Patents

Literature

4810results about "Waste water treatment from metallurgical process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

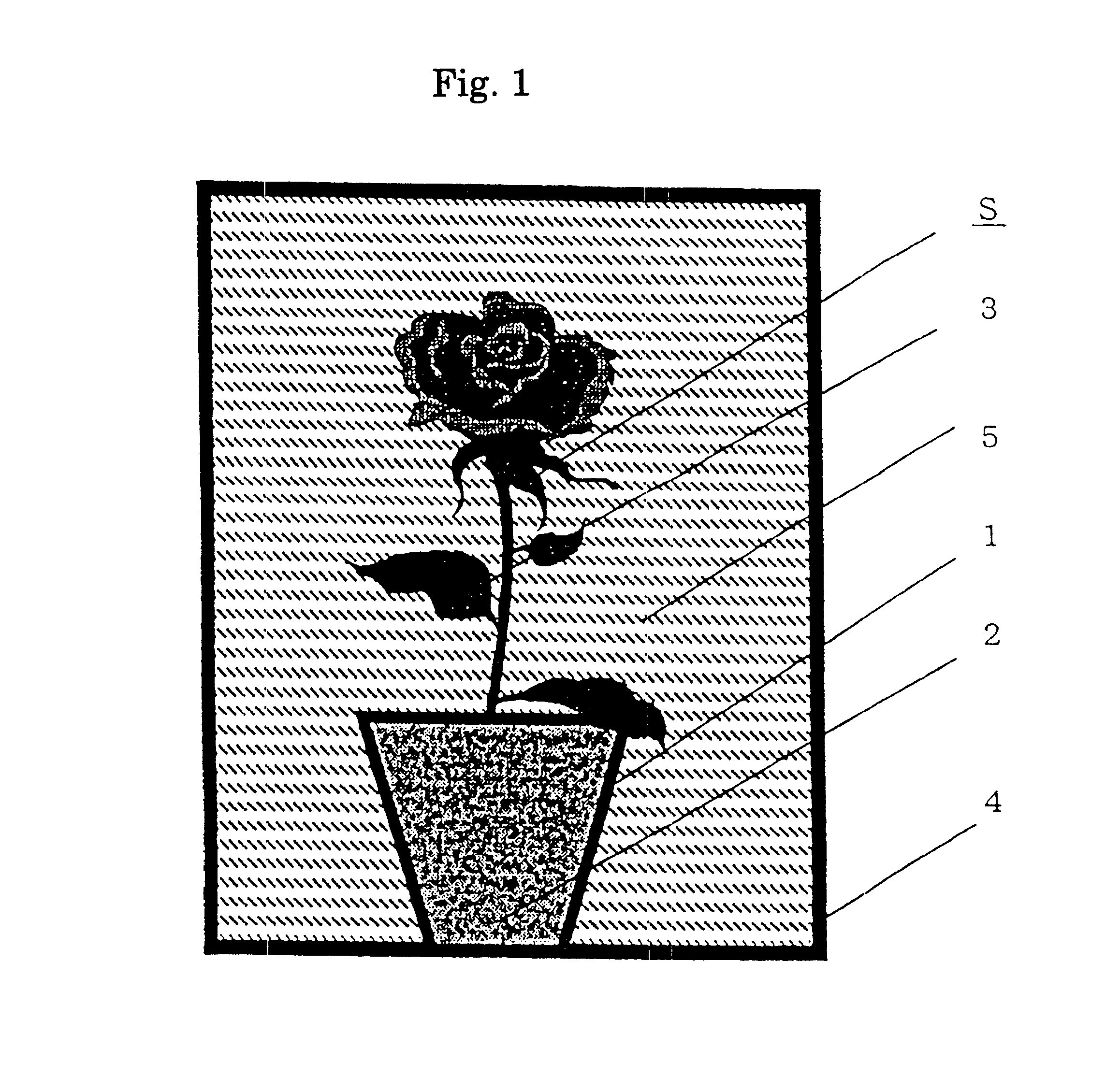

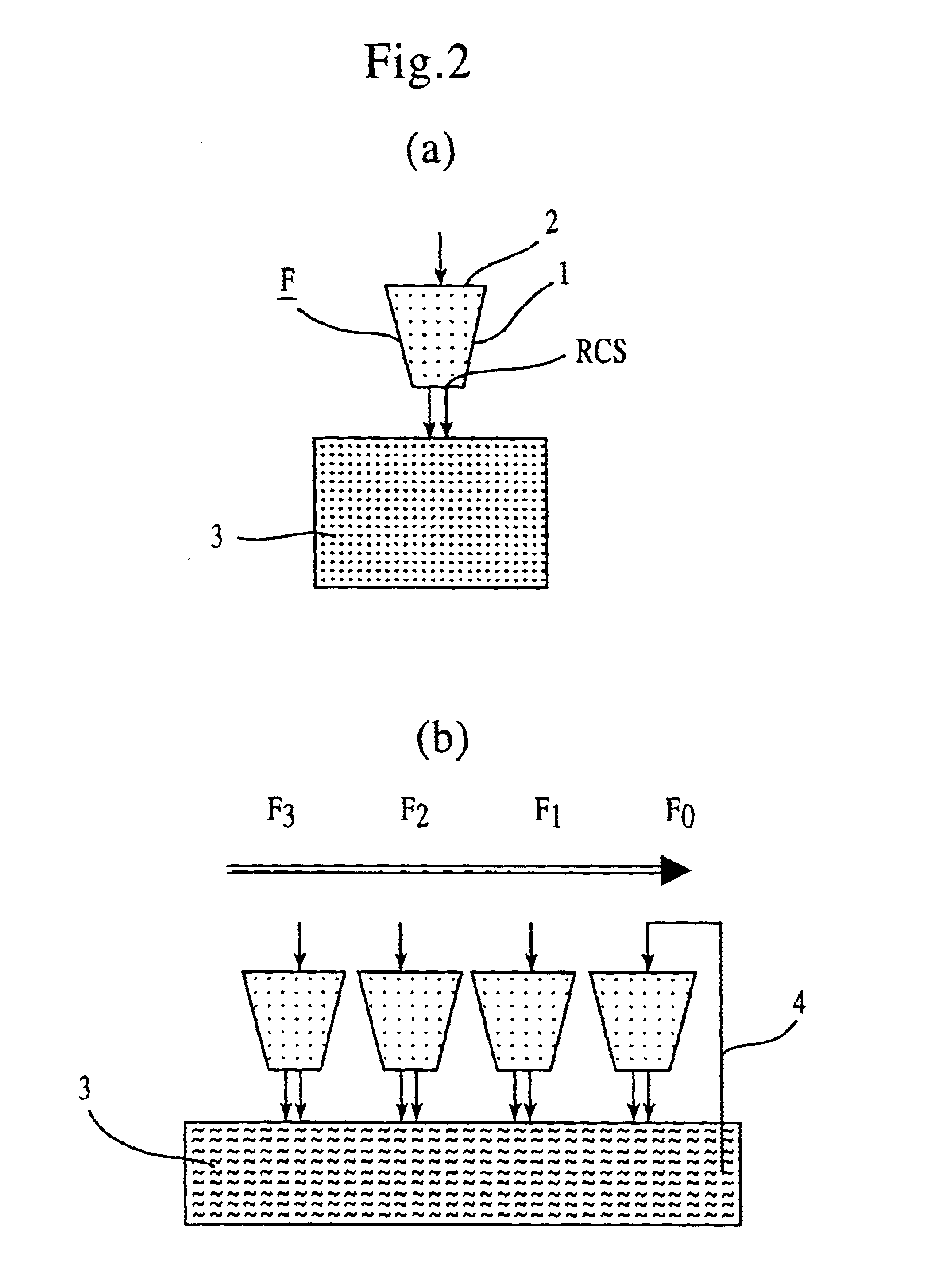

Microbial culture liquors containing microorganisms differing in characteristics and living in symbiosis and metabolites thereof, carriers and adsorbents containing the active components of the culture liquors and utilization of the same

Solutions containing microorganisms differing in characteristics from each other and living in symbiosis with each other and enzymes characterized by containing aerobic microorganisms, anaerobic microorganisms and at least one basidiomycete belonging to the family Pleurotaceae living in symbiosis, metabolites thereof and enzymes; carriers obtained by adsorbing the components of the above solutions onto finely ground carbonaceous materials; and porous materials obtained by adsorbing the components of the above solutions onto porous materials. Because of having various effects of absorbing, adsorbing and decomposing harmful matters, deodorizing, decolorizing, etc., these materials are applicable to various uses in the fields of agriculture and environment.

Owner:ORIENT GREEN

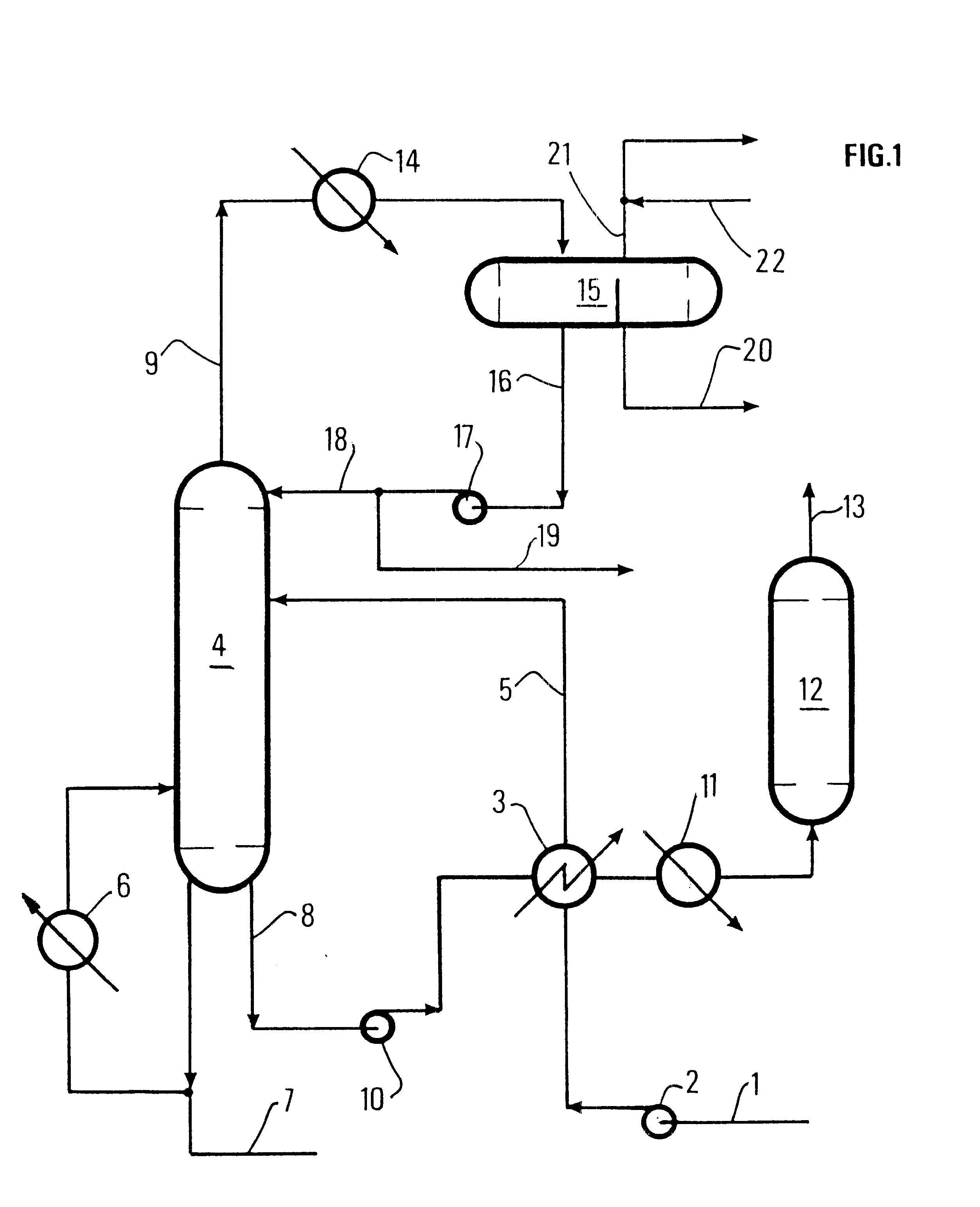

Process for the production of purified water and hydrocarbons from fossil resources

InactiveUS6462097B1Reduce adsorbate contentTreatment using aerobic processesIon-exchanger regenerationSorbentPurified water

A process for the production of purified water and hydrocarbons comprising at least one stage of separation of the water and hydrocarbons formed during a Fischer-Tropsch synthesis, at least one stage of purification of the separated water by bringing it into contact with at least one adsorbent selected from the group consisting of: the active carbons, clays which are hydrophobic or rendered hydrophobic, and zeolites which are hydrophobic or rendered hydrophobic. This process may optionally include a stripping stage before the adsorption step.

