Method for sludge reduction for cold rolling pickling wastewater in steel industry

A technology for pickling wastewater sludge and iron and steel industry, which is applied in water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, water/sewage treatment, etc. It can solve the problem that sludge cannot be separated and lime dissolution rate is low , unable to achieve separation and other problems, achieve good economic and environmental benefits, outstanding economic and environmental benefits, and reduce sludge disposal costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

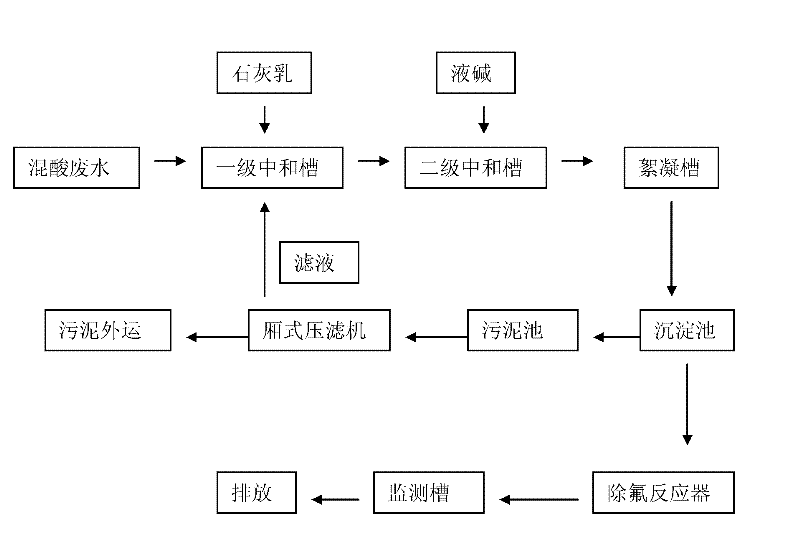

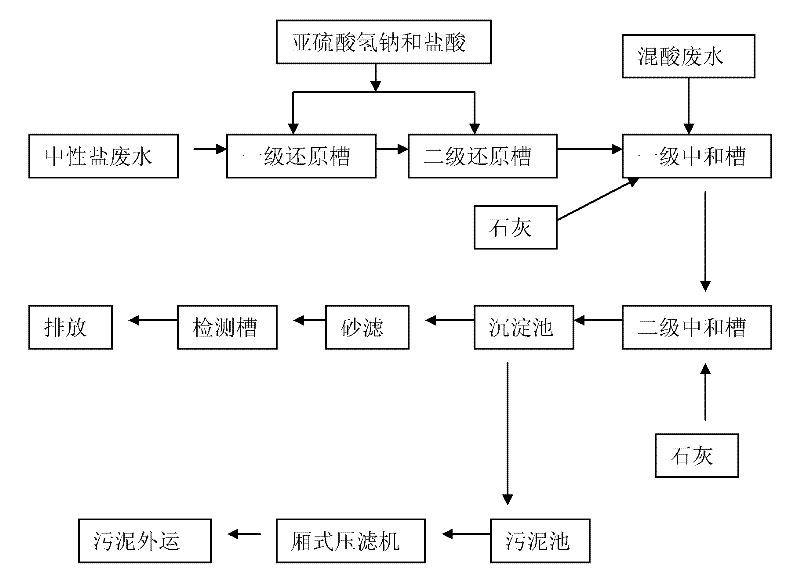

[0071] First, the neutral salt wastewater and mixed acid wastewater in the cold rolling pickling wastewater of the iron and steel industry are completely separated for disposal:

