Patents

Literature

667 results about "Molten silicon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

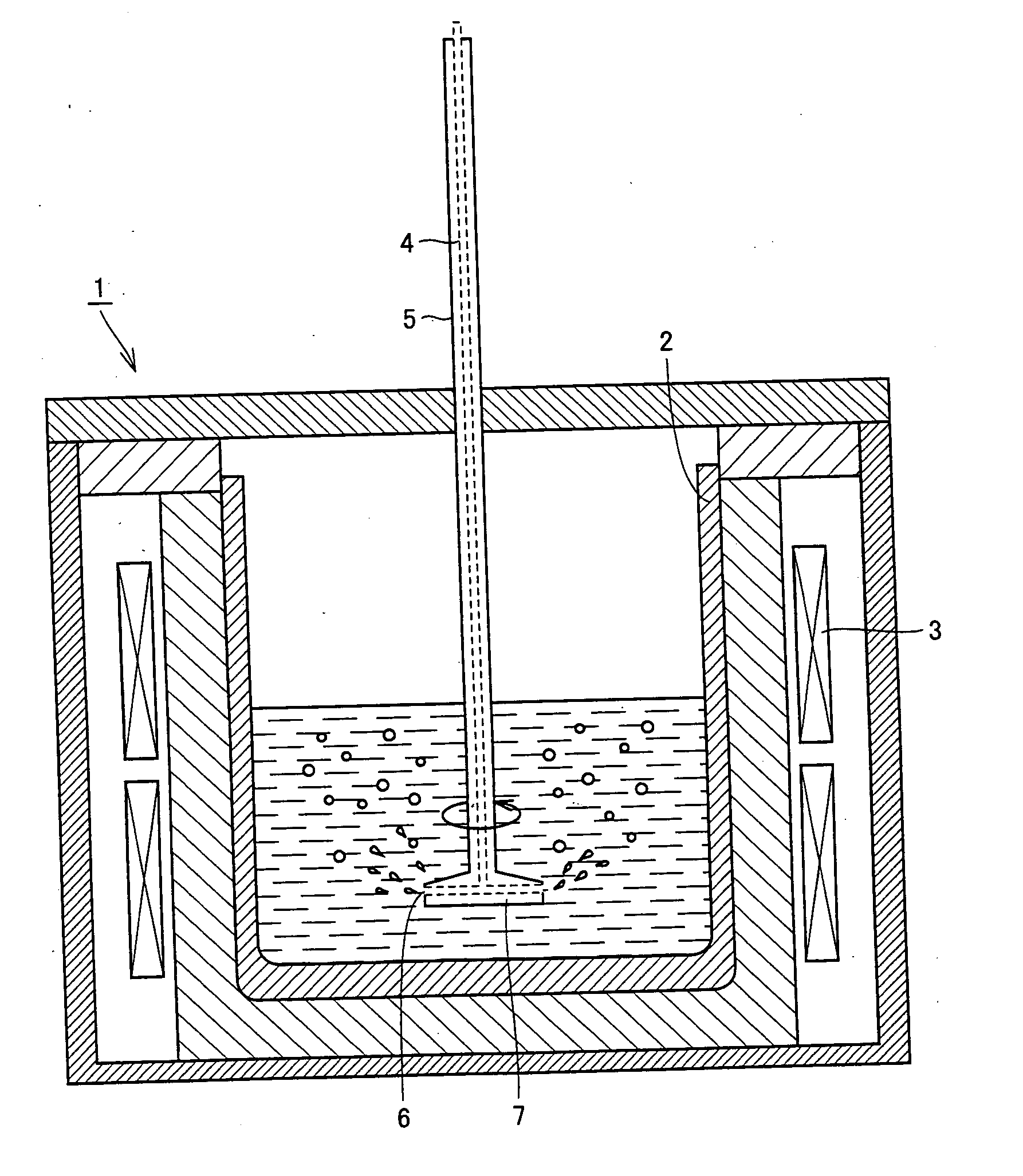

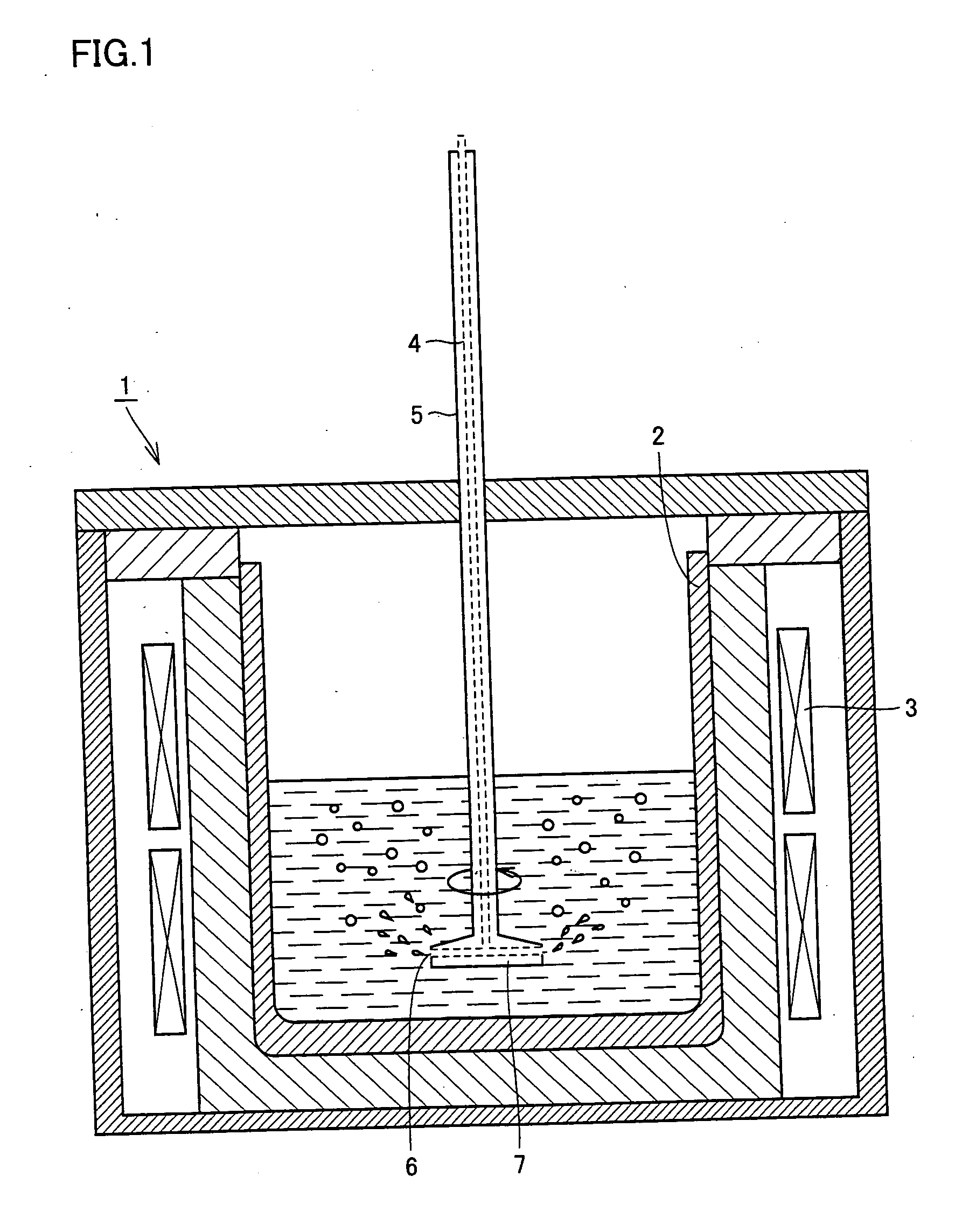

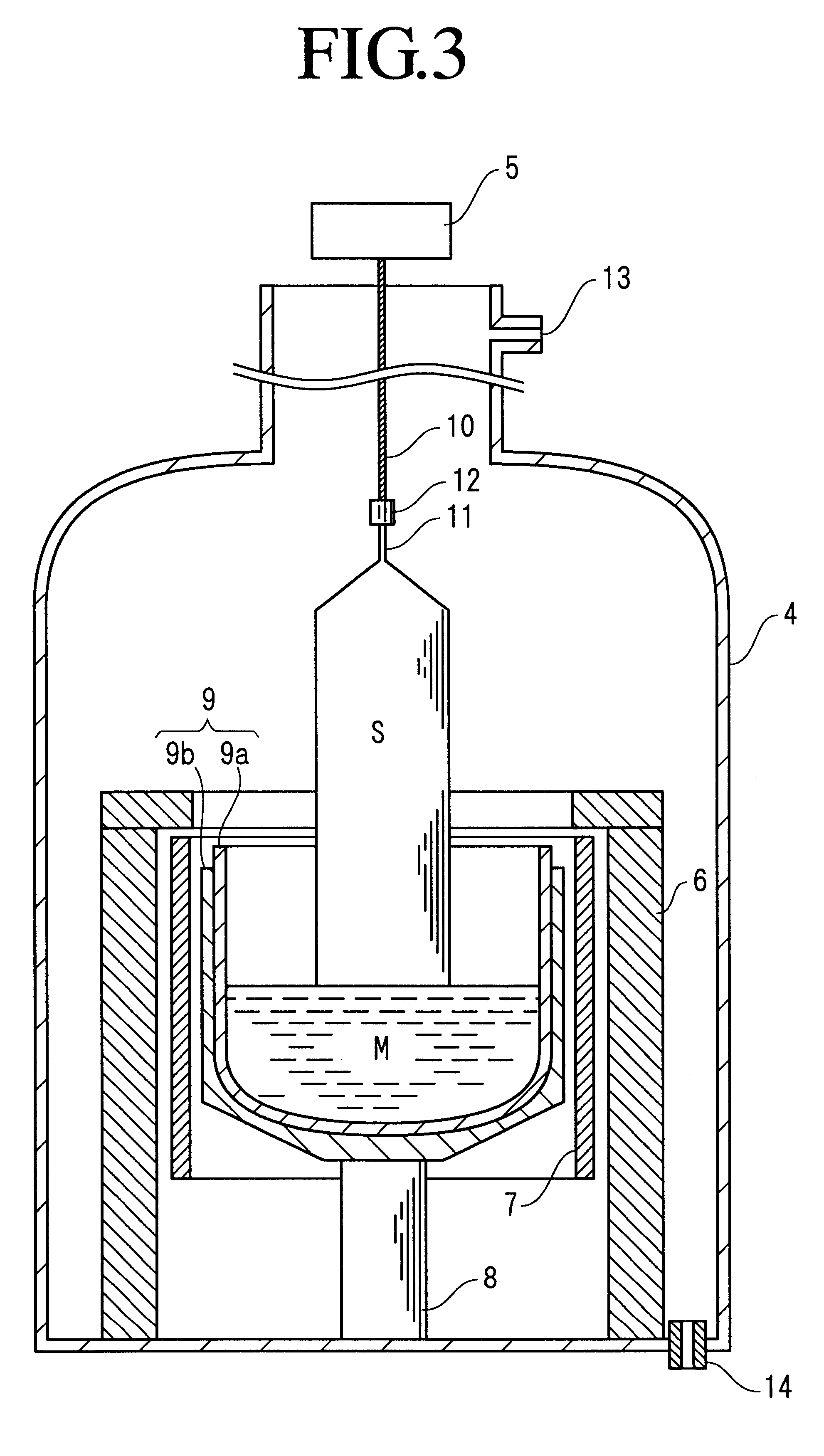

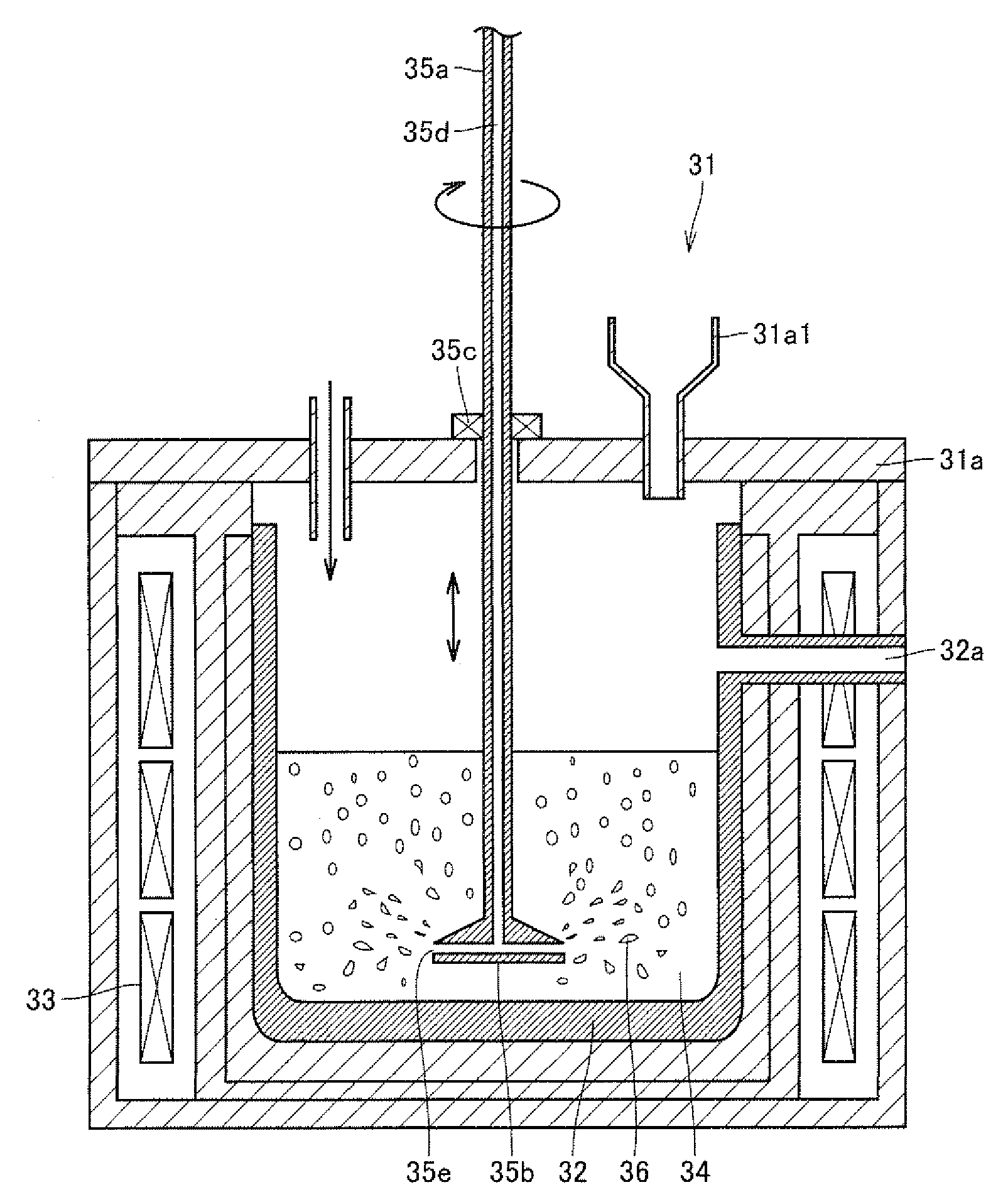

Silicon purifying method, slag for purifying silicon and purified silicon

InactiveUS20050139148A1Low-priced processEfficient purificationPolycrystalline material growthBy pulling from meltWater vaporSilicon oxide

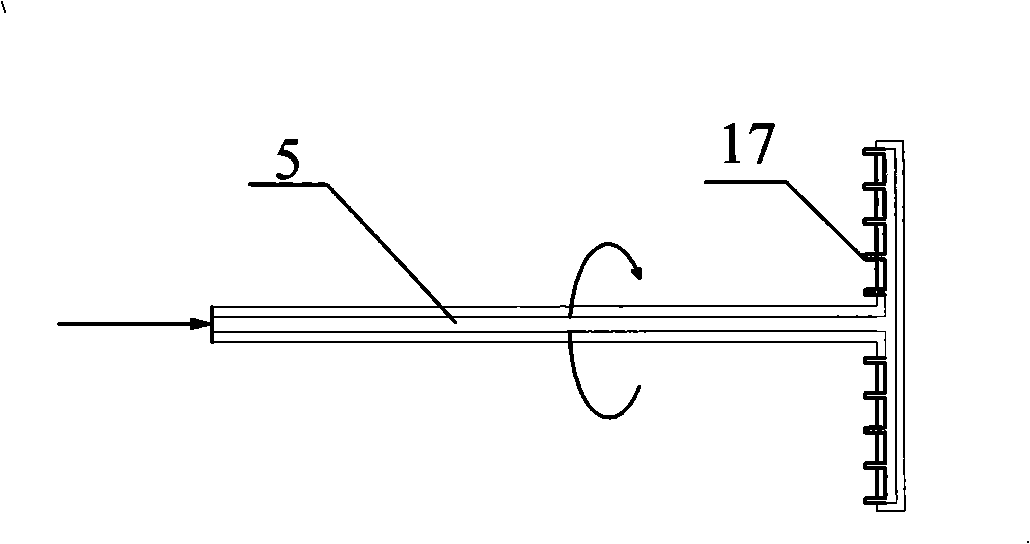

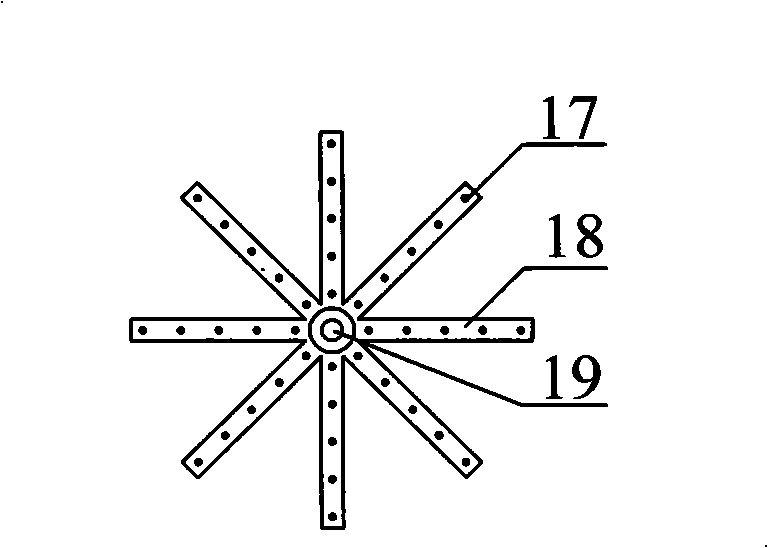

Method capable of preparing silicon having purity of about 6N applied to a solar cell efficiently at a low cost. Raw silicon containing boron and a slag are melted and a shaft is rotated by a rotating / driving mechanism for stirring the molten silicon. The molten slag is dispersed in the molten silicon, thereby accelerating the boron removal reaction. It is further effective to use a slag containing at least 45 percent by mass of silicon oxide or to blow gas mixed with water vapor into the molten silicon for refining reaction.

Owner:SHARP KK

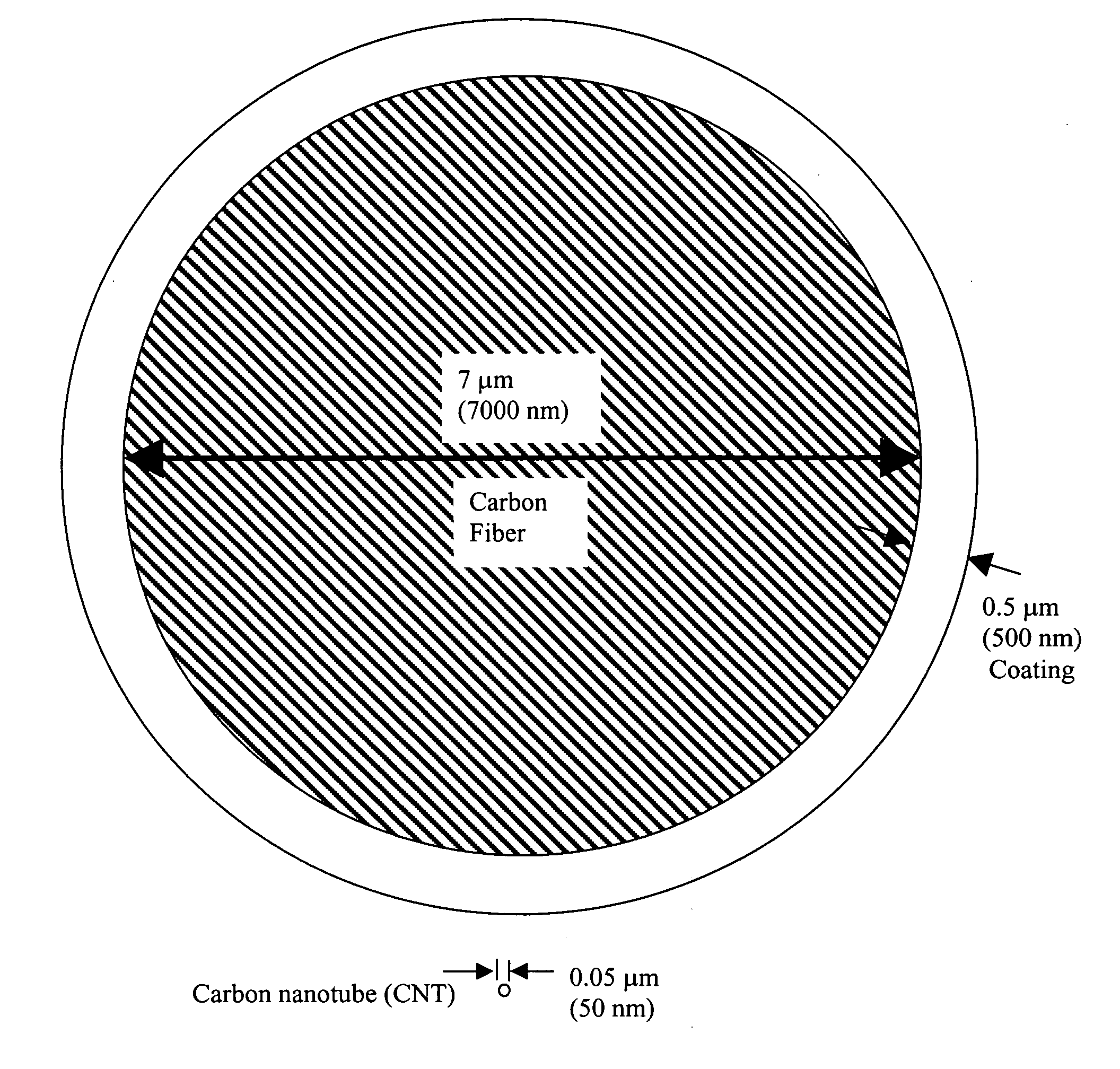

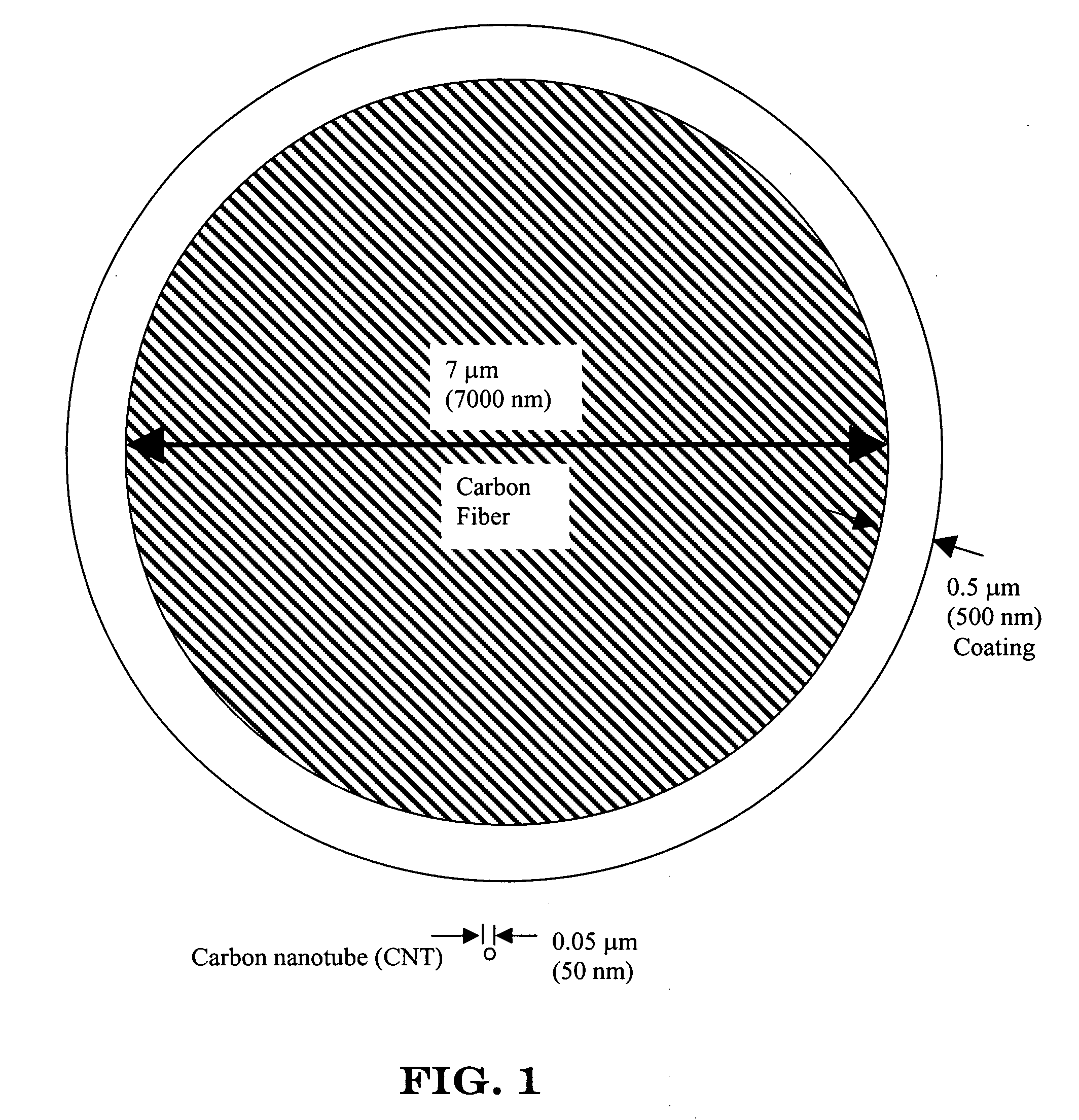

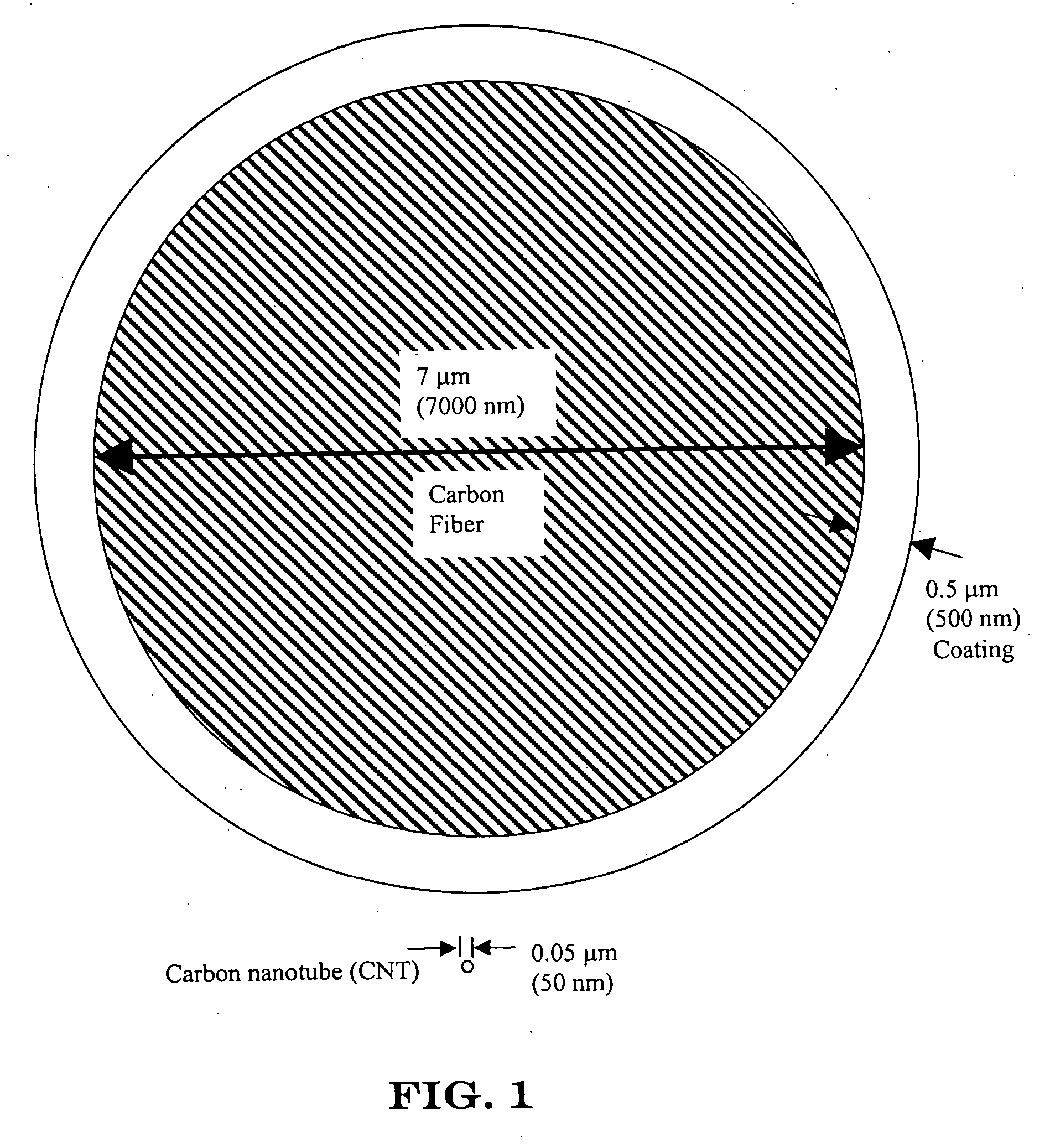

Nanotube-containing composite bodies, and methods for making same

A composite material featuring carbon nanotubes reinforcing a matrix featuring metal or silicon carbide, or both. Such composites can be produced using a molten silicon metal infiltration technique, for example, a siliconizing or a reaction-bonding process. Here, the carbon nanotubes are prevented from chemically reacting with the silicon infiltrant by an interfacial coating disposed between the carbon nanotubes and the infiltrant. Preferably, the coating is free carbon or a carbonaceous precursor material added during preform processing, or after. The reaction-bonding system is designed such that the molten infiltrant of silicon metal or silicon alloy reacts with at least some of the interfacial carbon layer to form in-situ silicon carbide, and that the formed SiC is sufficiently dense that it effectively seals off the underlying carbon nanotube from exposure to additional molten infiltrant. A reaction-bonded composite body containing even a small percentage of carbon nanotubes possessed a significant increase in electrical conductivity as compared to a reaction-bonded composite not containing such nanotubes, reflecting the high electrical conductivity of the nanotubes.

