Patents

Literature

842 results about "Cement based composites" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fly ash based lightweight cementitious composition with high compressive strength and fast set

InactiveUS20100071597A1Quick SetupEnhanced early and final compressive strengthSolid waste managementPolymer scienceCompressive strength

A method of making a rapid setting lightweight cementitious composition with improved compressive strength for products such as boards is disclosed. The method mixes fly ash, alkali metal salt of citric acid and lightweight aggregate with water. Compositions which include fly ash, alkali metal salts of citric acid and lightweight aggregate are also disclosed.

Owner:UNITED STATES GYPSUM CO

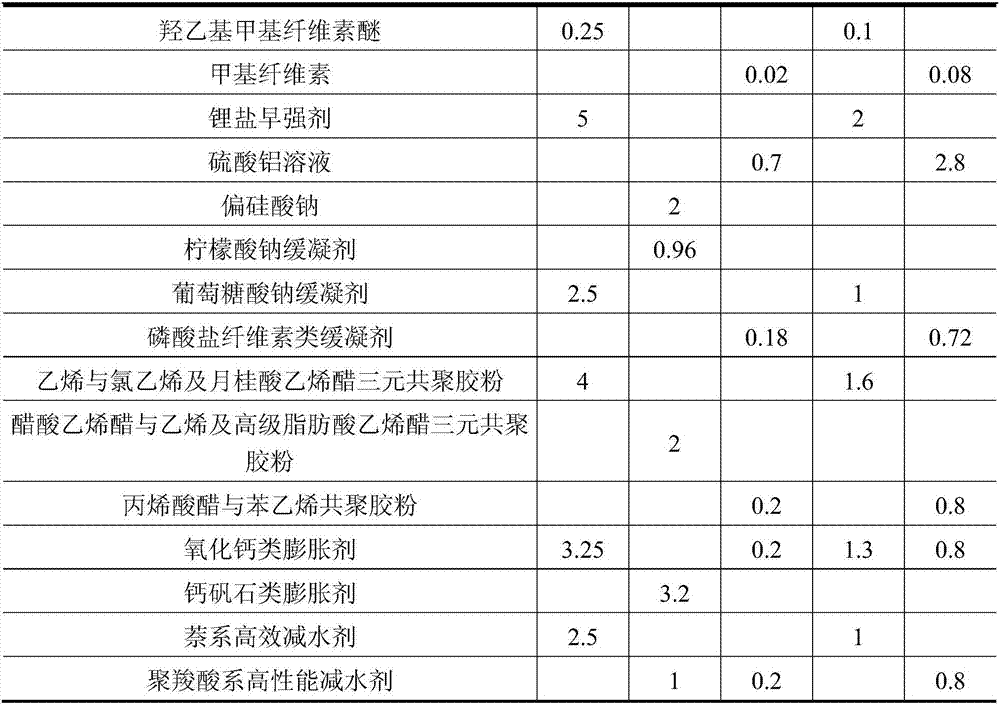

Cement-based composite material used for 3D printing technology as well as preparation method and application thereof

ActiveCN104310918AEasy to get materialsLow costSolid waste managementHouse buildingConstruction 3D printing

The invention provides a cement-based composite material used for a 3D printing technology as well as a preparation method and application thereof. The cement-based composite material is prepared from the following raw materials based on the total weight of the composite material: 33%-40% of cement, 0%-8% of inorganic powder, 32%-38% of tailing machine-made sand, 2.5%-3% of a high-molecular polymer, 0.1%-0.5% of a water reducing agent and 16.7%-20% of mixing water; a composite thickening time control agent, a thixotropic agent, a volume stabilizer and the like are added into a mixture to prepare an inorganic composite material; and then the inorganic composite material can be directly pumped into a 3D printer for building to be applied to construction. The cement-based composite material is an inorganic material and the materials are easily available; a lot of industrial waste materials can be used; therefore, the cement-based composite material is low in cost, energy-saving and environment-friendly; the condensation time can be flexibly controlled, and the material has super early strength, good caking property and strong stability; the requirements of 3D printing construction continuity of the building and the building strength are met so that the house building has good global stability and use safety; and the application and popularization of 3D printing technology can be greatly promoted.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

Oxidized graphene and graphene reinforced cement based composite material and preparation method thereof

The invention relates to an oxidized graphene and graphene reinforced cement based composite material and a preparation method thereof. The oxidized graphene and graphene reinforced cement based composite material comprises the oxidized graphene, the graphene, a dispersing agent, a thickening stabilizer, a water reducer, a defoaming agent and a cement matrix, the mass ratio of the total mass of the oxidized graphene and the graphene to the cement matrix is (0.0005-0.5):1, and the mass ratio of the total mass of oxidized graphene and the graphene to the dispersing agent to the water reducer to the thickening stabilizer to the defoaming agent is 1:(0.05-10):(0.1-20):(0.1-20):(0.05-5). In the composite material, the oxidized graphene and the graphene are dispersed in the cement matrix uniformly; compared with the traditional cement material, the tensile strength, rupture strength and conductivity of the composite material are all improved remarkably; and the composite material has more excellent mechanical property and electrical property, and is applicable to the field of multifunctional construction materials.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI +1

Bi-component cement based composite material for 3D printing as well as preparation method and application thereof

The invention discloses a bi-component cement based composite material for 3D (three dimensional) printing as well as a preparation method and application thereof. The bi-component cement based composite material for 3D printing comprises a component A and a component B, wherein the component A is prepared from 34 to 40 percent of sulphate aluminium cement, 0 to 6 percent of inorganic powder, 40 to 44 percent of tailing machine-made sand, 2.5 to 3 percent of high-molecular polymer and the balance of a retarder, a water reducer, a size stabilizer, a defoaming agent and water, the pumping performance can be well kept for a long time, an industrialized process of pre-stirring production in a mixing plant, transportation, and using in a construction site can be realized; the B component is prepared from a coagulate promoting agent, a thixotropic agent, a defoaming agent and water, the component is stable in form and can be stored for a long time or produced in a concentrated manner. After A and B are respectively pumped in a 3D printer, through high-speed stirring and being mixed by an extrusion head, the composite printing material can be extruded out, the time of coagulation is short, the strength is high, the adhesion is good, the stability is strong, the constructive continuity and building strength requirements of building 3D printing can be met, the industrial production and promotion of the cement based 3D printing material are facilitated, and the application of a 3D printing technology in buildings can be effectively promoted.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

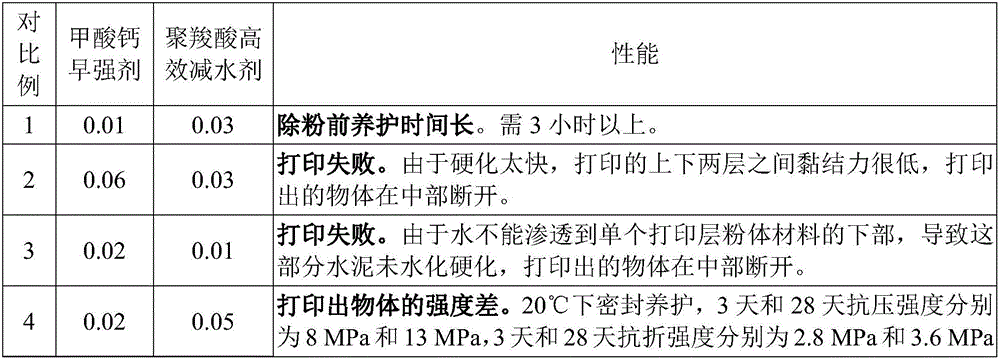

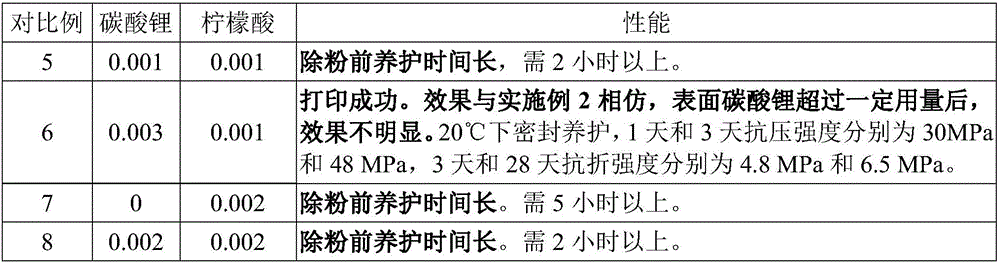

Cement-based composite material for powder-bonding three-dimensional (3D) printing, and powder-bonding 3D printing method applying cement-based composite material

ActiveCN106800391AAppropriate hardening speedAppropriate water distribution effectAdditive manufacturing apparatusPolymer adhesivePhosphate

The invention provides a cement-based composite material for powder-bonding three-dimensional (3D) printing. The material is prepared from the following components in parts by weight: 1 part of cement, 0-5 parts of sand, 0-5 parts of a mineral admixture, 0-0.2 part of an expanding agent, 0-0.2 part of a toughening agent, 0-0.2 part of mineral pigment, 0.1-0.5 part of water, 0-0.25 part of polymer emulsion, 0.001-0.05 part of an additive and 0-0.03 part of fibers, wherein the cement is selected from one or a mixture of more in silicate cements, sulphoaluminate cement, high belite sulphoaluminate cement, aluminate cement, fluoroaluminate cement, aluminosilicate cement, phosphate cement or magnesium oxide cement; the additive is selected from one or a mixture of more in a water reducing agent, an early strength agent or a coagulating regulating agent. After being contacted with water, the cement-based composite material can be hardened, thus not needing a great deal of polymer adhesive; the cement-based composite material is rapid and controllable in hardening speed; the cement-based composite material is small in deformation in the hardening process, thus being suitable for a powder-bonding 3D printing technology. The invention also provides a method for carrying out powder-bonding 3D printing by using the cement-based composite material.

Owner:万玉君

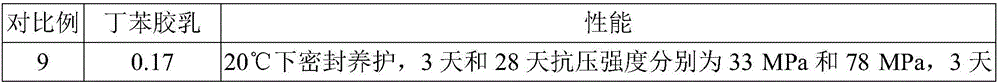

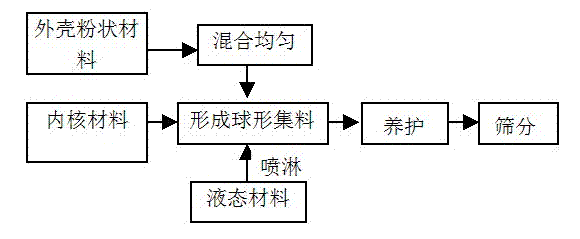

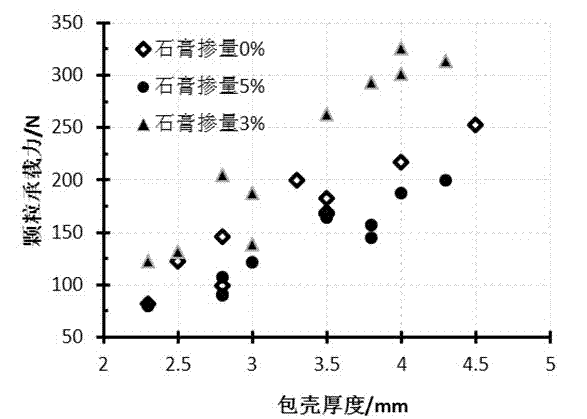

Preparation method of novel core-shell type cement-based high-strength lightweight aggregate

ActiveCN103496866AConducive to the protection of non-renewable resourcesSimple processSolid waste managementSpecific functionPollution

The invention provides a preparation method of novel core-shell type cement-based high-strength lightweight aggregate. A cement-based composite material (cement and an admixture) is used as a main cementing material of a shell material, a pelletizing process is adopted for surrounding a shell outside a lightweight core material, and the high-strength lightweight aggregate can be successfully prepared after curing is performed for a certain period of time. The prepared light aggregate has the advantages of high specific strength, good grain shape and good heat preservation and heat insulation, and can realize certain specific functions, such as heat storage, sound insulation and wave absorption. A production process of the high-strength light aggregate comprises the steps of mixing powder, uniformly stirring, spraying liquid to form pellets, curing (steam curing and moisturizing) and screening. According to the preparation method, the problems of great production energy consumption, complex process and serious pollution of the aggregate produced by a traditional sintering process or the problems of relatively large packing density, insufficiently high strength and insufficiently high product quality of unburned ceramsite products are solved.

