CZ method silicon single crystal growth furnace quartz crucible carbon protection crucible and manufacturing process thereof

A quartz crucible and silicon single crystal technology, which is applied in the direction of single crystal growth, crystal growth, chemical instruments and methods, etc., can solve the problems of increased energy consumption, slow response speed, and contamination of silicon crystals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

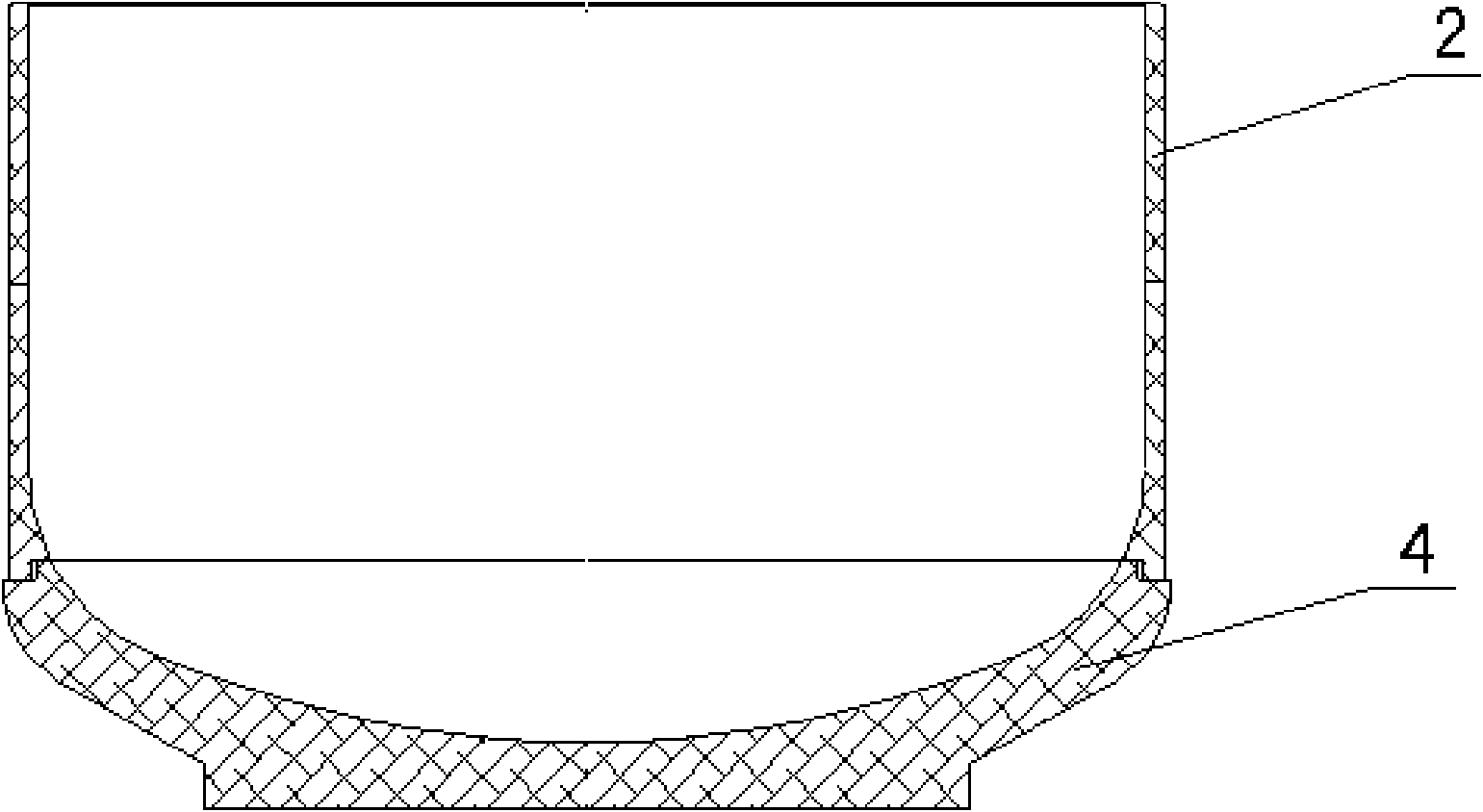

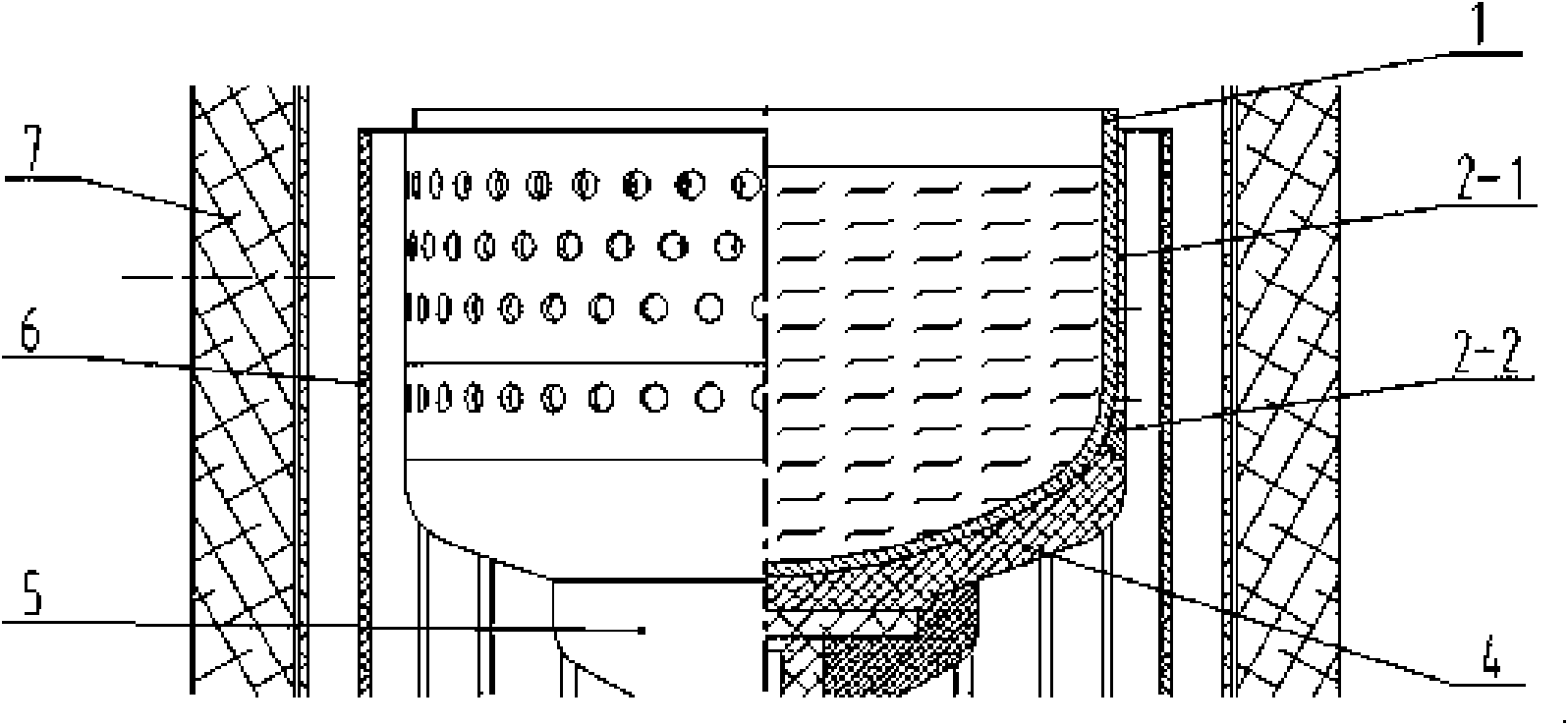

[0024] The embodiment of the quartz crucible and carbon protective crucible of the CZ method silicon single crystal growth furnace of the present invention is composed of the crucible side 2 and the crucible support 4, the wall thickness of the crucible side is 10 mm, and the diameter and height are compatible with the quartz crucible; the material for preparing the crucible side 2 It is a carbon fiber green body reinforced carbon matrix composite material; the carbon fiber green body reinforcement phase is composed of a quasi-three-dimensional needle-punched carbon fiber felt, and its weight material is 60% of the total weight of the crucible side; the carbon matrix is made of resin carbon and chemical vapor deposition Carbon composition, wherein the content of chemical vapor deposited carbon is 25% of the total weight of the crucible side; the material density of the upper crucible side is 1.5g / cm 3 The thickness of the silicon carbide coating on the inner surface of the cr...

