Patents

Literature

287 results about "Iron industry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Iron Industry. the sector of mining engaged in the obtaining of iron ore and in its primary processing—crushing, sorting, concentrating, homogenizing, and agglomerating particles by sintering or pelletizing. The iron industry is the raw-material basis of ferrous metallurgy. Iron ore has been extracted and iron produced from it since ancient times.

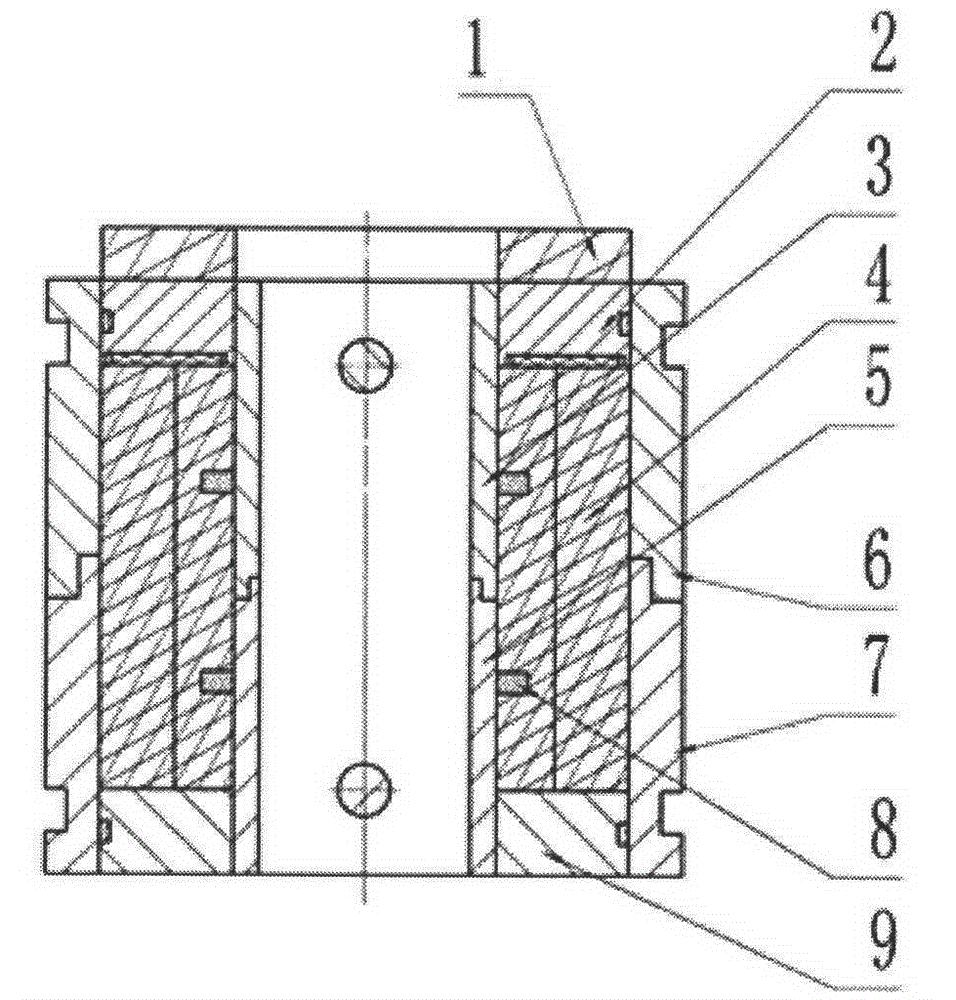

High-speed resin heavy-load grinding wheel

InactiveCN102161183AImprove mechanical propertiesImprove automationAbrasion apparatusGrinding devicesFiberZirconia alumina

Owner:江苏华东砂轮有限公司

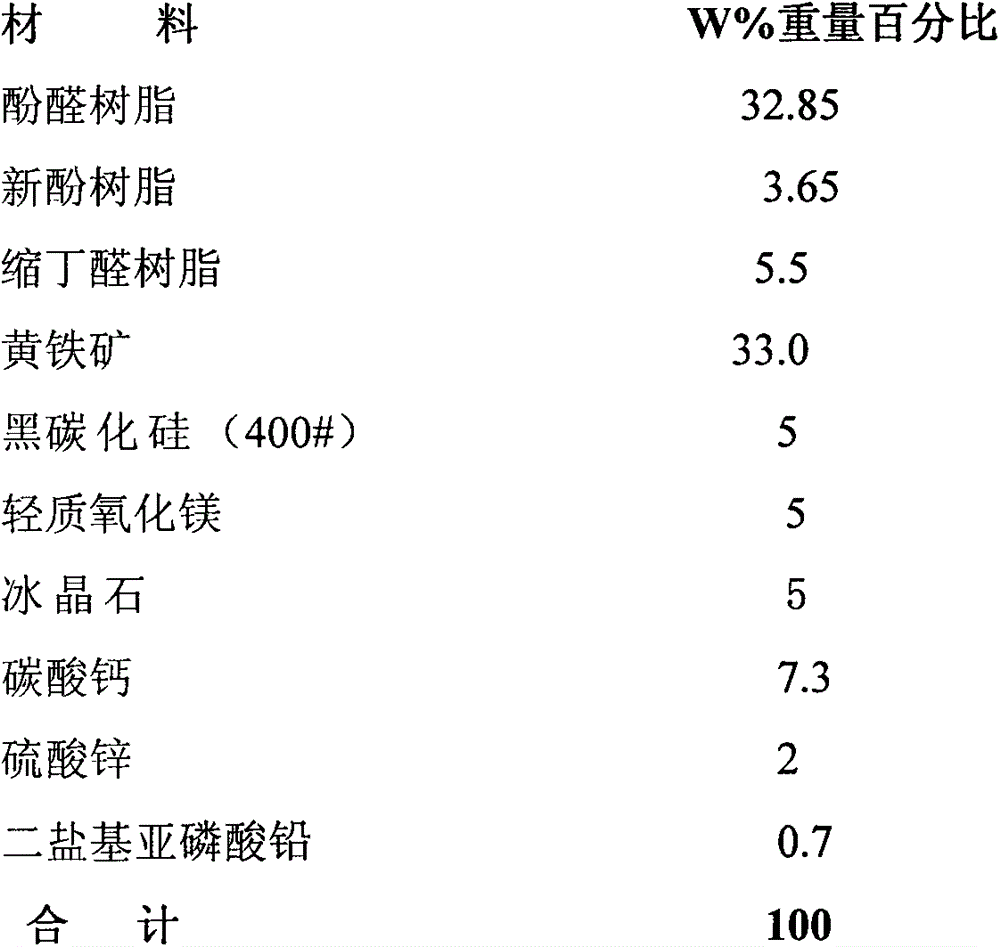

Large-standard high-speed resin heavy duty grinding wheel for grinding steel billet

ActiveCN104625978AHigh tensile and flexural strengthImprove the lubrication effectAbrasion apparatusGrinding devicesFiberMaximum diameter

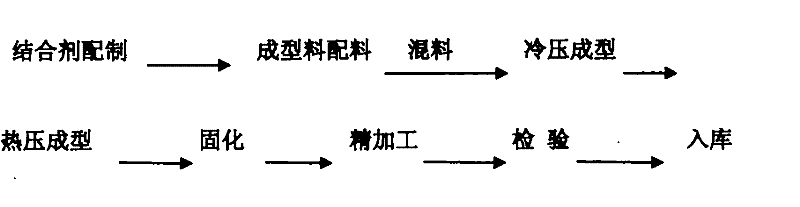

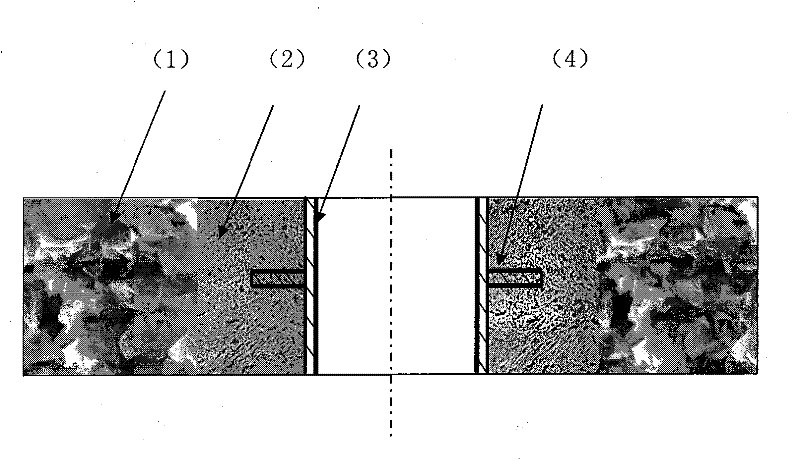

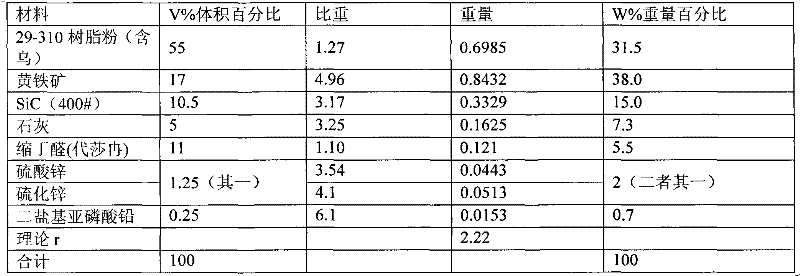

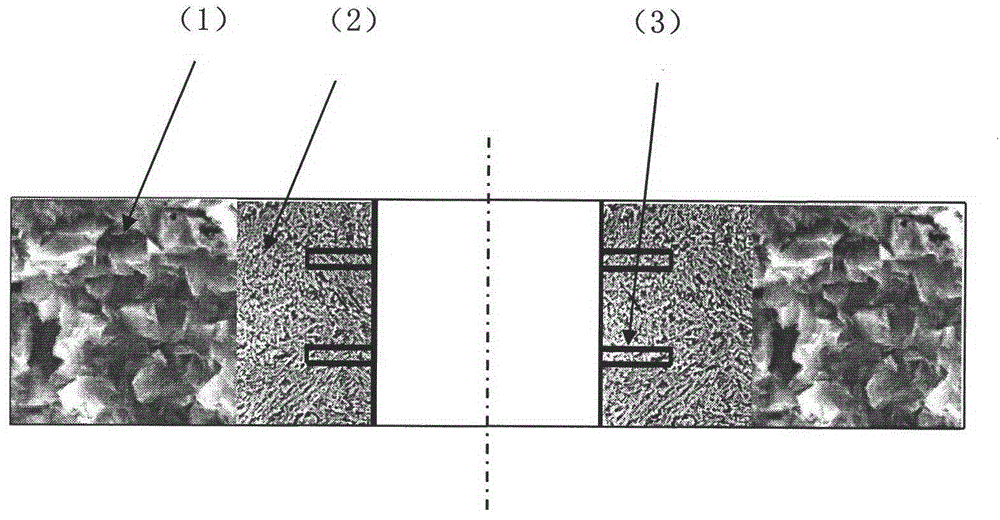

The preparation method for the large-standard high-speed resin heavy duty grinding wheel for grinding a steel billet comprises the steps that a dedicated binding agent for a high-performance modified high polymer matrix phenolic resin grinding wheel is prepared by using phenolic resin, xylok resin, butyral resin, iron pyrite, cryolite, light magnesium oxide, barite, 400 # carborundum and calcium carbonate, dedicated formulas for a grinding layer and a core layer are separately designed by using grinding materials such as fused alumina zirconia, aluminium oxide sintered corundum, black silicon carbide, furfural, dibutyl ester, fibers and steel rings, and the large-standard high-speed resin heavy duty grinding wheel for grinding the steel billet is prepared by adopting a dual-phase reinforced composite technology and structure. According to the large-standard high-speed resin heavy duty grinding wheel for grinding the steel billet, the linear velocity is equal or greater than 90 m / s to 120 m / s, the maximum diameter is 925 mm, the thickness is 125 mm, and the tensile and breaking strength and the grinding efficiency of the grinding wheel are greatly improved. When the large-standard high-speed resin heavy duty grinding wheel for grinding the steel billet is under heavy duty, the adaptability of the condition of grinding range is wide, and the linear velocity is high. The grinding efficiency reaches a thickness of 1 cm at a time, the problems that an existing grinding wheel cannot adapt to a steel billet, and the heavy duty grinding of steel is difficult are solved well, and the increasing development requirements of the iron and steel industry are met.

Owner:江苏华东砂轮有限公司

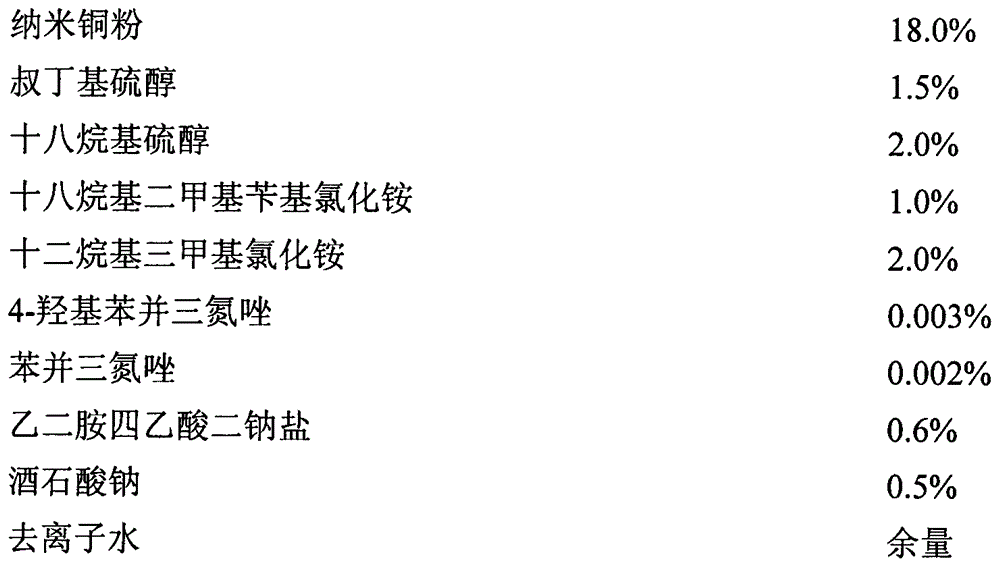

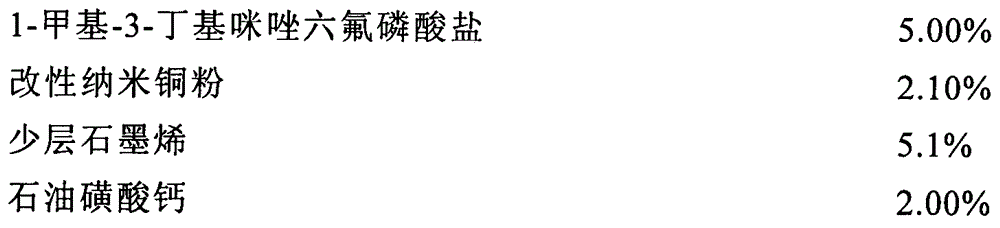

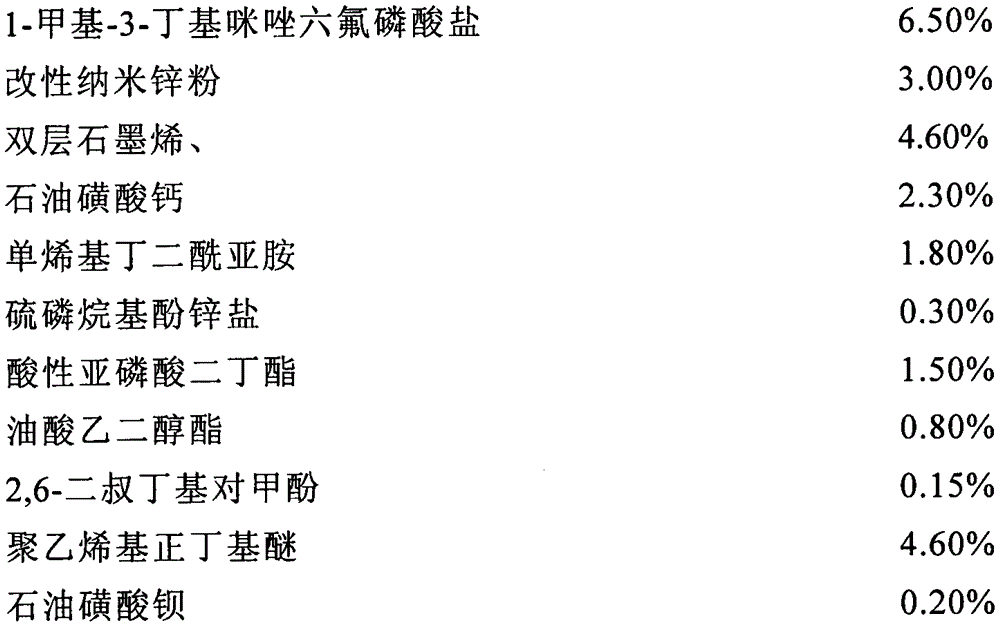

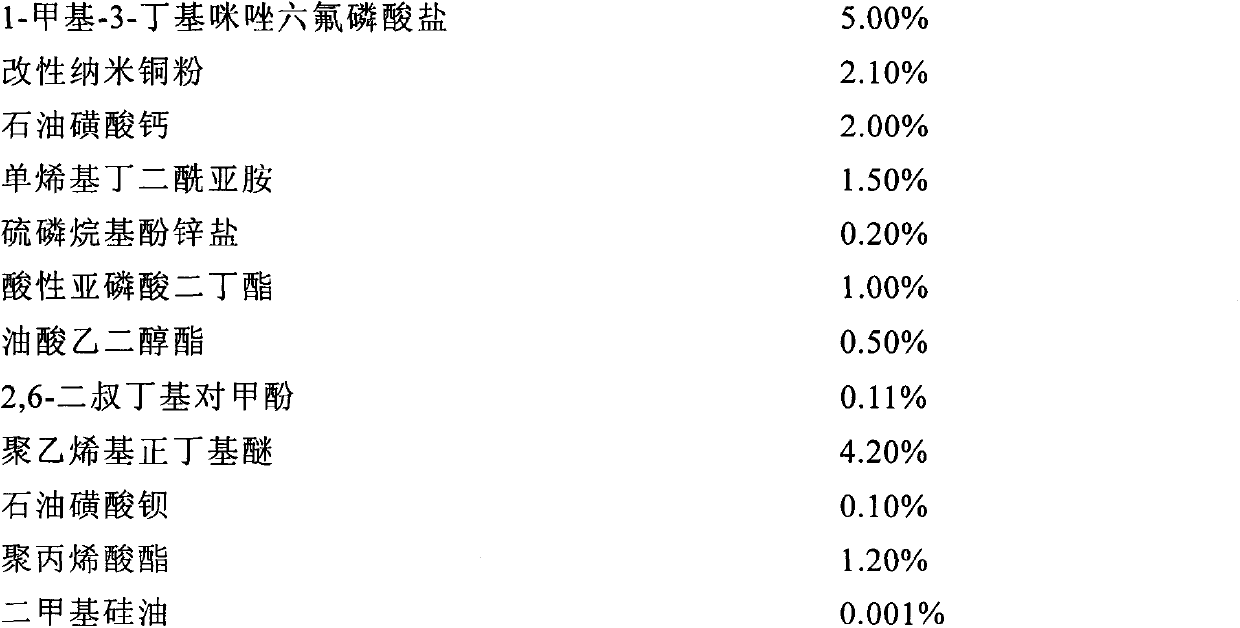

Preparation method for lubricating oil composition containing ionic liquid, modified nanometer copper powder and graphene

The invention discloses a preparation method for a lubricating oil composition containing ionic liquid, modified nanometer copper powder and graphene. The method comprises the following steps: compounding base oil, a detergent, a dispersant, a preservative, an extreme-pressure antiwear agent, an oiliness agent, an antioxidant, a viscosity index improver, an antirusting agent, a depressant, an antifoamer, the ionic liquid, the modified nanometer copper powder and the graphene so as to obtain the lubricating oil composition containing the ionic liquid, the modified nanometer copper powder and the graphene. The method in the invention has the advantages of simple and practicable production process, small equipment investment and low energy consumption, is pollution-free to the environment and is favorable for popularization and application. The lubricating oil composition prepared by using the method in the invention can be widely applied in the industrial fields of mechanical industry, automobile industry, precision instruments, electric power industry, metallurgy industry, die manufacturing and application industry, iron and steel industry, machine tool industry, etc., and has broad application prospects.

