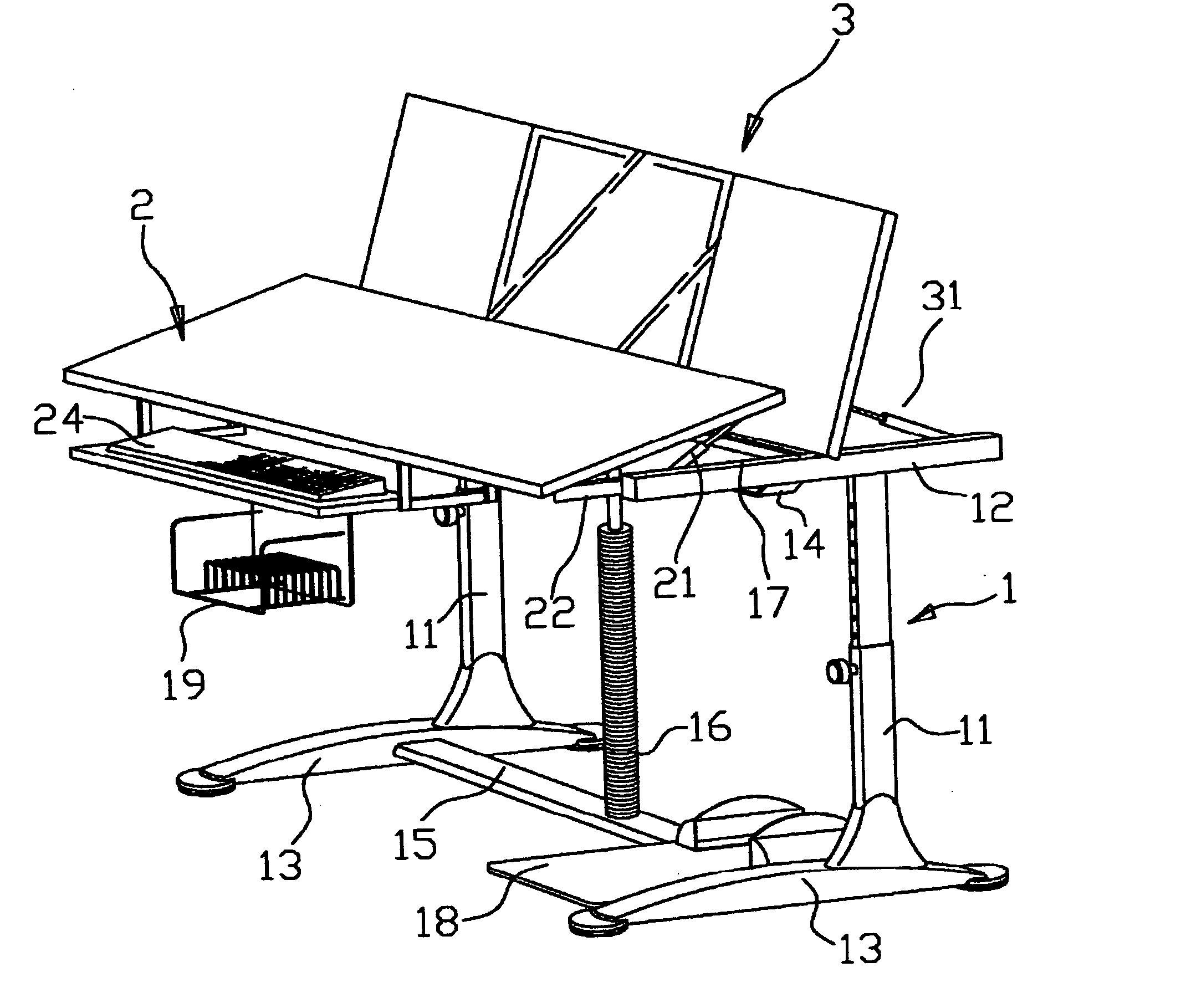

Patents

Literature

400 results about "Standing frame" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A standing frame (also known as a stand, stander, standing technology, standing aid, standing device, standing box, tilt table) is assistive technology that can be used by a person who relies on a wheelchair for mobility. A standing frame provides alternative positioning to sitting in a wheelchair by supporting the person in the standing position.

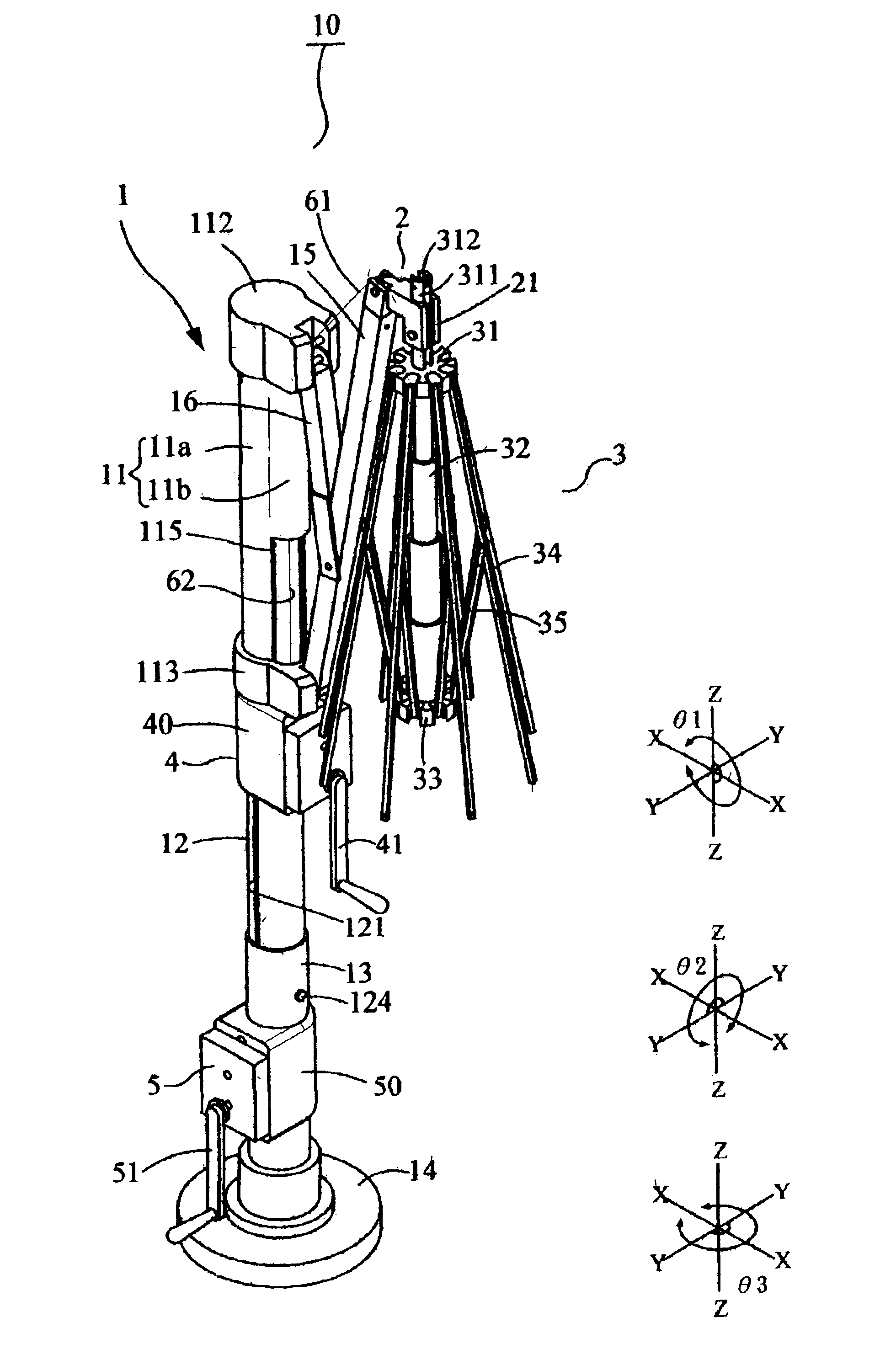

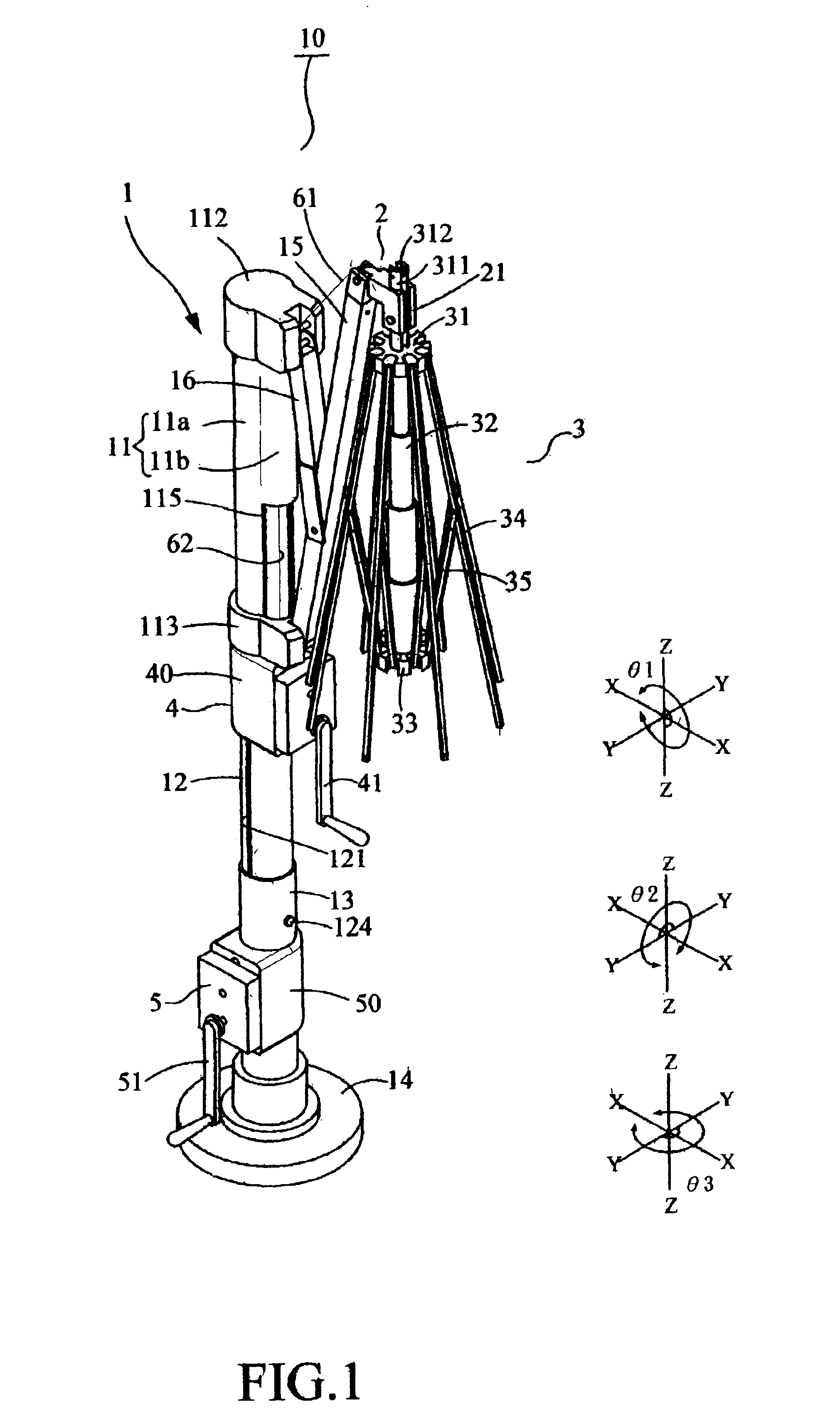

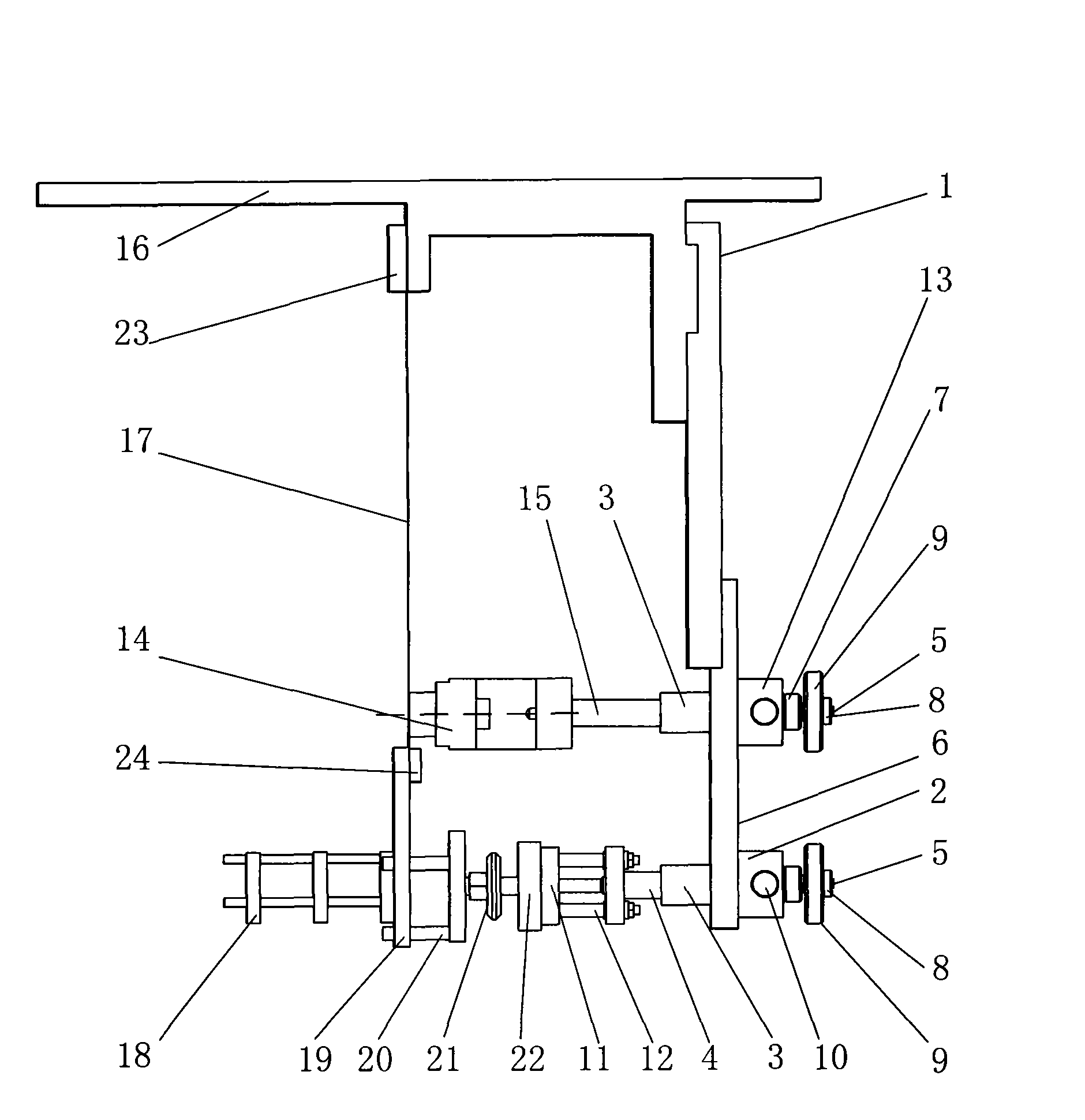

Outdoor used stand frame of an umbrella

A stand frame for an umbrella comprises a shaft, an umbrella frame, a foldable hanger arm hanging the umbrella frame, a height-adjustable device, and an angle-adjusting device. The stand frame for an umbrella utilizes the height-adjustable device and the angle-adjusting device to control the expansion / contraction and angular orientation of the umbrella frame thereof. The height-adjustable device provides a mechanism by which the middle section of the shaft can rotate horizontally, so as to move the umbrella frame about the shaft. A pull string extending from the shaft to the umbrella frame drives a vertical movement of the upper section of the shaft and the expansion of the umbrella frame simultaneously. A set of other pull strings are manipulated by the angle-adjusting device to vary the angular orientation of the umbrella frame in three dimensions.

