Patents

Literature

1339 results about "Ethylene polymerization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ethylene polymerization is the C−C bond formation reaction par excellence. It takes a volatile reactant, ethylene gas, and clips the so-called monomers together to form a polymer. A typical polyethylene chain may contain 1000's of monomers.

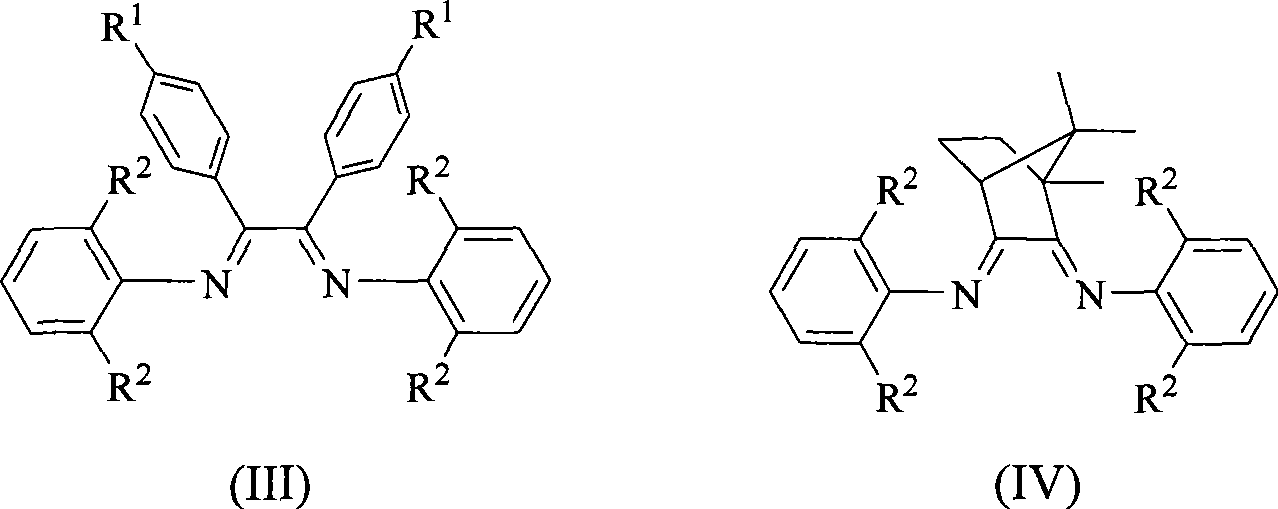

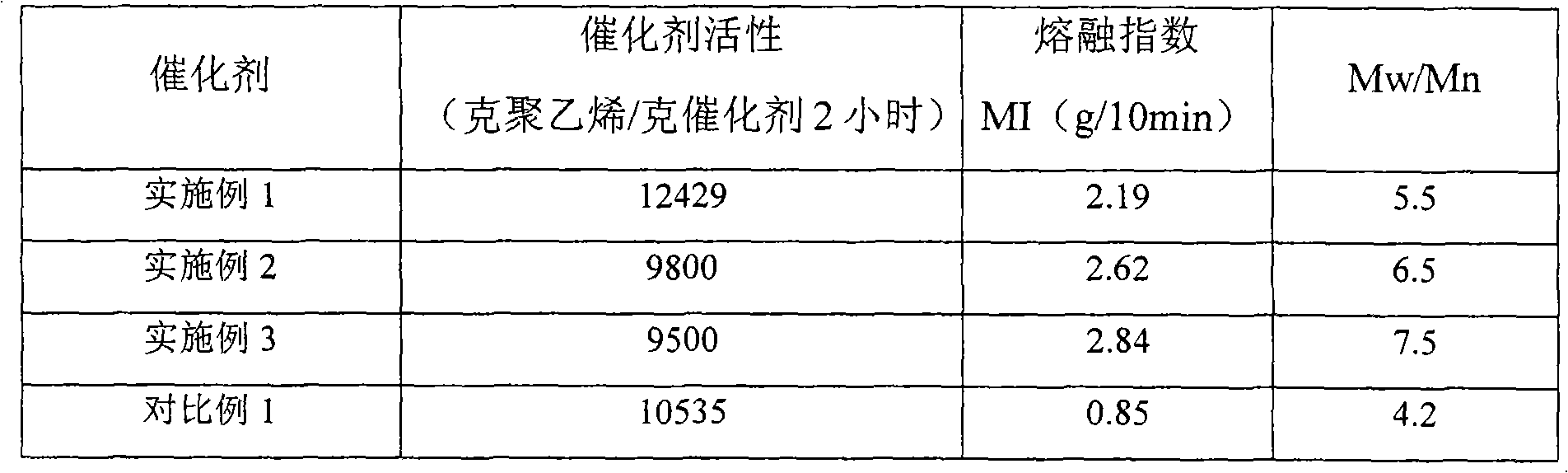

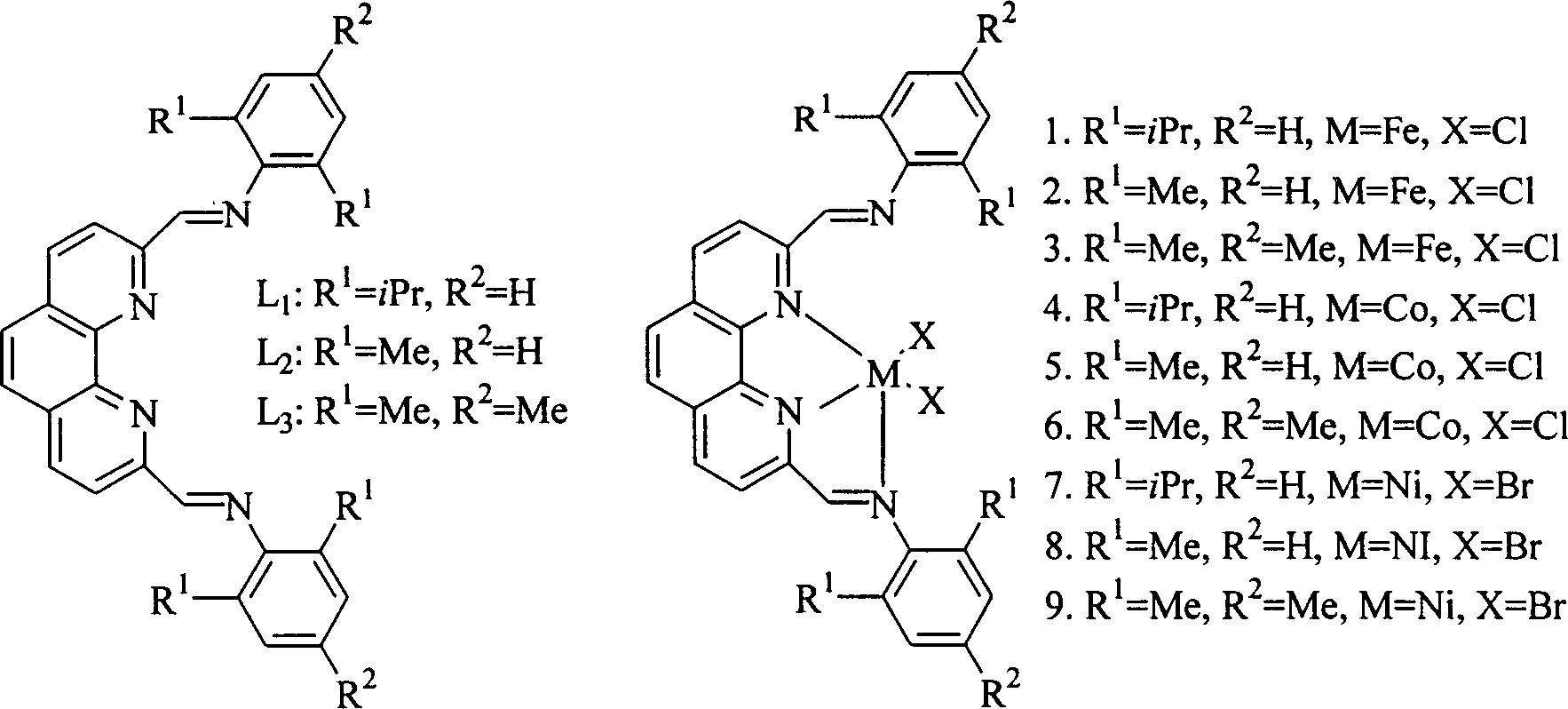

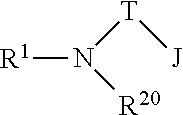

New olefine polymerization catalyst

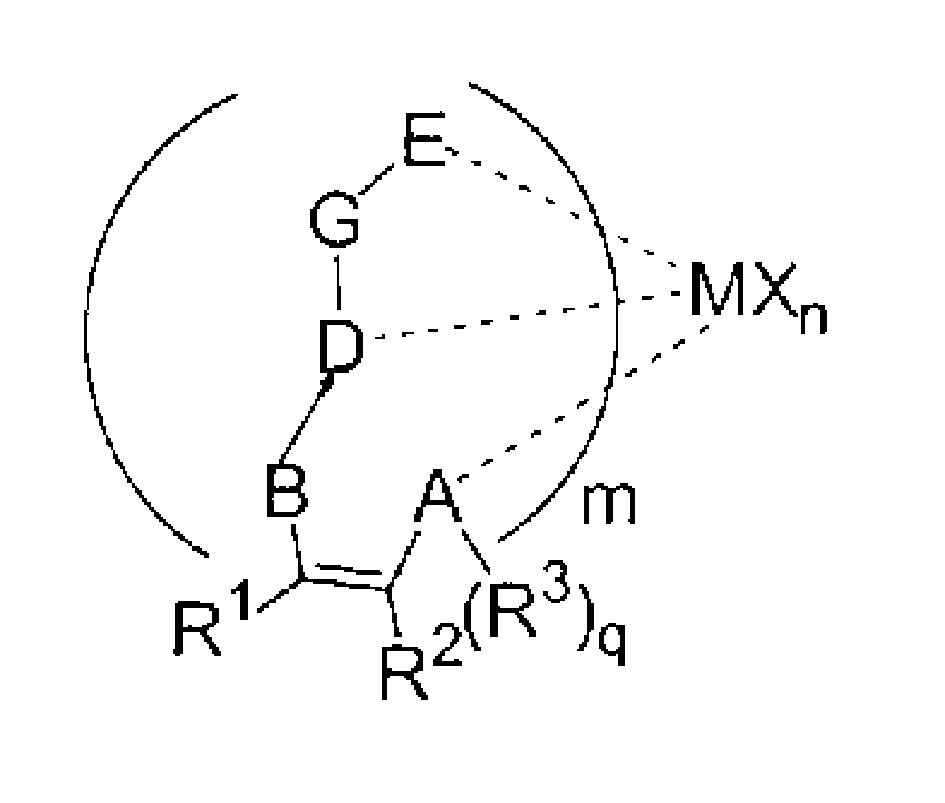

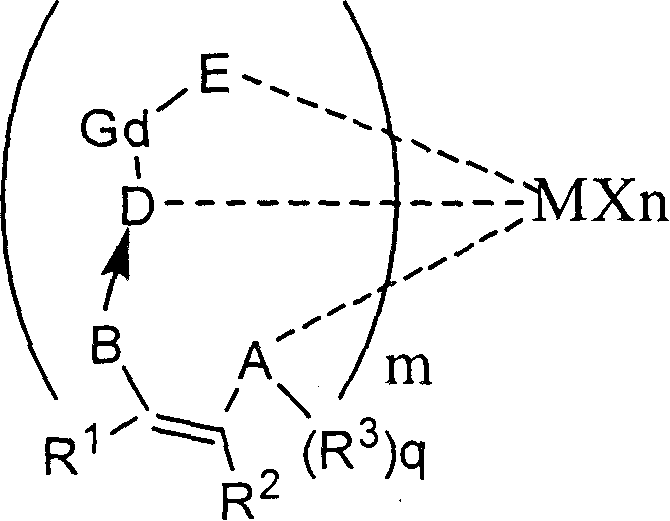

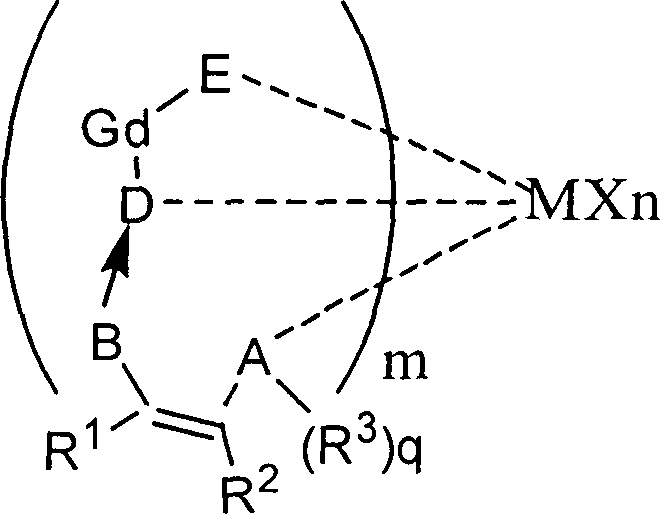

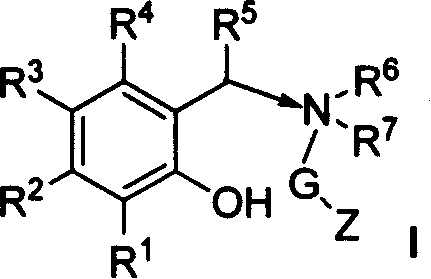

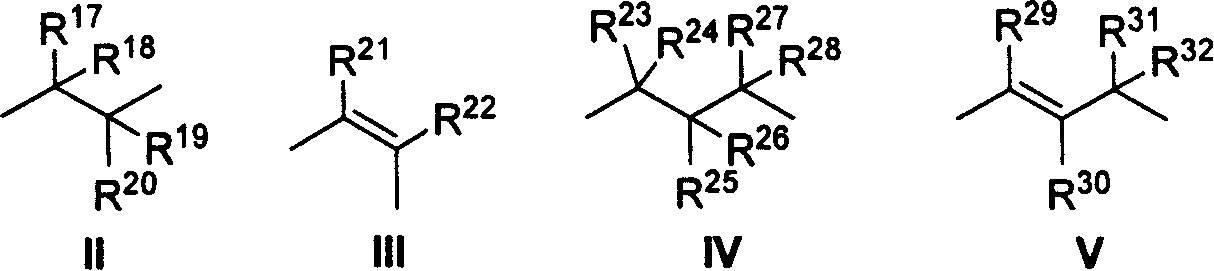

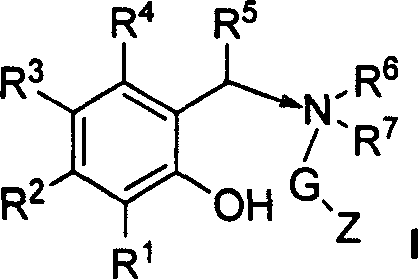

The present invention relates to a catalyst or catalyst system for polymerization and copolymerization of olefine and its synthesis process and the application in catalyzing olefine polymerization. The catalyst is a kind III to XI transition metal compound with multitooth ligand.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

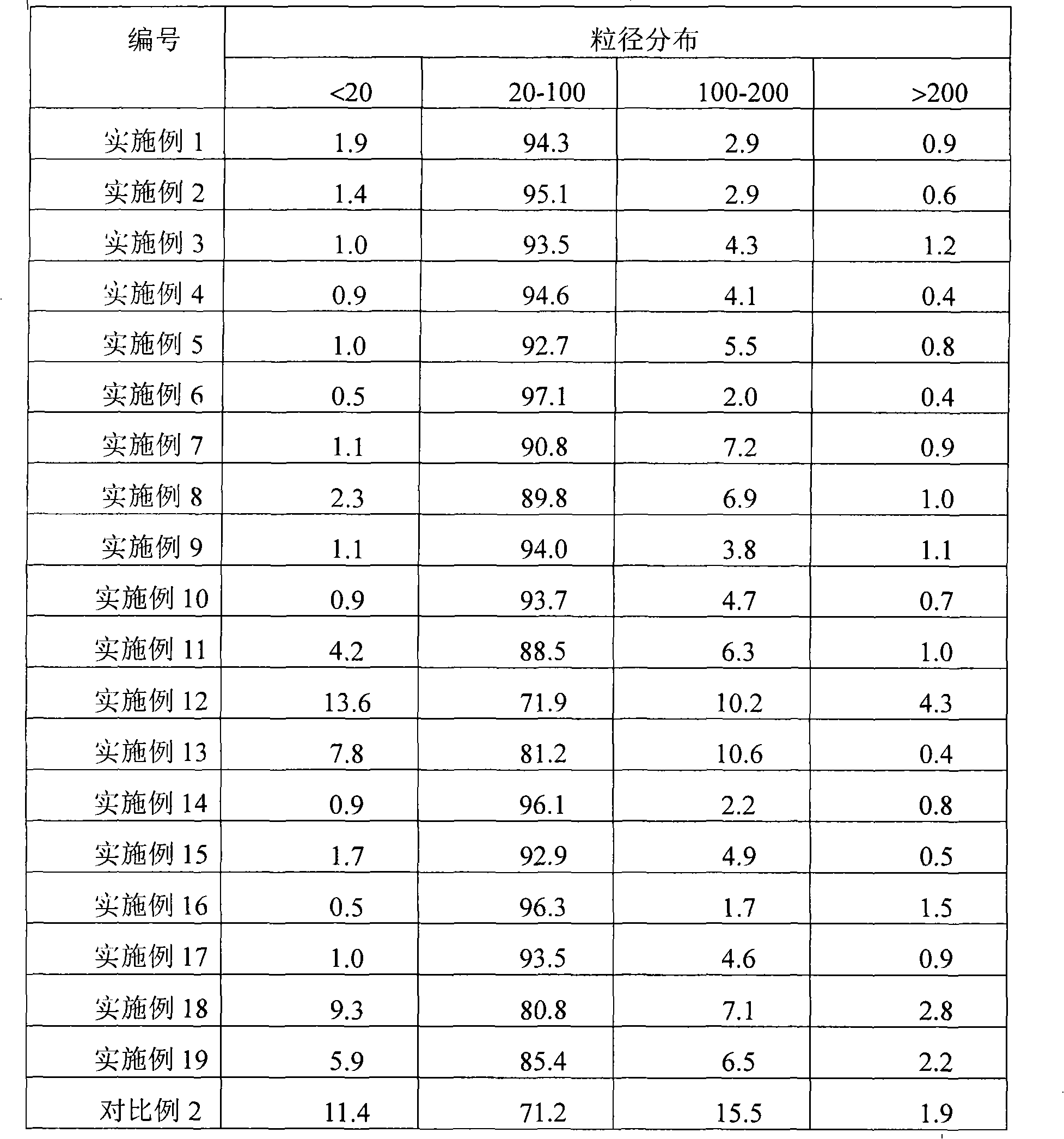

Application of supported non-metallocene catalyst in ethene polymerization process by slurry method

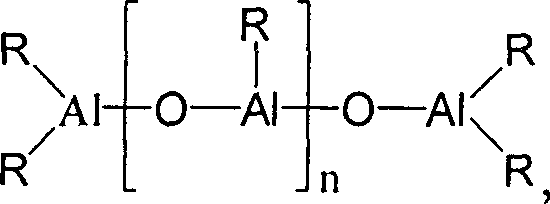

The invention discloses an application of load non- metallocene catalyst in the slurry process for vinyl polymerying, the load non- metallocene catalyst and catalyst promoter forming the catalytic system, the alkene polymerization comprising: vinyl homopolymerization, combined polymerization of vinyl with propylene, butylenes, hexane, octane or norbornene; the catalyst carrier being chosen from: inorganic oxide of metallic oxide from IIA, IIIA, IVA, and IVB groups, or oxided mixture and mixing oxide; the catalyst promoter being chosen from: methylaluoxane, ethylaluoxane, isobutylaluoxane, trimethylaluminum,triethylaluminum,triisobutylaluminum,methylaluoxane-trimethylaluminum or methylaluoxane-triethylaluminum; the mole proportion between the catalyst promoter and catalyst being Al / Ti= 1:1-500. The inventioin is characterized by the less methylaluoxane consumption, stable reaction, easy-to-control polymerization temperature and non still-sticking phenomenon. The produced polyolefine possesses perfect granual shape, and the maximum polymer clamp density can reach 0.385 g / ml.

