Patents

Literature

437results about How to "Improve extreme pressure performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

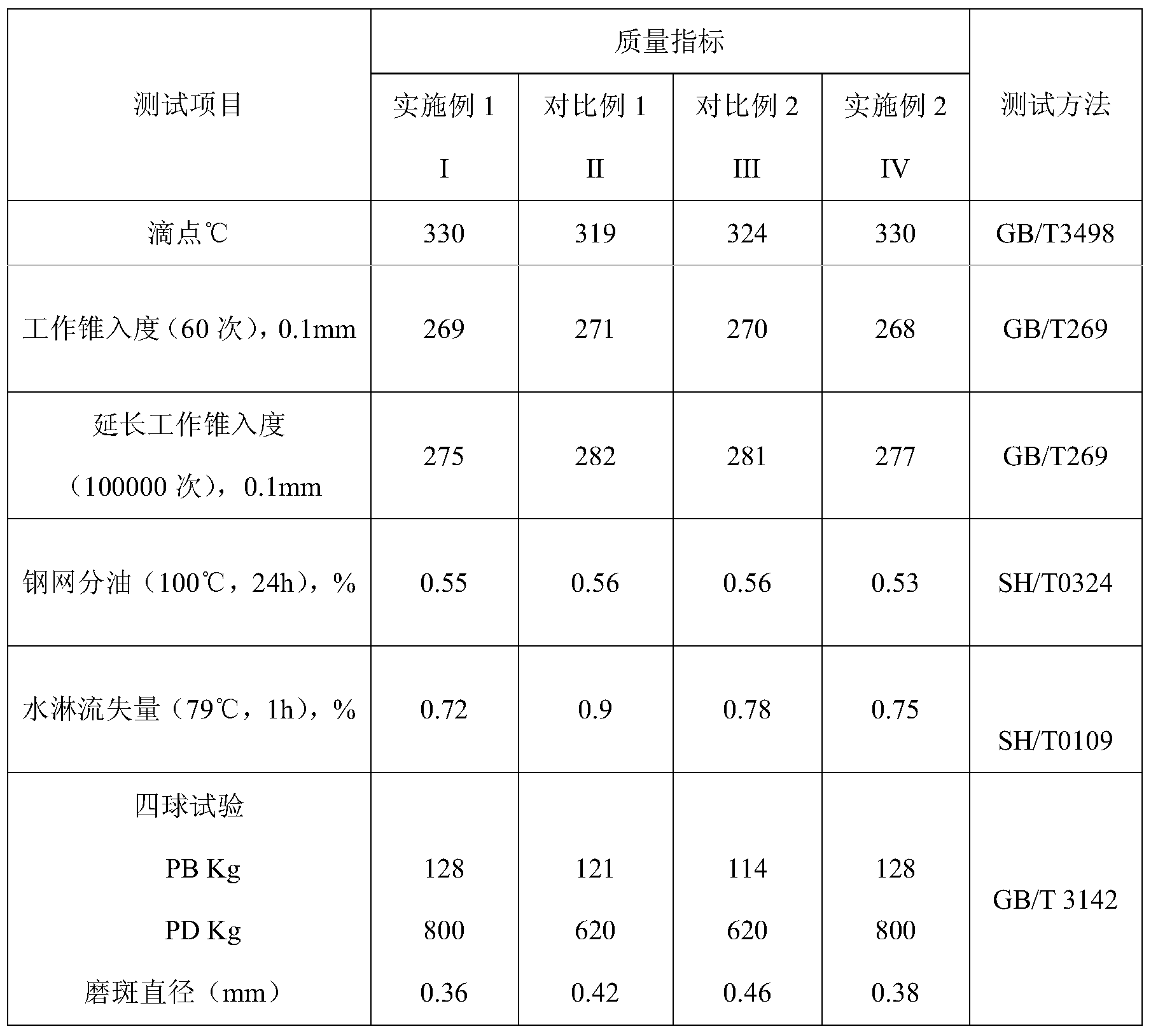

Lubricating grease composition for heavy-loading roller press bearing and preparation method thereof

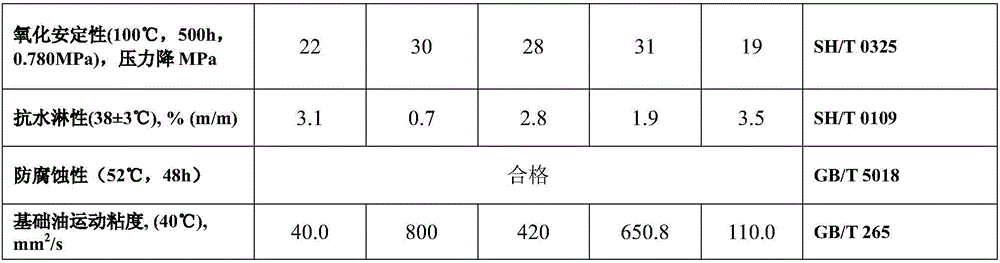

ActiveCN103275798AGood extreme pressure and anti-wear propertiesImprove the lubrication effectLubricant compositionLithiumAntioxidant

The invention provides a lubricating grease composition for a heavy-loading roller press bearing and a preparation method thereof. The composition has prominent extreme-pressure anti-wear property, lubricating property and water resistance. The lubricating grease composition contains the following ingredients: (a) complex lithium and calcium-based lubricating grease, (b) a tackifier, (c) an oiliness additive, (d) an extreme-pressure anti-wear agent, (e) an antioxidant and (f) a graphite additive.

Owner:SHANGHAI HITECRUN SPECIAL LUBRICATE SCI & TECH

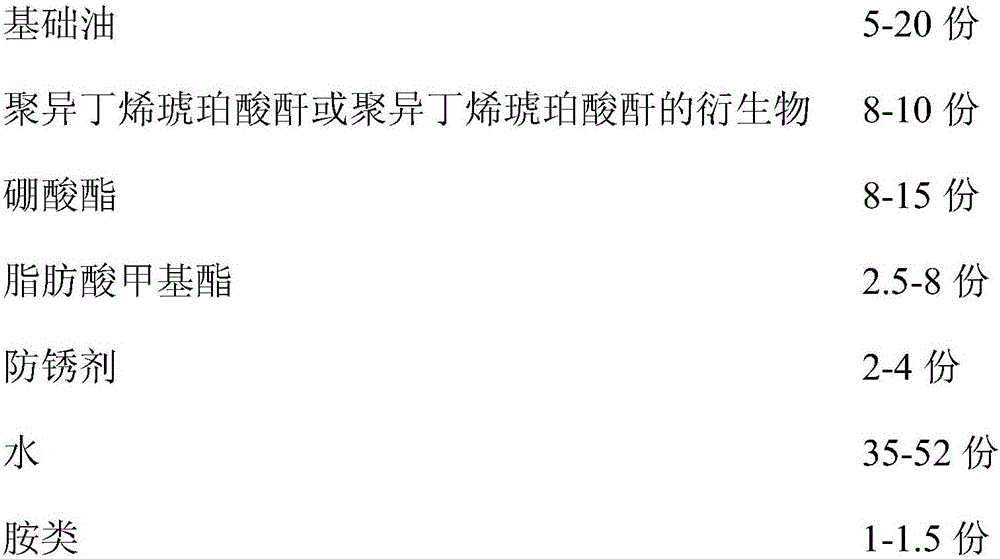

Multifunctional semi-synthetic metal processing liquid and preparation method thereof

ActiveCN106318586AImprove protectionImprove the lubrication effectLubricant compositionCooling effectFatty acid methyl ester

The invention discloses a multifunctional semi-synthetic metal processing liquid and preparation method thereof. The multifunctional semi-synthetic metal processing liquid comprises, by weight, 5-20 parts of base oil, 8-10 parts of polyisobutylene succinic anhydride or the derivative of the same, 8-15 parts of borate, 2.5-8 parts of fatty acid methyl ester, 2 to 4 parts of rust inhibitor, 35 to 52 parts of water, 1 to 1.5 parts of amine, 0.5 to 0.8 part anti-hardening agent, 0.2 to 4.5 parts of copper corrosion inhibitor, 2 to 3 parts of aluminum corrosion inhibitor, 5 to 6 parts of coupling agents, 3 to 4 parts of fungicides and 0.2 to 0.3 part of defoaming agent. The metal processing liquid provided by the invention not only has excellent cooling effects, very good lubricating effects and extreme pressure property, excellent high temperature stability and low temperature stability, but also generates little foam. The processing liquid is an environment friendly product which can be used for the cutting and grinding operation with medium and high difficulties in the high-speed cutting and large piece cutting.

Owner:广州亦盛环保科技有限公司

Lubricating oil additive and preparation method

ActiveCN1301319CGood dispersionImprove extreme pressure performanceAdditivesOil additiveSio2 nanoparticle

An extreme-pressure antiwear additive for lubricating oil is prepared from basic oil, SiO2 nanoparticles, disperser and synergist.

Owner:CHINA PETROLEUM & CHEM CORP

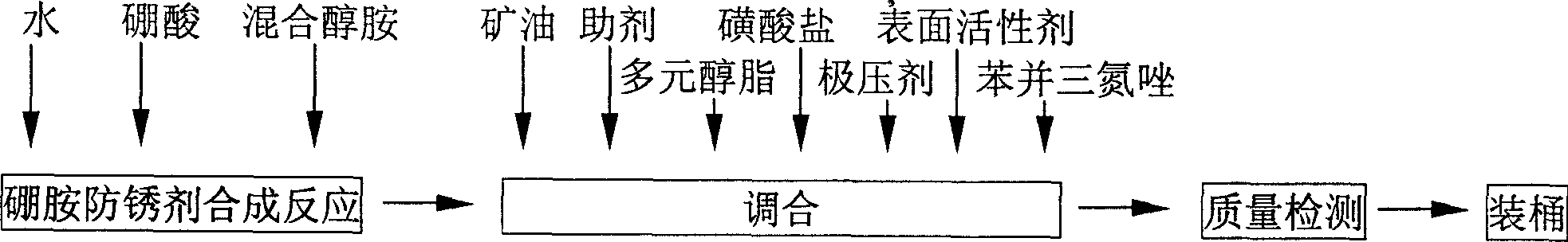

Extreme pressure cutting fuild microemulsion free of chlorine and its preparation method and uses

InactiveCN1730634AReduce emulsificationExtended service lifeLubricant compositionActive agentSurface-active agents

The invention provides a fluoro-free extreme-pressure microemulsion cutting liquid, whose constituents by weight percentage include water 20-40, mixed alkylolamide 6-12, boracic acid 2-6, sulfonates rust-preventing agent 8-12, auxiliary agent 1-5%, anionic surface active agent 8-12, polybasic alcohol 2-6, sulfurized grease 4-10, mineral oil 15-30, benzotrizaole 0.1-0.3. The invention also provides a process for preparing the liquid.

Owner:GUANGZHOU MECHANICAL ENG RES INST

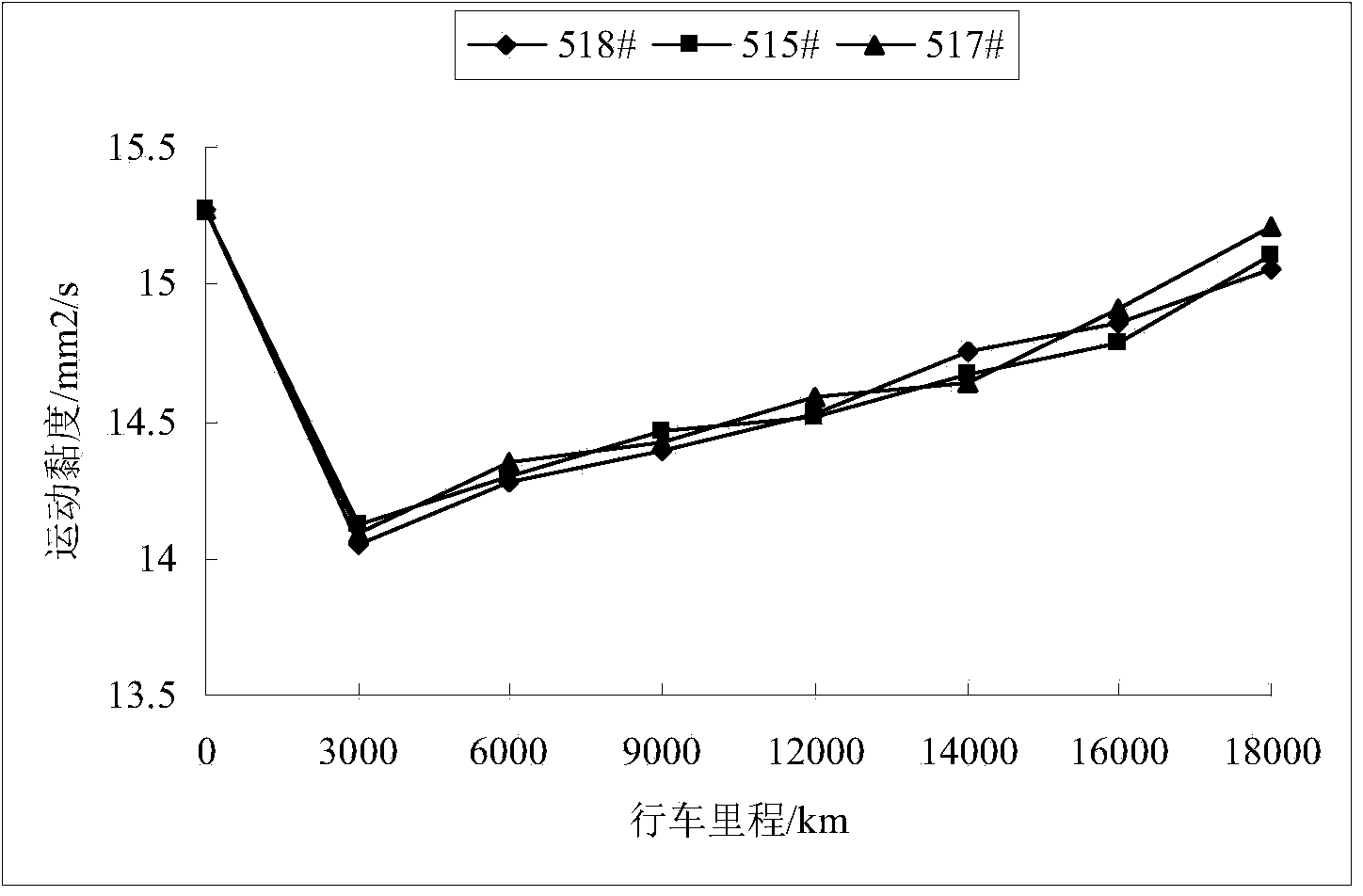

Special lubricating oil for fuel gas engine of public transport automobile

ActiveCN104342266AAntioxidant time is longImprove protectionLubricant compositionThiadiazolesPolyisobutylene succinimide

