Patents

Literature

197results about How to "Increase the degree of branching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

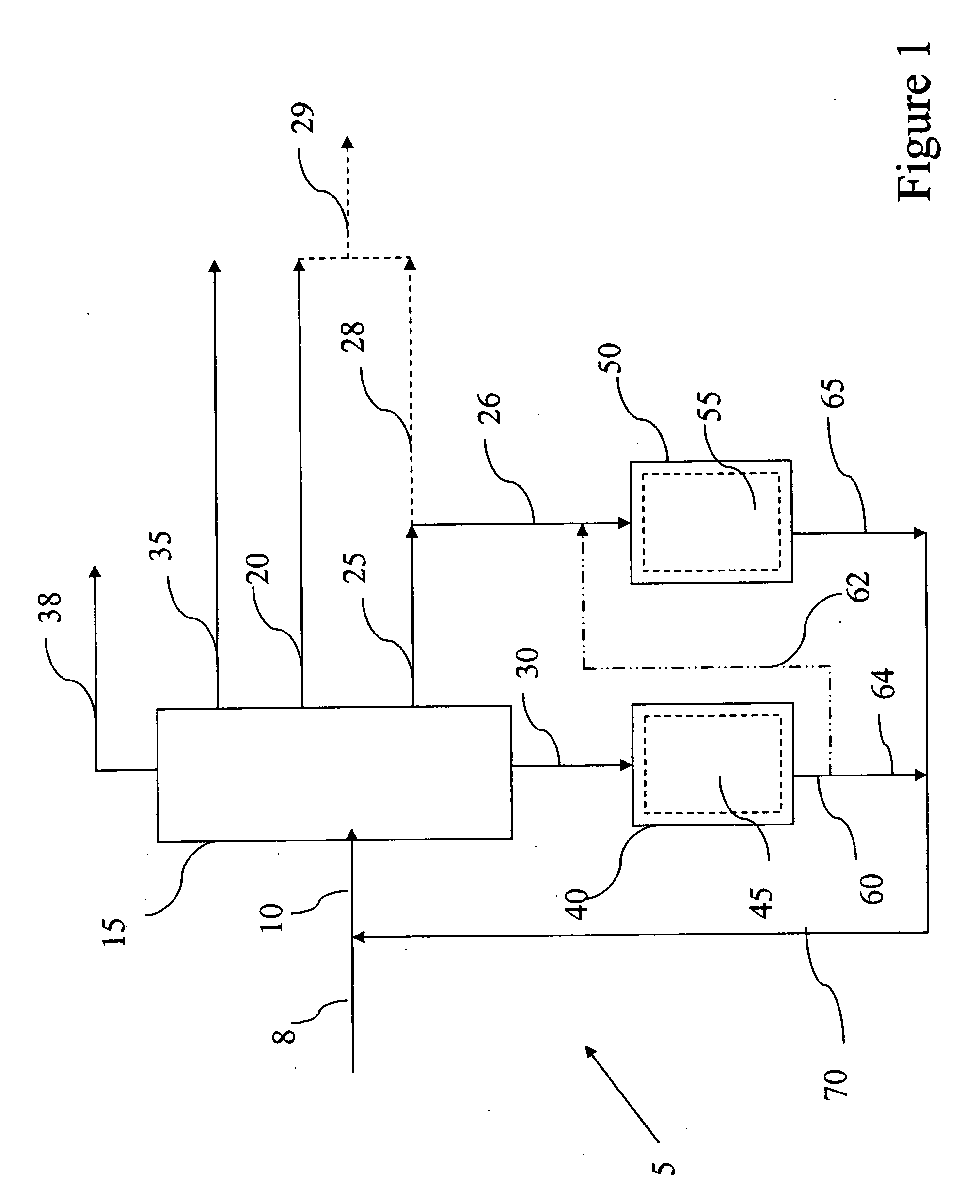

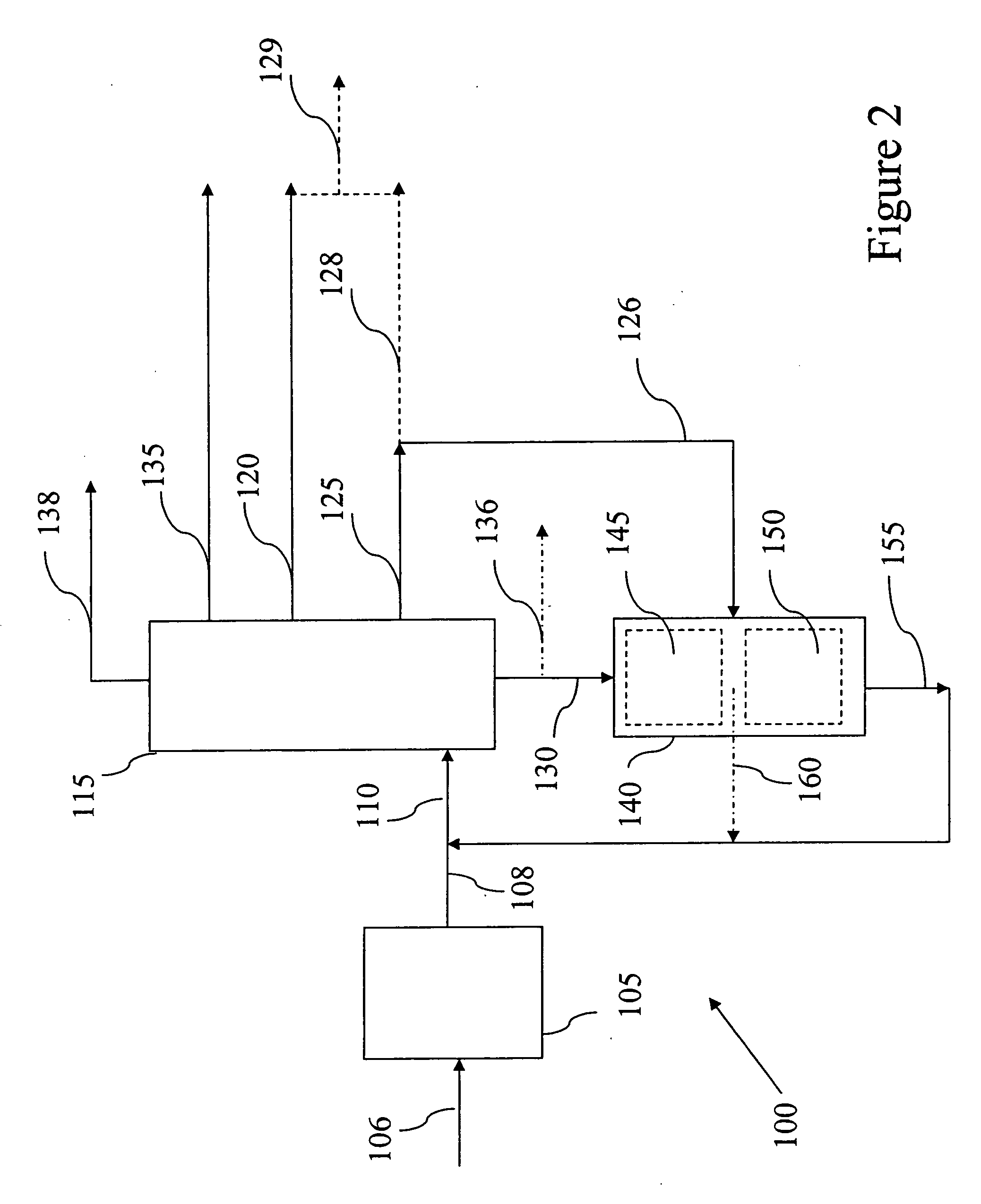

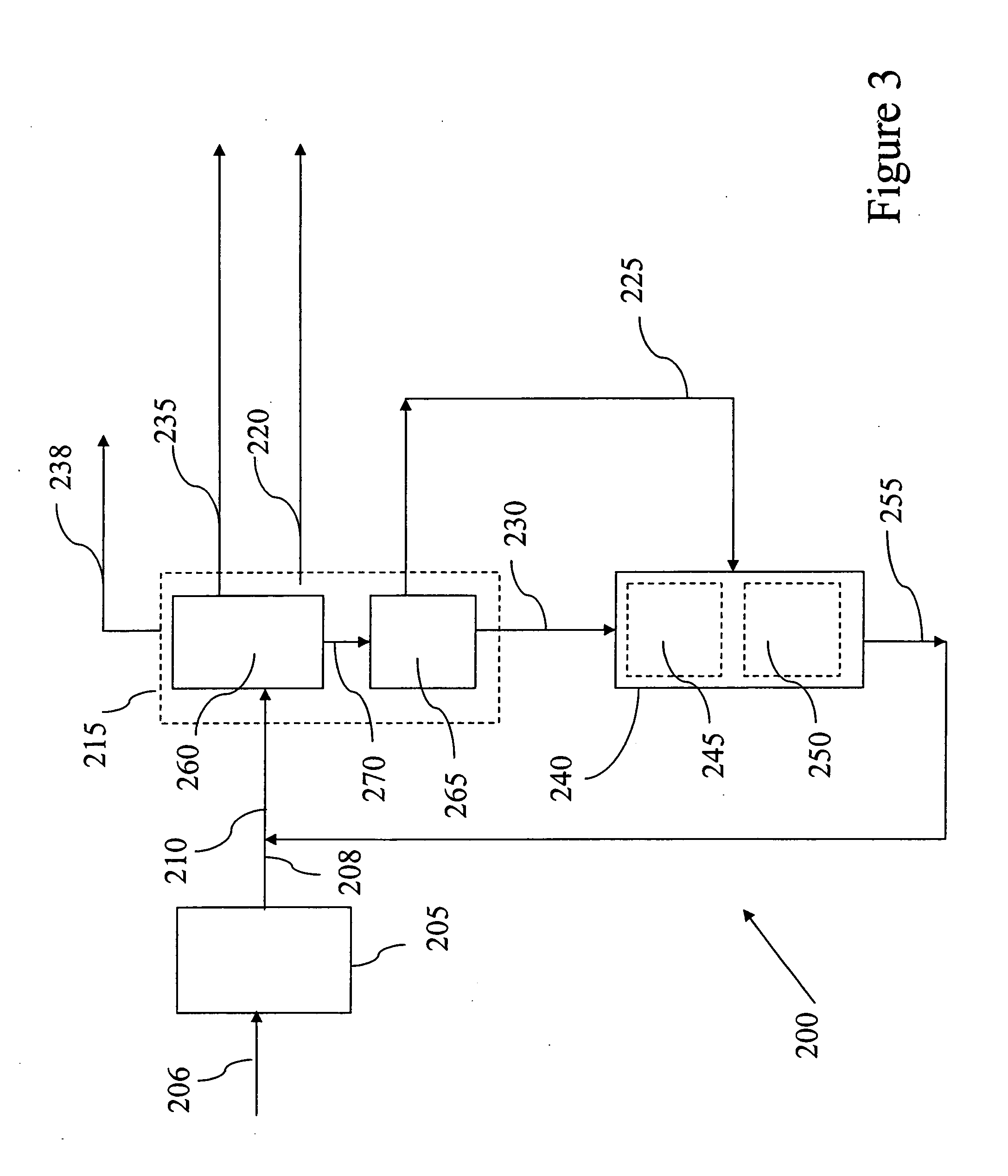

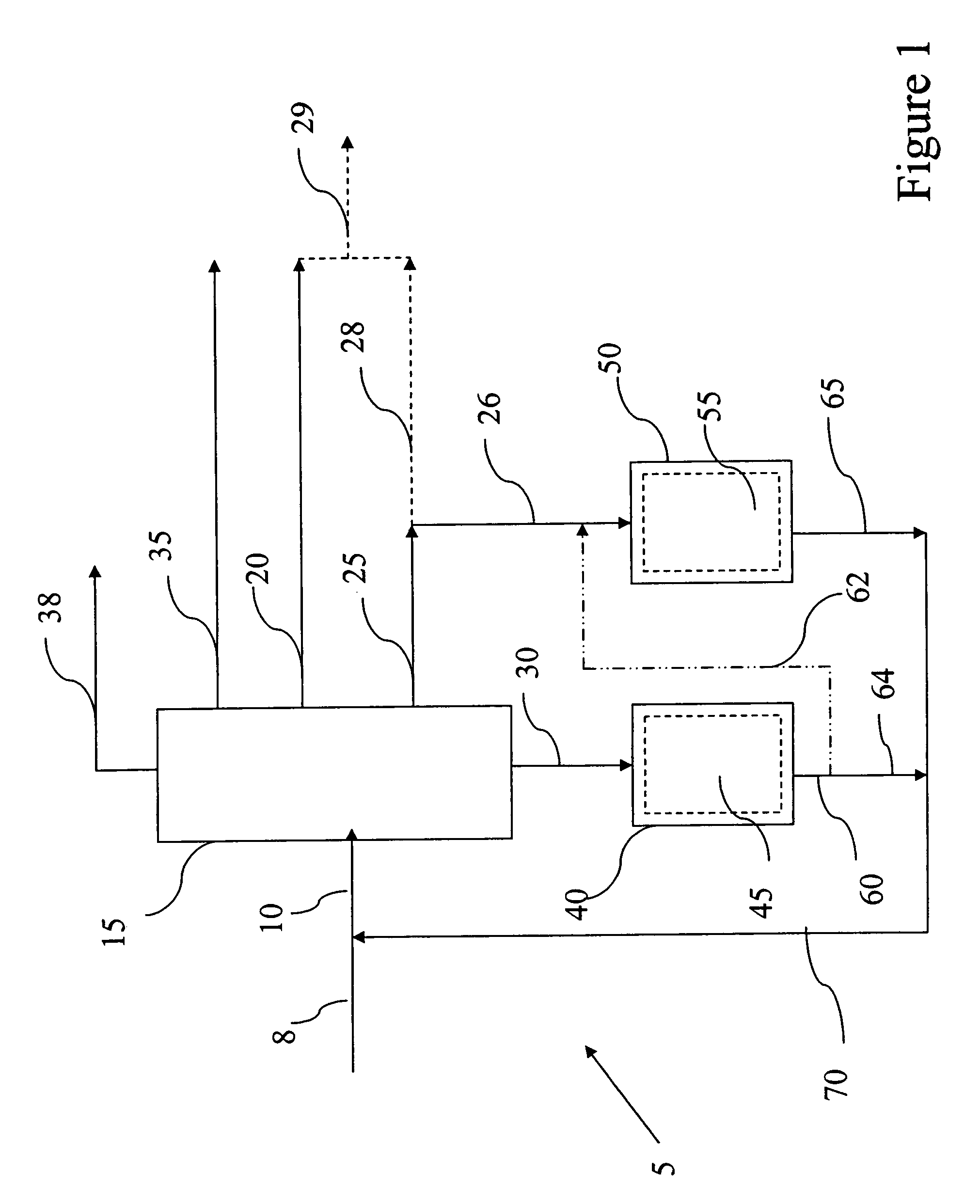

Hydroprocessing methods and apparatus for use in the preparation of liquid hydrocarbons

ActiveUS20050205462A1Easy to prepareEnhancing yield and cold-flow propertyTreatment with plural parallel cracking stages onlyTreatment with plural parallel stages onlyWaxProduction rate

The present invention is generally related towards enhancing the yield and / or cold-flow properties of certain hydrocarbon products, increasing the degree of isomerization in a diesel product and / or increasing the production rate of a diesel product. The embodiments generally include reducing the residence time of lighter hydrocarbon fractions during hydrocracking, thereby decreasing secondary cracking, by various configurations of introducing at least two hydrocarbon feedstreams of different boiling ranges at different entry points in a hydrocracking unit. A method further includes forming a hydrocarbons stream comprising primarily C5+ Fischer-Tropsch hydrocarbon products; fractionating hydrocarbons stream to form at least a wax fraction and an intermediate fraction which serve as separate feedstreams to a hydrocracking unit comprising at least two hydroconversion zones. One embodiment comprises the use of a bifunctional catalyst in one of the hydrocracking zones so as to favor hydroisomerization of hydrocarbons to favor the formation of branched paraffins boiling in the diesel range.

