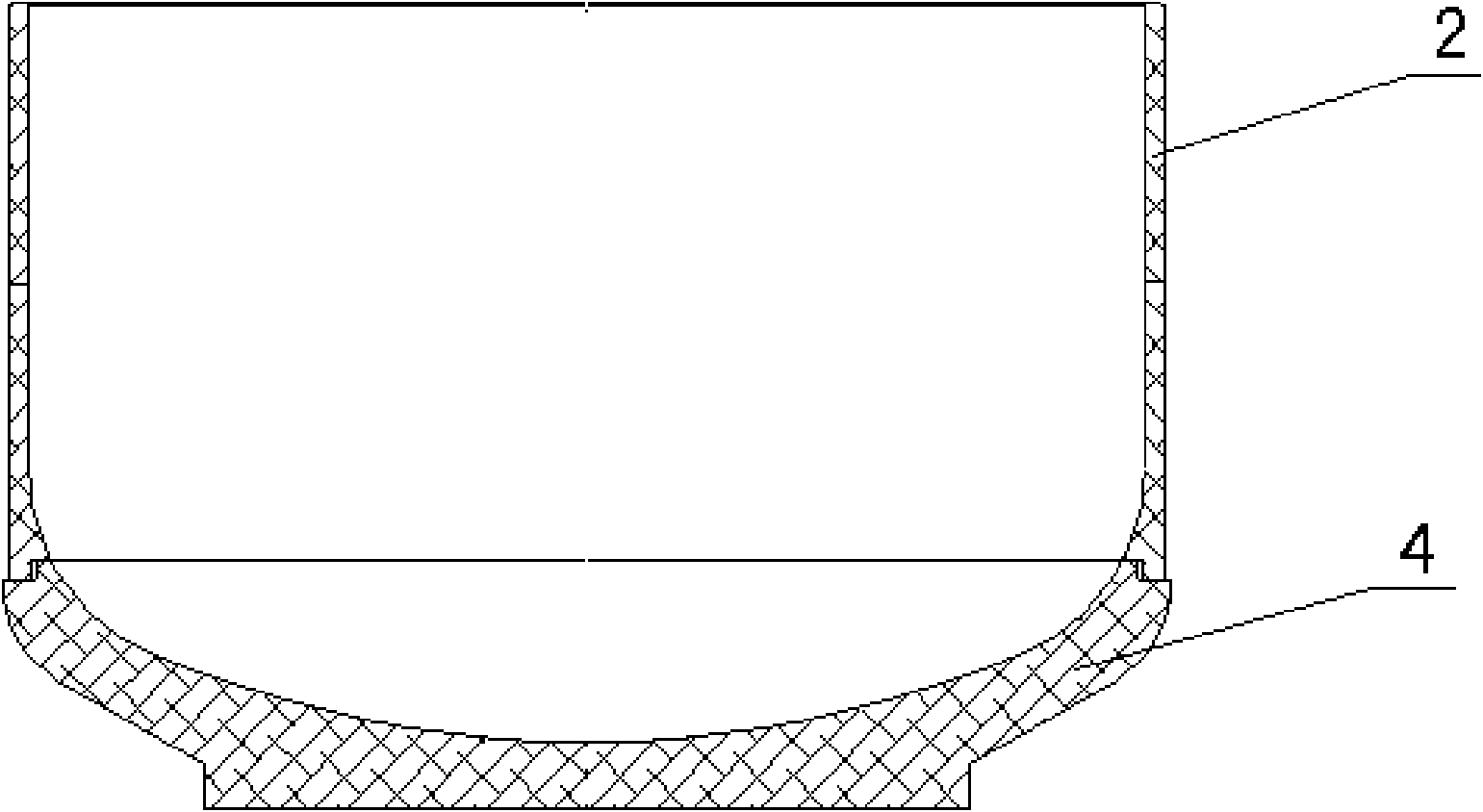

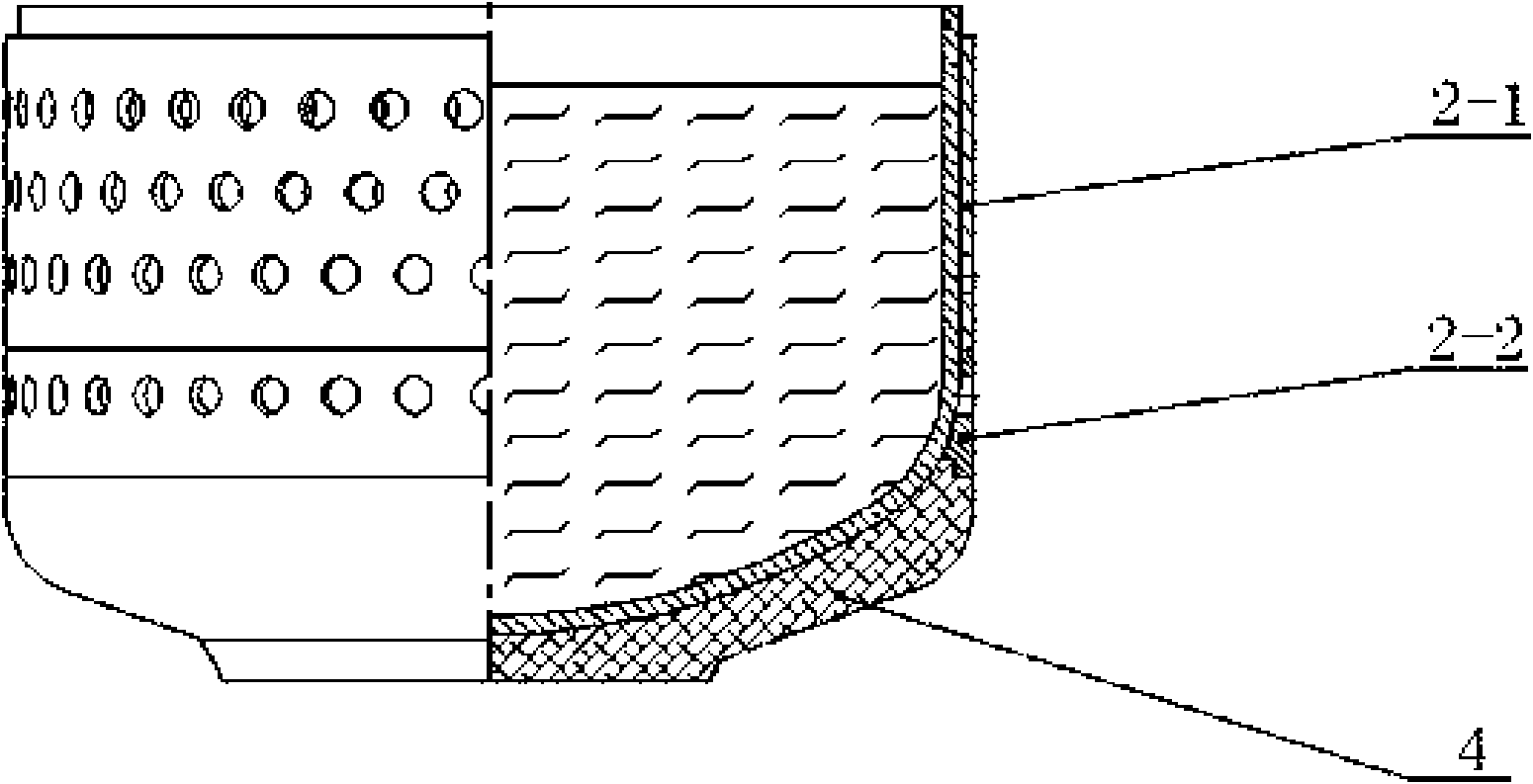

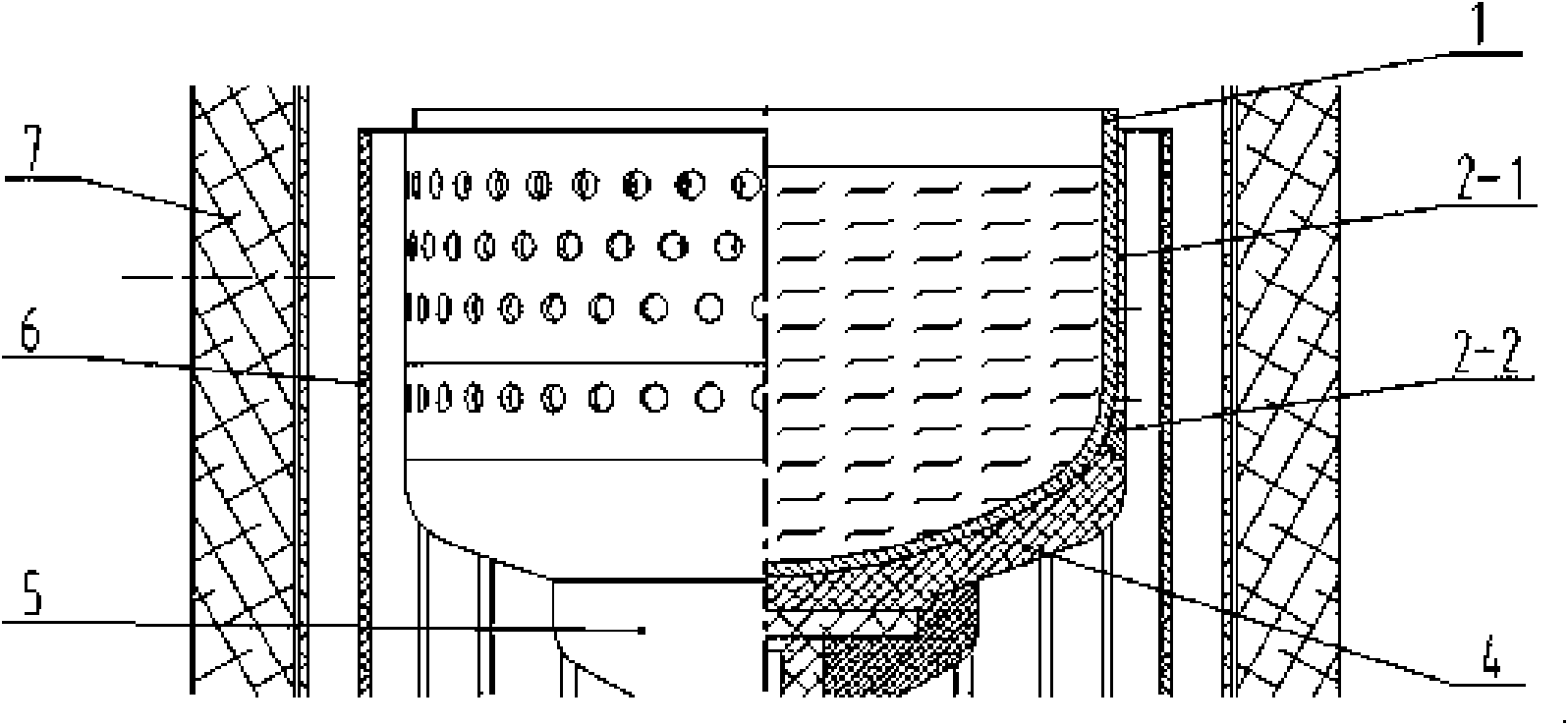

Non-transparent quartz crucible for polysilicon crystallization and manufacturing method thereof

InactiveCN101348324AHighlight substantive featuresSignificant progressGlass shaping apparatusSilicon compoundsCrack resistanceSlurry

The invention provides an opaque quartz crucible used in multicrystal silicon crystallization and a method for manufacturing the same. The crucible is of a regular square structure, and the compositions in mass ratio of the crucible are more than 99.7 Wt percent of silicon dioxide, less than 600ppm of aluminum oxide and less than 30ppm of ferric oxide. The method comprises the following steps: firstly, a raw material, i.e. high purity quartz is put into granulation equipment for wet method granulation, the grain size is controlled between 70 and 100mu m; then, slurry is fully stirred and then is fed into a gypsum mould under a pressure of between 2 and 3bar after being deposited for 24 to 48 hours; moreover, early grouting is assisted by slight vibration; the slurry is further settled for 5 to 8 hours, and is demoulded after fully dewatered; the slurry is dried inside a drier; and finally, a blank is put in a kiln for sintering so as to obtain the opaque quartz crucible. The proposal adopts grouting forming by a high-purity quartz material, and the sintered crucible has uniform inner structure; moreover, the crucible has excellent thermal shock stability and cracking resistance, and can meet the technological requirements for manufacturing multicrystal silicon cast ingots.

Owner:常熟华融太阳能新型材料有限公司

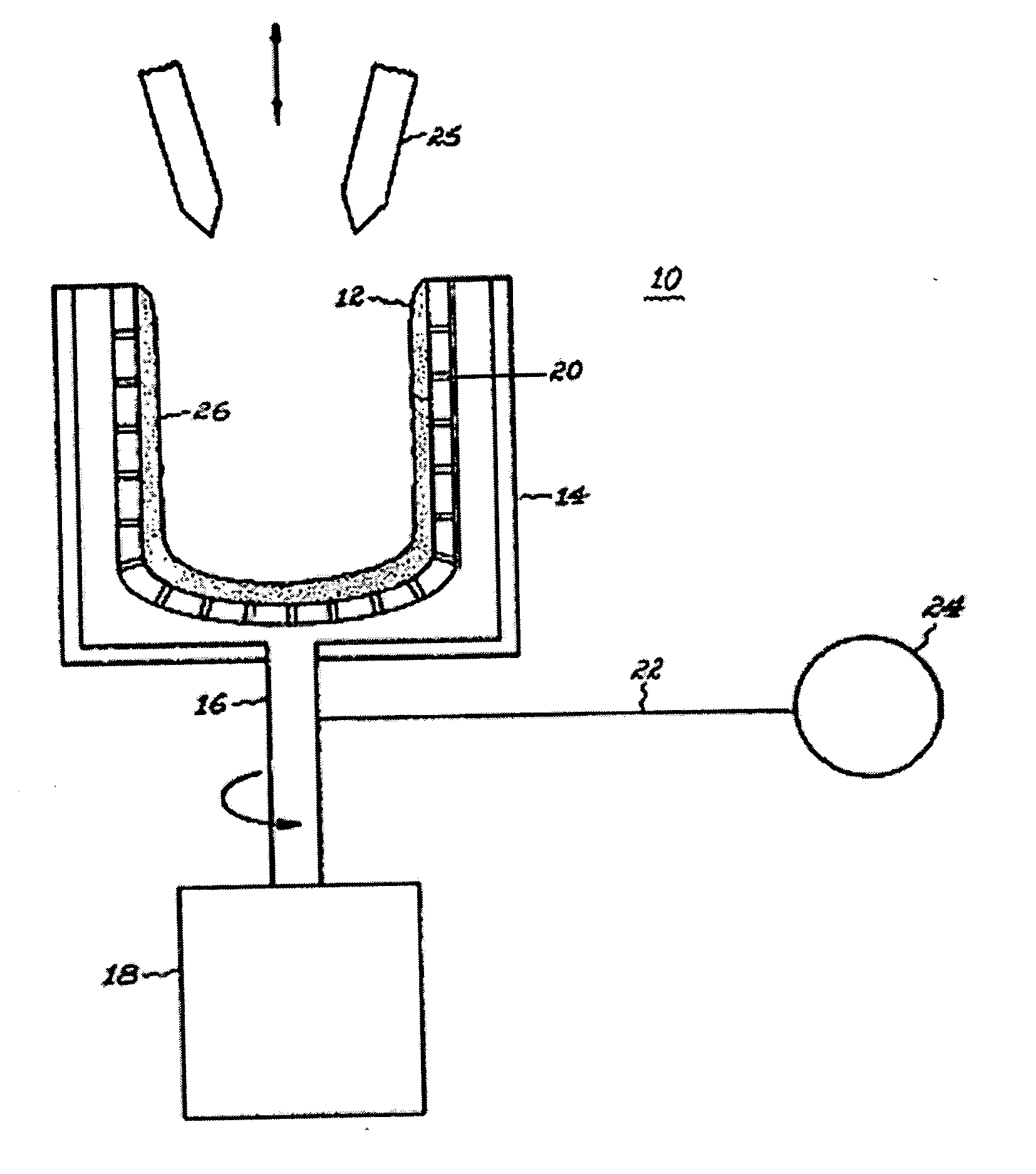

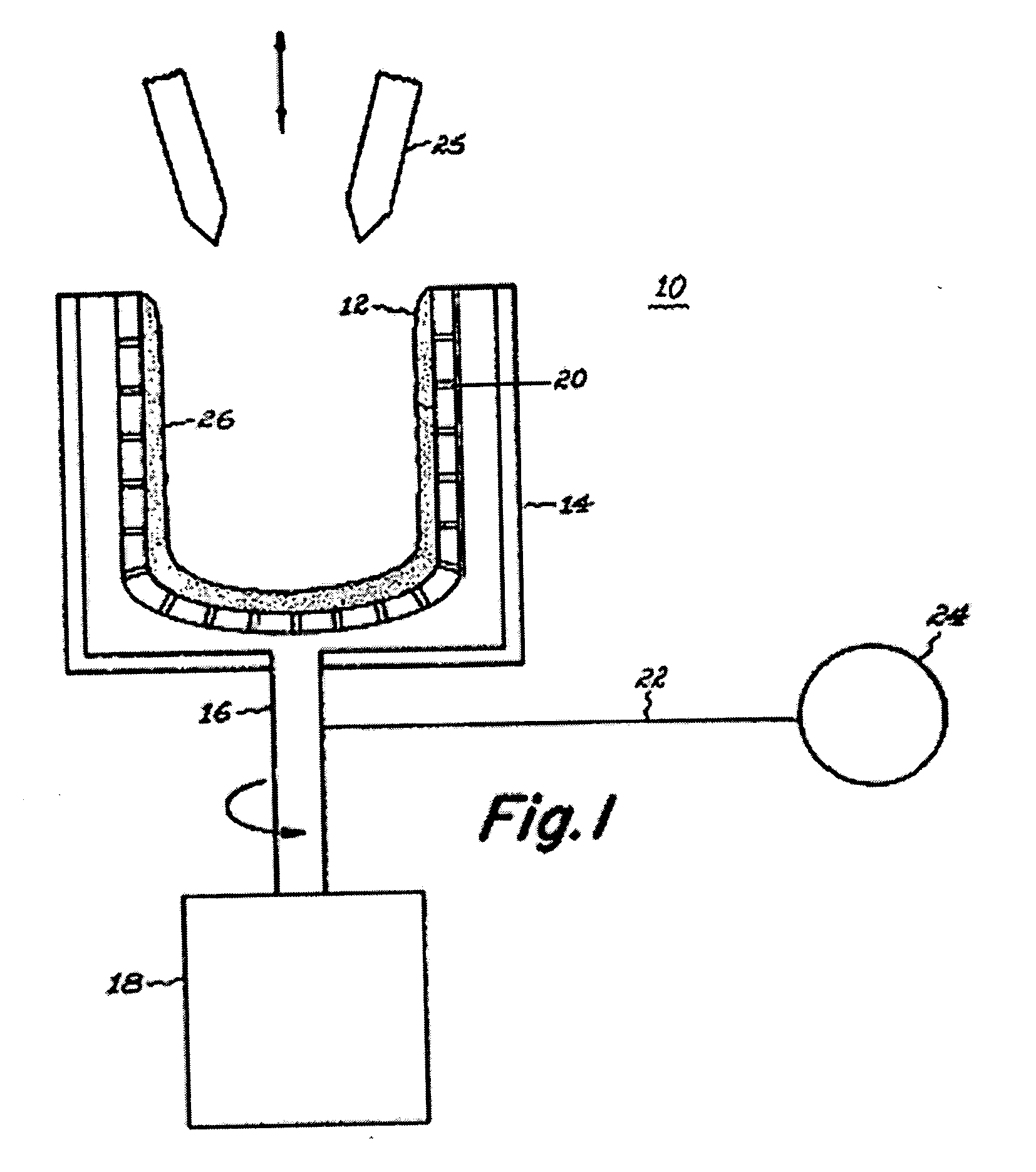

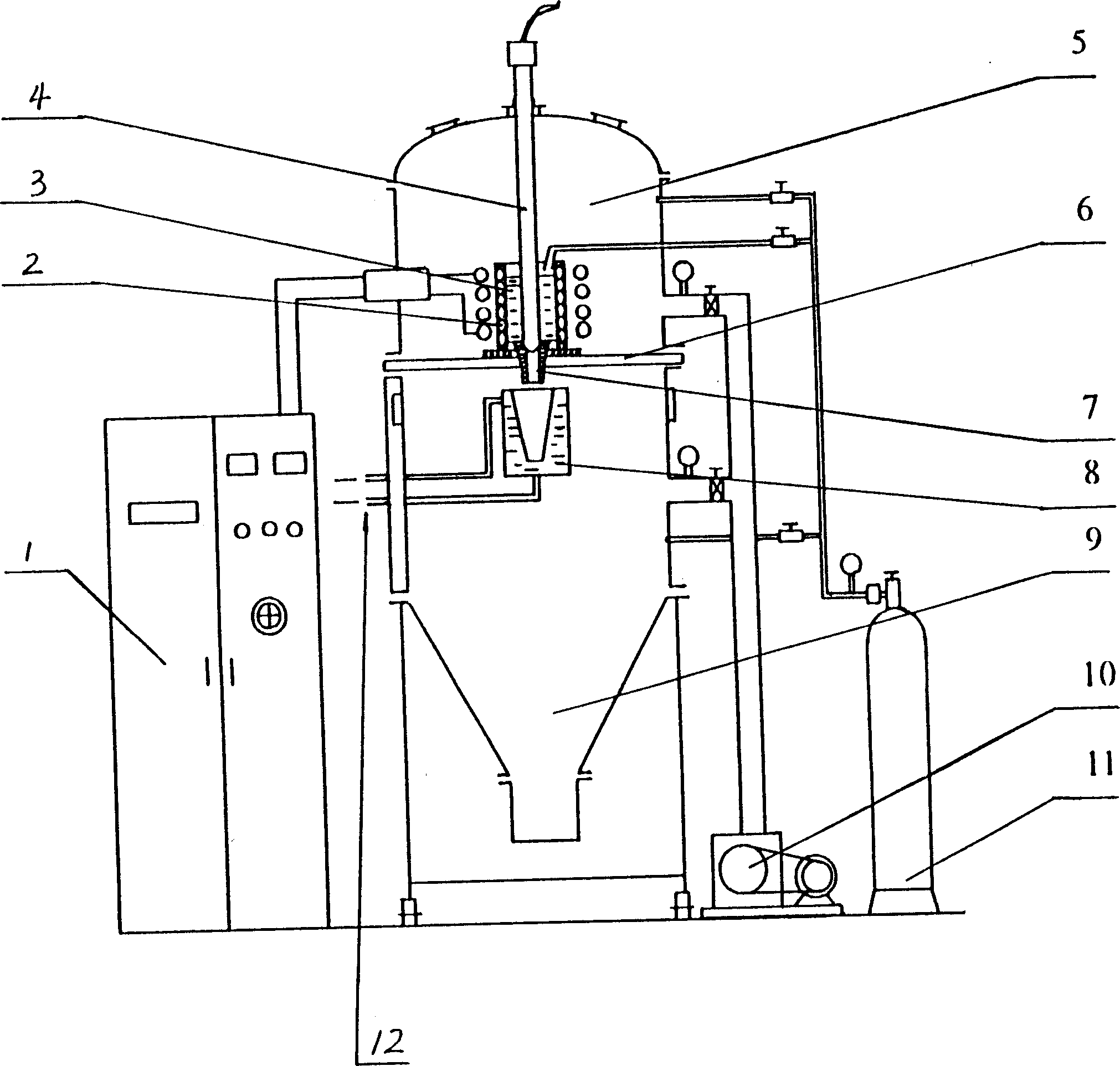

Process and device for removing phosphorus and metal impurities in polycrystalline silicon

