High-temperature solar thermal-collecting tube and manufacturing process thereof

A technology of solar collector tube and manufacturing process, which is applied in the field of solar thermal utilization, can solve the problems of low sealing temperature and difficulty in meeting the requirements of vacuum and high temperature exhaust of the collector tube, and achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

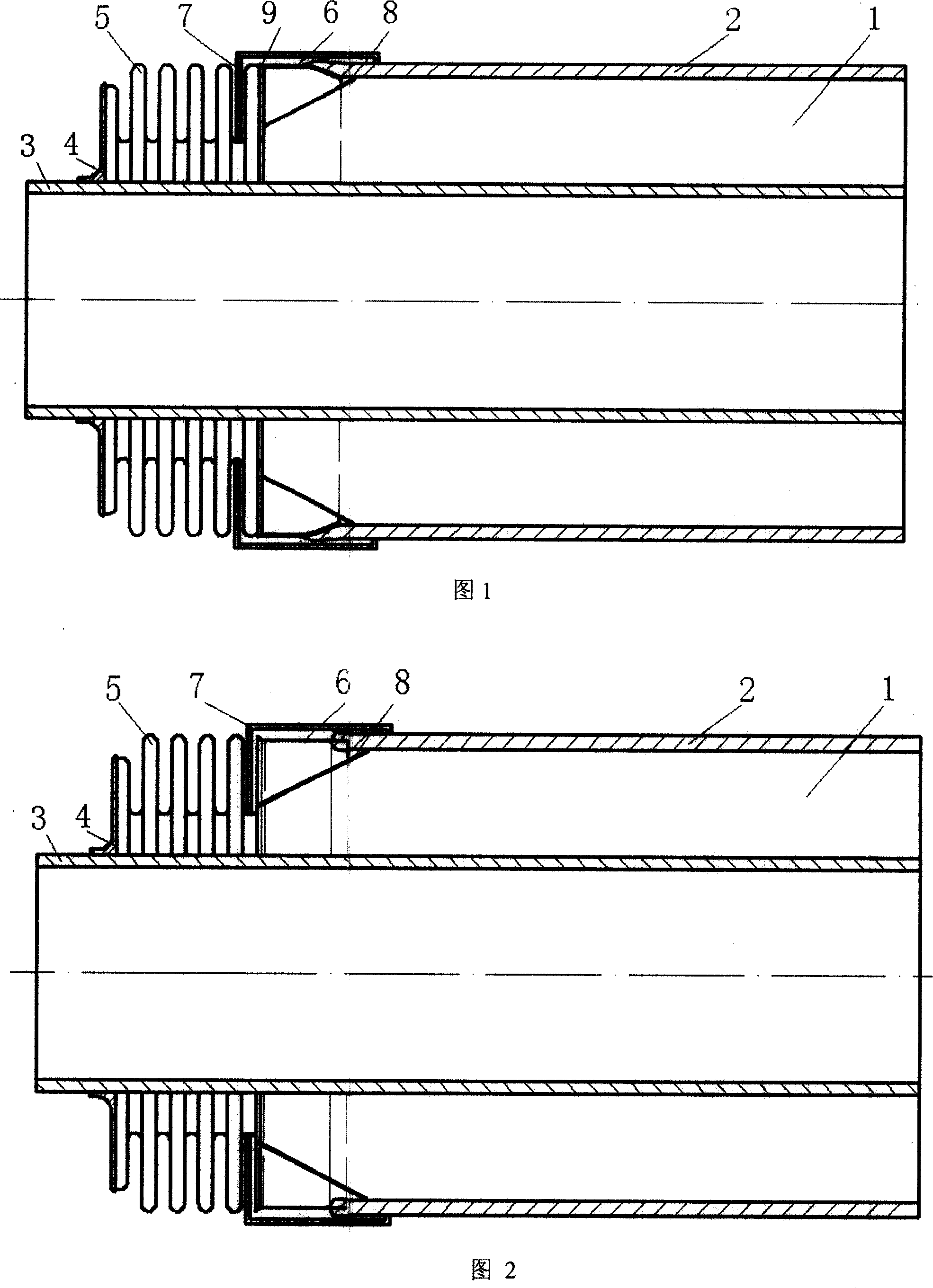

[0043] FIG. 1 shows the end of a heat collecting tube 1 in section. The heat collecting tube 1 includes a glass outer tube 2 and a metal inner tube 3 coaxially located in the glass outer tube 2. The metal inner tube 3 is made of stainless steel alloy, and its outer layer is coated with a high-temperature-resistant aluminum oxide cermet selective absorption coating.