Owner:KARANDIKAR PRASHANT G

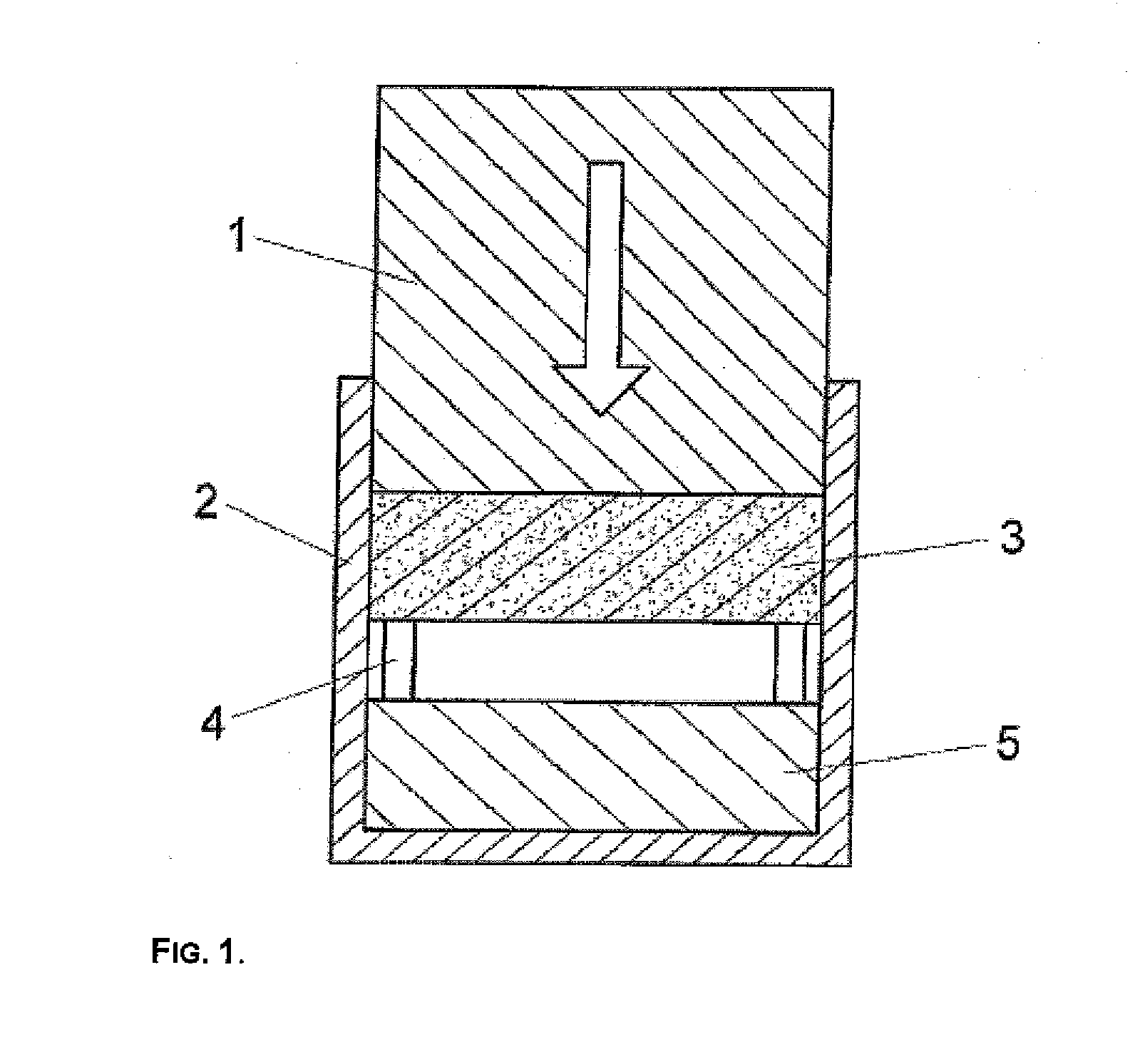

Abrasive compact

The invention relates to an abrasive compact comprising a mass of diamond particles and a silicon containing binder phase wherein the diamond particles are present in an amount less than 75 volume % and the binder phase contains less than 2 volume % unreacted (elemental) silicon. The invention further relates to a method of producing an abrasive compact including the steps of forming a feed diamond powder into a diamond preform, interposing a separating mechanism between the diamond preform and a silicon infiltrant source, heating the diamond preform and silicon infiltrant source until the infiltrant is molten and the preform and infiltrant are isothermal and allowing infiltration from the molten silicon infiltrant source to occur into the diamond preform.

Owner:ELEMENT SIX ABRASIVES

Silicon semiconductor wafer and method for producing the same

InactiveUS6548886B1Quality improvementLow costPolycrystalline material growthSemiconductor/solid-state device manufacturingCzochralski methodNitrogen

A silicon semiconductor substrate is obtained by deriving a silicon semiconductor substrate from a silicon single crystal grown by the Czochralski method from a molten silicon containing not less than 1x1016 atoms / cm3 and not more than 1.5x1019 atoms / cm3 of nitrogen and heat-treating the silicon semiconductor substrate at a temperature of not less than 1000° C. and not more than 1300° C. for not less than one hour and is characterized by the fact that the density of crystal defects measuring not less than 0.1 mum as reduced to diameter is not more than 104 pieces / cm3 at least in the region reaching a depth of 1 mum from the surface of the substrate and the nitrogen content at the center of thickness of the silicon semiconductor substrate is not less than 1x1013 atoms / cm3 and not more than 1x1016 atoms / cm3.

Owner:SILTRONIC AG

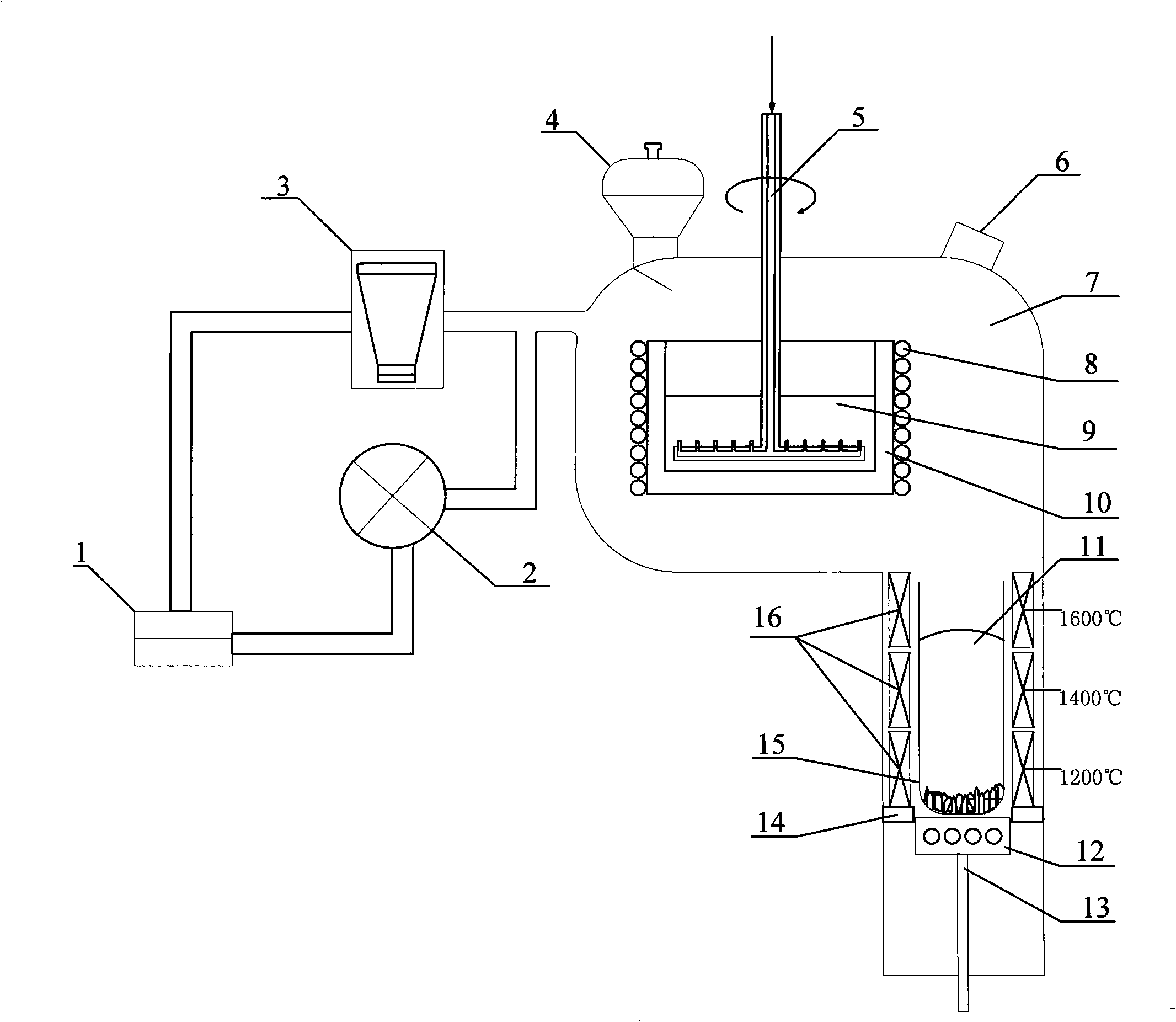

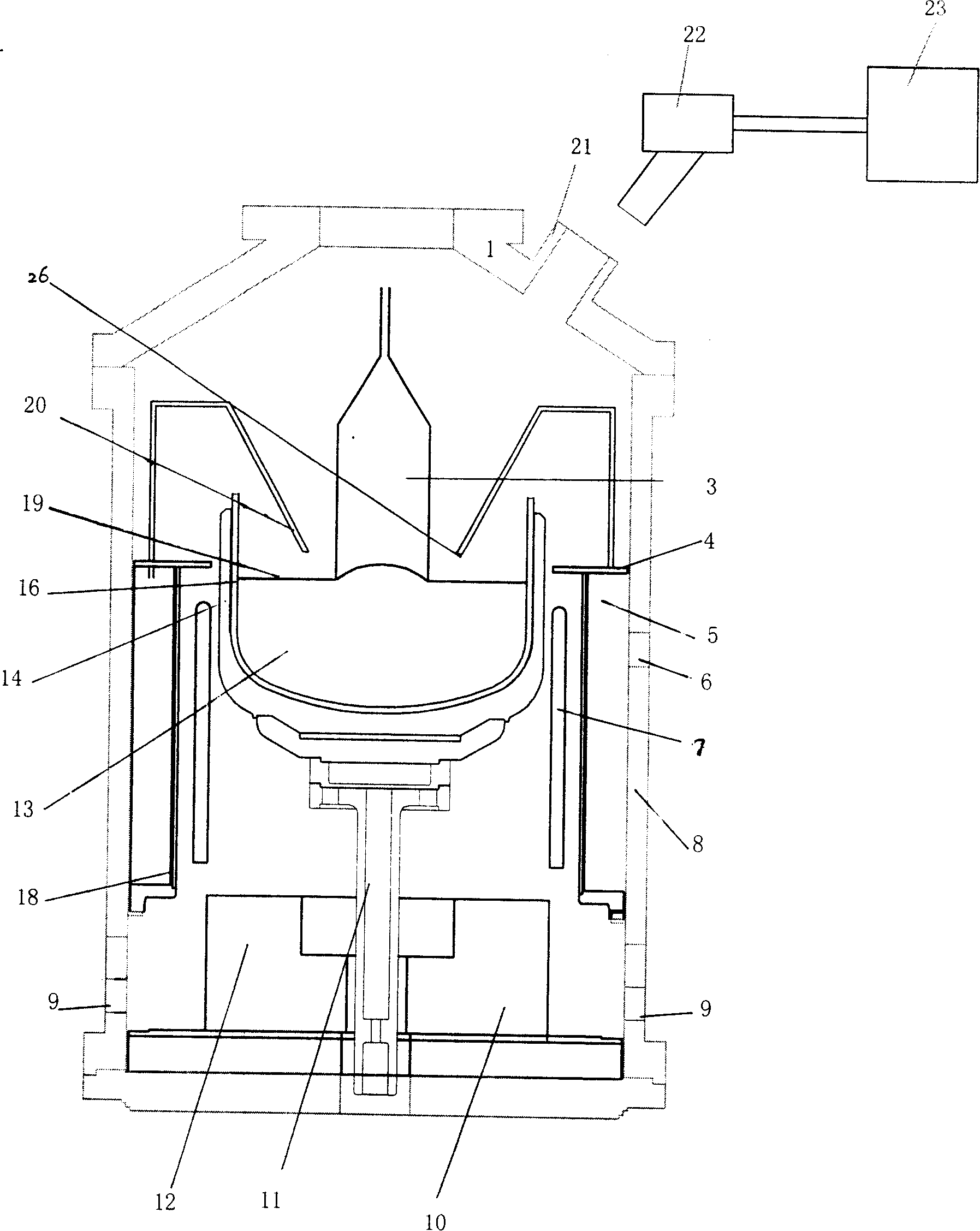

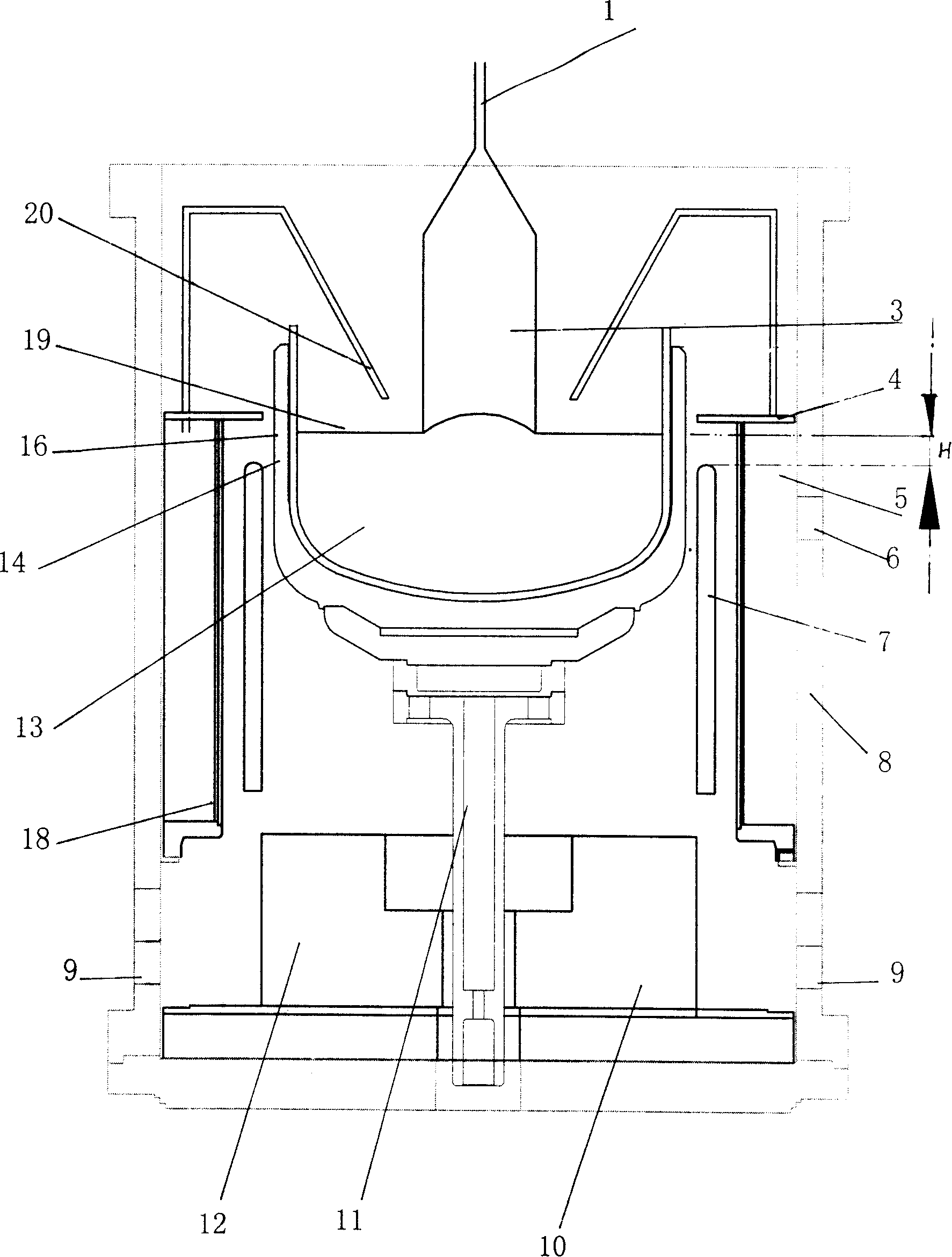

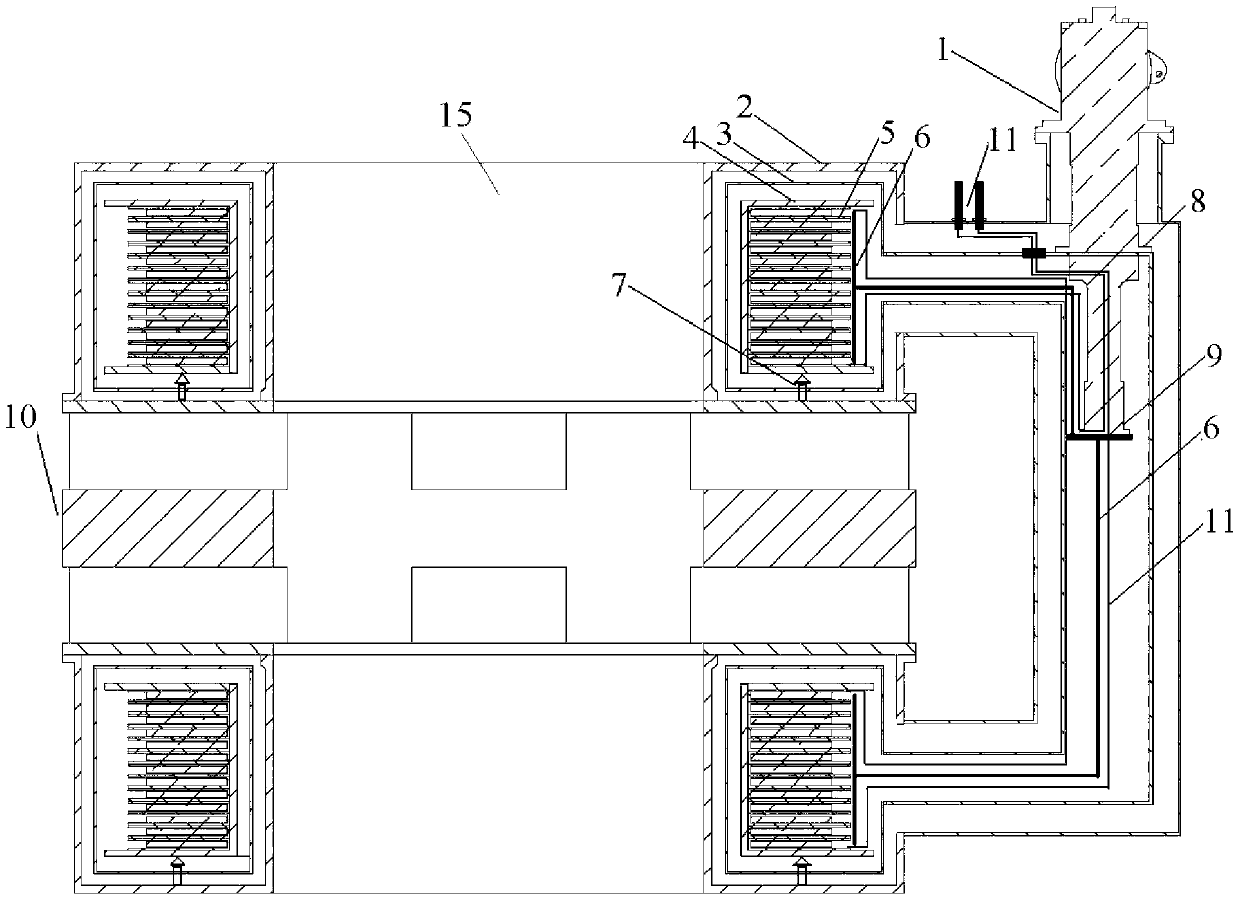

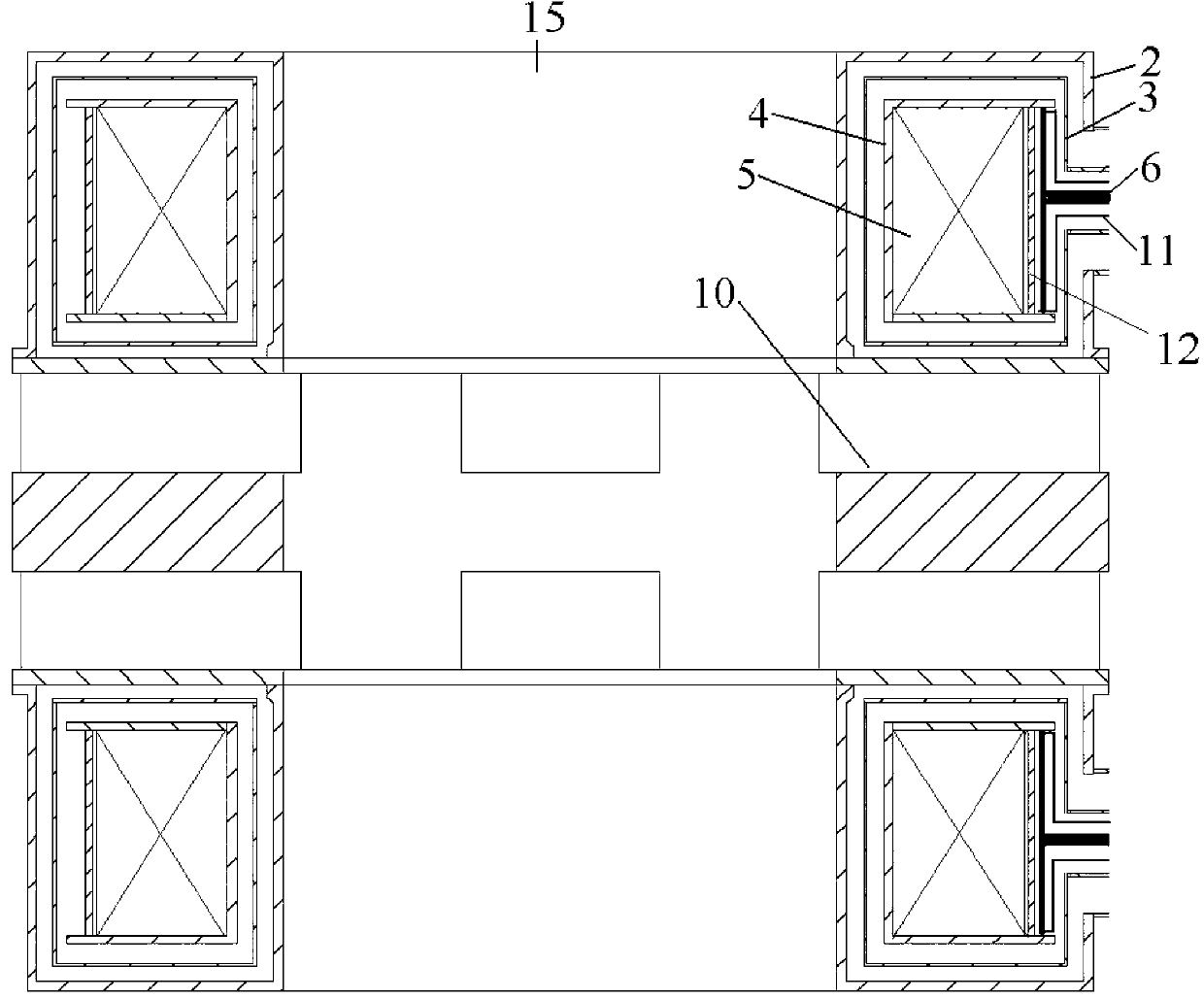

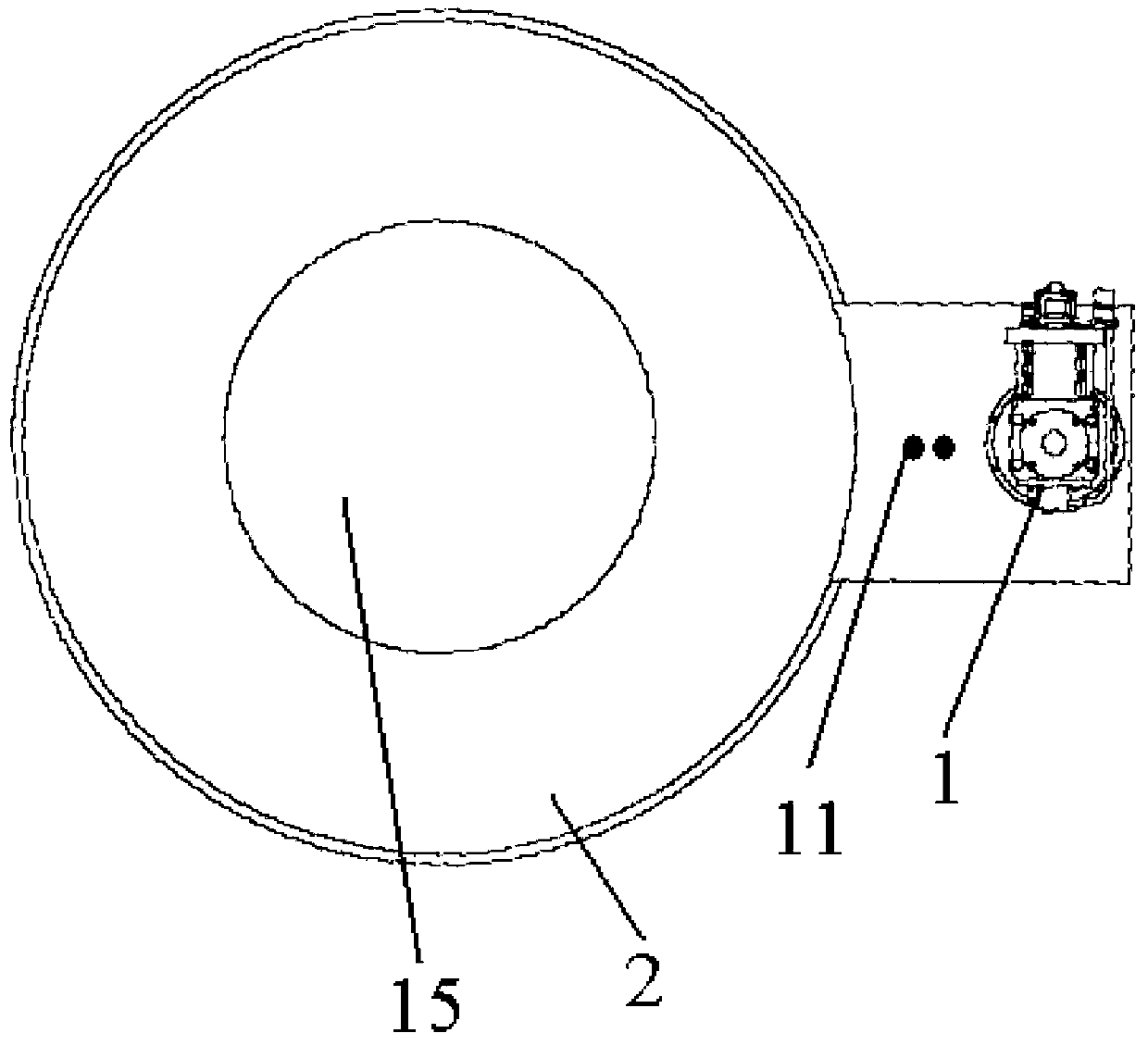

Purification apparatus and method for solar energy level polysilicon

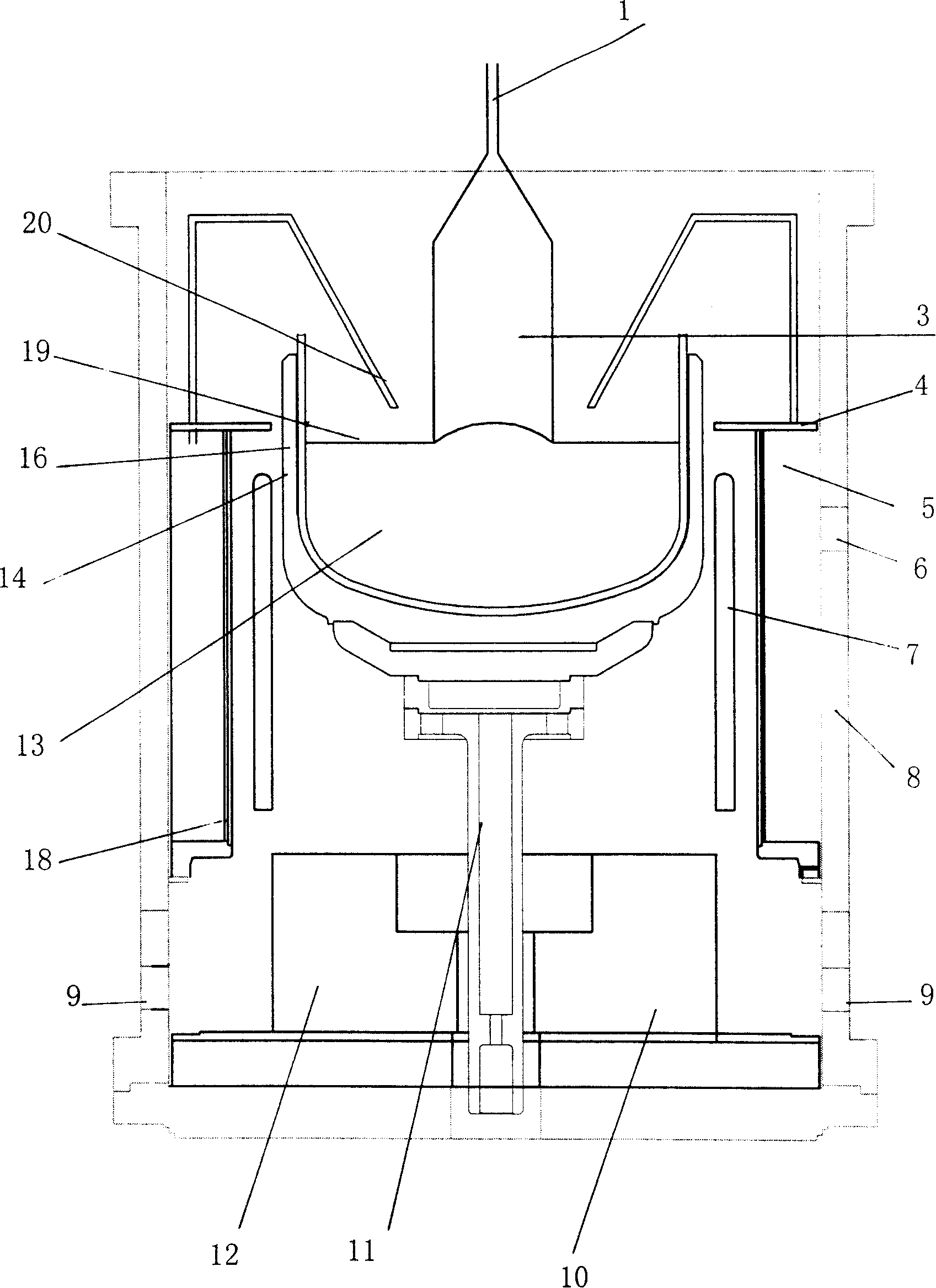

Disclosed are a purification device as well as a purification method of solar-grade polysilicon, relating to a polysilicon, which provides a purification device and a purification method of solar-grade polysilicon characterized by low cost, high purity, simple process, easy operation and suitability for large-scale production. The purification device is equipped with a vacuum system, a melting system and a directional solidification system; wherein the vacuum system is provided with a mechanical rotary vane pump, a lobed element pump and an oil diffusion pump, and the melting system is provided with a vacuum chamber, a secondary feeder, an observation window, a rotary ventilation device which can be raised and lowered, an induction coil and a graphite crucible; and the directional solidification system is disposed at the lower part of the vacuum chamber and is equipped with an electric resistance-wire heating and holding furnace, a graphite mold, a holding furnace frame, a water-cooled copper tray and an elevating lever which can control speed. The metal silicon is treated by induction heating to be molten, the oxidizing gas is fed under conditions of low vacuum and high temperature to remove boron, and then under conditions of high temperature and high vacuum to remove phosphorus, and finally the molten silicon solution is poured into a directional mold to strictly conduct directional solidification to remove metal impurities.