Owner:烟台广和润滑油有限公司

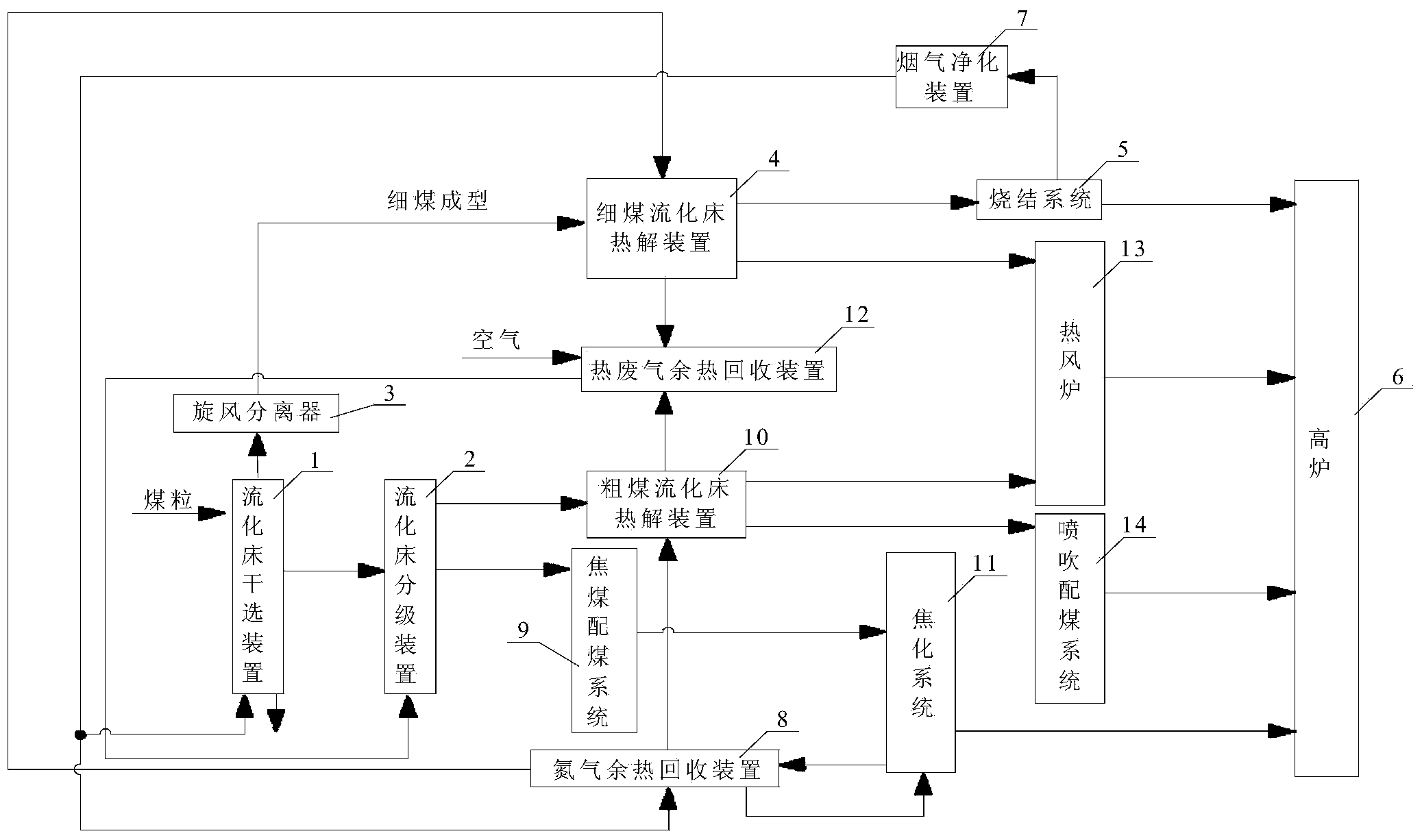

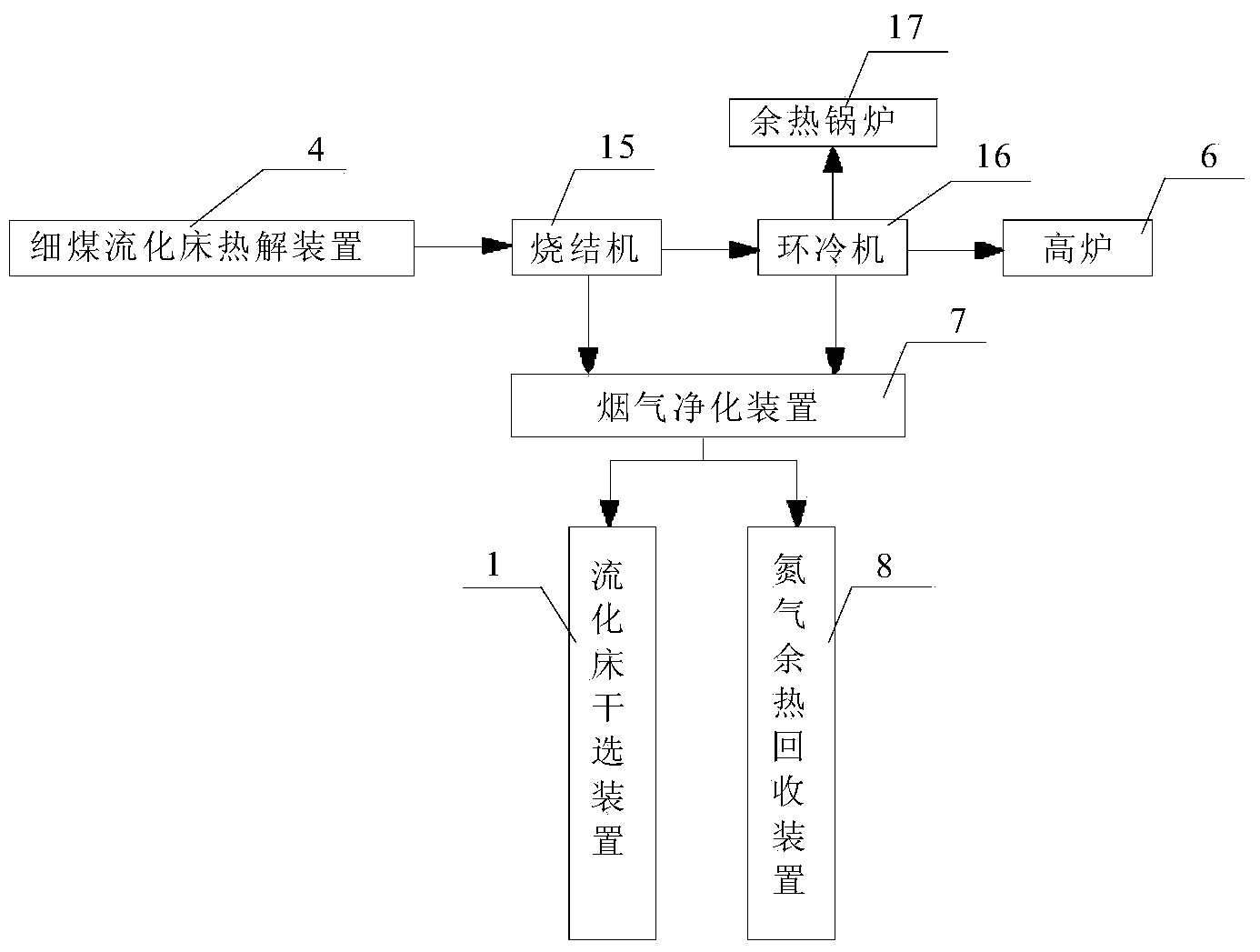

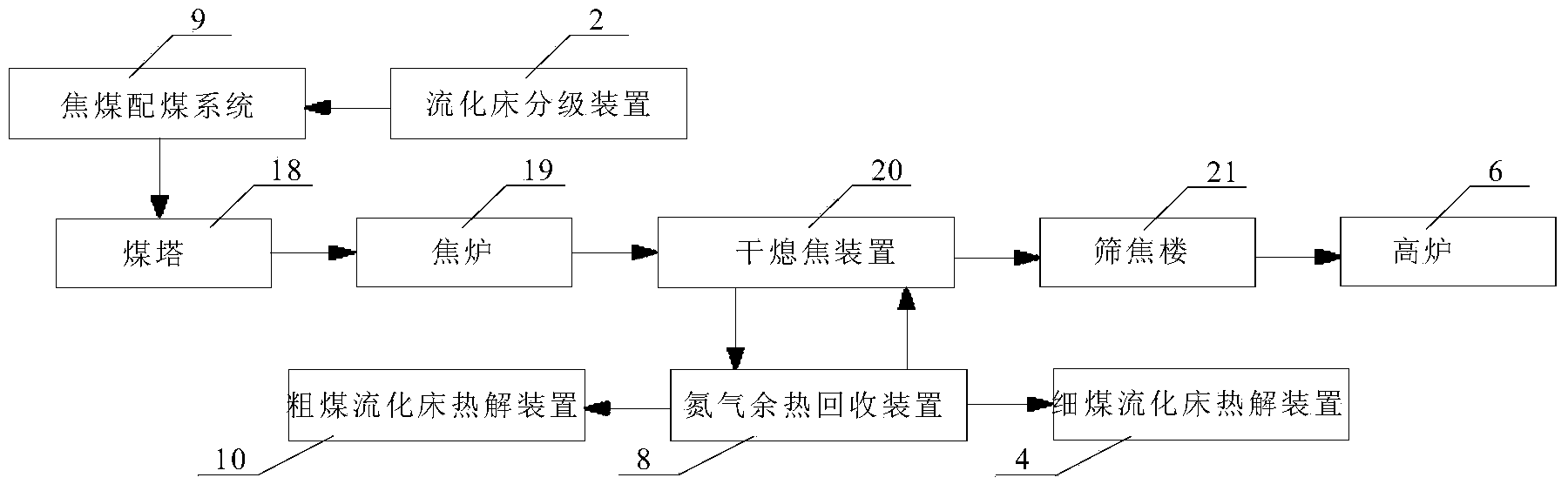

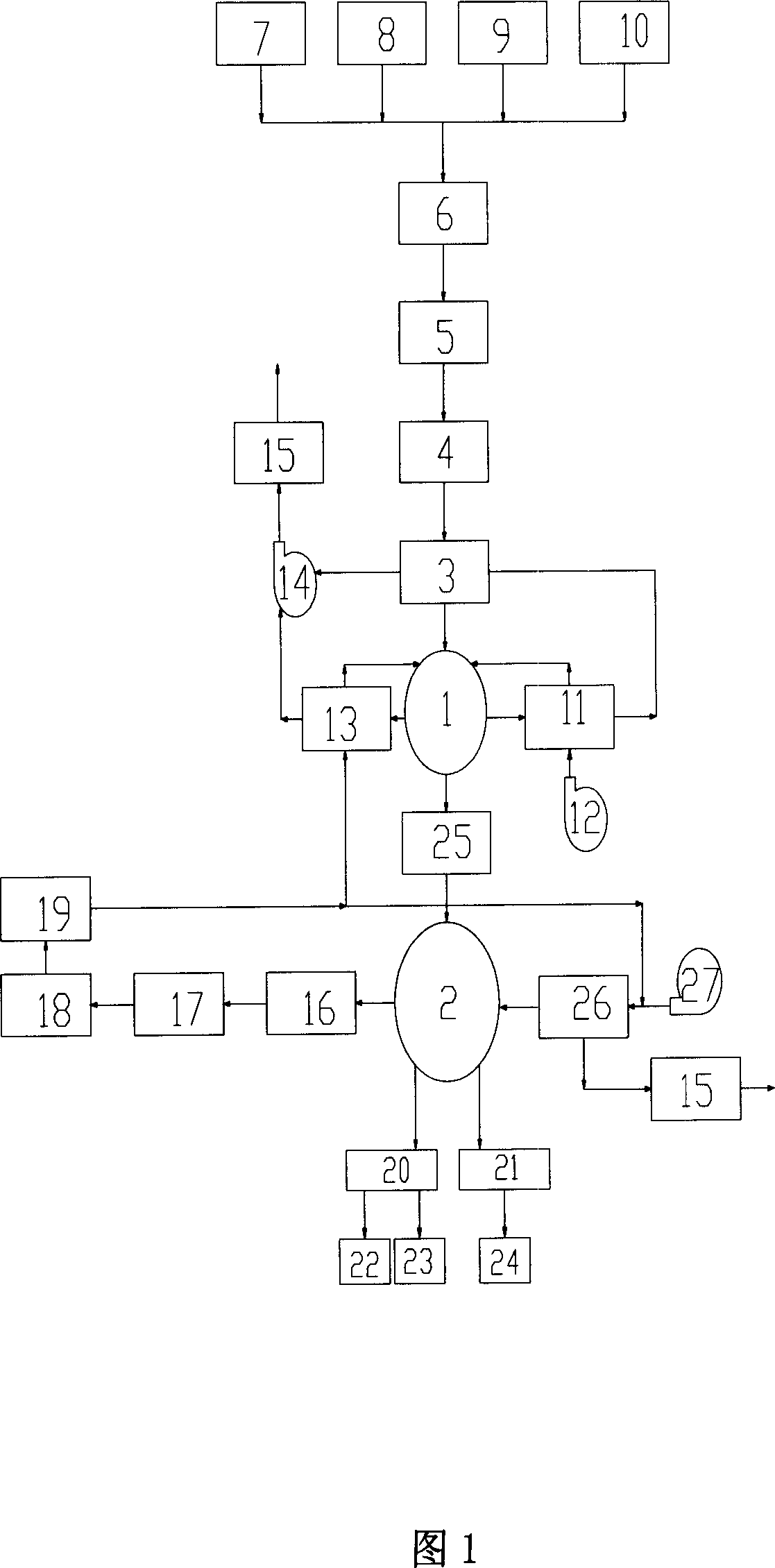

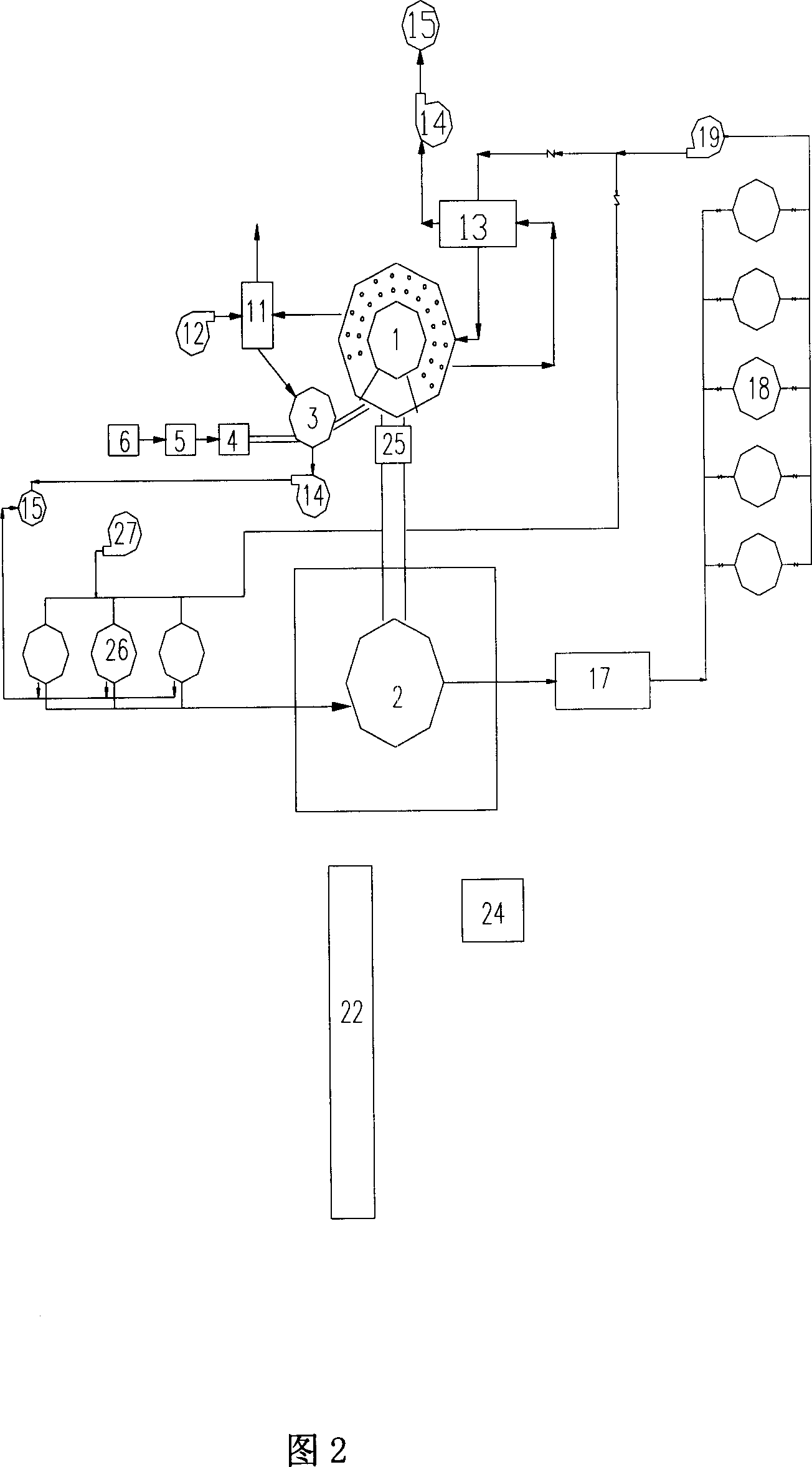

Fluidized-bed low-rank coal upgrading utilization system and method

InactiveCN103710037AAvoid "extensive use" situationsRealize utilization by qualityEnergy inputSpecial form destructive distillationProcess systemsCombustion

The invention provides a fluidized-bed low-rank coal upgrading utilization system and method, and belongs to the technical field of low-rank coal upgrading utilization. According to the invention, a washing system, a pyrolysis system and an iron-making system of the low-rank coal are coupled together. Firstly, the low-rank coal is subjected to washing treatment so that size grading of the coal is completed while waste stone is exhausted. The coal powder different in particle size is used for a coking system to prepare coke and joins in medium and low temperature pyrolysis to prepare semicoke. The semicoke obtained through pyrolysis is used as coal for sintering and blended coal for injection, respectively; the by-product gas of pyrolysis is fed into a hot blast stove for combustion, wherein waste heat generated by the sintering and coking process systems is recovered for the washing system and the pyrolysis system; and finally, the sinter, the hot air, the injection coal and the coke are fed into a blast furnace for iron-making. According to the invention, the separation, grading, drying and pyrolysis of the low-rank coal are realized; the low-rank coal is utilized after being upgraded in stead of partial high-rank coal; and therefore, the cost of iron per ton can be effectively reduced and the stress of the demand of the iron and steel industry for the high-rank coal can be reduced.

Owner:TSINGHUA UNIV +1

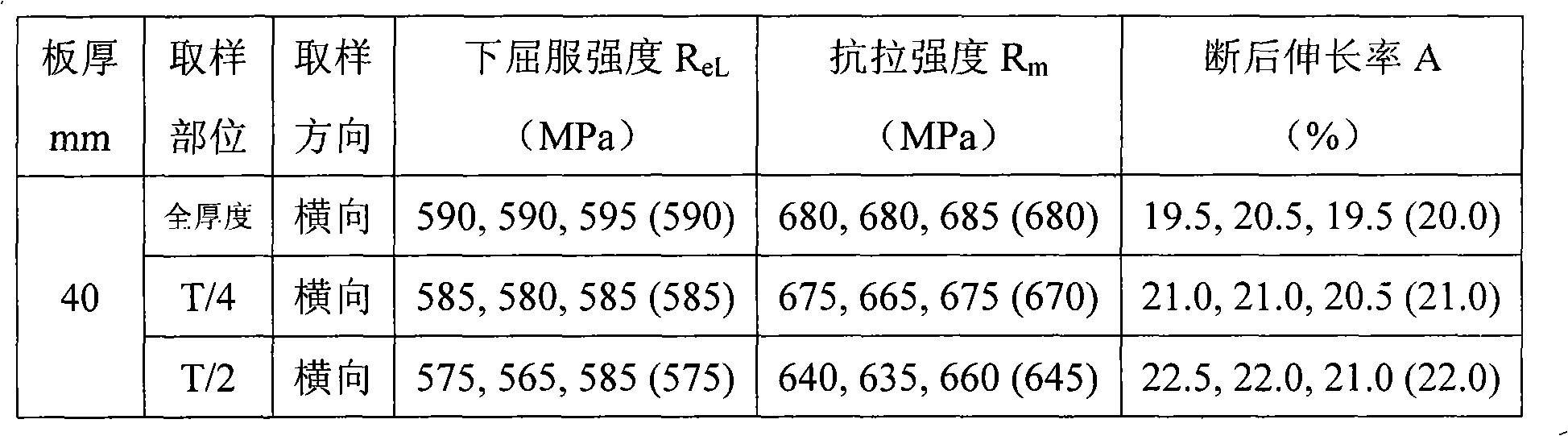

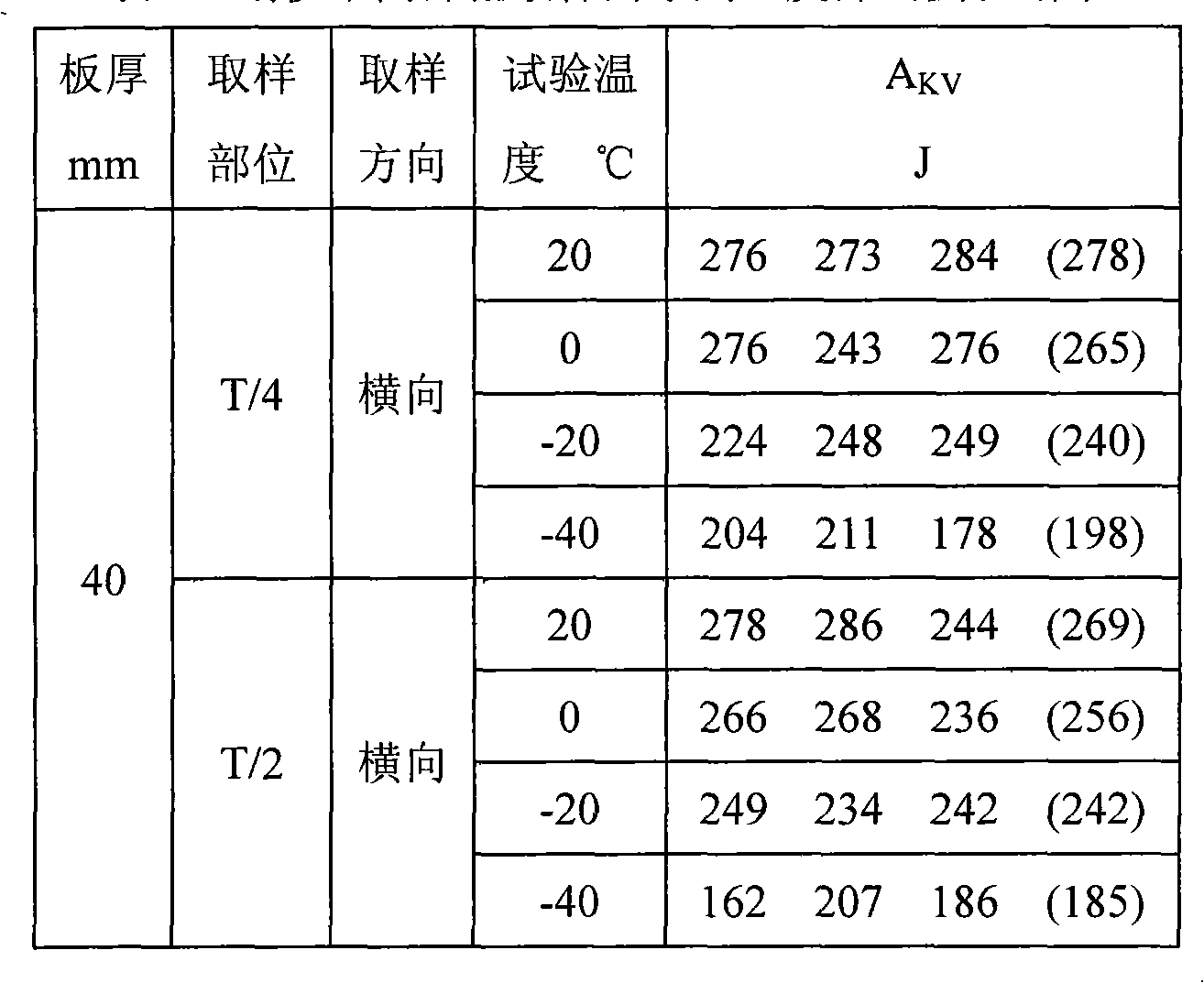

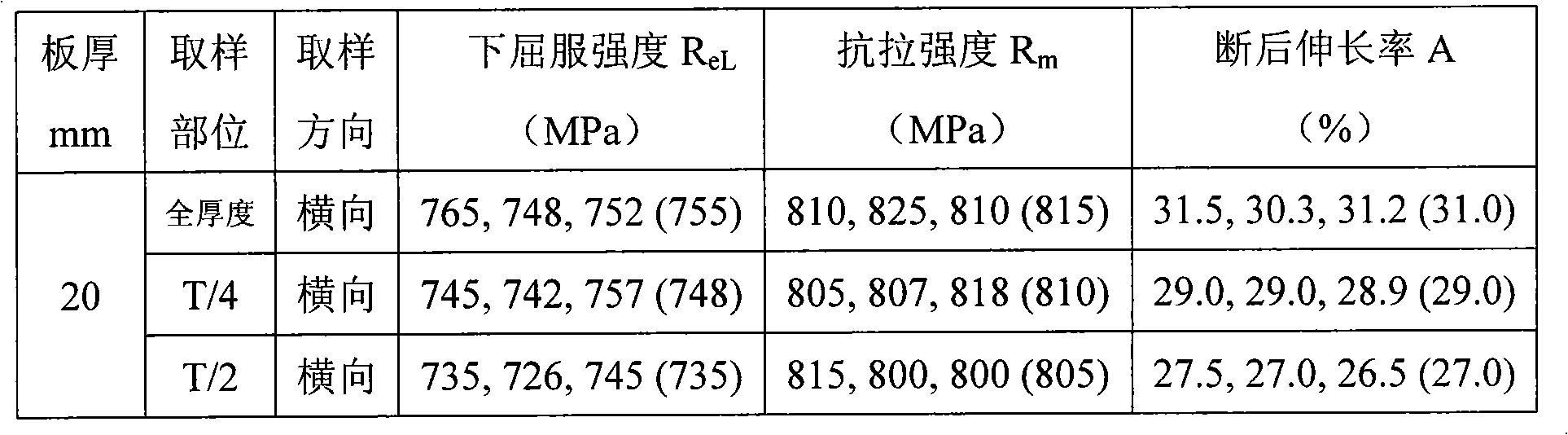

Direct quenching technology suitable for steel plates with different thicknesses and high durability