The invention discloses special lubricating oil for a fuel gas engine of a public transport automobile. The special lubricating oil is prepared from blended base oil, binary ethylene-propylene rubber, polymethacrylate, alkylphenol calcium sulfide, high-base-number calcium alkylbenzenesulfonate, polyisobutylene succinimide, boronated polyisobutylene succinimide, alkylated phenyl-alpha-naphthylamine, p,p'-dioctyl diphenylamine, a hindered phenol type antioxidant, dialkyl molybdenum dithiocarbamate, copper nanoparticle anti-wear additives, methyl silicone oil and thiadiazole polysulfide. According to the lubricating oil composition oil product, the sulfate ash content is lower than 0.5%, the content of phosphorus is lower than 0.03%, and the base number is 3-8mgKOH / g. According to the special lubricating oil for the fuel gas engine of the public transport automobile, aiming at the special requirements of the public transport automobile on engine oil, different additive varieties and charging sequences are adopted, so that physical and chemical indicators and use performance of the special lubricating oil are better than natural gas engine lubricating oil of the same grade, and the special lubricating oil has excellent cleaning and dispersion properties, lubricating property, abrasion resistance and oxidation resistance.

Owner:陕西通用润滑科技有限公司

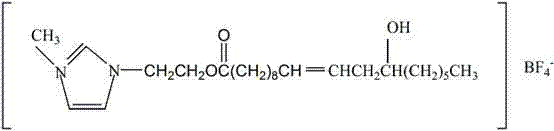

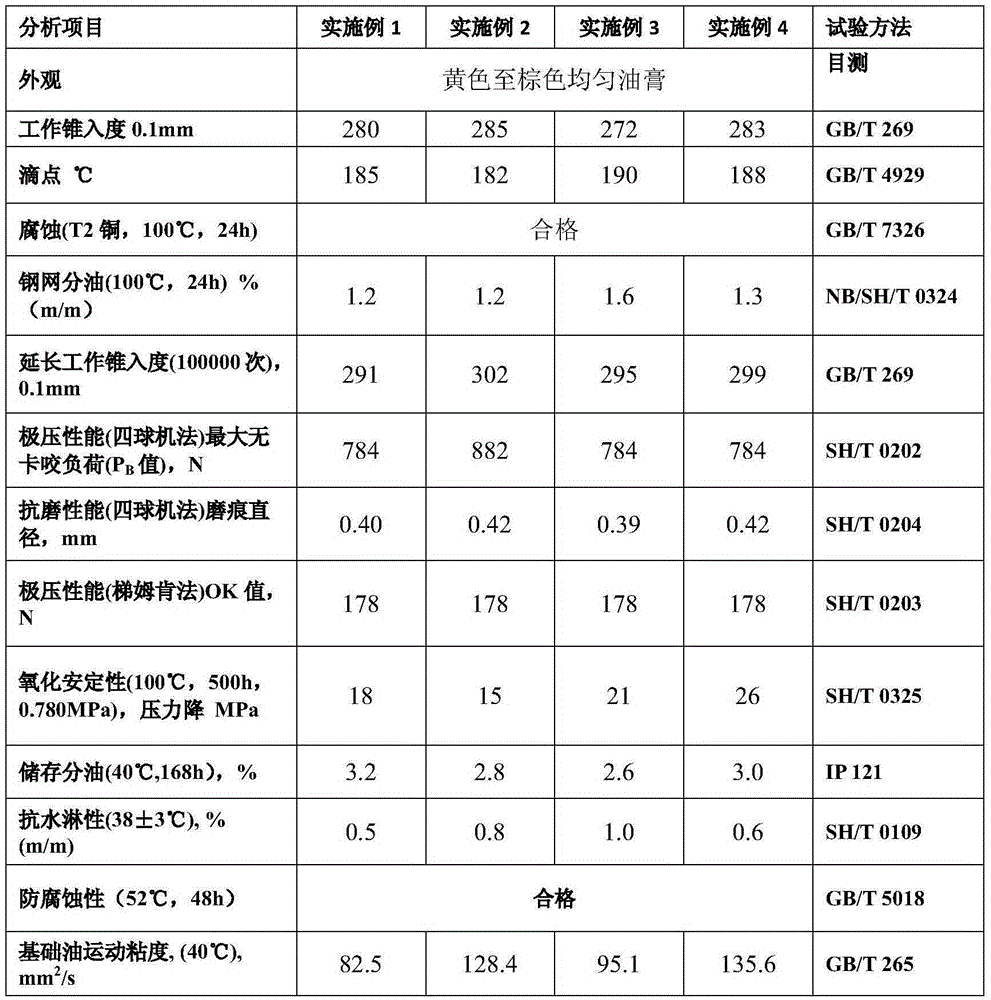

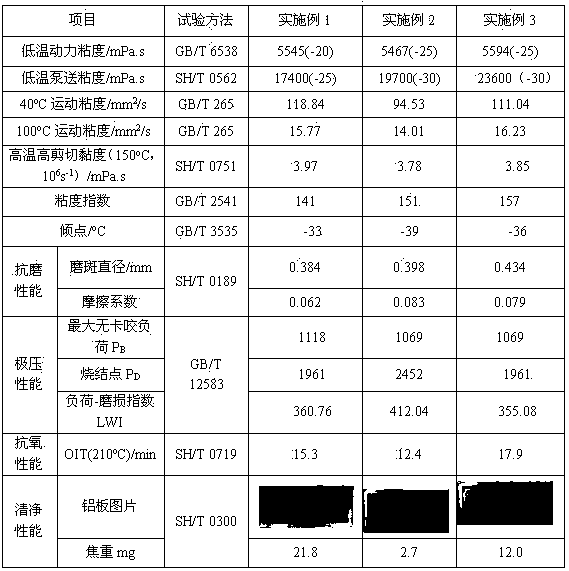

Composite extreme pressure anti-wear agent and total-synthesis anti-wear hydraulic oil containing same

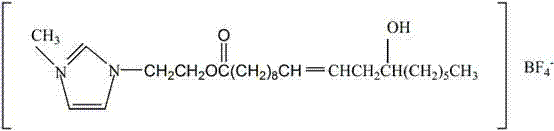

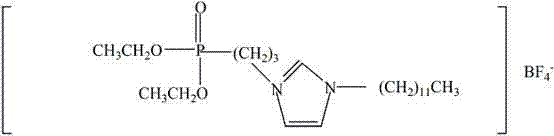

ActiveCN102776053AExcellent friction reductionImprove wear resistanceAdditivesTetrafluoroborateBase oil

The invention discloses a composite extreme pressure anti-wear agent and total-synthesis anti-wear hydraulic oil containing the composite extreme pressure anti-wear agent, belonging to the field of production of lubricating oil. The hydraulic oil is mainly prepared by mixing aqueous base oil and the composite extreme pressure anti-wear agent, wherein the composite extreme pressure anti-wear agent is a compound of two kinds of imidazolyl tetrafluoroborate ion liquid. Compared with the prior art, the total-synthesis anti-wear hydraulic oil has the characteristics of excellent lubricating performance, energy saving, environment friendliness and the like and has high popularization and application values.

Owner:SHANDONG YUANGEN PETROLEUM CHEM

Composite aluminum base grease and its preparing method

The composite aluminum base grease is prepared with high alkalinity calcium sulfonate 20-50 weight portions, thickener of composite aluminum soap 5-15 weight portions and base oil 35-75 weight portions. The preparation process includes the steps of converting the high alkalinity calcium sulfonate from Netwtonian substance into non-Netwtonian substance; adding stearic acid, benzoic acid and aluminum trimer to prepare composite aluminum soap; heating to refining and cooling to obtain the grease. The composite aluminum base grease has high water resistance, high antirust performance, high extreme pressure resistance, high mechanical stability and high temperature colloid stability.

Anti-rust extreme pressure lithium lubricating grease composition and preparation method

InactiveCN105331426AImprove extreme pressure performanceImprove shear stabilityLubricant compositionAntioxidantLithium hydroxide

The invention relates to an anti-rust extreme pressure lithium lubricating grease composition and a preparation method thereof. The composition is prepared from 5.5%-12.5% of thickening agents, 72.8%-91.3% of base oil, 0.5%-3.8% of extreme pressure anti-wear agents, 0.28%-1.25% of antioxidants and 0.02%-1.05% of anti-rust anti-corrosion agents, wherein the base oil is high-viscosity mineral oil. The preparation method of the composition comprises the steps that one third of the base oil and 12-hydroxy stearin or a mixture of 12-hydroxy stearin and stearic acid are heated to the temperature ranging from 60 DEG C to 80 DEG C, a lithium hydroxide solution is added, the temperature is raised to range from 180 DEG C to 220 DEG C after a reaction is completed, one third of quenching oil is added, the extreme pressure anti-wear agents, the anti-rust anti-corrosion agents and the rest of the base oil are added after cooling is conducted, and the composition is prepared after grounding is conducted. The novel lubricating grease containing the extreme pressure components and the anti-rust anti-corrosion components has the excellent extreme pressure property and anti-corrosion property and can be widely applied to severer environment conditions with a medium or heavy load and water.

Owner:CHINA PETROLEUM & CHEM CORP

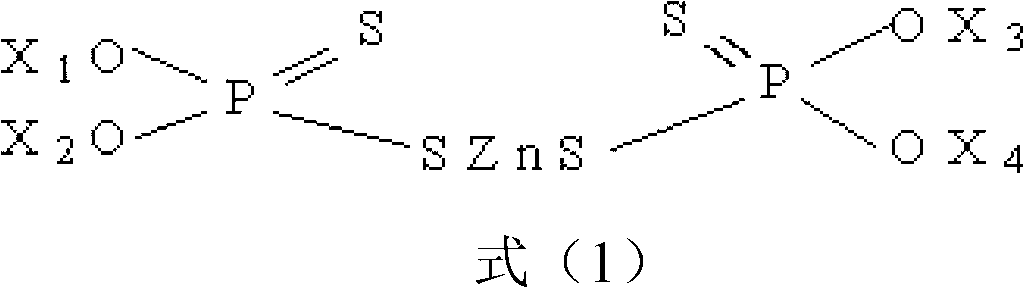

Gasoline engine lubricating coil composition and preparation method thereof

InactiveCN107760419AReduce usageGive full play to the synergistic effectLubricant compositionChemical compositionBoron containing

The invention discloses a gasoline engine lubricating coil composition and a preparation method thereof. The gasoline engine lubricating coil composition comprises the following components in percentby weight: (A) 0.1 to 6.0 percent of an ashless dispersing agent, (B) 0.1 to 8.0 percent of a clearing agent, (C) 0.01 to 1.5 percent of oil-soluble or dispersible oil stability boron-containing compound, (D) 0.003 to 0.5 percent of oil-soluble or dispersible oil stability molybdenum-containing compound, (E) 0.02 to 3.2 percent of zinc dialkyl dithiophosphate, (F) 0.01 to 3.0 percent of an antioxidant and (G) lubricating oil base oil with a main amount, wherein the boron molybdenum mass ratio of the component (C) to the component (D) ranges from 1:5 to 10:1. The blended gasoline engine oil composition contains all of the boron-containing compound, the molybdenum-containing compound and the zinc dialkyl dithiophosphate, completely exerts the synergistic effect between the additives, improves the anti-oxidation property, the anti-wear and friction-reducing properties and the extreme pressure property of the lubricating oil composition and reduces the ash content and the thionazin contentof the lubricating oil composition.

Owner:江西福安路润滑材料有限公司 +1

Anti-wear energy-saving engine lubricating oil

InactiveCN103923728AHigh viscosityImprove low temperature fluidityAdditivesThermodynamicsProcess engineering

The invention relates to anti-wear energy-saving engine lubricating oil, which comprises basic oil and an additive serving as raw materials, wherein the basic oil is hydrogenated isodewaxed III type basic oil; the additive is an anti-wear agent MODDP, namely, molybdenum dialkyldithiophosphate. The complex system has a good synergistic effect, so that the wear reduction, anti-wear, carbon deposit reduction, oil sludge dispersion and anti-wear energy-saving effects become more remarkable. Under the condition of high temperature and high pressure, MODDP is decomposed to form an MoS2 protective film, and meanwhile a novel metal produced by friction undergoes a friction chemical reaction to generate FePO4 and FeS reaction films, so that unique 'anti-wear, repair, energy-saving and environmental protection' effects are achieved on an engine, remarkable repairing and maintaining functions are realized, and the service lives of equipment such as engines are prolonged; equipment such as engines is protected, and the worn inner cylinder wall of equipment can be repaired automatically; a cylinder body can be kept clean, continuous protection is provided, and the service life is prolonged.

