Patents

Literature

1188 results about "Electroplating wastewater" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

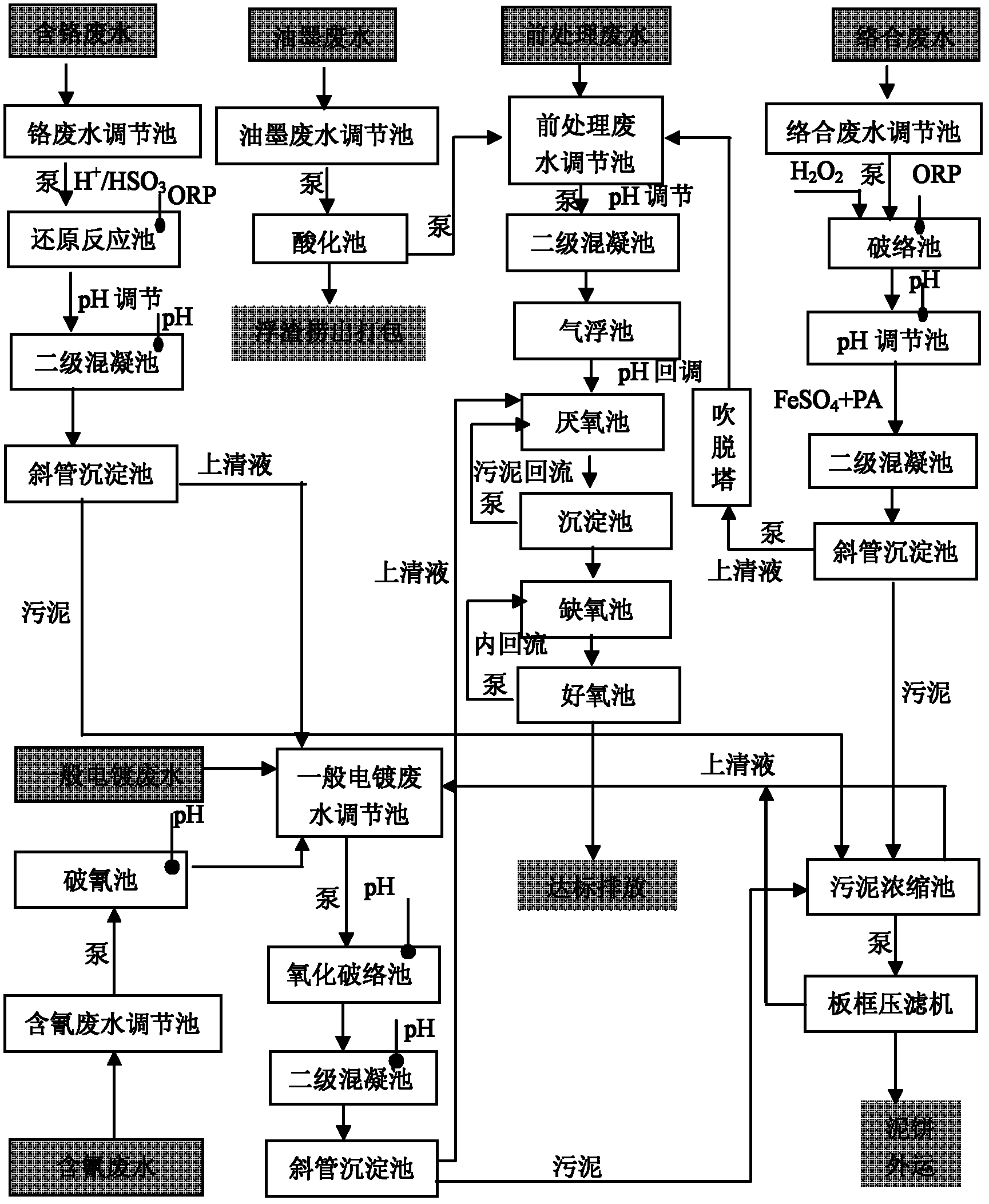

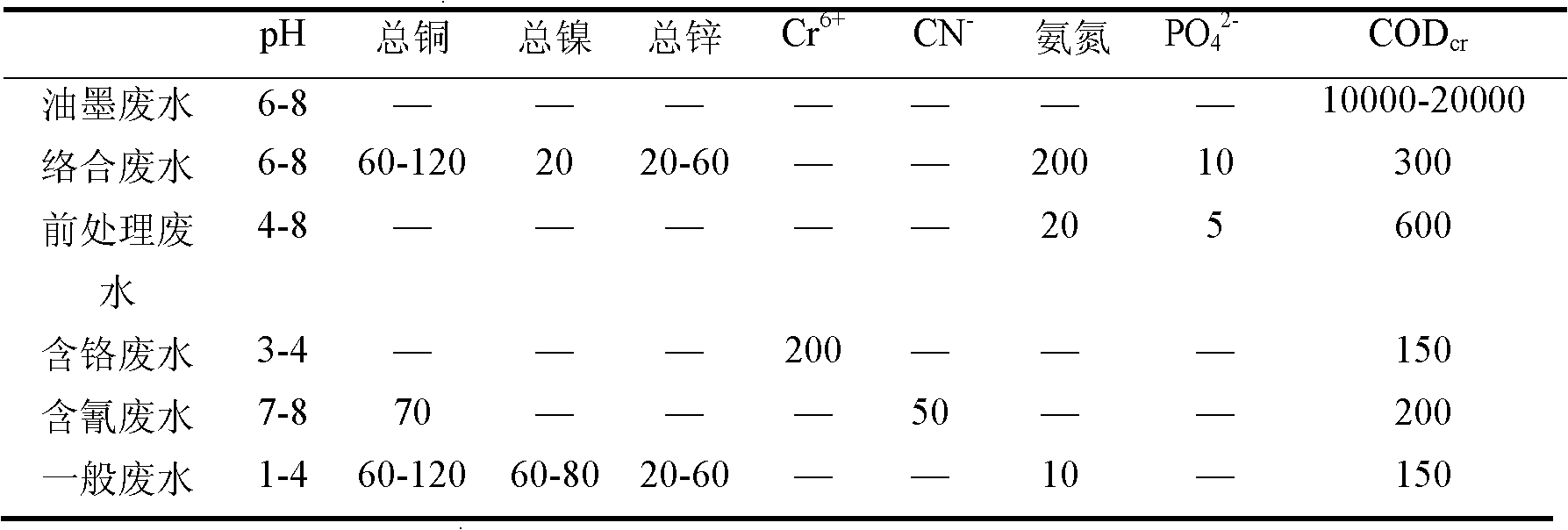

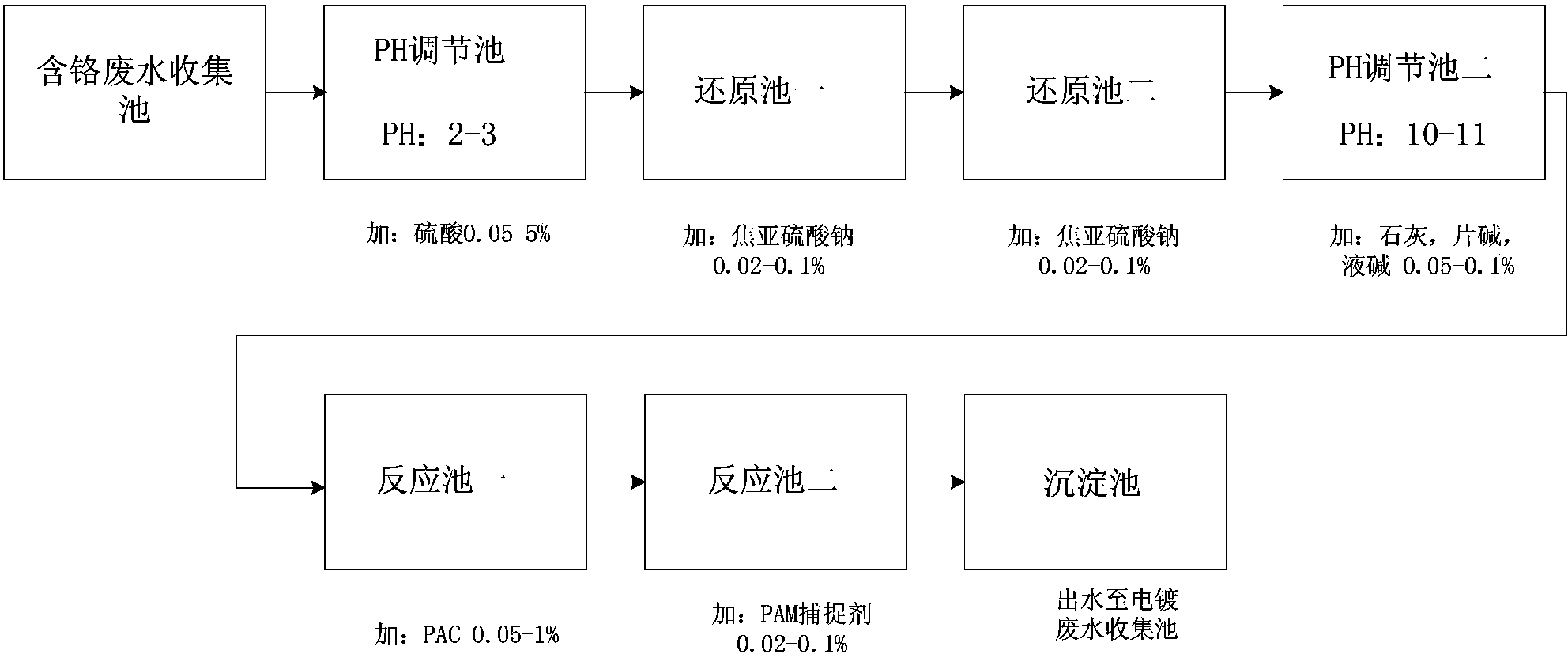

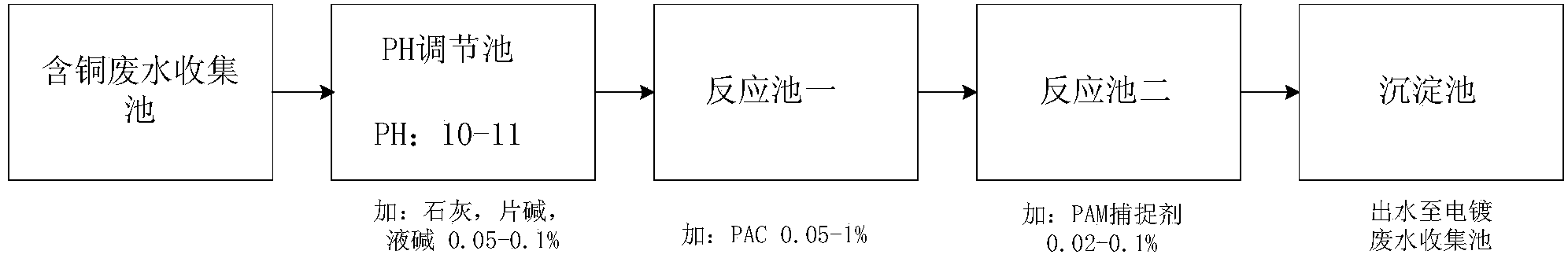

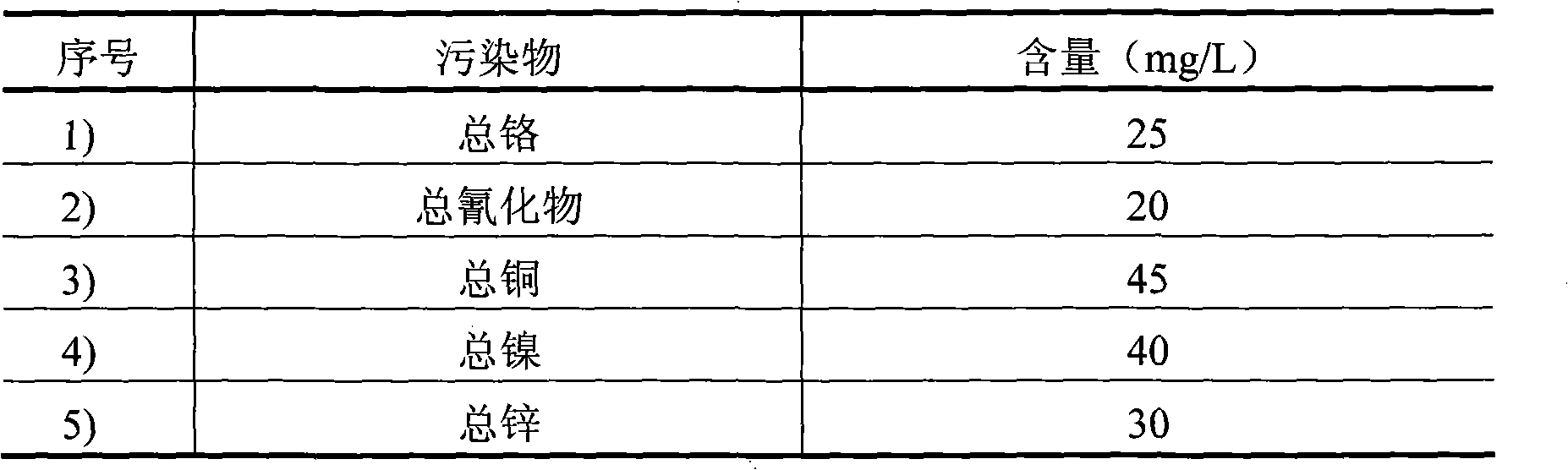

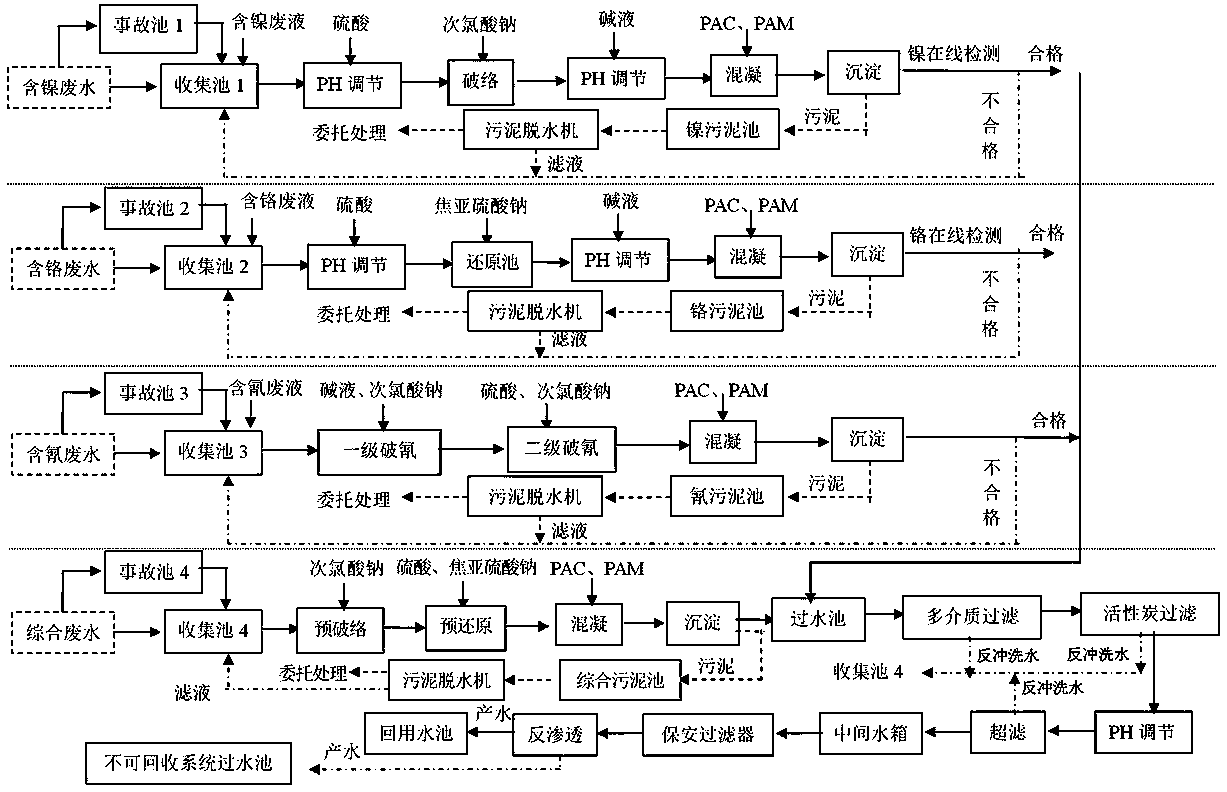

Electroplating Wastewater Treatment System Process Description. Electroplating wastewater comes from surface plating operations where the metal is dipped in an electroplating solution of various types of metals and then rinsed. Typical plating includes brass, nickel, cadmium, zinc, silver, copper, and gold.

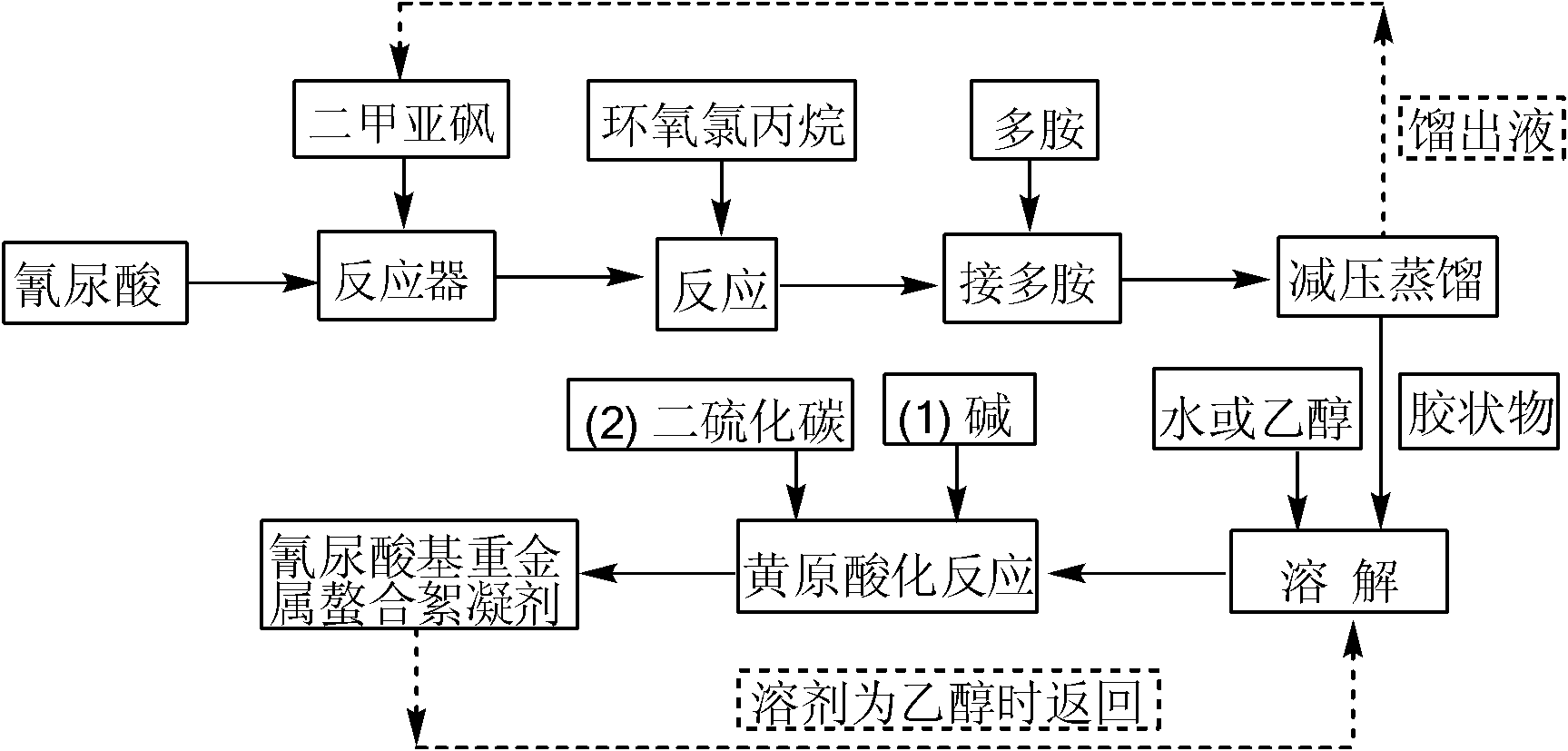

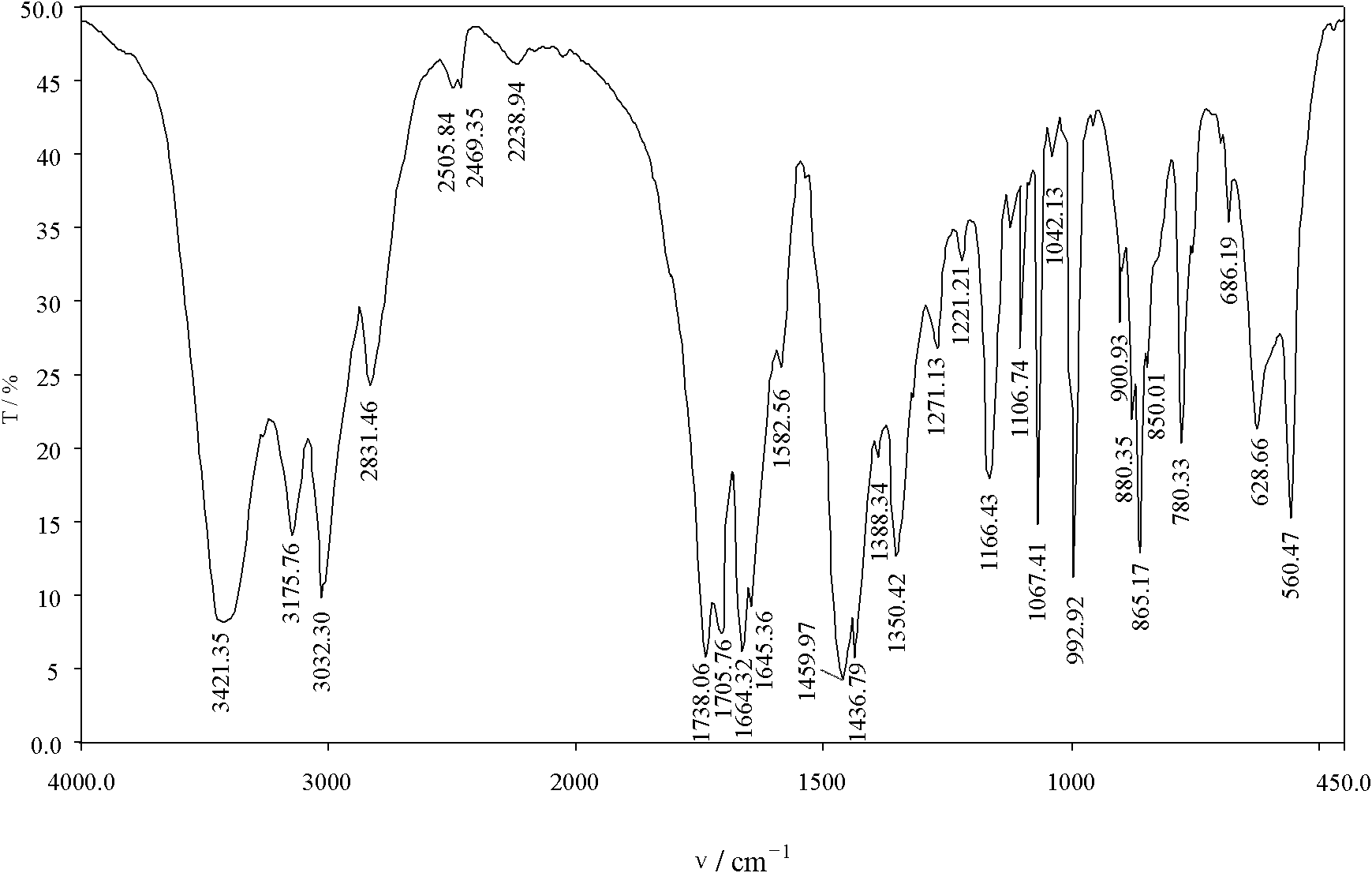

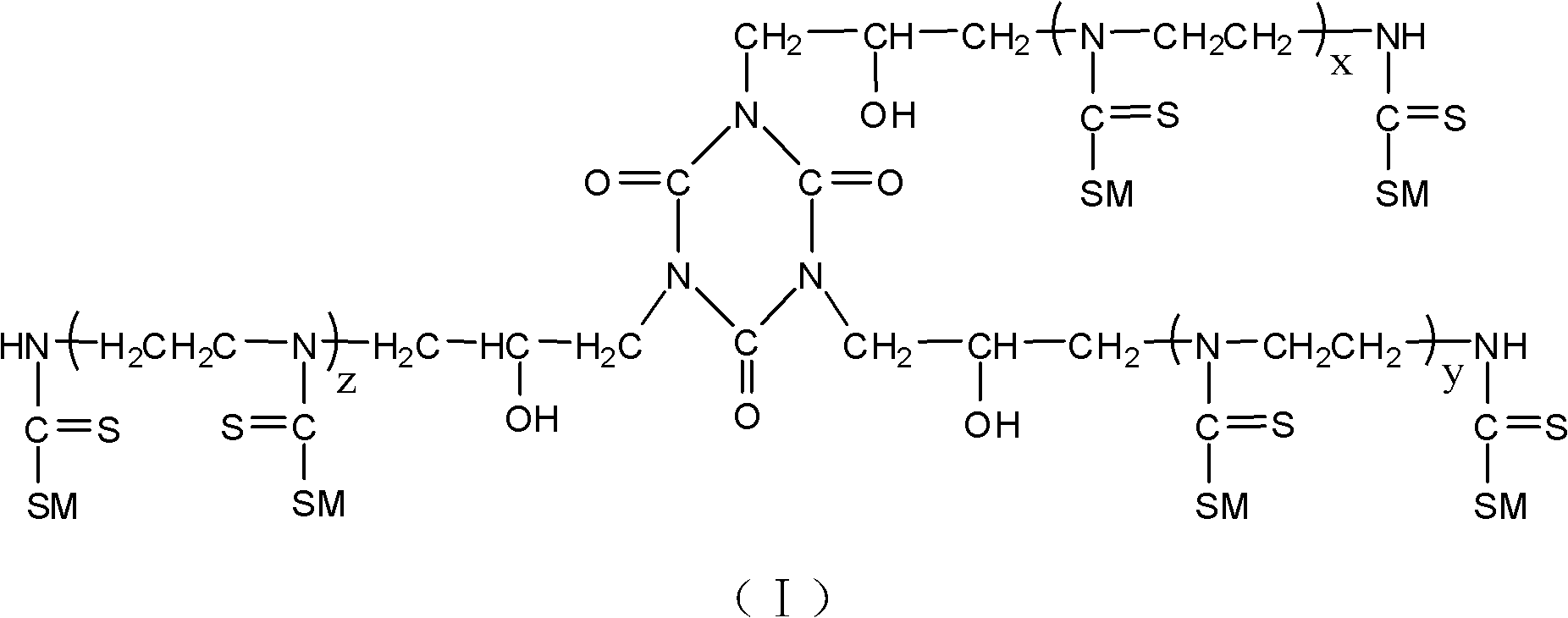

Cyanuric acid-based heavy metal chelating flocculant and preparation method thereof

InactiveCN101863544AOvercome the defect that the ion concentration is difficult to reach the standardIncrease steric hindranceWater/sewage treatment by flocculation/precipitationEpoxyHeavy metal chelation

The invention belongs to the technical field of heavy metal wastewater treatment, and in particular relates to cyanuric acid-based heavy metal chelating flocculant and a preparation method thereof. In the method, cyanuric acid is adopted as a basic framework; and polyamine is connected to a molecule through epoxy chloropropane, and reacts with carbon disulfide in an alkaline condition to prepare the heavy metal chelating flocculant of which the molecule contains a plurality of branches and a plurality of dithio formate functional groups. The method overcomes the defects that the conventional monofunctional flocculant has small flocculating body, and poor precipitation performance, and when polymeric chelant chelates heavy metals, steric clash is great, and the residual heavy metal ion concentration is difficult to meet the standard and the like. The flocculant has the advantages of simple preparation process, mild condition, easy operation and control, high yield, high raw material utilization, less three waste discharge and environmental protection of technical process, convenient popularization and industrialization realization and suitability for treatment of various types of heavy metal wastewater, such as smelting wastewater, electroplating wastewater, nonferrous metals processing wastewater, mining and beneficiating wastewater, printed circuit board wastewater, battery plants and the like.