InactiveCN101633976ATo achieve the cooling water requirementSimple production processSheet steelHigh density

The invention provides an online direct quenching technology for producing steel plates with different thicknesses and high durability, which adopts the technical scheme that billets are heated to 1150-1280DEG C; the billets are rolled into steel plates at two stages in an austenitic recrystallization zone and an austenitic non-recrystallization zone, and the finishing temperature is 800-880DEG C; and high-density laminar flow cooling is adopted for realizing the online quenching of the steel plates, the laminar flow cooling is formed by a cooling zone consisting of an upper flow collecting pipe and a lower injection collecting pipe, the cooling zone comprises an intensive cooling section, a rough cooling section and a precise cooling section, the water flow ratio of upper collecting pipes and lower collecting pipes of the rough cooling section and the precise cooling section is fixed to be 1:1.5, and the water flow of the upper collecting pipe and the lower collecting pipe of the intensive cooling section can be freely adjusted within a range of 1:3.0-1:1.4. The invention solves the technical bottleneck of large investment and high cost brought by a traditional quenching and tempering technology of reheating quenching and tempering for producing high-strength steel, and the direct quenching technology has the remarkable efficacy of saving energy sources, shortening a process flow and improving the production efficiency, and is suitable for being popularized and produced in steel industry.

Owner:UNIV OF SCI & TECH BEIJING

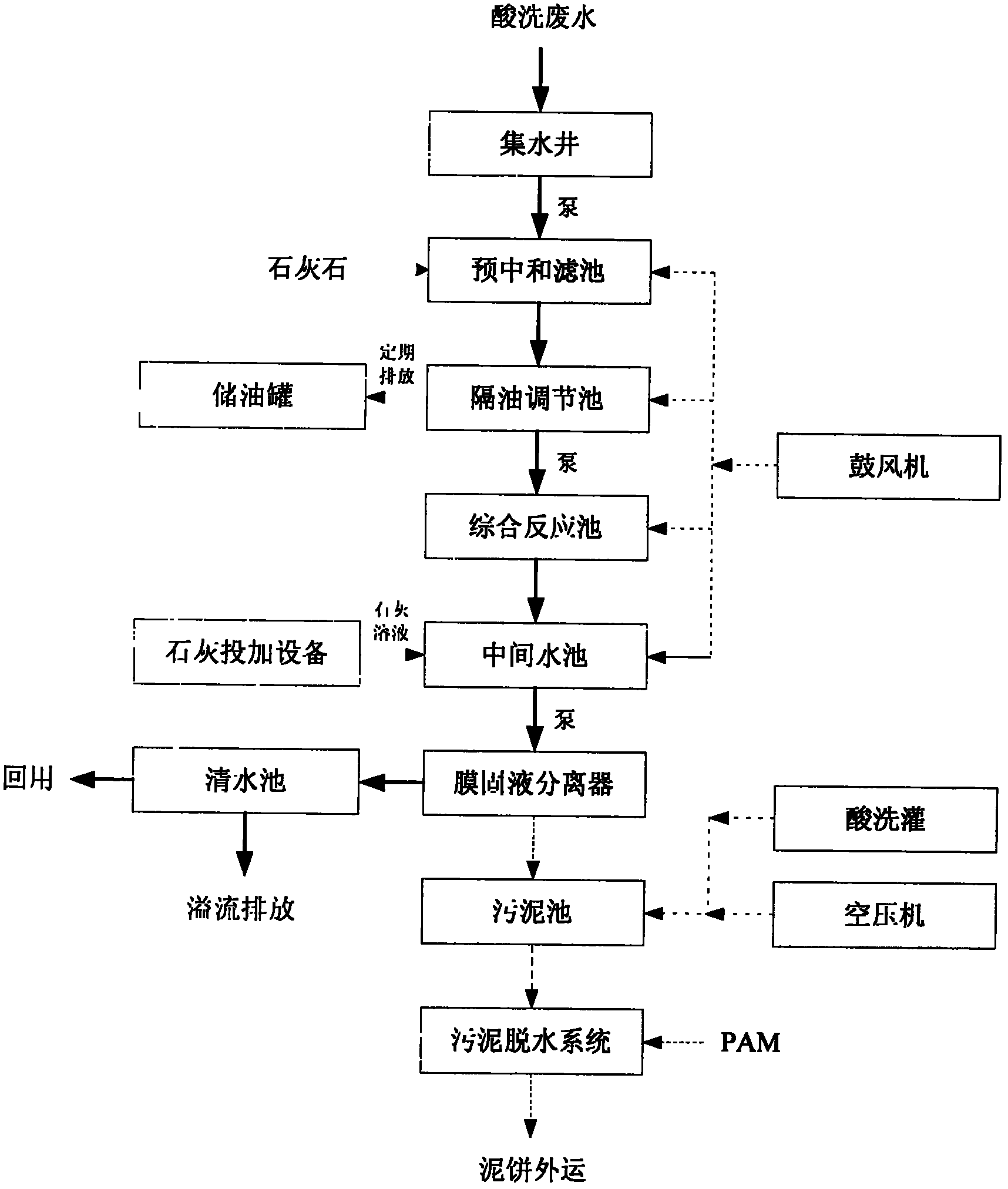

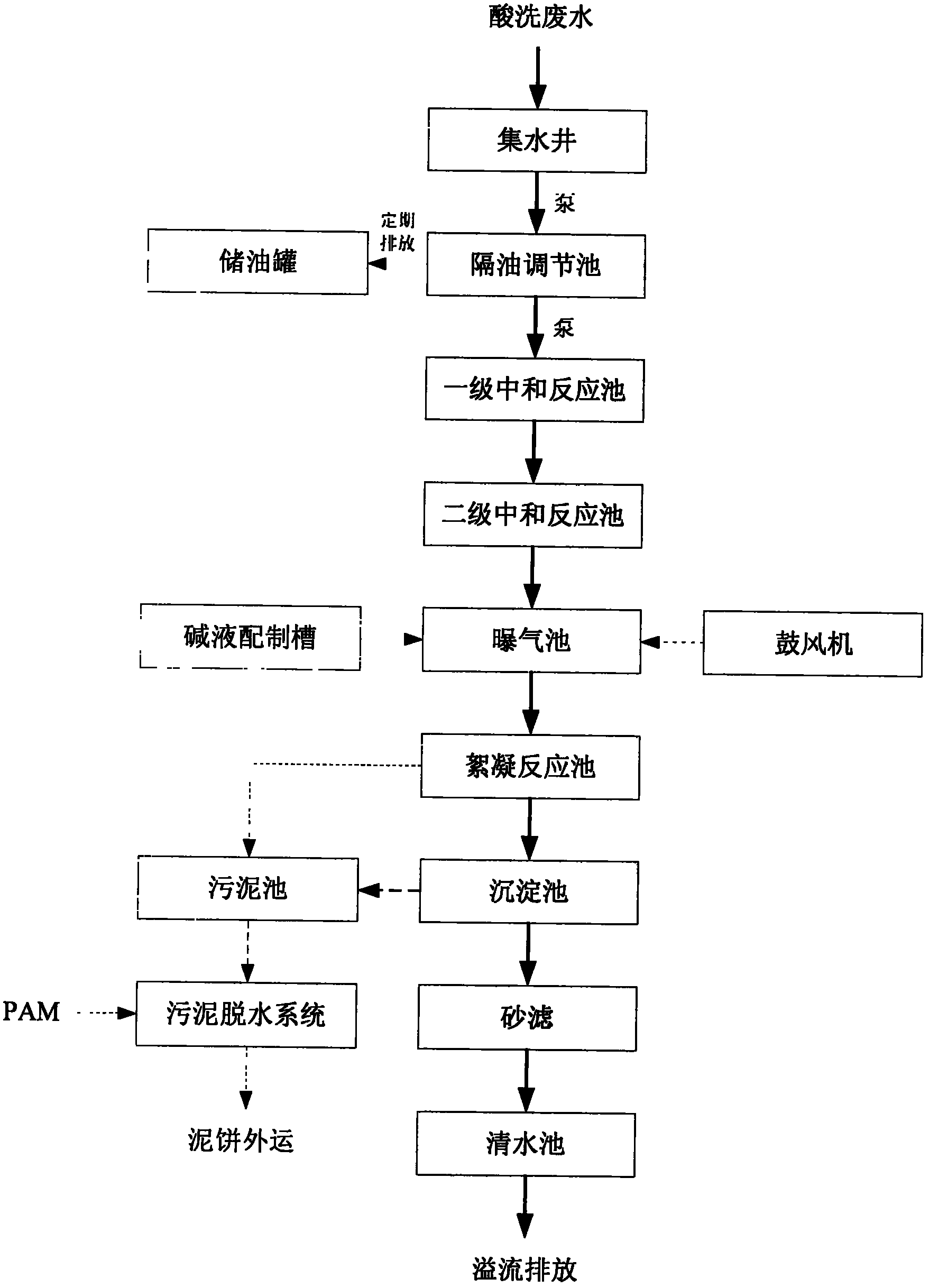

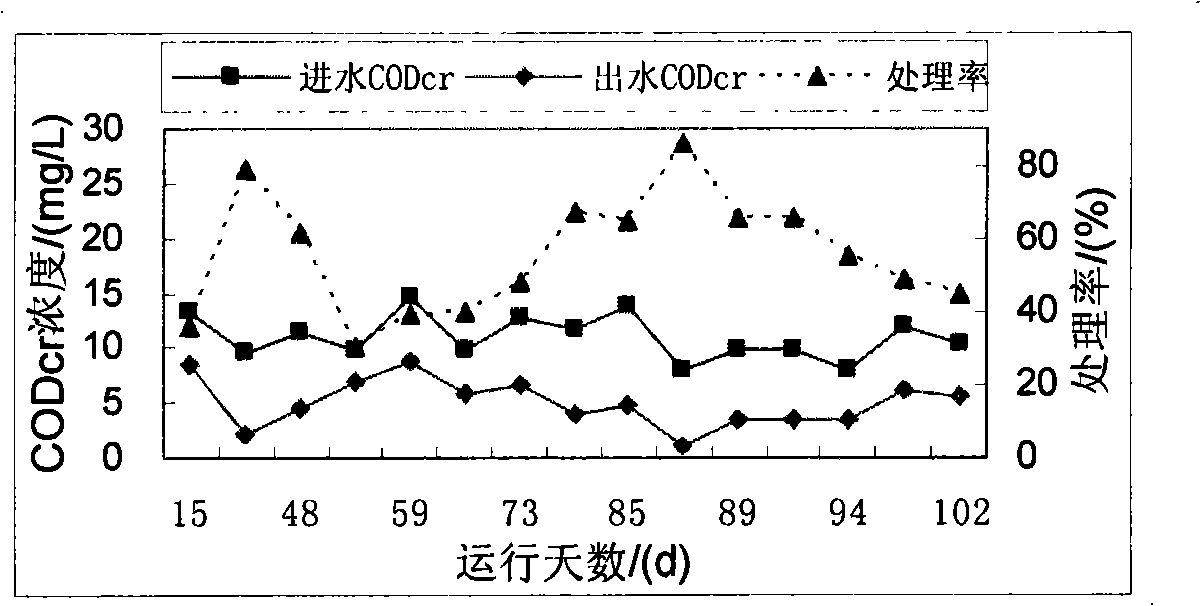

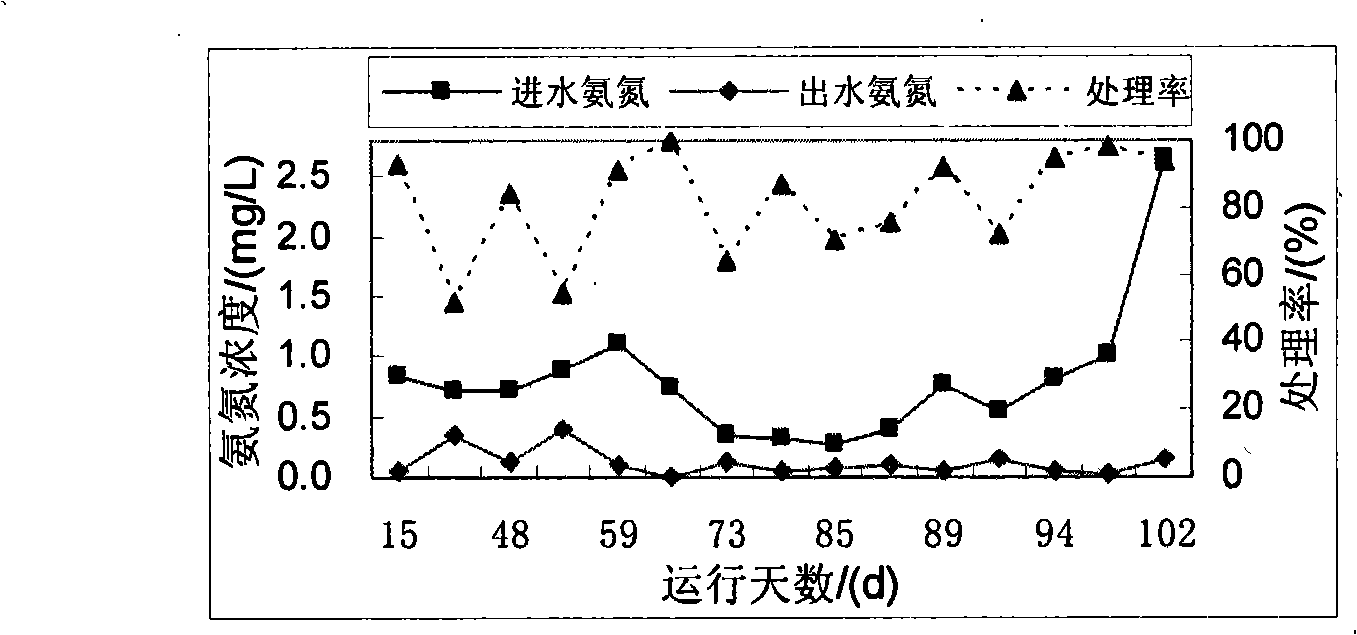

Method for treating acid-washing wastewater and metallic ions in iron and steel industry

InactiveCN102107963ALow running costGuaranteed uptimeWater contaminantsMultistage water/sewage treatmentFerric hydroxideZinc hydroxide

The invention provides a method for treating acid-washing wastewater and metallic ions in iron and steel industry, which comprises steps as follows: acid-washing wastewater naturally flows into a water collecting well and enters a preneutralization filter chamber under the elevation action of a pump, the preneutralization filter chamber is provided with 10-200mm limestone which is in a graded distribution mode, and after the acid-washing wastewater is preneutralized by the limestone, the pH value of the effluent water is controlled at 5-6, wherein the method provided by the invention greatly lowers the chemical expenses and operating cost as compared with the conventional method of directly adding an alkali solution; the acid-washing wastewater, which is subjected to initial pH value regulation, naturally flows into an oil separation regulating chamber, so that iron ions in the wastewater react with the alkali solution to form a precipitation mixture of ferric hydroxide, zinc hydroxide and the like; and the wastewater is elevated into a membrane solid-liquid separator to complete solid-liquid separation, so that the wastewater can be discharged after reaching the standard. The invention thoroughly solves the problems that the precipitate can not easily settle, the iron can not be easily removed, and the iron ions are dissolved out. The invention has the advantages of simple technique, high economy, low requirements for technical levels of workers, and high controllability, is reliable to operate, and has wide market prospects.