Owner:山东力牌石油化学有限公司

Preparation method of water dispersible nano copper cooling lubricant for cold rolling

InactiveCN101948712AReduce coefficient of frictionSoluble in waterAdditivesChemical reactionMetallurgy

The invention discloses a preparation method of a water dispersible nano copper cooling lubricant for cold rolling. In the lubricant, oleate is used as a surfactant, divalent copper salt is used as a copper element, and hydrazine hydrate is used as a reducing agent. Nano copper is selected as a main raw material of the lubricant, and meanwhile, certain dispersant and surfactant are added to prepare the water dispersible nano copper cooling lubricant applicable to a cold rolling process. The invention aims at improving the lubricity of cold rolling, a friction surface can be primed and repaired to a certain extent through products of a friction chemical reaction, and thus, rolled steel has self repairing action.

Owner:BEIHANG UNIV

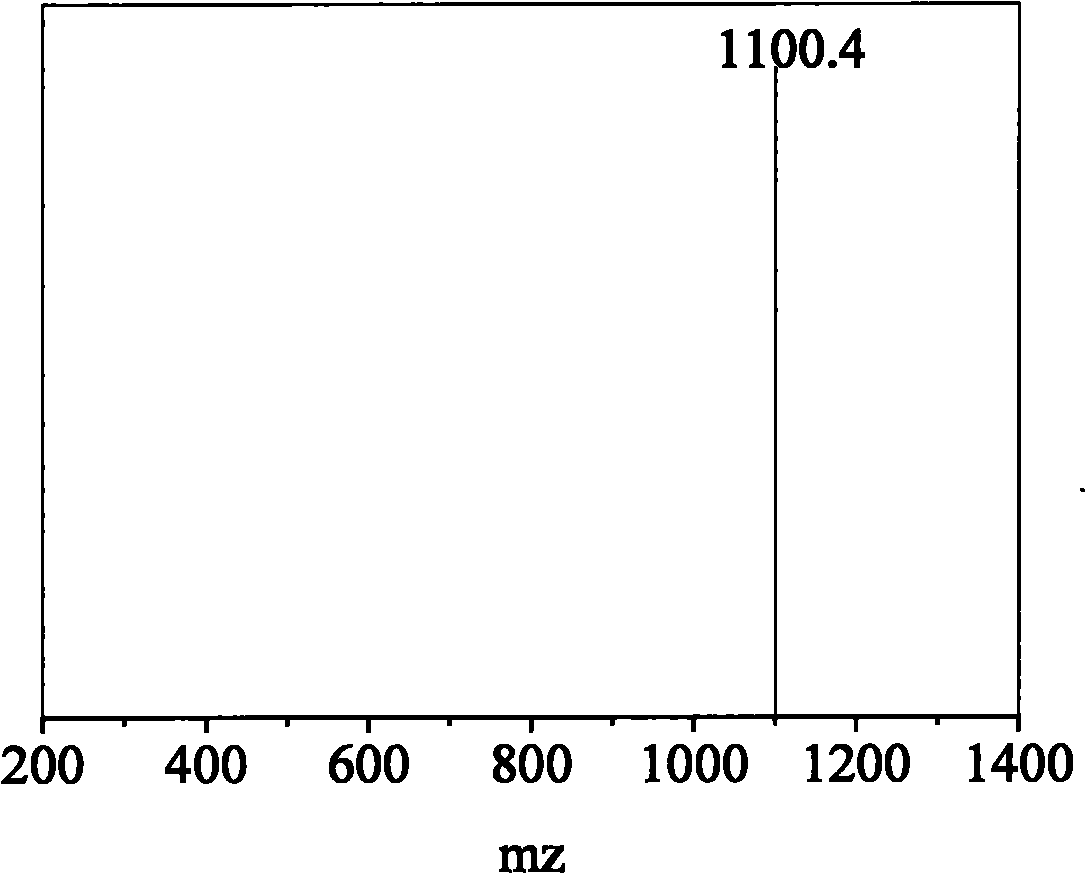

Non-sulfur and non-phosphorus organic molybdenum compound and preparation method and application thereof

InactiveCN104844656AImprove thermal stabilityImprove tribological propertiesAdditivesGroup 6/16 organic compounds without C-metal linkagesOrganic solventSulfur

The invention provides a non-sulfur and non-phosphorus organic molybdenum compound and preparation method and application thereof. The structural formula is shown in the formula, wherein R is a C1-C30 linear or branched alkyl or cycloalkyl. The preparation method comprises the step of reacting hydroxyalkyl amine with ammonium molybdate tetrahydrate in the presence of an organic solvent and a catalyst. The organic molybdenum compound provided by the present invention can be used as a lubricating oil additive and has good antiwear and extreme-pressure properties.

Owner:SHANGHAI JIAO TONG UNIV

Open type gear lubricating grease

ActiveCN1970706AIncrease stickinessImprove comprehensive wear indexAdditivesBase-materialsSolventAgricultural engineering

The invention discloses a solvent-diluted open-typed gear lubricant, which is characterized by the following: the basic oil is high-viscosity synthesized oil; the thickener is composite calcium sulfonate; the additive is auxiliary extreme-pressure agent, anti-oxidant and diluent; the lucribant possesses superior high-low temperature adaptability (low-temperature fluidity and high-temperature adhesive), which is not easy to volatilize under normal temperature.

Owner:辽宁海华科技股份有限公司

Fan main shaft lubricating grease composition and preparation method thereof

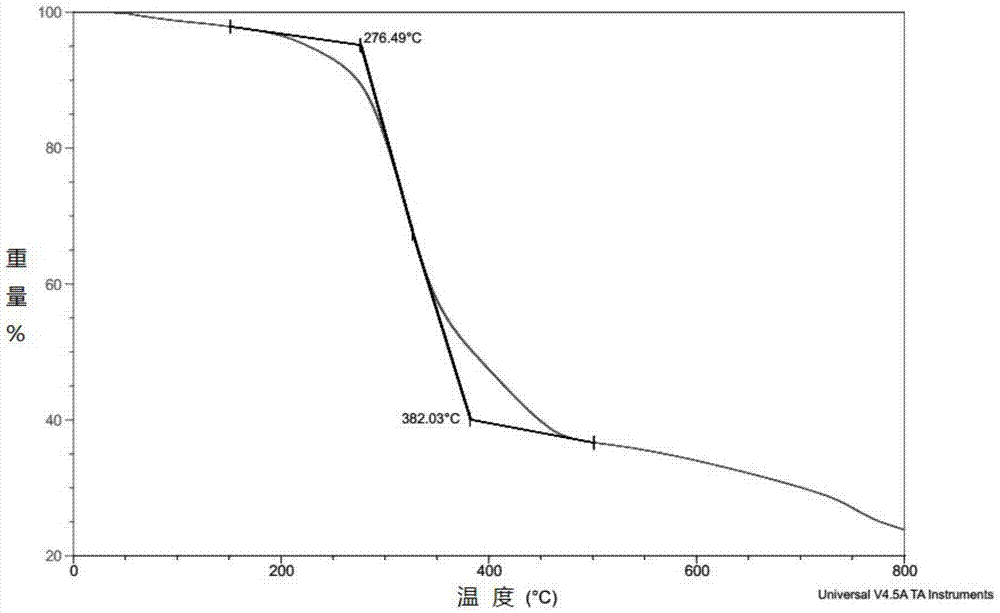

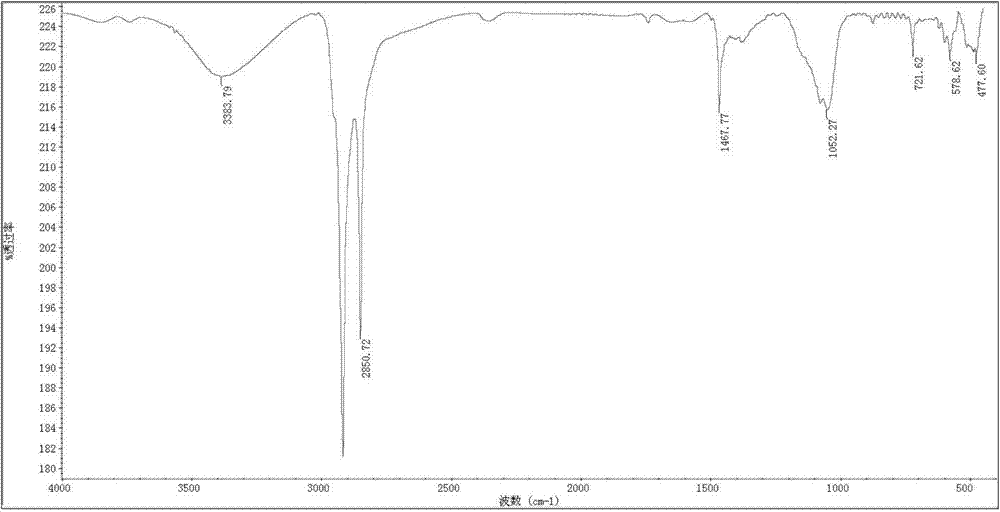

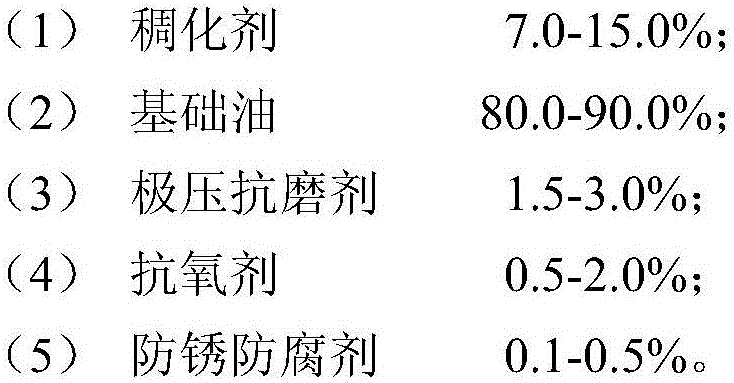

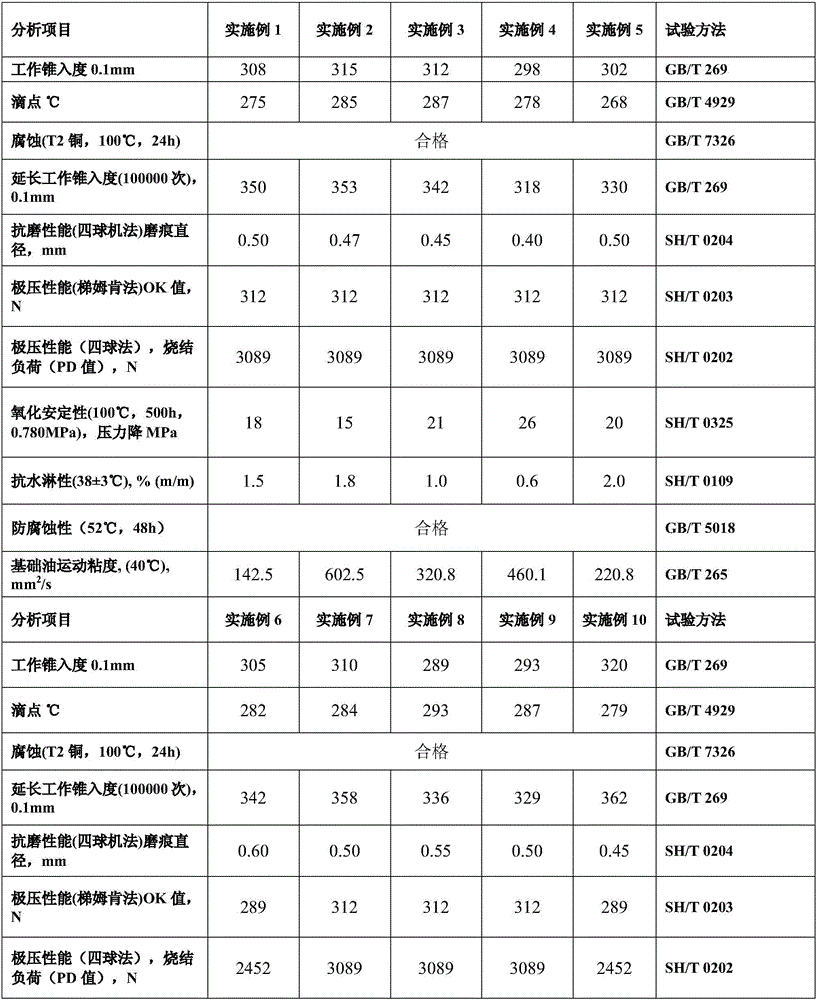

The invention relates to a fan main shaft lubricating grease composition and a preparation method thereof. The composition comprises 7-15% of a thickener, 80-90% of base oil, 1.5-3.0% of an anti-wear reagent at extreme pressure, 0.5-2.0% of an antioxidant and 0.1-0 .5% of an anti-rust preservative. The thickener is composite lithium-calcium soap. The preparation method comprises heating 75-85% of base oil and 12-hydroxystearic acid to 80 to 90 DEG C, adding 10-20% of a lithium hydroxide solution and all calcium hydroxide solution into the base oil and 12-hydroxystearic acid to start a reaction, controlling a temperature to 90 to 100 DEG C, adding a dibasic acid into the mixture, stirring the mixture for 30 to 40 minutes, then adding the rest of the lithium hydroxide solution into the mixture at a temperature of 90 to 120 DEG C drop by drop, after the reaction, heating the reaction product to 130 to 140 DEG C along with stirring, keeping the temperature for 60 to 90 minutes, adding the antioxidant into the reaction product, heating the mixture to 200 to 210 DEG C, adding the rest of the base oil into the reaction product, cooling the mixture, adding the anti-wear reagent at extreme pressure and anti-rust preservative into the mixture when the temperature is 80 DEG C or less, carrying out uniform stirring, carrying out treatment homogenization through a three-roller machine to obtain a finished product and carrying out filling. The fan main shaft lubricating grease composition is characterized in that the excellent compatibility anti-wear reagent at extreme pressure and the special anti-rust preservative are used so that the main shaft lubricating grease extreme pressure properties are greatly improved and the anti-rust performance is excellent.