Owner:PHILLIPS 66 CO

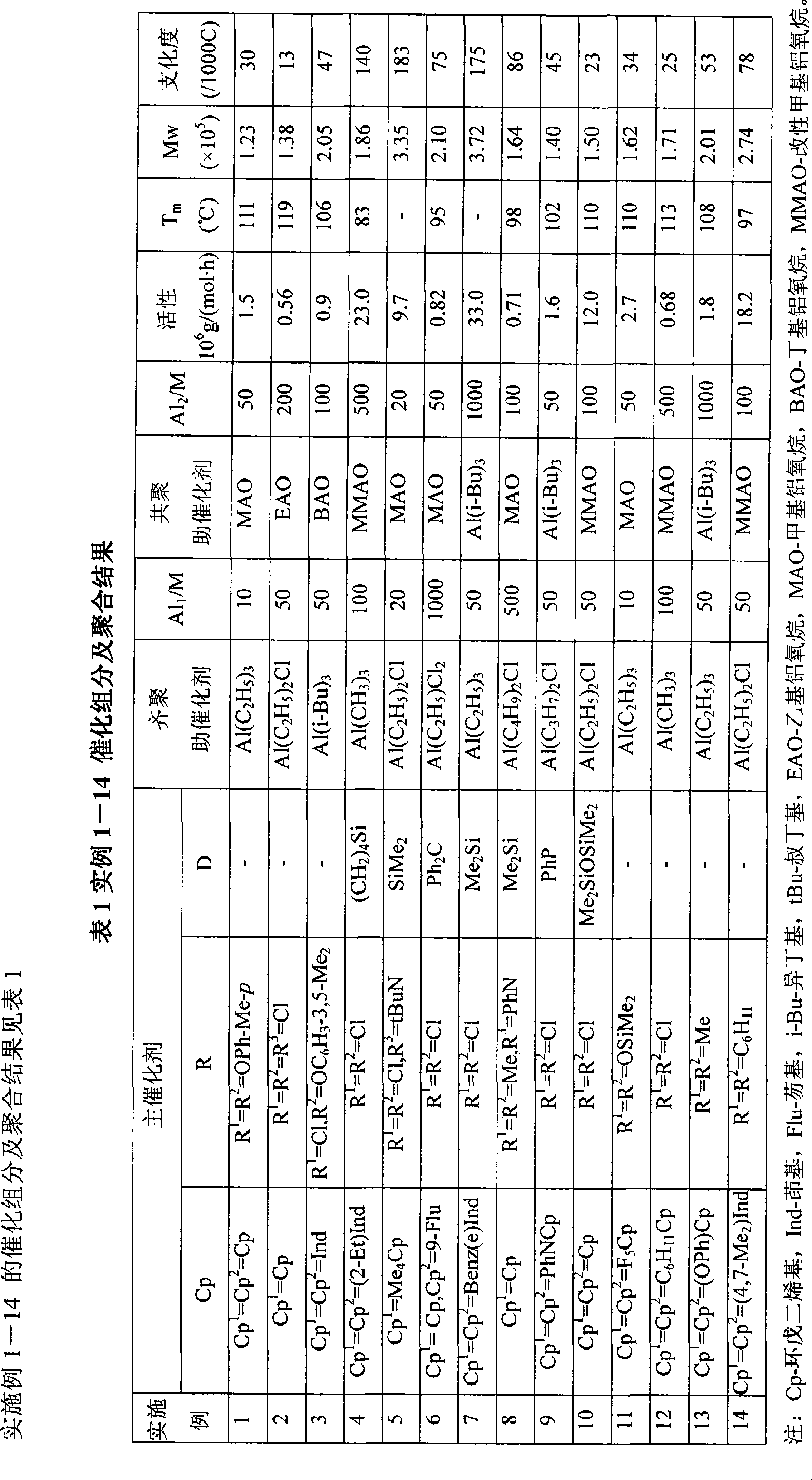

Metallocene domino catalytic system for preparing branched polyethylene using ethylene as only monomer and use thereof

InactiveCN101392036ALower synthesis costAchieve the effect of molecular tailoringTriisobutylaluminiumStructural formula

The invention discloses a domino catalyzing system of a primary metallocene catalyst, which takes ethane as a sole monomer to prepare branched polyethylene, and the application thereof, which relates to vinyl copolymer. the catalyzing system is a compound catalyzing system consisting of the single primary metallocene catalyst and two different catalyst promoters, wherein, the primary catalyst is a metallocene catalyst with a structural formula of Cp<1>MR<1>R<2>R<3>, Cp<1>Cp<2>MR<1>R<2> or Cp<1>-D-Cp<2>MR<1>R<2>; alkyl aluminium acts as an oligomerization catalyst promoter; methylaluminoxane or triisobutyl aluminium or triethyl aluminum that is not used together with the oligomerization catalyst promoter acts as a copolymerization catalyst promoter; the mole ratio between the oligomerization catalyst promoter and the primary catalyst is 10-1000 to 1, and the mole ratio between the copolymerization catalyst promoter and the primary catalyst is 20-1000 to 1. The catalytic activity of the metallocene domino catalyzing system for preparing the branched polyethylene is 5 multiplied by 10<5> to 5 multiplied by 10<7>gPE / (molM per hour), the degree of branching is 10-200 / 1000C, the molecular weight of the branched polyethylene prepared under the effect of the catalyzing system ranges from 1 multiplied by 10<5> to 4 multiplied by 10<5> and the melting point is below 120 DEG C or even no melting point exists.

Owner:HEBEI UNIV OF TECH

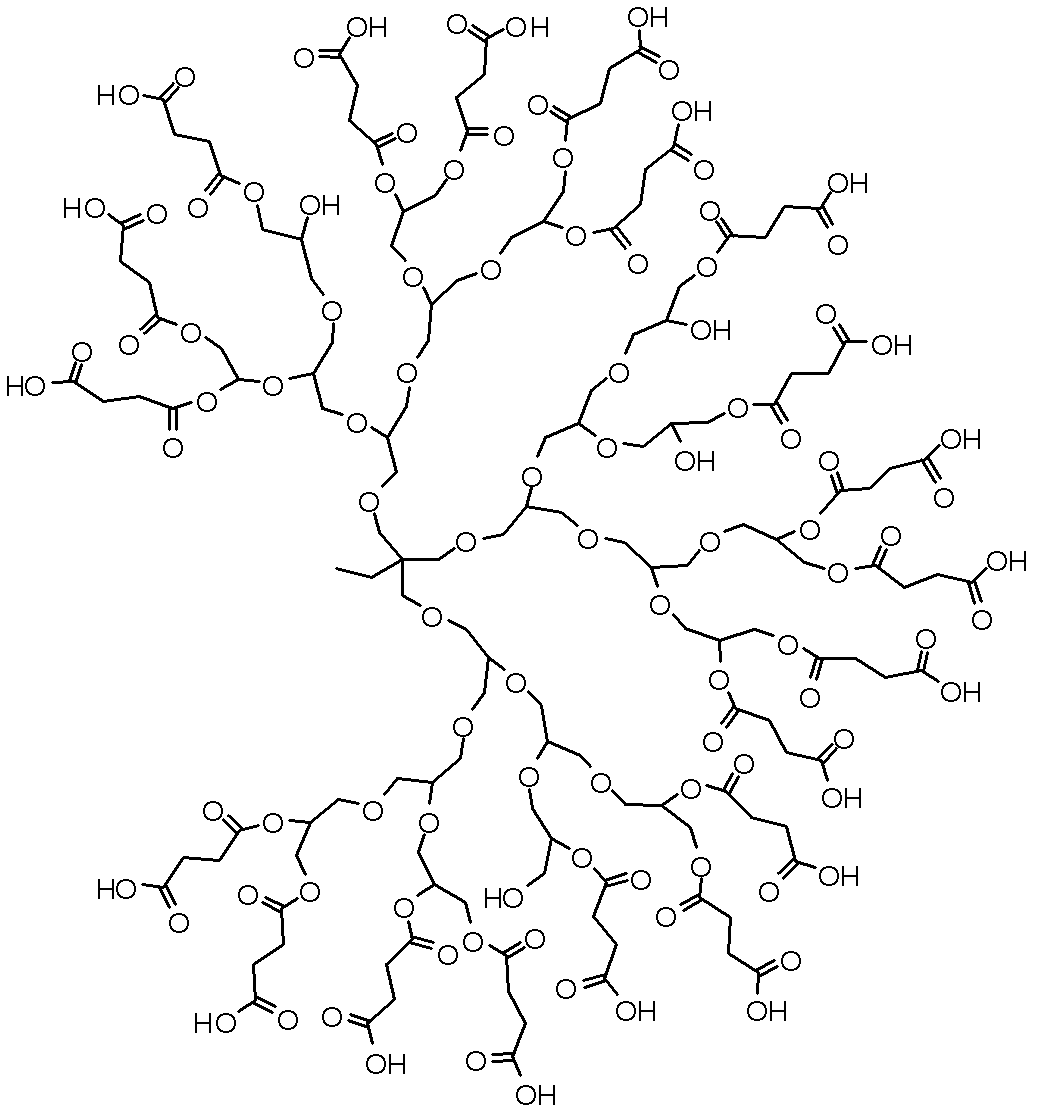

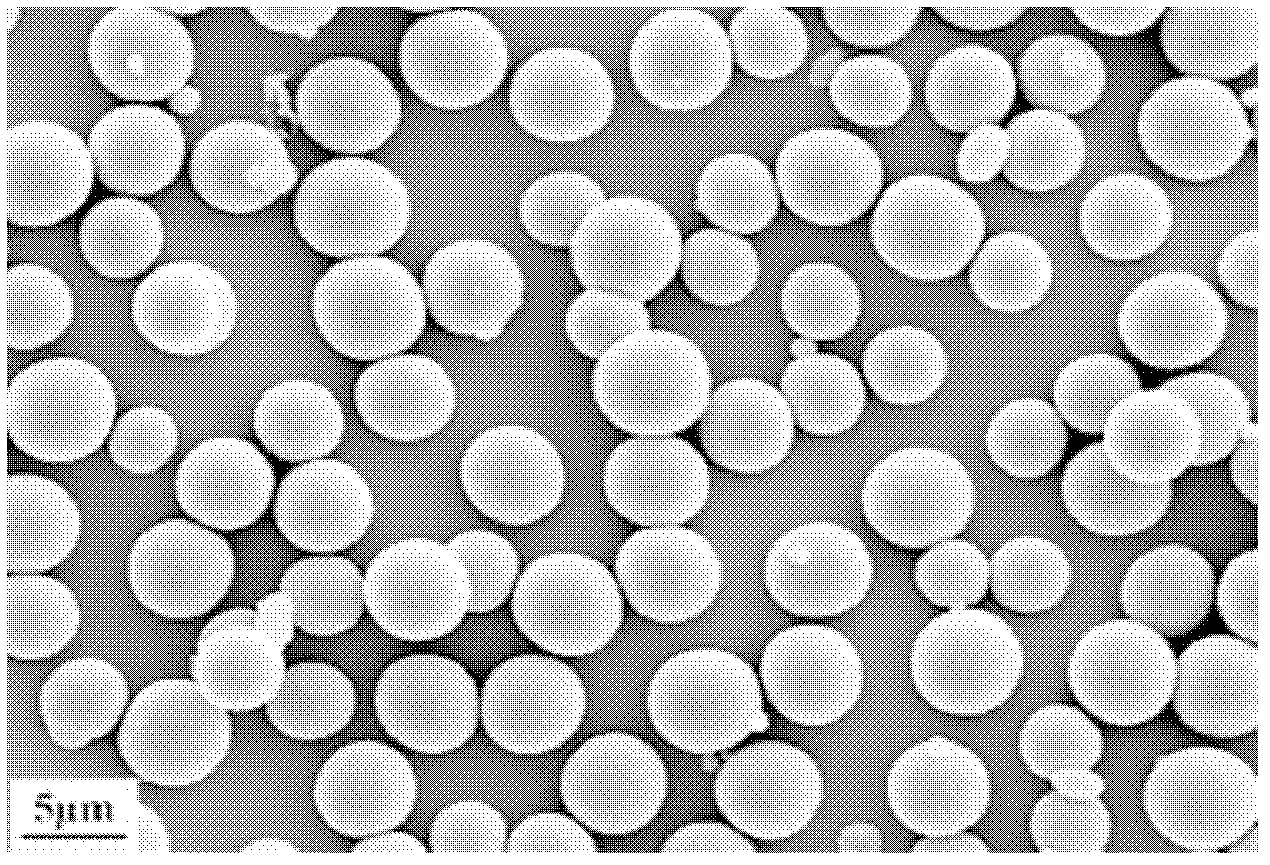

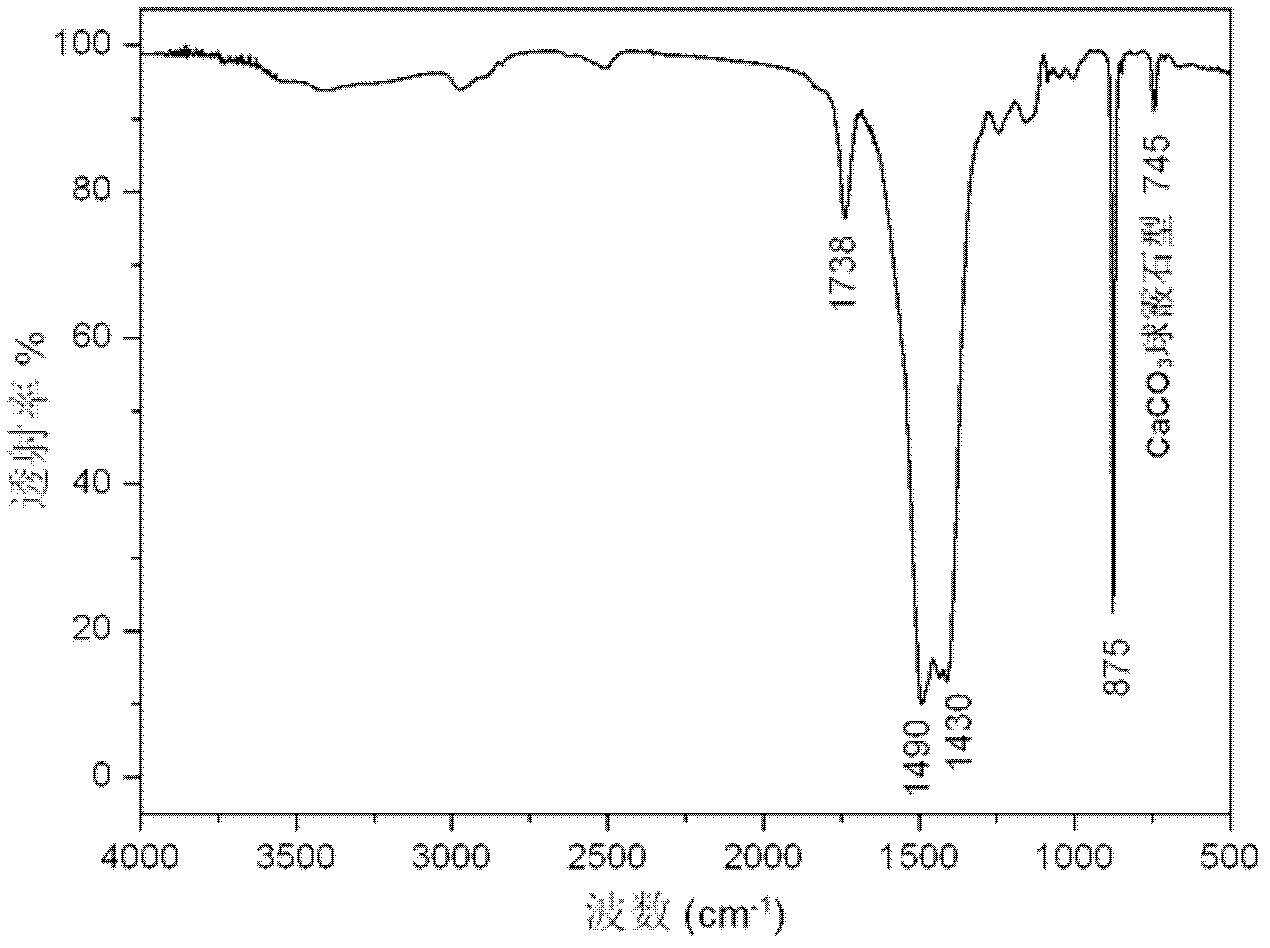

Monodispersed vaterite type calcium carbonate microsphere and preparation method thereof

InactiveCN102583485AIncrease the degree of branchingHigh density of surface functional groupsCalcium/strontium/barium carbonatesBicarbonateCalcium carbonate

The invention relates to a preparation method of a monodispersed vaterite type calcium carbonate microsphere, which comprises the following steps of: (1) preparing a calcium salt aqueous solution with the concentration of 30-150mmol / L, and then, adjusting the pH value of the calcium salt aqueous solution to 8.5-10; (2) preparing a carbonate or hydrocarbonate aqueous solution with the concentration of 30-150mmol / L, and then, adjusting the pH value of the carbonate or hydrocarbonate aqueous solution to 8.5-10; (3) preparing a functional hyperbranched polyglycerol aqueous solution with the concentration of 20-400mg / L, and then, adjusting the pH value of the functional hyperbranched polyglycerol aqueous solution to 8.5-10; (4) mixing and uniformly stirring the carbonate or hydrocarbonate aqueous solution, the calcium salt aqueous solution and the functional hyperbranched polyglycerol aqueous solution at the temperature of 10-35 DEG C, and aging for 1-12h; and (5) centrifuging or filtering the mixed solution, cleaning a sediment, and drying to obtain the monodispersed vaterite type calcium carbonate microsphere. The monodispersed vaterite type calcium carbonate microsphere prepared by using the preparation method provided by the invention has the advantages of uniform particle size, stable crystal form and industrial application value.