Owner:SINOPEC YANGZI PETROCHEM

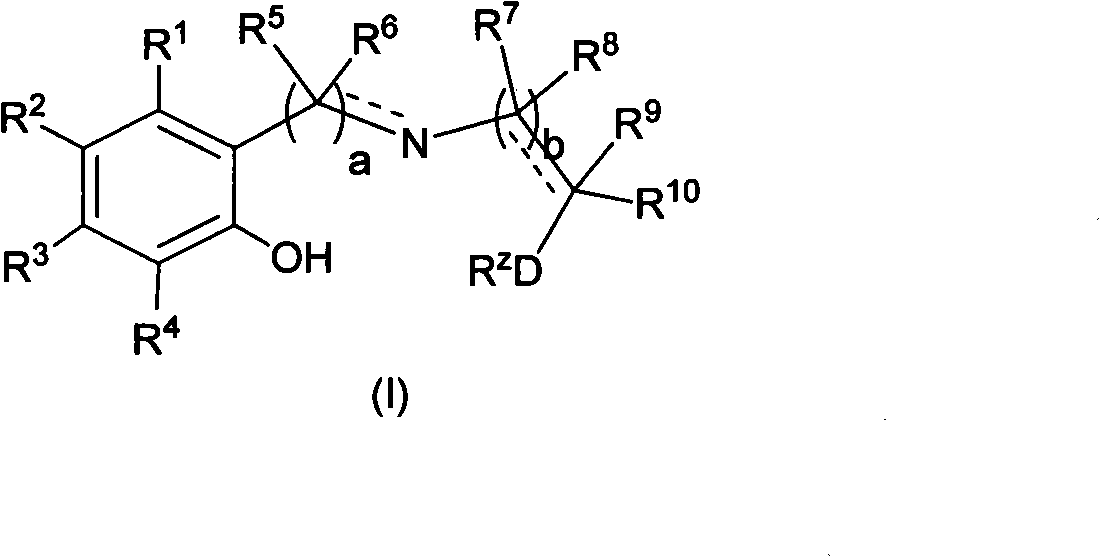

Mono-active center Ziegler-Natta catalyst for olefinic polymerization

The invention relates to a new catalyst for single active central Ziegler-Natta alkene polymerization. Said catalyst takes salicylal containing dentate or substituted salicylal derivatives as electrons, and is prepared by adding pretreated carrier, metallic compound and electrons into magnesium compound / tetrahydrofuran solution. The catalyst can produce ethane homopolymer and copolymer with narrow molecular weight distribution (1.6-3.8) and even comonomer distribution, with high activity and under action of adjuvant catalyst of alkyl aluminium and alkyl aluminoxanes. The ethane polymerization, homopolymerization or combined polymerization of ethane and 1- olefin, ring olefin and polar monomer through slurry method or gas phase method by using said catalyst can be realized.

Owner:SHANGHAI INST OF ORGANIC CHEMISTRY - CHINESE ACAD OF SCI

Catalyst components in use for polymerizing ethylene, and catalyst

This invention relates to a method for preparing catalyst for ethylene homopolymerization or copolymerization with other alpha-olefins. The catalyst comprises at least one Mg composite, at least one Ti compound, at least one organic alcohol compound, and at least one Si compound. The general formula of the Si compound is R1xR2ySi (OR3) z, where R1 and R2 are alkyl or halogen; R3 is alkyl; x is 0-2; y is 0-2; z is 0-4; x + y + z = 4. The catalyst has such advantages as high catalytic activity, high hydrogen sensitivity and narrow particle size distribution of polymer. The catalyst is suitable for slurry polymerization of ethylene, and combined polymerization process where catalyst with high activity is needed.

Owner:CHINA PETROLEUM & CHEM CORP +1

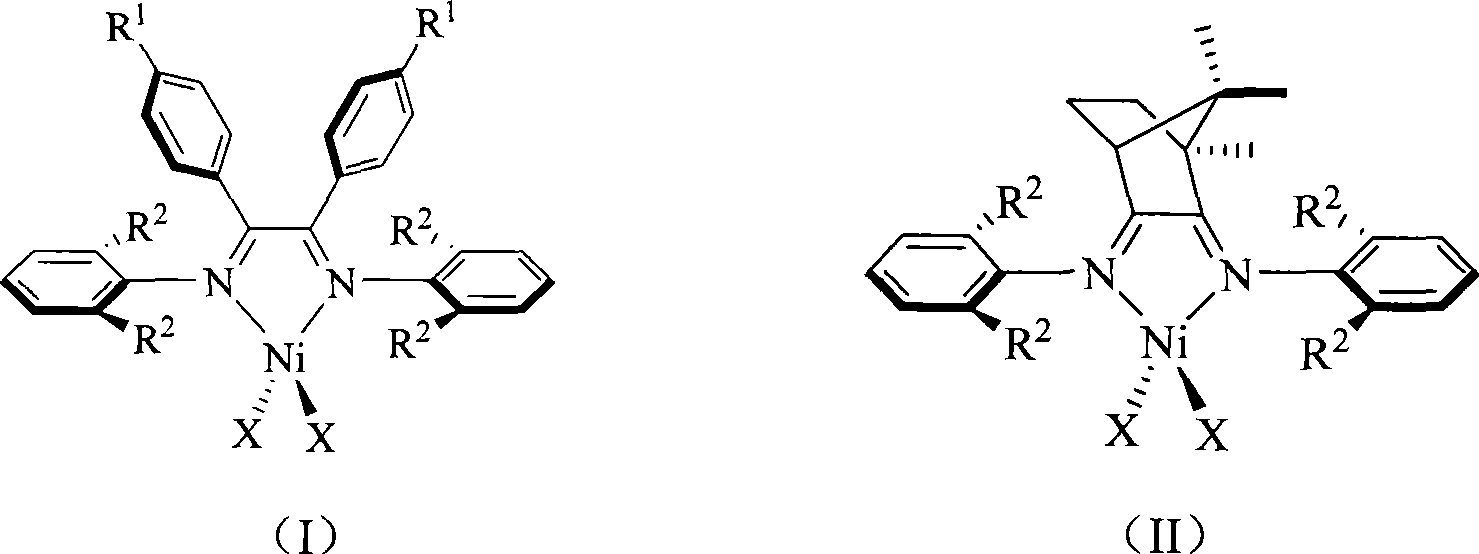

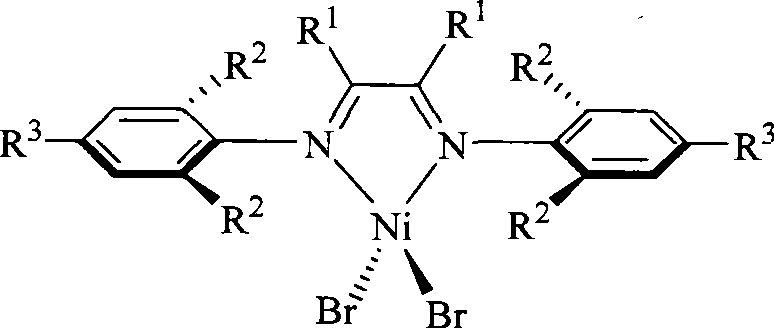

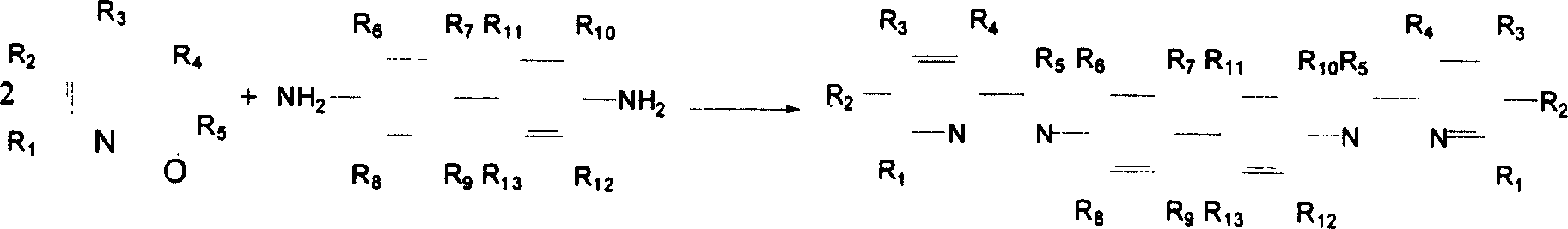

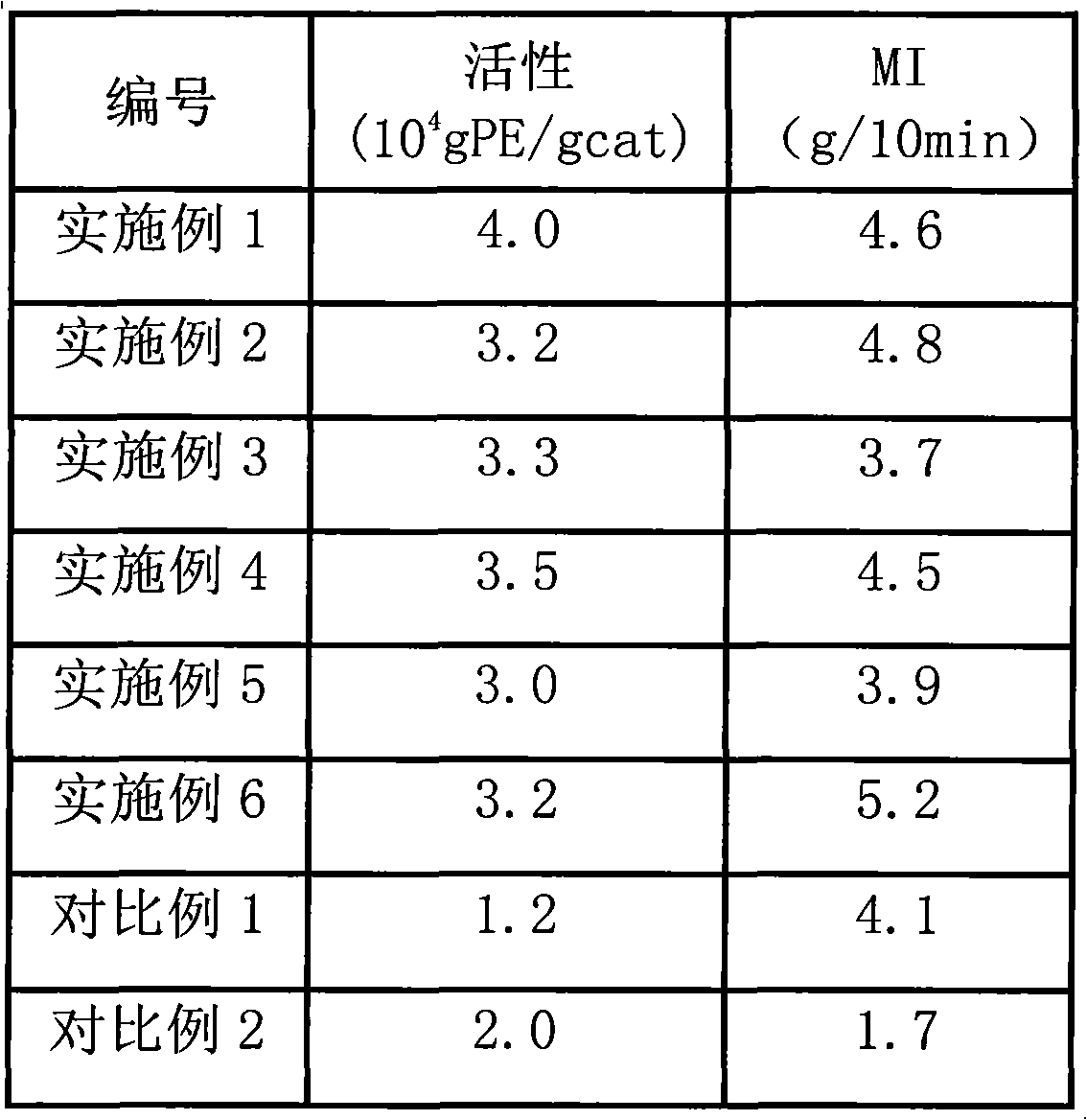

Alpha-nickel diimine compound olefin polymerization catalyst and preparation method thereof, and method for preparing branched polyethylene

The invention discloses an alpha-nickel diimine compound olefin polymerization catalyst and a preparation method thereof, and a method for preparing branched polyethylene. Structural formulas of the alpha-nickel diimine compound olefin polymerization catalyst are shown as a formula (I) and a formula (II), and the preparation method of the alpha-nickel diimine compound olefin polymerization catalyst is simple and low in cost, and can catalyze ethylene polymerization with high activity at a temperature of more than or equal to 80 DEG C to obtain high molecular weight polyethylene. The polyethylene prepared by catalyzing of the alpha-nickel diimine compound olefin polymerization catalyst has high molecular weight, and can prepare molecular weight which reaches more than 10<2>*kg / mol in the temperature range of between 0 and 80 DEG C.

Owner:SUN YAT SEN UNIV

Solid catalyst component for ethylene polymerization and catalyst therefor

InactiveCN1463991AOrganic-compounds/hydrides/coordination-complexes catalystsPolymer sciencePtru catalyst

The catalyst components for polymerization or copolymerization of ethylene includes at least one titanium compound, at least one electron donor and at least one activator carried onto one kind of Mg / Ti containing solid matter. The catalyst components has relatively narrow grain size distribution and relatively small average grain size, and the catalyst with the catalyst components has relativelyhigher activity and is especially suitable for slurry polymerization and gaseous polymerization to obtain polymer with lower fine powder content. The catalyst is especially suitable for ethylene polymerization with slurry feeding and gaseous fluidized bed polymerization.

