Catalyst additive and catalyst for olefin polymerization

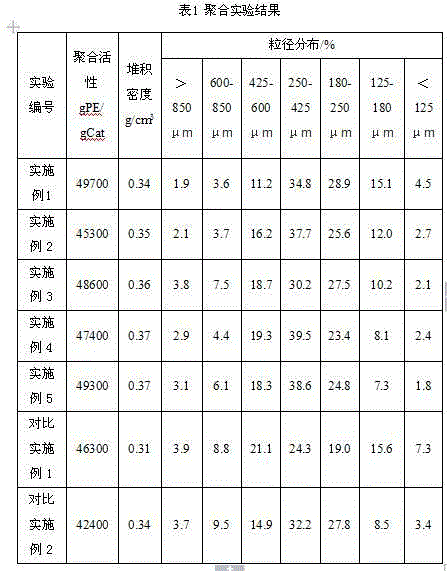

An olefin polymerization and catalyst technology, which is applied in the field of olefin polymerization catalysts, can solve the problems of high polymer fine powder, low bulk density, high production cost and environmental protection pressure, etc., and achieves the effects of good particle shape and high polymerization activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1) Precursor preparation: Add 4.8g MgCl to 200ml decane in a reactor fully replaced by nitrogen 2 (0.05mol), stirred and dissolved at 0°C for 1h, then added 18.4 g C 2 h 5 OH (0.4mol), the temperature was raised to 70°C under stirring, and the temperature was maintained for 3h; 7.6 g Ti(OC 2 h 5 ) 4(0.033mol), 2.7g o-cresol (0.025mol), continue the reaction for 1h, then cool down to 5°C, and slowly add 22.44g SiCl dropwise at 5°C 4 (0.132mol), then raise the temperature within 0.5 h, raise the temperature to 70°C at a constant speed, and maintain the reaction at a constant temperature of 70°C for 2 h, stop stirring, let the precipitation stand for 0.5 h, filter while it is hot, wash with hexane 3 times, and dry to obtain a solid particles.

[0029] 2) Catalyst additive preparation: Take 5g of the solid particles obtained above, disperse them in 100ml of decane, add 20ml of TiCl dropwise at -10°C 4 , and maintain the reaction at -10°C for 0.5h, then raise the tempe...

Embodiment 2

[0034] 1) Precursor preparation: Add 4.8g MgCl to 200ml decane in a reactor fully replaced by nitrogen 2 (0.05mol), stirred and dissolved at 30°C for 3h, then added 13.8 g C 2 h 5 OH (0.3mol), heated to 70°C with stirring, and kept at constant temperature for 3h; 7.6 g Ti(OC 2 h 5 ) 4 (0.033mol), 2.7g o-cresol (0.025mol), after continuing the reaction for 1h, the temperature was lowered to 5°C, and 22.44 g SiCl was slowly added dropwise at 5°C 4 (0.132mol), and then within 0.5 h, the temperature was raised at a constant speed to 70 ° C, and the reaction was maintained at a constant temperature of 70 ° C for 2 h, the stirring was stopped, and the precipitation was allowed to stand for 0.5 h, filtered while it was hot, washed 3 times with hexane, and dried to obtain a solid particles.

[0035] 2) Catalyst additive preparation: Take 5g of the solid particles obtained above, disperse them in 100ml of decane, add 20ml of TiCl dropwise at -10°C 4 , and maintain the reaction at...

Embodiment 3

[0038] 1) Precursor preparation: Add 4.8g MgCl to 200ml decane in a reactor fully replaced by nitrogen 2 (0.05mol), stirred and dissolved at 60°C for 6h, then added 19.5 g of isooctyl alcohol (0.15mol), heated to 100°C with stirring, kept at a constant temperature for 3h; added dropwise 7.6 g of Ti(OC 2 h 5 ) 4 (0.033mol), 2.7g o-cresol (0.025mol), continue to react for 1h, then cool down to 15°C, and slowly add 22.44g SiCl dropwise at 15°C 4 (0.132mol), then within 0.5 h, the temperature was raised to 80°C at a constant rate, and the reaction was maintained at a constant temperature of 80°C for 2 h, the stirring was stopped, and the precipitation was allowed to stand for 0.5 h, filtered while hot, washed 3 times with hexane, and dried to obtain solid particles .

[0039] 2) Catalyst additive preparation: Take 5g of the solid particles obtained above, disperse them in 100ml of decane, add 20ml of TiCl dropwise at -10°C 4 , and maintain the reaction at -10°C for 0.5h, then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com