Owner:NANJING UNIVERSTIY SUZHOU HIGH TECH INST +1

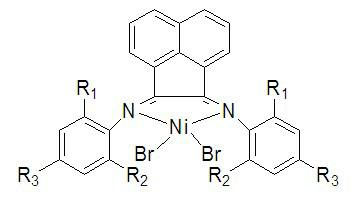

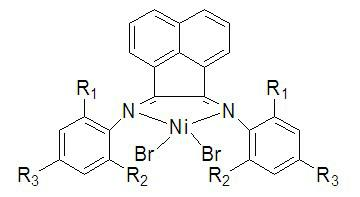

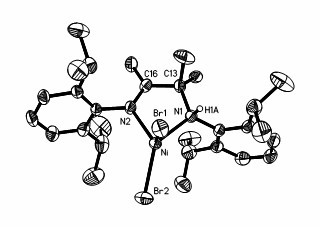

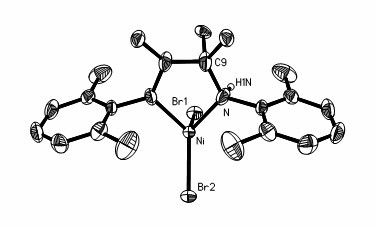

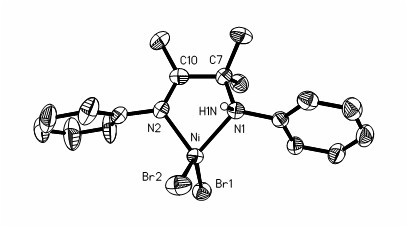

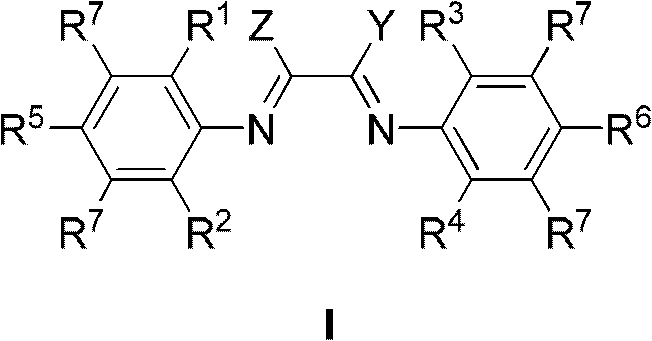

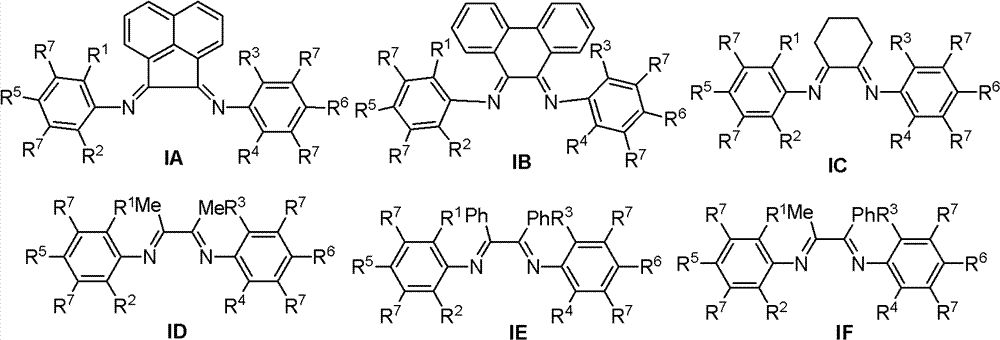

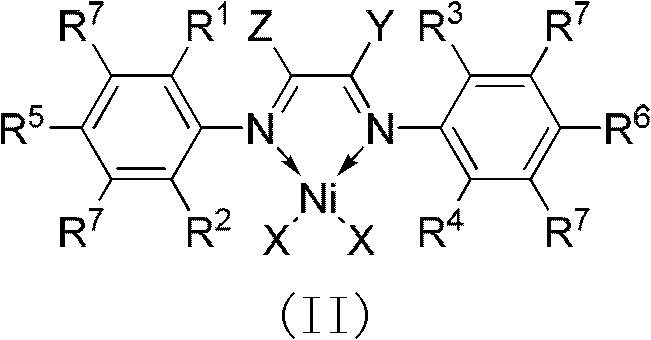

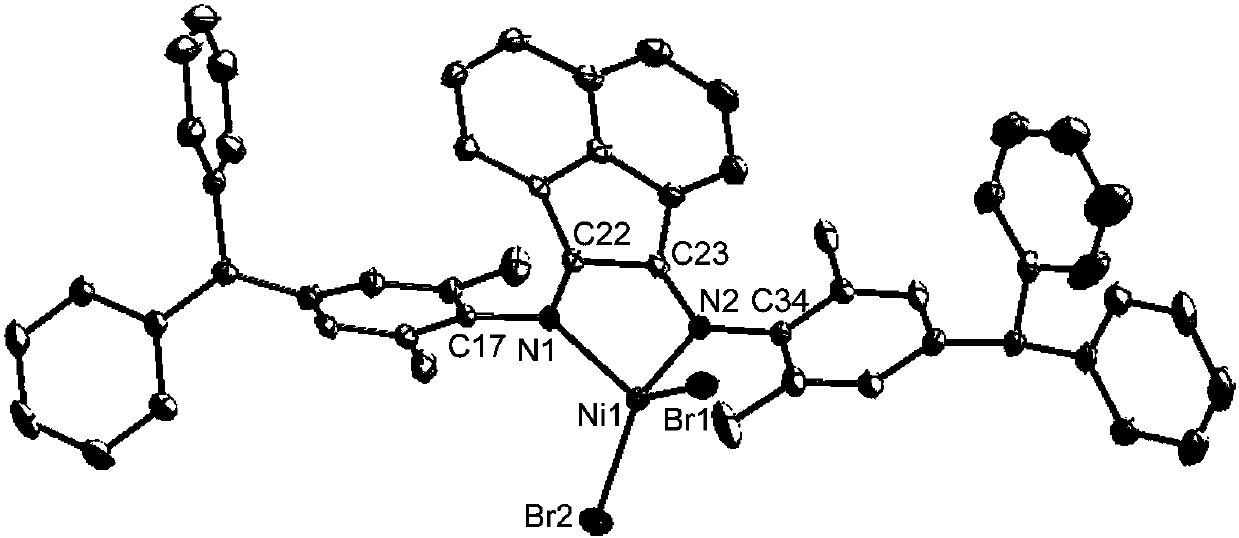

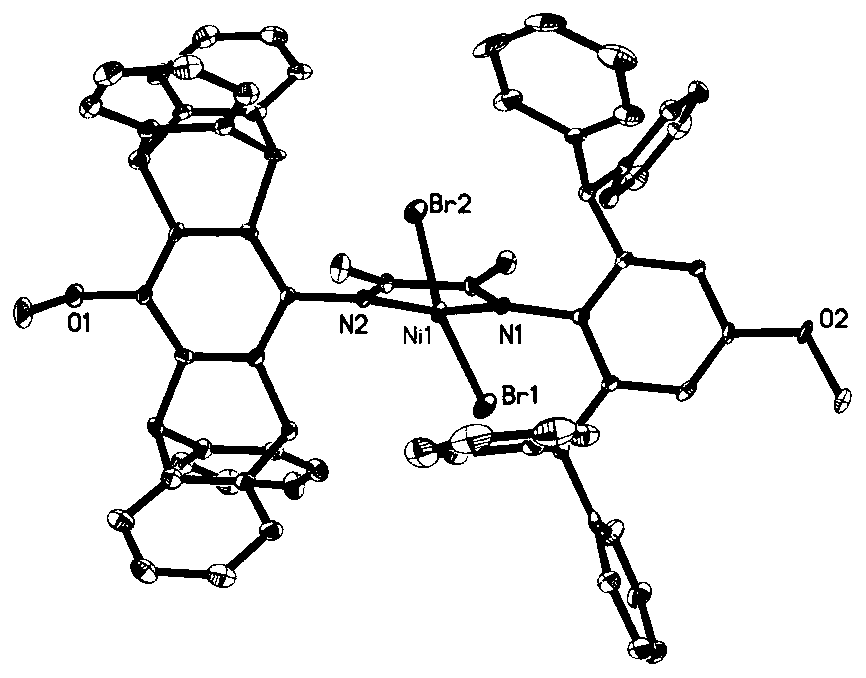

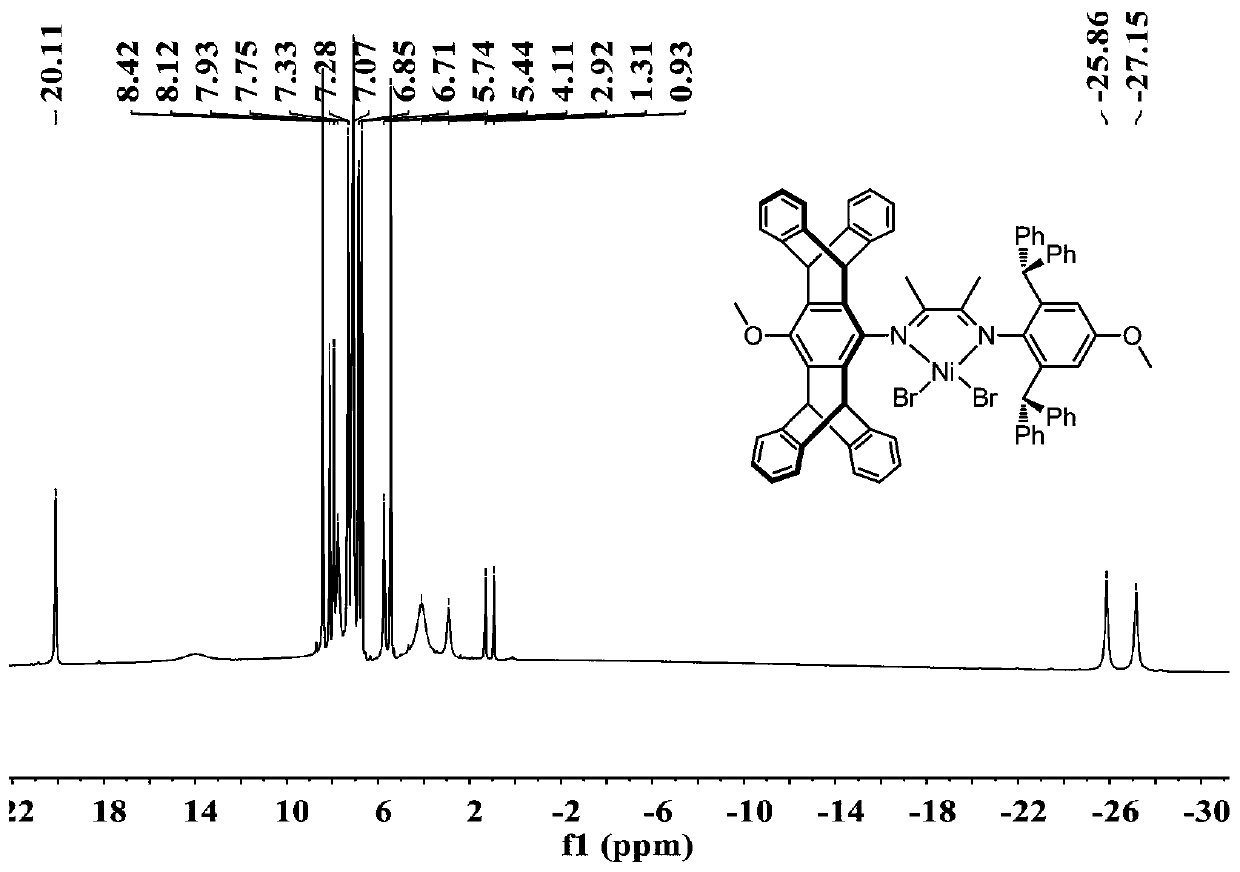

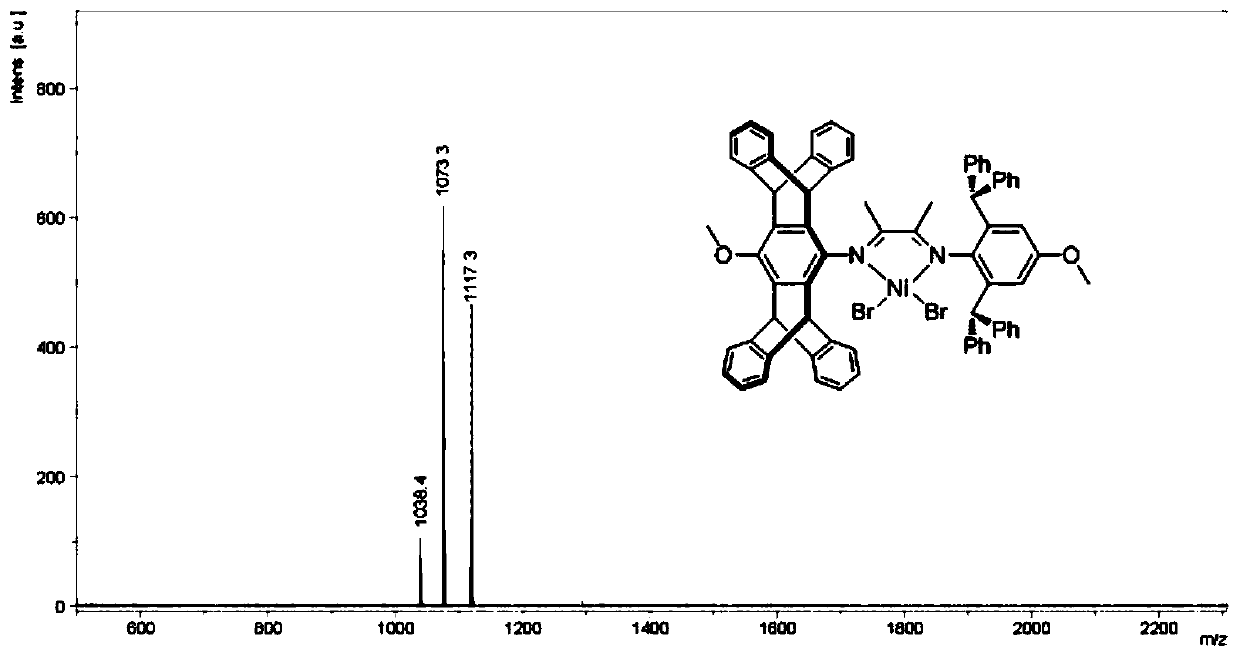

Alpha-diimine nickel (II) olefin polymerization catalyst as well as preparation method and application thereof

InactiveCN102060944AHigh activityIncrease the degree of branchingNickel organic compoundsAluminium chloridePolymer science

The invention discloses a novel late transition metal alpha-diimine nickel (II) olefin polymerization catalyst with a symmetrical structure. The catalyst is a didentate coordination compound formed by an alpha-diimine ligand with a symmetrical Schiff base structure and a halogenide of later transition metal nickel (II). In the presence of diethyl aluminium chloride (DEAC) used as a cocatalyst, the coordination compound catalyst of nickel has higher activity for catalyzing ethylene to polymerize, which can reach 107gPE / (mol Ni h Bar), and obtained polyethylene has higher degree of branching, which can reach 114 branched chains per 1,000C.

Owner:NORTHWEST NORMAL UNIVERSITY

Preparation method and application of amido-imine nickel vinyl polymerization catalyst

ActiveCN102250152AThe synthesis method is simpleRaw materials are cheap and easy to getNickel organic compoundsAnilineBiological activation

The invention discloses a preparation method of an amido-imine nickel catalyst and application of the amido-imine nickel catalyst to catalyzing vinyl polymerization. The complex has the structures of a formula (I) and a formula (II) shown in the specification, wherein R1 is hydrogen or alkyl, R2 is hydrogen or alkyl, R3 is hydrogen or alkyl, R4 is hydrogen or alkyl, and X is halogen. The preparation method of the complex comprises the following steps of: carrying out condensation reaction on a diketone compound and phenylamine through ketoamine to obtain an diimine compound; then reacting with trimethyl aluminum, and hydrolyzing to obtain an amido-imine ligand; finally carrying out coordination reaction on the amido-imine ligand and (DME)NiX2 under the condition without water and oxygen to obtain a nickel complex. The complex disclosed by the invention has a specific ligand replacement structure and can be used for catalyzing the vinyl polymerization under the activation of modified methyl aluminium oxane or alkyl aluminum, showing the characteristics of living polymerization under specific conditions and obtaining the high-molecular-weight narrowly-distributed branched polyethylene.

Owner:SUN YAT SEN UNIV

Reinforcing agent of amphoteric polyacrylamide cardboard paper

ActiveCN101666059AProduction safety and environmental protectionEnhancement effect is goodReinforcing agents additionPaper/cardboardCardboardPolyacrylamide

The invention discloses a reinforcing agent of amphoteric polyacrylamide cardboard paper. In the existing reinforcing agents, some have unobvious reinforcing effect, and some have extremely great pollution and damage to the environment. The reinforcing agent is prepared by deionized water, anion monomer, cation monomer, non-ion monomer, pH adjusting agent and an initiating system, and is characterized in that: the anion monomer selects the mixture of carboxylic group unsaturated monomer and sulfonic group unsaturated monomer for use; and the non-ion monomer selects the mixture of acrylamide or acrylamide derivative and methyl methacrylate or methyl methacrylate derivative for use. The reinforcing agent has favorable reinforcing effect and greatly improves the safety and environment protection of production.

Owner:ZHEJIANG TRANSFAR WHYYON CHEM

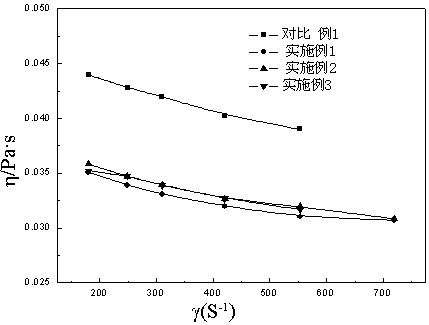

Highly branched oily alkane polymer, and preparation method and application thereof

ActiveCN103360517AHigh viscosity indexIncrease the degree of branchingLiquid hydrocarbon mixtures productionBase-materialsAlkaneProcedure Agents

The invention discloses a highly branched oily alkane polymer, and a preparation method and application thereof. The highly branched oily alkane polymer provided by the invention has the following characteristics that (a) the viscosity index ranges from 100 to 300, (b) the pour point ranges from minus 50 DEG C to minus 10 DEG C, (c) the molecular weight ranges from 300 to 500,000 g / mol, and (d) the number of methyls corresponding to every 1000 methylenes ranges from 100 to 500. The invention also discloses a preparation method and application of the highly branched oily alkane polymer, and a lubricating oil prepared from the highly branched oily alkane polymer. The highly branched oily alkane polymer provided by the invention is high in viscosity index and high in branching degree, and thus can be used as a base oil or a processing assistant for an advanced lubricating oil.