Owner:HUNAN UNIV OF SCI & TECH

Comprehensive electroplating wastewater treatment method

ActiveCN102531296AAchieve emission standardsReduce manufacturing costMultistage water/sewage treatmentChemical treatmentWater quality

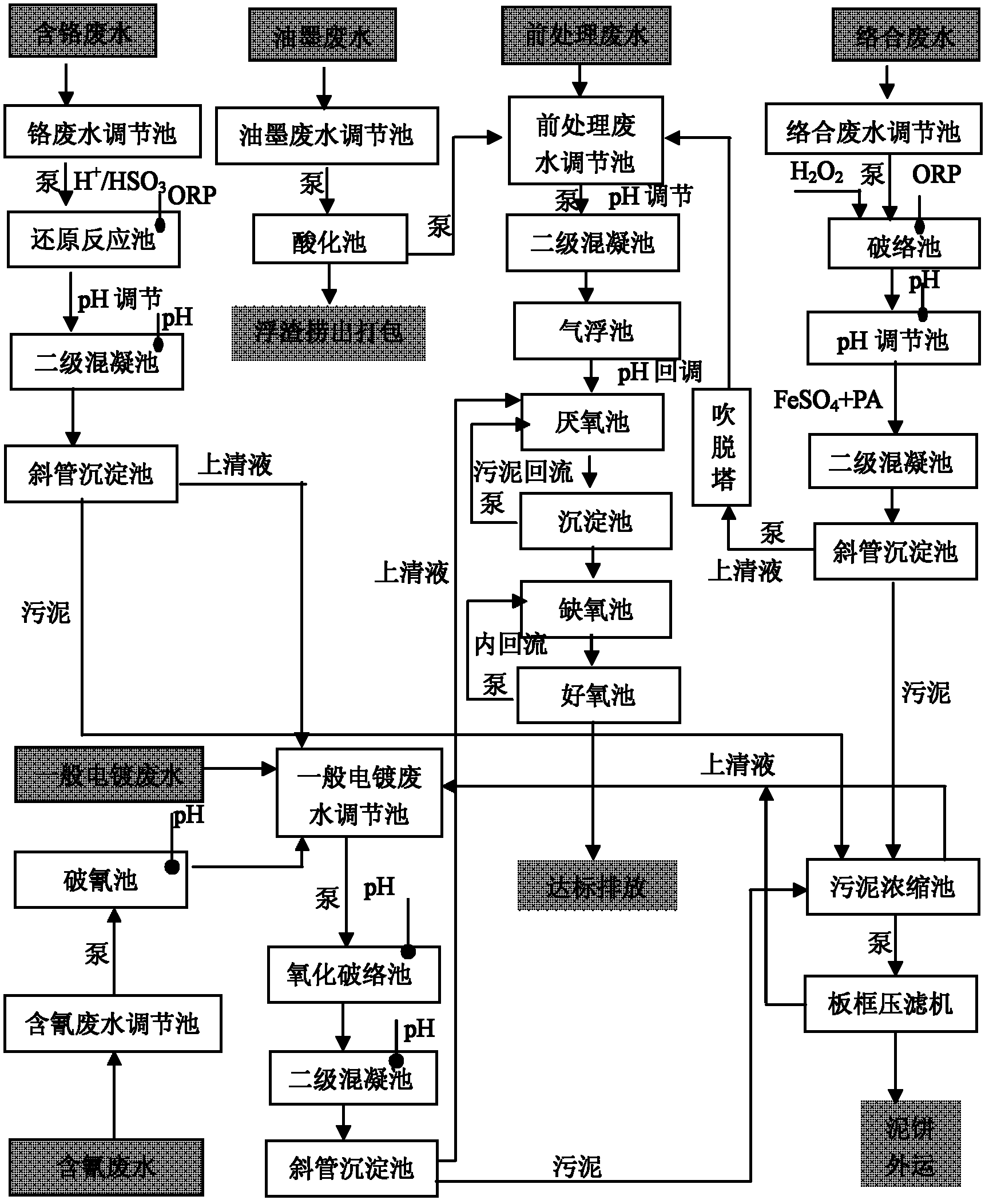

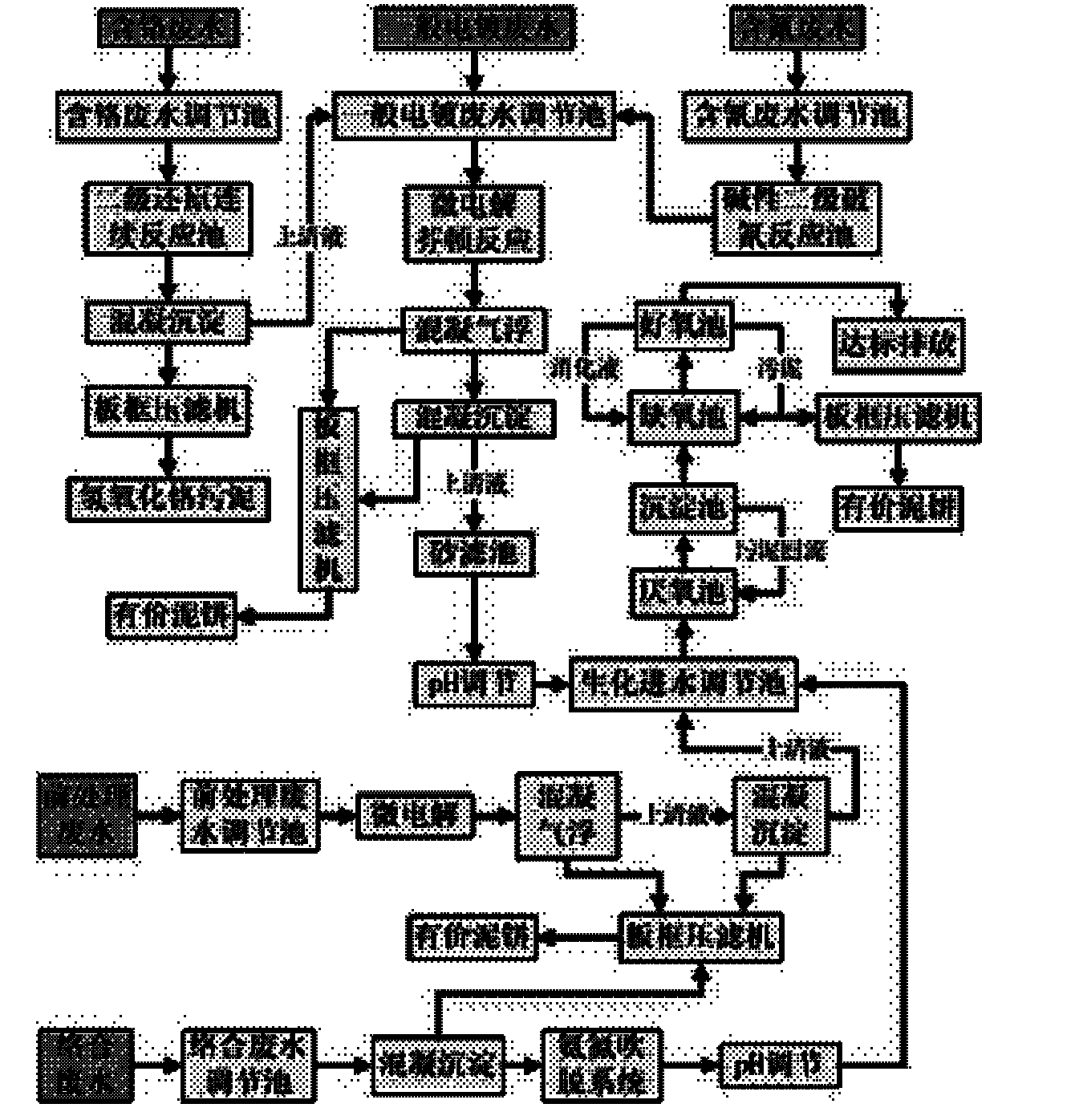

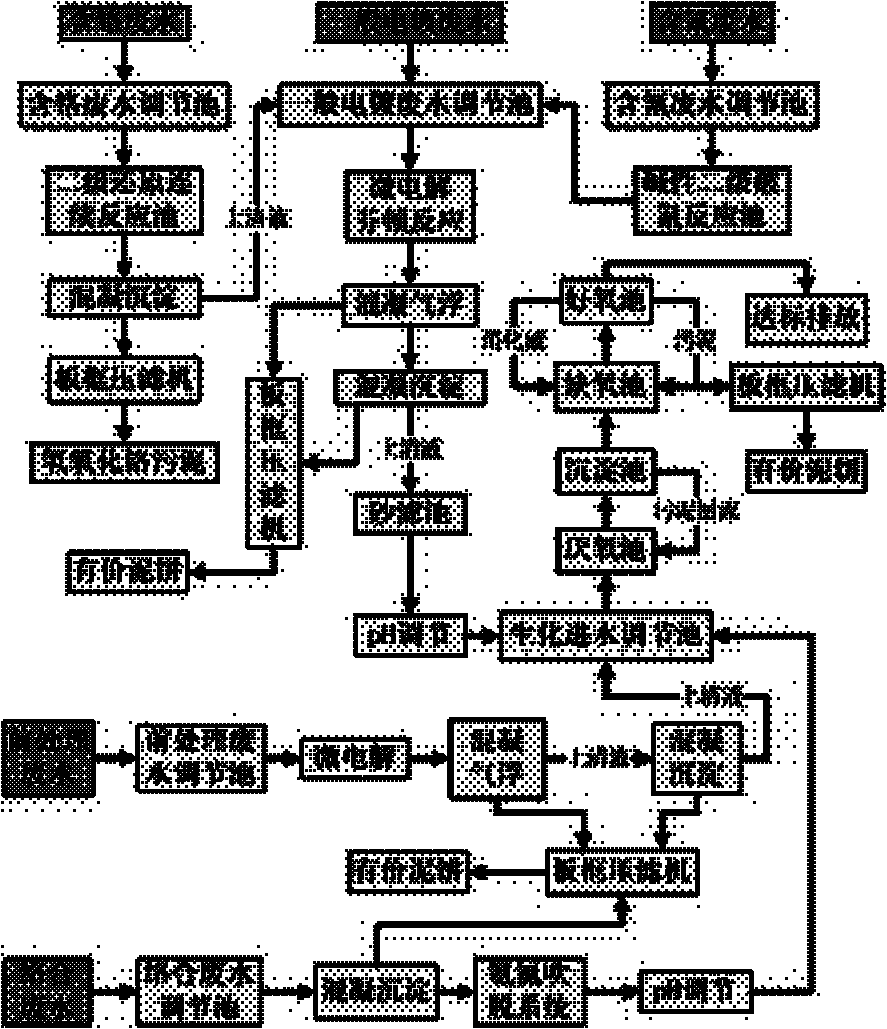

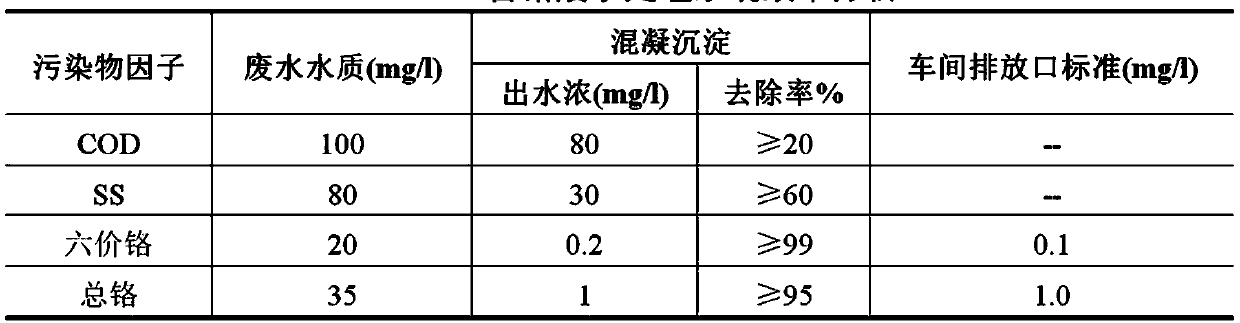

The invention relates to a comprehensive electroplating wastewater treatment method. The electroplating wastewater is divided into six brand-new classes, a chemical and biochemical combined process is adopted, a separate system drainage pipe network is adopted, the electroplating wastewater is divided into ink wastewater, complex wastewater, pretreatment wastewater, cyanogen-containing wastewater, chromium-containing wastewater and common electroplating wastewater, the six classes of wastewater respectively flows into respective underground adjusting tank through the pipe network, and is treated by respective process, and the effluent is discharged after reaching a standard. Because of the scientific water separating and stepwise pretreatment of a front-end chemical treatment part, different pollutants are respectively removed in different process sections according to characteristics, crossed enrichment and mutual reaction of the different pollutants are reduced to the greatest extent, and the pressure of microorganisms in the biochemical process is reduced. Treatment facilities for the six classes of wastewater are mutually connected and relatively dependent, and when inlet water quality fluctuates, a corresponding section is only required to be adjusted, the whole process is not influenced, the management is scientific and orderly, and operational risks are reduced.

Owner:SHENZHEN YINTAI ENVIRONMENTAL PROTECTION ENG TECH +2

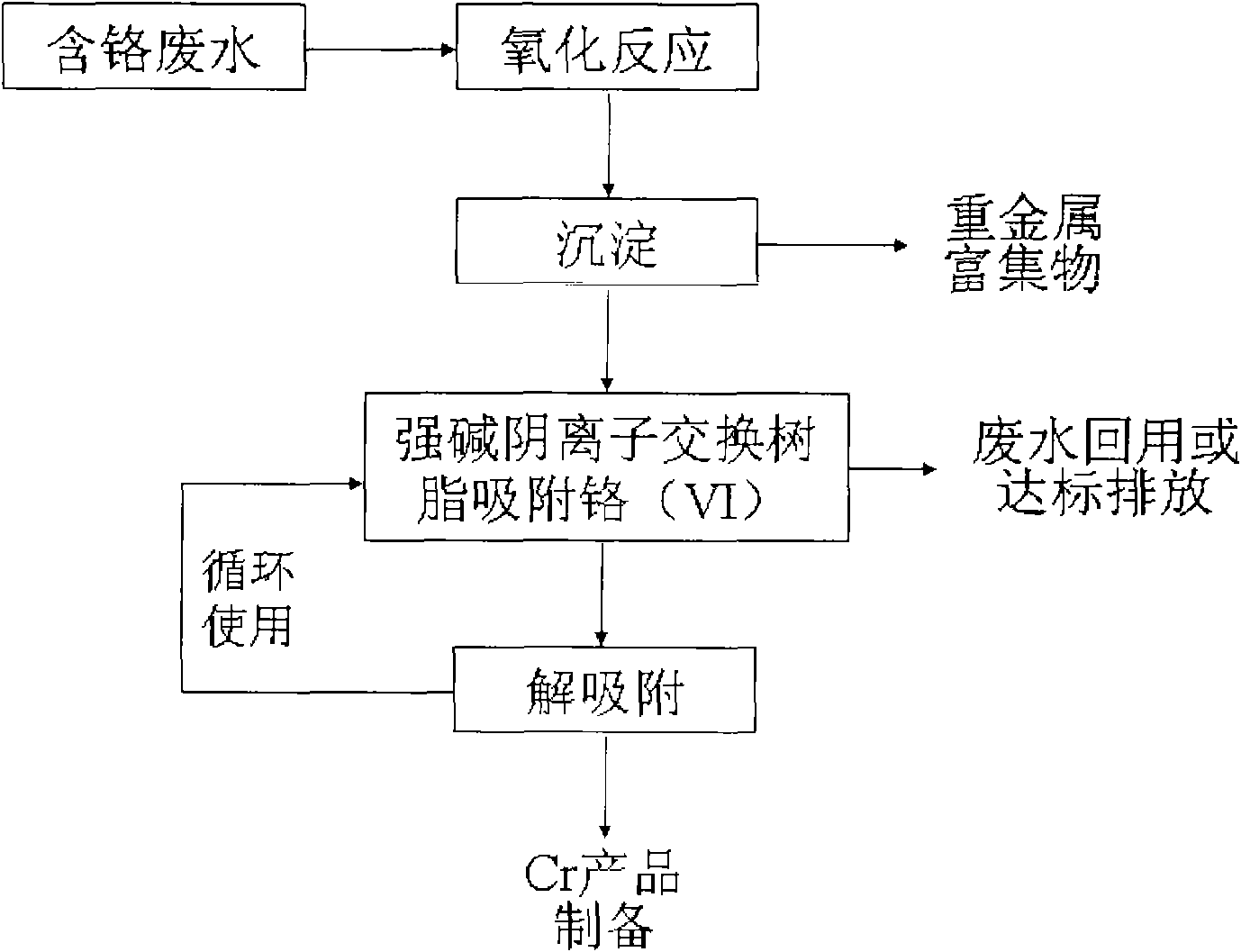

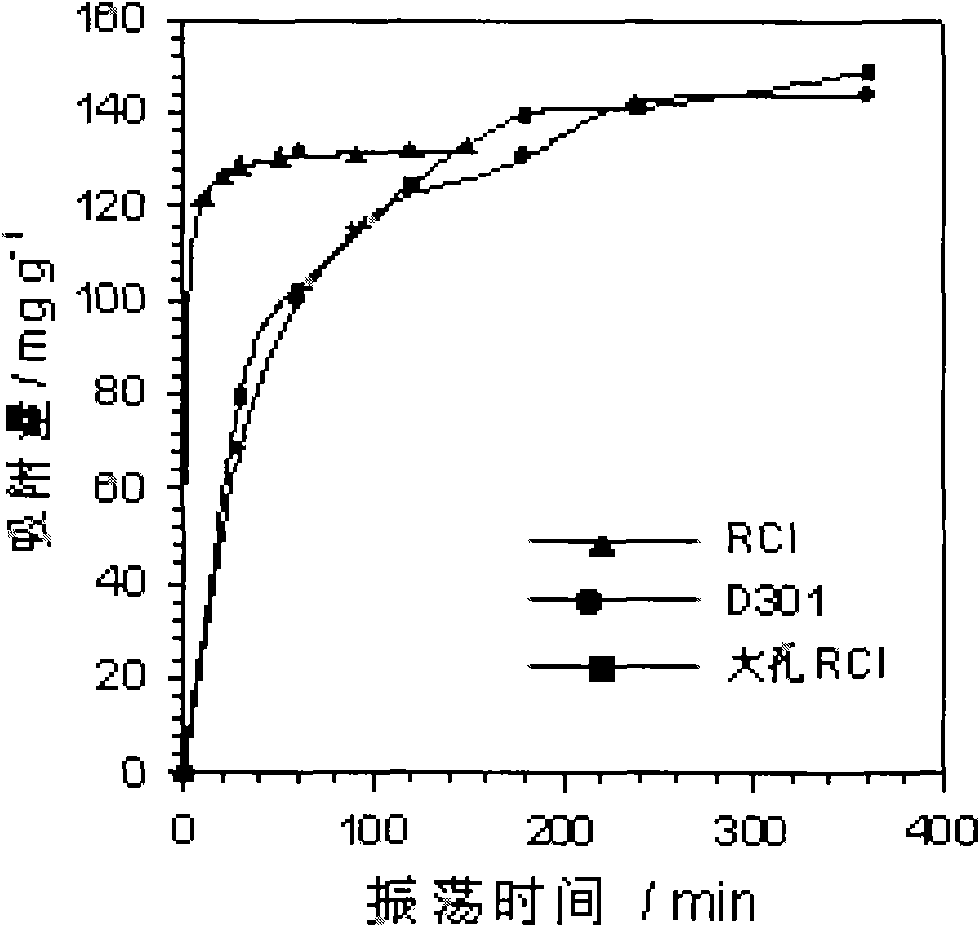

Method for purifying electroplating wastewater and comprehensively utilizing resources

ActiveCN101570372AImprove adsorption capacityEasy to separateWater contaminantsWater/sewage treatment by ion-exchangeChemical reactionWater quality

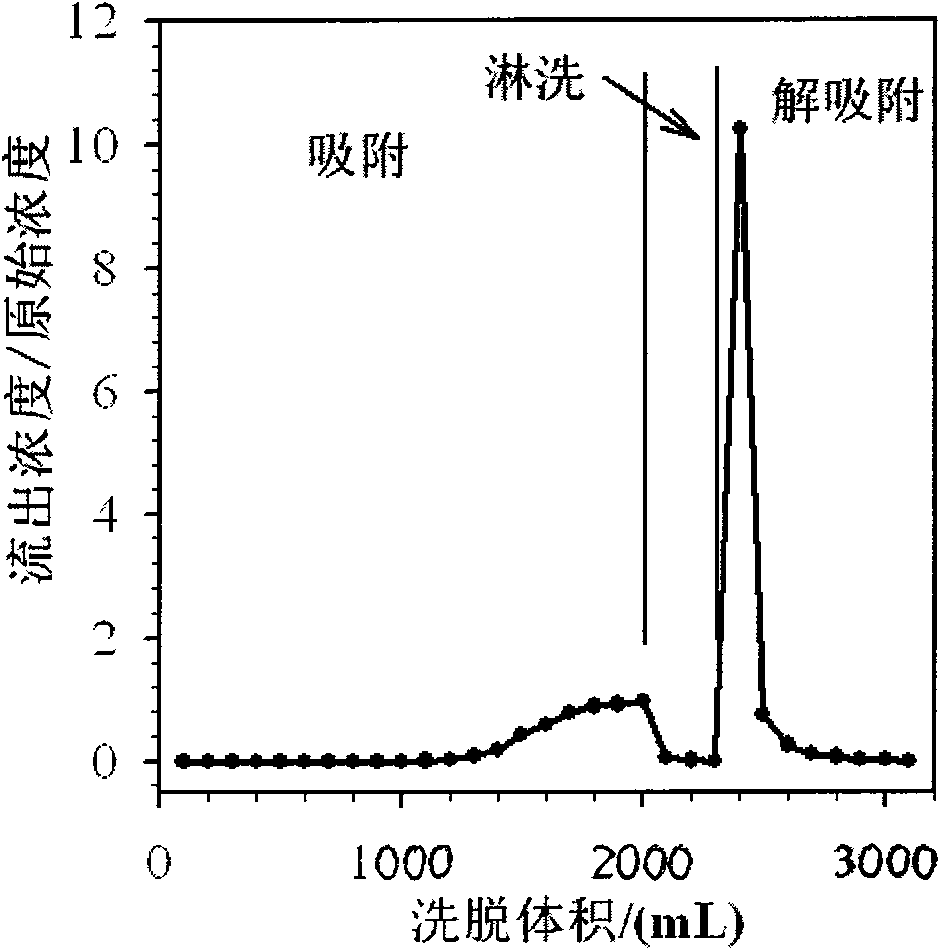

The invention relates to a method for purifying electroplating wastewater and comprehensively utilizing resources, which is to adopt low-cost strong basic anion-exchange resin containing macropores and imidazole structure to reclaim valuable resources in the electroplating wastewater by coupling technology based on a chemical oxidation-reduction method, a precipitation method and an ion exchange method. The method comprises the following steps: firstly, Cr(III) is oxidized into Cr(VI) under basic condition through a chemical reaction; then, Zn, Cu, Ni and other heavy metal elements in the wastewater are transformed into precipitation of hydroxide; and finally, the Cr(VI) in the wastewater is adsorbed by the strong basic anion-exchange resin, the purified water quality achieves the requirement of electroplating pollutant discharge standard and recycle, and the Cr and other heavy metal resources in the electroplating wastewater can be comprehensively reclaimed and utilized. The method overcomes the defects that the prior regenerating process of porous weak-basic resin requires acidification, and the method has the advantages of simple process, low treatment cost, large treatment quantity and acid and base consumption conservation, and is the electroplating wastewater treatment method with green environmental protection and efficient utilization of resources.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

