Aluminum alloy near-dry cutting processing microemulsion and preparation method thereof

A quasi-dry cutting, micro-emulsion technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of large liquid usage, waste and leakage, and achieve good extreme pressure, good lubrication and cooling effects, and environmental protection benefits significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

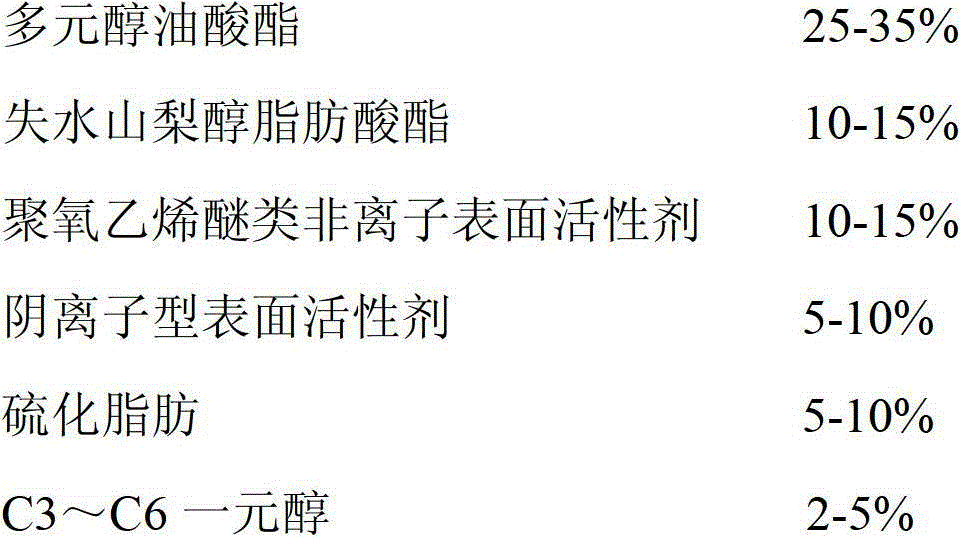

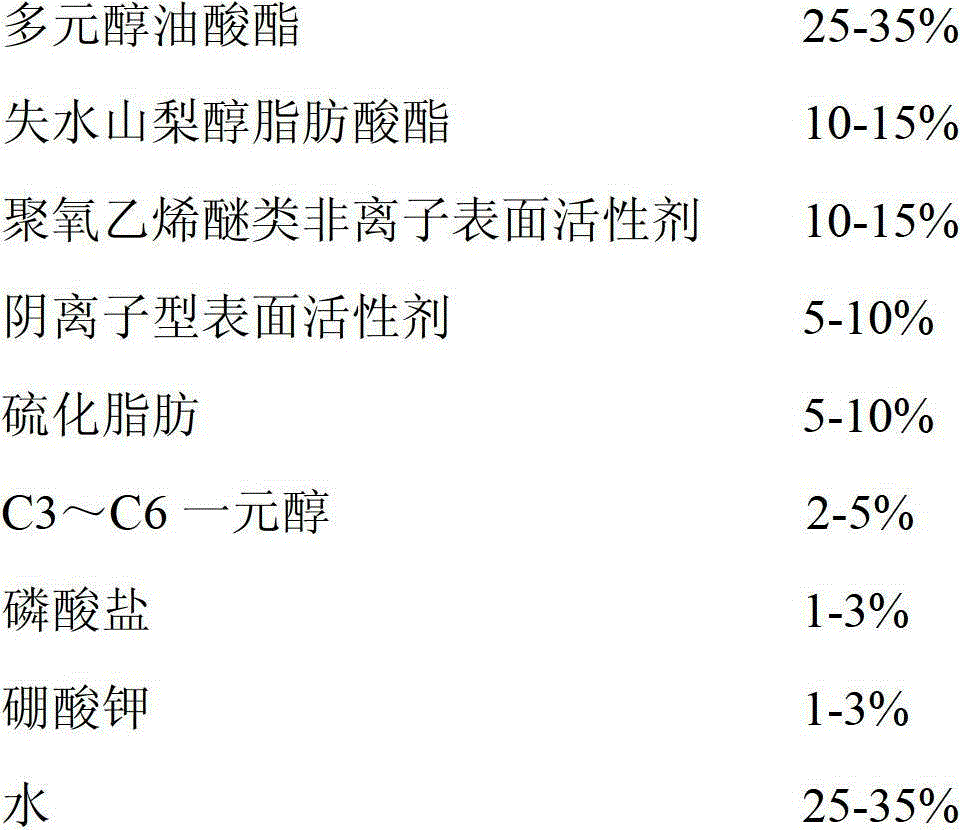

Method used

Image

Examples

Embodiment 1

[0029] Step 1: Weigh 35kg trimethylolpropane oleate, 10kg sorbitan monooleate (S-80), 10kg alkylphenol polyoxyethylene ether TX-10, 5kg sodium petroleum sulfonate, 5kg Put vulcanized lard and 5kg n-butanol into a stirrer and stir at 50°C for 10 minutes, then add 2kg of dipotassium hydrogen phosphate and 1kg of potassium borate dissolved in 27kg of water, stir fully for 60 minutes, observe that the solution is completely transparent, The microemulsion mother liquor for quasi-dry machining of aluminum alloy is obtained.

[0030] Step 2: Take 100kg of the aluminum alloy quasi-dry cutting processing microemulsion mother liquor and 100kg of water and fully stir it, and add 10 grams of antifoaming agent polysiloxane at the same time and fully stir to obtain a kind of aluminum alloy quasi-dry cutting processing microemulsion working fluid .

[0031] The microemulsion working fluid for quasi-dry cutting of aluminum alloy prepared by the above method has the following physical and che...

Embodiment 2