Owner:INST FR DU PETROLE +2

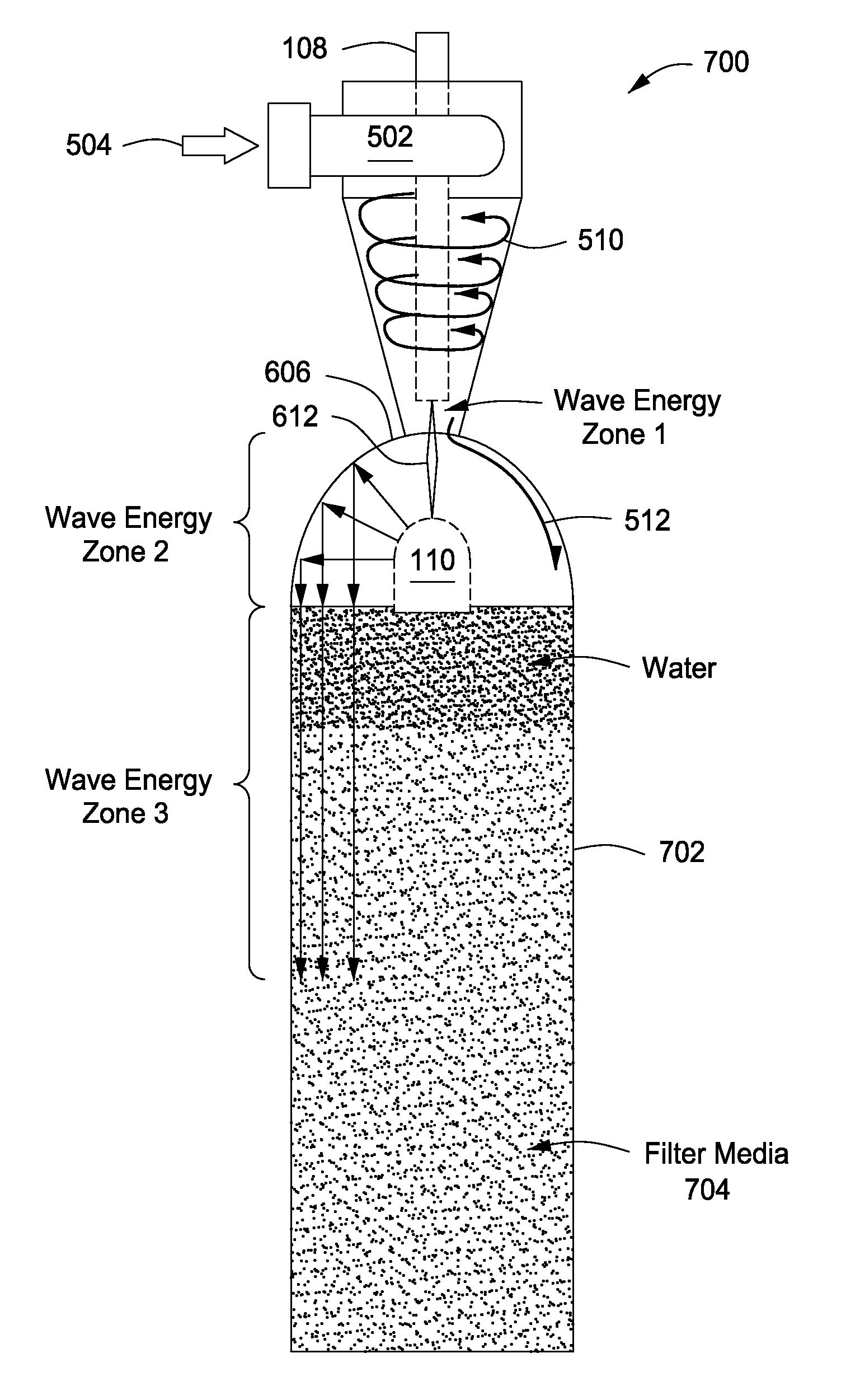

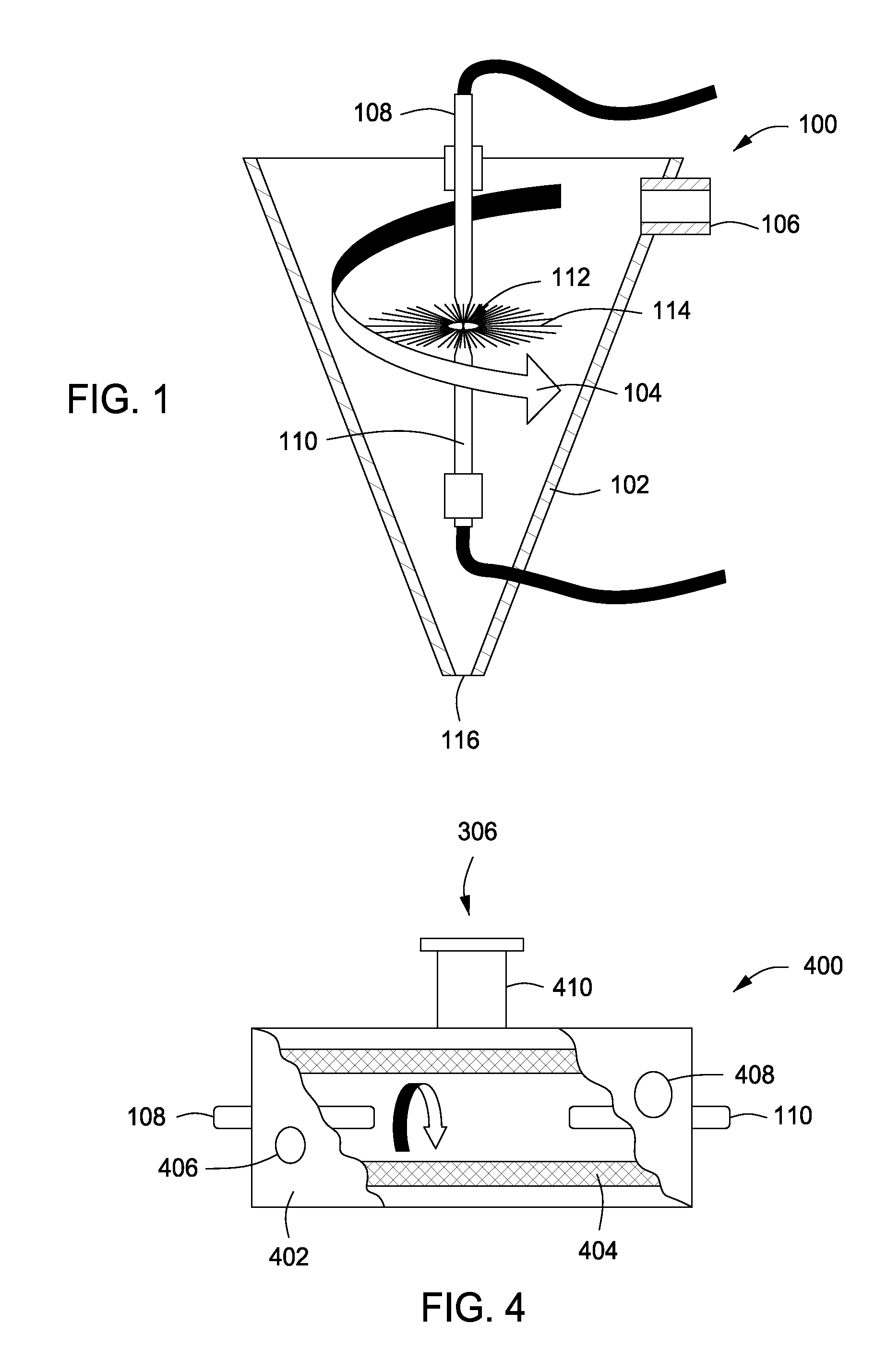

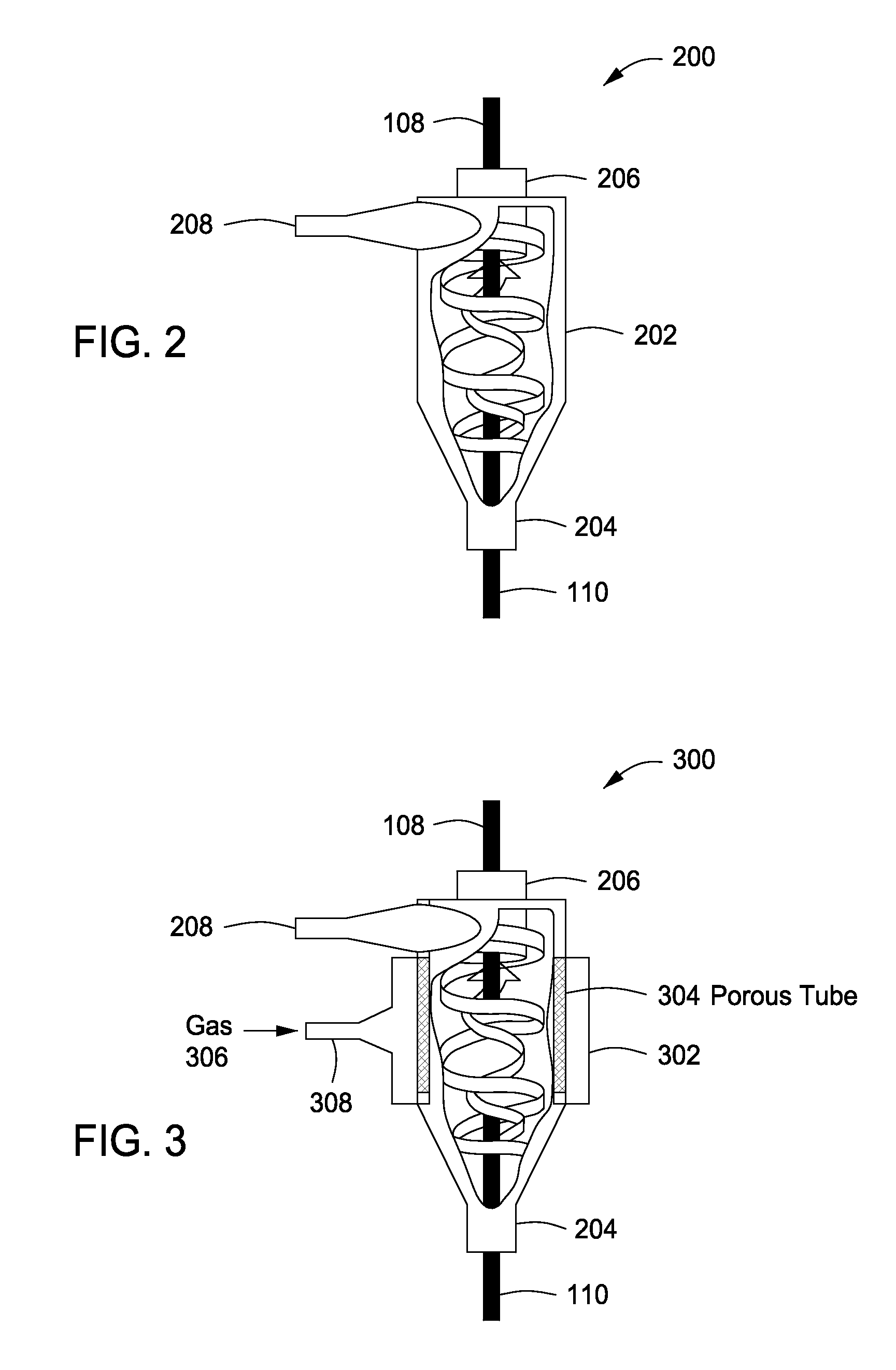

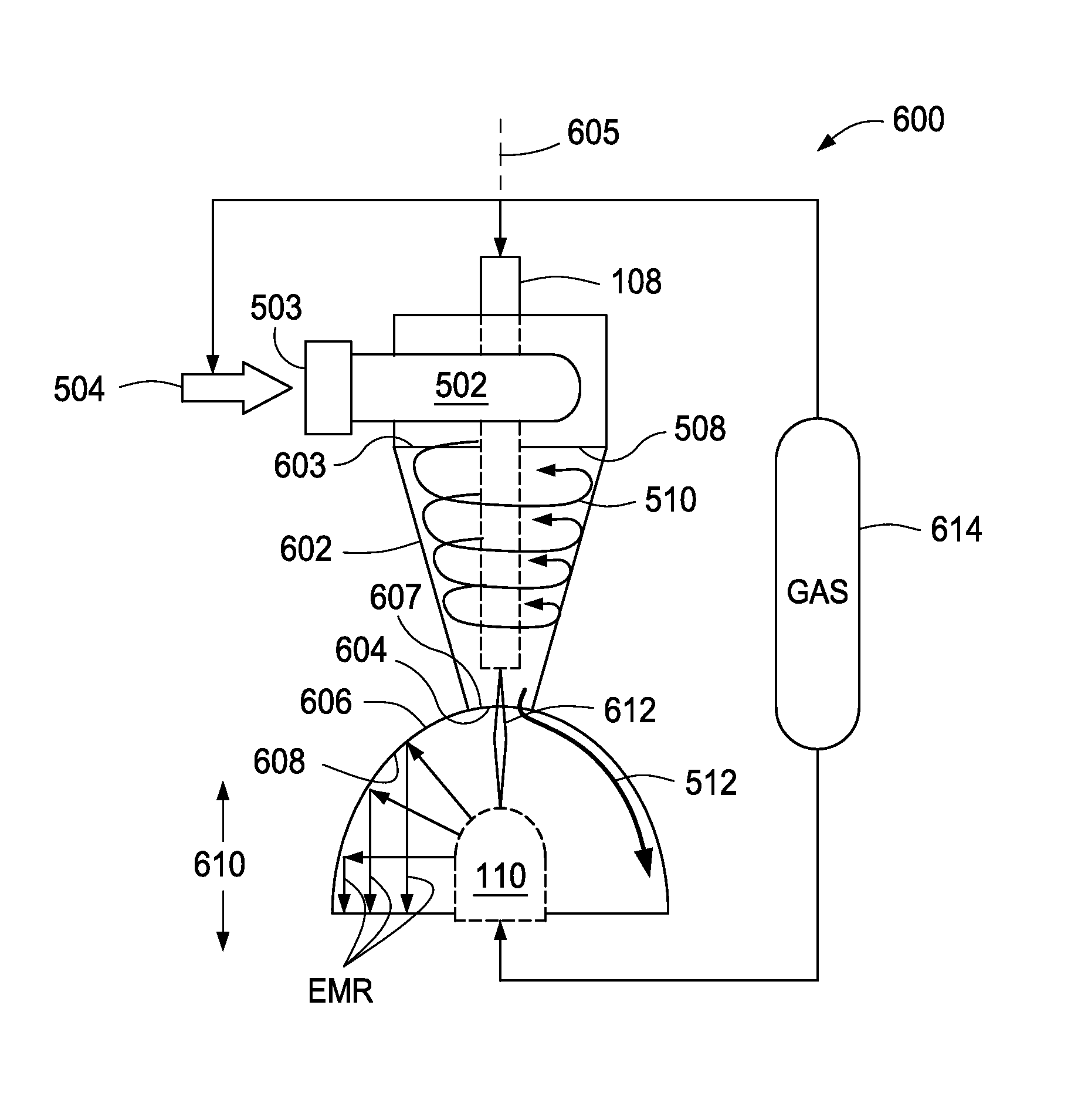

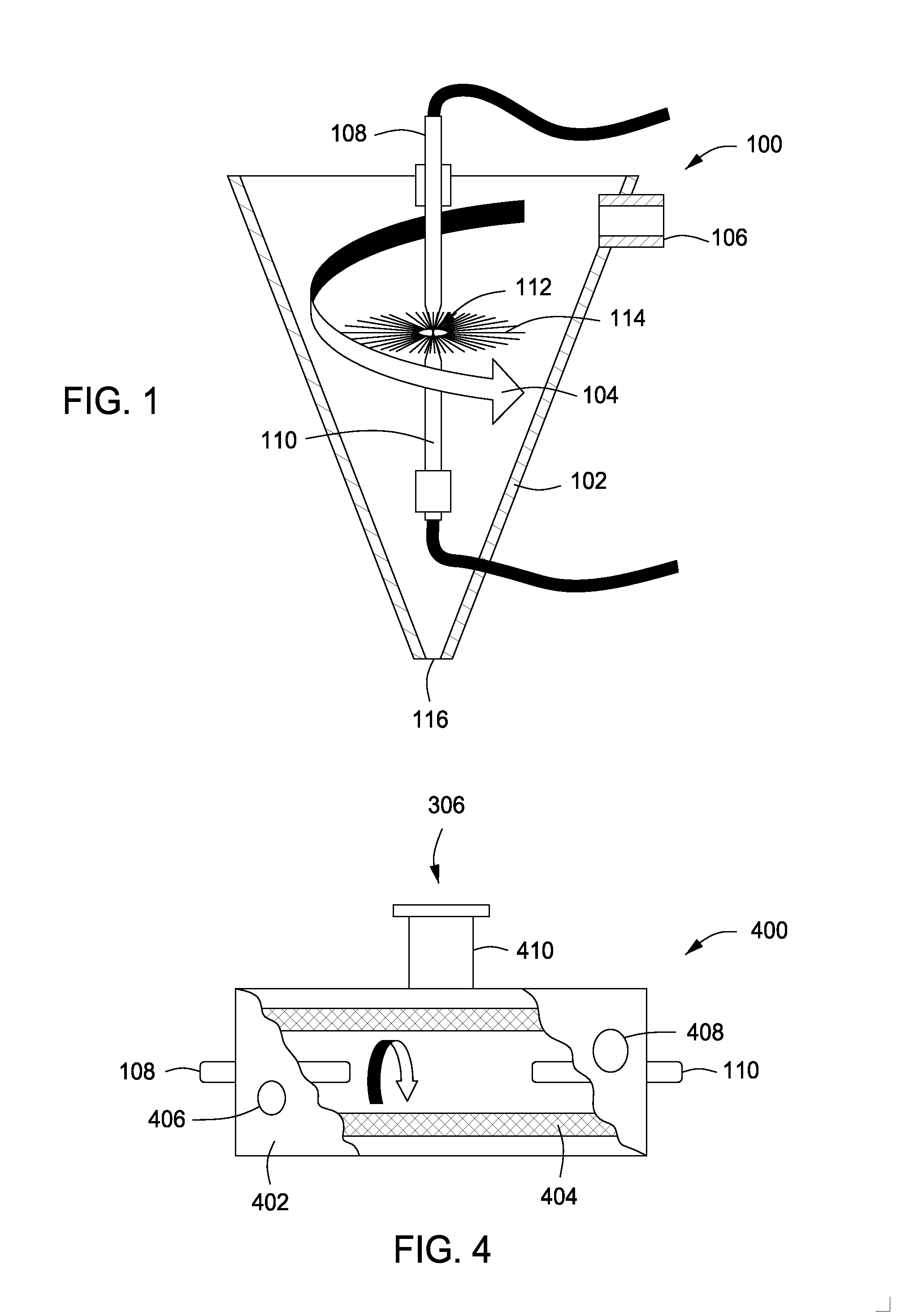

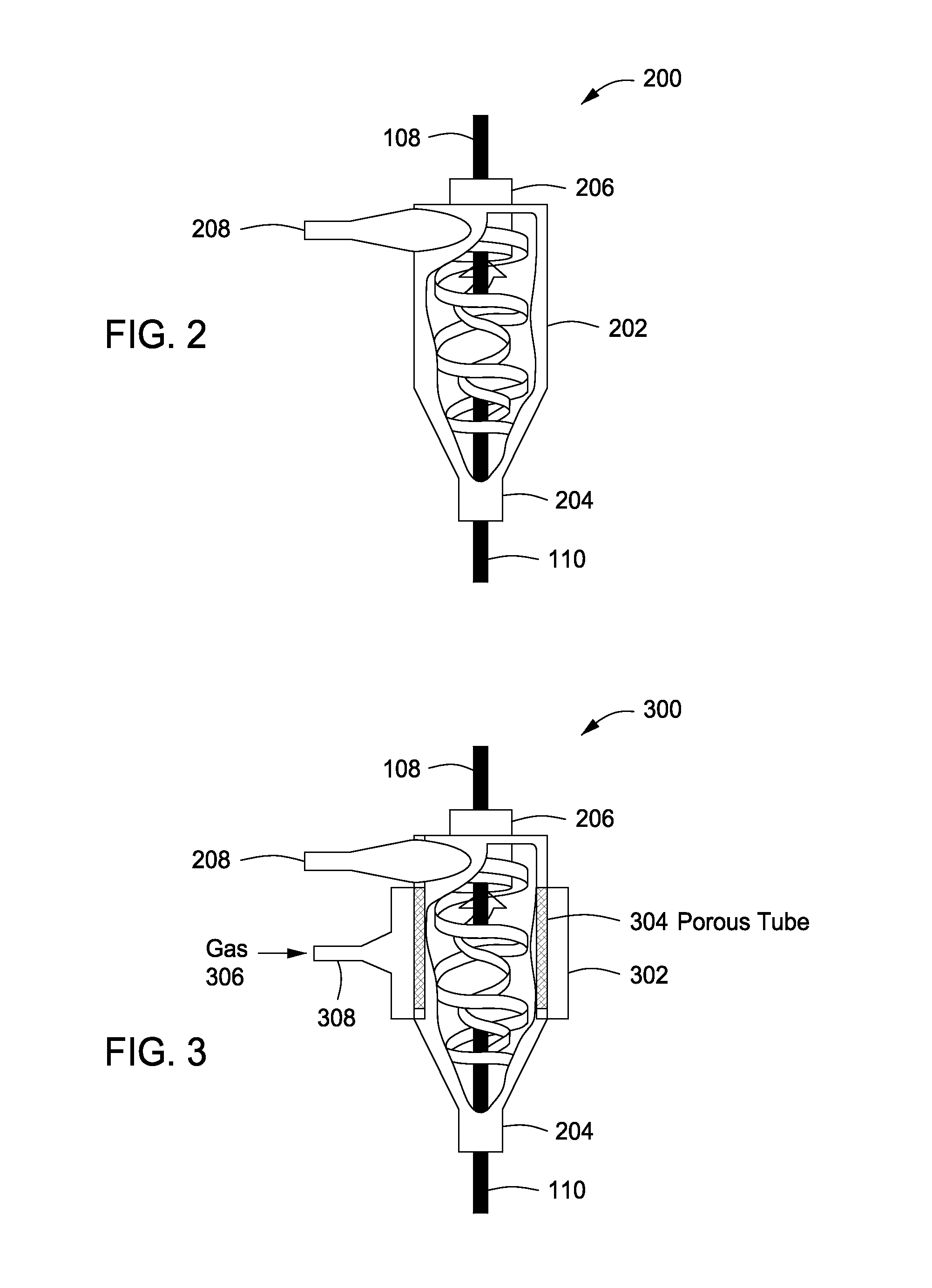

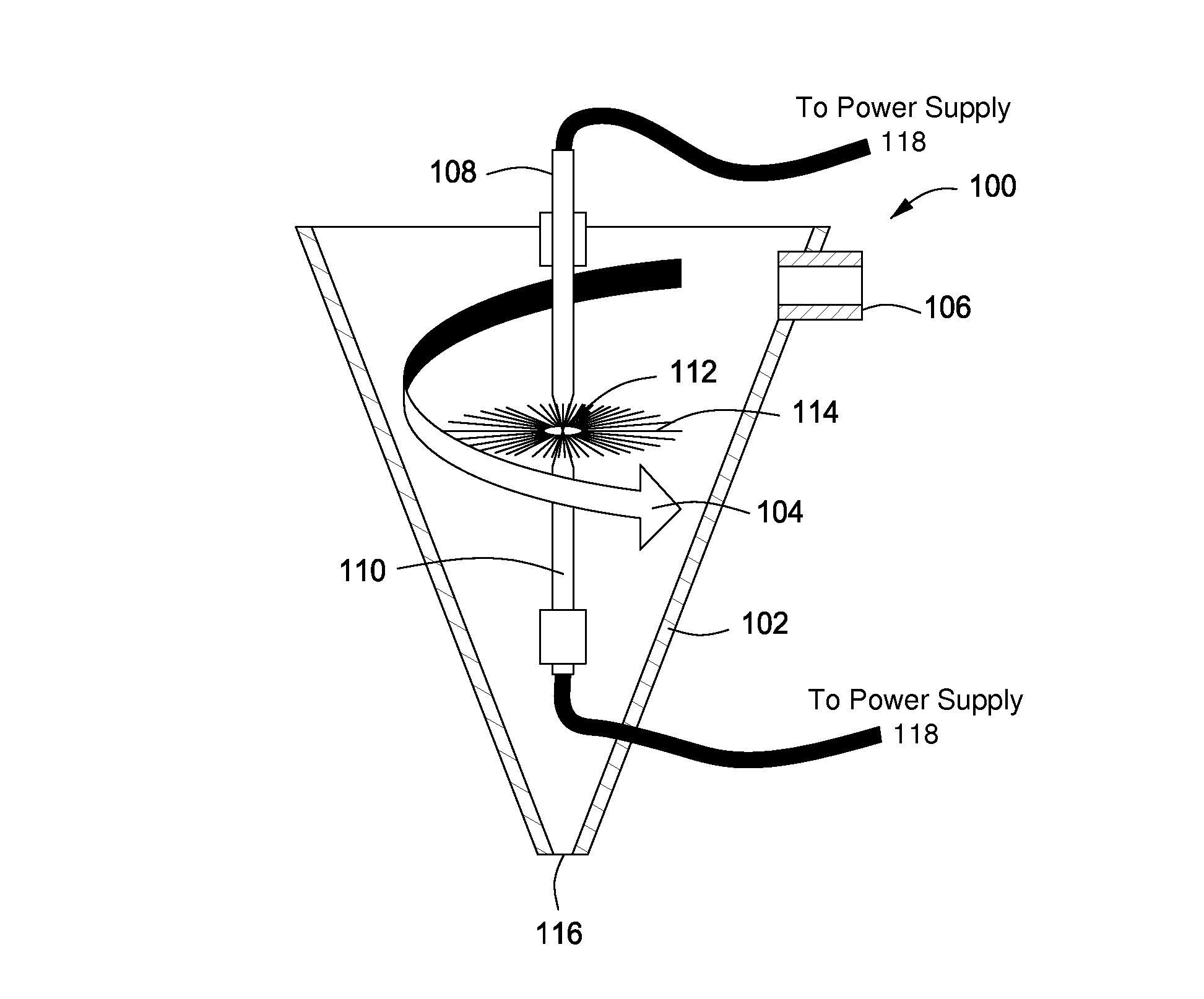

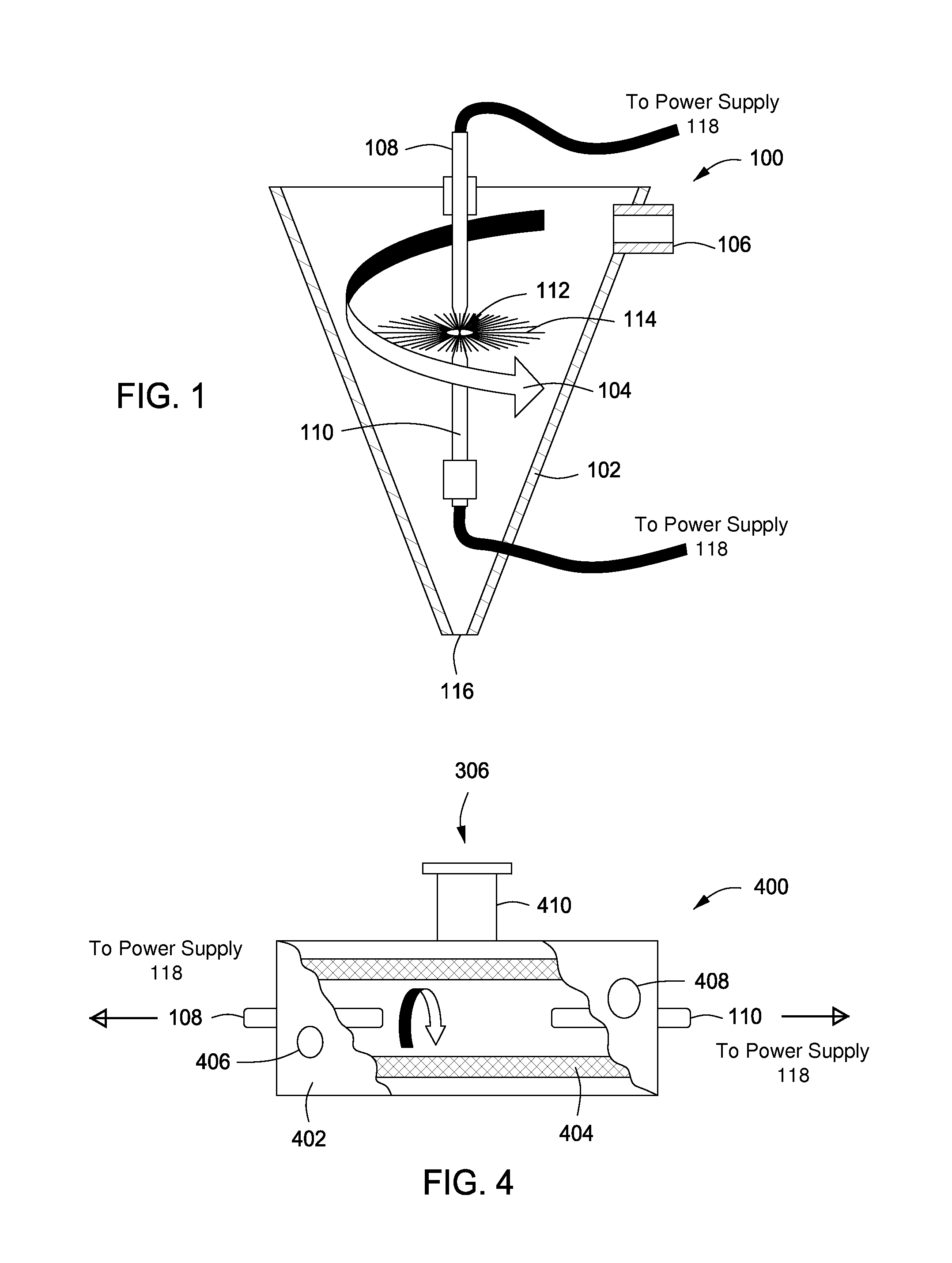

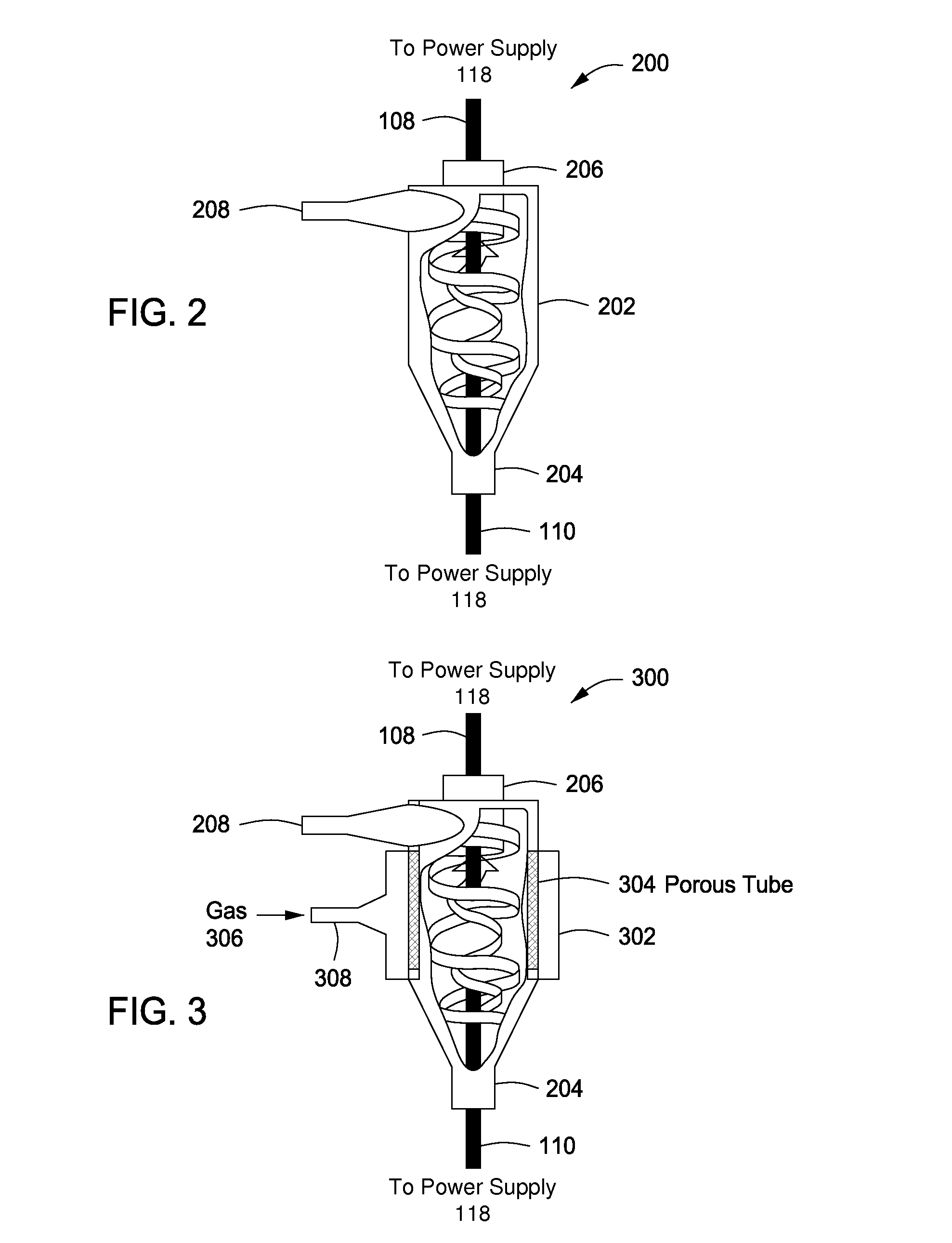

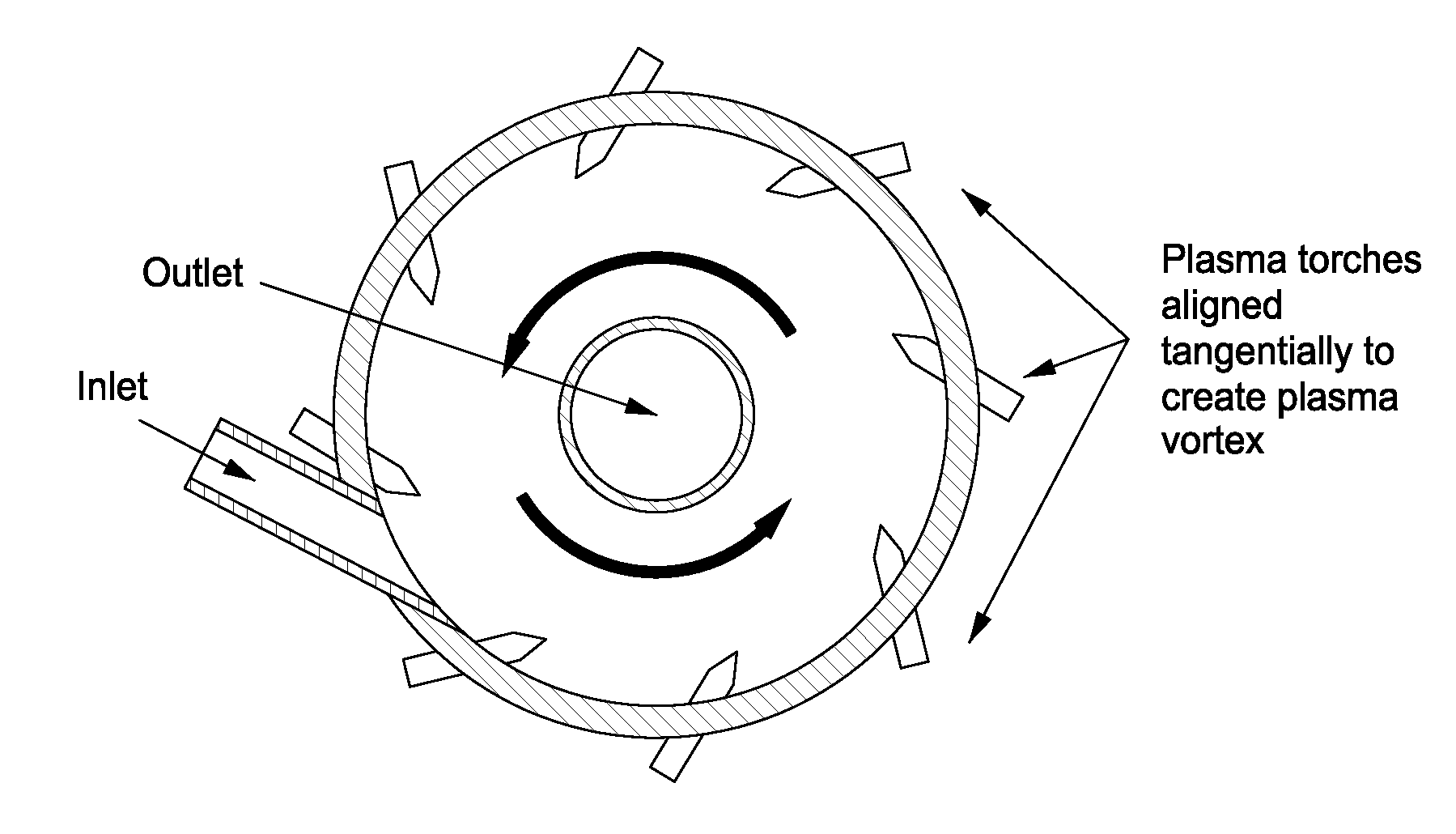

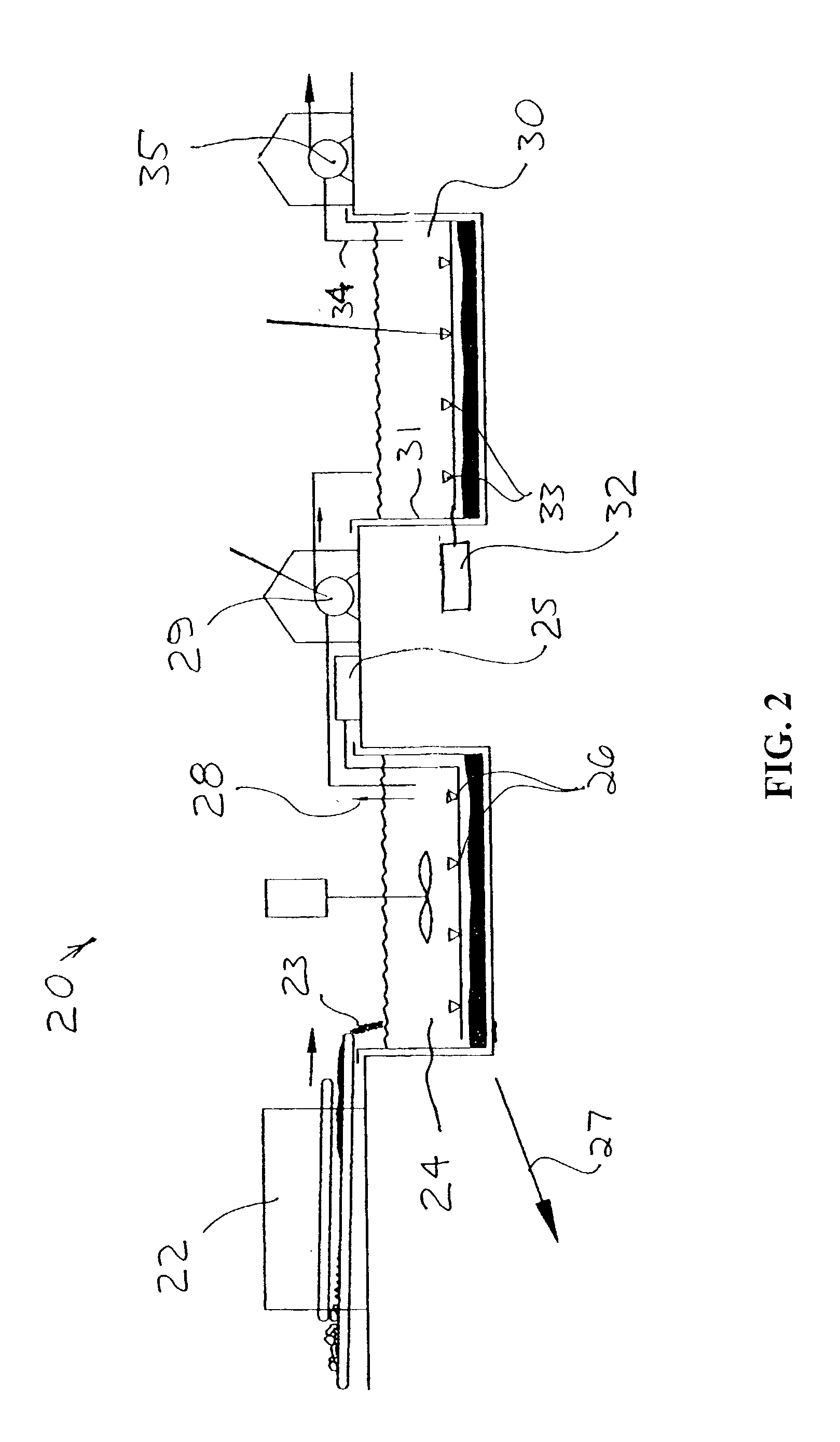

System, method and apparatus for treating liquids with wave energy from an electrical arc

ActiveUS20070240975A1Energy efficiencyReduce maintenanceWater distributersWaste water treatment from animal processingEngineeringEnergy source

The present invention provides a system, method and apparatus for treating a liquid by providing a wave energy source and creating a thin film of the liquid whirling around the wave energy source such that one or more wave energies irradiate the liquid. Likewise, the present invention provides a method of treating a liquid by providing three zones of wave energy and passing the liquid through the three zones of wave energy.

Owner:FORET PLASMA LABS

Apparatus for treating liquids with wave energy from an electrical arc

ActiveUS7857972B2Energy efficiencyReduce maintenanceWater distributersWaste water treatment from animal processingEngineeringEnergy source

The present invention provides a system, method and apparatus for treating a liquid by providing a wave energy source and creating a thin film of the liquid whirling around the wave energy source such that one or more wave energies irradiate the liquid. Likewise, the present invention provides a method of treating a liquid by providing three zones of wave energy and passing the liquid through the three zones of wave energy.

Owner:FORET PLASMA LABS

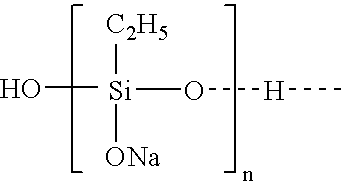

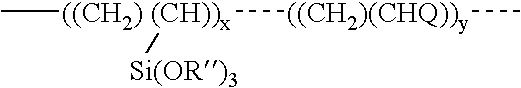

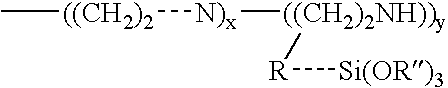

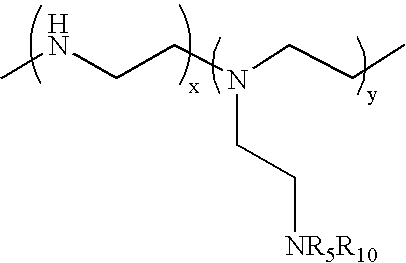

Method of preventing or reducing aluminosilicate scale in a bayer process

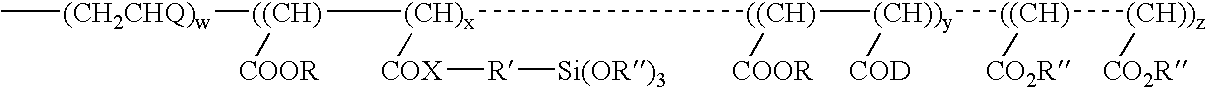

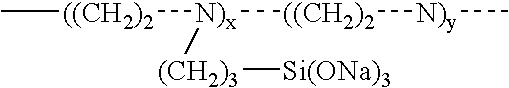

ActiveUS20050010008A2Reduce and eliminate aluminosilicate scalingReduce and even completely prevent formationSilicon organic compoundsAluminium compoundsPlate heat exchangerEnd-group

