Patents

Literature

120results about How to "Affect machining accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

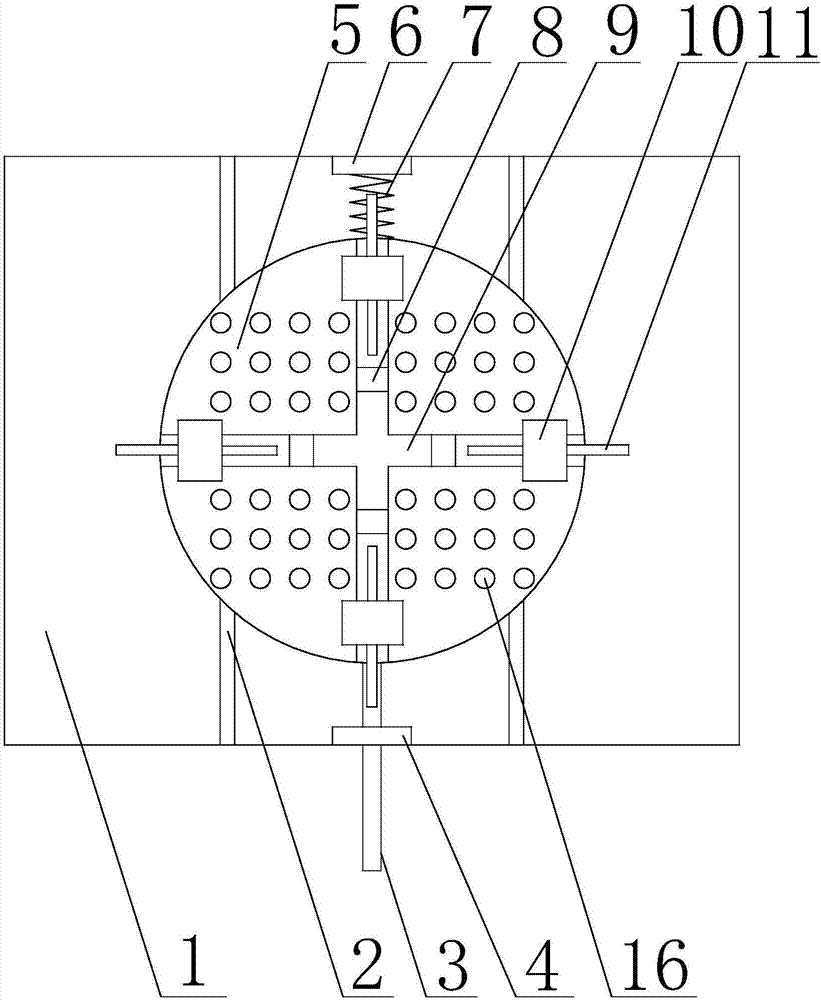

Abrasive flow micropore polishing device

ActiveCN104999379AHigh energyPromote aggregationAbrasive machine appurtenancesAbrasive blasting machinesHigh accelerationEngineering

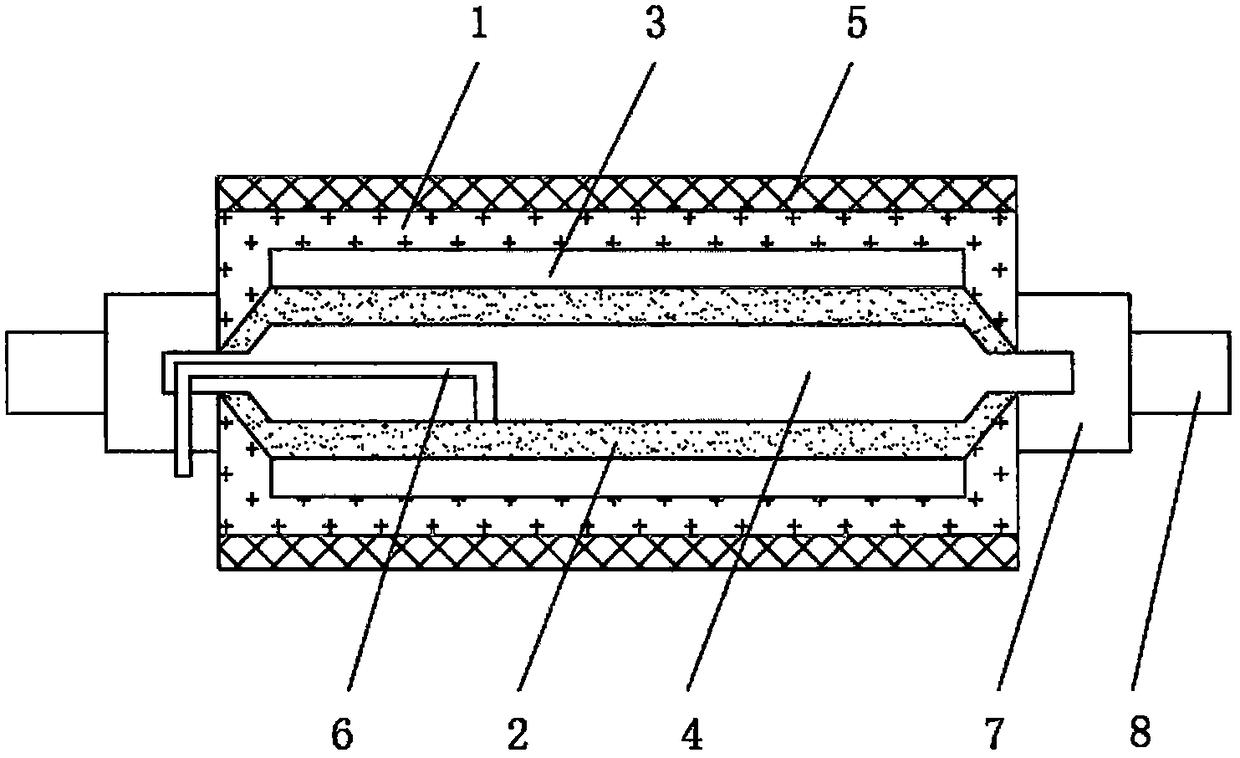

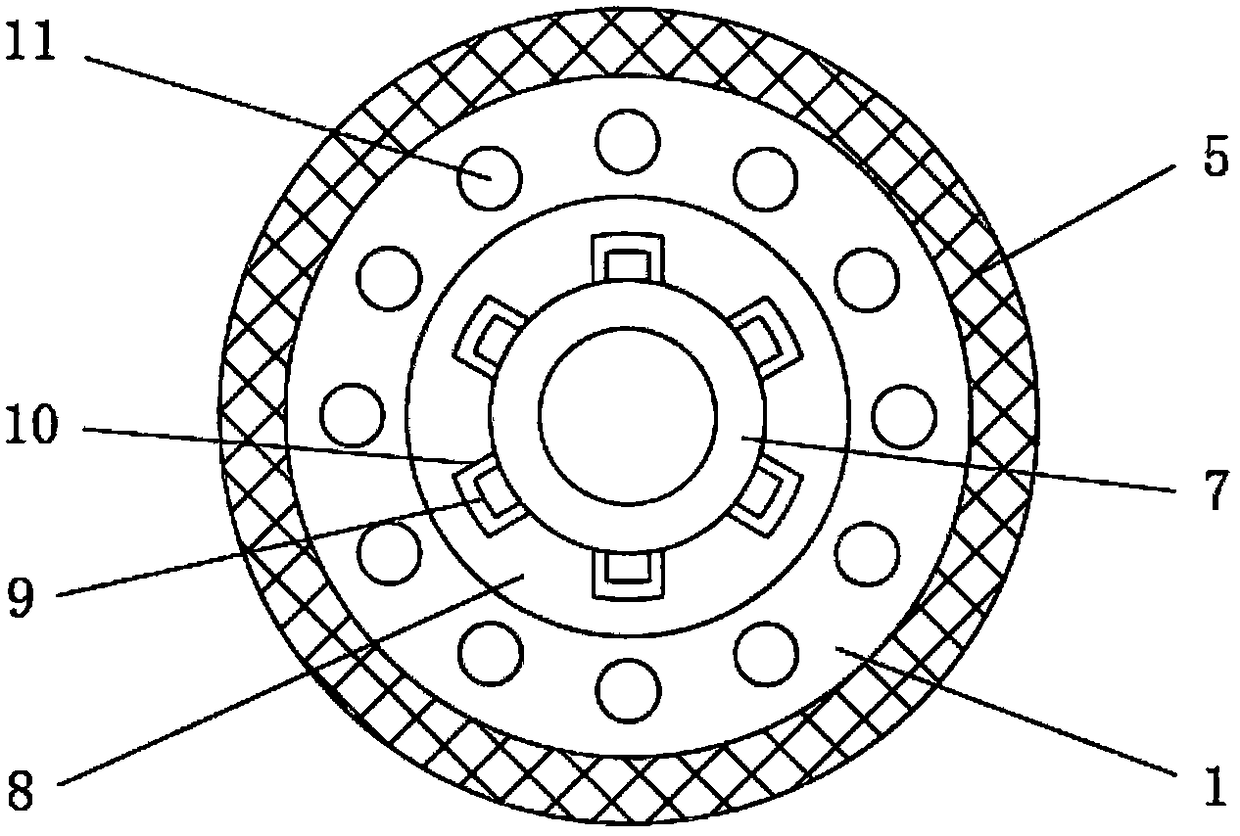

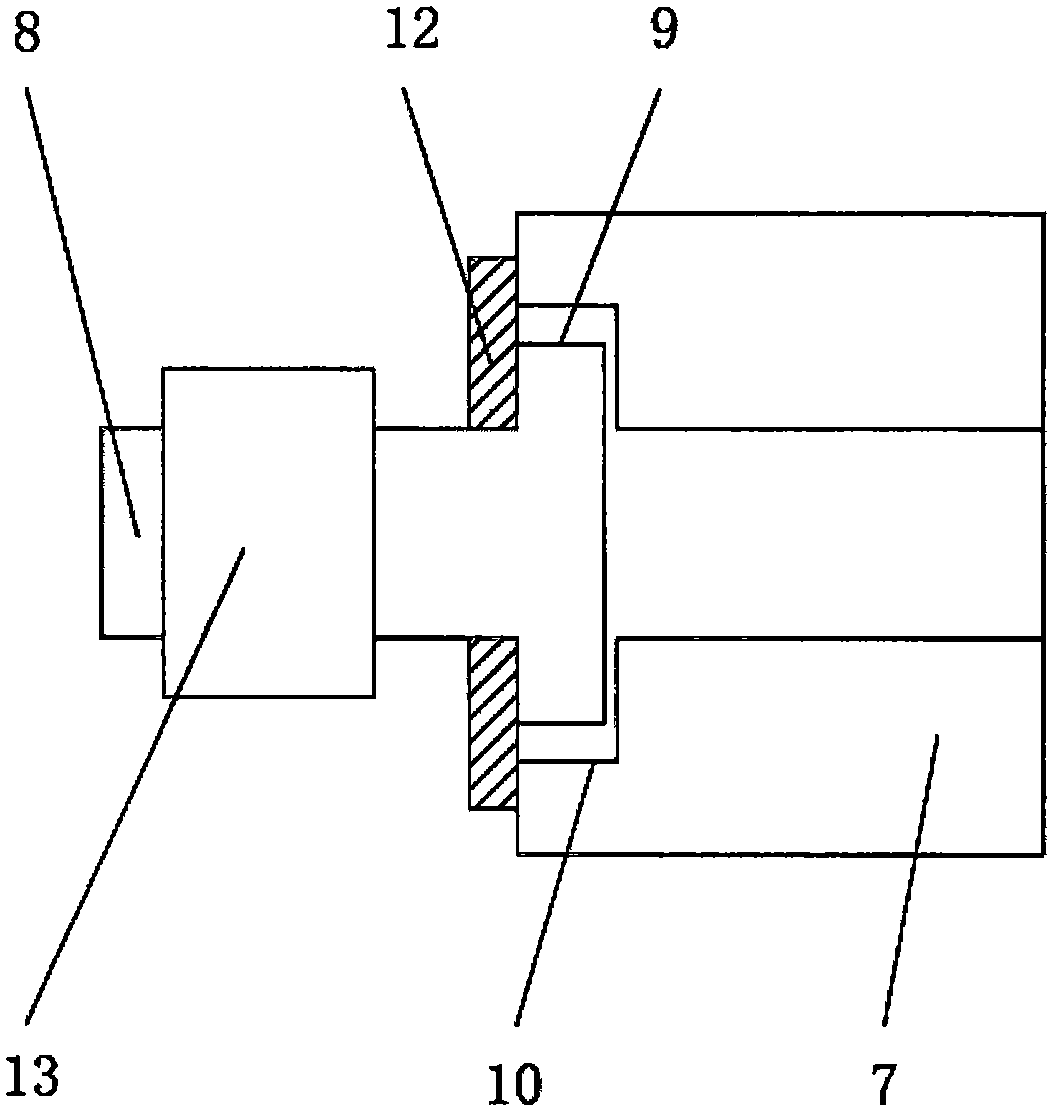

The invention provides an abrasive flow micropore polishing device. The device comprises a workpiece supporting base, a pressurization vibration base, an upper bracket, an adapter, a high-pressure jet pump, an abrasive flow feeding box and an abrasive flow collecting box, wherein an ultrasonic vibrator is arranged at the lower end of an abrasive flow channel in the pressurization vibration base. By arranging the ultrasonic vibrator at the lower end of the abrasive flow channel in the pressurization vibration base, high acceleration energy can be provided for abrasive flow flowing through under the high-frequency vibration of the ultrasonic vibrator, so that more energy is gathered by the abrasive flow and the abrasive flow enters a workpiece; before the abrasive flow enters the workpiece, a certain buffering effect is realized in an abrasive flow channel in the workpiece supporting base, so that the situation that as adverse effect is generated on the workpiece by the abrasive flow with overhigh vibration frequency, the surface quality of workpiece micropores is affected is avoided. A temperature sensor and a heater are arranged inside the abrasive flow feeding box, so that the situation that due to the fact that the viscosity of the abrasive flow is affected by temperature, the machining precision of the micropore workpiece is affected is avoided.