InactiveCN101289188AHigh purityImprove efficiencyChemical industrySilicon compoundsMetal impuritiesLow vacuum

The invention relates to a method and a device for removing impurity phosphorus and metal impurities in polycrystalline silicon, which pertains to the technical field of purifying the polycrystalline silicon by a physical metallurgy technology, particularly relates to the method for removing the impurity phosphorus and the metal impurities in the polycrystalline silicon by an electron-beam fusion technology. Cooperative ways of electron-beam fusion and induction heating are used for completing the fusion and solidification process of the polycrystalline silicon. Silicon powder with high purity is used for spreading in a hollow-out space at a water cooled copper base which is filled with quartz crucibles; polycrystalline silicon material is put into the quartz crucibles and the cover of a vacuum device is closed; in the process of vacuumization, a mechanical pump and a lodz pump are firstly used for vacuumizing a vacuum room to low vacuum and then a diffusion pump is used for vacuumizing to high vacuum; the device used is provided with a vacuum device cover and a vacuum drum which are formed into the outer shell of the device; the inner cavity of the vacuum drum is the vacuum room, in which a fusion system is arranged. The method and the device of the invention effectively improve the purity of the polycrystalline silicon, which have the advantages of high efficiency, simple device and saving energy.

Owner:QINGDAO NEW ENERGY SOLUTIONS

Crucible for electronic industry and method for purifying high-purity quartz sand as lining material

The invention discloses a crucible for the electronic industry and a method for purifying high-purity quartz as a lining material. The method for purifying the high-purity quartz sand comprises the following steps of: oredressing, water quenching, flotation, scouring, magnetic separation, high-temperature vacuum treatment, chlorination, superconductive purification, electric separation, ultrasonic treatment, rectification and purification and electric screening. The purification method provided by the invention has the advantages of simple process and remarkable purification effect; and the obtained high-purity quartz is used for a high-purity quartz crucible and the lining material in the electronic industry and improves the industrial value of quartzite.

Owner:JIANGSU SHENGDA QUARTZ PROD CO LTD

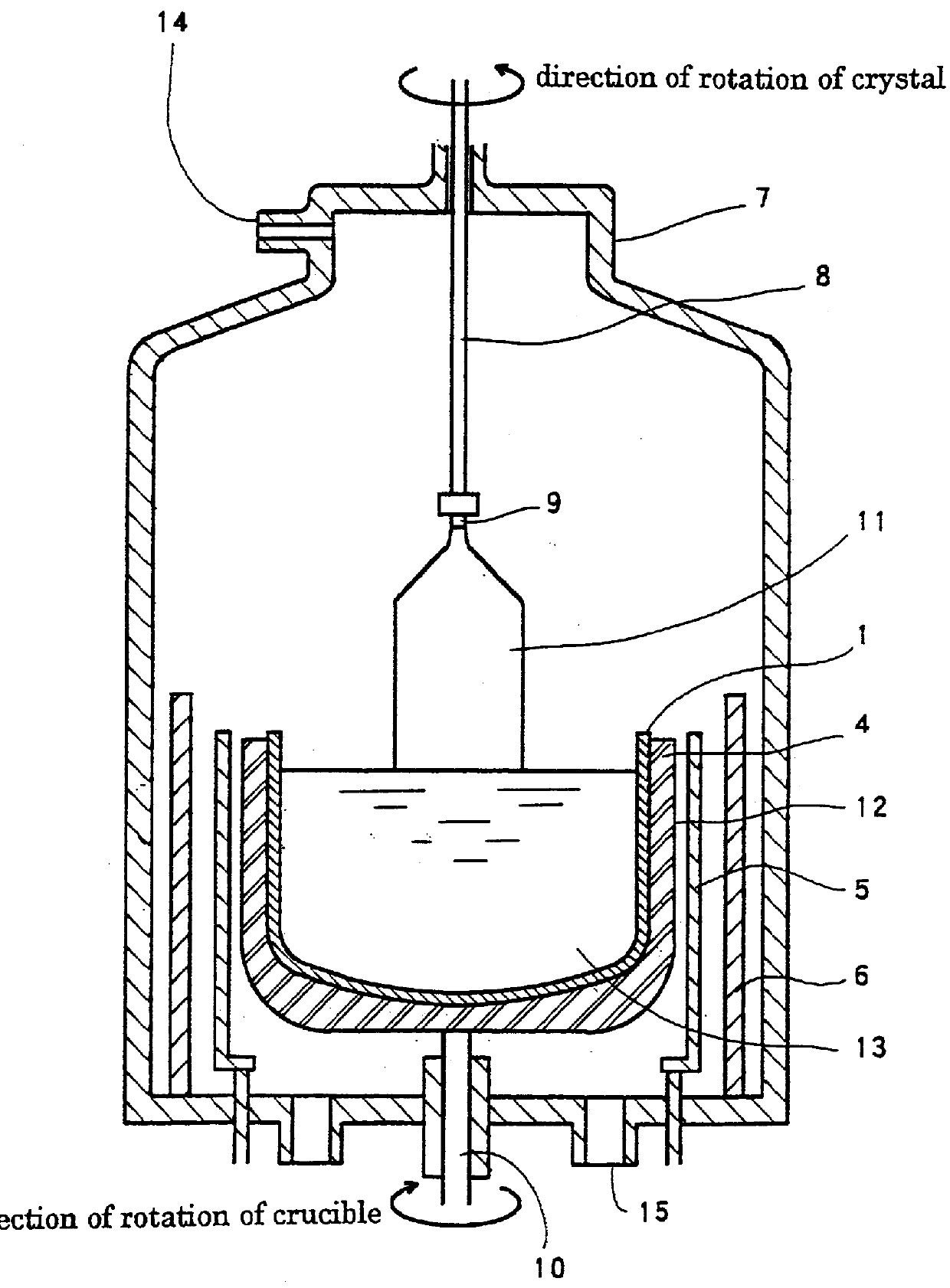

Method of effecting nitrogen doping in Czochralski grown silicon crystal

InactiveUS6059875APolycrystalline material growthBy pulling from meltSufficient timeCzochralski method

A method of introducing nitrogen into a melt for use in producing a nitrogen-doped silicon single crystal by the Czochralski method includes adding a silicon material to a vessel, such as a quartz crucible, adding a nitrogen-containing powder, preferably silicon nitride powder, to the vessel, and heating the vessel for a time sufficient to melt the silicon material and to dissolve the nitrogen-containing in the silicon material in order to form the melt. A nitrogen-doped silicon single crystal is then produced from the melt by the Czochralski method by pulling the silicon single crystal from the melt with a seed crystal.

Owner:SEH AMERICA

Method for growing a silicon single crystal

InactiveUS6086671AReduce amountReduce the amount requiredPolycrystalline material growthSemiconductor/solid-state device manufacturingDislocationSeed crystal

A method for melting a silicon starting material can suppress silica (SiO2) from melting out from a quartz crucible wherein the silicon starting material is melted and can provide a high-quality silicon single crystal in a high yield. The growth method comprises melting the silicon starting material charged in the crucible while applying thereto a static magnetic field, contacting a seed crystal to a surface of the silicon melt, and pulling the seed crystal upwardly to solidify the contacted melt. The silicon starting material charged in the crucible, which is under melting, is applied with a static magnetic field such as a Cusp magnetic field, a horizontal magnetic field and / or a vertical magnetic field. The application can control heat convection occurring in the crucible during the course of the melting of the starting material, thereby obtaining a silicon single crystal having a reduced number of dislocation defects.

Owner:SUMITOMO MITSUBISHI SILICON CORP

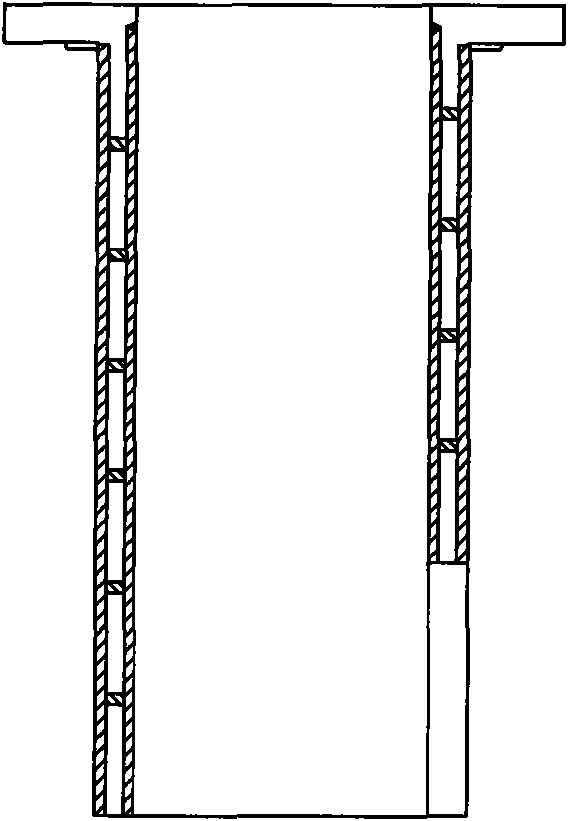

CZ method silicon single crystal growth furnace quartz crucible carbon protection crucible and manufacturing process thereof

InactiveCN101643933AExtended service lifeGuaranteed radiationBy pulling from meltCarbon coatingFiber

The invention relates to a CZ method silicon single crystal growth furnace quartz crucible carbon protection crucible and a manufacturing process thereof. The CZ method silicon single crystal growth furnace quartz crucible carbon protection crucible comprises an upper crucible edge, a lower crucible edge and a crucible support, wherein the upper crucible edge and the lower crucible edge comprise green bodies and matrix carbon, the surface is provided with a silicon carbide coating, each green body is formed by the superposition of two-dimensional carbon fiber fabrics or is formed by a quasi-three-dimensional punched carbon fiber felt body, and the weight is not lower than 40 percent of weight of the protection crucible; the matrix carbon comprises carbon resin and chemical vapor depositioncarbon, wherein the content of the chemical vapor deposition carbon is not higher than 30 percent of total weight of the product; the density of materials of the upper crucible edge and the lower crucible edge is higher than or equal to 1.3g / cm <3>; holes with the diameters ranging from 5 to 30 mm are uniformly distributed on the upper crucible edge and the lower crucible edge, the walls of the holes and the inner surfaces of the crucible edges are provided with silicon carbide coatings, and the thickness ranges from 10 to 100 mu m; and the crucible support comprises high strength and high purity graphite and surface deposited carbon coatings, the density thereof is higher than or equal to 1.7g / cm <3>, and the thickness of the surface deposited carbon coatings ranges from 10 to 100 mu m.

Owner:HUNAN NANFANG BOYUN NOVEL MATERIAL

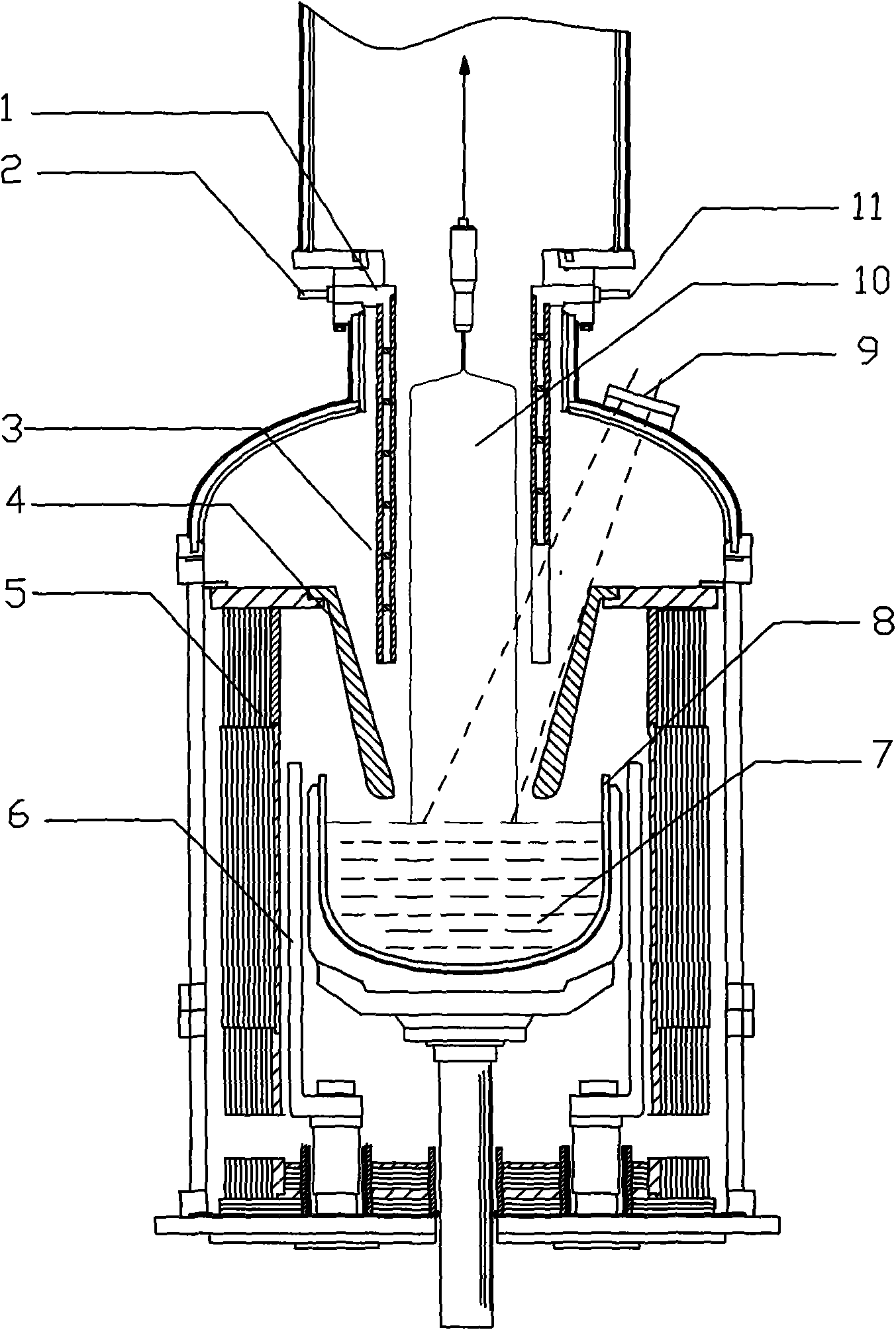

Vertical pulling silicon single crystal growing furnace with water-cooling jacket

InactiveCN101575731AHeat dissipation fastFast growthPolycrystalline material growthBy pulling from meltCooling effectEngineering

The invention relates to a device for preparing silicon single crystal and aims at providing a vertical pulling silicon single crystal growing furnace with a water-cooling jacket. The growing furnace comprises a heater, a quartz crucible and a heat insulating device. The above of the quartz crucible is provided with a thermal shielding device which guards a single crystal rod lifting region; the tube-shaped water-cooling jacket is arranged between the thermal shielding device and the single crystal rod lifting region; and the water-cooling jacket is a hollow jacket device, the interior of which is a channel for cooling water to flow and provided with a water inlet pipe and a water outlet pipe. The newly grown high temperature part of the single crystal rod is cooled by the water-cooling jacket, and large temperature difference ensures the single crystal rod to dissipate heat rapidly, and the growing speed of the single crystal rod can increase nearly one time. As the heat on the growing interface of the single crystal rod can be led away by the single crystal rod, the power consumption of the heater can be reduced greatly and the micro defect of the crystal can be reduced. If the temperature of the used cooling water is lower, the cooling effect is better.

Owner:ZHEJIANG JINGSHENG MECHANICAL & ELECTRICAL

Quartz crucible and method for casting quasi-single crystal

InactiveCN101979718AQuality improvementImprove electrical performanceFrom frozen solutionsConventional castingElectrical performance

The invention discloses a quartz crucible. The bottom of the quartz crucible is provided with a pit which is spontaneously generated by inducing seed crystal. The invention also discloses a method for casting quasi-single crystal by using the quartz crucible. By using the quartz crucible of the invention, the quality of grown cast crystalline silicon is effectively improved so as to improve the electrical performance of a solar cell. By the method for casting the quasi-single crystal in the invention, the diameter of the obtained crystal grain is about 5 to 10cm, tests show that the dislocation density is about 10<3>cm<-2> which is far less than a number range of 10<4> to 10<5>cm<-2> of silicon crystal obtained by the conventional casting method under the same condition; and accordingly, the minority carrier lifetime value of a silicon slice obtained by the method of the invention is about 18us which is greater than the minority carrier lifetime value of 11us of the silicon slice prepared from the same raw material by the conventional casting method.

Owner:ALTUSVIA ENERGY TAICANG

Preparation of hyperpure metallurgy silicon

InactiveCN101353167AWell mixedFully and effectively removePolycrystalline material growthFinal product manufacturePurification methodsSolar cell

A preparation method of ultrapure metallurgical silicon belongs to the purification technology of silicon, and the invention provides a primary purification method of a silicon material which totally contains less than 100ppma of impurities and is used for preparing solar cells. In the method, the physical metallurgical technology is used, industrial silicon powder (purity is higher than 99.5%) is taken as a raw material,, after being chemically pre-processed by acid, the silicon powder is evenly mixed with a slagging agent and put in a quartz crucible of a smelting furnace, protective gas is blown to the smelting furnace at micro-vacuum state or normal pressure; induction heating is carried out till the temperature of the smelting furnace is 1400-1700 DEG C, and the silicon metal is melted into a silicon melt; slagging is carried out to remove impurities; and finally directional solidification is carried out to obtain the ultrapure metallurgical silicon totally containing less than 100ppma of impurities. The method can remove most of metal impurity elements from silicon, especially can reduce the contents of B and P in the silicon effectively, and meet the demand of low-cost solar cells for silicon materials. The method saves equipment investment, reduces energy consumption, and has simple technology and easy operation in production.

