Patents

Literature

160results about How to "Simple process design" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

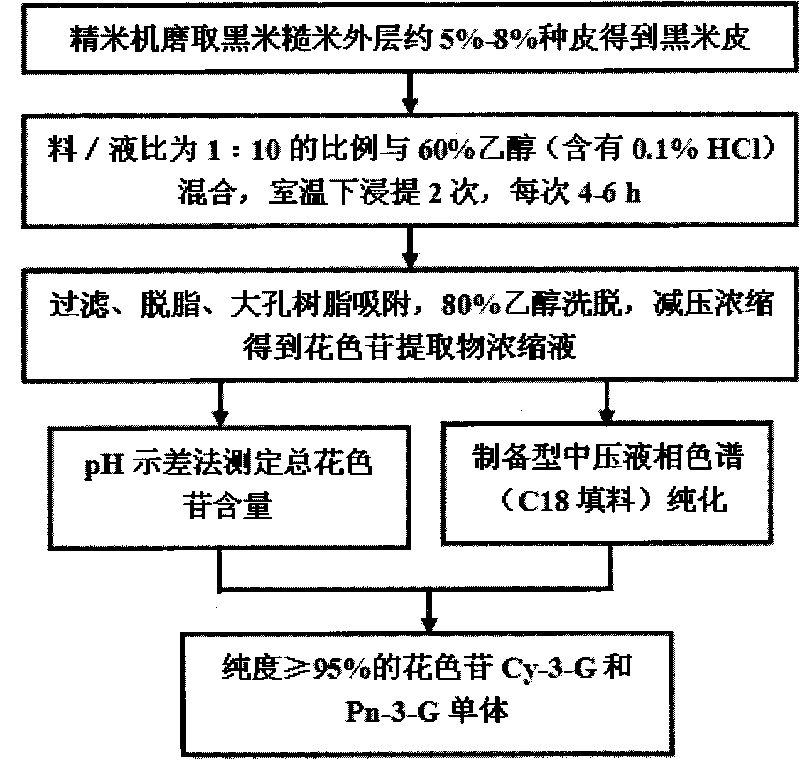

Method for separating high-purity anthocyanin monomers from black rice

ActiveCN101723996AGood choiceGood degreasing effectSugar derivativesSugar derivatives preparationFreeze-dryingEvaporation

The invention provides a method for separating high-purity anthocyanin monomers from black rice. The method comprises the following steps of: grinding 5 to 8 percent of episperm on the outer layer of black rice and brown rice to obtain black rice pericarp, leaching anthocyanin in the black rice pericarp by acidized ethanol, and extracting and defatting petroleum ether; performing primary purification of ethanol extracts of the black rice pericarp by using macroporous resin; separating the anthocyanin in coarse extracts of the anthocyanin of the black rice pericarp by the medium pressure preparation liquid phase chromatographic technique, collecting two leading anthocyanin components, which are cyanidin-3-glucoside and paeonidin-3-glucoside, in the black rice pericarp respectively according to the obtained chromatogram, and performing rotary evaporation of eluent at a temperature of below 45 DEG C until all methanol is gone, and performing freeze-drying to obtain powder of the anthocyanin monomers.

Owner:GUANGZHOU TRACE ELEMENTS BIOLOGICAL TECH CO LTD

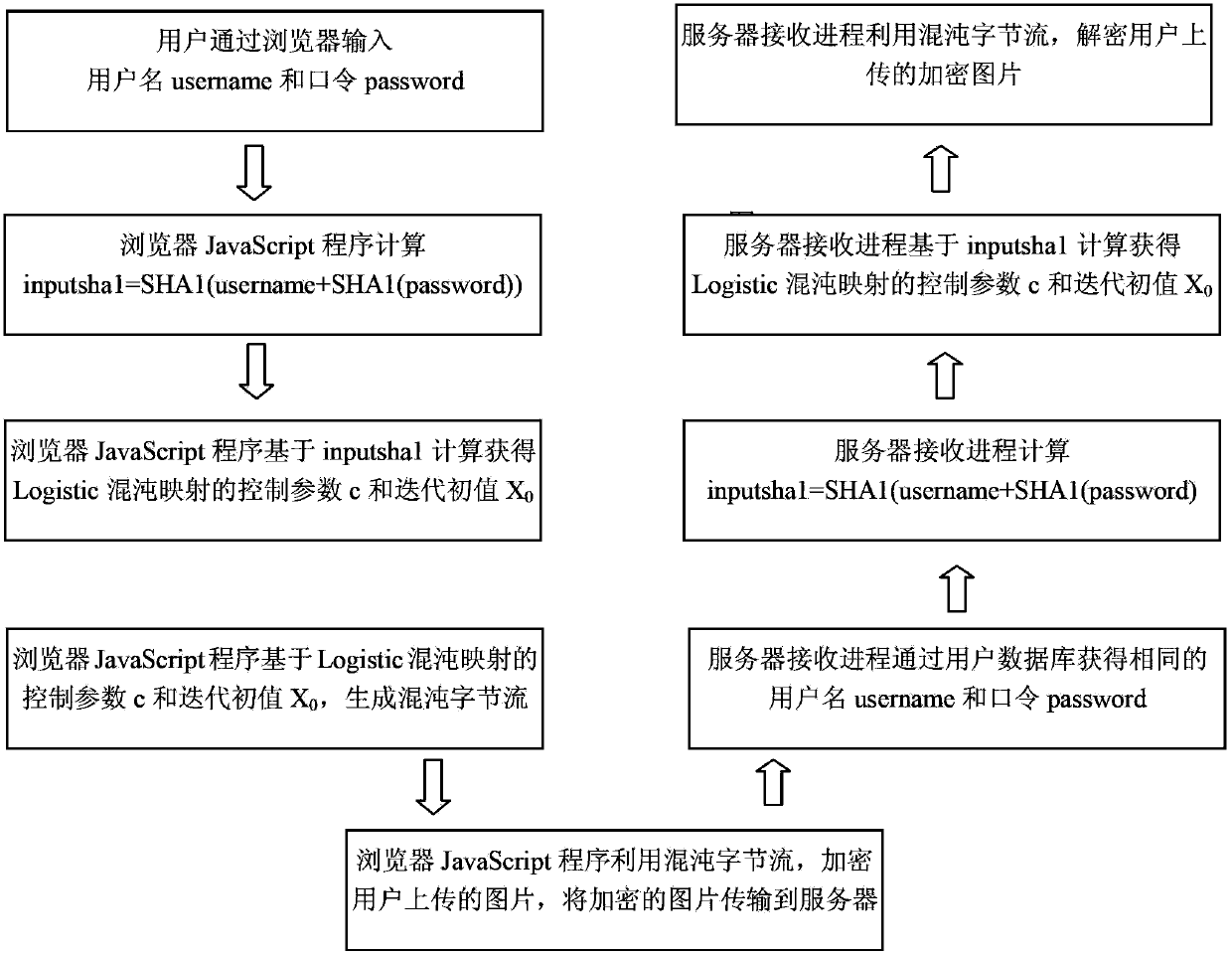

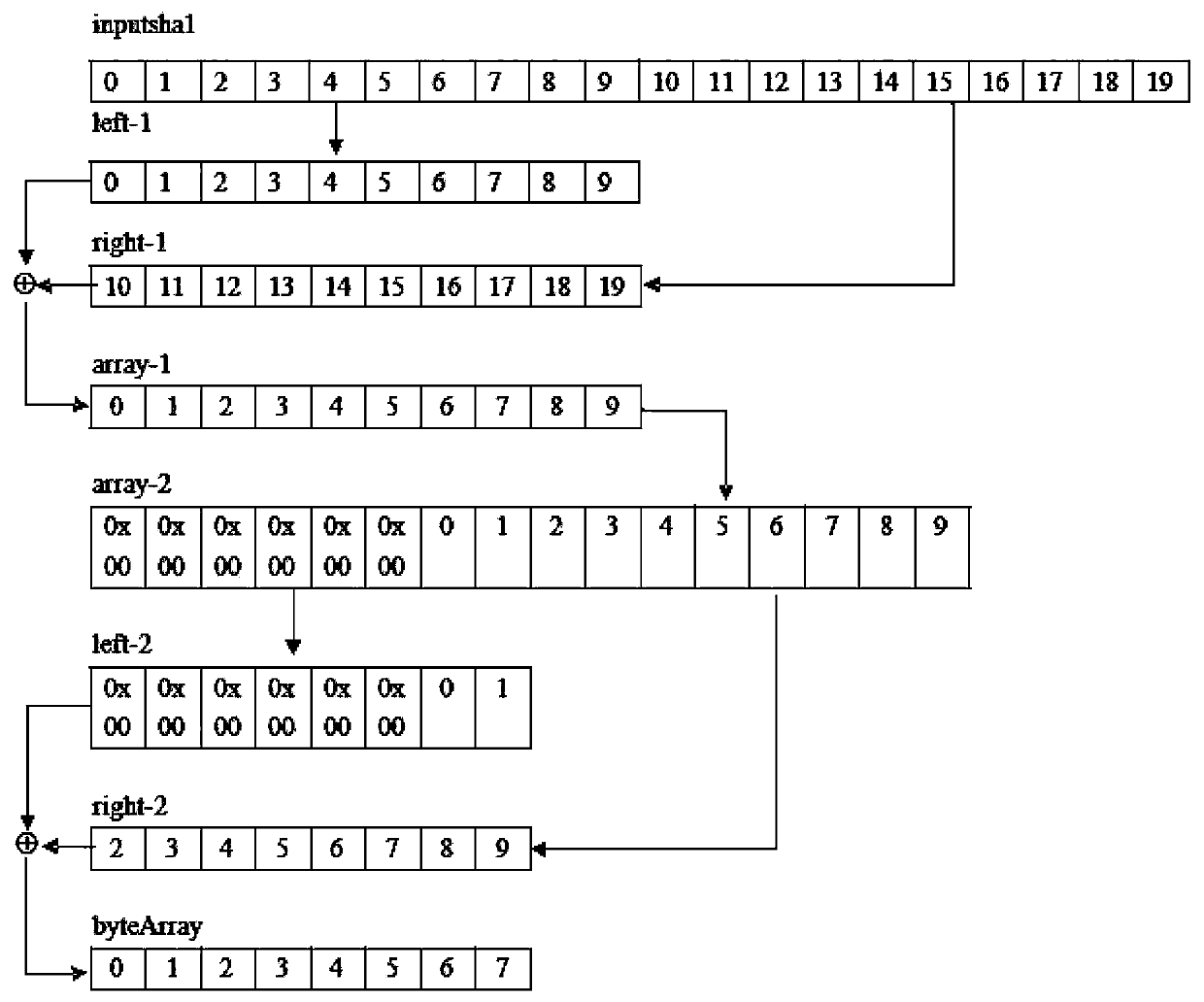

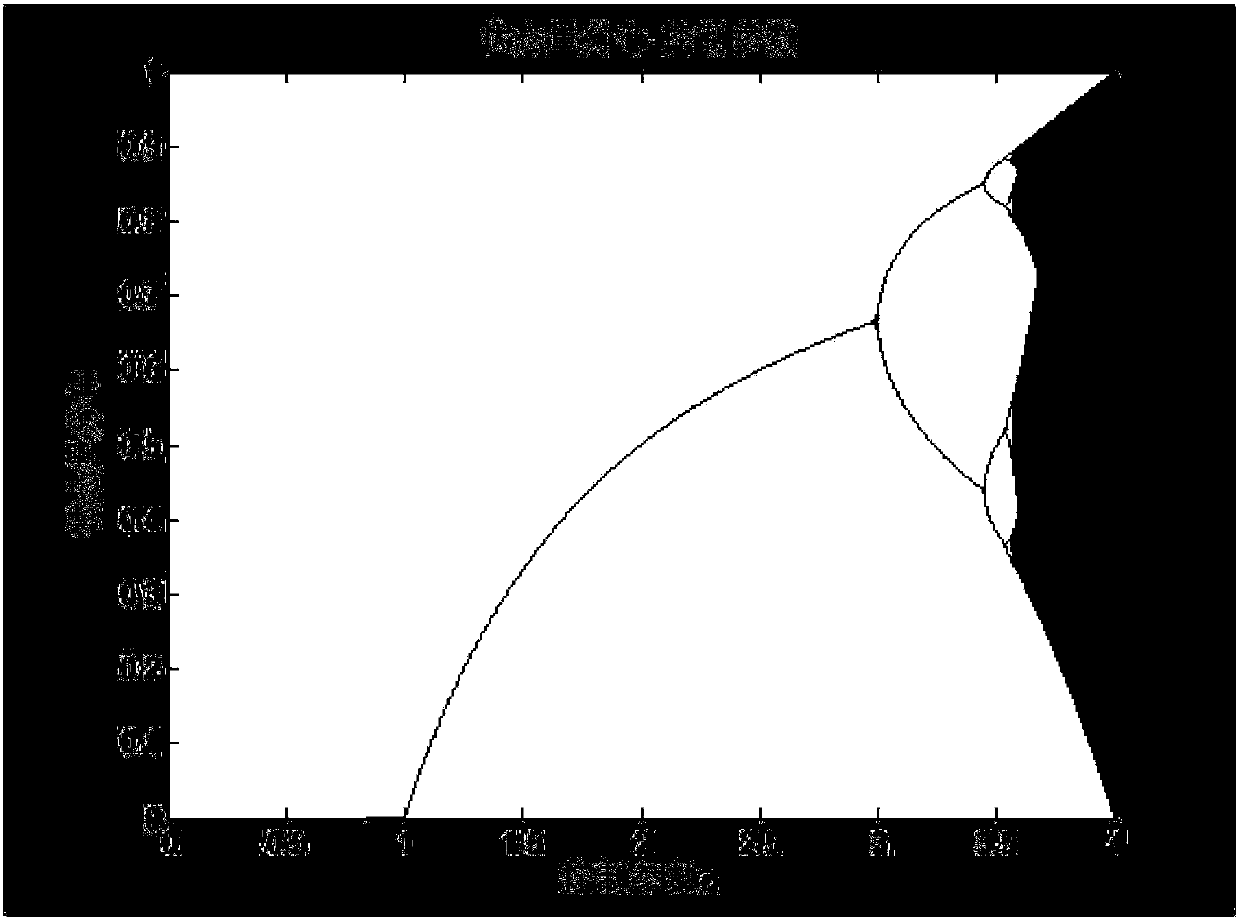

Internet picture transparent and safe transmission method based on chaotic encryption

ActiveCN103427979AImprove efficiencyImprove encryption securitySecuring communicationUser inputInternet users

The present invention relates to an internet picture transparent and safe transmission method based on chaotic encryption, and provides a chaotic digital image encryption transmission solution scheme which supports the automatic generation of a secret key and is fully transparent to the internet user operation. According to the internet picture transparent and safe transmission method based on the chaotic encryption, a browser client utilizes a JavaScript program to automatically map, calculate and obtain two key Logistic chaotic secret key parameters according to the information, such as the usernames, password Hash values, etc. inputted by the internet valid users, to realize the safe and transparent encryption and transmission on the to-be-uploaded pictures of users; a server terminal can query a user database according to the registered username to obtain the password Hash value of a user, so that a same chaotic random sequence can be obtained, and finally the encrypted pictures uploaded by the user can be decrypted; on the contrary, when the user registers validly to require the server pictures, the JavaScript program can automatically carry out the chaotic secret key parameter calculation and chaotic decryption operations at a browser terminal. According to the scheme of the present invention, the balance problem among the security, the encryption efficiency, the secret key management and the like of the internet picture transmission can be solved effectively.

