Patents

Literature

34 results about "Polysilicon halides" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

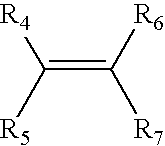

Polysilicon halides are silicon-backbone polymeric solids. At room temperature, the polysilicon fluorides are colorless to yellow solids while the chlorides, bromides, and iodides are, respectively, yellow, amber, and red-orange. Polysilicon dihalides (perhalo-polysilenes) have the general formula (SiX₂)ₙ while the polysilicon monohalides (perhalo-polysilynes) have the formula (SiX)ₙ, where X is F, Cl, Br, or I and n is the number of monomer units in the polymer.

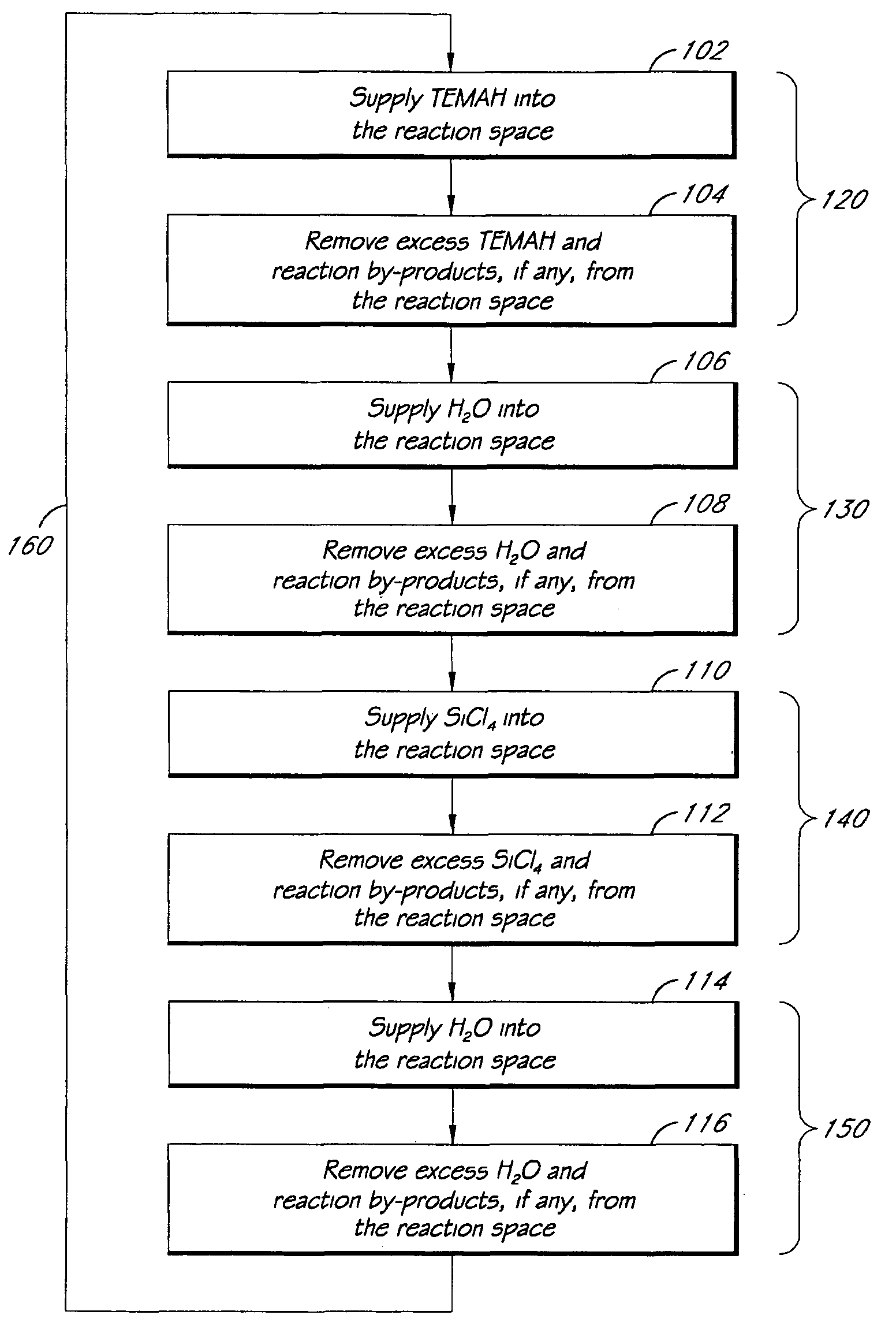

ALD of metal silicate films

ActiveUS7795160B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingGas phaseHafnium