Owner:NANJING CHEMRUN CO LTD +1

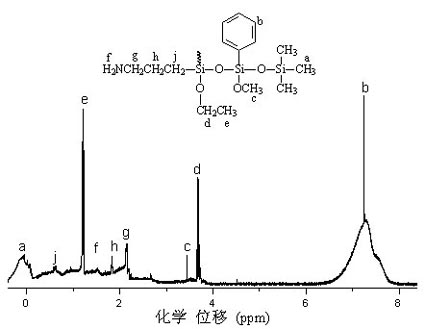

Flame-retardant bismaleimide resin and preparation method thereof

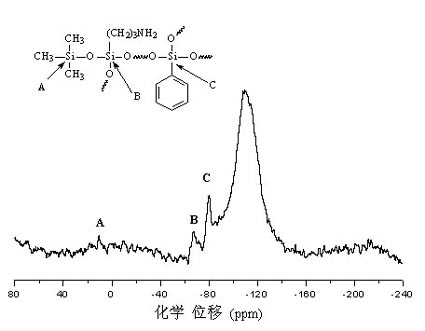

The invention discloses flame-retardant bismaleimide resin and a preparation method thereof. The flame-retardant bismaleimide resin is prepared by uniformly mixing 100 weight parts of bismaleimide resin, 0 to 200 weight parts of allyl compound and 1 to 100 weight parts of amino functional group-containing polysiloxane at the temperature of between 90 and 200 DEG C. The resin has high flame retardance, toughness, heat resistance and dielectric property, can be used as a high-performance resin matrix, an adhesive, an insulating varnish and the like, has great application prospect in the highly technical fields of aerospace, electronic and electrical appliances, transportation and the like; and the preparation method of the resin has the characteristics of high applicability, environmental friendliness, simple operation process and the like.

Owner:苏州亚傲鑫企业管理咨询有限公司

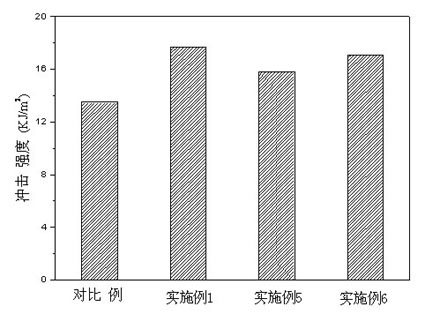

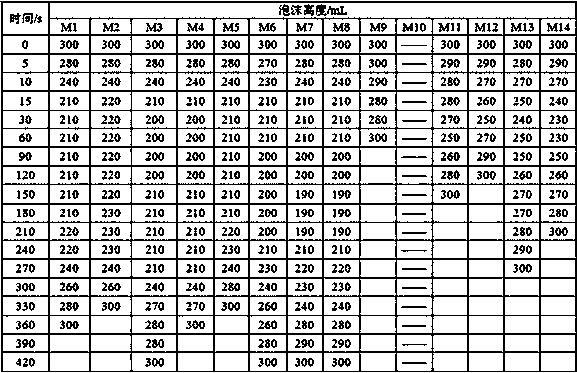

Organic silicon defoaming composition

ActiveCN105498305AIncrease the degree of branchingGood defoaming performanceFoam dispersion/preventionAlkyl transferCross-link

The invention relates to an organic silicon defoaming composition. Vinyl polysiloxane and hydrogen-containing silicon resin are subjected to a hydrogen silicon alkylation reaction, hydrogen-containing polysiloxane is dropwise added into the system to have a reaction to form a liquidity cross-linked polymer of a space structure, and finally the polymer is mixed with silicon resin, silicon dioxide and other filler to prepare the polysiloxane defoaming composition. The degree of branching of the cross-linked silicon oil can be greatly improved by the adoption of a small amount of hydrogen-containing silicon resin; when the method of dropwise adding the hydrogen-containing silicon oil is adopted for preparing the defoaming active matter, the reaction is mild and easy to control, the problems that reactant is prone to gelling and active matter is unstable in storage on the premise of adopting no polydimethylsiloxane or other solvents are solved, and the prepared active matter has the good and lasting defoaming performance in a high-temperature strong-base system.

Owner:JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD

Catalyst having a zeolitic core and zeolitic layer and the use of the catalyst for olefin oligomerization

InactiveUS6300536B1Raise the ratioLow degree of branchingMolecular sieve catalystsMolecular sieve catalystMolecular sieveSurface layer

A molecular sieve comprising a core having deposited thereon a surface layer, wherein the core is a zeolite containing silicon and at least one element selected from gallium and iron and the surface layer has a higher Si:Al ratio than that of the silicon:selected element ratio of the core, provides for lower branching in olefin oligomerization products.

Owner:EXXONMOBIL CHEM PAT INC

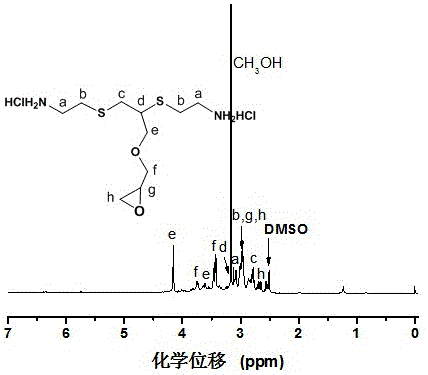

Hyperbranched polythioether polyamine, and preparation method and use thereof

ActiveCN106243354AIncrease the degree of branchingGood fluorescent effectBiocideOther chemical processesGlycidyl ethersFluorescence

The invention relates to the field of preparation methods of polyetheramine, and especially relates to a hyperbranched polythioether polyamine, and a preparation method and a use thereof. The preparation method is simple, raw materials are nontoxic and are easy to obtain, cysteamine hydrochloride can be prepared through hydrolyzing human and animal hair, alkynyl glycidyl ether can be directly purchased, and the method also has the advantages of low requirements of devices involved in the preparation process, no special or strict conditions, and mild reaction conditions. The molecular periphery of the hyperbranched polythioether polyamine has a plurality of primary amino groups, so the hyperbranched polythioether polyamine can be used as an epoxy resin flexible curing agent; and hyperbranched polythioether polyamine hydrochloride which is the precursor of the hyperbranched polythioether polyamine has a strong fluorescence effect, a good antibacterial performance and a good sterilizing performance.

Owner:YANTAI UNIV

In-situ polymerized organic-inorganic composite solid-state battery

ActiveCN111933894AIncrease elasticityGood compatibilityFinal product manufactureSecondary cellsElectrical conductorIn situ polymerization

The invention discloses an in-situ polymerized organic-inorganic composite solid-state battery, which is characterized in that a polymer solid-state electrolyte monomer or oligomer small molecule is compactly connected with an electrode active material, an inorganic fast ion conductor and a lithium salt in an in-situ polymerization manner, wherein the polymer solid electrolyte monomer or oligomersmall molecule at least comprises one compound containing an unsaturated carbon-carbon bond and carbonyl or sulfonyl or sulfinyl; the polymer solid electrolyte monomer or oligomer small molecule at least comprises one compound containing two or more unsaturated carbon-carbon bonds. The battery is small in interface resistance, high in conductivity and resistant to high voltage, the problem that asolid-state battery is poor in room-temperature and low-temperature performance is solved, and the production technological process is simple and reliable.

Owner:安普瑞斯(无锡)有限公司

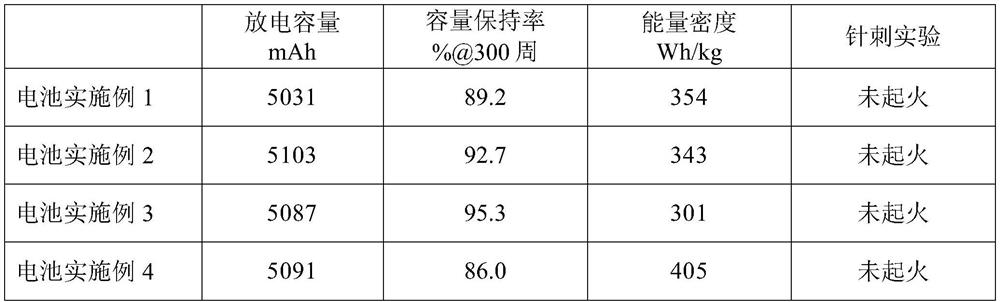

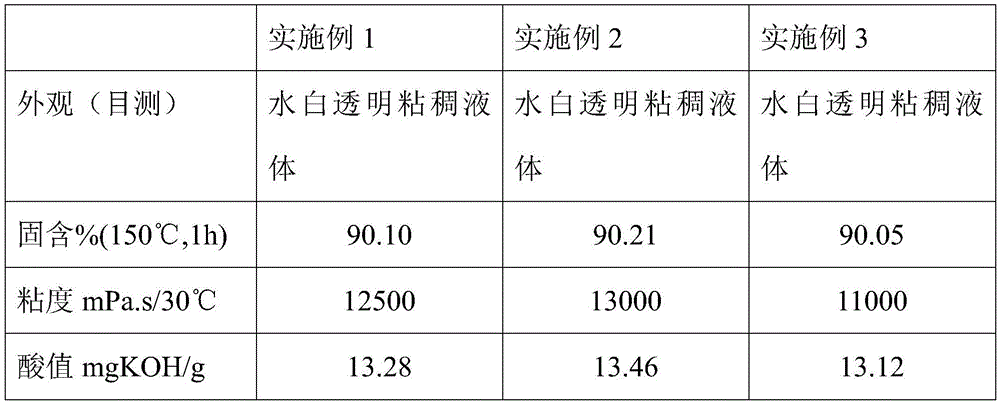

Highly branched alkyd resin with high solid content and low viscosity and preparation method of alkyd resin

InactiveCN105669961ALow viscosityIncrease the degree of branchingPolyurea/polyurethane coatingsBenzoic acidPolyester

The invention discloses highly branched alkyd resin with high solid content and low viscosity. The alkyd resin is prepared from components in parts by weight as follows: 100-120 parts of fatty acid, 120-140 parts of polyacids, 140-160 parts of polyols, 15-20 parts of benzoic acid, 1-2 parts of an antioxidant and 30-40 parts of ethyl acetate. Highly branched polyester is obtained from polyols and polyacids through copolymerization and is then modified with fatty acid and benzoic acid, an end group of polyester is enabled to contain a long-chain alkyl group and a benzyl group, the long-chain alkyl group provides a flexibility function and reduces the viscosity of highly branched polyester, the prepared highly branched alkyd resin with high solid content and low viscosity has high branching degree, the solid content is 90%-95%, the viscosity is 10,000 mPa*s / 30 DEG C, the coating VOC (VOC is lower than or equal to 420 g / L) of paint is reduced greatly, a paint film is thicker after one-time spraying, the fullness is improved, and good dryness and hardness can be kept.

Owner:CHENGDU SUPPON CHEM IND CO LTD

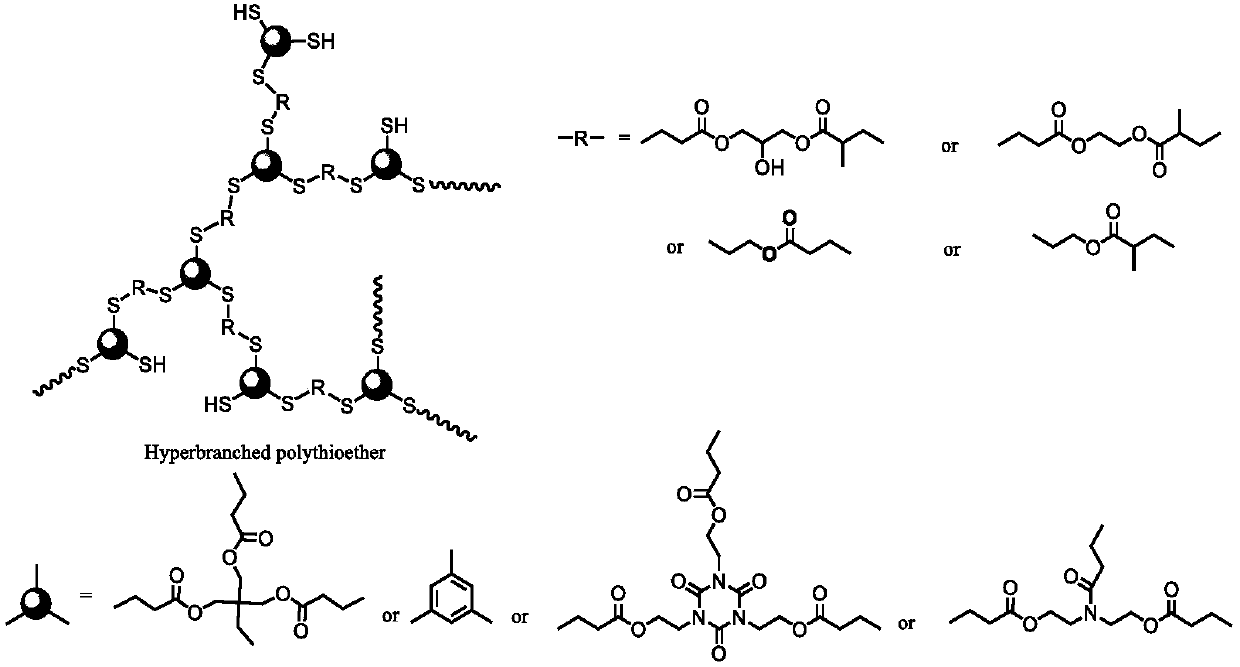

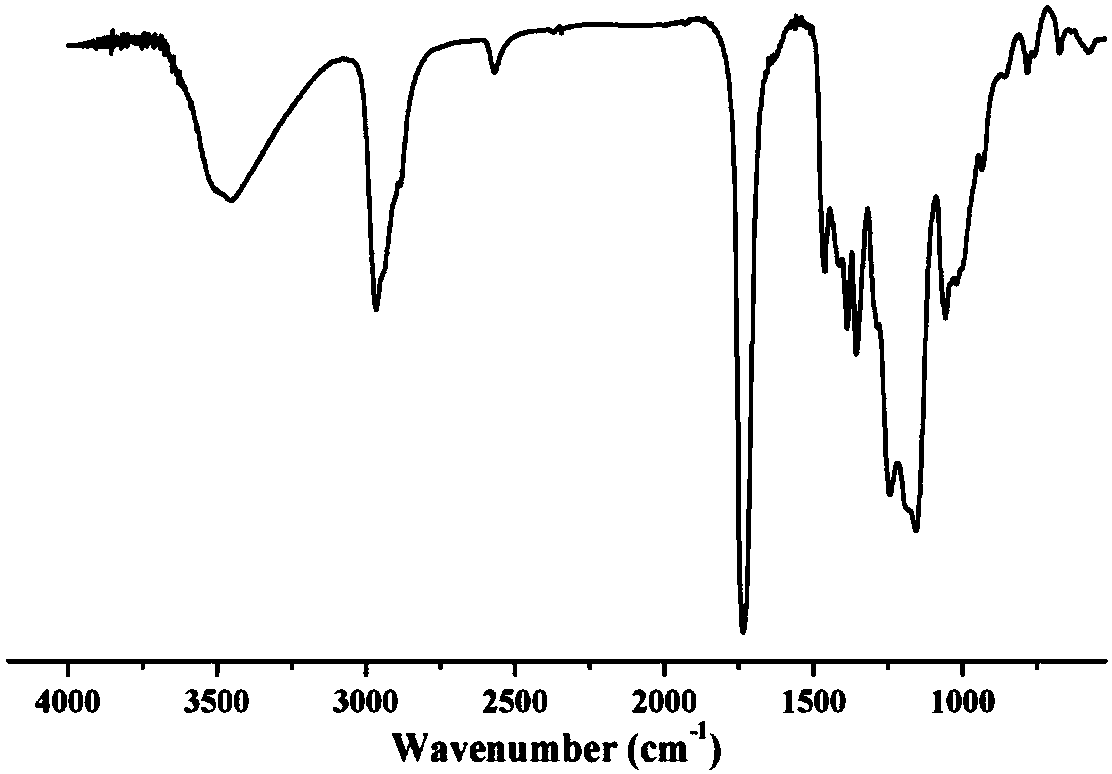

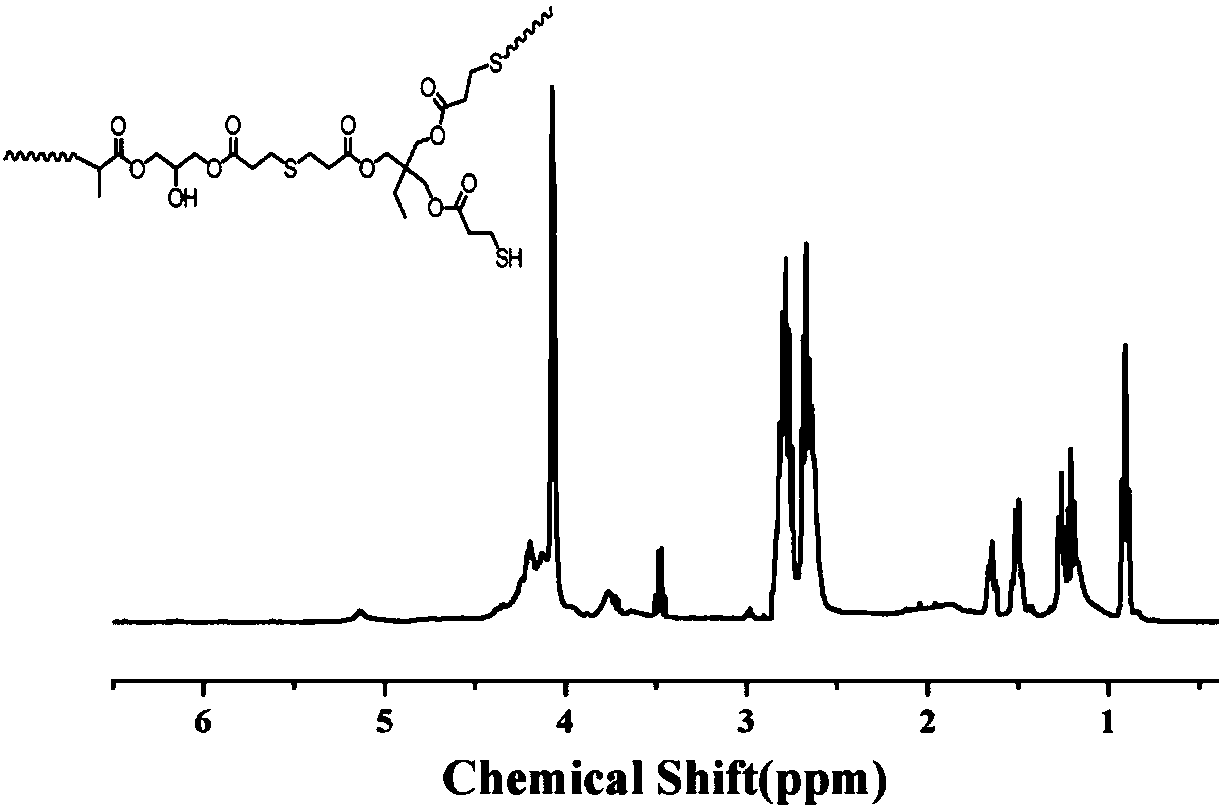

Hyperbranched polythioether preparation method

The invention relates to a hyperbranched polythioether preparation method. According to the preparation method disclosed by the invention, a bi-functionality asymmetric alkene compound and tri-functionality sulfur alcohol are utilized as raw materials, thiol-ene is utilized to perform unequal-reactivity addition reaction, and hyperbranched polythioether is synthesized by a one-pot method. The preparation method disclosed by the invention has the advantages that the raw materials are easy to obtain, and the steps are simple; a terminal group of the prepared hyperbranched polythioether is sulfydryl; functional modification can be further performed; thus, the hyperbranched polythioether with specific performance can be prepared.

