Anti-splashing device of milling machine cuttings

A technology of anti-splash and milling machine, which is applied in the direction of metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve problems such as hidden safety hazards, and achieve the effect of easy collection and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

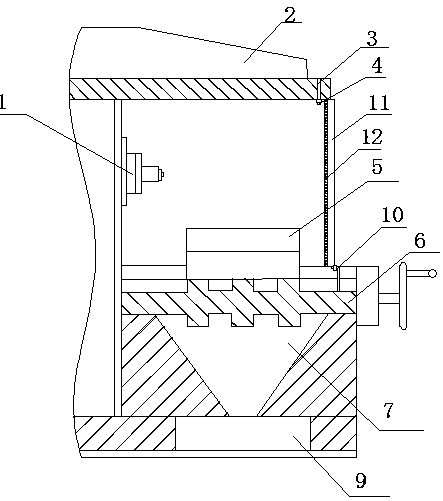

[0023] Such as figure 1 As shown, a chip anti-splash device of a milling machine is installed on a milling machine. The milling machine is equipped with a spindle 1, and a worktable 5 is arranged under the spindle 1, and is characterized in that: the anti-splash device includes the device installed on the spindle 1. The upper beam 2, the gas passage 3 arranged in the beam 2, and a plurality of nozzles 4 vertically installed below the gas passage 3; the beam 2 is a cantilever structure, and the nozzle 4 is away from the main shaft 1 along the beam 2 The air path 3 includes an air inlet connected with a pneumatic pump and a plurality of air outlets arranged along the side of the beam 2 away from the main shaft 1; both sides of the workbench 5 are provided with transparent cutting baffles 11, The upper end of the transparent cutting baffle 11 is in contact with the beam 2. The transparent cutting baffle 11 and the air wall sprayed from the air outlet form a horizontally placed "U"...

Embodiment 2

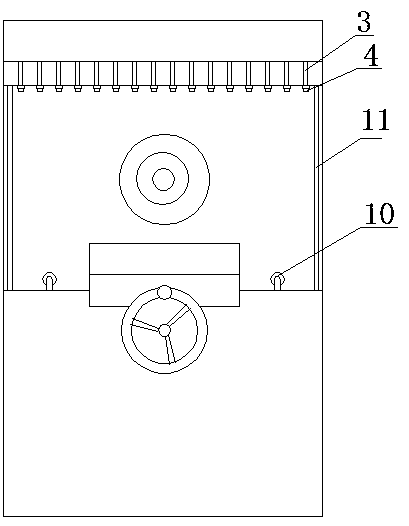

[0028] This embodiment is improved on the basis of embodiment 1, and its improvement lies in: figure 2 As shown, the nozzle 4 and the air outlet are connected by a hose that can change the angle between the nozzle 4 and the air outlet. The angle between the nozzle 4 and the beam 2 can be rotated according to the processing conditions to control the angle formed by the air wall to make the sealing effect better. Good, to meet the needs of different workpieces; the nozzle 4 can also be slightly offset to the direction of the spindle 1, so that the air wall and the worktable 5 form an obtuse angle, so that the cutting is easier to collect and enter the chip box 9. A second group of nozzles 10 connected with the air inlet of the air pump and arranged horizontally is fixedly installed on the rib 6 at one end far away from the main shaft 1; the air jet direction of the second group of nozzles 10 is the direction of the main shaft 1. The gas blown by the second set of nozzles 10 can ...

Embodiment 3

[0030] This embodiment is improved on the basis of embodiment 1, and its improvement lies in: figure 1 As shown, the beam 2 is provided with a second transparent cutting baffle 12 extending vertically downward along the outer edge of the nozzle 4; the second transparent cutting baffle 12 and the outer edge of the beam 2 can be rotatably connected by a rotating shaft, The lower end of the second transparent cutting baffle 12 is in contact with the rib 6. In milling machine processing, the use of air wall anti-splash can not completely block cutting splash, or a larger air pressure and air injection volume are required to achieve a better anti-cutting splash effect, and the air wall air pressure and air injection volume are large, but it is easy to cause gas impact cutting Cause cutting splashes and cause safety hazards. Therefore, the machine tool and the transparent cutting baffle 11 and the second transparent cutting baffle 12 are used to form a sealed anti-cutting splash area...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com