Owner:ASM IP HLDG BV

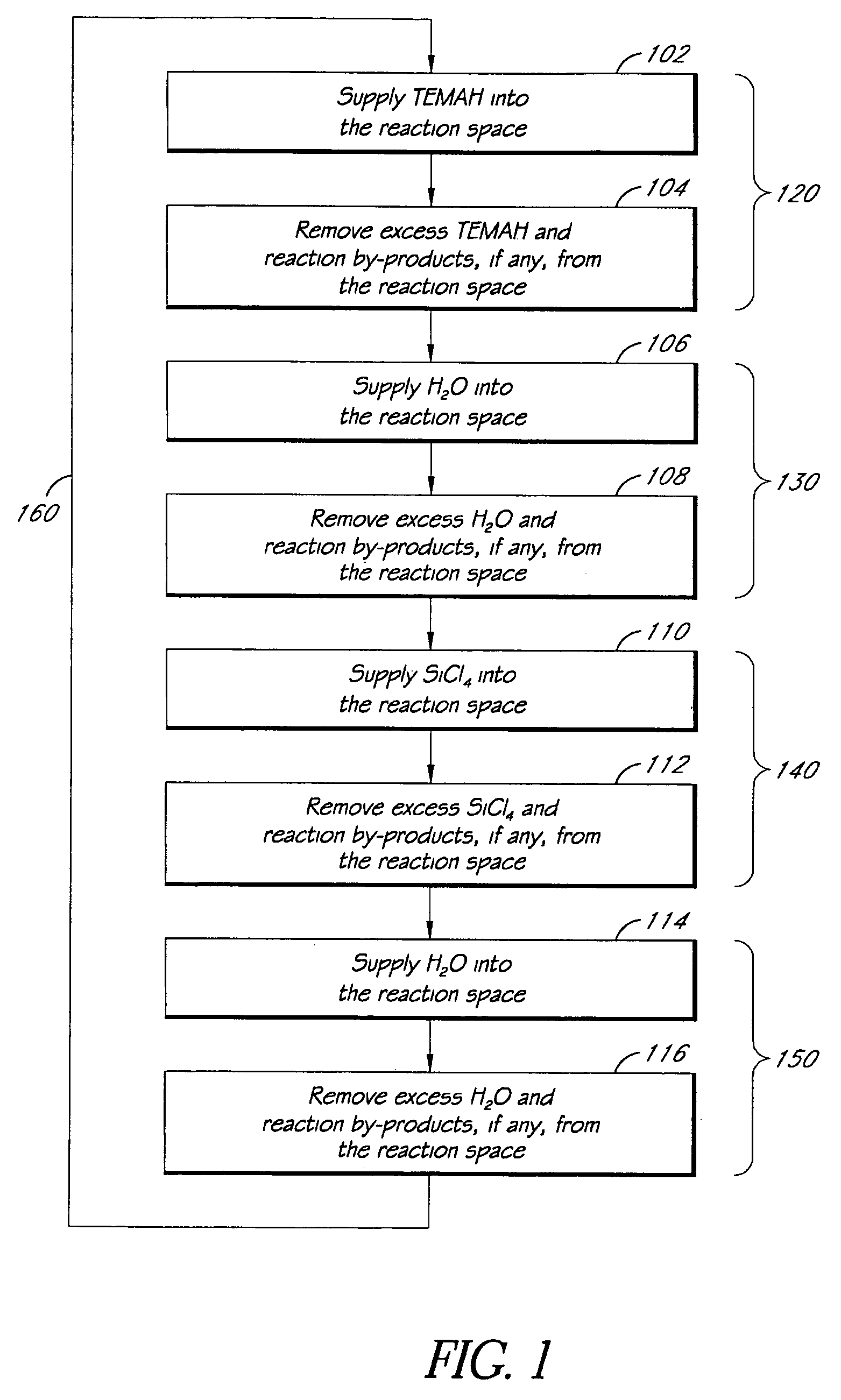

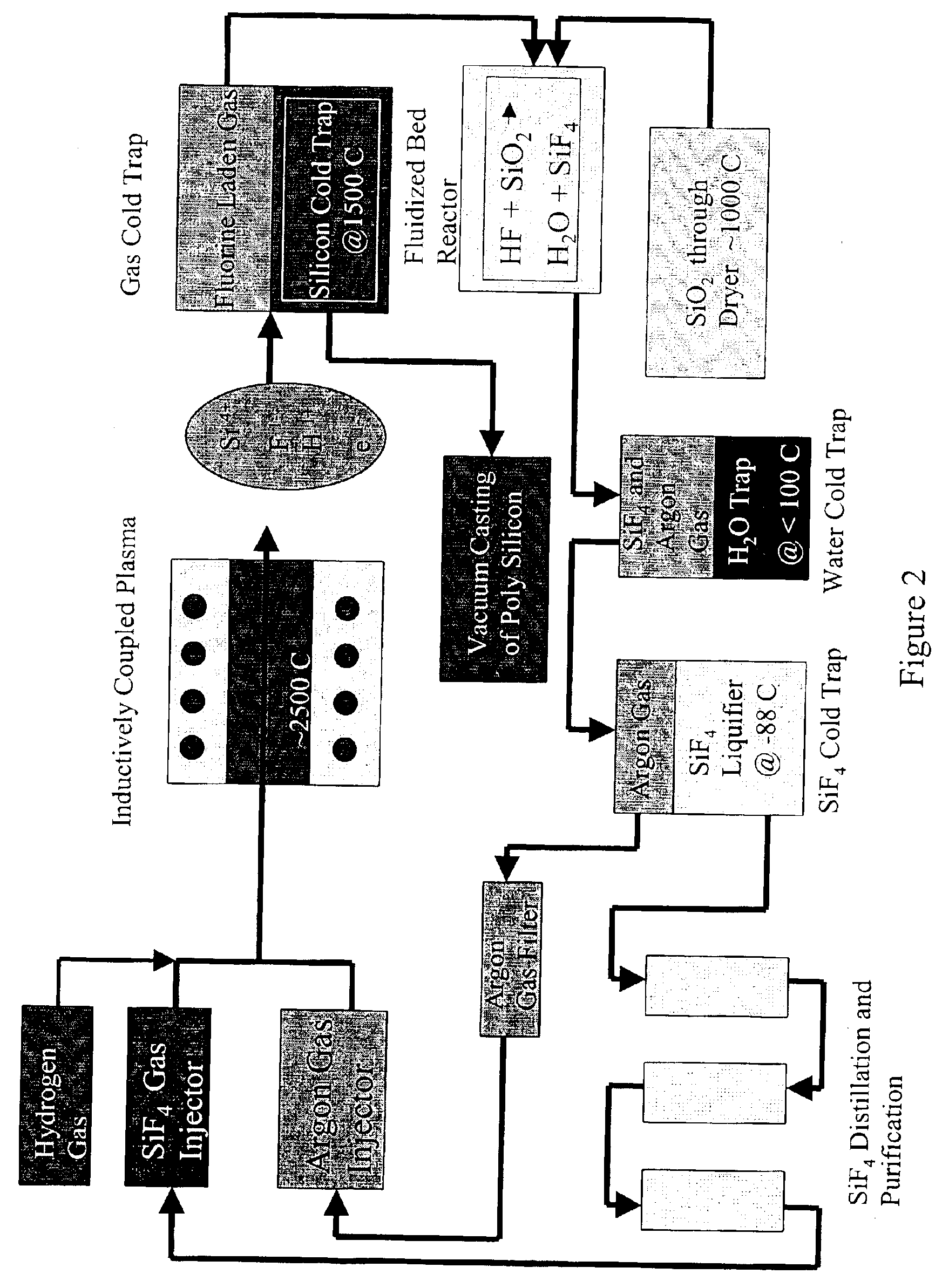

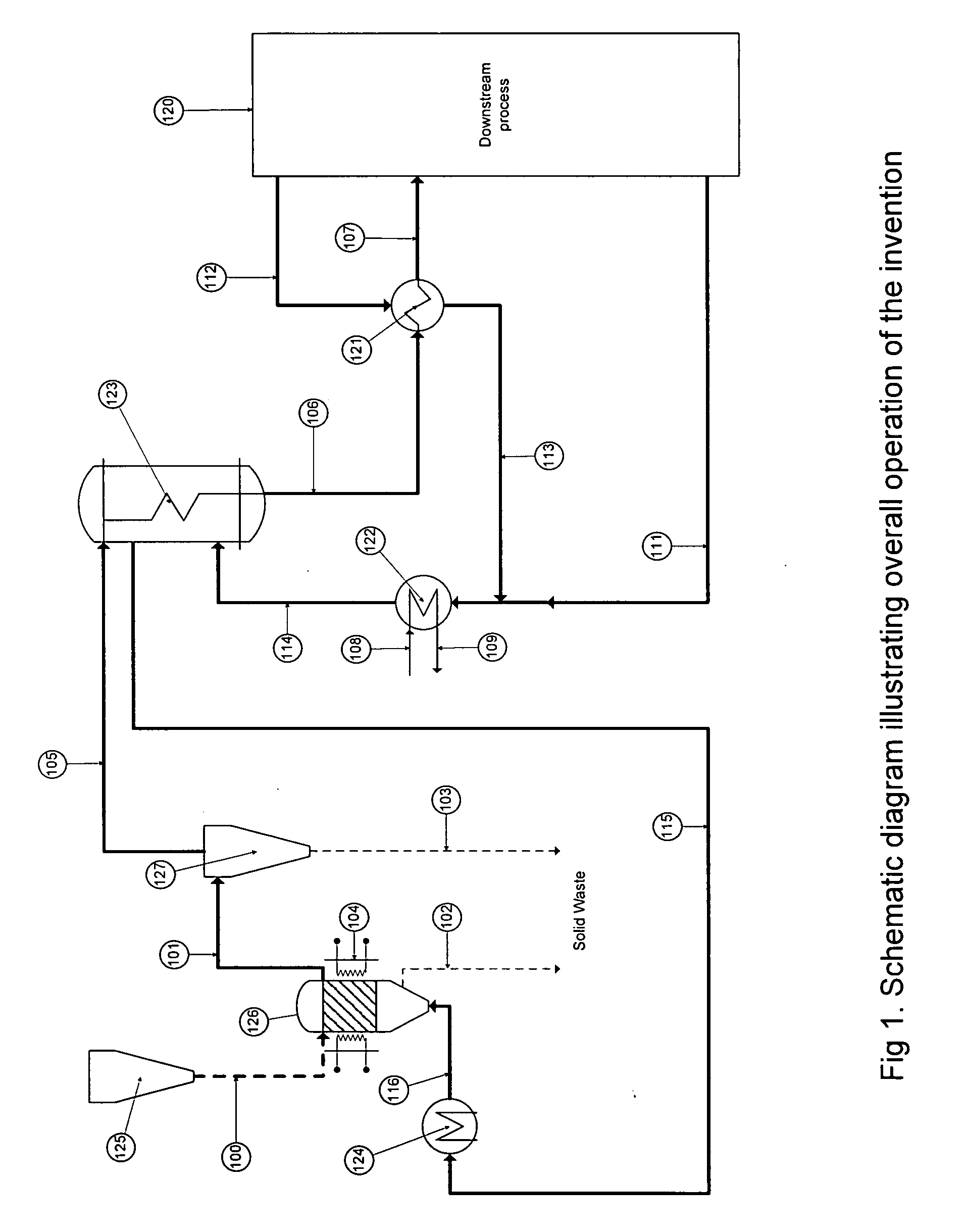

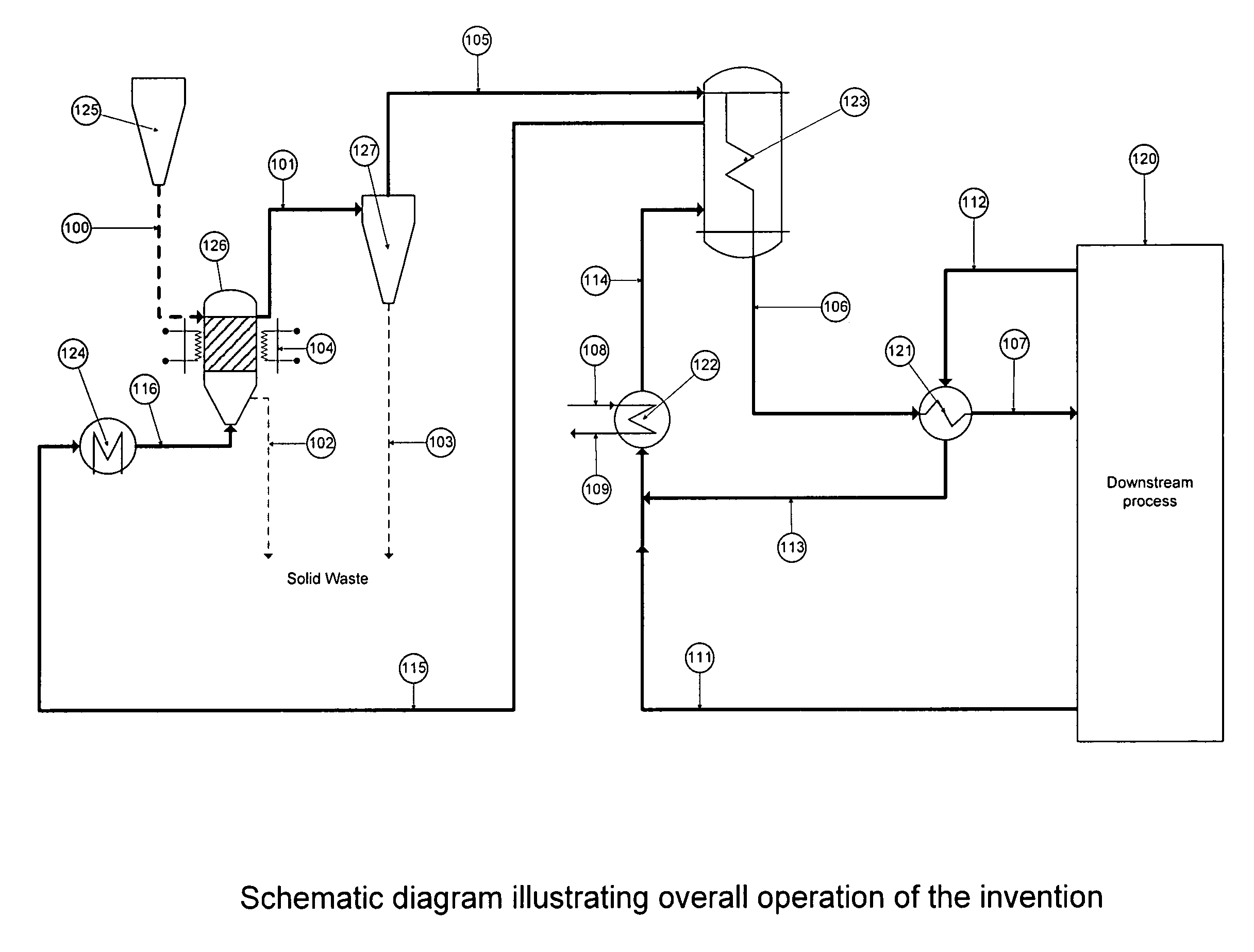

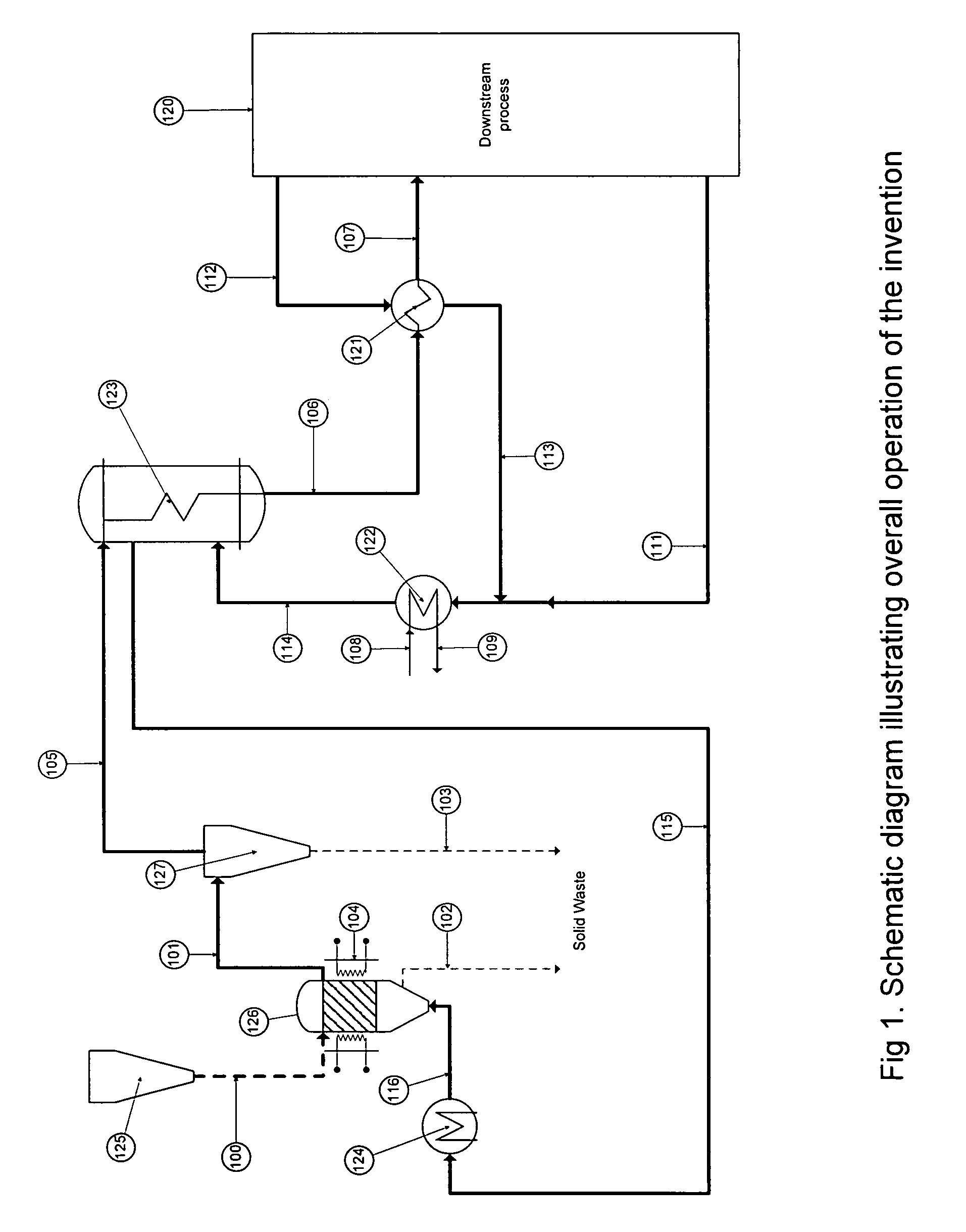

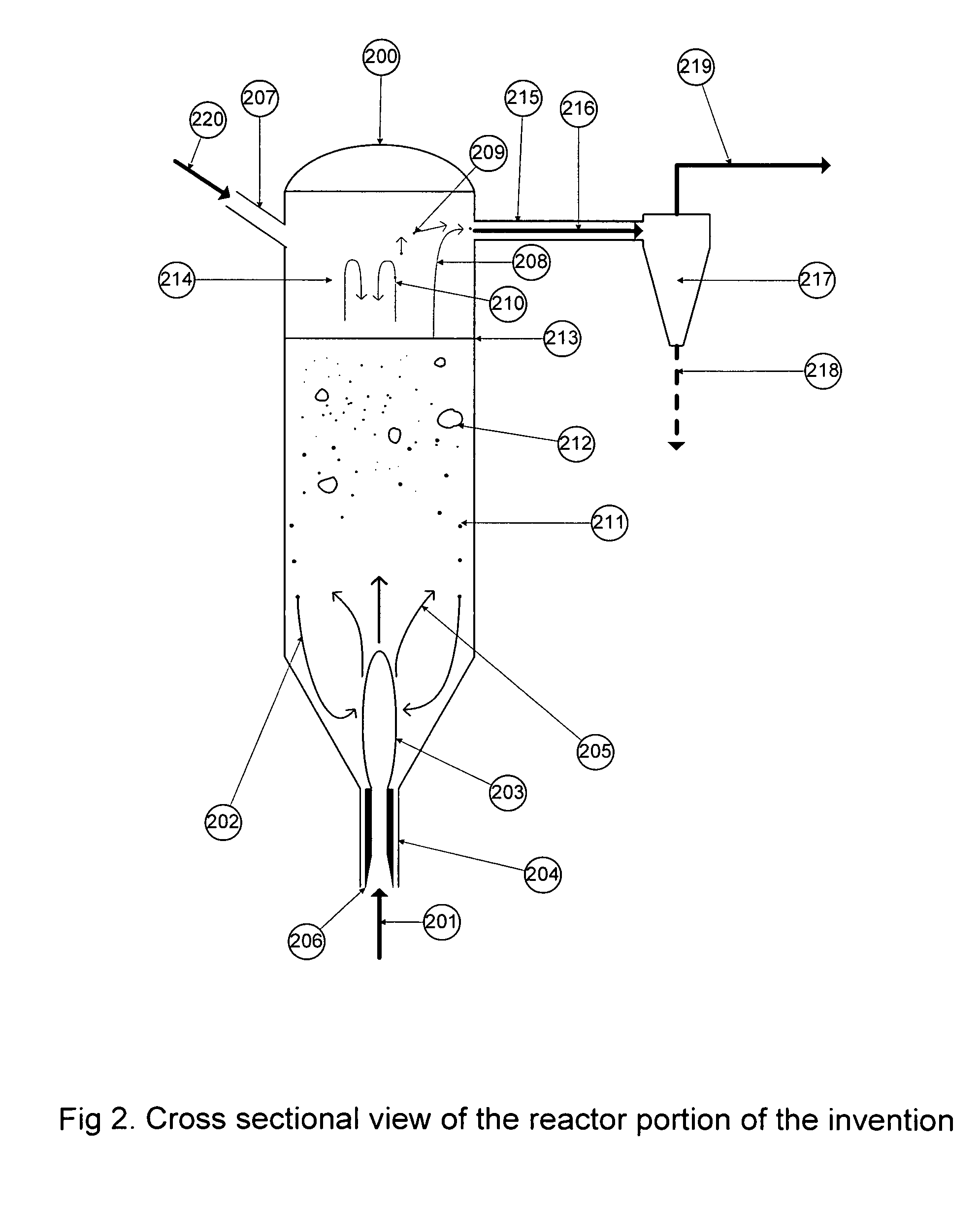

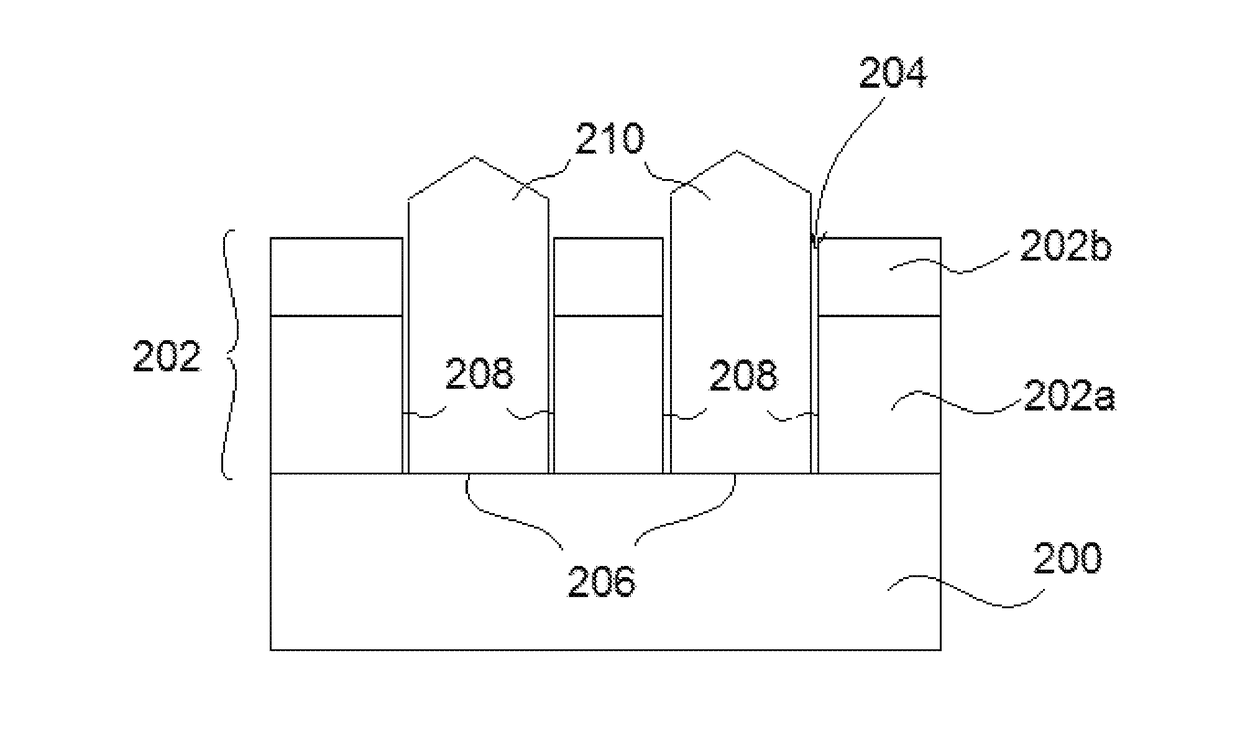

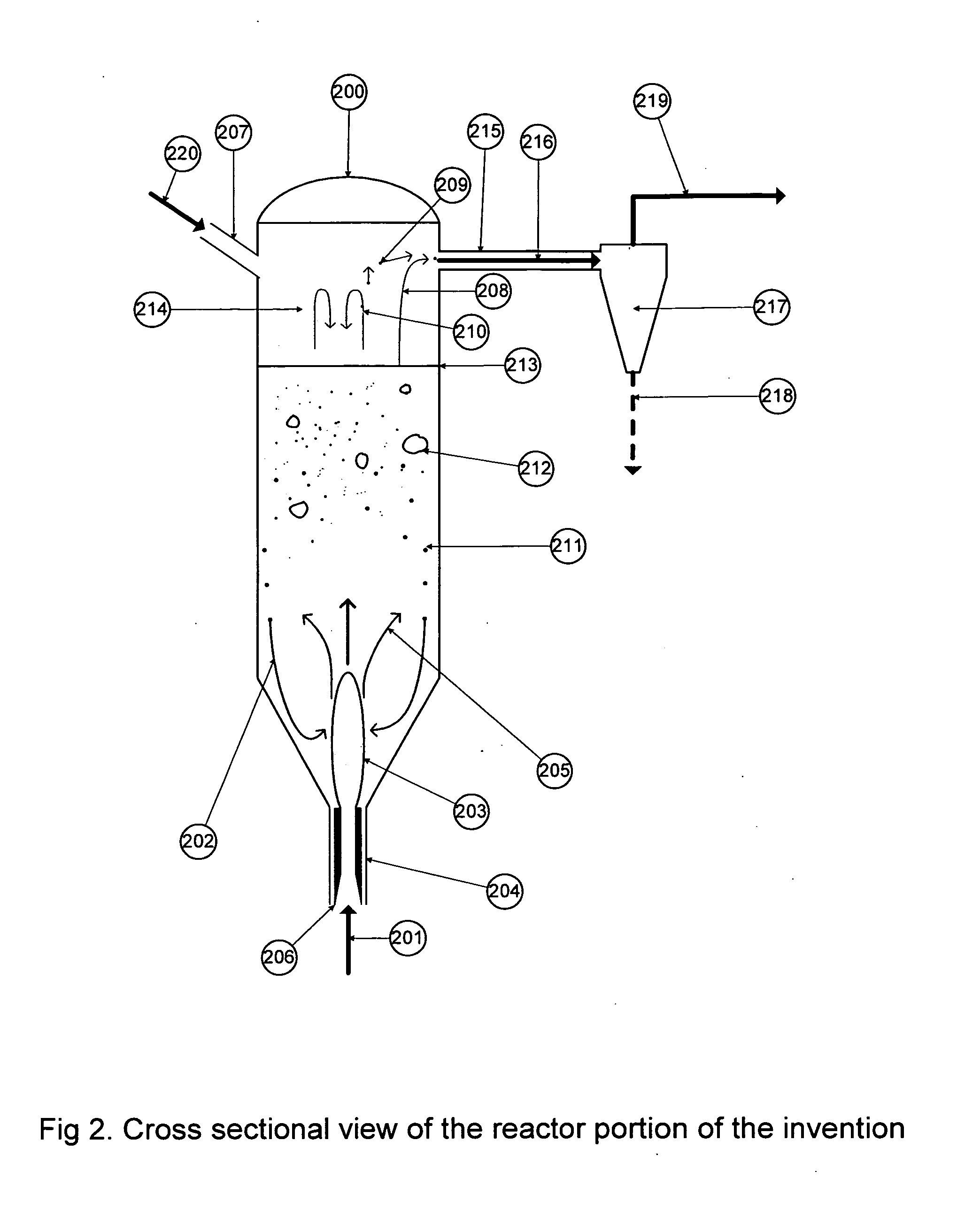

Plasma production of polycrystalline silicon

InactiveUS6926876B2High condensation temperatureCost containmentSiliconSemiconductor/solid-state device manufacturingPolysilicon halidesIngot

The invention is directed to a method of producing polycrystaline silicon metal from a silicon halide plasma source. The silicon halide is split into silicon and halide ions in an inductively coupled plasma and silicon ions are then condensed to form molten silicon metal that can be vacuum cast into polysilicon ingots. The halide ions are separated and recycled into silicon halide gas over a silicon dioxide bed. In this way, high grade polysilicon is produced without a metallurgical grade silicon precursor and the process these processes consumes the byproducts in a continuous manner madding it less expensive than traditional methods of producing polysilicon and more environmentally friendly.

Owner:TENOROC

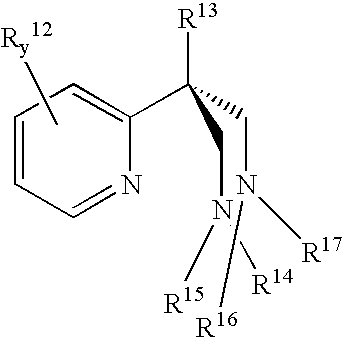

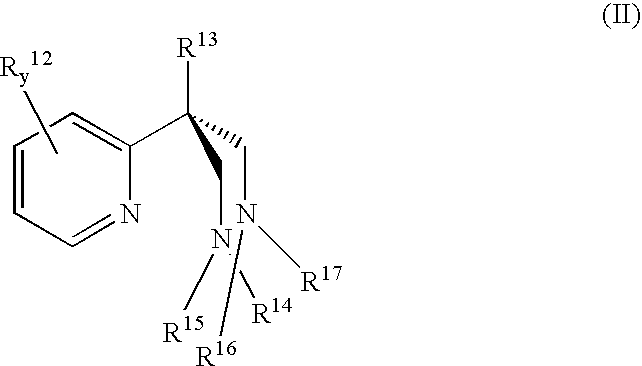

Catalyst component for olefin polymerization

ActiveUS6992034B2High activityLow molecular weight distributionOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationLinear low-density polyethylenePolymer science

A solid catalyst component useful for the (co)-polymerization of olefins is disclosed. The catalyst component is prepared by reacting an activated magnesium halide composite support with a halogenized transition metal compound and a chelating diamide compound in the presence of organo-magnesium as a promoting agent and halogenized silicon or boron compounds as an activator. The catalyst component can be used with an organo-aluminum compound to provide a solid catalyst system that is compatible with slurry and gas phase polymerization processes. Linear low density polyethylene (LLDPE) produced using the catalyst component of the present invention displays a low molecular weight distribution, improved co-monomer incorporation, low content of the low molecular weight component, and excellent morphological properties such as spherical shape and high bulk density.

Owner:FORMOSA PLASTICCS CORP

Metal effect pigments coated with SiO2, method for producing said metallic effect pigments and use

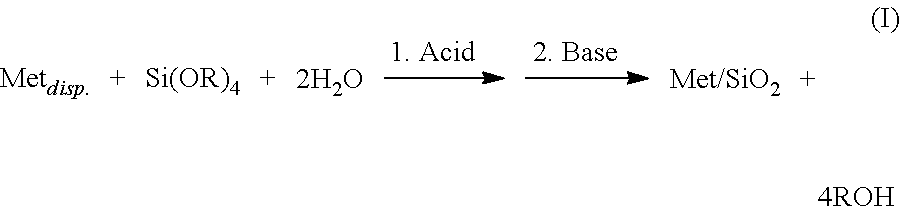

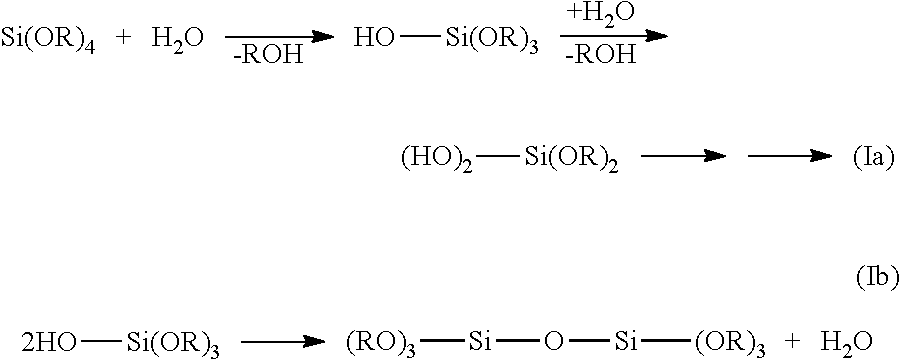

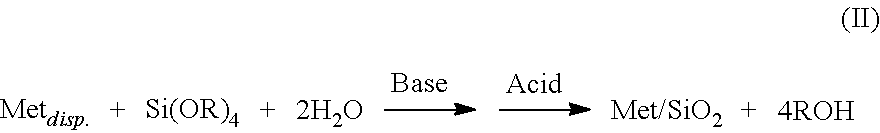

The invention relates to a method for coating metallic effect pigments with silicon oxide, in which alkoxysilane(s) and / or silicon halide(s) in organic solvent are reacted with water in the presence of metallic effect pigments, where the reaction includes at least two steps, where (a) the reaction is carried out with addition of acid in a first step and with addition of base in a second step or where (b) the reaction is carried out with addition of base in a first step and with addition of acid in a second step. The invention further relates to the coated metallic effect pigments producible by way of the method of the invention, and also to the use thereof.

