Patents

Literature

3276 results about "Vertical motion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

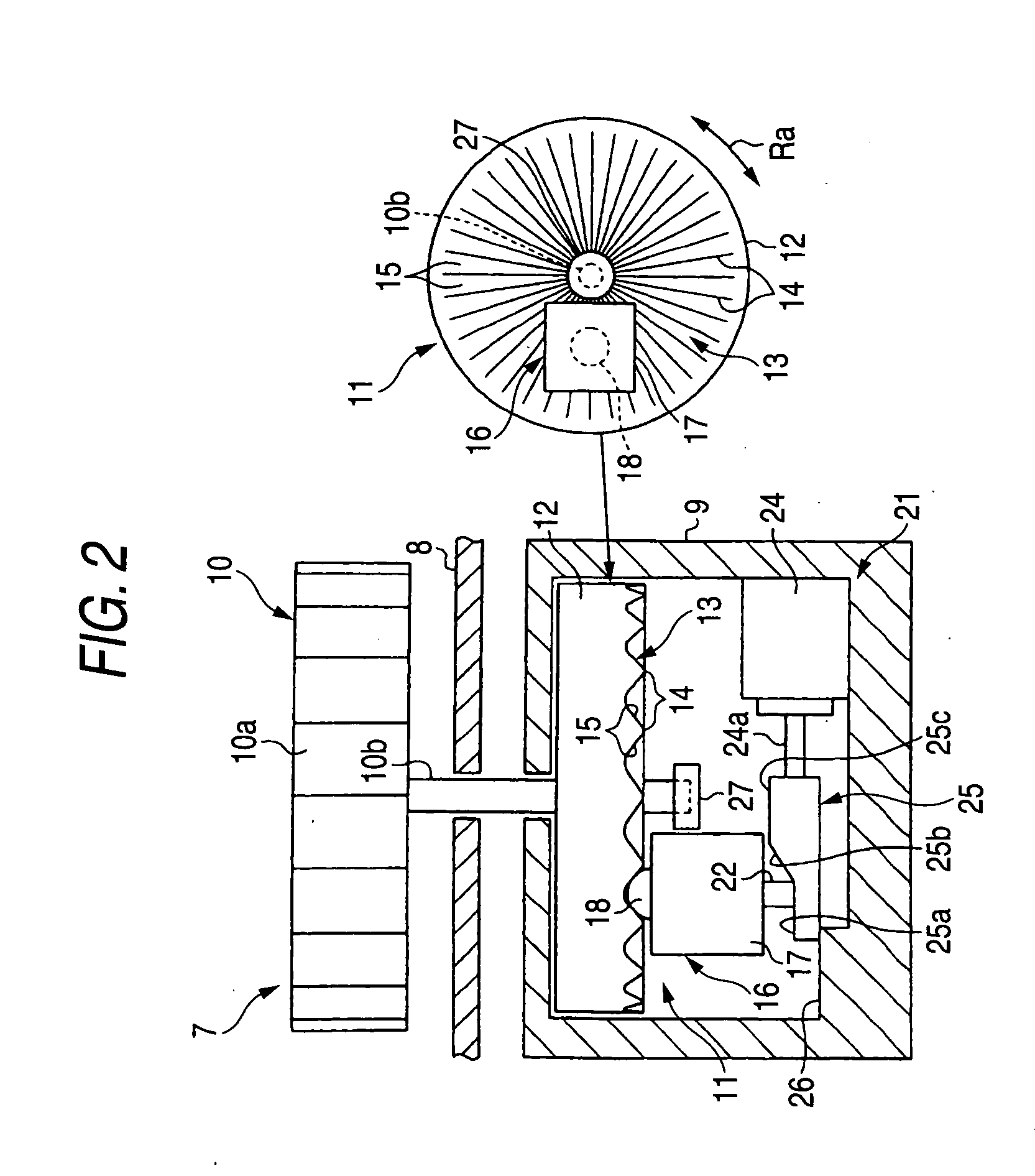

Load storage equipment

InactiveUS6722837B2Add supportEfficient storageCharge manipulationStorage devicesEngineeringVertical axis

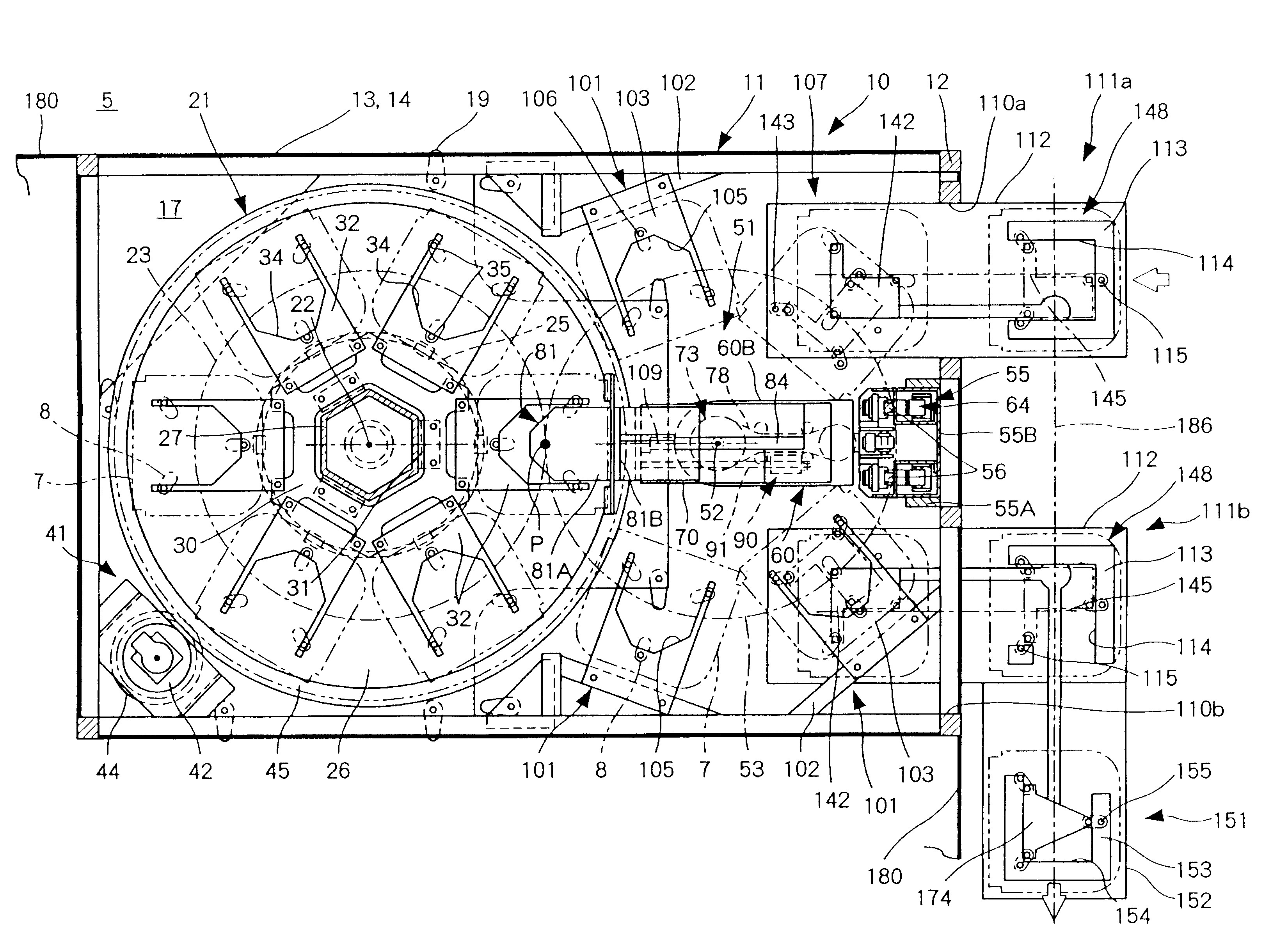

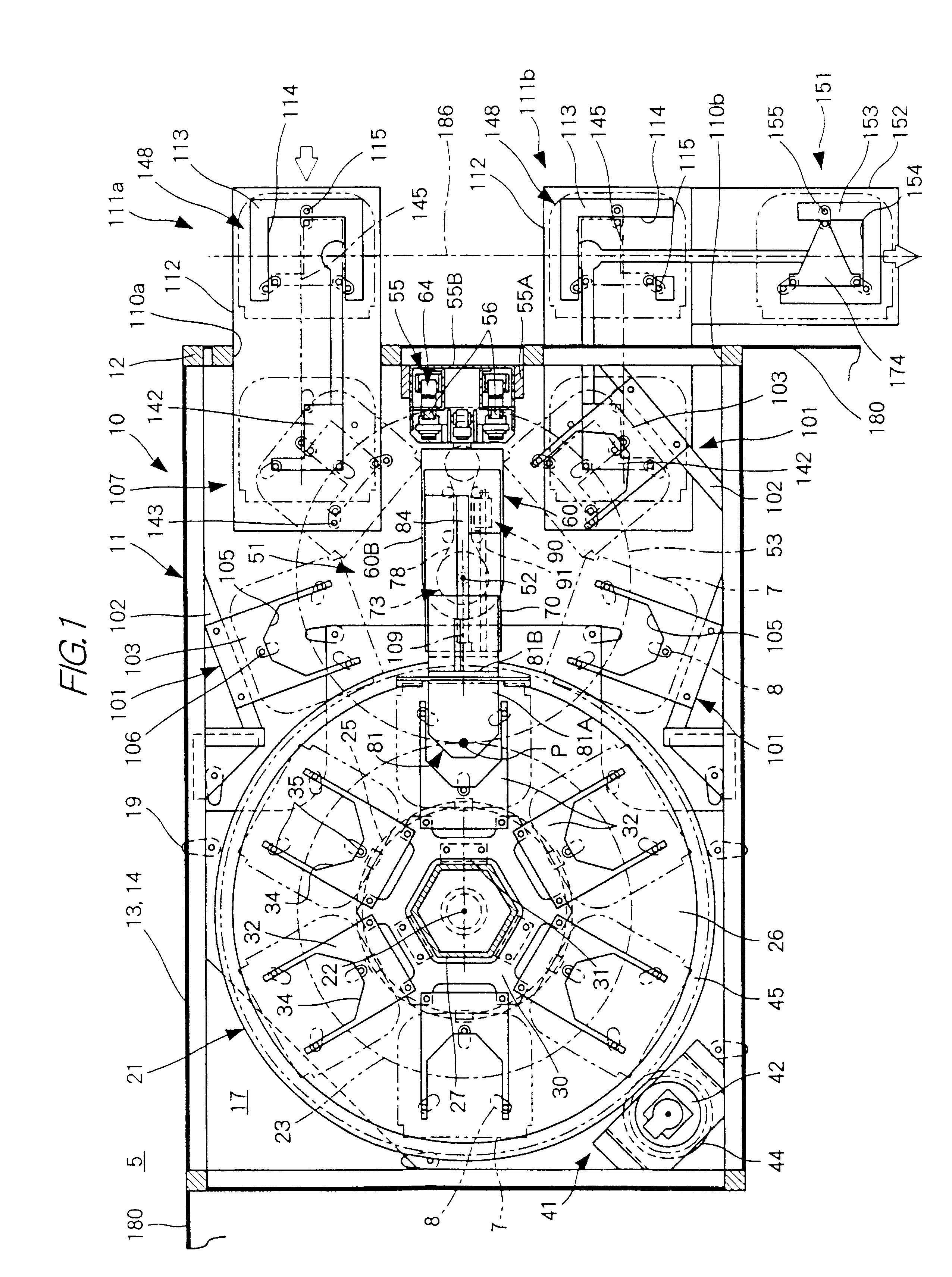

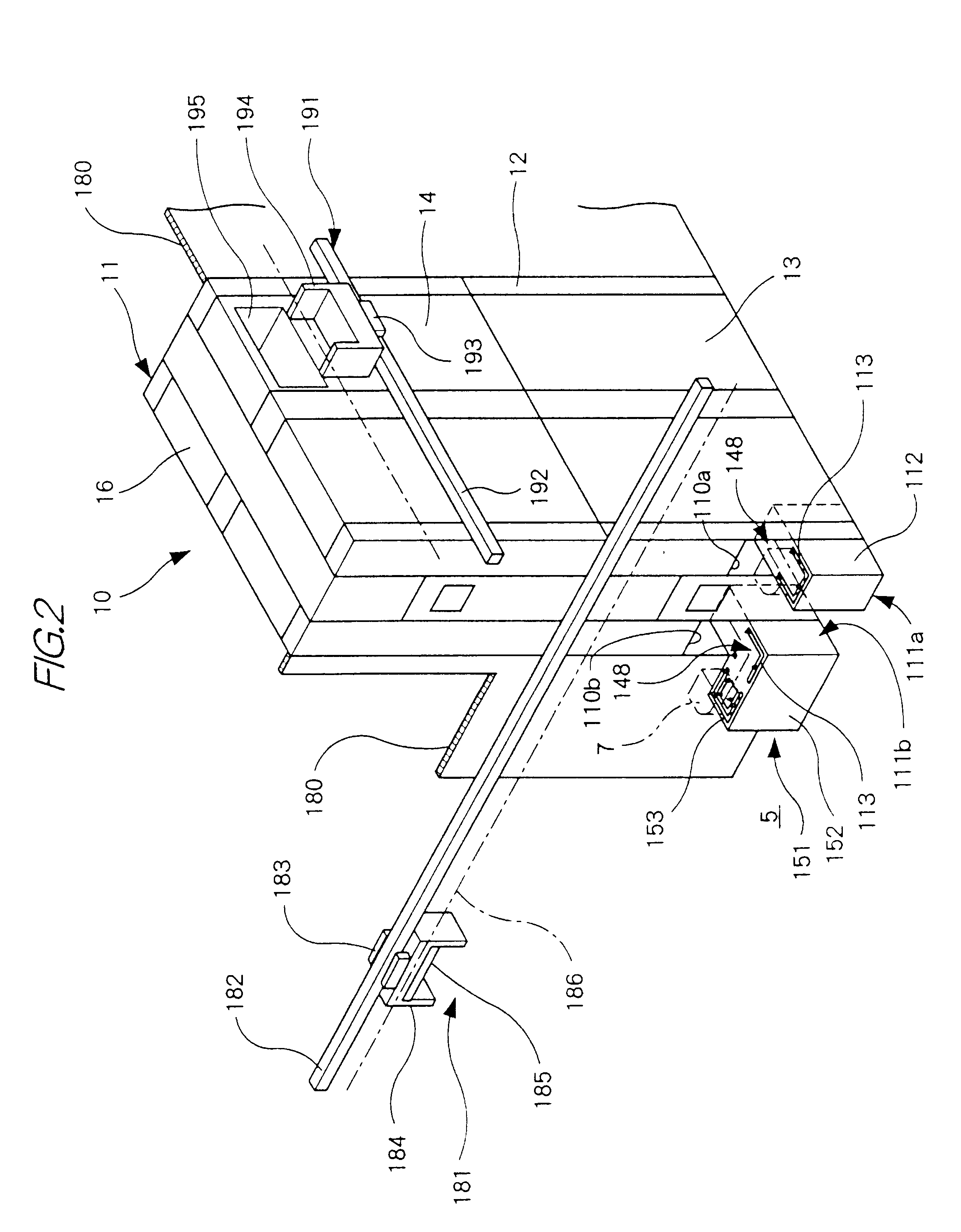

There is provided compact load storage equipment that can store a large number of loads. The storage equipment comprises a rotary rack 21, a transferrer 51, one or more fixed racks 101, an inlet port 111a and an outlet port 111b. The rotary rack 21 is supported rotatably about a first vertical axis and includes a number of vertically arranged stages of turning load supports 32. The transferrer 51 adjoins the rotary rack 21 and includes a carrier 81, which can vertically move and rotate about a second vertical axis. The fixed racks 101 are positioned around the transferrer 51 and each includes a number of vertically arranged stages of fixed load supports 103. In plan view, the ports 111a and 111b each overlap with one of the rotary and fixed racks 21 and 101. The transferrer 51 can transfer loads between the carrier 81 and any one of the turning and fixed load supports 32 and 103, and between the carrier 81 and each of the ports 111a and 111b, by the turning and vertical movement of the carrier 81, or by the combination of the turning and vertical movement of the carrier 81 and the turning of the turning load supports 32.

Owner:DAIFUKU CO LTD

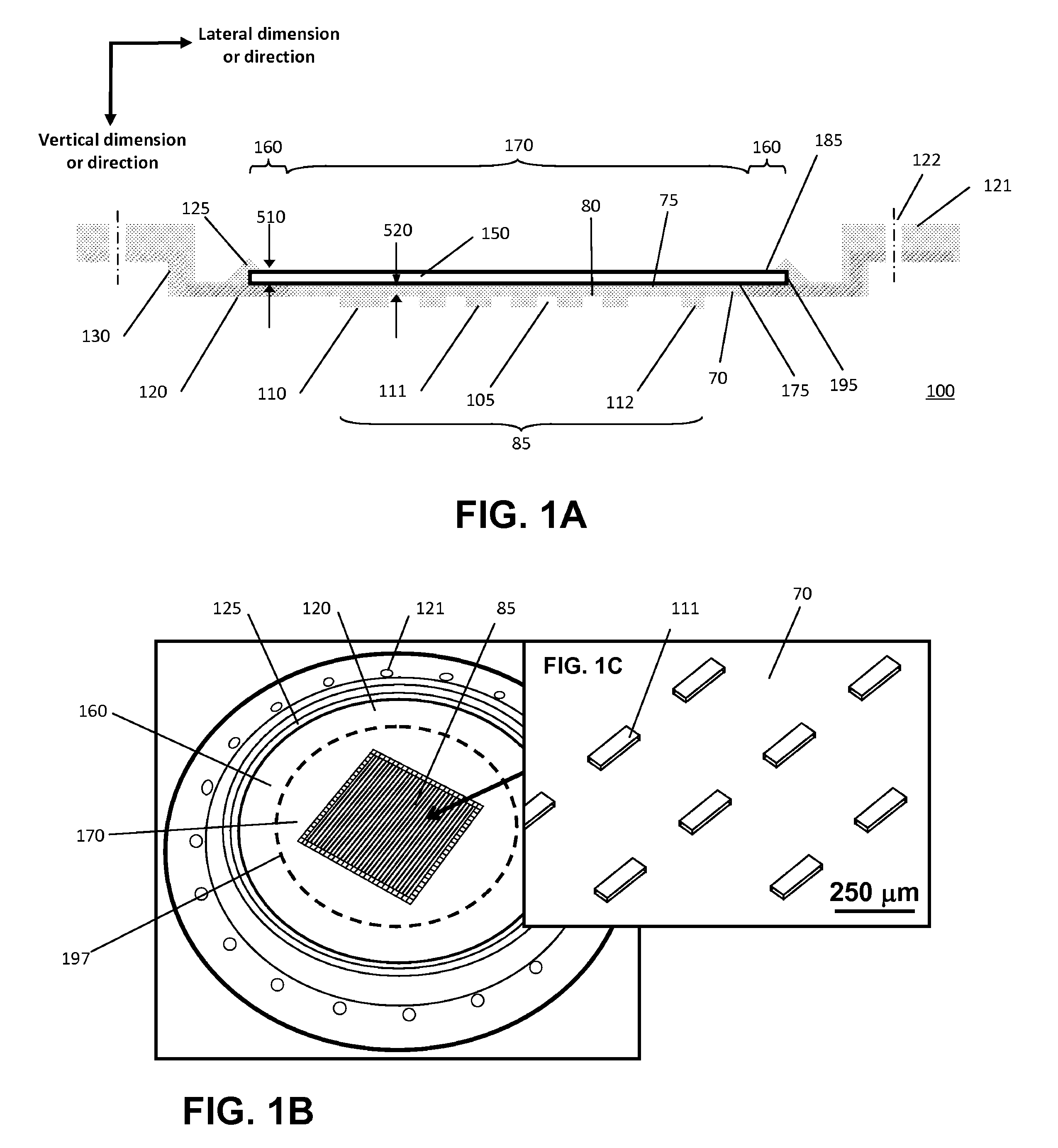

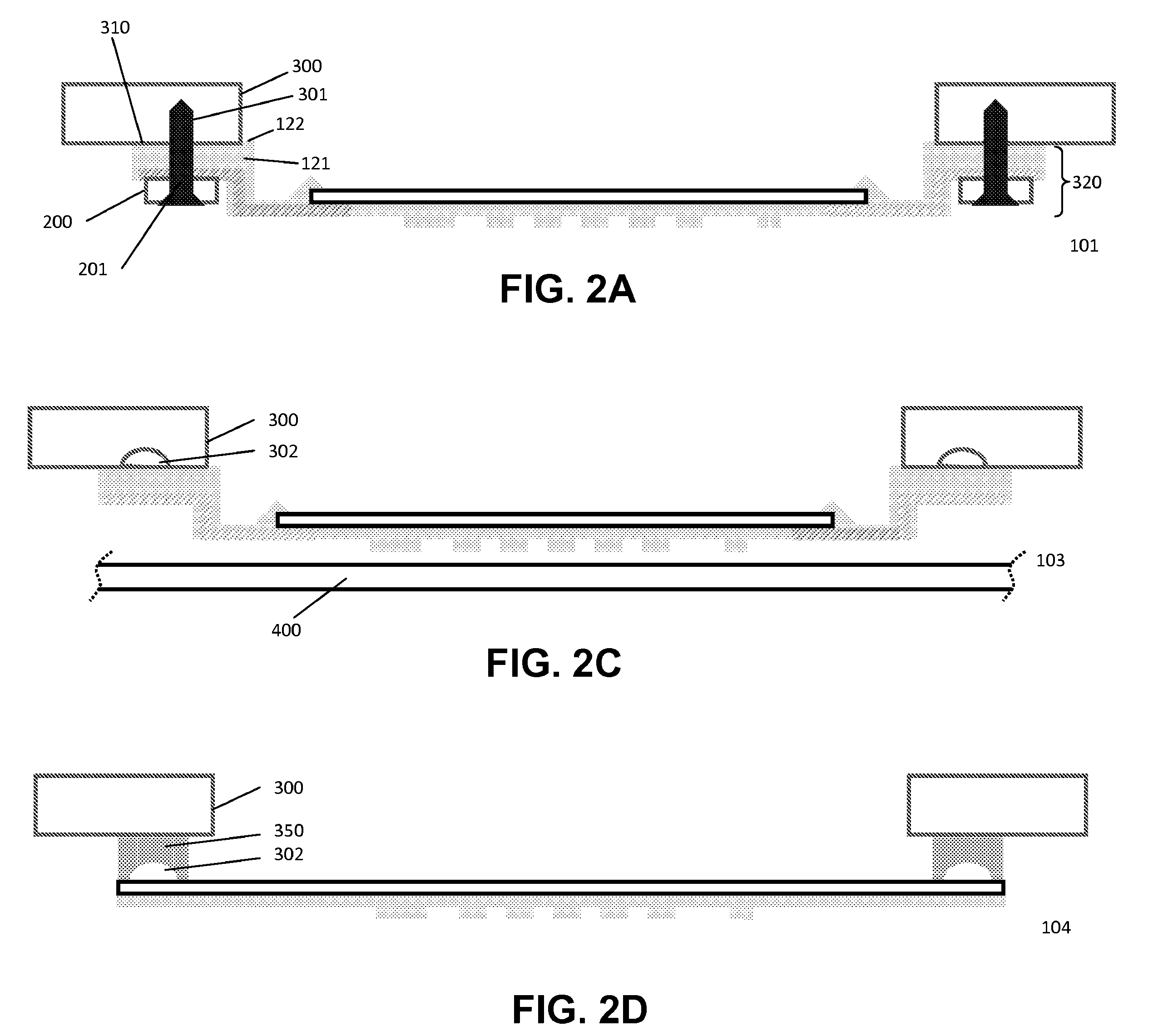

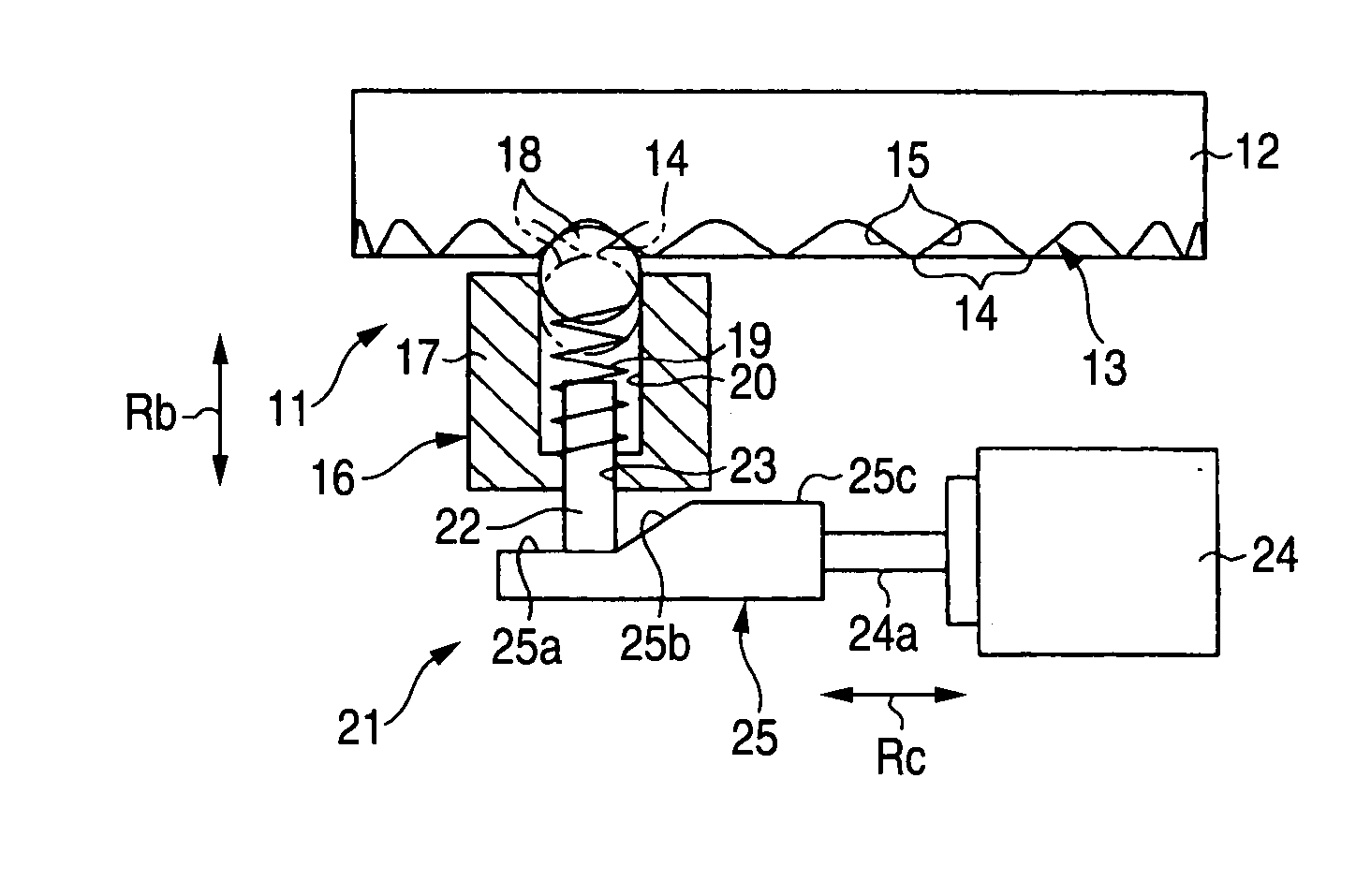

Reinforced composite stamp for dry transfer printing of semiconductor elements

ActiveUS7927976B2Easy to controlPrecise and repeatable vertical motionTurning machine accessoriesMouldsSemiconductor structureContact force

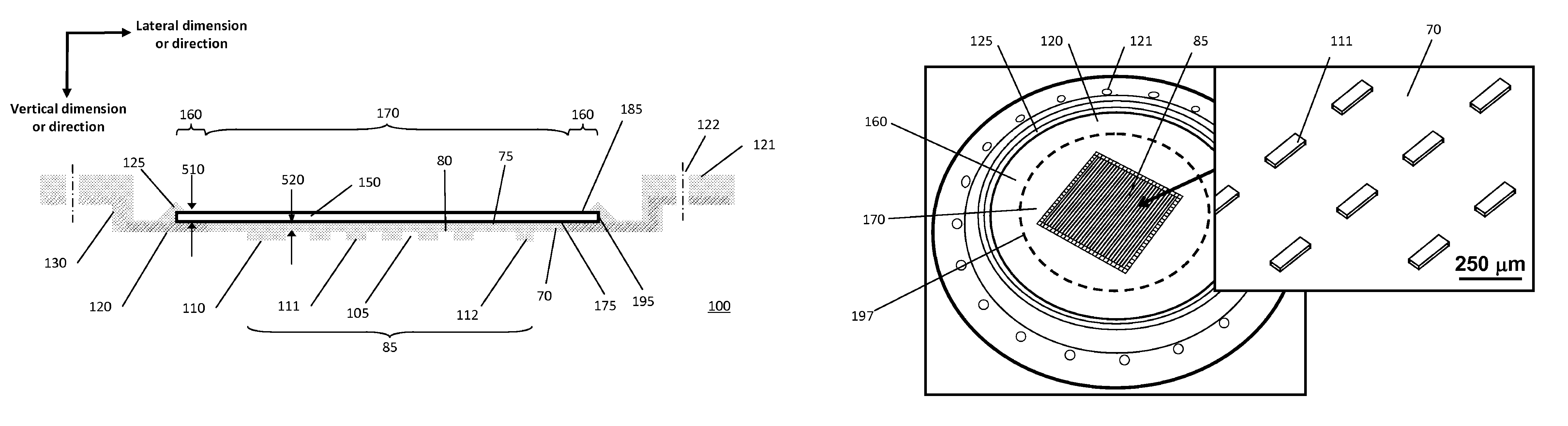

Provided are reinforced composite stamps, devices and methods of making the reinforced composite stamps disclosed herein. Reinforced composite stamps of certain aspects of the present invention have a composition and architecture optimized for use in printing systems for dry transfer printing of semiconductor structures, and impart excellent control over relative spatial placement accuracy of the semiconductor structures being transferred. In some embodiments, for example, reinforced composite stamps of the present invention allow for precise and repeatable vertical motion of the patterned surface of the printing apparatus with self-leveling of the stamp to the surface of a contacted substrate. Reinforced composite stamps of certain aspect of the present invention achieve a uniform distribution of contact forces between the printing apparatus patterned surface and the top surface of a substrate being contacted by the reinforced composite stamp of the printing apparatus.

Owner:X DISPLAY CO TECH LTD

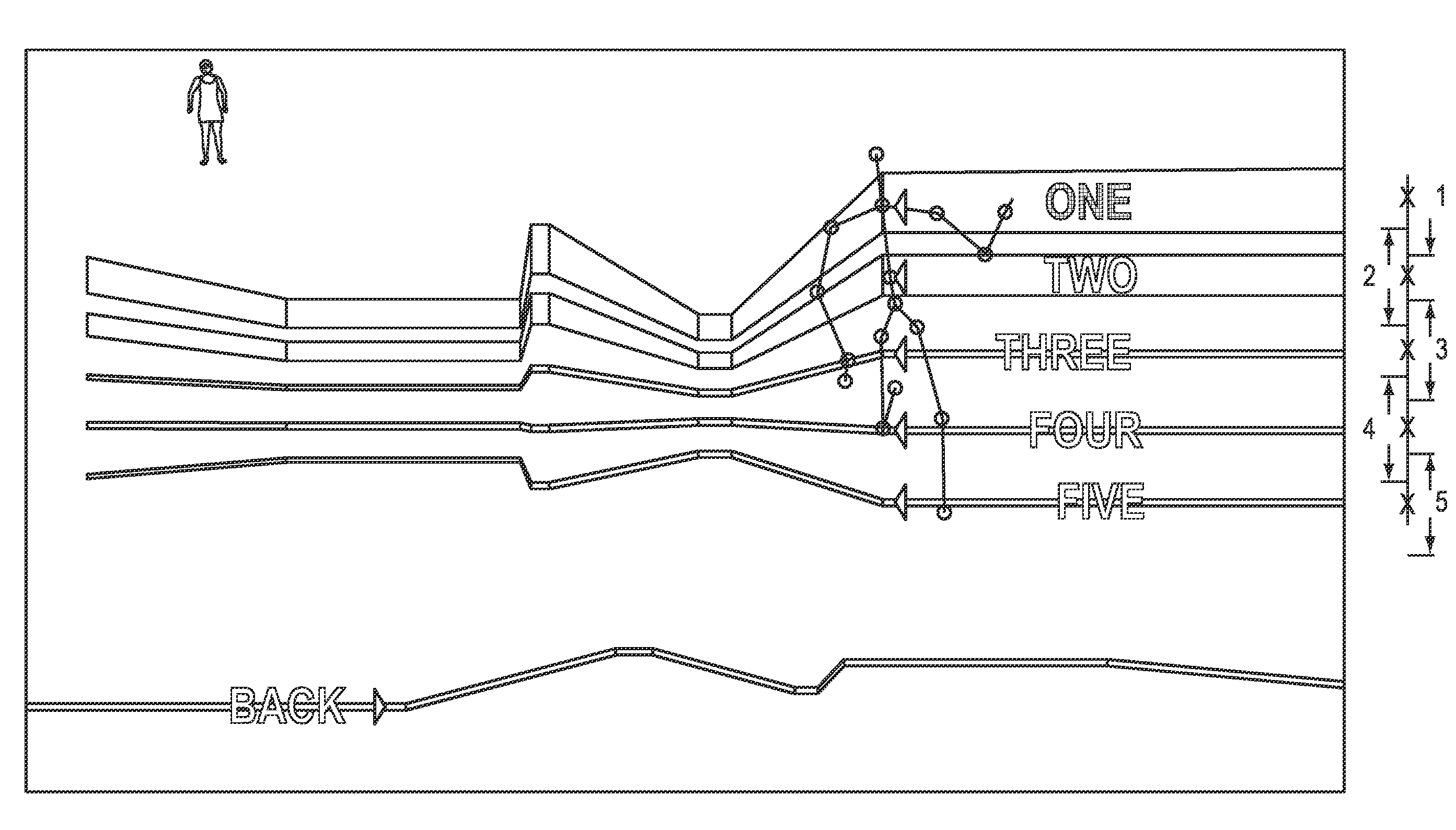

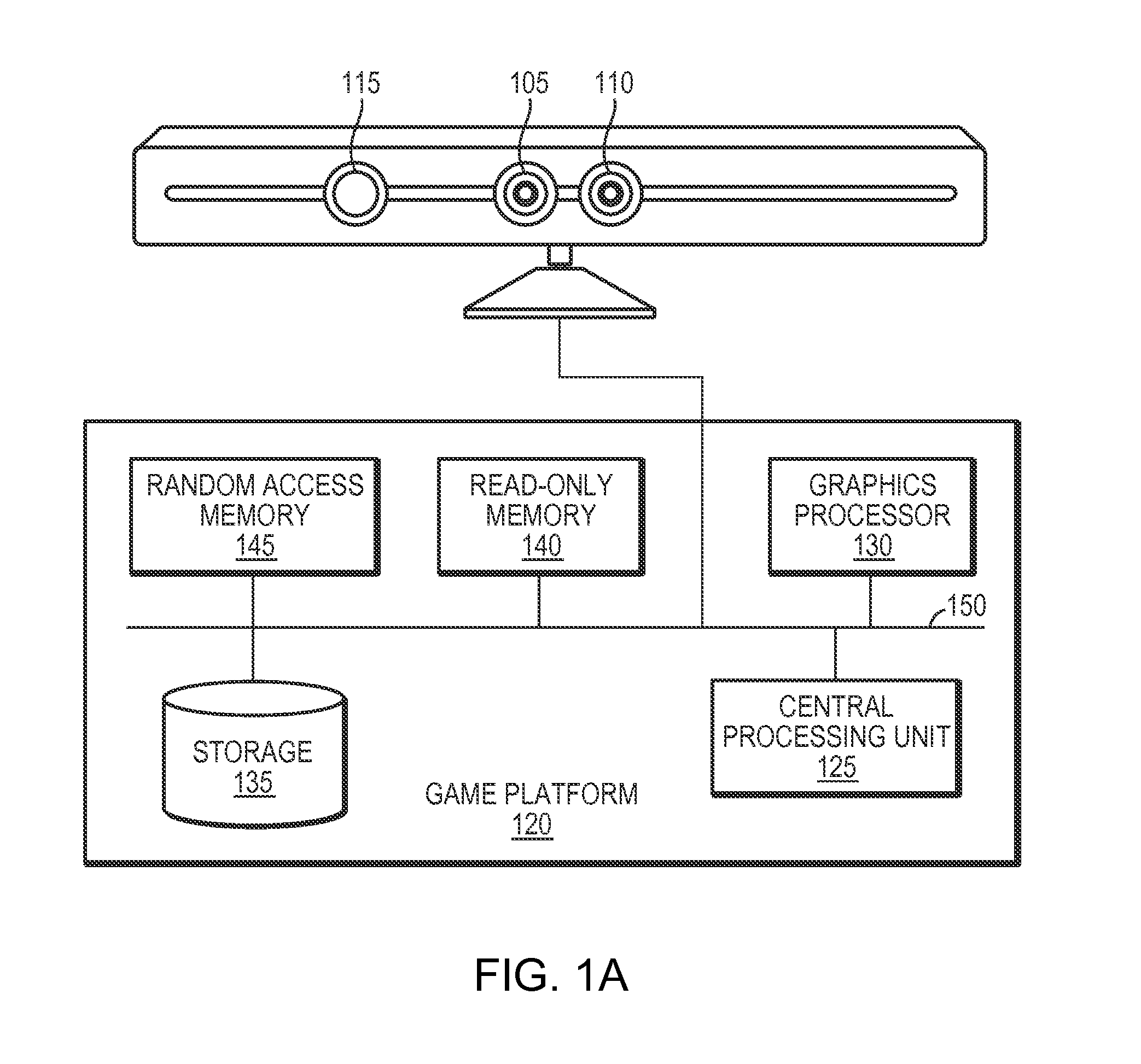

Gesture-based user interface

ActiveUS20110185309A1Simple meansScroll into the menu more quicklyVideo gamesInput/output processes for data processingBiological activationAppendage

The invention includes methods, systems, computer program products and means for providing an intuitive user interface for interacting with a game console that obviates the need for, or use of, a typical game controller. In one embodiment, the user interface comprises an analog-like mechanism for manipulating a menu and icon system. The menu system allows the user to highlight a menu option or icon using movement along one axis and to activate the menu option or icon via movement on a different axis. In one embodiment, highlighting is associated with a vertical motion and activation is associated with a horizontal motion. The vertical motion can be tied to the vertical movement of a particular appendage, e.g., the up and down movement of the user's right arm, and the horizontal motion can be tied to the horizontal movement of that or another appendage, e.g., movement of the right arm or hand across the body from right to left.

Owner:HARMONIX MUSIC SYSTEMS

Vision-based highway overhead structure detection system

InactiveUS7327855B1EffectivelyMinimizes and eliminates numberDetection of traffic movementAnti-collision systemsVision basedRadar detection

An image sequence is inputted from a camera and vertical motion is estimated. A windowed horizontal edge-projection is extracted from the inputted image sequence and corresponding horizontal edges are projected. The horizontal edge-projection and the vertical motion estimation are combined in a horizontal segmentation and tracking element, and are forwarded to an object parameter estimation element, where the object's distance and height are estimated. This data is combined in a fusion with a radar detection element. By correctly matching the overhead objects sensed by the radar detection element and the video camera, the proximity and relative speed can be ascertained. Once overhead objects have been identified they can be isolated and not considered for collision avoidance purposes.