Owner:XIAMEN UNIV

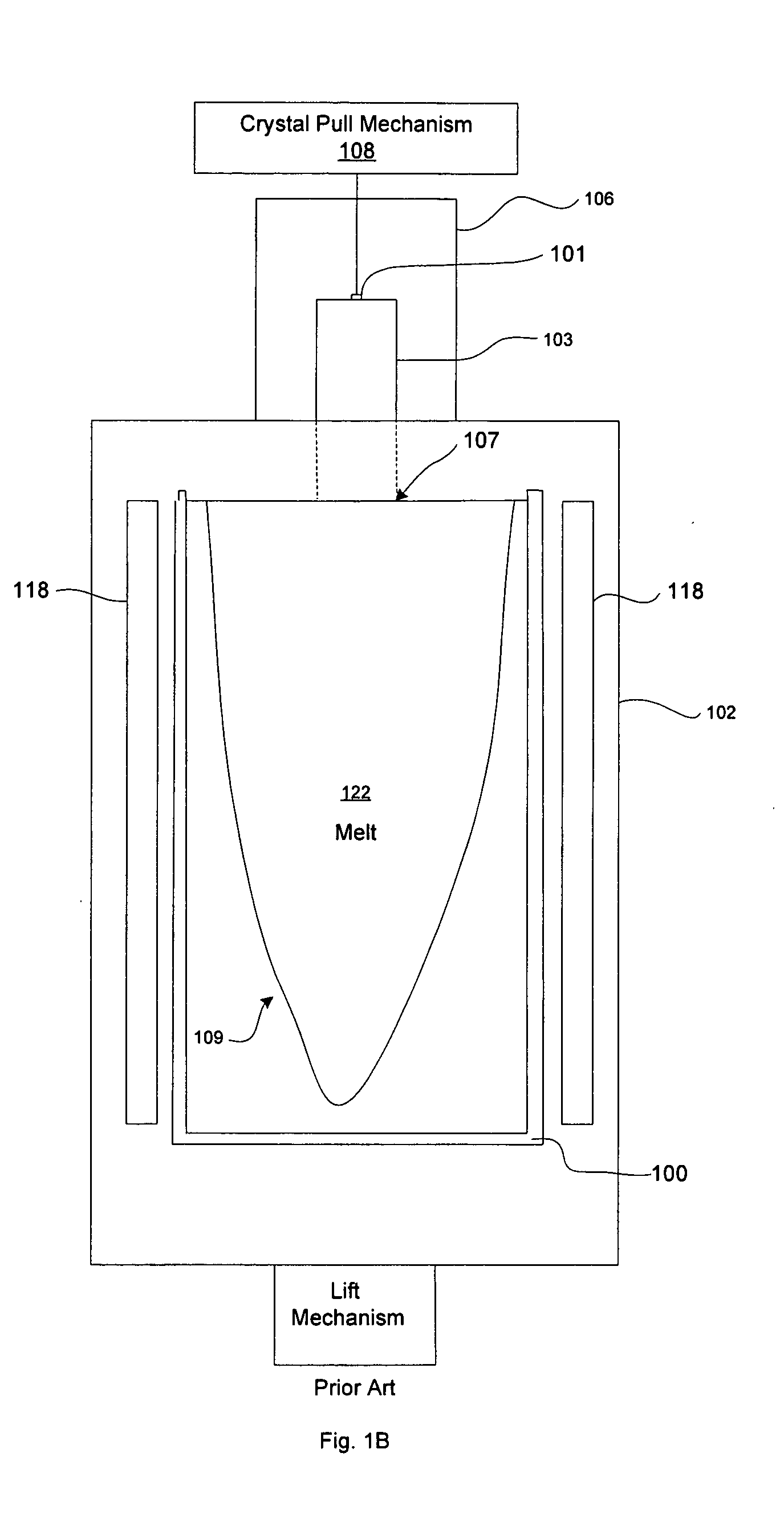

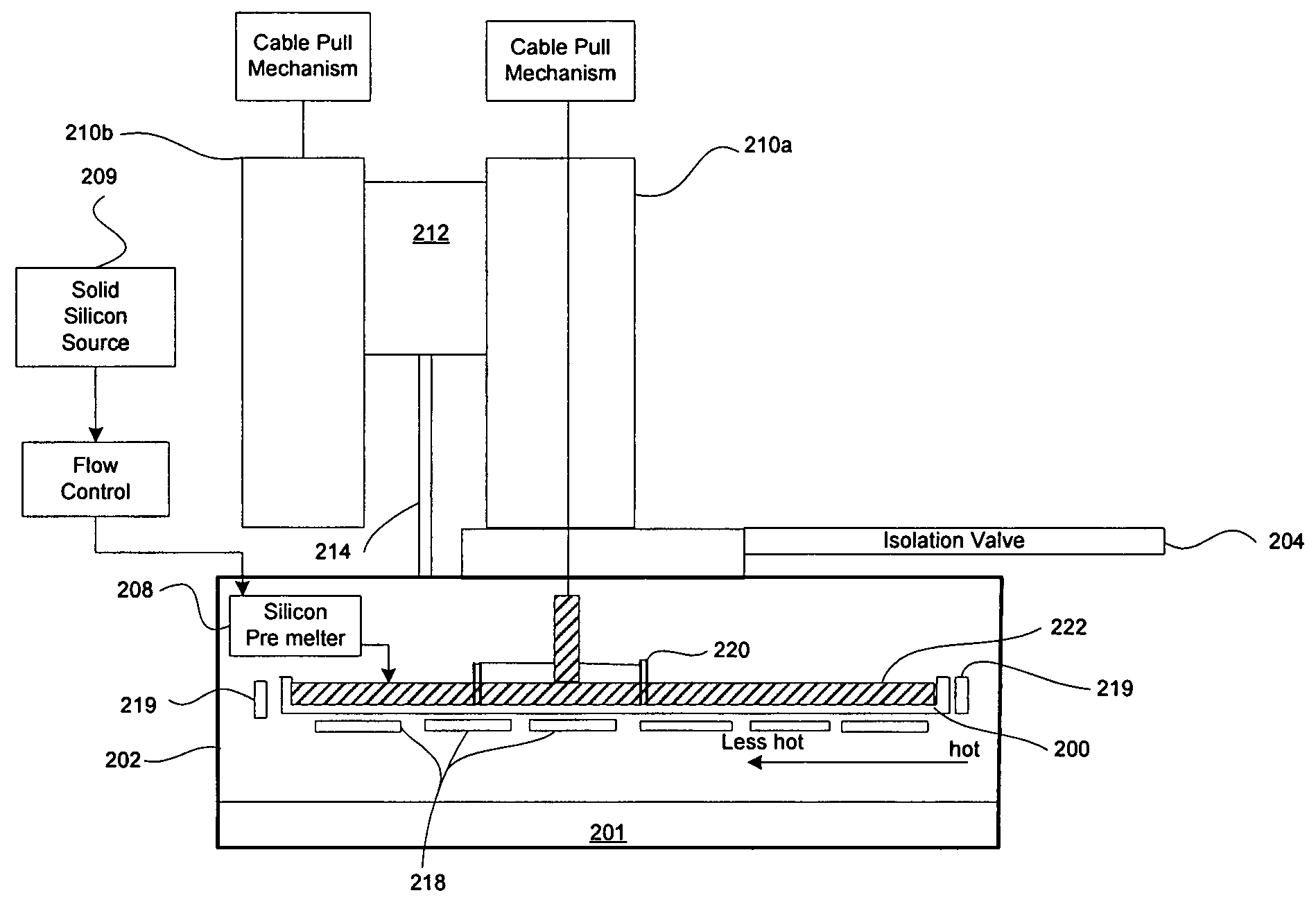

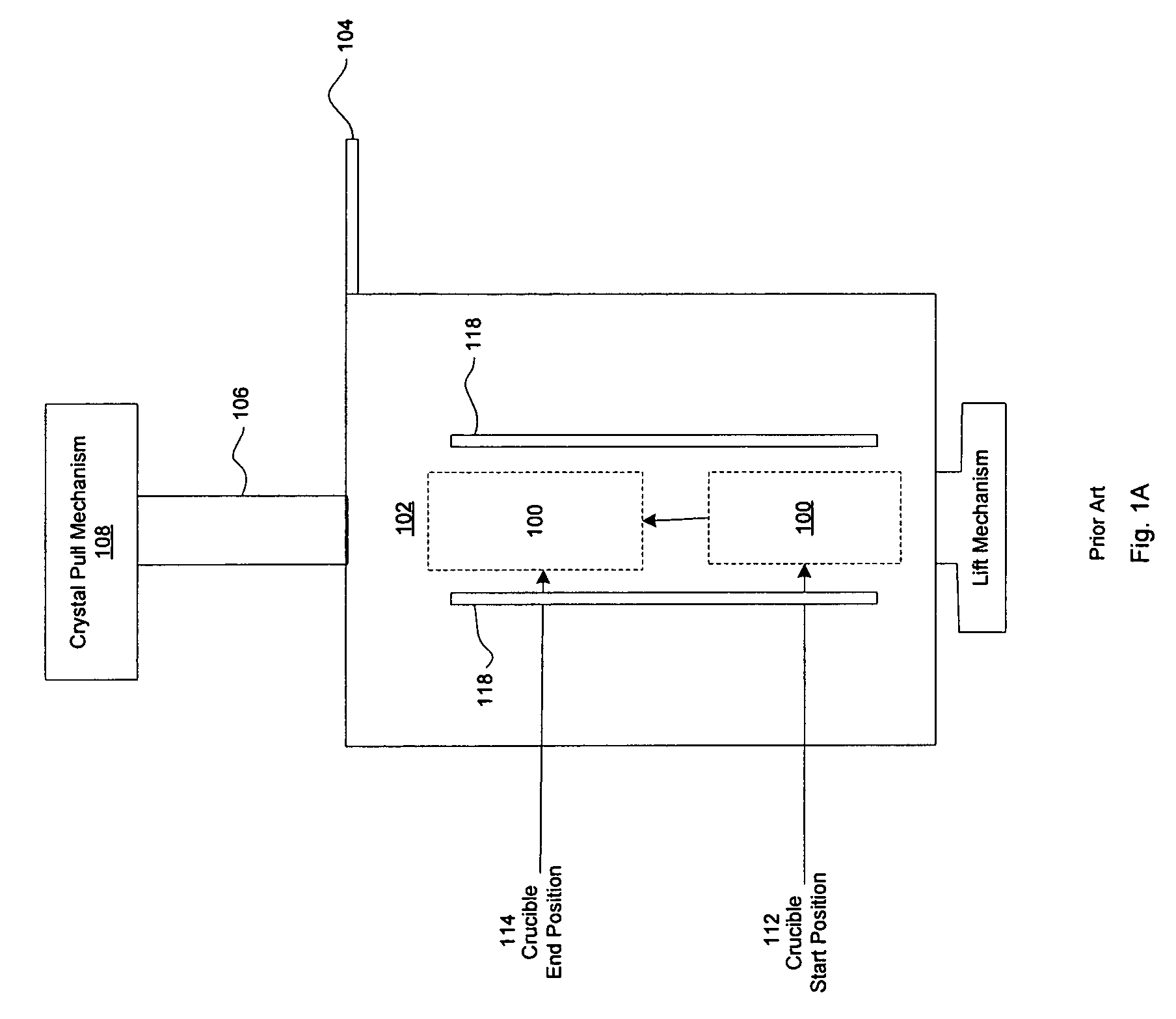

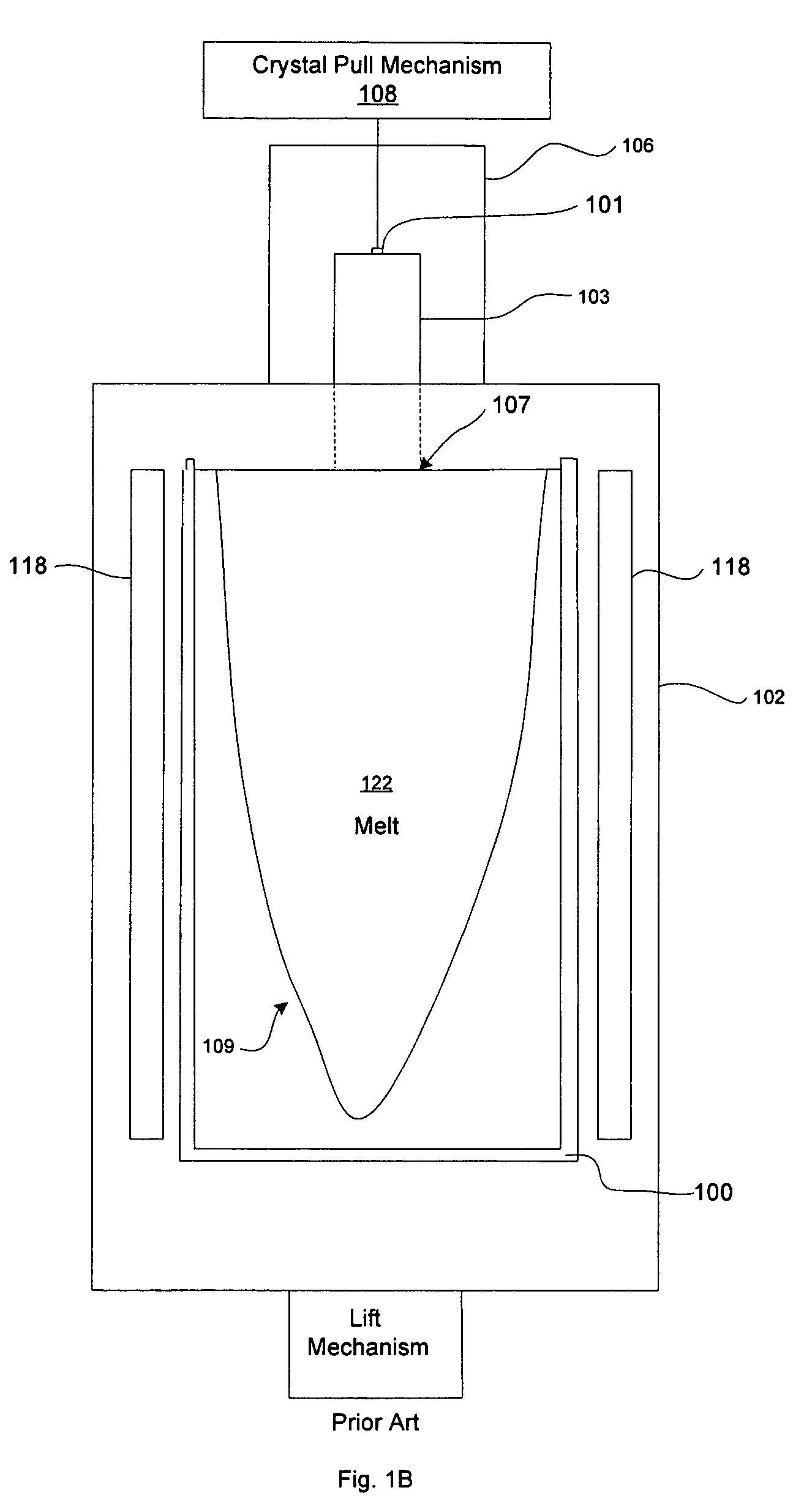

System for continuous growing of monocrystalline silicon

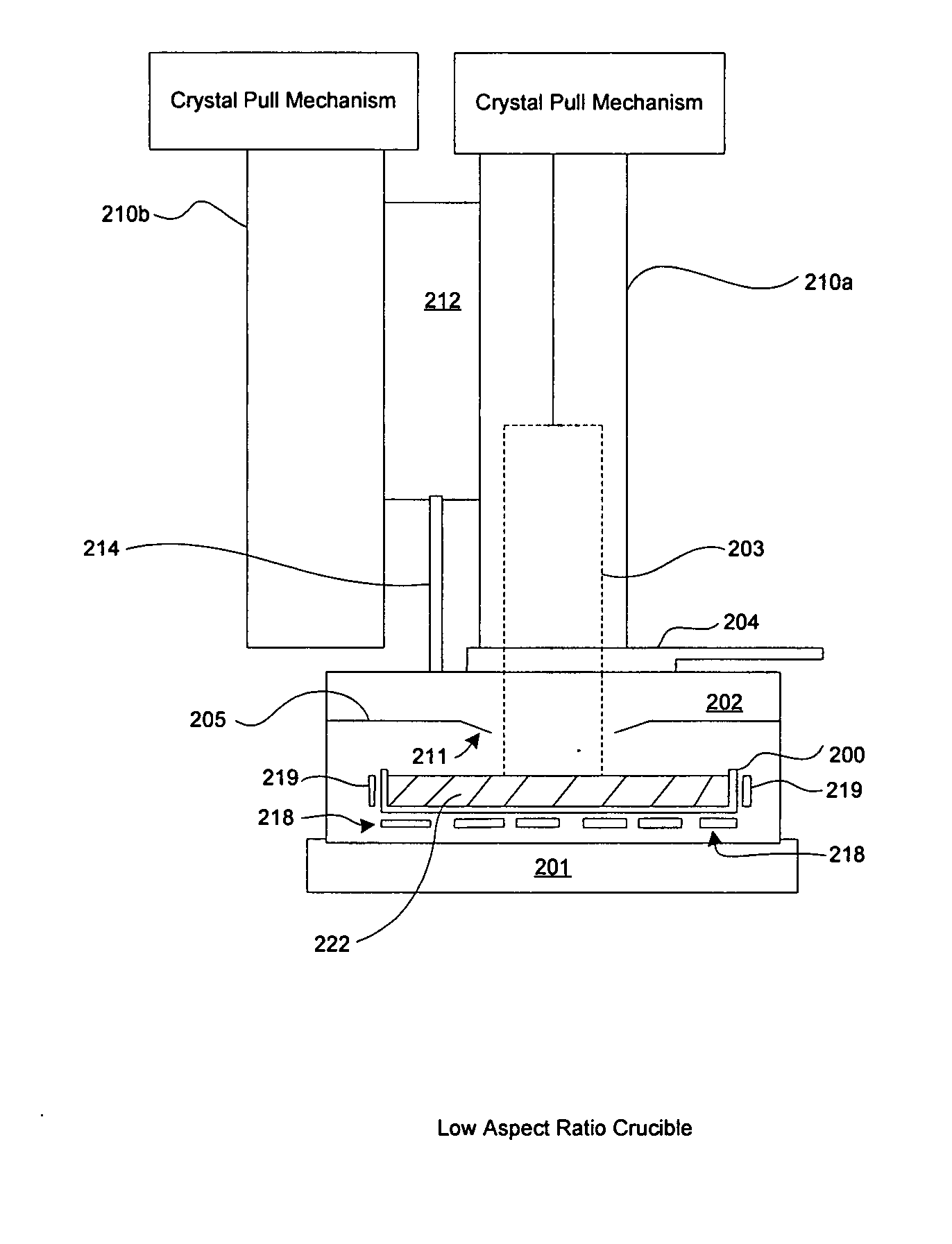

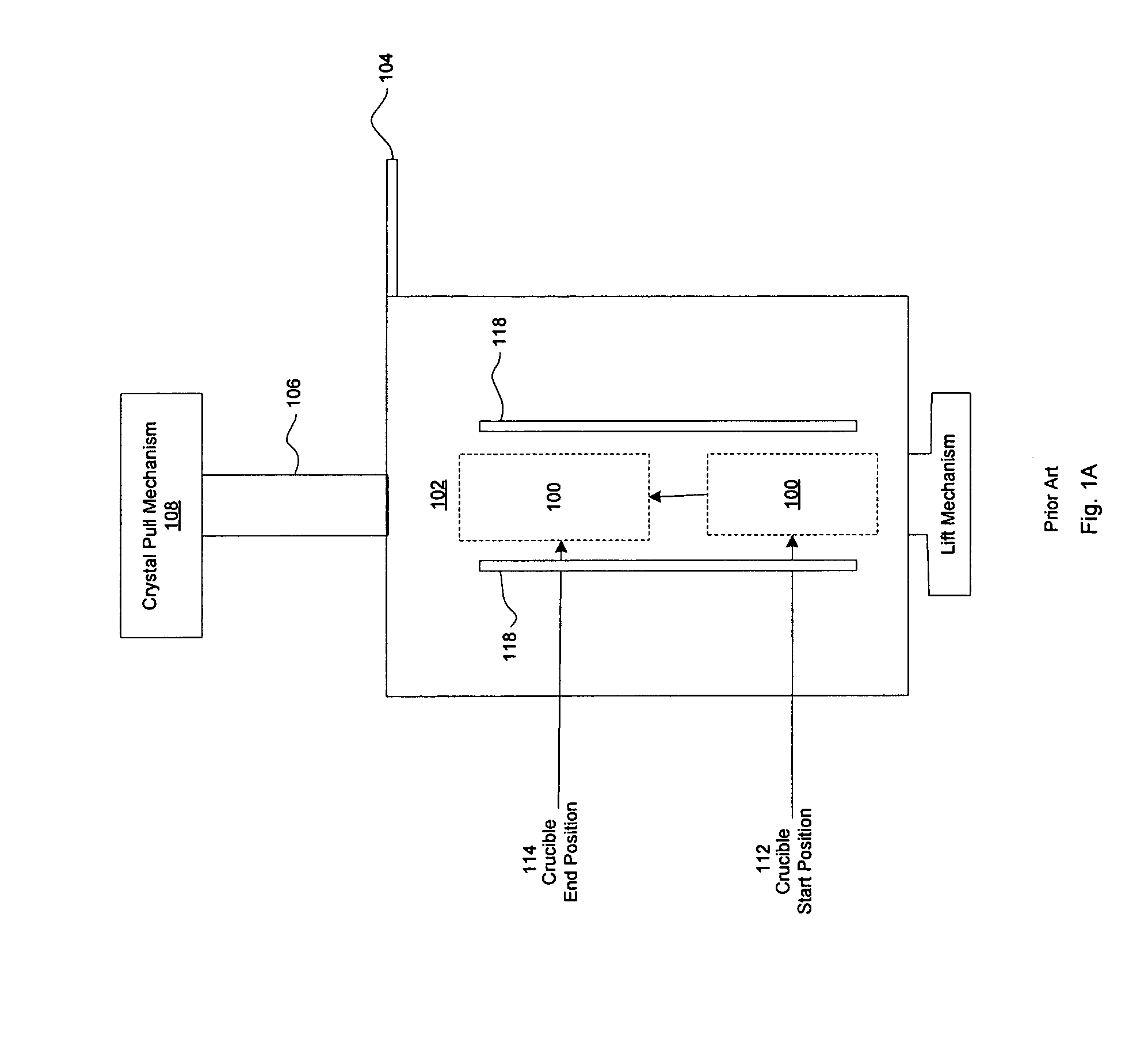

ActiveUS20050092236A1Easy temperature controlAccelerated crystal growthAfter-treatment apparatusPolycrystalline material growthHot zoneSingle crystal

An improved system based on the Czochralski process for continuous growth of a single crystal ingot comprises a low aspect ratio, large diameter, and substantially flat crucible, including an optional weir surrounding the crystal. The low aspect ratio crucible substantially eliminates convection currents and reduces oxygen content in a finished single crystal silicon ingot. A separate level controlled silicon pre-melting chamber provides a continuous source of molten silicon to the growth crucible advantageously eliminating the need for vertical travel and a crucible raising system during the crystal pulling process. A plurality of heaters beneath the crucible establish corresponding thermal zones across the melt. Thermal output of the heaters is individually controlled for providing an optimal thermal distribution across the melt and at the crystal / melt interface for improved crystal growth. Multiple crystal pulling chambers are provided for continuous processing and high throughput.

