Highly branched oily alkane polymer, and preparation method and application thereof

A technology for oily alkanes and alkane mixtures, which is applied in the production of liquid hydrocarbon mixtures, lubricating compositions, petroleum industry, etc., can solve problems such as unfavorable use of lubricating oil and reduction of lubricating oil viscosity index, and achieves high viscosity index and high branching degree. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

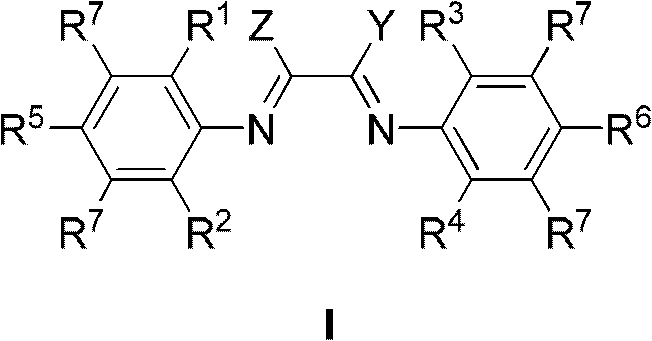

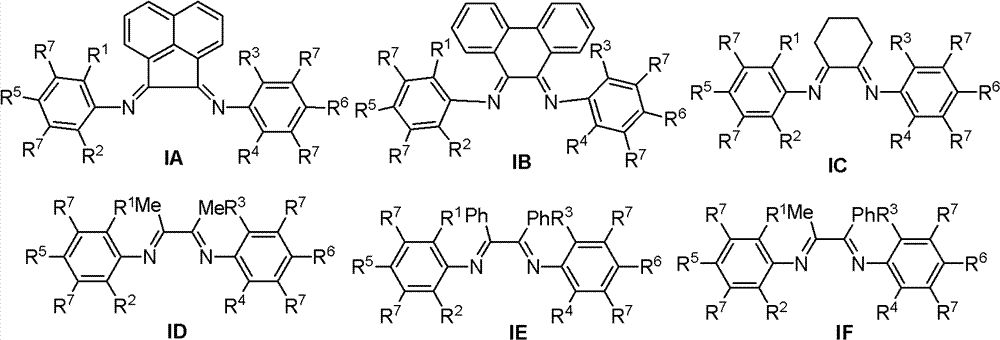

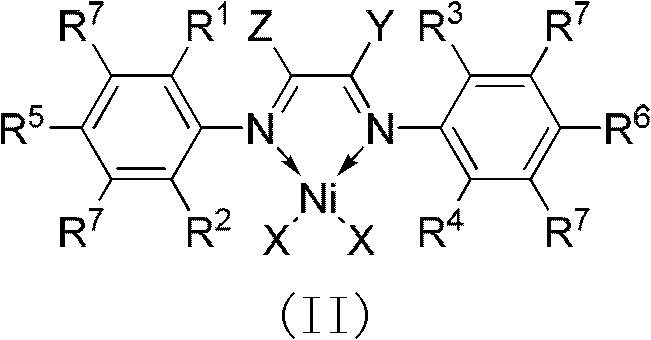

[0070] Preparation of Ligand Compounds and Complexes

[0071] The present invention also provides the synthesis of the ligand compound of formula I, comprising steps:

[0072] (a) C is obtained by reacting the corresponding diketone A with an amine compound B.

[0073] (b) Ligand I is obtained by reacting C with amine compound D.

[0074] Described compound A, B, C, D have the following structural formula:

[0075]

[0076] The reaction needs to add 0.001-100% corresponding catalysts to promote the condensation reaction, such as acetic acid, p-toluenesulfonic acid, TiCl 4 , orthosilicate, etc. Specifically, diketone A and amine B are first mixed in an inert solvent, and then activated by 0.001-100% acetic acid to generate monoimine C, and C continues to react with amine D to obtain the product represented by formula (I). Described inert solvent can be all solvents commonly used in condensation reaction, comprises alcohol, aromatic hydrocarbon, aliphatic hydrocarbon, hal...

Embodiment 1

[0132] Synthesis of Ligand L1a

[0133]

[0134] In a 100mL egg-shaped flask, add 3.644g (20mmol) of acenaphthoquinone, add 40mL of methanol, add 4.0mL (20mmol) of 2,6-diisopropylaniline, add 2 drops of anhydrous acetic acid, stir at room temperature, and track the reaction by TLC to End, concentrated under reduced pressure, neutral alumina column chromatography, EA: PE = 1: 20-EA: PE = 1: 10 to obtain the orange-yellow product monoimine, the yield is 60%. 1 H NMR (300MHz, CDCl 3 ): δ=8.21(2H, m), 8.01(1H, d), 7.82(1H, t), 7.41(1H, t), 7.27(3H, s), 6.64(1H, d), 2.84(2H, m), 1.18(6H,d), 0.90(6H,d).

[0135] In a 100mL egg-shaped bottle, add 1.708g (5.0mmol) of monoimine, add 40mL of methanol, add 7.5mmol of aniline, add 2 drops of anhydrous acetic acid, stir at room temperature, follow the reaction to the end by TLC, concentrate under reduced pressure, neutral alumina Column chromatography, EA:PE=1:15 gave the orange-yellow product L1a. 1 H NMR (300MHz, CDCl 3 ): δ=7.88...

Embodiment 2

[0137] Synthesis of Ligand L1b

[0138]

[0139] According to the synthesis method of ligand L1a in Example 1, the second step was to replace aniline with 2,6-dichloroaniline, and the other operating conditions were the same to obtain an orange solid. 1 H NMR (300MHz, CDCl 3 ): δ=8.32(1H, d), 8.10(1H, d), 7.96(1.5H, m), 7.53(2H, d), 7.41(3H, m), 7.38(2H, m), 6.91(0.5 H, m), 6.58 (1H, t), 2.77 (2H, m), 1.29 (2H, d), 0.97 (10H, d), 13 C NMR (75MHz, CDCl3): δ = 162.2, 157.8, 146.1, 133.1, 130.7, 127.5, 124.8, 124.4, 124.3, 123.39, 123.1, 122.7, 120.7, 77.4, 77.6, 28.5, 27.9, 23.5, 22.8. IR(KBr):v(cm -1 )=3052, 2960, 2923, 2865, 1674, 1640, 1602, 1463, 1433, 1242, 1077, 1033, 831, 779, 760, 730; C 30 h 26 Cl 2 N 2 (484.45): Anal. Calc. C 74.22, H 5.40, N 5.77; Found C 73.99, H5.39, N 5.65.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| bromine number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com