Abstract of the DisclosureMaterials and a process are provided whereby polymers with the pendant group or end group containing --Si(OR")3 (where R" is H, an alkyl group, Na, K, or NH4) are used to control aluminosilicate scaling in a Bayer process. When materials of the present invention are added to the Bayer liquor before the heat exchangers, they reduce and even completely prevent formation of aluminosilicate scale on heat exchanger walls. The present materials are effective at treatment concentrations that make them economically practical.

Owner:CYTEC TECH CORP

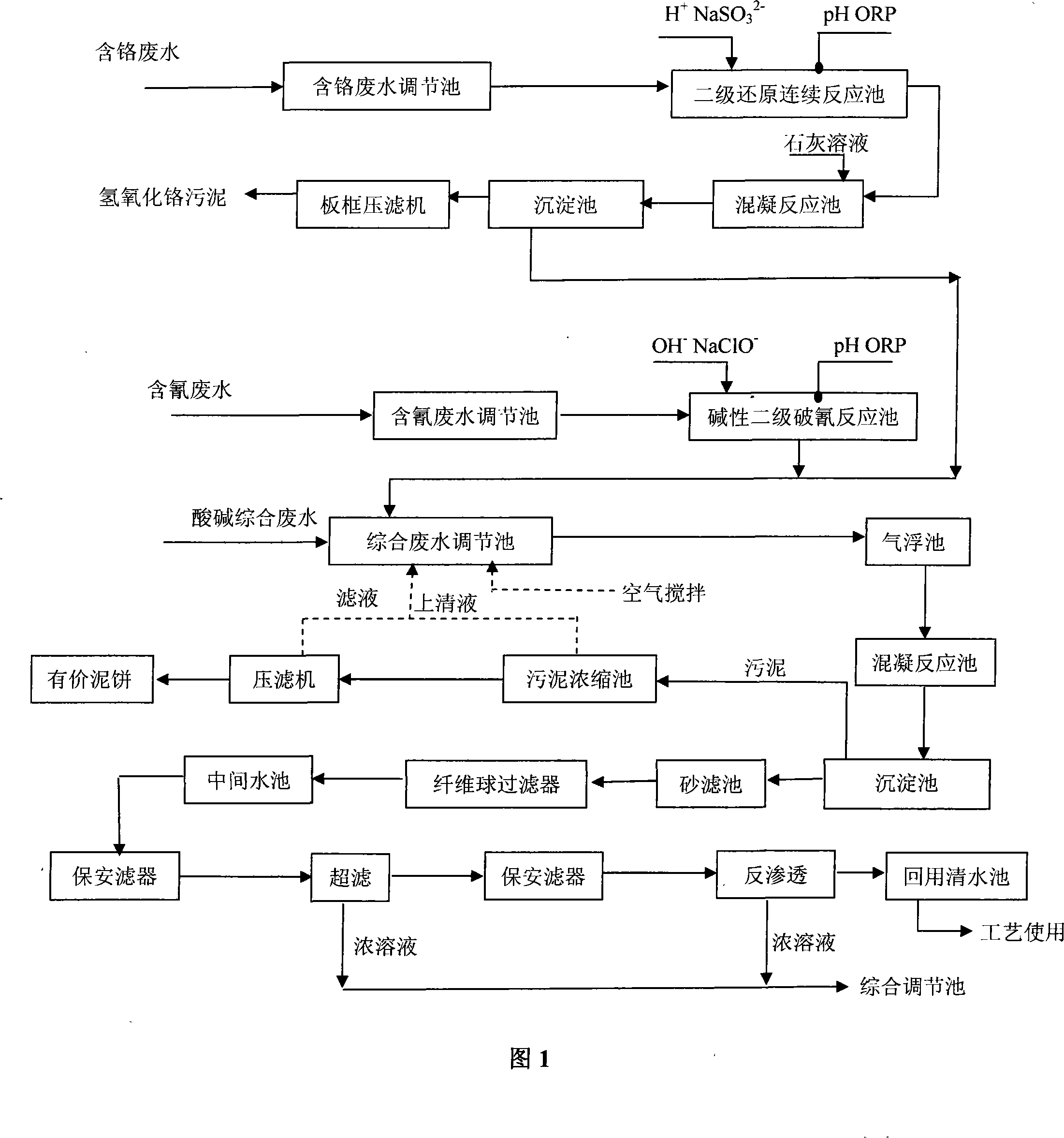

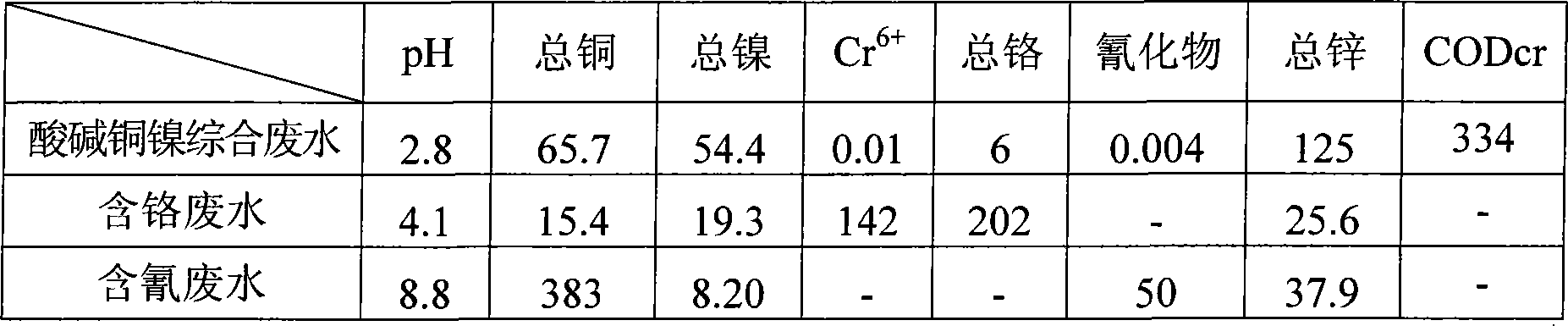

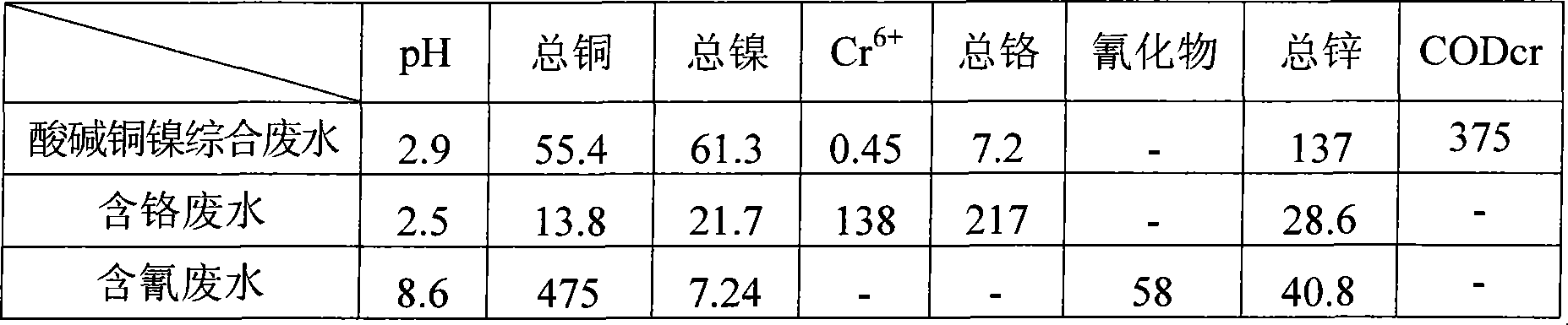

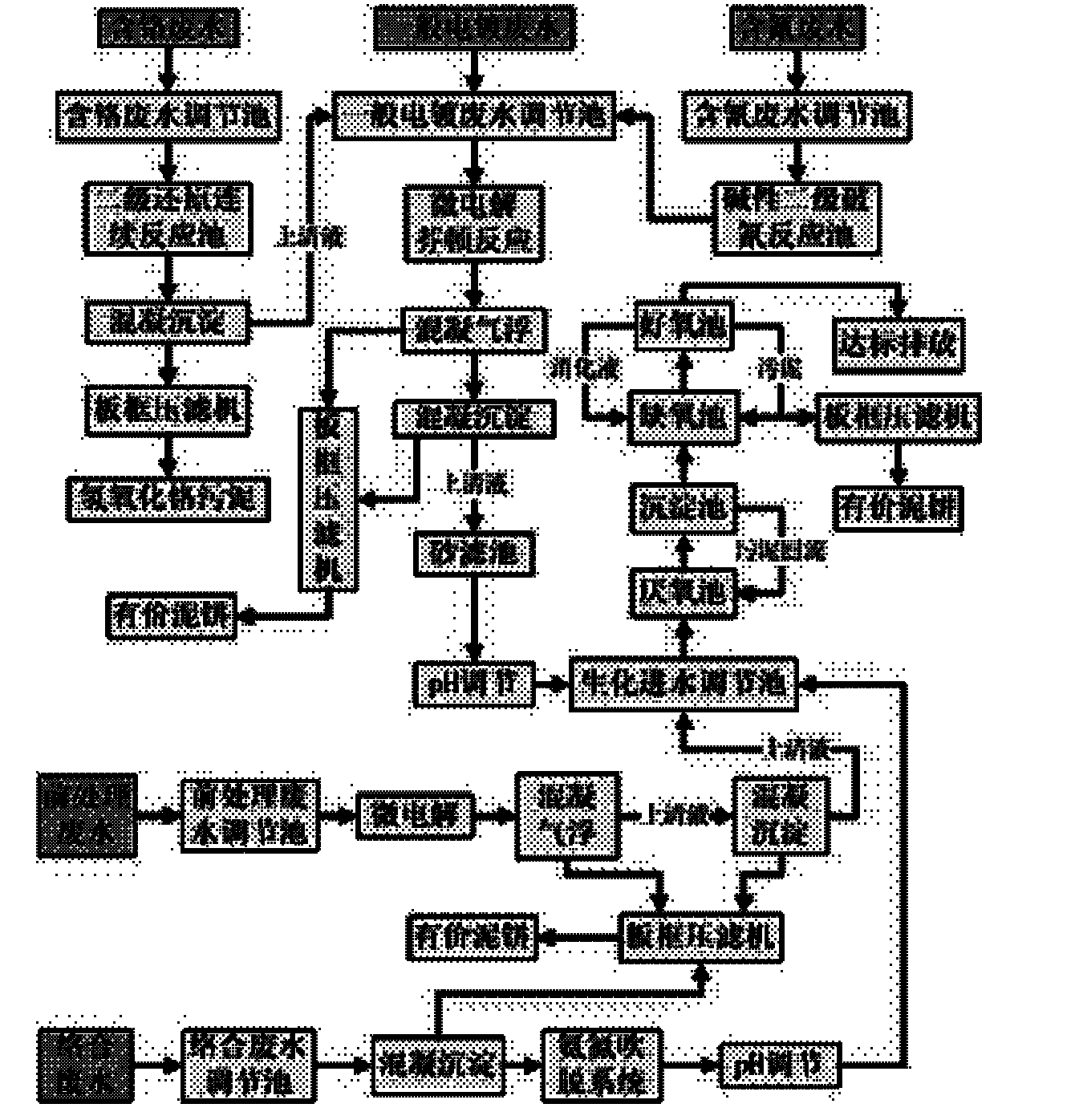

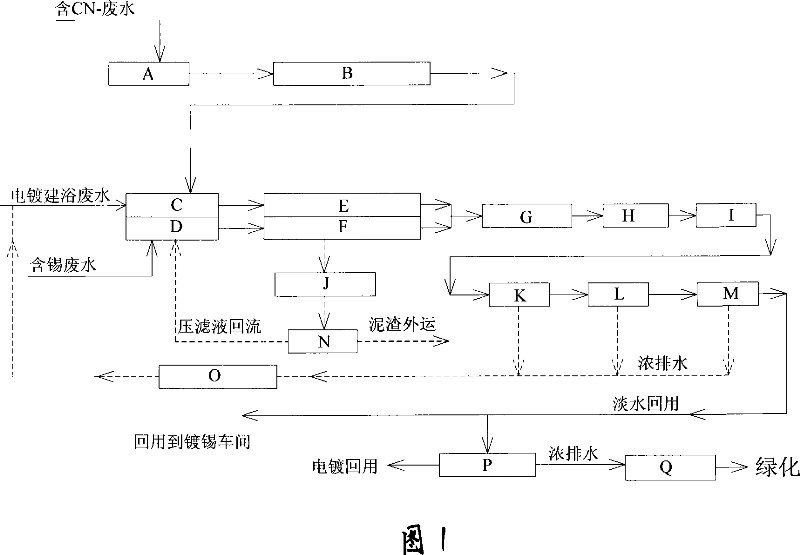

Integrated electroplating treatment method for waste water

InactiveCN101234828AReduce manufacturing costWater contaminantsWaste water treatment from metallurgical processWater productionWater quality

The invention relates to a method for treating comprehensive galvanization wastewater, particularly relating to a technique reclaiming resources of precious metal and recycly utilizing treated and comprehensively discharged galvanization wastewater. The method for treating the galvanization wastewater in the invention is characterized in that the following steps are included: (1) treating the wastewater containing chromium; (2) treating the wastewater containing cyanogen; (3) mixing and treating clear liquid obtained during treating the wastewater containing chromium in step (1) and the wastewater containing the cyanogen during treating the wastewater containing the cyanogen in step (2); (4) leading the clear liquid obtained during mixing and treating in step (3) into a reclaiming clean water pond; (5) leading the concentrated solution in step (4) into a comprehensive regulating pond of wastewater. Through treated by the technique of the method for treating comprehensive galvanization wastewater, each index of water quality of obtained water can reach or exceed the Drinking Water Sanitary Standard (GB5749-2006); the water can be reused in galvanization workshops; the water production rate of the reused water can reach over 80 percent; useful metal ions can be reclaimed; the target of environment protection can be met; benefits can be generated at the same time; the production cost can be reduced.