Owner:CORNER STAR LTD

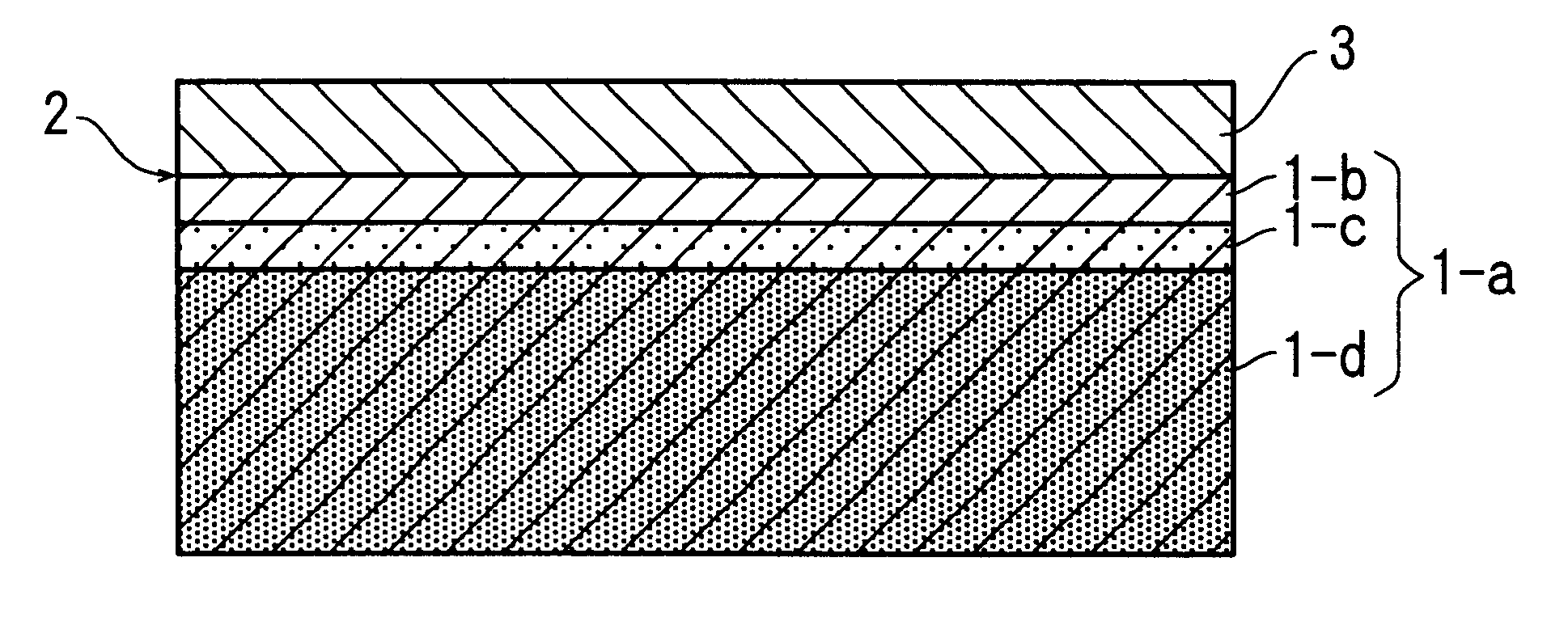

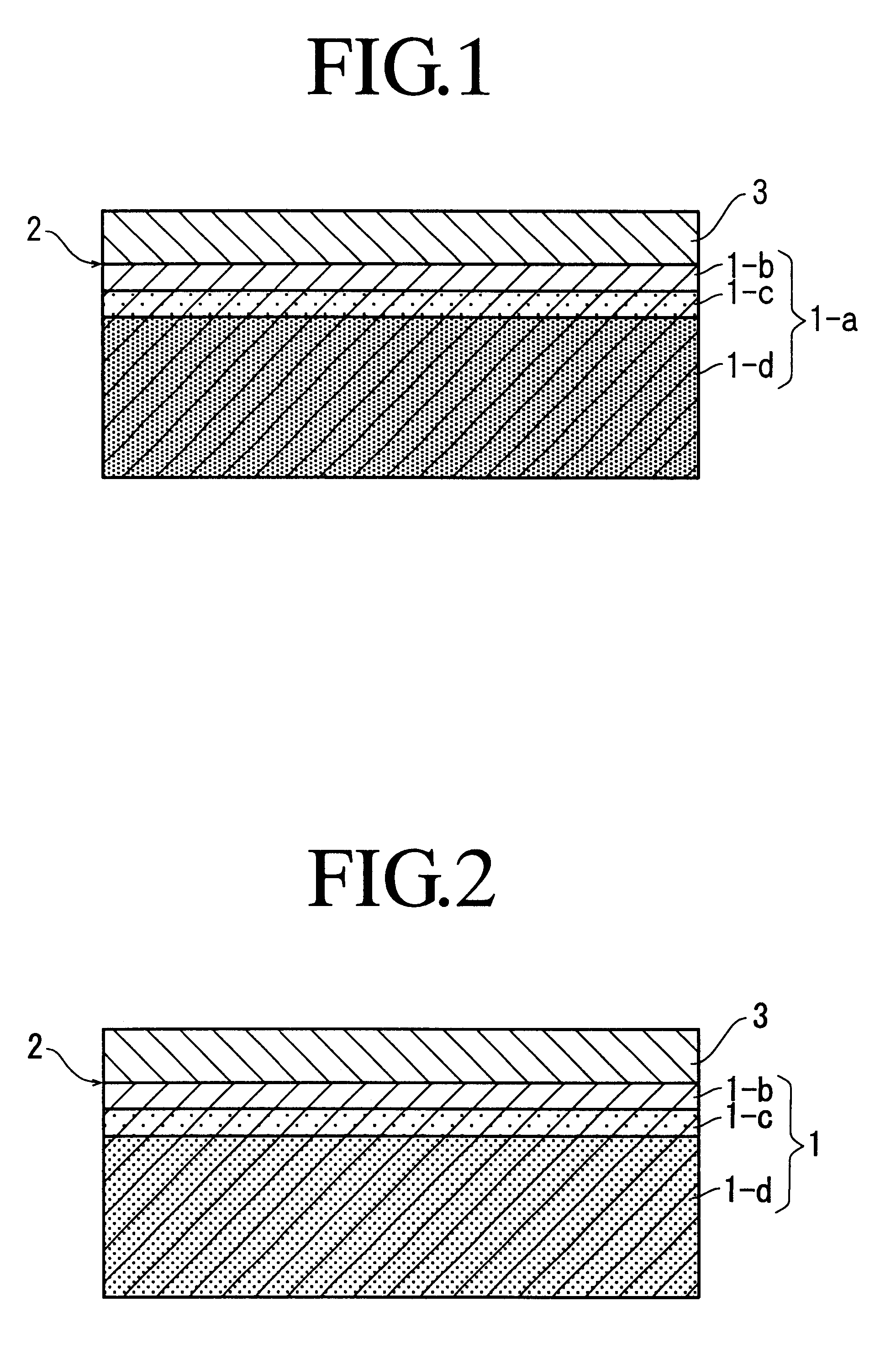

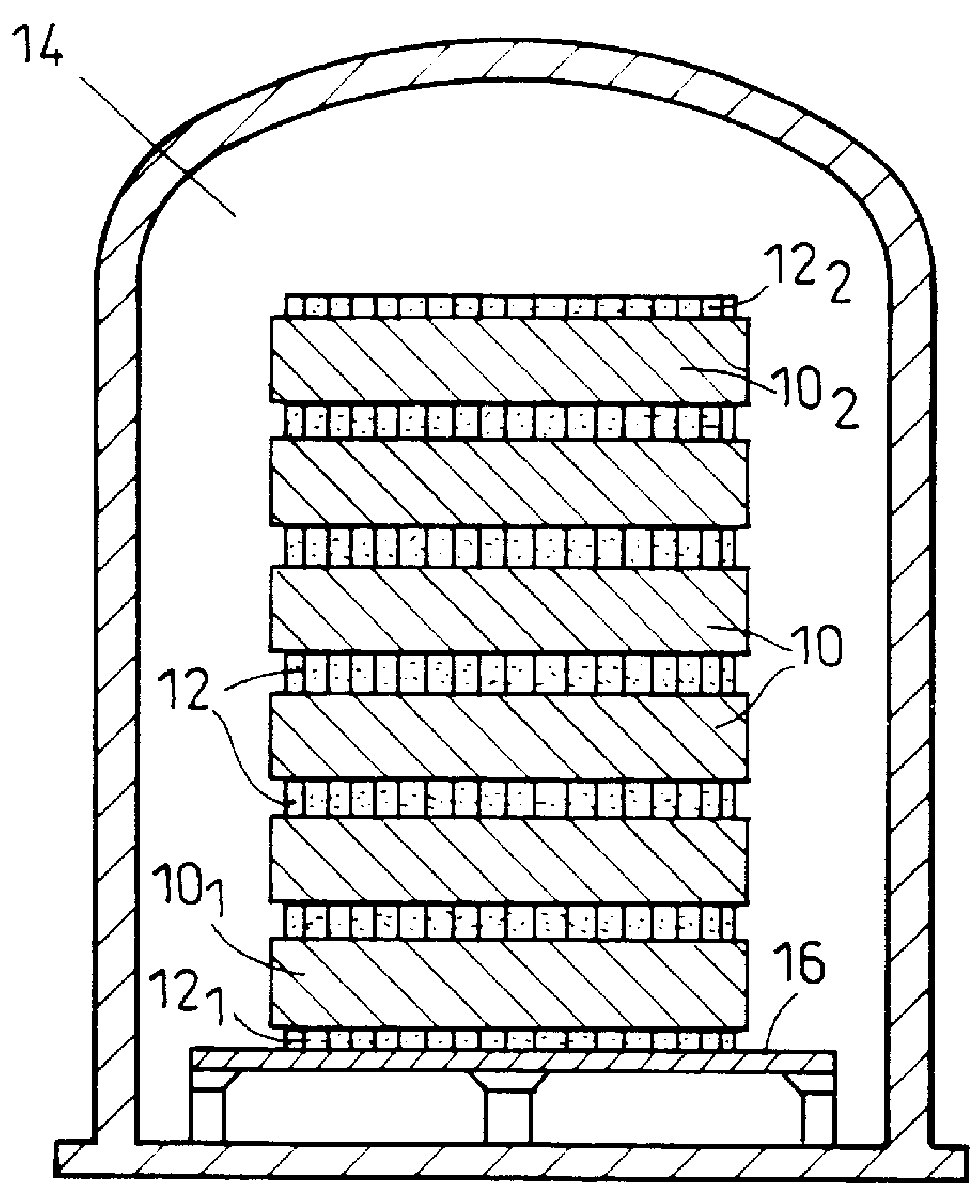

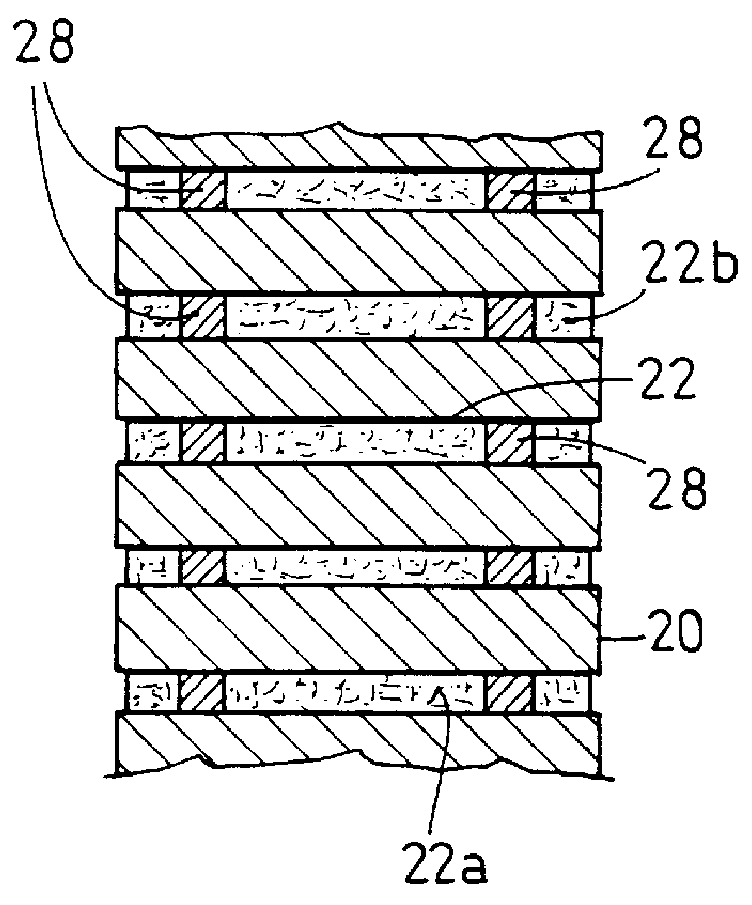

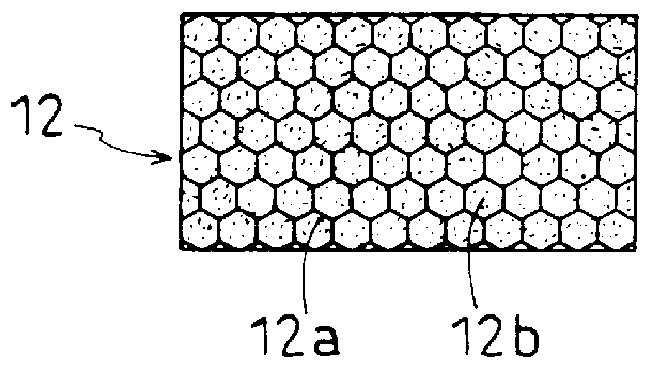

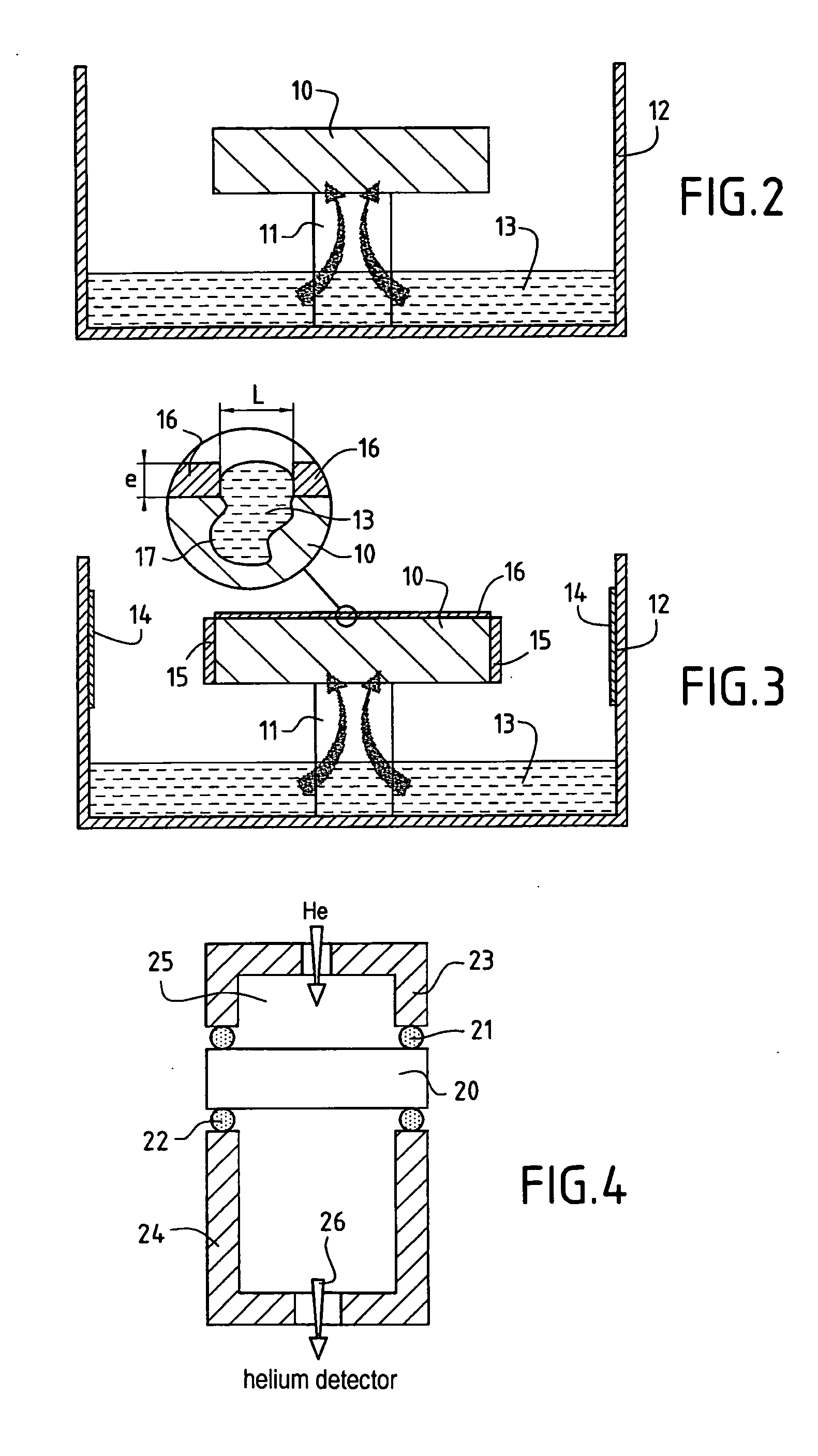

Method for delivering a molten silicon composition into porous substrates

InactiveUS6110535AImprove wettabilityLoss of working volumePretreated surfacesEfficient propulsion technologiesMolten statePorous substrate

PCT No. PCT / FR96 / 01598 Sec. 371 Date May 13, 1998 Sec. 102(e) Date May 13, 1998 PCT Filed Oct. 14, 1996 PCT Pub. No. WO97 / 18176 PCT Pub. Date May 22, 1997A plurality of substrates (10) are disposed in alternation and in contact with layers (12) which constitute sources of metal-based composition, each layer comprising a majority phase formed by the metal-based composition and a minority phase suitable for forming a structure for retaining and draining the metal-based composition when it is in the molten state. The batch is heated to a temperature greater than the melting temperature of the metal-based composition such that the metal-based composition in the molten state can migrate from each source through the adjacent surface of the, or each, substrate adjacent to the source towards the inside of the substrate. The invention seeks in particular to incorporate a silicon-based composition in a thermostructural composite material, in particular a carbon-carbon composite material for siliciding purposes.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

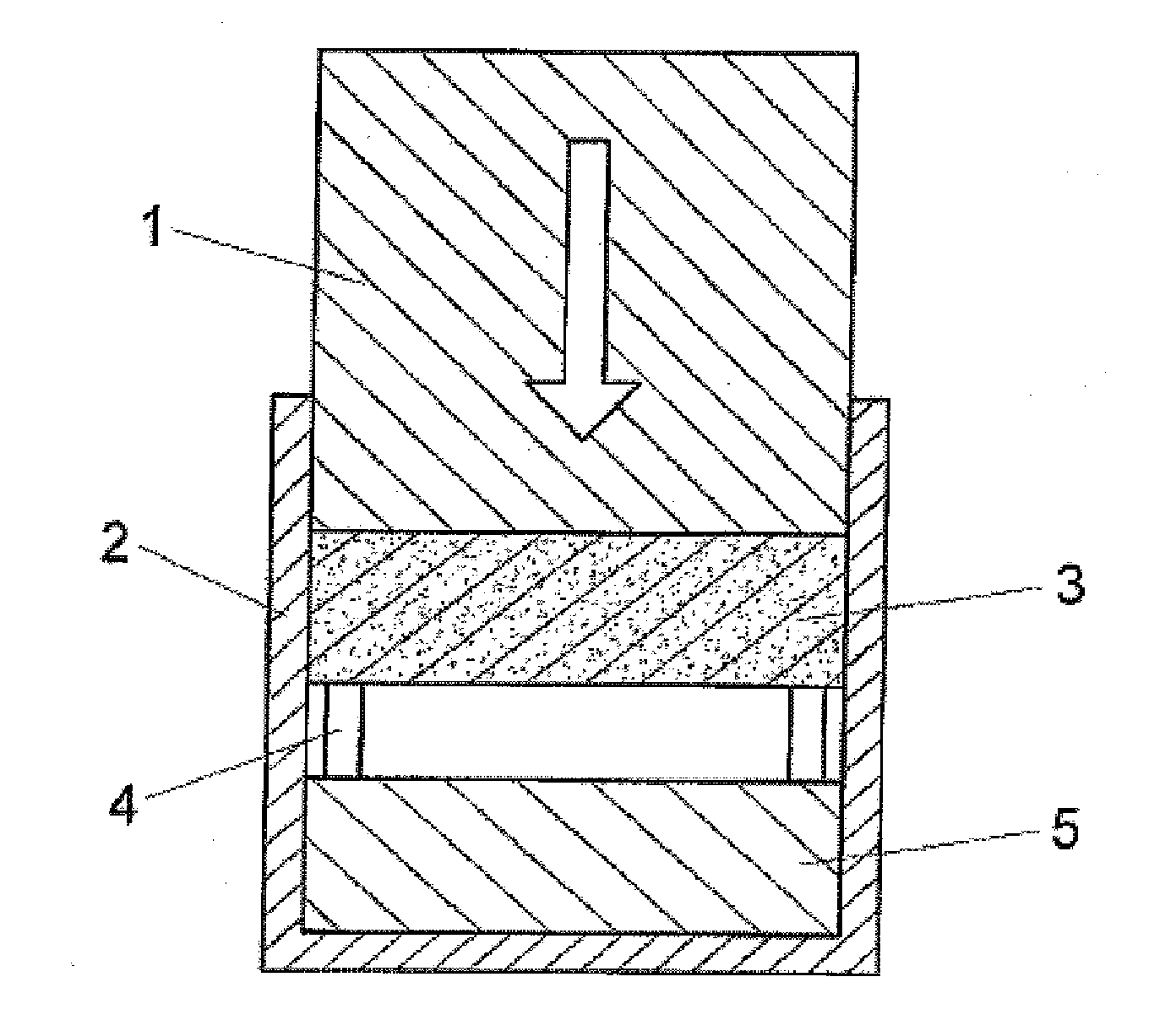

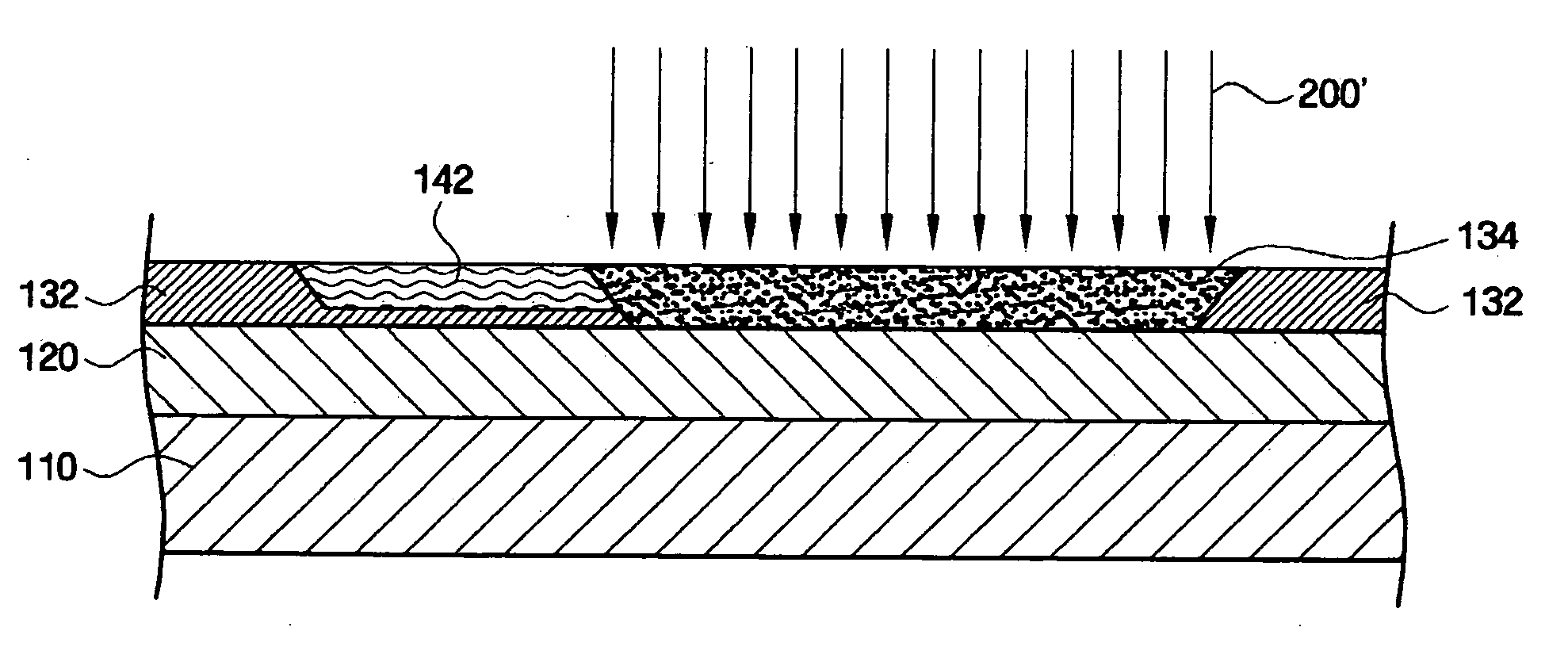

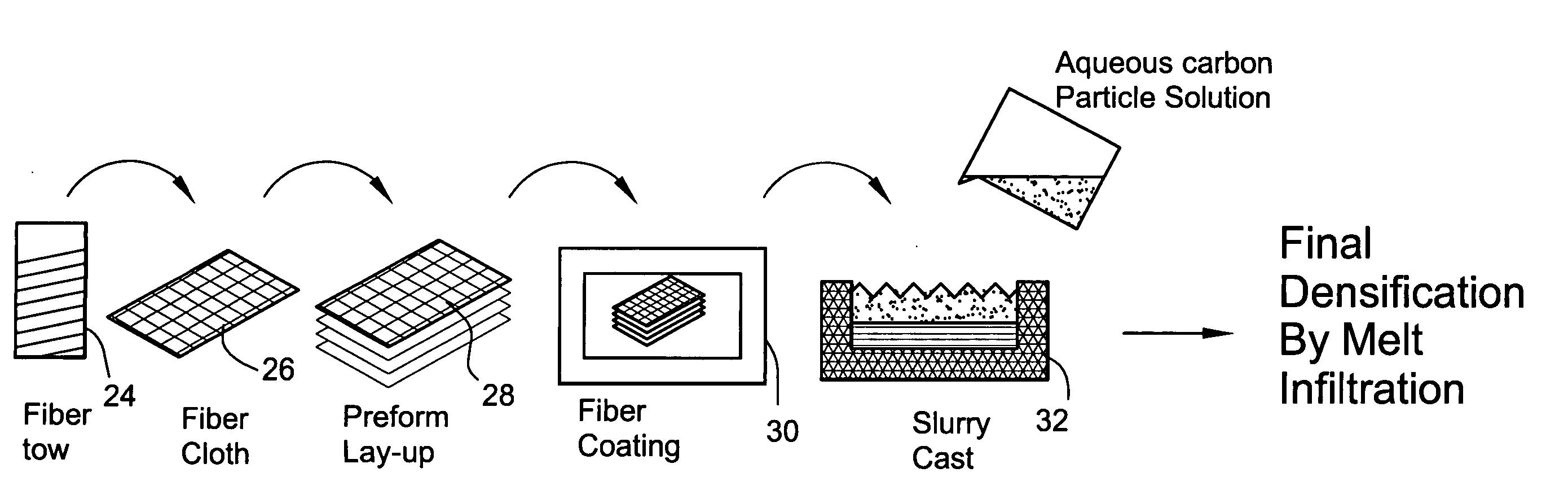

Nanotube-containing composite bodies, and methods for making same

InactiveUS20060062985A1Improve propertiesImprove fracture toughnessMaterial nanotechnologyNon-woven fabricsChemical reactionBonding process

A composite material featuring comminuted or otherwise well dispersed and separated nanotubes reinforcing a matrix featuring metal, ceramic and / or polymer. In a preferred embodiment, the nanotubes feature elemental carbon, and the composites can be produced using a molten silicon metal infiltration technique, which may be pressurized or not, for example, a siliconizing or a reaction-bonding process. In this preferred embodiment, carbon nanotubes may be prevented from chemically reacting with the silicon infiltrant by an interfacial coating disposed between the carbon nanotubes and the infiltrant. A reaction-bonded composite body containing even a small percentage of carbon nanotubes possessed a significant increase in electrical conductivity as compared to a reaction-bonded composite not containing such nanotubes, reflecting the high electrical conductivity of the nanotubes. When the nanotubes are well dispersed throughout the preform, mechanical property enhancements start to become noticeable, such as fracture toughness enhancement.

Owner:KARANDIKAR PRASHANT G

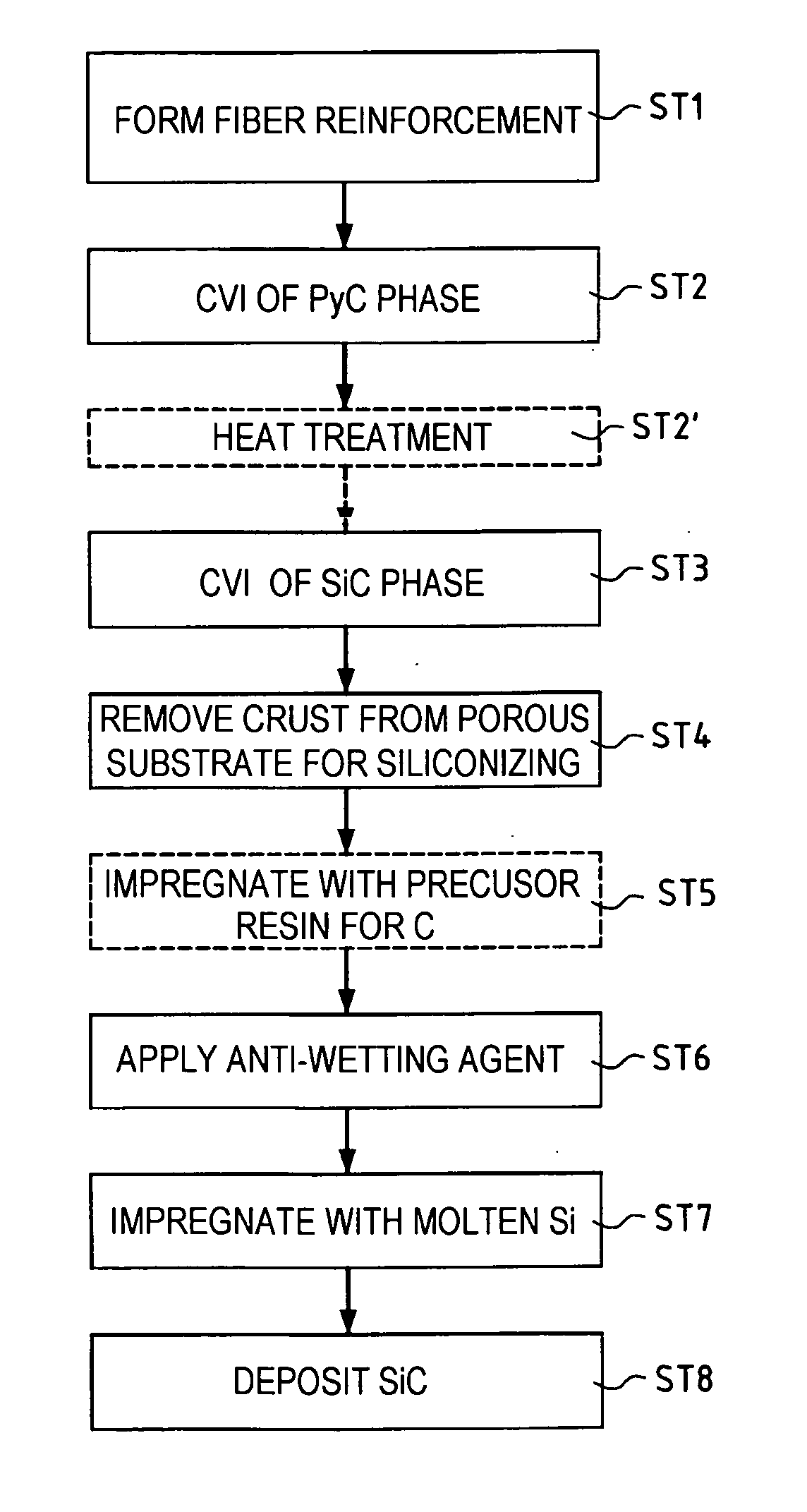

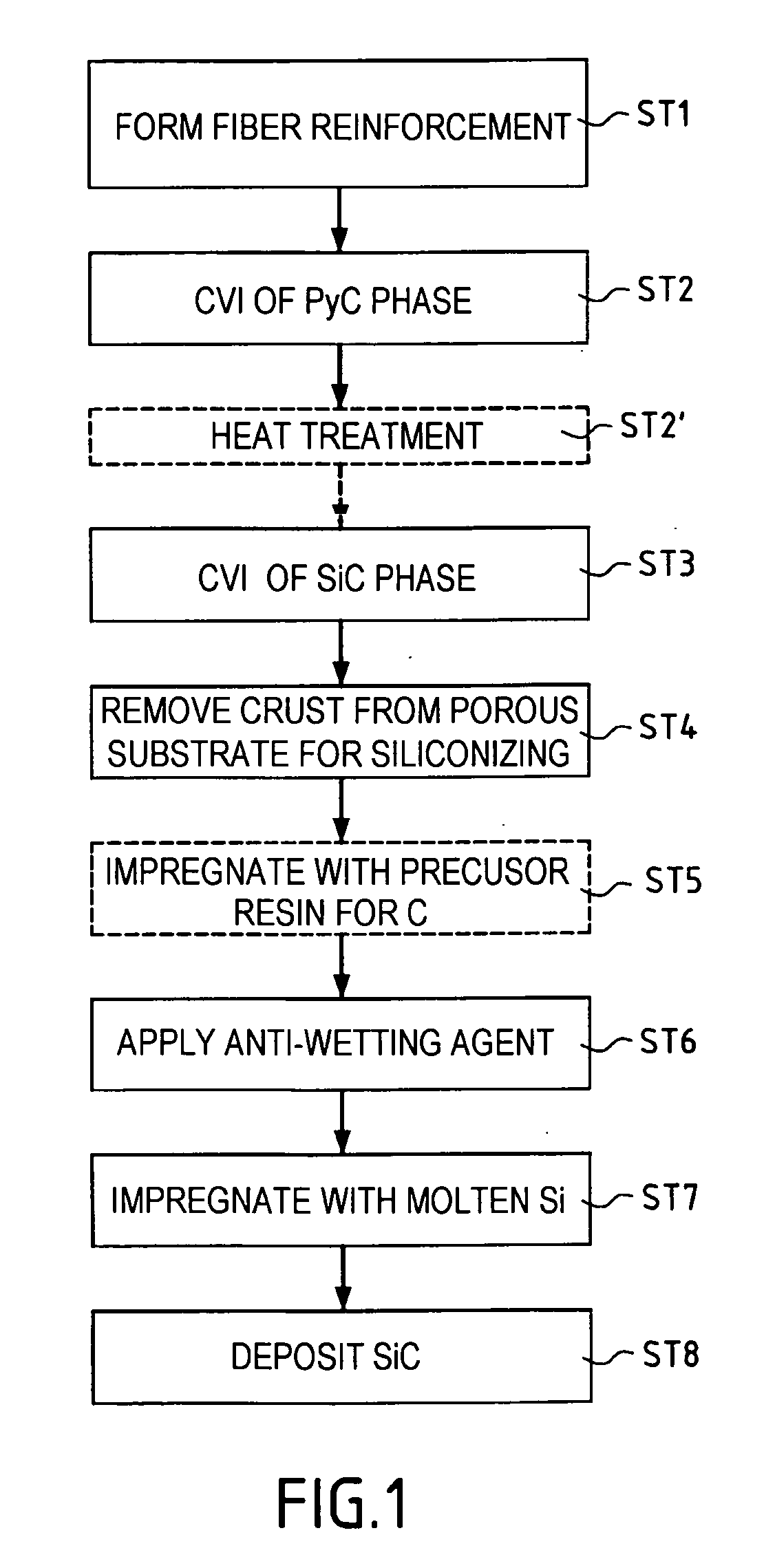

Method of manufacturing a part out of impervious thermostructural composite material

ActiveUS20050244581A1Risk of leakageImprove the level ofButtonsLayered productsPorous substrateFiber reinforcement

A method of manufacturing a part out of impervious thermostructural composite material, the method comprising forming a porous substrate from at least one fiber reinforcement made of refractory fibers, and densifying the reinforcement by a first phase of carbon and by a second phase of silicon carbide. The method then continues by impregnating the porous substrate with a composition based on molten silicon so as to fill in the pores of the substrate.