Owner:ZHEJIANG UNIV OF TECH

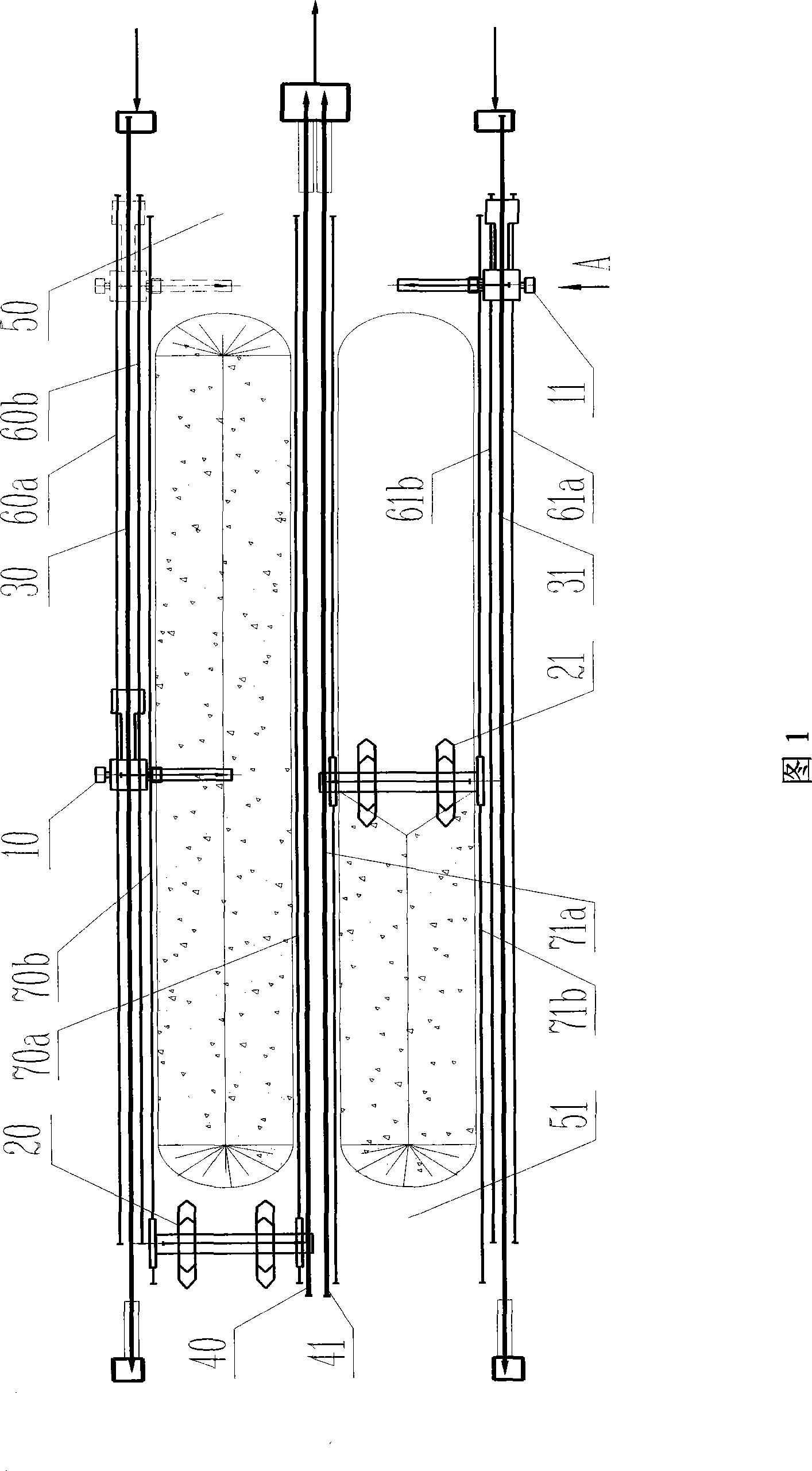

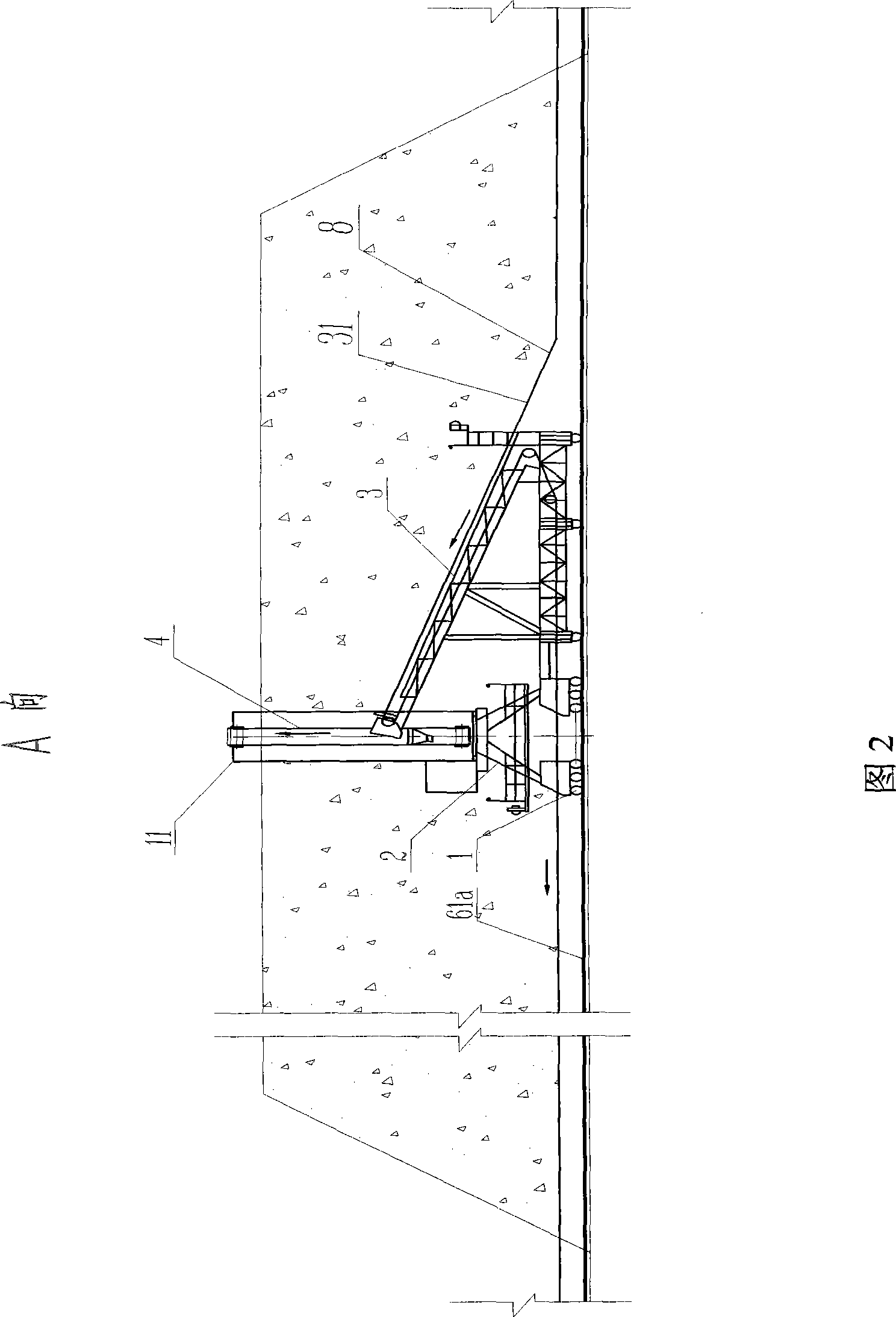

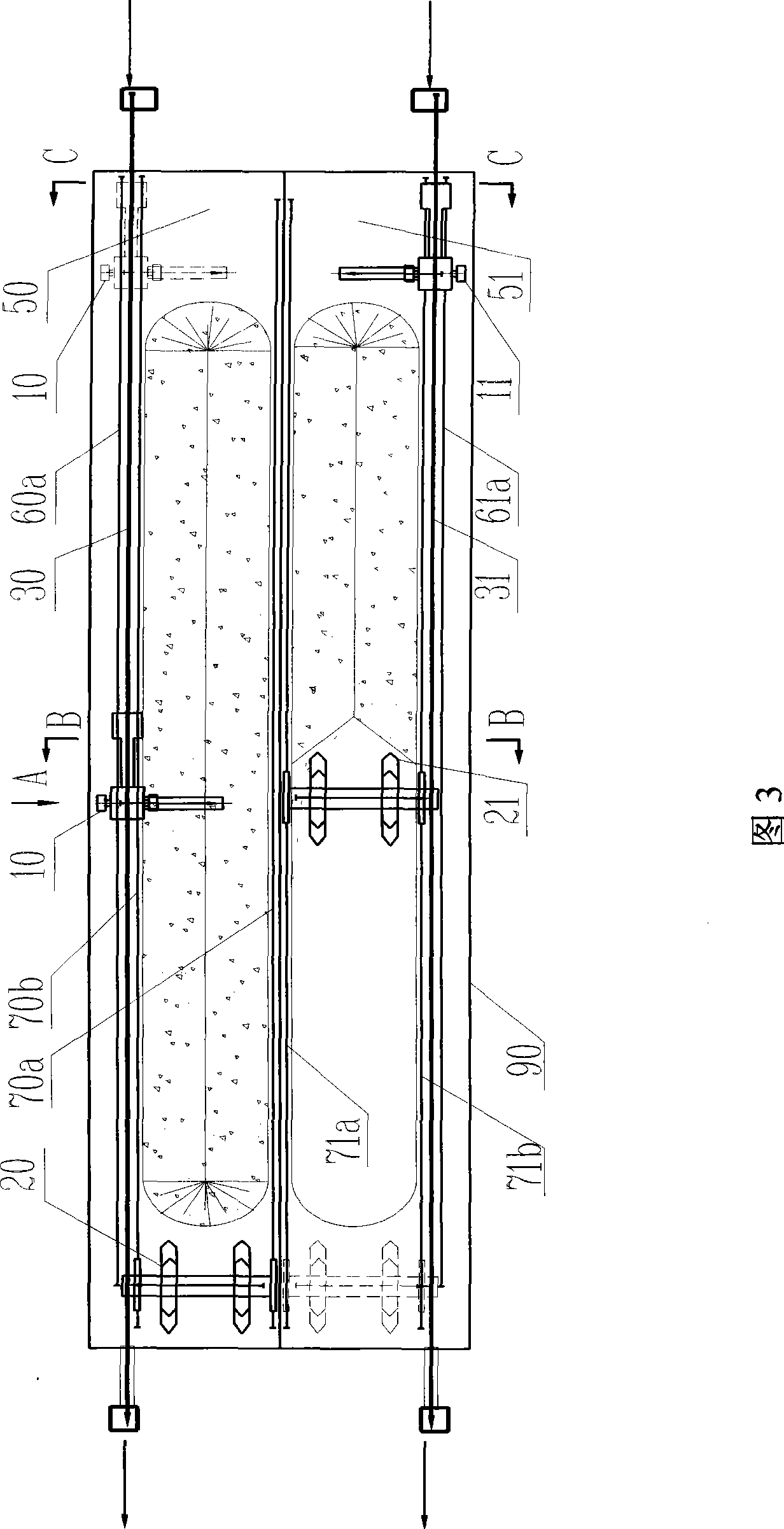

Blending-field delivery system

ActiveCN101422709AReduce the use of areaReduce widthMixing methodsMixer accessoriesEngineeringSmall footprint

The invention discloses an even blending stock ground transmission system which is arranged to be two spans, even blending material piling machines (10 and 11) and even blending reclaiming machines (20 and 21) are respectively arranged in each span; deformed tracks (60a and 61a) are arranged only at the outer sides of the even blending material piling machines (10 and 11), while the inner sides of the even blending material piling machines (10 and 11) utilize adjacent deformed tracks (70b and 71b); the deformed tracks (70b and 71b) are arranged at outer sides of the even blending reclaiming machines (20 and 21), while the inner sides thereof is provided with deformed tracks (70a and 71a) or only one deformed track according to different situations; each of the even blending material piling machines (10 and 11) has a belt-typed piled material conveyor (30 and 31); the even blending reclaiming machines (20 and 21) utilize the belt-typed piled material conveyors (30 and 31) that are arranged in a corresponding span when reclaiming materials; and stock dumps (50 and 51) are arranged between the two deformed tracks of the even blending reclaiming machines (20 and 21). The even blending stock ground transmission system has saved investment, small area occupation and simple design.

Owner:HUATIAN ENG & TECH CORP MCC

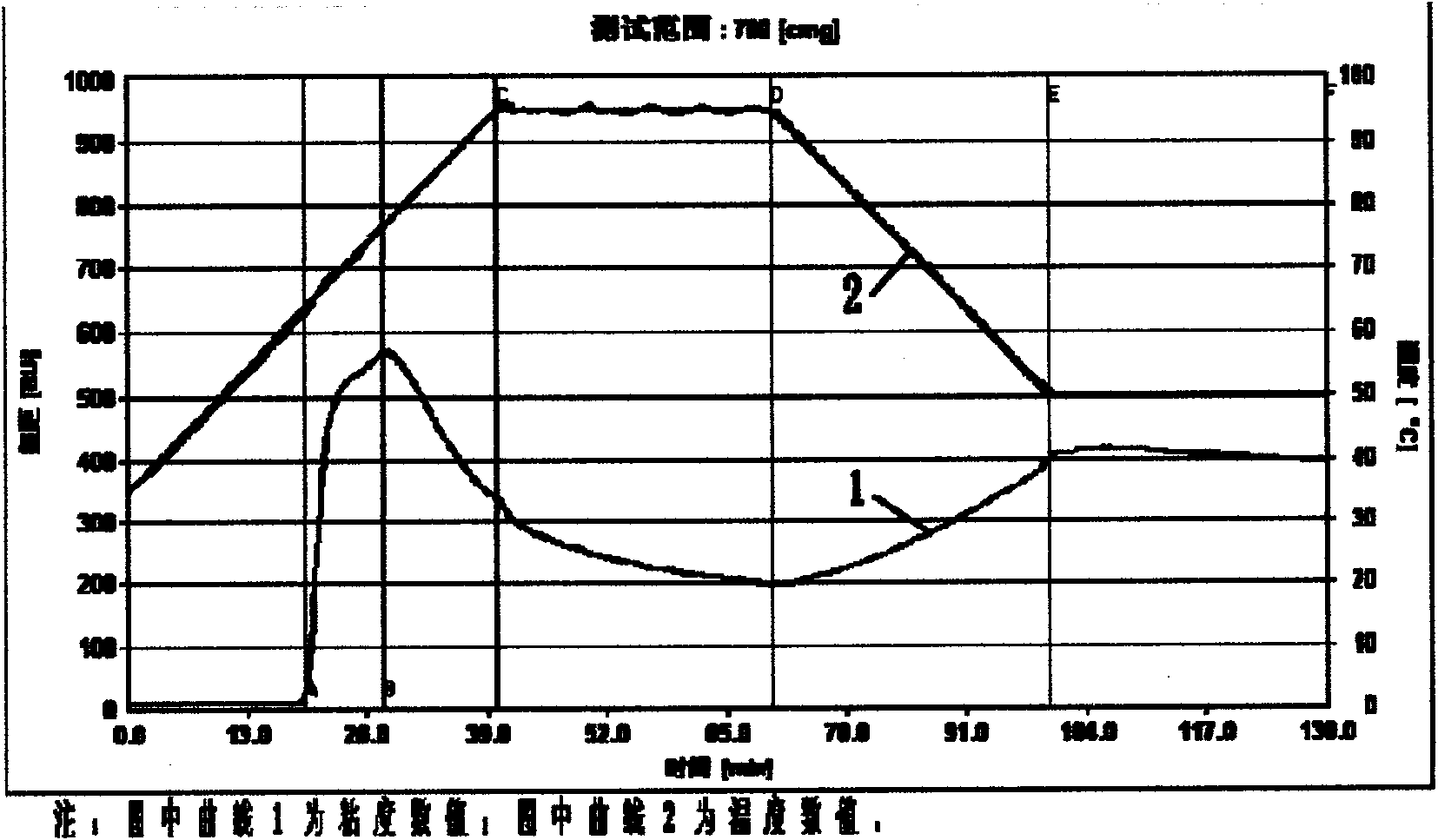

Special feed for loach and preparation method of same

The invention discloses a special feed for a loach. The special feed for loach is a dragon beard-shaped or granular soft feed and is prepared from the following raw materials in mass percentage: 20-30% of flour, 10-25% of soybean meal, 15-25% of rapeseed meal, 3-7% of fishmeal, 10-15% of cottonseed meal, 5-8% of soybean protein powder, 1-2% of soybean oil, 1-3% of calcium dihydrogen phosphate, 1-3% of premix, 5-8% of corn protein powder and 5-8% of corn protein feed. The invention further discloses a preparation method of the special feed for loach. The special feed for loach is reasonable in compatibility; the feed form adapts to body features and life habits of loach; the special feed for loach is lower in nutrient loss rate than expanded granular feed and softer than hard granular feed; the special feed for loach can effectively avoid a phenomenon of throat blockage caused by swallowing the hard granular feed; the loss rate of high nutrition is low and the utilization ratio of the special feed for loach is improved; the special feed for loach can effectively promote the growth rate of loach; the preparation method is more reasonable in process design and simple in process; and the obtained special feed for loach has the advantages of long service life, low nutrition loss rate and the like.

Owner:陈忆凤

Jelly and production technology thereof

InactiveCN106213385APromote digestion and absorptionNutritional balanceFood ingredient as taste affecting agentBiotechnologyFruit juice

The invention provides a jelly and a production technology thereof. The jelly comprises the following components in parts by weight: 4 to 6 parts of plant ferment powder, 4 to 5 parts of concentrated juice, 1 to 3 parts of moringa, 1 to 3 parts of white kidney bean, 1 to 2 parts of water soluble dietary fiber, 1 to 2 parts of collagen powder, 6 to 8 parts of fructose, 1 to 3 parts of xylitol, 1 to 2 parts of seaweed gel, 1.5 to 2 parts of konjak powder, and 75 to 80 parts of water. The raw materials are reasonably compounded, the nutrients are more comprehensive and balanced therefore, and the nutrients can be better digested and absorbed by the human body. The taste of the jelly is good, the fragrance is rich, the sweetness is proper, the intestinal environment is improved, the gastrointestinal functions are recovered, and moreover, the jelly has the functions of clearing heat, removing toxin, and improving skin conditions.