Owner:TIANJIN ACADEMY OF ENVIRONMENTAL SCI

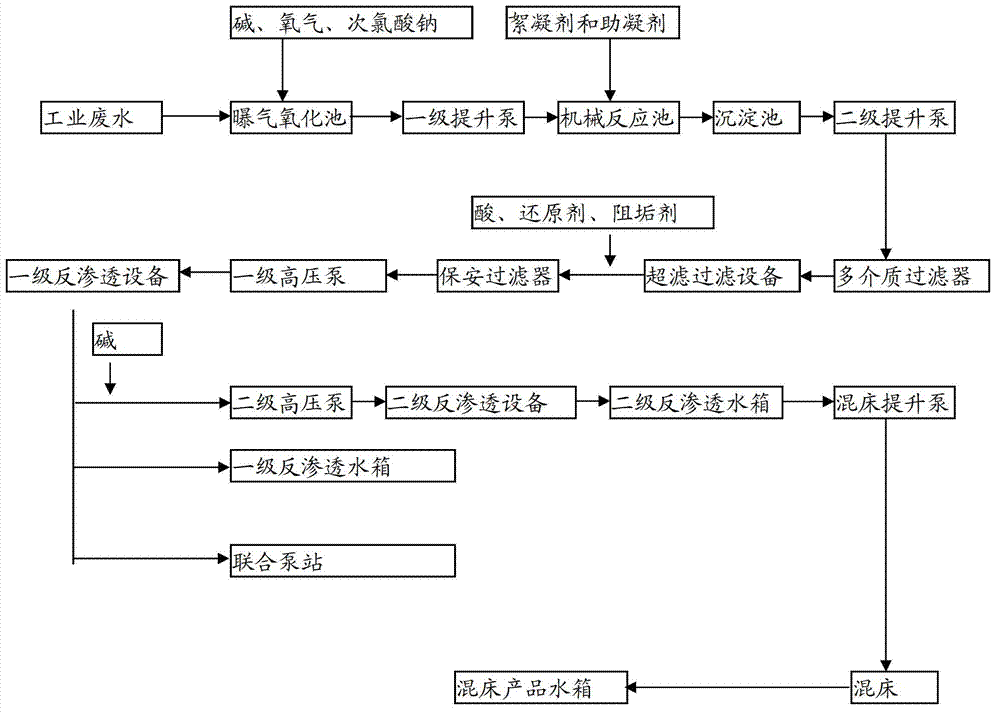

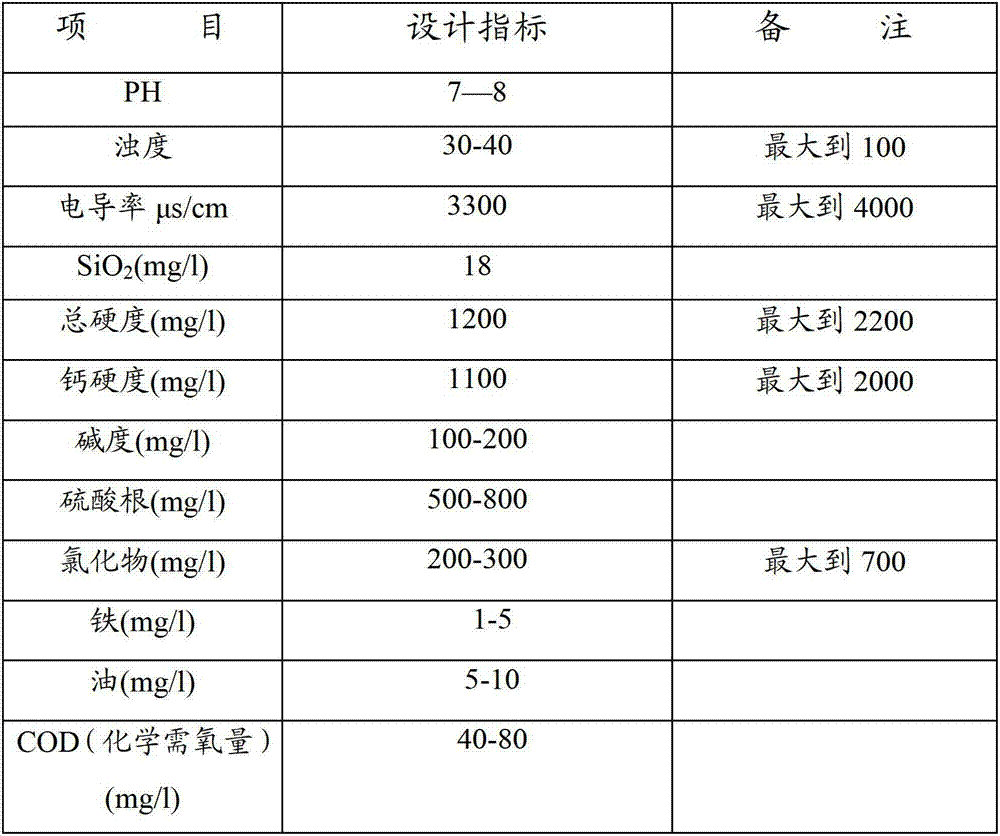

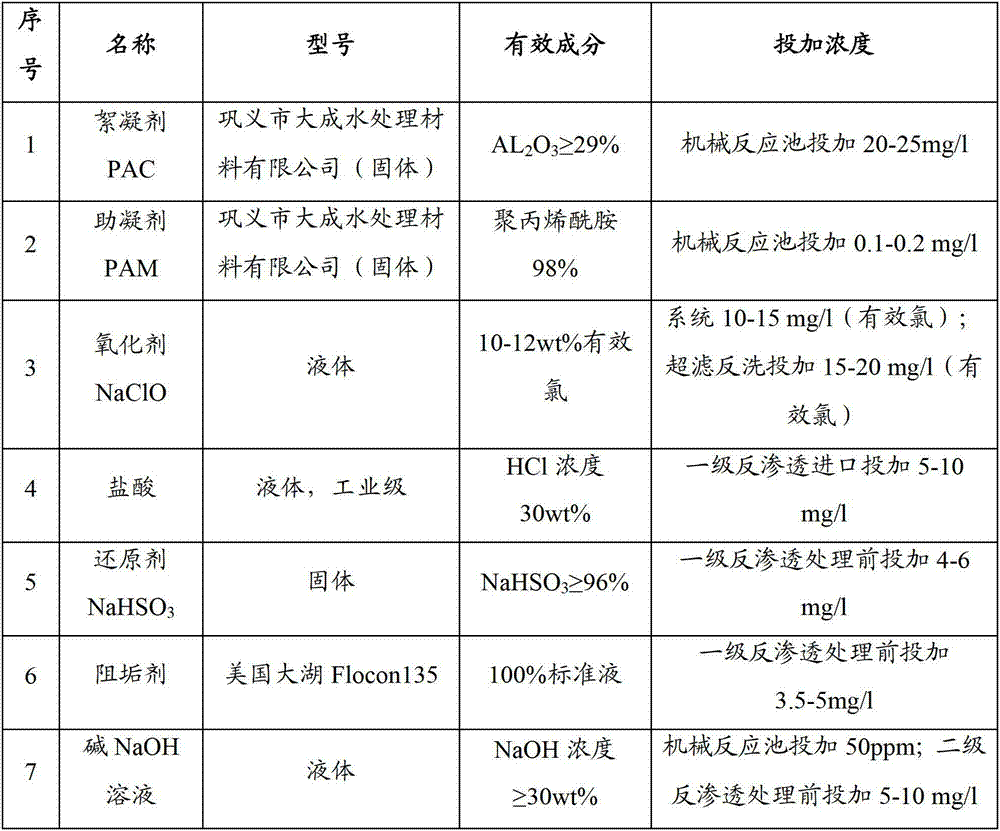

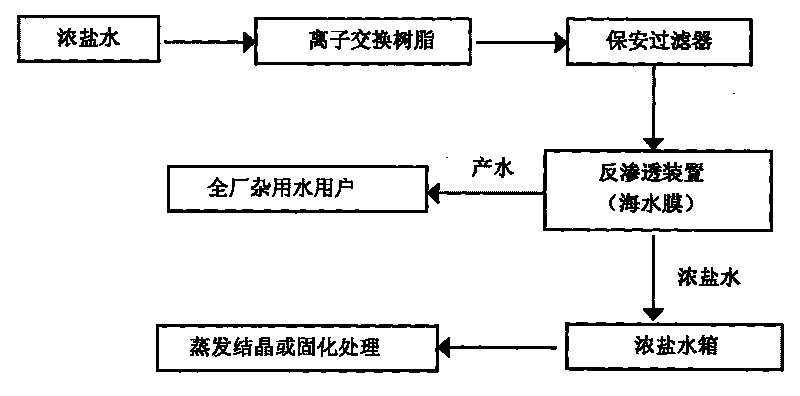

Double-membrane treatment method of iron and steel industrial wastewater

ActiveCN102826686AImprove recycling ratesReduce consumptionWaste water treatment from metallurgical processWater/sewage treatment bu osmosis/dialysisSaline waterWater resources

The invention provides a double-membrane treatment method of iron and steel industrial wastewater. The method comprises the following steps that the pH value of the wastewater is regulated to be greater than 7, and then, oxygen gas is introduced into the wastewater until the total iron content in the wastewater is reduced to a value smaller than 0.5mg / l; the pH value of the wastewater is regulated to 8.0 to 8.5, flocculating agents and coagulant aids are added into the wastewater under the stirring condition, and then, the static settlement is carried out; the wastewater subjected to preliminary treatment is subjected to filtering treatment in a filter so that the water outlet turbidity of the wastewater is smaller than 2NTU; the wastewater subjected to filtering treatment is subjected to full flow filtering treatment; the wastewater subjected to pretreatment is subjected to two-stage reverse osmosis treatment; and the wastewater subjected to the two-stage reverse osmosis treatment is subjected to fine treatment through a mixing bed. The double-membrane treatment method has the advantages that the treated wastewater reaches the demineralized water standard, the cyclic utilization rate of water resources is improved, the consumption of new water is saved, and the outward discharge water of a ton of steel is reduced.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

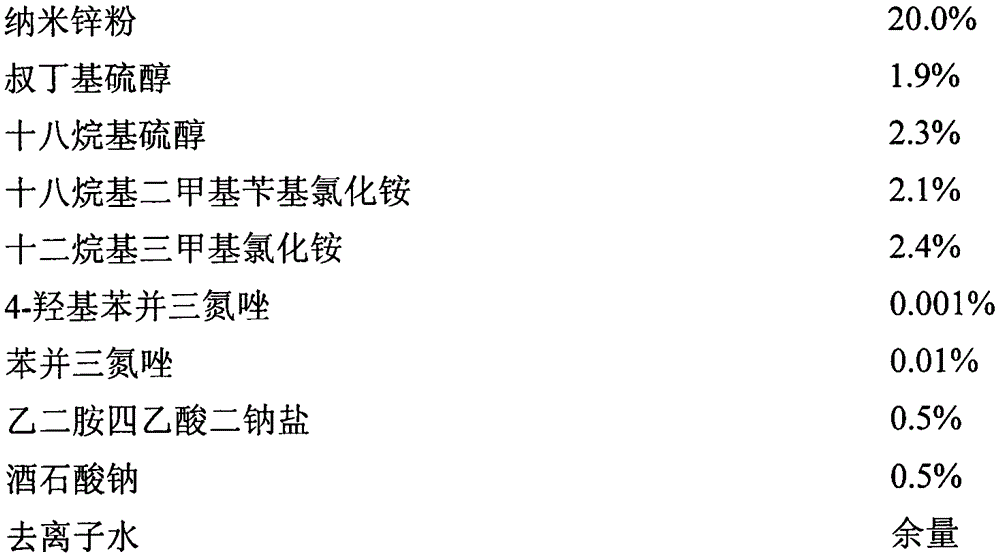

Preparation method of lubricating oil composition containing ionic liquid, modified nano-zinc powder and graphene

The invention discloses a preparation method of a lubricating oil composition containing ionic liquid, modified nano-zinc powder and graphene. According to the method, base oil, a cleaning agent, a dispersing agent, a preservative, an extreme pressure anti-wear agent, an oiliness agent, an antioxidant, a viscosity index improver, an anti-rust agent, a pour point depressant, an antifoaming agent, ionic liquid, modified nano-zinc powder and graphene are adopted for compounding to obtain the lubricating oil composition. The method has the advantages of simple and easy production process, low equipment investment, low energy consumption and no environmental pollution, and is conductive to popularization and application. The lubricating oil composition product containing the ionic liquid, modified nano-zinc powder and graphene can be widely applied in the industrial fields of mechanical industry, automobile industry, precision instruments, power industry, metallurgical industry, mold manufacturing and application industry, steel and iron industry, machine tool industry and the like, and has broad application prospects.

Owner:大庆招远圣通机械设备有限公司

Production process of vanadium-nitrogen alloy

InactiveCN101289713AHigh nitrogen contentApplicable to the steelmaking requirements of the iron and steel industrySolid state diffusion coatingIron powderPositive pressure

The invention discloses a method for making vanadium-nitrogen alloy. In the method, vanadium pentexide is ground and added with iron powders, carbon powders and binding agent and evenly mixed, making a ball; the ball is sent in a horizontal type push plate kiln which is filled with nitrogen gas, and the slightly positive pressure in the kiln is always kept; the ball undergoes carbonization and nitridation reactions in the kiln, and the temperature of the carbonization reaction is between 1350 and 1500 DEG C and the reaction time is 2 to 3.5 hours, and the temperature of the nitridation reaction is between 1000 and 1150 DEG C and the reaction time is 0.5 to 1.5 hours; the ball is gradually cooled, and the vanadium-nitrogen alloy is obtained. Due to the adoption of the technical proposal in which the vacuum equipment is unnecessary, the method lowers equipment cost and simplifies the operation flow; due to the continuous production, the method obviously improves the production efficiency; moreover, according to tests, the nitrogen content of the vanadium-nitrogen alloy made by the method is no more than 16 percent, so that the method is more suitable for steel-making requirements in the iron and steel industry.

Owner:郸城财鑫特种金属有限责任公司

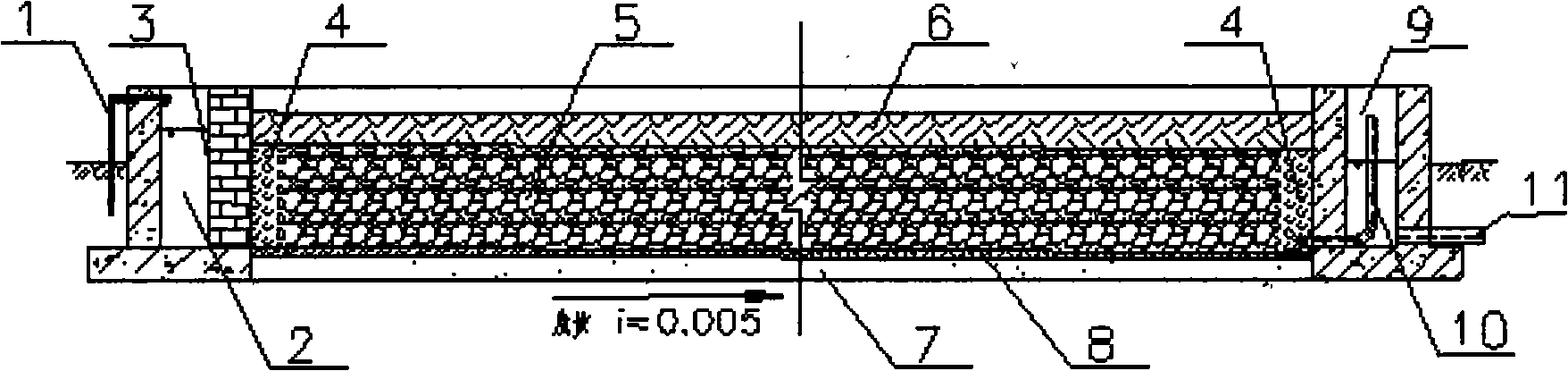

Artificial wet land and uses thereof

ActiveCN101293708ALow construction costReduce processing costsWaste water treatment from metallurgical processSustainable biological treatmentConstructed wetlandWater use

The invention provides a constructed wetland and the application thereof; wherein, the constructed wetland takes gravels and manganese sands as combined packing and can be used for treating wastewater in industries, such as iron and steel industry, etc., the wetland can reduce the nutrient content of organics, nitrogen, phosphorus, etc. in water, and meanwhile can remove metal ions, such as Fe, Mn, Cd, Pb, etc., more particularly, can reduce higher content of ions of Fe and Mn in iron and steel industry wastewater so that the index achieves the water quality standard of reclaimed water used as cooling water and the water intake quality requirement of reverse osmosis desalination process in Code for Engineering Design of Wastewater Reclamation and Reuse. The wetland has less engineering investment, simple management, low operation and maintenance cost, stable processing effect, so as to have better environmental, economic and social benefits. The wetland has better wastewater processing effect, stronger treatment capacity and stronger shock resistance loading capability, so the wetland can greatly solve the problem of excessively high concentration of Fe and Mn ions in wastewater reuse of the iron and steel industry, etc.

Owner:BAOSHAN IRON & STEEL CO LTD +1

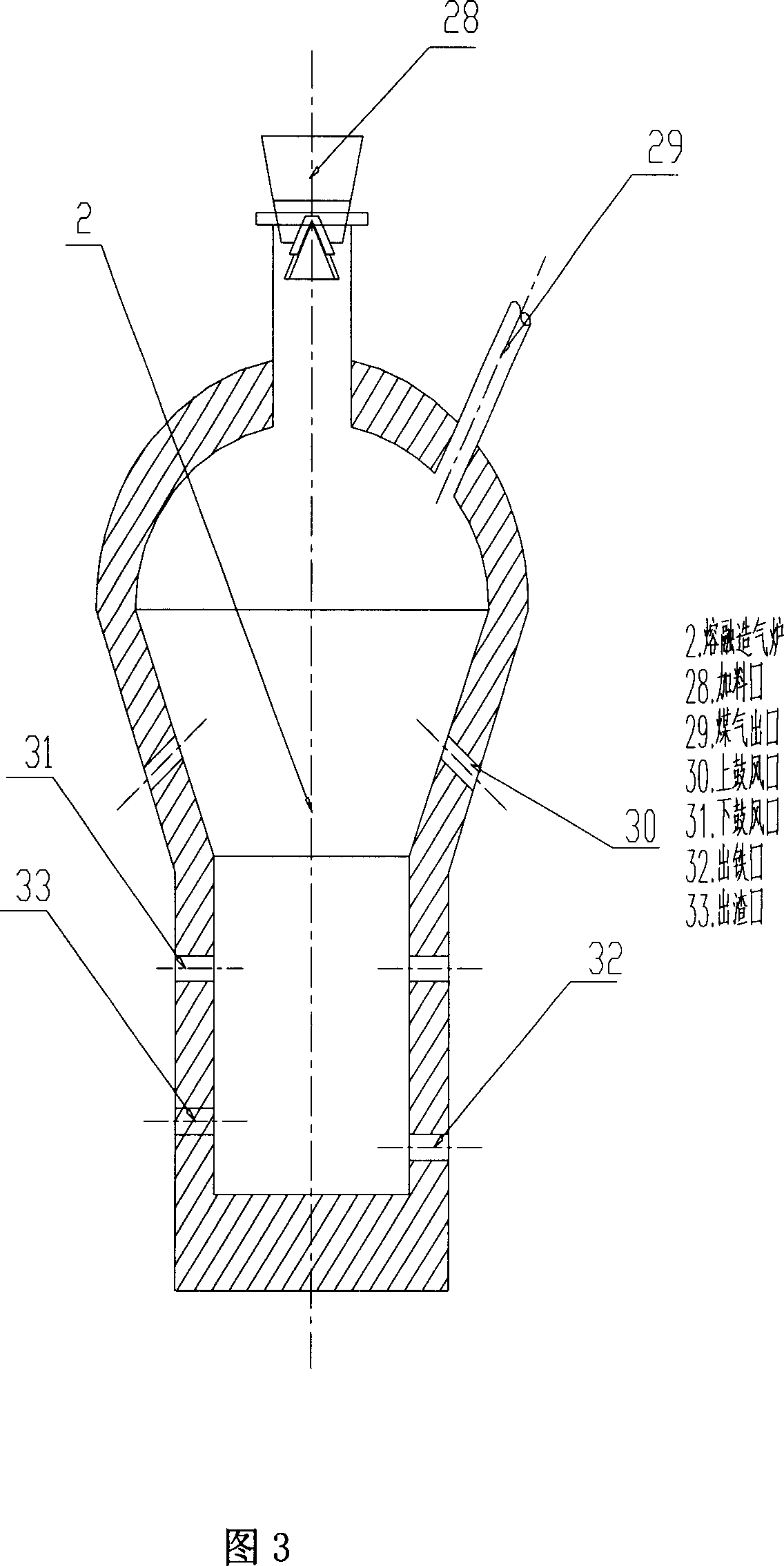

Fuse reducing iron-smelting process for rotating furnace

InactiveCN1940092ALatent heat utilizationReduce energy consumptionRotary drum furnacesGas emission reductionSmelting processSelf reduction

An iron smelting process by rotating-furnace melt and reduction is carried out by mixing iron-mine powder with powdered coal to obtain self-reduction palletizing, taking it as raw material, pre-reducing by rotating-furnace to obtain metal pellet with conversion rate >80%, heating, packing it into melt gas maker, finally reducing and melting while separating out iron slag to obtain liquefied iron and gas and utilizing it for hot-air furnace and rotating-furnace gas. It has no environmental pollution, and no need for oxygen and natural gas.

Owner:万天骥

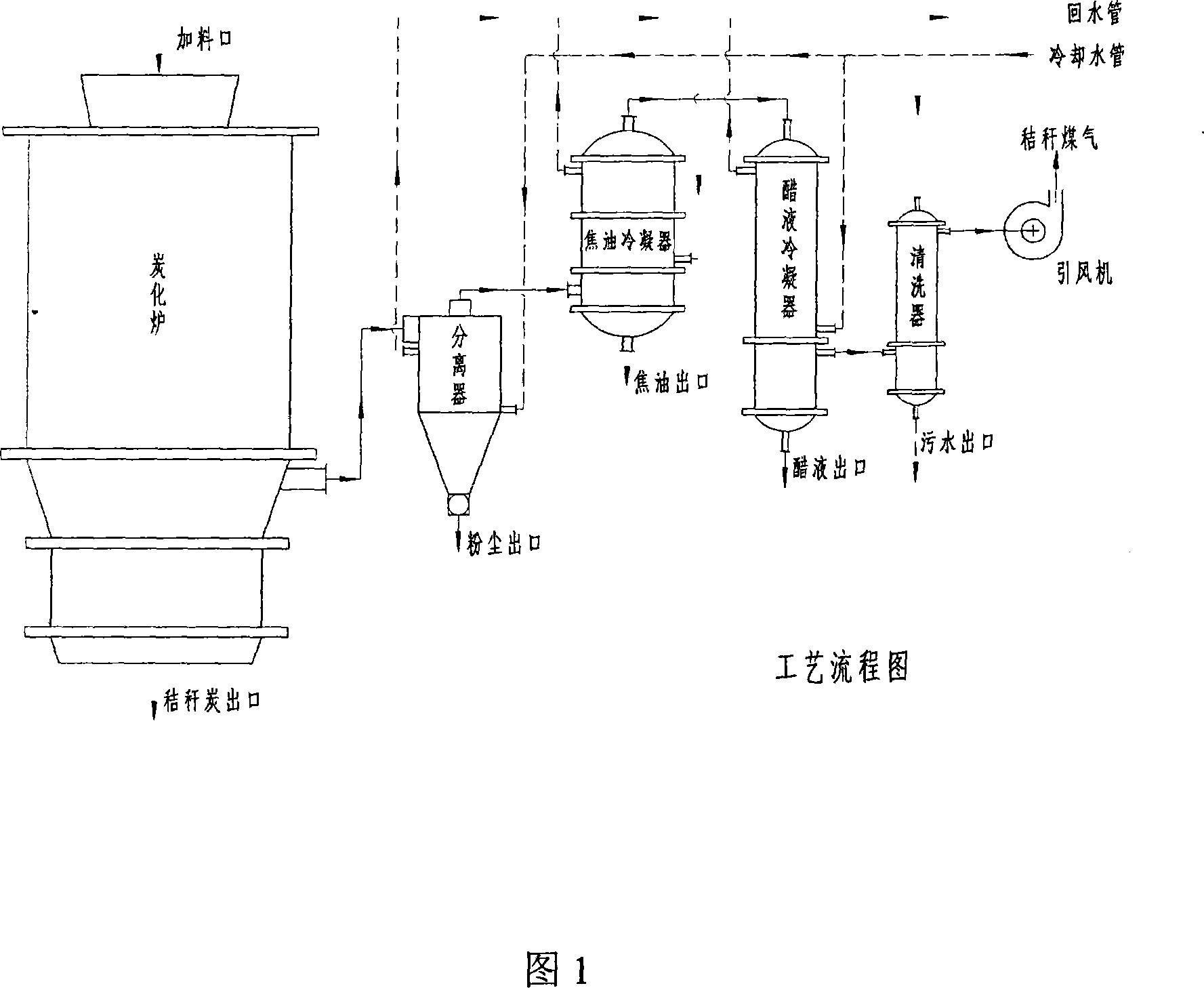

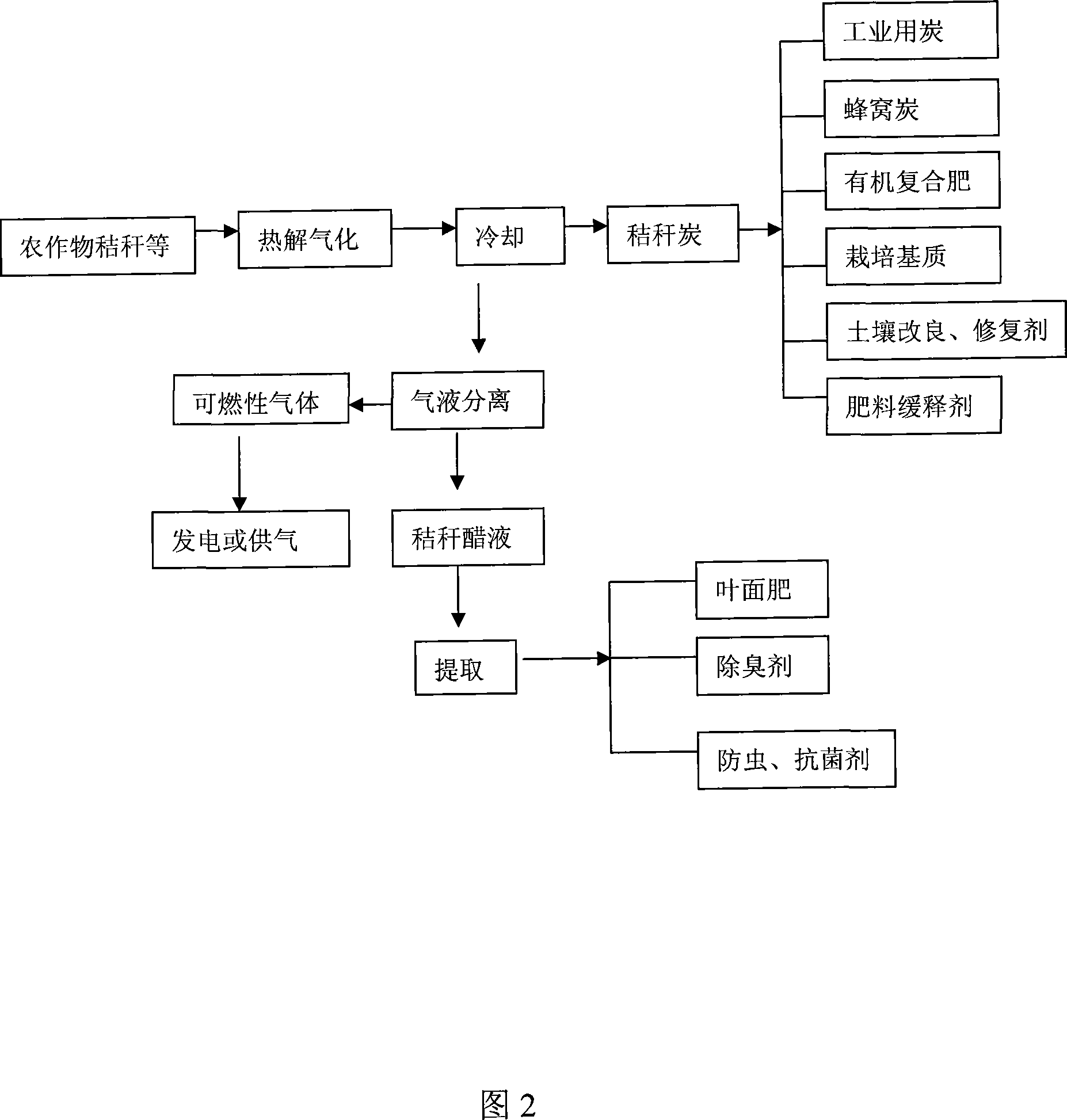

Method for simultaneously preparing charcoal, gas and liquid products from crop straw and application thereof