Owner:SOUTHEAST UNIV

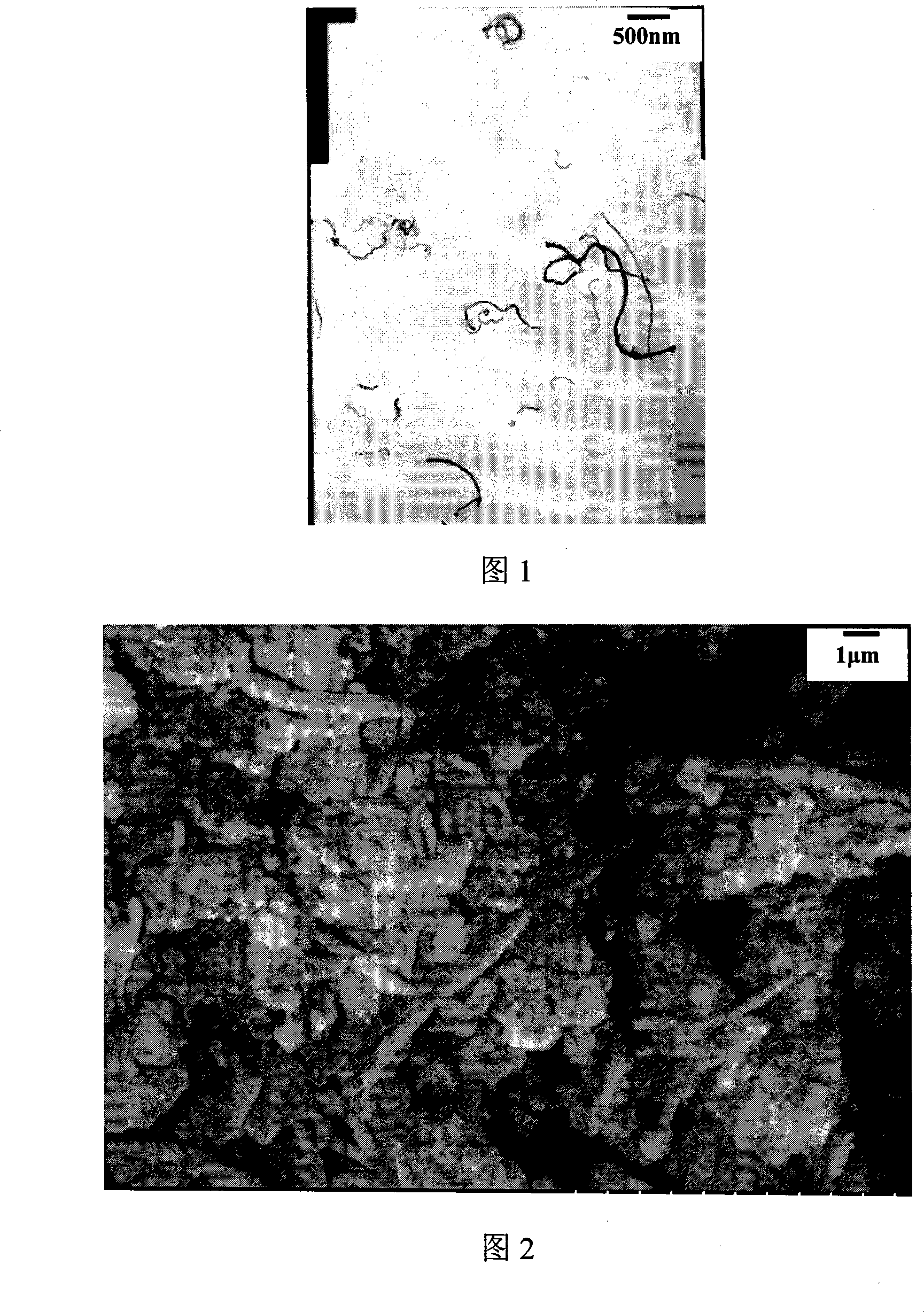

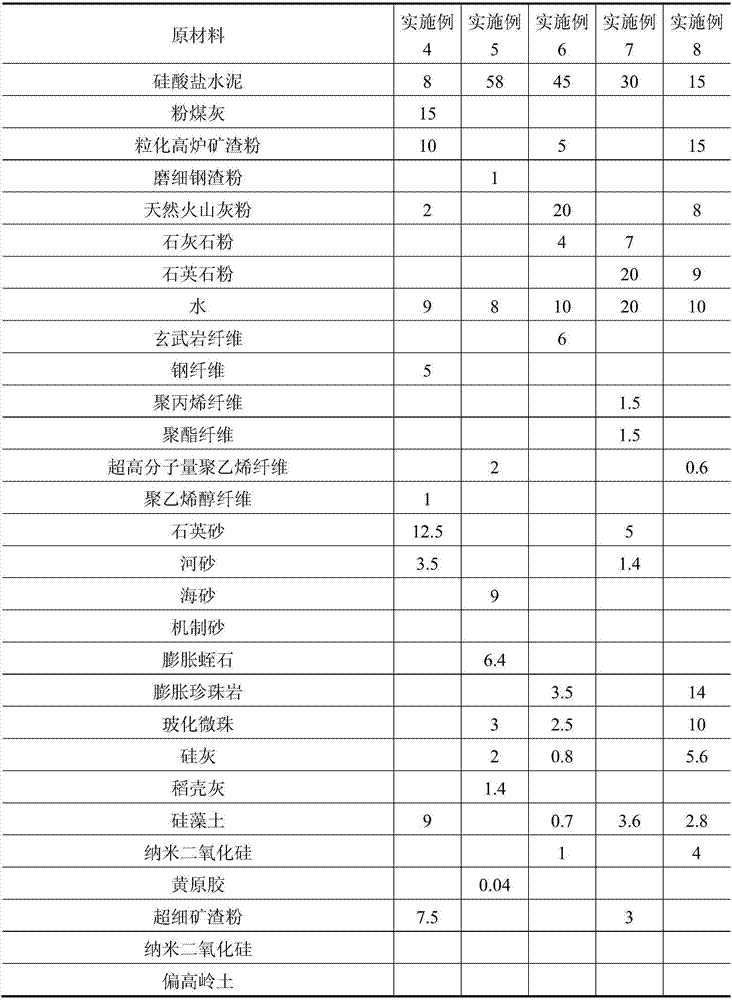

Carbon nano-tube enhanced cement-base composite material and preparation method thereof

InactiveCN101239800AResolve aggregationSolve the problem of tanglesSolid waste managementCarbon nanotubeMetal fibers

The present invention provides a carbon nano-tube reinforcing cement-based composite material and the preparing method thereof, which relates to an inorganic non-metal fiber-reinforced cement-based composite material and the preparing method thereof. The invention settles the problem that the carbon nano-tube is hard to uniformly dispersed in the cement substrate, and the carbon nano-tube reinforcing cement-based composite material of the invention is mainly composed of carbon nano-tube, dispersing agent, thickening stabilizing agent, cement blending material, superplasticiser, antifoaming agent and cement; the method of the invention comprises the following steps: slowly injecting the continuous phase mixed liquid of the thickening stabilizing agent into the carbon nano-tube disperse phase mixed liquid; adding the cement mixing material, mixing to uniform, heating and ultrasonic agitating, then vacuum discharging the bubble; then adding into the mixed liquid of the superplasticiser and the water for mixing to uniform, further eliminating the bubble with the antifoam agent; at last adding cement for mixing to uniform, adding the slurry into the oil mould and jolt ramming for molding; mode removing and standard maintaining to the prescribed lifetime. The carbon nano-tube in the product prepared by the method of the invention is uniformly dispersed in the cement substrate. The mechanical property and conductivity of the product is increased for several times.

Owner:HARBIN INST OF TECH

High-ductility fiber-enhanced cement based composite material used for 3D printing and preparation method of composite material

ActiveCN107500687AImprove performanceHigh compressive strengthAdditive manufacturing apparatusRebarWater reducer

The invention provides an additive composition used for a high-ductility fiber-enhanced cement based composite material. The additive composition comprises, by weight percentage, 20-85% of a rheological adjusting component, 2-30% of a setting and hardening adjusting component, 1-20% of an interlayer bonding strength adjusting component, 4-40% of a volume stabilizer, and 1-10% of a water reducer. The invention further provides a high-ductility fiber-enhanced cement based composite material based on the additive composition. Through optimal design of the additive composition and aggregate, the workability and the setting and hardening speed of a material is adjusted, and the printability, constructability, and the interlayer bonding strength of the high-ductility fiber-enhanced cement based composite material in 3D printing are improved. Compared with a 3D printing building material in the prior art, the composite material shows excellent whole performance. A component made from the composite material can meet the ductility of structural requirements without steel bars, thereby solving the problem that a component made from a 3D printing building material in the prior art is finally broken in a brittle failure manner.

Owner:万玉君

Cement-based composite material and pressure sensor made of same

ActiveCN104446176AHigh strengthIncreased durabilityForce measurement using piezo-resistive materialsPorosityCarbon fibers

The invention relates to a cement-based composite material and a pressure sensor made of the same. The problems that the cement-based composite material has poor electrical resistivity and stress sensing ability because carbon fibers are not uniformly dispersed in a matrix, the pressure sensor is poor in stability and low in sensitivity and the like are solved. The graphene oxide / carbon fiber cement-based composite material is composed of functional components, cement, a dispersing agent, a water reducing agent, a defoaming agent, fine aggregates and other mineral admixtures, wherein the functional components include graphene oxide and carbon fibers, graphene oxide accounts for 0.01-5% of the total mass of a cementing material, and the carbon fibers account for 0.01-5% of the total mass of the cementing material. The graphene oxide / carbon fiber cement-based composite material disclosed by the invention has the advantages of high strength, good durability, few porosity defect, good compactness and the like; the pressure sensor has the advantages of stable initial electrical resistivity, high stress sensing ability, high sensitivity, good stability and the like; and the cement-based composite material is superior to a cement-based composite material which only takes the carbon fibers, graphene oxide, carbon black or steel slag and the like as a conductive phase.

Owner:BEIJING UNIVERSITY OF CIVIL ENGINEERING AND ARCHITECTURE +1

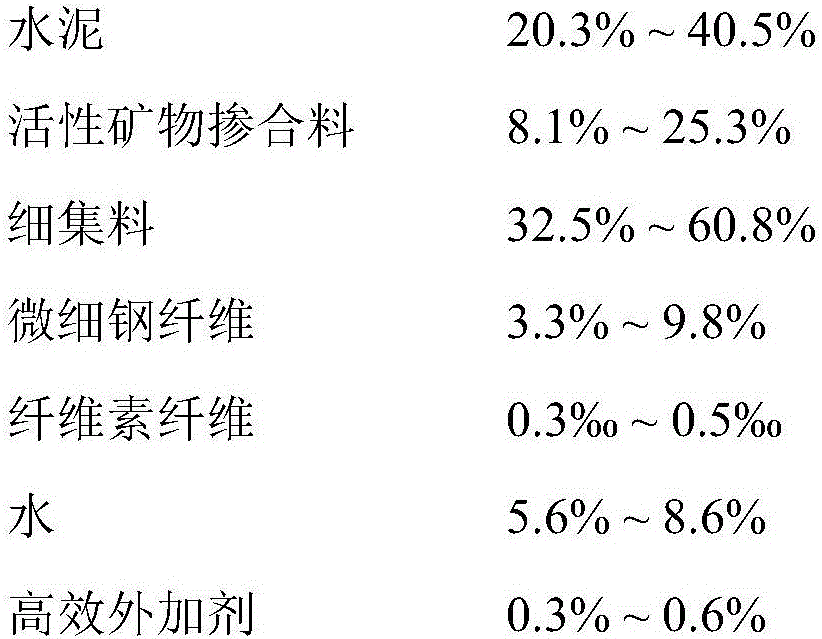

Ultra-light cement-based composite foam material and preparation method thereof

The invention relates to an ultra-light cement-based composite foaming material and a preparation method thereof. The preparation method comprises: uniformly stirring cement, fly ash, water reducer, foam pore regulator, pulp thickness regulator, fiber, foam stabilizing agent and mixing water to prepare pure pulp; diluting a physical foaming agent by 20 folds and making foam by a mechanical means;mixing the made foam into the stirred pure pulp, stirring uniformly again and obtaining foam pulp; adding a chemical foaming agent and a foaming accelerator into the obtained foam pulp, and pouring into a mold preheated to 40 DEG C; after the pouring is finished, curing the mold in a constant-temperature curing chamber at 40 DEG C, curing for 24 to 32 hours, demolding, and obtaining the ultra-light cement-based composite foaming material. In the invention, the foaming material is prepared by a method of combining physical foaming and chemical foaming; and the obtained product is low in density and very light, reaches a fireproof grade A, has a long service life and excellent comprehensive performance and is suitable to be widely used.