Owner:CHINA PETROLEUM & CHEM CORP

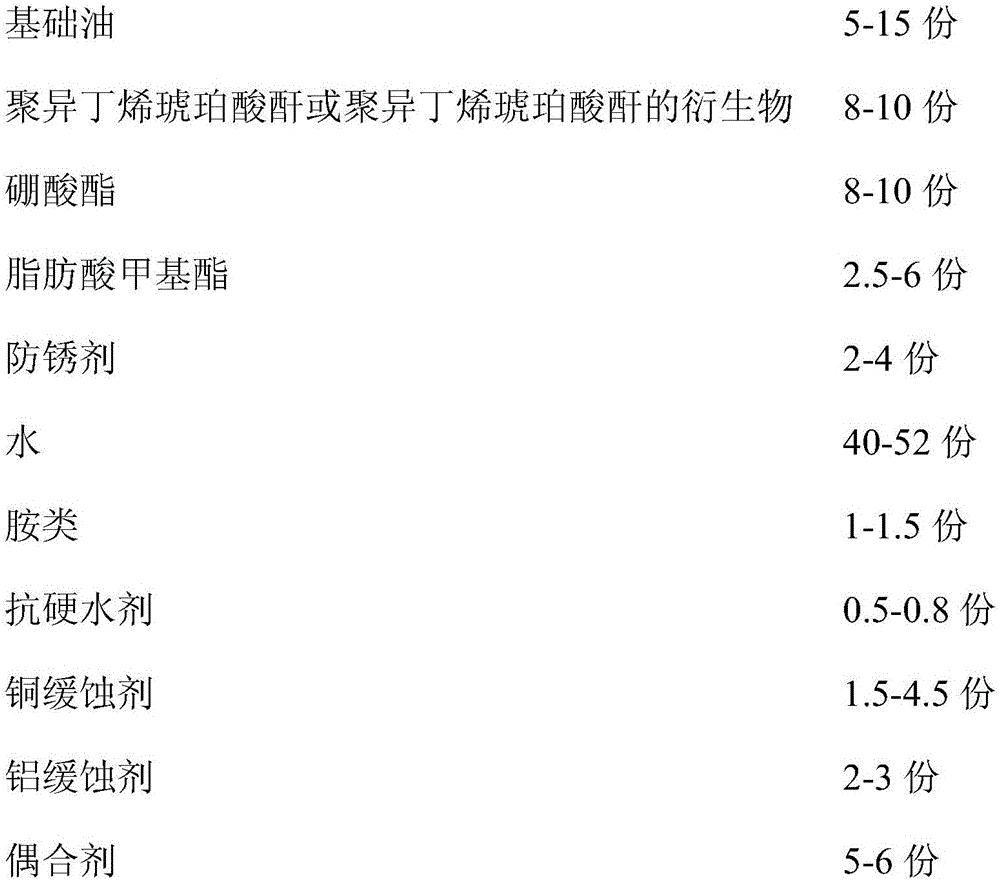

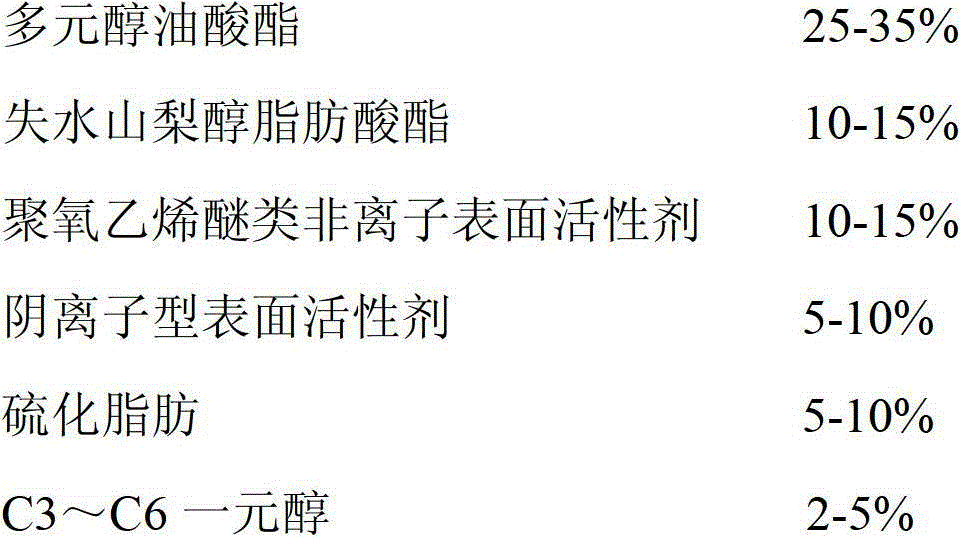

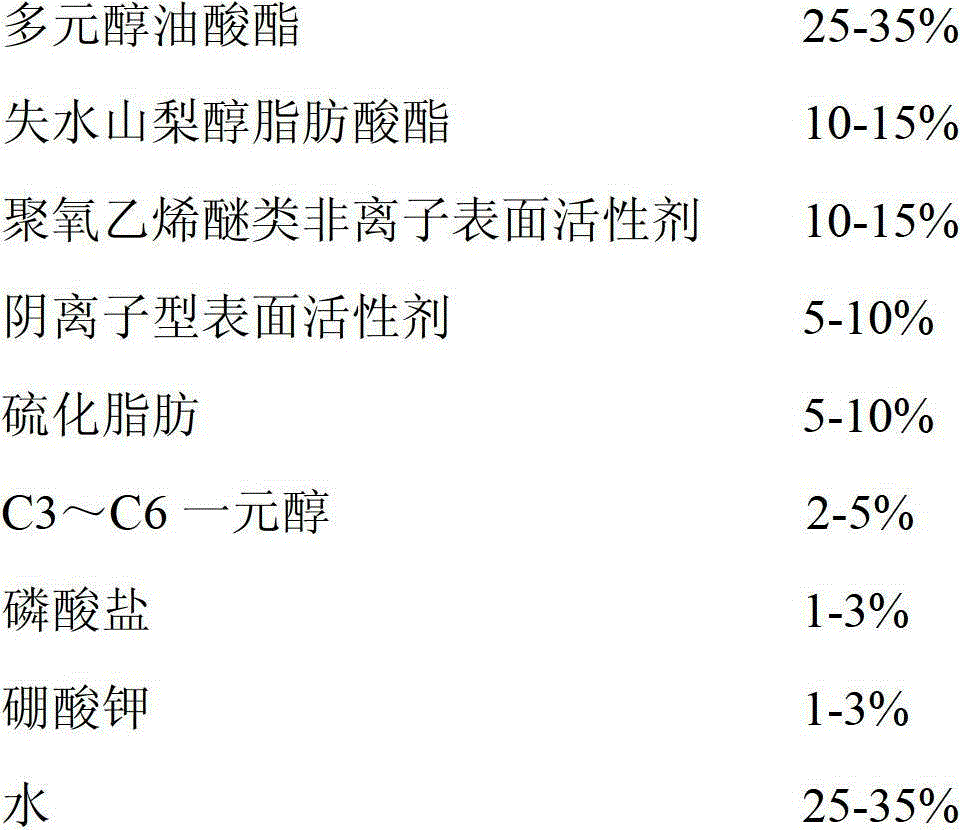

Aluminum alloy near-dry cutting processing microemulsion and preparation method thereof

ActiveCN103146467ASignificant protection benefitsImprove extreme pressure performanceLubricant compositionAlcoholPhosphate

The invention discloses an aluminum alloy near-dry cutting processing microemulsion and a preparation method thereof. The aluminum alloy near-dry cutting processing microemulsion is prepared through the following steps: preparing a mother solution, wherein the mother solution is prepared by mixing raw materials, heating to 30-50 DEG C and stirring, and the mother solution comprises the following raw materials in percentage by weight: 25-35% of polyalcohol oleate, 10-15% of sorbitan fatty acid ester, 10-15% of polyethenoxy ether nonionic surfactant, 5-10% of anionic surfactant, 5-10% of sulfurized fat, 2-5% of C3-6 monobasic alcohol, 1-3% of phosphate, 1-3% of potassium borate and 25-35% of water; and mixing the mother solution and water according to a weight ratio of 1:(1-3), sufficiently stirring, adding 0.005-0.01wt% of polysiloxane, and sufficiently stirring to obtain the aluminum alloy near-dry cutting processing microemulsion working fluid. The aluminum alloy near-dry cutting processing microemulsion disclosed by the invention has excellent extreme pressure performance, antiwear property and lubricating property; when the microemulsion is used with a near-dry cutting and lubricating device, the consumption of the microemulsion can be reduced to 10% or below of the original consumption; and favorable effects of lubricating and cooling as well as remarkable benefits of energy saving, emission reduction and environment protection can be achieved.

Owner:江苏麦格美节能科技有限公司

Compsn. of rust inhibiting lubricant special for chain

InactiveCN1415713AGood rust resistanceExcellent extreme pressure and wear resistanceAdditivesEnvironmental chemistryP-Cresol

A composite antirust hebricant for chain contains sulfonate as antirust agent, olefine butanedioic acid type antirust agent, dialkyldithiophosphate-formaldehyde-lipoamin condensate, plant oil, phenyltriazole lipoamine salt, polyisobutylene, vaseline, 2,6-ditert-butyl p-cresol, and basic oil. Its advantages are excellent resistance to rust, salt fog and abrasion, high adhesive, and good water displacing nature.

Owner:CHINA PETROLEUM & CHEM CORP +1

Extreme pressure antiwear agent and preparation method thereof and lubricating oil combination