Owner:TIANJIN UNIV

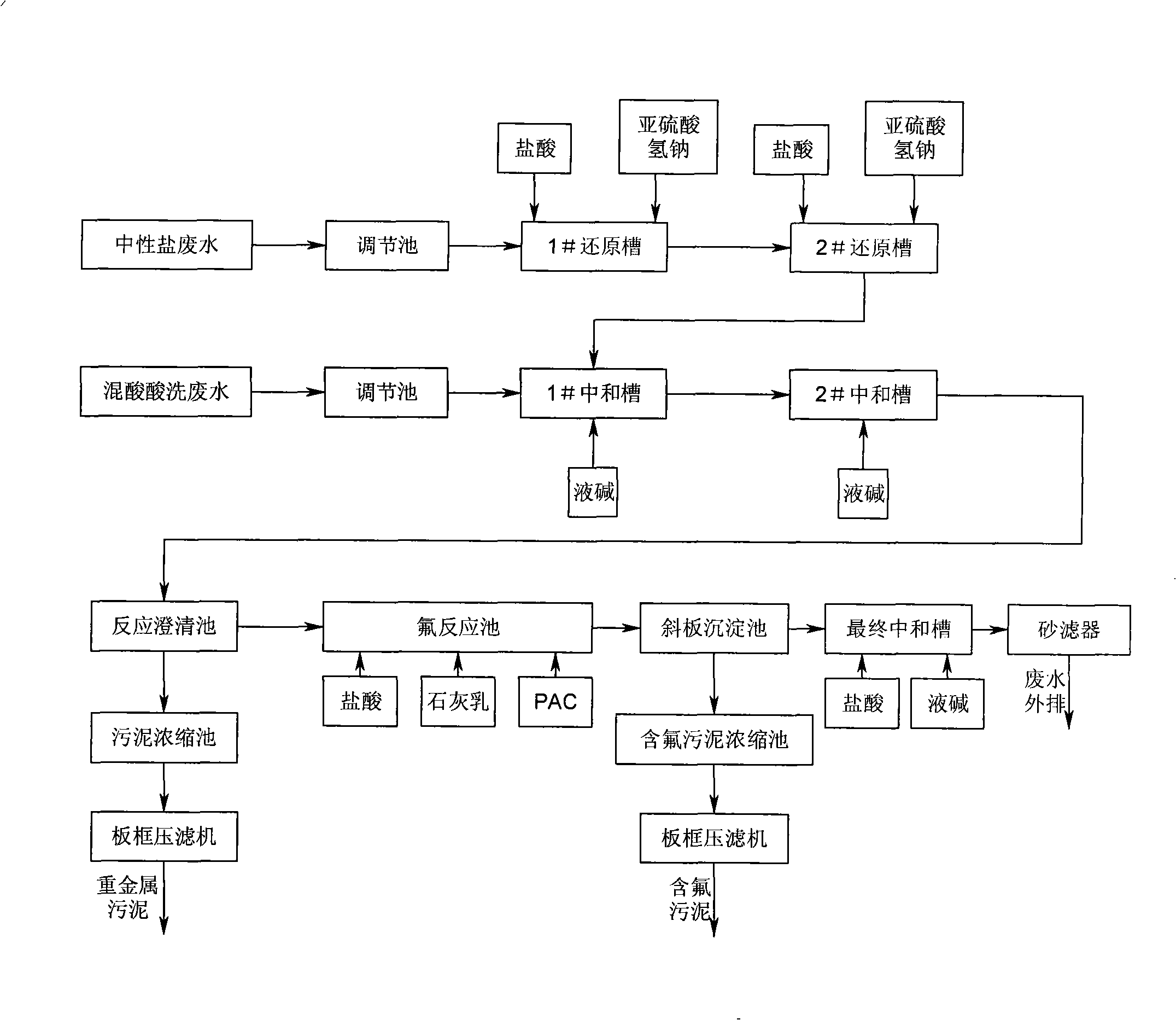

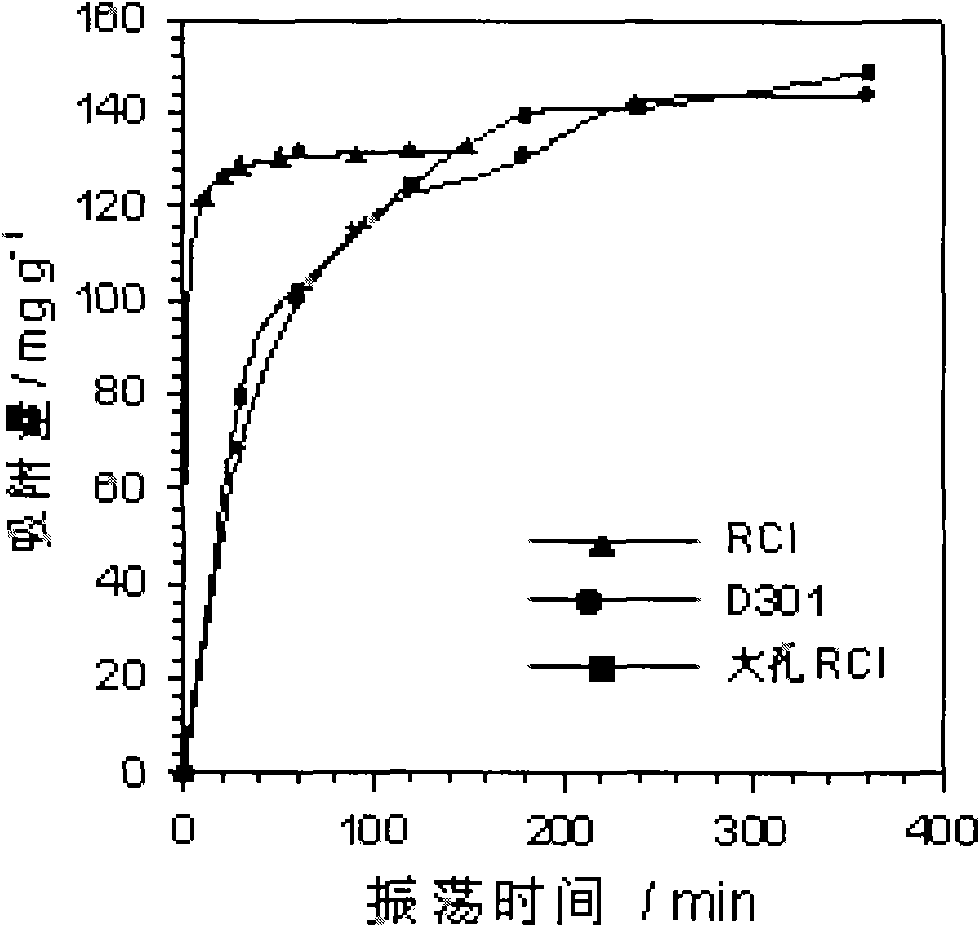

Processing method for stainless steel acid cleaning waste water and liquid

InactiveCN101269889AMeet emission compliance requirementsMeet compliance requirementsSludge treatment by de-watering/drying/thickeningIron oxides/hydroxidesLiquid wasteSludge

The invention relates to a processing method of stainless steel pickling waste liquid, which is characterized in that the processing method includes the steps that: neutral salt wastewater flows into a neutral reduction cell, and mixed acid pickling waste waters flow into a neutralizing tank; reducing agent is added into the neutral reduction cell, and then the reduced wastewater liquid is put into the neutralizing tank and is mixed with the adjusted mixed acid pickling waste waters, and liquid alkali is added into the neutralizing tank; the separated clear waste liquid removes fluorin ions in a settlement tank; neutralizing liquid is added into a final neutralizing tank to cause the pH value of treatment liquid to adjust to be neutralized wastewater liquid which passes through a sand filter to be discharged. The processing method has the advantages that metal ions and fluorin ions are performed the subsection treatment, and neutralizing agent is changed into the liquid alkali from lime cream, the requirement of reaching the standard of the waste liquid emission is not only achieved, but also the mud quantity produced by a mass of lime cream is greatly reduced, heavy metal mud of a retention pond only contains heavy metal compound, the salts of calcium fluoride and calcium sulphate, etc. are separated from the inclined plate settlement tank during the fluoridation stage, thereby the treatment cost is effectively lowered.

Owner:NINGBO BAOXIN STAINLESS STEEL

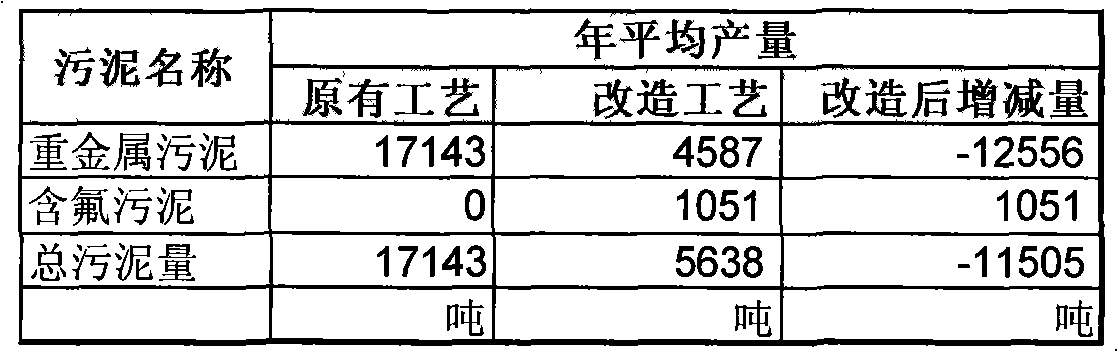

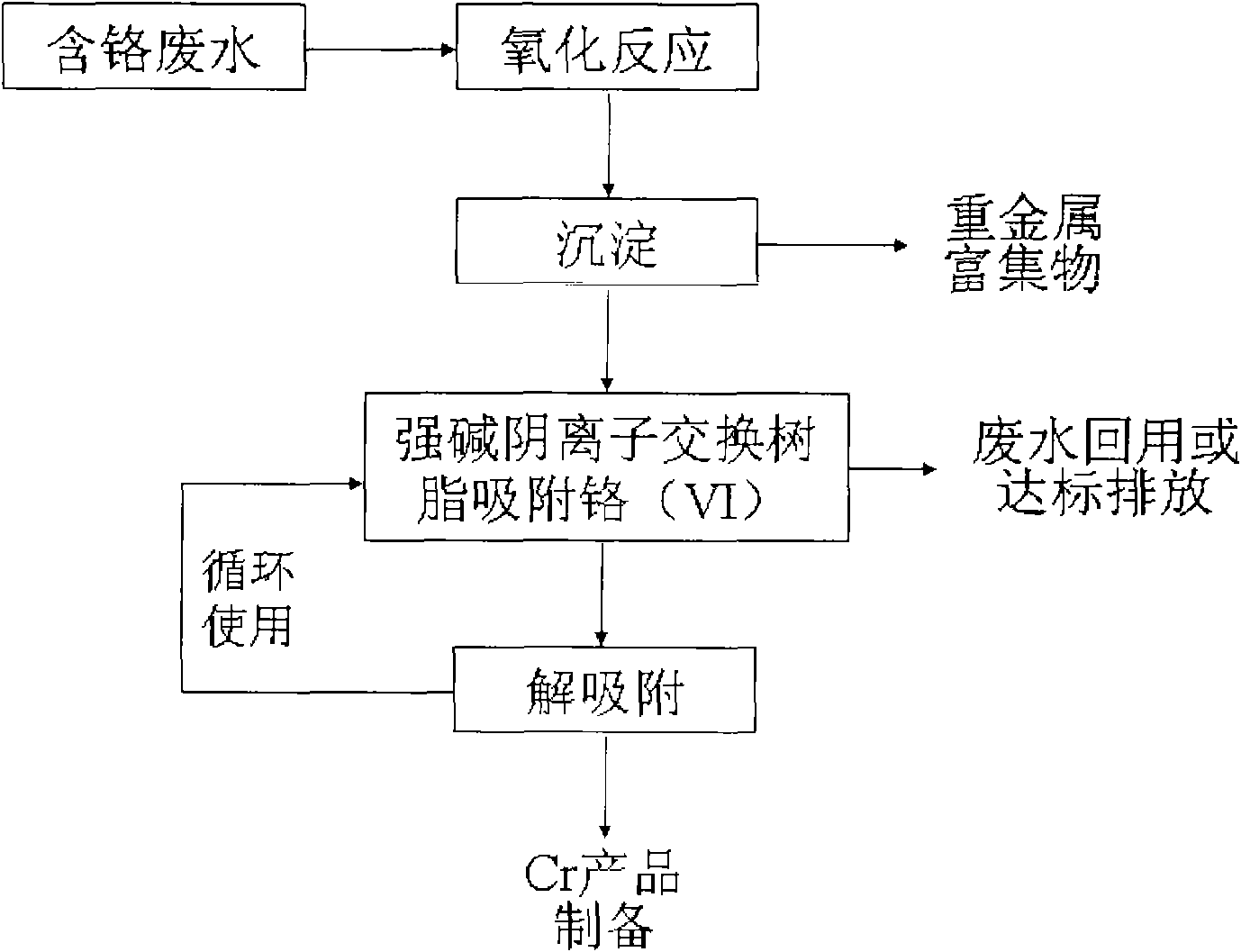

Method for purifying electroplating wastewater and comprehensively utilizing resources

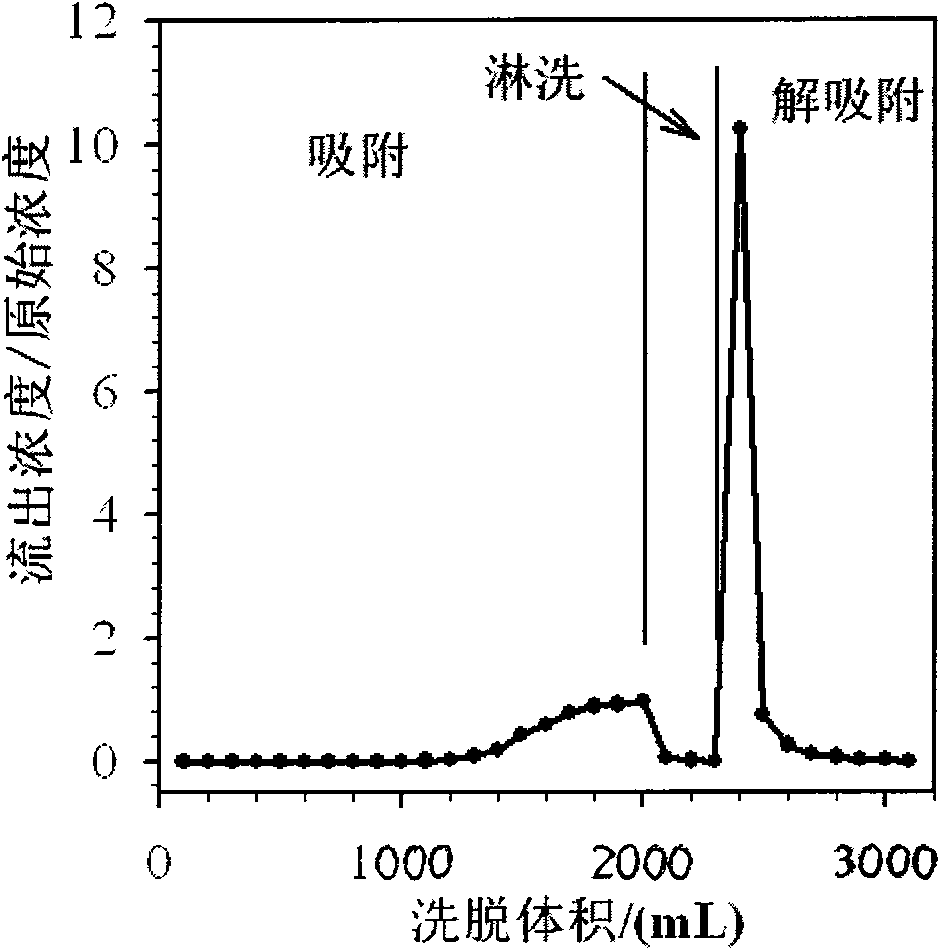

ActiveCN101570372AImprove adsorption capacityEasy to separateWater contaminantsWater/sewage treatment by ion-exchangeChemical reactionWater quality

The invention relates to a method for purifying electroplating wastewater and comprehensively utilizing resources, which is to adopt low-cost strong basic anion-exchange resin containing macropores and imidazole structure to reclaim valuable resources in the electroplating wastewater by coupling technology based on a chemical oxidation-reduction method, a precipitation method and an ion exchange method. The method comprises the following steps: firstly, Cr(III) is oxidized into Cr(VI) under basic condition through a chemical reaction; then, Zn, Cu, Ni and other heavy metal elements in the wastewater are transformed into precipitation of hydroxide; and finally, the Cr(VI) in the wastewater is adsorbed by the strong basic anion-exchange resin, the purified water quality achieves the requirement of electroplating pollutant discharge standard and recycle, and the Cr and other heavy metal resources in the electroplating wastewater can be comprehensively reclaimed and utilized. The method overcomes the defects that the prior regenerating process of porous weak-basic resin requires acidification, and the method has the advantages of simple process, low treatment cost, large treatment quantity and acid and base consumption conservation, and is the electroplating wastewater treatment method with green environmental protection and efficient utilization of resources.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

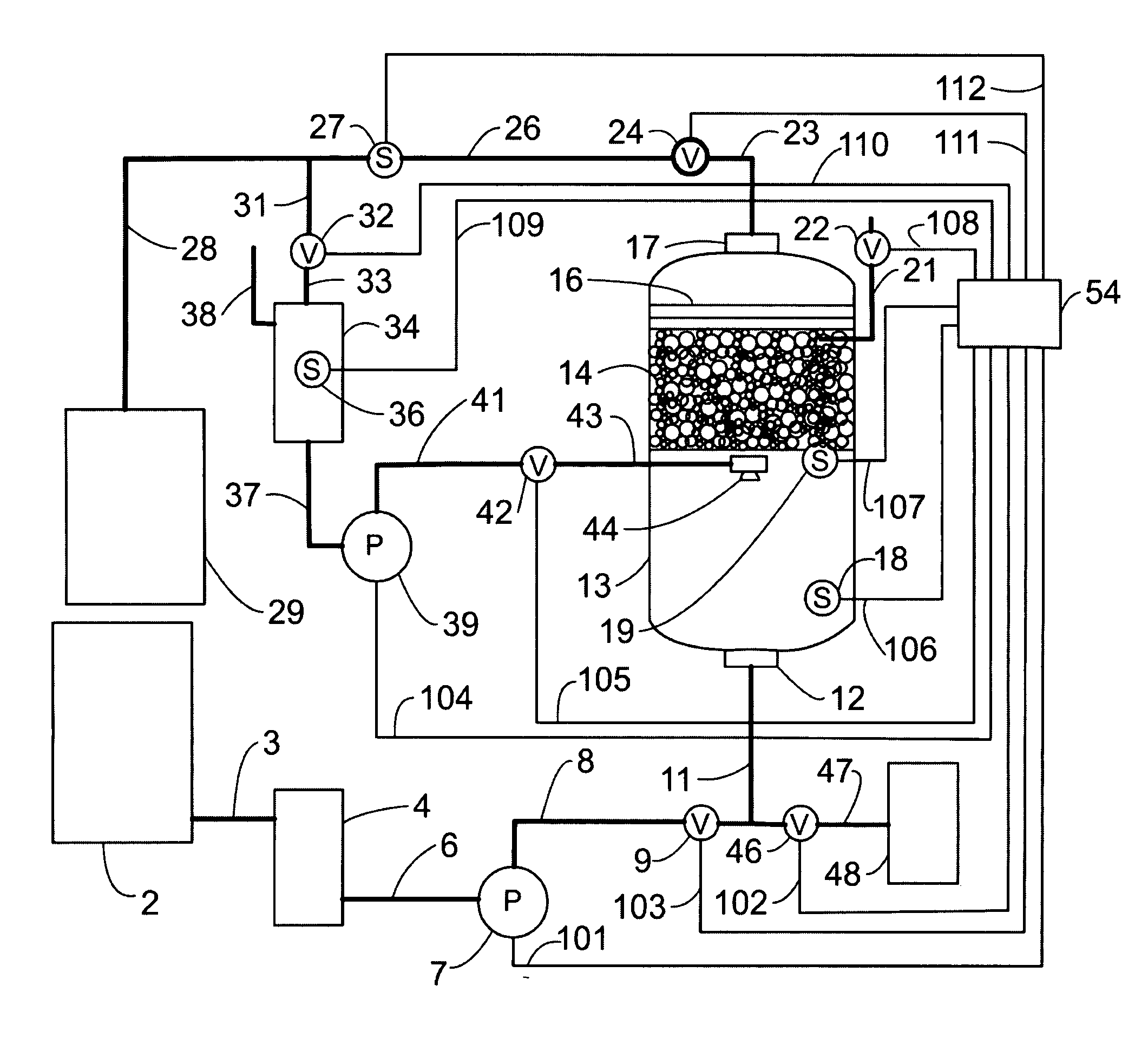

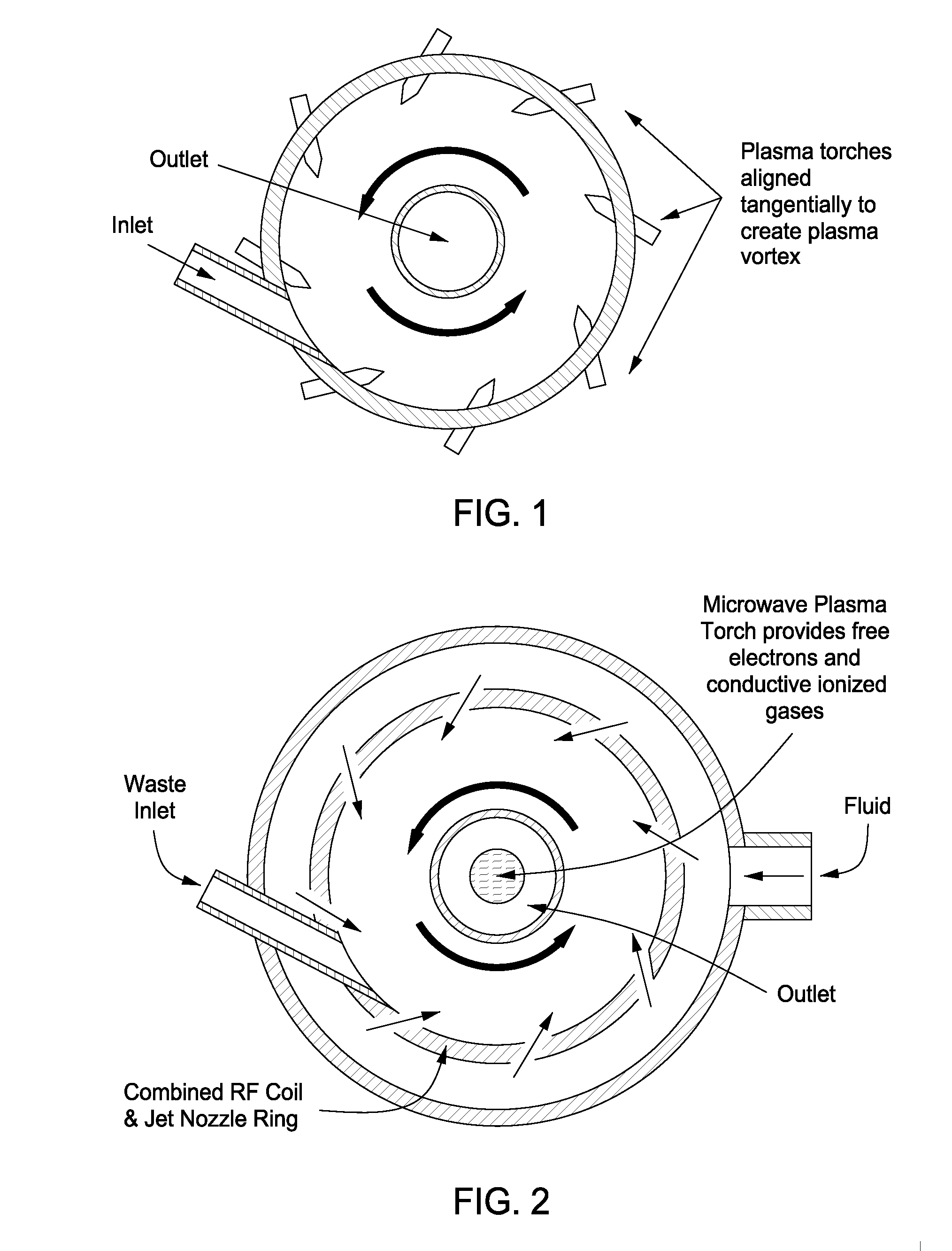

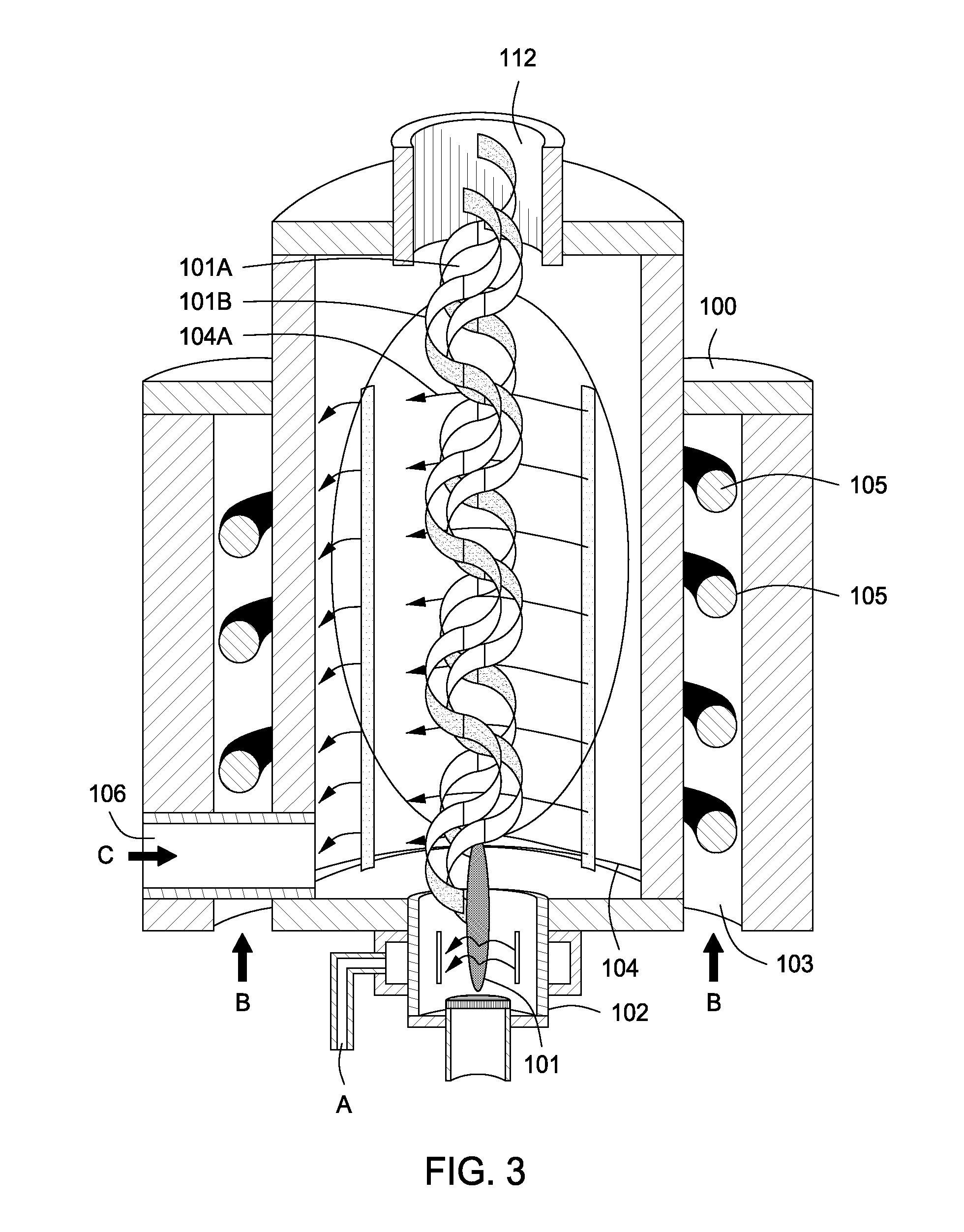

System for treating a substance with wave energy from an electrical arc and a second source

InactiveUS20110303532A1Energy efficiencyReduce maintenanceGeneral water supply conservationPaint waste treatmentSubstance useEngineering

A system for treating a substance using a storage vessel and two or more devices disposed in a top of the storage vessel. Each device has: (a) a volute or cyclone head, (b) a throat connected to the volute or cyclone head, (c) a parabolic reflector connected to the throat, (d) a first wave energy source comprising a first electrode within the volute or cyclone head that extends through the outlet into the opening of the throat along the central axis, and a second electrode extending into the parabolic reflector and spaced apart and axially aligned with first electrode, and (e) a second wave energy source disposed inside the throat, embedded within the throat or disposed around the throat. The substance is supplied to the inlet of the volute or cyclone head and is irradiated with one or more wave energies produced by the first and second wave energy sources.

