Patents

Literature

3681results about How to "Good sealing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

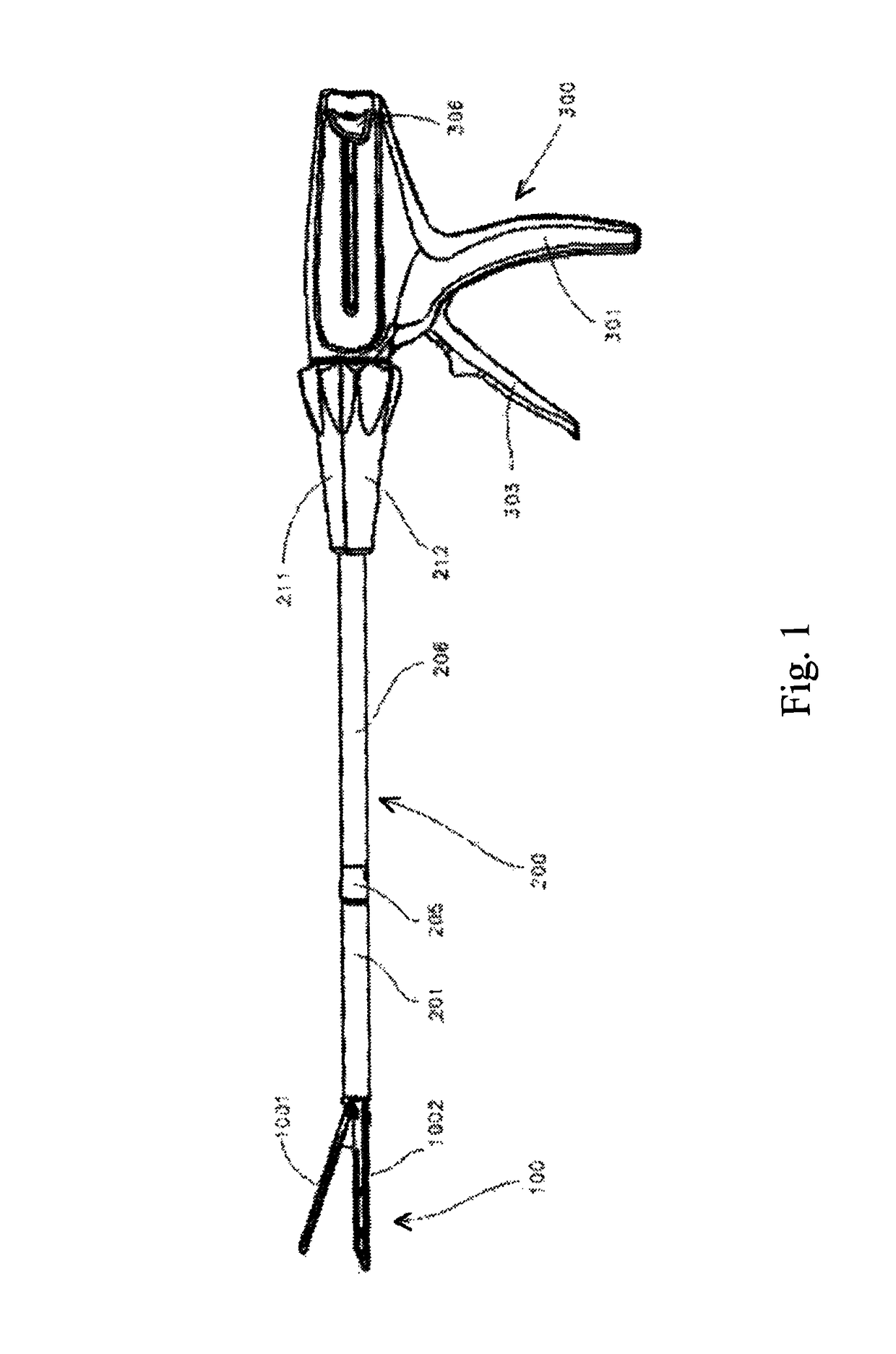

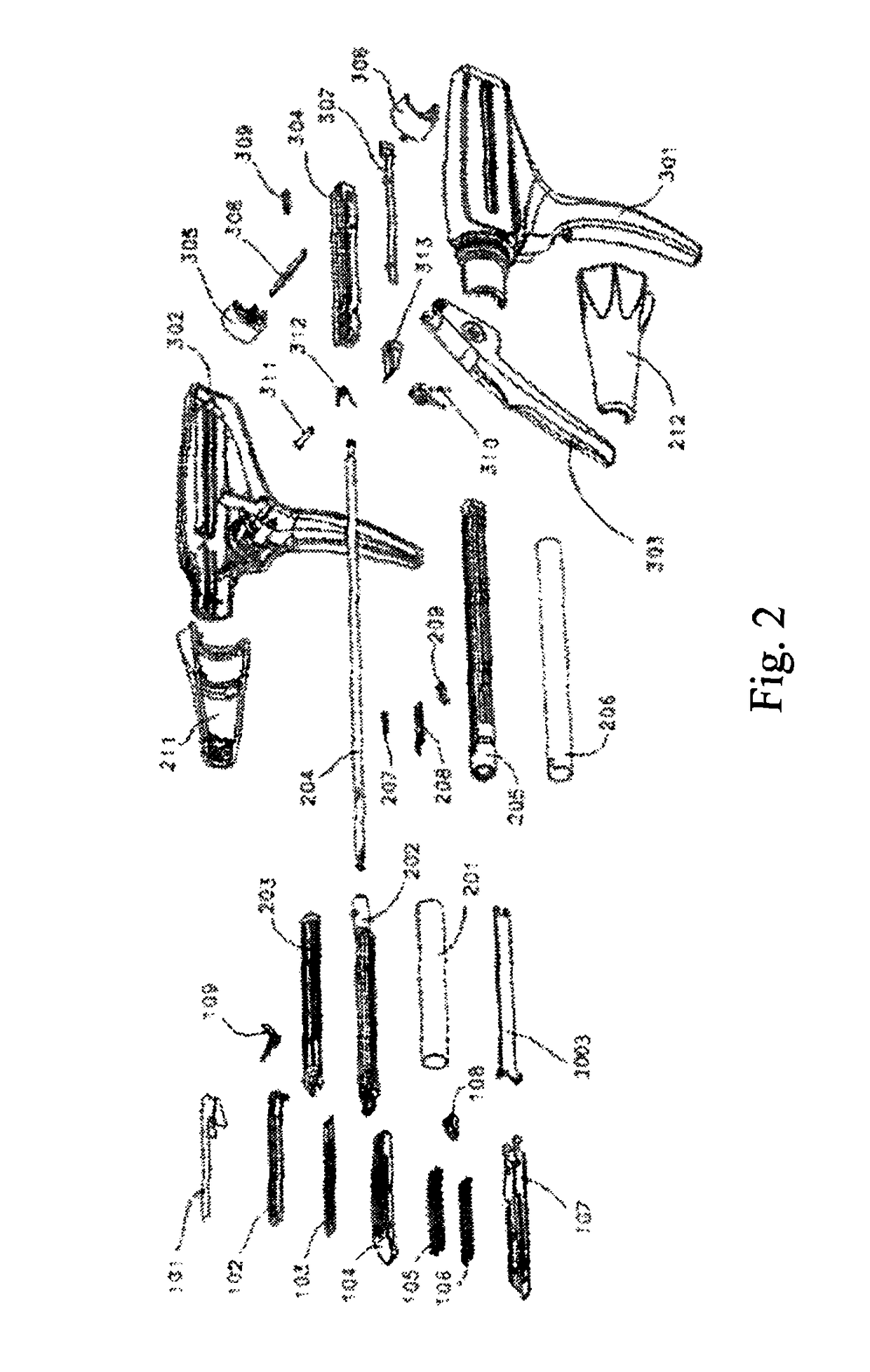

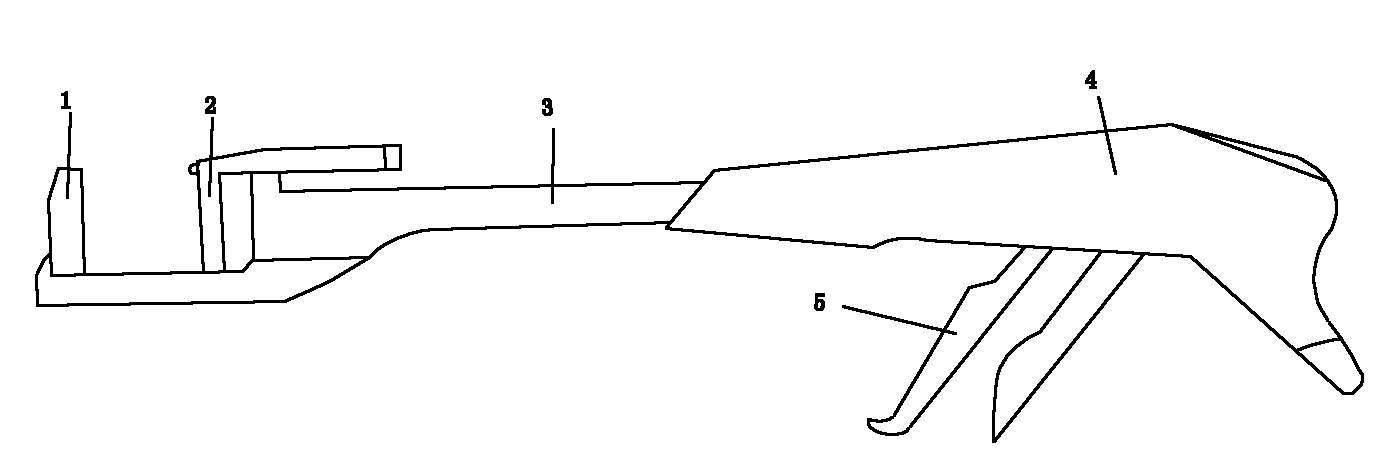

Surgical apparatus actuator

ActiveUS9924945B2Increase the difficultyImprove accuracySurgical staplesEngineeringMechanical engineering

Owner:EZISURG MEDICAL CO LTD

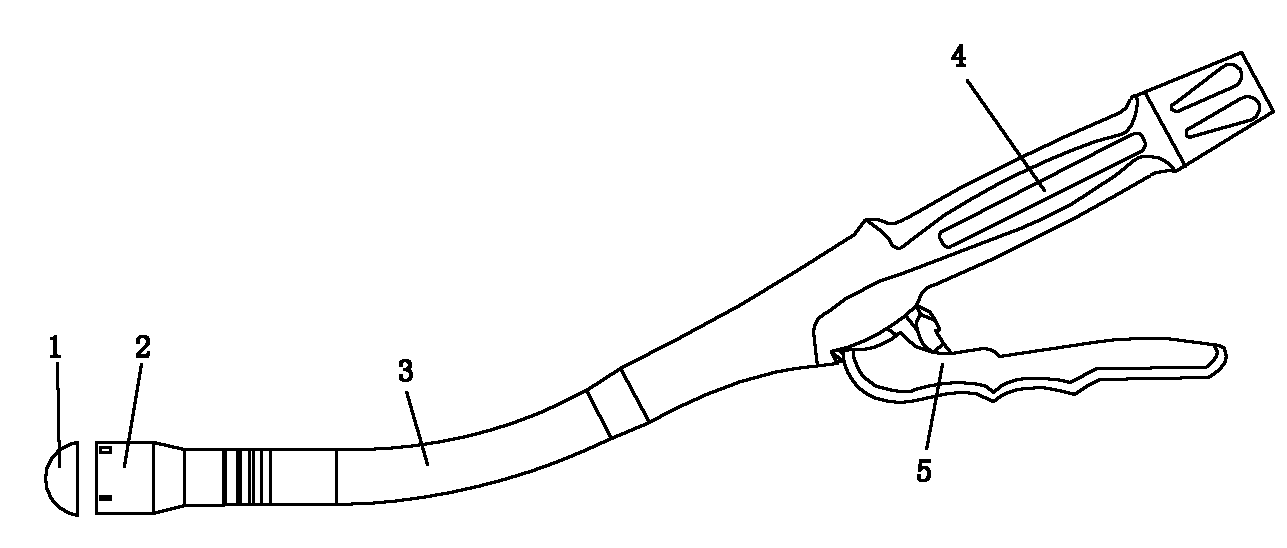

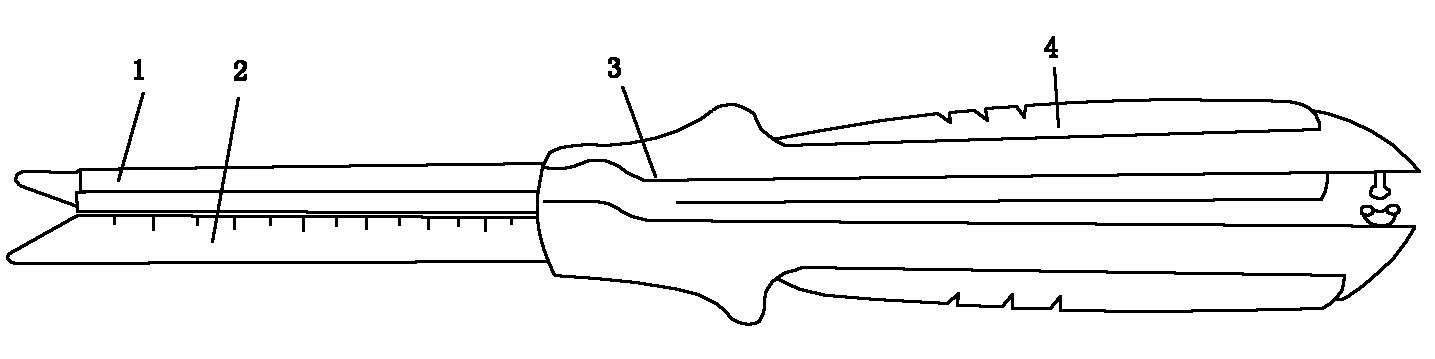

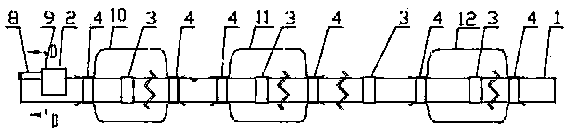

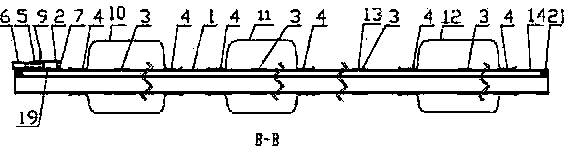

Sandwiched stapler type alimentary tract anastomosis dissecting sealer

The invention discloses a sandwiched stapler type alimentary tract anastomosis dissecting sealer, relating to the surgical instruments. The invention provides a sandwiched stapler type alimentary tract anastomosis dissecting sealer which can prevent the alimentary tract anastomotic stoma from tearing, leaking and errhysis from the cut section in surgical operations. The sandwiched stapler type alimentary tract anastomosis dissecting sealer is provided with a nail anvil (which is also called as a bottom needle holder), a nail cartridge (which is also called as a nail anvil box), a sealer body, a movable handle, an adjusting button, a cutter cushion and an anastomosing nail (which is also called as a suturing nail), wherein the nail anvil is connected with the front end of the sealer body, the adjusting button is arranged at the tail part of the sealer body, the movable handle is arranged at the back of the sealer body, a safety button is arranged at the connection of the movable handle and the sealer body, the cutter cushion is arranged on the nail anvil, the anastomosing nail is arranged at the front end part of the sealer body, a membrane is arranged on the surface of the nail anvil (which is also called as the bottom needle holder), and a membrane is also arranged on the surface of the nail cartridge (which is also called as the nail anvil box); and after stapling, a sandwich structure consisting of the membrane, an intestinal wall and the membrane is formed.

Owner:刘忠臣

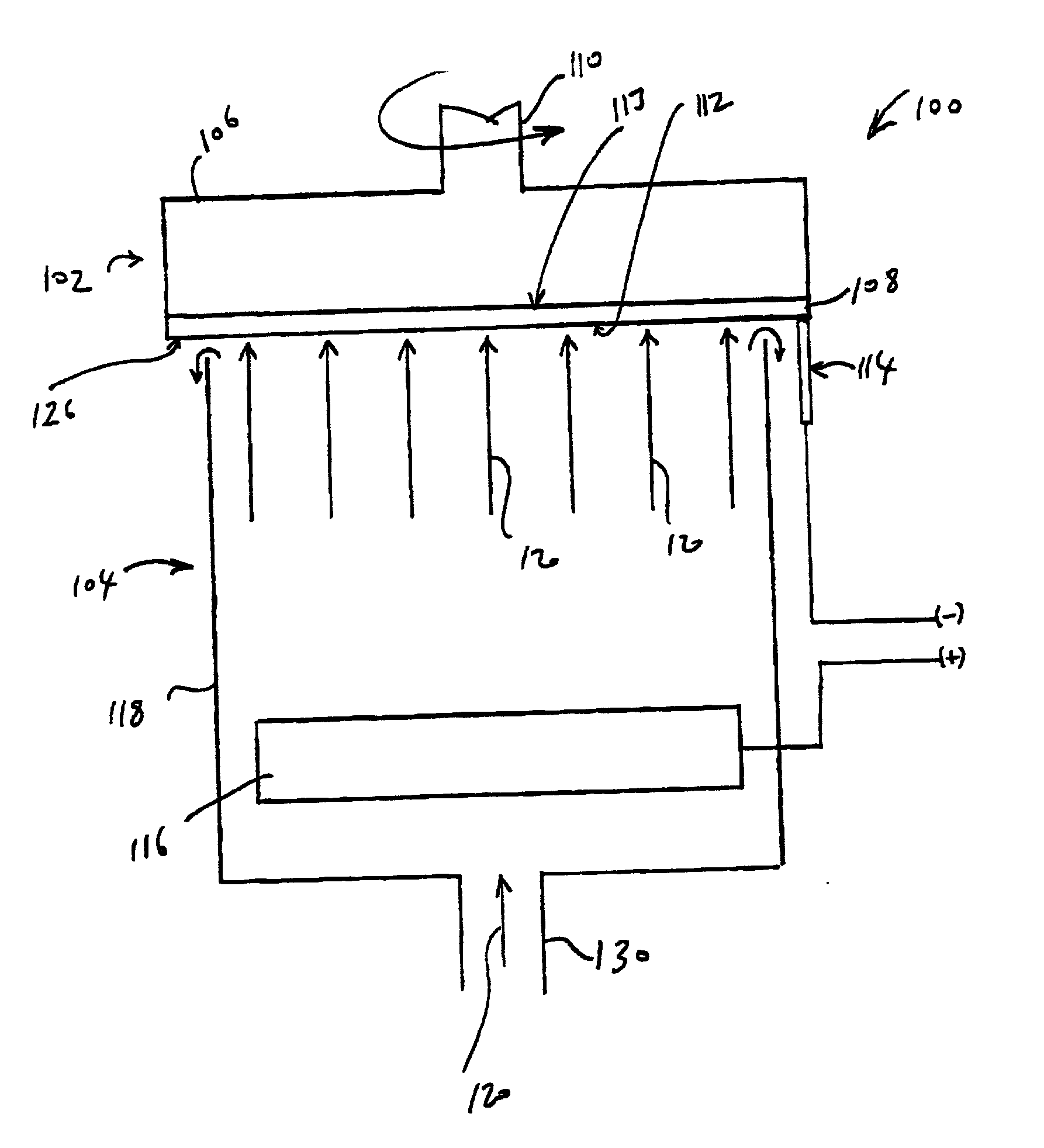

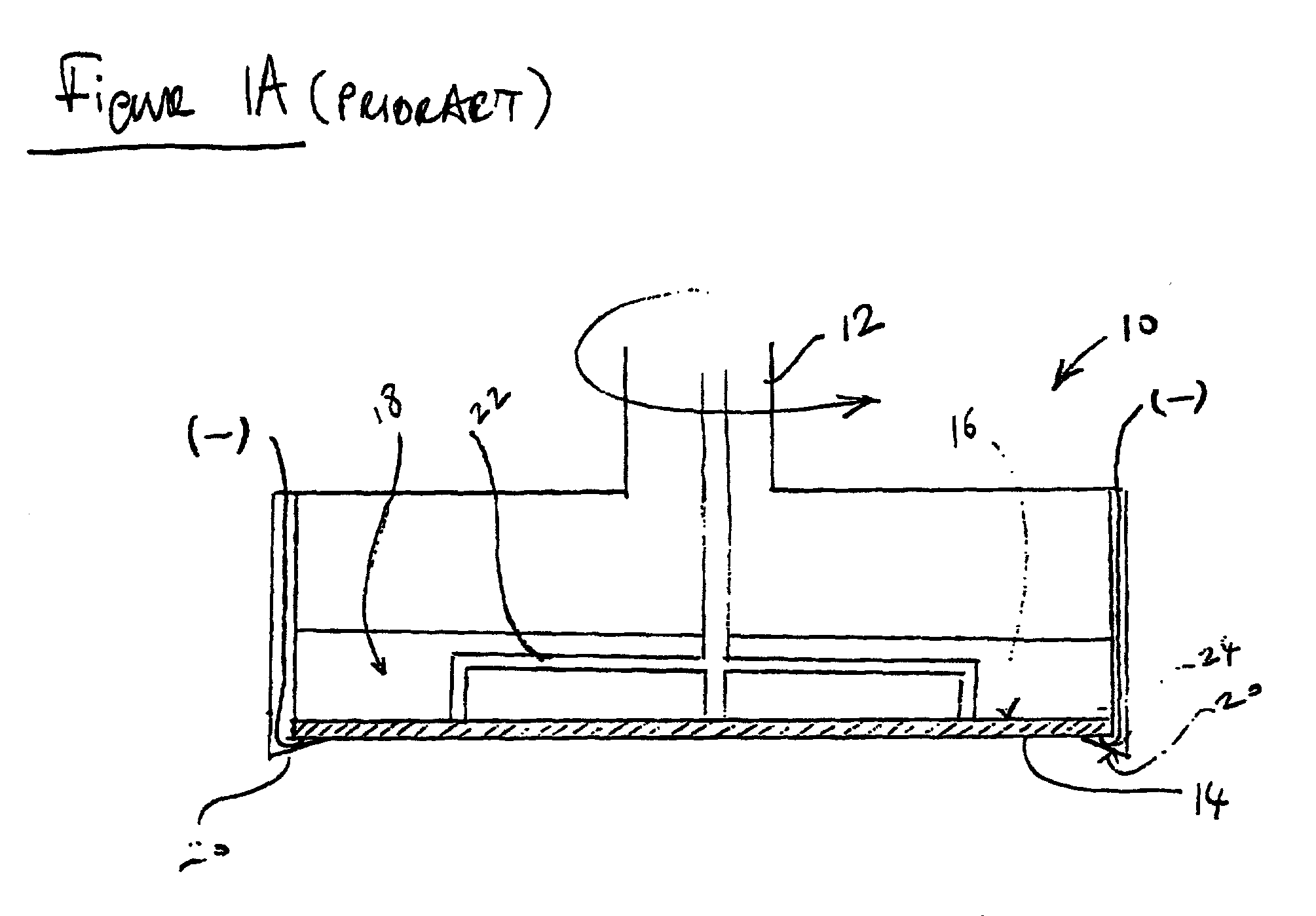

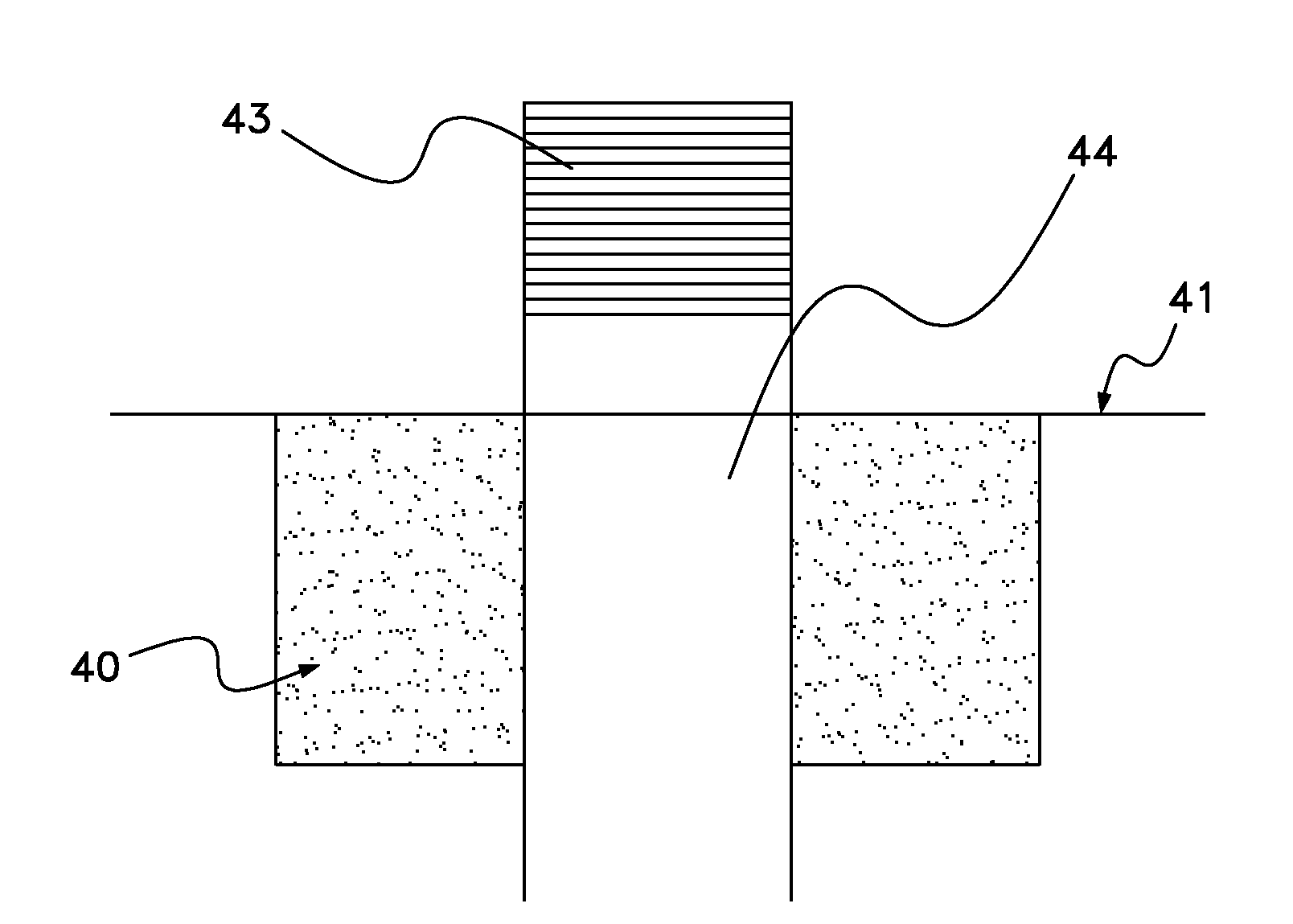

Method of sealing wafer backside for full-face electrochemical plating

InactiveUS20020127956A1Prevented from reachingGood sealingEdge grinding machinesElectrolysis componentsElectroplatingElectrical and Electronics engineering

The present invention provides a wafer carrier that includes an opening, which in one embodiment is a plurality of holes, disposed along the periphery of the wafer carrier. A gas emitted through the holes onto a peripheral back edge of the wafer assists in preventing the processing liquids and contaminants resulting therefrom from reaching the inner region of the base and the backside inner region of the wafer. In another embodiment, a plurality of concentric sealing members are used to prove a better seal, and the outer seal is preferably independently movable to allow cleaning of a peripheral backside of the wafer to occur while the wafer is still attached to the wafer carrier.