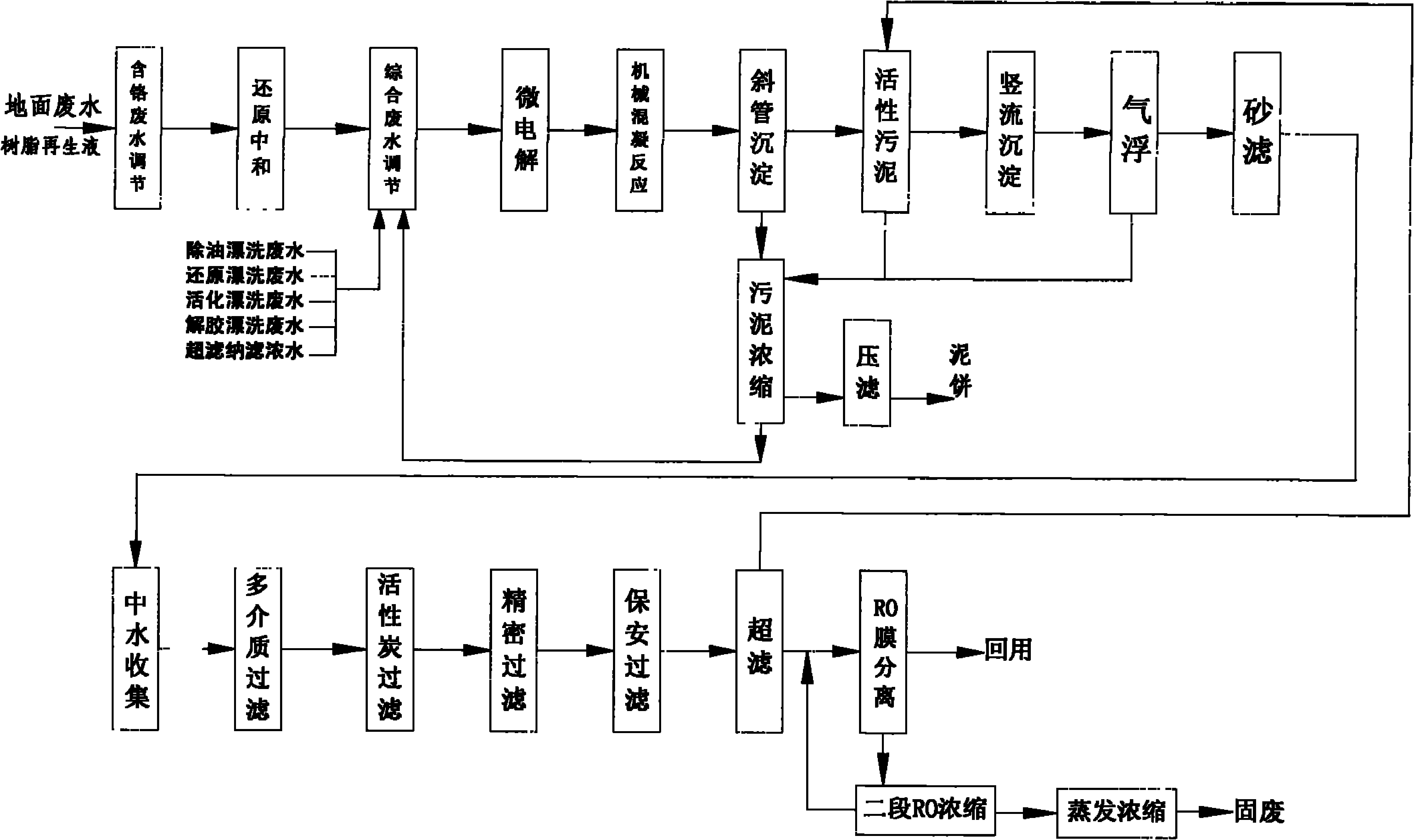

Method for treating comprehensive electroplating wastewater

InactiveCN101830600AAchieve environmental goalsAchieve emissionsWater contaminantsWaste water treatment from metallurgical processChemical oxygen demandElectrolysis

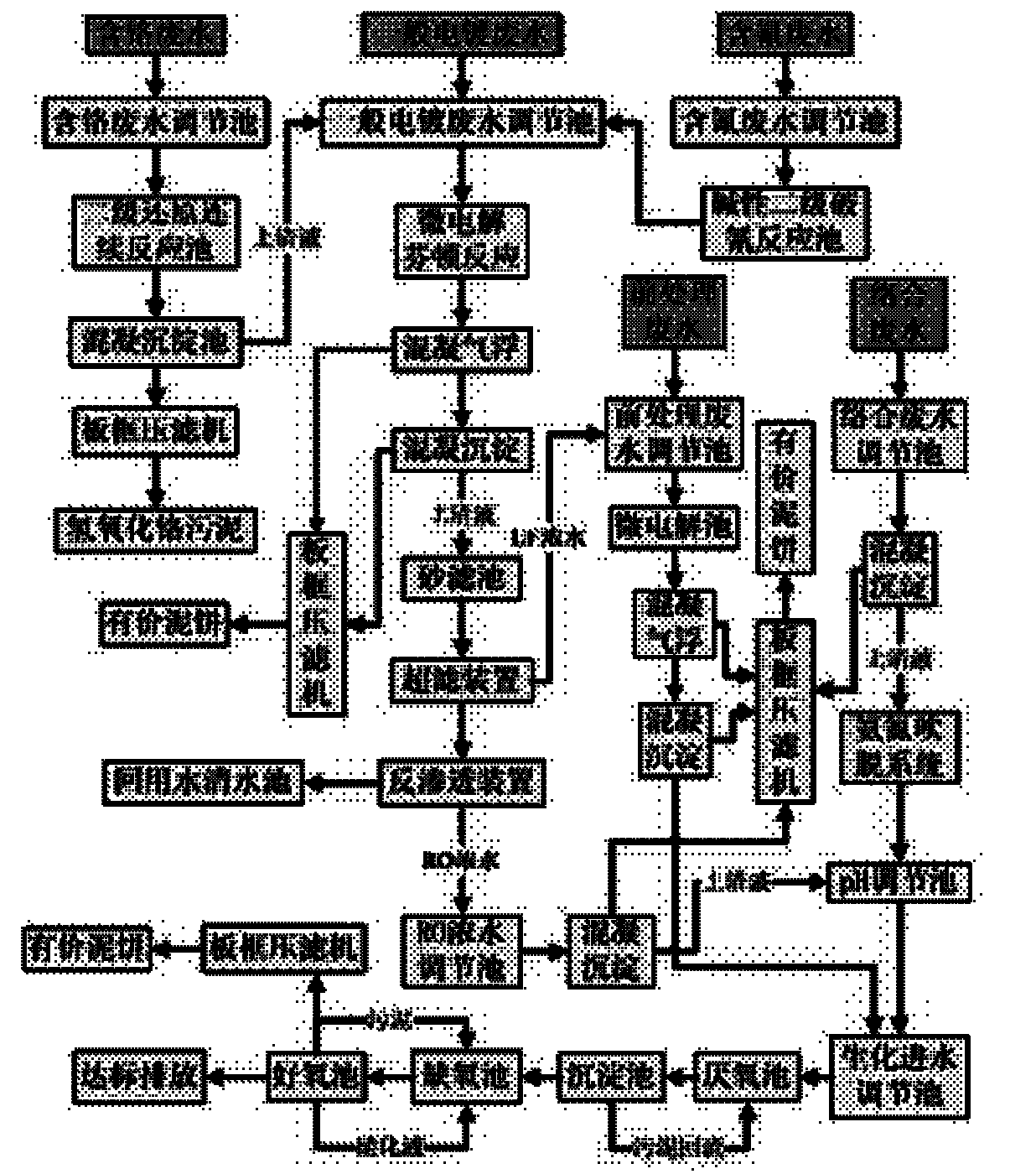

The invention relates to a method for treating comprehensive electroplating wastewater. The electroplating wastewater is separated and the recycling utilization rate of heavy metals resources can be improved by carrying out targeted treatment on each strand of separated water while improving the treatment efficiency. By using the micro-electrolysis function of iron and carbon, complex can be removed while removing COD (Chemical Oxygen Demand) and the biochemical property can be improved, which provides the guarantee for a subsequent biochemical reaction. By using the displacement action of the ion and the carbon, heavy metal ions in the water can be displaced and heavy metal resources can be recycled. Meanwhile, residual heavy metal ions in the water can be recycled by using the combining action of precipitating hydroxides and sulfides. On the basis, the water quality can meet the standard by using the ultrafiltration and reverse osmosis actions. The total hardness and the electric conductivity of the wastewater are superior to the water quality of tap water. Usable metal resources can be recycled, the economic benefit is obtained while achieving the aim of environmental protection and the production cost can be reduced.

Owner:TIANJIN UNIV

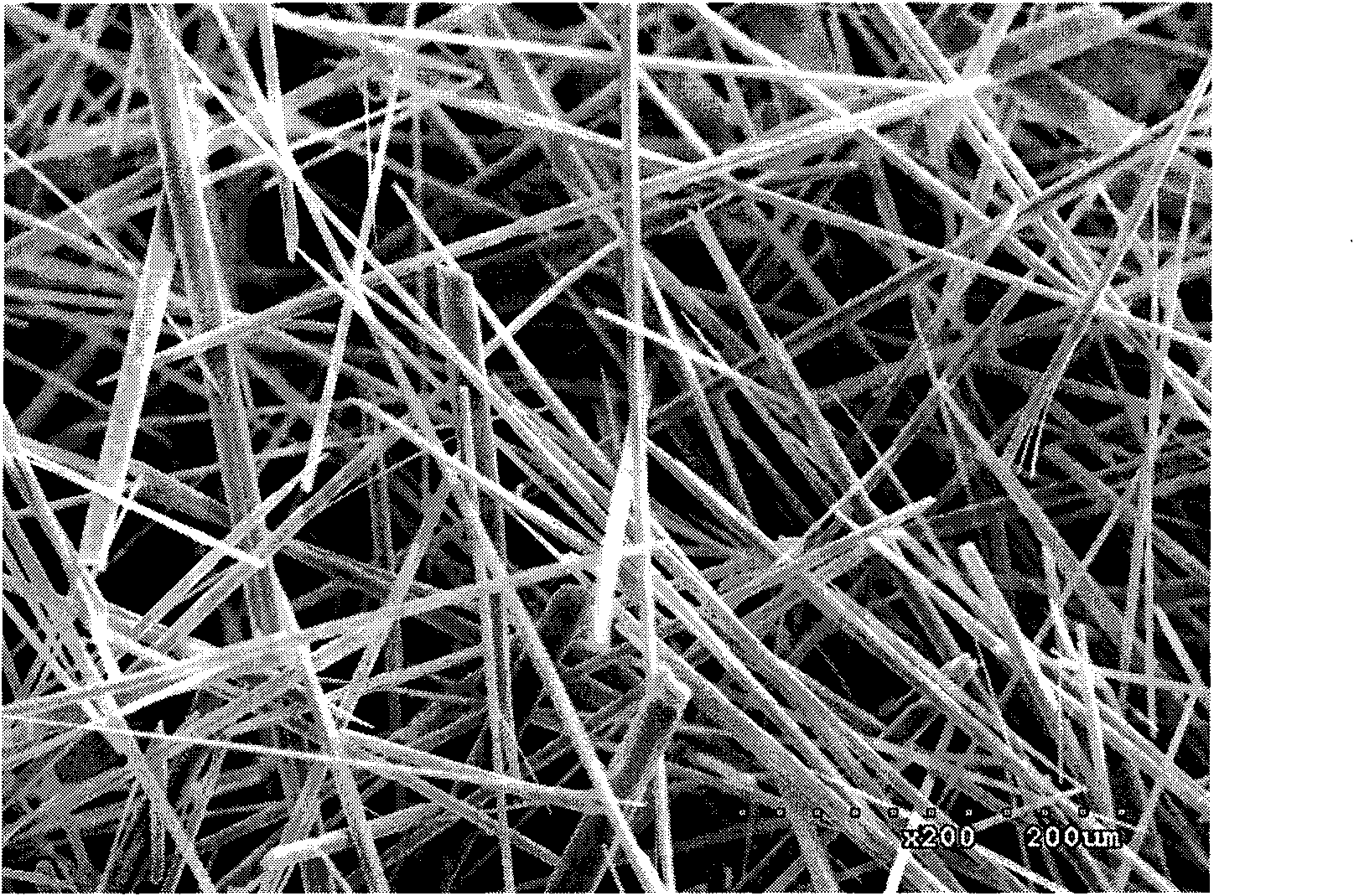

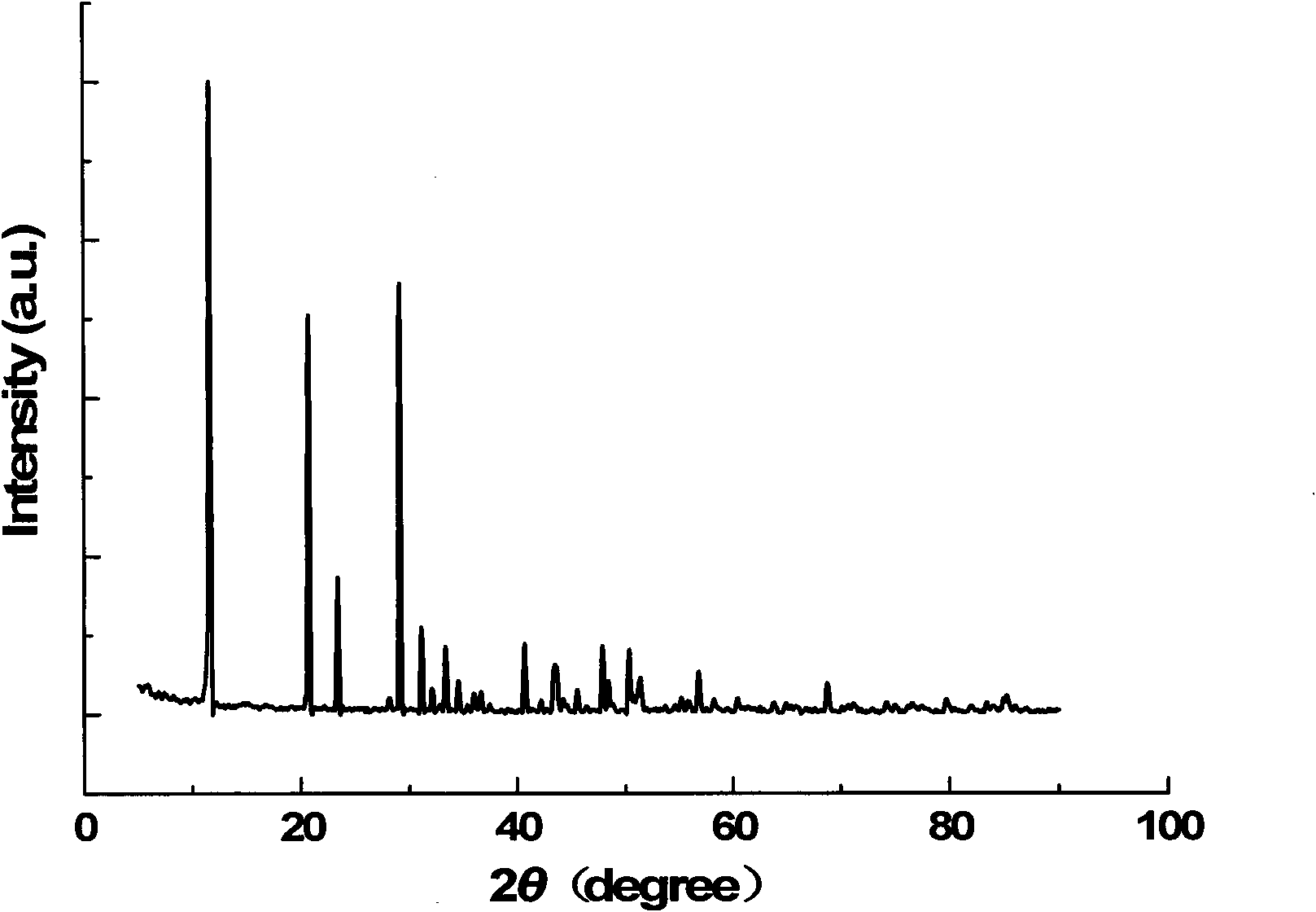

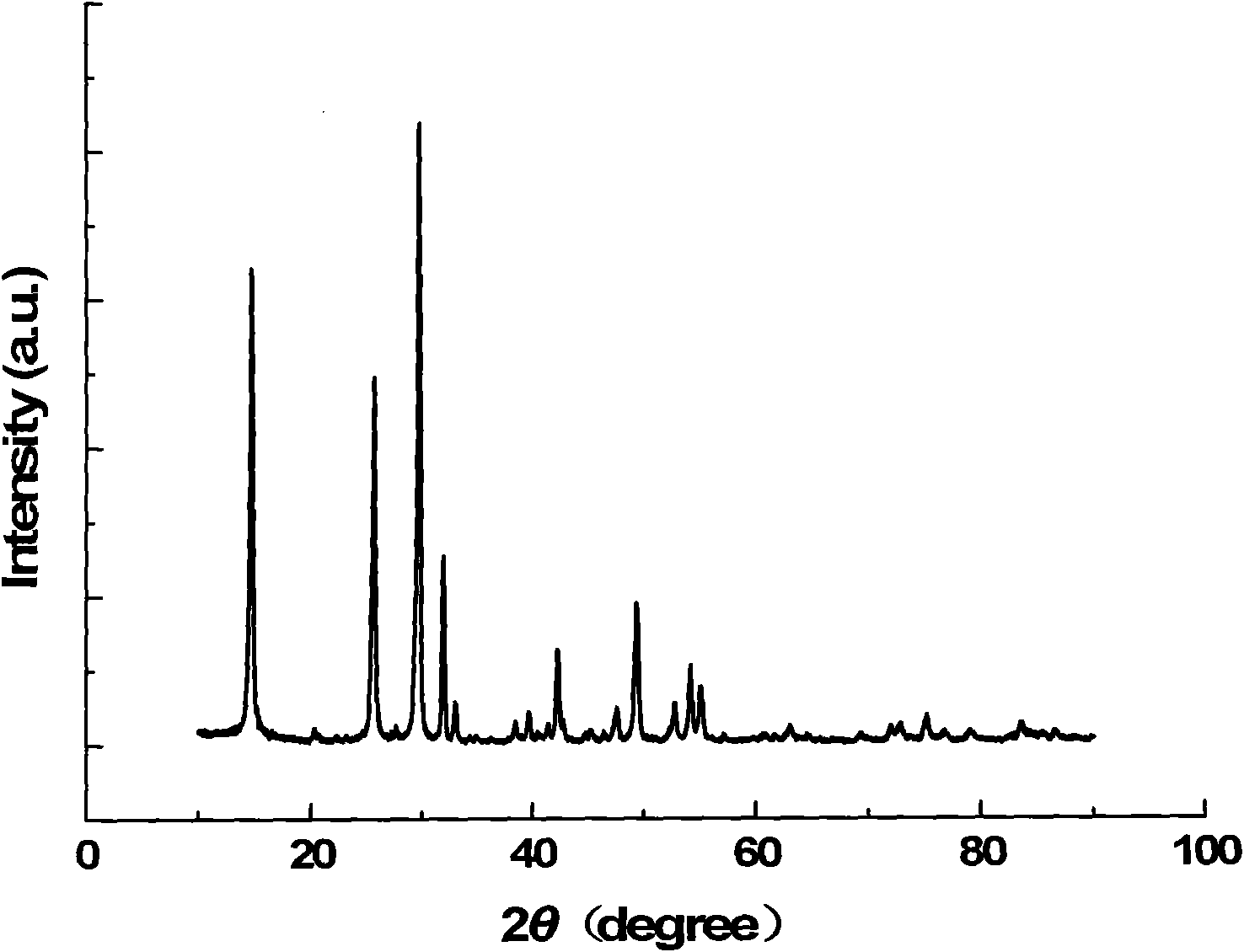

Method for producing dehydrated calcium sulfate whisker

InactiveCN101550585ANo emissionsReduce manufacturing costPolycrystalline material growthFrom normal temperature solutionsAnhydrous Calcium SulfateLixiviant

The invention provides a method for producing dehydrated calcium sulfate whisker, comprising: using copper, lead, zinc, aluminium, nickel, cobalt, stannum, non-ferrous metal secondary resource cycle utilizing, calcium nitrate solution produced in treating process of electroplating waste, calcium chloride solution, or mixed water solution of calcium nitrate and calcium chloride as raw material, using sulfuric acid as calcium ion precipitant, adding whisker shape regulating agent, controlling reaction condition, regenerating aqua fortis or hydrochloric acid lixiviant, and simultaneously producing ultralong and big length to diameter ratio calcium sulphate dihydrate whisker. After calcium sulphate dihydrate whisker is deposited from calcium nitrate solution, calcium chloride solution or the mixed solution of calcium nitrate and calcium chloride are deposited, the water solution is translated to be nitric acid solution, hydrochloric acid solution or a mixed solution of nitric acid and hydrochloric acid, returning back to leaching out or treating process for processing non-ferrous metal mineral substance, non-ferrous metal secondary resource or electroplating remove. The calcium sulphate dihydrate whisker is treated by microwave heating, forming calcium sulfate hemihydrate or anhydrous sulphate of calcium after dehydration.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Comprehensive electroplating wastewater treating agent

InactiveCN103991916AEasy to useSimple processWater contaminantsWaste water treatment from metallurgical processChemical oxygen demandPollution

The invention relates to a comprehensive electroplating wastewater treating agent. The comprehensive electroplating wastewater treating agent is composed of the following components in percentage by mass: 10-35% of reducing agent, 20-50% of sulfide, 10-30% of aluminum salt, 10-30% of adsorbing material and 5-15% of alkaline substances. The raw materials of the treating agent provided by the invention are low in cost and easy to obtain, and the treating agent is easy to prepare; through compounding the raw materials, a synergistic effect is exerted, and the treating agent is favorable in broad spectrum, capable of effectively removing heavy metals such as nickel, chromium, copper, zinc and the like, high in removal rate up to more than 96% and relatively good in COD (Chemical Oxygen Demand) removal effect; the comprehensive electroplating wastewater treating agent also has the characteristics of strong electroplating wastewater treating capacity, high heavy metal ion sedimentation speed and efficiency, no secondary pollution after treatment and the like; in addition, the treating agent provided by the invention is convenient to use, simple and feasible in treating process, capable of realizing operation by only using a vessel or pool with an aerating agitation device, reducing the floor area and reducing the investment, and easy to realize operation management.

Owner:浙江一清环保工程有限公司

Electroplating wastewater treatment reclaiming technique

ActiveCN101041534AReduce contentHigh desalination rateTreatment using aerobic processesGeneral water supply conservationFiltrationUltrafiltration

The invention discloses a reclaimed craft to dispose electroplating waste water, which comprises the following steps: adopting oxidation-reduction and chemical precipitation disposing method and film technology (fold filtration, hyperfiltration, Na filtration and reverse osmosis desalination) deep purifying method; avoiding accumulation of salt effectively; reverse osmosis sloughing monovalent salt at last grade; trapping bivalent salt in innocent treatment system; proceeding depositing treatment continually; removing accumulating BOD and COD in water body through biochemical treatment effectively; realizing zero discharge of waste water.

Owner:JINAN JINGHENG ELECTRONICS

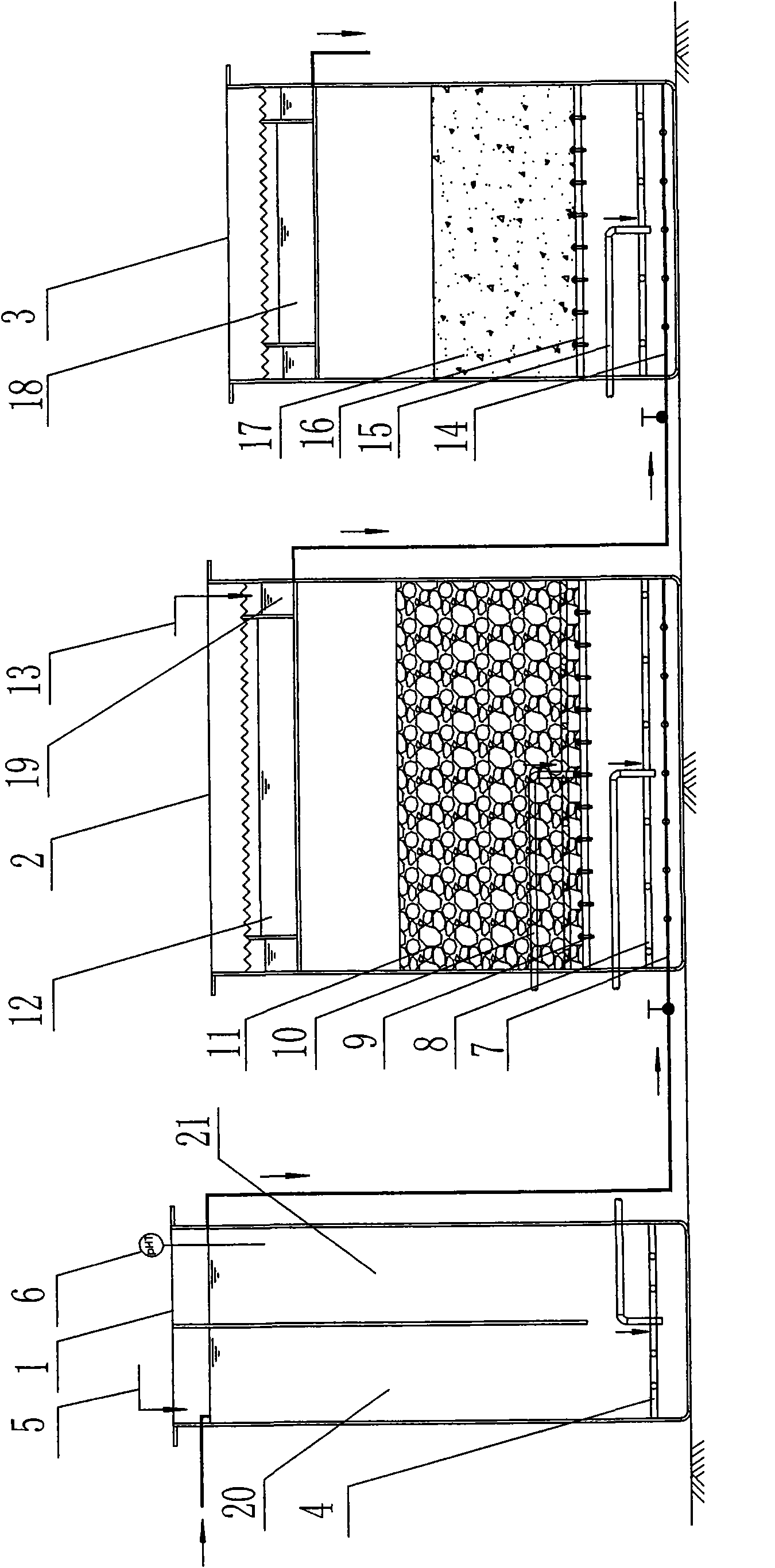

Method and device for multicomponent oxide pretreatment of organic electroplating waste water

InactiveCN101591082AImprove biodegradabilityGood water conditionsWaste water treatment from metallurgical processMultistage water/sewage treatmentPretreatment methodElectrolysis

The invention relates to a method and a device for multicomponent oxide pretreatment of organic electroplating waste water, which belong to the technical filed of electroplating waste water treatment in the environment engineering. The pretreatment method is characterized in that organic electroplating waste water is sequentially subjected to acidity adjustment, ferrum-carbon micro-electrolysis reaction and Fenton oxidation reaction. The corresponding device comprises a pH adjusting tank, a ferrum-carbon micro-electrolysis bath and a Fenton oxidation pond; an acid-alkali feeding device and a pH controller which are in link control are arranged above the pH adjusting tank; the middle low part of the ferrum-carbon micro-electrolysis bath is paved with a ferrum-carbon filler layer, while the bottom is provided with a micro-electrolysis bath perforation water distribution pipe; a hydrogen peroxide feeding device is arranged above the ferrum-carbon micro-electrolysis bath; the bottom of the Fenton oxidation pond is provided with a Fenton oxidation pond perforation water distribution pipe; and the middle lower part of the Fenton oxidation pond is provided with a granular active carbon catalytic carrier layer. The method and the device obviously improve the capability of biochemistry, simultaneously perform oxidation reaction to remove mostly organic pollutants and create favorable water inlet condition for subsequent coagulating sedimentation, air flotation and biochemical treatment.

