Method for purifying silicon compounds

A technology for silicon compounds and mixtures, which is applied in the fields of silicon compounds, chemical instruments and methods, and compounds of elements of Group 4/14 of the periodic table, etc., can solve the problems of the reactivity of halogenated silanes and high-boiling components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0062] These examples are intended to illustrate the invention to those skilled in the art and are not to be construed as limiting the scope of the invention described in the claims.

[0063] Reference example 1-dry activated carbon

[0064] Activated carbon samples received from suppliers contained varying concentrations of moisture. To reduce the risk of water reacting with chlorosilane starting materials and forming HCl vapor and siloxane gels, all activated carbon samples were continuously dried in a vacuum oven at 160 °C for 24 h before use. Once dry, the activated carbon samples were removed from the oven and placed in jars. The jar was then stored in a glove box kept at very low moisture content.

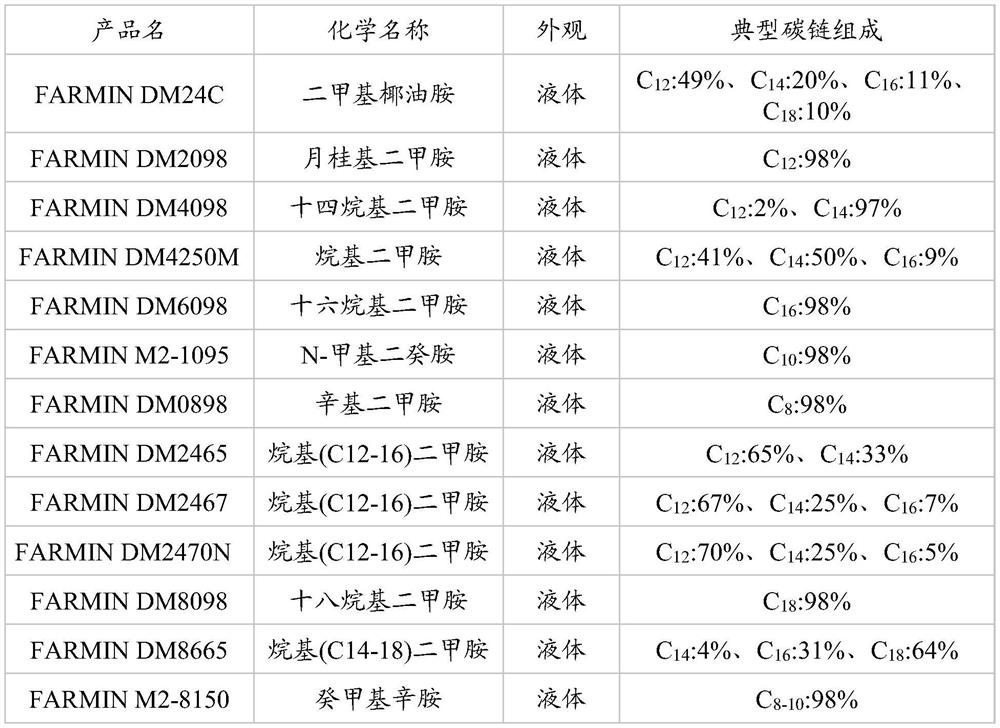

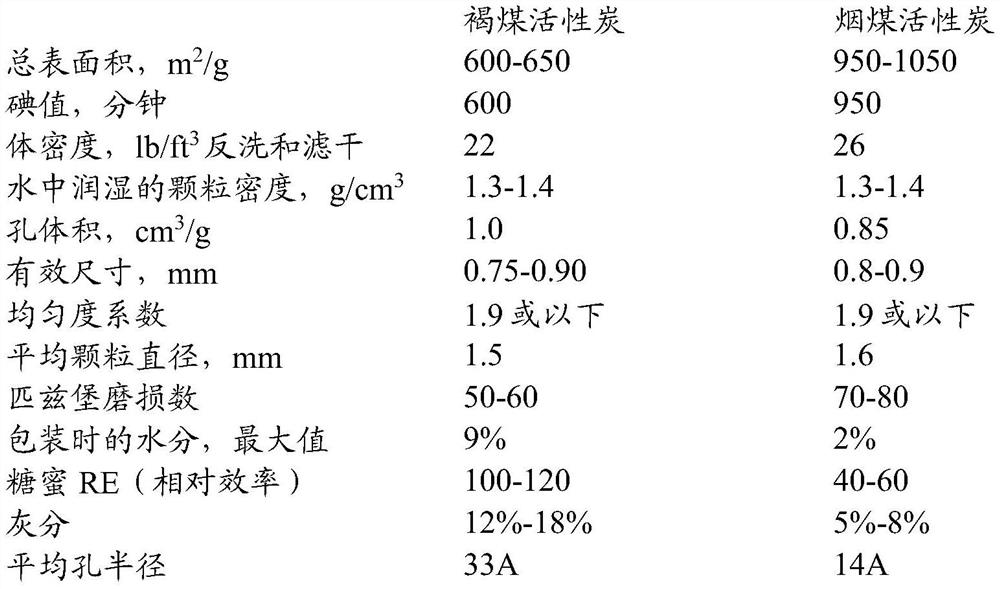

Embodiment 2- 1

[0065] Example 2 - General procedure

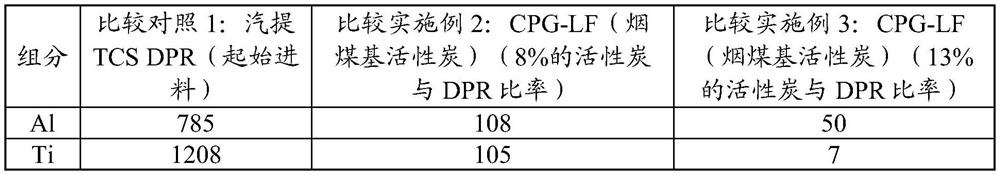

[0066] TCS DPR was stripped and then activated carbon with CPG-LF 12x40 (bituminous coal-based activated carbon from Calgon Carbon Corporation of Pittsburgh, Pennsylvania, USA) and Darco Li 12x20 (Cabot Corporation) ) of lignite-based activated carbon), both of which had been dried as described in Reference Example 1. Two different levels of solids (activated carbon) to liquid mass (direct process residue) ratio were used, namely 8% and 13%. Activated carbon was weighed and added to a glass vial inside the glove box. DPR was then added to the vial.