Owner:NOVELLUS SYSTEMS

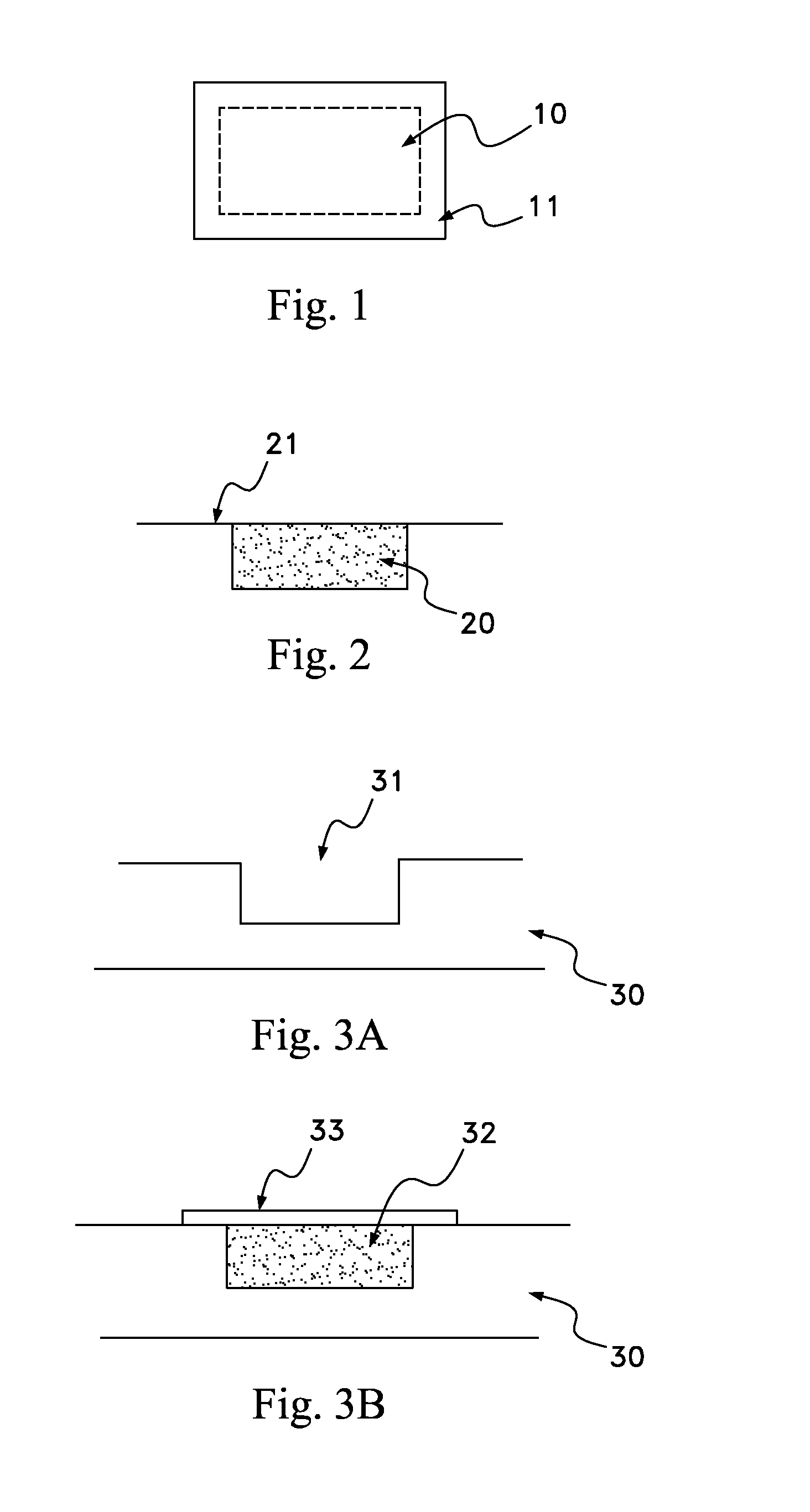

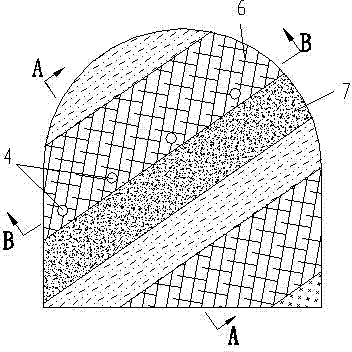

Biodegradable osteogenic porous biomedical implant with impermeable membrane

InactiveUS20080147197A1Good sealingEliminate subsequent surgeryDental implantsSurgical adhesivesBone morphogenetic proteinCeramic particle

A biomedical implant is disclosed with osteogenic factors and a solid impermeable membrane occluding a portion of its surface for the generation of new bone growth at the target site of the implant. The implant is porous, bioresorbable, and forms a three dimensional architectural scaffold for the formation of new bone tissue. The implant is formed with a polymer or collagen, bone morphogenetic protein and ceramic particles.

Owner:WARSAW ORTHOPEDIC INC

Channeling preventing and plugging agent and construction method for controlling plugging and sealing channeling by utilizing channeling preventing and plugging agent

ActiveCN105086967AExtend the production cycleEnhanced overall recoveryDrilling compositionSealing/packingEngineeringTemperature resistance

The invention provides a channeling preventing and plugging agent and a construction method for controlling plugging and sealing channeling by utilizing the channeling preventing and plugging agent. The channeling preventing and plugging agent comprises a high-temperature-resistance pre-plugging agent serving as a pre-posed pre-plugging plug, an enhanced gel plugging agent serving as an intermediate enhanced plug and a high-strength resin plugging agent serving as a postposed sealing plug. The channeling preventing and plugging agent has the characteristics of high temperature resistance, long-term stability, good plugging performance and the like. The invention further provides a construction method for controlling plugging and sealing channeling by utilizing the channeling preventing and plugging agent. The method has a simple constructing process, and can be used for constructing after the channeling preventing and plugging agent is directly prepared on the spot. The channeling preventing and plugging agent can be used for effectively solving the adverse impact of the steam / air channeling phenomenon of a heavy oil thermal production well on production, and has an important effect on prolonging the production cycle of a heavy oil well and improving the recovery efficiency.

Owner:PETROCHINA CO LTD

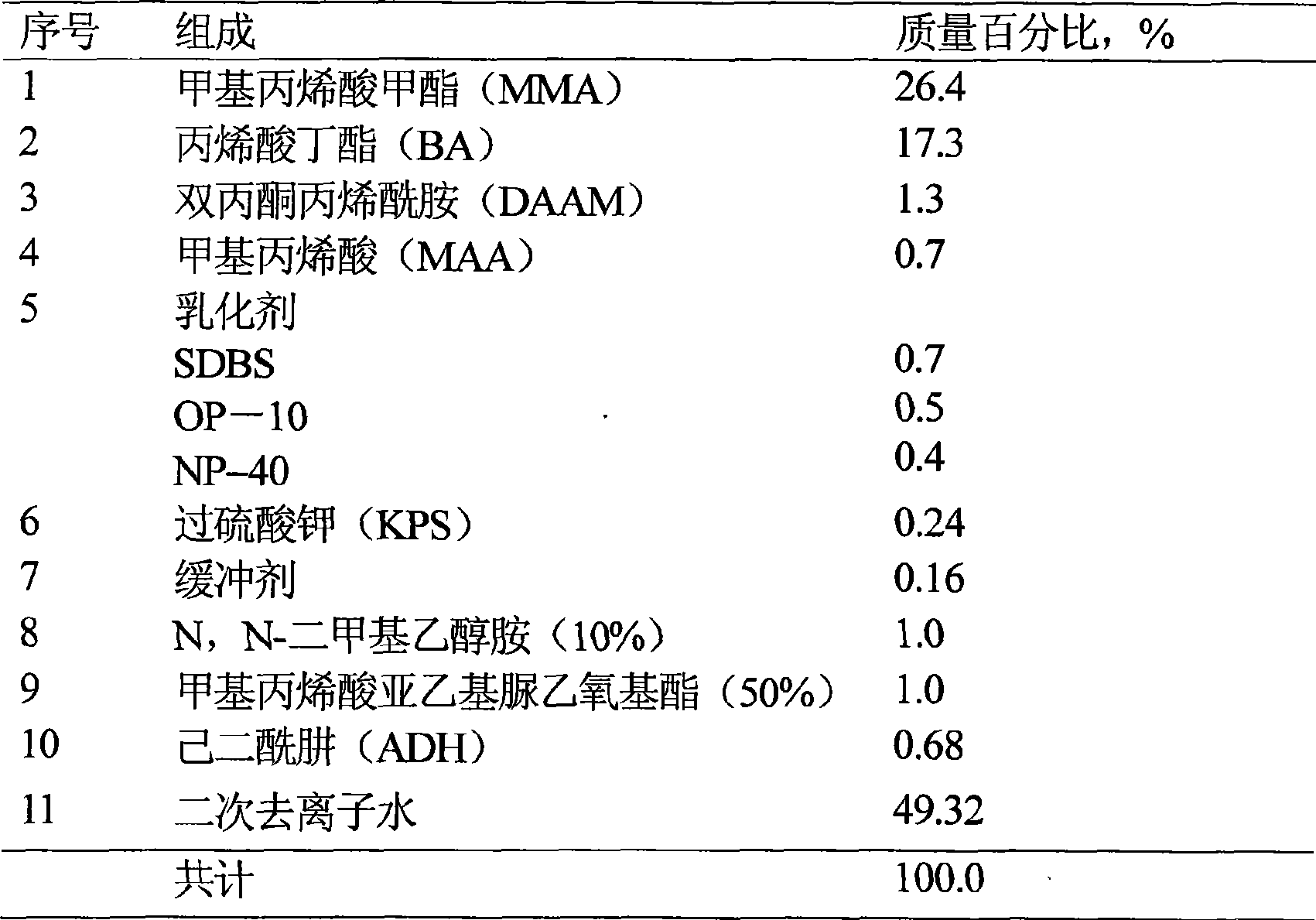

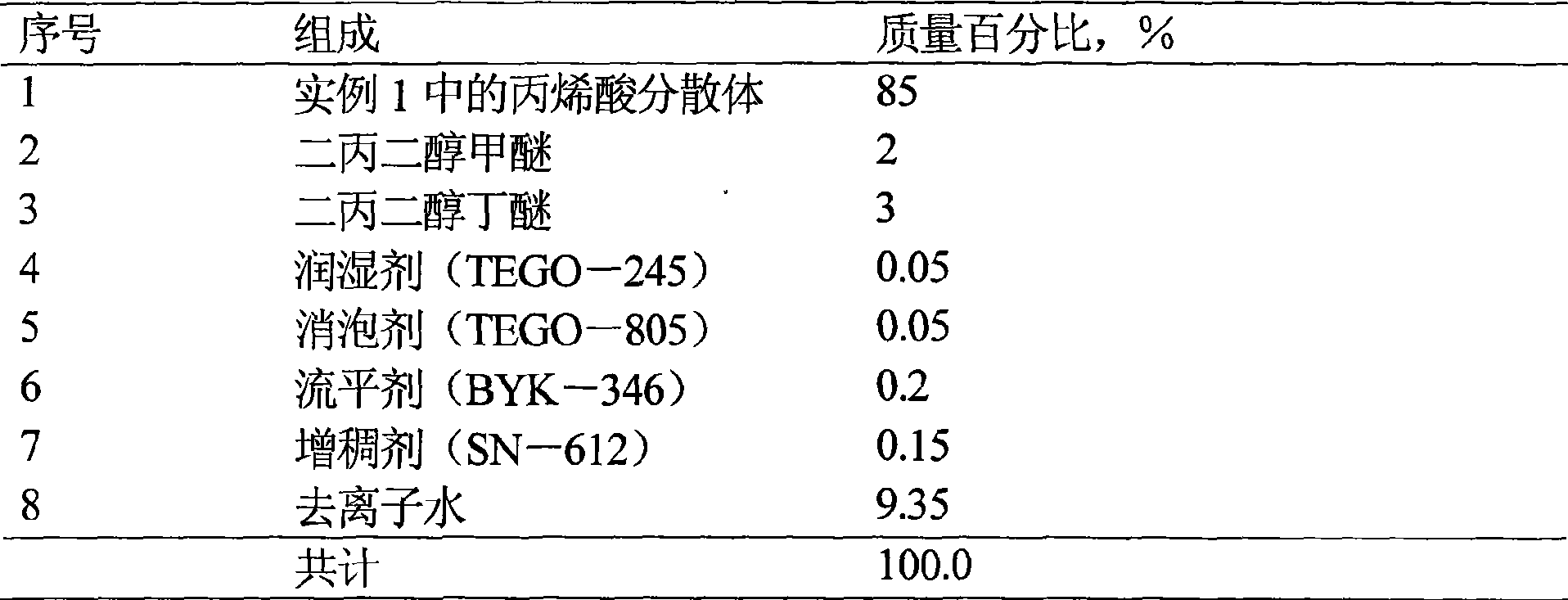

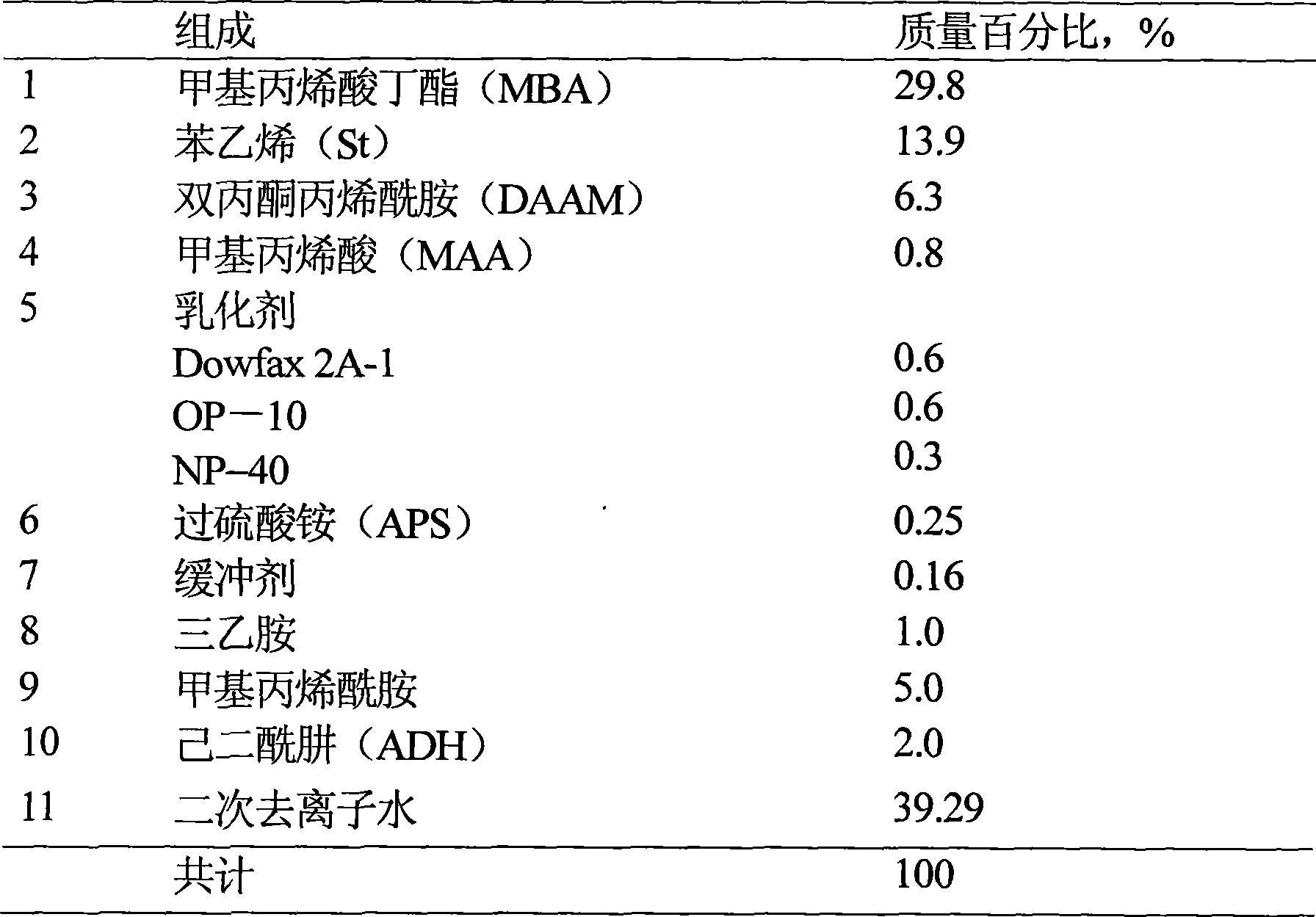

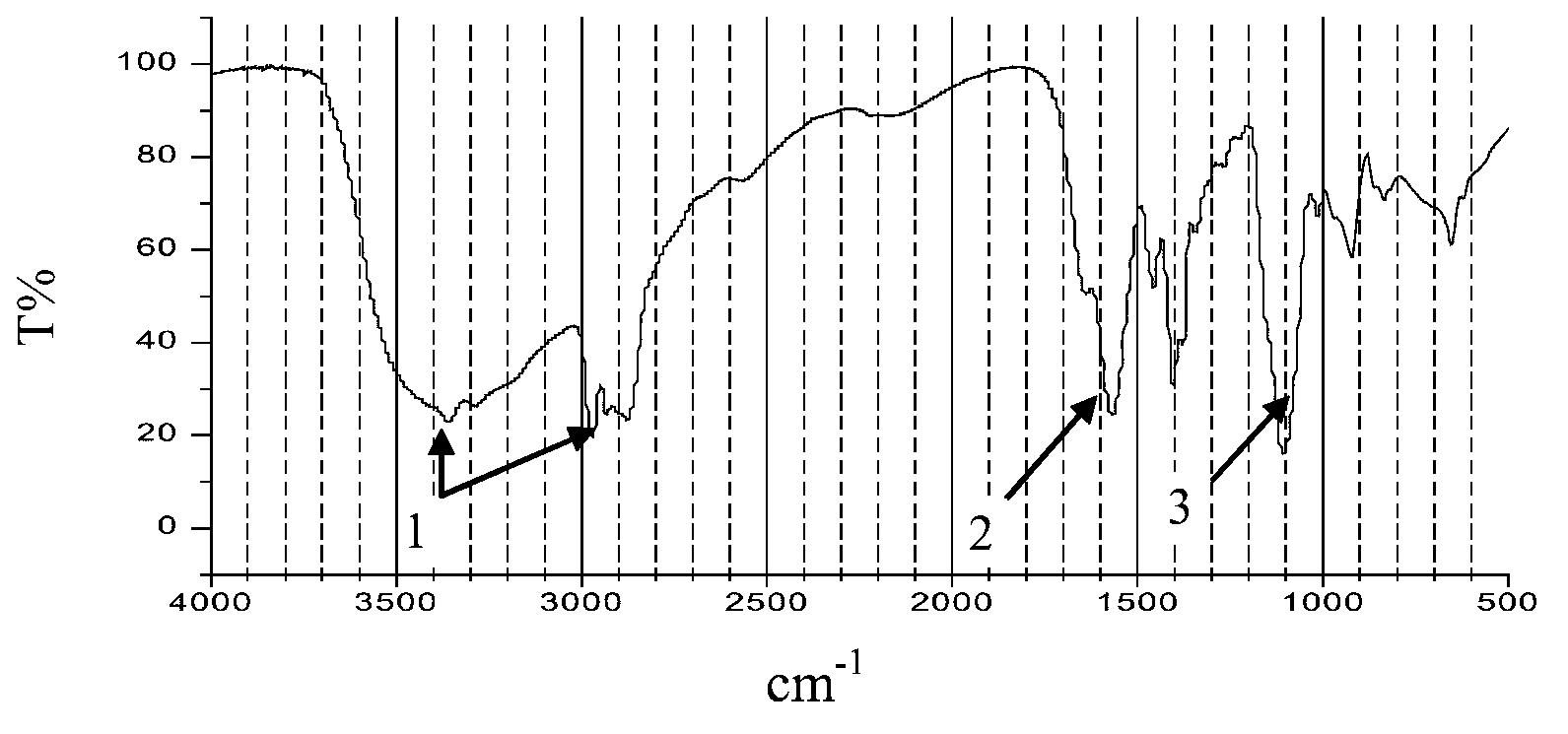

Preparation of high closeness polyacrylacid ester dispersion

The invention relates to a high-sealing polyacrylic ester dispersoid and a preparation method thereof; a multi-element emulsifier system which consists of an anionic emulsifier and a compound non-ionic emulsifier is adopted for controlling the charging process and components of the emulsifier in different polymerization periods, and the room-temperature self-crosslinking high-sealing polyacrylic ester dispersoid is prepared by a semi-continuous seeding emulsion polymerization process. The dispersoid has small particle size, good electrolyte-resistance (calcium ion) stability and high tolerance to various film forming accessory ingredients (various organic solvents with high boiling point). The dispersoid is used as seal coat of water-based wood coating and has good sealing performance to various woods; harmful volatile organic compounds (VOC) such as formaldehyde, and the like sealed against escaping from plates to pollute indoor environment, and the colored compounds such as turpentine, pine oil and tannin and the like are sealed against dissolving out of the plates to pollute pure top coating and white top coating of a water-based wooden ware; and in addition, the dispersoid can be used in water-based leather finishing agents.

Owner:SOUTH CHINA UNIV OF TECH

Drifting sand layer and gravel stratum water-moving double-liquid high pressure slip-casting water-blocking construction method

InactiveCN101255698AHigh strengthImprove water stabilitySolid waste managementUnderground chambersWater blockCement slurry

The present invention discloses a running sand layer and sandy gravel layer dynamic-water double-liquid high-pressure slurry-injecting water-shutoff construction method which comprises the following construction steps: drilling a hole, flushing the hole, executing double-liquid high-pressure slurry-injecting operation and sealing the hole. The running sand layer and sandy gravel layer slurry-injecting liquid adopts an ordinary portland cement (P.O.42.5) and 40''Be sodium silicate as material for preparing the slurry, according to the weight proportion of water: cement, namely the cement slurry is prepared with the water cement ratio for 0.5-1.2:1. Then the slurry-injecting liquid is prepared with the volume ratio of cement slurry: sodium silicate for 1:0.08-0.15. The sodium silicate is taken as additive for regulating the initial setting time of the slurry-injecting liquid. The cement slurry can also be doped with fly-ash with cement consumption (weight proportion) for 10%-15%. The invention executes water-insulating construction aiming at the characteristics of large pressure of the underground dynamic water and high flowing velocity in the running sand layer and sandy gravel layer, and can obtain the maximal application sphere and optimum water-shutoff effect.

Owner:HUNAN CONSTR ENG GRP COR

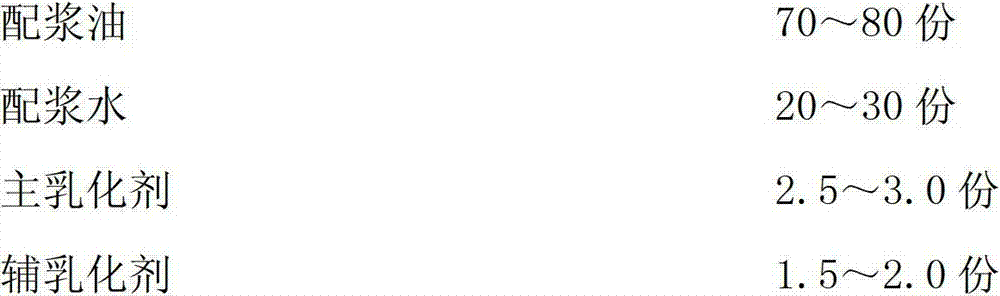

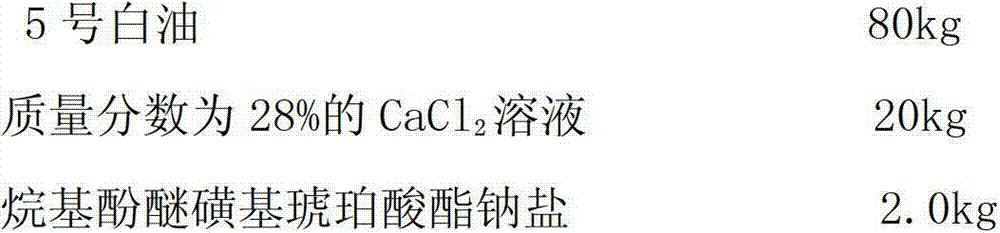

High-efficiency plugging oil-base drilling fluid and preparation method thereof

ActiveCN103045210AEffective blockingPrevent penetrationDrilling compositionAlkalinityDifferential pressure

The invention discloses a high-efficiency plugging oil-base drilling fluid and a preparation method thereof. The drilling fluid is prepared from the following raw materials in parts by mass: 70-80 parts of slurrying oil, 20-30 parts of slurrying water, 2.5-3.0 parts of main emulsifier, 1.5-2.0 parts of auxiliary emulsifier, 2.0-2.5 parts of wetting agent, 2.0-2.5 parts of flow pattern regulator, 2.5-3.0 parts of fluid loss agent, 1.5-2.0 parts of alkalinity regulator, 0.5-0.8 part of extracting agent and 7-9 parts of plugging material. A weighting material is added so that the density of the drilling fluid reaches 1.45-1.56 g / cm<3>. By utilizing the well-drilling positive differential pressure, the high-efficiency plugging oil-base drilling fluid quickly implements bridging, filling and filming to plug the formation fractures on the well wall surface and near the well wall, effectively prevents the drilling fluid and filtrate thereof from permeating into microfractures, enhances the bearing capacity of the formation, has favorable plugging effect, and is beneficial to the stability of the well wall.