Owner:CHANGCHUN UNIV OF SCI & TECH

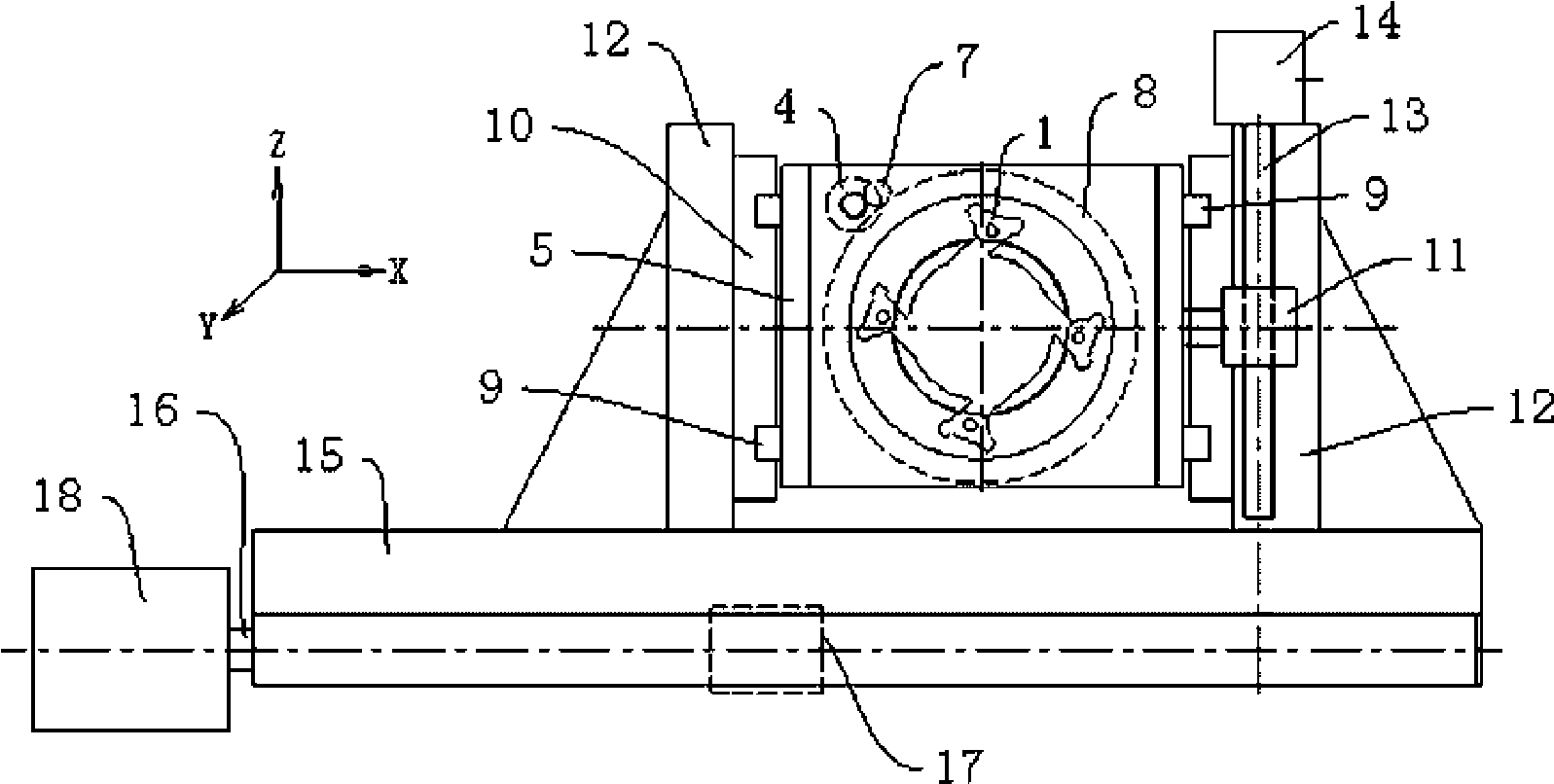

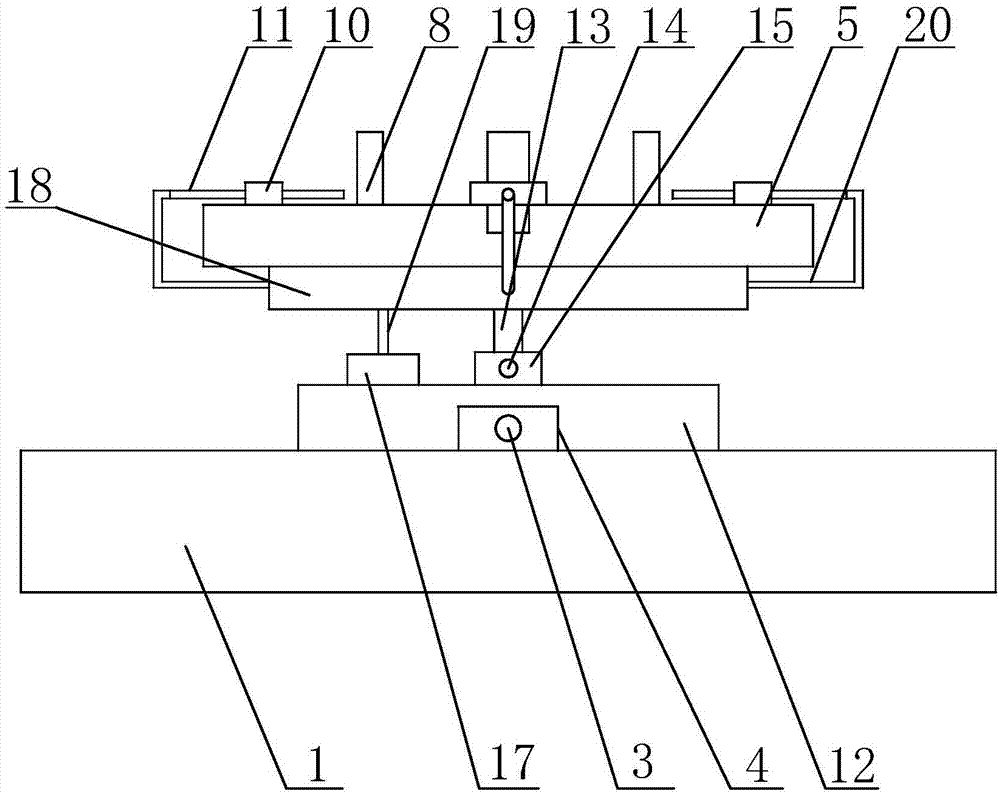

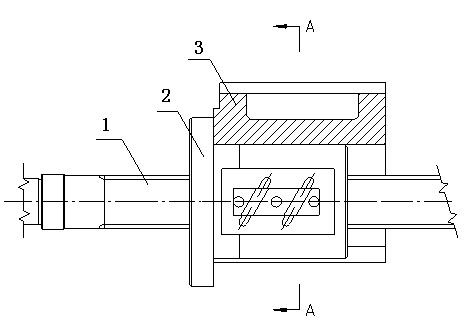

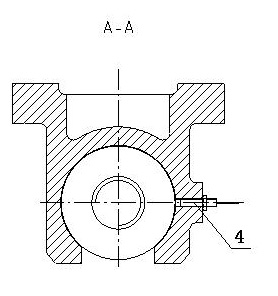

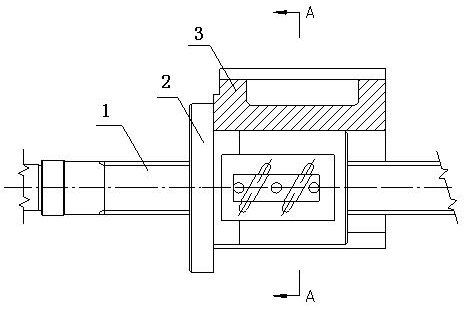

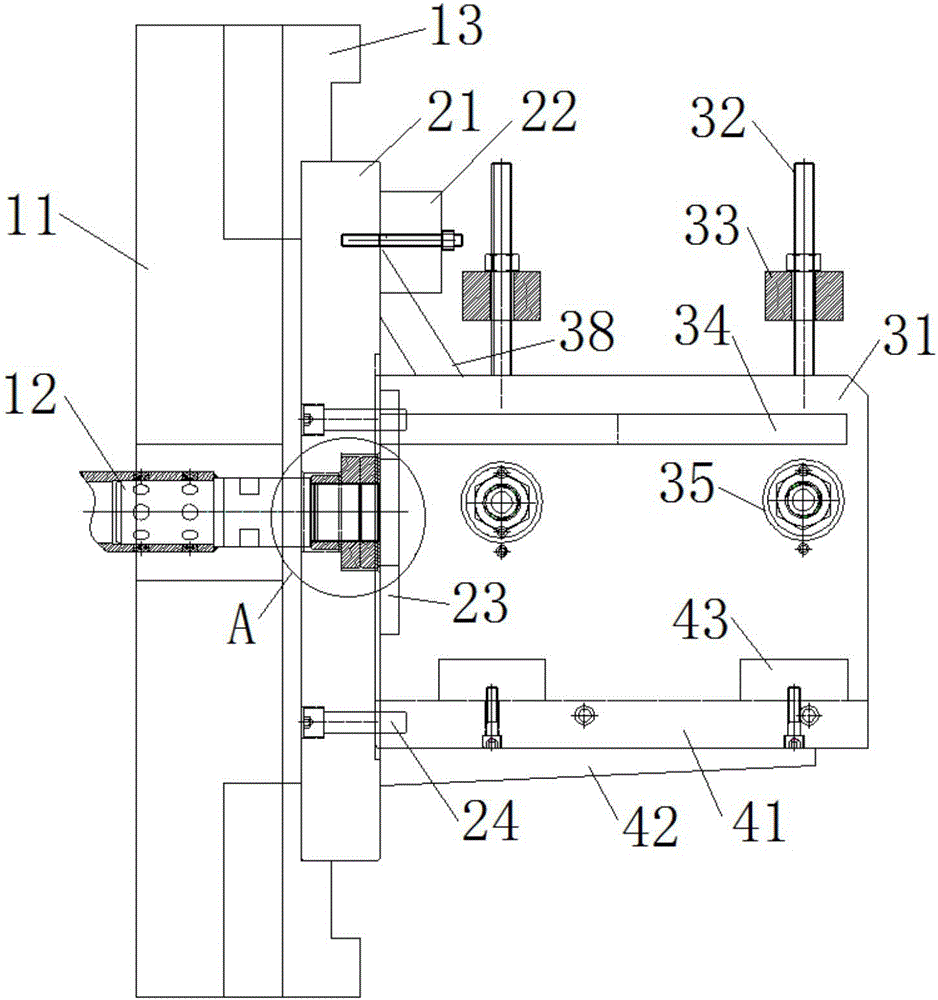

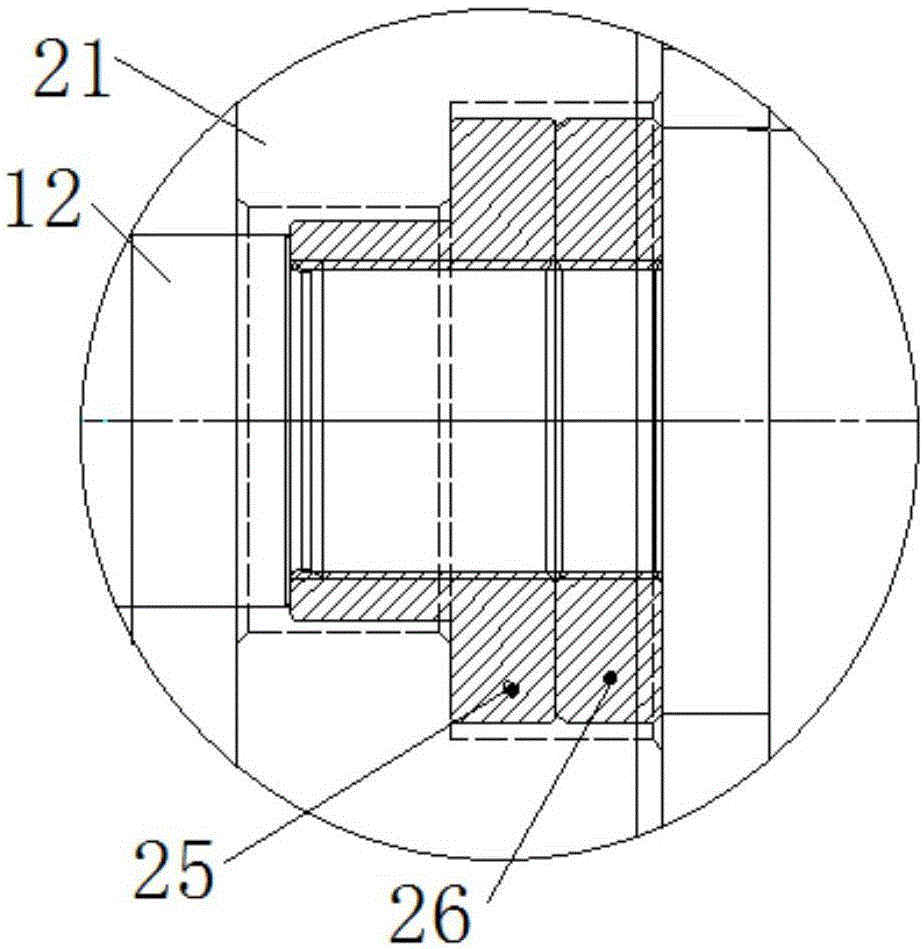

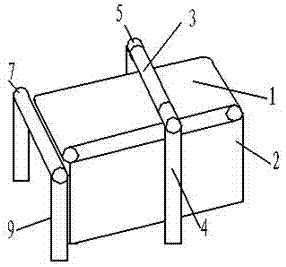

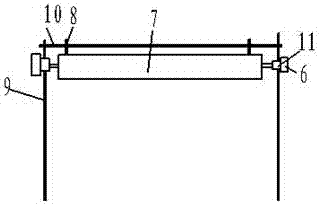

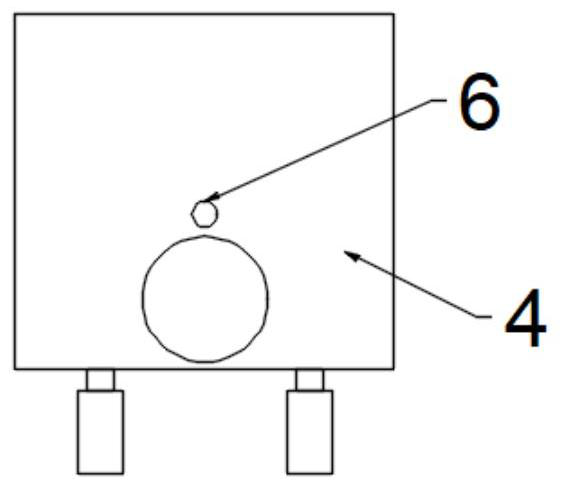

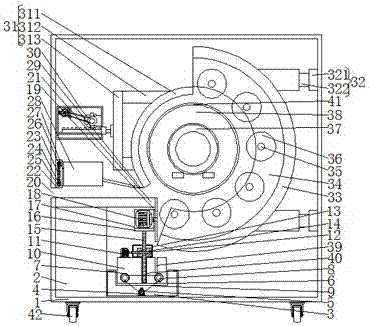

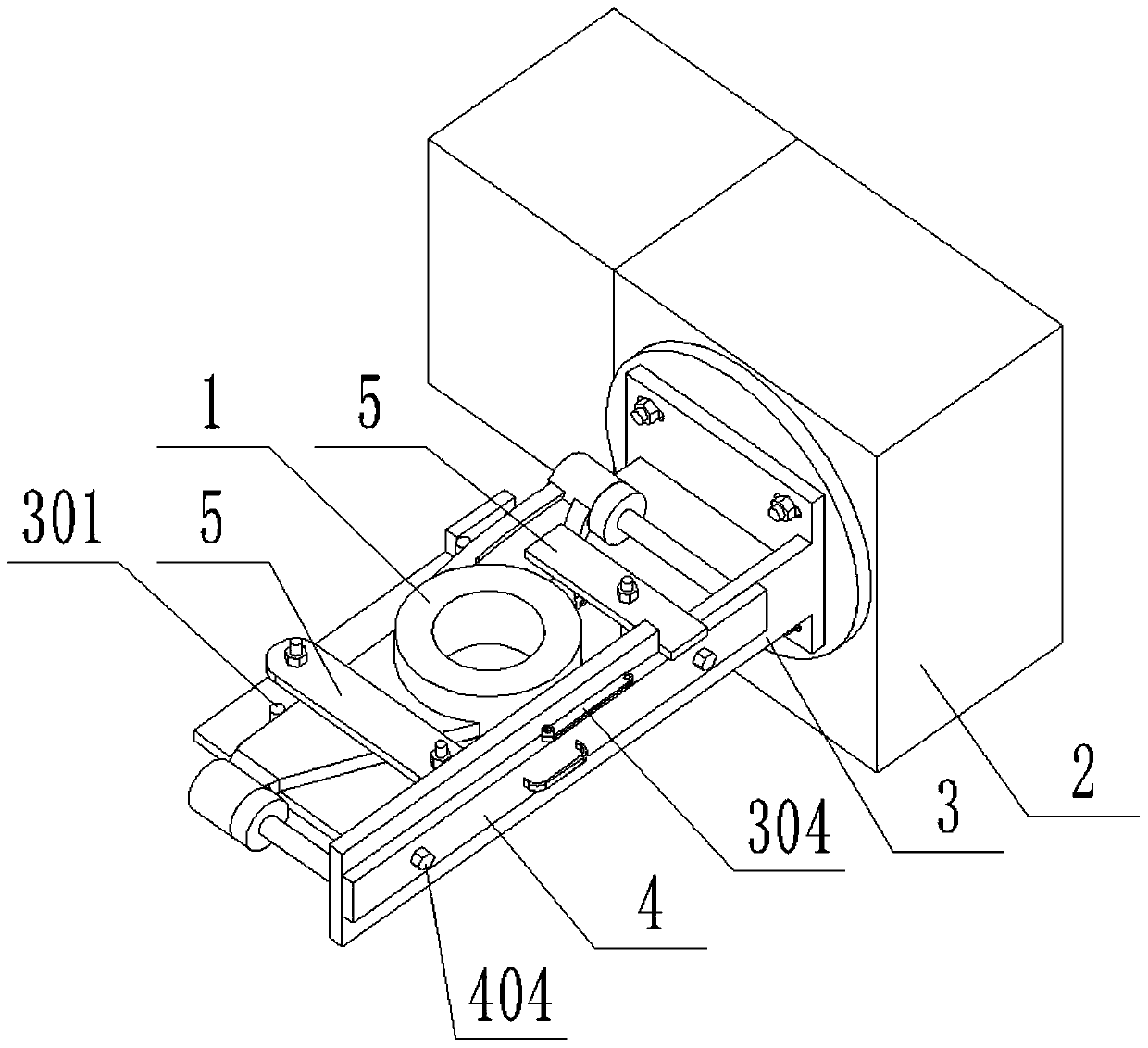

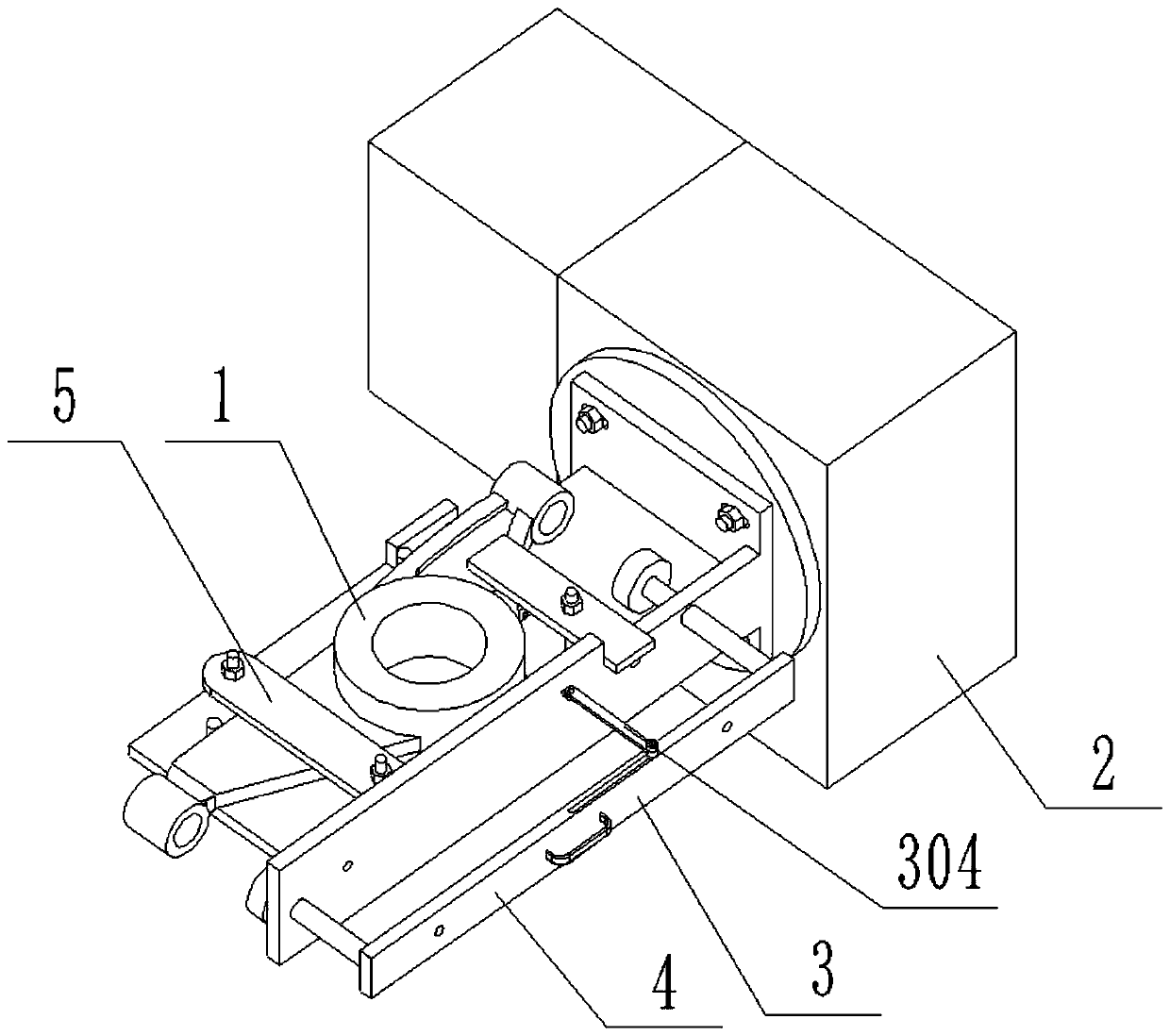

Workpiece non-rotating excircle machining mechanism

InactiveCN101543902AReduce power consumptionReduce consumptionFeeding apparatusMilling equipment detailsCycloneSlide plate

The invention provides an excircle machining mechanism which can machine overlength workpiece with low energy consumption, long service life and high machining precision and comprises an inner cyclone milling head and a primary motor connected with the cyclone milling head to drive for rotation around the y axis. The inner cyclone milling head is rotatably connected on a supporting seat. The primary motor and the supporting seat are fixed on a slide board which is in sliding connection with the engine base along the z axis direction vertical to the y axis. The slide board is connected with the transmission mechanism driving the slide board to slide along the z axis. An engine base is arranged on an x axis supporting plate moveable along the x axis direction vertical to the y axis. When processing the excircle, the workpiece is stationary, the inner cyclone milling head rotates at high speed (around y axis), the workpiece extending into the inner cyclone milling head is stationary and meanwhile inner cyclone milling head translates on two directions (x axis and z axis directions) vertical to the rotor axis, thus machining the excircle of the workpiece.

Owner:NANJING XUANFENG NUMERICAL CONTROL MACHINE TOOL

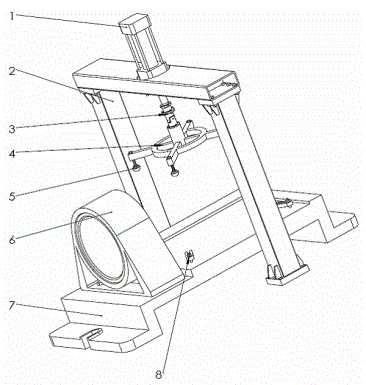

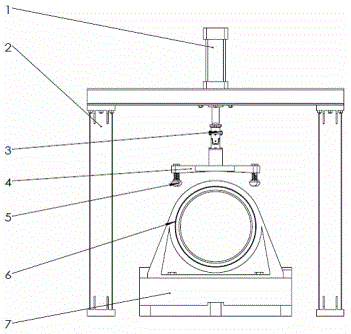

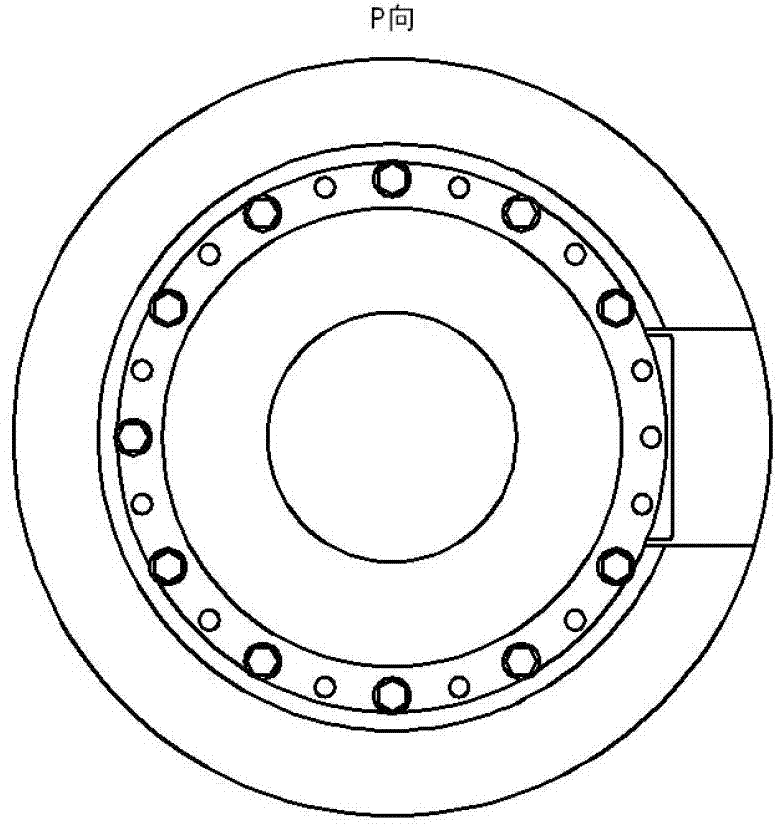

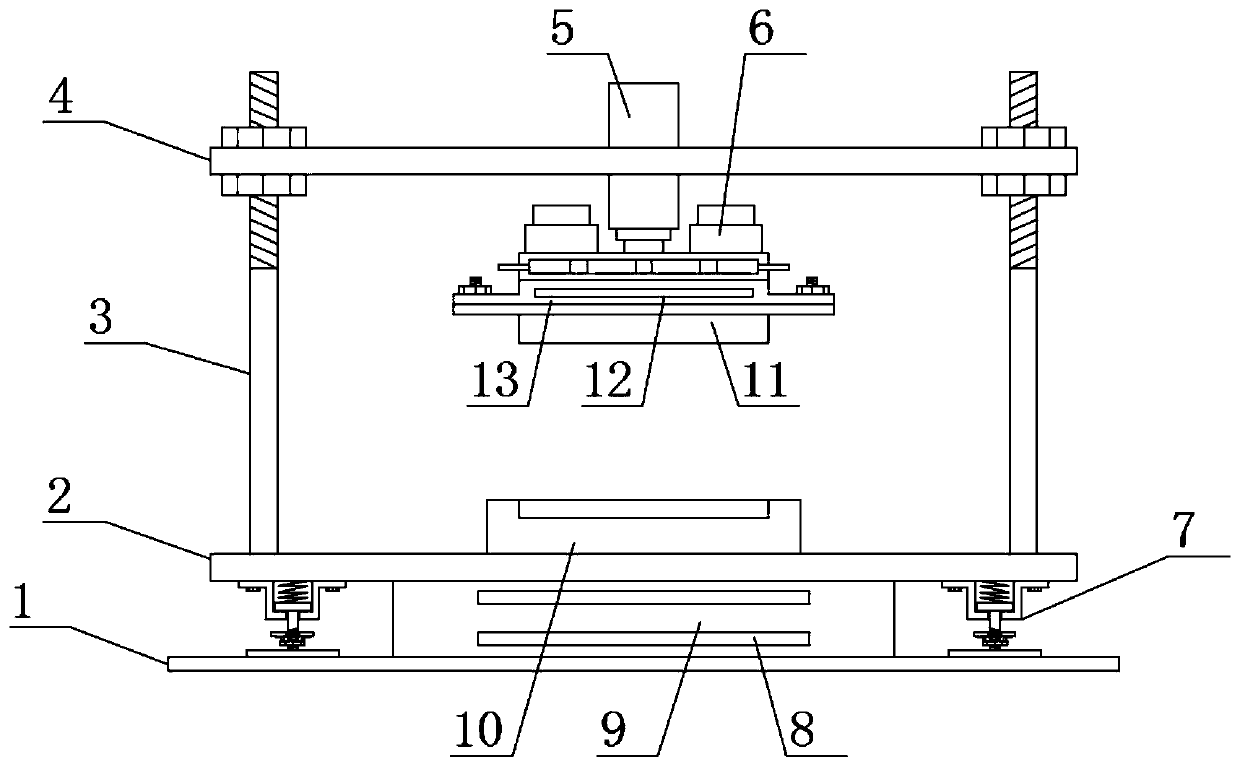

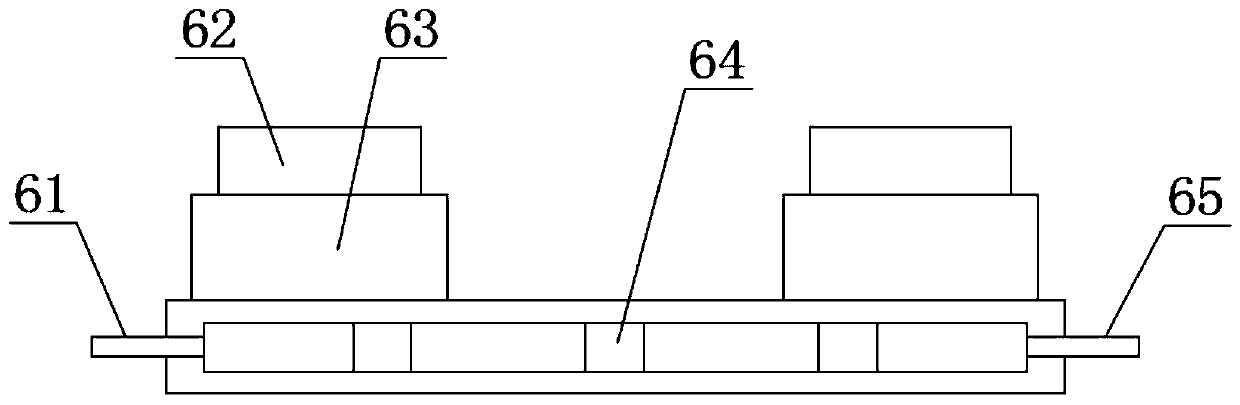

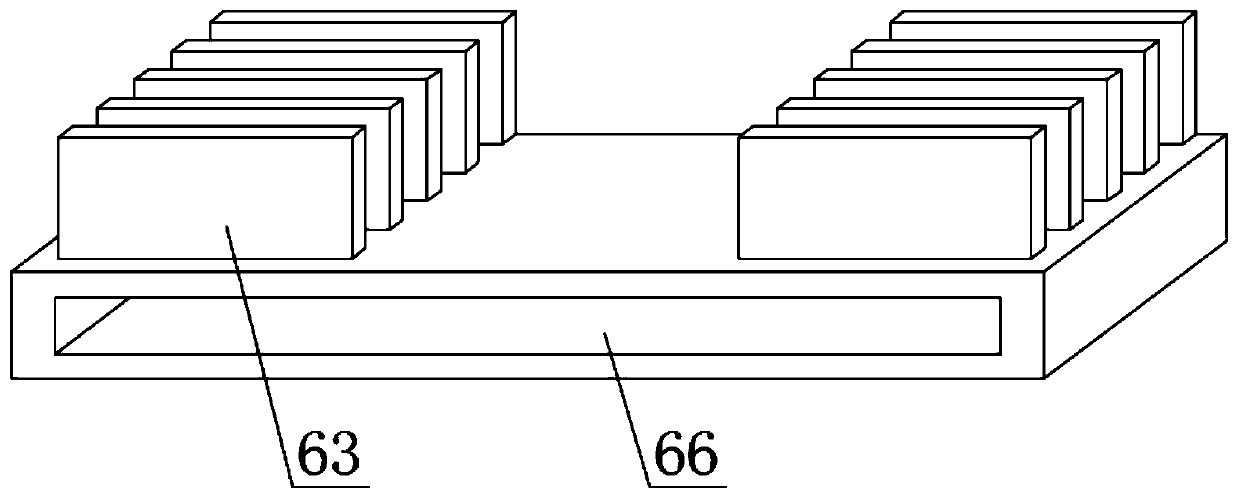

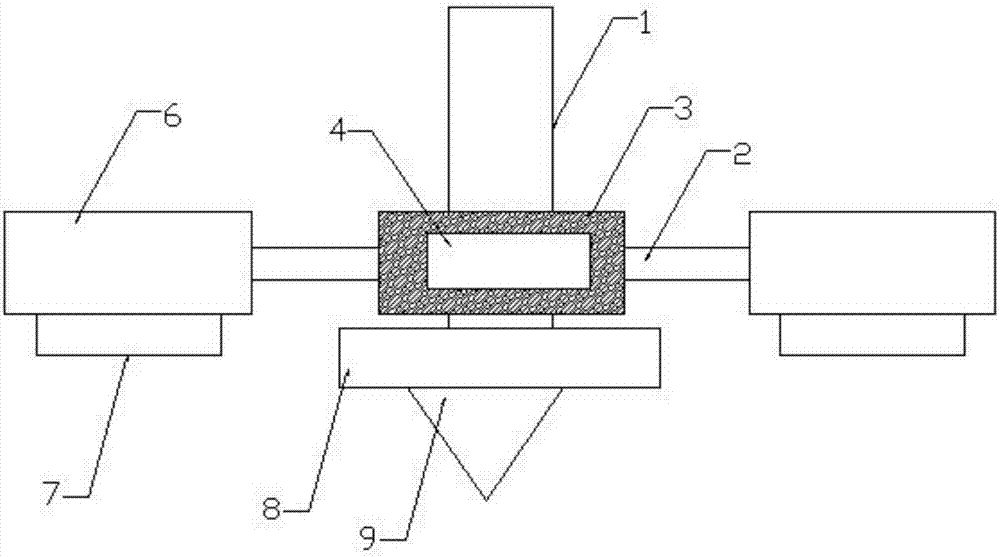

Flexible clamp for numerical control machining of large-scale thin-wall workpiece and clamping force servo control method thereof

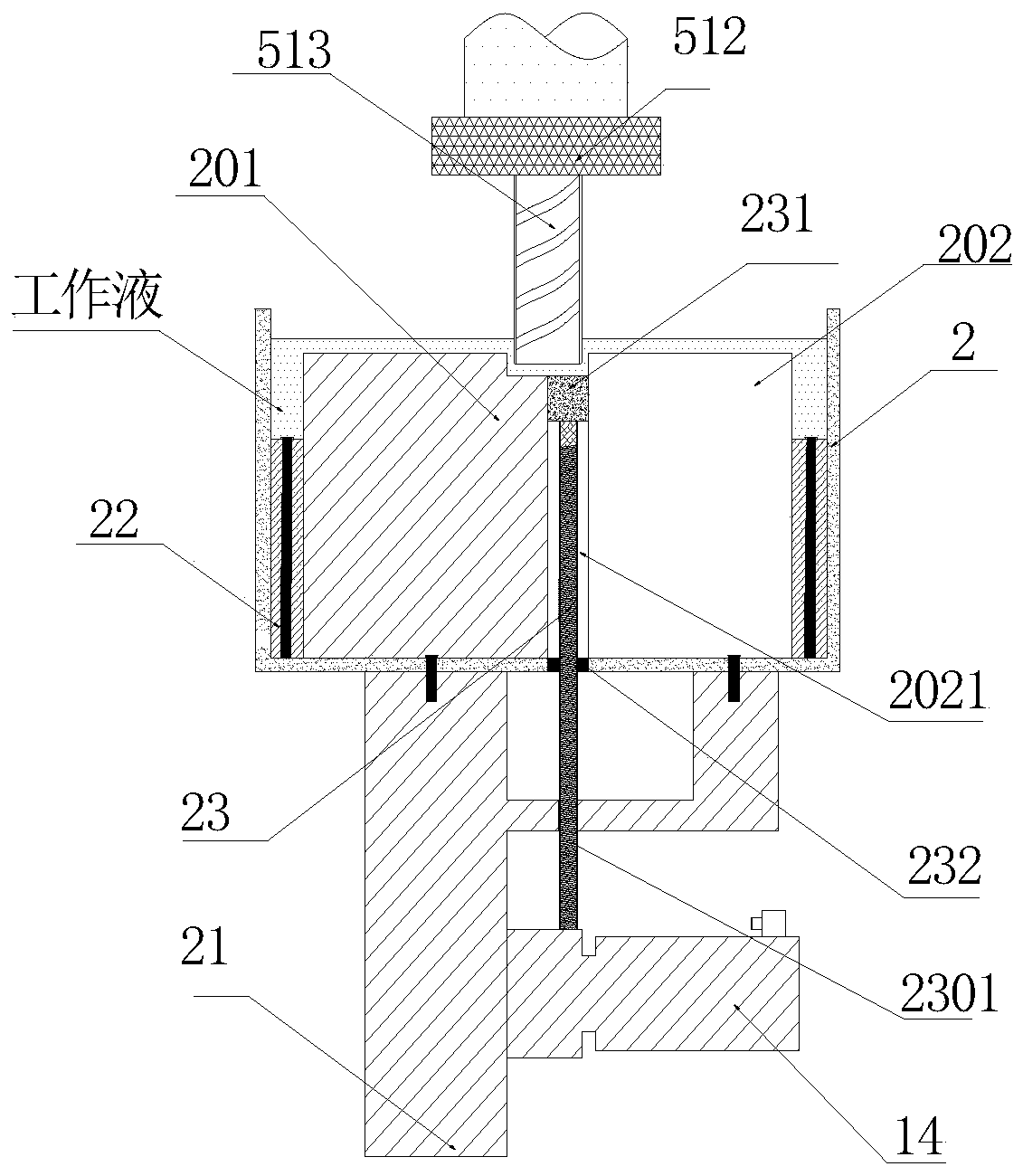

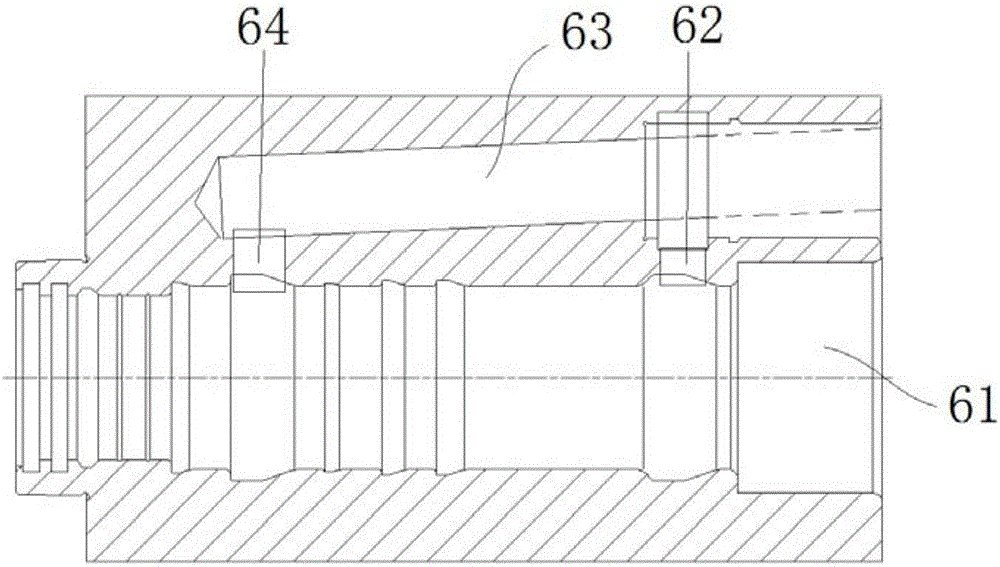

InactiveCN104589110AAffect machining accuracySimple structureServomotorsPositioning apparatusHydraulic cylinderStanding frame

The invention provides a flexible clamp for numerical control machining of a large-scale thin-wall workpiece and a clamping force servo control method of the flexible clamp. The flexible clamp comprises a servo hydraulic cylinder, a stand frame, a pressing disk, a pressing head, a boring guide device, a clamp body and multiple locating and compressing mechanisms. The flexible clamp is characterized in that the clamp body is fixedly installed on a worktable of a machine tool, the stand frame is arranged in the middle of the clamp body and fixedly installed on the worktable of the machine tool, the servo hydraulic cylinder is installed at the upper end of the stand frame, a piston rod of the servo hydraulic cylinder penetrates through the stand frame to be connected with the pressing disk, the pressing head is installed on the pressing disk, the boring guide device is installed at the front end of the clamp body, and the multiple locating and compressing mechanisms are arranged on the clamp body. The flexible clamp for numerical control machining of the large-scale thin-wall workpiece and the clamping force servo control method of the flexible clamp have the advantages that the structure is simple, the appropriate clamping force exerted on the workpiece can be determined according to the structural characteristics and the materials of the workpiece, and the situation that the machining precision of the workpiece is influenced by too large clamping force is avoided.