Owner:FORET PLASMA LABS

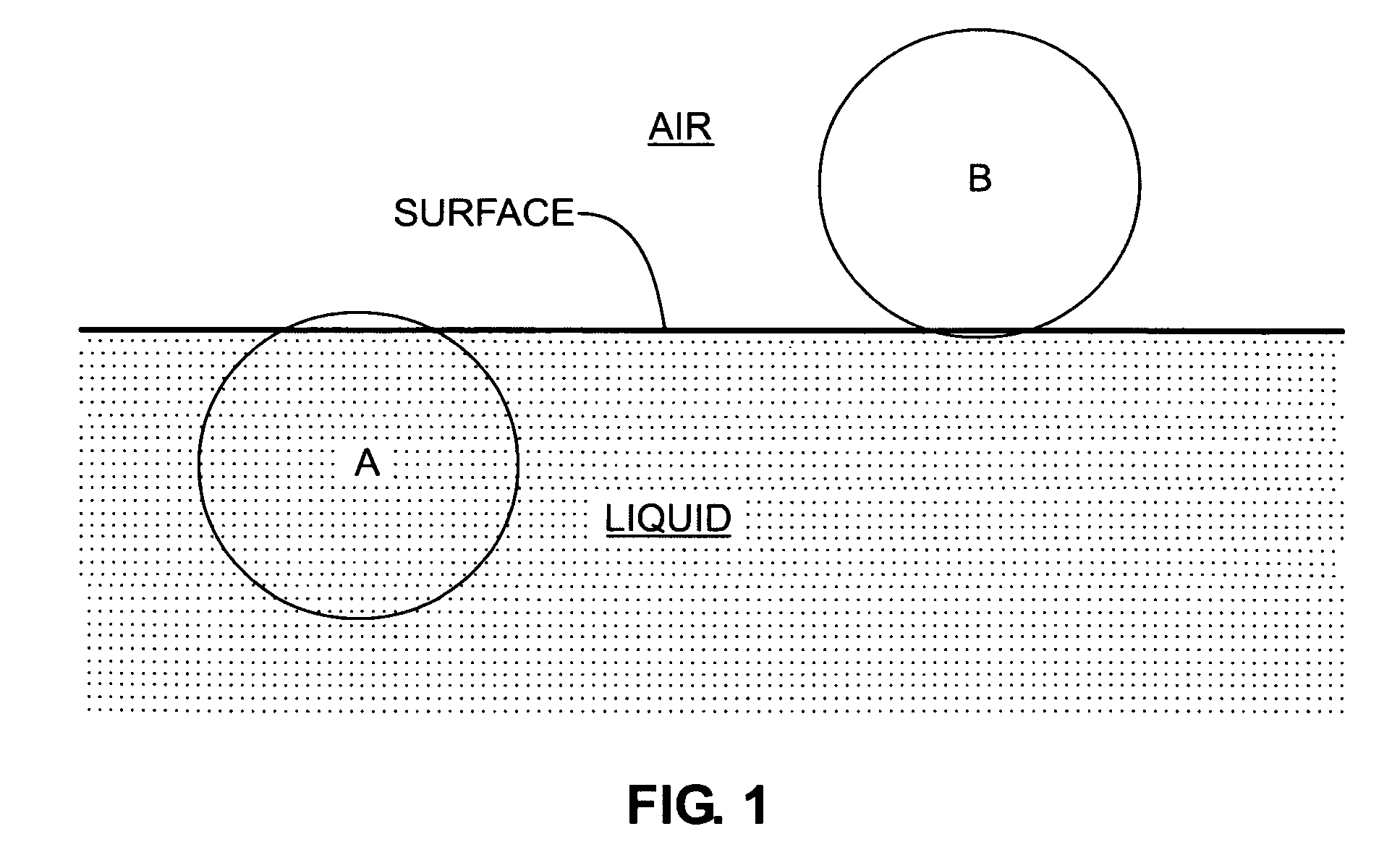

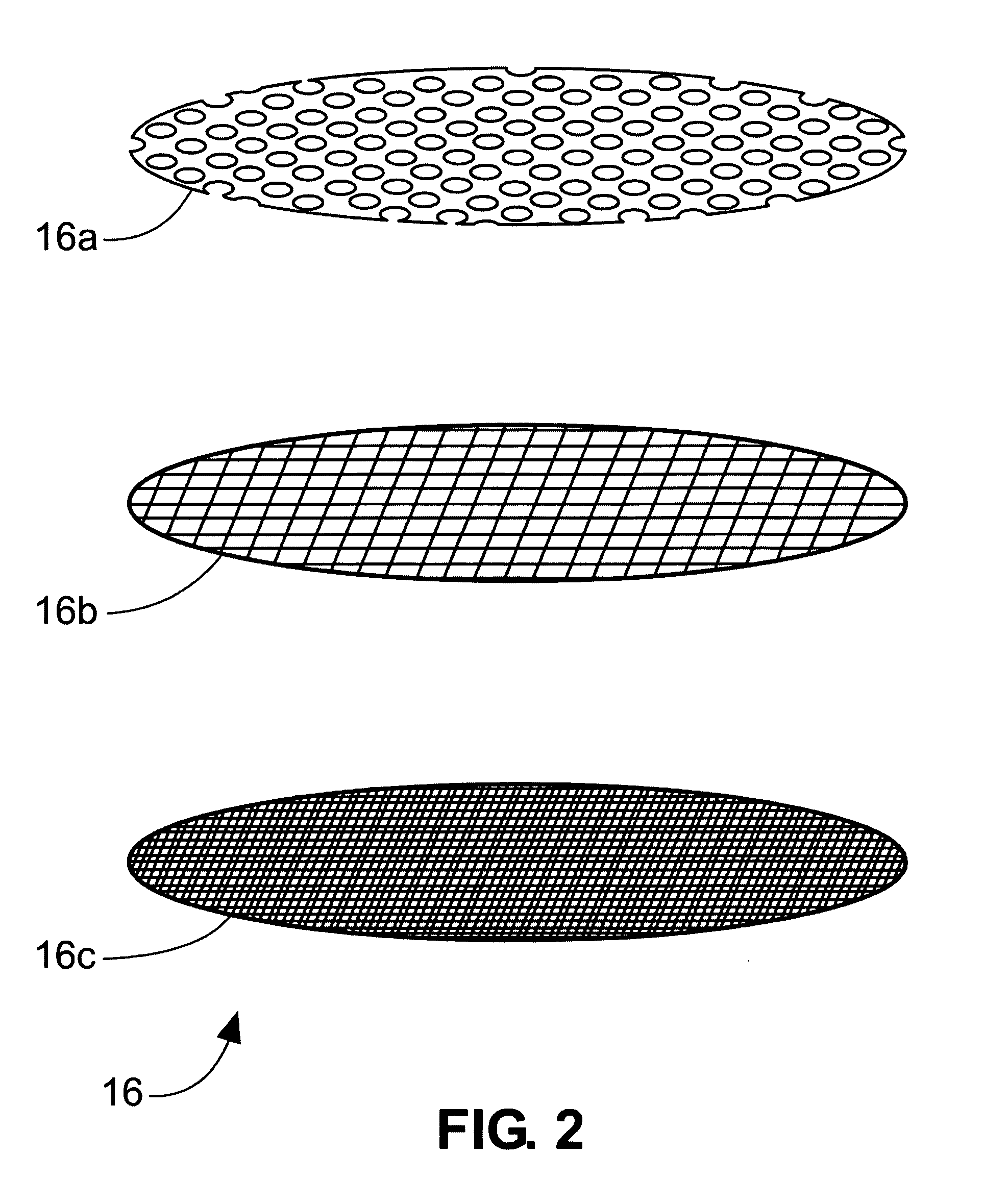

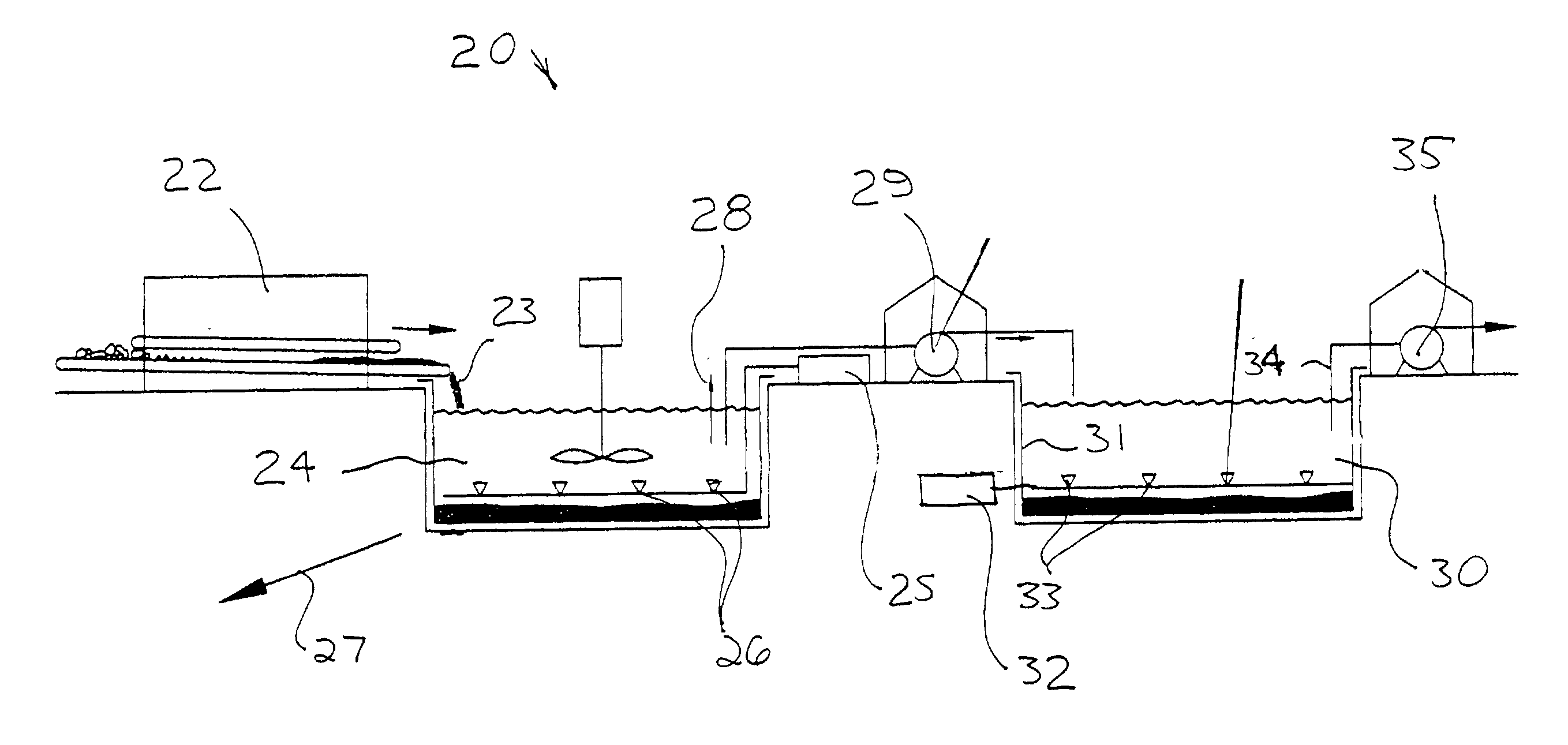

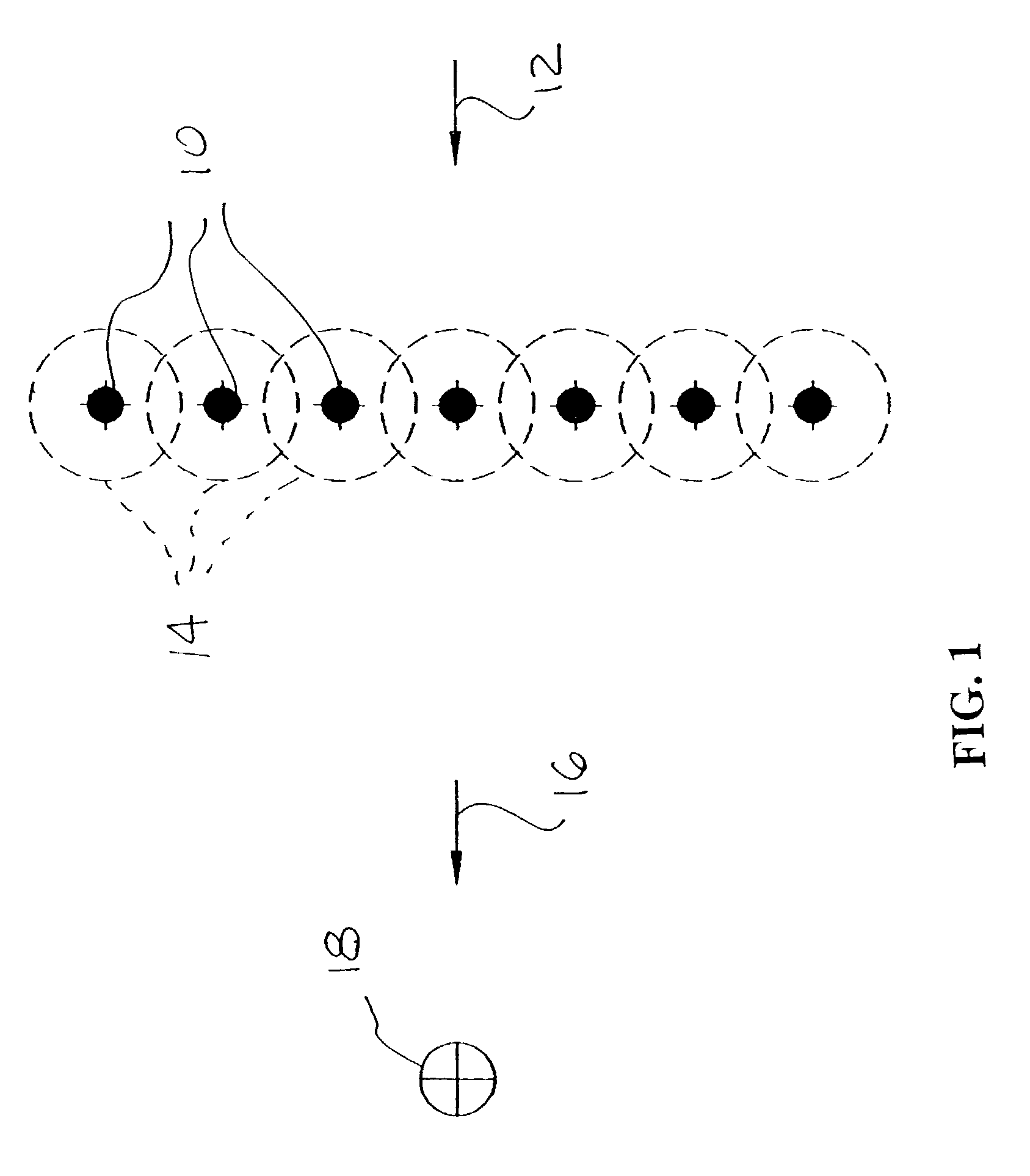

Liquid filtration apparatus and method embodying super-buoyant filtration particles

InactiveUS20050029204A1Easy to moveEasy to cleanGeneral water supply conservationTreatment involving filtrationFilter mediaFilter system

Presented is a liquid filtering apparatus and method that overcomes the disadvantages encountered with prior bed filtration systems by providing a filtering apparatus that incorporates a super-buoyant filter medium having a specific gravity very substantially lower than that of the process liquid being filtered. This feature enables a majority of the medium to float on top of the process liquid. Due to the significant differences in specific gravity between the media and the process liquid, super-buoyant media produce a highly advantageous means of naturally, gravimetrically separating both clean and contaminated filter media and process liquid into separate “phases”. Under normal filtering operation, the filter media is contained within a filter housing by a bed support near the top of the filter housing, and particulate material is filtered from a process liquid that passes through the housing. To regenerate the filter media, the housing is drained and a nozzle creates a backwash spray that washes the particulate material from the filter media. During the backwash process, the filter media rises past the nozzle as the level of the backwash liquid in the housing rises, so that the entire filter media is regenerated.

Owner:SCHWARTZKOPF STEVEN H

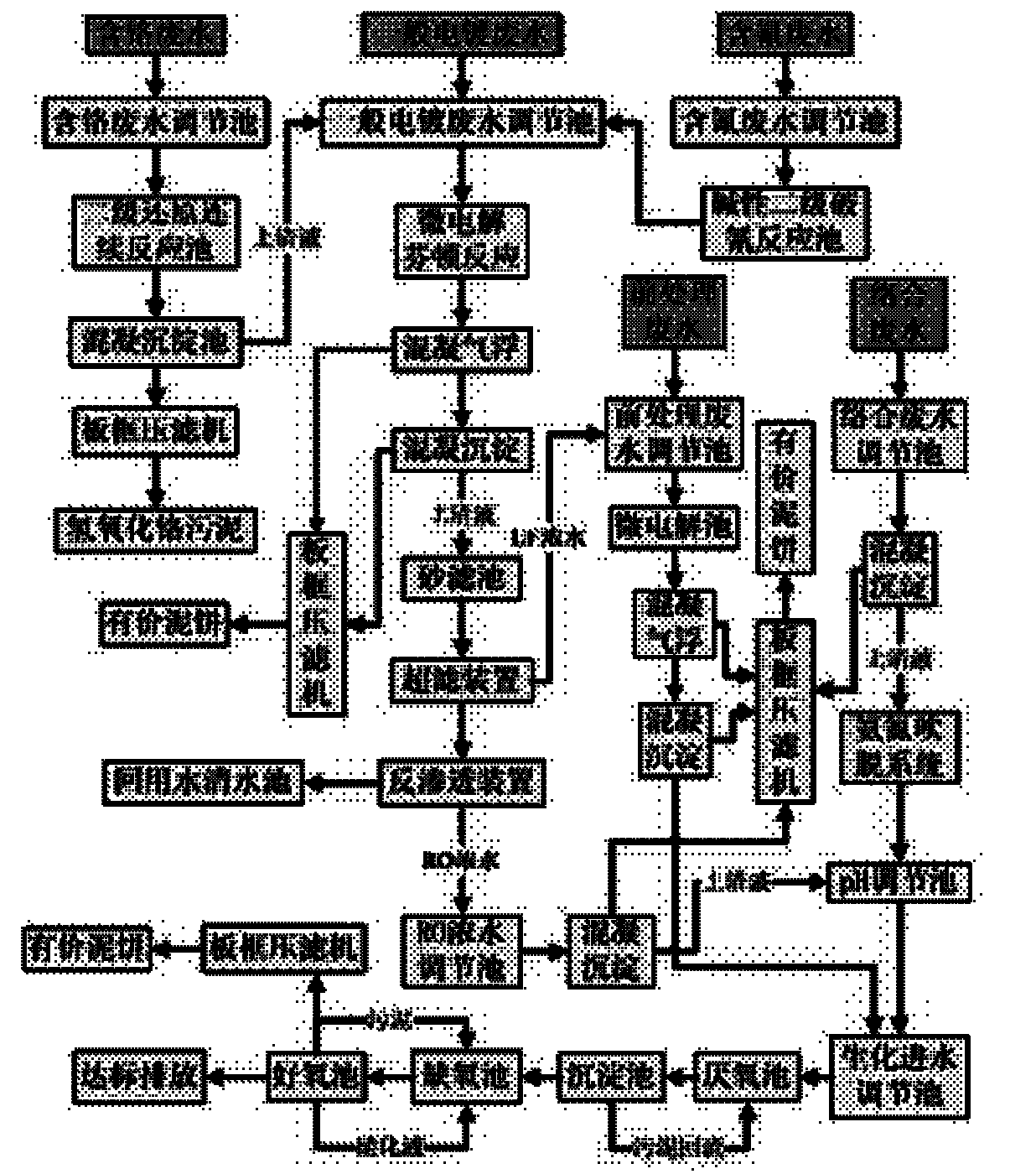

Method for treating comprehensive electroplating wastewater

InactiveCN101830600AAchieve environmental goalsAchieve emissionsWater contaminantsWaste water treatment from metallurgical processChemical oxygen demandElectrolysis

The invention relates to a method for treating comprehensive electroplating wastewater. The electroplating wastewater is separated and the recycling utilization rate of heavy metals resources can be improved by carrying out targeted treatment on each strand of separated water while improving the treatment efficiency. By using the micro-electrolysis function of iron and carbon, complex can be removed while removing COD (Chemical Oxygen Demand) and the biochemical property can be improved, which provides the guarantee for a subsequent biochemical reaction. By using the displacement action of the ion and the carbon, heavy metal ions in the water can be displaced and heavy metal resources can be recycled. Meanwhile, residual heavy metal ions in the water can be recycled by using the combining action of precipitating hydroxides and sulfides. On the basis, the water quality can meet the standard by using the ultrafiltration and reverse osmosis actions. The total hardness and the electric conductivity of the wastewater are superior to the water quality of tap water. Usable metal resources can be recycled, the economic benefit is obtained while achieving the aim of environmental protection and the production cost can be reduced.

Owner:TIANJIN UNIV

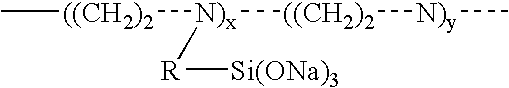

Method of preventing or reducing aluminosilicate scale in kraft pulp mills

InactiveUS20050274926A1Reduce and eliminate aluminosilicate scalingReduce and even prevent formationAluminium compoundsDigestersEnd-groupPulp mill

Materials and a method are provided whereby polymers with least 0.5 mole % of the pendant group or end group containing —Si(OR″)3 (where R″ is H, an alkyl group, Na, K, or NH4) are used to control aluminosilicate scaling in an industrial process having an alkaline process stream such as a pulping mill process stream. When materials of the present invention are added to the alkaline process stream, they reduce and even completely prevent formation of aluminosilicate scale on equipment surfaces such as evaporator walls and heating surfaces. The present materials are effective at treatment concentrations that make them economically practical.

Owner:CYTEC TECH CORP

Water purification method

InactiveUS20140175015A1Conveniently and efficiently purifyingInexpensivelyWaste water treatment from quariesWaste water treatment from ceramic industriesPurification methodsSorbent

A water purification method comprising adding a purification agent to water having a contaminant concentration of 1 μg / L to 10 g / L, the purification agent containing an adsorbent having an average particle size of 100 nm to 500 μm, an iron-based flocculant, and an alkaline substance; causing the adsorbent to adsorb at least a part of the contaminants in water; settling the adsorbent with the adsorbed contaminants by the iron-based flocculant; and removing the sediment from water, wherein the purification agent is added in an amount of 0.01 g to 20 g per liter of water, can purify contaminated water conveniently and efficiently.