[0067] Once the DPR addition was complete, the vial was removed from the glove box. Wrap a strip of parafilm over the vial cap to reduce leakage of material from the top. The vial was then placed on a vortex mixer in a fume hood and allowed to shake for 24 hours.

[0068] After 24 hours, the shaken vials were returned to the glove box. Filter the contents of the vial using a syringe a...

Embodiment 3- 1

[0074] Example 3 - General procedure

[0075] TCS DPR stripped as described in Reference Example 1 was treated with triethylamine (TEA). TEA was first added to TCSDPR (0.5% TEA / 99.5% TCS DPR, see Table 3; or 0.25% TEA / 99.75% TCS DPR, see Table 4), and the resulting TEA-treated DPR was evaluated by ICP (see Table 3 and Comparative Example 6 and Comparative Example 9 in Table 4).

[0076] The resulting TEA-treated DPR was then used as a masterbatch for carbon adsorption treatment using the mass ratios of activated carbon to TCS DPR as shown in Tables 3 and 4. Activated carbon was weighed and added to a glass vial inside the glove box. TCS DPR was then added to the vial.

[0077]Once the TCS DPR addition was complete, the vial was removed from the glove box. Wrap a strip of parafilm over the vial cap to reduce leakage of material from the top. The vial was then placed on a vortex mixer in a fume hood and allowed to shake for 24 hours.

[0078] After 24 hours, the shaken v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com