Owner:CHEN SHIOW HUI

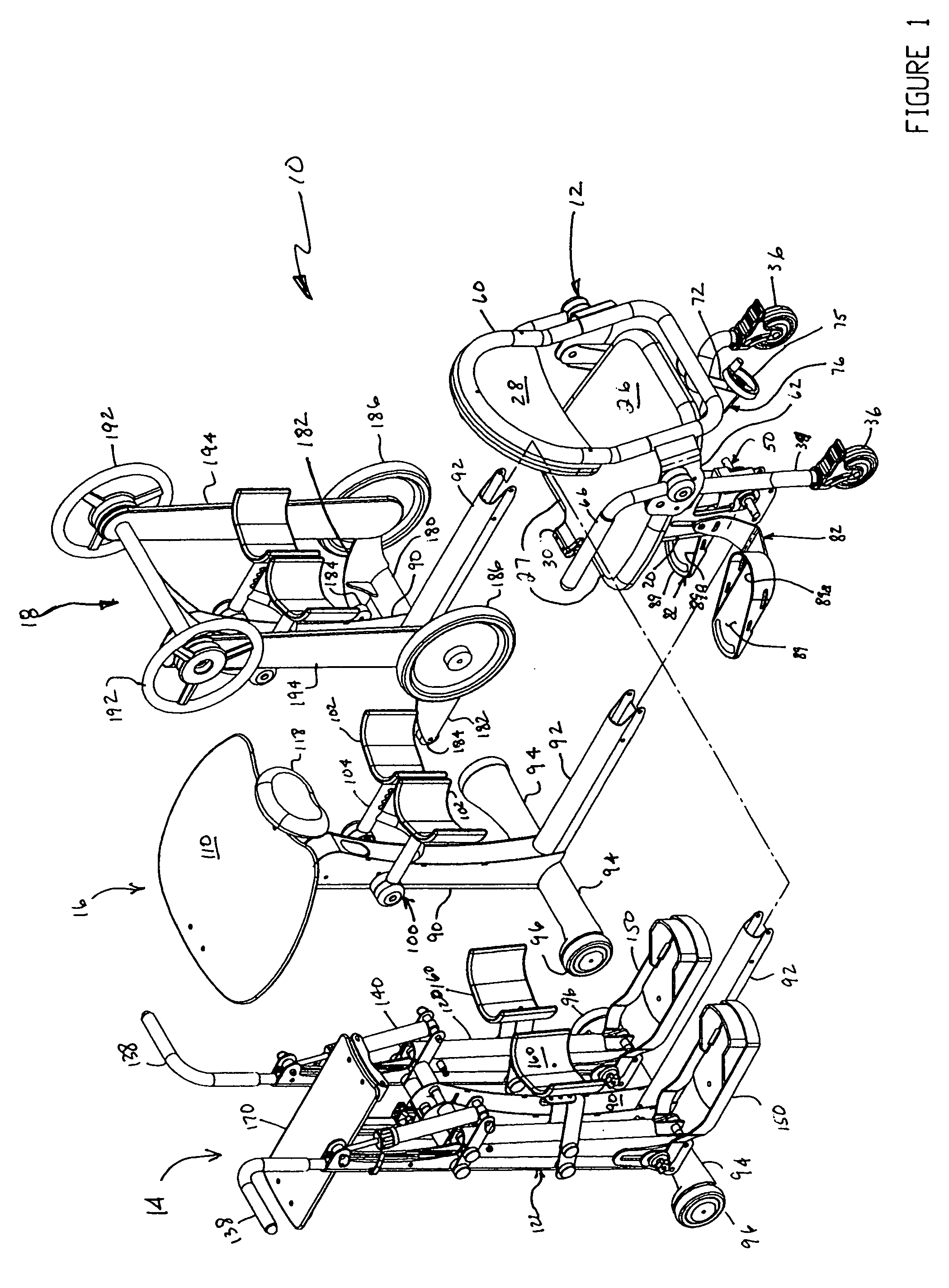

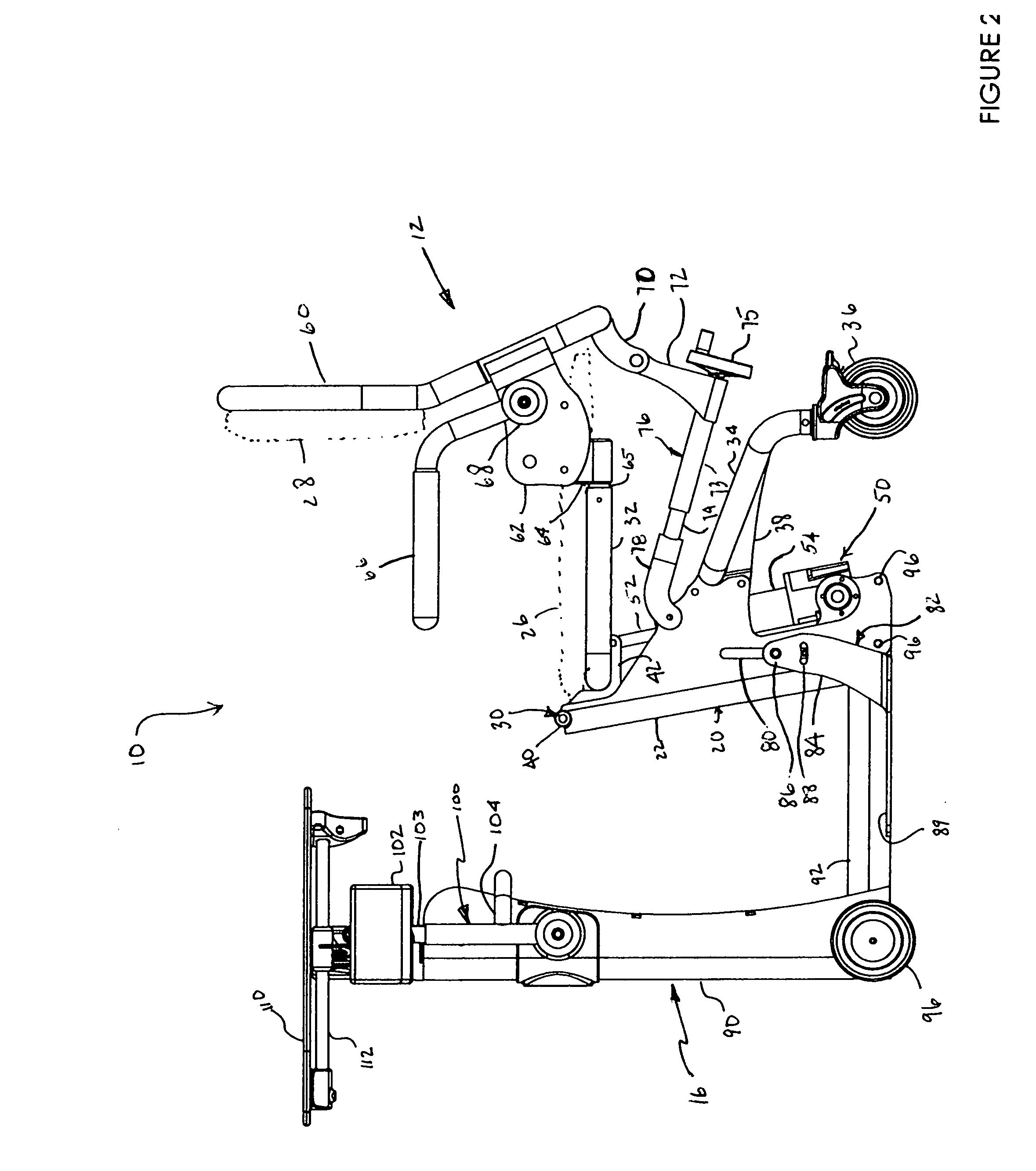

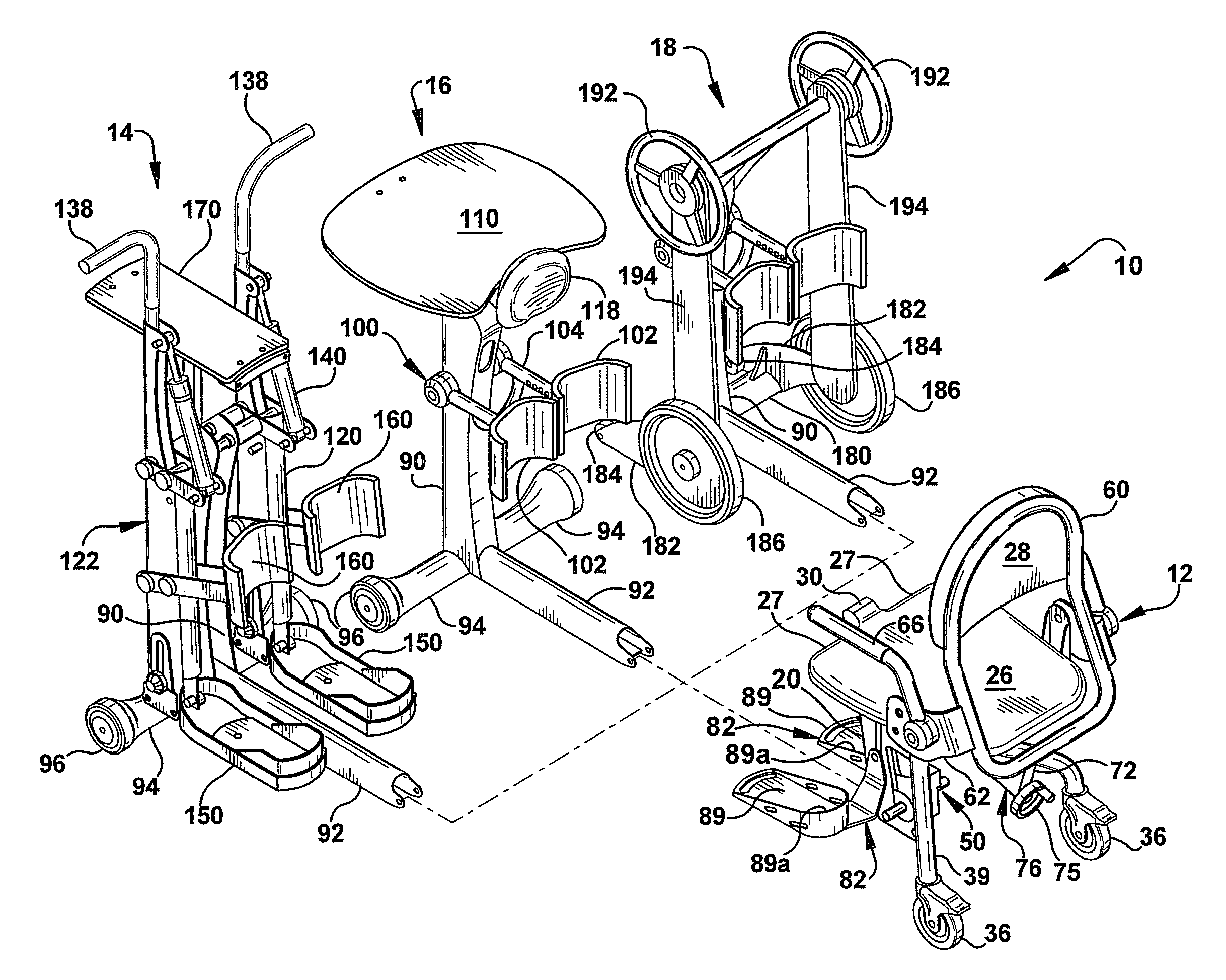

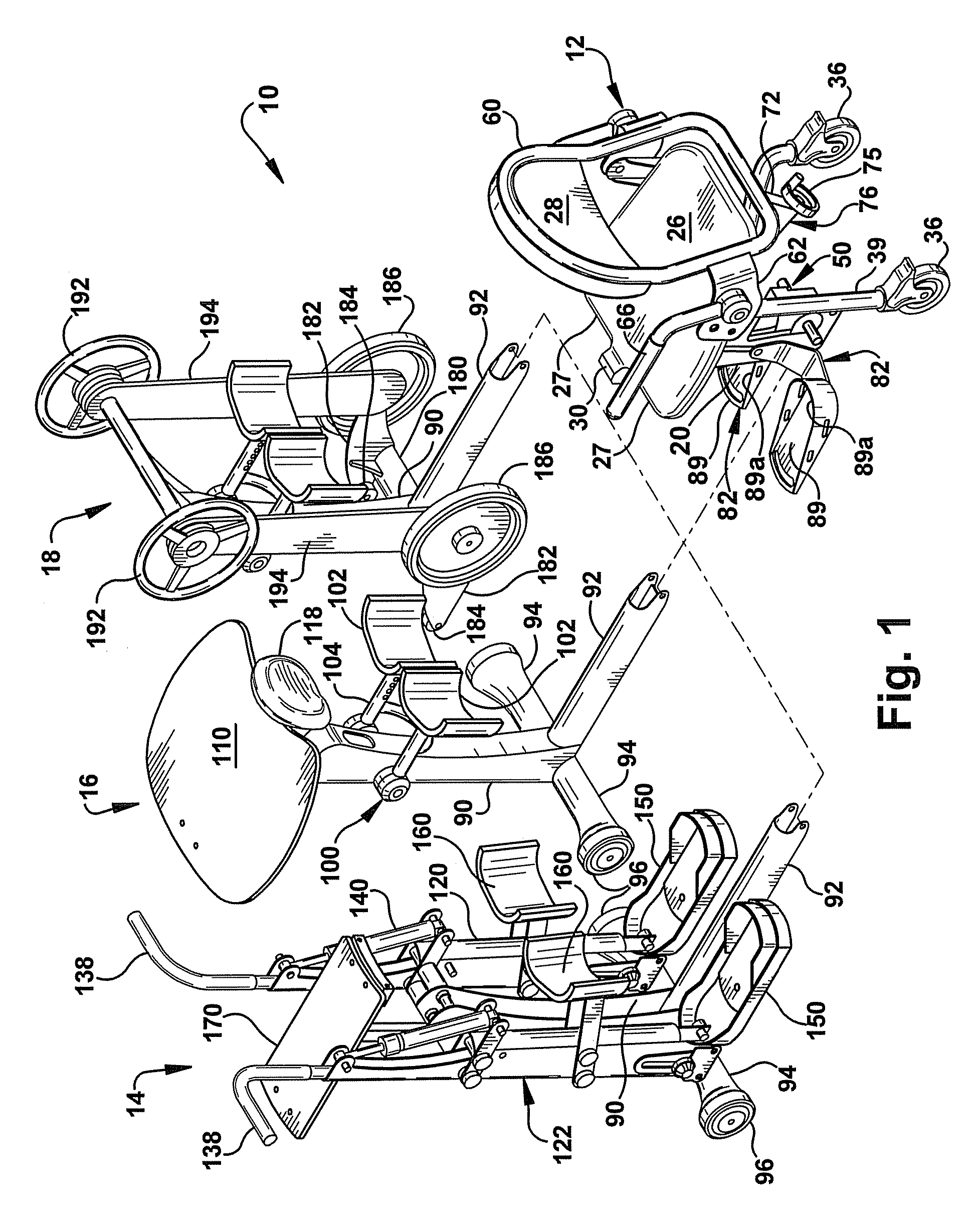

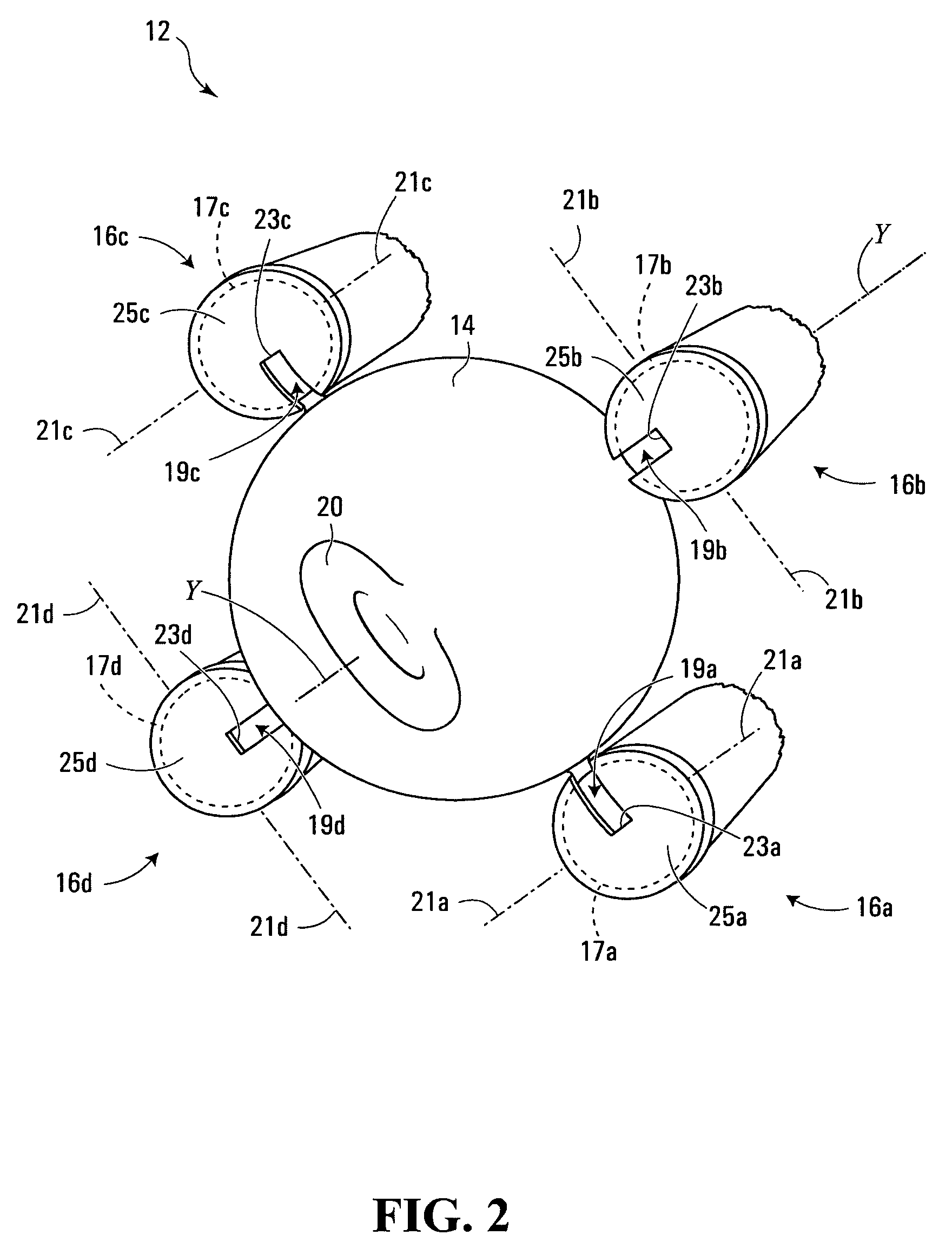

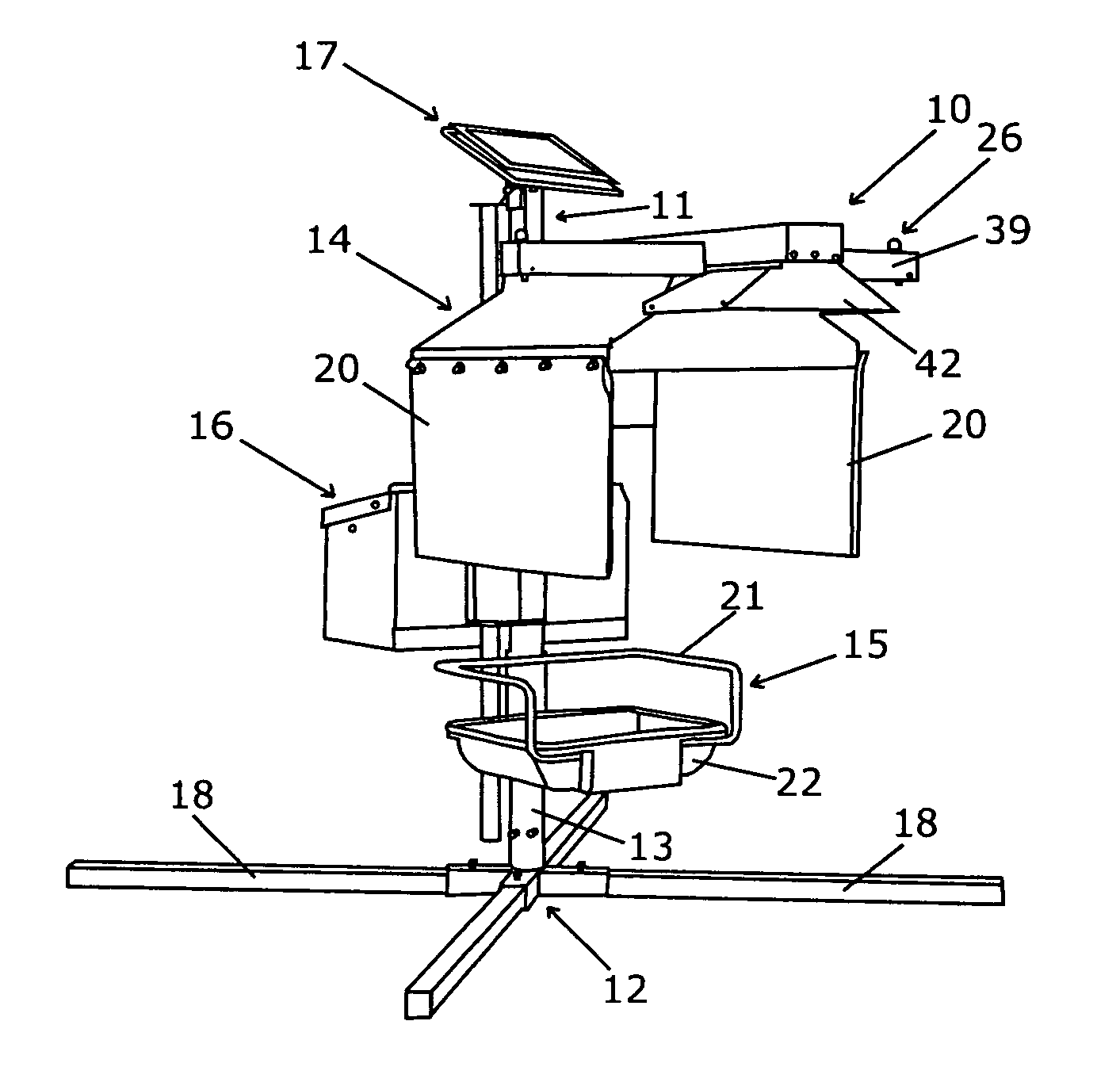

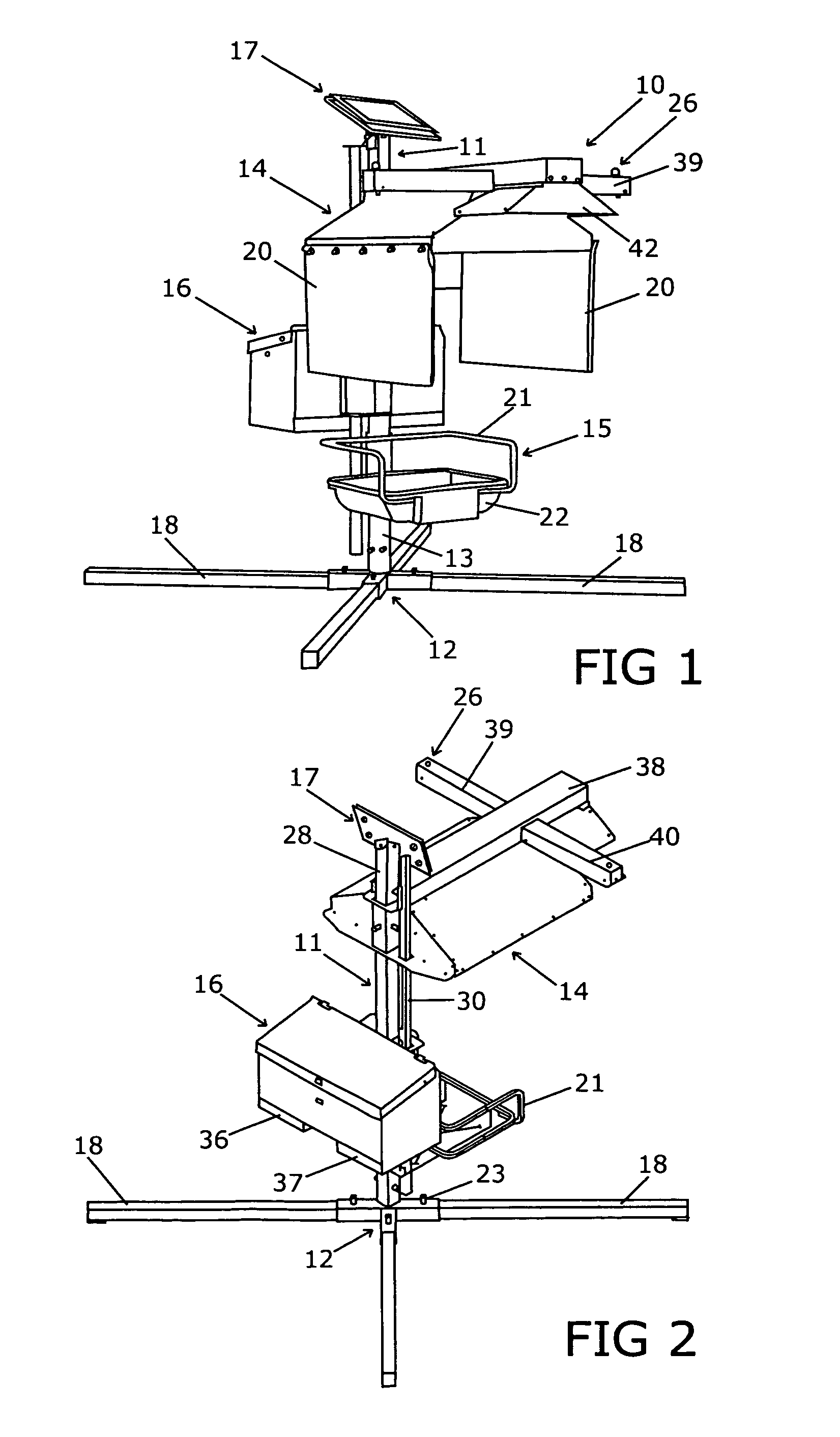

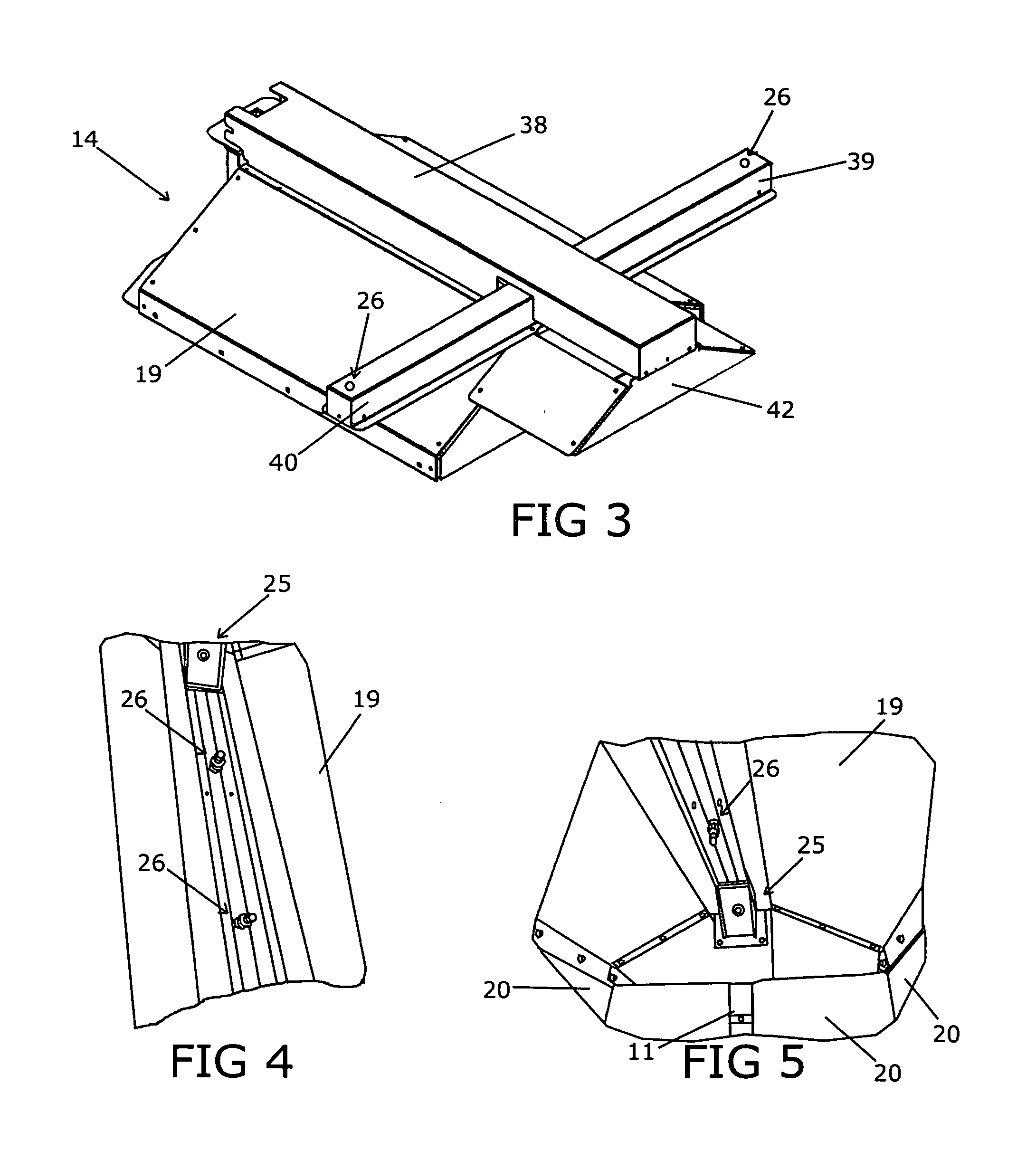

Modular standing frame

A modular standing frame is described herein. The modular standing frame has a chair module adapted to raise and lower a user between sitting and standing postures without inducing shear between the user and the seat and seat back of the chair module. The chair module may be selectively coupled to one of a glider module adapted to provide walking-type exercise to a standing user, a workstation module that provides a work surface for a sitting or standing user, and a mobility module that allows the standing frame to be moved about by a user much like a wheel chair.

Owner:ALTIMATE MEDICAL

Modular standing frame

Owner:ALTIMATE MEDICAL

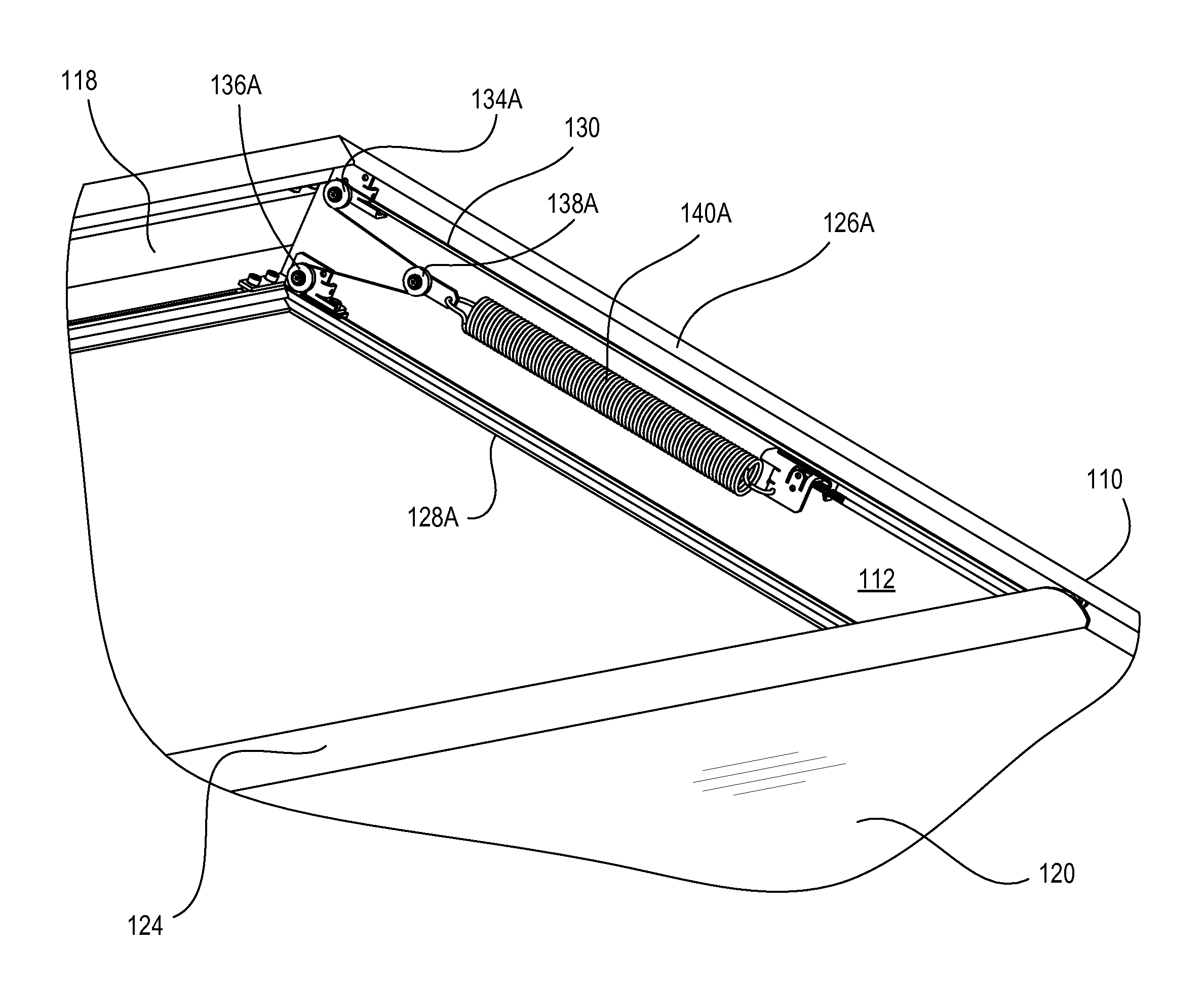

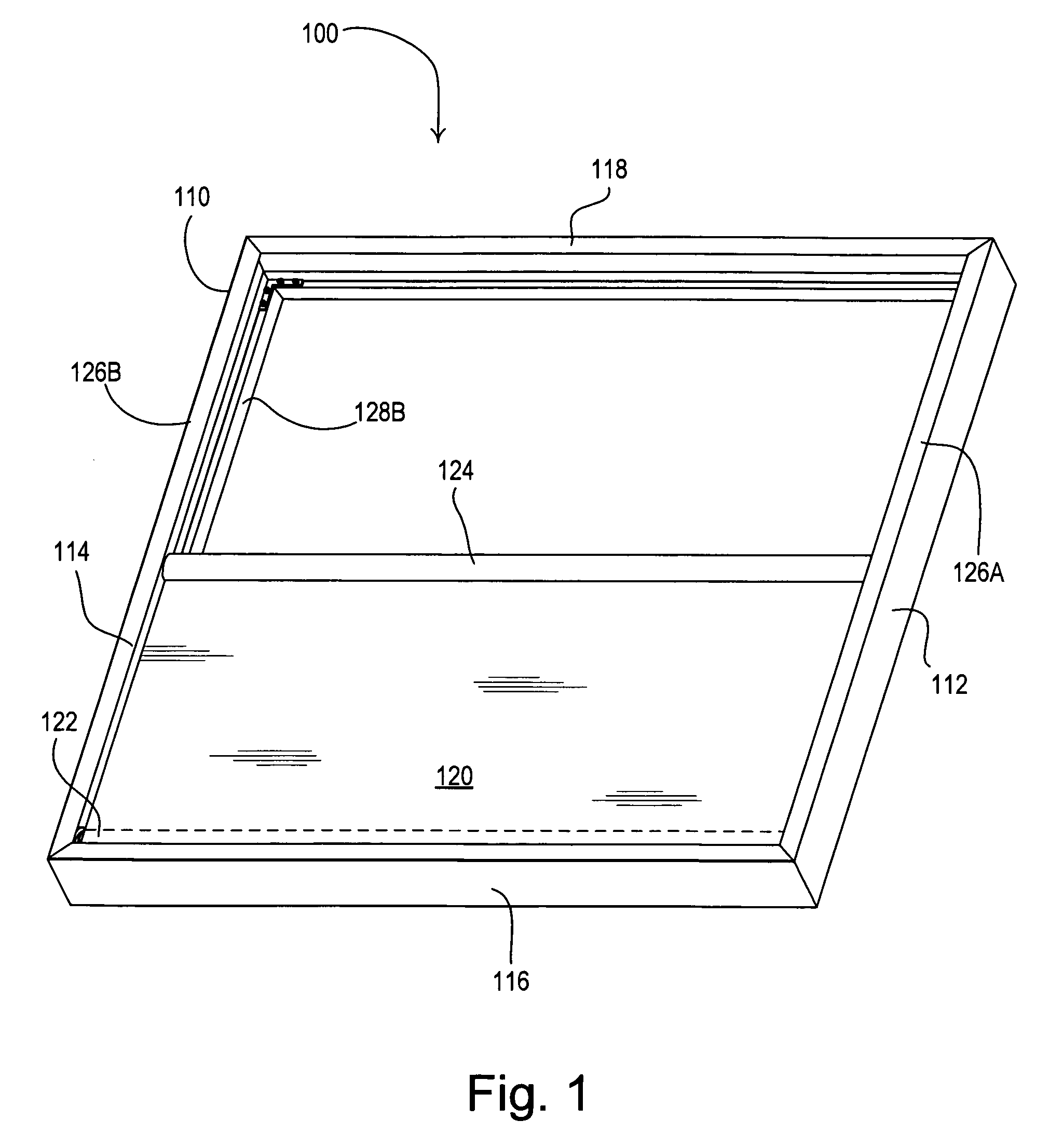