Owner:CHINA PETROLEUM & CHEM CORP +1

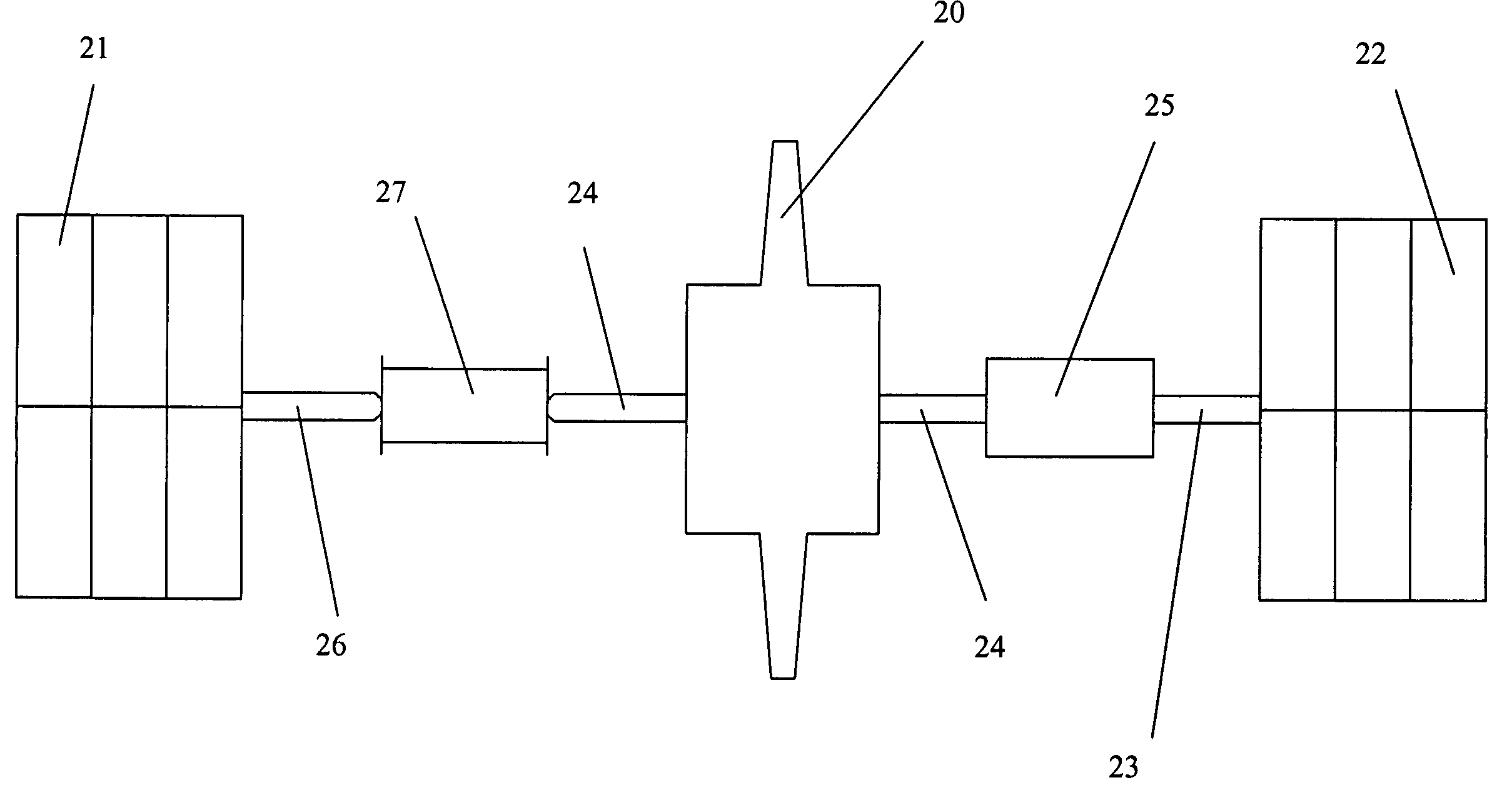

Compressor for high pressure polymerization

ActiveUS7563413B2Accurate predictionImprove reliabilityYielding couplingShaft for rotary movementGas compressorCoupling

Owner:EXXONMOBIL CHEM PAT INC

Catalyst for vinyl polymerization and method for preparing same

The invention provides a catalyst for vinyl polymerization. The catalyst contains titanium-containing active components and active agent components (organic aluminum compound), wherein an inorganic oxide carrier is loaded with at least one kind of magnesium dihalide, one kind of aluminum halide, at least one kind of titanium halide and at least one kind of electron donor, and the electron donor compound is ether, ester or ketone; and the general formula of the organic aluminum compound is AlRnX3-n, R is alkyl of which the number of hydrogen or carbon atoms is 1 to 20, X is halogen, and n is a numeral which is more than 1 and less than or equal to 3. When the catalyst is used for the vinyl polymerization, the catalyst has higher polymerization activity and hydrogen-adjusting sensitivity, and simultaneously the molecular weight distribution of the obtained polymers is wider.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst component for polymerization or copolymerization of ethylene and catalyst thereof

The invention relates to a catalyst for ethene polymerization, and comprises the following components: A, a titanium containing solid catalyst component, which is prepared by the following steps: magnesium halide, organic epoxy compounds, organic phosphorous compounds, organic alcohol compounds are reacted for forming a uniform solution; and the solution, aromatic ester compounds, halide compounds of transition metallic titanium or derivatives thereof are mixed, and thereby obtaining the solid catalyst component; B. organic aluminium compound, whose general formula is AlRnX3-n, wherein, R is an alkyl which contains 1-20 hydrogen or carbon atoms, X is a halogen atom, and n is an integer which is less or equal to 3 and more than 0. The catalyst has the advantages of high catalytic activity and good hydrogen response, and the polymer has high bulk density, and the catalyst is suitable for homopolymerization of ethylene or copolymerization of ethylene and other alpha-alkenes.

Owner:CHINA PETROLEUM & CHEM CORP +1

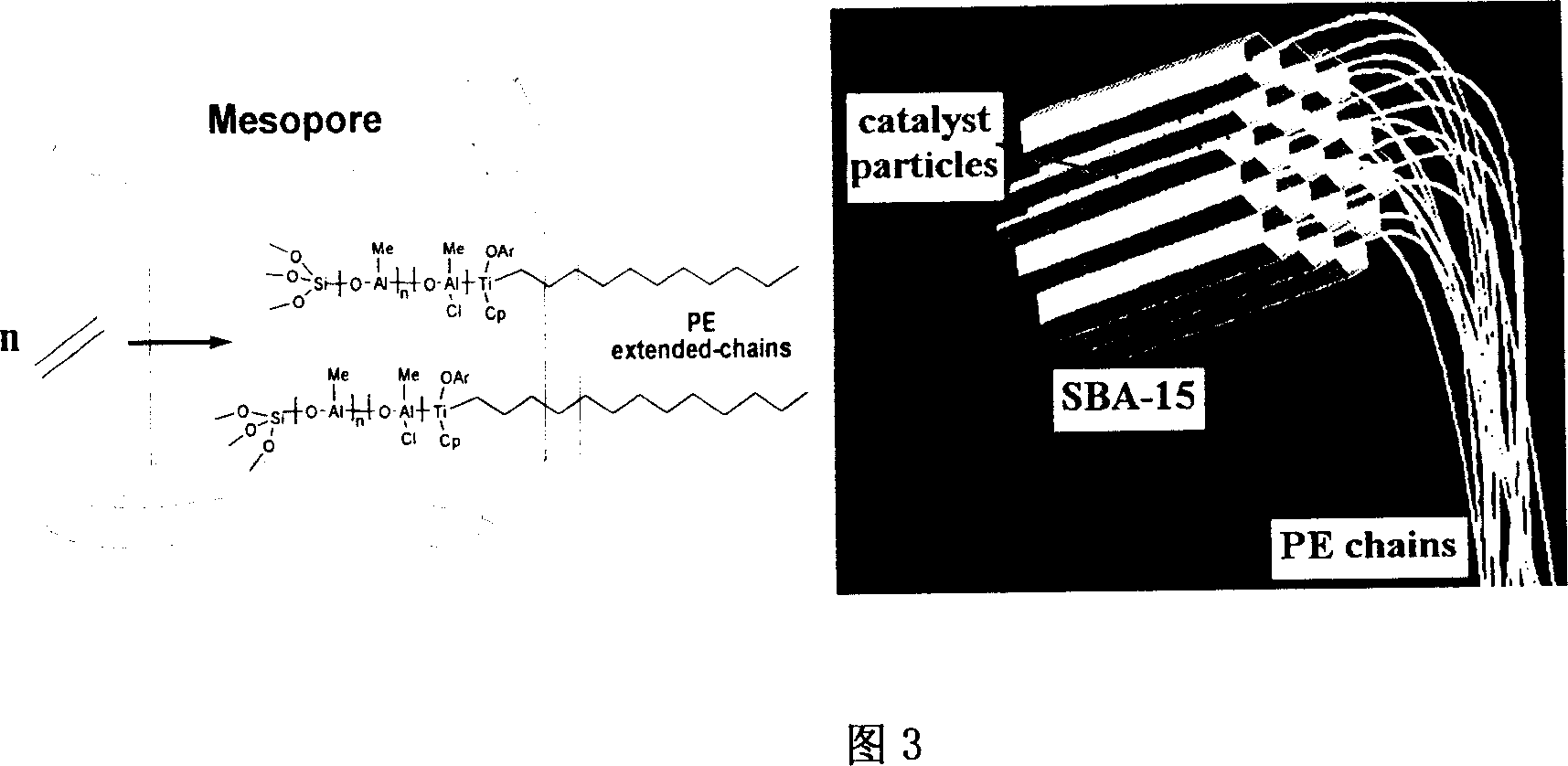

Mesoporous molecular sieve carried olefin polymerization catalyst, preparation method and application thereof

InactiveCN1923862AHigh molecular weightHigh melting pointBulk chemical productionGas phaseHomogeneous catalysis

The invention discloses an olefin polymeric catalyst and preparing method and reacting technology, which is characterized by the following: the expression formula of catalyst is [SiO2-Cat], wherein Cat represents semi-sandwich homogeneous phase catalyst of transient element metallic titanium (IV) or zirconium (IV); SiO2 represents dielectric molecular sieve SBA-15 decorated by methyl alundum alkyl, which can synthesize polyethylene; the catalyst possesses high ethylene polymeric activity, which displays ultrahigh molecule with different patterns.

Owner:FUDAN UNIV

Catalyzer for ethylene polymerization and copolymerization and preparing method thereof

A catalyst for the polymerization or copolymerization of ethene and a preparation method thereof belong to the field of an olefin polymerization catalyst. The catalyst includes a main catalyst component and at least one organic aluminum compound; the main catalyst component includes a magnesium compound, at least one titanium compound and at least one organic alcohol compound. The magnesium compound is an output obtained by dissolving magnesium halide in a mixed solvent which contains an organic epoxide and an organic phosphor compound. During the preparation process of the catalyst, an alkane compound is used as an agent for assisting precipitation. The catalyst is provided with high catalytic activity and better hydrogen response. Simultaneously, the invention also relates to a preparation technique for the catalyst for the polymerization or copolymerization of the ethene. The catalyst is applied to the techniques of slurry polymerization and gas phase fluidized bed or combination; the grain diameters of the obtained polymer are uniform; in addition, the grain diameters are narrowly arranged.

Owner:BEIJING UNIV OF CHEM TECH

Catalyst used for olefine polymerization or copolymerization, its preparation method and application

A catalyst for the polymerization or copdymerization of olefin is composed of Ti-contained solid component A, organoaluminium compound B and organosilicon compound C. Said A is prepared through dissolving magnesium halide in the mixture of organic epoxy compound, organophosphorus compound and inertial diluent, adding educing agent and magnesium halide or its derivatives to educe out Mg / Ti contained deposit, and carrying a surface modifier, a titanium halide or derivative and an electronic doner. It can be used for the polymerization of propene or copolymerization of propene-ethene.

Owner:CHINA PETROLEUM & CHEM CORP +1

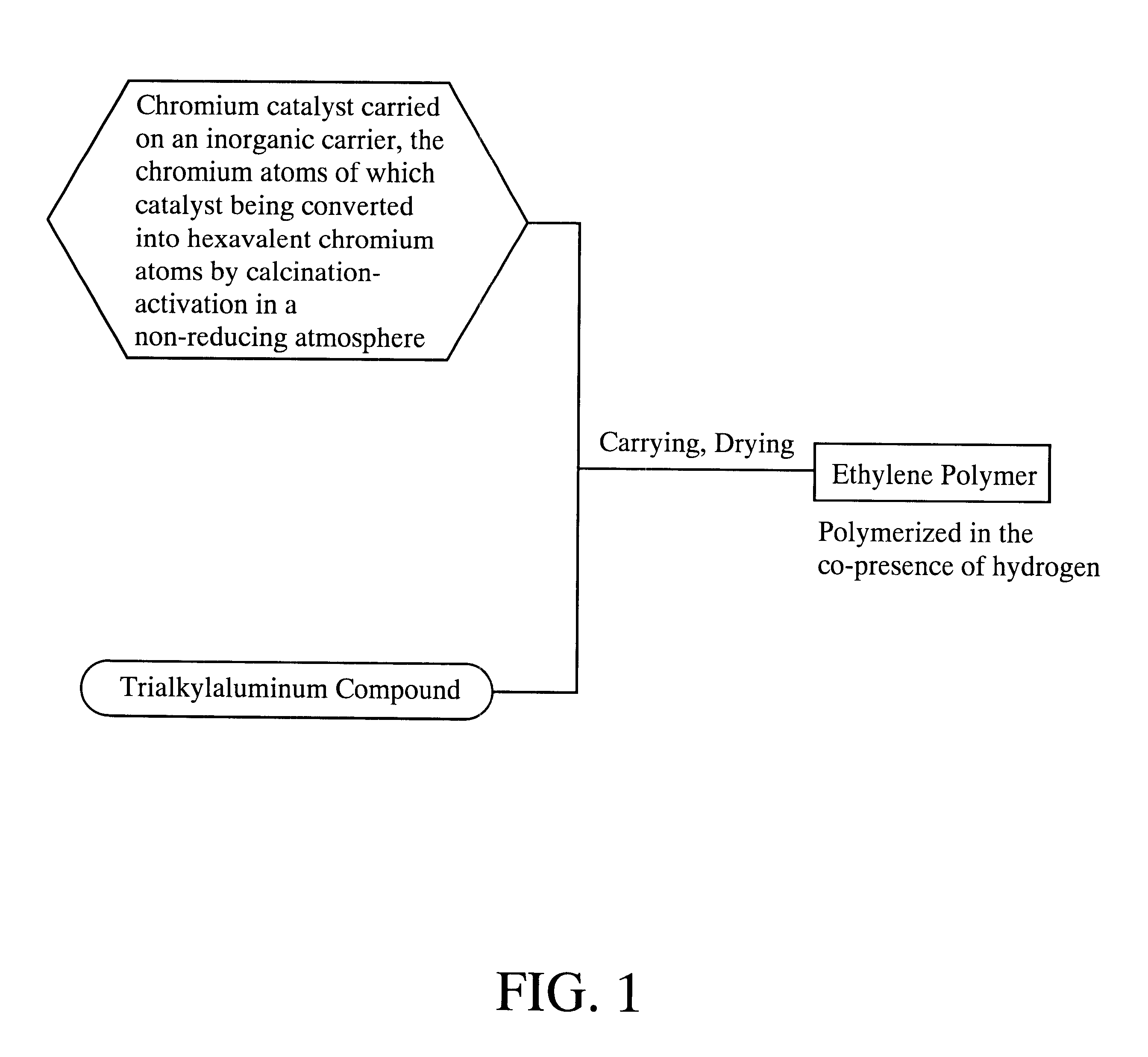

Ethylene polymers and method for producing the same

InactiveUS6646069B2Improve impact resistanceImprove balanceOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationChromium CompoundsCrack resistance

The invention relates to a method for producing an ethylene polymer, comprising performing polymerization of ethylene in co-presence of hydrogen using a trialkylaluminum compound-carried chromium catalyst, wherein the chromium catalyst is obtained by calcination-activating a chromium compound that is carried on an inorganic oxide carrier in a non-reducing atmosphere to convert chromium atoms in the chromium compound into hexavalent chromium atoms for at least a portion thereof, and treating with a trialkylaluminum compound in an inert hydrocarbon solvent to carry thereon and removing to dry the solvent so that the chromium atoms are not over-reduced by the trialkylaluminum compound, and to an ethylene polymer suitable for blow molded articles obtained by the production method. The ethylene polymer of the invention have improved environment stress crack resistance (ESCR) and impact resistance in a good balance and are suitable for molded blow articles, in particular large size blow molded articles.

Owner:JAPAN POLYOLEFINS CO LTD

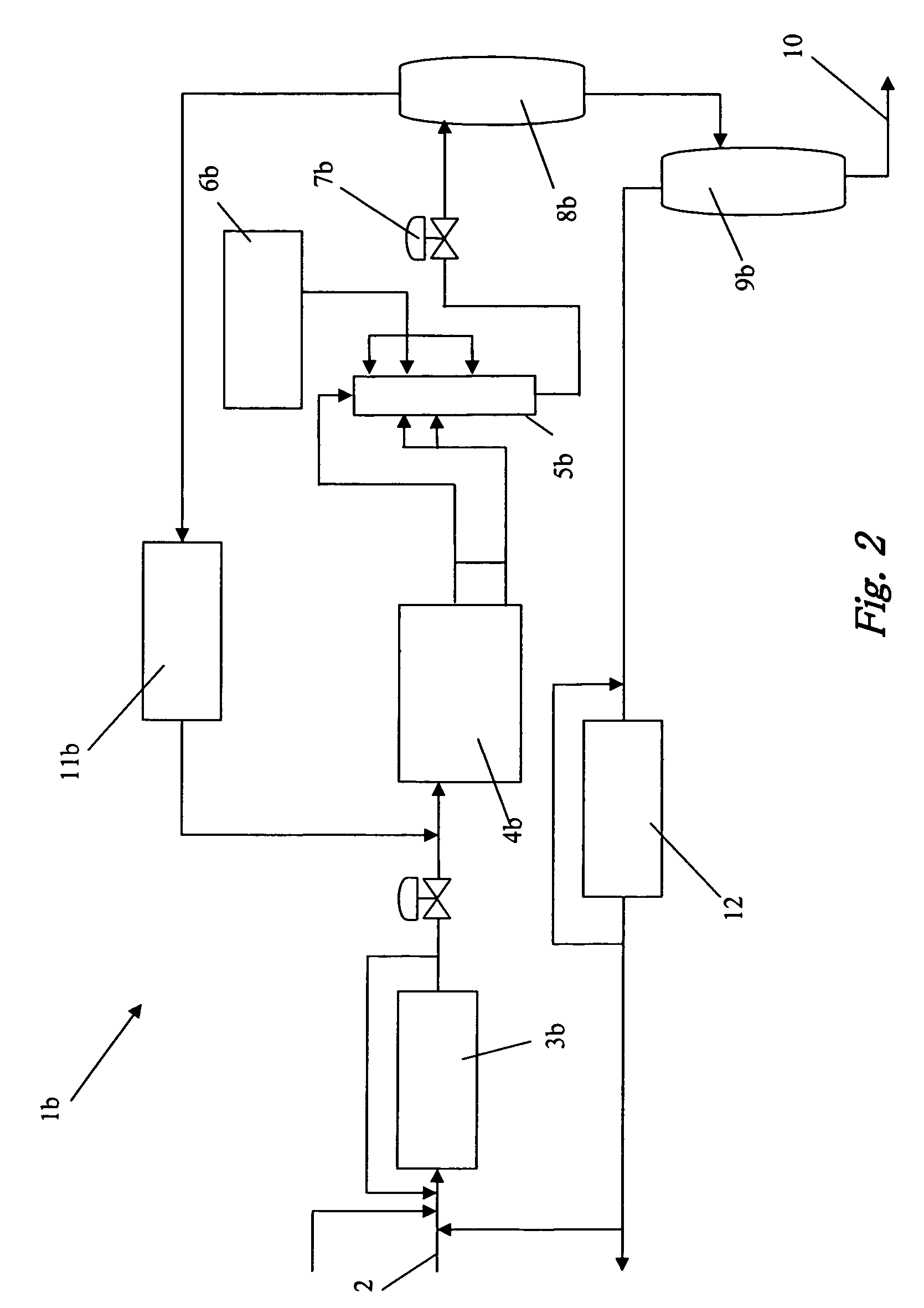

Process for producing a homogeneous polyethylene material in the presence of a catalyst

InactiveUS6455642B1Reduce partHigh molecular weightChemical/physical/physico-chemical processesPolymer scienceGas phase

The present invention concerns a process for producing homogeneous polyethylene materials and processes for making high density, medium density and low density films therefrom. The process involves producing a polyethylene composition in a multistage reaction sequence of successive polymerization stages in the presence of an ethylene-polymerizing catalyst system. According to the invention, the process is carried out using an unsupported catalyst having magnesium and titanium as active constituents, in at least one loop polymerization stage and at least one gas phase polymerization stage and, operated with different amounts of hydrogen and comonomers to produce a high molecular weight portion in one of the polymerization stages and a low molecular weight portion in another so as to provide a polyethylene composition with the low molecular weight part having a MFR2 of 250 g / 10 min or more. With this process it is possible to obtain homogeneous bimodal polyethylene material.