Owner:建筑材料工业技术监督研究中心

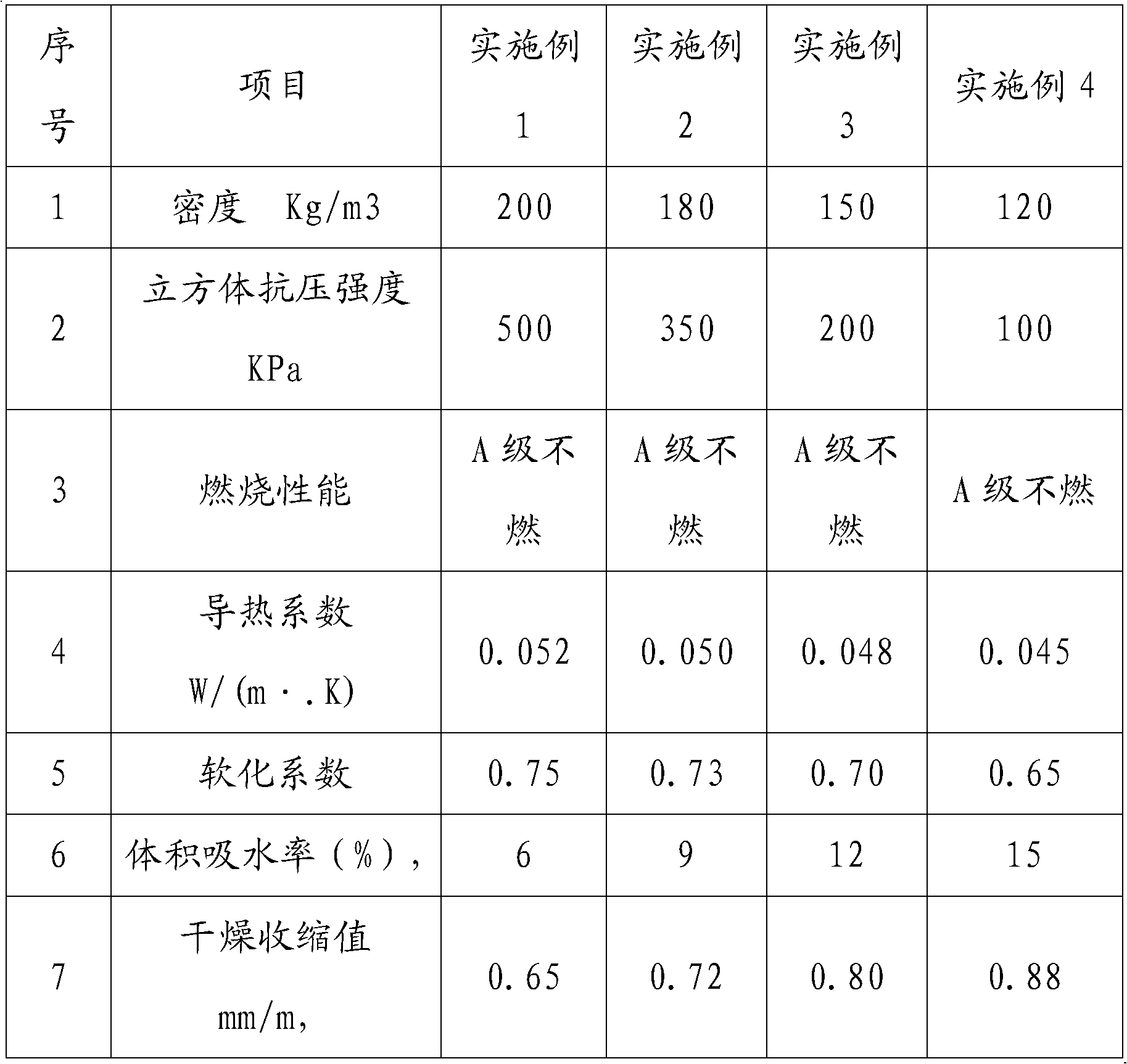

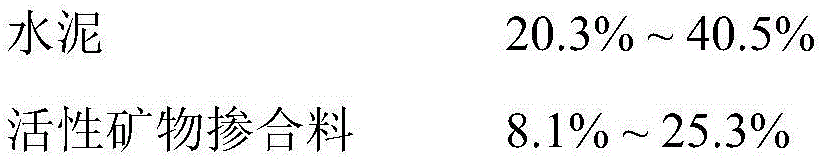

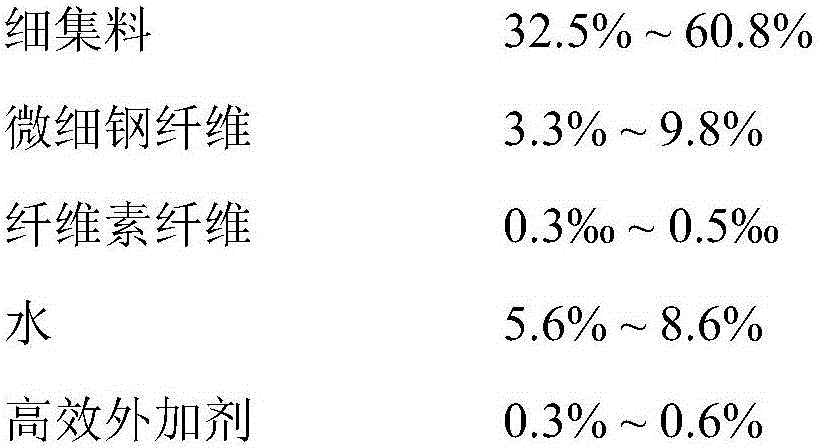

Cellulose fiber internal curing-based ultra-high-performance cement-based composite material and preparation method thereof

ActiveCN106396555AImprove early shrinkage deformationIncreased hydrationCement based compositesMaterials science

The invention discloses a cellulose fiber internal curing-based ultra-high-performance cement-based composite material and a preparation method thereof. The cellulose fiber internal curing-based ultra-high-performance cement-based composite material comprises the following components in weight percentage: 20.3-40.5% of cement, 8.1-25.3% of active mineral admixture, 32.5-60.8% of fine aggregate, 3.3-9.8% of micro-fine steel fibers, 0.03-0.05% of cellulose fibers, 5.6-8.6% of water and 0.3-0.6% of efficient admixture. According to the technical scheme of the ultra-high-performance cement-based composite material and the preparation method thereof, the advantages of good slurry workability, high breaking strength, low early hydration speed of cement-based materials, small early shrinkage and deformation amount, high overall hydration degree and the like are realized compared with the prior art. Meanwhile, the later compressive strength of cement-based materials is less affected by cellulose fibers. Therefore, the mechanical property and the durability during the later period are improved.

Owner:SOUTHEAST UNIV

Cement-based composite material used for 3D printing as well as preparation method and application thereof

ActiveCN105731942AGood lookingGreat tasteAdditive manufacturing apparatusSolid waste managementAggregate (composite)Alkali free

The invention discloses a cement-based composite material used for 3D printing as well as a preparation method and application thereof, and belongs to the field of building materials. The cemented-based composite material comprises the following components in percentage by weight: 19-25% of a composite gel material, 0.2-0.6% of a shrinkage inhibitor, 1-2% of an anti-carbonization agent, 57-66% of aggregates, 0.3-1.1% of fiber-reinforced materials, 0.9-1.8% of a liquid alkali-free accelerating agent, 0.8-1.7% of a retarder, 0.02-2% of a thickening agent, 0.2-0.4% of a plastic retaining agent, 0.04-0.09% of a defoaming agent, 0.04-0.2% of a water reducer and 5-14% of water. A cement product printed by the cement-based composite material has no holes and pitted surface in appearance.