Owner:CHINA COAL TECH & ENG GRP HANGZHOU ENVIRONMENTAL PROTECTION INST

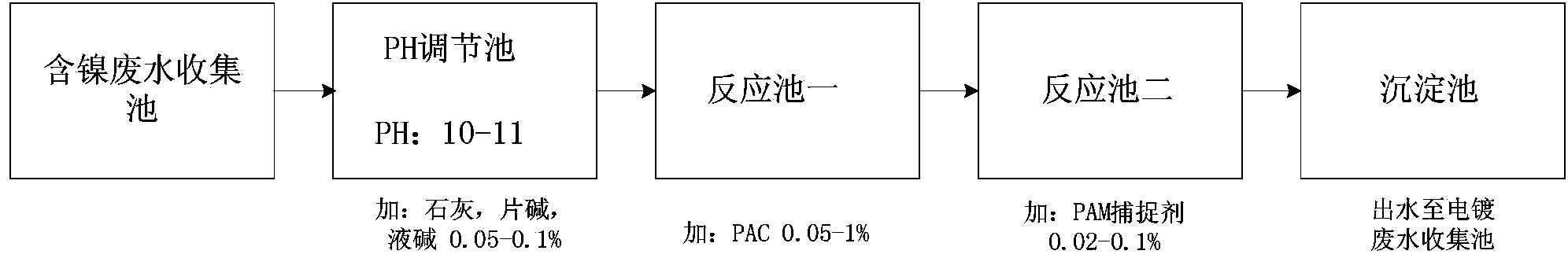

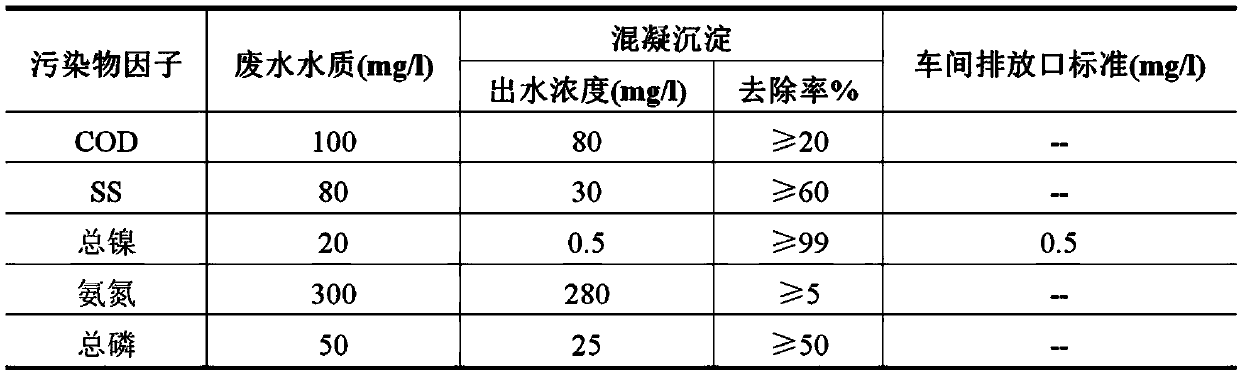

Method for treating complexed chemical nickel electroplating wastewater

InactiveCN103833123AImprove processing efficiencyGood effectWaste water treatment from metallurgical processWater/sewage treatment by oxidationPotassium ferrateAdsorption effect

The invention provides a method for treating complexed chemical nickel electroplating wastewater and aims at the problem in the existing complexed chemical nickel electroplating wastewater treatment processes that the nickel ion removal efficiency is inadequate. The method comprises the main processes of firstly adding calcium hydroxide into the wastewater, adjusting the pH to 8-9 so as to form calcium phosphate precipitates, adding sulfuric acid into a supernatant liquid so as to adjust the pH of the liquid to 4-5, then, adding a potassium ferrate liquid with strong oxidizing power so as to decomplex in a strong oxidizing manner and change complexed nickel ions into free-state nickel ions, then, adding calcium hydroxide, adjusting the pH to 10-11 so as to enable the free-state nickel ions to form precipitates to be removed from the wastewater, enabling trivalent ferric ions with excellent flocculation function generated after oxidation of ferric acid radical ions to have flocculation with hydroxide precipitates with an adsorption effect, and finally, adding polyacrylamide (PAM) to coagulate and precipitate, thereby removing nickel ions from the electroplating wastewater. The method has the advantages that the condition that the nickel ions obtained after the complexed chemical nickel electroplating wastewater is treated reach the national standards can be effectively guaranteed, the treatment efficiency is high, and the requirements on emission are met.

Owner:陈瀚翔

Preparation method of electromagnetic shielding conductive fabric

InactiveCN101876140ALess investmentSmall plating resistancePhysical treatmentSuperimposed coating processPolyesterCopper plating

The invention discloses a preparation method of an electromagnetic shielding conductive fabric. In the preparation method, the electromagnetic shielding conductive fabric is prepared by sequentially carrying out pretreating, vacuum nickel plating, copper electroplating and nickel electroplating on a full polyester fabric, and then the obtained electromagnetic shielding conductive fabric is cured, wherein plasma glow discharge treatment is carried out in the pretreating step, a magnetron sputtering technology is adopted in the vacuum nickel plating step, and a vertical placement mode is adopted among conductive rods in the processes of copper electroplating and nickel electroplating. By adopting the technology combining the vacuum nickel plating with the copper electroplating and the nickel electroplating, the defects of high cost and difficult treatment of electroplating wastewater, caused by the adoption of an electroless copper and nickel plating technology in the traditional preparation method of the electromagnetic shielding conductive fabric, are avoided; and compared with the traditional preparation method of the electromagnetic shielding conductive fabric, which adopts a full vacuum copper and nickel plating technology, the method of the invention which adopts the technology combining the vacuum nickel plating with the copper electroplating and the nickel electroplating has smaller equipment investment and plating resistance, is more suitable for large-scale production, and can better adapt to market demands.

Owner:昆山市同福电子材料厂

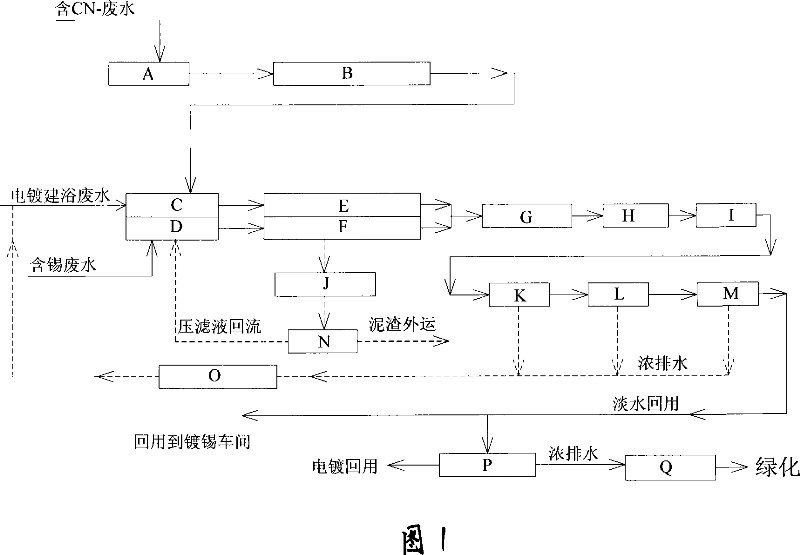

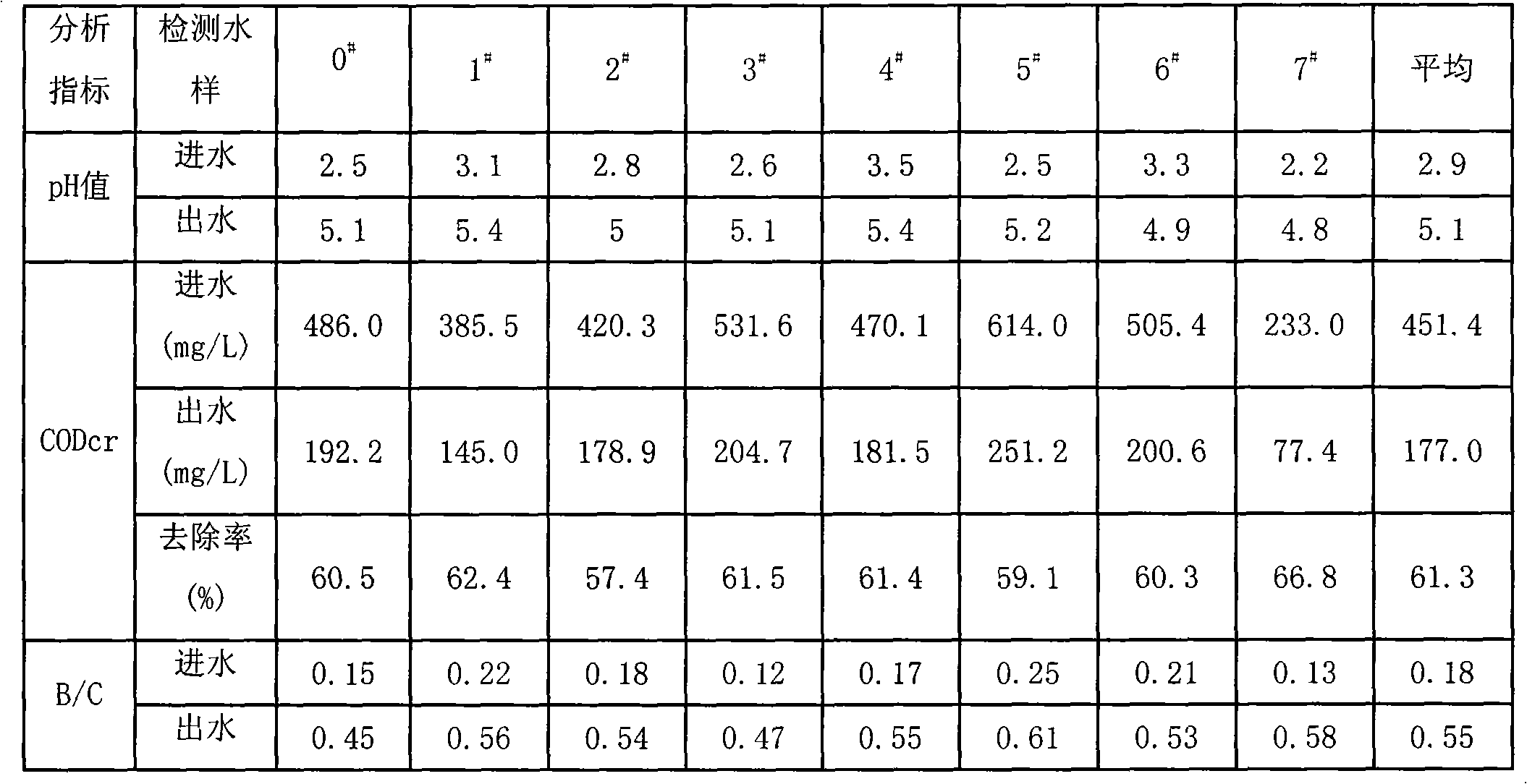

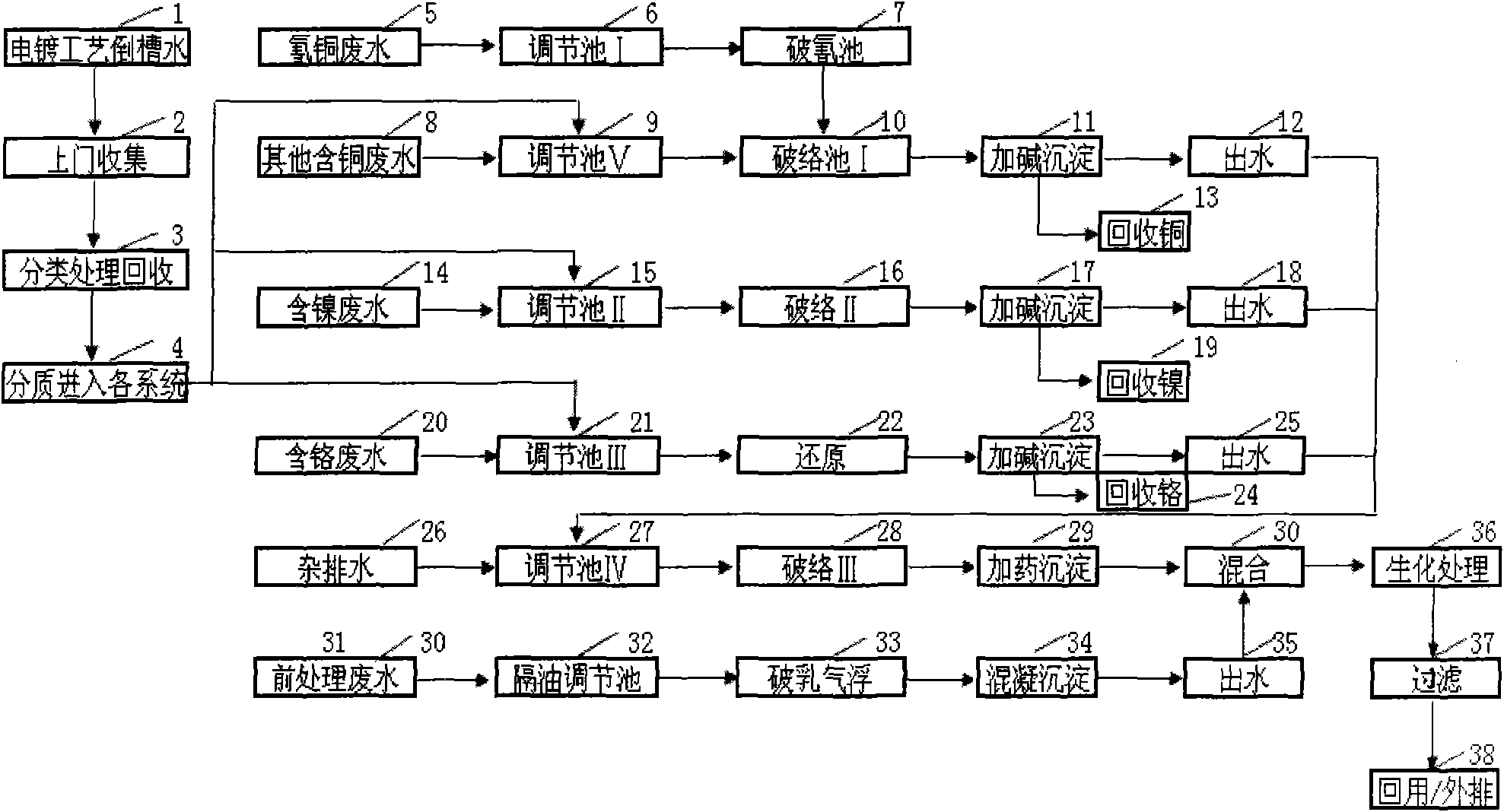

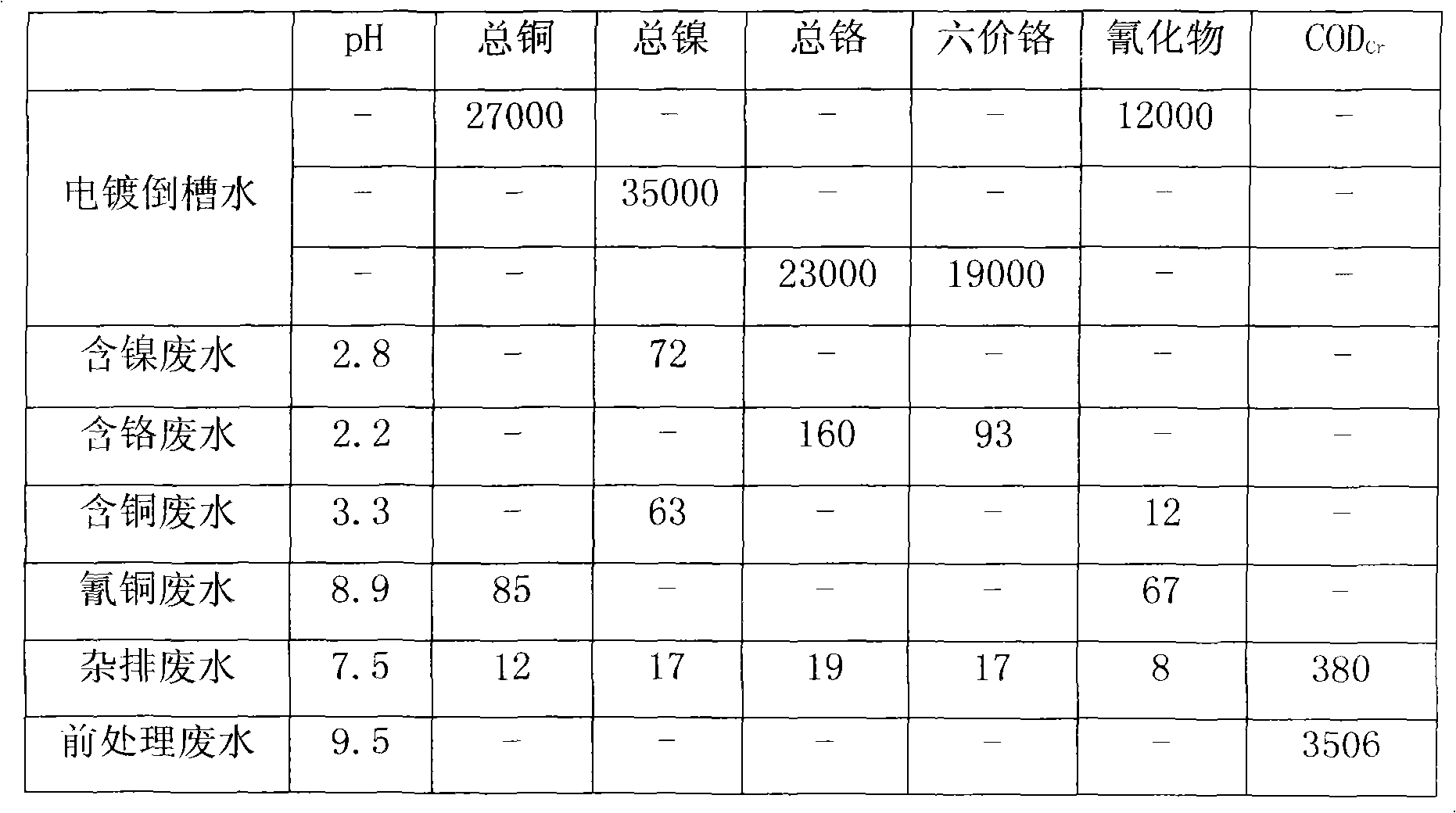

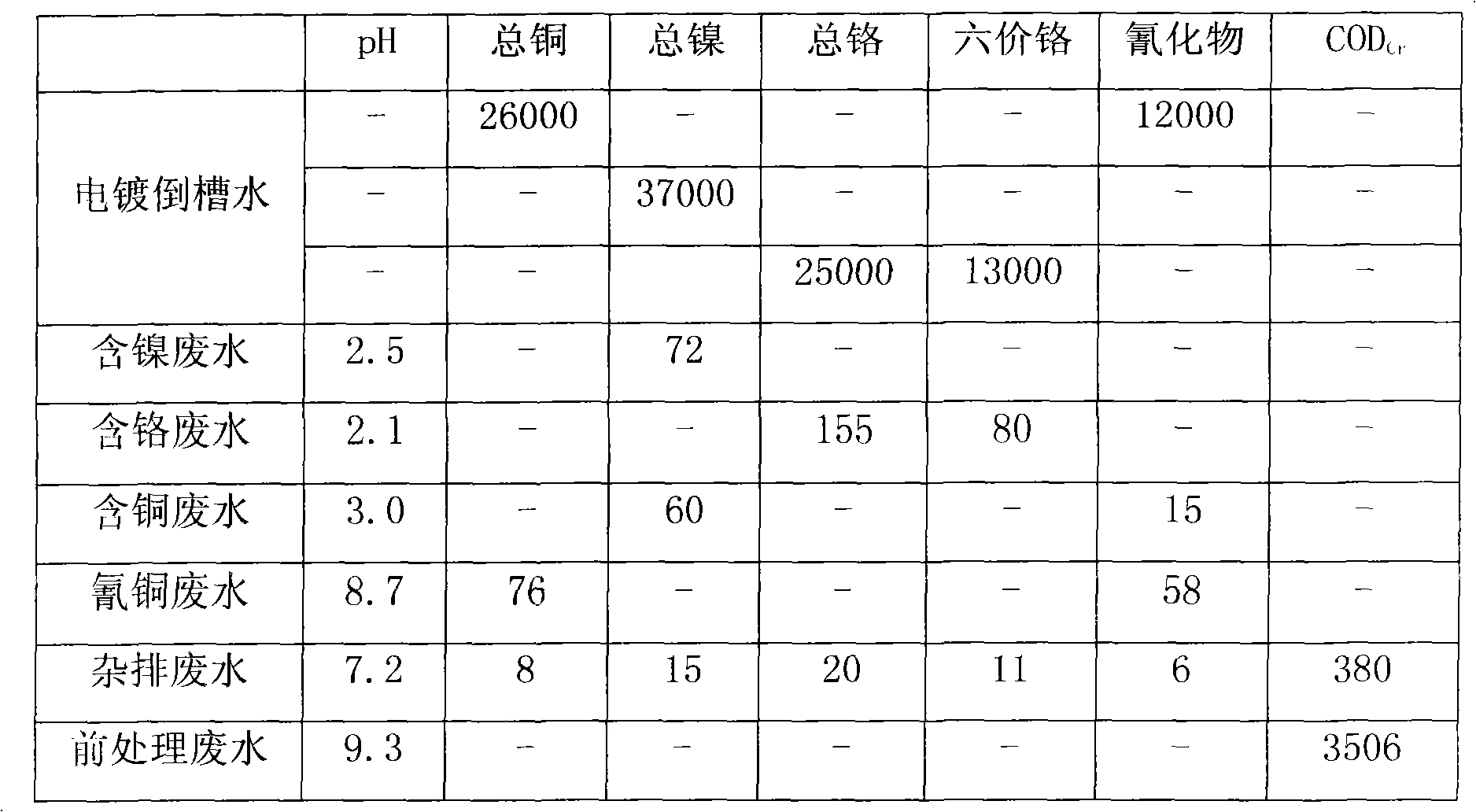

Processing method for recycling electroplating concentrated control zone electroplating waste water resource

ActiveCN101633544AMaximize quality recoveryIncrease contentFatty/oily/floating substances removal devicesWaste water treatment from metallurgical processHandling systemPollution

The invention relates to a processing method for recycling an electroplating concentrated control zone electroplating waste water resource, which comprises the following steps: firstly, preprocessing the inverted trough water in the electroplating production process, recycling valuable metals in the inverted trough water, and respectively filling the pretreated tail water in corresponding processing systems according to kinds; then, recycling copper, nickel and chromium resources in the corresponding processing system; afterwards, mixing other drain away water in a base station and the waste water with recycled copper, nickel and chromium resources, and then carrying out integrated structure breaking, neutralizing and coagulating sedimentation, and mixing the treated waste water and the pretreated water by treatment of oil separation, oil removal and coagulating sedimentation for biochemical treatment; and finally, discharging the effluent which reaches the standard. The method not only enables the electroplating waste water to reach the standard and can be discharged stably, but also recycles the valuable resources in the waste water in low cost, greatly reduces the secondary pollution and realizes the clean production of electroplating waste water control and the environmental requirements of the electroplating concentrated control zone.

Owner:ZHEJIANG HI TECH ENVIRONMENTAL TECH

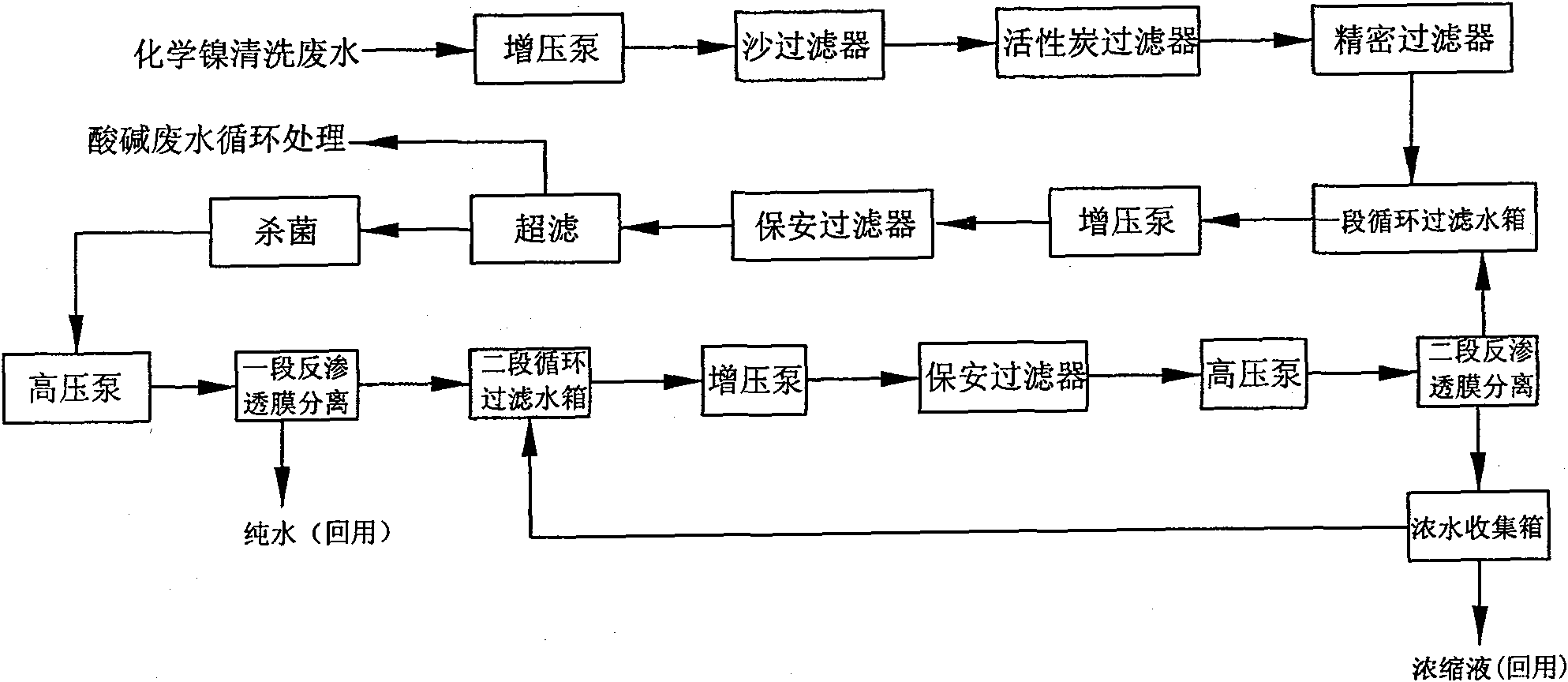

Method for classifying, treating and recycling plating washing water on line

ActiveCN101891323AAvoid cross contaminationStrong targetingWater contaminantsWater/sewage treatment by ion-exchangeCopper platingWater cycling

The invention discloses a method for classifying, treating and recycling plating washing water on line, which comprises the following steps of: removing oil, coarsening, reducing, activating, peptizing, chemically plating nickel, preplating nickel, plating copper, plating nickel and plating chromium in a plating process; and treating water and washing water during production and cleaning. The method specifically comprises the following steps of: preparing pure plating water, circularly processing acid and alkaline waste water, coarsening, circularly treating chromium-plating washing water, circularly treating chemically nickel-plating washing water, circularly treating copper-plating washing water and circularly treating nickel-plating washing water. Waste water in each procedure is directly used beside a tank edge in a closed cycle by an economical and effective means after being treated, no wastewater is discharged, and the cross contamination of different water qualities among the procedures is avoided. The method is a technological innovation for realizing zero emission of plating waste water and plating cleaner production.

