Metamaterial with dielectric substrate with nonuniform thickness

A technology of dielectric substrates and metamaterials, applied in the field of metamaterials, can solve problems such as high production costs, artificial microstructure design of complex manufacturing processes, etc., and achieve the effects of simple process design, rich functional applications, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

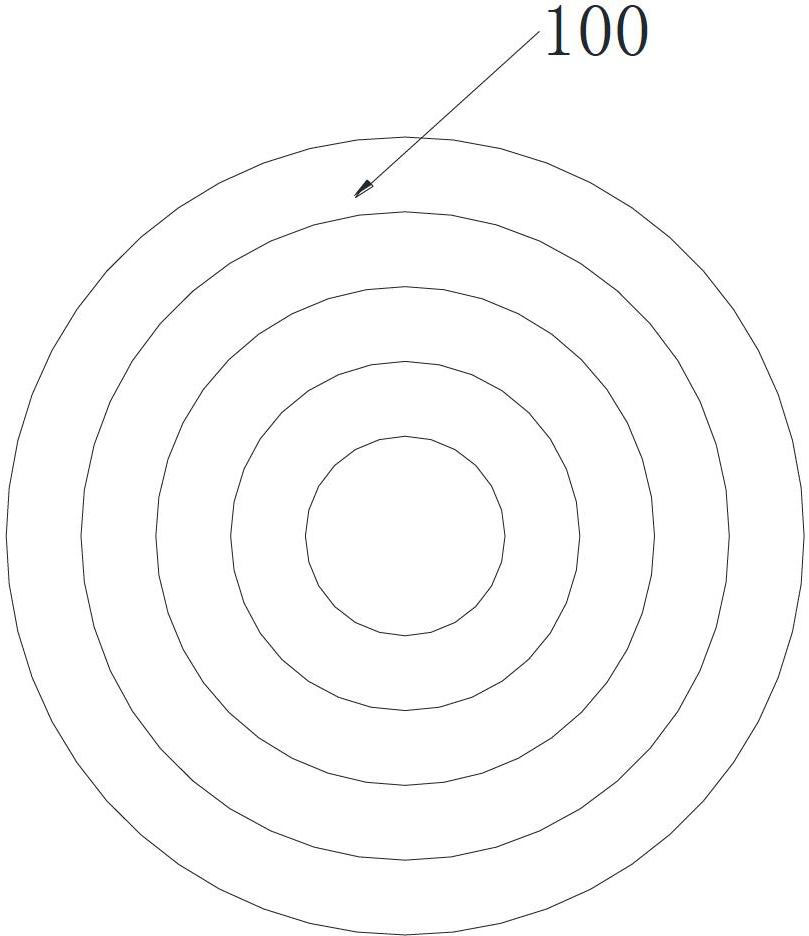

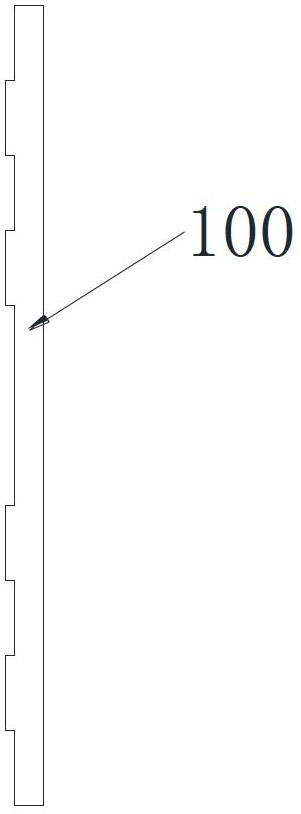

[0025] A metamaterial with a non-uniform thickness dielectric substrate, the overall structure of the metamaterial can be found in the attached figure 1 , including a stacked multilayer dielectric substrate 100 and a plurality of artificial microstructures 200 arranged on the dielectric substrate. For the structural diagram of the dielectric substrate 100, refer to the attached figure 2 , one side of the dielectric substrate 100 is convex ellipsoid, and the other side is flat, and the artificial microstructure 200 is arrayed on the flat side of the dielectric substrate 100 .

[0026] For metamaterials, we can regard the artificial microstructure, the dielectric substrate occupied by the artificial microstructure, and the space around them as a tiny unit that can generate electromagnetic responses to electromagnetic waves. The entire metamaterial is composed of many tiny units. By designing the structural shape of the artificial microstructures 200 in each tiny unit and orderl...

Embodiment 2

[0029] A metamaterial with a non-uniform thickness dielectric substrate, the overall structure of the metamaterial can be found in the attached image 3 , including a stacked multilayer dielectric substrate 100 and a plurality of artificial microstructures 200 arranged on the dielectric substrate. For the structural diagram of the dielectric substrate 100, refer to the attached Figure 4 , one side of the dielectric substrate 100 is concave ellipsoid, and the other side is flat, and the artificial microstructure 200 is arrayed on the flat side of the dielectric substrate 100 .

[0030] According to the above design principles and ideas, in this embodiment, by designing the dielectric substrate 100 as a concave ellipsoid similar to a concave lens, the electromagnetic waves passing through the dielectric substrate can have a diverging effect, so that the metamaterial can obtain electromagnetic wave divergence on the basis of the original functional characteristics. function to i...

Embodiment 3

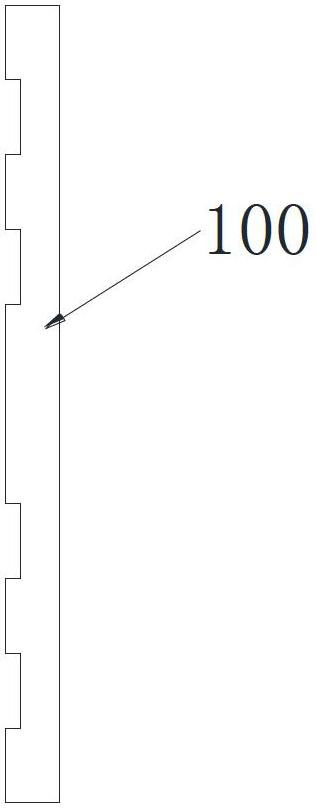

[0032] As a modification of the above-mentioned embodiment, the present invention can also design the dielectric substrate 100 as the following structure, refer to the attached Figure 5 And attached Image 6 , with Figure 5 is a cross-sectional view of the dielectric substrate 100, Image 6 It is a side view of the dielectric substrate 100. One side of the dielectric substrate 100 is in the shape of a boss, and the other side is in the shape of a plate. The artificial microstructure 200 is arrayed on the plate-shaped side of the dielectric substrate 100. Viewed from the side of the boss-shaped structure, the dielectric substrate 100 is back shape.

[0033] According to the above-mentioned design principles and ideas, in this embodiment, the equivalent permittivity and equivalent magnetic permeability of each back-shaped structure of the metamaterial are distributed in a ladder shape. On the one hand, by designing the structural shape and According to the arrangement rules...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com