Owner:CHINA PETROLEUM & CHEM CORP +1

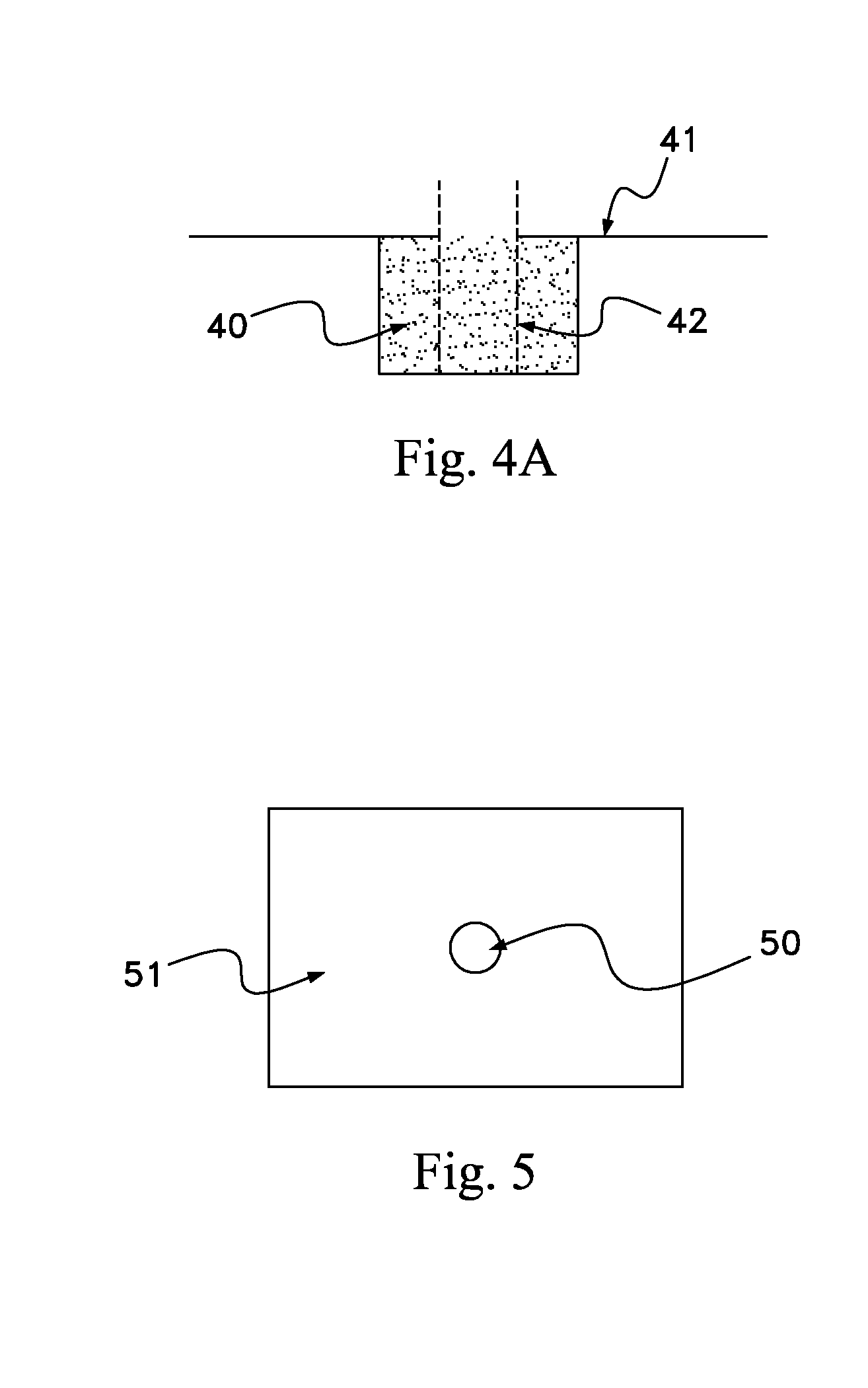

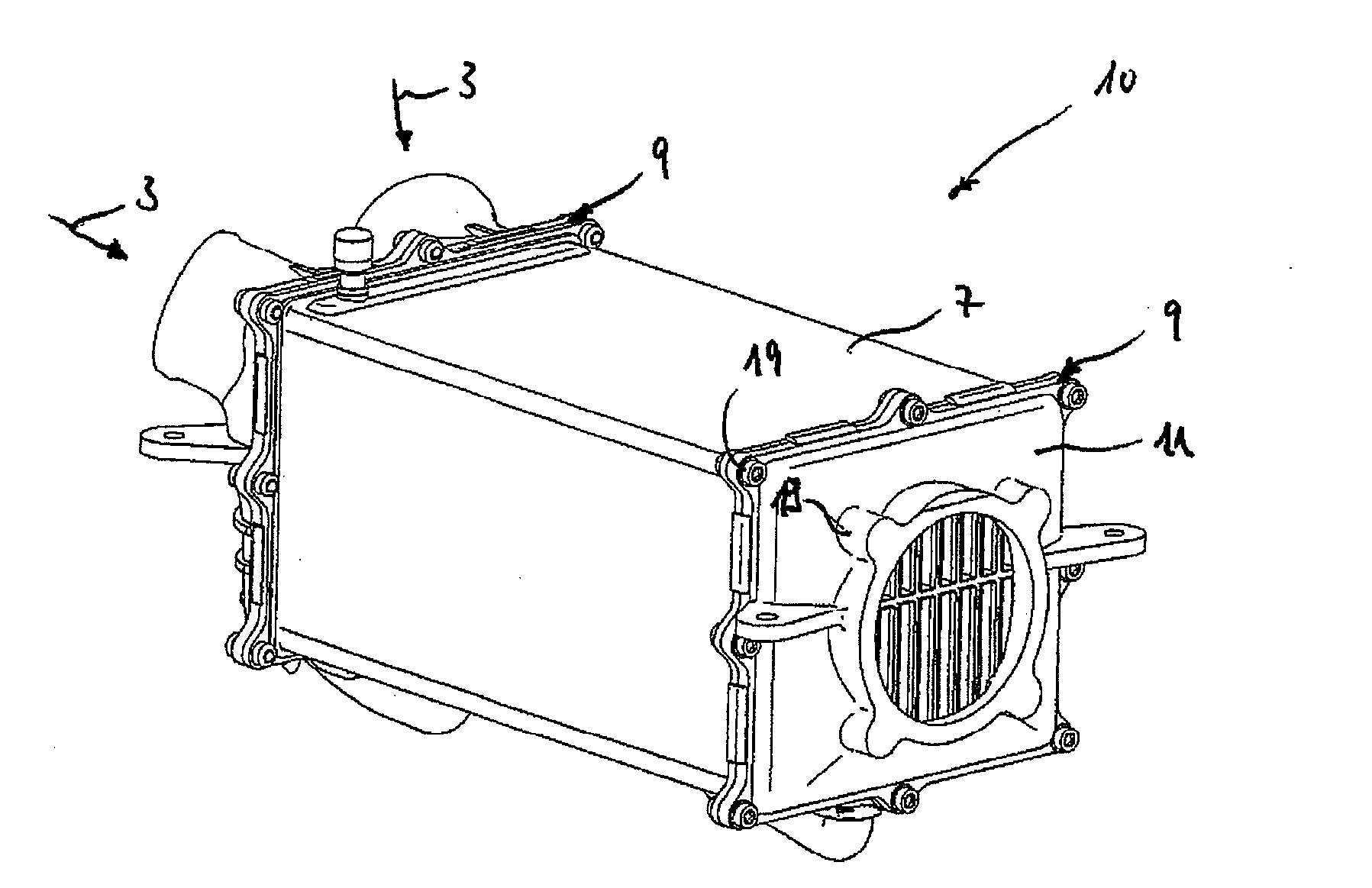

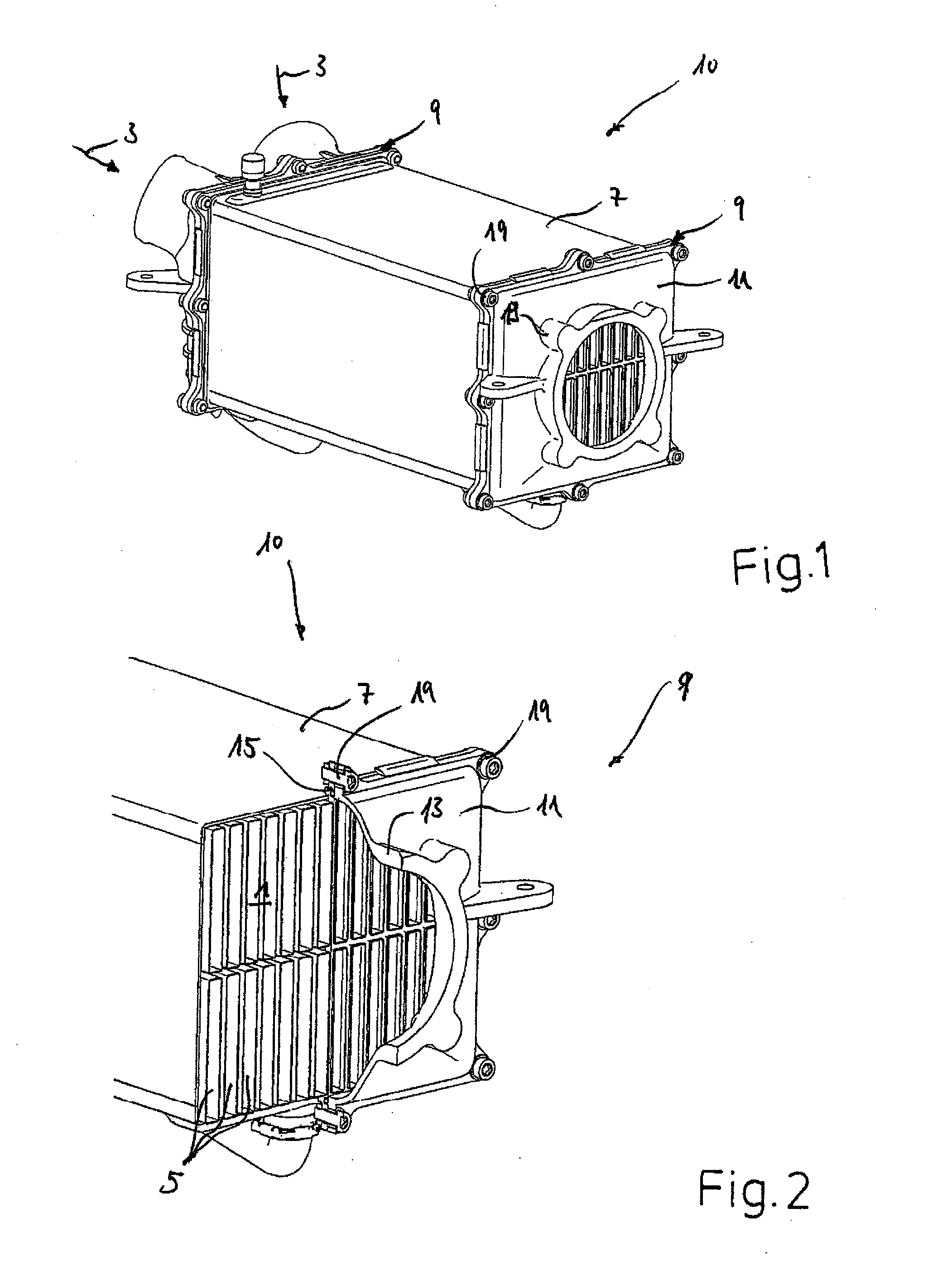

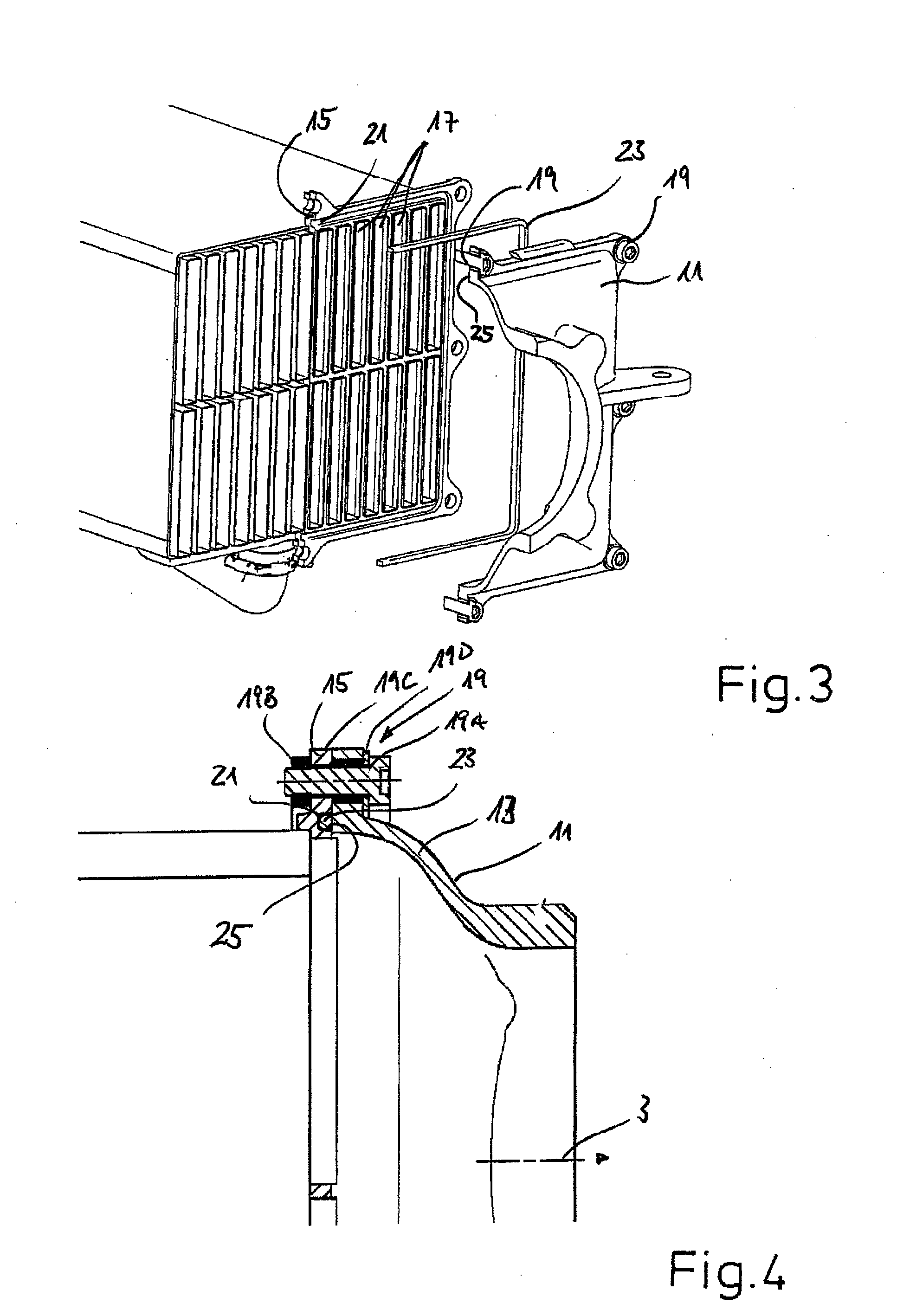

Heat exchanger

ActiveUS20100089548A1Improve sealingFirmly connectedInternal combustion piston enginesRecuperative heat exchangersPlate heat exchangerBiomedical engineering

A heat exchanger, particularly a charge air heat exchanger or exhaust gas heat exchanger, is provided for the heat exchange between a first fluid, particularly a charge air, or an exhaust gas, and a second fluid, particularly a coolant, comprising the following: heat exchanging guides for the first and second fluids, the guides being separated from each other in the core, the core having a plurality of flow channels through which the first fluid flows, and a housing that receives the flow channels and through which the second fluid flows at least one compartment lid, which is flow-connected to the flow channels, and a base that is attached to the compartment lid and that is equipped with one or more passage openings for flow channels. In order to achieve an advantageous connection of the compartment lid to the base, particularly in case the compartment lid and the base are made of different materials, the invention provides that the compartment lid is attached to the base via one or more connections as a bolted connection and / or a slotted crimping.