Owner:BOREALIS TECH OY

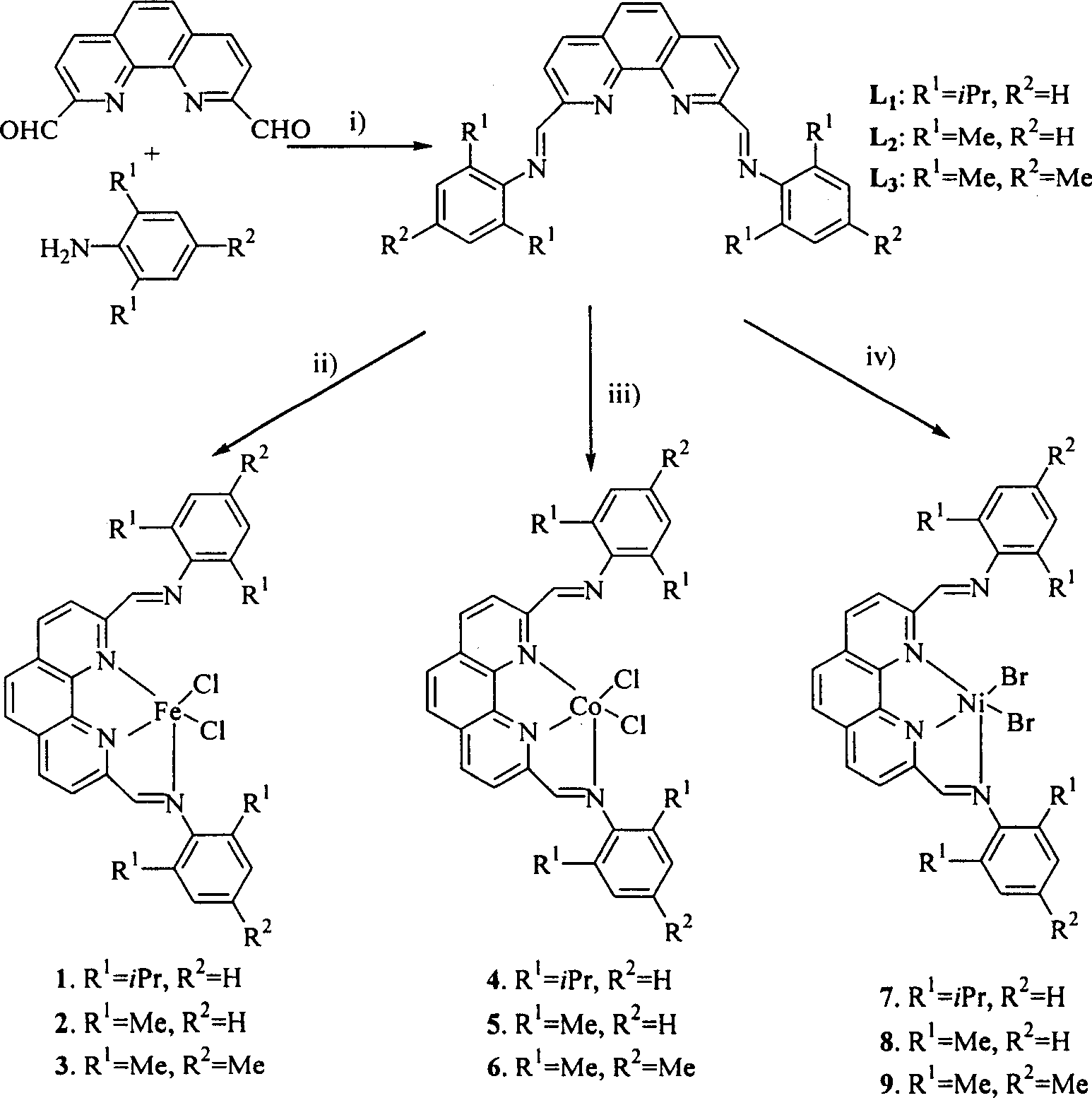

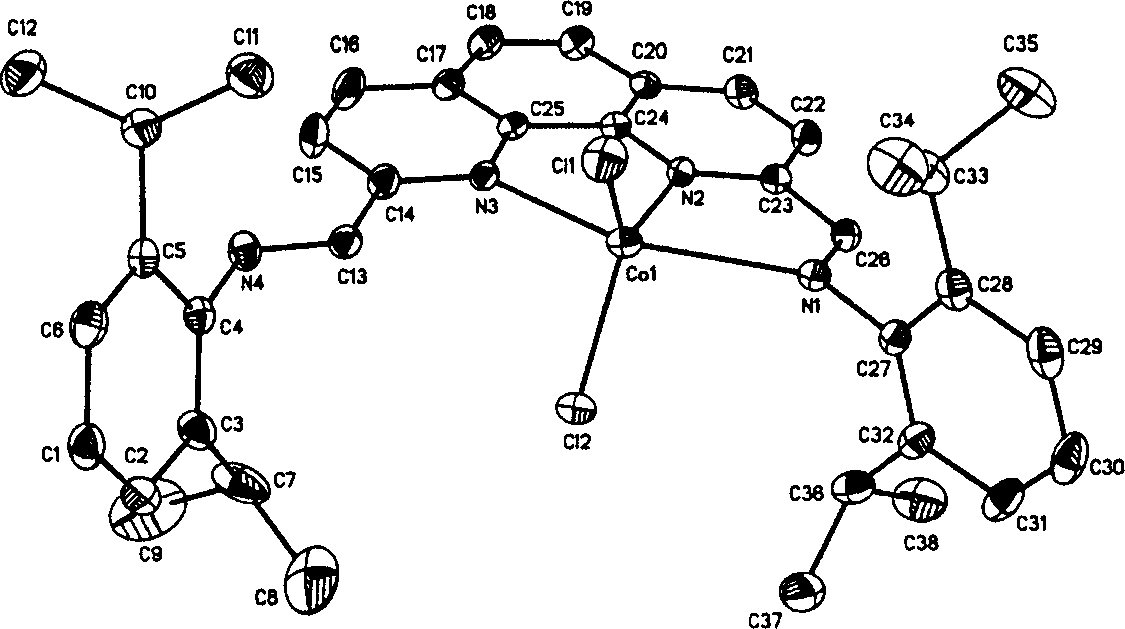

Ethene oligomerization and polymerization post transition metal complex catalyst

InactiveCN1401666AHydrocarbonsHydrocarbon preparationHigh volume manufacturingPolymerization catalysts

A post-transition metal coordination catalyst for ethylene oligomerization and polymerization is disclosed. It is halogenated 2,9-bis(imino)-1,10-orthophenanthralloline Fe, Ni and Co complexes. Its advantages are simple preparing process, easy purification, and high stability.

Owner:INST OF CHEM CHINESE ACAD OF SCI

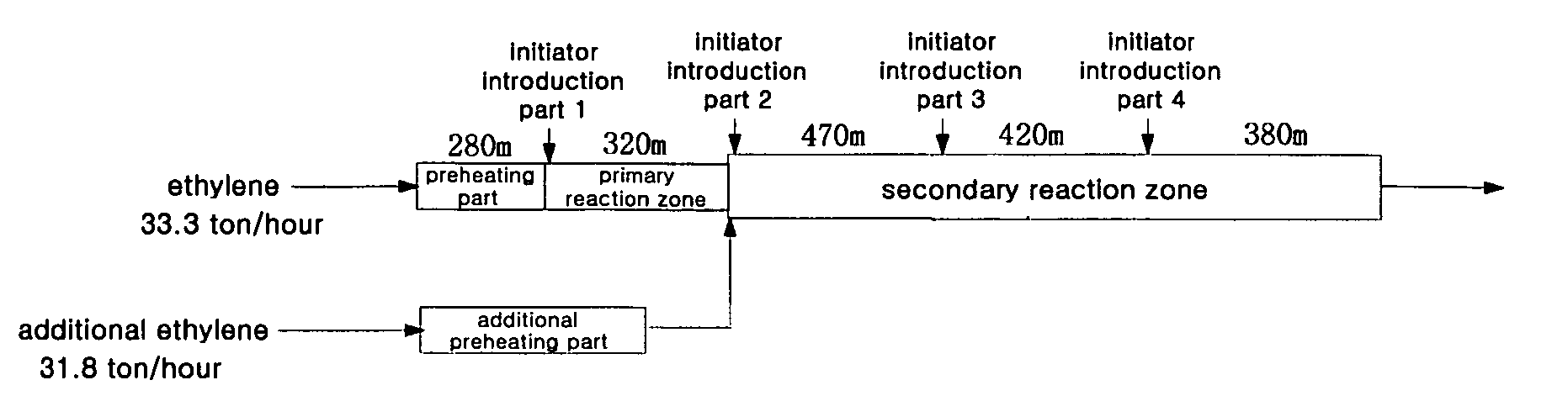

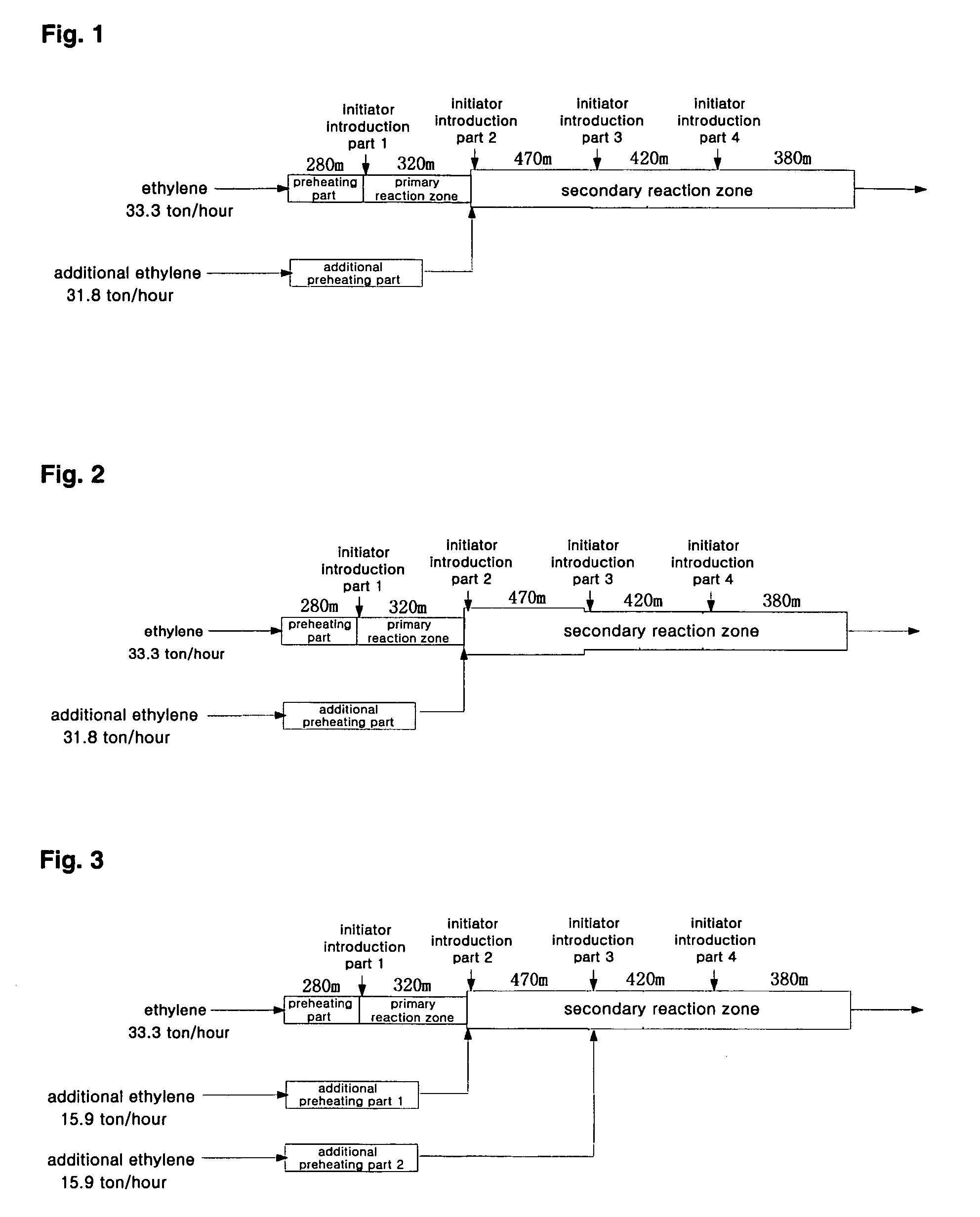

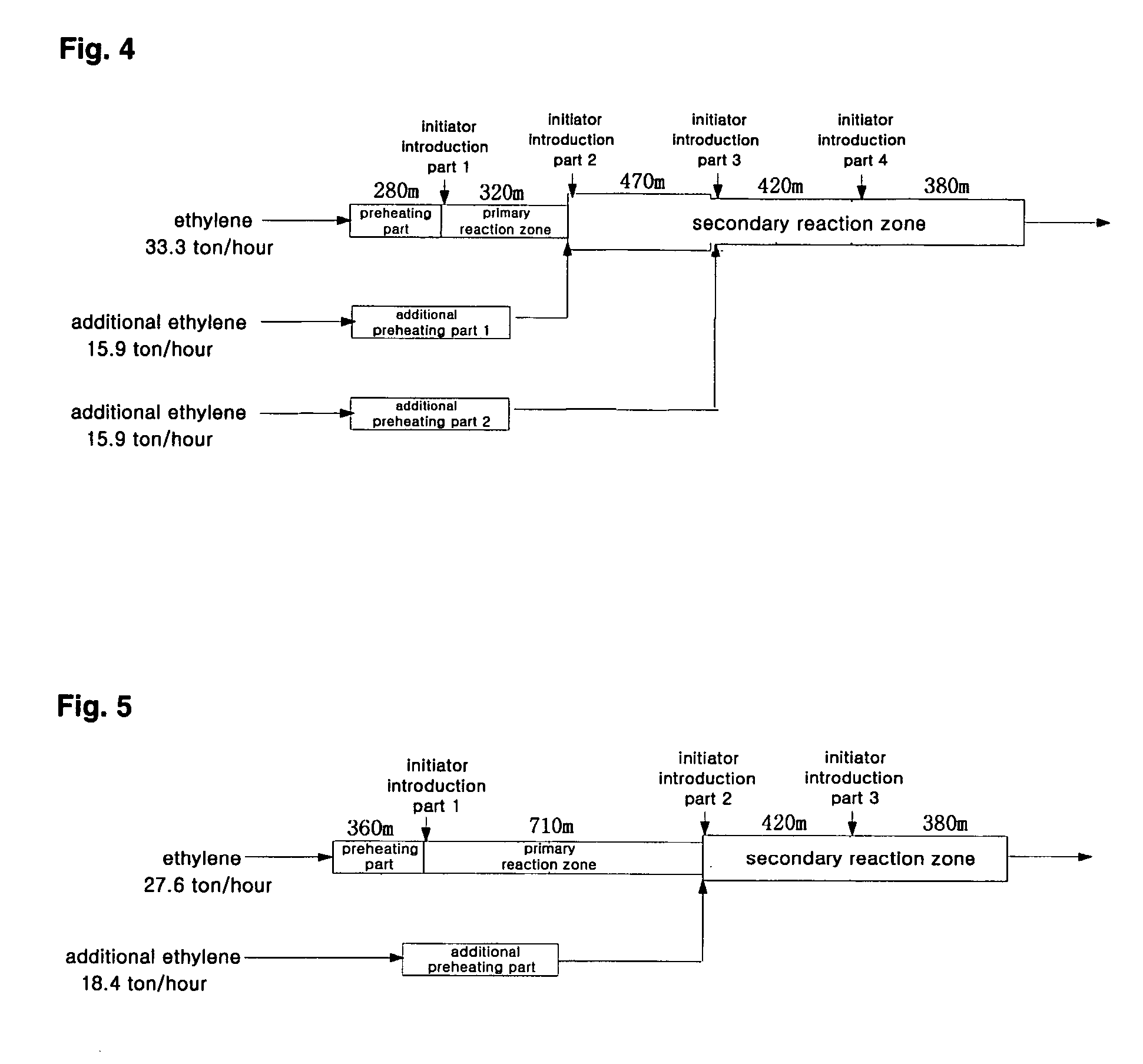

Method of ethylene polymerization for producing products having various properties with high productivity and a tubular reactor used therefor

ActiveUS20060149004A1Improve productivityMaintain physical propertiesChemical/physical/physico-chemical stationary reactorsChemical/physical/physico-chemical processesProduction rateReaction zone

A method for continuous ethylene polymerization under high pressure using a polymerization reaction zone comprises a primary reaction zone and a secondary reaction zone wherein the secondary reaction zone has a length of 1.5-6.5 times the length of the primary reaction zone and a cross-sectional area of 1.2-4 times the cross-sectional area of the primary reaction zone. Ethylene is fed continuously into the primary reaction zone at the starting point of the primary reaction zone. Low temperature initiator alone, or an initiator mixture containing mainly low temperature initiator is introduced into the primary reaction zone at the starting point of the primary reaction zone. Initiator alone or an initiator mixture is introduced into the secondary reaction zone at two or more different points of the secondary reaction zone. Ethylene polymer products of various physical properties are produced with high productivity, while the pressure drop is minimized.