Owner:CHINA BUILDING MATERIALS ACAD

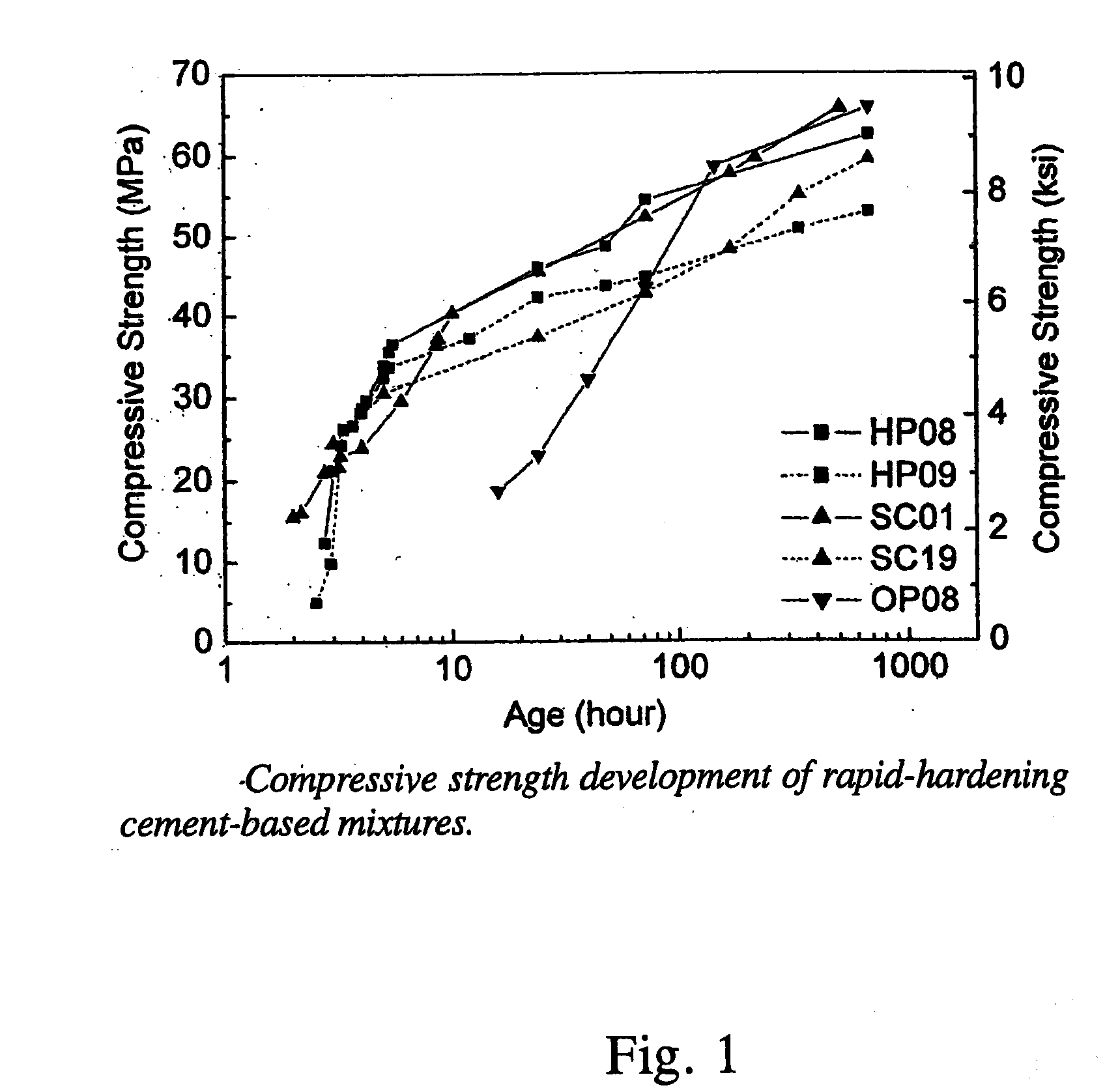

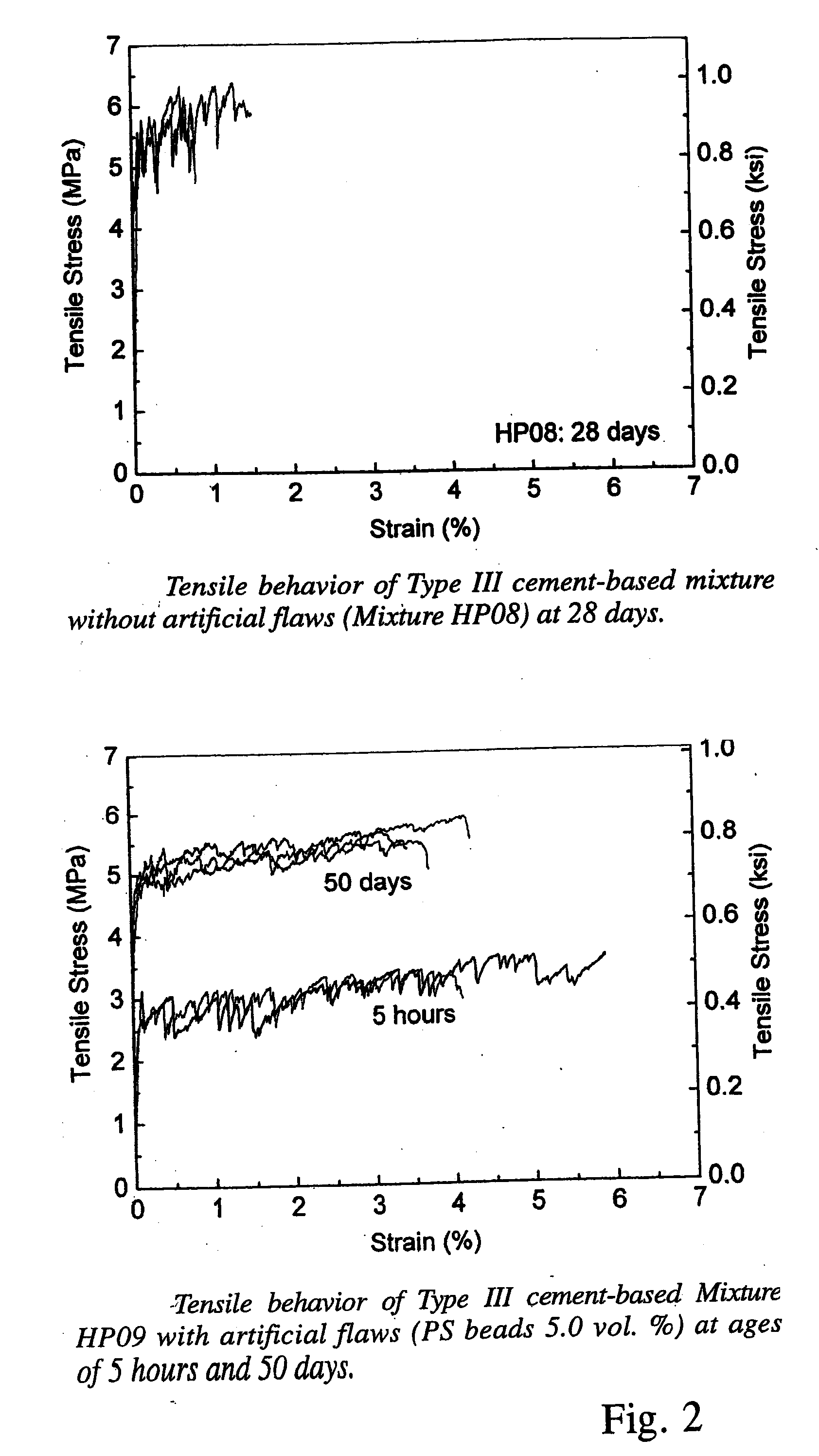

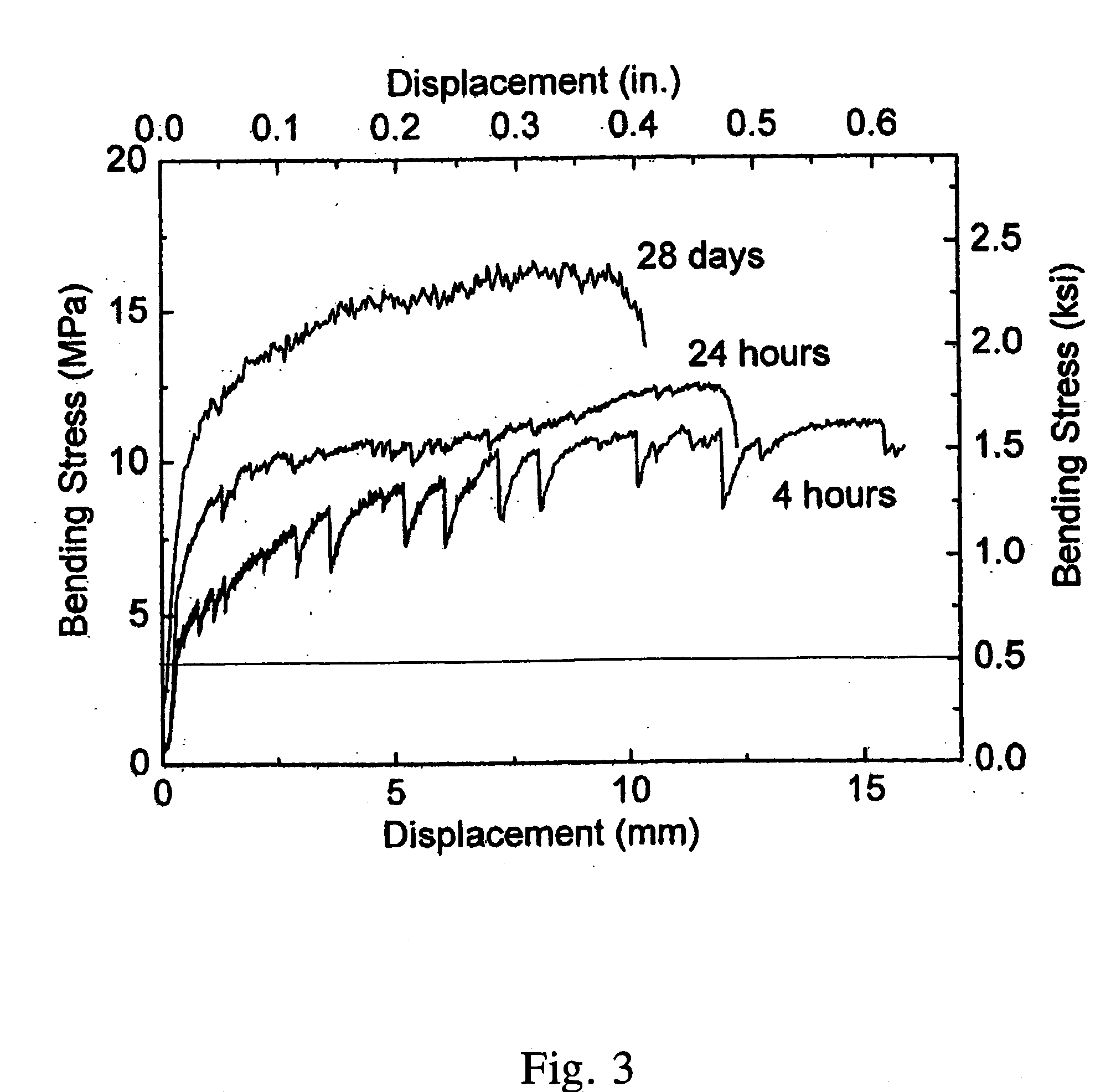

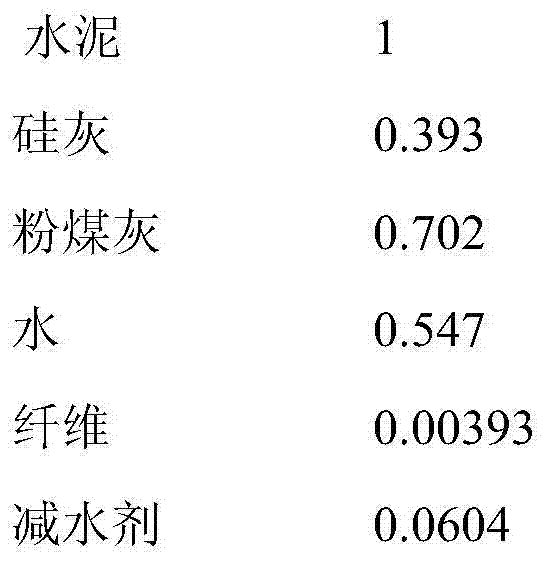

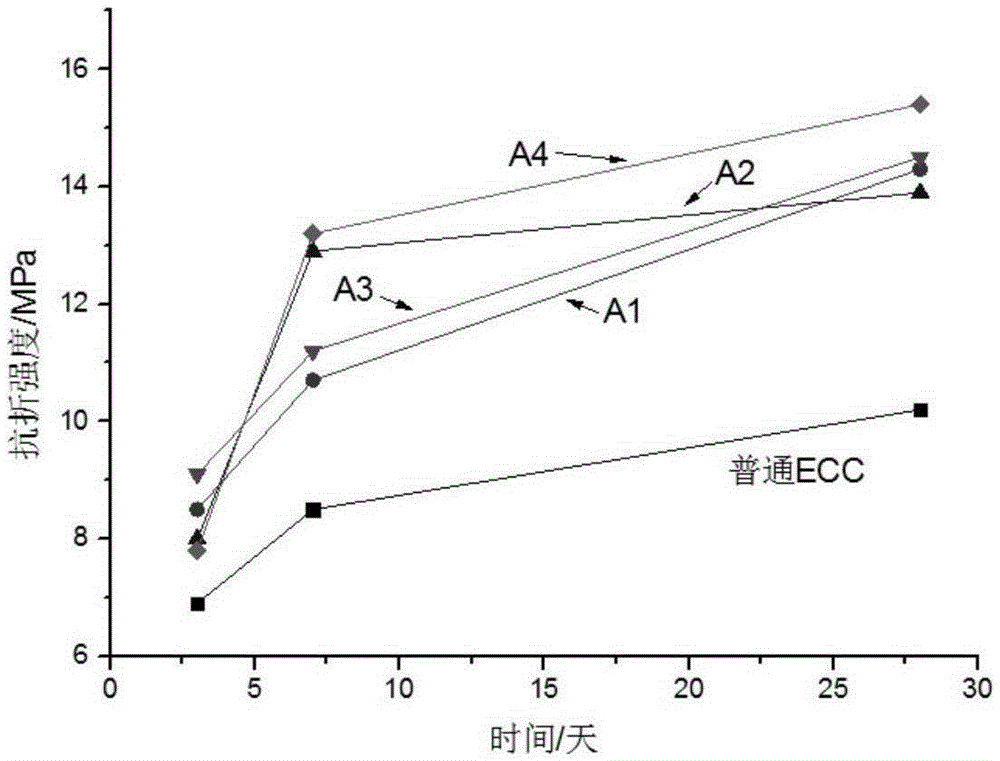

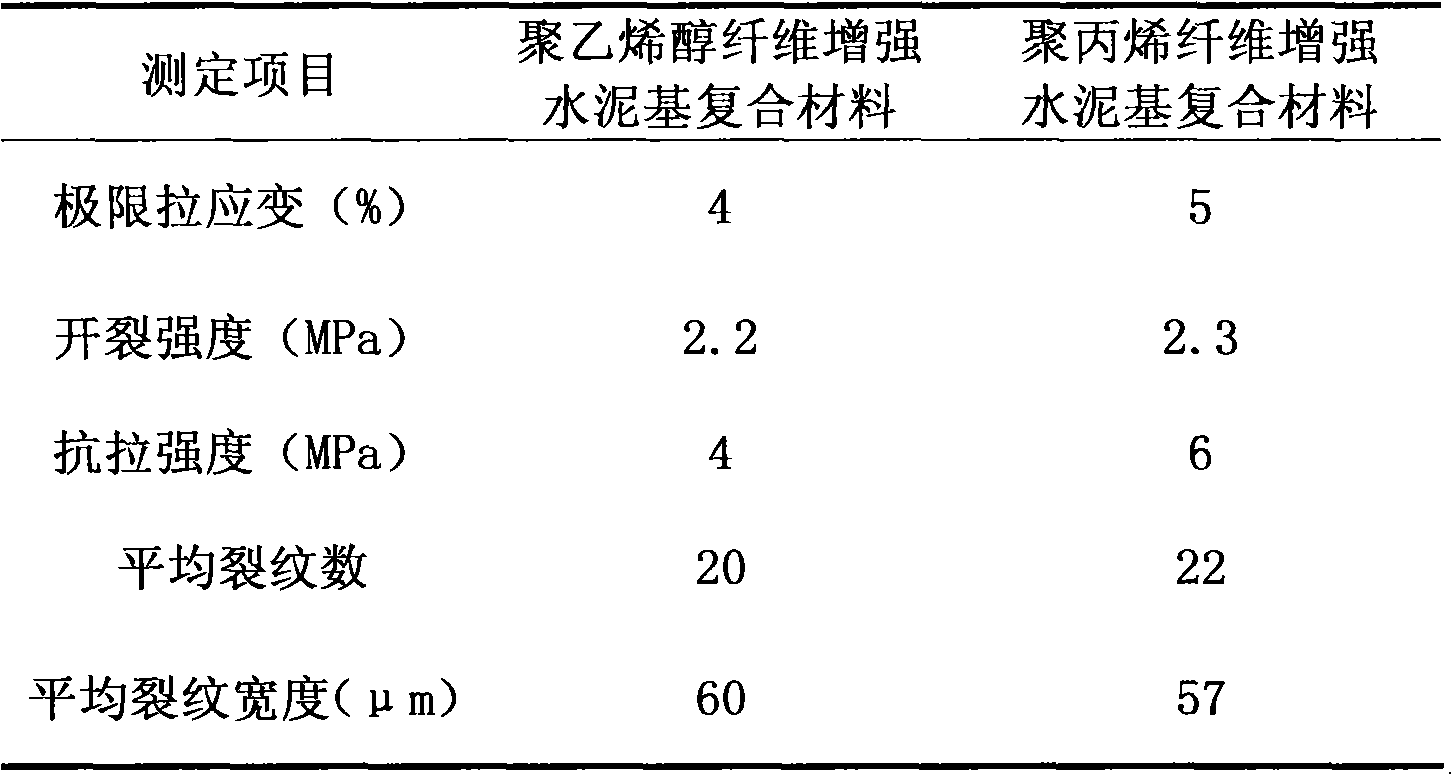

High Early Strength Engineered Cementitious Composites

ActiveUS20070181040A1High early-strengthLarge capacitySolid waste managementClimate change adaptationTensile strainCement composites

Rapid repair and retrofit of existing infrastructures demand durable high early strength materials that not only deliver sufficient strength within a few hours of placement but also significantly prolong the maintenance interval. The invention comprises a class of newly developed polyvinyl alcohol (PVA) fiber-reinforced high early strength engineered cementitious composites (ECC) materials featuring extraordinary ductility. The tailoring of preexisting flaw size distribution through non-matrix interactive crack initiators in the composite matrix results in high tensile ductility. The resulting high early strength ECC materials are capable of delivering a compressive strength of 21 MPa (3.0 ksi) within 4 hours after placement and retaining long-term tensile strain capacity above 2%.

Owner:RGT UNIV OF MICHIGAN

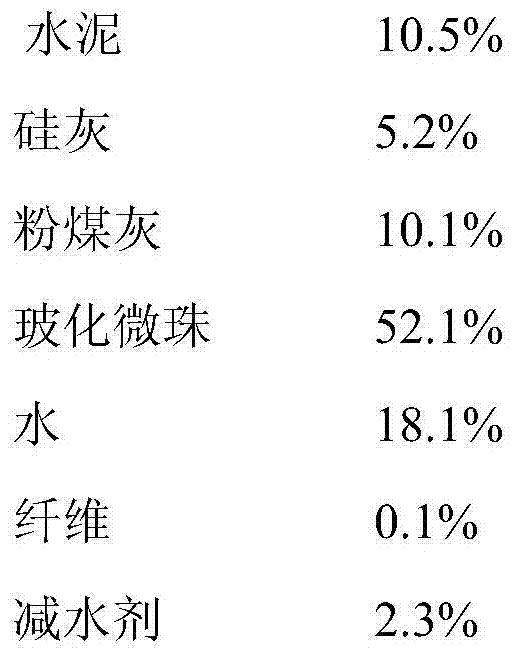

Lightweight high-strength cement based composite material

InactiveCN103896527AMeet the requirements of construction mobilityThe material surface is denseSolid waste managementChemical admixtureUltimate tensile strength

The invention relates to a lightweight high-strength cement based composite material. The grain composition of a multivariate cementing material and grain composition of aggregate are optimized, anddue to use of additives such as water reducing agent and thickener, the material can obtain high compressive strength of over 20MPa while obtaining the unit weight which is significantly lower than that of common concrete. The material has the technical advantages that the compressive strength of 28d standard curing is greater than or equal to 20MPa when the unit weight is smaller than or equal to 1650kg / m<3>; the requirements of the construction liquidity can be met by grain composition of the optimized gel material and the grain composition of the aggregate; the hardened material has a dense surface, and has excellent endurance performances such as anti-permeability, carbonation resistance, resistance to chloride ion erosion and the like.

Owner:SHANGHAI LUOYANG NEW MATERIAL TECH

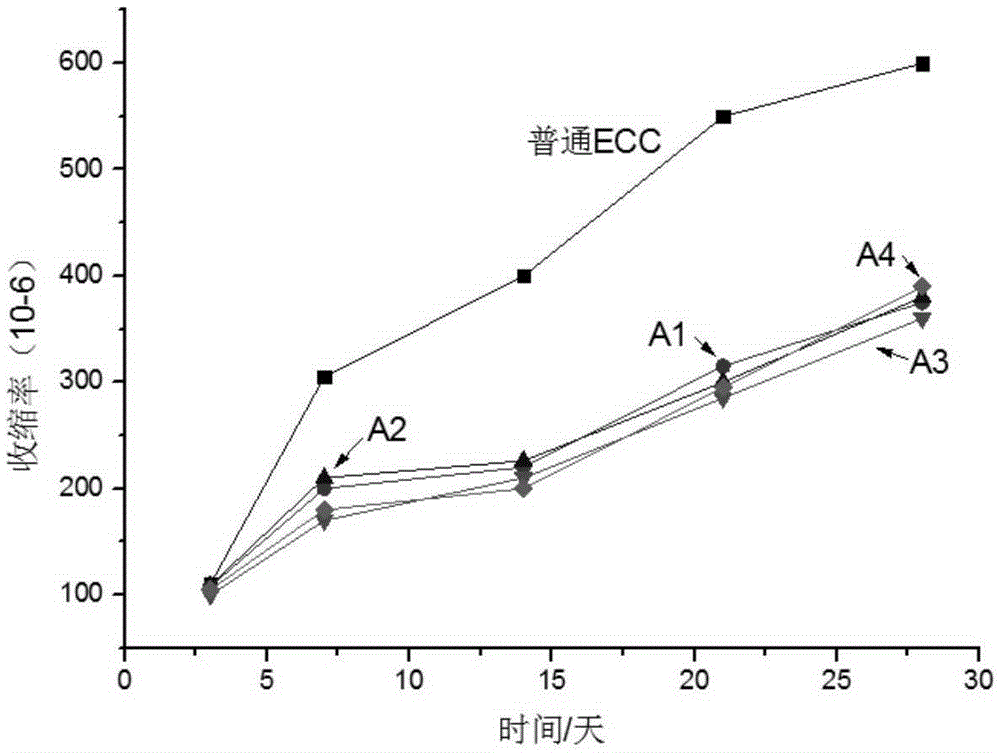

Graphene oxide modified cement-based composite material and preparation method thereof

ActiveCN105294027AHigh compressive strengthImprove flexural strengthClimate change adaptationSuperplasticizerEngineered cementitious composite

The invention relates to a graphene oxide modified cement-based composite material and a preparation method thereof. The graphene oxide modified cement-based composite material is prepared by mixing graphene oxide, polyvinyl alcohol fibers (PVA), cement, flyash, water, quartz sand, a polycarboxylate superplasticizer, a shrinkage reducing agent, a polymer and a defoaming agent according to a certain proportion. Compared with the prior art, the graphene oxide modified cement-based composite material has the advantages that the cement-based composite material has the advantages of higher compressive strength and breaking strength, low shrinkability, high toughness, high ductility, and the like compared with common ECC (engineered cementitious composite) and is especially suitable for repair and reinforcement of building structures with complex contours.