Owner:ECKART GMBH & CO KG

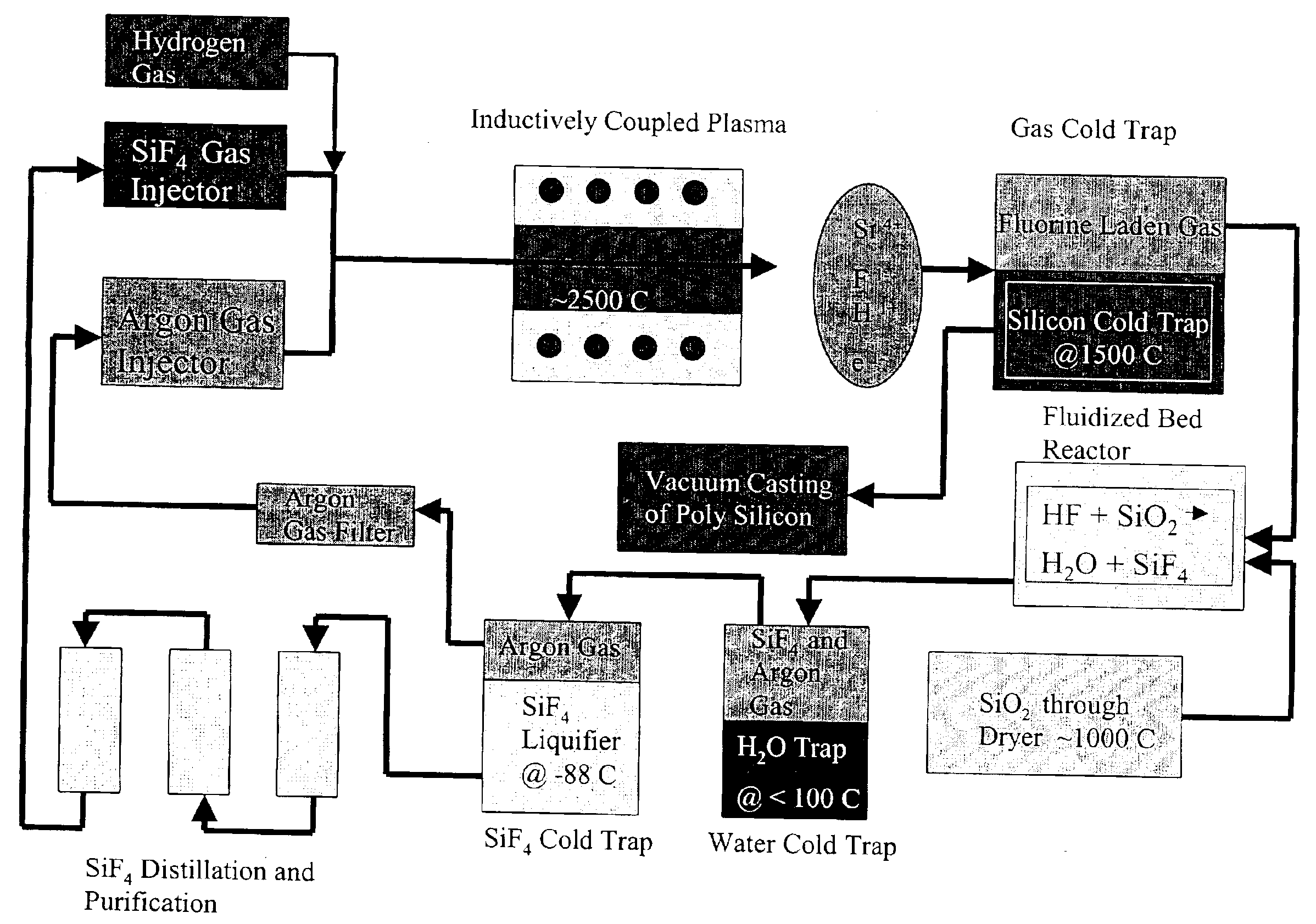

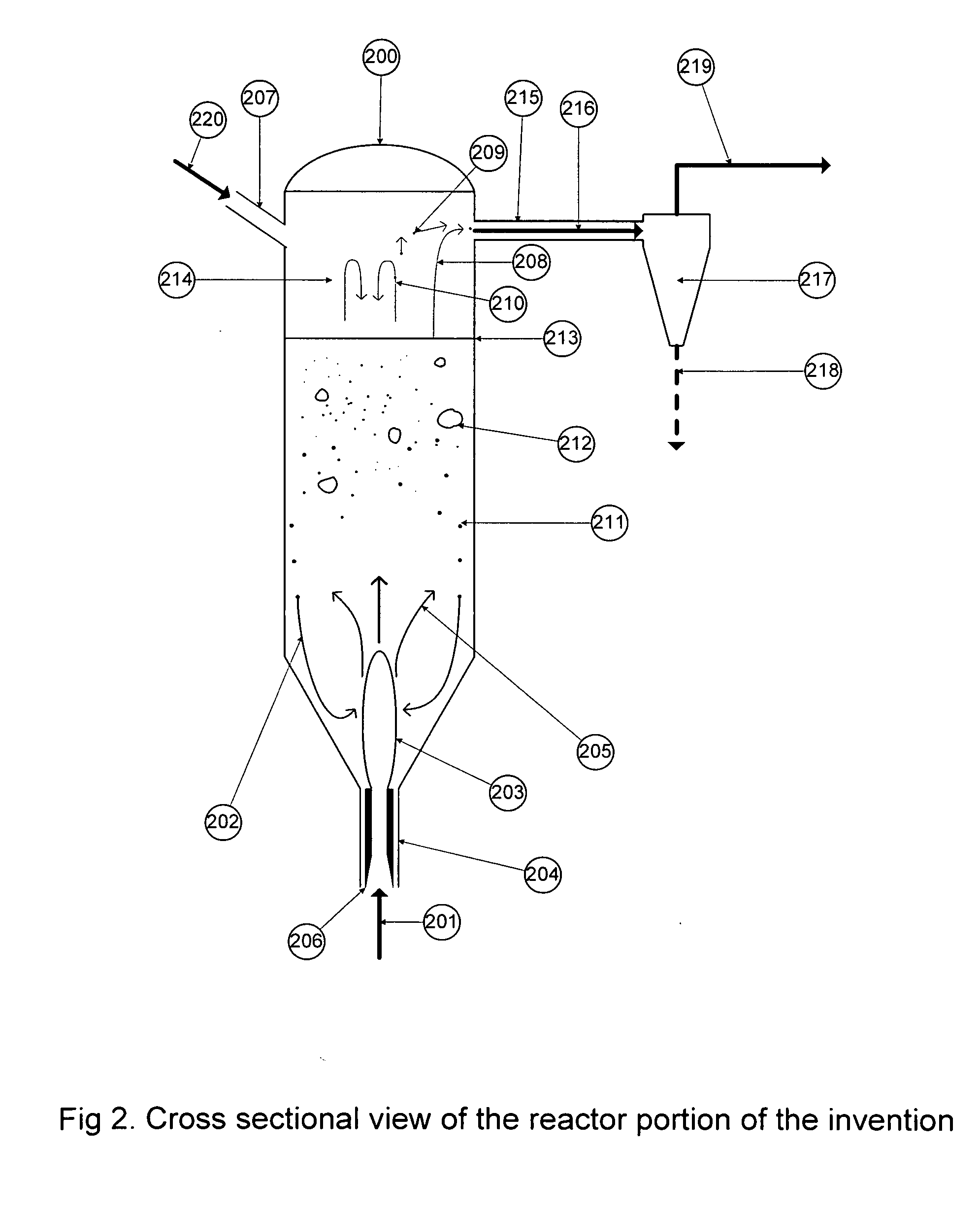

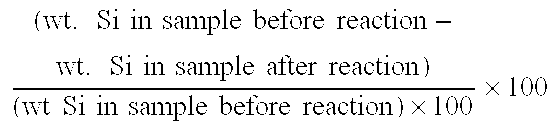

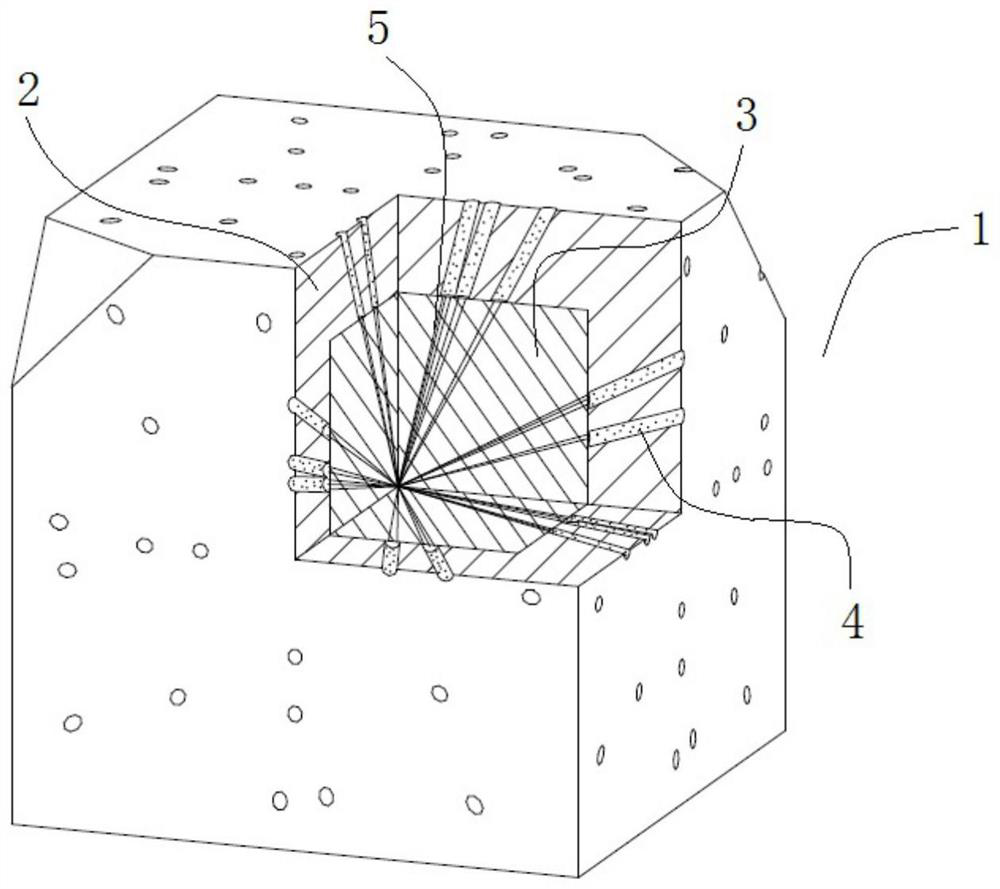

Apparatus and process for hydrogenation of a silicon tetrahalide and silicon to the trihalosilane

ActiveUS20100111804A1High yieldReduce manufacturing costFluidised-bed furnacesPressure vessels for chemical processHydrogenPolysilicon halides

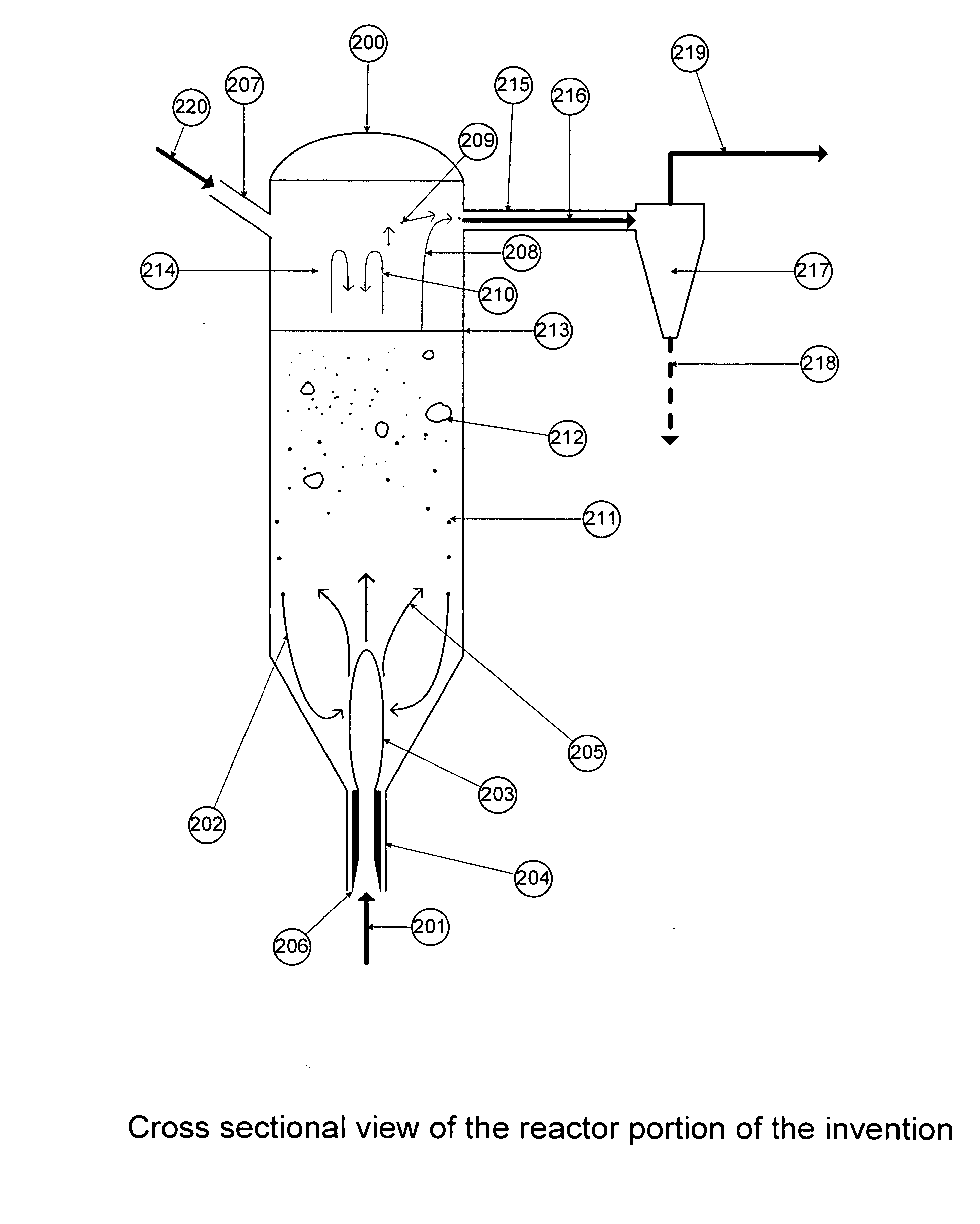

A reactor for hydrogenation of a silicon tetrahalide and metallurgical grade silicon to trihalosilane includes a bed of metallurgical silicon particles, one or more gas entry ports, one or more solids entry ports, one or more solids drains and one or more ports for removing the trihalosilane from the reactor. Fresh surfaces are generated on the bed particles by internal grinding and abrasion as a result of entraining feed silicon particles in a silicon tetrahalide / hydrogen feed stream entering the reactor and impinging that stream on the bed of silicon particles. This has the advantages of higher yield of the trihalosilane, higher burnup rate of the MGS, removal of spent MGS as a fine dust carryover in the trihalosilane effluent leaving the reactor and longer times between shutdowns for bed removal.

Owner:LORD LTD LP

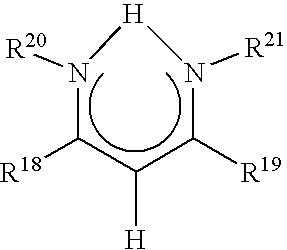

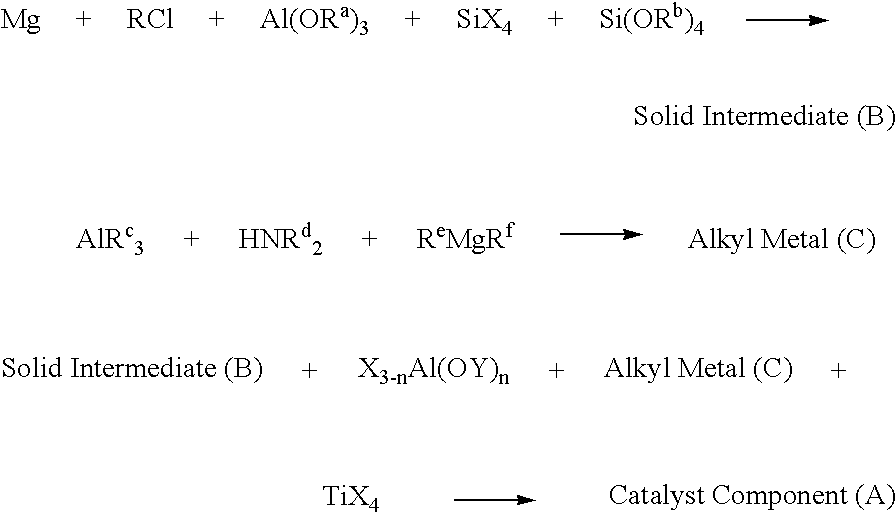

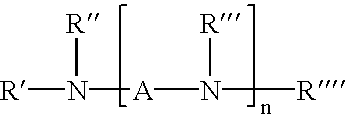

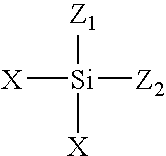

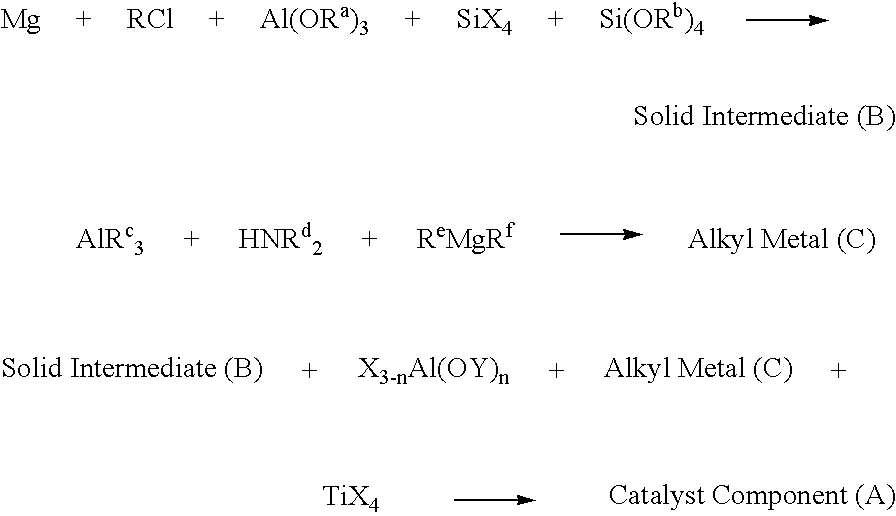

Catalyst system for producing ethylene (co) polymer with improved branch distribution

ActiveUS7651969B2Improve distributionSuitably producedGroup 4/14 element organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsPolymer sciencePtru catalyst

A process for synthesizing a catalyst component for manufacturing ethylene polymer and co-polymer. The present invention provides a process for synthesizing catalyst component (A), comprising forming a complex by contacting the solid intermediate (B) with an aluminum compound represented by formula X3-nAl(OY)n, and alkyl metal (C), wherein X is halide, Y is a hydrocarbon group or chelating carbonyl group, and wherein 1 is less than or equal to n which is less than or equal to 3, and then contacting the complex with titanium halide having formula TiX4 wherein X is halide. Solid intermediate (B) is formed by reacting magnesium metal with alkyl halide in the presence of alkoxy aluminum represented by formula Al(ORa)3, silicon halide represented by formula SiX4 and alkoxy silane represented by formula Si(ORb)4, wherein Ra and Rb are an aromatic or aliphatic alkyl group and wherein X is halide. Alkyl metal (C) is synthesized by reacting alkyl aluminum compounds represented by formula AlRc3 with a secondary amine having formula HNRd2 and then by reacting with alkyl magnesium compounds represented by formula ReMgRf, wherein Rc, Rd, Re and Rf are an aromatic or aliphatic alkyl group. The catalyst component is suitable for producing ethylene polymer and co-polymer with narrow molecular weight distribution as well as improved branching compositional distribution.