Owner:JIANGNAN UNIV

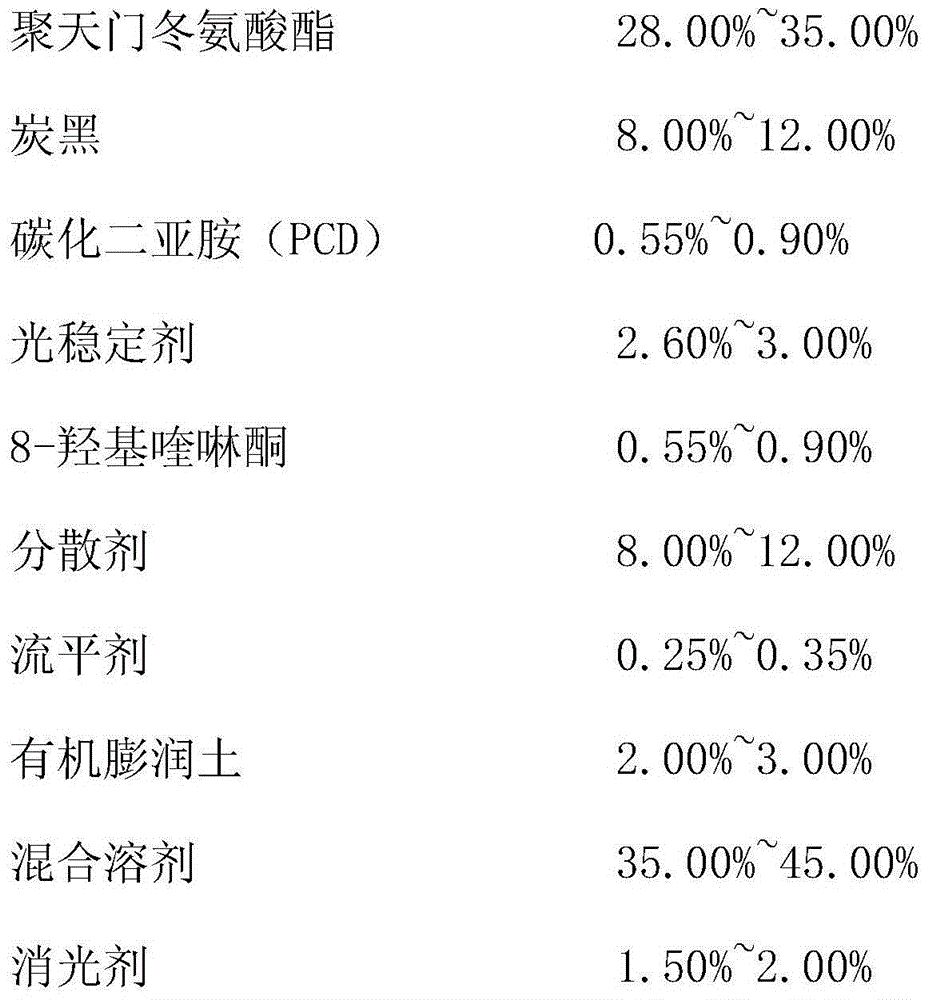

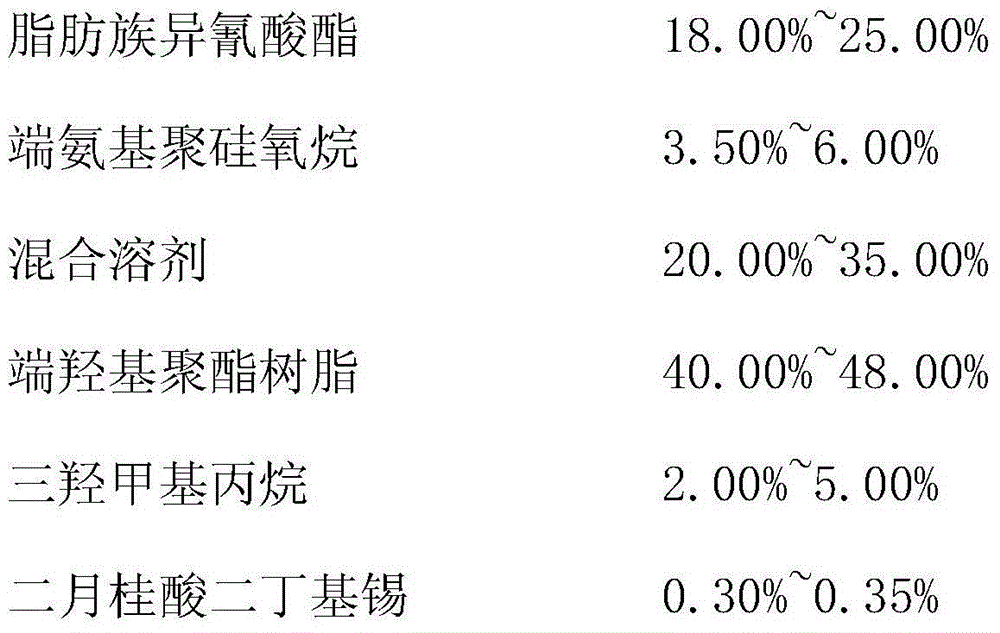

Oil-resistant and anti-aging protective coating for rubber shock absorber and preparation method thereof

ActiveCN104530954AIncrease elasticityImprove bindingAntifouling/underwater paintsPaints with biocidesEngineeringPower equipment

The invention relates to an oil-resistant and anti-aging protective coating for a rubber shock absorber and a preparation method thereof. Aiming at the defects that a rubber base material for the shock absorber is low in aging resistance and oil resistance, a protective coating is prepared, and the aging resistance and oil resistance of the shock absorber rubber are improved, so that the service life of the rubber shock absorber is prolonged, and the overall safety of power equipment and normal operation of each part are guaranteed. The oil-resistant and anti-aging protective coating for the rubber shock absorber mainly comprises a component A and a component B. The component A of the oil-resistant and anti-aging protective coating for the rubber shock absorber consists of polyaspartic acid ester, carbon black, carbodiimide, a light stabilizer, 8-hydroxyquinolinone, a dispersing agent, a flatting agent, organobentonite, a matting agent and a mixed solvent. The component B of the oil-resistant and anti-aging protective coating for the rubber shock absorber consists of a hydroxyl-terminated polyester resin, aliphatic isocyanate, trimethylolpropane, amino-terminated polysiloxane, dibutyltin dilaurate and a mixed solvent.

Owner:中昊北方涂料工业研究设计院有限公司

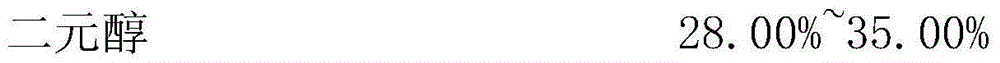

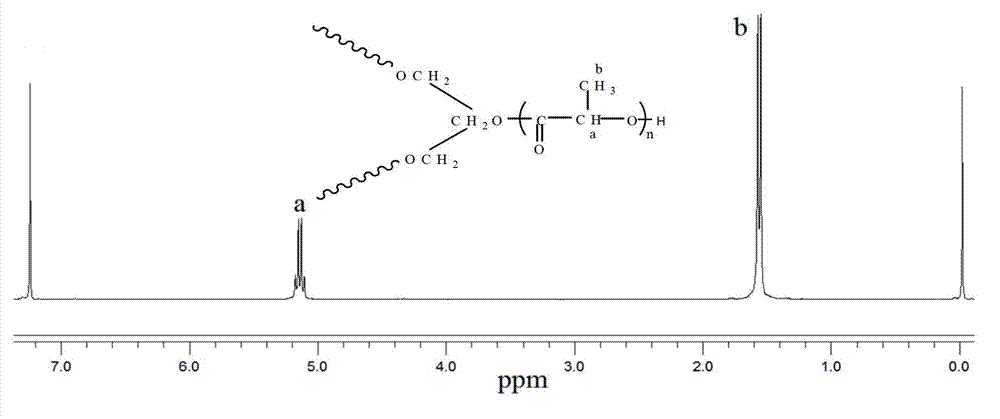

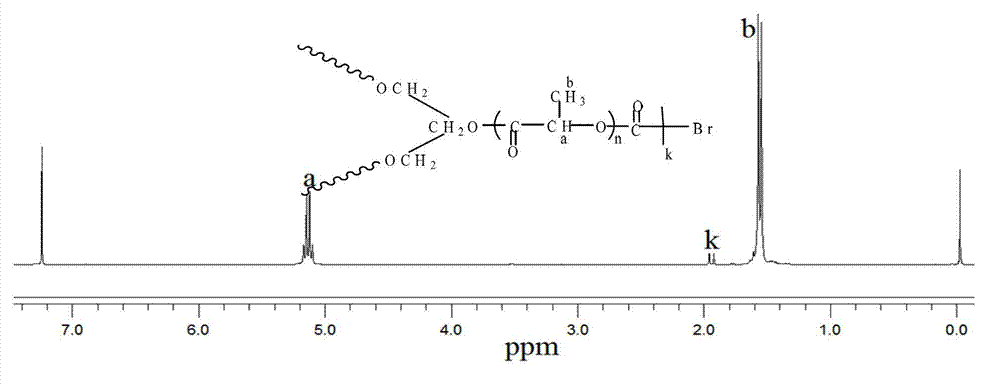

Polylactic acid segmented copolymer and modified polylactic acid preparation method

The invention provides a polylactic acid segmented copolymer and modified polylactic acid preparation method. The method includes: reacting branched polyactic acid with halogenated acid halide to obtain macroinitiator to further react with glycidyl methacrylate to obtain the polylactic acid segmented copolymer; and finally, blending the branched polyactic acid, the polylactic acid segmented copolymer and polylactic acid to obtain the modified polylactic acid. Compared with the prior art which using bis-glycidyl ester for modifying the polylactic acid, the method has the advantages that firstly, the polylactic acid-polyglycidyl methacrylate segmented copolymer is a macromolecular compound and can be in cross-linking reaction with the branched polylactic acid and the polylactic acid to form polymer with higher molecular weight and higher branching degree, so that the problems of proneness to migration and osmosis of micromolecular branched cross-linking agent are solved, and stability of the modified polylactic acid is improved; and secondly, the polylactic acid-polyglycidyl methacrylate segmented copolymer with an intrinsic branched polylactic acid structure unit has high compatibility to the branched polylactic acid and the polylactic acid.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

180-grade straight welded polyurethane wire enamel and preparation method thereof

InactiveCN104726000AIncrease crosslink densityHigh functionalityPolyurea/polyurethane coatingsPolyesterPolyol

The invention discloses a 180-degree straight welded polyurethane wire enamel and a preparation method thereof. The wire enamel is prepared from a polyester polyol resin, a polyurethane blocked resin, a solvent and a first catalyst; the polyester polyol resin is prepared from such synthesis raw materials as a polyol, a polyatomic acid ester, a polyanhydride and a second catalyst. The 180-degree straight welded polyurethane wire enamel has excellent heat shock resistance, cut-through resistance and soldering properties, and low dielectric loss.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY +1