Owner:HRL LAB

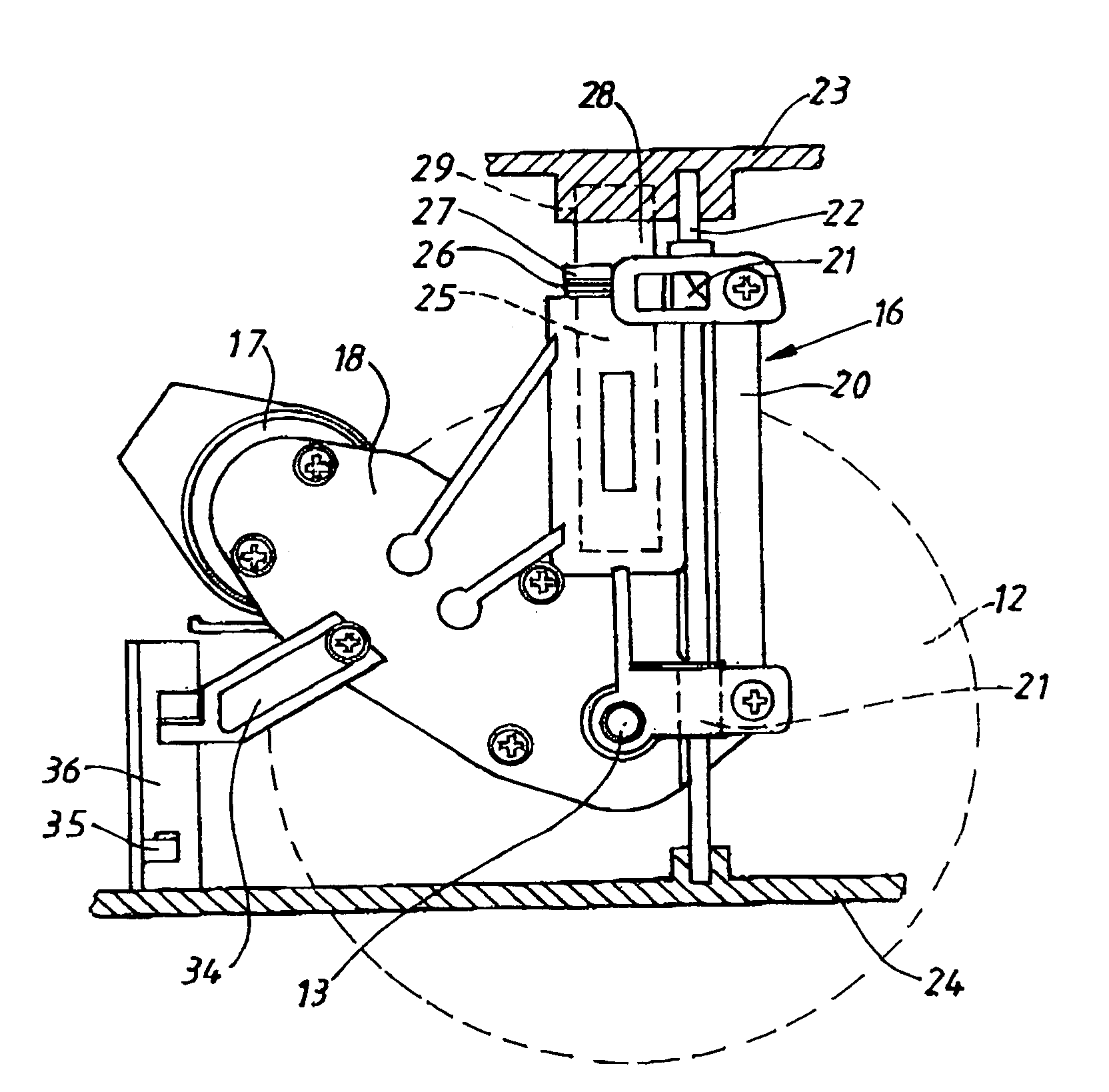

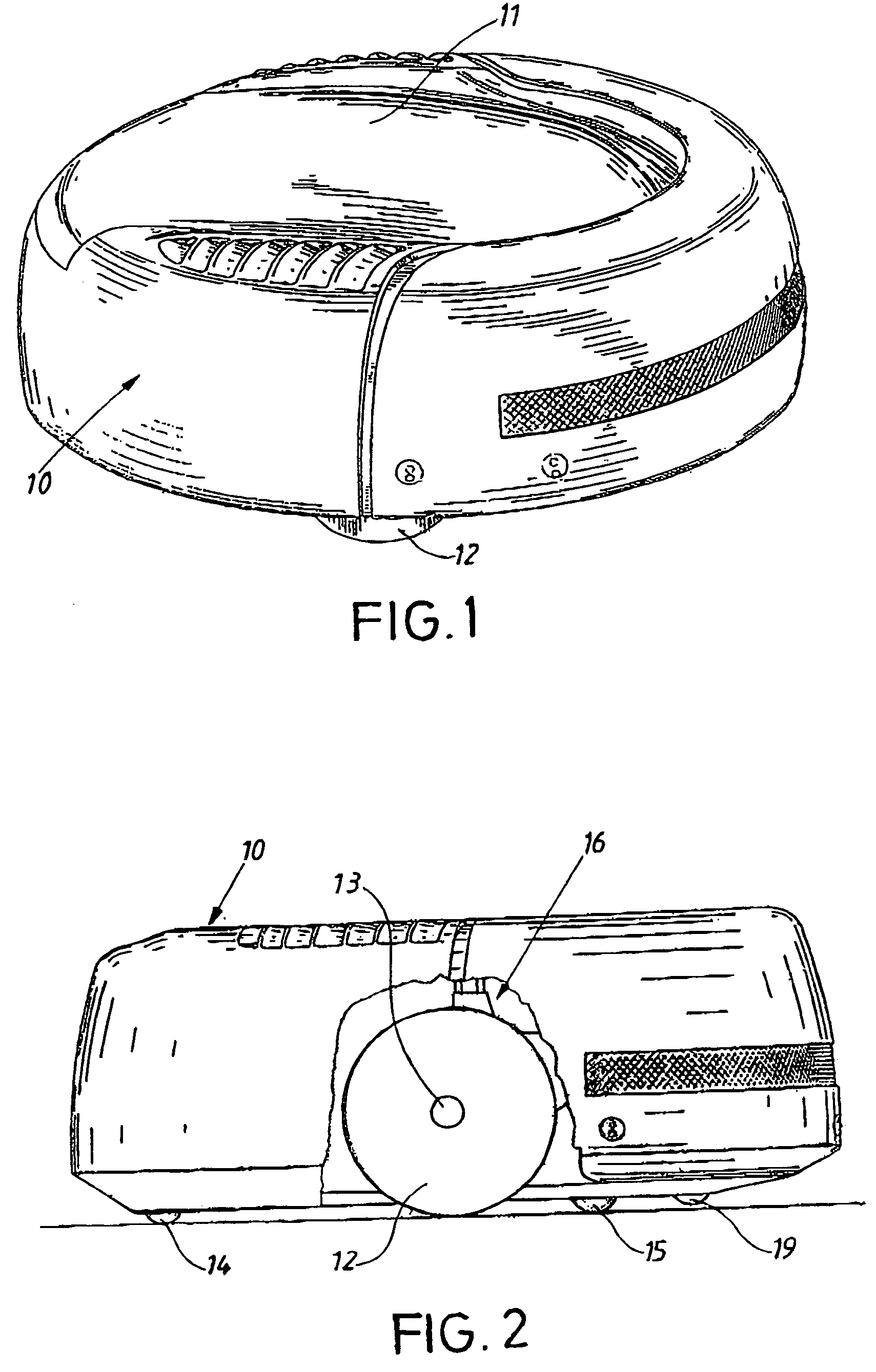

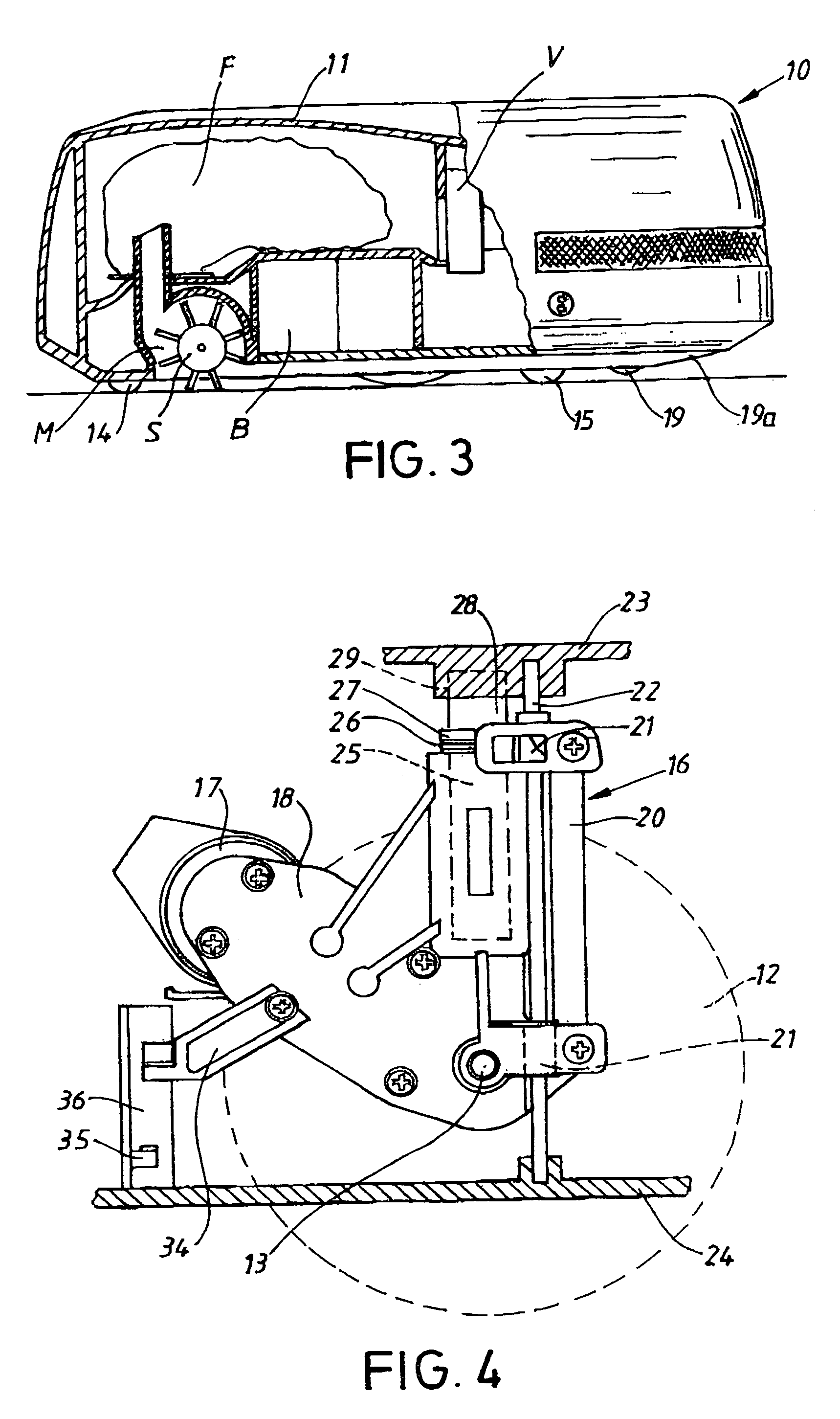

Wheel support arrangement for an autonomous cleaning apparatus

InactiveUS7275280B2Easily climbs over or otherwise avoids objectsPromote sportsAutomatic obstacle detectionTravelling automatic controlDrive wheelEngineering

A carrier, such as an autonomous cleaning apparatus, has a self-adjusting wheel assembly that can move vertically, thereby enabling the carrier to readily pass over a surface. The wheel assembly may include microswitch, which activates a control mechanism for the carrier when a wheel assembly is in a predetermined position along its path of vertical movement. Rollers can be located at the bottom of the carrier to function in cooperation with the wheel assemblies so as to facilitate the ability of the carrier to pass over obstacles. This ability may be enhanced by constructing the bottom of the front portion of the carrier so that it is slanted or inclined upwardly in a direction outward from the bottom of the carrier. A driving wheel may be rotatably attached to a wheel support, and which may also support a power source and a transmission.

Owner:AB ELECTROLUX

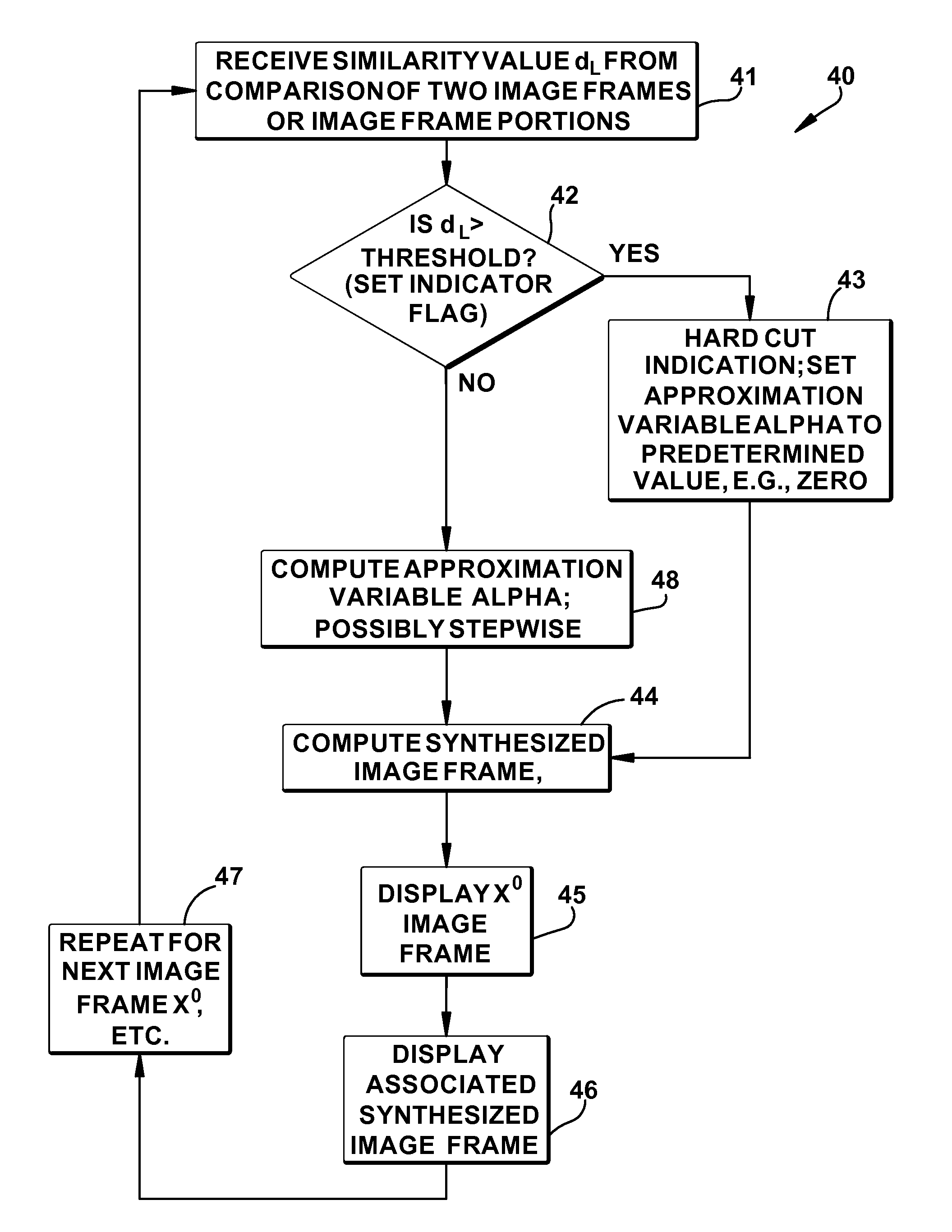

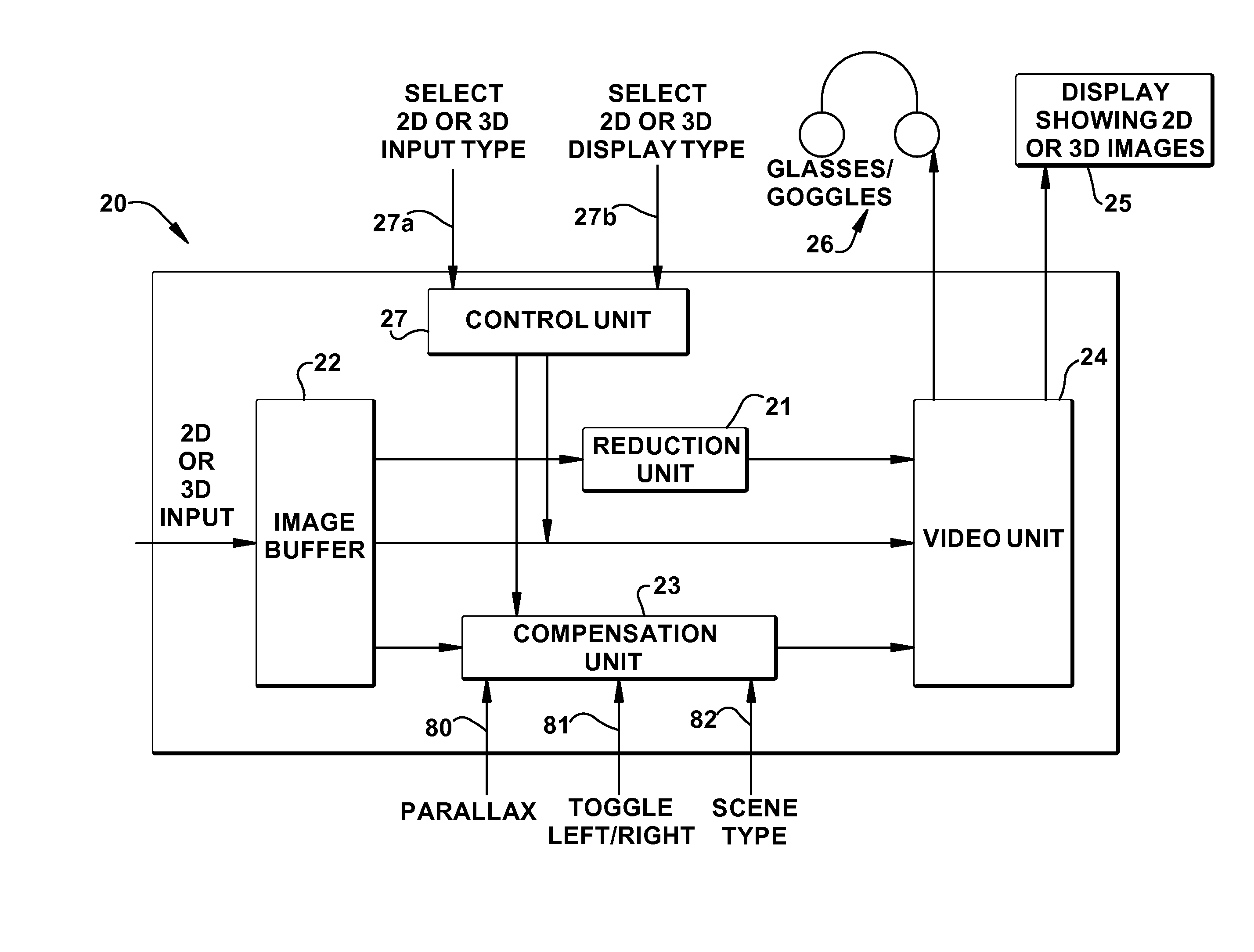

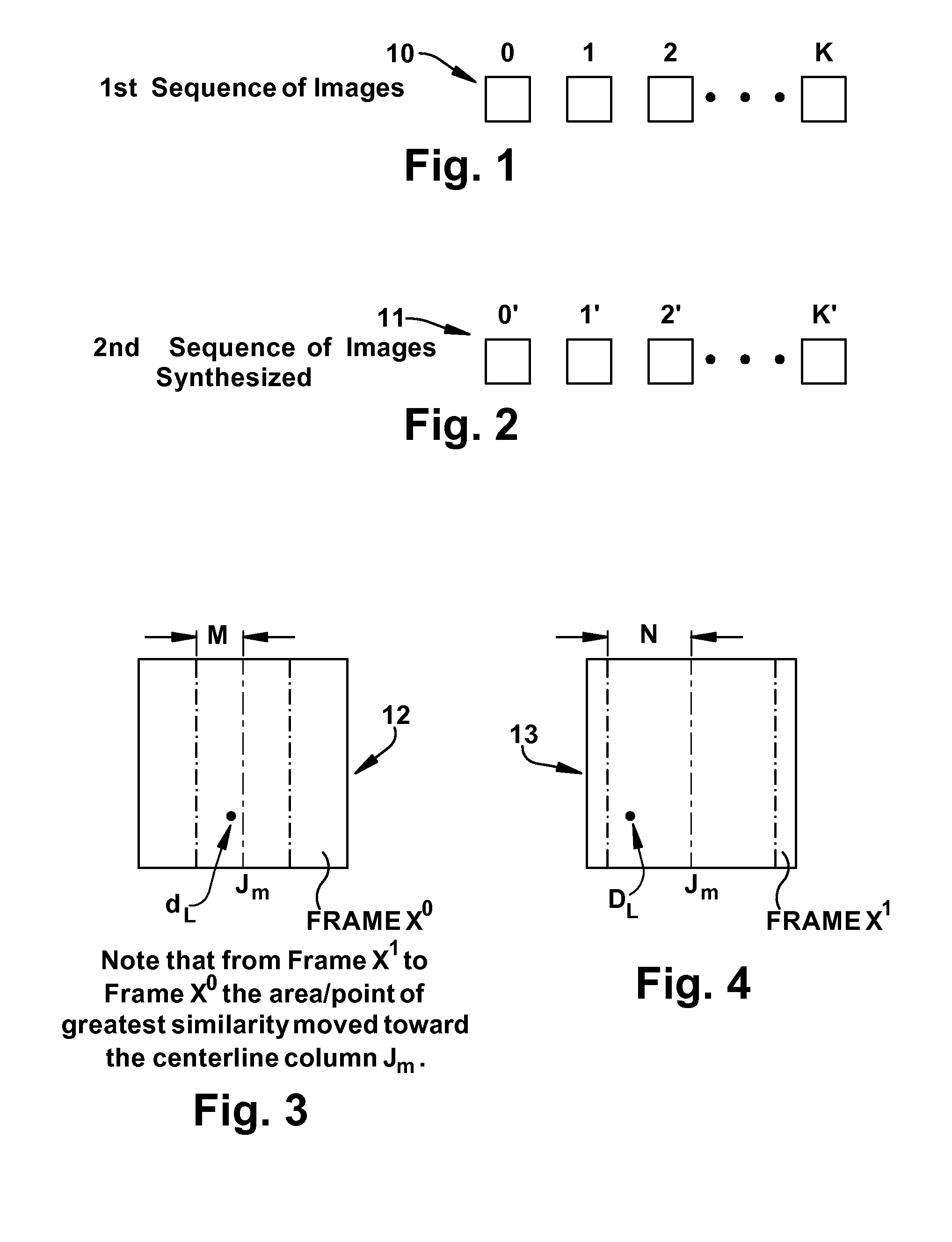

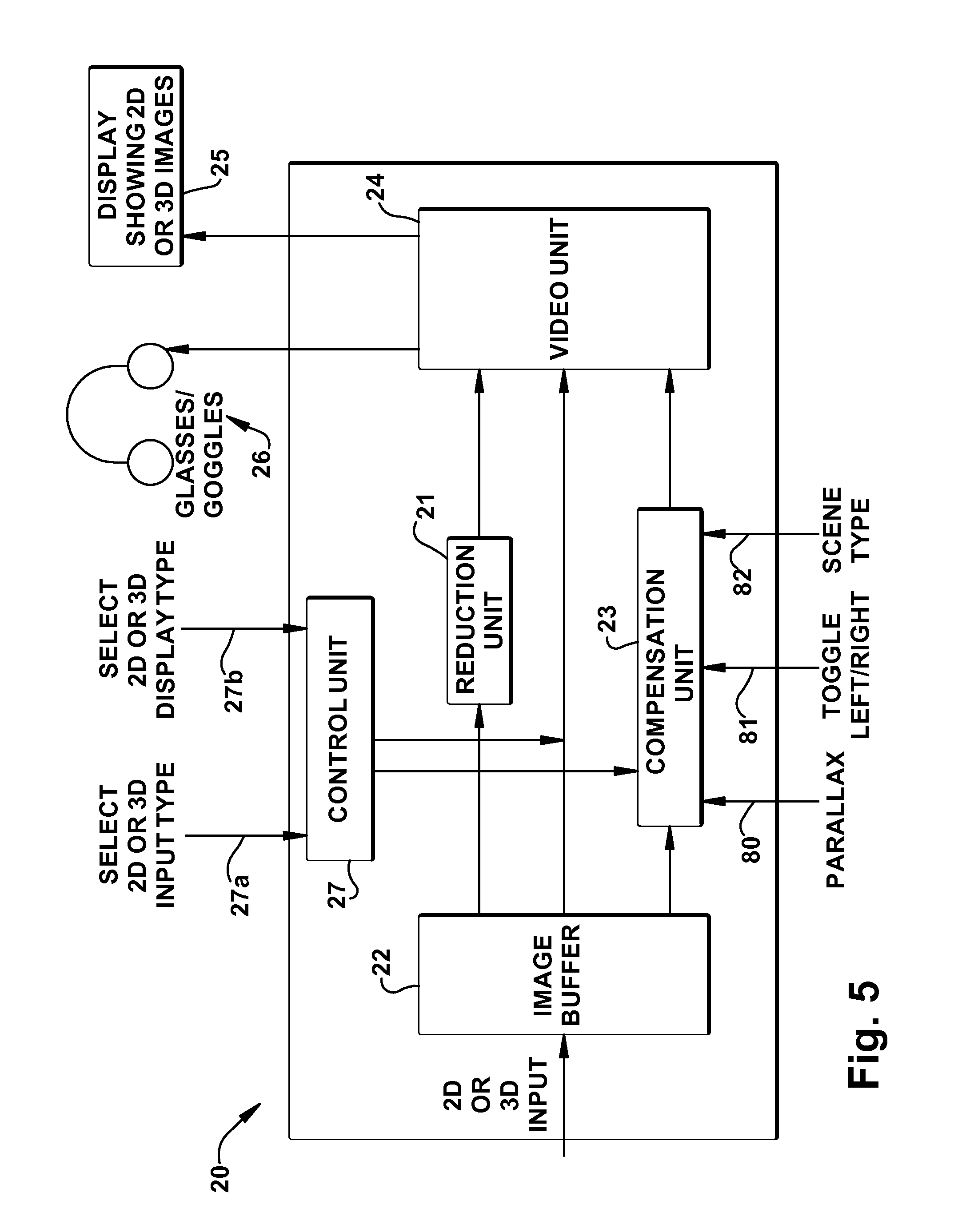

Methods and systems for 2D/3D image conversion and optimization

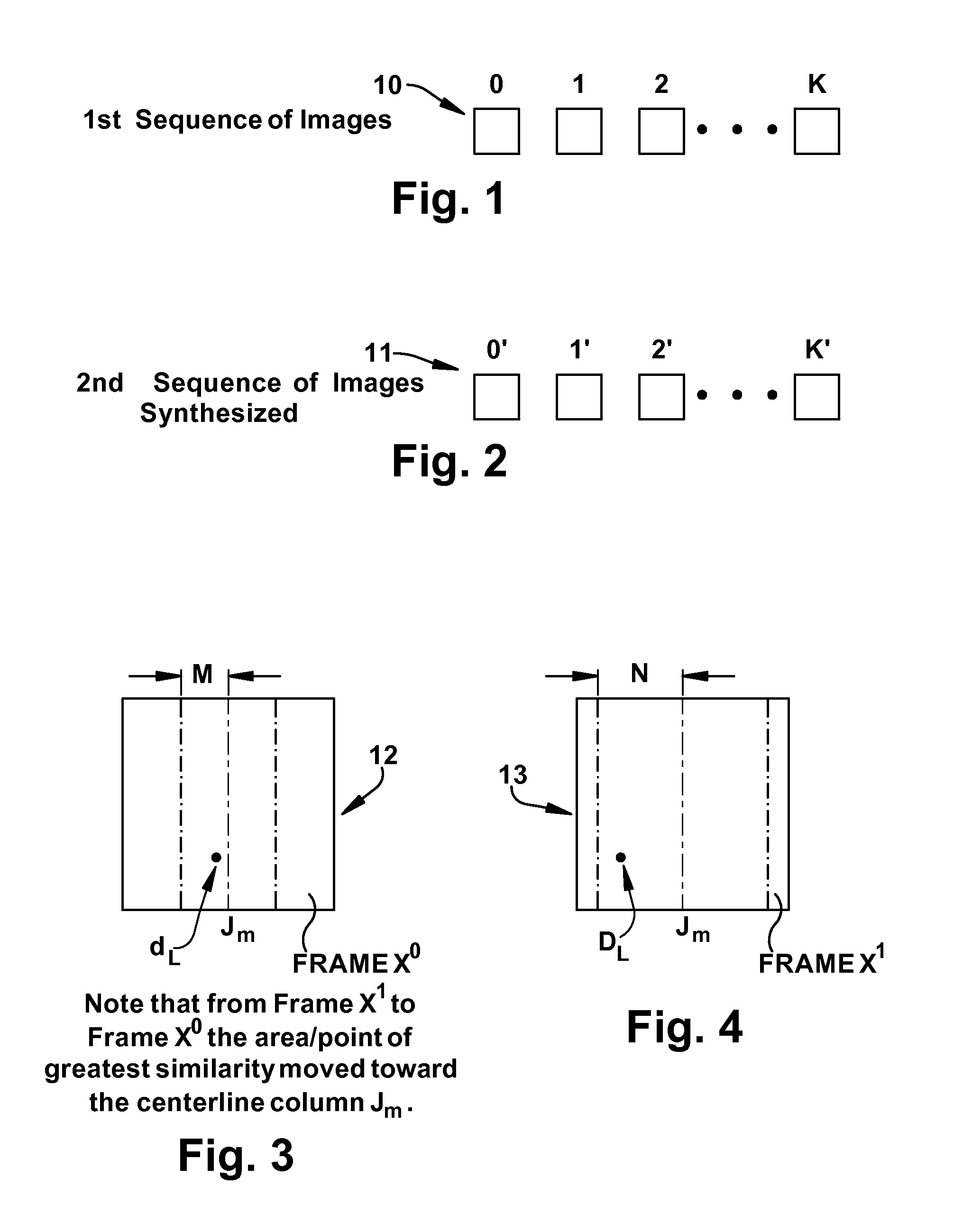

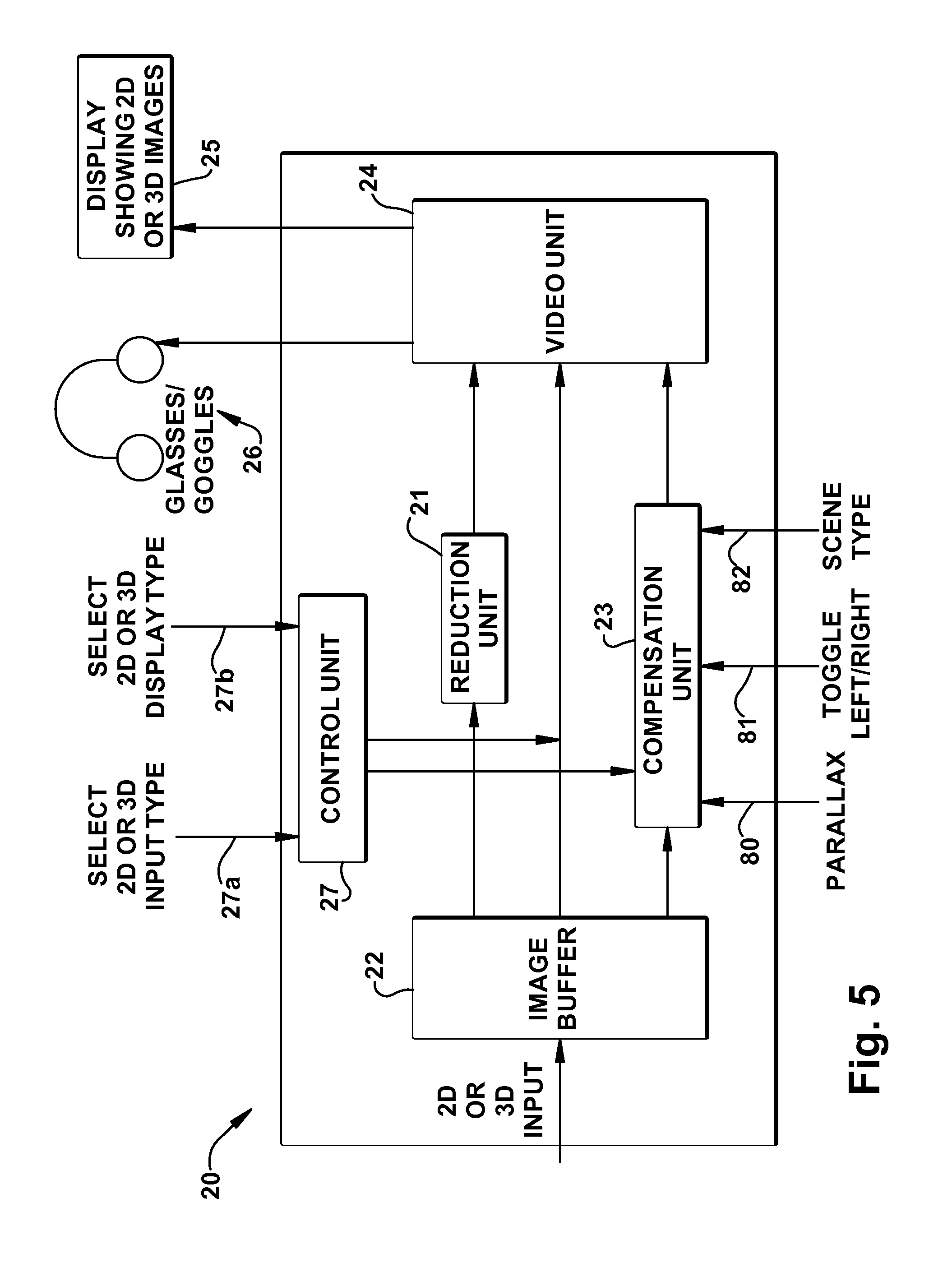

InactiveUS7254265B2Reduce the valueReduce valueCharacter and pattern recognitionSteroscopic systems3d imageVertical motion

A method that improves compensation for hard cuts and / or vertical motion effects in the conversion of 2D images to 3D images, displays 2D images to one eye and computed images to the other eye. Generating the computed images includes using an approximation variable that represents some relationship between the 2D images, such as the speed of motion across two images. Compensating for the hard cut or vertical motion effect includes temporarily setting the approximation variable to a value that makes the left and right eye images more similar (if identical, displaying a 2D image). The approximation variable can be pre-set to a value based on the speed of motion in a scene to be displayed. A method of displaying images in either 2D or 3D may include converting 3D images to 2D images by displaying images computed from images intended for either the left eye or the right eye.