Owner:FUJIFILM CORP

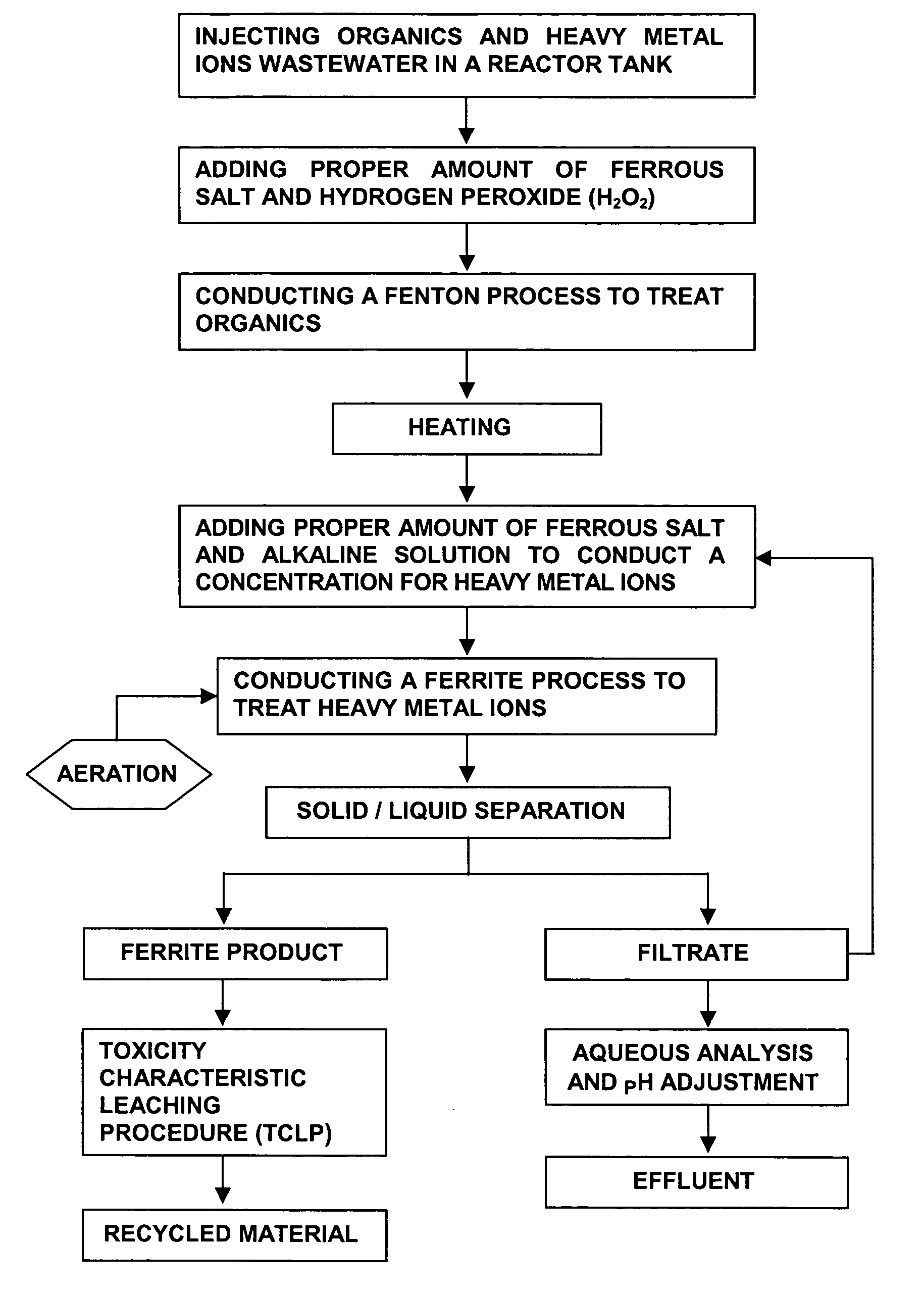

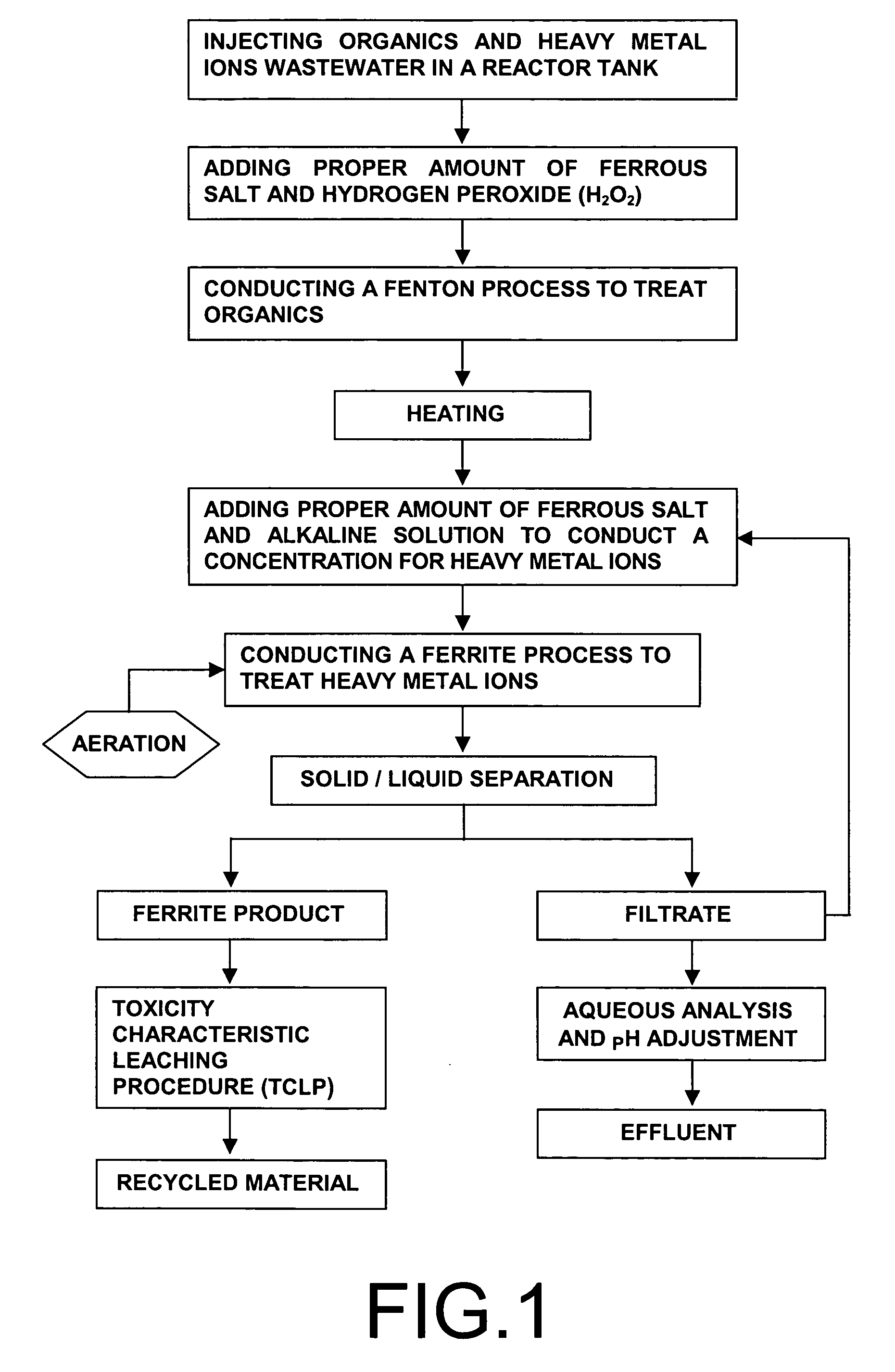

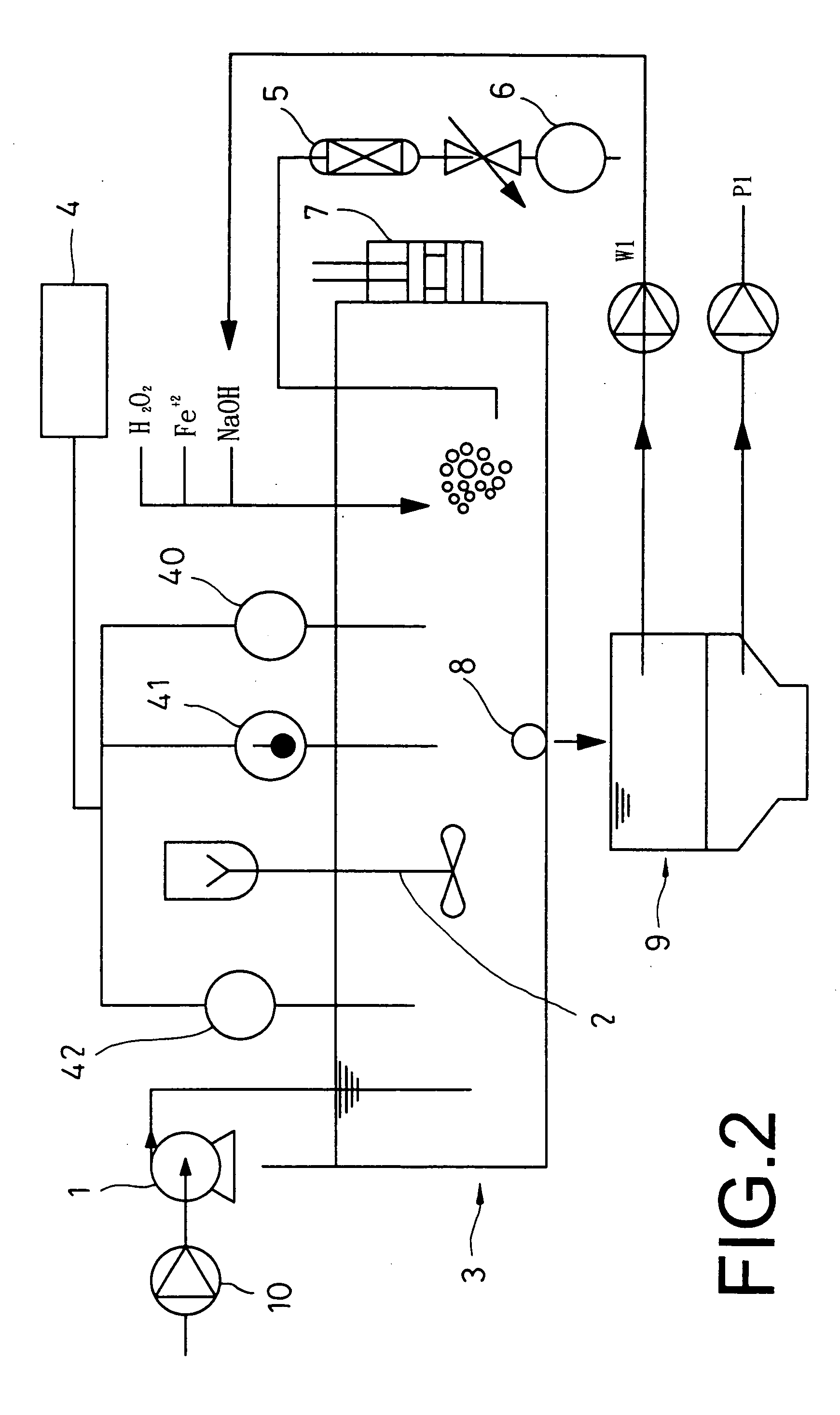

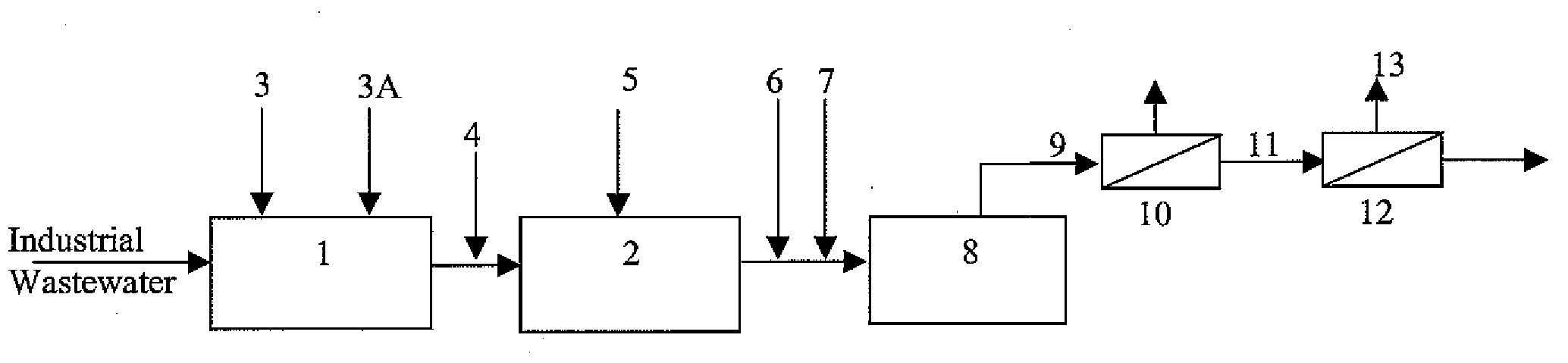

Integrated technology in sequential treatment of organics and heavy metal ions wastewater

InactiveUS20050274678A1Reduce impactQuality improvementWaste water treatment from metallurgical processSedimentation separationSurface finishSludge

This invention offers an integrated technology in sequential treatment of wastewater. Low biodegradable organics and heavy metal ions are both contained in wastewater from surface finishing processes. The aim of the invention is to find the solution for treatment of organics and heavy metal ions in complicated wastewater that contains organics and heavy metal ions sequentially. Low biodegradable organics are oxidized by a fenton process with pH ranging from 2 to 5 and temperature ranging from 20° C. to 100° C. Heavy metal ions are then treated by a ferrite process with pH ranging from 8 to 12 and temperature ranging from 20° C. to 100° C. The integrated technology of the fenton process and the ferrite process (2FP) is advantageous to treat the wastewater from surface finishing processes, decrease the production of iron sludge caused in the fenton process and increase the quality of ferrite products.

Owner:NAT CHENG KUNG UNIV

Method for treating a substance with wave energy from plasma and an electrical arc

InactiveUS20120024718A1From normal temperature solutionsLiquid separation by electricitySingle processAngular momentum

An apparatus for synergistically combining a plasma with a comminution means such as a fluid kinetic energy mill (jet mill), preferably in a single reactor and / or in a single process step is provided by the present invention. Within the apparatus of the invention potential energy is converted into kinetic energy and subsequently into angular momentum by means of wave energy, for comminuting, reacting and separation of feed materials. Methods of use of the apparatus in the practice of various processes are also provided by the present invention.

Owner:FORET PLASMA LABS

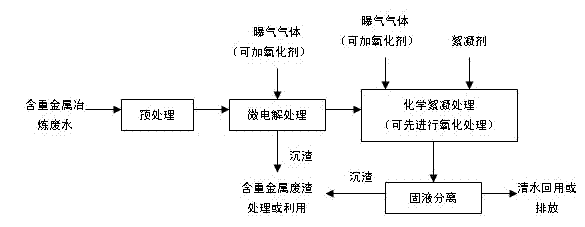

Method for treating smelting wastewater containing heavy metals

InactiveCN102381789AEasy to handleSimple processWaste water treatment from metallurgical processMultistage water/sewage treatmentChemical treatmentElectrolysis

The invention discloses a method for treating smelting wastewater containing heavy metals. The method comprises the following steps: 1, the smelting wastewater containing heavy metals is pretreated to remove particulate impurities in the wastewater and adjust the wastewater to be acidic; 2, the wastewater is transferred to an iron-carbon micro-electrolytic reactor to be subjected to single-stage or multi-stage micro-electrolytic electrochemical treatment under acidic conditions to remove most heavy metal ions in the wastewater, the wastewater is adjusted to be weakly alkaline or alkaline, is subjected to single-stage or multi-stage chemical flocculation treatment to further remove other heavy metal ions, and pollutants of arsenic, fluorine, chlorine and the like in the wastewater; and 3, solid-liquid separation is carried out to obtain production water which can be recycled. The method comprises steps of wastewater pretreatment, iron-carbon micro-electrolysis, chemical flocculation and solid-liquid separation which are organically coupled in series. The method which organically combines the micro-electrolysis with the chemical flocculation and allows them to mutually cooperate with each other and co-perform effects has the advantages of simple treating process and technology, low treatment cost, high treatment efficiency, and standard-reached discharge and recovery of the treated wastewater.

Owner:KUNMING UNIV OF SCI & TECH

Recycling method for treating stainless steel pickling acid pickle and wastewater

ActiveCN104310647AHigh operating costsSimple processWater treatment compoundsWaste water treatment from metallurgical processWash waterLaterite

The invention relates to a recycling method for treating stainless steel pickling acid pickle and wastewater, belonging to the field of treatment of industrial acid pickle and wastewater in iron and steel and metallurgy industries. The acid pickle and wash wastewater generated during stainless steel pickling are collected according to quality and category and the acid pickle is subjected to acid recycling. The acid pickle and wash wastewater are treated through fractional precipitation by adopting lime as a neutralizing agent. Calcium sulfate or calcium fluoride or a mixture of calcium sulfate and calcium fluoride is obtained through precipitation under the acidic condition (the pH value is equal to 3.0+ / -0.5) and can serve as a cement filler or a material for brickmaking or a building material after heavy metal polluted calcium salt is removed. A metal hydroxide is obtained through precipitation under the alkaline condition (the pH value is not more than 9.0) and can serve as a stainless steel smelting raw material as the quality of the product is better than that of the imported laterite-nickel ores in China. The calcium nitrate containing wastewater obtained after the acid pickle is treated is not needed to be discharged or treated and can be recycled. After being treated, the wash wastewater can be reused as production line wash water.

Owner:上海博士高环保科技有限公司

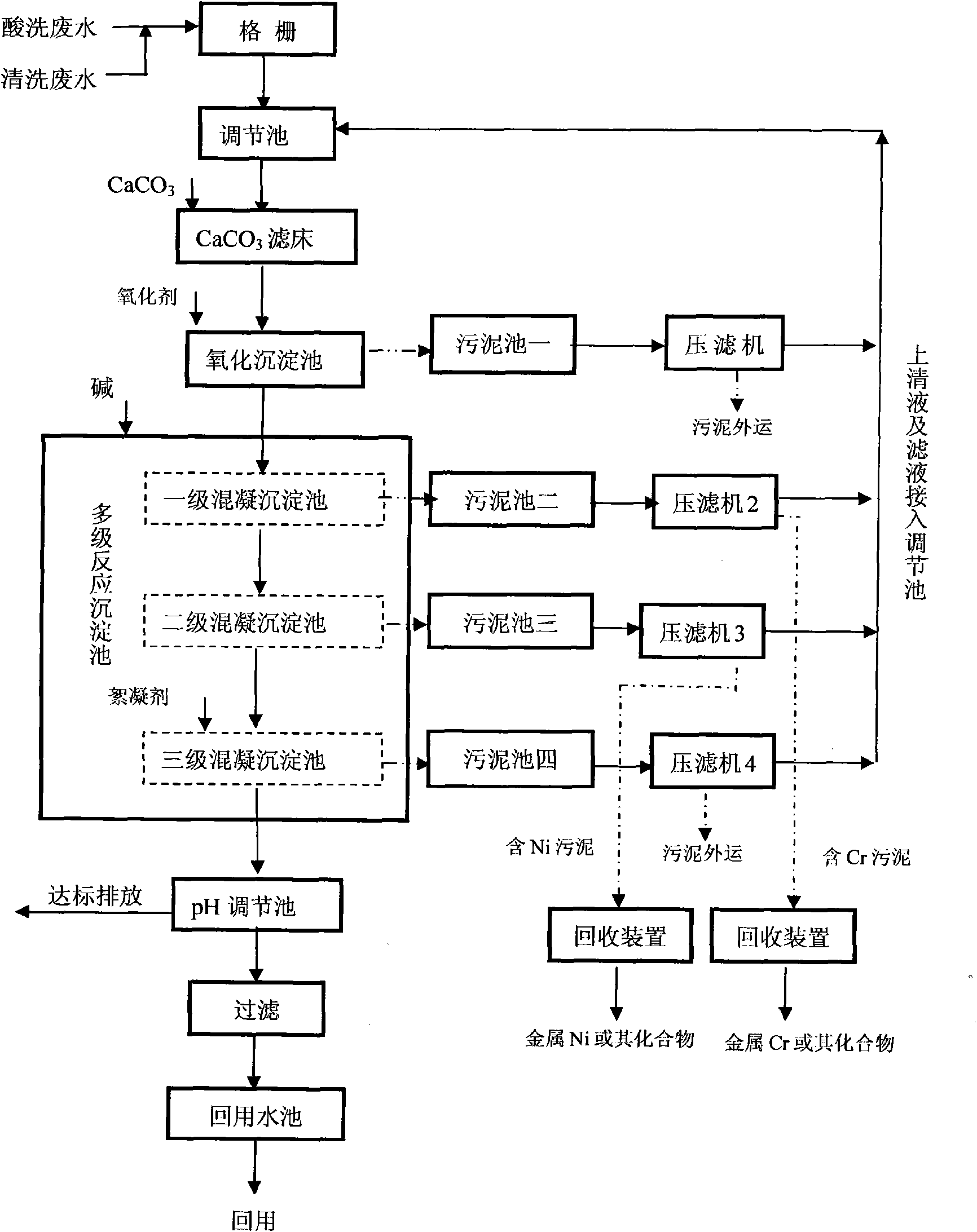

Recycling processing method for stainless steel processing process wastewater grading precipitation

InactiveCN101648757AHigh recycling valueSludge treatment by de-watering/drying/thickeningPhotography auxillary processesThree levelAcid washing

The invention relates to a recycling processing method for a stainless steel processing process wastewater grading precipitation, which comprises the following steps: (1) deslagging and homogenizing acid-washing residual liquid and washing wastewater; (2) adjusting the pH to 4.0-5.5 by a CaCO3 filter bed to generate CaF2; (3) oxidizing Fe<2+> into Fe<3+> by an oxidizing agent to generate sedimentsof Fe(OH)2 and Fe(OH)3; after the Fe(OH)2 , the Fe(OH)3 and the CaF2 are deposited, recovering; (4) carrying out three-level alkali adding coagulation precipitation on the supernatant liquid of an oxidation precipitation pool; adjusting the pH to obtain a Cr sediment in the first-level alkali adding coagulation precipitation; acquiring a Ni sediment in the second-level alkali adding coagulation precipitation; carrying out the third-level alkali adding coagulation precipitation and adding a flocculating agent to remove residual heavy metal ions so that discharge water reaches the standard, wherein the alkali added into a grading reaction precipitation pool is NaOH, Ca(OH)2, CaO or Na2 CO3; (5) regulating the pH of the discharge water of the grading reaction precipitation pool to 6.0-8.0; discharging 0-20 percent of wastewater and filtering residual F<-> and suspended matters of 80-100 percent of wastewater to reach the standard and recycle; and (6) recycling the Cr-Ni metal or the compound thereof from the Cr sediment and the Ni sediment acquired by a third-level coagulation precipitation pool by a recycling device.

Owner:ZHEJIANG UNIV

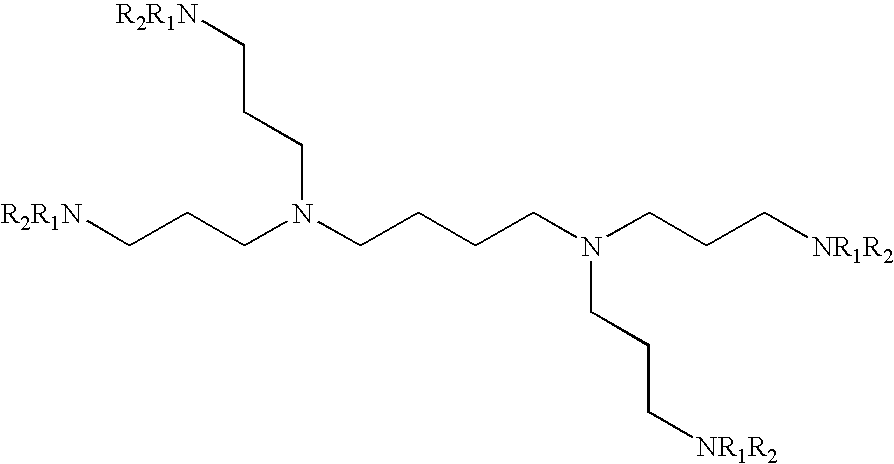

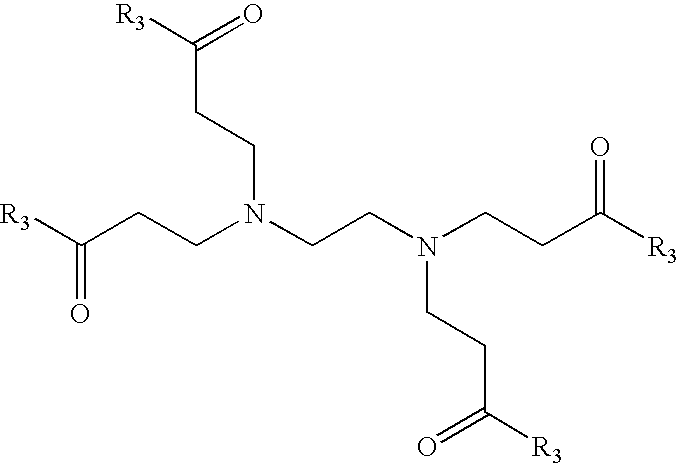

Method of clarifying oily waste water

ActiveUS20060289359A1Waste water treatment from quariesTreatment involving filtrationDemulsifierSulfate

A method of clarifying oily waste water comprising adding to the waste water an effective clarifying amount of one or more demulsifiers selected from the group consisting of dendritic polyamines, dendritic polyamidoamines and hyperbranched polyethyleneimines and the reaction products thereof with gluconolactone, alkylene oxides, salts of 3-chloro-2-hydroxypropanesulfonic acid, alkyl halides, benzyl halides and dialkyl sulfates.