Owner:WUHAN UNIV OF TECH

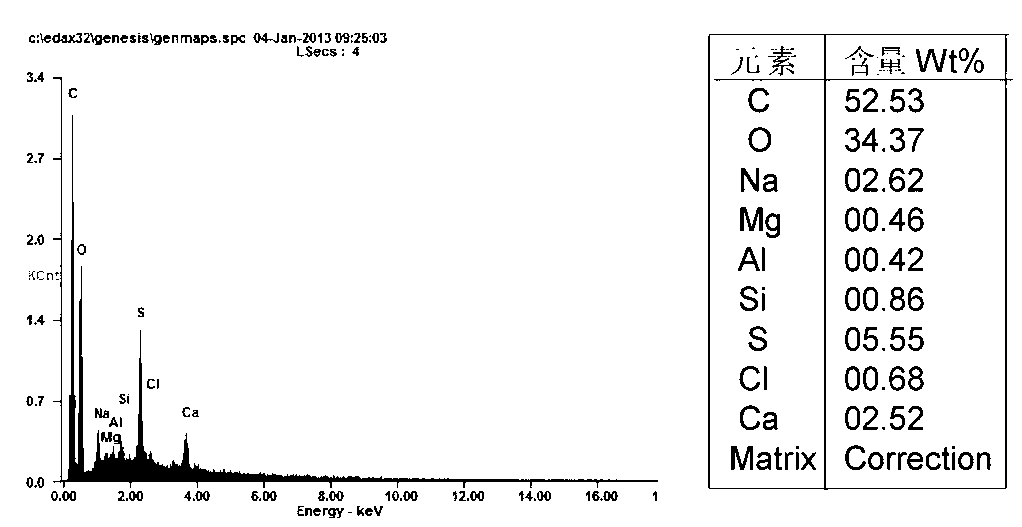

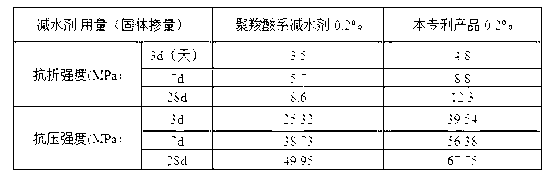

Preparation method of graphene oxide modified polycarboxylic acid type water-reducer

ActiveCN103241983AHigh flexural and compressive strengthRaw materials are easy to getCarbon compoundsCarboxylic acidWater reducer

The invention relates to a preparation method of a graphene oxide modified polycarboxylic acid type water-reducer. A polycarboxylic acid type water-reducer is a novel efficient water-reducer following a naphthalene type water-reducer, a melamine water-reducer and an amino sulfonic acid based water-reducer, but the mechanical property of concrete cannot be obviously improved by adding the polycarboxylic acid type water-reducer. The preparation method comprises the steps of preparing graphene oxide with natural flake graphite, sodium nitrate, concentrated sulfuric acid and potassium permanganate as raw materials; carrying out ultrasonic dispersion on the graphene oxide; and then adding the polycarboxylic acid type water-reducer with a certain proportion to form an intercalation compound of the graphene oxide and the polycarboxylic acid type water-reducer. With the adoption of the modified water-reducer, on the basisthat the existing water-reducing rate is kept, the flexural strength and the compressive strength of a cement-based composite are obviously strengthened, the relevant raw materials are easily obtained, a preparation technology is reasonable, pollution in a preparation process is little, the performance of products is excellent, and the graphene oxide modified polycarboxylic acid type water-reducer is suitable for industrial production.

Owner:广西科达新材料集团有限公司

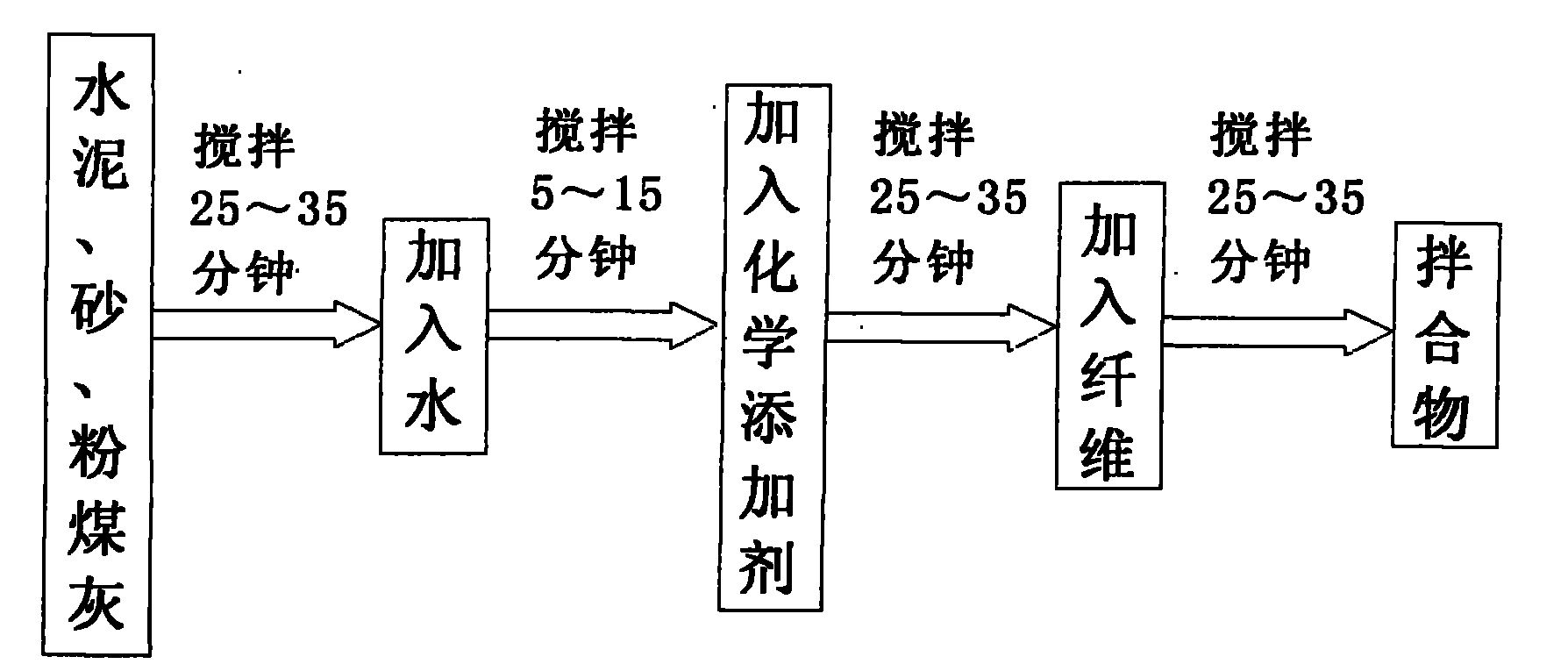

High-toughness polypropylene fiber reinforced cement-based composite material and preparation method thereof

ActiveCN101891417ARaw materials are easy to getLow costSolid waste managementSlurryMechanical property

The invention relates to a high-toughness polypropylene fiber reinforced cement-based composite material and a preparation method thereof, and provides the high-toughness polypropylene fiber reinforced cement-based composite material with the advantages of easily-obtained raw materials, low cost, low requirements on processing technology and an operating environment, stable mechanical property and high toughness and the preparation method thereof. The high-toughness polypropylene fiber reinforced cement-based composite material comprises the following components in percentage by weight: 16.7 to 52.5 percent of cement, 13.1 to 39 percent of fly ash, 22.2 to 26.3 percent of silica sand, 6.6 to 16.7 percent of water, 1.3 to 2.8 percent of water reducing agent, 0.03 to 0.1 percent of thickening agent and 1.47 to 2.5 percent of polypropylene fiber. The preparation comprises the following steps of: adding the cement, the fly ash and the silica sand into an agitating vessel of an agitator toperform dry mixing until all base materials are mixed uniformly; adding the water into the base materials to agitate until uniform pasty slurry with high flowability is formed; adding the water reducing agent and the thickening agent; and then continuously agitating until the fiber is dispersed uniformly.

Owner:沈阳罗泰智能系统有限公司

High-ductility cement-based composite material for repairing hydraulic concrete structure

The invention discloses a high-ductility cement-based composite material for repairing a hydraulic concrete structure. The cement-based composite material is prepared from the following components in parts by mass: 20 to 60 parts of cement, 0 to 80 parts of fly ash, 0 to 80 parts of pulverized slag powder, 5 to 10 parts of light-weight calcium powder, 1 to 5 parts of nanometer SiO2, 25 to 40 parts of a fine aggregate, 20 to 40 parts of water, 0.1 to 1 part of a water reducing agent and 0.5 to 2.5 parts of polyvinyl alcohol fibers. According to the high-ductility cement-based composite material for repairing the hydraulic concrete structure, the air content of a mixture is 7 to 10 percent; at the 28-day age, the uniaxial tensile strain is greater than or equal to 5.0 percent, the cube compressive strength is greater than or equal to 60MPa, the frost resistance is greater than or equal to F500, the sulfate corrosion resistance is greater than or equal to KS300, the chloride ion penetration resistance DRCM is less than or equal to 2.0*10<-12>m<2> / s, and the tensile bonding strength with base structure concrete is greater than or equal to 5.0MPa. Under the condition of not mixing any air-entraining agent, preservative or thickening agent, the high-ductility cement-based composite material for repairing the hydraulic concrete structure provided by the invention has high durability, enhanced capability in synergistically acting with an existing structure and a remarkable repairing and reinforcing effect.

Owner:NANJING HYDRAULIC RES INST

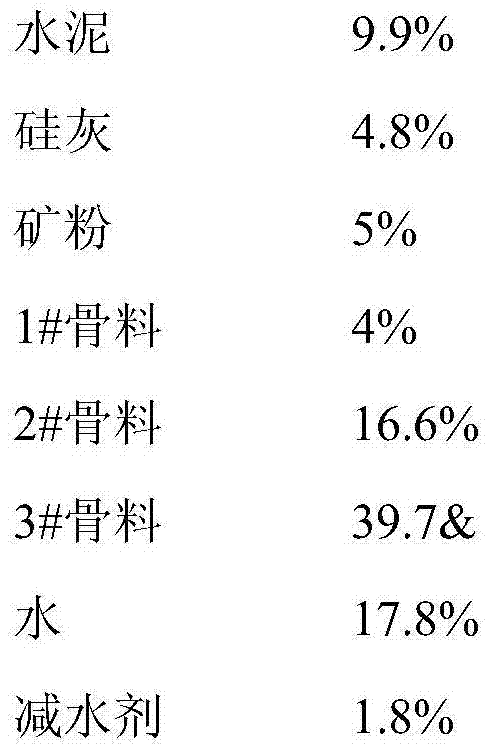

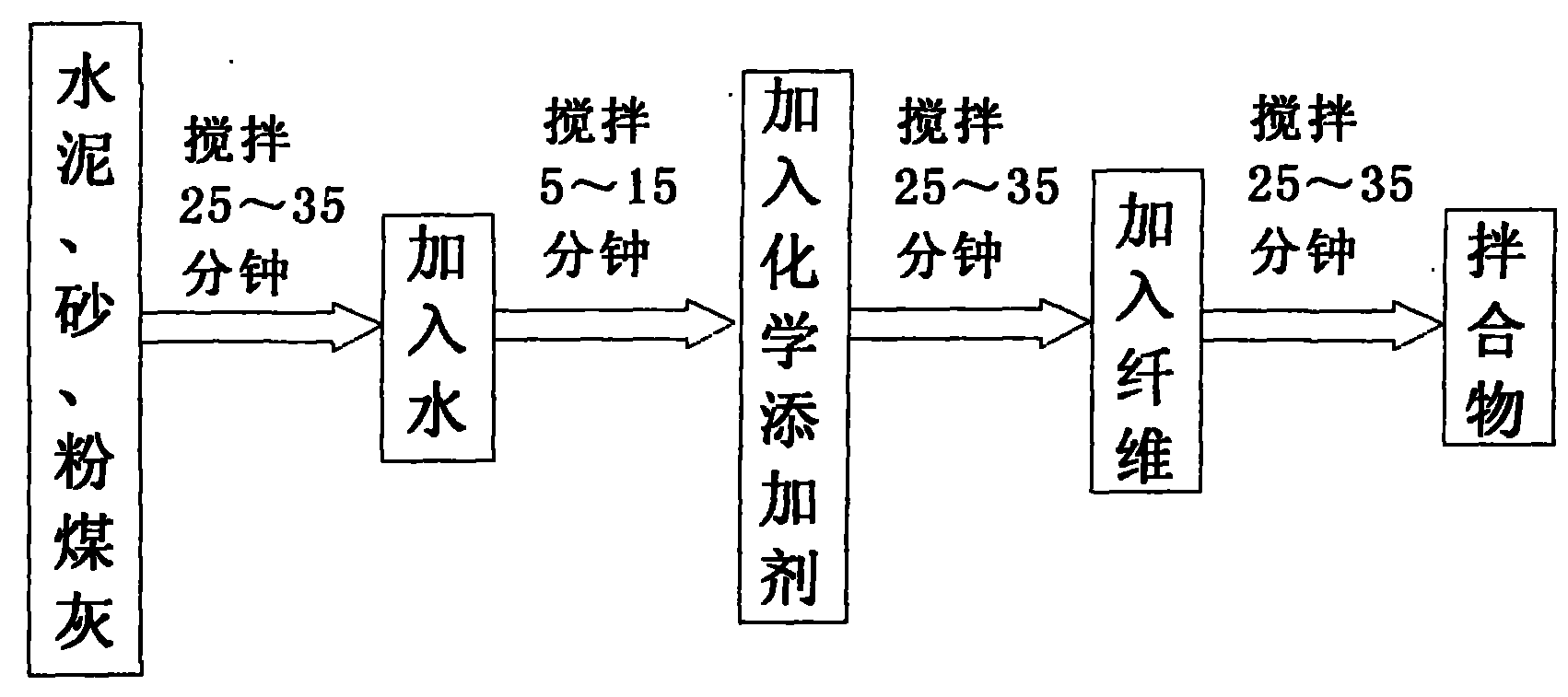

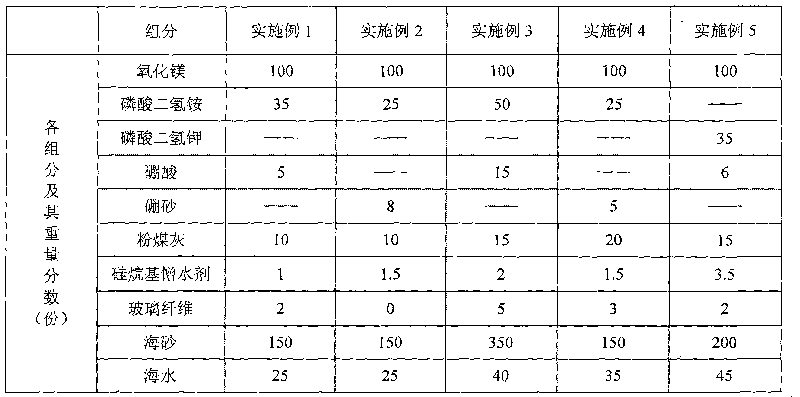

Quick-hardening high-early strength concrete-based composite material for maritime work