Owner:SAFRAN CERAMICS SA

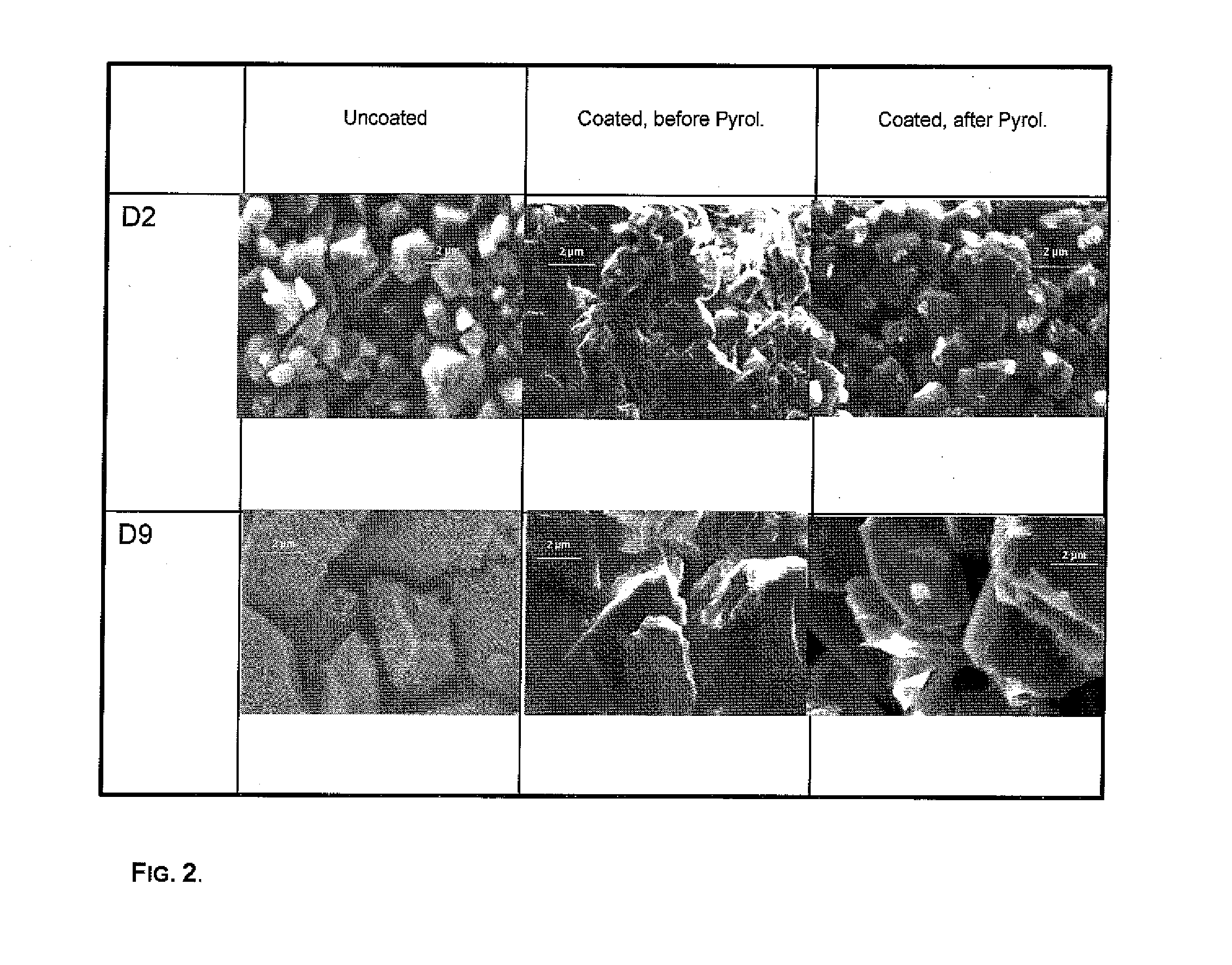

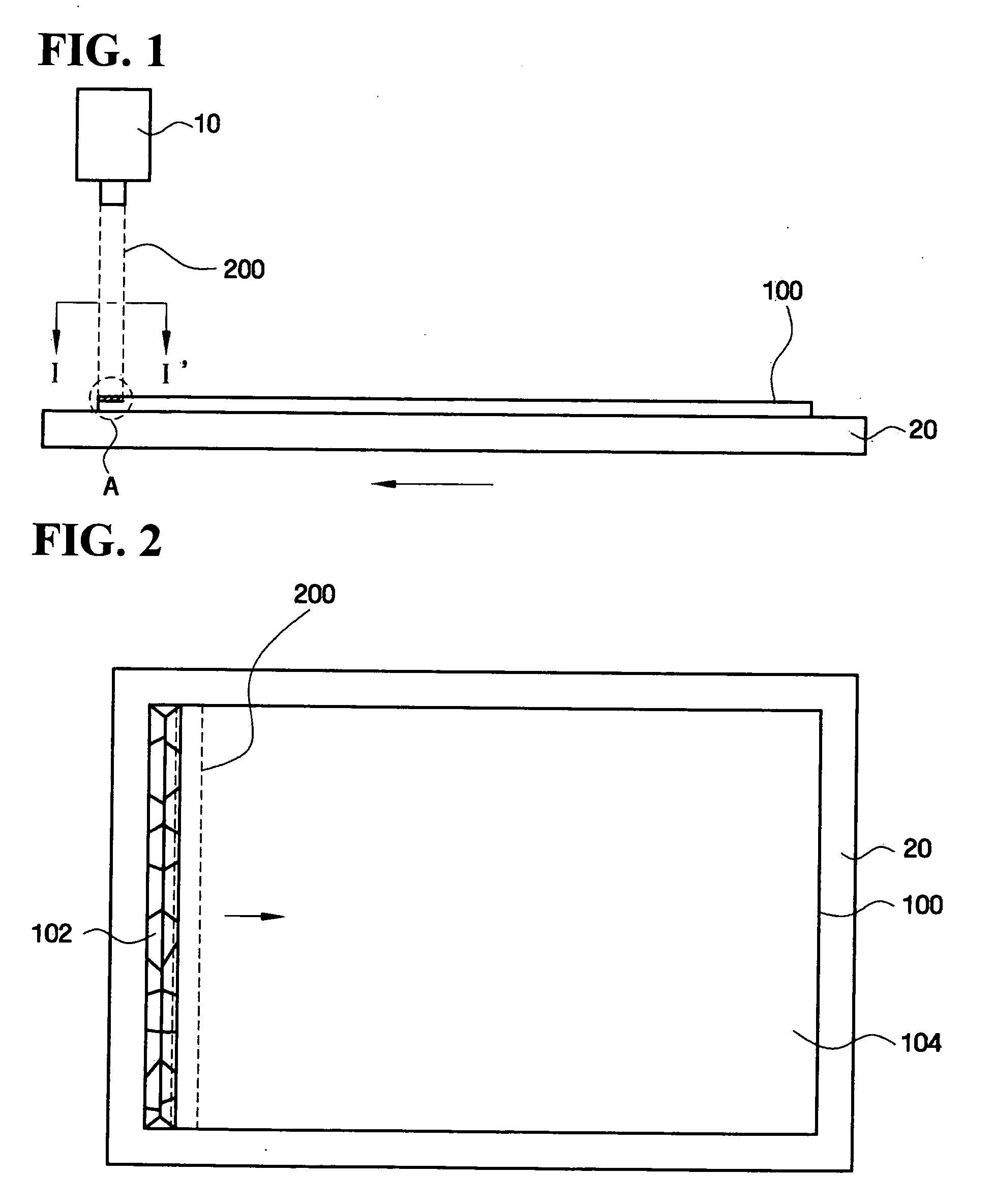

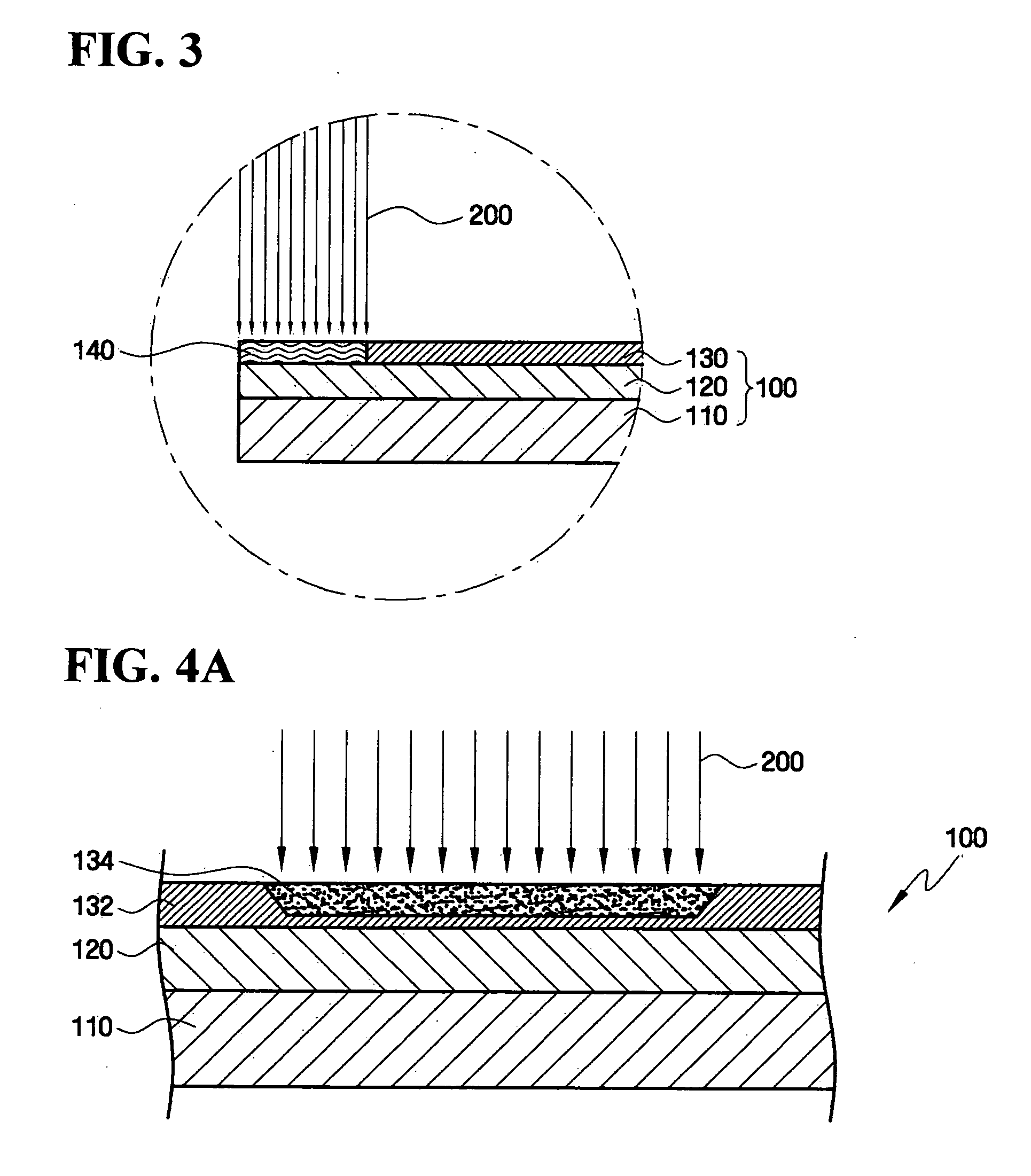

Method of forming polycrystalline silicon thin film and method of manufacturing thin film transistor using the method

ActiveUS20070054477A1Excellent electrical propertiesSolid-state devicesSemiconductor/solid-state device manufacturingHigh energyLaser beams

Provided are a method of forming a polycrystalline silicon thin film with improved electrical characteristics and a method of manufacturing a thin film transistor using the method of forming the polycrystalline silicon thin film. The method includes forming an amorphous silicon thin film on a substrate, partially melting a portion of the amorphous silicon thin film by irradiating the portion of the amorphous silicon thin film with a laser beam having a low energy density, forming polycrystalline silicon grains with a predetermined crystalline arrangement by crystallizing the partially molten portion of the amorphous silicon thin film, completely melting a portion of the polycrystalline silicon grains and a portion of the amorphous silicon thin film by irradiation of a laser beam having a high energy density while repeatedly moving the substrate by a predetermined distance, and growing the polycrystalline silicon grains by crystallizing the completely molten silicon homogeneously with the predetermined crystalline arrangement.

Owner:SAMSUNG DISPLAY CO LTD

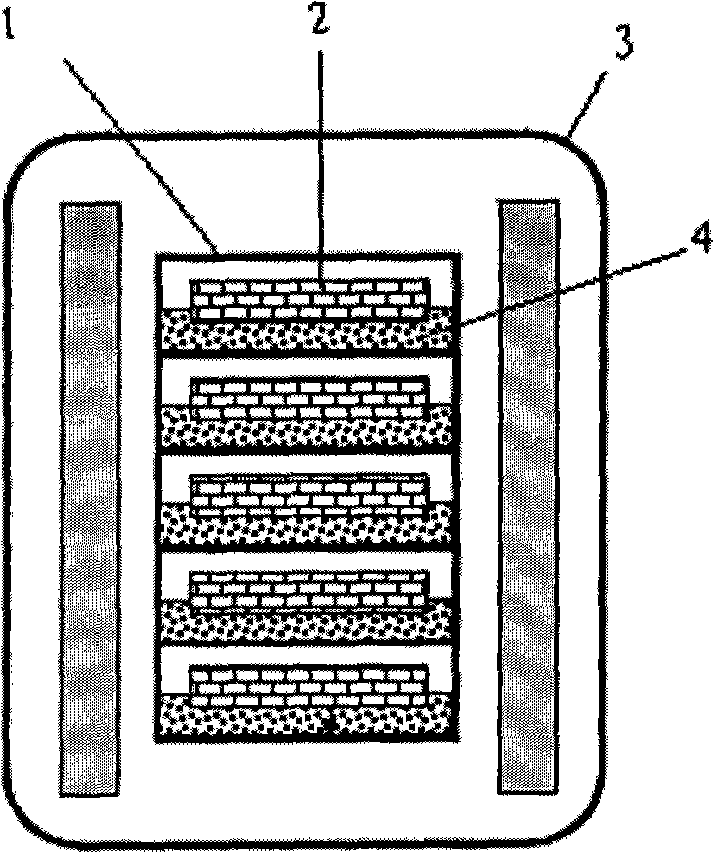

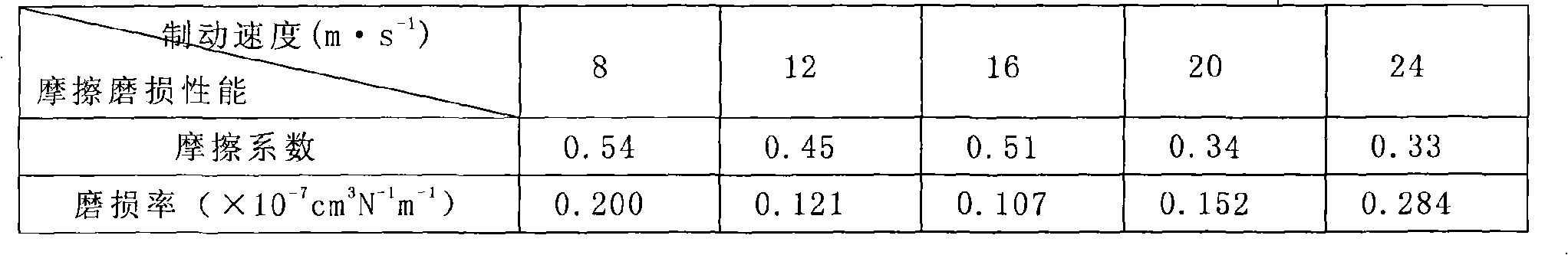

Charcoal/pottery brake lining manufacturing method for industrial brake

InactiveCN101493126AReduce processing intensityIncrease coefficient of frictionFriction liningGas phaseLow density

The invention discloses a method for manufacturing carbon / ceramic braking linings used in an industrial brake, which comprises the following steps: carbon fiber performs are prepared by a needle method; low-density C / C composite material is prepared by a chemical gas permeation method after the carbon fiber performs are treated in high temperature; the C / C composite material is treated in high temperature, machined and then the molten silicon infiltration is carried out on the C / C material in a high temperature vacuum furnace; Sic is formed by the Si and C reaction to prepare C / C-SiC baking material; and finally after the C / C-SiC baking material is machined, the C / C-SiC baking material is riveted with the steel backing by a rivet in a cold way to prepare the needed C / C-SiC baking material used in an industrial brake. The carbon / ceramic braking lining manufactured by the method has higher mechanical property and excellent frictional wear performance and is used in the industrial brake.

Owner:CENT SOUTH UNIV

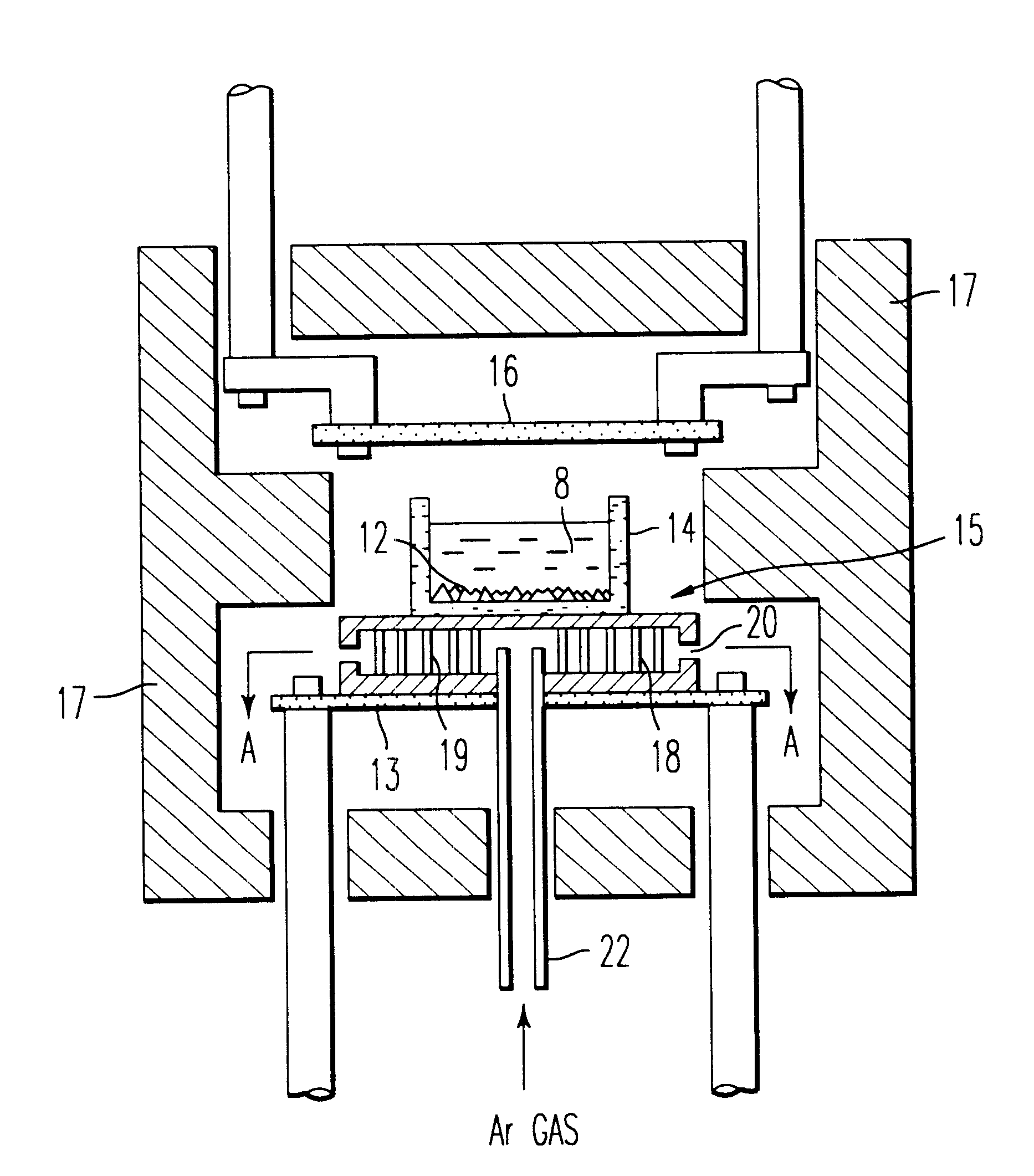

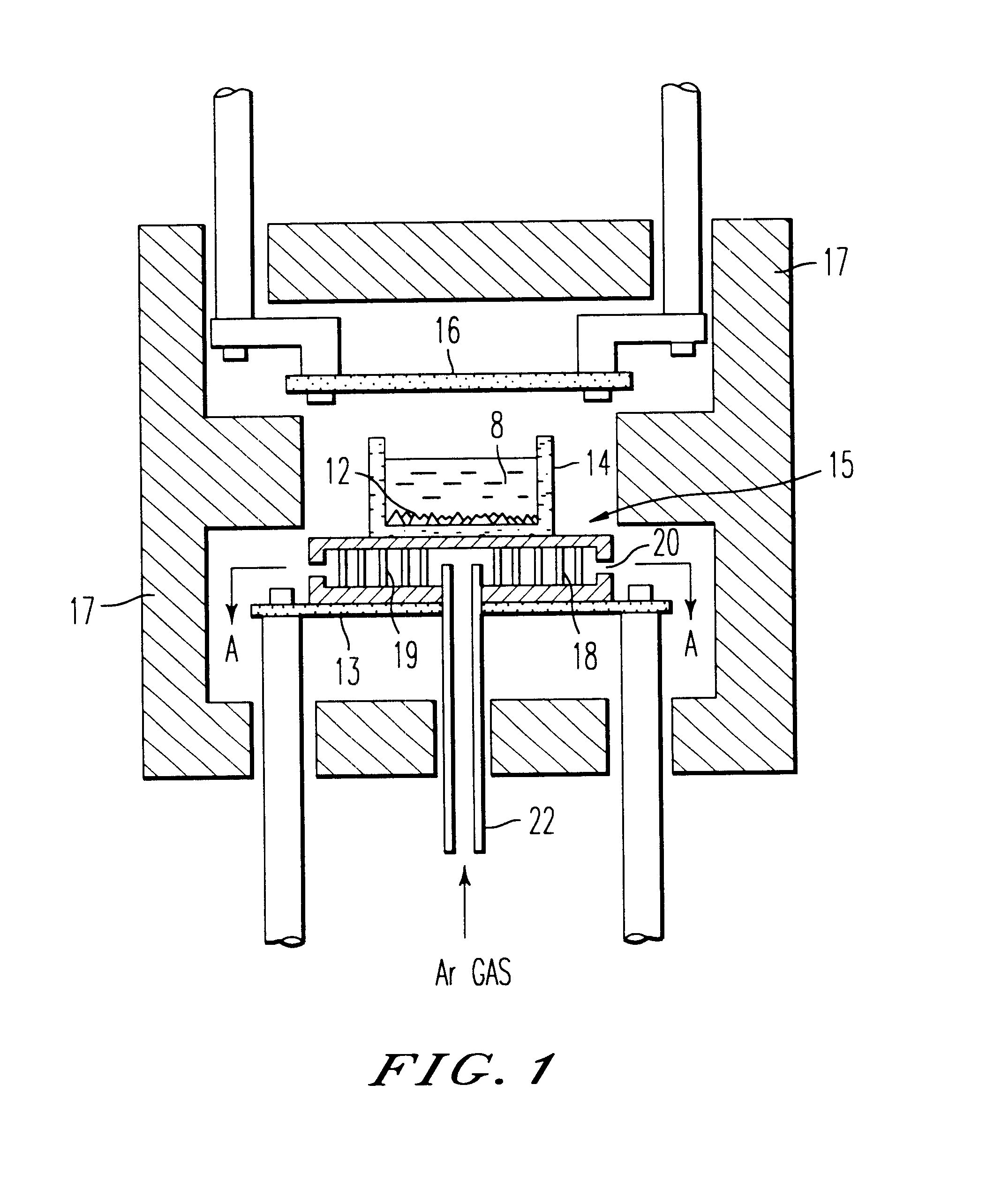

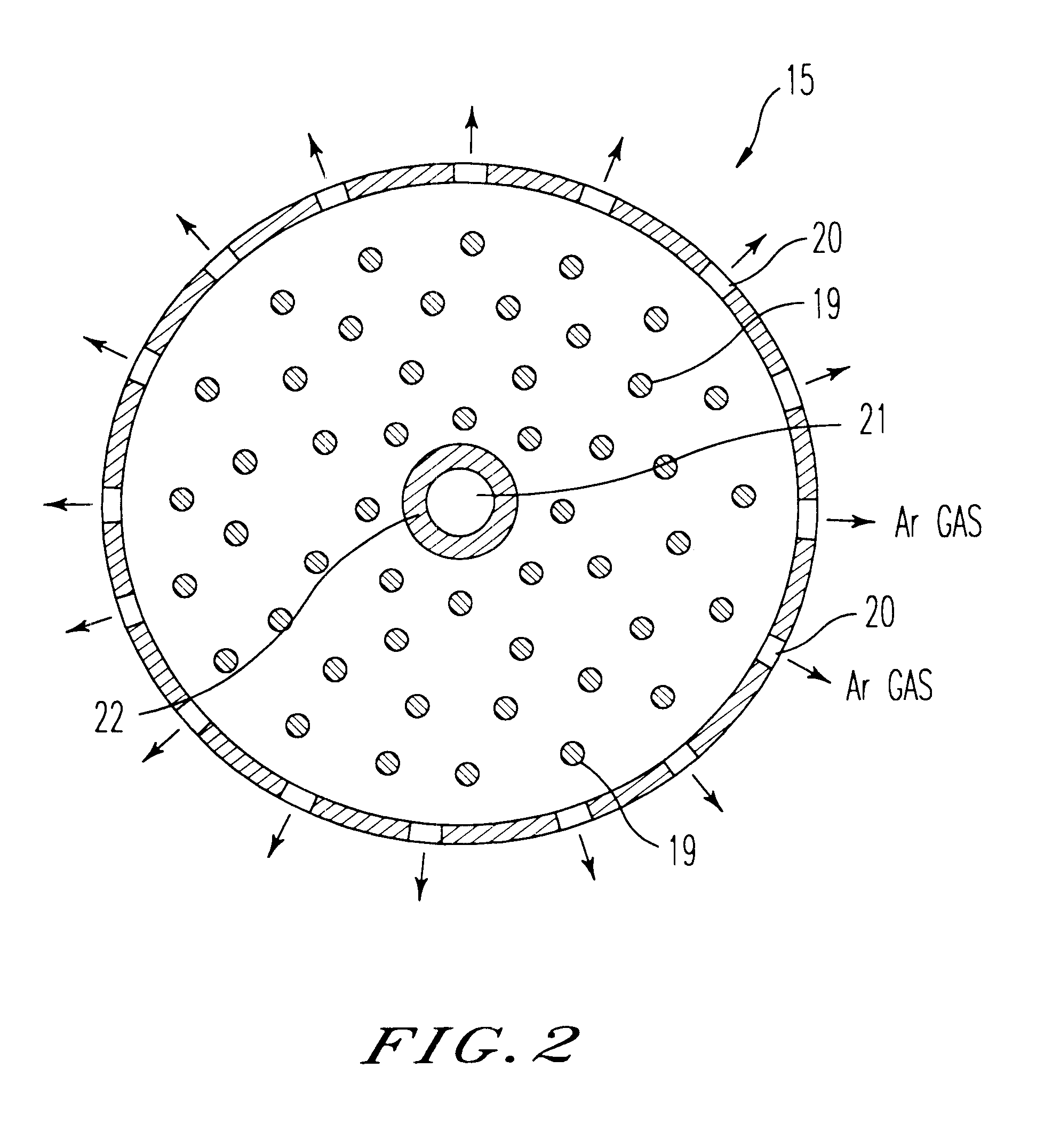

Method for performing silicon melt infiltration of ceramic matrix composites

InactiveUS20060163773A1Shorten the timeReduce attackHollow wall articlesBeltsCeramic matrix compositeMolten silicon

A method of melt infiltrating a fiber-reinforced ceramic matrix composite preform includes (a) dipping the preform into a bath of molten Silicon; (b) leaving the preform in the bath for a predetermined time; (c) withdrawing the preform from the bath; and (d) cooling the preform.

Owner:GENERAL ELECTRIC CO

Method for producing silicon ingot having directional solidification structure and apparatus for producing the same

A method for producing a silicon ingot having a directional solidification structure comprising the steps of: placing a silicon raw material into a crucible of a melting device constructed by mounting a chill plate on an underfloor heater, mounting a crucible with a large cross-sectional area on the chill plate, providing an overhead heater over the crucible, and surrounding the circumference of the crucible with a heat insulator; heat-melting the silicon raw material by flowing an electric current through the underfloor heater and overhead heater; chilling the bottom of the crucible by halting the electric current through the underfloor heater after the silicon raw material has been completely melted to form a molten silicon; chilling the bottom of the crucible by flowing an inert gas through the chill plate; and intermittently or continuously lowering the temperature of the overhead heater by intermittently or continuously decreasing the electric current through the overhead heater, and an apparatus for producing the silicon ingot.

Owner:MITSUBISHI MATERIALS CORP

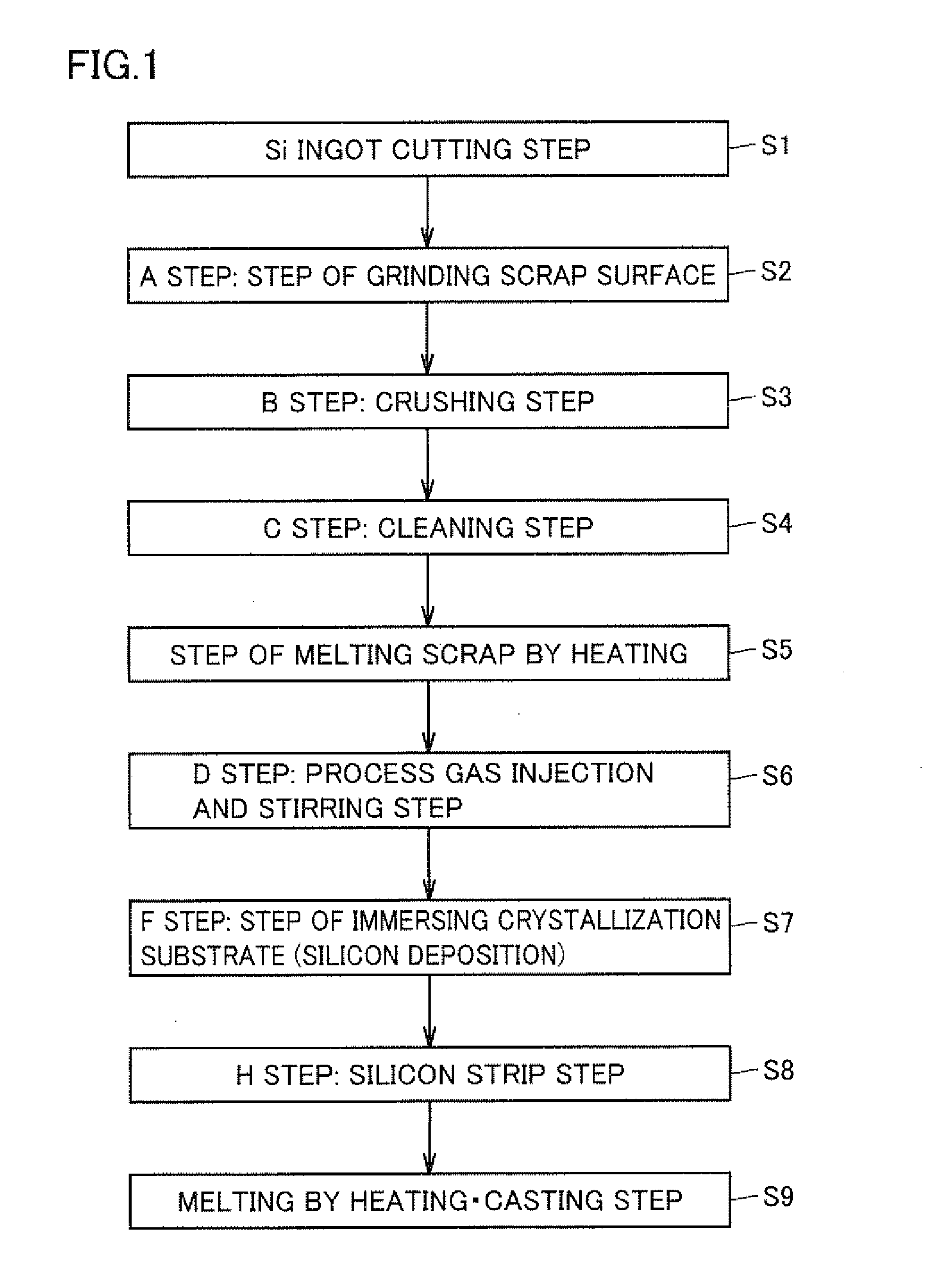

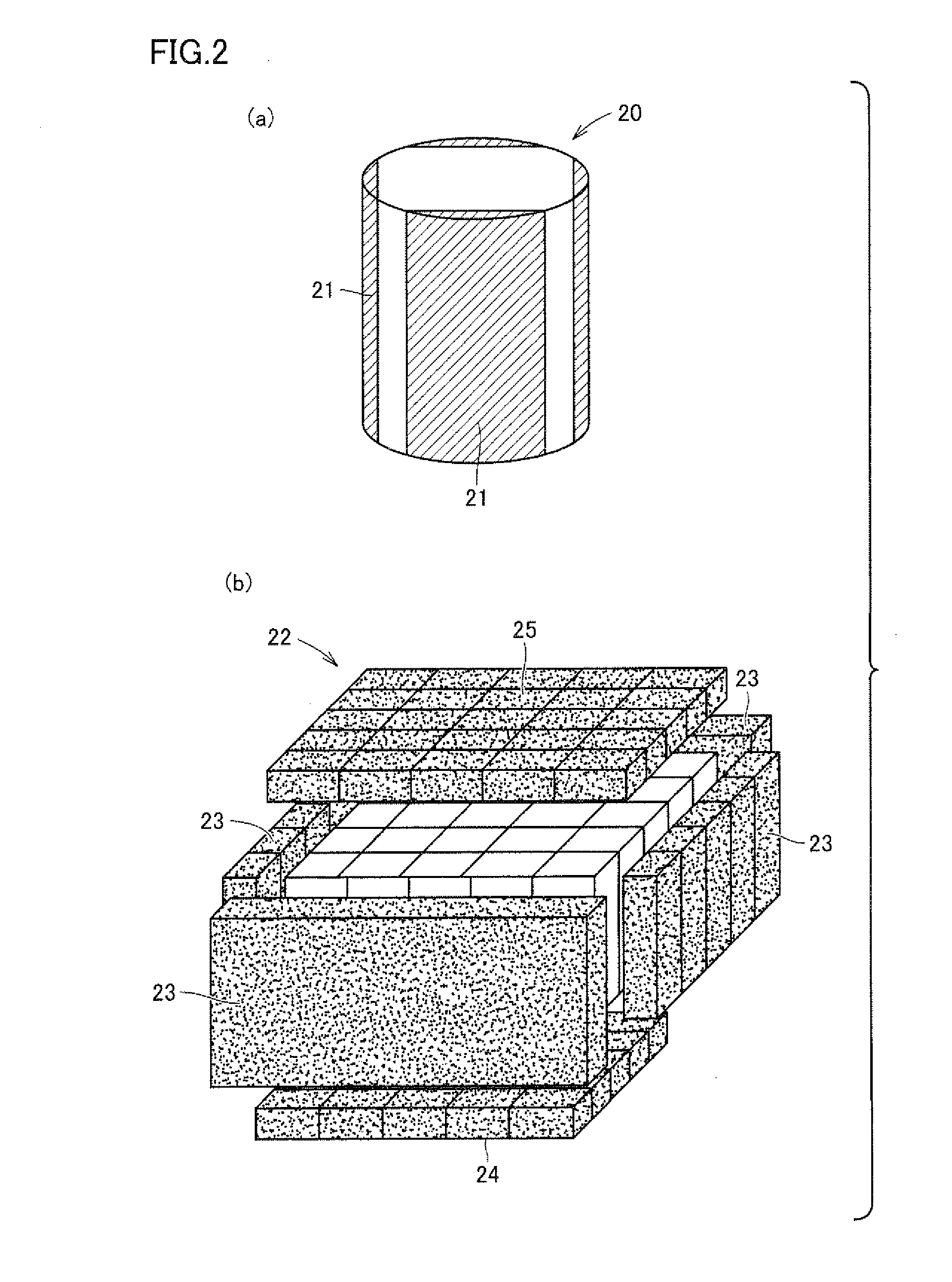

Silicon recycling method, and silicon and silicon ingot manufactured with that method

In order to efficiently recycle a silicon scrap obtained by cutting a silicon chunk as a raw material silicon for solar batteries, a silicon recycling method of the present invention, according to one aspect, includes the steps of melting a silicon scrap by heating, and immersing a crystallization substrate in molten silicon and depositing silicon on a surface of the crystallization substrate. The step of separating silicon on the surface of the crystallization substrate from the crystallization substrate is preferably included. In addition, a silicon ingot obtained by melting the silicon raw material for solar batteries in a mold and solidifying the same is suitable as the silicon chunk.