Owner:MAHLE BEHR GMBH & CO

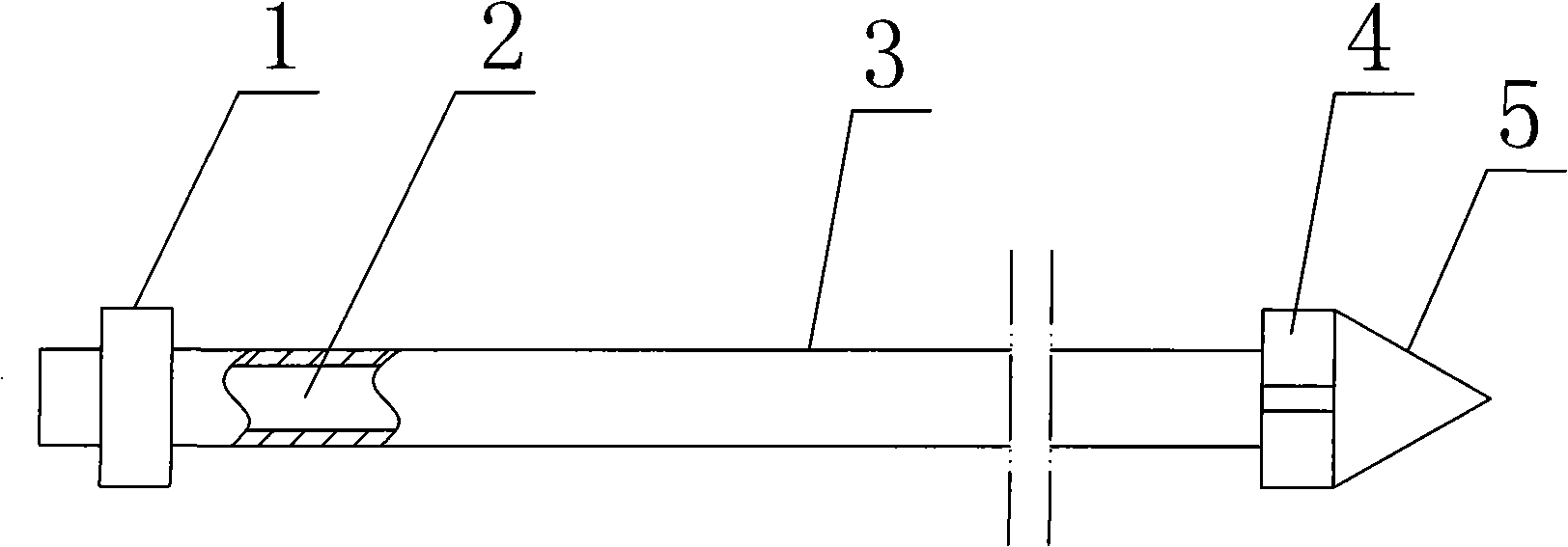

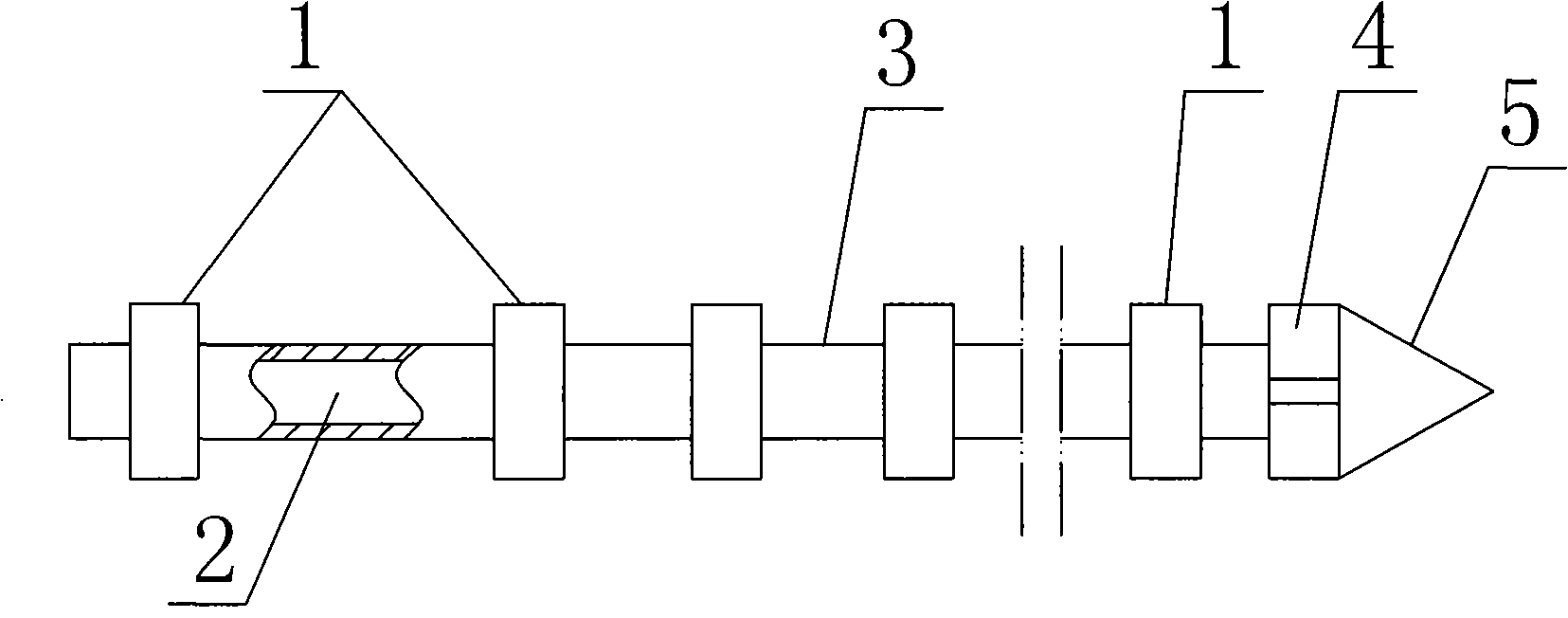

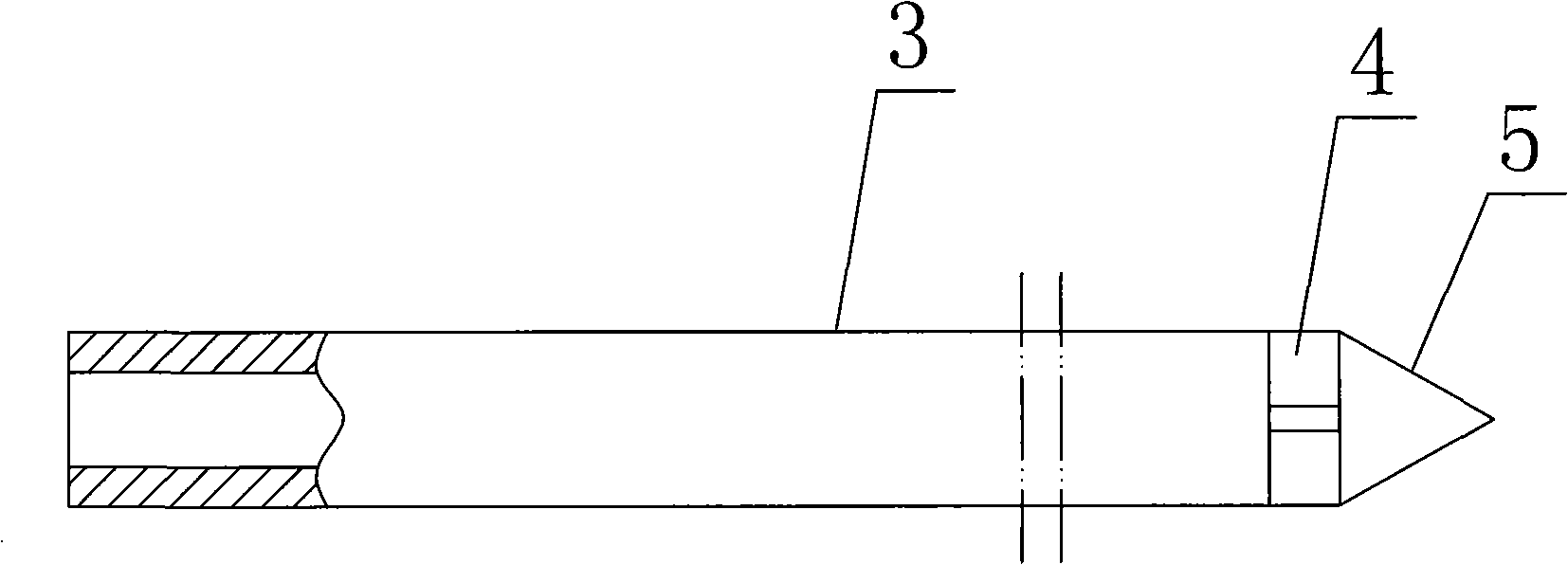

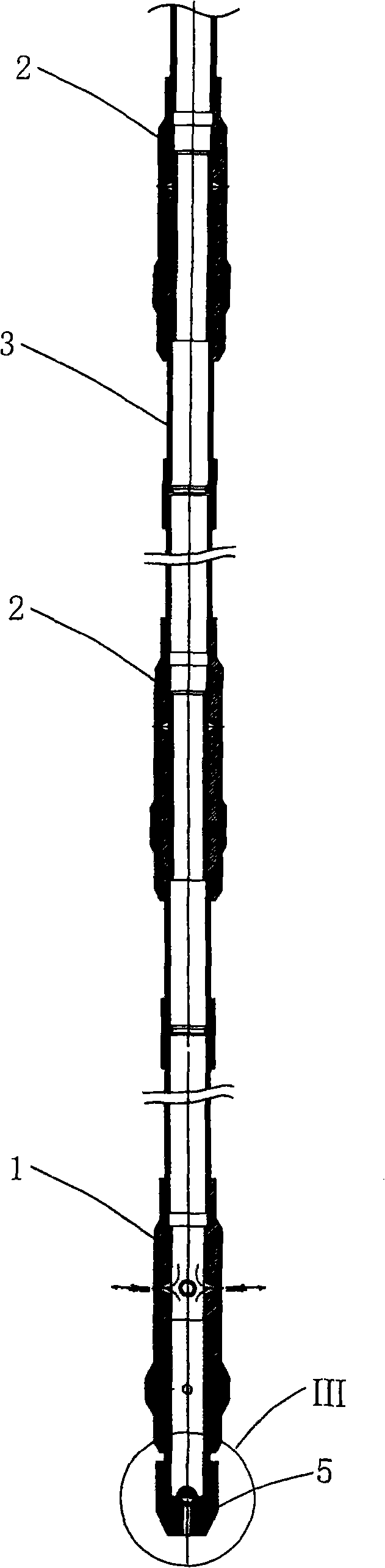

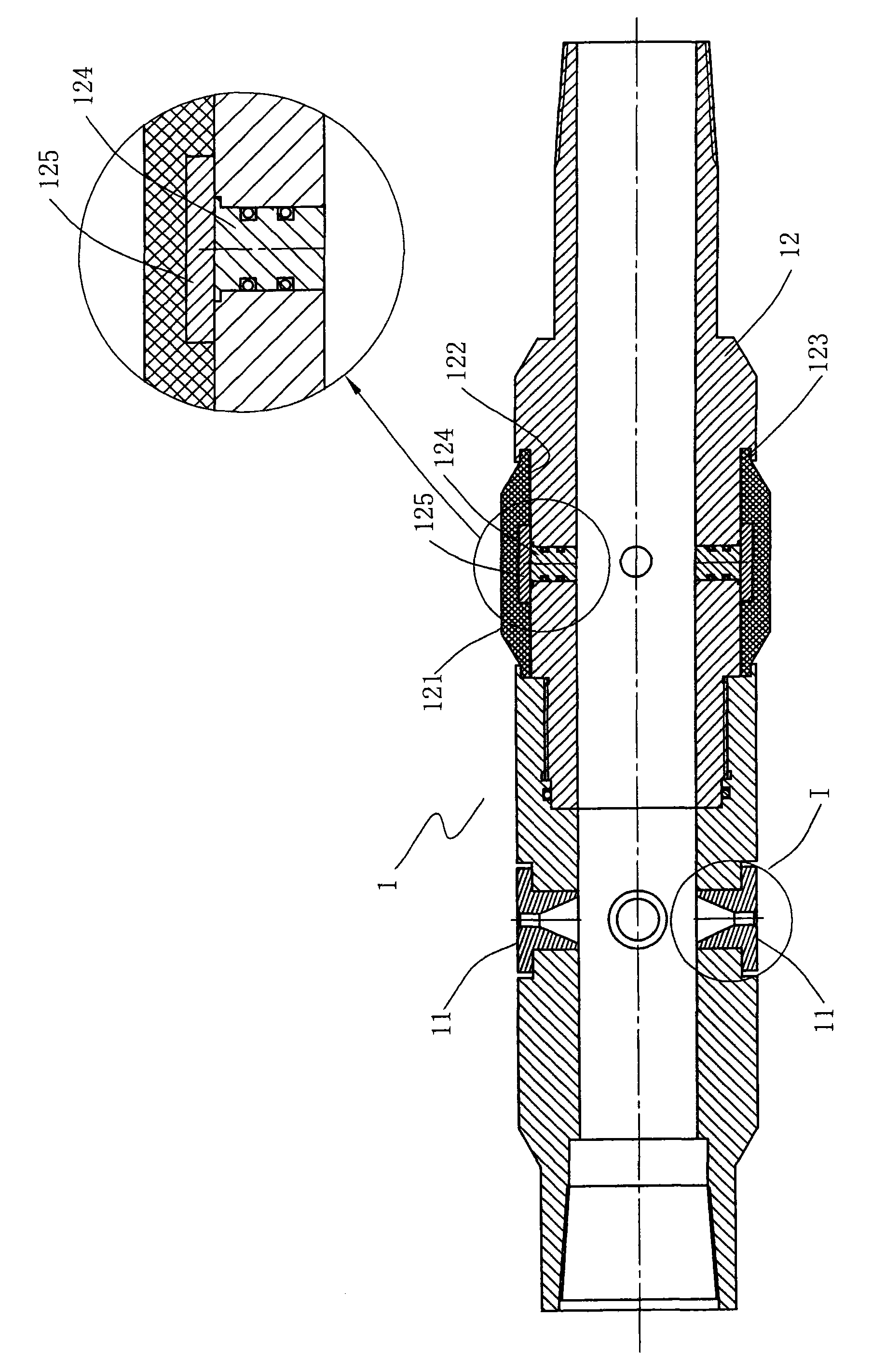

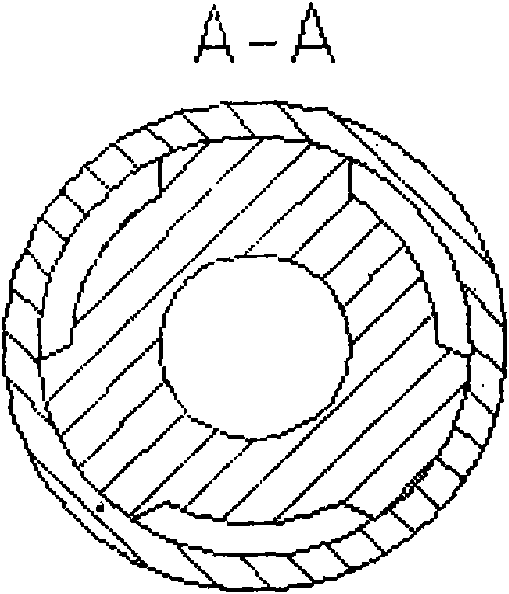

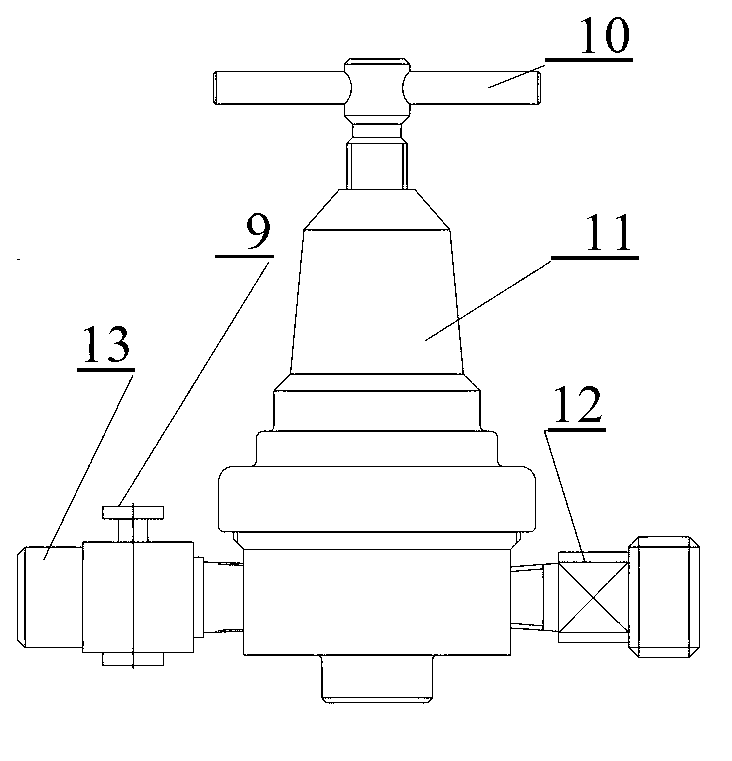

Abrasive jetting device and method for abrasive jetting flow and jetting perforation and multiple fracturing

InactiveCN101539007AAvoid defects that require moving the downhole stringGood sealingFluid removalLiquid spraying apparatusHorizontal wellsOil field

The invention relates to an abrasive jetting device and a method for abrasive water jet perforation and multiple fracturing; wherein the abrasive jetting device has multistage jet guns which are connected in series; the jet guns are all hollow columns; the side walls thereof are respectively provided with at least two nozzles; the lower part of each stage of jet gun is provided with a packer; the side wall of the packer is provided with a sealing sleeve which can expand outward under the action of high-pressure liquid; the jet guns comprise a first stage bottom jet gun arranged at the lower part of the abrasive jetting device and multistage upper jet guns arranged above the bottom jet gun; wherein all the upper jet guns are respectively provided with a sliding sleeve which can seal the nozzle of the stage of jet gun and sealing sleeve; and the sliding sleeve can slide to the lower part of the sealing sleeve under the action of external force so as to open the nozzle and the sealing sleeve. The invention can be used for casing straight wells or horizontal wells, solves the problem of layered or staged fracturing in the straight wells or the horizontal wells in oil fields, and achieves the purposes of saving fracturing cost, improving fracturing effect and reducing the construction risk.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

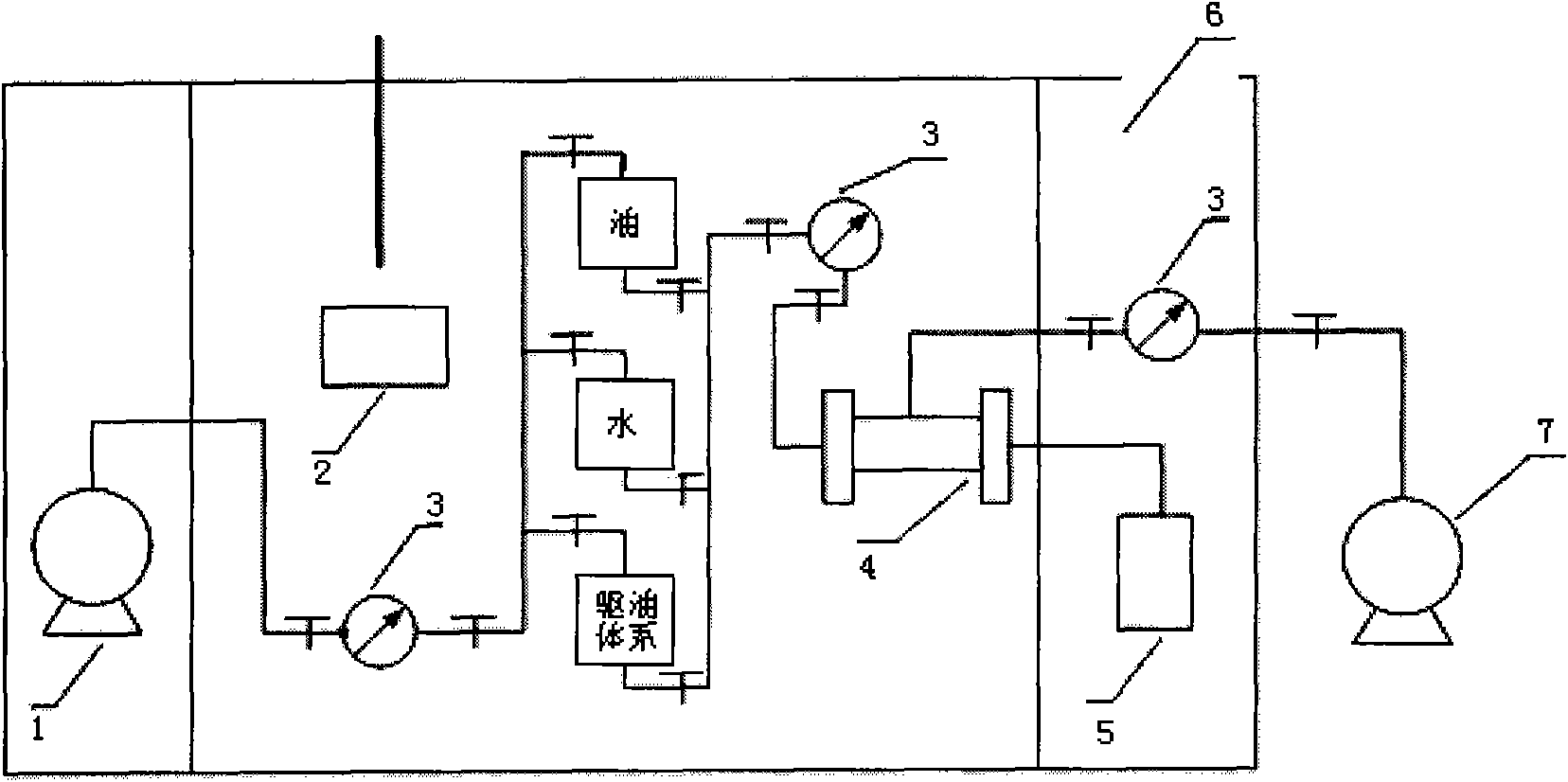

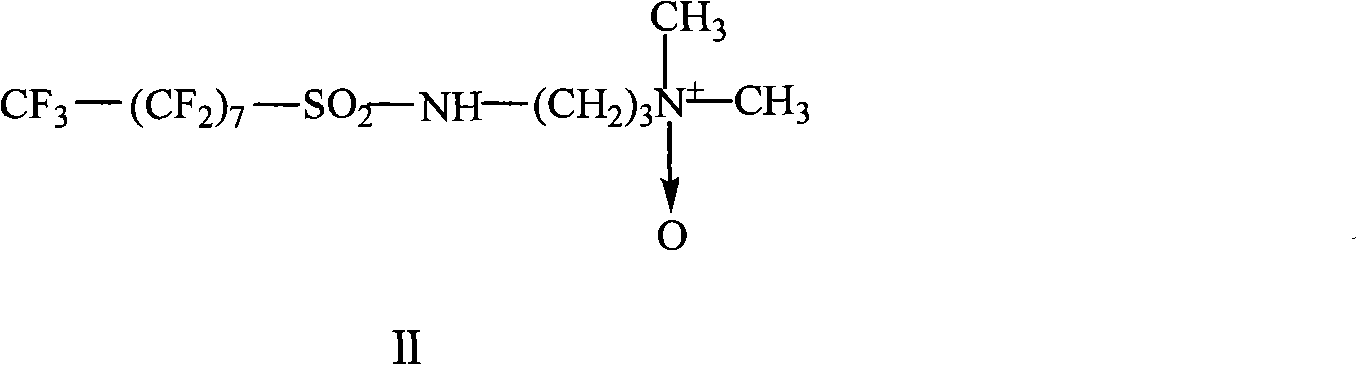

Fluorocarbon surfactant binary composite foam flooding system

ActiveCN102140338AImprove stabilityHigh apparent viscosityFluid removalDrilling compositionSulfonateFoaming agent

The invention relates to a fluorocarbon surfactant binary composite foam flooding system. The system is prepared by adopting fluorocarbon surfactant as a foaming agent, adopting a macromolecular compound as a foam stabilizer and adding water; the foaming agent is one or combination of sulphobetaine type fluorocarbon surfactant and amine oxide type fluorocarbon surfactant, or combination of alpha-alkenyl sulfonate and one of sulphobetaine type fluorocarbon surfactant and amine oxide type fluorocarbon surfactant; and the foam stabilizer is partially hydrolyzed polyacrylamide, polyvinyl pyrrolidone K30, polyvinyl pyrrolidone K90 or hydroxyethyl cellulose. An application method comprises that solution of the fluorocarbon surfactant binary composite foam flooding system and nitrogen are alternately injected into a stratum or a rock center so as to improve the recovery rate of crude oil.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

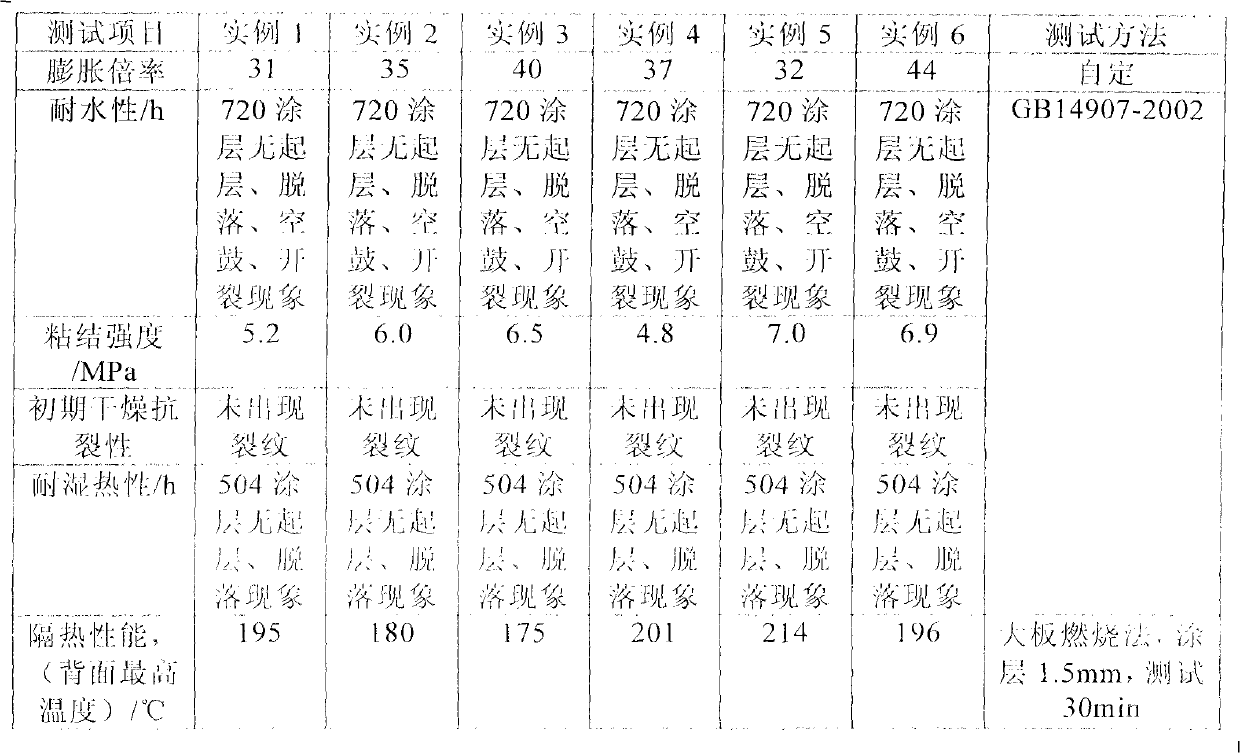

Polyurea expanding type fireproof paint as well as preparation method and application thereof

ActiveCN102559022AImprove insulation performanceImprove fire and heat insulation performanceFireproof paintsPolyurea/polyurethane coatingsFoaming agentPetrochemical

The invention relates to expanding type fireproof paint taking polyurea resin as a film forming substance and application of the expanding type fireproof paint. The expanding type fireproof paint contains a component A and a component B, wherein the component A contains an isocyanate prepolymer, the component B contains an amino-terminated polyether, a polyamine chain expanding agent, a diluting agent, a carbonizing catalyst, a carbonizing agent, a foaming agent, a flame retardant, a smoke suppressing agent, a pigment filler, an adjuvant and a mixed solvent, and the weight ratio of the component A to the component B is 1:5 to 1:7. The fireproof paint is suitable for the fireproof protection of indoor and outdoor steel structures and nonmetal structures and can be used for prohibiting the propagation of flame and the transmission of heat to a substrate. The expanding type fireproof paint is suitable for the fireproof protection in the fields of airport facilities, municipal engineering, vehicles, ships, petrochemical facilities and the like.

Owner:MARINE CHEM RES INST

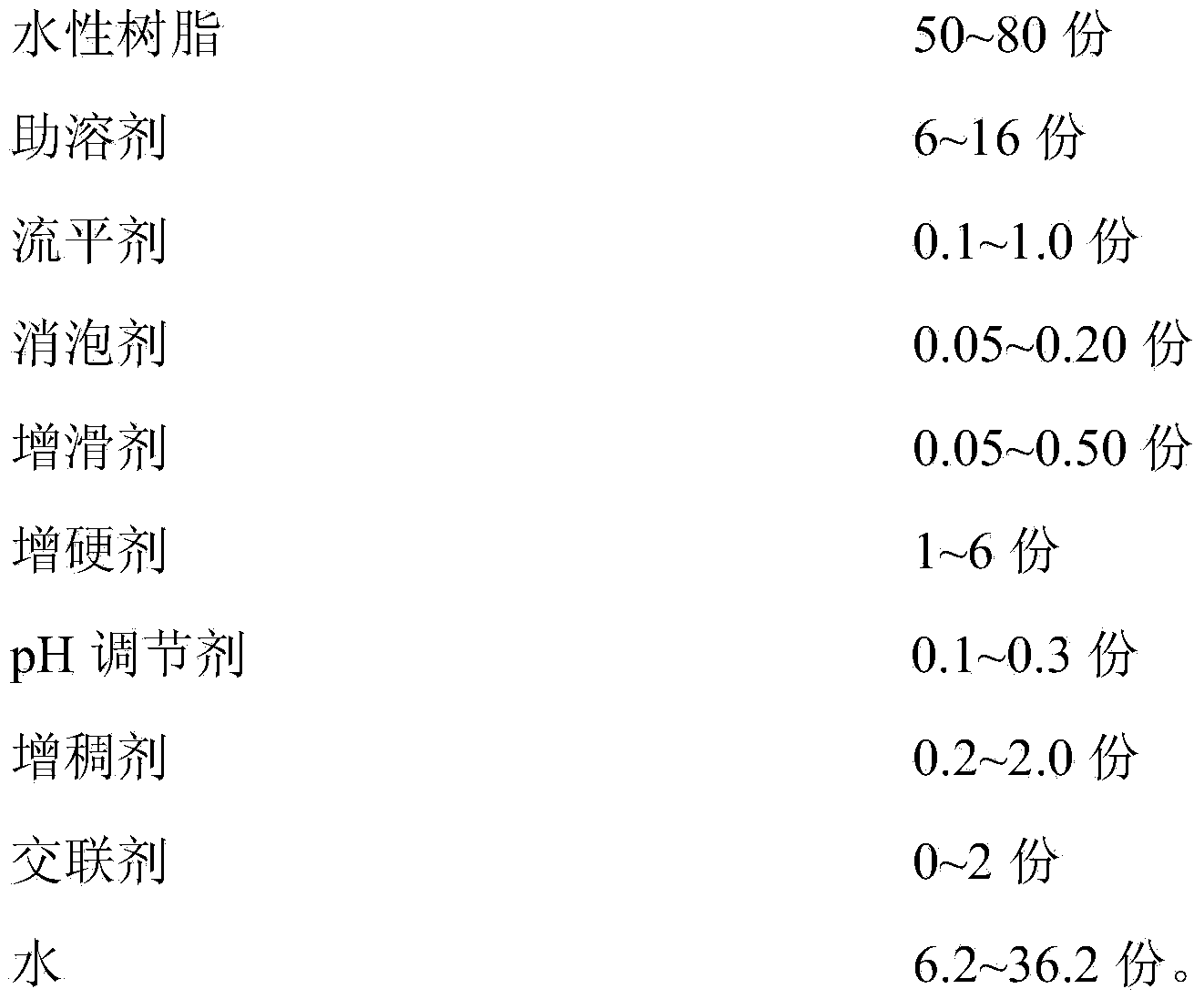

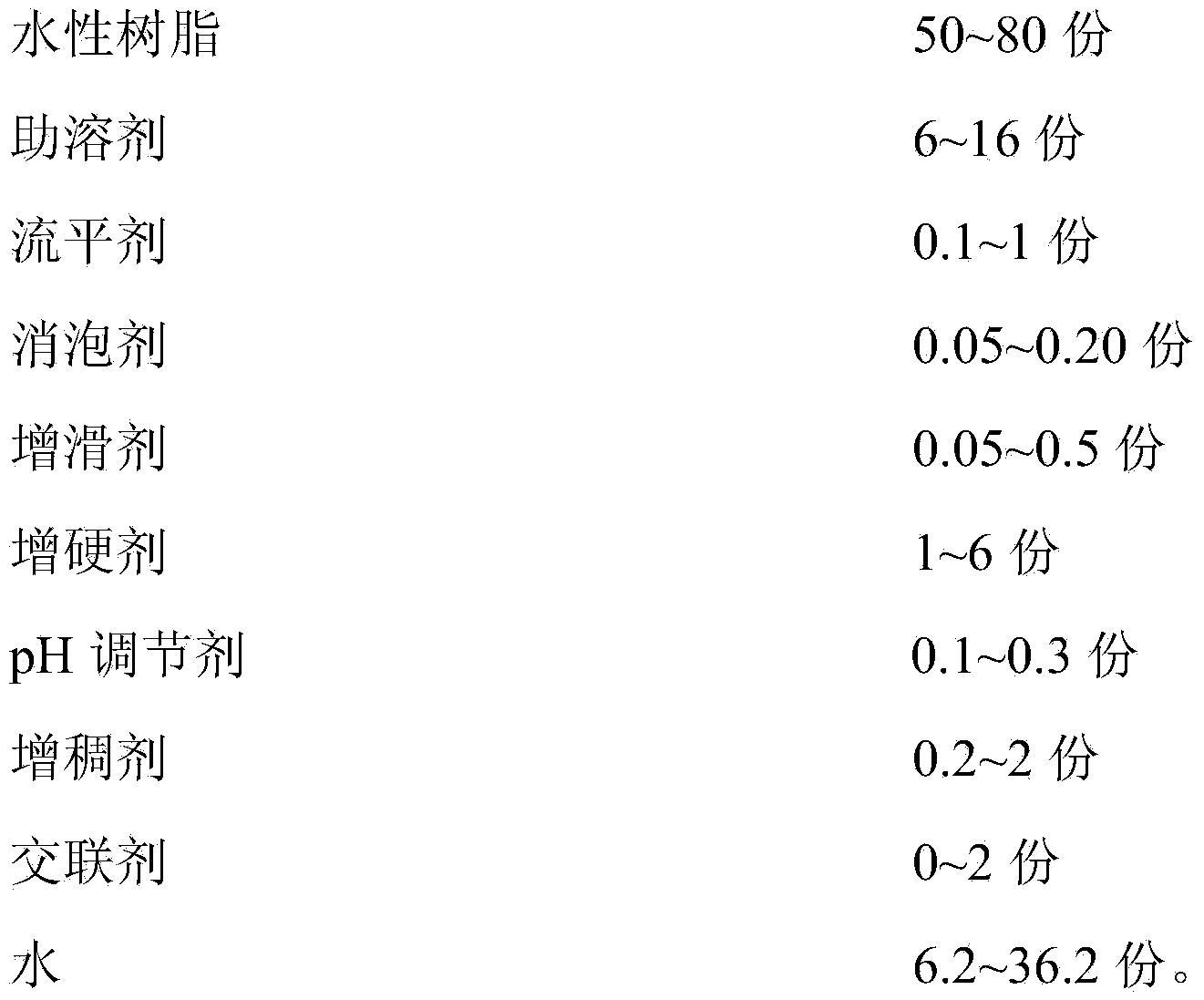

High-strength directly aluminizing water-based base coat and preparation method and application of high-strength directly aluminizing water-based base coat

ActiveCN103866607AGood sealingGood flexibilityNon-fibrous pulp additionPaper/cardboardWater basedWater vapor

The invention discloses high-strength directly aluminizing water-based base coat and a preparation method and application of the high-strength directly aluminizing water-based base coat. The directly aluminizing water-based base coat comprises the following components in parts by mass: 50-80 parts of water-based resin, 6-16 parts of cosolvents, 0.1-1 part of flatting agents, 0.05-0.20 part of antifoaming agents, 0.05-0.5 part of slipping agents, 1-6 parts of hardening agents, 0.1-0.3 part of pH regulator, 0.2-2 parts of thickening agents, 0-2 parts of crosslinking agents and 6.2-36.2 parts of water. With good closure, the direct aluminizing water-based base coat disclosed by the invention guarantees the filling of micropores in the paper surface as well as the separation of water vapor; due to the characteristic of flexibility, the bending resistance of paper is realized; the viscosity resistance ensures that the film rolls are not bonded with each other after base coating on the aluminizing body paper; moreover, by adjusting the leveling property of the selected resin system and the coating, the base coat has high aluminizing metal texture.