InactiveCN101708985ATake advantage ofReduce transport volumeSolid waste managementHigh strength concreteGlass fiber

The invention discloses a quick-hardening high-early strength concrete-based composite material for a maritime work, which mainly comprises the following components in parts by weight: 100 parts of magnesium oxide, 25-50 parts of phosphate, 5-15 parts of retarder, 0.5-3.5 parts of siloyl group moisture repellent, 10-20 parts of flyash, 0-5 parts of glass fibre, 150-350 parts of sea sands and 25-50 parts of seawater. The invention takes the sea sands without desalting treatment as aggregate and the seawater as mixing water, thereby fully utilizing island resources such as sea sands, seawater, and the like, greatly reducing traffic capacity, saving cost. In addition, the invention has the advantages of quick setting and hardening, high early strength, good seawater erosion capability, and the like, thereby being widely applied to quick repatching and building in projects such as island roads, landingstrips, docks, and the like.

Owner:LOGISTICAL ENGINEERING UNIVERSITY OF PLA

Cement-based composite material with high-temperature resistance and superhigh performance and preparation method thereof

InactiveCN102092996AReduce burstImprove compactnessSolid waste managementMetal fiberAggregate (composite)

The invention discloses a cement-based composite material with high-temperature resistance and superhigh performance and a preparation method thereof. The cement-based composite material comprises the raw materials of a gelled material, an aggregate, fibers, a water reducing agent and water, wherein the gelled material is a mixture of cement and active mineral admixture, the aggregate is yellow sand or a mixture of yellow sand and pebbles, and the fibers are organic fibers or mixtures of organic fibers and metal fibers. The cement-based composite material is produced through improvement on the basis of common concrete manufacturing, has the properties of superhigh mechanical property and high-temperature resistance, is applicable to high-temperature resistant engineering structures, and is favorable for preventing the collapse and the destruction of the construction structures in a fire disaster.

Owner:NANJING UNIV OF SCI & TECH

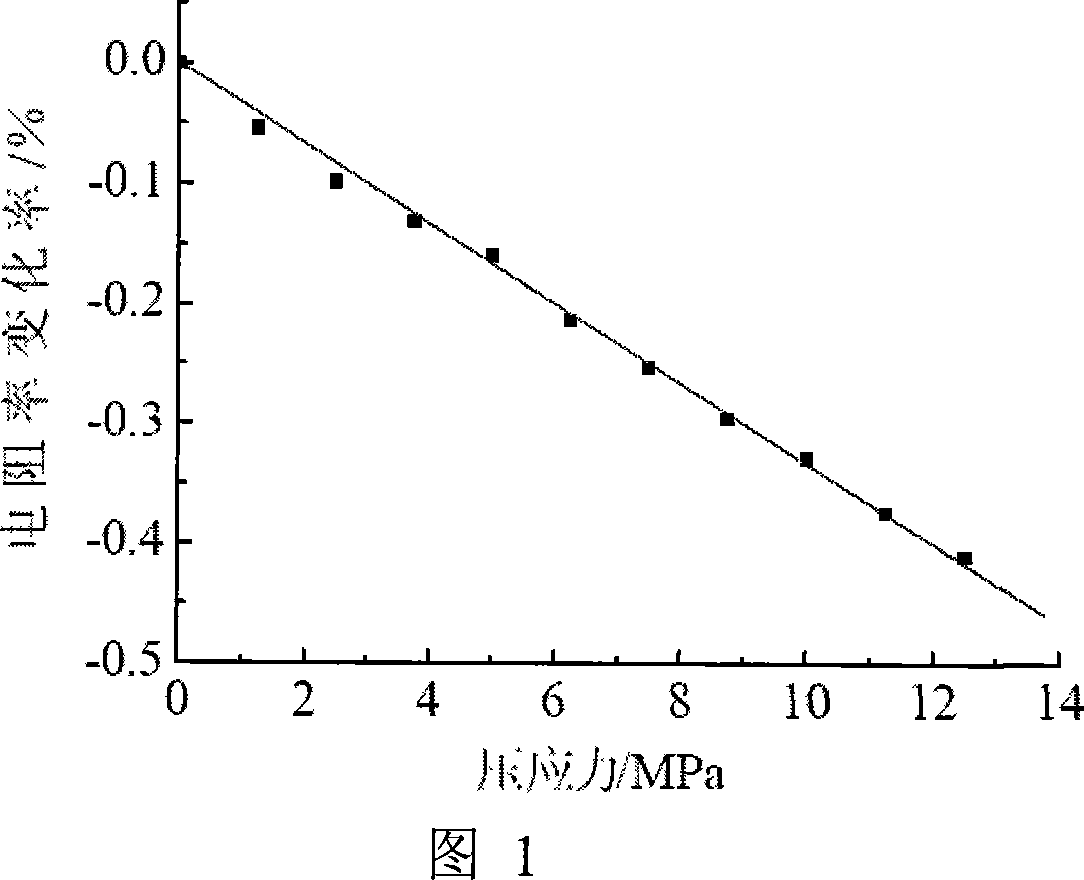

Method for measuring stressed deformation of cement-base composite material

InactiveCN1363832AGood adhesionTimely responseMaterial strength using tensile/compressive forcesMaterial resistanceBridge typeGraphite

The invention relates to a method for checking and measuring the distortion of cement-based composite material caused by force. A conducting film as sensor, which is composed of short-cut carbon fiber, graphite power and adhesion agent, is coated on the surface of specimen of cement-based composite material. Circuit signal collector in bridge type is adopted in the invention. With the specimen ofcement-based composite material being forced, loaded and impacted, uneven distortion and cracking in the specimen of cement-based composite material can be detected by checking and measuring variation of voltage and current caused by the variation of resistance of said conducting film.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Cement radical composite wave-suction material and preparation method thereof

The invention relates to a cement base composite wave-adsorption material and relative preparation, belonging to the cross technique field between materials science and microwave technique. The invention is characterized in that the invention uses organic and inorganic hollow wave-transmission balls with low dielectric constant to fill a cement base to improve the resistance match of the base, and coat an uniform conductive coat on the surface of the wave-transmission balls, and stuffs wave absorber or the like to improve the adsorption of base on electromagnetic wave. The inventive wave-adsorption material is in single-layer or dual-layer structure, while the match layer and adsorption layer of dual-layer structure are respectively stuffed with wave-transmission balls or wave absorber in different ratios to gradually change the resistance, and the two layers are combined tightly to improve the wave adsorption. The invention has the advantages of that the improved resistance match and gradual structure can absorb electromagnetic wave in wide frequency range, the light wave-transmission balls can reduce the specific weight of material, and the wave-transmission balls are packed by cement slurry to improve the stability and durability of material.

Owner:DALIAN UNIV OF TECH

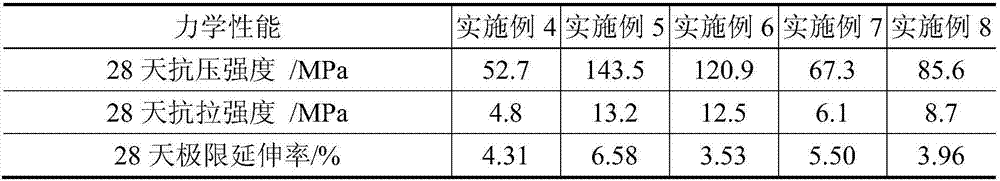

Fiber-hybrid high-ductility cement-based composite material and preparation method thereof

ActiveCN103664090AReduced compressive strengthLow costClimate change adaptationGlass fiberPolymer science

The invention provides a high-ductility cement-based composite material. The high-ductility cement-based composite material is prepared with the following raw materials by weight: 71.8-85 parts of base material, 12.9-25.2 parts of water, 0.89-2.67 parts of fiber and 0.11-1.23 parts of admixture, wherein the fiber is composed of two or more of polypropylene fiber, polyvinyl alcohol fiber, polyethylene fiber, aromatic polyamide fiber and glass fiber; the weight ratio between the polypropylene fiber, the polyvinyl alcohol fiber, the polyethylene fiber, the aromatic polyamide fiber and the glass fiber, and the total fiber is 15-89.5%, 0-68.4%, 0-75.6%, 0-73.5%, and 0-56.4% respectively. The high-ductility cement based composite material is high in compressive strength and low in preparation cost; the compressive strength can be up to higher than 50.5 MPa; the preparation cost is reduced to 15-50% of that of the prior art. The invention further provides a preparation method of the high-ductility cement based composite material.

