Device for treating high-concentration electroplating wastewater and application thereof

A technology of electroplating wastewater and high concentration, which is used in metallurgical wastewater treatment, neutralized water/sewage treatment, oxidized water/sewage treatment, etc. It can solve the problem of difficult to achieve ideal results, achieve remarkable removal effect and small footprint , Improve the effect of effective space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

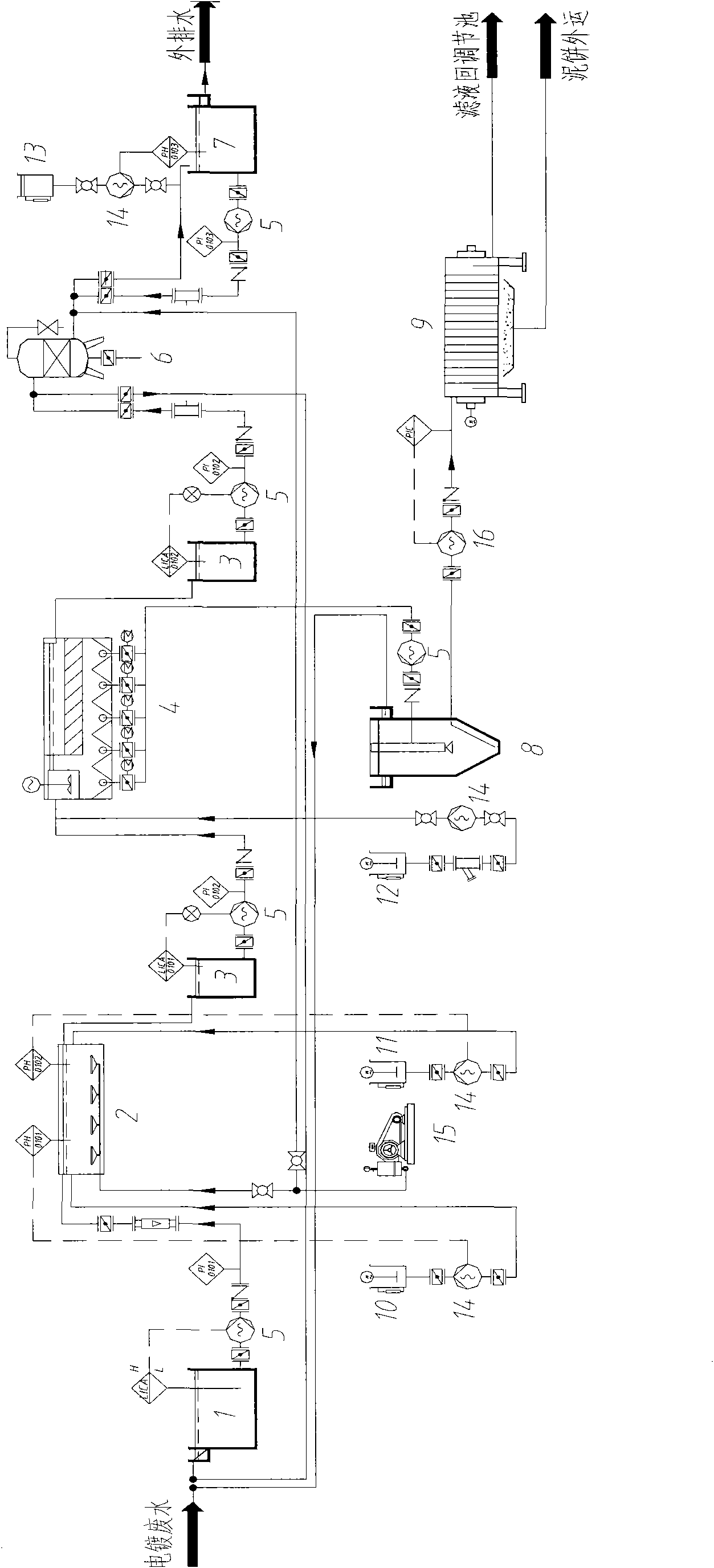

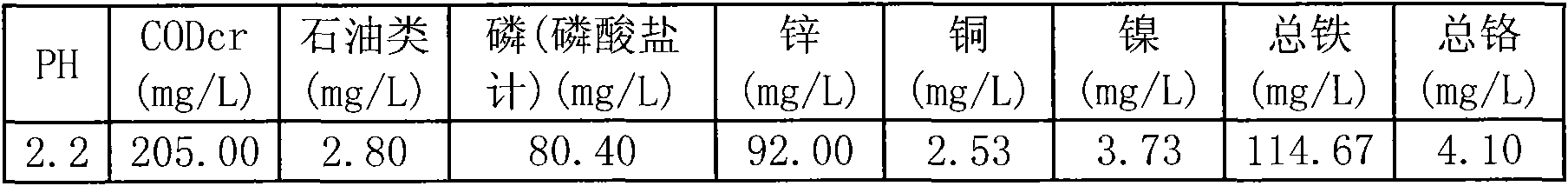

[0046] Equipment treatment water volume 60m 3 / h, press figure 1 process shown. Calcium hydroxide is added to the water inlet of the coagulation inclined plate sedimentation tank to adjust the pH value to 7.0-7.5, and sodium hydroxide is added