Owner:GUANGZHOU HUMAN CHEM

Aqueous rust-conversion rust-inhibiting primer

The invention relates to a water-based rust conversion antirust primer which is characterized in that: the primer comprises the following components with the corresponding percentage by weight : main conversion agent 5-35, auxiliary conversion agents 2-15, film forming material 40-55, penetrant 0.2-1.0, humectant 1-10, anti-forming agent 0.1-0.5, corrosion inhibitor 0.2-0.5 and solvent 0.5-8; the process is as follows: adding deionized water to a charging basket and heating the water to 60-80 DEG C with aliphatic alcohol polyethenoxy ether added, adding propylene glycol and starting a high-speed dispersion machine for agitation, later on adding tributyl phosphate, potassium sorbate, tannic acid and one of the auxiliary conversion agents and cooling down to 20-33 DEG C after agitating for 30-55 minutes, and adding vinyl chloride-modified acrylic resin latex and discharging material after agitating for 10-20 minutes. The invention has the advantages of direct application to steel surfaces with rust, thorough conversion of rust, excellent adhesive force of a conversion film, good flexibility, adaptation to various forms, and good compatibility with various top coatings.

Owner:安泰能(上海)高分子材料有限公司

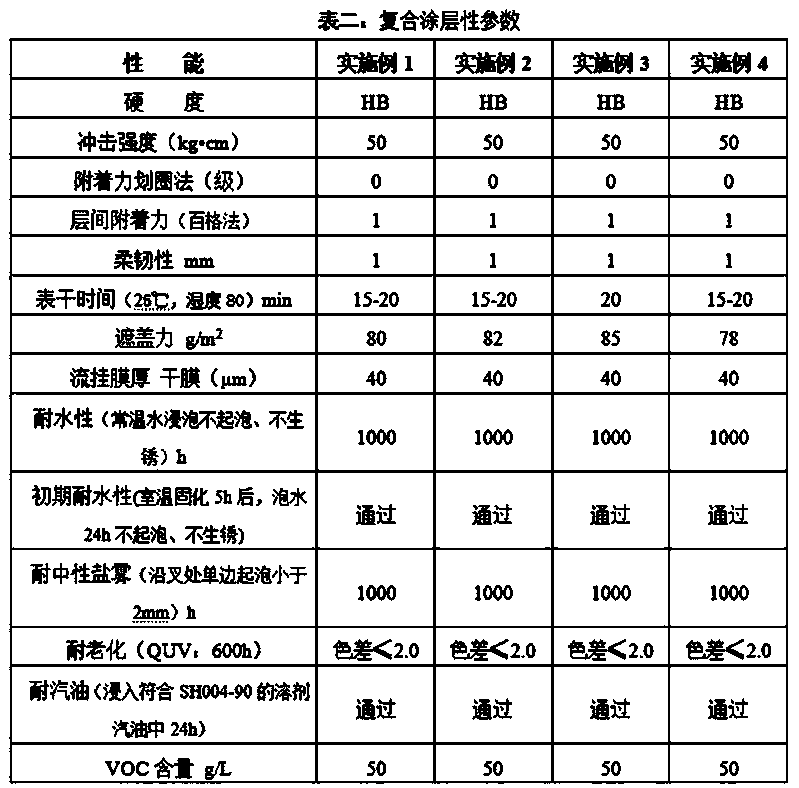

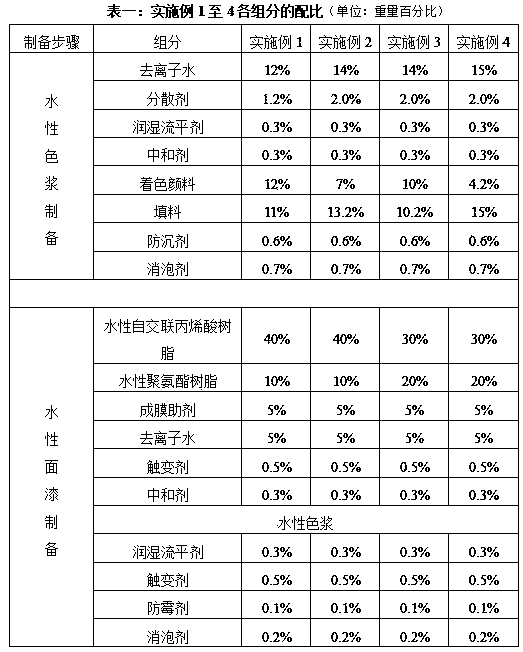

Single-component water-based natural drying finishing coat for construction crane and preparation method thereof

InactiveCN103788787AImprove water resistanceImprove aging resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsEpoxySolvent based

The invention discloses a single-component water-based natural drying finishing coat for a construction crane and a preparation method thereof. The raw material formula of the single-component water-based natural drying finishing coat comprises the following components by weight percent: 40-50% of water-based resin, 1-3% of dispersant, 4-20% of coloring pigment, 8-15% of filler, 0.5-1.5% of anti-settling agent, 0.5-1% of leveling wetting agent, 1-2% of thixotropic agent, 0.5-1% of defoamer, 0.1-0.8% of mildew preventive, 1-5% of coalescing agent, 0.5-1% of neutralizer and 10-20% of deionized water. The invention also discloses the preparation method of the single-component water-based finishing coat. The film of the water-based natural drying finishing coat is curable at the room temperature, energy-saving and environmental friendly, and capable of meeting the requirements of safe production of enterprises; in the meantime, the film is good in closure to a primer, and has excellent early-stage waterproofness and ageing resistance; the single-component water-based finishing coat is matched with a room temperature curable water-based double-component epoxy primer in use, so that the film formed is excellent in corrosion resistance, and the comprehensive properties of the single-component water-based natural drying finishing coat are up to the property indexes of similar solvent type finishing coats.

Owner:GUANGZHOU KINTE IND +1

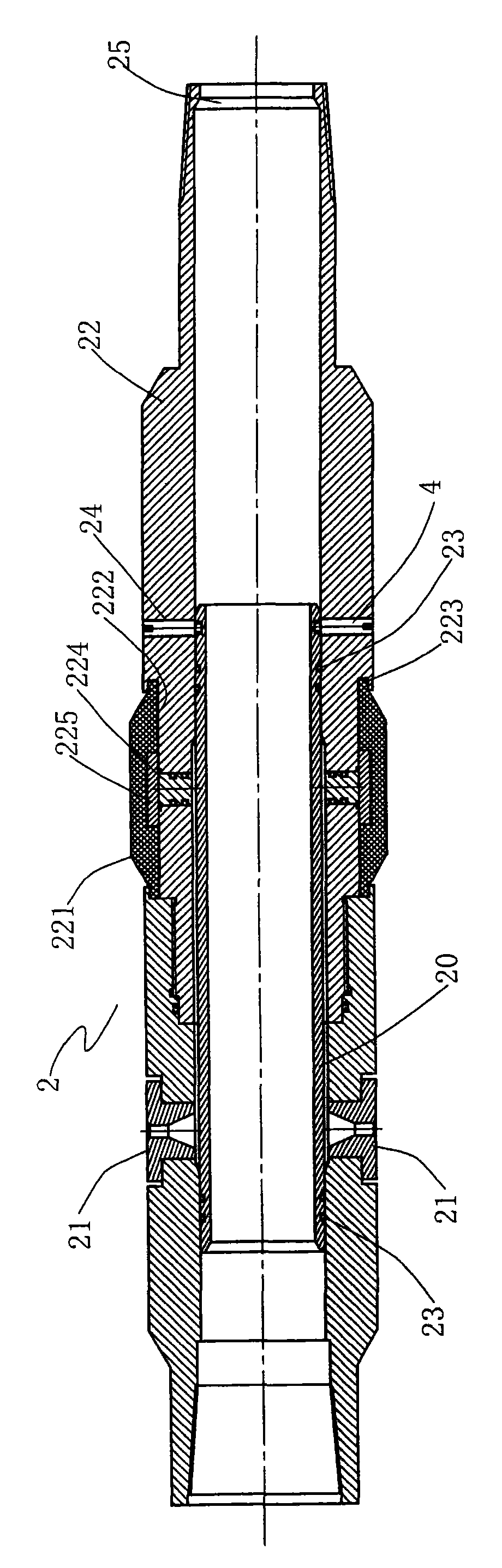

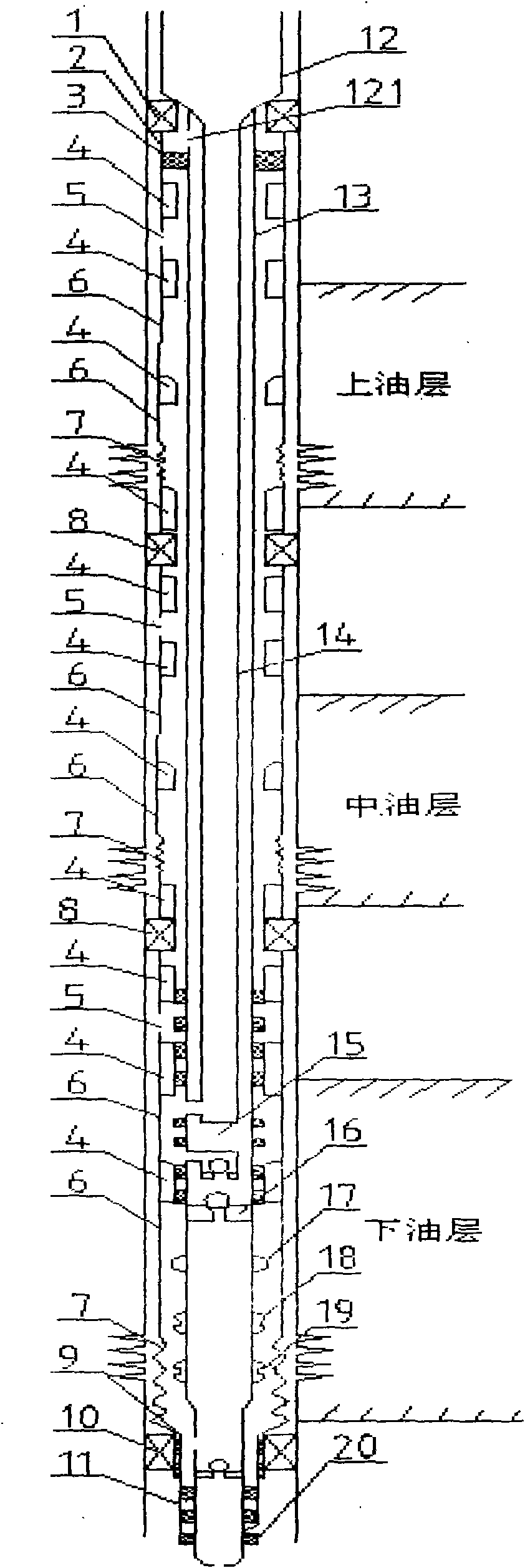

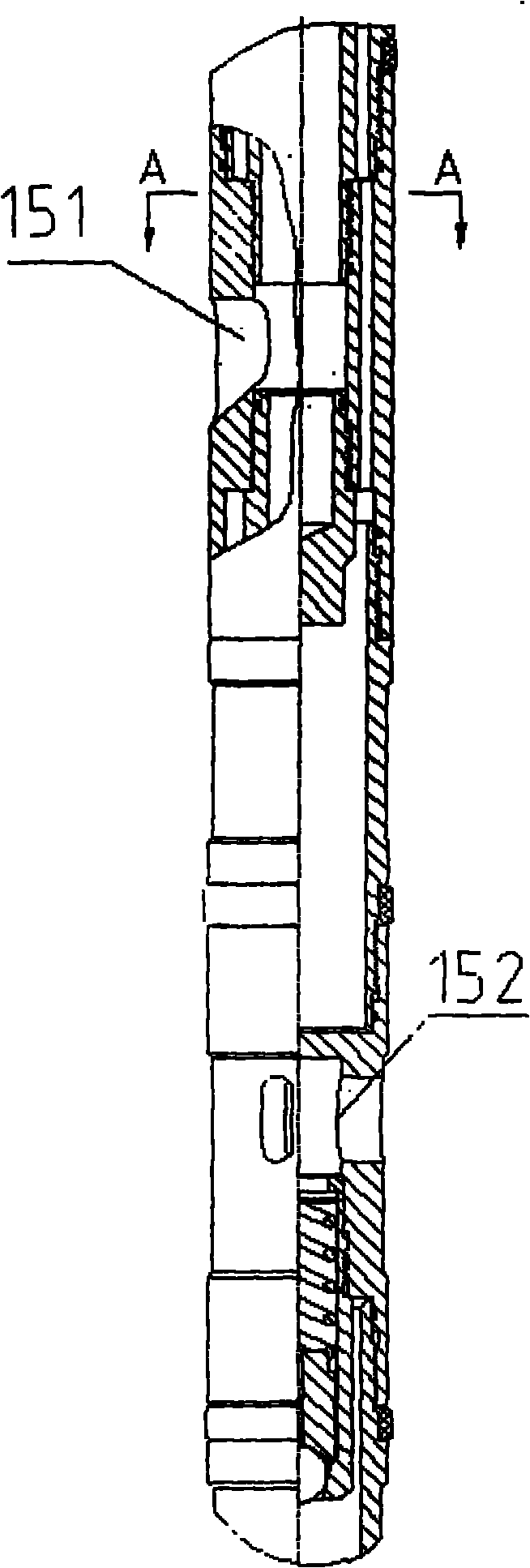

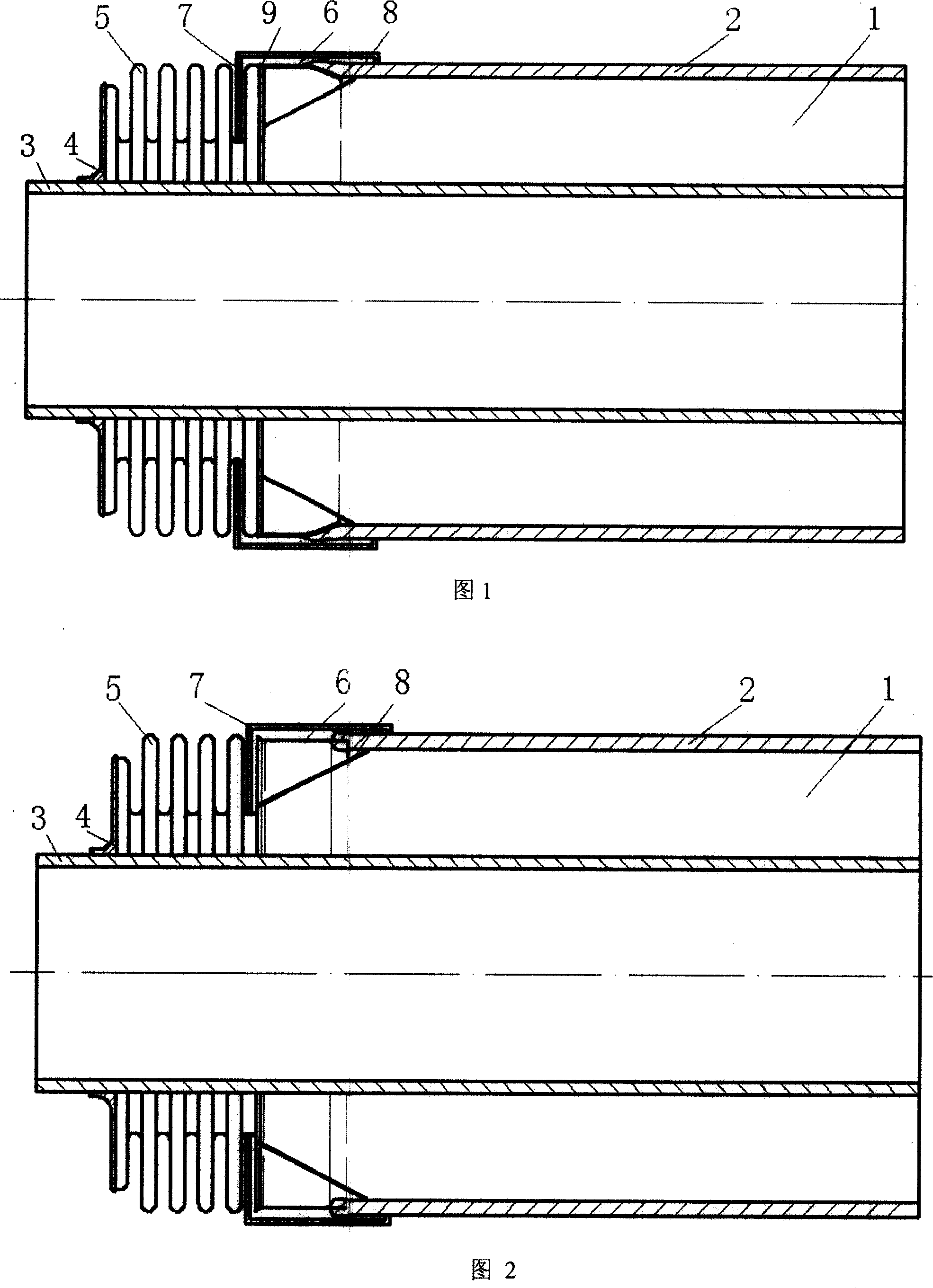

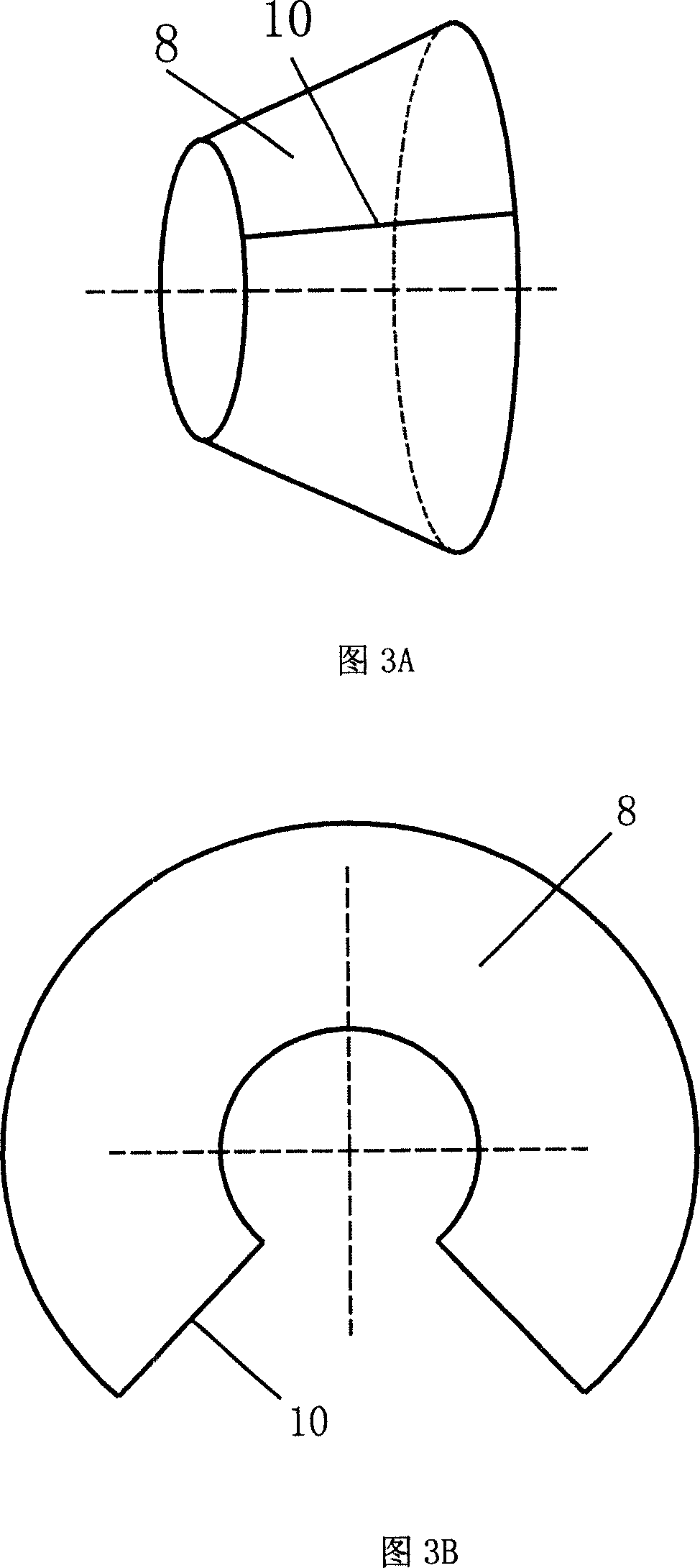

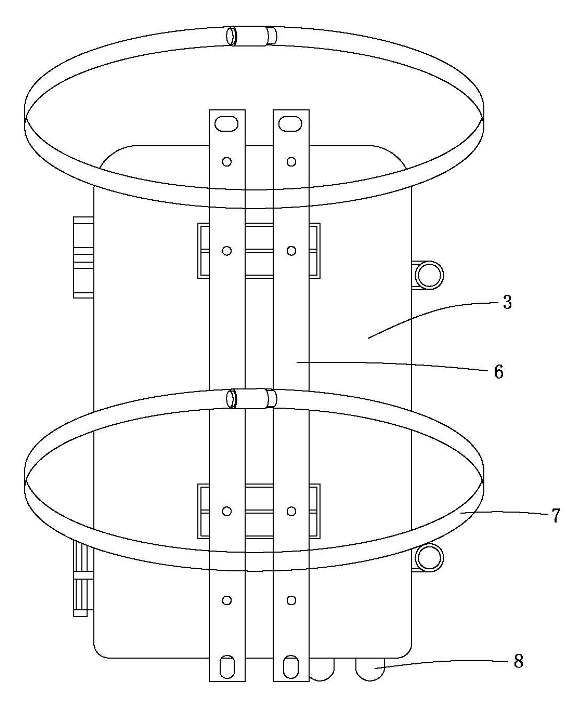

Multilayer gravel packing method and tool

InactiveCN102134982APrevent leakageGood sealingFluid removalSealing/packingPacking methodMechanical engineering

The invention provides a multilayer gravel packing method and tool. The method comprises the following steps in sequence: A. a) sinking a disposable multilayer gravel packing tool; and b) inserting insertion positioning seals and automatic guide shoes into sump packers; B. c) setting top packers, examining seal of the top packers and releasing the top packers; and d) setting interlayer isolation packers on the lower layer and examining seal of the interlayer isolation packers; and C. e) packing a lower oil layer; and f) carrying out reverse circulation; repeating the substeps d), e) and f), namely setting the interlayer isolation packers on the upper layer and examining seal of the interlayer isolation packers, packing a middle oil layer and carrying out reverse circulation; and repeating the substeps e) and f), namely packing an upper oil layer and carrying out reverse circulation. The tool is characterized in that a service tool is installed in an outer tube column, wherein the outer tube column comprises the top packers and bush sealing bores, bushes, sealing bores, sliding sleeves, short sections, sieve tubes, the interlayer isolation packers, the insertion positioning seals, the sump packers and the automatic guide shoes which are connected below the top packers; and the service tool comprises setting tools and wash tubes, a central tube, a packing conversion tool, pressure measuring assemblies, rotary positioning tools, one-way sliding sleeve switch tools, two-way sliding sleeve switch tools and bottom isolation seals which are installed below the setting tools.