Owner:厦门樱之美生物科技有限公司

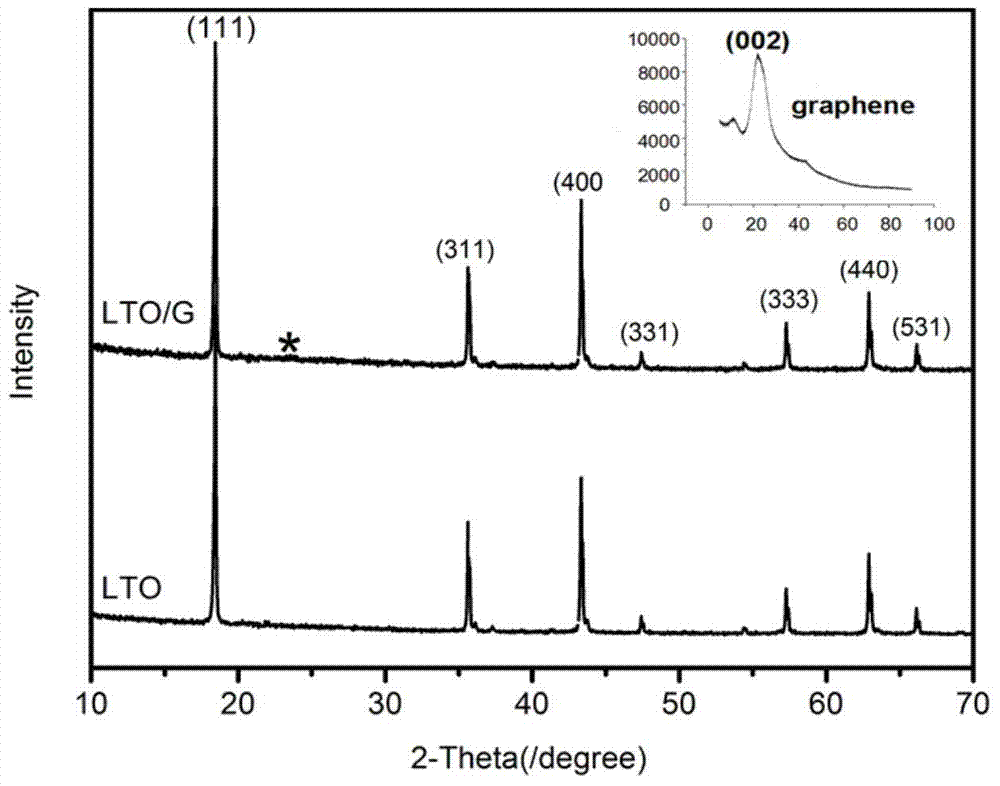

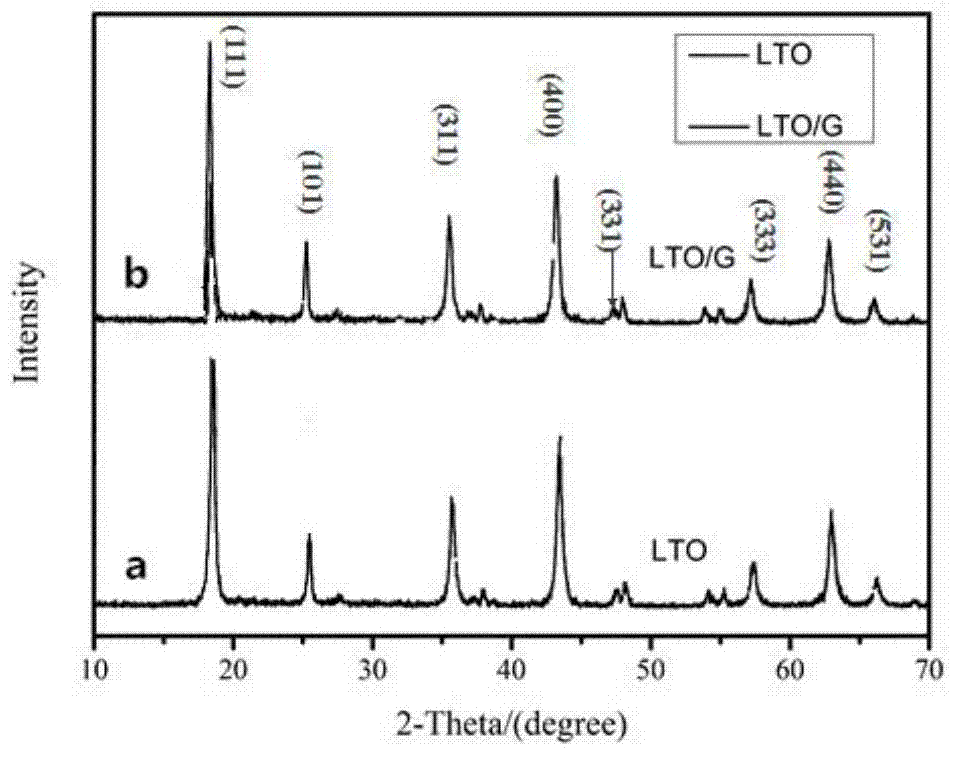

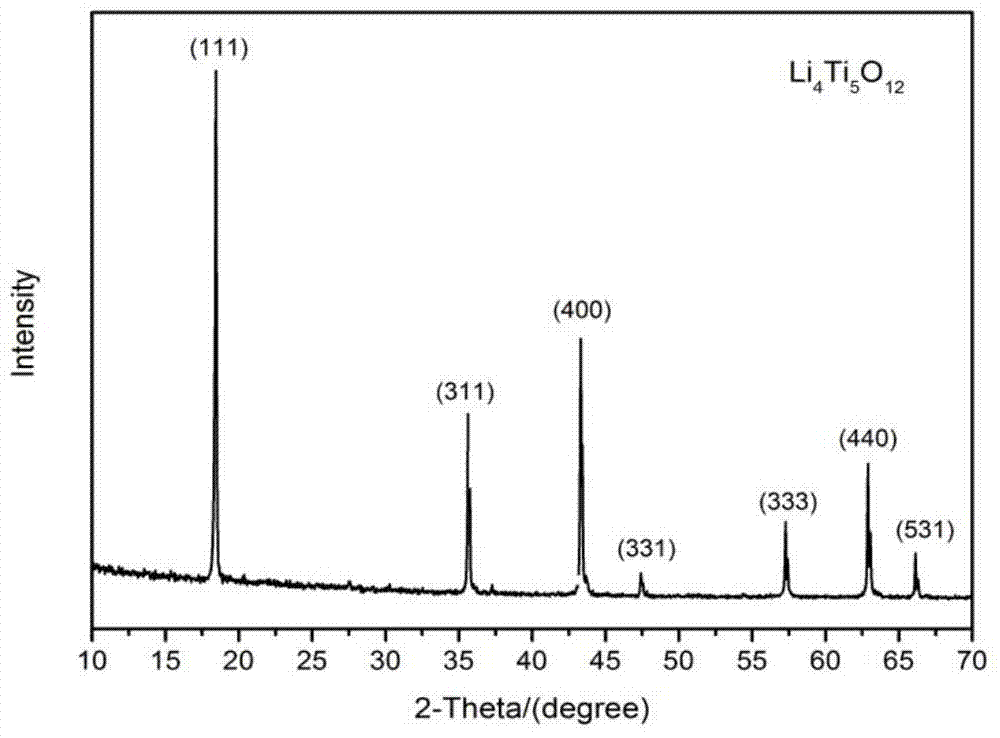

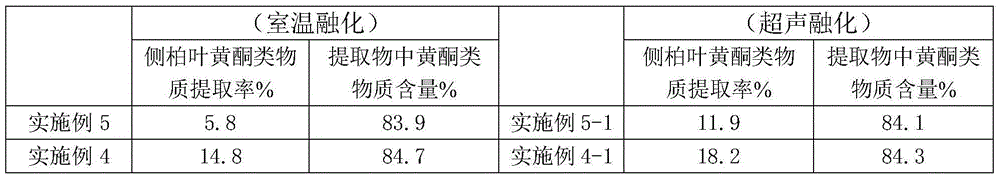

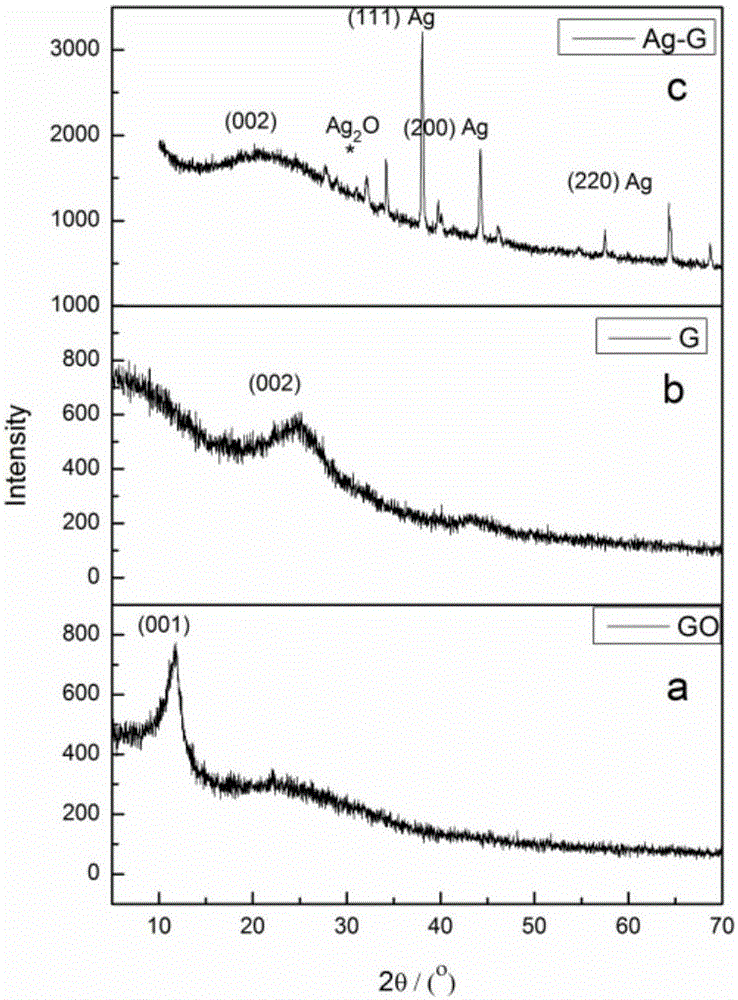

Lithium titanate/graphene composite cathode material for lithium ion battery

InactiveCN104852028AHigh specific capacityImproved magnification performanceSecondary cellsNegative electrodesHigh rateReducing agent

The invention discloses a lithium titanate / graphene composite cathode material for a lithium ion battery. The composite cathode material is obtained by mixing lithium titanate and graphene oxide and then performing reduction by a reducing agent. A preparation method of the composite cathode material comprises the steps of preparing pure-phase lithium titanate by a hydrothermal method, sufficiently mixing pure-phase lithium titanate and graphene oxide, adding an appropriate amount of reducing agent, and shifting pure-phase lithium titanate, graphene oxide and the reducing agent to a reaction kettle to react for a certain time at a certain temperature to obtain the lithium titanate / graphene composite cathode material. The method synthesizes the lithium titanate / graphene composite material by an industrially extensively used hydrothermal reaction, so that the method is simple to operate and low in equipment requirement, and is suitable for industrial production; and the prepared lithium titanate / graphene composite material has higher specific capacity, good high rate performance and excellent cycle performance, and is applicable to the fields of portable electronic equipment, electromobiles, energy storage equipment and the like.

Owner:HEFEI UNIV OF TECH

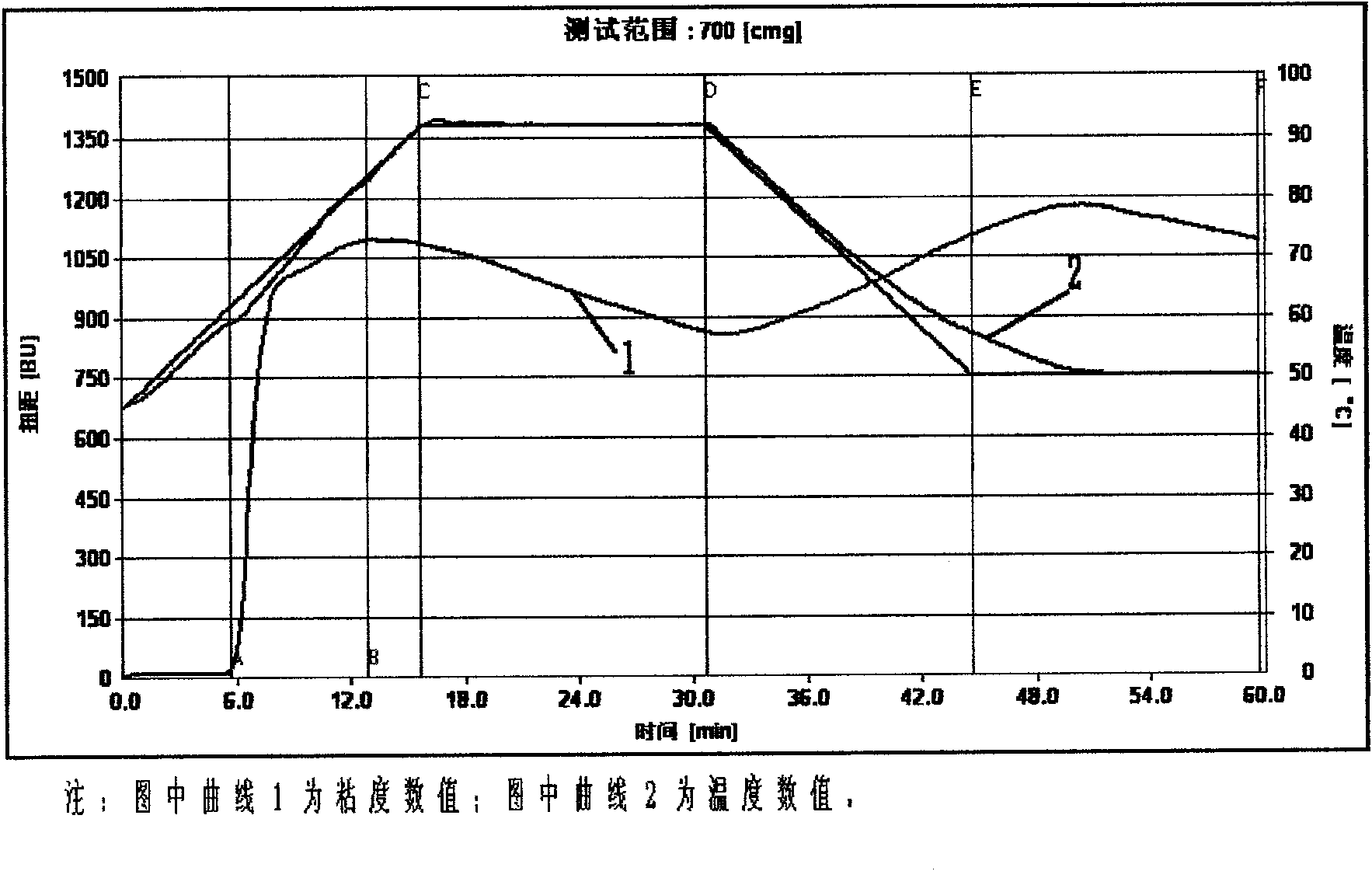

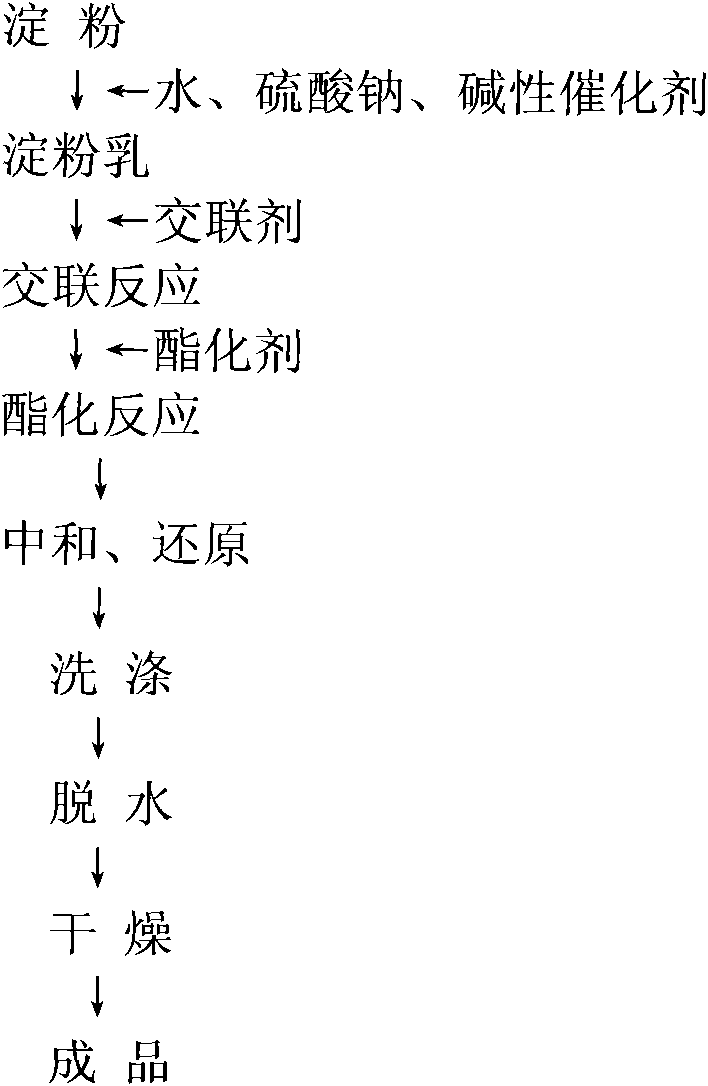

Composite modified starch, preparation method and application thereof

InactiveCN101967199ACompact structureImprove freeze-thaw stabilityFood preparationSuccinic anhydrideSodium trimetaphosphate

The invention provides a preparation method of composite modified starch, comprising: carrying out crosslinking by crosslinker sodium trimetaphosphate; and then esterfying by succinic anhydride. The invention also provides a composite modified starch prepared with the method and application thereof.

Owner:内蒙古奈伦农业科技股份有限公司

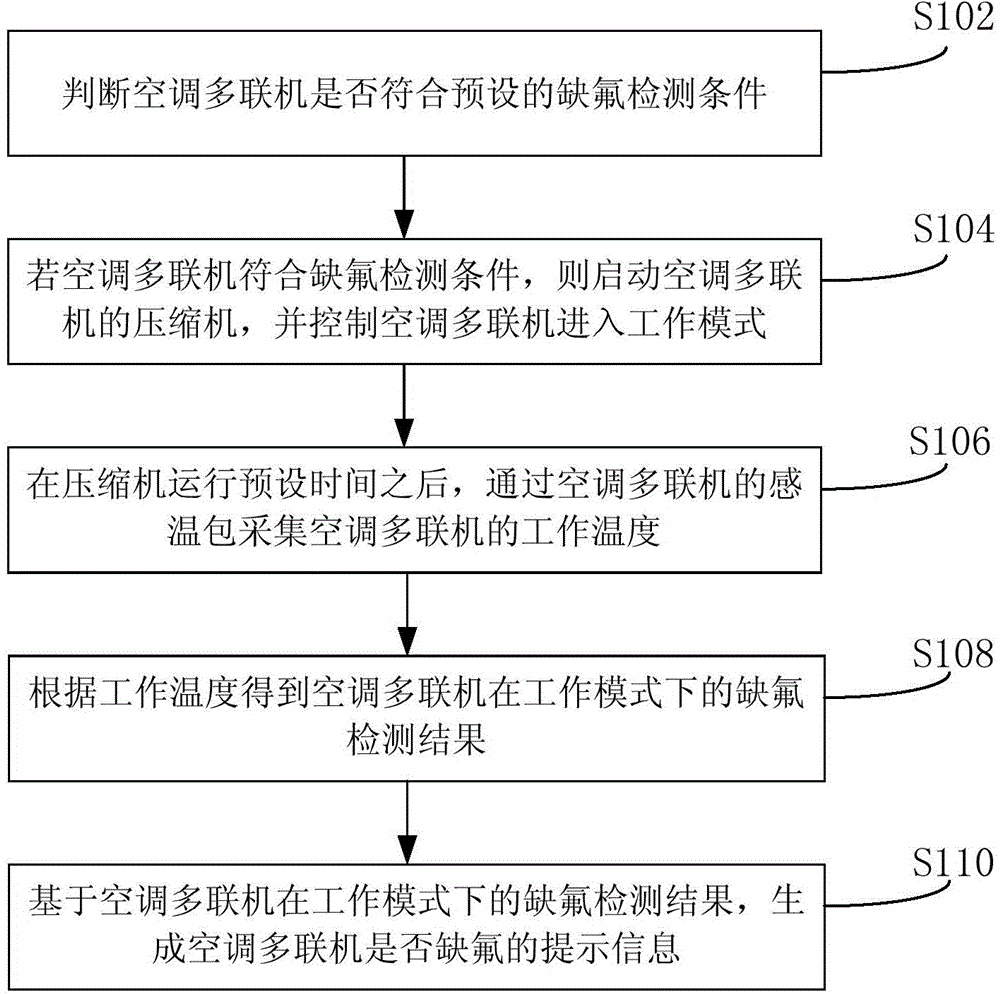

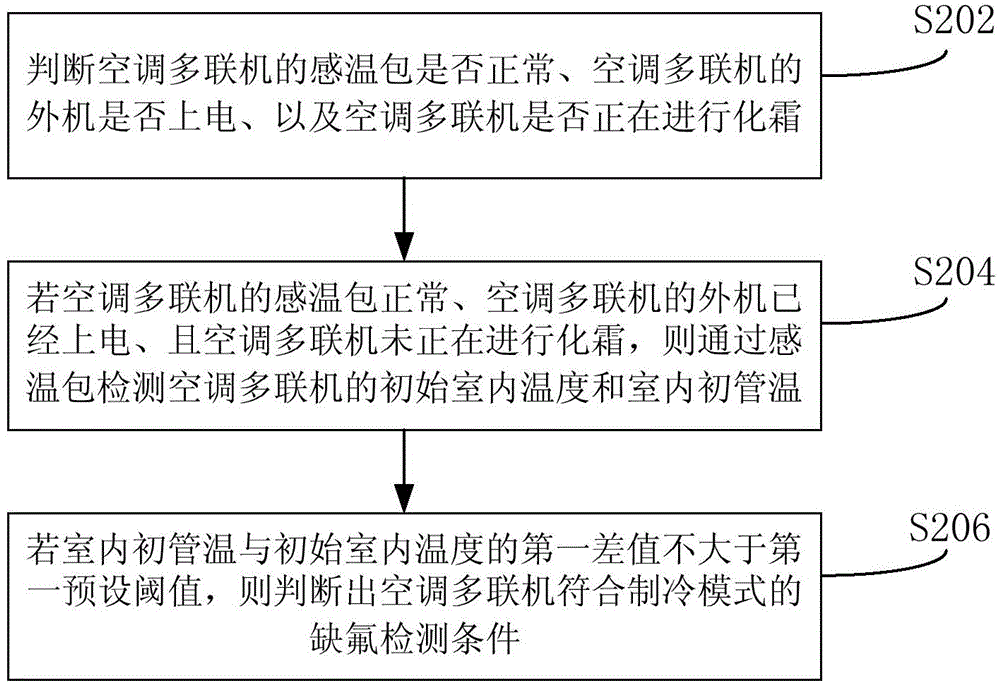

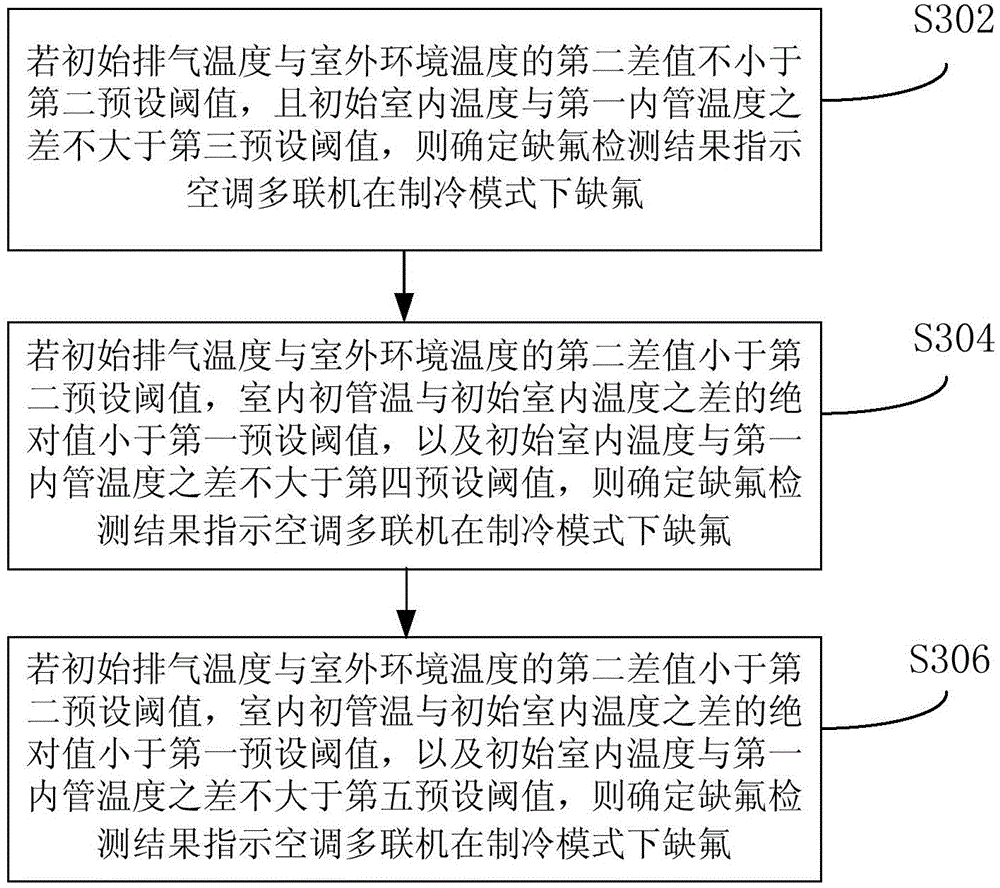

Fluorine lack detecting method and device for VRF (variable refrigerant flow) system

ActiveCN104654537ASimple process designReduce manufacturing costMechanical apparatusSpace heating and ventilation safety systemsTemperature senseEngineering

The invention discloses a fluorine lack detecting method and device for a VRF (variable refrigerant flow) system, wherein the method comprises the following steps that whether the VRF system conforms to the preset fluorine lack detecting conditions or not is judged; if the VRF system conforms to the preset fluorine lack detecting conditions, a compressor of the VRF system is started, and in addition, the VRF system is controlled to enter a work mode; after the compressor operates for a preset time, the work temperature of the VRF system is collected through a temperature sensing bulb of the VRF system; the fluorine lack detecting result of the VRF system in the work mode is obtained according to the work temperature; the prompt information whether the VRF system is lack of fluorine or not is generated on the basis of the fluorine lack detecting result of the VRF system in the work mode. The fluorine lack detecting method and the fluorine lack detecting device have the advantages that the fluorine lack detection is realized through the temperature sensing bulb of the VRF system, so that the goals of simplifying the process design and reducing the cost are achieved.

