Catalyst component for ethylene polymerization, and catalyst thereof

A technology of ethylene polymerization and catalyst, which is applied in the field of olefin polymerization, can solve the problems that the shape of polymer particles is not ideal and cannot fully meet the needs of industrial production, and achieve the effects of reducing the amount of addition, improving the sensitivity of hydrogen adjustment, and increasing the bulk density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

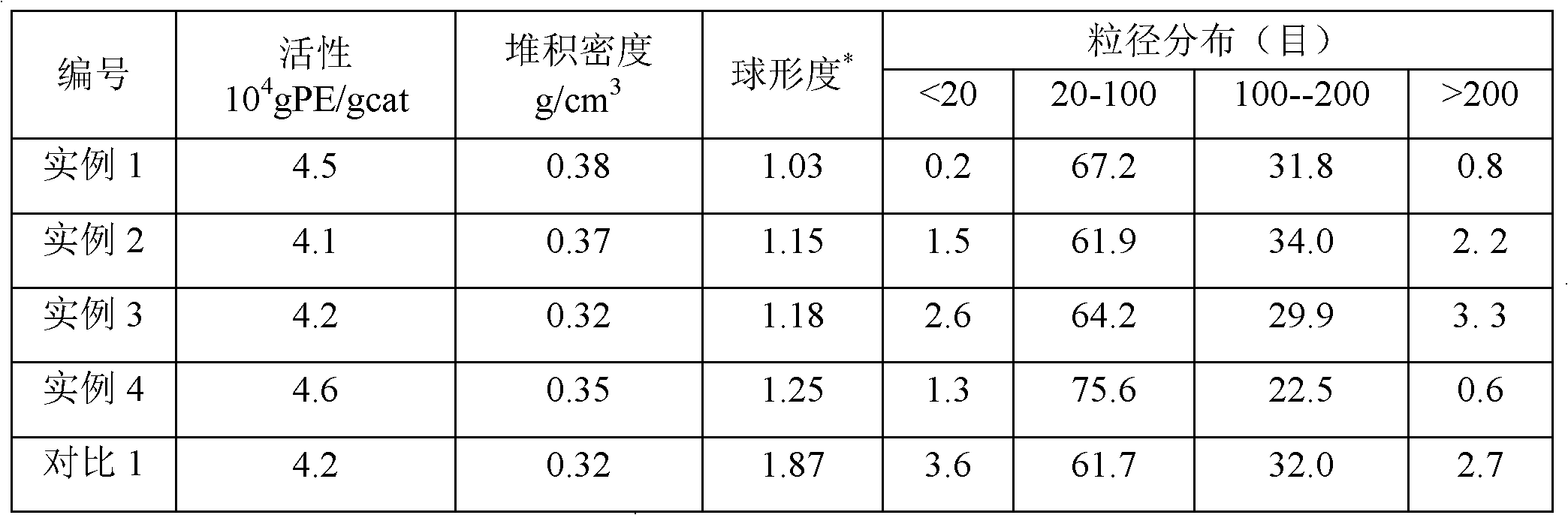

Examples

Embodiment 1

[0029] (1) Preparation of catalyst components: in the reactor fully replaced by high-purity nitrogen, add ethanol, magnesium powder and iodine successively, after reacting for about 6h, wash with toluene, dry to obtain white solid powder (specific implementation method See patent JP3074341). Take 6g of magnesium complex and add it to the reactor that has been fully replaced by high-purity nitrogen, then add 90ml of toluene, 5.0ml of epichlorohydrin, and 10.0ml of tributyl phosphate, and heat up to 70°C under stirring. When the solid is completely dissolved and forms a uniform The solution was reacted at 70°C for 1 hour. Then the system was cooled to -10°C, 80ml of titanium tetrachloride was slowly added dropwise, and then 5.0ml of ethyl orthosilicate was added to react for 1 hour. Slowly heat up to 80°C and react for 2 hours. Stop stirring, let it stand, the suspension will quickly separate into layers, remove the upper clear layer, wash twice with toluene, wash four times w...

Embodiment 2

[0033] (1) The synthesis of catalyst is the same as in Example 1. The amount of magnesium complex was changed to 5.0g, and the amount of ethyl orthosilicate was changed from 5.0ml to 4.0ml.

[0034] (2) Ethylene polymerization is with embodiment 1. Catalyst composition and polymerization results are shown in Table 1 and Table 2.

Embodiment 3

[0036] (1) The synthesis of catalyst is the same as in Example 1. The amount of magnesium complex was changed to 4.0g.

[0037] (2) Ethylene polymerization is with embodiment 1. Catalyst composition and polymerization results are shown in Table 1 and Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com