Owner:PHOENIX 3D

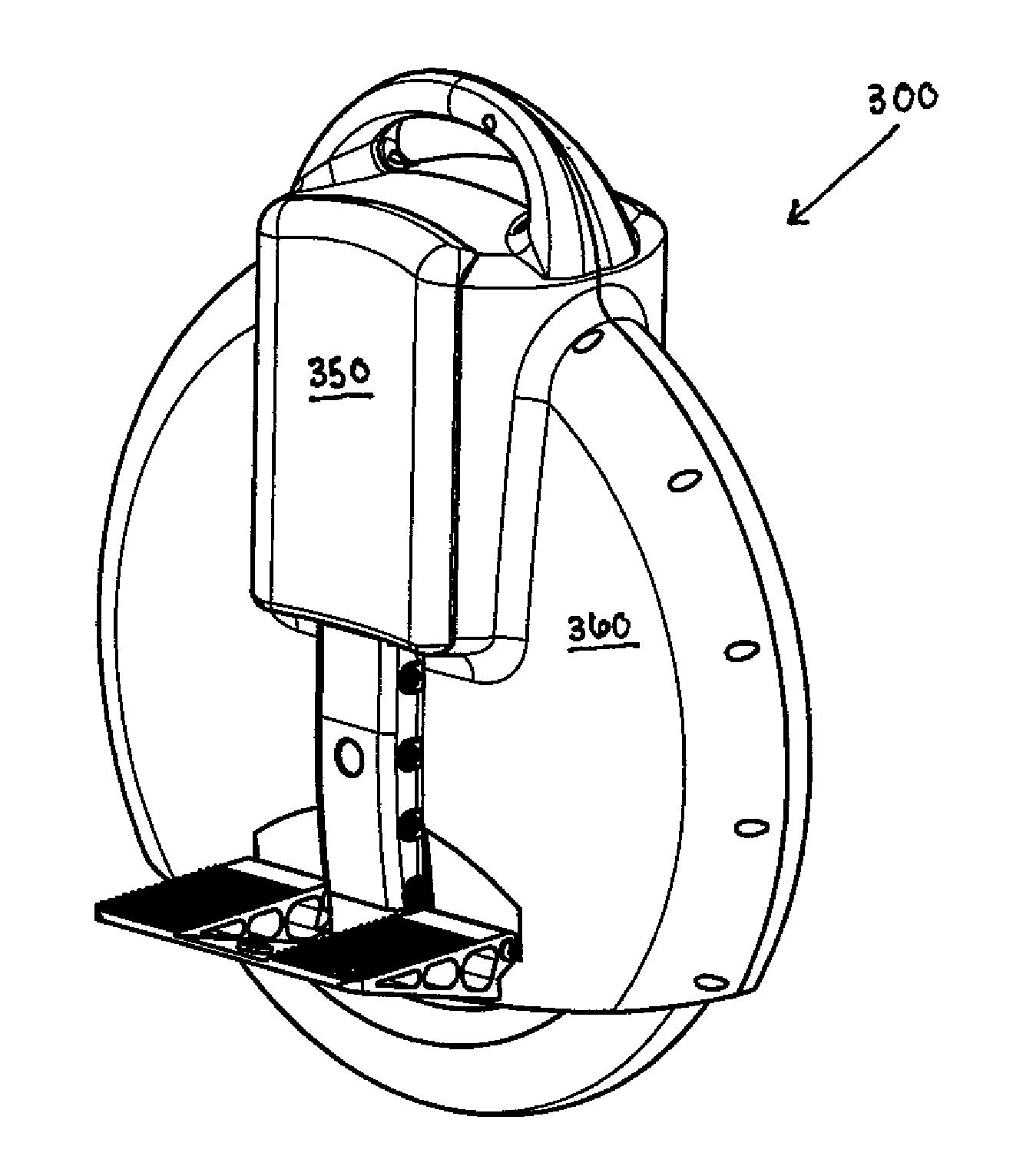

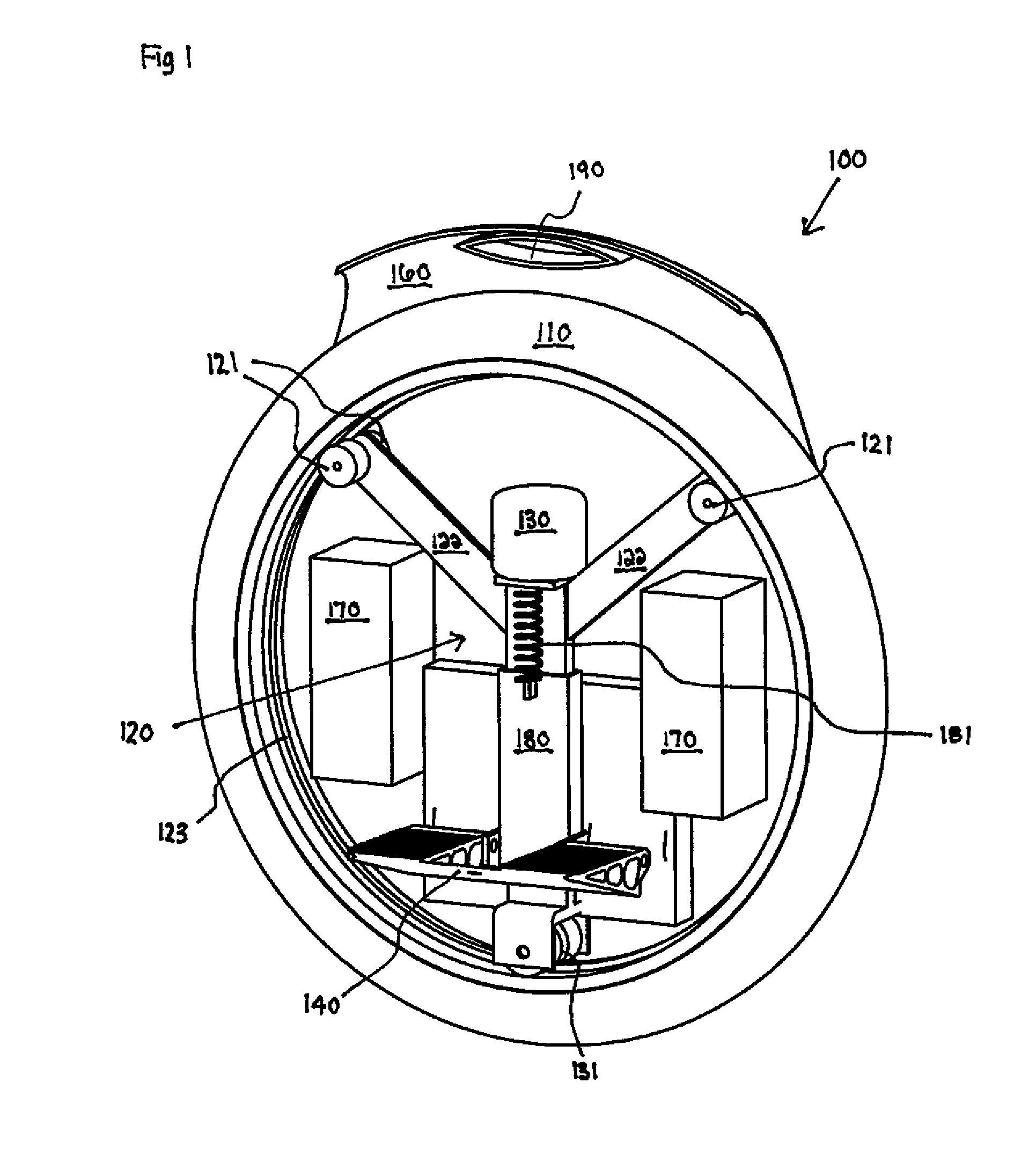

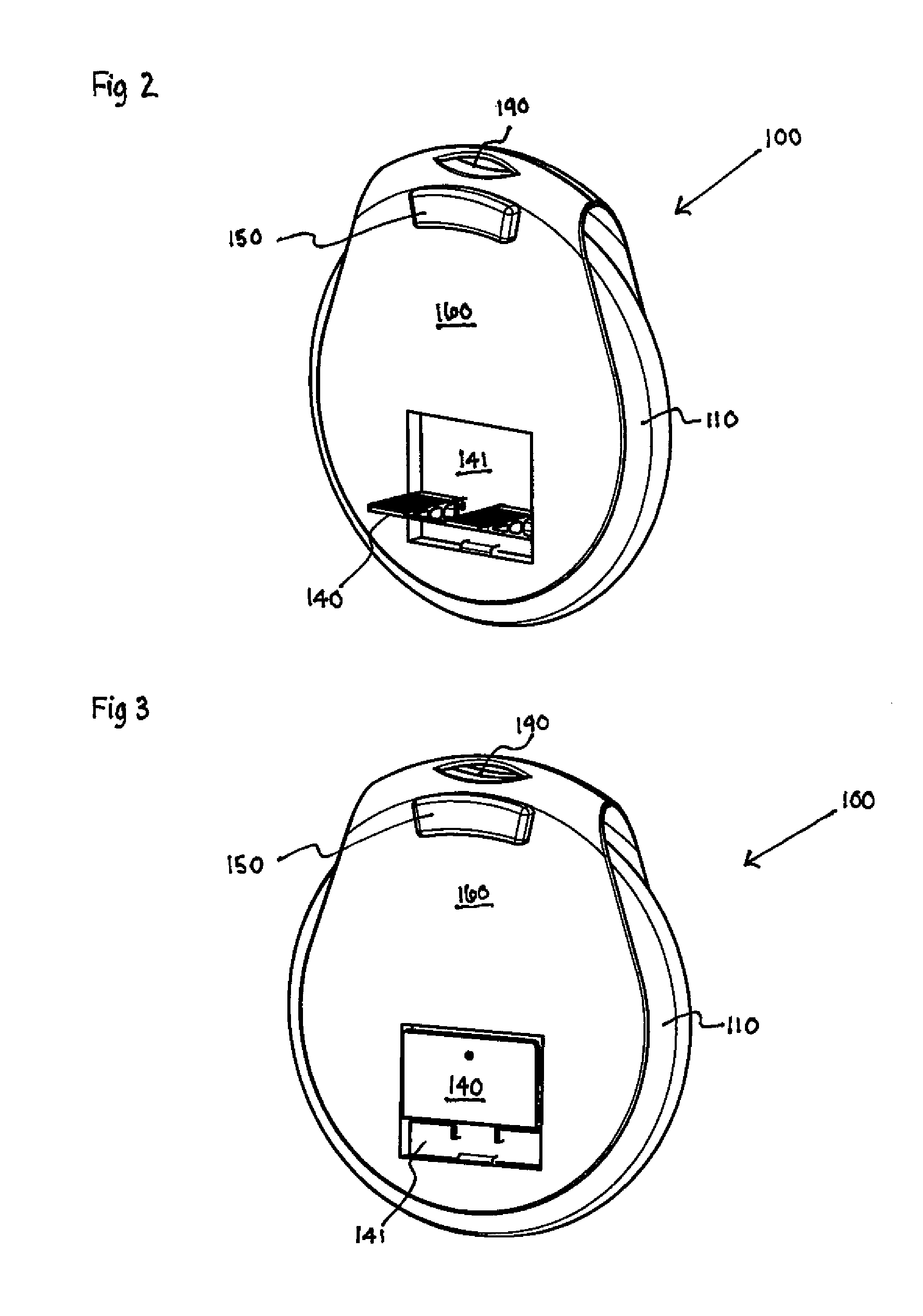

Powered single-wheeled self-balancing vehicle for standing user

ActiveUS8807250B2Less to manufactureEasy to useUnicyclesElectric propulsion mountingDrive wheelGyroscope

Owner:SHANE CHEN

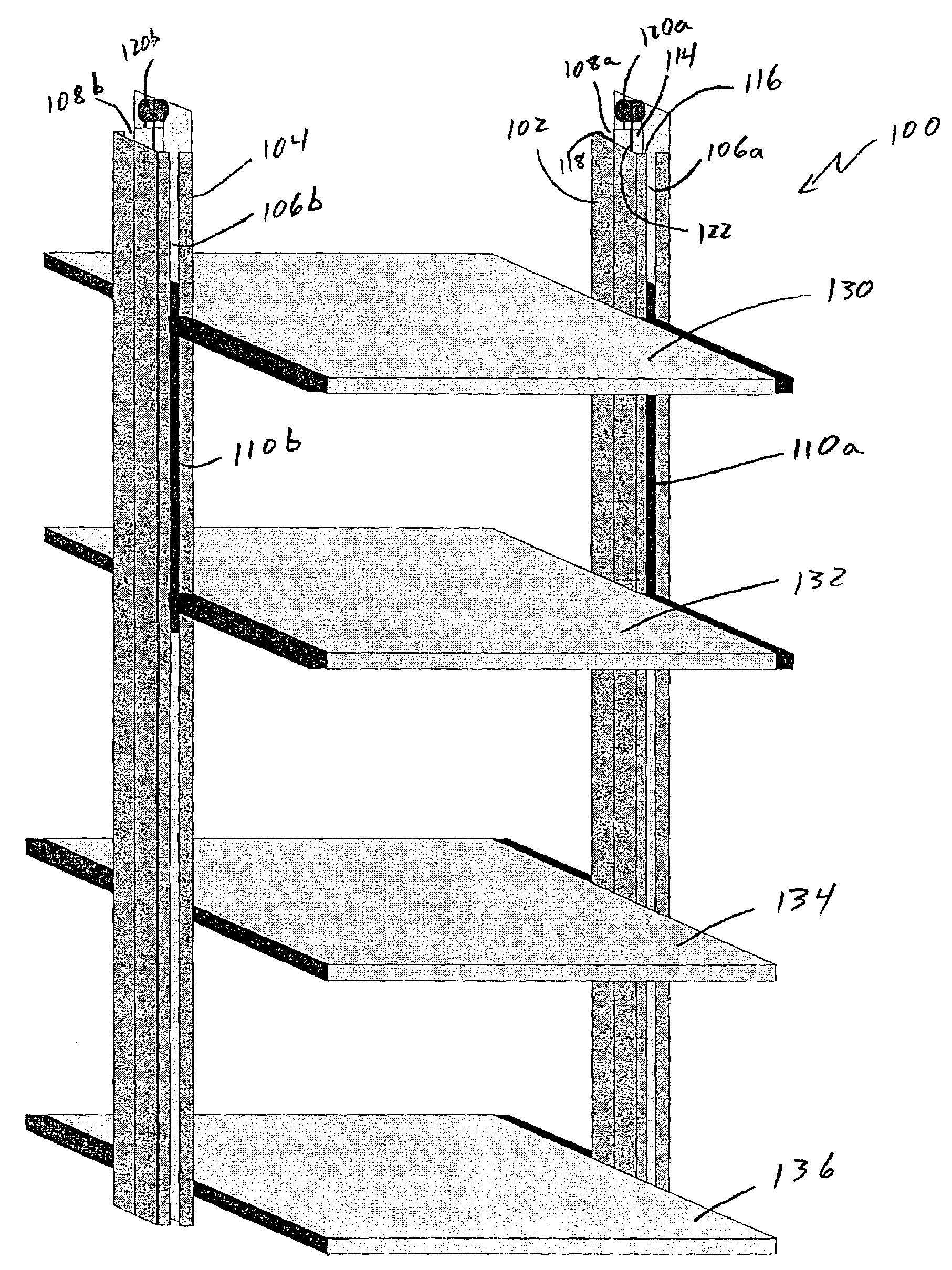

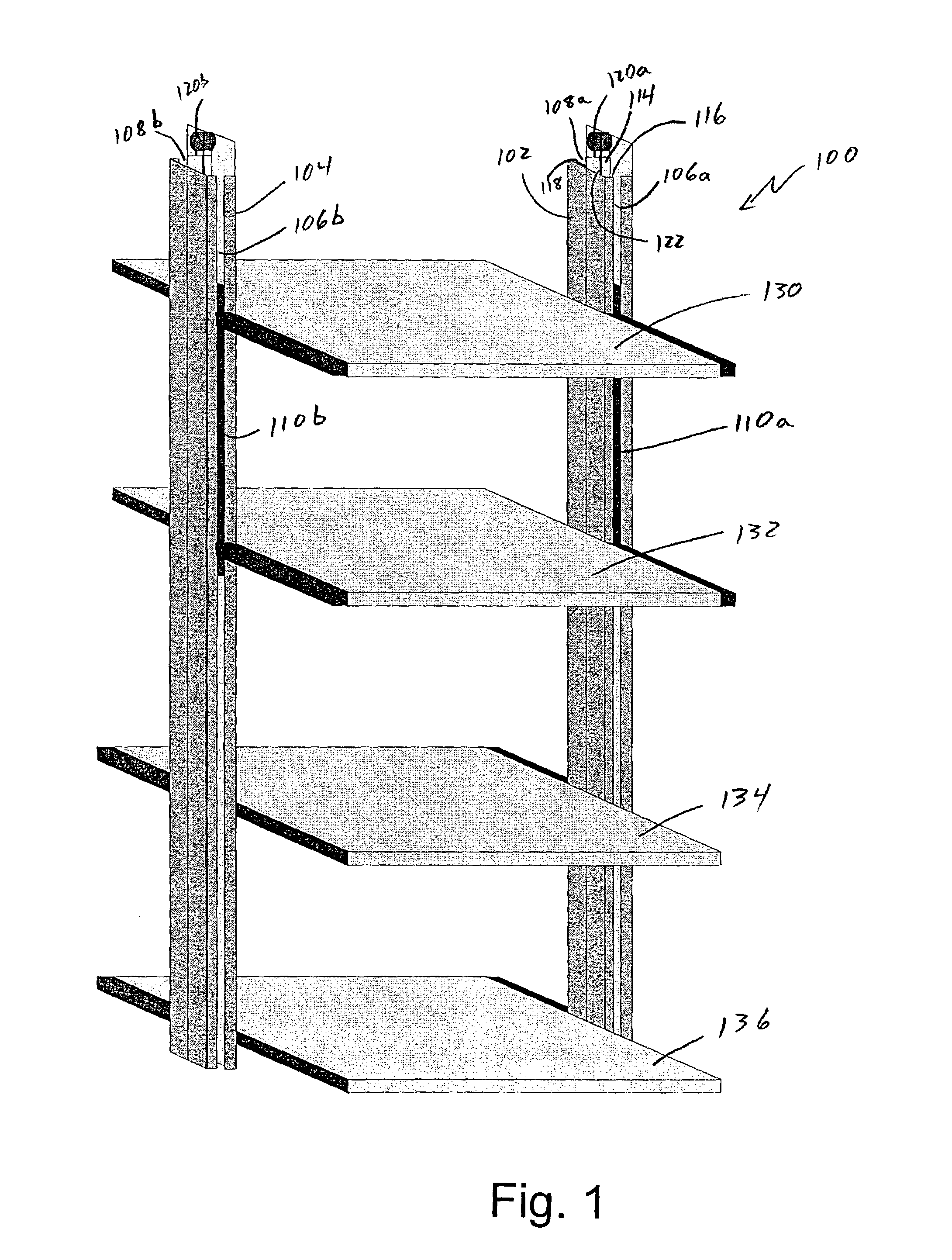

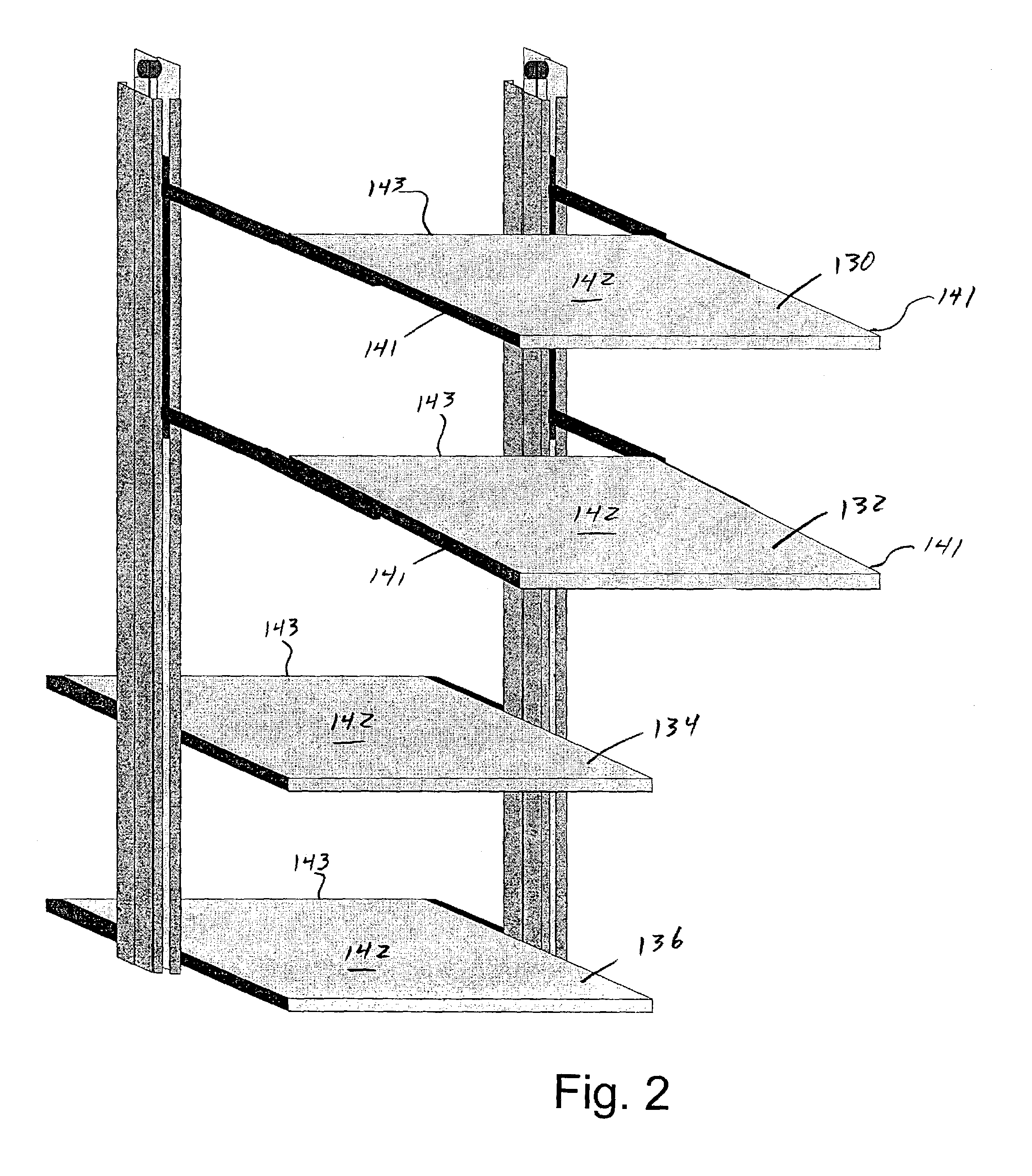

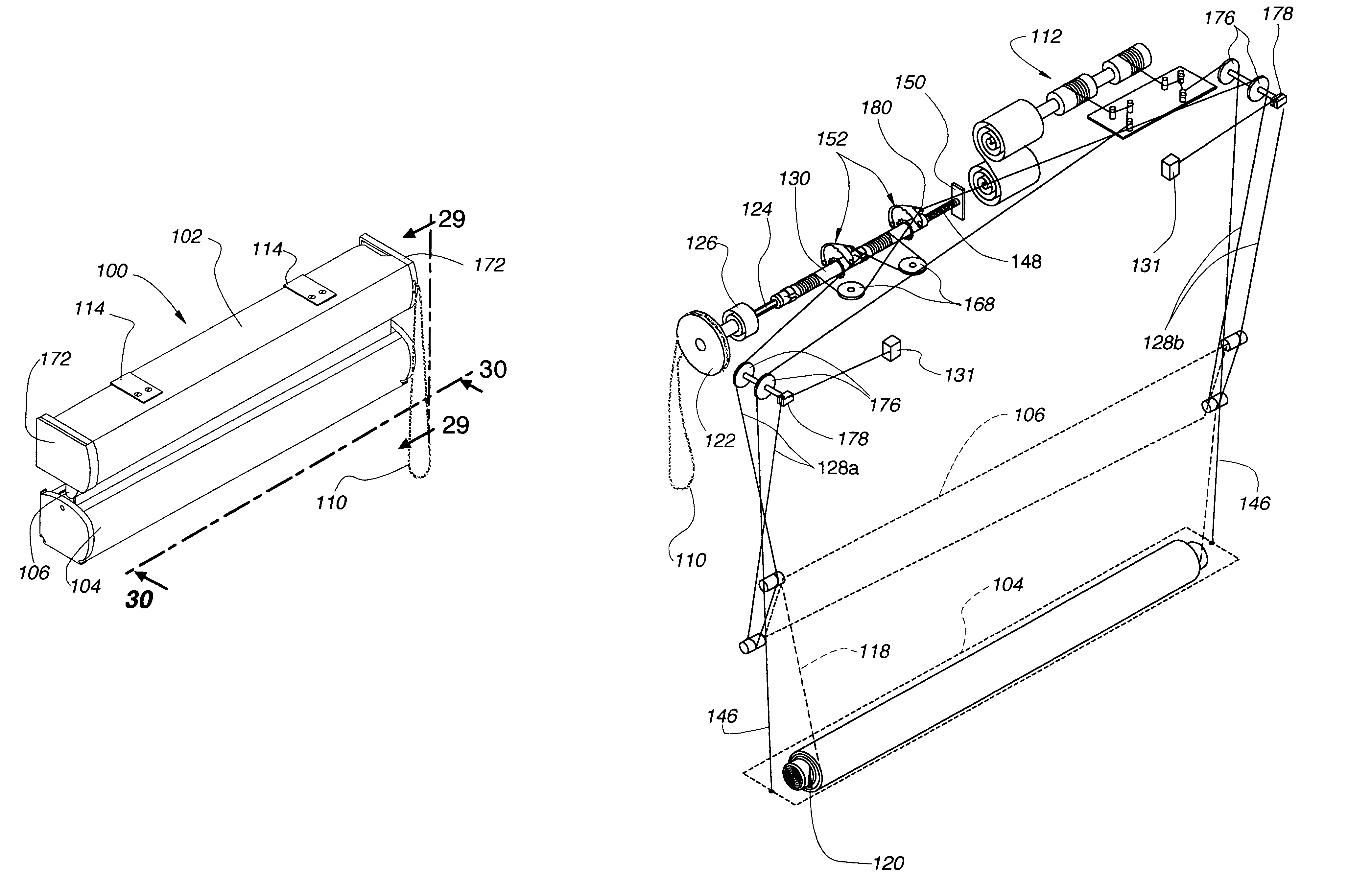

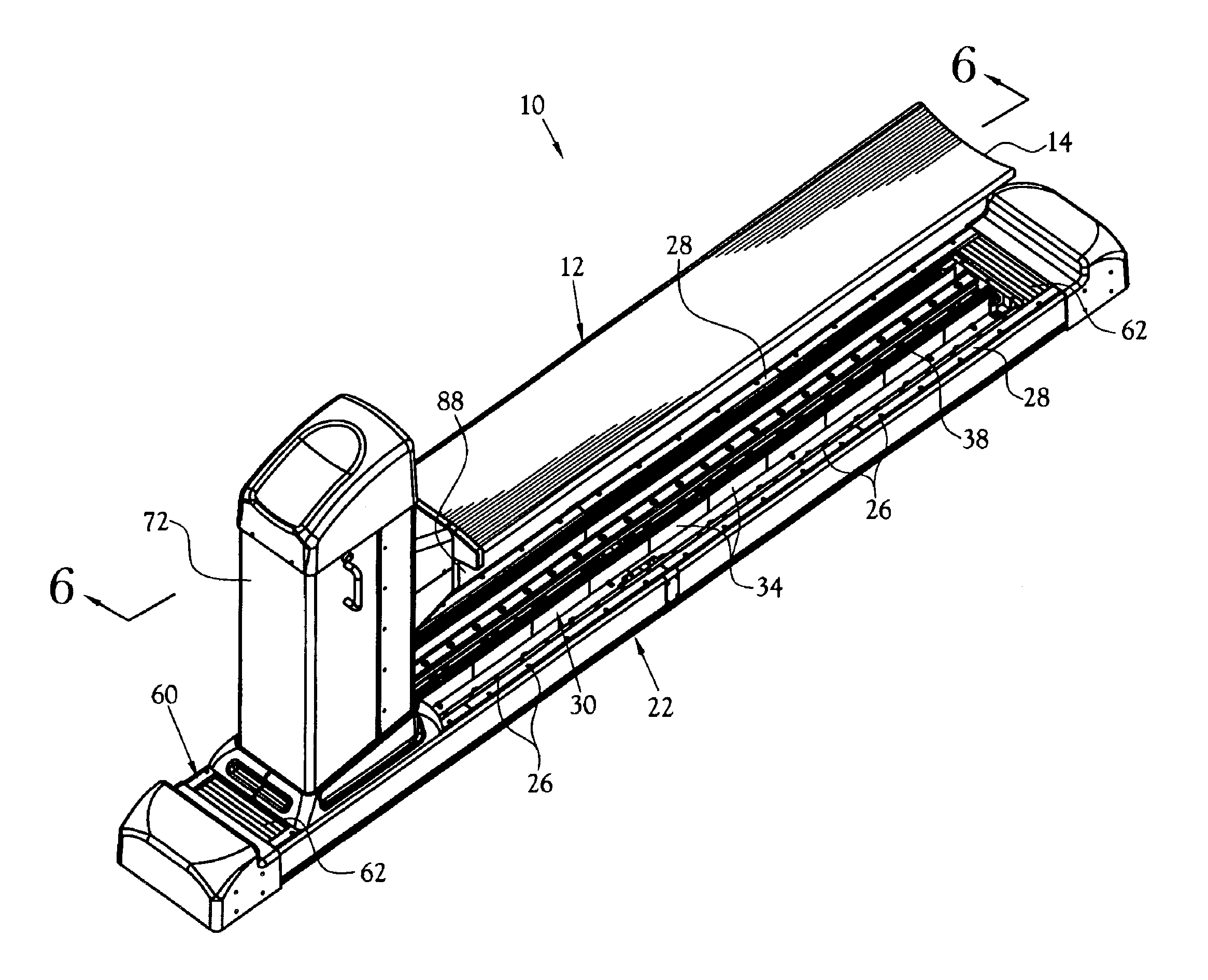

Shelving system

InactiveUS6976598B2Easy accessEfficient and reliableFolding cabinetsDismountable cabinetsEngineeringManufacturing cell

The present disclosure provides enhanced storage systems that facilitate efficient storage of, and access to, a variety of items and products. Exemplary systems according to the present disclosure include Mechanisms that permit reliable and efficient repositioning of one or more shelves, thereby enhancing utilization and efficiencies associated therewith. Shelving systems facilitate synchronized vertical motion of shelving units, e.g., based on coordinated pulley / cable systems, and advantageously include spring designs that facilitate controlled vertical motion of shelving units, e.g., based on fluid movement and / or discharge from the spring design. Shelves and / or shelving units may be readily repositioned at elbow or eye level, and repositioned at their respective initial positions in an efficient and advantageous manner. The shelving systems may be original manufacture units or may be designed for use in retrofitting existing shelving systems.

Owner:ENGEL ZACKARY

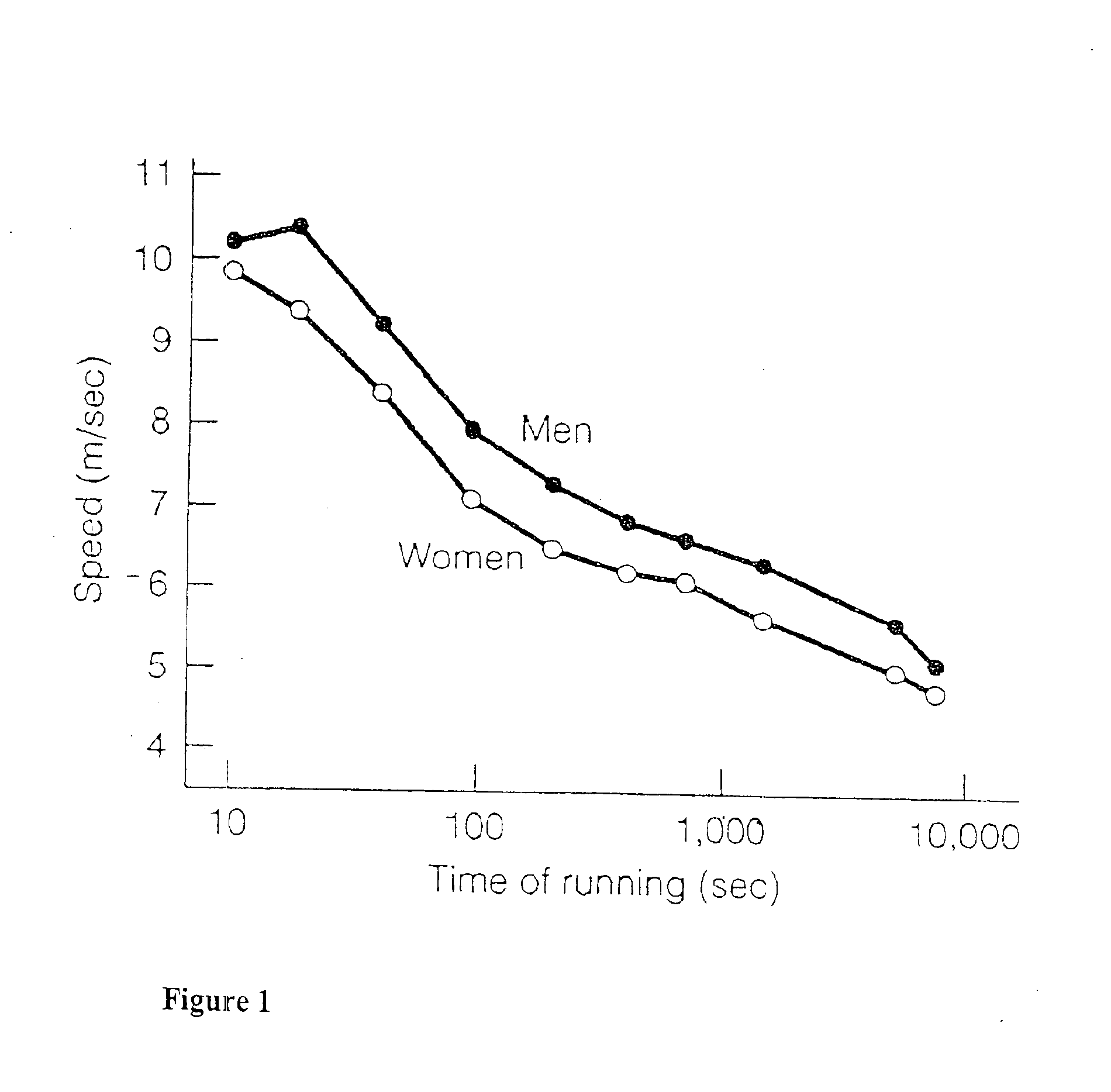

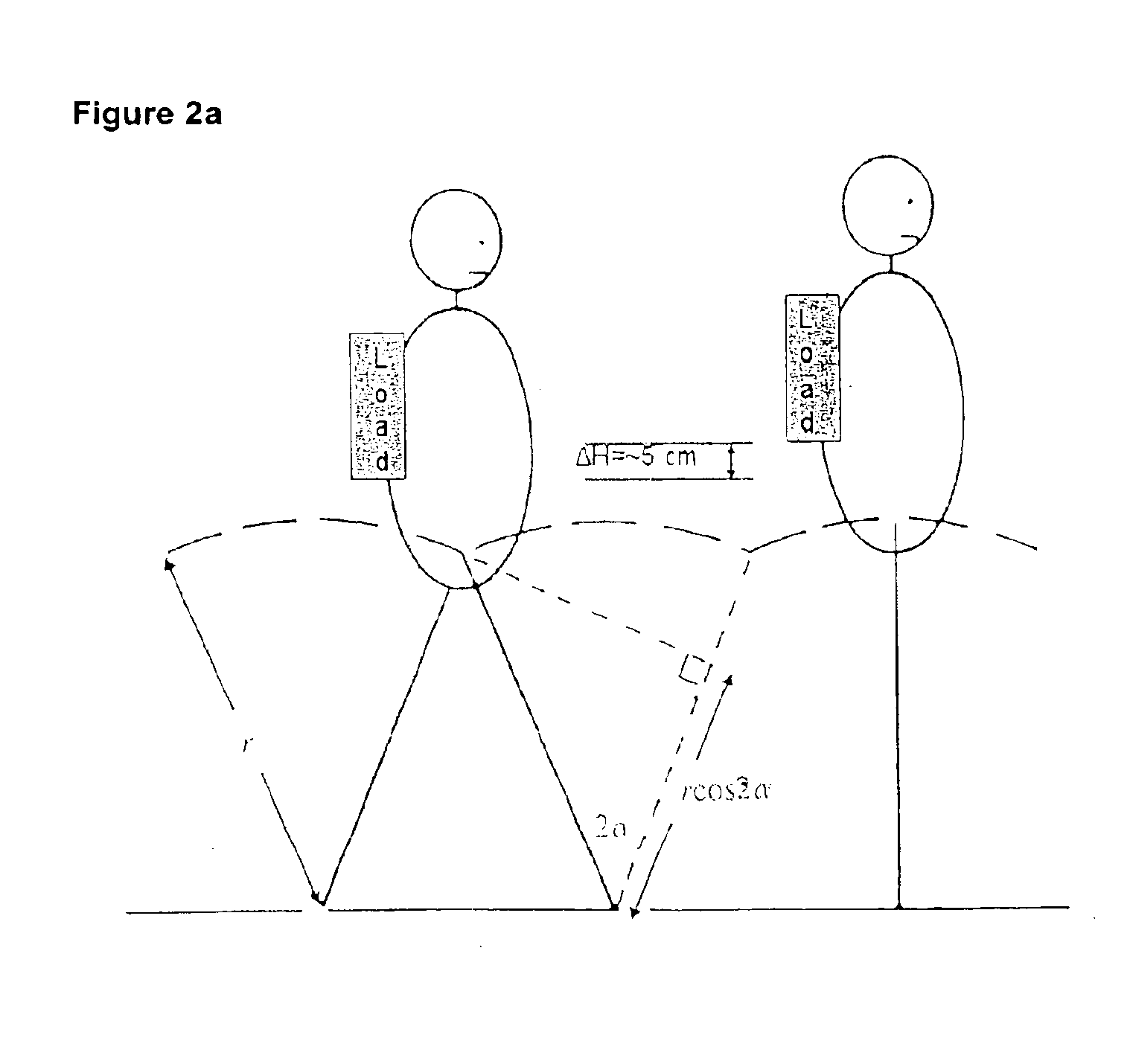

Backpack for harvesting electrical energy during walking and for minimizing shoulder strain

ActiveUS6982497B2Large movementReduce absolute vertical motionTravelling sacksPursesGear wheelShoulder strain