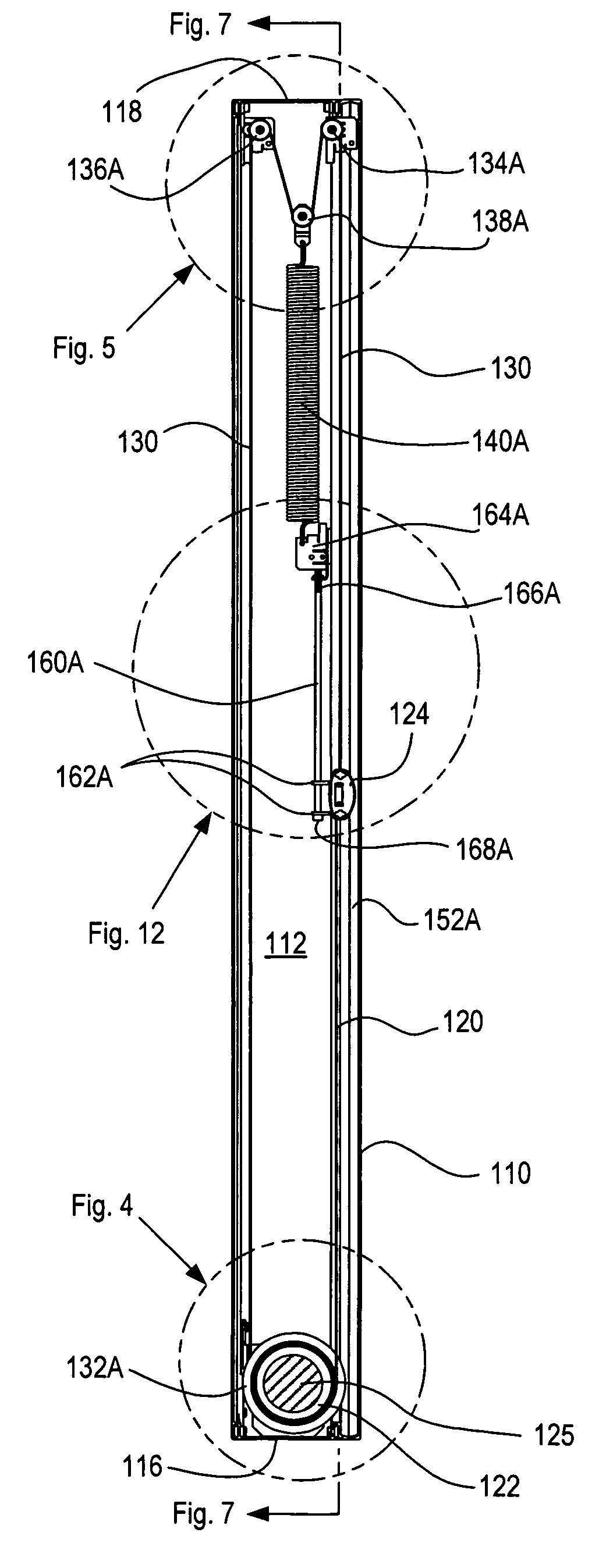

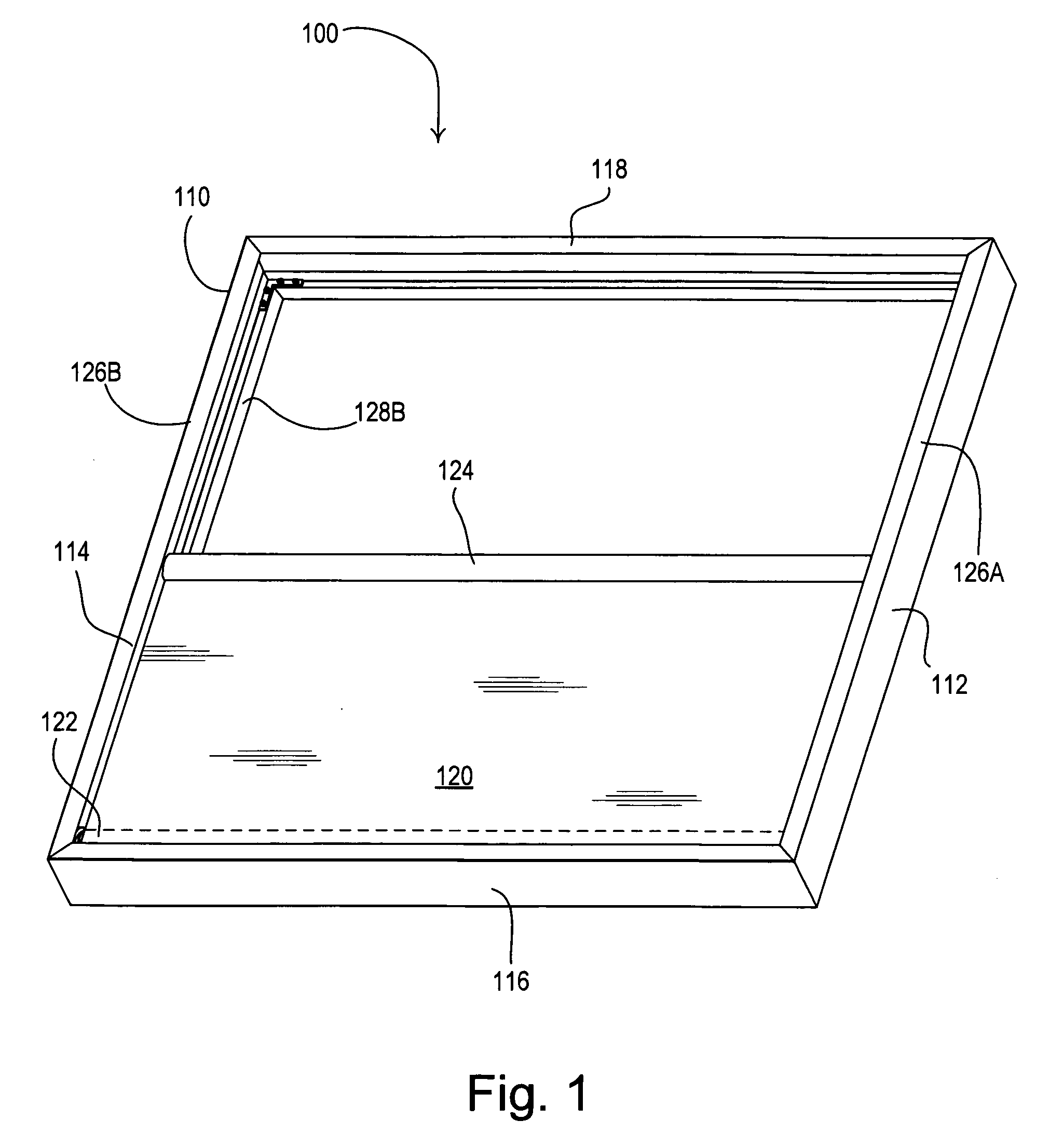

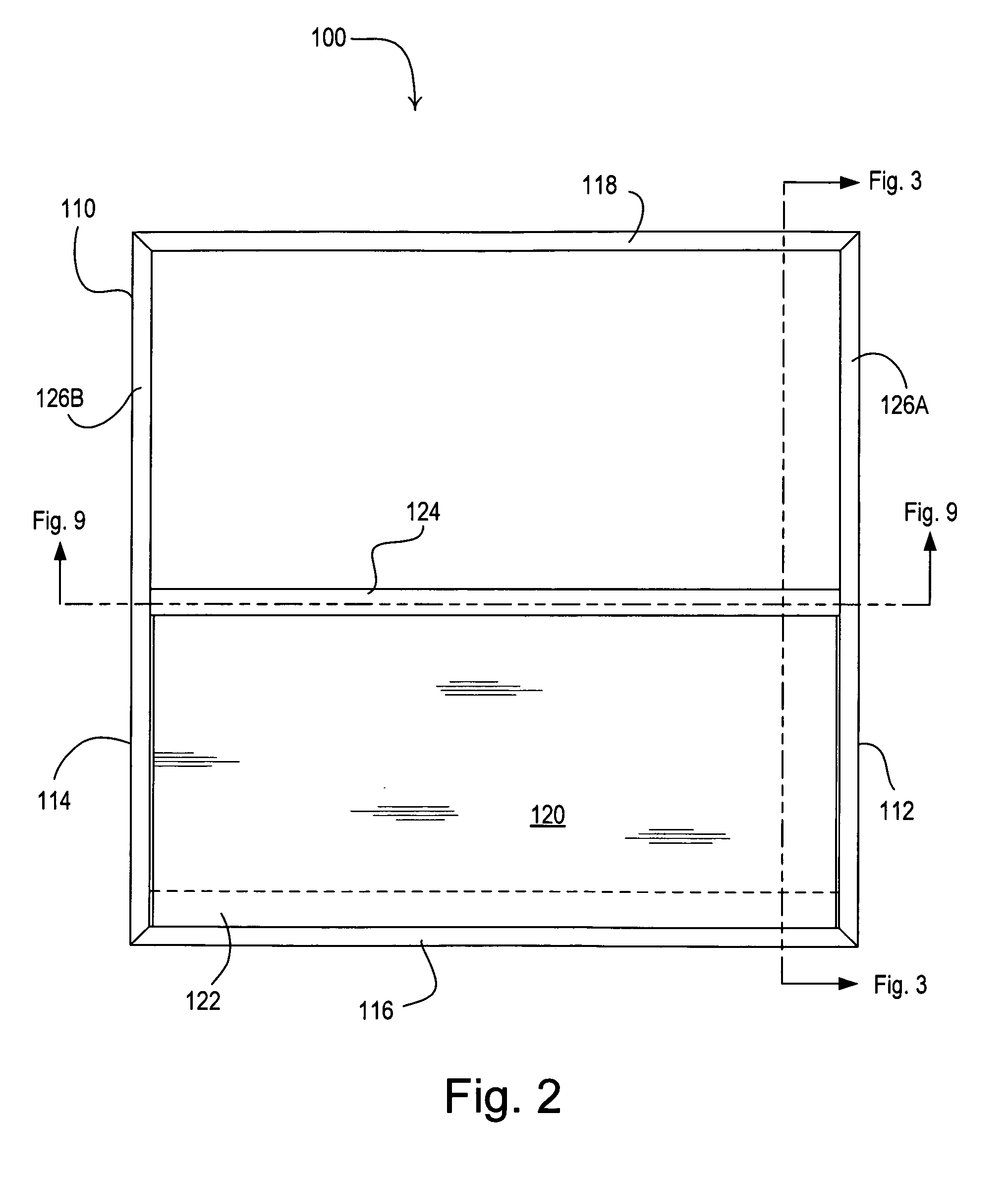

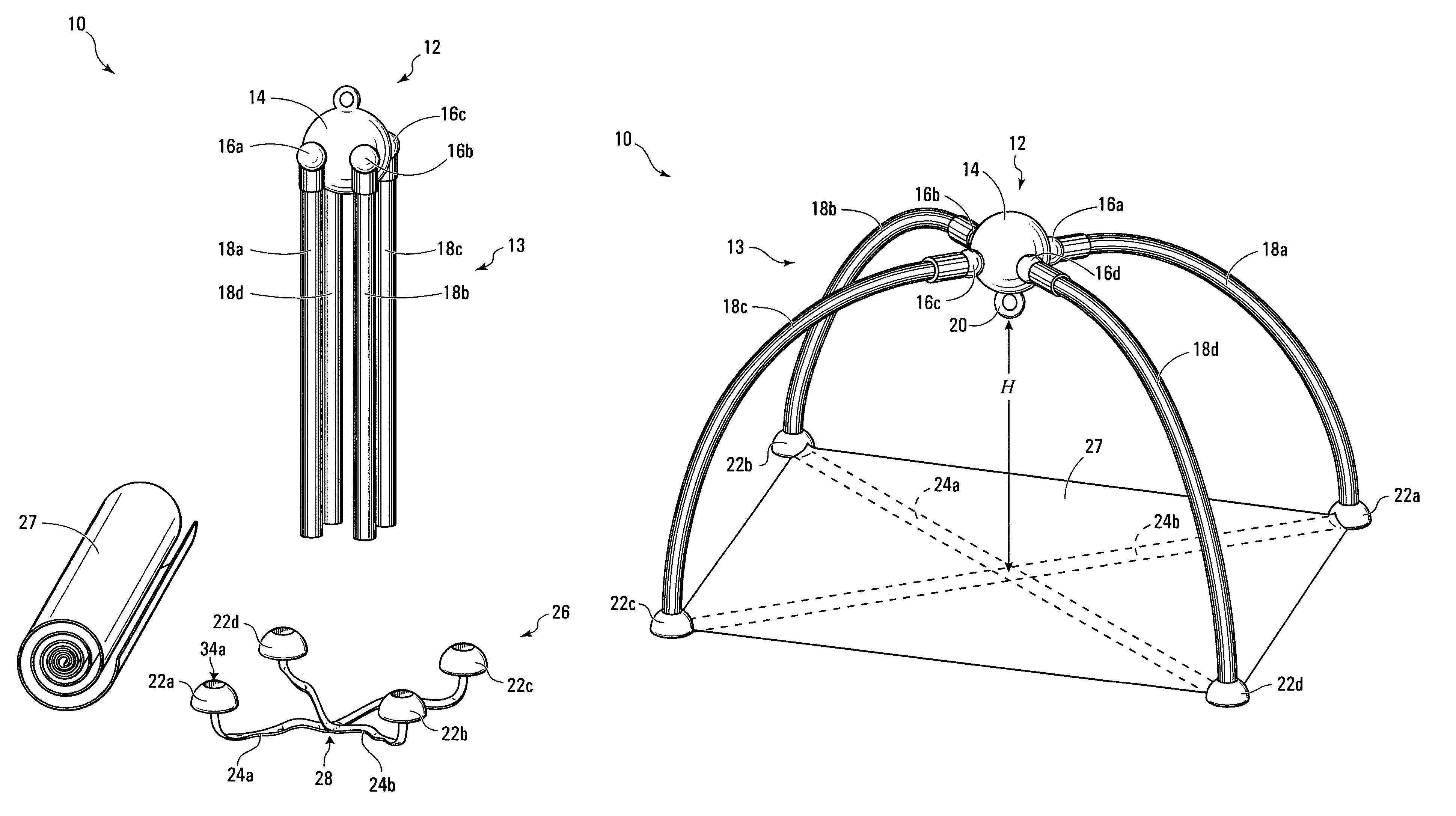

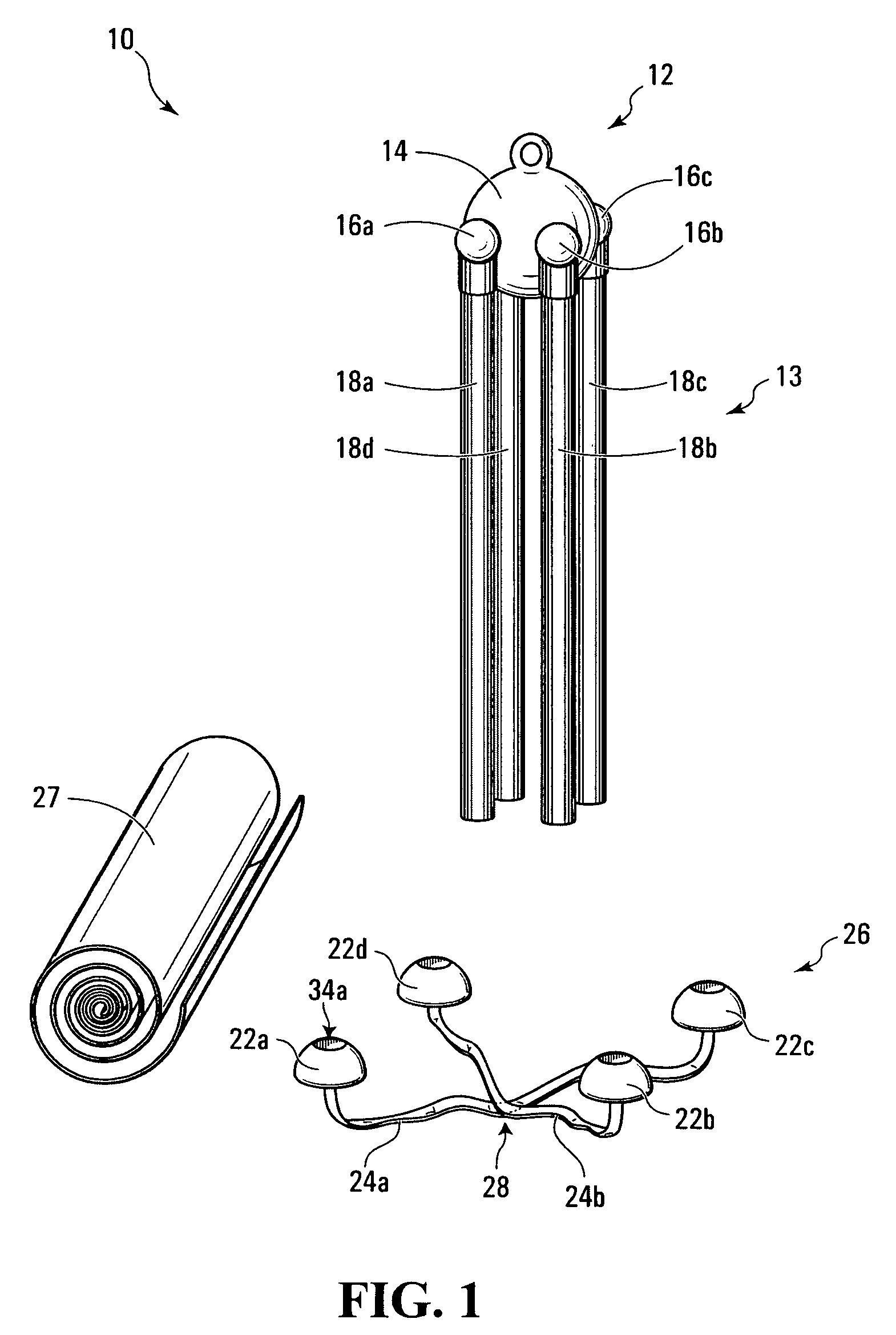

Self-contained tensioned roller shade system

A self-contained tensioned roller shade system that can be easily installed in an opening, such as a window or a skylight. The roller shade system comprises a free-standing frame, a roller tube rotatably mounted between first and second side channels of the frame adjacent a first end of the frame, and a shade fabric is windingly received around the roller tube. A tensioning cord is operatively coupled between the roller tube and a second fabric end opposite the first fabric end, and is windingly received about the roller tube. A pulley is operatively coupled to the frame adjacent the second frame end and windingly receives the tensioning cord. The tensioning cord is adapted to bias the second fabric end toward the second frame end, the second fabric end of the shade fabric adapted to move between the first and second frame ends as the roller tube is rotated.