InactiveCN101186833AImprove fertilityImprove physical and chemical propertiesBiofuelsPyroligneous acid productionDiseaseLiquid product

The invention relates to a process for simultaneously preparing charcoal, gas, and liquid products with crop stalks and the application thereof. The process is that the crop stalks (rice husk, nut shell, branches of fruit trees, wooden and bamboo waste materials, and the like) are conveyed to a gasification furnace, the gasification furnace is provided with oxygen by the employment of controlling the height of the a batch layer and the air quantity of an air extractor, and the air achieved via gas-liquid separation is conveyed into a gas turbine for generating or directly supplied to users, vinegar fluid is achieved by condensing and reclaiming the liquid, the vinegar fluid can be processed to be antiseptic solution and deodorizer which are used in livestock places, and also can be processed to be pesticide agent or pesticide which can resist insect and disease, further can be used for foliage fertilizer which can promote the growth of crops and has perfect effect in the production of organic vegetable, fruits and agronomic crops. Straw charcoal achieved from imperfect burnt straws is rich in essential nutrients for the growth of crops, which has a long term slow releasing action for water and fertilizer, has improvement and renovation effect for the soil which is polluted and degenerated by heavy metal, and can be processed to be organic compound fertilizer or insulating material of iron and steel industry and the like.

Owner:杭州南林能源科技有限公司

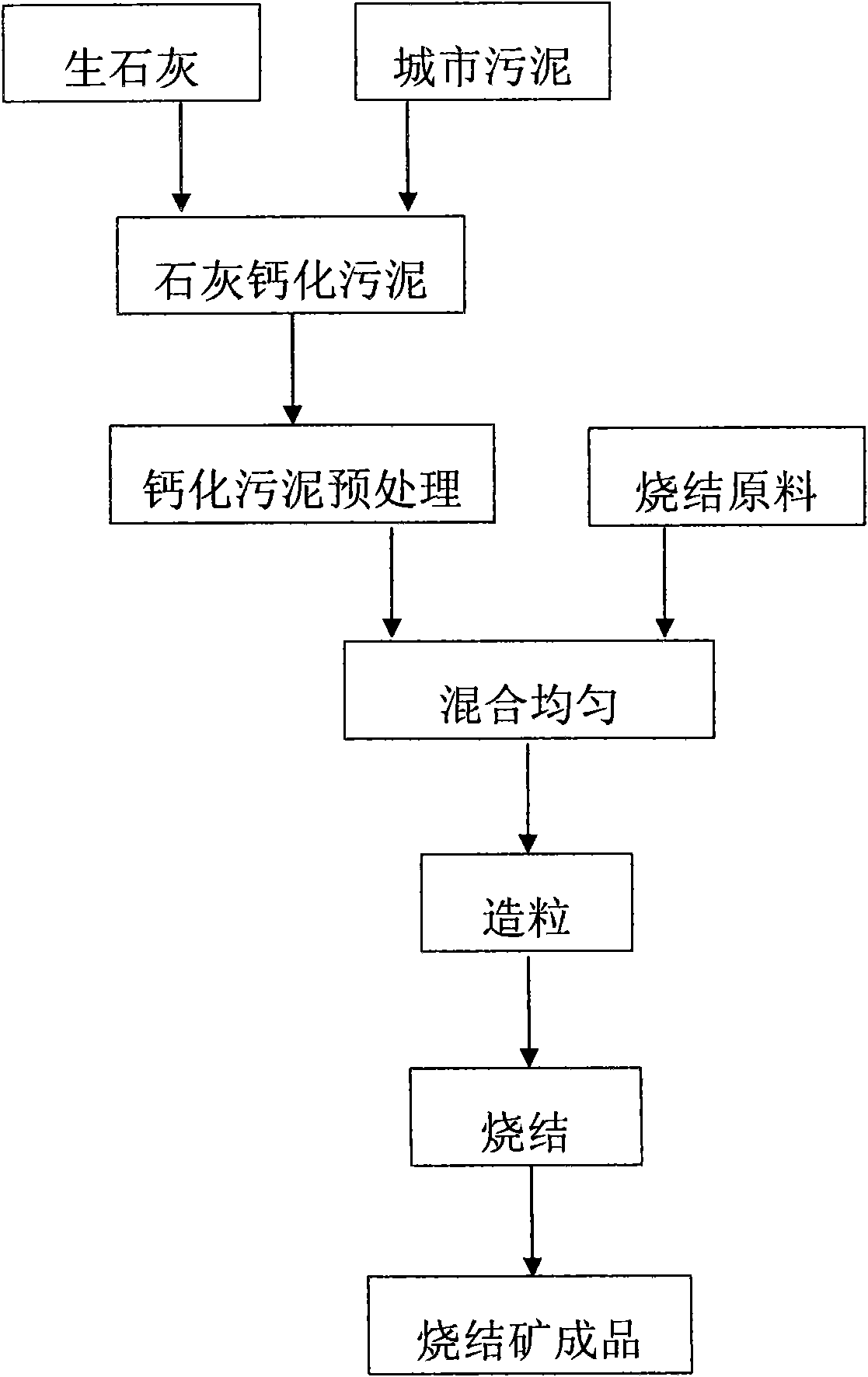

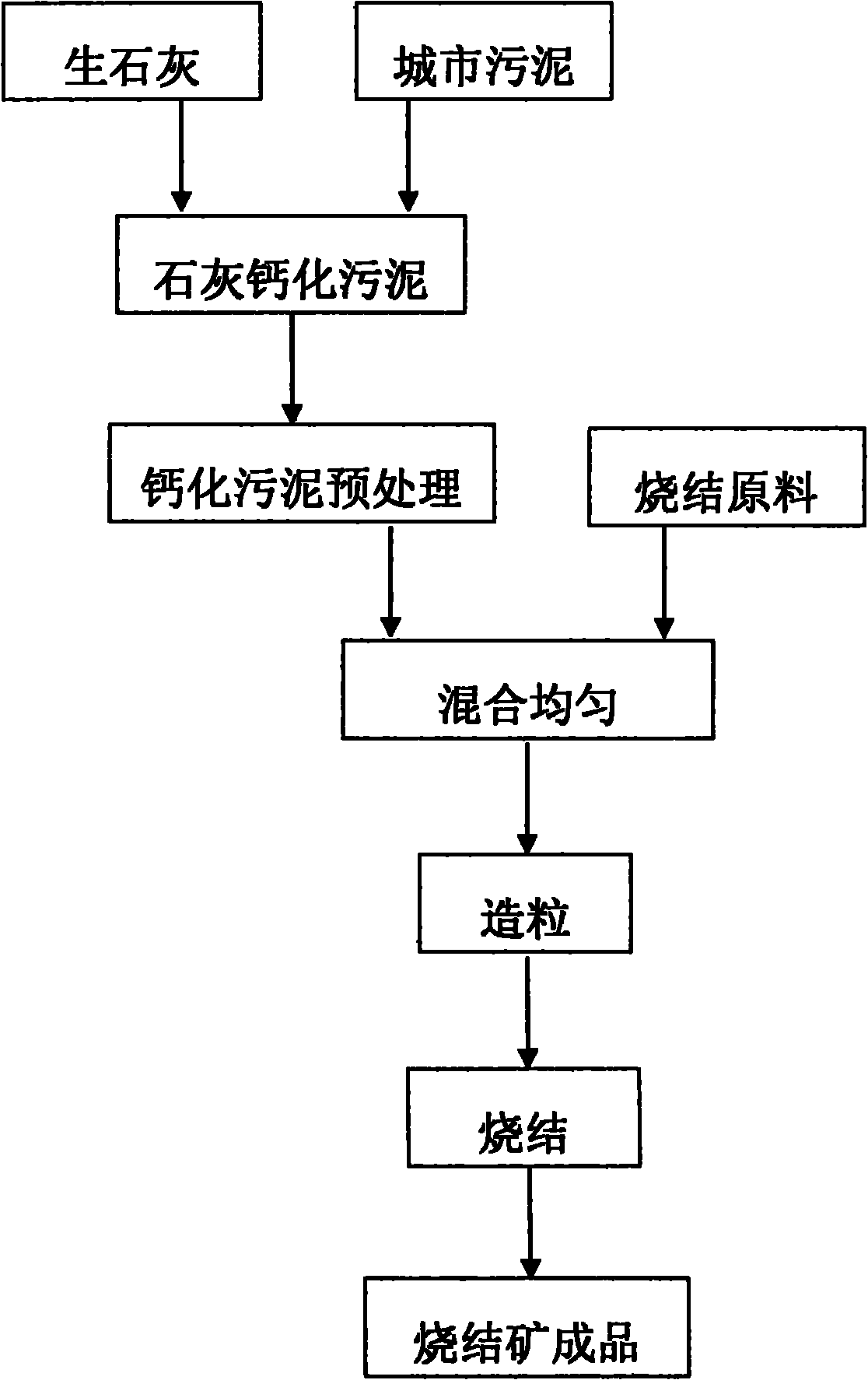

Method for utilizing municipal sludge as raw material of steel industrial sintering ore

ActiveCN102030450AAchieve recyclingAchieving processing powerSludge treatment by de-watering/drying/thickeningProcess efficiency improvementSludgeIron industry

The invention relates to a method for utilizing municipal sludge as a raw material of a steel industrial sintering ore and belongs to the technical fields of harmless treatment and high-additional-value utilization of municipal solid waste. The method comprises the following steps of: mixing the municipal sludge and quicklime according to a ratio; drying and dehydrating the mixture to obtain calcified sludge; adding the calcified sludge into sintering raw materials with correspondingly adjusted components according to a certain ratio and a certain mode, and allowing the mixture to enter the sintering process with other sintering raw materials; and producing the sintering core products serving as iron-making raw materials. The method has the advantages that: the lime calcified municipal sludge is added, so the sludge treatment cost is reduced and the secondary pollution problem during the sludge treatment is solved; the harmless treatment and the recycling utilization of municipal solid waste are realized; and the calcified sludge is added, so that the vertical sintering speed, the finished product ratio and the utilization coefficient can be effectively increased in the process of sintering the sintering core, the added amount of flux and fuel in the sintering raw materials is reduced, the raw material cost is reduced, and multiple purposes are fulfilled.

Owner:SHOUGANG ENVIRONMENTAL IND

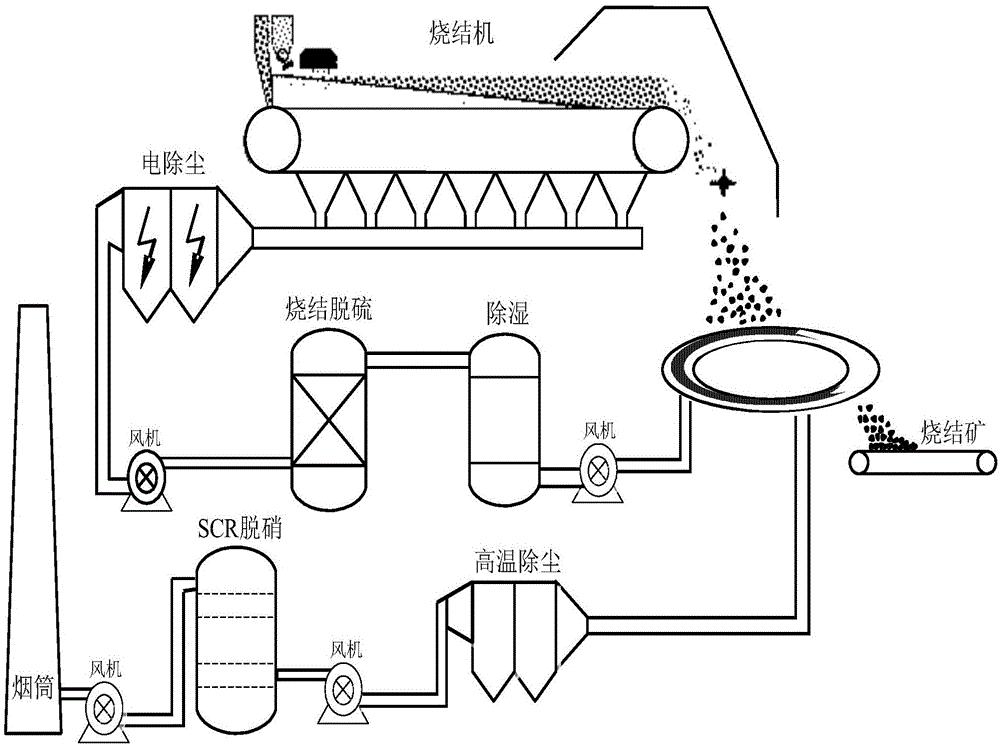

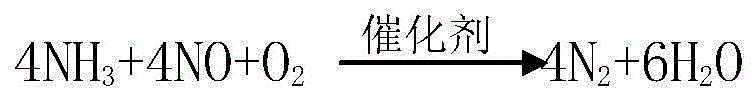

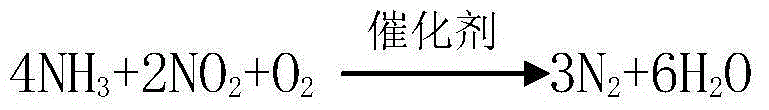

Technical method for denitration of sintering flue gas

ActiveCN106524771ATake advantage ofLow running costIncreasing energy efficiencyWaste heat treatmentFlue gasIron industry

The invention relates to a technical method for denitration of sintering flue gas. The method is particularly applicable to the treatment of the flue gas generated by sintering of iron ore in the steel and iron industry. The method can be used as the supporting construction for an enterprise with an existing sintering desulfuration technique, and can also be newly established together with a selected mature desulfuration technique of the sintering flue gas. Sintered and desulfurated tail gas is subjected to dehumidification and then used for heat exchanging of high-temperature sintering ore in a ring cooling machine, a straight-line cooler and a vertical-tank type sintering ore cooling device. The heat exchanging tail gas is dedusted and kept at the temperature of 300 DEG C or over. Selective catalytic reduction (SCR) is used for denitration of the tail gas, the removal rate of Nox in the flue gas is 85% or over, and the temperature of the denitrated tail gas is higher than 250 DEG C and can be used for waste heat electricity generation or heat-air sintering of a sintering machine, ignition and combustion supporting, and sintering ore preheating. The technical method for denitration of the sintering flue gas has the advantages that treatment capacity is large, applicability is high, sensible heat of the sintering ore is adequately used, and operating cost is low.

Owner:钢研晟华科技股份有限公司

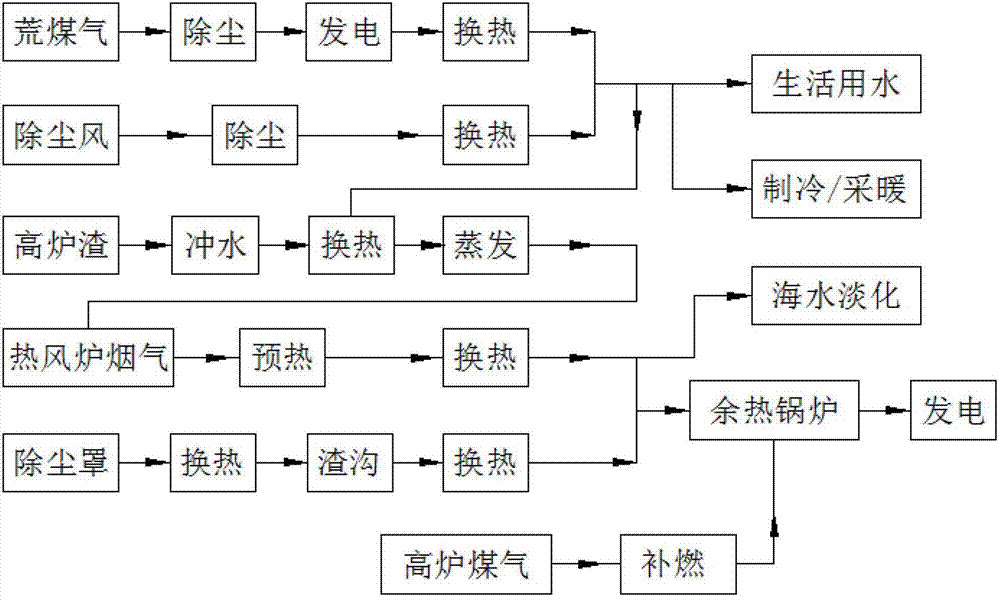

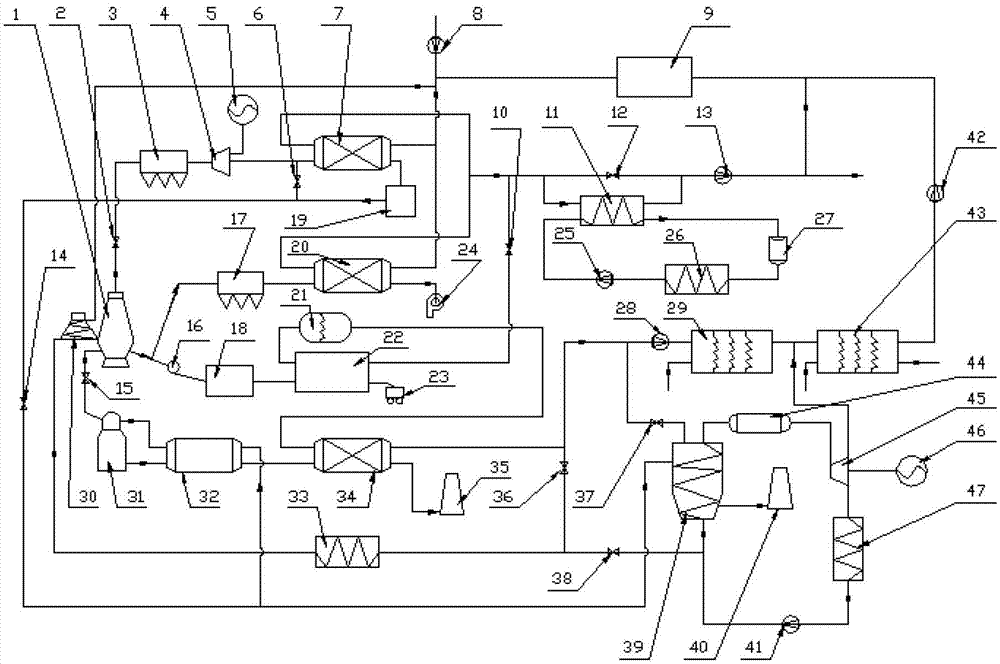

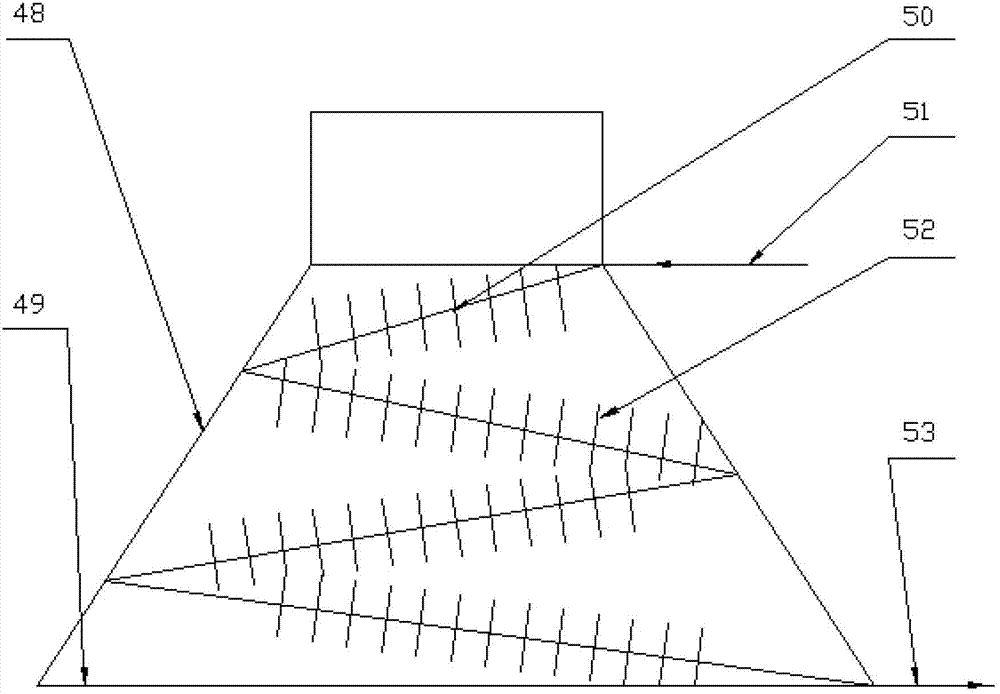

Steelmaking residual heat step recycling method

ActiveCN102851420ASolve effective useEnable fair useBlast furnace detailsIncreasing energy efficiencySteelmakingDitch

The invention discloses a steelmaking residual heat step recycling method. The invention belongs to the technical field of steel industry iron-making residual heat and residual energy utilization. The method is adopted under a condition for further utilizing iron-making low-grade residual heat, and comprises step recycling and high-efficiency utilizations of blast furnace gas residual heat, dust removal air residual heat, water slag residual heat, hot air furnace low-temperature flue gas waste heat, and dust cover and slag ditch residual heat. According to the technical scheme, blast furnace gas residual heat and dust removal air residual heat obtained after furnace top residual pressure power generation are connected in parallel, and are supplied for domestic water, cooling, or heating. Recycled water slag residual heat and flue gas residual heat obtained after hot air furnace gas heat exchanger are connected in parallel, and are used for supplying a heat source for low-temperature seawater desalination. Recycled dust cover residual heat and slag ditch surface radiation heat are connected in parallel, and are supplied for blast furnace gas supplementary firing residual heat boiler power generation. After powder generation, high-temperature seawater desalination is realized by a steam method. Cooling water and domestic water are treated and are adopted as inlet water replenishment. Through step recycling and graded utilization of the low-grade residual heat and residual energy, steel system comprehensive energy consumption can be reduced to a maximal extent, and energy resource reasonable utilization and comprehensive optimized utilization can be realized.

