Technology and device for desalinating seawater by means of slag heat

A seawater and process technology, applied in seawater treatment, general water supply saving, water/sewage treatment, etc., can solve problems such as high investment and operation costs of steam boilers, inability to fully utilize steam heat, and difficulty in reducing seawater desalination costs, etc. Achieve significant economic benefits and environmental protection benefits, low operation and maintenance costs, and low manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

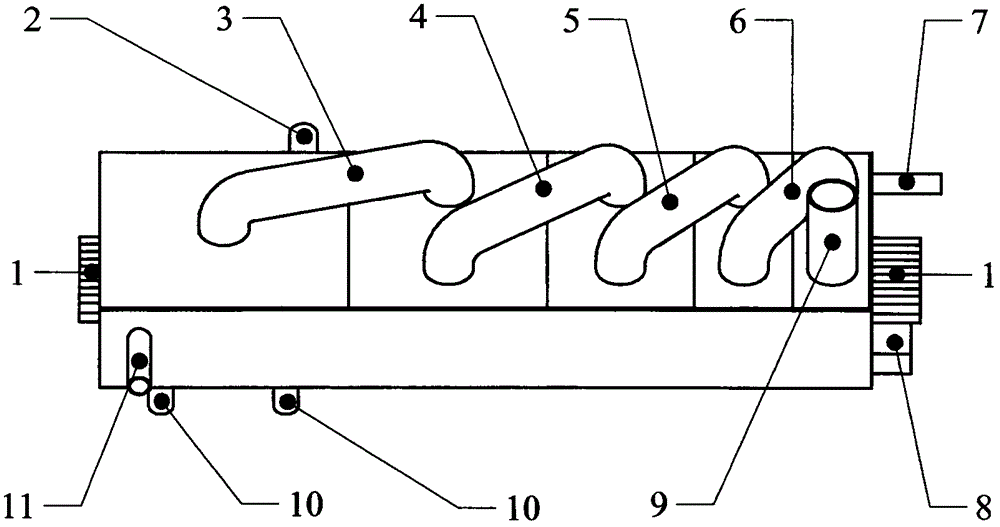

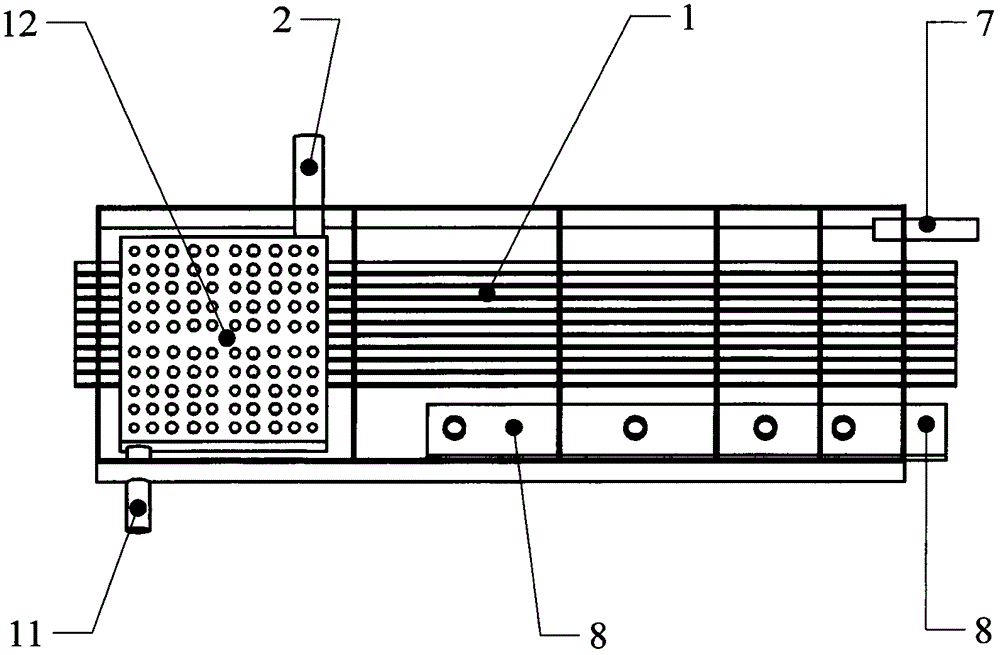

[0017] This embodiment is a case in which a seawater desalination device with five seawater evaporation tanks is matched with a slag washing granulation device, a water slag separation device, a water pump, and a slag washing pool to form a set of seawater desalination equipment utilizing slag heat.

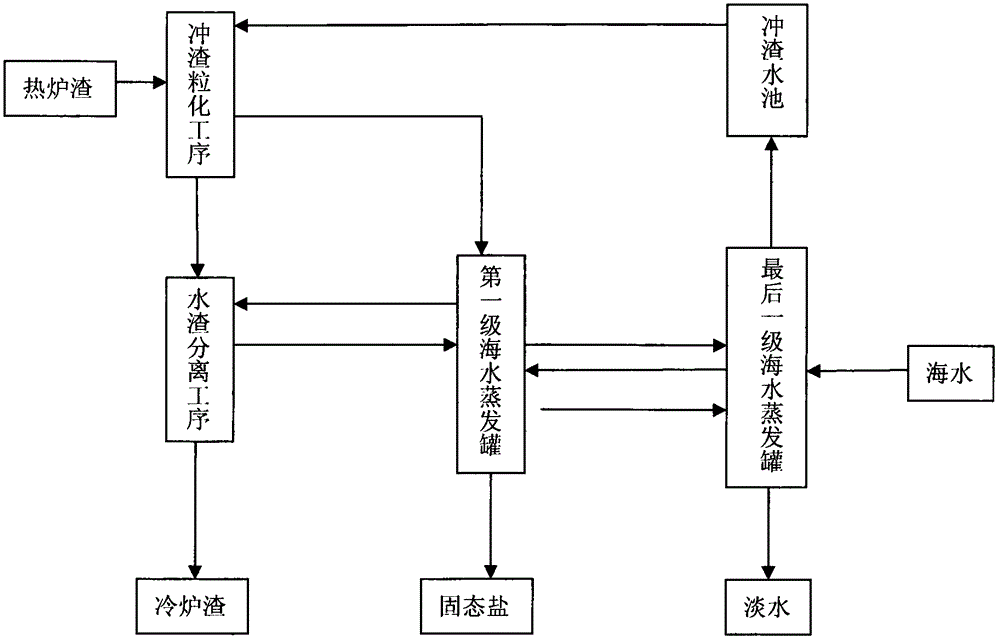

[0018] figure 1 is the process flow chart. The vertical frame is the process or important equipment of the process, which is fixed; the horizontal frame is various materials, which must be moved along the direction indicated by the arrow. The specific process is that the slag washing water from the slag washing pool and the hot slag from the blast furnace are mixed in the slag washing granulation device to produce a mixture of water vapor and water slag. Water vapor enters the first-stage seawater evaporation tank to heat seawater, condenses into water and then enters the water slag separation device; the water slag mixture enters the water slag separation device and is separate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com