Owner:HANWHA TOTALENERGIES PETROCHEMICAL CO LTD

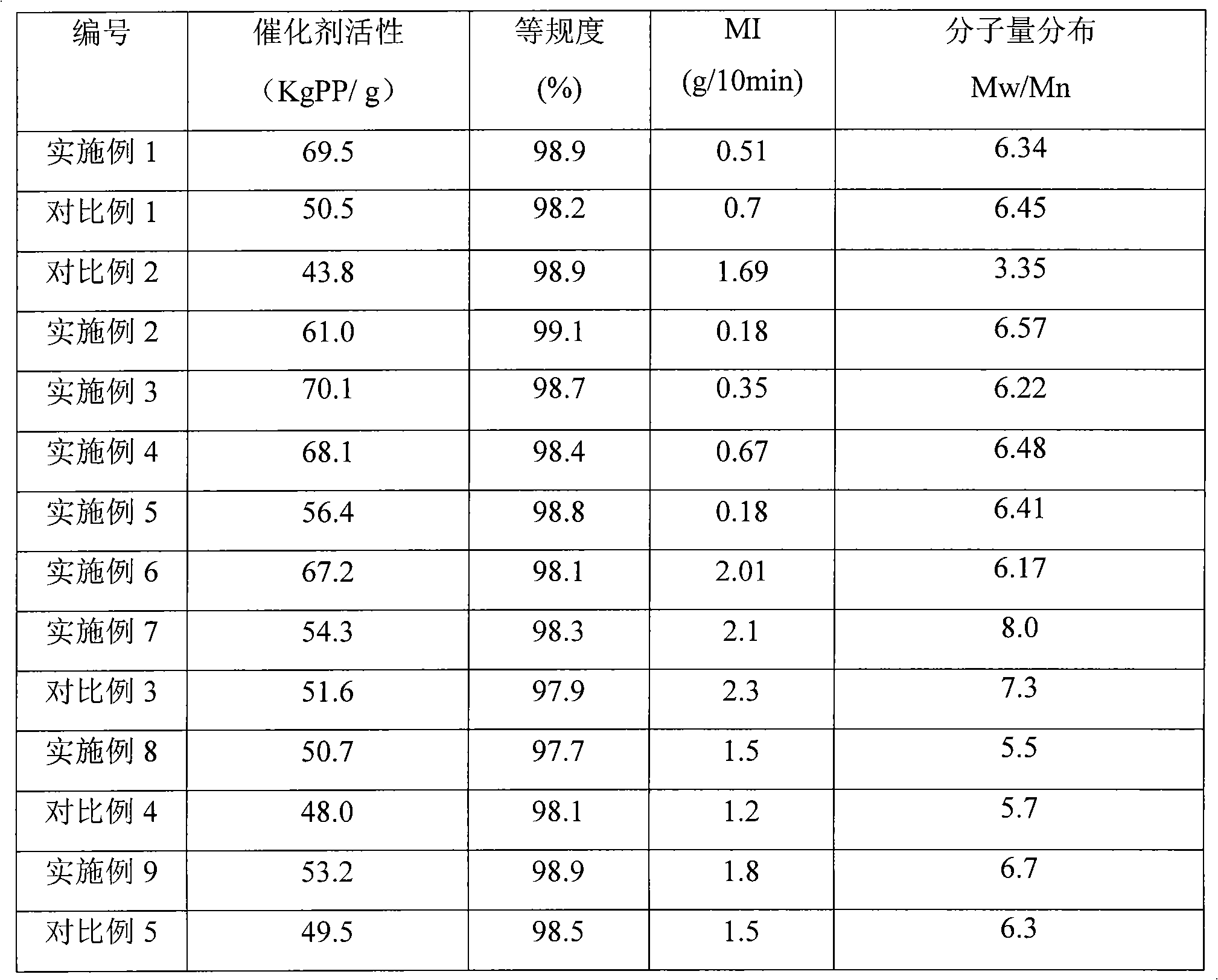

Catalyst component for olefin polymerization and catalyst thereof

The invention provides a catalyst component for olefin polymerization. The method for preparing the catalyst component comprises the following steps of: (1) dissolving magnesium halides into a solvent system consisting of an organic epoxy compound, an organic phosphorous compound and an inert diluent to obtain a uniform solution, mixing the uniform solution and a titanium compound, precipitating solids in the presence of an auxiliary precipitation agent, and adding an organic alcoholic compound before the solids are precipitated; and (2) treating the precipitated solids by using at least one electron donor compound diatomic alcohol ester compound to make the compound attached to the solids; and treating the solids by using the titanium compound and the inert diluent. The catalyst of the invention has a simple preparation method; when the catalyst is used for the olefin polymerization, particularly propylene polymerization, the polymerization activity of the catalyst is obviously improved; and the molecular weight distribution of the polymers obtained from the catalyst is quite wide.

Owner:CHINA PETROLEUM & CHEM CORP +1

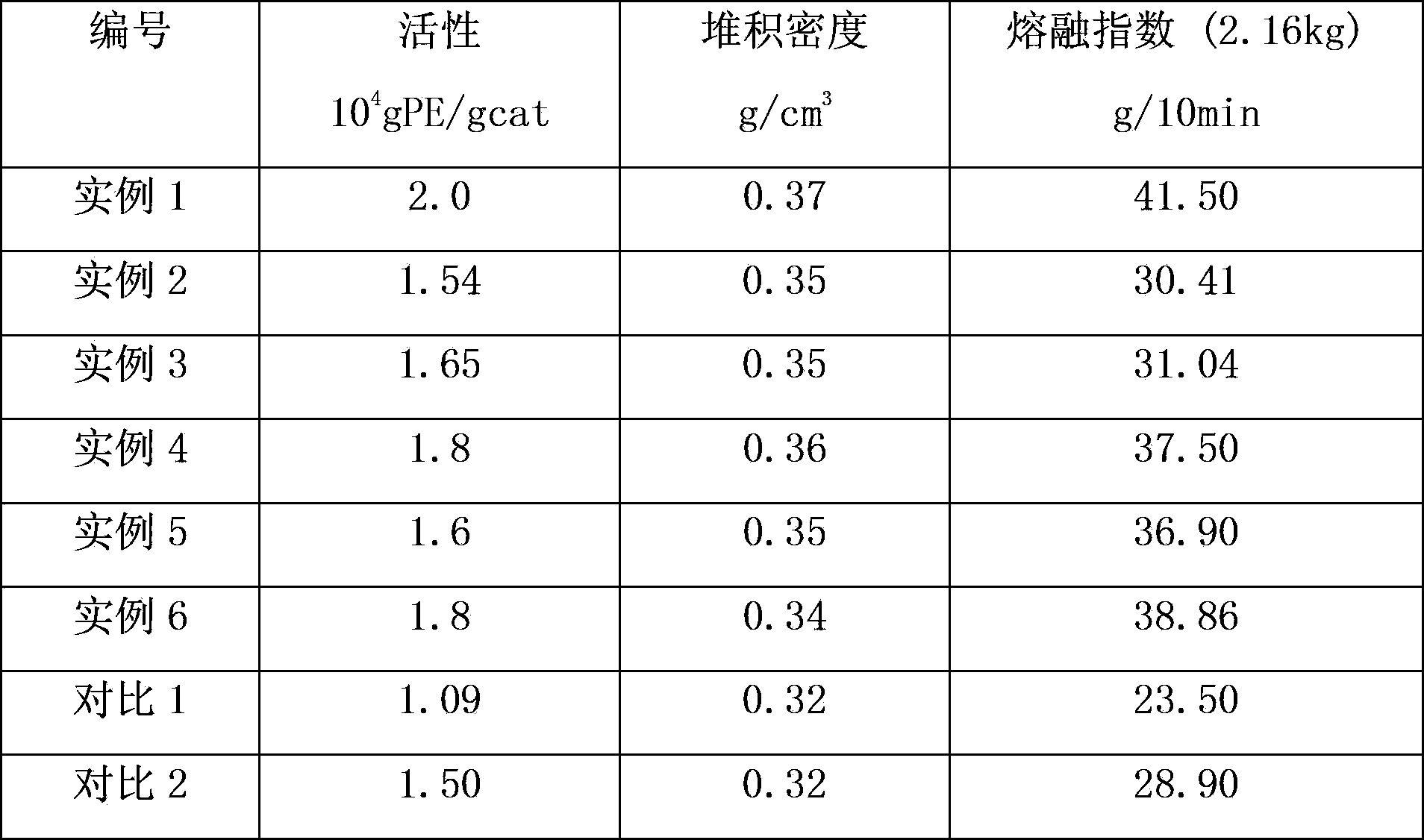

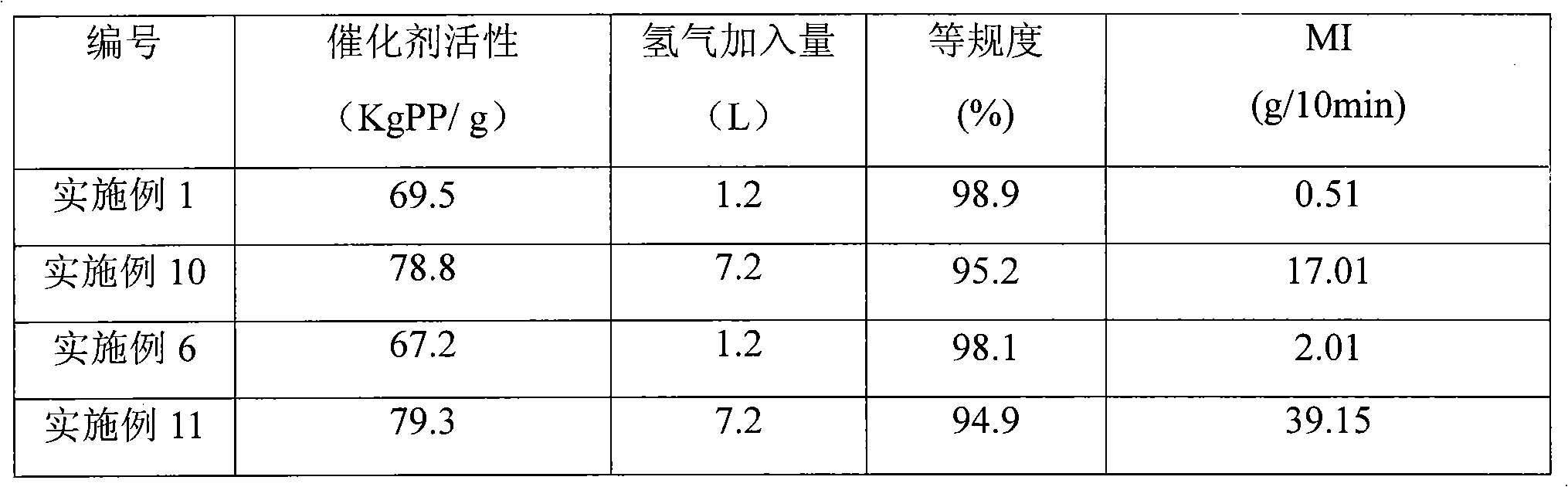

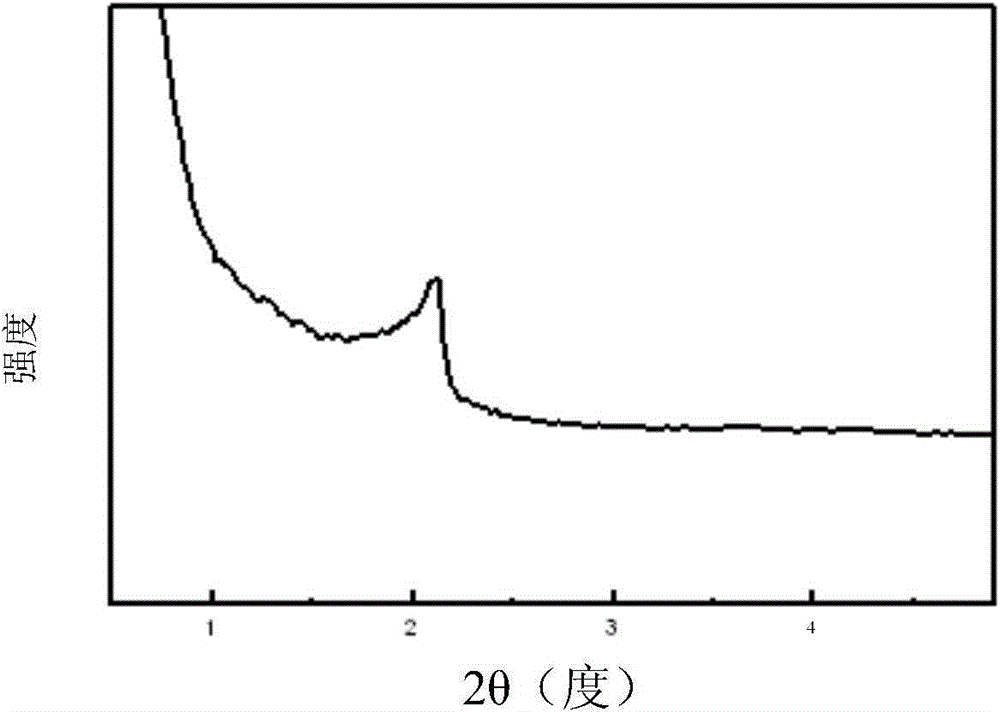

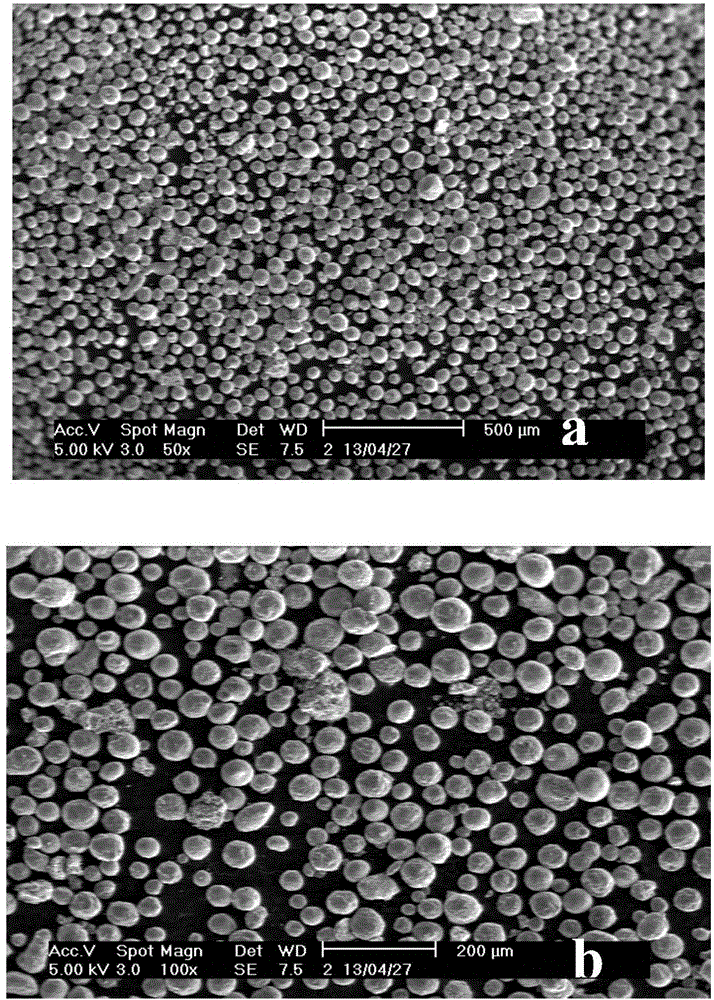

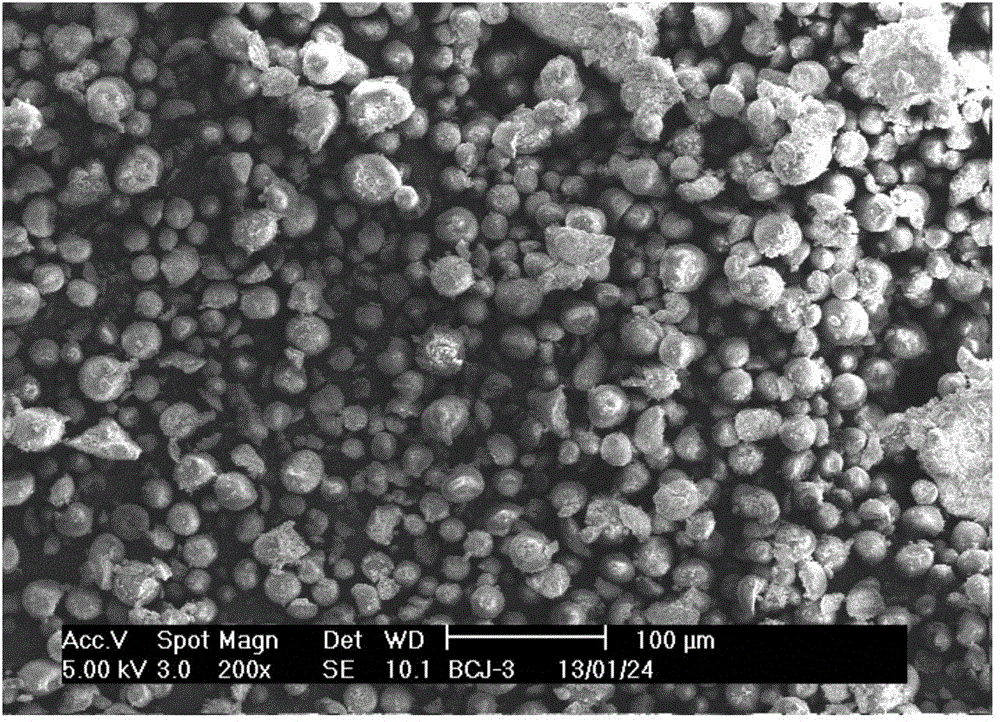

Meso-porous composite material, preparation method thereof, catalyst ingredient preparation method, and polyethylene preparation method

ActiveCN105175586AHigh catalytic activityOrdered mesoporous structureBulk chemical productionMolecular sieveTitanium

The invention discloses a meso-porous composite material, a preparation method thereof, a catalyst ingredient preparation method, and a polyethylene preparation method. The meso-porous composite material comprises a molecular sieve material with a hexagonal tunnel structure and silica gel, the meso-porous composite material is spherical, the pore volume of the meso-porous composite material is 0.5-1.8mL / g, the specific surface area is 200-650m<2> / g, the average particle size is 20-60[mu]m, the apertures are distributed in a double peak manner, two peaks respectively correspond to a first most probable aperture and a second most probable aperture, the first most probable aperture is 1-3nm, and the second most probable aperture is 10-30nm. The meso-porous composite material still keeps an ordered meso-structure after loading. Active components Mg and Ti are loaded on the composite material to prepare a catalyst ingredient, and the catalyst ingredient makes a catalyst keep high catalytic activity in ethylene polymerization and allows polyethylene particle powder to be obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for ethylene polymerization

A catalyst for polymerizing ethylene features that in preparing the mother liquid of its active component, a treating agent is used and the mole ratio of alkoxy to Ti is controlled to be less than 1. As a result, the resultant catalyst component and the organoaluminium cocatalyst can be used for the copolymerizing reaction of ethylene and high-grade alpha-olefine with less resultant hexane and higher catalyst efficiency.