Owner:贵阳高新阳光科技有限公司

Melt near quick setting method and special apparatus

A near-fast solidifying method and apparatus for molten body are disclosed. Said apparatus is composed of a vacuum chamber consisting of upper and lower vacuum cavities and central sealing unit, heater in the upper vacuum cavity, quartz crucible in the heater, mould in the lower vacuum cavity, and circulating cooler. Its method includes vacuumizing said vacuum chamber repeatedly, filling argon gas, heating mother alloy to a temp which is 50-200 deg.C higher than its melting point, pulling up plunger rod while filling pressure argon gas to pour the molten alloy in mould instantaneously, and quick cooling.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

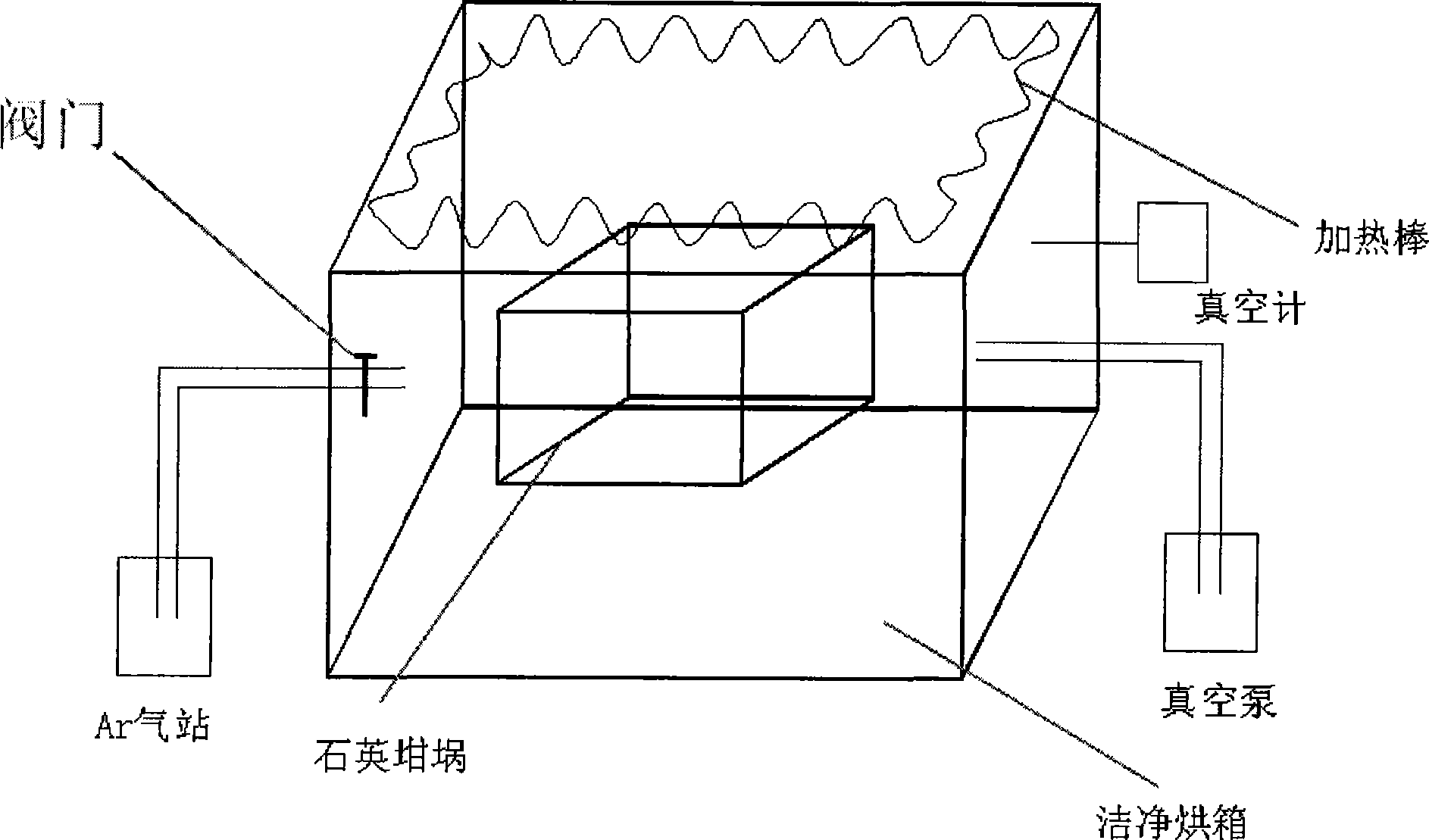

Preparation method of silicon nitride coating quartz crucible

The invention provides a preparation method of a silicon nitride coating quartz crucible, which is characterized by comprising the steps of ceramic slurry preparation, coating spraying, drying and sintering. The preparation method comprises the flowing detail steps of mixing monocrystalline silicon powder with the granularity of 0.01-3 micrometers and silicon dioxide powder with the granularity of 0.01-3 micrometers to form a ceramic bond; then preparing the ceramic bond, silicon nitride powder with the granularity of 1-5 micrometers and ethanol into in a ball mill to obtain silicon nitride ceramic slurry; carrying out vacuum treatment, and then spraying to the surface of an unfired quartz crucible to form the silicon nitride coating with the thickness of 10-100 micrometers; drying at the temperature of 80-100 DEG C, and then sintering at the temperature of 1140-1300 DEG C in a nitrogen atmosphere for 6-8 hours to prepare the silicon nitride coating quartz crucible. The prepared silicon nitride coating quartz crucible is used for smelting monocrystalline silicon and polycrystalline silicon; in addition, the preparation method the characteristics of has high coating bond strength and low cost because the silicon nitride coating and the quartz crucible are sintered simultaneously.

Owner:SHANDONG UNIV OF TECH

Method for preparing graphite electrode of quartz crucible

ActiveCN101980583ATake advantage ofEasy to operateElectric discharge heatingCeramic shaping apparatusGraphite electrodeGraphite

The invention relates to a method for preparing a graphite electrode of a quartz crucible. The method is characterized by comprising the following steps of: crushing and portioning calcined petroleum coke and graphite powder, and adding 20 to 30 percent of molten asphalt into the mixture for kneading; extruding the mixture for molding through an extruder, and baking the extruded mixture for 240 to 300 hours at the temperature of between 830 and 880 DEG C; soaking the baked product into 10 to 20 percent of molten asphalt; baking the soaked product for 180 to 220 hours at the temperature of between 750 and 800 DEG C; and finally, purifying and graphitizing the product for 50 to 70 hours at the temperature of between 2,500 and 2,700 DEG C. The preparation method has the advantages of simple process operation, high yield and strong practicability, makes full use of resources, saves the cost and keeps high volume density at the same time.

Owner:兴和县青山特种石墨碳素有限公司

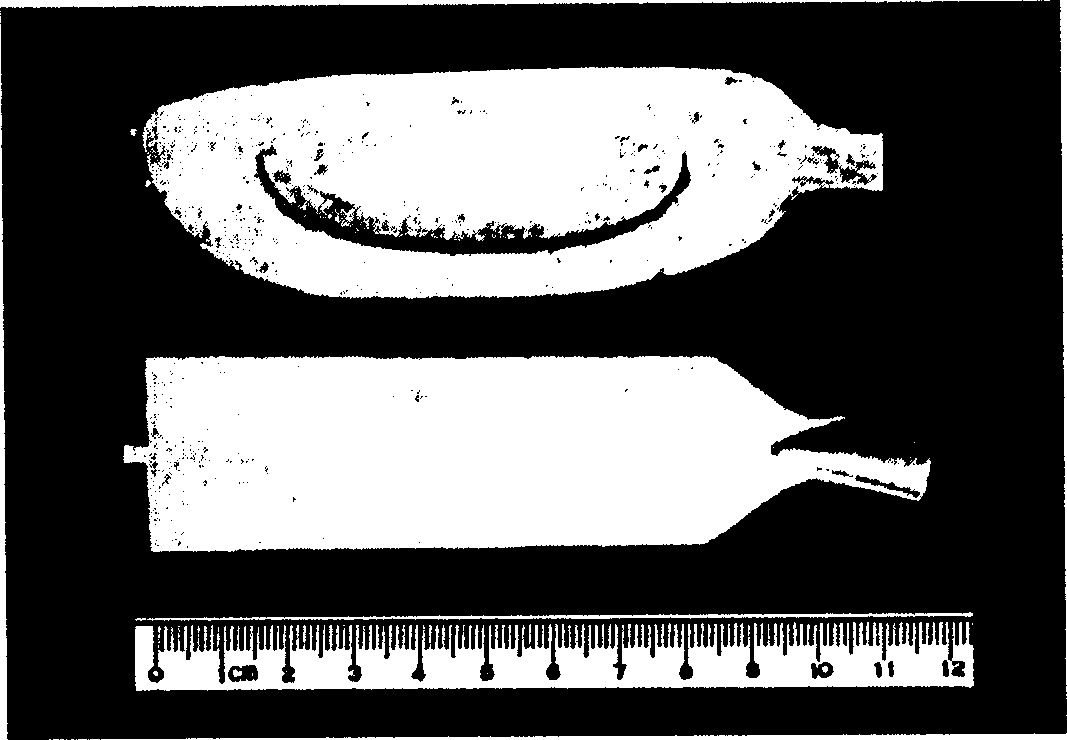

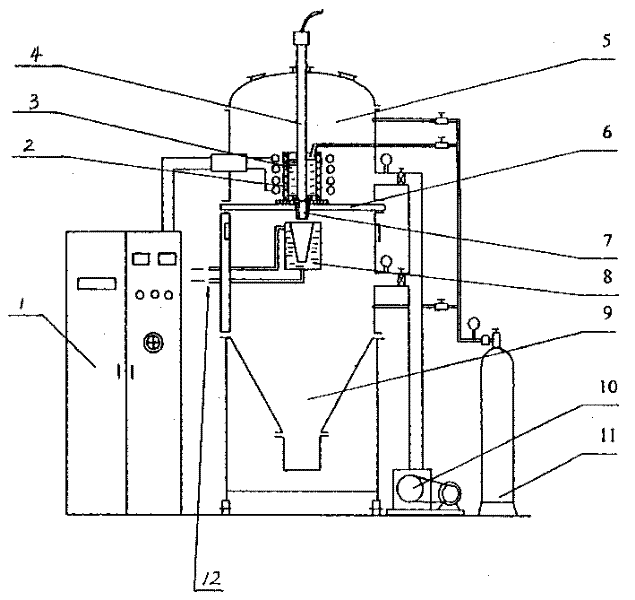

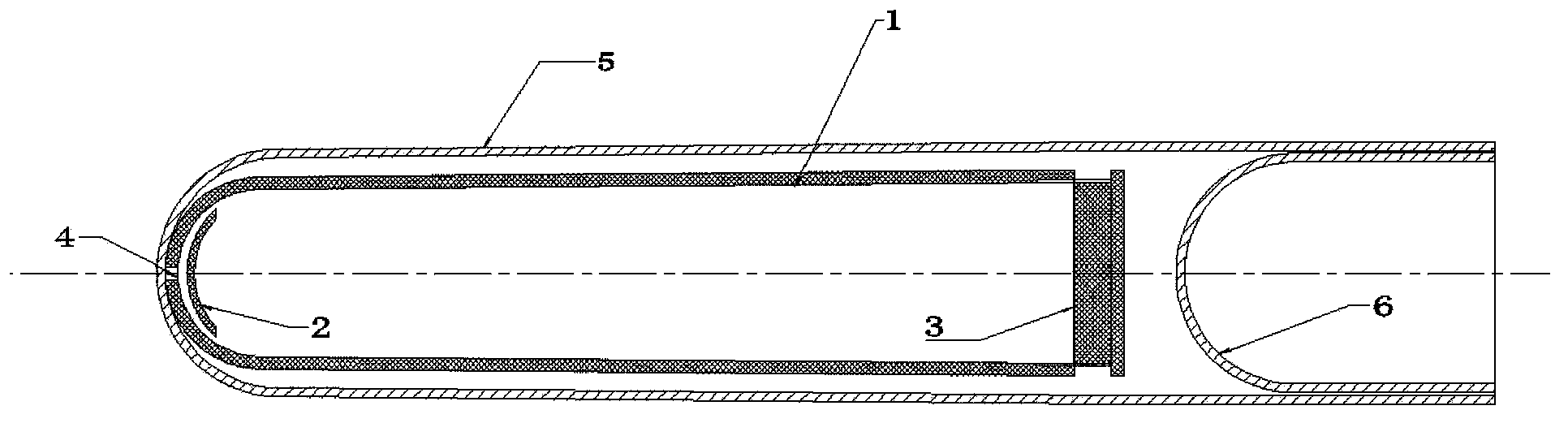

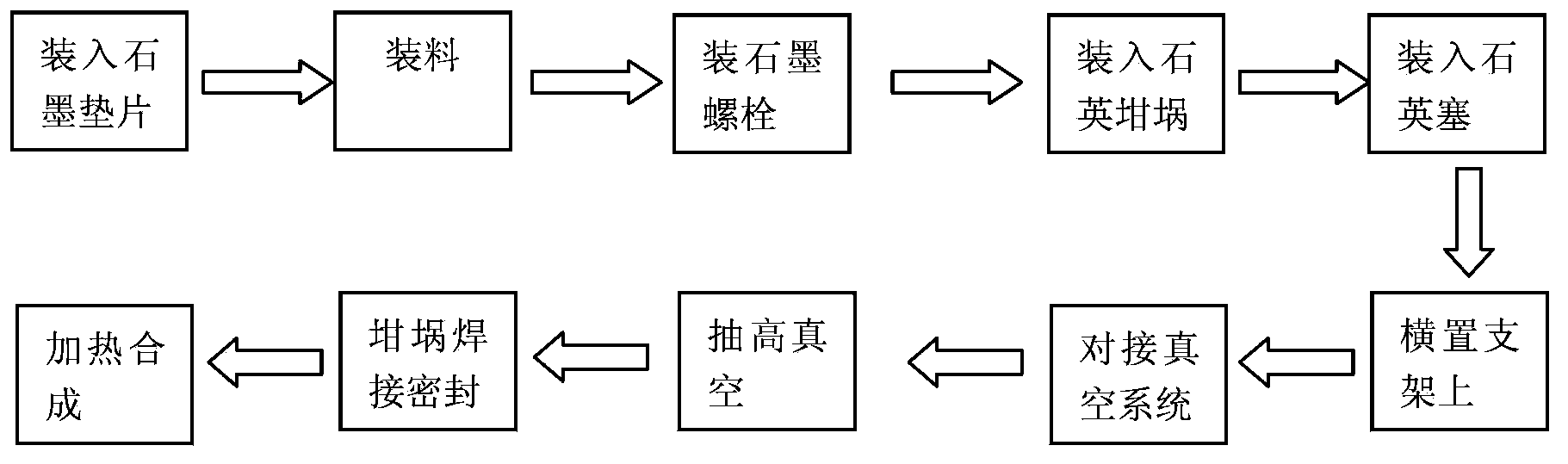

Large-diameter CdTe or CdZnTe polycrystalline rod synthesis apparatus and preparation method thereof

ActiveCN103409800AAvoid pipe cracking or even pipe explosionAvoid damagePolycrystalline material growthSingle crystal growth detailsChemical combinationLatent heat

The invention discloses a large-diameter CdTe or CdZnTe polycrystalline rod synthesis apparatus and a preparation method thereof. The apparatus is characterized in that an aspirating hole is arranged at the bottom of a graphite crucible, a graphite pad is placed at the bottom of the graphite crucible, a graphite cover is positioned at the mouth of the graphite crucible, the whole graphite crucible is placed in a quartz crucible and has a corresponding gap with a quartz plug, and the quartz plug is positioned at the mouth of the quartz crucible. The quartz crucible and the quartz plug are sealed through welding by adopting oxyhydrogen flame; the obtained quartz crucible is sent to a synthesis furnace and is heated to realize a raw material synthesis technology in order to prepare CdTe or CdZnTe polycrystalline rods; and the graphite crucible is completely sealed in the quartz crucible to make the solid material in graphite crucible in a high vacuum state at normal temperature, so the violent release and the heat impact of latent heat in a raw material mixture chemical-combination process can be effectively born during the heating synthesis, the frequent-appearing quartz crucible explosion or cracking event is completely avoided in the highly-pure raw material mixture synthesis process, and the highly pure graphite crucible can be repeatedly used, thereby the batch production cost is reduced.

Owner:WUHAN GAOXIN TECH

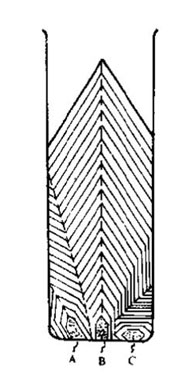

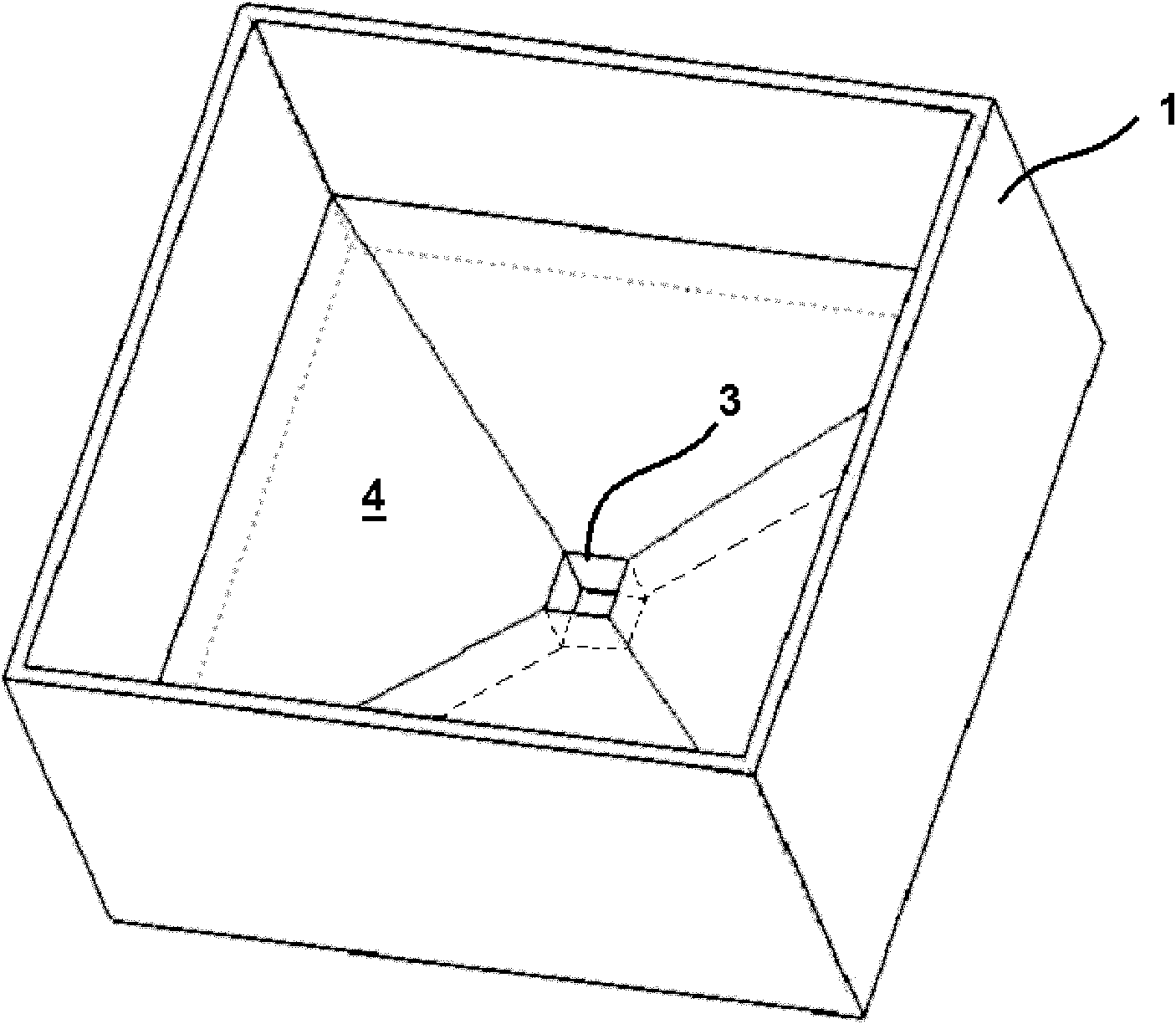

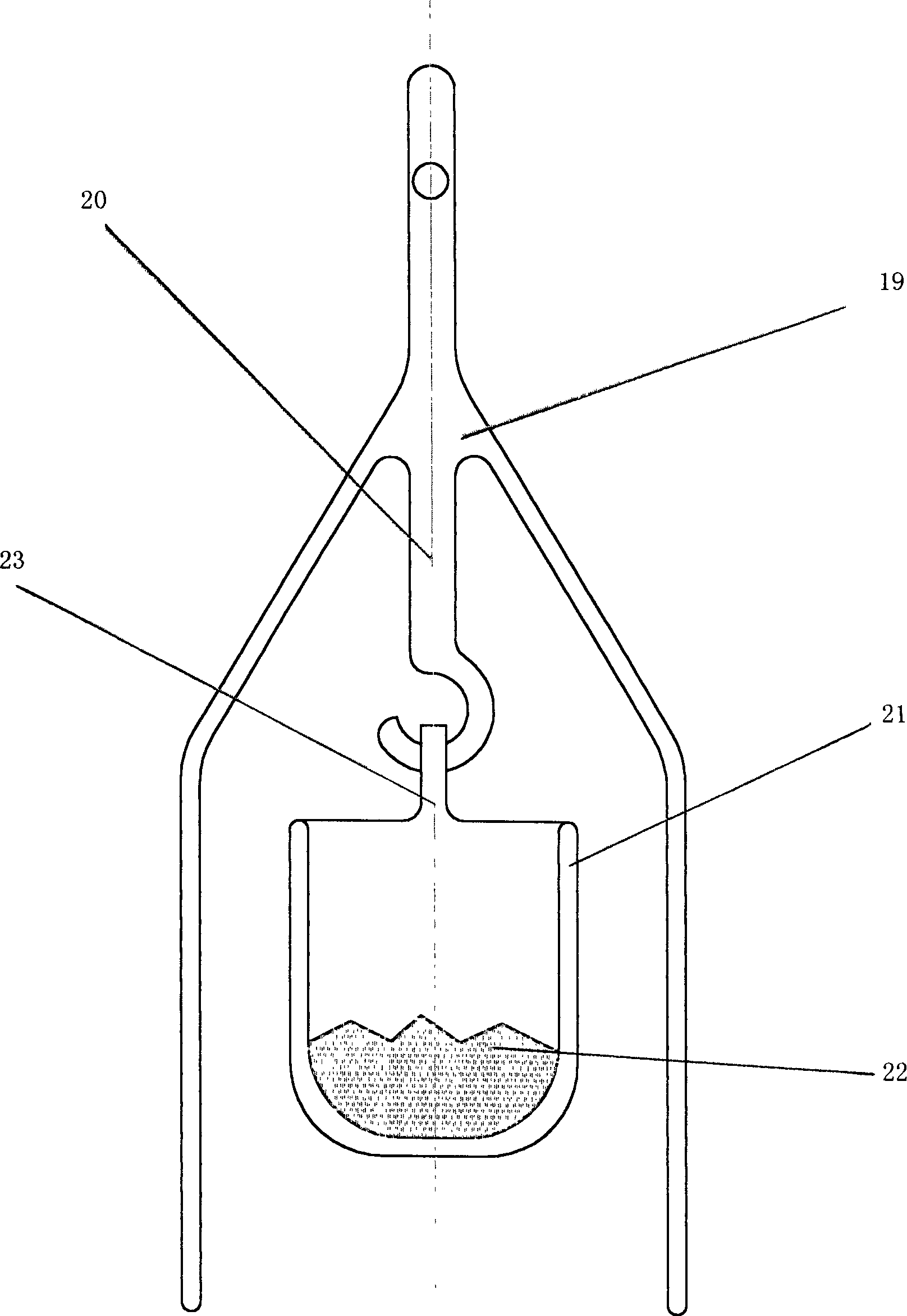

Seeding guidance die for growing silicon crystal by directional solidification method