Owner:ECOLAB USA INC

Method and apparatus for treating and recycling carbonized wastewater

ActiveCN101428945ASolve processing problemsImprove biochemical propertiesFatty/oily/floating substances removal devicesWaste water treatment from metallurgical processSludgeTreatment design

The invention relates to a coking waste water treatment reuse method and a device thereof. The method comprises the following process steps: 1. strengthening pretreatment; 2. biological treatment; and 3. reuse water treatment. The structure of the method is as follows: electrochemical equipment at the strengthening pretreatment step is connected with a water outlet of an air float and a water inlet of biological treatment; and a water outlet pipe of an MBR water outlet tank at the biological and sludge treatment step is connected in serial with an ozone contact tower, an active carbon filter tower and an RO at the reuse water treatment step. The method has the advantages of providing a novel combination process for the coking waste water, effectively combining the technologies of de-oiling, biochemistry, electrochemistry and membrane, improving the biodegradability of difficultly degraded pollutants by utilizing the electrochemical strengthening pretreatment, strengthening the biochemical treatment by MBR, reasonably designing the reuse treatment of ozone-active carbon-RO, solving the problem of the difficult treatment of coking waste water and achieving the aim of the reuse of the coking waste water.

Owner:上海缘脉环境科技有限公司

Comprehensive electroplating wastewater treating agent

InactiveCN103991916AEasy to useSimple processWater contaminantsWaste water treatment from metallurgical processChemical oxygen demandPollution

The invention relates to a comprehensive electroplating wastewater treating agent. The comprehensive electroplating wastewater treating agent is composed of the following components in percentage by mass: 10-35% of reducing agent, 20-50% of sulfide, 10-30% of aluminum salt, 10-30% of adsorbing material and 5-15% of alkaline substances. The raw materials of the treating agent provided by the invention are low in cost and easy to obtain, and the treating agent is easy to prepare; through compounding the raw materials, a synergistic effect is exerted, and the treating agent is favorable in broad spectrum, capable of effectively removing heavy metals such as nickel, chromium, copper, zinc and the like, high in removal rate up to more than 96% and relatively good in COD (Chemical Oxygen Demand) removal effect; the comprehensive electroplating wastewater treating agent also has the characteristics of strong electroplating wastewater treating capacity, high heavy metal ion sedimentation speed and efficiency, no secondary pollution after treatment and the like; in addition, the treating agent provided by the invention is convenient to use, simple and feasible in treating process, capable of realizing operation by only using a vessel or pool with an aerating agitation device, reducing the floor area and reducing the investment, and easy to realize operation management.

Owner:浙江一清环保工程有限公司

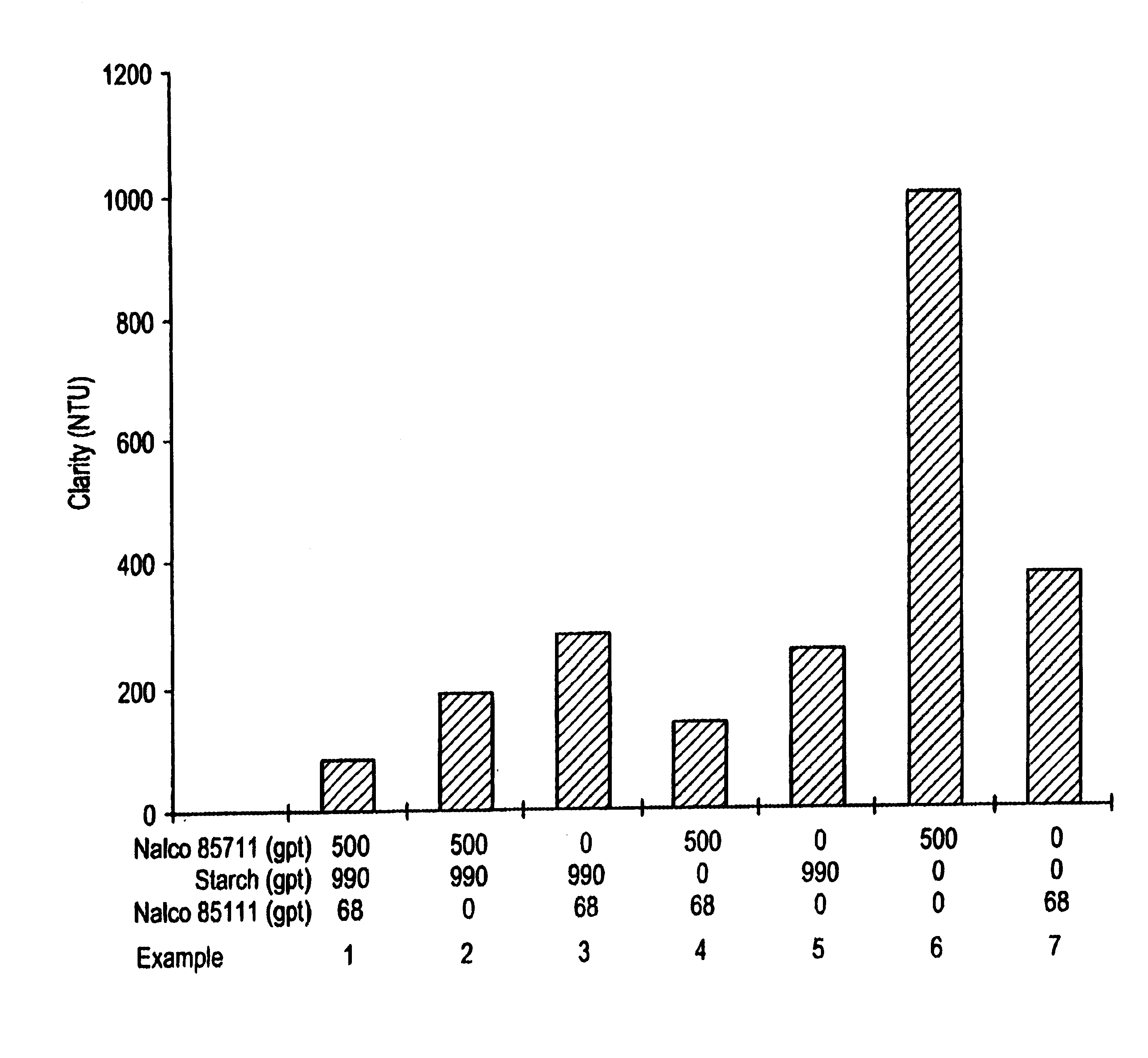

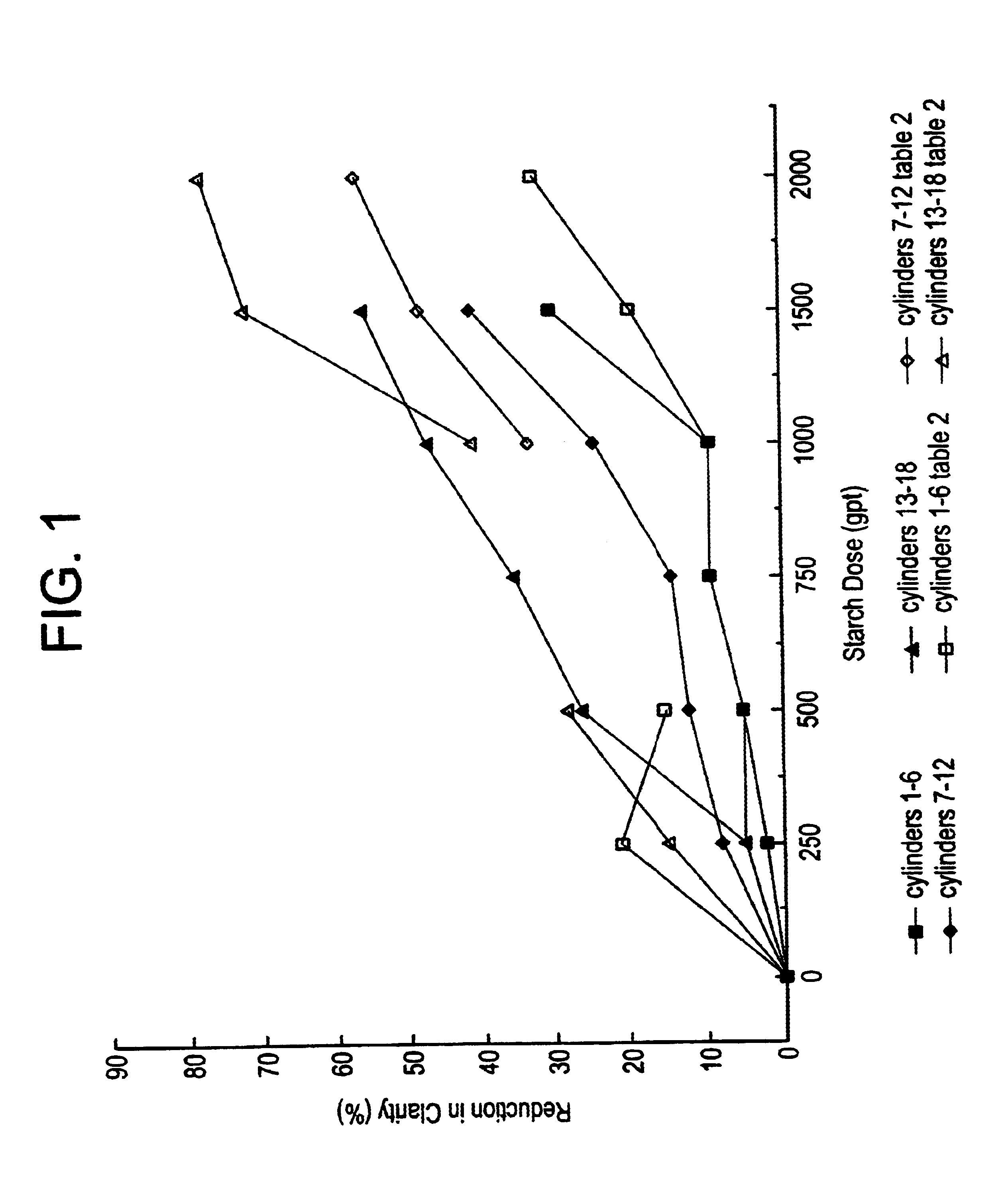

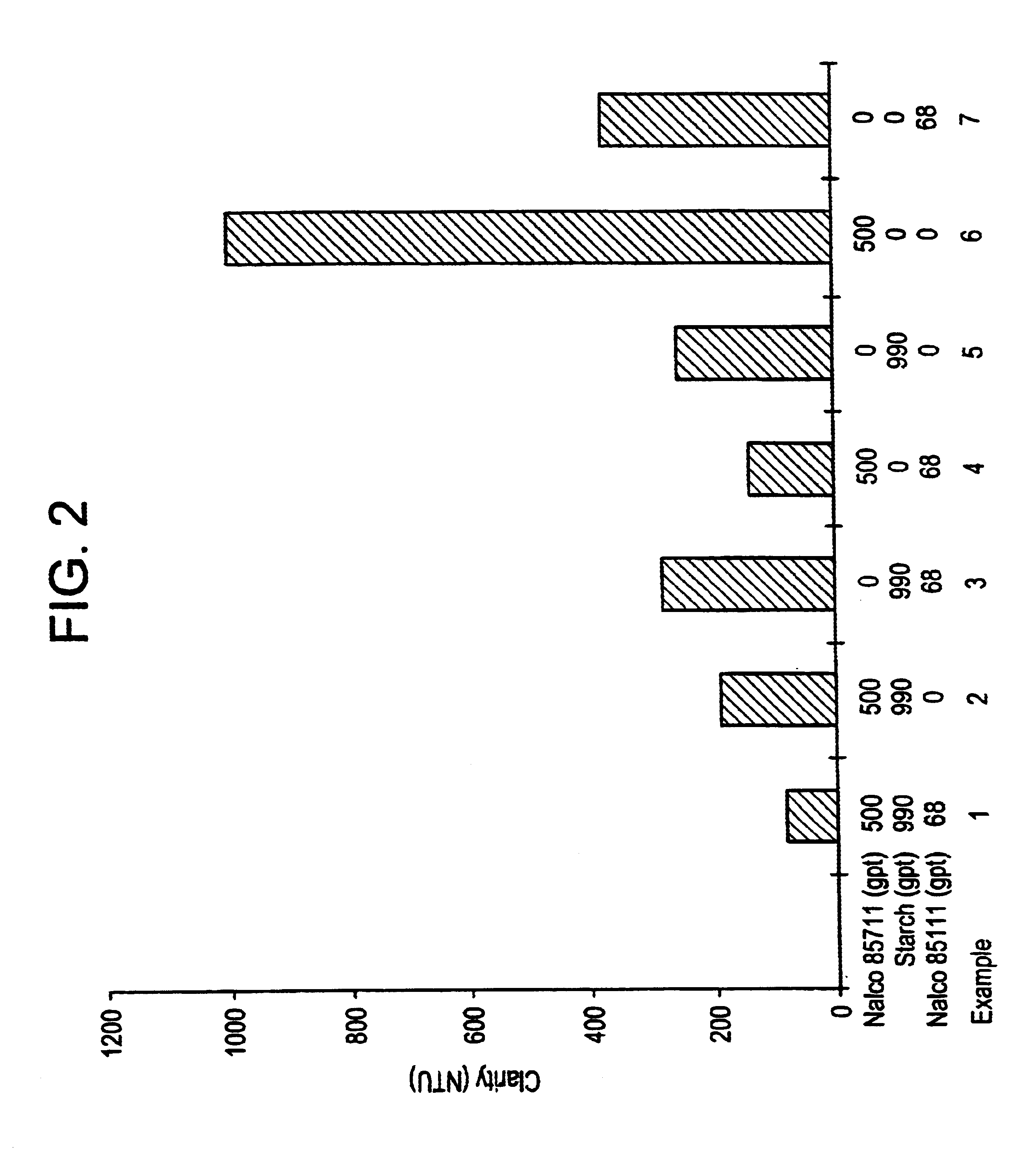

Dextran starch and flocculant combination for improving red mud clarification

InactiveUS6726845B1Easy to separateGallium/indium/thallium compoundsCentrifugal force sediment separationFiltrationCentrifugation

The claimed invention is a method for separating Bayer process red mud from a Bayer process liquor which comprises adding to a Bayer process liquor containing red mud an effective amount of a water soluble synthetic flocculant, dextran and starch combination. The flocculant is added anywhere in the slurry containing the red mud suspended in Bayer process liquor, or in a liquor slurry containing bauxite prior to or during digestion. Once the flocculant combination is added, it is mixed sequentially with the Bayer process liquor and the red mud contained in the Bayer process liquor is removed by sedimentation, centrifugation or filtration.