Owner:FORMOSA PLASTICCS CORP

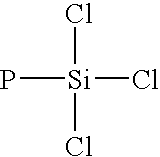

Method of preparing a diorganodihalosilane

A method of preparing a diorganodihalosilane, the method comprising the following separate and consecutive steps: (i) treating a preformed metal silicide with a mixture comprising hydrogen gas and a silicon tetrahalide at a temperature from 300 to 1400° C. to form a treated metal silicide, wherein the preformed metal silicide comprises a metal selected from at least one of Ni, Pd, or Pt; and (ii) reacting the treated metal silicide with an organohalide according to the formula RX at a temperature from 250 to 700° C. to form a diorganodihalosilane, wherein R is C1-C10 hydrocarbyl and X is halo.

Owner:DOW CORNING CORP

Method for Preparing a Trihalosilane

InactiveUS20130156676A1Less energyProcess economyGroup 4/14 element organic compoundsSiliconHydrogen halidePlatinum

A method of preparing a trihalosilane comprising the separate and consecutive steps of (i) contacting a copper catalyst with hydrogen gas and a silicon tetrahalide at a temperature of from 500 to 1400° C. to form a silicon-containing copper catalyst comprising at least 0.1% (w / w) of silicon, wherein the copper catalyst comprises a metal selected from copper and a mixture comprising copper and at least one element selected from gold, magnesium, and platinum; and (ii) contacting the silicon-containing copper catalyst with a hydrogen halide at a temperature of from 100 to 600° C. to form a trihalosilane.

Owner:DOW CORNING CORP

Method for preparing a diorganodihalosilane

InactiveUS8772525B2Good choiceLess energySilicon organic compoundsCatalyst activation/preparationPtru catalystPolysilicon halides

A method of preparing a diorganodihalosilane comprising the separate and consecutive steps of (i) contacting a copper catalyst with a mixture comprising hydrogen gas and a silicon tetrahalide at a temperature of from 500 to 1400° C. to form a silicon-containing copper catalyst comprising at least 0.1% (w / w) of silicon, wherein the copper catalyst is selected from copper and a mixture comprising copper and at least one element selected from gold, magnesium, calcium, cesium, tin, and sulfur; and (ii) contacting the silicon-containing copper catalyst with an organohalide at a temperature of from 100 to 600° C. to form at least one diorganodihalosilane.

Owner:DOW SILICONES CORP

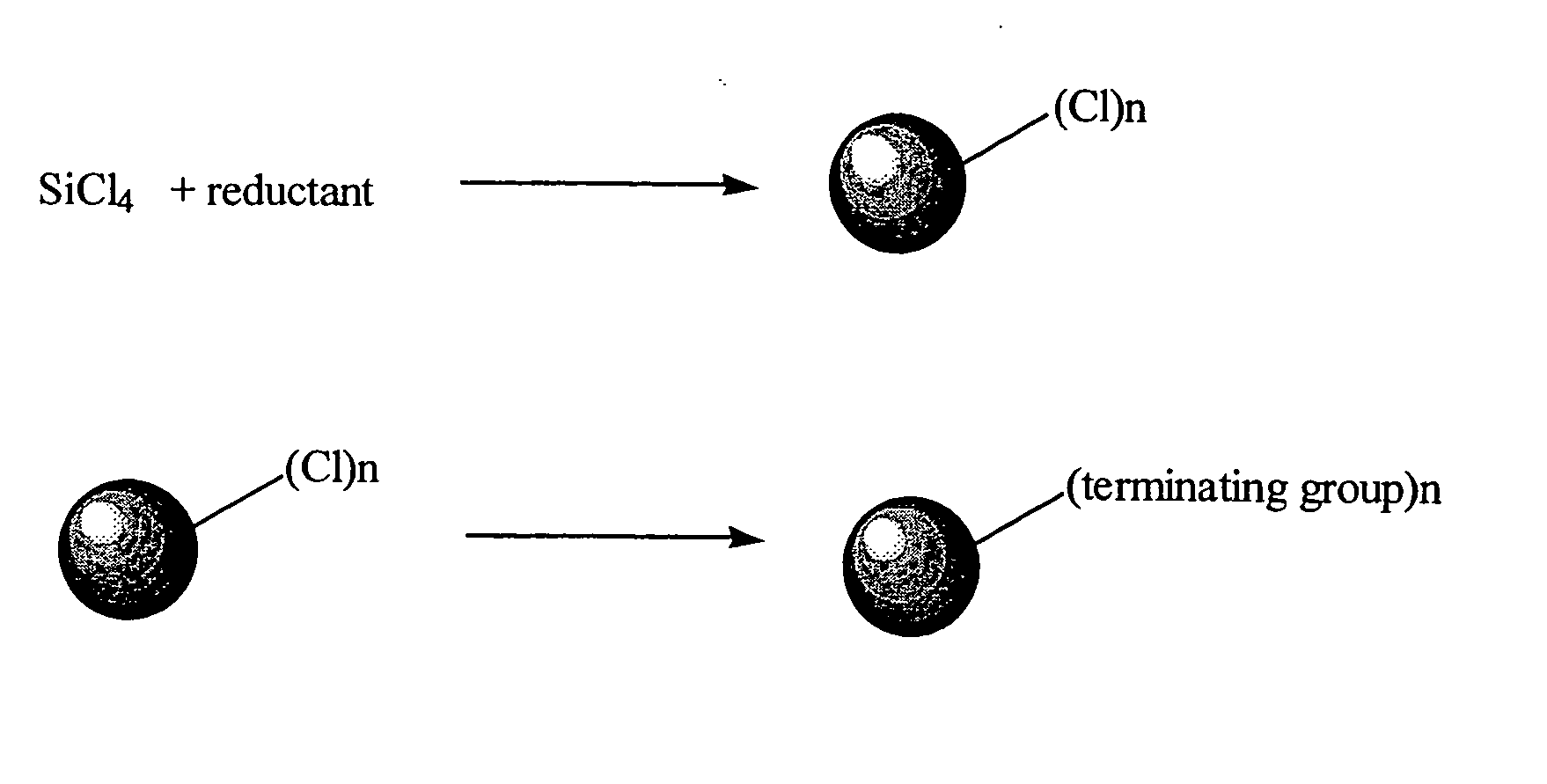

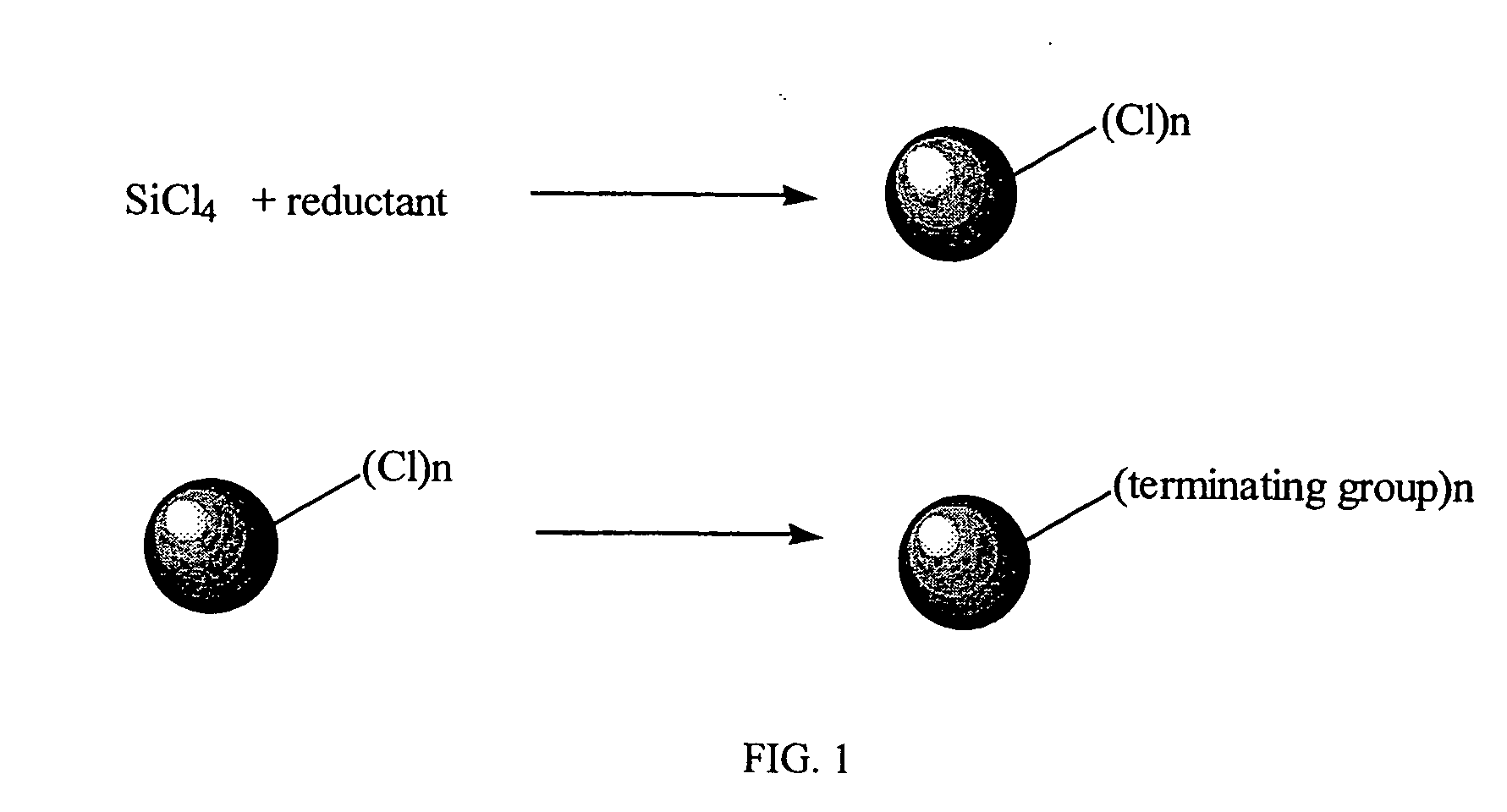

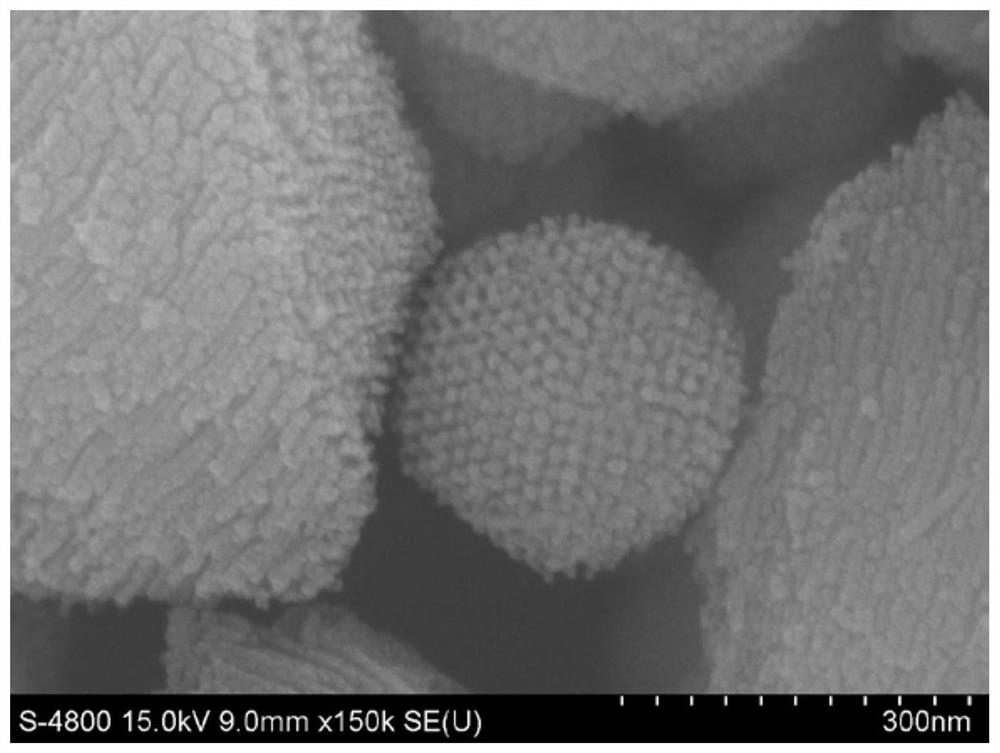

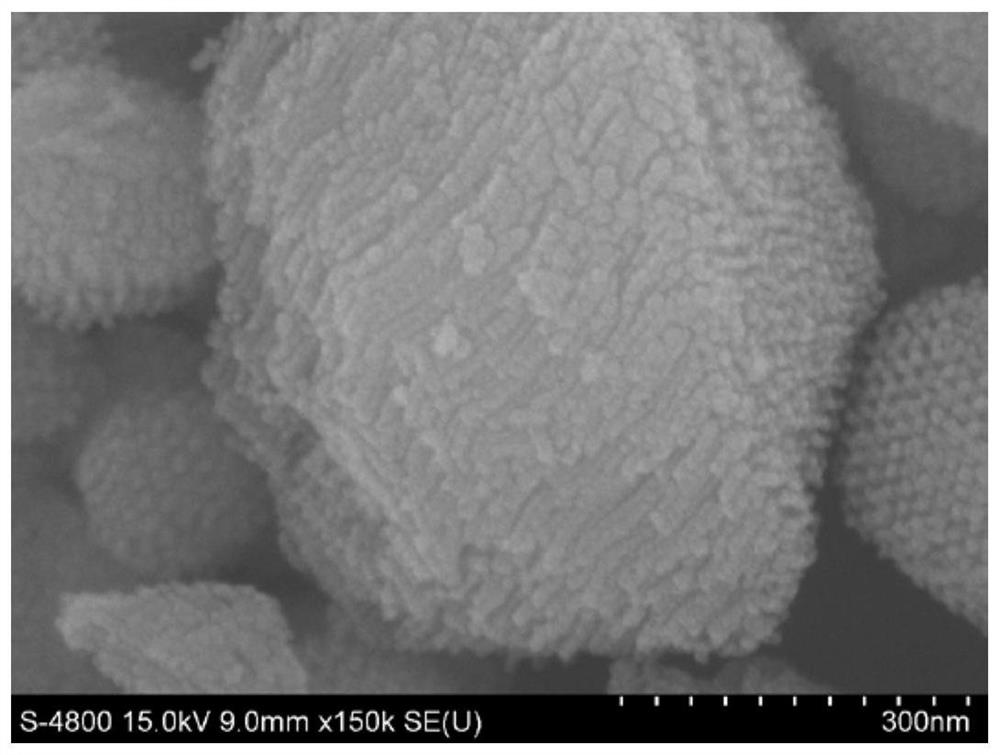

High yield method for preparing silicon nanocrystal with chemically accessible surfaces