InactiveCN101928980ALow costGuaranteed efficient growthPolycrystalline material growthFrom frozen solutionsIngotEngineering

The invention discloses a seeding guidance die for growing crystal by a directional solidification method, which is arranged at the bottom of a quartz crucible and comprises a seed container and a seeding section, wherein the seed container is provided with a first cavity for placing the seeds; the seeding section is composed of one or a plurality of blocks connected around the seed container; the contact surface of the block and a silicon raw material in the quartz crucible is a dome; the dome is bent to form an approximate trapezoid conical surface of which the bottom contacts with the top end of the first cavity; and the top of the trapezoid cone contacts with the side wall of the quartz crucible. The invention can solve the seed placement problem without changing the structure of the existing directional solidification furnace and the quartz crucible, and eliminates seed dislocation in the seeding process so as to effectively grow monocrystalline silicon or polycrystalline silicon ingots with large crystal grains. The seeding guidance die of the invention has low cost and easy manufacture.

Owner:GREENERGY CRYSTAL TECH

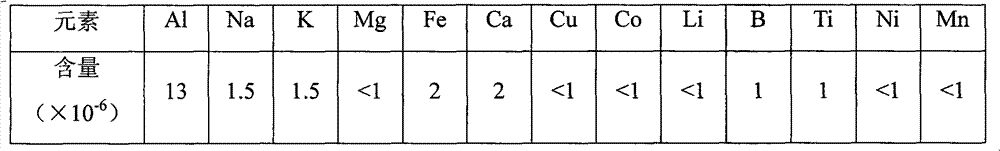

Method for preparing high-purity quartz sands by using natural vein quartz ores

The invention relates to a method for preparing high-purity quartz sands by using natural vein quartz ores, which belongs to the technical field of ore machining and raw materials for a quartz glass crucible for producing a drawn monocrystalline silicon. The method comprises the following steps of: using the natural vein quartz ores as raw materials; carrying out high temperature calcining-water quenching on the natural vein quartz ores so as to remove inclusions in the natural vein quartz ores and impurities in gaps of the vein quartz ores; removing almost trace element impurities through a flotation and mixed acid impregnation technology; and finally, washing the vein quartz ores by using ethanol-deionized water to furthest remove organic impurities introduced in the flotation and acid pickling process and other soluble impurities, so as to obtain the high-purity quartz sands, wherein the raw materials are provided for preparing the quartz glass crucible for producing the drawn monocrystalline silicon.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

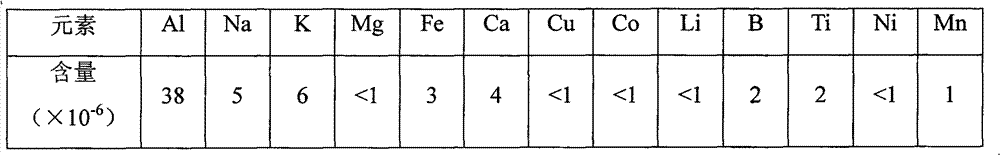

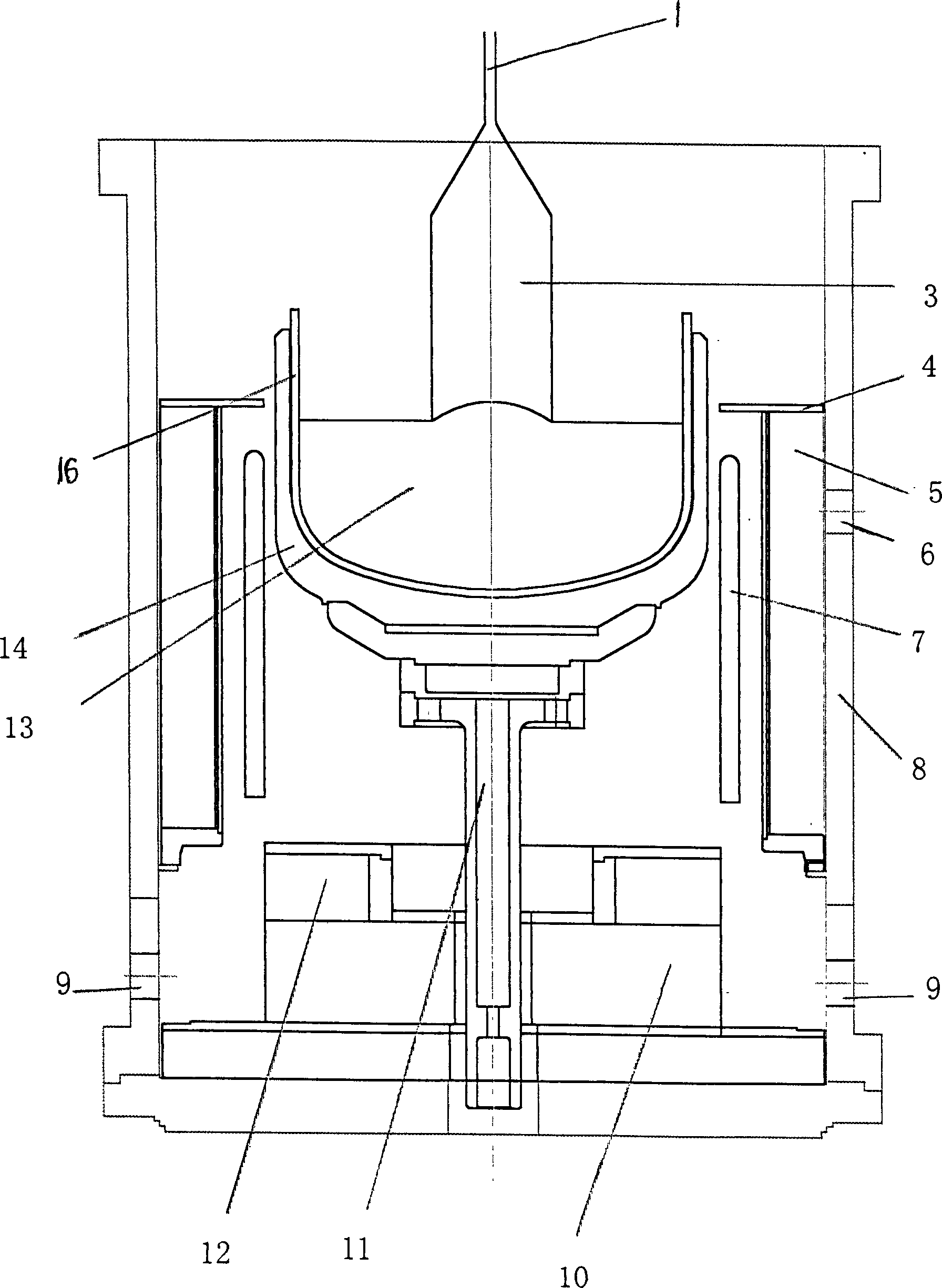

Doping method used in vertical pulling silicon single crystal preparation and its installation

InactiveCN1414147AImprove doping efficiencyReduce the number of remeltsBy pulling from meltGas phaseCrystal orientation

A process for doping the monosilicon in its vertical pulling procedure includes such steps as loading the element to be doped in the internal cylinder of doping apparatus, lowering the doping apparatus to the level of molten monosilicon, rotating quartz crucible to voltilize all said element, installing the seed crystal with particular crystal orientation, and pulling. It has high doping efficiency.

Owner:GRINM SEMICONDUCTOR MATERIALS CO LTD

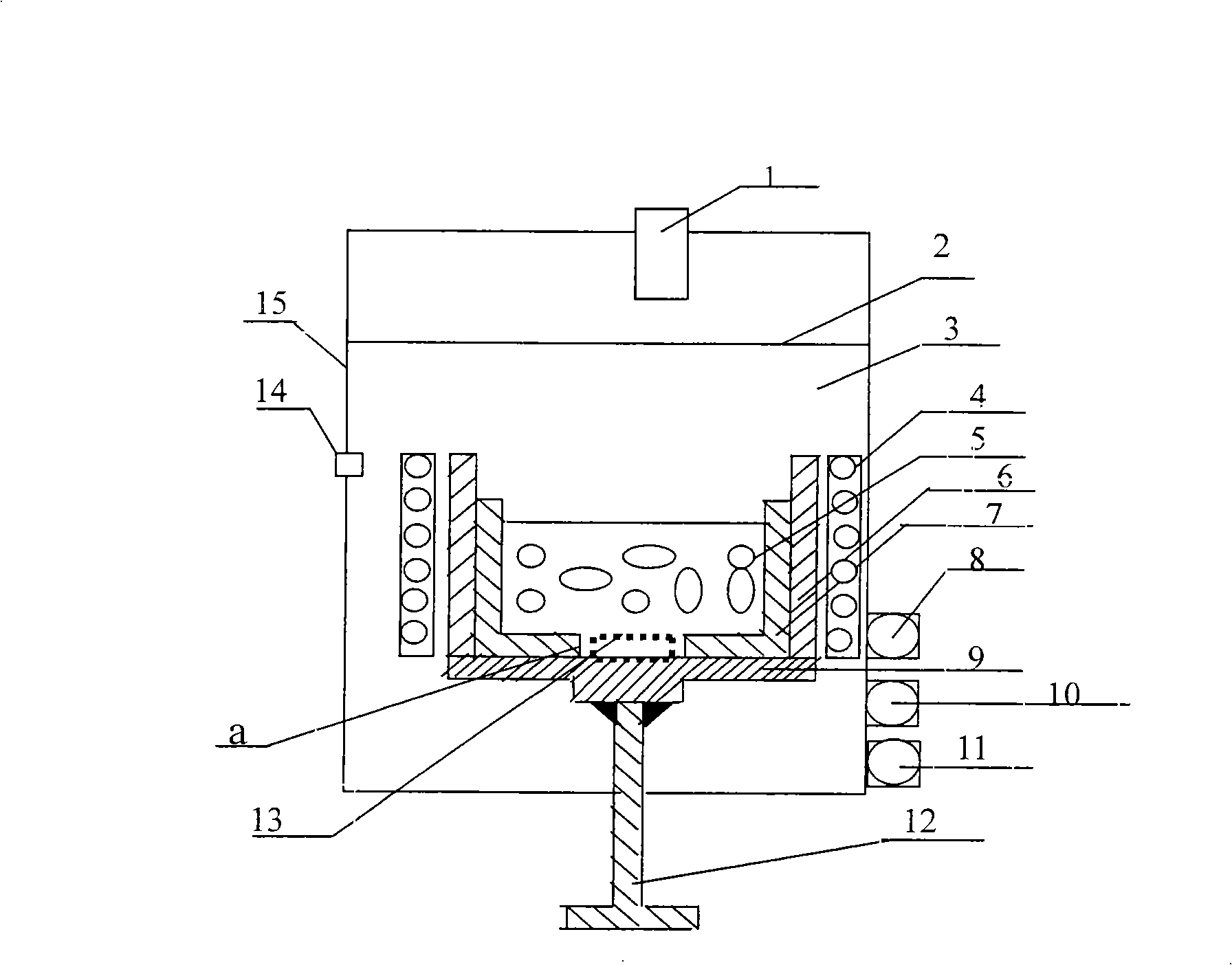

Preparation method of polycrystalline silicon

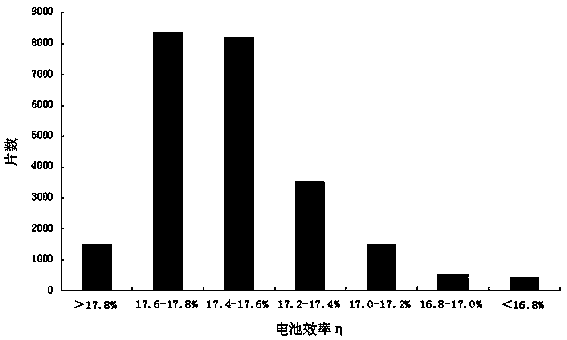

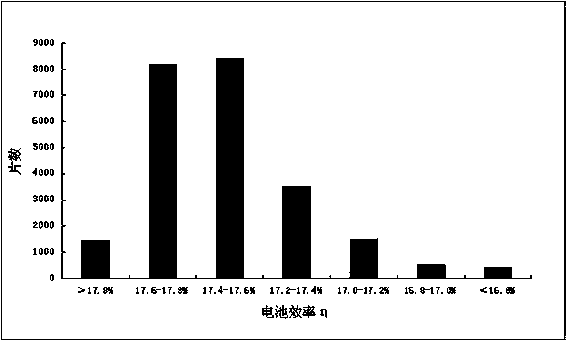

ActiveCN103469293AEasy to operateGuaranteed not to be completely meltedPolycrystalline material growthFrom frozen solutionsThermal insulationPhysical chemistry

The invention discloses a preparation method of polycrystalline silicon. The preparation method of the polycrystalline silicon comprises the following steps: firstly carrying out pre-treatment on a quartz crucible, then paving a crystalline silicon chip material layer at the bottom of the quartz crucible, then placing silicon and mother alloy into the quartz crucible, charging, vacuumizing, and heating to melt silicon; after melting is finished, controlling the temperature of a heater to be 1540-1570 DEG C, lifting a thermal insulation cage until aperture a is 5-20mm, and controlling temperature TC2 to be no more than 1425 DEG C until broken polycrystals at the bottom are just molten, performing a temperature-fall period, and slowly opening the thermal insulation cage while slowly cooling in gradient; finally growing crystals, so that the polycrystalline silicon containing massive twin crystals is formed. A polycrystalline silicon slice prepared by adopting the preparation method is uniform in grain size, the battery efficiency is 0.2-0.3% higher than that of common polycrystalline silicon, the average battery efficiency of the whole silicon slice is more than 17.5%, and ratio of the silicon slice with the efficiency more than 17.4% is more than 65.0%.