Owner:LUTRON TECH CO LLC

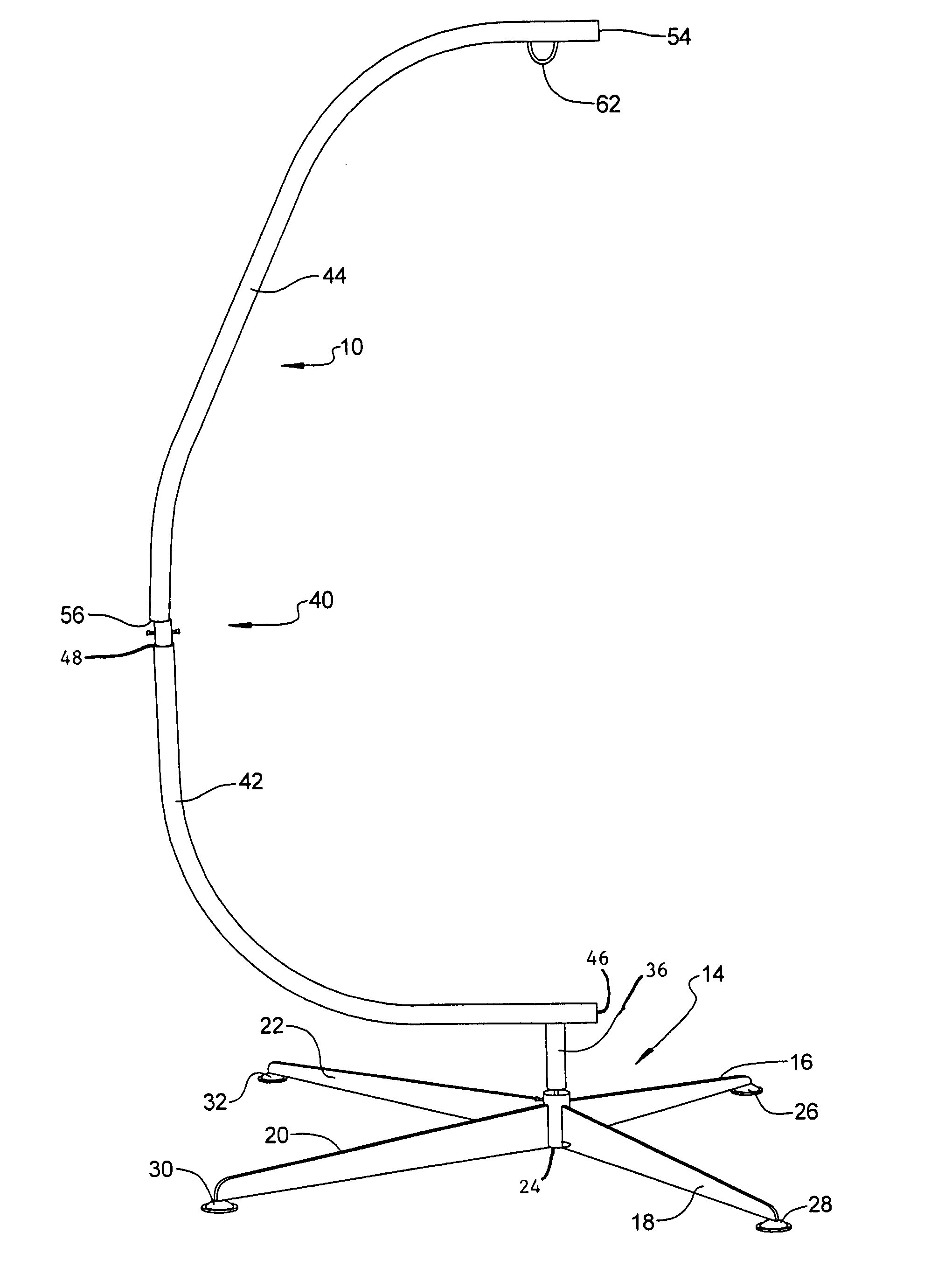

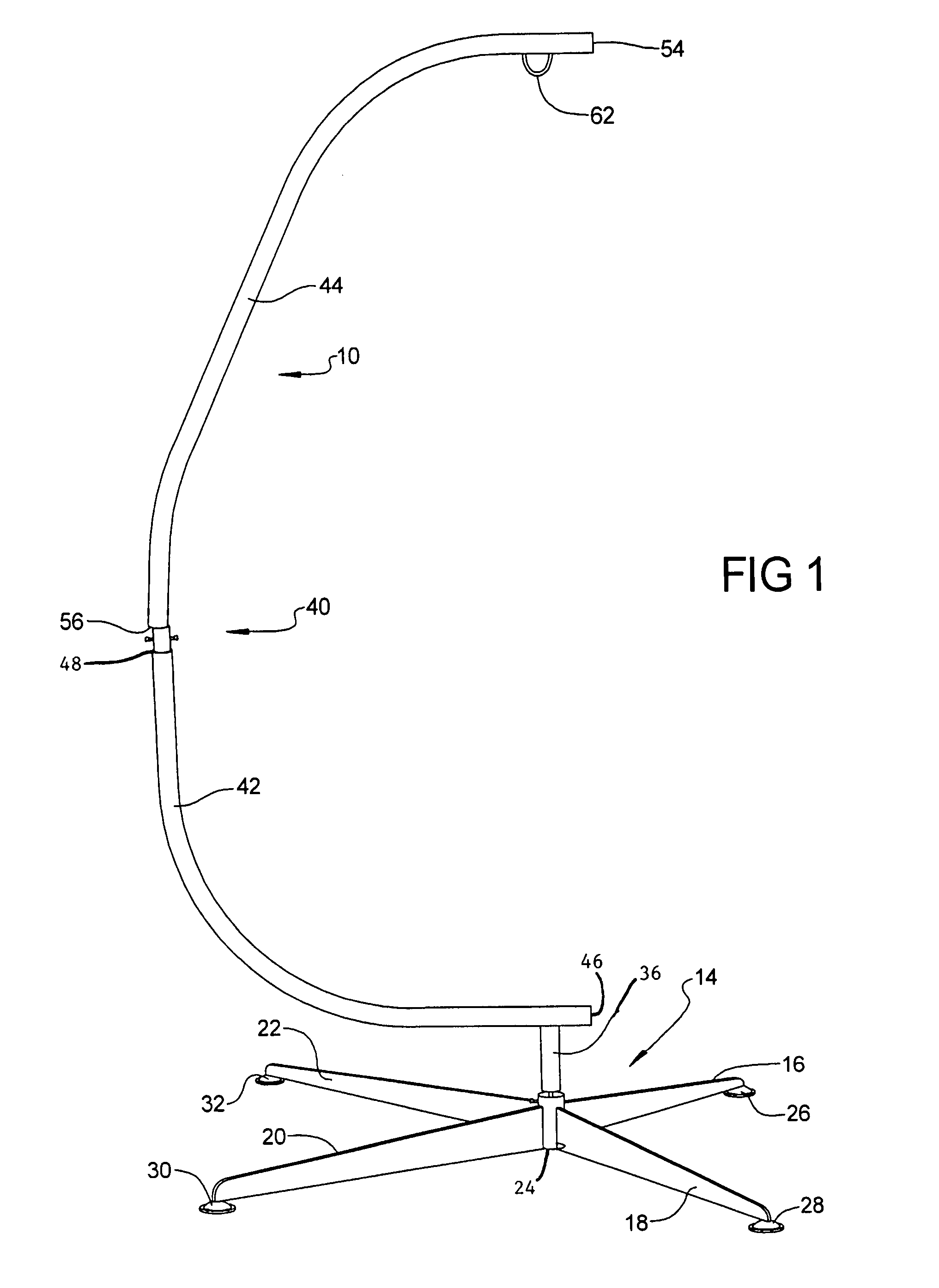

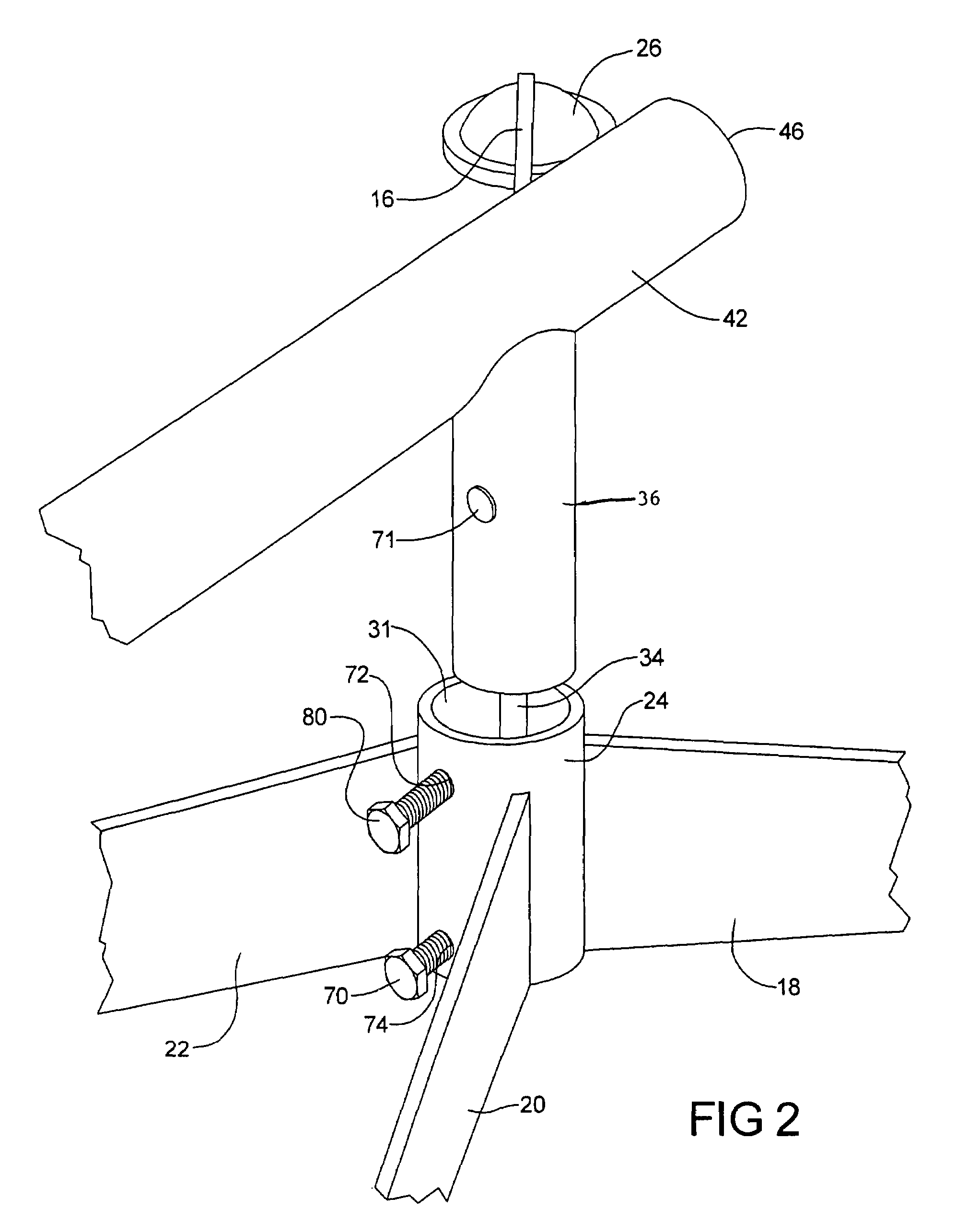

Free standing seating suspension frame

Owner:MOLEN ROGER VANDER

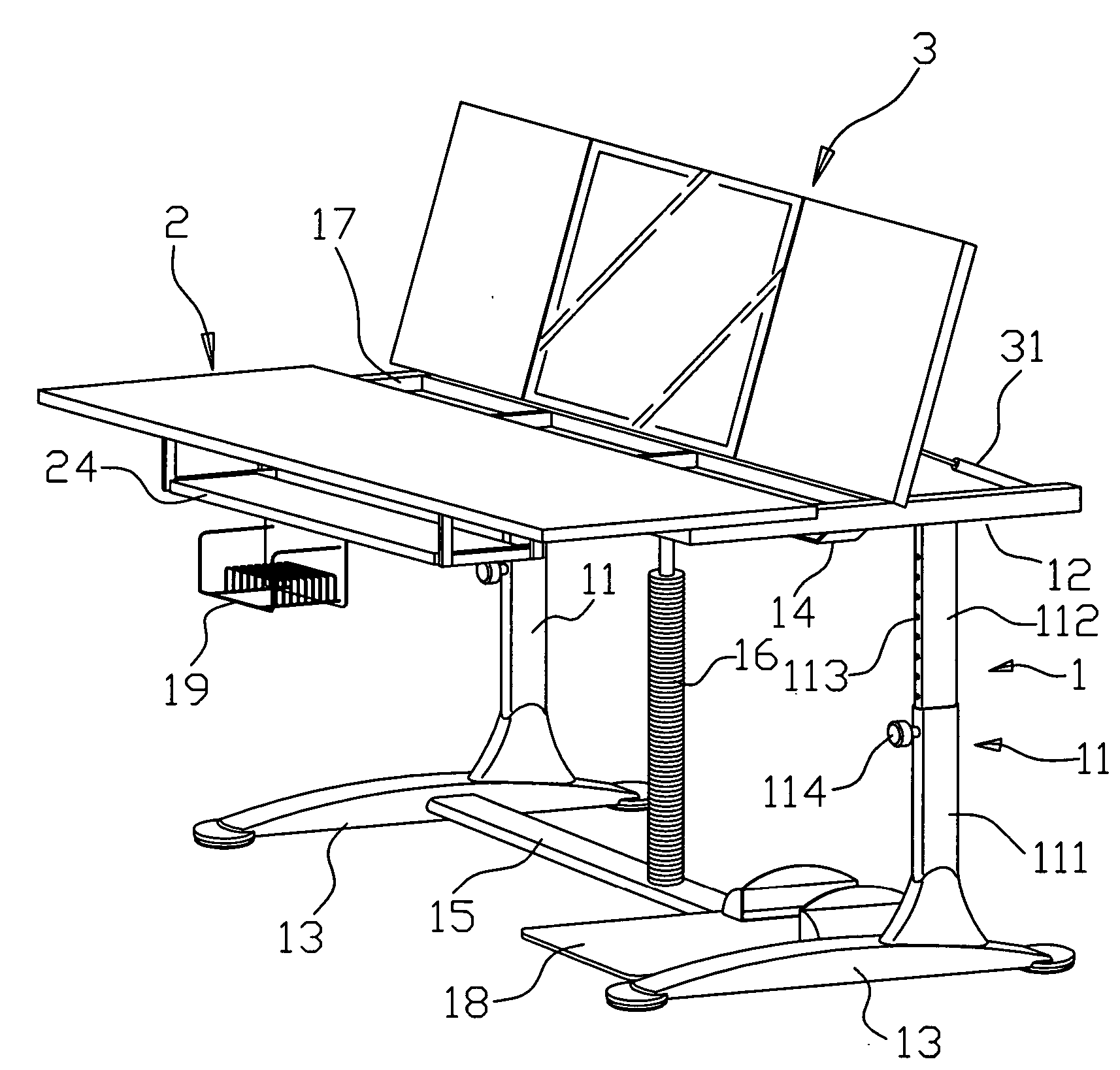

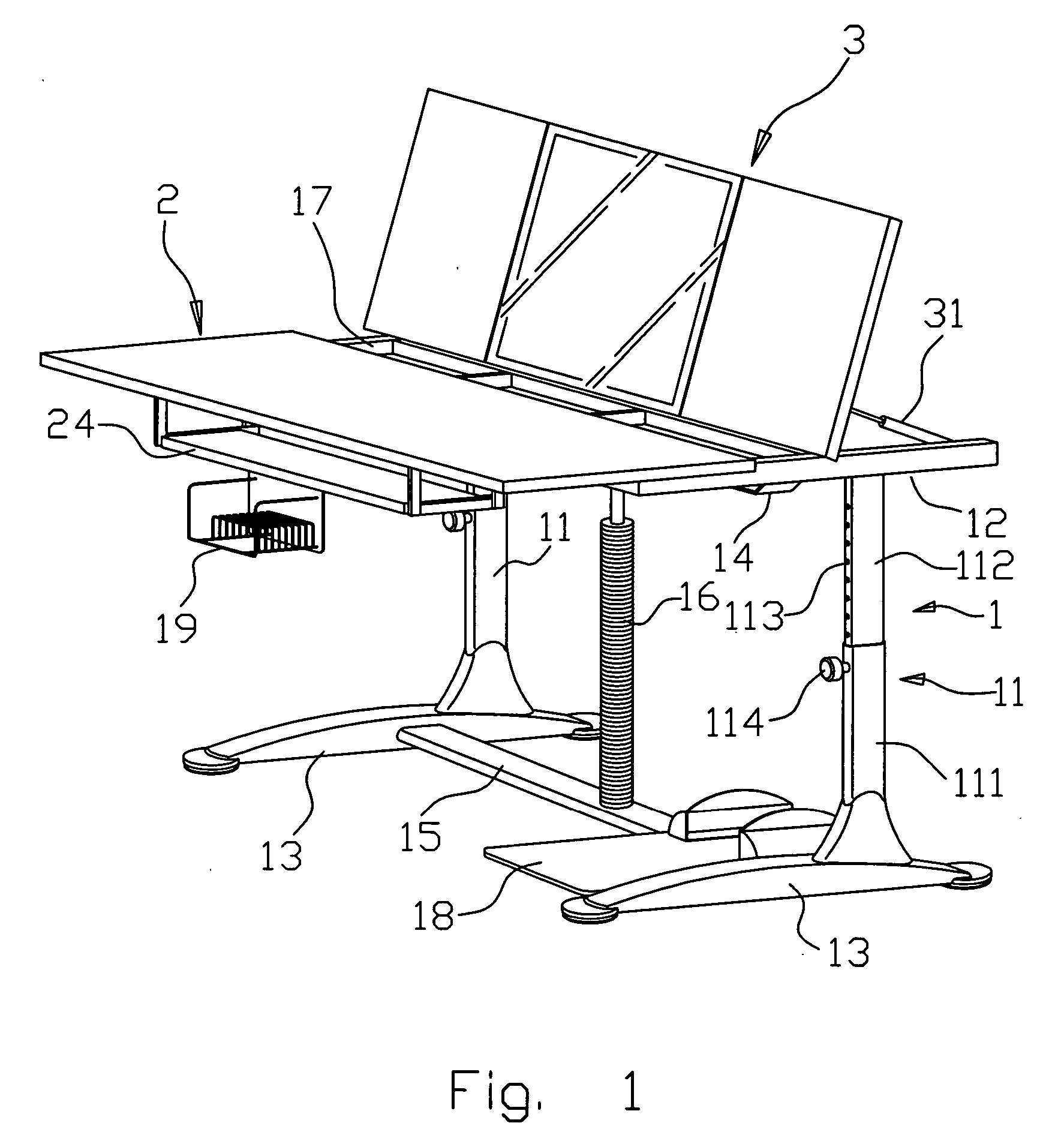

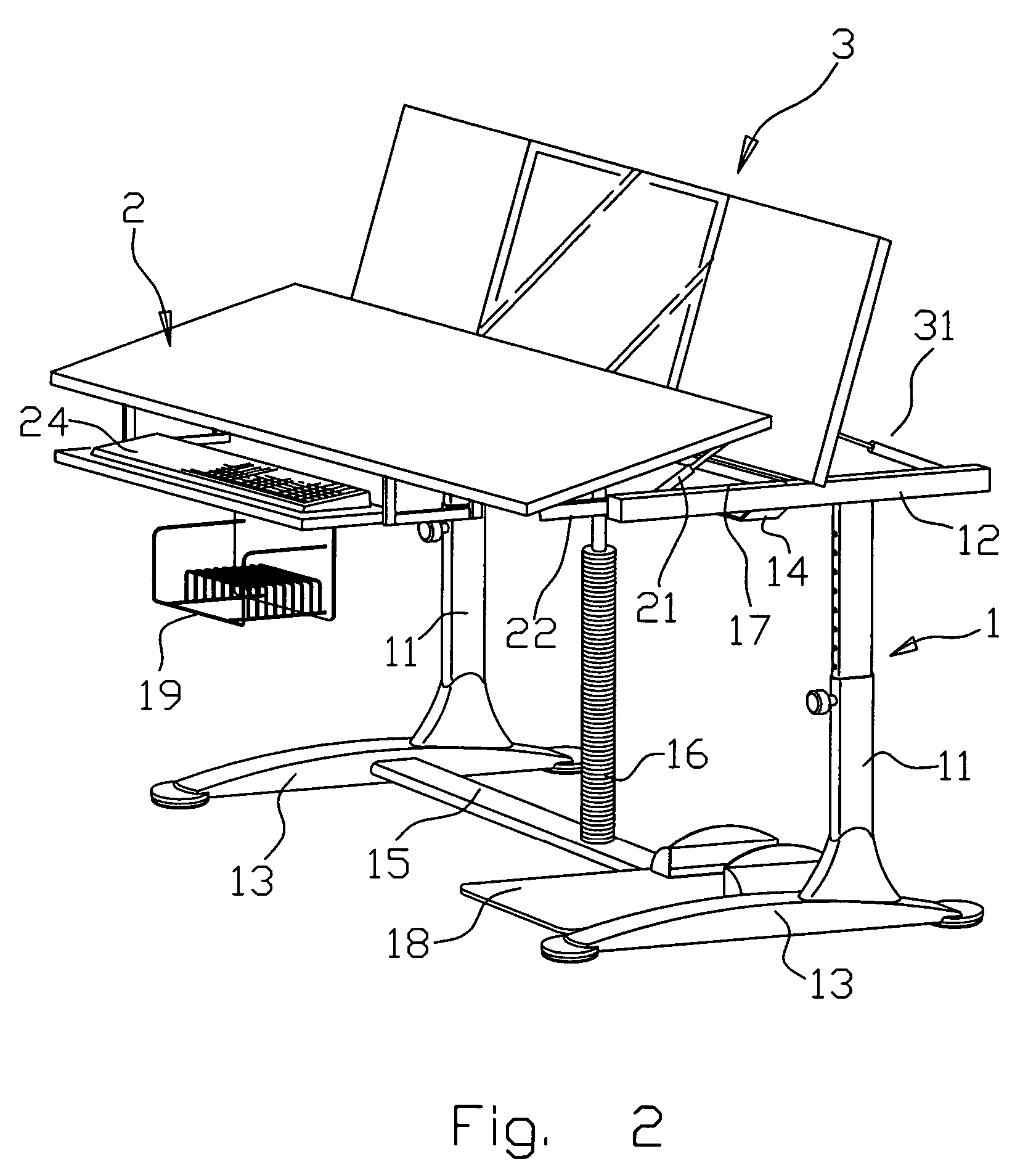

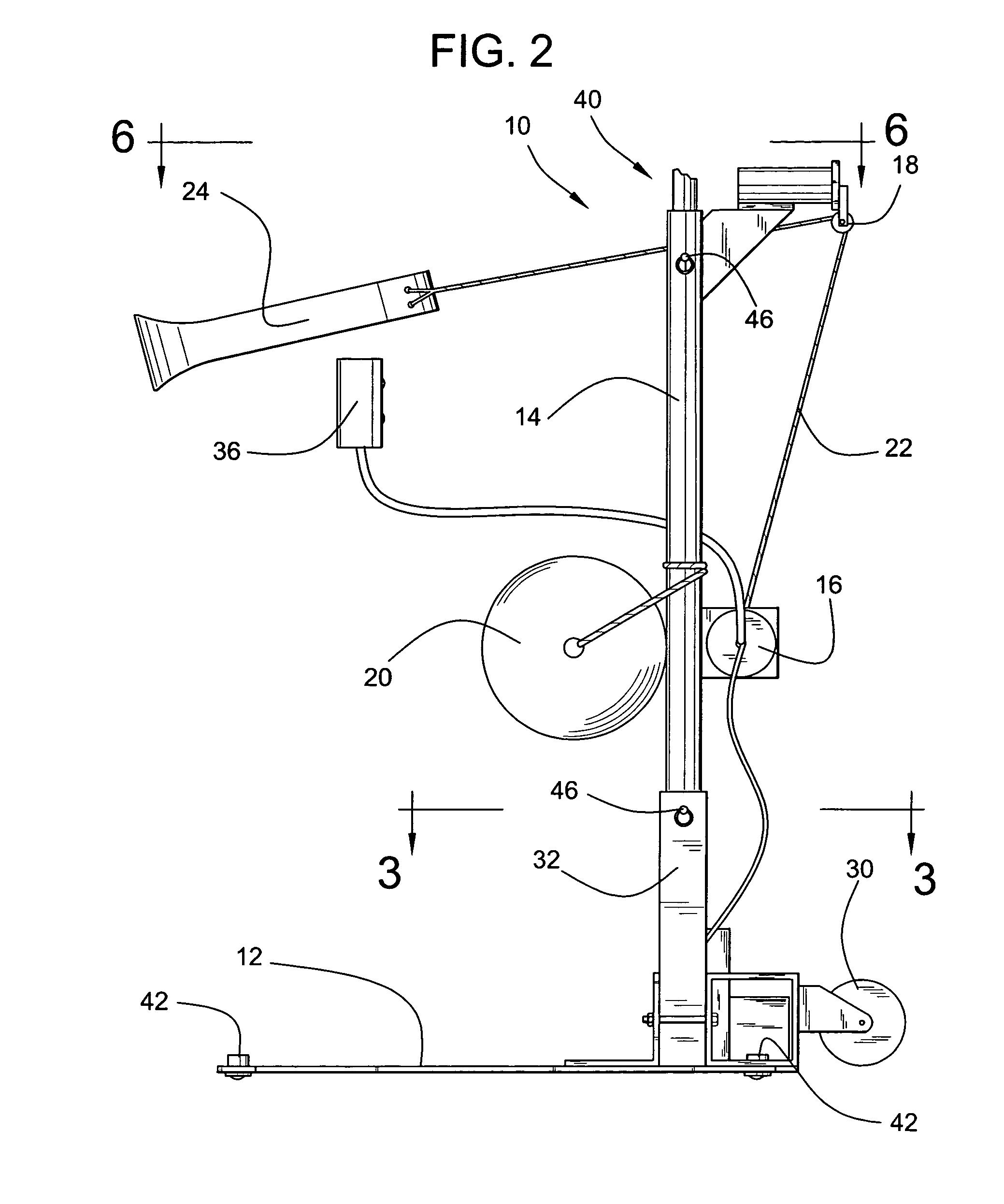

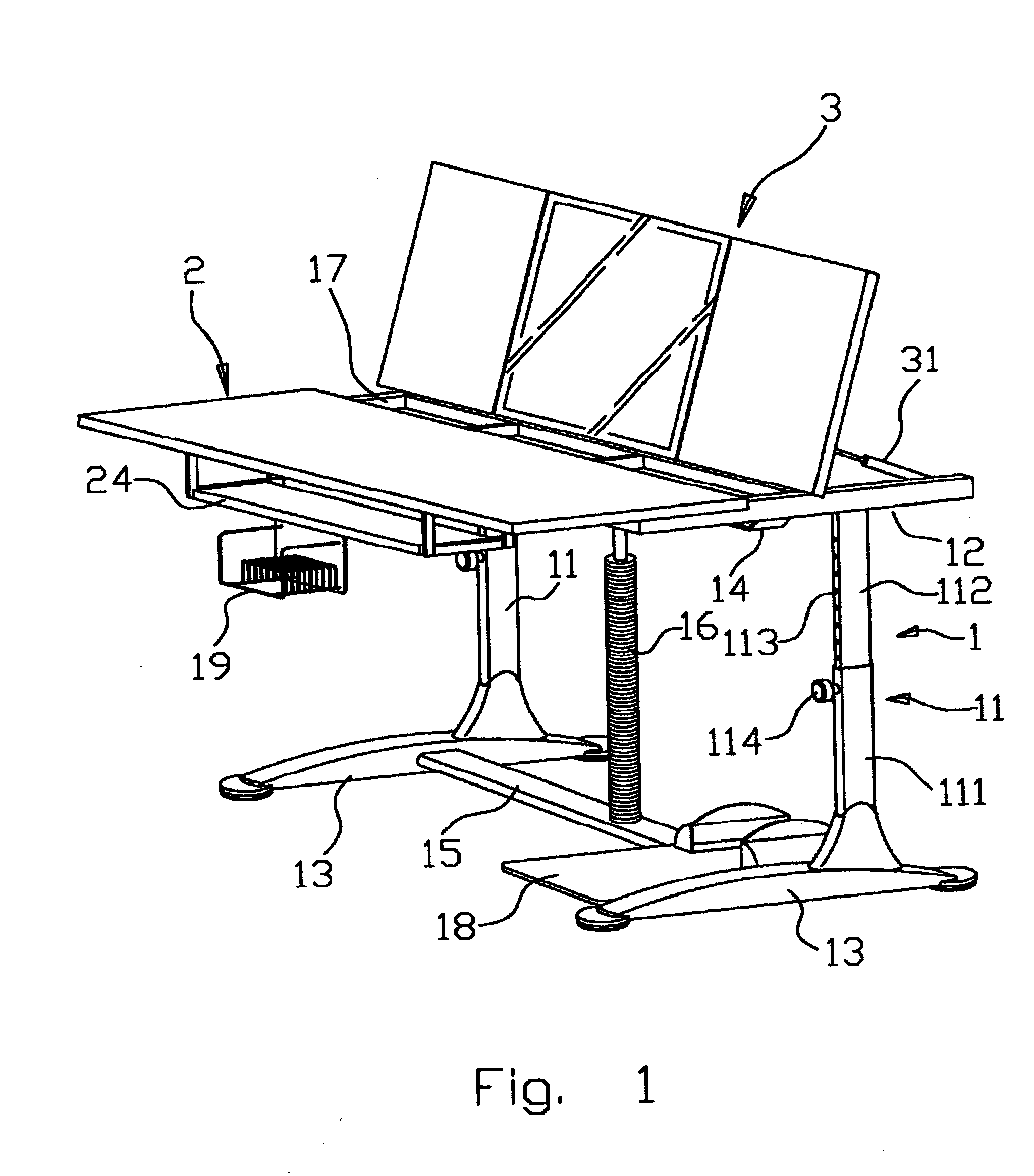

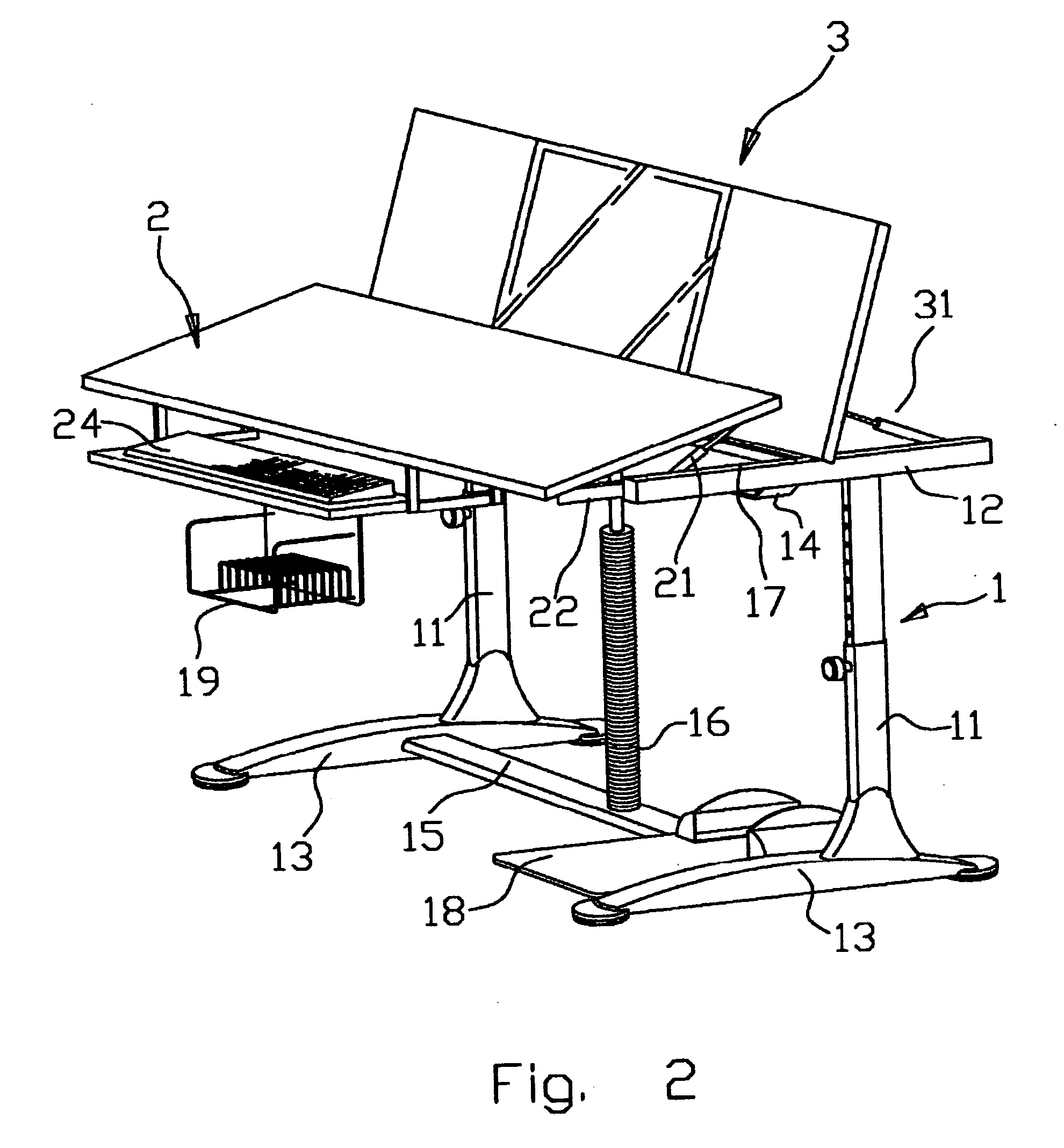

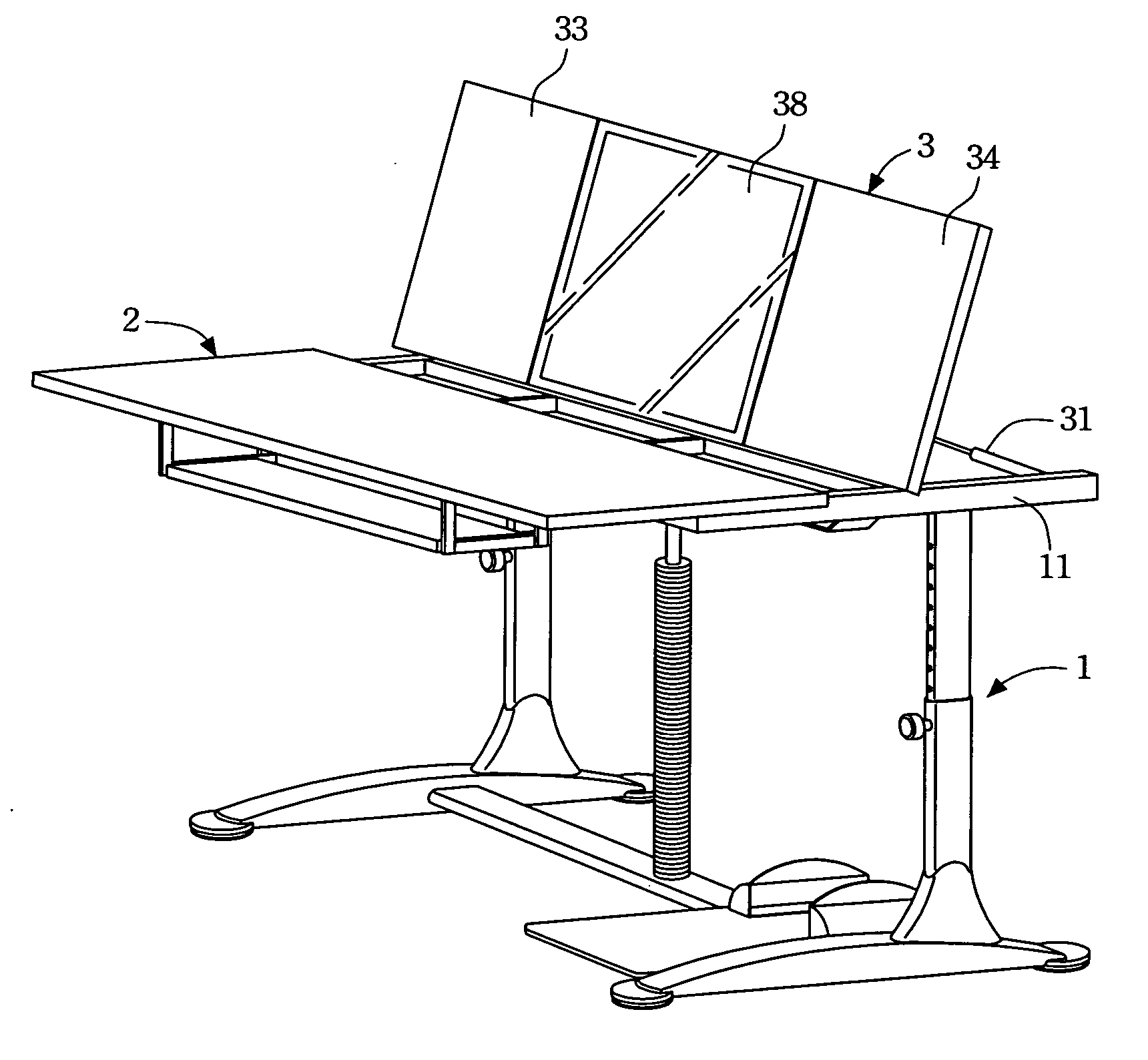

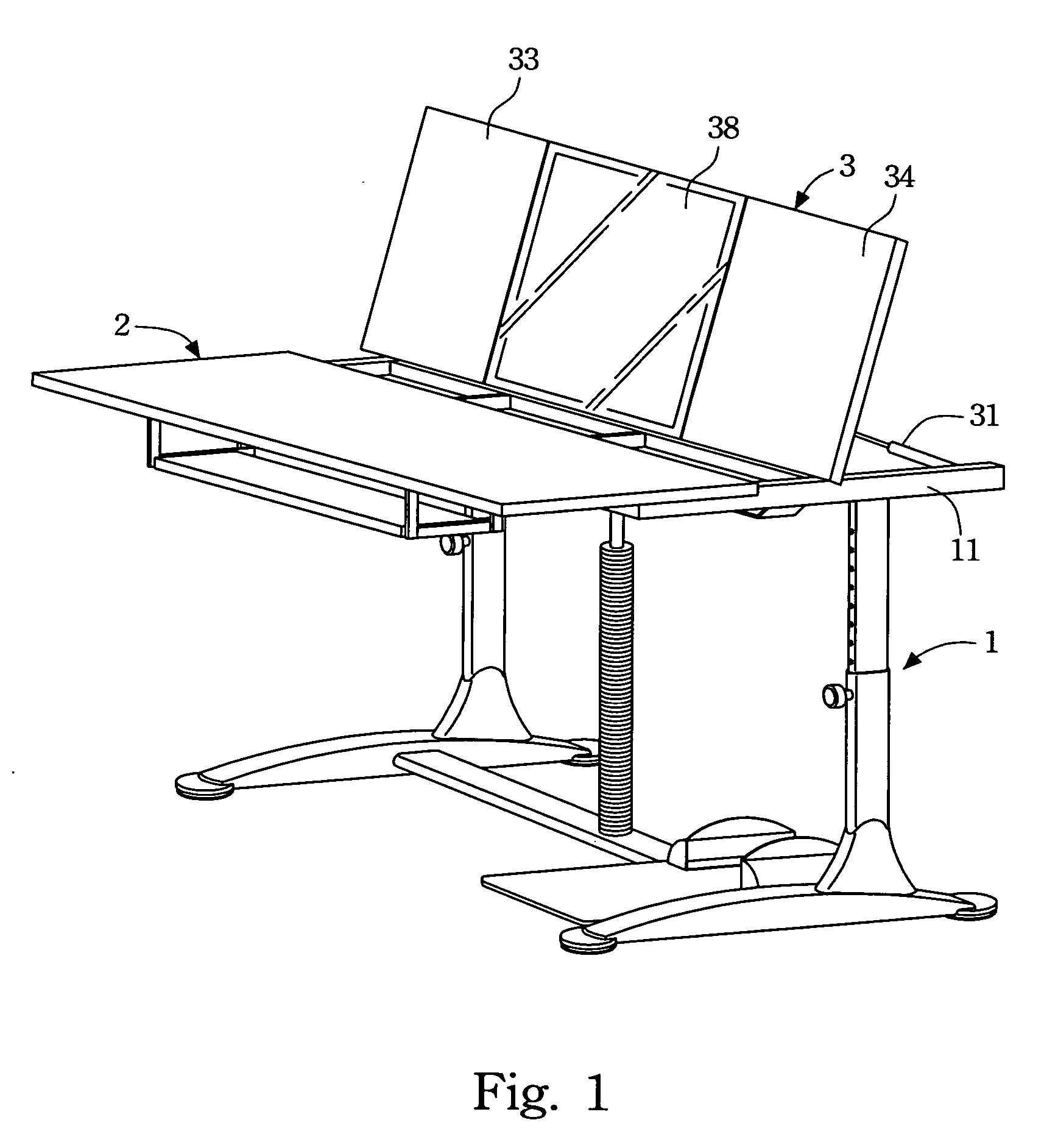

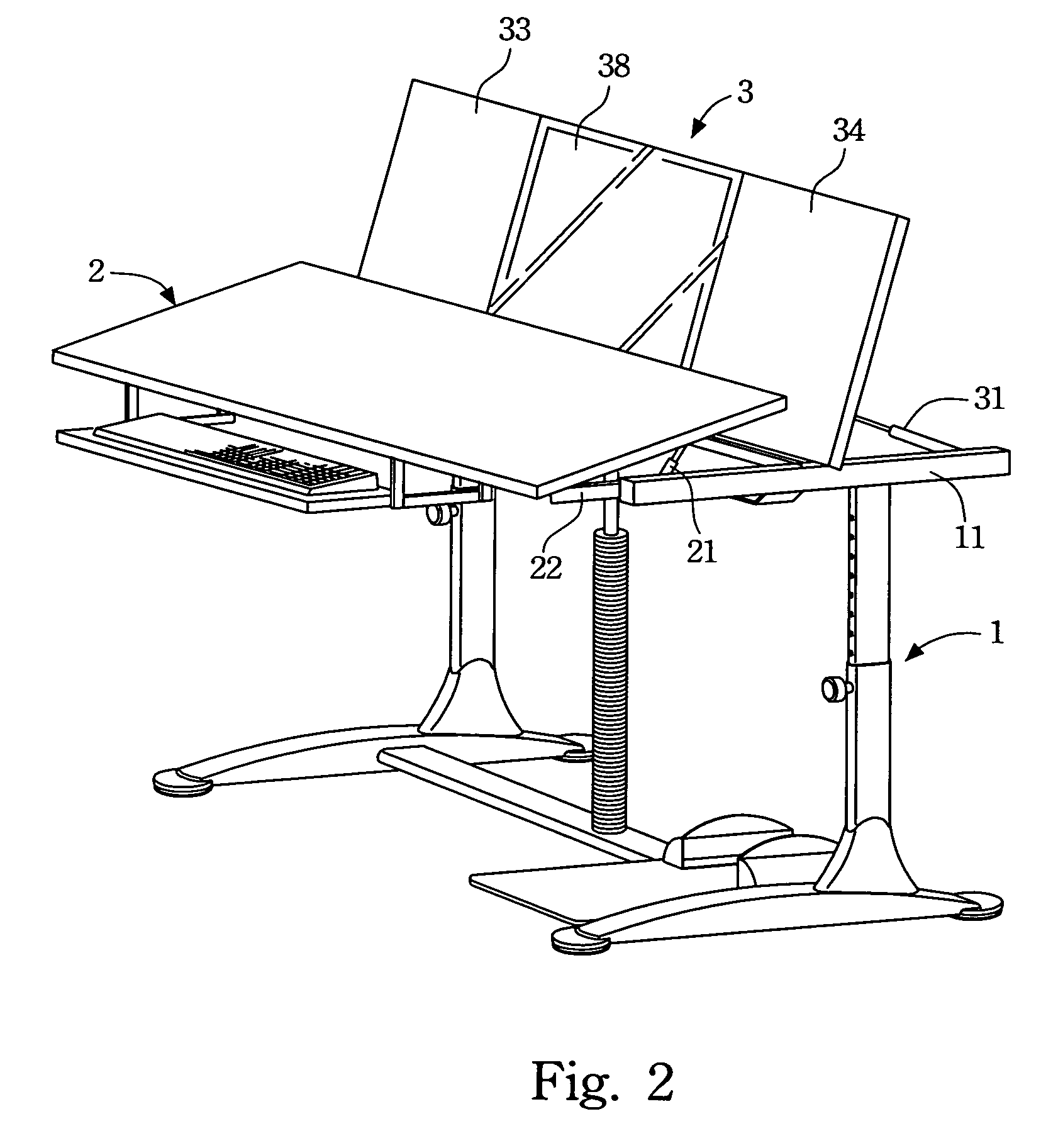

Desk with tilt-adjustable tops

InactiveUS20060065163A1Comfortable writingComfortable readingOffice tablesFurniture partsStanding frameDesk

A desk with tilt-adjustable tops includes a stand frame; a front top mounted to an upper front portion of the stand frame via a front tilt control device; and a rear top mounted to an upper rear portion of the stand frame via a rear tilt control device. The stand frame is height-adjustable and has a storage box located below a rear portion of the front top. The front and the rear top may be separately adjusted to different tilt angles best for writing, drawing, or reading at the desk. In normal time, the front and the rear top may be simultaneously restored to a horizontal state or adjusted to the same plane with the storage box invisibly located below the front top, so that the desk is used as a general desk with a flat top.