Owner:GREE ELECTRIC APPLIANCES INC

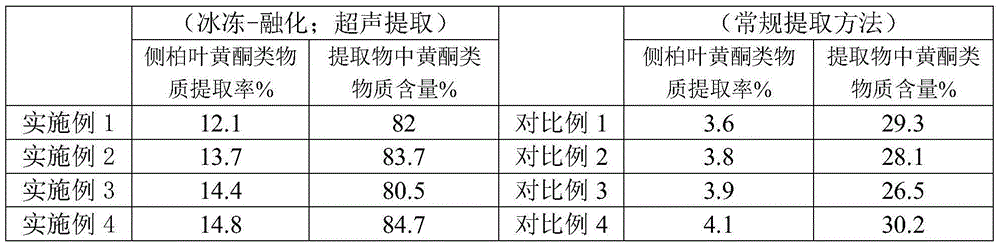

Method for extracting flavones substances in cacumen biotae

ActiveCN104523767AHigh extraction rateReduce dosageConiferophyta medical ingredientsPlant ingredientsAlcoholFreeze-drying

The invention provides a method for extracting flavones substances in cacumen biotae. The method comprises the following steps: cleaning cacumen biotae, drying and crushing the cacumen biotae to obtain cacumen biotae powder; then, adding water to uniformly mix with the cacumen biotae powder to obtain a mixed solution; freezing the mixed solution for 10-24 hours at a temperature of (-)40 DEG C to (-)20 DEG C, and putting the frozen mixed solution at the room temperature until the frozen mixed solution is molten; repeating the freezing step and room-temperature melting step for 2-3 times; adding alcohol to sufficiently mix, performing ultrasonic extraction after soaking for 1-3 hours, centrifugally separating, getting liquid supernatant, and freeze-drying, thereby obtaining a crude product; preparing the crude product into a solution with concentration of 1-3mg / mL, dropwise adding the solution into a macroporous resin column and then performing saturation adsorption, washing and removing with water after the adsorption, taking 60-80% alcohol as an eluent, recycling a solvent from the eluate, concentrating the eluate, and finally performing freeze-drying to obtain flavones substances. The method disclosed by the invention is high in extracting rate, pollution-free and low in cost.

Owner:南京新图雅生物科技有限公司

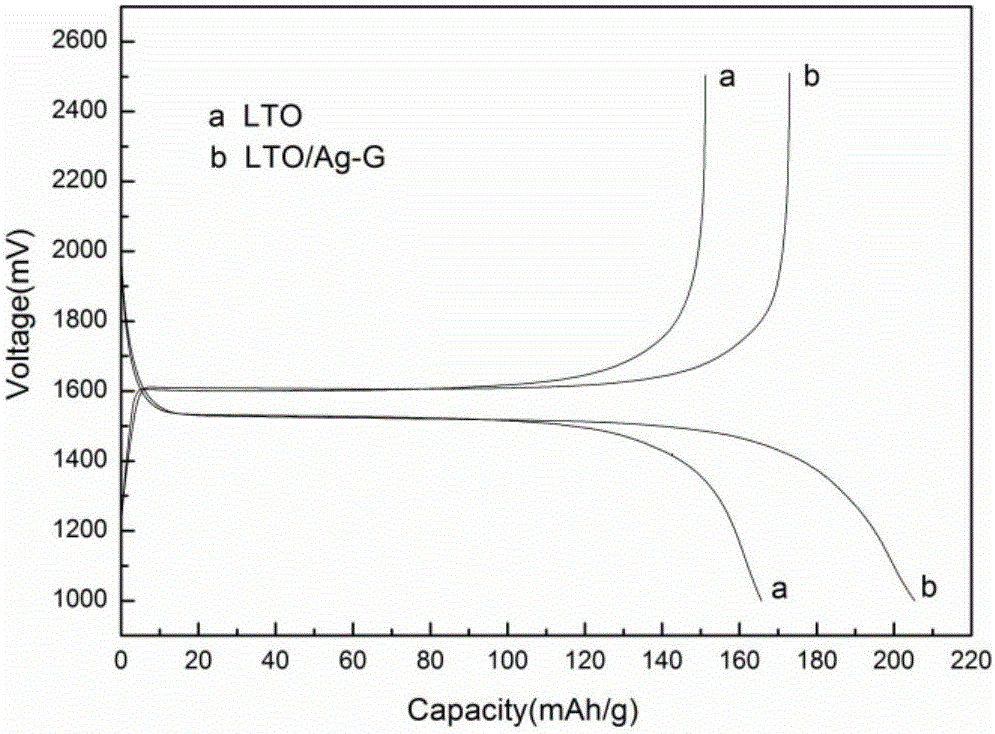

Lithium titanate/M-graphene composite cathode material for lithium ion battery and preparation method of lithium titanate/M-graphene composite cathode material

InactiveCN105762351AEvenly dispersedImprove adhesionCell electrodesSecondary cellsHigh rateComposite cathode

The invention discloses a lithium titanate / M-graphene composite cathode material for a lithium ion battery and a preparation method of the lithium titanate / M-graphene composite cathode material. The lithium titanate / M-graphene composite cathode material is prepared by dually compounding graphene and metal particles. The preparation method comprises the following steps: preparing a pure-phase lithium titanate material by a hydrothermal method, then fully mixing the pure-phase lithium titanate material with graphene oxide and metal salt (or metal alkali), and performing reaction in a reaction kettle under the action of a proper amount of reducing agents to obtain the lithium titanate / M-graphene composite cathode material. According to the preparation method, the lithium titanate / M-graphene composite cathode material is prepared by reduction by a simple solvothermal method; the preparation method is easy to operate, low in requirement on conditions, low in cost and very suitable for industrial production; furthermore, the prepared lithium titanate / M-graphene composite cathode material is high in conductivity, high in specific capacity, high in high-rate discharging performance and excellent in circulating performance, and can be widely applied to various types of portable electronic equipment and electric automobiles.

Owner:HEFEI UNIV OF TECH

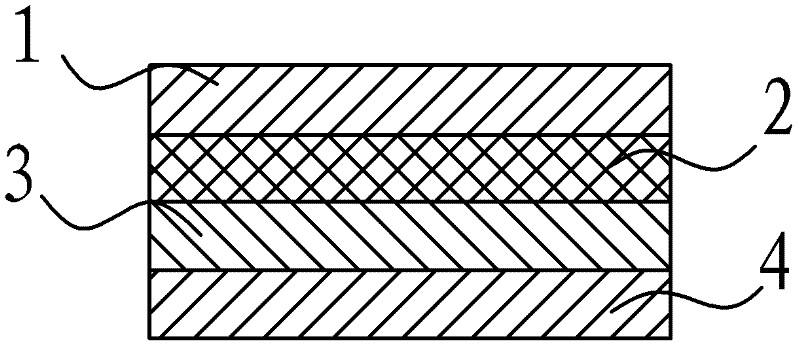

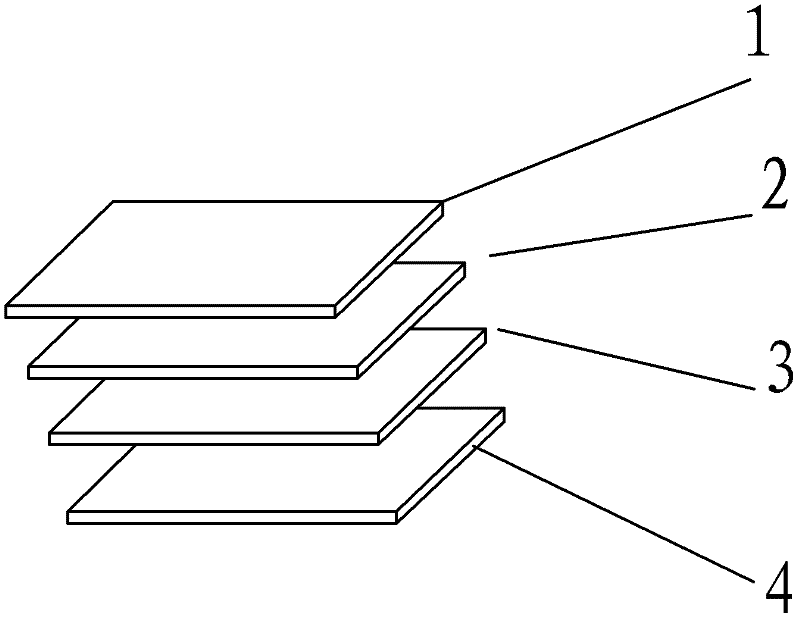

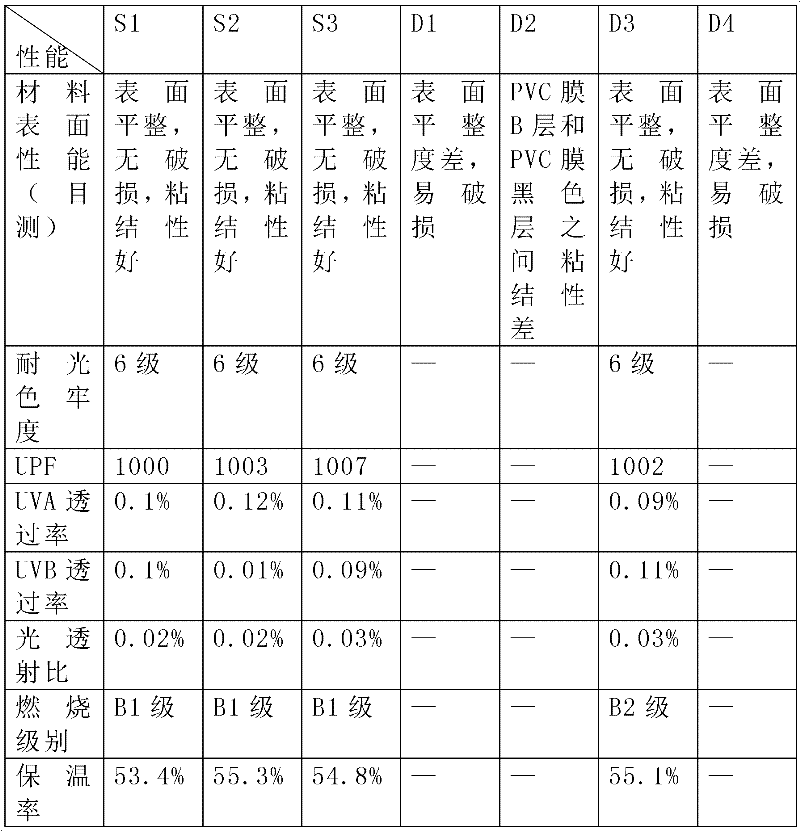

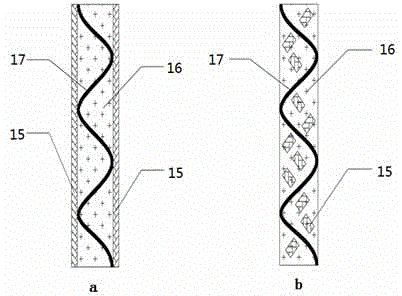

Glass fiber/PVC (polyvinyl chloride) composite membrane material and preparation method thereof

ActiveCN102555352AWith shadingWith heat insulation effectSynthetic resin layered productsLaminationFiberGlass fiber

The invention provides a glass fiber / PVC (polyvinyl chloride) composite membrane material. The glass fiber / PVC composite membrane material comprises a first PVC membrane layer, a second PVC membrane layer, a glass fiber base fabric layer and a third PVC membrane layer from bottom to top in sequence, wherein the second PVC membrane layer is a black PVC membrane layer. The invention also provides a preparation method for the glass fiber / PVC composite membrane material. The glass fiber / PVC composite membrane material provided by the invention has good shading and thermal insulation performances on the premise of ensuring good comprehensive color fastness and combustion performances. The preparation method for the glass fiber / PVC composite membrane material, provided by the invention, is simplified in the process and easy to perform.

Owner:NINGBO XIANFENG NEW MATERIAL

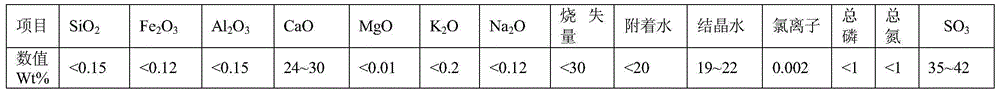

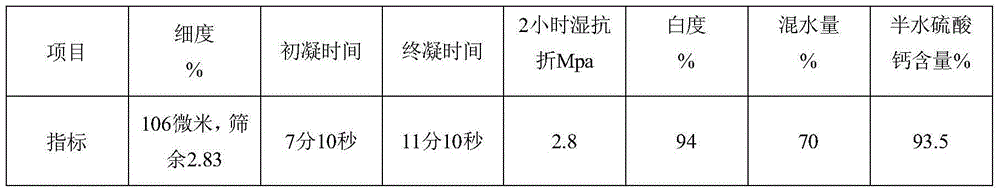

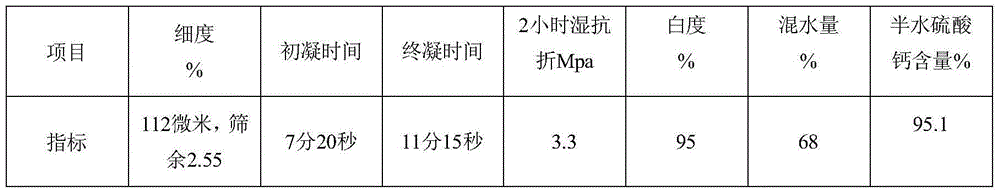

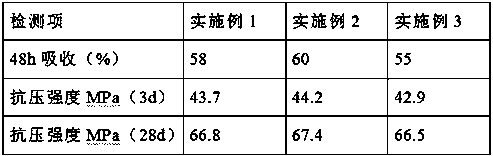

Method for producing beta-high-purity gypsum powder by using phosphogypsum

ActiveCN104310830ACalcination temperature is lowReduce energy consumptionFlexural strengthPhosphogypsum

The invention relates to a method for producing beta-high-purity gypsum powder by using phosphogypsum. The method comprises the following steps: (1) drying phosphogypsum until the mass content of free water is less than or equal to 3%, and calcining at a temperature of 130 to 150 DEG C under pressure of 99.0KPa to 100. 2KPa for 2.5 to 3.5 hours; (2) crushing a material calcined in the step (1) until the particle size is less than or equal to 125 microns and the screen residue is less than or equal to 3.00%; (3) hermetically aging the material obtained in the step (2) at normal temperature for 3 to 5 days, crushing the aged material to different grades of particle size between 75 to 125 microns, and carrying out graded mixing on products of different particle sizes to obtain beta-high-purity gypsum powder. The calcination is carried out under the negative pressure condition of 99.0KPa to 100. 2KPa, the energy consumption is low, and the obtained product has high performance index, strong stability and high performance cost ratio; the whiteness is more than or equal to 94, the content of calcium sulfate hemihydrate is more than or equal to 92%, the radioactivity index is low, and the wet flexural strength is up to 4.0Mpa at 2 hours.

Owner:KINGENTA ECOLOGICAL ENG GRP

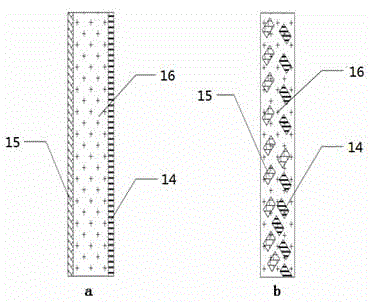

Electrical filter board and application of same in highly concentrated organic wastewater

ActiveCN104003481AImprove biodegradabilityOvercoming activityWater/sewage treatmentChemical reactionParallel plate

The invention relates to an electrical filter board which is an anode-cathode integrated filter board prepared from an anode electrocatalysis material, a cathode electrocatalysis material and a microelectrolysis material or a plate-shaped anode or cathode filter board prepared from the anode or cathode electrocatalysis material, the microelectrolysis material and a conductive material. When the electrical filter board is cooperatively used with a novel parallel plate-type ultrasonic reactor in treatment of highly concentrated organic wastewater, a substantial synergistic effect is obtained; organic compounds in the wastewater are degraded into micromolecular compounds through reactions like electrocatalysis, microelectrolysis and electric flocculation initiated by the electrical filter board and through strongly oxidizing .OH generated by ultrasonic treatment, so biodegradability of the wastewater is improved; moreover, a mechanical shearing effect generated by ultrasonic treatment can effectively clean oxides on the electrical filter board, so disadvantages that a traditional electrocatalysis material easily undergoes inactivation and passivation and a traditional microelectrolysis material easily undergoes hardening are overcome, electrochemical reactivity is guaranteed, and treating efficiency is improved.

