Flexible clamp for numerical control machining of large-scale thin-wall workpiece and clamping force servo control method thereof

A technology of large thin-walled parts and flexible fixtures, applied in manufacturing tools, servo motors, metal processing equipment, etc., can solve the problems of difficult to control clamping force, affecting machining accuracy, large clamping force of workpieces, etc., to avoid machining accuracy. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

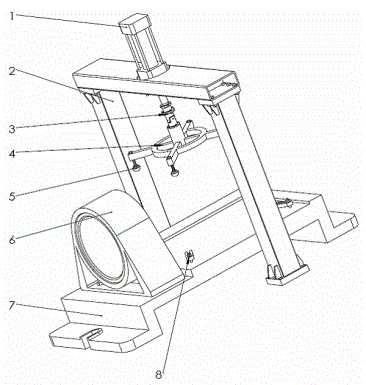

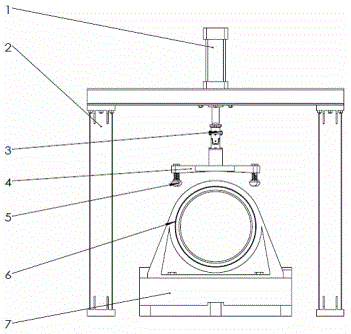

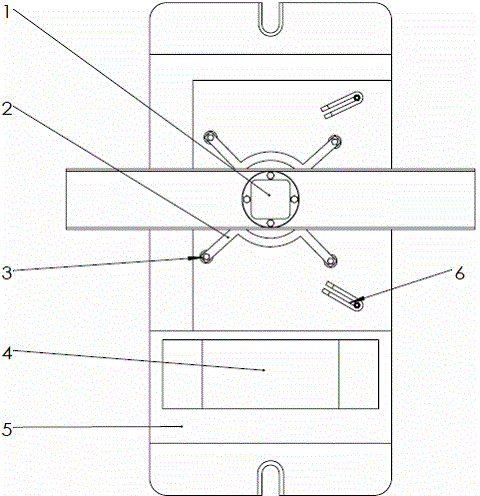

[0020] Refer to the attached figure 1 to attach Figure 5 The present invention will be described in detail below.

[0021] A flexible fixture for CNC machining of large thin-walled parts, including a servo hydraulic cylinder 1, a stand 2, a pressure plate 3, a pressure head 4, a boring guide device 5, a clamp body 6, and a positioning and pressing mechanism 7, and is characterized in that , the clamp body 6 is fixedly installed on the machine tool table, the stand 2 is arranged in the middle of the clamp body 6 and fixedly installed on the machine tool workbench, the servo hydraulic cylinder 1 is installed on the upper end of the stand 2, and the servo The piston rod of the hydraulic cylinder 1 runs through the stand 2 and is connected with the pressure plate 3, the pressure head 4 is installed on the pressure plate 3, the boring guide device 5 is installed at the front end of the clamp body 6, and the positioning and pressing There are several mechanisms 7 arranged on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com