Blending-field delivery system

A conveying system and mixing technology, which is applied in the field of conveying system in the mixing yard, can solve the problems of large floor area, not too large width, and the influence of surrounding environment, so as to save land use area, simplify process design, and save engineering The effect of investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

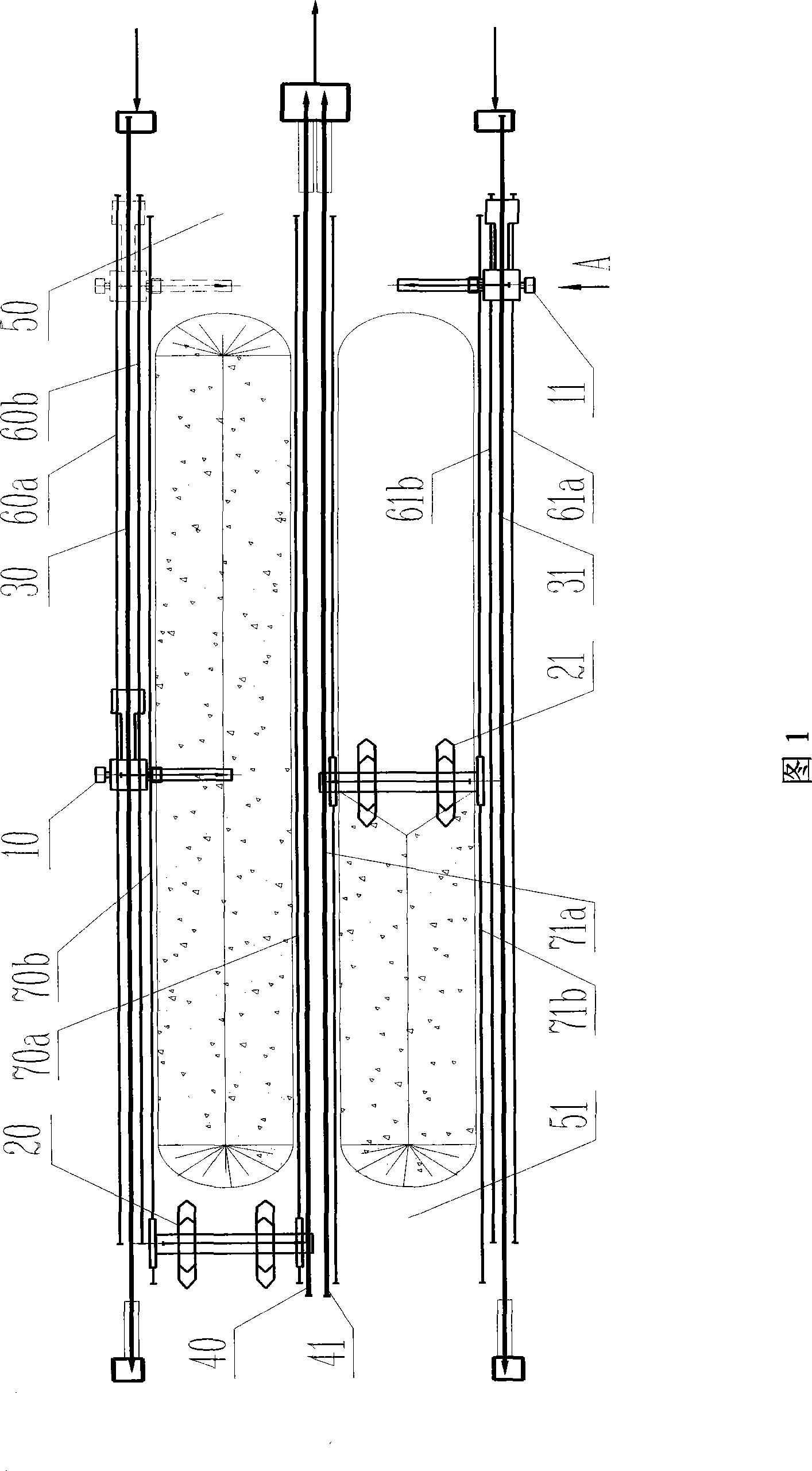

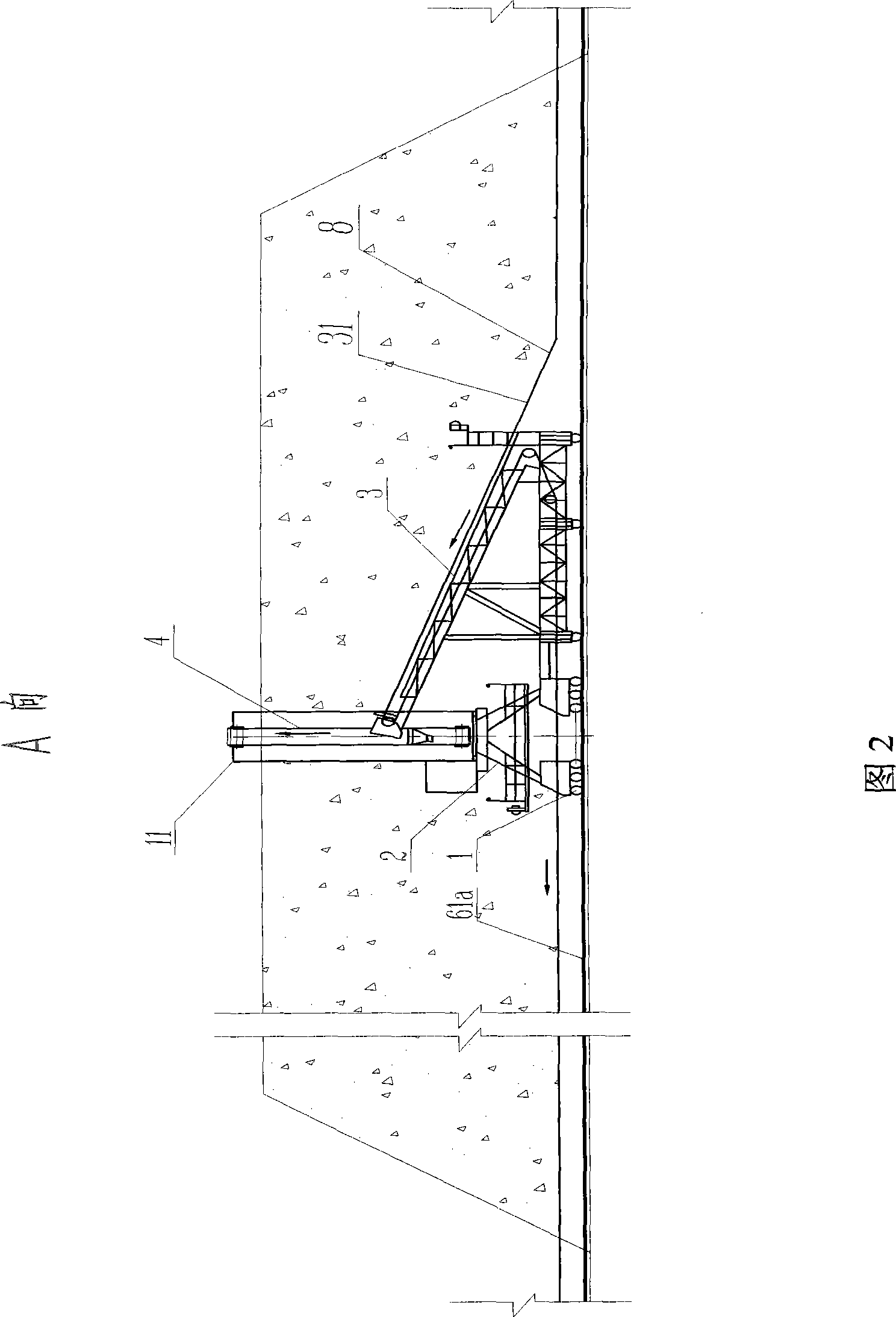

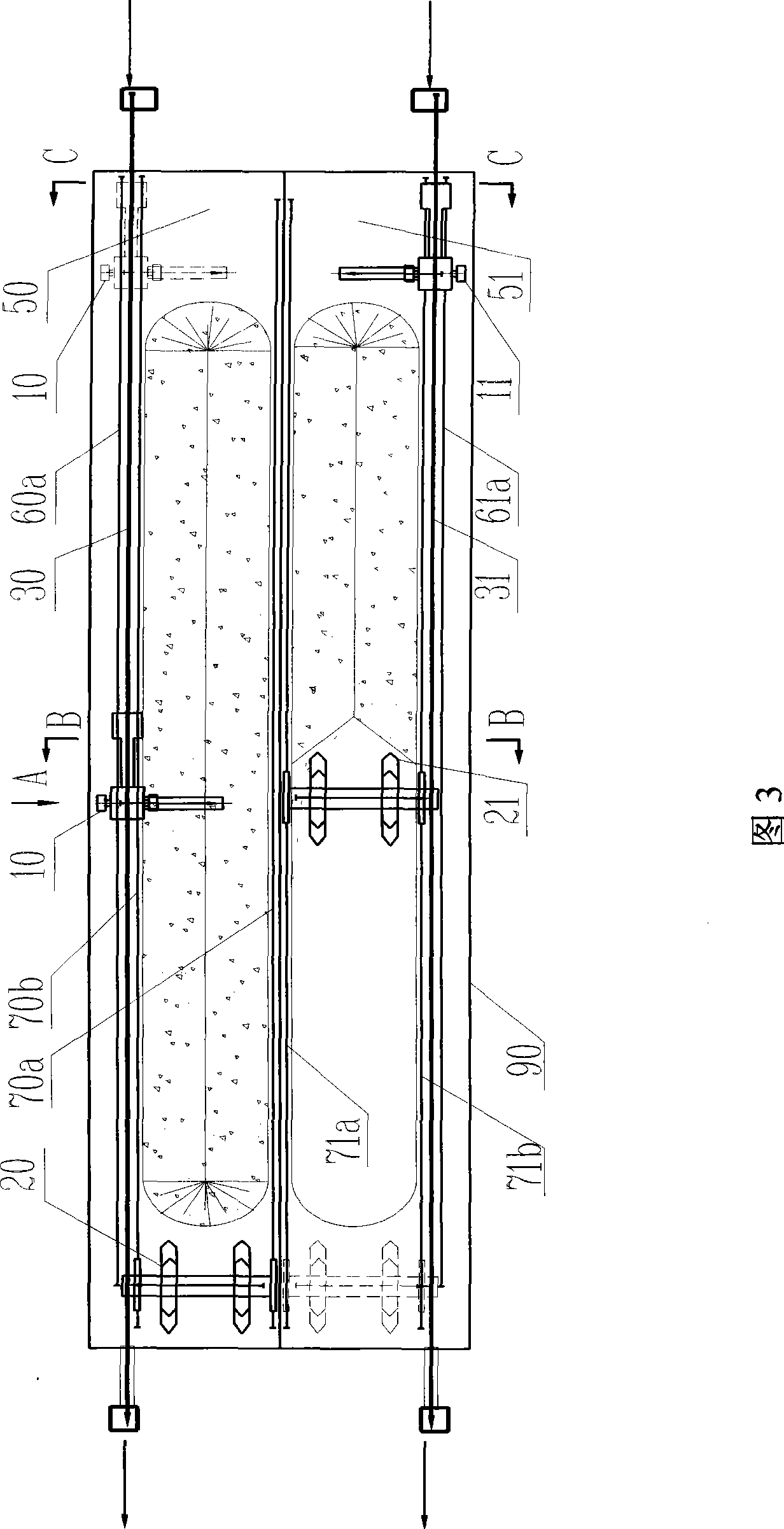

[0028] As can be seen from Fig. 3 to Fig. 5: the conveying system of the mixing stockyard of the present invention is arranged as two spans, each span is respectively provided with a mixing stacker 10,11 and a mixing reclaimer 20,21; The mixing and reclaiming machines 20 and 21 are all provided with two independent walking tracks 