Owner:KUNMING UNIV OF SCI & TECH

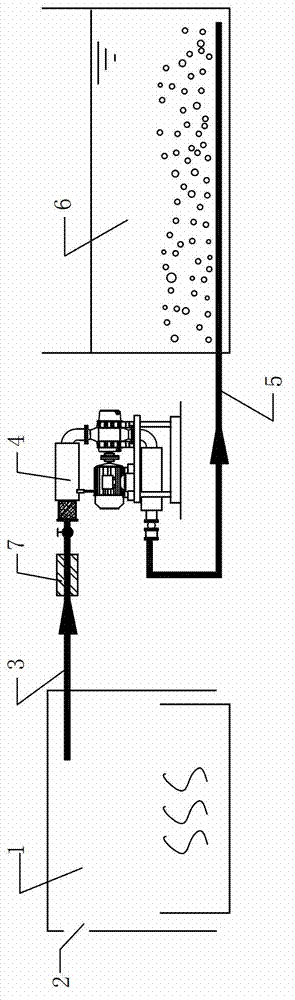

Integrated device for deodorization and sewage treatment in municipal sewage plant and technology thereof

InactiveCN103041696ASolve the problem of deodorization upgrading and transformationSimple processTreatment using aerobic processesDispersed particle separationOdor sourceMunicipal sewage

The invention discloses an integrated device for deodorization and sewage treatment in a municipal sewage plant. The integrated device comprises a semi-hermetic gas collection building mounted on an odor source, an air blower and an aeration tank, wherein malodorous gas is collected in the semi-hermetic gas collection building; a ventilation opening and a gas pipeline are arranged above the semi-hermetic gas collection building; the gas pipeline conveys the malodorous gas to an aeration pipeline through the air blower; and the aeration pipeline conveys the malodorous gas to the aeration tank. According to the invention, through the method, the design, operation and management of a deodorization facility can be simplified, the investment and operation cost is reduced, the various malodorous substances can be effectively processed, and the processing effect is good. An odor collection pipeline can be connected with the original blast aeration equipment, so that the amount of construction engineering is reduced, and the integrated device and the technology are very suitable for upgrading and reconstruction of deodorization of the built sewage treatment plant and the construction of the integrated deodorization facility of the newly-built sewage treatment plant.

Owner:SUZHOU RES INST OF TONGJI UNIV

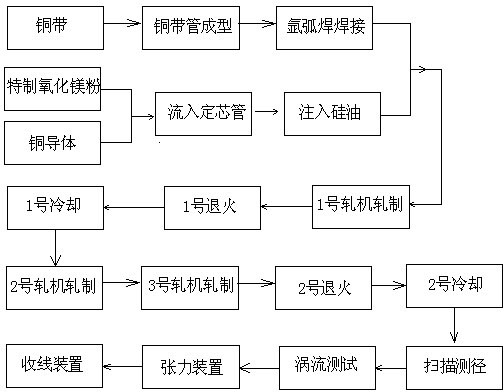

Manufacturing technology of long-length jointless mineral insulation cable

InactiveCN102496422ASimple and reasonable designEasy to manufactureInsulating conductors/cablesMagnesiumOxide

The invention, which belongs to a cable manufacturing technology field, relates to a manufacturing technology of a long-length jointless mineral insulation cable. The above technology comprises the following steps that: (1) 12-16% H2SO4 and tap water are successively used to clean a copper strip through a cleaning machine, the cleaned copper strip is dried at a temperature of 35-45 DEG C, and then the dried copper strip enters into a moulding roller so as to perform pipe forming; a tension force alignment copper rod flows into a stainless steel set core pipe and a special magnesium oxide powder is filled while the copper rod is entering into the stainless steel set core pipe, and silicone oil is injected into the special magnesium oxide powder in the set core pipe; (2) argon arc welding continuous welding is performed to the pipe moulding copper strip, and then continuous cycle rolling and annealing are performed. A production period is short. Product manufacturing cost is low. High-pressure resistant and insulation properties are good. A cable production length is long.

Owner:BAOSHENG SCI & TECH INNOVATION

Porous concrete waterproofing agent and preparation method thereof

The invention discloses a porous concrete waterproofing agent and a preparation method thereof. The waterproofing agent is prepared from, by weight, 25-40 parts of modified gel, 4-6 parts of an oxidizing agent, 5-9 parts of a cross-linking agent and 3-5 parts of a photoinitiator; the modified gel is prepared from, by weight, 30-40 parts of pretreated microspheres, 25-30 parts of 3,4-dihydroxyphenylacetic acid, 15-20 parts of N-hydroxysuccinimide, 15-20 parts of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride, 18-25 parts of sodium alginate and 10-14 parts of propyne. According to the porous concrete waterproofing agent and he preparation method thereof, process design is simple, and component proportion is reasonable; chitosan and sodium alginate are modified, and a Michael addition reaction and a chemical click reaction are used for forming a compact double-gel network, so the waterproof and seepage-proof performance of concrete can be effectively improved in use, meanwhile, the waterproofing agent can be self-repaired, and the waterproofing agent can be widely applied to concrete construction and has high practicability.

Owner:佛山市志必合材料有限公司

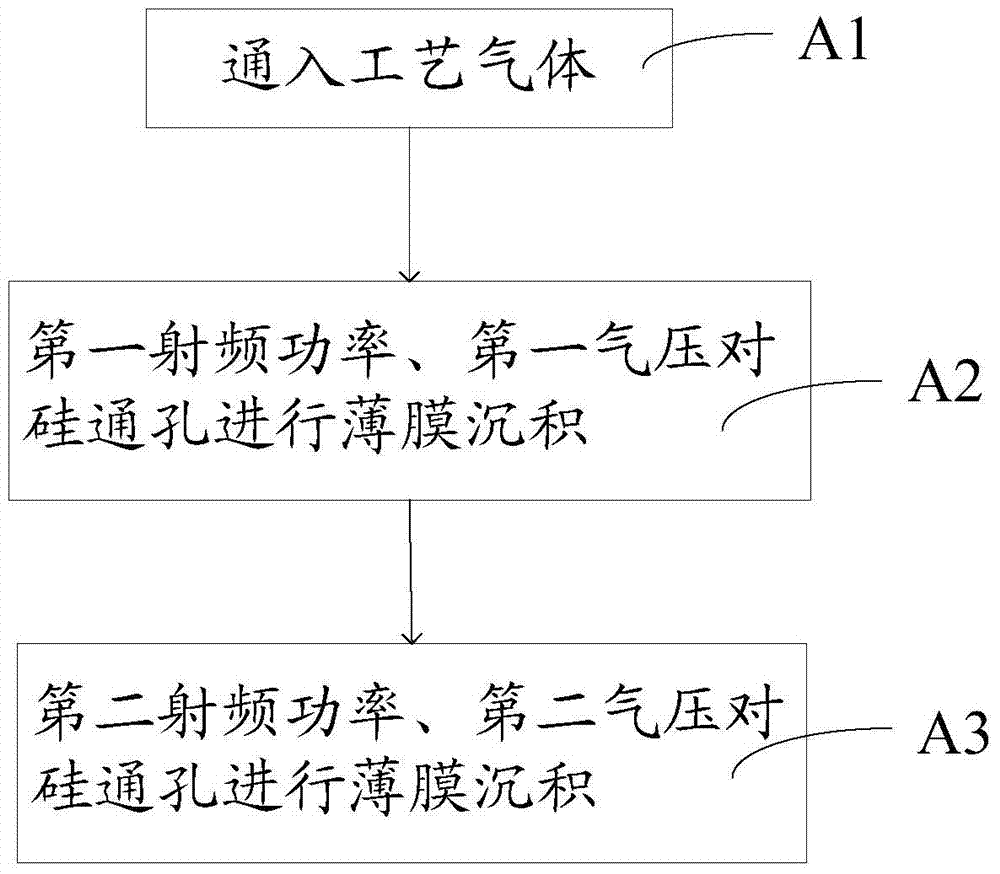

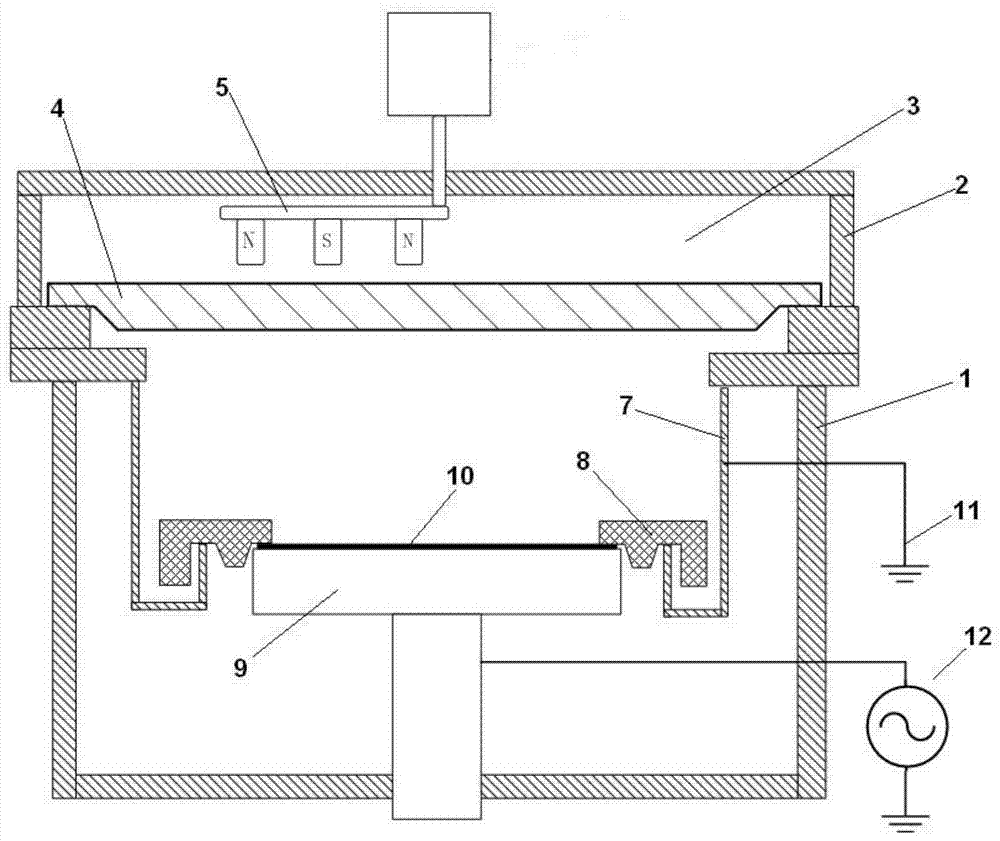

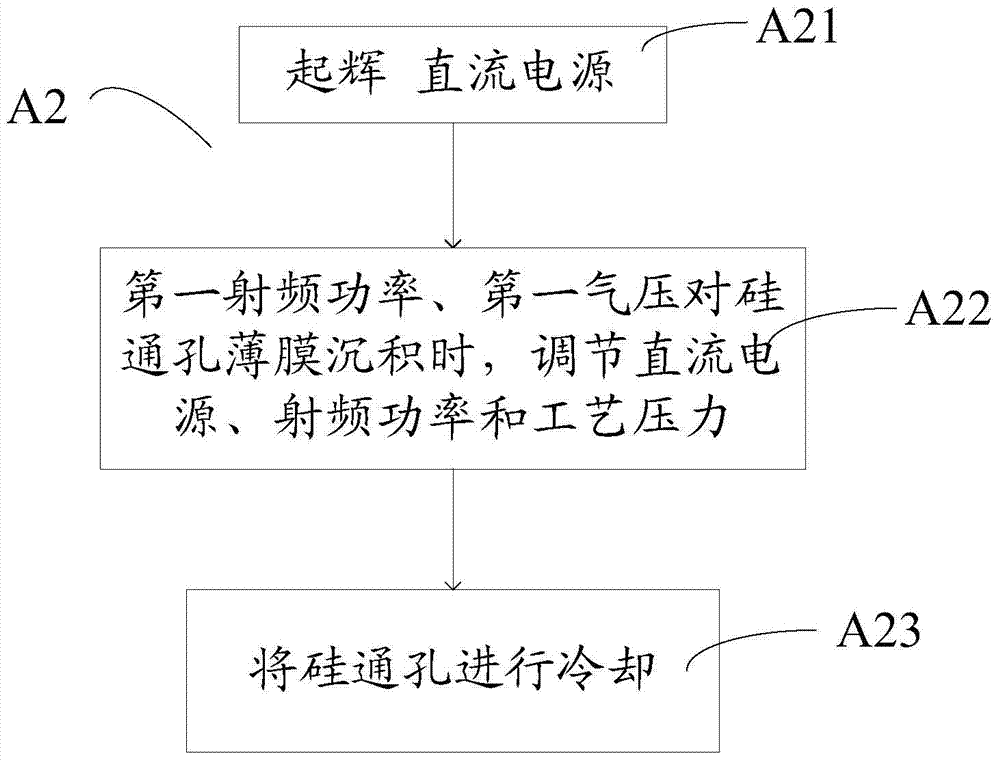

Silicon through hole deep-hole filling process

ActiveCN104752330ASimple and reasonable process designImprove film coverageVacuum evaporation coatingSemiconductor/solid-state device manufacturingPhysicsRadio frequency

The invention provides a silicon through hole deep-hole filling process which is used for improving the film coverage rate during silicon through hole deep-hole filling. The silicon through hole deep-hole filling process comprises the working steps that A1, a process gas is led into a magnetron sputtering device; A2, film deposition is conducted on silicon through holes under the conditions of first radio-frequency power and first air pressure; A3, film deposition is conducted on silicon through holes under the conditions of second radio-frequency power and second air pressure, and repeating the steps A2 and A3 till the film coverage rates in the silicon through holes are even and the required thickness requirement is met. The silicon through hole deep-hole filling process is simple and reasonable in design and adopts the first radio-frequency power and the second radio-frequency power to alternatively perform film deposition, the film coverage rate during silicon through hole deep-hole filling is improved, the process can perfectly support a follow-up electroplating process, and yield is improved.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

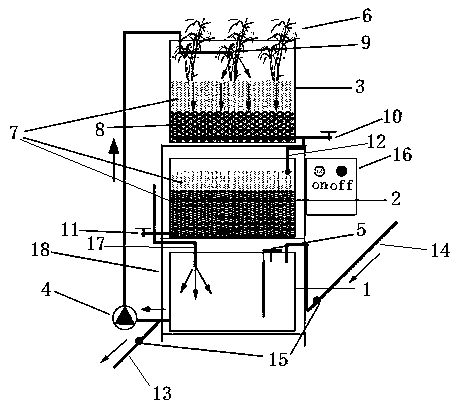

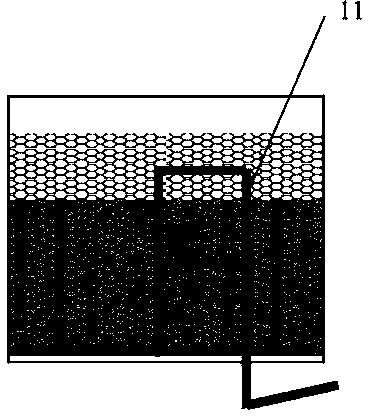

Backflow vertical wetland sewage treatment process and device, and application of process and device

ActiveCN104211182AGuarantee the effect of hanging filmAvoid cloggingSustainable biological treatmentBiological water/sewage treatmentConstructed wetlandWater quality

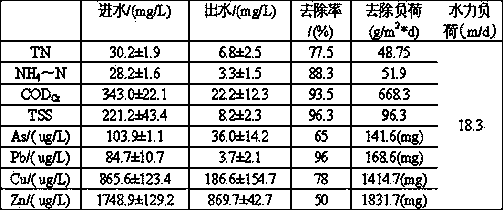

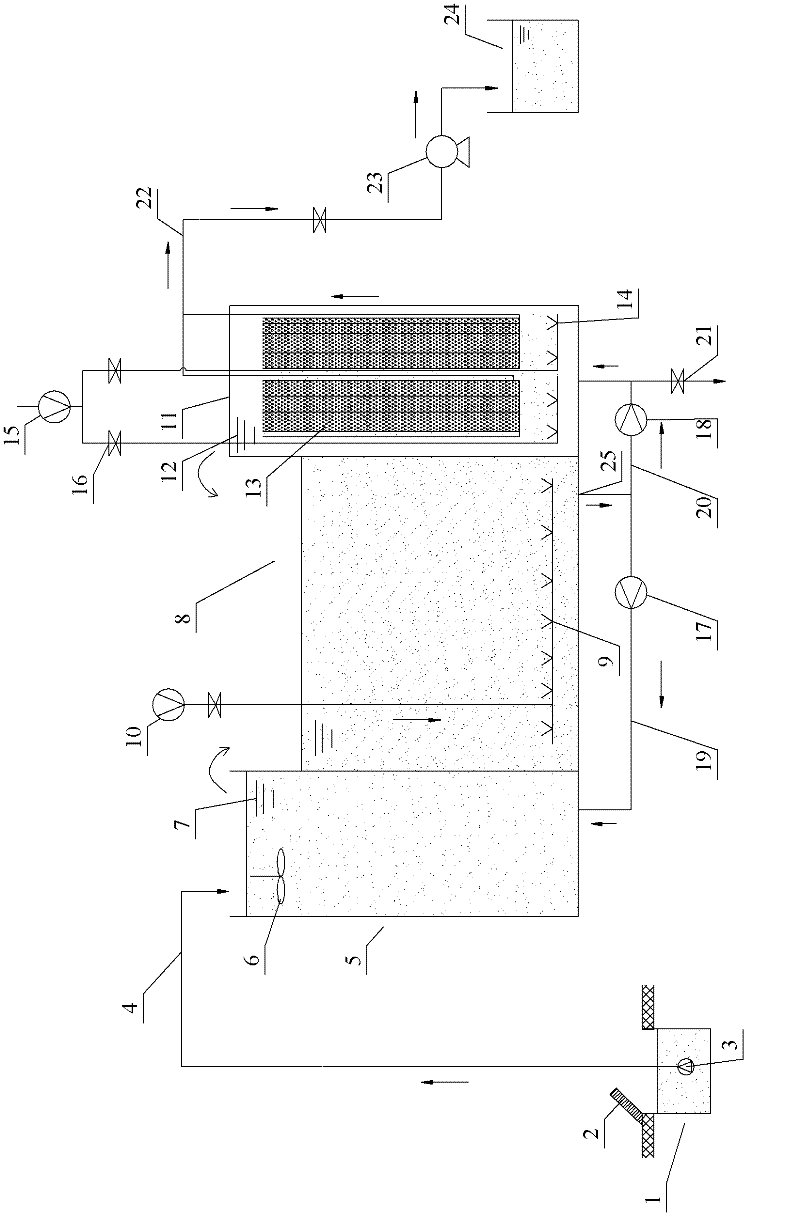

The invention discloses a backflow vertical wetland sewage treatment process and device, and application of the process and the device. A vertical flow artificial wetland, a horizontal subsurface flow wet land and a reservoir are combined into a vertical structure from top to bottom. Circular treatment of sewage is achieved by laying a water level monitor to control the operation condition of a circulating pump, and each batch of sewage treatment capacity and treatment time are controlled and regulated by matching with a relay. Compared with a traditional artificial wetland, the backflow vertical wetland sewage treatment process has the advantages of being small in floor area, large in hydraulic loading, low in energy consumption, easy to operate and quick to remove pollutants; the conventional effluent water quality indicators CODCr, SS, TN and NH4<+>-N are much lower than the concentration threshold (GB18918-2002) defined by the first grade A standard of urban sewage treatment; the pesticide content in the effluent accords with the hygienic standard for drinking water (GB5749-2006); and the heavy metal content of the effluent reaches the surface water class II water standard (GB3838-2002). According to the backflow vertical wetland sewage treatment process, automatic treatment of the artificial wetland sewage is achieved, and the problem of poor single removal effect on organic matters and nitrogen pollutants in sewage through the artificial wetland is solved.