Owner:CHINA PETROLEUM & CHEM CORP +1

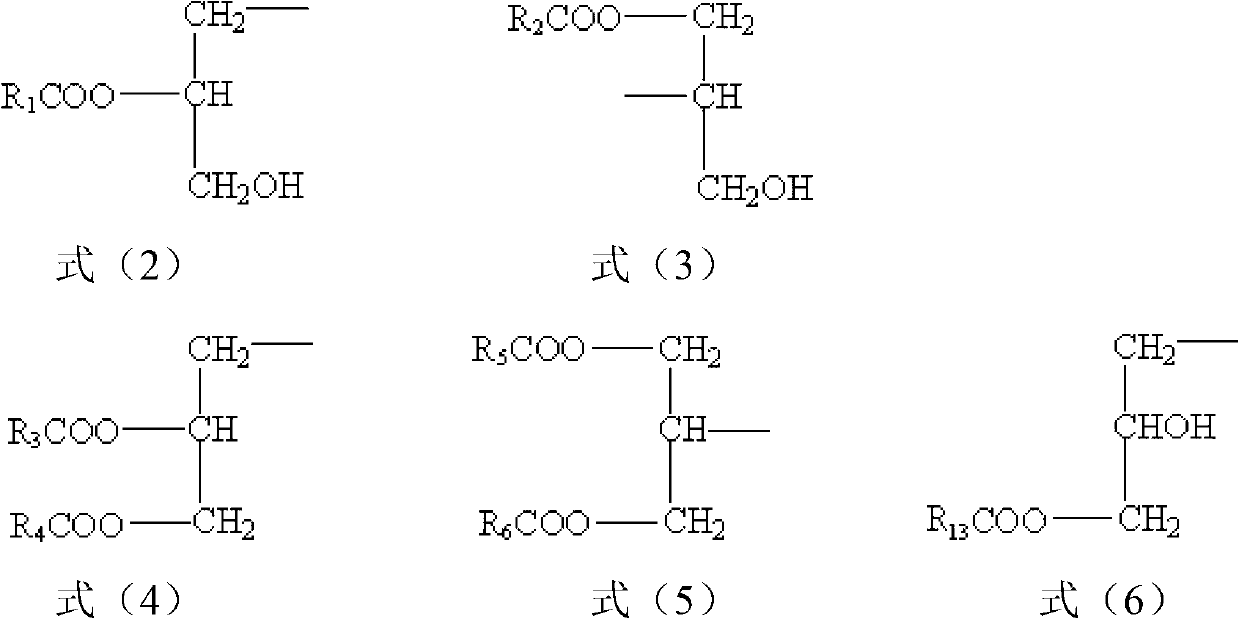

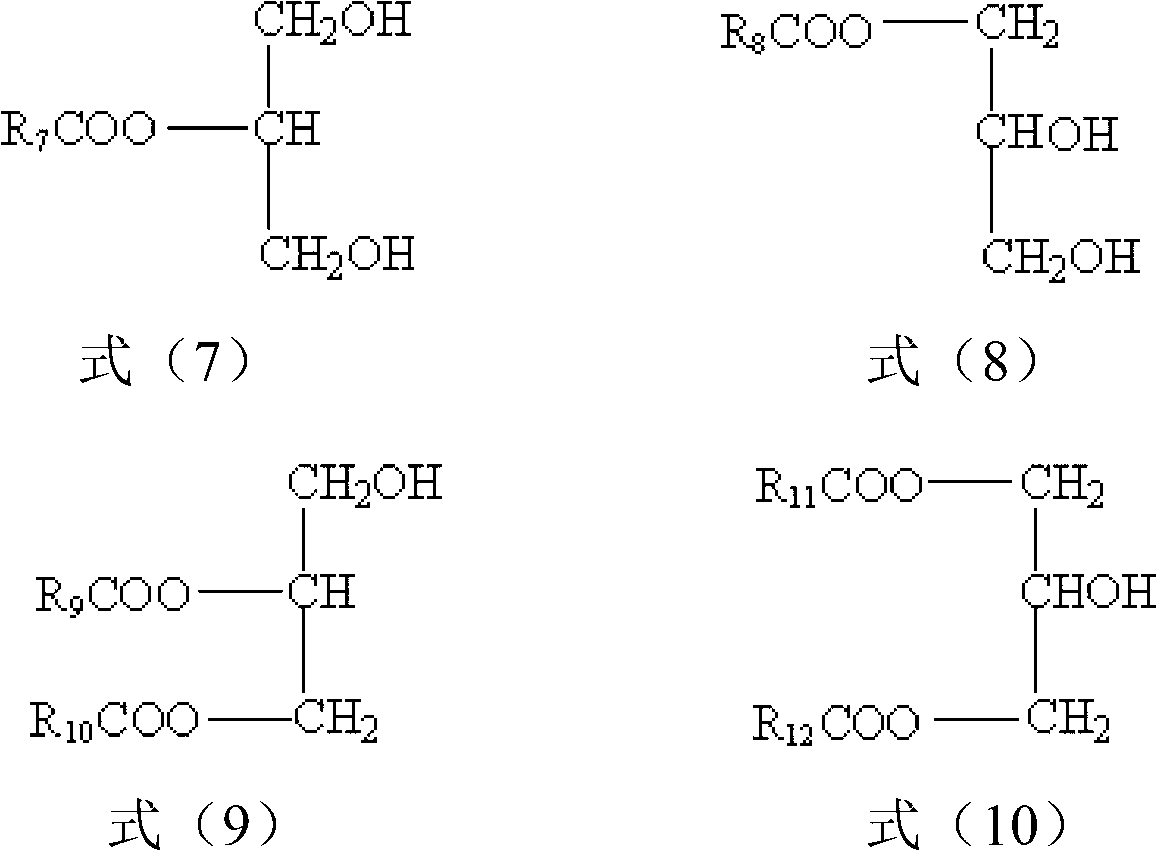

Biological type micro lubricating oil and preparation method and application thereof

InactiveCN101654636AImprove the lubrication effectImprove extreme pressure performanceAdditivesBase-materialsPhosphatePollution

The invention belongs to the technical field of lubricating oil, in particular to biological type micro lubricating oil which comprises the following raw materials in percentage by weight: 62-70 polyalpha olefin (PAO), 24-30 of composite synthetic ester, 1-2 N-lauroyl alanine, 1-2 composite phosphate and 1-2 dispersant. Compared with the prior art, the invention not only has better lubricating property and extreme pressure property so that few lubricating agents can meet high-end requirement of metal processing, but also can reduce the consumption of the lubricating agent to less than 5 percent of the previous consumption, reduces the harm to the environment and worker, can be degenerated biologically, and lowers the pollution to the environment to be maximum.

Owner:SHANGHAI JINZHAO ENERGY SAVING TECH

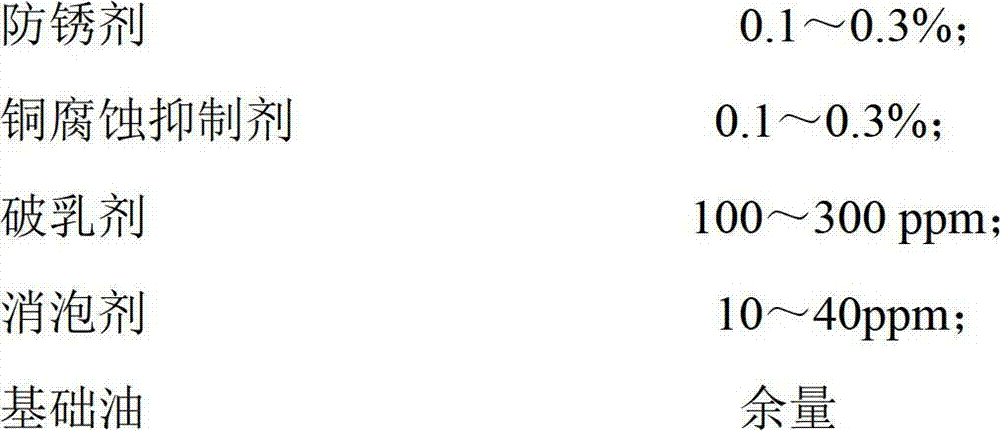

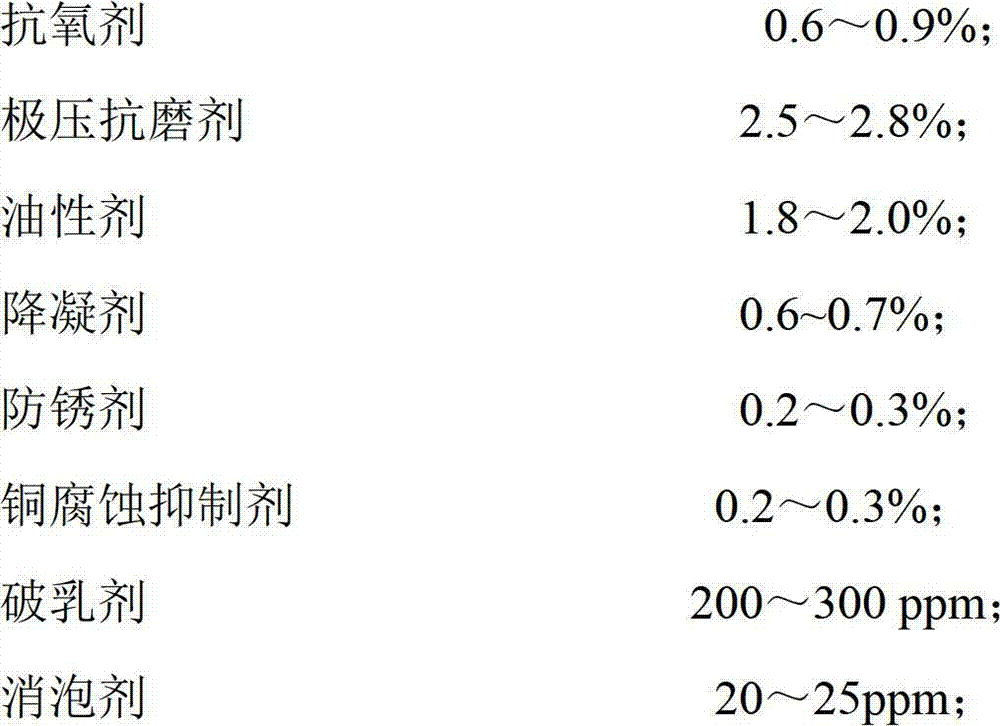

Special gear oil for shield and preparation method thereof

The invention discloses special gear oil for a shield and a preparation method of the special gear oil. The special gear oil for the shield comprises the following components in percentage by weight: 0.5-1.0% of antioxidant, 1.5-3.0% of extreme pressure anti-wear additive, 1.0-2.0% of oiliness agent, 0.3-0.7% of pour point depressant, 0.1-0.3% of anti-rusting agent, 0.1-0.3% of copper corrosion inhibitor, 100-300ppm of emulsion breaker, 10-40ppm of defoaming agent and the balance of base oil. The wear resistance and the extreme pressure property of a product are obviously improved due to the gear oil, and equipment bearings and gears are obviously better protected. In a shield tunneling process, even if a section with a quite rigid soil texture appears, the torque ripples of the shield bearings and the gears can also be guaranteed to be small, so the stable tunneling of a shield machine is guaranteed.