Owner:SINOMA INT ENG

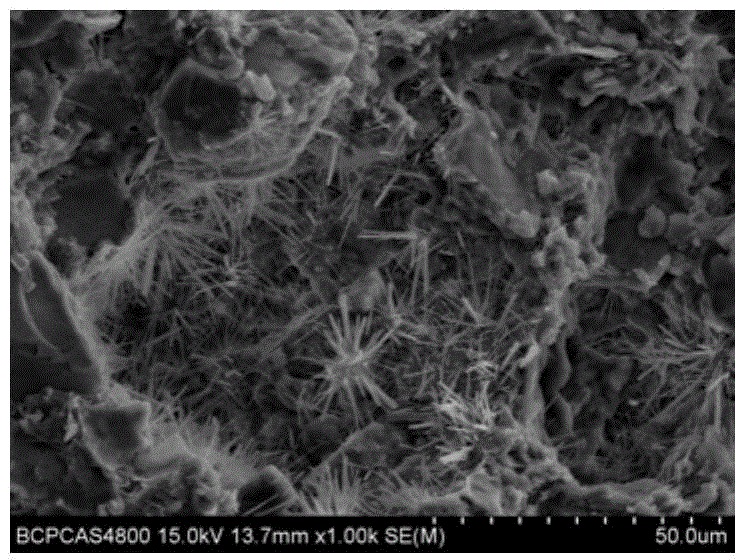

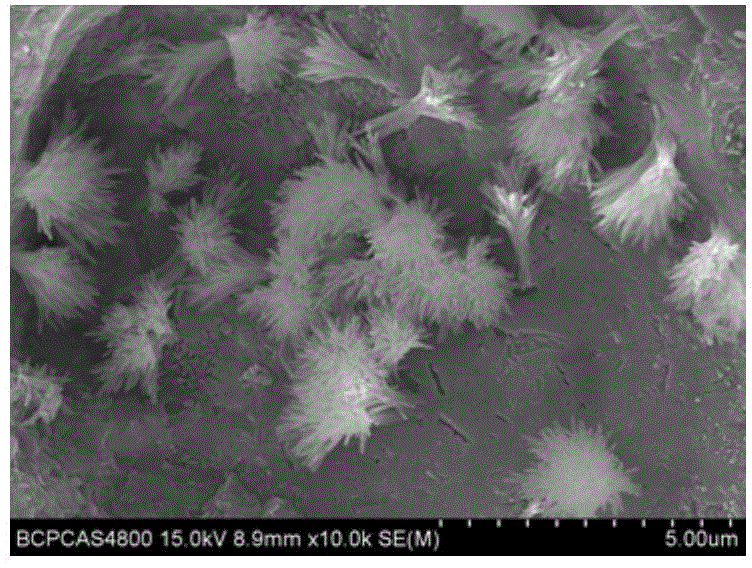

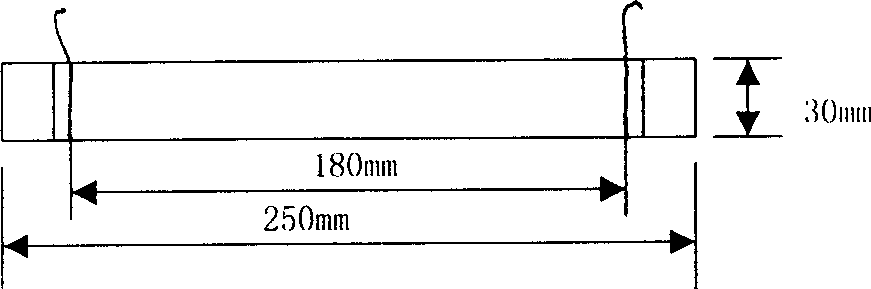

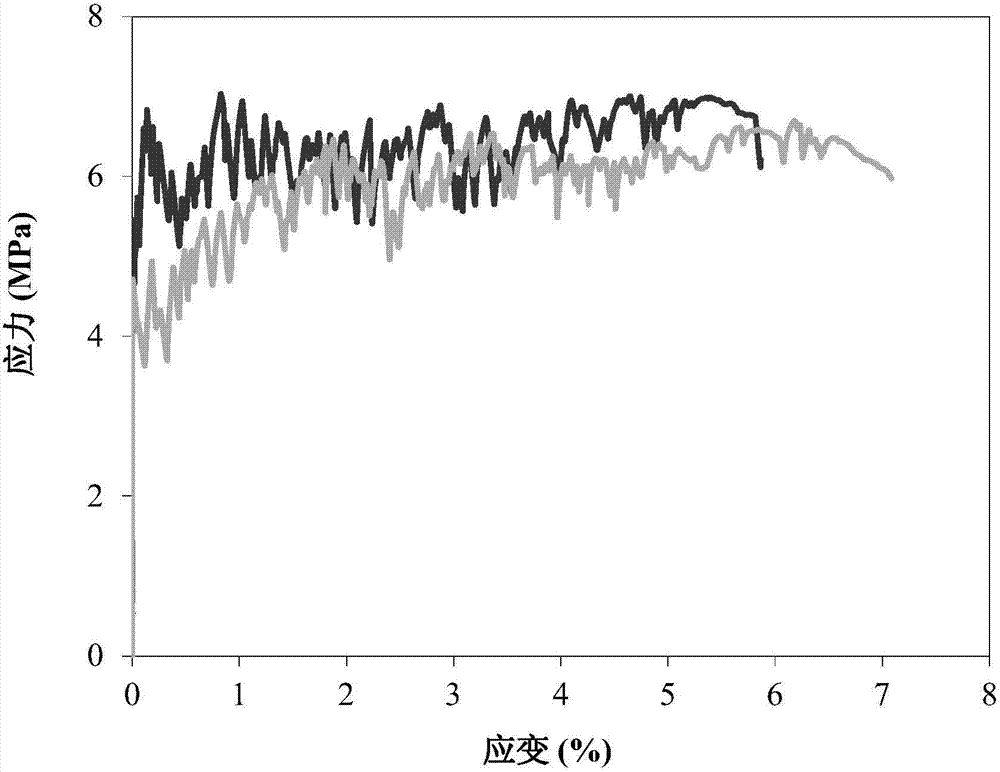

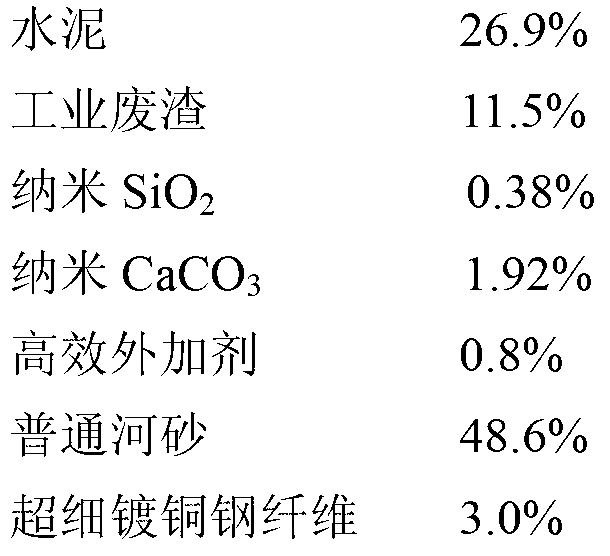

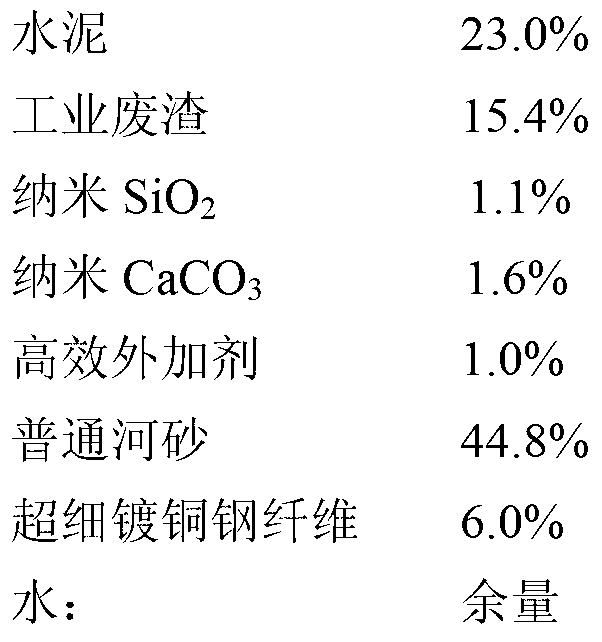

Ecological type nanometer super high performance cement based composite material and preparation method thereof

The invention discloses an ecological type nanometer super high performance cement based composite material and preparation method thereof, and the composite material comprises the following ingredients: cement: 19.2%-26.9%; industrial waste residue: 11.5-19.2%; nanometer SiO2: 0.38-1.92%; nanometer CaCO3: 0.38%-1.92%; additive: 0.8-1.2%; river sand: 38.4%-55.5%; copper facing steel fiber: 3.0%-9.0%; water: rest. The invention provides an ecological type nanometer super high performance cement based composite material and preparation method thereof, and compared with the same technique, the invention has the advantages of high cost performance, simple preparation technology, ecological environmental protection, etc. Because of composite superposed effect of nanometer ingredient and industrial waste residue, and the mechanical properties of the cement based composite material at early stage and later stage are improved, thereby improving the mechanical properties and the endurance performance of the cement based composite material.

Owner:SOUTHEAST UNIV

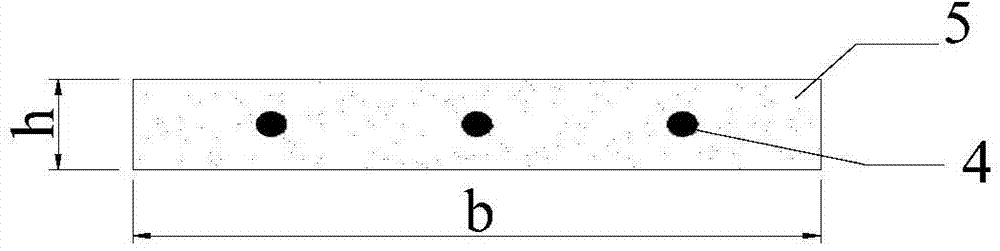

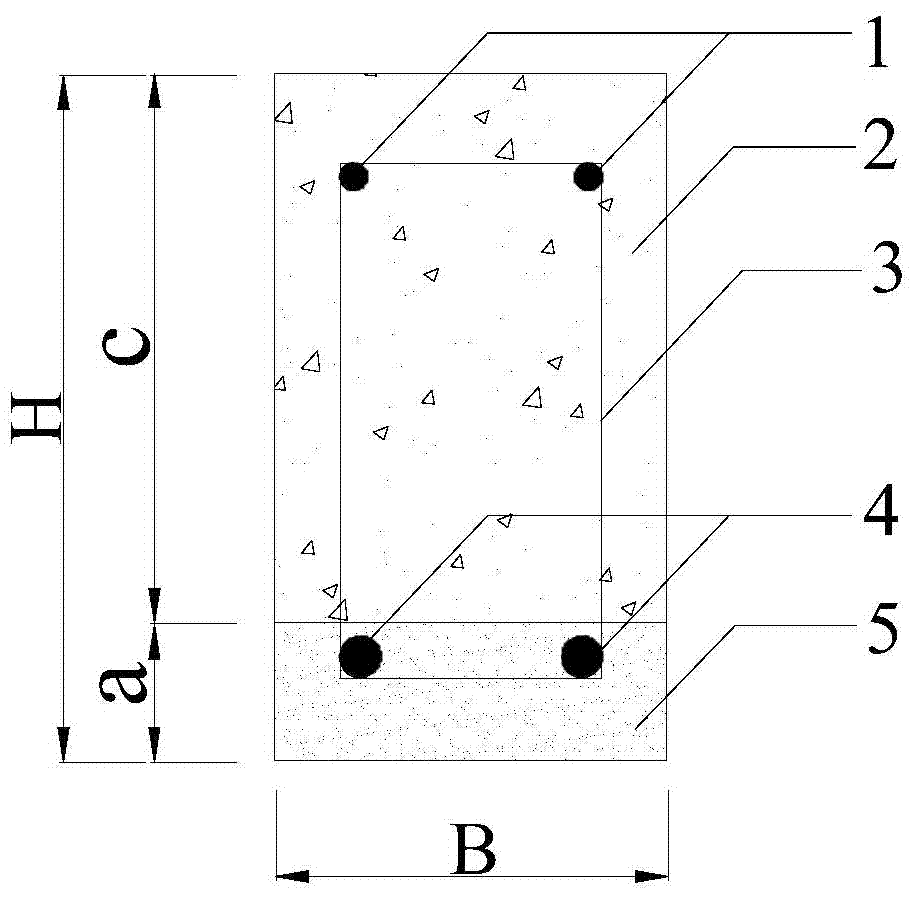

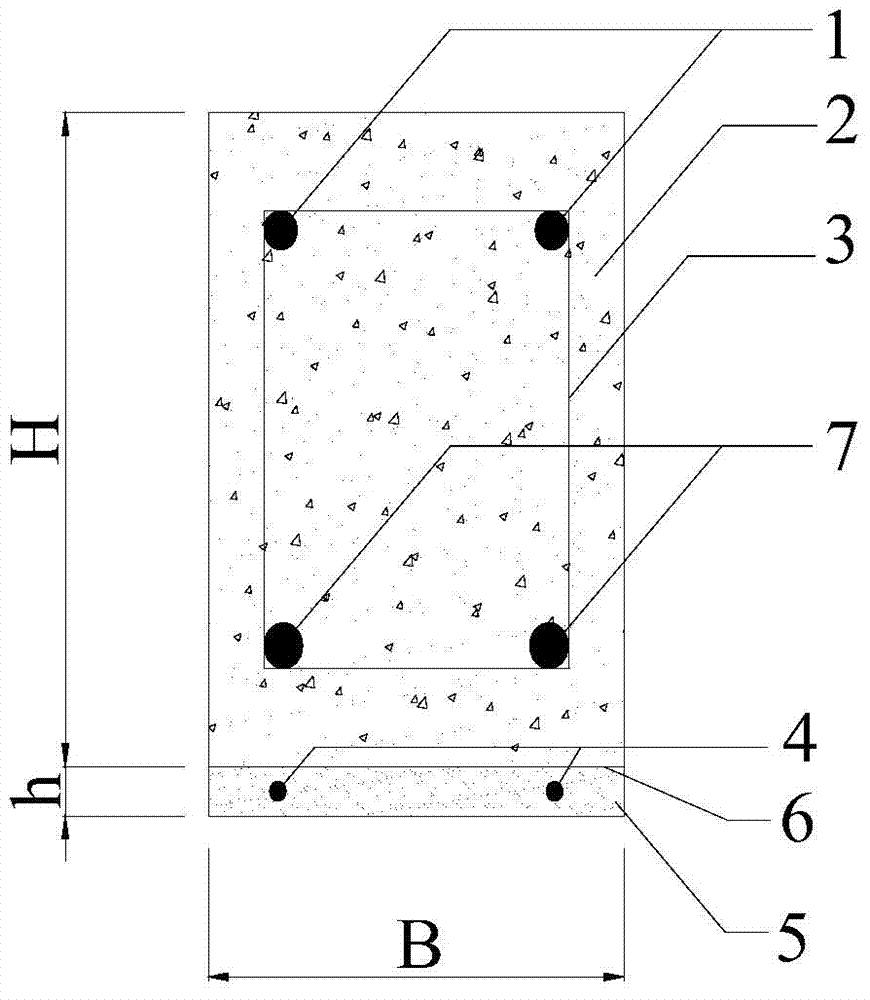

High toughness cement-based material-nonmetal fiber rib composite structure as well as application and application method thereof

InactiveCN103938803AImprove carrying capacityIncreased durabilityBuilding repairsGirdersCarbon fibersPolyvinyl alcohol

The invention discloses a high toughness cement-based material-nonmetal fiber rib composite structure. According to the structure, a high toughness cement-based material is adopted as a base material, nonmetal fiber rib is adopted as directional reinforcing rib; the high toughness cement-based material comprises the following components in percentage by weight: 35% of cement, 45-55% of fly ash, 5-10 % of silicon ash and 5-10% of metakaolin; high-strength short fiber is one or more out of polyvinyl alcohol fiber, polyethylene fiber, carbon fiber and aramid fiber; the nonmetal fiber rib is carbon fiber reinforced plastic rib, aramid fiber reinforced plastic rib, glass fiber reinforced plastic rib or basalt fiber reinforced plastic rib. The invention further discloses applications and an application method of the high toughness cement-based material-nonmetal fiber rib composite structure. The high toughness cement-based material and the nonmetal fiber rib are utilized to reinforce the reinforced concrete structure, so that the bearing capacity and the durability of the structure are increased and the aging speed of the structure is reduced.

Owner:ZHEJIANG UNIV +1

Slag mixed active powder concrete

Disclosed is reactive powder concrete mixed with slag, which is a novel engineering material with super-high intensity and super-high durability, particularly cement-based composite material having super-high property prepared and formed via using all kinds of industrial residue as reactive powder. Corresponding to Portland cement, proportion by weight of all composites of the concrete is: the Portland cement holding 1 part, the slag holding 0.40-0.60 part, silicon powder holding 0.20-0.35 part, quartz flour holding 0.20-0.35 part, river sand holding 1.20-1.60 parts, water holding 0.20-0.28 part and a water reducing agent holding 0.02-0.03 part.

Owner:SOUTHEAST UNIV

Functional porous cement based composite material and preparation method thereof

The invention belongs to the technical field of material science and engineering and particularly relates to a functional porous cement based composite material and a preparation method thereof. The composite material is prepared from the following raw materials: cement, aggregates, water, additives and a catalyst in a ratio of (1-1.2):(0.5-0.6): (0.2-0.8):(0-0.04):(0-0.2), wherein the content of the catalyst is not zero and the catalyst is a compound of titanium dioxide and graphene oxide. The invention provides the functional porous cement based composite material which not only has a separating function, but also has the characteristics of being photocatalytic, pollution-resistant and self-cleaning. The functional porous cement based composite material is simple in preparation process and low in cost and has wide application prospect in the technical industry of environmental protection and management.