Owner:SHOUGANG CORPORATION

Preparation method of nitriding vanadium alloy

The present invention provides process of preparing vanadium nitride alloy. The process includes mixing vanadium oxide, carbon powder and density reinforcer, pressing to form, setting the shaped mixture into a reaction furnace, heating to 650 deg.c while introducing nitrogen or ammonia as the reacting and protecting gas into the furnace, further heating to 1000-1250 deg.c to produce carbonizing and nitriding reaction for 3 hr, cooling to 100 deg.c, and discharging the vanadium nitride alloy. The vanadium nitride alloy contains V 73-80 %, N 12-20 %, C 3-8 % and O 0.5-2.0 %, and has apparent density of 3000-4000 kg / cu m. The process has the features of low reaction temperature, short reaction period, low cost, etc, and the prepared vanadium nitride alloy with high nitrogen content is suitable for use in steel making.

Owner:SICHUAN UNIV

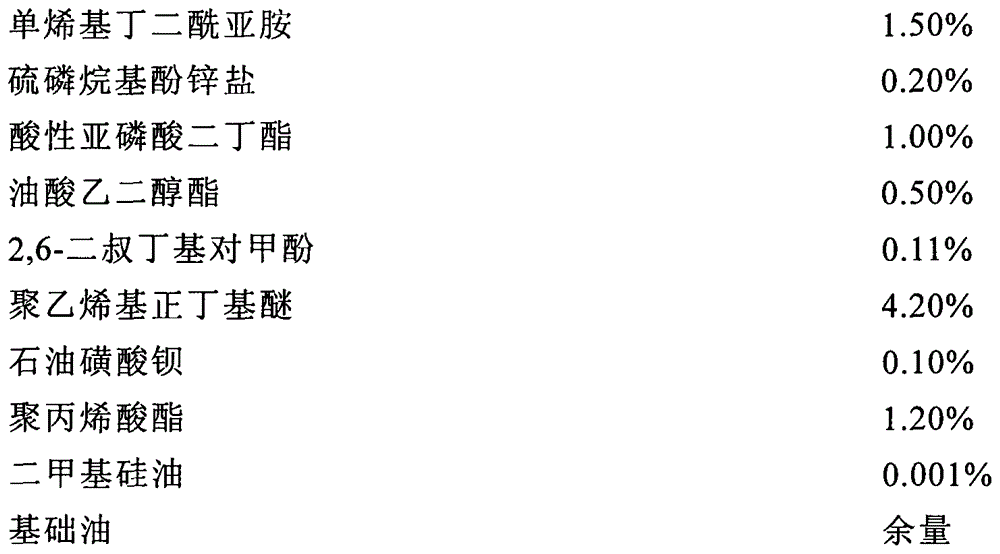

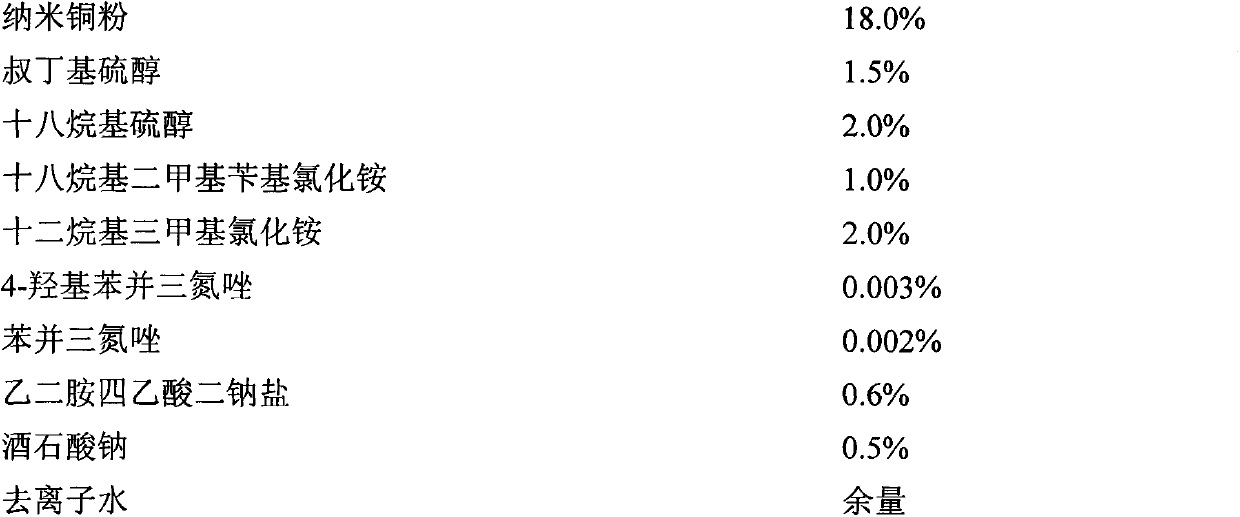

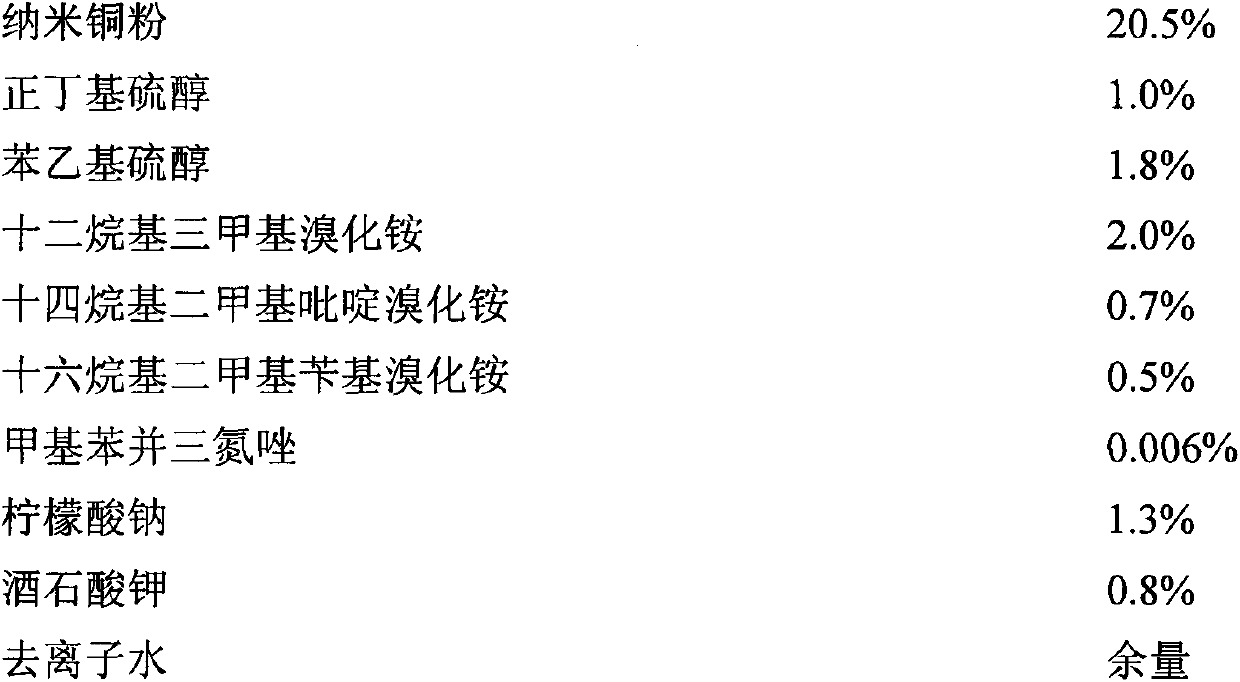

Lubricating oil composition and preparation method thereof

ActiveCN103773565AGood dispersionImprove dispersion stabilityAdditivesPigment treatment with non-polymer organic compoundsChemical compositionOil additive

The invention discloses a lubricating oil composition and a preparation method thereof. According to the method, base oil, detergent, dispersant, preservative, extreme-pressure antiwear additive, oily agent, antioxidant, viscosity index improver, rust inhibitor, pour-point depressant, antifoaming agent and novel lubricating oil additive are compounded to obtain the lubricating oil composition. The method has the advantages of simple and feasible production technique, low equipment investment, low energy consumption and no environmental pollution, and is beneficial to popularization and application. The lubricating oil composition can be widely used in the fields of mechanical industry, automobile industry, precision instruments, power industry, metallurgical industry, die making and application industry, iron and steel industry, machine tool industry and the like, and has wide application prospects.

Owner:GUANGZHOU LEARNBER SCI & TECH DEV

Method for producing ferro-silicon alloy and calcium aluminate material with red mud and aluminum ash

InactiveCN101429582AEfficient use ofNo emissionsProcess efficiency improvementElectric furnaceSteelmakingRed mud

The invention relates to a method for preparing ferro-silicon alloy and a calcium aluminate material through utilizing red mud and aluminum ash. The method comprises the following technical proposal: 25 to 70 weight percent of the red mud and 30 to 75 weight percent of the aluminum ash are mixed, are added with 15 to 50 weight percent of a calcic compound or are not added with the calcic compound, are mixed, are put to an electric furnace, are melted and reduced at a temperature of between 1,400 and 1,800 DEG C, are kept at the temperature for 1 to 4 hours and are naturally cooled, broken and separated, to obtain the ferro-silicon alloy and the calcium aluminate material. The method uses the aluminum ash and the red mud as raw materials, utilizes waste and has a simple process and low cost. In the reaction process, metal aluminum and aluminum nitride are utilized as reducing agents; the process is exothermic, thereby reducing electricity consumption, having no emission of CO2 and reducing environmental pollution; and the ferro-silicon alloy and the calcium aluminate material have wide application range and high added values. The prepared calcium aluminate material can be used as a corhart and a raw material for producing calcium aluminate cement and can also be used as premelt slag in steel industry; and the ferro-silicon alloy can be used as a deoxidant and an alloy agent for steelmaking.

Owner:WUHAN UNIV OF SCI & TECH

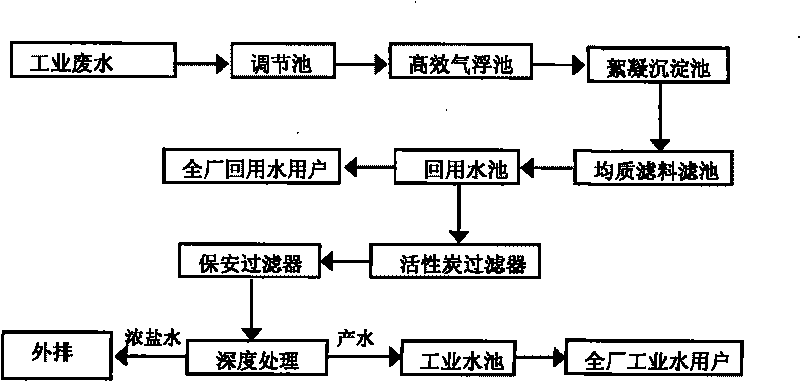

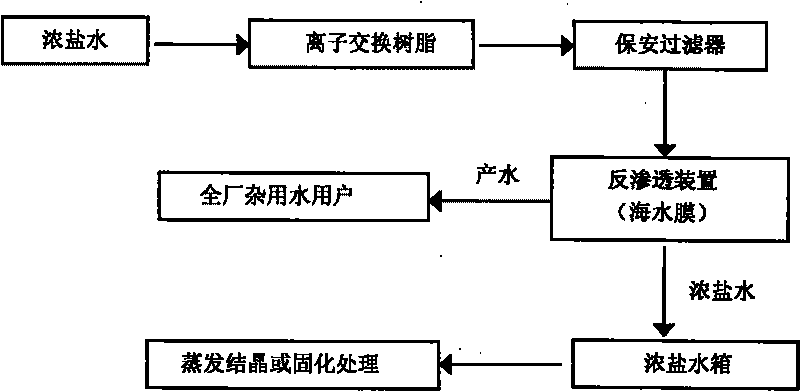

Zero-discharge treatment process for industrial wastewater of iron and steel plant

InactiveCN101696071AAchieving zero emissionsAchieve emissionsWater/sewage treatment by ion-exchangeWaste water treatment from metallurgical processTreatment effectIndustrial waste water

The invention belongs to the field of water supply and discharge in the iron and steel industry, and in particular relates to a zero-discharge treatment process for industrial wastewater of an iron and steel industry. The industrial wastewater process is characterized in that: strong brine is subjected to advanced treatment by strong brine treatment process. The strong brine treatment process comprises the following steps that: the strong brine is treated by adopting ion exchange resin to remove Ca2+, Si2+ and other ions which have great influence on film operation, and is subjected to secondary reverse osmosis treatment by adopting a seawater film or a bitter film to furthest reduce the strong brine, and is treated by adopting solidification or low-temperature multiple effect evaporation crystallization. The process saves investment, is convenient for implementation, has clear treatment effect, and can realize zero discharge of the industrial wastewater of the iron and steel plant through source control, strengthening treatment, strong brine reduction, evaporation crystallization and other technology and measures. The process can be widely applied to industrial wastewater treatment for domestic iron and steel enterprises.