Owner:QINGDAO RUIXIN PETROLEUM EQUIP MFG CO LTD +2

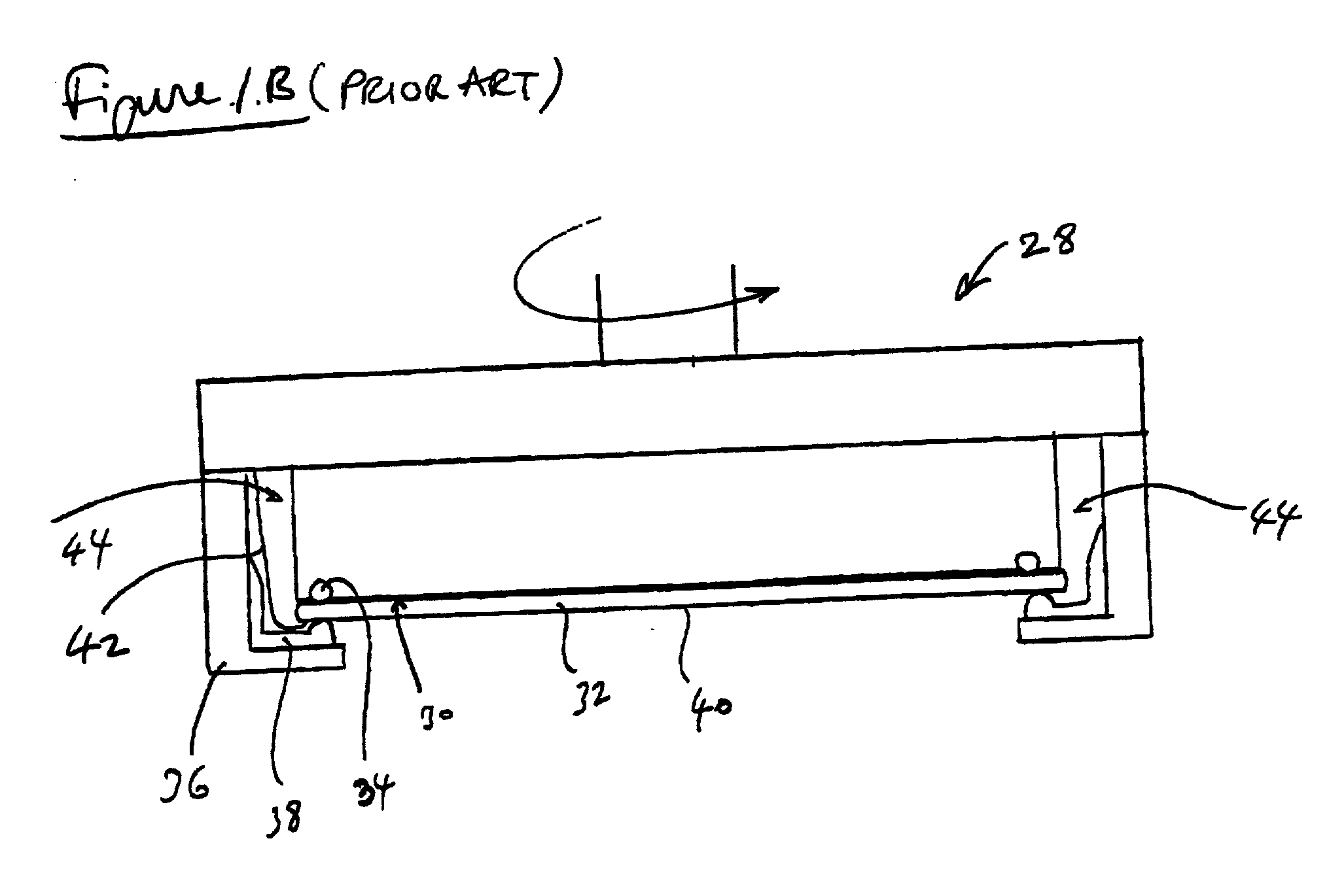

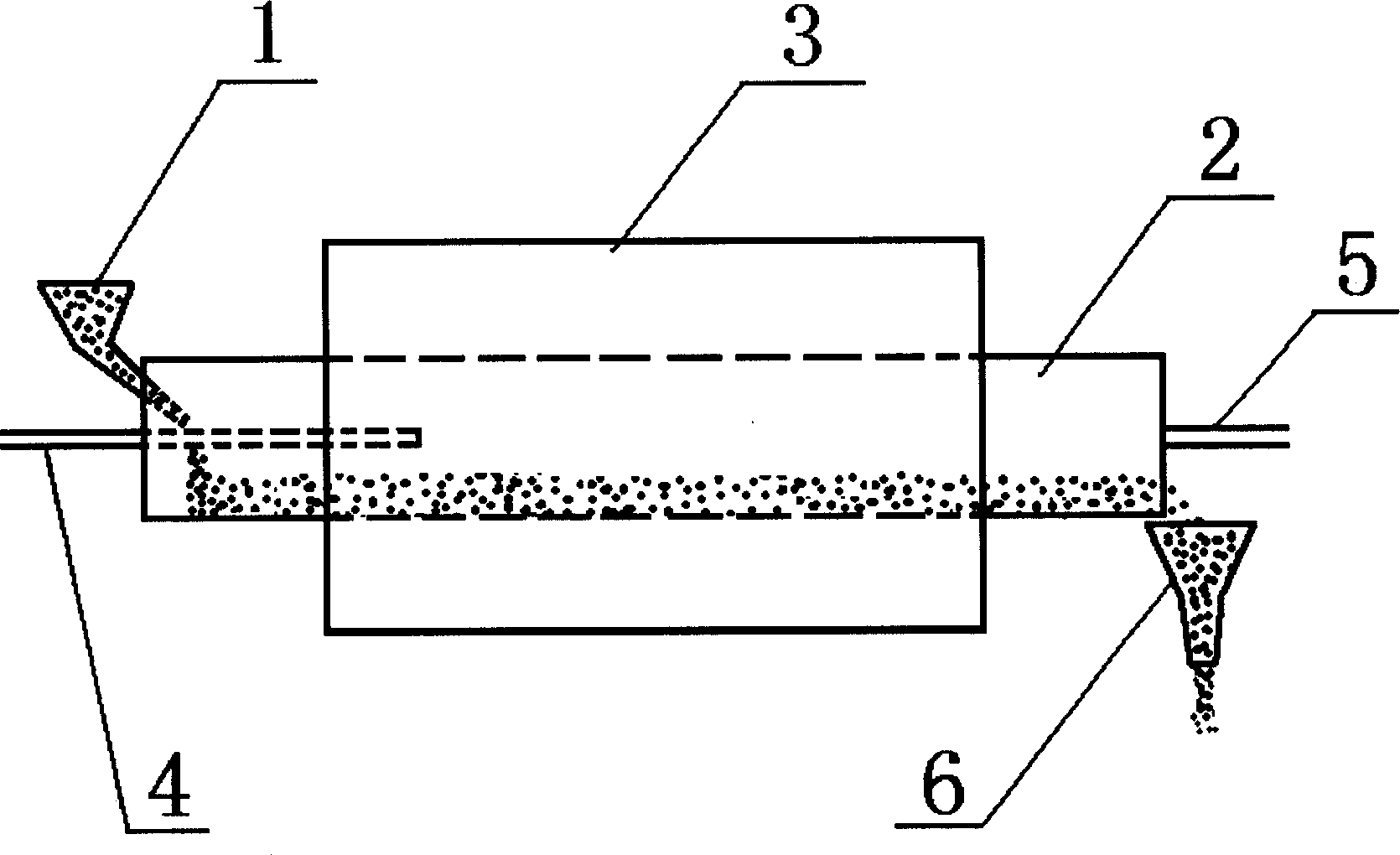

Method for synthesizing lithium ion cell positive cell polar material rotary furnace

InactiveCN1710735AImprove consistencyEvenly heatedElectrode manufacturing processesTemperature controlRotary furnace

The method includes steps: (1) loading hydrate, oxide of lithium or mixed salt with hydrate, oxide or salt of transition metal into revolving furnace; (2) controlling temperature inside revolving furnace at 600 - 950 deg.C and rotation speed at 2 - 5 turns / minute, calcining admixture in revolving furnace for 20 - 40 hours, and then cooling it; (3) anode material of lithium battery is obtained through steps of crushing and sieving cooled materiel. Since calcined materiel is heated evenly inside revolving furnace, thus, physical and chemical characters of obtained materiel are even features are: shortened time for processing in high temperature, and lowered energy consumption.

Owner:广州鸿森材料有限公司

High-temperature solar thermal-collecting tube and manufacturing process thereof

InactiveCN101135501ARadiation immuneExtended service lifeSolar heating energySolar heat devicesEngineeringCobalt

A high temperature solar heat collecting tube and its producing technology mainly applies to tank type solar high temperature heat electric power generation field. The heat collecting tube includes external glass tube and coaxial metal internal tube, corrugated pipe with expansion compensation function is joined with the metal tube by connecting parts, the other end of the corrugated pipe is welded with metal-glass transition parts kovar ring, then the kovar ring is sealed-in with the glass tube, in order to protect glass and glass sealing-in part against radiation, a sunshade hood is mounted at the outer side of sealing-in part, a thin-wall lightproof ring is welded on the corrugated tube. The said glass tube is made of DM308; DM305 or DM320 molybdenum group glass, the kovar ring is made of 4j29 or 4j30 iron-nickel-cobalt low expansion alloy.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

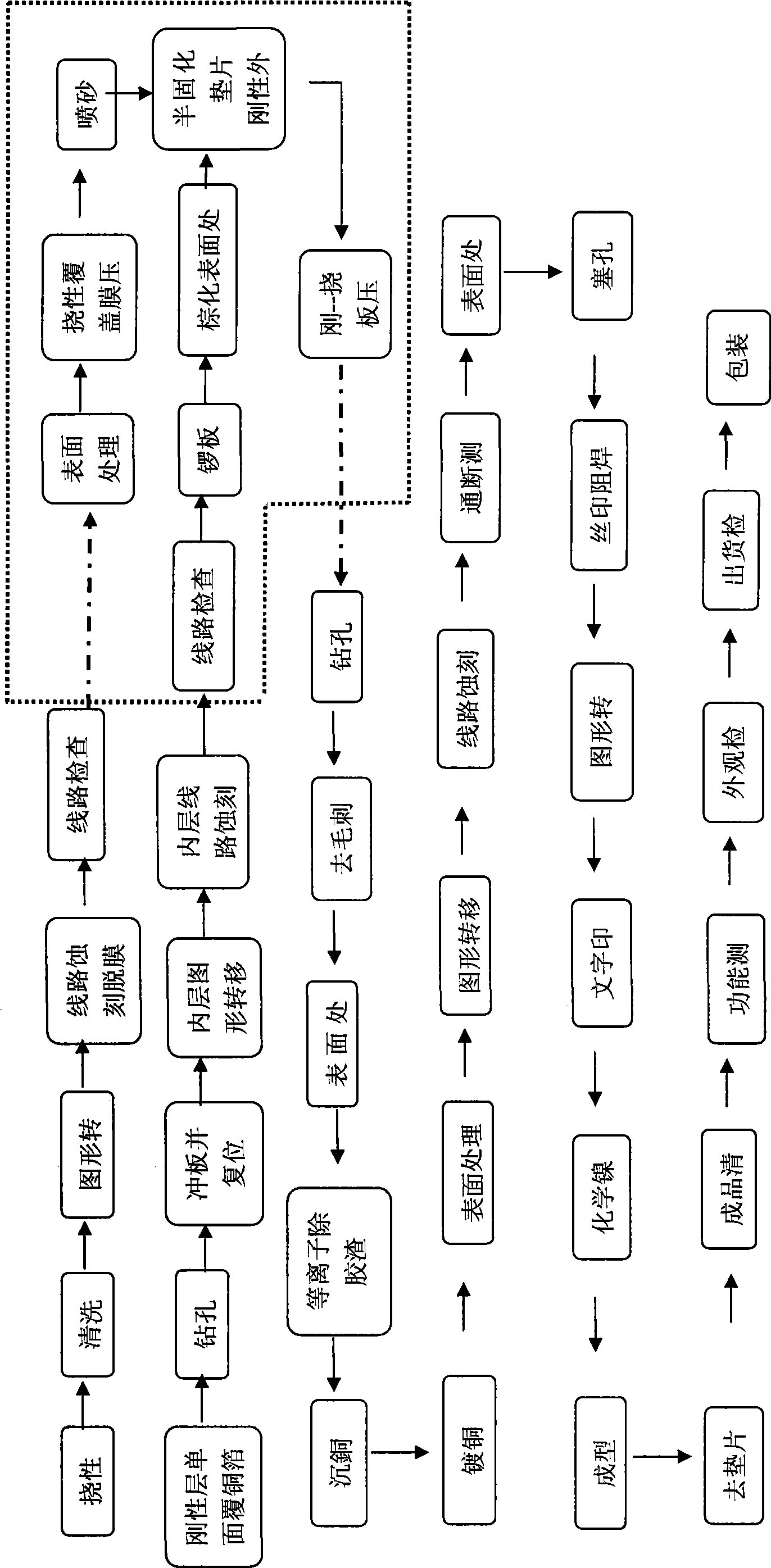

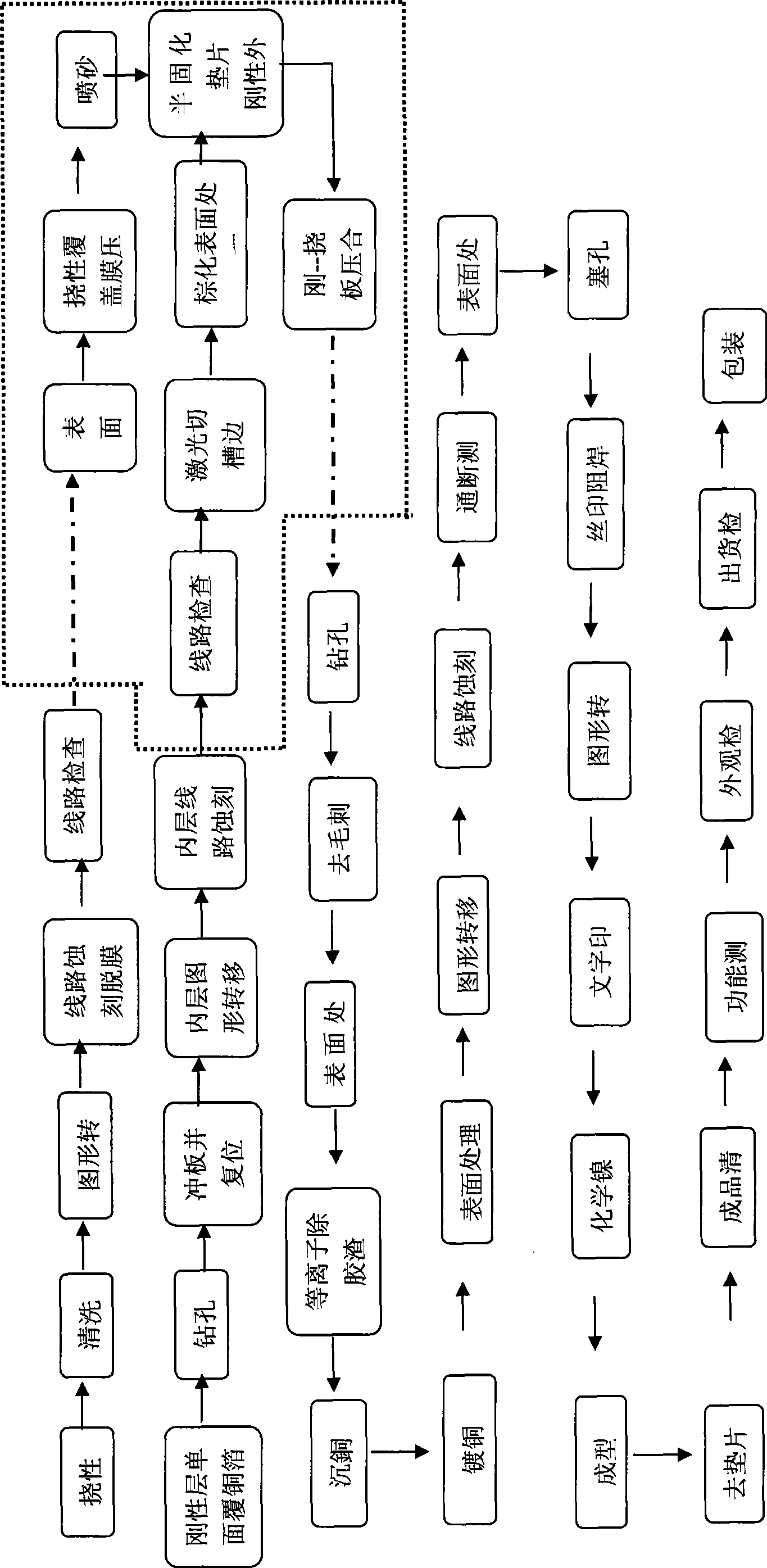

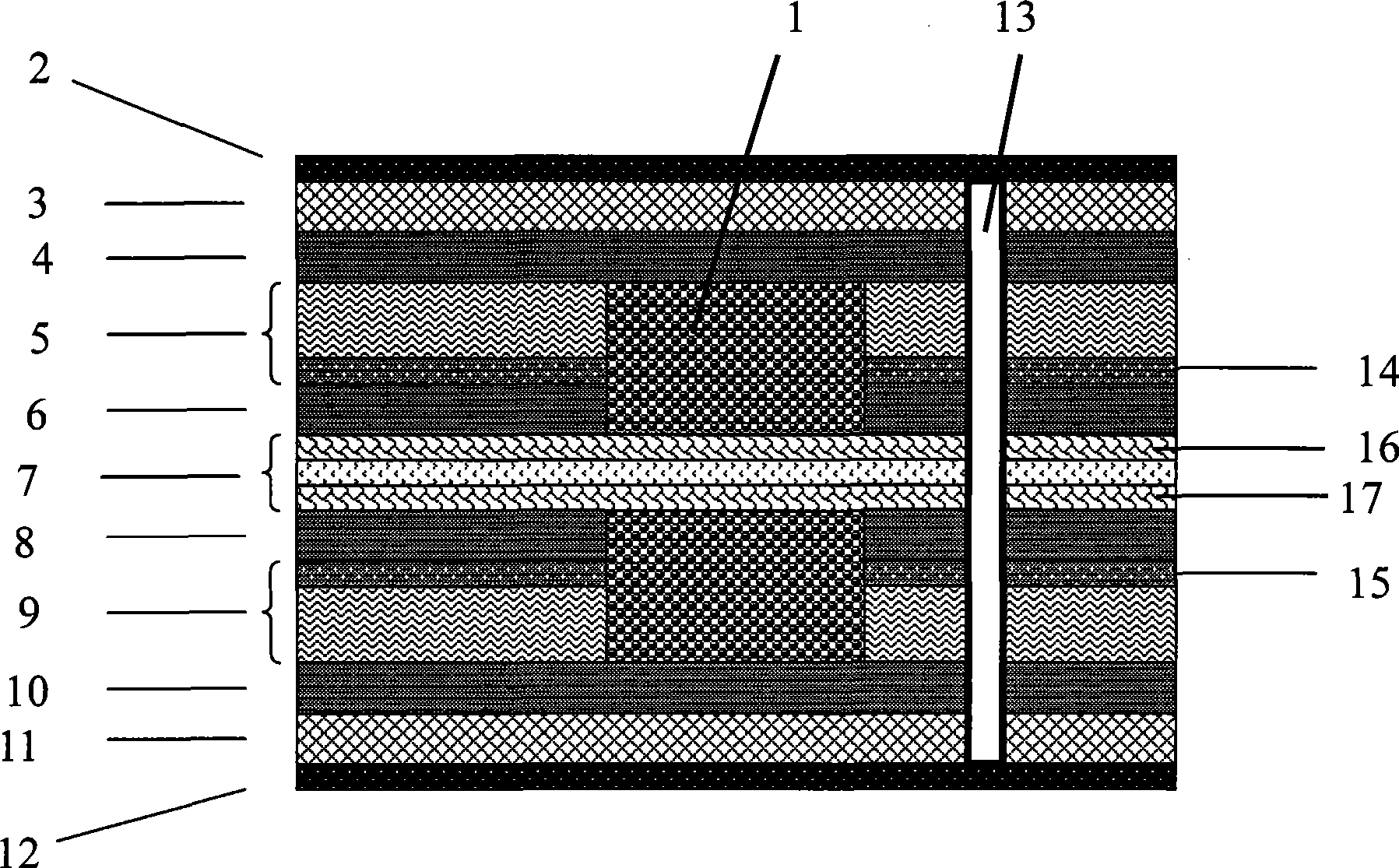

Manufacturing method for multilayered rigidity and flexibility combined printed circuit board

ActiveCN101505576AReduce dust occurrenceGood sealingMultilayer circuit manufactureCopper foilSurface finishing

The invention discloses a method for manufacturing multilayer flex-rigid printed circuit boards, and aims to solve the technical problem of filling efficiency and product quality in the process of processing the multilayer flex-rigid printed circuit boards. The method comprises that: preprocesses of a rigid circuit board part and a flexible circuit board part are carried out respectively, laminated and formatted, and then thermally compressed and overlapped, and a filler piece is processed by a punching method for the rigidity wiring board part; and when a rigid circuit board is processed, a rigid single-side copper-clad material is adopted, and then the following steps are completed in order: drilling, punching, transfer of inner layer patterns, etching of an inner layer circuit, circuit inspection, surface multibond, and semi-solid preparation of a rigid outer layer film of a washer and pure copper foil. Compared with the prior technology, hardware mould is directly used to perform die cutting on the filler piece on the position of a filling area; therefore, the method reduces the generation of bug dust in the processing process, has good leak tightness of the filling position, and greatly improves the reliability of performance and product percent of pass.

Owner:吉安新宇腾跃电子有限公司

Metal salt-free sealing agent for aluminum alloy anodic oxide film

ActiveCN101864589AImprove corrosion resistanceGood gloss and color retentionSurface reaction electrolytic coatingCobaltOrganic compound

The invention provides a metal salt-free sealing agent for an aluminum alloy anodic oxide film, belonging to the technical field of aluminum alloy anodic oxide film post treatment. The sealing agent of the invention is prepared by water solution composed of 1.0-10g / L of a hydration accelerator, 0.01-2g / L of a wetting agent, 0.01-3g / L of an ash inhibitor and 1-15g / L of a pH buffering agent, wherein the pH of workpiece fluid is 5.5-6.5, the operating temperature is 70-90 DEG C, and the sealing speed is 1.0-2.0min / um. The metal salt-free sealing agent creatively adopts organic compounds which are easily subject to biodegradation, does not contain any metal ions of nickel, cobalt, magnesium, calcium, lithium and the like as well as fluorinions, and obtains satisfactory sealing effect of the nano-pores of the aluminum alloy anodic oxide film by virtue of the scientific and coordinated component formula of the water solution; the aluminum alloy anodic oxide film obtained by seal treatment through the sealing agent has the advantages of good corrosion resistance, capability of meeting the requirements of GB 14952.1-94, good light-protection and color-protection properties of a film layer, no ash and pruina, no water stain after drying as well as light flowing color and small color difference change in case of sealing the organic dyeing film; and the metal salt-free sealing agent is widely applicable to sealing treatment of an original-color anodic oxide film, an electrolytic coloring anodic oxide film, a hard oxide film and a dyeing anodic oxide film.

Owner:WUHAN RES INST OF MATERIALS PROTECTION

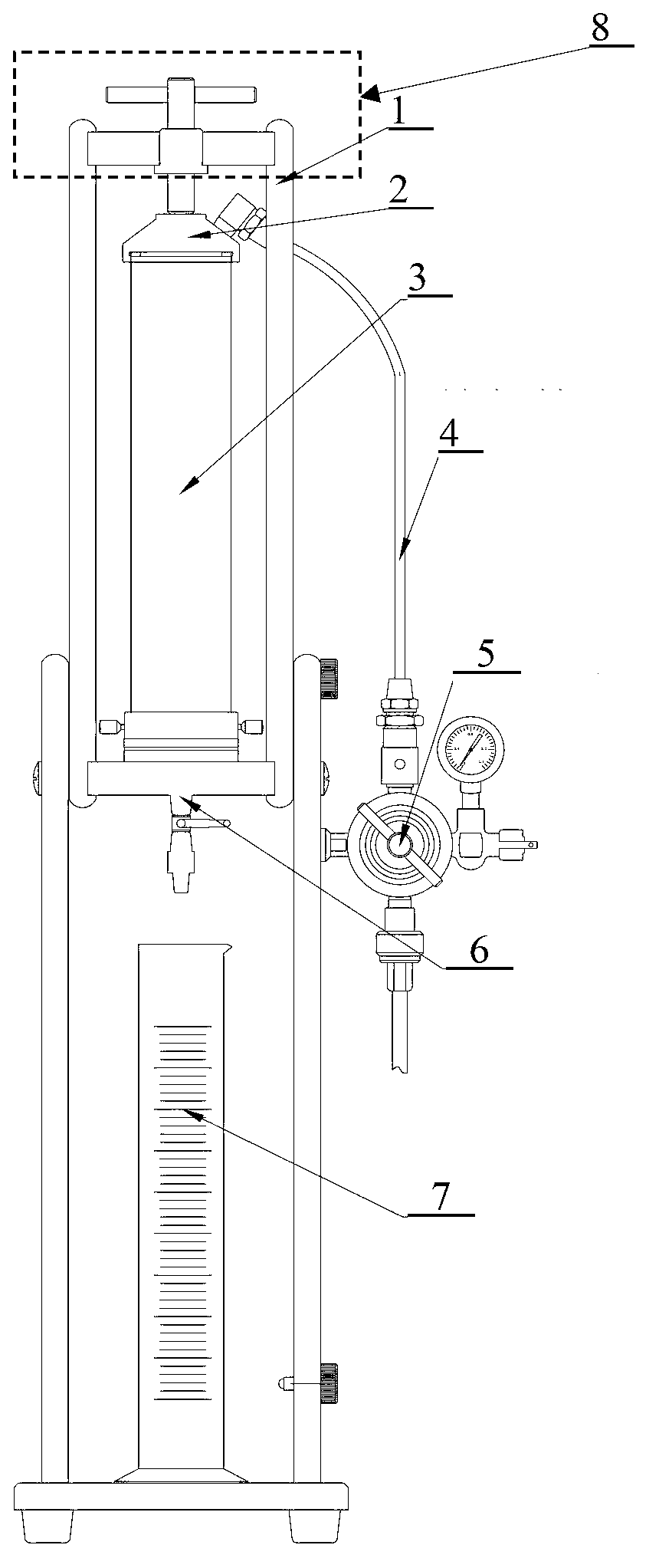

Gas pumping fixing occluder and use method thereof

ActiveCN103452525AEffective blocking purposeAvoid it happening againGas removalSealing/packingGas leakPipe

The invention discloses a gas pumping fixing occluder and a use method thereof. A three-hole pipe penetrates through three bags, a recyclable grouting pipe is communicated with a grouting channel of the three-hole pipe by a drainage device; a gas leaking handling pipe is communicated with a gas leaking handling channel of the three-hole pipe by a drainage device; a grouting hole of the drainage device and a grouting communicating small hole of the three-hole pipe are coaxial by a grouting small hole; a gas leaking handling hole of the drainage device and a gas leaking handling communicating small hole of the three-hole pipe are coaxial by a gas leaking handling small hole; check valves are arranged at the grouting channel in the three bags; a pressure check valve is mounted on the grouting channel between the No.2 bag and the No.3 bag. According to the gas pumping fixing occluder and the use method thereof, more effective grouting sealing can be realized on drill holes of a hole sealing section, generation of coal wall seams around drill holes at the hole sealing section can be more effectively avoided, and the occluder can also fill extremely small coal seams, so the hole sealing effect is optimal.