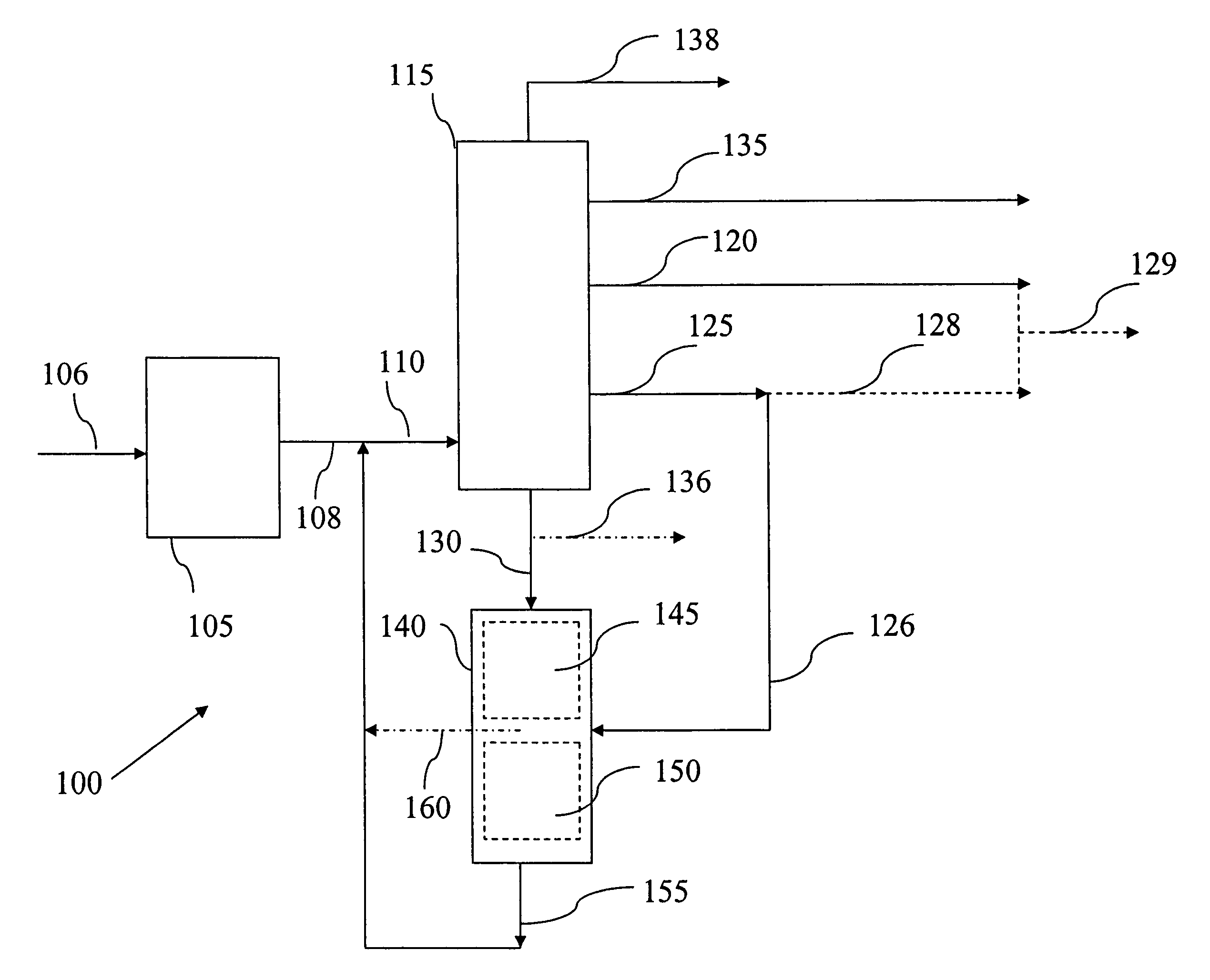

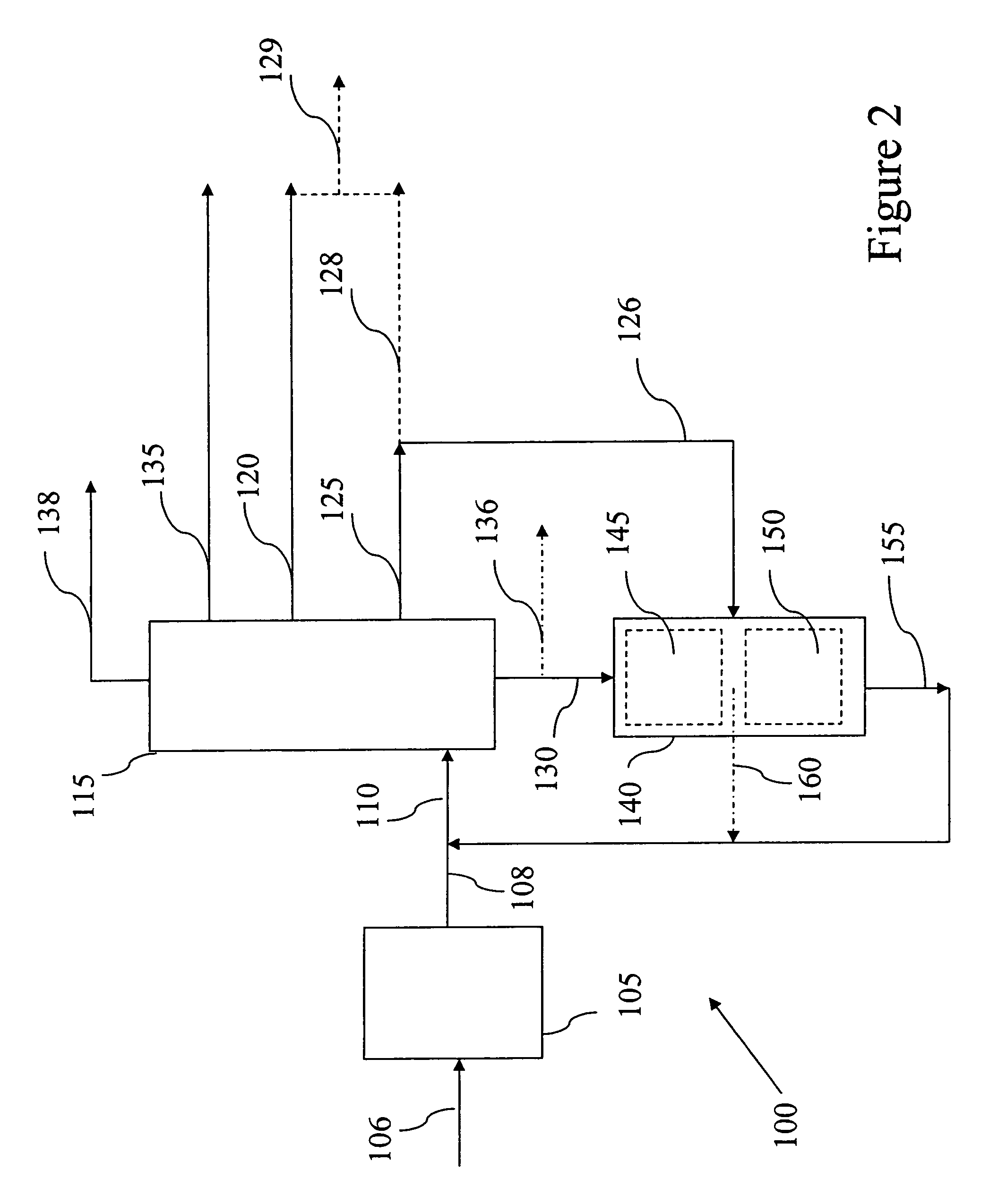

Hydroprocessing methods and apparatus for use in the preparation of liquid hydrocarbons

ActiveUS7354507B2Easy to prepareEnhancing yield and cold-flow propertyTreatment with plural parallel cracking stages onlyTreatment with plural parallel stages onlyWaxProduction rate

Owner:PHILLIPS 66 CO

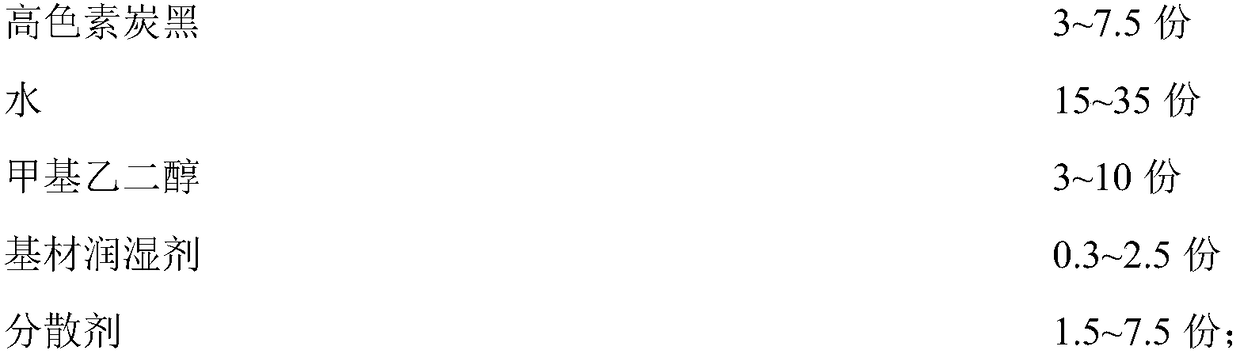

Single-component water-based black paint for automobile and preparation method thereof

ActiveCN108276889APlay the role of dispersion and stabilityInhibit bindingPolyurea/polyurethane coatingsWater basedPolyurethane dispersion

The invention relates to single-component water-based black paint for an automobile and a preparation method thereof. The single-component water-based black paint for the automobile is prepared by mixing three components A, B and C according to the weight ratio of 4 to (4 to 7) to (0.05 to 0.2), wherein the component A is prepared from the following components in parts by weight: 3 to 7.5 parts ofhigh-pigment carbon black, 15 to 35 parts of water, 3 to 10 parts of methyl ethylene glycol, 0.3 to 2.5 parts of base material wetting agent and 1.5 to 7.5 percent of dispersant; the component B is an aliphatic polyurethane dispersion body; the component C is a rheological agent. According to the single-component water-based black paint for the automobile, the compatibility problem of raw materials is remarkably improved, and the flowability, storage stability, luster, blackness and a blue phase are improved.

Owner:GUANGDONG YATU CHEM

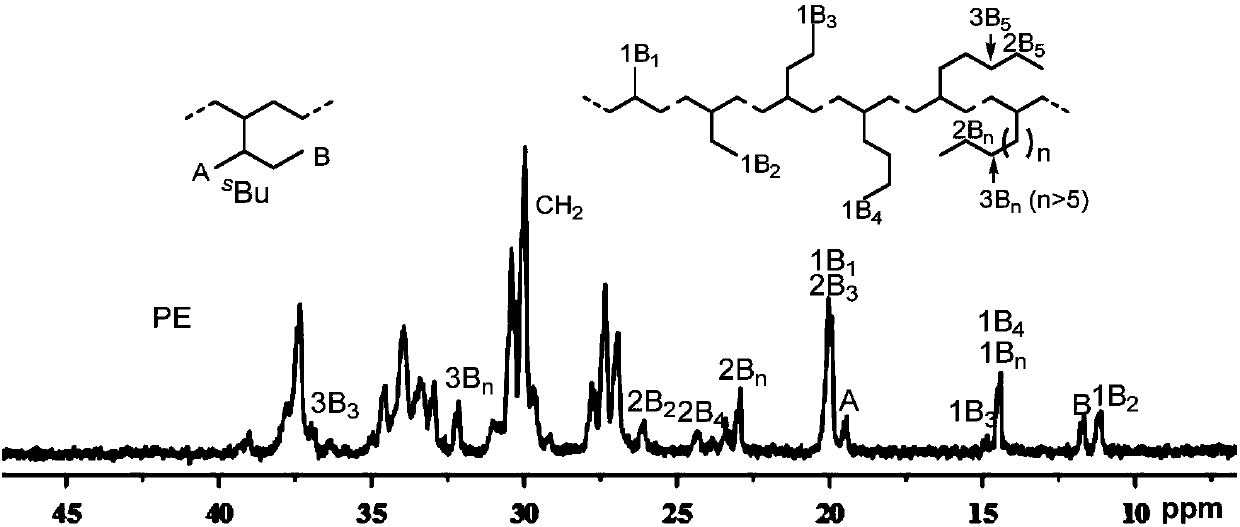

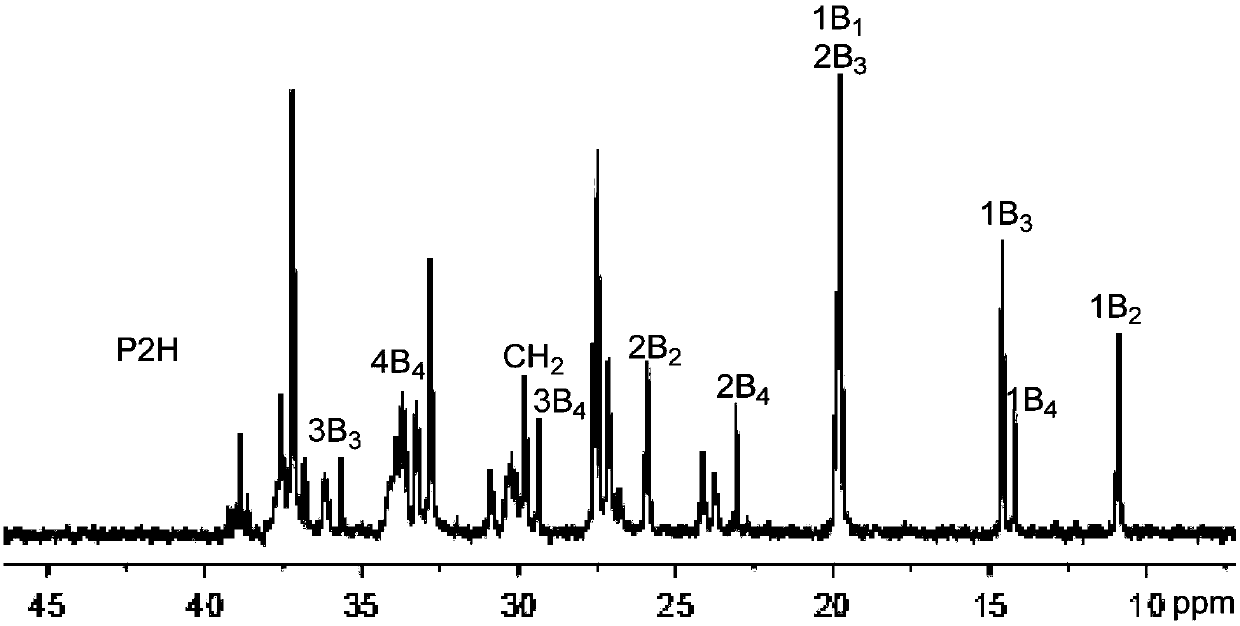

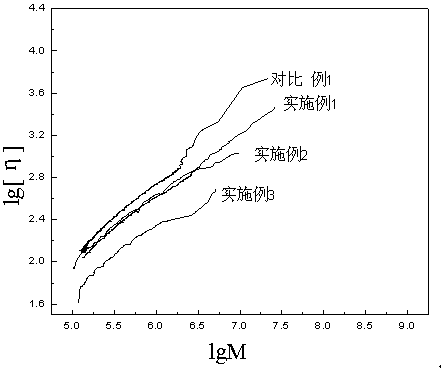

Alpha-diimine nickel (II) complexes containing p-benzhydryl substitutes and used for catalyzing polymerization of ethylene and 2-hexene

ActiveCN107698699AIncrease the degree of branchingDensity protectionNickel organic compoundsPolymer sciencePolyolefin

Novel late-transition-metal alpha-diimine nickel (II) complexes containing p-benzhydryl substitutes are disclosed. According to the complexes, two bulky groups which are benzhydryl are introduced to the para positions of imine nitrogen atoms on aromatic rings, and therefore ethylene insertion is accelerated, catalyst activity is improved, the transferring rate of active chains to a monomer is reduced, and a polymer having a high molecular weight is prepared. Under activation by a cocatalyst that is diethylaluminium chloride, a catalytic system catalyzing ethylene polymerization has high catalytic activity (can be 10<6> g PE / (mol Ni h)), and prepared polyethylene having a high molecular weight has a high degree of branching (can be 131 branches per 1000 C). Because of ortho-position small-steric-hindrance substitution and immobilization by para-position bulky benzhydryl, 2-hexene can be easily inserted to a metal center, and therefore chain shuttling polymerization of the 2-hexene has ahigh conversion ratio (88%), and a branch polymer having a high molecular weight and a low degree of dispersion is obtained. Accordingly, the catalyst has good potential application value in industrial polyolefin production.

Owner:CHANGZHOU UNIV

Preparation method for butadiene rubber

The invention provides a preparation method for butadiene rubber, belonging to the field of synthesis of polymers. The preparation method is characterized in that butadiene and a branching agent undergo polymerization in an organic solvent in the presence of a nickel-series catalyst, wherein the branching agent is liquid polybutadiene. Compared with nickel-series butadiene rubber prepared in the prior art, the branched nickel-series butadiene rubber prepared in the invention has a larger application scope since the butadiene rubber liquid has low viscosity and is not prone to adhesion on wallsand the raw butadiene rubber has improved cold flow properties and good processing performance; and when the branched nickel-series butadiene rubber prepared in the invention is applied to preparation of vulcanized rubber, the prepared vulcanized rubber has good mechanical properties.

Owner:CHINA PETROLEUM & CHEM CORP

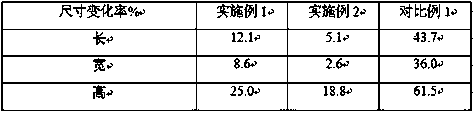

Asymmetric alpha-diimine nickel catalysts as well as preparation method and application thereof

The invention relates to asymmetric alpha-diimine nickel catalysts as well as a preparation method and application thereof, and belongs to the technical field of catalysts. On the basis of ensuring the thermal stability of the catalysts and the catalytic performance of the catalysts capable of obtaining a polymer with a high molecular weight through catslysis, the catalysts solve the technical problem of a low degree of branching of a polymer obtained by catalyst-catalyzed ethylene polymerization in the prior art. The asymmetric alpha-diimine nickel catalysts have a structural formula represented by a formula (I) shown in the specification, on one hand, the catalysts adopt large steric hindrance skeletons of 2,6-bis(diphenylmethyl)phenyl and derivatives of the 2,6-bis(diphenylmethyl)phenylwhich can rotate freely, the electronic and steric effects of the large steric hindrance are changed, on the other hand, the catalysts adopt skeletons of pentiptycene and derivatives of the pentiptycene which can limit geometric rotation, and the electronic and steric effects of the pentiptycene are changed, so that the target that the polymer with the high molecular weight and a branching degreecapable of being regulated and controlled in a large scale is obtained at high temperature can be realized.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