Owner:JINAN UNIVERSITY

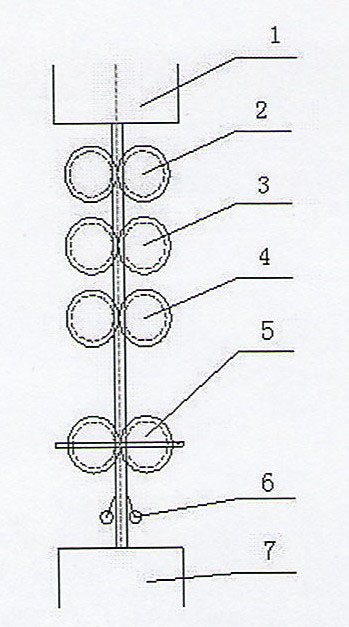

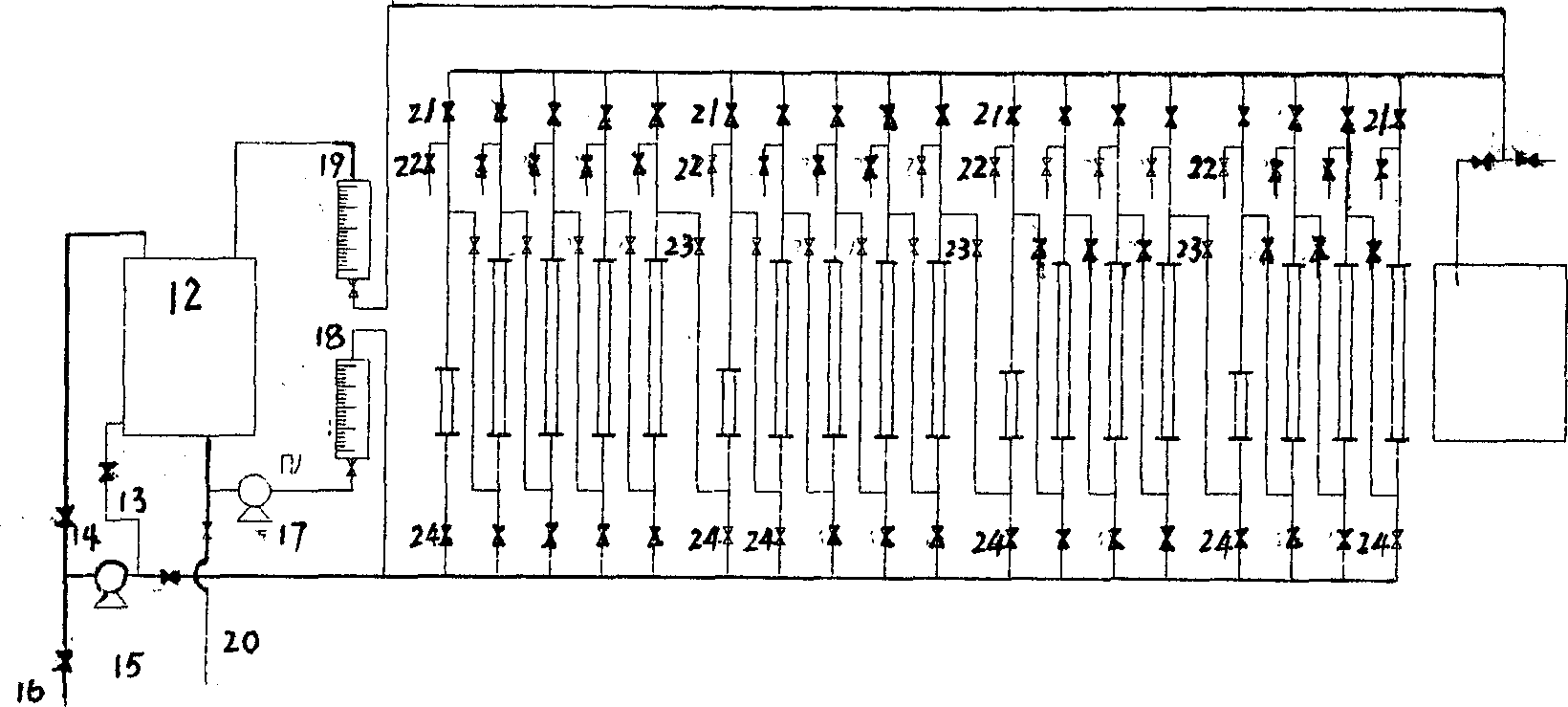

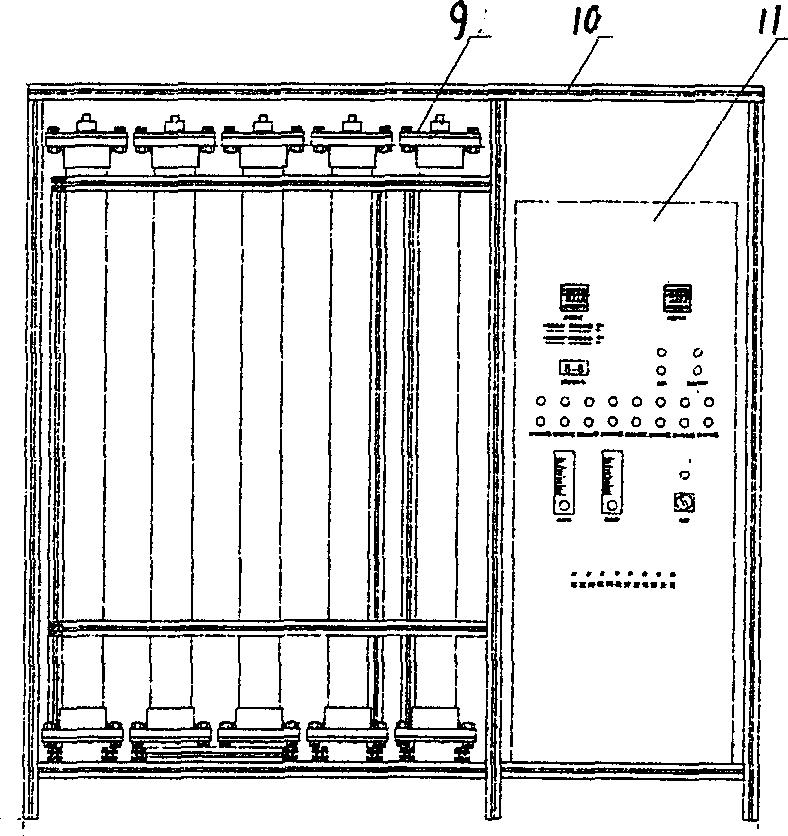

Aerobic membrane bioreactor and process

InactiveCN102260016AIncrease sludge concentrationSimple process designMultistage water/sewage treatmentBiochemical engineeringNitration

The invention discloses an aerobic membrane bioreactor and a technology thereof. The aerobic membrane bioreactor comprises an anoxic tank, an aerobic tank and a membrane tank. The anoxic tank is provided with an upper opening and a first upper overflow port. Liquid level of the anoxic tank is higher than that of the aerobic tank. An outlet is arranged on the bottom of the aerobic tank. The outletis respectively connected to the bottom of the anoxic tank and the bottom of the membrane tank. The membrane tank is provided with a second upper overflow port. Liquid level of the membrane tank is higher than that of the aerobic tank. A membrane component is arranged in the membrane tank. The membrane tank is connected to a clean water tank. According to the invention, the membrane tank is separated from the aerobic reaction tank. The aerobic membrane bioreactor is suitable for large-batch sewage processing, and is convenient to maintain. Liquid levels of the anoxic tank and the membrane tank are higher than that of the aerobic tank, and communications between the tanks are realized through overflowing. Sludge concentration in the membrane tank can be controlled effectively. According tothe invention, high accumulating density of the components can be maintained, quality of produced water is good, area occupied by the equipment is small, amount of discharged sludge is small, nitration capacity of the bioreactor is good, and the structure of the bioreactor is simple.

Owner:上海膜达克环保工程有限公司

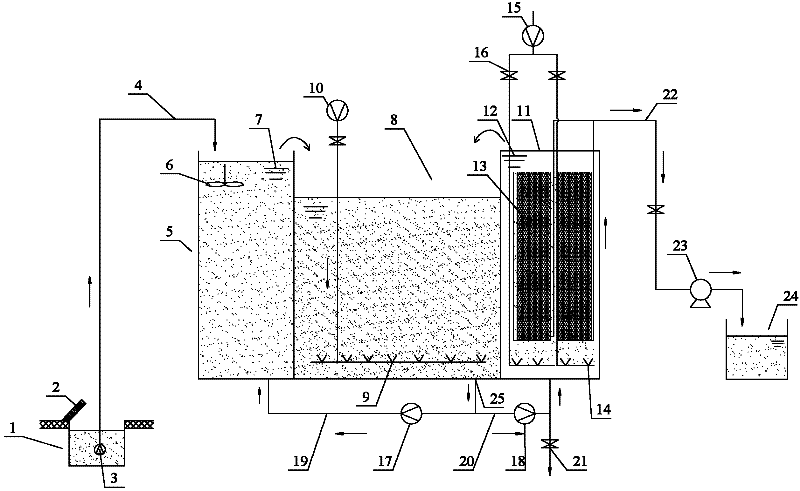

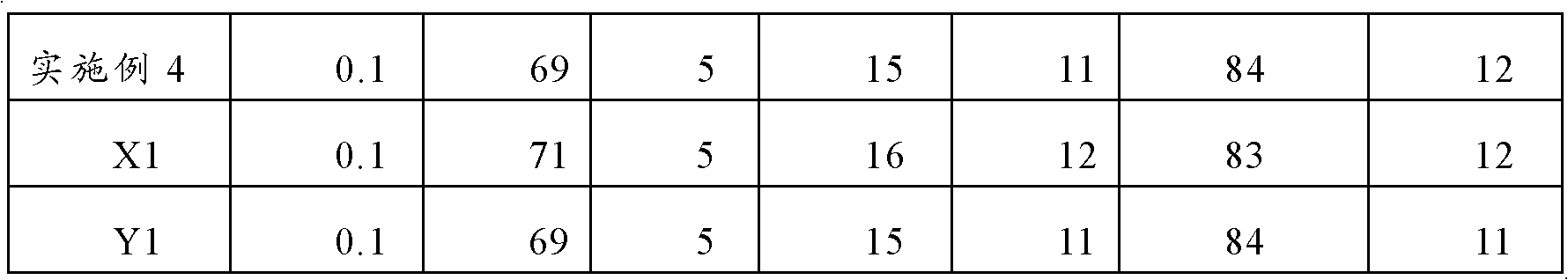

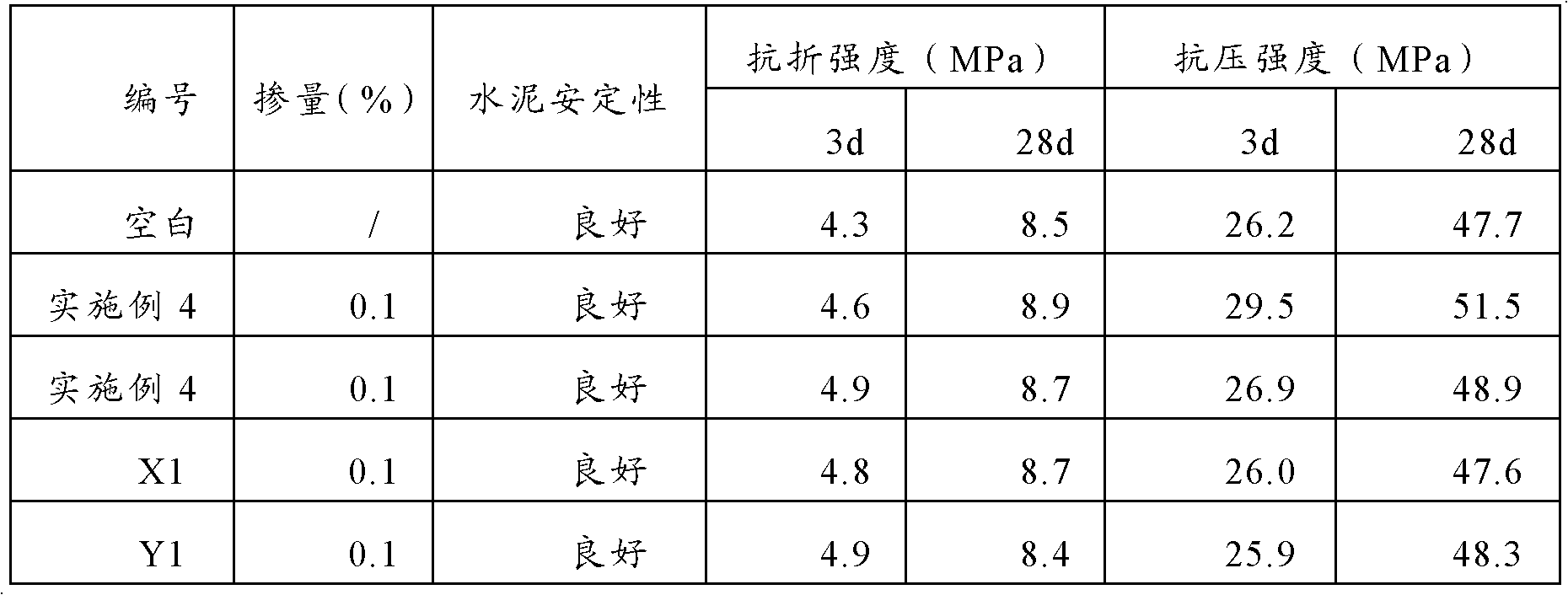

Cement grinding aid and preparing method thereof

InactiveCN102491672AGood wear resistance and compression resistanceImprove grinding effectCement grindingPolymer chemistry

The invention provides a modified lignin, which is prepared by methanal, alcamines compound and lignin. Mass ratio of the lignin, the alcamines compound and the methanal which form a repetitive unit and are in the modified lignin is (10-15):(10-15):(24-30). A cement grinding aid comprising the modified lignin is further provided. The cement grinding aid comprising the modified lignin is low in preparing cost, small in adding amount and excellent in grinding aiding performance. A preparing method for the modified lignin and a preparing method for the cement grinding aid comprising the modifiedlignin are further provided.

Owner:GUIZHOU CHUZHI BUILDING MATERIAL SCI & TECH

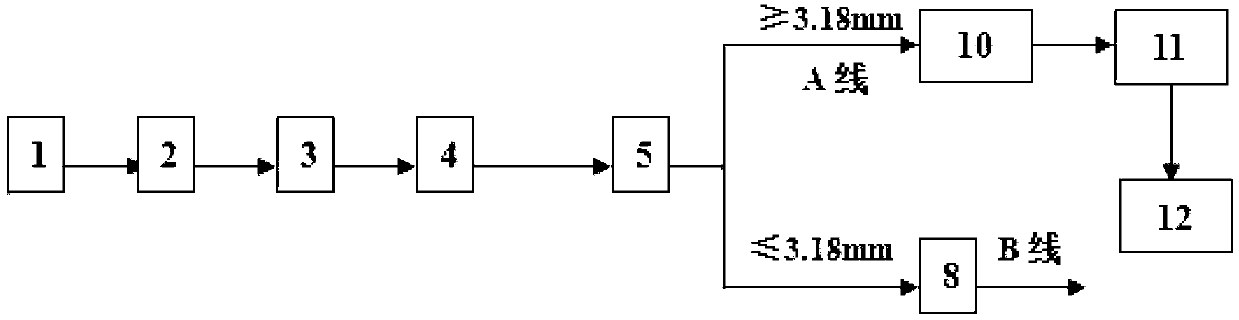

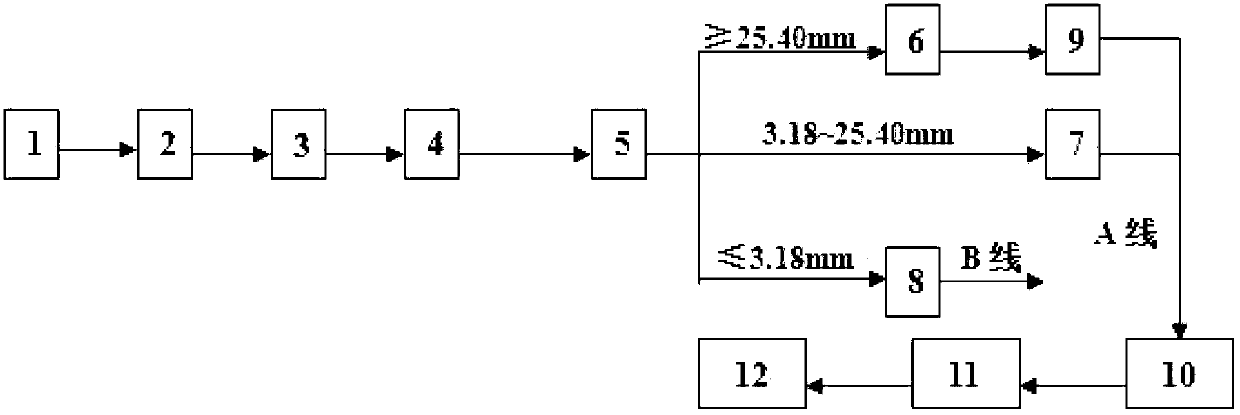

Method for increasing sheeting rate of redried finished tobacco sheets

InactiveCN102871211AImprove the middle rateReduce blocking rateTobacco preparationTobacco treatmentEngineeringTemporary storage

The invention discloses a method for increasing the sheeting rate of redried finished tobacco sheets. The method comprises the steps that the tobacco sheets before drying and after peduncles and leaves are separated are fed to a screening device; the screened tobacco sheets greater than or equal to 25.40mm enter slitting equipment, the tobacco sheets between 3.18mm and 25.40mm enter a material collecting conveyer belt through a first temporary storage cabinet, and the tobacco sheets less than or equal to 3.18mm enter a tobacco chipping processing line through a chipping collector; the tobacco sheets greater than or equal to 25.40mm are cut into the tobacco sheets less than 25.40mm by the slitting equipment and enter the material collecting conveyer belt through a second temporary storage cabinet; the tobacco sheets mixed and matched uniformly on the material collecting conveyer belt are redried uniformly according to the conventional technology; and the redried finished tobacco sheets that are uniform in leaf size are obtained and then packaged for storage and alcoholization. With the method, the sheeting rate of the redried finished tobacco sheets is increased; harmony of middle and long shred proportion in the shredding process is improved; the problem that the shrinkage ratio of the tobacco sheets before and after redrying is high is solved; and the method is simple in procedure design, convenient to operate and relatively low in loss.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD +1