Owner:HENAN POLYTECHNIC UNIV

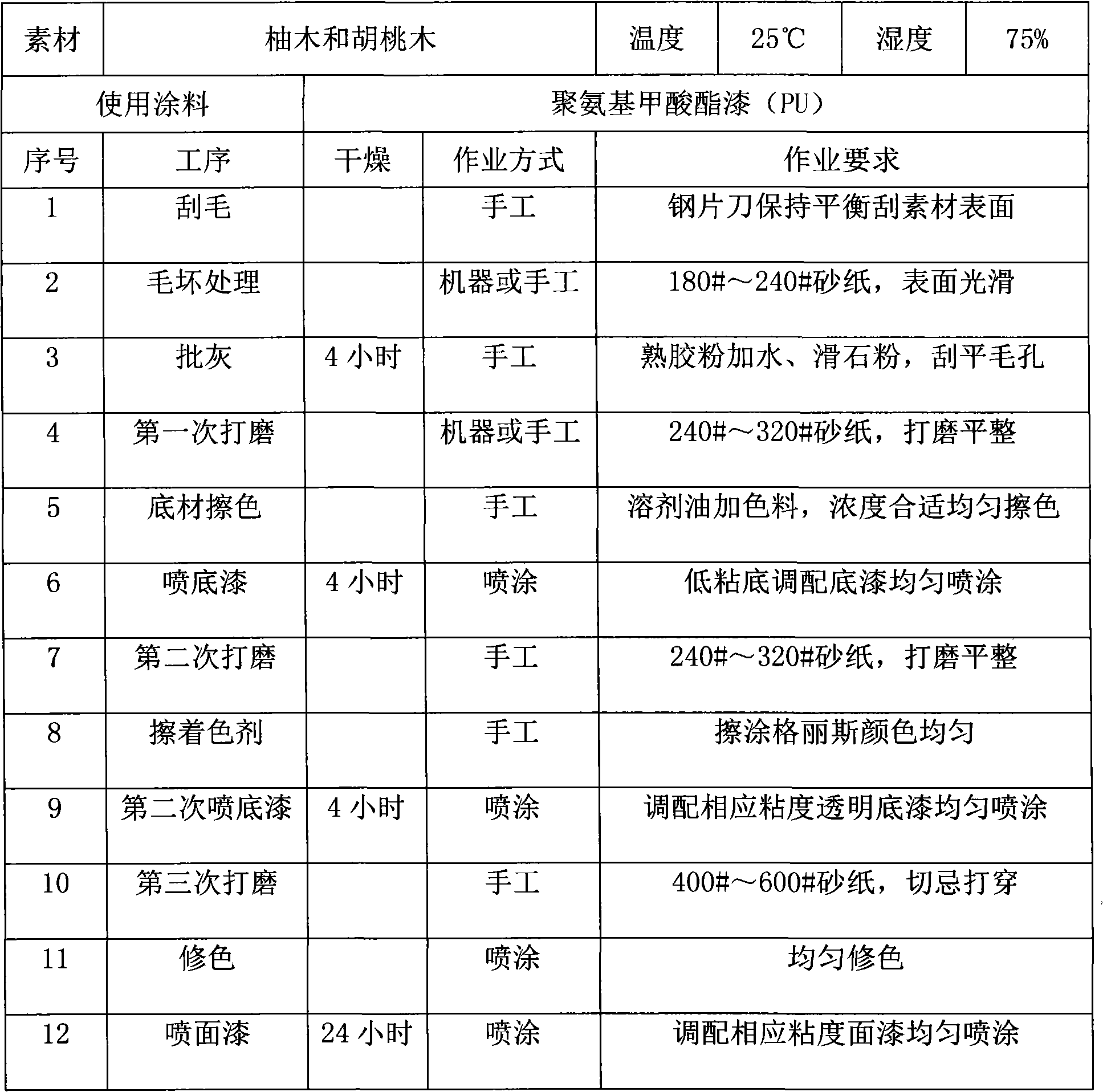

Paint coating process for wooden furniture

InactiveCN101670335AShorten the timeConsistent colorPretreated surfacesCoatingsRoughcastMaterials science

The invention relates to the field of paint coating processes, in particular to a paint coating process for wooden furniture. The paint coating process for the wooden furniture comprises the followingworking procedures: (1) scraping, (2) blank treatment, (3) plastering, (4) primary polishing, (5) base material coloring, (6) base paint spraying, (7) secondary polishing, (8) colorant coating, (9) secondary base paint spraying, (10) third polishing, (11) tinting, and (12) finish paint spraying. The paint coating process for the wooden furniture provided by the invention overcomes the defects that the blank treating and polishing time is long and the plane is not easy to be smoothened, improves the color definition of the furniture, and improves the visual effect and appreciation of the furniture.

Owner:莫有根

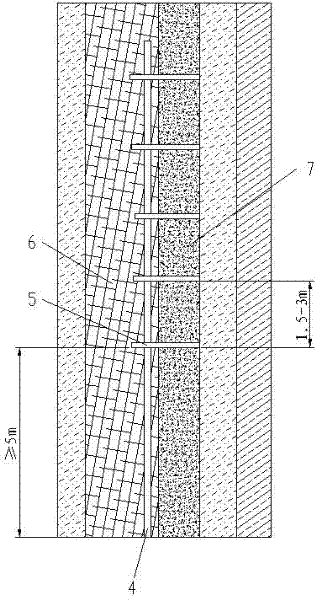

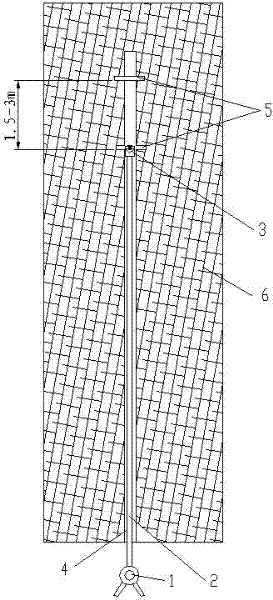

Depressurized extraction method for cutting through roof or floor of coal seam by abrasive water jet

InactiveCN102493833AGood sealing effectReduce gas extraction costsFluid removalGas removalAbrasive water jetCoal

The invention discloses a depressurized extraction method for cutting through a roof or a floor of a coal seam by an abrasive water jet, which comprises the following steps: a. drilling a bedding drill hole to set depth on the roof or the floor of a coal-rock mass or a hard layer by using a drilling machine through a drill stem and a slotting drill bit; b. delivering a high-pressure abrasive water jet of which the pressure is 25-30MPa to the slotting drill bit through the drill stem, wherein the drill stem rotates in situ; forming a radial slit on the hole wall of the bedding drill hole, wherein the slit penetrates the roof or the floor of the coal-rock mass or the hard layer and a soft layer; c. enabling the drill stem to rapidly retreat for 1.5-3m so as to form a new slit; d. repeating the step c until a plurality of radial slits are formed on the bedding drill hole, and moreover, reserving a safety rock pillar of at least 5m at the slit located at the position of the orifice of the bedding drill hole at a certain distance from the orifice; e. retreating the drill stem and the slotting drill bit and sealing the hole; and f. extracting gas by a gas extraction system. The depressurized extraction method for cutting through the roof or the floor of the coal seam by the abrasive water jet has the beneficial effects that the drill hole does not have potential safety hazards and is easy to form; a hole sealing effect is good; the time of reaching the standards of extraction is short; the production efficiency is high; and the extraction is safe.

Owner:重庆市能源投资集团科技有限责任公司

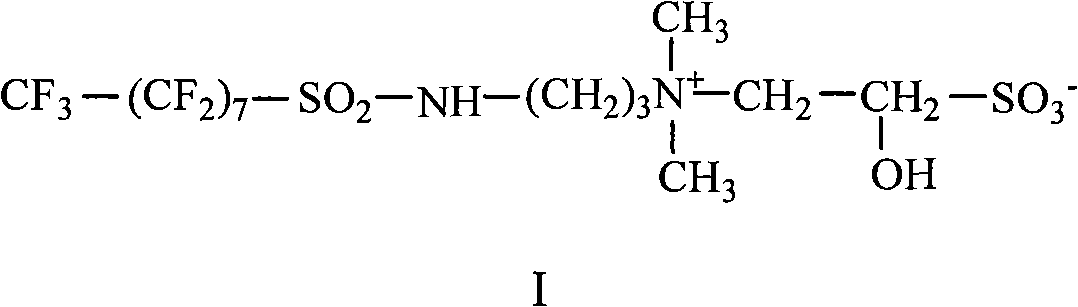

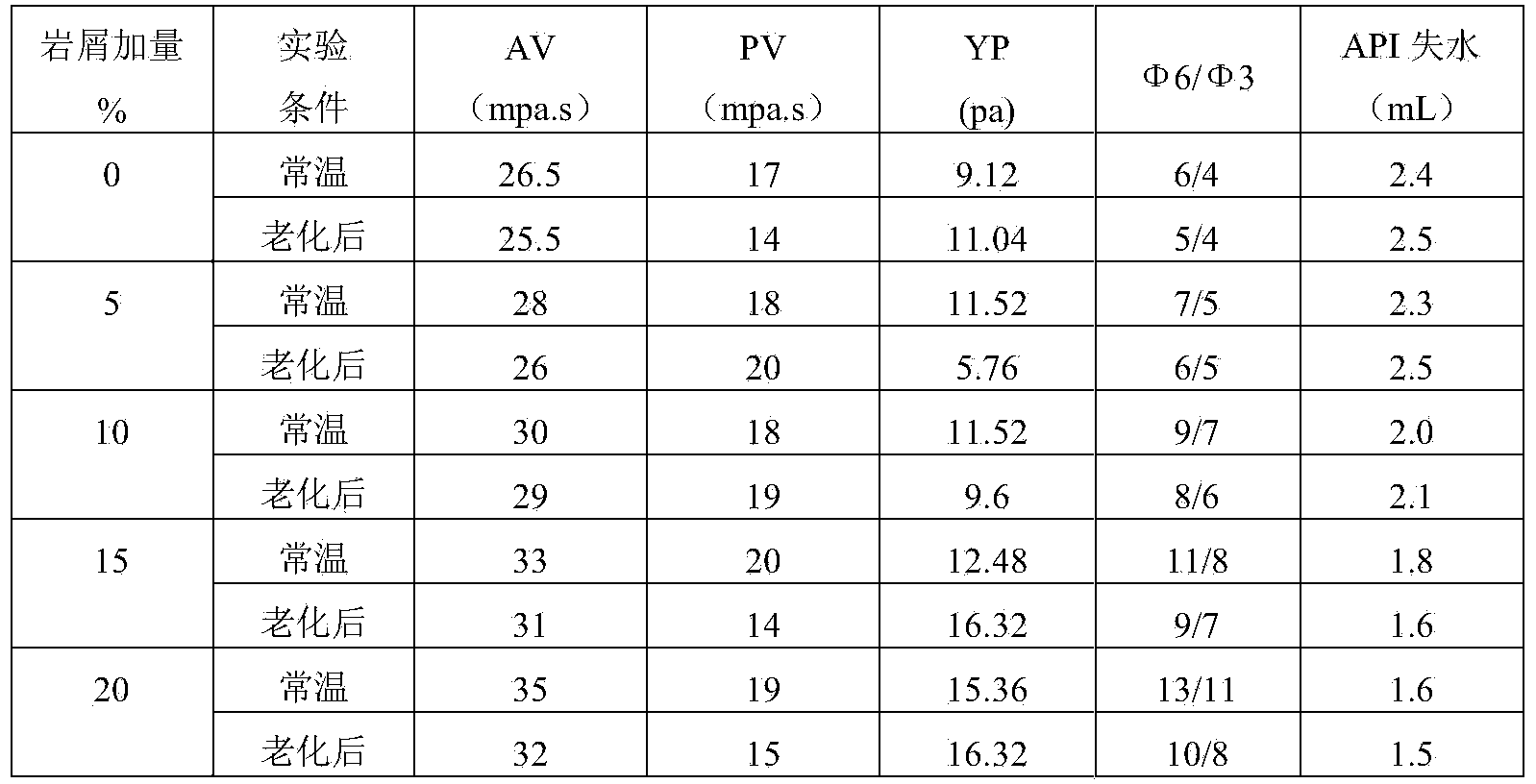

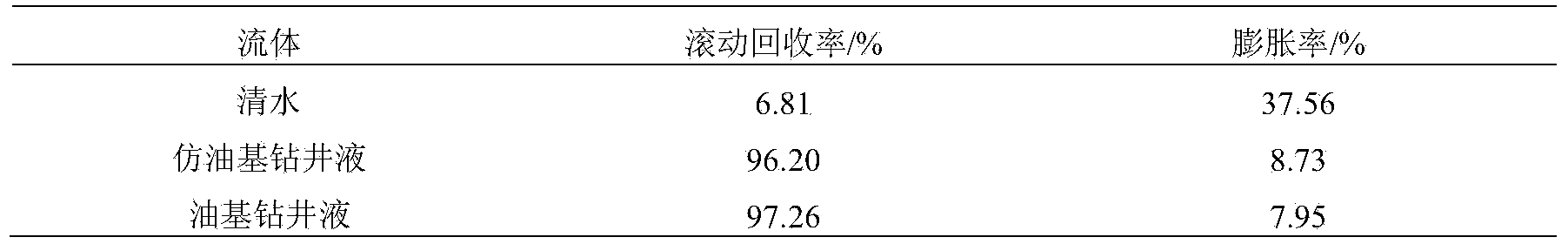

Strong-inhibition drilling fluid system

ActiveCN103013470AEnhanced inhibitory effectImprove stabilityDrilling compositionSlurryHigh pressure

The invention relates to a strong-inhibition drilling fluid system, comprising the following components by mass percent of 2.5-4.5% of bentonite slurry, 0.1-0.3% of alkaline regulator, 0.3-2.0% of shale inhibitor, 0.2-0.4% of metal ion polymer, 2.0-5.0% of walchowite, 2.0-5.0% of sulfomethal phenolaldehy resin, 1.0-3.0% of cation emulsified asphalt, 0.5-3.0% of lubricating agent, 0.2-0.8% of emulsifier, 2.0-8.0% of crude oil, and 1.0-3.0% of calcium carbonate superfine powder according to 100% of water. The compound in a general formula (I) is also provided; R1 is H or CH3; R2 is H, CH3 or C2H5; and X is an integer between 2 and 20 and applied to the shale inhibitor. The compound and the cation emulsified asphalt are applied to the drilling liquid system; the drilling liquid system is strong in shale inhibition; the shale recovery rate can be up to 90.33% and is improved by over 35.02% in comparison with that of water shale; the high temperature resistance can be up to 150 DEG C; the lubricating friction coefficients before and after aging respectively are smaller than 0.1; the strong-inhibition drilling fluid system is strong in capacity of resisting poor soil, salt and calcium contamination, strong in rejection capability, and good in blocking effect; the API (American petroleum institute) water loss of the drilling fluid is smaller than 4.5mL, and the HTHP (high temperature and high pressure) water loss is smaller than 12mL.

Owner:CHINA PETROLEUM & CHEM CORP

Concrete maintenance and reinforcement treatment method

InactiveCN102220813AGood sealingIncreasing the thicknessBuilding repairsBridge erection/assemblyFiberAdhesive

The invention relates to a concrete maintenance and reinforcement treatment method. The method comprises the following steps: (1) carrying out nondestructive treatment on the concrete base surface defects; (2) carrying out rust-proof treatment on reinforcing bars; (3) carrying out concrete alkalinity recovery treatment; (4) carrying out concrete crack repairing treatment; (5) daubing new and old concrete adhesives; (6) daubing inorganic polymer mortar and carrying out curing; (7) sticking carbon fiber cloth; (8) brushing an inorganic water and salt injury resistant concrete protective agent; and (9) brushing a surface self-cleaning material, thus completing construction. The method has the following beneficial effects: rust can be removed or prevented from the reinforcing bars to protect the reinforcing bars and prevent further corrosion; by adopting the carbon fiber cloth for reinforcement, the concrete structure has the characteristics of high strength, light weight, simpleness and convenience in construction and corrosion resistance; the bearing capability of the beam body is improved; the deflection of the structure is reduced; the construction efficiency is greatly improved by adopting the airless spraying and coating operations; the coating is saved by 30%; and by brushing the self-cleaning material, the structure has the self-cleaning capability, thus avoiding cleaning or reducing the cleaning frequency.

Owner:SHANGHAI FAHE BRIDGE & TUNNEL MAINTENANCE ENG TECH

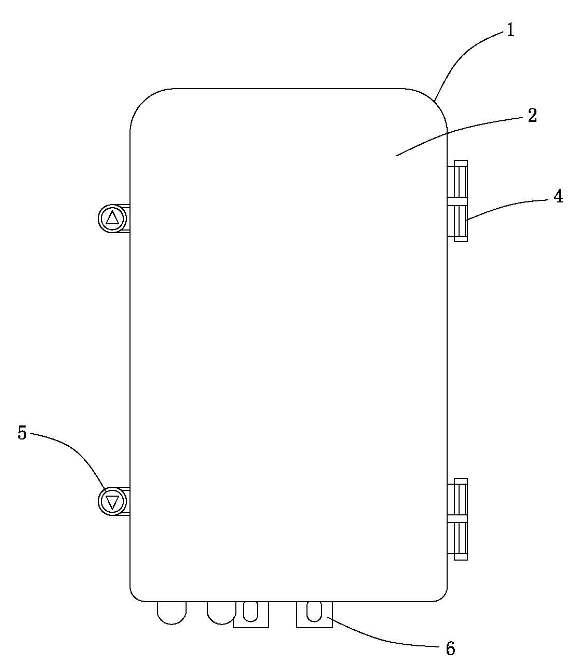

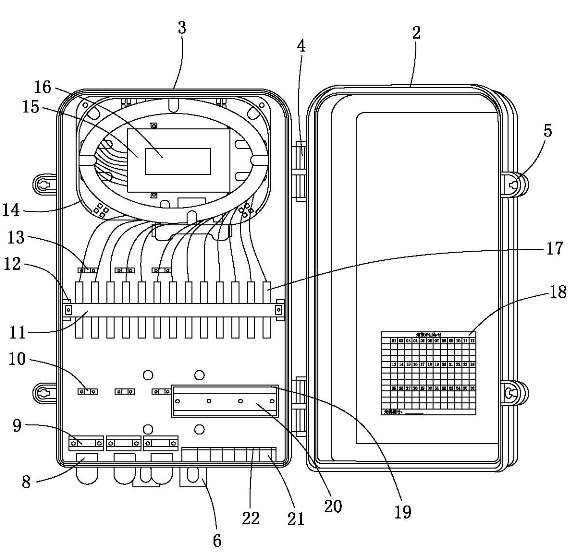

Multifunctional fiber splitting box

InactiveCN102062913ASmall and beautiful appearanceGood sealing performanceFibre mechanical structuresPhysicsWeather proofing

The invention relates to a multifunctional fiber splitting box relating to the technical field of optical fiber communication equipment. The multifunctional fiber splitting box is characterized in that the upper half part inside a box body is provided with a fiber storing and fusing disc; one surface of the fiber storing and fusing disc is provided with an optical branching device installation groove, and the other surface is provided with a fiber fusing disc; the part which is near to middle inside the box body is provided with an adapter bracket; an outdoor optical cable guide hole and a dish-shaped optical cable output end are arranged below the box body; an outdoor optical cable guided into the fiber splitting box, an optical fiber bundle tube with a protective layer removed, a steel wire playing a strengthening role on the outdoor optical cable and a dish-shaped optical cable are all fixed by special fixing structures; and the box body can be hung on a wall or a rod through a wall hanging fixing part or an anchor ear. The invention has the advantages of small and exquisite appearance, reasonable internal setting, very convenient wire arrangement, routing and connection, weather proofing and corrosion resistance and is especially suitable for the reconstruction of urban old areas and countries with dispersed residences; and in addition, one multifunctional fiber splitting box can meet the requirements of 16-32 dispersed resident families on FTTH (Fiber To The Home) directly carried out through the outdoor optical cable and can be popularized and applied due to low manufacture and usage cost.