Owner:HUNAN RED SUN PHOTOELECTRICITY SCI & TECH

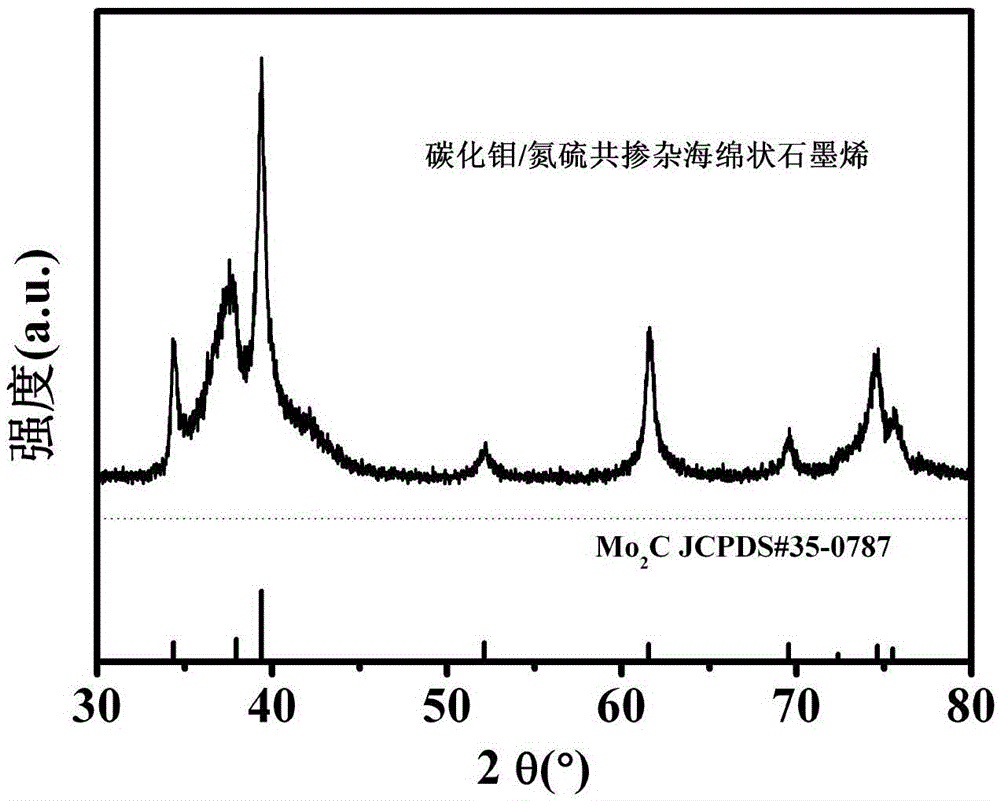

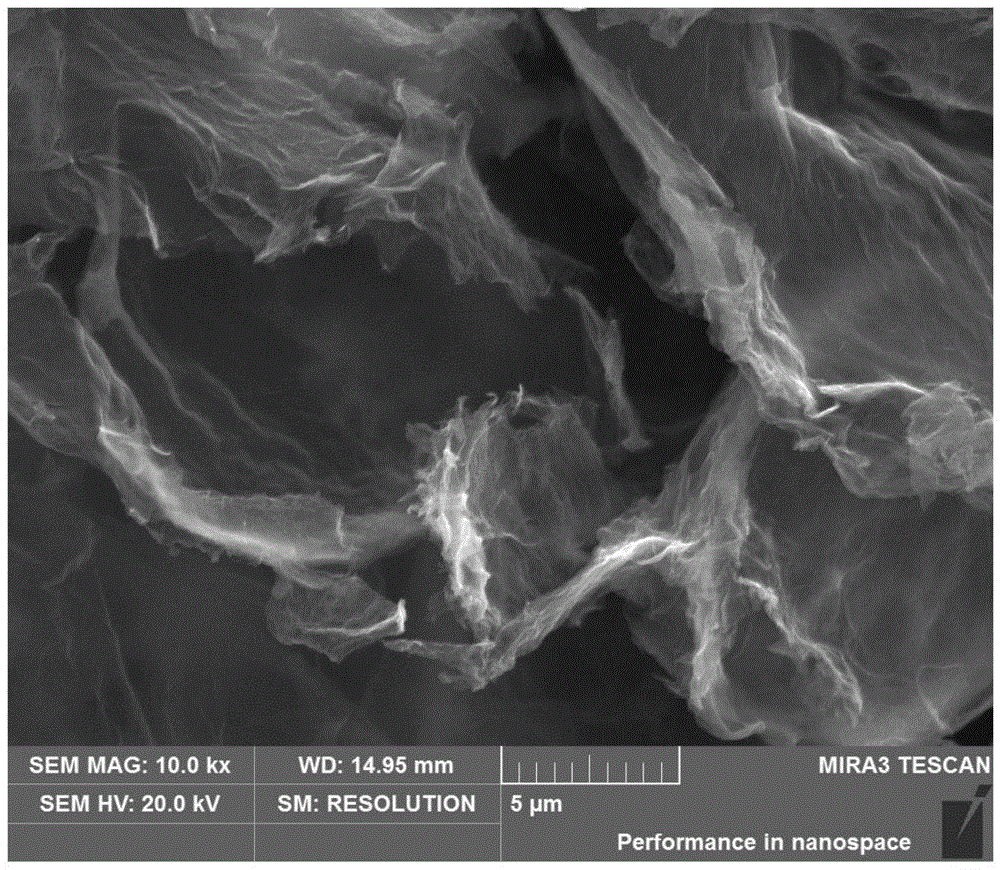

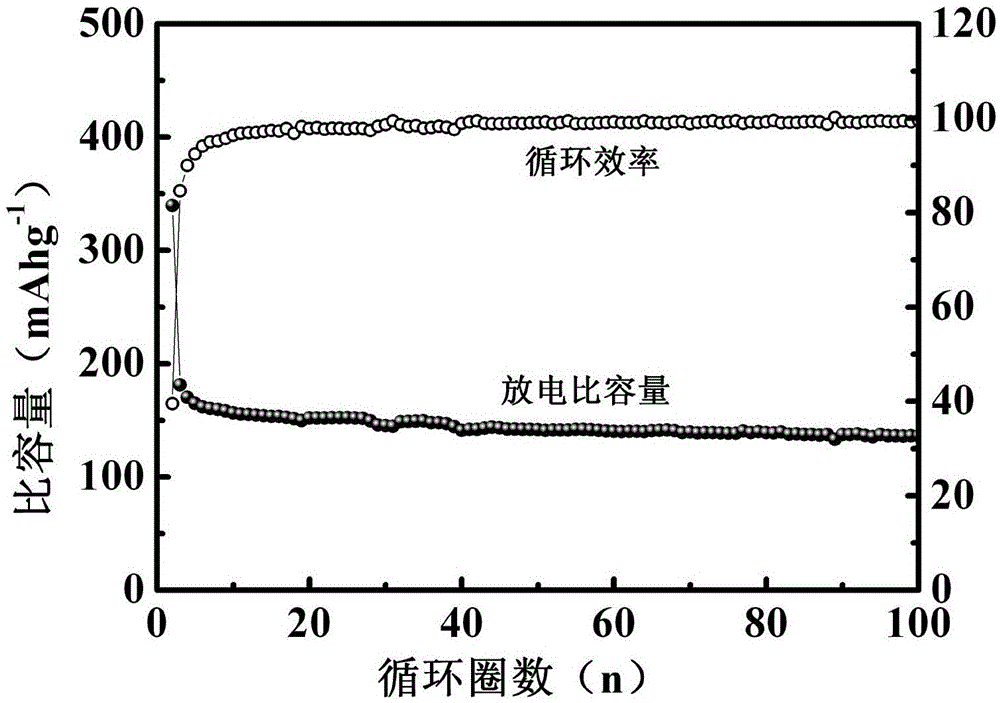

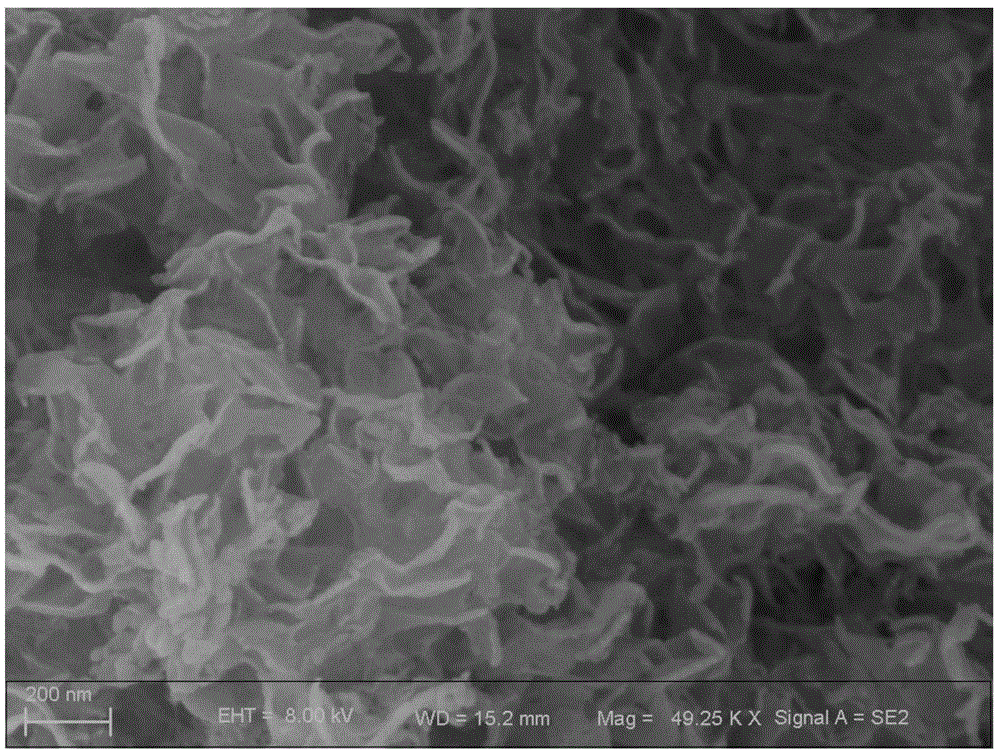

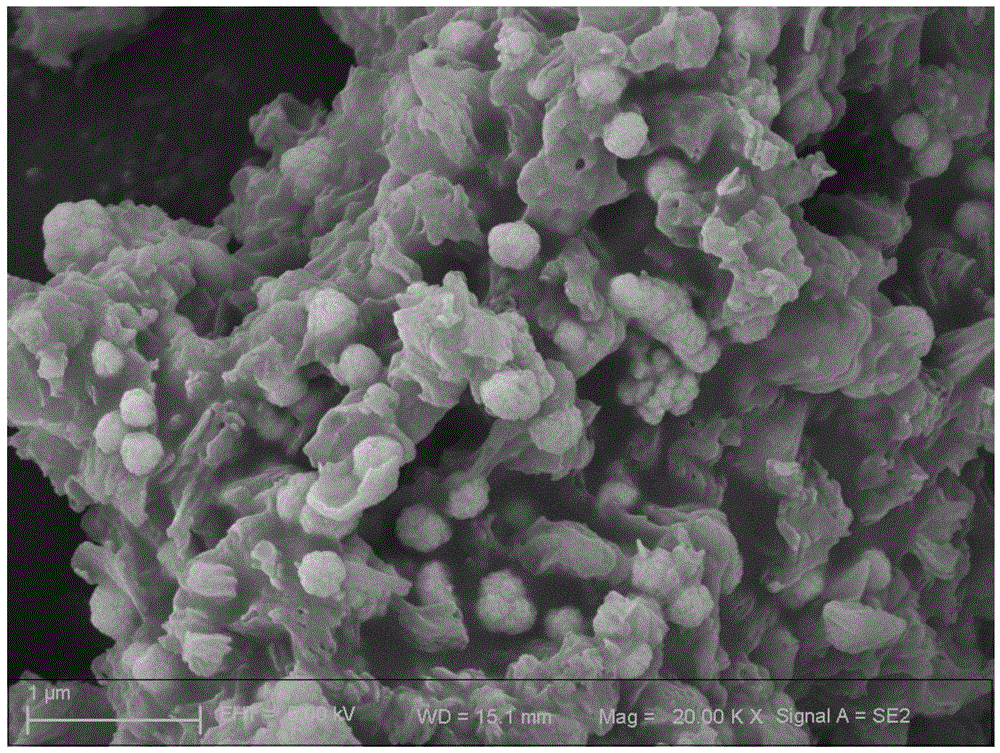

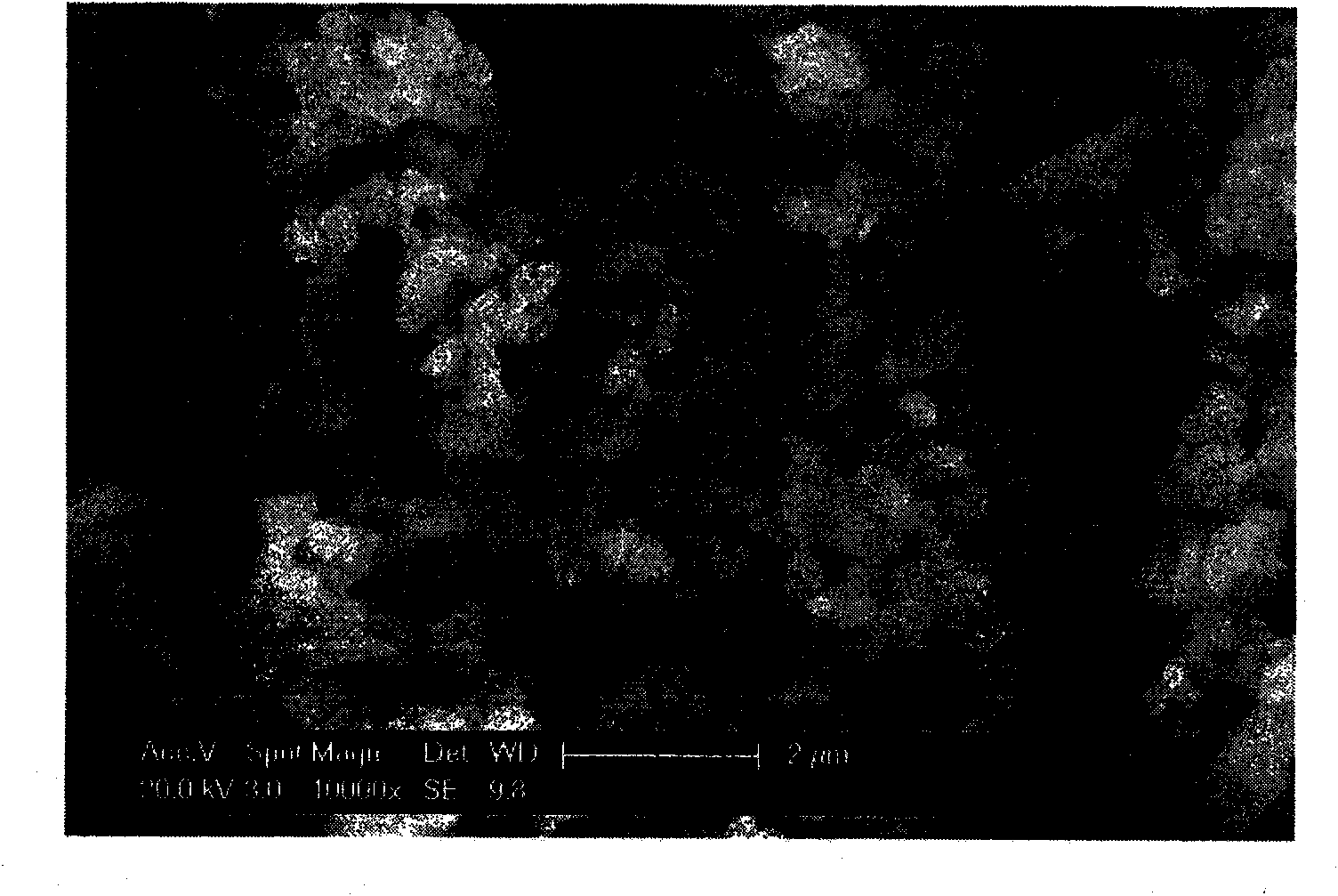

Preparation method of molybdenum carbide/nitrogen-sulfur codoped spongy graphene cathode composite for sodium-ion battery

ActiveCN105591077ASmall volume expansionImproved magnification performanceCell electrodesSecondary cellsDoped grapheneFreeze-drying

The invention discloses a preparation method of a molybdenum carbide / nitrogen-sulfur codoped spongy graphene cathode composite for a sodium-ion battery. According to the molybdenum carbide / nitrogen-sulfur codoped spongy graphene cathode composite prepared through the preparation method, molybdenum carbide particles are uniformly distributed in carbide / nitrogen-sulfur codoped spongy graphene which has a great number of surface folds, has a great number of active sites and is of a three-dimensional structure. The preparation method comprises the steps of dissolving a molybdenum source and a carbon source into a graphene oxide solution, adding a nitrogen source and a sulfur source, adjusting ph value, then conducting a hydrothermal reaction on an obtained mixed solution, conducting freeze-drying on a product, then putting the product in a quartz crucible for high temperature heat treatment, and conducting natural cooling after a reaction is ended, so that the composite is obtained. In the hydrothermal reaction process, graphene doping and reduction, formation of a precursor and composition of the precursor and doped graphene are conducted synchronously. The composite can be obtained by combining the hydrothermal method with the subsequent heat treatment process, and the preparation method is simple in process and low in cost and has good research prospect.

Owner:CENT SOUTH UNIV

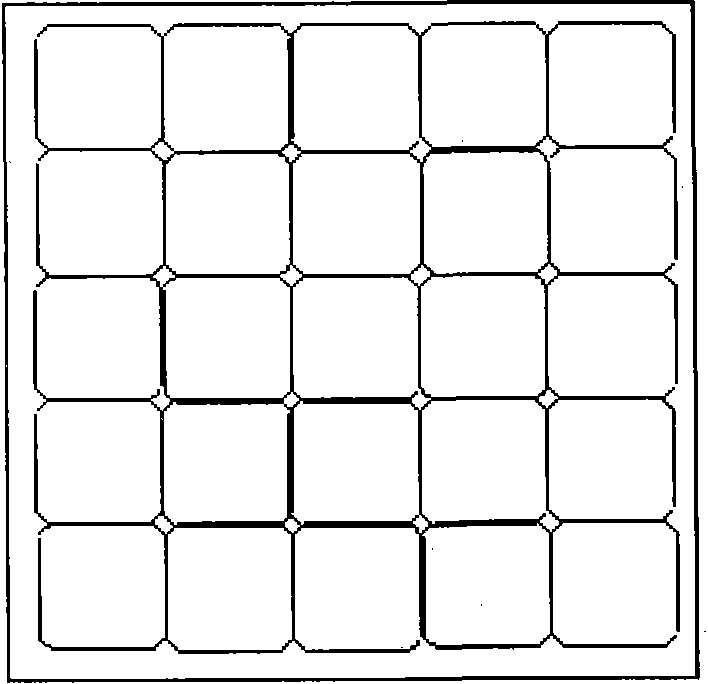

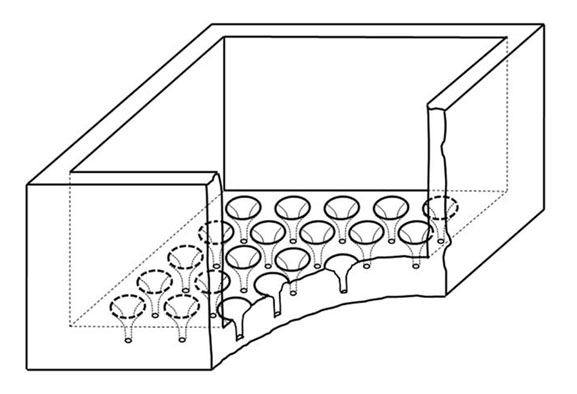

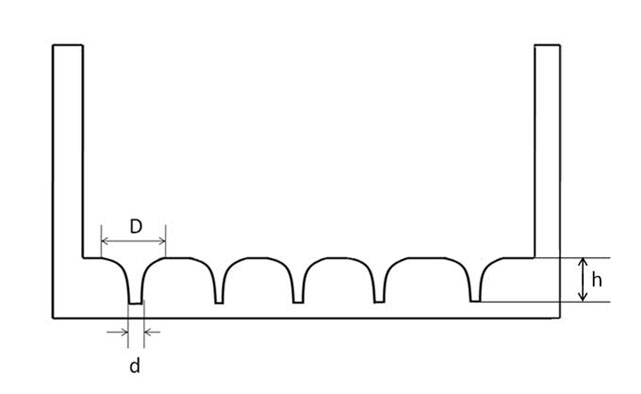

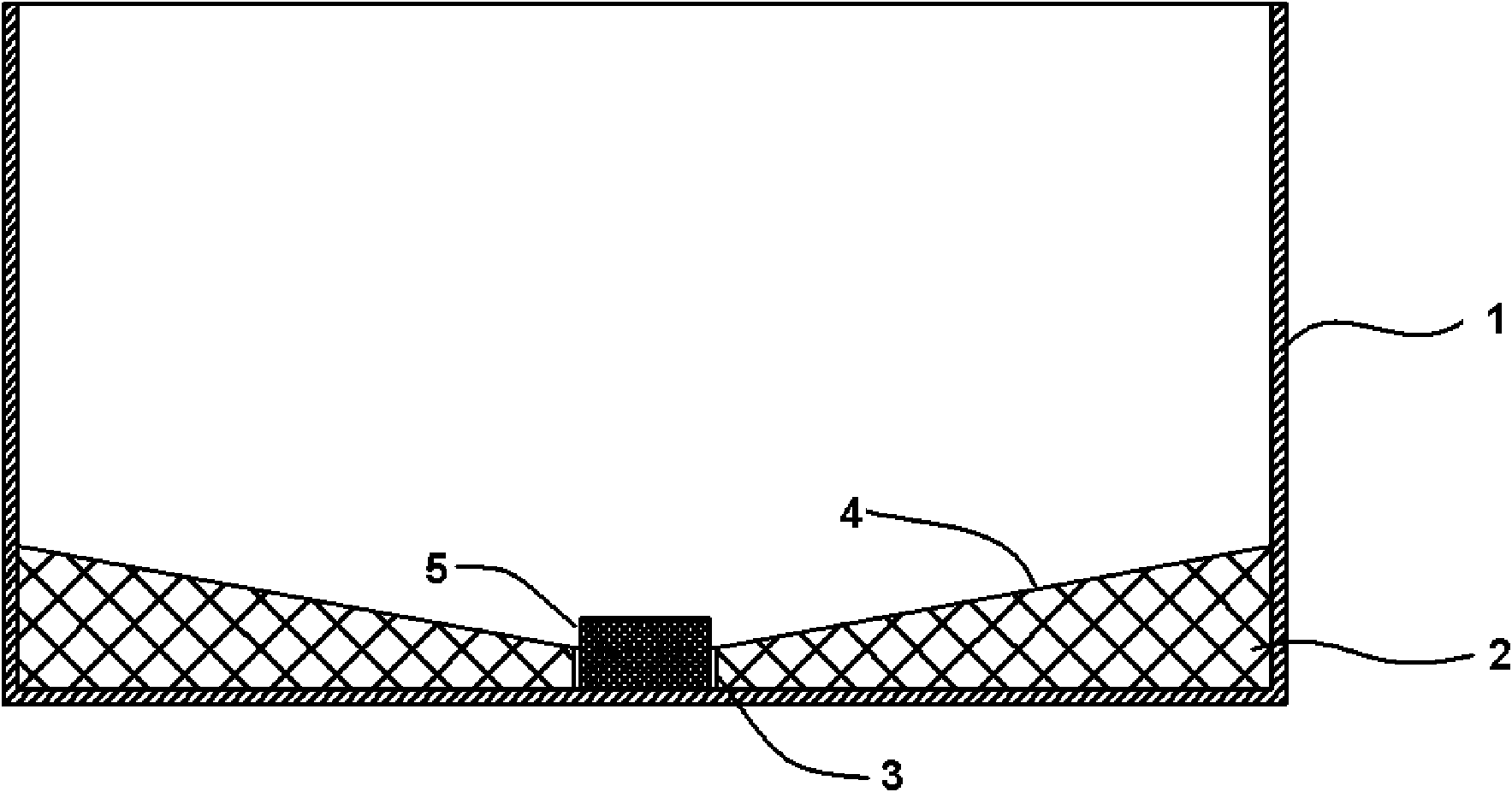

High-efficiency crucible for polycrystal ingot casting and preparation method thereof

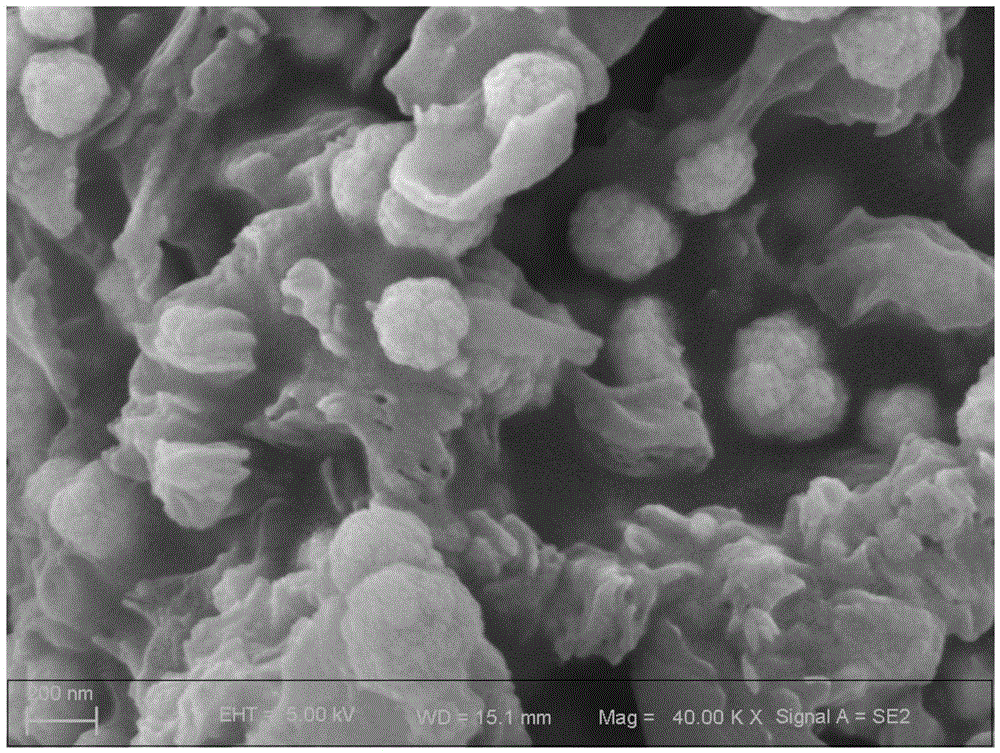

ActiveCN103088417AReduce sizeGood for later growth qualityPolycrystalline material growthSingle crystal growth detailsIngot castingPhysical chemistry

The invention discloses a high-efficiency crucible for polycrystal ingot casting. The high-efficiency crucible comprises a conventional quartz crucible, wherein high-purity granules are uniformly inlaid at the bottom of the quartz crucible. The invention also discloses a preparation method of the high-efficiency crucible for the polycrystal ingot casting. Compared with the traditional quartz crucible, the high-efficiency crucible disclosed by the invention has the advantages that the high-purity granules are uniformly distributed at the bottom of the quartz crucible so that regularly-distributed fluctuated recesses and bulges are formed at the bottom of the quartz crucible, and the fluctuated recesses and bulges formed by the high-purity granules can guide crystal-shaped nucleuses to form uniform crystal nucleuses with moderate size, thereby being favorable to the growth quality of crystals at a later stage and easier to realize the increase of the conversion efficiency of silicon slices; after the high-purity granules are inlaid at the bottom of the quartz crucible, the high-purity granules are firmly fixed on the quartz crucible without being desquamated after being used, thereby being favorable to the demoulding of the quartz crucible after ingot casting and preventing the silicon materials positioned at the bottom from being scraped because the high-purity granules enter a silicon ingot; and the high-purity granules are uniformly arrayed in a matrix shape at the bottom of the quartz crucible, thereby being favorable to forming the uniformly-distributed crystal nucleuses with moderate sizes and favorable to enhancing the growth quality of the crystals at the later stage.