Owner:ECOLAB USA INC

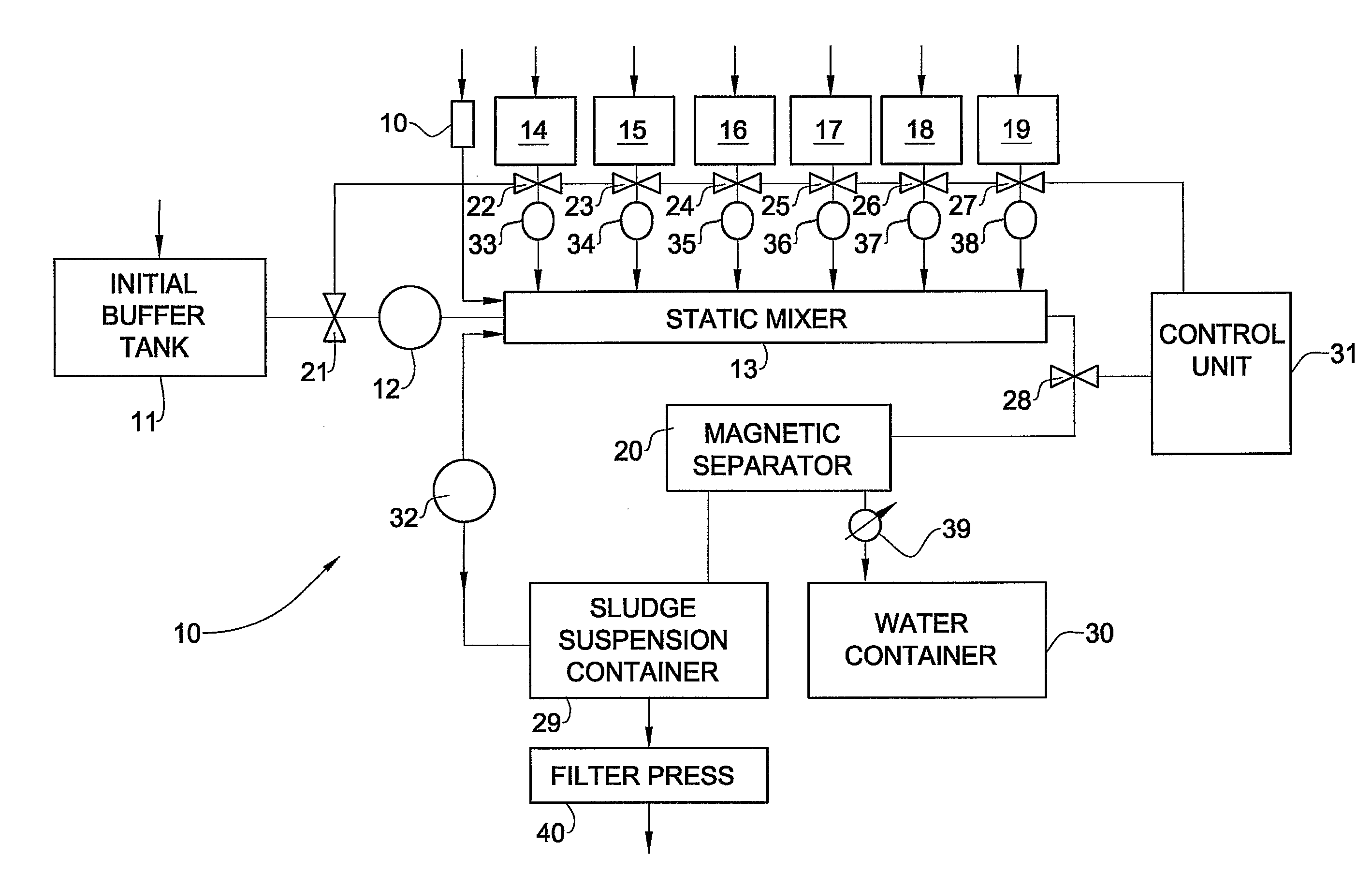

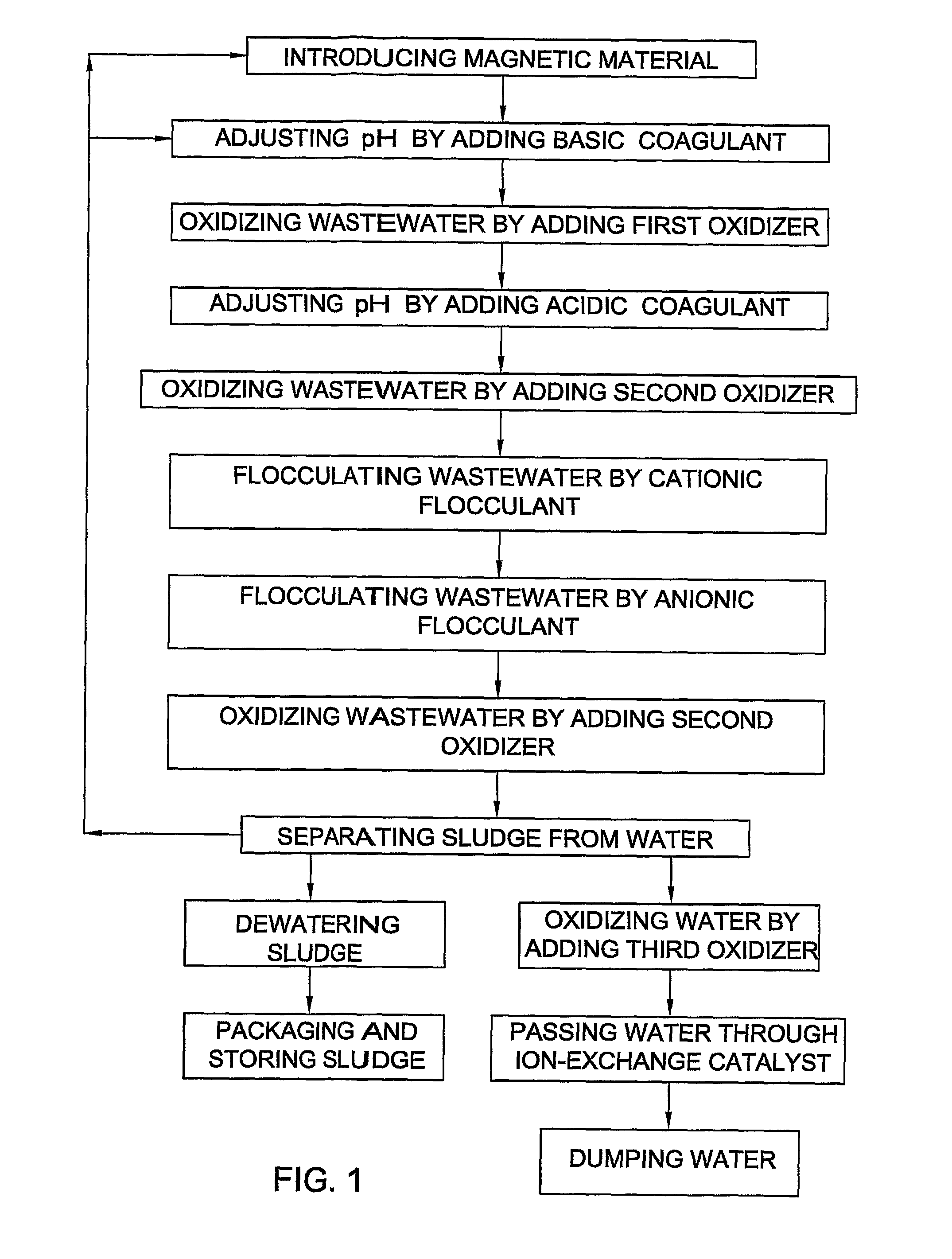

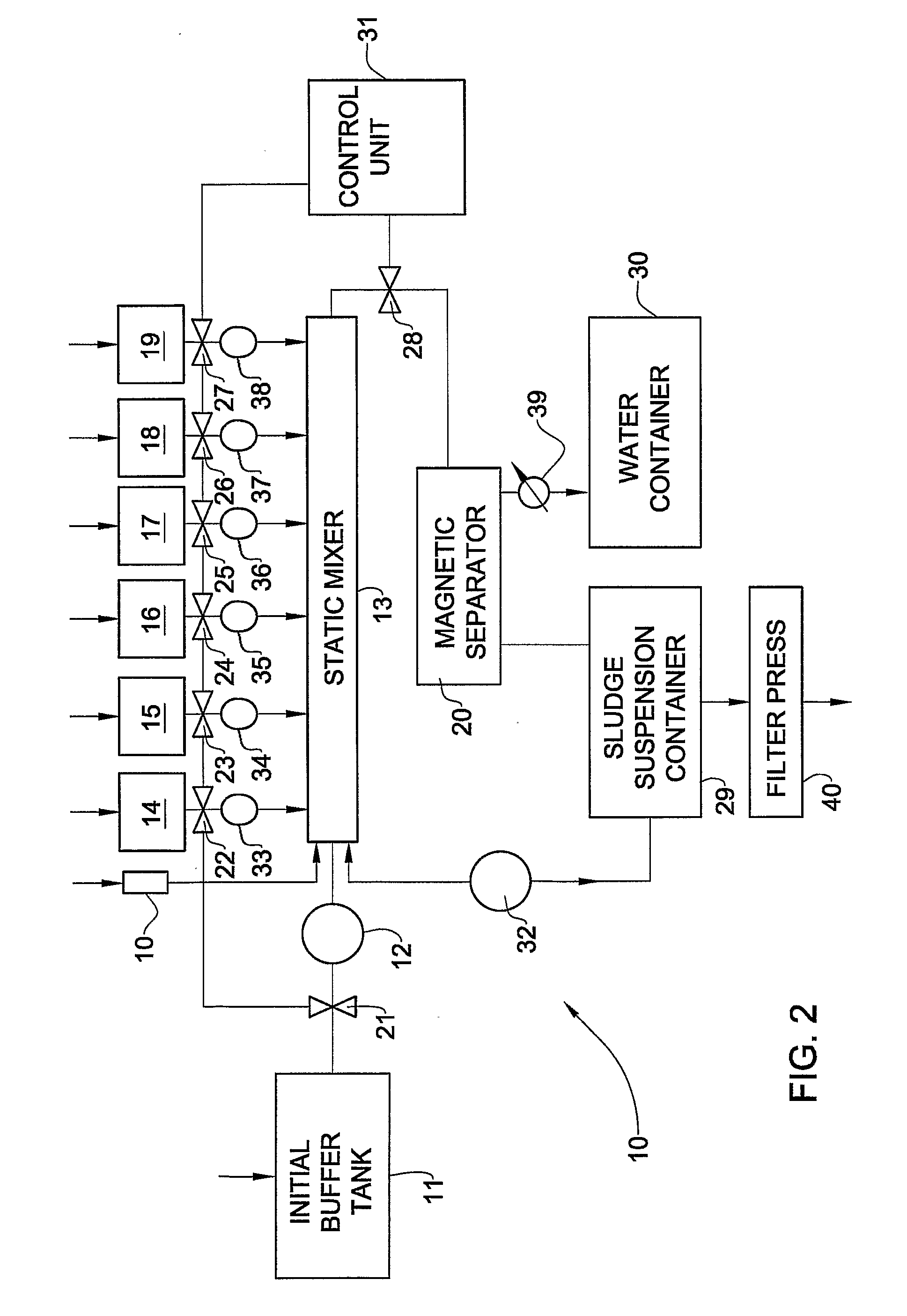

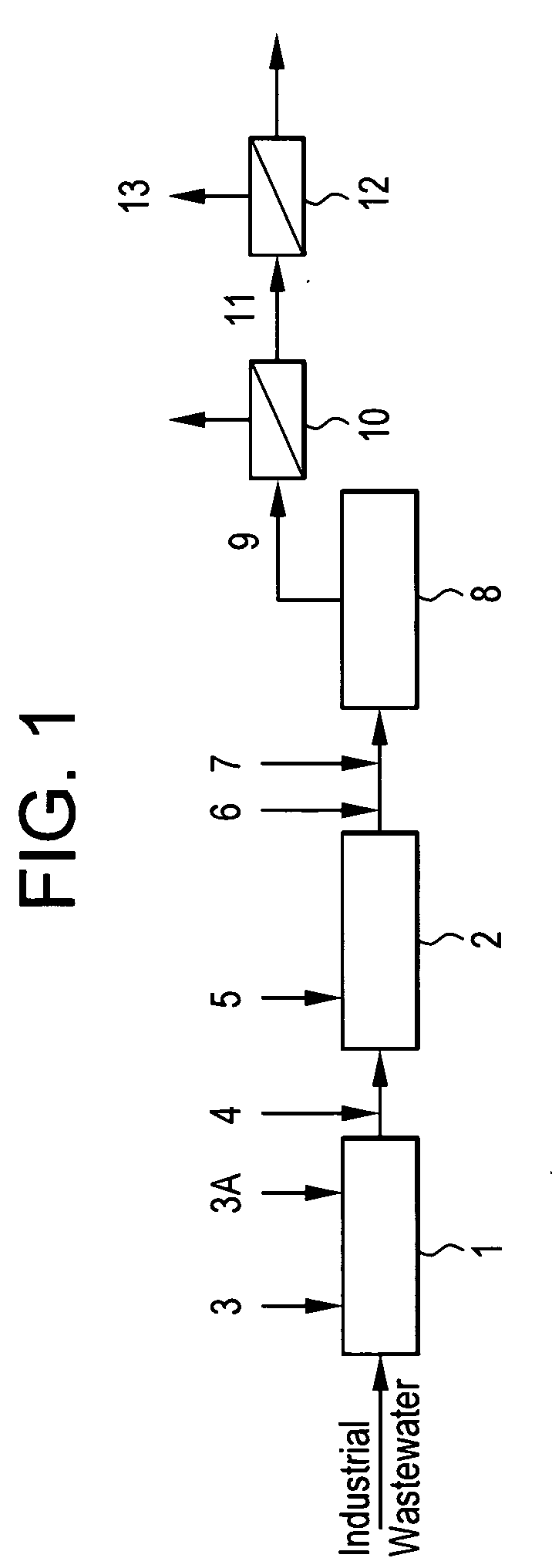

System and Method for Treatment of Industrial Wastewater

InactiveUS20080035577A1Improve efficiencyImprove standardsSolid sorbent liquid separationWaste water treatment from metallurgical processPHENOL LIQUIDSludge

Owner:UNIQKLEEN WASTEWATER TREATMENT

Removing mercury and other heavy metals from industrial wastewater

InactiveUS20080197075A1Sludge treatment by de-watering/drying/thickeningMembranesIndustrial effluentFiltration

A method of removing one or more heavy metals including mercury from industrial wastewater by use of a filtration and / or a solid-liquid separation system by use of a water soluble ethylene dichloride ammonia polymer.

Owner:ECOLAB USA INC

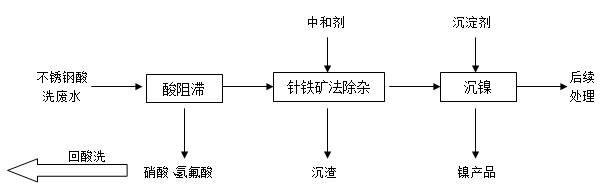

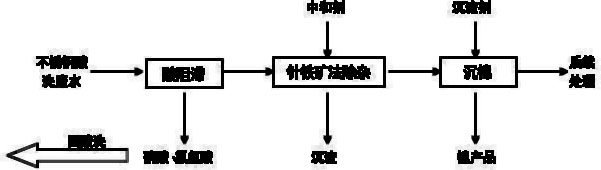

Recycling harmless treatment method of stainless steel pickling waste water

ActiveCN102659274AHigh recovery rateSmall footprintSludge treatmentSolid waste disposalIndustrial waste waterSS - Stainless steel

The invention discloses a recycling harmless treatment method of stainless steel pickling waste water, belonging to the toxic and harmful industrial waste water treatment field. The method comprises the following steps of: 1) recycling inorganic acids by an acid separation method: pumping stainless steel pickling waste water in which suspended matters are removed through filtering into a resin column so that the inorganic acids are absorbed on the resin; 2) removing impurities by a goethite method: pumping heavy metal ion solution into a reaction kettle, adjusting pH to a range from 3.5 to 5.0, and continuing reacting for 30-90 min, thereby removing iron, chromium and fluorine in the heavy metal ion solution in the form of dregs; 3) recycling nickel by a neutralized sedimentation method: feeding an alkaline liquor to nickel solution to adjust pH to a range from 9.5 to 12.5, and filtering and washing the filter residues, thereby obtaining nickelous hydroxide; and 4) performing harmlesstreatment on the dregs: after washing the dregs, adding lime powder to the dregs to realize stabilization treatment of harmful elements. The method is simple in operation and convenient for management; the high-concentration inorganic acids and nickel and the like contained in the waste water are all recycled, and simultaneously the generated dregs are harmlessly treated; and therefore the integration of economic benefit,environmental benefit and social benefit is realized.

Owner:NANJING UNIV

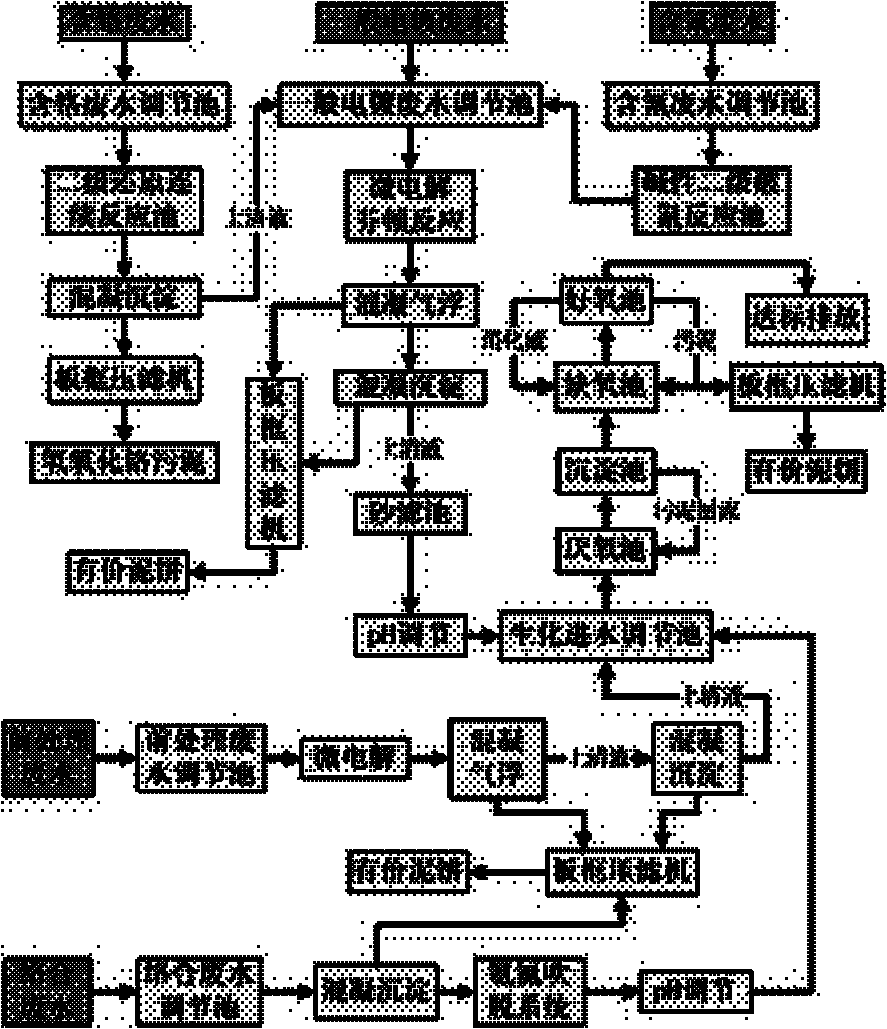

Electroplating wastewater treatment reclaiming technique

ActiveCN101041534AReduce contentHigh desalination rateTreatment using aerobic processesGeneral water supply conservationFiltrationUltrafiltration

The invention discloses a reclaimed craft to dispose electroplating waste water, which comprises the following steps: adopting oxidation-reduction and chemical precipitation disposing method and film technology (fold filtration, hyperfiltration, Na filtration and reverse osmosis desalination) deep purifying method; avoiding accumulation of salt effectively; reverse osmosis sloughing monovalent salt at last grade; trapping bivalent salt in innocent treatment system; proceeding depositing treatment continually; removing accumulating BOD and COD in water body through biochemical treatment effectively; realizing zero discharge of waste water.

Owner:JINAN JINGHENG ELECTRONICS

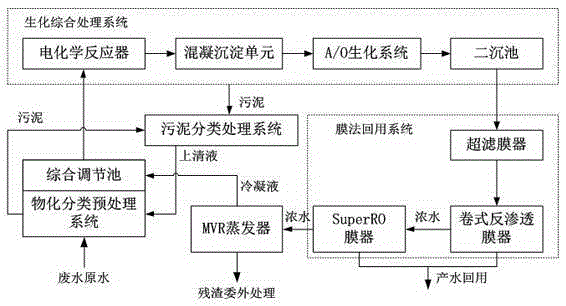

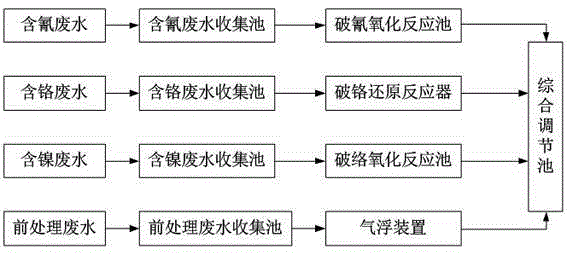

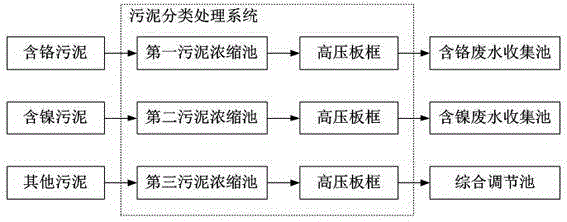

Technique and system for zero discharging treatment of electroplating effluent

ActiveCN105271622AReduce processing costsAvoid wastingSludge treatment by de-watering/drying/thickeningWaste water treatment from metallurgical processSludgeWastewater

The invention discloses a technique and a system for zero discharging treatment of electroplating effluent. The system comprises a material classifying pre-treatment system, a biochemical comprehensive treatment system, a membrane method system, a membrane concentrated liquor vaporization system and a sludge classifying treatment system which are connected with each other in turn, wherein the sludge classifying treatment system is connected with the material classifying pre-treatment system and the biochemical comprehensive treatment system; the raw wastewater enters into the material classifying pre-treatment system; water generated by the membrane method system is recycled; the condensed liquid from the membrane concentrated liquor vaporization system is re-injected into the material classifying pre-treatment system. According to the technique provided by the invention, the wastewater is firstly treated in classifying form, so that the heavy pollution ions, such as, chromium, cyanogen, nickel, and the like, and the oily matters in the wastewater are effectively removed, and then the biochemical comprehensive treatment system is used for further treating, and lastly, the RO+SuperRo two-level combination mode is utilized to achieve the gross recovery at 94%, and meanwhile, the liquid amount for evaporation treatment is less than 6% of the gross wastewater quantity, the cost of the evaporation treatment is saved, the sludge is recycled, the waste of resources is avoided and the sludge treating cost is saved.

Owner:CHENGDU MEIFUTE MEMBRANE TECHNOLOGY CO LTD

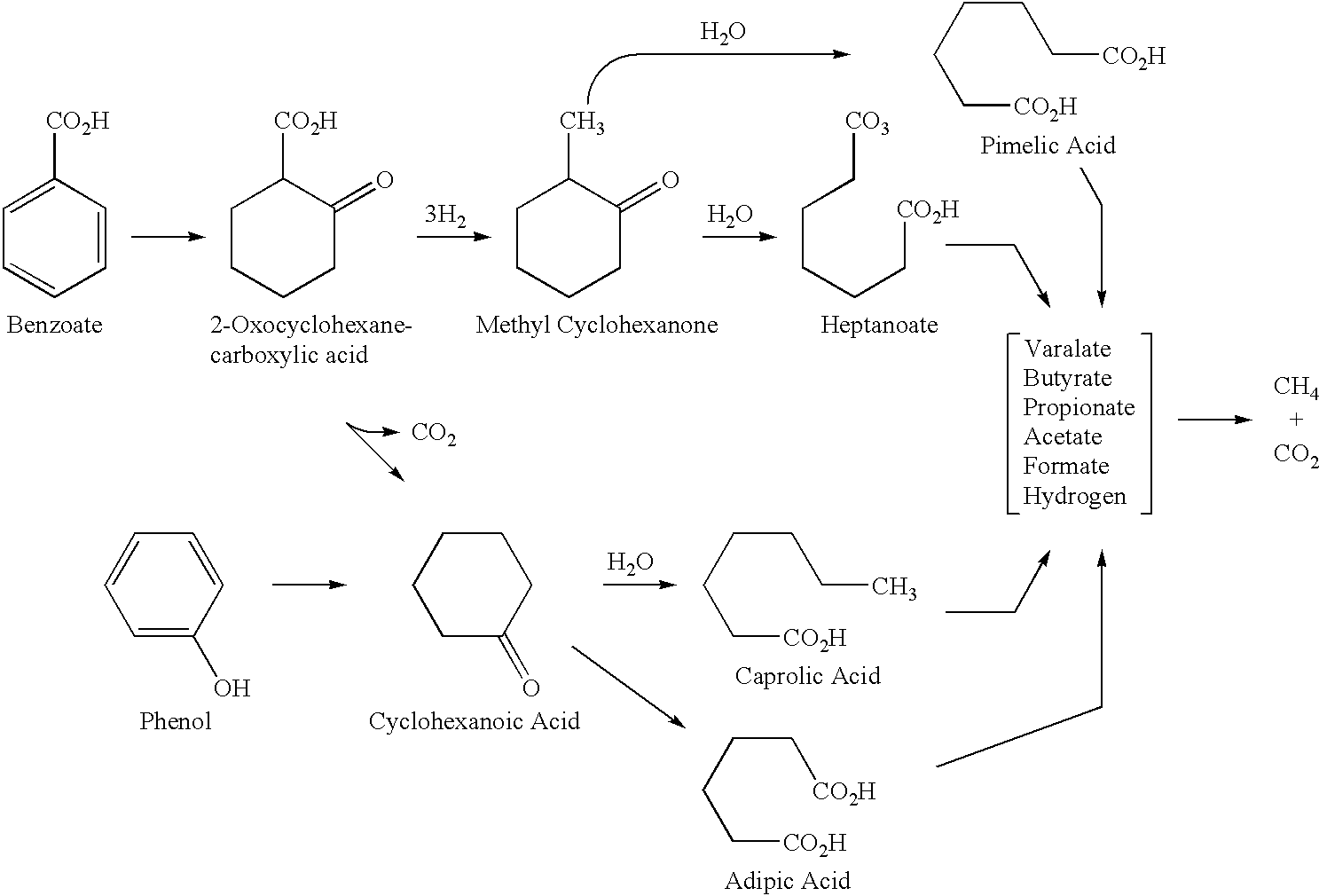

Remediation of metal contaminants with hydrocarbon-utilizing bacteria

Methods and apparatus are disclosed for remediating metal contaminants using hydrocarbons which stimulate the growth of hydrocarbon-utilizing bacteria. The metal contaminants may include heavy metals such as arsenic, antimony, beryllium, cadmium, chromium, copper, lead, mercury, iron, manganese, magnesium, radium, nickel, selenium, silver, thallium and zinc. The hydrocarbon may include alkanes, alkenes, alkynes, poly(alkene)s, poly(alkyne)s, aromatic hydrocarbons, aromatic hydrocarbon polymers and aliphatic hydrocarbons. Butane is a particularly suitable hydrocarbon which stimulates the growth of butane-utilizing bacteria. Remediation may occur in-situ or ex-situ, and may occur under aerobic, anaerobic or dual aerobic / anaerobic conditions. Examples of applications include the remediation of heavy metals, the remediation of arsenic impacted surface water, groundwater and / or soil, the remediation of acid mine drainage, and the treatment of spent metal plating solutions.

Owner:GLOBAL BIOSCI

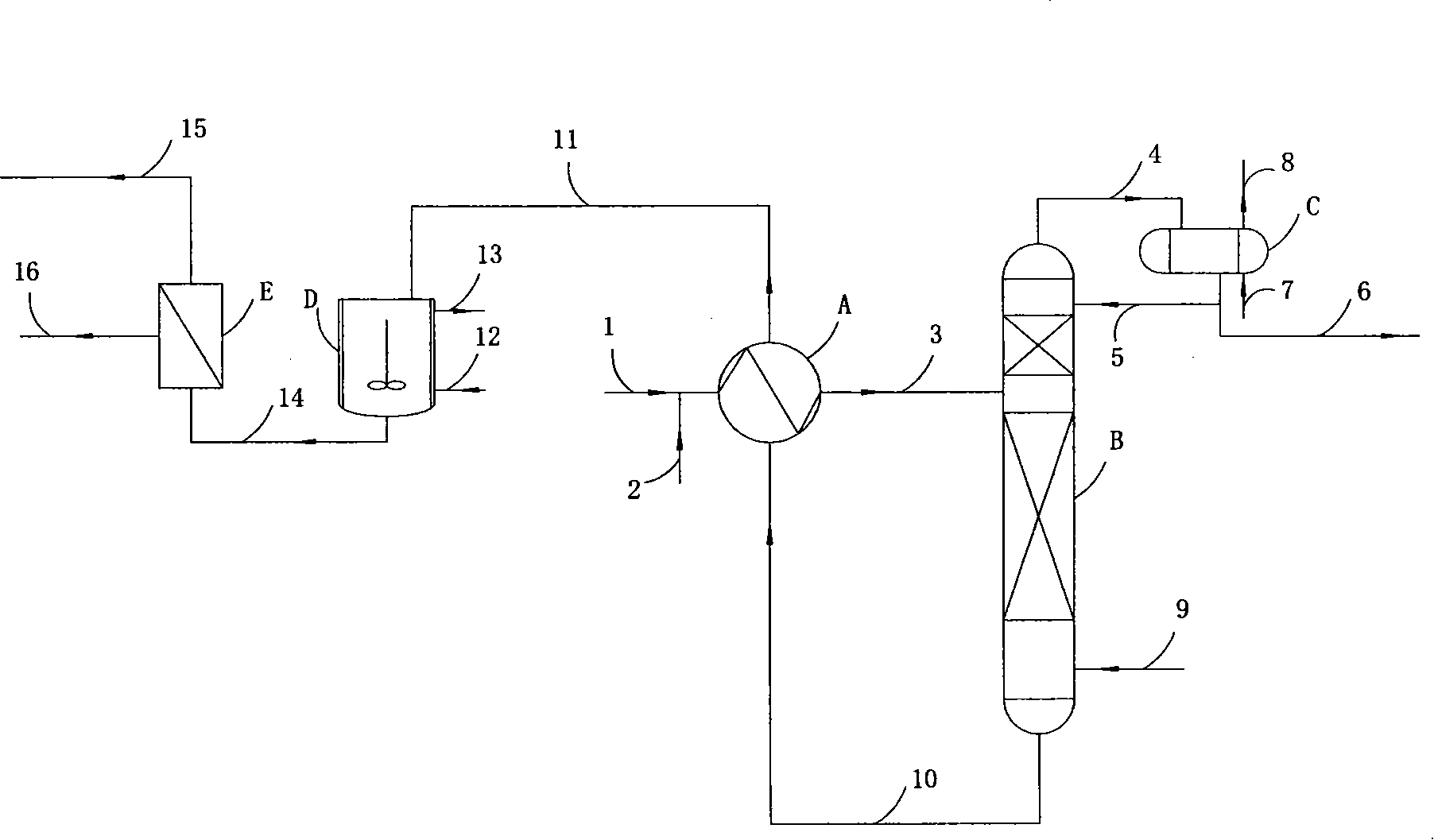

A method for resource processing non-ferro metals processing wastewater containing ammonia and sulfate radical

ActiveCN101161596AHigh practical valueEliminate pollutionWater contaminantsWaste water treatment from metallurgical processSulfate radicalsSodium sulfate

The invention relates to a novel process for recycling treatment for waste water which contains ammonia and sulfate radicals and is produced in the process of non-ferrous metal processing. The invention is characterized in that: sodium hydroxide is added into the waste water to convert ammonium ions in the waste water into molecular ammonia; then the waste water is heated by heat resource in a rectification tower; the ammonia in the waste water enters into a condenser in the form of gas from the top of the tower to be cooled into liquid ammonia and partial liquid ammonia returns, thus the remainder becomes the product; the water removed of ammonia exchanges heat with the waste water to be treated and then continues to be cooled, thus sodium sulfate crystals are obtained; the water removed of sodium sulfate removed is removed also sulfate radicals and ammonia, and can directly return to a production plant. The invention has a combined process of ammonia rectification recycle and sodium sulfate cooling crystallization, ensures the recycling use of the water as the ammonia in the water is reclaimed in the form of liquid ammonia or ammonia water as well as the sulfate radicals are reclaimed in the form of sodium sulfate, retains valuable metal ions in the water, and improves the recycling rate of the resource. In a word, the process can realize the recycling utilization of ammonia-nitrogen waste water produced by non-ferrous metal processing, has a simple process flow, is suitable for large-scale industrial production, and has both economic and environmental benefits.

Owner:BEIJING CYCLE COLUMBUS ENVIRONMENTAL SCI & TECH

Formulations and methods for removing heavy metals from waste solutions containing chelating agents

ActiveUS20140124447A1Waste water treatment from quariesSolid sorbent liquid separationHeavy metalsChemistry

Described are chemical formulations that remove heavy metals from waste solutions containing a chelating agent. Also disclosed are methods for removing heavy metals from waste solutions utilizing such chemical formulations.

Owner:THATCHER CO INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com