Owner:CISDI ENG CO LTD

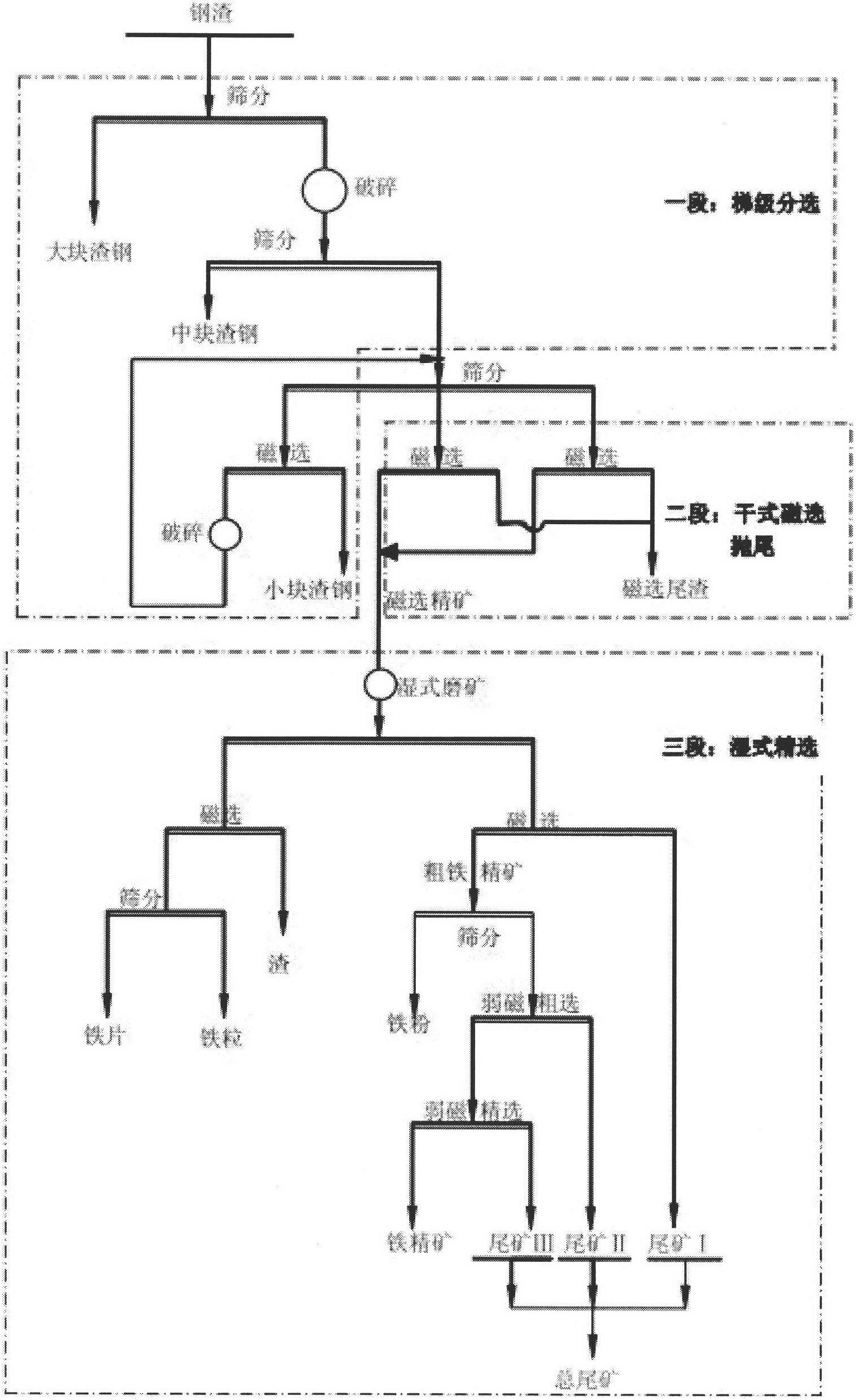

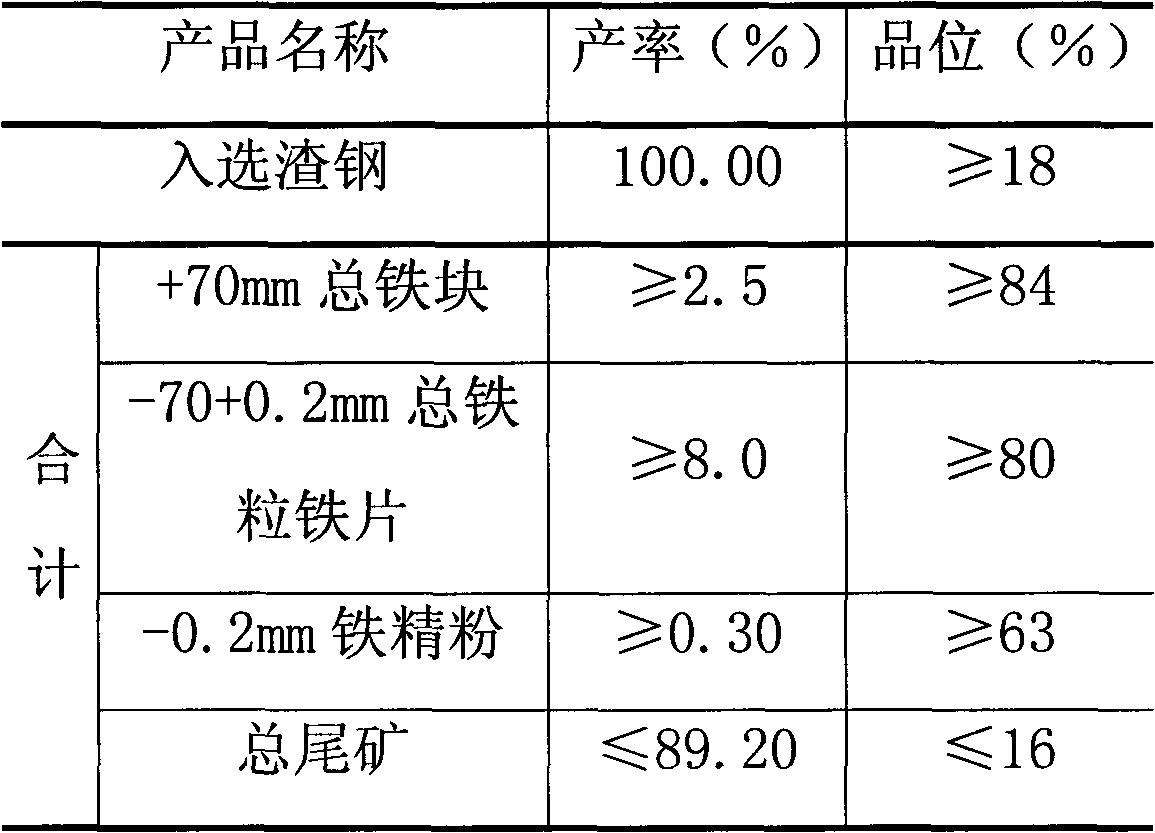

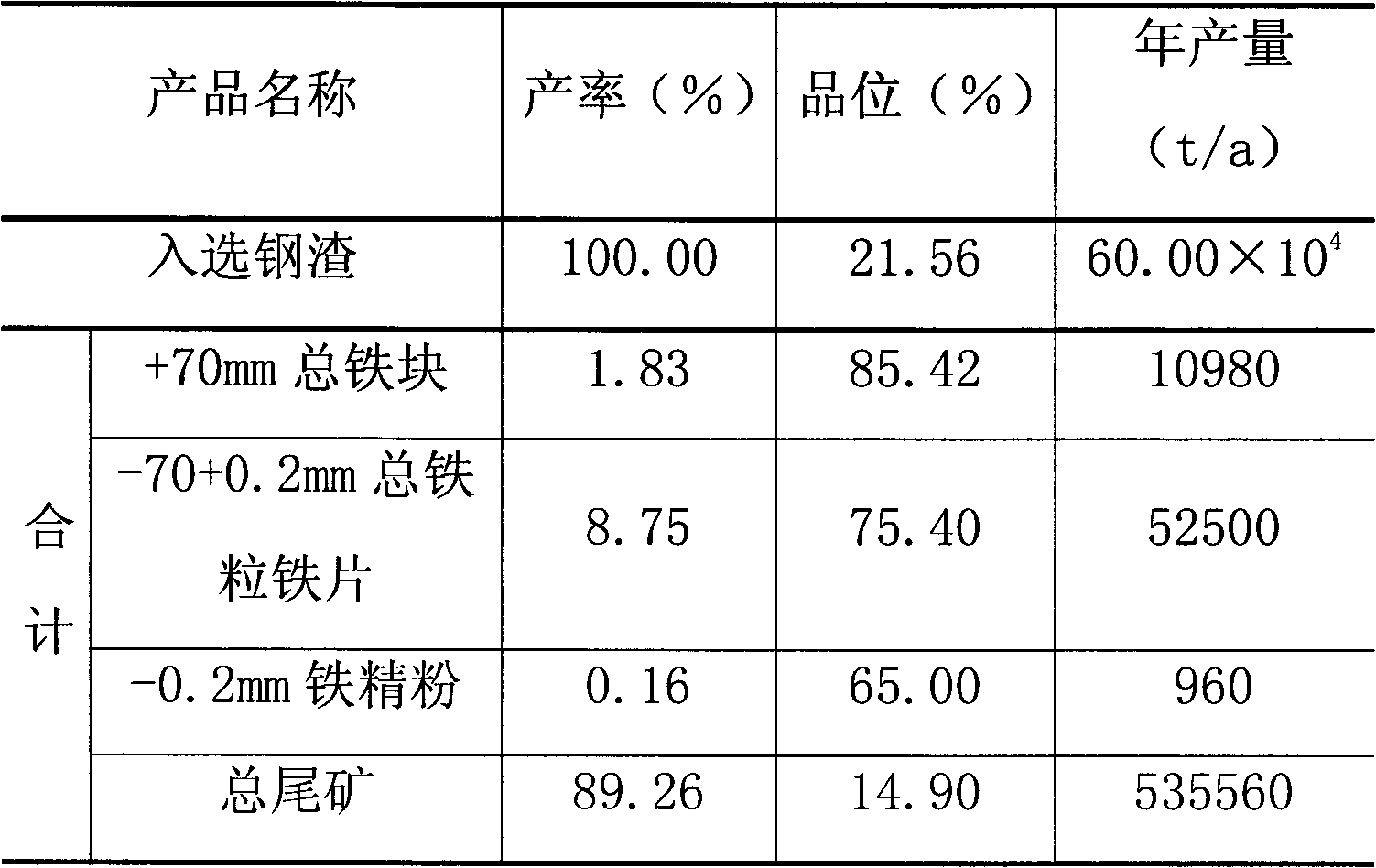

Method for recycling metal iron from steel slag of converter

ActiveCN102688804AHigh recovery rateImprove product qualityRecycling and recovery technologiesMagnetic separationSlagIron industry

The invention relates to a method for recycling metal iron resources from waste residues of the iron and steel industry, particularly relates to a method for recycling metal iron from steel slag of a converter, and belongs to the technical field of benefication and comprehensive utilization of resources. The method includes recycling the metal iron from the slag of the converter by a cascade separation technological method, a dry magnetic separation technological method for discarding tailings and a wet concentration technological method, and is characterized in that +70mm large high-grade steel slag of the steel slag of the converter is in cascade separation and recycling, -70mm large high-grade steel slag is in classification dry magnetic separation for discarding tailings, rough concentration is further in full-grain wet ore grinding for separating slag from iron, cascade screening and cascade magnetic separation, and finally the metal iron with different grain sizes and magnetic iron concentration are obtained. The method has the advantages of high recycling rate and the grade of the metal iron, simplicity in technological process, simplicity and convenience in operation, low production cost, applicability to processing different types of steel slag of converters, and the like.

Owner:KUNMING METALLURGY INST

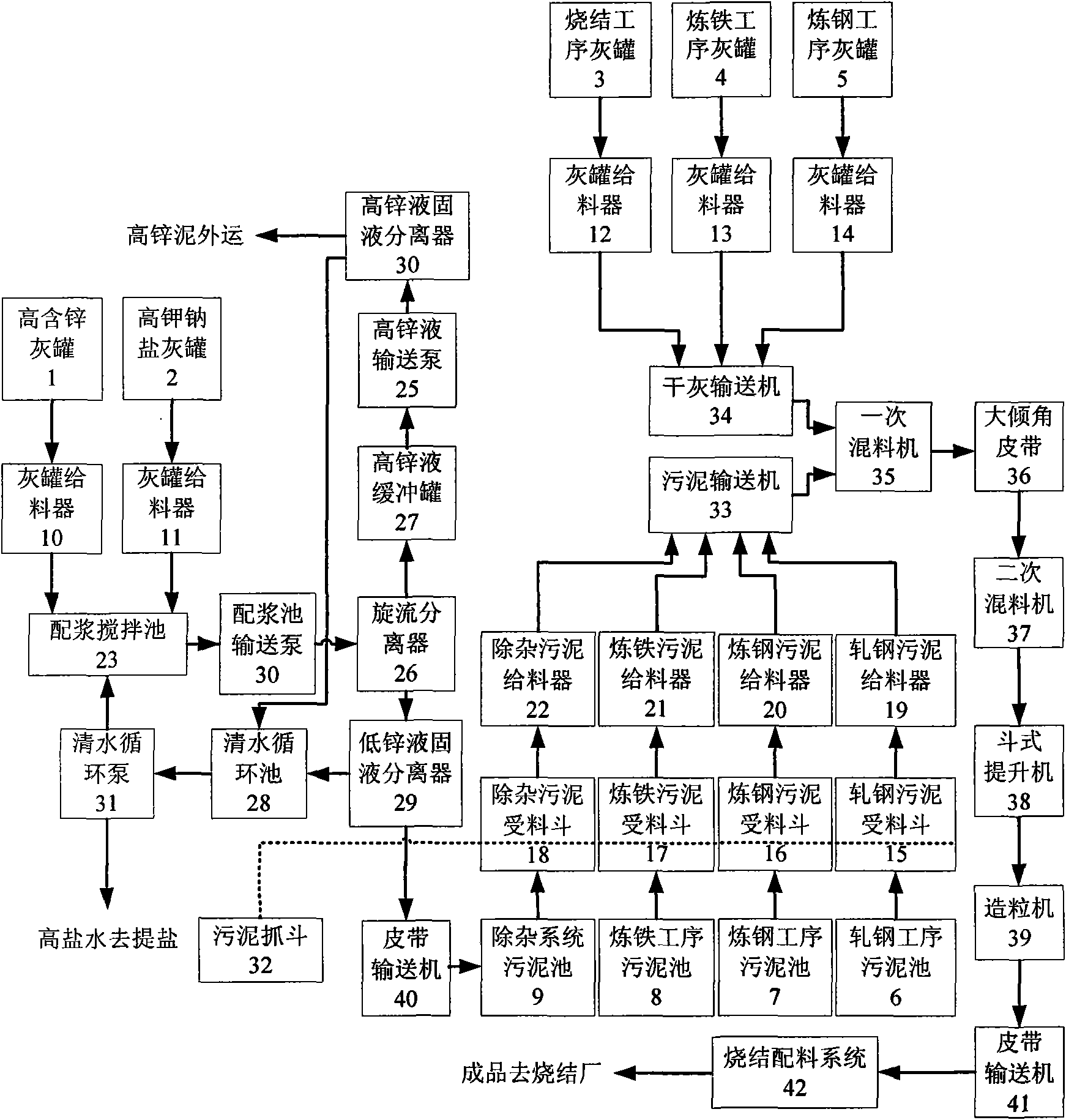

System and method for centralized classification treatment of steel metallurgic dust mud

InactiveCN101624637AUnified classification collection implementationRealize unified collectionRecycling and recovery technologiesProcess efficiency improvementIron industryCircular economy

The invention relates to a system and a method for the centralized classification treatment of steel metallurgic dust mud, which belong to the technical fields of the comprehensive utilization and the innocent treatment of metallurgical industry solid waste. The system comprises an impurity removing system, a homogenizing system, a granulating system and a sintering proportioning system, wherein an outlet of the impurity removing system is connected with an inlet of the homogenizing system, an outlet of the homogenizing system is connected with an inlet of the granulating system, and an outlet of the granulating system is connected with an inlet of the sintering proportioning system; the impurities in high-impurity materials are firstly removed through the impurity removing system, the materials and the rest ferruginous dust mud together enter a mixing system for homogenization treatment, the homogenized materials enter the granulating system for granulation treatment, and the granular materials made by the granulating system enter the sintering proportioning system and are used as sintering raw materials. The system has the advantages of simple and practical technology, large processing capacity, cleanness, environmental protection and lower initial investment and running cost, and fully expresses the ideas of cleaner production and cyclic economy in iron and steel industry.

Owner:SHOUGANG CORPORATION

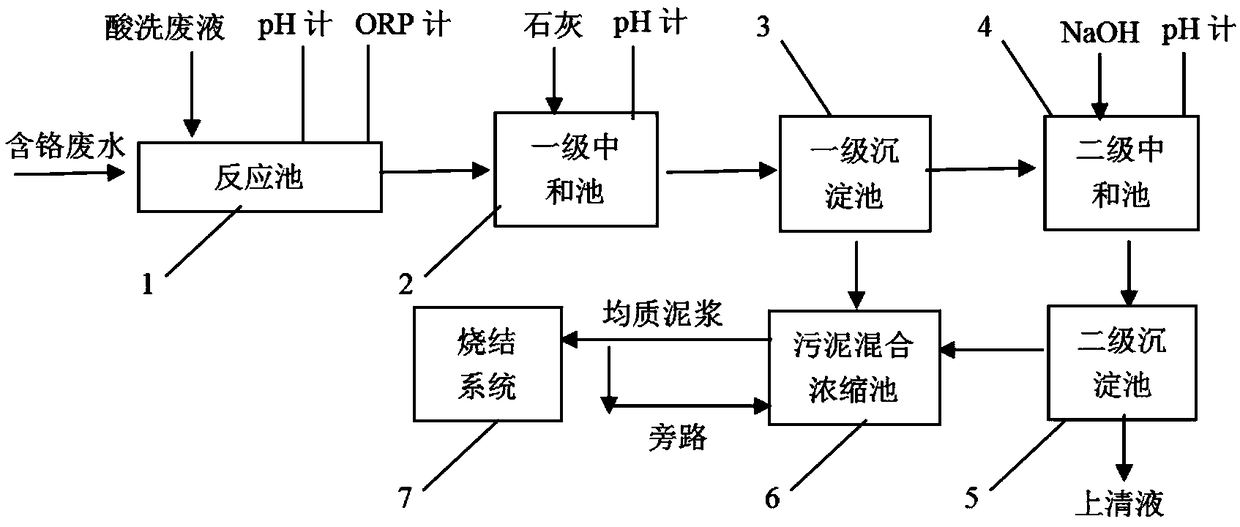

Harmless and resource utilization method of steel industry chromium-containing wastewater

InactiveCN109052711ALess investmentGuaranteed uptimeSludge treatment by de-watering/drying/thickeningWater contaminantsSteelmakingResource utilization

The invention discloses a harmless and resource utilization method of steel industry chromium-containing wastewater. The harmless and resource utilization method of the steel industry chromium-containing wastewater comprises the following steps: 1) adding steel rolling system acid-washing waste liquid into the chromium-containing wastewater, reducing Cr<6+> in the chromium-containing wastewater into Cr<3+> by utilizing the acidic environment provided by the acid-washing waste liquid and the Fe<2+> therein, and oxidizing the Fe<2+> into Fe<3+>; 2) adding alkali into the reduced wastewater, neutralizing, enabling the Cr<3+> to generate Cr(OH)3 precipitate and the Fe<3+> to generate Fe(OH)3 precipitate, and performing mud and water separation to obtain sludge containing chromium and iron; 3)performing concentration treatment on the sludge containing chromium and iron to obtain homogenous slurry; and 4) feeding the homogenous slurry into a sintering system, mixing the homogenous slurry and the sintering raw materials according to a certain proportion and sintering to obtain a sintered ore finished product for ironmaking and steelmaking. By the method, up-to-standard discharge of the chromium-containing wastewater is realized and resource utilization of the chromium element in the wastewater is realized.

Owner:武汉钢铁有限公司

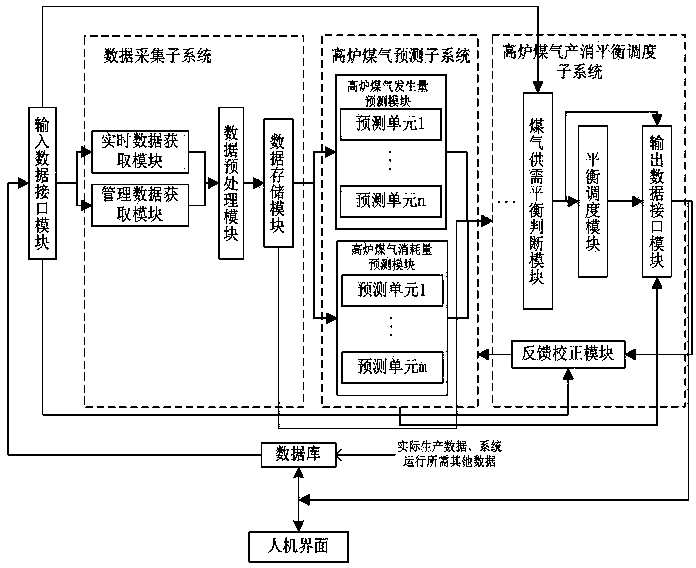

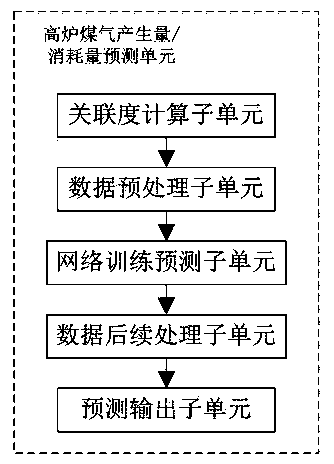

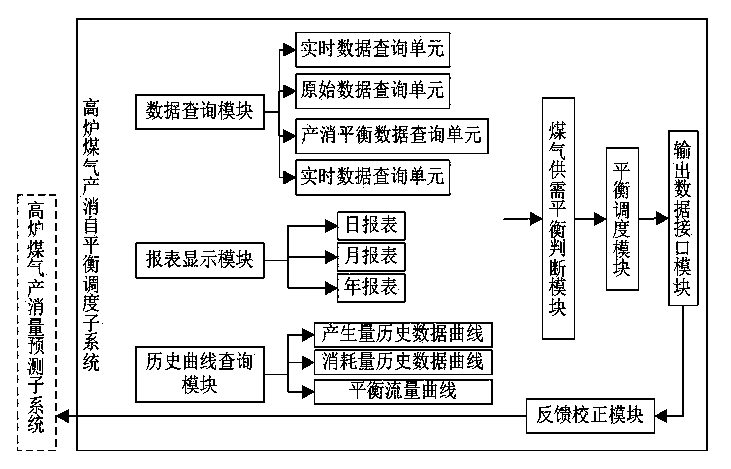

Self-balanced byproduct blast furnace gas dispatching system in iron and steel industry and method for predicting yield and consumption

InactiveCN103426035ASolve the problem of production and consumption forecastingEnsure balanceForecastingManufacturing computing systemsPredictive methodsOriginal data

The invention discloses a self-balanced byproduct blast furnace gas dispatching system in the iron and steel industry and a method for predicting a yield and consumption. The self-balanced byproduct blast furnace gas dispatching system comprises a data acquisition subsystem, a blast furnace gas prediction subsystem and a yield-consumption-balanced blast furnace gas dispatching subsystem. The data acquisition subsystem is used for acquiring real-time production data of blast furnace gas, required prediction parameters, production planning data and the like, and the required prediction parameters, the production planning data and the like are used as original data; the blast furnace gas prediction subsystem is used for creating a corresponding prediction model and predicting the yield and the consumption of the blast furnace gas according to the collected original data; the yield-consumption-balanced blast furnace gas dispatching subsystem is used for judging a supply and demand balance condition of a gas quantity according to the yield and the consumption at a future moment and the original gas storage quantity, and producing a balanced dispatching scheme, and the yield and the consumption at the future moment are predicted by the gas prediction subsystem. The self-balanced byproduct blast furnace gas dispatching system and the method have the advantage that the self-balanced byproduct blast furnace gas dispatching system and the method are beneficial to improving the adjustment level of a byproduct blast furnace gas system in the steel and iron industry, improving the blast furnace gas yield and consumption prediction accuracy and dispatching the blast furnace gas in a balanced manner.

Owner:ZHEJIANG UNIV

Process for producing vanadium nitrate

InactiveCN1587064AWide variety of sourcesLow priceNitrogen-metal/silicon/boron binary compoundsVanadium compoundsApparent densityAdhesive

The production process of vanadium nitride as one kind of vanadium alloy additive including pre-treatment of mixing of ammonium vanadate powder and carbon powder in a rotary kiln at 600-800 deg.c and slight negative pressure for 2-3 hr; grinding the mixture, mixing with adhesive and pressing into block; treating the blocks inside nitrogen containing protective atmosphere in a vertical tubular kiln at 1100-1900 deg.c for 4-6 hr to produce carbonization and nitridation producing vanadium nitride; and cooling to below 100 deg.c and taking out. The vanadium nitride product contains V in 77-81 wt%, N in 9-16 wt%, C in 2-8 wt% and O in 0.2-1.0 wt% and has apparent density of 3-3.9 g / cu cm, and is suitable for use in making steel.

Owner:CHANGZHOU MAOSHENGTE ALLOY PROD

Liquid molten slag dry-type centrifugal granulation and afterheat recycle system having molten slag buffer-storage and flow control functions

ActiveCN108330233AEnsure structural stabilityGuaranteed operational safetyExhaust gas handlingRecycling and recovery technologiesMetallurgyIron industry

The invention discloses a liquid molten slag dry-type centrifugal granulation and afterheat recycle system having molten slag buffer-storage and flow control functions. The system comprises a molten slag buffer-storage and flow control unit, a granulation unit, a mobile bed unit and an afterheat utilization unit; the molten slag buffer-storage and flow control unit is arranged at the upper part ofthe granulation unit and is used for buffer-storage of the liquid molten slag and controlling the flow rate and speed of the liquid molten slag falling to the granulation unit; the granulation unit is used for granulating the falling liquid molten slag; the mobile bed unit is arranged at the lower part of the granulation unit and is used for cooling and temporarily storing the granulated molten slag; hot air inside the granulation unit and the mobile bed unit communicates with the afterheat utilization unit; and the afterheat utilization unit comprises a hot air flue, a primary dust collector, an afterheat boiler, a secondary dust collector, an exhaust fan and a chimney which are arranged in sequence. The system disclosed by the invention does not use water resources, is free of environmental pollution, can effectively recycle high-quality afterheat resources contained in the high-temperature liquid molten slag, and can meet the urgent requirements of energy conservation and emissionreduction of the present steel and iron industry.