Owner:CHI YUEH +2

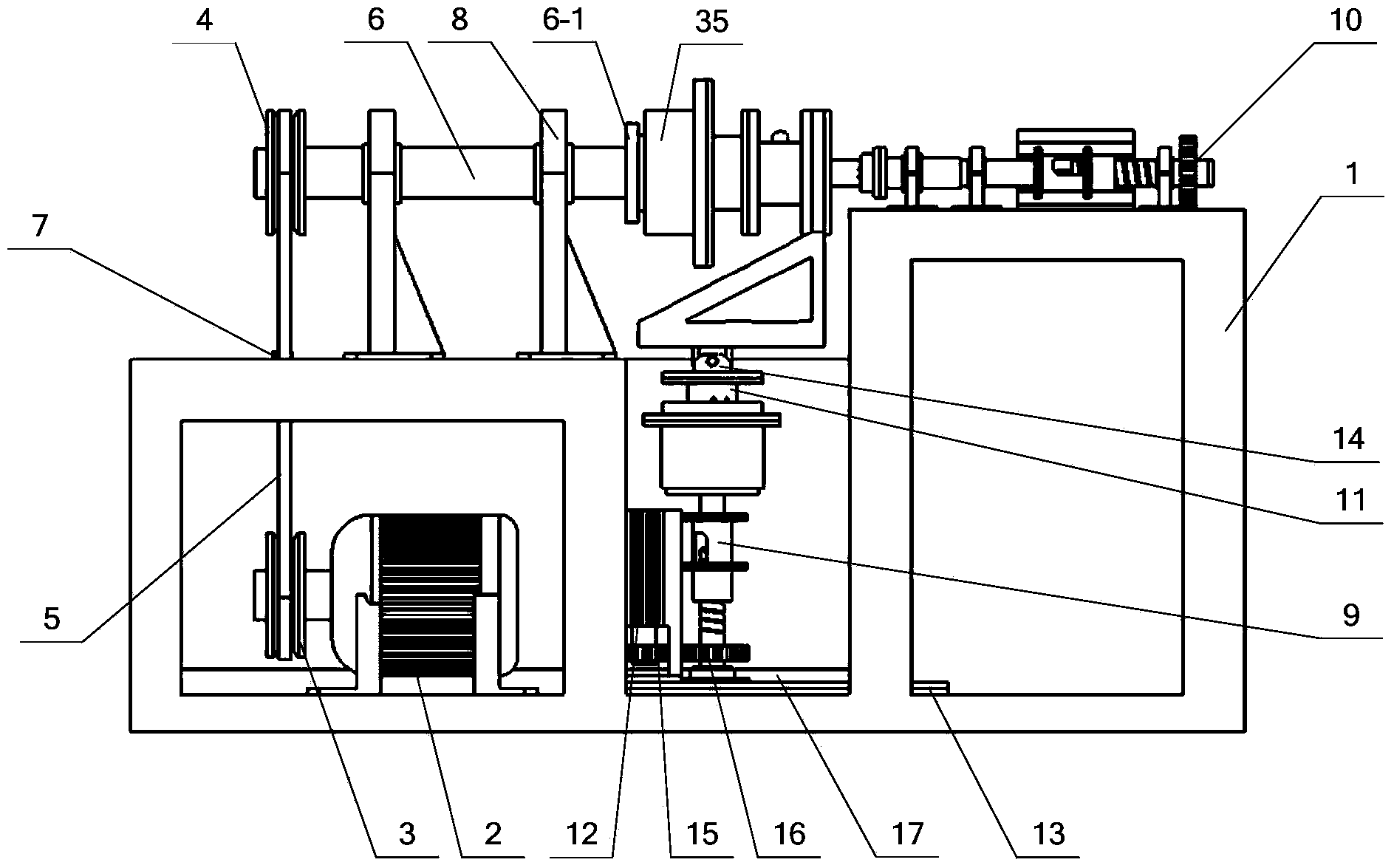

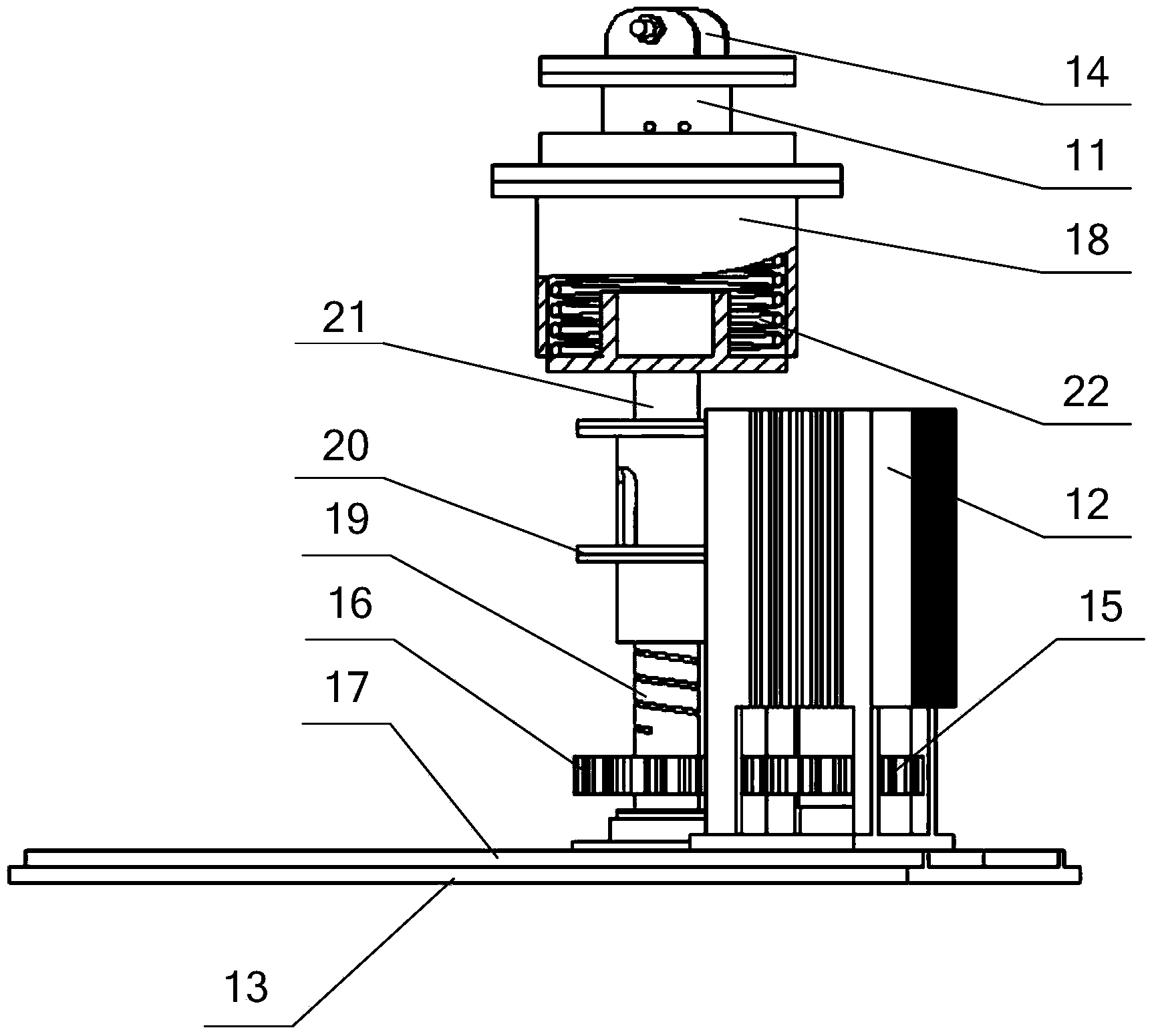

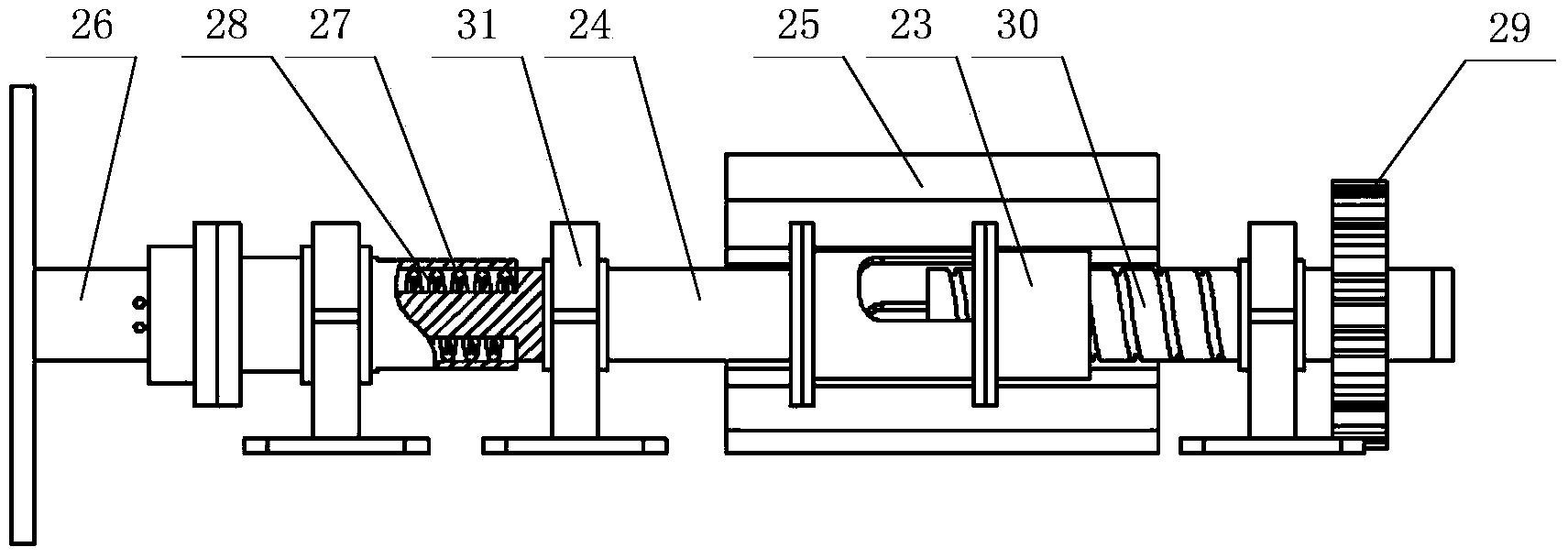

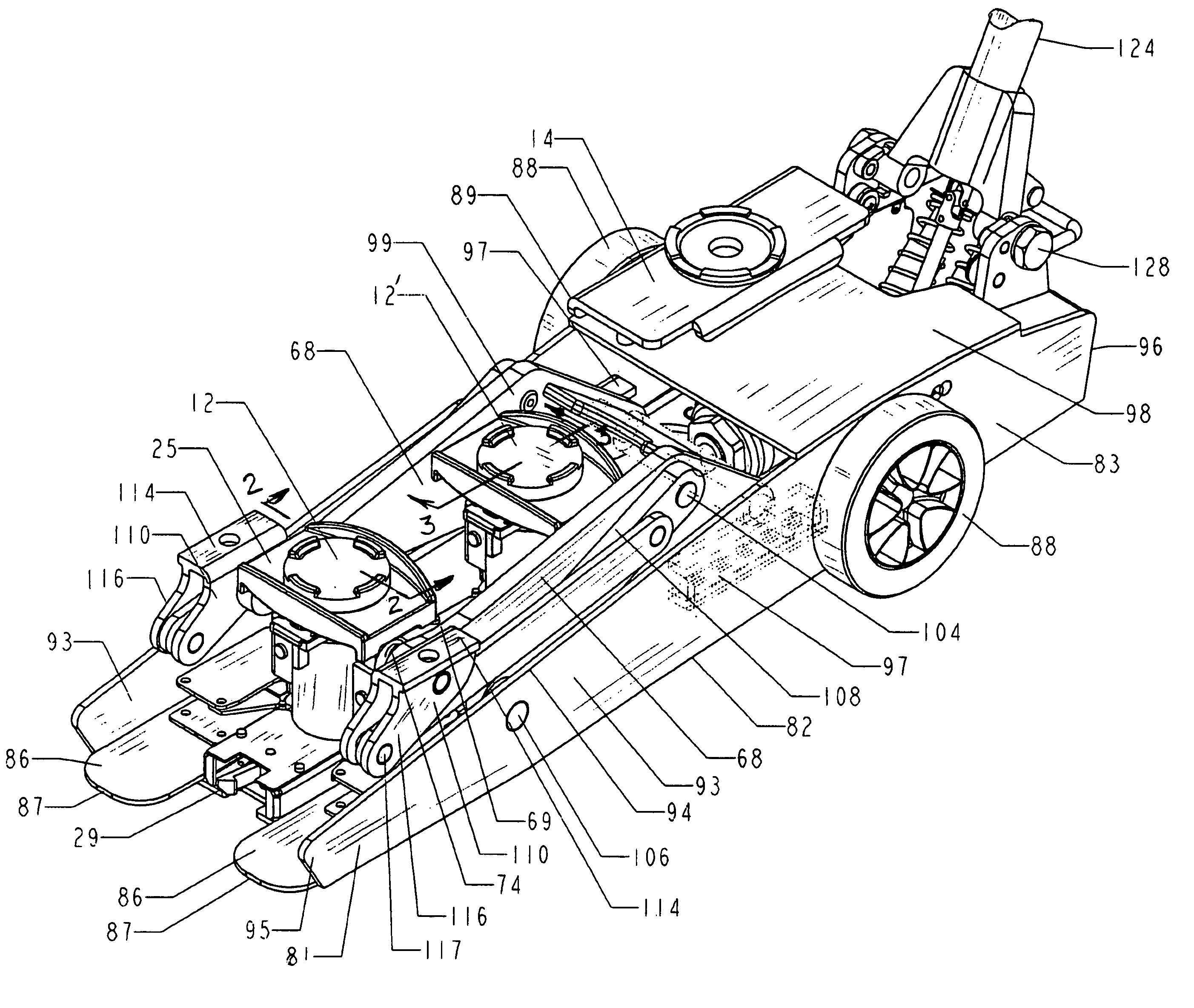

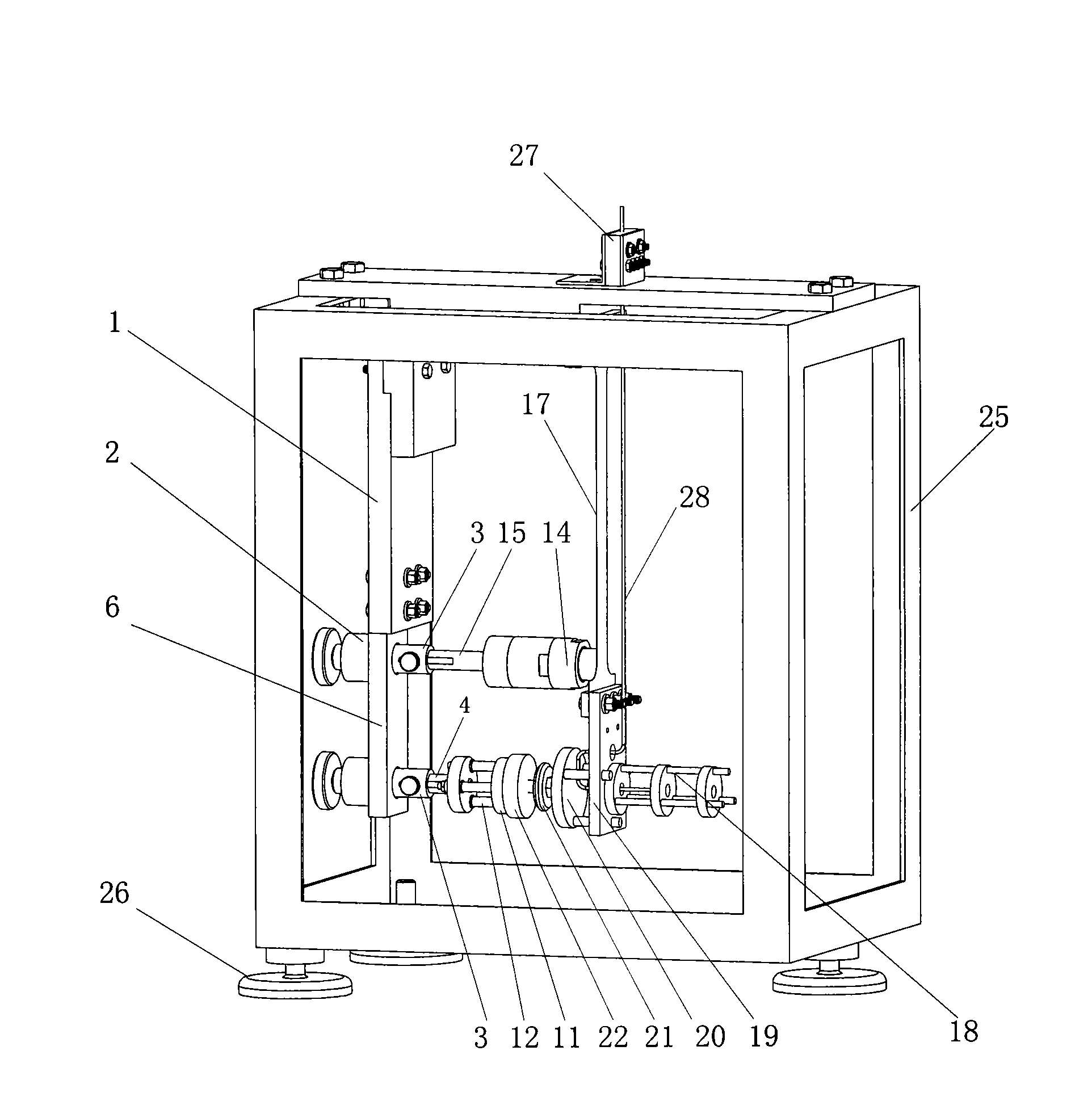

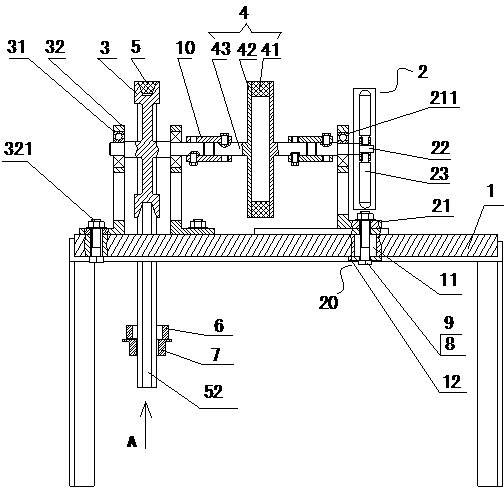

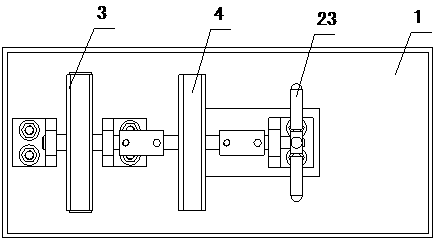

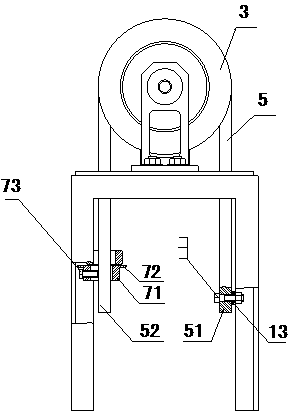

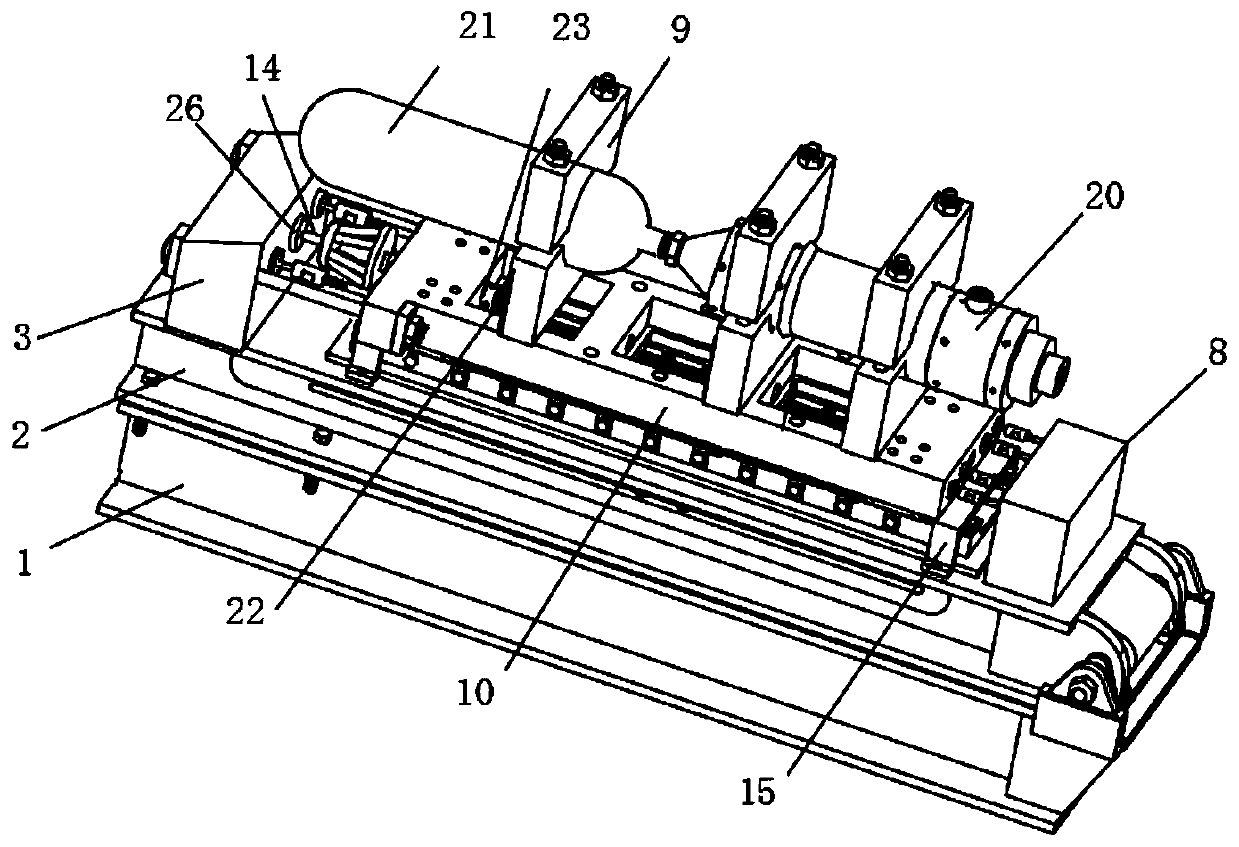

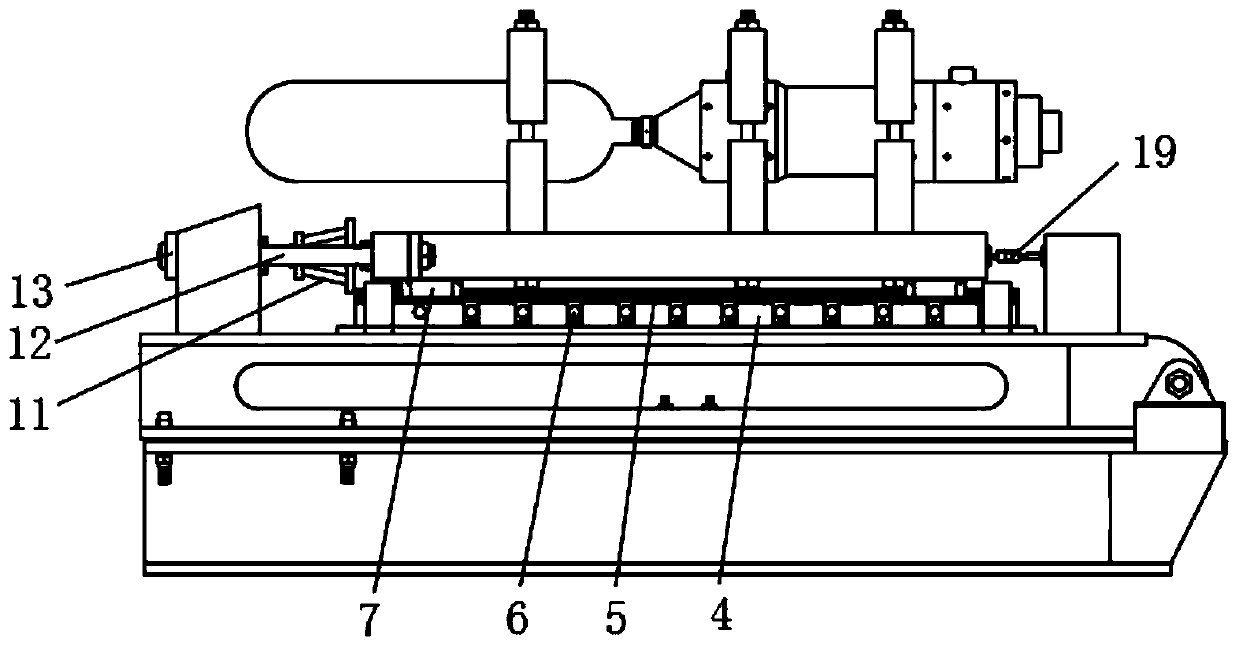

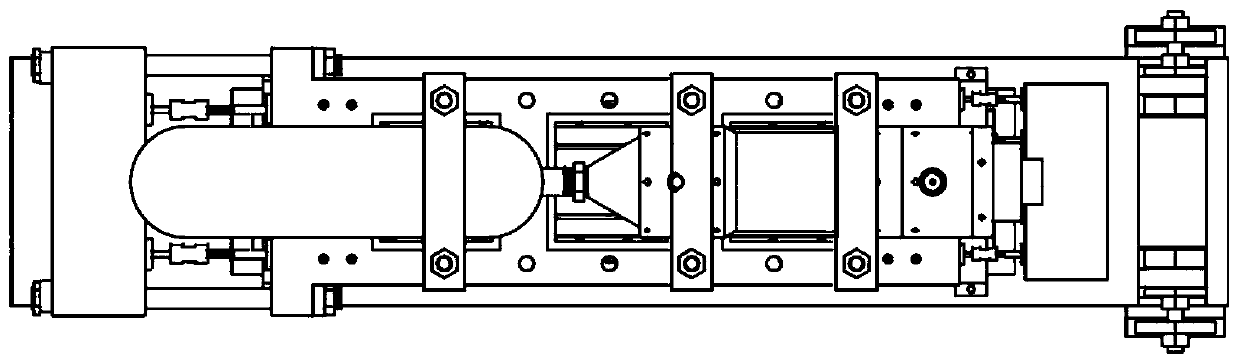

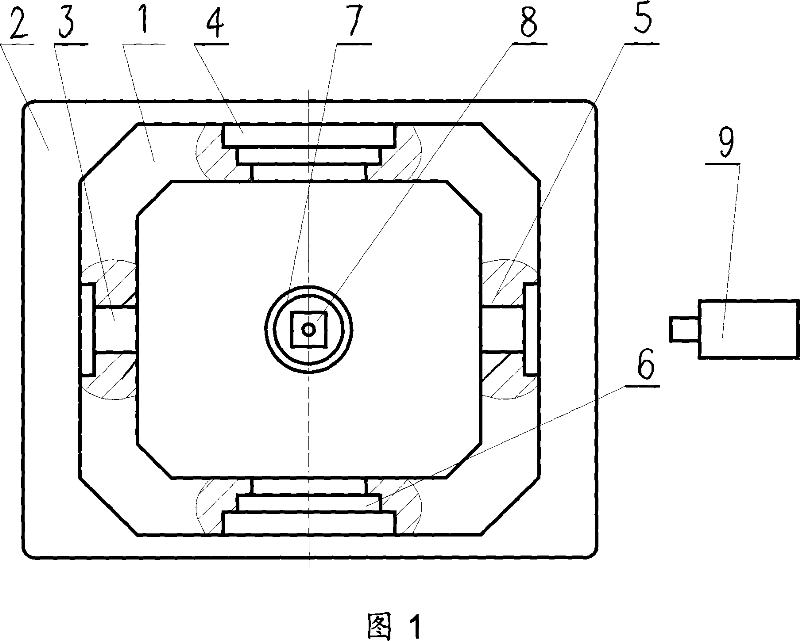

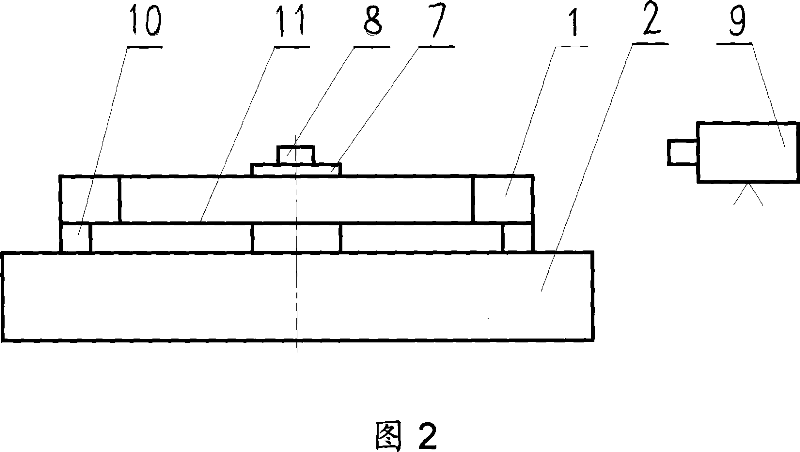

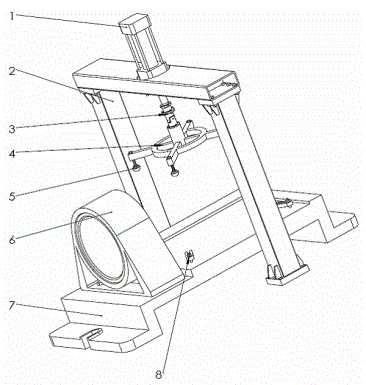

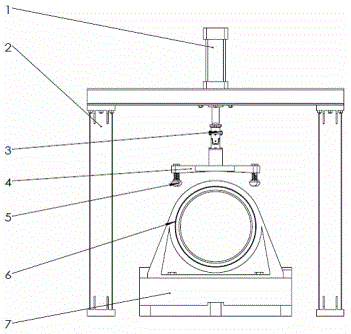

Testing stand of friction torque of automotive wheel hub bearing

Disclosed in the invention is a testing stand of a friction torque of an automotive wheel hub bearing. According to the traditional friction torque testing machine, the loaded situation during the actual vehicle driving process can not be simulated and the machine also can not adapt to the third-generation hub bearing flanges without various specifications. The testing stand is composed of a testing stand frame, a driving mechanism, a main shaft, a radial loading mechanism, an axial loading mechanism and a measured bearing fixing device; and the driving mechanism drives the main shaft to rotate. The measured bearing fixing device includes a support, a bearing fixed flange, and a torque sensor; the bottom of the support is hinged with a revolving body of the radial loading mechanism; one side of the top is fixed with an axial pressure sensor of the axial loading mechanism; the torque sensor is fixed at the other side of the top of the support; and the bearing fixed flange is fixed with the torque sensor. The axial loading mechanism applies an axial force to the measured bearing fixing device; and the radial loading mechanism exerts the radial force and the bending moment to the measured bearing fixing device. The provided testing stand is suitable for various automotive hub bearings and the complex loaded situation of the wheel hub bearing can be simulated.

Owner:HANGZHOU DIANZI UNIV

Self-Contained Tensioned Roller Shade System

A self-contained tensioned roller shade system that can be easily installed in an opening, such as a window or a skylight. The roller shade system comprises a free-standing frame, a roller tube rotatably mounted between first and second side channels of the frame adjacent a first end of the frame, and a shade fabric is windingly received around the roller tube. A tensioning cord is operatively coupled between the roller tube and a second fabric end opposite the first fabric end, and is windingly received about the roller tube. A pulley is operatively coupled to the frame adjacent the second frame end and windingly receives the tensioning cord. The tensioning cord is adapted to bias the second fabric end toward the second frame end, the second fabric end of the shade fabric adapted to move between the first and second frame ends as the roller tube is rotated.

Owner:LUTRON TECH CO LLC

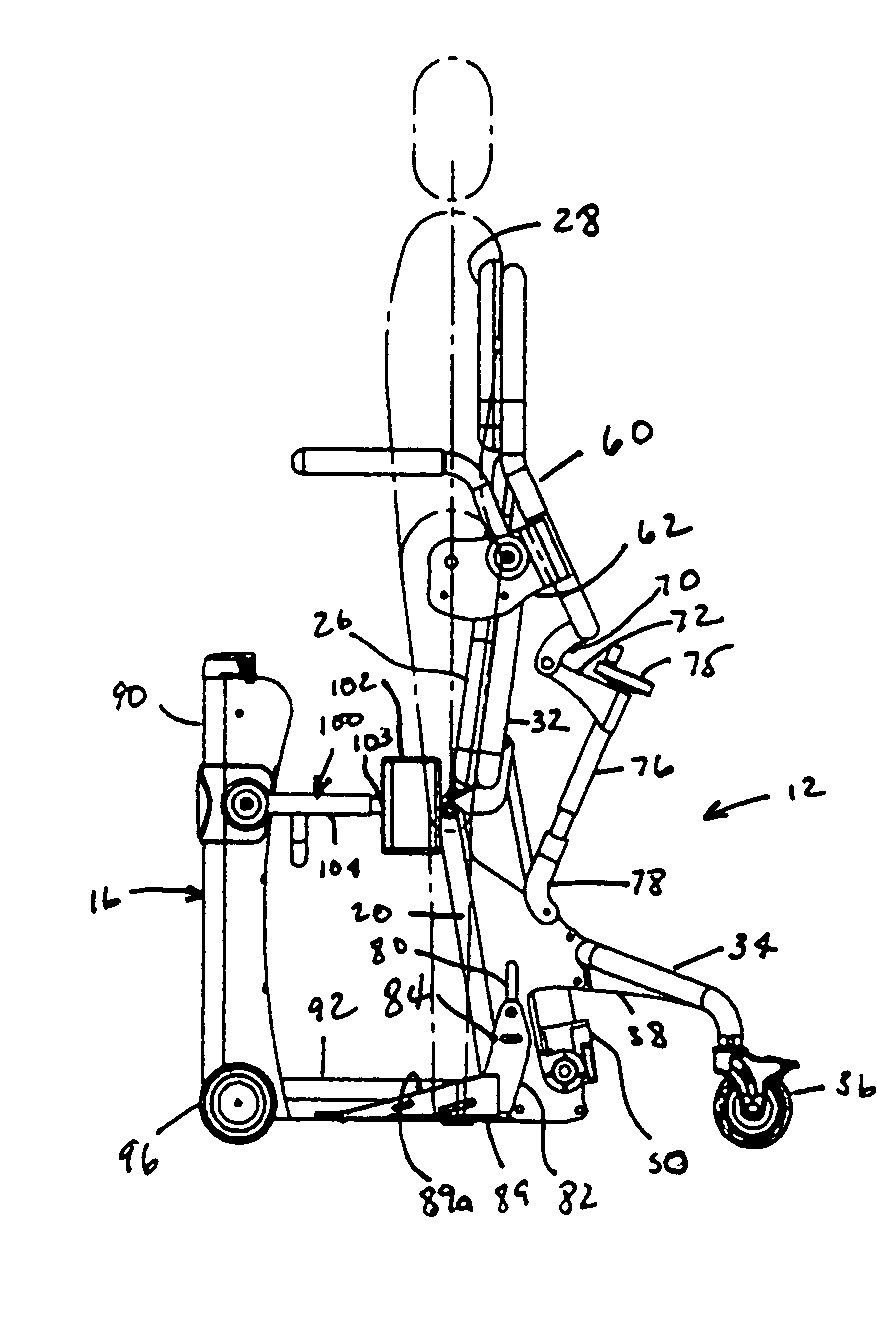

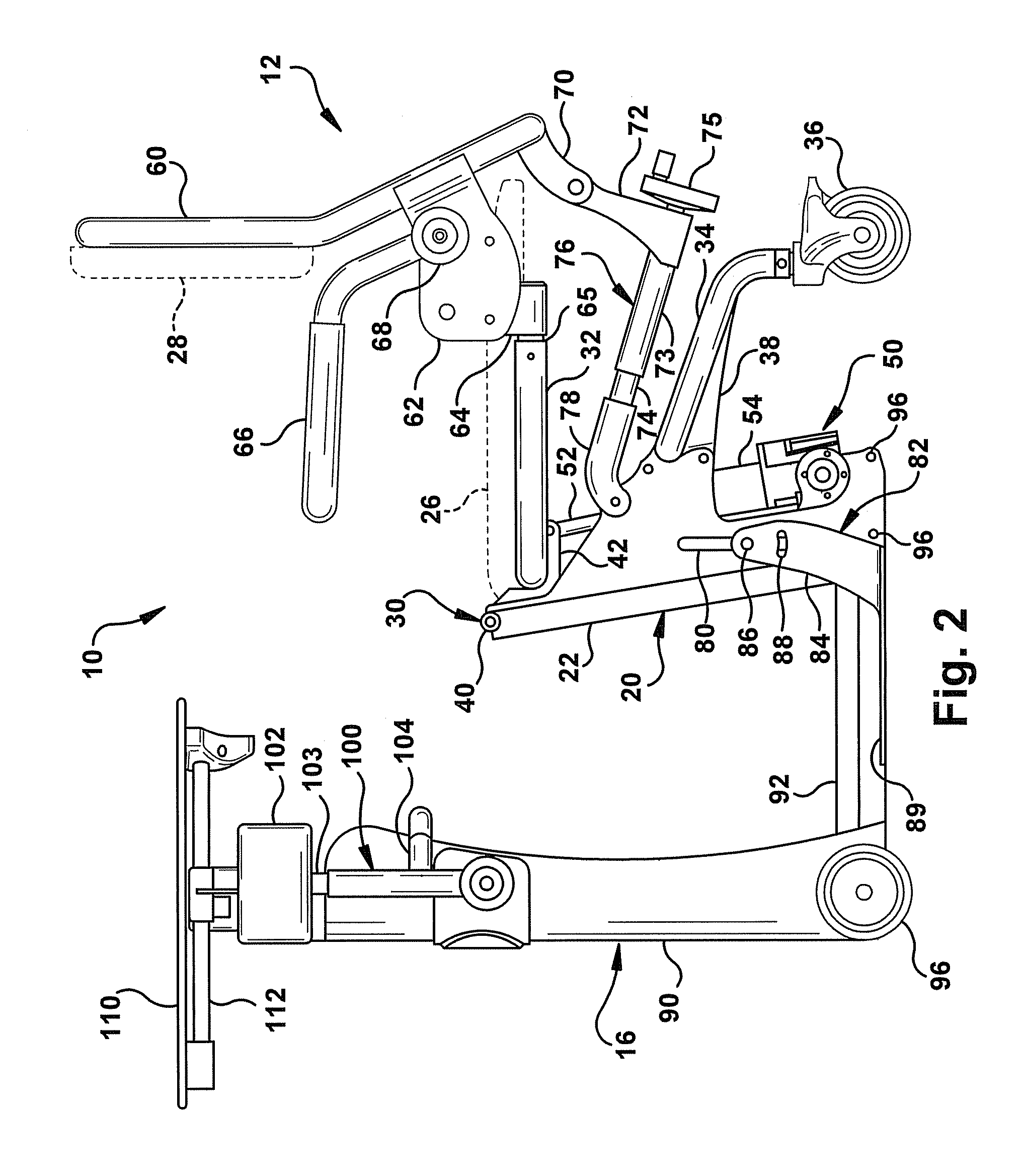

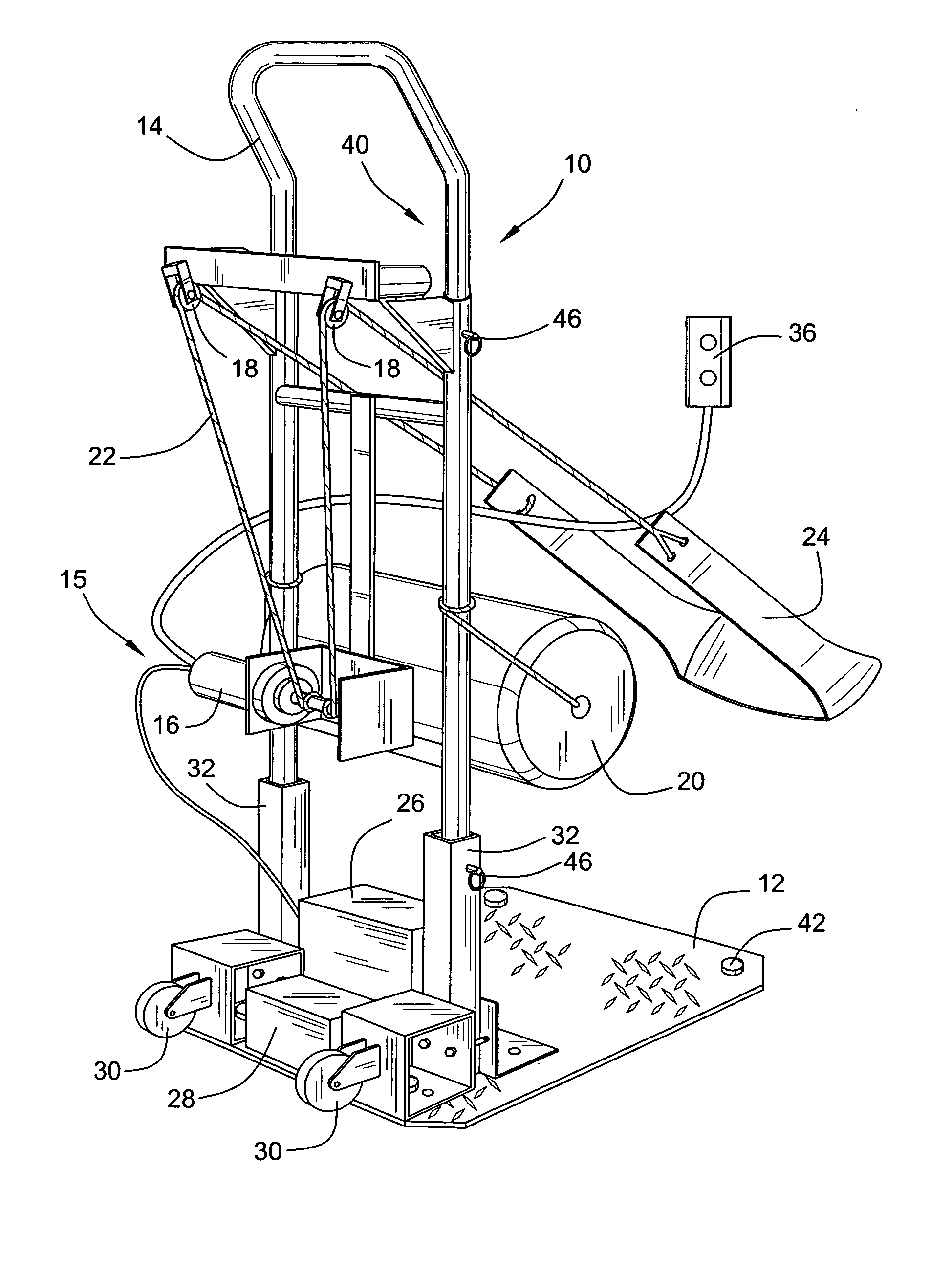

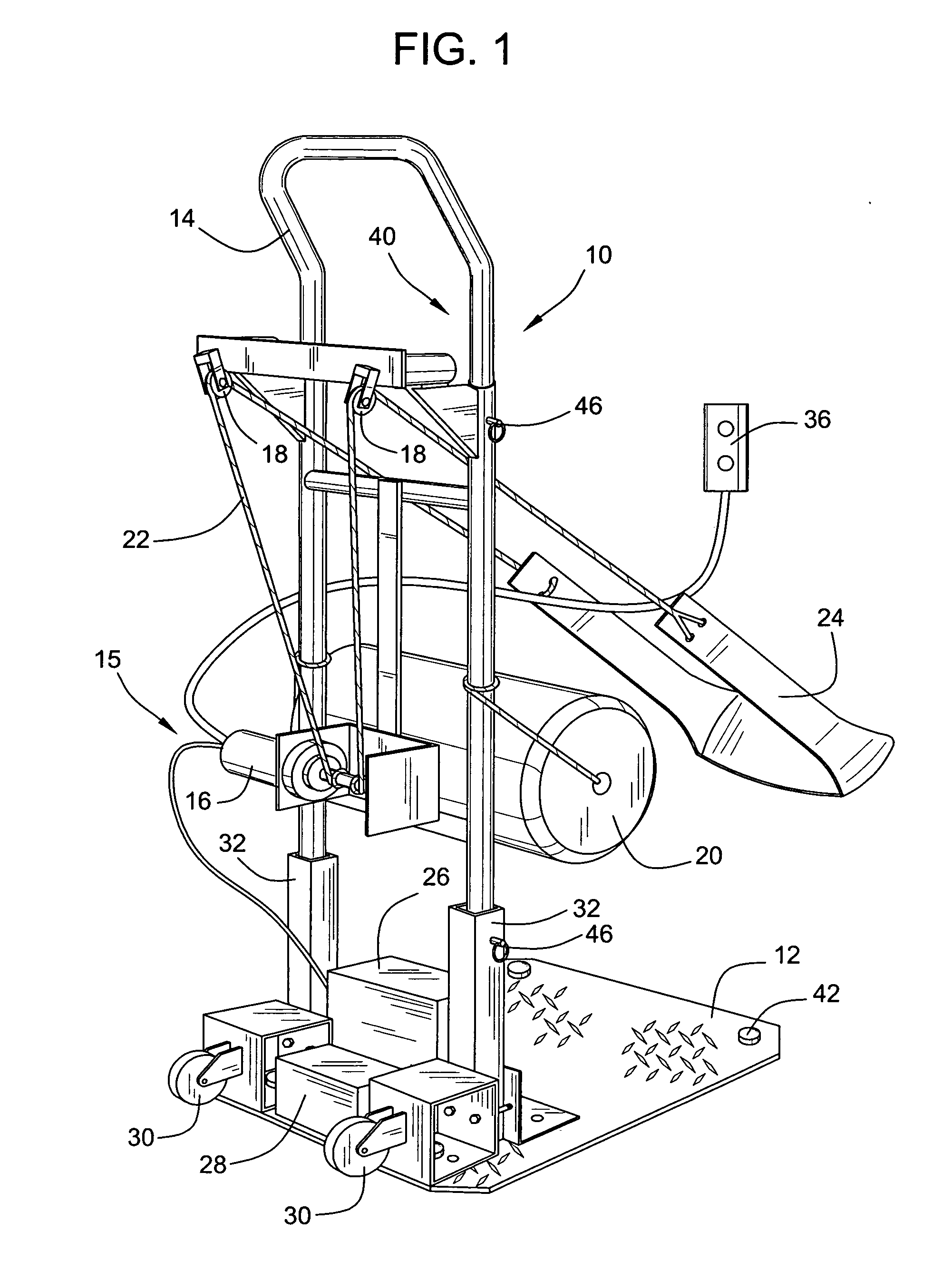

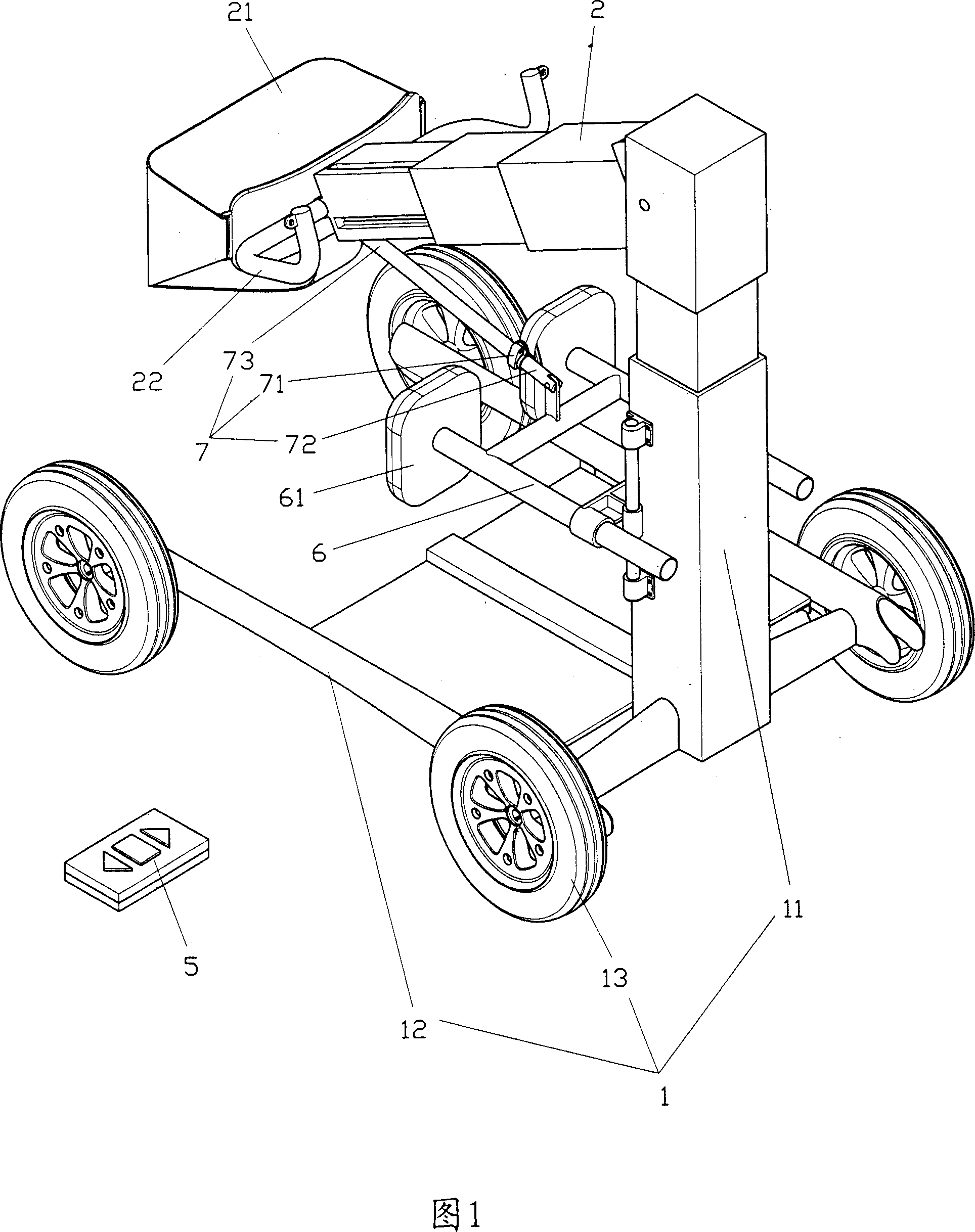

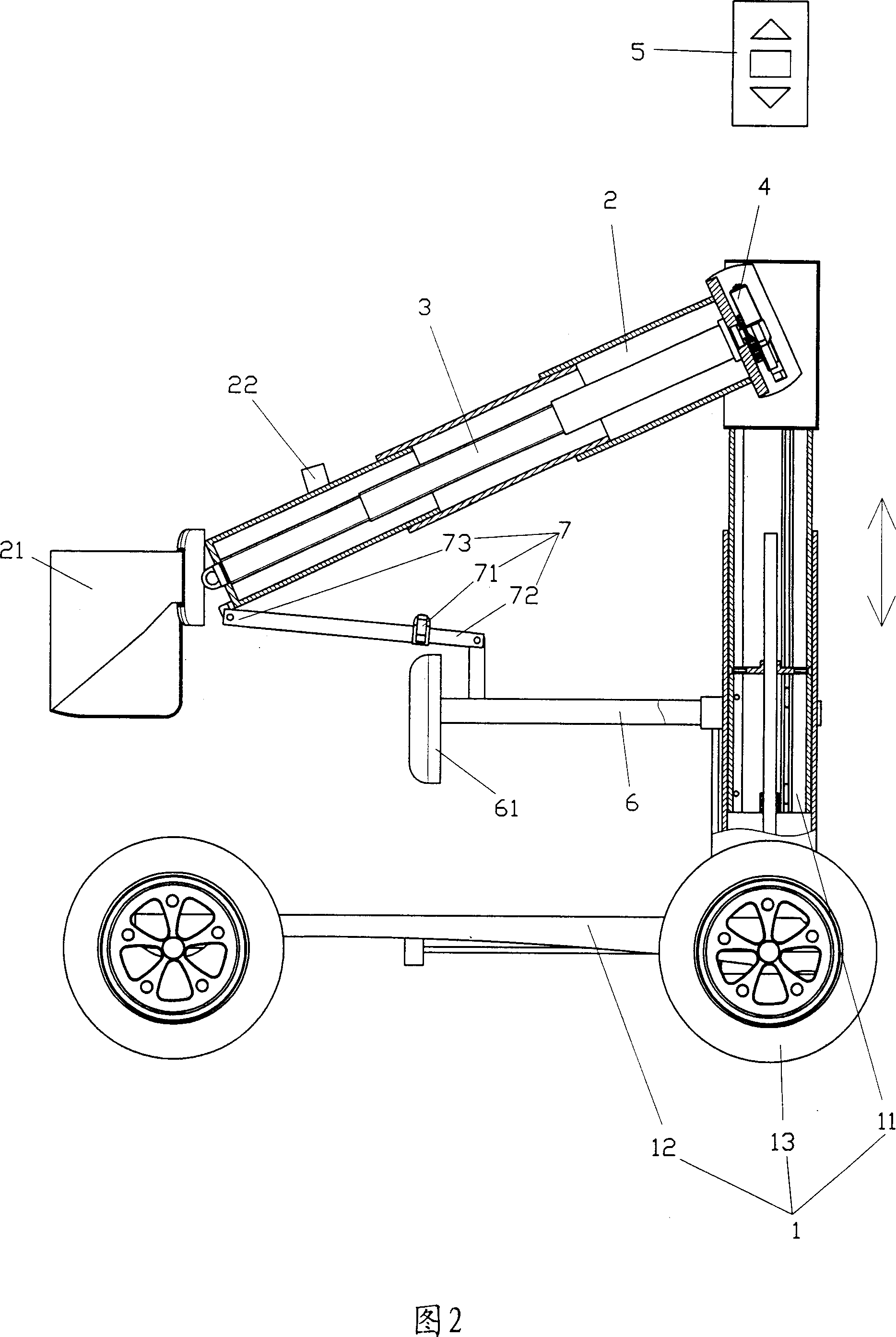

Standing frame with lift, support and transport of user

A standing frame to aid a person with inability to stand or walk to rise to a standing position and transfer from or to other locations such as chairs, toilets, beds. The standing frame has a flat rigid base with fixtures mounted to it that support a vertical rail frame. The vertical rail frame may be adjusted vertically and the frame incorporates a winch and pulley system that uses rope and a belt to lift a person to a standing position and lower the person to a sitting position. The vertical frame also provides handholds for the person being raised to steady himself. The base is preferably provided with roller balls to easily reposition the frame with a person aboard for relocating the person.

Owner:BARATTIA EDWARD C

Desk with tilt-adjustable tops

A desk with tilt-adjustable tops includes a stand frame; a front top mounted to an upper front portion of the stand frame via a front tilt control device; and a rear top mounted to an upper rear portion of the stand frame via a rear tilt control device. The stand frame is height-adjustable and has a storage box located below a rear portion of the front top. The front and the rear top may be separately adjusted to different tilt angles best for writing, drawing, or reading at the desk. In normal time, the front and the rear top may be simultaneously restored to a horizontal state or adjusted to the same plane with the storage box invisibly located below the front top, so that the desk is used as a general desk with a flat top.