Owner:CHINA PETROLEUM & CHEM CORP +1

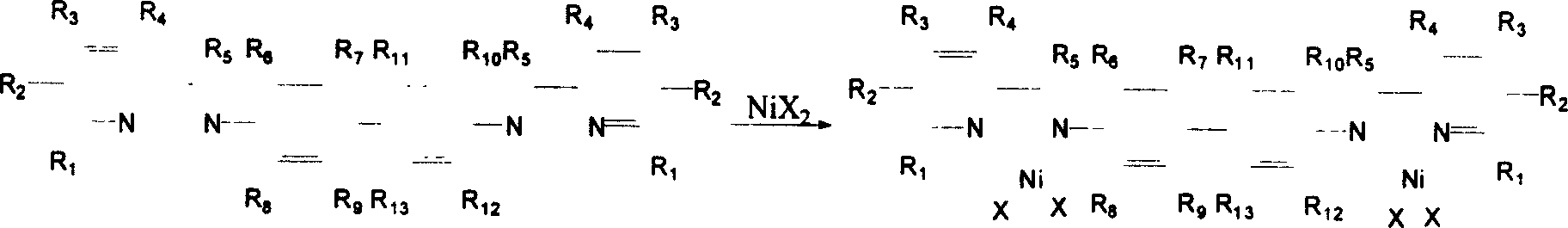

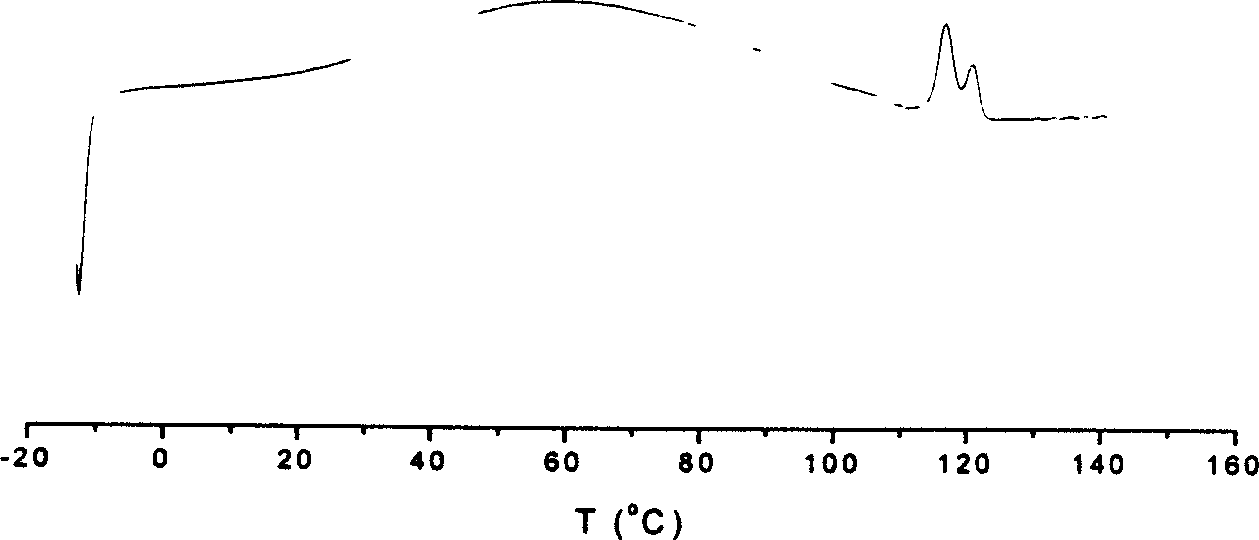

Nickel ethylene polymerization catalyzed system, preparation and use thereof

ActiveCN1603347AHigh polymerization activityIncrease the degree of branchingNickel catalystAluminoxane

This invention relates to a transition metal nickel catalyst component after ethylene polymerization. Component (A) is halogenated [N, N-(R bed -2-pyridine methylene)-substitution benzidine] nickel complexes, component (B) is alumina alkyl. The catalysis system is used to ethylene polymerization. There are high polymerization activity and high branching degree of complexes, and double peak feature of the complexes.

Owner:CHINA PETROLEUM & CHEM CORP +2

Catalyst component applied to vinyl polymerization reaction and catalyst thereof

The invention relates to a catalyst component applied to a vinyl polymerization reaction, a preparation method of the catalyst component and a catalyst thereof. The catalyst component comprises a magnesium-alcohol compound, a titanium compound, an organic aluminum compound, a long-carbon-chain monoester compound and a short-carbon-chain monoester compound. The catalyst has high activity and high hydrogen regulation sensitivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

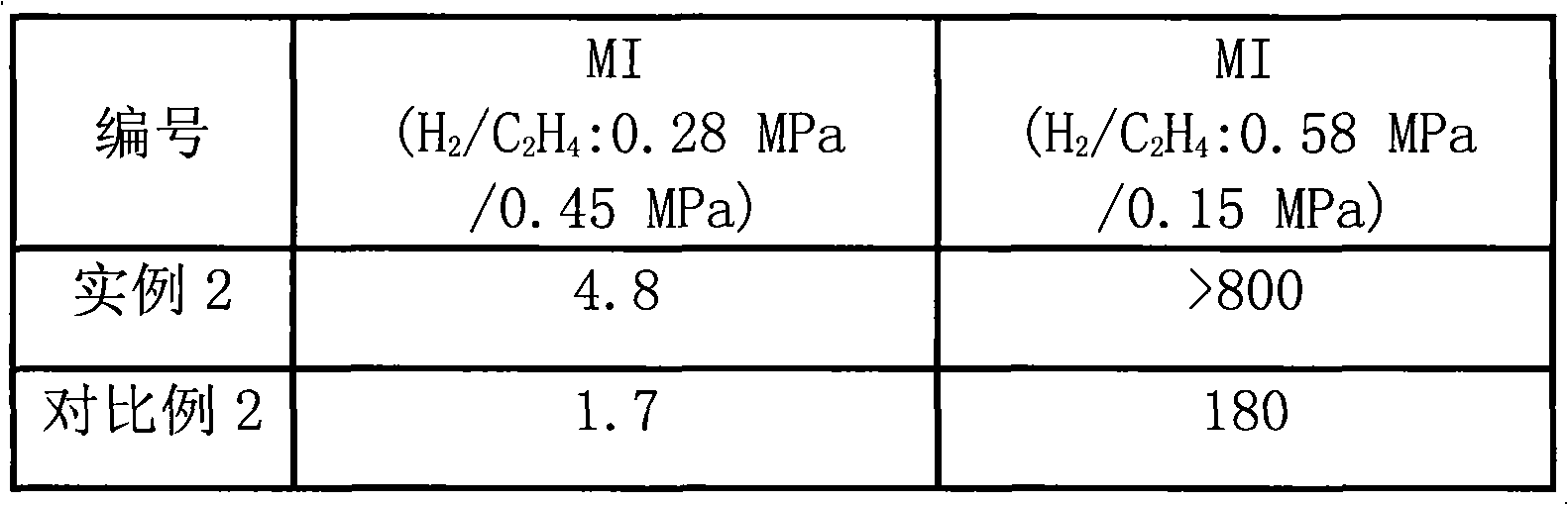

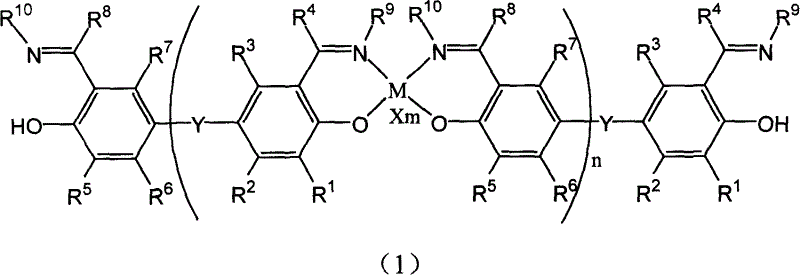

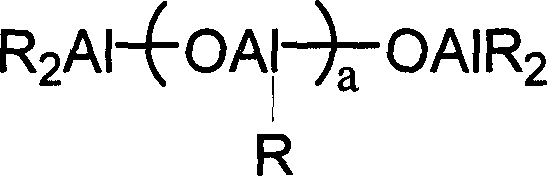

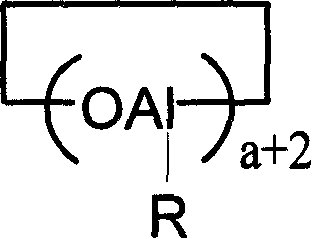

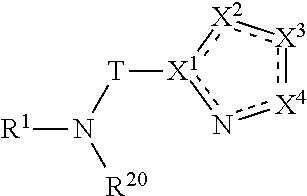

Pretransistion metal catalytic system for ethene polymerisation and copolymerisation, its preparation method and uses

The invention provides a loaded non-metallocene early transition metal catalytic system, which comprises non-metallocene early transition metal complex represented by structural formula (1) disclosed in the specification, loaded organic aluminoxane and at least a organo-aluminium compound. The catalytic system has good catalytic activity when applied for olefin aggregation or co-polymerization.

Owner:CHINA PETROLEUM & CHEM CORP +1

Olefin oligomerization reaction processes exhibiting reduced fouling

ActiveUS8227653B2Hydrocarbon purification/separationHydrocarbons from unsaturated hydrocarbon additionPolymer scienceAlpha-olefin

The invention relates to olefin oligomerization methods and methods for reducing / inhibiting fouling in olefin oligomerization reactions comprising: contacting, in an oligomerization reactor (e.g., under oligomerization conditions), an alpha-olefin feed, a catalyst having an olefin selectivity of at least 90 mol % to a desired oligomerization product, a polymer anti-foulant, and optionally a diluent; selectively producing an effluent comprising the desired oligomerization product, unreacted olefin, and alpha-olefin-based polymer byproduct that causes fouling. The amount of polymer anti-foulant can be chosen to limit fouling to ≦20 g / kg desired oligomerization product, to remediate ≧3 grams fouled polymer / kg desired oligomerization product, and / or to reduce / inhibit polymer fouling by ≧10% over a selective oligomerization with substantially no added polymer anti-foulant. Advantageously, desired oligomerization product so obtained can also be polymerized / copolymerized with an alpha-olefin such as ethylene.

Owner:EXXONMOBIL CHEM PAT INC

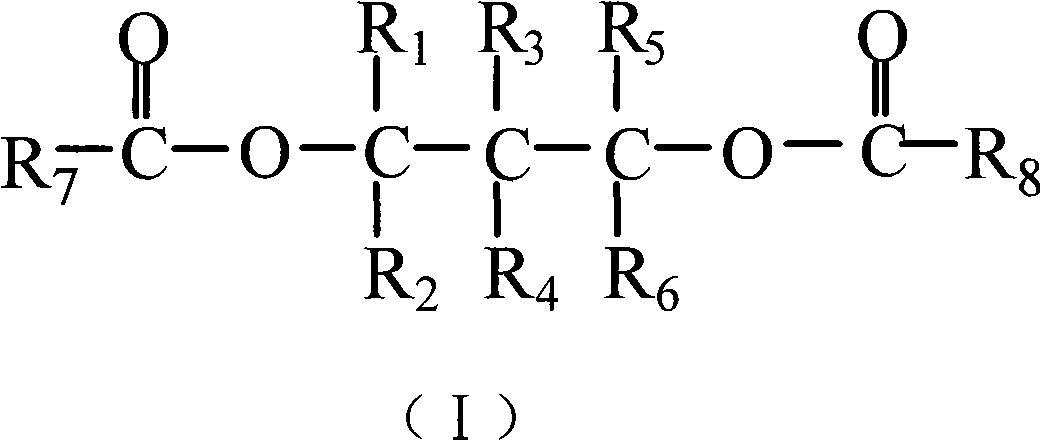

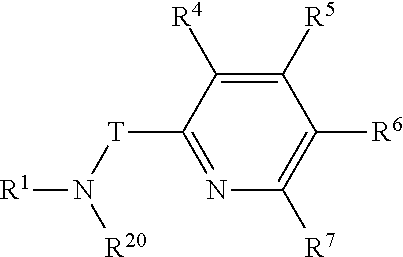

Ziegler-Natta olefin polymerization catalysts with single-site center property

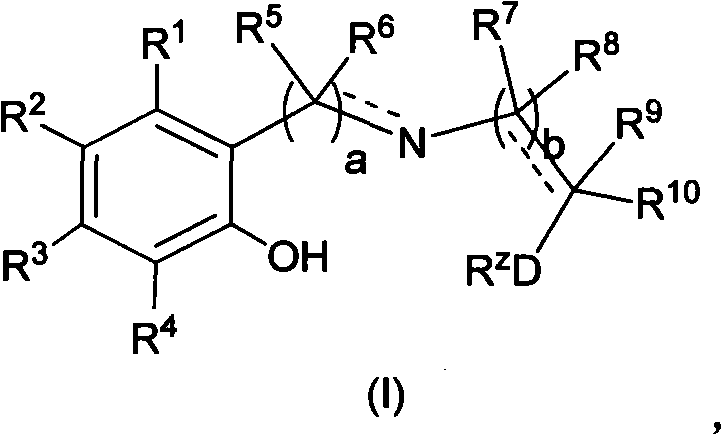

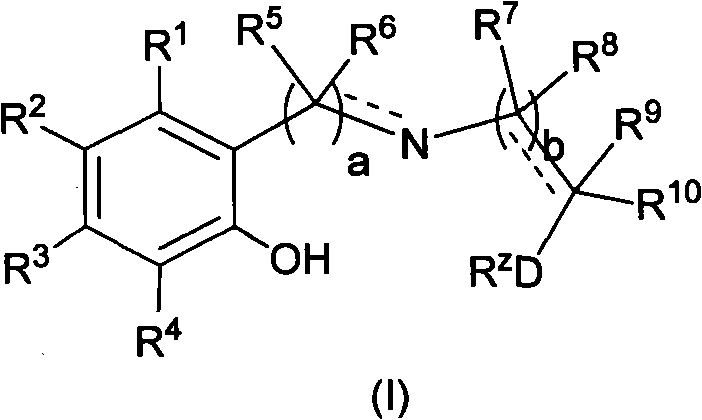

The invention relates to novel Ziegler-Natta olefin polymerization catalysts with single-site center property. The catalysts are characterized in that the catalysts are obtained by adopting a one-pot method and adding novel multidentate ligands (I), magnesium compounds, metal compounds and carriers to tetrahydrofuran solution for treatment. Under the action of alkylaluminium or alkylaluminoxane and other cocatalysts, the catalysts can obtain ethylene copolymer and homopolymer products with controllable molecular weight distribution (1.6-40) and uniformly distributed comonomers through high activity. The catalysts can realize catalytic ethylene polymerization, as well as the slurry-process or gas-phase-process homopolymerization or copolymerization of ethylene and 1-olefin, annular olefin, polar monomer and the like.

