Assembled permanent formwork overlapped FRP rib seawater sea sand recycled concrete beam and manufacturing method thereof

A recycled concrete, permanent technology, applied in the engineering field, can solve the problems of difficult transportation and large space occupied by the integral formwork, and achieve the effect of facilitating transportation, excellent resistance to chlorine salt corrosion, and reducing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings.

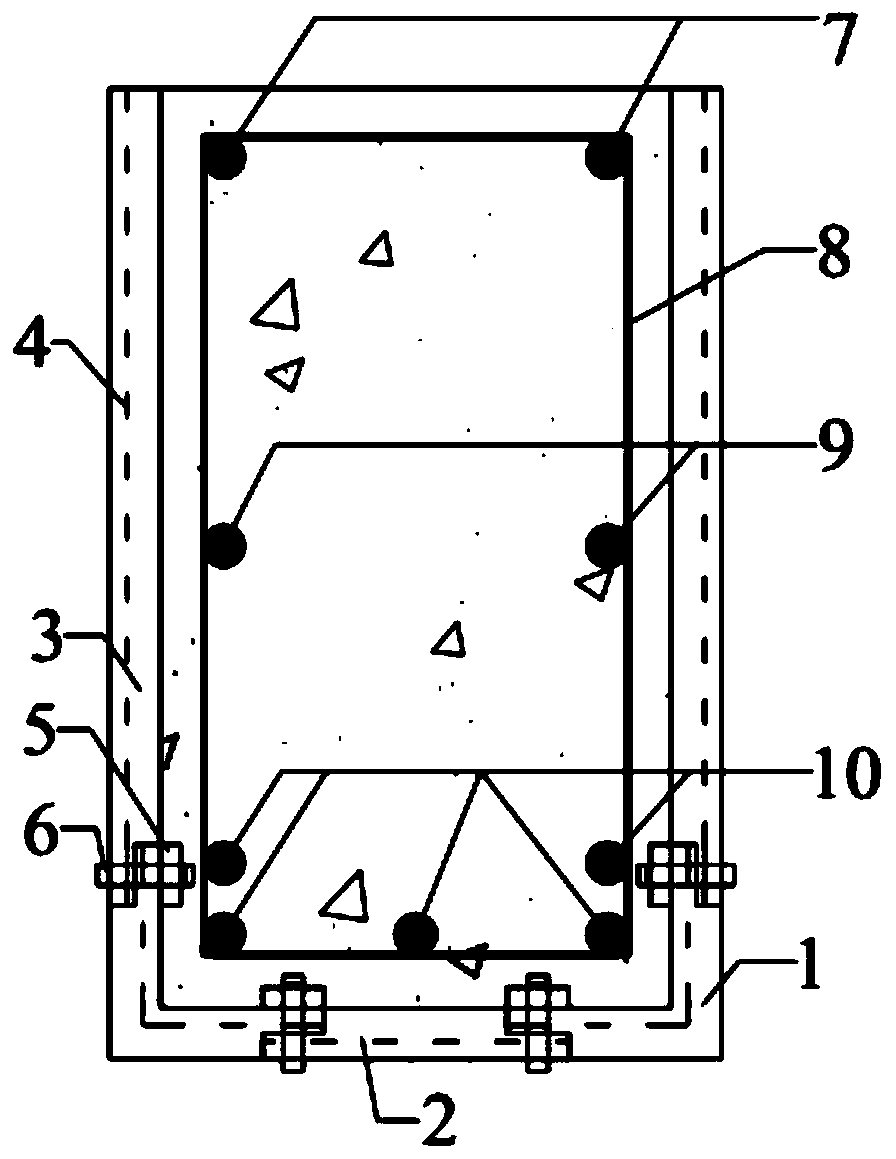

[0041] like Figure 1-3 Shown is an assembled permanent formwork laminated FRP reinforced seawater and sea sand recycled concrete beam, including a prefabricated assembled permanent formwork body and FRP reinforced seawater and sea sand recycled concrete beam.

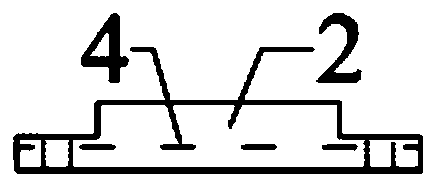

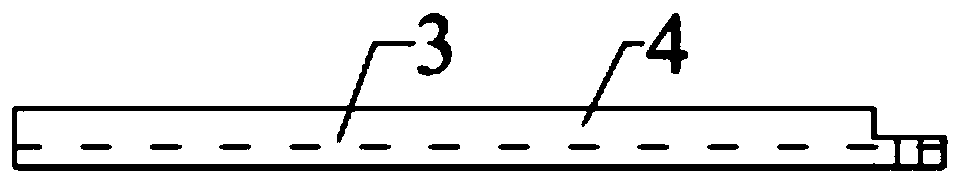

[0042] Wherein, the prefabricated and assembled permanent formwork includes a corner piece 1, a first panel 2, a second panel 3, and a positioning connector 5, and the bottom of the second panels 3 on both sides pass through the corner piece 1 and the middle first The panels 2 are vertically connected; the panels, the lap grooves of the corner strip pieces and the positioning connectors have holes, which are connected by the bolt assembly 6; the first panel and the third panel correspond to the side of the beam, and the second panel The bottom surface of the beam corresponding to the fourth panel; the panels, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com