Owner:LIGHTNING PACKS

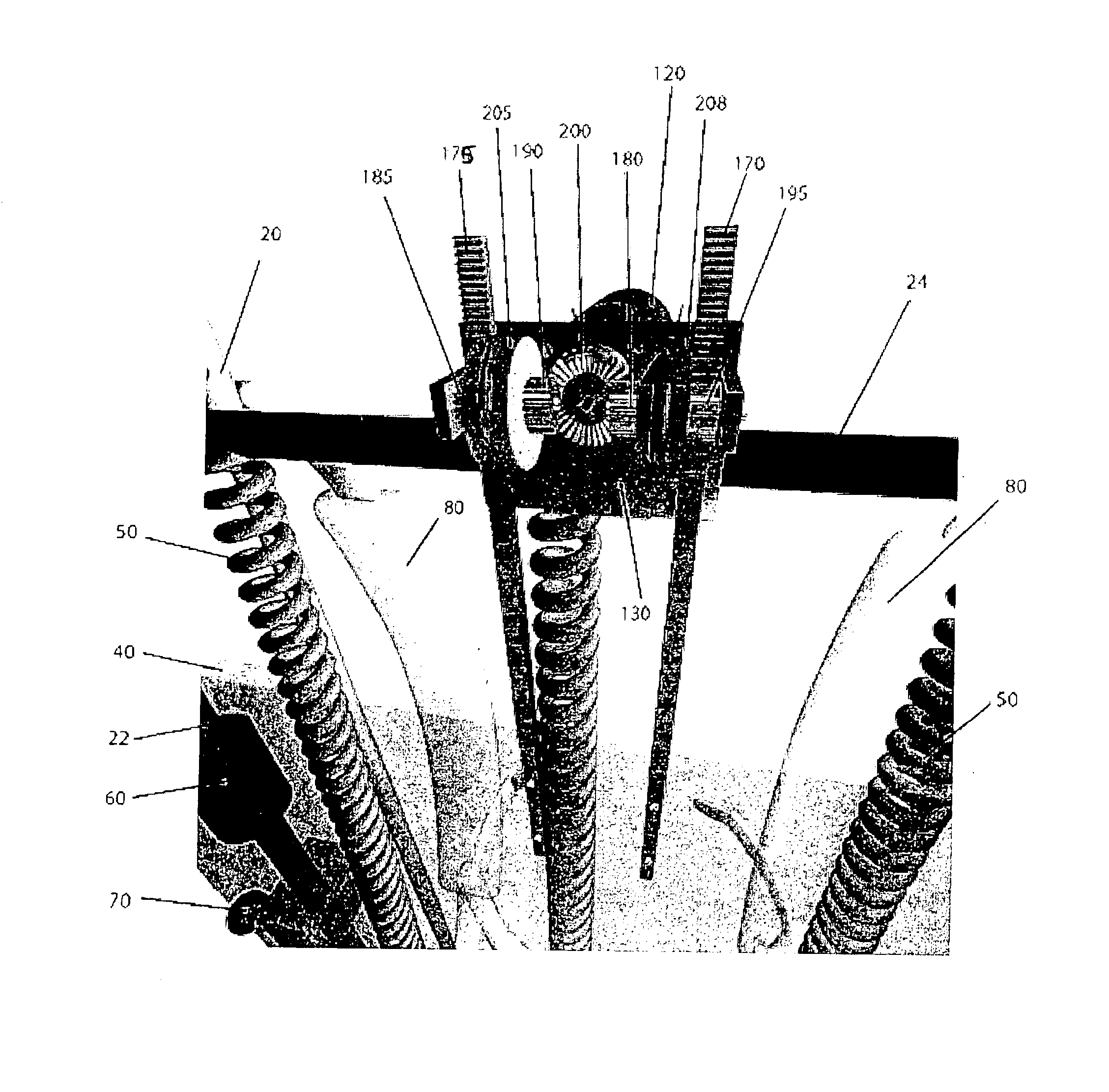

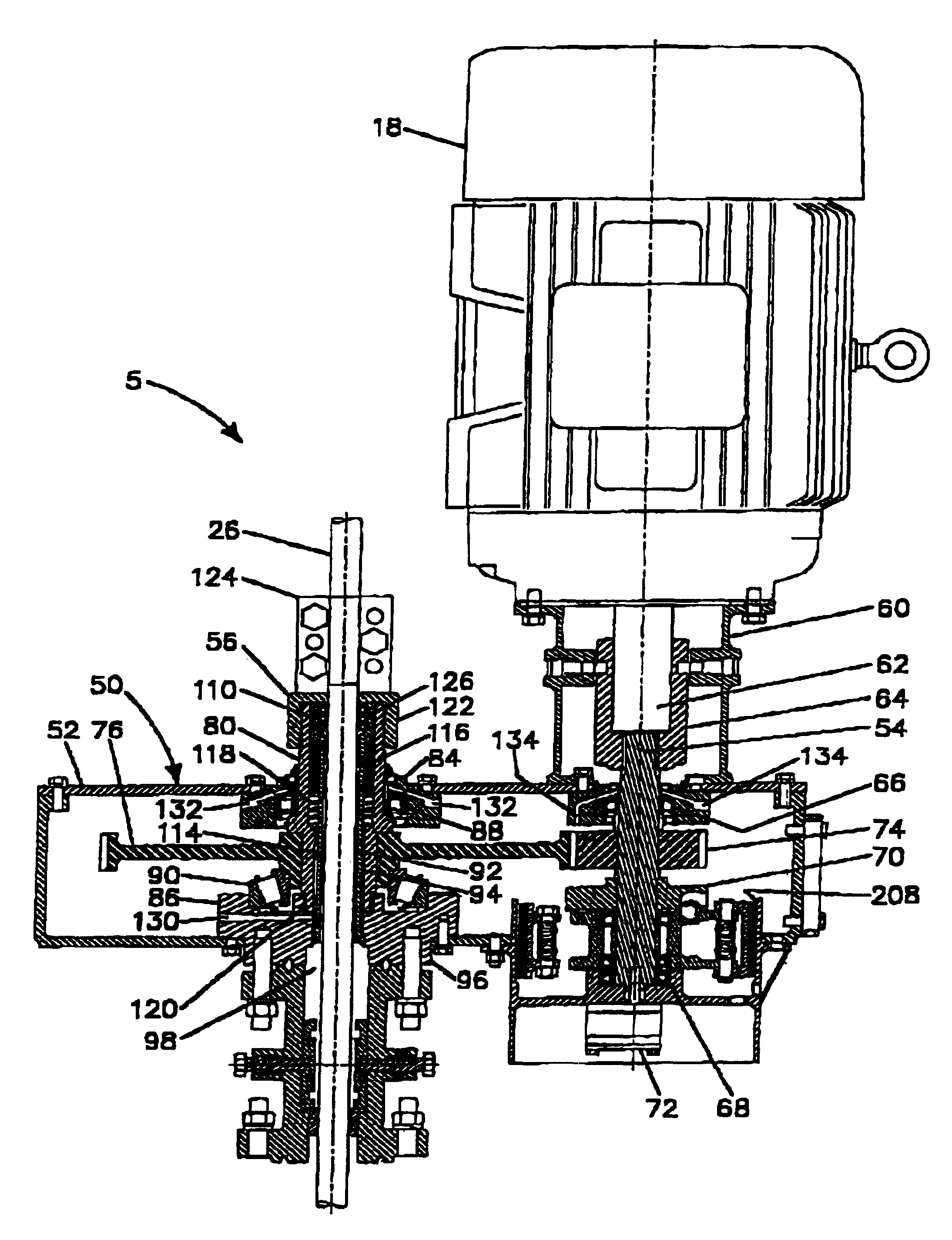

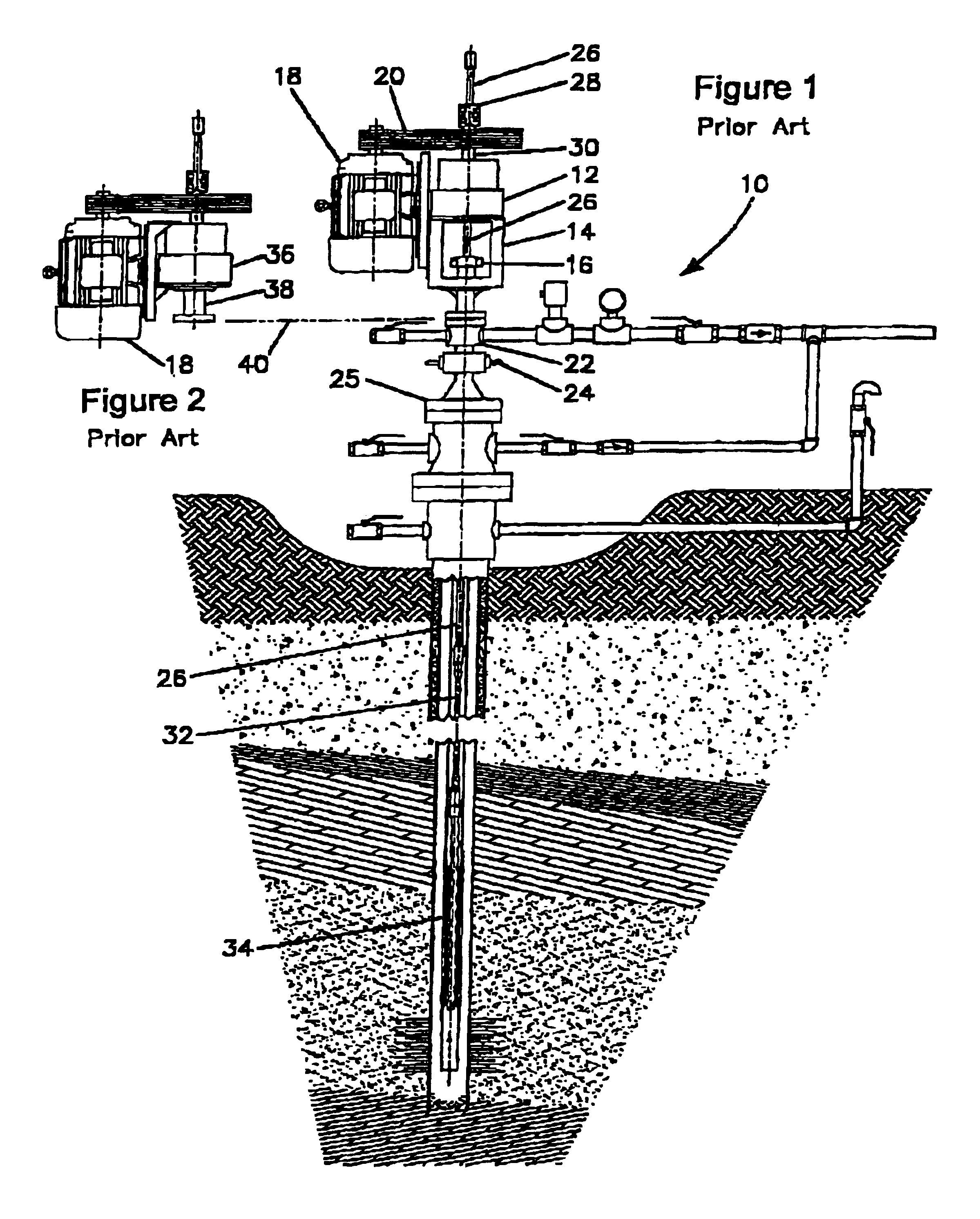

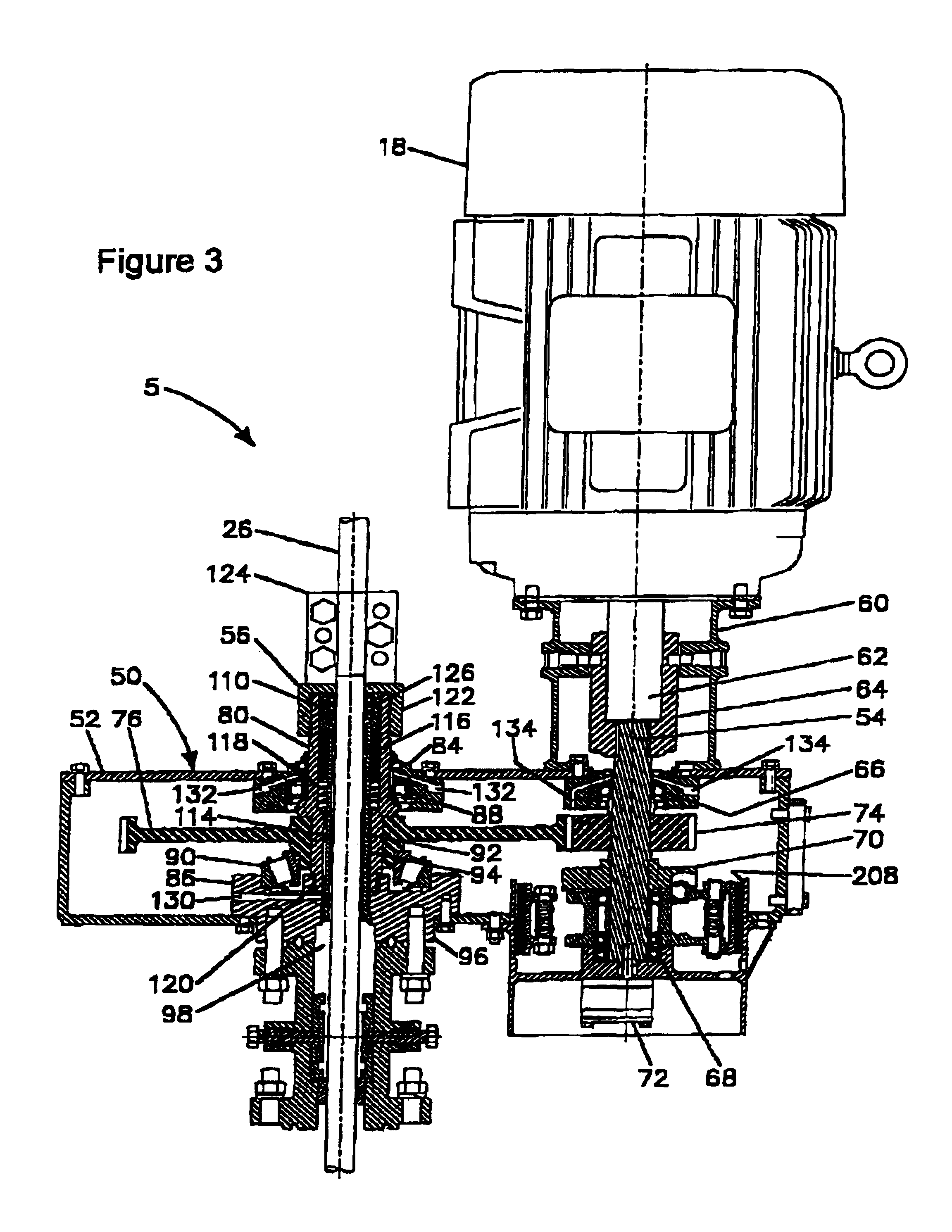

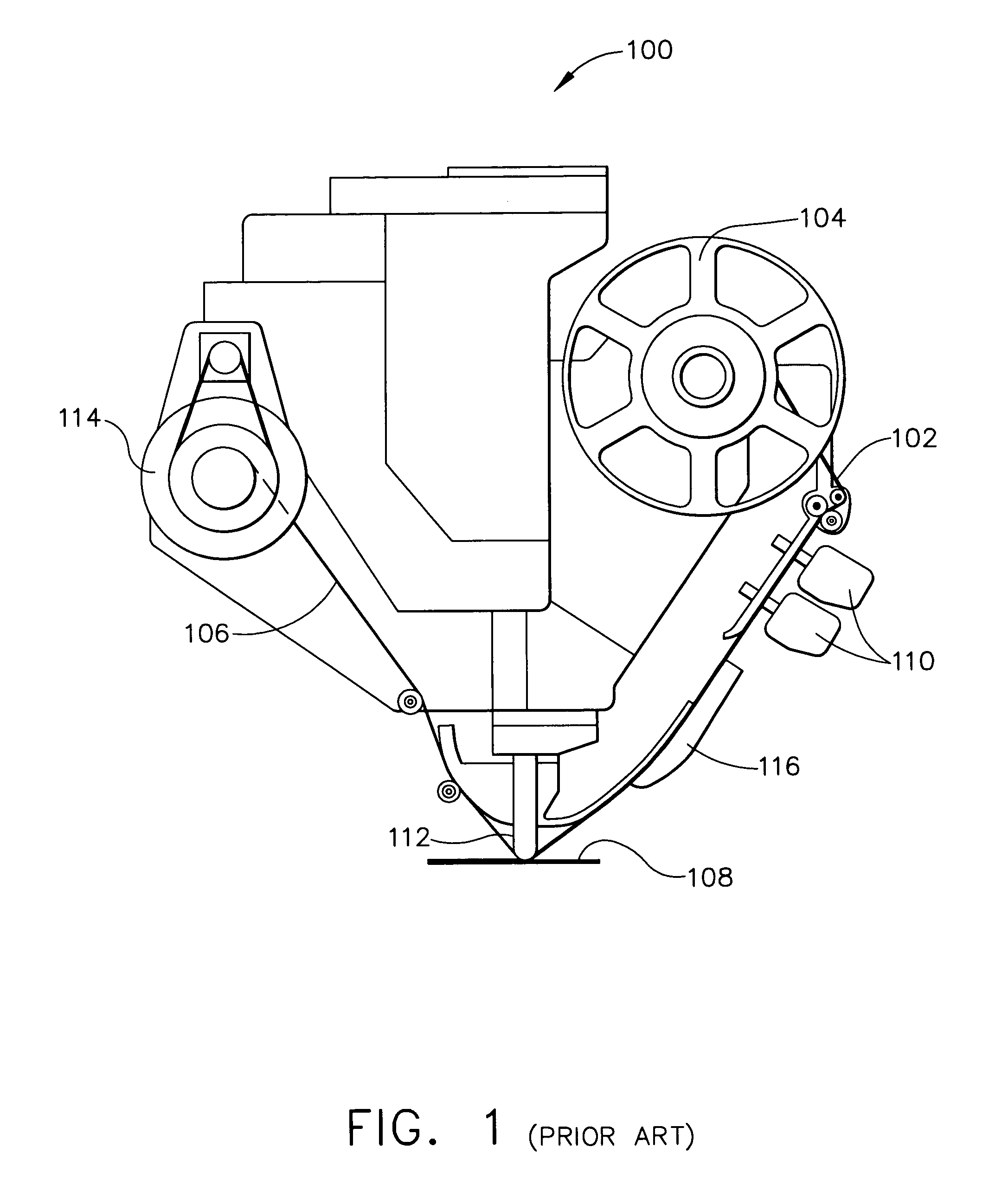

Pump drive head with stuffing box

InactiveUS6843313B2Eliminating belt tensioningEliminate replacementDrilling rodsFluid removalGear driveEngineering

A pump drive head for a progressing cavity pump comprises a top mounted stuffing box rotatably disposed around a compliantly mounted standpipe with a self or manually adjusting pressurization system for the stuffing box. To prevent rotary and vertical motion of the polish rod while servicing the stuffing box, a polished rod lock-out clamp is provided with the pump drive head integral with or adjacent to a blow-out-preventer which can be integrated with the pump drive head to save space and cost. A centrifugal backspin braking system located on the input shaft and actuated only in the backspin direction and a gear drive between the input shaft and output shaft are provided.

Owner:OIL ELEVATOR TECH

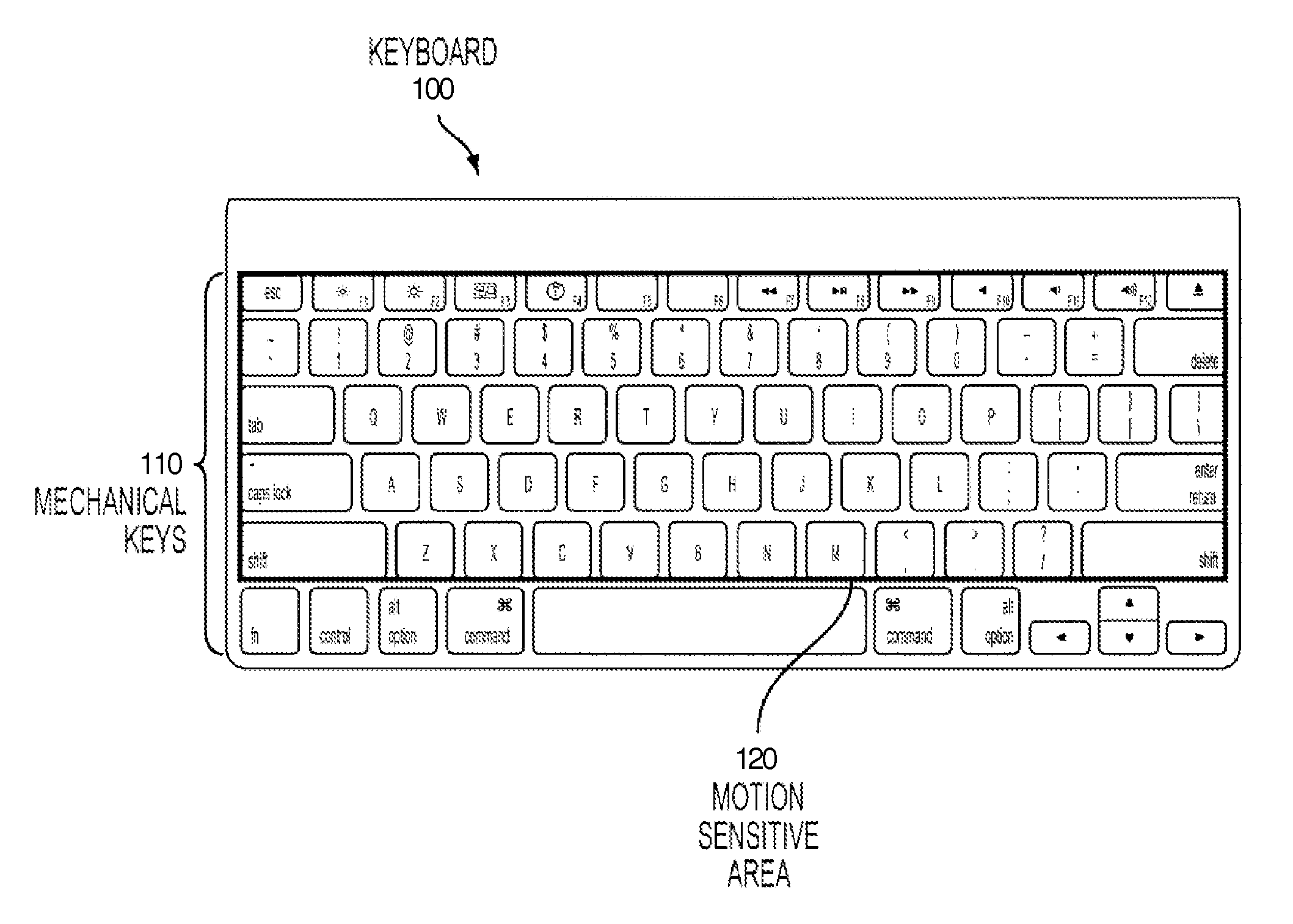

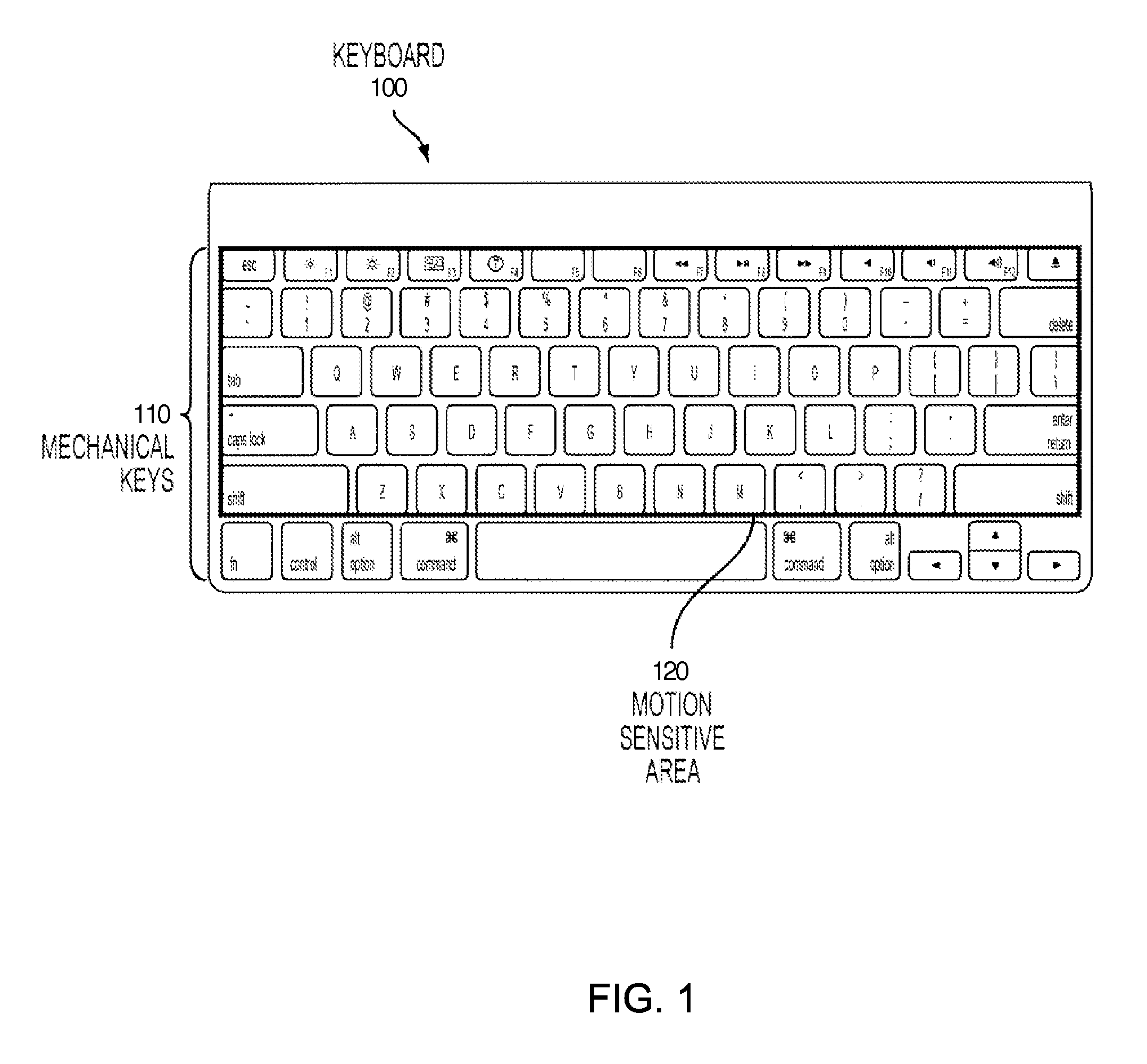

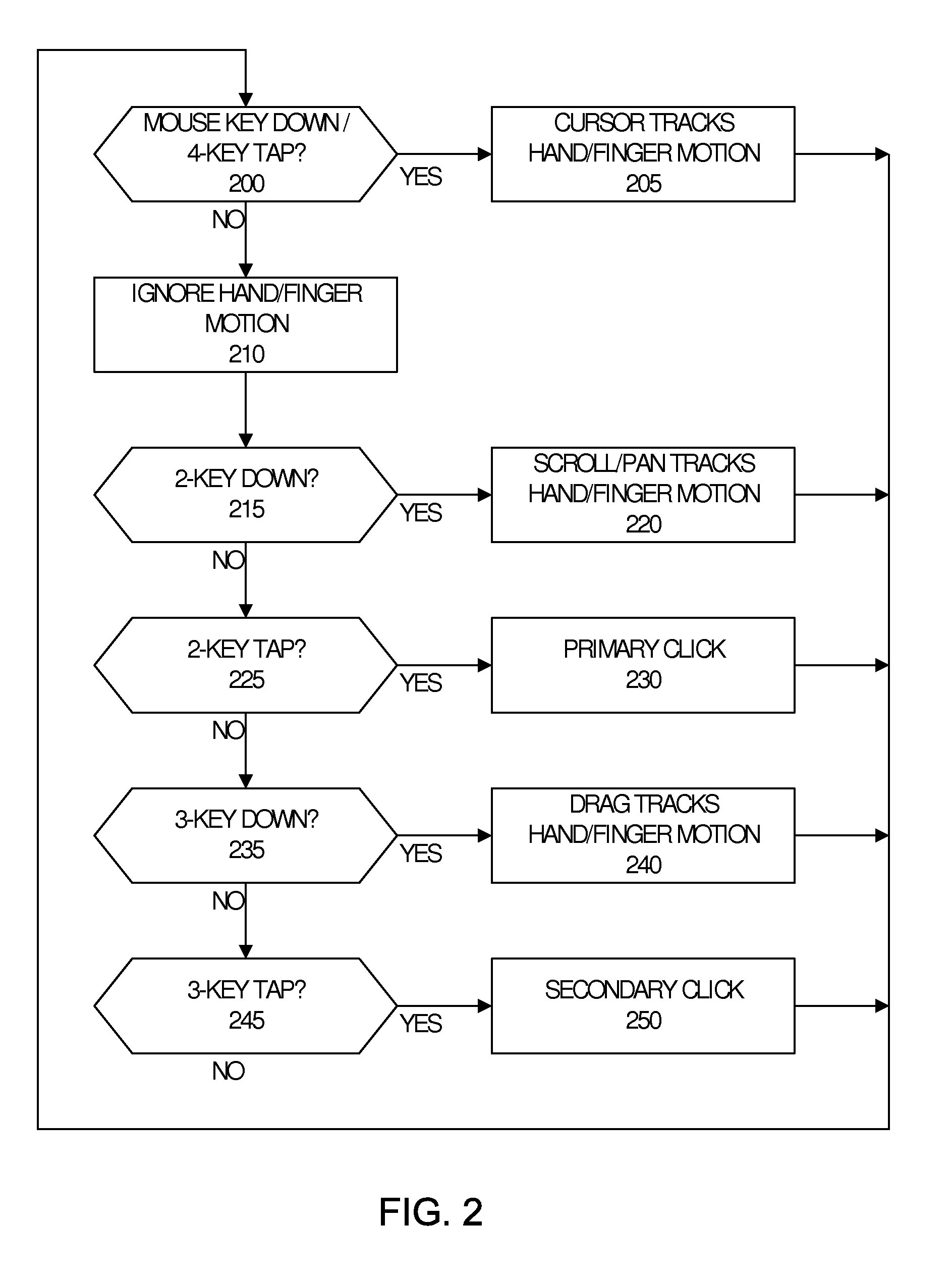

Image Processing for Camera Based Motion Tracking

InactiveUS20110006991A1Improves user interface experienceMinimize and remove undesirable cursor movementInput/output for user-computer interactionDigital data processing detailsImaging processingComputer graphics (images)

Image processing techniques that can improve the user interface experience associated with key-based input devices. In one embodiment, a motion sensitive mechanical keyboard can utilize orthogonally-oriented cameras to sense hand / finger motion over the surface of the keys. This arrangement can enable a standard look and feel mechanical keyboard to receive command and cursor input (e.g., pointing and gestures) from the user without requiring the user to move the user's hand off the keyboard. The image processing techniques can be utilized to minimize or remove undesirable cursor movement that can occur based on certain detected hand / finger motion from such cameras, including looming and / or vertical motions for example.

Owner:APPLE INC

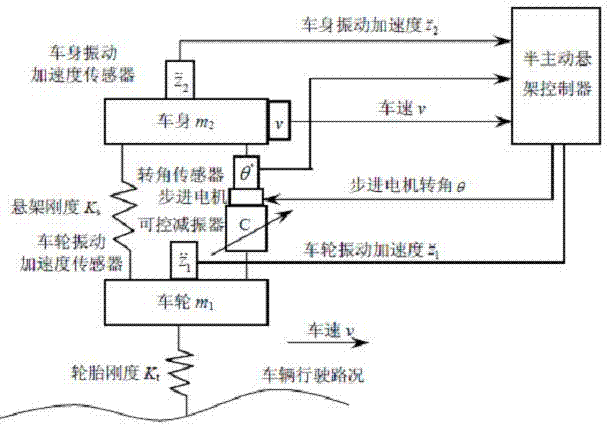

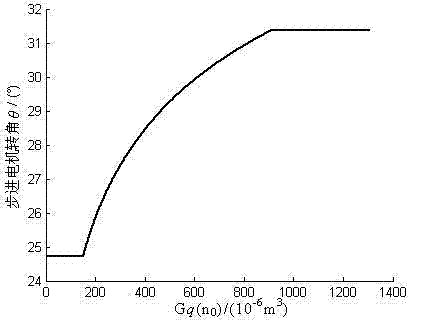

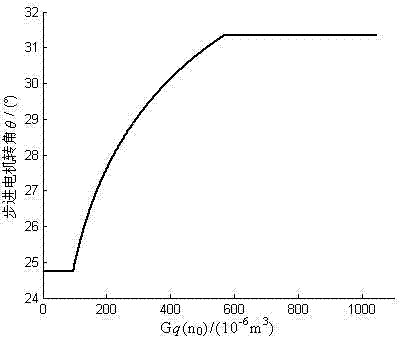

Real-time optimal damping control algorithm of automobile semi-active suspension system

InactiveCN102729760AImprove performanceSolve ride comfortResilient suspensionsVibration accelerationControl signal

The invention relates to an optimal damping control algorithm of a continuous-control-type semi-active suspension system, and the optimal damping control algorithm is researched and developed for meeting the taking comfort of people and automobile driving safety requirements well. The control algorithm comprises the following steps of: measuring automobile body vibration acceleration signals, automobile speed signals and rotation angle signals by utilizing a sensor; sensing the automobile driving road condition and suspension system damping ratio according to the signals measured by the sensor; according to the measured automobile body and automobile wheel vibration acceleration, obtaining the automobile body and automobile wheel vertical motion speed and the relative motion speed between an automobile body and automobile wheels; determining the optimal damping coefficient and the damping force of a shock absorber required under the current automobile speed and road condition according to automobile parameters, outputting stepping motor rotation angle control signals through a controller, and controlling and regulating the area of the damping throttling hole of a controllable shock absorber, so that the semi-active suspension system achieves the required optimal damping and damping force. The semi-active suspension optimal damping control algorithm provided by the invention is simple and easy to implement, has low requirements for the dynamic property of an actuating element, and is beneficial to the applications and popularization of the semi-active suspension.

Owner:SHANDONG UNIV OF TECH

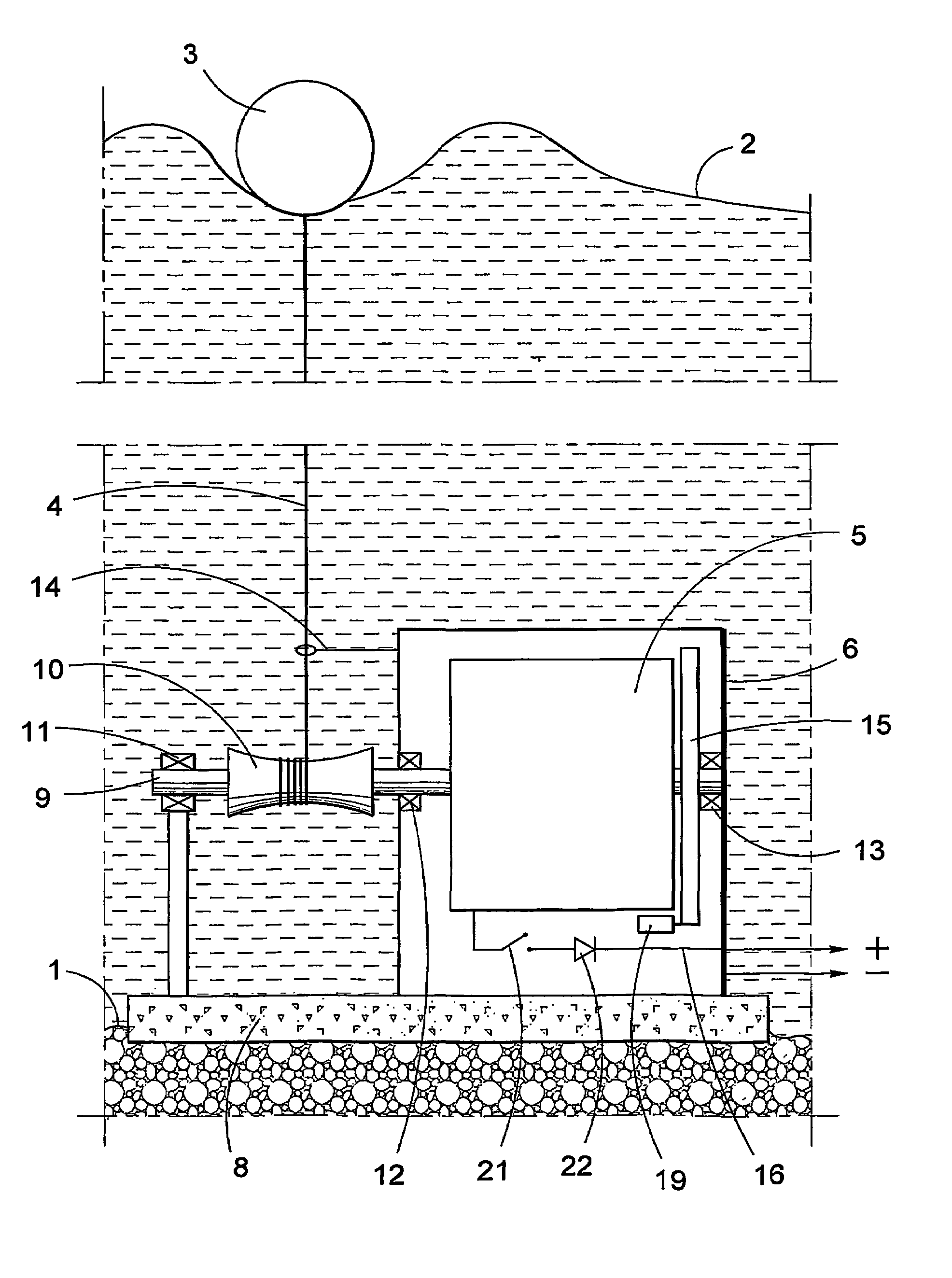

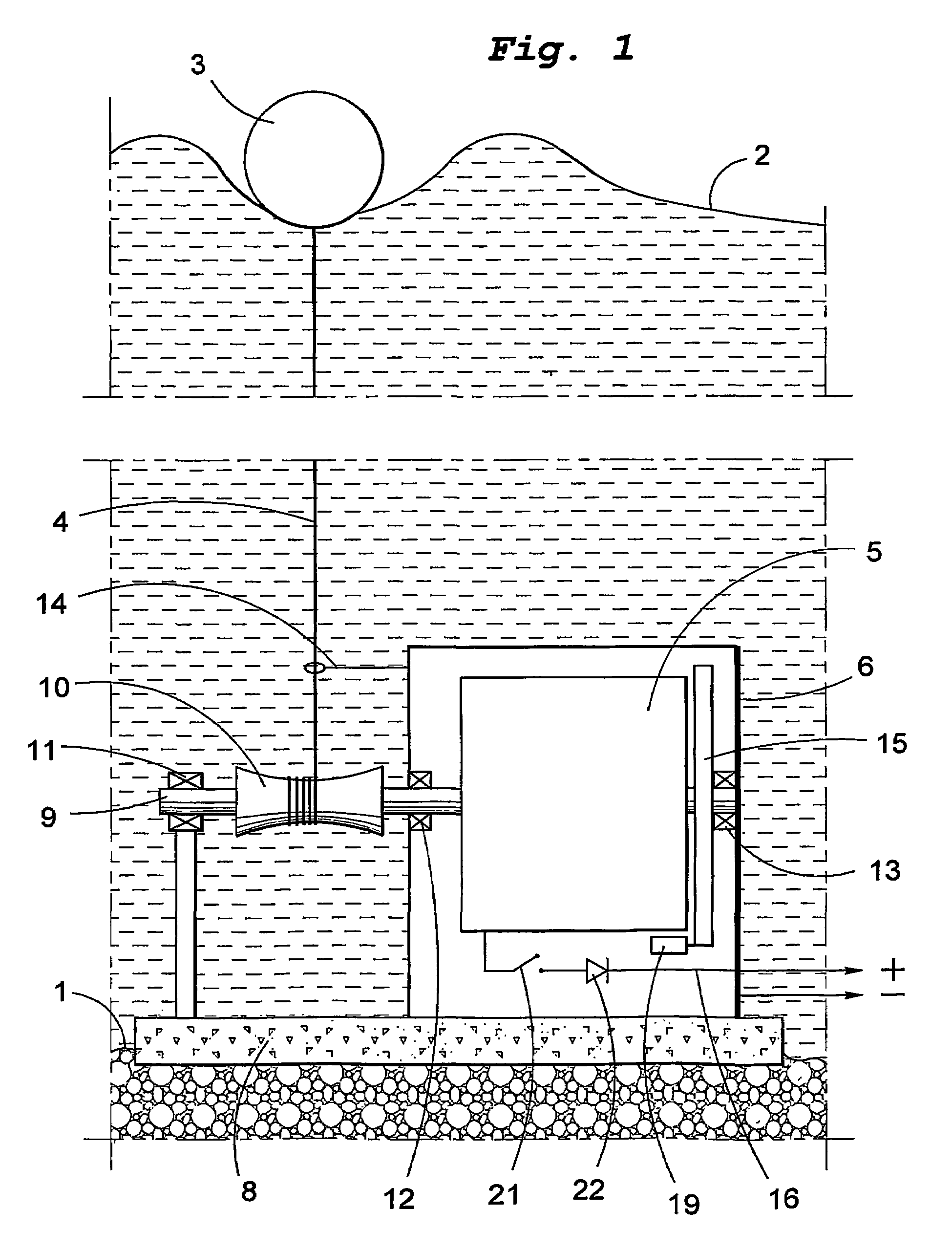

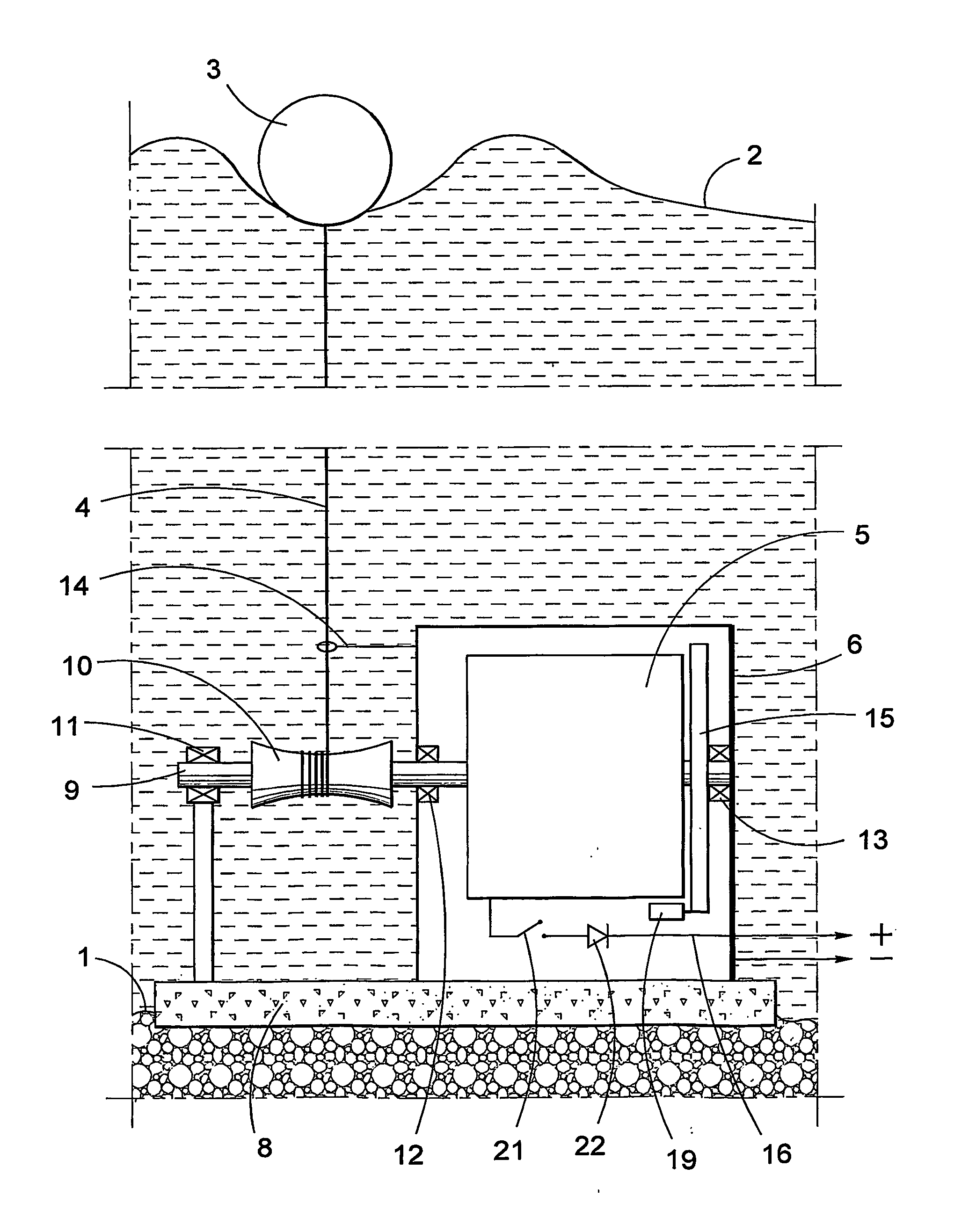

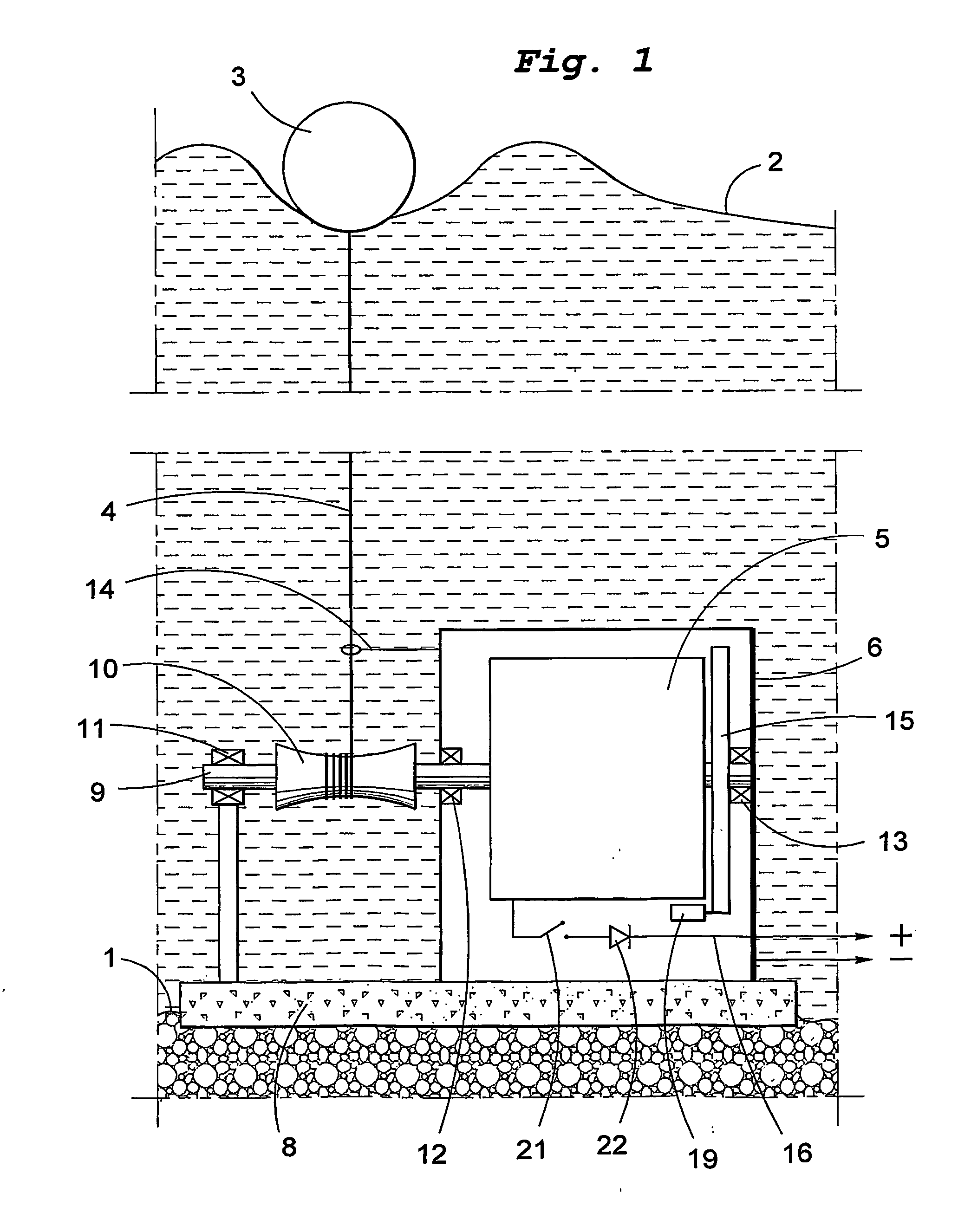

Wave-power electric device and method

InactiveUS7045912B2Improve overall utilizationProtection attackMachines/enginesEngine componentsEngineeringWave power

The present invention relates to a wave-power unit having a floating body (3) and a rotating electric generator (5) mechanically connected to the floating body (3). In accordance with the invention a mechanically movement transmitting means (4) is arranged for transmission of vertical movements of the floating body (3) to rotary movements of the generator rotor. The invention also relates to a wave-power plant composed of a number of wave-power units in accordance with the invention. The invention also relates to the use of the claimed wave-power unit and method of generating electric energy.