Owner:SHARP KK

System for continuous growing of monocrystalline silicon

ActiveUS7635414B2Low oxygenEliminate downtimeAfter-treatment apparatusPolycrystalline material growthHot zoneSingle crystal

An improved system based on the Czochralski process for continuous growth of a single crystal ingot comprises a low aspect ratio, large diameter, and substantially flat crucible, including an optional weir surrounding the crystal. The low aspect ratio crucible substantially eliminates convection currents and reduces oxygen content in a finished single crystal silicon ingot. A separate level controlled silicon pre-melting chamber provides a continuous source of molten silicon to the growth crucible advantageously eliminating the need for vertical travel and a crucible raising system during the crystal pulling process. A plurality of heaters beneath the crucible establish corresponding thermal zones across the melt. Thermal output of the heaters is individually controlled for providing an optimal thermal distribution across the melt and at the crystal / melt interface for improved crystal growth. Multiple crystal pulling chambers are provided for continuous processing and high throughput.

Owner:CORNER STAR LTD

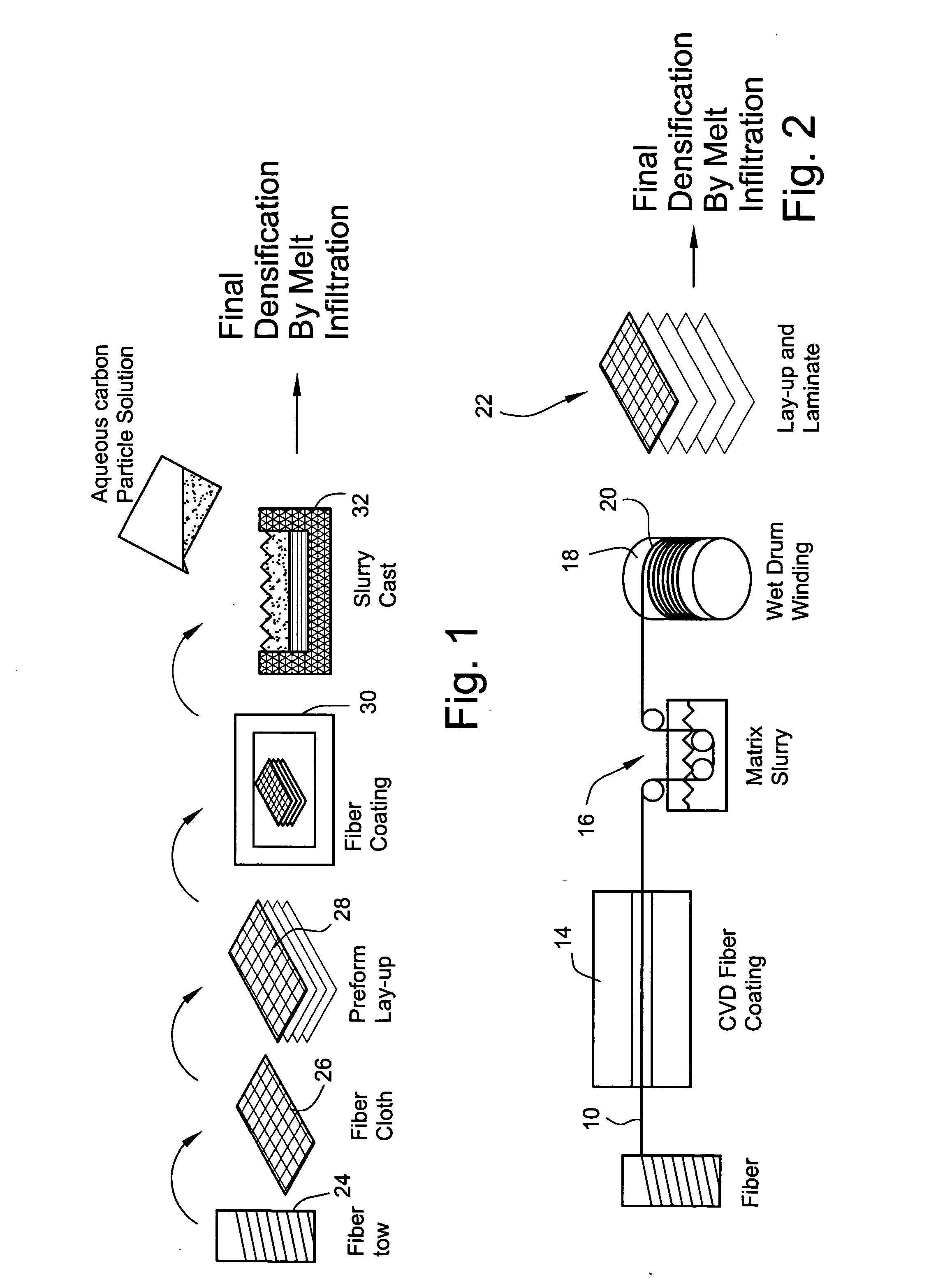

Process for producing fiber-reinforced silicon carbide composites

InactiveUS6576076B1Easy to produceImprove toughnessLayered productsCeramic shaping apparatusPolyresinAtmosphere

A fiber-reinforced silicon carbide composite is produced by preparing a fiber prepreg containing a powdered silicon and a resin and molding the prepreg to yield a green body having a desired shape, or laminating a fiber prepreg containing a resin and a woven fabric prepreg containing a powdered silicon and a resin in alternate order and molding the laminate to yield a green body having a desired shape; carbonizing the green body at 900° to 1350° C. in an inert atmosphere; subjecting the carbonized body to reaction sintering at a temperature of 1300° C. or more in vacuo or in an inert atmosphere to form open pores; and infiltrating molten silicon into the sintered body having open pores at a temperature of about 1300° to 1800° C. in vacuo or an inert atmosphere.

Owner:NAT INST OF ADVANCED IND SCI & TECH

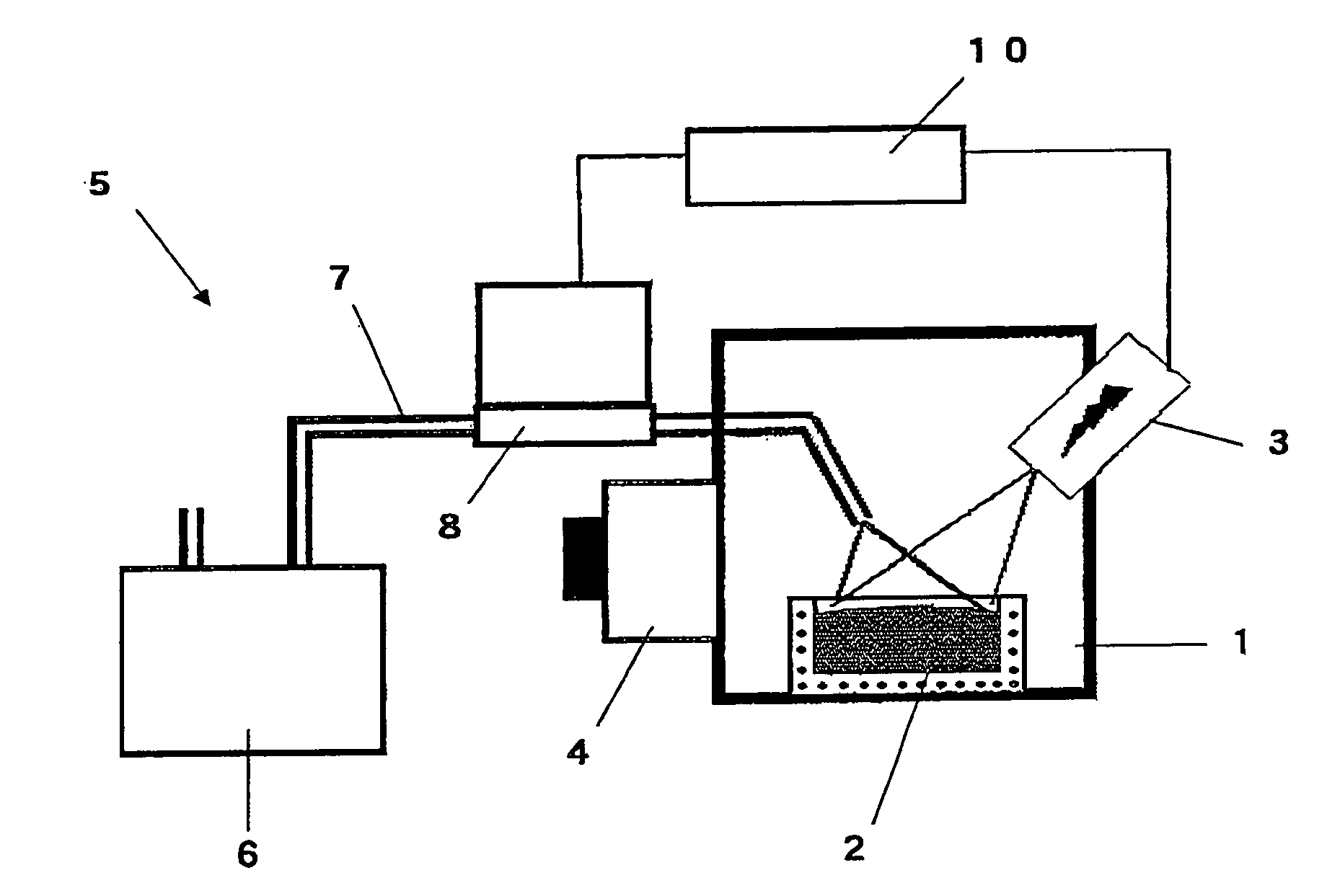

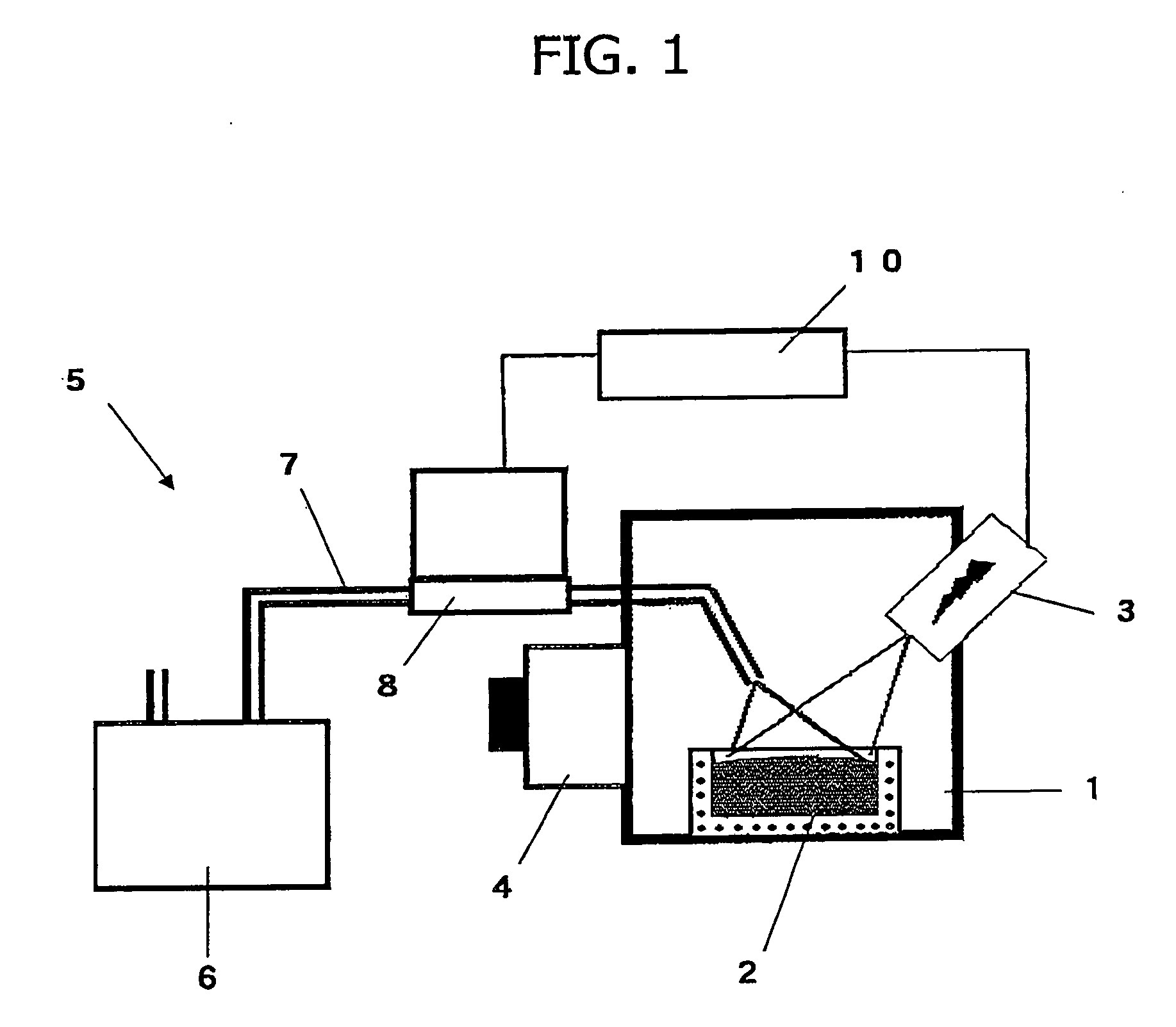

Method and apparatus for refining boron-containing silicon using an electron beam

InactiveUS20060123947A1Efficient removalInhibition formationBoron/boridesElectric furnaceBoron containingIrradiation

In a refining method for boron-containing silicon, boron-containing silicon is irradiated with an electron beam in a vacuum vessel to melt the boron-containing silicon. A boron compound-forming substance is introduced into the vacuum vessel, and boron contained in the molten silicon is formed into a boron compound. After at least a portion of the boron compound has vaporized, irradiation with the electron beam is stopped. The high-purity molten silicon can then be solidified.

Owner:IIS MATERIALS CORP

Silicon refining process

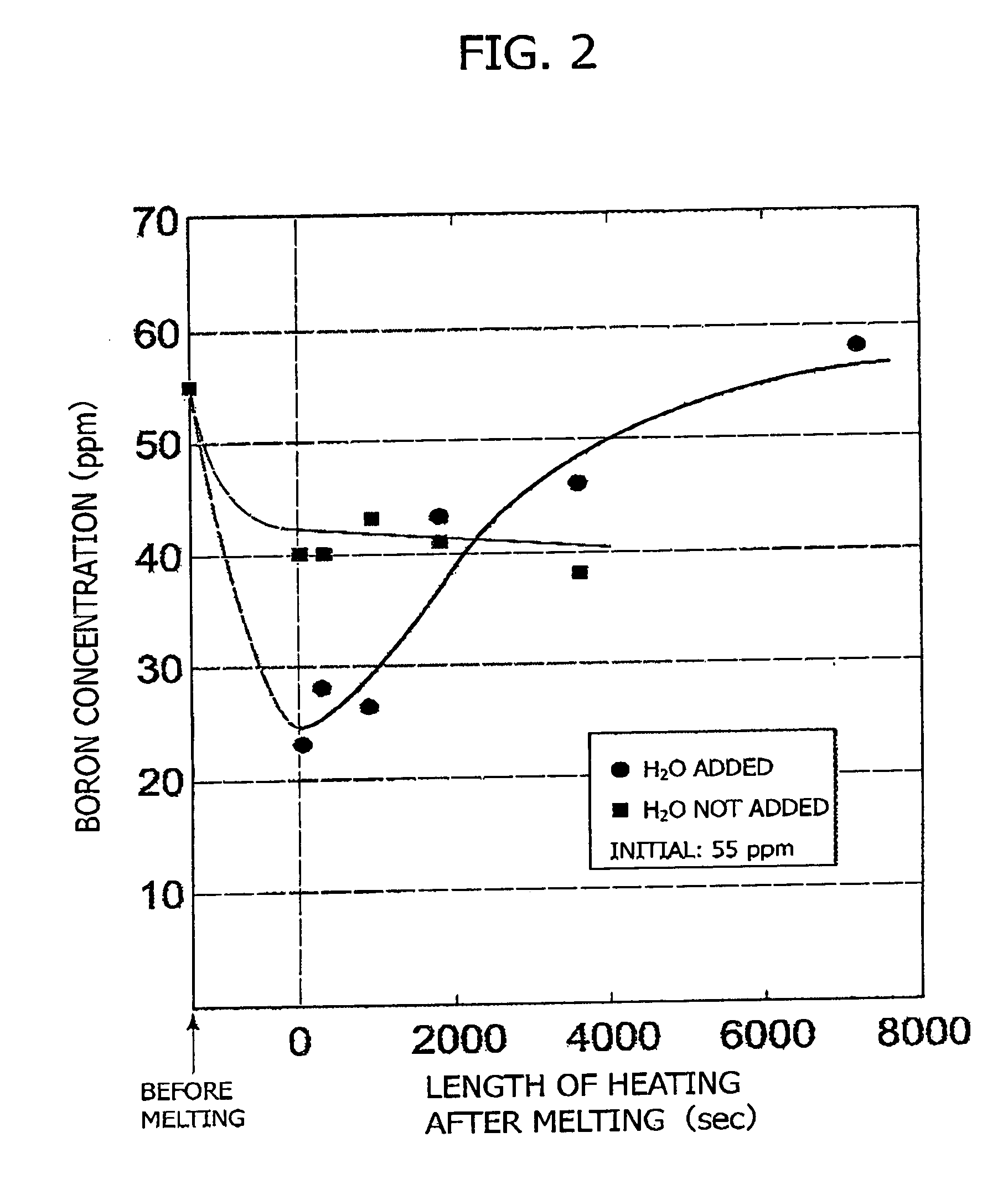

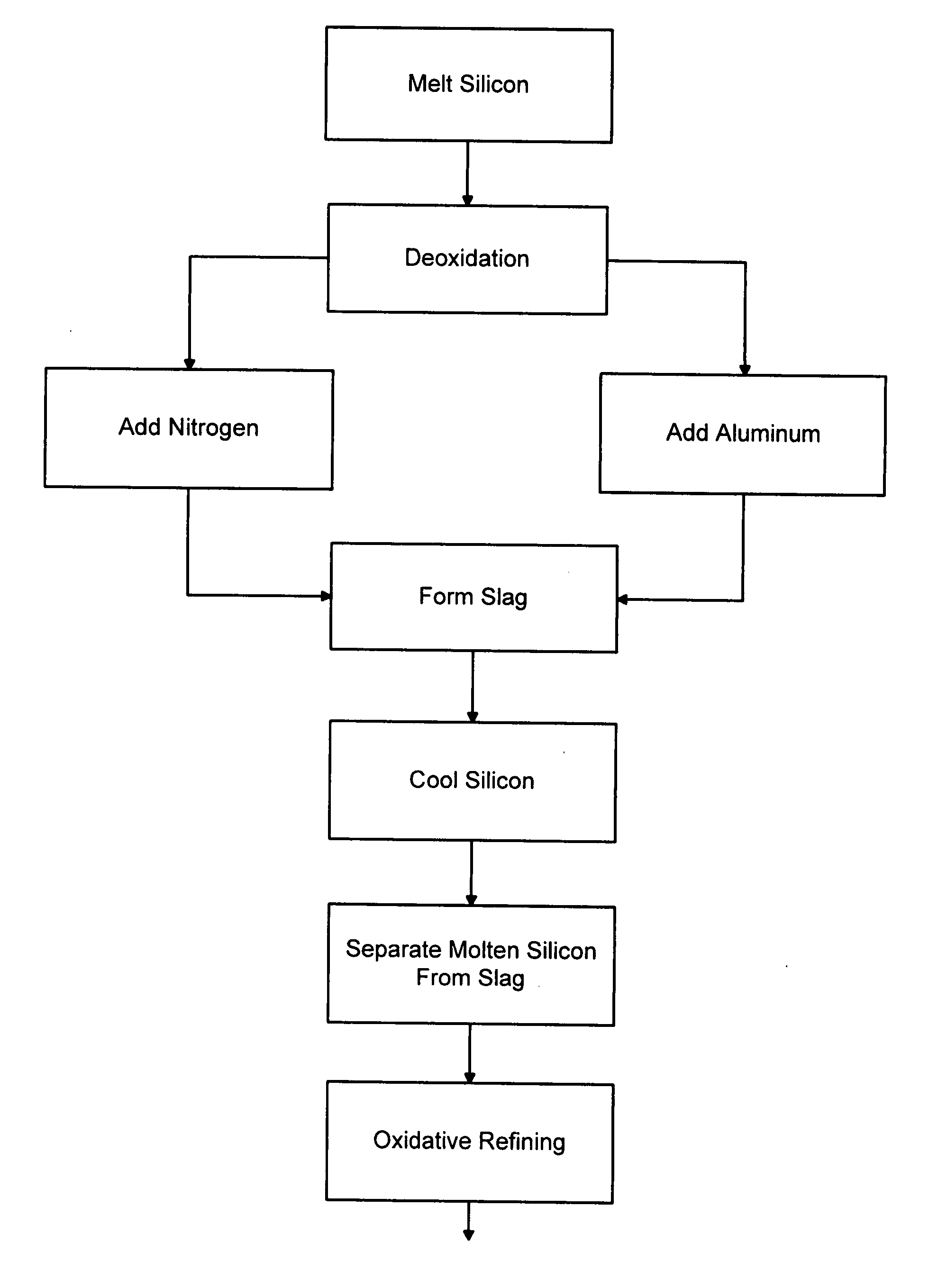

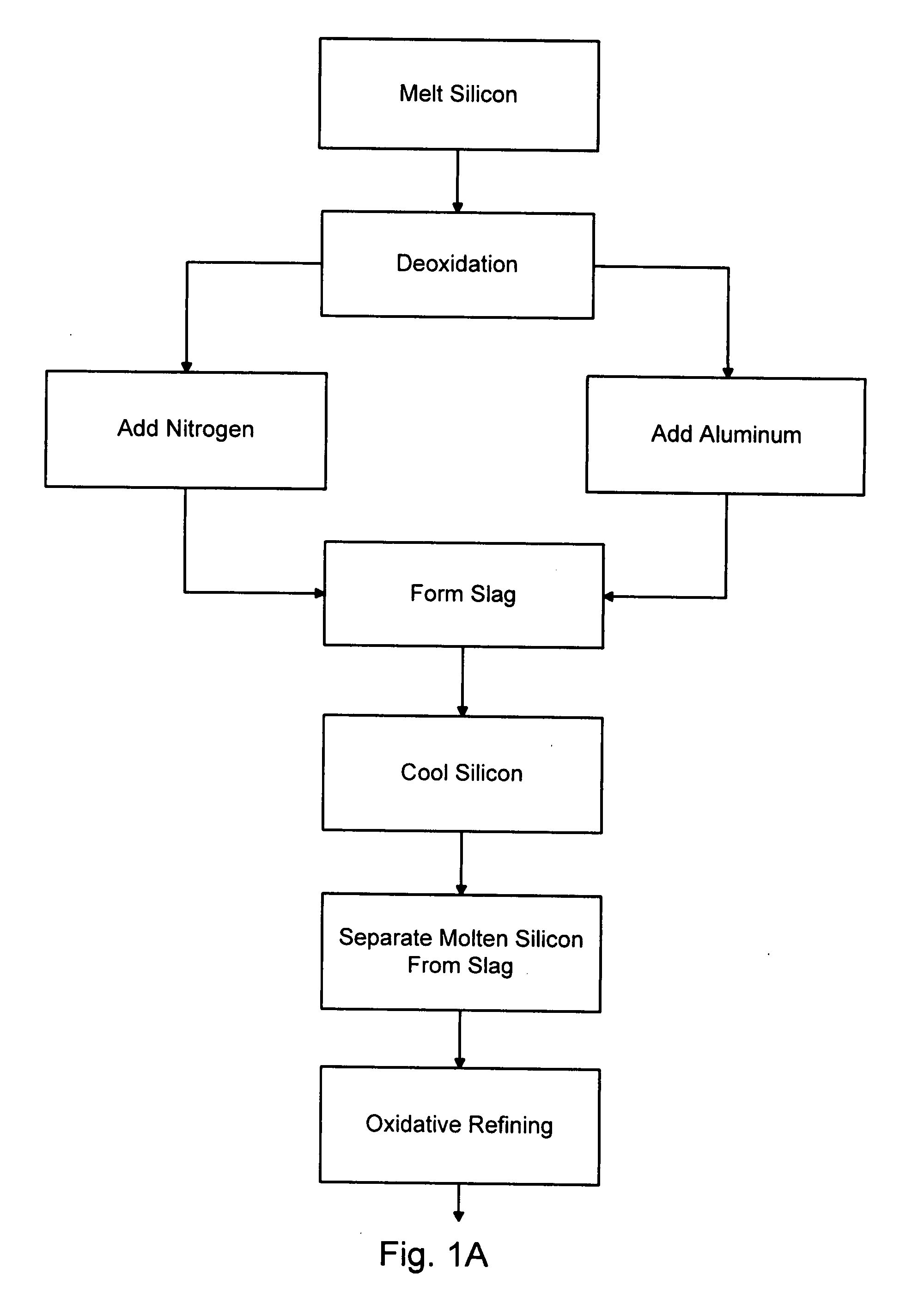

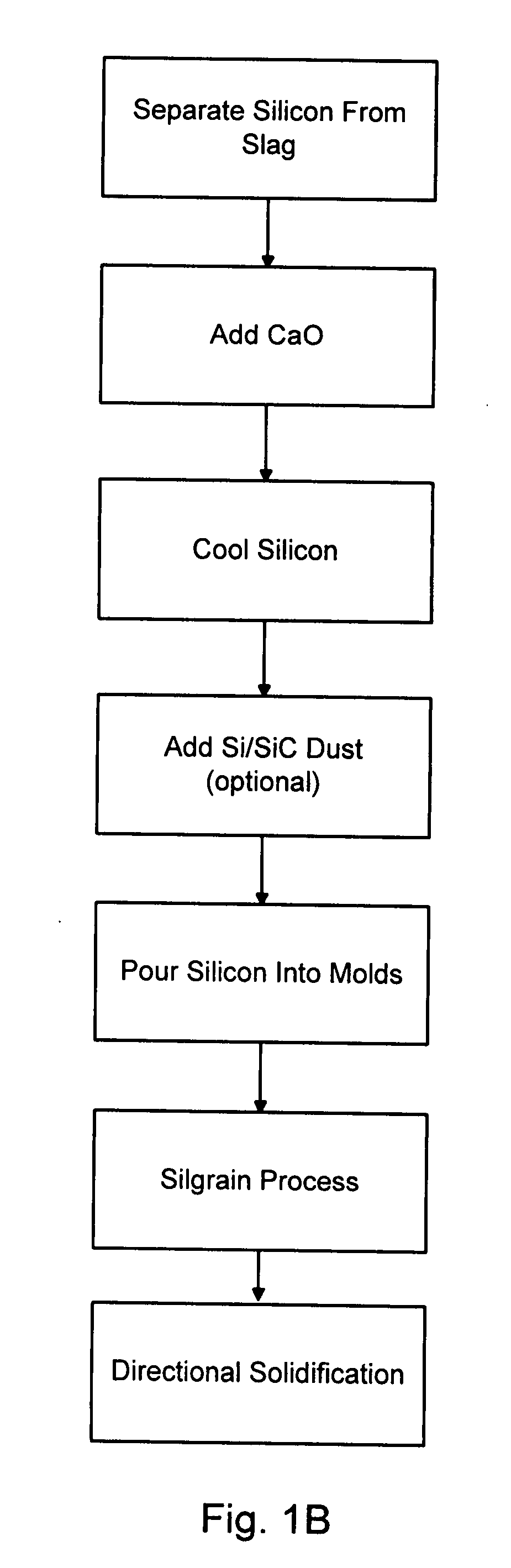

Nitrogen and aluminum and fluxing agents (Al2O3, SiO2, CaO and MgO) are added to molten silicon to create an oxy-nitride slag that acts as a sink for dissolved boron and phosphorus. The nitrogen can be added by bubbling nitrogen gas through the molten silicon; the aluminum can be added as aluminum metal or as Al2O3. Normally, the silicon must initially be deoxidized to allow the boron and phosphorus refining reactions to occur. The process may be followed by oxidative refining, SiC settling, the Silgrain process and directional solidification to remove other impurities and produce silicon suitable for use in solar cells. In an alternative version of the process, the molten silicon is passed through a particulate bed formed of a nitrogen-containing compound and an aluminum-containing compound.

Owner:THE ARIZONA BOARD OF REGENTS ON BEHALF OF THE UNIV OF ARIZONA

Processing of fine silicon powder to produce bulk silicon

InactiveUS20080295294A1Reduce pressureQuality improvementPolycrystalline material growthSiliconIngotArgon gas

A method for using substantial quantities of silicon powders as charge and processing it to produce a high quality silicon ingots suitable for photovoltaic use is disclosed. In a fused silica crucible, silicon feedstock containing more than about 5% by weight silicon powder is charged. The crucible with the charged silicon feedstock is placed into a furnace chamber and a vacuum is drawn to remove air. The vacuum is applied slowly. Then, the furnace chamber is backfilled with argon gas and heated to form molten silicon. Afterward, the molten silicon is solidified and annealed to form a multicrystalline silicon ingot.

Owner:GT SOLAR INC

Method for removing boron from silicon

InactiveUS20070180949A1Low concentration of boronLarge coefficientElectric furnaceSilicon compoundsMolten stateSilicon dioxide

The present invention provides a method for removal of boron from metal silicon inexpensively and extremely efficiently by a simple method, specifically, heating metal silicon containing boron as an impurity to its melting point to 2200° C. to place it in a molten state, then adding a solid mainly comprised of silicon dioxide and a solid mainly comprised of one or both of a carbonate of an alkali metal or a hydrate of a carbonate of an alkali metal into said molten silicon so as to form a slag and remove the boron in the silicon.