Owner:昆山市大唐通讯设备有限公司

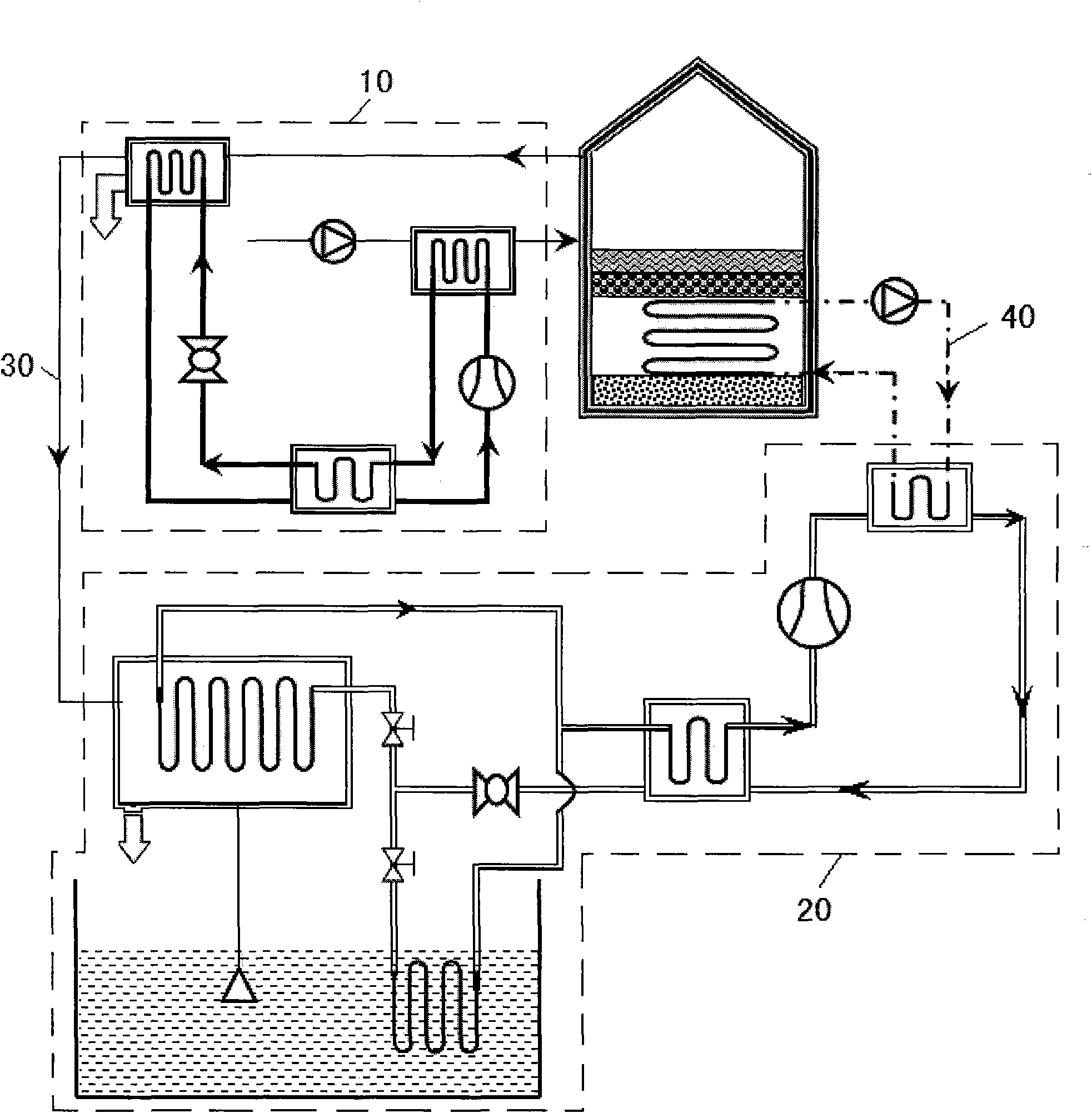

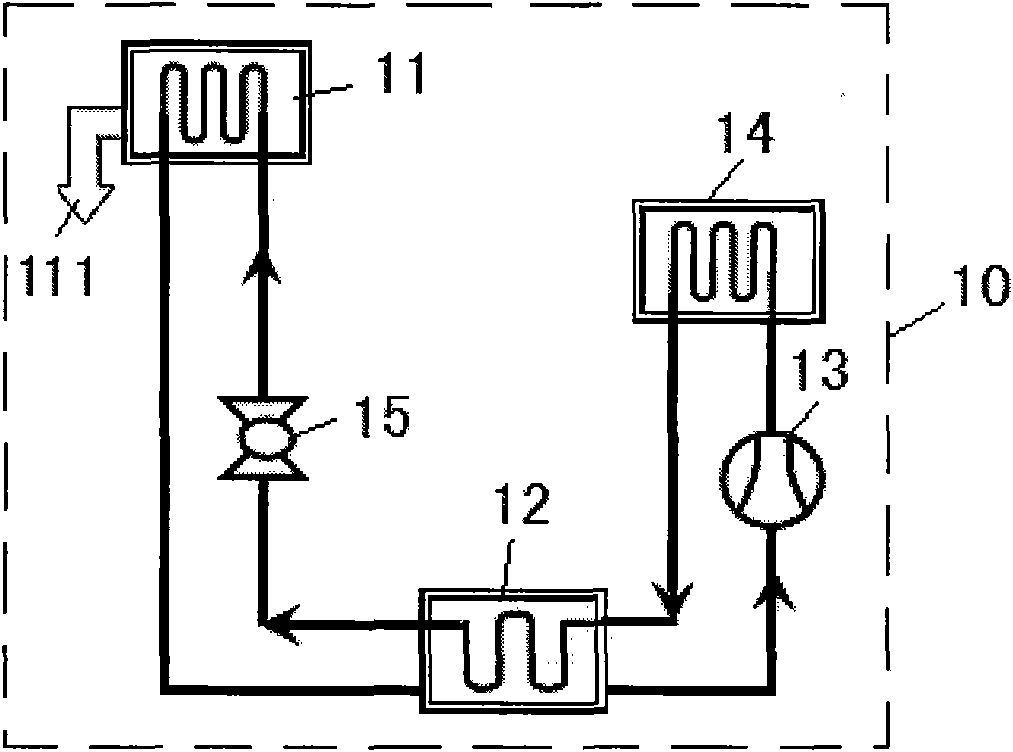

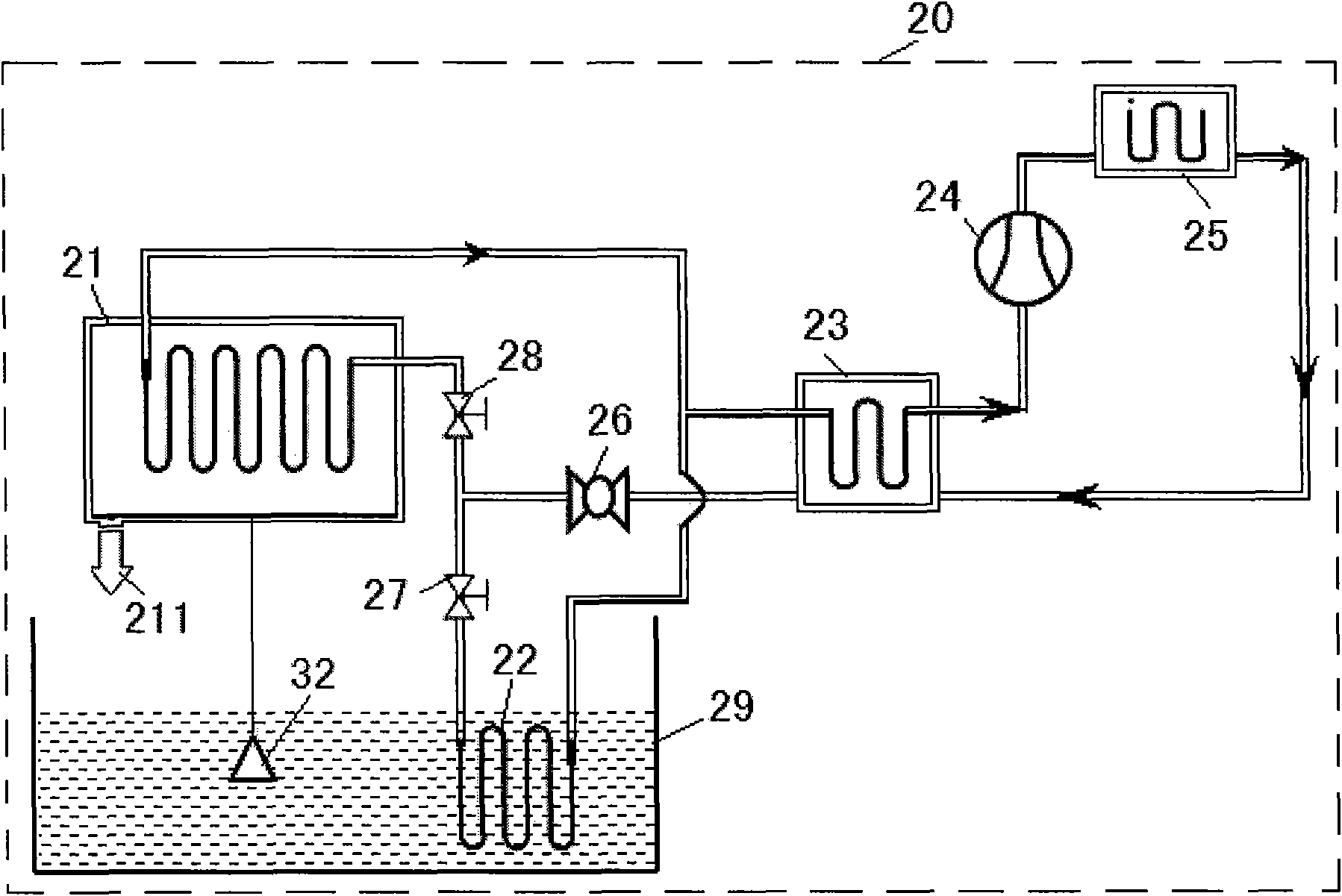

Mud drying system and use method thereof

ActiveCN101618930AHigh drying yieldReduce drying energy consumptionSludge treatment by de-watering/drying/thickeningHeat pumpsSludgeWater circulation

The invention relates to a mud drying system and a use method thereof. The mud drying system comprises a transcritical heat pump auxiliary heat supplying loop, a heat pump auxiliary heat supplying loop, an air heating and waste heat recovering loop and a hot water circulation loop; the transcritical heat pump auxiliary heat supplying loop comprises an evaporator, an internal heat exchanger, a compressor, a gas cooler and a throttle valve; the heat pump auxiliary heat supplying loop comprises an evaporator, a wastewater and waste heat recovering evaporator, an internal heat exchanger, a compressor, a condenser, a throttle valve, two stop valves and a wastewater tank; the air heating and waste heat recovering loop comprises a hothouse, an air compressor, a gas discharging and carrying port, a first evaporator, the other evaporator and a condenser; and the hot water circulation loop comprises a pump, a hothouse and the condenser in the heat pump auxiliary heat supplying loop. The invention adopts the hothouses to obtain solar energy to heat mud and utilizes the transcritical heat pump auxiliary heat supplying loop and the heat pump auxiliary heat supplying loop to recover the sensible heat and the latent heat in humid air to heat mud, thereby lowering the energy consumption for drying the mud. The invention can be widely applied to various mud processing fields.

Owner:TSINGHUA UNIV +3

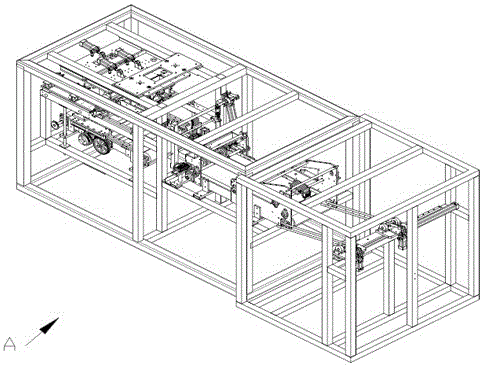

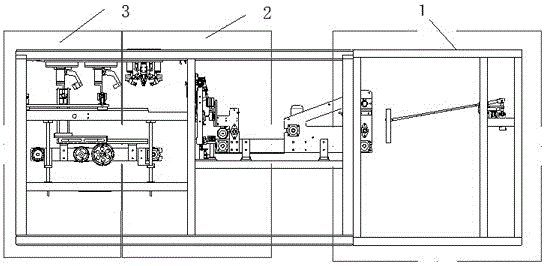

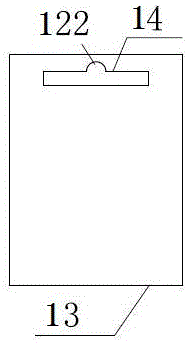

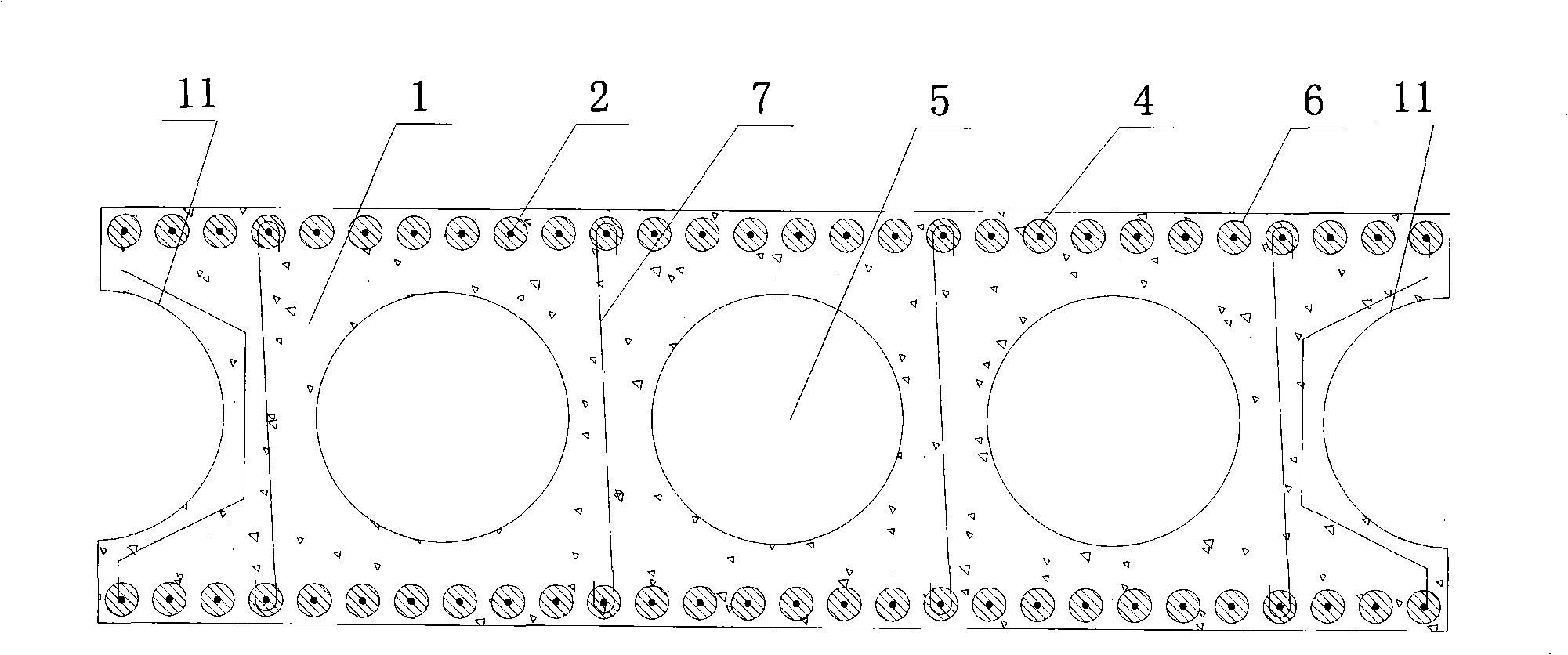

Automatic packaging machine and operating method thereof

ActiveCN106829059ASimple structureStable and efficient workWrapper twisting/gatheringEngineeringMachine tool

The invention relates to an automatic packaging machine and an operating method thereof. The machine comprises a bag feeding device, a bag sheathing device, and a sealing bag-delivery device. The bag feeding device comprises a bag crossing catch rod for catching on a bag-carrying opening of a packaging bag. The bag crossing catch rod is driven by a first driving mechanism to swing up and down. A first sucking disc is arranged above a first belt conveyor mechanism. The first sucking disc is driven by a second driving mechanism to move laterally and vertically and driven by a third driving mechanism to swing up to place the sucked packaging bag on the first belt conveyor mechanism. The bag feeding device is provided with two bag hanging mechanisms operating alternatively. The bag sheathing device comprises a bag opening mechanism, a bag distracting and conveying mechanism and a bag fixing and arranging mechanism which are arranged on a frame. The sealing bag-delivery device comprises a bag fixing and arranging mechanism, a heat-sealing mechanism and a cold pressing mechanism which are arranged above a second belt conveyor mechanism in order in an output direction. Finger cylinder groups for clamping a packaging bag are arranged on the upper portions of both sides of the second belt conveyor mechanism, and each finger cylinder group comprises a first finger cylinder, a second finger cylinder, and a third finger cylinder, and is fixed to a second slider. The automatic packaging machine is capable of achieving automatic packaging, and also can ensure the quality of sealing.

Owner:ZHANGZHOU JIALONG TECH INC

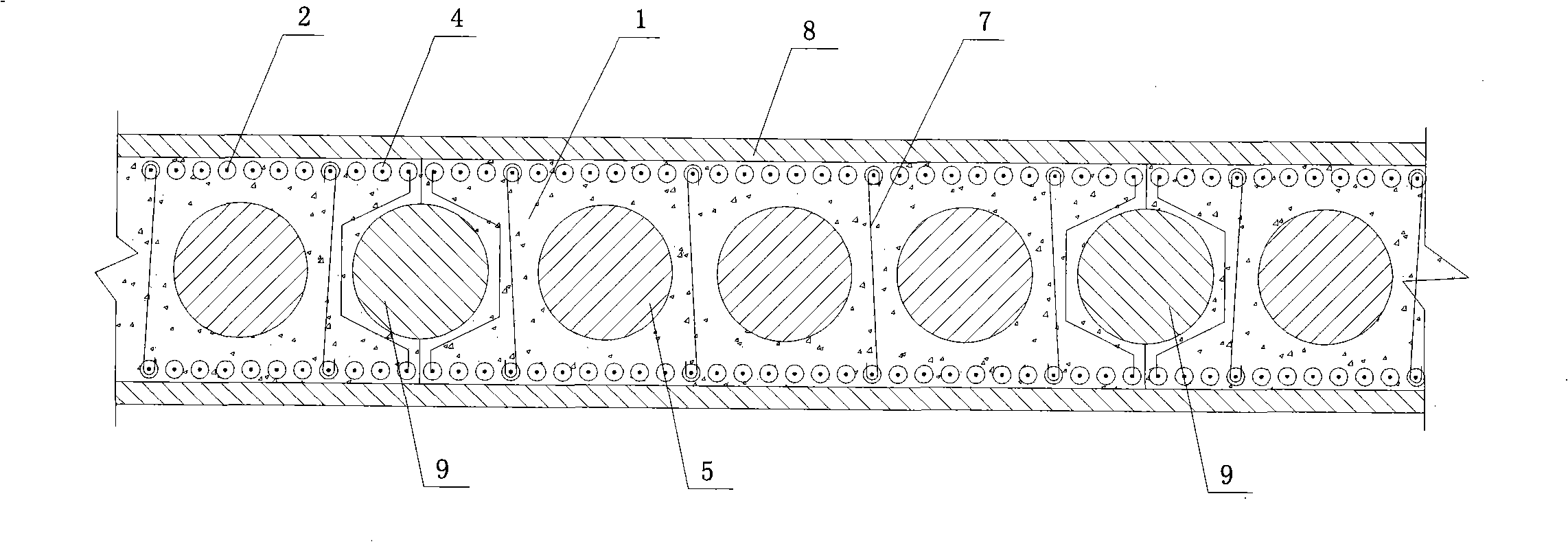

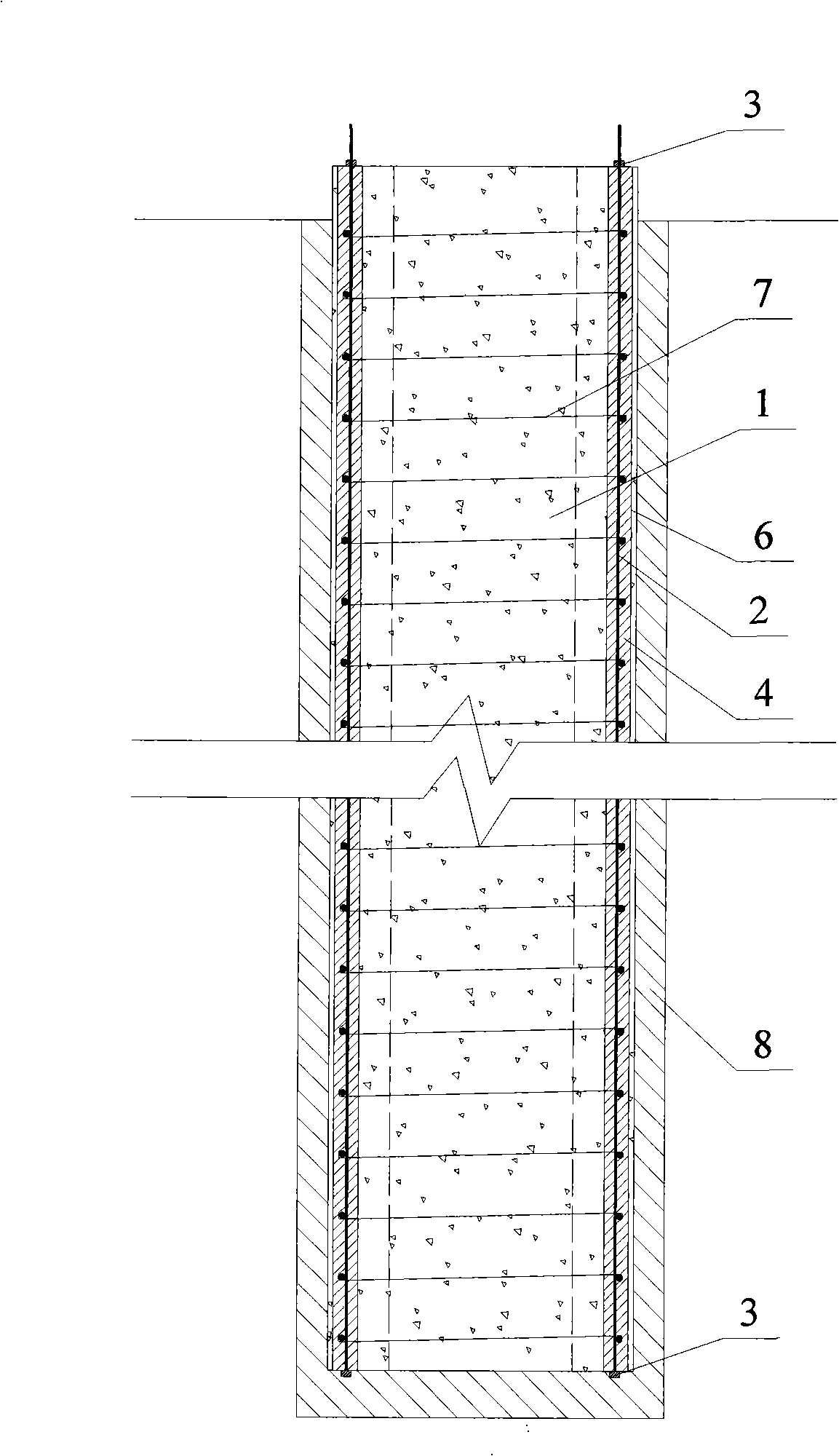

Lattice type prefabricated prestressed underground continuous wall and its construction method

The invention discloses a latticed type precast prestressed underground diaphragm wall, comprising a precast wall body, wherein two rows of prestressing steel strands vertically pass through the inside of the precast wall body; the prestressing steel strands apply prestress after the concrete strength of a concrete wall body reaches over 80 percent, and the upper and lower end faces of the precast wall body are locked by prestressing anchorage device; two rows of the prestressing steel strands are connected at intervals through transverse structure reinforcing steel bars along the height direction; joint parts on two sides of the precast wall body are of a concave semicircular shape; a protective layer is concreted on the periphery of each prestressing steel strand; and a hollow through hole throughout the height direction of the wall body is arranged inside the precast wall body. The diaphragm wall is concreted and precast on the ground, which can well guarantee the shape, size and density of the wall body, ensures that the quality of the wall body cannot be affected by strata or slurry wall, and can thoroughly eradicate joint mud inclusion, wall body sand inclusion, reinforcing steel bar exposure, loosening, wall surface protuberance, water leakage, sand shifting and other quality qualitative common faults.

Owner:万勇 +3

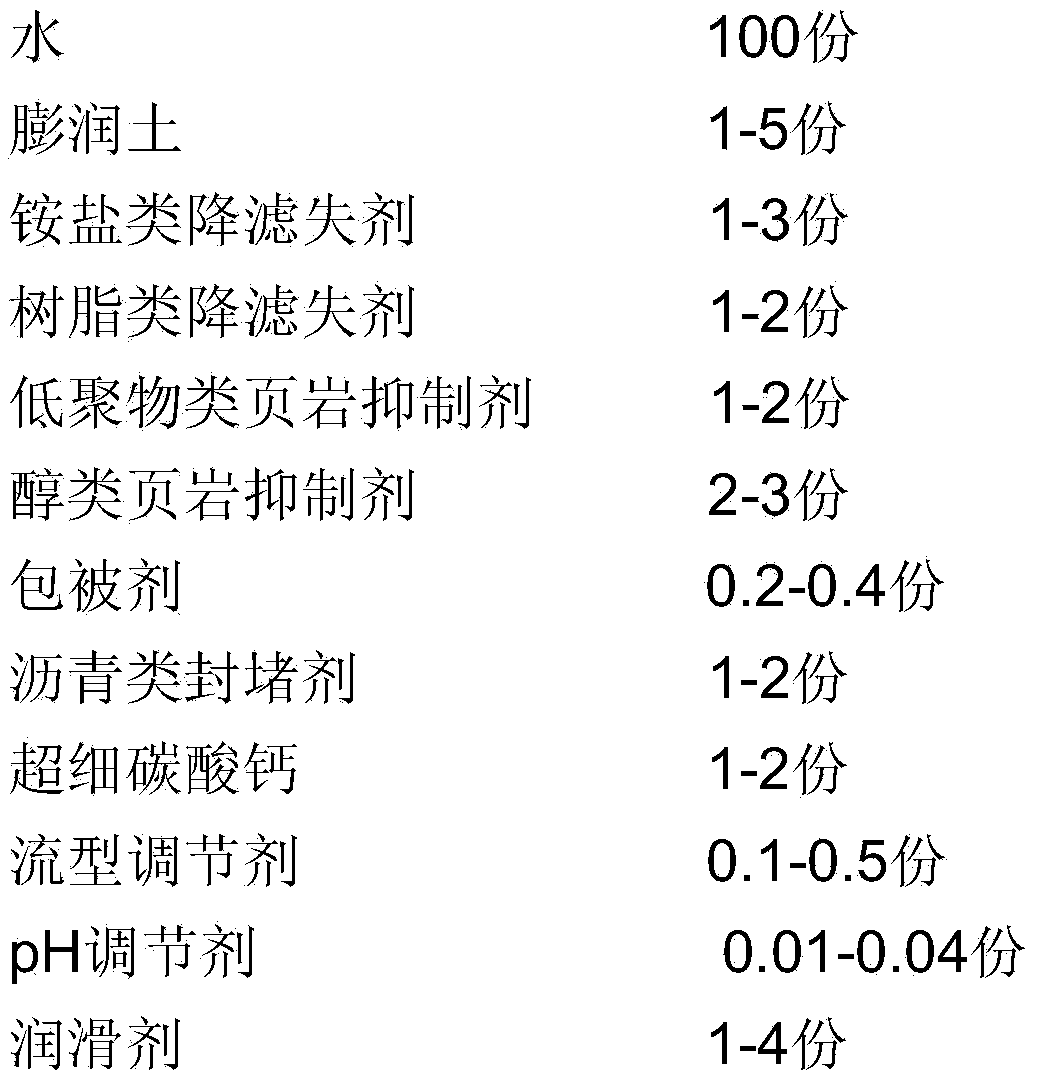

Oil-base imitating drilling fluid with characteristics of strong inhibition, strong blocking and high lubricity

InactiveCN104388065AEnhanced inhibitory effectStrong blockingDrilling compositionWater basedUltra fine

The present invention relates to an oil-base imitating drilling fluid with characteristics of strong inhibition, strong blocking and high lubricity. In the prior art, the existing amine compound-containing water-base drilling fluid provides the weak blocking capability for the mud shale micro-crack, and the lubricity can not completely meet the construction requirement. With the oil-base imitating drilling fluid of the present invention, the problems in the prior art are mainly solved. The oil-base imitating drilling fluid comprises, by weight, 100 parts of water, 1-5 parts of bentonite, 1-3 parts of an ammonium salt filtrate reducer, 1-2 parts of a resin filtrate reducer, 1-2 parts of an oligomer shale inhibitor, 2-3 parts of an alcohol shale inhibitor, 0.2-0.4 part of a coating agent, 1-2 parts of an asphalt blocking agent, 1-2 parts of ultra-fine calcium carbonate, 0.1-0.5 part of a flow type adjusting agent, 0.01-0.04 part of a pH value adjusting agent, and 1-4 parts of a lubricant. According to the present invention, the oil-base imitating drilling fluid of the present invention is the water-base drilling fluid having the performance equivalent to the oil-base drilling fluid, the safe, rapid and efficient drilling construction in the mud shale stratum and the unconventional dense oil reservoir is ensured, and the new technical support is provided for the effective development of the oil and gas reservoir.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com