Owner:UNIV OF JINAN

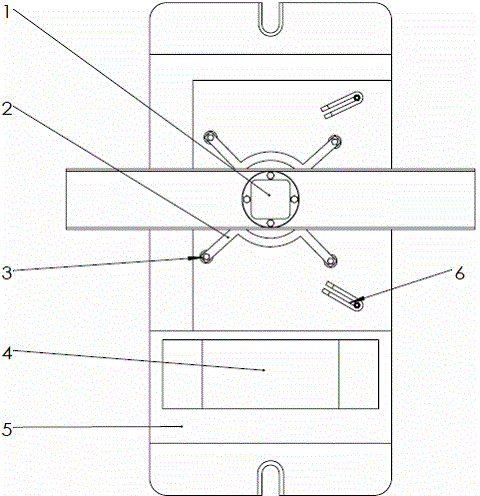

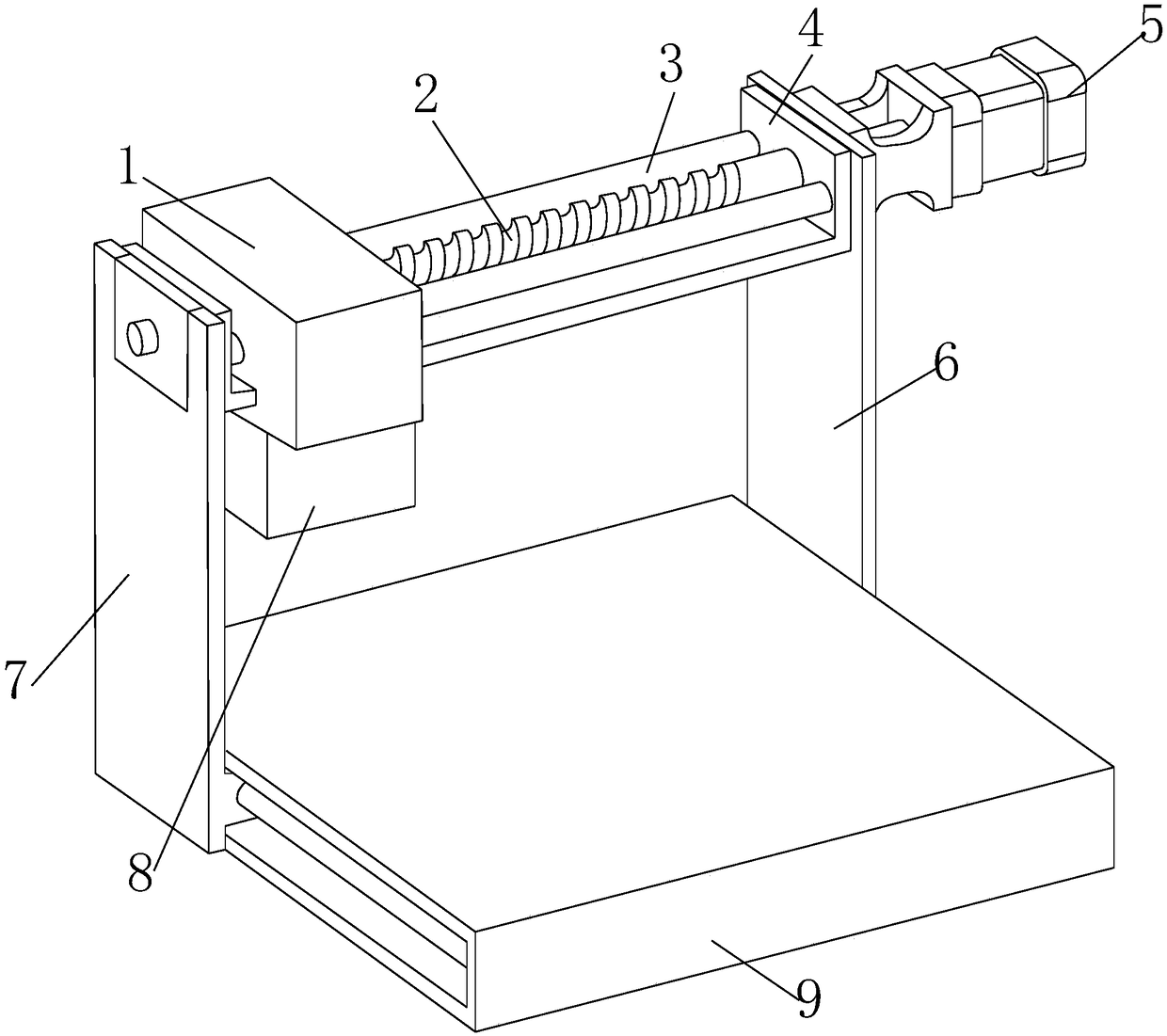

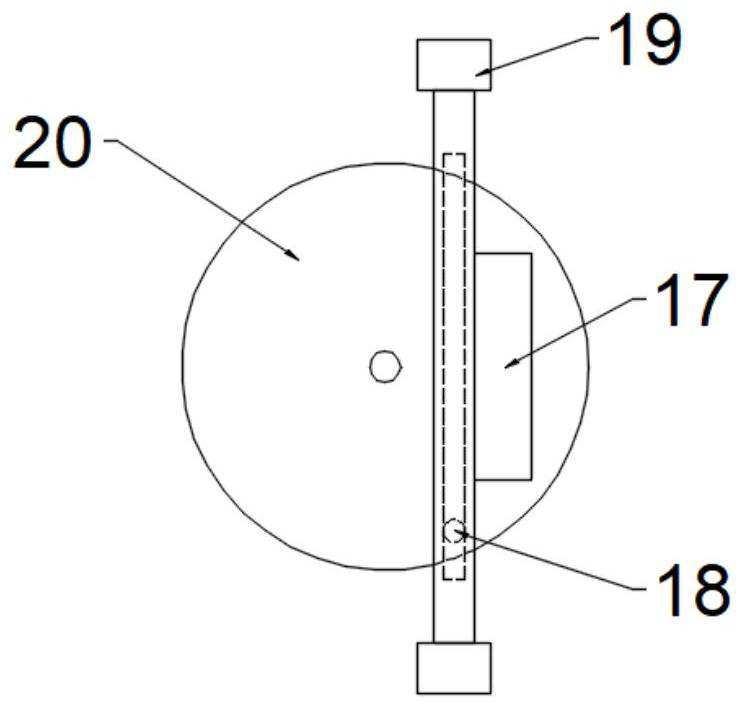

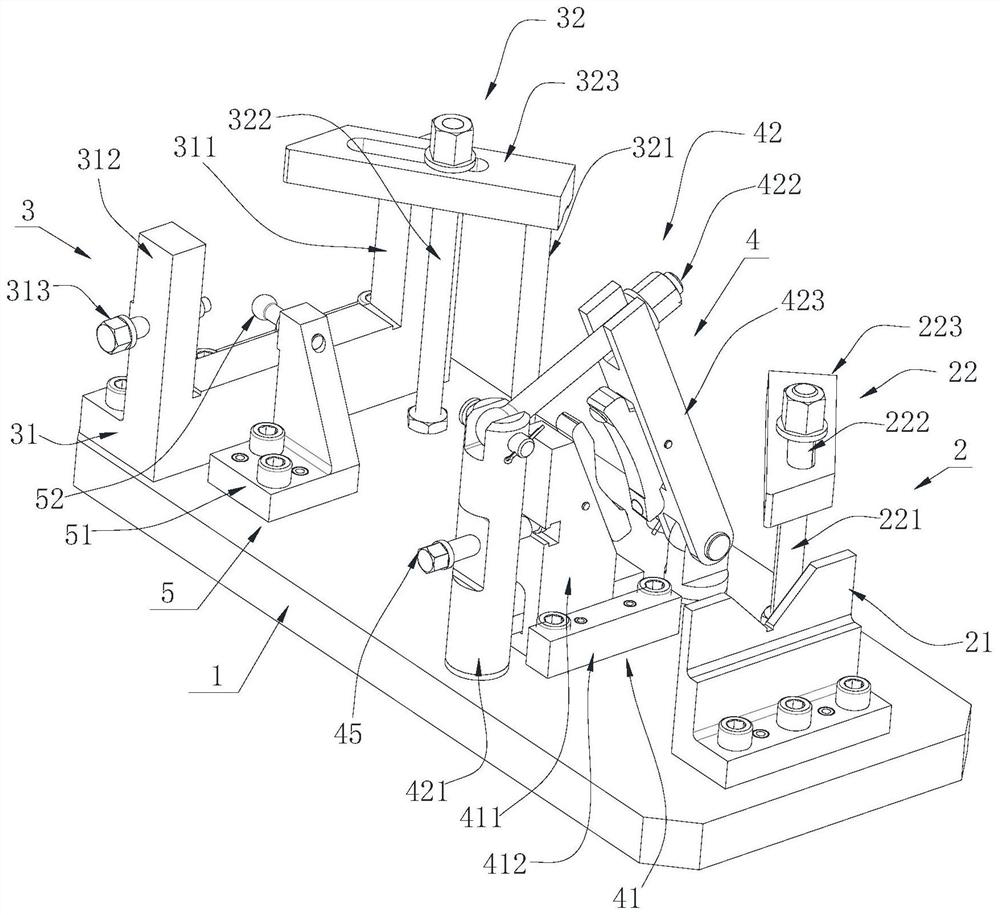

Numerical control processing fixture for two perpendicularly-crossed shafts

ActiveCN103028987AReduce distortionAffect machining accuracyPositioning apparatusMetal-working holdersNumerical controlMachine tool

The invention discloses a numerical control processing fixture for two perpendicularly-crossed shafts. A workpiece is positioned inside a fixed support; the excircle surface at one side of the fixed support is provided with a second shaft installation hole; and the centre line of the second shaft installation hole and the center line of the fixed support are perpendicular to each other. A compression screw is arranged on the end surface of the opening end of the fixed support; and the bottom of the fixed support is provided with an adjusting screw by which a compression block is in close fit with the excircle surface of a first shaft of the workpiece. A step surface at the upper end of an inner hole of the fixed support is a positioning flange of the workpiece. By use of the numerical control processing fixture, the clamping force of a machine tool claw does not directly act on the workpiece, so the deformation of the workpiece caused by clamping is effectively reduced, and meanwhile deformation resulting from torque transferring through the workpiece is eliminated by a main shaft clamping fixture. The other end of the workpiece is provided with auxiliary supporting, the influences of cutting vibration on the processing precision of the workpiece are reduced and the processing quality of products is improved.

Owner:XIAN AEROSPACEMOTOR MACHINE FACTORY

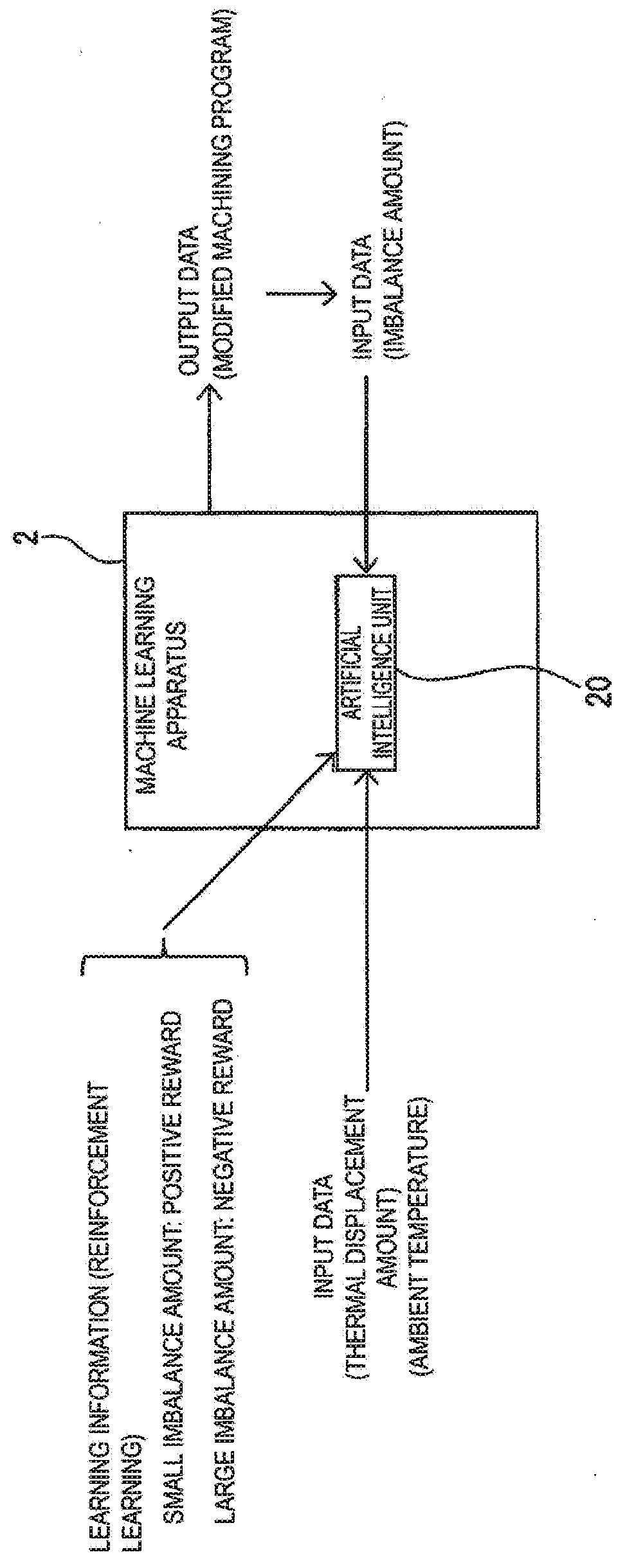

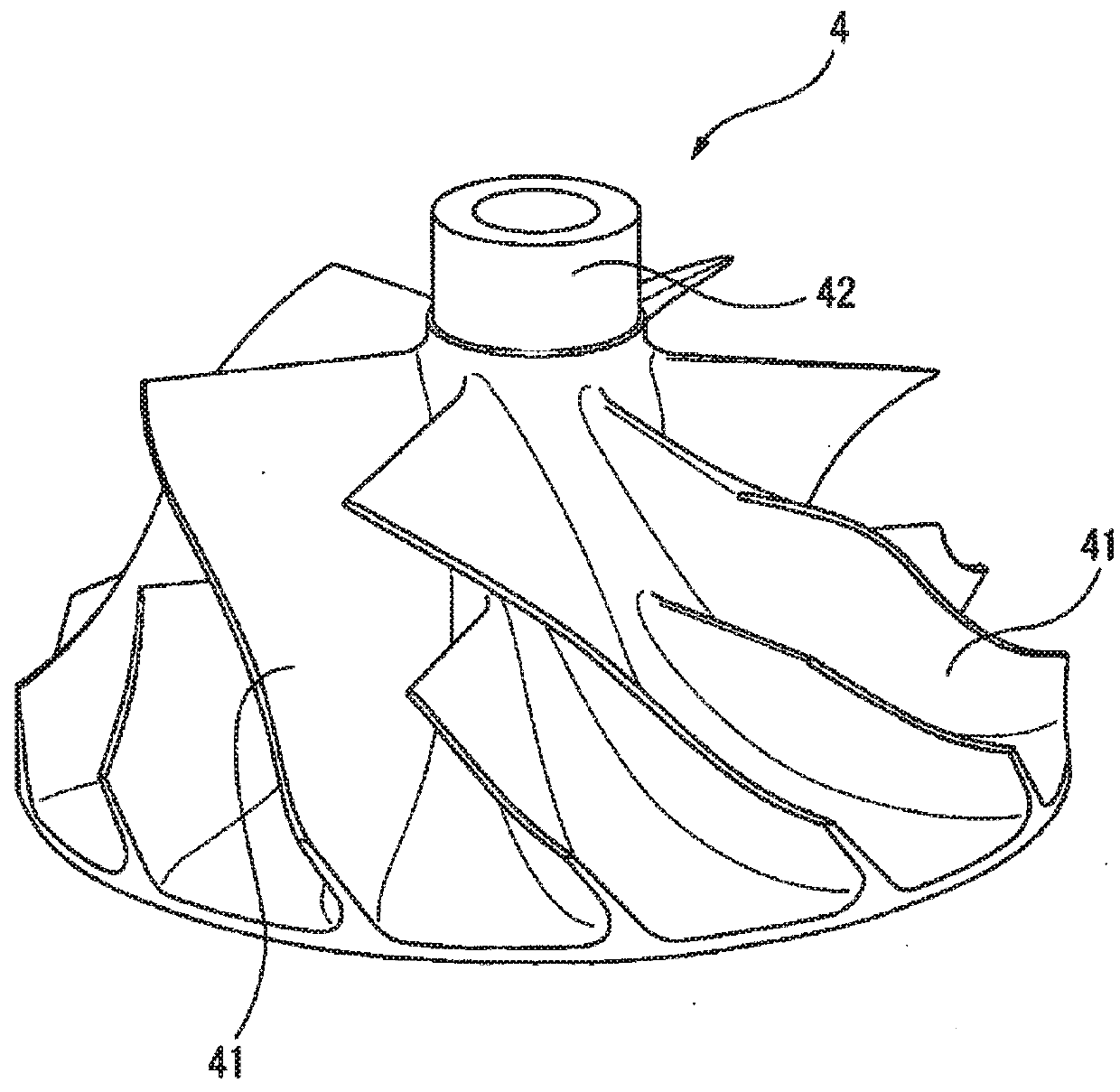

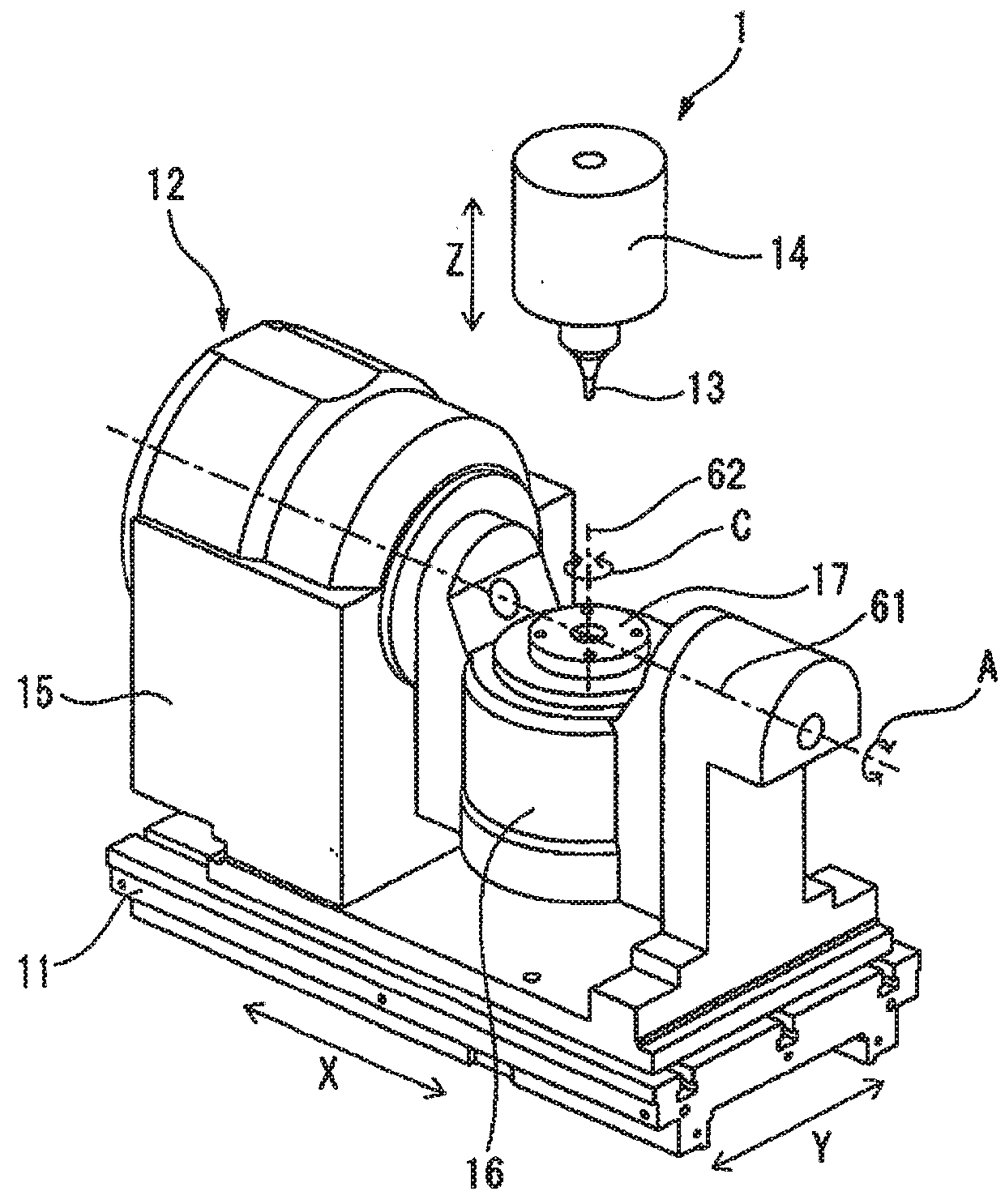

Machine learning apparatus that learns setting value in machining program of machine tool, and machining system

ActiveUS20180107947A1Affect machining accuracyAutomatic control devicesMachine learningImpellerEngineering

A machine learning apparatus learns a setting value in a machining program of a machine tool configured to machine an impeller. The machine learning apparatus includes a state observation unit configured to acquire the thermal displacement amount during a period of machining a workpiece, as a state variable, and a determination data acquisition unit configured to receive the imbalance amount in the impeller after machining as determination data. The machine learning apparatus includes a learning unit configured to learn the setting value in the machining program on the basis of output from the state observation unit and output from the determination data acquisition unit.

Owner:FANUC LTD

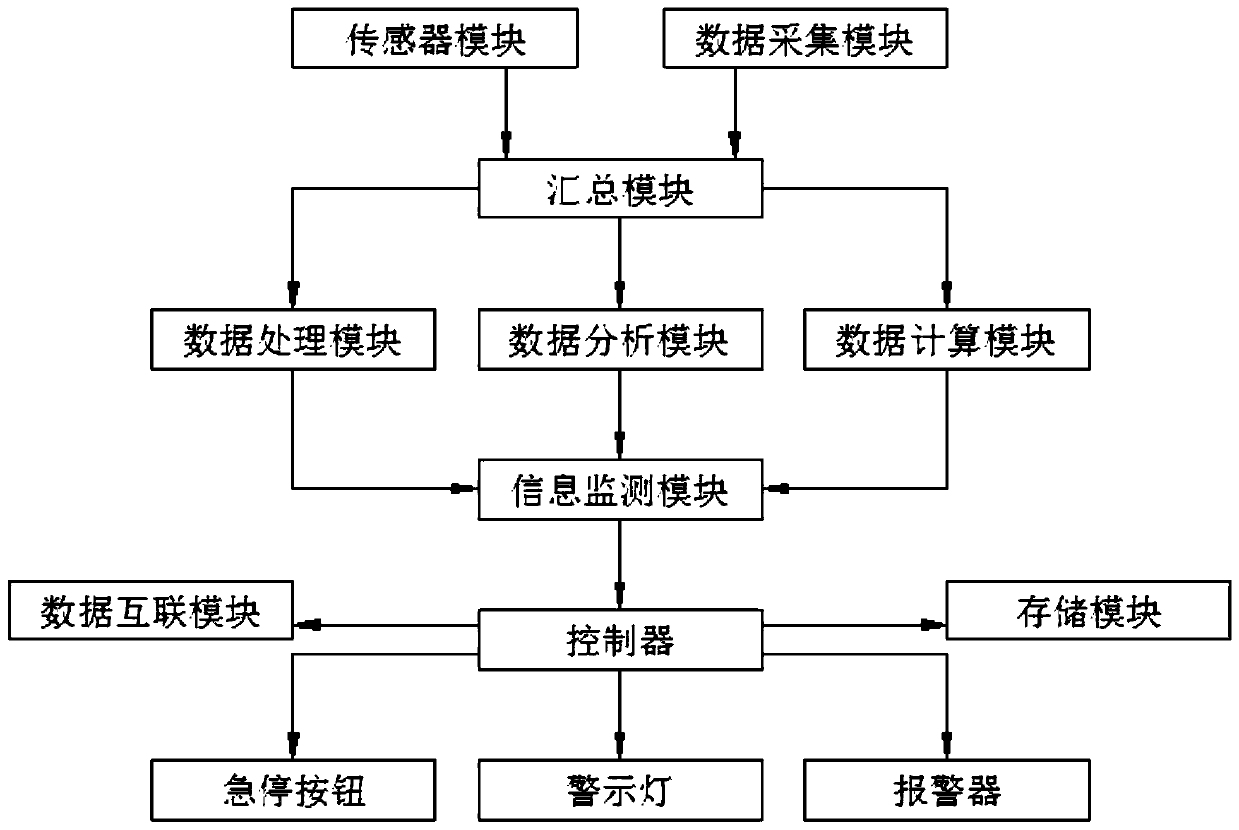

Large-scale numerical control machine tool fault monitoring system based on multi-sensor

ActiveCN109739183AUnderstanding of wear and tearEasy to processProgramme controlComputer controlNumerical controlSignal on

The invention discloses a large-scale numerical control machine tool fault monitoring system based on multi-sensor. The large-scale numerical control machine tool fault monitoring system based on themulti-sensor comprises a sensor module, a data acquisition module, a summary module, a data analysis module, an information monitoring module, a controller, a data interconnection module, a storage module, a data processing module, an emergency stop button, an alarm, a data calculation module and a warning light; after obtaining Ti and Yi, the data analysis module in the invention transmits the Tiand Yi to the information monitoring module; the information monitoring module compares Ti and Yi with preset values t and y separately, generates an overhauling signal and a replacement signal, andtransmits the overhauling signal and the replacement signal to the data interconnection module through the controller; and the data interconnection module displays the received overhauling signal andreplacement signal on the mobile phone of the staff, which is convenient for the staff to understand the wear condition of the tool over a period of time, and to overhaul and replace the tool with a large degree of wear.

Owner:上海赛卡精密机械有限公司

Method for improving machining efficiency of exhaust manifold air inlet flange

InactiveCN107443105AImprove work efficiencyImprove processing efficiencyWork clamping meansCleaning using gasesAirflowMachining process

The invention discloses a method for improving the machining efficiency of an exhaust manifold air inlet flange. The method comprises the following steps that 1, a to-be-machined flange is put at the top of a clamping disc; 2, adjusting rods are rotated in sequence, the tail ends of the adjusting rods enter air outlet channels of clamping plates, the clamping plates are pushed to move in grooves, and then, the to-be-machined flange is fastened; 3, in the flange machining process, a push rod is rotated to push a movable table to move in moving grooves, meanwhile, a threaded rod is loosened, the clamping disc is rotated, and the flange is machined flexibly; 4, in the flange machining process, a draught fan is started, airflow generated by the draught fan enters a fan cover, the airflow in the fan cover is blown into the grooves and the clamping disc, and iron filings generated during flange machining are removed; and 5, after machining of the flange is completed, the adjusting rods are adjusted again, so that the flange is not clamped by the clamping plates and taken down, and another to-be-machined flange is installed. Machining can continue to be conducted without removing the iron filings on the clamping disc.