Owner:HAILIAN INST OF LUBRICATING MATERIALS SHANGHAI +1

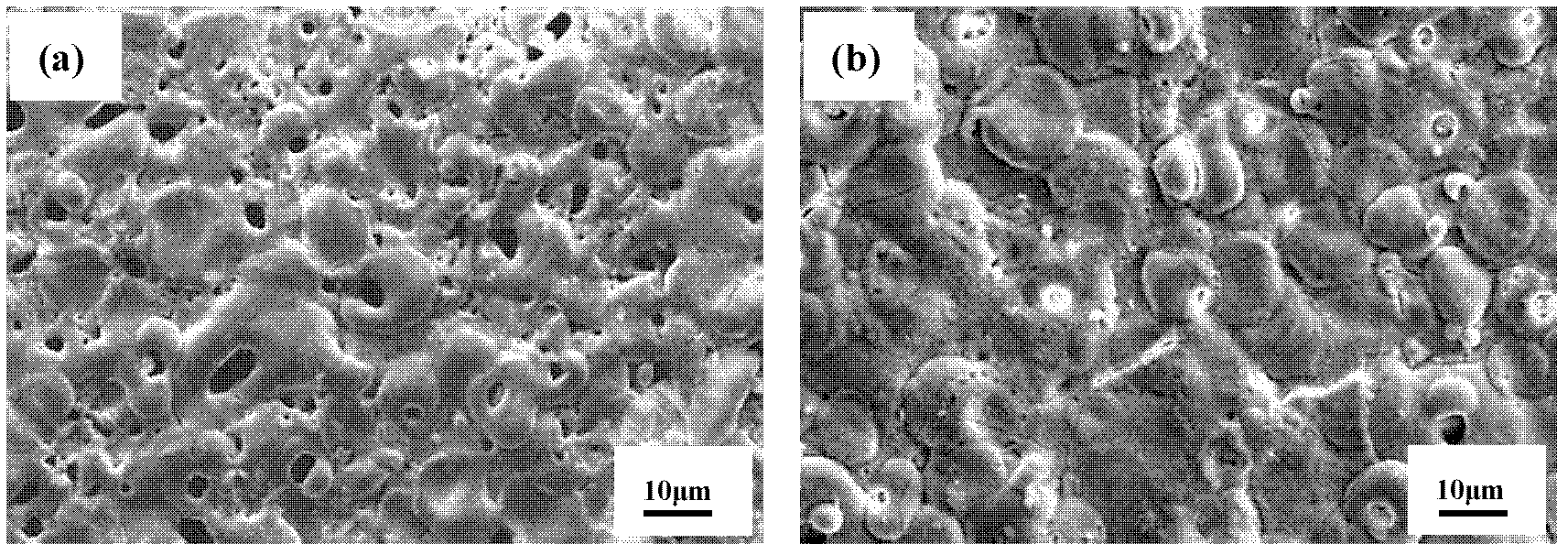

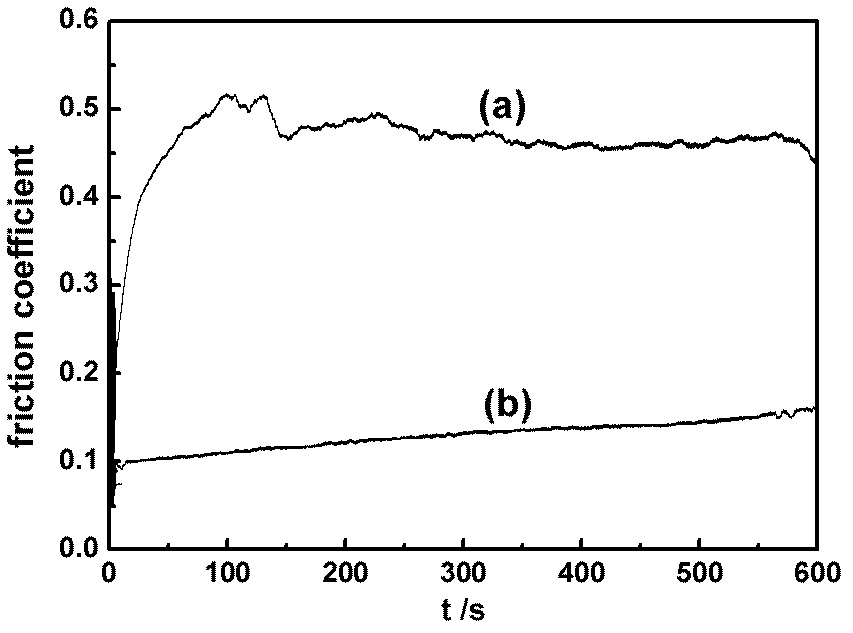

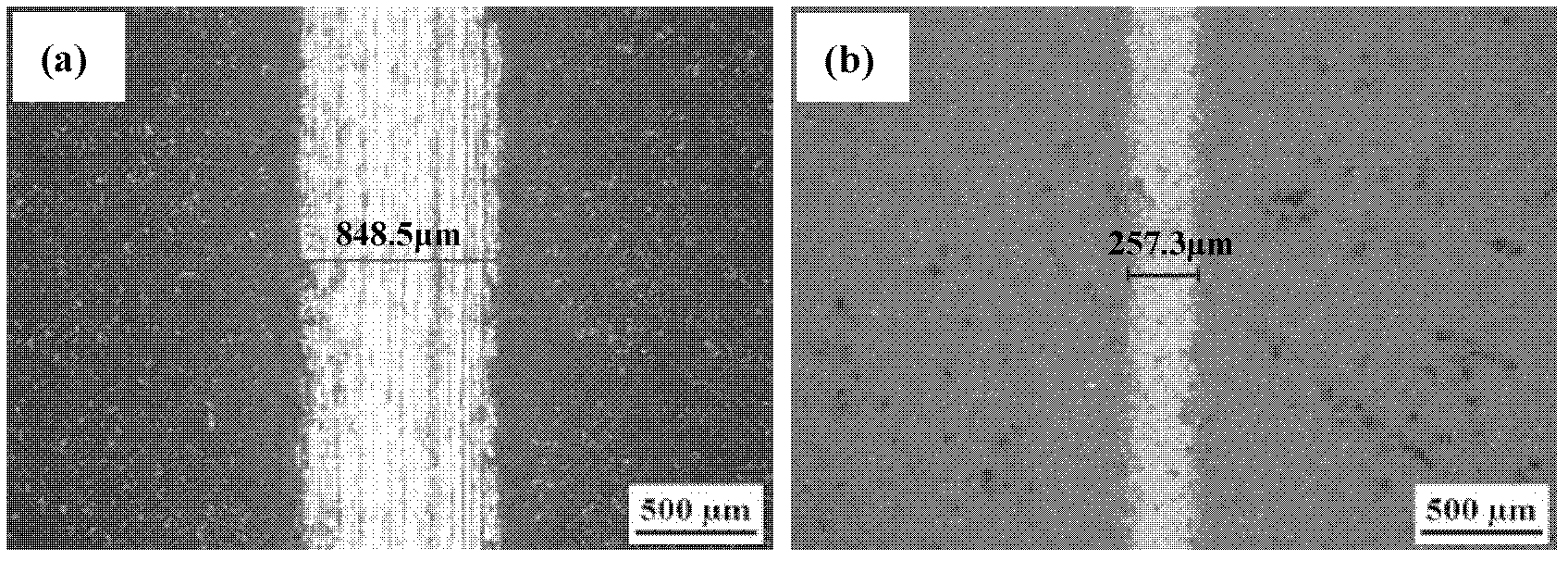

Micro-arc oxidation preparation method of high wear resistant and corrosion resistant self-lubricating ceramic layer and electrolyte thereof

InactiveCN102304739AReduce coefficient of frictionImprove extreme pressure performanceAnodisationElectrolytic agentMicro arc oxidation

The invention discloses a micro-arc oxidation preparation method of a high wear resistant and corrosion resistant self-lubricating ceramic layer and electrolyte thereof, belonging to the technical field of metal surface treatment. The preparation method comprises the following steps: performing pretreatment on a sample; preparing electrolyte; setting electrical parameters; then starting a circulating cooling water device, connecting the metal sample with a conductor pole, and soaking in the electrolyte to serve as an anode, wherein a stainless steel electrolytic cell is also used as a cathode; starting a bidirectional pulse power supply, and performing micro-arc oxidation treatment; and taking out the treated sample, washing and naturally airing. The electrolyte is characterized in that: any one of potassium hydroxide and sodium citrate is mixed with the electrolyte; sodium silicate, sodium fluoride and an anionic dispersant are mixed and dissolved; and then WS2 particles are added while ultrasonic treatment and mechanical agitation are applied to prepare the electrolyte. The WS2 self-lubricating solid material used in the method has the following advantages: the material has extremely low friction coefficient and relatively high extreme pressure resistance and oxidation resistance, the price is lower than that of MoS2, and the material is difficult to decompose and cannot react with the metal substrate and reagents, etc.

Owner:UNIV OF SCI & TECH BEIJING

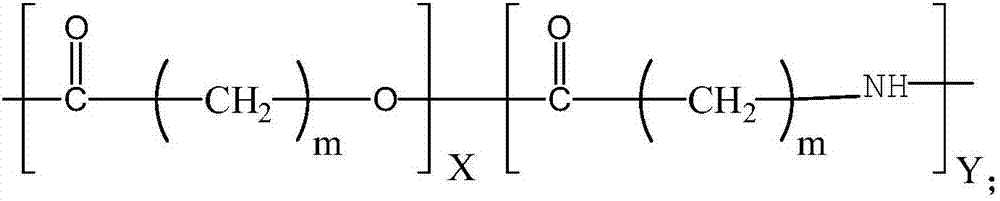

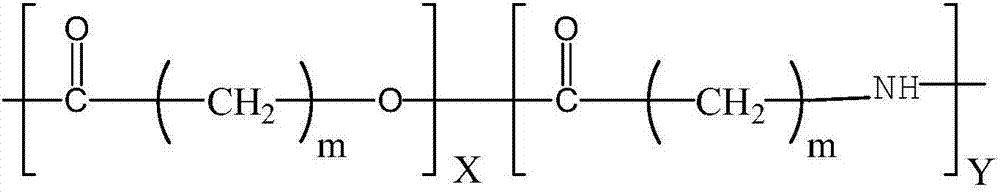

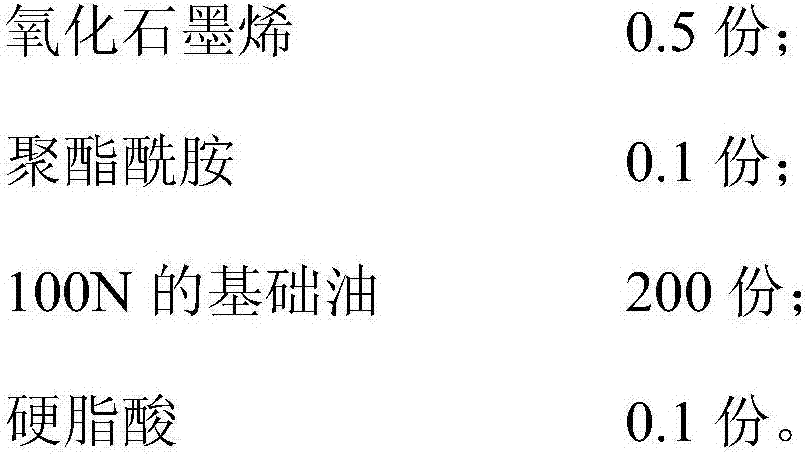

Graphene lubricating oil additive, preparation method and application of graphene lubricating oil additive and lubricating oil with graphene lubricating oil additive

The invention relates to a graphene lubricating oil additive, a preparation method and application of the graphene lubricating oil additive and lubricating oil with the graphene lubricating oil additive. The graphene lubricating oil additive is prepared from, by mass, 0.01-0.5 part of graphene substances, 0.1-5 parts of polyesteramide and 50-200 parts of base oil. By the aid of polyesteramide, the graphene substances can be well dispersed in the base oil of the lubricating oil, preparation can be realized without adoption of a high-temperature high-pressure method, and adoption of complex processes for graphene modification is avoided. The graphene lubricating oil additive obtained according to the formulation is excellent in dispersion performance and free of precipitates or layering after standing for longer than 14 months, and abrasion resistance and extreme pressure resistance of the lubricating oil can be substantially improved by mixing of the graphene lubricating oil additive with graphene lubricating oil carrier oil according to a volume ratio of (1-5):(1000-10000).

Owner:秦继恩

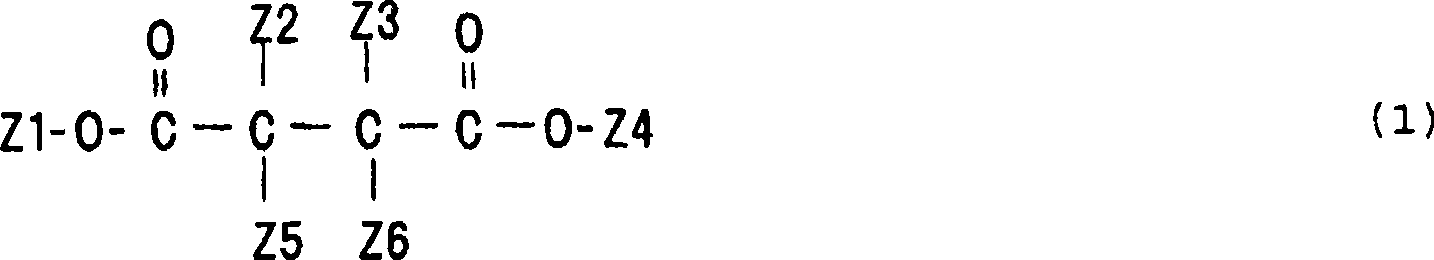

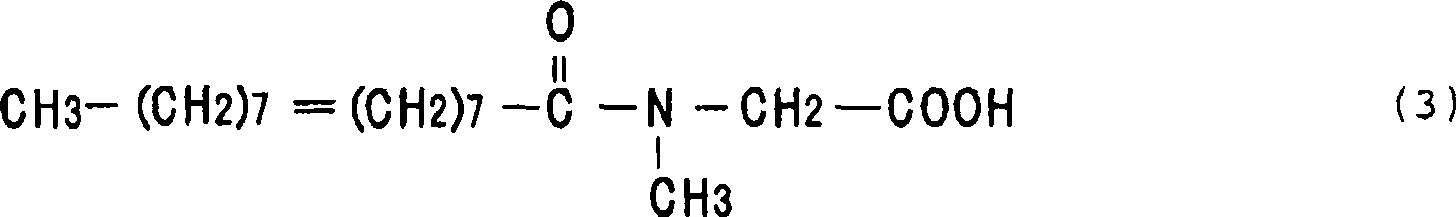

Lubricating oil composition

The present invention provides a lubricating oil composition comprising at least one type of base oil selected from mineral oils and synthetic oils, and a succinate ester and a sarcosinic acid as rust prevention agents. The succinate ester content is preferably set at 0.01 to 0.1 wt. %, and the sarcosinic acid content is preferably set at 0.001 to 0.01 wt. %. Further, they are preferably set such that the resulting weight ratio of the succinate ester content and sarcosinic acid content is 1 : 0.01 to 0.7. The lubricating oil composition according to the present invention shows excellent rust prevention properties and a satisfactorily long oxidation lifetime. Further it allows to attain a high level of anti- sludge performance and extreme pressure performance and lubrication performance, even when it is used for example in turbine bearings in combined cycle generators having multiplier gears operated under severe high temperature and high pressure conditions.

Owner:SHELL INT RES MAATSCHAPPIJ BV

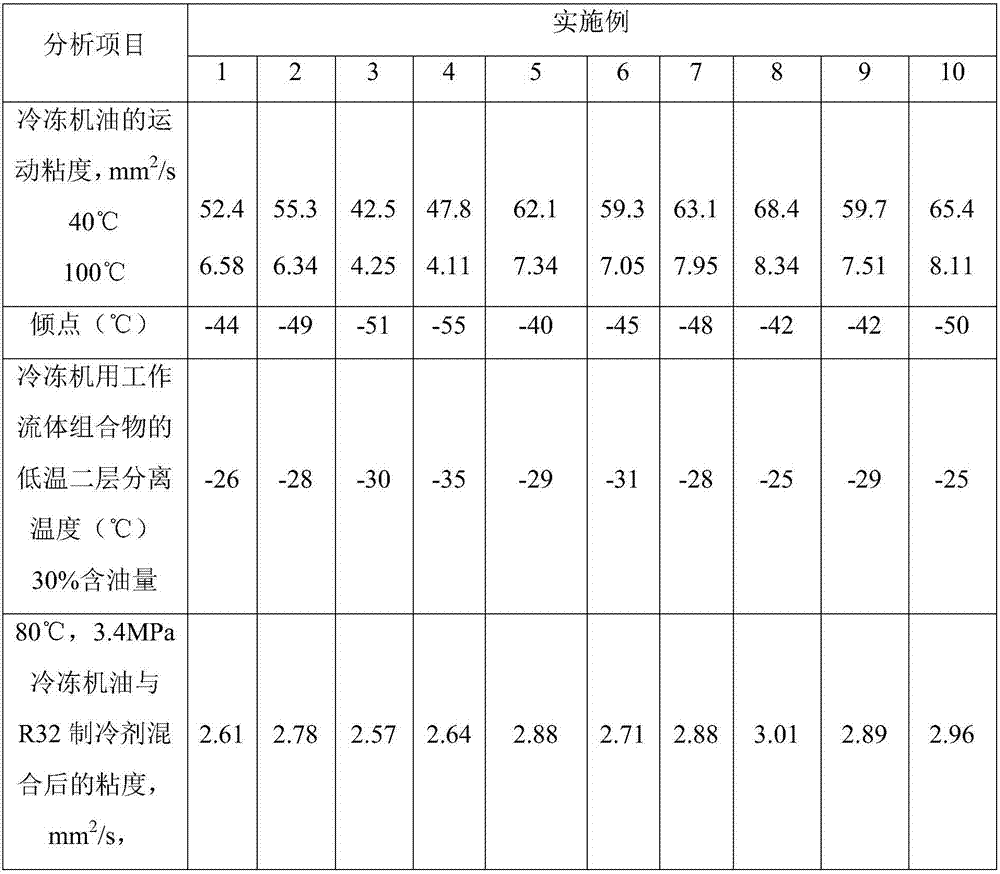

Refrigerating machine oil, preparation method thereof and working fluid composition for refrigerating machine