Owner:SEABASED AB

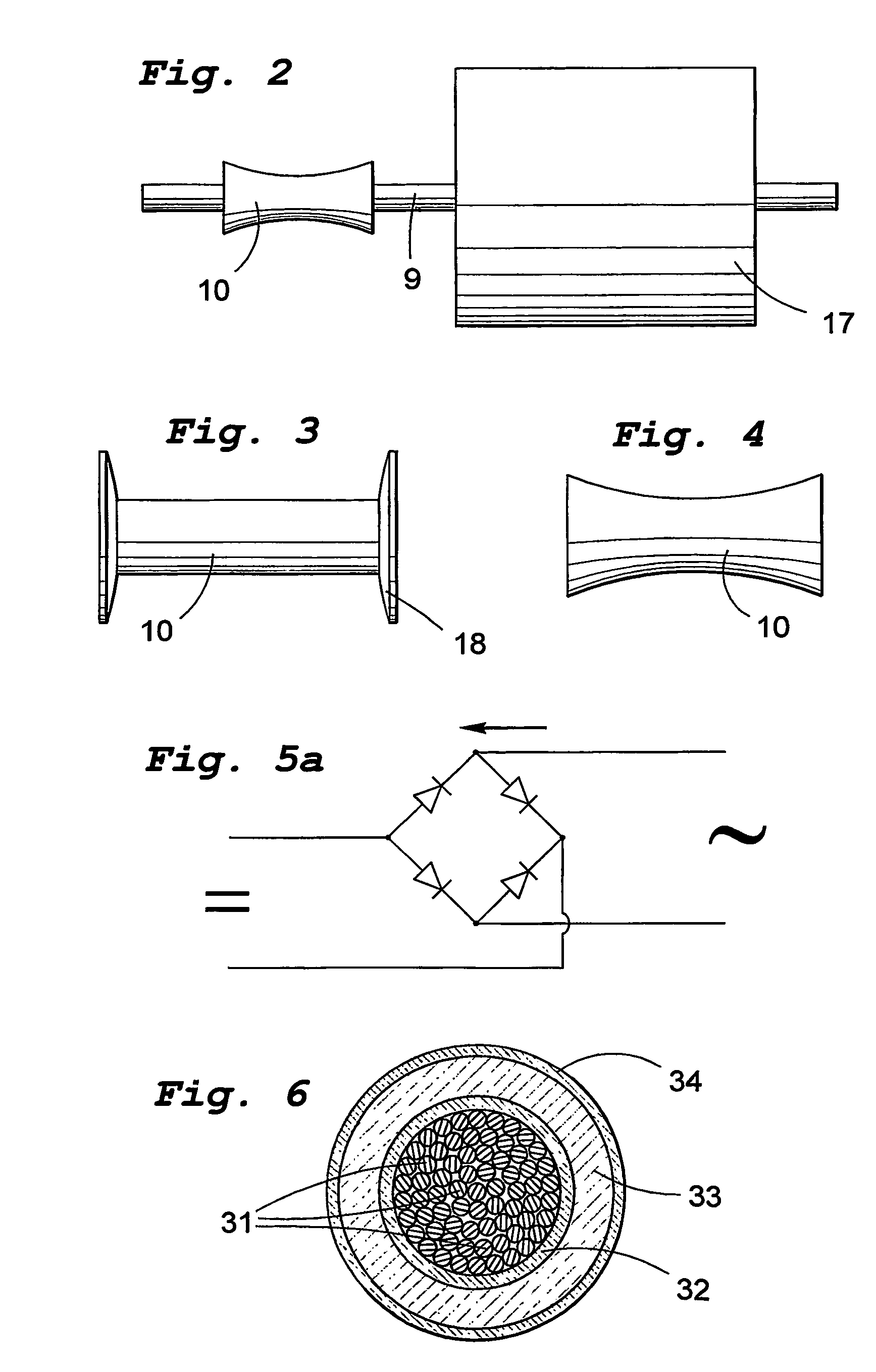

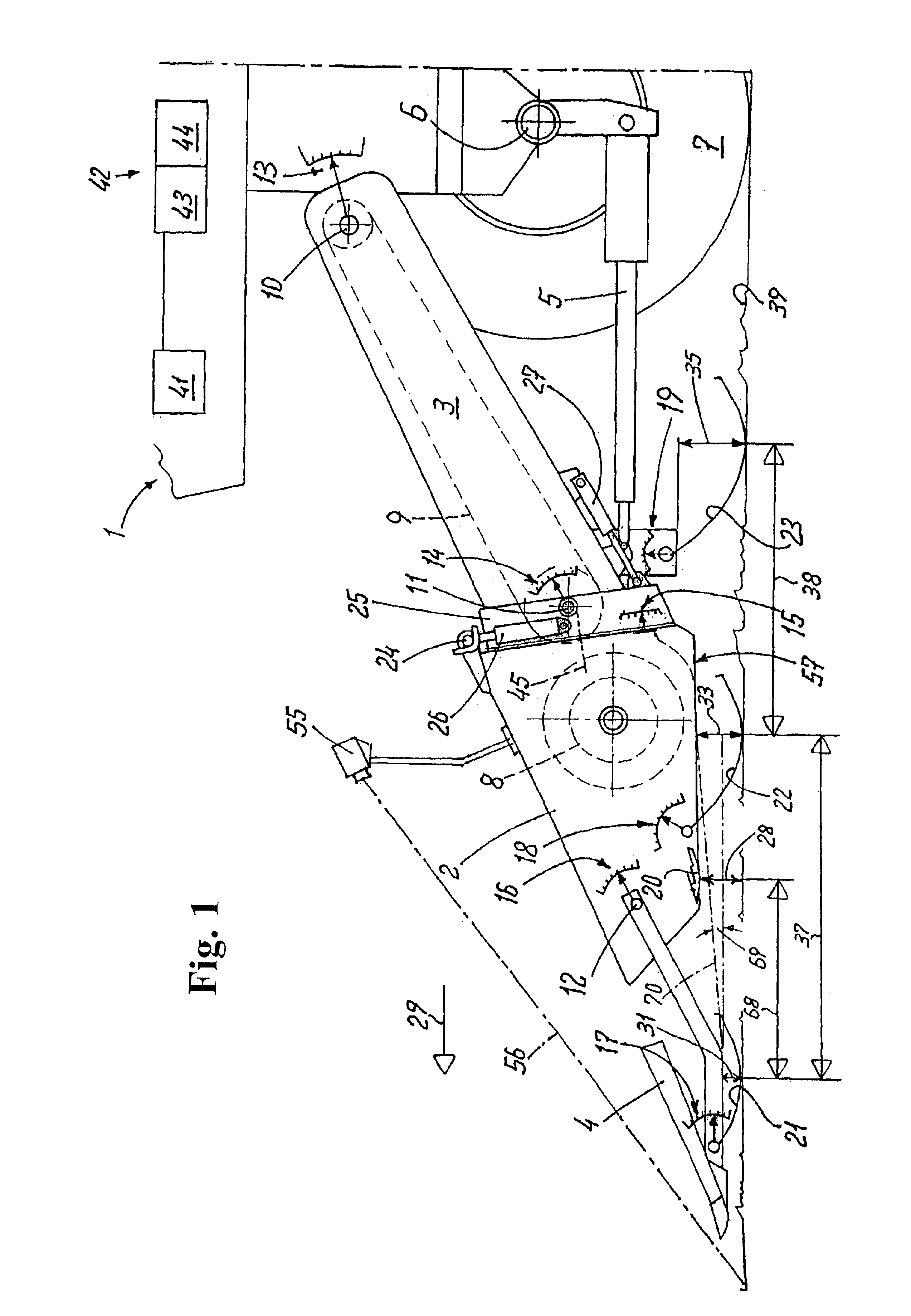

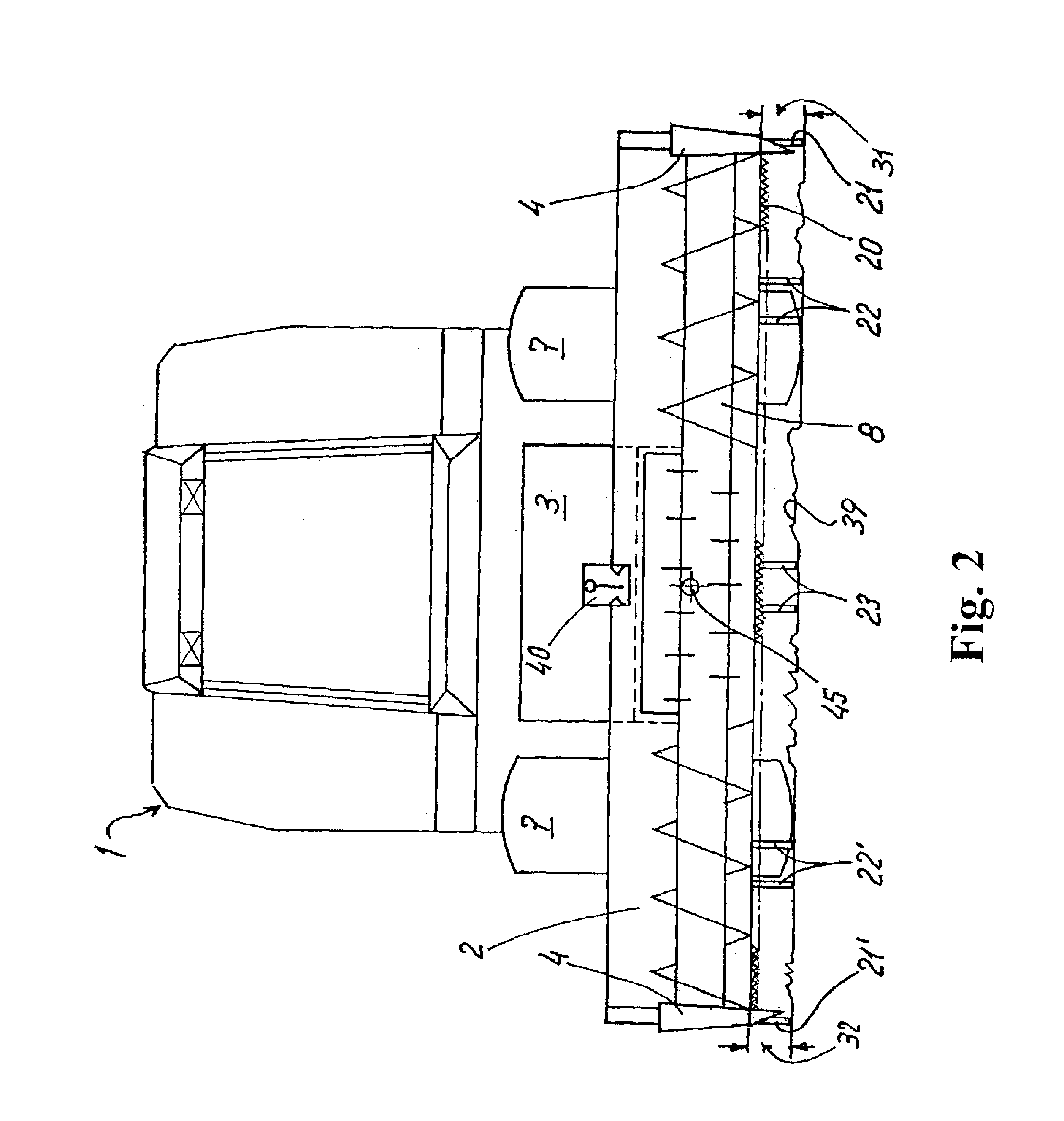

Position control for a crop pickup device

A position control for a crop pickup device which is mounted for vertical movement relative to an agricultural harvester. A measuring device is provided for determining the distance from the crop pickup device to the ground, wherein the position of the crop pickup device relative to the ground is adjustable by one control device as a function of the measured ground distance. The distance to the ground is determined by the measuring device at two points spaced from each other in the direction of travel. As a result, advantageously the inclination of the ground can be determined and used for optimized control of ground simulation of the crop pickup device. Additionally, the cutting angle can be adapted automatically to the slope of the ground, to avoid crop losses and impede damage to the grain header.

Owner:CLAAS SELBSTFAHRENDE ERNTEMASCHINEN GMBH

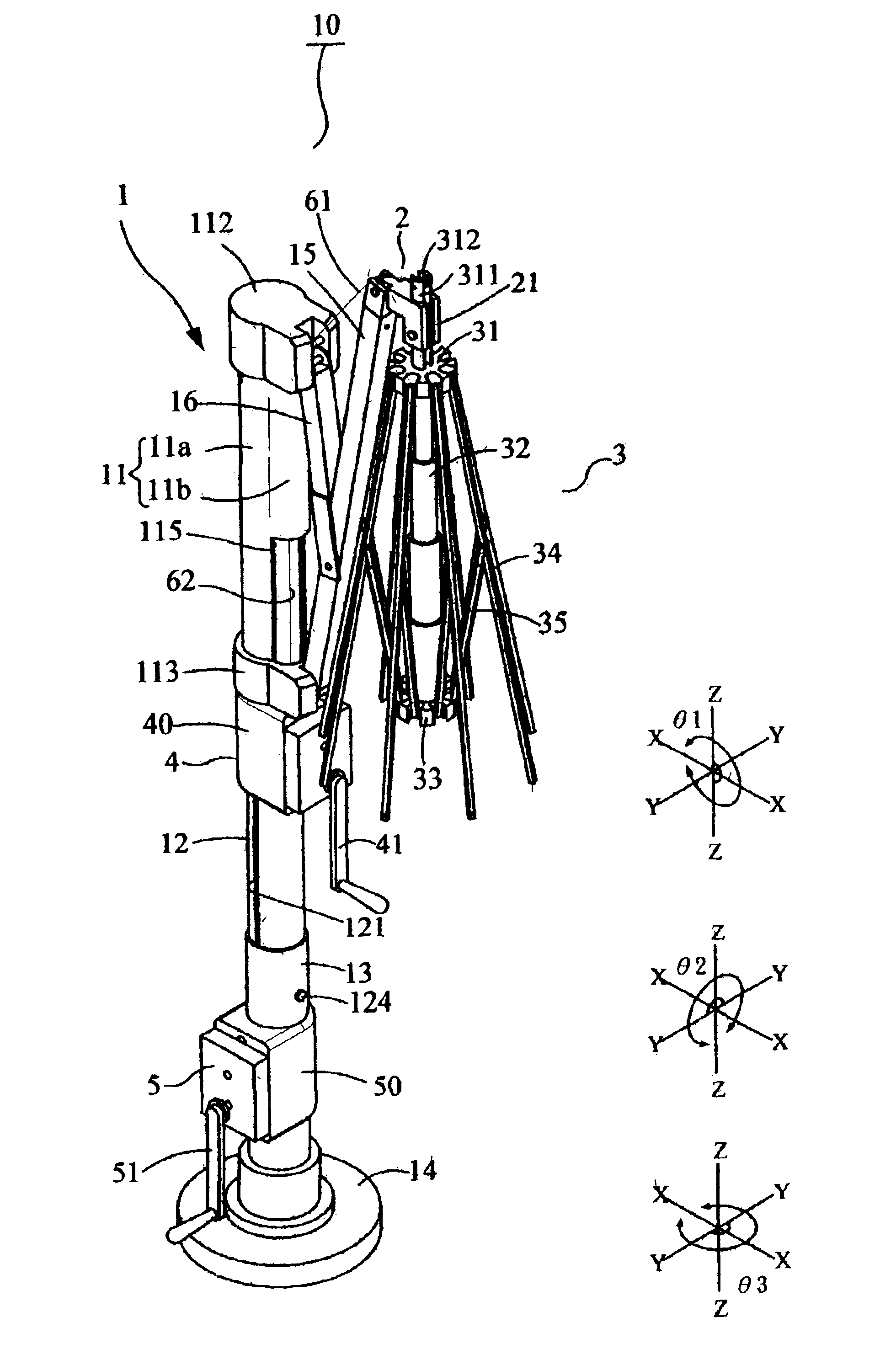

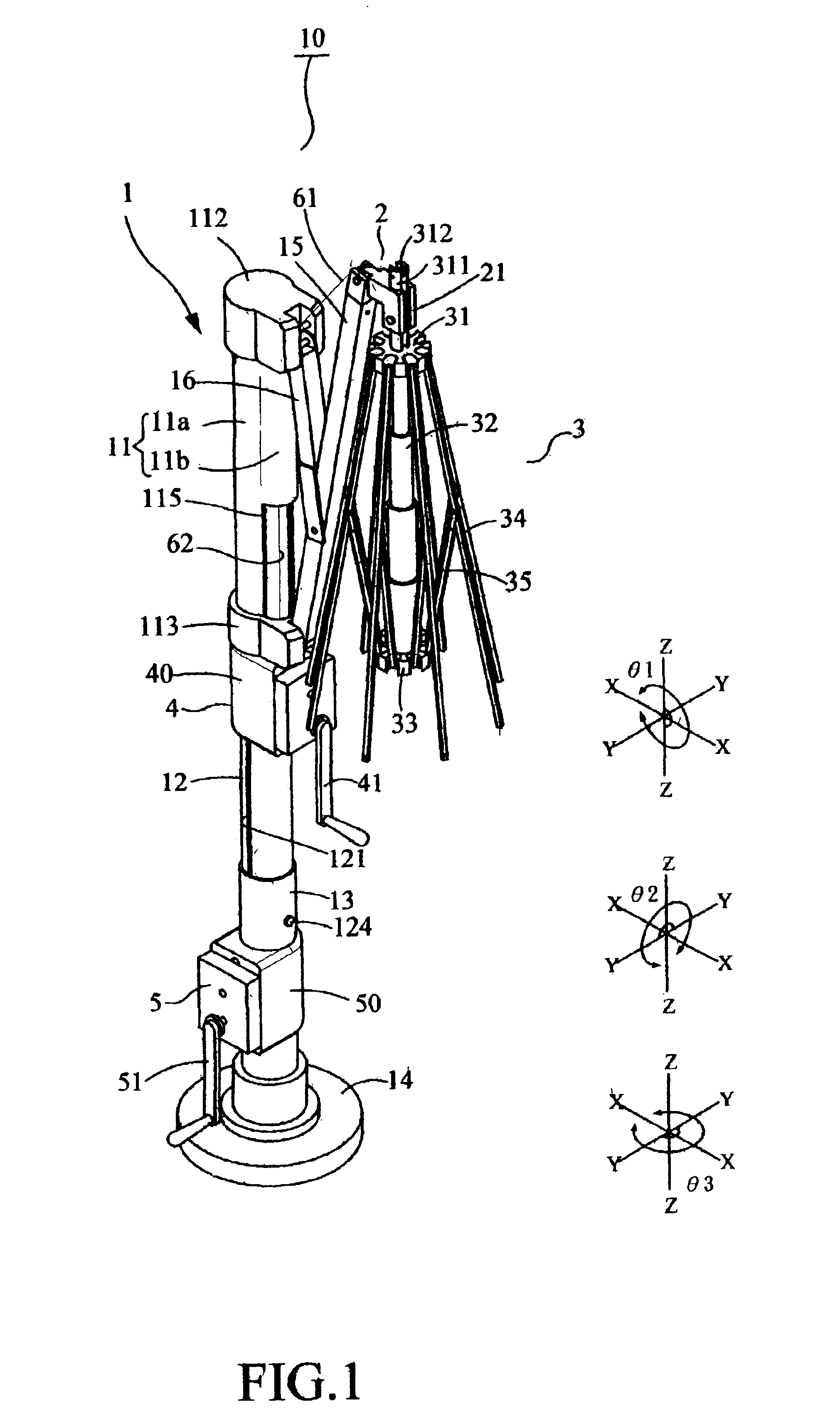

Outdoor used stand frame of an umbrella

A stand frame for an umbrella comprises a shaft, an umbrella frame, a foldable hanger arm hanging the umbrella frame, a height-adjustable device, and an angle-adjusting device. The stand frame for an umbrella utilizes the height-adjustable device and the angle-adjusting device to control the expansion / contraction and angular orientation of the umbrella frame thereof. The height-adjustable device provides a mechanism by which the middle section of the shaft can rotate horizontally, so as to move the umbrella frame about the shaft. A pull string extending from the shaft to the umbrella frame drives a vertical movement of the upper section of the shaft and the expansion of the umbrella frame simultaneously. A set of other pull strings are manipulated by the angle-adjusting device to vary the angular orientation of the umbrella frame in three dimensions.

Owner:CHEN SHIOW HUI

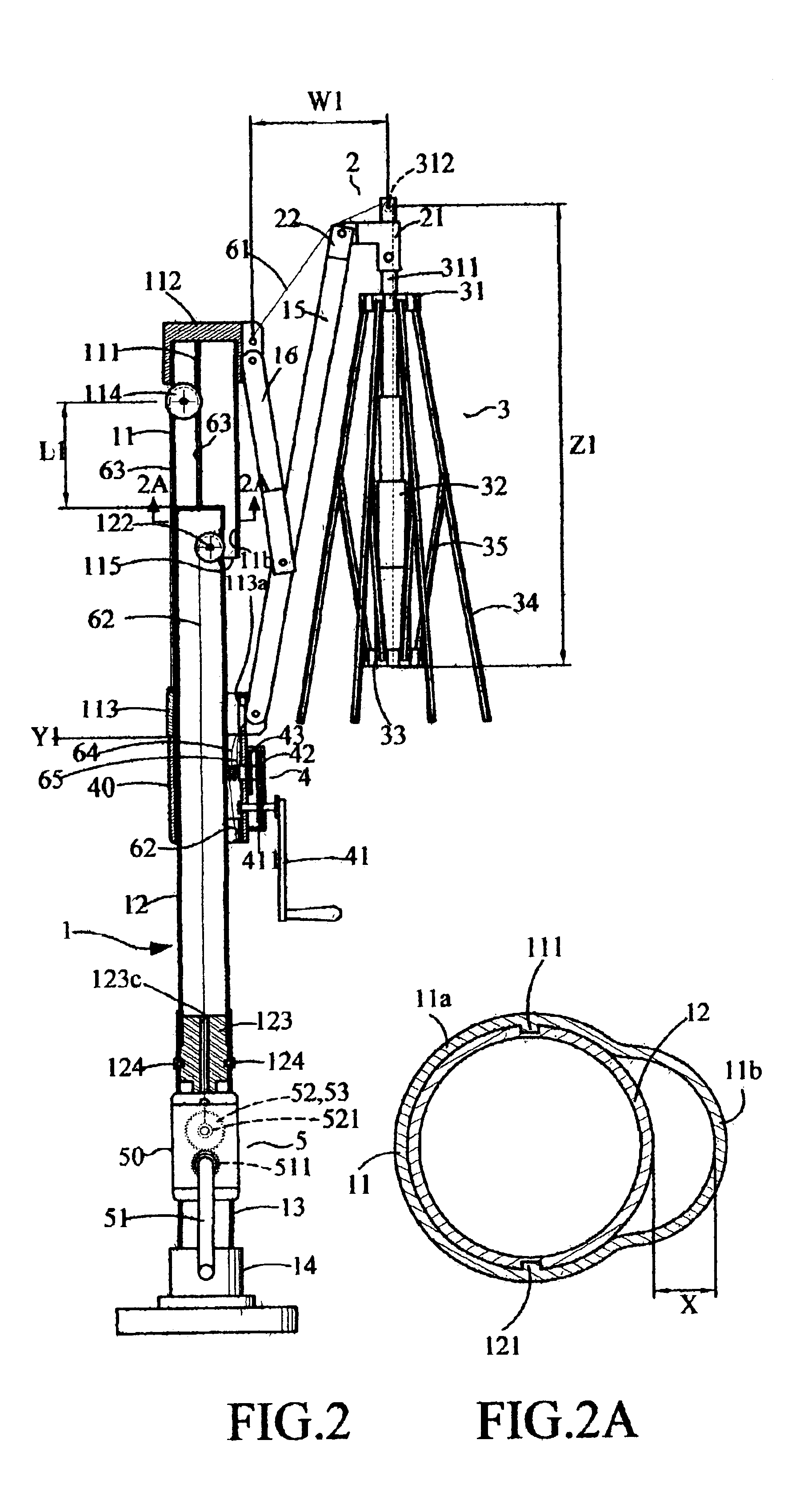

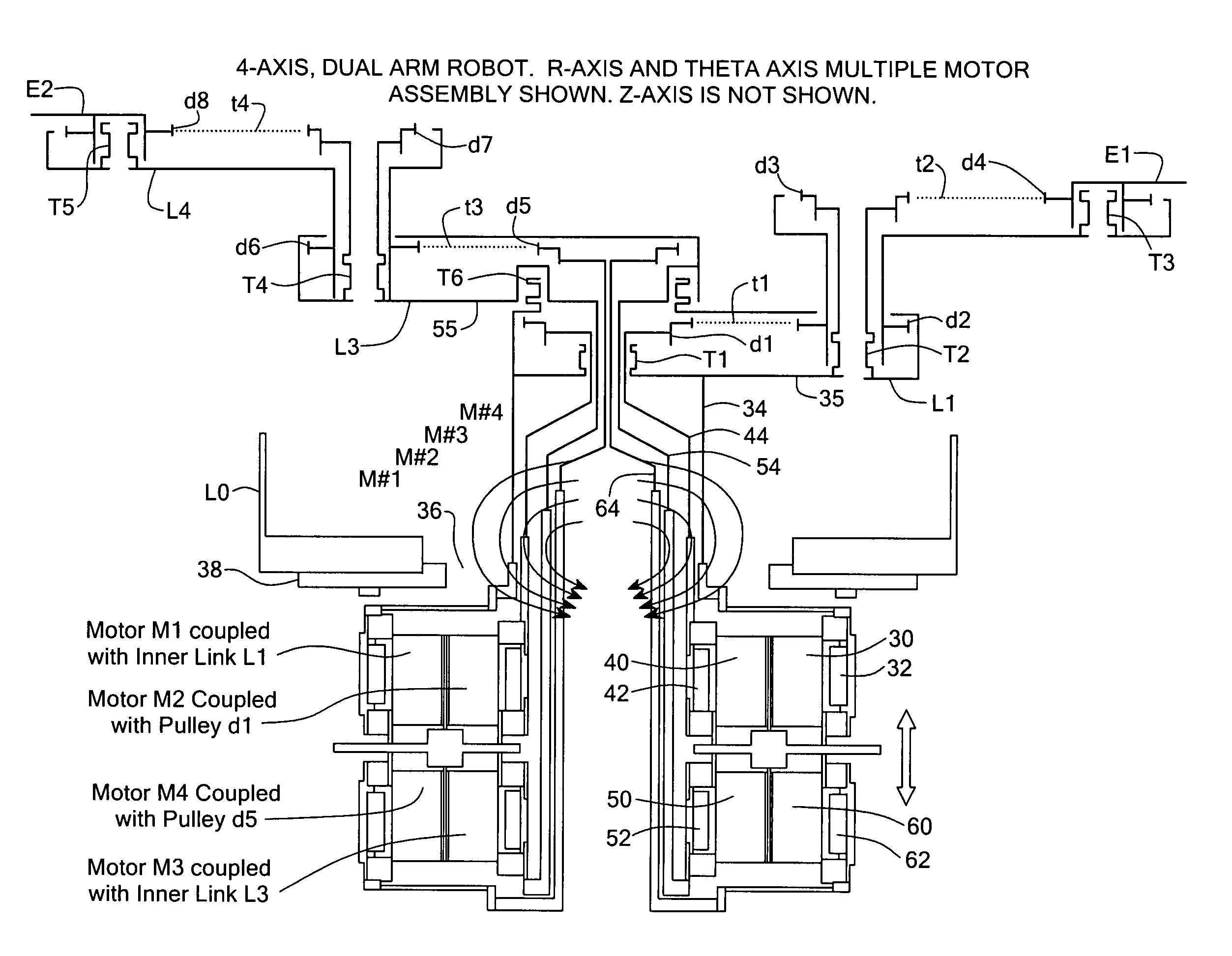

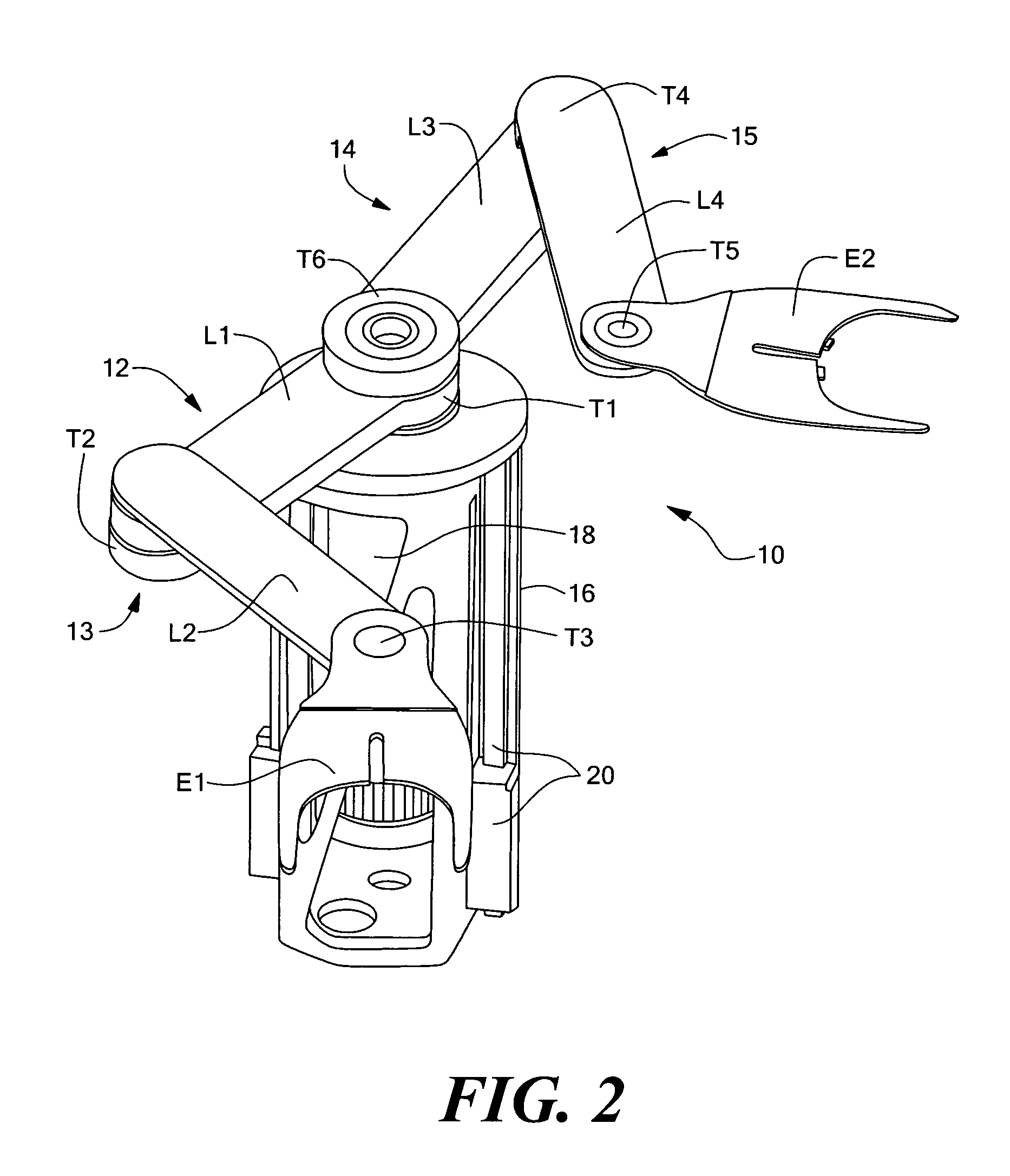

Dual arm robot

InactiveUS7891935B2Avoid collisionProgramme-controlled manipulatorMechanical apparatusThree degrees of freedomActuator

A dual arm robot assembly has two arms each having a set of joint / link pairs that, in conjunction with an actuator assembly, define at least three degrees of freedom to provide independent horizontal translation and rotation of a distalmost link. A vertical motion mechanism is also provided.

Owner:BOOKS AUTOMATION US LLC

Wave-power unit and plant for the production of electric power and a method of generating electric power

InactiveUS20050121915A1Improve overall utilizationProtection attackMachines/enginesEngine componentsPower stationEngineering

A wave-power unit has a floating body and a rotating electric generator mechanically connected to the floating body. A mechanical movement transmitter is arranged for transmission of vertical movements of the floating body to rotary movements of the generator rotor. A wave-power plant employs a plurality of wave-power units. Use of the wave-power unit and a method of generating electric energy as described.

Owner:SEABASED AB

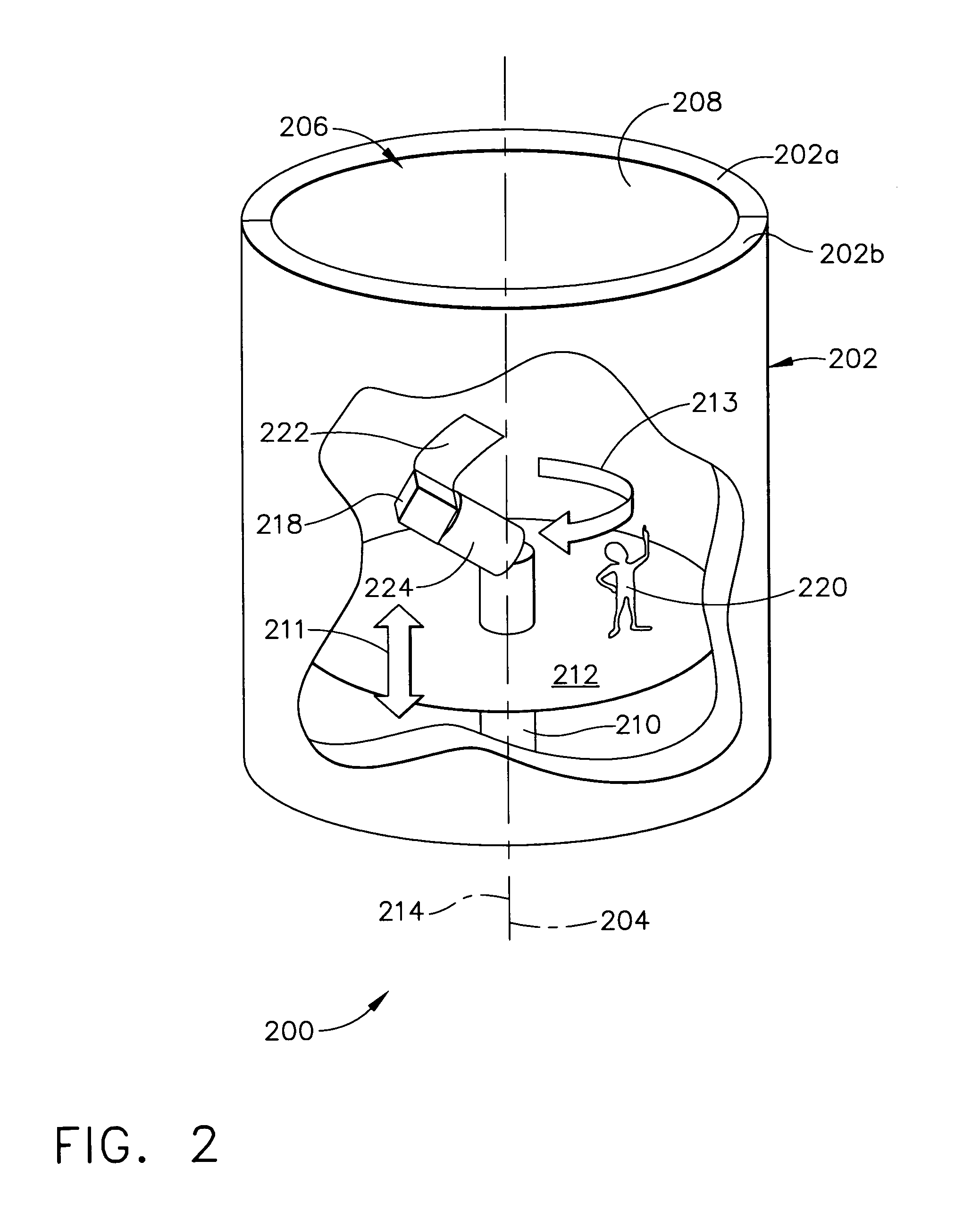

Composite fuselage machine

ActiveUS20050023414A1Metal rolling stand detailsEfficient propulsion technologiesEngineeringVertical axis

A device for automated composite lay up of a part to be manufactured —such as a large aircraft fuselage—includes a mandrel having a vertical axis and an interior mandrel surface that conforms to an outside mold line of the part. A vertical movement shaft is disposed inside the mandrel. A platform is supported, moved up and down, and rotated on the vertical movement shaft. One or more arm mechanisms are attached to the platform. One or more material delivery heads are supported by the arm mechanisms, and the arm mechanisms moves and positions the material delivery heads relative to the interior mandrel surface so that composite material is delivered directly to the outside mold line on the interior mandrel surface.