[0034] Step 1: Weigh 25kg of pentaerythritol oleate, 15kg of sorbitan monolaurate (S-20), 11kg of nonionic surfactant AEO-9, 8kg of sodium N-lauroyl glutamate, 6kg of vulcanized Put cottonseed oil and 4kg n-amyl alcohol into a stirrer and stir at 30°C for 15 minutes, then add 2kg of sodium phosphate and 2kg of potassium borate dissolved in 27kg of water by weight percentage, stir fully for 30 minutes, and observe that the solution is completely transparent. That is, the aluminum alloy quasi-dry machining microemulsion mother liquor is obtained.

[0035] Step 2: Take the above-mentioned aluminum alloy quasi-dry cutting processing microemulsion mother liquor 100kg and 150kg of water and stir fully, add 15 grams of antifoaming agent polysiloxane, 50 grams of sodium polyacrylate, and 100 grams of isothiazolinone, and fully stir , that is, the microemulsion working fluid for quasi-dry machining of aluminum alloy is obtained.

[0036] The microemulsion working fluid for quasi-dry c...

Embodiment 3

[0040] Step 1: Weigh 28kg of dipentaerythritol oleate, 12kg of sorbitan monostearate (S-60), 12kg of nonionic surfactant OP-9, 6kg of sodium N-lauroylalanine, Put 10kg of vulcanized rapeseed oil and 3kg of n-amyl alcohol into a stirrer and stir at 45°C for 12 minutes, then add 3kg of potassium dihydrogen phosphate and 1kg of potassium borate dissolved in 25kg of water, stir fully for 45 minutes, and observe that the solution is completely Transparent, that is, the aluminum alloy quasi-dry cutting microemulsion mother liquor is obtained.

[0041] Step 2: Take 100kg of the above-mentioned aluminum alloy quasi-dry cutting processing microemulsion mother liquor and 200kg of water to fully stir, add 30 grams of antifoaming agent polysiloxane, 600 grams of sodium carboxymethyl cellulose, and 300 grams of isothiazolinone Derivatives, fully stirred to obtain microemulsion working fluid for aluminum alloy quasi-dry cutting.

[0042] The aluminum alloy quasi-dry cutting processing micr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com