Owner:CHENGDU LINGCHUAN SPECIAL IND

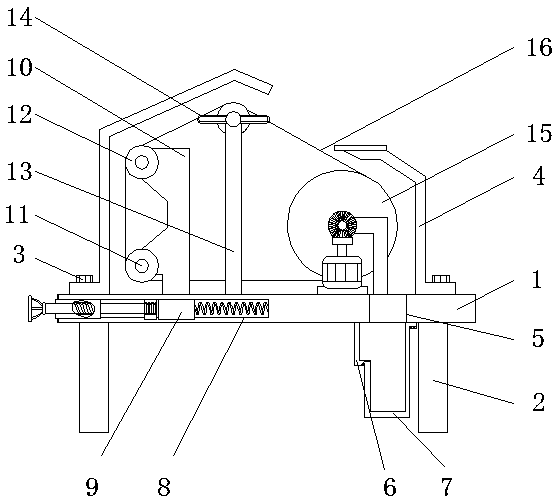

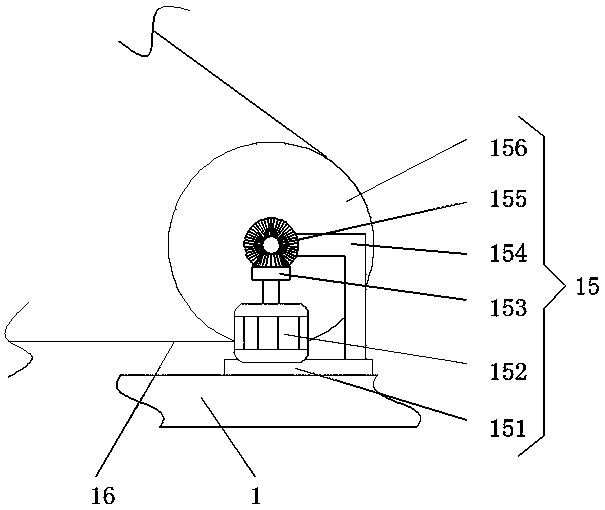

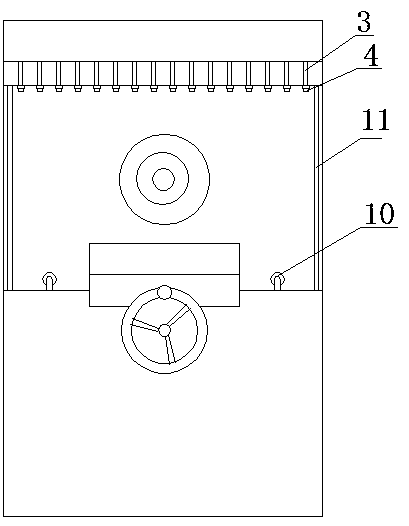

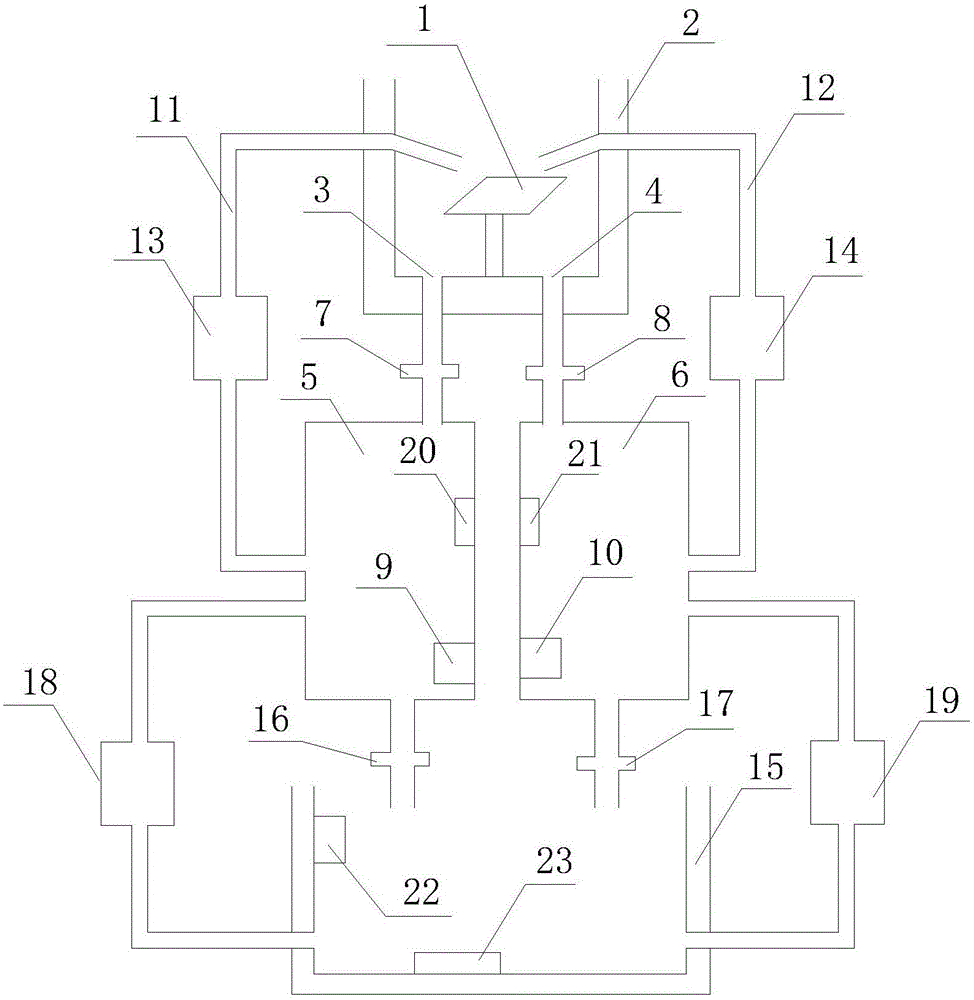

Abrasive belt grinding machine convenient to adjust

PendingCN108673306AEasy to adjustIdeal grinding effectBelt grinding machinesGrinding work supportsEngineeringMachining process

The invention relates to the technical field of machining, and discloses an abrasive belt grinding machine convenient to adjust. The abrasive belt grinding machine convenient to adjust comprises a base, supports are fixedly installed on the two sides of the bottom of the base, stopping covers are fixedly installed on the two sides of the top of the base through screws, a waste material groove is formed in one side of the base, a fixing plate is fixedly installed on one side of the bottom of the base, one side of the bottom of the base is fixedly connected with one end of a collecting box through a screw, the other end of the collecting box and the bottom end of the fixing plate are movably clamped, and the other side of the base is provided with a sliding groove and is in sliding connection with a sliding device through the sliding groove. By means of the abrasive belt grinding machine convenient to adjust, a rotating wheel is driven by a limiting rod to move left and right in the inner side of a limiting sleeve, the position of the rotating wheel is freely adjusted, the function of controlling the abrasive belt angle is achieved in cooperation with a fixing support, the conditionsthat in the part machining process, the abrasive belt angle cannot be adjusted, consequently the ideal machining need cannot be met, and the part machining accuracy is influenced are avoided, and thedevice accuracy is improved.

Owner:郑州博尔德磨料磨具有限公司

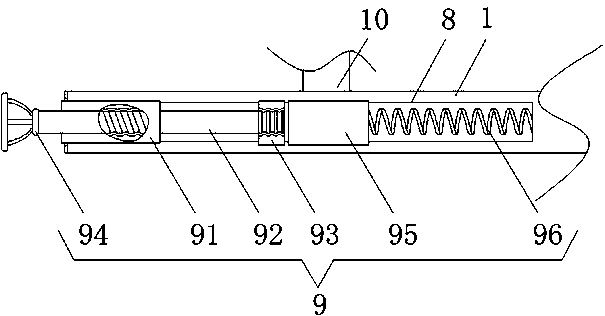

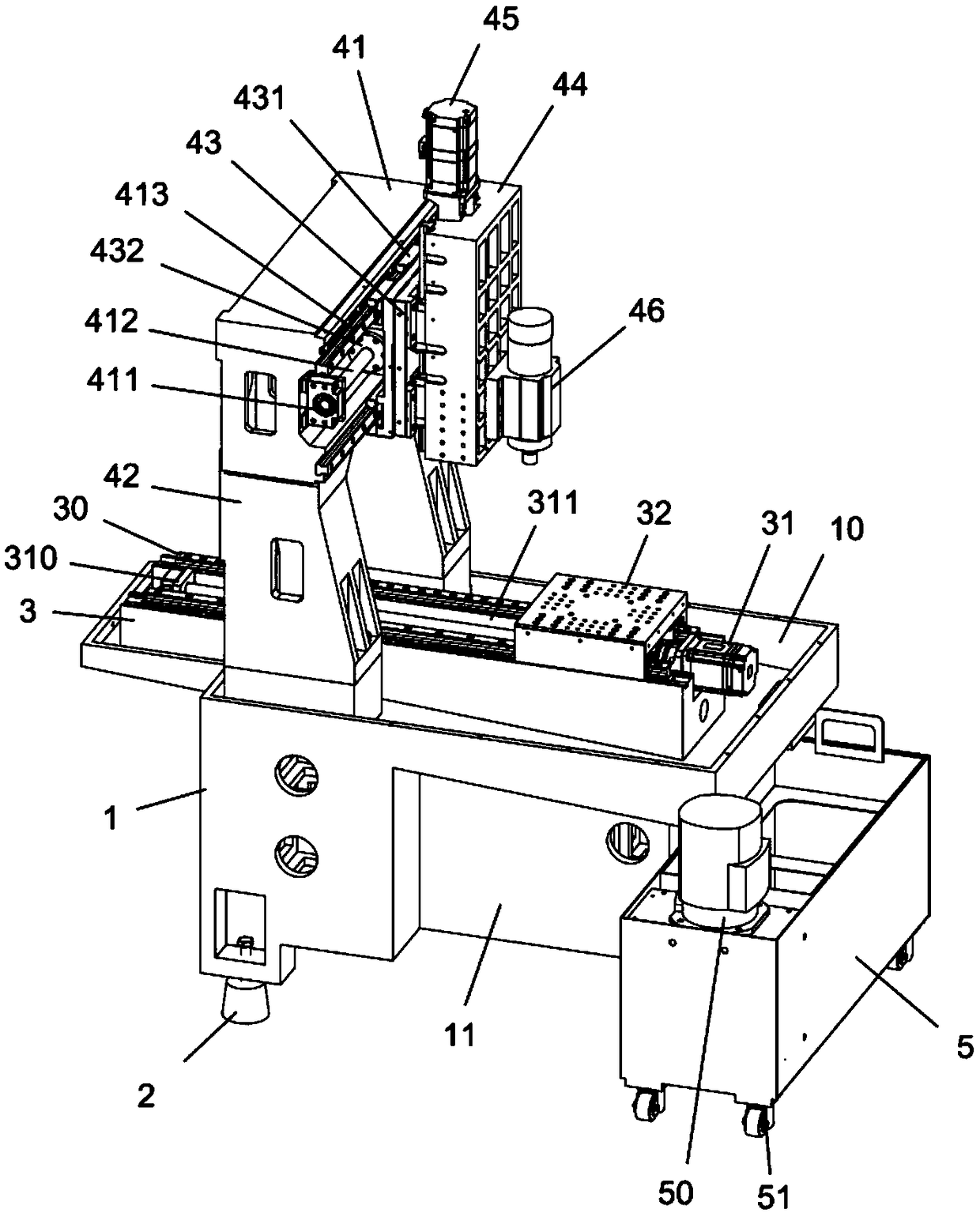

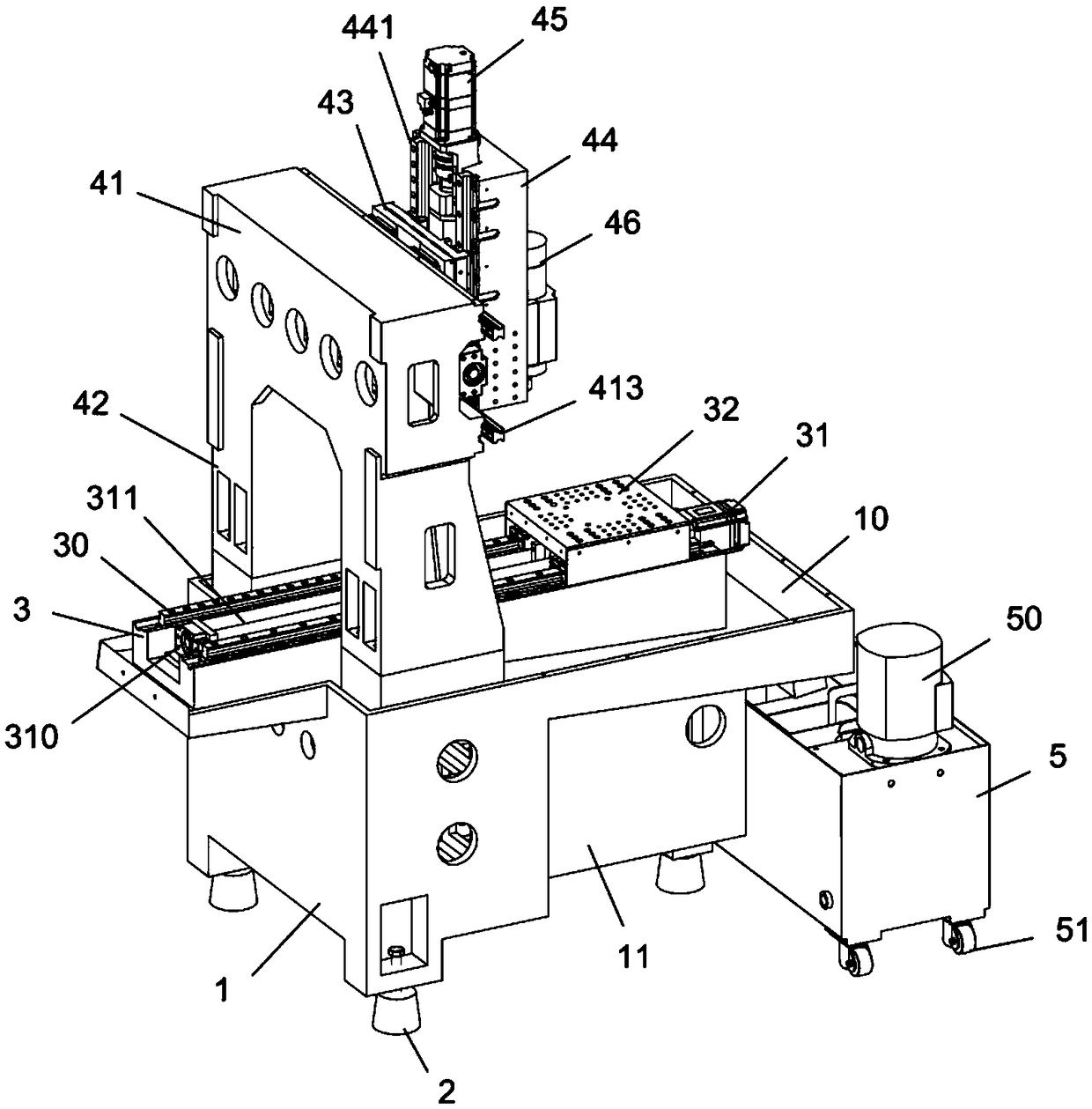

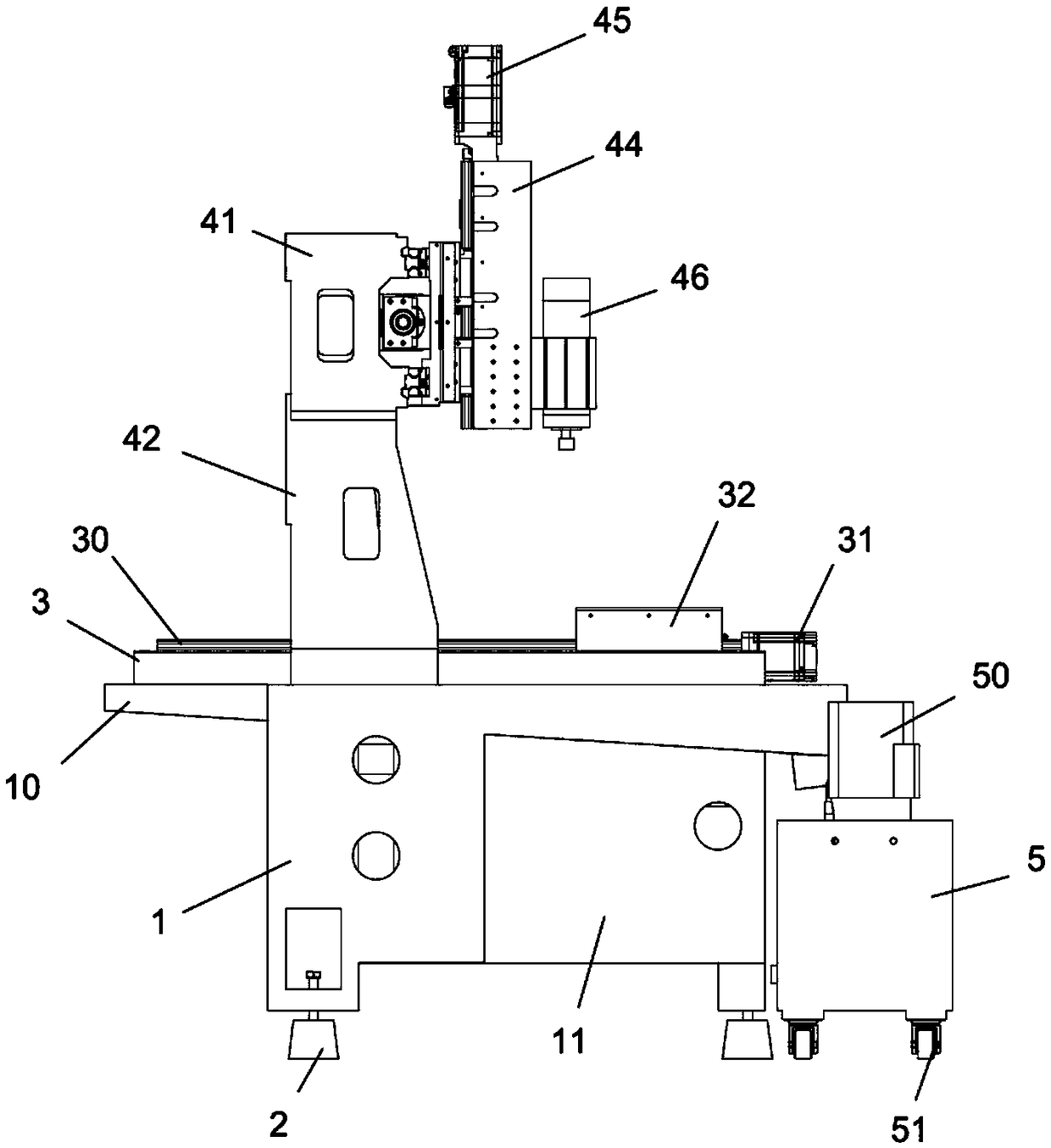

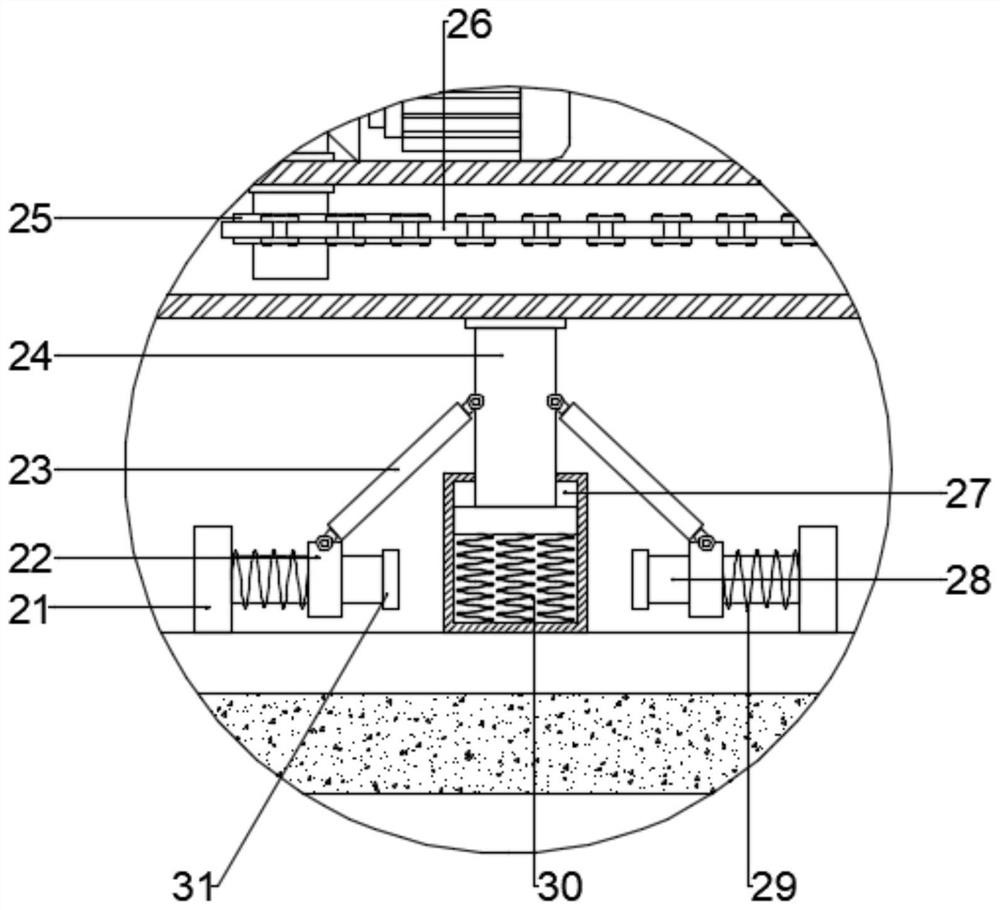

Numerical control milling machine tool suitable for automatic operation

ActiveCN108817485ANo-impact debuggingNo impact maintenanceMilling machinesFeeding apparatusNumerical controlEngineering

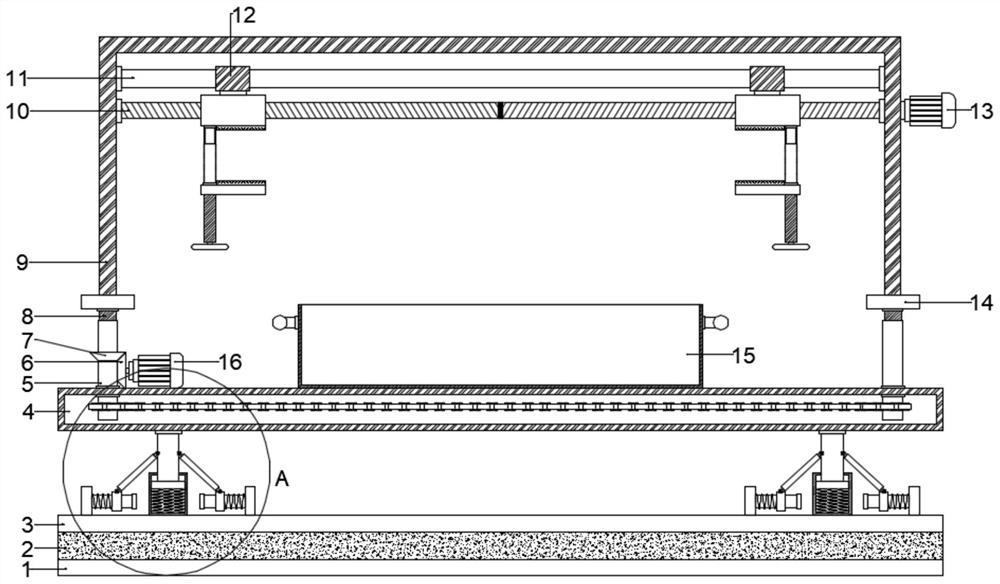

The invention discloses a numerical control milling machine tool suitable for automatic operation. The numerical control milling machine tool comprises a rack, and buffering mechanisms are fixedly arranged at the four corners of the lower portion of the rack. An n-shaped frame is arranged on the upper portion of the rack, and a milling head is slidingly arranged on the upper portion of the n-shaped frame. A machining table extending along the axis Y is arranged at the position, below the n-shaped frame, of the rack. The rear portion of the machining table protrudes out of the rack for a certain distance, and the rear portion of the machining table is connected with an automatic feeding and discharging mechanism. The machining table comprises a machining table base fixedly mounted on the rack. According to the numerical control milling machine tool, the axis Y of the numerical control milling machine tool is lengthened, a workbench moves behind the machine tool when machining is finished and a workpiece needs to be automatically replaced, the automatic feeding and discharging device can be mounted behind the machine tool to operate, and debugging and maintenance of the machine toolare completely not influenced. In addition, the numerical control milling machine tool is further provided with the buffering mechanisms, the machine tool can be buffered and damped through the buffering mechanisms, and the machine tool machining precision is prevented from being influenced by mechanical vibration.