Owner:THE BOEING CO

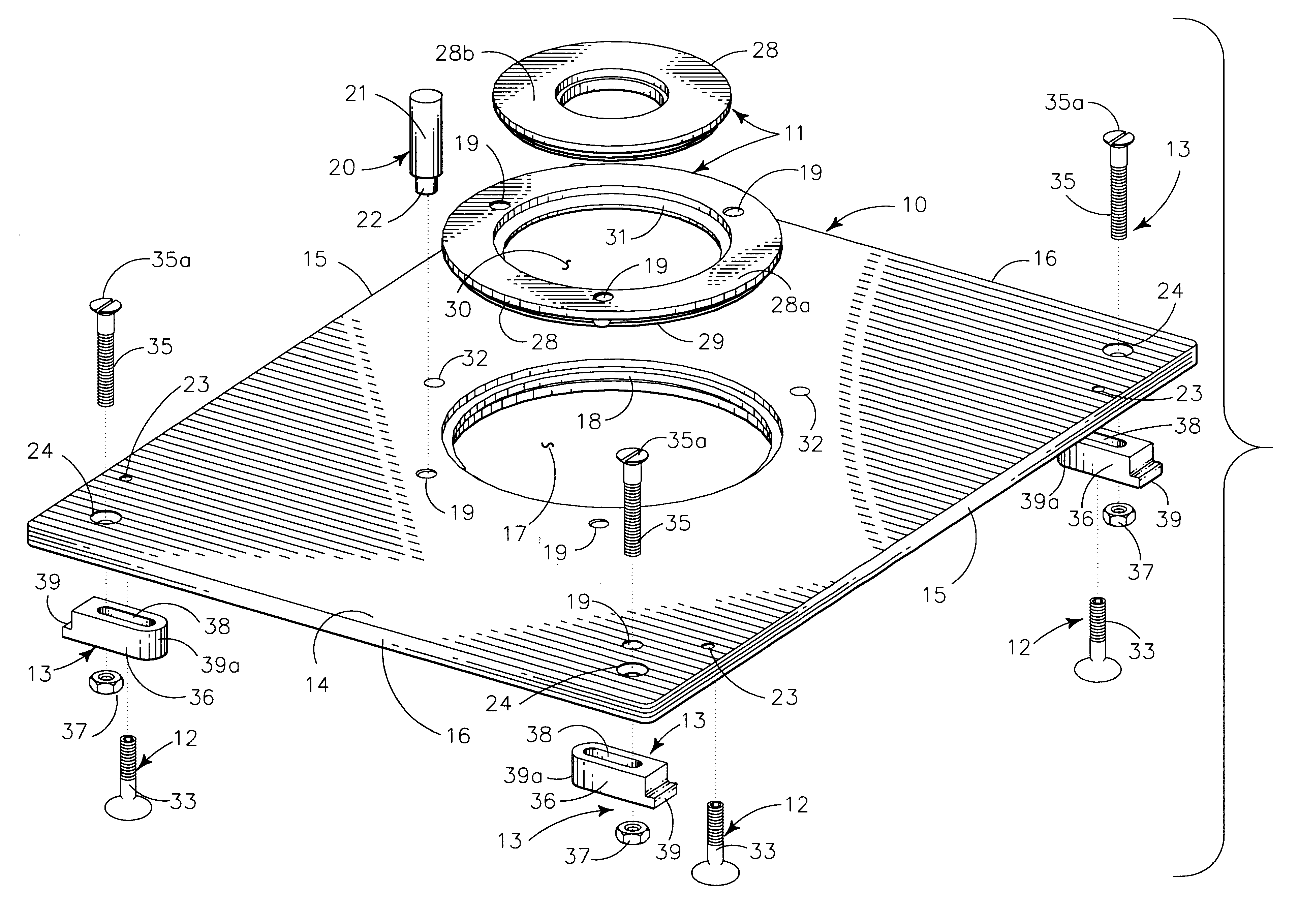

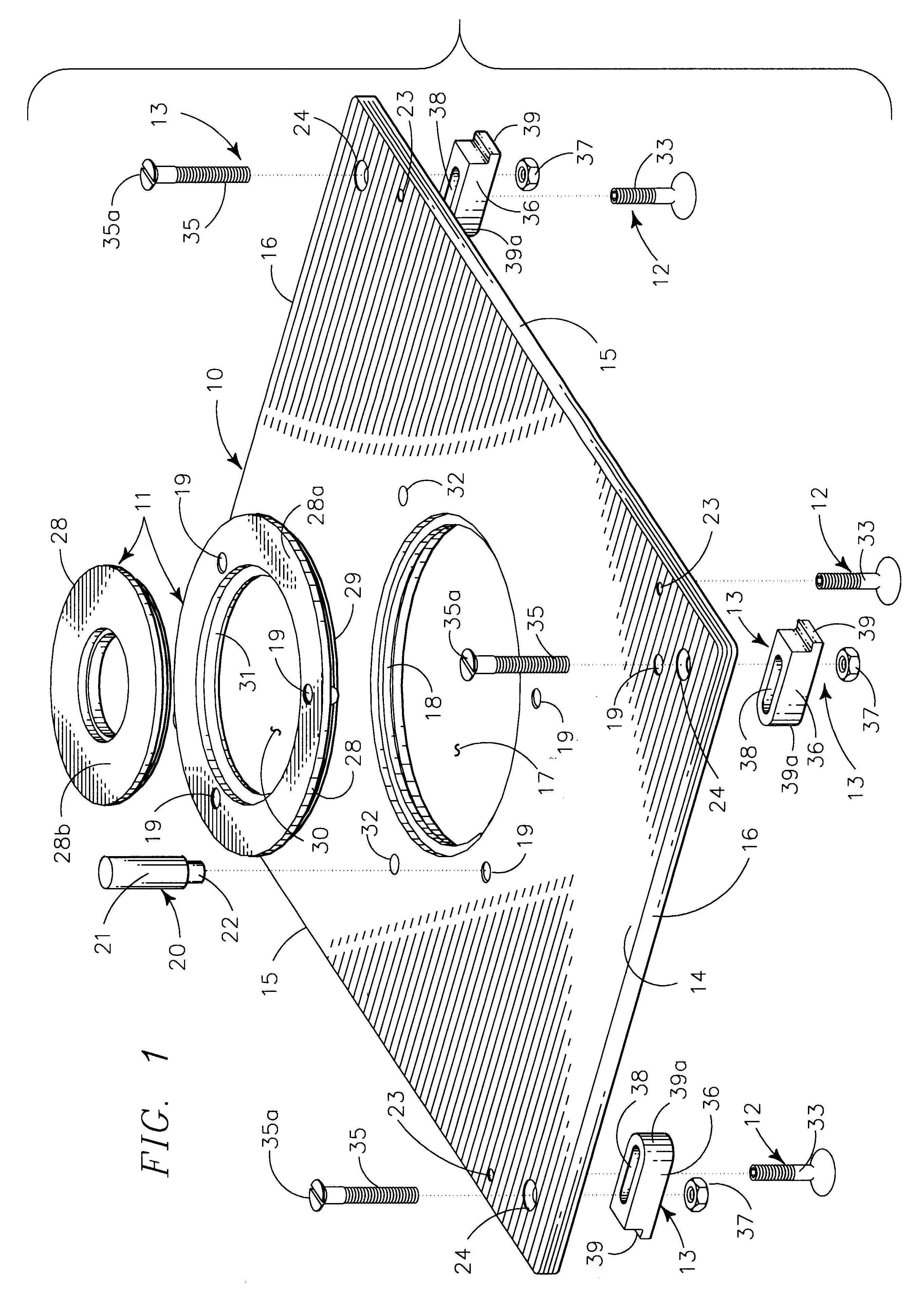

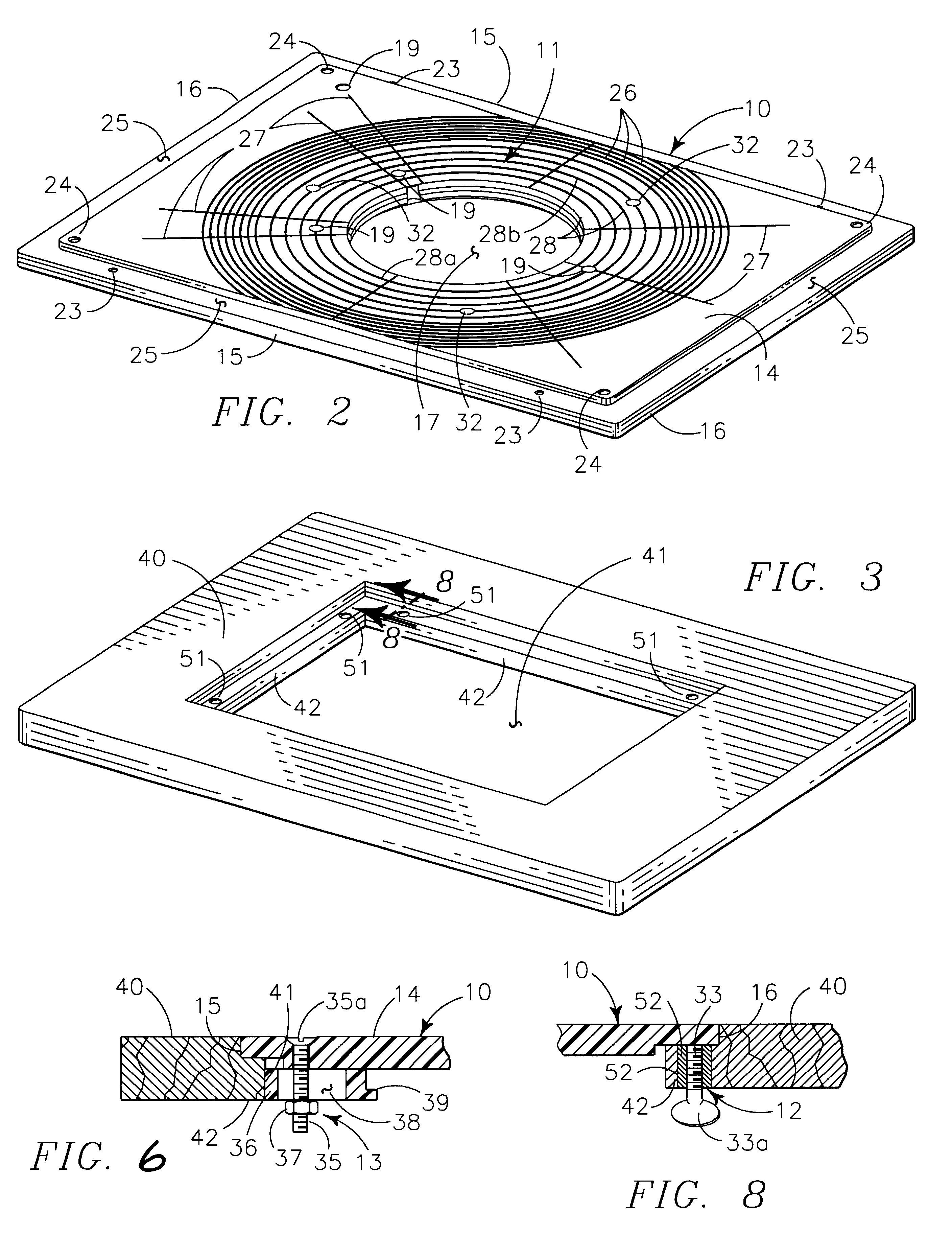

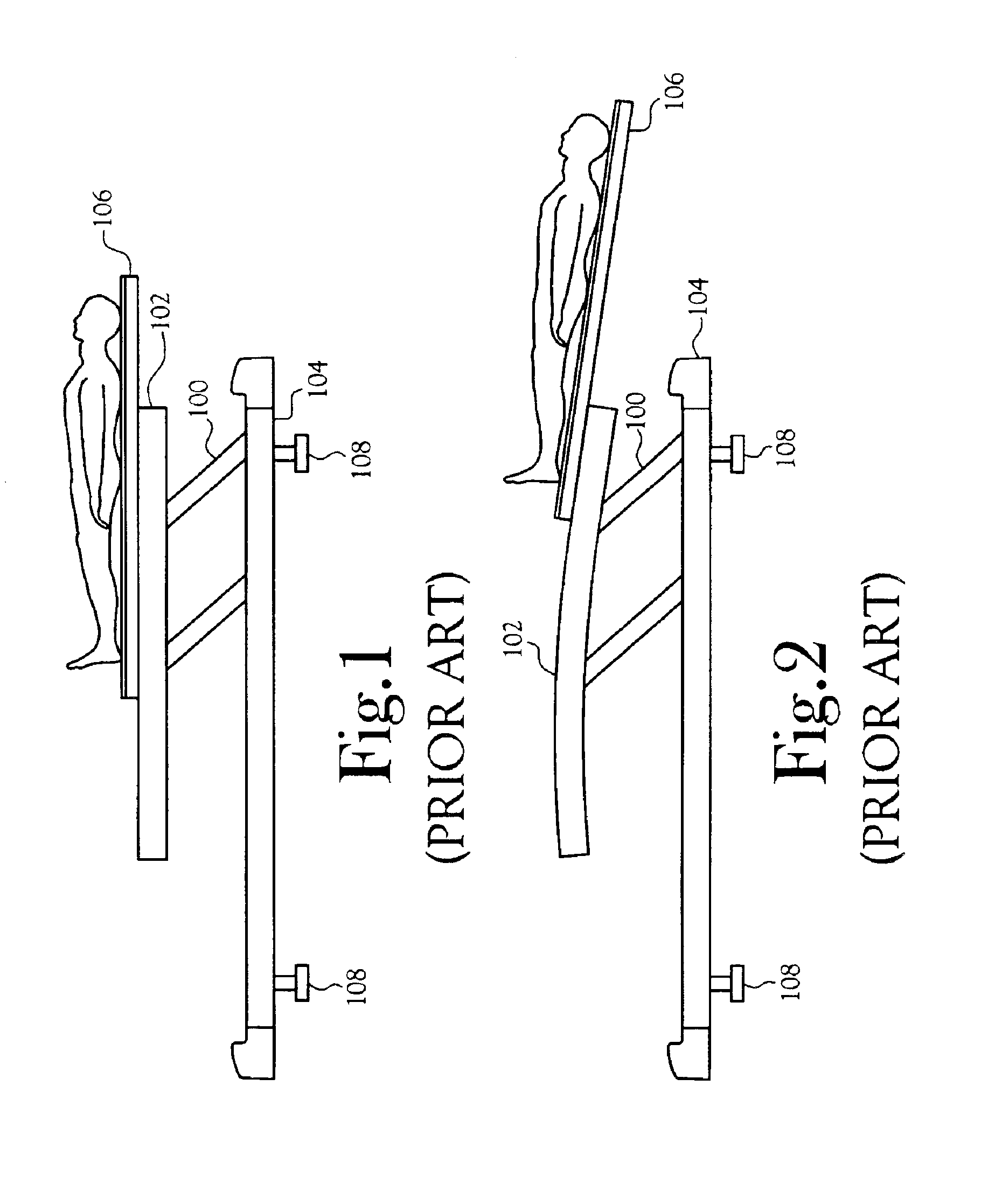

Base plate for mounting router in a support table

InactiveUS6305447B1Excessive damageExcessive wearMulti-purpose machinesProfiling/shaping machinesEngineeringSupport surface

A base plate for mounting a router in a support table provides a plate configured to fit in an orifice, having an inwardly extending ledge thereabout, defined in the support table with the router supported by the base plate to depend therefrom. The base plate defines a medial orifice for passage of the router shaft through the orifice for operative positioning of a cutter carried on the router shaft above the base plate. The base plate medial orifice releasably carries plural annular inserts to cover space between the router shaft and the support plate portion defining the medial orifice. Plural adjustment screws are carried in threaded engagement in the ledge of the support surface orifice for vertical motion to adjustably move adjacent portions of the base plate periphery upwardly from the ledge to create a coplanar relationship of adjacent portions of the base plate and support table. The base plate carries at least one releasably adjustable fastener to fasten the support plate on the ledge in the orifice defined in the support table.

Owner:ROUSSEAU TONY

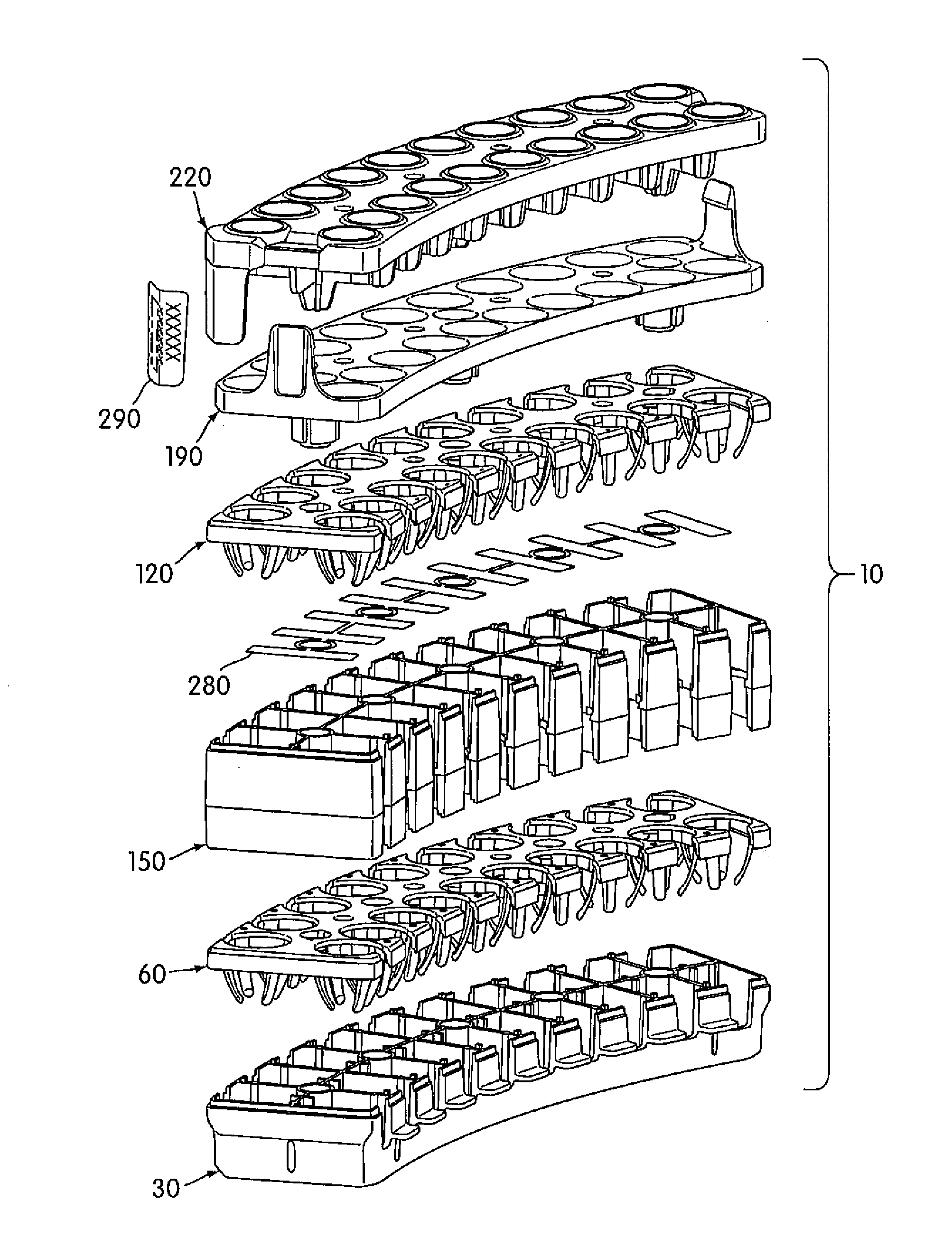

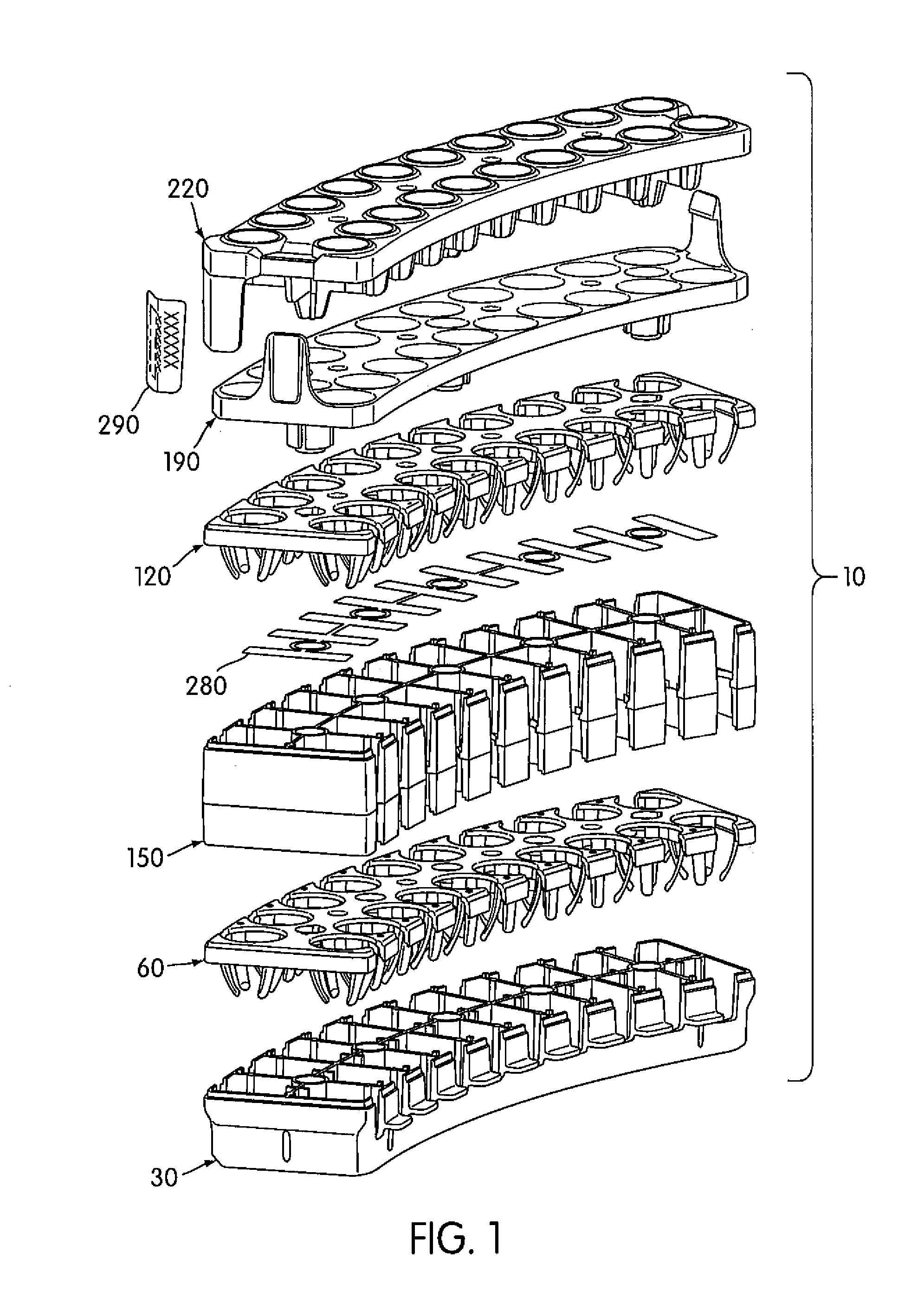

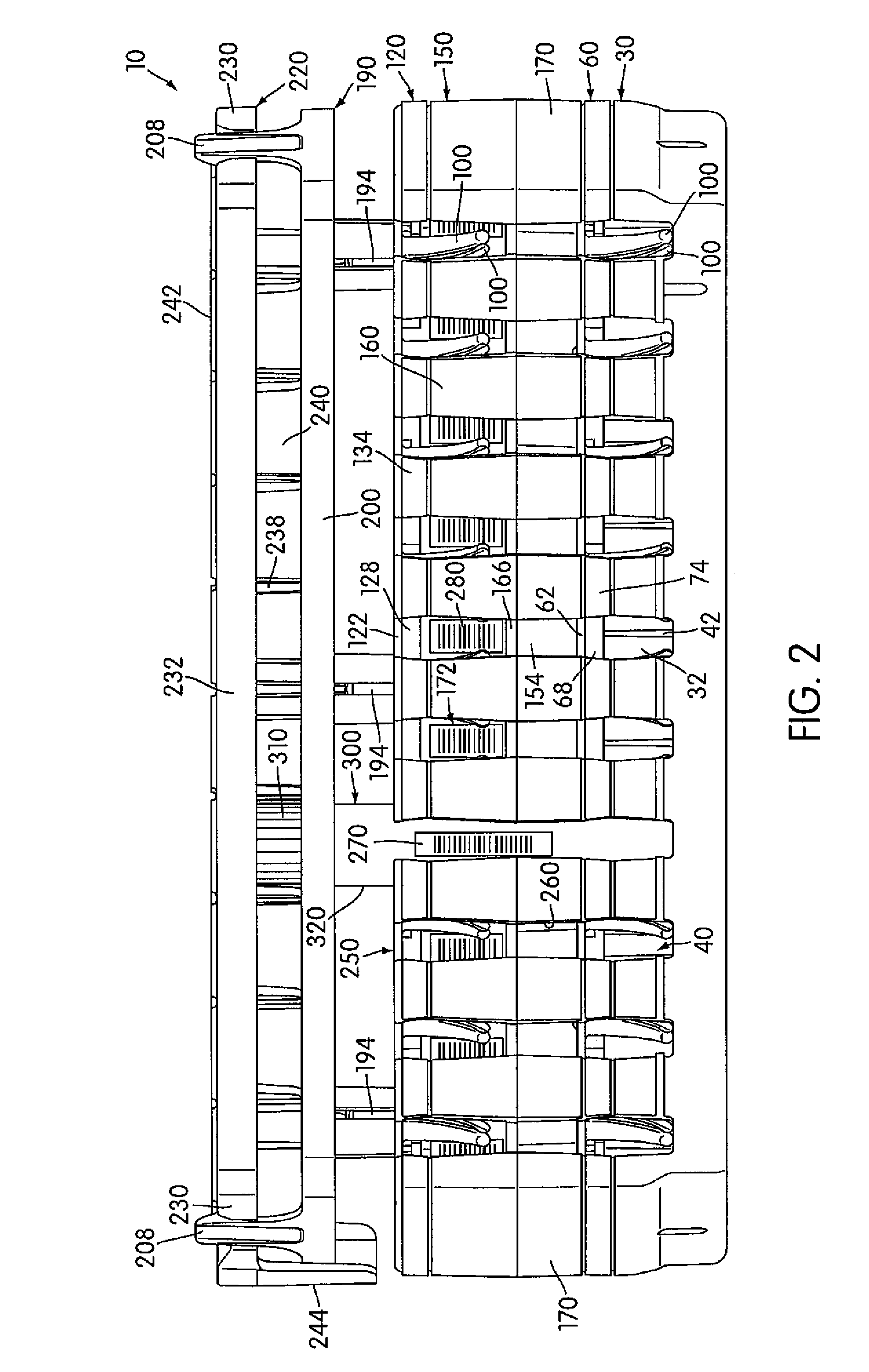

Sample tube holder

InactiveUS20060266719A1Avoid residual contaminationRelieve pressureEnzymologyLavatory sanitoryEngineeringLateral movement

A sample tube holder having sample tube compartments with sets of spaced finger springs provided therein for maintaining sample tubes in substantially upright orientations. A guide structure having a series of openings is used to direct sample tubes into the sample tube compartments and to restrict lateral movement of sample tubes held thereby. A retainer is releasably engaged by the guide structure and has openings sized to provide access to sample tubes held by the sample tube compartments but which restrict vertical movement of the sample tubes. Tabs at a base of the sample tube holder and hold-downs fixed to a stationary structure adjacent a conveyor cooperate to restrict vertical movement of the sample tube holder during automated sampling procedures.

Owner:GEN PROBE INC

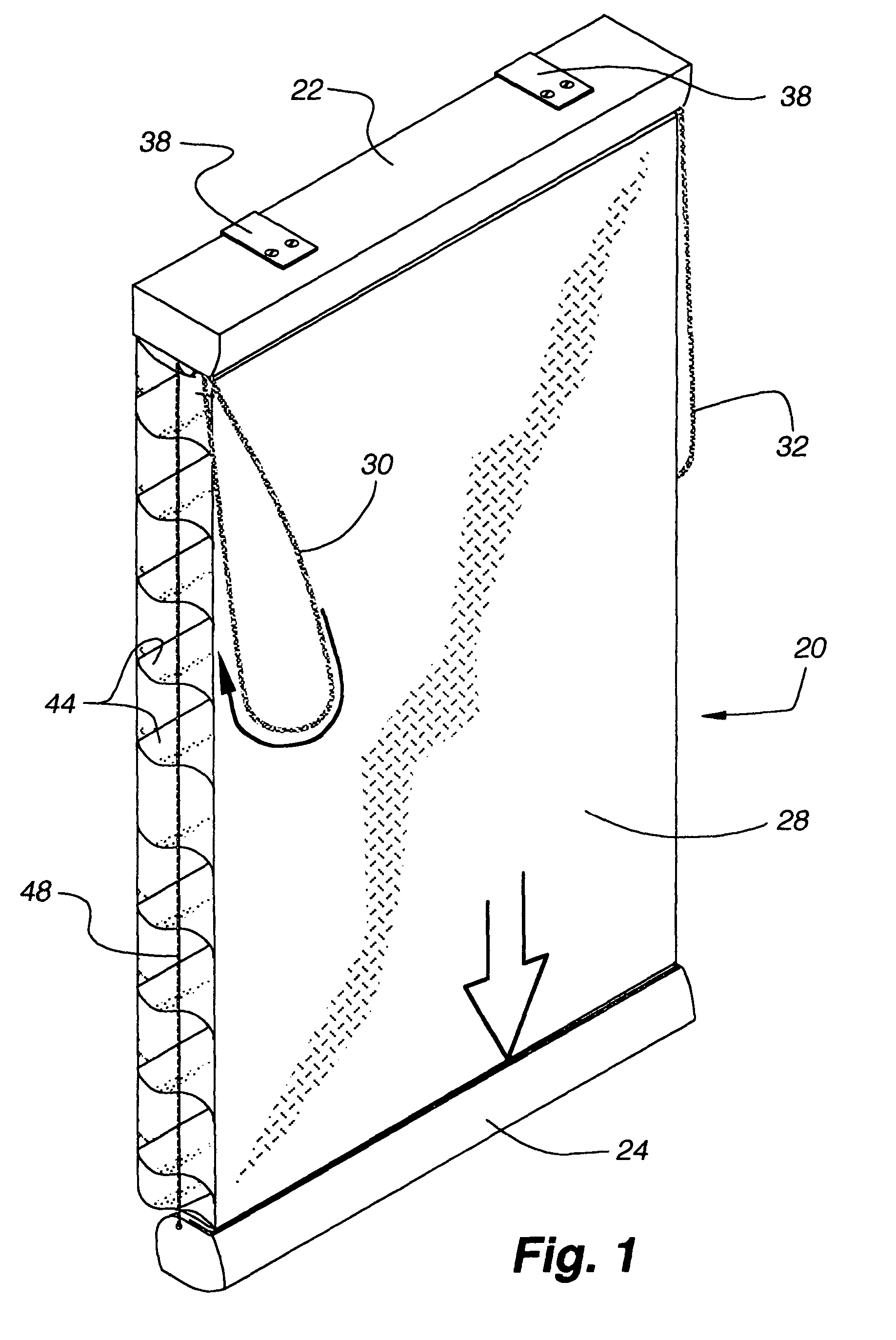

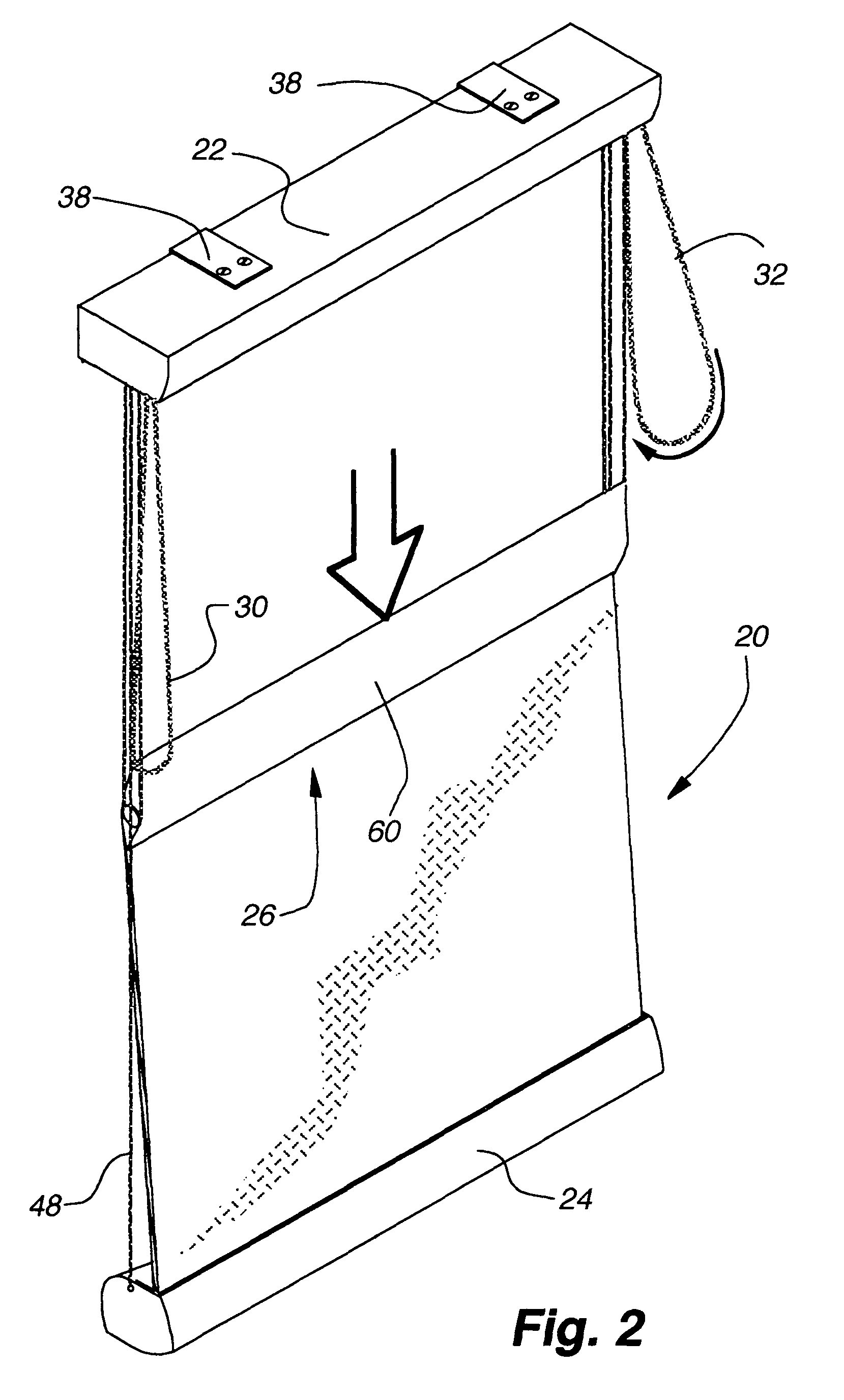

Bottom-up/top-down retractable cellular shade

A covering for an architectural opening includes a head rail, a bottom rail with a take-up roller therein and an intermediate rail with both the intermediate rail and bottom rail suspended from the head rail, a fabric material interconnecting the intermediate rail with the bottom rail and being adapted to be wrapped around the roller in the bottom rail, said fabric including a pair of vertically oriented sheets that are horizontally spaced by a plurality of vertically spaced horizontal vanes with the vanes being movable between open and closed positions by opposite vertical movement of the sheets of material. In a first embodiment a first control system is provided for raising and lowering the bottom rail and a second control system for raising and lowering the intermediate rail as well as tilting the intermediate rail to effect an opening or closing of the vanes. In alternative embodiment, the bottom rail is controlled with a spring balanced system so that it remains in any position in which it is normally set.