Owner:NIPPON STEEL CORP

Method of making carbon fiber-carbon matrix reinforced ceramic composites

InactiveUS7297368B2Excessive crackingAggressive in diffusingCeramic shaping apparatusChemical vapor deposition coatingCeramic compositeCarbide

A method of making a carbon fiber-carbon matrix reinforced ceramic composite wherein the result is a carbon fiber-carbon matrix reinforcement is embedded within a ceramic matrix. The ceramic matrix does not penetrate into the carbon fiber-carbon matrix reinforcement to any significant degree. The carbide matrix is a formed in situ solid carbide of at least one metal having a melting point above about 1850 degrees centigrade. At least when the composite is intended to operate between approximately 1500 and 2000 degrees centigrade for extended periods of time the solid carbide with the embedded reinforcement is formed first by reaction infiltration. Molten silicon is then diffused into the carbide. The molten silicon diffuses preferentially into the carbide matrix but not to any significant degree into the carbon-carbon reinforcement. Where the composite is intended to operate between approximately 2000 and 2700 degrees centigrade for extended periods of time such diffusion of molten silicon into the carbide is optional and generally preferred, but not essential.

Owner:ULSTREETCARET

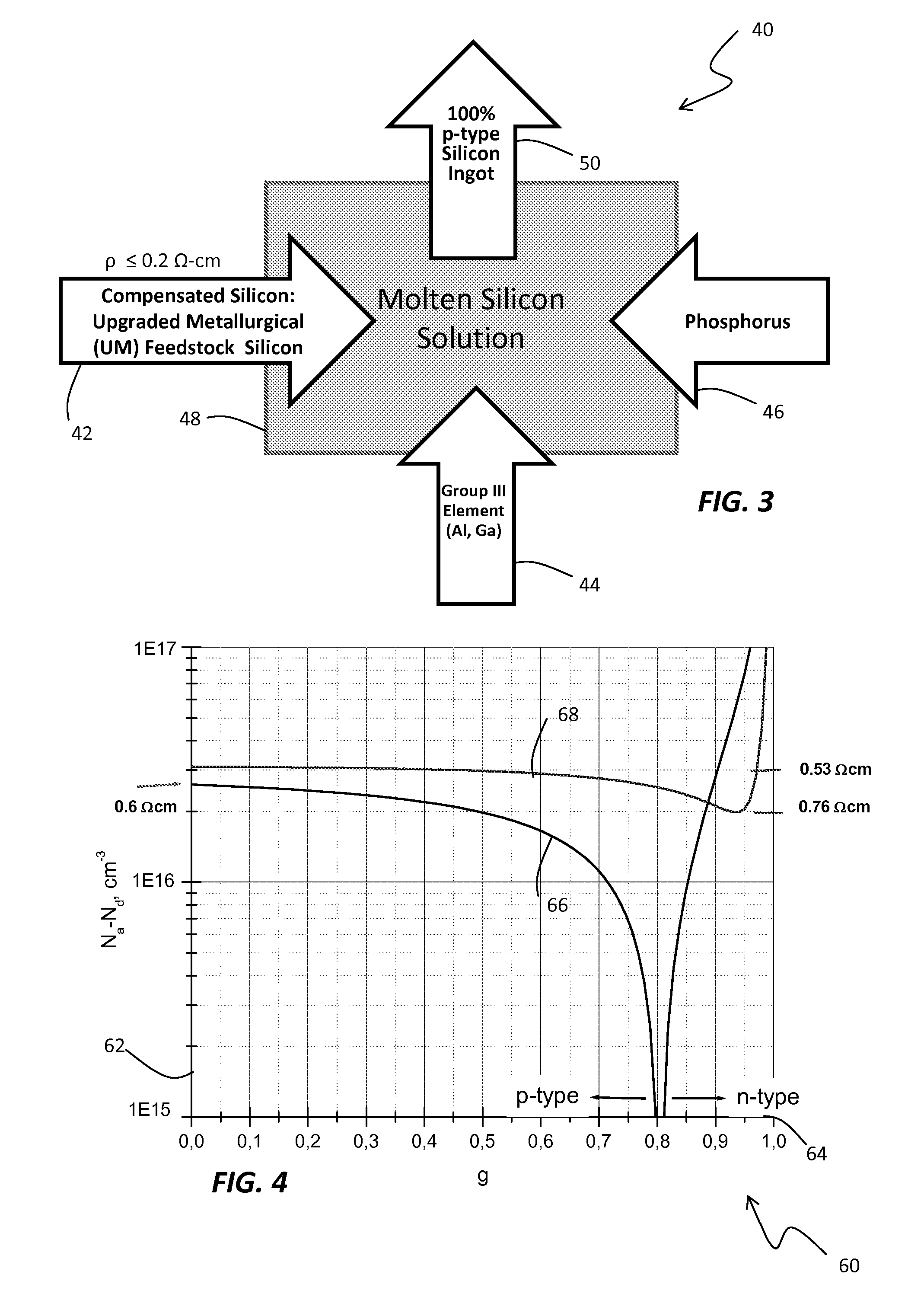

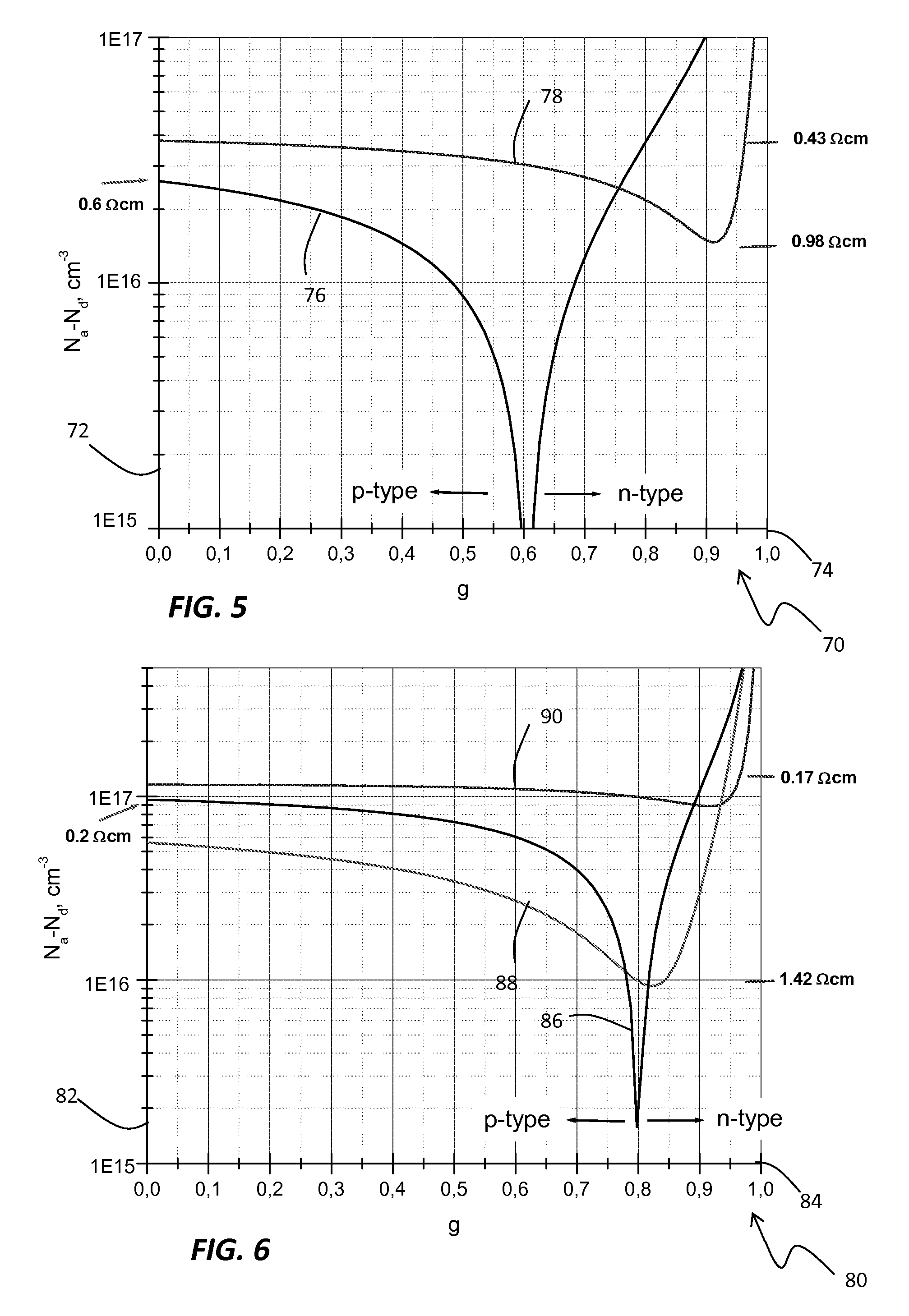

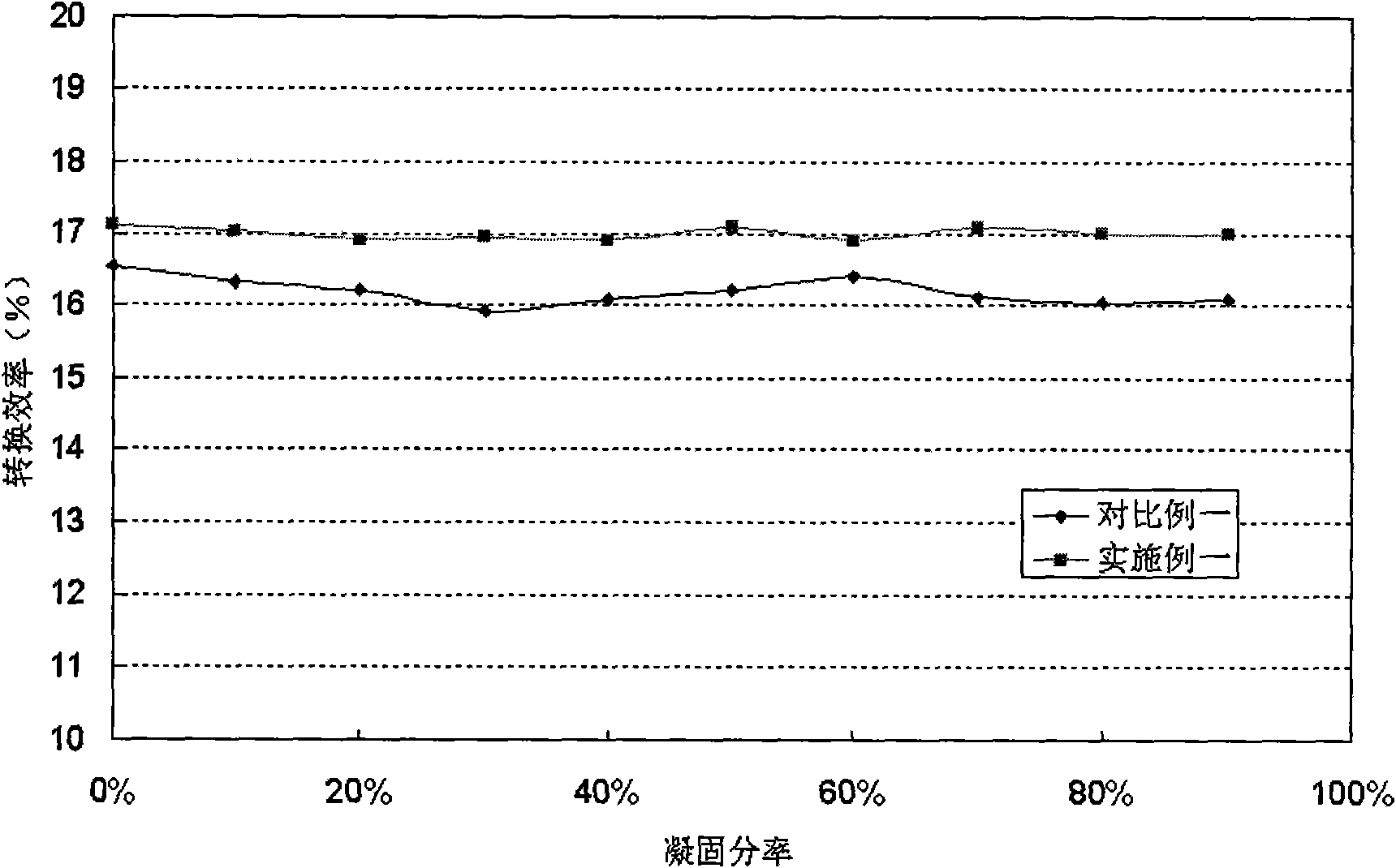

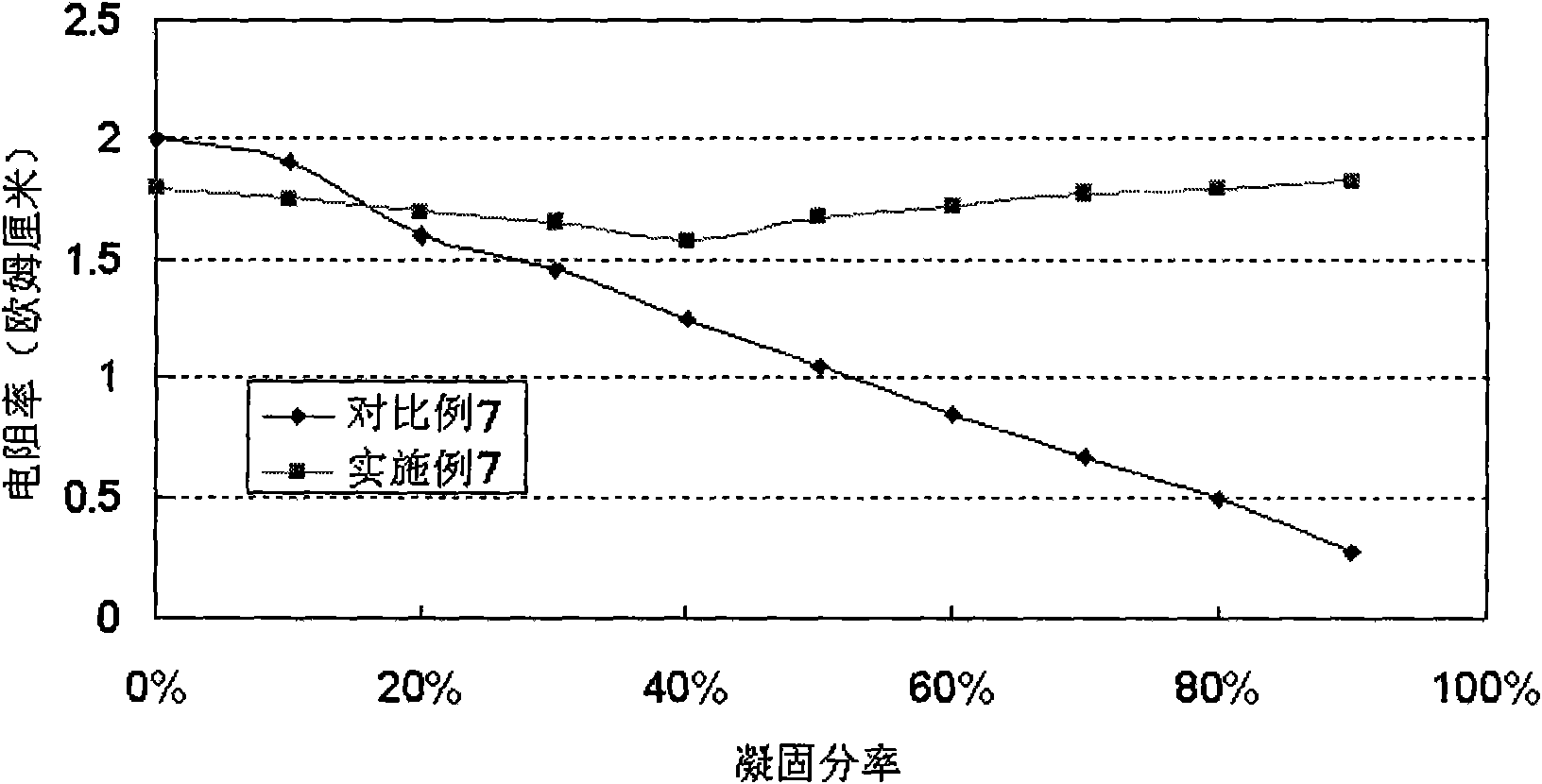

Method and system for controlling resistivity in ingots made of compensated feedstock silicon

InactiveUS20090026423A1Improved performance/cost ratioRaise the ratioPolycrystalline material growthConductive materialIngotDirectional solidification

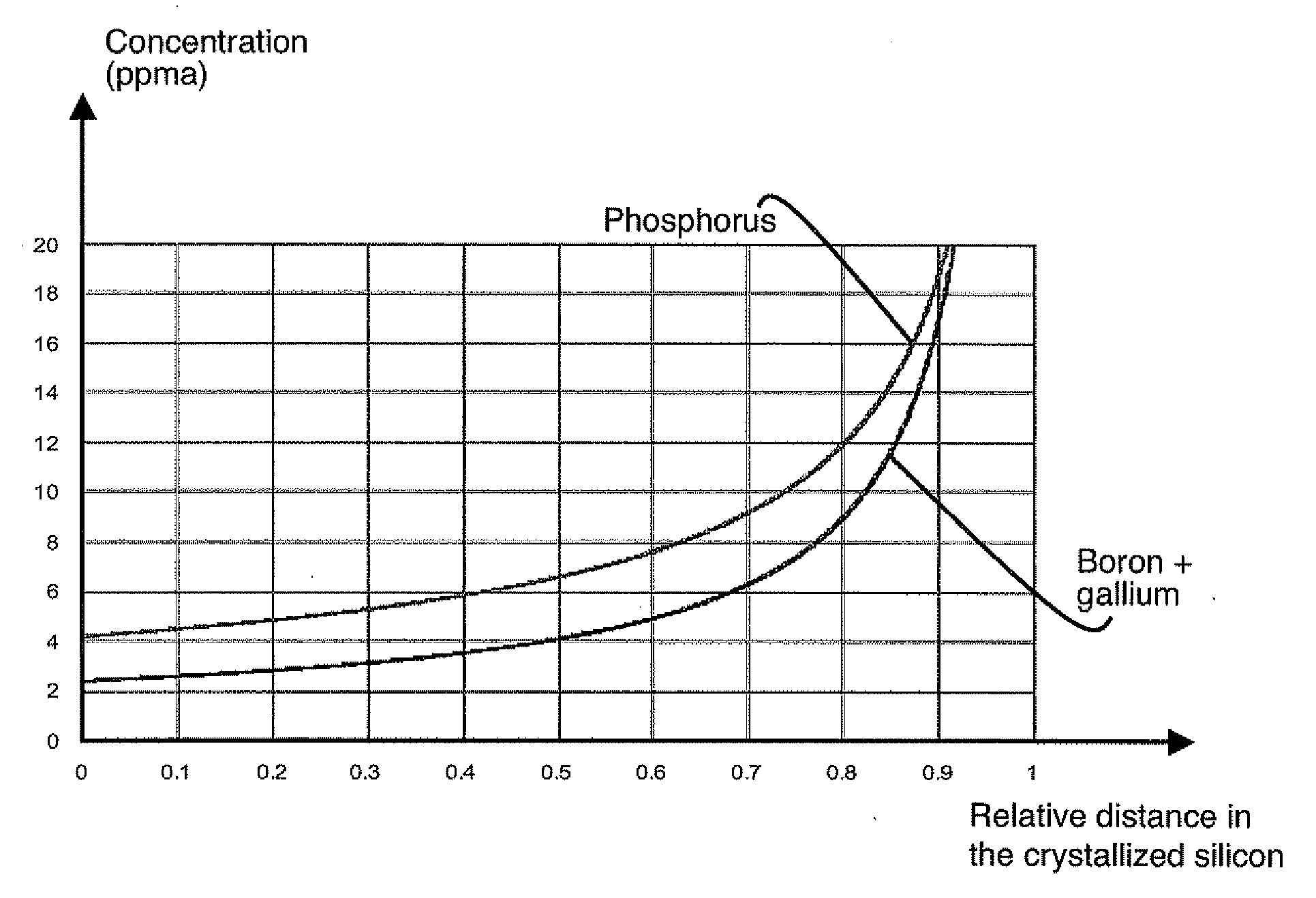

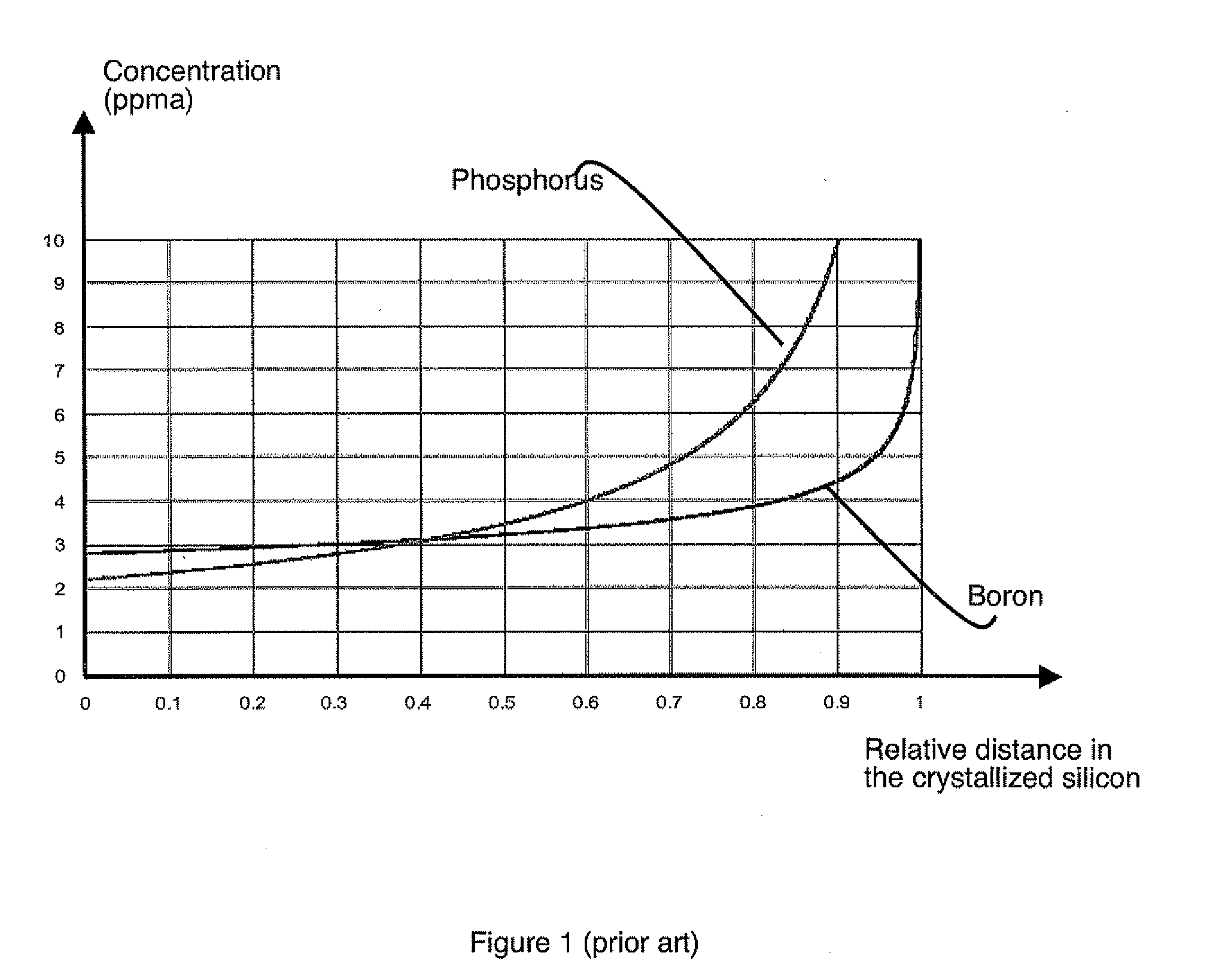

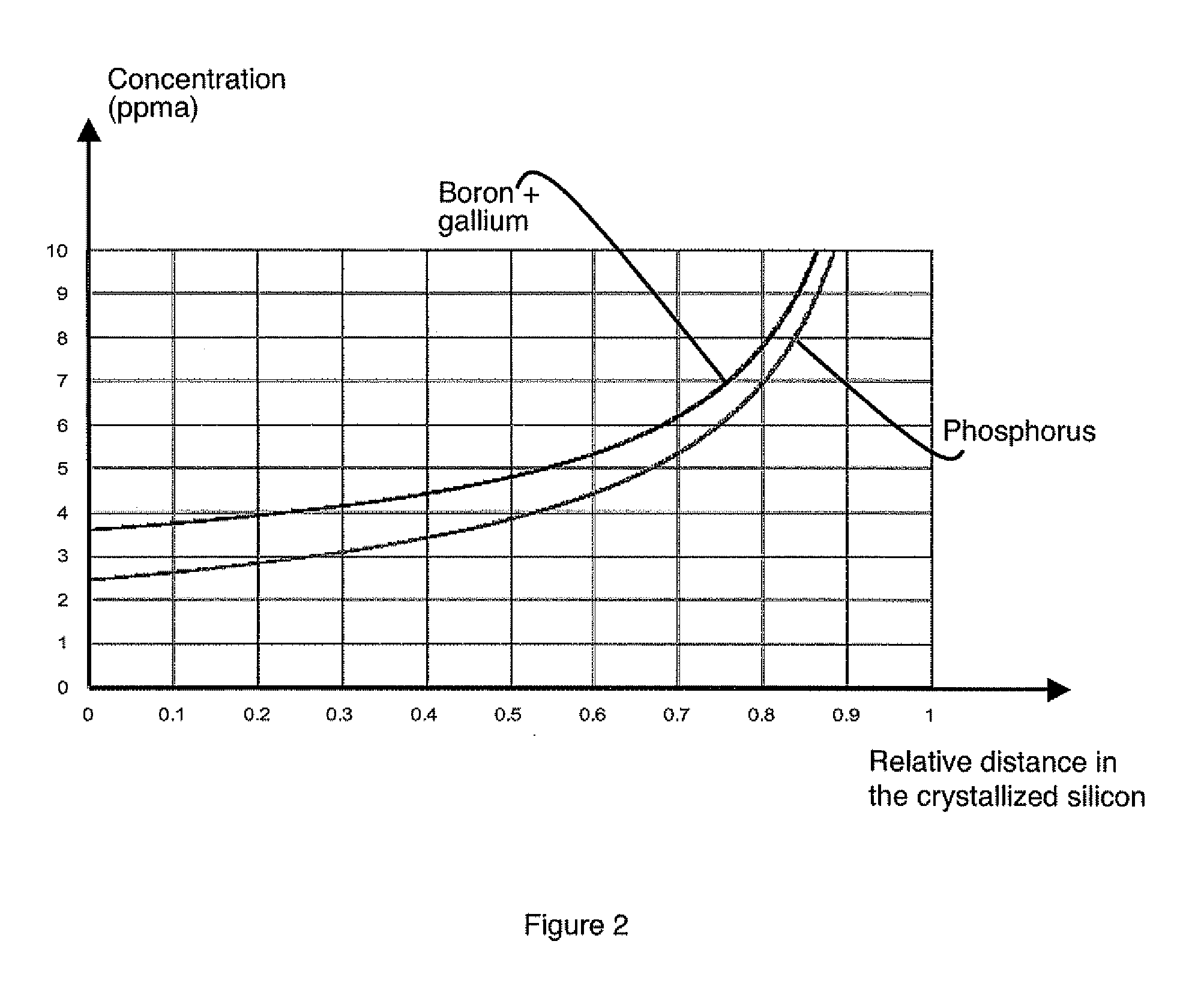

Techniques for controlling resistivity in the formation of a silicon ingot from compensated feedstock silicon material prepares a compensated, upgraded metallurgical silicon feedstock for being melted to form a silicon melt. The compensated, upgraded metallurgical silicon feedstock provides a predominantly p-type semiconductor for which the process assesses the concentrations of boron and phosphorus and adds a predetermined amount of aluminum or / and gallium. The process further melts the silicon feedstock together with a predetermined amount of aluminum or / and gallium to form a molten silicon solution from which to perform directional solidification and, by virtue of adding aluminum or / and gallium, maintains the homogeneity the resistivity of the silicon ingot throughout the silicon ingot. In the case of feedstock silicon leading to low resistivity in respective ingots, typically below 0.4Ω cm, a balanced amount of phosphorus can be optionally added to aluminum or / and gallium. Adding phosphorus becomes mandatory at very low resistivity, typically close to 0.2Ω cm and slightly below.

Owner:SUNNUVELLIR SLHF

Method for producing photovoltaic-grade crystalline silicon by addition of doping impurities and photovoltaic cell

InactiveUS20110030793A1Easy to implementImprove conversion efficiencyPolycrystalline material growthFinal product manufactureDopantCrystalline silicon

Production of photovoltaic grade crystalline silicon is achieved by crystallization of a molten silicon feedstock, the sum of the initial donor doping element and acceptor doping element concentrations whereof is greater than 0.1 ppma, and both the acceptor and donor doping element concentrations whereof are less than 25 ppma. At least a predefined quantity of a doping material having a segregation coefficient of less than 0.1 is added to the feedstock. This addition enables a crystallized silicon to be produced the difference between the donor and acceptor doping profiles whereof is comprised between 0.1 and 5 ppma over at least 50% of the solidified silicon. A silicon presenting a concentration of at least one of the dopants is greater than or equal to 5 ppma and a difference less than or equal to 5 ppma between these two types of dopant is integrated in a photovoltaic cell.