Owner:东莞市智升智能机械科技有限公司

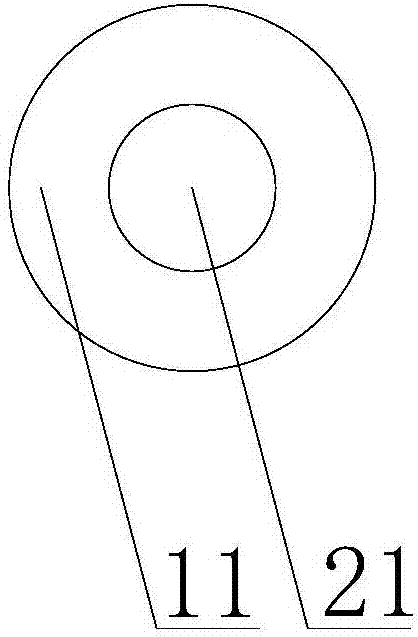

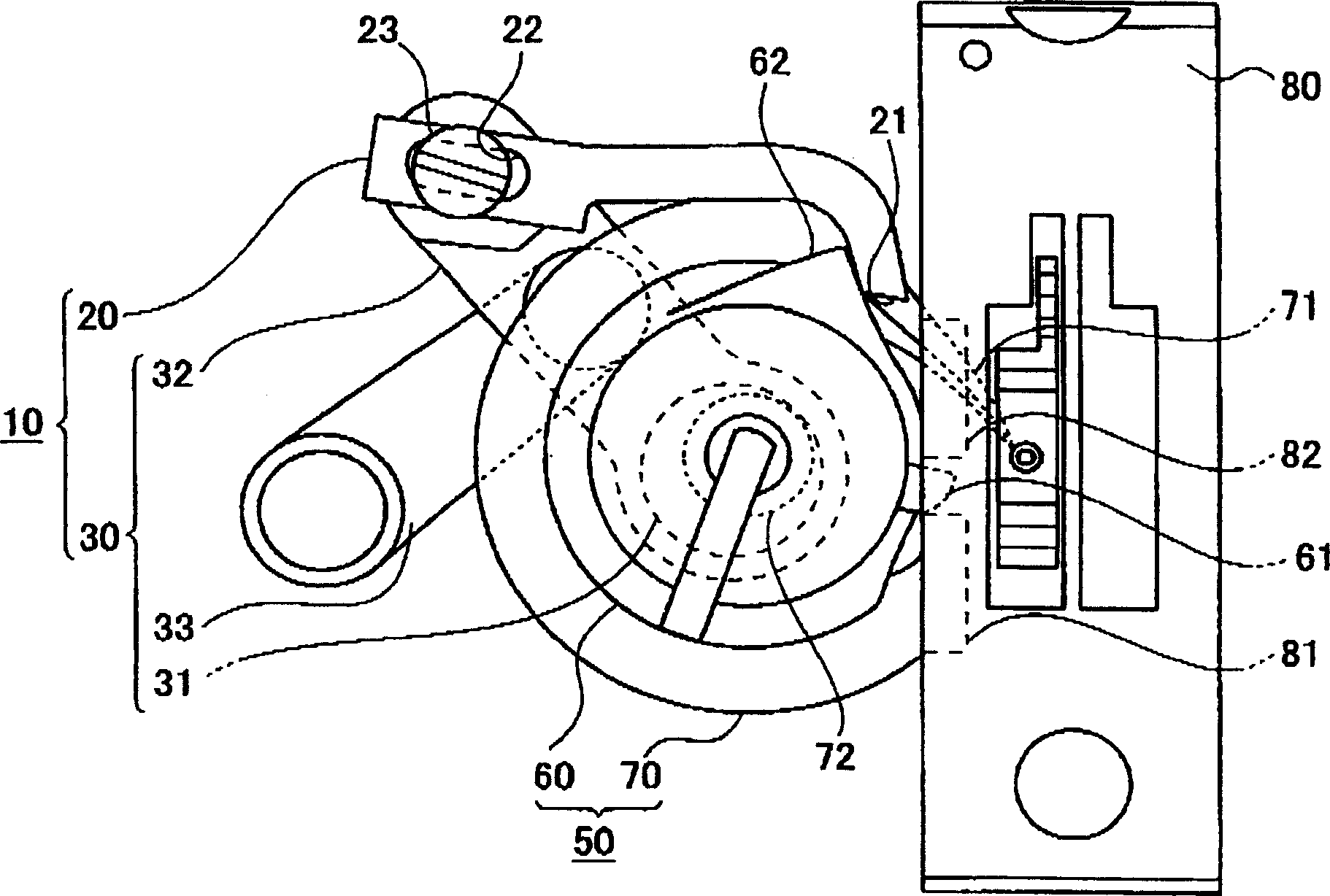

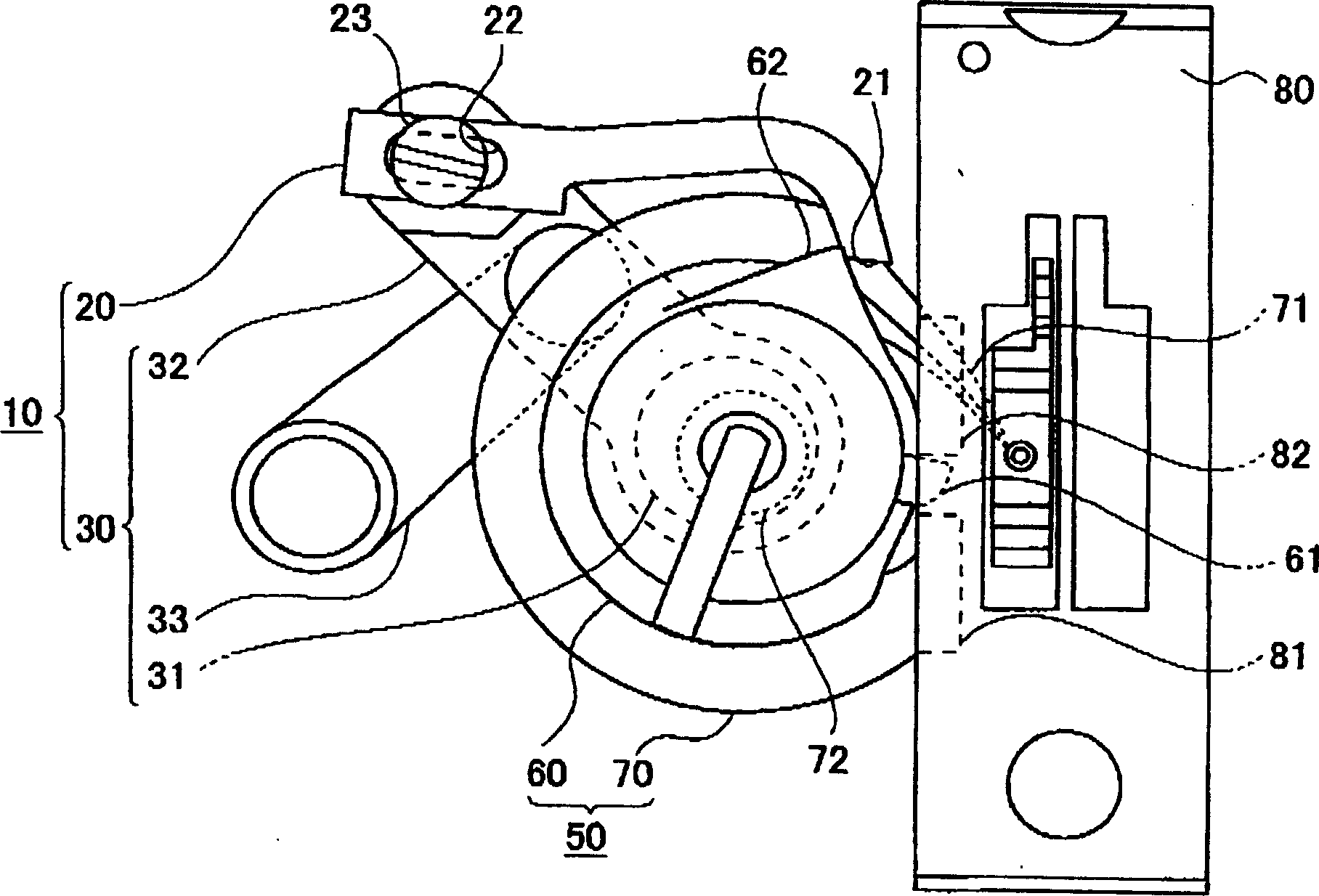

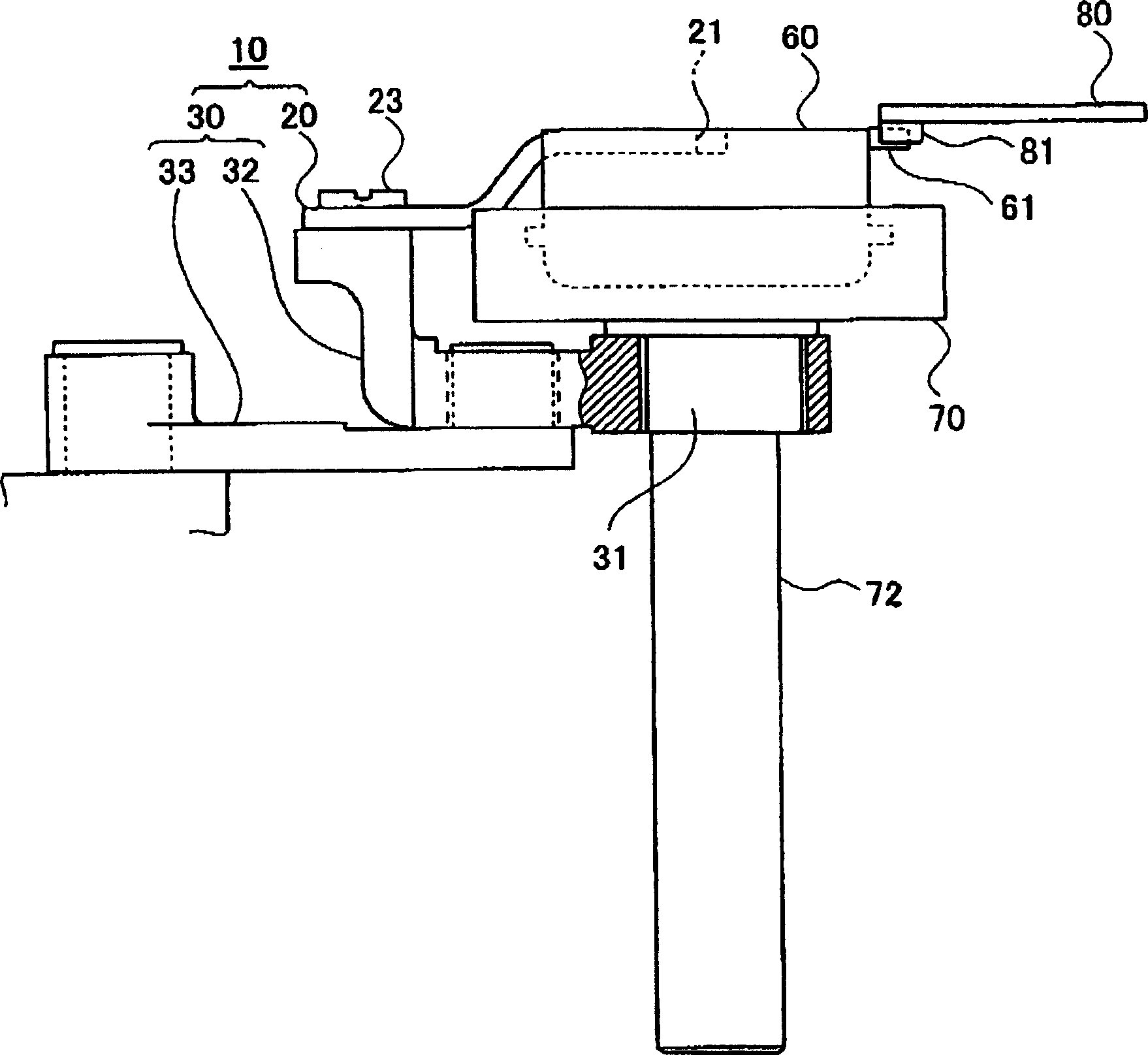

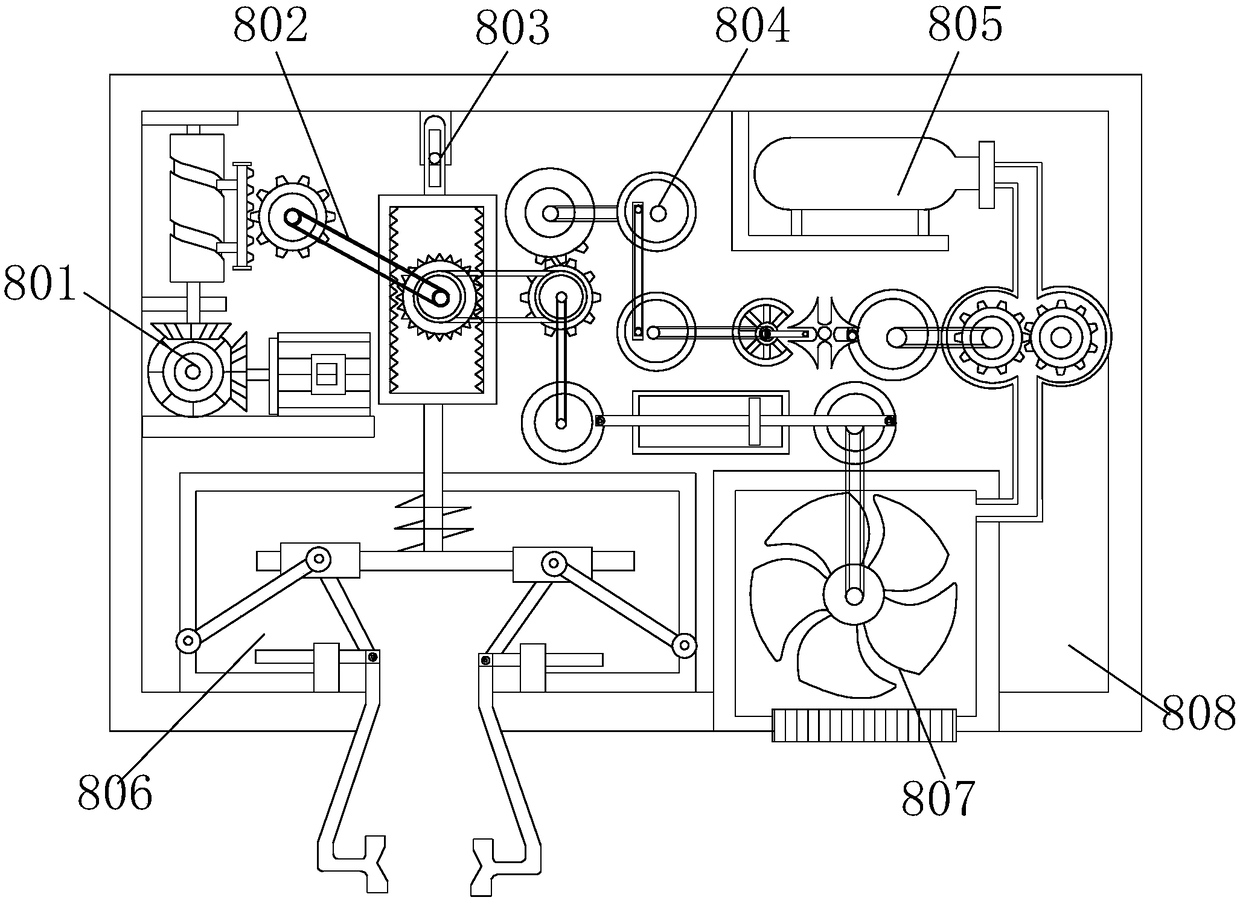

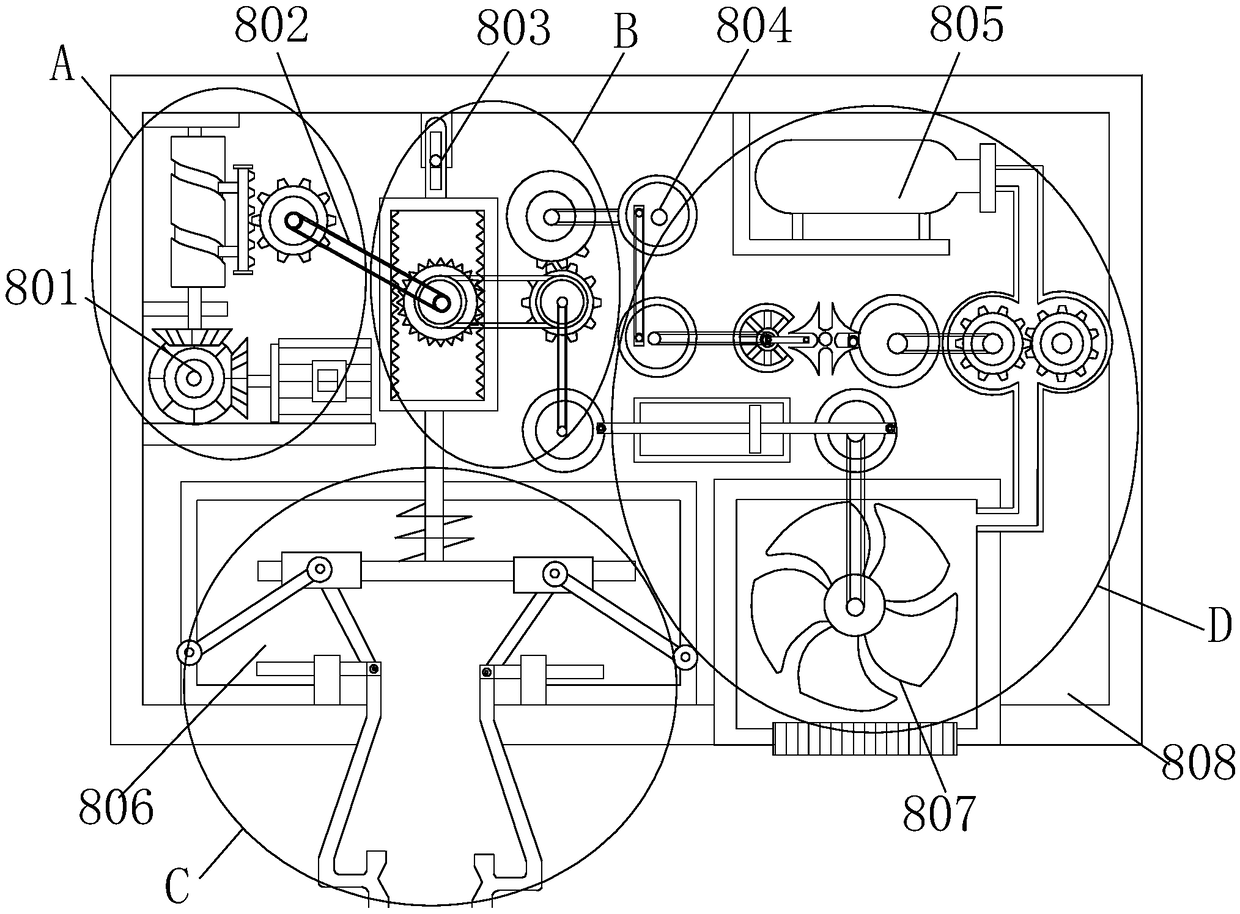

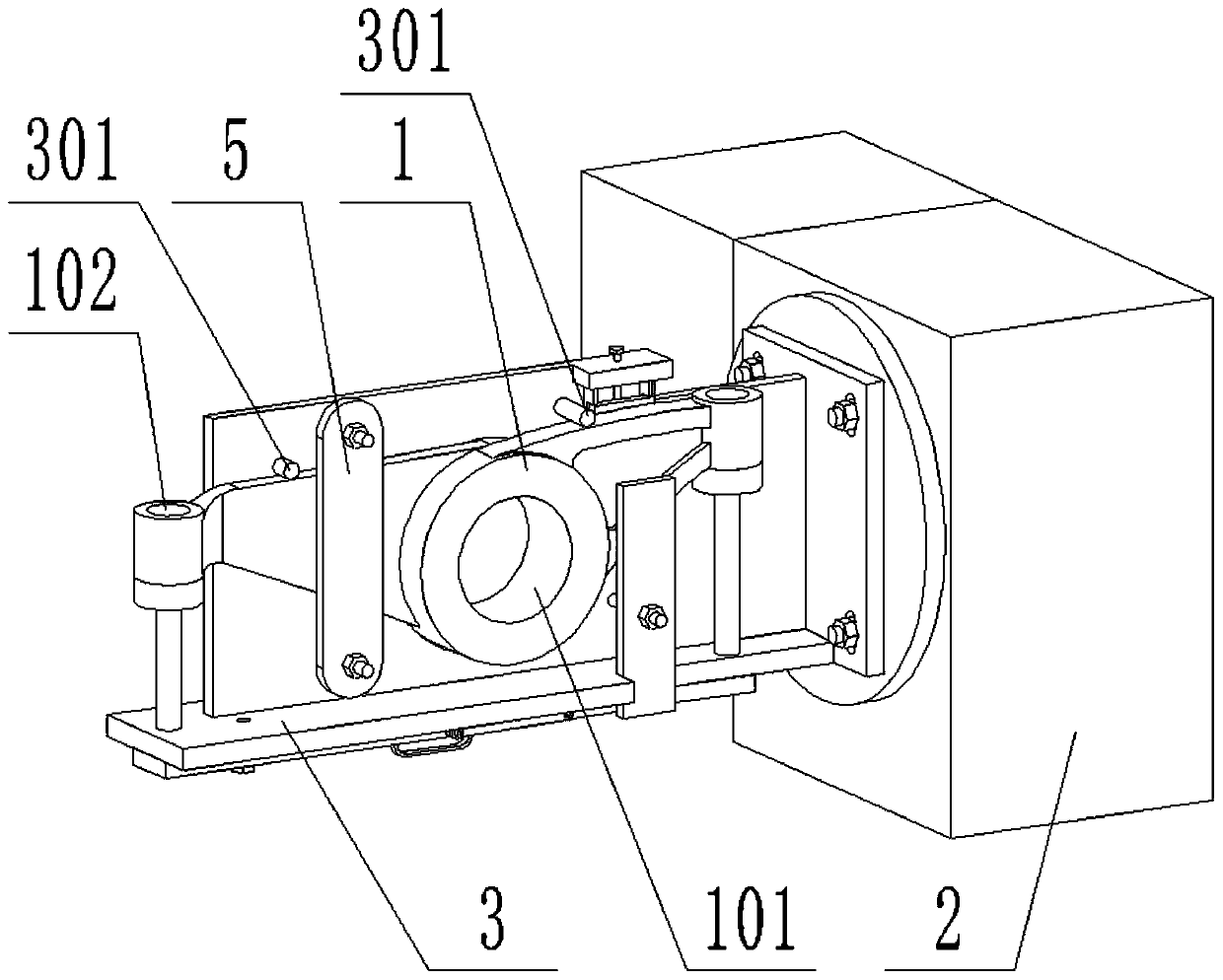

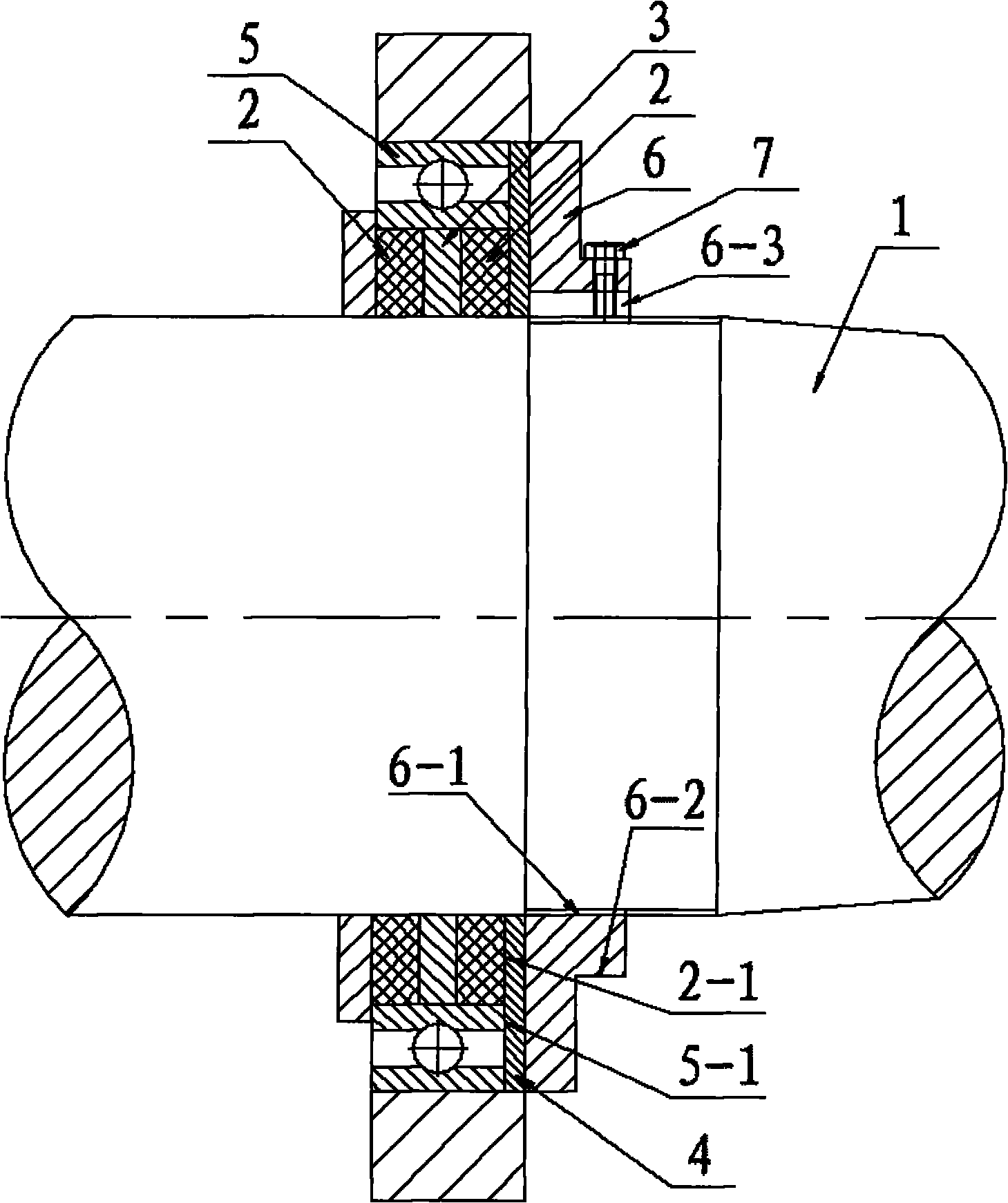

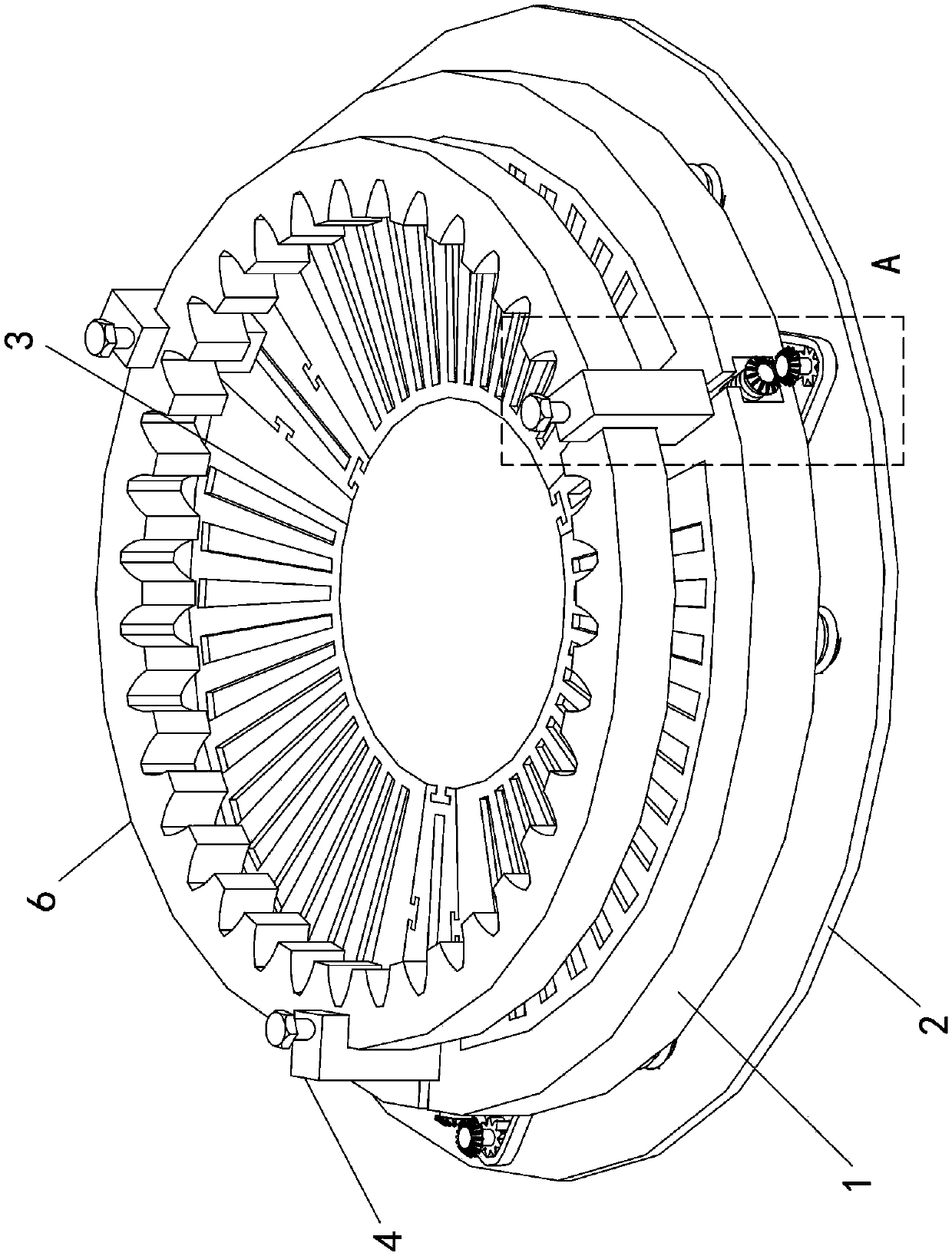

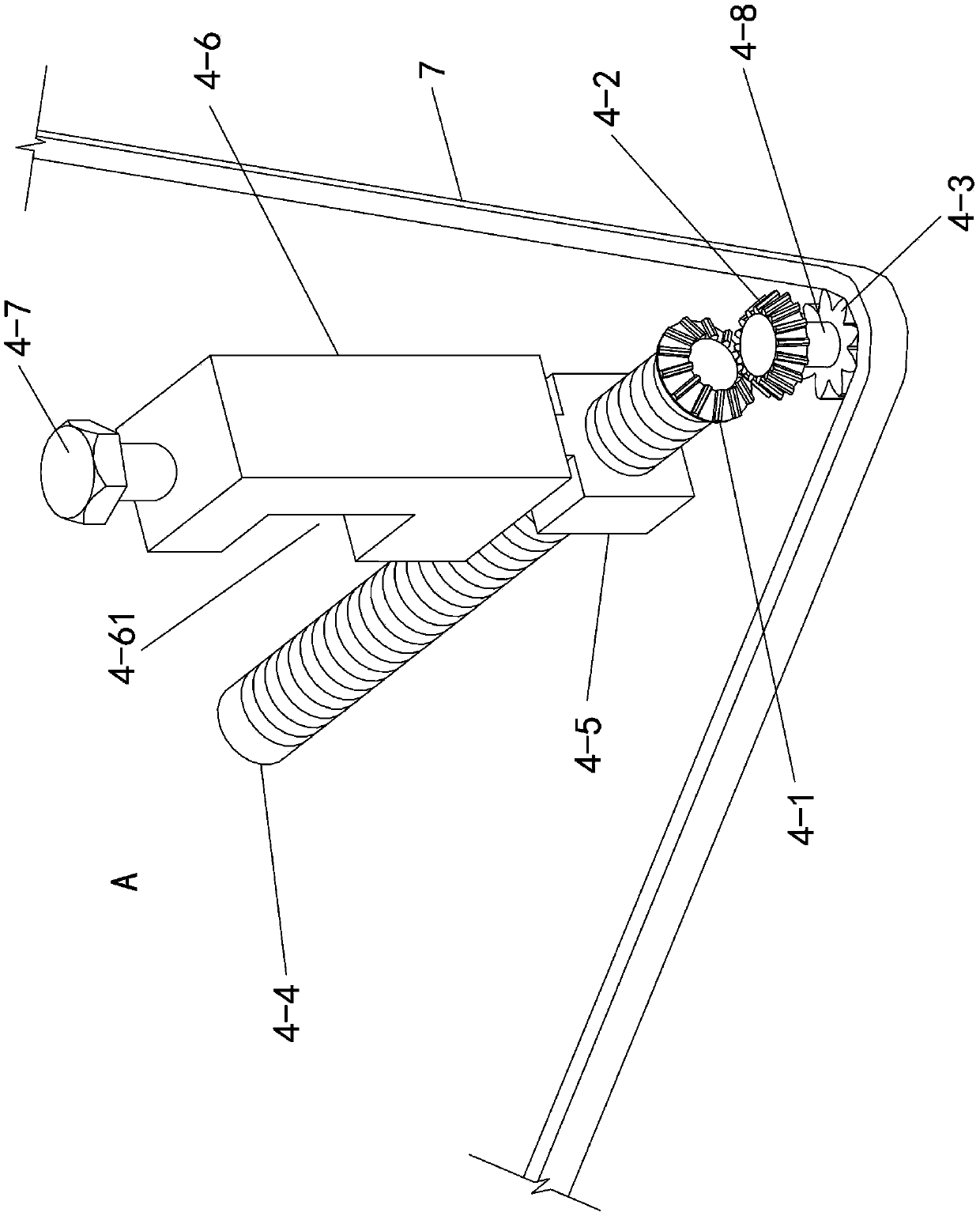

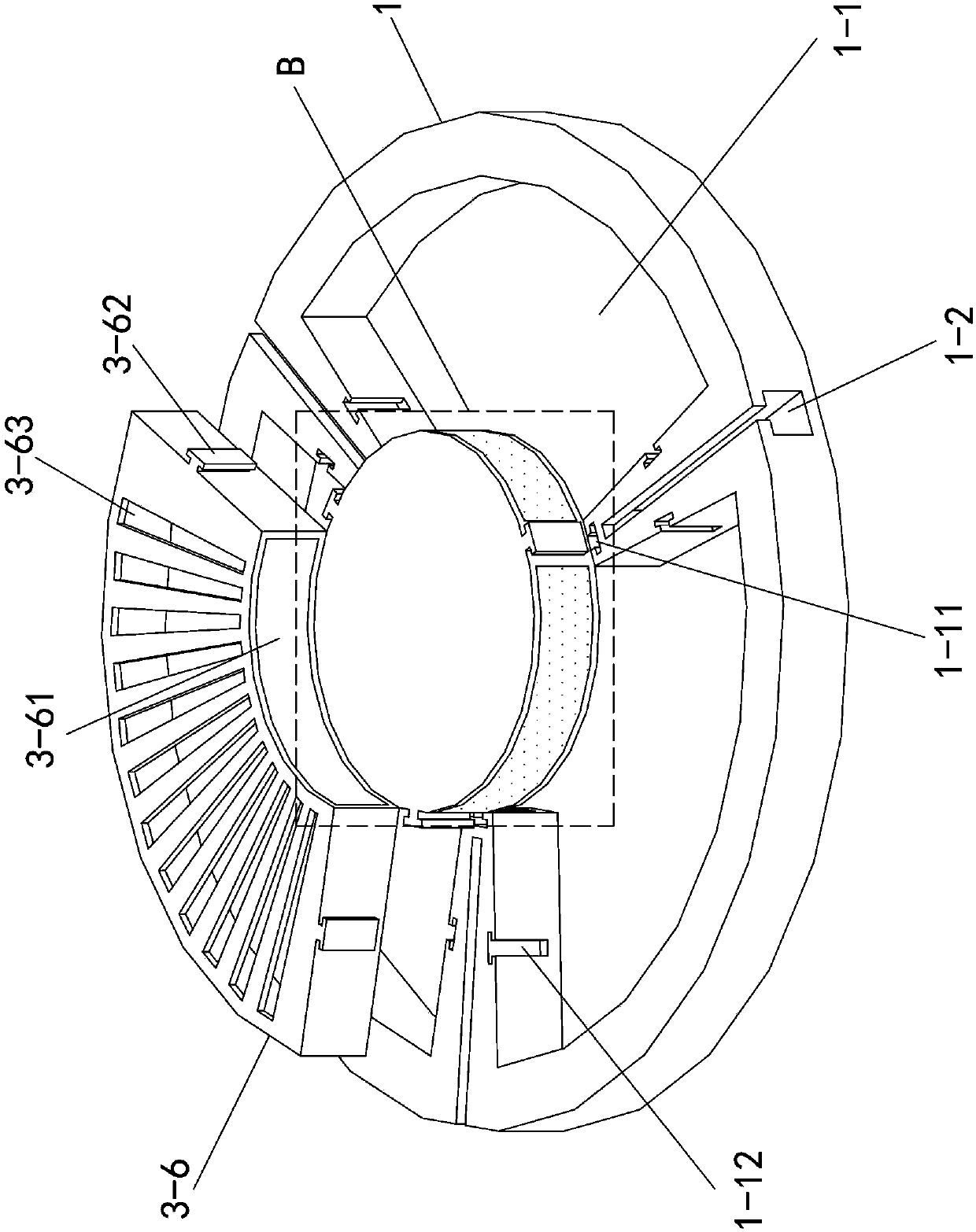

Separator for horizontally rotating shuttle of sewing machine and regulating method thereof

To provide an opener of a horizontal shuttle of a sewing machine and method of adjustment thereof, capable of easily adjusting the opening of a projection of a shuttle body. The opener 10 comprises an engagement member 20 drawing the shuttle body 60 close in the direction opposite from the direction of rotation of the outer shuttle via an engaged part 62 as the distal end moves in a prescribed trajectory according to the phase of rotation of a driving shaft of rotating / driving the outer shuttle 70 of the horizontal shuttle 50. The transmission mechanism 30 moves the end of the engagement member in the trajectory by the driving of the driving shaft of rotating the outer shuttle and holds the engagement member in such a way that the engagement member can be moved / adjusted. The opener performs the following processes: a phase setting process of setting the rotation phase of the driving shaft at the engagement starting phase for the end of the engagement member to form a gap with a target width via the engaged part, a shuttle body positioning process for making the projection of the shuttle body abut on an abutting part for restraint, and an engagement member position adjusting process for moving / adjusting the engagement member to the engagement starting position with the engaged part.

Owner:JUKI CORP

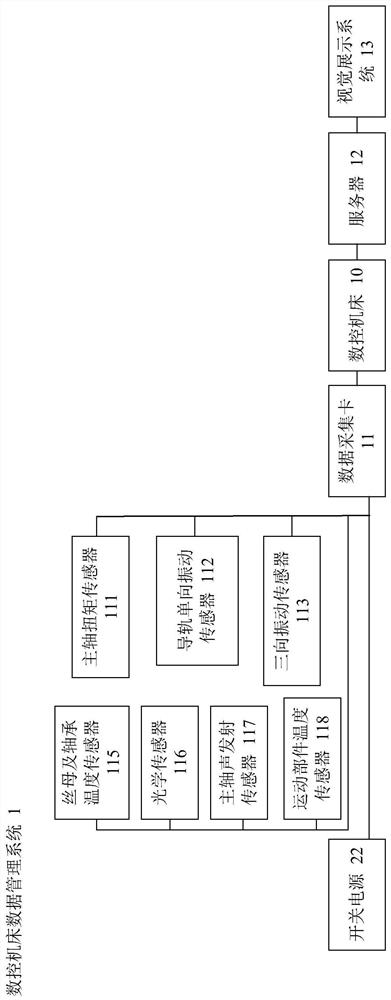

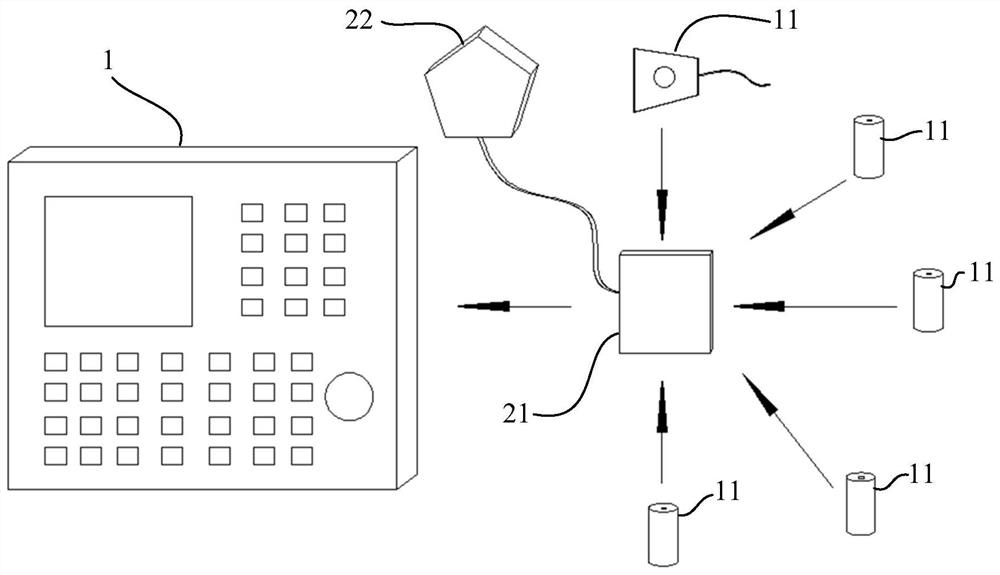

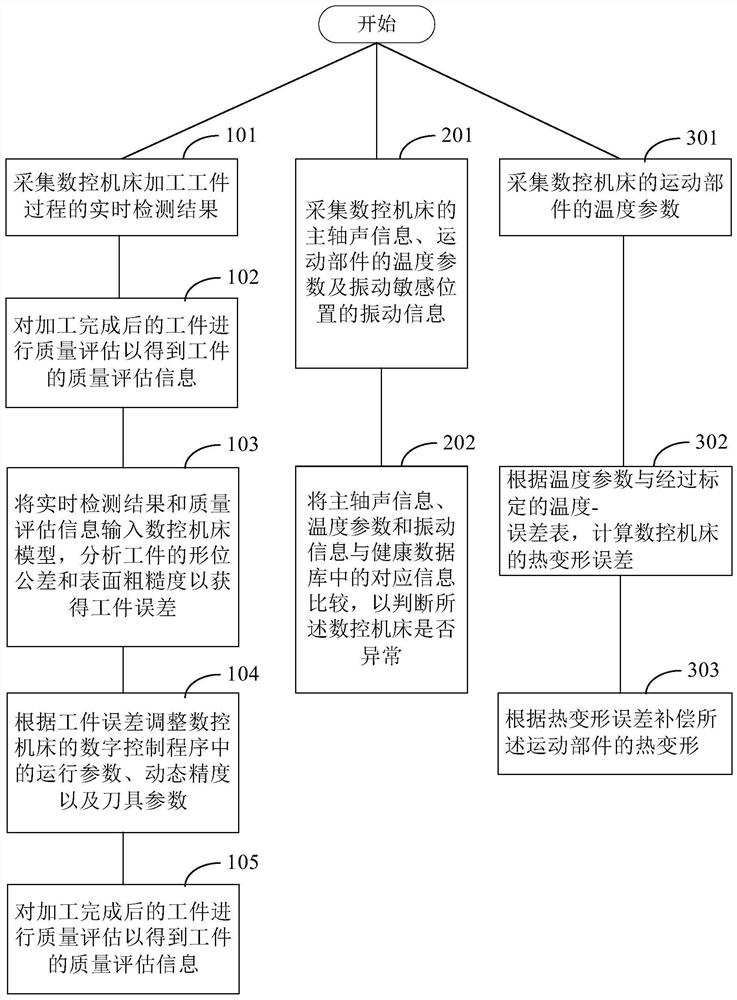

Numerical control machine tool data management system and method

PendingCN113126563AMonitor real-time statusMonitoring accuracyProgramme controlComputer controlNumerical controlControl engineering

The invention provides a numerical control machine tool data management method. The method comprises the steps of collecting a real-time detection result of a workpiece machining process of a numerical control machine tool; performing quality evaluation on the machined workpiece to obtain quality evaluation information of the workpiece; inputting a real-time detection result and a quality evaluation information into a numerical control machine tool model, and analyzing the form and location tolerance and the surface roughness of the workpiece to obtain a workpiece error; adjusting operating parameters, dynamic precision and cutter parameters in a digital control program of the numerical control machine tool according to the workpiece errors; and enabling the numerical control machine tool to carry out secondary machining on the surface with the workpiece error so as to compensate the workpiece error.