Owner:晶海洋半导体材料(东海)有限公司

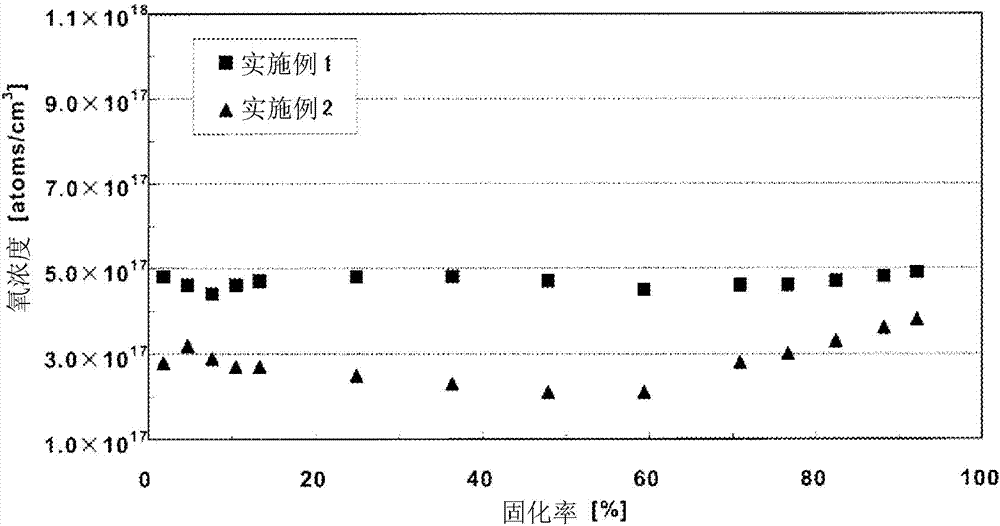

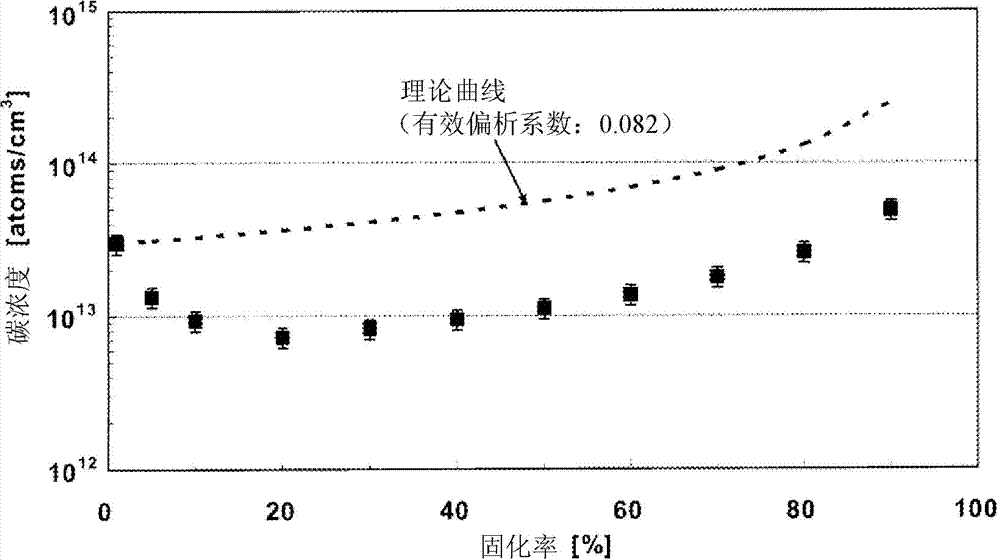

Silicon single crystal and method for manufacture thereof

ActiveCN104278321AEvaporation advantageLow costPolycrystalline material growthSemiconductor/solid-state device manufacturingTransverse magnetic fieldMonocrystalline silicon

A silicon single crystal manufacturing method includes: applying a transverse magnetic field to a melt of polysilicon with a carbon concentration of at most 1.0 × 10 15 atoms / cm 3 as a raw material; rotating the crucible at 5.0 rpm or less; allowing inert gas to flow at rate A (m / sec) of formula (1) at a position 20-50% of Y above the melt surface; controlling the rate A within the range of 0.2 to 5, 000 / d (m / sec) (d: crystal diameter (mm)); and reducing the total power of side and bottom heaters by 3 to 30% and the side heater power by 5 to 45% until the solidified fraction reaches 30%. A = Q ‹ 760 1000 ‹ 60 ‹ P ‹ ± / À ‹ X ‹ Y ‹ 10 6 Q: Inert gas volumetric flow rate (L / min) P: Pressure (Torr) in furnace X: Radiation shield opening diameter Y: Distance (mm) from raw material melt surface to radiation shield lower end ± : Correction coefficient

Owner:GLOBALWAFERS JAPAN

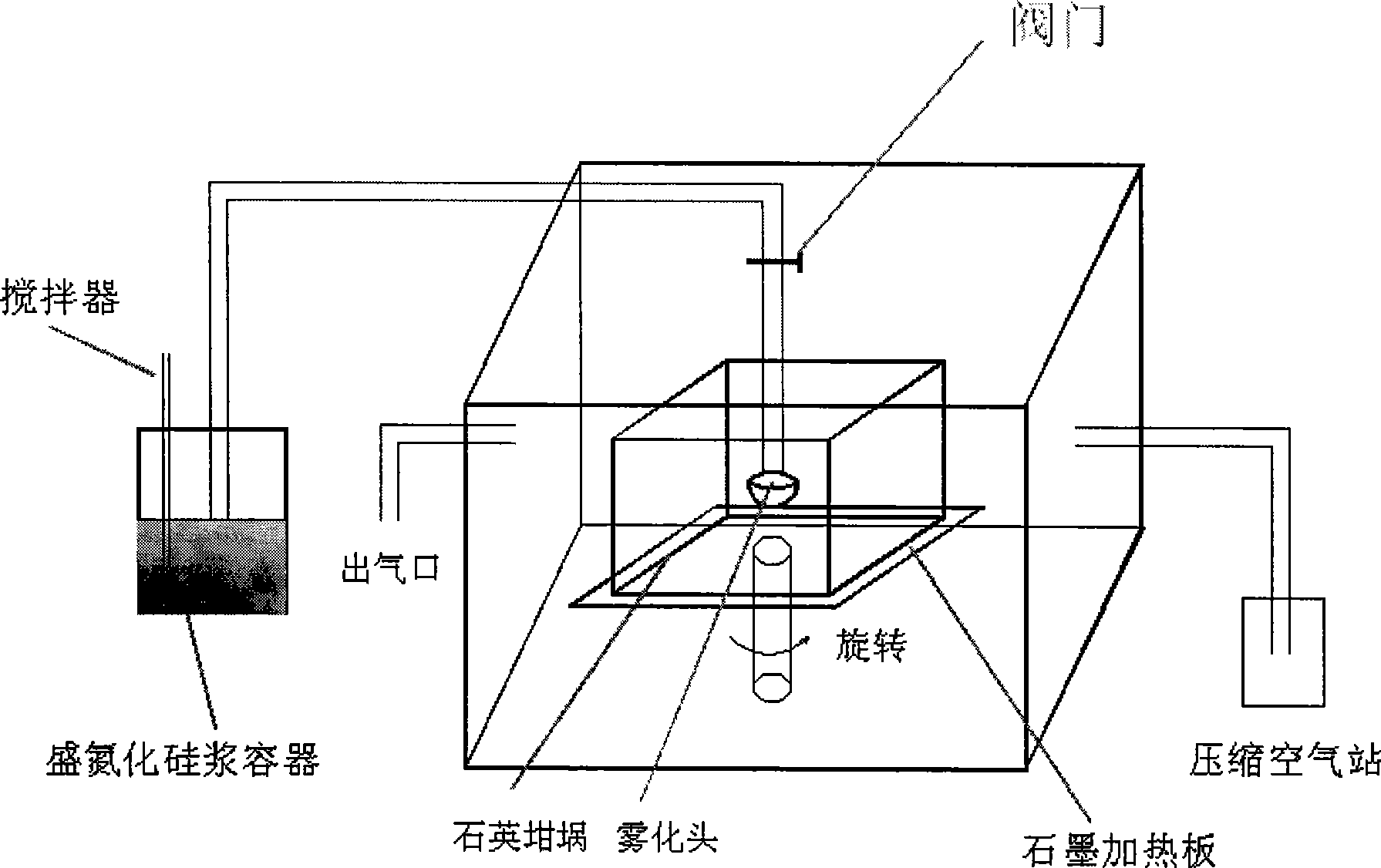

Silicon nitride spray finishing method for quartz crucible for polysilicon solar battery casting ingot

InactiveCN101428273AAvoid sticky pot phenomenonLow costPretreated surfacesCoatingsMetallurgyIngot casting

The invention relates to a method for spraying silicon nitride on a quartz crucible used in polysilicon solar cell ingot casting. The method comprises the following steps: proportioning ultrapure silicon nitride powder and deionized water (DI water) according to a certain quantity, stirring uniformly, using a high-pressure gun to spray on the preheated inner wall of the quartz crucible in a cleaning cavity, sintering by an oven in a certain procedure, forming a compact silicon nitride film spraying coating on the quartz crucible inner wall, vacuumizing the oven, and introducing Ar air into the oven. The film can stop the reaction between a high-temperature fused silica liquid and a quartz crucible, thereby avoiding the crucible-adhesion phenomenon; a silicon nitride film is substituted for an ultrapure quartz crucible, so that the cost is saved; and the interfusion of oxygen elements and impurity elements, which are harmful to a finished cell slice, is avoided, so that the quality of a cell slice is ensured.