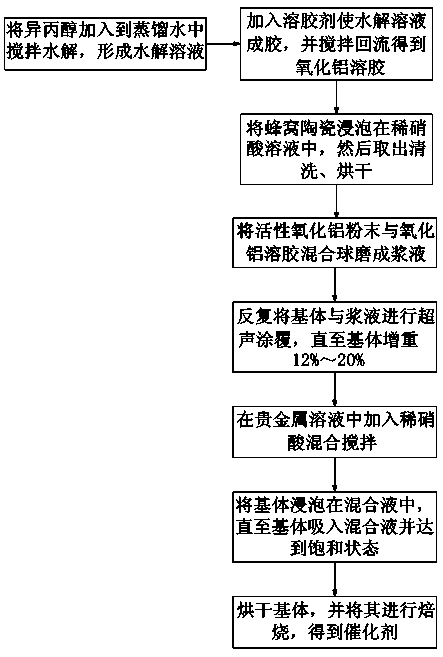

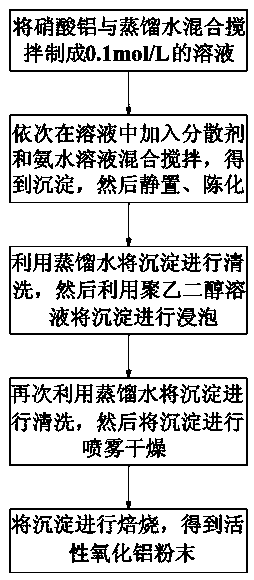

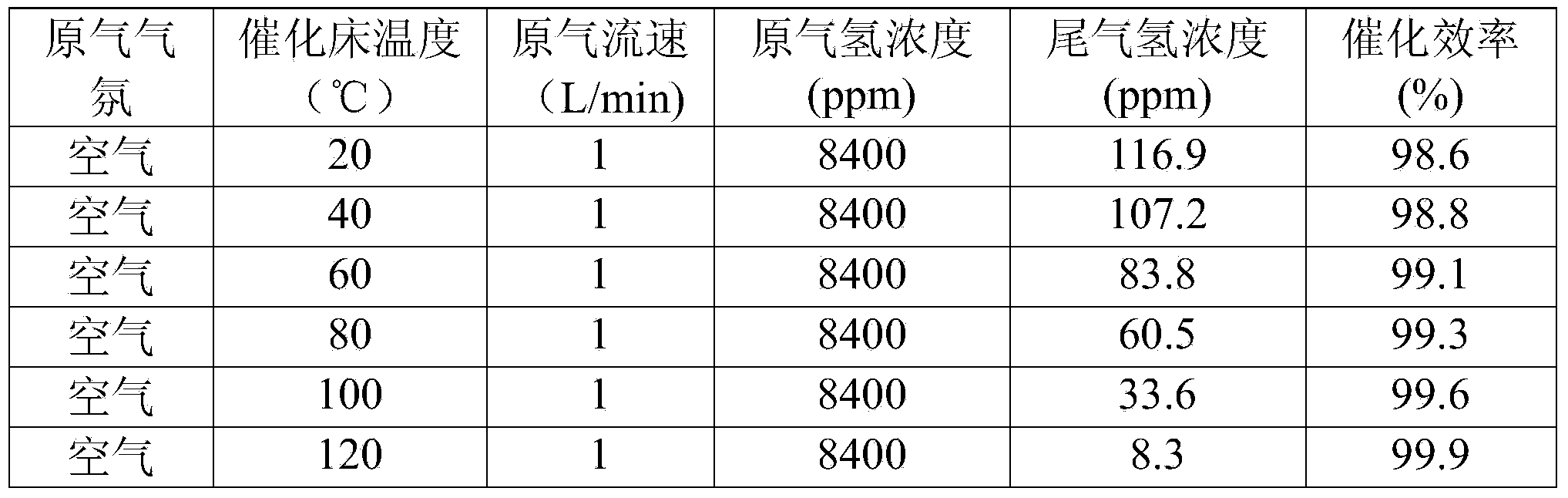

Preparation method of catalyst for removing tritium in tritium-containing air

InactiveCN104383917AReasonable workmanshipEasy to operateCatalyst carriersDispersed particle separationWeight gainingDistilled water

A disclosed preparation method of a catalyst for removing tritium in tritium-containing air comprises: (1) adding aluminium isopropoxide into distilled water and stirring for hydrolysis; (2) adding a peptizing agent to enable the hydrolysis solution to be colloidal, and performing stirring refluxing to obtain an aluminium oxide sol; (3) using honeycomb ceramic as a catalyst matrix and immersing in a diluted nitric acid solution, and then taking out, cleaning and baking; (4) mixing active aluminium oxide powder and the aluminium oxide sol, and performing ball milling to form a slurry; (5) uniformly coating the catalyst matrix with the slurry, and then baking and weighing; (6) repeating the step (5) until the weight gain of the catalyst matrix is 12%-20%; (7) adding diluted nitric acid into a noble metal solution, and mixing with stirring; and (8) immersing the catalyst matrix in the mixed solution to enable the catalyst matrix to absorb the mixed solution to reach a saturation state, and then roasting, so as to obtain the catalyst. The preparation method helps to substantially improve the processing capacity of the catalyst on gases without increasing the gas resistance of the tritium-removal system.

Owner:SICHUAN INST OF MATERIALS & TECH

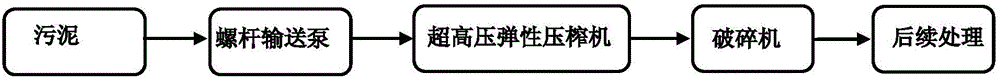

Deep sludge dewatering technology

InactiveCN105314811AAchieve water saving and energy savingSave conditioning costsSludge treatment by de-watering/drying/thickeningWater savingUltra high pressure

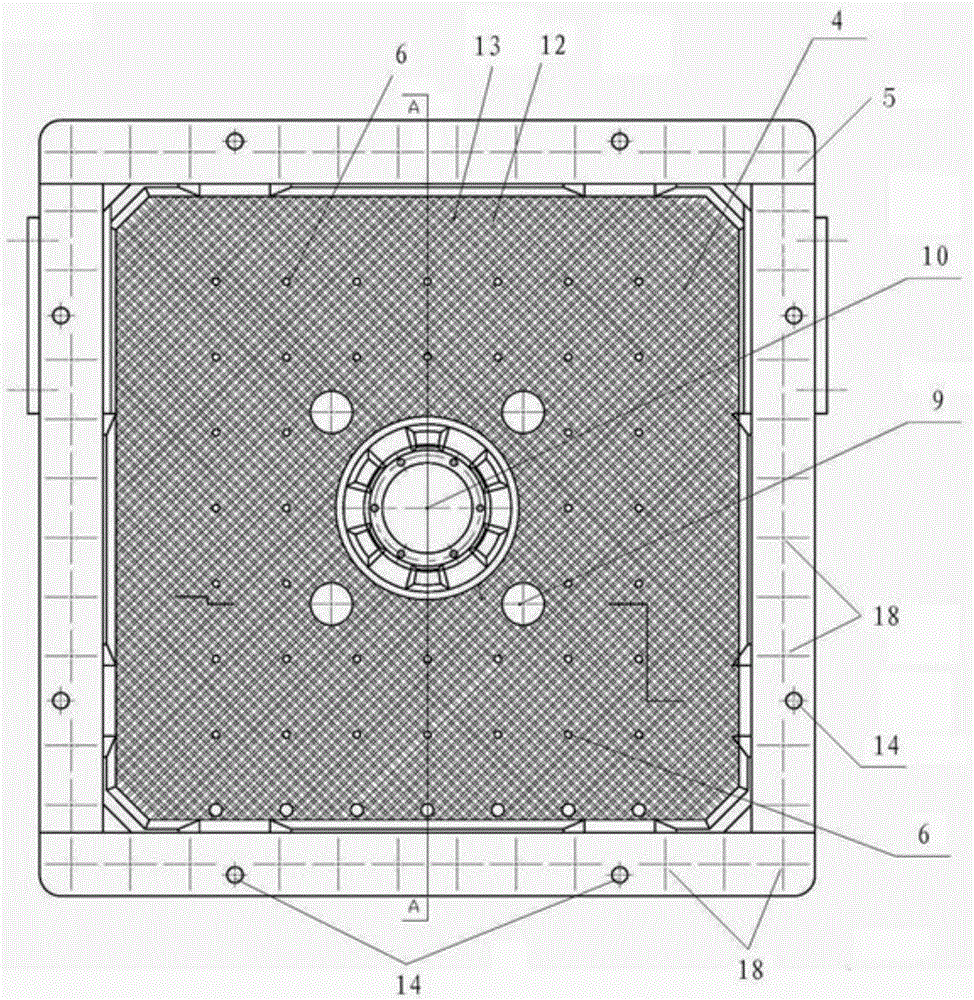

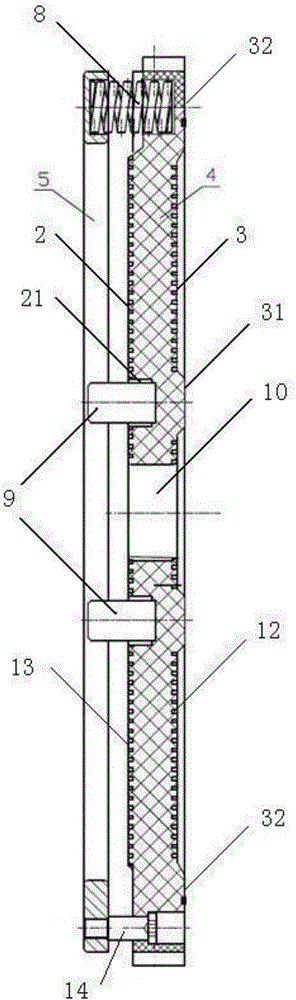

The invention discloses a deep sludge dewatering technology. The technology includes the steps that dewatered sludge with the water content being 80% or so is delivered to an ultrahigh-pressure elastic squeezer through a screw type sludge delivery pump to be deeply dewatered so that the water content of the sludge can be reduced to 50-55%; according to a filter plate of the ultrahigh-pressure elastic squeezer, a plurality of middle elastic supports are symmetrically and evenly arranged in the middle of a pressure bearing plate, and a plurality of protruding blocks are also symmetrically and evenly arranged in the middle of the pressure bearing plate; the deeply dewatered sludge is smashed to be incinerated or recycled. According to the technology, the screw type delivery pump is applied to feeding of the ultrahigh-pressure elastic squeezer, the middle elastic supports are symmetrically and evenly arranged on the filter plate of the ultrahigh-pressure elastic squeezer, the filter plate can bear the pressure difference with the maximum value not exceeding 1 MPa from the two sides under the supporting and buffering action of the middle elastic supports, then the poor-uniformity sludge with the water content being 80% or so can be directly squeezed, the sludge does not needed to be added with water to be diluted or conditioned before entering the squeezer, and therefore the effects of saving water and energy and omitting conditioning cost are achieved.

Owner:SHANGHAI TECHASE ENVIRONMENT PROTECTION

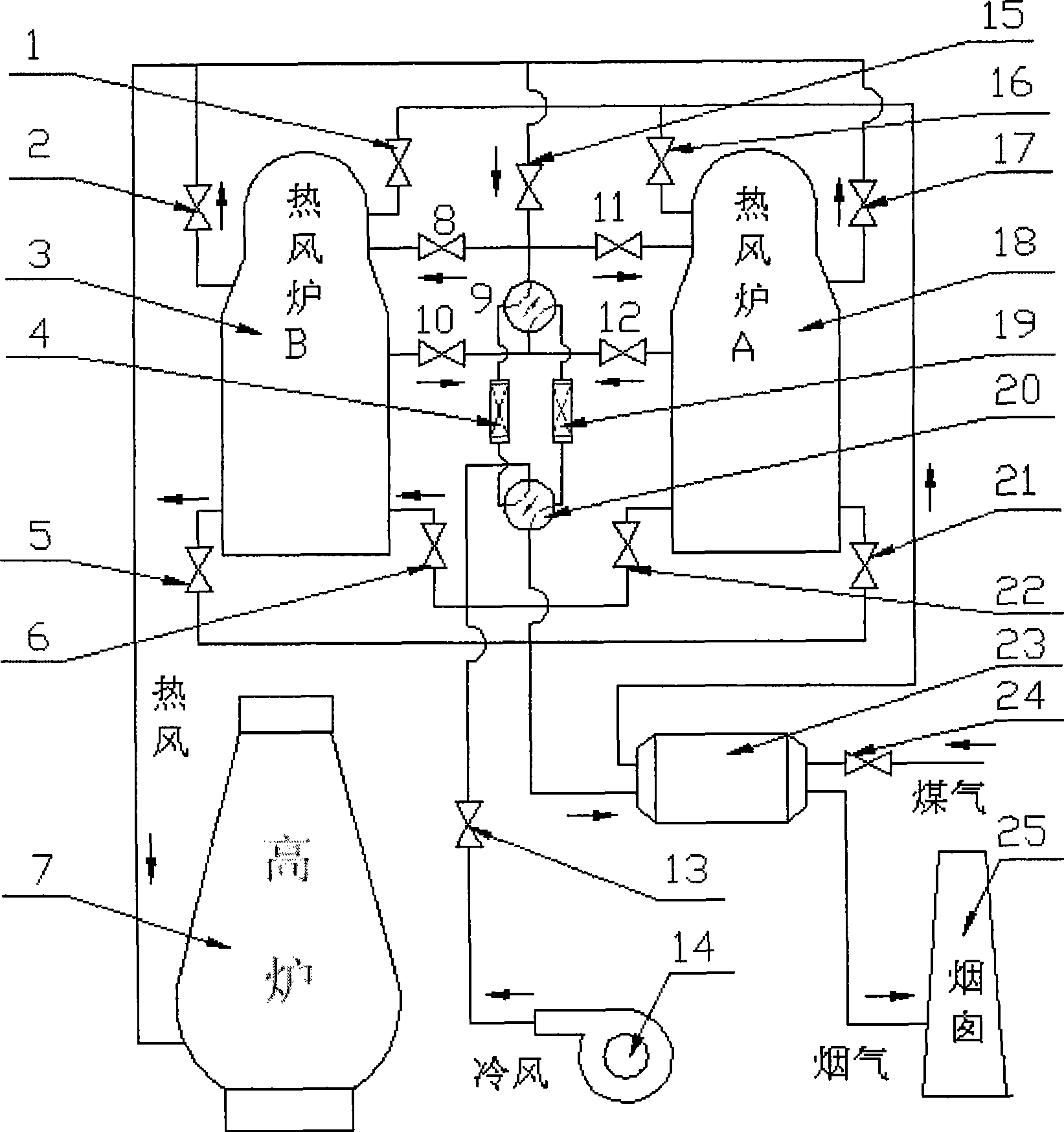

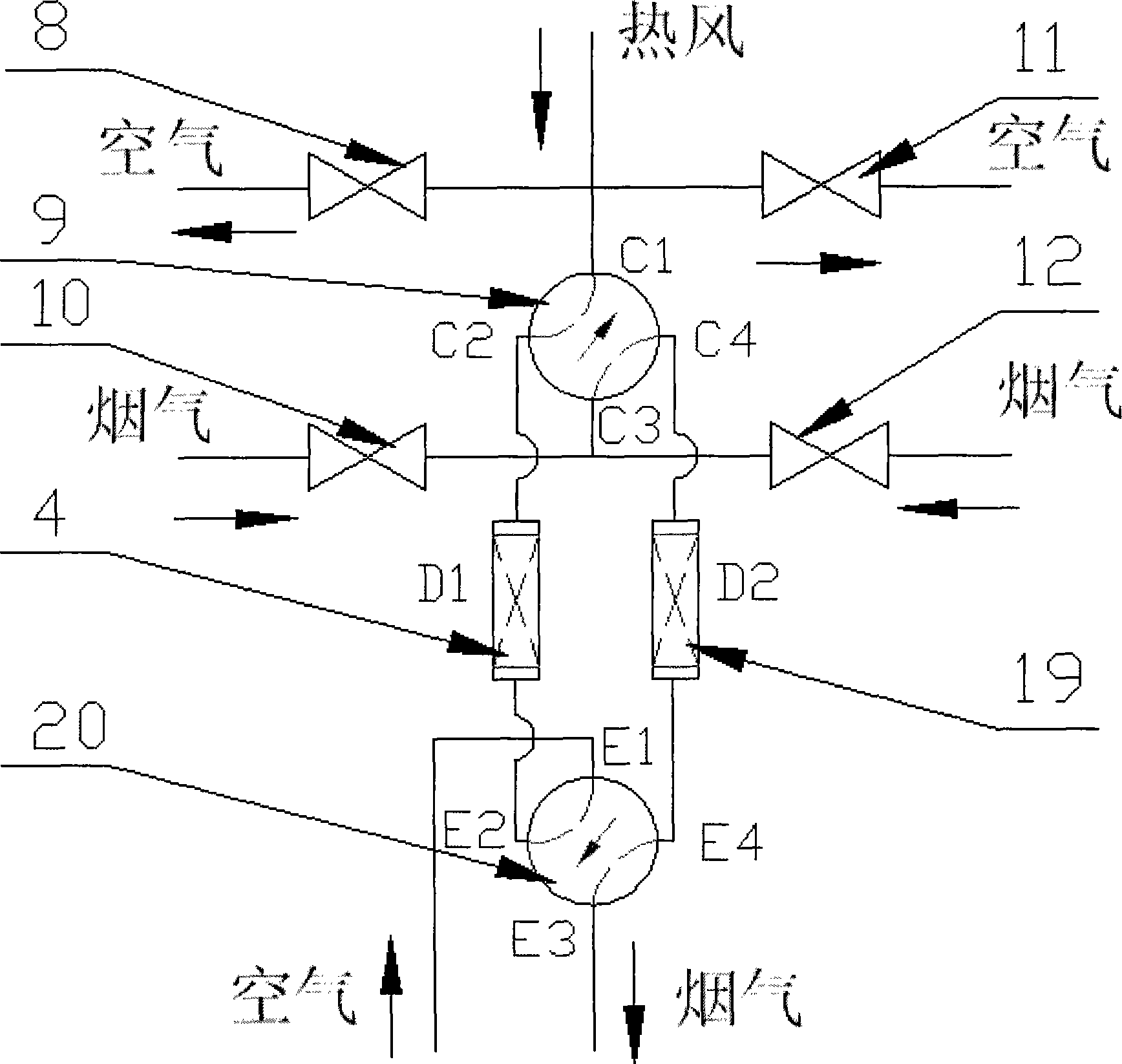

High blast temperature system of blast furnace hot blast stove

ActiveCN101487065ACompact layoutNo additional installation area requiredBlast furnace detailsHeating stovesFour-way valveCombustion

A high blast temperature system of a blast furnace hot blast stove belongs to the blast furnace iron making technique field in iron and steel industry. The system comprises a blast furnace, a hot blast stove, a detachable heat pipe exchanger, a blower, a chimney, a four-way valve, a connection pipeline and the like. The system is provided with two to four hot blast stoves, wherein, after one heating furnace is heated, 10 to 25 percents of hot air flows back to a combustion-supporting air line of another hot blast stove; simultaneously, 10 to 25 percents of high-temperature smoke of the hot blast stove in combustion period is introduced to preheat the combustion-supporting air through installing a ceramic heat accumulator in a discharging pipeline; the preheated combustion-supporting air is mixed with the reflow hot air as high-temperature combustion-supporting air which preheats coal gas together with the discharged air from the ceramic heat accumulator through the detachable heat exchange of the heat pipe; and then the preheated coal gas and the high-temperature combustion-supporting air enter into the hot blast stove to be combusted. The top of the hot blast stove can be raised to 1400 to 1600 DEG C through such a method, thereby raising the air temperature of the hot blast stove by 100 to 400 DEG C, and realizing the air temperature of the dead-burned blast furnace gas hot blast stove of 1200 to 1500 DEG C.

Owner:SHOUGANG CORPORATION

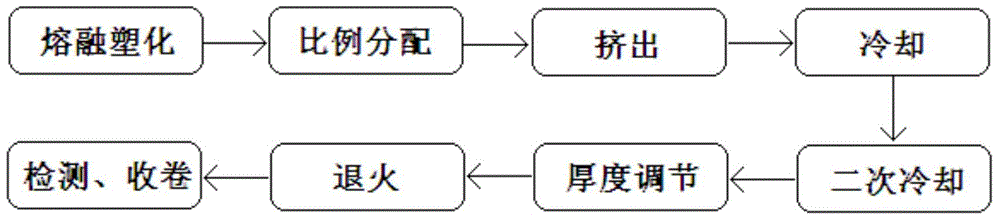

Production technology for high-viscosity CPP self-sticking protection film

InactiveCN105128496AViscous stabilityImprove flatnessLaminationLamination apparatusBlack pointDistributor

The invention relates to a production technology for a high-viscosity CPP self-sticking protection film. The production technology includes the steps that firstly, a sticking-resisting layer raw material, a base layer raw material and a sticking layer raw material are added into a single screw extruder to be melted and plasticized, and the raw materials are filtered through a filter and then conveyed into a distributor to be subjected to interlayer proportional distribution; secondly, melts of the three layers of raw materials are conveyed to a die head to be evenly distributed and plasticized and are then extruded through a die lip, and the melts make contact with a main cooling roller to be cooled; thirdly, an obtained cast film is secondarily cooled through an auxiliary cooling roller, and then thickness adjustment is conducted; fourthly, annealing processing is conducted, flaw detection is conducted, and rolling is conducted. The production technology is simple in design, the operation efficiency is high, losses are small, the stability of the product quality is good, and cost is low. By means of the production technology, the prepared high-viscosity CPP self-sticking protection film can have extremely-low shrinkage, the flatness of a film body is good, viscosity is stable, and rolling and unrolling are convenient. In addition, the transparency of the product can be effectively improved, and the occurrence of problems of fish eyes, crystal points, black points, impurities and the like on the film body is inhibited.