Owner:APOLLON SOLAR SAS

Method for controlling fused silicon liquid level position of czochralski silicon mono-crystal furnace

The invention relates to a molten silicon liquid level position control method of a CZ-Si single crystal furnace. The invention comprises the following steps: heat shield inverted image data is obtained; the data is processed to obtain D; D is compared with D0, D-D0 difference value is inputted into an analog / digital converter to be an electric signal for controlling the speed raising of a vortex increasing motor, to increase or decrease the speed of the vortex increasing motor; a feed back circuit integrates the increase speed increment, and a practical D value is obtained; a computer calculates a D-D0 difference value, if the D-D0 difference value is 0, the proportion of the rising speed of the vortex increasing motor and the crystal increasing speed is not changed; or else, the proportion is increased or decreased (according to the plus minus of the D-D0 difference value). The method has the advantages that the operation is convenient, the precision is high, if the method is used, the variety of the defaults in a CZ-Si single crystal and the distribution of the CZ-Si single crystal can be controlled.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG +1

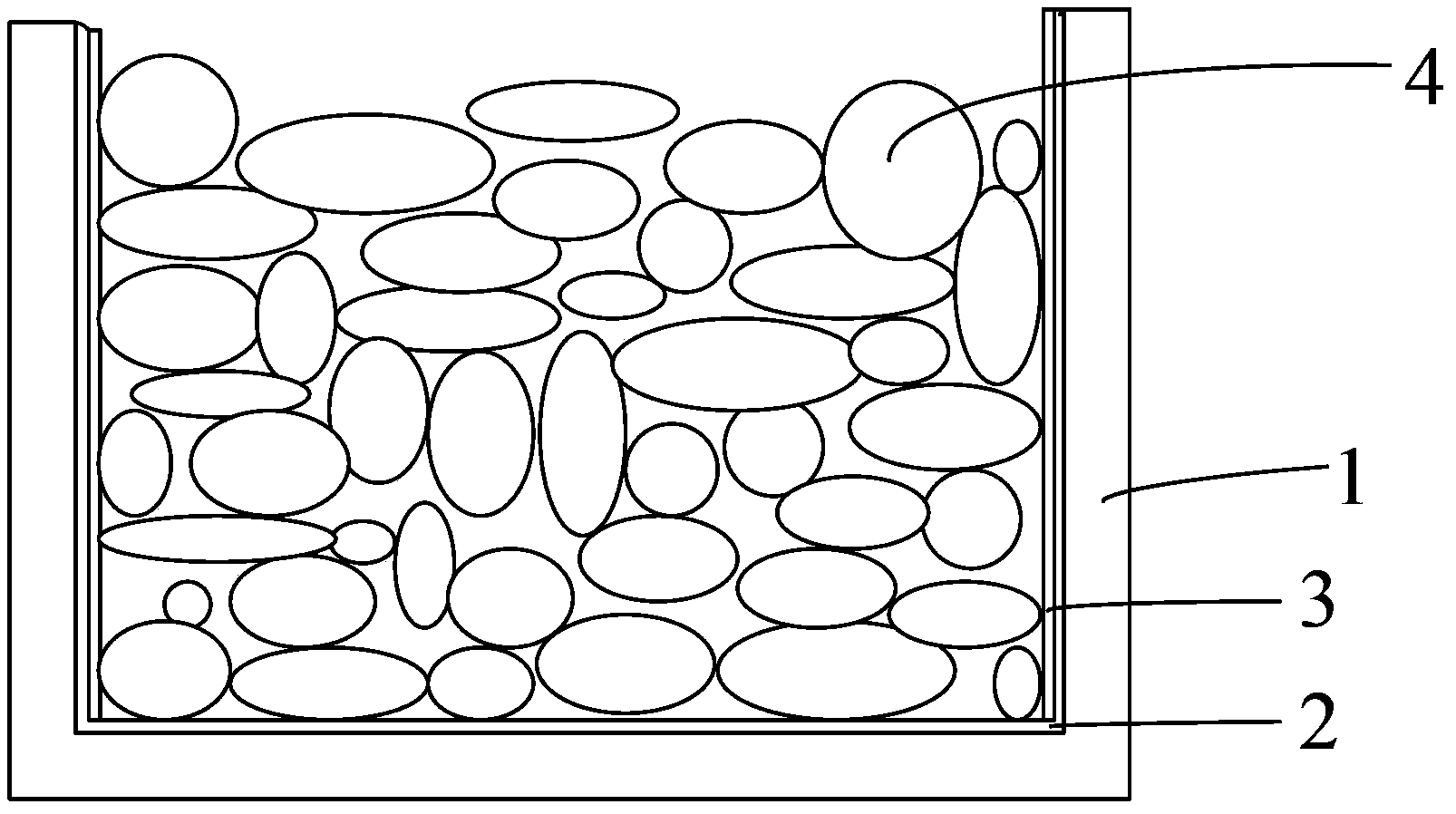

Polycrystalline silicon ingots and preparation method thereof, polycrystalline silicon chips and polycrystalline silicon ingot casting crucible

ActiveCN103361722AUniform grain sizeGrain rulePolycrystalline material growthAfter-treatment detailsMolten stateDislocation

The invention provides a preparation method of polycrystalline silicon ingots. The preparation method comprises the following steps: before or after the inner wall of a crucible is sprayed with a silicon nitride layer, a barrier layer is arranged on the inner side of the side wall of the crucible, wherein the barrier layer is a silicon powder coating layer, or a quartz powder coating layer, or a silicon powder and quartz powder mixed coating layer, and purities of silicon powder and quartz powder are above 99.99%; then a molten silicon material is arranged in the crucible; temperature in the crucible is controlled to increase gradually, along a direction which is perpendicular to the bottom of the crucible and is upward, to form a temperature gradient to make the molten silicon material to begin crystallization; and after the crystallization is finished, and the polycrystalline silicon ingots are obtained through annealing and cooling . The invention also provides the high quality polycrystalline silicon ingots obtained by the preparation method, and polycrystalline silicon chips prepared from the polycrystalline silicon ingots and the polycrystalline silicon ingot casting crucible. The polycrystalline silicon ingots prepared by the preparation method are characterized in that crystalline grains near areas of crucible wall are smaller, uniform and regular, dislocation density is low, and impurities is less.

Owner:JIANGXI SAI WEI LDK SOLAR HI TECH CO LTD

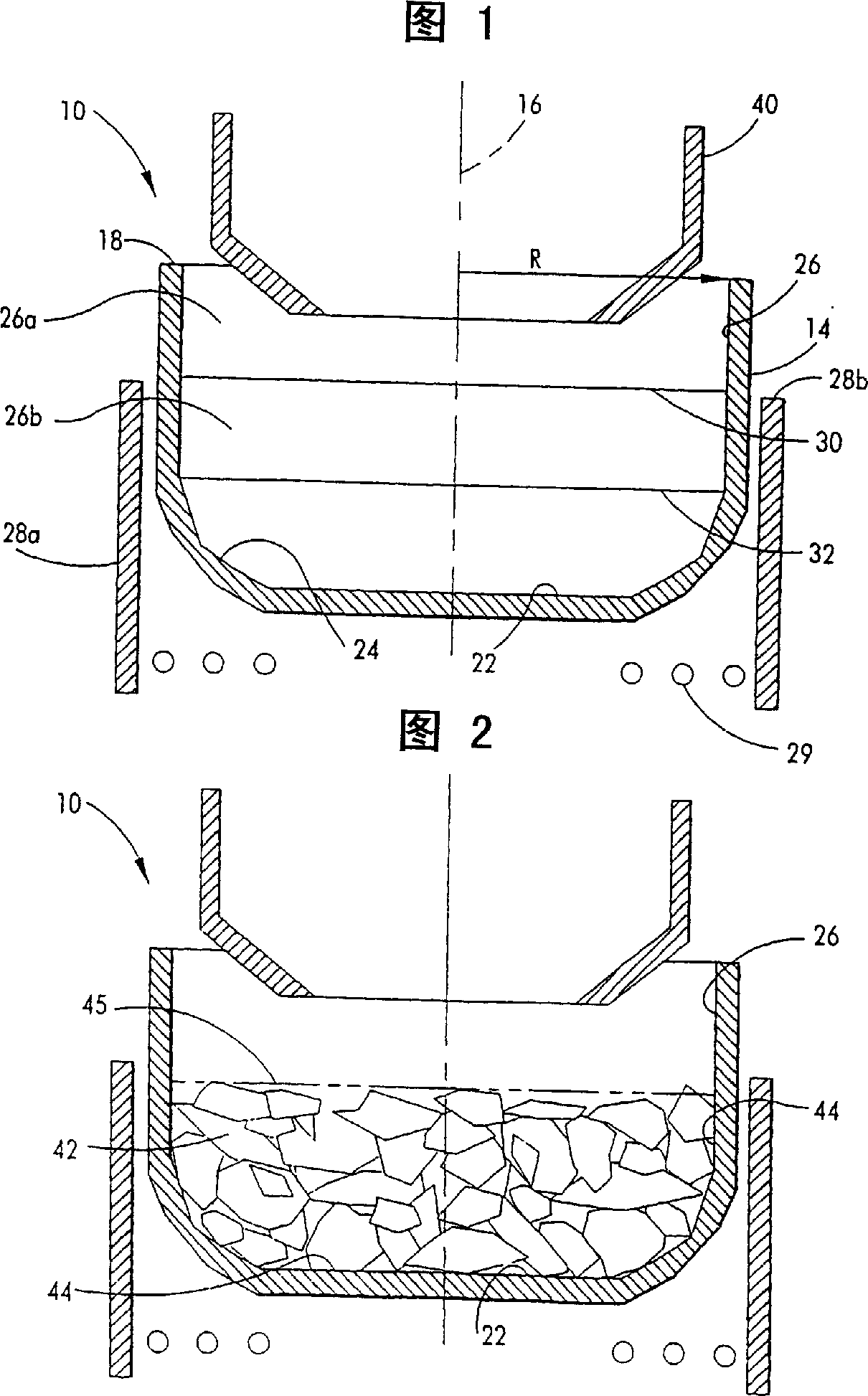

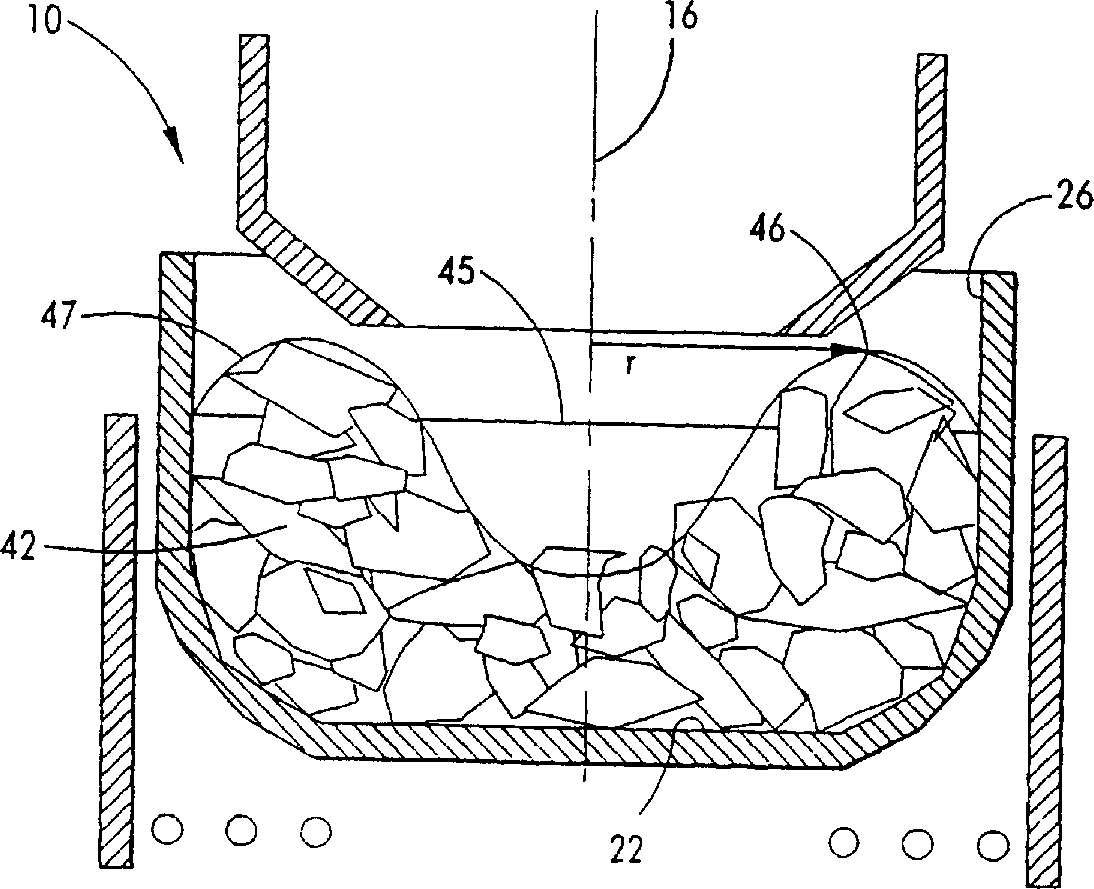

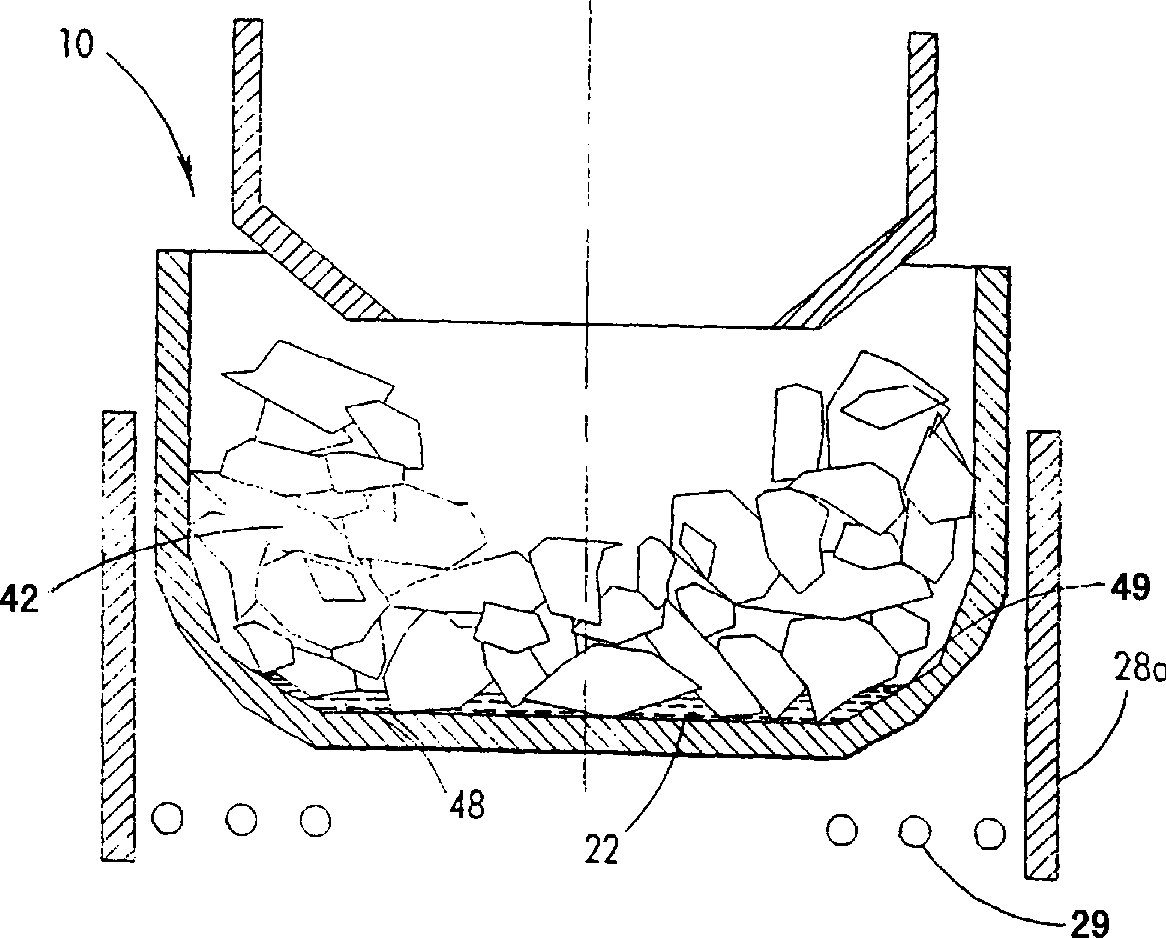

Process for preparing silicon melt from polysilicon charge

InactiveCN1276026AReduce hydrogen contentIncrease productionPolycrystalline material growthBy pulling from meltHydrogenCzochralski method

A process for preparing a silicon melt from a polysilicon charge, for use in the production of single crystal silicon ingots by the Czochralski method, in a crucible which has a bottom, a sidewall formation, a centerline which is substantially parallel to the sidewall formation and which intersects a geometric centerpoint of the bottom, and a radius extending from the centerline to the sidewall formation. In the process, the crucible is loaded with chunk polysilicon to form a charge having a bowl-like shape, wherein initially the load generally slopes radially upwardly and outwardly from the centerline toward the sidewall formation to an apex and then slopes generally downwardly and outwardly from the apex to the sidewall formation. The bowl-shaped chunk polysilicon charge is heated to form a partially melted charge, and granular polysilicon is fed onto the partially melted charge to form a mixed charge of chunk and granular polysilicon. As the mixed charge is further heated to form a silicon melt, the unmelted chunk polysilicon present above the melt surface acts to deflect any molten silicon that may be splattered as granular polysilicon rapidly melts and hydrogen is released.

Owner:MEMC ELECTONIC MATERIALS INC

MgB2 superconducting magnet for magnetic-control Czochralski (CZ) processing of monocrystal

ActiveCN103106994AIncrease the magnetic field strengthReduce manufacturing costBy pulling from meltSuperconducting magnets/coilsSingle crystalOxygen

The invention discloses an MgB2 superconducting magnet for magnetic-control Czochralski (CZ) processing of a monocrystal. The MgB2 superconducting magnet for the magnetic-control CZ processing of the monocrystal comprises a low-temperature container, wherein a refrigerator is arranged on the low-temperature container. The MgB2 superconducting magnet for the magnetic-control CZ processing of the monocrystal has the advantages of being high in magnetic field intensity, low in manufacturing cost, simple in system, low in power consumption, easy to operate and the like. Due to the fact that heat convection of molten silicon is effectively limited, the produced monocrystal silicon has higher purity and uniformity, and the defects of oxygen and dots in the position of an interface of the crystal melt and other impurities are effectively controlled.

Owner:XIAN JUNENG SUPERCONDUCTING MAGNET TECH

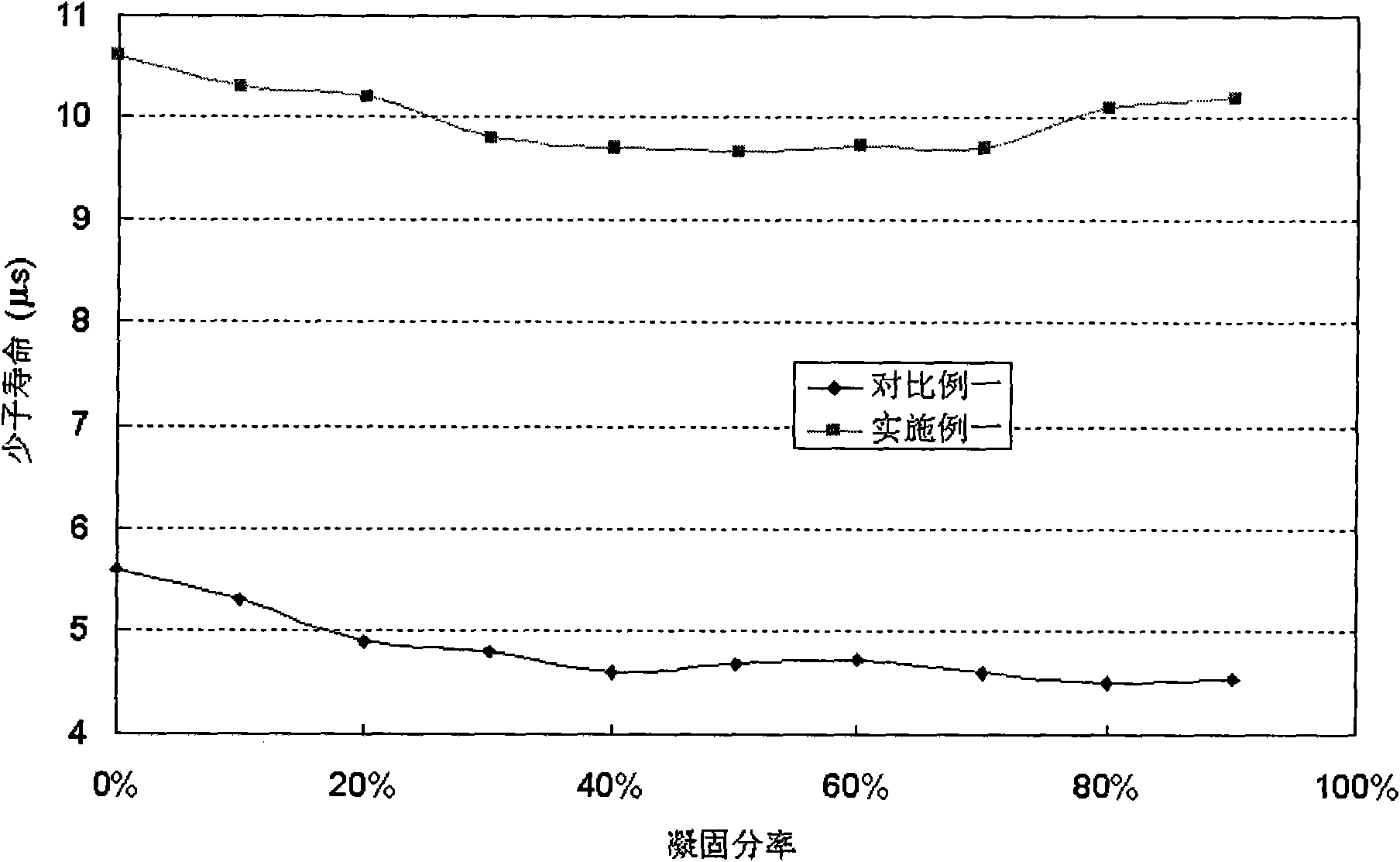

Method for preparing solar energy level silicon crystals containing doped element

InactiveCN101560693AImprove life expectancyAvoid/Minimize Performance ImpactPolycrystalline material growthUnder a protective fluidShielding gasManufacturing cell

The invention discloses a method for preparing solar energy level silicon crystals containing doped element, which is to place molten silicon containing the doped element into a crucible reactor and adopt a directional solidification method or a pulling method to prepare the silicon crystals. In the preparation process of the silicon crystals, protective gas is introduced into a crystal growing furnace and flows through the surface of the molten silicon, and is as follows: a) gas containing hydrogen atoms; or b) a mixture of the gas containing the hydrogen atoms and inert gas. The method obviously improves the minority-carrier lifetime of the silicon crystals by the functions of H on passivation, gettering and the like of impurities and defects in the silicon crystals, and improves the photoelectric conversion efficiency of subsequently manufactured cell slices. The method also adjusts the resistivity of silicon crystals doped with gallium and makes the resistivity of the silicon crystals more uniform in the crystal growing direction. Moreover, the method is simple in operation and easy in industrialized production, and can obviously improve the product quality.

Owner:GREENERGY CRYSTAL TECH

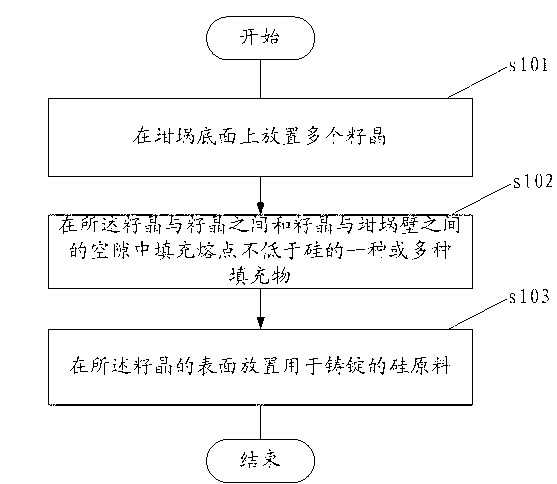

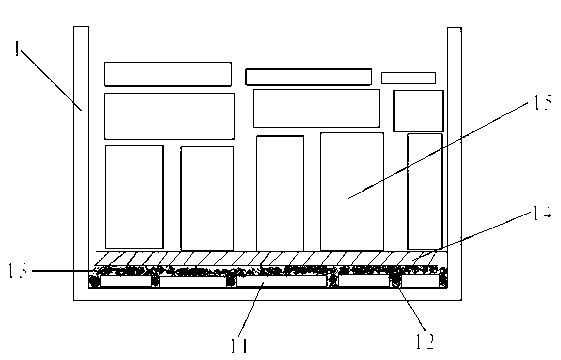

Charging method in monocrystalline silicon ingot casting, and monocrystalline silicon ingot casting method

ActiveCN102758242APrevent floatingAvoid meltingPolycrystalline material growthFrom frozen solutionsIngot castingFilling materials

The invention discloses a charging method in monocrystalline silicon ingot casting. The method comprises the steps that: a plurality of seed crystals are placed on a bottom surface of a crucible; one or more filling materials with a melting point no lower than that of silicon is filled in gaps among the seed crystals and between the seed crystals and a crucible wall; and a silicon raw material used in ingot casting is placed on the surface of the seed crystals. The invention also provides a monocrystalline silicon ingot casting method. With the method, when the silicon raw material is filled into the crucible, the filling materials with the melting point no lower than that of silicon is filled in gaps among the seed crystals and between the seed crystals and the crucible wall. Therefore, when the silicon raw material is molten, the molten silicon is prevented from entering the gaps among the seed crystals and between the seed crystals and the crucible wall, so that seed crystal floating and melting caused by the molten silicon are prevented. According to the value of silicon raw material thermal conductivity, a leveled charging method is adopted, so that temperature gradient during a monocrystalline silicon ingot casting procedure is increased. Therefore, molten silicon is prevented from contacting the seed crystals in a premature stage, and seed crystals can be prevented from melting too fast. Therefore, difficulty in controlling monocrystalline silicon ingot casting process can be prevented.

Owner:JIANGXI SAI WEI LDK SOLAR HI TECH CO LTD

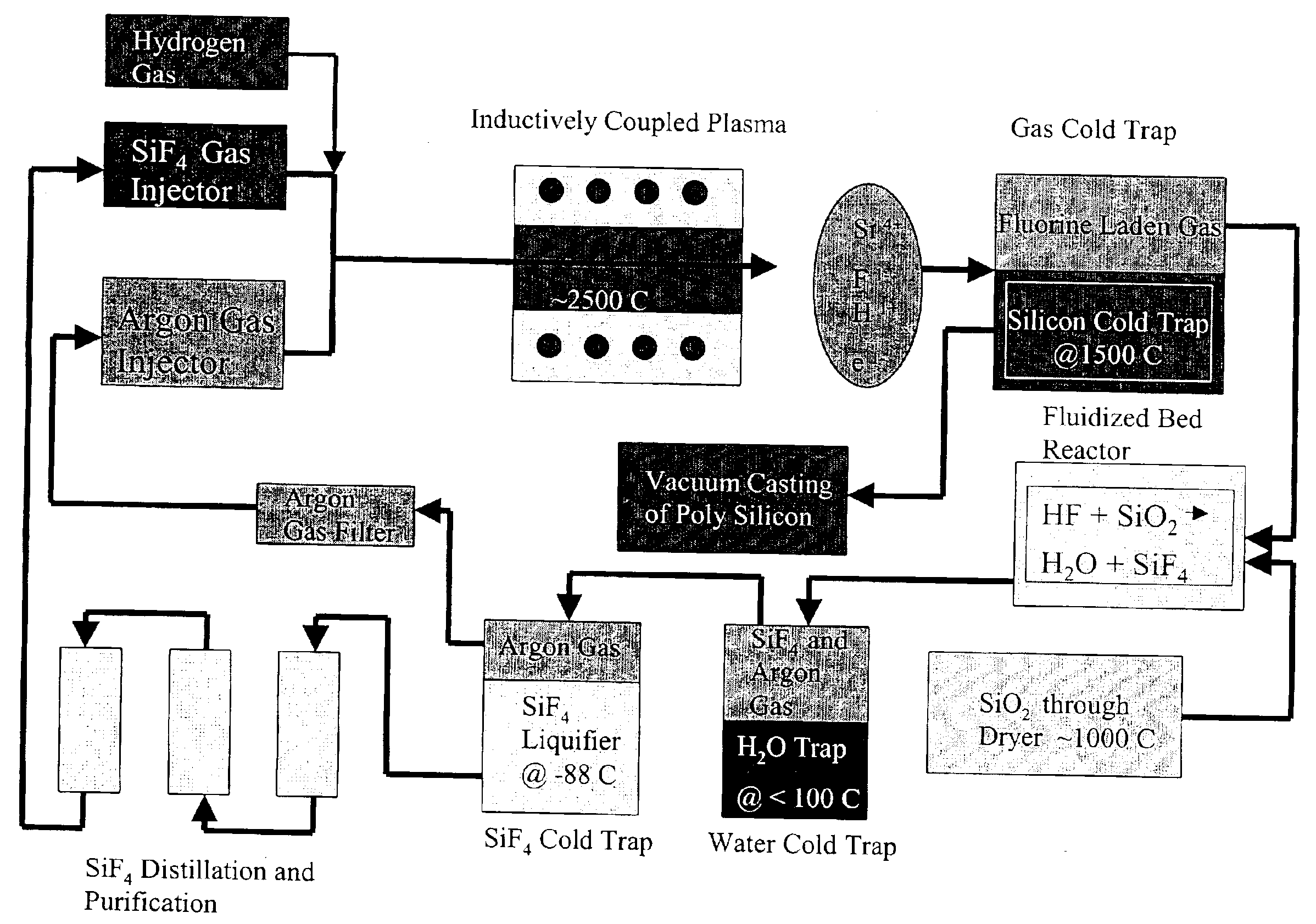

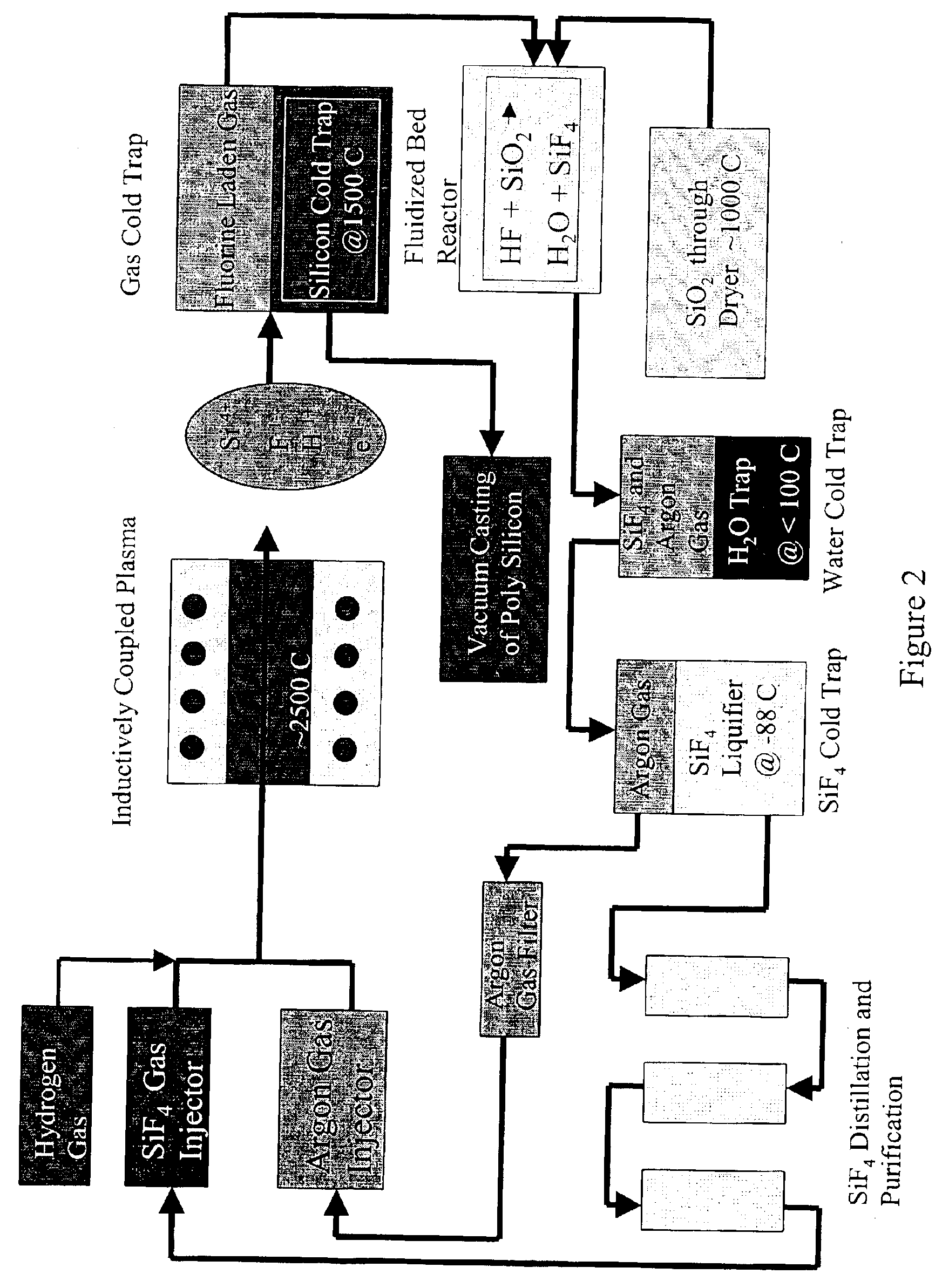

Plasma production of polycrystalline silicon

InactiveUS6926876B2High condensation temperatureCost containmentSiliconSemiconductor/solid-state device manufacturingPolysilicon halidesIngot

The invention is directed to a method of producing polycrystaline silicon metal from a silicon halide plasma source. The silicon halide is split into silicon and halide ions in an inductively coupled plasma and silicon ions are then condensed to form molten silicon metal that can be vacuum cast into polysilicon ingots. The halide ions are separated and recycled into silicon halide gas over a silicon dioxide bed. In this way, high grade polysilicon is produced without a metallurgical grade silicon precursor and the process these processes consumes the byproducts in a continuous manner madding it less expensive than traditional methods of producing polysilicon and more environmentally friendly.

Owner:TENOROC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com