Owner:江阴海润太阳能电力有限公司

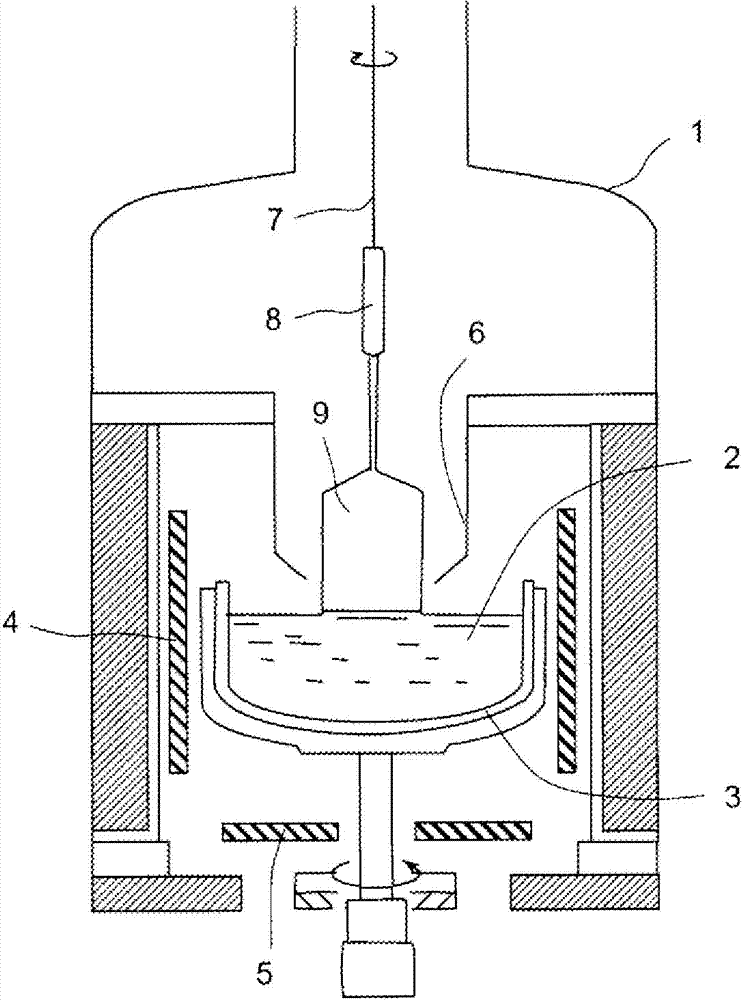

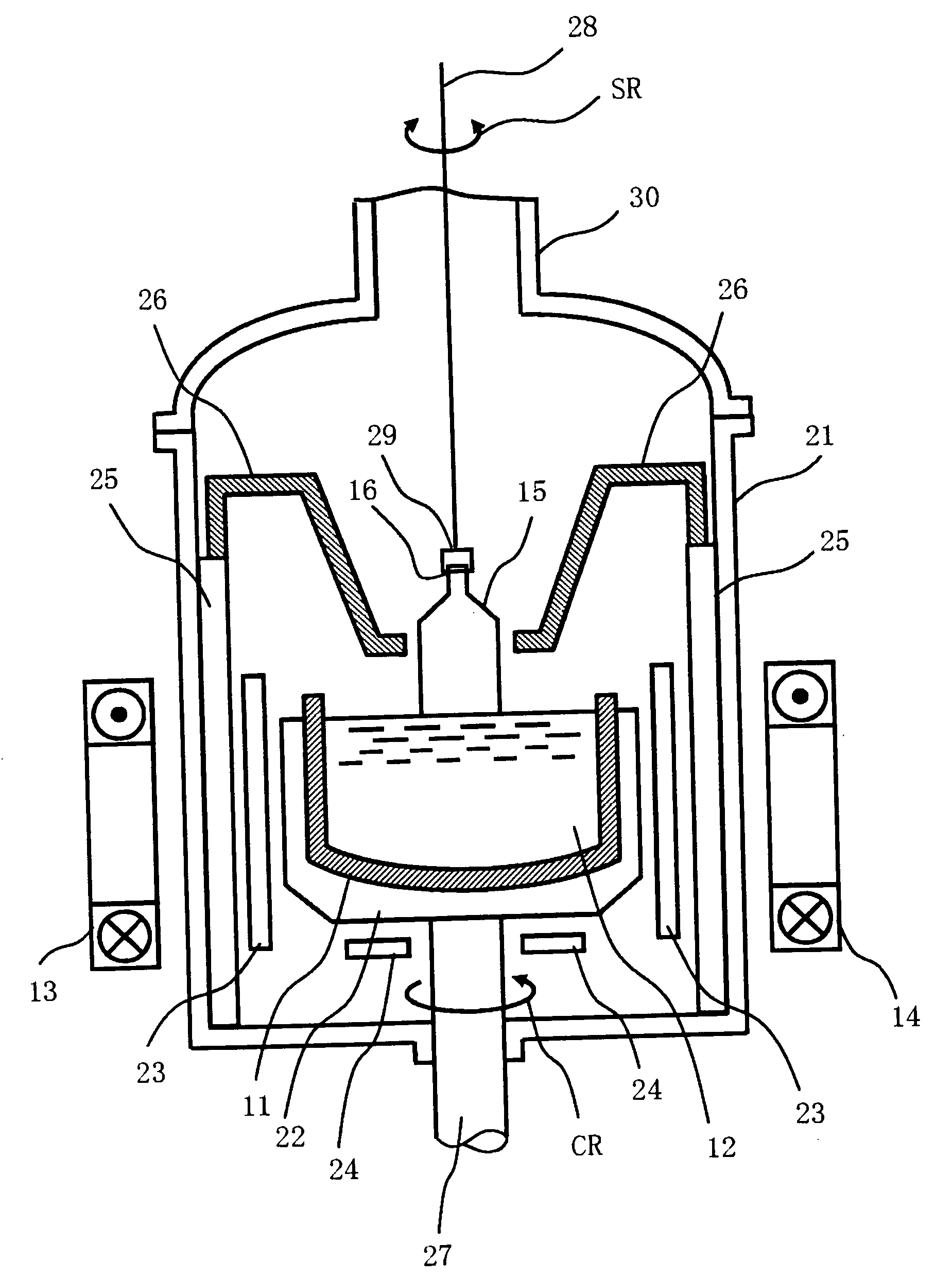

Manufacturing method of silicon single crystal

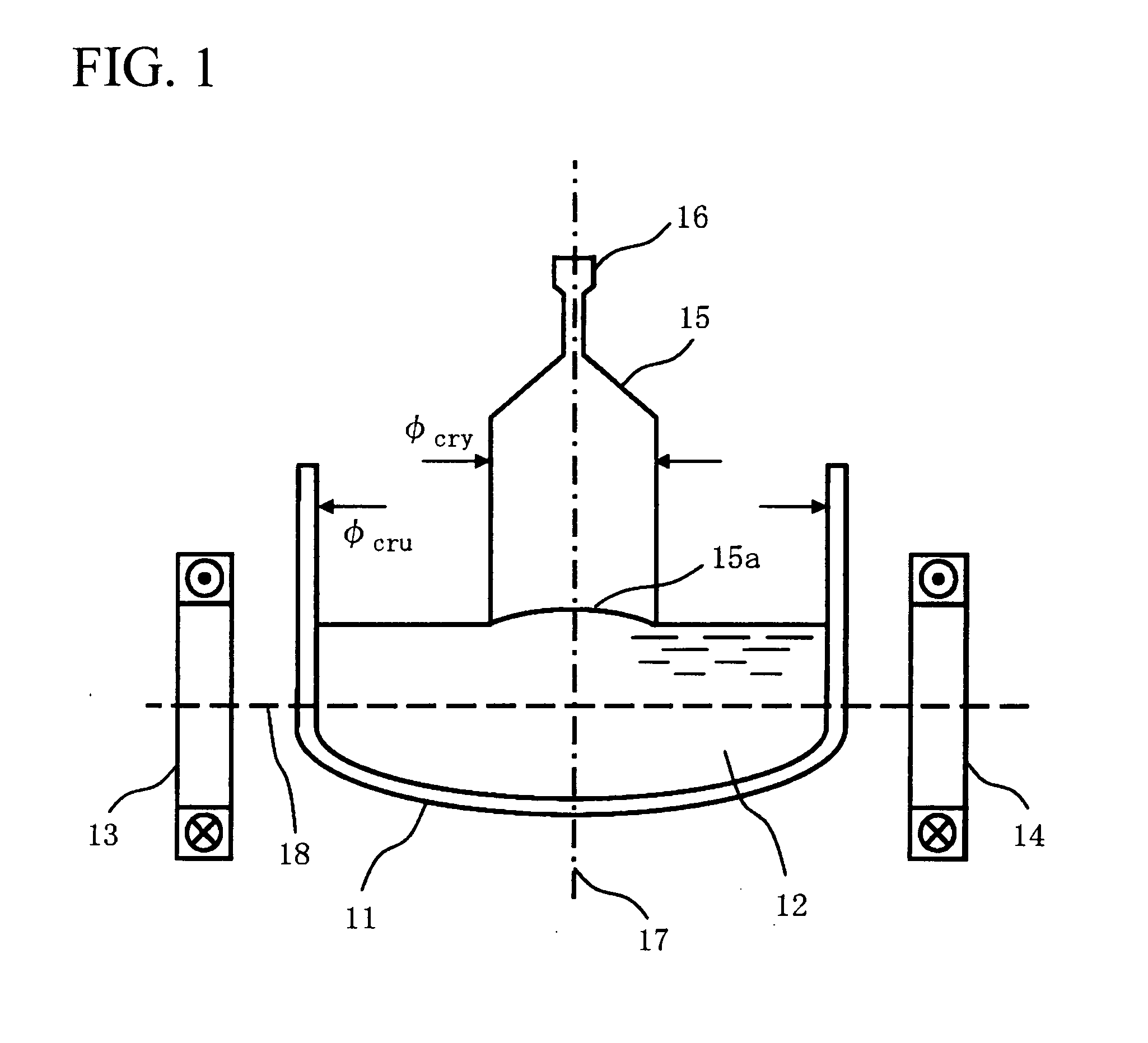

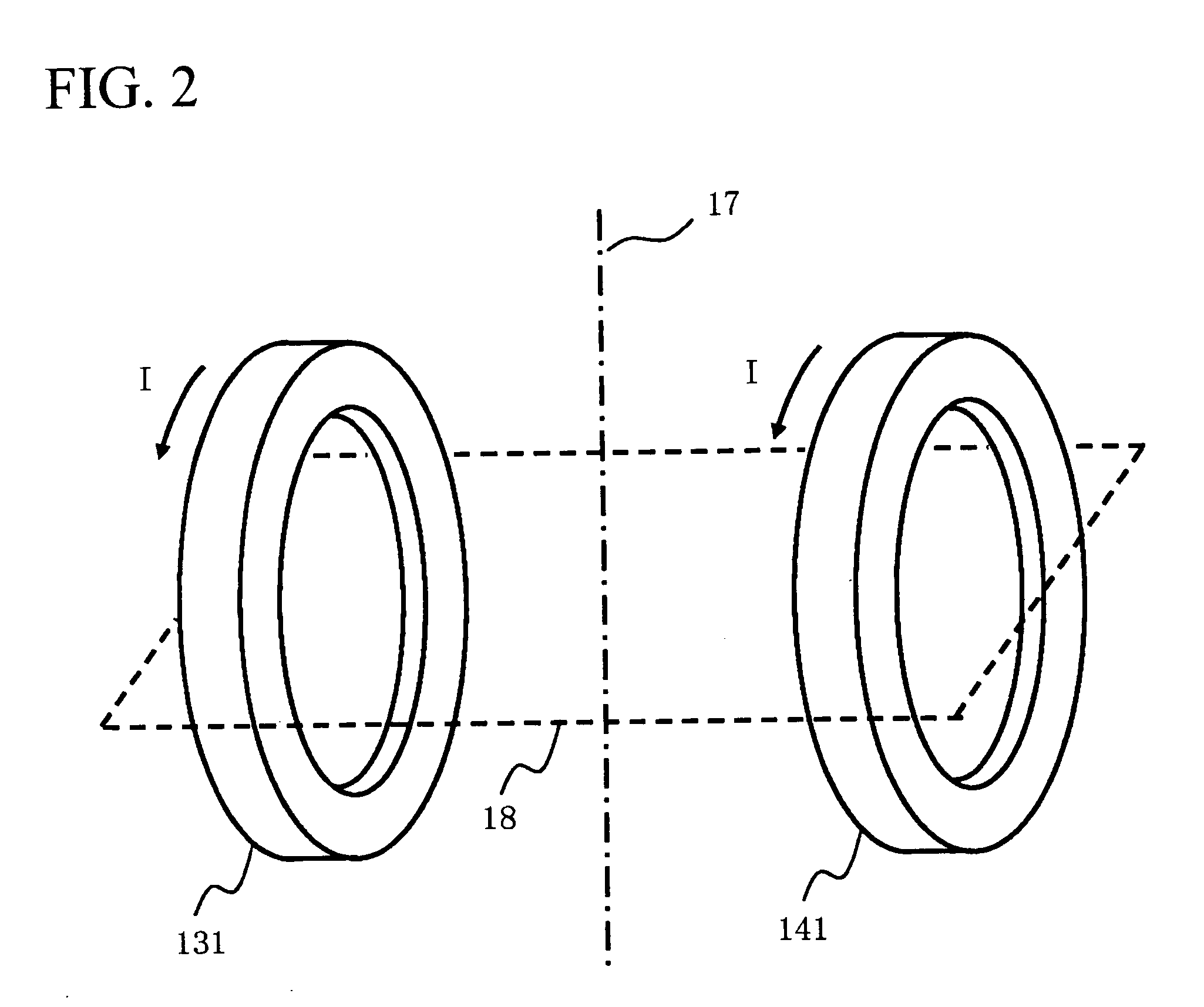

InactiveUS20100101485A1Reduce surface temperatureEasily dislocatedPolycrystalline material growthBy pulling from meltQuartz cruciblePhysics

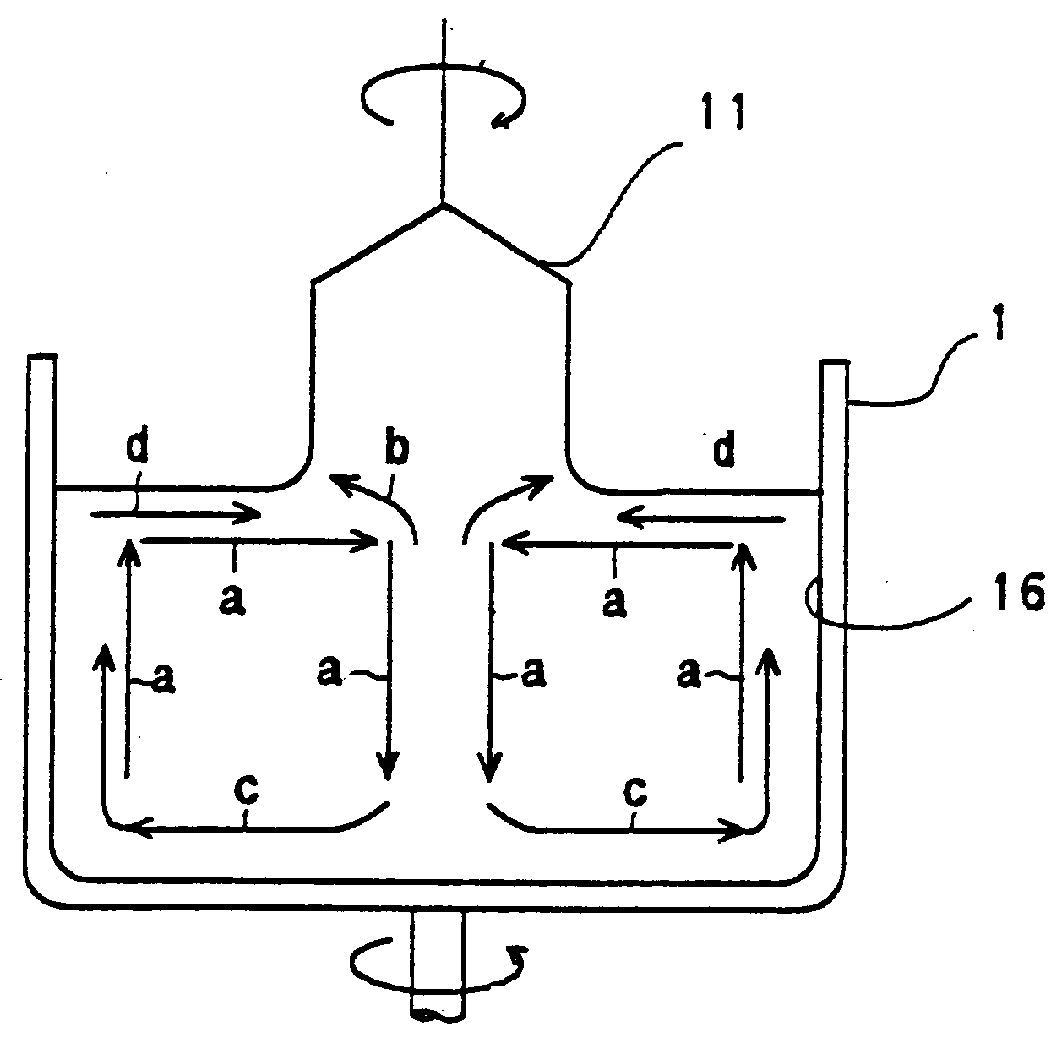

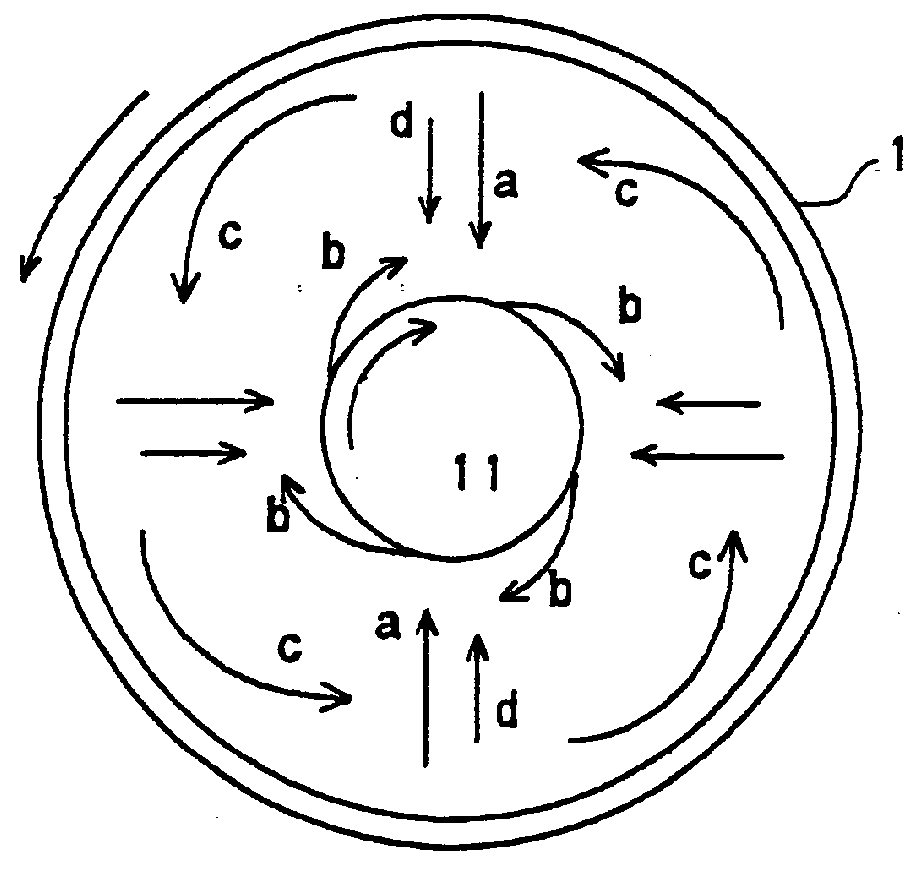

In appropriate setting of magnetic field applied to a molten silicon 12 stored in a cylindrical quartz crucible 11, the maximum value B0 of magnetic flux density on a vertical symmetric axis 17 as a cylindrical axis of the quartz crucible 11 in horizontal magnetic field generated by a pair of exciting coils 13 and 14 calls B0. On circle at which horizontally symmetric plane 18 traversing and perpendicular to a vertically symmetric axis 17 becoming magnetic flux B0 crosses an inner diameter of the quartz crucible 11, the minimum value of magnetic flux density calls Bmin, and the maximum value of magnetic flux density calls Bmax. Those magnetic flux densities B0, Bmin and Bmax are adjusted to be given ranges, and upward flow and temperature of a molten silicon 12 at the lower part of a solid-liquid interface 15a are appropriately controlled.

Owner:COVALENT MATERIALS CORP

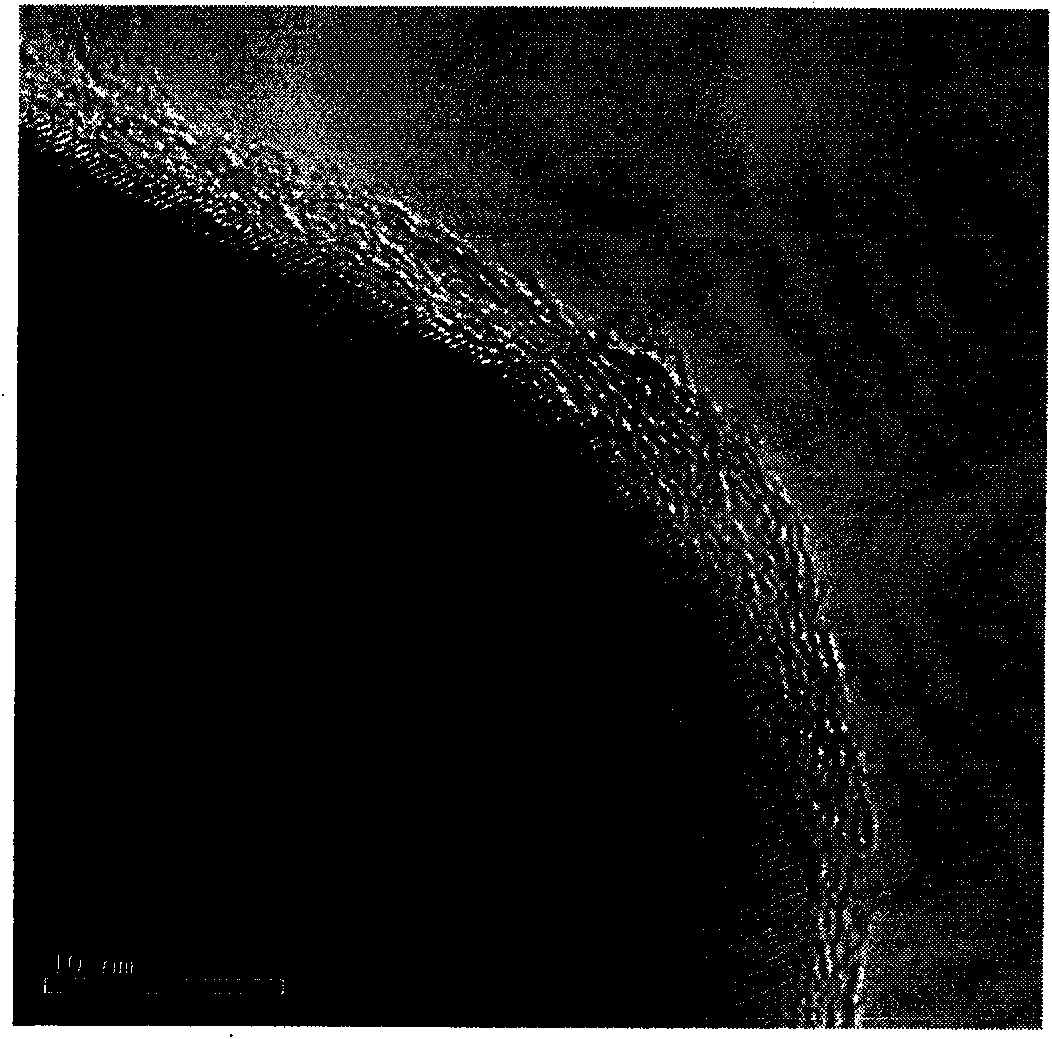

Method for preparing cadmium sulfide graphite-like carbon nitride compound photocatalyst

InactiveCN105562055AHigh activityEffective recoveryPhysical/chemical process catalystsMuffle furnaceCadmium sulfide

The invention discloses a method for preparing a cadmium sulfide graphite-like carbon nitride compound photocatalyst. The photocatalyst is applied to the field of carbon dioxide reduction achieved through photocatalysis. Urea is placed in a quartz crucible drying box to be dried, and then a crucible is moved to a muffle furnace to be forged; after forging ends, the crucible is naturally cooled, and a g-C3N4 catalyst is obtained; the g-C3N4 catalyst is taken and placed in a round-bottom flask containing deionized water to be stirred to obtain suspension, and then a cadmium nitrate solution and a thioacetamide solution with the molar ratio being 1:1.5 are weighed and have a constant-temperature reaction in the suspension; after the reaction, the product is cooled to room temperature, centrifuged and washed with alcohol and deionized water for many times, the product is dried, ground and put into a bag, and the CdS / g-C3N4 compound photocatalyst is obtained. Raw materials used in the method are cheap and easy to obtain, operation is easy and convenient, activity evaluation is conducted on the prepared photocatalyst, results show that the photocatalyst can effectively reduce CO2, and the activity of the photocatalyst is greatly improved compared with a pure CdS catalyst and a pure g-C3N4 catalyst.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

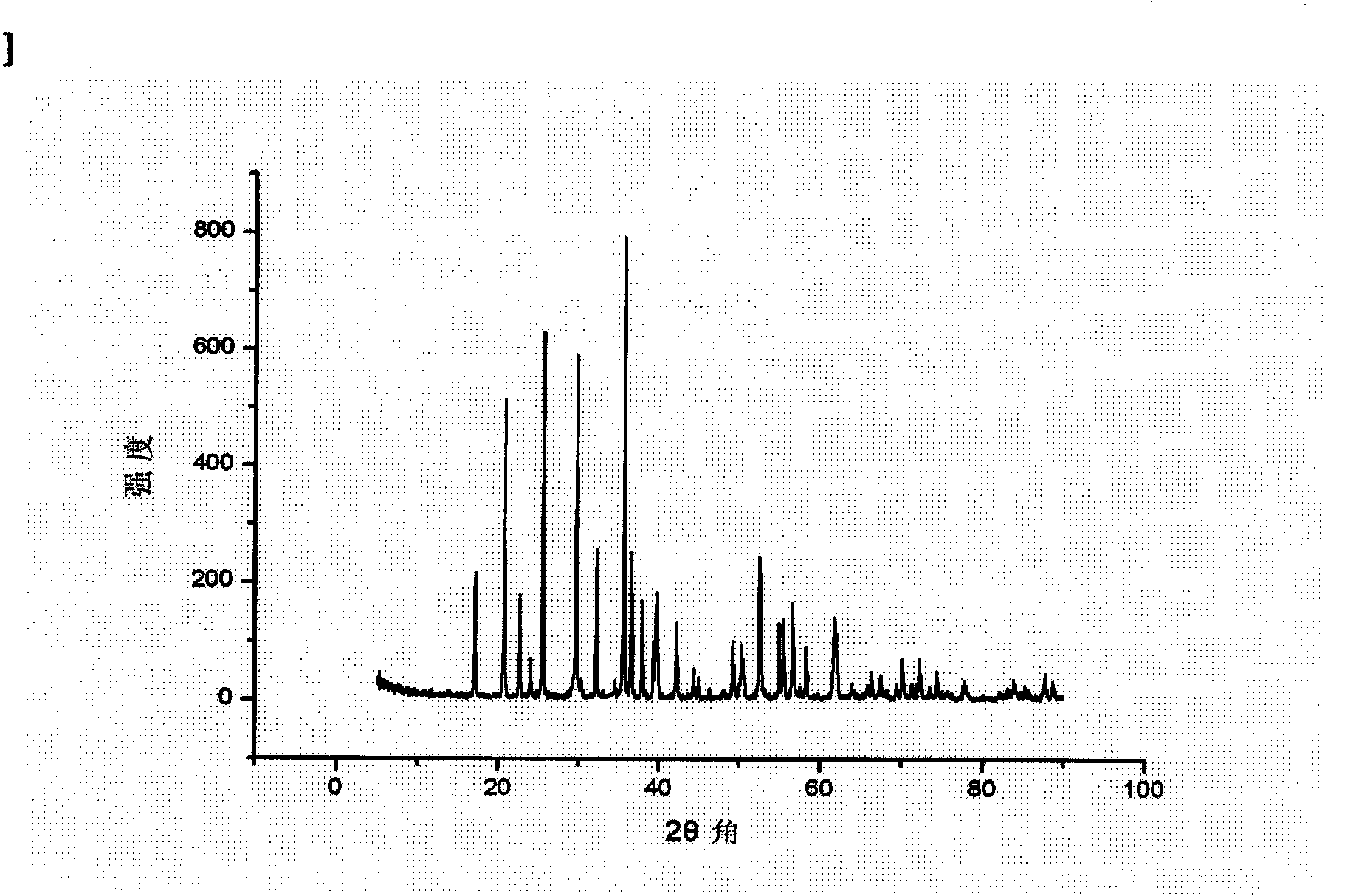

One-step preparation method of LiFePO4 powder coated with carbon

InactiveCN101567441AEfficient capturePerfect particle sizeElectrode manufacturing processesPhosphateLithium compound

The invention relates to a one-step preparation method of LiFePO4 powder coated with carbon. Lithium compounds, ferrite and phosphorous compounds are taken as raw materials, additive is antioxidant and glutin that accounts for 1-6% of the mass of theoretically generated lithium ferrous phosphate; the glutin is dissolved in de-ionized water which is then heated and stirred at the temperature of more than 40 DEG C to obtain the aqueous solution of the glutin. The prepared ferrite solution and the glutin solution are added to a Li3PO4 system to be mixed uniformly; the mixed solution reacts at the temperature of 120-170 DEG C for 2-5h; the obtained product is dry lithium ferrous phosphate powder coated with the glutin; the prepared powder is filled in a quartz crucible and calcined at the temperature of 550-750 DEG C under the protection of N2 atmosphere, and finally the lithium ferrous phosphate powder coated with carbon is obtained. The shape of the prepared lithium ferrous phosphate particles is uniform and columnar with the grain diameter being 400nm, the surface coating is thin and uniform amorphous carbon, has high tap density, is beneficial to improving the electrochemical performance of materials and is suitable for being used as anode material. The method has simple process route and no pollution and is suitable for scale production.