The invention relates to refrigerating machine oil, a preparation method thereof and a working fluid composition for a refrigerating machine. According to the main technical scheme, the refrigerating machine oil contains polyol ester and an additive, wherein the additive contains an extreme pressure anti-wear reagent, an antioxidant, an acid capturing agent and a defoaming agent; the content of polyol ester is 91.5%-99.84% of the total mass of the refrigerating machine oil; the adding amount of the extreme pressure anti-wear reagent is 0.1%-5% of the total mass of the refrigerating machine oil; the adding amount of the antioxidant is 0.05%-0.5% of the total mass of the refrigerating machine oil; and the total adding amount of the acid capturing agent and the defoaming agent is 0.01%-3% of the refrigerating machine oil. The preparation method of the refrigerating machine oil comprises the steps of carrying out esterification reaction by virtue of polyol and fatty acid, and mixing polyol ester with the additive, so as to obtain the refrigerating machine oil. The invention mainly provides the refrigerating machine oil with relatively good consistency with an R32 refrigerating agent, and the working fluid composition containing the refrigerating machine oil and the R32 refrigerating agent for the refrigerating machine has relatively good lubricating property and low-temperature fluidity.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

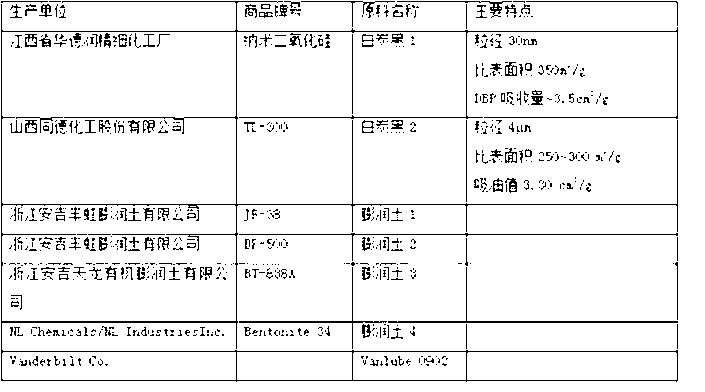

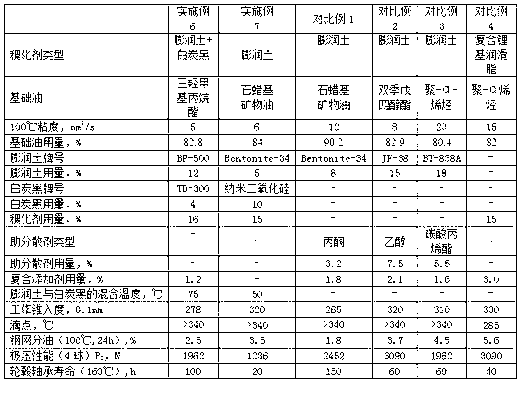

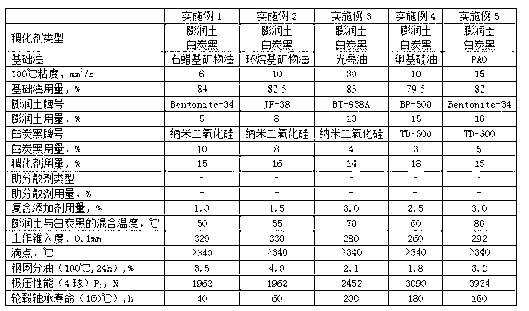

Lubricating grease composition and preparation method thereof

The invention relates to a lubricating agent, in particular to lubricating grease and a preparation method thereof. The lubricating grease comprises a lubricating grease thickening agent and base oil, wherein the lubricating grease thickening agent accounts for 5-30% of the weight of the composition; and the base oil accounts for 70-95% of the weight of the composition; and the lubricating grease thickening agent comprises bentonite and white carbon black, and the weight ratio of the bentonite to the white carbon black is 10:1-1:4. The preparation method comprises the steps as follows: 30% of the base oil, all the bentonite and all the white carbon black are added into a grease preparation kettle; the mixture is heated to 40-100 DEG C under the condition of full stirring; residual amount of the base oil is added gradually after a reactant becomes thick gradually; an additive is added, and grinding is performed for three times, so that a lubricating grease sample is obtained. According to the lubricating grease composition and the preparation method thereof, the lubricating grease is prepared with a method of mixing silica gel and bentonite, so that the usage of a volatile dispersion auxiliary during preparation of bentonite in the previous is omitted; carbon emission caused by preparation of the lubricating grease and even the environmental pollution problems are reduced; and at the same time, the problem of corrosion caused by the dispersion assisting agent is avoided. The lubricating grease has a good thickening capacity.

