Lattice type prefabricated prestressed underground continuous wall and its construction method

A technology of underground diaphragm wall and construction method, which is applied in basic structure engineering, artificial island, sheet pile wall, etc., to achieve the effect of shortening construction period, tight integration and strong durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

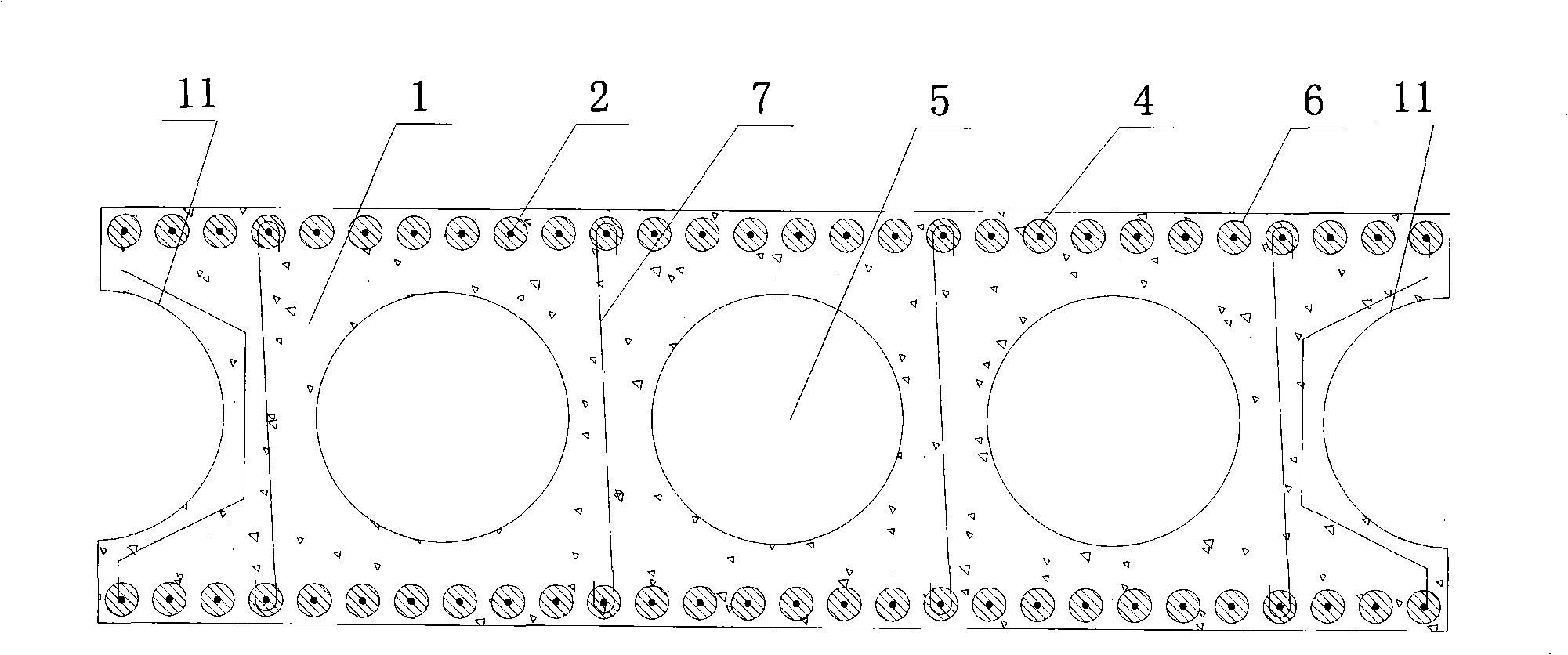

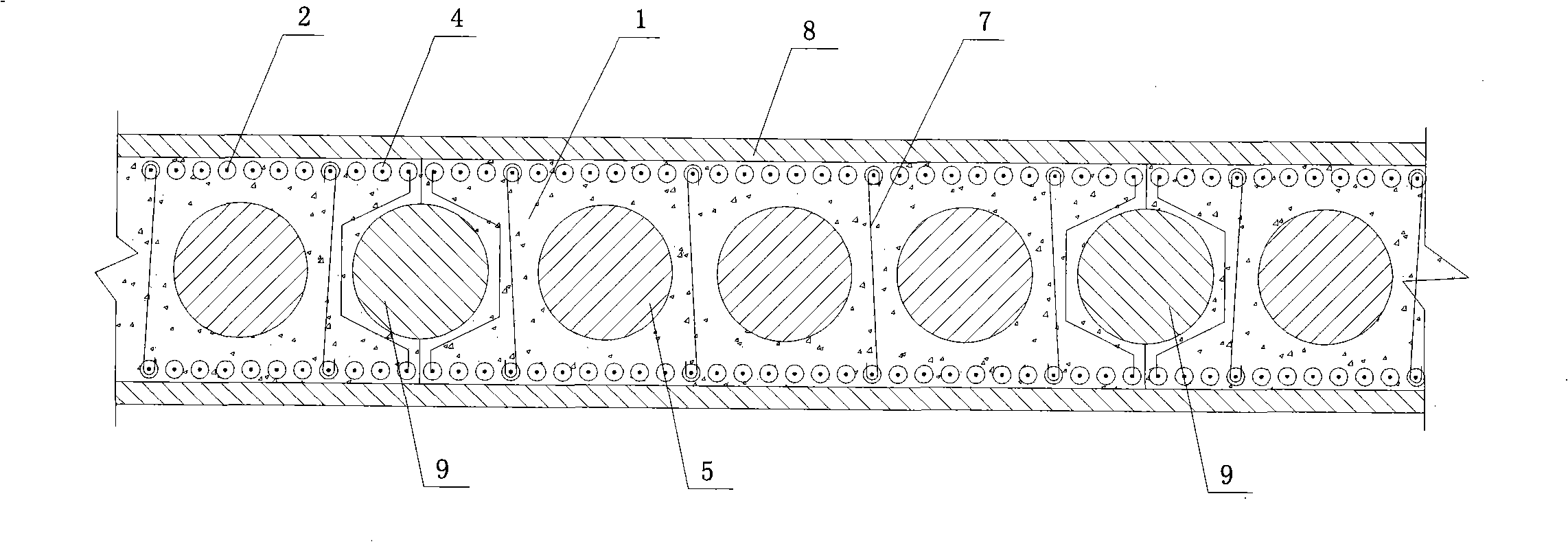

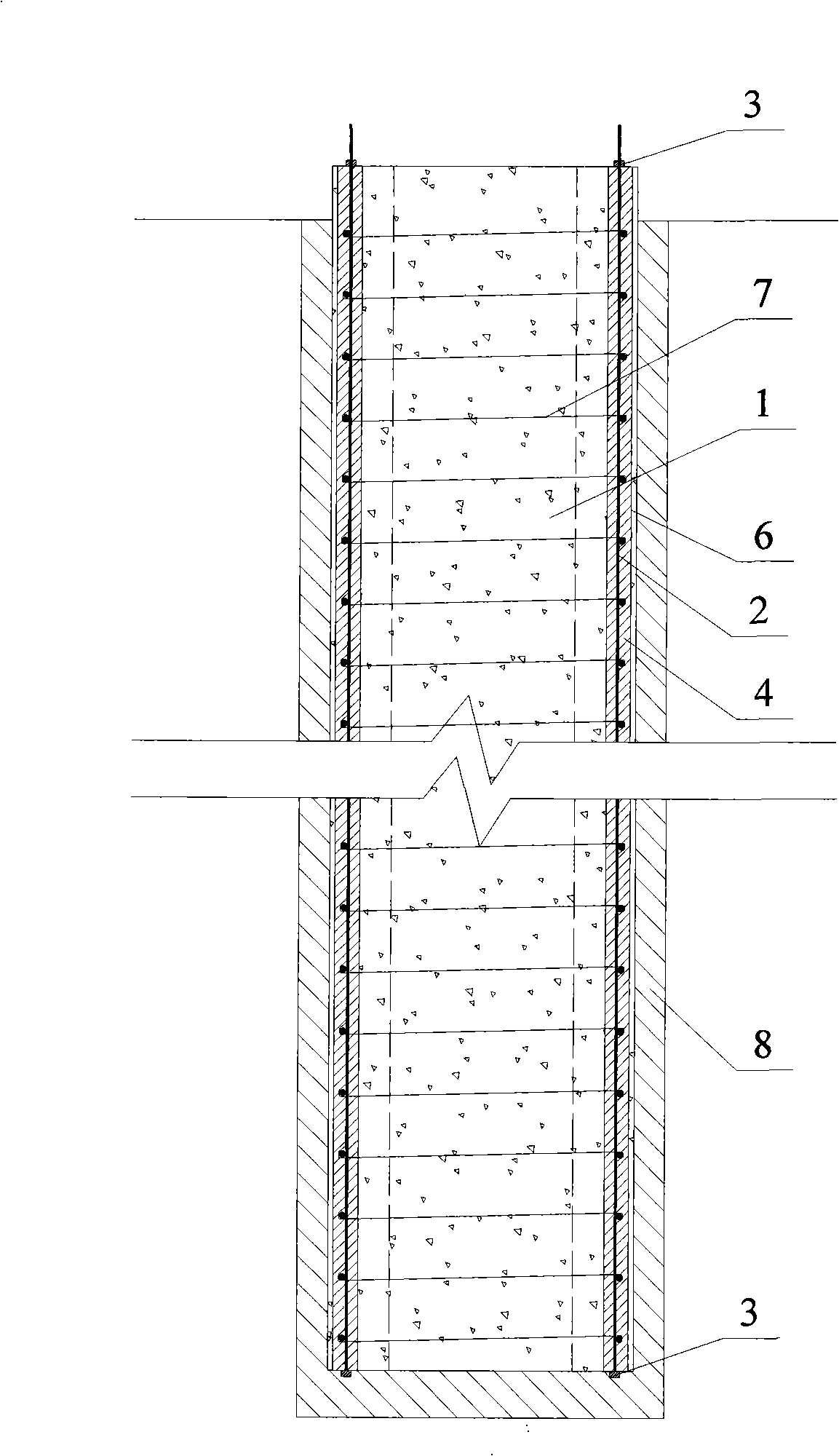

[0027] Further illustrate the present invention below in conjunction with accompanying drawing.

[0028] Such as figure 1 As shown, the lattice type prefabricated prestressed underground continuous wall of the present invention includes a prefabricated wall 1, and two rows of prestressed steel strands 2 are vertically pierced in the prefabricated wall 1, and the prestressed steel strands 2 After the concrete strength of the concrete wall 1 reaches more than 80%, the prestress is applied, and the upper and lower end faces of the prefabricated wall 1 are locked by the prestressed anchor 3, and the two rows of partially prestressed steel strands 2 pass through the transverse direction along the height direction The structural steel bars 7 are connected, and the joints 11 on both sides of the prefabricated wall 1 are in a concave semicircular shape, and a protective layer 4 is poured on the periphery of the prestressed steel strand 2. The hollow through hole 5 in the height direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com