Owner:CHI YUEH +1

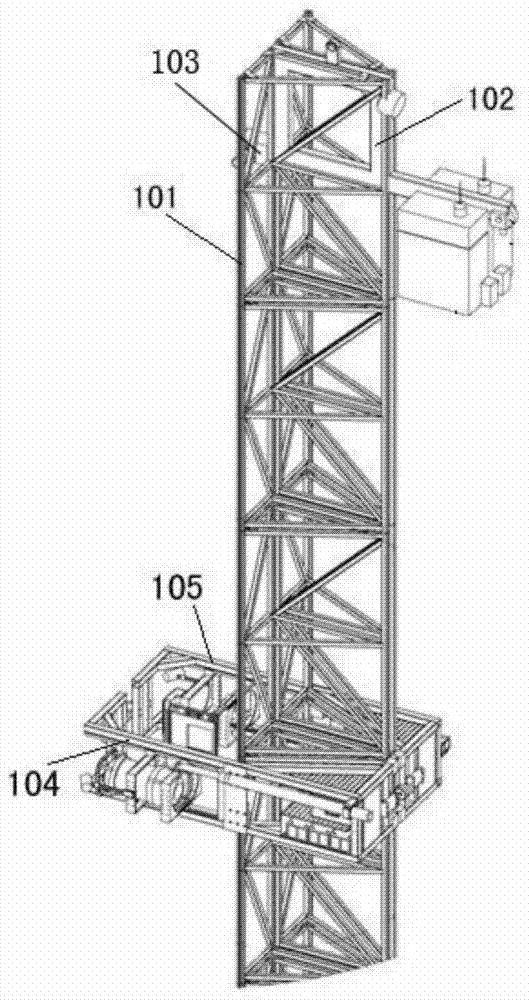

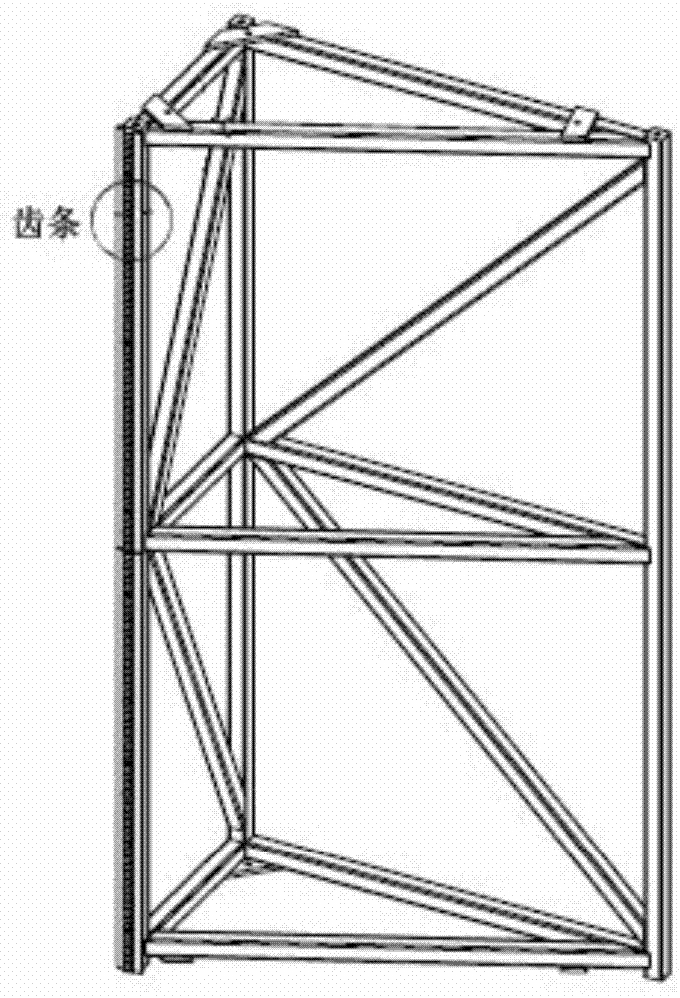

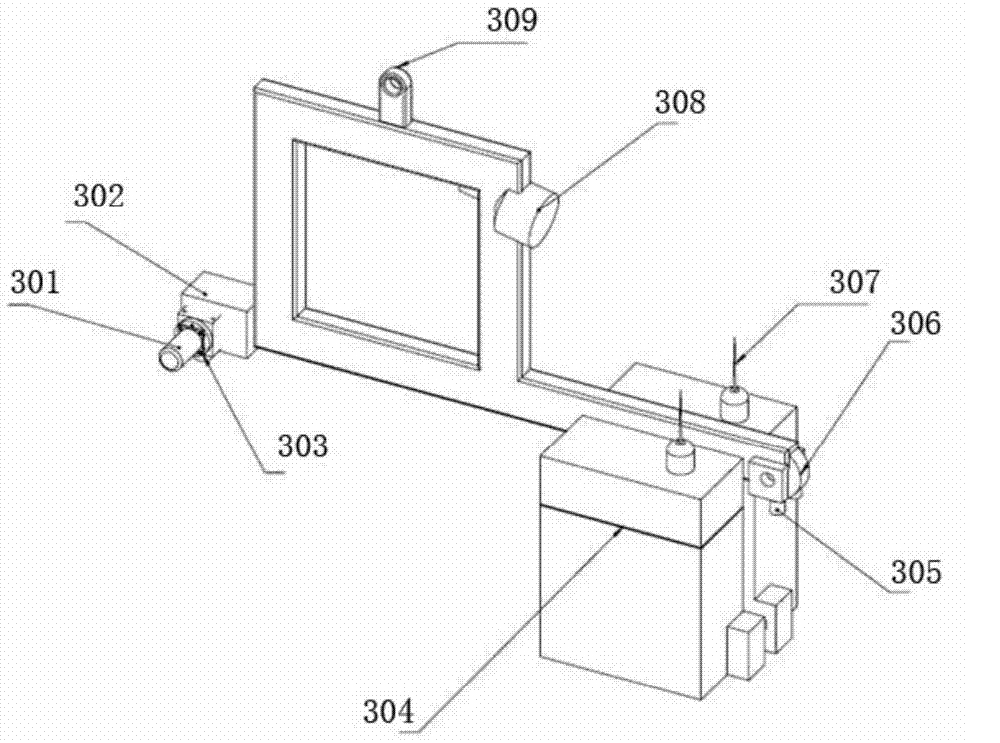

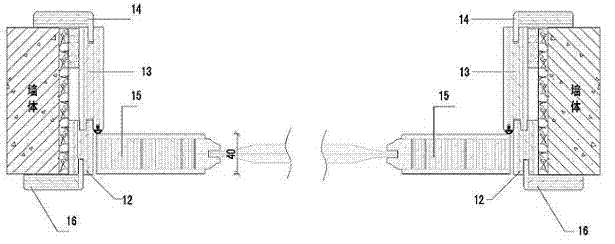

X-ray detection robot for weld seam of storage tank

InactiveCN103760178AExempt from operabilityAvoid dangerMaterial analysis by transmitting radiationBogieStanding frame

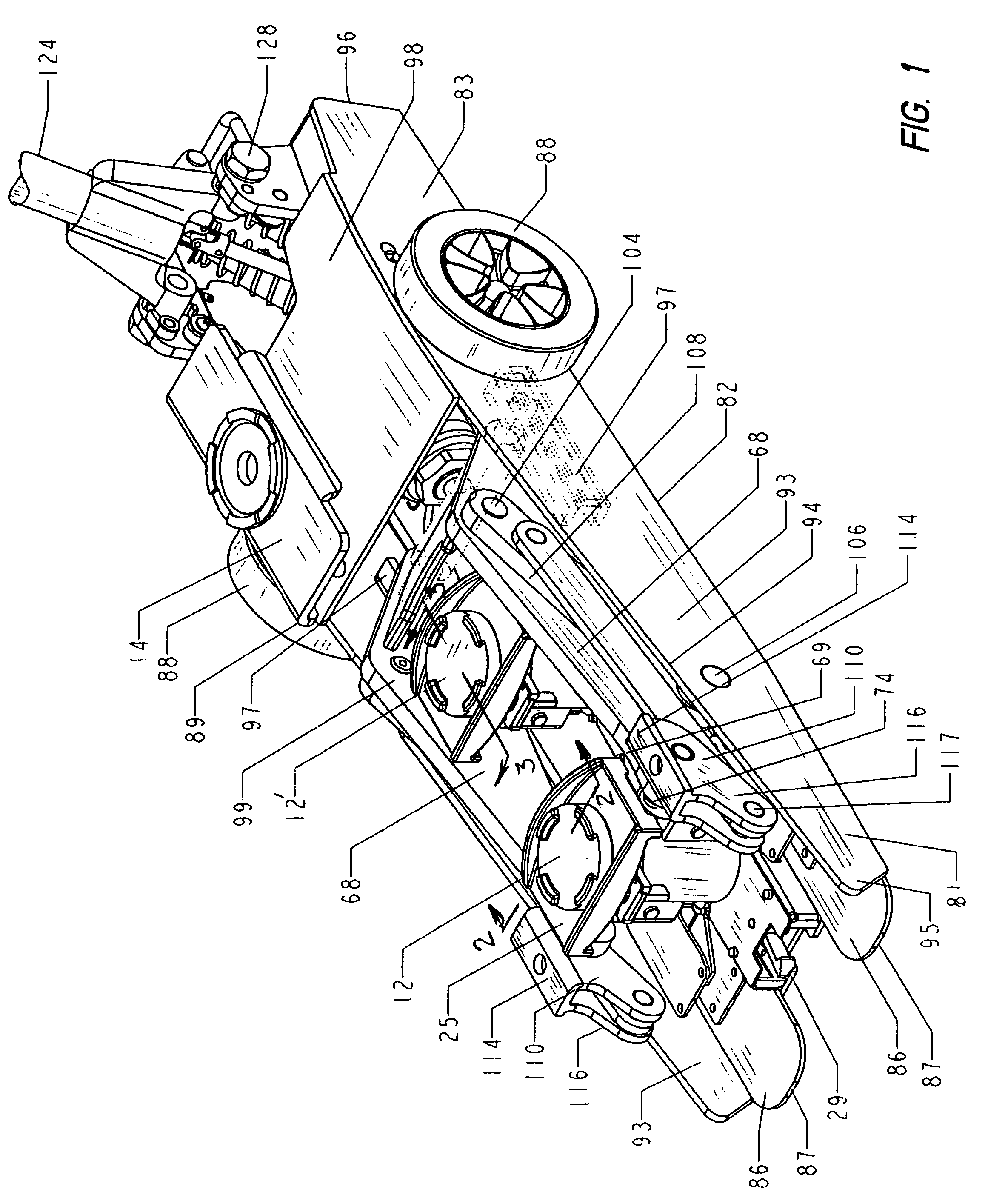

The invention relates to an X-ray detection robot for the weld seam of a storage tank, belonging to the field of nondestructive detection. The robot comprises a framework type symmetrical device, a connection device, an X-ray generator bogie and an imaging bogie, wherein the framework type symmetrical device consists of two symmetrical stand frames, each stand frame comprises a plurality of stand frame modules with racks and can be assembled according to the wall height of the detected tank, the connection device is connected with the two symmetrical stand frames and is provided with a driving device, the X-ray generator bogie and the imaging bogie are respectively connected with the two stand frames, gears of the X-ray generator bogie and the imaging bogie are meshed with the racks of the stand frame modules, and are matched with the stand frame modules through guide sliders. The robot can complete automatic detection on the longitudinal weld seam and annular weld seam instead of manual labor, and wirelessly transmit the detection result to a ground host, and provide a safe, simple and convenient detection mode, and the detection efficiency and detection quality can be greatly improved.

Owner:北京恒正精机科技有限责任公司

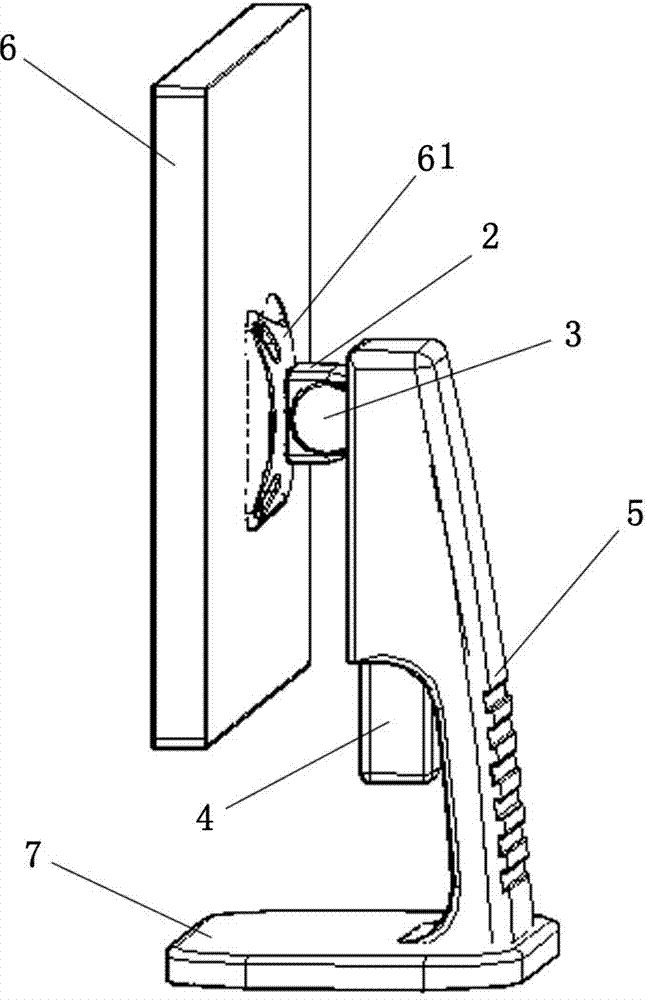

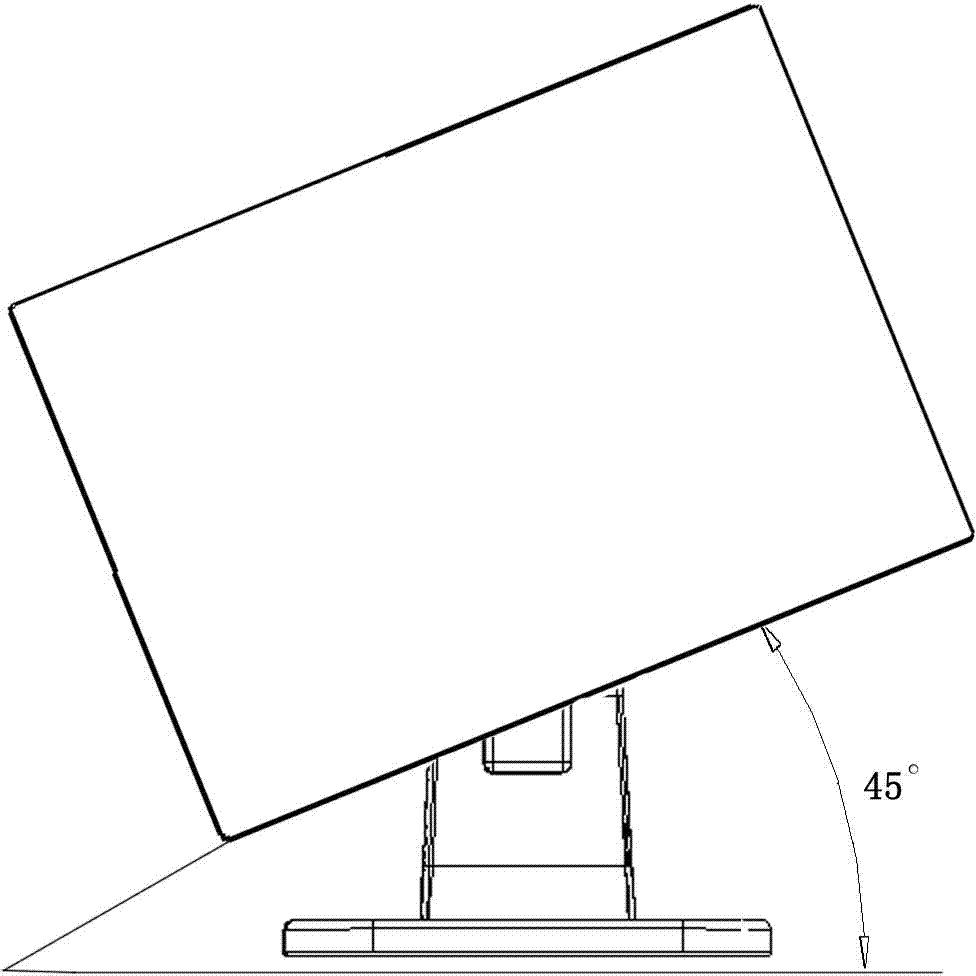

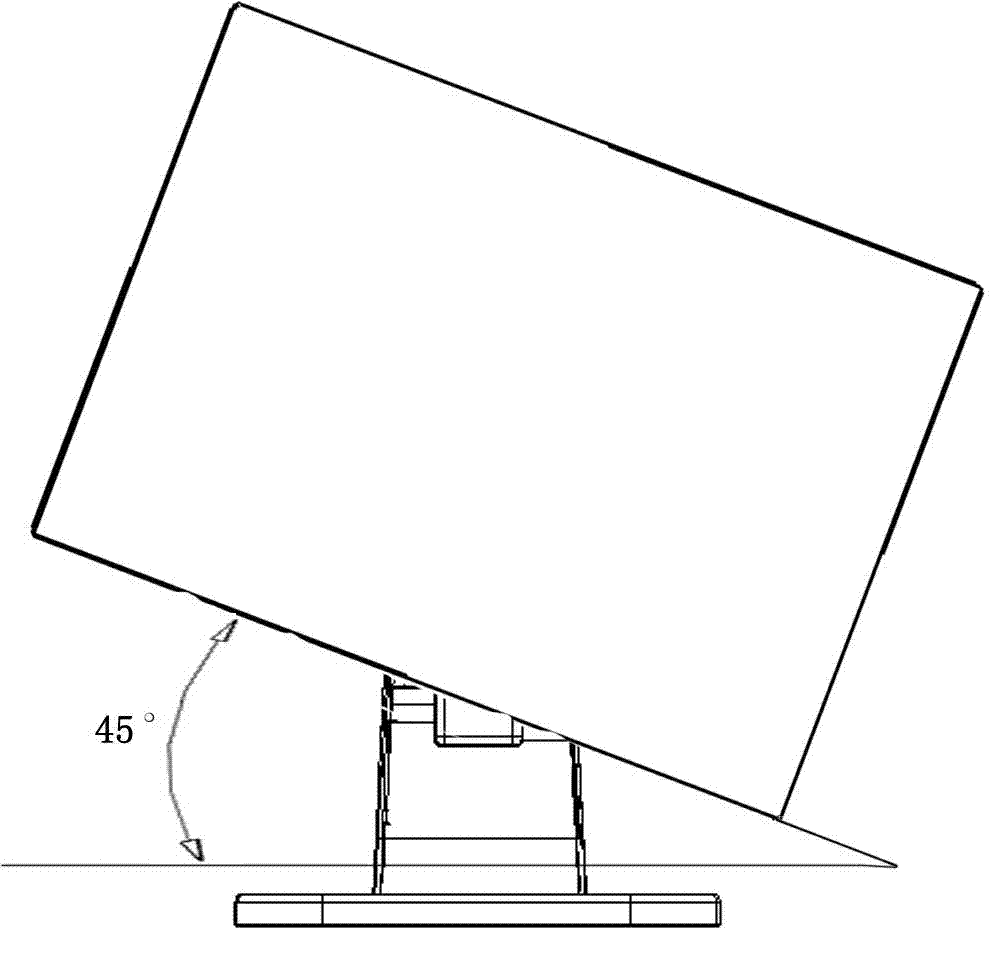

Display support achieving automatic screen swinging

Owner:XIAMEN NANCH BIT PRECISION TOOLS

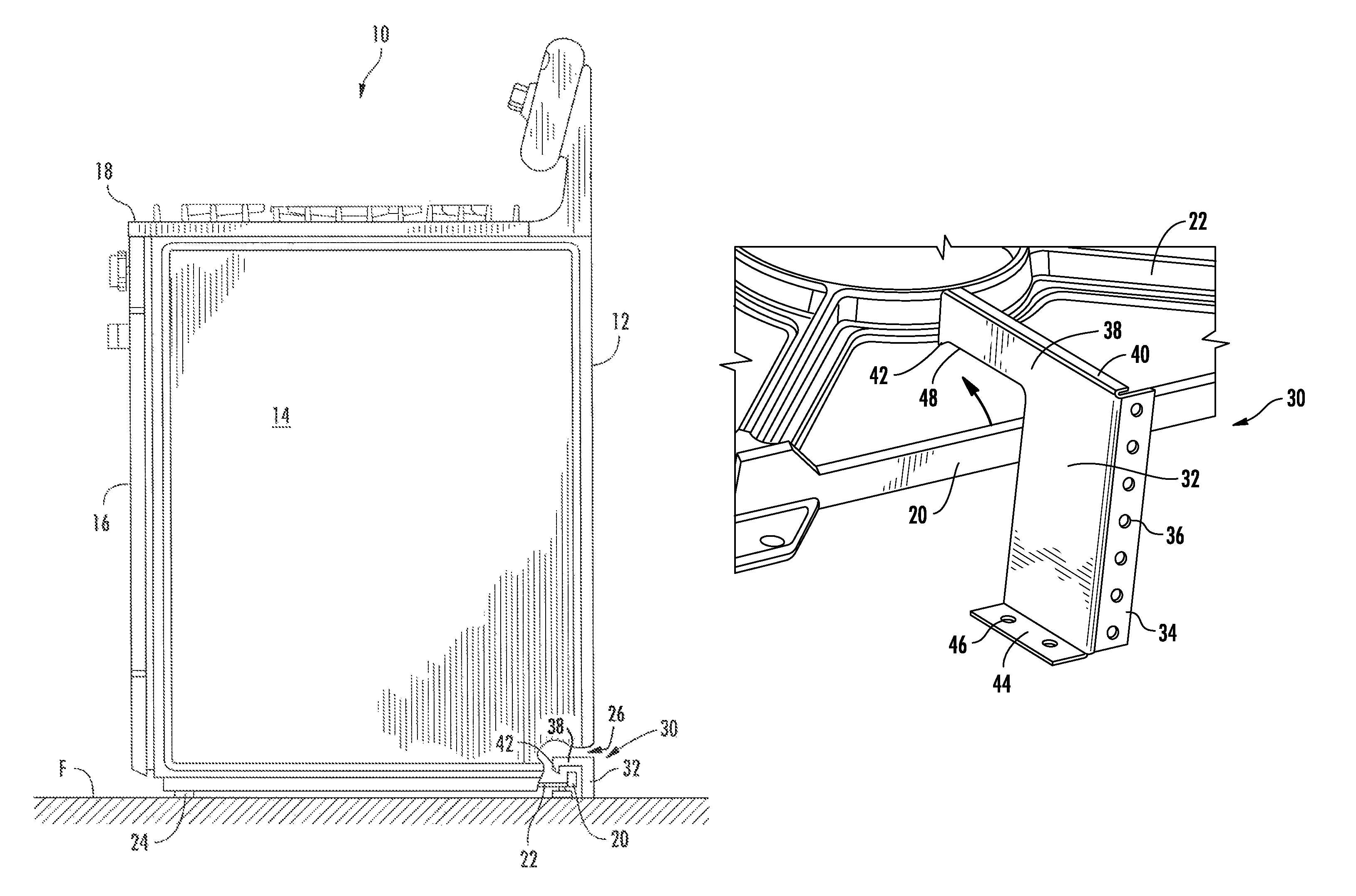

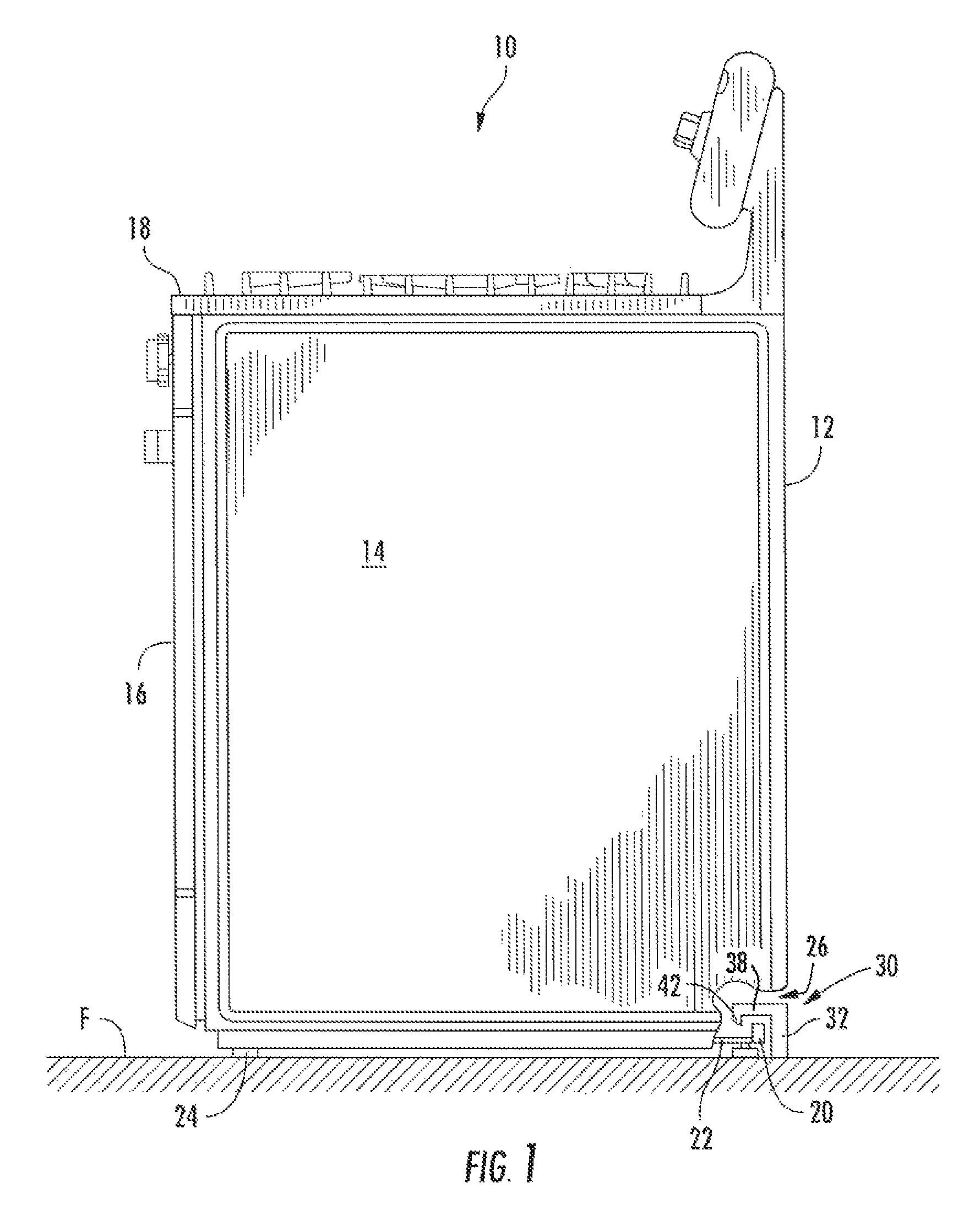

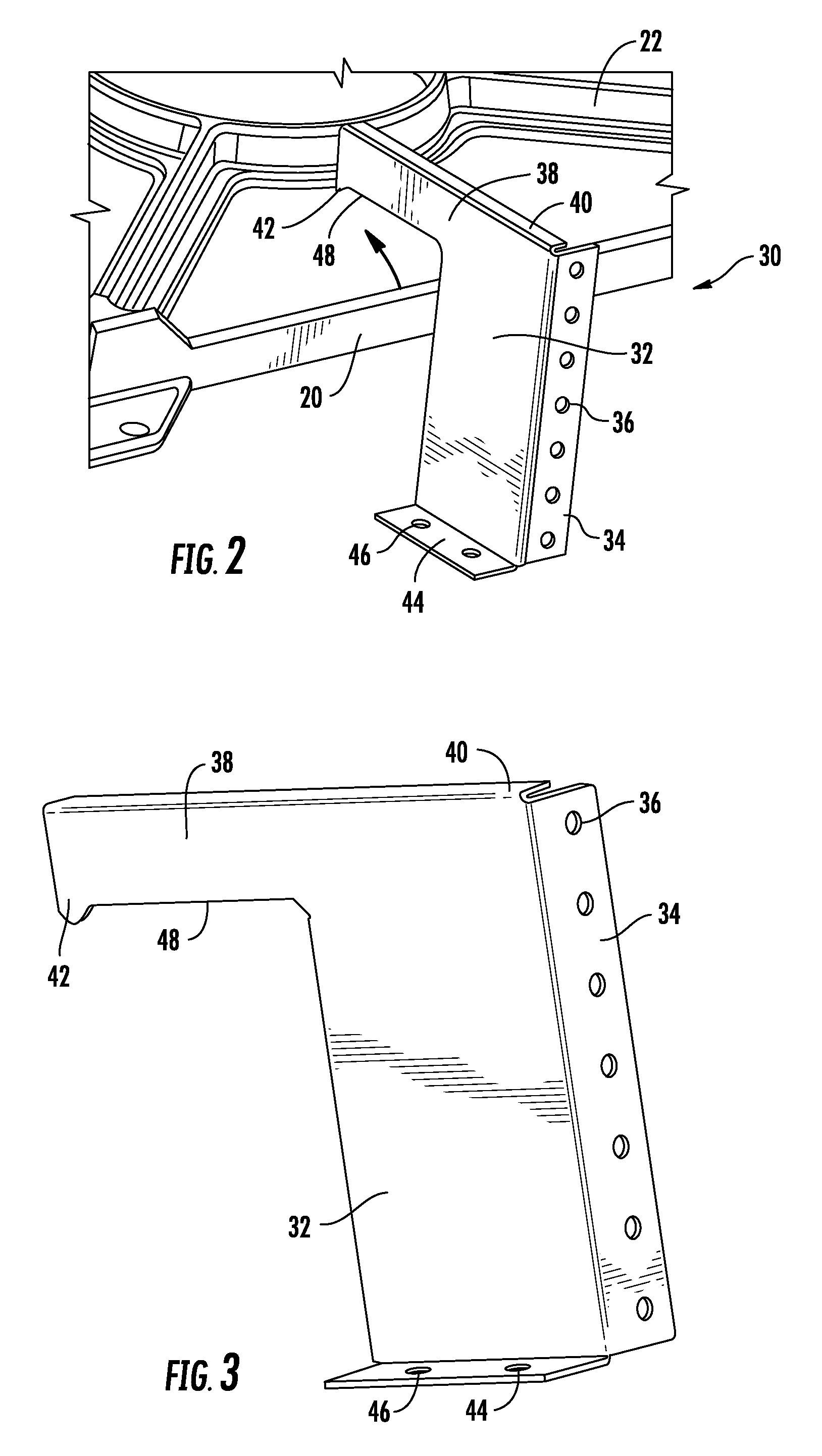

Home appliance with unitary anti-tip bracket

InactiveUS9163842B2Improve toleranceAvoid tearingStoves/ranges foundationsDomestic stoves or rangesStanding frameEngineering

A home appliance, such as a range, for floor-standing operation, including an appliance body, a floor-standing frame supporting the appliance body, the frame including a traverse frame member and an anti-tip bracket mounted to a support surface, the anti-tip bracket including a stanchion and an engagement member projecting from the stanchion in an generally horizontal manner and a tooth projecting downwardly from a distal end of the engagement member for engagement with a portion of the traverse frame member.