Owner:SHANGHAI INST OF ORGANIC CHEMISTRY - CHINESE ACAD OF SCI

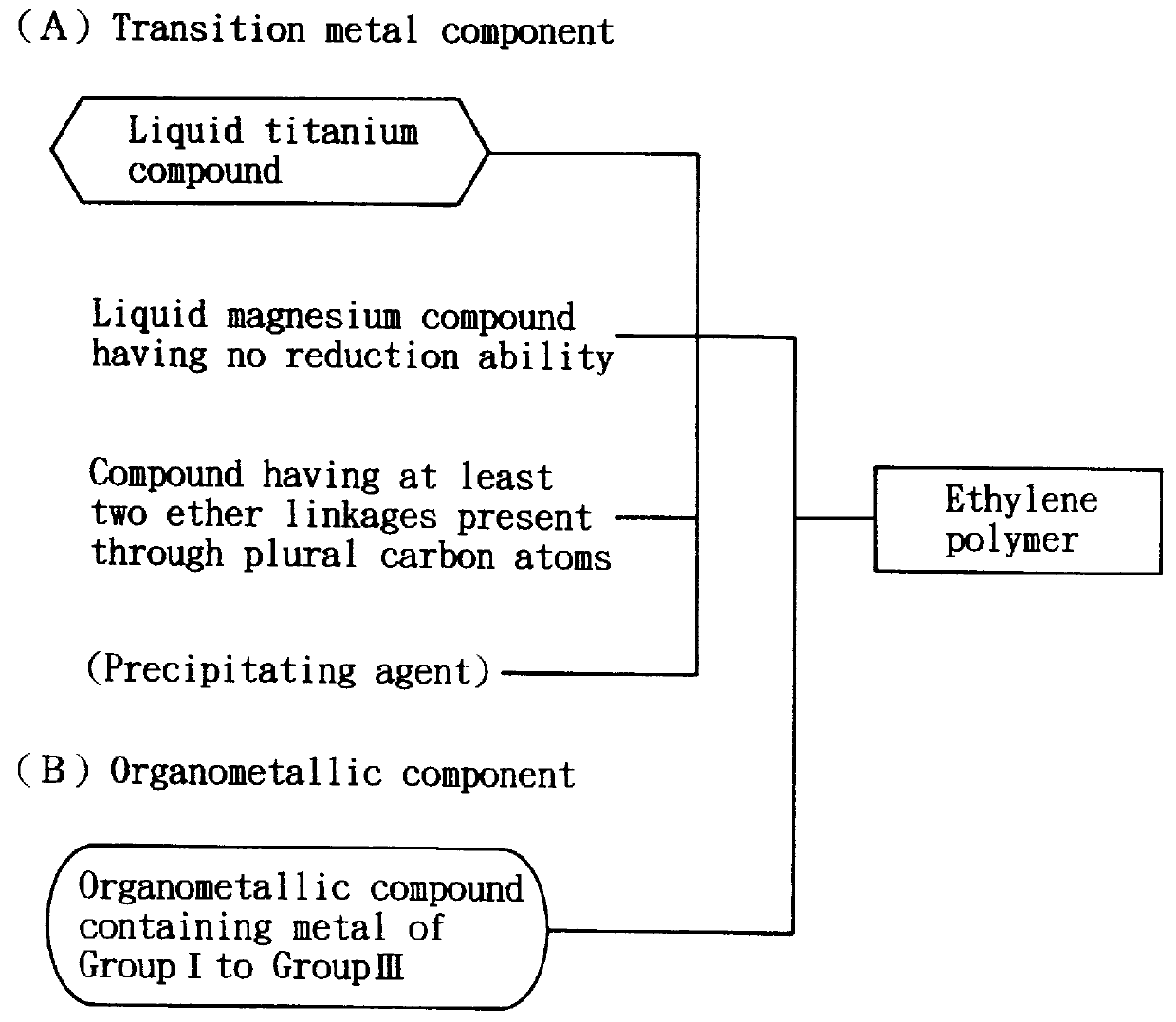

Ethylene polymer and process for preparing the same

InactiveUS6054542AGood molding effectPoor appearanceOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationSwelling ratioPolymer science

An ethylene polymer having small values of Mw / Mn and Mz / Mw, a small proportion of long-chain branches, a high melt tension and a high swell ratio and a process for preparing the same by polymerizing ethylene in the presence of an ethylene polymerization catalyst comprising a solid titanium catalyst component containing titanium, magnesium, halogen and a compound having at least two ether linkages present through plural atoms with an organometallic compound catalyst component.

Owner:MITSUI CHEM INC

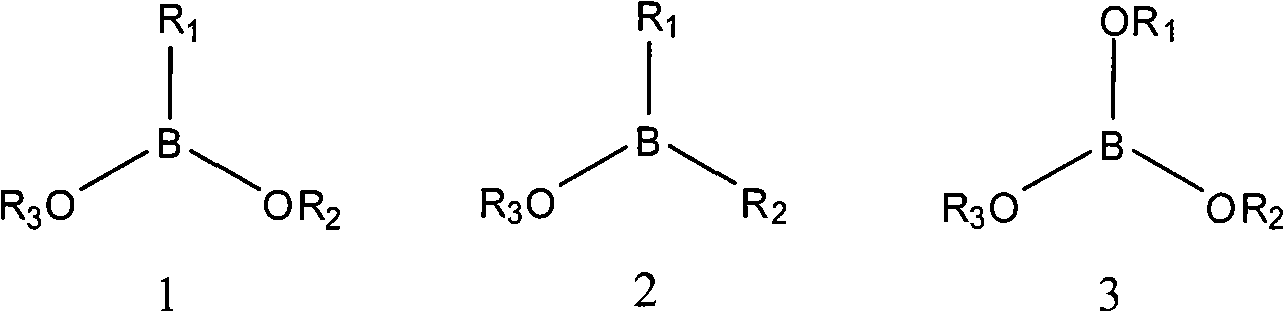

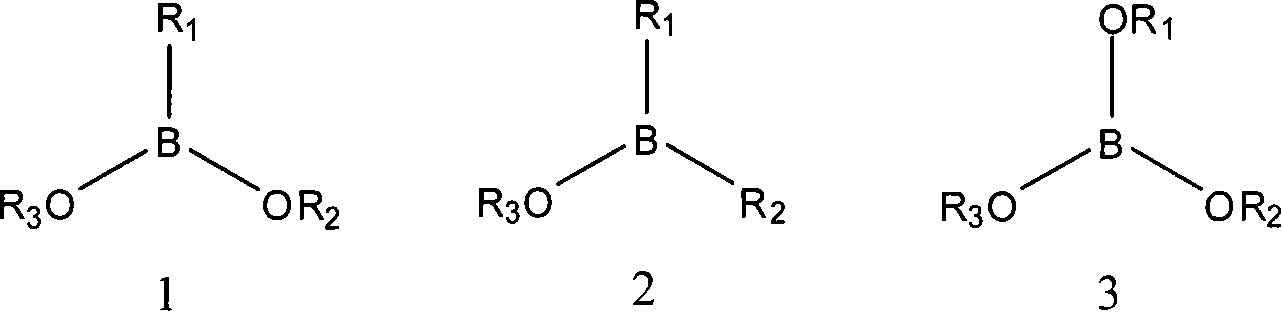

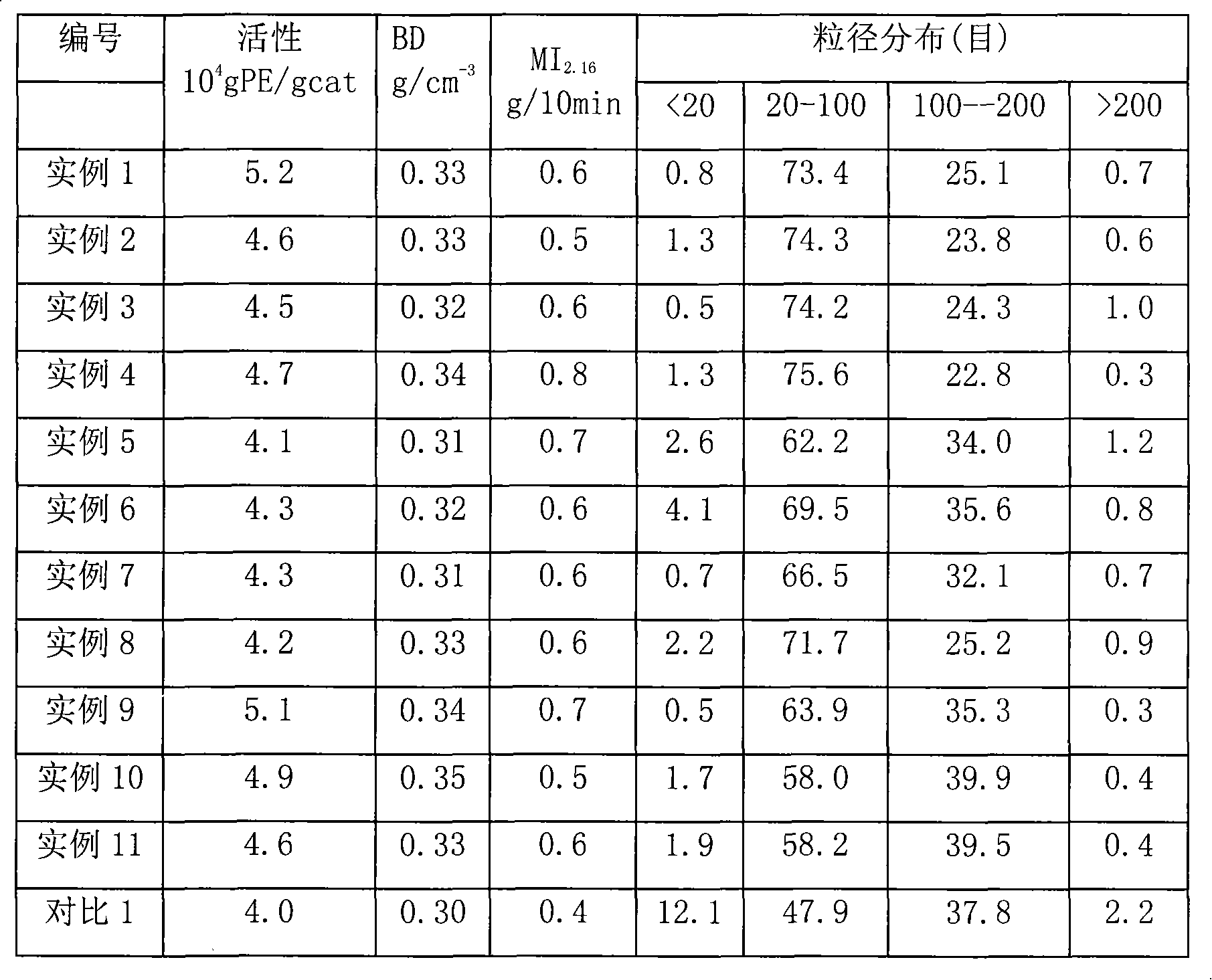

Catalyst component used for ethylene polymerization reaction and catalyst thereof

The invention relates to a catalyst component used for ethylene polymerization reaction and a catalyst thereof. The catalyst component contains magnesium composite, titanium compound, organic alcoholic compound and boron compound. The organic boron compound is selected from at least one of structural formula 1, structural formula 2 and structural formula 3. The catalyst of the invention is quite applicable for a slurry polymerization process of ethylene, and the catalyst has better hydrogen regulation sensitivity and higher catalytic activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

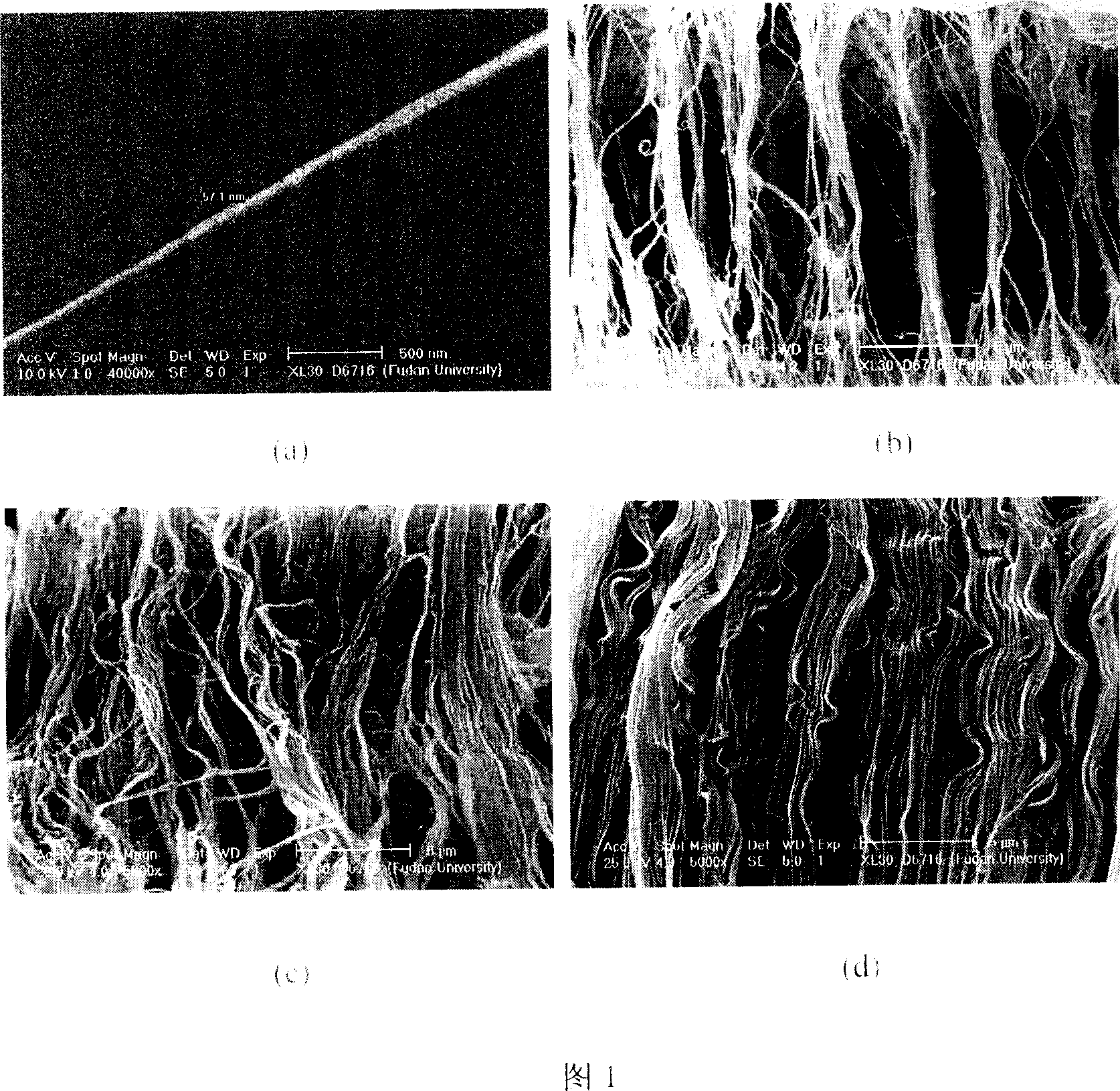

In situ polymerization preparing method for carbon nano tube and polytene composite material

InactiveCN1640923AExcellent ElectricalImprove mechanical propertiesIn situ polymerizationCarbon nanotube

The present invention relates to the preparation process of one kind of composite carbon nanotube / polyethylene material. Single or multiple wall carbon nanotube is treated with oxidant to obtain functional carbon nanotube with hydroxyl, carbonyl and carboxyl groups on the surface; and further reacted with alkyl metallizing compound in inert atmosphere to connect metal organic matter component capable of catalyzing ethylene polymerization to obtain carbon nanotube supporting olefin polymerization catalyst. In the presence of alkyl metallizing compound as catalyst assistant, the prepared carbon nanotube supporting olefin polymerization catalyst catalyzes ethylene polymerization to obtain the composite carbon nanotube / polyethylene material. The composite material has two components homogeneously dispersed, electric and mechanical performance higher than other polyethylene material.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