Owner:AECC COMML AIRCRAFT ENGINE CO LTD

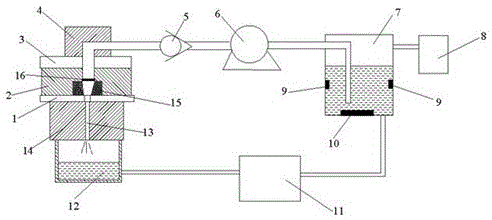

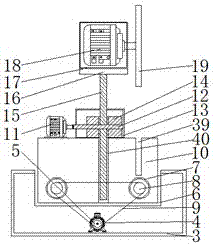

Screw lubrication detecting device for numerical control machine tool

InactiveCN101972949AAffect machining accuracyAffect the operating lifeMeasurement/indication equipmentsA d converterLubrication

The invention relates to a screw lubrication detecting device for a numerical control machine tool, belonging to the field of machine tools and comprising a lead screw, wherein the lead screw is sheathed with a screw frame nut seat and a lead screw nut; a temperature sensor is embedded on the lead screw nut; and the temperature sensor is electrically connected with a programmable logic controller through an A-D converter. The invention has the advantages that the structure is simple; the operation components of the machine tool can be prevented from influencing the production precision of workpieces because of frictional heating caused by poor lubrication condition; and the lead screw can be prevented from operating in a no lubricant state in a long time so as to influence the service life of the integral screw.

Owner:WEIHAI HUADONG AUTOMATION

A clamping device for a thin part of a watch

InactiveCN108890331AAvoid deformationAffect machining accuracyPositioning apparatusGrinding work supportsEngineeringMechanical engineering

The invention discloses a clamping device for a thin part of a watch, the invention relates to a clamping device of a thin part of a watch, its structure includes transverse sliding block, transversescrew, transverse guide roll, transverse slide, First motor, first sliding support, second sliding support, clamping device, a worktable with a clamping device connected to the lower end surface of the transverse sliding block, A lateral slide seat penetrates that lateral slide block transversely, transverse screw, the transverse guide rollers are connected to the upper end surface of the transverse slide, the left and right ends of the transverse sliding seat are respectively connected with the second sliding support plate, first sliding support plate connection, one end of the first motor extends transversely through the first sliding support plate and is nested with the transverse sliding seat, The invention realizes that the device can clamp the watch thin part on the premise of preventing the watch thin part from deformation in the working process through the mutual combination of the parts, and can also effectively prevent the dust on the workbench from influencing the machiningaccuracy of the watch thin part in the next stage.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