Owner:NANJING YUANQUAN TECH CO LTD

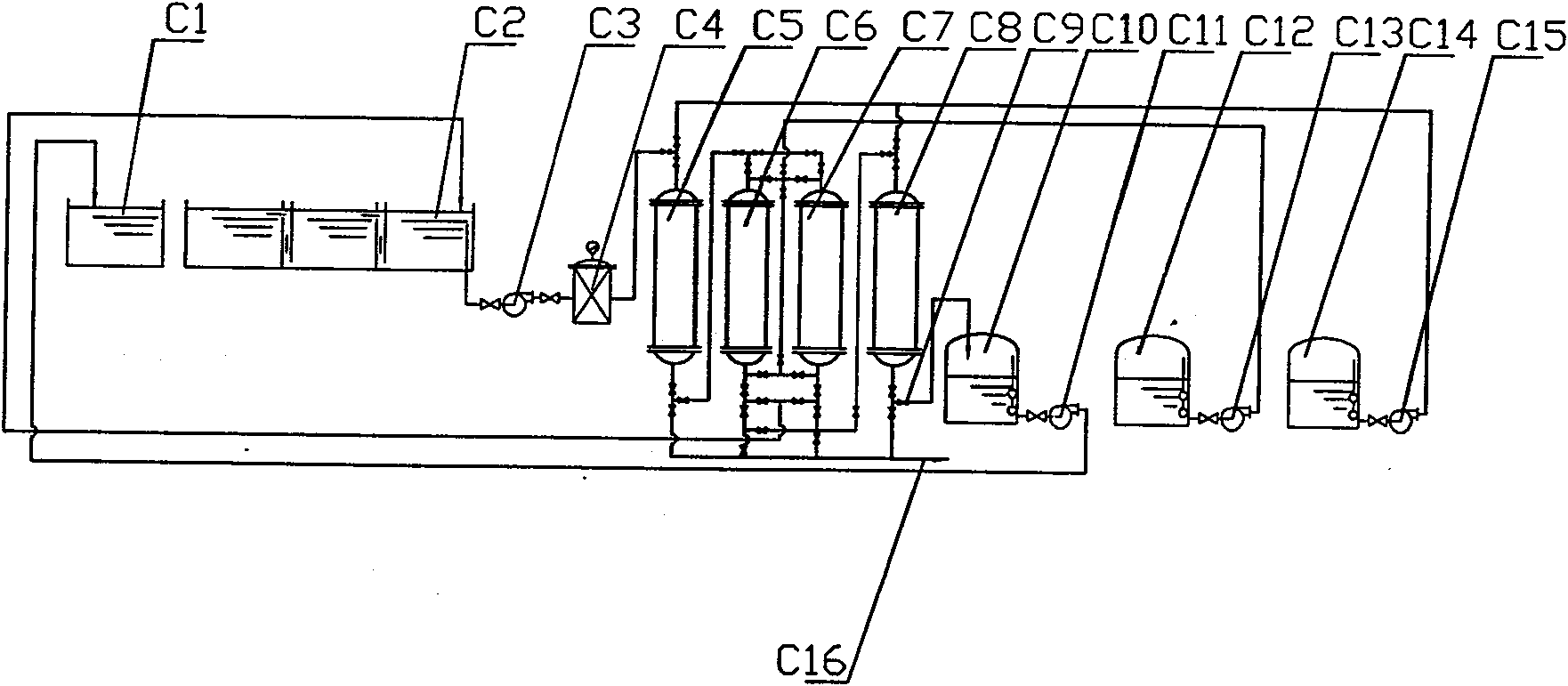

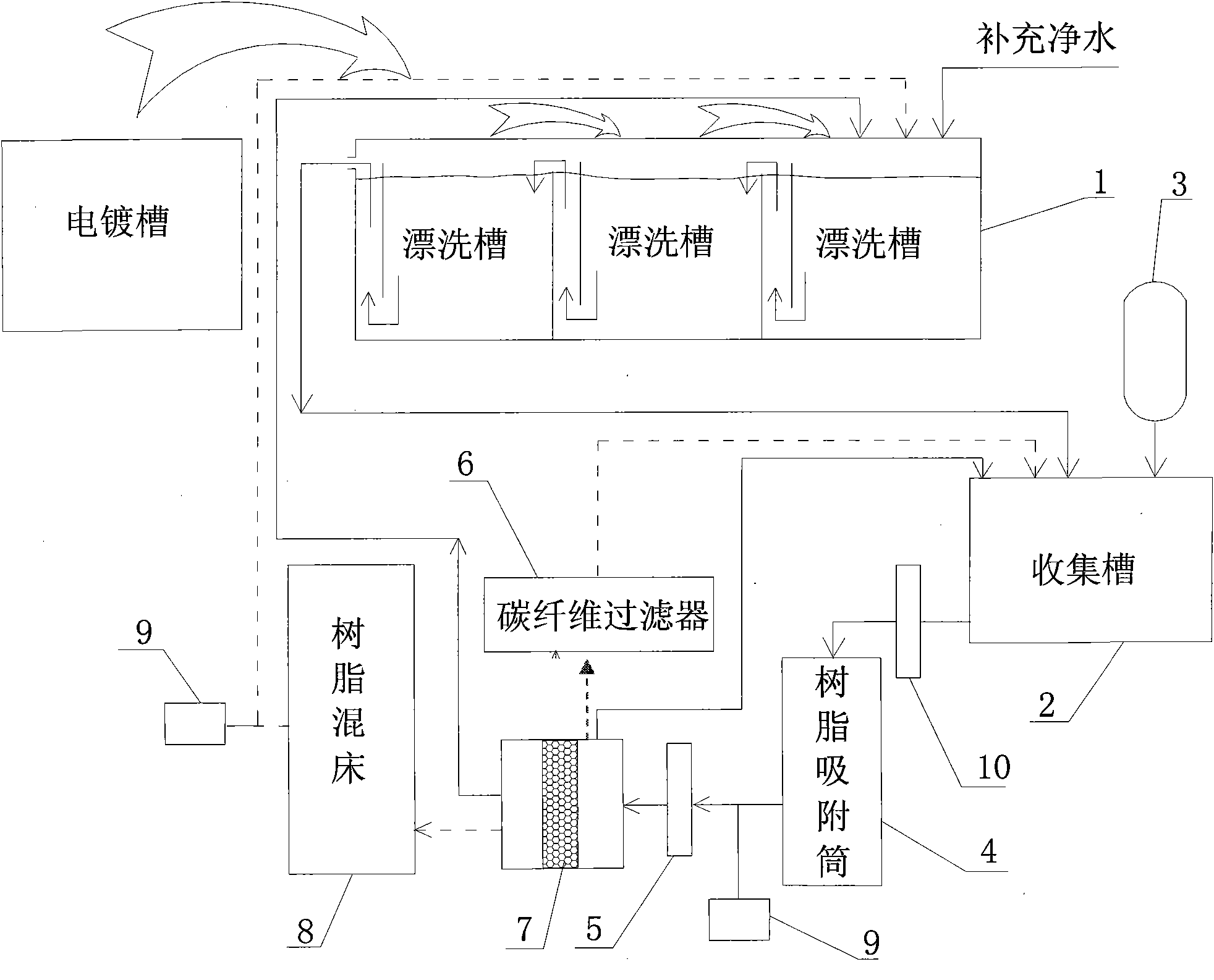

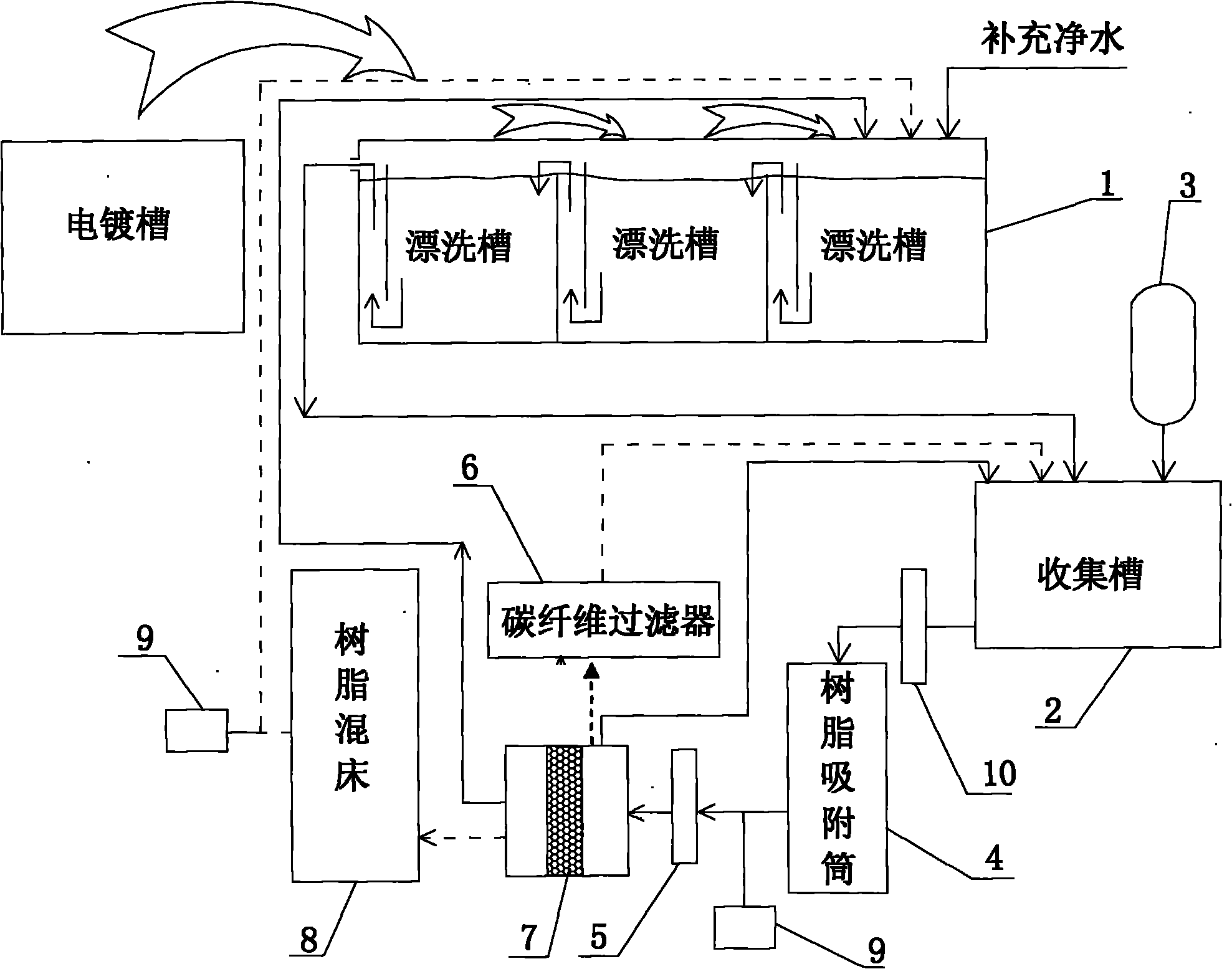

Processing method and device for recovering precious metals contained in electroplating wastewater

InactiveCN101935119AAchieving zero emissionsEfficient recyclingWaste water treatment from metallurgical processWater/sewage treatment bu osmosis/dialysisFiberUltrafiltration

The invention provides a processing method for recovering precious metals contained in electroplating wastewater and realizing zero draining, comprising the following steps of: preprocessing the electroplating wastewater; carrying out two-stage resin adsorption; carrying out safety filtration; carrying out ultrafiltration; carrying out reverse osmosis; carrying out activated carbon fiber adsorption; and processing a resin mixed bed. The invention also provides a processing device for recovering the precious metals contained in the electroplating wastewater, comprising a plurality of stages of rinsing channels and a pipeline which are arranged on an electroplating production line, wherein overfalls positioned on the top of the first-stage rinsing channel is connected with a collecting tank through the pipeline; the collecting tank is provided with a medicine addition device; and the outlet end of the collecting tank is sequentially connected with a preprocessing filtering machine, a resin adsorption drum, a safety filter, a reverse osmosis membrane assembly, a carbon fiber filter and the resin mixed bed. In the invention, processed pure water is returned to the rinsing channels for recycling by adopting an efficient adsorbing material and membrane osmosis combination technology, the precious metals contained in the electroplating wastewater are completely recovered, elemental metals or concentrates and crystallizes are reduced into metal salt through extraction and backextraction, the recovery processing and the zero draining of the electroplating wastewater are realized.

Owner:游京初

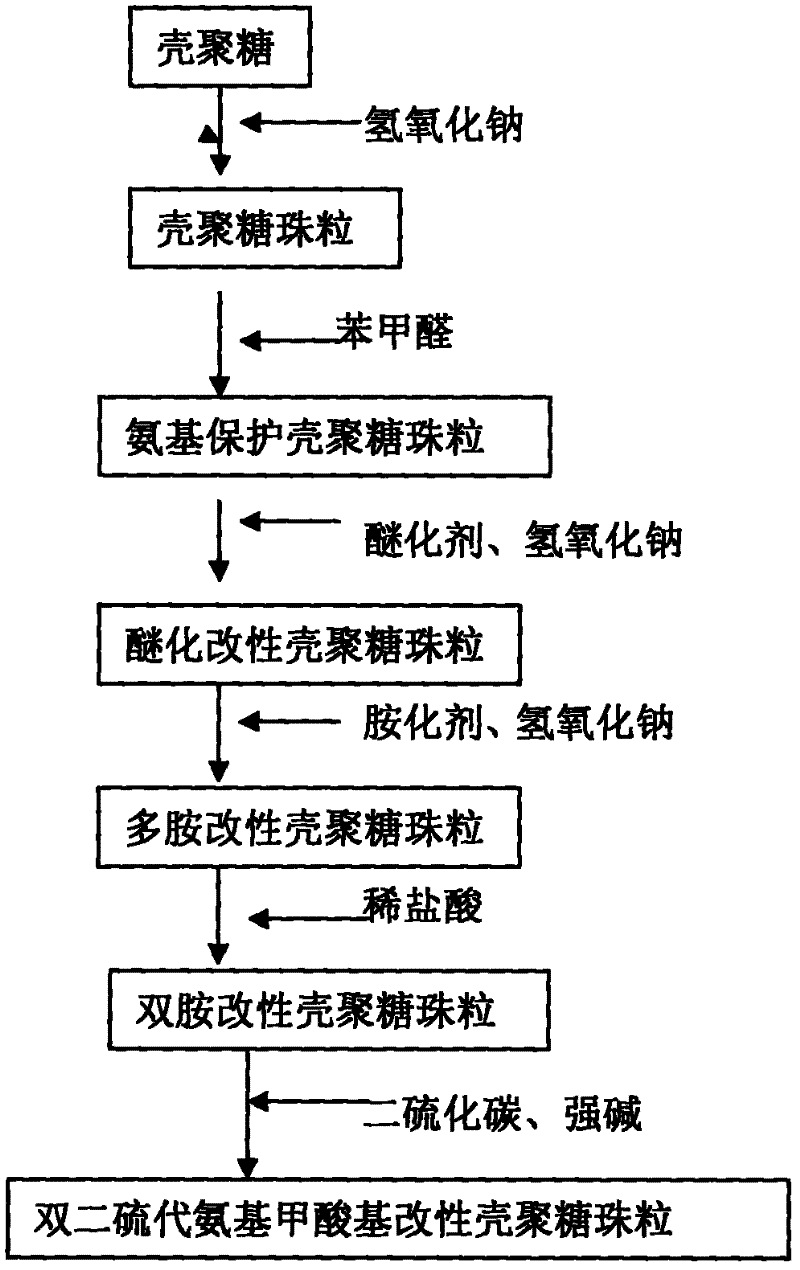

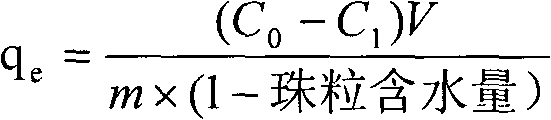

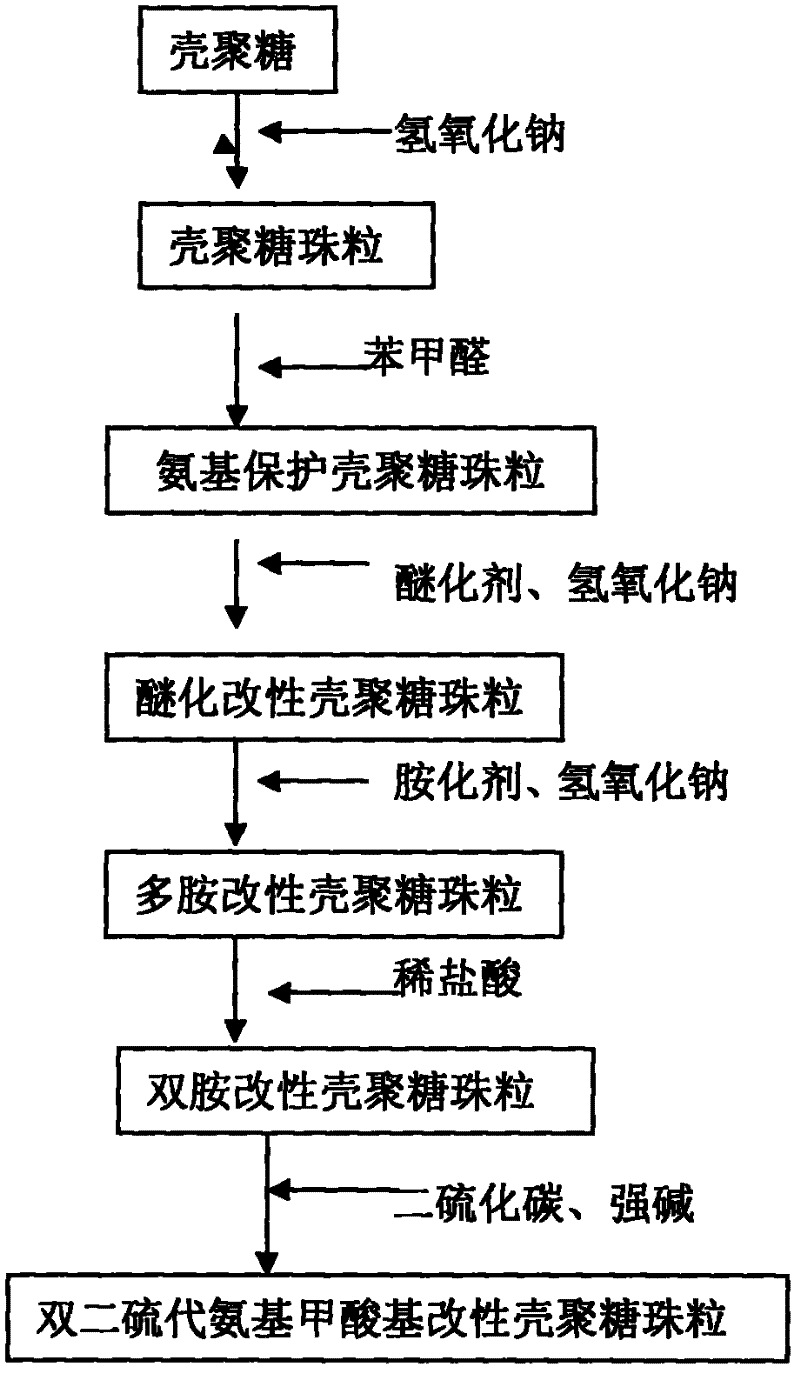

Method for preparing di-dithiocarbamate modified chitosan beads

InactiveCN102504312AGood dispersionLarge specific surface areaOther chemical processesWater/sewage treatment by sorptionBenzaldehydeMining industry

The invention relates to a method for preparing di-dithiocarbamate modified chitosan beads. The method comprises the following steps of: after dissolving 5 g of chitosan in an acetic acid solution at first, solidifying the chitosan in a sodium hydroxide solution to form chitosan beads with the diameter of 2-3 mm, wherein the solidifying time is 8-26 h; and, after carrying out Shiff alkali reaction, etherification, amination and elimination of benzaldehyde of the chitosan beads, grafting carbon disulfide under an alkaline condition to obtain di-dithiocarbamate modified chitosan. Compared with the original chitosan, the chitosan disclosed by the invention as a water treatment agent has stronger adsorption property and can be applied to treatment of heavy metal ions in wastewater, such as electroplating wastewater, battery wastewater, wastewater in mining industries and the like; the adsorption selectivity of the chitosan is increased; furthermore, the chitosan can be recycled for many times; and the purpose of rationally utilizing resources is achieved.