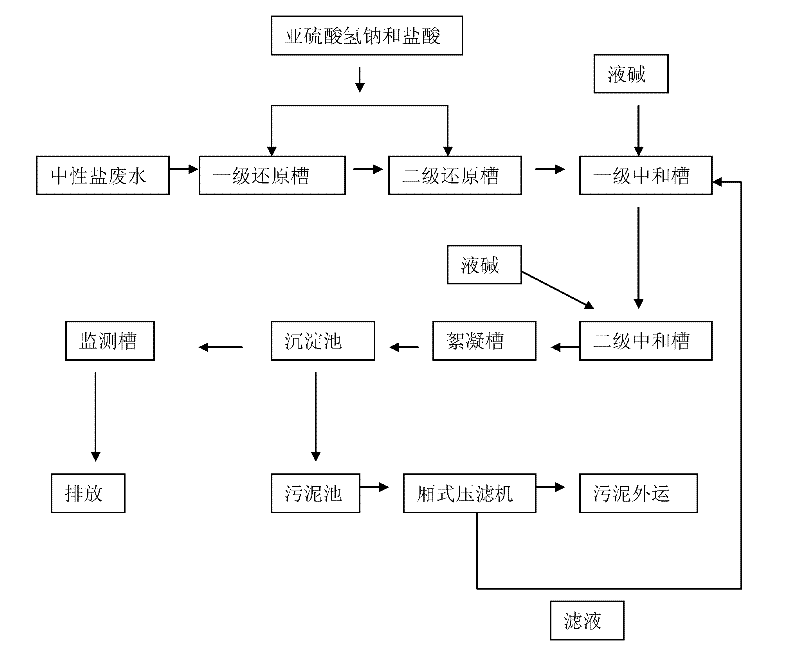

[0072] Neutral salt wastewater treatment process see figure 1 .

[0073] Depend on figure 1 It can be seen from the process flow in the above that the neutral salt wastewater is collected from the production line and enters the adjustment tank for homogenization and equalization, and flows into the primary reduction tank. At this time, the pH value range is controlled at 3.00, the ORP value is 450mV, the reaction time is 15 minutes, and sulfurous acid is added Sodium hydrogen and hydrochloric acid reduce the chromium ions in the wastewater; the wastewater after primary reduction flows into the secondary reduction tank, at this time the pH value is set at 2.00, the ORP value is 250mV, and the reaction time is 15 minutes; continue to add sodium bisulfite and hydrochloric acid, after the secondary r...

Embodiment 2

[0096] First, the neutral salt wastewater and mixed acid wastewater in the cold rolling pickling wastewater of the iron and steel industry are completely separated for disposal:

[0097] Neutral salt wastewater treatment process see figure 1 .

[0098] Depend on figure 1 It can be seen from the process flow in the above that the neutral salt wastewater is collected from the production line and enters the adjustment tank for homogenization and equalization, and then flows into the primary reduction tank. At this time, the pH value range is controlled at 2.50, the ORP value is 420mV, and the reaction time is 15 minutes; add sulfurous acid Sodium hydrogen and hydrochloric acid reduce the chromium ions in the wastewater, and the wastewater after primary reduction flows into the secondary reduction tank. At this time, the pH value is set at 1.80, the ORP value is 280mV, and the reaction time is 15 minutes; continue to add sodium bisulfite and hydrochloric acid, after the second...

Embodiment 3

[0121] First, the neutral salt wastewater and mixed acid wastewater in the cold rolling pickling wastewater of the iron and steel industry are completely separated for disposal:

[0122] Neutral salt wastewater treatment process see figure 1 .

[0123] Depend on figure 1 The process flow in the above shows that the neutral saline wastewater is collected from the production line and enters the adjustment tank for homogenization and equalization, and then flows into the primary reduction tank. At this time, the pH value is controlled at 2.0, the ORP value is 350mV, and the reaction time is 15 minutes; add hydrogen sulfite Sodium and hydrochloric acid reduce the chromium ions in the wastewater, and the wastewater after primary reduction flows into the secondary reduction tank. At this time, the pH value is set at 1.50, the ORP value is 270mV, and the reaction time is 15 minutes; continue to add sodium bisulfite and Hydrochloric acid, after the secondary reduction, the wastewa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com