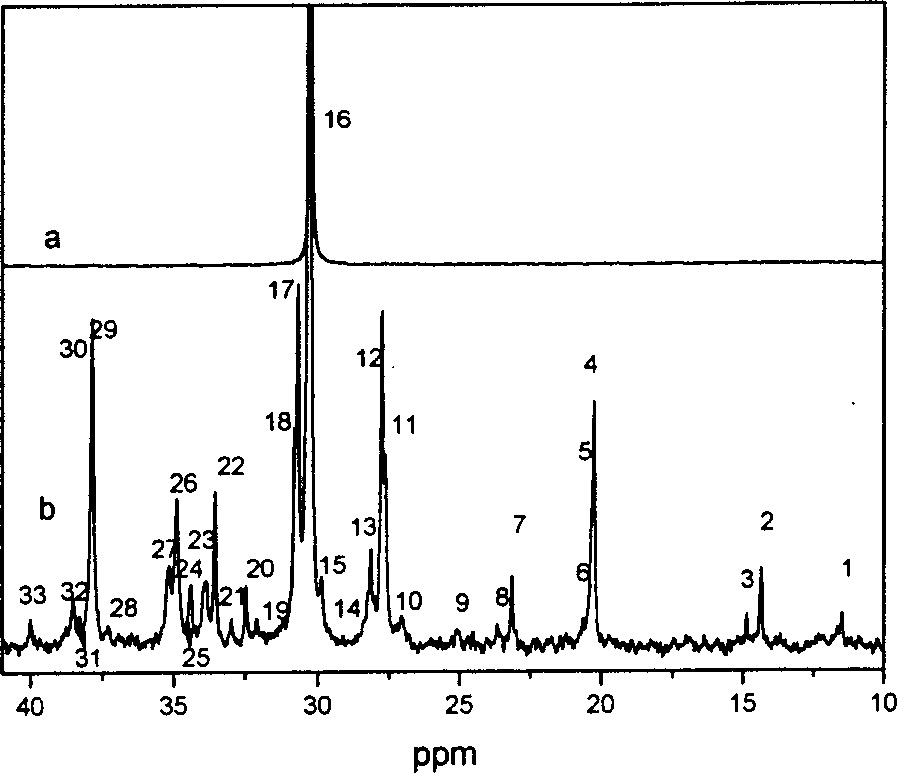

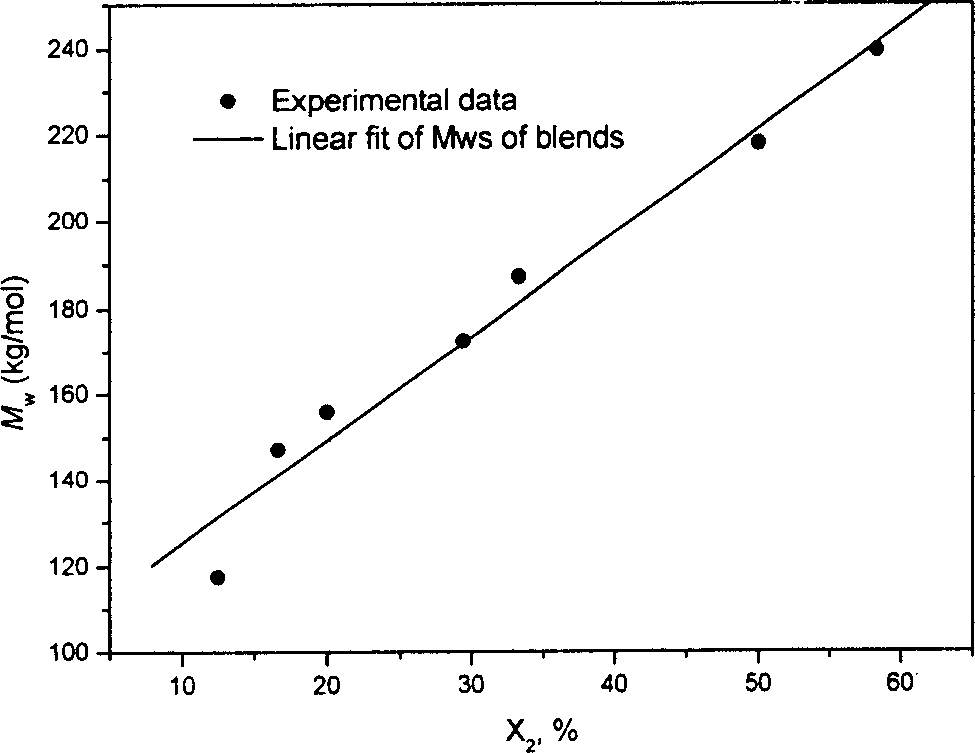

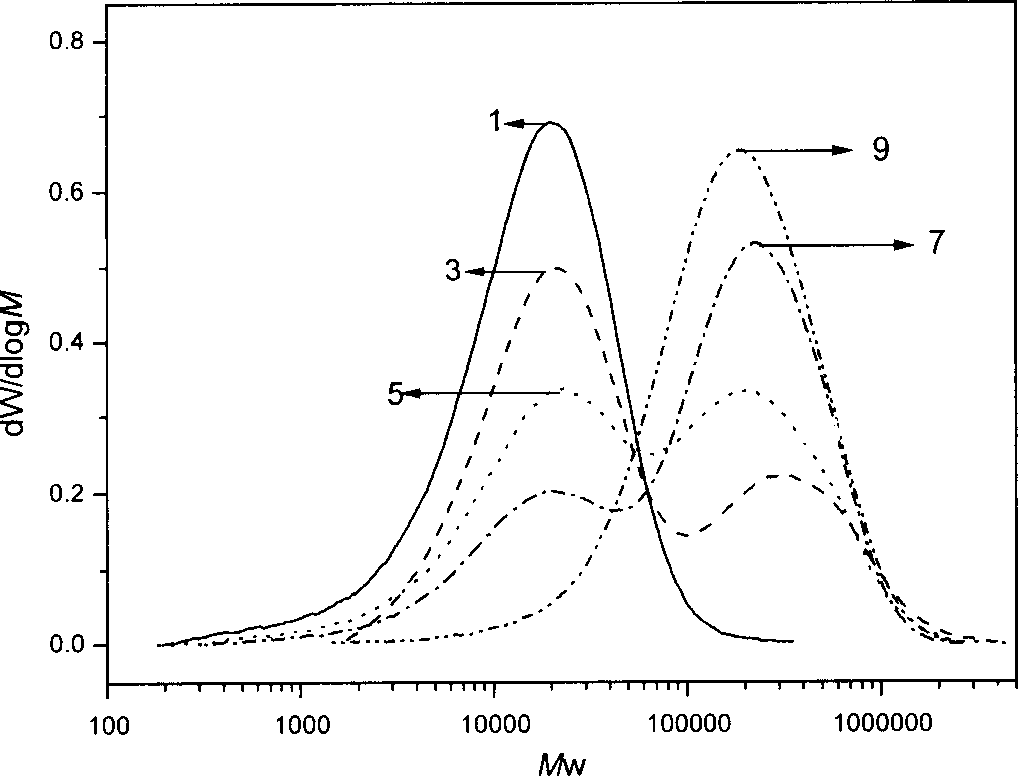

Method for preparing bipeak molecular weight distribution polyethylene by calalyst comixing system

InactiveCN1911970AComposition is easy to controlIncrease the degree of branchingAluminoxanePolymer science

The present invention relates to high pressure polymerization reaction process catalyzed with the mixture of two kinds of post-transition metal catalyst to prepare polyethylene with double molecular weight distribution peaks. These two kinds of catalyst are mixed in different ratio and are acted with co-catalyst modified methyl aluminoxane to catalyze the ethylene polymerization in single high pressure reaction kettle, so as to obtain blended polyethylene with double peak molecular weight distribution through one-step reaction. The produced blended polyethylene includes high molecular weight component with high branching degree and low molecular weight component with linear structure and greatly improved mechanical performance and machining performance.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

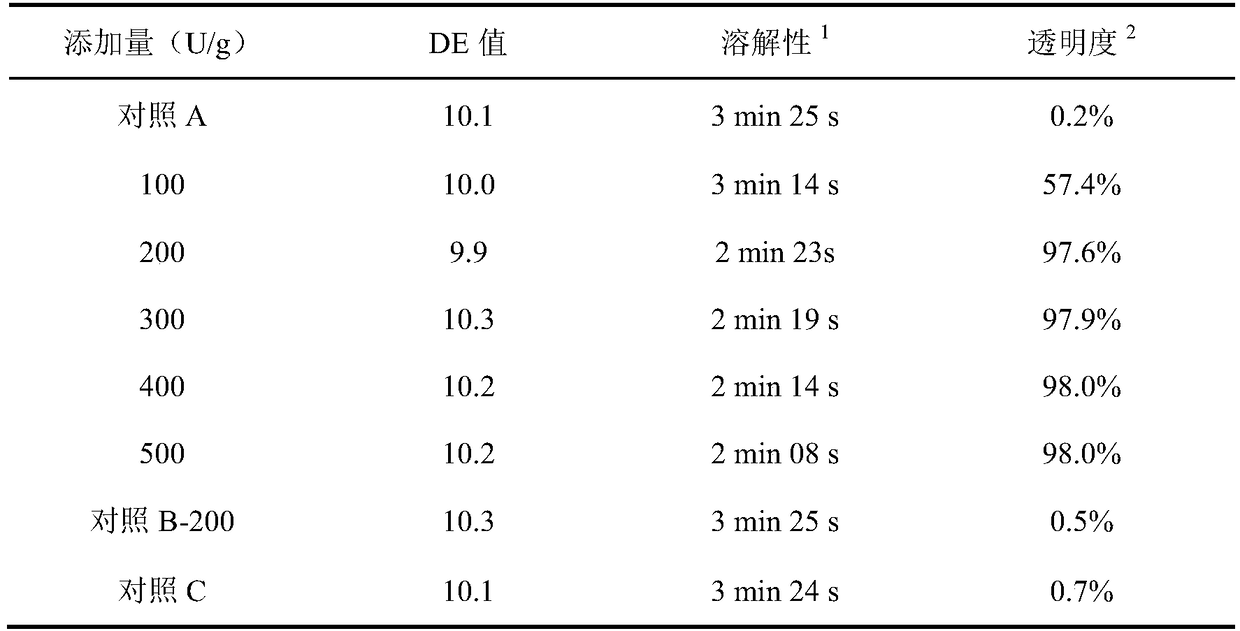

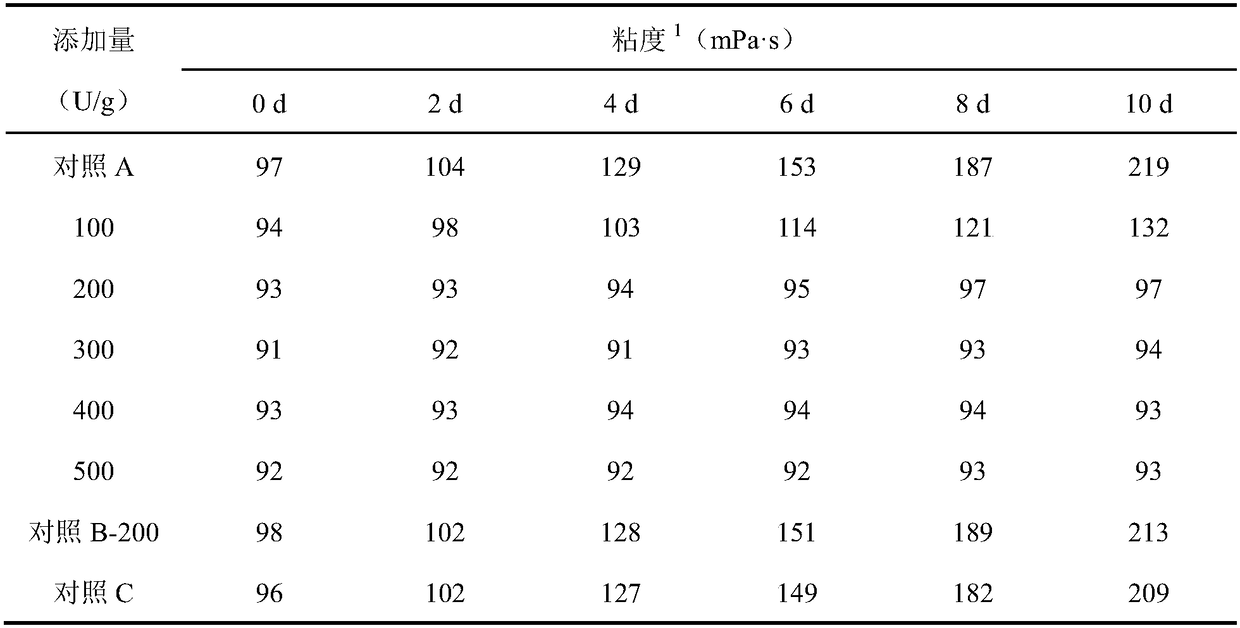

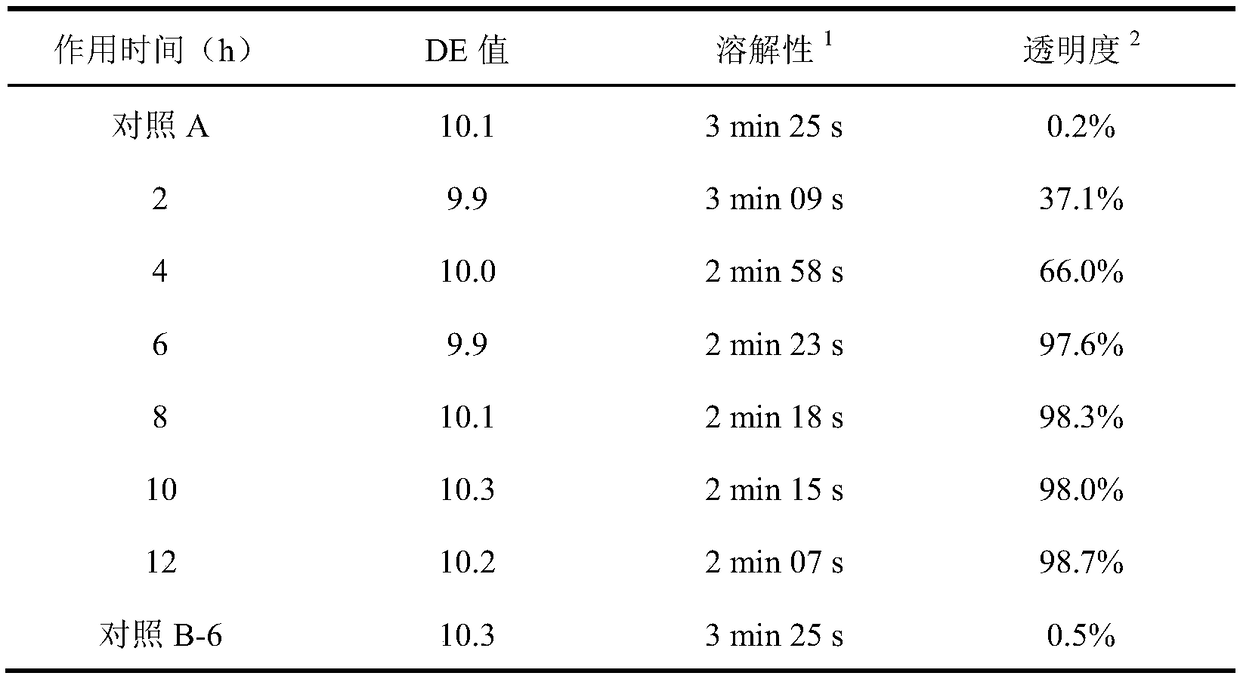

Method for producing high-quality maltodextrin

The invention discloses a method for producing high-quality maltodextrin, and belongs to the technical field of maltodextrin. According to the method provided by the invention, on the basis of a traditional enzyme method for producing maltodextrin, a starch branching enzyme from Rhodothermus obamensis is introduced, alpha-1,4-glucosidic bonds are cut off, and the cut short chains are connected toreceptor chains to form alpha-1,6-branching points, so that the branching degree of the maltodextrin is increased, the maltodextrin has more cluster structures, and then the aim of enhancing the stability of the maltodextrin and preventing the maltodextrin from being regenerated is achieved. The method specifically comprises the steps of size mixing, jet liquefaction, starch branching enzyme action, filtration, decolorization, ion exchange, concentration, spray drying and the like, and can produce high-quality maltodextrin with high solubility, and high transparency and high viscosity stability in a storage process.