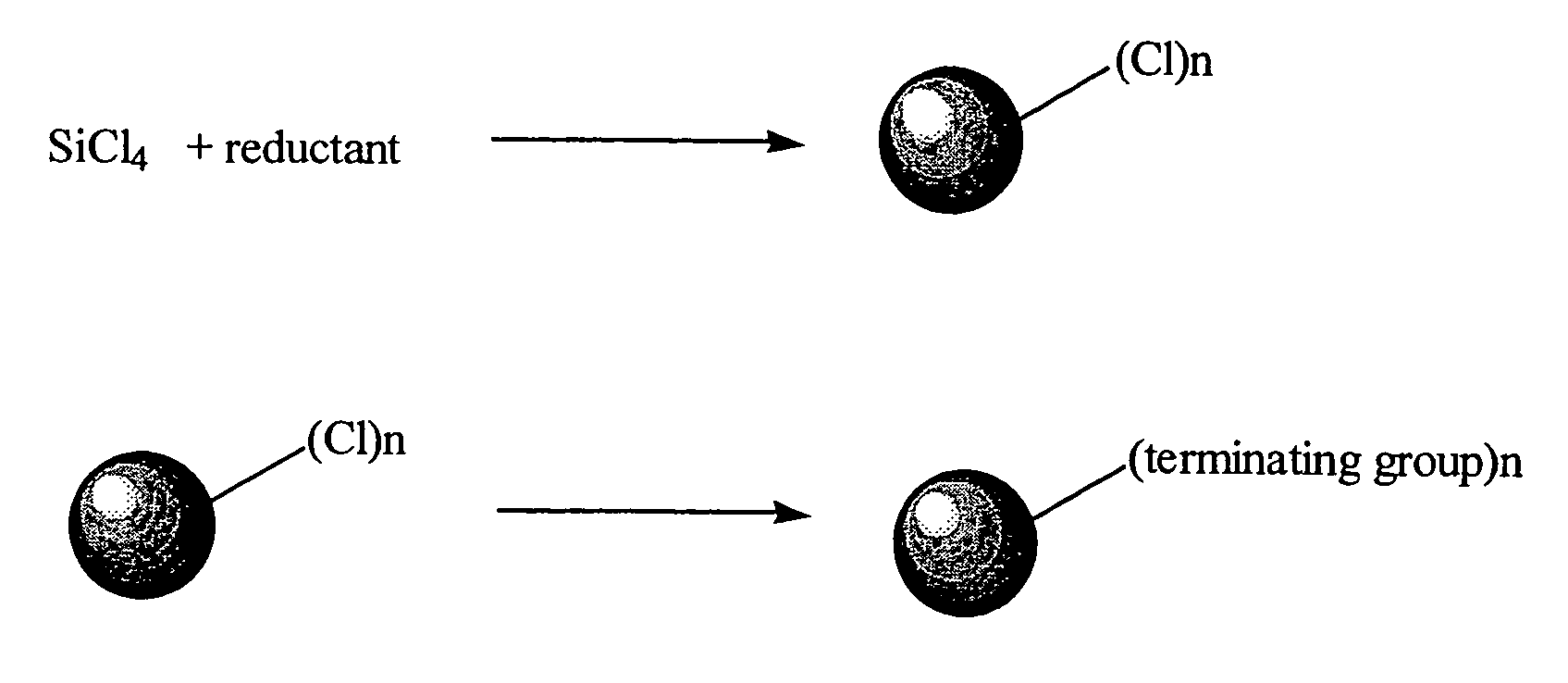

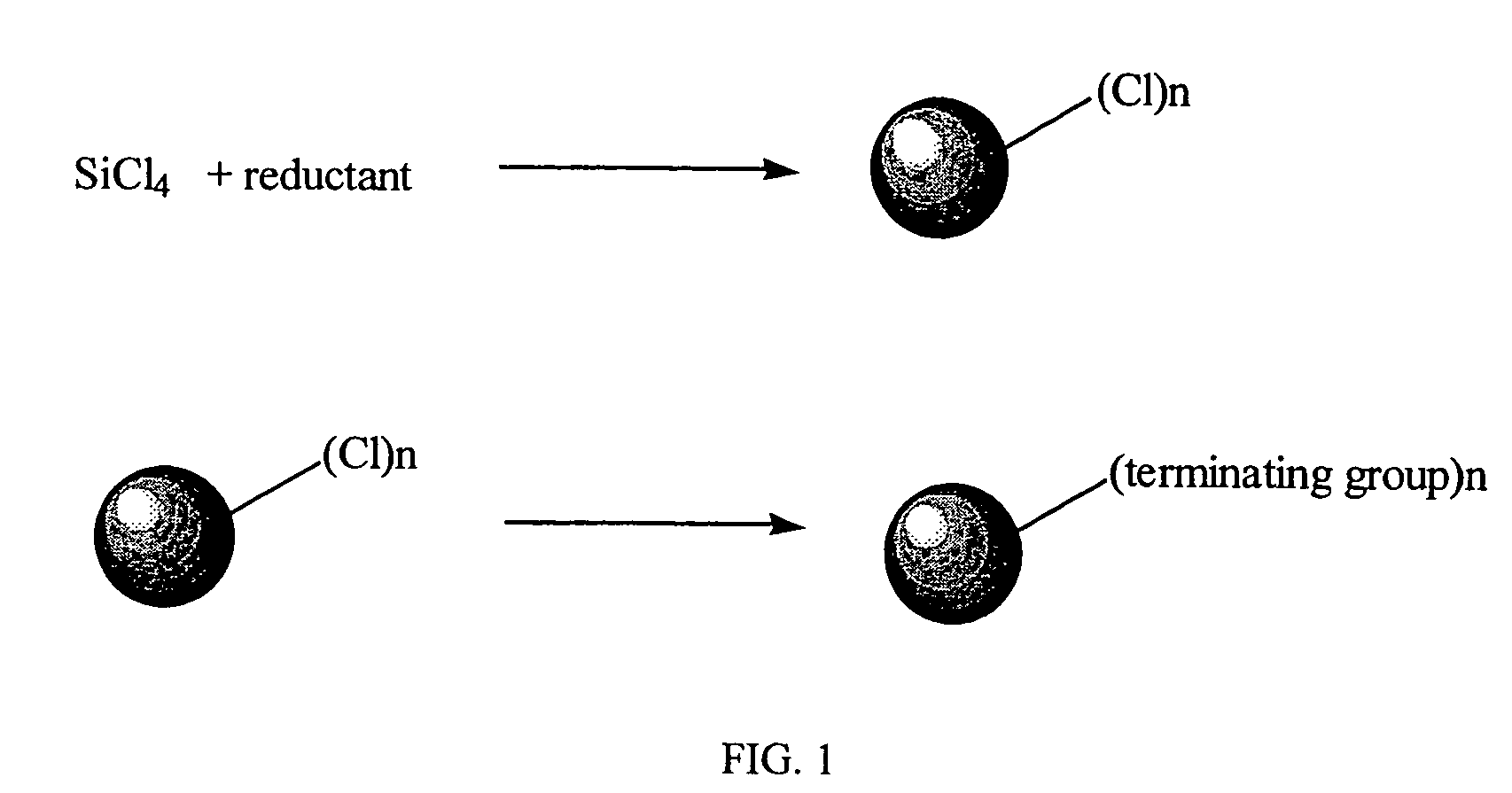

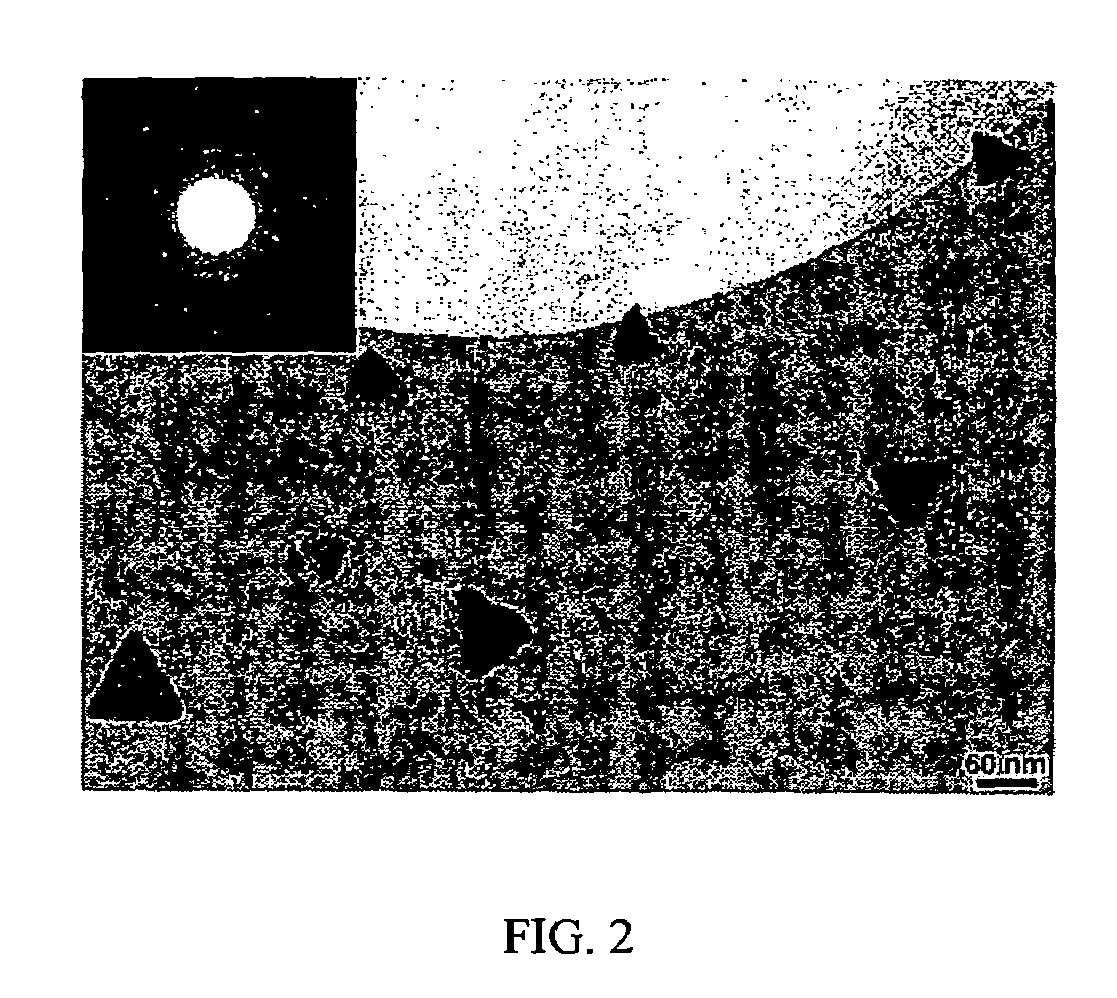

InactiveUS20050000409A1Material nanotechnologyPolycrystalline material growthSodium naphthalenideLithium

Silicon nanocrystals with chemically accessible surfaces are produced in solution in high yield. Silicon tetrahalide such as silicon tetrachloride (SiCl4) can be reduced in organic solvents, such as 1,2-dimethoxyethane(glyme), with soluble reducing agents, such as sodium naphthalenide, to give halide-terminated (e.g., chloride-terminated) silicon nanocrystals, which can then be easily functionalized with alkyl lithium, Grignard or other reagents to give easily processed silicon nanocrystals with an air and moisture stable surface. The synthesis can be used to prepare alkyl-terminated nanocrystals at ambient temperature and pressure in high yield. The two-step process allows a wide range of surface functionality.

Owner:EVERGREEN SOLAR

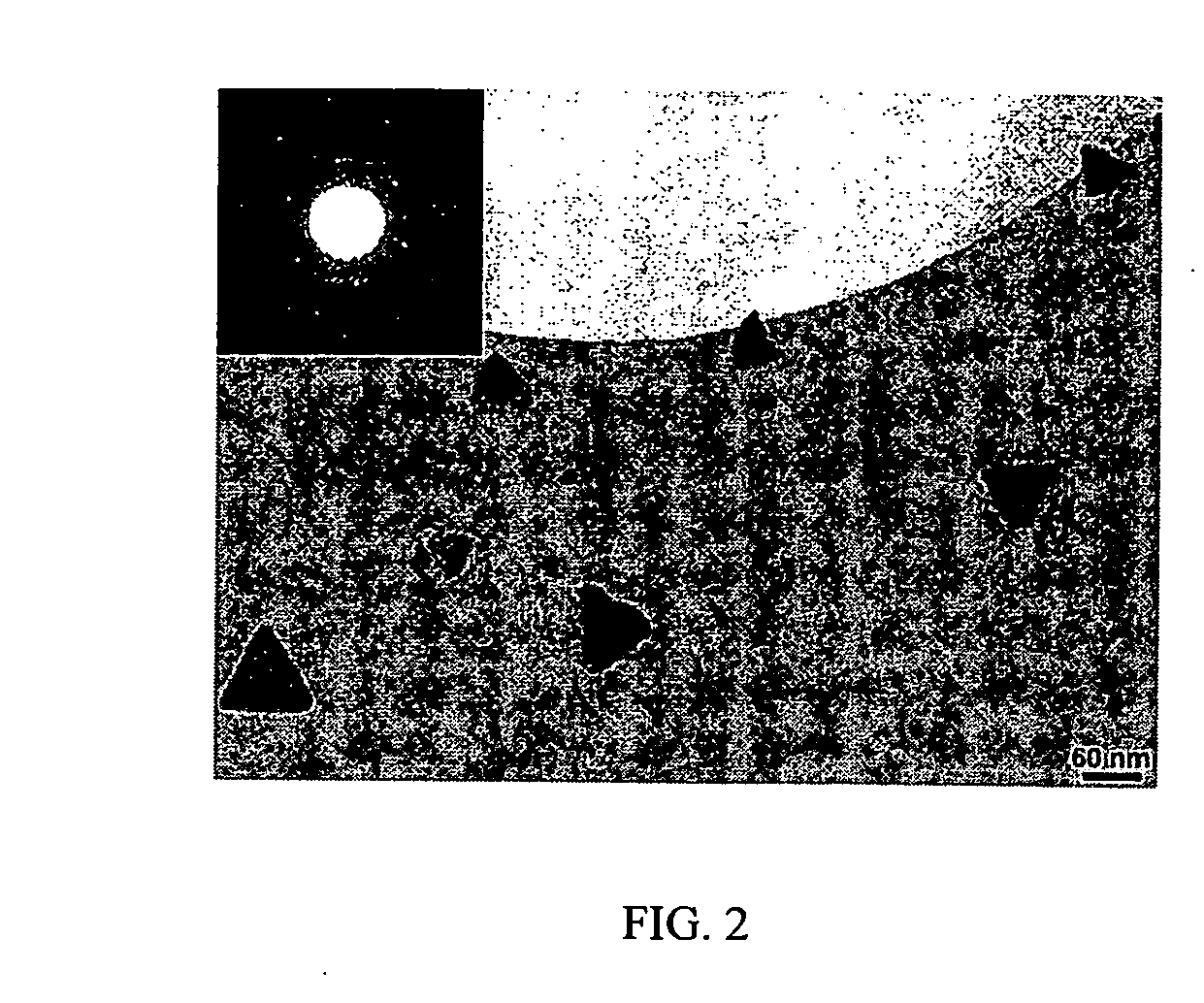

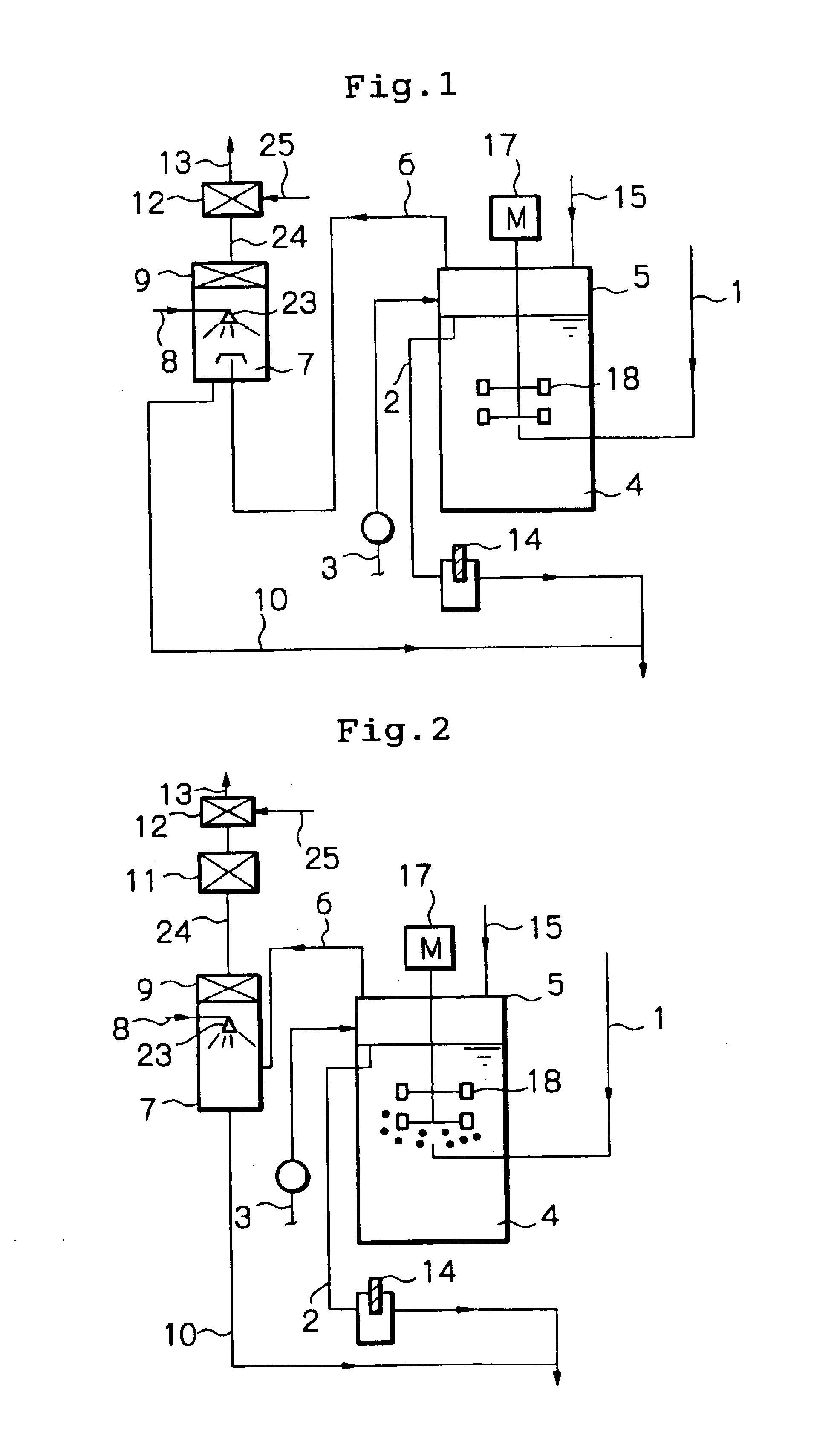

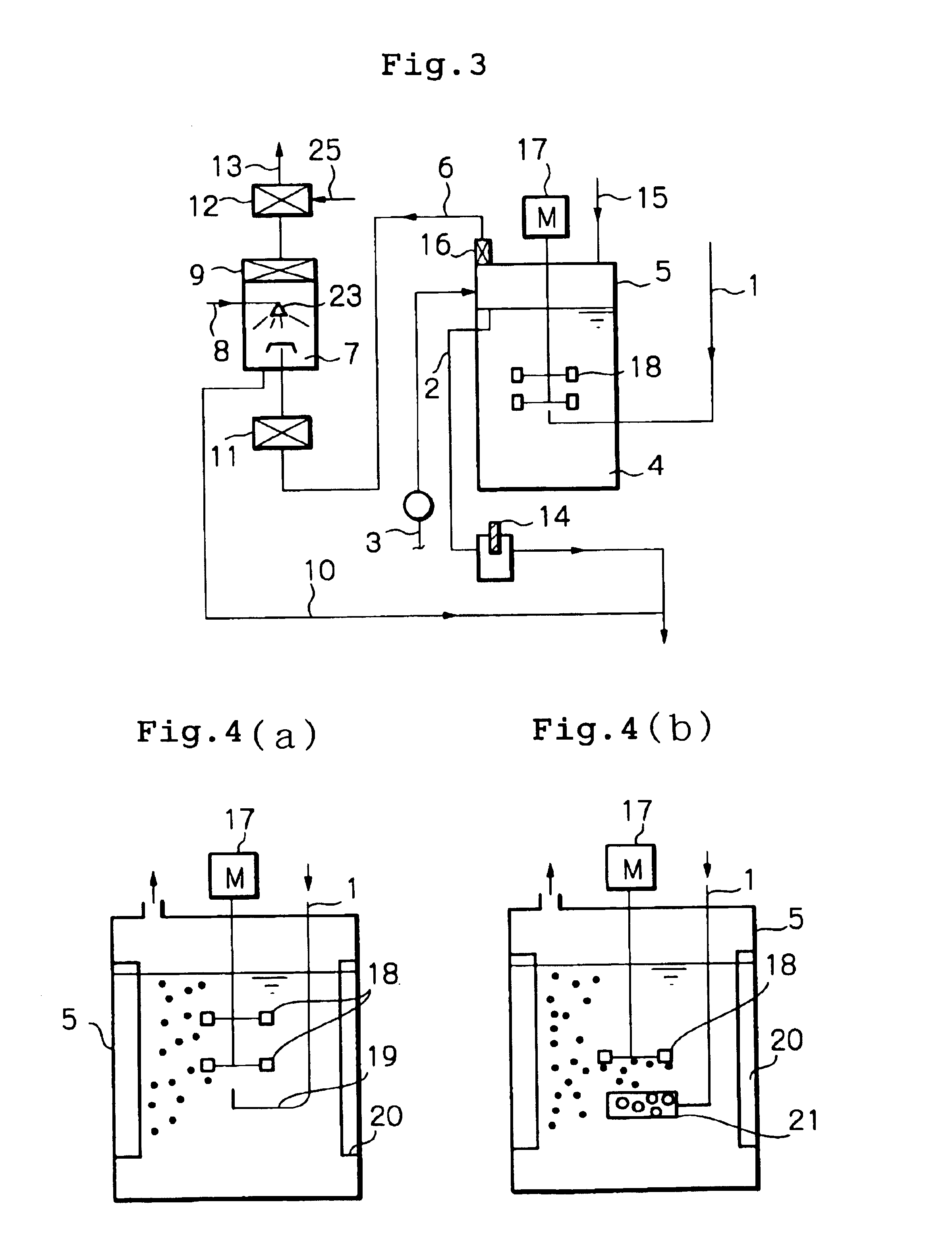

Process and apparatus for treating semiconductor production exhaust gases

InactiveUS6953557B1High removal rateLow running costChlorine/hydrogen-chlorideCombination devicesHalogenPolysilicon halides

A process and an apparatus for treating exhaust gases, comprising an aeration stirring tank (5) employing an aqueous alkaline liquid, and, as a posterior stage, a gas-liquid contact device (7) and / or a packed column (11). The apparatus can remove at the posterior stage harmful gases that the aeration stirring tank fails to remove, for example, water-soluble organic compounds such as ethanol, halogenated silicon compounds such as SiCl4, and halogen gases such as F2 and Cl2. The process and apparatus are particularly suitable for purifying exhaust gases discharged from a semiconductor production device.