Owner:TIANJIN UNIV

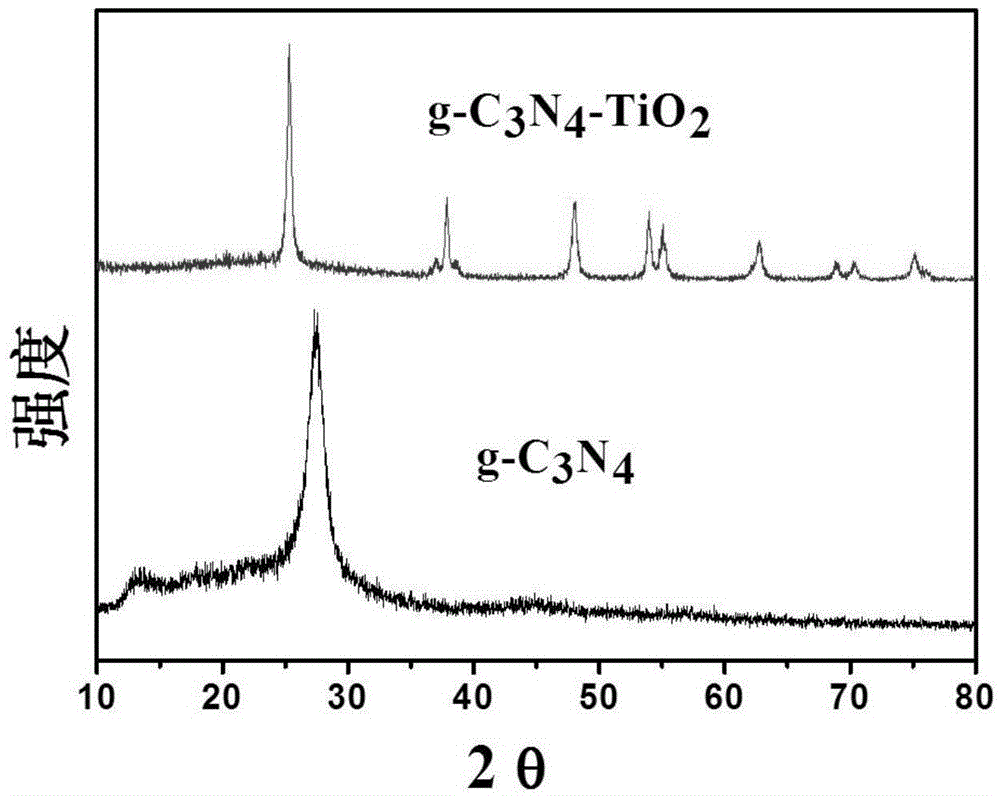

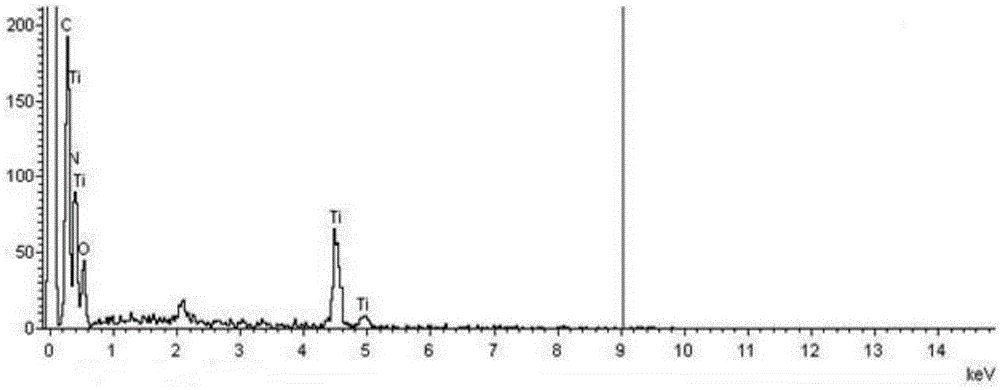

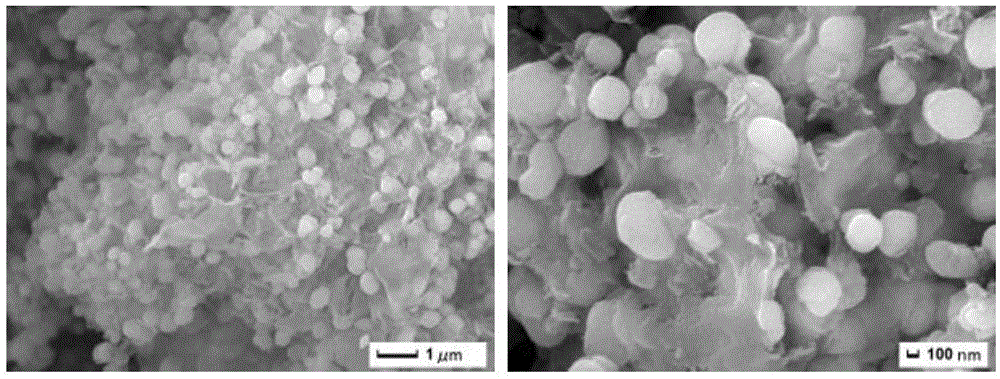

Preparation method of g-C3N4-TiO2 mesoporous composite visible light catalyst

InactiveCN105618097AIncrease marginImprove photocatalytic efficiencyPhysical/chemical process catalystsOrganic acidVisible light photocatalytic

The invention provides a preparation method of a g-C3N4-TiO2 mesoporous composite visible light catalyst. The preparation method comprises the following steps: firstly performing high-temperature annealing on urea in a quartz crucible; dispersing g-C3N4 nano sheets obtained into organic acid, adding tetrabutyl titanate, agitating, moving a solution into a reaction kettle and sealing; after thermostatic reaction, finally separating an obtained reaction product, washing, and drying, so as to obtain the g-C3N4-TiO2 mesoporous composite visible light catalyst through high-temperature annealing. The preparation method provided by the invention is low in cost, simple and easy to control in production process, high in product yield and suitable for large-scale industrial production.

Owner:ZHENJIANG COLLEGE

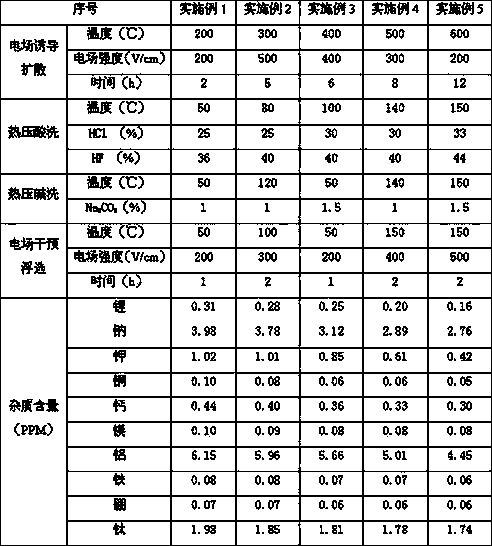

Preparation method for high-purity quartz sand

The invention relates to a preparation method for high-purity quartz sand, and concretely relates to a purification technology for high-purity quartz sand applicable to prepare a monocrystalline silicon arc quartz crucible. The preparation method comprises: employing quartz as a basic raw material, performing crude washing, crushing, roasting, water quenching, crushing grading, electric-field induction diffusion, hot-pressing acid washing, hot-pressing alkali washing, electric-field intervention flotation, chlorination processing, sand baking, magnetic separation and the like, so as to obtain the high-purity quartz sand with the impurity total quantity controlled in 16 ppm and the purity larger than 99.99%. In the method, the electric-field induction diffusion technology is employed to induce impurity ions in quartz to be diffused to the surfaces of quartz sand particles, then the hot-press acid washing and hot-pressing alkali washing technology is employed for substantially improving the leaching efficiency of impurities in quartz sand, and the electric-field intervention flotation technology helps to improve the floatation removal efficiency of impurity particles.

Owner:新沂市中大石英科技有限公司

Method for preparing high-purity fused silica by recovering waste quartz crucible

InactiveCN102557389AReduce overdependenceAchieve recyclingGlass furnace apparatusDischarge problemsContamination

The invention discloses a method for preparing high-purity fused silica by recovering waste quartz crucible, which comprises steps of smash classification, scouring edulcoration, washing stoving and amorphization treatment and the like. The high-purity fused silica meeting use requirements of the quartz crucible can be obtained through that fact that purification edulcoration and the amorphization treatment are carried out on quartz crucible waste, so that excessive depending on quartz raw ore can be obviously remitted, cyclic utilization of quartz sands can be achieved, the method is applicable to protection of territorial resources, greatly reduces cost of manufacture of quartz ceramic crucible, simultaneously solves contamination and discharge problems of solid waste of quartz crucible production and using enterprises.

Owner:徐州协鑫太阳能材料有限公司

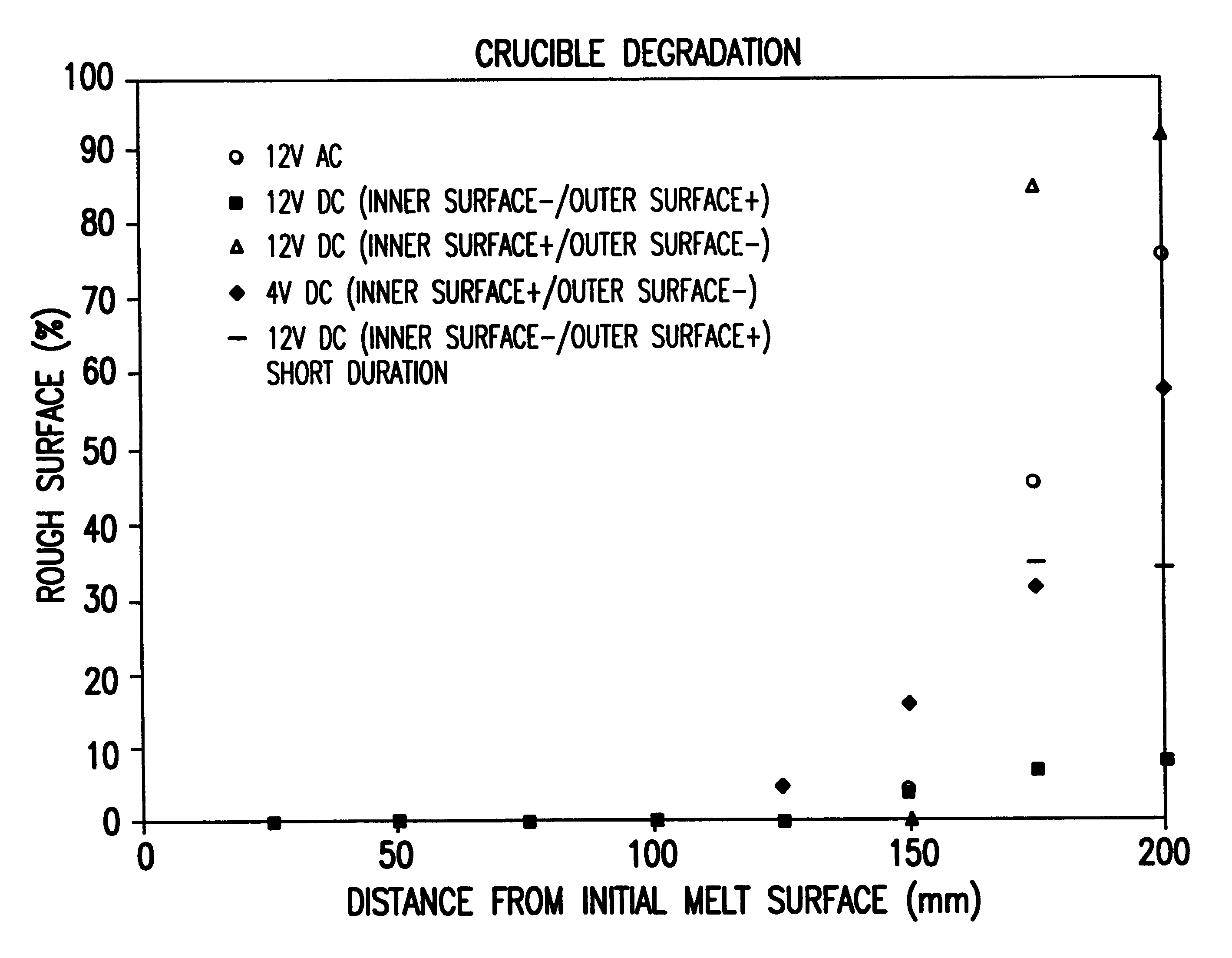

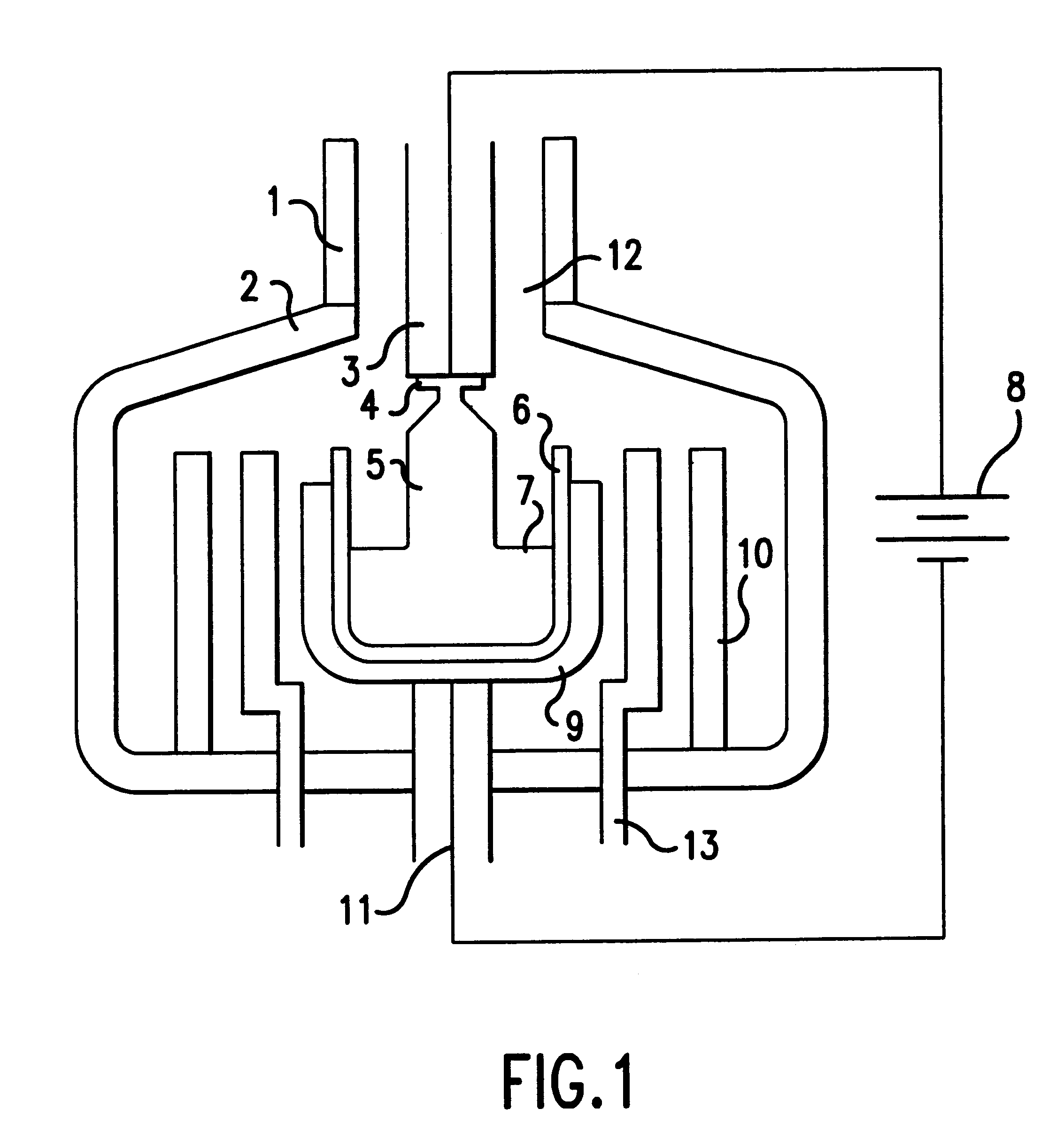

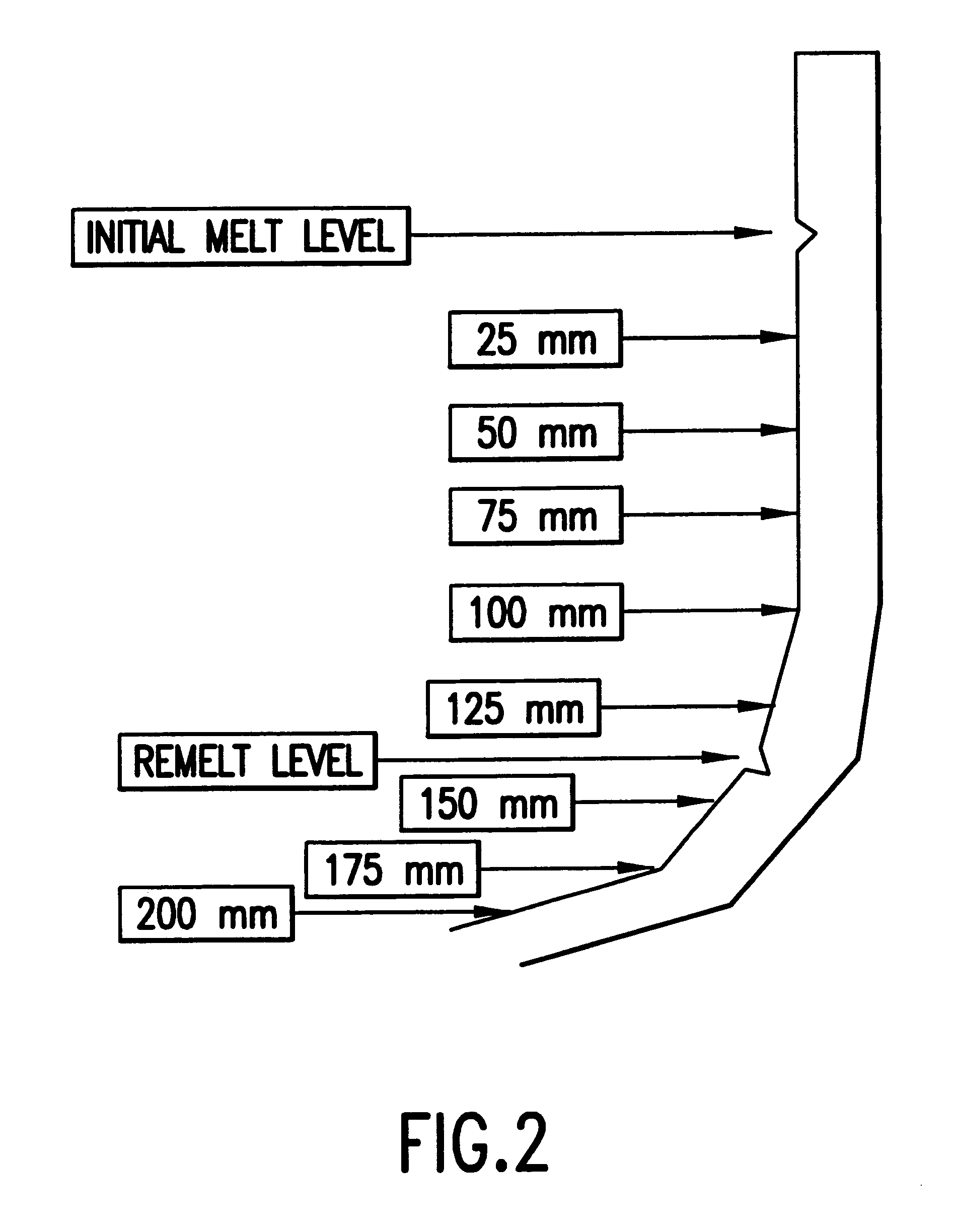

Method of manufacturing crystal of silicon using an electric potential

InactiveUS6228165B1Raise the possibilityPolycrystalline material growthBy pulling from meltCzochralski methodElectric potential

A method of manufacturing a crystal of silicon in accordance with a Czochralski method, includes the steps of applying an electric potential across a quartz crucible containing a silicon melt, and pulling a crystal of silicon from the silicon melt.

Owner:SEH AMERICA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com