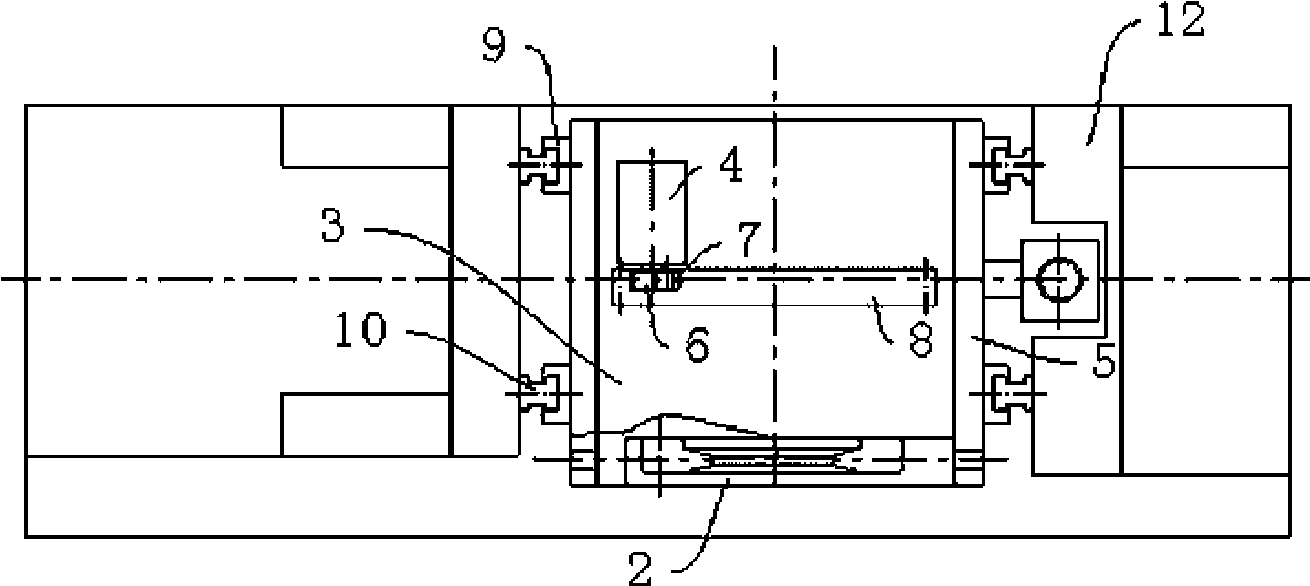

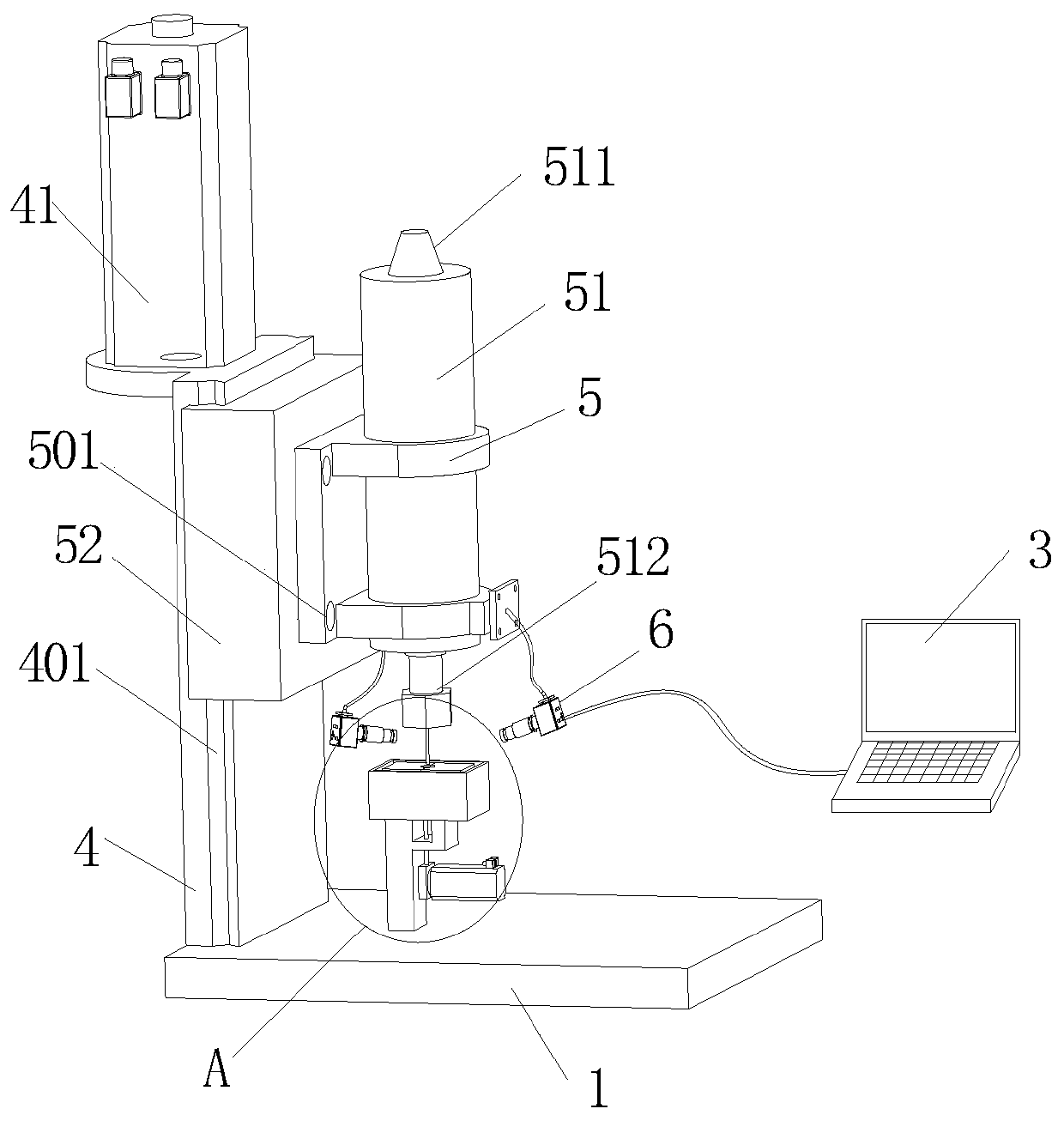

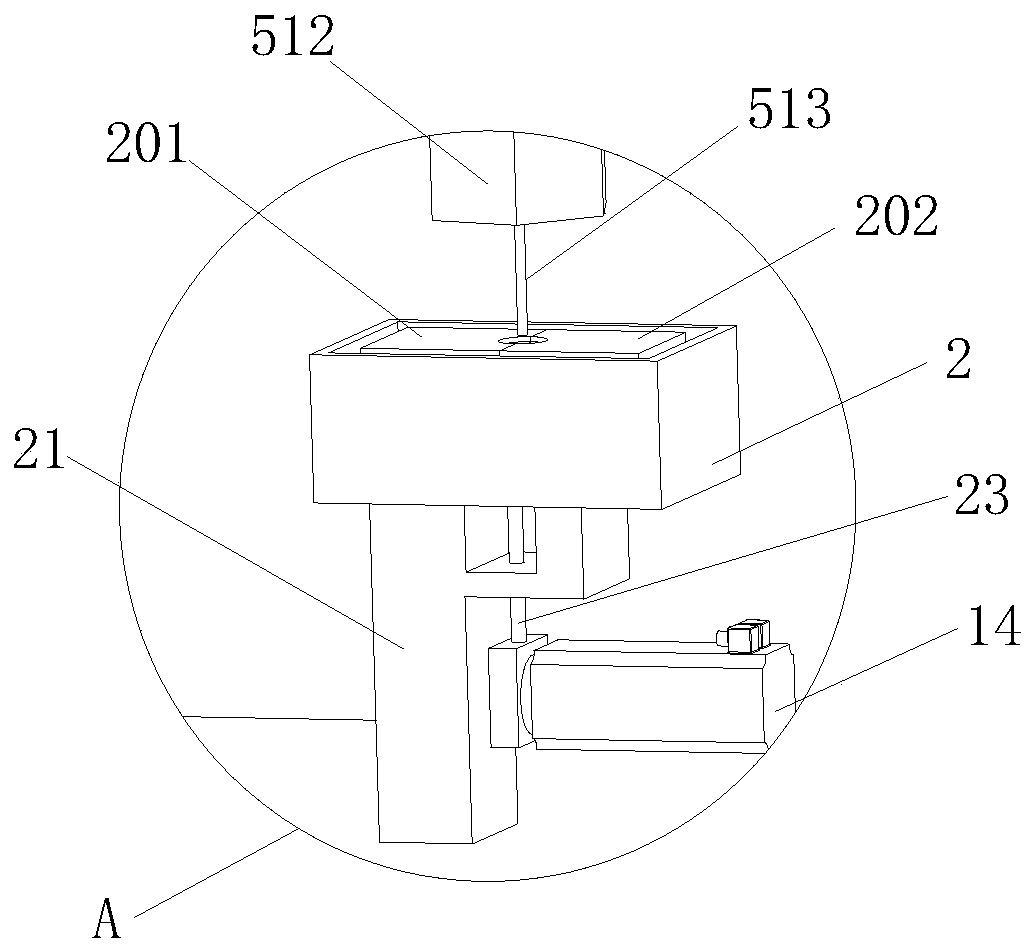

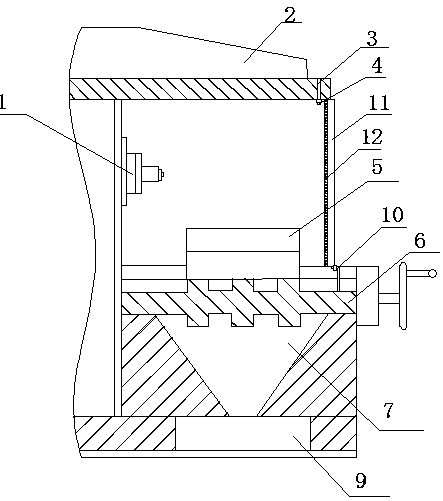

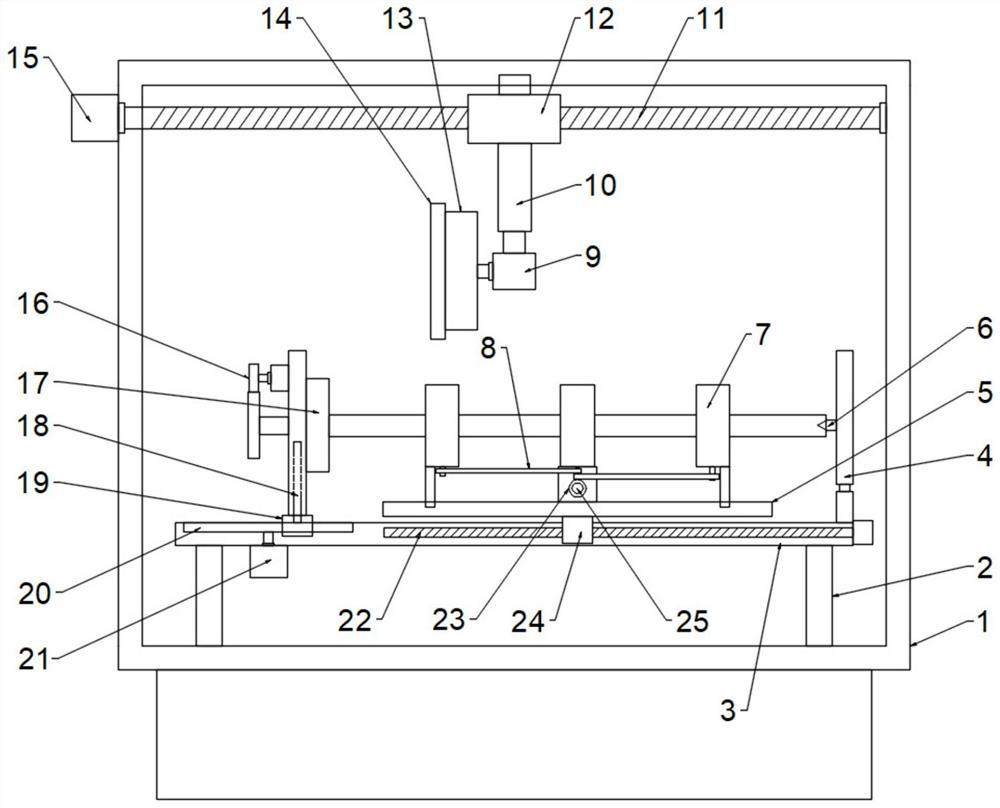

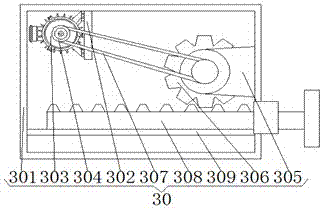

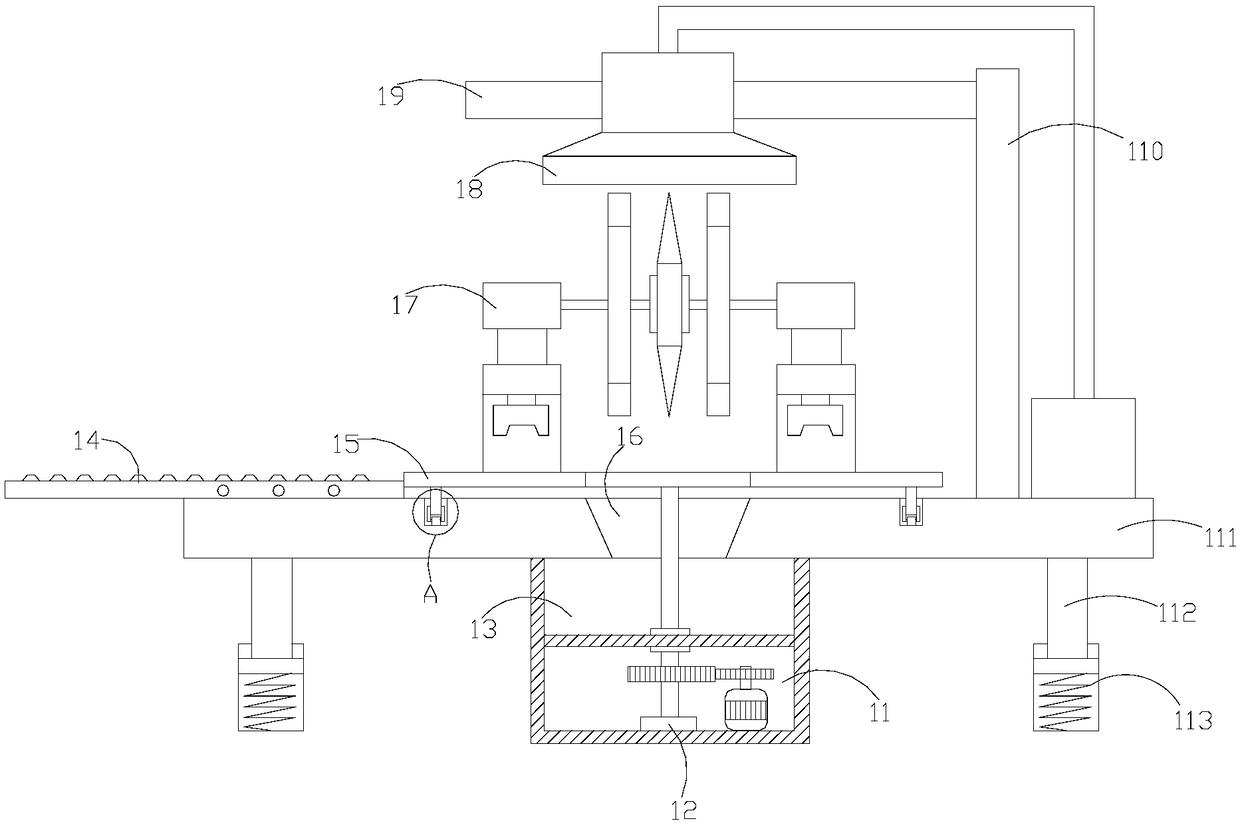

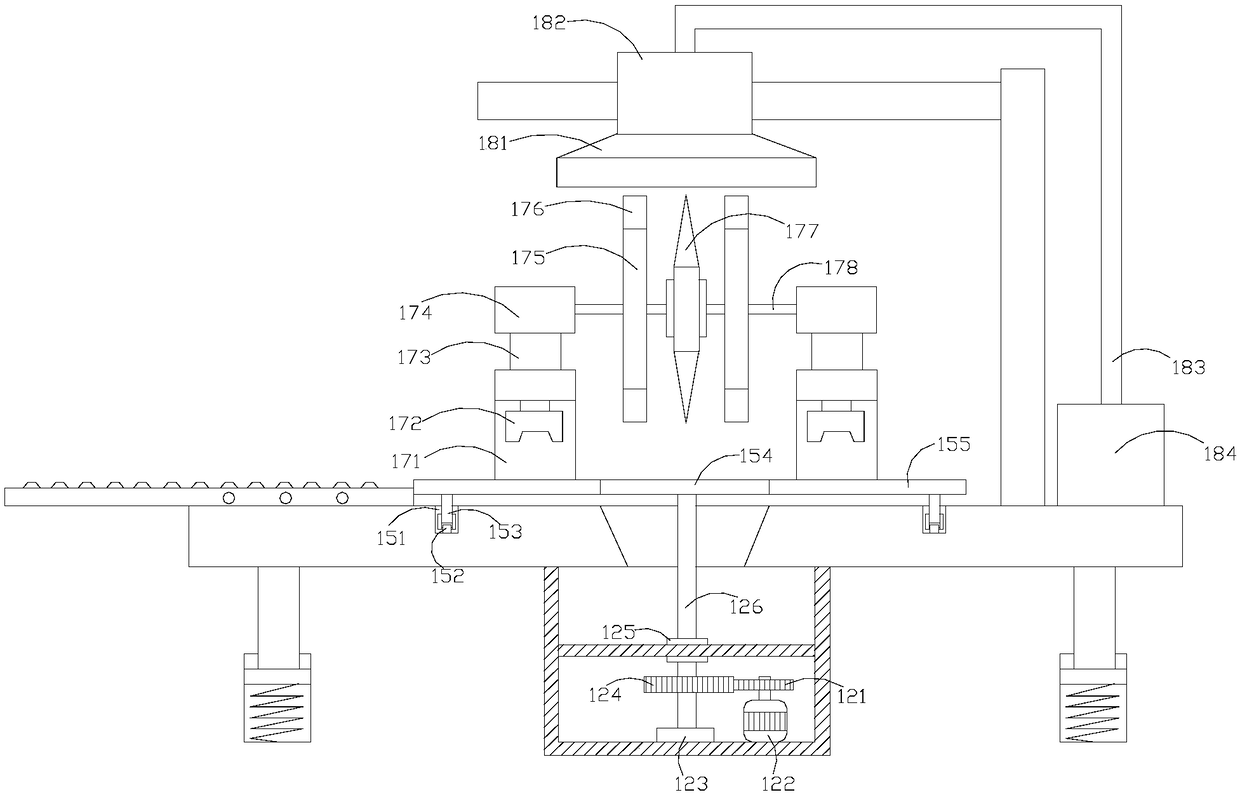

Combined machining testing device of spark electrolysis discharging, applied to semicircle orifice

PendingCN110293272ANo intermittent feed defectsHigh transmission precisionMaterial analysis by optical meansElectricityMotor drive

The invention discloses a combined machining testing device of spark electrolysis discharging, applied to a semicircle orifice. The device comprises a testable base, wherein a guide rail platform is disposed on the testable base; an electric main shaft clamp is in slide connection to a side edge of the guide rail platform; a high-speed electric main shaft is installed in the electric main shaft clamp; an electric main shaft clamping head is installed on the bottom of the high-speed electric main shaft; a tool electrode is clamped by the electric main shaft clamping head; a to-be-processed workpiece and a prefabricated mold which are adhered mutually are clamped inside a box body structure of an electrolytic bath; a micro lead screw vertically passes through a channel in which a semicircleguide hole of the prefabricated mold is located; a semicircle servo plate is disposed on the top of the micro lead screw; and the semicircle servo plate is in clearance fitting inside the semicirclecolumnar guide hole. In the device, the micro lead screw which is driven by a second servo motor drives the semicircle servo plate to make axial feeding; synchronous and homodromous constant-speed feeding is realized between the micro lead screw and the high-speed electric main shaft; and intermittent feeding defects are not generated during transmission of the micro lead screw, so actual transmission accuracy is increased.

Owner:ANHUI UNIV OF SCI & TECH

Method for processing piston inner cavity of middle cylinder

The invention discloses a method for processing a piston inner cavity of a middle cylinder and belongs to the field of quartering hammer processing. The method comprises the steps as follows: firstly, a piston hole and an oil inflow hole are drilled on a boring machine; then, a middle cylinder fixing mechanism is used for location and fixing to guarantee that the middle cylinder is attached to the datum plane; next, static balance debugging is performed for processing; the piston hole is processed firstly, a valve hole and a step surface hole are then processed, and the oil inflow hole and an oil outflow hole are processed with a special tool on a lathe tool shaft bar. The piston inner cavity of the middle cylinder is processed in cooperation with a high-strength cylinder fixing mechanism, the weight of the middle cylinder can be balanced, and the processing precision is high; by means of the processed oil holes, the performance of the middle cylinder can be further improve, and accordingly, the processing quality is greatly improved.

Owner:ANHUI ANTONG MACHINERY

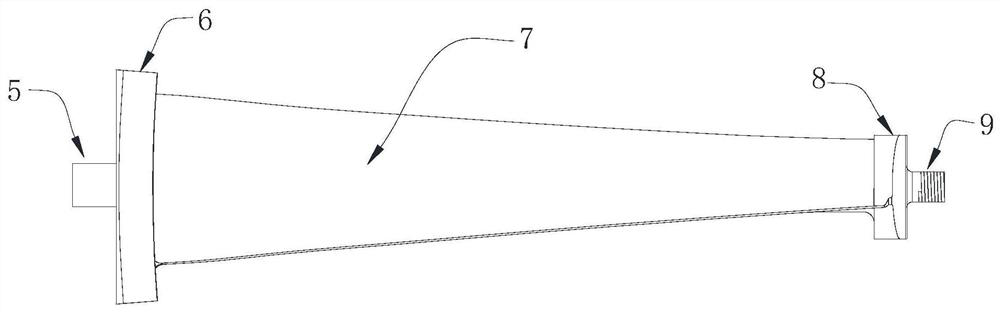

Corrugated roller with plum-shaped grooves

The invention discloses a corrugated roller with plum-shaped grooves. The corrugated roller comprises an outer roller barrel, the outer roller barrel is internally provided with an inner roller barrel, and a roller cavity is arranged between the inner roller barrel and the outer roller barrel. A cavity is formed inside the inner roller barrel, a siphon is movably installed at the position, close to one side, of the inner surface of the cavity, a coupler is fixedly installed at the position, close to the middle, of the outer surface of one side of the outer roller barrel, and a center shaft isarranged at the position, close to the middle, of the interior of the coupler. Through the arrangement of a series of structures, when the corrugated roller is used, firstly a user can replace the center shaft conveniently, the work burden is lowered, and resources are saved; secondly, the phenomenon that in the operation process, the coupler and the center shaft slide due to vibration can be prevented, and influence of the sliding phenomenon on the processing precision of corrugated boards is avoided; and in addition, the user can locally detach and replace roller teeth which are seriously worn conveniently, the trouble of replacing all the plum-shaped grooves is omitted, and the use process is optimized.

Owner:SHANGHAI DASONG CORRUGATING ROLL IND

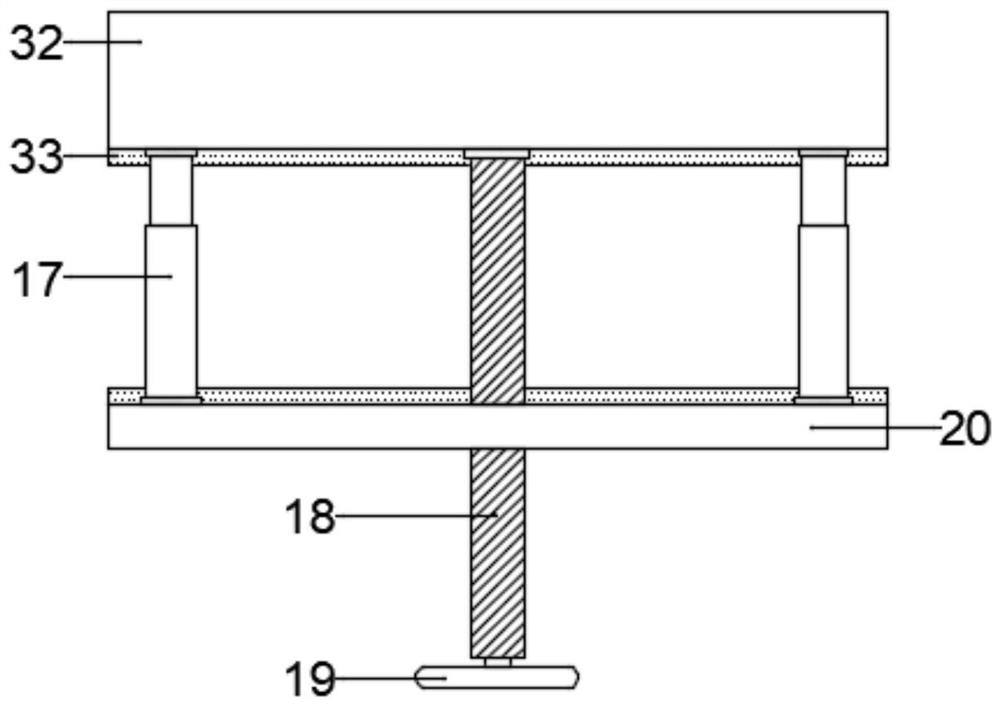

Clamping device for medical instrument machining

InactiveCN111702729AMeet the clamping needsAffect machining accuracyWork holdersWork benchesApparatus instrumentsMachining

The invention discloses a clamping device for medical instrument machining. The clamping device comprises a bearing table, a U-shaped plate, a damping unit and a clamping unit, wherein the U-shaped plate is arranged above the bearing table; a lifting assembly is arranged between the U-shaped plate and the bearing table; the clamping unit is arranged in the U-shaped plate; and the damping unit is arranged on the lower portion of the bearing table. The device is reasonable in structural layout, the clamping requirements of various parts of different sizes can be met, clamping jaws do not need tobe replaced, time and labor are saved, and excellent damping performance is achieved; and during use, the overall vibration amplitude of the device can be effectively reduced, the situation that themachining precision of the parts is influenced due to too large device shaking is avoided, operation is simple, and use is convenient.

Owner:王清弘

Wood processing machine tool

InactiveCN106938480AReduce manual pushAffect machining accuracyFeeding devicesCircular sawsWood processorEngineering

The invention belongs to the field of wood processing, in particular to a wood processing machine tool, comprising a transmission belt, a platform for installing and fixing the transmission belt, a wood limit structure, an auxiliary roller, an auxiliary roller mounting frame, and a motor; the auxiliary roller is installed on the auxiliary roller On the installation frame, it is located at the feeding end of the conveyor belt, and can be driven by the motor to rotate in line with the transmission direction of the conveyor belt; there are two wood limit structures, and the two wood limit structures are respectively installed on the auxiliary rollers The end of the installation frame; the wood limit structure includes a vertical baffle and a horizontal baffle. It can be applied to the smooth conveying and processing of various plates.

Owner:SUZHOU YASIKE PRECISION CNC CO LTD

Metal plate stamping device with good cooling effect

InactiveCN110560573ASimple structureEasy to useShaping toolsNon-rotating vibration suppressionEngineeringCooling effect

Owner:顾丽娟

Anti-splashing device of milling machine cuttings

InactiveCN107662130AGood sealingEasy to collectMaintainance and safety accessoriesEngineeringCantilever

The invention discloses a chip anti-splash device for a milling machine, which is installed on the milling machine. The milling machine is equipped with a main shaft and a workbench. The anti-splash device includes a beam installed above the main shaft, an air channel arranged in the beam, and A plurality of nozzles installed vertically under the air channel; the beam is a cantilever structure, and the nozzles are installed along the side of the beam away from the main shaft; transparent cutting baffles are arranged on both sides of the workbench, and the transparent cutting baffle The top of the plate is in contact with the beam. In the present invention, nozzles are installed at one end of the beam of the machine tool and transparent cutting baffles are installed on both sides of the workbench, relying on the pressurized air flow ejected from the nozzles and the transparent cutting baffles to form a "U"-shaped anti-cutting and splashing area to seal the working area of the machine tool , to avoid the chips splashing to the outside of the machine tool, causing hidden dangers of safety accidents, and the air wall and transparent cutting baffle will not affect the operator's sight, reducing the impact on processing after adding this device.

Owner:成都立威斯科技有限公司

Machine tool for producing shaft parts

InactiveCN114800068AFull multi-point supportAffect machining accuracyEdge grinding machinesGrinding carriagesRatchetMachine tool

The invention is applicable to the technical field of shaft part production equipment, and provides a machining tool for shaft part production, which comprises a rack, a workbench and a clamp unit, and further comprises a supporting unit mounted on the workbench, the supporting unit comprises a mounting plate, a plurality of supporting pieces, an adjusting assembly and a moving assembly, the clamp unit comprises a chuck assembly and a tip assembly, and each supporting piece comprises an inner sleeve, an outer sleeve, a mounting rod, a supporting roller, a spherical protrusion, a first spring, a first hemispherical protrusion, a ratchet ring, a pawl and a second spring. Multi-point supporting can be fully carried out on the shaft, the situation that the machining precision is affected due to deformation of the shaft is reduced, and the distance between the adjacent supporting pieces is adjusted through the adjusting assemblies to adapt to shafts of different lengths; the clamp unit is arranged, so that shafts with different lengths can be clamped and fixed; and the supporting piece can support shafts with different diameters.

Owner:葛恒伟

Machining device for cement machining cylindrical equipment

PendingCN107263104AWon't hurtNo position shiftOther manufacturing equipments/toolsCouplingEngineering

The invention relates to the field of cement production equipment machining and discloses a machining device for cement machining cylindrical equipment. The machining device comprises a box body; the end, away from a turbine box, of a second threaded rod is rotatably connected with a platform; a third motor is fixedly connected to the bottom of an inner cavity of a motor box; an output shaft of the third motor is rotatably connected with a cutter through a coupler; the side, away from a roller lead screw, of a sliding block is fixedly connected with a welding box; the side, away from the box body, of a telescopic device is fixedly connected with a first arc guiding plate; the end, away from the box body, of a hydraulic telescopic device is fixedly connected with a second arc guiding plate; and an output shaft of a four motor is rotatably connected with a curved round wheel through a coupling. According to the device, automatic raw material cutting can be achieved, the welding working procedure is automatically completed, manual work is not needed, the situation that in the cutting and welding processes, due to the splashing phenomenon, workers are injured is avoided, the situation that in the machining process, the positions of raw materials are deviated to influence the machining accuracy is avoided, the time is saved, and the efficiency is improved.

Owner:长兴捷明机械有限公司

Machining tool device used for automobile rocker arm

ActiveCN110253295AEasy to fixAffect machining accuracyOther manufacturing equipments/toolsPositioning apparatusEngineeringMachine tool

The invention provides a machining tool device used for an automobile rocker arm. The machining tool device comprises the rocker arm, a rotating hole and press plates. A rotary disc of an indexing rotary platform is fixedly connected with a support. The upper end face of the support presses the rocker arm through the two press plates. The front end face of the support is slidably connected with an auxiliary plate and is fixedly connected with the support through two fastening bolts. The rotating hole is formed in the middle of the rocker arm. The left side and the right side of the rocker arm are provided with connecting holes respectively. Machining faces of the rocker arm include the hole diameter of the rotating hole, two end faces of the rotating hole, the hole diameters of the two connecting holes and the end faces of the connecting holes. By means of one tool, all machining faces of the rocker arm are machined at one time, the former way which needs frequent loading and unloading as well as distributed machining is changed, operation is reduced, the preparation workload is relieved, the working efficiency is improved, errors caused by secondary alignment are avoided, and the product quality is improved.

Owner:湖北泰克摩擦材料有限公司

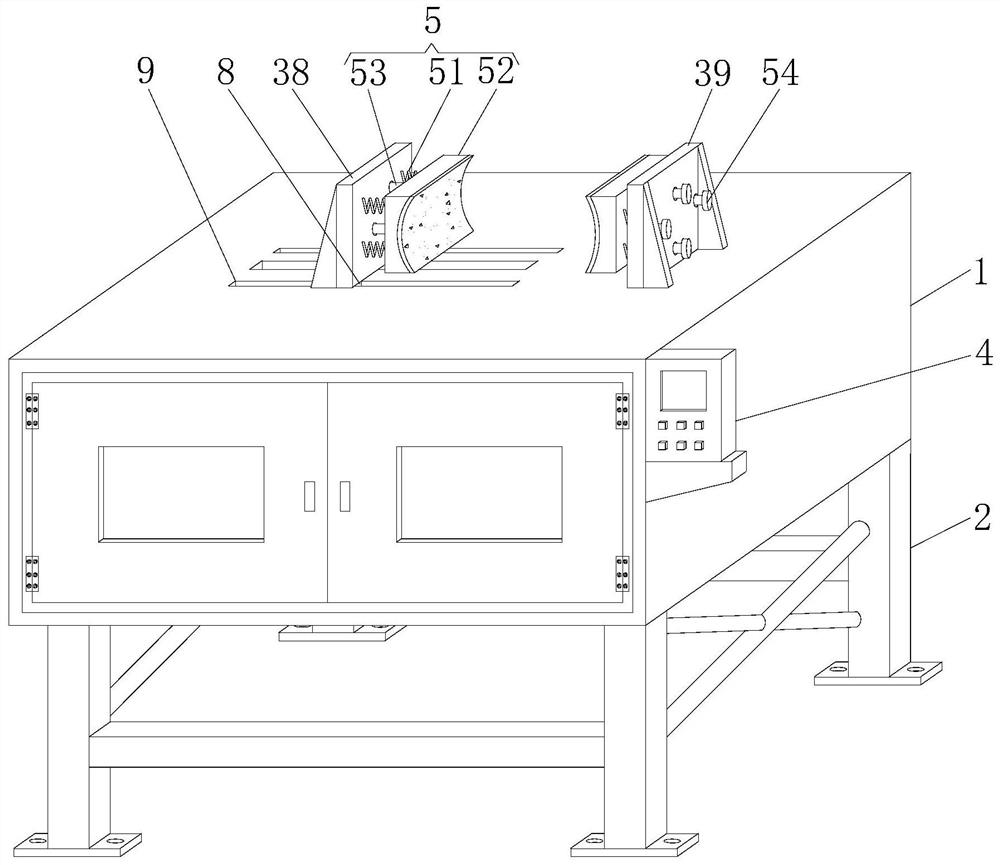

Automatic circulation cooling machine tool

ActiveCN106736842AAffect machining accuracyReduce machining accuracyMaintainance and safety accessoriesLiquid storage tankEngineering

The invention discloses an automatic circulation cooling machine tool. The automatic circulation cooling machine tool comprises a collecting device, a cooling device and a control device. The collecting device comprises a workbench and a liquid accumulation tank. The workbench is used for placing a workpiece to be machined. The liquid accumulation tank with the top opened is arranged below the workbench and used for collecting liquid discharged in the cooling process. A first liquid drain outlet and a second liquid drain outlet are formed in the bottom of the liquid accumulation tank. The cooling device comprises a first liquid storage tank, a second liquid storage tank, a first valve and a second valve. A first temperature sensor is arranged inside the first liquid storage tank, and a second temperature sensor is arranged inside the second liquid storage tank. A liquid outlet of the first liquid storage tank is connected with a first pipeline, and the first pipeline is provided with a first pump. A liquid outlet of the second liquid storage tank is connected with a second pipeline, and the second pipeline is provided with a second pump. The control device controls the first pump, the second pump, the first valve and the second valve to work according to the detection value of the first temperature sensor and the detection value of the second temperature sensor.