Owner:EBARA CORP

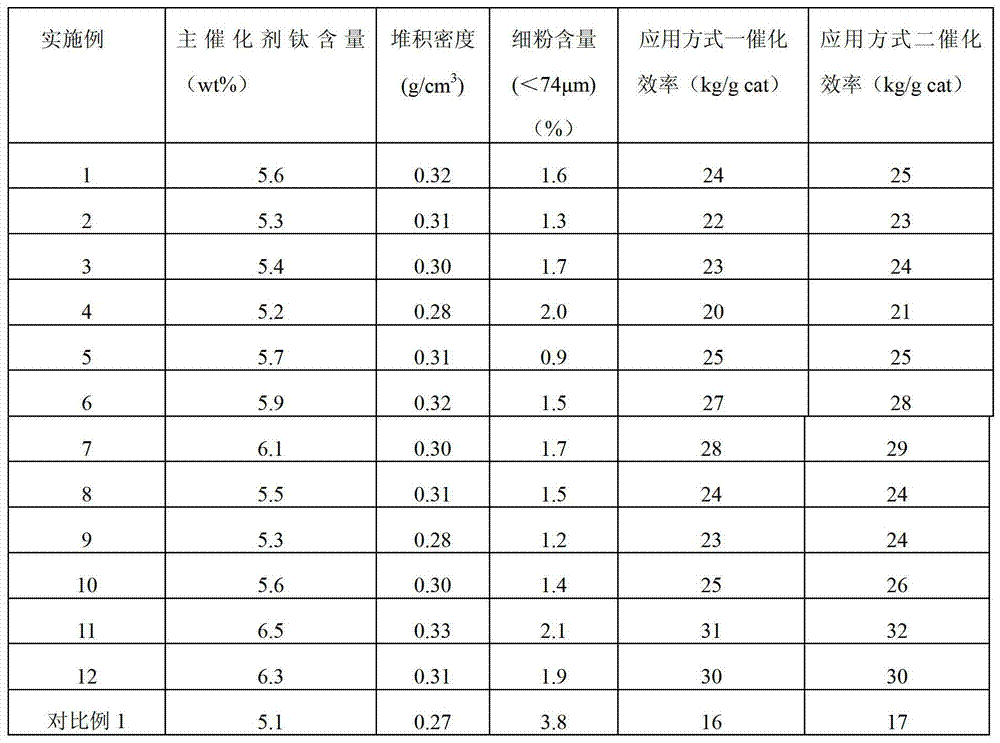

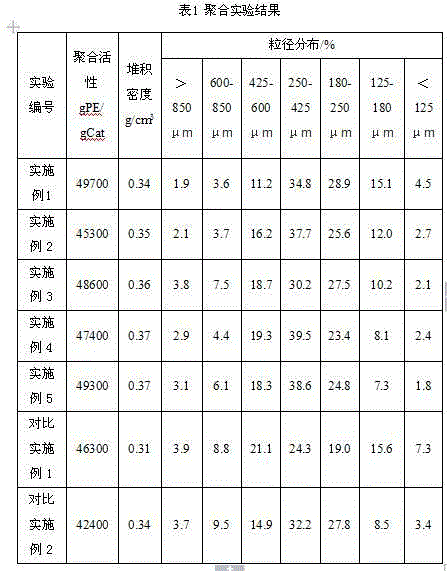

Loaded type polyolefin catalyst, preparation method and application

The invention relates to a loaded type polyolefin catalyst, a preparation method and an application, a main catalyst is composed of a carrier and a transition metal halide, a carrier is composed of a magnesium halide compound, a silicon halide compound, alcohol with carbon atoms number less than or equal to C5, and alcohol with carbon atoms number of C6-C20, wherein the mol ratio is 1: (0.1-20): (0.1-5): (0.01-10); the mol ratio of magnesium halide compound to transition metal halide is 1: (0.1-30); an organic alcohol ether compound is added during a preparation process of the main catalyst, wherein the mass ratio of the magnesium halide compound to the organic alcohol ether compound is 100: (0.1-20); and the mol ratio of the transition metal halide to cocatalyst in the main catalyst is 1:30-500. The catalyst has good particle form and uniform particle size distribution, the segmentation content of the obtained polymer through catalysis is low, the bulk density is high, and the loaded type polyolefin catalyst is suitable for an alkene slurry polymerization technology, gas phase polymerization technology or a combination polymerization technology.

Owner:PETROCHINA CO LTD

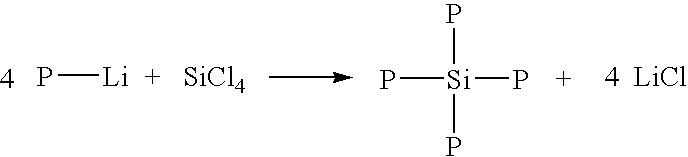

Process for improved coupling of rubbery polymers

Rubbery polymers made by anionic polymerization can be coupled with tin halides or silicon halides to improve the characteristics of the rubber for use in some applications, such as tire treads. In cases where the rubbery polymer was synthesized utilizing a polar modifier it is difficult to attain a high level of coupling. This invention is based upon the unexpected finding that coupling efficiency can be significantly improved by conducting the coupling reaction in the presence of a lithium salt of a saturated aliphatic alcohol, such as lithium t-amylate. This invention discloses a process for coupling a living rubbery polymer that comprises reacting the living rubbery polymer with coupling agent selected from the group consisting of tin halides and silicon halides in the presence of a lithium salt of a saturated aliphatic alcohol. The lithium salt of the saturated aliphatic alcohol can be added immediately prior to the coupling reaction or it can be present throughout the polymerization and coupling process. Lithium t-amylate reacts with water to form t-amyl alcohol during steam stripping. Since t-amyl alcohol forms an azeotrope with hexane, it co-distills with hexane and can contaminate recycle feed streams. This problem of recycle stream contamination can be solved by using metal salts of cyclic alcohols that do not co-distill with hexane or form compounds during steam stripping which co-distill with hexane. Thus, the use of metal salts of cyclic alcohols is preferred for this reason and because they are considered to be environmentally safe.

Owner:THE GOODYEAR TIRE & RUBBER CO

High yield method for preparing silicon nanocrystal with chemically accessible surfaces

InactiveUS7214599B2Material nanotechnologyPolycrystalline material growthPolysilicon halidesSilicon nanocrystal

Silicon nanocrystals with chemically accessible surfaces are produced in solution in high yield. Silicon tetrahalide such as silicon tetrachloride (SiCl4) can be reduced in organic solvents, such as 1,2-dimethoxyethane(glyme), with soluble reducing agents, such as sodium naphthalenide, to give halide-terminated (e.g., chloride-terminated) silicon nanocrystals, which can then be easily functionalized with alkyl lithium, Grignard or other reagents to give easily processed silicon nanocrystals with an air and moisture stable surface. The synthesis can be used to prepare alkyl-terminated nanocrystals at ambient temperature and pressure in high yield. The two-step process allows a wide range of surface functionality.

Owner:EVERGREEN SOLAR

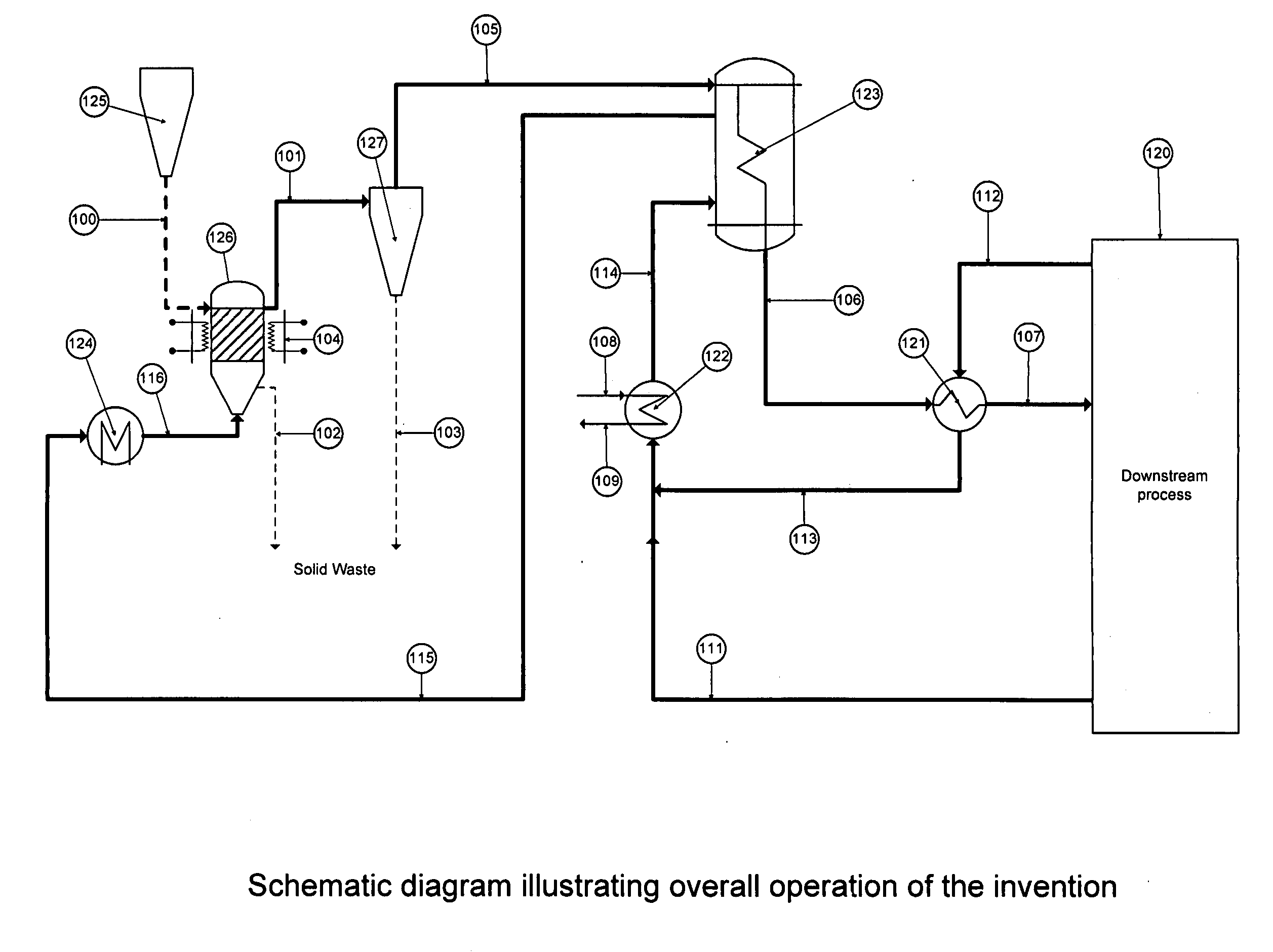

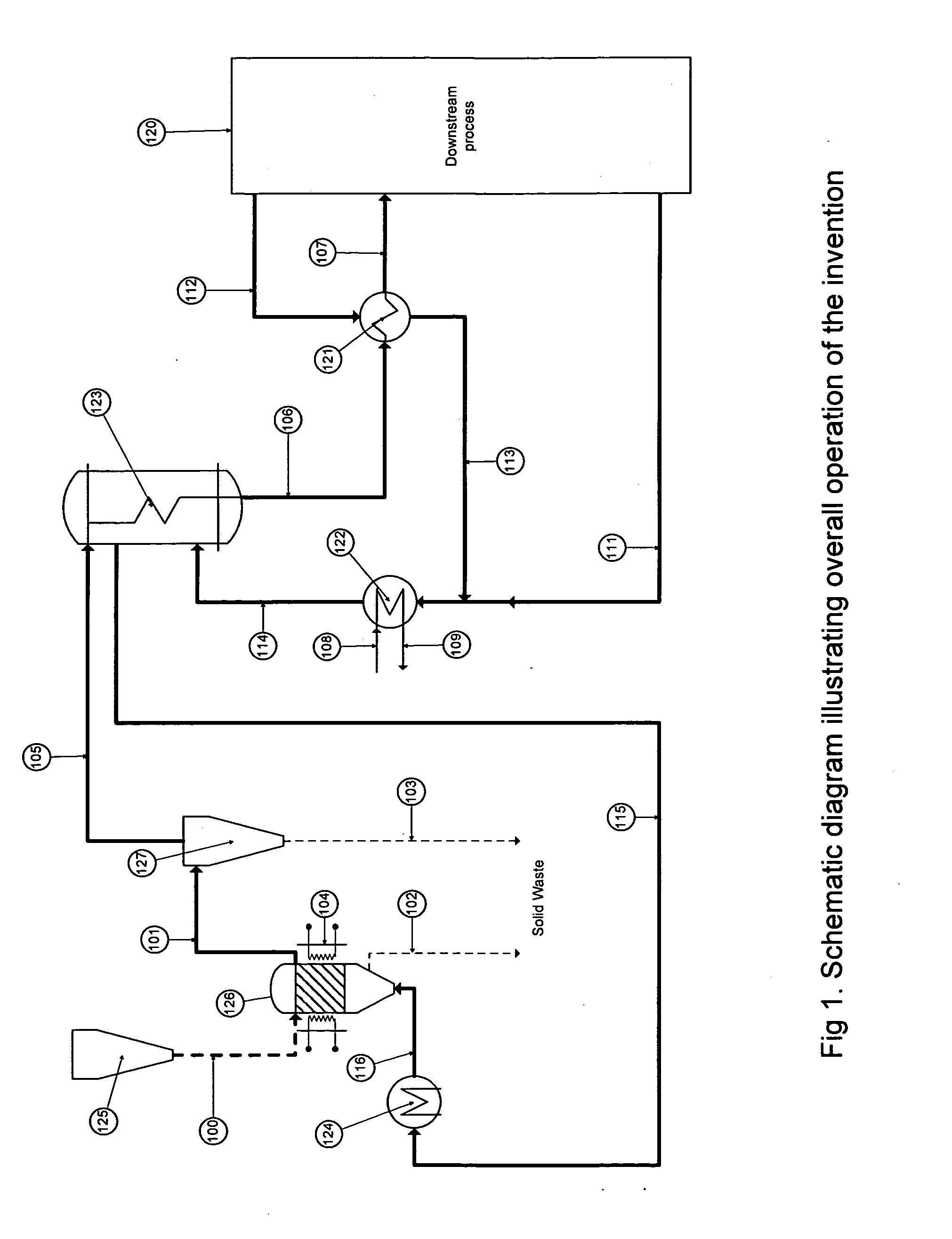

Apparatus and process for hydrogenation of a silicon tetrahalide and silicon to the trihalosilane

ActiveUS8178051B2High yieldReduce manufacturing costFluidised-bed furnacesChemical/physical processesHydrogenPolysilicon halides

A reactor for hydrogenation of a silicon tetrahalide and metallurgical grade silicon to trihalosilane includes a bed of metallurgical silicon particles, one or more gas entry ports, one or more solids entry ports, one or more solids drains and one or more ports for removing the trihalosilane from the reactor. Fresh surfaces are generated on the bed particles by internal grinding and abrasion as a result of entraining feed silicon particles in a silicon tetrahalide / hydrogen feed stream entering the reactor and impinging that stream on the bed of silicon particles. This has the advantages of higher yield of the trihalosilane, higher burnup rate of the MGS, removal of spent MGS as a fine dust carryover in the trihalosilane effluent leaving the reactor and longer times between shutdowns for bed removal.