Owner:闻建勋

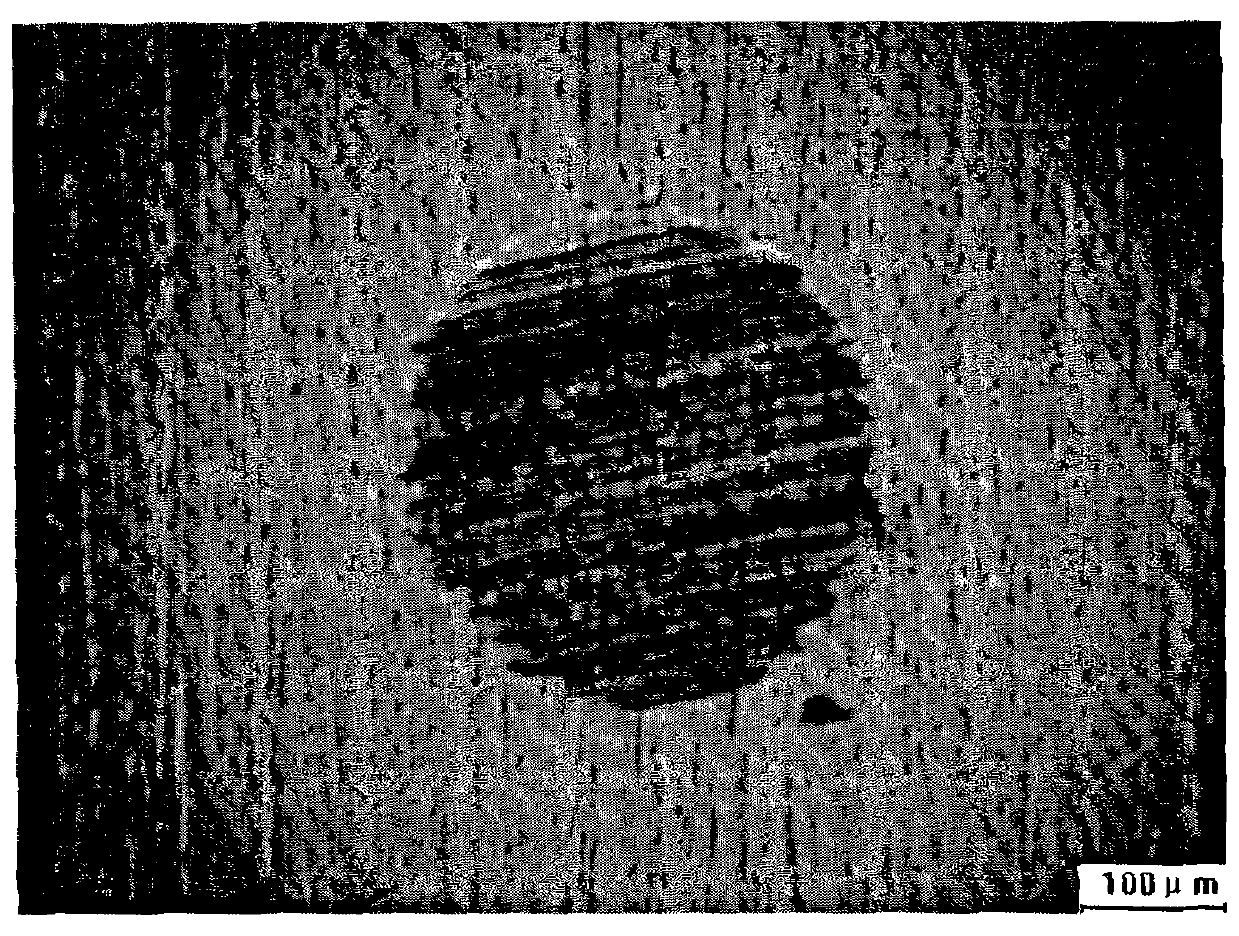

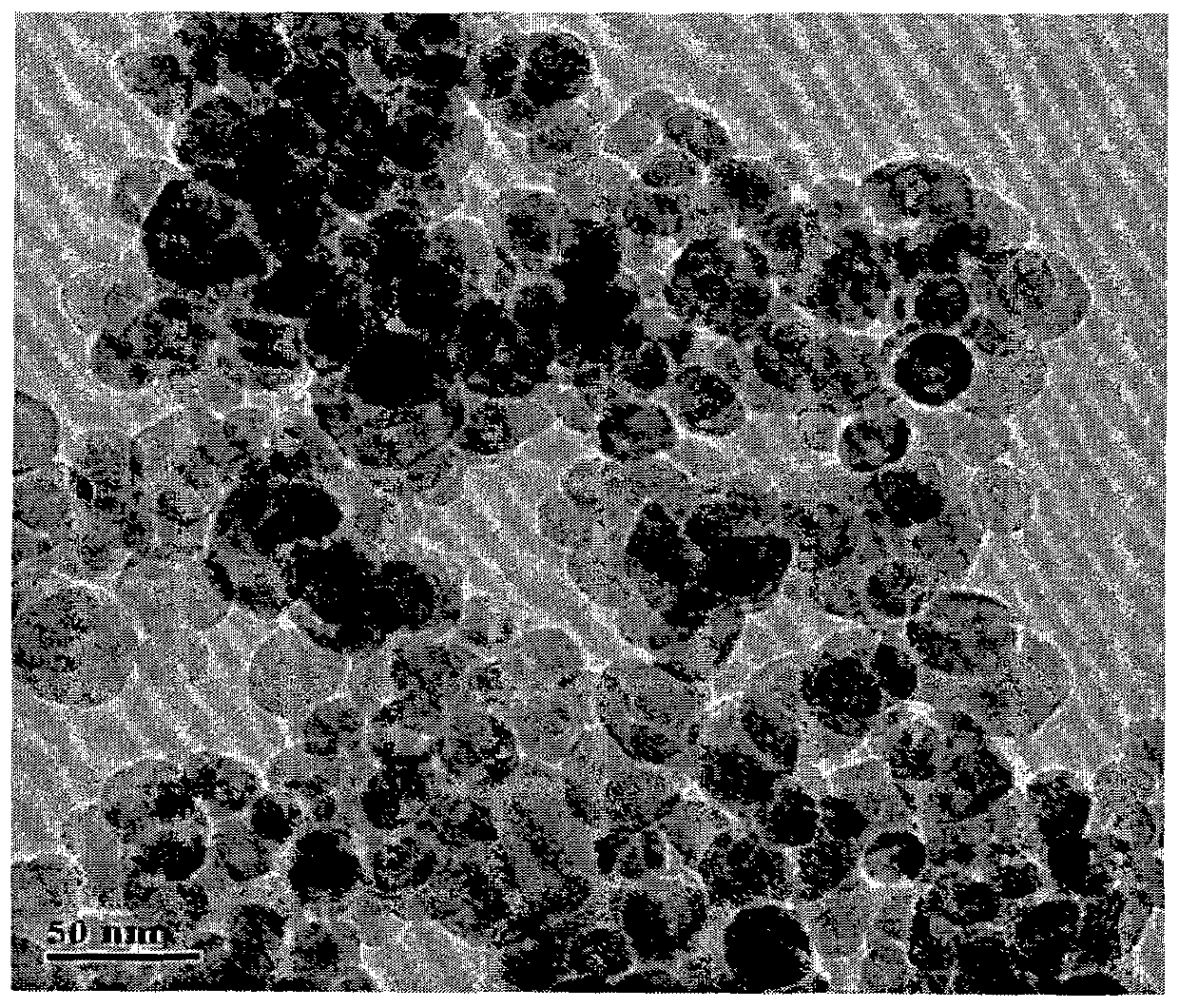

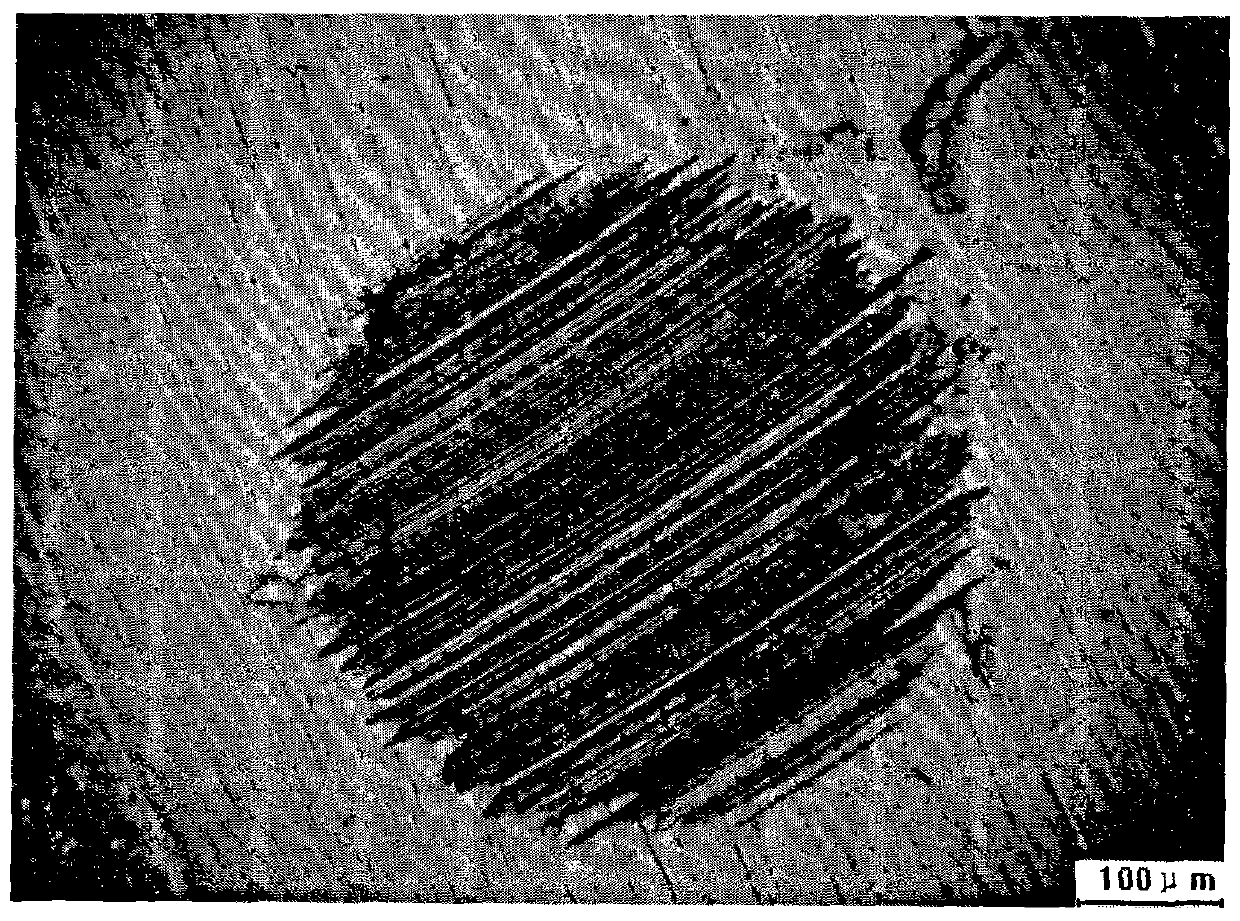

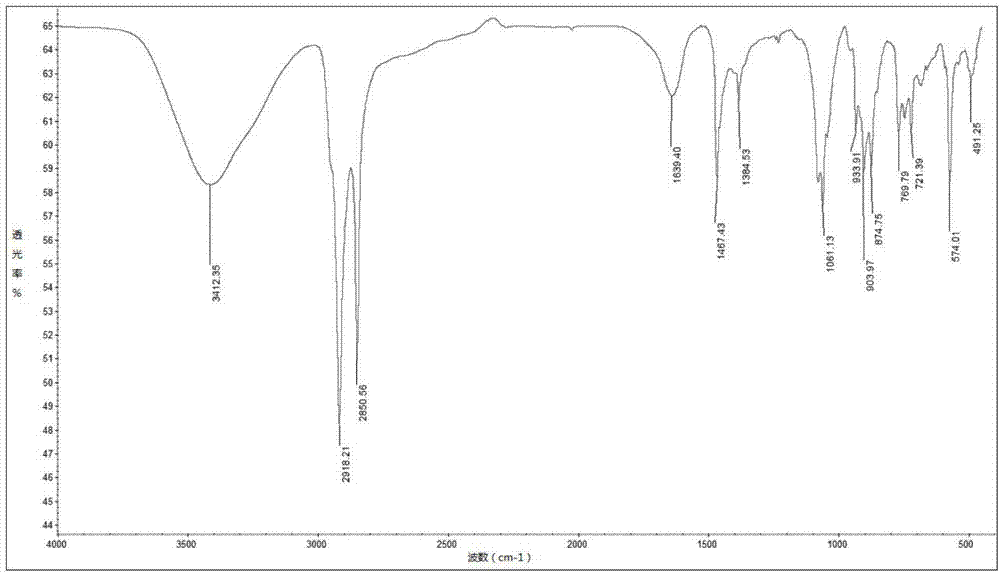

Nano solid lubricant with hollow cage-shape structure and preparation method thereof

InactiveCN1928038AIncrease elasticityReduce coefficient of frictionBase-materialsHigh humidityVulcanization

The present invention discloses one kind of hollow cage-shaped nanometer solid lubricant and its preparation process. Spherical nanometer MoO3 or WO3 particle is first prepared through an ultrasonic and chemical precipitation process and surface coated with S or Se, and hollow cage-shaped nanometer solid lubricant of IF-MoS2, IF-MoSe2, IF-WS2 or IF-WSe2 of particle size 40-100 nm is then prepared through further vulcanization or selenation reaction. This kind of solid lubricant may be used alone or as additive added into lubricant oil or grease to form composite lubricant oil or grease to reduce friction coefficient, reduce wear and raise extreme pressure resistance. At the same time, the solid lubricant can meet the lubricant requirement in high temperature, low temperature, high vacuum, high humidity, high corrosion, high radiation, high load and other harsh conditions.

Owner:JILIN UNIV

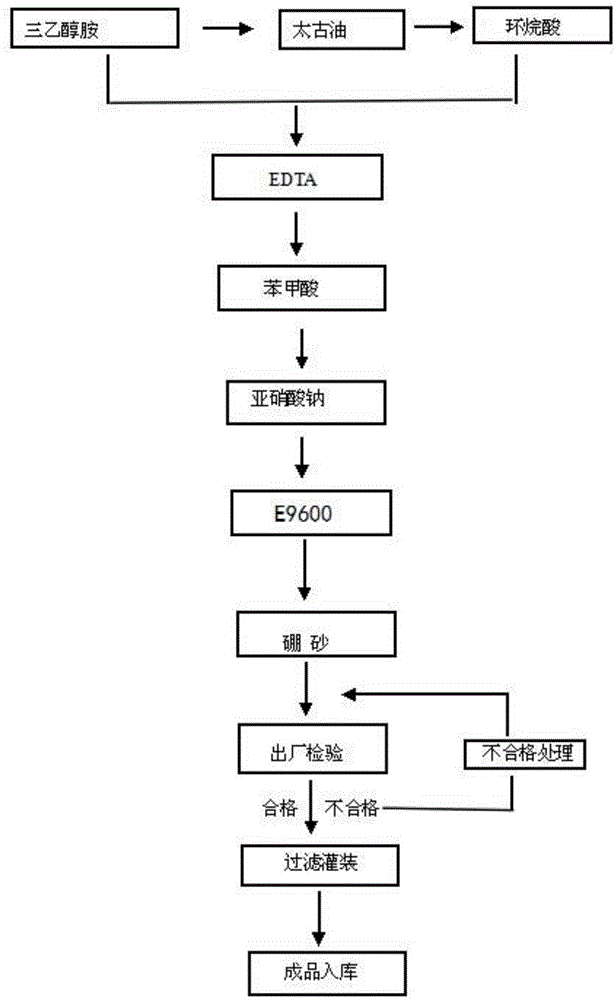

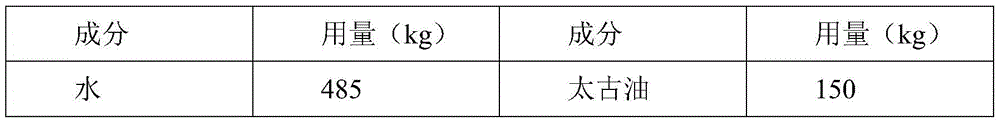

Environment-friendly emulsified oil for hydraulic support and preparation method of environment-friendly emulsified oil

ActiveCN105462673ASolve the short service lifeReduce wearLubricant compositionOrganosolvSodium nitrite

The invention discloses environment-friendly emulsified oil for a hydraulic support and a preparation method of the environment-friendly emulsified oil. The emulsified oil is prepared from the following raw materials in percentage by mass: 15.0 to 25.0 percent of Turkey red oil, 2 to 4 percent of sodium hydroxide, 2 to 5 percent of emulsifier E9600, 3 to 6 percent of sodium benzoate, 3 to 6 percent of naphthenic acid, 9 to 11 percent of sodium nitrite, 4 to 6 percent of EDTA, 5 to 7 percent of triethanolamine, 0.5 to 2.0 percent of borax, 0.1 to 1 percent of benzotriazole and the balance of water. According to the emulsified oil and the preparation method thereof, provided by the invention, the defects that the production technology process is complex, the materials are various and the odor is great in the prior art can be overcome, and the production cost is reduced; in the formula of the emulsified oil, the plant Turkey red oil is adopted, the quality of the emulsified oil is improved due to the selection of the raw materials, the using amount of organic solvents in the whole formula is reduced and the demand of environment protection is met.

Owner:ZIZHOU XINRUN BIOTECH CO LTD

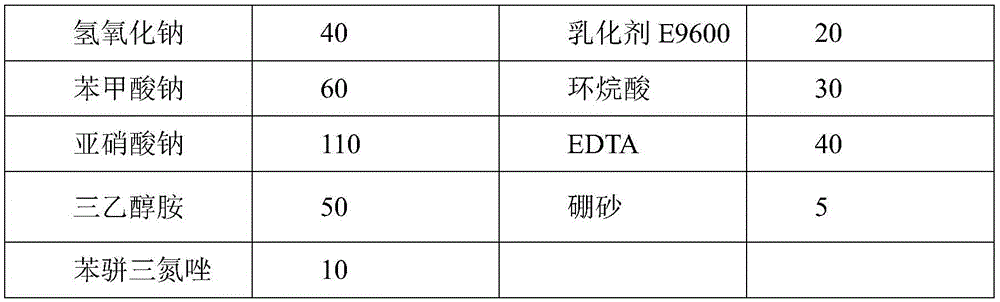

Graphene/Fe2O3 nanometer particle composite lubricating oil, lubricating oil additive and preparing method of the additive

InactiveCN106520256AReduce coefficient of frictionStable coefficient of frictionAdditivesOil additiveHydrolysis

A graphene / Fe2O3 nanometer particle composite lubricating oil additive is disclosed. The additive includes graphene the surface of which is loaded with Fe2O3 nanometer particles. The mass percentage of the graphene the surface of which is loaded with the Fe2O3 nanometer particles in lubricating oil is 0.002-1%. A method of preparing the additive is also disclosed. The additive is prepared by subjecting graphene oxide and a FeCl3 hydrate to a hydrolysis reaction, then centrifuging to obtain a solid product, washing the solid product with distilled water and ethanol for a plurality of times, and annealing. The additive has advantages of extremely good dispersibility and stability, good friction resistance and abrasion resistance and a high extreme pressure property, can be directly added into lubricating oil, and is capable of reducing the friction coefficient of a mechanical friction surface, restoring a worn surface, prolonging the service lifetime of machinery and reducing energy consumption. The method is simple, feasible, high in repetition rate and suitable for large-scale industrial production.

Owner:北京圣盟科技有限公司

Universal nonferrous metal and stainless steel cold rolling oil composite additive and preparation method thereof

ActiveCN106566598AImprove anti-friction and anti-wear effectImprove anti-wear and anti-friction performanceAdditivesAntioxidantSolvent

The invention provides a universal nonferrous metal and stainless steel cold rolling oil composite additive and a preparation method thereof and belongs to the field of lubricating agents. According to the universal nonferrous metal and stainless steel cold rolling oil composite additive, lauryl alcohol, butyl stearate, pentaerythritol oleate and lauric acid are selected as oily agents; 2,6-di-tert-butyl-4-methylphenol is selected as an antioxidant; benzotriazole and thiadiazole derivatives are used as metal deactivators; dialkyl phosphorodithioate serves as an antiwear agent; and hydrogenated base oil serves as a solvent. The alcohol-ester type oily agents are mainly used for compounding with a little amount of acid oily agents as supplementation; a little amount of dialkyl phosphorodithioate is used as the antiwear agent to reinforce an oil film so as to improve the surface quality of a rolled stock; the service life of rolling oil is prolonged through a little amount of the antioxidant and the metal deactivators, the cyclic use frequency is increased, and rolled pieces are protected against corrosion. The universal nonferrous metal and stainless steel cold rolling oil composite additive is convenient to use, low in cost and little in dosage, and has the characteristics of high oil film strength, good antiwear and antifriction effect, high oxidation resistance and excellent annealing performance.

Owner:UNIV OF SCI & TECH BEIJING

Open type gear lubricating oil

ActiveCN1970704AGood fluidity at low temperatureIncrease oil film thicknessBase-materialsEngineeringBase oil

Owner:辽宁海华科技股份有限公司

Tetra-urea lubricating grease and preparation method thereof

The invention provides a tetra-urea lubricating grease and a preparation method thereof. The tetra-urea lubricating grease comprises lubricating oil basic oil and a tetra-urea thickening agent, and does not contain di-urea thickening agent and fatty acid metal salt. In the preparation method, the tetra-urea lubricating grease is obtained by the reaction of diisocyanate, diamine and monoamine. Compared with the di-urea lubricating grease, the tetra-urea lubricating grease has higher dropping point, better extreme pressure property, colloid stability and shearing stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com