Owner:上海同纳环保科技有限公司

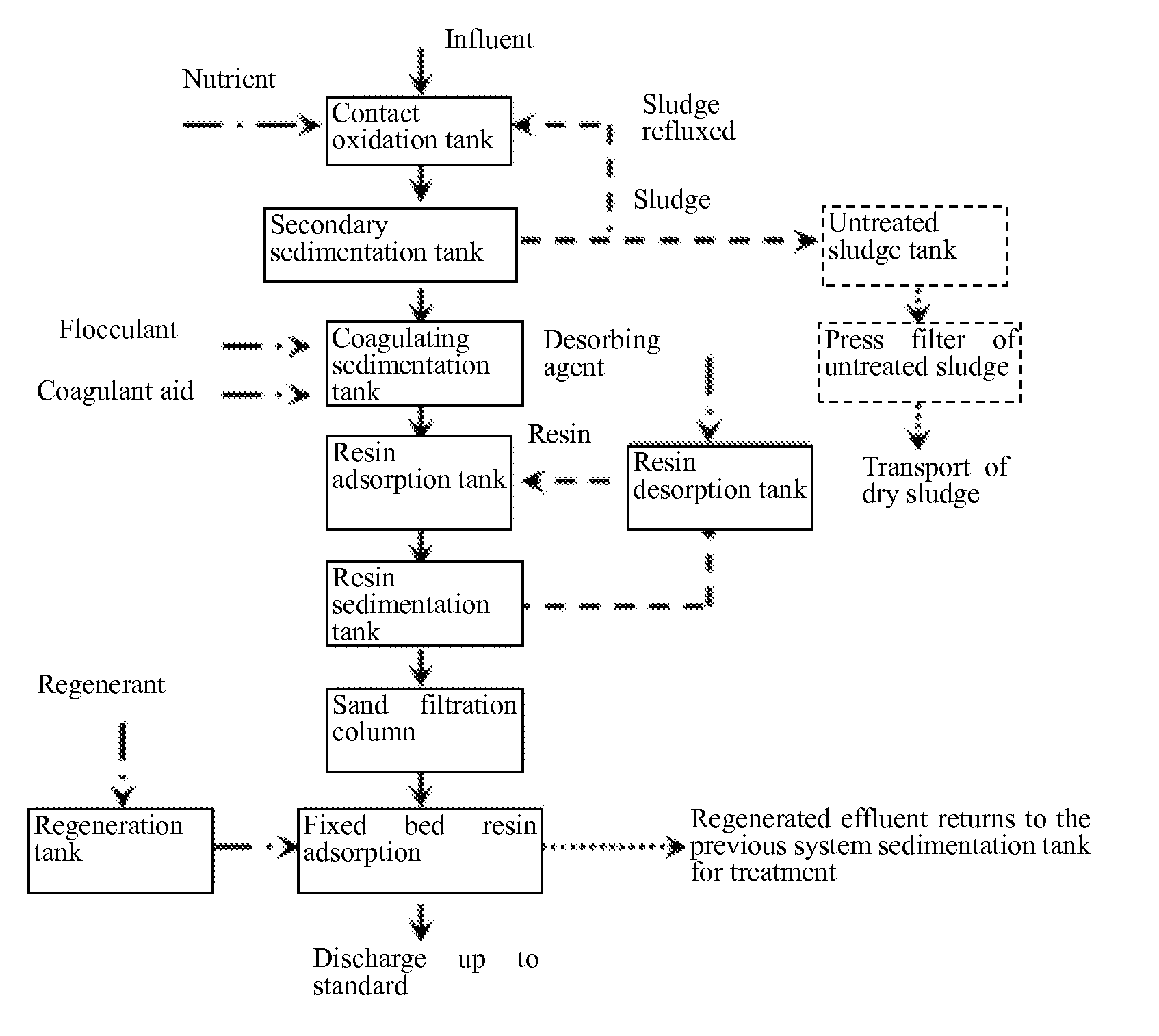

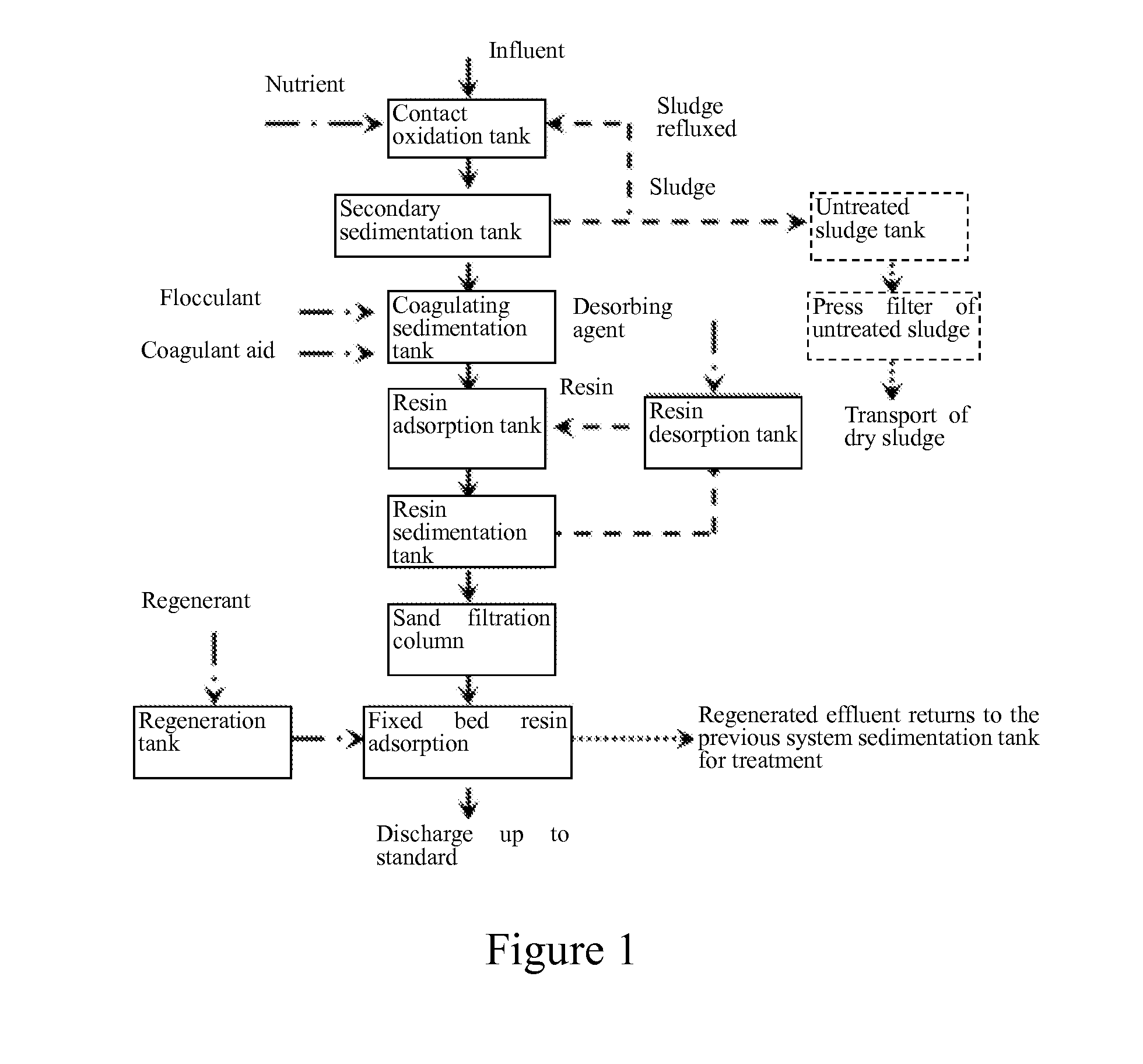

Efficient combined advanced treatment method of electroplating waste water

ActiveUS20150291449A1Overcome defectsEnsure water qualityTreatment using aerobic processesWater contaminantsCyanideSludge

An efficient combined advanced treatment method of electroplating wastewater is disclosed, which belongs to the technical field of electroplating wastewater treatment. The method includes: after pretreatments including cyanide breaking, dechromisation and coagulating sedimentation, introducing the electroplating wastewater to a contact oxidation tank for biochemical treatment, and settling the effluent from the contact oxidation tank down in an inclined pipe of a secondary sedimentation tank to realize the separation of the sludge from water; charging the effluent to a coagulating sedimentation tank, and undergoing coagulating sedimentation with the aid of a flocculant and a coagulant aid added; feeding the effluent, as an influent, to a resin adsorption tank for adsorption with a magnetic resin; and after passing through a filter, flowing the effluent after adsorption to a fixed bed resin adsorption unit, so as to realize the discharge up to standard and recycle of the effluent.

Owner:NANJING UNIV +1

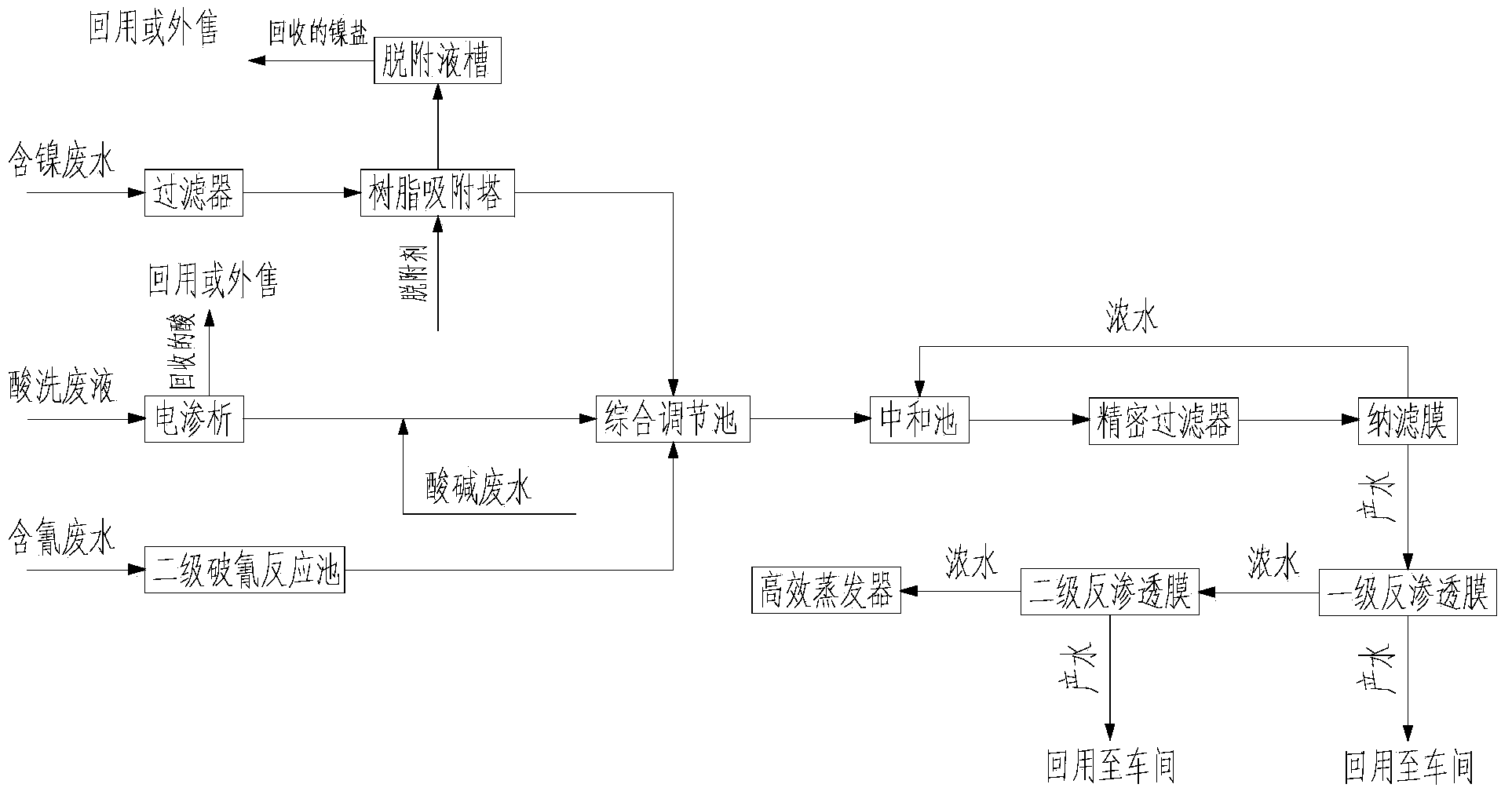

Electroplating wastewater treating and recycling process and system

InactiveCN103539303AReduce salt contentHigh recovery rateCellsWaste water treatment from metallurgical processNickel saltCyanide

The invention discloses an electroplating wastewater treating and recycling process and system which are designed especially for solving the problems that the cost of the process for pretreating the electroplating wastewater is high, the sludge quantity is high, and the recovery rate of a film system is low in an existing chemical method. The electroplating wastewater recycling process comprises the following steps: adsorbing nickel-containing wastewater through resin to recover nickel salt; treating pickling waste liquid by electrodialysis to recover acid and then mixing with acid-alkali wastewater; transferring into an adjusting tank together with cyanide-containing wastewater subjected to alkaline second-stage cyanide breaking; enabling the water quality and volume to be uniform; transferring into a neutralizing tank; adding alkali to adjust pH (Potential of Hydrogen) to reach neutral value; then feeding into a film treating system in the combination of first-stage nanofiltration and second-stage reverse osmosis, wherein the water produced by reverse osmosis is recovered into an electroplating workshop, and the concentrated water produced by nanofiltration is recovered into the neutralizing tank; performing second-stage reverse osmosis on the concentrated water subjected to first-stage reverse osmosis; and transferring the concentrated water subjected to second-stage reverse osmosis into an efficient evaporator to evaporate. By adopting the process and system, the nickel and acid resources can be effectively recovered, the recovery rate of wastewater can be greatly raised, and the operation stability of the film system also can be greatly improved.

Owner:HUATIAN ENG & TECH CORP MCC

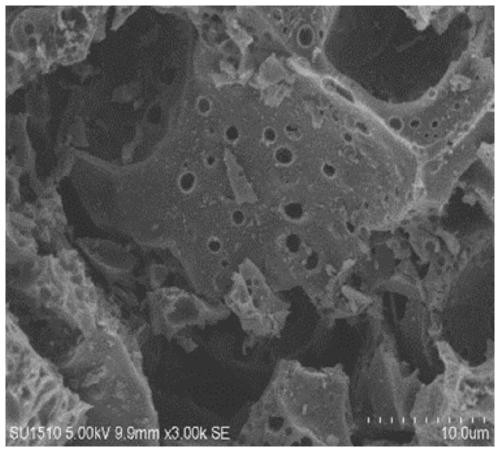

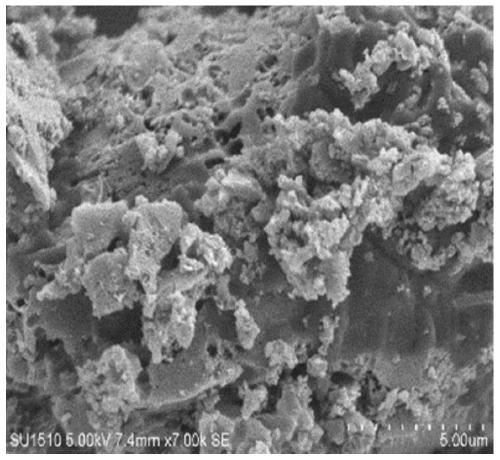

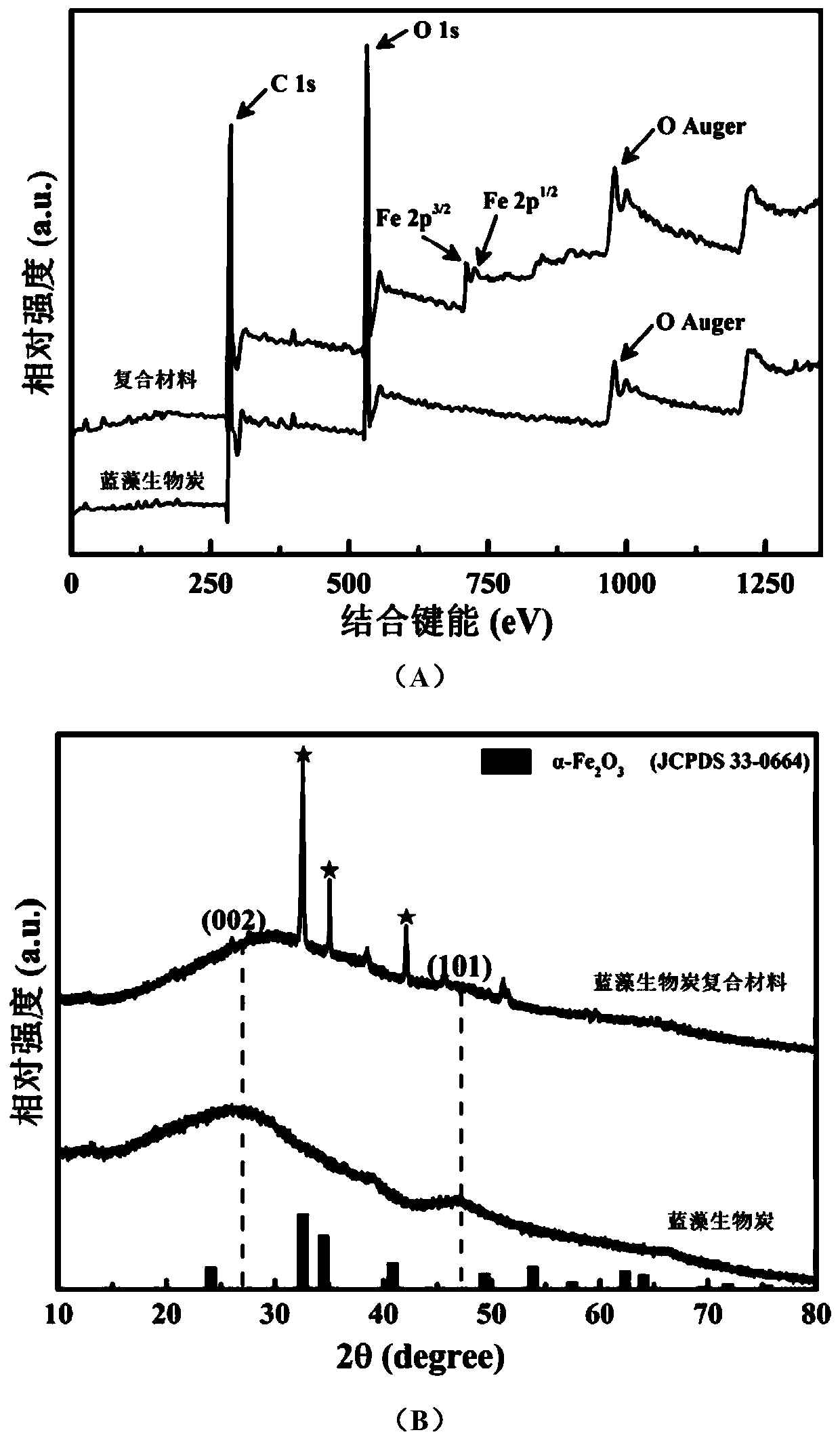

Modified blue-green algae biochar composite and application thereof to treatment of electroplating wastewater

ActiveCN110272085AHigh carbon contentLow ashWater treatment compoundsWater contaminantsBlue green algaeElectroplating wastewater

The invention discloses a modified blue-green algae biochar composite and application thereof to treatment of electroplating wastewater, and belongs to the technical field of preparation of biochar composite preparation. Blue-green algae in Taihu lake are dried, ground and sieved, then mixed with an activating agent and then subjected to thermal cracking to obtain modified blue-green algae biochar; the modified blue-green algae biochar is soaked in an iron-containing solution for further modification to obtain the modified blue-green algae biochar composite. The prepared modified blue-green algae biochar composite has the adsorption and catalysis capacity. The composite can efficiently remove metal ions in the wastewater through adsorption and Fenton-like reaction during the treatment of the electroplating wastewater. The composite is high in stability and can be repeatedly used.

Owner:JIANGNAN UNIV

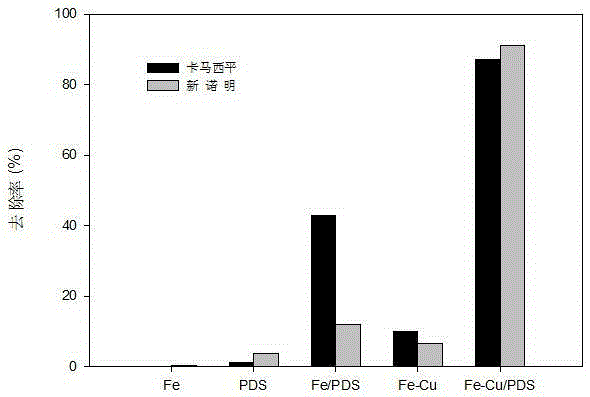

Water treatment method of zero-valent iron-copper bi-metal activated persulfate

InactiveCN105253983ASolve the problem of low production volumeRemove completelyWater contaminantsContaminated groundwater/leachate treatmentSulfate radicalsPolychlorinated biphenyl

The invention discloses a water treatment method of zero-valent iron-copper bi-metal activated persulfate. The water treatment method specifically comprises the steps that bi-metals including zero-valent iron and copper are added into water containing micro-pollutants, then persulfate is added, full mixing is performed, the bi-metals including the zero-valent iron and the copper are utilized to activate the persulfate so as to remove the micro-pollutants in the water. The water treatment method utilizes the bi-metals including the zero-valent iron and the copper to efficiently activate the persulfate so as to produce free sulfate radicals having strong oxidizing property, can achieve the purpose of quickly and thoroughly removing micro-pollutants, including multiple types of poisonous and harmful micro-pollutants in water, such as polychlorinated biphenyl, brominated flame retardants, drugs and personal care products (PPCPs) and algal toxin, and has the advantages of high activation efficiency, high oxidation and degradation efficiency of pollutants, wide pH using range, convenient operation and the like. The water treatment method can be applied to underground water remediation, treatment of industrial water (including electroplating wastewater, hospital wastewater, printing and dyeing wastewater and the like), drinking water treatment, wastewater treatment and the like.

Owner:SUN YAT SEN UNIV

Industrial wastewater treating agent

InactiveCN104591362AGood effectImprove water qualityWater/sewage treatment by flocculation/precipitationSodium bicarbonateIron sulfate

The invention relates to the technical field of sewage treatment and particularly relates to an industrial wastewater treating agent. The industrial wastewater treating agent comprises the following components in parts by mass: 0.8-3 parts of polyacrylamide, 25-35 parts of aluminium polychlorid, 25-55 parts of alums, 3-8 parts of iron trichloride, 0.8-3.4 parts of polymeric ferric sulfate, 1.2-2.5 parts of a coagulant aid, 2-10 parts of plant fiber, 10-30 parts of coal ash, 0.8-2.5 parts of sodium silicate, 2.5-5 parts of sodium sulfite, 0.5-3.5 parts of sodium hypochlorite, 5-10 parts of hydrogen peroxide, 8-15 parts of a sodium carbonate-sodium bicarbonate buffer system and 10-20 parts of sodium-based bentonite. The treating agent has the beneficial effects of wide treated pollutant range, good effect, wide production raw material source, environmental friendliness, no toxicity, good discharged water quality, short process flow, and high process operating safety. The treating agent disclosed by the invention can treat various kinds of wastewater such as chemical wastewater produced in oil fields, mining, steel, electroplating wastewater, dyes, pesticides, wine-making and chemical engineering, and sanitary sewage, papermaking wastewater, river and lake water, rubbish seeping water, leather-making wastewater, and the like; and the treating agent is good in treatment effect.

Owner:湖北源绿高科技节能环保有限公司

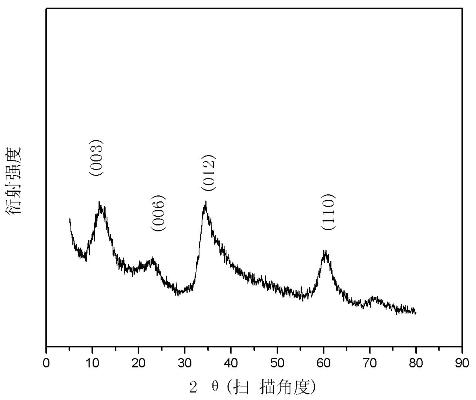

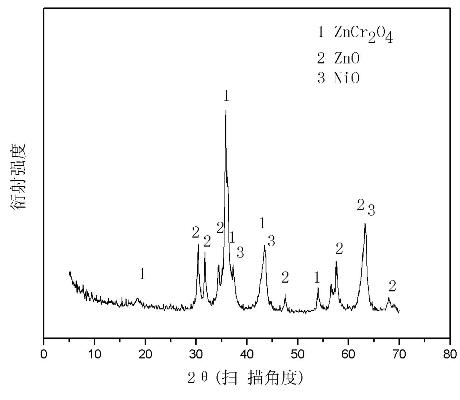

Method for preparing catalyst by using electrolysis waste water and electrolysis sludge

ActiveCN102179253ATake advantage ofReduce pollutionMetal/metal-oxides/metal-hydroxide catalystsElectrolysisSludge

The invention relates to a process method for preparing a catalyst by using electrolysis waste water and electrolysis sludge, and belongs to the technical field of waste recycling and environmental engineering. The process method comprises the following process steps: mixing, stirring, settling, separating solid from liquid, drying, calcining and the like. Through the coordinated treatment of electrolysis waste water and sludge, which are industrial wastes, and industrial CO2, the use of the process method has a great significance for the treatment of electrolysis waste water and the emission reduction and capture of green house gases, fully utilizes wastes and fulfils the aim of recycling; and a catalyst can be obtained, the environment pollution can be relieved, and the aim of treating waste with waste is fulfilled.

Owner:SHANGHAI UNIV

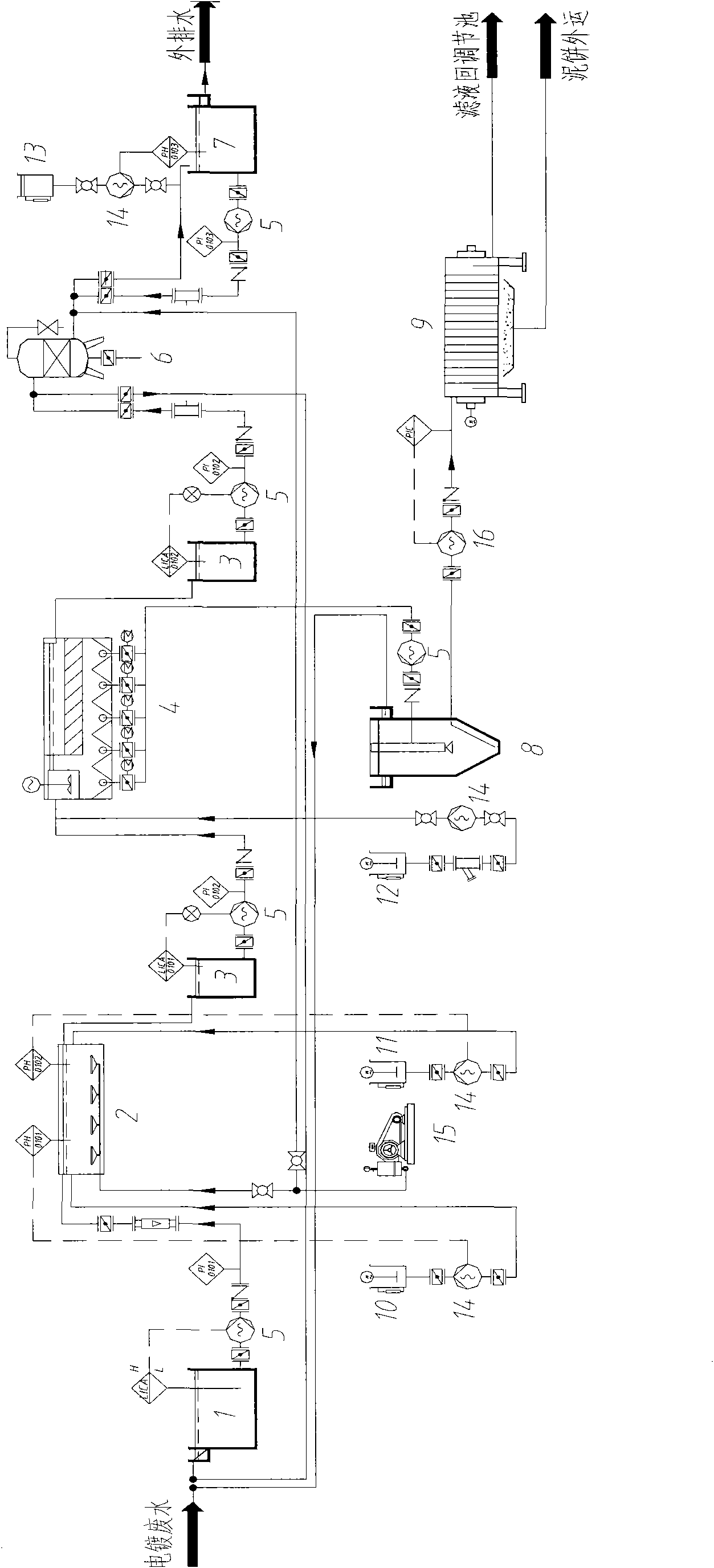

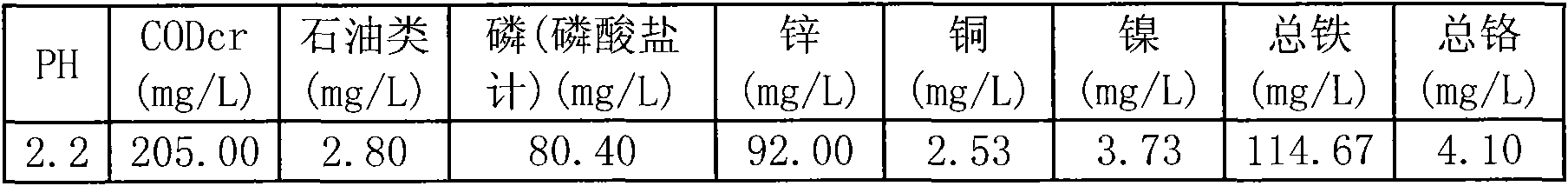

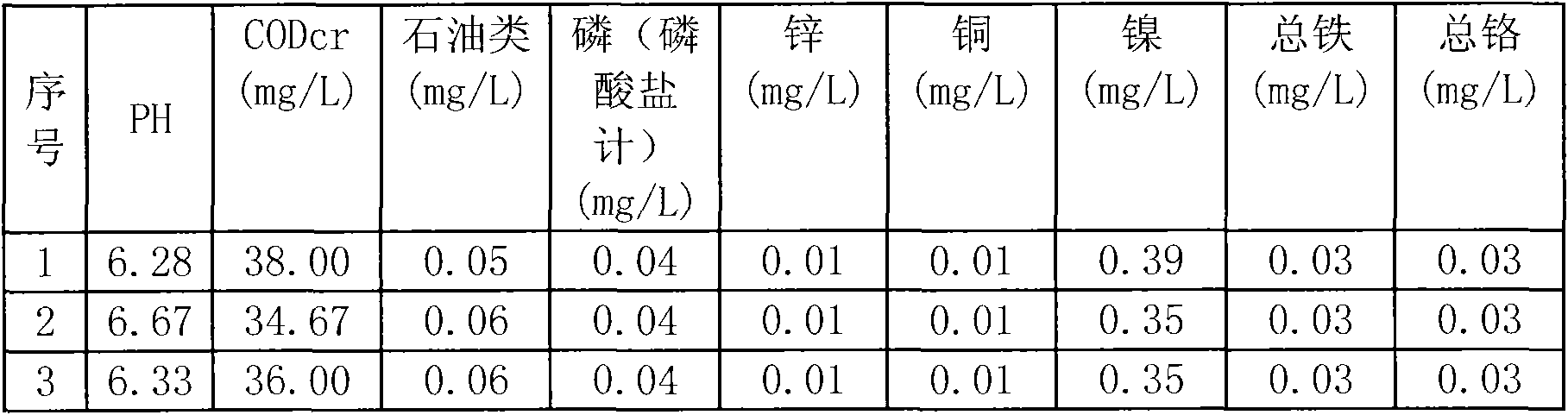

Device for treating high-concentration electroplating wastewater and application thereof

