Technique and system for zero discharging treatment of electroplating effluent

A technology for electroplating wastewater and treatment systems, applied in metallurgical wastewater treatment, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of high evaporation cost, increase process load, etc., to ensure water inflow Water quality, simple structure, and the effect of avoiding waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

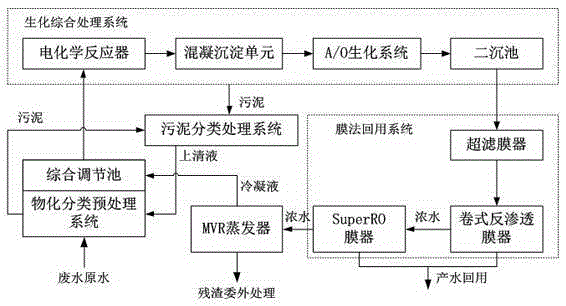

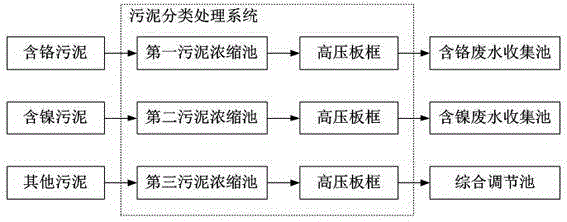

[0032] Such as Figure 1 to Figure 3 As shown, the zero-discharge treatment system for electroplating wastewater includes a physical and chemical classification pretreatment system, a biochemical comprehensive treatment system, a membrane recycling system, and a membrane concentrate evaporation system connected in sequence, as well as a physical and chemical classification pretreatment system and a biochemical comprehensive treatment system. A sludge classification treatment system connected to each other, wherein the raw waste water enters the physical and chemical classification pretreatment system, the membrane reuse system produces water for reuse, and the condensate output of the membrane concentrate evaporation system is reinjected into the physical and chemical classification pretreatment system. processing system.

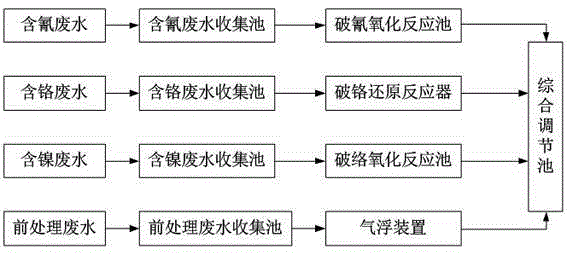

[0033] Further, the physical and chemical classification pretreatment system includes a cyanide-containing wastewater collection pool, a chromium-containin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com