Owner:BSH HOME APPLIANCES CORP

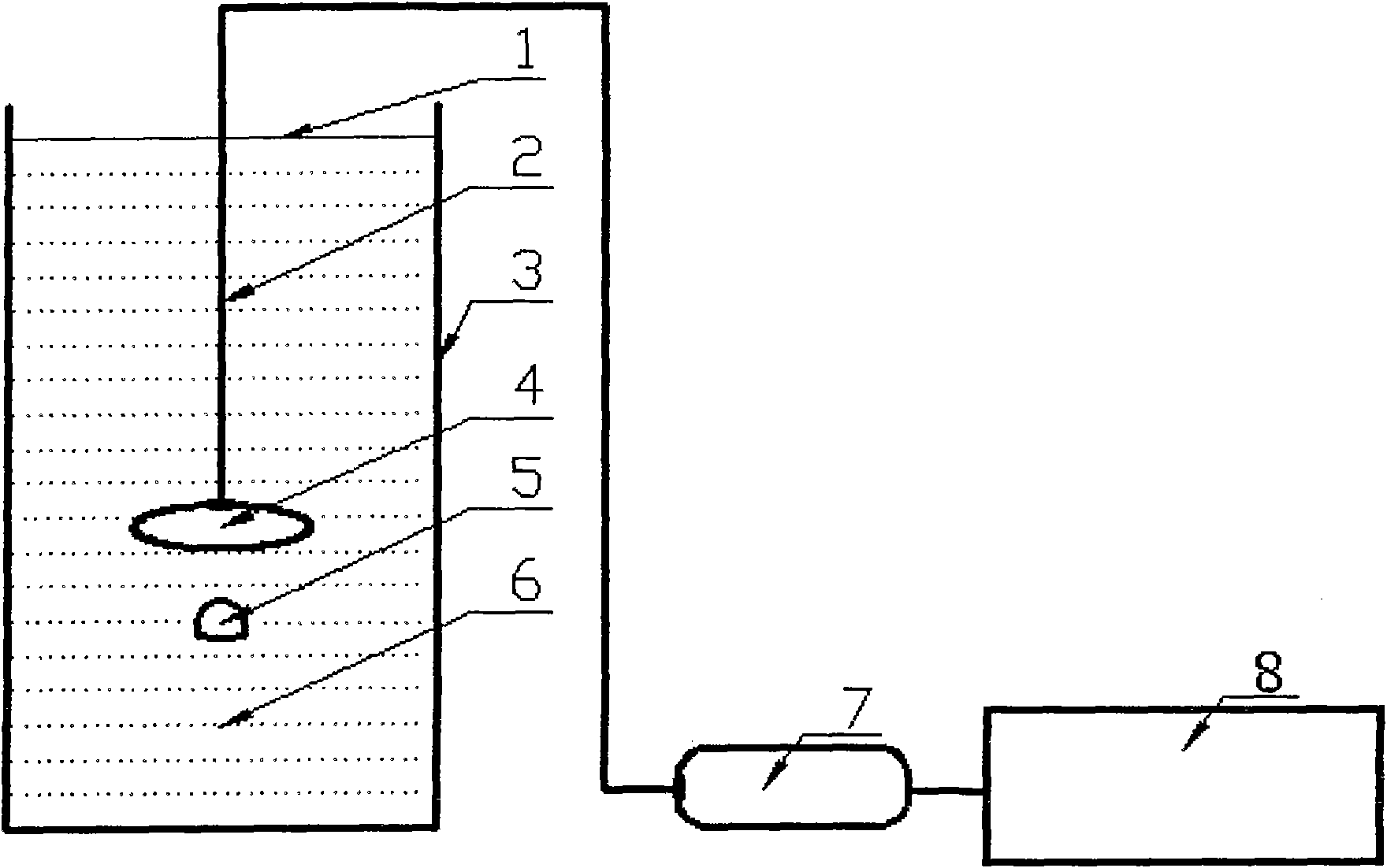

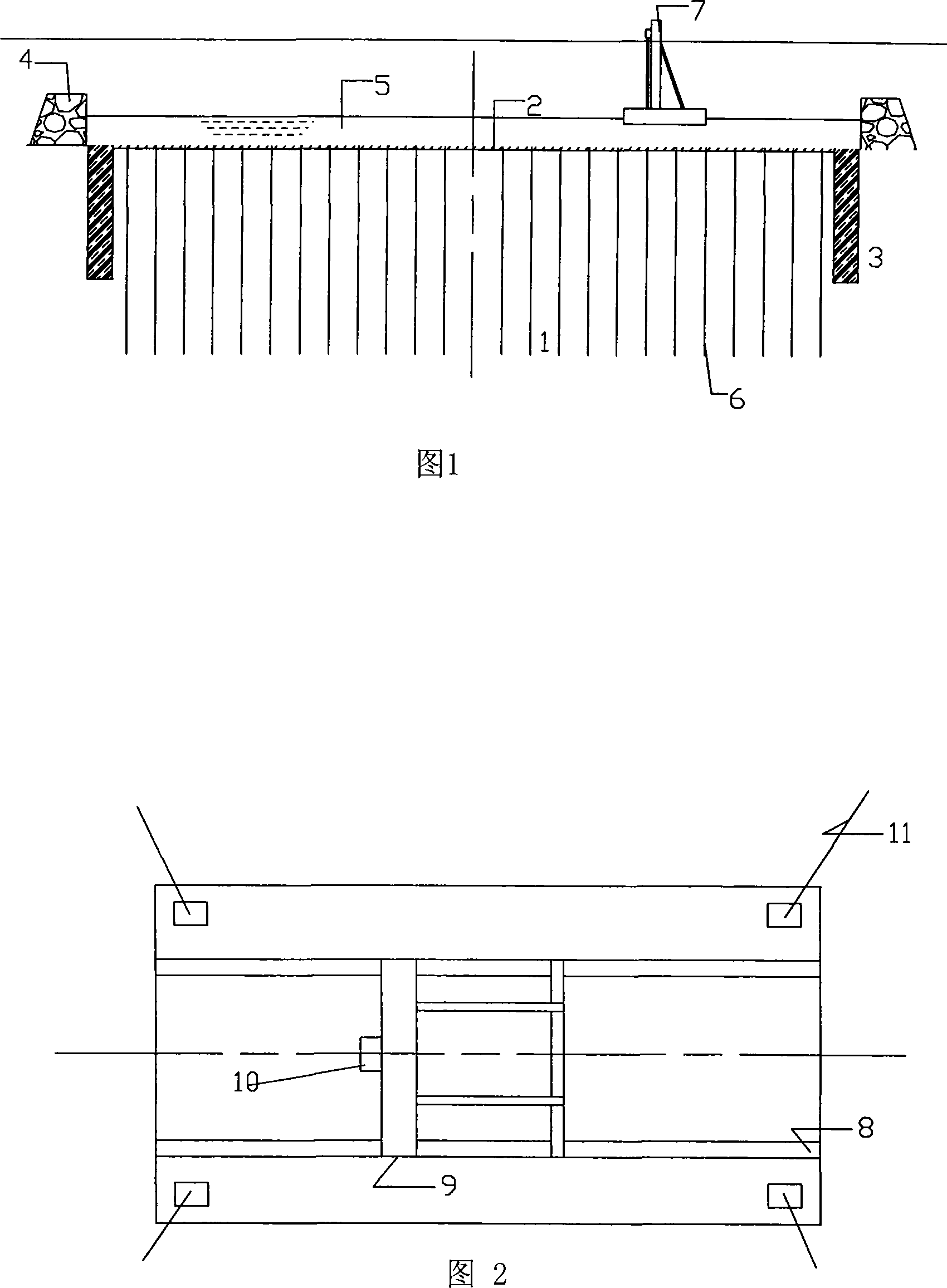

Hidden water body or water filling karst pipe system in similar model test and embedding method thereof

InactiveCN101625289ASolve the structureSolve the problem of embeddingStructural/machines measurementStanding frameKarst

The invention relates to a hidden water body or water filling karst pipe system in a similar model test, comprising a test stand frame. The test stand frame is internally paved with a plurality of layers of similar materials; tunnels are tunneled in the similar materials; the similar materials are internally provided with a hidden water body or a water filling karst pipe; the hidden water body or water filling karst pipe is connected with a pressure pump at the external part of the test stand by a water inlet pipe and water outlet pipe; and the pressure pump is connected with a control device. Simultaneously, the invention also discloses an embedding method of the system. The invention researches the hidden water body or water filling karst pipe system in the similar model test and the embedding method thereof, and solves the problem for embedding and simulating the hidden water body or water filling karst pipe. Compared with the research of former researchers, the hidden water body or water filling karst pipe is embedded into the similar materials of the model test., thereby being more near engineering practice and an obtained water burst theoretical research result have a wider application range.

Owner:SHANDONG UNIV

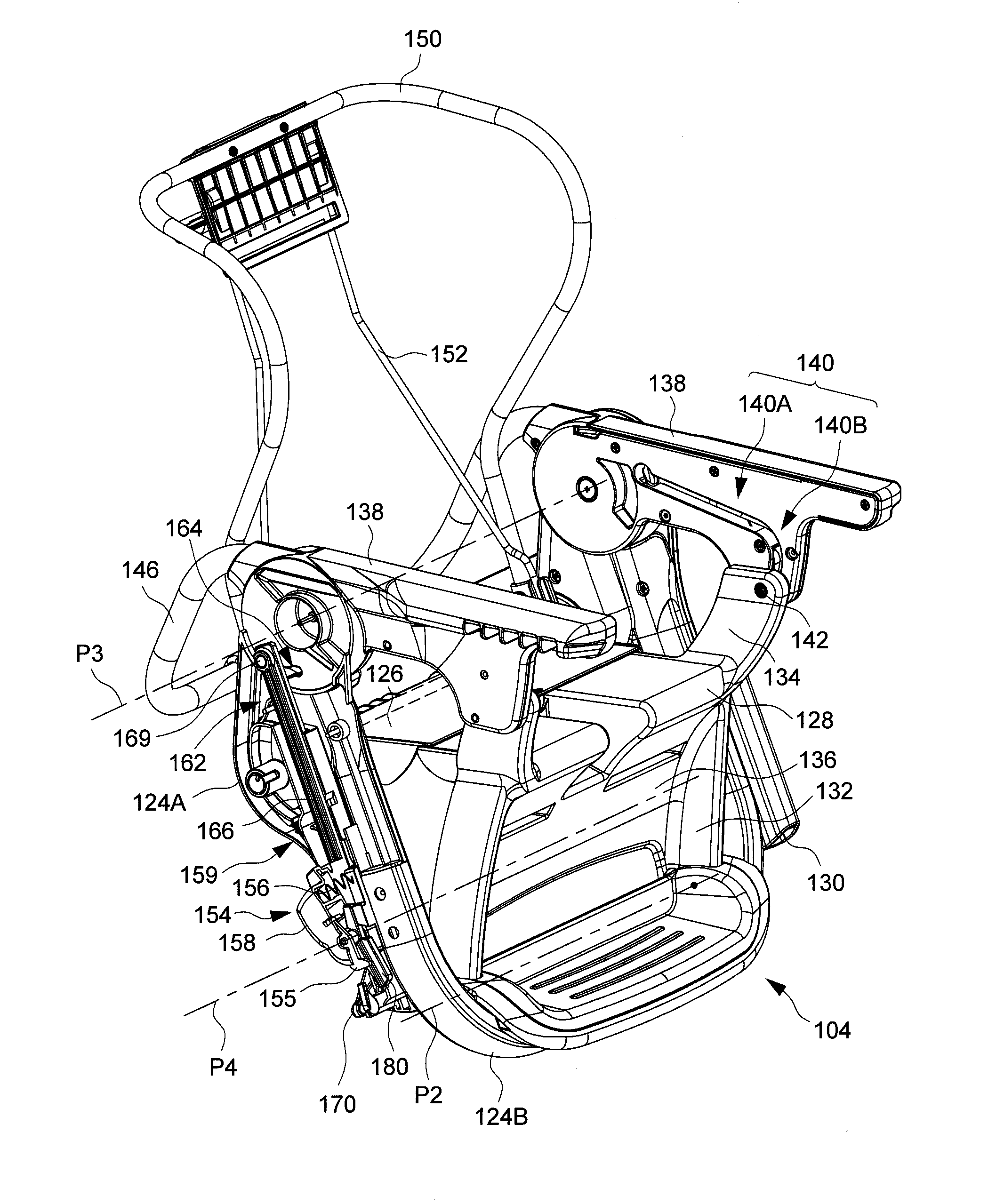

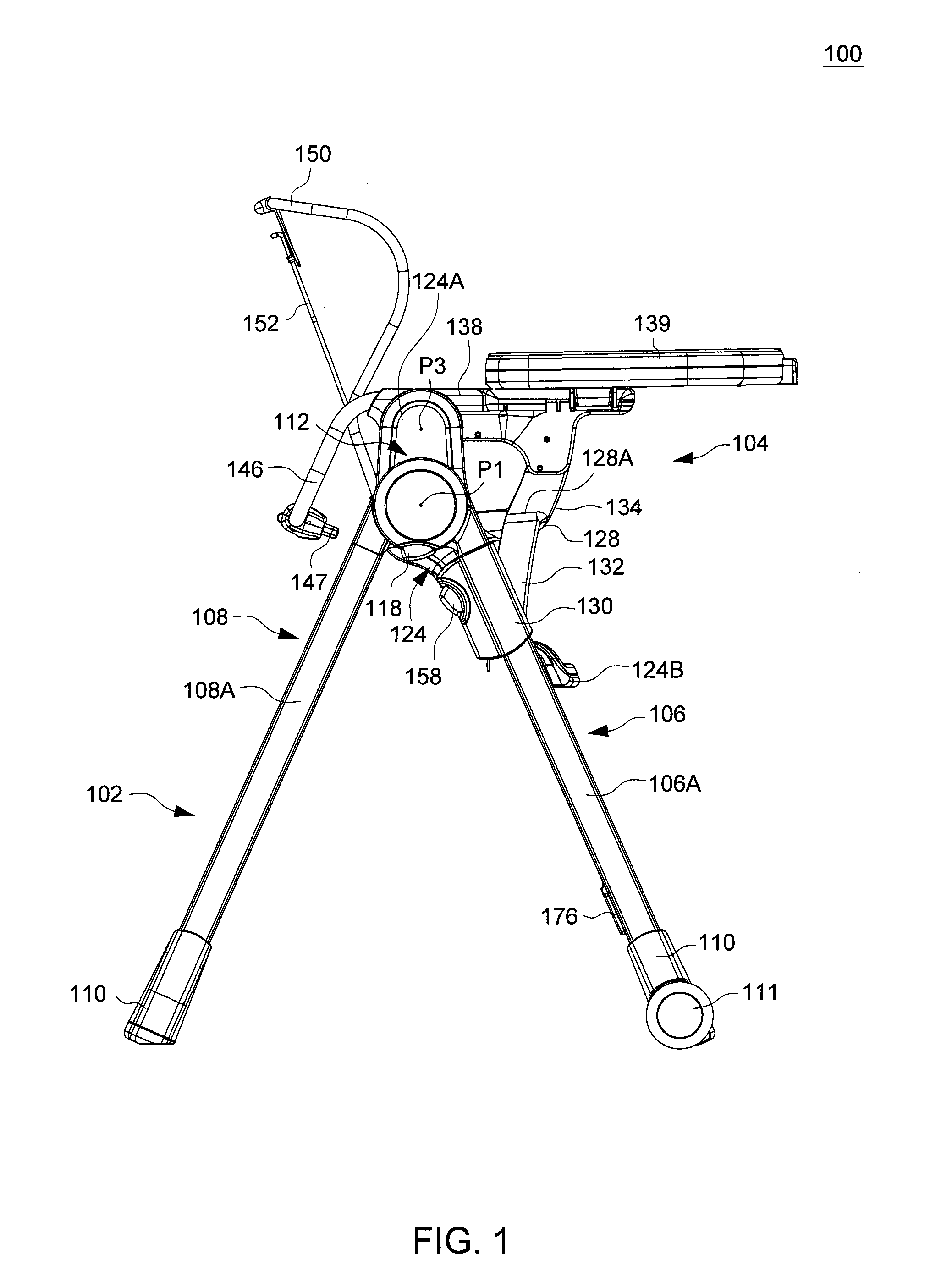

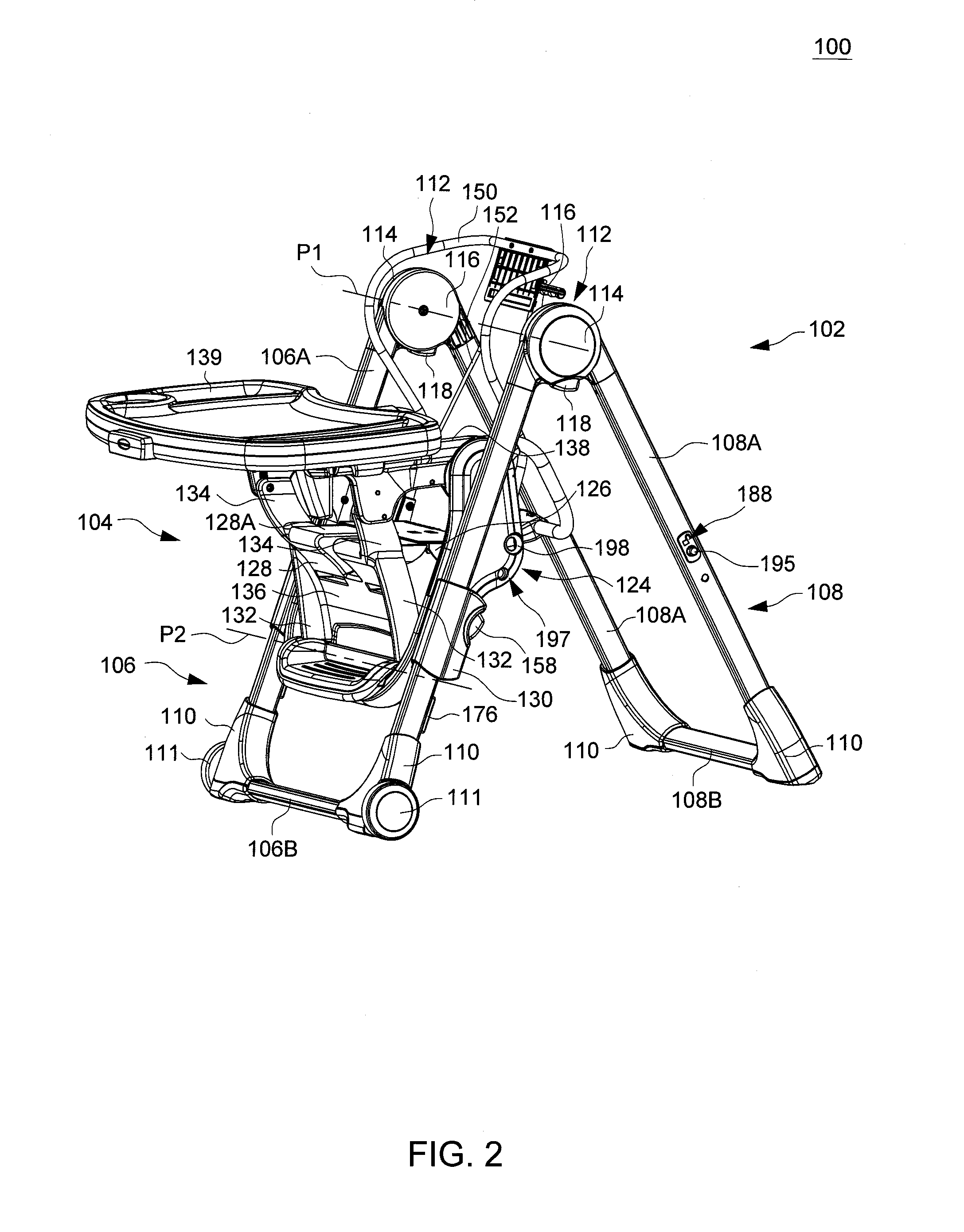

Infant high chair and method of operating the same

An infant high chair includes a standing frame, a seat assembly and a side segment. The seat assembly includes a seat support frame movably connected with the standing frame, and a rear and a front seat portion respectively connected with the seat support frame, the front seat portion being respectively connected with the seat support frame and the side segment at two vertically spaced-apart locations. The side segment is pivotally connected with the seat support frame about a pivot axis, and is rotatable between a folded state and a deployed state. A rotation of the side segment in a folding direction drives a rearward sliding displacement of the front seat portion relative to the rear seat portion. Moreover, a downward displacement of the seat assembly to a predetermined lower position while the side segment remains in the folded state can trigger unlocking of the standing frame.

Owner:WONDERLAND SWITZERLAND AG

Commercial lifting device-jack stand frame locking mechanism

An extendible jack stand comprises first, second, and third vertical frames arranged in telescoping relationship. A locking mechanism includes an upwardly extending finger fixedly secured to an outer surface of the upper end of the first frame. A guide member is secured to the upper end of the second frame and extends horizontally outward. A latch member is slideable within the guide member and has a slotted opening therein for receiving the finger, with springs urging the latching member inward. When the third frame is fully extended, the latch member is urged into a groove in the third frame and permits the second frame to be extended. The upper end of the finger has an outward surface that inclined at about 32° for sliding the latch member outward along the guide member. The inward surface then inclines at an angle of about 45°. The inward surface further extends inclined at an angle of about 23. The guide member, the finger and the latch member are formed of 4130-4140 steel and are heat treated to a hardened of about 40-45 Rockwell C.

Owner:CALA SALVATORE

Method for calibrating micro thrust

InactiveCN101514928ASimple and fast operationEasy to controlForce measurement by elastic gauge deformationStanding frameEngineering

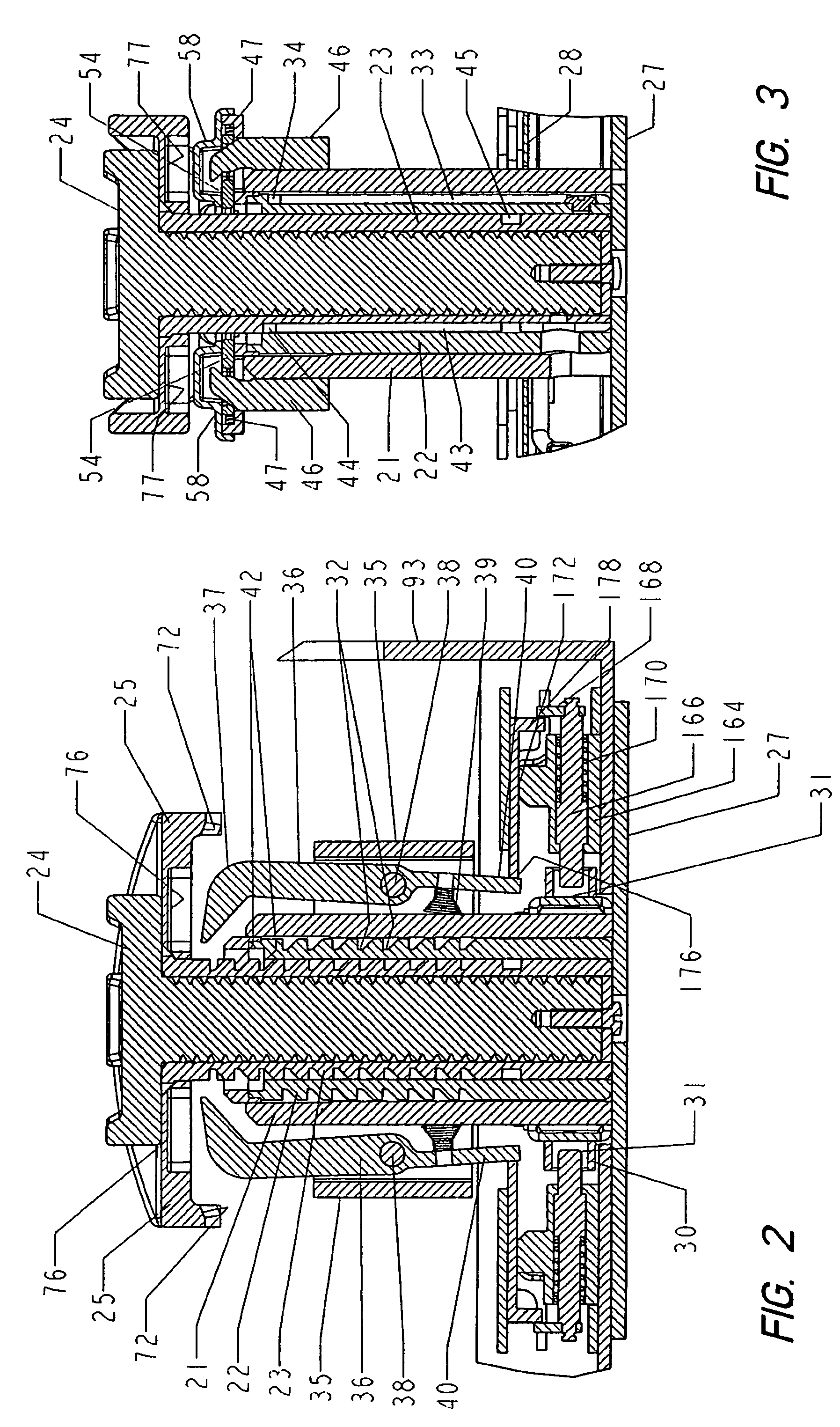

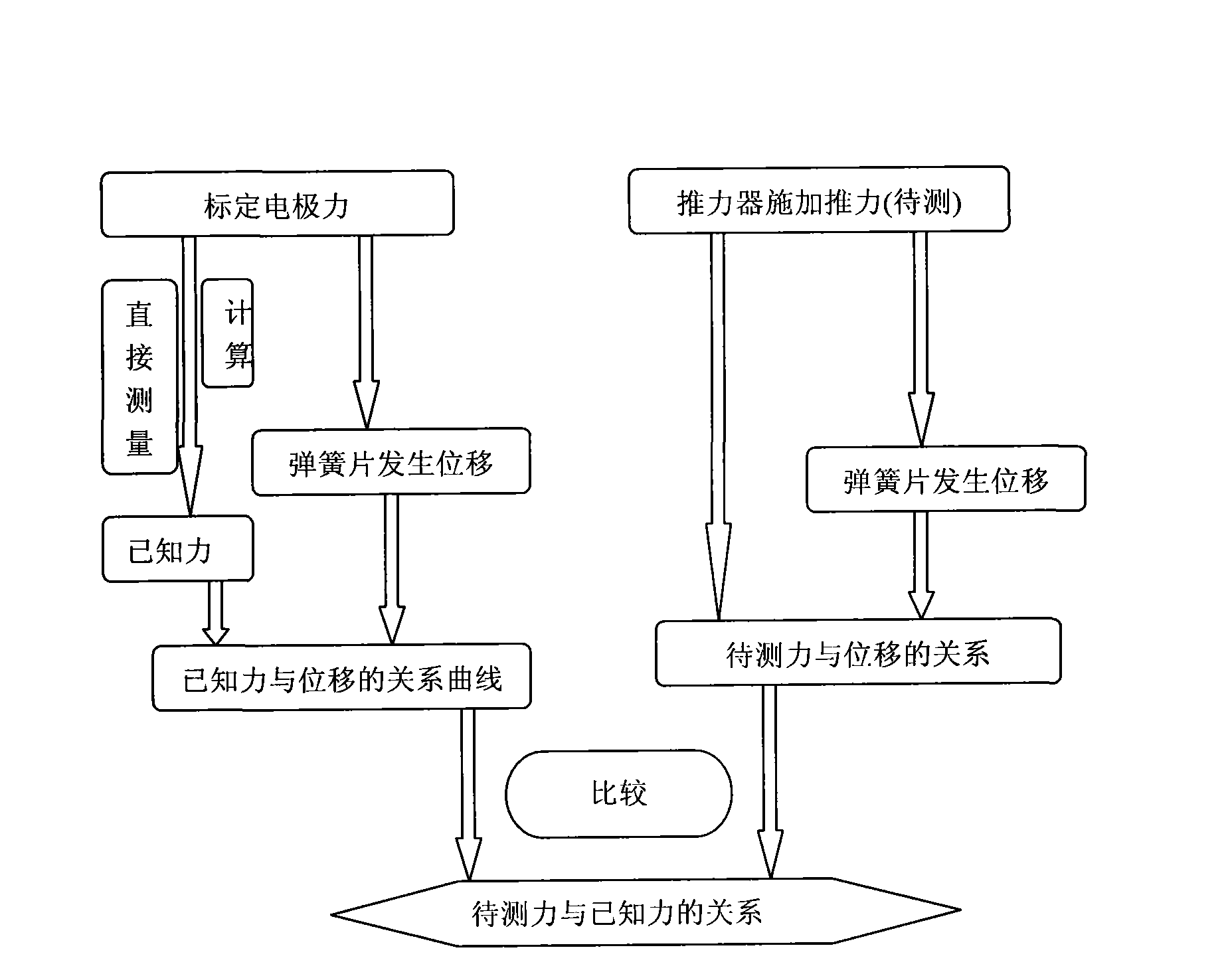

A method for calibrating micro thrust is characterized in that the method specifically comprises the following steps: (1) adjusting a thrust stand frame to be horizontal by an adjusting bracket and aligning the anode of a calibration electrode with the cathode thereof in parallel by adjusting balance weight and a fixed plate below a spring piece; (2) adjusting the distance between the anode and the cathode of the calibration electrode and the distance between a displacement sensor and the spring piece to facilitate the displacement sensor and the calibration electrode to work in an effective range; (3)applying voltage to the calibration electrode for calibration to obtain the electrostatic force, voltage and displacement calibration curve; (4) switching off the powder supply on the calibration electrode and apply voltage to a thruster to obtain the flow, extracting voltage and displacement curve and then obtain the flow, extracting voltage and thrust curve by calibrating curve.

Owner:BEIHANG UNIV

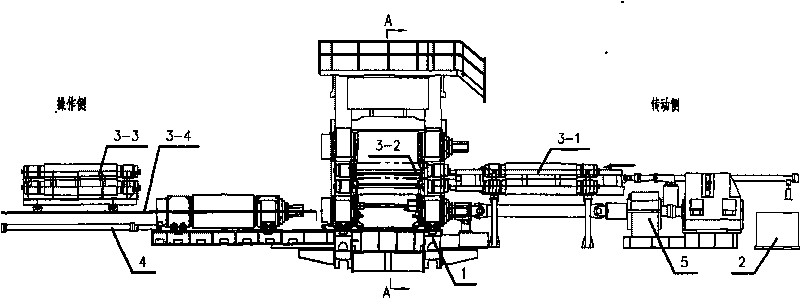

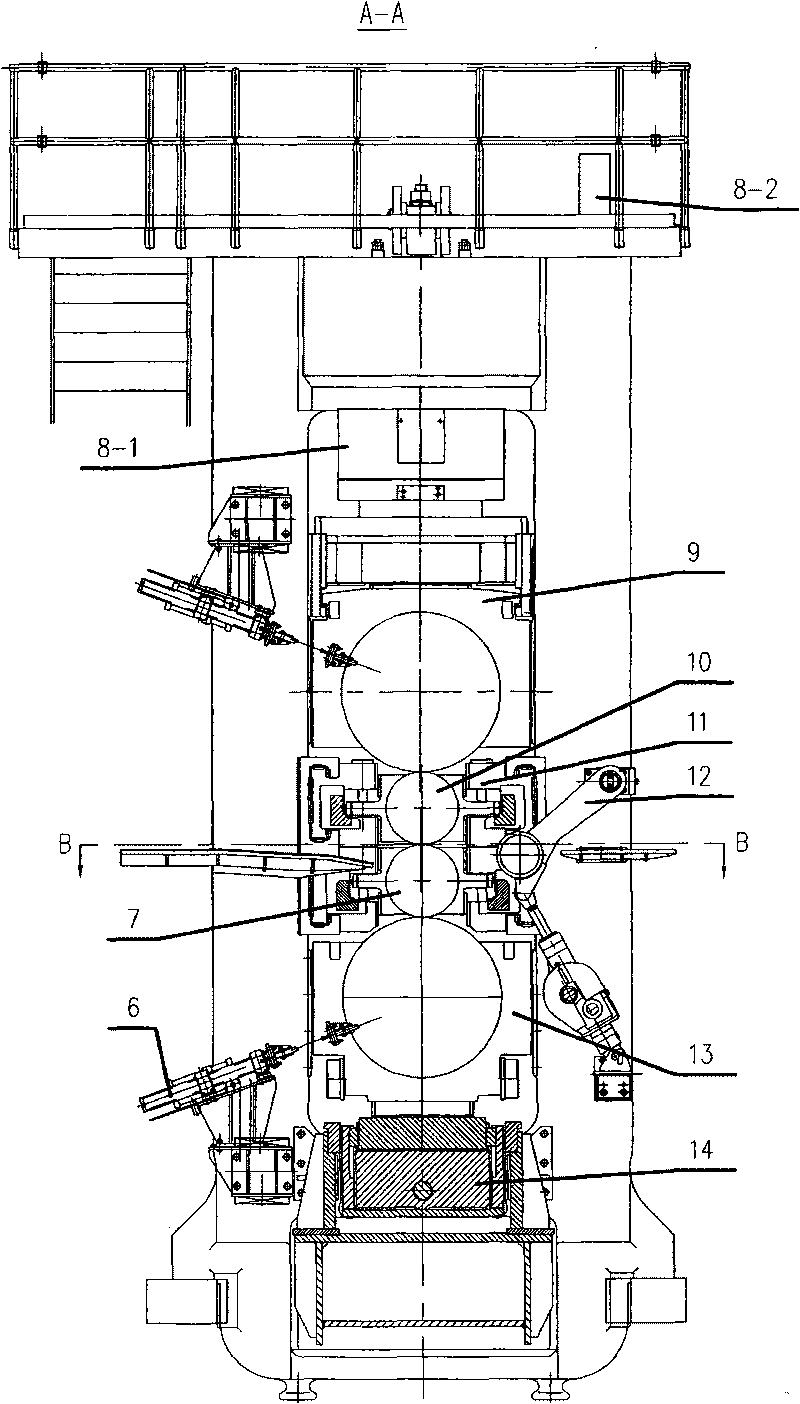

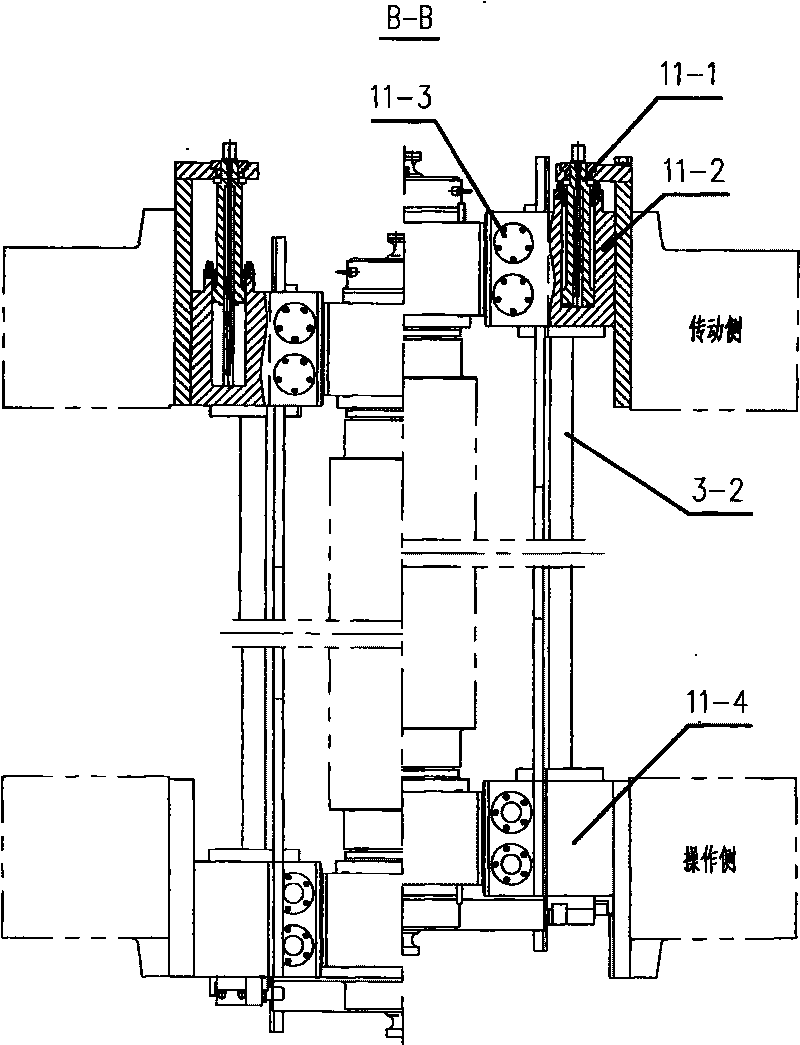

Temper mill with roll bending and shifting functions

ActiveCN101733285AImprove effective utilizationCompact structureMetal rolling stand detailsRolling equipment maintainenceStanding frameWork roll

The invention belongs to the technical field of forming and discloses a temper mill with the roll bending and shifting functions. The temper mill mainly comprises a stand frame, a working roll changing device, a back-up roll changing device, a main transmission gear, upper and lower working roll fittings, a thickness control device, upper and lower back-up roll fittings and a rolling line elevation adjusting device. A working roll shifting and bending device is inlaid in a housing window of the temper mill. Positive and negative roll bending cylinder bodies at the transmission side and a roll shifting cylinder body are integrated on a bending and shifting integrated block. A piston rod of the roll shifting cylinder is fixedly mounted on a housing by an E-shaped block. Positive and negative roll bending cylinders at the operating side are integrated on a roll bending integrated block, without roll shifting cylinders. The integrated blocks at the transmission side and the operating side are connected together by a roll changing rail in the housing of the temper mill to form the working roll shifting and bending device. The invention ensures the means of adjusting the roll gaps to be more flexible, can prolong the service life of the working roll, realize rapid roll changing, shorten roll changing time and reduce the production cost. The invention can be widely applied to strip temper mills.

Owner:CISDI ENG CO LTD

Dual functional desk with tilt-adjustable tops

A dual functional desk with tilt-adjustable tops includes a stand frame; a front top mounted to an upper front portion of the stand frame via a front tilt control device; and a rear top including a screen support and mounted to an upper rear portion of the stand frame via a rear tilt control device. A computer, TV, or PDA screen may be mounted on the screen support, and the front and the rear top may be separately adjusted to different tilt angles best for writing, reading, or drawing at the front top, or watching the screen mounted on the rear top. When the screen is not in use, the front and the rear top may be simultaneously restored to a horizontal state or adjusted to the same plane with the screen invisibly located below the rear top to increase the usable area on the desk.