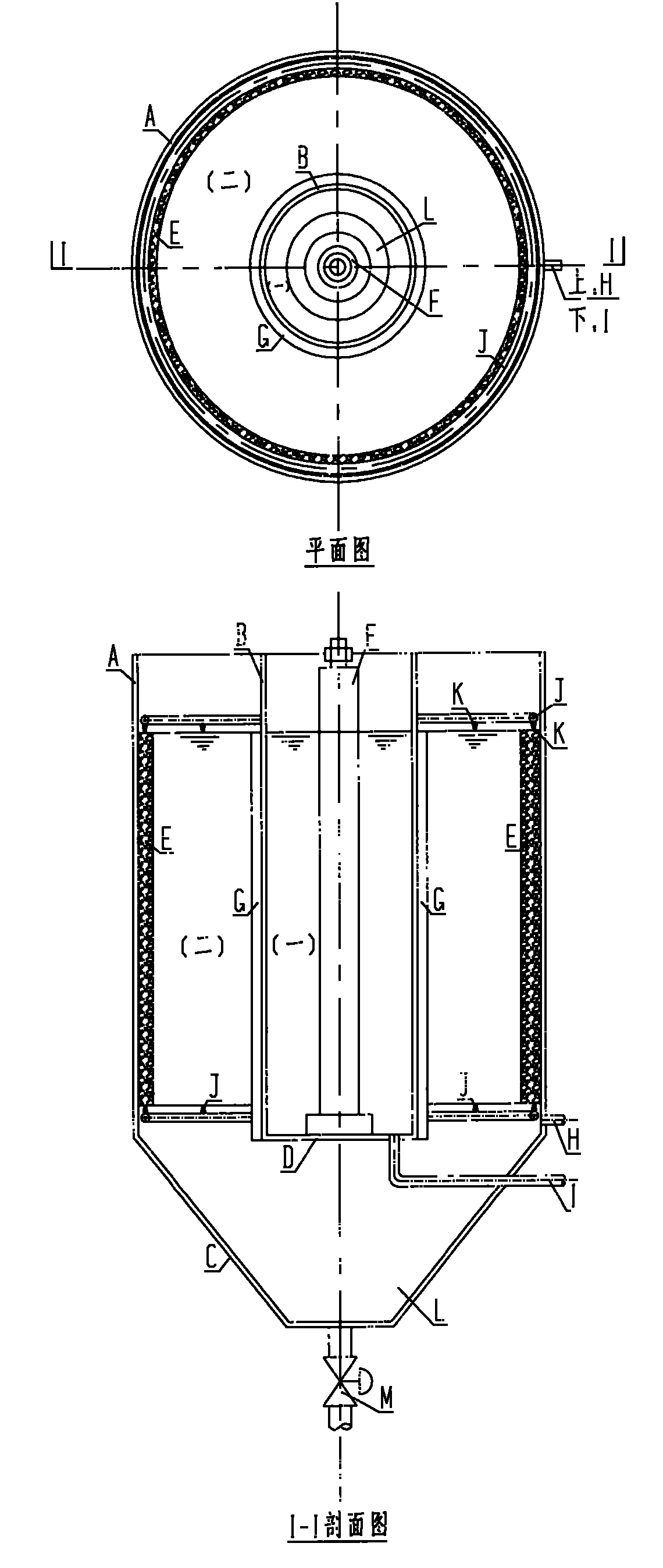

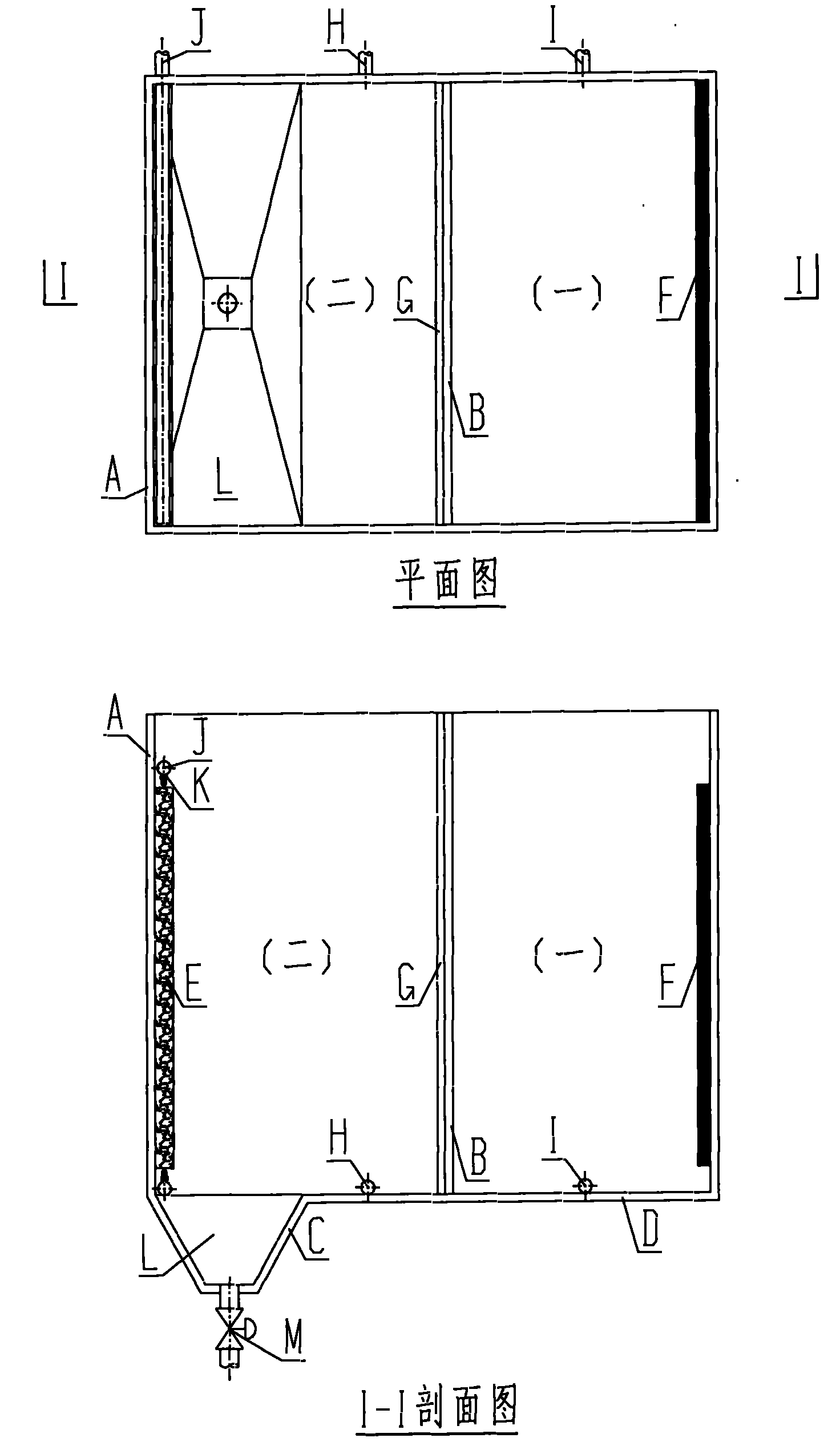

InactiveCN101844844ASave engineering investmentSmall footprintSludge treatment by de-watering/drying/thickeningWaste water treatment from metallurgical processHigh concentrationChemical oxygen demand

The invention relates to a device for treating high-concentration electroplating wastewater and application thereof. The device comprises an electroplating wastewater regulating tank, a micro-porous aeration neutralization reaction tank, an intermediate water tank, a coagulation inclined-plate sedimentation tank, a sludge concentration tank, a multi-media filtering tank, a clear water tank, a calcium hydroxide dosing tank, a sodium hydroxide dosing tank, a polyacrylamide dosing tank, a hydrochloric acid storage tank, a chamber filter press, a water pump, a dosing pump, an air blower and a consistency pump, wherein the high-concentration electroplating wastewater can be treated by using the components based on the combined process of micro-porous aeration neutralization reaction, coagulation inclined-plate sedimentation and multi-media filtering. The device for treating the high-concentration comprehensive electroplating pickling wastewater has the advantage of significant removal effect, particularly, the removal rate based on COD (chemical oxygen demand) is higher than 80%; the removal rate of petroleum-related pollutant is higher than 95%; the removal rate of phosphorus, zinc and copper in total and the removal rate of iron in total are higher than 99.5%; the removal rate of chromium in total is higher than 99%; and the removal rate of nickel is higher than 90%. Therefore, the device of the invention is applicable in treating high-concentration electroplating wastewater and pickling wastewater.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

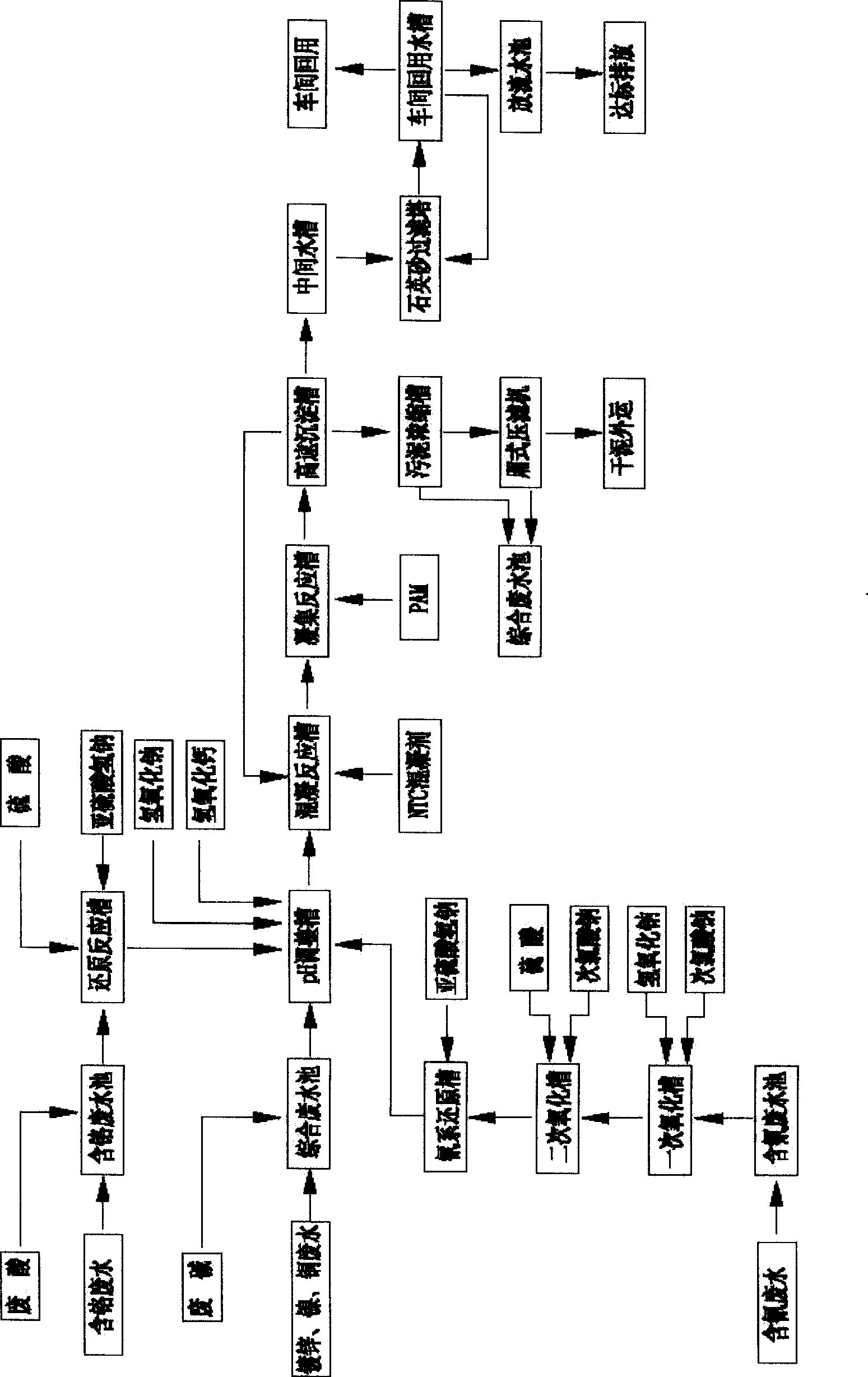

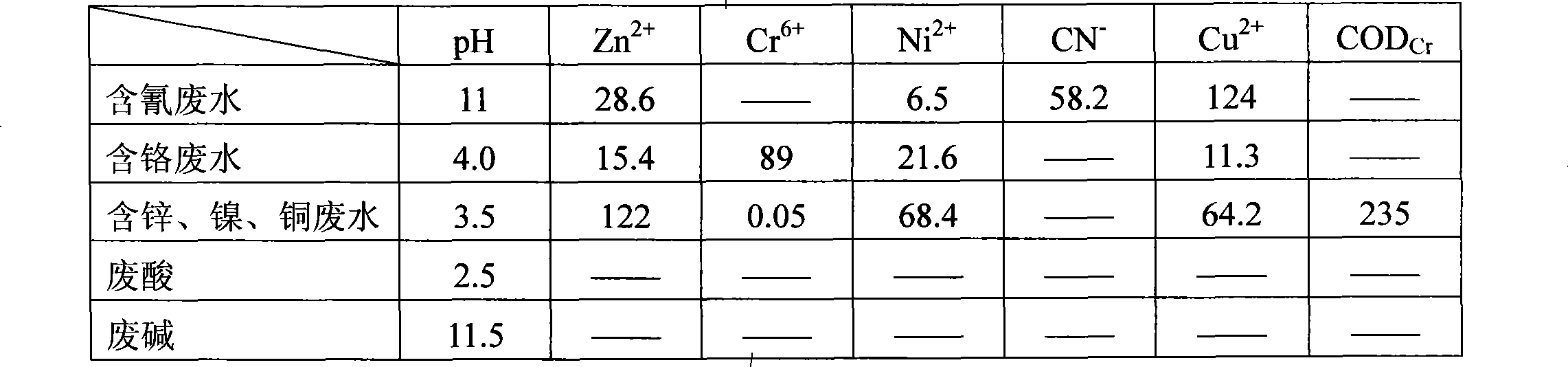

Integrative electroplating waste treatment process

InactiveCN101475274ALow investment costReduce processing costsWaste water treatment from metallurgical processMultistage water/sewage treatmentReduction treatmentWaste treatment

The invention discloses a process for treating comprehensive electroplating wastewater, which solves the technical problems existing in the prior process for treating the comprehensive electroplating wastewater. The process comprises the following steps: (1) establishing wastewater disposal basins for the electroplating wastewater by classification, and automatically adding waste acid and waste alkali into the basins; (2) reducing hexavalent chrome for pretreatment; (3) carrying out secondary oxidation decyanation and reduction treatment on wastewater containing cyanogen; (4) mixing pretreated wastewater containing chromium and wastewater subjected to the secondary oxidation decyanation treatment without cyanogen with the comprehensive electroplating wastewater containing copper, nickel and zinc, adjusting the mixed wastewater to neutrality, and adding an NTC coagulating agent into the mixed wastewater; (5) after coagulation, carrying out solid-liquid separation on the wastewater in a high-speed sedimentation tank; and (6) filtering the wastewater which is subjected to the solid-liquid separation in an intermediate water tank, and recycling the qualified wastewater or discharging the qualified wastewater in accordance to standard. The process has the advantages that the problem that different metal ions require respective treatment or multiple circulating treatments because of different concentrations can be solved, the problem of independently setting air flotation to remove oil can be solved, the problem of recycling the waste acid and the waste alkali can be solved; and investment, operating cost and floor area are saved.

Owner:LIDA ENVIRONMENT ENG DALIAN ECONOMIC TECH DEV ZONE

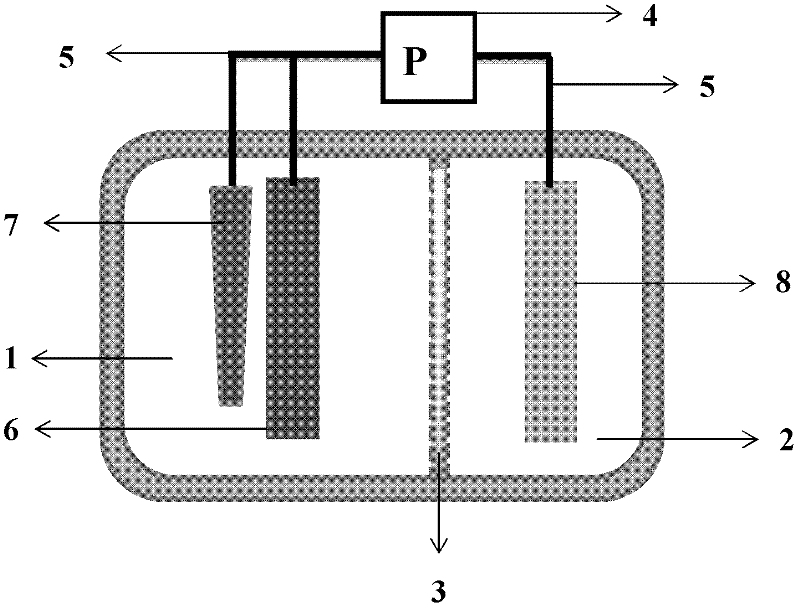

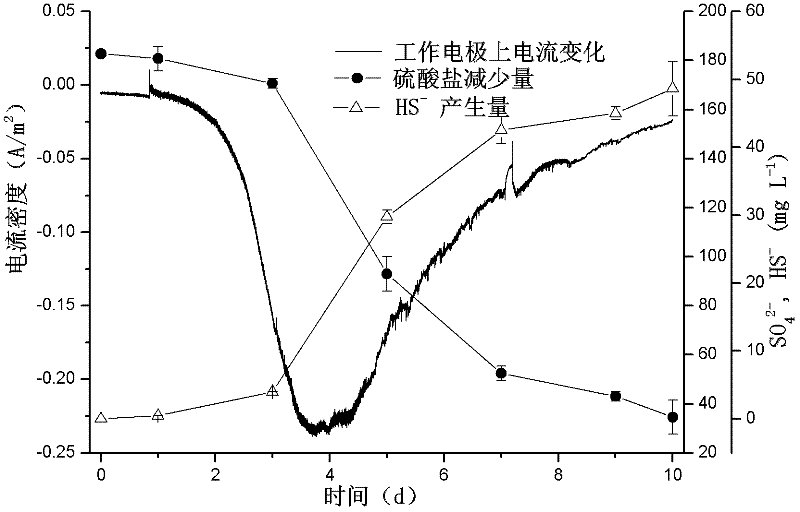

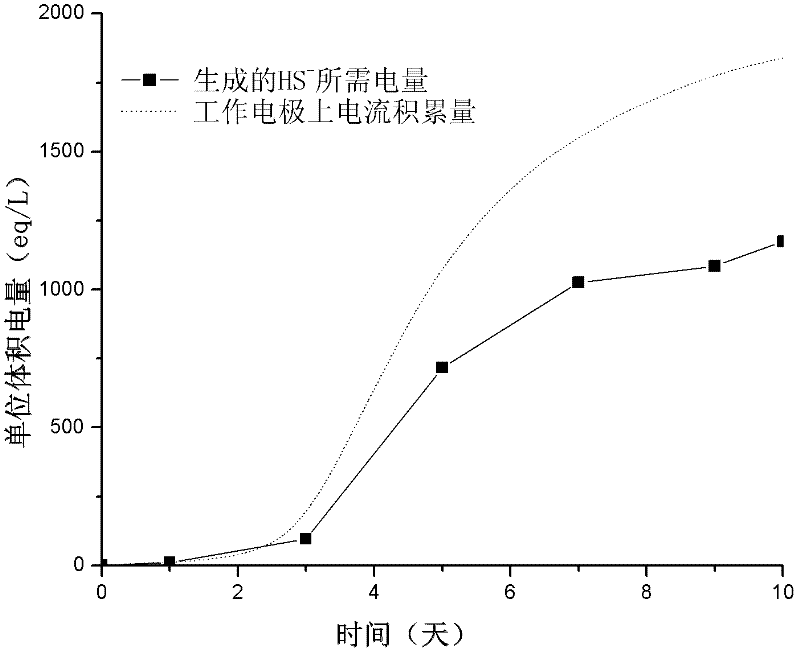

Method for treatment of metal waste water by sulfate reducing bacteria growing up with electric current

InactiveCN102642930AAvoid secondary pollutionEasy to operateWaste water treatment from quariesWater contaminantsSulfate-reducing bacteriaPollution

The invention belongs to the technical field of treatment of waste water, and particularly relates to a method for reduction of sulfate into sulfide and treatment of metal waste water by sulfate reducing bacteria growing up with electric current. The sulfate reducing bacteria provided by the invention is a mixing bacteria group, which comprises Desulfobulbus propinonicus, geobacter sulfurreducens. Under the condition of lacking organic carbon resource, an electrode is used as the only electronic donator for growing, sulfate is reduced into sulfide via bioelectrical chemistry, and the sulfide is applied to the treatment of metal waste water. According to the method provided by the invention, the defect that organic carbon resource is needed to be used as the electronic donator is overcome,the operation is simple, the secondary pollution is zero, the cost is low, and is particularly suitable for the treatment on organic carbon metal waste water of mine waste water, metal smelting wastewater, electric plating waste water and the like.

Owner:CHENGDU INST OF BIOLOGY CHINESE ACAD OF S

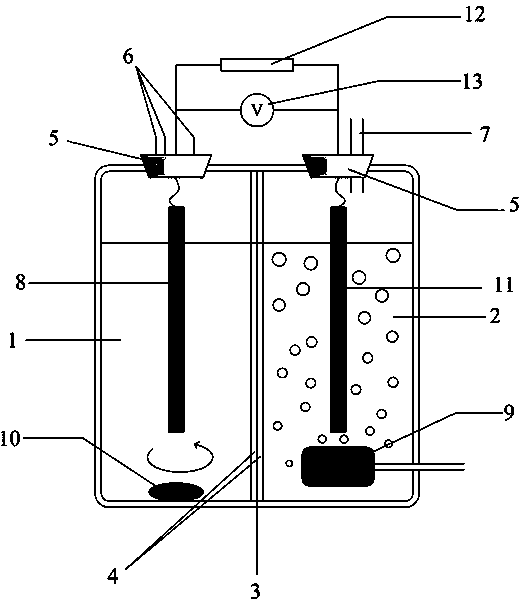

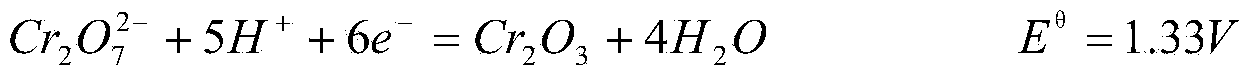

Microbial fuel cell based method for treatment and detection of chromium-containing electroplating wastewater

InactiveCN104386826AAvoid toxic effectsNo pollution in the processTreatment by combined electrochemical biological processesWater contaminantsHigh concentrationSodium acetate

The invention discloses a microbial fuel cell based method for treatment and detection of chromium-containing electroplating wastewater. The steps include: 1) injecting anaerobic sludge and a sodium acetate solution into an anode chamber of a two-chambered microbial fuel cell to inoculate microorganisms, injecting a cathode liquid into a cathode chamber, and connecting resistance at the cathode and the anode to form a closed loop, reacting the cell in a thermotank, injecting sodium acetate into the anode chamber each day till the output voltage is stable; 2) changing the anode chamber solution to an oxygen removed anode liquid, and changing the cathode solution to chromium-containing wastewater; and 3) after starting, adjusting the pH value of wastewater, injecting the wastewater into the cathode chamber, connecting the external resistance and starting the treatment process. The method provided by the invention realizes no direct contact of microorganisms and hexavalent chromium, avoids poisoning of hexavalent chromium on microorganisms, and makes microbiological treatment of high concentration hexavalent chromium wastewater become possible. The standard redox potential of hexavalent chromium is 1.33V, the microbial fuel cell is utilized to treat hexavalent chromium wastewater, and the purposes of synchronous wastewater treatment and electric energy recovery are realized.