70a and 70b, 71a and 71b; Uniform stacker 10,11 inner side then utilizes the shape track 70b and 71b on the outside of adjacent mixing reclaimer 20,21; Conveyor 30,31; each mixing reclaimer 20,21 utilizes the stacking belt conveyor 30,31 that is set up when each mixing reclaimer 20,21 is reclaimed and delivered to the user; each mixing reclaimer 20,21 There is respectively a storage yard 50,51 between the two shaped tracks.

[0029] Since the first mixing stocker 10 and the second mixing stocker 11 have the same structure, the first mixing stocker 10 is now used as an example to illustrate its structural composition, please refer to Fig. 6, the first...

Embodiment 2

[0036] Fig. 7 has provided the plane layout diagram of the second embodiment of another kind of mixing material field conveying system, the mixing material field conveying system of the present invention is that the mixing material field conveying system is set into two spans, and each span is respectively provided with a One mixing stacker 10,11 and one mixing reclaimer 20,21; each mixing stacker 10,11 is independently provided with outer profile tracks 60a and 61a, and the mixing stacker 10, 11 inboards then utilize the outboard track 70b and 71b of the mixing reclaimer 20,21 adjacent thereto; ; Each mixing reclaimer 20 and 21 are only independently provided with out-of-shape tracks 70b and 71b on the outside, and a out-of-shape track 80 is arranged on the adjacent inboards of two mixing and reclaimers 20 and 21; When the reclaimers 20 and 21 are reclaimed and transported to the user, the corresponding stacking belt conveyors 30 and 31 are used; between the track 70b and 80 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com