Owner:LORD LTD LP

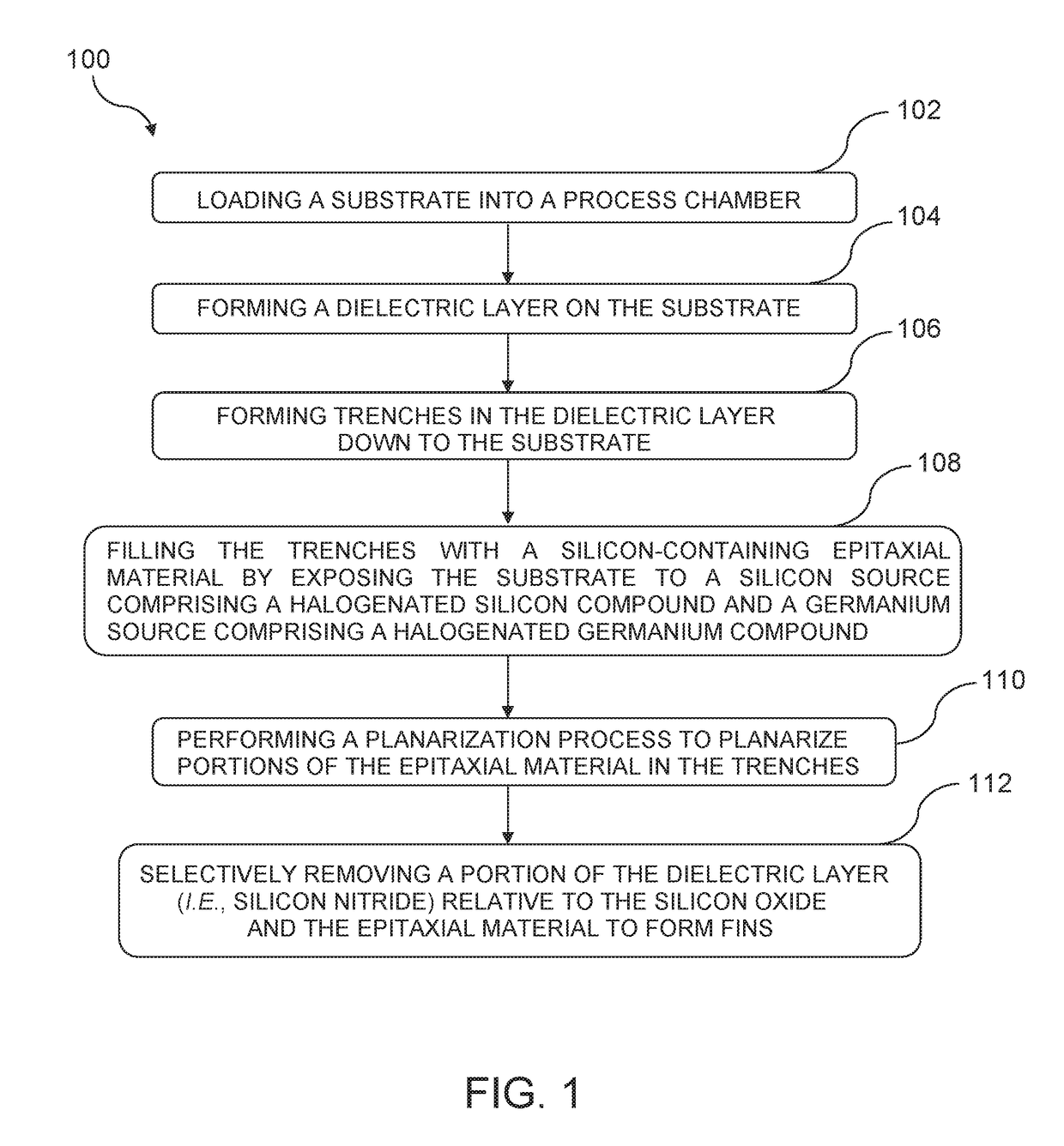

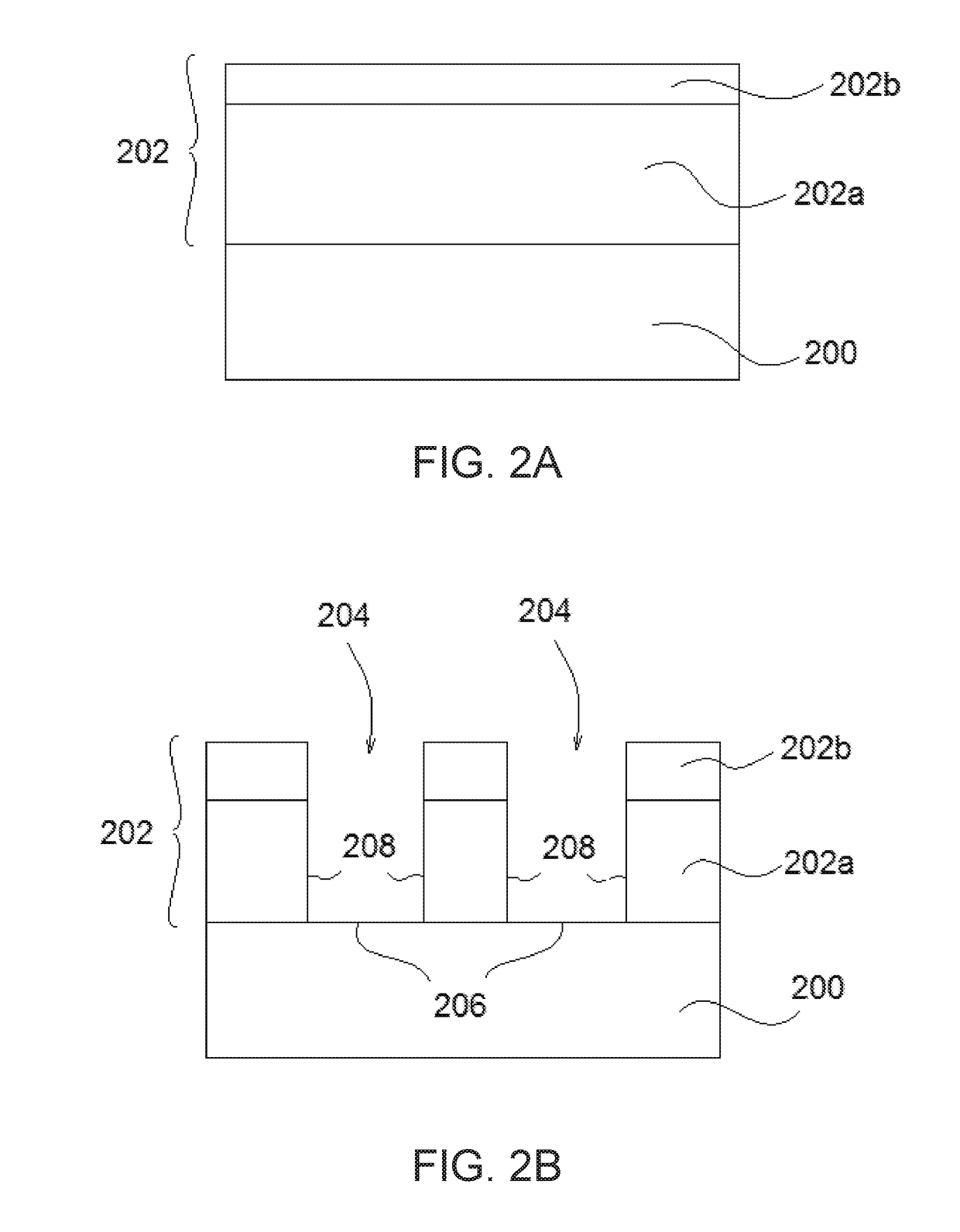

Method of selective epitaxy

InactiveUS20180047569A1Semiconductor/solid-state device manufacturingSemiconductor devicesSilanesPolysilicon halides

Owner:APPLIED MATERIALS INC

Process for hydrogenation of a silicon tetrahalide and silicon to trihalosilane

InactiveUS20120171100A1High yieldReduce manufacturing costChemical/physical processesHalogenated silanesParticulatesHydrogen

Owner:LORD STEPHEN MICHAEL

Dendrimers of rubbery polymers

InactiveUS20070010629A1Polymer/filler interactionGood processing characteristicsSpecial tyresWheelsPolymer scienceAlcohol

This invention discloses a process for synthesizing a dendrimer of a rubbery polymer comprising: (a) reacting a lithium terminated rubbery polymer with a halogenated silicon containing compound to produce a polymer which is terminated with halogenated silicon moieties, wherein the halogenated silicon contain compound has at least four halogen atoms which are bonded directly to silicon atoms, wherein the ratio of the lithium terminated rubbery polymer to halogen atoms in the halogenated silicon containing compound is within the range of 2:n to (n-1):n, wherein n represents the number of halogen atoms that are bonded directly to silicon atoms in the halogenated silicon containing compound, wherein the halogenated silicon containing compound contains at least three halogen atoms which are bonded directly to a silicon atom; (b) reacting the polymer which is terminated with halogenated silicon moieties with a molar excess of a tertiary alcohol to produce a polymer which is terminated with hydroxy silyl moieties; and (c) allowing the polymer which is terminated with the hydroxy silyl moieties to couple under conditions sufficient to produce a dendrimer containing siloxane linkages. It has also be found that similar dendrimers having improved processability can be make utilizing halogenated tin containing compounds in stead of the halogenated silicon containing compound.

Owner:THE GOODYEAR TIRE & RUBBER CO

Method for Generating Free Radical Capable Polymers Using Tin or Silicon Halide Compounds

Provided is a method comprising reacting the anionic living end of a polymer with a compound selected from the group consisting of tin halides and silicon halides to produced a polymer with a homolytically cleavable group containing a Sn—C bond or a Si—C bond. An engineered plastic may then be produced by adding the polymer containing a homolytically cleavable group containing a Sn—C bond or a Si—C bond to a solvent comprising at least one vinyl monomer; (b) optionally adding at least one additional inert solvent; (c) optionally adding additives selected from the group consisting of extender oils, modifiers, and antioxidants; and (d) initiating polymerization of the at least one vinyl monomer by the use of an initiator and / or heat, wherein a free radical is produced from the polymer containing a homolytically cleavable group containing a Sn—C bond or a Si—C bond.

Owner:BRIDGESTONE CORP

Method for producing aryl-functional silanes

ActiveUS10081643B2More economical method of producing halosilanesReduce and avoidGroup 4/14 element organic compoundsCatalyst regeneration/reactivationPtru catalystSilicon alloy

A method for preparing a reaction product including an aryl-functional silane includes sequential steps (1) and (2). Step (1) is contacting, under silicon deposition conditions, (A) an ingredient including (I) a halosilane such as silicon tetrahalide and optionally (II) hydrogen (H2); and (B) a metal combination comprising copper (Cu) and at least one other metal, where the at least one other metal is selected from the group consisting of gold (Au), cobalt (Co), chromium (Cr), iron (Fe), magnesium (Mg), manganese (Mn), nickel (Ni), palladium (Pd), and silver (Ag); thereby forming a silicon alloy catalyst comprising Si, Cu and the at least one other metal. Step (2) is contacting the silicon alloy catalyst and (C) a reactant including an aryl halide under silicon etching conditions.

Owner:DOW SILICONES CORP

Method for Preparing a Diorganodihalosilane

InactiveUS20130066096A1Good choiceLess energySilicon organic compoundsCatalyst activation/preparationPtru catalystPolysilicon halides

A method of preparing a diorganodihalosilane comprising the separate and consecutive steps of (i) contacting a copper catalyst with a mixture comprising hydrogen gas and a silicon tetrahalide at a temperature of from 500 to 1400° C. to form a silicon-containing copper catalyst comprising at least 0.1% (w / w) of silicon, wherein the copper catalyst is selected from copper and a mixture comprising copper and at least one element selected from gold, magnesium, calcium, cesium, tin, and sulfur; and (ii) contacting the silicon-containing copper catalyst with an organohalide at a temperature of from 100 to 600° C. to form at least one diorganodihalosilane.

Owner:DOW SILICONES CORP

Method For Producing Aryl-Functional Silanes

ActiveUS20170275306A1Reduce and avoid needMore economical method of producing halosilanesGroup 4/14 element organic compoundsCatalyst regeneration/reactivationPtru catalystSilicon alloy

A method for preparing a reaction product including an aryl-functional silane includes sequential steps (1) and (2). Step (1) is contacting, under silicon deposition conditions, (A) an ingredient including (I) a halosilane such as silicon tetrahalide and optionally (II) hydrogen (H2); and (B) a metal combination comprising copper (Cu) and at least one other metal, where the at least one other metal is selected from the group consisting of gold (Au), cobalt (Co), chromium (Cr), iron (Fe), magnesium (Mg), manganese (Mn), nickel (Ni), palladium (Pd), and silver (Ag); thereby forming a silicon alloy catalyst comprising Si, Cu and the at least one other metal. Step (2) is contacting the silicon alloy catalyst and (C) a reactant including an aryl halide under silicon etching conditions.

Owner:DOW SILICONES CORP

Method for purifying silicon compounds

PendingCN114258396AGroup 4/14 element organic compoundsSilicon compoundsActivated carbonPolysilicon halides

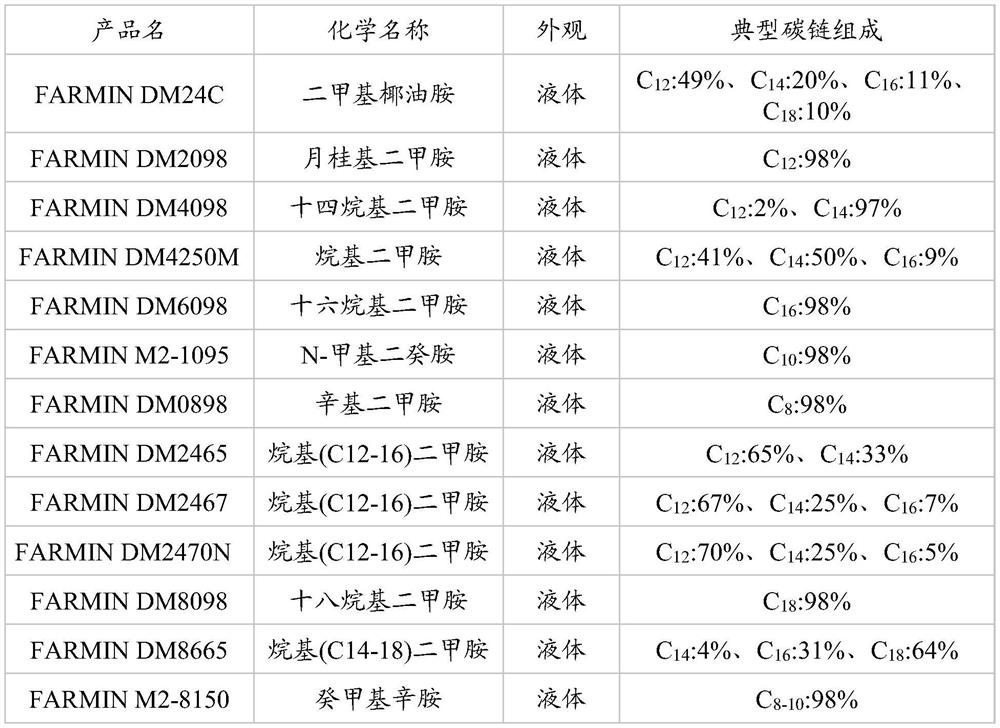

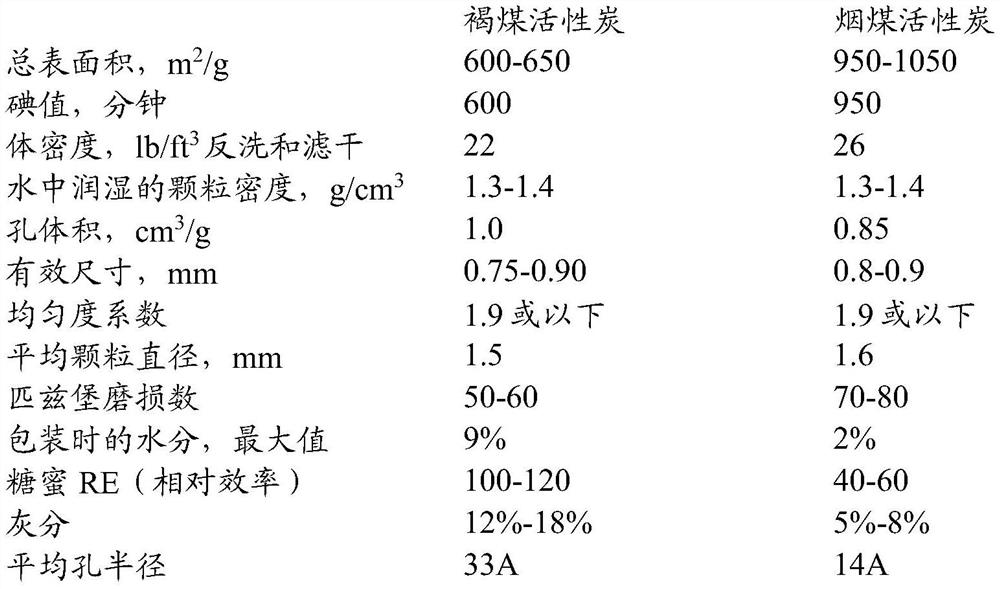

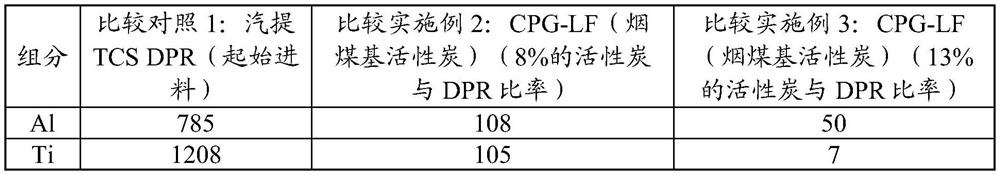

A method for removing metal impurities from silicon halide compounds such as chlorosilane monomers and / or chlorinated polysilanes is disclosed. The process involves treating a silicon halide compound with a tertiary amine and subsequently with a suitable grade of activated carbon.

Owner:DOW SILICONES CORP

Catalyst system for producing ethylene (co) polymer with improved branch distribution

ActiveUS20080132406A1Improved branching compositional distributionSuitably producedSilicon organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsPolymer sciencePtru catalyst

A process for synthesizing a catalyst component for manufacturing ethylene polymer and co-polymer. The present invention provides a process for synthesizing catalyst component (A), comprising forming a complex by contacting the solid intermediate (B) with an aluminum compound represented by formula X3-nAl(OY)n, and alkyl metal (C), wherein X is halide, Y is a hydrocarbon group or chelating carbonyl group, and wherein 1 is less than or equal to n which is less than or equal to 3, and then contacting the complex with titanium halide having formula TiX4 wherein X is halide. Solid intermediate (B) is formed by reacting magnesium metal with alkyl halide in the presence of alkoxy aluminum represented by formula Al(ORa)3, silicon halide represented by formula SiX4 and alkoxy silane represented by formula Si(ORb)4, wherein Ra and Rb are an aromatic or aliphatic alkyl group and wherein X is halide. Alkyl metal (C) is synthesized by reacting alkyl aluminum compounds represented by formula AlRc3 with a secondary amine having formula HNRd2 and then by reacting with alkyl magnesium compounds represented by formula ReMgRf, wherein Rc, Rd, Re and Rf are an aromatic or aliphatic alkyl group. The catalyst component is suitable for producing ethylene polymer and co-polymer with narrow molecular weight distribution as well as improved branching compositional distribution.