Owner:ZHEJIANG UNIV

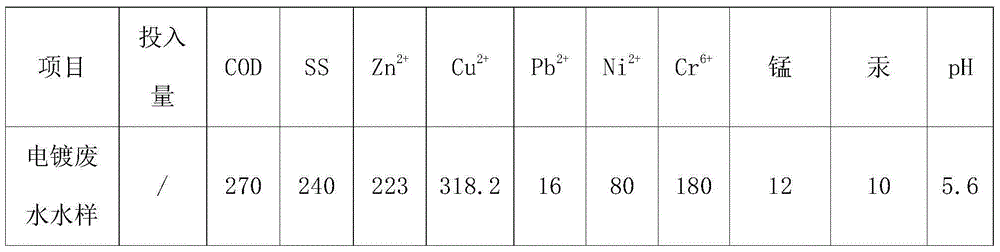

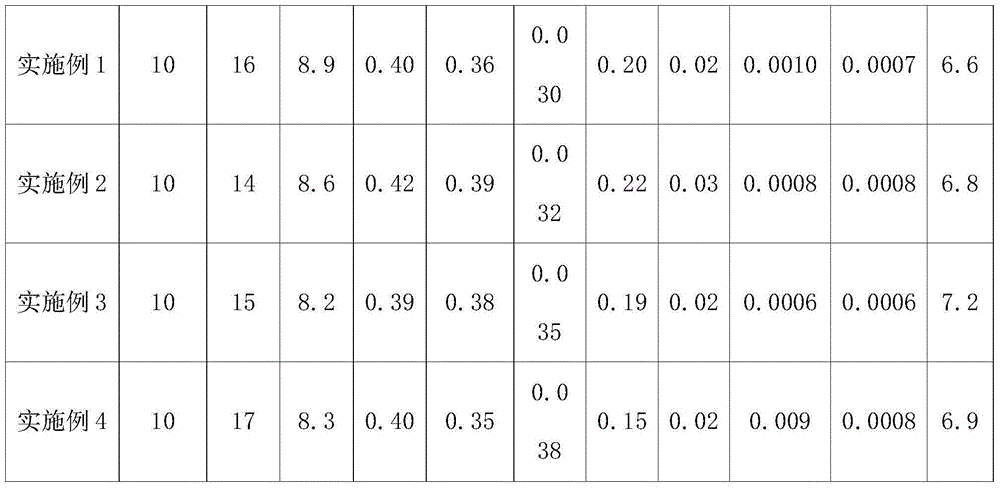

Treatment method for electroplating industrial wastewater

ActiveCN104045182AMeet emission requirementsReduce complexityMultistage water/sewage treatmentChemical reactionCyanide

The embodiment of the invention discloses a treatment method for electroplating industrial wastewater, which comprises the following steps: pretreating nickel-containing wastewater; pretreating chromium-containing wastewater; pretreating copper-containing wastewater in a manner the same with the nickel-containing wastewater pretreatment manner; pretreating cyanide-containing wastewater; treating electroplating mixed wastewater, wherein the electroplating mixed wastewater comprises pretreatment wastewater, cleaning wastewater, electroplating wastewater and the like generated in a workshop production process and also comprises the pretreated nickel-containing wastewater, chromium-containing wastewater, copper-containing wastewater and cyanide-containing wastewater; discharging these pretreated four wastewater to a comprehensive wastewater collection tank together with other pretreatment wastewater, cleaning wastewater and the like, wherein a stirring system is arranged in the comprehensive collection tank; and finally, performing comprehensive electroplating wastewater treatment. According to the invention, non-toxic and harmless chemical reaction treatment is performed on the heavy metals and virulent cyanide, thus realizing one-stop circular electroplating wastewater treatment, improving the treatment efficiency of the electroplating industrial wastewater and reducing the water pollution.

Owner:浙江菲尔特过滤科技股份有限公司

High-efficiency electroplating wastewater treatment and resource utilization device

InactiveCN101798131APromote regenerationEasy to recycleWater contaminantsDispersed particle separationElectrolysisResource utilization

Owner:深圳市蓝水晶环保有限公司

Method for recycling and treating electroplating wastewater

PendingCN107902807AEfficient removalEfficient recyclingWater treatment parameter controlSludge treatment by de-watering/drying/thickeningEcological environmentElectrochemistry

The invention discloses a method for recycling and treating electroplating wastewater. The method comprises a nickel-containing wastewater treatment technology, a chromium-containing wastewater treatment technology, a cyanogen-containing wastewater treatment technology, a comprehensive wastewater treatment technology and a wastewater recycling and treatment technology. According to the method disclosed by the invention, heavy metal ions and organic pollutants in the electroplating wastewater are effectively removed by adopting a technology combining physical chemistry, electrochemistry, physical filtering, membrane separation and the like, so that the electroplating wastewater is efficiently recycled and utilized; pollution and dangers, caused by the fact that the electroplating wastewateris discharged, to the peripheral ecological environment are avoided; the method disclosed by the invention is reasonable in design, the recycling rate of the electroplating wastewater is improved, and energy saving and emission reduction are saved.

Owner:靖江市华晟重金属防控有限公司

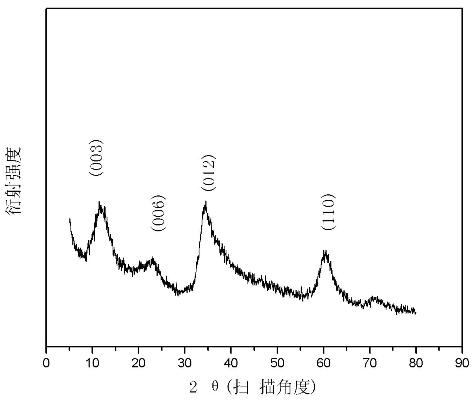

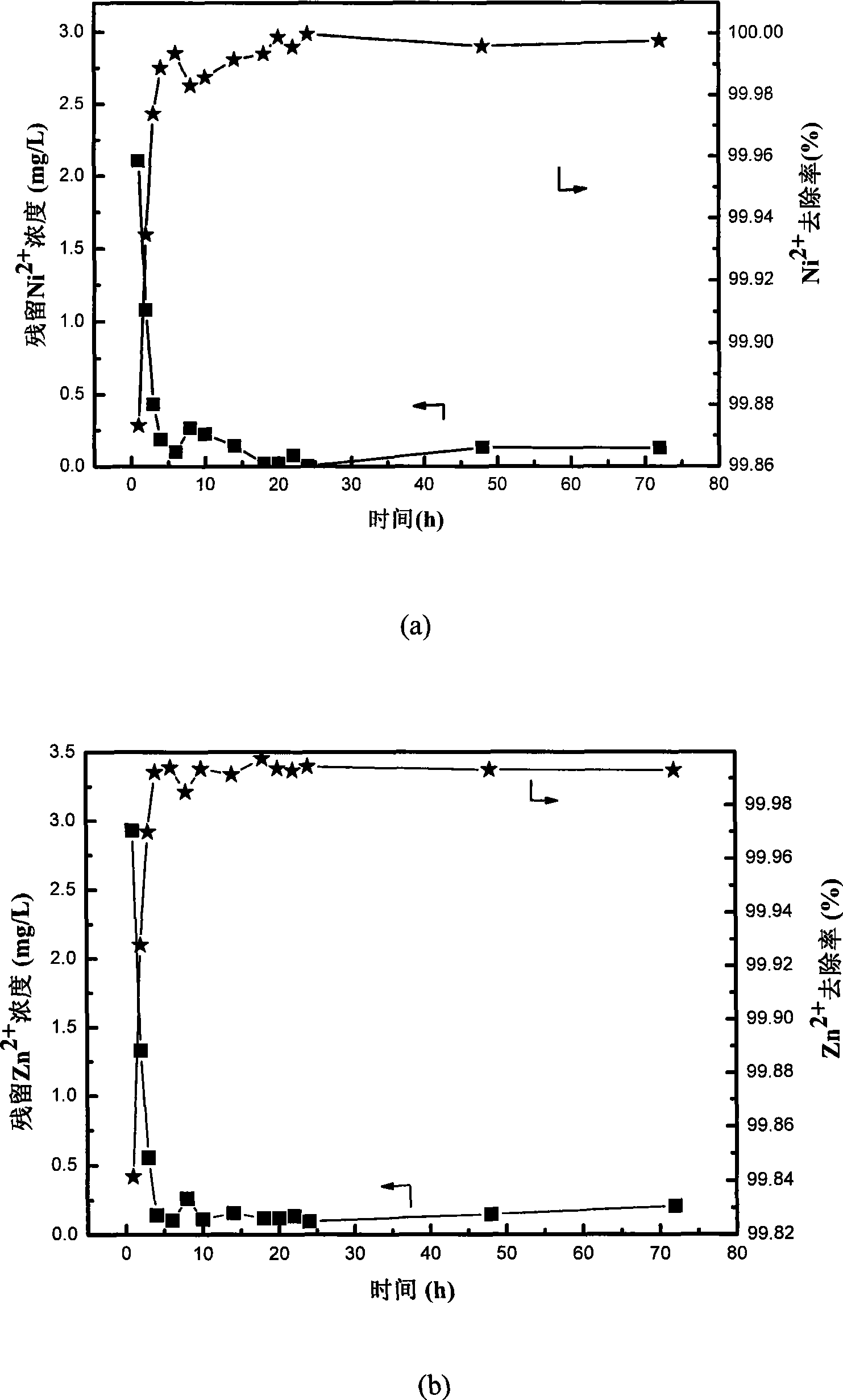

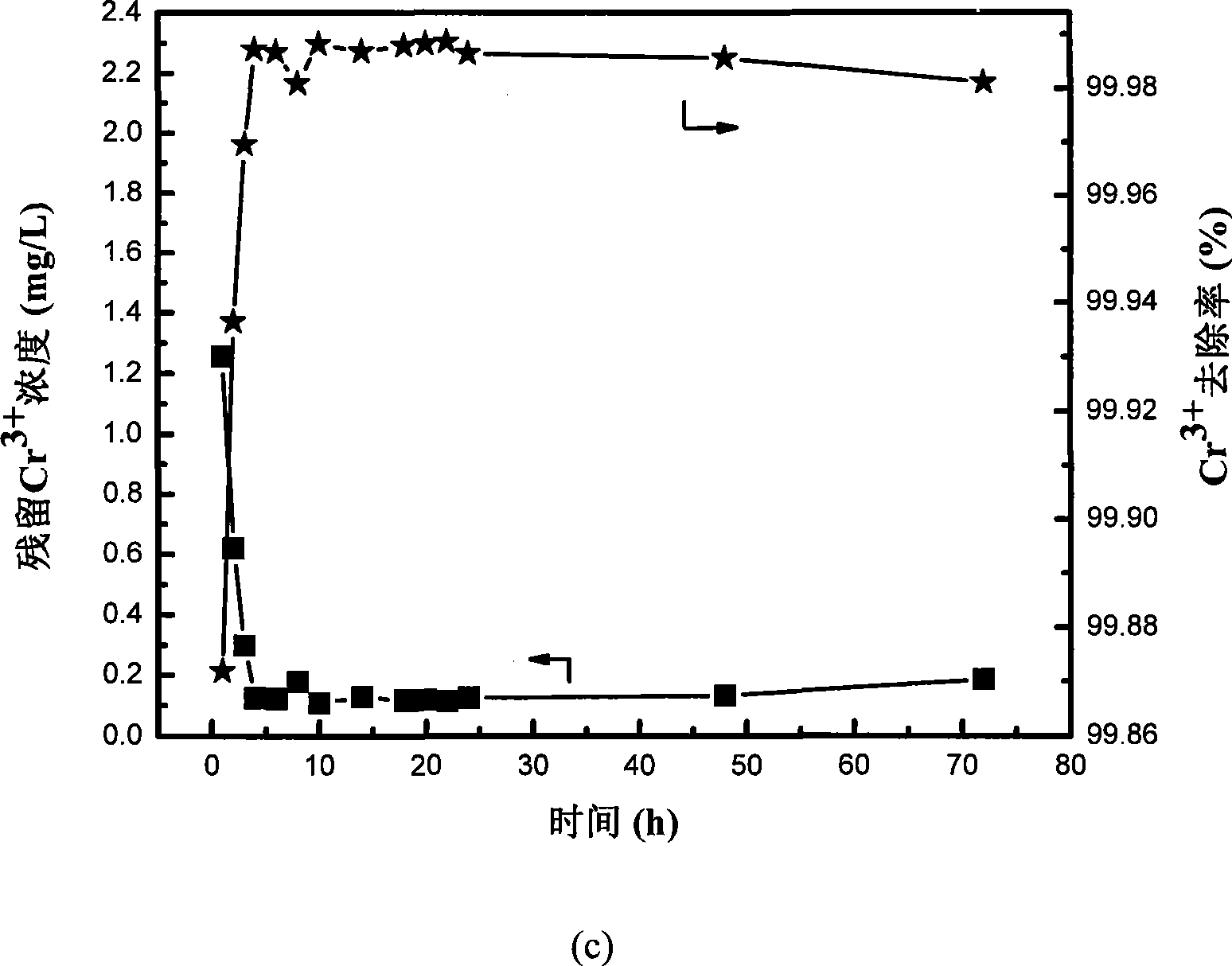

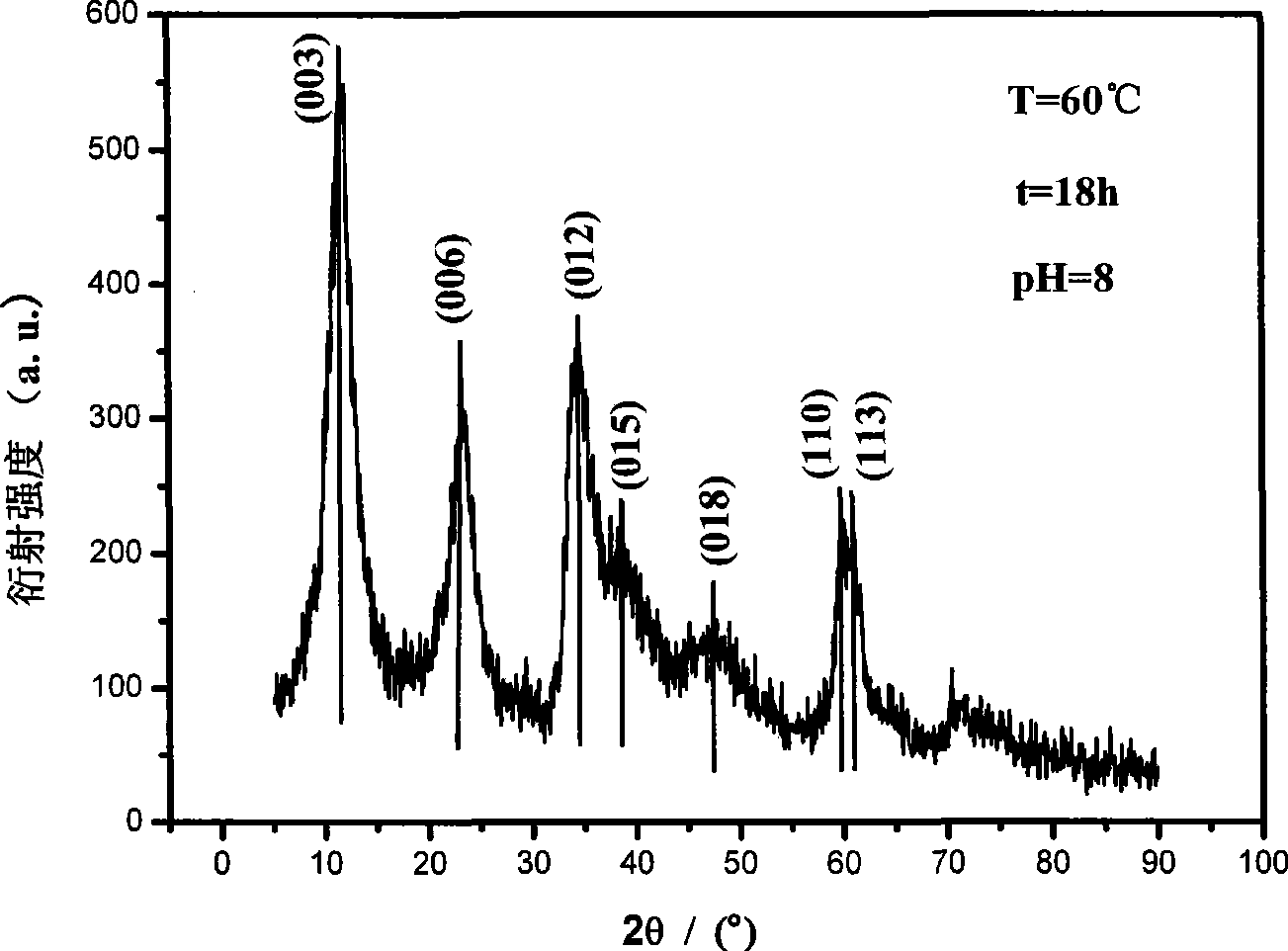

Method for processing electroplating waste containing Ni2+, Zn2+ and Cr3+

InactiveCN101376537ASelf-contained and stableRealize self-purificationProductsReagentsEmission standardCarbonization

The invention relates to a processing method of electroplating wastewater containing Ni<2plus>, Zn<2plus> and Cr<3plus>, which belongs to the technology field of electroplating wastewater treatment and environmental protection engineering and has the characteristics that a Ni-Zn-Cr-LDH intercalation compound is promoted to be formed through controlling a certain reaction conditions by utilizing the accelerated carbonization technology to achieve that heavy metal ions are self-bound and stabilized and harmful heavy metals cannot be lixiviated, thereby protecting the environment. In addition, heavy metal infectants in an electroplating wastewater system are reduced through coprecipitation reaction, and are led to accord with wastewater discharge standard.

Owner:SHANGHAI UNIV

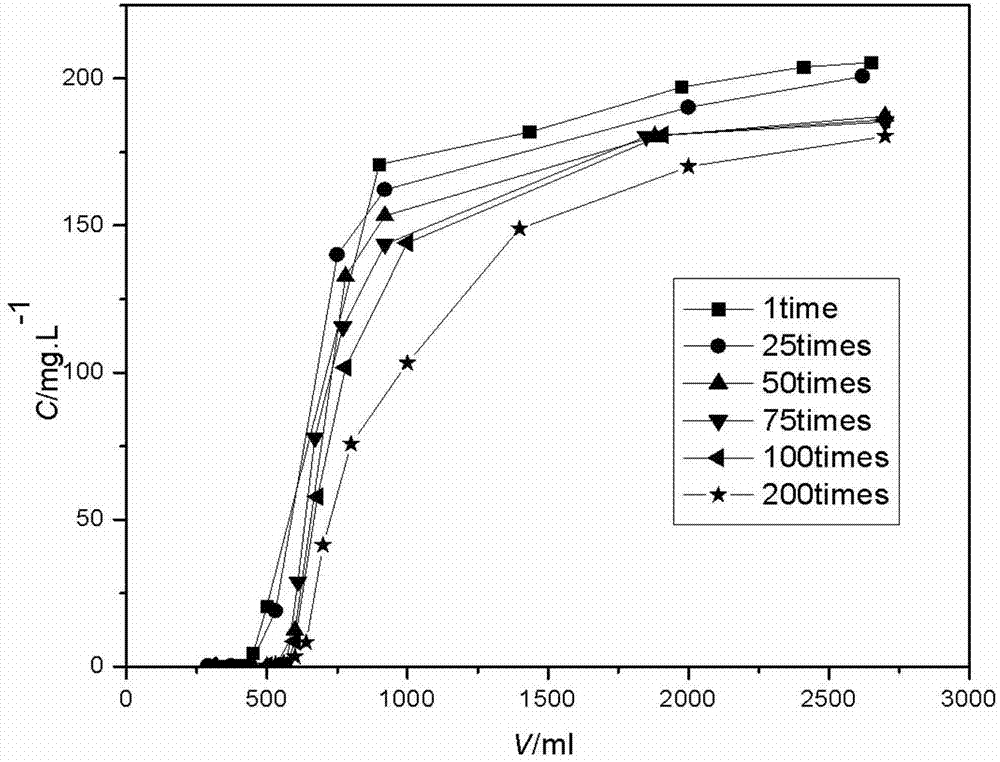

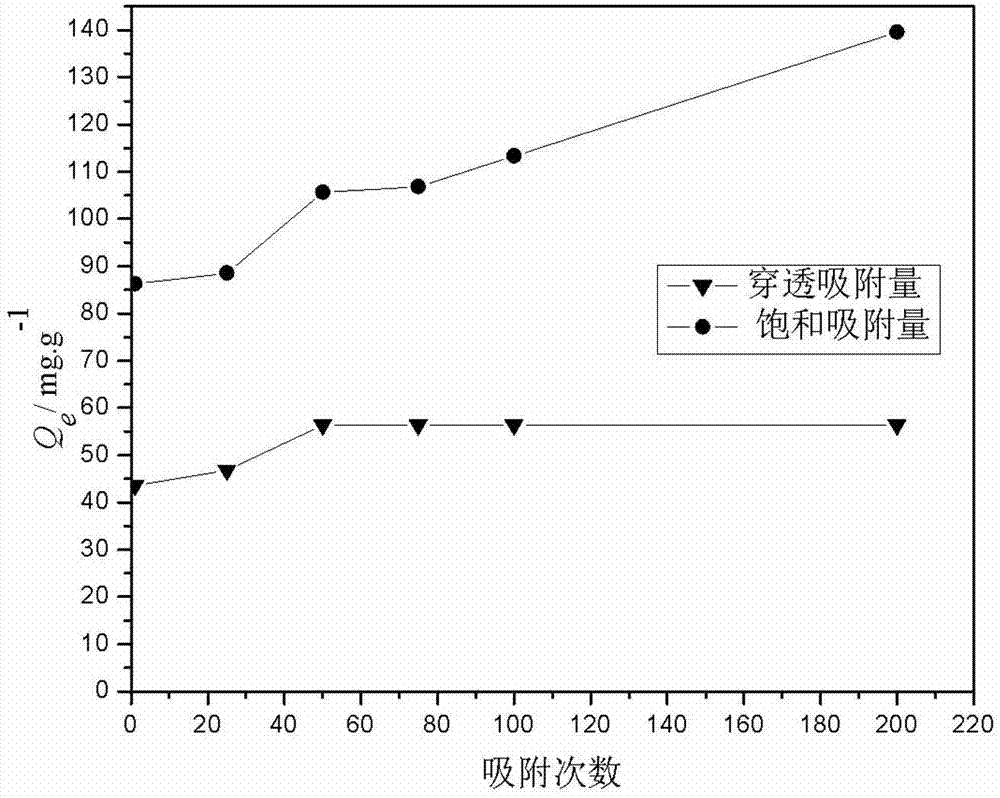

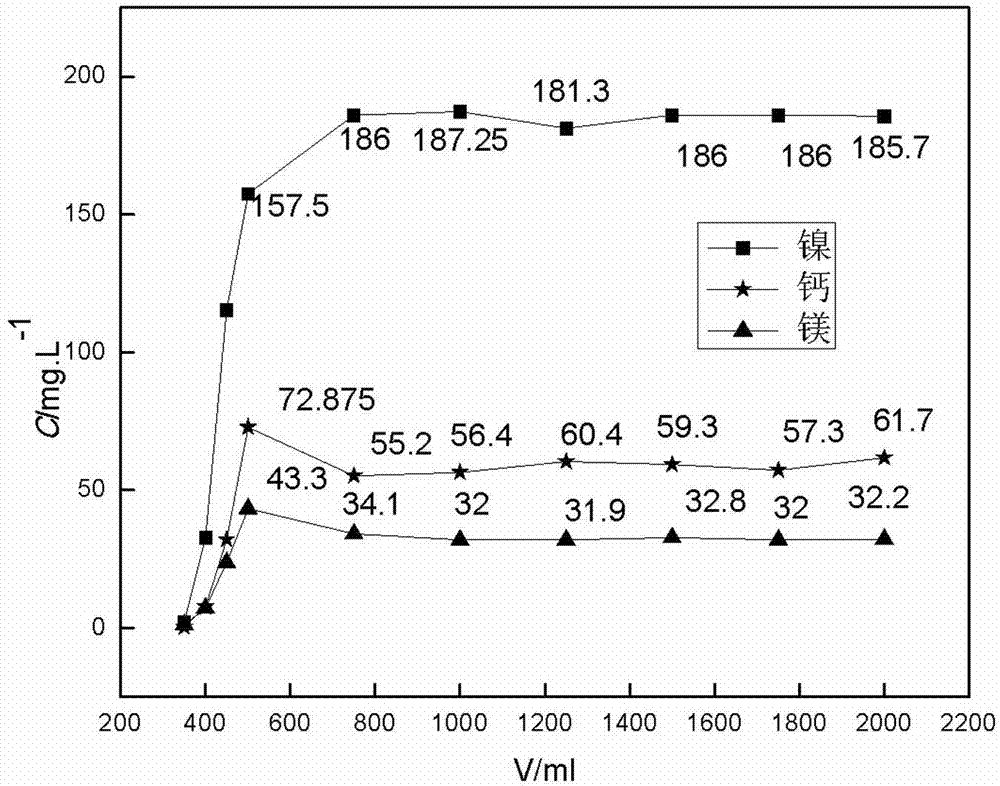

Method for treating nickel/copper-containing electroplating wastewater by using weak acid ion exchange fibers

InactiveCN103693711AEasy to makeFast adsorption and desorption rateWater/sewage treatment by ion-exchangeMultistage water/sewage treatmentFiberPhysical chemistry

The present invention discloses a method for treating nickel / copper-containing electroplating wastewater by using weak acid ion exchange fibers. The method comprises: carrying out a pre-treatment on electroplating wastewater; filling fibers in an ion exchange column to carry out treatment transformation to obtain a treated ion exchange column, wherein the original fibers are transformed into the Na type fibers; connecting 1-4 treated ion exchange columns in series to form an ion exchange system; introducing the treated electroplating wastewater into the ion exchange system to carry out an absorption treatment, and directly discharging when the metal ion concentration in the effluent is less than 0.5 mg / L; adjusting the flow rate of the wastewater to make the first absorption column achieve a saturated state when the wastewater penetrates through the last absorption column, and carrying out elution regeneration recycling on the saturated absorption column; and carrying out absorption cycle operation. According to the present invention, the method is the process method for quickly and efficiently removing heavy metal ions in electroplating wastewater and concurrently obtaining a high purity and high concentration eluent, and the obtained eluent can be used for electrolysis so as to obtain zero-valent metal nickel / copper.

Owner:佛山市中耀卓邦企业管理有限公司

Electroplating wastewater treatment agent

InactiveCN105000651AReasonable ratioEfficient removalWaste water treatment from metallurgical processWater/sewage treatment by flocculation/precipitationCross-linkTreatment effect

The invention discloses an electroplating wastewater treatment agent, consisting of a reducing agent, a composite flocculant, a heavy metal ion collector DTCR, starch xanthate, cross-linked rectorite, quaternary ammonium salt lignin, sodium silicate, an alkaline substance and an adsorption filler. According to the treatment agent, the materials realize a synergistic effect, multiple heavy metal ions can be effectively removed, heavy metal ions with multiple ions coexisting also can be effectively removed, the treatment effect on electroplating wastewater is excellent, the performance is stable, the sedimentation effect is good, and the sedimentation speed is high; besides, the electroplating wastewater treatment agent is reasonable in ratio, non-poisonous and free of environment pollution.

Owner:宁波保税区维迪克环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com