Owner:CHI YUEH +1

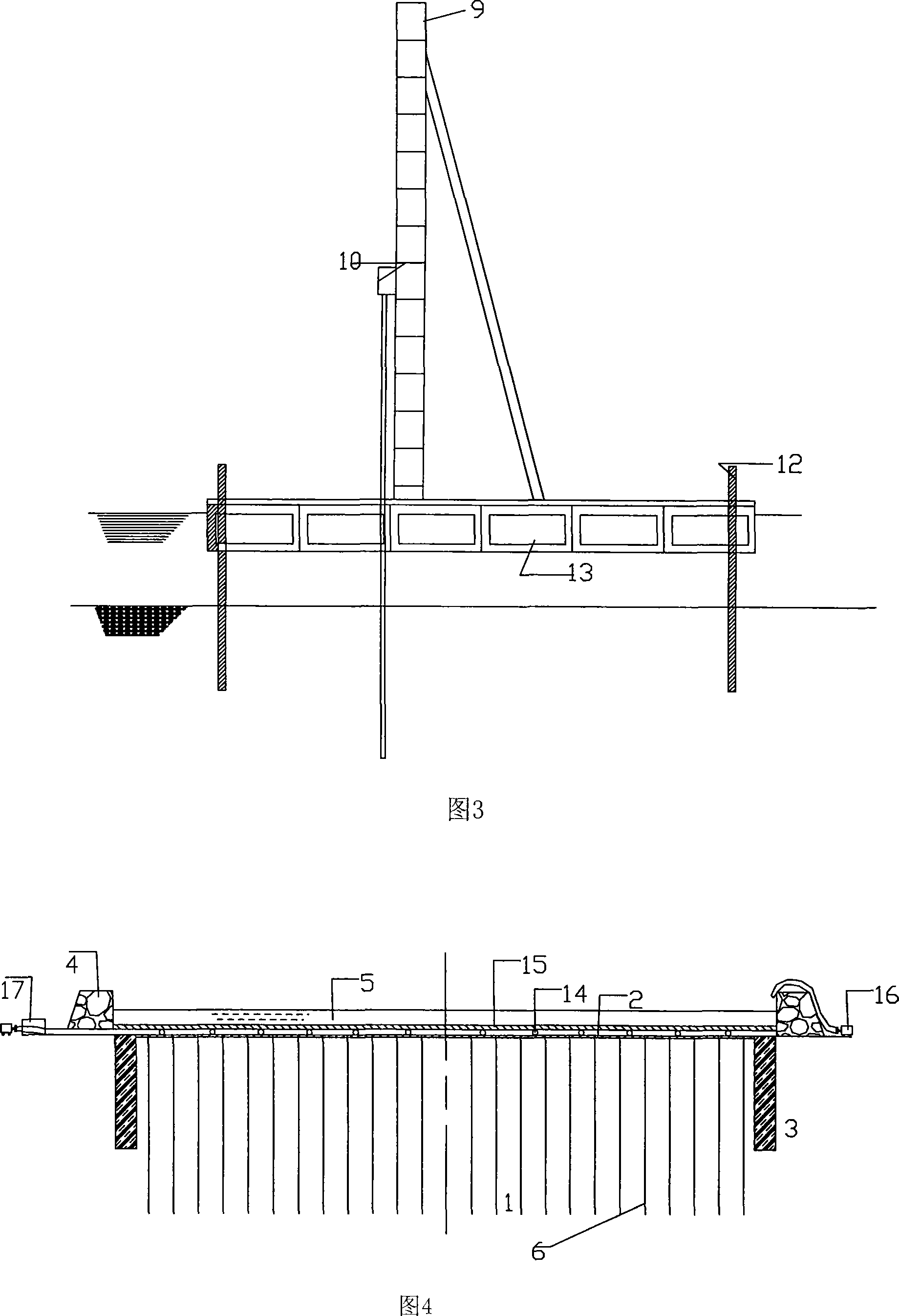

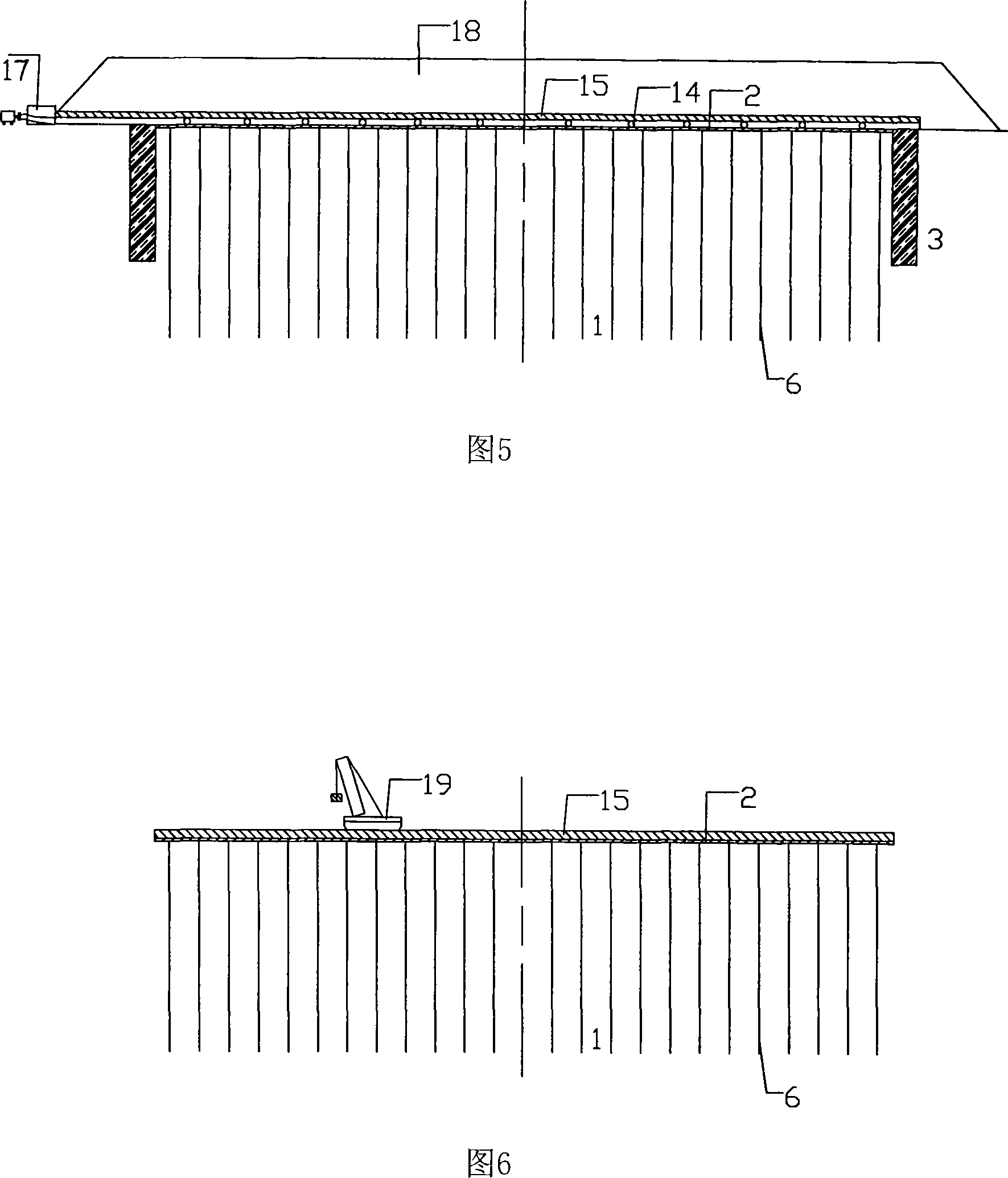

Floating flashboard machine and large area ultra-weak foundation fast directly draining concretion method

InactiveCN101144281AEasy to insertSmooth handlingFoundation engineeringStanding frameCarrying capacity

The present invention discloses a floating type flash board machine. The present invention comprises a main body rack, a flash board machinery and a buoyancy device supported at the bottom part of the main rack, and the flash board machinery comprises a guide rail, a stand frame and a flash board mechanism, the guide rail is laid on the main body rack, the stand frame is connected with the main body rack to slide along the guide rail, and the flash board mechanism is fixed on the stand frame. The present invention also discloses a large area ultra-weak foundation quick and direct drainage consolidation method, which operate the board flash by utilizing the floating type flash board machine. As for the soft soil foundation having large moisture content and poor carrying capacity, the floating type flash board machine of the present invention can also operate above in the same way, so as to conveniently insert the drainage board, and thereby the drainage consolidation method can be implemented smoothly to treat the large area ultra-weak foundation. The present invention does not require non woven fabric and an earthwork grate to be pre-laid on the foundation to be treated, and a sand cushion is also not required to be laid in the treating process, therefore, the construction period can be shortened without restraints of the sand source condition, and the present invention has important significance to cost reduction and environmental protection.

Owner:CCCC FOURTH HARBOR ENG CO LTD +3

Frame structure

Owner:DDF

Elastic coupling working condition test stand

ActiveCN103558025AEasy to optimize and improveEasy to analyzeMachine gearing/transmission testingForce measurement by elastic gauge deformationStanding frameExperimental research

The invention provides an elastic coupling working condition test stand which comprises a stand frame. A power source and a load wheel are arranged on the stand frame, an elastic coupling is connected between the power source and the load wheel, the stand frame is provided with a movable structure, and the power source and / or the load wheel are / is fixed to the movable structure. According to the elastic coupling working condition test stand, by means of the arrangement of the load wheel, the power source, the elastic coupling and the movable structure on the stand frame, working condition testing of the elastic coupling is achieved, quantitative and qualitative analysis of experiment data can be carried out, and optimization and improvement of the elastic coupling are facilitated. By means of the arrangement of the movable structure, different deviation types and different deviation values are formed between the axis of the power source and the axis of the load wheel so as to facilitate experimental research analysis and facilitate optimization and improvement of the elastic coupling.

Owner:QINGDAO UNIV OF SCI & TECH

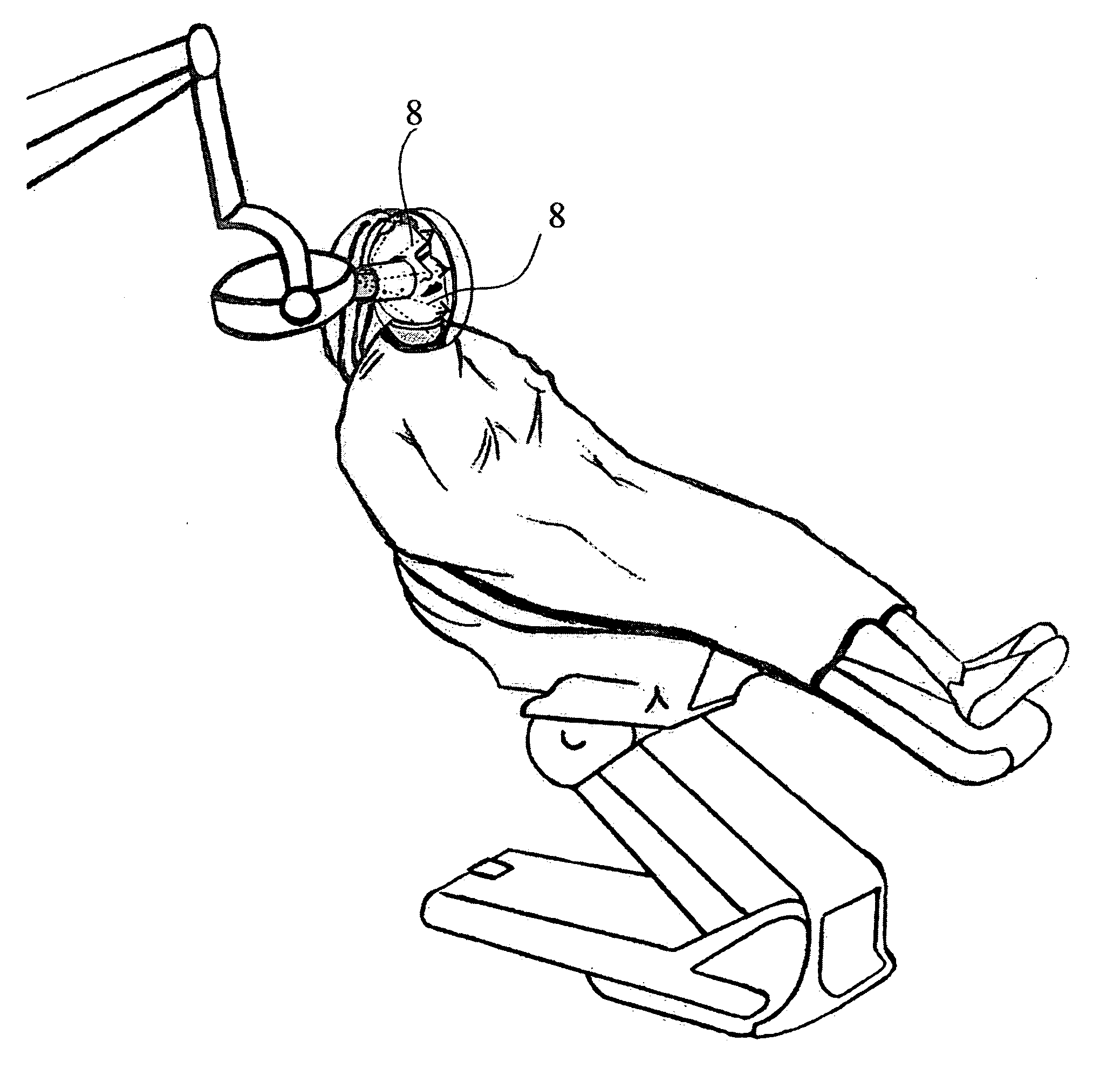

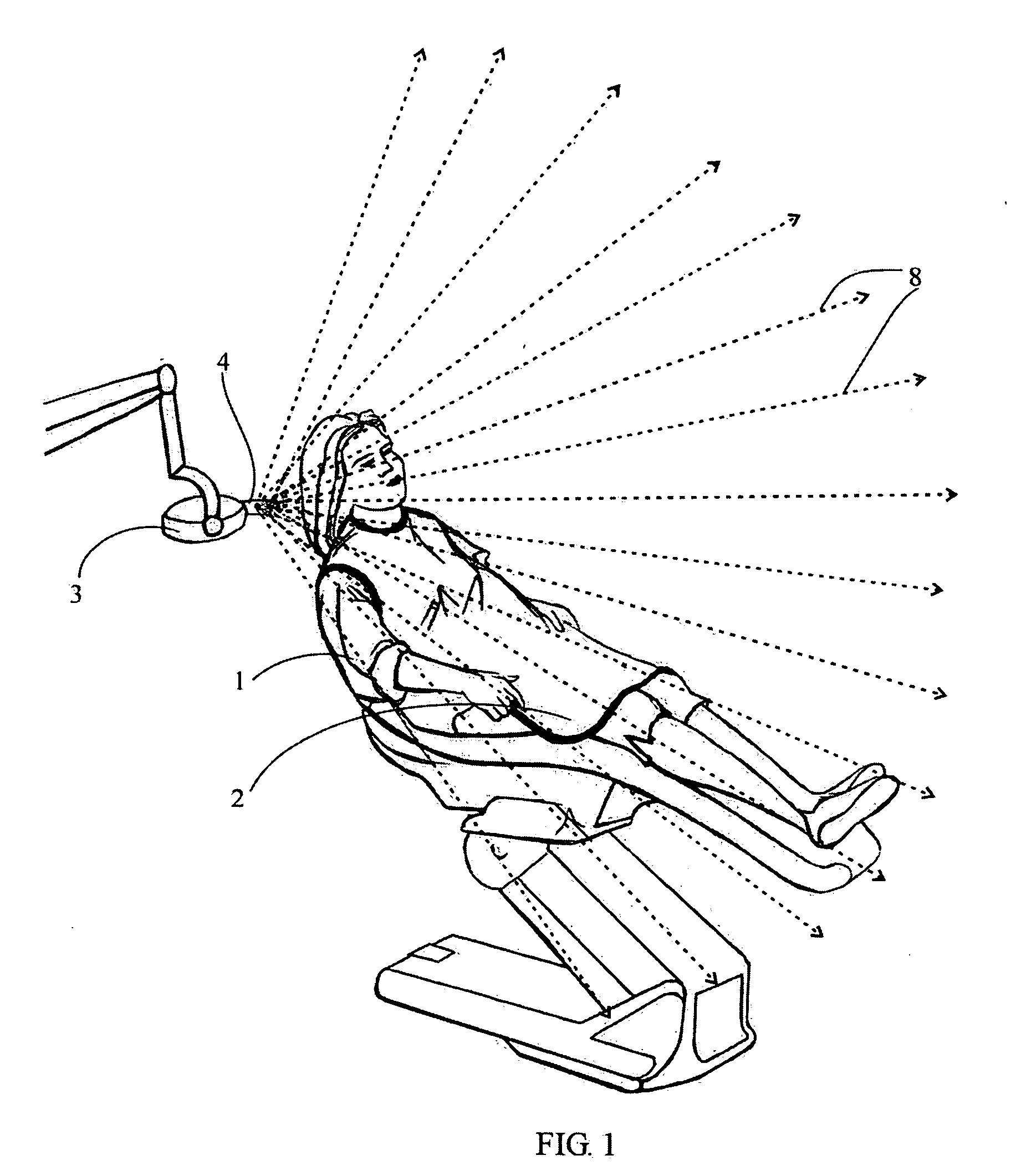

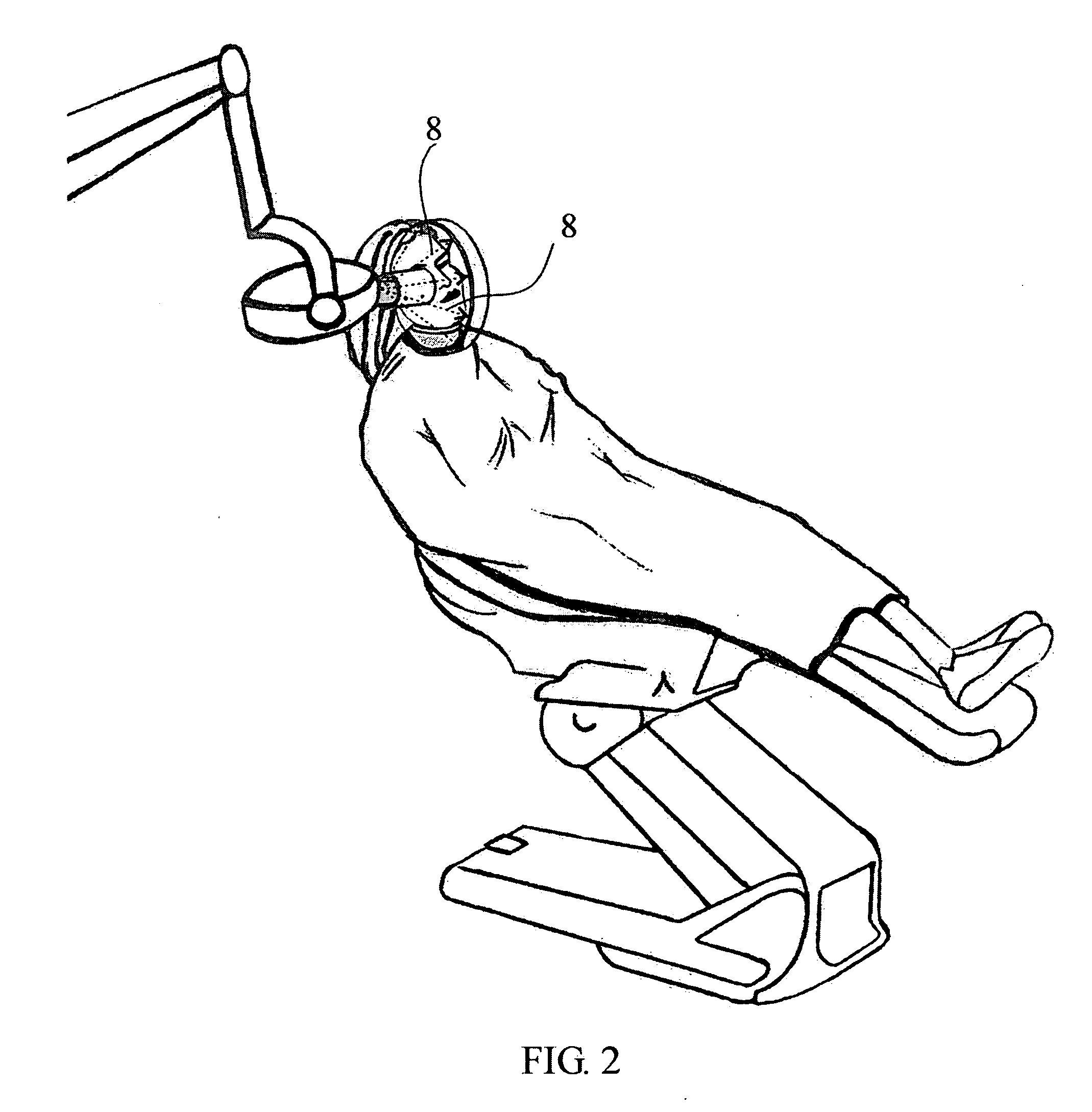

Dental x-ray radiation protection device

InactiveUS20070080308A1Minimizes amount of exposureMaximum protectionNuclear engineering problemsNuclear engineering solutionsAttenuation coefficientStanding frame

A dental x-ray radiation protection device / system reduces radiation exposure to patient(s) and the surrounding environment around patient(s) in dental clinics during x-ray radiography procedures. It provides maximum protection for the areas of the patient's body which are not protected with radiation protection (Lead) apron. The invented device / system is adjustable at different angles and directions to target teeth and comprises of two main segments that provide radiation reduction. The device could be attached to a dental x-ray machine as a mount frame or stand frame or even be hung from the ceiling or wall of the x-ray room. Thicknesses of the radiation protection shield for all parts of device are calculated using radiation physics equations by solving for thickness of radiation shield material(s) with respect to x-ray beam intensity, x-ray beam energy, mass or linear attenuation coefficient and density of radiation protection material(s) to get up to 99.9% radiation reduction.

Owner:MS SAEIDEH MOUSAVI YEGANEH

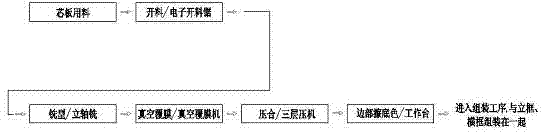

Manufacturing process of solid wood composite door

ActiveCN104742210AReduce crackingReduces shedding defectsWood working apparatusSolid woodStanding frame

The invention discloses a manufacturing process of a solid wood composite door. The manufacturing process of the solid wood composite door comprises the following steps that 1, a door leaf, a door casing, a plate A and a plate B are prepared at the same time, the prepared door leaf, door casing, plate A and plate B are spliced after paint spraying, and in the mounting process, the two sides of a stand frame of the spliced door leaf are spliced with a side door sleeve plate B through silica gel strips, the side door sleeve plate B and a side door sleeve plate A are spliced, a side casing wire is arranged on one side of the side door sleeve plate B, and a side door casing wire is arranged on one side of the side door sleeve plate A; in the mounting process, the side casing wire and the side door casing wire are fixed to a wall to complete mounting of a wooden door. The manufacturing process is simple and easy and convenient to operate, labor productivity is improved, production time is saved, production cost is lowered, and greater benefits are obtained.

Owner:JIANGSU KENTIER SENGONG TECH

Fast detection reagent kit of anionic surfactants and detection method by using fast detection reagent kit

InactiveCN102692412AGuaranteed comparabilityGuaranteed contactMaterial analysis by observing effect on chemical indicatorColor/spectral properties measurementsStanding frameSurface water

The invention relates to a fast detection reagent kit of anionic surfactants. The fast detection reagent kit comprises a special anion reagent prefabricated tube, a demulsifying bar, washing liquid, a test tube standing frame and a liquid moving device, wherein chloroform and methylene blue color development agents in corresponding proportion are preset in the special anion reagent prefabricated tube, and the height of a chloroform layer formed by chloroform is at least 1mm higher than the height of a detecting opening of a photometer. Through the fast detection reagent kit and a detection method by using the fast detection reagent kit provided by the invention, the direct contact of operators with extracting agents can be avoided, meanwhile, the test speed is accelerated, the environment is protected, the pollution is avoided, and the fast detection reagent kit and the detection method can be widely applied to the detection of the anionic surfactants in surface water, waste water and tableware.

Owner:宁波市环境监测中心

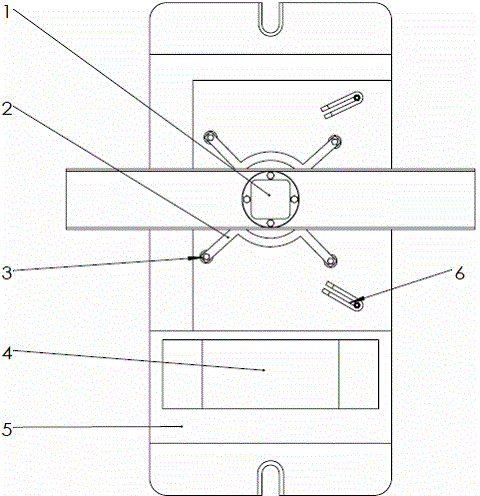

Inclination angle adjustable rocket engine ground test stand frame

InactiveCN110397520AConsistent Test StanceConsistent launch attitudeRocket engine plantsStanding frameEngine mount

The invention relates to an inclination angle adjustable rocket engine ground test stand frame, and belongs to the technical field of rocket engine thrust tests. The inclination angle adjustable rocket engine ground test stand frame comprises a stand frame supporting device, a thrust transmitting device, a guide rail assembly, a force bearing pier, a guide rod and an engine support, wherein the stand frame supporting device is horizontally arranged, the engine support is fixed at the top of the stand frame supporting device through the guide rail assembly, and the force bearing pier is fixed on one side of the upper end surface of the stand frame supporting device and is connected with the thrust transmitting device. According to the inclination angle adjustable rocket engine ground test stand frame, a hydraulic rod of the stand frame supporting device is used for adjusting the angles of rotating frames, so that different test inclination angles of an engine are achieved, horizontal, vertical and inclined thrust measurement of the engine can be realized, and the test attitude and the emission posture of the engine can be consistent; and meanwhile, effective thrust measurement can be carried out on the rocket engines with different flight postures, the operation is convenient, the advantages of low cost, short flow, high efficiency, convenience and the like are achieved, and large-scale industrial application is easy to implement.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Finish machining method of the frame of the rotating table

ActiveCN101036948AAchieve finishingHigh precisionPrecision positioning equipmentMeasurement/indication equipmentsStanding frameAutocollimation

A fine machining method of the rolling stand frame belongs to machine finishing technology field. At first determining center of turning circle position of the fine boring machine table and mounting end face multiple tooth circular dividing table thereon, the tetrahedron is mounted on the end face multiple tooth circular dividing table, and adjusting it to collimate with the photoelectricity autocollimation to determine machineable machine zero position point; the rolling stand frame is mounted on the worktable, and adjusting it to symmetry with the center of gyration; boring the frame side face of each axle hole for the rolling stand frame and the axle hole until achieving to the required precise size, when the frame rotates from one side to another side, rotating relevant angle of the worktable contrasting to graduation value of the end face multiple tooth circular dividing table, the tetrahedron is measured by the photoelectricity autocollimation, fine tuning the worktable to collimate the corresponding face of the tetrahedron with the sending beam of the photoelectricity autocollimation, at this point, the rotating angle is exact value, then processing. The invention operates conveniently and audio-visually, with reliable processing manufacturability, and reducing accumulation of error and improving process precision of the frame.

Owner:BEIJING INST OF AEROSPACE CONTROL DEVICES

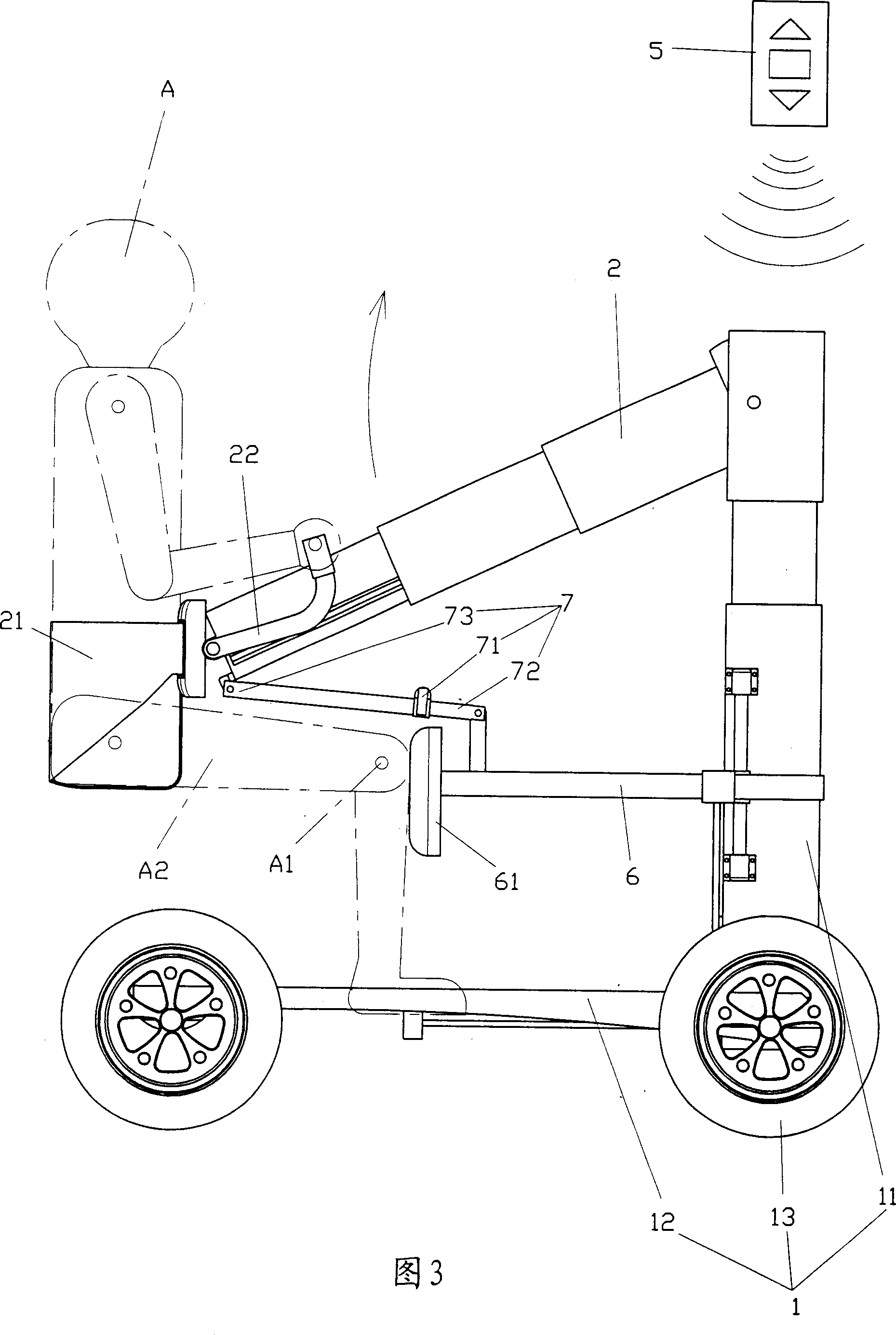

Electric auxiliary standing frame

InactiveCN1943532AEasy to move aroundEasy steeringChiropractic devicesWalking aidsStanding frameEngineering

An auxiliary standing apparatus of power-driven style is presented and comprising: main standing body with a column support and a horizontal foot stand at the lower end of said support; stretching arm, which can stretch out and draw back, connecting to the upper end of said support, one side thereof installed sitting apparatus( including tie-tie for waist and hip ); drawing unit, linking to stretching arm and bringing its stretching out and drawing back; power unit, linking to drawing unit and providing power to it; controlling unit, controlling on and off of power unit ; knee stand , to be installed at place nearing end of column support of main standing body, bumper is installed on said stand; pole support, the first end is connected with knee stand, the second one with stretching arm; power unit affects drawing unit , and the latter affects stretching arm's stretching out and drawing back and making stretching arm raising upward and inclining down, the second end of pole support sustains stretching arm whereby supporting the stretching arm user.

Owner:苏芳庆 +2

Spraying and feeding station

InactiveUS9339009B1Easy to assembleEasy to transportAnimal feeding devicesVeterinary instrumentsStanding frameSpray nozzle

A movable spraying and feeding station having a free standing frame structure. A spraying hood structure and a feed holder are mounted to the frame structure. A motion sensor and spray nozzles are mounted on the spraying hood structure. A housing is mounted to the frame structure for the insecticide reservoir, a pumping assembly, a timing circuit, as well as a battery which is charged by a solar panel mounted on the top of the frame structure.

Owner:ELEVATOR & STORE

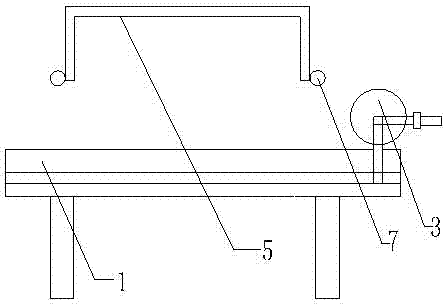

Flexible clamp for numerical control machining of large-scale thin-wall workpiece and clamping force servo control method thereof

InactiveCN104589110AAffect machining accuracySimple structureServomotorsPositioning apparatusHydraulic cylinderStanding frame

The invention provides a flexible clamp for numerical control machining of a large-scale thin-wall workpiece and a clamping force servo control method of the flexible clamp. The flexible clamp comprises a servo hydraulic cylinder, a stand frame, a pressing disk, a pressing head, a boring guide device, a clamp body and multiple locating and compressing mechanisms. The flexible clamp is characterized in that the clamp body is fixedly installed on a worktable of a machine tool, the stand frame is arranged in the middle of the clamp body and fixedly installed on the worktable of the machine tool, the servo hydraulic cylinder is installed at the upper end of the stand frame, a piston rod of the servo hydraulic cylinder penetrates through the stand frame to be connected with the pressing disk, the pressing head is installed on the pressing disk, the boring guide device is installed at the front end of the clamp body, and the multiple locating and compressing mechanisms are arranged on the clamp body. The flexible clamp for numerical control machining of the large-scale thin-wall workpiece and the clamping force servo control method of the flexible clamp have the advantages that the structure is simple, the appropriate clamping force exerted on the workpiece can be determined according to the structural characteristics and the materials of the workpiece, and the situation that the machining precision of the workpiece is influenced by too large clamping force is avoided.

Owner:UNIV OF JINAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com