Owner:FORMOSA PLASTICCS CORP

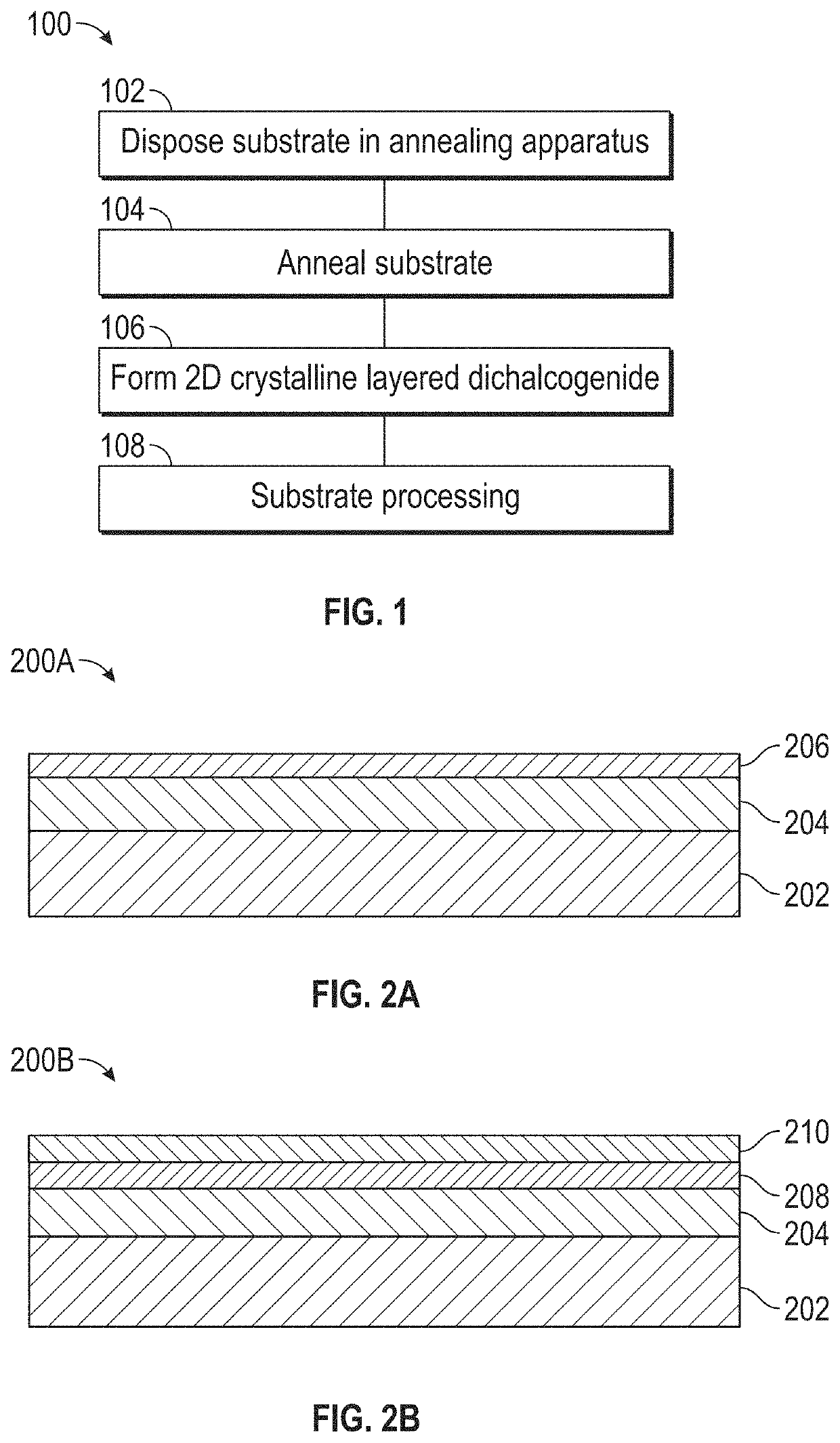

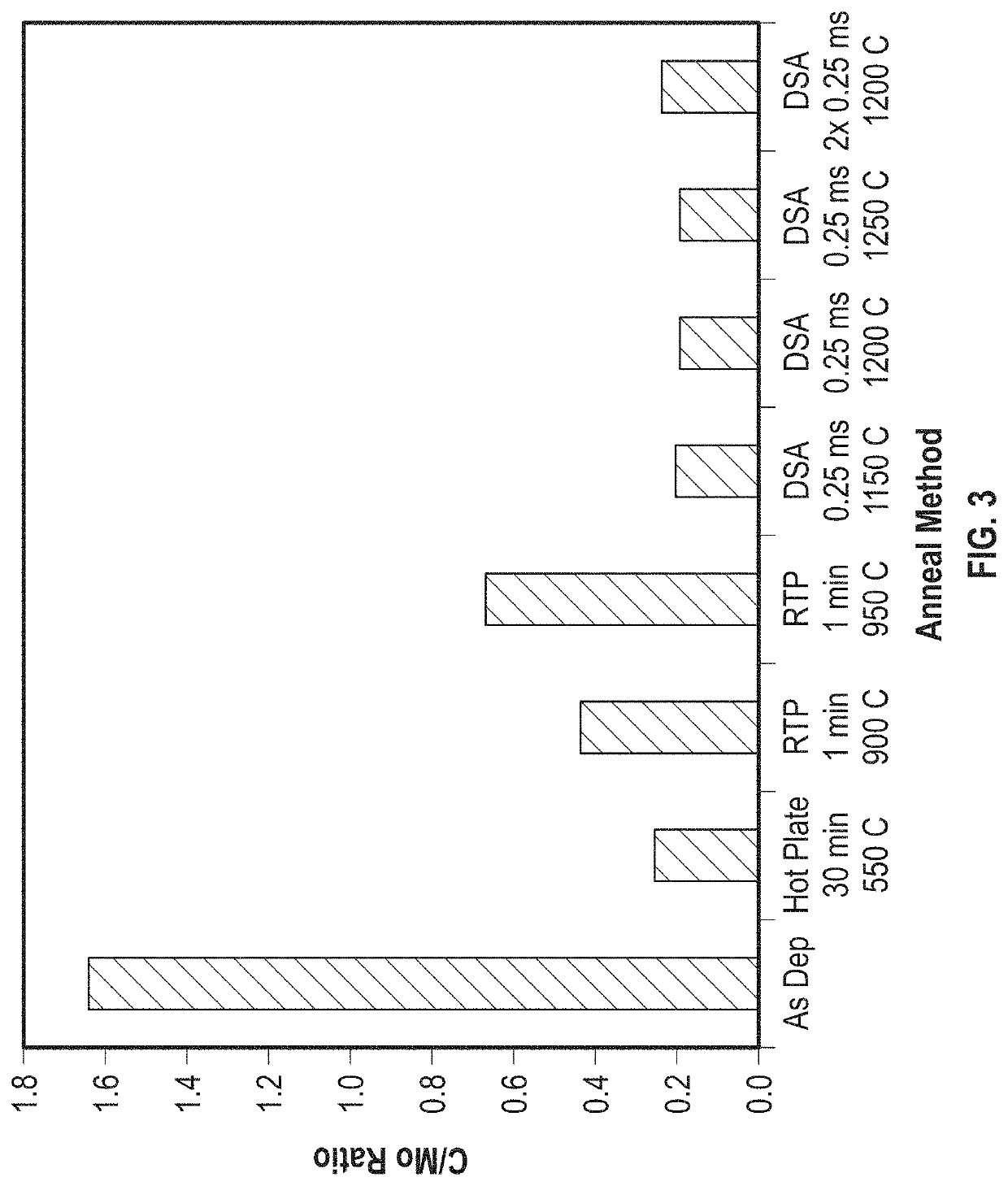

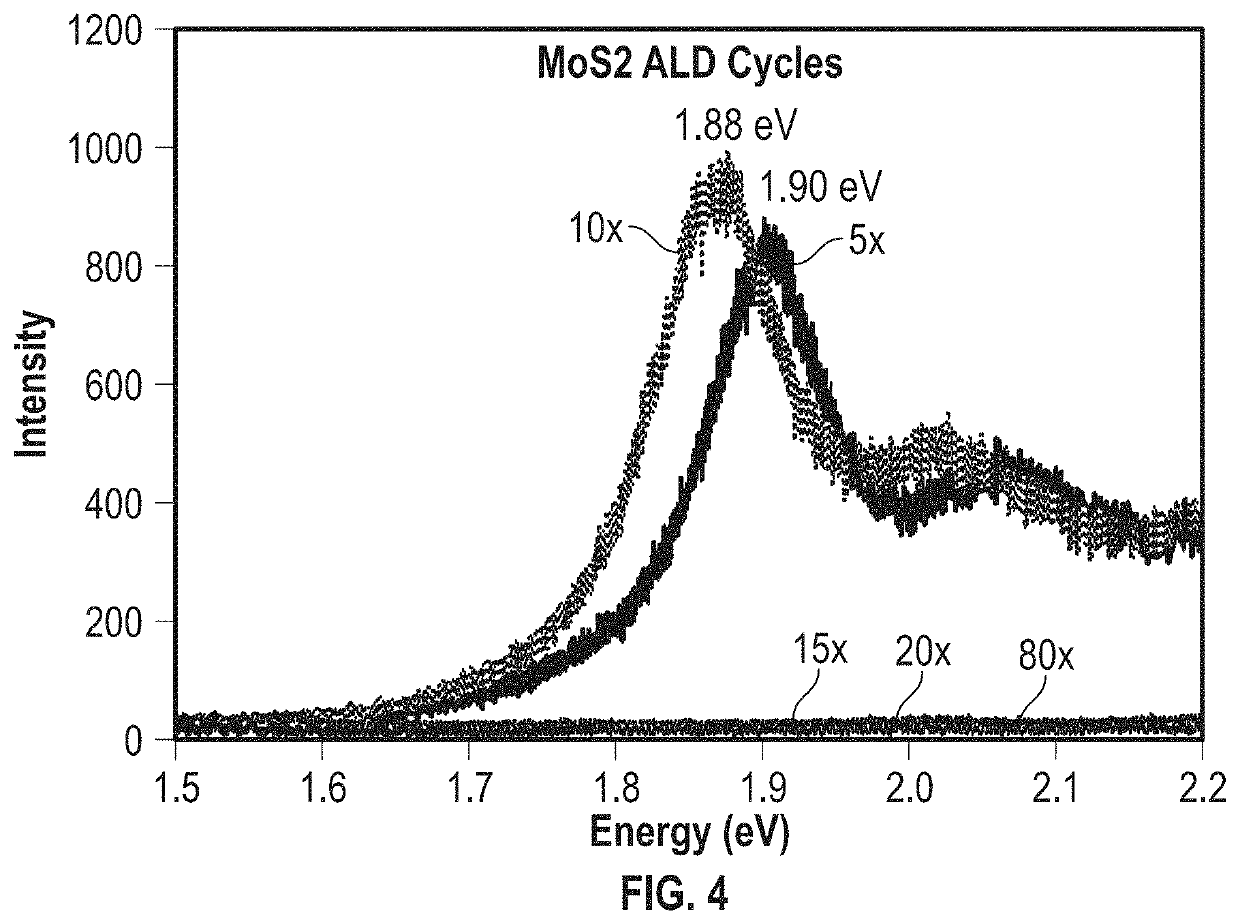

Formation of crystalline, layered transition metal dichalcogenides

ActiveUS10916426B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingPolysilicon halidesMaterials science

Embodiments of the present disclosure relate to forming a two-dimensional crystalline dichalcogenide by positioning a substrate in an annealing apparatus. The substrate includes an amorphous film of a transition metal and a chalcogenide. The film is annealed at a temperature from 500° C. to 1200° C. In response to the annealing, a two-dimensional crystalline structure is formed from the film. The two-dimensional crystalline structure is according to a formula MX2, M includes one or more of molybdenum (Mo) or tungsten (W) and X includes one or more of sulfur (S), selenium (Se), or tellurium (Te).

Owner:APPLIED MATERIALS INC

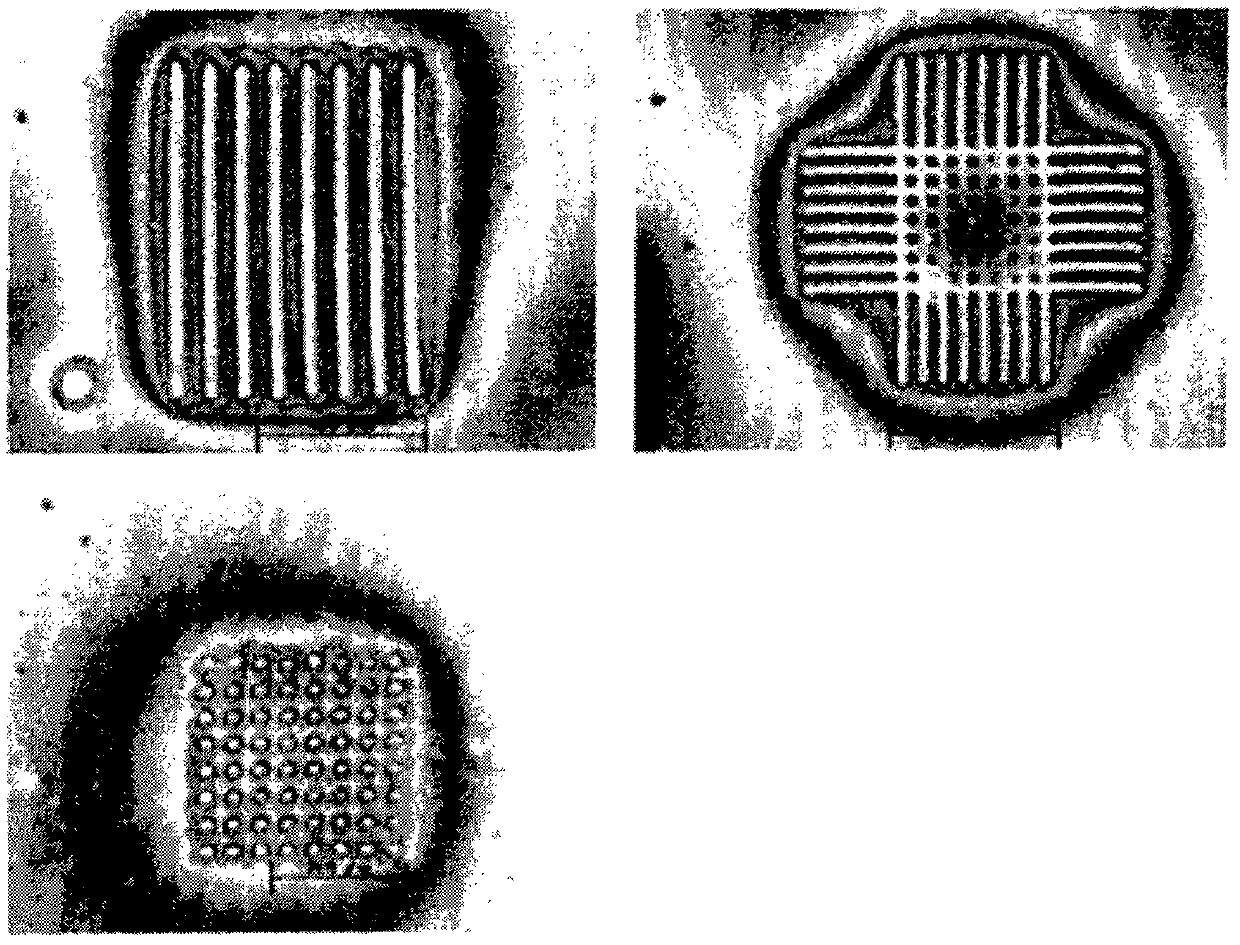

Composite pore molecular sieve and preparation method thereof

The invention discloses a composite hole molecular sieve and a preparation method thereof. The preparation method of the composite hole molecular sieve comprises the following steps: (1) making a molecular sieve be in contact with a reagent containing silicon tetraauragen or ammonium fluorosilicate to form a pretreatment molecular sieve; (2) making the pretreatment molecular sieve be in contact with a first alkali solution to form a primary treatment molecular sieve; (3) making the primary treatment molecular sieve be in contact with a second alkali solution, cleaning pore canals of a preparedproduct with an acid solution, and performing calcining to obtain the composite hole molecular sieve. By adopting the method, a part close to the surface of the molecular sieve can be formed into a mesoporous-microporous composite structure, and a part far away from the surface of the molecular sieve can be formed into a microporous structure.

Owner:BAOTOU RES INST OF RARE EARTHS +1

Method for preparing a halosilane

ActiveUS9688703B2More economical method of producing halosilanesReduce and avoidSilicon organic compoundsCatalyst activation/preparationPtru catalystHalogen

A method for preparing a reaction product includes: steps (1) and (2). Step (1) is contacting, at a temperature from 200° C. to 1400° C., a first ingredient including a silane of formula HaRbSiX(4-a-b), where subscript a is an integer from 0 to 4, subscript b is 0 or 1, a quantity (a+b)<4, each R is independently a monovalent organic group, and each X is independently a halogen atom, with the proviso that when the quantity (a+b)<4, then the ingredient further includes H2; with a spinel catalyst including copper; thereby forming a reactant. Step (2) is contacting the reactant with a second ingredient including an organohalide at a temperature from 100° C. to 600° C.; thereby forming the reaction product and a spent reactant. The reaction product is distinct from the silane used in step (1). The method may be used to prepare diorganodihalosilanes from silicon tetrahalides.

Owner:DOW SILICONES CORP

Pattern formation method, pattern, and device

Disclosed is a pattern formation method comprising: a first step of arranging at least one silane compound selected from the group consisting of silicon hydride compounds and silicon halide compounds in a gap formed between a substrate and a pattern-shaped mold; and a second step of applying at least one treatment selected from a heat treatment and an ultraviolet ray radiation treatment to the arranged silane compound. When the second step is carried out under an inert atmosphere or a reductive atmosphere, a pattern comprising silicon can be formed. When at least a part of the second step is carried out under an oxygen-containing atmosphere, a pattern comprising a silicon oxide can be formed.

Owner:JAPAN SCI & TECH CORP

Silicon isocyanate composition and method for producing same

PendingCN114174307ALow costGroup 4/14 element organic compoundsSilicon oxidesPolymer sciencePolysilicon halides

Provided is a method for producing a silicon isocyanate compound-containing composition having a high purity of a monomer of a silicon isocyanate compound at an industrial grade and at low cost. A composition containing a silicon isocyanate compound is produced by reacting a silicon halide compound with a cyanate or isocyanate in the presence of a solvent and an alkanediol compound by a method comprising the following steps (A) to (D): (A) a step of mixing the cyanate or isocyanate, an azeotropic solvent, the alkanediol compound, and the solvent to produce a liquid; (B) a step of heating the liquid to remove water and the azeotropic solvent; (C) a step of adding the silicon halide compound to the liquid to generate the silicon isocyanate compound; and (D) a step of heating the liquid to distil and recover the silicon isocyanate compound.

Owner:松本精密化学株式会社

Catalyst additive and catalyst for olefin polymerization

ActiveCN104140482AParticles in good shapeHigh polymerization activityPtru catalystPolysilicon halides

The invention relates to a titanium family olefin polymerization catalyst additive, a catalyst comprising the titanium family olefin polymerization catalyst additive and the application of the catalyst. A preparing method comprises the steps that (1) magnesium halide is dissolved in an inert organic solvent and is in contact with alcoholic compounds, phenol compounds and a titanate mixture, and a magnesium compound solution is obtained; (2) silicon halide is in contact with the magnesium compound solution prepared in the step (1) to prepare spherical solid body particulate matter; and the spherical solid body particulate matter prepared in the step (2) is dispersed in the inert organic solvent, a titanium tetrachloride solution is added in a dripping mode, filtering, washing and drying are carried out, and the catalyst additive is obtained. The catalyst comprising the additive and a promoter is used for olefins, especially in vinyl polymerization. The olefin polymerization catalyst is good in particle morphology, high in polymerization activity and suitable for a slurry process or a vapor phase polymerization technology or a combination polymerization technology.

Owner:ZIBO XINSU CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com