Owner:张武昌

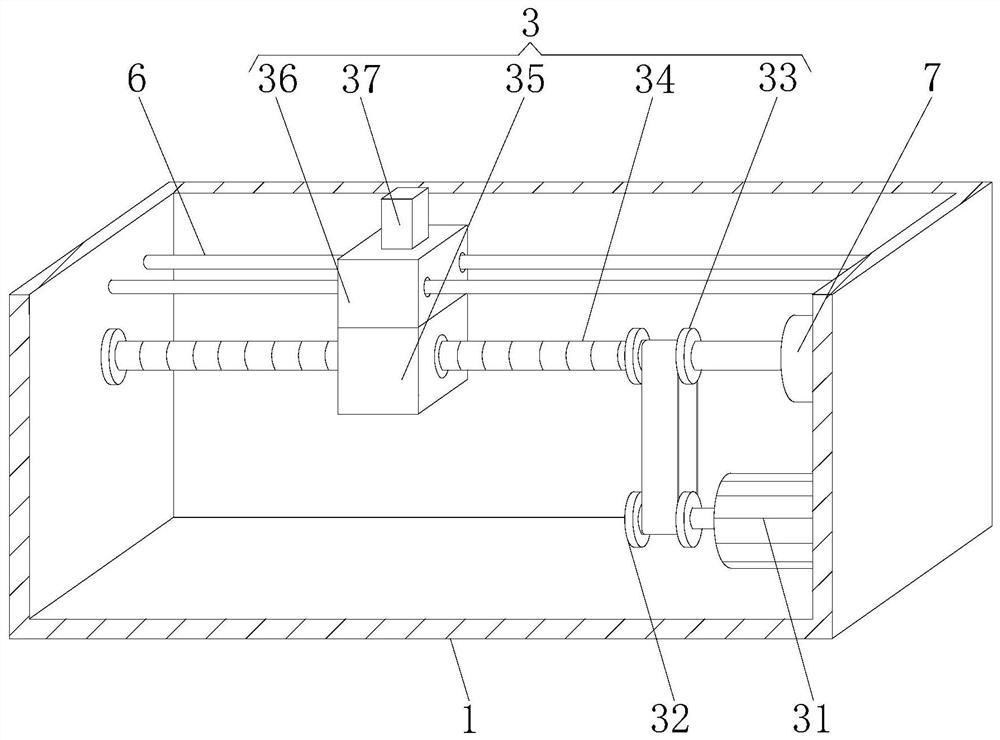

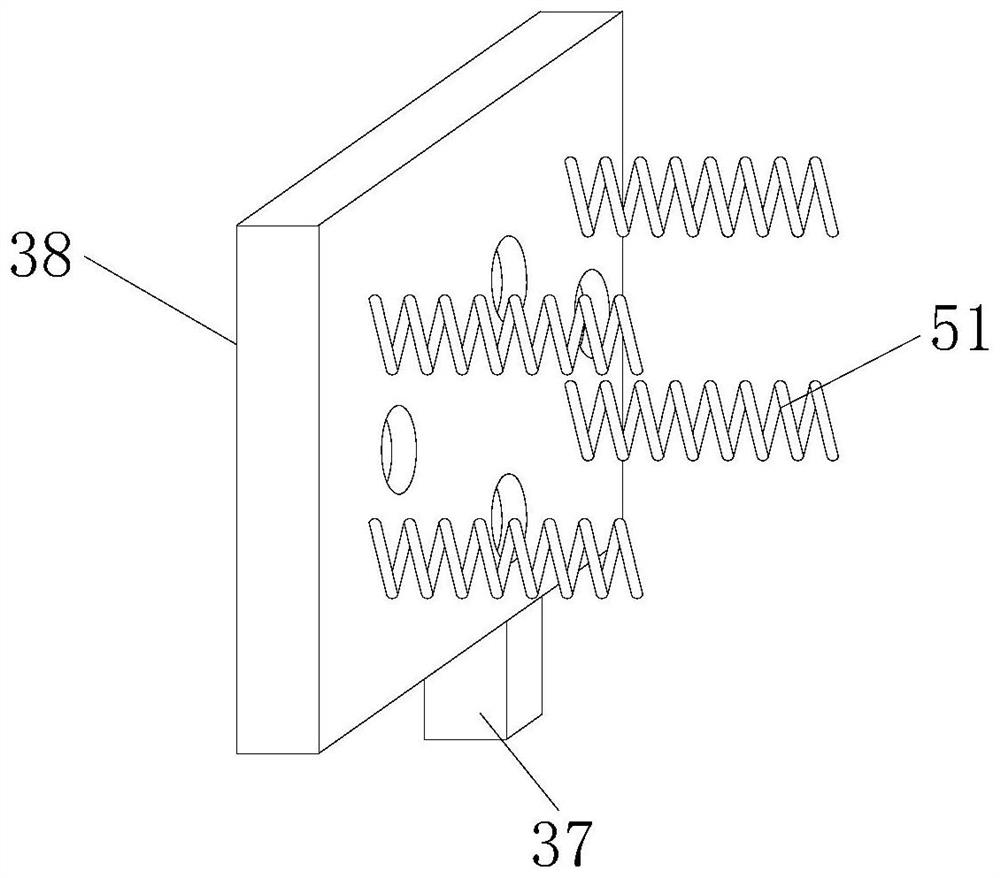

Fixing fixture for machining

The invention provides a fixing fixture for machining. The fixture comprises a fixing box, wherein support legs are connected around the bottom of the fixing box through bolts, a clamping mechanism isarranged in an inner cavity of the fixing box, a through groove is transversely formed in the left side of the top of the fixing box, the top of the clamping mechanism penetrates through the throughgroove and extends upwards, and fastening mechanisms are arranged at the tops of the opposite sides of the clamping mechanism. According to the fixture, through the cooperation of a motor, a driving wheel, a driven wheel, a screw rod, a threaded sleeve, a moving block, a moving column, a moving plate and a fixing plate, the moving plate is convenient to move by a user through using the motor, so that a clamping seat is driven to move inwardly, quick clamping limit of a workpiece is carried out, and the clamping effect of the fixing fixture is improved; and at the same time, through the cooperation of a spring, the clamping seat, a limit column and a limit block, secondary clamping limit of the workpiece is conveniently carried out by the user through elastic rebound of the spring.

Owner:NANJING ZHIJIN TECH INNOVATION SERVICE CENT

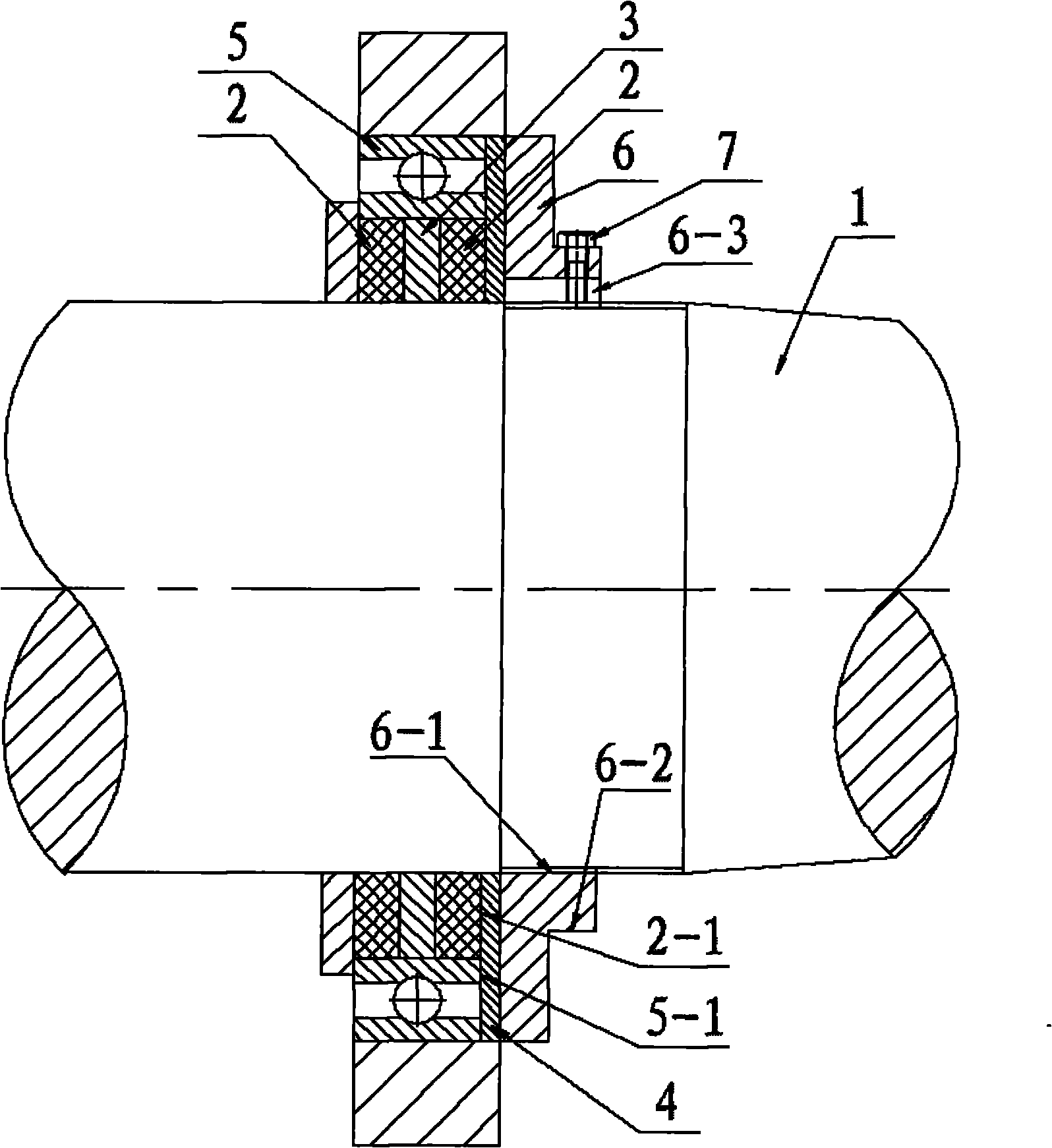

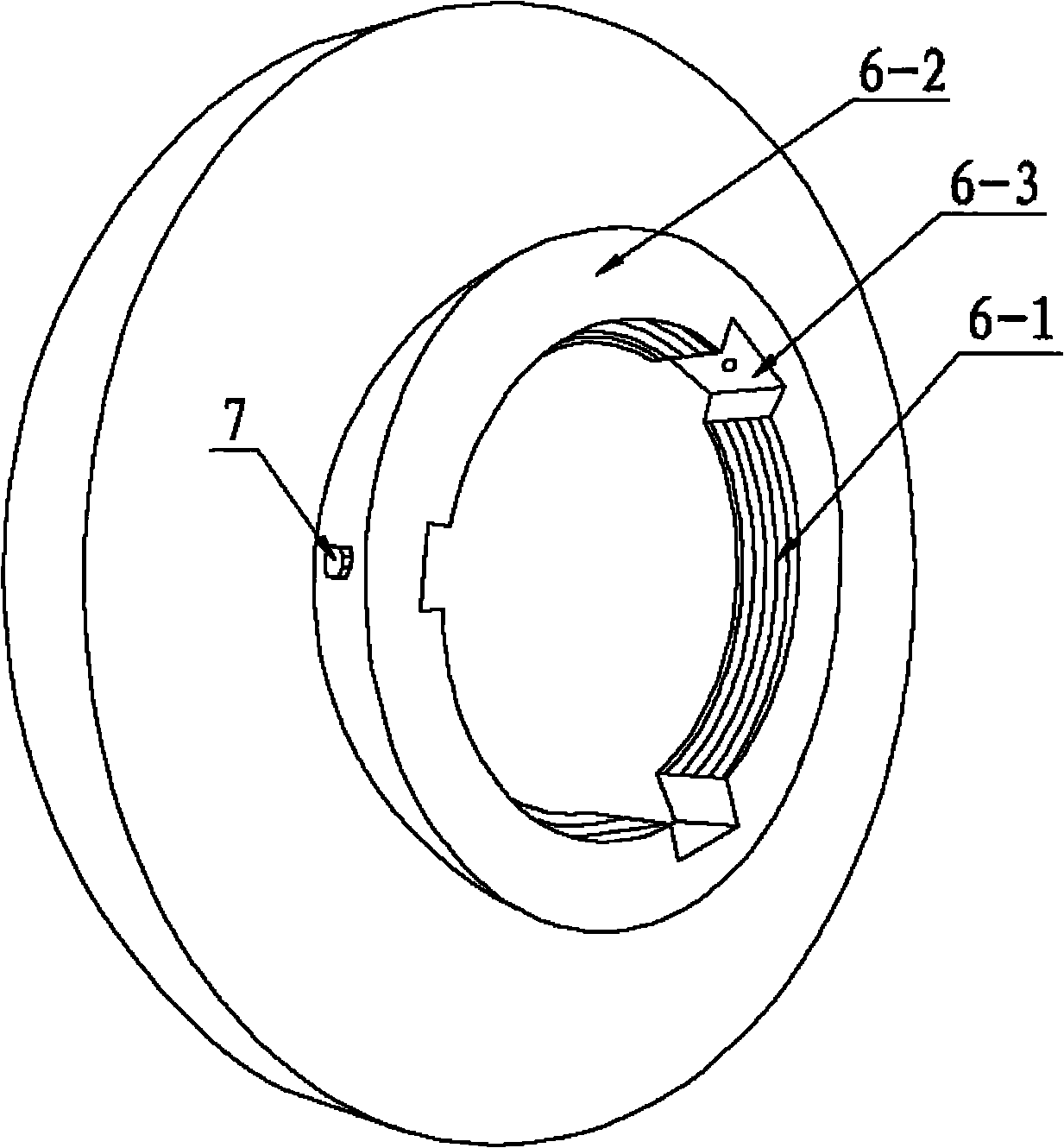

Sealing device for main shaft of numerical control machine tool

The invention relates to a sealing device for a main shaft of a numerical control machine tool. The sealing device is assembled on the main shaft of the numerical control machine tool and comprises at least one sealing ring, a gasket and a sealing ring bracket, wherein the sealing ring and the gasket are tightly contacted with each other and rigidly matched in an inner ring of an end part supporting bearing of the main shaft of the numerical control machine tool; one side end face of the sealing ring is flush with the end face of the bearing; the sealing ring bracket is contacted with the end face of the sealing ring and the end face of the bearing; and the main shaft of the numerical control machine tool passes through and is tightly matched with the sealing ring, the gasket and the sealing ring bracket. Lubricating oil in a main shaft box can be prevented from leaking along the main shaft and external impurities, such as dust, coolant, metal filings and the like are prevented from entering the main shaft box and affecting the processing accuracy of the main shaft, so that the workpiece processing accuracy is improved and the service life of the main shaft is prolonged.

Owner:常州市科邦精密数控机械有限公司

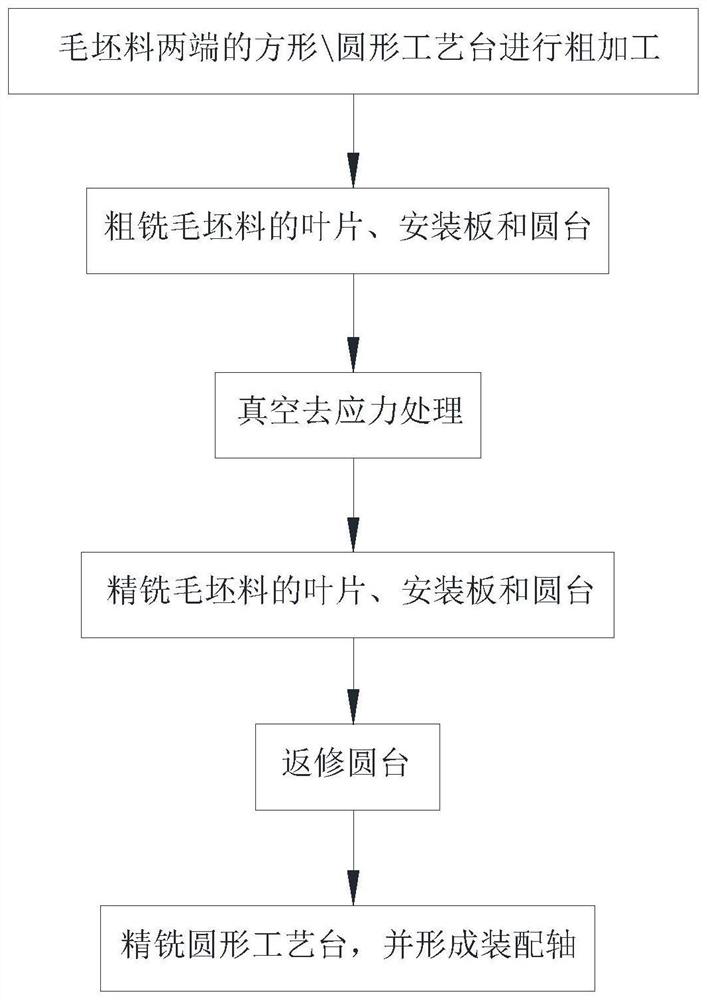

Machining process of aero-engine blade

PendingCN113618127AGuaranteed machining accuracyEasy clamping and positioningMilling equipment detailsPositioning apparatusMachining processStructural engineering

The invention discloses a machining process of an aero-engine blade, and particularly relates to the technical field of aero-engine blade precision machining. The machining process of the aero-engine blade comprises a blank material, and the blank material comprises a square process table, a mounting plate, the blade, a circular table and a circular process table which are sequentially arranged; the machining process comprises the following steps that S1, the blade is clamped, and rough machining is conducted on the square / circular process table; S2, the square / circular process table is clamped, and the mounting plate, the blade and the circular table are roughly milled; S3, the blank material is subjected to destressing treatment; S4, re-clamping is carried out, and finish machining is carried out on the mounting plate, the blade and the circular table; S5, the mounting plate and the blade are clamped, and the circular table is repaired; and S6, the circular table and the mounting plate are clamped, the circular process table is machined to form an assembly shaft, the square process table is milled off, and machining is completed. The machining process can effectively solve the problems that when the aero-engine blade is machined, large deformation occurs, and the machining quality and precision of the blade are reduced.

Owner:AECC AERO SCI & TECH CO LTD

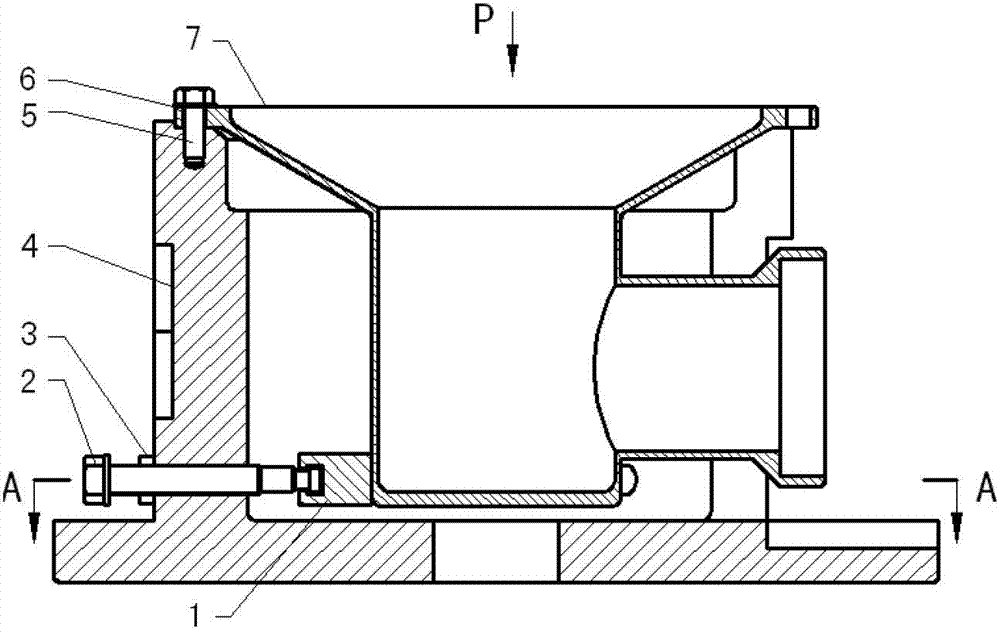

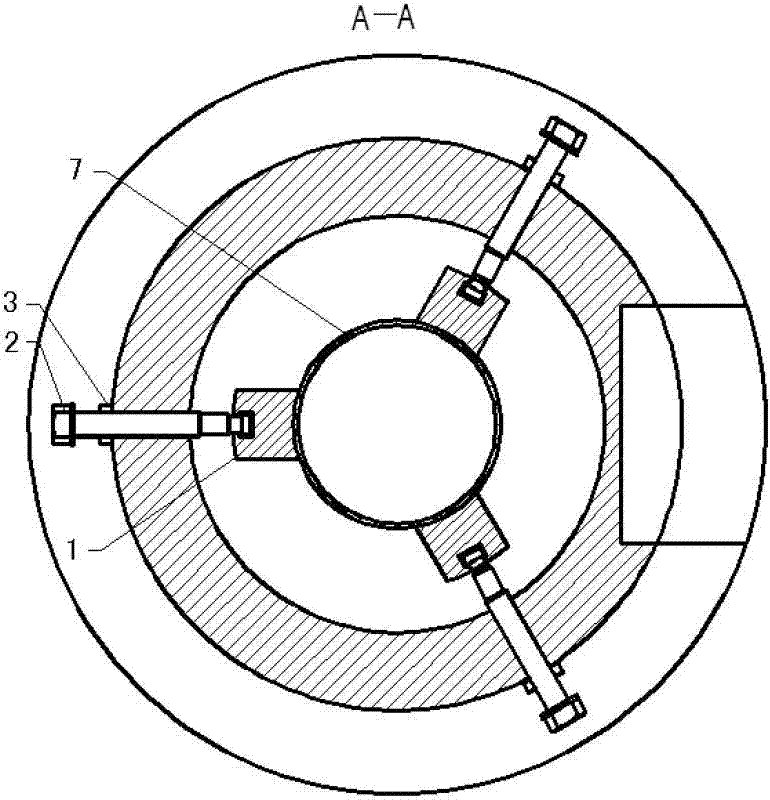

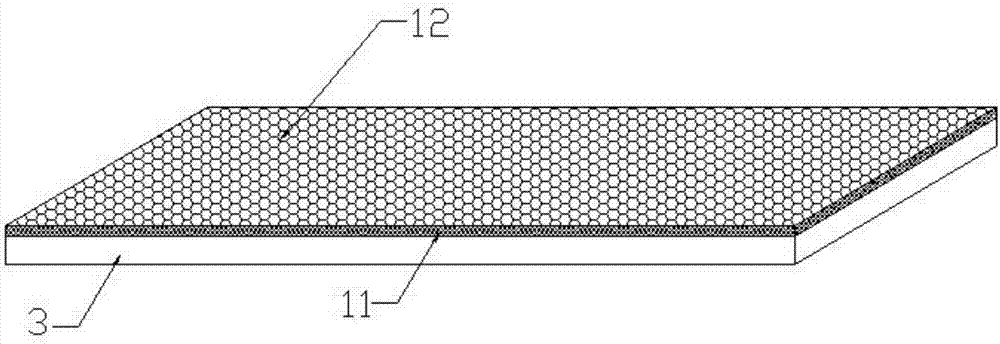

Clamping device used for internal gear machining

InactiveCN109590901AAvoid errorsAffect machining accuracyPositioning apparatusGrinding work supportsGear wheelEngineering

The invention discloses a clamping device used for internal gear machining and belongs to the technical field of gear machining auxiliary tools. A base is a cylinder. Three clamping mechanisms are uniformly arranged in the circumferential direction of the base. Each clamping mechanism is in sliding connection with the base. The three clamping mechanisms are used for fixing a to-be-machined internal gear. A through groove is formed in the end surface of the base. The inner side wall of the through groove is in sliding connection with a dust collecting device. The base is fixedly connected witha bottom seat through a plurality of supporting columns.

Owner:HARBIN UNIV OF SCI & TECH

Cooling and chip-absorbing device for numerical control tool

InactiveCN107127634AAffect machining accuracyReduce the temperatureMaintainance and safety accessoriesNumerical controlHigh heat

The invention discloses a cooling and chip suction device for numerically controlled cutting tools, which comprises a cutter bar, one end of the cutter bar is connected to a knife seat, a cutting knife is installed on the knife seat, and first connecting rods are symmetrically connected to both sides of the knife bar , the first connecting rod is connected to the mounting plate, a powerful magnet is installed on the mounting plate, a second connecting rod is symmetrically connected to the other two sides of the cutter bar, the second connecting rod is connected to the cooling plate, and several blowing holes are arranged on the cooling plate, A cooling device is installed in the cooling plate. The cooling device is composed of a casing, a condensing pipe and a fan. There are several condensing pipes installed in the casing. The condensing pipe is filled with condensate. There is a dust-proof net, and the first connecting rod and the second connecting rod are both movably connected with the tool bar. The structure of the invention is simple, the cooling device reduces the temperature of the workpiece, and the powerful magnet absorbs the splashed iron filings, avoiding the high temperature and iron filings from affecting the machining accuracy of the workpiece. Improved work efficiency.

Owner:卢云丽

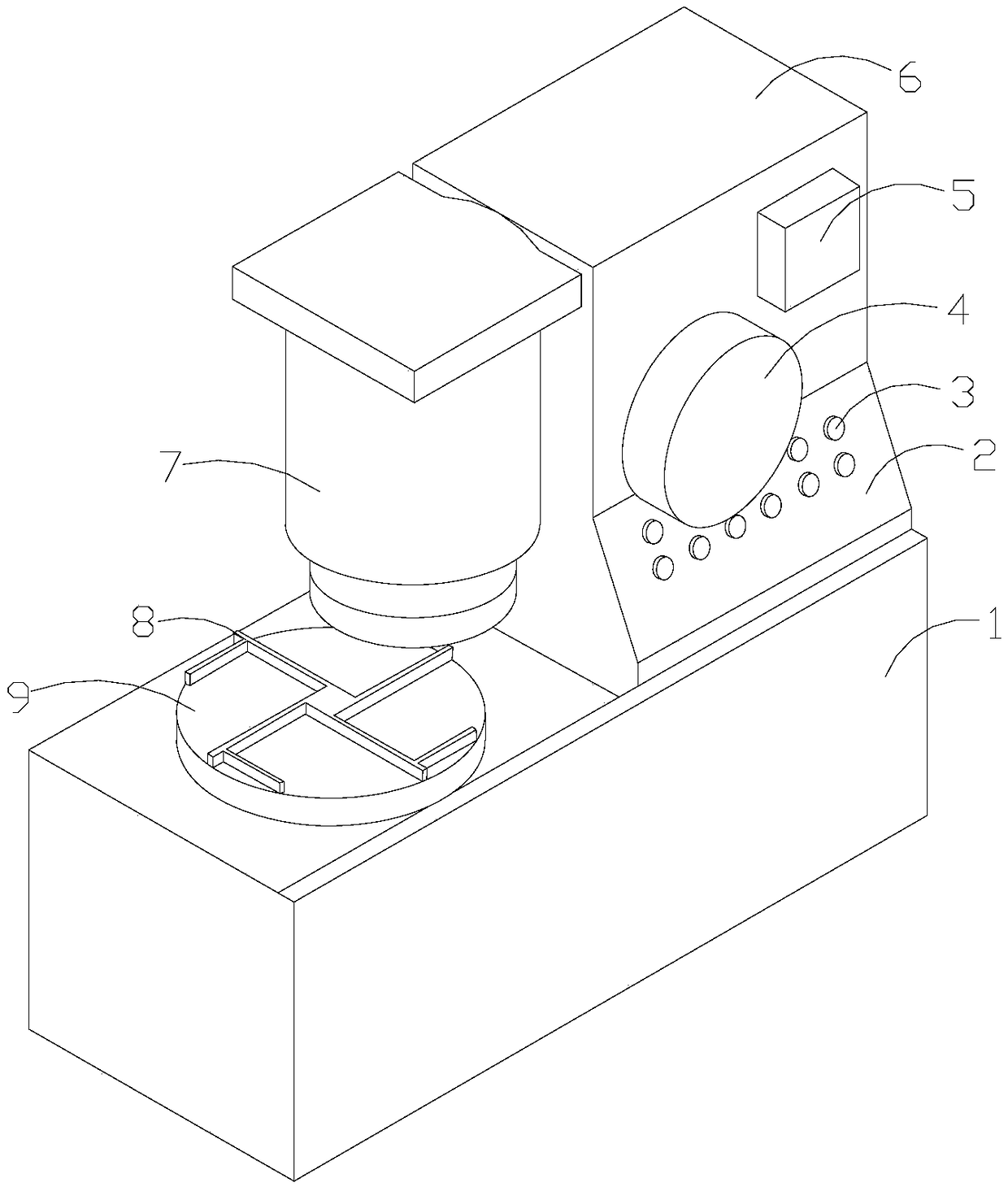

Diamond machining platform with all-around fine polishing function

InactiveCN108857897AAffect machining accuracyWith rotation functionWorking accessoriesGrinding machinesMaterial resourcesSlide plate

The invention discloses a diamond machining platform with an all-around fine polishing function. The diamond machining platform structurally comprises a fine polishing machining mechanism, a control panel, a control switch, an operating rotating disc, a speed regulator, an electric control box, a machining suction cup, a stopping block and a machining platform. According to the diamond machining platform, through arrangement of a rotating adjustment mechanism and a dust adsorption mechanism, the diamond machining platform can have the rotating function, the problem that position adjusting canbe conducted through manual rotating and then fixing is avoided, the situation that the machining precision of diamond is affected by crushing and crushed diamond is avoided, and meanwhile, dust and the crushed diamond are effectively prevented from polluting the working environment; the diamond moves to the lower portion of a cutter through a sliding plate, manpower and material resources are greatly saved, and the working efficiency is improved; and after the diamond is fixed through a compressing block, the control panel on the electric control box drives a second motor to start, rising andfalling of a hydraulic telescopic rod are controlled, thus the cutter rotating at the high speed slowly gets close to the diamond, and at the moment, the cutter cuts the diamond.

Owner:FOSHAN KERUIFEI NEW ENERGY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com