Owner:XI AN JIAOTONG UNIV

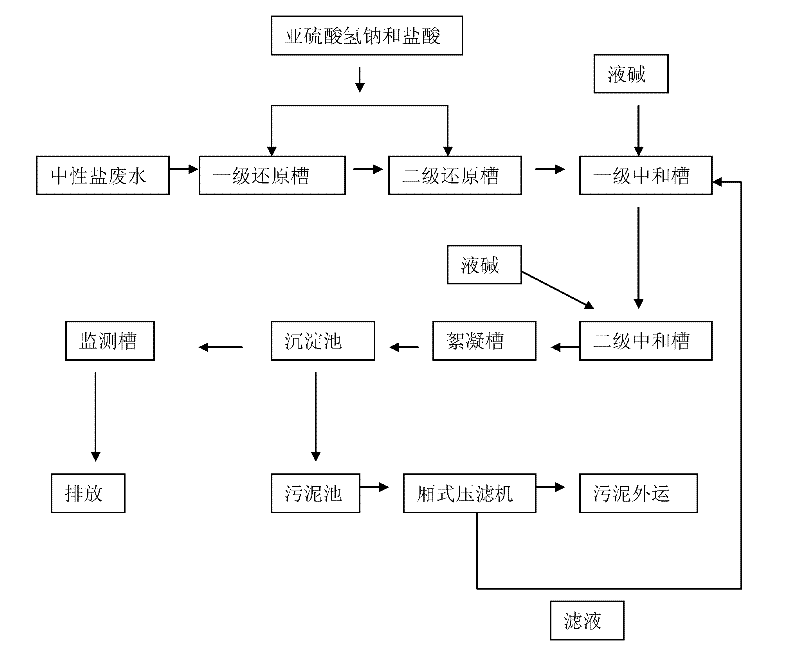

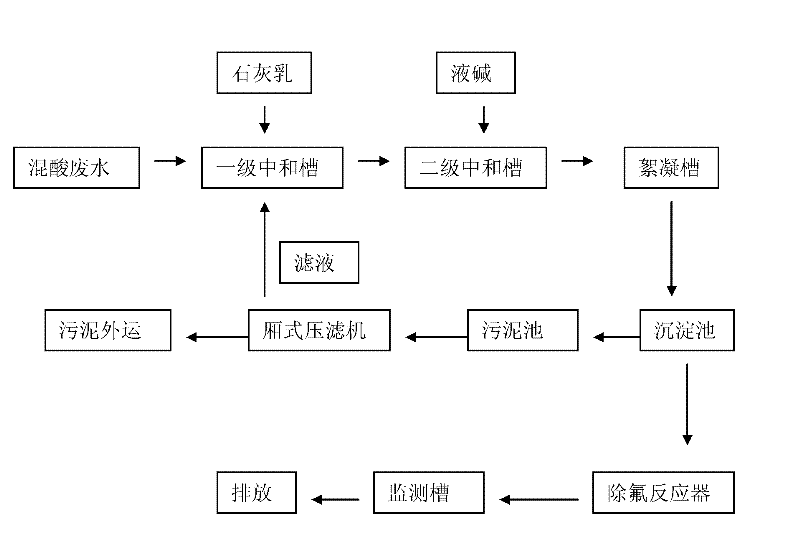

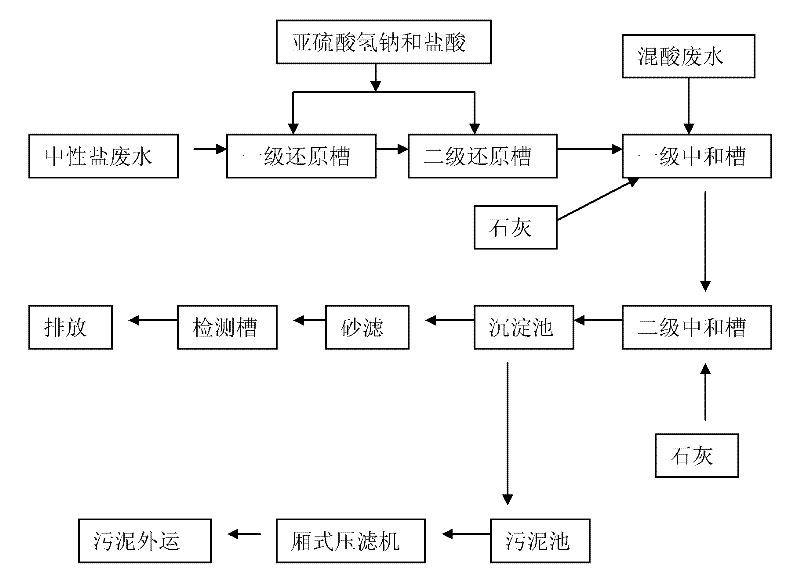

Method for sludge reduction for cold rolling pickling wastewater in steel industry

ActiveCN102211828AReduce productionReduce processingSludge treatment by de-watering/drying/thickeningWaste water treatment from metallurgical processSludgePolyacrylamide

The invention belongs to the technical field of sludge reduction for cold rolling pickling wastewater in the steel industry, and discloses a method for sludge reduction for the cold rolling pickling wastewater in the steel industry. In the method disclosed by the invention, neutral salt wastewater and wastewater mixed with acid are completely and separately treated to obtain sludge containing hazardous wastes and general sludge respectively, and the sludge output of each unit is reduced by accurately adding chemical agents at each unit; in the technology for treating the neutral salt wastewater, caustic soda liquid is respectively added in a first stage neutralizing tank and a second stage neutralizing tank; in the technology for treating the wastewater mixed with acid, the treatment is performed by using a lime and austic soda liquid combination method; and in the treatment of a neutralizing tank, the pH value is controlled between 1.5 and 3.0, and the pH value during neutralization reaction is controlled between 8.2 and 8.7; and a flocculation process is adopted after the neutralization reaction, polyaluminum chloride, polyacrylamide and other flocculants are added for reacting and are mixed so as to enlarge pollutant particles. By use of the method, the output water can stably reach the standard, and the water treatment cost per ton is reduced.

Owner:SHANGHAI MEIJIA WATER TREATMENT TECH

Method for improving dephosphorization efficiency in duplex converter by using CO2

ActiveCN104928439ARealize resource utilizationPromote sustainable developmentManufacturing convertersProcess efficiency improvementResource utilizationEngineering

The invention provides a method for improving the dephosphorization efficiency in a duplex converter by using CO2 and belongs to the field of metallurgy technologies and energy conservation and emission reduction. According to the method for improving the dephosphorization efficiency in the duplex converter by using the CO2, top-blowing of the mixed gas of the CO2 and oxygen is conducted in a dephosphorization furnace, bottom-blowing of the CO2 and nitrogen in are conducted in a time-dividing-section switching mode, the CO2 is adopted in blowing, and the nitrogen is adopted for keeping the smoothness of a bottom blow gun when converter reversing and gun lifting are conducted until smelting blowing is started (the non-blowing period). When the phosphorus content is reduced to be lower than 0.030%, molten iron after dephosphorization is added into a decarburization furnace, the top-blowing of the mixed gas of the CO2 and oxygen is conducted for deep dephosphorization in the smelting earlier stage of the decarburization furnace, the gas is switched into pure oxygen for decarburization warming in the middle and later period, the bottom-blowing of the nitrogen or the CO2 or argon is conducted, and the end point phosphorus can be reduced to be lower than 0.010%. According to the method for improving the dephosphorization efficiency in the duplex converter by using the CO2, through the adjustment of the blown gas types and the proportion, the concentration of the oxidizing agent is reasonably controlled to reach the effects of improving converter dephosphorization reaction thermodynamics and dynamic conditions, the dephosphorization efficiency and the molten steel quality are improved, the resource utilization of the CO2 in steel-making processes is achieved, and the sustainable development of the iron and steel industry is promoted.

Owner:UNIV OF SCI & TECH BEIJING

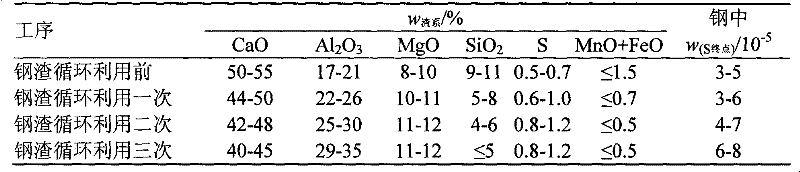

Method for recycling steel slag of LF (Low Frequency) furnace

InactiveCN102206729AAchieve recyclingReduce consumptionRecycling and recovery technologiesSlagIron industry

The invention relates to a method for recycling steel slag of an LF (Low Frequency) furnace. The technical scheme of the invention is as follow: the method comprises the following steps of: removing metallic iron contained in the steel slag through cooling, grinding, magnetic separation and screening processes by taking the steel slag of the LF furnace as raw materials; then mixing modifiers, i.e. sulfur-containing CaO-Al2O3-SiO2-MgO series LF steel slag, a right amount of lime, and the like, and then completely oxidizing sulfur contained in the CaO-Al2O3-SiO2-MgO series LF steel slag or oxidizing to a predetermined degree at certain temperature in an appropriate heating furnace to finally obtain premelting refining slag of the LF furnace, which has excellent property, so as to achieve the purpose of recycling the steel slag in an iron and steel industry. According to the method disclosed by the invention, the recycling of the LF steel slag is completely realized; the environmental problems caused by waste slag stacking are prevented; the consumption of the raw materials, i.e. the lime and the like, is reduced; heat in the production process of the premelting refining slag is effectively utilized; and energy consumption is reduced.

Owner:NORTHEASTERN UNIV

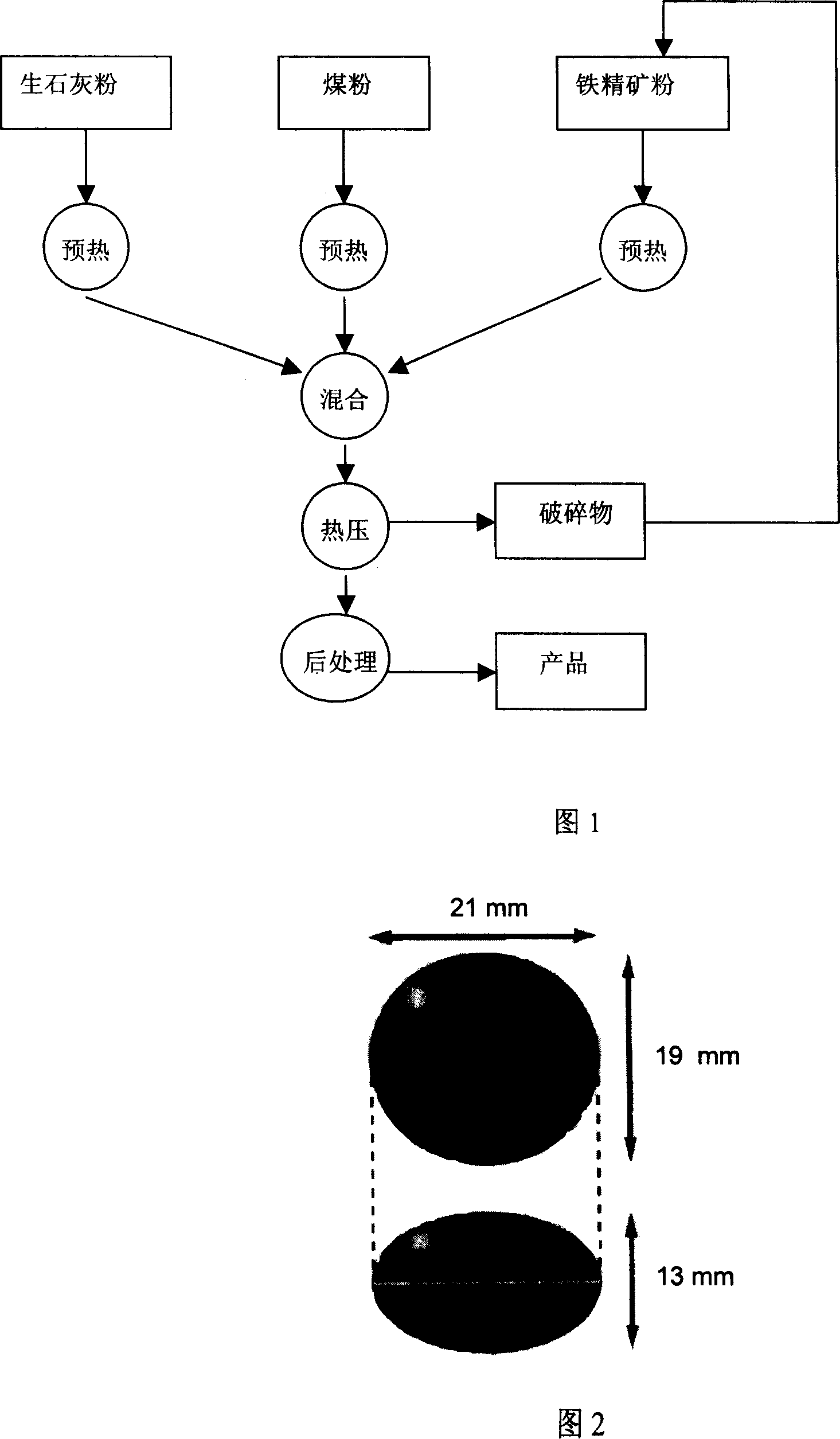

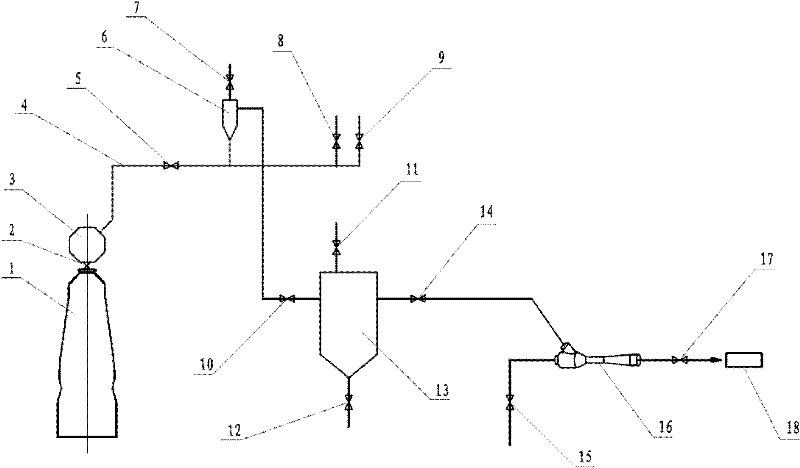

Method for preparing hot pressed balls of iron ore concentrate and powdered coal

InactiveCN101003852AHigh cold compressive strengthHigh compressive strengthGood reductionIron industry

This invention discloses a method for preparing hot briquettes from iron concentrate and coal powder. The method comprises: pre-heating coal powder, iron concentrate and quicklime powder, mixing, hot-pressing by a double-roller press, and performing post-treatment at 550-600 deg.C for 20-30 min. The hot briquettes can be used as the raw material for iron smelting in blast furnace, and have such advantages as excellent high-temperature strength, good reduction capacity, good melt-dripping property, and low energy consumption. The method can improve the raw material suitability of iron industry.

Owner:NORTHEASTERN UNIV

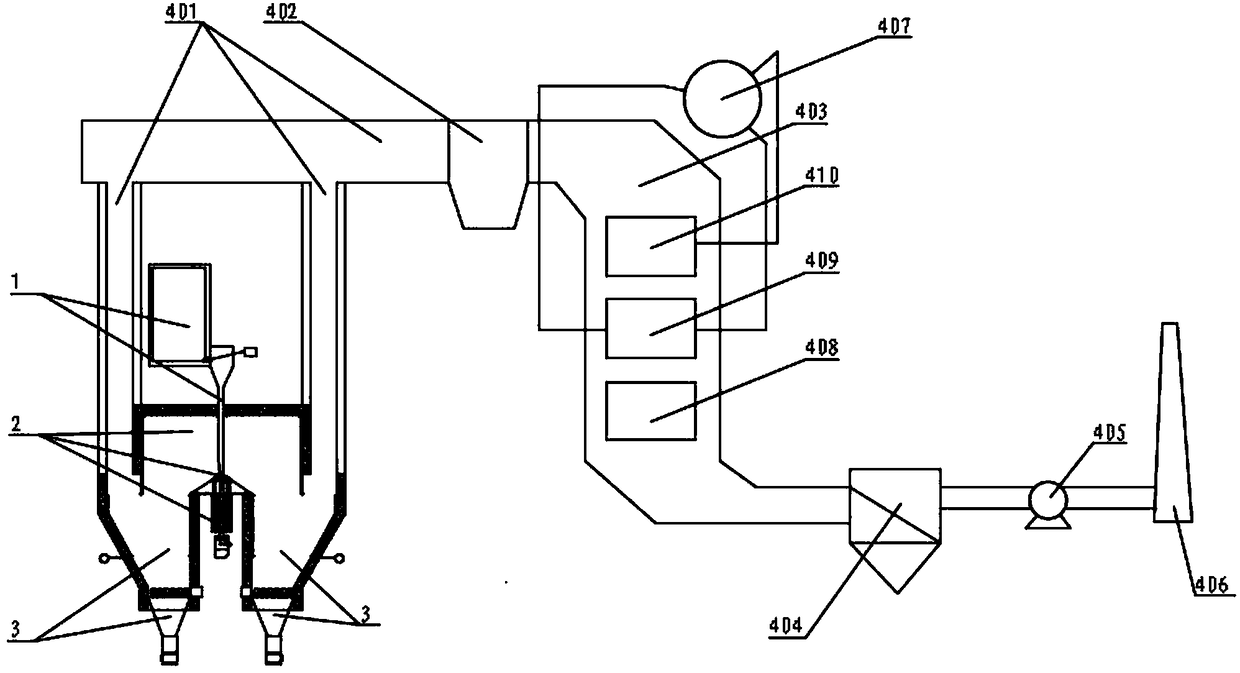

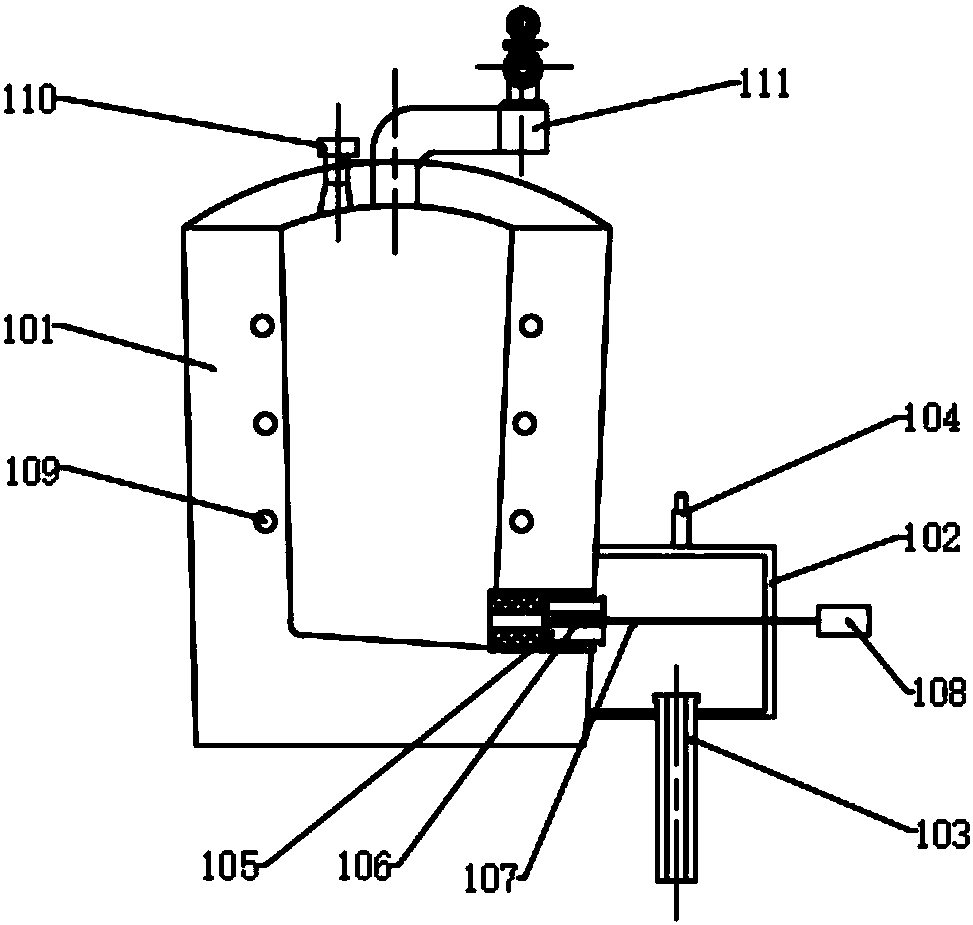

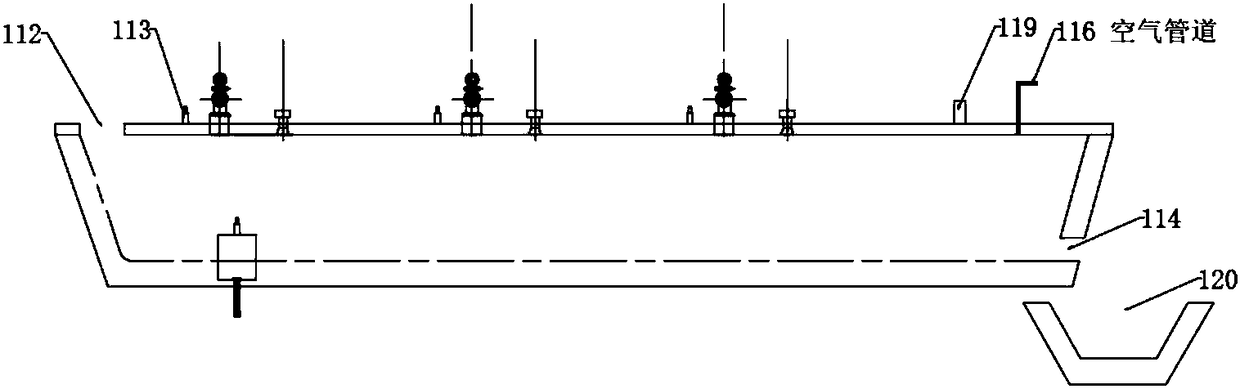

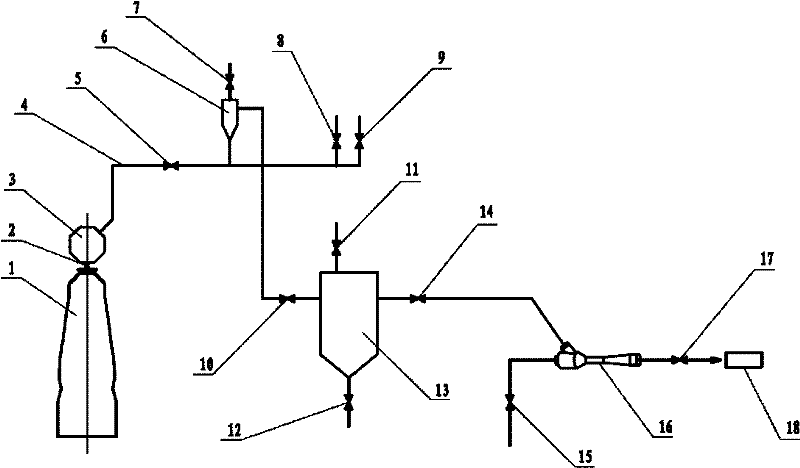

Device for recovering coal gas in equalizing and relieving process of furnace top of blast furnace

InactiveCN102337364ASolve the problem of air emissionsSolve pollutionBlast furnace detailsDust arrestersSocial benefitsBaghouse

The invention relates to a device for recovering coal gas in the equalizing and relieving process of a furnace top of a blast furnace and belongs to the technical field of the iron and steel industry. The device comprises a blast furnace weighing charging bucket, a equalizing and relieving pipeline connected with the charging bucket, a plurality of types of valves, a cyclone dust collector and a cloth bag dust collector connected in series behind the cyclone dust collector and is characterized in that an ejector is connected in series behind the cloth bag dust collector; crude gas which is equalized and relieved from the blast furnace weighing charging bucket enters the cyclone dust collector to carry out primary dust removal through the equalizing and relieving pipeline and then enters the cloth bag dust collector connected in series behind the cyclone dust collector to form clean gas; and under the action of the ejector, the clean gas is rapidly ejected and enters a clean gas pipe network, so that the rapid relief and recovery of the equalized and relieved coal gas in the weighing charging bucket are realized. The process is simple, is convenient to operate and has low operation and maintenance cost. Besides the economic benefits caused by the recovery of the coal gas, the coal gas and dust discharge can also be reduced so as to generate good social benefits; a conventional process is changed less; and the process is convenient to improve the existing conventional equalized and relieved coal gas system of the blast furnace.

Owner:WISDRI ENG & RES INC LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com