Owner:HUNTER DOUGLAS INC

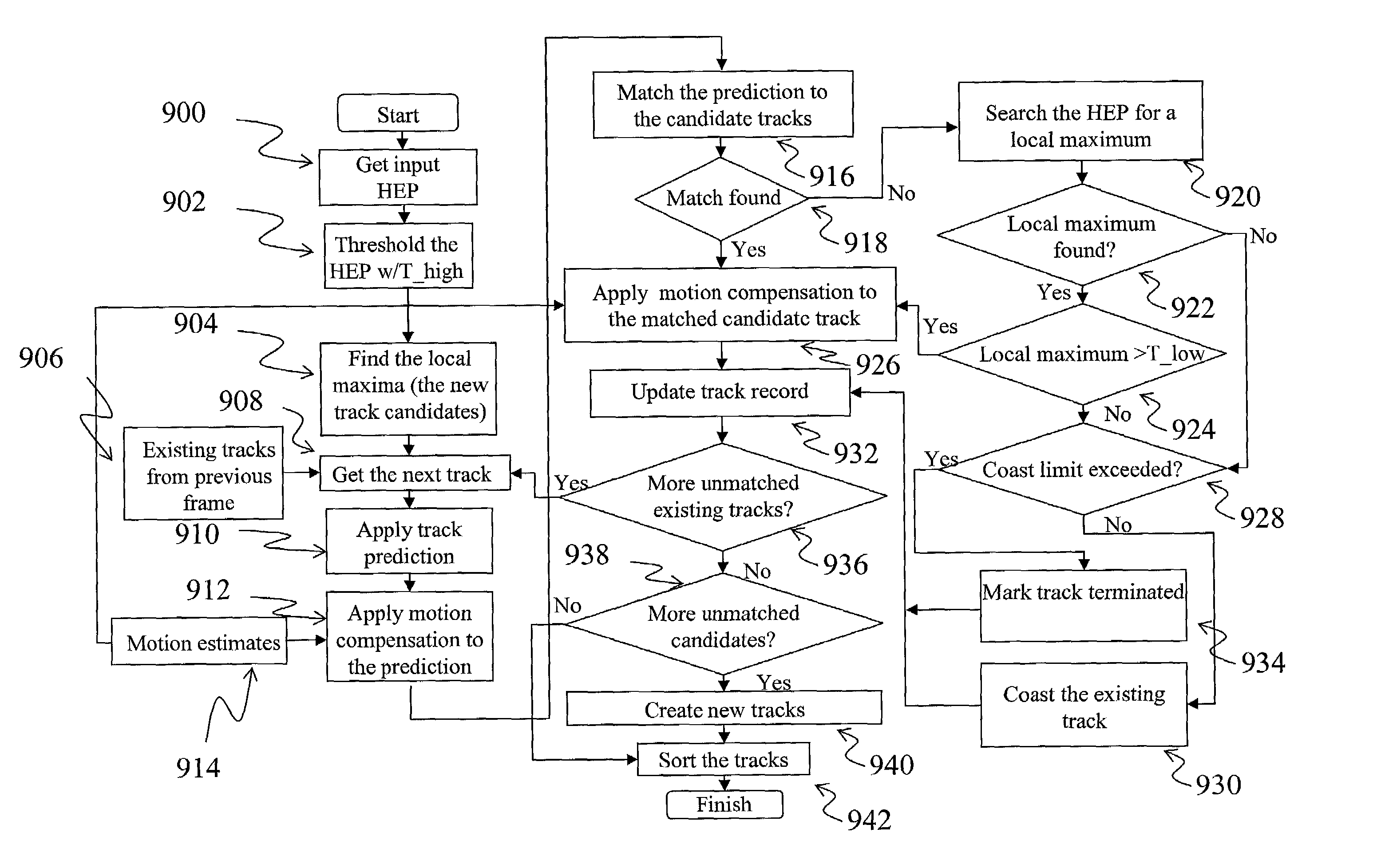

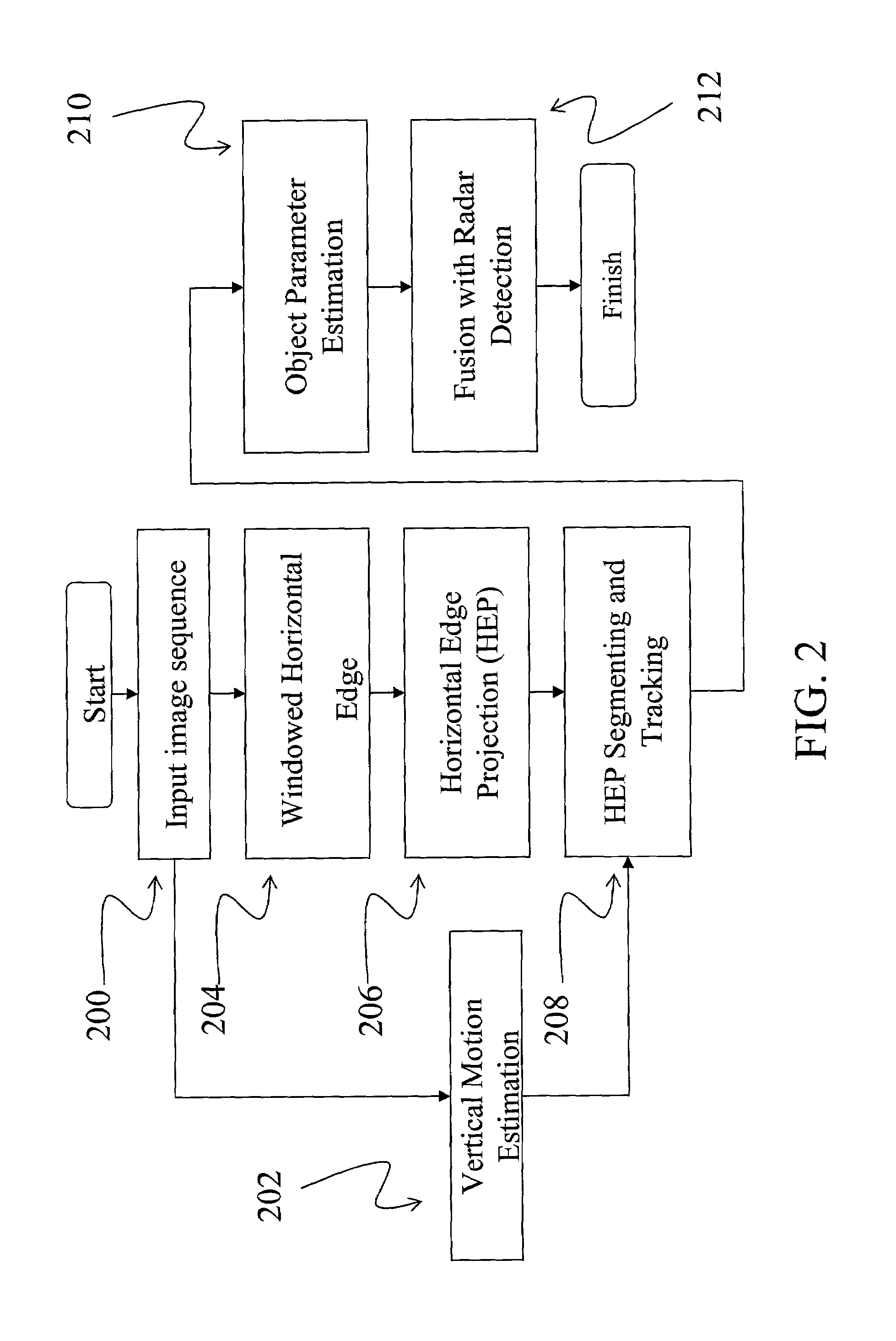

Vision-based highway overhead structure detection system

InactiveUS7027615B2EffectivelyMinimizes and eliminates numberDetection of traffic movementAnti-collision systemsVision basedRadar detection

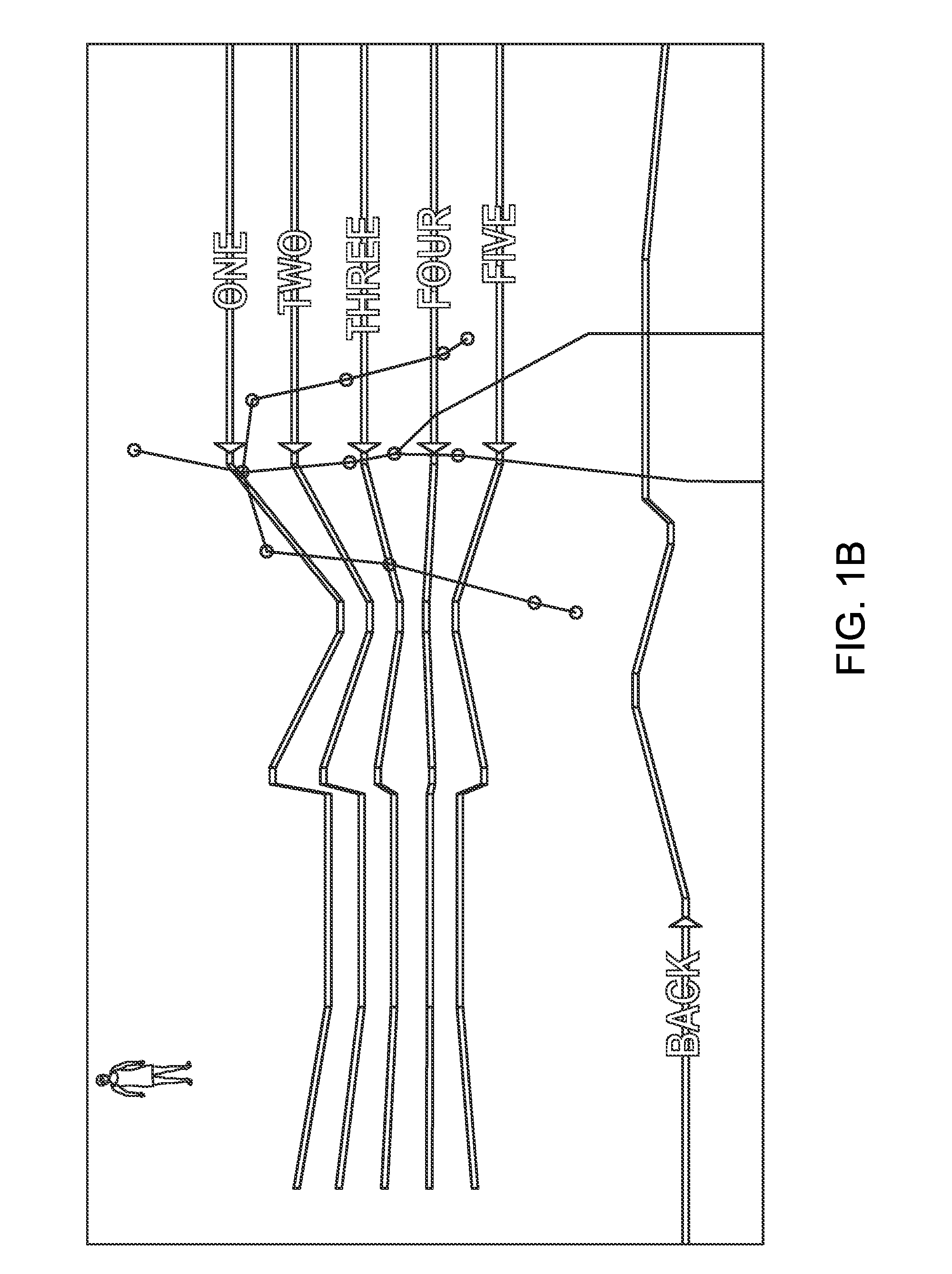

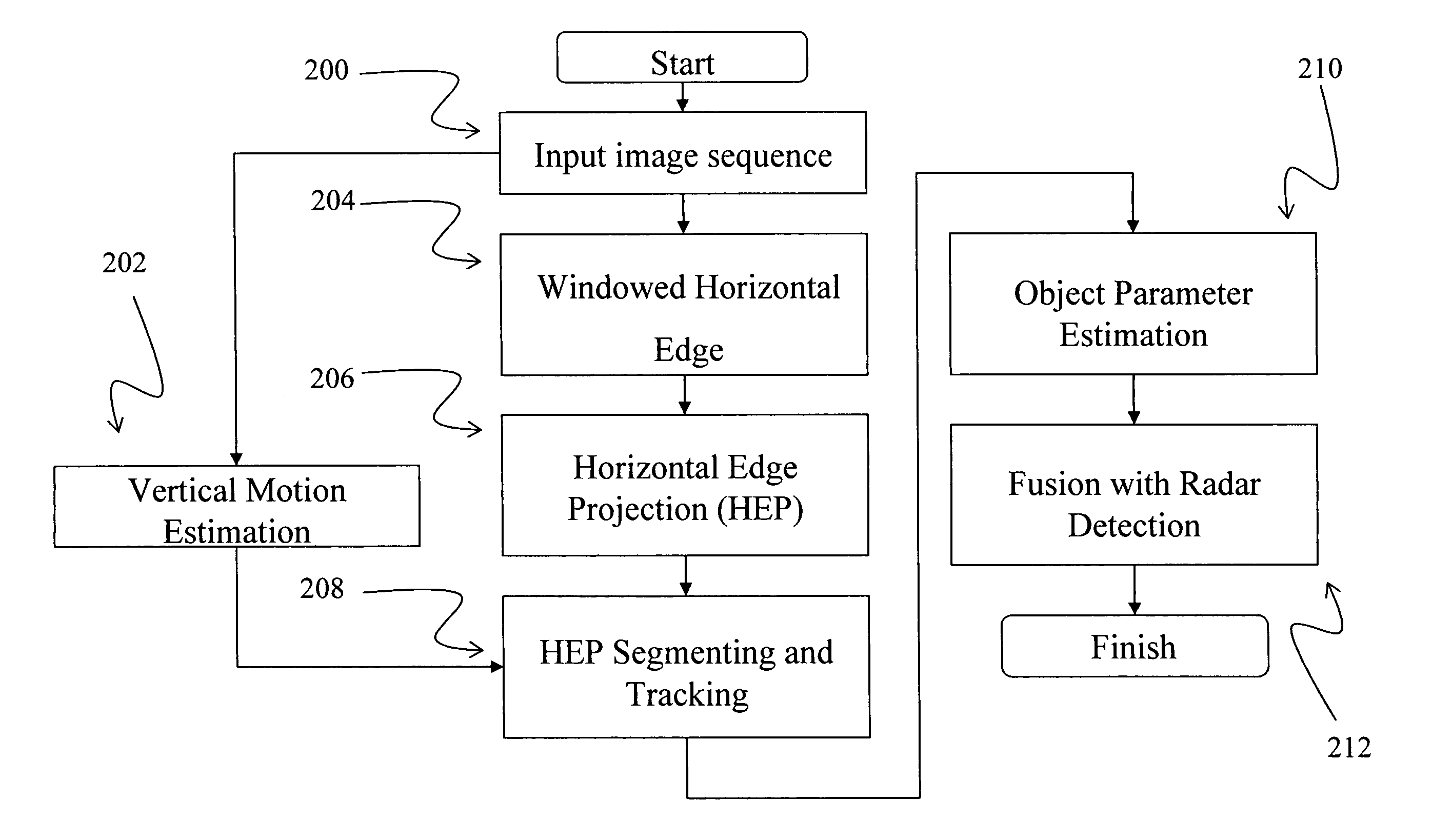

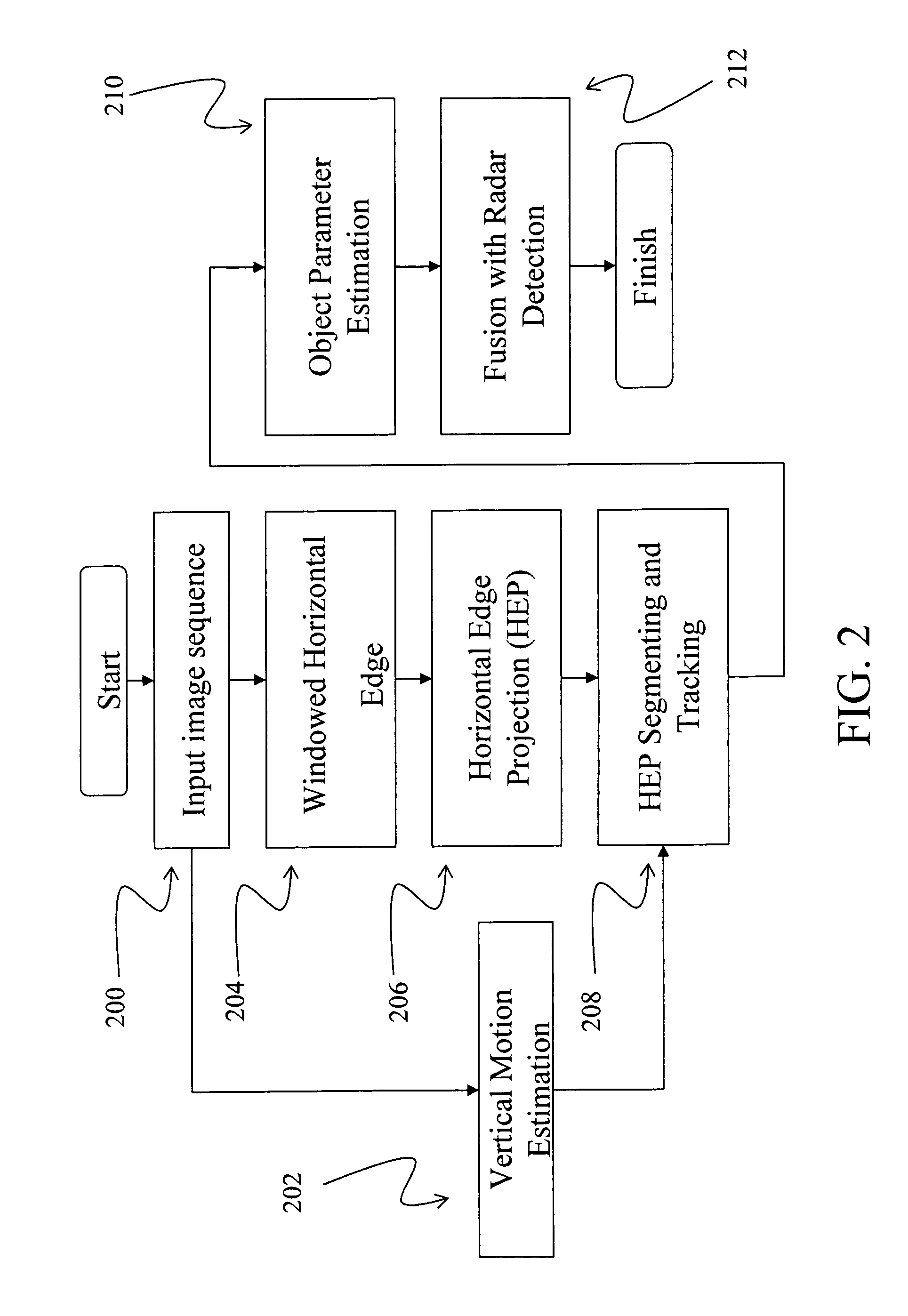

An image sequence is inputted 200 from the camera and vertical motion is estimated 202. A windowed horizontal edge projection 204 is extracted from the inputted image sequence 200 and the horizontal edges are projected 206. The horizontal edge projection 206 and the vertical motion estimation 202 are combined in a horizontal segmentation and tracking element 208, and forwarded to an object parameter estimation element 210 where the object's distance and height are estimated. This data is combined in a fusion with radar detection element 212. By correctly matching the overhead objects sensed by the radar and video camera, the proximity and relative speed can be ascertained. Once overhead objects have been identified they can be isolated and not considered for collision avoidance purposes.

Owner:HRL LAB

Methods and systems for 2d/3d image conversion and optimization

InactiveUS20080085049A1Reduce valueReduce the valueCharacter and pattern recognitionSteroscopic systemsComputer graphics (images)3d image

A method that improves compensation for hard cuts and / or vertical motion effects in the conversion of 2D images to 3D images, displays 2D images to one eye and computed images to the other eye. Generating the computed images includes using an approximation variable that represents some relationship between the 2D images, such as the speed of motion across two images. Compensating for the hard cut or vertical motion effect includes temporarily setting the approximation variable to a value that makes the left and right eye images more similar (if identical, displaying a 2D image). The approximation variable can be pre-set to a value based on the speed of motion in a scene to be displayed. A method of displaying images in either 2D or 3D may include converting 3D images to 2D images by displaying images computed from images intended for either the left eye or the right eye.

Owner:NASKE ROLF DIETER +2

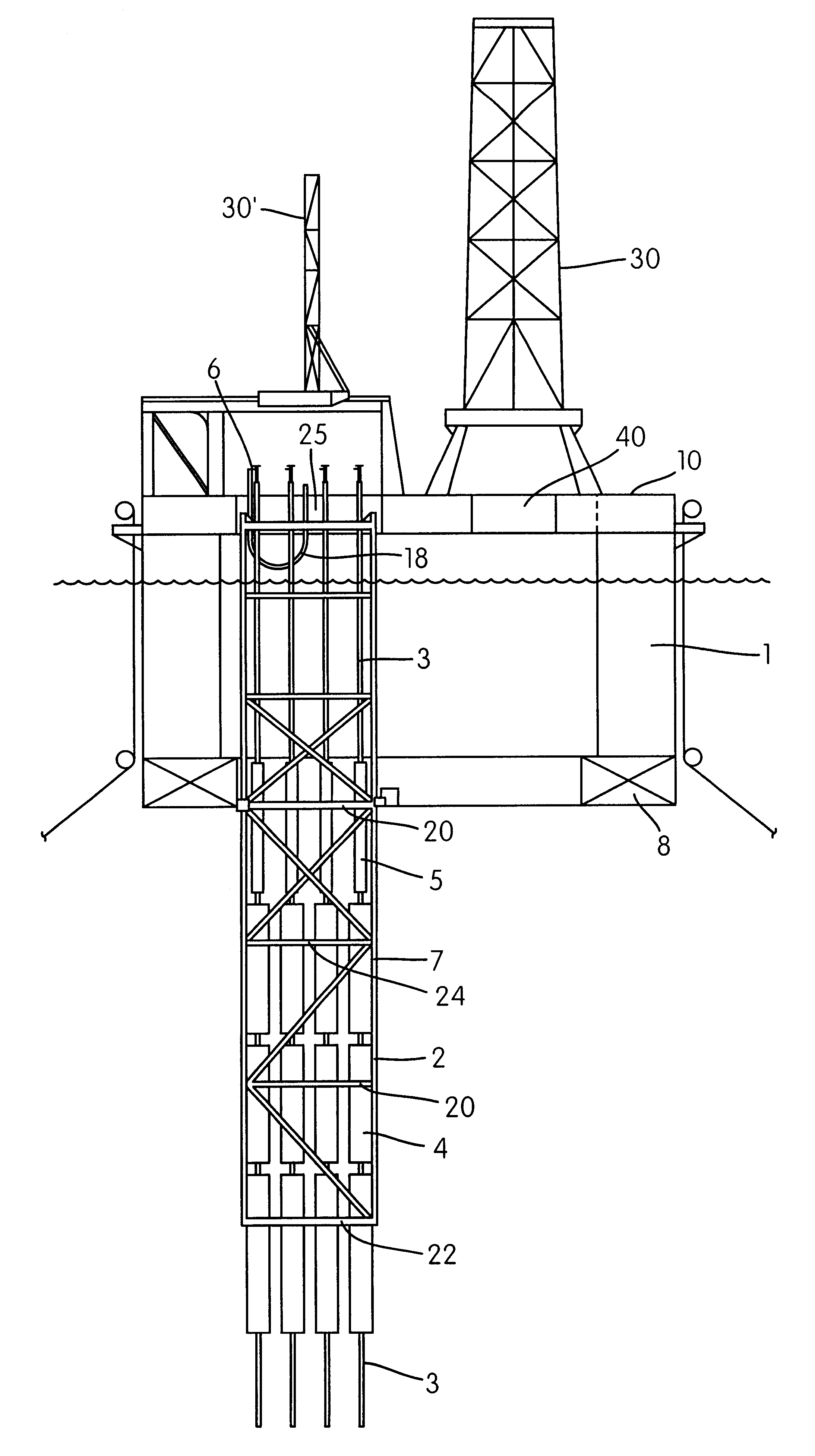

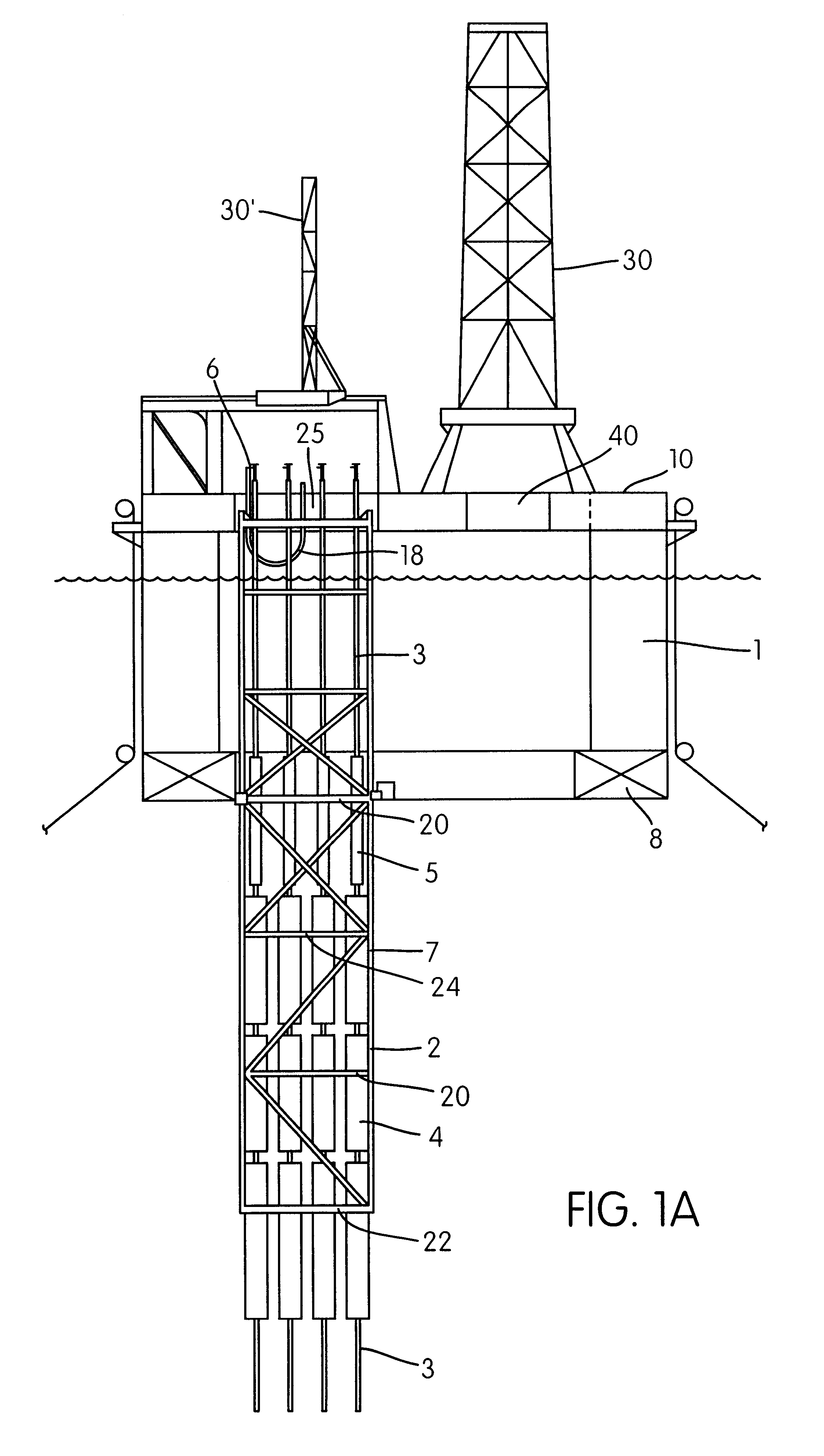

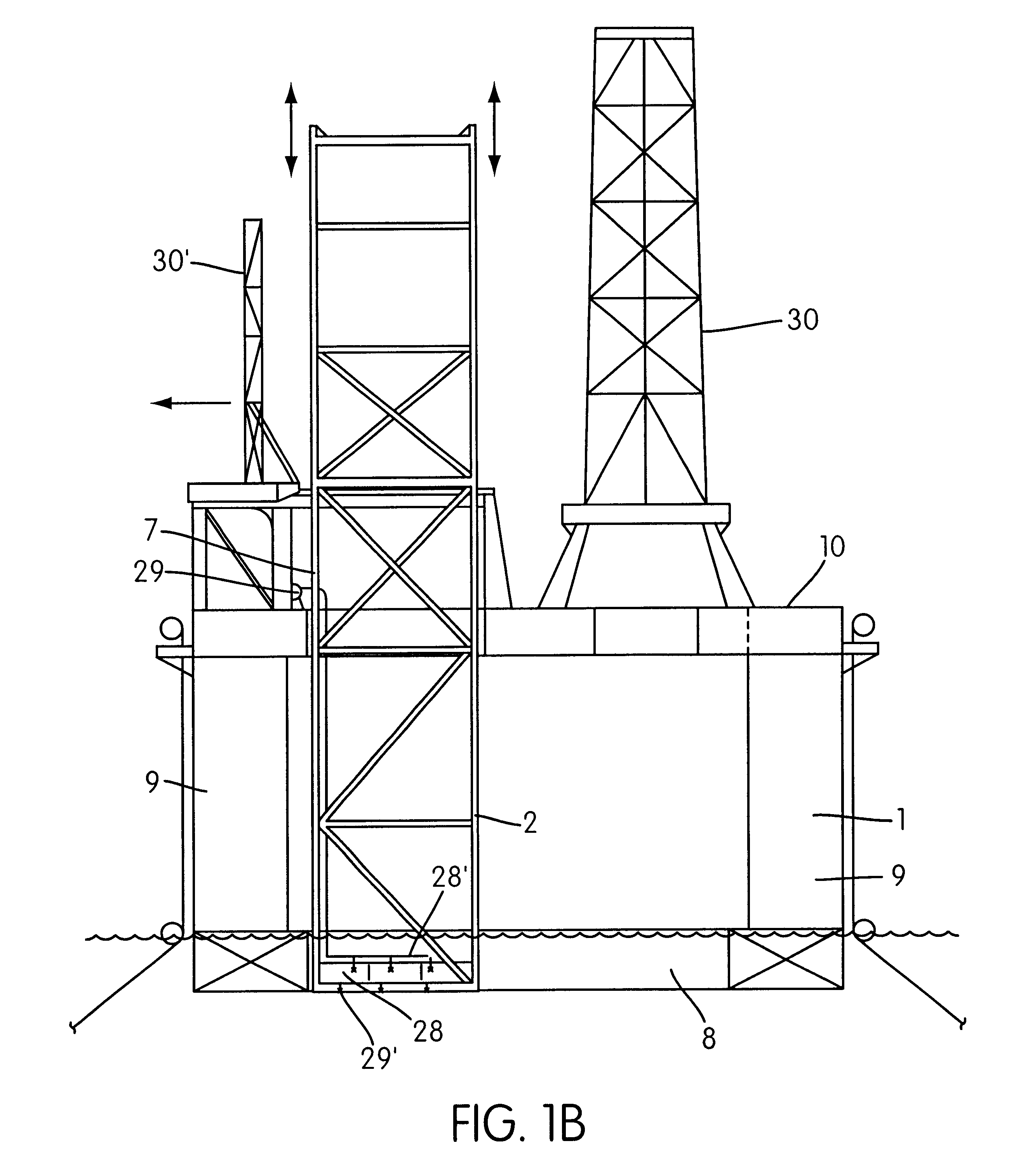

Guide device for production risers for petroleum production with a "dry tree semisubmersible" at large sea depths

A system for use in petroleum production at sea includes a guide frame for one or more riser pipes, on a semisubmersible production vessel. One or more main buoyancy member are arranged separately on at least one riser to carry the main part of the riser's weight. Each riser separately carries a Christmas tree on its top, near a main deck of the vessel. The guide frame comprises vertical main elements extending vertically downwards from the deck, through the splash zone and through the upper, more wave- and current-influenced zone of the sea. The guide frame also includes horizontal guide plates comprising vertically open cells formed of a horizontally arranged framework of beams. Lateral stabilization devices guide the risers' and the main buoyancy members' vertical movement relative to the vessel and restrict horizontal movement of the risers with respect to the guide frame. The guide plates are arranged in at least two levels on the guide frame. A lower guide plate is arranged at the lower ends of the vertical main elements', and a guide plate is arranged just below or near the splash zone. At least one main buoyancy member is held on the riser in level with, and guided by, lateral stabilization devices arranged in one or more guide plates below the upper, more wave- and current-influenced zone near the sea surface. The risers are without buoyancy elements through the splash zone, and thus are less exposed to the water forces in the upper zone of the sea.

Owner:PGS OFFSHORE TECH

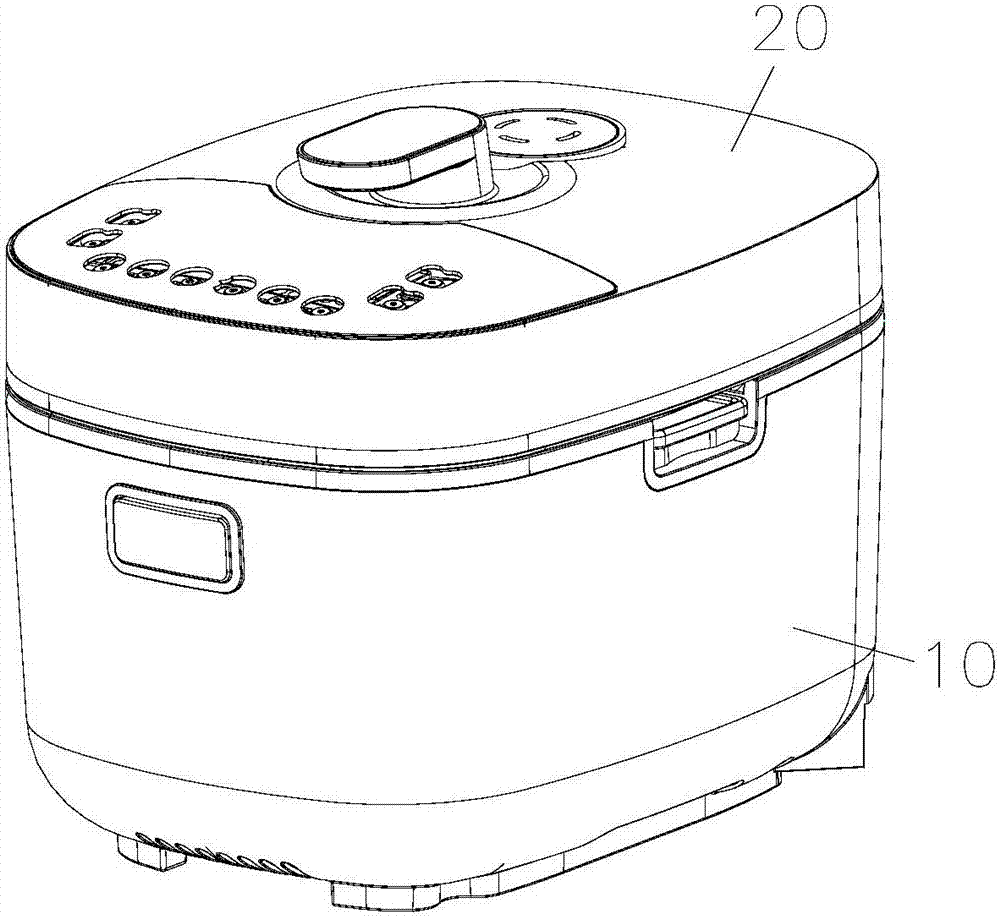

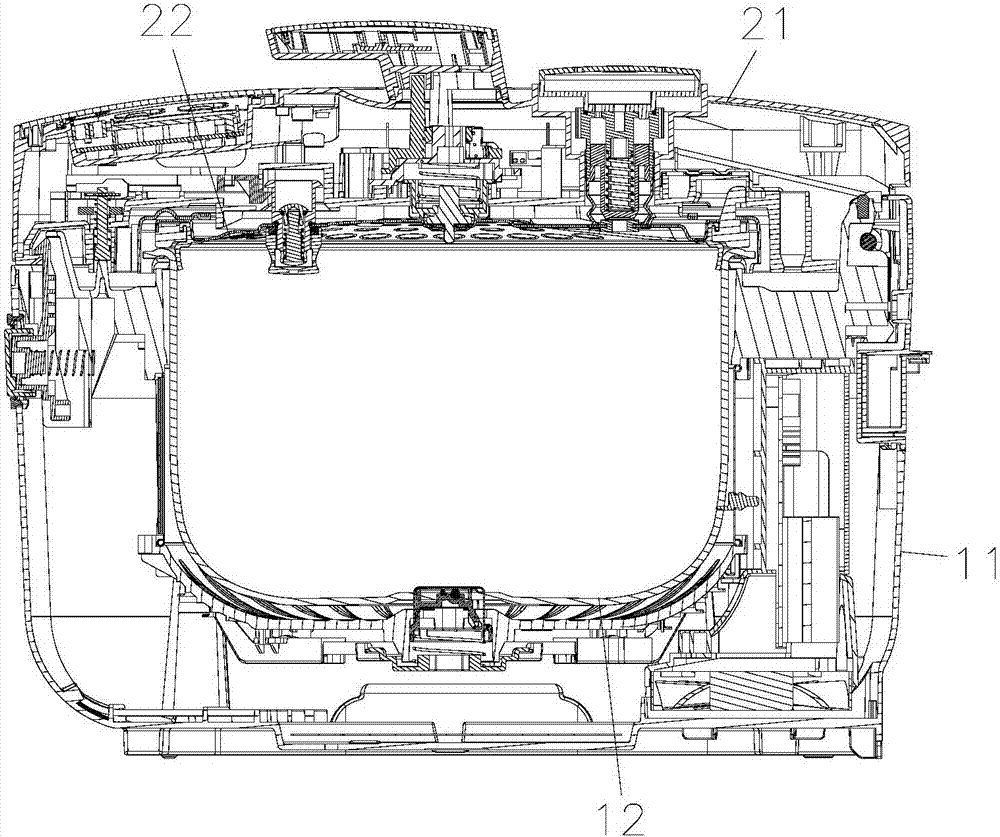

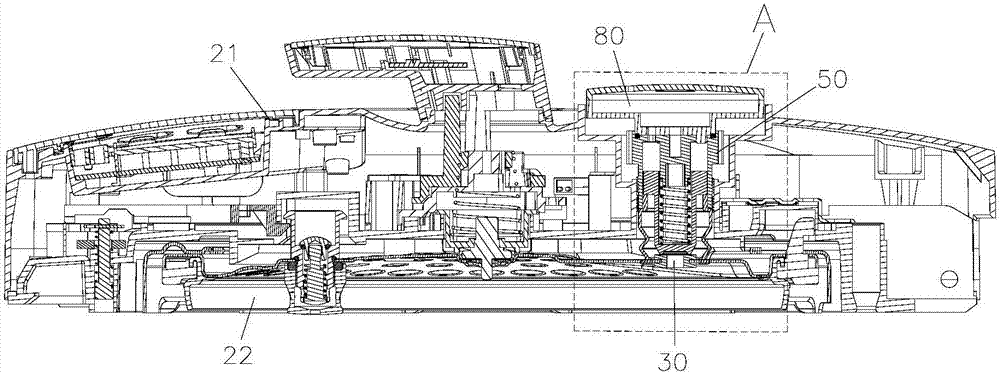

Electric pressure cooker

ActiveCN107019419ASmall linear motion distanceLarge rotation angleFood processingPressure-cookersEngineeringCooked food

The invention discloses an electric pressure cooker, which comprises a cooker body, a cooker cover and a driving mechanism, wherein the cooker body comprises an outer pot and an inner pot which is arranged in the outer pot, and the inner pot is used for accommodating cooked foods; the cooker cover is arranged on the cooker body and the cooker cover covers the inner pot in a sealing mode; an exhaust passage which communicates with the interior of the inner port and a pressure limiting valve which is in charge of controlling a ventilation state of the exhaust passage are arranged on the cooker cover; the driving mechanism comprises a power mechanism which is used for offering rotating motion of a rotating shaft and a threaded transmission mechanism which is used for converting rotation of the rotating shaft into vertical motion of the pressure limiting valve; and the threaded transmission mechanism comprises threaded pillars and threaded holes which are mutually matched. With the application of the technical scheme provided by the invention, a problem in the prior art that an electric pressure cooker, which cannot achieve continuous exhausting, is poor in cooking effect since foods cannot be kept turning continuously is solved.