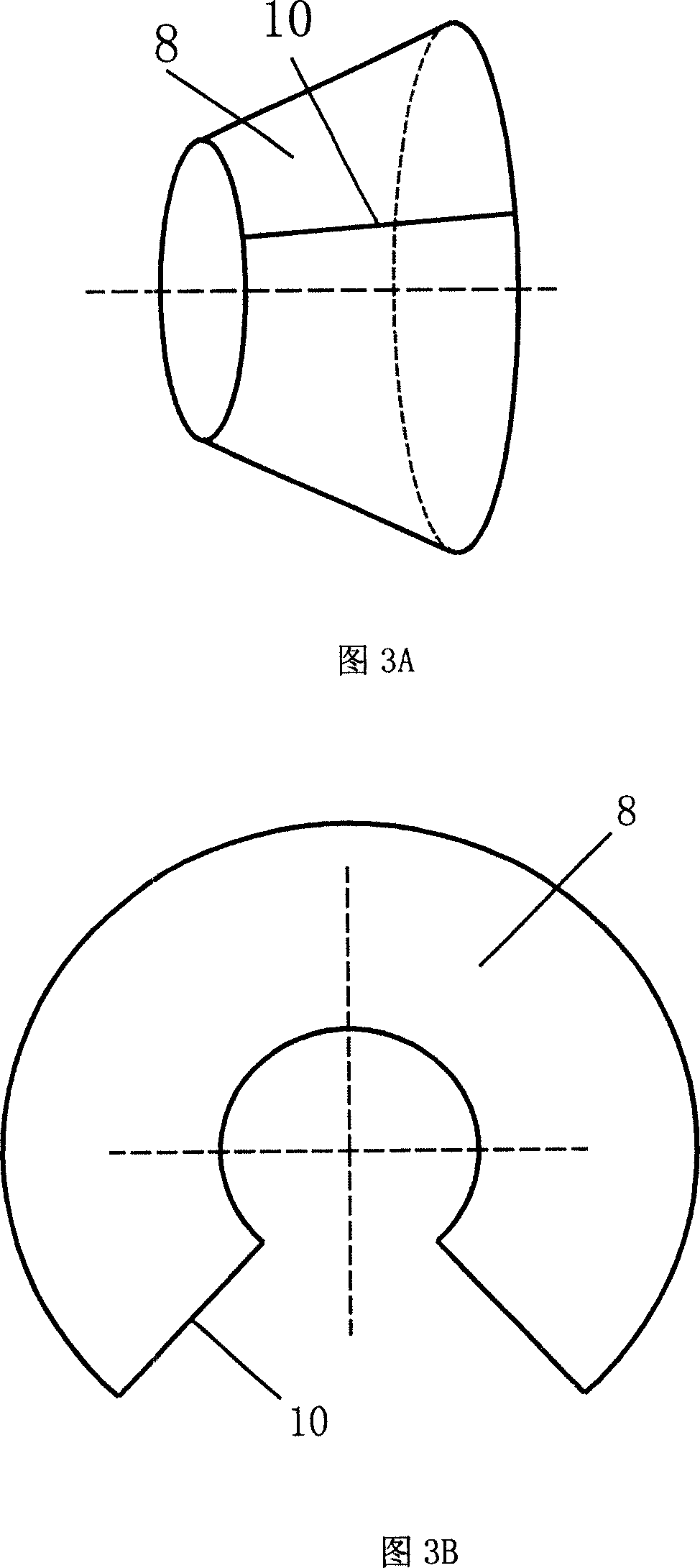

[0044]The connecting piece 4 connects the metal inner tube 3 and the bellows 5 with expansion compensation; the connecting piece 9 welds the bellows 5 and the Kovar ring 6 together, and the thin-walled light-shielding ring 8 is also welded on the bellows 5, The inclination of the shading ring is calculated according to the law of reflection to ensure that it can not only block the light but also reflect the light to the metal tube as much as possible. The heat shield 7 is set on the Kovar ring to protect the seal from radiation.

[0045] Specific process flow:

[0046] In this embodiment, glass outer tube 2 sele...

Embodiment 2

[0057] Fig. 2 shows a partial sectional view of the heat collecting tube of the second embodiment in section.

[0058] In the present embodiment, glass outer tube 2 selects No. DM305 glass, and its coefficient of thermal expansion is 4.9×10 -6 K -1 , the diameter is 90-150mm, the wall thickness is 1.5-4mm; the Kovar ring is made of 4j30 alloy, and its thermal expansion coefficient is 4.8×10 -6 K -1 , with a diameter of 90-150 mm and a wall thickness of 0.5-1 mm; the structure of the heat collecting tube is basically similar to that of Embodiment 1, the difference is that the metal-glass transition piece Kovar ring 6 is directly inserted into the end of the glass tube body 2 for about 3-9 mm, In this way, a double-sided seal is formed, which ensures the seal strength and air leakage rate. In addition, the Kovar ring 6 is directly welded to the bellows 5 without using a connecting piece.

[0059] Specific process flow:

[0060] 1. With embodiment 1;

[0061] 2. Mechanicall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal expansion coefficient | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com