Owner:HENAN POLYTECHNIC UNIV

Multi-scale fiber-reinforced high-performance cement-based composite material and preparation method thereof

The invention relates to a multi-scale fiber-reinforced high-performance cement-based composite material and a preparation method of the multi-scale fiber-reinforced high-performance cement-based composite material, and belongs to the technical field of fiber-reinforced cement-based composite materials. The multi-scale fiber-reinforced high-performance cement-based composite material comprises a base body and a multi-scale fiber system, wherein the base body comprises cement and sand, the multi-scale fiber system comprises steel fibres, polyvinyl alcohol fibers (PVA fibres) and calcium carbonate whiskers, the dosage of the multi-scale fiber system accounts for 2.4-5.6 vol.% of the volume of the fibre-reinforced cement-based material, and the volume ratio of the steel fibres to the PVA fibres to the calcium carbonate whiskers is 1 to (0.1-1.2) to (0.3-5.3). The multi-scale fiber-reinforced high-performance cement-based composite material and the preparation method provided by the invention have the advantages that the manufacturing technique is simple, special equipment is not needed, the multi-scale fiber-reinforced high-performance cement-based composite material is as the same as the common cement-based material, the source of materials is wide, the finished product price is low, the industrialized production is realized, the multi-scale fiber-reinforced high-performance cement-based composite material with different properties is obtained by adjusting the ratio, and the product can be used for manufacturing a cast-in-place structure and a cladding material and also can be prefabricated into a product.

Owner:DALIAN UNIV OF TECH

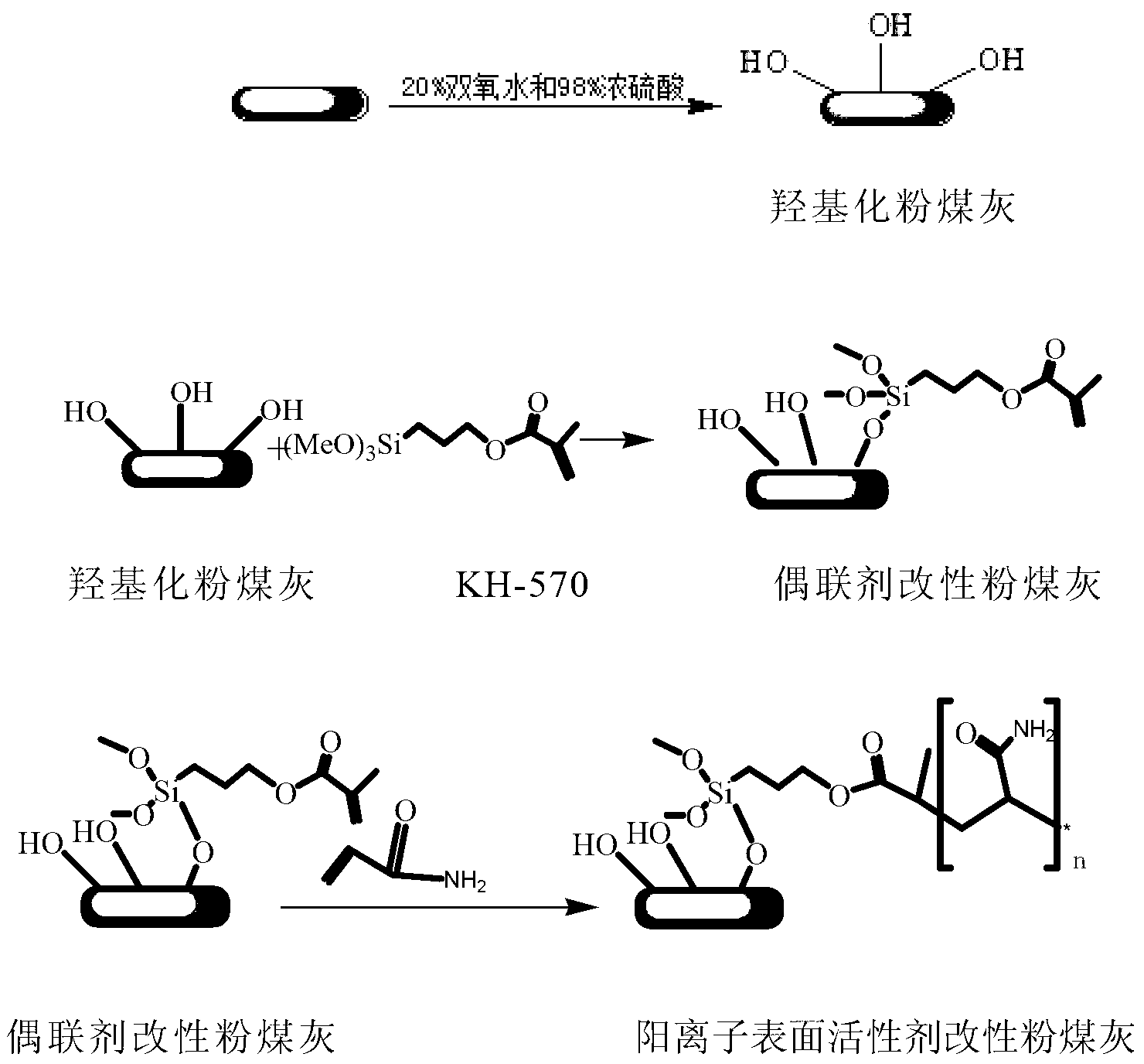

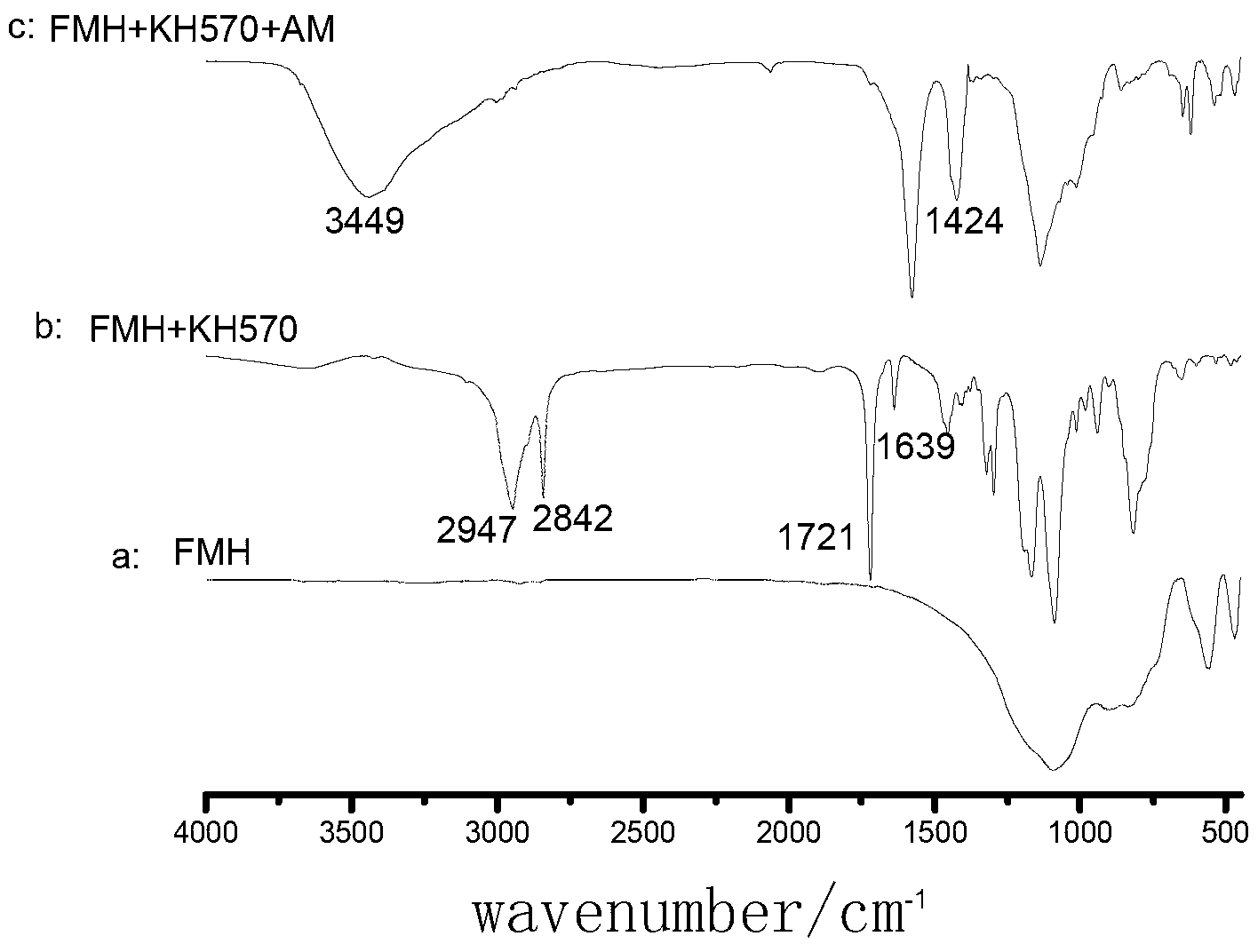

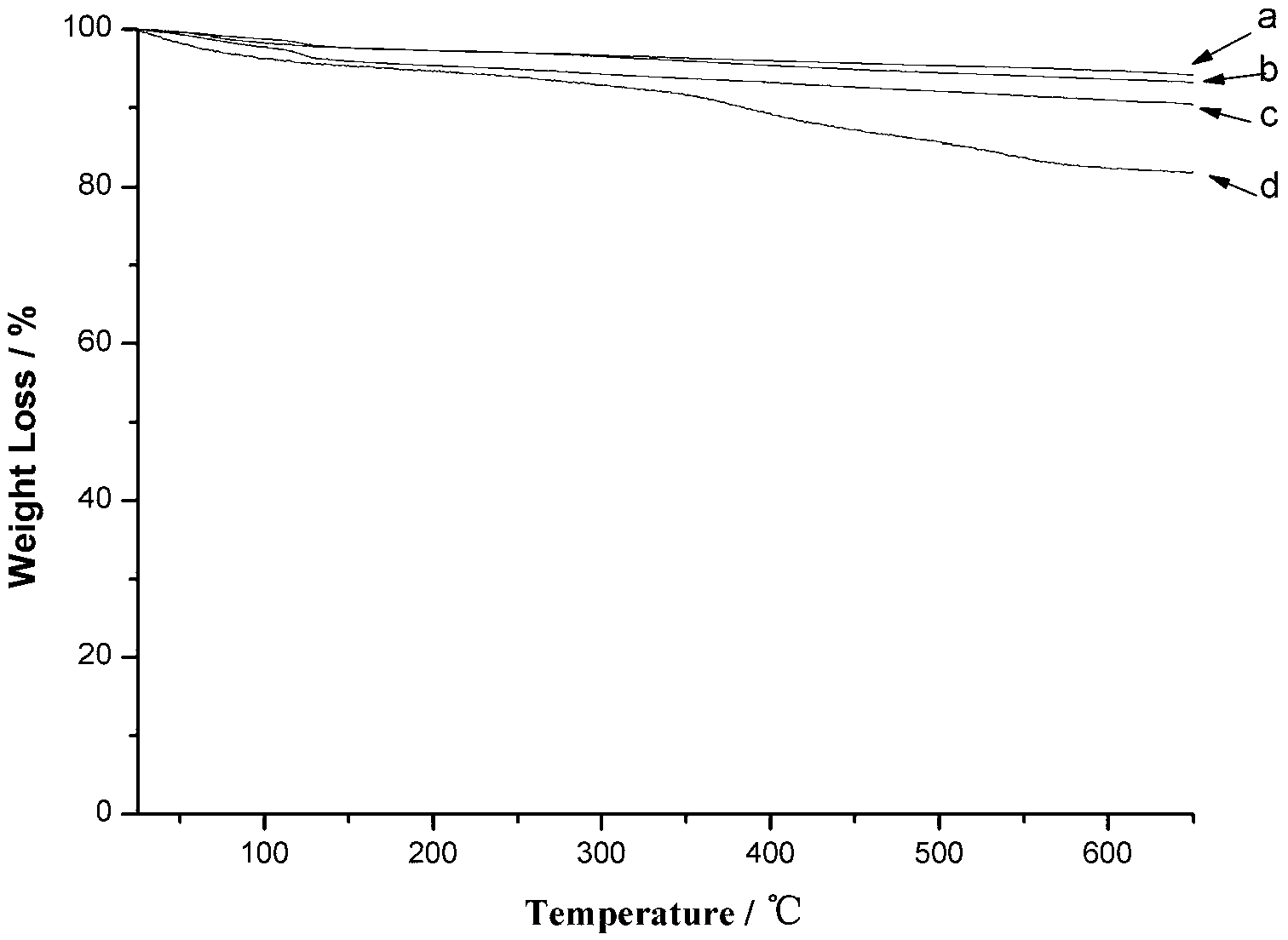

Preparation method of cationic surfactant modified fly ash

InactiveCN103304175AImprove adsorption capacityImprove flexural performanceAfter treatmentGraft reaction

The invention discloses a preparation method of cationic surfactant modified fly ash, which comprises the following steps of: firstly performing pretreatment and hydroxylation treatment on the surface of fly ash to obtain hydroxylated fly ash to obtain a grafting point; then modifying the fly ash by use of a coupling agent; and finally performing grafting reaction with a cationic surfactant polyacrylamide to obtain cationic surfactant modified fly ash. According to the preparation method disclosed by the invention, the polyacrylamide is grafted on the surface of the fly ash, and the adsorption property of the grafted fly ash is greatly changed; particularly the fly ash is applied to a cement-based composite material, and the fracture resistance of the cement-based composite material is obviously improved; and the preparation method disclosed by the invention has the advantages of low reaction temperature, mild conditions, simple after-treatment and low industrialization cost.

Owner:HEFEI UNIV OF TECH

Pressure-sensitive cement-base composite material

InactiveCN101121582AHigh sensitivity to force-electric coupling effectHigh sensitivitySolid waste managementCelluloseElectricity

The present invention discloses a pressed cement composite material, which relates to a cement composite material; the present invention is to solve the shortcoming in the existing pressed cement material that: the sense ability for the force-electricity coupling effect is much lower, the existing method is influenced by the humidity greatly, and the base polarization is easy to influence the test of the electricity signal. The present invention consists of a function component and cement material; the function component is a nickel powder or a mixture between the nickel powder and one or more than one material including carbon cellulose, carbon, graphite and steel residual; the cement material is a glue material or a composite material between the glue material and the bone material; thereinto, the function component occupies between 1 percent and 80 percent in the total weight; and the rested is the cement material. The sense ability of the pressed cement composite material in the present invention is much higher; the sensitivity can reach to more than hundred or thousand, which is higher than the sensitivity of the existing pressed cement composite material with the function component including carbon cellulose, carbon and steel residual and so on. Besides, the force-electricity coupling effect for the material is much smaller by the humidity; the test of the electricity signal is not easy to be influenced by the base polarization.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com