Owner:昆山金华安电子科技有限公司

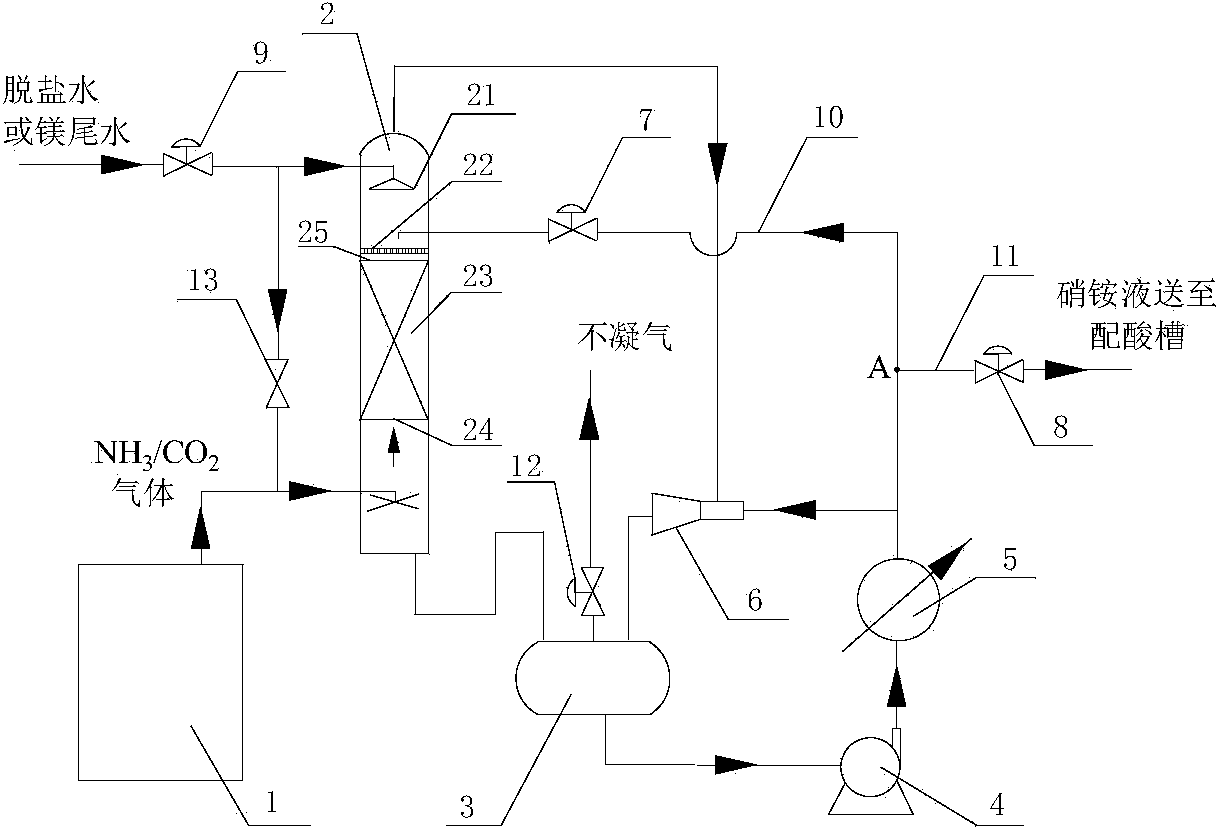

Tail gas recovery device for urea ammonium nitrate solution production

The invention provides a tail gas recovery device for urea ammonium nitrate solution production. The tail gas recovery device for the urea ammonium nitrate solution production comprises a urea ammonium nitrate solution preparing tank, an absorbing tower, a buffer tank, a circulating pump, a cooler and an injecting pump. The absorbing tower comprises a filling support plate, a filling pressing plate, filling and a distributor; the outlet of the urea ammonium nitrate solution preparing tank is connected with the lower inlet of the side wall of the absorbing tower; the top outlet of the absorbing tower is connected with the inlet of the choke of the injecting pump; the outlet of the circulating pump is connected with the inlet of the cooler; the outlet of the coller is connected with the inlet of the upper end of the side wall of the absorbing tower through a first pipe; the first pipe is connected with a second pipe towards an acid tank, the connecting position of the first pipe and the second pipe is a node A, and the portion of the first pipe between the node A and the cooler is connected with the inlet of the other end of the injecting pump. The tail gas recovery device for the urea ammonium nitrate solution production is simple in technical design, effectively recovers gaseous ammonia in tail gas and reduces consumption and environmental pollution.

Owner:ANHUI WANBEI COAL REFCO GRP LTD HANSHAN HENGTAI NONMETALLIC MATERIALS BRANCH

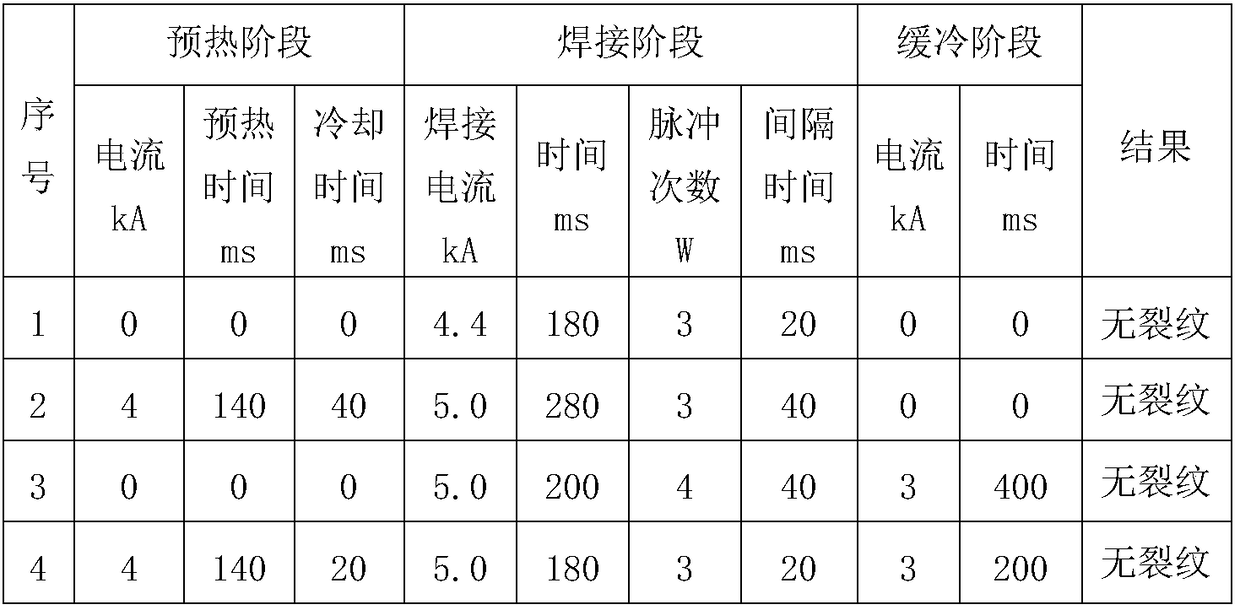

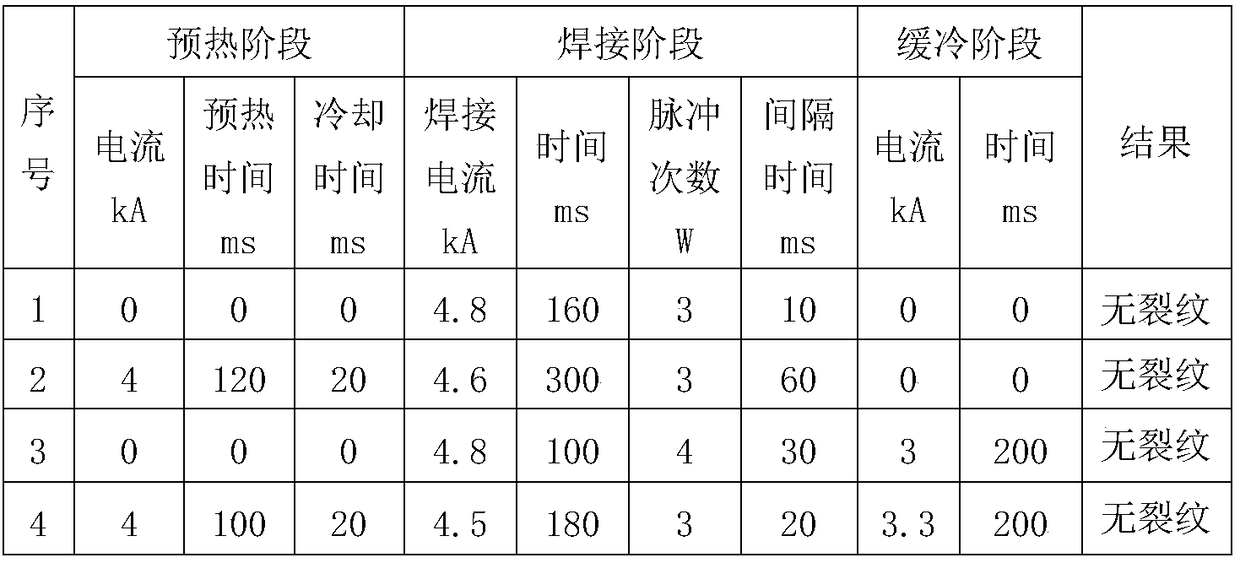

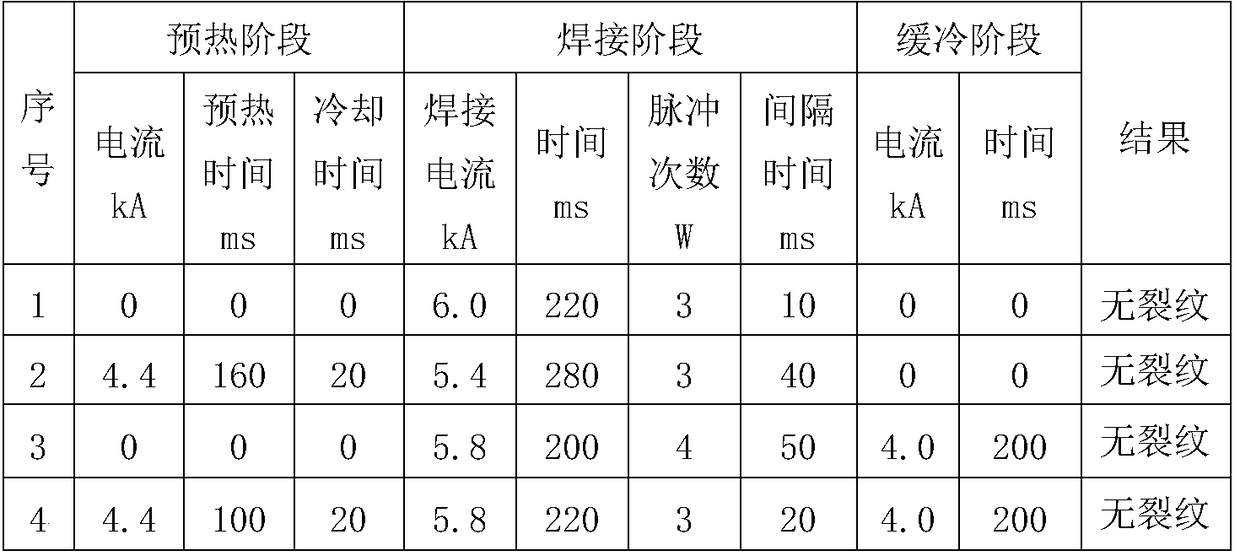

Spot welding process method for high carbon equivalent cold-rolling dual phase steel

InactiveCN109079304AImprove stress statusAvoid crackingResistance welding apparatusHigh carbonThree stage

The invention relates to a spot welding process method for high carbon equivalent cold-rolling dual phase steel. The cold-rolling dual phase steel has carbon equivalent Ceq greater than or equal to 0.5; the spot welding process comprises three stages, namely a preheating stage, a welding stage and a slow cooling stage, and at least comprises the welding stage; at the preheating stage, structure rigidity of a steel plate is eliminated to obtain uniform contact resistance; at the welding stage, a molten core is formed, and textures and stress of the molten core of the steel plate are improved byusing a multi-pulse process; at the slow cooling stage, the cooling speed of a molten core metal is reduced after the molten core is formed at a welding spot, and then various properties of the welding spot are improved. By adopting the spot welding process, texture constitution and stress states of a molten core part can be improved, the problem that cracks can be easily caused at a molten coreline part when spot welding is carried out on the cold-rolling dual phase steel of which the carbon equivalent Ceq is not smaller than 0.5, is solved, and the spot welding quality can be improved.

Owner:ANGANG STEEL CO LTD

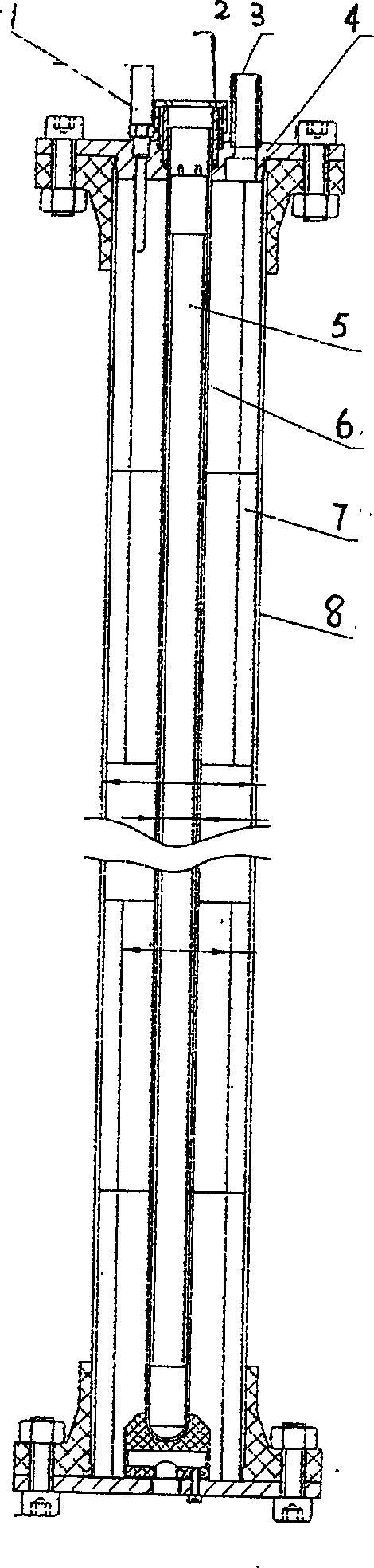

Efficient photocatalytic water-treating process and apparatus

InactiveCN1810665AStrong loadLow costPhysical/chemical process catalystsWater/sewage treatment by irradiationDouble tubeIndustrial waste water

The present invention relates to one kind of efficient photcatalytic water-treating process and apparatus. Inside a ceramic or stoneware tube with TiO2 coated to the inner wall, a transparent tube is set coaxially and an ultraviolet light source is set inside the double tube to constitute a membrane reaction tube. The membrane reaction tube is mounted vertically, the water to be treated inflows from the lower end of the membrane reaction tube and the treated water outflows from the upper end of the membrane reaction tube. The water flow rate is controlled so that the water settling time or photcatalytic reaction time is controlled. The apparatus is suitable for degrading organic matter and sterilizing of slightly contaminated industrial waste water, domestic waste water and natural water. The apparatus has jetting device to ventilate the solution, reflux device to reinforce the mass transfer effect of the reaction system, and control system including power source and light source controller.

Owner:NANJING UNIV

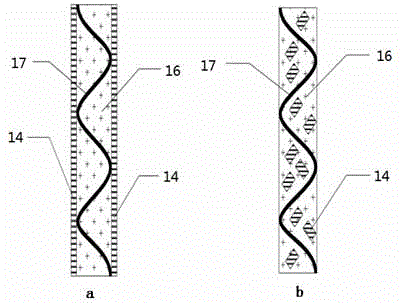

Metamaterial with dielectric substrate with nonuniform thickness

ActiveCN102637959ARich applicationSimple process designAntennasLensDielectric substrateProcess design

The invention provides a metamaterial with a dielectric substrate with nonuniform thickness, which comprises a multilayer dielectric substrate and multiple artificial microstructures, wherein the multiple artificial microstructures are arranged on the dielectric substrate; and the metamaterial is characterized in that the thickness of the dielectric substrate is distributed nonuniformly. The metamaterial disclosed by the invention has the advantages that through designing the thickness of the dielectric substrate into a nonuniformly-distributed mode, the metamaterial has more abundant function applications; and as a concrete implementation mode of the metamaterial disclosed by the invention, the convergence, divergence and deflection effects of the metamaterial on electromagnetic waves can be achieved through the nonuniform distribution of the thickness, so that the metamaterial is simpler in process design and lower in production cost.

Owner:KUANG CHI INST OF ADVANCED TECH

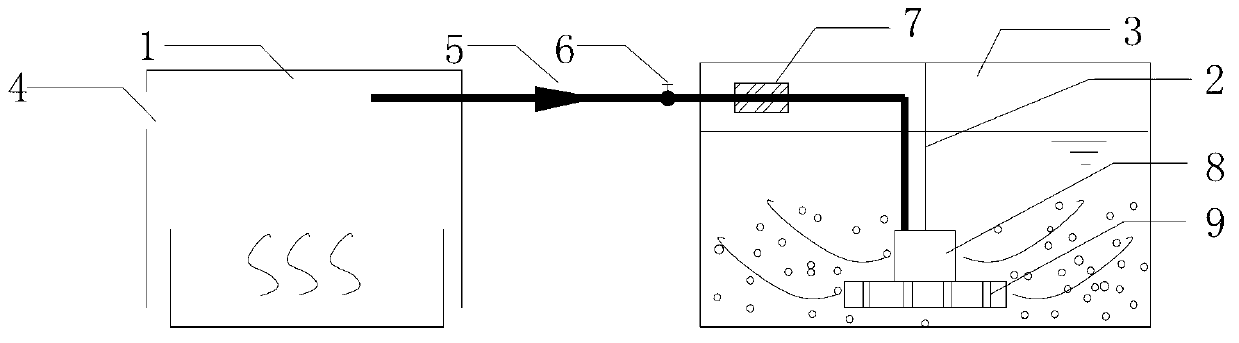

Method and device for integral deodorization and sewage treatment of municipal sewage plants

InactiveCN103127820AGood mixing effectImprove mass transfer efficiencyDispersed particle separationSustainable biological treatmentOdor sourceMunicipal sewage

The invention discloses a method for integral deodorization and sewage treatment of municipal sewage plants. The method comprises the following steps of: erecting a half-sealed gas collection area around or above an odor source, or using a former half-sealed building, and collecting generated odor; and conveying the odor into a submersible jet type aerator through a conveying pipeline, uniformly enabling the mixed odor and sewage to enter an aeration basin through the submersible jet type aerator, and removing fusty matters through adsorption, dissolving and biological degradation. With the adoption of the manner, the method for the integral deodorization and sewage treatment of the municipal sewage plants can be used for simplifying the design, the operation and the management of a deodorization facility, reducing the investment cost and the operation cost, and effectively treating various fusty matters. Furthermore, the method for the integral deodorization and sewage treatment of the municipal sewage plants has a good treatment effect and is very applicable to deodorization updating improvement of the built sewage plants and construction of an integrated deodorization facility of newly built sewage plants.

Owner:SUZHOU TONGDE ENVIRONMENTAL PROTECTION TECHCO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com