Owner:ZHEJIANG SHAOXING SUPOR DOMESTIC ELECTRICAL APPLIANCE CO LTD

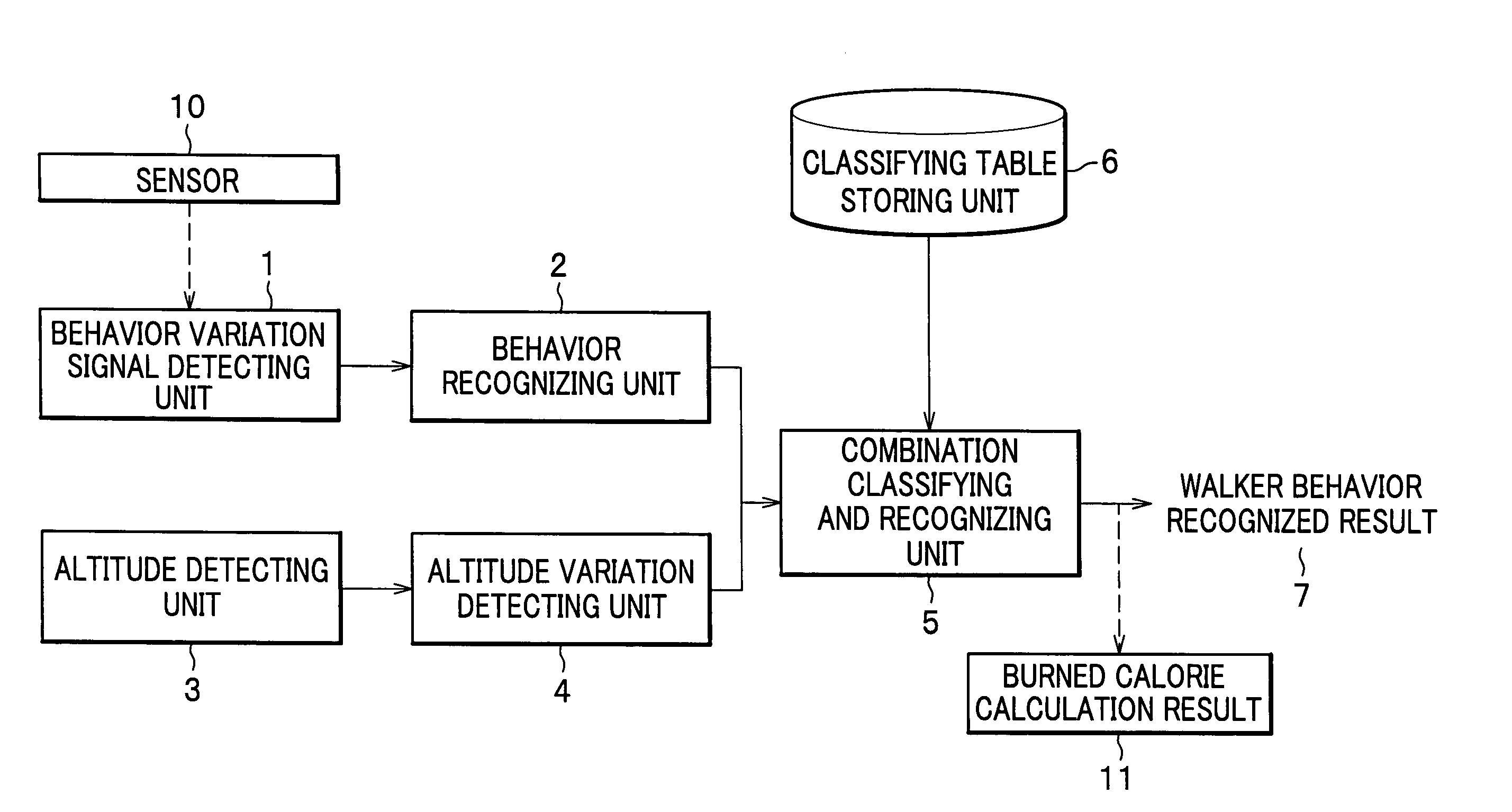

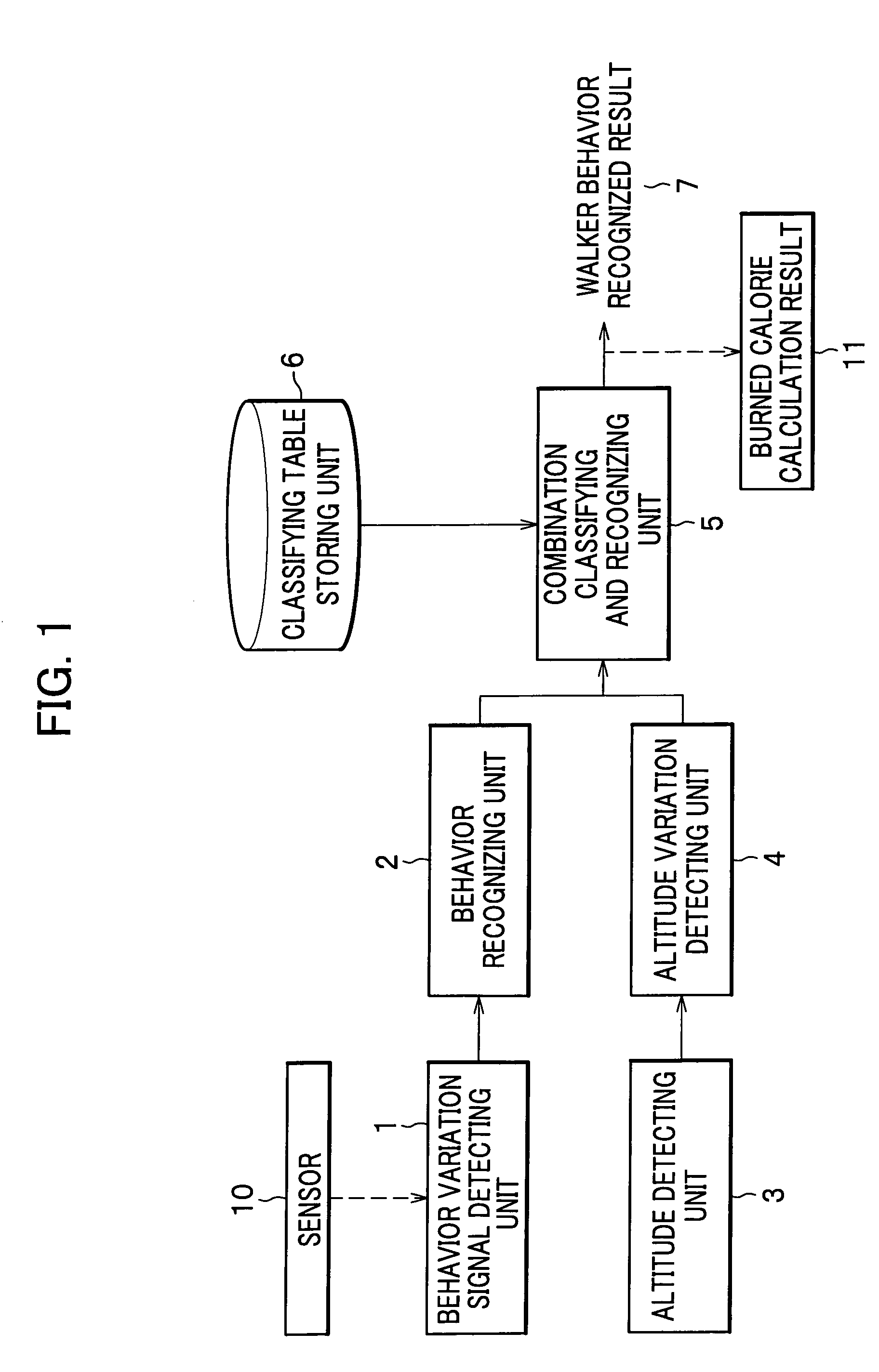

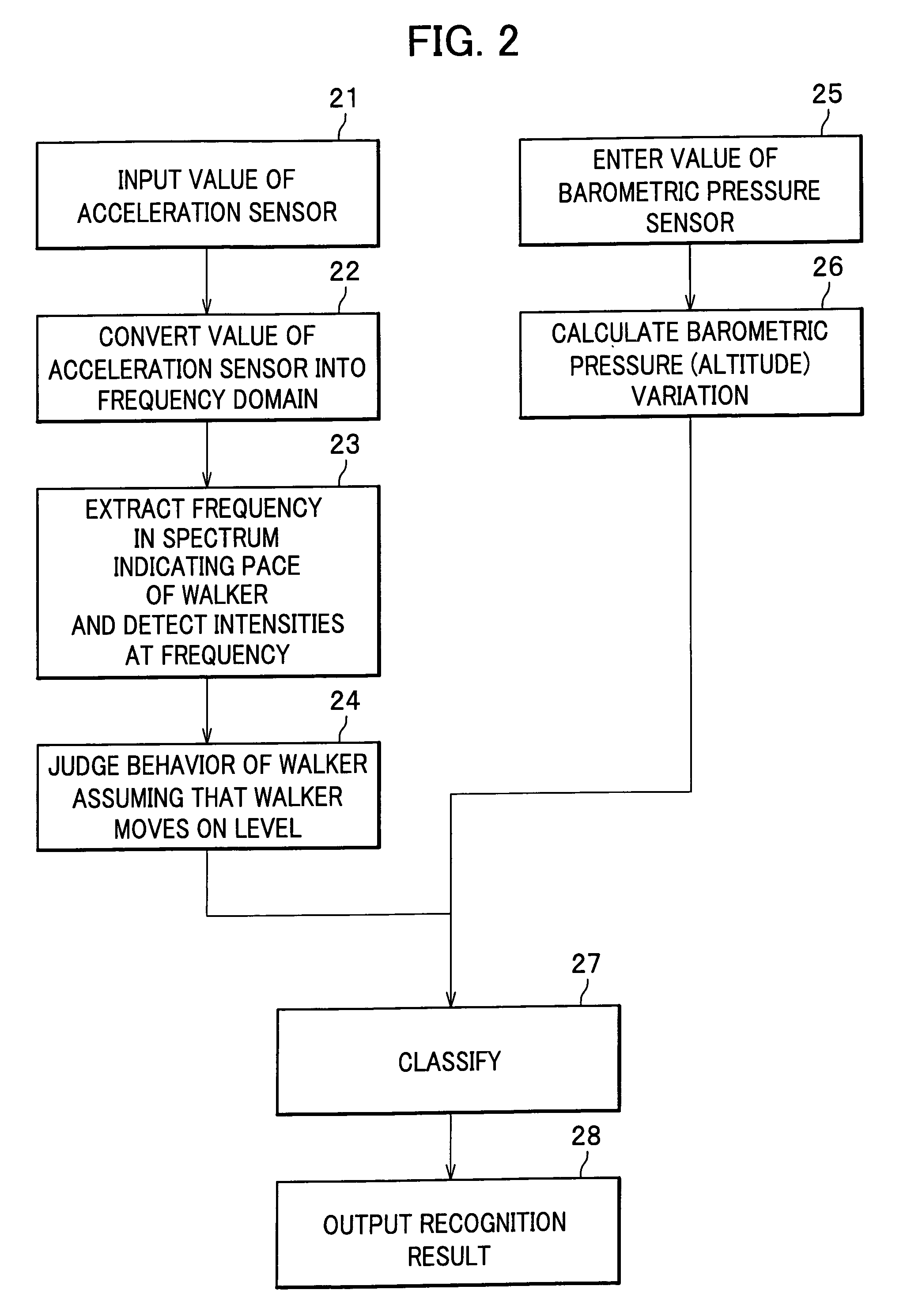

Walker behavior detection apparatus

InactiveUS7811203B2Instruments for road network navigationCosmonautic condition simulationsEngineeringNavigation system

A behavior of a walker is detected according to combination of detection of the walking behavior on a level and an altitude variation of the walker to more accurately detect the behavior of the walker. A burned calorie can be obtained according to the type of the walking behavior. An altitude variation can be obtained more accurately by integrating altitude variation only at sections with vertical movement during walking. A stride is estimated according to the behavior of the walker in consideration of the vertical movement. Obtained position and traveling direction are used for compensating values in inertial navigation system. The behavior with and without vertical movement is used in a walker navigator and a worker observing system including a worker terminal carried by the walker for detecting the behavior of the worker and a worker observing terminal for providing the detected position and behavior of the walker.

Owner:HITACHI ADVANCED SYST +1

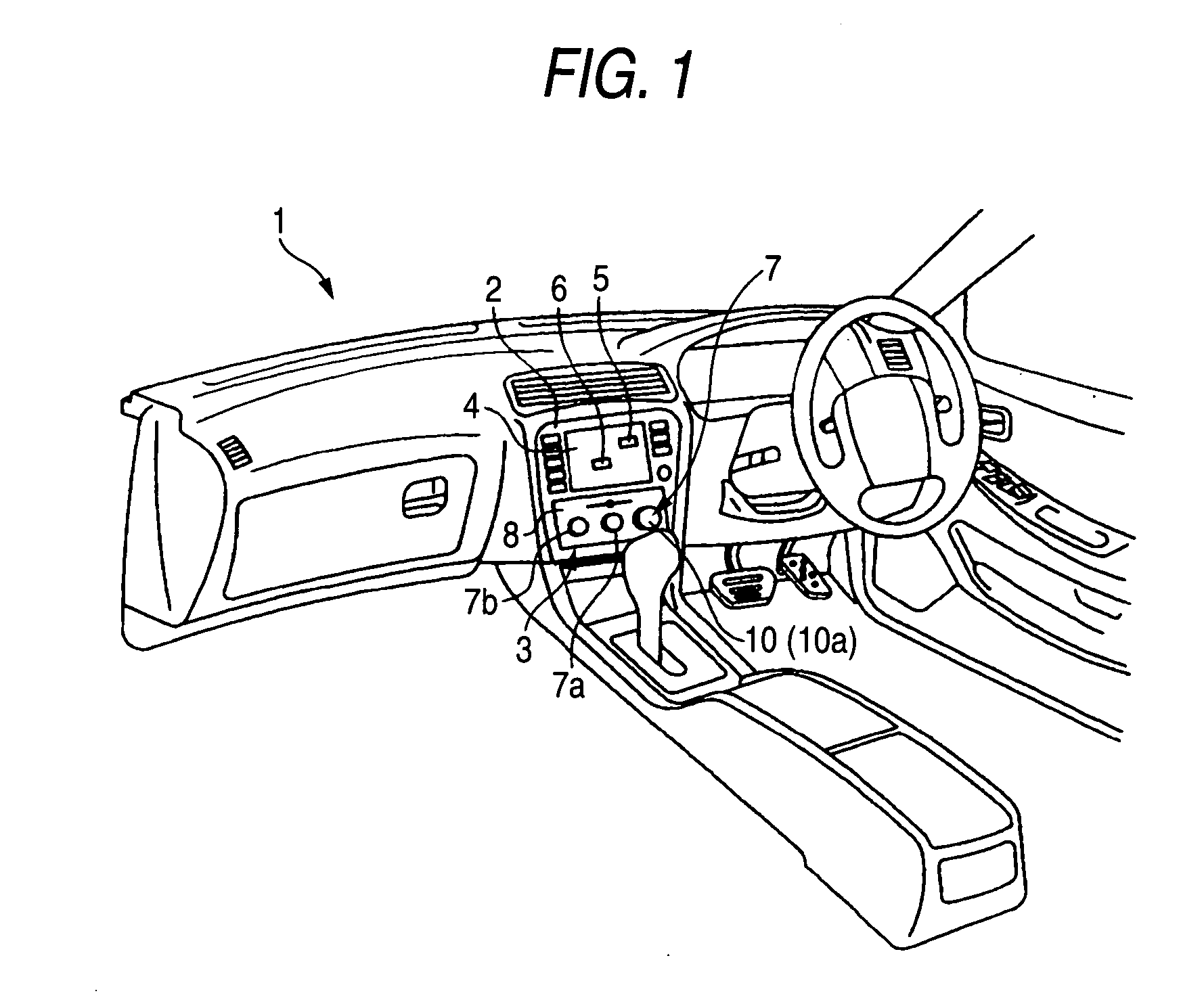

Control switch apparatus

InactiveUS20080197004A1Easy to implementControlling membersContact driving mechanismsDetentEngineering

A control switch is equipped with a detent mechanism that generates a click feeling in a dial knob as a result of a detent piece of a plunger member gets over detent crests of a detent crest member. A stopper is provided in the plunger member, and the position of vertical motion of the stopper is switched by means of a rectilinear actuator, thereby switching rotational operation of the dial knob between an enabled state and a disabled state.

Owner:KK TOKAI RIKA DENKI SEISAKUSHO

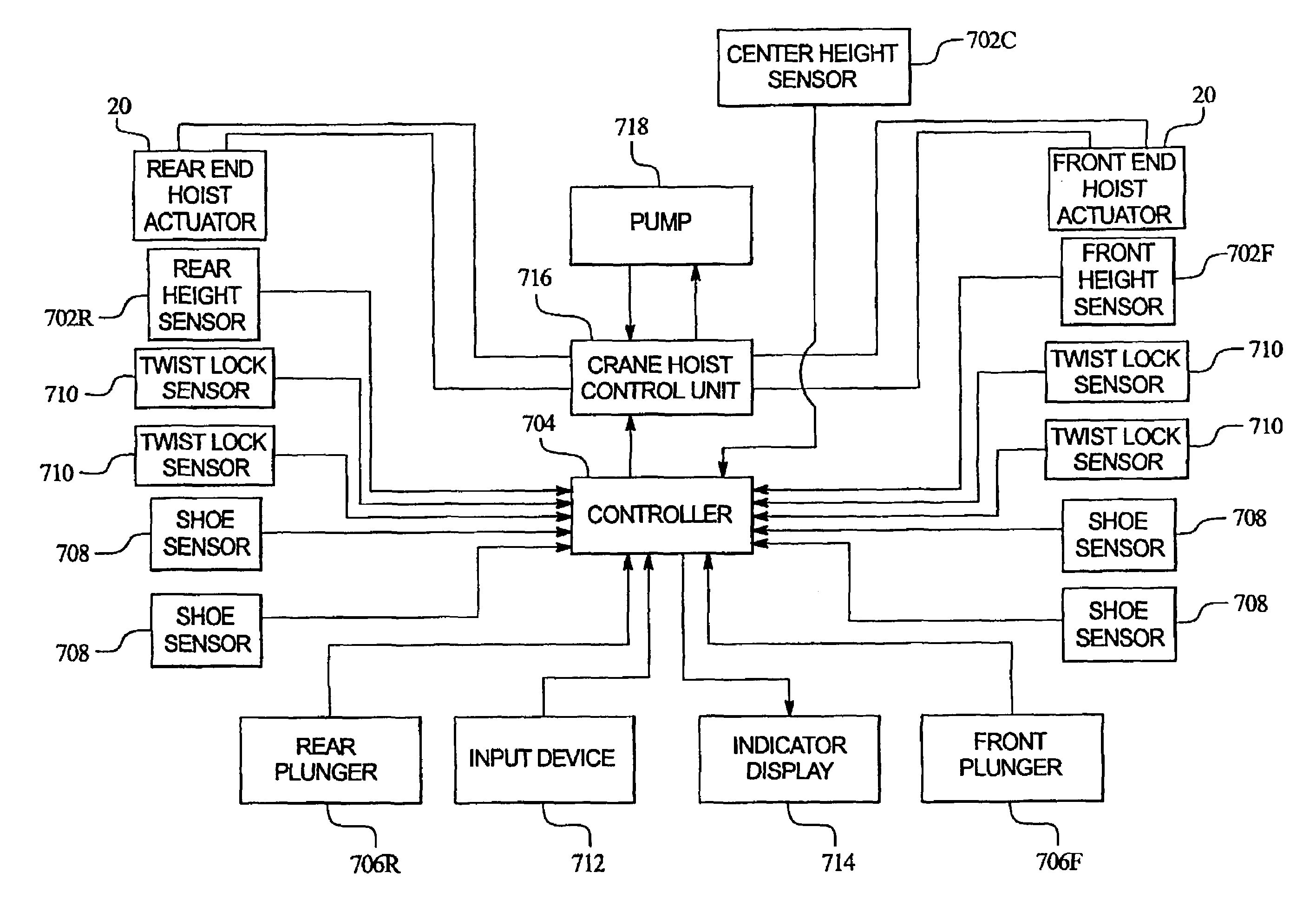

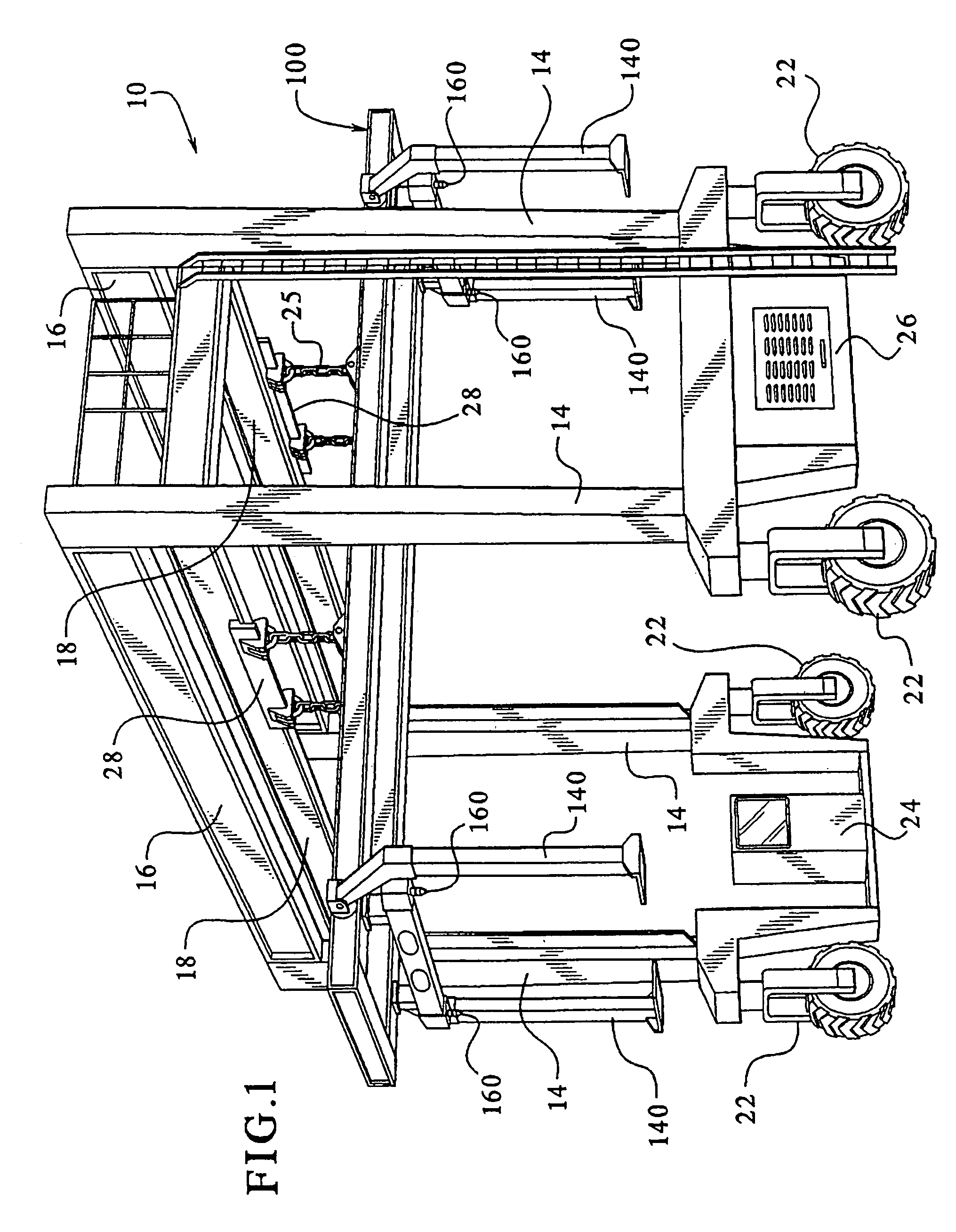

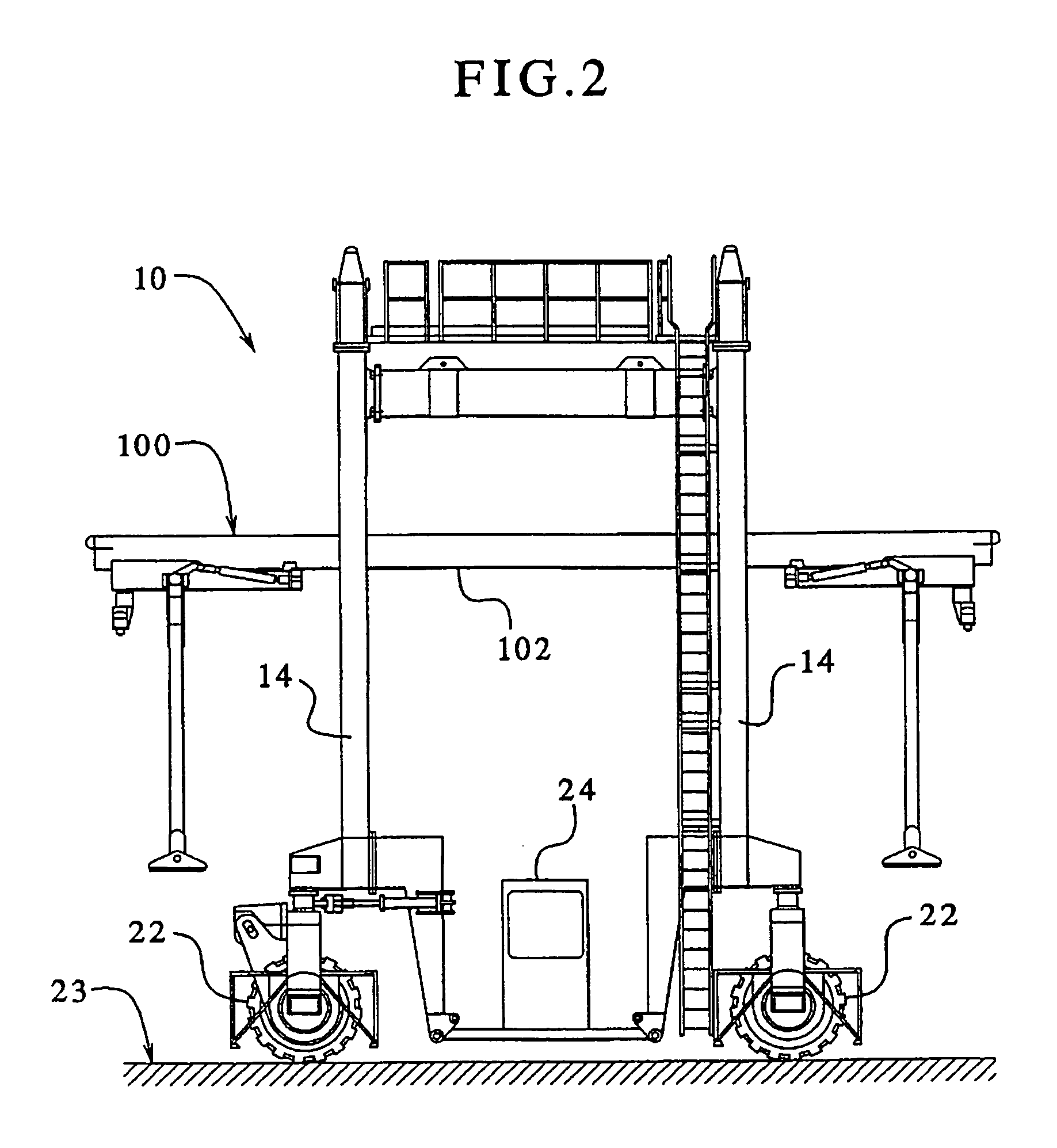

Grappler control system for a gantry crane

InactiveUS6968963B1Potential damageExtended reaction timeTrolley cranesThin material handlingVertical motionGantry crane

A system and process are provided for controlling motion of a grappler of a gantry crane to avoid damaging an object to be lifted. In an embodiment, a speed of grappler movement is automatically reduced when in close proximity to the object. Furthermore, the grappler automatically stops when positioned appropriately to permit a latching mechanism to engage the object for lifting. Normal speed grappler motion is restored when the latching mechanism is fully engaged. In a particular embodiment, the grappler includes a plurality of height sensors at various positions along the grappler to determine the respective height of the grappler above a top of the object. Vertical motion of front and rear ends of the grappler are independently actuated and controlled to permit appropriate control when the grappler and / or the object are not level.

Owner:MI JACK PRODS

Patient bed for multiple position emission scans

InactiveUS6885165B2Motor/generator/converter stoppersDC motor speed/torque controlElectronic controllerWhole body

A patient bed for use with at least one imaging device in which a plurality of scans to be correlated are performed, as well as in a continuous motion scanner used to compile whole-body scans. The patient bed includes a horizontal rail base and a movable patient surface. Electronic controllers are provided for controlling the horizontal and vertical positioning of the patient surface. The horizontal rail base is secured to the support proximate the scanner. A linear motor is used to generate horizontal motion of the patient bed. The linear motor is controlled using a motion controller in communication with a computer associated with the imaging device. A pedestal is provided for mounting a vertical carriage assembly. A vertical track is carried by the pedestal for controlling vertical travel of the patient bed. A motor is provided for controlling vertical motion. A pallet support member is cantilevered from the vertical carriage assembly for carrying a pallet.

Owner:SIEMENS MEDICAL SOLUTIONS USA INC

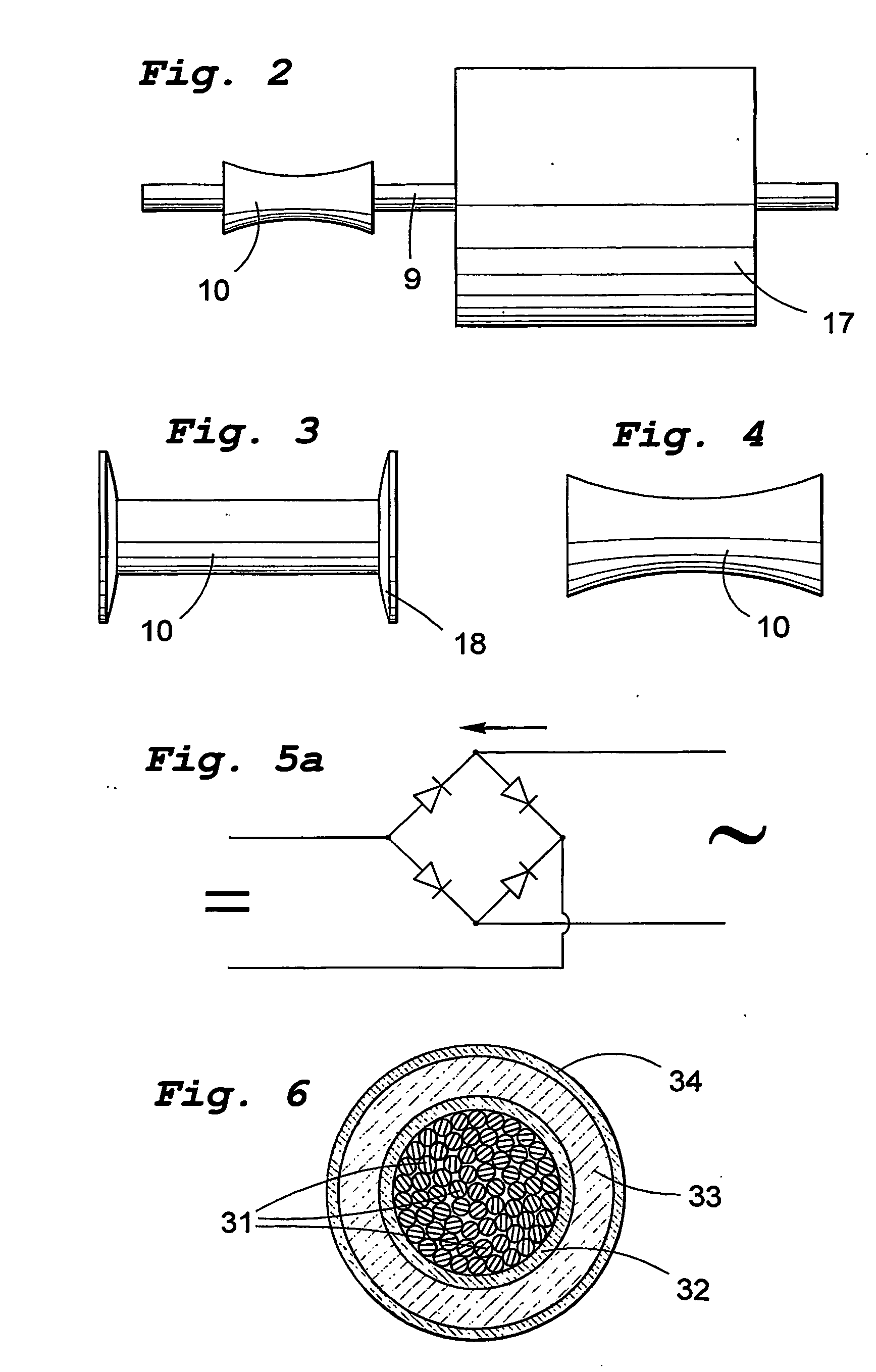

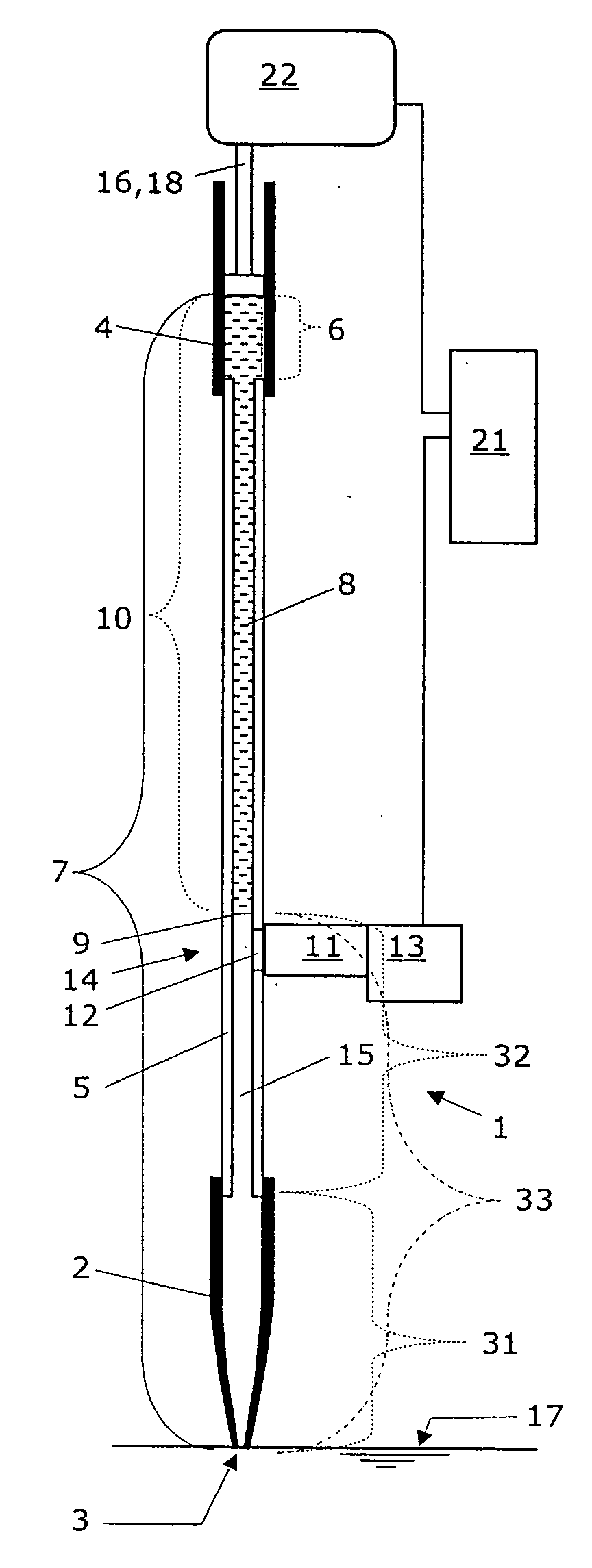

Pipetting apparatus with integrated liquid level and/or gas bubble detection

ActiveUS20060127281A1Analysis using chemical indicatorsWithdrawing sample devicesVertical motionEngineering

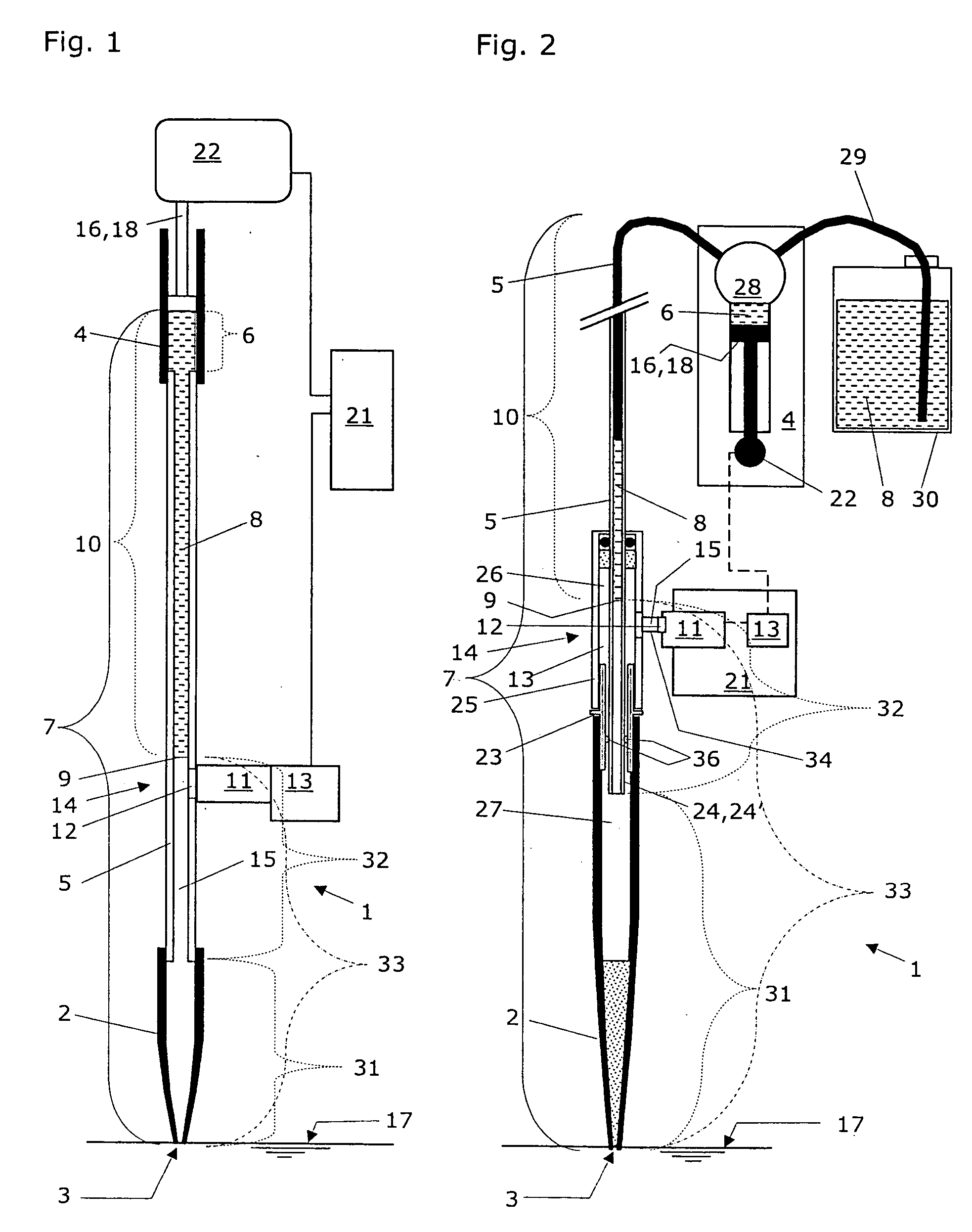

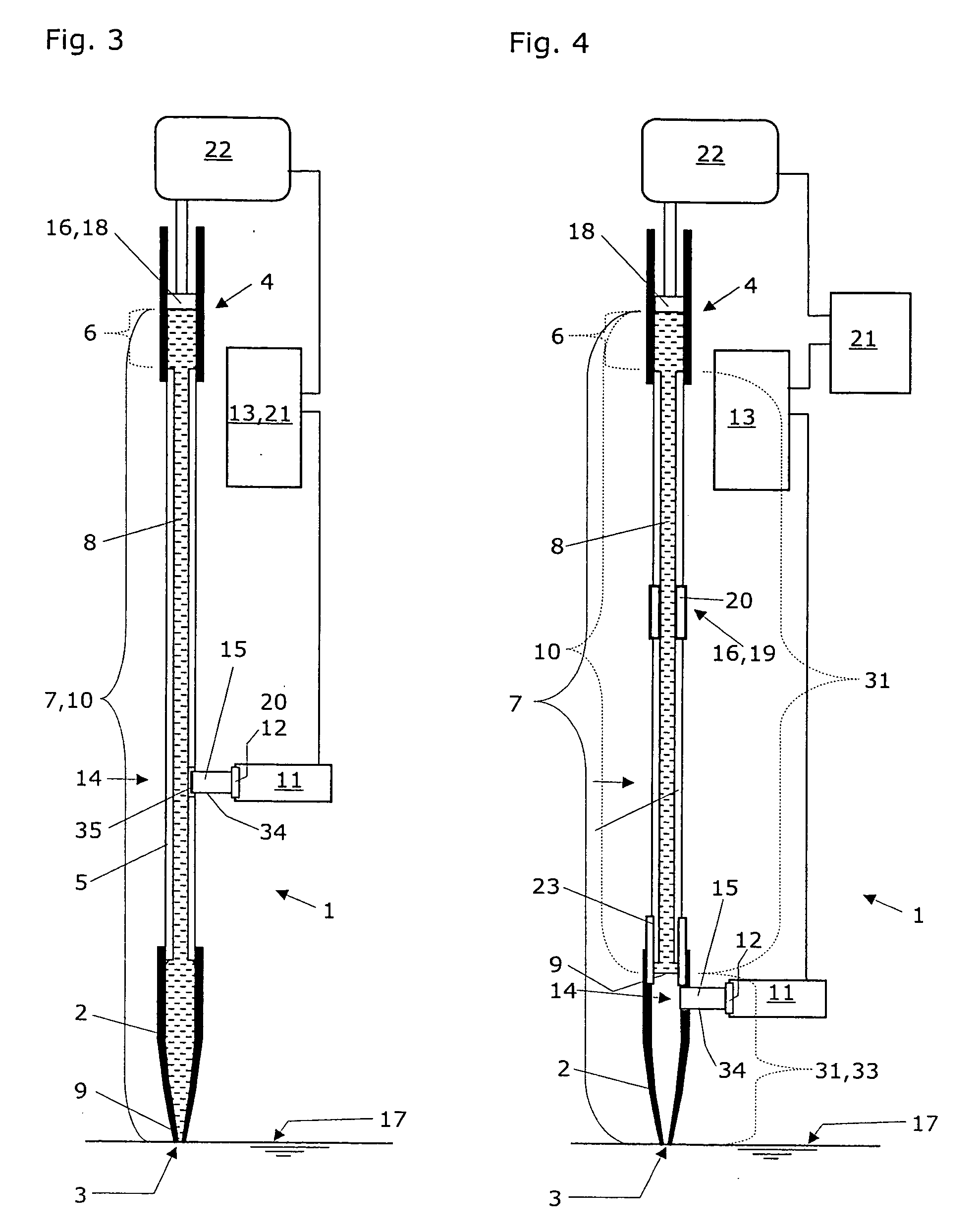

A pipetting apparatus (1) comprises a fluidic space (7), to which a pressure transducer (11) with a pressure sensor (12) is attached with a gas filled space (15). The fluidic space (7) is defined by a pipette tip (2), a first tubing (5) that connects the pipette tip (2) to a pump (4), and an active part (6) of the pump (4). The pipetting apparatus (1) according to the present invention is characterized in that the pipetting apparatus (1) further comprises an impulse generating means (16,18,19) that is in operative contact with a column (10) of system liquid (8) inside the fluidic space (7). The impulse generating means (16,18,19) is designed to induce a vertical movement in this system liquid column (10), which results in a pressure variation in the gas filled space (15) that is pneumatically connected with the fluidic space (7). This pressure variation—as recorded with the pressure transducer (11) and as processed by a first data processing unit (13) during utilization of this pipetting apparatus—is taken as an indicator for the detection of penetration or of quitting of a surface (17) of a liquid, with an orifice (3) of the pipette tip (2), of which liquid an amount is to be aspirated and dispensed. This pressure variation is also taken as an indicator for the detection of the presence or the absence of gas bubbles in the system liquid (8) contained in the fluidic space (7) of this pipetting apparatus.

Owner:TECAN TRADING AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com