to the middle part to fine-tune the pH value to 8.5-9.0. Add polyacrylamide 2mg / L to the coagulation inclined plate sedimentation tank, and control the pH value of the clear water tank between 6.0 and 9.0. The coagulation inclined plate sedimentation tank automatically discharges mud once every 4 hours. The multimedia filter tank is backwashed once every 12 hours. The working pressure of thick slurry pump is controlled at 2kgf / cm 2 .

[0047] The equipment runs continuously and stably, and the processing results are shown in Table 2.

[0048] Table 2 Equipment treatment water quality

[0049]

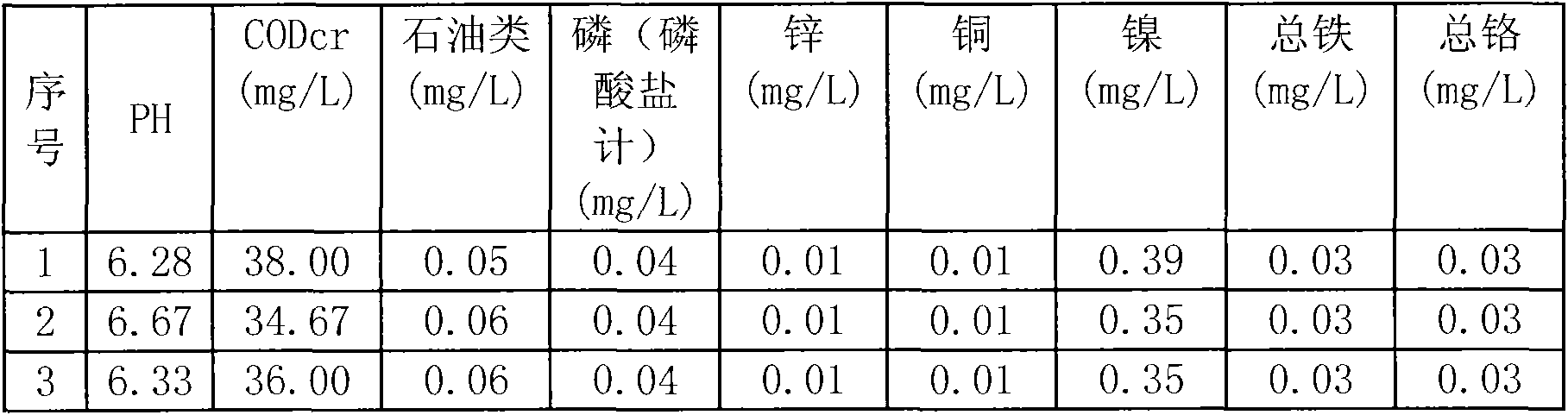

[0050] The removal rate of each index is shown in Table 3.

[0051] Table 3 Removal rate of various pollutants

[0052]

[0053] F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com