Owner:JIANGNAN UNIV

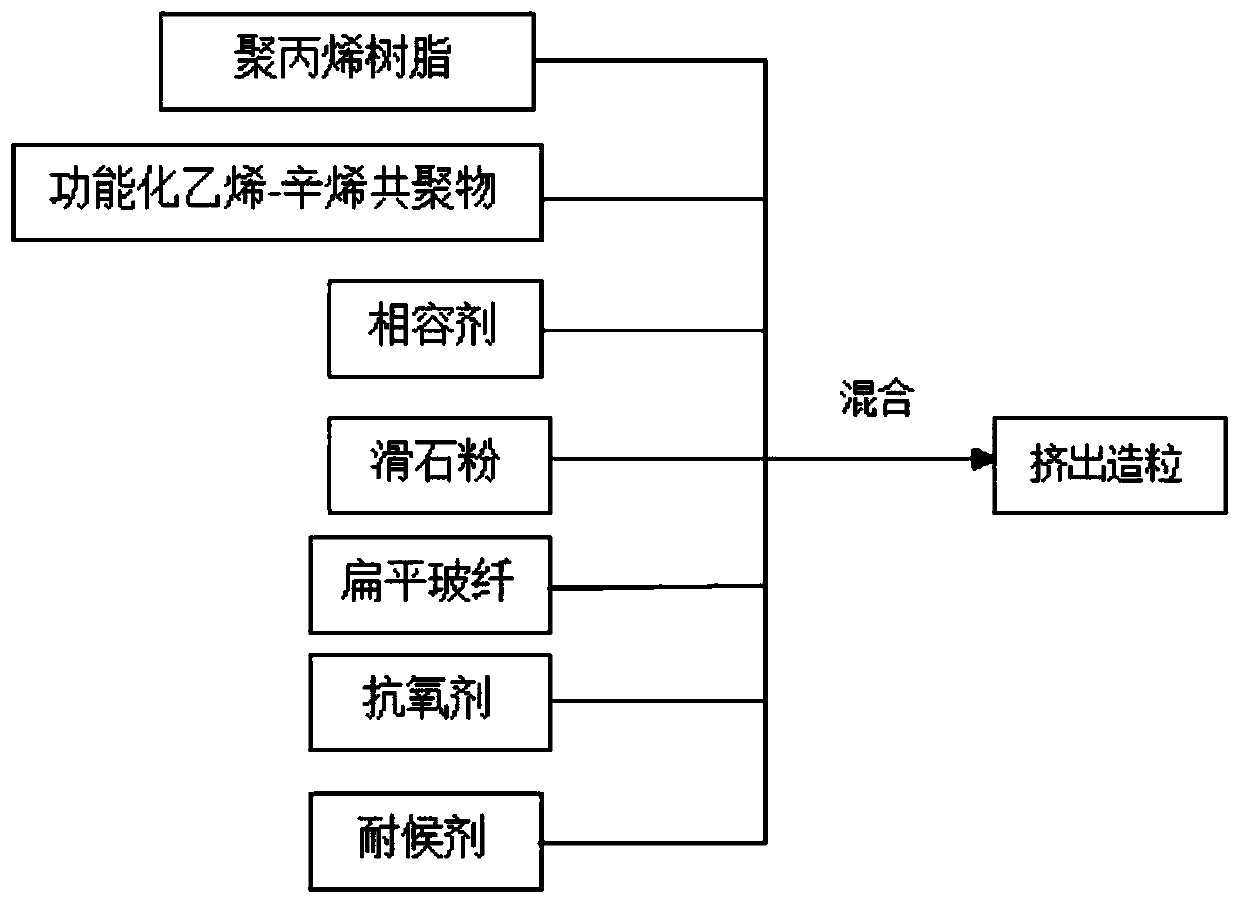

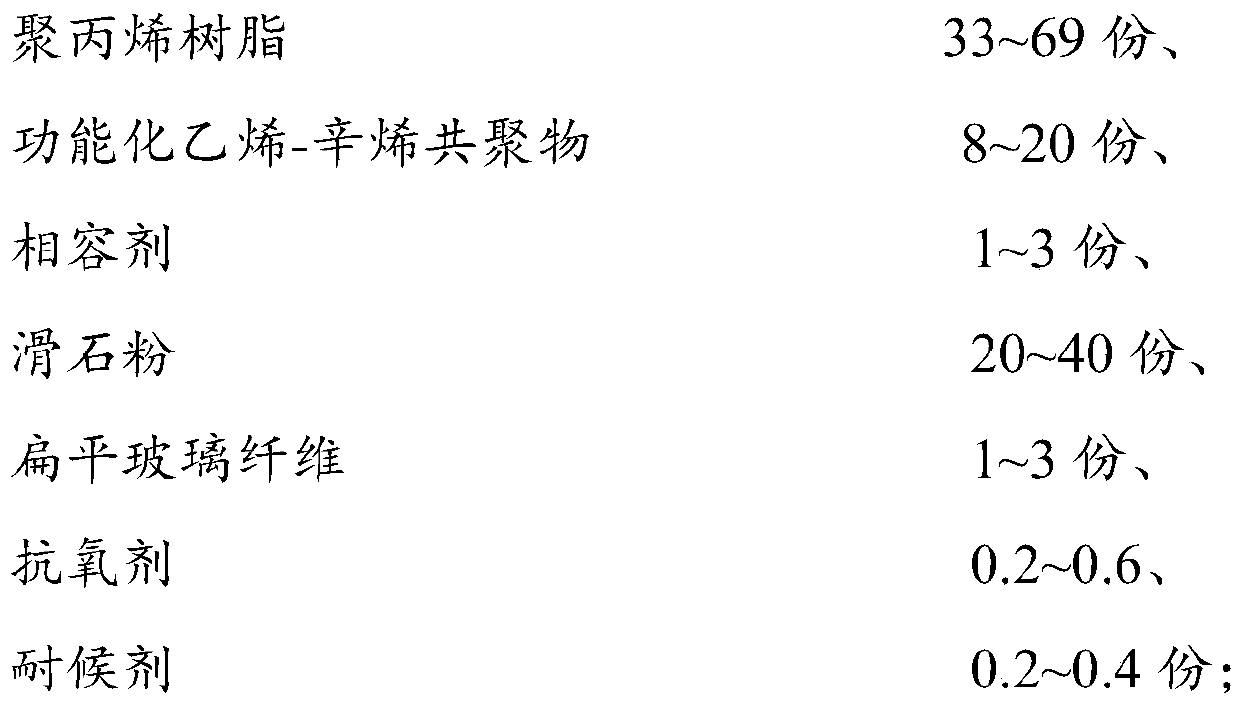

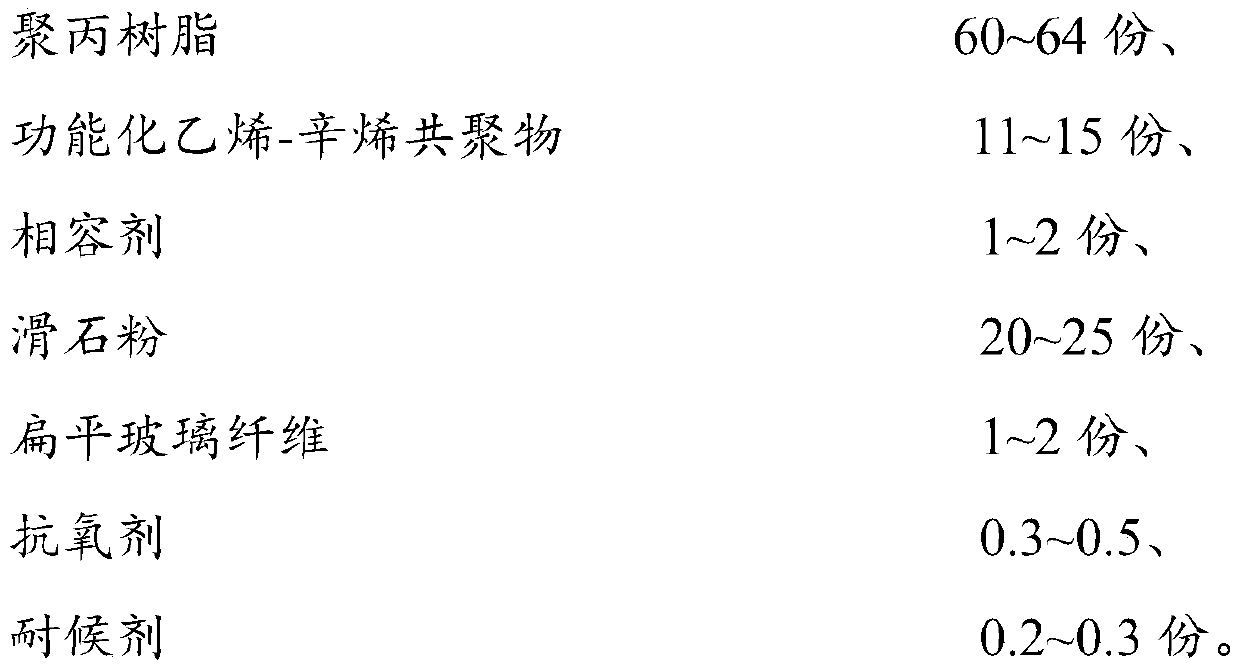

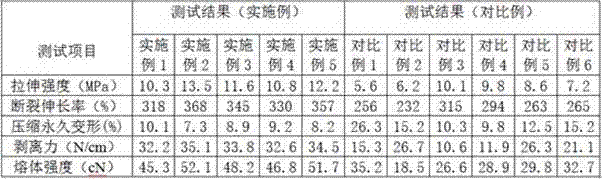

Polypropylene material with low linear expansion coefficient and preparation method of polypropylene material

The invention relates to a polypropylene material with a low linear expansion coefficient and a preparation method of the polypropylene material. The polypropylene material with the low linear expansion coefficient is prepared from the following raw materials: polypropylene resin, a functional ethylene-octylene copolymer, a compatilizer, talcum powder, flat glass fiber, an antioxidant and a weather resistant agent. By adjusting components and proportions of the raw materials, the polypropylene material has the low linear expansion coefficient and good mechanical properties, and can be appliedto automobile bumpers, apron boards and the like.

Owner:GUANGDONG ALDEX NEW MATERIAL CO LTD

Polyester resin capable of rapidly cured at low temperature and preparation method thereof

InactiveCN109503820AIncrease the degree of branchingHigh activityPowdery paintsPolyester coatingsPolyolLow temperature curing

The invention provides polyester resin capable of rapidly cured at low temperature and a preparation method thereof. The polyester resin is prepared from the following raw materials in parts by weight: 6.5-9.5 parts of polyalcohol, 13.5-14.5 parts of acid, 0.015-0.025 part of an esterification catalyst and 0.2-0.3 part of a curing accelerant. Compared with the prior art, according to the polyesterresin capable of rapidly cured at low temperature, high-activity monomers are combined, so that the finally prepared polyester resin is high in activity; softening point of the polyester resin is slightly reduced; a powder paint prepared by the polyester resin can be fully cured in short time under the low-temperature condition; the energy consumption is greatly reduced; in addition, good low-temperature leveling property and storage stability of the powder paint can also be ensured; meanwhile, the powder paint has excellent curing property and film formation property.

Owner:ANHUI HENGMING MOLD TECH

High-melt-strength high-bonding-property thermoplastic elastomer and preparation method thereof

InactiveCN107118495AIncrease molecular weight and degree of branchingImprove melt strengthChemistryPolypropylene

The invention discloses a high-melt-strength high-bonding-property thermoplastic elastomer and a preparation method thereof. The high-melt-strength high-bonding-property thermoplastic elastomer contains the following components in parts by weight: 25-35 parts of a high molecular weight styrene copolymer, 20-30 parts of polypropylene, 6-14 parts of thermoplastic polyurethane, 5-12 parts of a chain extender, 3-8 parts of a tackifier 1, 2-9 parts of a tackifier 2, 14-20 parts of tackifier filling oil, 3-14 parts of a compatilizer and 2-6 parts of an antioxidant. The preparation method comprises the following steps: weighing the materials in the formula in parts by weight; uniformly mixing the materials; inputting the mixed raw materials into a feeding hopper of a twin-screw extruder; and performing melt extrusion and granulation. The thermoplastic elastomer disclosed by the invention is high in melt strength, good in mechanical strength, difficult to shrink and good in encapsulating adhesive property, and is suitable for the fields of toy tires, bathroom hoses and automobile sealing strips, etc.

Owner:泉州盈创新材料技术开发有限公司

Preparation method of high-performance starch slurry

The invention discloses a preparation method of high-performance starch slurry. The preparation method comprises the steps of dispersing starch with the mass concentration of 10-40% into water; stirring and heating to 40-60 DEG C; reacting for 3-8 hours through stirring a starch branching enzyme at the constant temperature of 40-60 DEG C, wherein 30-150U / g starch is added into the starch branching enzyme; and filtering, centrifugally dehydrating and drying to obtain modified high-performance starch slurry with high branching degree. Compared with unmodified starch, the high-performance starch slurry has the advantages that the gelatinization temperature is reduced, the slurry is not frozen at room temperature, the flowability is favorable, and the adhesion to a pulpified yarn is improved to a relatively high extent.

Owner:JIANGNAN UNIV

Functional emulsion styrene-butadiene rubber and preparation method thereof

The invention relates to a functional emulsion styrene-butadiene rubber, characterized in that: the number-average molecular weight is 3*10<4>-35*10<4>, based on 100% of total monomer, the sum of the weight percentages of bound styrene and styrene derivative is 10-50%, and the weight percentage of butadiene is 50-90%; based on 100% of the sum of the weight percentages of bound styrene and styrene derivative, the weight percentage of bound styrene is X%, and the weight percentage of styrene derivative is (100-X)%, wherein the X is no less than 0 and less than 100; the styrene derivative is selected from styrene containing nitrogen atom substituent, and at least contains one tertiary amine group substituent.

Owner:DALIAN UNIV OF TECH

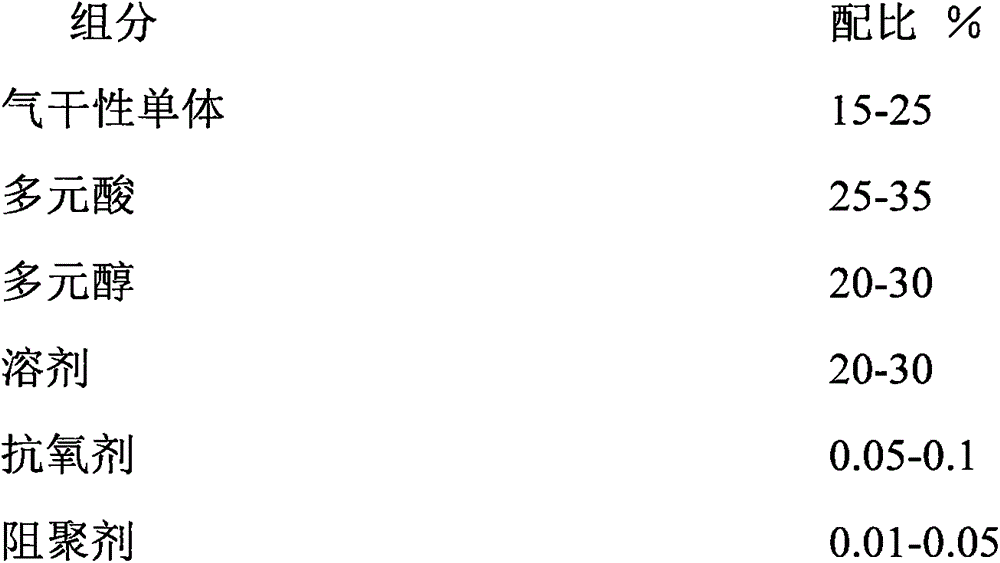

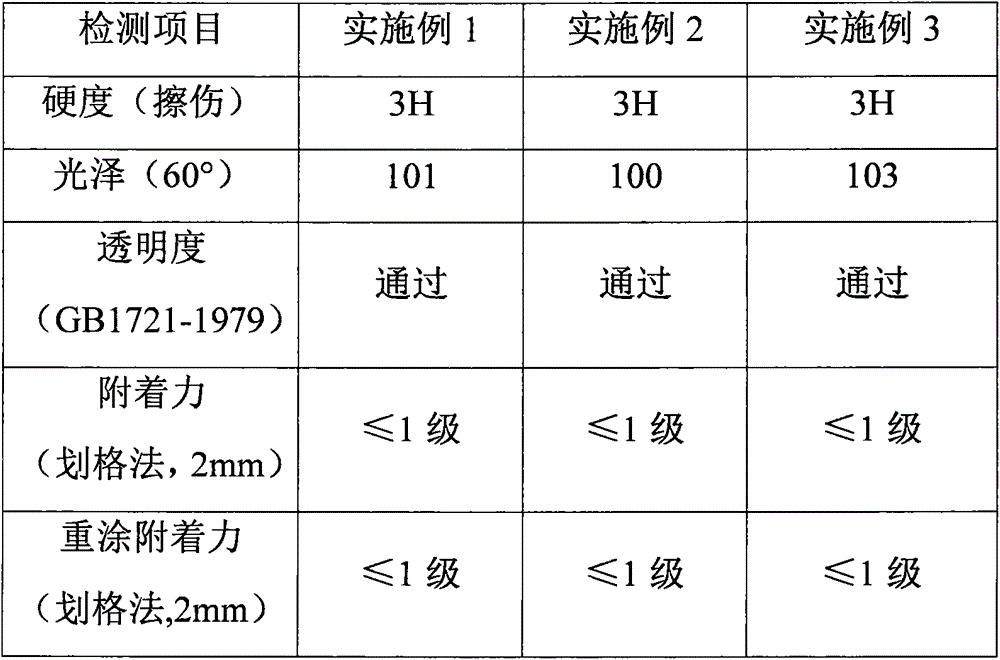

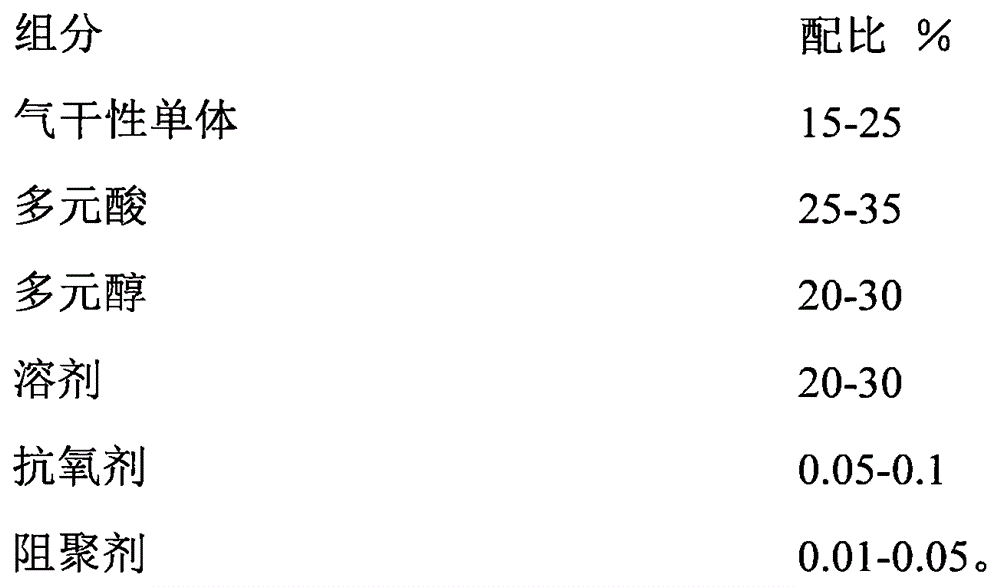

Recoat-able polishing-free unsaturated polyester resin for piano lacquer and preparation method of unsaturated polyester resin

InactiveCN105199053AHigh glossHigh glass transition temperature monomers (such as dicyclopentadiene) to improve glossCoatingsLacquerFiltration

The invention discloses recoat-able polishing-free unsaturated polyester resin for piano lacquer and a preparation method of the unsaturated polyester resin. The unsaturated polyester resin comprises the following components in percentage by weight: 15 to 25 percent of an air-dry monomer, 25 to 35 percent of polyatomic acid, 20 to 30 percent of polyhydric alcohols, 20 to 30 percent of a solvent, 0.05 to 0.1 percent of an antioxidant and 0.01 to 0.05 percent of a polymerization inhibitor. The preparation method comprises the following steps: adding the polyatomic acid, the polyhydric alcohols, the solvent and the polymerization inhibitor into a reaction kettle in sequence, switching on stirring and heating at the same time, heating to 180 to 200 DEG C, and preserving the heat; continuously detecting an acidity value, cooling to 120 DEG C when the acidity value is reduced to 120 to 130mgKOH / g, then cooling to 120 DEG C and adding the air-dry monomer, uniformly heating to 200+ / -5 DEG C by 3 hours, preserving the heat until the viscosity and the acidity value are qualified, then cooling and diluting the materials, performing filtration, and discharging a product. The piano lacquer prepared from the unsaturated polyester resin serving as a base material is high in surface hardness, and is higher in glossiness and transparency without polishing, construction period is short, the unsaturated polyester resin is recoat-able, convenient to prepare, and can be generally used in the bottom surface, and the production efficiency is greatly improved.

Owner:QINGDAO ZHANCHEN NEW MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com