Embodiment 2

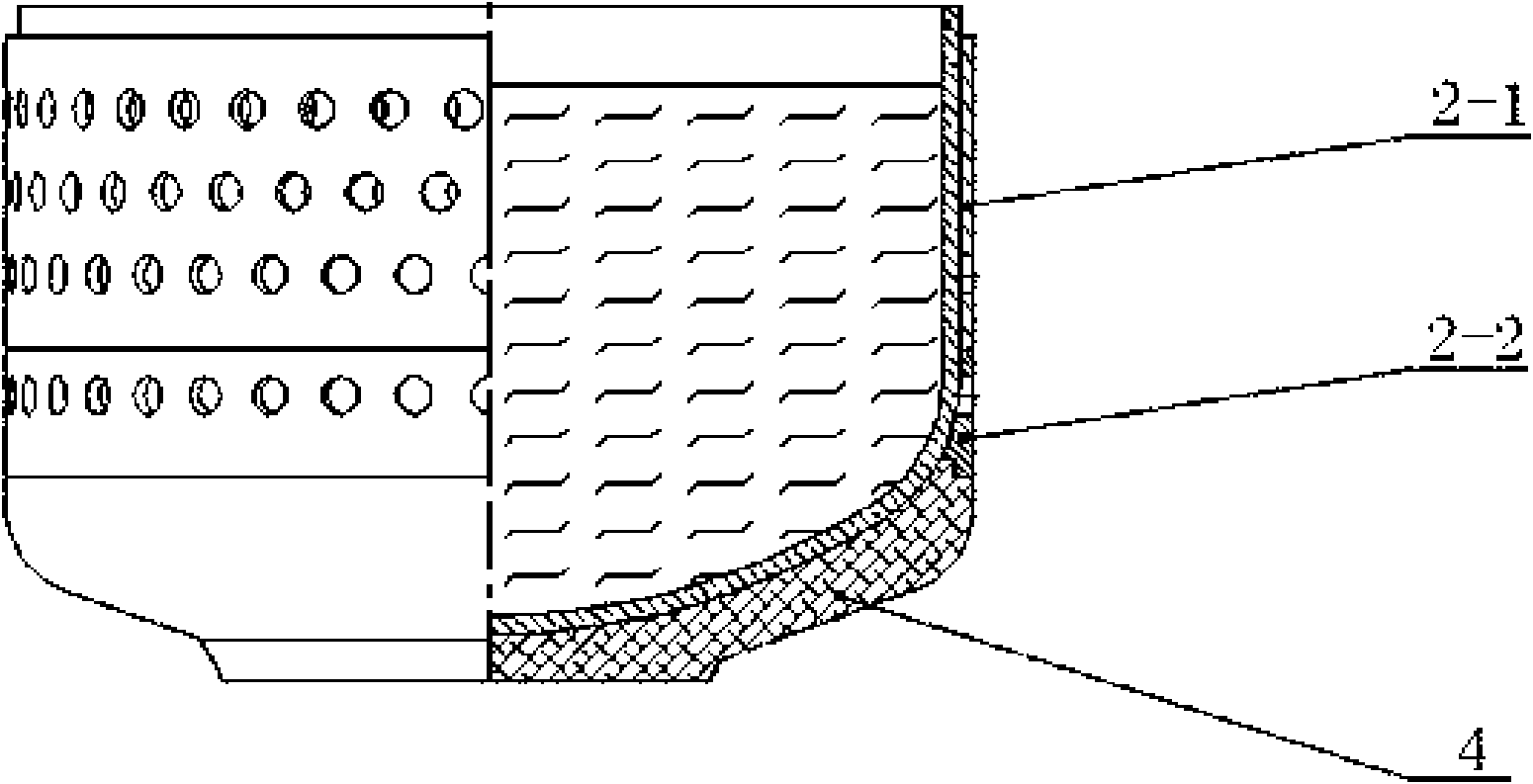

[0028] The difference from Embodiment 1 is that the crucible side is composed of the upper crucible side 21 and the lower crucible side 22, and the crucible side is processed with uniformly arranged through holes with a diameter of 15 mm. The green body of the crucible side is made of laminated two-dimensional carbon fiber fabrics, and the weight of the green body is 55% of the total weight of the crucible side; the matrix is composed of resin carbon and chemical vapor deposition carbon, and the content of the chemical vapor deposition carbon is 50% of the total weight of the crucible side. 20%. The material density of the upper and lower crucible sides is 1.5g / cm 3 ; The inner surface of the upper and lower crucible sides and the wall of the through hole are coated with silicon carbide, the thickness is 20μm; the density of the crucible support is 1.7g / cm 3 , the thickness of the carbon coating on the surface is 20 μm. The rest are the same as embodiment 1.

[0029] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com