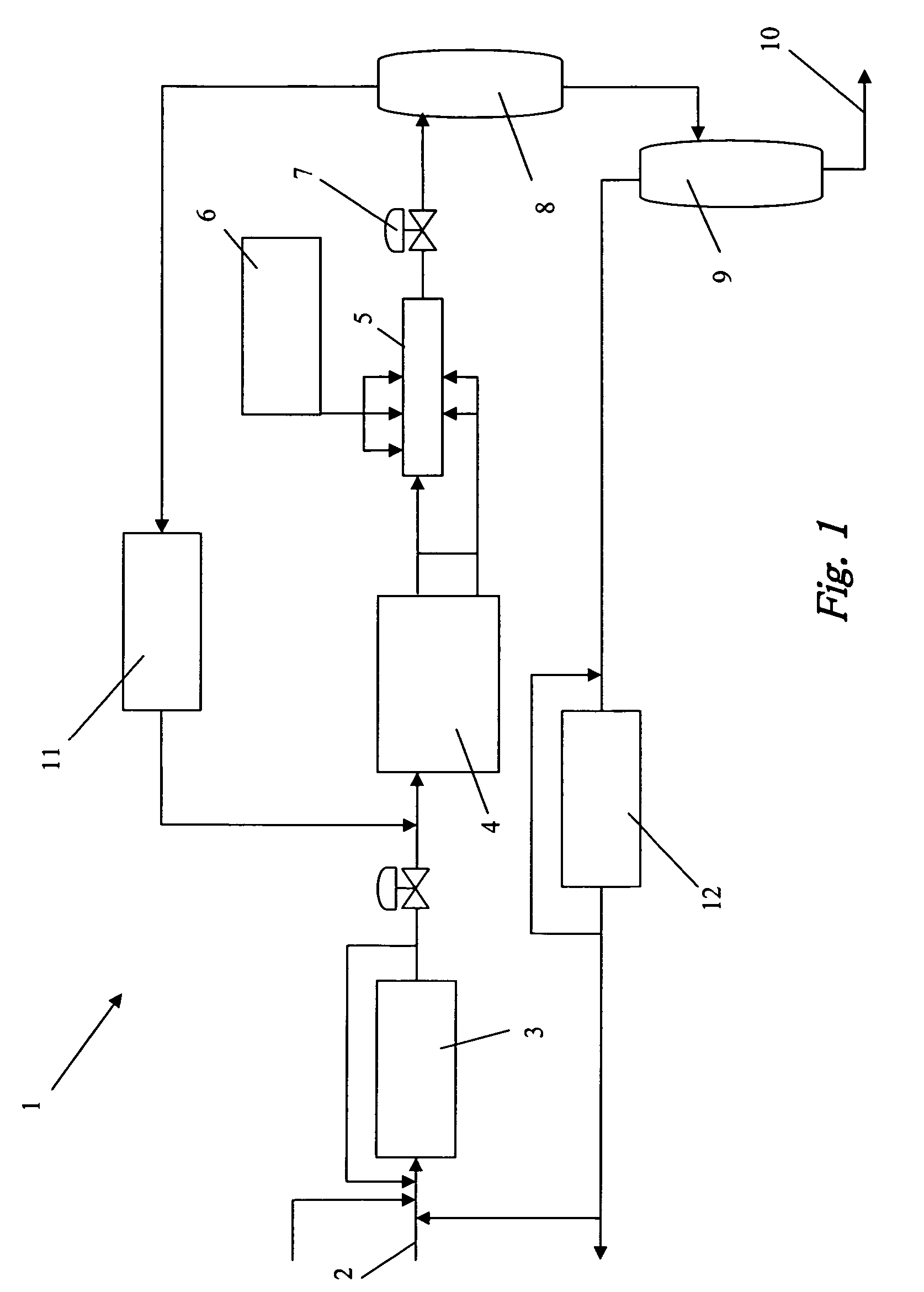

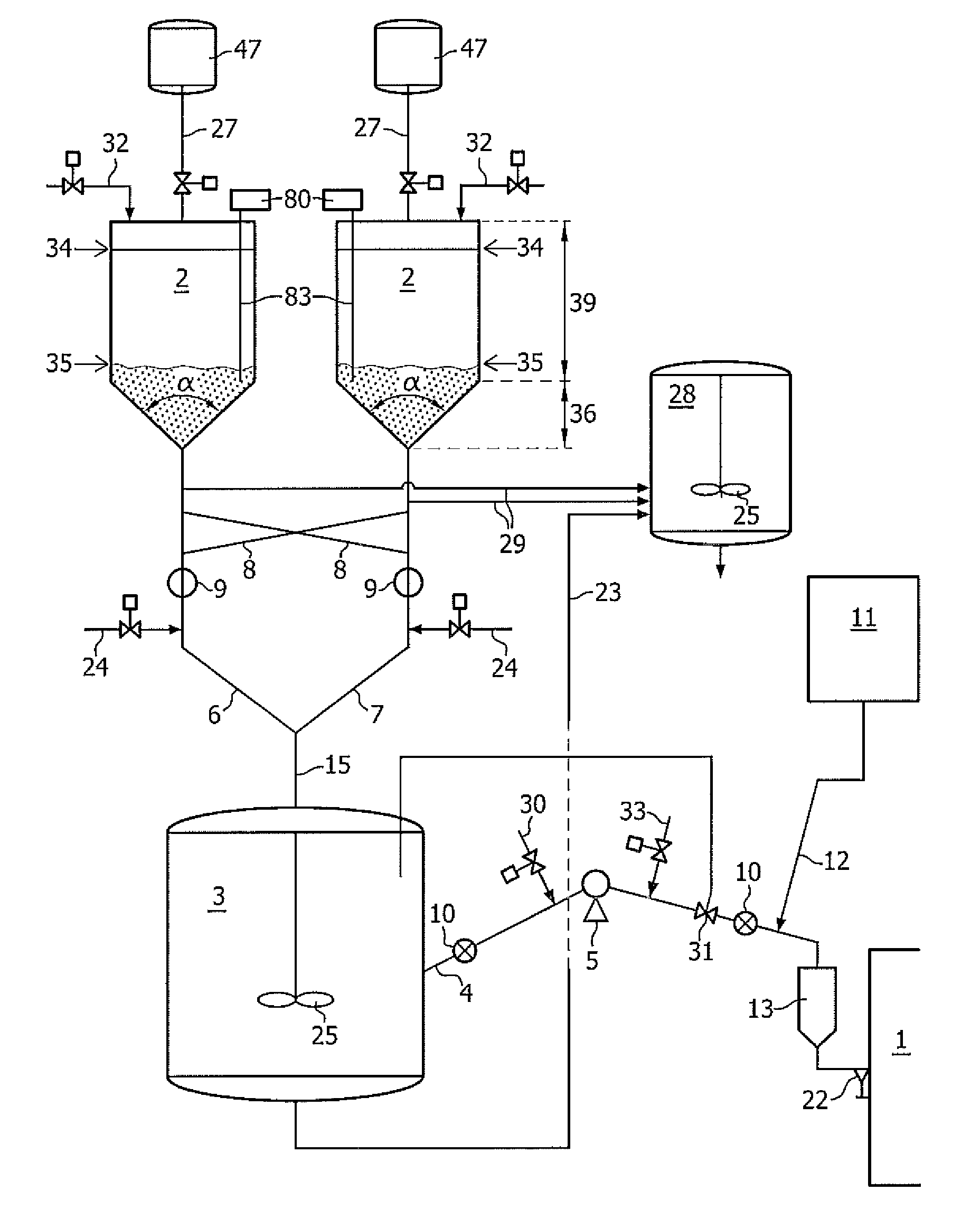

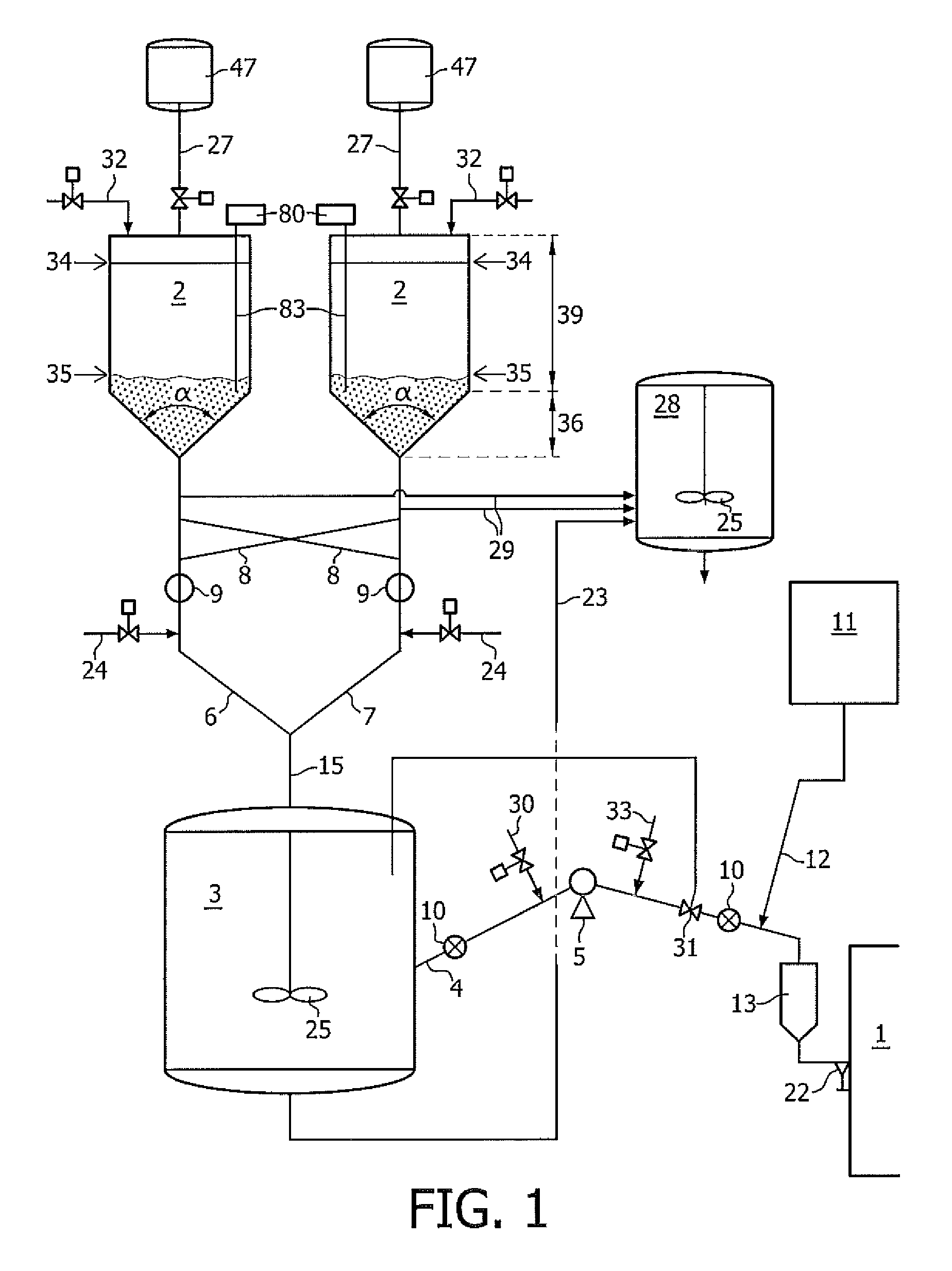

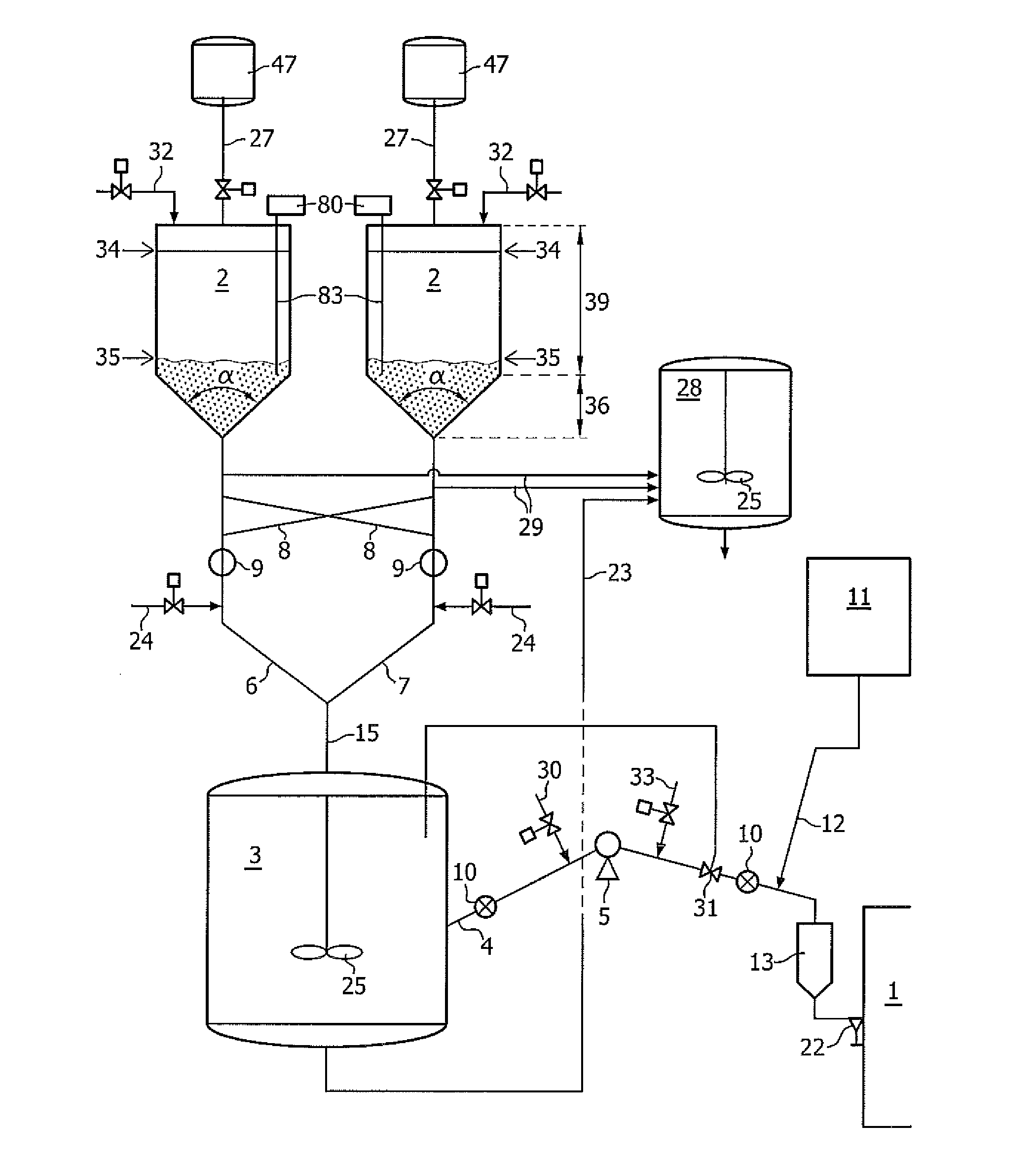

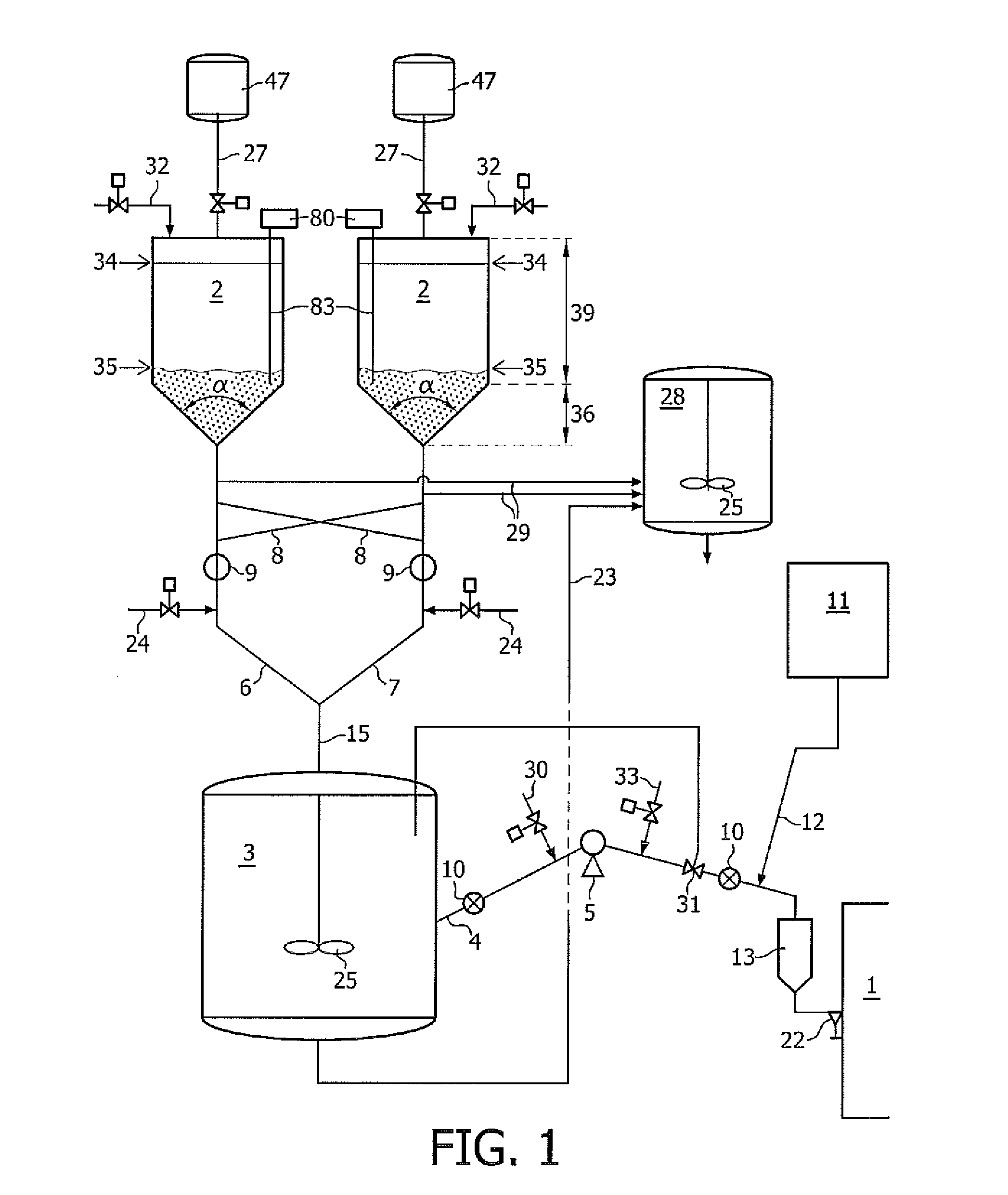

Method for replacing incompatible ethylene polymerization catalysts

The present invention relates to a method for optimizing the sequential use of at least two ethylene polymerization catalysts to an ethylene polymerization loop reactor, comprising:transferring to a mixing vessel a first ethylene polymerization catalyst and a first diluent, thereby providing a first catalyst slurry,transferring said first catalyst slurry from said mixing vessel to an ethylene polymerization loop reactor at a concentration suitable for polymerizing ethylene,increasing the ratio of said diluent to said first ethylene polymerization catalyst in said first catalyst slurry,stopping the supply of said first catalyst slurry to said mixing vessel,stopping the supply of said first catalyst slurry to said ethylene polymerization loop reactor,stopping the supply of ethylene to said ethylene polymerization loop reactor,removing said first catalyst slurry from said ethylene polymerization loop reactor,emptying said mixing vessel,optionally rinsing said mixing vessel with fresh diluent,transferring to said mixing vessel a second ethylene polymerization catalyst and a second diluent, thereby providing a second catalyst slurry,decreasing the ratio of said second diluent to said second ethylene polymerization catalyst in said mixing vessel to obtain a concentration of said second ethylene polymerization catalyst in said second diluent suitable for polymerizing ethylene,transferring said second ethylene polymerization catalyst slurry from said mixing vessel to said ethylene polymerization reactor,restoring the supply of ethylene to said ethylene polymerization loop reactor,restarting ethylene polymerization in said ethylene polymerization loop reactor.

Owner:TOTAL RES & TECH FELUY

Method for replacing compatible ethylene polymerization catalysts

ActiveUS20120252989A1The implementation process is simpleReduce the amount requiredChemical/physical/physico-chemical processesPolymer sciencePolymerization catalysts

The present invention relates to a method for optimizing the sequential feeding of at least two ethylene polymerization catalysts to an ethylene polymerization reactor, comprising:transferring to a mixing vessel a first ethylene polymerization catalyst and a first diluent,decreasing the concentration of said first ethylene polymerization catalyst in said mixing vessel,transferring to said mixing vessel a second ethylene polymerization catalyst and a second diluent,progressively replacing said first ethylene polymerization catalyst by said second ethylene polymerization catalyst and said first diluent by said second diluent,increasing the concentration of said second ethylene polymerization catalyst in said mixing vessel,sequentially transferring said first ethylene polymerization catalyst and said second ethylene polymerization catalyst from said mixing vessel to an ethylene polymerization reactor.

Owner:TOTAL RES & TECH FELUY

Catalyst for ethylene polymerization or copolymerization and its preparing method

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com